knd KND-K100M Users Manual

CNC Series

CNC Series

KND—100M Computer Numerical Products

— boring and milling machines

USER’S MANUAL

Beijing KND CNC Technique Co. Ltd.

B—99100M/01

C KND LTD,1999

I GENERAL ……………………………………………………………………………… |

1- 0 |

|

1. GENERAL…………………………………………………………………………………… |

1- 1 |

|

1.1 |

GENERAL FLOW OF OPERATION OF CNC MACHINE TOOL …………………… 1- 1 |

|

1.2 |

NOTES ON READING THIS MANUAL ……………………………………………… 1- 1 |

|

II PROGRAMMING ……………………………………………………………………… |

1- 0 |

|

1.GENERAL…………………………………………………………………………………… 1- 1

1.1TOOL MOVEMENT ALONG WORKPIECE PARTS FIGURE-INTERPOLATION……1- 2

1.2FEED-FEED FUNCTION………………………………………………………………… 1- 3

1.3PART DRAWING AND TOOL MOVEMENT…………………………………………… 1- 3

1.4CUTTING FEED─SPINDLE FUNCTION……………………………………………… 1- 7

1.5SELECTION OF TOOL USED FOR VARIOUS MACHINING-TOOL FUNCTION … 1- 7

1.6COMMAND FOR MACHINE OPERATIONS-MISCELLANEOUS FUNCTION……… 1- 8

1.7PROGRAM CONFIGURATION ………………………………………………………… 1- 8

1.8TOOL FIGURE AND TOOL MACHINE-TOOL LENGTH COMPENSATION………… 1- 10

1.9TOOL MOVEMENT RANGE -STROKE………………………………………………… 1- 11

2.CONTROLLED AXES……………………………………………………………………… 2- 0

2.1CONTROLLED AXES…………………………………………………………………… 2- 1

2.2INCREMENT SYSTEM…………………………………………………………………… 2- 1

2.3MAXIMUM STROKE……………………………………………………………………… 2- 1

3. PREPARATORY FUNCTION (G FUNCTION) ……………………………………… |

3- 0 |

|

4. INTERPOLATION FUNCTIONS………………………………………………………… |

4- 0 |

|

4.1 |

POSITIONING (G00) …………………………………………………………………… |

4- 1 |

4.2 |

LINEAR INTERPOLATION (G01)……………………………………………………… |

4- 1 |

4.3 |

CIRCULAR INTERPOLATION (G02,G03)……………………………………………… 4- 2 |

|

5. FEED FUNCTIONS……………………………………………………………………… |

5- 0 |

|

5.1GENERAL………………………………………………………………………………… 5- 1

5.2RAPID TRAVERSE………………………………………………………………………… 5- 2

5.3CUTTING FEED …………………………………………………………………………… 5- 3

5.4 |

DWELL (G04) …………………………………………………………………………… 5- 4 |

|

6. REFERENCE POSITION………………………………………………………………… |

6- 0 |

|

6.1 |

REFERENCE POINT RETURN(G28,G29) …………………………………………… |

6- 1 |

7. COORDINATE SYSTEM………………………………………………………………… |

7- 1 |

|

7.1 |

WORKPIECE COORDINATE SYSTEM SETTING (G92)……………………………… 7- 1 |

|

7.2 |

PLANE SELECTION (G17,G18,G19) ………………………………………………… |

7- 2 |

8. COORDINATE VALUE AND DIMENSION…………………………………………… |

8- 1 |

|

8.1ABSOLUTE AND INCREMENTAL PROGRAMMING (G90, G91)…………………… 8- 1

8.2INCH/METRIC CONVERSION (G20,G21)……………………………………………… 8- 1

8.3DECIMAL POINT PROGRAMMING …………………………………………………… 8- 2

9. SPINDLE SPEED FUNCTION (S FUNCTION) ……………………………………… 9- 0

9.1SPINDLE SPEED COMMAND…………………………………………………………… 9- 1

10.TOOL FUNCTION (T FUNCTION) ……………………………………………………… 10- 1

11.AUXILIARY FUNCTION …………………………………………………………………… 11- 0

11.1AUXILIARY FUNCTION (M FUNCTION) ……………………………………………… 11- 1

11.2AUXILIARY FUNCTION PARAMETER ………………………………………………… 11- 3

11.3NOTES ON AUXILIARY FUNCTION …………………………………………………… 11- 4

12.PROGRAM CONFIGURATION………………………………………………………… 12- 1

12.1GENERAL …………………………………………………………………………………12- 1

12.2PROGRAM END…………………………………………………………………………… 12- 7

12.3FILE END ………………………………………………………………………………… 12- 8

13.FUNCTIONS TO SIMPLIFY PROGRAMMING……………………………………… 13- 1

13.1CANNED CYCLE (G73,G74,G76.G80-G89) …………………………………………… 13- 1

14.COMPENSATION FUNCTION………………………………………………………… 14- 1

14.1TOOL LENGTH COMPENSATION(G43,G44,G49)…………………………………… 14- 1

14.2CUTTER COMPENSATION B(G39,G40-G42)………………………………………… 14- 4

14.3CUTTER COMPENSATION C(G40-G42)……………………………………………… 1411

14.3.1CUTTER COMPENSATION FUNCTION……………………………………… 1411

14.3.2OFFSET AMOUNT(H code)…………………………………………………… 1411

14.3.3OFFSET VECTOR…………………………………………………………………14-12

14.3.4PLANE SELECTION AND VECTOR ……………………………………………14-12

14.3.5G40,G41 and G42 …………………………………………………………………14-12

14.3.6DETAILS OF CUTTER COMPENSATION C ……………………………………14-14

14.4OFFSET AMOUNT INPUT BY PROGRAM(G10) ………………………………………14-39

15. MEASURE FUNCTION ………………………………………………………………… |

15- 1 |

15.1SKIP FUNCTION (G31)…………………………………………………………………… |

15- 1 |

16. WORKPIECE COORDINATE SYSTEM SELECTION …………………………… |

16- 1 |

16.1 WORKPIECE COORDINATE SYSTEM(G54-G59) …………………………………… 16- 1 |

|

17.CUSTOM MACRO………………………………………………………………………… |

17- 1 |

17.1CUSTOM MACRO COMMAND ………………………………………………………… 17- 1

17.2CUSTOME MACRO BODY ……………………………………………………………… 17- 1

17.3CUSTOM MACRO EXAMPLES ………………………………………………………… 1710

III OPERATION……………………………………………………………………………… 1- 0

1.GENERAL…………………………………………………………………………………………1- 1

1.1MANUAL OPERATION ……………………………………………………………………1- 1

1.2TOOL MOVEMENT BY PROGRAMING-AUTOMATIC OPERATION ……………… 1- 2

1.3AUTOMATIC OPERATION ……………………………………………………………… 1- 3

1.4TESTING A PROGRAM ………………………………………………………………… 1- 4

1.5PROGRAM EDITING……………………………………………………………………… 1- 6

1.6DATA DISPLAY AND SETTING ………………………………………………………… 1- 6

1.7DISPLAY …………………………………………………………………………………… 1- 8

1.8DATA INPUT/OUTPUT …………………………………………………………………… 1-10

2. OPERATOR’S PANEL …………………………………………………………………… |

2- 1 |

|

2.1 |

LCD MDI PANEL ……………………………………………………………………… 2- 1 |

|

2.2 |

ADDITIONAL PANEL …………………………………………………………………… |

2- 5 |

3. POWER ON AND OFF ……………………………………………………………………… 3- 1 |

||

3.1 |

POWER ON……………………………………………………………………………… |

3- 1 |

3.2POWER OFF……………………………………………………………………………… 3- 1

4.MANUAL OPERATION ……………………………………………………………………… 4- 1

4.1 MANUAL REFERENCE POSITION RETURN ……………………………………… 4- 1

4.2JOG FEED …………………………………………………………………………… … 4- 1

4.3INCREMENTAL FEED…………………………………………………………………… 4- 3

4.4HANDLE FEED…………………………………………………………………………… 4- 4

4.5MANUAL PROGRAM ZERO RETURN………………………………………………… 4- 5

4.6MANUAL ABSOLUTE SWITCH………………………………………………………… 4- 5

4.7MANUAL AUXILIARY FUNCTION OPERATION……………………………………… 4- 7

5.AUTOMATIC OPERATION………………………………………………………………… 5- 1

5.1OPERATION MODE……………………………………………………………………… 5- 1

5.2START-UP………………………………………………………………………………… 5- 3

5.3AUTO OPERATION EXECUTION……………………………………………………… 5- 3

5.4STOP …………………………………………………………………………………… 5- 3

6.DRY RUN ……………………………………………………………………………………… 6- 1

6.1MACHINE LOCK ………………………………………………………………………… 6- 1

6.2AUXILIARY FUCTION LOCK …………………………………………………………… 6- 1

6.3FEEDRATE OVERRIDE ………………………………………………………………… 6- 1

6.4RAPID TRAVERSE OVERRIDE………………………………………………………… 6- 2

6.5ANALOGUE SPINDLE OVERRIDE …………………………………………………… 6- 2

6.6DRY RUN ………………………………………………………………………………… 6- 3

6.7SINGLE BLOCK…………………………………………………………………………… 6- 3

6.8RESTART AFTER FEEDHOLD OR STOP …………………………………………… 6- 4

6.9OPTIONAL BLOCK SKIP………………………………………………………………… 6- 4

7.SAFTY OPERATION ………………………………………………………………………… 7- 1

7.1 EMERGENCY STOP …………………………………………………………………… 7- 1

7.2OVERTRAVEL …………………………………………………………………………… 7- 1

8.ALARM ……………………………………………………………………………………………

8- 1

9. PROGRAM STORAGE AND EDITING……………………………………………………9- 1

9.1 PREPARATION …………………………………………………………………………… 9- 1

9.2 STORE PROGRAM IN MEMORY ……………………………………………………… 9- 1

9.3 STORE FILE IN MEMORY …………………………………………………………… 9- 2

9.4 PROGRAM SEARCH …………………………………………………………………… |

9- 2 |

9.5 PROGRAM DELETING ………………………………………………………………… |

9- 3 |

9.6 DELETING ALL PROGRAMS…………………………………………………………… |

9- 3 |

9.7 PROGRAM OUTPUT …………………………………………………………………… |

9- 3 |

9.8 ALL PROGRAMS OUTPUT……………………………………………………………… |

9- 3 |

9.9 SEQUENCE NUMBER SEARCH ……………………………………………………… |

9- 3 |

9.10PROGRAM COMPARATION ………………………………………………………… 9- 4

9.11WORD INSERTING, MODIFYING AND DELETING ………………………………… 9- 5

9.12SEQUENCE NUMBER INSERTING AUTOMATICALLY …………………………… 9- 9

9.13NUMBER OF STORED PROGRAMS ………………………………………………… 9- 9

9.14STORAGE CAPACITY…………………………………………………………………… 9- 9

10.DATA DISPLAY AND SETTING………………………………………………………… 10-1

10.1OFFSET AMOUNT ……………………………………………………………………… 10- 1

10.2SET PARAMETER SETTING …………………………………………………………… 10- 2

10.3CUSTOM MACRO VARIABLES DISPLAY AND SETTING ………………………… 10- 4

10.4PARAMETER …………………………………………………………………………… 10- 5

10.5PITCH ERROR COMPENSATION DATA……………………………………………… 10- 7

10.6DIAGNOSE………………………………………………………………………………… 10- 7

10.7MACHINE SOFT OPERATOR’S PANEL DISPLAY AND SETTING…………………10- 8

11.DISPLAY ………………………………………………………………………………………11- 1

11.1STATUS DISPLAY………………………………………………………………………… 11- 1

11.2DATA DISPLAY …………………………………………………………………………… 11- 1

11.3PROGRAM No. and SEQUENCE No. DISPLAY ……………………………………… 11- 1

11.4PROGRAM MEMORY DISPLAY………………………………………………………… 11- 2

11.5COMMAND VALUE DISPLAY…………………………………………………………… 11- 2

11.6POSITION DISPLAY …………………………………………………………………… 11- 3

11.7RUN TIME AND PARTS NUMBER……………………………………………………… 11- 5

11.8ALARM DISPLAY ………………………………………………………………………… 11- 6

11.9INDEX CONTENT DISPLAY …………………………………………………………… 11- 6

12.DATA OUTPUT AND FLASH MEMORY …………………………………………… 12- 1

12.1DATA OUTPUT ………………………………………………………………………… 12- 1

12.2FLASH MEMORY………………………………………………………………………… 12- 2

13.GRAPH FUNCTION ………………………………………………………………………… 13- 1

13.1GRAPH PARAMETER SETTING ……………………………………………………… 13- 2

13.2GRAPH PARAMETER…………………………………………………………………… 13- 2

13.3TOOL PATH ……………………………………………………………………………… 13- 4

13.4EXAMPLES …………………………………………………………………………… 13- 4

14.DESCRIPTION ON DRIVER DEVICE……………………………………………………14- 1

14.1UPPER LIMIT OF CUTTING FEED………………………………………………………14- 1

14.2RAPID TRAVERSE RATE SETTING…………………………………………………… 14- 1

14.3ELECTRIC GEAR RATIO………………………………………………………………… 14- 1

14.4AC/DECELERATION TIME CONSTANT ……………………………………………… 14- 2

14.5PARAMETER SETTING ………………………………………………………………… 14- 2

14.6DRIVER ALARM ………………………………………………………………………… 14- 4

15.DESCRIPTION ……………………………………………………………………………… 15- 1

15.1STANDARD PARAMETER SETTING AND MEMORY CLEARING………………… 15- 1

15.2NO CHECK ON OVERTRAVEL………………………………………………………… 15- 1

15.3BACKLASH COMPENSATION ………………………………………………………… 15- 1

15.4INPUT SIGNAL FILTER………………………………………………………………… 15- 1

15.5NOT ENTERED NORMAL SCREEN…………………………………………………… 15- 1

15.6ROM PARITY ALARM AND RAM CHECK …………………………………………… 15- 1

IV CONNECTION ………………………………………………………………………… 1- 0

1.SYSTEM INSTALLATION

1.1CONFIGURATION………………………………………………………………………… 1- 1

1.2INSTALLATION DIMENSION ………………………………………………………… 1- 2

1.3ADDITIONAL PANEL DIMENSION …………………………………………………… 1- 3

2.INTERNAL CONNECTION

2.1CONNECTION DIAGRAM………………………………………………………………… 2- 1

2.2POWER OUTLET SIGNAL ARRANGEMENT…………………………………………… 2- 3

2.3OVERRIDE SWITCH SIGNAL ARRANGEMENT ……………………………………… 2- 3

2.4OUTLET CONNECTION BETWEEN MAIN BOARD AND EXTERNAL ……………… 2- 4

3.EXTERNAL CONNECTION

3.1EXTERNAL CONNECTION DIAGRAM………………………………………………… 3- 1

3.1.1WITH STEPPER MOTOR ……………………………………………………… 3- 1

3.1.2WITH SERVO MOTOR ………………………………………………………… 3- 2

3.2INTERFACE SIGNAL FROM CNC TO DRIVER ……………………………………… 3- 3

3.2.1INTERFACE SIGNAL LOGIC DIAGRAM……………………………………… 3- 3

3.2.2CONNECTOR SIGNAL ………………………………………………………… 3- 5

3.2.3SIGNAL DESCRIPTION ………………………………………………………… 3- 6

3.2.4CABLE MAKING ………………………………………………………………… 3- 10

3.3RS232-C SERIES PORT……………………………………………………………………3- 13

3.4ANALOGUE SPINDLE INTERFACE CONNECTION ………………………………… 3- 13

3.5ADDITIONAL PANEL CONNECTION …………………………………………………… 3- 14

3.5.1CONNECTOR SIGNAL ………………………………………………………… 3- 14

3.5.2SIGNAL DESCRIPTION ………………………………………………………… 3- 14

3.5.3SIGNAL CONNECTION ………………………………………………………… 3- 15

4.MACHINE TOOL INTERFACE

4.1INPUT SIGNAL INTERFACE DESCRIPTION……………………………………………4- 1

4.1.1INPUT SIGNAL A………………………………………………………………… 4- 1

4.1.2 INPUT SIGNAL B……………………………………………………………… 4- 1

4.2INPUT SIGNAL INTERFACE DESCRIPTION ………………………………………… 4- 2

4.2.1DARLINGTON OUTPUT PARAMETER ……………………………………… 4- 2

4.2.2OUTPUT DRIVER RELAY CIRCUIT…………………………………………… 4- 3

4.2.3OUTPUT DIRVER INDICATOR LAMP………………………………………… 4- 4

4.3INPUT/OUTPUT SIGNAL LIST…………………………………………………………… 4- 5

4.3.1INPUT SIGNAL DIAGNOSE LIST……………………………………………… 4- 5

4.3.2OUTPUT SIGNAL DIAGNOSE LIST ……………………………………………

4- 5

4.3.3OUTLET PIN SIGNAL ARRANGEMENT ………………………………………4- 6

4.4INPUT/OUTPUT SIGNAL DESCRIPTION ……………………………………………… 4- 6

4.4.1INPUT SIGNAL…………………………………………………………………… 4- 6

4.4.2OUTPUT SIGANL………………………………………………………………… 4- 9

4.4.3M code VOLTAGE LEVEL/PULSE OUTPUT DESCRIPTION ……………… 4-10

V APPENDIX………………………………………………………………………………… 1- 0

APPENDIX1 |

STORED PITCH ERROR COMPENSATION …………………………………… 1- 1 |

APPENDIX2 |

G FUNCTION TABLE ……………………………………………………………… 2- 1 |

APPENDIX3 |

RANGE OF COMMAND VALUE TABLE ………………………………………… 3- 1 |

APPENDIX4 |

BINARY AND DECIMAL CONVERSION………………………………………… 4- 1 |

APPENDIX5 |

ALARM LIST………………………………………………………………………… 5- 1 |

APPENDIX6 |

STATUS OF POWER-ON AND RESET ………………………………………… 6- 1 |

APPENDIX7 |

PARAMETER LIST ………………………………………………………………… 7- 1 |

APPENDIX8 |

PLC PARAMETER LIST …………………………………………………………… 8- 1 |

APPENDIX9 |

OPERATION TABLE…………………………………………………………………9- 1 |

APPENDIX10 SPECIFICATION TABLE …………………………………………………………… 10- 1 APPENDIX11 CNC STATUS DIAGNOSE MESSAGE ……………………………………………11- 1

APPENDIX12 COMMUNICATION SOFTWARE DESCRIPTION ……………………………… 12- 1

GENERAL 1(GENERAL) 1 - 0

GENERAL

GENERAL 1(GENERAL) 1 - 1

1 GENERAL

1. INTRODUCTION

KND 100M, a economic CNC to control digital servo motor or stepper motor for milling machines, boring machines and machining centers has been developed by Beijing KND CNC technique Co. Ltd. to satisfy the needs of NC markets in China. The control circuit uses high-speed microprocessors, custom LSIs, multiple-layer PCBs and high resolving power LCD to reduce the volume in order to compact the whole system and provide high reliability. As for control software, KND 100M brings overall-function CNC system to stepper motor control system for the first time, and increases many functions fit stepper motor according to the character of stepper motor in order to give full play to its performance at the same time. KND 100M provides high-performance and significantly improves the performance / cost ratio.

This manual explains programming, operation, and connection. For convenience the basic and optional specifications are explained at APPENDIX. The detailed descriptions can be referred to as required. This manual covers everything pertaining to the system KND 100M. As for the specifications for the machine operator’s panel and actual function corresponding to different machine tools refer to the manual issued by the individual machine tool builder.

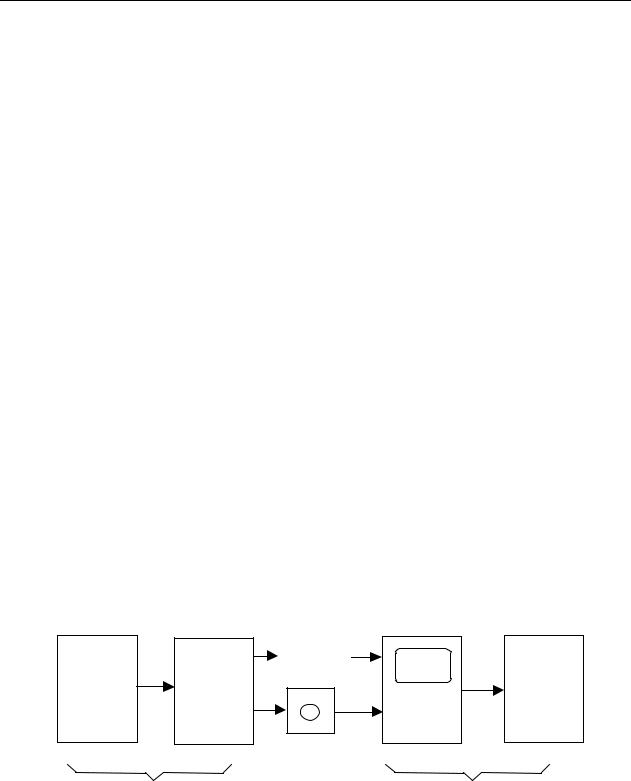

1.1 GENERAL FLOW OF OPERATION OF CNC MACHINE TOOL

When machining the part using the CNC machine tool, first prepare the program, then operate the CNC machine by using the program.

1)First, prepare the program from a part drawing to operate the CNC machine tool. Store the program to a media appropriate for the CNC. How to prepare the program is described in the Chapter II. PROGRAMMING.

2)The program is to be read into the CNC system. Then, mount the workpieces and tools on the machine, and operate the tools according to the programming. Finally, execute the machining actually. How to operate the CNC system is described in the Chapter III. OPERATION.

|

|

MDI/LCD |

Part |

Part |

Machine |

drawing |

program |

tool |

|

|

CNC |

|

|

Floppy disk |

CHAPTER II PROGRAMMING |

CHAPTER III OPERATION |

|

1.2NOTES ON READING THIS MANUAL

1The function of an CNC machine tool system depends not only on the CNC, but on the combination of the machine tool, its magnetic cabinet, the servo system, the CNC, the operator’s panels, etc. It is too difficult to describe the function, programming, and operation relating to all combinations. This manual generally describes these from the stand-point of the CNC. So, for details on a particular CNC machine tool, refer to the manual issued by the machine tool builder, which should take precedence over this manual.

GENERAL 1(GENERAL) 1 - 2

Optional |

. . . |

Optional |

|

function1 |

function2 |

|

|

CNC basic function |

interface |

||

|

|||

|

|

|

|

CNC system

2 This manual is KND 100M series CNC system common description. Under the concrete conditions, refer to the description of individual machine tool builder.

3 KND 100M series CNC system provide several types. Be caution to select system. For details, refer to the order of KND Ltd.

PROGRAMMING-1 GENERAL 1-

II PROGRAMMING

PROGRAMMING-1 GENERAL 1-

1GENERAL

PROGRAMMING-1 GENERAL 1-

1.1 TOOL MOVEMENT ALONG WORKPIECE PARTS FIGUREINTERPOLATION

The tool moves along straight lines and arcs constituting the workpiece parts figure (See II-4).

EXPLANATIONS

● Tool movement along a straight line

Workpiece |

Program

G01 X_ _ Y_ _ ; X_ _ ;

Tool

Fig.1.1 (a) Tool movement along a straight line

●Tool movement along an arc

|

Program |

|

G03 X_ Y_ R_ |

W orkpiece |

Tool |

|

Fig. 1.1 (b) Tool movement along an arc

Symbols of the programmed commands G01, G02, ... are called the preparatory function and specify the type of interpolation conducted in the control unit.

|

Control unit |

|

(a) Movement along straight |

|

|

|

|

|

line |

interpolation |

X-axis(motor) |

G01 Y__; |

|

|

X__Y__; |

|

Y-axis(motor) |

|

|

|

(b) Movement along arc |

|

|

G03X__Y__R__; |

a)Movement along |

|

|

straight line |

|

|

b) Movement along |

|

|

arc |

Tool movement |

|

|

|

Fig. 1.1 (c) Interpolation function

NOTE:

Some machines move tables instead of tools but this manual assumes that tools are moved against workpieces.

PROGRAMMING-1 GENERAL 1-

1.2 FEEDFEED FUNCTION

Movement of the tool at a specified speed for cutting a workpiece is called the feed.

F

mm/min Tool

Workpiece

Table

Fig. 1.2 (a) Feed function

Feedrates can be specified by using actual numerics. For example, to feed the tool at a rate of 150 mm/min, specify the following in program: F150.0

The function of deciding the feed rate is called the feed function (See II-5).

1.3 PART DRAWING AND TOOL MOVEMENT

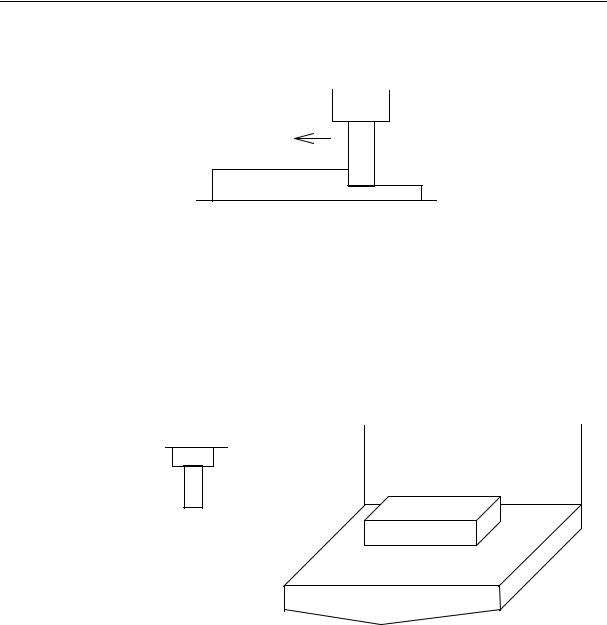

1.3.1 Reference Position (Machine-specific position)

A CNC machine tool is provided with a fixed position. Normally, tool change and programming of absolute zero point as described later are performed at this position. This position is called the reference position.

Reference position

Tool

Workpiece

Table

Fig. 1.3.1 (a) Reference position

EXPLANATIONS

The tool can be moved to the reference position in two ways:

(1) Manual reference position return (See III-1)

Reference position return is performed by manual button operation.

(2) Automatic reference position return (See II-6)

In general, manual reference position return is performed first after the power is turned on. In order to move the tool to the reference position for tool change thereafter, the function of automatic reference position return is used.

PROGRAMMING-1 GENERAL 1-

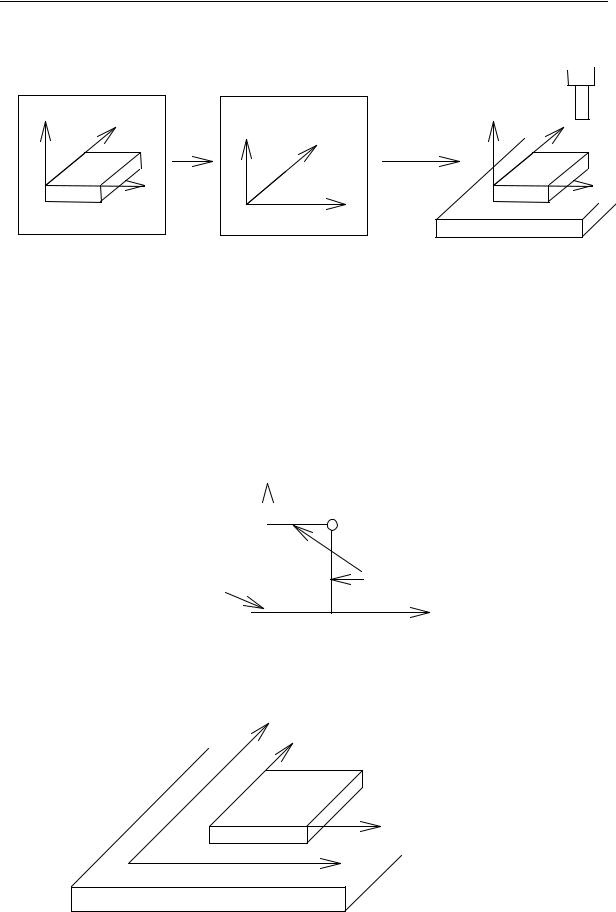

1.3.2 Coordinate System on Part Drawing and Coordinate System Specified by CNC Coordinate System

|

|

|

|

Tool |

|

Z |

Y |

Y |

Z |

Y |

|

Program Z |

|

|

|||

|

|

|

|

||

|

X |

command |

|

workpiece |

X |

|

X |

|

|

||

|

|

|

|

|

|

|

Coordinate system |

|

|

|

|

|

Part drawing |

CNC |

Machine tool |

|

|

|

Fig. 1.3.2 (a) Coordinate system |

|

|

|

|

EXPLANATIONS

●Coordinate system

The following two coordinate systems are specified at different locations: (See II-7)

(1) Coordinate system on part drawing

The coordinate system is written on the part drawing. As the program data, the coordinate values on this coordinate system are used.

(2) Coordinate system specified by the CNC

The coordinate system is prepared on the actual machine tool table. This can be achieved by programming the distance from the current position of the tool to the zero point of the coordinate system to be set.

|

200 |

|

|

|

Present tool position |

Program zero point |

300 |

Distance to the zero point of a |

|

0 |

coordinate system to be set |

|

|

|

|

|

|

Fig. 1.3.2 (b) Coordinate system specified by the CNC

The positional relation between these two coordinate systems is determined when a workpiece is set on the table.

Y |

|

|

Tool |

|

|

||||

|

|

||||||||

Y |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Workpiece |

|

|

|

||||||

Coordinate system on part drawing |

|||||||||

|

established on the workpiece |

||||||||

|

X |

||||||||

|

Coordinate system specified by the |

||||||||

X |

CNC established on the table |

||||||||

Table

Fig. 1.3.2 (c) Coordinate system specified by CNC and coordinate system on part drawing

PROGRAMMING-1 GENERAL 1-

The tool moves on the coordinate system specified by the CNC in accordance with the command program generated with respect to the coordinate system on the part drawing, and cuts a workpiece into a shape on the drawing. Therefore, in order to correctly cut the workpiece as specified on the drawing, the two coordinate systems must be set at the same position.

• Methods of setting the two coordinate systems in the same position

To set the two coordinate systems at the same position, simple methods shall be used according to workpiece shape, the number of machinings.

(1) Using a standard plane and point of the workpiece.

Workpiece’s standard point

Fixed distance

Bring the tool center to the workpiece standard point. And set the coordinate system specified by CNC at this position.

(2) Mounting a workpiece directly against the jig

Program zero point

Jig

Meet the tool center to the reference position. And set the coordinate system specified by CNC at this position. (Jig shall be mounted on the predetermined point from the reference position.)

(3) Mounting a workpiece on a pallet, then mounting the workpiece and pallet on the jig

|

|

pallet |

|

|

|

|

|

|

|

Jig |

|

|

|

(Jig and coordinate system shall be |

|

|

Workpiece |

specified by the same as (2)). |

|

|

|

|

|

|

|

|

|

|

|

PROGRAMMING-1 GENERAL 1-

1.3.3 How to Indicate Command Dimensions for Moving the Tool – Absolute, Incremental instructions

EXPLANATIONS

Coordinate values of command for moving the tool can be indicated by absolute or incremental designation (See II-8.1).

• Absolute coordinates

The tool moves to a point at“the distance from zero point of the coordinate system” that is to the position of the coordinate values.

Tool

Z

A (15 60 40)

B (10 30 20)

Y

X

Command specifying movement from point A to point B G90 X10.0 Y30.0 Z20.0 ;

coordinates of point B

• Incremental coordinates

Specify the distance from the previous tool position to the next tool position.

Tool

Z

30 A 10

40

B

Y

X

Command specifying movement from point A to point B

G91 X40.0 Y-30.0 Z-10.0 ;

Distance and direction for movement along each axis

PROGRAMMING-1 GENERAL 1-

1.4 CUTTING SPEED – SPINDLE SPEED FUNCTION

The speed of the tool with respect to the workpiece when the workpiece is cut is called the cutting speed. As for the CNC, the cutting speed can be specified by the spindle speed in rpm unit.

Tool |

Diameter |

RPM |

V (mm/min) |

Workpiece |

EXAMPLES

<When a workpiece should be machined with a tool 100 mm in diameter at a cutting speed of 80 mm/min. >

The spindle speed is approximately 250 rpm, which is obtained from N=1000v/πD. Hence the following command is required: S250;

Commands related to the spindle speed are called the spindle speed function ( See II-9).

1.5 SELECTION OF TOOL USED FOR VARIOUS MACHINING (TOOL FUNCTION)

When drilling, tapping, boring, milling or the like, is performed, it is necessary to select a suitable tool. When a number is assigned to each tool and the number is specified in the program, the corresponding tool is selected.

Tool number

01

ATC magazine

02

.

EXAMPLES

<When No.01 is assigned to drilling tool>

When the tool is stored at location 01 in the ATC magazine, the tool can be selected by specifying T01. This is called the tool function (See II-10)

PROGRAMMING-1 GENERAL 1-

1.6 COMMAND FOR MACHINE OPERATIONS –MISCELLANEOUS FUNCTION

When machining is actually started, it is necessary to rotate the spindle, and feed coolant. For this purpose, on-off operations of spindle motor and coolant valve should be controlled (See II-11).

Spindle rotate

Tool coolant

Workpiece |

The function of specifying the on-off operations of the components of the machine is called the miscellaneous function. In general, the function is specified by an M code. For example, when M03 is specified, the spindle is rotated clockwise at the specified spindle speed.

1.7 PROGRAM CONFIGURATION

A group of commands given to the CNC for operating the machine is called the program. By specifying the commands, the tool is moved along a straight line or an arc, or the spindle motor is turned on and off. In the program, specify the commands in the sequence of actual tool movements.

Block |

Block

Tool movement sequence

Block

Program Block

Block

Fig. 1.7 (a) Program configuration

A group of commands at each step of the sequence is called the block, The program consists of a group of blocks for a series of machining. The number for discriminating each block is called the sequence number, and the number for discriminating each program is called the program number (See II-12).

PROGRAMMING-1 GENERAL 1-

EXPLANATIONS

• Block

The block and the program have the following configurations.

1 Block

NOOOO GOO XOO.O YOO.O MOO SOO TOO;

N:Sequence number

G: Preparatory function

X,Y: Dimension word

M:Miscellaneous function

S:Spindle function

T:Tool function

; : End of block

Fig. 1.7 (b) Block configuration

A block has a sequence number at its head, which identifies the block, and an end-of-block code at the end, indicating the end of the block. This manual indicates the end-of-block code by ;.

• Program

Normally, a program number is specified after the end-of-block (;) code at the beginning of the program, and a program end code (M02 or M30) is specified at the end of the program.

O□□□□ Program number Block

Block

Block

M30 |

End of program |

Fig. 1.7 (c) Program configuration

• Main program and subprogram

When machining of the same pattern appears at many portions of a program, a program for the pattern is created. This is called the subprogram. On the other hand, the original program is called the main program. When a subprogram execution command appears during execution of the main program, commands of the subprogram are executed. When execution of the subprogram is finished, the sequence returns to the main program.

|

|

PROGRAMMING-1 GENERAL 1- |

|||

Main program |

subprogram#1 |

|

|

||

|

|

O1001 |

program for |

||

|

M98P1001 |

||||

|

|

|

|||

|

M99 |

pole #1 |

|||

|

|

||||

|

M98P1002 |

|

|

||

|

subprogram#2 |

|

|

||

|

|

|

|

||

|

M98P1001 |

O1002 |

program for |

||

|

|

||||

|

|

|

|

pole#2 |

|

|

|

M99 |

|||

|

|

|

|

||

|

|

|

|

|

|

Pole #1 Pole #1

Pole #2Pole #2

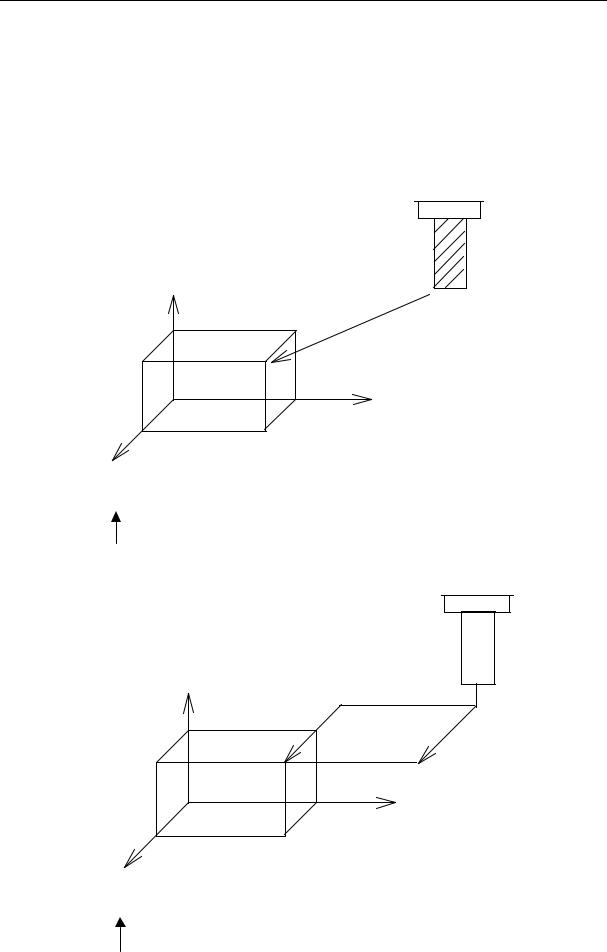

1.8 TOOL FIGURE AND TOOL MOTION BY PROGRAM

EXPLANATIONS

• Machining using the end of cutter-Tool length compensation function (See II-14.1)

Usually, several tools are used for machining one workpiece. The tools have different tool length. It is very troublesome to change the program in accordance with the tools. Therefore, the length of each tool used should be measured in advance. By setting the difference between the length of the standard tool and the length of each tool in the CNC (data display and setting: see III-11), machining can be performed without altering the program even when the tool is changed. This function is called tool length compensation.

H2 |

H3 |

H1 |

H4 |

|

|

|

Workpiece |

PROGRAMMING-1 GENERAL 1-

• Machining using the Side of cutter-Cutter compensation function (See II-14.2)

Because a cutter has a radius, the center of the cutter path goes around the workpiece with the cutter radius deviated.

Tool

Cutter path using cutter compensation

Machined part figure

Workpiece

If radius of cutters are stored in the CNC (Data Display and Setting : see III-11), the tool can be moved by cutter radius apart from the machining part figure. This function is called cutter compensation.

1.9 TOOL MOVEMENT RANGE-STROKE

Limit switches are installed at the ends of each axis on the machine to prevent tools from moving beyond the ends. The range in which tools can move is called the stroke.

Table

motor

Reference position |

Besides strokes defined with limit switches, the operator can define an area which the tool cannot enter using a program or data in memory (see III-11). This function is called stroke check.

PROGRAMMING-2 (CONTROLLED AXES) 2-0

2CONTROLLED AXES

PROGRAMMING-2 (CONTROLLED AXES) 2-1

2.1 CONTROLLED AXES

Number of controlled axes |

4 axes |

|

|

Simultaneously controlled axes |

4 axes |

|

|

2.2 NAME OF AXES

Names of the three basic axes are fixed as X, Y, and Z. Names of additional axes can be optionally selected from A, B, C, U, V, and W. They can be set by parameter No. 008 #2, #3, #4.

2.3 INCREMENT SYSTEM

Least command increment |

Least input increment |

Maximum stroke |

|

|

|

0.001mm |

0.001mm |

9999.99mm |

|

|

|

0.0001inch |

0.0001inch |

999.9999inch |

|

|

|

Combined use of the inch system and the metric system is not allowed. There are functions that cannot be used between axes with different unit systems (circular interpolation, cutter compensation, etc.). For the increment system, see the machine tool builder’s manual.

2.4 MAXIMUM STROKE

Maximum stroke = Least command increment x 99999999

See 2.3 Increment System.

PROGRAMMING-3 PREPARATORY FUNCTION 3-

3PREPARATORY FUNCTION G FUNCTION

PROGRAMMING-3 PREPARATORY FUNCTION 3-

3 PREPARATORY FUNCTION G CODES

A number following address G determines the meaning of the command for the concerned block. G codes are divided into the following two types.

Type

One-shot G code

Modal G code

Meaning

The G code is effective only in the block in which it is specified.

The G code is effective until another G code of the same group is specified.

Example:

G01 and G00 are modal G codes in group 01.

G01X _;

Z _; |

G01 is effective in this range. |

X _; |

|

G00Z_ |

|

Explanations

1.Modal G codes have the following initial conditions when the power is turned on or the system is reset to the clear state (bit 6 of parameter No. 045).

1)Those G codes marked* in Table 3 are specified automatically.

2)G20 and G21 retain their original conditions.

3)G00 or G01 is automatically selected according to parameter setting.

2.The G codes of group 00, are one-shot G codes.

3.If a G code that does not appear in the G code list is specified, or a G code whose options are not supported is specified, alarm No. 010 is displayed.

4.Multiple G codes of different groups can be specified in a single block. When multiple G codes of one group are specified in a block, the G code specified last is effective.

5.If any G code of group 01 is specified in a canned cycle mode, the canned cycle is automatically cancelled and the G80 condition is entered. However, a G code of group 01 is not affected by any of the canned cycle G codes.

6.A G code is displayed from each group.

PROGRAMMING-3 PREPARATORY FUNCTION 3-

|

|

Table 3 G code list(1/2) |

|

G code |

Group |

|

Function |

|

|

|

|

G00 |

|

|

Positioning |

*G01 |

01 |

|

Linear interpolation |

G02 |

|

Circular interpolation CW |

|

|

|

||

G03 |

|

|

Circular interpolation CCW |

G04 |

00 |

|

Dwell, Exact stop |

G10 |

|

Offset value setting |

|

|

|

||

*G17 |

|

|

XY plane selection |

G18 |

02 |

|

ZX plane selection |

G19 |

|

|

YZ plane selection |

G20 |

06 |

|

Input in inch |

G21 |

|

Input in mm |

|

|

|

||

G27 |

|

|

Reference position return check |

G28 |

|

|

Return to reference position |

|

00 |

|

|

G29 |

|

Return from reference position |

|

G31 |

|

|

Skip function |

G39 |

|

|

Corner circular interpolation |

*G40 |

|

|

Cutter compensation cancel |

G41 |

07 |

|

Cutter compensation left |

G42 |

|

|

Cutter compensation right |

G43 |

|

|

Tool length compensation + direction |

G44 |

08 |

|

Tool length compensation - direction |

*G49 |

|

|

Tool length compensation cancel |

*G54 |

|

|

Workpiece coordinate system 1 selection |

G55 |

|

|

Workpiece coordinate system 2 selection |

G56 |

05 |

|

Workpiece coordinate system 3 selection |

G57 |

|

Workpiece coordinate system 4 selection |

|

|

|

||

G58 |

|

|

Workpiece coordinate system 5 selection |

G59 |

|

|

Workpiece coordinate system 6 selection |

G65 |

00 |

|

Macro call |

PROGRAMMING-3 PREPARATORY FUNCTION 3-

|

|

Table 3 G code list(2/2) |

|

G code |

Group |

Function |

|

|

|

|

|

G73 |

|

Peck drilling cycle |

|

G74 |

|

Counter tapping cycle |

|

G76 |

|

Fine boring cycle |

|

|

|

|

|

*G80 |

|

Canned cycle cancel |

|

|

|

|

|

G81 |

|

Drilling cycle, spot boring cycle or external operation function |

|

|

|

|

|

G82 |

09 |

Drilling cycle or counter boring cycle |

|

G83 |

Peck drilling cycle |

||

|

|||

G84 |

|

Tapping cycle |

|

G85 |

|

Boring cycle |

|

G86 |

|

Boring cycle |

|

G87 |

|

Back boring cycle |

|

G88 |

|

Boring cycle |

|

|

|

|

|

G89 |

|

Boring cycle |

|

|

|

|

|

G90 |

03 |

Absolute command |

|

G91 |

Increment command |

||

|

|||

G92 |

00 |

Setting for work coordinate system |

|

G98 |

10 |

Return to initial point in canned cycle |

|

G99 |

Return to R point in canned cycle |

||

|

PROGRAMMING-4(INTERPOLATION FUNCTIONS) 4-0

4INTERPOLATION FUNCTIONS

PROGRAMMING-4(INTERPOLATION FUNCTIONS) 4-1

4.1 POSITIONING (G00)

The G00 command moves a tool to the position in the workpiece system specified with an absolute or an incremental command at a rapid traverse rate. In the absolute command, coordinate value of the end point is programmed. In the incremental command the distance the tool moves is programmed.

Format

G00 IP _;

IP _: For an absolute command, the coordinates of an end position, and for an incremental command, the distance of the tool moves.

Explanations

Tool path generally does not become a straight line. Start position

on linear position

End position

NOTE:

1 The rapid traverse rate in the G00 command is set by the parameter No. 038 to 040 for each axis independently by the machine tool builder. The rapid traverse rate cannot be specified in the address F. Feed rate specified by address F is valid.

2The above parameter is in 3-axis NC system. When 4-axis is selected, parameter number is in APPENDIX 7 note2 and 3. Parameter number without special description in this manual is in 3-axis CNC system.

4.2 LINEAR INTERPOLATION (G01)

Format

G01 IP _F_;

IP _: For an absolute command, the coordinates of an end position, and for an incremental command, the distance of the tool moves.

F_; Speed of tool feed (Feedrate)

Explanations

A tools move along a line to the specified position at the feedrate specified in F. The feedrate specified in F is effective until a new value is specified. It need not be specified for each block. It is set by the parameter of No.65. The feedrate commanded by the F code is measured along the tool path. If the F code is not commanded, the feedrate is regarded as zero. The feedrate of each axis direction is as follows.

G01 Xα Yβ Zγ F f

Feed rate of X-axis direction : Fx = α × f L

Feed rate of Y-axis direction :FY = β × f L

Feed rate of Z-axis direction :Fz = γ × f L

Loading...

Loading...