Page 1

ST SERIES

SERVO MOTOR

BEIJING KND CNC TECHNIQUE CO.,LTD.

01.2012

Page 2

CONTENTS

◆ NOTE …………………………………………………………………………………………………………

1

◆ PROHIBITED ………………………………………………………………………………………………

1

◆ SOCKET FIG. ………………………………………………………………………………………………

1

◆ CAUTION ……………………………………………………………………………………………………

1

◆ GENERAL …………………………………………………………………………………………………

2

◆ CHARACTERISTICS ……………………………………………………………………………………

2

◆ SUPERIORITY ……………………………………………………………………………………………

2

◆ MODEL DESCRIPTION …………………………………………………………………………………

3

◆ WIRING ………………………………………………………………………………………………………

4

1. Power connector (4 cores) ………………………………………………………………………………

4

2. Incremental encoder connector (15 cores) ……………………………………………………………

4

3. Wire-saving type incremental encoder connector (9 cores) …………………………………………

4

4. Absolute encoder of DANAHER connector (15 cores) ………………………………………………

4

5. Absolute encoder of TAMAGAWA connector (7 cores) ………………………………………………

5

6. Holding brake connector (3 cores) ………………………………………………………………………

5

◆ PARAMETERS FOR FOUNDATION EQUIPPED HOLDING BRAKE ……………………

5

◆ SIZE AND SPECIFICATION ……………………………………………………………………………

6

1. Size and specification for 80 series ……………………………………………………………………

6

2. Size and specification for 90 series ……………………………………………………………………

7

3. Size and specification for 110 series ……………………………………………………………………

8

4. Size and specification for 130 series ……………………………………………………………………

9

5. Size and specification for 130 series ……………………………………………………………………

10

6. Size and specification for 150 series ……………………………………………………………………

11

◆ TORQUE-SPEED CHARACTERISTICS ……………………………………………………………

12

Page 3

ST SERIES MOTOR

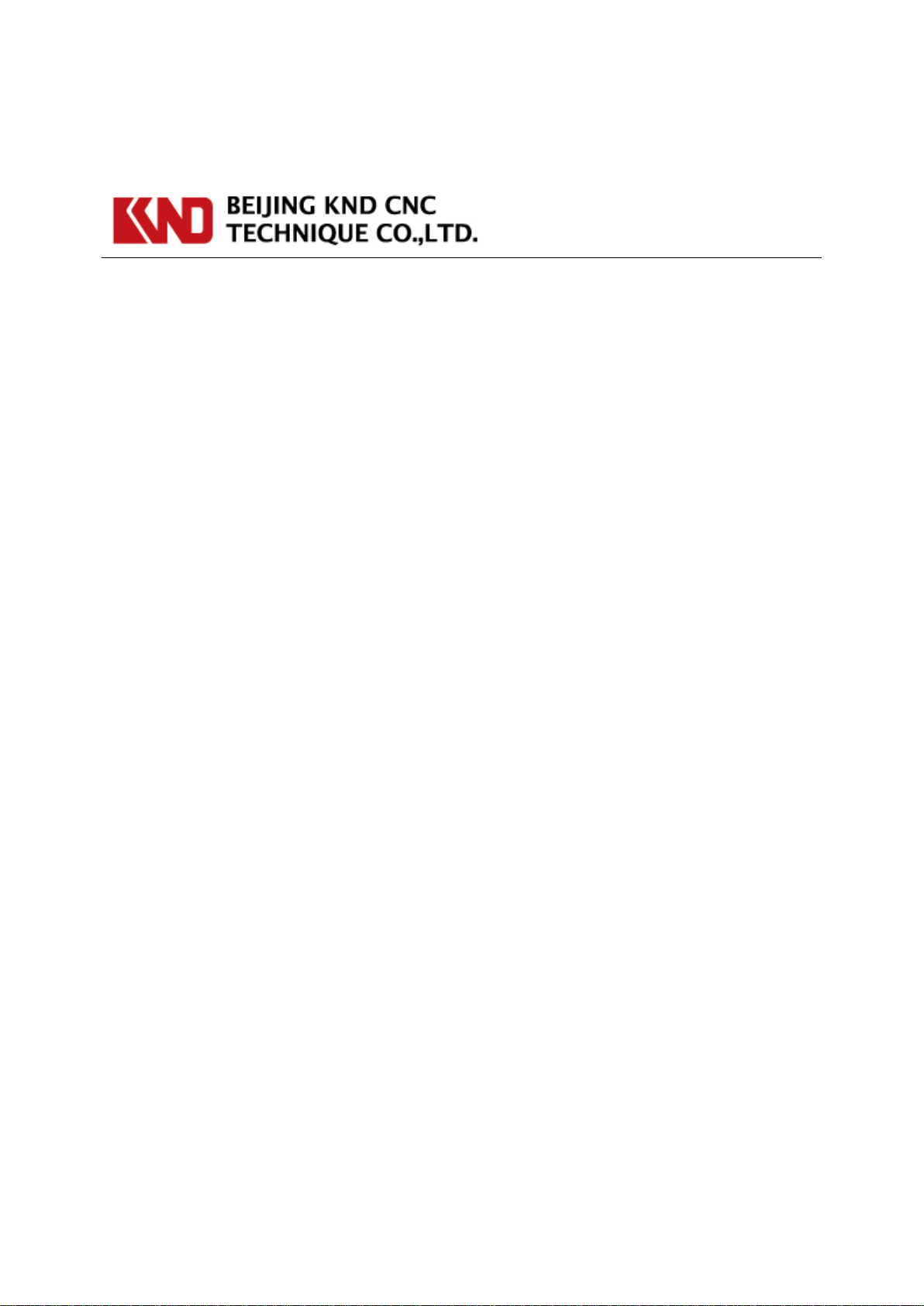

▲ NOTE!

Motors should be installed on an armor plate When a motor equipped with a holding brake, the

as big as possible because it is self-cooled. power of the holding brake should be provided by

Motors will generate heat when working for a the servo driver itself, otherwise the motor may

long time, and it is normal phenomenon. work abnormally.

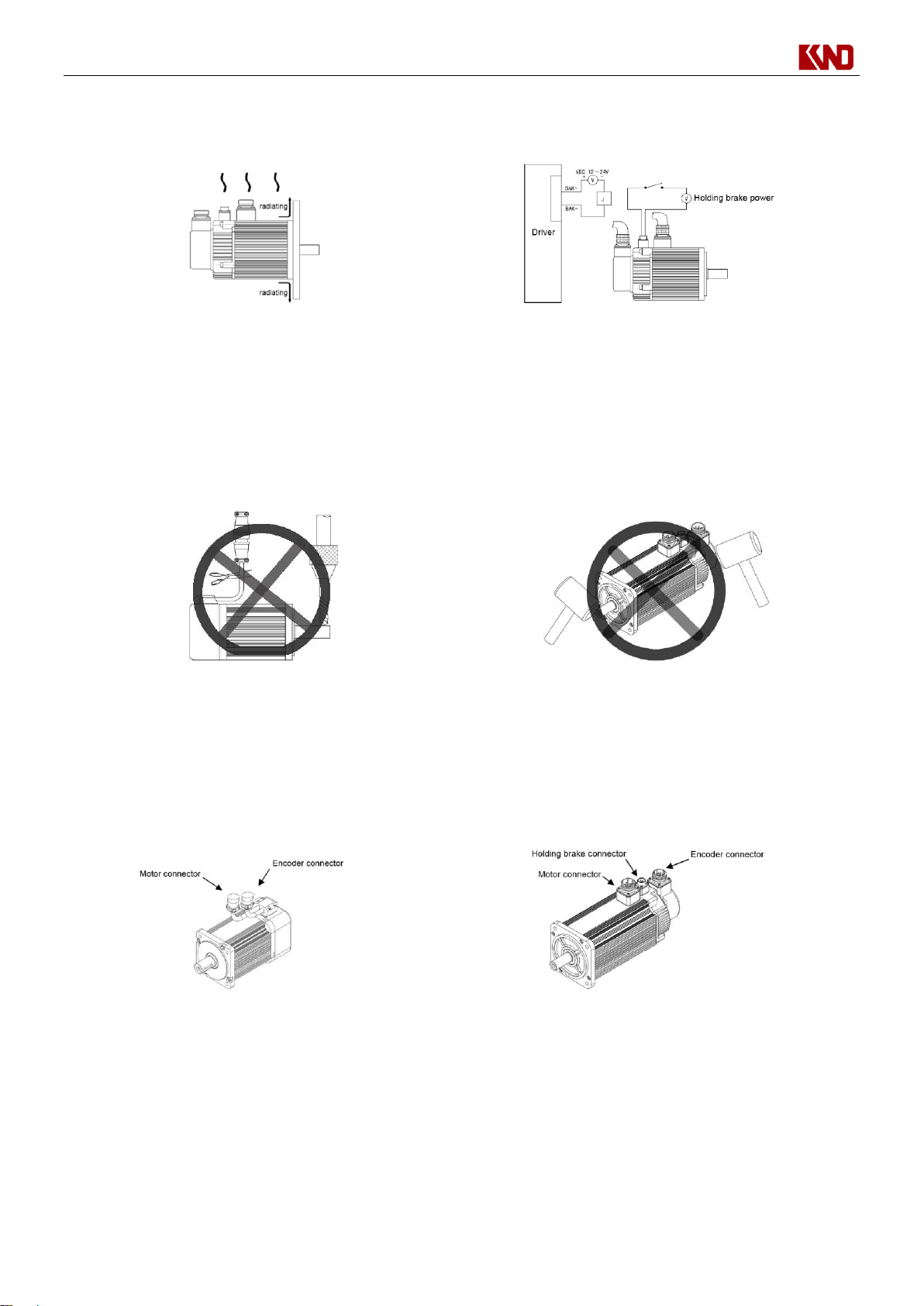

▲ PROHIBITED!

Optional changing, dismantling or machining There is precise feedback component inside the

the motor is prohibited. If must do it, please motor, do not apply any strong whack to the shaft

contact with KND company. extension or the terminal of the motor.

▲ SOCKET FIG.!

Cable Socket Aviation Socket

▲ CAUTION!

Do not store or install the motor in the following places:

● Locations subject to exposure to water or coolant.

● Locations subject to installation humidity conditions.

● Locations subject to shock or vibration.

1

Page 4

ST SERIES MOTOR – DESCRIPTION

◆ General

ST series AC servo motors developed by Beijing KND CNC technique Co., LTD. are used for equipping

CNC machines. Foundation sizes contain 80, 90, 110, 130 and 150 five series, altogether more than 30 varieties.

Selection quality raw materials and parts can effectively keep motors working well during long-term,

high-speed, continuous running. The motor and KND SD series AC servo driver used together can make the

machine work in good performance.

◆ Characteristics of product

1. Full airproof and compact structure, beautiful contour.

2. Low harmonic, low magnetic resistance torque, high performance back electromotive force sine, sine-wave

current drive and excellent low speed performance.

3. Using high performance permanent magnet material and high grade cold rolled silicon-steel sheet, high power

and large overload ability.

4. Using optimization electromagnetism design, low noise, running steady, high efficiency, and keeping good

working condition during long-term continuous running.

5. Using optimization inertia design, quick motor response speed, suitable for various domains especially driving

CNC machine.

6. Using IP66 protection class to meet industry environment such as temperature -15℃ – 40℃, dust and oil

mist.

7. Using high-speed and high precision photoelectric encoder, working in with KND driving unit to achieve high

speed high precision and position control.

◆ Superiority of product

1. Standard equipping 2500 p/r incremental type encoder, and optional equipping absolute encoder containing

17-bit single-turn and 17-bit multi-turn encoder.

2. Work in with SD series servo driver and KND CNC system to make working more reliable and performance

more excellent.

2

Page 5

ST SERIES MOTOR – DESCRIPTION

◆ Description of servo motor model

EXAMPLE:

110ST -M 040 30 M A Z

________ ____ ______ ____ ___ ___ ___

1 2 3 4 5 6 7

1. Sine-wave permanent magnet synchronous AC servo motor

Foundation number: 80, 90, 110, 130 and 150

2. Types of encoder: M – Photoelectric type X – Magnetoelectric type

3. Rated torque: 040 × 0.1 = 4 Nm

4. Rated speed: 30 × 100 =3000 r/min

5. Resolution of encoder:

F – 2500 p/r incremental type (Default) F1 – 2500 p/r wire-saving type

M – 17-bit multi-turn (TAMAGAWA) M1 – 17-bit multi-turn (DANAHER)

E – 17-bit single-turn (TAMAGAWA)

6. Structure of shaft extension: Default – Standard smooth and straight shaft

A – Straight with standard keyway

C – Straight with special keyway

7. Holding brake: Default – Without brake Z – With brake

3

Page 6

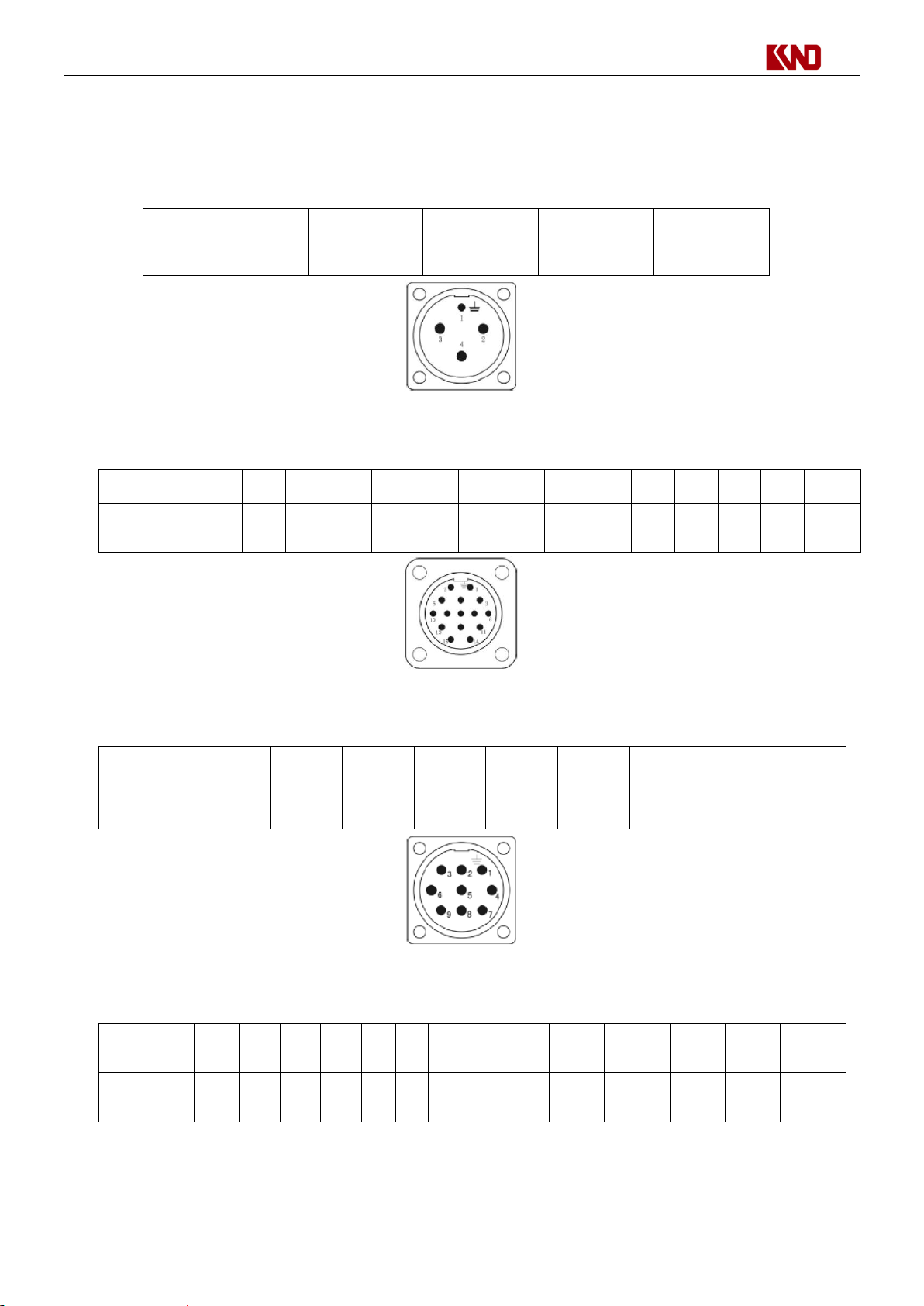

ST SERIES MOTOR – CONNECTOR

Winding lead-wire

U V W

Ground

Connector number

2 3 4

1

Signal

+5V

0V

A+

B+

Z+

A-

B-

Z-

U+

V+

W+

U-

V-

W-

Shield

Connector

number

2 3 4 5 6 7 8 9 10

11

12

13

14

15

1

Signal

+5V

0V

A+

B+

Z+

A-

B-

Z-

Shield

Connector

number

2 3 4 5 6 7 8 9 1

Signal

+5V

0V

A+

B+

A-

B-

Sensor

+S 5V

SLA

Dat+

May

Clk+

Sensor

S0V

SLB

Dat-

Maz

Clk-

Shield

Connector

number

2 3 4 5 7 8 10

11

12

13

14

15

1

◆ Wiring way of servo motor

1. Power connector (4 cores)

2. Incremental encoder connector (15 cores)

3. Wire-saving type incremental encoder connector (9 cores)

4. Absolute encoder of DANAHER connector (15 cores)

4

Page 7

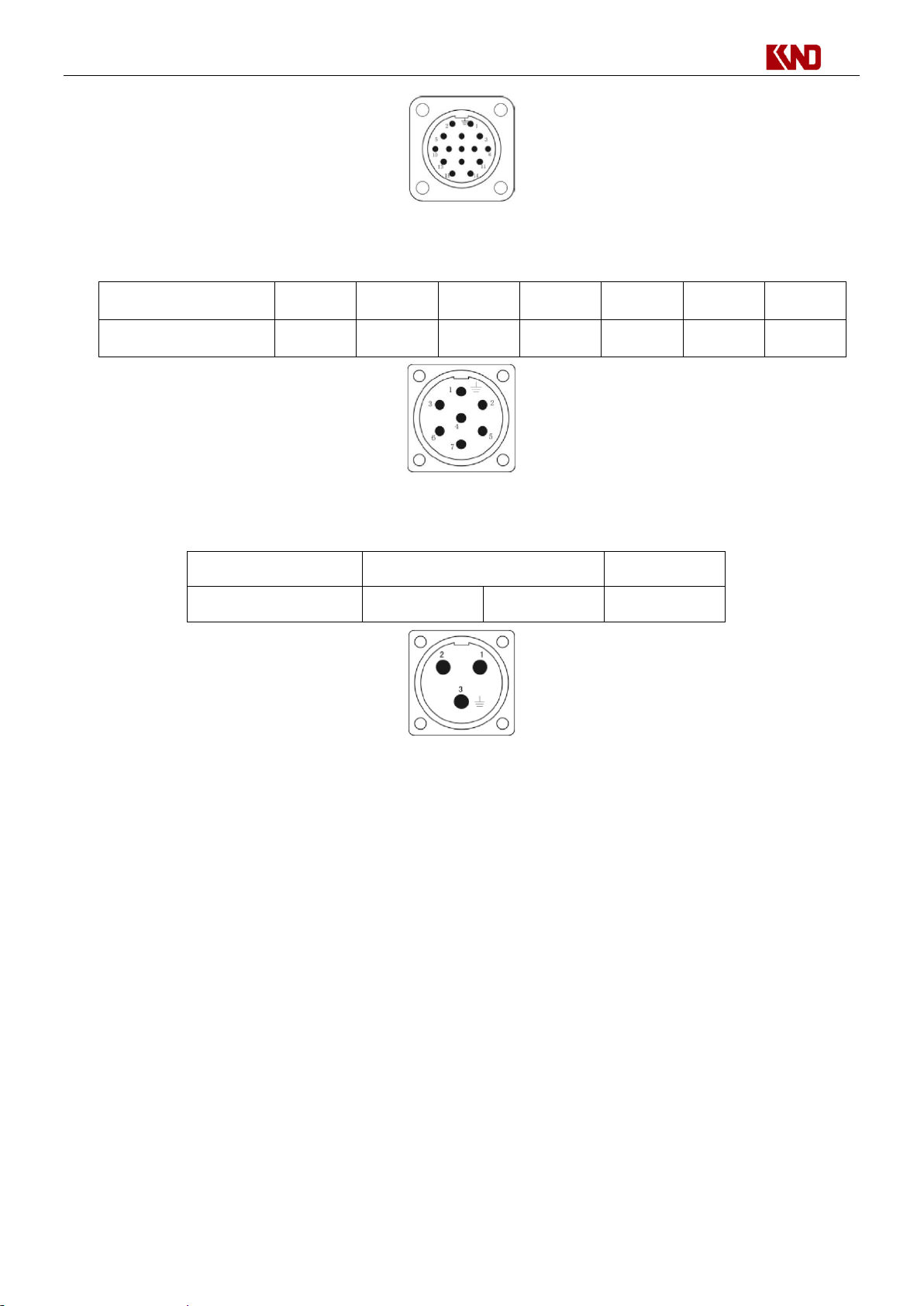

ST SERIES MOTOR – CONNECTOR

Signal

+5V

0V

SD+

SD-

E+

E-

Shield

Connector number

7 6 5 4 3 2 1

Signal

DC24V (Nonpolarity)

Ground

Connector number

1 2 3

5. Absolute encoder of TAMAGAWA connector (7 cores)

6. Holding brake connector (3 cores)

◆ Parameters for foundation equipped holding brake

Parameter for foundation 80/90 series equipped holding brake: 4Nm DC24V 0.8A (2 cores)

Parameter for foundation 110 series equipped holding brake: 8Nm DC24V 0.9A

Parameter for foundation 130 series equipped holding brake: 16Nm DC24V 1.2A

Parameter for foundation 150 series equipped holding brake: 30Nm DC24V 1.6A

5

Page 8

ST SERIES MOTOR – 80ST SERIES

Model

80ST-01030

80ST-01330

80ST-02430

80ST-03330

Rated output (KW)

0.3

0.4

0.75

1.0

Rated torque (N.m)

1.0

1.3

2.4

3.3

Instantaneous peak

Torque (N.m)

2.0

2.6

4.8

6.6

Rated speed (rpm)

3000

3000

3000

3000

Max. speed (rpm)

3600

3600

3600

3600

Rated current (A)

2.5

2.6

4.0

4.5

Instantaneous max current(A)

5.0

5.2

8.0

9.0

Rotor inertia (Kg.cm2)

0.85

1.13

1.87

2.55

Number of poles

4

Working voltage of adapted

driver (VAC)

220

Insulation class

F

Protection class

IP66

Encoder

2500 p/r

Mounting method

Flange method

Environment

Ambient temperature

-15 to 40℃ (no freeze), Stored temperature: -15 to 70℃ (no freeze)

Ambient humidity

80% RH below (no condensation),

Stored humidity: 90% RH below (no condensation)

Air

Indoor (no direct sunlight), No corrosive or flammable gases, No dust or oil

Standard height

Elevation of 1000 meters below

Vibration

Vibration speed 1.8 mm/s below

LL

Without holding break

138mm

148mm

175mm

204mm

With holding break

198mm

208mm

235mm

264mm

Torque-Speed

characteristics (T-M)

Chart 1

Chart 2

Chart 3

Chart 4

◆ Size of 80 series motor

Fig. 1. The dimension of 80 series AC servo motor (unit:mm)

◆ Specification of 80 series motor

Tab. 1. The specification table of 80 series AC servo motor

6

Page 9

ST SERIES MOTOR – 90ST SERIES

Model

90ST-M01530

90ST-M02430

90ST-M03530

Rated output (KW)

0.45

0.75

1.1

Rated torque (N.m)

1.5

2.4

3.5

Instantaneous peak

torque (N.m)

3.0

4.8

7.0

Rated speed (rpm)

3000

3000

3000

Max. speed (rpm)

3600

3600

3600

Rated current (A)

2.8

3.0

4.2

Instantaneous max. current(A)

5.6

6.0

8.4

Rotor Inertia (Kg.cm2)

1.53

2.56

3.07

Number of poles

4

Working voltage of adapted

driver (VAC)

220

Insulation class

F

Protection class

IP66

Encoder

2500 p/r

Mounting method

Flange method

Environment

Ambient temperature

-15 to 40℃ (no freeze), Stored temperature: -15 to 70℃ (no freeze)

Ambient humidity

80%RH below (no condensation),

Stored humidity: 90%RH below (no condensation)

Air

Indoor (no direct sunlight), No corrosive or flammable gases, No dust or oil

Standard height

Elevation of 1000 meters below

Vibration

Vibration speed 1.8 mm/s below

LL

Without holding break

141mm

161mm

171mm

With holding break

201mm

221mm

231mm

Torque-Speed

characteristics (T-M)

Chart 5

Chart 6

Chart 7

◆ Size of 90 series motor

Fig. 2. The dimension of 90 series AC servo motor (unit:mm)

◆ Specification of 90 series motor

Tab. 2. The specification table of 90 series AC servo motor

7

Page 10

ST SERIES MOTOR – 110ST SERIES

Model

110STM02020

110STM02030

110STM04020

110STM04030

110STM05030

110STM06020

110STM06030

Rated output (KW)

0.4

0.6

0.8

1.2

1.5

1.2

1.8

Rated torque (N.m)

2 2 4 4 5 6 6

Instantaneous peak

torque (N.m)

5 5 10

10

12.5

15

15

Rated speed (rpm)

2000

3000

2000

3000

3000

2000

3000

Max. speed (rpm)

2400

3600

2400

3600

3600

2400

3600

Rated current (A)

2.3

2.7

3.5

5.0

6.0

5.5

7.0

Instantaneous max current(A)

5.75

6.75

8.75

12.5

15.0

13.75

17.5

Rotor inertia (Kg.cm2)

3.81

3.81

7.61

7.61

9.51

11.4

11.4

Number of poles

4

Working voltage of adapted

driver (VAC)

220

Insulation class

F

Protection class

IP66

Encoder

2500 p/r

Mounting method

Flange method

Environment

Ambient temperature

-15 to 40℃ (no freeze), Stored temperature: -15 to 70℃ (no freeze)

Ambient humidity

80%RH below (no condensation),

Stored humidity: 90%RH below (no condensation)

Air

Indoor (no direct sunlight), No corrosive or flammable gases, No dust or oil

Standard height

Elevation of 1000 meters below

Vibration

Vibration speed 1.8 mm/s below

LL

Without holding break

157mm

157mm

187mm

187mm

202mm

217mm

217mm

With holding break

231mm

231mm

261mm

261mm

276mm

291mm

291mm

Torque-Speed

characteristics (T-M)

Chart 8

Chart 9

Chart 10

Chart 11

Chart 12

Chart 13

Chart 14

◆ Size of 110 series motor

Fig. 3. The dimension of 110 series AC servo motor (unit:mm)

◆ Specification of 110 series motor

Tab. 3. The specification table of 110 series AC servo motor

8

Page 11

ST SERIES MOTOR – 130ST SERIES

Model

130ST-

M04015

130ST-

M04025

130ST-

M05015

130ST-

M05025

130ST-

M06015

130ST-

M06025

Rated output (KW)

0.6

1.0

0.75

1.3

1.0

1.5

Rated torque (N.m)

4 4 5 5 6

6

Instantaneous peak

torque (N.m)

10

10

12.5

12.5

15

15

Rated speed (rpm)

1500

2500

1500

2500

1500

2500

Max. speed (rpm)

1800

3000

1800

3000

1800

3000

Rated current (A)

2.5

4.0

3.5

5.5

4.0

6.0

Instantaneous max. current (A)

6.25

10

8.75

13.75

10

15

Rotor inertia (Kg.cm2)

10.8

10.8

13.6

13.6

14.9

14.9

Number of poles

4

Working voltage of adapted

driver (VAC)

220

Insulation class

F

Protection class

IP66

Encoder

2500 p/r

Mounting method

Flange method

Environment

Ambient temperature

-15 to 40℃ (no freeze), Stored temperature: -15 to 70℃ (no freeze)

Ambient humidity

80%RH below (no condensation),

Stored humidity: 90%RH below (no condensation)

Air

Indoor (no direct sunlight), No corrosive or flammable gases, No dust or oil

Standard height

Elevation of 1000 meters below

Vibration

Vibration speed 1.8 mm/s below

LL

Without holding break

164mm

164mm

177mm

177mm

177mm

177mm

With holding break

239mm

239mm

252mm

252mm

252mm

252mm

Torque-Speed

characteristics (T-M)

Chart

15

Chart

16

Chart

17

Chart

18

Chart

19

Chart

20

◆ Size of 130 series motor

Fig. 4. The dimension of 130 series AC servo motor (unit:mm)

◆ Specification of 130 series motor

Tab. 4. The specification table of 130 series AC servo motor

9

Page 12

ST SERIES MOTOR – 130ST SERIES

Model

130ST-

M07715

130ST-

M07725

130ST-

M10015

130ST-

M10025

130ST-

M15015

130ST-

M15025

Rated output (KW)

1.2

2.0

1.6

2.6

2.4

3.9

Rated torque (N.m)

7.7

7.7

10

10

15

15

Instantaneous peak

torque (N.m)

19.3

19.3

25

25

37.5

37.5

Rated speed (rpm)

1500

2500

1500

2500

1500

2500

Max. speed (rpm)

1800

3000

1800

3000

1800

3000

Rated current (A)

4.6

6.5

6.0

10

9.0

14.5

Instantaneous max. current (A)

11.5

16.25

15

25

22.5

36.25

Rotor inertia (Kg.cm2)

21.7

21.7

27.9

27.9

34.1

34.1

Number of poles

4

Working voltage of adapted

driver (VAC)

220

Insulation class

F

Protection class

IP66

Encoder

2500 p/r

Mounting method

Flange method

Environment

Ambient temperature

-15 to 40℃ (no freeze), Stored temperature: -15 to 70℃ (no freeze)

Ambient humidity

80%RH below (no condensation),

Stored humidity: 90%RH below (no condensation)

Air

Indoor (no direct sunlight), No corrosive or flammable gases, No dust or oil

Standard height

Elevation of 1000 meters below

Vibration

Vibration speed 1.8 mm/s below

LL

Without holding break

203mm

203mm

223mm

223mm

239mm

239mm

With holding break

278mm

278mm

298mm

298mm

314mm

314mm

Torque-Speed

characteristics (T-M)

Chart

21

Chart

22

Chart

23

Chart

24

Chart

25

Chart

26

◆ Size of 130 series motor

Fig. 5. The dimension of 130 series AC servo motor (unit:mm)

◆ Specification of 130 series motor

Tab. 5. The specification table of 130 series AC servo motor

10

Page 13

ST SERIES MOTOR – 150ST SERIES

Model

150ST-

M18015

150ST-

M23015

150ST-

M27015

150ST-

M32015

Rated output (KW)

2.8

3.6

4.2

5.0

Rated torque (N.m)

18

23

27

32

Instantaneous peak

torque (N.m)

45

57.5

67.5

80

Rated speed (rpm)

1500

1500

1500

1500

Max. speed (rpm)

2000

2000

2000

2000

Rated current (A)

8.8

11.8

15

18.5

Instantaneous max. current (A)

22

29.5

37.5

46.3

Rotor inertia (Kg.cm2)

69.7

90.7

105

119

Number of poles

4

Working voltage of adapted

driver (VAC)

220

Insulation class

F

Protection class

IP66

Encoder

2500 p/r

Mounting method

Flange method

Environment

Ambient temperature

-15 to 40℃ (no freeze), Stored temperature: -15 to 70℃ (no freeze)

Ambient humidity

80%RH below (no condensation),

Stored humidity: 90%RH below (no condensation)

Air

Indoor (no direct sunlight), No corrosive or flammable gases, No dust or oil

Standard height

Elevation of 1000 meters below

Vibration

Vibration speed 1.8 mm/s below

LL

Without holding break

247mm

277mm

297mm

317mm

With holding break

332mm

362mm

382mm

402mm

Torque-Speed

characteristics (T-M)

Chart 27

Chart 28

Chart 29

Chart 30

◆ Size of 150 series motor

Fig. 6. The dimension of 150 series AC servo motor (unit:mm)

◆ Specification of 150 series motor

Tab. 6. The specification table of 150 series AC servo motor

11

Page 14

ST SERIES MOTOR – CHARACTERISTICS

◆ Torque-Speed characteristics of AC servo motor

(1) 80 series characteristics are as follows:

80ST-M01030 80ST-M01330

Chart 1 Chart 2

80ST-M02430 80ST-M03330

Chart 3 Chart 4

ANNOTATION :

A : Intermittent Duty Zone B : Continuous Duty Zone

12

Page 15

ST SERIES MOTOR – CHARACTERISTICS

◆ Torque-Speed characteristics of AC servo motor

(2) 90 series characteristics are as follows:

90ST-M01530 90ST-M02430

Chart 5 Chart 6

90ST-M03530

Chart 7

A : Intermittent Duty Zone B : Continuous Duty Zone

ANNOTATION :

13

Page 16

ST SERIES MOTOR – CHARACTERISTICS

◆ Torque-Speed characteristics of AC servo motor

(3) 110 series characteristics are as follows – (a):

110ST-M02020 110ST-M02030

Chart 8 Chart 9

110ST-M04020 110ST-M04030

Chart 10 Chart 11

110ST-M05030

Chart 12

ANNOTATION :

A : Intermittent Duty Zone B : Continuous Duty Zone

14

Page 17

ST SERIES MOTOR – CHARACTERISTICS

◆ Torque-Speed characteristics of AC servo motor

(3) 110 series characteristics are as follows – (b):

110ST-M06020 110ST-M06030

Chart 13 Chart 14

ANNOTATION :

A : Intermittent Duty Zone B : Continuous Duty Zone

15

Page 18

ST SERIES MOTOR – CHARACTERISTICS

◆ Torque-Speed characteristics of AC servo motor

(4) 130 series characteristics are as follows – (a):

130ST-M04015 130ST-M04025

Chart 15 Chart 16

130ST-M05015 130ST-M05025

Chart 17 Chart 18

130ST-M06015 130ST-M06025

Chart 19 Chart 20

ANNOTATION :

A : Intermittent Duty Zone B : Continuous Duty Zone

16

Page 19

ST SERIES MOTOR – CHARACTERISTICS

◆ Torque-Speed characteristics of AC servo motor

(4) 130 series characteristics are as follows – (b):

130ST-M07715 130ST-M07725

Chart 21 Chart 22

130ST-M10015 130ST-M10025

Chart 23 Chart 24

130ST-M15015 130ST-M15025

Chart 25 Chart 26

ANNOTATION :

A : Intermittent Duty Zone B : Continuous Duty Zone

17

Page 20

ST SERIES MOTOR – CHARACTERISTICS

◆ Torque-Speed characteristics of AC servo motor

(5) 150 series characteristics are as follows:

150ST-M18015 150ST-M23015

Chart 27 Chart 28

150ST-M27015 150ST-M32015

Chart 29 Chart 30

ANNOTATION :

A : Intermittent Duty Zone B : Continuous Duty Zone

18

Page 21

The content may be modified due to product improvement.

Beijing KND CNC Technique Co.,LTD.

Address: No.3-5, 11th Block, 188 West Nansihuan Road, Fengtai

District, Beijing (Postal Code: 100070)

Phone: +86-10-63701999 Fax: +86-10-63701998

Http: //www.knd.com.cn E-mail: bj@knd.com.cn

Printed in Jan. 2012

Loading...

Loading...