Page 1

Titrimetric Determination of Hypo Index, Thiosulfate, and Sulfite in EASTMAN Color Films,

Process ECN-2 Fixer

ECN-0002/1

Process ECN-2 ECP-2D VNF-1/LC RVNP

Formulas F-34a/F-34aR — — —

INTRODUCTION

This method describes the titrimetric determination of hypo

index (total reductants), thiosulfate, and sulfite in

EASTMAN Color Films, Process ECN-2, fixers. It is

recommended that these determinations be carried out by a

potentiometric titrimetric approach, using an auto-titrator.

However, for those unable to use instrumentation, the

manual titrimetric technique, using the visual starch

indicator, is included.

For the potentiometric measurement, a Metrohm

Potentiograph, Model E536 or equivalent should be us ed.

The potentiometric titration requires a platinum indicator

electrode and a double-junction reference electrode.

The Hypo Index (HI) or total reductants of a fixer is

defined as the millilitres of 0.1 N iodine consumed by the

thiosulfate and sulfite combined (reaction 1 & 2), in a

specified volume of fixer. The fixer is added to an excess of

iodine (liberated from the reaction of potassium iodate and

potassium iodide under acidic conditions - reaction 3). The

unreacted iodine is titrated either potentiometrically or

visually with standardized sodium thiosulfate from the

appropriate capacity burette. The difference between the

blank titration and the sample titration represents the

milliequivalents of iodine consumed by the sample.

Dividing the milliequivalents of iodine by 0.1 meq/mL

yields the HI of the sample. Hypo index is reported in the

terms of HI(1), mL which is the millilitres of 0.1000 N I

consumed by 1.0 mL of sample.

2

The thiosulfate is determined by the visual titration by

adjusting the pH of a sample aliquot to 8.5. At this pH, the

sulfite rapidly forms the stable sulfite - formaldeh yde

adduct. Upon acidification, which prevents the adduct from

reacting with iodine, the thiosulfate from the sample is

titrated with standardized iodine reagent to a starch end

point.

The sulfite content is calculated by subtracting the

milliequivalents of iodine consumed by the thiosulfate from

the milliequivalents of iodine consumed by the thiosulfate

and sulfite. The sulfite is reported as sodium sulfite.

Use of this method requires handling potentially

hazardous chemicals. Consult the Material Safety Data

Sheet for each chemical before use. MSDS’s are available

from your chemical supplier.

PRECISION AND BIAS

Repeatability

To obtain the repeatability data, a single skilled analyst

performed five (5) replicates on each of the following

solutions (this procedure was done by both potentiometric

and visual end point detection):

a. A “fresh” EASTMAN Color Films, Process ECN-2,

Fixer prepared with all components at their respective

aim concentrations in a working tank.

b. A “seasoned” EASTMAN Color Films, Process ECN-2,

Fixer analyzed as received at 125.67 g/L thios ulfate ion

and 28.92 g/L sodium sulfite.

c. The same “seasoned” solution as in number b, above,

reanalyzed after making standard additions of

37.850 g/L thiosulfate ion and 8.415 g/L sodium sulfite.

2 S

=

+ I2 → 2I- + S4O

2O3

=

6

(reaction 1)

Reproducibility

Three EASTMAN Color Films, Process ECN-2, Fixer

=

+ I2 + H2O → SO

HSO

3

=

+ 2I- + 3H

4

+

(reaction 2)

samples were analyzed by four analysts, each us ing different

titration stations, on two different days. Each analyst

analyzed each sample by both the potentiometric and the

-

+ 5I- + 6H+ → 3I2 + 3H2O (reaction 3)

IO

3

visual end point technique. Duplicate analyses were

performed on each sample, on each of the two days. These

samples were:

Na

adding 6 percent formaldehyd e to a second sample aliquo t in

reagent water. Under these conditions, the sulfite in the

sample forms a formaldehyde bisulfite complex (reaction 4).

This sample is then added to an excess of acidified iodine.

The unreacted iodine is titrated either potentiometrically

with standardized sodium thiosulfate from a 50-mL capacity

burette. The difference between the blank titration and the

sample titration represents the milliequivalents of iodine

consumed by the thiosulfate in the sample. The thiosulfate is

expressed as g/L thiosulfate ion (S

+ HCHO + H2O → CH3(OH) SO3Na + NaOH (reaction 4)

2SO3

The thiosulfate is determined potentiometrically by

=

).

2O3

a. a “fresh” tank solution prepared at 109.212 g/L

thiosulfate ion and 21.335 g/L sodium sulfite.

b. an EASTMAN Color Films, Process ECN-2 “seasoned”

tank fixer sample analyzed, as received, in the same

manner as the “fresh” fixer.

c. the same (as in number b, above) EASTMAN Color

Films, Proces s EC N -2 “seasoned” tank fixer sample

reanalyzed in the same manner as the “fresh” fixer, after

standard additions of thiosulfate and su lfite were mad e.

The “seasoned” sample of EASTMAN Color Films,

Process ECN-2 fixer, analyzed to be 115.17 g/L

thiosulfate ion and 15.69 g/L sodium sulfite. Standard

Processing KODAK Motion Picture Films, Module 3, Analytical Procedures • H24.03 1

Page 2

additions of 34.57 g/L thiosulfate ion and 5.444 g/L

sodium sulfite were made to that “seasoned” sample.

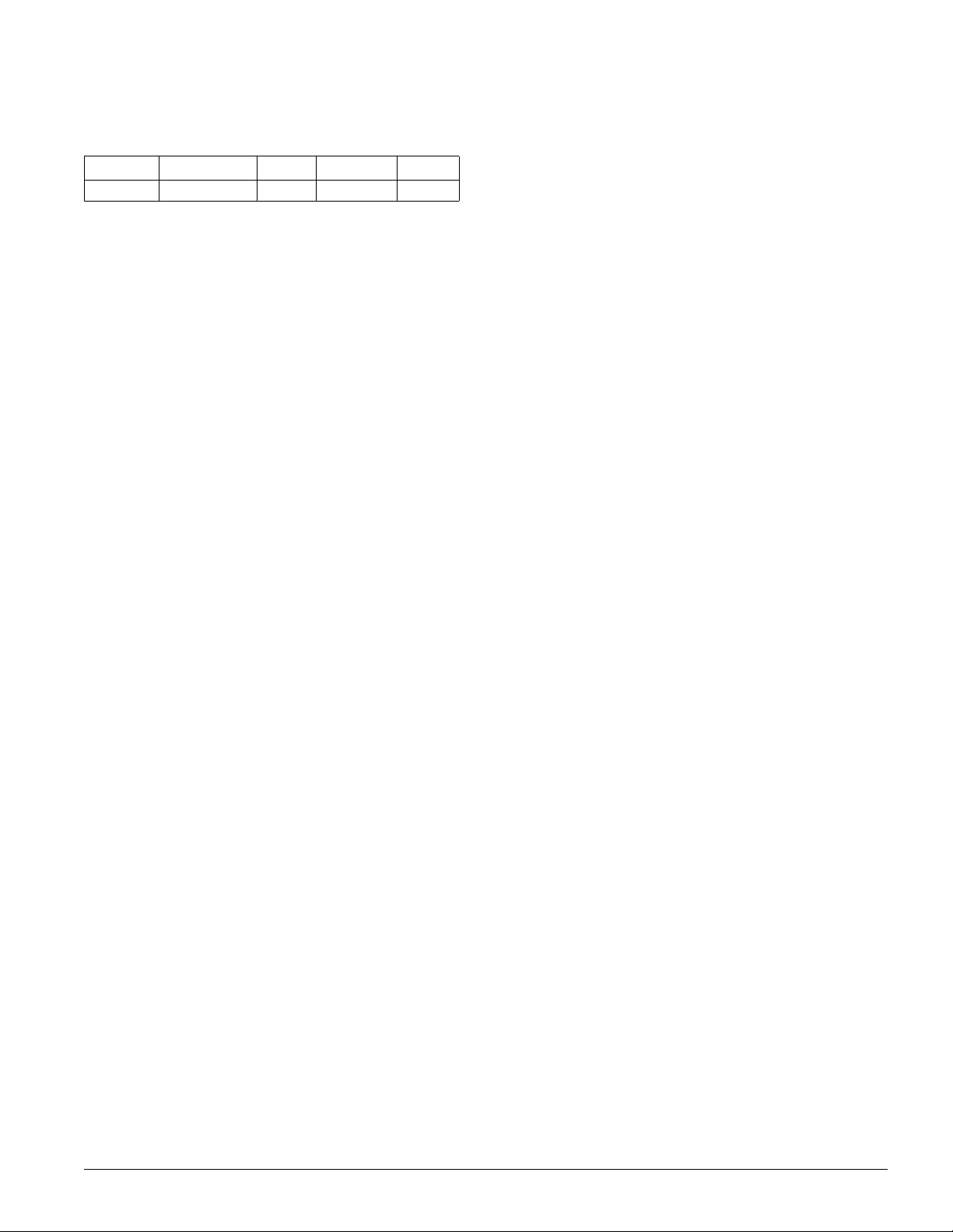

POTENTIOMETRIC TITRATION STATISTICS

Repeatability Standard Deviation, 1sr & 95 Percent Confidence Estimate (not including bias)

Repeatability standard deviation is an estimate of the

variability one trained analyst should be able to obtain under

favorable conditions (analyzing a sample, with one

instrument, within one day).

The 95 percent confidence estimate (calculated using the

repeatability standard deviation) around a single test will

include the mean value 95 percent of the time.

HYPO INDEX (1 mL)

Samples

(Process ECN-2 Fixer)

“Fresh” at “Aim” 10.02 5 0.086 ± 0.24

“Seasoned”, As

Received

“Seasoned” with

Standard Addition

Mean Level

(mL 0.1 N I

15.80 5 0.073 ± 0.20

19.38 5 0.14 ± 0.39

(N)

)

2

Repeatability

Standard Deviation, 1S

(mL 0.1 N I2)

Confidence Estimate

r

95 Percent

(mL 0.1 N I

)

2

THIOSULFATE

Samples

(Process ECN-2 Fixer)

“Fresh” at “Aim” 81.18 5 0.67 ± 1.9

“Seasoned”, As

Received

“Seasoned” with

Standard Addition

Samples

(Process ECN-2 Fixer)

“Fresh” at “Aim” 17.55 5 0.69 ± 1.9

“Seasoned”, As

Received

“Seasoned” with

Standard Addition

Mean Level

(g/L S

2O3

125.67 5 0.47 ± 1.3

153.79 5 0.60 ± 1.7

Mean Level

(g/L Na

28.92 5 0.65 ± 1.8

35.69 5 1.18 ± 3.3

2SO3

=

)

)

(N)

SULFITE

(N)

Repeatability

Standard Deviation, 1S

(g/L S2O

Repeatability

Standard Deviation, 1S

(g/L Na2SO3)

=

)

3

Confidence Estimate

r

Confidence Estimate

r

Bias

Bias is a statistically significant deviation of the mean from

the known mix level at a 95 percent confidence level. It is

determined for “fresh” samples only. Bias is not determined

for “seasoned” samples, since the component concentration

level was not determined independently of the test method.

A statistically significant bias for thiosulfate of

(-1.09 percent) was found for a “fresh” tank Process ECN-2

Fixer sample. The biases fo r Hypo Index and Sodi um Sulfite

were not statistically significant. However, the bias for

thiosulfate was judged not to be practically significant.

95 Percent

(g/L S

2O3

95 Percent

(g/L Na

2SO3

=

)

)

2 Processing KODAK Motion Picture Films, Module 3, Analytical Procedures • H24.03

Page 3

Recovery

Recovery is used instead of bias for “seasoned” samples, since the

component concentration level was not determined independently of

the test method. It is defined as the calculated mean for the

“seasoned” sample with a standard addition of the component minus

the mean for the “seasoned” sample, divi ded by the actual am ount of

the standard addition. It is expressed as a percentage. The table below

shows whether or not a recovery is statistically or practically different

from 100 percent.

POTENTIOMETRIC RECOVER Y, Process ECN-2

Analyte Recovery Value Statistically Significant Practically Significant

Hypo Index (1 mL) 76% Yes No

Thiosulfate (S

Sodium Sulfite (Na

=

)74% Yes No

2O3

) 80.4% No No

2SO3

Reliability

Customer Standard Deviation, 1s

& 95 Percent

c

Confidence Estimate (not including bias)

The customer standard deviation is an estimate of the variability a

customer could expect when submitting a sample to any

Photoprocessing Quality Services laboratory, where any trained

analyst could test the sample using any instrument on any day.

The 95 percent confidence estimate (calculated using the customer

standard deviation) around a single test result will include the mean

value 95 percent of the time.

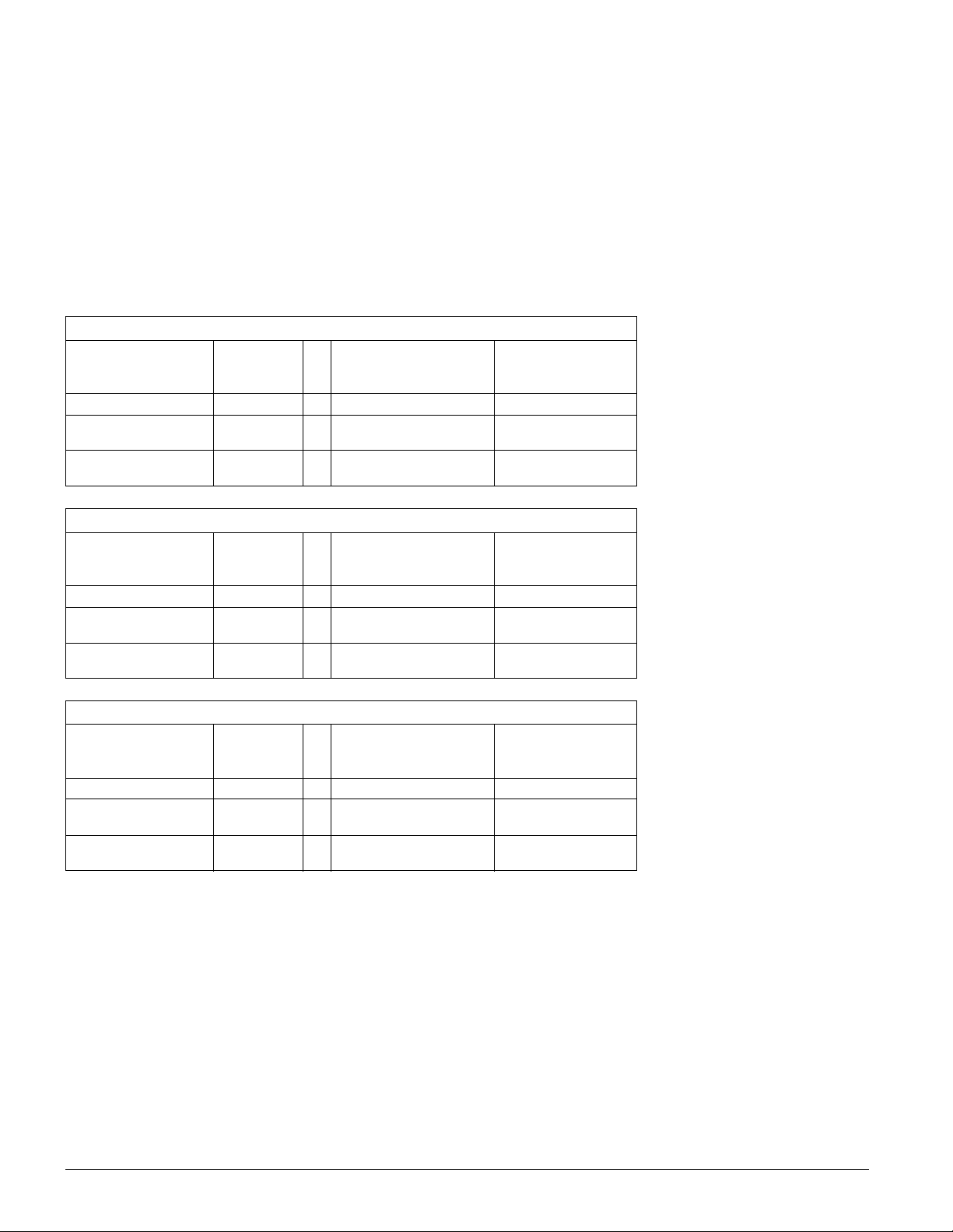

HYPO INDEX

Samples (Process

ECN-2 Fixer)

Mean Level

(mL 0.1 N I

(N)

Reproducibility

2

(mL 0.1 N I2)

Standard Deviation, 1S

)

c

95 Percent

Confidence Estimate

(mL 0.1 N I

“Fresh” at “Aim” 12.88 16 0.25 ± 0.54

“Seasoned”, As

Received

“Seasoned” with

Standard Addition

12.73 16 0.13 ± 0.27

15.83 16 0.16 ± 0.33

THIOSULFATE

Samples (Process

ECN-2 Fixer)

Mean Level

(g/L S

2O3

(N)

Reproducibility

=

)

Standard Deviation, 1S

(g/L S2O

=

)

3

c

95 Percent

Confidence Estimate

(g/L S

“Fresh” at “Aim” 108.14 16 0.94 ± 2.00

“Seasoned”, As

Received

“Seasoned” with

Standard Addition

Samples (Process

ECN-2 Fixer)

114.86 16 0.73 ± 1.56

142.23 16 0.78 ± 1.67

)

2SO3

Reproducibility

(g/L Na2SO3)

Confidence Estimate

c

(g/L Na

Mean Level

(g/L Na

2SO3

SULFITE (Na

(N)

Standard Deviation, 1S

)

95 Percent

“Fresh” at “Aim” 20.79 15 0.59 ± 1.26

“Seasoned”, As

Received

“Seasoned” with

Standard Addition

15.70 16 0.68 ± 1.4 5

19.85 16 0.76 ± 1.6 3

2O3

2SO3

)

2

=

)

)

Processing KODAK Motion Picture Films, Module 3, Analytical Procedures 3

Page 4

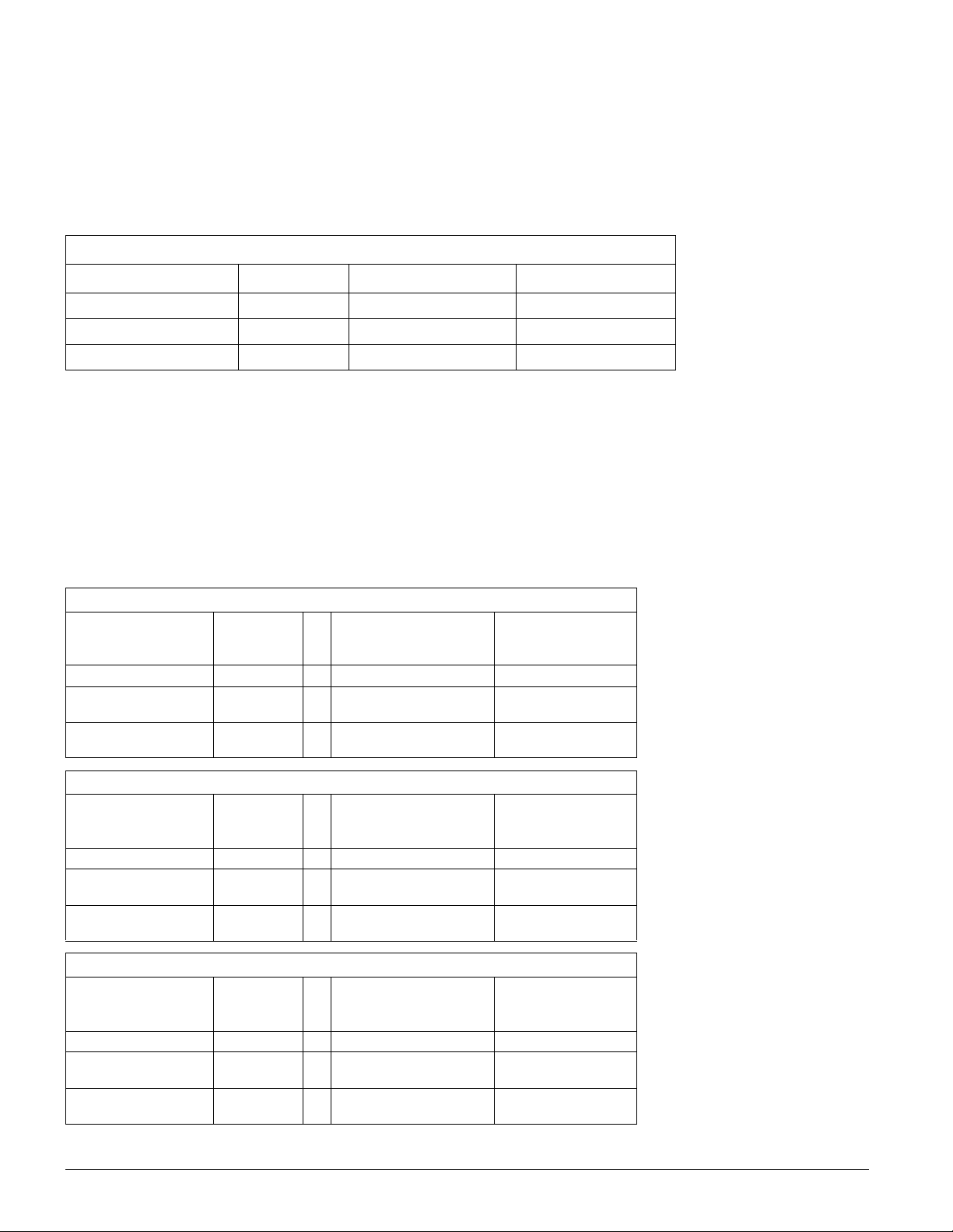

VISUAL TITRATION STATISTICS

Repeatability Standard Deviation, 1sr and

95 Percent Confidence Estimate

Repeatability standard deviation is an estimate of the

variability one trained analyst should be able to obtain under

favorable conditions (analyzing a sample, with one

instrument, within one day).

HYPO INDEX (3.0 mL)

Samples (Process

ECN-2 Fixer)

Mean Level

(mL 0.1 N I

)

2

“Fresh” at “Aim” 29.42 5 0.089 ± 0.25

“Seasoned”, As

Received

“Seasoned” with

Standard Addition

47.29 5 0.060 ± 0.17

57.65 5 0.084 ± 0.23

THIOSULFATE (S

Samples (Process

ECN-2 Fixer)

Mean Level

(g/L S

2O3

=

)

“Fresh” at “Aim” 81.37 5 0.10 ± 0.28

“Seasoned”, As

Received

“Seasoned” with

Standard Addition

125.29 5 0.24 ± 0.67

155.73 5 0.19 ± 0.53

Repeatability Standard

(N)

Deviation, 1S

(mL 0.1 N I2)

2O3

Repeatability Standard

(N)

Deviation, 1S

(g/L S2O

r

=

)

r

=

)

3

Confidence Estimate

Confidence Estimate

95 Percent

(mL 0.1 N I

95 Percent

(g/L S

2O3

)

2

=

)

)

2SO3

Deviation, 1S

(g/L Na2SO3)

r

Confidence Estimate

Samples (Process

ECN-2 Fixer)

Mean Level

(g/L Na

2SO3

SULFITE (Na

Repeatability Standard

(N)

)

“Fresh” at “Aim” 16.08 5 0.18 ± 0.50

“Seasoned”, As

Received

“Seasoned” with

Standard Addition

28.93 5 0.24 ± 0.67

33.43 5 0.31 ± 0.86

Bias

Bias is a statistically significant deviation of the mean from

the known mix level at a 95 percent confidence level. It is

determined for “fresh” samples only. Bias is not determined

for “seasoned” samples, since the component concentration

level was not determined independently of the test method.

Statistically significant biases were found for hypo index,

thiosulfate, and sodium sulfite (see the table below) for a

“fresh” tank Process ECN-2 Fixer sample. How ever, the

individual biases for hypo index, thiosulfate, or sodium

Hypo Index

(mL 0.1 N I

Thiosulfate

(g/L S

Sodium Sulfite

(Na

sulfite were judged not to be practically significant.

95 Percent

(g/L Na

Analyte

2

=

)

2O3

)

2SO3

)

2SO3

Bias

(Measurement Unit of Analyte)

)

– 0.82 – 2.71%

– 0.696 – 0.85%

– 1.322 – 7.6%

Bias

(%)

4 Processing KODAK Motion Picture Films, Module 3, A nalytical Procedures

Page 5

Recovery

Recovery is used instead of bias for “seasoned” samples, since the

component concentration level was not determined independently of

the test method. It is defined as the calculated mean for the

“seasoned” sample with a standard addition of the component minus

the mean for the “seasoned” sample, divi ded by the actual am ount of

the standard addition. It is expressed as a percentage. The table below

show whether or not a recovery is statistically or practically

significant from 100 percent.

VISUAL RECOVERY, Process ECN-2

Analyte Recovery Value Statistically Significant Practically Significant

Hypo Index (1 mL) 73.3% Yes No

Thiosulfate (S

Sodium Sulfite (Na

=

) 80.4% Yes No

2O3

) 53.4% Yes No

2SO3

Customer Standard Deviation, 1s

& 95 Percent

c

Confidence Estimate (not including bias)

The customer standard deviation (1s

) is an estimate of the variability

c

a customer could expect when submitting a sample to any

Photoprocessing Quality Services laboratory, where any trained

analyst could test the sample using any instrument on any day.

The 95 percent confidence estimate (calculated using the customer

standard deviation) around a single test result will include the mean

value 95 percent of the time.

HYPO INDEX (1.0 mL)

Samples (Process

ECN-2 Fixer)

Mean Level

(mL 0.1 N I

(N)

)

2

“Fresh” at “Aim” 12.97 16 0.18 ± 0.39

“Seasoned”, As

Received

“Seasoned” with

Standard Addition

12.70 16 0.15 ± 0.31

15.93 16 0.20 ± 0.43

THIOSULFATE (S

Samples (Process

ECN-2 Fixer)

Mean Level

(g/L S

2O3

(N)

=

)

“Fresh” at “Aim” 107.95 16 0.93 ± 1.99

“Seasoned”, As

Received

“Seasoned” with

Standard Addition

114.95 16 0.97 ± 2.06

142.59 16 1.07 ± 2.28

Reproducibility

Standard Deviation, 1S

(mL 0.1 N I2)

=

)

2O3

Reproducibility

Standard Deviation, 1S

(g/L S2O

=

)

3

Confidence Estimate

c

Confidence Estimate

c

95 Percent

(mL 0.1 N I

95 Percent

(g/L S

2O3

)

2

=

)

)

2SO3

Reproducibility

(g/L Na2SO3)

95 Percent

Confidence Estimate

c

(g/L Na

2SO3

)

Samples (Process

ECN-2 Fixer)

Mean Level

(g/L Na

2SO3

SULFITE (Na

(N)

Standard Deviation, 1S

)

“Fresh” at “Aim” 21.17 16 1.18 ± 2.52

“Seasoned”, As

Received

“Seasoned” with

Standard Addition

15.46 16 1.14 ± 2.4 3

20.23 16 1.58 ± 3.3 8

Processing KODAK Motion Picture Films, Module 3, Analytical Procedures 5

Page 6

APPARATUS

All volumetric glassware should meet all “Class A”

specifications, as defined by American Society for Testing

and Materials (ASTM) Standards E 287, E 288, and E 969,

unless othe rwise stated.

For Potentiometric Titration:

• Metrohm Potentiograph, Model E536 or equivalent

titrator

• Metrohm Model 665 Dosimat with a 50-mL burette size

(no substitution)

• Electrodes:

Indicator electro d e =

Reference electrode =

Platinum inlay (i.e., Beckman

Model 39273 or equivalent)

Double-junction (i.e. , Orion

900200 or equivalent) (10%

outer filling solution)

KNO

3

For Visual Titration:

• Burette, Class A, 50 mL capacity, Teflon stopcock

• Magnetic Stirrer

REAGENTS

Use ACS Reagent Grade reagents unless otherwise

specified.

• Potassium Iodate, KIO

decimal places

• Acetic Acid, CH

• Potassium Iodide, KI (0.6 M)

• Sodium Thiosulfate, Na

four decimal places

• Formaldehyde (6%), pH 3.9

• Starch Indicator

• Phenolphth alein Indicat or

• Sodium Hydroxide, NaOH (1.0 N)

• Sulfuric Acid, H

• Iodine, I

(0.1 N) - standardized to four decimal places

2

• Water, Type I Reagent – This method was developed, an d

the resulting statistical data were obtained using reagent

water equivalent to or purer than Type I Grade, as defined

in ASTM Standard D 1193. Other grades of water, e.g.,

reverse osmosis (RO), demineralized, or distilled water,

may give equivalent results, but the effects of water

quality on method performance have not been studied.

(0.1 N), - standardized to four

3

COOH (2.0 N)

3

(0.1 N) - standardized to

2S2O3

(1.0 N)

2SO4

PROCEDURE

For Potentiometric Titration

A. Hypo Index (HI) or Total Reductants

1. To a 400-mL beaker with a magnetic stir-bar, add

100 mL reagent water.

2. Pipette 40.0 mL (use a 20-mL pipette, twice) of

standardized 0.1 N potassium iodate into the 400-mL

beaker.

3. While stirring, add 10 mL of 2.0 N acetic acid and

25 mL of 0.6 M potassium iodide (KI) to the 400-mL

beaker.

4. With continued stirring, immediately pipette 1.0 mL

of sample near the surface of the liquid. Rinse the

sides of the beaker with reagent water.

5. Titrate with standardized 0.1 N sodium thiosulfate on

an E536 Metrohm Potentiograph or equivalent titrator.

If using an E536, titrate the solution from step 4, using

the following parameters:

Rate = 10 min/100% vol

Auto Control = OFF

Mode = mV/pH

Range = 500 mV

Burette Size = 50 mL

Indicator Electrode = Platinum inlay or platinum

wire (i.e., Beckman Model

39273)

Reference Electrode = Double-junction reference

(i.e., Orion Model 90-02)

6. Determine the volume of 0.1 N sodium thiosulfate at

the end point using concentric arcs (see Universal

Method ULM-0003-01, Pot e ntiometric Titrations for

Photoprocessing Solutions, or subsequent revision).

7. Run a blank (do steps 1–6, but omit the addition of the

sample in step 4).

6 Processing KODAK Motion Picture Films, Module 3, Analytical Procedures • H24.03

Page 7

B. Thiosulfate Determination

1. Sample Pretreatment:

a. To a 250-mL beaker with a magnetic stir-bar,

add 75 mL of reagent water.

b. Pipette 2.0 mL of sample into the 250-mL

beaker.

c. Add 5 mL of 6% formaldehyde (pH 3.9) to the

beaker.

d. Start stirring the contents of the 250-mL beaker,

set and start a timer for 2 minutes of stirring.

2. Titration of Sample:

a. Into a 400-mL beaker with a magnetic stir-bar,

pipette 40.0 mL of standardized 0.1 N

potassium iodate while the timer from step 1.d.

is running.

b. While stirring, add 10 mL of 2.0 N acetic acid to

the 400-mL beaker (continue stirring through

step 2e.).

c. When the timer goes off, add 25 mL of 0.6 M KI

to the 400-mL beaker.

d. Immediately after the 0.6 M KI has been added,

add the solution in the 250-mL beaker, from

step 1, Sample Pretreatment:, to the 400-mL

beaker.

e. Rinse the 250-mL beaker three times with

reagent water and add the rinses to the 400-mL

beaker.

f. Titrate the contents of the 400-mL beaker with

standardized 0.1 N sodium thiosulfate on an

E536 Metrohm Potentiograph or equival ent

titrator. If using a Metrohm E536, titrate the

solution from step 2e. using the parameters

found in step 5 of the Hypo Index (HI) or Total

Reductants procedure.

g. Determine the volume of 0.1 N sodium

thiosulfate at the end point using concentric arcs

(see Universal Method ULM-0003-01,

Potentiometric Titrations for Photoprocessing

Solutions, or any subsequent revision.

3. Run a blank, following all the steps in 1 and 2 above,

except omit the addition of sample in step 1b.

C. Sulfite

1. Sulfite is a calculated value and requires no additional

measurement.

For Visual Titration

A. Hypo Index (HI) or Total Reductants

Treatment and Titration of Sample:

1. Pipette (wipe before leveling) 40.0 mL of standardized

0.1 N potassium iodate solution into a 250-mL conical

flask containing a magnetic stir bar.

2. Add 10 mL of 2.0 N acetic acid solution from a tip-up

(or equivalent) pipette.

3. Stir the solution with a magnetic stirrer and add 25 mL

of 0.6 M potassium iodide solution from a tip-up

pipette.

4. Immediately pipette (wipe) 1.0 mL of the fixer sample

into the 250-mL flask while the solution is stirring

(hold the tip of the pipette against the wall of the flask

and as close to the surface of the stirring solution as

possible while the sample is draining but do not

immerse the tip of the pipette in the stirring solution).

5. Titrate with standardized 0.1 N sodium thiosulfate

solution to a light yellow color.

6. Add 5 mL of the starch indicator, from a tip-up pipette

and continue the titration until the blue color just

disappears for 15 seconds.

7. Run a blank (do steps 1–6, but omit the addition of the

sample in step 4).

B. Thiosulfate (Hypo)

1. Treatment of the Sample:

a. Pipette 2.0 mL of the fixer sample into a 250-mL

conical flask containing a magnetic stir bar.

b. Add 5 mL of formalin from a tip-up pipette.

c. Add 3 or 4 drops of phenolphthalein indicator to

the flask.

• If the solution is pink, titrate with 1.0 N

sulfuric acid to colorless.

• If the solution is colorless, titrate with 1.0 N

sodium hydroxide to the first light pink

color.

d. Let the solution stand for 2 minutes.

e. Add 10 mL of 2.0 N acetic acid from a tip-up

pipette.

2. Titration with Iodine:

a. Add, from a tip-up pipette, 5 mL of the starch

indicator to the conical flask.

b. Titrate with standardized 0.1 N iodine solution

to the first distinct blue color that persists for

15 seconds.

C. Sulfite

1. Sulfite is a calculated value and requires no additional

measurement.

Processing KODAK Motion Picture Films, Module 3, Analytical Procedures • H24.03 7

Page 8

CALCULATIONS

For Potentiometric Titration

A. Hypo Index (HI) or Total Reductants:

HI (1), mL =

(mL Blank A – mL Sample A) (N Na

0.1000 N Na

2S2O3

2S2O3

Where:

HI (1), mL = mL of 0.1000 N I2 consumed by 1.0 mL

mL Blank A = millilitres of titrant at the end point of the

mL Sample A = millilitres of titrant at the end point of the

N Na

2S2O3

0.1000 = nominal value for the normali t y of the titrant ,

B. Thiosulfate (S2O

2O3

=

g/L S

sample

blank titration of potentiometric Procedure A.

sample titration of po t entiomet ric

Procedure A.

= normality of the titrant (meq/mL)

in meq/mL

=

):

3

(mL Blank B – mL Sample B)(N Na

=

sample size (10 00)

2S2O3

Where:

mL Blank B = millilitres of titrant at the end point of the

mL Sample B = millilitres of titrant at the end point of the

N Na

2S2O3

112.13 = equivalent weight of thiosulfate expressed in

1000 = conversion factor of milligrams to grams

1000 = conversion factor of millilitres to litres

sample size = sample size used in po te nt i om et ric

blank titration of potentiometric Procedure B

sample titration of po t entiomet ric

Procedure B.

= normality of the titrant (meq/mL)

mg/meq

Procedure B (2.0 mL)

)

)(112.13)(1000)

C. Sodium Sulfite (Na2SO3):

mL Blank A – mL Sample A = D mL A

mL Blank B – mL Sample B = D mL B

g/L Na

2SO3

[(D mL A)(2.0) – (D mL B)](N Na

=

sample size (1000)

2S2O3

)(63.02)(1000)

Where:

N Na

sample size = sample size used in po te nt i om et ric

= normality of the titrant

2S2O3

2.0 = conversion of hypo index to 2.0 m L sample

size

63.02 = equivalent weight of sodium sulfite in mg/

meq

1000 = conversion factor of milligrams to grams

Procedure B (2.0 mL)

1000 = conversion factor of millilitres to litres

8 Processing KODAK Motion Picture Films, Module 3, Analytical Procedures • H24.03

Page 9

Example Potentiometric Calculations:

Titration mL 0.1 N Na2S2O3 Titrant

Blank A = 40.50

Sample A = 21.85

Blank B = 40.55

Sample B = 19.80

Hypo Index (HI) or Total Reductants:

HI (1), mL =

(40.50 – 21.85)(0.098 9)

= 18.4 mL 0.1000 N I

Thiosulfate (S

g/L S2O

2O3

(40.55 – 19.80)(0.0989)(112.13)(1000)

=

=

3

= 57.5 g/ L

Sodium Sulfite (Na

2SO3

=

= 51.4 g/ L

g/L Na

0.1000

2

=

):

(2.0)(1000)

):

2SO3

[(40.50 – 21.85)(2.0) – (40.55 – 19. 80)](0.0989)(63.02)(1000)

(2.0)(1000)

Processing KODAK Motion Picture Films, Module 3, Analytical Procedures • H24.03 9

Page 10

For Visual Titration

A. Hypo Index (HI) or Total Reductants:

HI (1), mL =

(mL Blank A – mL Sample A) (N Na

0.1000 N Na

2S2O3

2S2O3

Where:

HI (1), mL = mL of 0.1000 N I2 consumed by 1.0 mL

mL Blank A = millilitres of titrant at the end point of the

mL Sample A = millilitres of titrant at the end point of the

N Na

2S2O3

0.1000 = nominal value for the normali t y of the titrant ,

B. Thiosulfate (S2O

2O3

=

g/L S

sample

blank visual titration, Procedure A.

sample visual titration, Proc edu re A.

= normality of the titrant (meq/mL)

in meq/mL

=

):

3

)(N I2)[eq. wt. S2O

(mL I

=

2

=

](1000)

3

(mL Sample size)(1000)

Where:

[eq. wt. S

mL I2= millilitres of iodine titrant measur ed at th e

N I

2O3

1000 = factors to convert mg/mL to g/L

visual end point

= normality of the titrant (meq/mL)

2

=

] = equivalent weight of thiosulfate expressed

in mg/meq (112.13)

)

C. Sodium Sulfite (Na2SO3):

g/L Na

2SO3

[(HI)(N* I

=

)(3)] – [(mL I2)(N I2)](eq. wt. S2O

2

(mL Sample size)(1000)

Where:

HI = mL of 0.1000 N I2 consumed by 1.0 mL

sample

= nominal 0.1000 nor m ality of iodine used in

N* I

2

the Hypo Index calculation (meq/mL)

3 = conversion of Hypo Index to a 3.0 mL

sample size

= millilitres of iodine titrant measured at the

mL I

2

visual end point, Procedure B

= normality of the iodine titrant (meq/mL) used

N I

2

in Procedure B, visual end point

=

eq. wt. S

mL Sample = sample size used in Procedure B, visual end

= equivalent weight of thiosulfate expressed in

2O3

mg/meq (112.13)

point

1000 = convers ion factors fo r milligrams to grams

and milliliters to liters

=

)(1000)

3

10 Processing KODAK Motion Picture Films, Module 3, Analytical Procedures • H24.03

Loading...

Loading...