Page 1

21(6+2762/,'6<67(0

,16758&7,210$18$/

INTRODUCTION

The One Shot Solid System combined with the Power Bowl Ultra will gravity feed a solid cleaning product into a

laundry machine or kitchen sink. The combined units are pre-mounted on a stainless steel mounting bracket for

mounting both units to a wall surface or side of the laundry machine.

INSTALLATION

Mounting:

Always install the system at a safe, convenient height for operators to load and unload solid containers. Using

appropriate hardware, mount the system high enough for the discharge line on the Power Bowl Ultra to gravity feed

into the sink or laundry machine.

For installations on laundry machines, mount the system above the supply compartment, or above the wash tub.

Plumbing:

The system includes a 28” coil of 1/4” OD poly tubing for the water connection from the dispenser’s solenoid to the

vacuum breaker on the Power Bowl Ultra (follow instructions included with the Power Bowl Ultra for installing the

vacuum breaker).

Check chemical manufactures specifications on water temperature and pressure. Usually 120 – 135 °F (48°-57°C)

at 18-25 PSI (1.2 – 1.7 BAR) is recommended.

Uncoil the poly tubing and insert one end into the push-connect elbow tube fitting on the discharge side of the

solenoid valve (to disconnect, push the tube up and hold the gray tab with your finger as you pull the tube out of

the fitting). Connect the other end of the tubing into the inlet side of the vacuum breaker on the Power Bowl Ultra.

Route the tubing as shown

and secure properly.

Use a 3/8” ID garden or utility water hose to connect the incoming water supply to the inlet side of the solenoid.

Slip the blunt end of hose over the brass barb and secure it with a hose clamp.

is 40 PSI;

Maximum water pressure

Note:

0900518-CO Rev: A (05/00) Page 1

Page 2

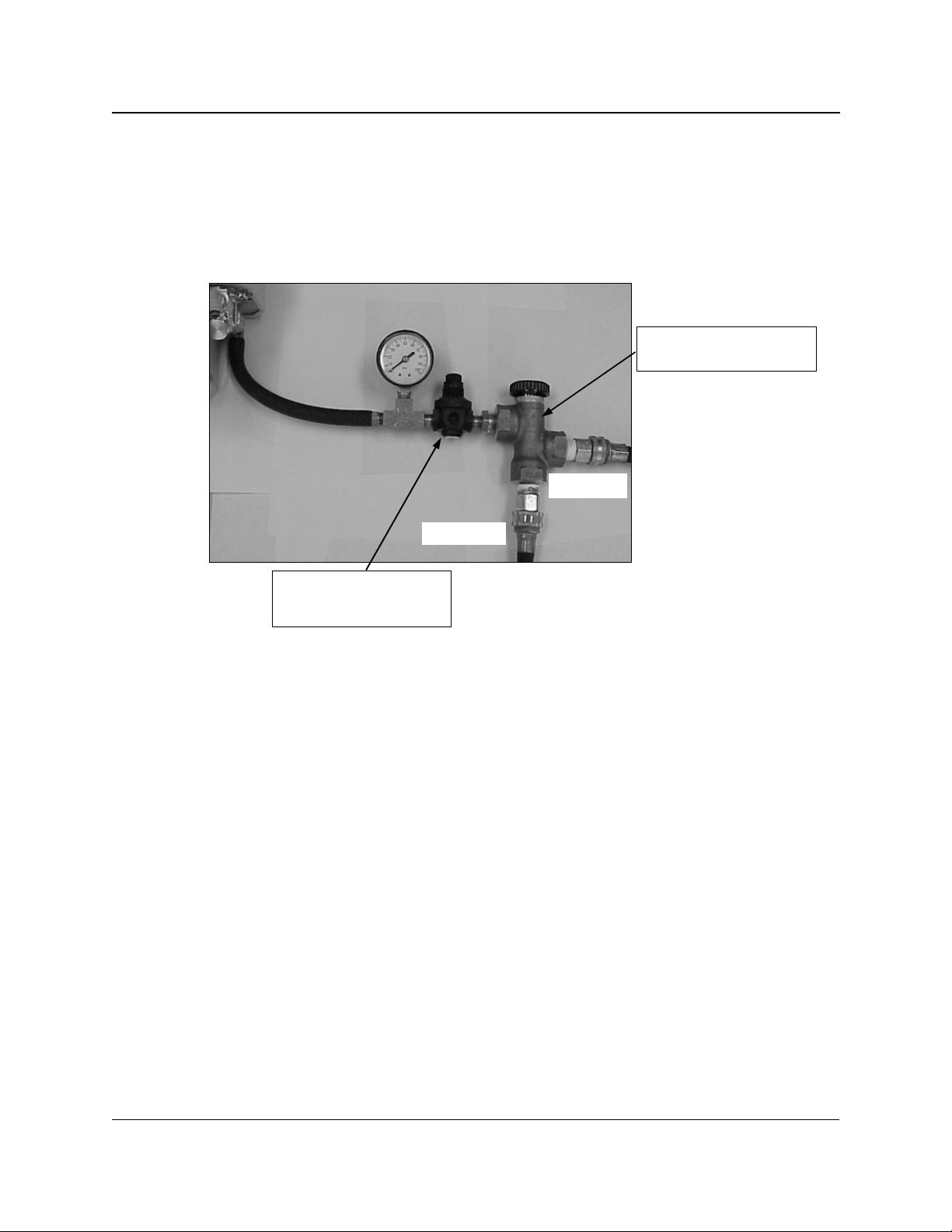

Optional Water Tempering Valve and Pressure Regulator Installation

We recommend the use of a water tempering valve and pressure regulator. Connect Tempering Valve and Pressure Regulator before the solenoid (see illustration below) The Tempering Valve will allow the water temperature to

be increased or decreased by turning the adjustment dial. The adjustment temperature is 120 to 160° F. The Pressure Regulator will regulate the water pressure from 0 to 60 PSI. Most manufactures recommend pressure of 18-25

PSI (1.2 – 1.7 BAR) at a temperature of 120-135° F (48-57° C).

Pressure gauge assembly can be purchased at your local hardware store (see parts list below)

1 - 1/2” MNPT x 1/4” Brass Reducer

1 - 1/4” Pressure Gauge

2 - 1/4” Brass Close Nipple

7407118 Pressure

Regulator

Cold Water

Hot Water

7407119 Water Tempering

Valve

1 - 1/4” MNPT x 3/8” Barb

1 - 1/4” FPT Brass Tee

OPERATION

Insert chemical container into the Power Bowl Ultra. Refer to One Shot and Power Bowl Ultra instruction manual for

programming and operation.

Run a few test cycles and inspect the operation of both the dispenser and Power Bowl Ultra to ensure proper

chemical feed is achieved. Check all plumbing for leaks.

CALIBRATION (of solid detergents)

As general rule of thumb program 10 seconds of run time for one ounce (28.3 grams) of detergent. For 2 ounces

(56.7 grams) set the run time for 20 seconds. Weigh the capsule (electronic scale may be needed) first then start

or signal the dispenser. Weigh the capsule again after the run time is completed. Then calculate amount dispensed. Run the capsule 2 or 3 times to see if the amount is consistent.

0900518-CO Rev: A (05/00) Page 2

Page 3

TROUBLESHOOTING

Water leaking from inlet fittings

Check for proper connection at fittings

•

Check for holes or splits on plumbing lines

•

Chemical is not feeding

Check to see if solenoid is opening properly

•

Check to see if water supply is on

•

Check inside of vacuum breaker for any debris or blockage

•

Check for proper water pressure

•

Check operation of Power Bowl water valve

•

Check operation of Power Bowl jet

•

Concentration too high or too low

Check water temperature. Consult with solid chemical manufacturer for recommended temperature.

•

Check water supply for fluctuations in pressure.

•

Check feed time of control and adjust as needed.

•

DISCLAIMER

Knight Inc. does not accept responsibility for the mishandling, misuse, or non-performance of the described items

when used for purposes other than those specified in the instructions. For hazardous materials information consult

label, MSDS, or Knight Inc.

WARRANTY

All Knight controls and pump systems are warranted against defects in material and workmanship for a period of

ONE year. All electronic control boards have a TWO year warranty. Warranty applies only to the replacement or

repair of such parts when returned to factory with a Knight Return Authorization (KRA) number, freight prepaid, and

found to be defective upon factory authorized inspection. Bearings and pump seals or rubber and synthetic rubber

parts such as “O” rings, diaphragms, squeeze tubing, and gaskets are considered expendable and are not covered

under warranty. Warranty does not cover liability resulting from performance of this equipment nor the labor to replace this equipment. Product abuse or misuse voids warranty.

A Unit of IDEX Corporation

London Branch:

#15 Brunel Centre

Newton Road, Crawley

West Sussex UK RH102UB

TEL: (44) 1293-615570

FAX: (44) 1293-615585

Sydney Branch:

Unit 28, 317-321

Woodpark Rd., Smithfield

NSW Australia 2164

TEL: 61-29-725-2588

FAX: 61-29-725-2025

Amsterdam Branch:

Marssteden 68

7547 TD Enschede

The Netherlands

TEL: 31-53-428-58-00

FAX: 31-53-428-58-09

World Headquarters:

20531 Crescent Bay Dr.

Lake Forest, CA

92630-8825 USA

TEL: (949) 595-4800

FAX: (949) 595-4801

Atlanta Branch:

8111 Technology Dr. NE

Covington, GA

30014 USA

TEL: (770) 787-9400

FAX: (770) 787-1155

KNIGHT INC.

Toronto Branch:

2880 Argentia Road, Unit 6

Mississauga, Ontario

L5N 7X8 Canada

TEL: (905) 542-2333

FAX: (905) 542-1536

0900518-CO Rev: A (05/00) Page 3

Loading...

Loading...