Knight Equipment 2WV-6000 User Manual

Chemical Dispensing and Control for Sanitation in the Food & Beverage Processing Industry.

The ILCS is a multiple chemical distribution system designed to optimize in-plant cleaning chemical control. This system completely

automates the dispensing of chemical and records critical usage data. The ILCS can control chemical usage by areas in the plant, by

specified equipment to be cleaned, or by each sanitation worker that uses the system. ILCS promotes effective and safe allocation

while providing sanitation managers an invaluable monitoring tool.

Features & Benefits:

Features & Benefits:

•

Automates Chemical Dispensing

•

Daily User Log With Date and Time

•

Controls Costs

•

Accumulates Chemical Usage Data

•

Eliminates Unsafe Chemical Transferring

•

Fifty Formula Capability

•

Windows Compatible PC Software

•

Easy To Operate

Advanced Microprocessor Features:

Advanced Microprocessor Features:

Automates Chemical Dispensing

An intuitive user control allows sanitation workers to

operate the system with a minimum of training and

effort. The operator simply enters a user ID code,

selects the appropriate formula number and presses

the start button.

Cost Control

At the push of a button, this system dispenses concentrated cleaners in

precise measured amounts into geri cans or other portable containers.

The ILCS system can be used to simply transfer each product to a

container or to blend any combination of up to eight products and water.

The ILCS can be programmed to deliver up to fifty chemical formulations

tailored to the specific requirement of each cleaning task. Fifty user ID

codes prevent unauthorized use of the system.

Data Management

All product usage is recorded as products are used. Usage reports

include product cost, consumption, batch tracking and setup. This critical

information will help management gain control of costs and provide

improved sanitation.

W

orker Safety

The ILCS system promotes worker safety by limiting the users’ exposure

to corrosive cleaners used for sanitation. Reliable, self priming peristaltic

pumps transfer cleaning products safely and efficiently. The simplicity

of the system allows even unskilled employees to use it with minimal

training.

ILCS W

ILCS W

indows compatible software connects the

indows compatible software connects the

Sanitation Manager directly to the ILCS system.

Sanitation Manager directly to the ILCS system.

•

Track chemical usage by each sanitation worker

•

Verify chemical usage in all areas of the plant

•

Remote connection via modem

•

Export sanitation reports to Excel

Security Key

Initiates Dispensing Cycle

LCD Screen – Displays

Menus And Programming Data

Main Power Switch

Dispenses Water On Demand

LED Display – Indicates

Formula To Be Dispensed

User Function Keys

Alpha Numeric Key Pad

For Programming, Entering

Passwords and ID’

s

Industrial Liquid Control System

Industrial Liquid Control System

Reliable Peristaltic Pumps or

High Output Air Operated Double

Diaphragm Pump(s)

Options F

Options F

or The IL

or The IL

CS Sy

CS Sy

stem

stem

Ordering Information

Ordering Information

Knight Headquarters Georgia Branch Canada Branch UK Branch Australia Branch N. Europe Branch S. Europe Branch Asia Branch

Toll Free (800)854-3764 Toll Free (800)241-7789 Tel (905)542-2333 Tel 44 1293 615570 Tel 61 2 9725 2588 Tel 31 53 4285800 Tel 34 936 342 130 Tel 82 2 3481 6683

Tel (949)595-4800 Tel (770)787-9400 Fax (905)542-1539 Fax 44 1293 615585 Fax 61 2 9725 2025 Fax 31 53 4285809 Fax 34 936 643 477 Fax 82 2 3482 5742

Fax (949)595-4801 Fax (770)787-1155

www.knightequip.com

ILCS Brochure 12/2001

ILCS Systems, Peristaltic Pumps, Air Pump Controls & Air Operated Double Diaphragm Pumps

Model Part No. Description

ILCS-6900 7551000-01 Six Pump ILCS. Includes Cabinet, Controls, and Dual Manifold Flushing Systems, 12 Ports Total. System Can Control Up To 8 Pumps. Peristaltic

Pumps Must Be Specified From the List Below.

ILCS 6900X 7551009 ILCS w/o Pumps, w/o water flush. Includes User Interface and Pump Controller Unit. System Designed For Applications of Air Operated

Pumps (AOP). AOP Must Be Specified From The List Below.

ILCS-6900 7551013-01 ILCS-6900 115 VAC w/one 3 Way Valve.

ILCS-6900 7551014-01 ILCS-6900 115 VAC w/two 3 Way Valve.

KP-9130X 8600127-01 900 series pump, 130 rpm, 148 oz./minute (4.8 l/min). Mounts to ILCS cabinet.

KP-9270X 8600128-01 900 series pump, 270 rpm, 226 oz./minute (6.7 l/min). Mounts to ILCS cabinet.

APC-200 7641060-01 Air Pump Control, Single Pump, 110 VAC 50/60 Hz w/built-in regulator, pressure gauge, air solenoid and filter/dryer. Interfaces ILCS to

Air Pump.

APC-200 7641061-01 Air Pump Control, Double Pump 110 VAC 50/60 Hz w/built-in regulator, pressure gauge, air solenoid and filter/dryer. Interfaces ILCS to

Air Pump.

LAOP-25C 7640474 1/4” Air Operated Double Diaphragm Pump w/Stainless Steel Enclosure, 1/2"Fittings, Suction Check Valve Assy. 0-4 gal/min (0-15 Ltrs/min)

LAOP-25B 7640612 1/4" Air Operated Double Diaphragm Pump w/Stainless Steel "L" Bracket, 1/2"Fittings, Suction Check Valve assy. 0-4 gal/min (0-15 Ltrs/min)

LAOP-50C 7640475 1/2" Air Operated Double Diaphragm Pump w/Stainless Enclosure, 1/2"Fittings,Suction Check Valve Assy. 0-14 gal/min (0-53 Ltrs/min)

LAOP-50B 7640613 1/2" Air Operated Double Diaphragm Pump w/Stainless Steel "L" Bracket, 1/2"Fittings, Suction Check Valve Assy. 0-14 gal/min (0-53 Ltrs/min)

Options

Model Part No. Description

3WV-6000 2210013 3-way Air Operated Diaphragm Valve w/Air Solenoid for automatic flushing to drain. Retrofits to ILCS-6900 Pump Case.

2WV-6000 1600955 2-Way Air Operated Diaphragm Valve for “Point of Dispense” Anti-Siphon Protection w/Mounting Bracket, and Fittings For Air Operated or

Peristaltic Pumps. Fitting size for 1/2” I.D. Tubing. Operates with Air Pressure

Expert 6000I 7681067 Windows Based Software/Hardware Package, with RM-6000I and cables

KP-9270I 857785-01 KP-9270, 115V/60Hz Pump with Watertight Case. 226 oz/min (6.7L/min)

CS-5000 7541100 Stainless Steel Container Shelf for 2, 2.5 or 5 Gallon Containers

– 0700250 Pistol Grip For 3/4” O.D. Tubing

Industrial Liquid Control System

Industrial Liquid Control System

Knight controls and pump systems are warranted against defects in material and workmanship for a period of ONE YEAR. All Electronic Control Boards have a TWO YEAR warranty.

Warranty applies only to the replacement or repair of such parts when returned to the factory with a KRA number, freight prepaid and found to be defective upon factory inspection. Rubber

and synthetic rubber parts such as "O" rings, diaphragms, squeeze tubing and gaskets are considered expendable and are not covered under warranty. Warranty does not cover

liability resulting from performance of this equipment nor the labor to replace this equipment. Product abuse or misuse voids warranty.

KNIGHT LIMITED WARRANTY DISTRIBUTOR

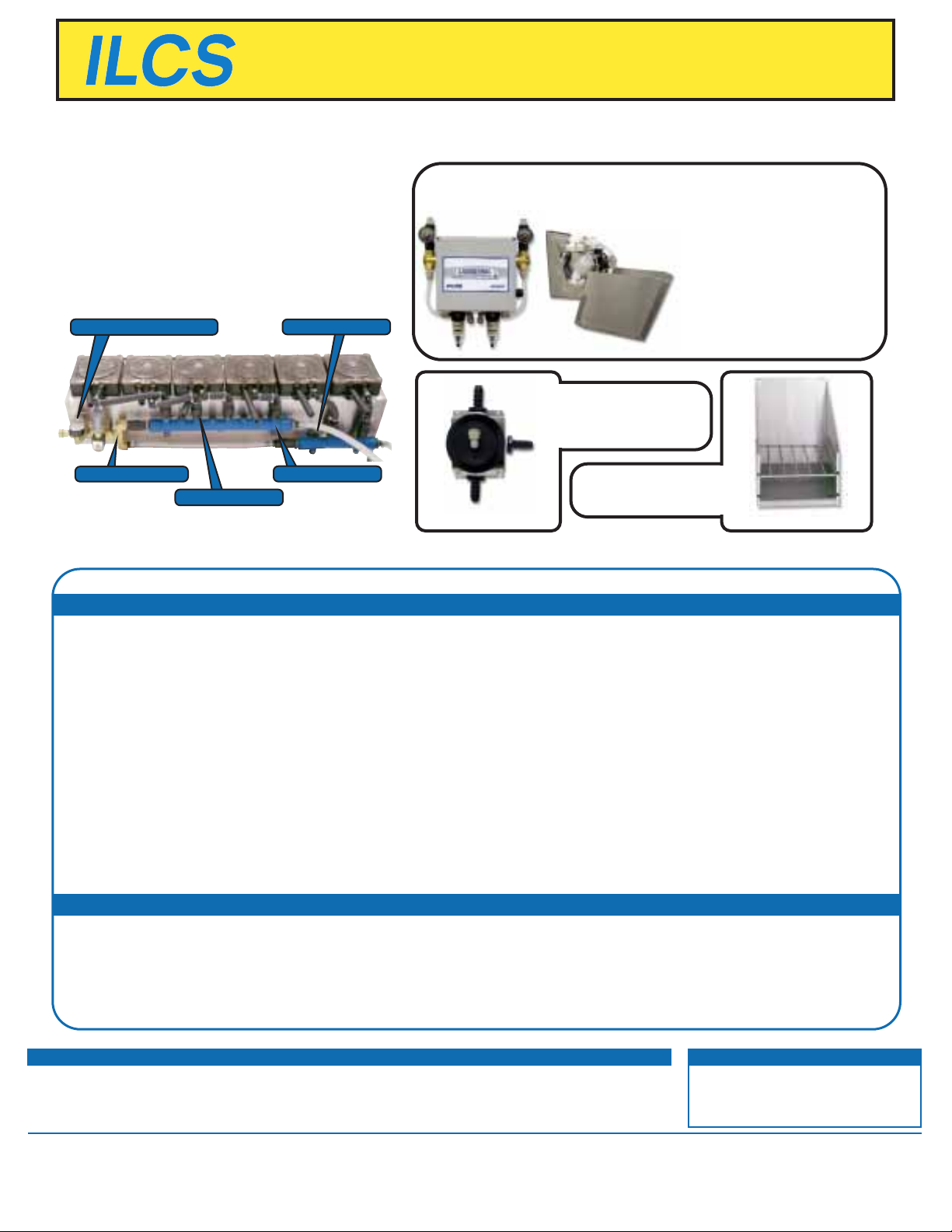

Integrated Flush System

Integrated Flush System

The ILCS features a dual manifold design to isolate

incompatible chemicals. Chemical supplies are

protected by a check valve mounted between the

peristaltic pump and the manifold. A pressure

regulator and pressure gauge assembly is mounted

on the incoming water line to control flush water

pressure.

Pressure Regulator/Gauge

Water Inlet Solenoid

Check Valves

8 Port Manifold

4 Port Manifold

Liquidtrol Series

Liquidtrol Series

Air Pump Control &

Air Pump Control &

Air Operated Double Diaphragm Pump

Air Operated Double Diaphragm Pump

Stainless Steel Shelf

Stainless Steel Shelf

Rugged container shelf with

adjustable rack and drip tray

3 W

3 W

ay V

ay V

alve

alve

Allows automatic flushing of

chemical residual to drain.

Prevents cross contamination

The APC-200 operates as an

interface to control Liquidtrol

style air pumps from the

ILCS. Built-in air solenoid,

filter/dryer, regulator and

gauge with electrical interface

provide a simple remote or

local installation of air pumps.

Loading...

Loading...