Page 1

KODAK VISION

Color Print Control Strips,

Process ECP-2D

Technical Data and

Crossover Information

©Eastman Kodak Company, 2006

Professional

Motion

Page 2

0 KODAK VISION Color Print Control Strips, Process ECP-2D

Page 3

Note: While the data presented are typical of production coatings, they do not represent standards which must be met by Kodak.

Varying storage, exposure, and processing conditions will affect results. The company reserves the right to change and improve

characteristics at any time.

Table of Contents

KODAK VISION Color Print Control Strips . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Processed Control Strip - 35 mm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Important Improvements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Control Strip Sensitometric Curve Comparison . . . . . . . . . . . . . . . . . . . . . . . . . . 3

ECP-2D Control Strip Exposed on EASTMAN EXR Color Print Film / 5386 4

ECP-2D Control Strip Exposed on KODAK VISION Color Print Film / 2383 5

Effects of Mechanical and Chemical Variations . . . . . . . . . . . . . . . . . . . . . . . . . 6

Effects of Time and Temperature Variations . . . . . . . . . . . . . . . . . . . . . . 7

Effects of pH and CD-2 Variations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Effects of NaBr and Na

Effects of Na

Variations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2SO3

Effects of AF-9 and PB-2 Prebath Contamination . . . . . . . . . . . . . . . . . . 11

Effects of CD-3 for CD-2 and Stop Bath Contamination . . . . . . . . . . . . . 12

Effects of Persulfate Accelerator and Hydroxylamine Sulfate Contamination 13

Effects of F-35B Fixer and NaCl Contamination . . . . . . . . . . . . . . . . . . . 14

Effects of KI Contamination and Water Dilution . . . . . . . . . . . . . . . . . . . 15

Effects of Bacterial Na

Effects of Under- and Over-Replenishment . . . . . . . . . . . . . . . . . . . . . . . 17

Control-Strip Crossover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Control-Strip Crossover for Process ECP-2D . . . . . . . . . . . . . . . . . . . . . 19

Crossover to Non-Prebath Process Sequence . . . . . . . . . . . . . . . . . . . . . . . 20

Variations . . . . . . . . . . . . . . . . . . . . . . . . . 9

2CO3

S and Na2SO4 Contamination . . . . . . . . . . . . . . 16

2

KODAK VISION Color Print Control Strips, Process ECP-2D 1

Page 4

KODAK VISION Color Print Control Strips

Introduction

KODAK VISION Color Print Control Strips (Figure 1) are

intended for the control of Process ECP-2D using the

procedures described in KODAK Publication No. H-24,

Processing KODAK Motion Picture Films, Module 1,

Process Control.

The catalog numbers for KODAK VISION Color Print

Control Strips are CAT 156 1323 for 35 mm, and

CAT 820 8498 for 16 mm.

Figure 1 Processed Control Strip - 35 mm

ECP-2D

6101

Steps

8

HD

KODAK VISION Color Print Control Strips

KODAK VISION Color Print Control Strips, Process

ECP-2D, are packaged in 100-foot rolls containing at least

120 exposures and a processed reference strip. The

exposures on the roll are spaced at 9.5-inch intervals. Each

exposure has 21 gray-scale steps at 0.15 log H increments

(1/2 camera stop).

The reference strip accompanying each roll was exposed

along with all other control strips in the package; it was then

processed under specified well-controlled conditions. Keep

the reference strip at room temperature in its envelope to

help protect it from heat, light, and dirt.An instruction

sheet enclosed with the package contains process deviation

(correction) factors, if they are required, to determine your

laboratory process aim numbers. A four-digit code number

appearing on the carton, can, control strips, reference strips,

and instruction sheet, identifies each production batch of

strips.

Please be aware no two batches of control strips are

identical because of slight differences in product, exposures,

process, etc. And therefore, the aim value numbers will not

match (however, on rare occasions they could), even with

the application of the deviation factors. Beginning with

batch codes 6101 (35 mm) and 6102 (16 mm), you may

notice a shift in your aim values. IF you continue to be

satisfied with the way your images look, simply cross

over to the new aim values and continue processing as

you have.

F002_0923CC

11

MD

14

LD

21

D-min

2 KODAK VISION Color Print Control Strips, Process ECP-2D

Page 5

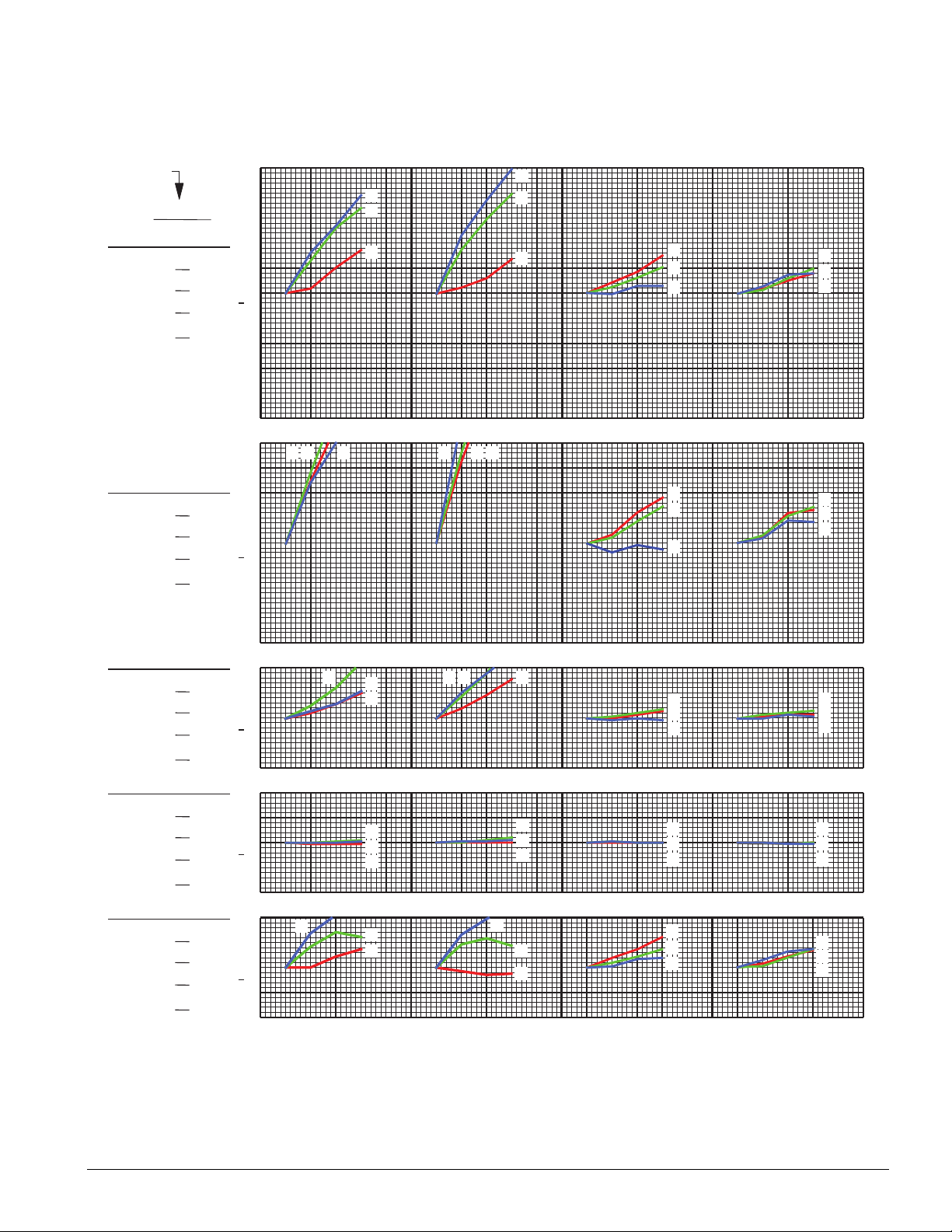

Effects of Mechanical and Chemical

Variations

Figures 2 through 12 illustrate some of the photographic

effects of mechanical and chemical variations on KODAK

VISION Color Print Control Strips exposed on 2383 Film

compared to effects on batch codes 6101 (35 mm) and 6102

(16 mm) and above. Each plot shows the effect of a change

in a process variable (horizontal axis), on the dye density of

the processed film (vertical axis). These density plots are

deviated against the standard level for each variable (e.g.,

standard level for the variable is represented by a zero

density deviation).

The magnitude of the changes shown in these plots should

not be considered to be process control limits. Also, the data

presented are qualitative, not quantitative. The plots were

derived from experiments using small laboratory machines

in which all constituents were held constant except the

variable being studied. Hence, the figures should be used

only as trend charts and guides. If two or more process

variables are changed, the resulting photographic effect

illustrated may not be additive. Interactions can occur that

produce effects other than those predicted by addition. The

plots in this publication are representative only; they do not

contain all possible solution problems. Most of the important

photographic effects take place in the developer.

KODAK VISION Color Print Control Strips, Process ECP-2D 3

Page 6

Developer Mechanical Factors

Figure 2 Effects of Time and Temperature Variations

—Current VISION Control Strips versus batch codes 6101 (35 mm) and 6102 (16 mm) in Process ECP-2D Developer

AIM

VALUE S

REFERENCE

STRIP

CODE NO.

0000

HD

RED

GREEN

BLUE

B/W

MD

RED

GREEN

BLUE

B/W

LD

RED

GREEN

BLUE

B/W

D-Min

RED

GREEN

BLUE

B/W

HD-MD

RED

GREEN

BLUE

B/W

H326_TEMP_TIME

.25

.20

.15

.10

.05

+

.05

.10

.15

.20

.25

.20

.15

.10

.05

+

.05

.10

.15

.20

.10

.05

+

.05

.10

.10

.05

+

.05

.10

.10

.05

+

.05

.10

Time

R

G

B

R

B

New 2383

G

120

140

sec

G

160

Old 2383 New 2383

RG

G

R

B

B

R

G

B

G

R

R

R

B

B

G

R

R

B

G

R

200

G

B

R

G

G

R

B

B

G

G

180

B

R

B

GR

G

R

B

98

96

Old 2383

G R

B

0

GB R R R

R

G

B

0

GBR

B

G

0

R

G

B

0

0

B

120

160

140

sec F

R

B

R

G

G

R

B

G

R

200

180

G

B

100

°

Temperature

B

B

R

G

B

G

R

R

G

R

GB

B

G

B

R

G

R

B

R

B

102

104

96

R

G

R

B

BG

98

°

R

G

100

F

G

B

G

R

G

R

B

B

102

104

4 KODAK VISION Color Print Control Strips, Process ECP-2D

Page 7

Developer Chemical Factors

Figure 3 Effects of pH and CD-2 Variations

—Current VISION Control Strips versus batch codes 6101 (35 mm) and 6102 (16 mm) in Process ECP-2D Developer

CD-2

New 2383Old 2383

B

G

R

R

B

G

AIM

VALUES

REFERENCE

STRIP

CODE NO.

HD

RED

GREEN

BLUE

B/W

0000

.25

.20

.15

.10

.05

+

.05

.10

.15

.20

.25

pH

Old 2383

R

G

0

B

G

B

B

New 2383

R

G

B

B

G

R

B

R

G

MD

RED

GREEN

BLUE

B/W

LD

RED

GREEN

BLUE

B/W

D-Min

RED

GREEN

BLUE

B/W

HD-MD

RED

GREEN

BLUE

B/W

H326_PH_CD2

.20

.15

.10

.05

+

.05

.10

.15

.20

.10

.05

+

.05

.10

.10

.05

+

.05

.10

.10

.05

+

.05

.10

B

R

10.7

B

G

B

R

G

R

G

B

G

B

10.8

R

G

B

3.2

B

R

G

B

G

R

R

G

B

2.6

2.4

2.8

g/L

B

R

G

B

R

G

B

G

R

B

R

G

2.4

2.6

3.0

2.8

g/LpH

R

10.7

G

B

G

R

R

B

G

R

G

B

10.8

B

G

R

R

G

B

R

B

G

R

10.4

10.5

10.6

pH

0

B

R

G

R

0

B

G

0

B

0

R

G

10.4

10.5

10.6

3.0

G

R

B

G

R

B

G

R

B

B

R

G

3.2

KODAK VISION Color Print Control Strips, Process ECP-2D 5

Page 8

Developer Chemical Factors

Figure 4 Effects of NaBr and Na2CO3 Variations

—Current VISION Control Strips versus batch codes 6101 (35 mm) and 6102 (16 mm) in Process ECP-2D Developer

NaBr

G

R

B

G

R

B

R

G

B

R

G

B

G

R

B

B

R

G

B

R

G

B

G

R

B

R

G

G

R

B

G

R

B

R

G

B

R

G

B

G

R

B

AIM

VALUES

REFERENCE

STRIP

CODE NO.

HD

RED

GREEN

BLUE

B/W

MD

RED

GREEN

BLUE

B/W

LD

RED

GREEN

BLUE

B/W

D-Min

RED

GREEN

BLUE

B/W

HD-MD

RED

GREEN

BLUE

B/W

0000

.25

.20

.15

.10

.05

+

.05

.10

.15

.20

.25

.20

.15

.10

.05

+

.05

.10

.15

.20

.10

.05

+

.05

.10

.10

.05

+

.05

.10

.10

.05

+

.05

.10

Na CO

2 3

Old 2383 New 2383

G

R

B

B

R

G

B

R

G

R

G

RR

G

R

B

R

G

B

B

B

New 2383

R

G

B

G

R

B

G

B

R

R

B

G

R

G

B

Old 2383

B

0

R

G

0

B

R

0

G

0

B

0

R

G

G

R

B

G

R

B

GG

B

R

B

G

G

R

B

H326_Na2C03_NaBr

13.1

15.1

g/L

17.1

19.1

21.1

13.1

15.1

g/L

17.1

19.1

21.1

1.32

1.52

g/L

1.72

1.92

2.12

1.32

1.52

g/L

1.72

1.92

2.12

6 KODAK VISION Color Print Control Strips, Process ECP-2D

Page 9

Developer Chemical Factors

Figure 5 Effects of Na2SO3 Variations

—Current VISION Control Strips versus batch codes 6101 (35 mm) and 6102 (16 mm) in Process ECP-2D Developer

Na SO

2 3

AIM

VALUES

REFERENCE

STRIP

CODE NO.

HD

RED

GREEN

BLUE

B/W

MD

RED

GREEN

BLUE

B/W

LD

RED

GREEN

BLUE

B/W

D-Min

RED

GREEN

BLUE

B/W

HD-MD

RED

GREEN

BLUE

B/W

0000

.25

.20

.15

.10

.05

+

.05

.10

.15

.20

.25

.20

.15

.10

.05

+

.05

.10

.15

.20

.10

.05

+

.05

.10

.10

.05

+

.05

.10

.10

.05

+

.05

.10

Old 2383

B

R

0

G

B

G

0

R

0

0

B

G

0

R

R

G

B

G

B

R

B

G

R

B

G

R

R

G

B

G

R

G

B

R

G

B

R

G

B

R

B

New 2383

G

R

B

G

R

B

B

R

G

B

G

R

G

R

B

4.45

4.7

H326_Na2SO3

3.7

3.95

g/L

4.35

4.45

4.7

3.7

3.95

4.35

g/L

KODAK VISION Color Print Control Strips, Process ECP-2D 7

Page 10

Developer Chemical Factors

Figure 6 Effects of AF-2000 and Prebath 2 Contamination

—Current VISION Control Strips versus batch codes 6101 (35 mm) and 6102 (16 mm) in Process ECP-2D Developer

AIM

VALUES

REFERENCE

STRIP

CODE NO.

0000

HD

RED

GREEN

BLUE

B/W

MD

RED

GREEN

BLUE

B/W

LD

RED

GREEN

BLUE

B/W

D-Min

RED

GREEN

BLUE

B/W

HD-MD

RED

GREEN

BLUE

B/W

H326_PREBATH2_AF2000

.25

.20

.15

.10

.05

+

.05

.10

.15

.20

.25

.20

.15

.10

.05

+

.05

.10

.15

.20

.10

.05

+

.05

.10

.10

.05

+

.05

.10

.10

.05

+

.05

.10

AF2000

Old 2383

R

G

mL/L

6.25

B

G

R

B

B

R

G

G

R

B

R

G

B

7.5

0

0

0

0

0

0.0

5.0

New 2383

B

R

G

B

G

R

B

G

R

B

G

R

B

R

G

0.0

5.0

6.25

7.5

mL/L mL/L mL/L

Old 2383 New 2383

B

G

R

0

50

100

B

GR

G

R

G

R

B

G

B

R

B

200

Prebath 2

B

G

R

G

R

B

R

G

B

R

G

B

50

G B

100

200

R

0

8 KODAK VISION Color Print Control Strips, Process ECP-2D

Page 11

Developer Chemical Factors

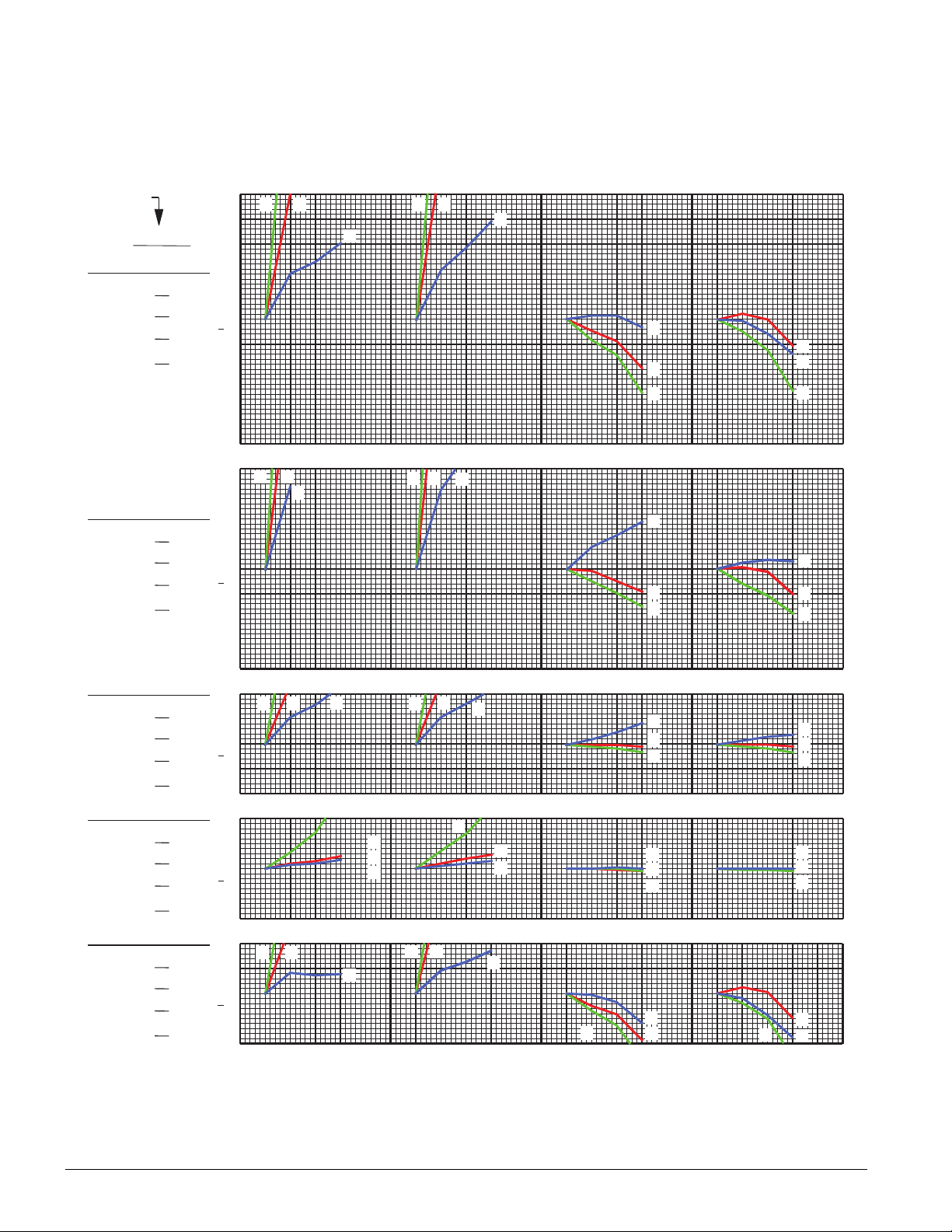

Figure 7 Effects of CD-3 for CD-2 and Stop Bath Contamination

—Current VISION Control Strips versus batch codes 6101 (35 mm) and 6102 (16 mm) in Process ECP-2D Developer

AIM

VALUES

REFERENCE

STRIP

CODE NO.

0000

HD

RED

GREEN

BLUE

B/W

MD

RED

GREEN

BLUE

B/W

LD

RED

GREEN

BLUE

B/W

D-Min

RED

GREEN

BLUE

B/W

HD-MD

RED

GREEN

BLUE

B/W

H326_STOPBATH_CD2_CD3

.25

.20

.15

.10

.05

+

.05

.10

.15

.20

.25

.20

.15

.10

.05

+

.05

.10

.15

.20

.10

.05

+

.05

.10

.10

.05

+

.05

.10

.10

.05

+

.05

.10

Substitute CD-3 for CD-2

Old 2383

0

R

B

G

0

B

R

G

0

0

0

B

0.0

17.0

% CD-3 % CD-3

34.0

B

R

G

B

R

G

R

G

52.0

New 2383

B

0.0

17.0

Old 2383 New 2383

R

G

B

B

R

G

R

B

G

R

G

B

G

R

34.0

52.0

G

G

R

G

0.0

25.0

mL/L mL/L

R

50.0

B

B

R

R

B

G

B

G

R

B

100.0

Stop Bath

B

G

R

B

R

G

G

R

B

G

B

R

25.0

50.0

B

100.0

R

G

0.0

KODAK VISION Color Print Control Strips, Process ECP-2D 9

Page 12

Developer Chemical Factors

Figure 8 Effects of Persulfate Accelerator and Hydroxylamine Sulfate Contamination

—Current VISION Control Strips versus batch codes 6101 (35 mm) and 6102 (16 mm) in Process ECP-2D Developer

AIM

VALUES

REFERENCE

STRIP

CODE NO.

HD

RED

GREEN

BLUE

B/W

0000

.25

.20

.15

.10

.05

+

.05

.10

.15

.20

.25

Accelerator

Old 2383

0

R

B

G

New 2383

R

B

G

Hydroxylamine Sulfate

Old 2383 New 2383

G

B

R

G

B

R

MD

RED

GREEN

BLUE

B/W

LD

RED

GREEN

BLUE

B/W

D-Min

RED

GREEN

BLUE

B/W

HD-MD

RED

GREEN

BLUE

B/W

.20

.15

.10

.05

+

.05

.10

.15

.20

.10

.05

+

.05

.10

.10

.05

+

.05

.10

.10

.05

+

.05

.10

G

R

0

0

0

0

G

0

5

10

R

B

G

G

R

B

G

R

B

R

B

G

0

5

20

10

R

B

G

G

R

B

G

R

B

R

B

20

0.0

0.2

0.4

B

G

R

B

G

B

R

G

B

R

0.8

0.0

0.2

R

0.4

G

R

B

G

R

B

G

R

B

B

G

0.8

H326_HYDROXY_SULF_ACCELERATOR

mL/L mL/L

g/L g/L

10 KODAK VISION Color Print Control Strips, Process ECP-2D

Page 13

Developer Chemical Factors

Figure 9 Effects of F-35B Fixer and NaCl Contamination

—Current VISION Control Strips versus batch codes 6101 (35 mm) and 6102 (16 mm) in Process ECP-2D Developer

AIM

VALUES

REFERENCE

STRIP

CODE NO.

HD

RED

GREEN

BLUE

B/W

0000

.25

.20

.15

.10

.05

+

.05

.10

.15

.20

.25

Fixer

Old 2383

B

G

R

0

New 2383

Old 2383 New 2383

B

G

R

NaCl

R

G

B

G

B

R

MD

RED

GREEN

BLUE

B/W

LD

RED

GREEN

BLUE

B/W

D-Min

RED

GREEN

BLUE

B/W

HD-MD

RED

GREEN

BLUE

B/W

.20

.15

.10

.05

+

.05

.10

.15

.20

.10

.05

+

.05

.10

.10

.05

+

.05

.10

.10

.05

+

.05

.10

R BG

0

G

B

R

0

0.5

G

B

R

G

R

1.0

1.5

0

B

0

0.0

B G R

G

B R

0.0

B

0.5

G

B

R

G

R

1.0

1.5

0.0

R

G

B

G

R

B

R

GG

B

R

G

B

1.0

2.0

3.0

0.0

1.0

2.0

G

R

B

G

R

B

R

B

B

G

R

3.0

H326_NaCI_FIXER

mL/L

mL/L g/L

g/L

KODAK VISION Color Print Control Strips, Process ECP-2D 11

Page 14

Developer Chemical Factors

Figure 10 Effects of KI Contamination and Water Dilution

—Current VISION Control Strips versus batch codes 6101 (35 mm) and 6102 (16 mm) in Process ECP-2D Developer

AIM

VALUES

REFERENCE

STRIP

CODE NO.

HD

RED

GREEN

BLUE

B/W

MD

RED

GREEN

BLUE

B/W

LD

RED

GREEN

BLUE

B/W

D-Min

RED

GREEN

BLUE

B/W

HD-MD

RED

GREEN

BLUE

B/W

H326_H2O_KI

0000

.25

.20

.15

.10

.05

+

.05

.10

.15

.20

.25

.20

.15

.10

.05

+

.05

.10

.15

.20

.10

.05

+

.05

.10

.10

.05

+

.05

.10

.10

.05

+

.05

.10

Kl

Old 2383

R

G

B

0

RG

B

0

0.0

2.5

B

G

R

B

B

7.5

5.0

G R

0

0

G R

0

New 2383

GR

RG

R

G

G R

0.0

B

B

B

G

R

B

B

G

5.0

7.5

0.0

100.0

mL/L

2.5

mg/Lmg/L

Water Dilution

B

R

G

B

R

G

B

R

G

B

G

R

B

R

200.0

400.0

0.0

New 2383Old 2383

100.0

mL/L

G

200.0

R

B

G

B

R

G

B

R

G

B

R

G

R

B

400.0

12 KODAK VISION Color Print Control Strips, Process ECP-2D

Page 15

Developer Chemical Factors

Figure 11 Effects of Bacterial Na2S and Na2SO4 Contamination

—Current VISION Control Strips versus batch codes 6101 (35 mm) and 6102 (16 mm) in Process ECP-2D Developer

AIM

VALUES

REFERENCE

STRIP

CODE NO.

0000

HD

RED

GREEN

BLUE

B/W

MD

RED

GREEN

BLUE

B/W

LD

RED

GREEN

BLUE

B/W

D-Min

RED

GREEN

BLUE

B/W

HD-MD

RED

GREEN

BLUE

B/W

H326_Na2SO4_Na2

.25

.20

.15

.10

.05

+

.05

.10

.15

.20

.25

.20

.15

.10

.05

+

.05

.10

.15

.20

.10

.05

+

.05

.10

.10

.05

+

.05

.10

.10

.05

+

.05

.10

R

G

B

G

R

B

G

B

R

G

B

R

R

B

G

10.0

Na S

2

0.0

2.5

mg/L

5.0

B

R

G

G

R

B

G

B

R

G

B

R

B

R

G

10.0

Na SO

Old 2383

0

0

B

0

0

0

B

R

5

0

g/L

10

15

G

R

20

G

R

B

G

R

B

G

R

B

B

2

4

0

New 2383

G

B

5

10

g/L

Old 2383 New 2383

G

R

B

G

R

B

G

R

B

B

R

G

R

20

15

0.0

2.5

mg/L

5.0

KODAK VISION Color Print Control Strips, Process ECP-2D 13

Page 16

Developer Chemical Factors

Figure 12 Effects of Under- and Over-Replenishment

—Current VISION Control Strips versus batch codes 6101 (35 mm) and 6102 (16 mm) in Process ECP-2D Developer

Under and Over Replenishment

AIMAIM

VALUESVALUES

REFERENCE

STRIP

CODE NO.

HD

RED

GREEN

BLUE

B/W

MD

RED

GREEN

BLUE

B/W

LD

RED

GREEN

BLUE

B/W

D-Min

RED

GREEN

BLUE

B/W

HD-MD

RED

GREEN

BLUE

B/W

0000

.25

.20

.15

.10

.05

+

.05

.10

.15

.20

.25

.20

.15

.10

.05

+

.05

.10

.15

.20

.10

.05

+

.05

.10

.10

.05

+

.05

.10

.10

.05

+

.05

.10

Old 2383

G

R

0

B

G

R

0

B

G

R

B

R

0

G

B

0

G

R

0

B

R G

B

G

R

B

G

R

B

G

R

B

G

R

B

G

R

B

R

B

R

R

B

G

B

New 2383

G

G

B

G

R G

G

R

R

G

R

B

G

R

B

G

R

B

R

B

Normal

20 % Over

H326_OVER_UNDER

20% Under

Normal

20 % Over

20% Under

14 KODAK VISION Color Print Control Strips, Process ECP-2D

Page 17

Control-Strip Crossover

Important: During the inventory crossover from the

previous batch Control Strips to the new VISION Control

Strips, every effort should be taken in your operations to

avoid switching back and forth. Your process control will be

greatly simplified by depleting your supply of the EXR

Control Strips (except for what is needed for crossover

purposes) prior to utilizing the VISION Control Strips.

There will come a time when you will need to begin using

a new batch of control strips. A new batch means a new code

number, not a fresh box of strips with the same code number.

Please be aware no two batches of control strips are

identical because of slight differences in product, exposures,

process, etc. And therefore, the aim value numbers will not

match (however, on rare occasions they could), even with

the application of the deviation factors. Keep the reference

strip at room temperature in its envelope to help protect

it from heat, light, and dirt.

When you first started using control strips, you had no

previous reference and you set up your aim value parameters

by reading the densities of the specified (D-min, LD, MD,

HD, or D-max) control reference steps and applying the

deviation numbers supplied with that batch. Using a new

batch of strips is really no different, except you will have a

new set of aim numbers,

As the time approaches to change to a new batch (code),

you will want to make a “crossover” from the current, or old

batch. Crossover simply means to adapt to a change in aim

numbers, not a change in processing technique. You should

begin the crossover with at least a week’s supply of strips

still available (never wait until you run out).

The crossover to a new batch lets you get familiar with the

new set of aim numbers. Do not attempt to match the new

aim numbers to the old ones. If you do, you probably will

find it necessary to change the mechanical and/or chemical

specifications of the process, and this will most likely lead to

a non-conforming unacceptable process. You will notice

some differences in the way the new batch trends as

compared to the previous batch. This is a normal batch-tobatch variation, and is to be expected. If you are unable to

maintain a plot within your control limits with the new

control-strip batch, call your Kodak representative to assist

you.

Use the following crossover procedure each time a new

code number is put into service:

• Determine the aim values for the new batch, the same as

you did for the current or old batch, by reading the

specified steps (D-min, LD, MD, and HD or D-max) of the

reference strip and applying the correction factors. If there

is more than one roll of the same batch, average the

corresponding step densities for all reference strips in the

batch, then apply the correction factors. Please remove all

of the reference strips before freezing the control strip

rolls. This will eliminate the chance of moisture spots

forming on the reference strip.

• Process an old and new control strip simultaneously at

least three separate times. Do this at different times of the

day until you have a number of pairs. During this time,

continue to control the process with data from the old

strips.

• Post the new aim values on the same form as the old,

leaving an appropriate space between the two aim sets (as

illustrated in Figure 13). This way you can see the

differences of each control strip reaction at a glance. You

will observe the tracking of the “old” batch as compared

to the “new” batch, with each plotted to its individual set

of aim numbers. Both should be tracking in similar

directions, but not exactly. However, they still should be

within the same action and control limits. Please

remember, no matter how the aim densities differ in

numerical value, you still use each set as your zero (0)

reference line.

• Once you are comfortable with the new batch of control

strips, use a new H-24F or Y-55 form to separate and not

confuse the old and new aim numbers while making the

daily notations.

• If, for some reason, there is a need to adjust the process to

conform to the new batch of control strips to new action

and control limits, cease processing and evaluate the

entire system. Such a need for change indicates a

fundamental system difficulty, which most likely involves

all aspects of the process, not necessarily a problem with

the new batch of control strips. If difficulty continues,

contact your Kodak technical representative.

KODAK VISION Color Print Control Strips, Process ECP-2D 15

Page 18

Figure 13 Control-Strip Crossover for Process ECP-2D

EASTMAN Process Record Form (H-24F)

AIM

VALUES

HD

RED

GREEN

BLUE

B/W

MD

RED

GREEN

BLUE

B/W

LD

RED

GREEN

BLUE

B/W

D-Min

RED

GREEN

BLUE

B/W

HD-MD

RED

GREEN

BLUE

B/W

CONTROL NUMBER

3.04

2.70

2.45

0.97

0.95

0.88

0.21

0.21

0.27

0.06

0.07

0.16

2.07

1.75

1.57

DATES

CURRENT

.25

.20

.15

.10

.05

+

0

.05

.10

.15

.20

.25

.20

.15

.10

.05

+

0

.05

.10

.15

.20

CB action = 0.06

CB control = 0.08

.10

.05

+

0

.05

.10

.10

.05

+

0

.05

.10

CB action = 0.07

CB control = 0.09

.10

.05

+

0

.05

.10

12

10 101211 11 111212 12 12

Control Strip Crossover Process ECP-2D

R-3.10

G-3.15

B-3.31

Code 9011

R-1.10

G-1.30

B-1.31

R-0.23

G-0.29

B-0.34

R-0.05

G-0.05

B-0.06

R-2.00

G-1.85

B-2.00

NEW

12

12

12

11

10

12

H326_ECP-2D

4pm

1pm

PROCESS

MACHINE

Reference Strip Code No.

ECP-2D

# 1

4am

8111

1pm

4pm

8am

1pm

4pm

1pm

EASTMAN KODAK COMPANY ROCHESTER, NY 14650

KODAK Publication No. H-24F

1pm

1pm

Printed in U.S.A.Kodak and Eastman are trademarks.

16 KODAK VISION Color Print Control Strips, Process ECP-2D

Page 19

KODAK VISION Color Print Control Strips, Process ECP-2D 17

Page 20

KODAK VISION Color Print Control Strips, Process ECP-2D

Technical Data and Crossover Information

MORE INFORMATION

For more information on motion picture products, call or

write to the Professional Motion Imaging office nearest you.

Or access Kodak’s home page on the Internet, web site

address—

http://www.kodak.com/go/motion/

You may want to bookmark our location so you can find

us more easily.

KODAK VISION Color Print Control

Strips, Process ECP-2D

©Eastman Kodak Company, 2006

KODAK Publication No. H-326

CAT 877 0018

Professional

Motion Imaging

Kodak, Vision, Eastman, EXR, 2383, and 5386 are trademarks.

Major Revision 12/06

Printed in U.S.A.

Loading...

Loading...