Page 1

TECHNICAL DATA / CHEMICALS FOR MINILABS

Choosing the Right Chemicals for

Your Minilab

April 2000 • J-36

This publication describes KODAK Chemicals designed

specifically for minilabs. It provides recommended cycles

for processing the following films with KODAK

FLEXICOLOR Chemicals in Processes C-41RA, C-41B,

and C-41

KODAK EKTACOLOR Papers with KODAK

EKTACOLOR PRIME SP, EKTACOLOR PRIME, an d

EKTACOLOR RA Chemicals for Process RA-4.

manufacturing films, papers, and chemicals that reduce the

impact of photoprocessing on the environment. KODAK

EKTACOLOR PRIME SP Developer Replenisher is a new

developer for EKTACOLOR Papers that offers even more

beneficial features. Formulated in a single part, it is

convenient and easy to use. Intended for minilabs with

average to high utilization, it will give consistent print

quality with less effluent discharged and less packaging

waste than KODAK EKTACOLOR PRIME Developer

Replenisher. (See CHOOSING A PAPER PROCESS for

more information on the availability and features of this new

product.)

your minilab’s design an d i ts level of utilization, choosing

the chemicals recommended in this publication ens ures that

you are using chemicals that provide optimum results with

the smallest possible environmental impact. We continue to

develop new products that will further reduce chemical use

and discharge.

*

:

KODAK ROYAL GOLD Films

KODAK GOLD Films

KODAK MAX Films

KODAK Black & White + 400 Film

KODAK ADVANTIX 100, 200, and 400 Films

KODAK ADVANTIX Black & White + 400 Film

KODAK PROFESSIONAL SUPRA Films

KODAK PROFESSIONAL PORTRA Films

It also includes the recommended cycles for processing

For decades, Kodak has been designing and

Although your choice of chemicals may be limited by

CHOOSING A FILM PROCESS

To determine which chemicals to use for your film process,

locate the process cycle that best matches the sequence of

processing steps and process times of your minilab.

The following section describes the three basic process

cycles for films, and includes a listing of the appropriate

KODAK FLEXICOLOR Chemicals for each cycle. You can

use any of these cycles with or without a wash step. If you

select a washless cycle, carefully follow the

recommendations in the footnotes.

Note: This publication does not discuss KODAK

FLEXICOLOR SM and EKTACOLOR SM Chemicals,

which are designed for use only in specific minilabs. For

detailed information on these chemicals, see KODAK

Publication No. Z-101, Using KODAK SM Chemicals in SM

Minilabs.

Use the cycles in this publication as guides. You may

have to modify a cycle slightly to suit the design of your

processor. The replenishment rates for each cycle are

intended for a typical mix of Kodak color negative films.

For more detailed information, see KODAK Publication

No. Z-100, Using KODAK Chemicals in Minilabs, or Z-131,

Using KODAK FLEXICOLOR Chemicals.

* Do not process films of older design th at require a stabilizing agent for

image stability in minilab processes using KODAK FLEXICOLOR Fi nal

Rinse and Replenisher . These films a re KODAK VERICOLOR III Film,

VERICOLOR Slide Film / SO-279/5072, and VERICOLOR Print

Film 4111. Pro cess these films only in a processor that uses

FLEXICOLOR Stabilizer III and Replenisher.

©Eastman Kodak Company, 2000

Page 2

Process C-41RA

This film process cycle is the shortest of the Process C-41

cycles, and the one most commonly used in minilabs. You

must use KODAK FLEXICOLOR RA Bleach Replenisher

NR and KODAK FLEXICOLOR RA Fixer and

Replenisher in this cycle.

Process C-41RA requires special equipment that

accommodates the shorter solution times, and the processor

must provide higher agitation in the bleach, fixer, and final

rinse. Check with your minilab manufacturer to determine if

your processor meets Process C-41RA specifications.

Although Process C-41RA is intended to be a washless

cycle, you can use it with a processor that includes a final

wash if it meets the time and agitation requirements.

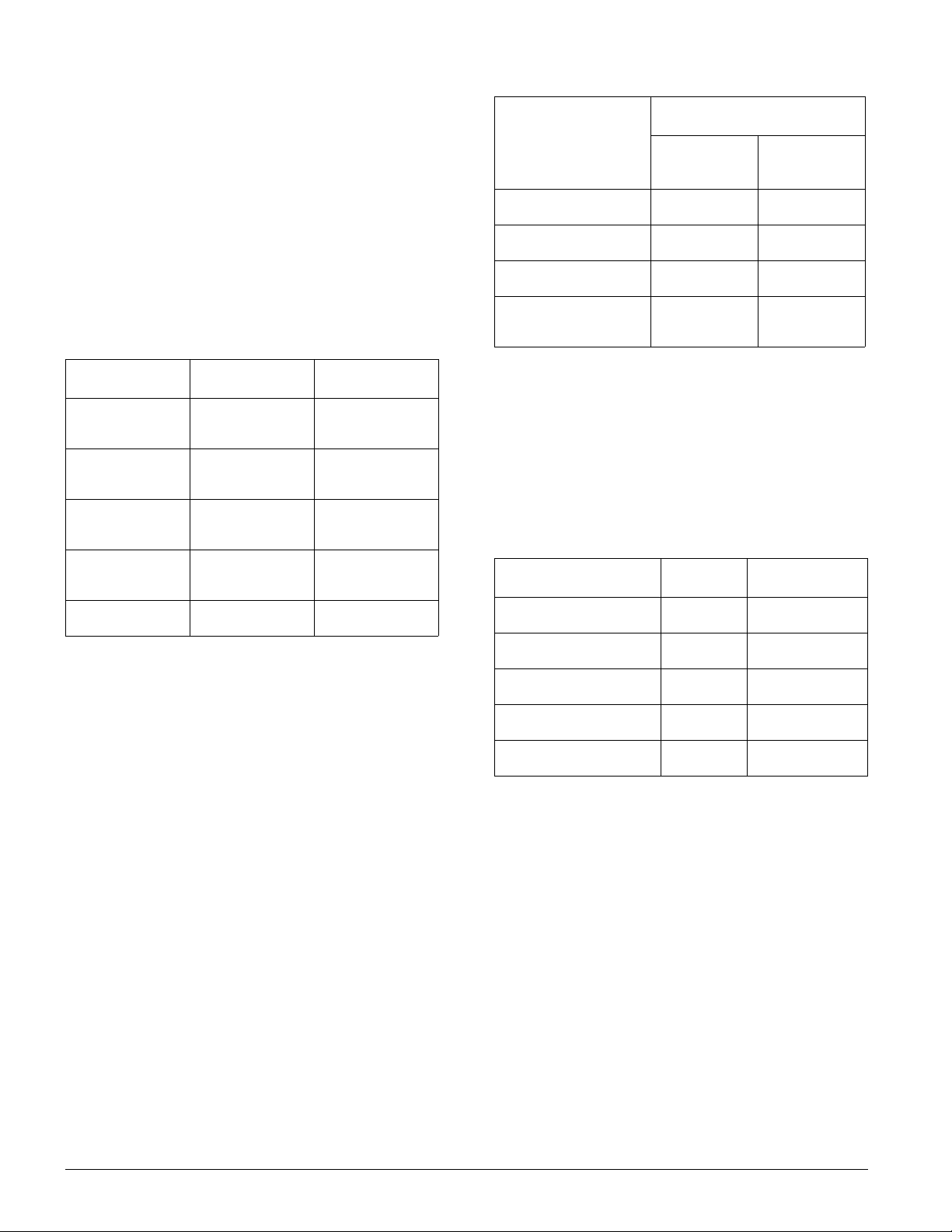

Process C-41RA Cycle

*

Solution/Step

Time

min:sec

FLEXICOLOR

Developer

3:15

Replenis her LORR

FLEXICOLOR RA

Bleach Replenisher

†

NR

1:00

FLEXICOLOR RA

Fixer and

Replenisher

‡

1:30 to 2:00

FLEXICOLOR

Final Rinse and

Replenisher

§

1:00

Dry As needed

* Immersion time plus crossov er time to the ne xt tank. Bleach, fixer, and

final rinse times are minimums; longer times are acceptable.

† U se only KODAK FLEXICOLOR RA Bleach Replenisher NR. Your

equipment must provide the hi gher agitation required for this solution.

‡ U se only KODAK FLEXICOLOR RA Fixer and Replenis her. Use two

countercurrent-flow fixer tanks with equal times in both tanks (0:45 to

1:00 in each tank). Your equipment must provide the higher ag itation

required for this solution.

§ U se three countercurrent-flow final rinse tanks with equal times in

all tanks (0:20). Your equipment must provide the higher agitation

required for this solution. Replenish the third final rinse tank at

40 mL/135-24 roll (36 mL/m). If your processor has two

countercurrent-flow final rinse tanks followed by a single tank,

replenish the second countercurrent tank at 40 mL/135-24 roll

(36 mL/m) and the single tank at 20 mL/135-24 roll (18 mL/m). For

minilabs with a final wash after the fixer, use a wash time of 1: 40 and

reduce the final rinse time to 40 sec onds. Use a wash rate of

1250 mL/135-24 roll (330 mL/ft) for a two-stage countercurrent-flow

wash. Double this rate for a single wash. Use a final rinse

replenishment rate of 33 mL/135-24 roll.

Temperature

°C (°F)

37.8 ± 0.15

(100.0 ± 0.25)

38 ± 3

(100 ± 5)

38 ± 3

(100 ± 5)

38 ± 3

(100 ± 5)

40 to 68

(104 to 155)

Starting-Point Reple nish men t Rates—

Process C-41RA

Starting-Point

Replenishment Rate

Solution

FLEXICOLOR Developer

Replenis her LORR

FLEXICOLOR RA

Bleach Replenisher NR

FLEXICOLOR RA Fixer

and Replenisher

mL/135-24 Roll

(mL/m)

19 (17) 11.1 (10.2)

5 (4.5) 3.4 (3.1)

35 (32) 24 (22)

mL/25-Exp

ADVANTIX Film

(mL/m)

*

FLEXICOLOR

Final Rinse and

40 (36) 27 (25)

Replenisher

* These rates are averages based on an es timated film-speed mix in

25-exposure rolls of KODAK ADVANTIX Films.

Process C-41B

The primary feature of this cycle is that it is shorter than

the standard Process C-41 cycle. It eliminates both washes

and uses a shorter fixer time. Most minilabs that use

Process C-41B use the washless version. However, if your

minilab includes a final wash, see footnote

Process C-41B Cycle

Solution/Step

FLEXICOLOR Developer

Replenis her LORR

FLEXICOLOR Bleach III

NR Replenisher

FLEXICOLOR Fixer and

Replenisher

FLEXICOLOR Final Rinse

and Replenisher

†

‡,§

Dry As needed

* Immersion time plus crossover time t o the next t ank. Bleach, fi xer , and

final rinse times are minimums; l onger times are acceptable.

† U se two coun te rcurre nt- flow fix er t anks with eq ual times in both t a nks

(2:00 to 2:10 in each tank).

‡ U se three countercurrent-flow final rinse tanks with equal times in all

tanks (0:47 in each t ank).

§ If your min ilab u ses a fina l wash, a lso i nsta ll a wash bet ween the fixer

and final rinse with a wash time of 1:40. Reduc e the final rinse time

to 40 seconds, and use a replenishment rate of 35 mL/135-24 roll

(32 mL/m). Use a wash-flow rate of 1250 mL/135-25 roll (1080 mL/m)

for a two-stage countercurrent wash or 2500 mL/135-24 roll

(2160 mL/m) for a single-stage wash.

Time

min:sec

3:15

3:00 to 4:20

4:00 to 4:20

2:20

§

, below.

*

Temperature

°C (°F)

37.8 ± 0.15

(100.0 ± 0.25)

38 ± 3

(100 ± 5)

38 ± 3

(100 ± 5)

38 ± 3

(100 ± 5)

40 to 68

(104 to 155)

2 Choosing the Right Chemicals for Your Minilab • J-36

Page 3

Starting-Point Reple nish men t Rates—

Process C-41B

Starting-Point Reple nish men t Rates—

Process C-41

Starting-Point

Replenishment Rate

Solution

FLEXICOLOR Developer

Replenis her LORR

FLEXICOLOR Bleach III

NR Replenisher

FLEXICOLOR Fixer and

Replenisher

FLEXICOLOR Final Rinse

and Replenisher

* These rates are averages based on an estimated film-speed mix in

25-exposure rolls of KODAK ADVANTIX Films.

mL/135-24

Roll

(mL/m)

mL/25-Exp

ADVANTIX Film

(mL/m)

19 (17) 1 1.1 (10.2)

5 (4.5) 3.4 (3.1)

35 (32) 24 (22)

40 (36) 27 (25)

*

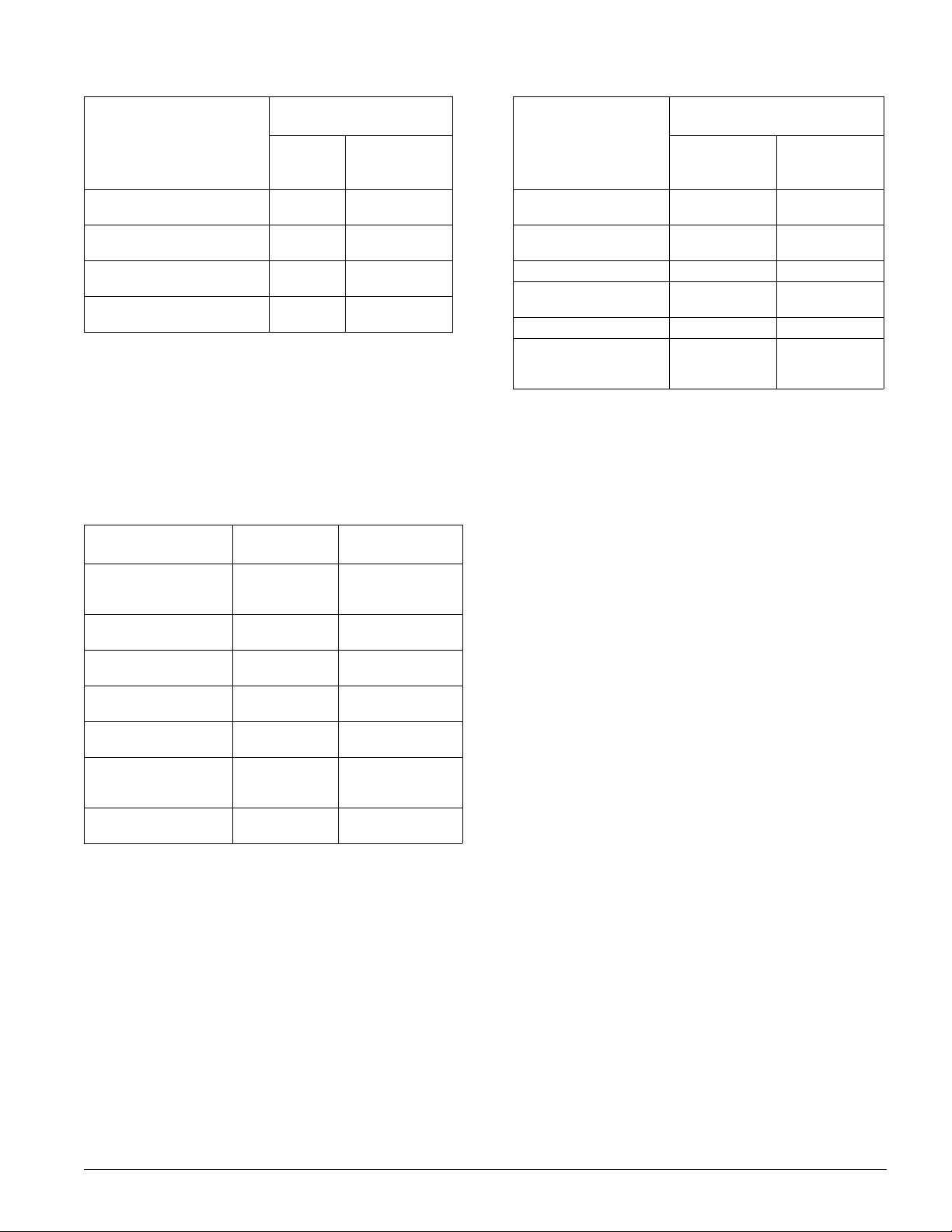

Process C-41

This process cycle is sometimes used in older minilabs. It most

commonly includes water washes. To use the washless version

of this cycle, follow the recommendations in the second

footnote under the table.

Process C-41 Cycle

*

Solution/Step

Time

min:sec

FLEXICOLOR

Developer Replenisher

3:15

LORR

FLEXICOLOR Bleach

III NR Replenisher

†

Wash

FLEXICOLOR Fixer

and Replenisher

†

Wash

‡

4:20 to 6:30

1:00 to 3:15

4:20 to 6:30

2:10 to 3:15

FLEXICOLOR

Final Rinse and

1:05

Replenisher

Dry As needed

* Immersion time plus c rossover time to t he next tank. Bleach, fixer, and

final rinse times are minimums; longer times are acceptable.

† Use a two-stage countercurrent-flow wash. For a single-stage wash,

double the replenishment rate.

If your minilab uses a final rinse step i nstead of a f inal wash, eli minate

both washes. Use three coun tercurrent-flow final rinse tanks with a

minimum final rinse time of 2:20 (0:47 in each tank). Use a final rinse

temperature of 38 ± 3°C (100 ± 5°F) and a replenishment rate of

40 mL/135-24 roll (36 mL/m).

‡ U se two countercurrent-flow fixer tanks with equal times in both tan ks

(2:10 to 3:15).

Temperature

°C (°F)

37.8 ± 0.15

(100.0 ± 0.25)

38 ± 3

(100 ± 5)

24 to 41

(75 to 105)

38 ± 3

(100 ± 5)

24 to 41

(75 to 105)

24 to 41

(75 to 105)

40 to 68

(104 to 155)

Starting-Point

Replenishment Rate

Solution/Step

mL/135-24 Roll

(mL/m)

FLEXICOLOR Developer

Replenis her LORR

FLEXICOLOR Bleach III

NR Replenisher

19 (17) 11.1 (10.2)

5 (4.5) 3.4 (3.1)

Wash 1250 (1080)

FLEXICOLOR Fixer and

Replenisher

35 (32) 24 (22)

Wash 1250 (1080)

FLEXICOLOR

Final Rinse and

35 (32)

‡

mL/25-Exp

ADVANTIX Film

(mL/m)

†

850 (734)

†

850 (734)

27 (25)

*

†

†

‡

Replenisher

* These rates are averages based on an es timated film-speed mix in

25-exposure rolls of KODAK ADVANTIX Films.

† F or a two-stage countercurrent -flow wash. Double this rate for a

single-stage wash.

‡ If your minilab uses a final rinse instead of was hes, use a

replenishment rate of 40 mL/135-24 roll (36 mL/m) or

27 mL/25-exposure roll (25 mL/m) of ADVANTIX Film.

Monitoring Your Film Process

Use KODAK Control S t rips , P ro cess C -41, to monitor your

film process. Follow the procedures described in KODAK

Publication No. Z-100, Using KODAK Chemicals in

Minilabs, or Z-131, Using KODAK FLEXICOLOR

Chemicals.

Choosing the Right Chemicals for Your Minilab • J-36 3

Page 4

CHOOSING A PAPER PROCESS

KODAK EKT ACOLOR PRIME SP Developer Replenisher

is a new paper developer that is replacing the following

products:

KODAK EKTACOLOR PRIME Developer

Replenisher

KODAK EKTACOLOR PRIME Developer

Replenisher LORR

KODAK EKTACOLOR PRIME Developer

Regenerator

Because the new developer will not be available in all

regions at the same time, this publication includes

recommendations for EKTACOLOR PR IME SP Develop er

Replenisher and the products it will replace.

Most minilabs have been able to use EKTACOLOR

PRIME Chemicals and realize cost savings and reductions in

processing-solution waste. EKTACOLOR PRIME SP

Developer Replenisher offers even greater advantages:

easier mixing with a single-part concentrate, further

reductions in replenishment rates and effluents for users of

EKTACOLOR PRIME Developer Replenisher, and less

packaging waste. (For information about converting, see

Converting to KODAK EKTACOLOR PRIME SP Developer

Replenisher.)

If your lab operates at low utilization or if your equipmen t

has a roller-transport design, KODAK EKTACOLOR RA

Developer Replenisher RT w ill cont inu e t o pro vide t h e bes t

process performance.

Before choosing a Process RA-4 cycle, it is important to

understand processor utilization and the level of operation of

your minilab paper processor.

Developer Options for Process RA-4 Based on

Processor Utilization

4 x 6 - inch

(102 x 152 cm)

prints per day:

Tank

olume

(Litres)

SP

F002_0994AC

125

5

10

15

20

25

30

40

50

EKTACOLOR RA Developer Replenisher RT

EKTACOLOR PRIME SP Developer Replenisher (New)

250

SP SP

SP

SP

375

SP

SP

SP

SP

SP

500

750

1000

SP

SP SP

SP

SP

SP

SP

SP

SP

SP

SP

SPSPSP

1250

SP

SP

SP

SP

SP

SP

SP SP

1875

SP SP

SP

SP

SP

SP

SP

SP

SP

SP

SP

SP

SP

SP

SP

2500

If EKTACOLOR PRIME SP Developer Replenisher is

not yet available in you r co unt r y, u se the t abl e and products

below:

4 x 6 - inch

(102 x 152 cm)

prints per day:

Tank

Volume

(Litres)

125

5

10

15

20

25

30

40

50

EKTACOLOR RA Developer Replenisher RT

EKTACOLOR PRIME Developer Replenisher

250

375

500

750

1250

1000

**

**

*

2500

1875

******

*****

**

*

*

***

*

**

*

Processor Utilization

Utilization is a way of expressing how much of your

processor’s capacity is used. If your processor utilization is

low, oxidation and evaporation will affect the activity of

your processing solutions.

The simplest way to determine your processor utilization

is to measure “tank turnovers” of your developer tank

solution. One tank turnover is the point at which the volume

of replenisher added to the tank equals the volume of the

processor tank.

EKTACOLOR PRIME SP Developer Replenisher is

designed for minilabs that have average to high utilization,

i.e., a developer tank turnover occurs at least once every four

weeks. If your paper processor operates at low utilization—

i.e., it takes longer than four weeks for a developer tank

turnover to occur—you should use KODAK EKTACOLOR

RA Developer Replenisher RT and EKTACOLOR RA

Bleach-Fix and Replenisher. These chemicals contain more

preservative and are replenished at a higher rate to minimize

the effects of low utilization.

To determine the option that is suitable for your minilab,

use the information in the following charts. To use these

charts, you need to know the number of prints you process

each week. Utilization is based on a 10-percent makeover

rate and a six-day work week.

EKTACOLOR PRIME Developer Replenisher

*

or

EKTACOLOR PRIME Developer Replenisher LORR

F002_0938AC

Note: If you use EKTACOLOR PRIME Developer

Replenisher, use EKTACOLOR PRIME Bleach-Fix

Replenisher. If your processor operates at low utilization,

use EKTACOLOR RA Developer Replenisher RT and

EKTACOLOR RA Bleach-Fix and Replenisher.

4 Choosing the Right Chemicals for Your Minilab • J-36

Page 5

Process RA-4 Cycle—Average Utilization

This cycle is appropriate for processors with average

utilization—i.e., a developer tank turnover occurs at least

once every four weeks.

Process RA-4 Cycle—High Utilization

This cycle is appropriate for processors with high

utilization—i.e., a developer tank turnover occurs at least

once every two weeks.

Solution/

Step

Time*

min:sec

Temperature

°C (°F)

Replenishment

Rate

2

(mL/ft2)

mL/m

EKTACOLOR

Starting-Point

PRIME SP

Developer

Replenisher

†

or

EKTACOLOR

PRIME

0:45

37.8 ± 0.3

(100.0 ± 0.5)

108 (10)

161 (15)

Developer

Replenisher

EKTACOLOR

PRIME

Bleach-Fix

0:45

30 to 36

(86 to 97)

108 (10)

Replenisher

EKTACOLOR

PRIME

Stabilizer and

Replenisher

Dry

* Immersion time plus crossov er ti me to th e ne xt tank. For best result s,

use the recommended times with crossover times of 6 seconds or less.

† This developer may not yet be available in your country. If not, use

EKTACOLOR PRIME Developer Replenisher in a processor with

average ut il ization.

‡ Use fou r countercurrent-flow stabilizer tanks with equal times in all

tanks (0:23 in each tank). With three countercurrent- flow tanks, use a

replenishment rate of 495 mL/m

countercurrent-flow tanks, use 970 mL/m

If your minilab uses a countercurrent-flow wash instead of a

stabilizer, use a wash-water temperature of 30 to 40°C (86 to 104°F ).

For wash times of 1:30 or longer, the wash-flow rate should be

between 2160 and 10,800 mL/m

rate depends on the numb er of tanks and the wash ti me (s ee KODAK

Publication No. Z-100, Using KODAK Chemicals in Minilabs, o r Z-130,

Using KODAK EKTACOLOR RA Chemicals).

1:30

‡

As

needed

30 to 37

(86 to 99)

248 (23)

Not over

96 (205)

2

(46 mL/ft2); with two

2

(90 mL/ft2).

2

(200 and 1000 mL/ft2). The actual

Solution/

Step

Time*

min:sec

Temperature

°C (°F)

Replenishment

Rate

2

(mL/ft2)

mL/m

EKTACOLOR

PRIME SP

Starting-Point

Developer

Replenisher

or

EKTACOLOR

†

0:45

37.0 ± 0.3

(100.0 ± 0.5 )

108 (10)

PRIME

Developer

Replenisher

LORR

EKTACOLOR

RA 100

Bleach-Fix

and

Replenisher

0:45

‡

30 to 36

(86 to 97)

54 (5)

EKTACOLOR

PRIME

Stabilizer and

Replenisher

Dry

* Immersion time plus crossover time to the next tank. For best results,

use the recommended t imes with cro ssover ti mes of 6 second s or less.

† This developer may not yet be available in your country. If not, use

EKTACOLOR PRIME Developer Replenisher LORR in a pr ocessor

with high utilization.

‡ This product will be renamed KODAK EKT ACOL OR PRIME

Bleach-Fix Replenisher LORR.

§ Use four countercurrent-flow stabilizer tanks with equal times in all

tanks (0:23 in each t ank). With three countercurrent-flow tanks, use a

replenishment rate of 495 mL/m

countercurrent-flow tanks, use 970 mL/m

If your minilab uses a countercurrent -flow wash instead of a

stabilizer, use a wash-water temperature of 30 to 40°C (86 to 104°F).

For wash times of 1:30 or longer , the wash-flow rat e should be between

2160 and 10,800 mL/m

depends on the number of tanks and the wash time (see KODAK

Publication No. Z-100, Using KODAK Chemicals in Minilabs, or Z-130,

Using KODAK EKTACOLOR RA Chemicals).

§

1:30

As

needed

30 to 37

(86 to 99)

248 (23)

Not over

96 (205)

2

(46 mL/ft2); with two

2

(90 mL/ft2).

2

(200 and 1000 mL/ft2). The actual rate

Choosing the Right Chemicals for Your Minilab • J-36 5

Page 6

Process RA-4 Cycle—Low Utilization

This cycle is appropriate for processors with low

utilization—i.e., a developer tank turnover requires longer

than four weeks.

Solution/

Step

Time*

min:sec

Temperature

°C (°F)

EKTACOLOR

RA Developer

Replenisher

RT

0:45

35 ± 0.3

(95 ± 0.5)

EKTACOLOR

RA

Bleach-Fix

and

0:45

30 to 36

(86 to 97)

Replenisher

EKTACOLOR

PRIME

Stabilizer and

Replenisher

Dry

* Immersion time plus crossover time to the next tank. For best results,

use the recommended times with crossover times of 6 seconds or less.

† Use fou r countercurrent-flow stabilizer tanks with equal times in all

tanks (0:23 in each tank). With three countercurren t-flow tanks, use a

replenishment rate of 495 mL/m

countercurrent-flow tanks, use 970 mL/m

If your minilab uses a countercurrent-flow wash instead of a

stabilizer, use a wash-water temperature of 30 to 40°C (86 to 104°F).

For wash times of 1:30 or longer , the wash-flow rate should be between

2160 and 10,800 mL/m

depends on the number of tanks and the wash time (see KODAK

Publication No. Z-100, Using KODAK Chemicals in Minilabs, or Z -130,

Using KODAK EKTACOLOR RA Chemicals).

†

1:30

As

needed

30 to 37

(86 to 99)

Not over

96 (205)

2

(46 mL/ft2); with two

2

(200 and 1000 mL/ft2). The actual rate

Starting-Point

Replenishment

mL/m

2

(90 mL/ft2).

Rate

2

(mL/ft2)

215 (20)

215 (20)

248 (23)

Converting to KODAK EKT ACOLOR PRIME SP

Developer Replenisher

Before converting to EKTACOLOR PRIME SP Developer

Replenisher, use all of your current stock of EKTACOLOR

PRIME Developer Replenis her (and EKTACOLOR PRIME

Developer Regenerator) or EKTACOLOR PRIME

Developer Replenisher LORR. You do not need to dump

your current working tank solution.

When you begin to use EKTACOLOR PRIME SP

Developer Replenisher to r epleni s h yo ur ex i sti ng develop er

tank solution, adjust your replenishment rate to the

appropriate setting in the following table. If you currently

use EKTACOLOR PRIME Developer Replenisher LORR,

you do not need to adjust your replenishment rate .

Current

Developer

Solution

Current

Replenishment Rate

mL/

mL/

m

2

mL/

*

2

ft

m

PRIME

Developer

Replenisher

and

161 15 20.5 6.3

Developer

Regenerator

PRIME

Developer

Replenisher

108 10 13.7 4.17

LORR

* Normally, mL per linear metre of paper 127 mm (5 in.) wide.

† Normally, mL per linear foot of paper 127 mm (5 in.) wide.

Note: If your process is in control with EKTACOLOR

PRIME Developer Replenisher, you can also calculate the

replenishment rate for EKTCOLOR PRIME SP Developer

Replenisher by mul tip lyi ng yo ur current rate by 0 .67 . T hen,

reset the rate (or pump setting) to the new rate. If you need

help adjusting the replenishment rate, contact your minilab

manufacturer.

Replenishment Rate

with PRIME SP

Developer

Replenisher

mL/

mL/

†

ft

mL/

2

2

m

ft

108 10 13.7 4.17

mL/

m

mL/

*

†

ft

Monitoring Your Paper Process

Use KODAK Control Strips, Process RA-4, to monitor your

paper process. Follow the procedures described in KODAK

Publication No. Z-100, Using KODAK Chemicals

in Minilabs, or Z-130, Using KODAK EKTACOLOR RA

Chemicals.

6 Choosing the Right Chemicals for Your Minilab • J-36

Page 7

KODAK CHEMICALS FOR YOUR FILM

PROCESSOR

KODAK FLEXICOLOR Chemicals are supplied as

all-liquid concentrates for easy mixin g. They are available in

sizes that are economical and convenient for minilabs. For

more information on processing with these chemicals, visit

www.kodak.com/go/photochemicals.

KODAK FLEXICOLOR Developer Replenisher LORR

This developer has low replenishment rates that help reduce

developer effluent discharge by as much as 50 percent.

Lower replenishment rates mean less chemical mixing and

lower cost per roll of film processed. Use only

FLEXICOLOR Developer Starter LORR to prepare a fresh

tank solution with FLEXICOLOR Developer Replenisher

LORR.

Available in sizes to make 5 and 10 litres and 25 U.S. gallons

(two 12.5-gallon sizes).

KODAK FLEXICOLOR Developer Starter LORR

Use this starter to prepare a fresh tank solution from

FLEXICOLOR Developer Replenisher LORR.

Available in a size to prepare 8.3 U.S. gallons of developer

tank solution from developer replenisher.

KODAK FLEXICOLOR Bleach III NR Replenisher

For use in minilabs using Process C-41B or C-41, this bleach

offers reduced cost per roll of film and reduced

replenishment rates and volume of effluent discharged. It

requires no mixing; it is packaged ready to use. Use

FLEXICOLOR Bleach Starter to prepare a fresh tank

solution.

Available in a 5-litre size.

KODAK FLEXICOLOR Final Rinse and Replenisher

This final rinse is designed with state-of-the-art surfactants

to reduce deposits and drying marks on processed color

negative films. It also reduces the potential for biological

growth in the mixed solution. This means less maintenance

and less frequent dumping of working tanks. Because the

new final rinse contains no stabilizing agent, labs will not

need to provide formaldehyde training or do the associated

record keeping required by OSHA guidelines. You can use

the final rinse in minilabs that operate with a wash or a

washless cycle.

Note: Do not process films of older design that require a

stabilizing agent for image stability. These films are

KODAK VERICOLOR III Film, VERICOLOR Slide

Film / SO-279/5072, and VERICOLOR Print Film 4111.

Process these films only in a processor that uses

FLEXICOLOR Stabilizer III and Replenisher. Films of more

recent design, such as KODAK GOLD, MAX, ROYAL

GOLD, PROFESSIONAL PORTRA, PROFESSIONAL

EKTAPRESS, and PROFESSIONAL SUPRA Films require

no stabilization for image stability. They will have optimum

image-stability performance when processed with

FLEXICOLOR Final Rinse and Replenisher.

Available in sizes to make 5 and 10 litres and 12.5 and

75 U.S. gallons.

KODAK CHEMICALS FOR YOUR PAPER

PROCESSOR

These chemicals are supplied as all-liquid concentrates for

easy mixing and handling. They are available in sizes that are

convenient and economical for minilabs.

KODAK FLEXICOLOR RA Bleach Replenisher NR

This bleach is designed for use in minilabs that use Process

C-41RA. It requires no mixing; it is packaged ready to use.

This bleach is also odorless. Use FLEXICOLOR Bleach

Starter to prepare a fresh tank solution.

Available in a 5-litre size.

KODAK FLEXICOLOR Bleach Starter

Use this starter to prepare a bleach tank solution with

FLEXICOLOR Bleach III NR Replenisher or

FLEXICOLOR RA Bleach Replenisher NR. This product is

odorless, non-corrosive, and non-foaming for easy use.

Available as a 1-gallon concentrate to make 20 U.S. gallons

of Bleach III NR tank solution or 8.3 U.S. gallons of RA

Bleach NR tank solution.

KODAK FLEXICOLOR Fixer and Replenisher

Use this fixer for Process C-41 or C-41B.

Avai lab le in siz es to m ake 5 li tres and 5 and 25 U .S. gall ons.

KODAK FLEXICOLOR RA Fixer and Replenisher

This fixer is designed for use in minilabs that use Process

C-41RA.

Available in sizes to make 5 and 10 litres.

KODAK EKTACOLOR PRIME SP Developer

Replenisher

This new developer re plenisher is desig ned for minilabs w ith

average to high utilization. Supplied as a single-part

concentrate, it offers easy and convenient mixing.

Replenishment rates are significantly lower than those of

EKTACOLOR PRIME Developer Replenisher.

Available in sizes to prepare 10 litres and 20 gallons (two

10-gallon mixes) of replenisher solution.

Note: EKTACOLOR PRIME SP Developer Replenisher

will replace EKTACOLOR PRIME Developer Replenisher,

EKTACOLOR PRIME Developer Replenisher LORR, and

EKTACOLOR PRIME Developer Regenerator. The

discontinuance of these three products will occur at different

times in different regions.

KODAK EKTACOLOR PRIME Developer Replenisher

If new EKTACOLOR PRIME SP Developer Replenisher is

not yet available in your region, use this developer if your

minilab processor has a developer tank turnover every

four weeks (or more frequently).

Available in sizes to prepare 10 litres and 25 gallons (two

12.5-gallon mixes) of solution.

Choosing the Right Chemicals for Your Minilab • J-36 7

Page 8

Choosing the Right Chemicals for Your Minilab

KODAK EKTACOLOR PRIME Developer Replenisher

LORR

If new EKTACOLOR PRIME SP Developer Replenish er is

not yet available in you r region, use this develope r if your

minilab consistently operates at high utilization, i.e., a

developer tank turnover occurs at least once every two

weeks.

Available in sizes to prepare 10 litres and 25 gallons (two

12.5-gallon mixes) of replenisher solution.

KODAK EKTACOLOR PRIME Developer Regenerator

If new EKTACOLOR PRIME SP Developer Replenish er is

not yet available in yo ur region, your can use this regenerator

to regenerate and reuse EKTACOLOR PRIME

Developer overflow.

Available in sizes to prepare 10 litres and 25 gallons of

replenisher solution from developer overflow.

KODAK EKTACOLOR RA Developer Replenisher RT

If your minilab takes longer than four weeks for a tank

turnover, use this developer.

Available in sizes to prepare 5 and 10 litres and 25 gallons.

KODAK EKTACOLOR RA Developer Starter

To make developer tank solutions, mix this starter with

KODAK EKT ACOLOR PRIME SP Developer Replenisher,

EKTACOLOR PRIME Developer Replenisher,

EKTACOLOR PRIME Developer Replenisher LORR, or

EKTACOLOR RA Developer Replenisher RT according to

the directions on the starter label.

KODAK EKTACOLOR PRIME Bleach-Fix Replenisher

Use this bleach-fix if you use EKTACOLOR PRIME SP or

PRIME Developer Replenisher. The replenishment rate with

this bleach-fix is 50 percent lower than the rate for

EKTACOLOR RA Bleach-Fix and Replenisher.

Available in sizes to prepare 10 litres and 12.5 gallons of

solution.

KODAK EKTACOLOR RA 100 Bleach-Fix and

Replenisher

You can use this bleach-fix if your processor has a tank

turnover at least every four weeks. The replenishment rate is

75 percent lower than that of EKTACOLOR RA Bleach-Fix.

This product will be renamed KODAK EKTACOLOR

PRIME Bleach-Fix Replenisher LORR.

Available in sizes to prepar e 5 litres and 5 gallons of solution.

KODAK EKTACOLOR RA Bleach-Fix and Replenisher

If it takes more than four weeks to turn over the bleach-fix tank

solution, use this replenisher. Dilute this concentrate to

prepare a tank or replenisher solution.

Available in sizes to prepare 5 and 10 litres and 25 gallons of

solution.

KODAK EKTACOLOR PRIME Stabilizer and

Replenisher

Use this stabilizer in place of a final wash in washless

minilabs.

Available in sizes to prepare 5 and 10 litres and

12.5 gallons of solution.

MORE INFORMATION

For the latest version of te chn i cal support publications for

KODAK Products, visit Kodak on-line at:

http://www.kodak.com

The Material Safety Da ta Sheets for these products are

available on the Kodak web site:

www.kodak.com/go/MSDS

Many technical support publications for

KODAK Products can be sent to your fax machine

from the Kodak Informatio n C en te r. C all :

U.S. 1-800-242-2424, Ext . 33 / Canada 1-800-295-5531

—Available 24 hours a day, 7 days a week—

If you have questions ab out KO D AK Products, call Kodak.

In the U. S.A.:

1-800-242-2424, M onday–Friday

9 a.m.–7 p.m. (Eastern time)

In Canada:

1-800-465-6325, M onday–Friday

8 a.m.–5 p.m. (Eastern time)

Choosing the Right Chemic a ls for

Your Minilab

KODAK Publication No. J-36

CAT 849 8800

Consumer Imaging

EASTMAN KODAK COMPANY • ROCHESTER, NY 14650

Kodak, Advantix, Ektacolo r, Ektacolor SM , Flexi co lor,

Flexicolor SM, Gold, Max, Prime, an d Royal are trademarks.

Major Revision 4-00

Printed in U.S.A.

Loading...

Loading...