Page 1

{IllustratedPartsList}{ Production}{Carestream H ealth Inc.}{None}

Publication No. 6H4869

17MAR2010

Supersedes 6H4869-01

23DEC09

Service Manual

for the

KODAK Point-of-Care CR 360 System

Important

• Qualified service personnel must install this modification.

• See the Service Portal for possible updates before doing this modification.

• When doing the procedures in this document, yo u must use safe work practices and wear the correct personal

protective equipment (for example, safety eyewear) according to your company’s standard operating

procedures.

None

© CARESTREAM HEALTH, INC. 2010

Page 2

Service Guide

KODAK Point-of-Care CR 360 System Service Manual

Publication Number: 6H4869

© Carestream Health, Inc., 2010

US FEDERAL LAW RESTRICTS THIS DEVICE TO SALE BY OR ON THE ORDER OF A PHYSICIAN ONLY.

All rights reserved. No part of this manual may be repr oduced or copied in any form by any means–graphic, electronic

or mechanical, including photocopying, typing, or informati on retrieval systems–without written permission of

Carestream Health, Inc.

Use of Manual

The KODAK Point-of-Care CR 360 System is designed to meet international safety and performance standards.

Personnel operating the unit must have a thorough understanding of th e proper operation of the system. This manual

has been prepared to aid medical and t echnical personnel to understand and operate the system. Do not operat e the

system before reading this manual and gaining a clear understanding of the operation of the system. If any part of

this manual is not clear, please contact your Carestream Health representative for clarification.

Authorized European Representative

Carestream Health France

LES MERCURIALES

40, rue Jean Jaures

93176 BAGNOLET CEDEX

France

The Kodak trademark and trade dress are used under license f rom Kodak.

Carestream Health, Inc.

150 Verona Street

Rochester, NY 14608

2 6H4869

Page 3

Table of Contents

Description Page

Safety and Regulatory Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Introduction

General Safety Guidelines

Electrical Hazards

Explosion and Implosion Hazards

Overheating

Laser Safety Instructions

Recycling the Unit

Labelling Summary

IEC Symbols Used

Device-specific Safety Information

Regulatory Information

System Description

Introduction

Operational Principles

System Overview

Component Description

Service Procedures

Service Tools

Removing the Scanner Cover

Installing the Scanner Cover

Activating the Scanner Without the Cover

Replacing the Power Line Filter Module

Replacing the Fuses

Replacing the Controller Board

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Introduction

CE Conformity

USA Regulations

Component Names and Descriptions

Views of the Point-of-Care CR 360

Power Line Filter Module

IMCS Board

Linear Slide Assembly

Overview

Two Types of Linear Screws

Linear Motor

Optical Head Assembly

Photo Multiplier Assembly (PM)

Loader Stepper Assembly

Roller Drive Motor Assembly

Right and Left Limit Sensors

Activation Procedures

Activating the Scanner Without the Cover (Laser Deactivated)

Before Service Operations

After Service Operations

Activating the Scanner without the Cover (Laser Activated)

Before Service Operations

After Service Operations

Tools Required

Removing the Power Line Filter Module

Installing the Power Line Filter Module

Tools Required

Procedure

Tools Required

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

. . . . . . . . . . . . . . . . 27

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

. . . . . . . . . . . . . 26

6H4869 3

Page 4

Service Guide

Removing the Controller Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Installing the Controller Board

Replacing the IMCS Board

Tools Required

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Removing the IMCS Board

Separating the Sensor Board from the Motion Board

Installing the IMCS Board

Replacing the Photo Multiplier Board

Tools Required

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Removing the PM Board

Installing the PM Board

Replacing the Photo Multiplier Assembly

Tools Required

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Removing the PM Tube

Installing the PM Tube

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Replacing the Optical Head Assembly

Tools Required

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Removing the Optical Head Assembly

Installing the Optical Head Assembly

Replacing the Linear Screw Type A

Tools Required

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Removing the Linear Screw Type A

Installing the Linear Screw Type A

Replacing the Linear Screw Type B

Tools Required

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Removing the Linear Screw Type B

Installing the Linear Screw Type B

Test Procedure

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Replacing the Linear Motor Type A

Tools Required

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Removing the Linear Motor Type A

Installing the Linear Motor Type A

Replacing the Linear Motor Type B

Tools Required

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Removing Type B Linear Motor

Installing the Linear Motor Type B

Replacing the Roller Drive Motor Assembly

Tools Required

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Removing the Drive Roller Motor Assembly

Installing the Roller Drive Motor

Replacing the Loader Stepper Assembly

Tools Required

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Removing the Loader Stepper Assembly

Installing the Loader Stepper Assembly

Replacing the Laser Board

Tools Required

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Removing the Laser Board

Installing the Laser Board

Replacing the Power Supply

Tools Required

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Removing the Power Supply Unit

Installing the Power Supply Unit

Replacing the Erase Lamps Assembly

Tools Required

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Removing the Erase Lamps Assembly

Installing the Erase Lamps Assembly

Replacing the Erase Lamps Fuse

Tools Required

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Installing the Erase Lamps Fuse

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

. . . . . . . . . . . . . . . . . . . . 37

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

4 6H4869

Page 5

Test Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Replacing the Erase Lamp Board

Tools Required

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Removing the Erase Lamp Board

Installing the Erase Lamp Board

Replacing the Erase Lamps Inverter Board

Tools Required

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Removing the Erase Lamps Inverter Board

Installing the Erase Lamps Inverter Board

Replacing the Roof Assembly and Tray Assembly

Introduction

Tools Required

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Removing the Roof Assembly

Removing the Tray Assembly

Installing the Tray Assembly and the Roof Assembly

Test Procedure

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Replacing the Right and Left Limit Sensors

Tools Required

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Removing the Right Limit Sensor

Installing the Right Limit Sensor

Removing the Left Limit Sensor

Installing the Left Limit Sensor

Replacing the LED Indicator

Tools Required

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Removing the LED Indicator

Installing the LED Indicator

LED Indicator Test Procedure

Replacing the Cassette Status Sensors

Tools Required

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Removing the Cassette Status Sensors

Installing the Cassette Status Sensors

Cassette Status Sensors Test Procedure

Replacing the Cassette Fixation Lever Assembly

Tools Required

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Removing the Cassette Fixation Lever Assembly

Installing the Casette Fixation Lever Assembly

Replacing the W0 Sensor

Tools Required

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Removing the W0 Sensor

Installing the W0 Sensor

W0 Sensor Test Procedure

Replacing the Z0 Sensor

Tools Required

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Removing the Z0 Sensor

Installing the Z0 Sensor

Z0 Sensor Test Procedure

Installing the IGUS Energy Chain

Tools Required

Procedure

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Testing and Closing the Scanner Cover

Replacing the Barcode Reader

Tools Required

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Removing the Barcode Reader

Installing the Barcode Reader

Calibrations

Introduction

Origin Calibration

6H4869 5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

The Calibrations Tab

Equipment Required

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

. . . . . . . . . . . . . . . . . . . . . . . . . . . 83

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

. . . . . . . . . . . . . . . . . . . . . 86

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

. . . . . . . . . . . . . . . . . . . . . . . . . . . 95

. . . . . . . . . . . . . . . . . . . . . . . 95

. . . . . . . . . . . . . . . . . . . . . . . . . 97

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Page 6

Service Guide

Offset Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

System Gain Tuning

Purpose

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

System Gain Tuning Procedure

OCPC Process Calibration

Purpose

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

OCPC Process Calibration Procedure

Adjustments

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Adjusting the Cassette Release Mechanism

Tools Required

Adjustment Procedure

Auto-loop Solenoid Test

Introduction

Tools Required

Solenoid Off Test (Go/No Go)

Solenoid On Test (Touch/No Touch)

Adjusting the Plate Pusher

Tools Required

Adjustment Procedure

Preventive Maintenance

Cleaning the Rollers

Roller Cleaning Cycles

Roller Cleaning Procedure

Dismissing the Roller Cleaning Reminder

Cleaning the Phosphor Screens

Introduction

Cleaning the Phosphor Screens

Cleaning the Scanner

Key Operator Settings

Accessing Advanced Settings

User Tab

Setup Tab

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Anatomical Tab

Diagnostics Tab

SW Update & Backup Tab

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Backing Up (Export) Scanner and Anatom Settings

To Restore (Import) Scanner and Anatom settings:

Updating Firmware, FPGA, and NIOS Settings

Calibration Tab

Admin Tab

About Tab

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

DICOM Settings—Settings Tab

DICOM Settings—Destinations Tab

Electrical Diagrams

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Block Diagram #1: Modular Power Supply

Block Diagram #2

Block Diagram #3

Block Diagram #4

Block Diagram #5

Block Diagram #6

Block Diagram #7

Block Diagram # 8

Block Diagram #9

Troubleshooting

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Observable Conditions

Hardware Error Messages

Introduction

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

. . . . . . . . . . . . . . . . . . . . . 145

. . . . . . . . . . . . . . . . . . . . . . 145

. . . . . . . . . . . . . . . . . . . . . . . . . 145

6 6H4869

Page 7

Hardware Error Message Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

Hardware Error Messages

Scenario

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

Recommended Action by Field Engineer

Scenario

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

Recommended Actions for Field Engineer

Scenario

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

Recommended Actions for Field Engineer

Scenario

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Recommended Actions for Field Engineer

Scenario

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

Recommended Actions for Field Engineer

Scenario

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Recommended Actions for Field Engineer

Scenario

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

Recommended Actions for Field Engineer

Scenario

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Recommended Actions for Field Engineer

Scenario

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

Recommended Actions for Field Engineer

Scenario

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Recommended Actions for Field Engineer

Scenario

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

Recommended Actions for Field Engineer

Scenario

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

Recommended Actions for Field Engineer

Scenario

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

Recommended Actions for Field Engineer

Scenario

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Recommended Actions for Field Engineer

Scenario

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

Recommended Actions for Field Engineer

Scenario

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

Recommended Actions for Field Engineer

Scenario

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Recommended Actions for Field Engineer

Controller and IMCS Embedded Software Update

Updating the Controller Files

Updating Firmware and FPGA

Updating the IMCS Embedded Files

Using the SC Shell Application

Introduction

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

Installing the SC Shell Application

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

Establishing Communication Between the Host Computer and the IMCS Board

VSP Option

Direct Cable Option

Creating a Communication Terminal in the SC Shell Application

Opening the Communication Terminal in the SC Shell Application

Loading Custom Commands

Downloading Firmware

Verifying the Firmware Download

Downloading Macros

Verifying the Macro Download

Downloading Parameters

Verifying Parameters Download

Measuring the Linear Motor Current

Acceptance Test Procedure

Scope

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

. . . . . . . . . . . . 187

. . . . . . . . . . 188

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

185

6H4869 7

Page 8

Service Guide

Tools Required. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

Preparing the Unit for Testing

Dark Noise

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

System Response and Linearity

Uniformity and Artifacts

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

Multiple Test Tools: Resolution Grid, Step Wedge, and Contrast Resolution

Inspecting the Spatial Resolution

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

Inspecting the Low Contrast Resolution

Inspecting the Step Wedge

Erasure Efficiency

Image Quality Results Reporting

Appendix

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

Calibration Results Report

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

Test Target Tool for Barcode Alignment Procedure

Publication History

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

. . 208

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

. . . . . . . . . . . . . . . . . . . . . . . . . . 213

8 6H4869

Page 9

Safety and Regulatory Information

Section 1: Safety and Regulatory Information

Introduction

The information contained herein is based on the experience and knowledge relating to the subject matter gained by

Carestream Health prior to publication. No patent license is granted by t his information.

Carestream Health reserves the right to change this information with out not ice, and make s no war rant y, express or

implied, with respect to this information. Carestream Health shall not be liable for any loss or damage, including

consequential or special damages, resulting from any use of this information, even if loss or damage is caused by

Carestream Health's negligence or other fault.

Caution

Cautions point out procedures that you must follow precisely to avoid damage to the system or any of its components,

yourself or others, loss of data or corruption of files in software applica tions.

Note

Notes provide additional information, such as expanded explanations, hints, or remin ders.

Important

Importants highlight critical policy information that affects how you use this guide and this product.

General Safety Guidelines

• This product was designed and manufactured to ensure maximum safety of operation. Operate and maintain it

in strict compliance with the safety precautions and operating instru ctions contained in this guide.

• This product meets all the safety requirements applicable to medical equip ment. However, anyone attempting to

operate the system must be fully aware of potential safety hazards.

• There are no user serviceable parts in this system. The product must be installed, maintained, and serviced by

qualified service personnel according to procedures and preventive maintenance schedules in the product

service manual. If your product does not operate as expected, contact your Service Representative.

• The product in whole or in part shall not be modifie d in any way without prior written approval from Carestream

Health, Inc.

• Personnel operating and maintaining this system should receive training and be familiar with all aspects of

operation and maintenance.

• To ensure safety, read all user guides carefully before using the system and observe all Cautions, Importants,

and Notes located throughout the guide.

• Keep this guide with the equipment. Reading this guide does not qualify you to operate, test, or calibrate this

system.

• Unauthorized personnel shall not be allowed access to the system.

• If the product does not operate properly or fails to respond to t he controls as described in this guide:

– Follow the safety precautions as specified in this guide.

– Stop using the system and prevent any changes to it.

– Immediately contact the service office, report the pro blem, and await further instructions.

• Use only legally marketed cassettes. Periodically check the quality of the cassettes, an d replace if any defects

are apparent.

• The images provided by this system are intended as tools for the trained user. They are explicitly not to be

regarded as a sole incontrovertible basis for clinical diagnosis.

• Be aware of the product specifications and of system accuracy and stability limitations. Consider these limitations

before making a decision based on quantitat ive values. If you have any doubts, consult the Sales Representative.

• This system is Class I continuous operated stationary equipment without ap plied parts and has one signal input/

output part.

6H4869 9

Page 10

Service Guide

Electrical Hazards

Caution

• Do not remove or open system covers or plugs. Internal circuits use high voltage capable of causing serious

injury.

• Fuses blown within 36 hours of being replaced by a qualified technician may indicate malfunctioning electrical

circuits within the system. Have the system checked by qualified service personnel. Do not attempt to replace

any fuse.

• Fluids that seep into the active circuit components of the system may cause short circuits that can result in

electrical fires. Therefore, do not place any liquid or food on any part of the system.

Explosion and Implosion Hazards

CautionCaution

• Do not operate the equipment in the presence of explosive liquids, vapors, or gases.

• Do not plug in or turn on the system if hazardous substances are detected in the environment. If these

substances are detected after the system has been turned on, do not attempt to turn off the unit or unplug it.

Evacuate and ventilate the area before turning off the system.

Overheating

Do not block the air circulation around the scanner. Always maintain at least 6 inches (15 cm) clearance ar ound the

scanner to prevent overheating and damage to the system.

Laser Safety Instructions

• During nominal operation, the unit is closed and sealed with a protective cover for safety reasons.

• During nominal operation, the cover should not be removed. Removing of the cover shall be done only for service

purposes, and by a qualified technician for service operations.

• Service operations that do not require the laser should b e done without activa ting the la ser un it. Switchin g OFF

the DIP switch on the laser board will disconnect the power supply to the laser, and deactivate the laser unit for

service operations.

• In case the laser must be operated during service operation, the ser vice technician shall make sure that the

optical unit is located within the scanner drum, where the laser beam is blocked.

Laser Warning

When a service operation is taking place with the cover removed, disconnect the laser according to the procedur e in

Activating the Scanner Without the Co ver (L aser Deact ivated )

service procedure, wear protective safety glasses at all times. The required laser safety eyewear must be intended

for HeliumNeon/PDT lasers, have an optical density of 4-5 wavelengths of 610-695 nm, and be marked as having

CE approval.

on Page 26. If the laser must be activated during the

10 6H4869

Page 11

Safety and Regulatory Information

Recycling the Unit

In the European Union, this symbol indicates that when the last user wishes to discard this

product, it must be sent to appropriate facilities for recovery and recycling.

Contact your local Carestream Health representative or refer to http://recycle.carestreamhealth.com for additional

information on the collection and recovery programs available for this product.

Labelling Summary

Safety Labels Consignes de Sécurité

Laser

Laser-emitting product

Class 3B laser product inside scanner Rayonnement de laser évitez l’exposition au

High voltage Haut voltage

Laser

Appareil émetant de laser

faisceau laser de la classe 3B. Appareil à laser

de classe 3B a l’intérieur du scanner.

Chassis ground stud Point de mise en terre du chassis

Attention: Consult accompanying documents Attention: consulter les documents joints

IEC Symbols Used

The system may have labels with one or more of the following symbols. These symbols indicate the IEC standards

to which the system conforms.

Warning, Caution – consult accompanying documents

Protective ground points

Power ON

Power OFF

Caution – Electrical shock hazard

6H4869 11

Page 12

Service Guide

Device-specific Safety Information

Safety Information Consignes de Sécurité

LIFTING HAZARD

DANGER POIDS LOURD

The KODAK Point-of-Care CR 360 scanner

weighs 39 kg (86 lb). Do not try to lift the scanner

by yourself. Always seek assistance from another

person. Lifting equipment that is too heavy may

result in injury to personnel and/or da mag e t o th e

scanner.

WARNING

The KODAK Point-of-Care CR 360 scanner is a

CLASS 1 Laser product.

• Do not remove the scanner cover.

• Cover removal shall be done only by

authorized service personnel!

Le scanner KODAK Point-of-Care CR 360 pèse

39 kg (86 lb). N’essayez pas de porter le scanner

par vous-même. Demandez toujours de l’aide

d’une autre personne. Porter un équipement trop

lourd peut provoquer des dommages physiques

et/ou endommager le matériel.

ATTENTION

Le scanner KODAK Point-of-Care CR 360 est un

produit laser de la Classe 1.

• Ne pas retirer le couvercle du scanner.

• Le retrait du couvercle doit s’effectuer

uniquement par un personnel compétent.

Regulatory Information

Introduction

This product conforms to the following safety standards: IEC 601–1 Medical Electrical Equipment General

Requirements for Safety, EN60601–1–2 Medical Electrical Equipment Electro-Magnetic Compatibility Requirements

and Tests, IEC 60825-1 Safety of Laser Products.

This device complies with 21CFR 1040.10.

CE Conformity

This product conforms to the requirements of council directive 93/42/EEC. The KODAK Point-of-Care CR 360 is a

Class I medical device. The KODAK Point-of-Care CR 360 bears the following mark of conformity:

The name and address of the CE represent ative appears on the back of the front page of this manual.

USA Regulations

The FDA cleared the system for sale in the USA.

Caution

Federal US law restricts this device for sale by or on the order of a physician.

12 6H4869

Page 13

System Description

Section 2: System Description

Introduction

Throughout this manual the KODAK Point-of-Care CR 360 System will be referred to as the Point-of-Care CR 360.

The Point-of-Care CR 360 is designed for the reading of phosphor X-ray screens (CR) by medical professionals.

The system consists of the Point-of-Care CR 360 scanner and the software package that includes:

• The KODAK QC Software that operates the scanner.

• An image viewing and archiving software package t hat supports t he DICOM 3.1 st andard and was approved b y

Carestream Health.

• The system features 8 x 10 in., 10 x 12 in., 14 x 17 in., 9.5 x 9.5 in., 11 x 14 in., 14 x 14 in., 14 x 33 cm, 24 x 30 cm,

and 15 x 30 cm digital image reading and viewing archive.

Note

Throughout this manual Front of the unit ref ers to the side where the cassettes are inserted. Right and Left are as

viewed when facing the front of the unit.

Operational Principles

The Point-of-Care CR 360 is a digital imaging system for image acquisition and processing of static projection

radiography that uses a phosphor screen with energy storage capability as an X-ray image receptor.

After exposure, a laser beam, which stimulates luminescence proportional to the local X-ray exposure, reads the

screen. The luminescence signal is digitized. The data is then subjected to digital image processing.

The Point-of-Care CR 360 enables the user t o read a screen quickly, and then erase it to be ready fo r the next scan.

The scanner is compact and easy to use.

Using the Point-of-Care CR 360 enables medical professionals to “go digital” without changing their work practices

or X-ray equipment.

6H4869 13

Page 14

Service Guide

System Overview

Component Names and Descriptions

Part Name Description

Controller Board The controller board is the main board on the scanner. The controller board

connects the scanner to the host PC workstation via the USB port. The

controller board runs the firmware, and receives operational commands from

the host PC workstation via the USB cable, and transforms the commands to

the appropriate scanner hardware commands. The controller board generates

the +/- 15 Vac to the DPMT and the +/- 12 Vac to the IMCS. It builds the

scanned images and sends them via the same USB cable to the PC

workstation. The controller board serves as the link between all peripherals in

the scanner (i.e., Erase lamp, IMCS, Laser Board, and DPMT)

Integrated Motion Control

System (IMCS) Board

Linear Slide Assembly The linear slide assembly moves the optical head and PM assembly along the

Optical Head Assembly The optical head assembly includes the laser module and the rotation motor

Photo Multiplier Assembly (PM) The photo multiplier (PM) tube collects the photons emitted from the screen and

Roof Assembly and Tray

Assembly

Power Supply The AC/DC power supply provides DC power to the scanner components.

Loader Stepper Assembly The loader stepper assembly extracts the phosphor screen from th e cassette in

Roller Drive Motor Sub-System The roller drive motor pulls the phosphor screen, when loading the phosphor

Laser The laser beam stimulates the phosphor screen.

Laser Board The laser board activates the optical head assembly. The laser board receives

Barcode Reader The barcode reader reads the screen size after th e cassett e is inse rt ed into t he

The motion (IMCS) board controls and drives the four motors:

• Loader motor

• Linear motor

• Rotation motor

• Roller drive motor

The IMCS board receives feedback from the encoders and sensors.

The sensor board is a plug-in board in the IMCS board.

X-axis (slow scan) during the scan.

that rotates the laser tube and a mirror during scanning. The laser module’s

beam is reflected by the revolving mirror to different points on the phosphor

screen inside of the drum. Simultaneously, the optical he ad travels along a

linear axis, so the laser beam covers the full area of the screen one line at a

time (fast scan). Another mirror collects and reflects the light returned from the

screen to the PM assembly window.

transforms the light into a current, which is then converted to voltage and

digitized to pixel value by an ADC.

These two interconnected components receive and direct the cassette into

position in preparation for loading into the drum.

preparation for insertion into the drum, and assists in inserting the phosphor

screen into the cassette. It is powered by the loader motor which works in an

open loop (no encoder).

screen into the drum, and pulls the phosphor screen back into the cassette

when unloading the phosphor screen back into the cassette. The roller motor

has a closed loop control which enables you to change the motor speed and

thus control the erase time.

rotation motor phases and laser power, and enables laser signals. It transfers

the rotation motor encoder signals to th e controller board.

scanner and locked into place.

14 6H4869

Page 15

System Description

Part Name Description

LED Indicator The LED indicator indicates the scanner’s main status such as ready for scan,

erasing, and so on.

Erase Lamps Assembly The erase lamps assembly brightly illuminates the phosphor screen after

scanning, to erase the image so that the screen is ready to be used again.

Erase Lamps Inverter Board The erase lamps inverter board converts the 21 VDC input to high voltage

output which drives the erase lamps (CCFL tubes).

CCFL Board The CCFL board monitors the erase lamps current (CCFL tubes) and the erase

lamps assembly temperature.

Sensor Board The sensor board is a plug-in board in the IMCS board.

Sensors

Roller Motor Forward Limit

Sensor (J502)

Forward limit sensor that stops the roller motor upon reaching th e end of travel

during screen loading.

Autoloop Sensor (J504) Detects that the auto-loop mechanism is in activated position.

Left and Right Limit Sensors

(J515/J516)

Left and right limit sensors indicate that the linear slide assembly has reached

the end of its travel. The right limit sensor (J516) is Home position.

W0 Sensor (J511) The W0 sensor determines the activation and deactivati on of the rollers

according to screen presence at the entrance to the drum.

Z0 Sensor (J505) Detects the presence of the screen in th e drum.

Loader Back Sensor (J508) Back limit sensor that stops the roller motor when moving in a backwards

direction.

Cover Safety Interlock

Sensor (J510)

Detects presence of system cover. When the cover is not detected, the system

motors, laser, and erase assembly will not work.

15x30 Sensor (J512) Detects if the 15 x 30 in. dental adapter is installed.

Cassette In Place Sensor

(J513)

Cassette Hold Sensor

(J514)

Signals to the control system when the cassette is inserted and locked into the

scanner.

Reverse limit sensor that stops the loader motor upon re aching the end of travel

position in a forward direction.

6H4869 15

Page 16

Service Guide

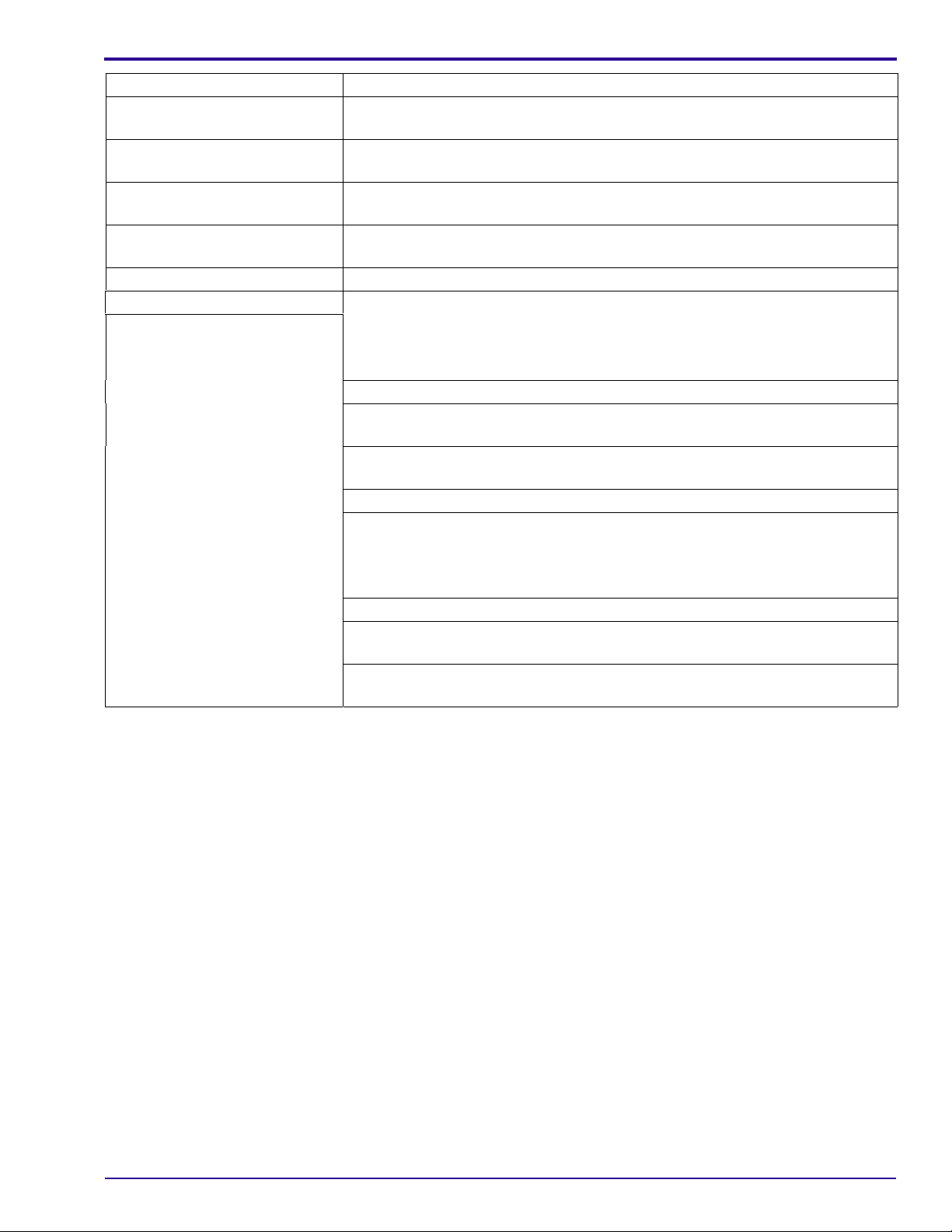

Views of the Point-of-Care CR 360

Scanner Front View

Lead screw

LED indicator

Drum

Laser board

Roof assembly

Tray assembly

Scanner Rear View

Erase lamps

inverter board

Erase lamp

board

Off/On switch

Power cord

socket

Connector panel

Controller board

USB outlet

16 6H4869

Page 17

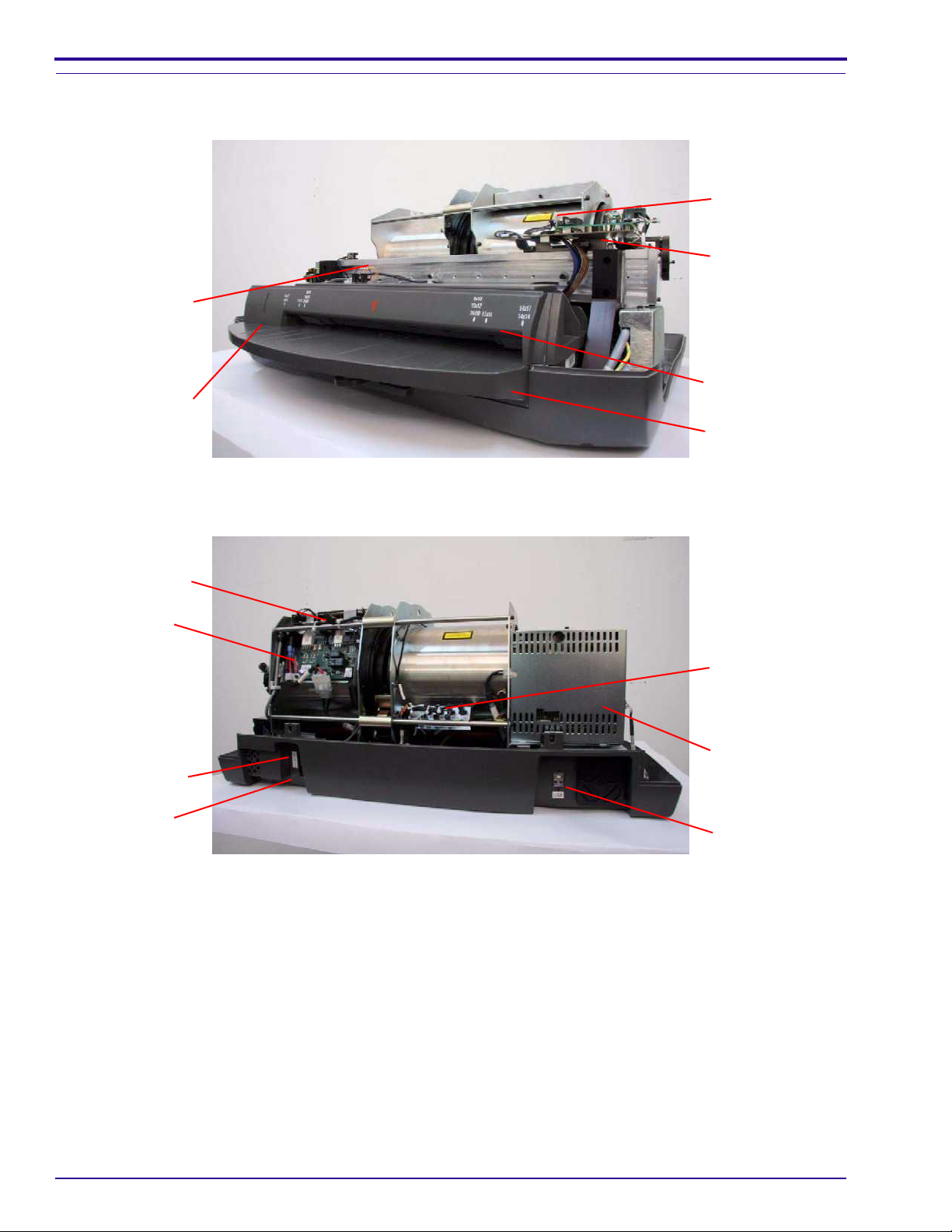

Scanner Left View

PM tube

System Description

Linear motor

Roller drive motor

Scanner Right View

Power supply

unit

IMCS board

Laser unit

6H4869 17

Page 18

Service Guide

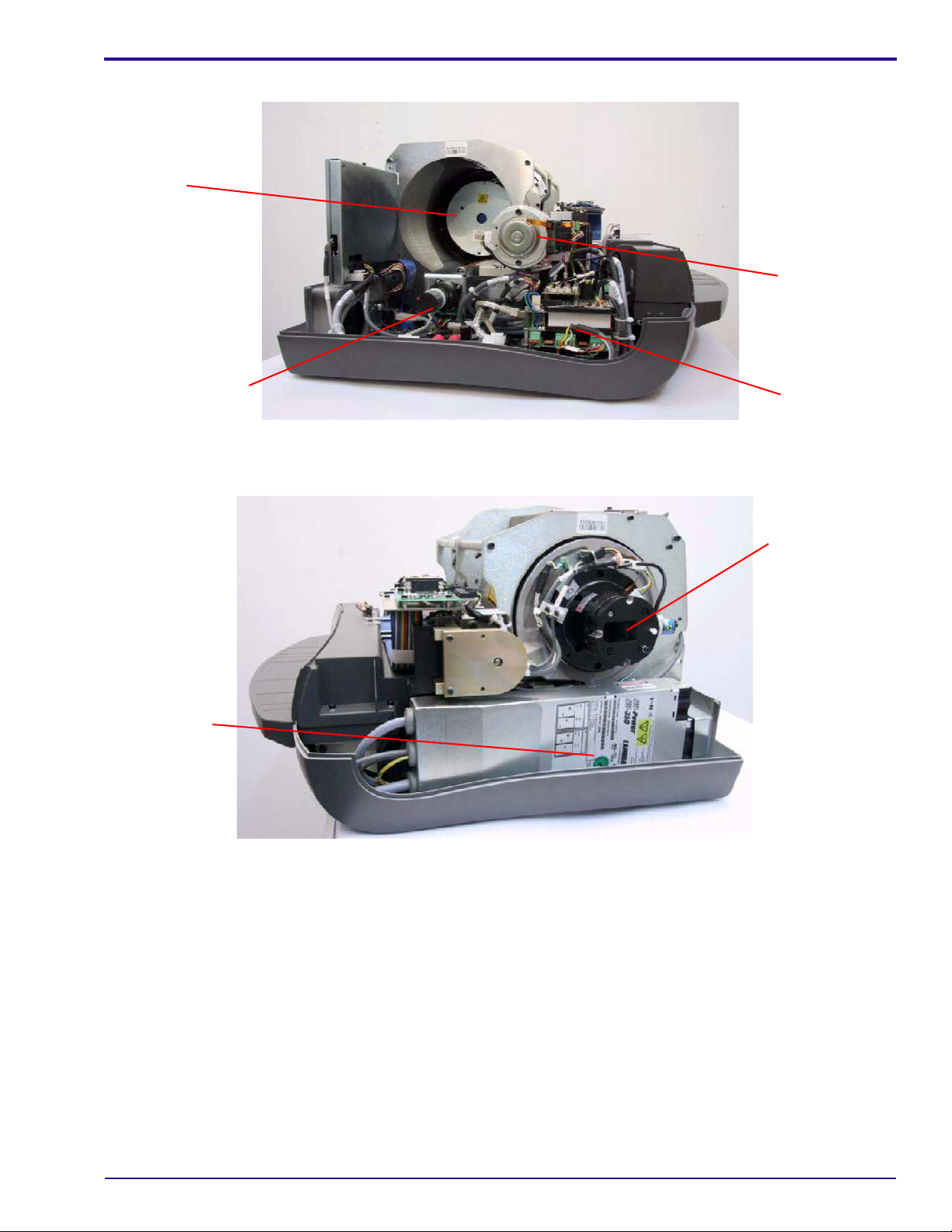

Component Description

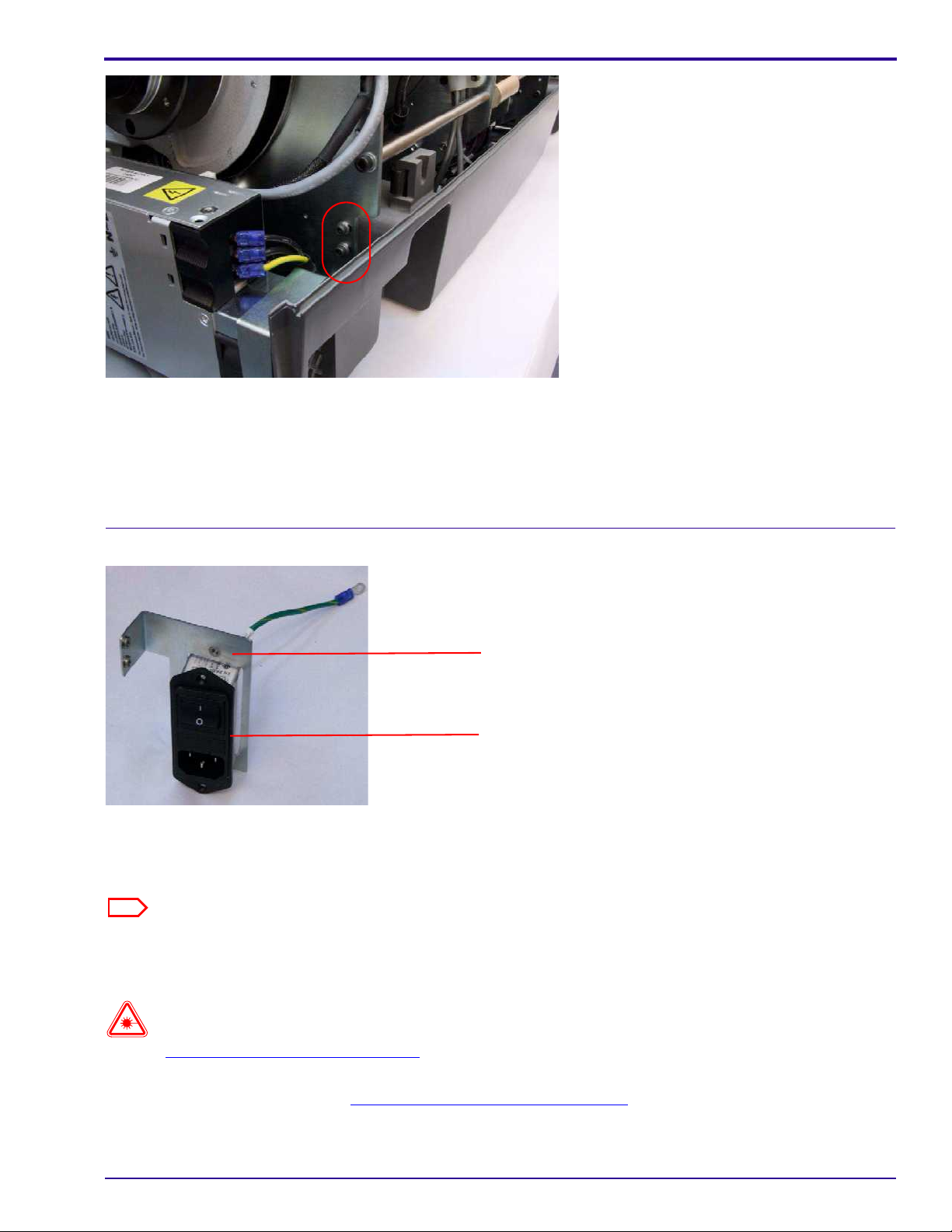

Power Line Filter Module

The power line filter module filters the AC supply to the scanner. The power inlet socket, ON-OFF switch, and two

fuses are located on the module.

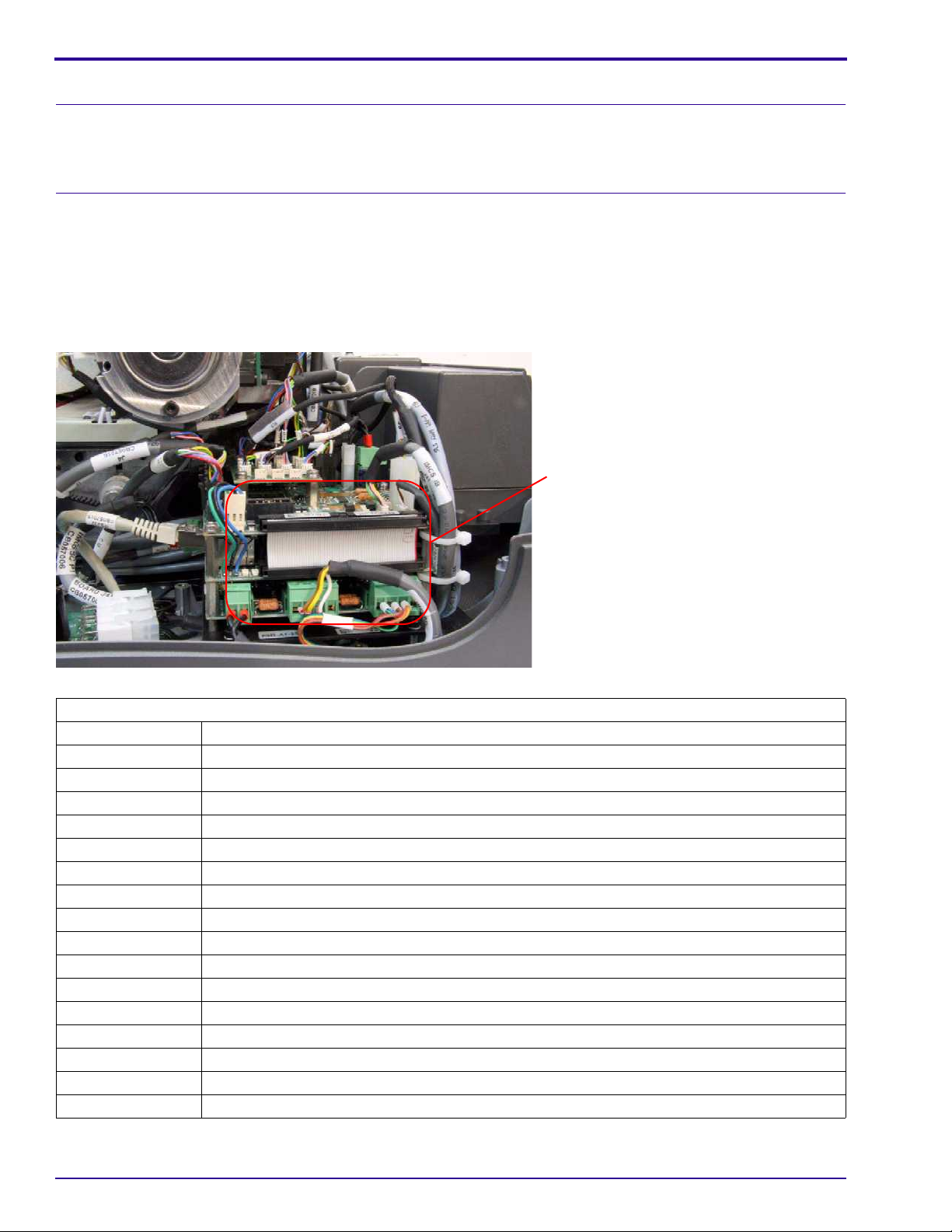

IMCS Board

The IMCS board is a module stacked in four layers. It comprises the motion boar d and the sensor bo ard, which is on

the top layer. The IMCS board controls all four scanner motors and is responsible for all scanner sequences: loading,

scanning, erasing, unloading, and ejecting the cassette.

The motion board and sensor board can be replaced ei ther separately or as a single component. The supplied

replacement unit is an entire IMCS board assembly. If you need to replace one of these boards separately you must

first separate the replacement board from the replacement unit.

Motion board

Sensor Board Connectors

J501 Reserved

J502 Roller Forward Sensor

J503 Reserved

J504 Loop Solenoid

J505 Screen Carriage Sensor (Z0)

J506 Reserved

J507 Reserved

J508 Loader Back Position

J510 Cover Sensor

J511 W0 Sensor

J512 15 x 30 Cassette Adapter Sensor

J513 Cassette Presence Sensor

J514 Cassette Hold Sensor

J515 Left Limit Sensor

J516 Right Limit Sensor (Home Sensor)

J517 Reserved

J519 Reserved

18 6H4869

Page 19

System Description

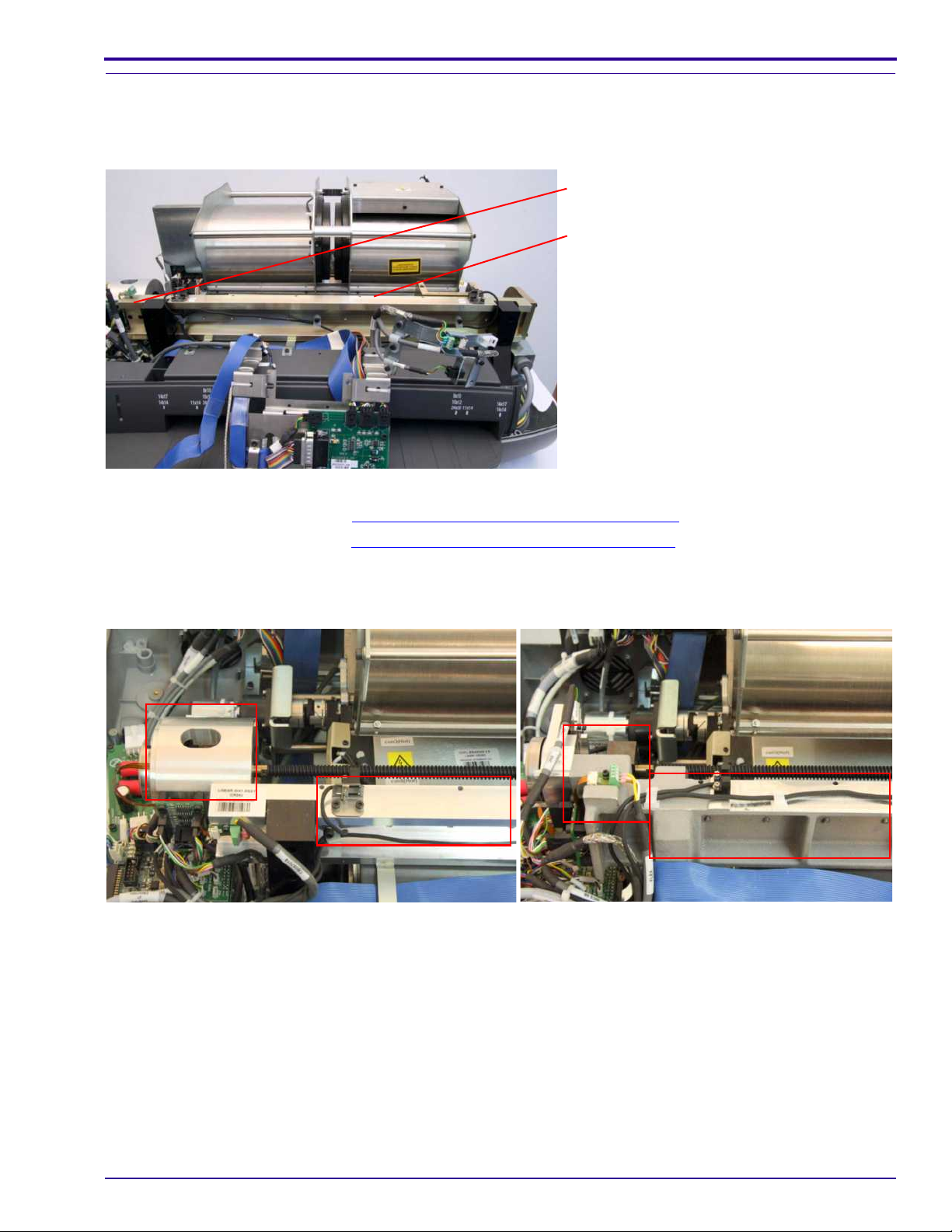

Linear Slide Assembly

Overview

The linear slide assembly moves the PM assembly and the laser within the drum to read the phosphor screen.

Linear motor

Linear screw

There are two replacement procedures for the linear slide assembly:

• Linear screw replacement. See Replacing the Linear Screw Type A

• Linear motor replacement. See Replacing the Linear Motor

Type A on Page 54.

on Page 48.

Two Types of Linear Screws

Type A Type B

6H4869 19

Page 20

Service Guide

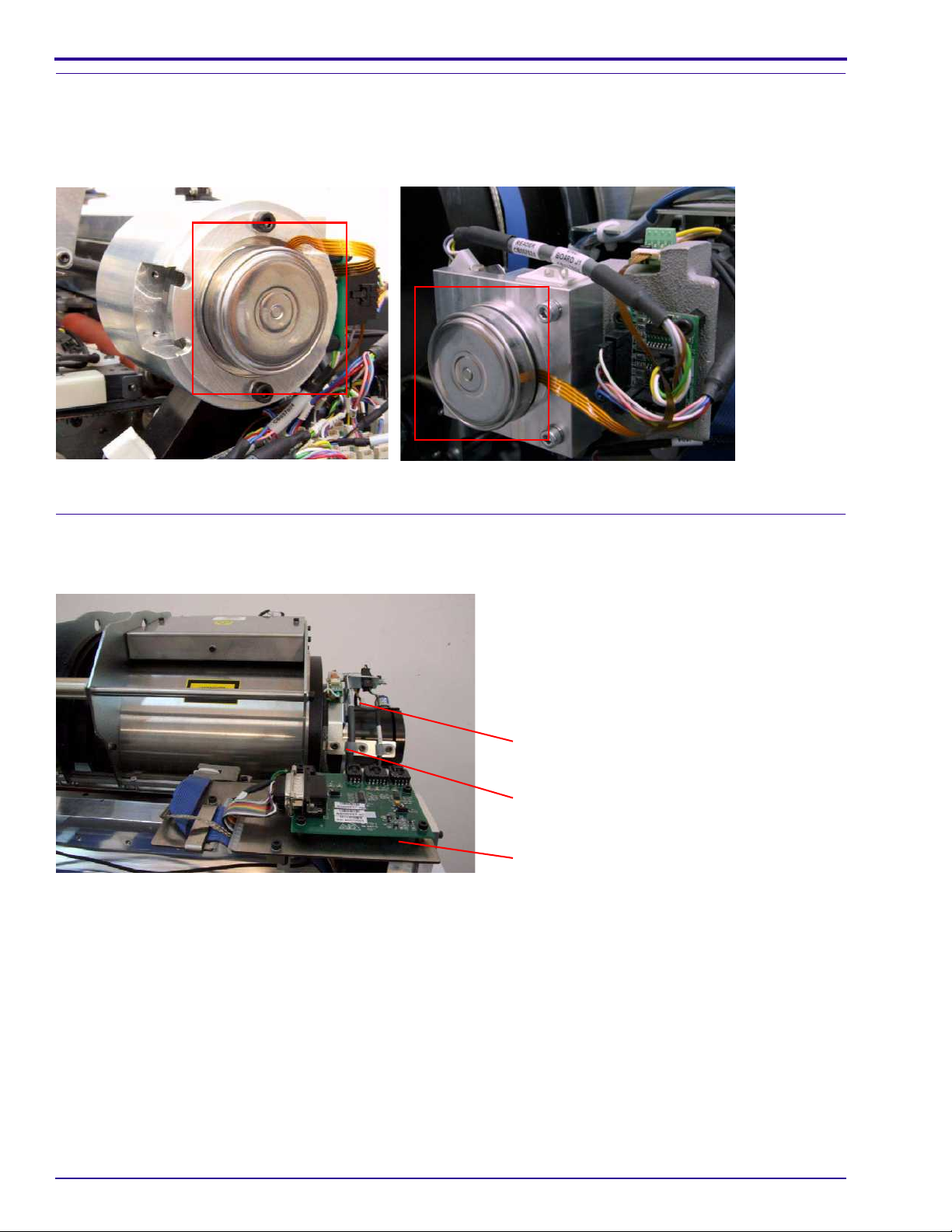

Linear Motor

The linear motor operates the linear slide assembly.

Two Types of Linear Motors

Type A

Type B

Optical Head Assembly

The optical head assembly controls the laser module beam. The laser module beam emits the light to energize the

phosphor screen.

Optical head

assembly

Optical head

connector bracket

Laser board

20 6H4869

Page 21

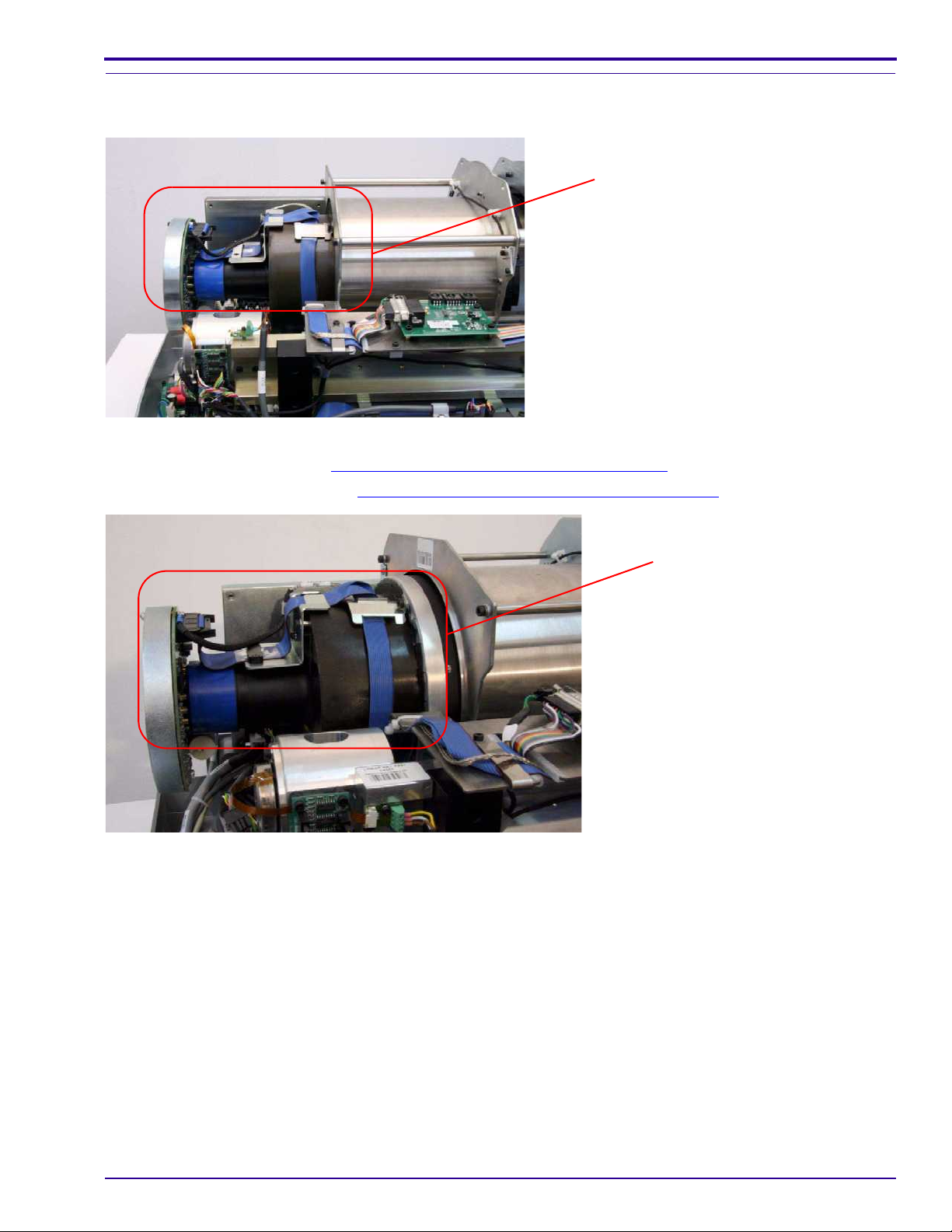

Photo Multiplier Assembly (PM)

The photo multiplier (PM) tube collects the photons emitted from the screen.

PM tube

There are two replacement procedures for the photo multiplier:

• PM board replacement. See Replacing the Photo Multiplier Board

• PM assembly replacement. See Replacing the Photo Multiplier Assembly

on Page 39.

System Description

on Page 41.

Photo Multiplier

assembly

6H4869 21

Page 22

Service Guide

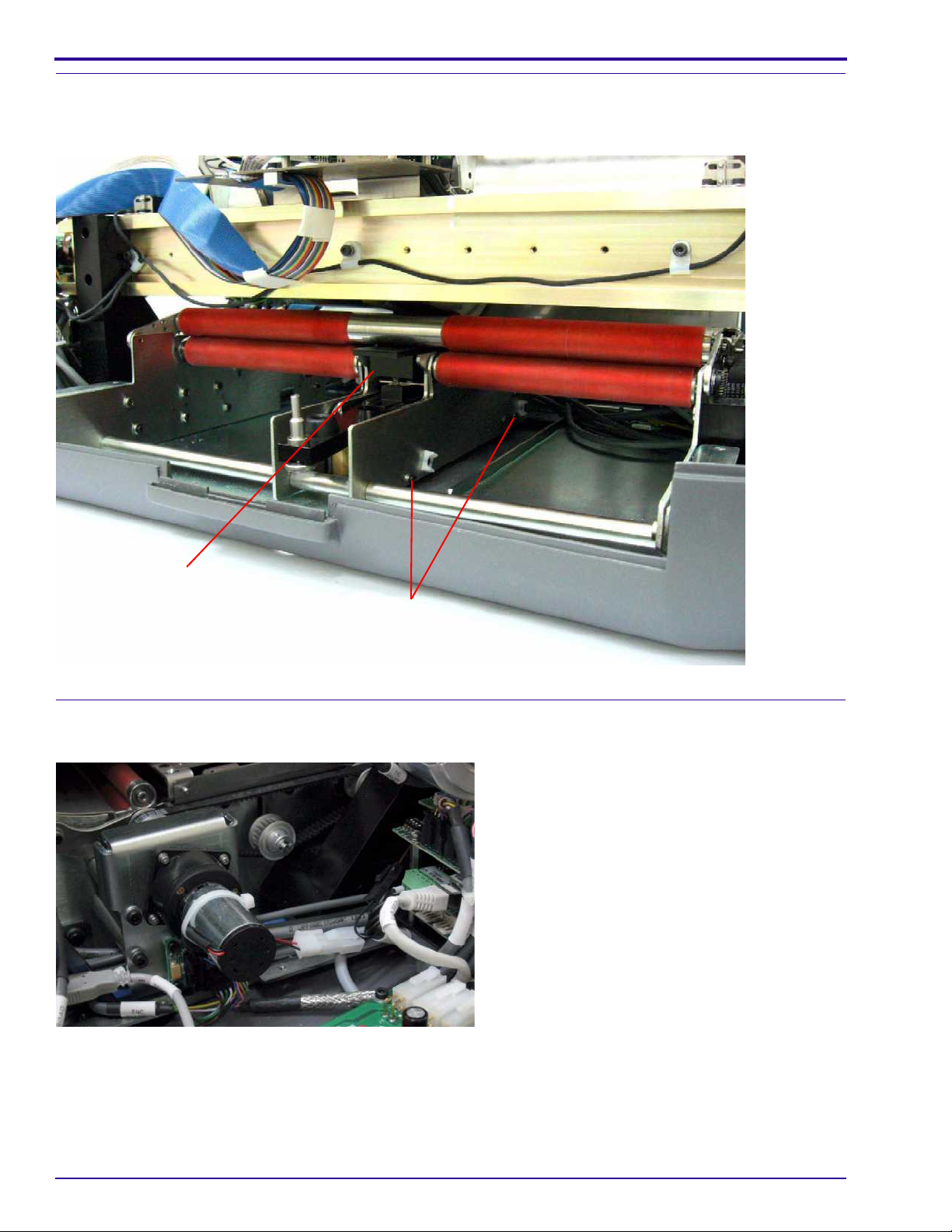

Loader Stepper Assembly

The loader stepper assembly extracts the screen from the cassette and assists in inserting the screen into the

cassette.

Loader pusher

Retainer screws

Roller Drive Motor Assembly

The roller drive motor assembly pulls the phosphor screen from the cassette into the drum.

22 6H4869

Page 23

System Description

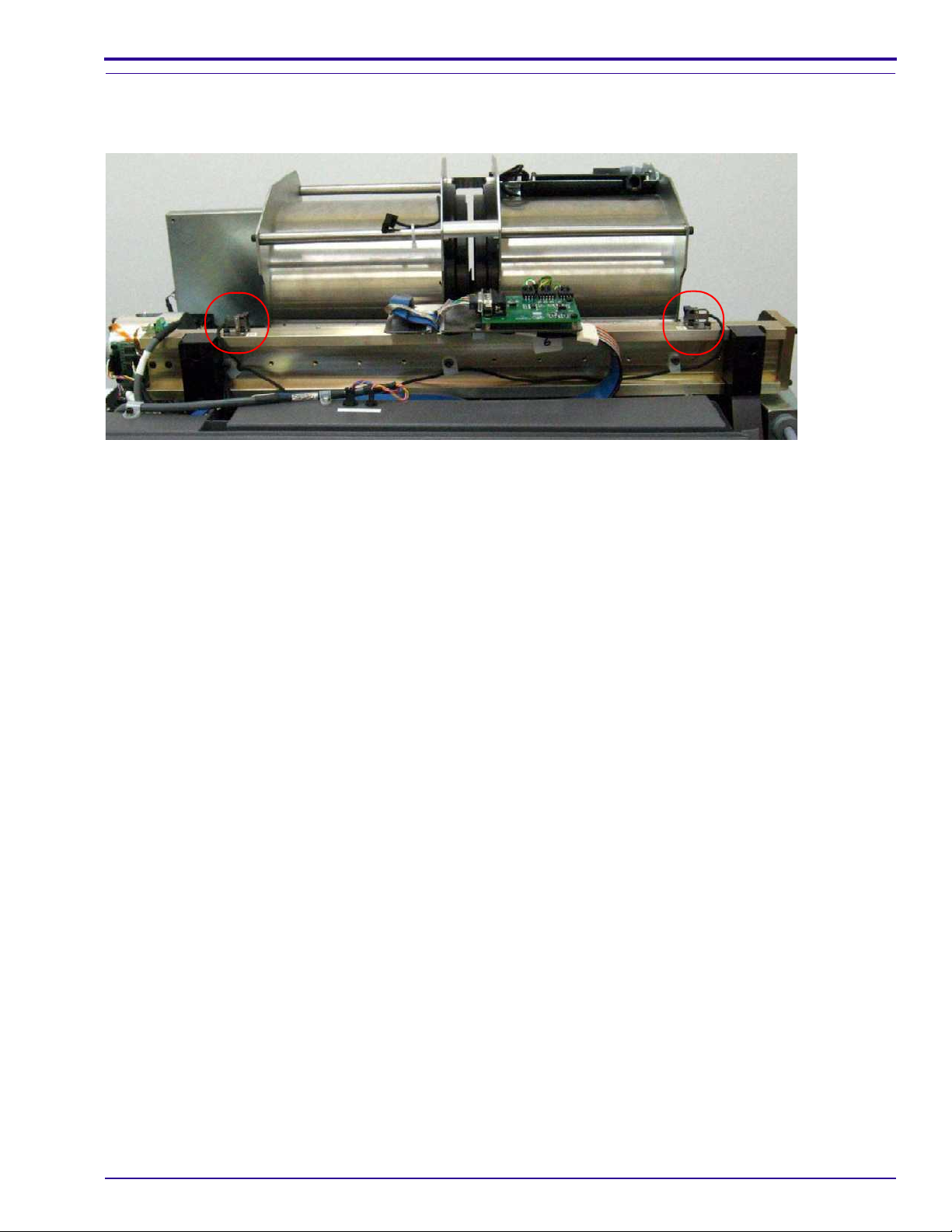

Right and Left Limit Sensors

The right and left limit sensors control the maximum left/ri ght (X-axis) movement of the linear motor of the PM

mounted on the slide.

6H4869 23

Page 24

Service Guide

Section 3: Service Procedures

Service Tools

The following is a list of tools required for service operations:

• Phillips (cross-head) screwdriver (medium)

• Flat screwdriver

• Allen wrenches (metric): 0.89, 1.5, 2, 2.5, 3, 3.5, 4, 5

• Open-ended wrenches (metric): 5.5, 7

• Wire cutters

• Long-nose pliers

• Multi-meter / avo (DVM)

• Safety activation key (SK000100)

• Scanning head alignment gauge (SK00009 9 )

• Trolley roller gauge (0.3 mm and 0.4 mm) (SK000024)

• Safety eyewear (The required laser safety eyewear must be intended for HeliumNeon/PDT lasers, have an

optical density of 4-5 wavelengths of 610-695 nm, and be mar ked as having CE approval.)

24 6H4869

Page 25

Service Procedures

Removing the Scanner Cover

[1] Switch OFF the scanner.

[2] With the system upright, pull the scanner to the edge of the table so that the front side is e xtended slightly o v er

the table edge.

Scanner

cover

screws

[3] Remove the 2 scanner cover screws using a 5 mm Allen wrench.

[4] Remove the 2 scanner co v er screw s at the bac k of the scanner (o ne on each side) using a 5 mm Allen wre nch.

[5] Lift off the cover.

Installing the Scanner Cover

[1] Check (in this order):

a. The scanner is switched OFF.

b. The safety interlock key is not in the interlock.

c. The laser board DIP switch is switched ON.

[2] Install the scanner cover.

[3] Install the 4 scanner cover screws.

[4] Switch ON the scanner.

6H4869 25

Page 26

Service Guide

Activating the Scanner Without the Cover

Activation Procedures

Laser Warning

Do not operate the unit while the la ser is co nnected without proper eye pr otection. Safe ty glasses (see Laser Safety

Instructions on Page 10) must be worn by all personnel in the ar ea of the unit! Only authorized per sonnel may remove

the cover. Before operating the unit without the cove r, disconn ect the laser (see Activating the Scanner Without the

Cover (Laser Deactivated) on Page 26).

When the scanner cover is removed, the safety electrical interl ock switch disconn ects th e er asing CCF L asse mbly,

the laser, and all motors.

To activate the scanner without the cover, use the applicable procedure:

• If the laser is not needed. See Activating the Scanner Without the Cover (Laser Deactivated)

• If the laser is needed. See Activating the Scanner without the Cover (Laser Activated)

on Page 27.

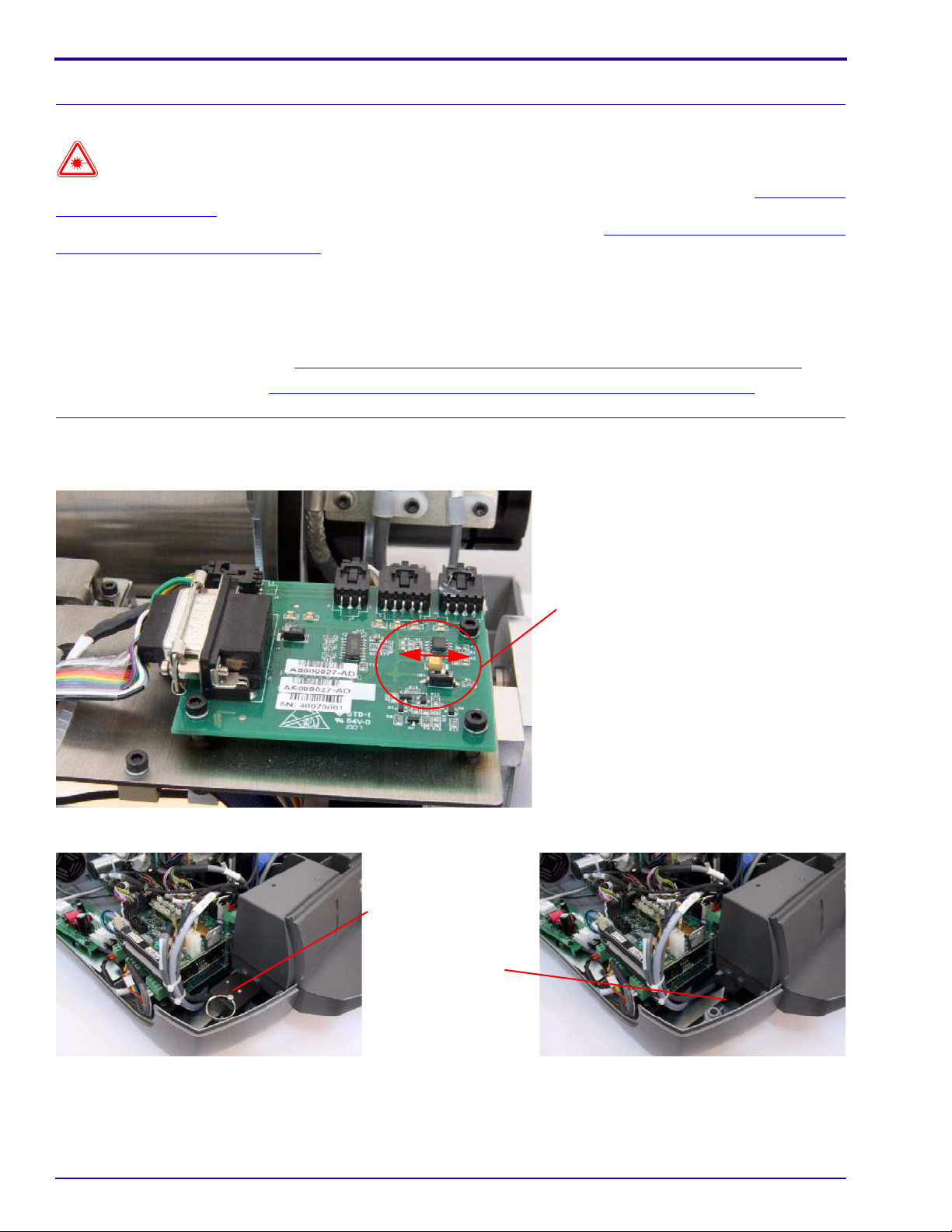

Activating the Scanner Without the Cover (Laser Deactivated)

Before Service Operations

on Page 26.

[1] Switch OFF the DIP switch on the laser board.

Activation key

inserted

Laser board DIP switch

Activation key

not inserted

[2] Insert the safety interlock activation key into the safety interlock to the left of the roof assembly.

[3] Switch ON the scanner and perform the necessar y ope r atio n s.

26 6H4869

Page 27

After Service Operations

After performing service operations, before installing the scanner cover:

[1] Switch OFF the scanner.

[2] Remove the safety interlock activation key from the safety interlock.

[3] Switch ON the DIP switch on the laser board.

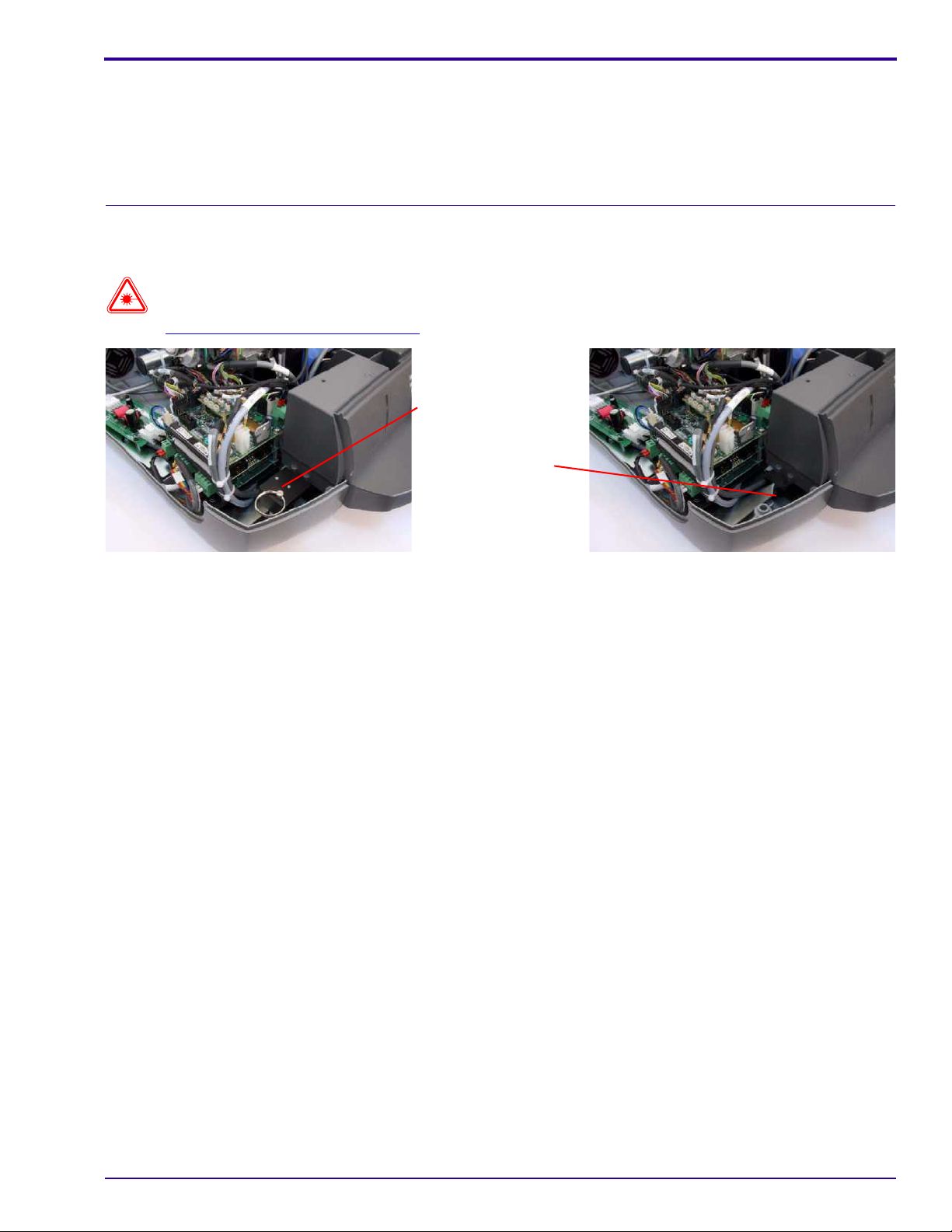

Activating the Scanner without the Cover (Laser Activated)

Before Service Operations

Laser Warning

Refer to Laser Safety Instructions on Page 10.

Activation key

inserted

Activation key

not inserted

Service Procedures

[1] Insert the safety interlock activation key into the safety interlock.

[2] Switch ON the scanner and perform the necessary operations.

[3] If the laser is no longer needed, switch OFF the DIP switch.

After Service Operations

After performing service operations, before installing the scanner cover:

[1] Switch OFF the scanner.

[2] Remove the safety interlock activation key from the safety interlock.

[3] If the DIP switch on the laser board is OFF, switch it ON.

6H4869 27

Page 28

Service Guide

Replacing the Power Line Filter Module

Tools Required

• Socket wrench

• 2.0 mm Allen wrench

• 2.5 mm Allen wrench

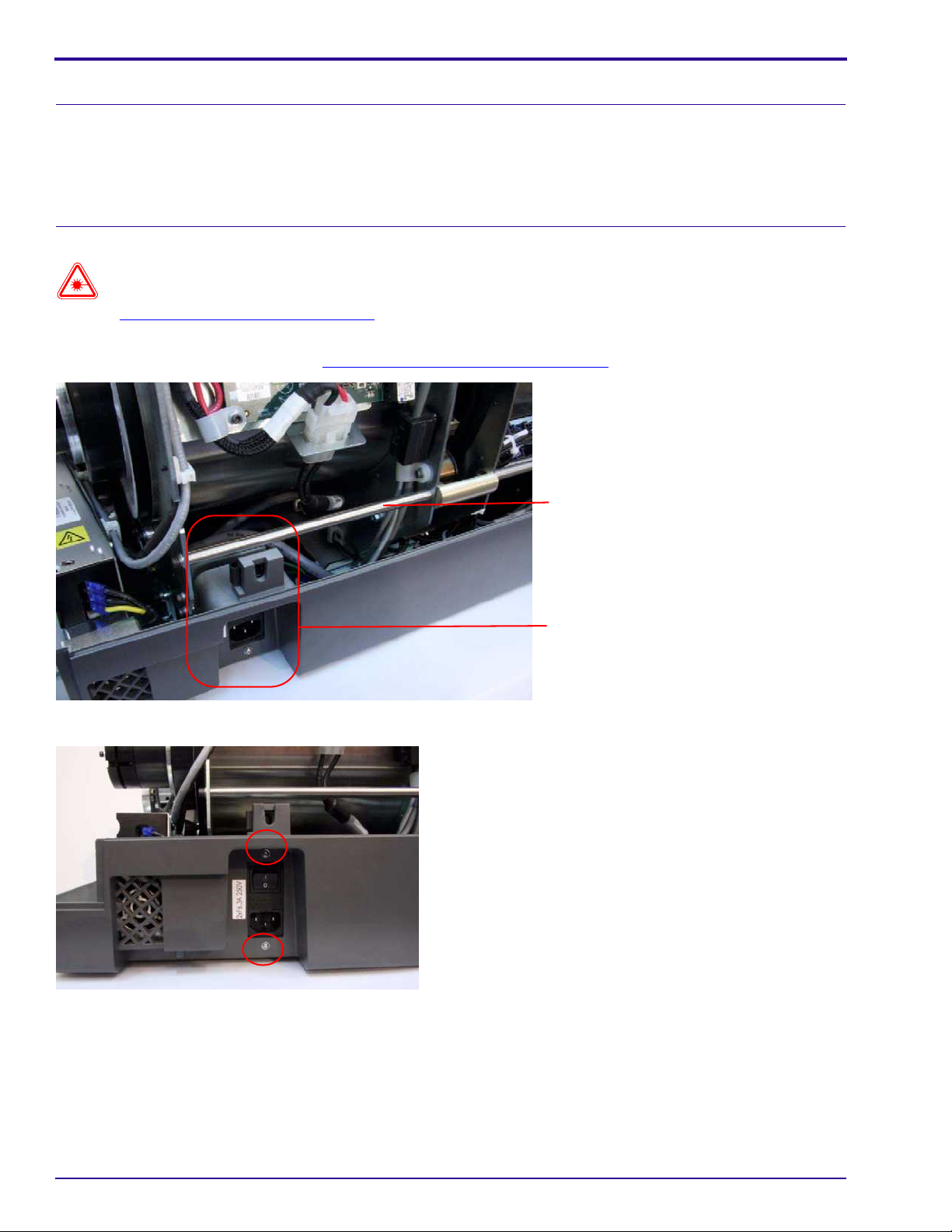

Removing the Power Line Filter Module

Laser Warning

.Refer to Laser Safety Instructions on Page 10.

[1] Switch OFF the power and disconnect the power cable from the power inlet socket of the scanner.

[2] Remove the scanner cover. (See Removing the Scanner Co ver

on Page 25.)

[3] Remove the lower left structure bar using a 2.5 mm Allen wrench.

Structure bar

Power line filter module

[4] Remove the 2 screws above and below the ON/OFF switch using a 2 mm Allen wrench.

28 6H4869

Page 29

[5] Remove the 2 screw s retaining the module bracket using the 2.5 mm Allen wrench.

[6] Remove the nuts retaining the ground cables to the ground stud using a socket wrench.

[7] Remove the ground cable of the power line filter from the stud.

[8] Disconnect the 2 power connectors.

[9] Remove the module together with the module bracket from the scanner.

Service Procedures

Installing the Power Line Filter Module

Module bracket

Power line filter module

[1] Set the new power line f ilter module into the module bracket.

[2] Insert the module into the scanner.

[3] Connect the 2 power connectors to the module.

Note

Connect black wire No. 1 to P and black wire No. 2 to N.

[4] Connect the 3 ground wires to the stud and tighten the nut.

[5] Insert the bracket screws.

Laser Warning

Refer to Laser Safety Instructions on Page 10.

[6] Connect the system to the main power and confirm that the system is operating properly.

[7] Install the scanner cover. See Installing the Scanner Cover

6H4869 29

on Page 25.

Page 30

Service Guide

Replacing the Fuses

Tools Required

• Flat screwdriver

• Replacement fuses (2)

Procedure

[1] Switch OFF the scanner.

[2] Disconnect the scanner from the main power.

Fuse drawer

[3] Locate the fuse drawer on the power inlet module.

[4] Open the drawer using a flat screwdriver, prying gently from the plastic tab.

30 6H4869

Page 31

[5] Remove the blown fuse.

[6] Install a new fuse.

[7] Close the fuse drawer.

[8] Turn on the system.

[9] Verify that the system functions properly.

Service Procedures

6H4869 31

Page 32

Service Guide

Replacing the Controller Board

Tools Required

• 2.5 mm Allen wrench

• 5 mm Allen wrench

Removing the Controller Board

Important

When changing the controller board, first back up the scanne r settings, if it is possible to do so, by copying the Calib

folder to a secure location.

[1] Disconnect the scanner from the main power.

[2] Remove the scanner cover. (See Removing the Scanner Cover

on Page 25.)

[3] Remove the 2.5 mm Allen retaining screw from the top of the controller board housing bracket.

[4] Remove the controller board housing bracket.

[5] Move the PM assembly all the way to the right in order to reach the controller board connectors.

32 6H4869

Page 33

Service Procedures

Cable on right side

of the controller board

Cables on the back

of the controller board

Note

Unfasten the clips on the sides of the wide blue cable to remove it.

Hold the cables by their connectors when remo ving them, not by the cables themselves.

[6] Disconnect the cables from the back of the controller board (accessible from the front side of the scanner).

[7] Disconnect the cables from the right and left sides of the contr oller board.

6H4869 33

Page 34

Service Guide

[8] Remove the 4 screws from the corners of the controller board that fasten it to the bracket using the 2.5 mm Allen

wrench.

[9] Remove the controller board.

Installing the Controller Board

[1] Position t he controller board in the brac ket and install the 4 scre ws connecting the controller boa rd to the brack et

using the 2.5 mm Allen wrench.

[2] Connect the connectors on the left side of th e controller board.

[3] Connect the cable on the right side and the cables at the back of the controller board.

[4] Install the housing bracket and the retainer screw.

[5] Connect the scanner to the PC:

(a) Connect the scanner to the same PC as before.

(b) Switch ON the scanner.

(c) The EEPROM screen appears. Choose Copy disk file to EEPROM, then click OK.

Laser Warning

.Refer to Laser Safety Instructions on Page 10.

34 6H4869

Page 35

Service Procedures

[6] Before installing the scanner cover, perform a test scan. Check that the system functions properly. The preview

image should be black.

[7] Check (in this order):

a. The safety interlock key is not in the interlock.

b. The laser DIP switch is switched ON.

[8] Position the scanner cover without installing the scanner cover screws.

[9] Switch ON the scanner.

[10] Perform a test scan. The preview image should be white.

[11] Install the scanner cover screws.

[12] Go to Settings>Calibration and check that the calibration values are marked with a green check mark. If not

perform a full calibration. (See Calibrations

on Page 114.)

[13] Go to Settings>About and check that all version numbers of the hardware and software are correct.

6H4869 35

Page 36

Service Guide

Replacing the IMCS Board

Tools Required

• 2.5 mm Allen wrench

• 5 mm Allen wrench

• Phillips (cross-head) screwdriver

• Wire cutter

Note

If you replace only the motion board or only the sensor board, return the unused board together with the replaced

board to your Service Representative, noting clear ly which is new and which was replaced.

Removing the IMCS Board

[1] Disconnect the scanner from the main power.

[2] Remove the scanner cover. (See Removing the Scanner Cover

on Page 25.)

Allen screw

[3] Disconnect the connectors from the IMCS board.

[4] Cut the plastic ties.

[5] Remove the four 2.5 mm Allen screws retaining the IMCS board.

[6] Lift the board from the scanner.

36 6H4869

Page 37

Separating the Sensor Board from the Motion Board

[1] Disconnect the scanner from the main power.

[2] Remove the scanner cover. (See Removing the Scanner Cover

[3] Remove the 2 Phillips screws from the sensor board.

Service Procedures

on Page 25.)

Sensor board

[4] Lift the sensor board without disconnecting its connectors and position it on its side.

[5] Remove the connectors from the motion board.

[6] Cut the plastic ties.

[7] Remove the four 2.5 mm Allen screws retaining the motion board and lift the board from the scanner.

6H4869 37

Page 38

Service Guide

Installing the IMCS Board

[1] Connect the connectors to the back of the motion board.

[2] Insert the IMCS board in to the scanner housing.

[3] Install the 4 retaining screws.

[4] Install new plastic ties.

[5] Connect the rest of the connectors to the board.

Note

The connectors on the right are identical. Each connector socket on the board is has a connector number.

[6] If you replaced only the motion board, then attach the sensor board to the motion board by inserting the 2

retaining screws.

Laser Warning

.Refer to Laser Safety Instructions on Page 10.

[7] Before installing the scanner cover, activate the scanner and:

(a) Insert the safety interlock activation key into the safety interlock.

(b) Switch ON the scanner.

(c) Perform a scan to verify that the IMCS board functions properly and that all systems move freely.

(d) Switch OFF the scanner.

(e) Check that the safety interlock key is not in the interlock.

(f) Check that the laser DIP Switch is switched ON.

[8] Install the scanner cover.

[9] Install the scanner cover screws.

[10] Switch ON the scanner.

[11] Perform a scan to verify that the IMCS board functions properly and that all systems move freely.

38 6H4869

Page 39

Replacing the Photo Multiplier Board

Tools Required

• Replacement PM tube

• 3.0 mm right-angle Allen wrench

• 3.5 mm right-angle Allen wrench

Removing the PM Board

Service Procedures

[1] In Settings>Diagnostics, move the linear slide assembly to the left limit.

[2] Disconnect the scanner from the main power.

[3] Remove the scanner cover. (See Removing the Scanner Cover

[4] Disconnect the blue ribbon cable on the PM board.

[5] Remove the two 2.5 mm Allen screws and the 5.5 mm nut retaining the PM board cover.

[6] Remove the cover.

on Page 25.)

Nut

6H4869 39

Page 40

Service Guide

[7] Remove the top bolt screw and the ground connector.

The ground connector

is behind the board

[8] Remove the PM board.

Installing the PM Board

[1] Position the PM board in correct alignment to fit with the PM tube pins.

[2] Install the PM board and the ground connector.

[3] Install the PM board cover and tighten the screws.

[4] Connect the blue PM ribbon.

[5] Check (in this order):

a. The scanner is switched OFF.

b. The safety interlock key is not in the interlock.

c. The laser DIP switch is switched ON.

[6] Install the scanner cover.

[7] Install the scanner cover screws.

[8] Switch ON the scanner.

[9] Perform an offset calibration and a PM gain calibration. (See Offset Calibration

Tuning Procedure on Page 117.)

[10] Perform a scan on a phantom object.

on Page 116 and System Gain

40 6H4869

Page 41

Replacing the Photo Multiplier Assembly

Tools Required

• Replacement PM assembly

• 2.5 mm Allen wrench

• 3.0 mm right-angle Allen wrench

• 3.5 mm right-angle Allen wrench

• Scanning head alignment gauge

Removing the PM Tube

Service Procedures

[1] In Settings>Diagnostics move the linear slide assembly to the left limit.

[2] Disconnect the scanner from the main power.

[3] Remove the scanner cover. (See Removing the Scanner Cover

[4] Disconnect the ground wire connector from the PM board using a 2.5 mm wrench.

[5] Cut the plastic ties retaining the ground wire to the bracket.

[6] Disconnect the blue ribbon cable from the PM board.

[7] Loosen the Allen screws holding the blue ribbon cable in position.

[8] Remove the ribbon cable.

on Page 25.)

Ribbon connector

Allen screws

Ground wire connector

6H4869 41

Page 42

Service Guide

Bracket 2Bracket 1

[9] Loosen Brack et 1 and Brac ket 2 holding the cab les to the PM assem bly using a 3 mm Alle n wrench and 2.5 mm

Allen wrench.

[10] Remove the blu e ribbon cable and ground cable from the PM assembly.

Laser board bracket

screws

Laser board

[11] To remove the PM assembly bracket arm, first remove the 4 screws retaining the laser board bracket to the

linear slide assembly.

[12] Remove the 4 screws that hold the PM assembly bracket arm to the linear slide assembly using a 3 mm Allen

wrench.

Bracket arm

Caution

Stand the PM assembly on the wider end or on the side to prevent damage.

[13] Carefully remove the PM assembly.

42 6H4869

Page 43

Service Procedures

Installing the PM Tube

[1] Insert but do not tighten the 3.5 mm bottom bracket retaining screw.

[2] Insert but do not tighten the 3.5 mm right-side bracket retaining screw.

[3] Move the PM tube forward towards the drum by man ually turning the lead scre w unt il the scre ws align with the

holes.

[4] Insert but do not tighten the retaining screws.

[5] Align the PM with the edge of the drum.

Alignment

gauge

[6] Insert the scanning head alignment gauge with the narr ow parts of the pr ongs betw een the PM t ube and the

drum.

[7] Hold the PM tube against the alignment gauge and tighten the screws.

[8] Move the linear slide assemb ly to the right unt il the gauge is released from between the PM tube an d the drum.

[9] Connect the blue ribbon cable to the top of the PM board.

6H4869 43

Page 44

Service Guide

[10] Install the blue ribbon cable an d the ground cable into the bracket and plastic clip on the PM tube.

[11] Attach to the PM assembly the brackets and plastic clip that hold the blue ribbon cable and the ground cable.

[12] Connect the ground wire connector to the slide body.

[13] Check (in this order):

a. The scanner is switched OFF.

b. The safety interlock key is not in the interlock.

c. The laser DIP switch is switched ON.