Page 1

{ServiceManual}{Produ ction}{Health Group}{In ternal}

Important

Publication No. 6H4866-02

JUN2008

Service Manual

for the

Kodak Point-of-Care CR 120/140 Systems

When doing the procedures in this document, you must use safe work practices and wear the correct Personal

Protective Equipment (i.e. SAFETY EYEWEAR) according to your Company’s Standard Operating Procedures.

© CARESTREAM HEALTH, INC. 2008

Page 2

Point-of-Care CR 120/140 Service Manual

Publication Number: 6H4866-02

© Carestream Health, Inc. 2008

All rights reserved. No part of this manual may be reproduced or copied in any form by any means -graphic, electronic

or mechanical, including photocopying, typing, or information retrieval systems -without written pe rmission of

Carestream Health.

Use of the Guide

The Kodak Point-of-Care CR 120/140 System is designed to meet international safety and performance stan dards.

Personnel operating the unit must have a thorough understanding of the proper o peration of the system. This manual

has been prepared to aid medical and technical p ersonnel to understand and operate the system. Do n ot operate the

system before reading this manual and gaining a clear understanding of the operation of the system. If any part of

this manual is not clear, please contact your Carestream Health representative for clarification.

Authorized European Representative

Carestream Health France

LES MERCURIALES

40, rue Jean Jaures

93176 BAGNOLET CEDEX

France

CARESTREAM is a trademark of Carestream Health.

KODAK is a trademark of Kodak used under license.

Carestream Health, Inc.

150 Verona Street

Rochester, NY 14608

2 6H4866-02

Page 3

Description Page

Table of Contents

Safety and Regulatory Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Introduction

General Safety Guidelines

Electrical Hazards

Explosion and Implosion Hazards

Overheating

Laser Safety Instructions

Recycling the Unit

Labelling Summary

IEC Symbols Used

Device-specific Safety Information

Regulatory Information

System Description

Introduction

Operational Principles

System Overview

Component Description

Service Procedures

Service Tools

Removing the Service Panel and Scanner Cover

Disconnecting the Laser

Replacing the Fuses

Power Inlet Module Replacement

USB Board Replacement

Motion Board Replacement

Sensor Board Replacement

PM Tube and PM Board Replacement

Laser Board Replacement

Roller Motor Replacement

Linear Slide Assembly Replacement

Loader Stepper Motor Replacement

Power Supply Assembly Replacement

Erase Lamps Assembly Replacement

Erase Lamps Inverters Replacement

Erase Lamps Sensors Replacement

Left Limit Sensor Replacement

Right Limit Sensor Replacement

Screen Size Sensor Replacement

Roller Sensor Replacement

Z0 Sensor Replacement

W0 Sensors Replacement (Top/Receiver and Bottom/Transmitter)

Screen Guide Replacement for non Auto-loop systems

Auto-loop Key Assembly Replacement

Auto-loop Solenoid Replacement

Tray Assembly Replacement for non Auto-loop Systems

Tray Assembly Replacement for Auto-loop Systems

Calibrations

Nominal Calibration

Facility Calibrations for Kodak QC Version 2.1.2/2.4.2 Software

Gain Tuning Calibration Process for Kodak QC Version 2.5

Adjustments

Auto-loop Solenoid Adjustment

Screen Guide Adjustment (non Auto-loop)

Loader Pin and Loader Pusher Adjustments

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

. . . . . . . . . . . . . . . . . . . . . . . . . . . 41

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

. . . . . . . . . . . . . . 85

. . . . . . . . . . . . . . . . . . . . . . . 89

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

. . . . . . . . . . . . . . . . . . . . . 98

. . . . . . . . . . . . . . . . . . . . . . . . . 103

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

. . . . . . . . . . . . . . . 115

. . . . . . . . . . . . . . . . . . . 123

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

6H4866-02 3

Page 4

Electric Schematic Diagrams

Description Page

Preventive Maintenance

Publication History

List of Figures

Block Diagram of the Point-of-Care CR 120/140. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Roller Sensor Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Cleaning the Rollers

Cleaning the Phosphor Screens

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Scanner Front View

Scanner Rear View

Scanner Left View

Scanner Right View

USB Board

Motion Board

Sensor Board

PM and PM Board

Laser Board

Laser

Roller Motor

Roller Motor Connector

Linear Slide Assembly

Linear Slide Stepper Motor Connector

Carriage Stepper Motor

Carriage Stepper Motor Wiring

Power Supply Assembly

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Auto-loop Key Assembly and Tray Assembly

Auto-loop Key Assembly

Erase Lamps

Erase Lamp Assembly

Erase Lamps Inverter Assembly

Inverter Assembly Connections

Erase Lamp Sensor

Erase Lamp Sensor Connectors

Left Limit Sensor

Right Limit Sensor

Screen Size Sensor

Roller Sensor

4 6H4866-02

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Page 5

Z0 Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Top WO Sensor

Bottom W0 Sensor

Service Panel Screws

Access to Cover Screws

Cover Screws

Laser Connector on the Laser Board

Location of Fuses

Nuts Securing the Module

Line Filter Wire Attached to Ground

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Side View of Power Module Showing Connection Tabs

USB Cover

USB Board Connectors

Motion Board Bracket Screws

Motion Board Connectors

Sensor Board Connections

Sensor Board Screws

PM Ground Wire

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

. . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Connector to the PM Board

PM Assembly Screw (one side shown)

PM Assembly Lower Screw

Laser Board Connectors

Laser Board Screws

Laser Operation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Roller Motor Connector

Roller Motor Screws

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Roller Motor Drive retaining screw

Roller Motor Drive

Drive Adaptor

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Operating the Roller Motor

Connector to USB Board

Laser Board Cable and Connectors

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Stepper Motor and Left Limit Sensor Connectors

Right Limit Sensor Connector

Screw Attaching the Ground Wire

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Slide Assembly Attaching Screws

Slide Assembly

Linear Slide Test

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Connector J505 on the Connector Board

6H4866-02 5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Page 6

Stepper Motor Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Bottom of Unit

Pulling the Carriage Down

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Carriage Assembly Attaching Screws

Loader Assembly with Stepper Motor

Power Supply Assembly

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Power Supply Screws on Unit Bottom

Cable Connection to USB Board

Connectors on the Motion Board

Ground Wire Screw

Main Ground Stud

Fuse Connector

Erase Lamp Connectors

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Erase Lamp Sensor Connector

W0 Upper Sensor Cable Connector

Erase Lamp Assembly Screws

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Erase Lamp Assembly Wiring Harness

Inverter Cover Screws

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Erase Lamp Connectors

Inverter Attaching Screws

Checking the Erase Lamps

Flex Cable Bracket

Erase Lamp Sensor

Erase Lamp Sensor Screws

Checking the Erase Lamps

Left Limit Sensor Connector

Left Limit Sensor Screws

Linear Motor Section of Diagnostics Screen

Right Limit Sensor

Linear Motor Section of Diagnostics Screen

Screen Size Sensor (1 of 4)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Screen Guide Passing Under Screen Size Sensor

Z0 Light

Screen Guide

Roller Sensor

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Z0 Sensor

Z0 Light

Screen Guide

Top W0 Sensor in the Drum

6 6H4866-02

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Page 7

W0 Top Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Scanner tipped on its back

W0 Bottom Sensor

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Black Probe Attachment Point

Disconnect the Flex Cable

Remove the Silver Bracket

Remove the L Bracket

Disconnect the Flex Cable

Release the Key Assembly screws

Pull the Key Assembly towards you

Remove the Allen screws from the Screen Guide Bracket

Install the New Screen Guide to the Key Assembly

Stick Adhesive Tape to the Screen Guide

Rotate the Rollers Manually

Install the L Bracket

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Disconnect flex cable

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

. . . . . . . . . . . . . . . . . . . . . . . . . 91

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Disconnect the Connectors from the Sensor board and Motion board

Release the screws securing the Auto-loop Key Assembly

. . . . . . . . . . . . . . . . . . . . . . . . 95

. . . . . . . . . . . . . . . . 94

Pull the Auto-loop Key Assembly towards you

Pass the cable around to the Motion card (1)

Pass the cable around to the Motion card (2)

Pass the cable around to the Motion card (3)

Auto-loop Solenoid

Auto-loop adaptation identification

System Serial Number

Remove J513 and J514 sensors

Remove J513 and J514 tie wraps

Remove the silver bracket.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Remove the two screws retaining the black L-bra cke t

Release the flex cable from the connector

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Remove the four screws retaining the Key assembly.

Pull out the Key assembly

Remove the ground strap.

Remove Tray Assembly screws

Plate sides mounting screws

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Remove Tray Assembly sensors

Remove the four screws retaining the Key assembly.

Remove the ground strap.

Remove Tray Assembly screws

6H4866-02 7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Page 8

Plate sides mounting screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Set Origin on Calibration Tab

Exposure Settings

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

New X and Y Coordinates

Origin Calibration Field

Selecting Set Offset

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Insert Cassette Message

Push Cassette Message

Offset Calibration Completed

Position of the Dosimeter

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Placing the Copper and Aluminum sheets

Calibration Tab

Find PM Gain

Calibration Successful Screen

Calibration Failed

Setup Tab

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Screen Image in the Image Viewer screen

Image Viewer Selections

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Centered Histogram

Histogram Too Much to the Left (Over Exposed)

Decrease PM Gain Value and Save

Histogram Too Much to the Right (Under Exposed)

Increase PM Gain and Save

Real Organ Image in Image Viewer Screen

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Image Appearing Four Way Split Screen in the Image Viewer

Choosing Filter Types from the Filter Menu

Save Cv Filter Setting Screen

X-ray setup

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Set Image and Diagnostic settings

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Measure Pixel Value in Center of Field

Change the PM Value

Save PM settings

Loop solenoid error message

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Resistance measuring points on Auto-loop assembly

Plastic gap jigs

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

. . . . . . . . . . . . . . . . . . . . . 121

Facilitate final stroke position

Screen Guide tool

Diagnostic tab

Loader Position

8 6H4866-02

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Page 9

Disconnect the Flex Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Remove the Silver Bracket

Loosen the L Bracket screws

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Direction of Screen Guide movement under L Bracket

Tray Gauge

Trolley Roller Gauge

Diagnostics Screen Loader Control

Checking Pin Height (Go)

Checking Pin Height (No Go)

Diagnostics Screen -activate erase lamps

Inserting the Trolley Roller

Insert the 0.4 mm Adjustment Screen

Screen inserted between the rollers

Sensor LED active and inactive

Main Schematics

USB and Motion Schematics

Sensors Schematics

PM, Laser Schematics

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

. . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Lamps Board Schematics

PS, Lamps Schematics

Grounding Schematics

User Tab

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Insert Cleaning Tray Message

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Removing the Protective Strips

Inserting the Cleaning Tray

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Pull Out Cleaning Plate Message

Disconnecting the Cleaning Tray

Extraction Tool

Installing the Extraction Tool

Extracting the Screen

Releasing the Extraction Tool

Installing the Screen

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

6H4866-02 9

Page 10

Page 11

Safety and Regulatory Information

Caution

Note

Important

Section 1: Safety and Regulatory Information

Introduction

The information contained herein is based on the experience and knowledge relating to the subject matter gained by

Carestream Health prior to publication. No patent license is granted by this information.

Carestream Health reserves the right to change this information without notice, and makes no warranty, express or

implied, with respect to this information. Carestream Health shall not be liable for any loss or damage, including

consequential or special damages, resulting from any use of this information, even if loss or damage is caused by

Carestream Health's negligence or other fault.

Cautions point out procedures that you must follow precisely to avoid damage to the system or any of its components,

yourself or others, loss of data or corruption of files in software applications.

Notes provide additional information, such as expanded explanations, hints, or reminders.

Important highlights critical policy information that affects how you use this guide and this product

General Safety Guidelines

• This product is designed and manufactured to ensure maximum safety of operation. Operate and maintain it in

strict compliance with the safety precautions and operating instructions contained in this guide.

• This product meets all the safety requirements applicable to medical equipment. However, anyone attempting to

operate the system must be fully aware of potential safety hazards

• There are no user serviceable parts in this system. The product must be installed, maintained, and serviced by

qualified service personnel according to procedures and preventive maintenance schedules in the product

service guide. If your product does not operate as expected, contact your Service Representative.

• The product in whole or in part may not be modified in any way without prior written approval from Carestream

Health.

• Personnel operating and maintaining this system should receive training and be familiar with all aspects of

operation and maintenance.

• To ensure safety, read all user guides carefully before using the system and observe all Cautions, “Importants”,

and Notes located throughout the guide.

• Keep this guide with the equipment. Reading this guide does not qualify you to operate, test, or calibrate this

system.

• Unauthorized personnel are not allowed access to the system.

• If the product does not operate properly or fails to respond to the controls as described in this guide:

– Follow the safety precautions as specified in this guide.

– Stop using the system and prevent any changes to it.

– Immediately contact the service office, report the problem, and await further instructions.

• Use only legally marketed cassettes. Check periodically the quality of the cassettes, and replace if any defects

are apparent.

• The images provided by this system are intended as tools for the trained user. They are explicitly not to be

regarded as a sole incontrovertible basis for clinical diagnosis.

• Be aware of the product specifications and of system accuracy and stability limitations. Consider these limitations

before making a decision based on quantitative values. If you have any doubts, consult the Sales Re presentative.

• This system is Class I continuous operated stationary equipment without applied parts and has one signal input/

output part.

6H4866-02 11

Page 12

Electrical Hazards

Caution

Caution

Laser Warning

• Do not remove or open system covers or plugs. Internal circuits use high voltage capable of causing serious

injury.

• Fuses blown within 36 hours of being replaced by a qualified technician may indicate malfunctioning electrical

circuits within the system. Have the system checked by qualified service personnel. Do not attempt to replace

any fuse.

• Fluids that seep into the active circuit components of the system may cause short circuits that can result in

electrical fires. Therefore, do not place any liquid or food on any part of the system.

Explosion and Implosion Hazards

• Do not operate the equipment in the presence of explosive liquids, vapors, or gases.

• Do not plug in or turn on the system if hazardous substances are detected in the environment. If these

substances are detected after the system has been turned on, do not attempt to turn of the unit or unplug it.

Evacuate and ventilate the area before turning off the system.

Overheating

Do not block the air circulation around the unit. Always maintain at least 6 inches (15 cm) clearance around the unit

to prevent overheating and damage to the system

Laser Safety Instructions

• During nominal operation, the Scanner is closed and sealed with a protective cover for safety reasons.

• During nominal operation, the cover should not be removed. Removing of the cover shall be done only for service

purposes, and by a qualified technician for service operations.

• Service operations that do not require the Laser should be done without activating the Laser unit. Disconnecting

the relevant connector on the Laser Board will disconnect the power supply to the Laser, and deactivate the

Laser unit for service operations.

• In case the Laser must be operated during service operation, the service technician shall make sure that the

optical unit is located within the Scanner Drum, where the laser beam is blocked.

When a service operation is taking place with the cover removed, disconnect the Laser according to the procedure

in “

Disconnecting the Laser” on Page 44. If the Laser must be activated during the service procedure, wear protective

safety glasses at all times. The required laser safety eye wear must be intended for HeliumNeon/PDT lasers, have

an optical density of 4-5 wavelengths of 610-695 nm, and be marked as having CE approval.

Recycling the Unit

In the European Union, this symbol indicates that when the last user wishes to discard

this product, it must be sent to appropriate facilities for recovery and recycling.

Contact your local Carestream Health representative or refer to www.kodak.com/go/

recycle for additional information on the collection and recovery programs available for

this product.

12 6H4866-02

Page 13

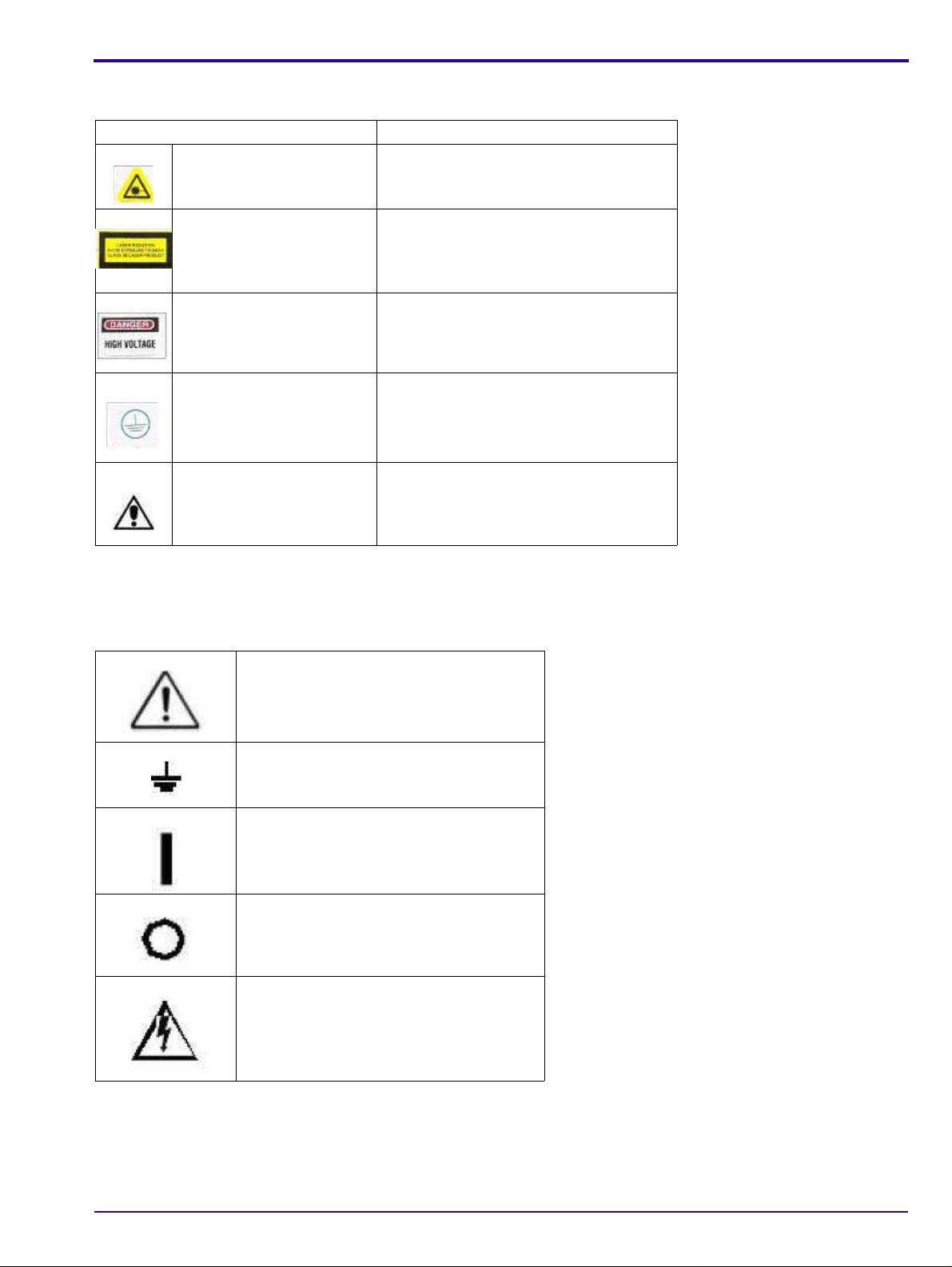

Labelling Summary

Safety Labels Consignes de Sécurité

Laser

Laser-emitting product

Safety and Regulatory Information

Laser

Appareil émetant de laser

Class 3B laser product

inside Scanner

High voltage Haut voltage

Chassis ground stud Point de mise en terre du chassis

Attention: consult

accompanying documents.

Rayonnement de laser évitez l’exposition

au faisceau laser de la classe 3B.

Appareil à laser de classe 3B a l’intérieur

du Scanner.

Attention: consulter les documents joints.

IEC Symbols Used

The system may have labels with one or more of the following symbols. These symbols indicate the IEC standards

to which the system conforms.

Warning, Caution – consult accompanying

documents

Protective ground points

Power ON

Power OFF

Caution – Electrical shock hazard

6H4866-02 13

Page 14

Device-specific Safety Information

Caution

Safety Information Consignes de Sécurité

LIFTING HAZARD

DANGER POIDS LOURD

The Kodak Point-of-Care 120/140

Scanner weighs 40 Kg (88lb). Do

not try to lift the Scanner by

yourself. Always seek assistance

from another person. Lifting

equipment that is too heavy may

result in injury to personnel and/or

damage to the Scanner.

WARNING

The Kodak Point-of-Care 120/140

Scanner is a CLASS 1 Laser

product.

• Do not remove the Scanner

cover.

• Cover removal shall be done

only by authorized service

personnel!

Le Scanner Kodak Point-of-Care 120/140 pèse 40

kg (88lb). N’essayez pas de porter le Scanner par

vous-même. Demandez toujours de l’aide d’une

autre personne. Porter un équipement trop lourd

peut provoquer des dommages physiques et/ou

endommager le matériel.

ATTENTION

Le Scanner Kodak Point-of-Care 120/140 est un

produit laser de la Classe 1.

• Ne pas retirer le couvercle du Scanner.

• Le retrait du couvercle doit s’effectuer

uniquement par un personnel compétent.

Regulatory Information

Introduction

This Product conforms to the following safety standards: IEC 601-1 Medical Electrical Equipment General

Requirements for Safety, EN60601-1-2 Medical Electrical Equipment Electro-Magnetic Compatibility Requirements

and Tests, IEC 60825-1 Safety of Laser Products.

This device complies with 21CFR 1040.10.

CE Conformity

This product conforms to the requirements of council directive 93/42/EEC. The Point-of-Care CR 120/140 is a Class

I medical device. The Point-of-Care CR 120/140 bears the following mark of confor mit y.

The name and address of the CE representative appears on th e back of the front page of this manual.

USA Regulations

The FDA cleared the system for sale in the USA.

Federal US law restricts this device for sale by or on the order of a physician.

14 6H4866-02

Page 15

System Description

Section 2: System Description

Introduction

Throughout this manual the Kodak Point-of-Care CR 120/140 Systems will be referred to as the

Point-of-Care CR 120/140.

The Point-of-Care CR 120/140 is designed for the reading of phosphor x-ray screens (CR) by medical professionals.

The system consists of the Point-of-Care CR 120/140 unit and the software package that includes:

•The Kodak QC software that operates the unit.

• An image viewing and archiving software package that su pports the DICOM 3.1 stand ard and was appr oved by

Carestream Health.

• The system features 8 x 10 in.; 10 x 12 in.; 14 x17 in.; 9.5 x 9.5 in. digital image reading and viewing archive.

Operational Principles

The Point-of-Care CR 120/140 is a digital imaging system for image acquisition and processing of static projection

radiography that uses a phosphor screen with energy storage capability as an x-ray image receptor.

After exposure, a laser beam, which stimulates luminescence proportional to the local x-ray exposure, reads the

screen. The luminescence signal is digitized. The data is then subjected to digital image processing.

The Point-of-Care CR 120/140 enables the user to read a screen quickly, and erase it to be ready for the next scan.

The unit is compact and easy to use.

Using the Point-of-Care CR 120/140 enables medical professionals to “go digital” without changing their work

practices or x-ray equipment.

System Overview

System Components

The Point-of-Care CR 120/140 consists of 17 major assemblies as well as sensors, which may be replaced in the

field:

USB Board Erase Lamps Assembly

Motion Board Erase Lamps Inverter Assembly

Sensor Board Sensors:

Photo Multiplier Assembly W0 Sensor

Optic Head Assembly Z0 Sensor

Roller Motor Assembly Rollers Sensor

Linear Slide Assembly Screen Size Sensors

Loader Stepper Motor Assembly R-Limit (Home) Sensor

Key Assembly and Tray Assembly L-Limit Sensor

Power Supply Assembly Loader Back Sensor

Cassette Lock Cassette Present

Auto-loop

6H4866-02 15

Page 16

Component Names and Descriptions

Part Name Description

USB Board The USB Board receives operational commands from the host PC workstation via

the USB port, and sends the commands to the appropriate Scanner component. It

also transmits image data from the Scanner to the PC.

Motion Board The Motion Board controls the Loader and Roller Motors and Erase Lamps. It reads

the scanner sensors and passes the information to the USB Board.

Linear Slide Assembly The Linear Slide Assembly moves the PM and the Optical Head Assemblies back and

forth within the Drum.

Optical Head Assembly The Optical He ad Assembly includes the Laser Module and the Rotational Motor th at

rotates the Laser Tube and a mirror during scanning. The Laser Module’s beam

illuminates the Phosphor screen and the mirror collects the light reflected from the

phosphor screen and directs it to the Photo Multiplier.

Photo Multiplier Tube

(PMT)

Key Assembly and Tray

Assembly

Power Supply The AC/DC power supply provides DC power to the Scanner components.

Loader Stepper Motor

Assembly

Roller Motor Assembly The Roller Motor Assembly pulls the phosphor screen from the cassette into the

Erase Lamps Assembly The Erase Lamps Assembly brightly illuminates the phosphor screen after scanning,

Erase Lamps Inverters

Assembly

Sensor Board The Sensor Board is a through board used to connect the sensors to the Motion

Sensors

Eraser Lamps Sensor The Erase Lamp Sensor detects an Erase Lamp failure.

Left and Right Limit

Sensors

Roller Sensor Detects when the screen enters and exits the Rollers.

W0 Sensors Top and

Bottom

Z0 Sensor Detects the presence of the screen in the Drum.

Screen Size Sensors There are four Screen Size Sensors that determine the size of the CR screen by the

15 x 30 Presence

Sensor

The Photo Multiplier (PM) Tube collects the photons emitted from the screen.

These complementary assemblies guide the cassette into the scanner and secure it

in position for the duration of the scanning process. The Auto-loop mechanism which

is attached to the Key Assembly, controls the distance that the screen is returned

into the cassette at the end of the process.

The Loader Stepper Motor Assembly extracts the phosphor screen from the cassette

in preparation for insertion into the drum and assists in inserting the screen into the

cassette.

Drum.

to erase the image so that the screen is ready to be used again.

The Erase Lamps Inverter Assembly converts the 15 VDC input to high voltage

output to power the Erase Lamps.

Board.

The Left and Right Limit Sensors indicate the end of travel of the Linear Assembly

movement.

The W0 Sensor determines the activation and deactivation of the rollers according to

screen presence at the entrance to the Drum.

location of the screen guide that is positioned by the screen as it is inserted into the

drum.

Installed in the Key Assembly, this Sensor detects the presence of a 15 x 30 in

cassette adapter.

16 6H4866-02

Page 17

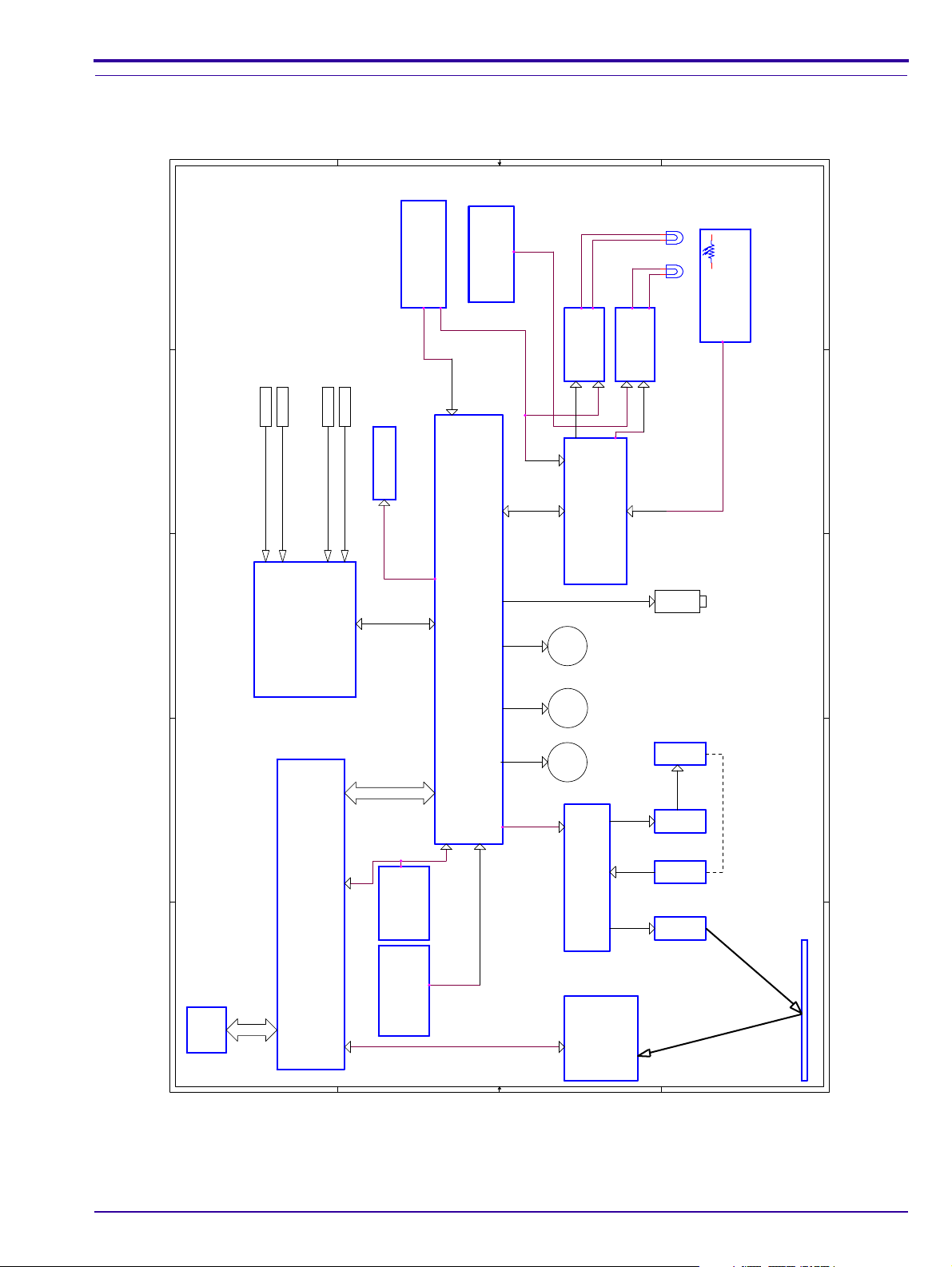

Block Diagram of PoC 120/140

1

1

2

2

3

3

4

4

5

5

A A

B B

C C

D D

J2 J4

J3

J5

J1

J500

PC

P1

USB Board

Motion Board

Sensor

Board

J501

J502

J515

J516

...

Power Supply

+5V / +12V

Power Supply

+12V

(Rotation Motor)

Carrier - Laser

PM Board

Sensor

Sensor

Sensor

Sensor

...

Power Supply

+15V

Group No. 2

Lamps Board

Inverters

Group

No. 1

Laser

Encoder

Rotation

Driver

Rotation

Motor

J300 J305 J304

U211

J213

J200

J203 J206 J204J201

J208

J211

J202

J205

J1 J401

J403

J404 J402

Roller

Motor

Load/UnloadLinear

DC

SMSM

Power Supply

+15V Lamps

(Motors+Lamps)

Group No. 1

Lamp Sensors

Board

CB090064

CB090064

Inverters

Group

No. 2

LED Panel

LAMPx8 LAMPx6

J212

Solenoid

LP9-14LP9-14LP1-8LP1-8

Block Diagram of the Point-of-Care CR 120/140

System Description

6H4866-02 17

Page 18

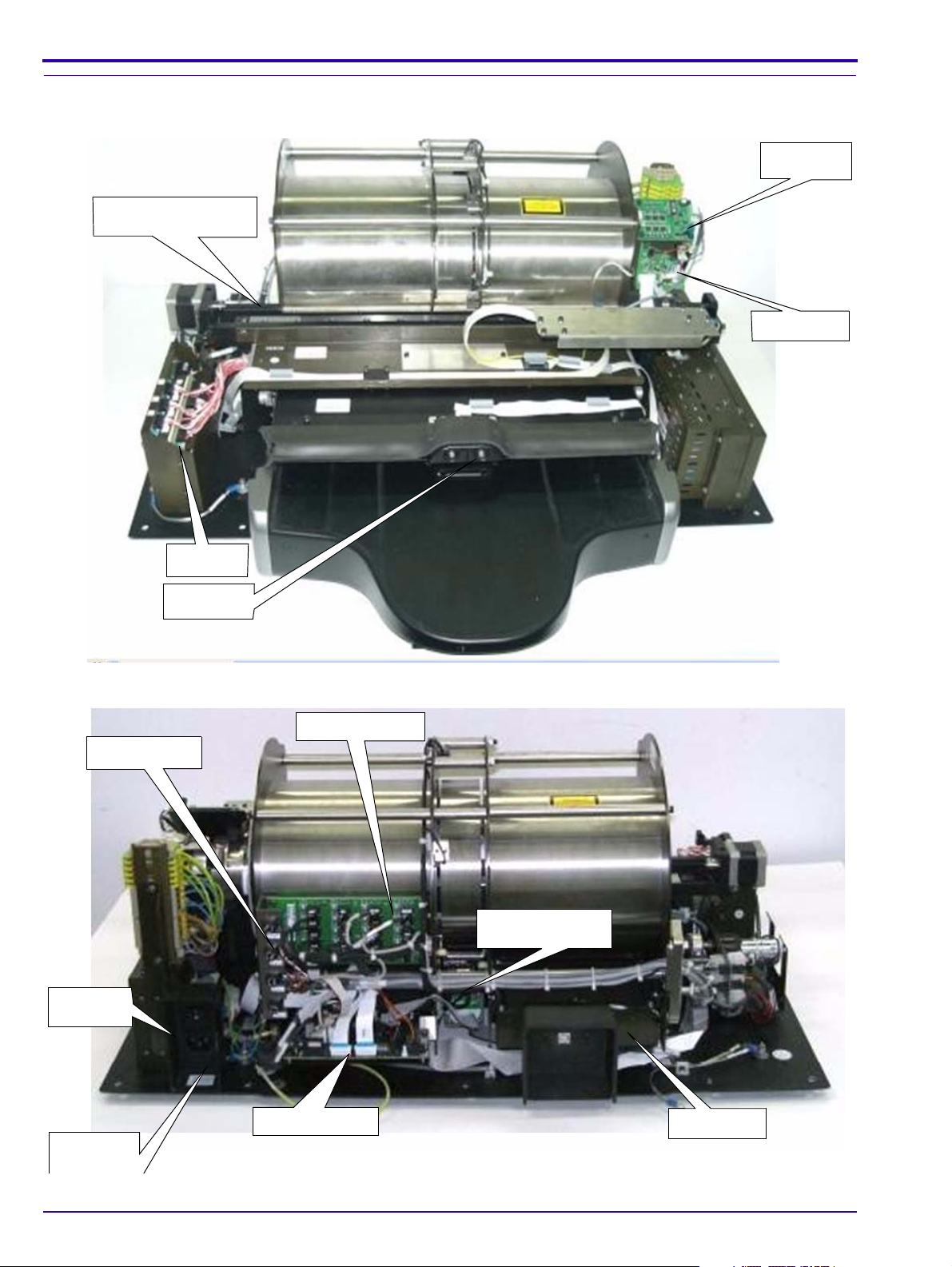

Views of PoC 120/140

LED Panel

Motor Driver

Laser Board

Inverters

Linear Slide Assembly

Sensor Board

Loader

Stepper Motor

USB Board

Motion Board

Erase Lamp

Fuses

Power Cord

Socket

On/Off

Switch

Scanner Front View

Scanner Rear View

18 6H4866-02

Page 19

Scanner Left View

Linear

Motor

Erase Lamp

Inverters

Roller

Sensor

Roller

Motor

Laser Unit

Power Supply

Unit

System Description

Scanner Right View

6H4866-02 19

Page 20

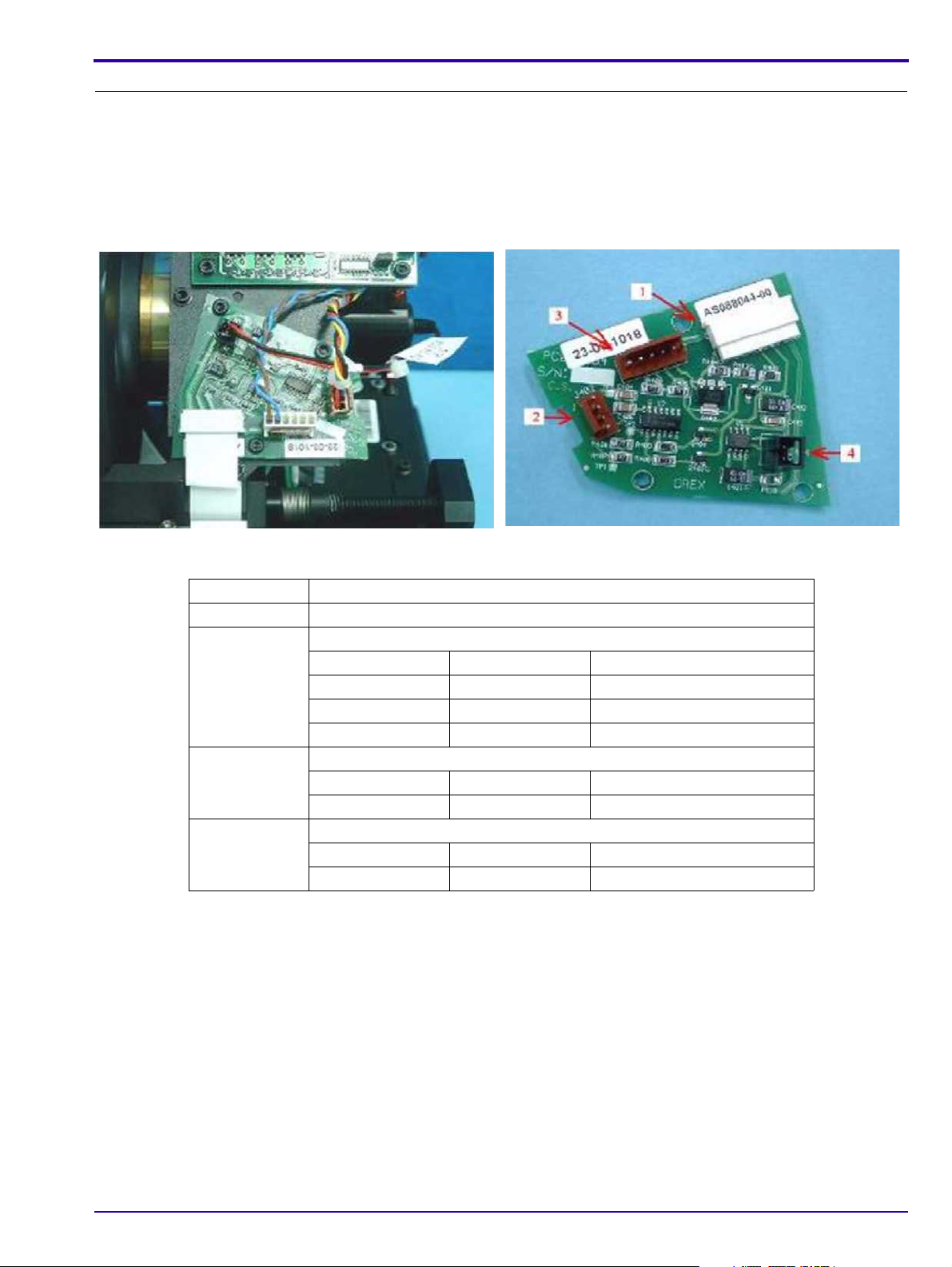

Component Description

1

2

3

4

5

6

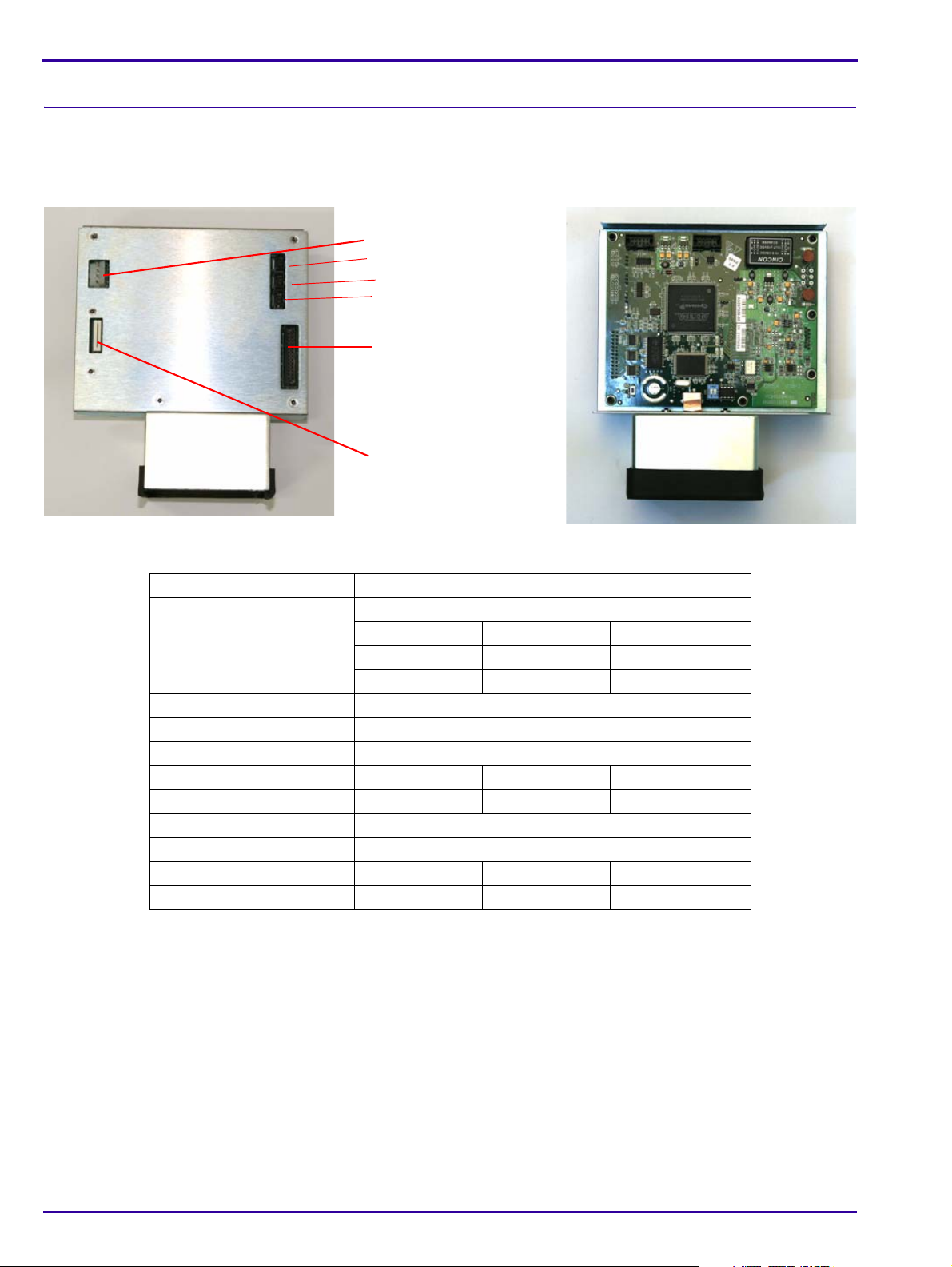

USB Board

The USB Board receives operational commands from the host PC workstation via the USB port, and sends the

commands to the appropriate Unit component. It also transmits image data from the Unit to the PC.

USB Board

USB Board Connections

Connector Destination

Connector 1 J7 5 V/12 V Power Supply

Connector 2 J3 Flat cable to J1 on PM Board

Connector 3 J1 Flex cable to J200 on Motion Board

Connector 4 J11 Barcode Connection

Connector 5 J6 Not in use

Connector 6 J4 Barcode Connection

Pin 1 White 5 V

Pin 2 Brown GND

Pin 4 Green 12 V

Pin 1 Red 5V

Pin 2 Black Gnd

Pin 1 Purple Signal

Pin 2 Brown Signal

20 6H4866-02

Page 21

Motion Board

1

2

3

4

6

8

7

5

9

10

11

12

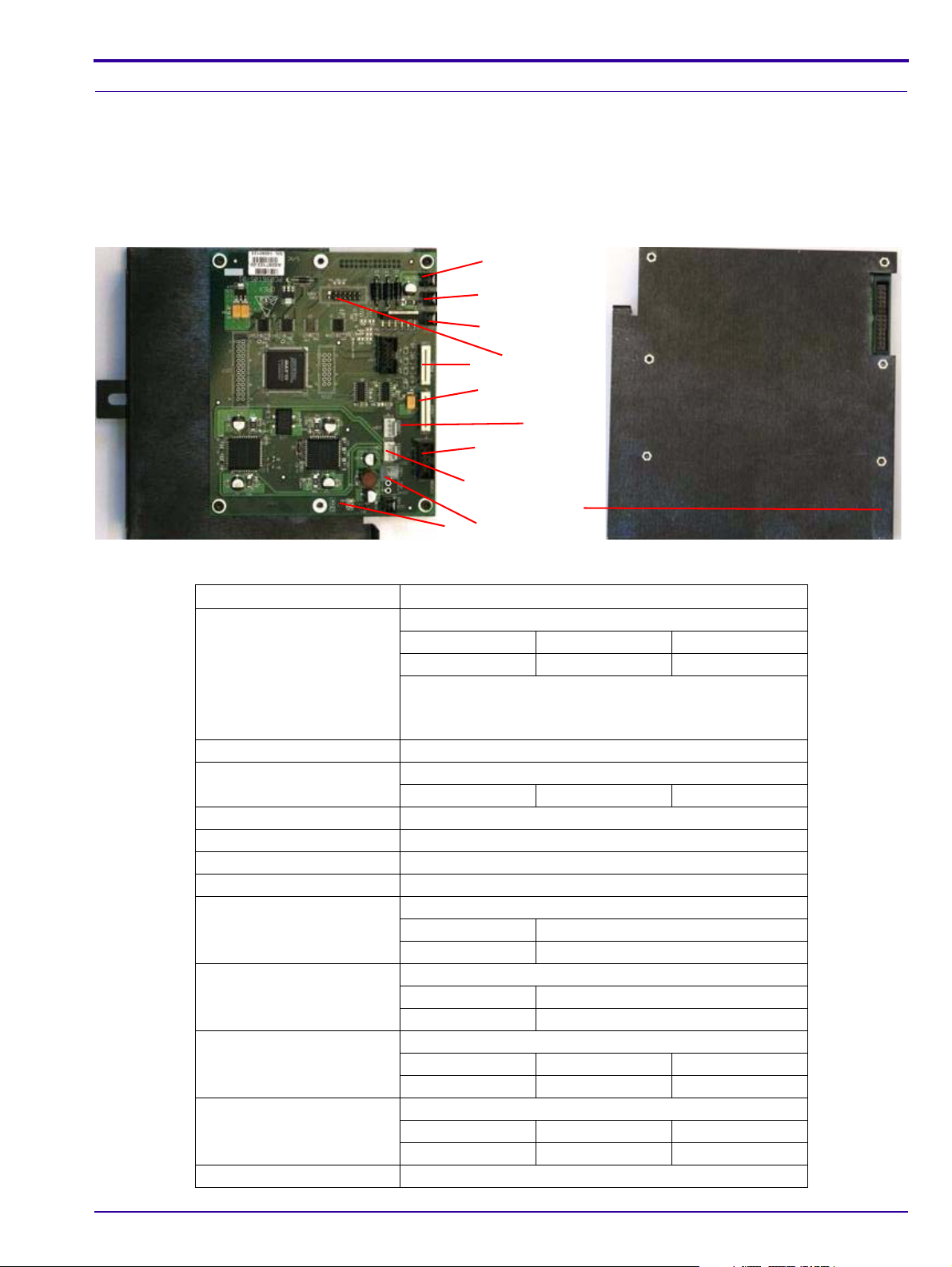

The Motion Board has the following functions:

• Controls the Loader and Roller Motors

• Controls the Erase Lamps

• Reads the Unit sensors and passes the information to the USB Board

Motion Board

System Description

Motion Board Connections

Connector Destination

Connector 1 J206 Connectors Panel (Rollers Motor)

Pin 1 orange 12 V

Pin 2 pink GND

Rollers forward +12 V

Rollers backwards -12 V

Rollers stop 0 V

Connector 2 J212 J212 on the Auto-loop Assemb ly

Connector 3 J213 12 V Power Supply

Pin 1 red 12 V

Connector 4 J205 J1 on Front Panel LED Board

Connector 5 J203 J401 on Laser Board

Connector 6 J208 J500 on Sensor Board

Connector 7 J202 J2 on Erase Lamps Inverters Assembly

Connector 8 J204 Loader carrier

Orange + blue 130 Hz load/unload

Red + yellow 130 Hz load/unload

Connector 9 J201 Stepper Motor

Connector 10 J211 15 V Power Supply

Connector 11 J215 5 V Power Supply

Connector 12 J302 on USB Board

6H4866-02 21

Yellow + green 11 KHz moving left/right; 0 KHz stop

Brown+ white 11 KHz moving left/right; 0 KHz stop

Pin 1 black 1 GND

Pin 2 black 2 15 V

Pin 1 brown GND

Pin 2 white 5 V

Page 22

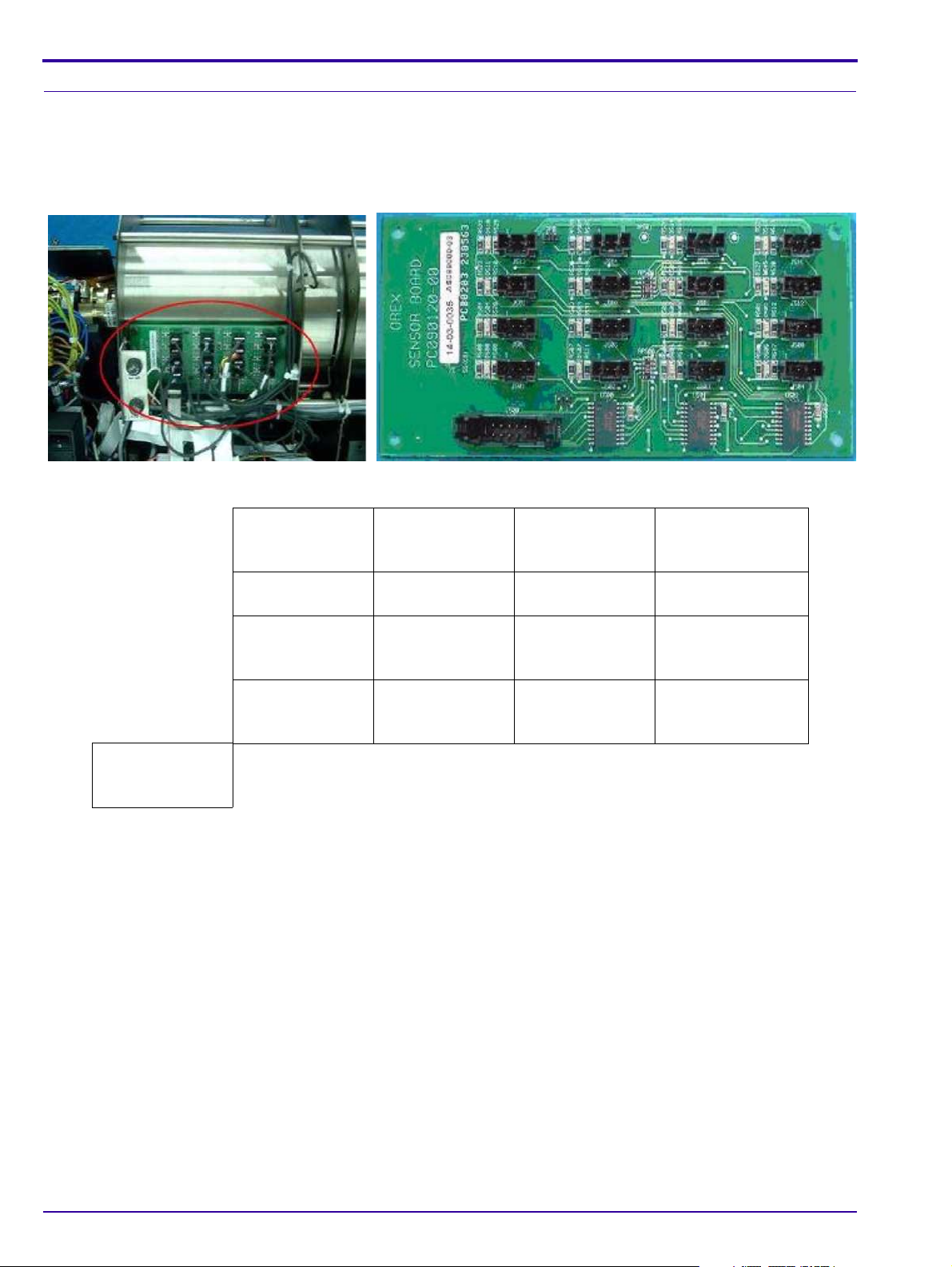

Sensor Board

Sensor Board Connections

The Sensor Board is a through board used to connect the sensors to the Motion Board.

Sensor Board

Sensor Board Connections

J500

To J208 on Motion

Board

J513

Cassette

Presence Sensor

J509

Roller Sensor

J505

Sensor 1 on the

Drum

J501

Sensor 4 on the

Drum

J514

Cassette Lock

Sensor

J510 J511

J506

Sensor 2 on the

Drum

J502

Sensor 5 on the

Drum

J515

Right Limit Sensor

W0 Sensor

J507

Sensor 3 on the

Drum

J503 J504 Auto-loop

J516

Left Limit Sensor

J512 15 x 30

Cassette Sensor

J508

Loader Sensor in

Back Position

Sensor

22 6H4866-02

Page 23

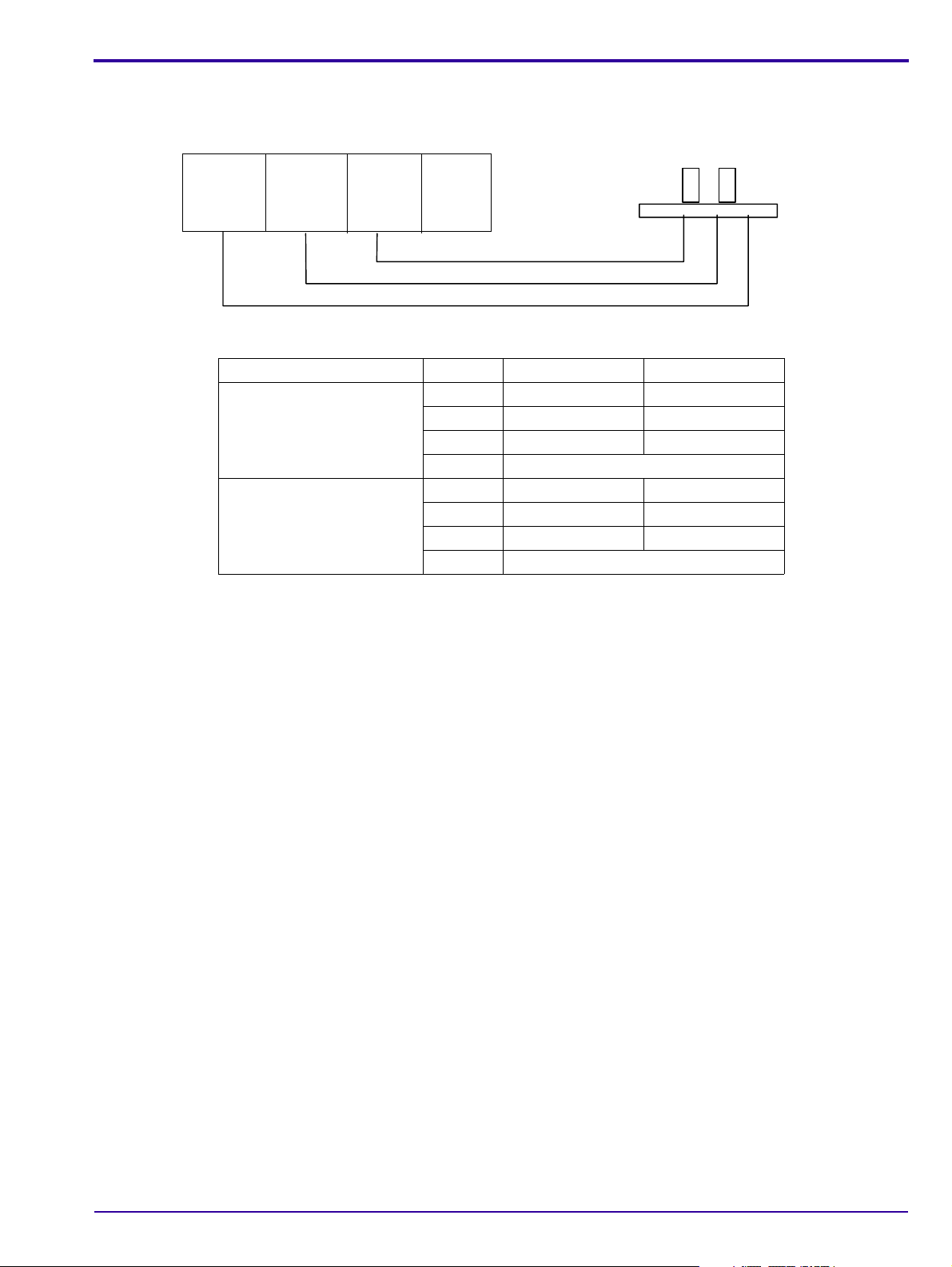

Typical Sensor Connections

1

(Brown)

5 V

2

(White)

Signal

3

(Blue)

GND

4

Not in

use

Connector

Sensor

Sensor Wiring Colors

Sensor Wire No. Wire Color Signal

Sensor On

(Flag in Sensor)

Sensor Off

(Flag not in sensor)

System Description

1 Brown 5 V always

2White 0 V

3 Blue GND always

4 Not in use

1 Brown 5 V always

2White 5 V

3 Blue GND always

4 Not in use

Measuring voltage:

1. All sensors except J511: measure between pin 2 & 3 and insert object between sensors.

2. For J511 only: measure between pin 2 & pin 3 and insert a scr een to system. The voltage shou ld be between 4.5

- 5 V.

6H4866-02 23

Page 24

PM Assembly

The Photo Multiplier (PM) Tube collects the photons emitted from the screen.

PM and PM Board

24 6H4866-02

Page 25

System Description

Optical Head Assembly

The Optical Head Assembly includes the Laser Module and the Rotational Motor that rotates the Laser Tube and a

mirror during scanning. The Laser Module’s beam illuminates the Phosphor screen and the mirror collects the light

reflected from the phosphor screen and directs it to the Photo Multiplier.

Laser Board

Laser Board

Laser Board Connections

Connector Destination

1 J401 on Motion Board CB080008

2 J402 Encoder Reader CB090014

Pin 1 Red GND

Pin 2 Black Index 41 ±0.5 Hz

Pin 3 Blue Encoder 41 ± 0.5 KHz

Pin 4 Yellow 5 V

3 J403 Rotation Motor Board CB090040

Pin 1 Blue GND

Pin 2 Brown 12 V Rotation Motor - On

4 J404 Laser Assembly CB090029

Pin 1 Red Laser On 3.3 V

Pin 2 Black GND

Laser Tube

The Laser Tube emits the light to energize the phosphorus screen.

6H4866-02 25

Page 26

Laser

26 6H4866-02

Page 27

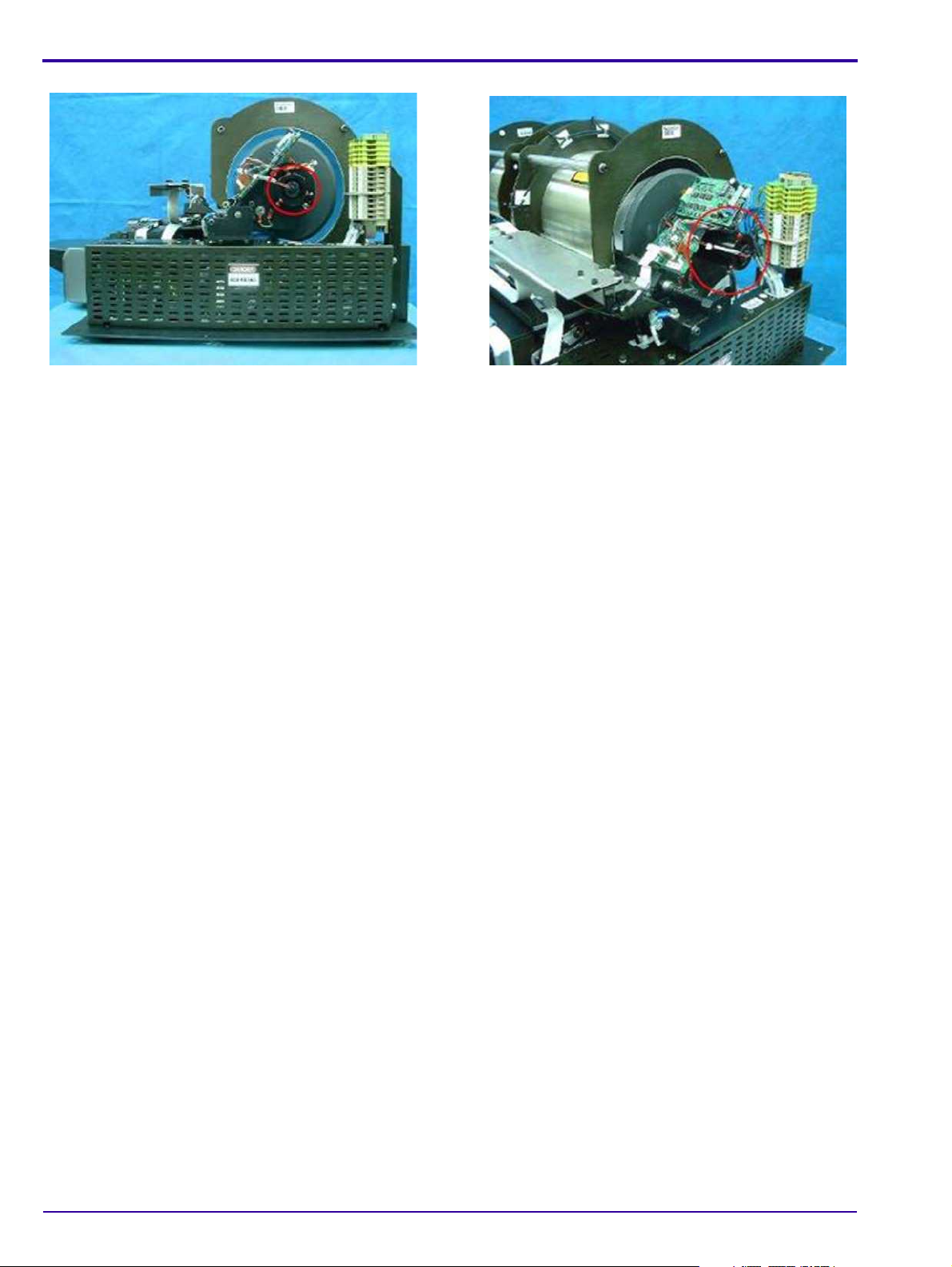

Roller Motor Assembly

Note

The Roller Motor Assembly pulls the phosphor screen from the Cassette into the Drum.

Roller Motor

Roller Motor Connector

System Description

Measure the voltage when the rollers are turning at full speed.

Roller Motor Connector

Connector Panel to the Roller Motor

Pin 1 Orange Rollers forward +15V

Rollers backwards -15 V

Rollers stop 0 V

Pin 2 Brown GND

6H4866-02 27

Page 28

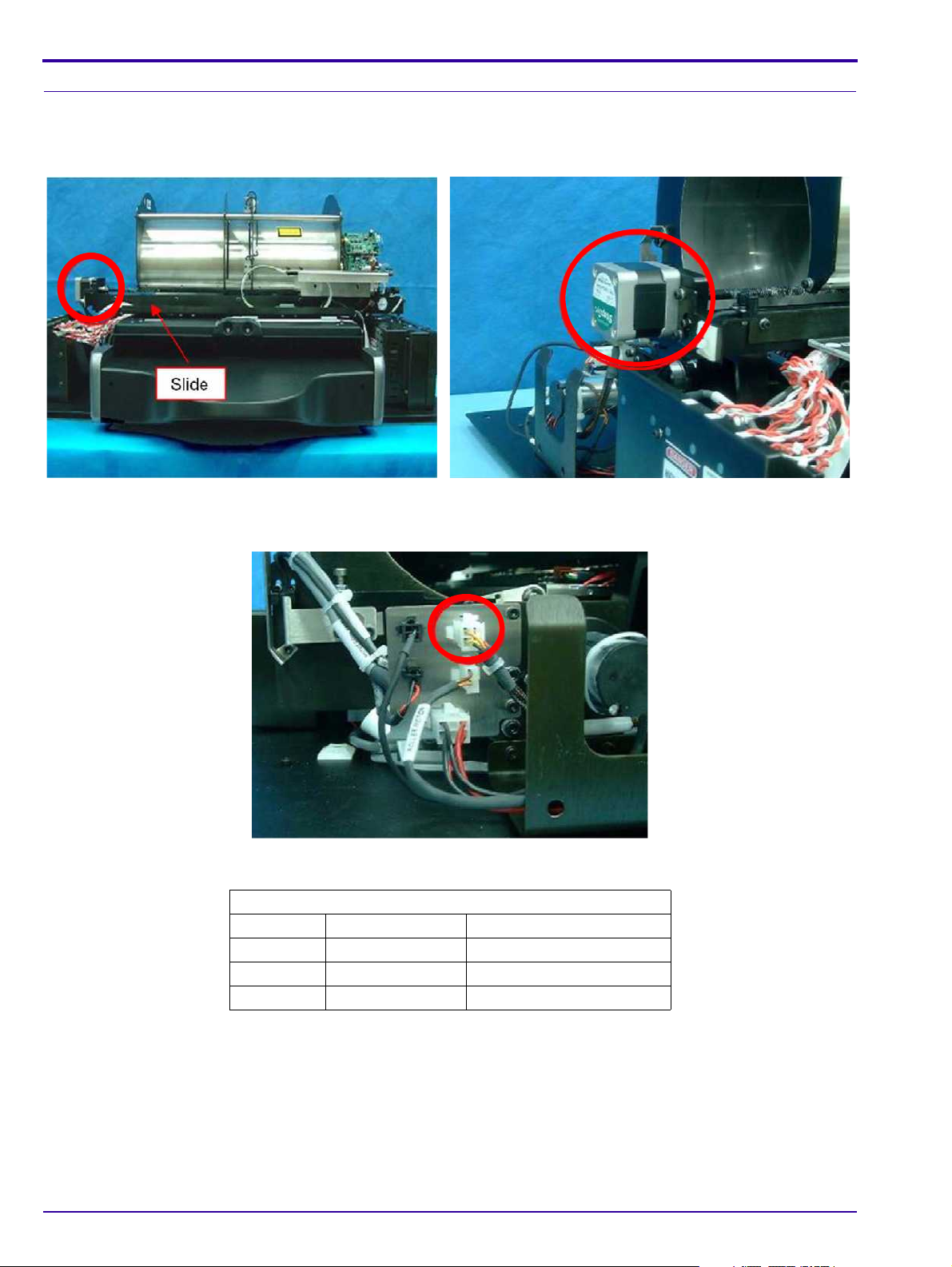

Linear Slide Assembly

The Linear Slide Assembly moves the PM and the Laser within the Drum to read the Phosphor Screen.

Linear Slide Assembly

Linear Slide Stepper Motor Connector

Slide Stepper Motor Connector

Connector Panel to the Slide Stepper Motor CB 090077

Pin 1 White Phase A

Pin 2 Orange Phase A

Pin 3 Yellow Phase B

Pin 4 Black Phase B

28 6H4866-02

Page 29

System Description

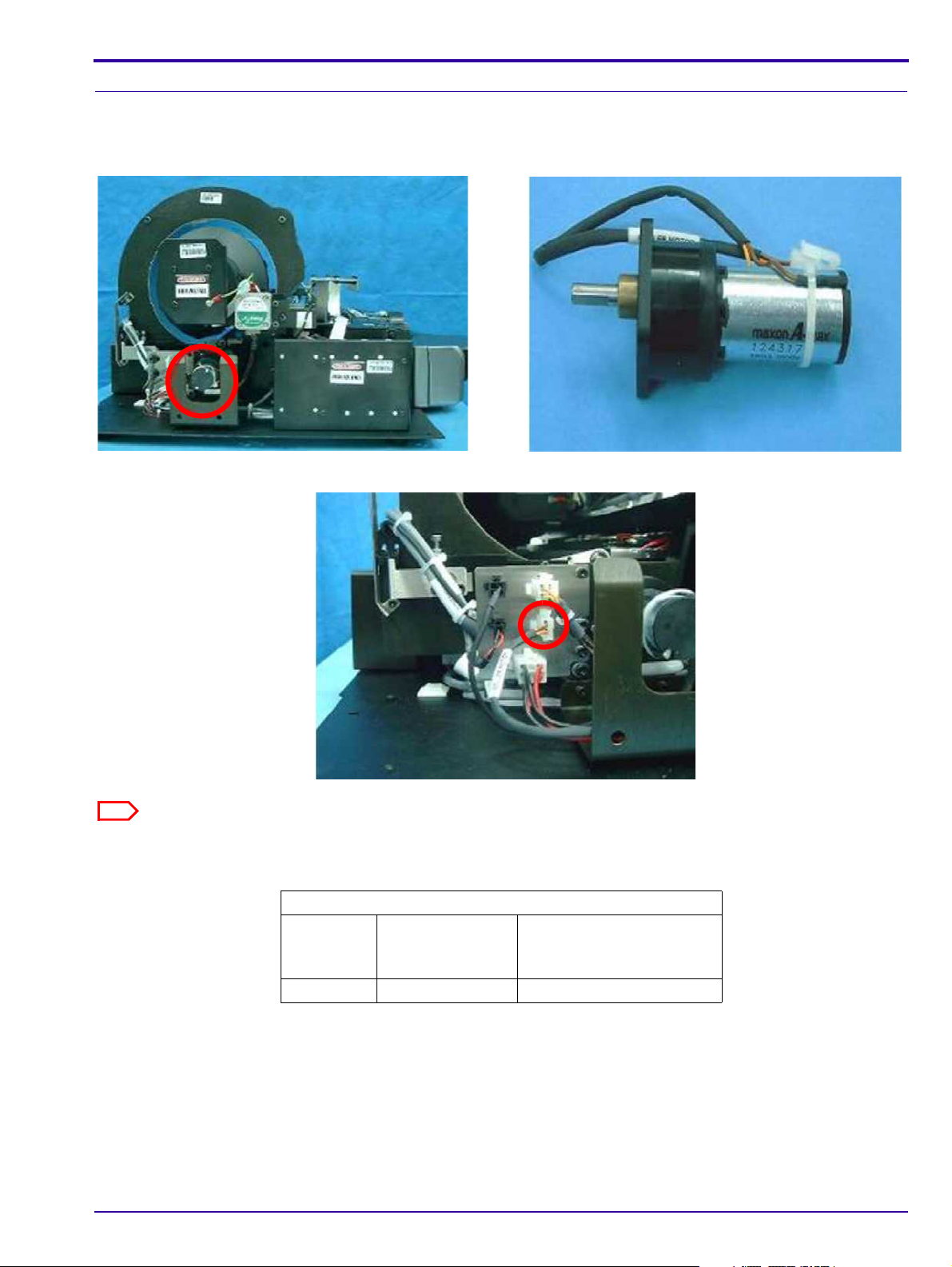

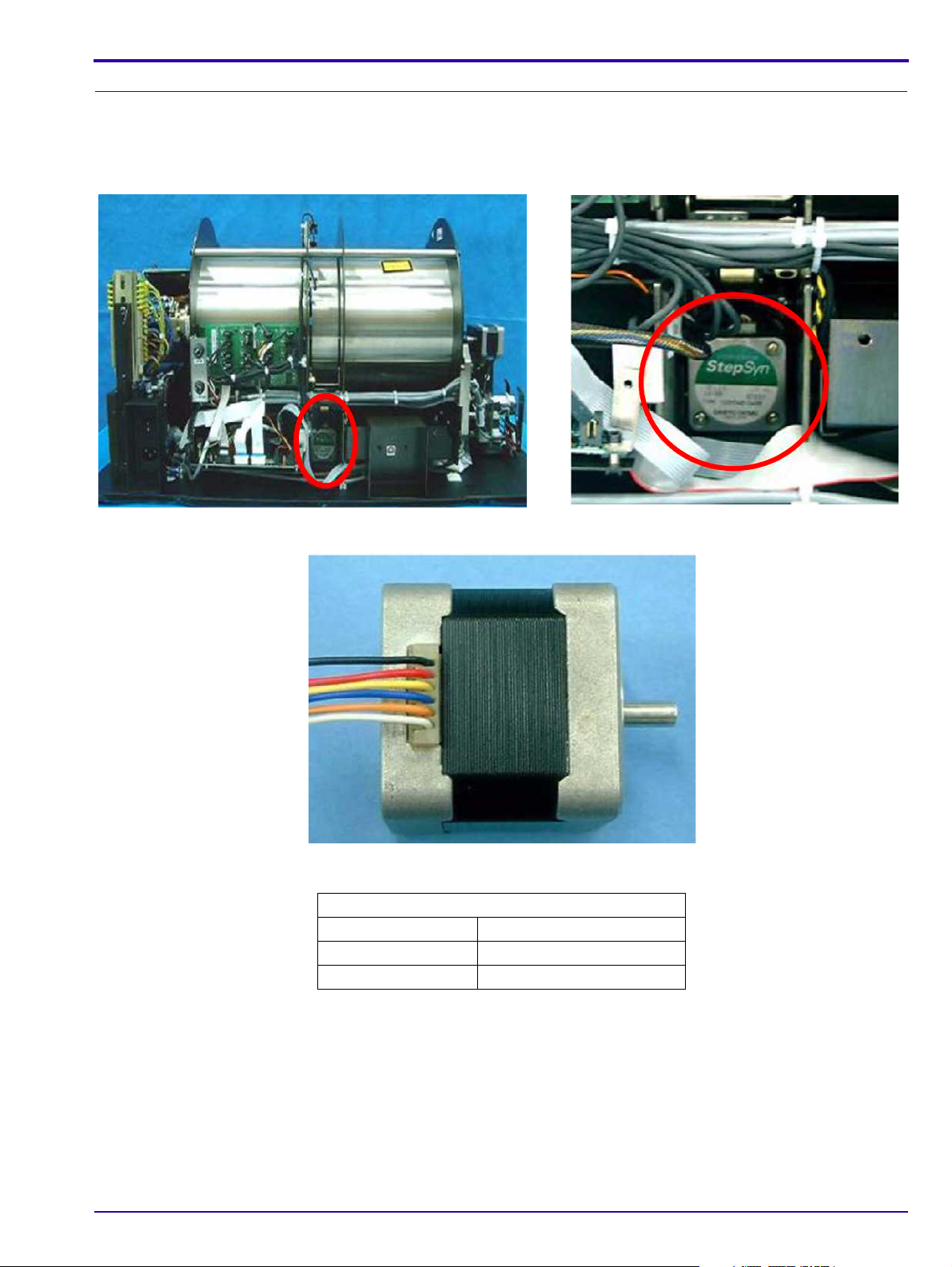

Loader Stepper Motor Assembly

The Loader Stepper Motor Assembly operates the mechanism which extracts the phosphor screen from the cassette

and assists in inserting the screen into the cassette.

Carriage Stepper Motor

Carriage Stepper Motor Wiring

Loader Stepper Motor Wiring

J204 on Motion Board

Orange + blue 130 Hz load/unload

Red + yellow 130 Hz load/unload

Black + white not in use

6H4866-02 29

Page 30

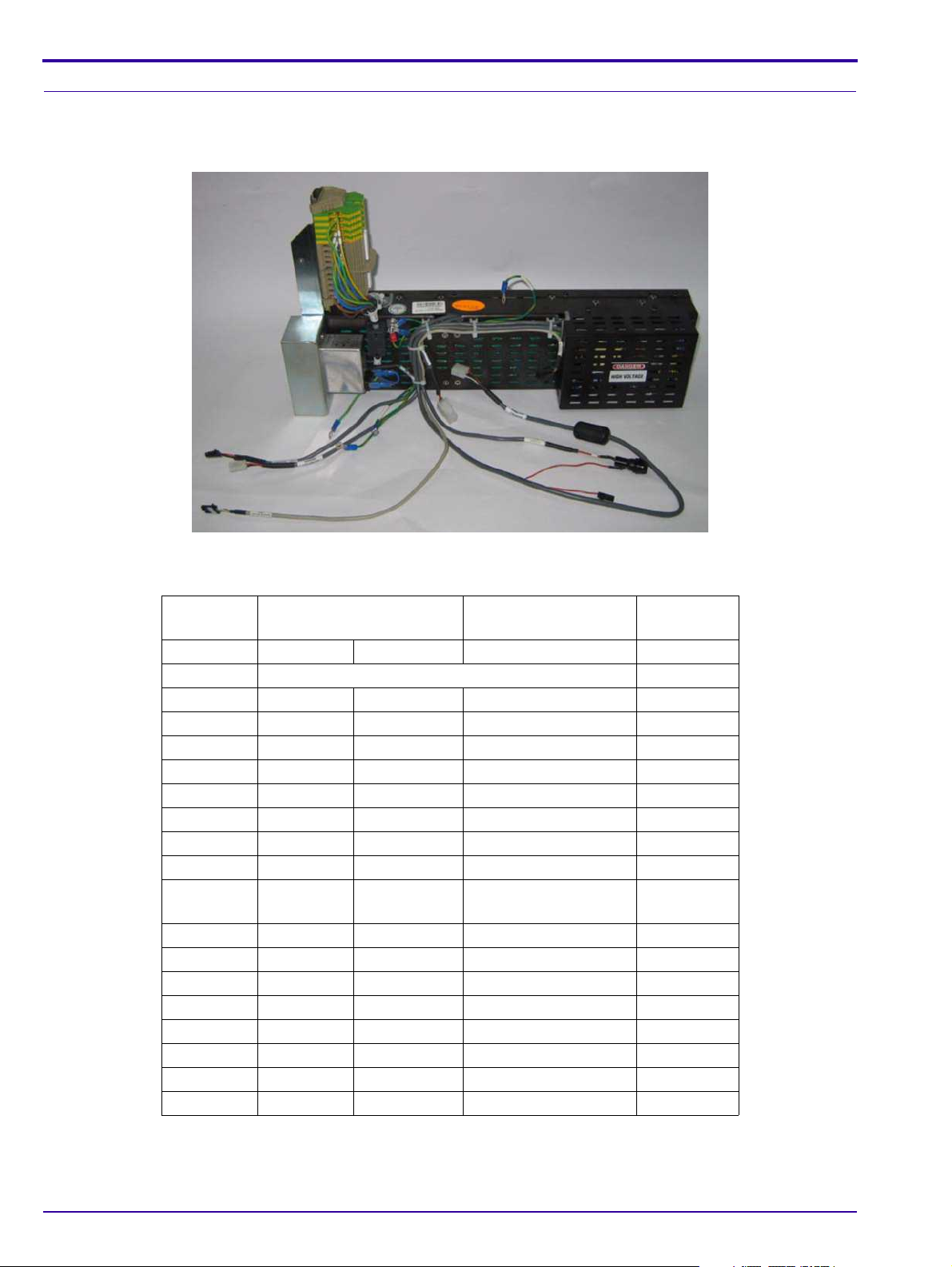

Power Supply Assembly

The AC/DC Power Supply provides DC power to the components of the unit.

Power Supply Assembly

Power Supply Connectors

Pin

Number System Type Destination Function

Pin 1 Red Black 1 15 V

Pin 2 Black 2 GND 0 V

Pin 1 Black 1 12 V

Pin 3 Red Brown 5 V

Pin 5 Black White GND 0 V

Pin 1 Red White 12 V

Pin 2 Black Brown 5 V

Pin 4 White Green GND 0 V

Pin 1 Red Black 1 15 V

Pin 2 Black Black 3 GND

Pin 3 White Black 2 15 V

Pin 4 Green Black 4 GND 0 V

ACL2/4 PoC120/140

Source: AC INPUT POWER

CB090065 CB090137 J211 on Motion Board

CB090071 CB 090141_a J213 on Motion Board

CB090064 CB090136-a J215 on Motion Board

CB090064 CB 090064_b J305 on USB Board

(power input)

CB090065 CB 090065_b Fuses Connector

30 6H4866-02

Page 31

System Description

Auto-loop Solenoid

Key Assembly

Tray Assembly

Key Assembly and Tray Assembly

These complementary assemblies guide the cassette into the sca nner and secure it in position for the duration of the

scanning process. The Auto-loop mechanism which is attached to the Key Assembly, controls the distance that the

screen is returned into the cassette at the end of the process.

Auto-loop Key Assembly and Tray Assembly

Auto-loop Key Assembly

6H4866-02 31

Page 32

Erase Lamps Assembly

3 2 4 1 3

The Erase Lamps brightly illuminate the phosphor screen to erase the image so that the screen is ready to be used

again.

Erase Lamps

Erase Lamp Assembly

Erase Lamp Voltages

Connector Destination

1 W0 Top to Connectors panel CB 090138

Pin 1 Brown 5 V

Pin 2 White GND 0 V

2 J1 CB 090140 Destination: Inverters

Pin 1 White 5 V

Pin 2 Brown Lamp on 0 V

Lamp off 2.5-5 V

Pin 3 Green Lamp on 0 V

Lamp off 2.5-5 V

Pin 4 Yellow GND

3Inverters

AC high voltage

4Not in use

32 6H4866-02

Page 33

System Description

Erase Lamps Inverter Assembly

The Inverter Assembly converts the 15 VDC input to a high voltage output to power the Erase Lamps.

Erase Lamps Inverter Assembly

Inverter Assembly Connections

Inverter Assembly Voltages

Connector Destination

1 J1 ON Lamp Sensor Board

Pin 1 White 5 V

Pin 2 Brown Lamp on 0 V

Lamp off 2.5 - 5 V

Pin 3 Green Lam p on 0 V

Lamp off 2.5 - 5 V

Pin 4 Yellow GND

2 J2 to J202 on Motion Board

3 P2 on 15 V power supply

Pin 1 Red 15 V

Pin 2 Black GND

4 AC - High voltage to Erase Lamps

6H4866-02 33

Page 34

Erase Lamp Sensor

2

1

The Erase Lamp Sensor detects an Erase Lamp failure.

Erase Lamp Sensor

Erase Lamp Sensor Connectors

Erase Lamp Sensor Voltages

1 Connected to Erase Lamp Board on the Inverter

Assembly

Pin 1 White 5 V

Pin 2 Brown Sensor 1 Lamp on 0 V

Lamp off 2.5 - 5 V

Pin 3 Green Sensor 2 Lamp on 0 V

Lamp off 2.5 - 5 V

Pin 4 Yellow Ground

2 Not in use

34 6H4866-02

Page 35

Left Limit Sensor and Right Limit Sensor

Refer to “Sensor Board Connections” on Page 22 for information on wiring connections.

Left Limit Sensor

System Description

Refer to “

Right Limit Sensor

Sensor Board Connections” on Page 22 for information on wiring connections.

6H4866-02 35

Page 36

Screen Size Sensor

There are four Screen Size Sensors that determine the size of the CR screen by the location of the screen guide that

is positioned by the screen as it is inserted into the drum.

Screen Size Sensor

Refer to “

Sensor Board Connections” on Page 22 for information on wiring connections.

36 6H4866-02

Page 37

Roller Sensor

The Roller Sensor detects when the screen enters and exits the rollers.

Roller Sensor

System Description

6H4866-02 37

Page 38

ZO Sensor

Z0 Sensor

The Z0 Sensor detects the presence of the screen in the Drum.

Refer to “

Z0 Sensor

Sensor Board” on Page 22 for information on wiring connections.

38 6H4866-02

Page 39

System Description

Top W0 Sensor

(receiver)

Bottom W0 Sensor

(transmitter)

WO Sensor

The W0 Sensor determines the activation and deactivation of the rollers according to screen presence at the

entrance to the Drum. The sensor has two parts, the Transmitter below the screen path which is accessible from the

bottom Service Panel; and the Receiver above the screen path which is inside the Drum.

Refer to “

Top WO Sensor

Sensor Board” on Page 22 for information on wiring connections.

Bottom W0 Sensor

6H4866-02 39

Page 40

Page 41

Section 3: Service Procedures

Service Tools

The following is a list of tools required for service operations:

• Phillips (cross) screwdriver (medium)

• Allen wrenches (metric): 1.5, 2, 2.5, 3, 4

•Cutters

• Long-nose pliers

• Digital voltmeter (DVM)

• ROM Chip (flash) extractor

Removing the Service Panel and Scanner Cover

Tools Required

Phillips screwdriver (medium)

Removing the Service Panel

Service Procedures

[1] Switch OFF the Unit.

[2] Remove the power cord from the Main Socket.

[3] Detach the Power Cord from the back of the Unit.

[4] Detach the USB cable.

Service Panel Screws

[5] Remove the screws securing the Service Panel on the rear of the unit, and remove the Service Panel.

6H4866-02 41

Page 42

Removing the Scanner Cover

Laser Warning

Caution

Do not operate the unit while the laser is connected without proper eye protection. Safety glasses, (see “Laser Safety

Instructions” on Page 12) must be worn by all personnel in the area of the unit! Authorized personnel only may

remove the cover. Before operating the unit without the cover, disconnect the lase r. (See “

on Page 44.)

[1] Pull the scanner to the edge of the t able so tha t one side is exten ded over the t able edge to gai n access to the

cover screws on that side and remove them.

[2] Pull the scanner to another side of the table, and remove the screws on that side; and so on, until all fourteen

screws are removed.

To remove screws from the bottom of the unit, do not turn it on its back. Move the unit to the edge of the worktable

to gain access from below.

Access to Cover Screws

Disconnecting the Laser”

Cover Screws

[3] Lift the cover off.

42 6H4866-02

Page 43

Reinstalling the Scanner Cover and Service Panel

[1] Reverse the above steps to reinstall the cover.

Service Procedures

6H4866-02 43

Page 44

Disconnecting the Laser

Important

The Laser must be disconnected befo re per fo rm in g an y pr oc ed ures that do not demand a functioning las er duri ng

servicing.

[1] Remove the Main Cover, (see See “

Laser Connector on the Laser Board

Removing the Service Panel and Scanner Cover” on Page 41.).

[2] Disconnect the Laser Connector from the Laser Board. Depress the latch of the connector firmly to release it.

[3] Reconnect the Laser only after all repairs are complete.

[4] Reinstall the Main Cover.

44 6H4866-02

Page 45

Replacing the Fuses

Pry out gently from

this plastic tab.

Tools Required

• Flat screwdriver

• Replacement fuse

Procedure

[1] Switch OFF the power and remove the power connector from the system.

[2] Locate the Fuse Drawer on the power inlet module.

Location of Fuses

Service Procedures

[3] Open the drawer using flat screw driver, prying gently from the plastic tab.

[4] Remove the blown fuse and replace it with a new one.

[5] Close the Fuse Drawer.

[6] Turn on the system and verify that it functions properly.

6H4866-02 45

Page 46

Power Inlet Module Replacement

Laser Warning

Important

Tools Required

• 5.5 mm Socket wrench

• 7.0 mm Socket wrench

• 2.5 x 75 mm flat screwdriver

Procedure

To avoid possible eye damage, before performing this procedure di sconnect the Laser as described in “Laser Board

Replacement” on Page 54. For additional laser precautions see “Disconnecting the Laser” on Page 44.

Before performing this procedure:

• Switch off the Scanner.

• Remove the power cord from the main socket.

• Detach the Power Cord from the back of the Scanner.

[1] Remove the Back Panel and the Main Cover (See “

Page 41.)

Removing the Service Panel and Scanner Cover” on

Nuts Securing the Module

[2] Open:

• Nuts on the side of the module

• Nut on the ground stud and remove the Line Filter Wire from the stud. Do not try to detach it from the Power

Module. (See Figure “

Nuts Securing the Module” on Page 46.)

46 6H4866-02

Page 47

Line Filter Wire Attached to Ground

Power Inlet

Module

[3] Disconnect the black numbered wires from the line filter on the input module.

[4] Remove the module and install the new one.

Side View of Power Module Showing Connection Tabs

Service Procedures

[5] Connect:

• Black numbered wires to the connection tabs of the new module.

• Yellow ground wire to the ground stud and tighten the nut

[6] Secure the input module to its location with the two nuts.

[7] Close the covers.

[8] Connect the system to the main power and confirm that the system is operating properly.

6H4866-02 47

Page 48

USB Board Replacement

Tools Required

2.0 mm Allen wrench

Removing the USB Board

[1] Disconnect the Scanner from the main power.

[2] Remove the Service Panel (see “

USB Cover

Removing the Service Panel and Scanner Cover” on Page 41).

[3] Remove the 2 USB cover screws.

USB Board Connectors

[4] Pull the USB Board out and disconnect the cables from the bottom of the board.

[5] Slide the USB Board out of the scanner.

Replacing the USB Board

[1] Slide the USB Board into the scanner.

[2] Reconnect the connectors.

[3] Insert the USB cover and fasten the USB cover screws.

[4] Perform the test procedures in the section below before assembling the Scanner Cover.

48 6H4866-02

Page 49

Service Procedures

Laser Warning

[5] Assemble the Service Panel.

[6] Perform calibration as outlined in “

Calibrations” on Page 10 7.

Test Procedure

When a service operation is taking place with the cover removed, disconnect the Laser according to the procedure

in “

Laser Board Replacement” on Page 54. If the Laser must be activated during the servic e procedure, wear

protective safety glasses at all times.

[1] Confirm that the USB Board functions by performing the following test:

(a) Make sure that the computer recognizes that a USB device has been connected. The USB device icon

should appear in the system tray in the lower right corner of the screen.

(b) Perform:

• Scan without the cover in place. The preview imag e sh ou ld be bla ck.

• Scan with the cover in place, without tightening the screws. The preview image should be white.

(c) Tighten the screws.

(d) Perform a scan with an actual image and check image quality and position.

(e) Open the “About” screen in Setup, and check that the version number of the hardware and software are

correct.

6H4866-02 49

Page 50

Motion Board Replacement

Tools Required

2.0 mm Allen wrench

Removing the Motion Board

[1] Disconnect the Scanner from the main power.

[2] Remove the service panel (see See “

Motion Board Bracket Screws

Removing the Service Panel and Scanner Cover” on Page 41.).

[3] Remove the two 2.5 mm Allen screws securing the Motion Board bracket and pull the Motion Board forward

Motion Board Connectors

[4] Disconnect the cables from the Motion Board.

Replacing the Motion Board

[1] Slide the Motion Board into the scanner housing.

[2] Reconnect the connectors to the Motion Board.

[3] Insert the two Motion Board retaining screws.

[4] Assemble the Service Cover.

Test Procedure

[1] Verify that the Motion Board functions properly by operating the system.

50 6H4866-02

Page 51

Service Procedures

Note

Sensor Board Replacement

Tools Required

2 mm Allen wrench

Removing the Sensor Board

[1] Remove the Service Panel (see See “Removing the Service Panel and Scanner Cover” on Page 41.).

Sensor Board Connections

[2] Remove the electrical connectors from the Sensor Board.

Sensor Board Screws

[3] Remove the four 2.5 mm Allen screws securing the Sensor Board.

Replacing the Sensor Board

[1] Insert the four Sensor Board retaining screws.

[2] Insert the connectors to the Sensor Board.

Each connector is marked with a number to indicate its location.

[3] Assemble the Service Cover.

Test Procedure

[1] Verify that the Motion Board functions properly by operating the system.

6H4866-02 51

Page 52

PM Tube and PM Board Replacement

Laser Warning

Tools Required

3.5 mm Allen wrench

Removing the PM Tube

To avoid possible eye damage, be fore operating the unit witho ut the cover, disconnect the laser (see “Disconnecting

the Laser” on Page 44). For additional laser precautions see “Laser Safety Instructions” o n Page 12. Only authorized

personnel may remove the cover.

[1] In the Diagnostic tab and move the optical head to the left position.

[2] Remove the scanner Main Cover (see “

PM Ground Wire

Removing the Service Panel and Scanner Cover” on Page 41).

[3] Disconnect the 3.0 mm Ground wire connector to the Slide body from the PM Tube.

Connector to the PM Board

[4] Disconnect the flex cable from its connector at the bottom of the PM Board.

52 6H4866-02

Page 53

Service Procedures

Note

PM Assembly Screw (one side shown)

[5] Remove the 4.0 mm retaining screws securing the PM Assembly to the bracket.

[6] Remove the PM Tube.

PM Assembly Lower Screw

Replacing the PM Tube

Bracket retaining screws: There are two sizes of screw; the right-side screw is long, and the bottom screw is short.

[1] Insert the short 4.0 mm Bottom Bracket retaining screw, but do not tighten it yet.

[2] Insert and leave loose the long 4.0 mm right-side bracket retaining screw.

[3] Push the PM Tube forward towards the Drum until the screws line up with the holes, and tighten the retaining

screws.

[4] Reconnect the Blue Ribbon USB Connector to the bottom of the PM Tube.

[5] Insert the Blue Ribbon USB Cable into the plastic clip on the PM Tube.

[6] Reconnect the 3.0 mm ground wire connector to the Slide body.