Page 1

CNC Series

KND—100M Computer Numerical Products

—

boring and milling machines

USER’S MANUAL

Beijing KND CNC Technique Co. Ltd.

B—99100M/01

KND LTD,1999

C

Page 2

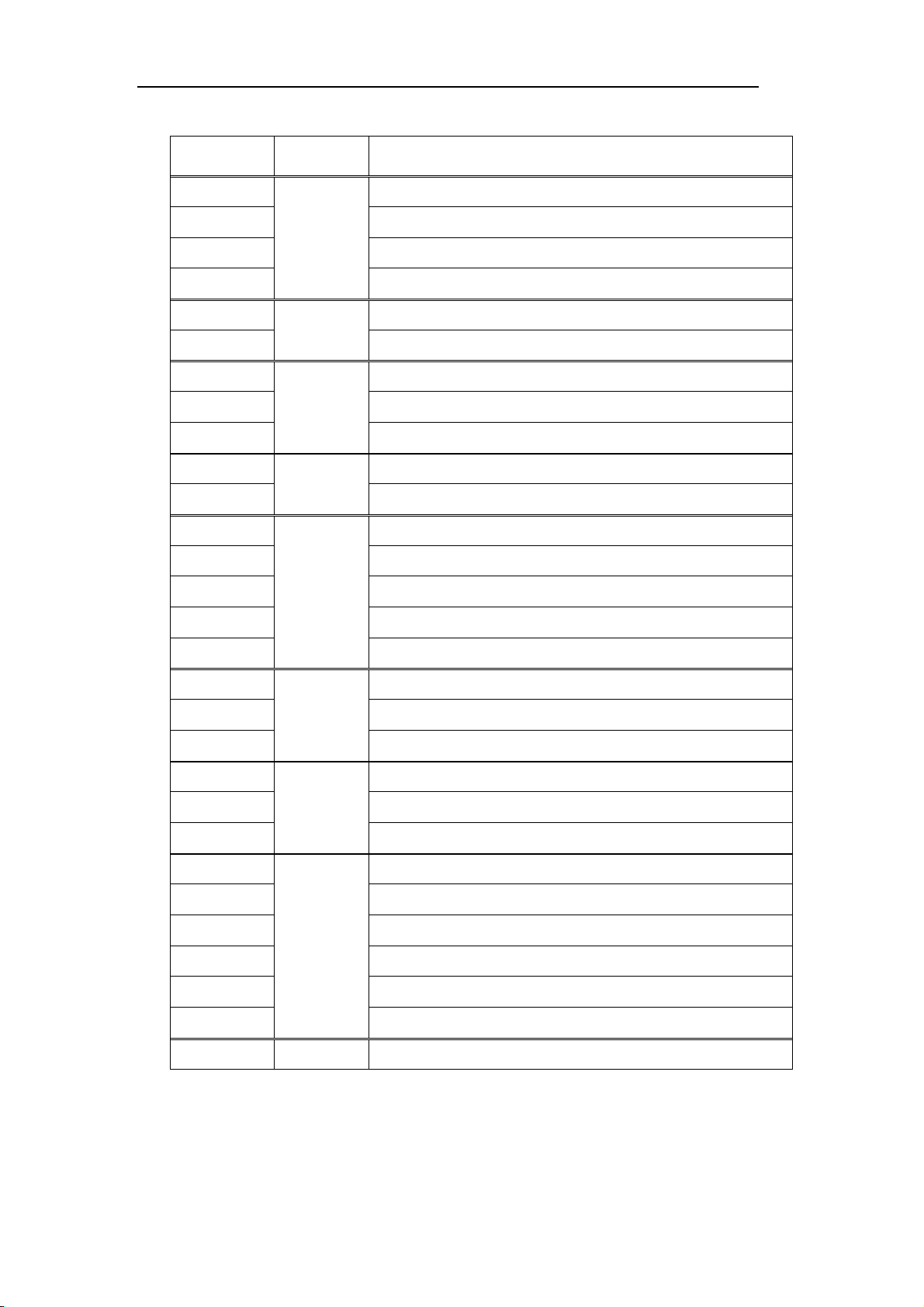

I GENERAL

1. GENERAL

1.1 GENERAL FLOW OF OPERATION OF CNC MACHINE TOOL

1.2 NOTES ON READING THIS MANUAL

II PROGRAMMING

1. GENERAL

1.1 TOOL MOVEMENT ALONG WORKPIECE PARTS FIGURE-INTERPOLATION

1.2 FEED-FEED FUNCTION

1.3 PART DRAWING AND TOOL MOVEMENT

1.4 CUTTING FEED─SPINDLE FUNCTION

1.5 SELECTION OF TOOL USED FOR VARIOUS MACHINING-TOOL FUNCTION … 1- 7

1.6 COMMAND FOR MACHINE OPERATIONS-MISCELLANEOUS FUNCTION

1.7 PROGRAM CONFIGURATION

1.8 TOOL FIGURE AND TOOL MACHINE-TOOL LENGTH COMPENSATION

1.9 TOOL MOVEMENT RANGE -STROKE

2. CONTROLLED AXES

2.1 CONTROLLED AXES

2.2 INCREMENT SYSTEM

2.3 MAXIMUM STROKE

3. PREPARATORY FUNCTION (G FUNCTION)

4. INTERPOLATION FUNCTIONS

4.1 POSITIONING (G00)

4.2 LINEAR INTERPOLATION (G01)

4.3 CIRCULAR INTERPOLATION (G02,G03)

5. FEED FUNCTIONS

5.1 GENERAL

5.2 RAPID TRAVERSE

5.3 CUTTING FEED

5.4 DWELL (G04)

6. REFERENCE POSITION

6.1 REFERENCE POINT RETURN(G28,G29)

7. COORDINATE SYSTEM

7.1 WORKPIECE COORDINATE SYSTEM SETTING (G92)

7.2 PLANE SELECTION (G17,G18,G19)

8. COORDINATE VALUE AND DIMENSION

8.1 ABSOLUTE AND INCREMENTAL PROGRAMMING (G90, G91)

8.2 INCH/METRIC CONVERSION (G20,G21)

8.3 DECIMAL POINT PROGRAMMING

9. SPINDLE SPEED FUNCTION (S FUNCTION)

9.1 SPINDLE SPEED COMMAND

10.TOOL FUNCTION (T FUNCTION)

11. AUXILIARY FUNCTION

11.1 AUXILIARY FUNCTION (M FUNCTION)

11.2 AUXILIARY FUNCTION PARAMETER

11.3 NOTES ON AUXILIARY FUNCTION

………………………………………………………………………………

……………………………………………………………………………………

……………………

………………………………………………

………………………………………………………………………

……………………………………………………………………………………

…………………………………………………………………

……………………………………………

………………………………………………

………

…………………………………………………………

…………

…………………………………………………

………………………………………………………………………

……………………………………………………………………

……………………………………………………………………

………………………………………………………………………

………………………………………

…………………………………………………………

……………………………………………………………………

………………………………………………………

………………………………………………

………………………………………………………………………

…………………………………………………………………………………

…………………………………………………………………………

……………………………………………………………………………

……………………………………………………………………………

…………………………………………………………………

……………………………………………

…………………………………………………………………

………………………………

…………………………………………………

……………………………………………

……………………

………………………………………………

……………………………………………………

………………………………………

……………………………………………………………

………………………………………………………

……………………………………………………………………

………………………………………………

…………………………………………………

……………………………………………………

1- 0

5- 0

1- 1

1- 1

1- 1

1- 0

1- 1

……

1- 2

1- 3

1- 3

1- 7

1- 8

1- 8

1- 10

1- 11

2- 0

2- 1

2- 1

2- 1

3- 0

4- 0

4- 1

4- 1

4- 2

5- 1

5- 2

5- 3

5- 4

6- 0

6- 1

7- 1

7- 1

7- 2

8- 1

8- 1

8- 1

8- 2

9- 0

9- 1

10- 1

11- 0

11- 1

11- 3

11- 4

Page 3

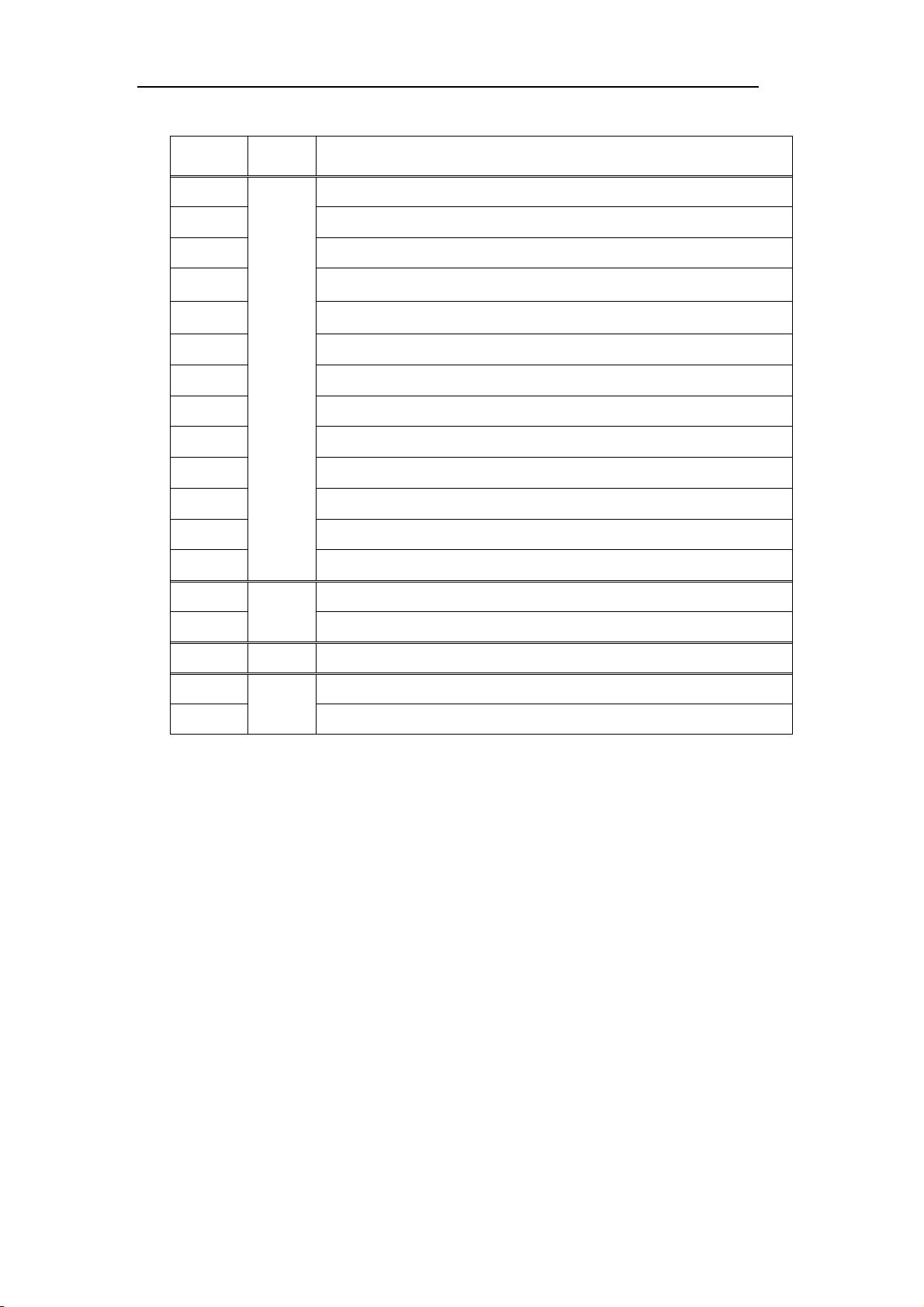

12. PROGRAM CONFIGURATION

12.1 GENERAL

12.2 PROGRAM END

12.3 FILE END

…………………………………………………………………………………

……………………………………………………………………………

…………………………………………………………………………………

13. FUNCTIONS TO SIMPLIFY PROGRAMMING

13.1 CANNED CYCLE (G73,G74,G76.G80-G89)

14. COMPENSATION FUNCTION

14.1TOOL LENGTH COMPENSATION(G43,G44,G49)

14.2 CUTTER COMPENSATION B(G39,G40-G42)

14.3 CUTTER COMPENSATION C(G40-G42)

14.3.1 CUTTER COMPENSATION FUNCTION

14.3.2 OFFSET AMOUNT(H code)

14.3.3 OFFSET VECTOR

14.3.4 PLANE SELECTION AND VECTOR

14.3.5 G40,G41 and G42

14.3.6 DETAILS OF CUTTER COMPENSATION C

14.4 OFFSET AMOUNT INPUT BY PROGRAM(G10)

15. MEASURE FUNCTION

15.1SKIP FUNCTION (G31)

…………………………………………………………………

……………………………………………………………………

16. WORKPIECE COORDINATE SYSTEM SELECTION

16.1 WORKPIECE COORDINATE SYSTEM(G54-G59)

17.CUSTOM MACRO

17.1 CUSTOM MACRO COMMAND

17.2 CUSTOME MACRO BODY

17.3 CUSTOM MACRO EXAMPLES

III OPERATION

1. GENERAL

1.1 MANUAL OPERATION

1.2 TOOL MOVEMENT BY PROGRAMING-AUTOMATIC OPERATION

1.3 AUTOMATIC OPERATION

1.4 TESTING A PROGRAM

1.5 PROGRAM EDITING

1.6 DATA DISPLAY AND SETTING

1.7 DISPLAY

1.8 DATA INPUT/OUTPUT

2. OPERATOR’S PANEL

2.1 LCD/MDI PANEL

2.2 ADDITIONAL PANEL

3. POWER ON AND OFF

3.1 POWER ON

3.2 POWER OFF

4. MANUAL OPERATION

4.1 MANUAL REFERENCE POSITION RETURN

4.2 JOG FEED

4.3 INCREMENTAL FEED

…………………………………………………………………………………………

…………………………………………………………………………

………………………………………………………………………………

……………………………………………………………………

………………………………………………………………………

……………………………………………………………………………………

……………………………………………………………………

……………………………………………………………………

………………………………………………………………………

……………………………………………………………………

………………………………………………………………………

………………………………………………………………………………

………………………………………………………………………………

………………………………………………………………………

…………………………………………………………………………… …

……………………………………………………………………

…………………………………………………………

………………………………………

……………………………………………

…………………………………………………………

……………………………………

…………………………………………

………………………………………………

………………………………………

……………………………………………………

…………………………………………………………………

……………………………………………

…………………………………………………………………

……………………………………

………………………………………

……………………………

……………………………………

…………………………………………………………

………………………………………………………………

…………………………………………………………

………………………………………………………………

…………………………………………………………………

…………………………………………………………

………………………………………

17- 1

1- 0

………………

12- 1

12- 1

12- 7

12- 8

13- 1

13- 1

14- 1

14- 1

14- 4

14- 11

14- 11

14- 11

14-12

14-12

14-12

14-14

14-39

15- 1

15- 1

16- 1

16- 1

17- 1

17- 1

17- 10

1- 1

1- 1

1- 2

1- 3

1- 4

1- 6

1- 6

1- 8

1-10

2- 1

2- 1

2- 5

3- 1

3- 1

3- 1

4- 1

4- 1

4- 1

4- 3

Page 4

4.4 HANDLE FEED

4.5 MANUAL PROGRAM ZERO RETURN

4.6 MANUAL ABSOLUTE SWITCH

4.7 MANUAL AUXILIARY FUNCTION OPERATION

5. AUTOMATIC OPERATION

5.1 OPERATION MODE

5.2 START-UP

5.3 AUTO OPERATION EXECUTION

5.4 STOP

6. DRY RUN

6.1 MACHINE LOCK

6.2 AUXILIARY FUCTION LOCK

6.3 FEEDRATE OVERRIDE

6.4 RAPID TRAVERSE OVERRIDE

6.5 ANALOGUE SPINDLE OVERRIDE

6.6 DRY RUN

6.7 SINGLE BLOCK

6.8 RESTART AFTER FEEDHOLD OR STOP

6.9 OPTIONAL BLOCK SKIP

……………………………………………………………………………………

………………………………………………………………………………………

7. SAFTY OPERATION

7.1 EMERGENCY STOP

7.2 OVERTRAVEL

8. ALARM

8- 1

……………………………………………………………………………………………

9. PROGRAM STORAGE AND EDITING

9.1 PREPARATION

9.2 STORE PROGRAM IN MEMORY

9.3 STORE FILE IN MEMORY

9.4 PROGRAM SEARCH

9.5 PROGRAM DELETING

9.6 DELETING ALL PROGRAMS

9.7 PROGRAM OUTPUT

9.8 ALL PROGRAMS OUTPUT

9.9 SEQUENCE NUMBER SEARCH

9.10 PROGRAM COMPARATION

9.11 WORD INSERTING, MODIFYING AND DELETING

9.12 SEQUENCE NUMBER INSERTING AUTOMATICALLY

9.13 NUMBER OF STORED PROGRAMS

9.14 STORAGE CAPACITY

10. DATA DISPLAY AND SETTING

10.1 OFFSET AMOUNT

10.2 SET PARAMETER SETTING

10.3 CUSTOM MACRO VARIABLES DISPLAY AND SETTING

10.4 PARAMETER

10.5 PITCH ERROR COMPENSATION DATA

……………………………………………………………………………

…………………………………………………

…………………………………………………………

………………………………………

…………………………………………………………………

………………………………………………………………………

…………………………………………………………………………………

………………………………………………………

…………………………………………………………………………

……………………………………………………………

…………………………………………………………………

…………………………………………………………

……………………………………………………

…………………………………………………………………………………

……………………………………………………………………………

……………………………………………

…………………………………………………………………

…………………………………………………………………………

……………………………………………………………………

……………………………………………………………………………

……………………………………………………

……………………………………………………………………………

………………………………………………………

……………………………………………………………

……………………………………………………………………

…………………………………………………………………

……………………………………………………………

……………………………………………………………………

………………………………………………………………

………………………………………………………

…………………………………………………………

…………………………………………………

……………………………………………………………………

…………………………………………………………

………………………………………………………………………

……………………………………………………………

……………………………………………………………………………

………………………………………………

9- 3

…………………………………

……………………………

…………………………

4- 4

4- 5

4- 5

4- 7

5- 1

5- 1

5- 3

5- 3

5- 3

6- 1

6- 1

6- 1

6- 1

6- 2

6- 2

6- 3

6- 3

6- 4

6- 4

7- 1

7- 1

7- 1

9- 1

9- 1

9- 1

9- 2

9- 2

9- 3

9- 3

9- 3

9- 3

9- 4

9- 5

9- 9

9- 9

9- 9

10-1

10- 1

10- 2

10- 4

10- 5

10- 7

Page 5

10.6 DIAGNOSE

10.7 MACHINE SOFT OPERATOR’S PANEL DISPLAY AND SETTING

11. DISPLAY

11.1 STATUS DISPLAY

11.2 DATA DISPLAY

11.3 PROGRAM No. and SEQUENCE No. DISPLAY

11.4 PROGRAM MEMORY DISPLAY

11.5 COMMAND VALUE DISPLAY

11.6 POSITION DISPLAY

11.7 RUN TIME AND PARTS NUMBER

11.8 ALARM DISPLAY

11.9 INDEX CONTENT DISPLAY

12. DATA OUTPUT AND FLASH MEMORY

12.1 DATA OUTPUT

12.2 FLASH MEMORY

13. GRAPH FUNCTION

13.1 GRAPH PARAMETER SETTING

13.2 GRAPH PARAMETER

13.3 TOOL PATH

13.4 EXAMPLES

14. DESCRIPTION ON DRIVER DEVICE

14.1 UPPER LIMIT OF CUTTING FEED

14.2 RAPID TRAVERSE RATE SETTING

14.3 ELECTRIC GEAR RATIO

14.4 AC/DECELERATION TIME CONSTANT

14.5 PARAMETER SETTING

14.6 DRIVER ALARM

15. DESCRIPTION

15.1 STANDARD PARAMETER SETTING AND MEMORY CLEARING

15.2 NO CHECK ON OVERTRAVEL

15.3 BACKLASH COMPENSATION

15.4 INPUT SIGNAL FILTER

15.5 NOT ENTERED NORMAL SCREEN

15.6 ROM PARITY ALARM AND RAM CHECK

IV CONNECTION

1. SYSTEM INSTALLATION

1.1 CONFIGURATION

1.2 INSTALLATION DIMENSION

1.3 ADDITIONAL PANEL DIMENSION

2. INTERNAL CONNECTION

2.1 CONNECTION DIAGRAM

2.2 POWER OUTLET SIGNAL ARRANGEMENT

2.3 OVERRIDE SWITCH SIGNAL ARRANGEMENT

2.4 OUTLET CONNECTION BETWEEN MAIN BOARD AND EXTERNAL

…………………………………………………………………………………

………………………………………………………………………………………

…………………………………………………………………………

……………………………………………………………………………

………………………………………

…………………………………………………………

……………………………………………………………

……………………………………………………………………

………………………………………………………

…………………………………………………………………………

……………………………………………………………

……………………………………………

…………………………………………………………………………

…………………………………………………………………………

…………………………………………………………………………

………………………………………………………

……………………………………………………………………

………………………………………………………………………………

……………………………………………………………………………

……………………………………………………

………………………………………………………

……………………………………………………

…………………………………………………………………

………………………………………………

…………………………………………………………………

…………………………………………………………………………

………………………………………………………………………………

…………………………………………………………

…………………………………………………………

…………………………………………………………………

……………………………………………………

……………………………………………

…………………………………………………………………………

…………………………………………………………………………

…………………………………………………………

……………………………………………………

…………………………………………………………………

……………………………………………

………………………………………

…………………

…………………

1- 0

………………

10- 7

10- 8

11- 1

11- 1

11- 1

11- 1

11- 2

11- 2

11- 3

11- 5

11- 6

11- 6

12- 1

12- 1

12- 2

13- 1

13- 2

13- 2

13- 4

13- 4

14- 1

14- 1

14- 1

14- 1

14- 2

14- 2

14- 4

15- 1

15- 1

15- 1

15- 1

15- 1

15- 1

15- 1

1- 1

1- 2

1- 3

2- 1

2- 3

2- 3

2- 4

Page 6

3. EXTERNAL CONNECTION

3.1 EXTERNAL CONNECTION DIAGRAM

3.1.1 WITH STEPPER MOTOR

3.1.2 WITH SERVO MOTOR

3.2 INTERFACE SIGNAL FROM CNC TO DRIVER

3.2.1 INTERFACE SIGNAL LOGIC DIAGRAM

3.2.2 CONNECTOR SIGNAL

3.2.3 SIGNAL DESCRIPTION

3.2.4 CABLE MAKING

3.3 RS232-C SERIES PORT

3.4 ANALOGUE SPINDLE INTERFACE CONNECTION

3.5 ADDITIONAL PANEL CONNECTION

3.5.1 CONNECTOR SIGNAL

3.5.2 SIGNAL DESCRIPTION

3.5.3 SIGNAL CONNECTION

4. MACHINE TOOL INTERFACE

4.1 INPUT SIGNAL INTERFACE DESCRIPTION

4.1.1 INPUT SIGNAL A

4.1.2 INPUT SIGNAL B

4.2 INPUT SIGNAL INTERFACE DESCRIPTION

4.2.1 DARLINGTON OUTPUT PARAMETER

4.2.2 OUTPUT DRIVER RELAY CIRCUIT

4.2.3 OUTPUT DIRVER INDICATOR LAMP

4.3 INPUT/OUTPUT SIGNAL LIST

4.3.1 INPUT SIGNAL DIAGNOSE LIST

4.3.2 OUTPUT SIGNAL DIAGNOSE LIST

4- 5

4.3.3 OUTLET PIN SIGNAL ARRANGEMENT

4.4 INPUT/OUTPUT SIGNAL DESCRIPTION

4.4.1 INPUT SIGNAL

4.4.2 OUTPUT SIGANL

4.4.3 M code VOLTAGE LEVEL/PULSE OUTPUT DESCRIPTION

V APPENDIX

APPENDIX1 STORED PITCH ERROR COMPENSATION

APPENDIX2 G FUNCTION TABLE

APPENDIX3 RANGE OF COMMAND VALUE TABLE

APPENDIX4 BINARY AND DECIMAL CONVERSION

APPENDIX5 ALARM LIST

APPENDIX6 STATUS OF POWER-ON AND RESET

APPENDIX7 PARAMETER LIST

APPENDIX8 PLC PARAMETER LIST

APPENDIX9 OPERATION TABLE

APPENDIX10 SPECIFICATION TABLE

APPENDIX11 CNC STATUS DIAGNOSE MESSAGE

…………………………………………………………………………………

…………………………………………………………………………

…………………………………………………

………………………………………………………

…………………………………………………………

………………………………………

………………………………………

…………………………………………………………

…………………………………………………………

…………………………………………………………………

……………………………………………………………………

……………………………………………………

…………………………………………………………

…………………………………………………………

…………………………………………………………

……………………………………………

…………………………………………………………………

………………………………………………………………

…………………………………………

………………………………………

……………………………………………

…………………………………………

……………………………………………………………

………………………………………………

……………………………………………

………………………………………

………………………………………………

……………………………………………………………………

…………………………………………………………………

………………………………………………………………

…………………………………………

…………………………………………

…………………………………………

…………………………………………………………………

……………………………………………………………

…………………………………………………………………

……………………………………………………………

……………………………………………

…………………………………

4- 1

………………

1- 0

……………………………………

3- 1

3- 1

3- 2

3- 3

3- 3

3- 5

3- 6

3- 10

3- 13

3- 13

3- 14

3- 14

3- 14

3- 15

4- 1

4- 1

4- 2

4- 2

4- 3

4- 4

4- 5

4- 5

4- 6

4- 6

4- 6

4- 9

4-10

1- 1

2- 1

3- 1

4- 1

5- 1

6- 1

7- 1

8- 1

9- 1

10- 1

11- 1

Page 7

APPENDIX12 COMMUNICATION SOFTWARE DESCRIPTION

………………………………

12- 1

Page 8

Ⅰ

Ⅰ GENERAL

GENERAL -1(GENERAL) 1 - 0

Page 9

1、GENERAL

1. INTRODUCTION

GENERAL -1(GENERAL) 1 - 1

Ⅰ

KND-100M,

machines, boring machines and machining centers has been developed by Beijing KND

CNC technique Co. Ltd. to satisfy the needs of NC markets in China. The control circuit uses

high-speed microprocessors, custom LSIs, multiple-layer PCBs and high resolving power

LCD to reduce the volume in order to compact the whole system and provide high reliability.

As for control software,

control system for the first time, and increases many functions fit stepper motor according to

the character of stepper motor in order to give full play to its performance at the same time.

KND-100M

ratio.

This manual explains programming, operation, and connection. For convenience the basic

and optional specifications are explained at APPENDIX. The detailed descriptions can be

referred to as required. This manual covers everything pertaining to the system

As for the specifications for the machine operator’s panel and actual function corresponding

to different machine tools refer to the manual issued by the individual machine tool builder.

a economic CNC to control digital servo motor or stepper motor for milling

KND-100M

provides high-performance and significantly improves the performance / cost

brings overall-function CNC system to stepper motor

KND-100M.

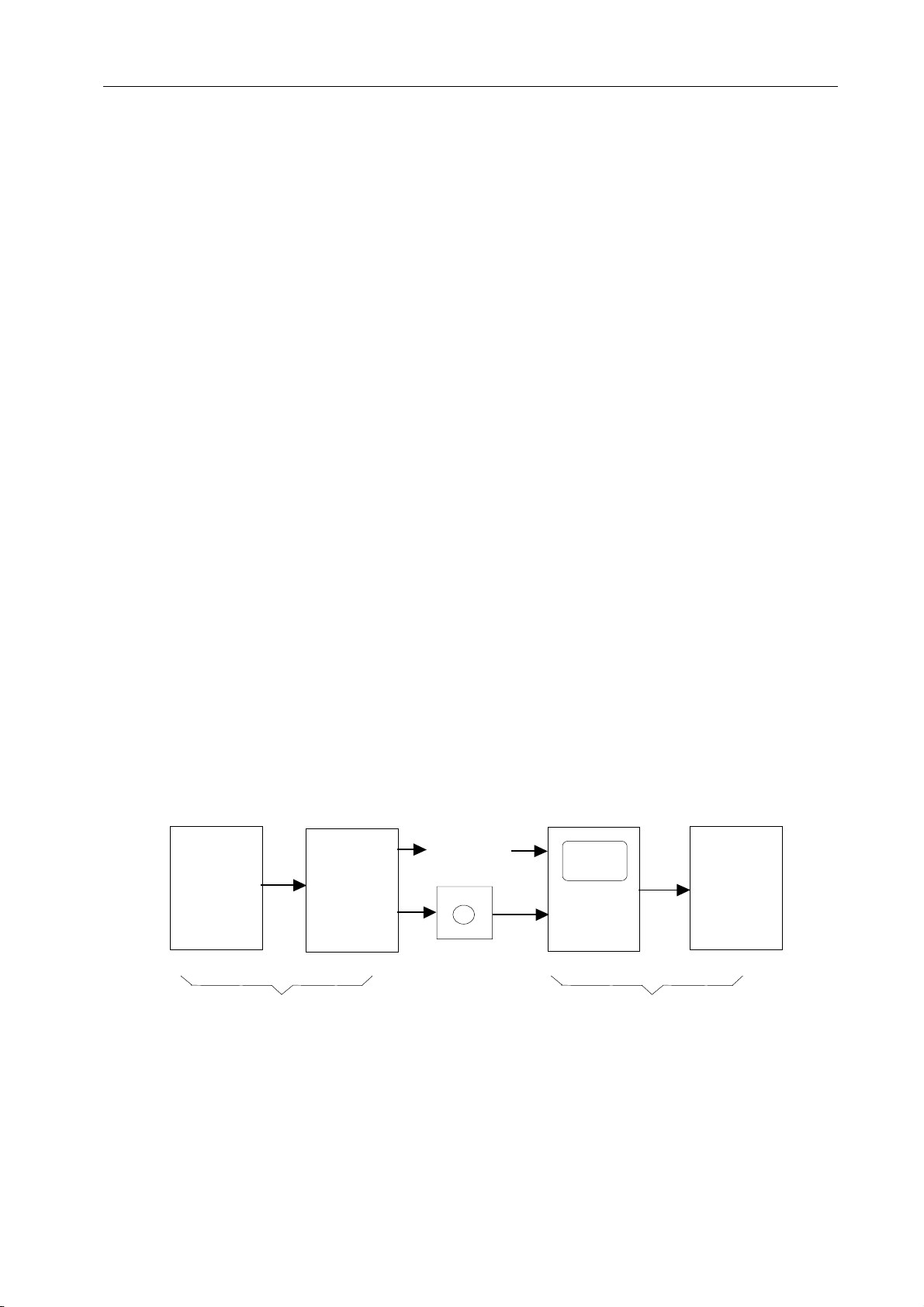

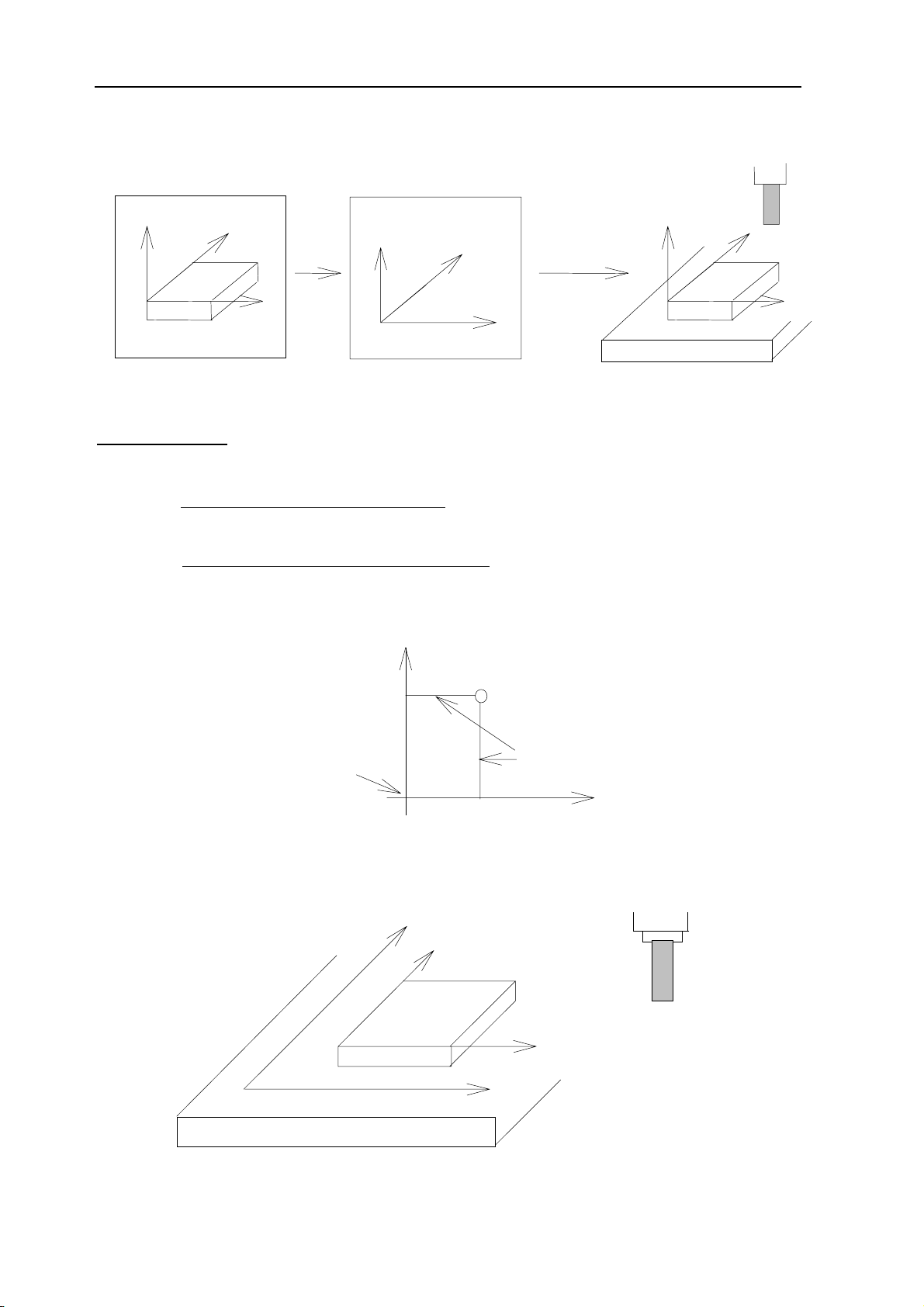

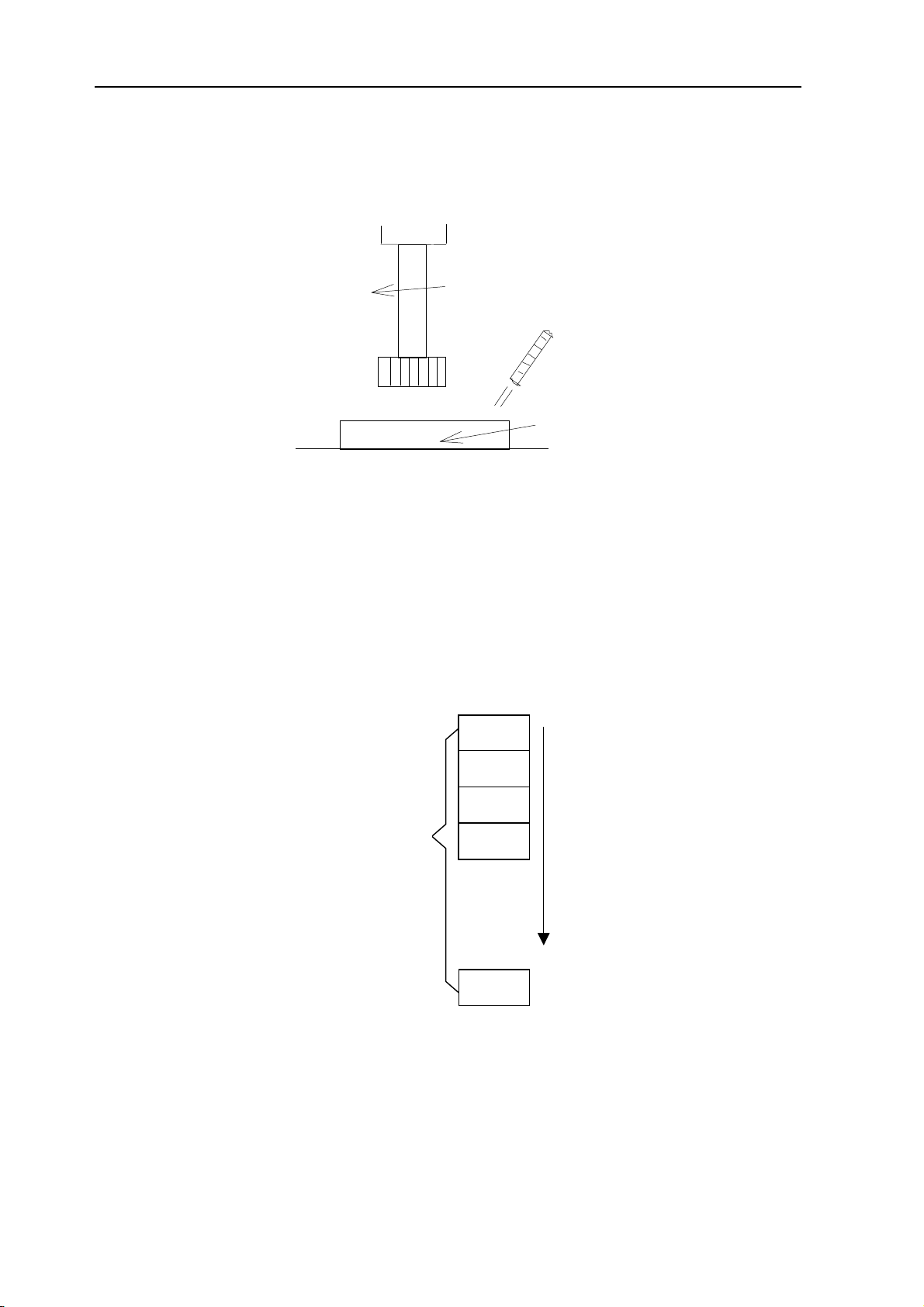

1.1 GENERAL FLOW OF OPERATION OF CNC MACHINE TOOL

When machining the part using the CNC machine tool, first prepare the program, then

operate the CNC machine by using the program.

1) First, prepare the program from a part drawing to operate the CNC machine tool. Store

the program to a media appropriate for the CNC. How to prepare the program is

described in the Chapter II. PROGRAMMING.

2) The program is to be read into the CNC system. Then, mount the workpieces and tools on

the machine, and operate the tools according to the programming. Finally, execute the

machining actually. How to operate the CNC system is described in the Chapter III.

OPERATION.

MDI/LCD

Part

drawing

Part

program

Machine

tool

CNC

Floppy disk

CHAPTER II PROGRAMMING

CHAPTE R III OPERAT ION

1.2 NOTES ON READING THIS MANUAL

1 The function of an CNC machine tool system depends not only on the CNC, but on the

combination of the machine tool, its magnetic cabinet, the servo system, the CNC, the

operator’s panels, etc. It is too difficult to describe the function, programming, and

operation relating to all combinations. This manual generally describes these from the

stand-point of the CNC. So, for details on a particular CNC machine tool, refer to the

manual issued by the machine tool builder, which should take precedence over this

manual.

Page 10

GENERAL -1(GENERAL) 1 - 2

Ⅰ

Optional

function1

. . .

Optional

function2

interface

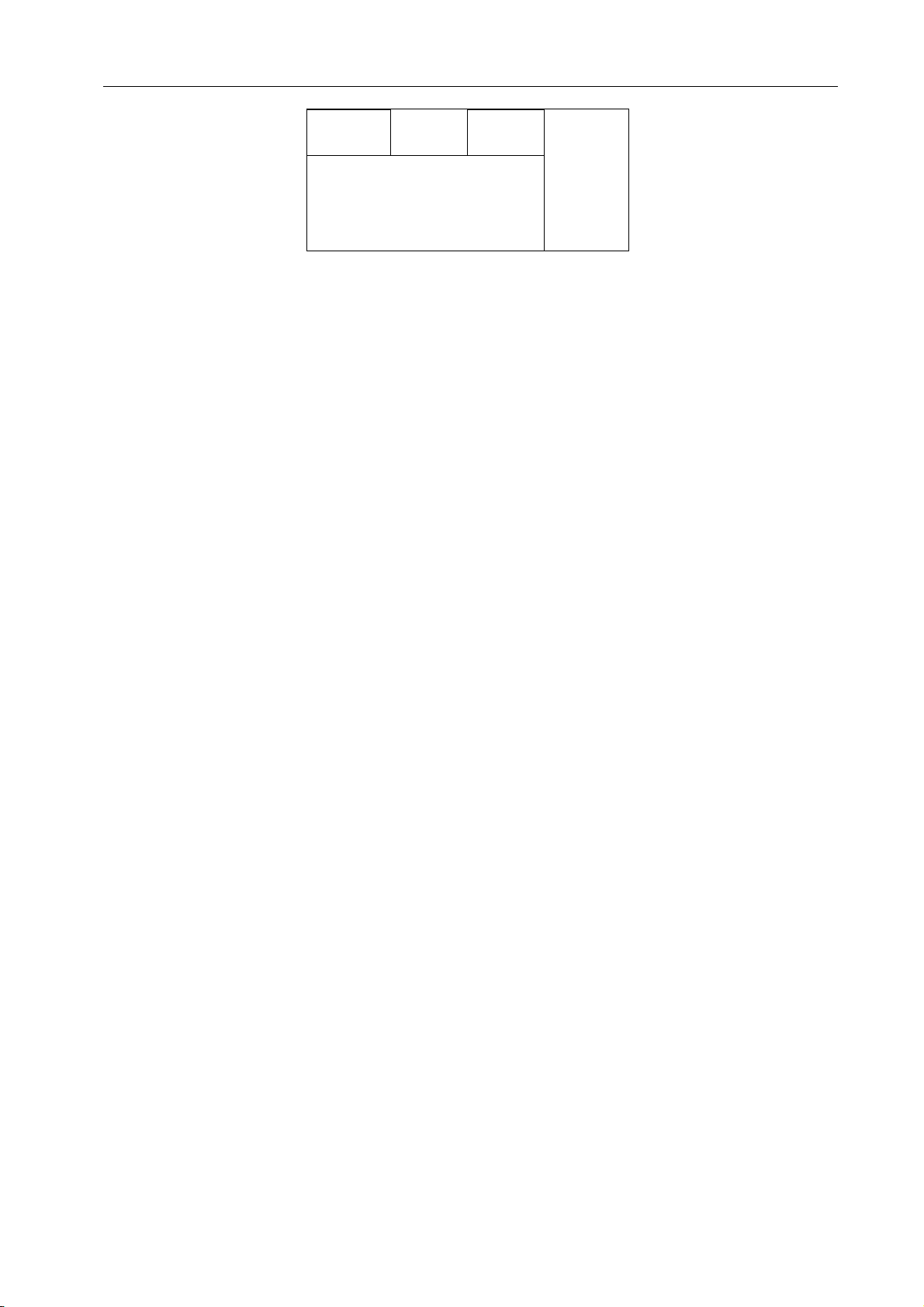

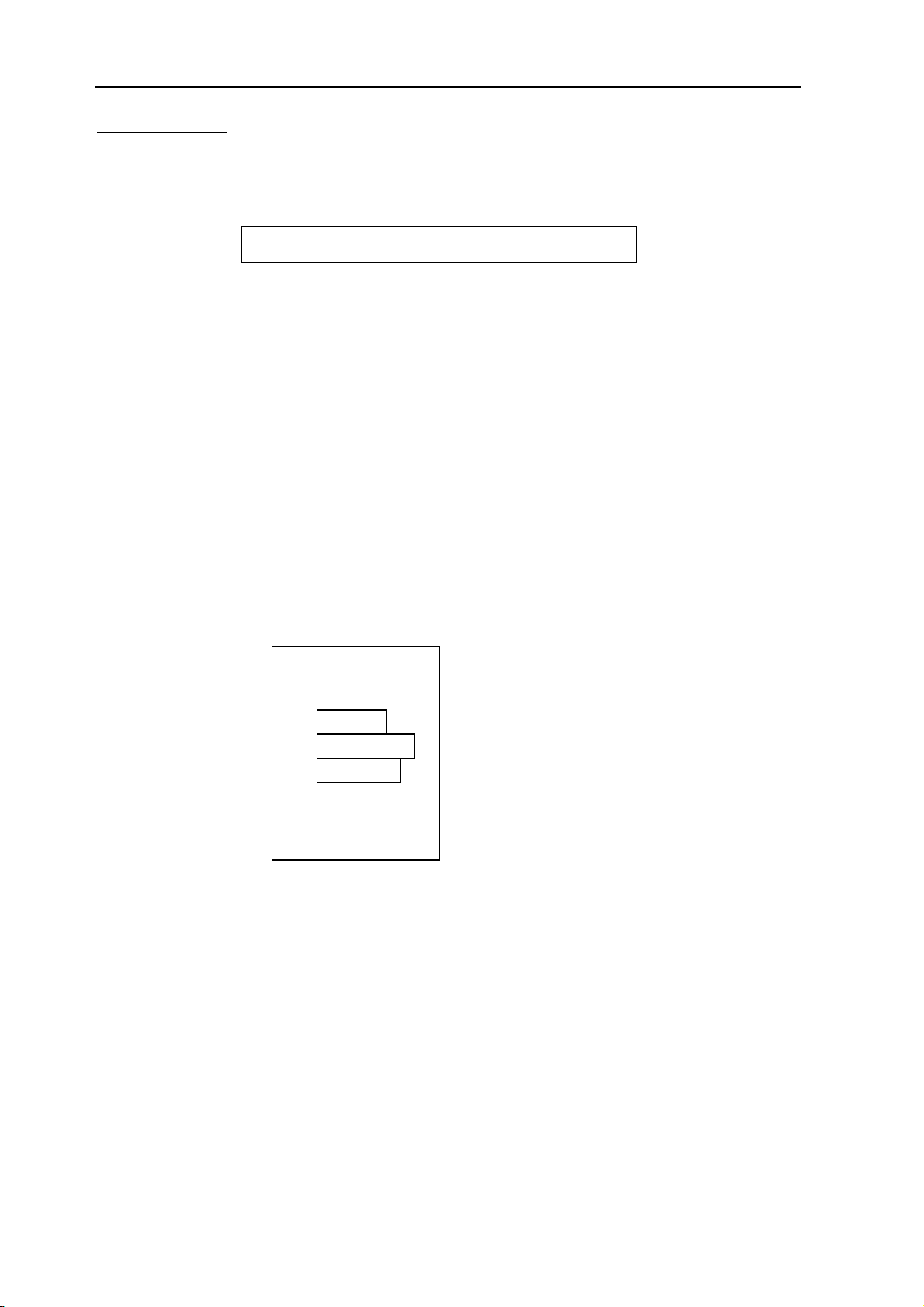

CNC basic function

CNC system

2 This manual is

KND-100M

series CNC system common description. Under the concrete

conditions, refer to the description of individual machine tool builder.

3

KND-100M

series CNC system provide several types. Be caution to select system. For

details, refer to the order of KND Ltd.

Page 11

ⅡPROGRAMMING-1(GENERAL)

1-0

II PROGRAMMING

Page 12

1

GENERAL

ⅡPROGRAMMING-1(GENERAL)

1-1

Page 13

ⅡPROGRAMMING-1(GENERAL)

t

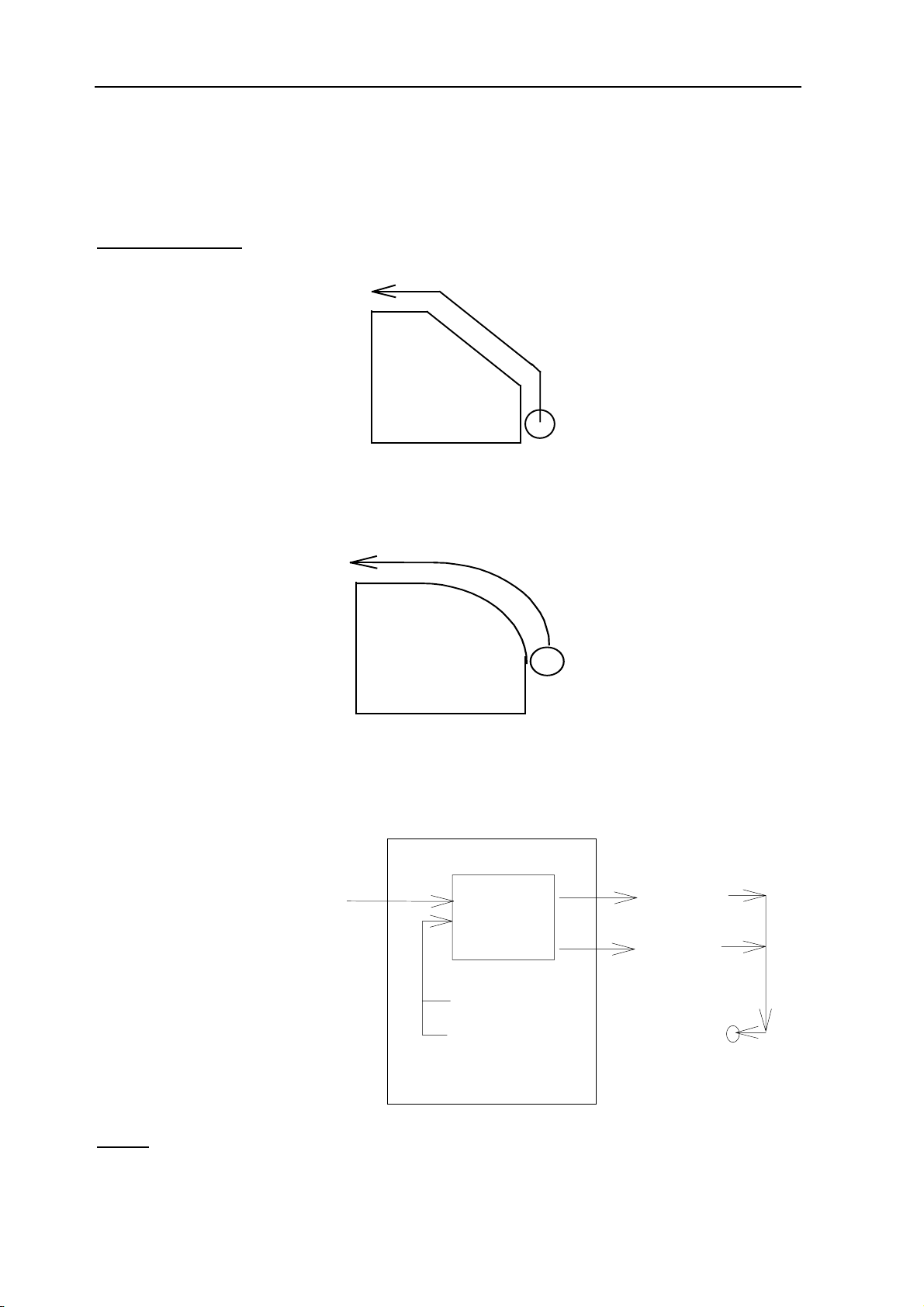

1.1 TOOL MOVEMENT ALONG WORKPIECE PARTS FIGUREINTERPOLATION

The tool moves along straight lines and arcs constituting the workpiece parts figure (See

II-4).

EXPLANATIONS

● Tool movement along a straight line

Program

G01 X_ _ Y_ _ ;

X_ _ ;

Workpiece

Tool

Fig.1.1 (a) Tool movement along a straight line

●Tool movement along an arc

1-2

Program

G03 X_ Y_ R_ ;

W orkpiece

Fig. 1.1 (b) Tool movement along an arc

Symbols of the programmed commands G01, G02, ... are called the preparatory function

and specify the type of interpolation conducted in the control unit.

(a) Movement along straight

line

G01 Y__;

X__Y__;

(b) Movement along arc

G03X__Y__R__;

Control u nit

interpolation

a)Move ment along

straight lin e

b) Movement along

arc

Tool

X-axis(motor)

Y-axis(motor)

Tool movemen

Fig. 1.1 (c) Interpolation function

NOTE:

Some machines move tables instead of tools but this manual assumes that tools are moved

against workpieces.

Page 14

ⅡPROGRAMMING-1(GENERAL)

1.2 FEED- FEED FUNCTION

Movement of the tool at a specified speed for cutting a workpiece is called the feed.

1-3

F

mm/min

Workpiece

Table

Fig. 1.2 (a) Feed function

Feedrates can be specified by using actual numerics. For example, to feed the tool at a rate

of 150 mm/min, specify the following in program: F150.0

The function of deciding the feed rate is called the feed function (See II-5).

Tool

1.3 PART DRAWING AND TOOL MOVEMENT

1.3.1 Reference Position (Machine-specific position)

A CNC machine tool is provided with a fixed position. Normally, tool change and

programming of absolute zero point as described later are performed at this position. This

position is called the reference position.

Reference position

Tool

Workpiece

Fig. 1.3.1 (a) Reference position

EXPLANATIONS

The tool can be moved to the reference position in two ways:

(1) Manual reference position return (See III-1)

Reference position return is performed by manual button operation.

(2) Automatic reference position return (See II-6)

In general, manual reference position return is performed first after the power is turned

on. In order to move the tool to the reference position for tool change thereafter, the

function of automatic reference position return is used.

Table

Page 15

ⅡPROGRAMMING-1(GENERAL)

1-4

1.3.2 Coordinate System on Part Drawing and Coordinate System Specified by

CNC Coordinate System

Tool

Z

Part drawing

EXPLANATIONS

Y

Program

X

Z

Coordinate system

Fig. 1.3.2 (a) Coordinate system

Y

command

X

CNC

Z

Machine tool

● Coordinate system

The following two coordinate systems are specified at different locations: (See II-7)

(1) Coordinate system on part drawing

The coordinate system is written on the part drawing. As the program data, the

coordinate values on this coordinate system are used.

(2) Coordinate system specified by the CNC

The coordinate system is prepared on the actual machine tool table. This can be

achieved by programming the distance from the current position of the tool to the

zero point of the coordinate system to be set.

Y

workpiece

X

200

Present tool position

Program zero point

Fig. 1.3.2 (b) Coordinate system specified by the CNC

The positional relation between these two coordinate systems is determined when a

workpiece is set on the table.

300

0

Y

Distance to the zero point of a

coordinate system to be set

Tool

Y

Workpiece

Coordinat e system on part drawin g

established on the workpiece

X

Coordinat e system specified by the

CNC establ ished on the t able

X

Table

Fig. 1.3.2 (c) Coordinate system specified by CNC and coordinate system on part drawing

Page 16

ⅡPROGRAMMING-1(GENERAL)

p

The tool moves on the coordinate system specified by the CNC in accordance with the

command program generated with respect to the coordinate system on the part drawing, and

cuts a workpiece into a shape on the drawing. Therefore, in order to correctly cut the

workpiece as specified on the drawing, the two coordinate systems must be set at the same

position.

• Methods of setting the two coordinate systems in the same position

To set the two coordinate systems at the same position, simple methods shall be used

according to workpiece shape, the number of machinings.

(1) Using a standard plane and point of the workpiece.

Workpiece’s standard point

Fixed distance

Bring the tool center to the workpiece standard point. And set the coordinate system

specified by CNC at this position.

(2) Mounting a workpiece directly against the jig

Program zero point

Jig

Meet the tool center to the reference position. And set the coordinate system specified by

CNC at this position. (Jig shall be mounted on the predetermined point from the reference

position.)

(3) Mounting a workpiece on a pallet, then mounting the workpiece and pallet on the jig

pallet

1-5

Jig

Work

iece

(Jig and coordinate system shall be

specified by the same as (2)).

Page 17

ⅡPROGRAMMING-1(GENERAL)

X

A

A

1-6

1.3.3 How to Indicate Command Dimensions for Moving the Tool – Absolute,

Incremental instructions

EXPLANATIONS

Coordinate values of command for moving the tool can be indicated by absolute or

incremental designation (See II-8.1).

• Absolute coordinates

The tool moves to a point at“the distance from zero point of the coordinate system” that is to

the position of the coordinate values.

Tool

Z

(15,60,40

)

B (10,30,20)

Y

Command specifying movement from point A to point B

G90 X10.0 Y30.0 Z20.0 ;

coordinates of point B

• Incremental coordinates

Specify the distance from the previous tool position to the next tool position.

Z

30

40

Tool

10

B

Y

X

Command specifying movement from point A to point B

G91

X40.0 Y-30.0 Z-10.0 ;

Distance and direction for movement along each axis

Page 18

ⅡPROGRAMMING-1(GENERAL)

A

1.4 CUTTING SPEED – SPINDLE SPEED FUNCTION

The speed of the tool with respect to the workpiece when the workpiece is cut is called the

cutting speed. As for the CNC,

rpm unit.

the cutting speed can be specified by the spindle speed in

Tool

Diameter

RPM

1-7

V (mm/min)

Workpiece

EXAMPLES

<When a workpiece should be machined with a tool 100 mm in diameter at a cutting speed

of 80 mm/min. >

The spindle speed is approximately 250 rpm, which is obtained from N=1000v/πD. Hence

the following command is required: S250;

Commands related to the spindle speed are called the spindle speed function ( See II-9).

1.5 SELECTION OF TOOL USED FOR VARIOUS MACHINING

(TOOL FUNCTION)

When drilling, tapping, boring, milling or the like, is performed, it is necessary to select a

suitable tool. When a number is assigned to each tool and the number is specified in the

program, the corresponding tool is selected.

Tool number

01

TC magazin e

02

.

EXAMPLES

<When No.01 is assigned to drilling tool>

When the tool is stored at location 01 in the ATC magazine, the tool can be selected by

specifying T01. This is called the tool function (See II-10)

Page 19

ⅡPROGRAMMING-1(GENERAL)

1.6 COMMAND FOR MACHINE OPERATIONS –MISCELLANEOUS

FUNCTION

When machining is actually started, it is necessary to rotate the spindle, and feed coolant.

For this purpose, on-off operations of spindle motor and coolant valve should be controlled

(See II-11).

Spindle rotate

1-8

Tool

The function of specifying the on-off operations of the components of the machine is called

the miscellaneous function. In general, the function is specified by an M code. For example,

when M03 is specified, the spindle is rotated clockwise at the specified spindle speed.

coolant

Workpiece

1.7 PROGRAM CONFIGURATION

A group of commands given to the CNC for operating the machine is called the program. By

specifying the commands, the tool is moved along a straight line or an arc, or the spindle

motor is turned on and off. In the program, specify the commands in the sequence of actual

tool movements.

Fig. 1.7 (a) Program configuration

A group of commands at each step of the sequence is called the block, The program

consists of a group of blocks for a series of machining. The number for discriminating each

block is called the sequence number, and the number for discriminating each program is

called the program number (See II-12).

Program

Block

Block

Tool movement sequence

Block

Block

Block

Page 20

ⅡPROGRAMMING-1(GENERAL)

EXPLANATIONS

• Block

The block and the program have the following configurations.

NOOOO GOO XOO.O YOO.O MOO SOO TOO;

1 Block

N: Sequence number

G: Preparatory function

X,Y: Dimension word

M: Miscellaneous function

S: Spindle function

T: Tool function

; : End of block

Fig. 1.7 (b) Block configuration

A block has a sequence number at its head, which identifies the block, and an end-of-block

code at the end, indicating the end of the block. This manual indicates the end-of-block code

by ;.

• Program

Normally, a program number is specified after the end-of-block (;) code at the beginning of

the program, and a program end code (M02 or M30) is specified at the end of the program.

;

O□□□□;

M30;

Program number

Block

Block

Block

End of program

Fig. 1.7 (c) Program configuration

• Main program and subprogram

When machining of the same pattern appears at many portions of a program, a program for

the pattern is created. This is called the subprogram. On the other hand, the original program

is called the main program. When a subprogram execution command appears during

execution of the main program, commands of the subprogram are executed. When

execution of the subprogram is finished, the sequence returns to the main program.

1-9

Page 21

ⅡPROGRAMMING-1(GENERAL)

1-10

Main program subprogram#1

M98P1001

M98P1002

M98P1001

O1001

M99

subprogram#2

O1002

M99

Pole #1 Pole #1

Pole #2

Pole #2

program for

pole #1

program for

pole#2

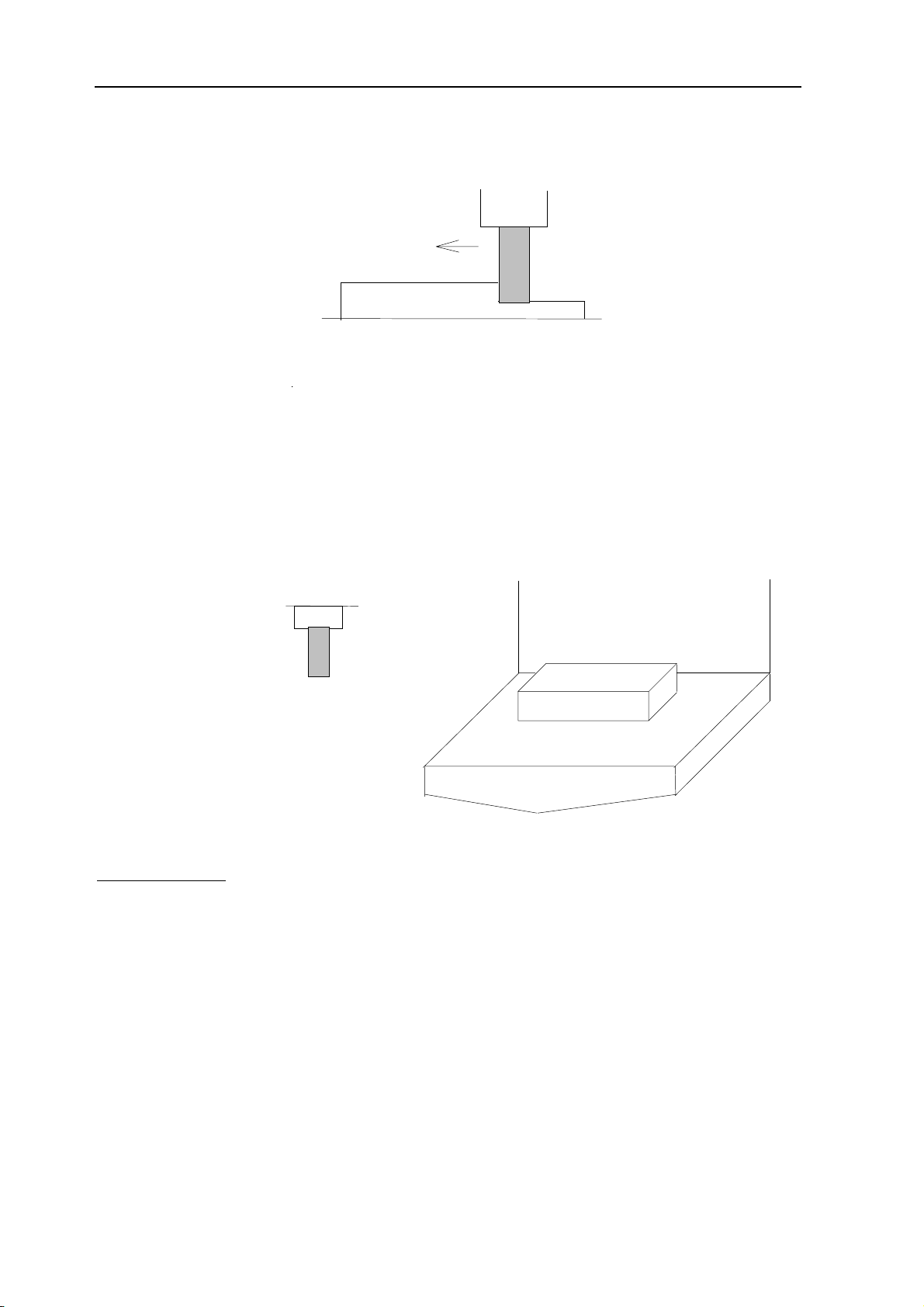

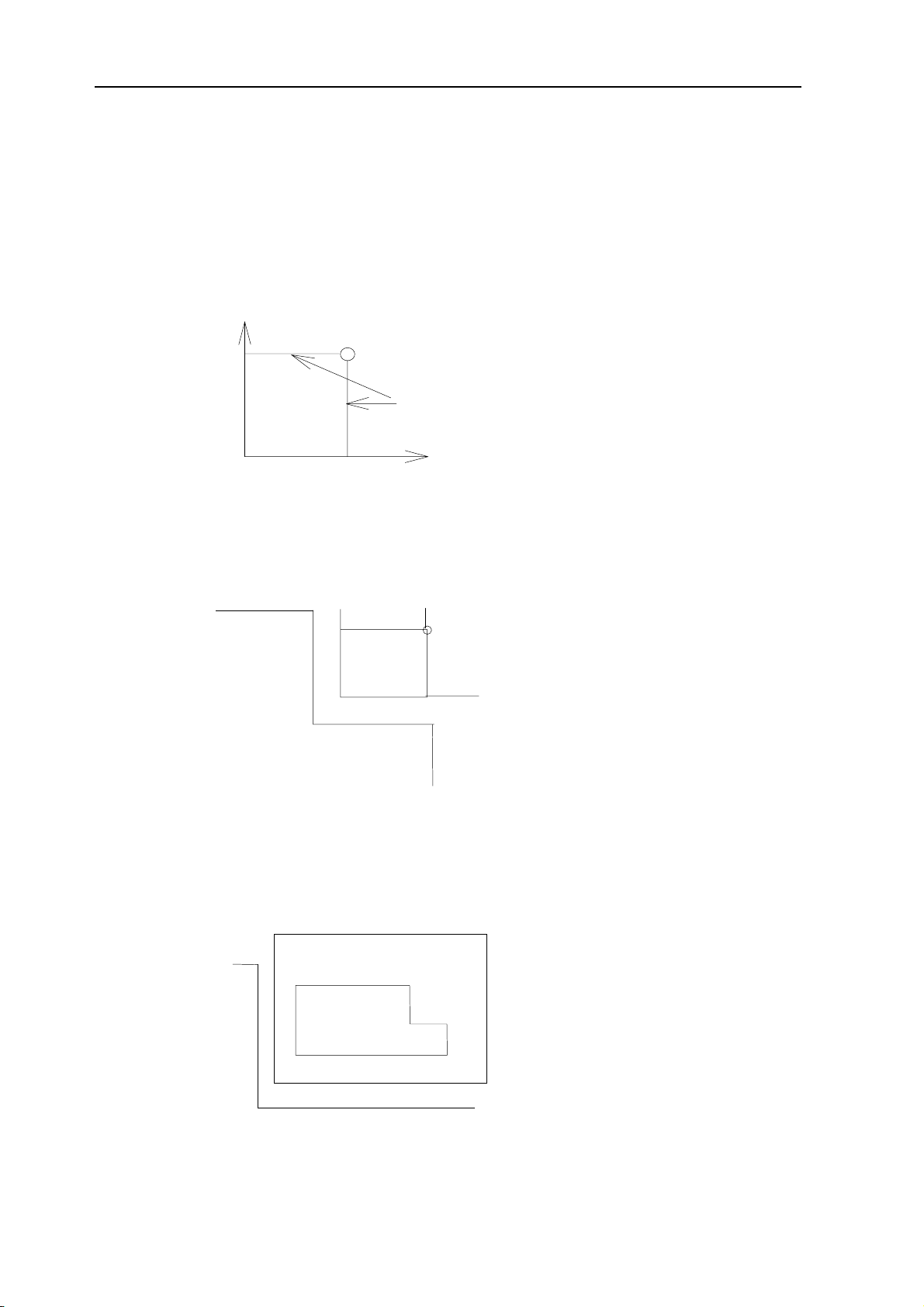

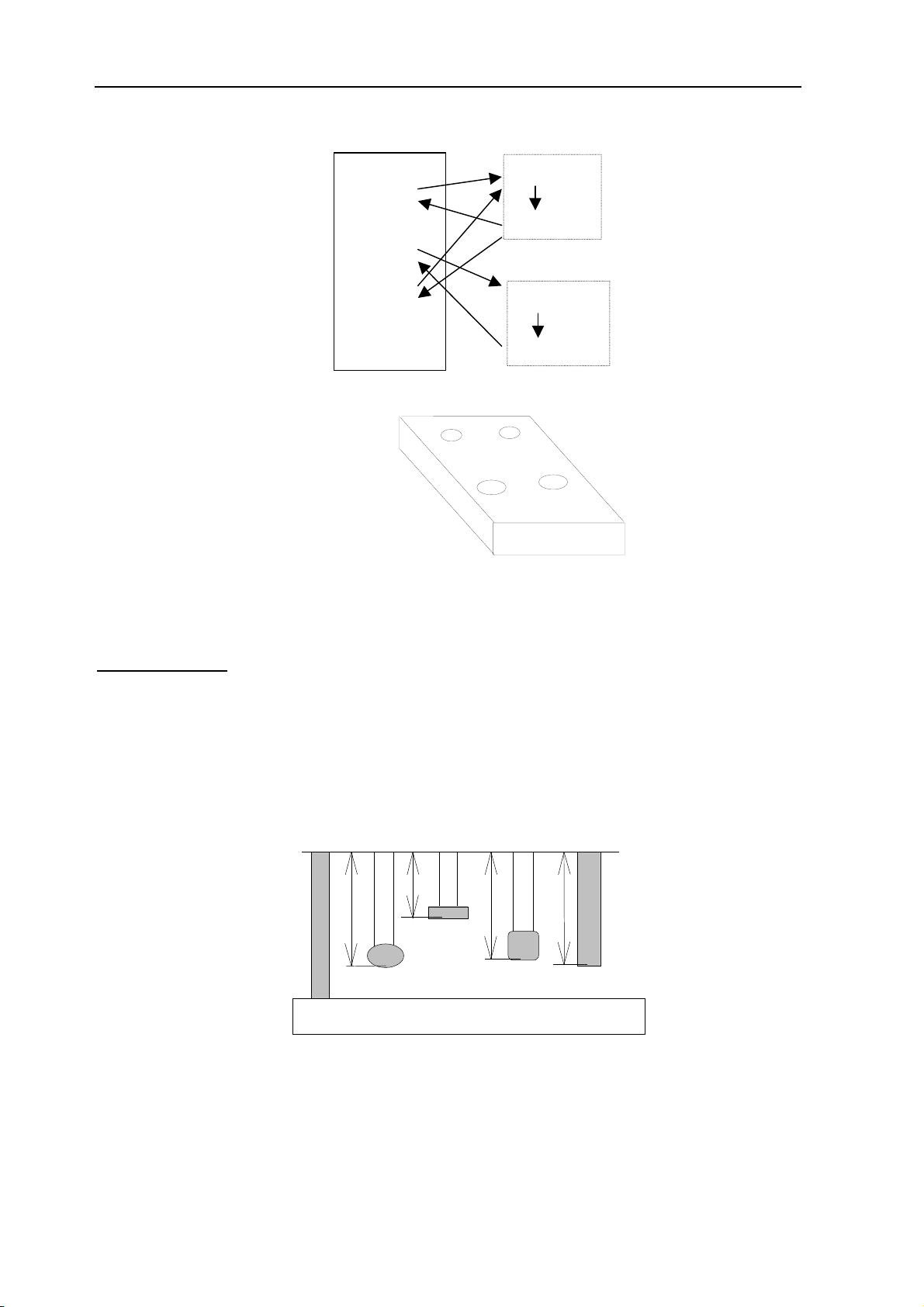

1.8 TOOL FIGURE AND TOOL MOTION BY PROGRAM

EXPLANATIONS

• Machining using the end of cutter-Tool length compensation function (See II-14.1)

Usually, several tools are used for machining one workpiece. The tools have different tool

length. It is very troublesome to change the program in accordance with the tools. Therefore,

the length of each tool used should be measured in advance. By setting the difference

between the length of the standard tool and the length of each tool in the CNC (data display

and setting: see III-11), machining can be performed without altering the program even when

the tool is changed. This function is called tool length compensation.

H2

H1

H3

H4

Workpiece

Page 22

ⅡPROGRAMMING-1(GENERAL)

• Machining using the Side of cutter-Cutter compensation function (See II-14.2)

Because a cutter has a radius, the center of the cutter path goes around the workpiece with

the cutter radius deviated.

Tool

Cutter path using cutter compensation

Machined part figure

Workpiece

1-11

If radius of cutters are stored in the CNC (Data Display and Setting : see III-11), the tool can

be moved by cutter radius apart from the machining part figure. This function is called cutter

compensation.

1.9 TOOL MOVEMENT RANGE-STROKE

Limit switches are installed at the ends of each axis on the machine to prevent tools from

moving beyond the ends. The range in which tools can move is called the stroke.

motor

Reference position

Table

Besides strokes defined with limit switches, the operator can define an area which the tool

cannot enter using a program or data in memory (see III-11). This function is called stroke

check.

Page 23

CONTROLLED AXES

2

ⅡPROGRAMMING-2 (CONTROLLED AXES)

2-0

Page 24

2.1 CONTROLLED AXES

f

t

Number of controlled axes 4 axes

Simultaneously controlled axes 4 axes

2.2 NAME OF AXES

ⅡPROGRAMMING-2 (CONTROLLED AXES)

2-1

Names of the three basic axes are fixed as X, Y, and Z. Names o

additional axes can be optionally selected from A, B, C, U, V, and W.

They can be set by parameter No. 008 #2, #3, #4.

2.3 INCREMENT SYSTEM

Least command increment Least input increment Maximum stroke

0.001mm 0.001mm 9999.99mm

0.0001inch 0.0001inch 999.9999inch

Combined use of the inch system and the metric system is not allowed.

There are functions that cannot be used between axes with different uni

systems (circular interpolation, cutter compensation, etc.). For the

increment system, see the machine tool builder’s manual.

2.4 MAXIMUM STROKE

Maximum stroke = Least command increment x 99999999

See 2.3 Increment System.

Page 25

PREPARATORY FUNCTION(G FUNCTION)

3

Ⅱ PROGRAMMING-3(PREPARATORY FUNCTION)

3-0

Page 26

Ⅱ PROGRAMMING-3(PREPARATORY FUNCTION)

3 PREPARATORY FUNCTION(G CODES)

A number following address G determines the meaning of the command for the

concerned block. G codes are divided into the following two types.

Type Meaning

3-1

One-shot G code

Modal G code

Example:

G01 and G00 are modal G codes in group 01.

G01X _;

Z _; G01 is effective in this range.

X _;

G00Z_ ;

The G code is effective only in the block in which it

is specified.

The G code is effective until another G code of the

same group is specified.

Explanations

1. Modal G codes have the following initial conditions when the power is turned

on or the system is reset to the clear state (bit 6 of parameter No. 045).

1) Those G codes marked* in Table 3 are specified automatically.

2) G20 and G21 retain their original conditions.

3) G00 or G01 is automatically selected according to parameter setting.

2. The G codes of group 00, are one-shot G codes.

3. If a G code that does not appear in the G code list is specified, or a G code

whose options are not supported is specified, alarm No. 010 is displayed.

4. Multiple G codes of different groups can be specified in a single block. When

multiple G codes of one group are specified in a block, the G code specified

last is effective.

5. If any G code of group 01 is specified in a canned cycle mode, the canned

cycle is automatically cancelled and the G80 condition is entered. However, a

G code of group 01 is not affected by any of the canned cycle G codes.

6. A G code is displayed from each group.

Page 27

Ⅱ PROGRAMMING-3(PREPARATORY FUNCTION)

3-2

Table 3 G code list(1/2)

G code

G00

*G01

Group Function

Positioning

Linear interpolation

01

G02

G03

Circular interpolation CW

Circular interpolation CCW

G04 Dwell, Exact stop

00

G10

Offset value setting

*G17 XY plane selection

G18

G19

02

ZX plane selection

YZ plane selection

G20 Input in inch

06

G21

G27

Input in mm

Reference position return check

G28 Return to reference position

G29 Return from reference position

00

G31

G39

*G40

G41 Cutter compensation left

07

G42

G43

G44

08

*G49

*G54

G55

G56

Skip function

Corner circular interpolation

Cutter compensation cancel

Cutter compensation right

Tool length compensation + direction

Tool length compensation - direction

Tool length compensation cancel

Workpiece coordinate system 1 selection

Workpiece coordinate system 2 selection

Workpiece coordinate system 3 selection

05

G57

G58

G59

Workpiece coordinate system 4 selection

Workpiece coordinate system 5 selection

Workpiece coordinate system 6 selection

G65 00 Macro call

Page 28

Ⅱ PROGRAMMING-3(PREPARATORY FUNCTION)

3-3

Table 3 G code list(2/2)

G code

G73

G74

Group Function

Peck drilling cycle

Counter tapping cycle

G76 Fine boring cycle

*G80

G81

G82

Canned cycle cancel

Drilling cycle, spot boring cycle or external operation function

Drilling cycle or counter boring cycle

09

G83

G84

G85

Peck drilling cycle

Tapping cycle

Boring cycle

G86 Boring cycle

G87

Back boring cycle

G88 Boring cycle

G89

Boring cycle

G90 Absolute command

03

G91

Increment command

G92

G98

G99

00

10

Setting for work coordinate system

Return to initial point in canned cycle

Return to R point in canned cycle

Page 29

ⅡPROGRAMMING-4(INTERPOLATION FUNCTIONS)

INTERPOLATION FUNCTIONS

4

4-0

Page 30

ⅡPROGRAMMING-4(INTERPOLATION FUNCTIONS)

4-1

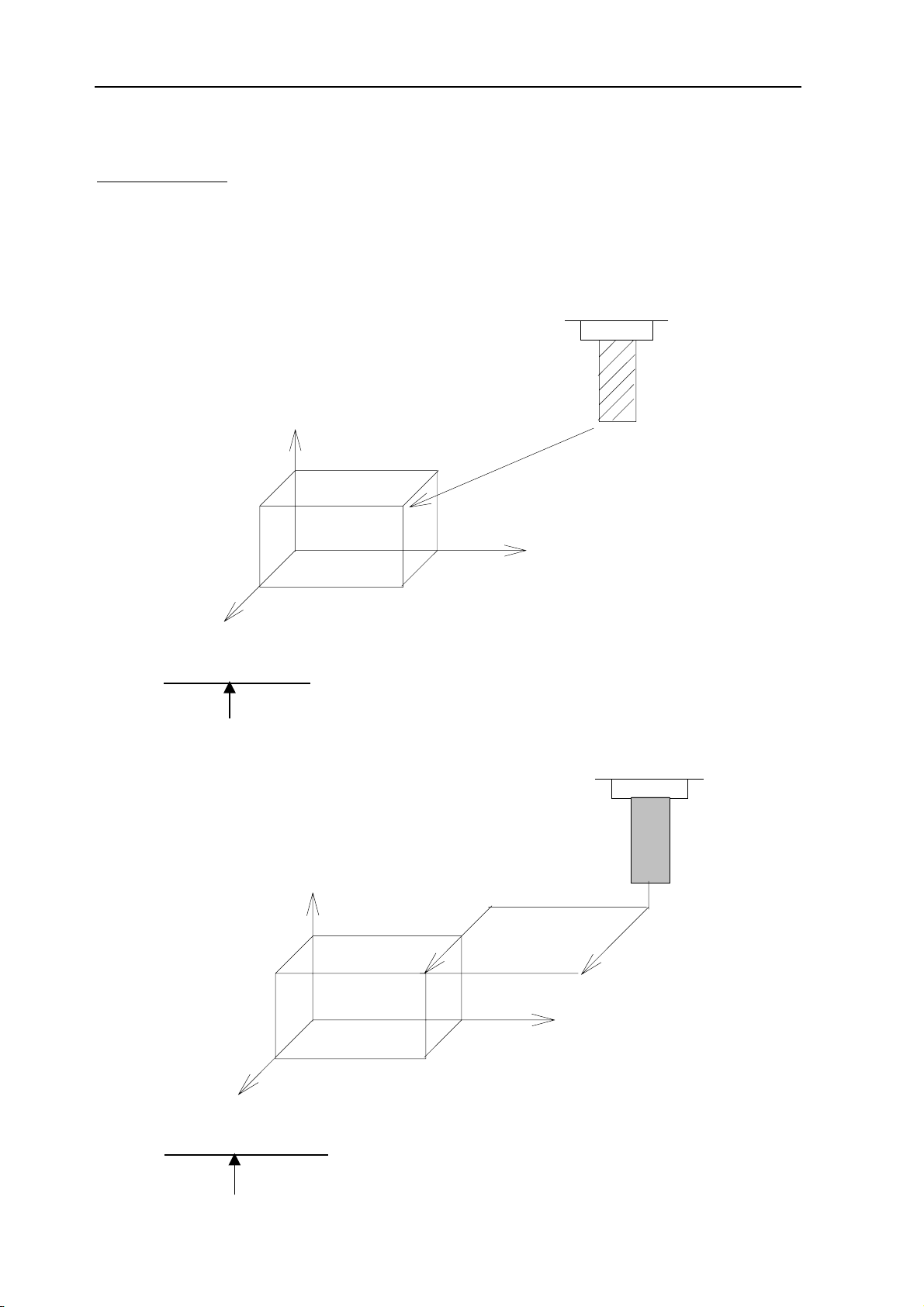

4.1 POSITIONING (G00)

The G00 command moves a tool to the position in the workpiece system

specified with an absolute or an incremental command at a rapid traverse rate.

In the absolute command, coordinate value of the end point is programmed. In

the incremental command the distance the tool moves is programmed.

Format

G00 IP _;

IP _: For an absolute command, the coordinates of an end position, and

for an incremental command, the distance of the tool moves.

Explanations

Tool path generally does not become a straight line.

on linear position

End position

NOTE:

1 The rapid traverse rate in the G00 command is set by the parameter No. 038 to

040 for each axis independently by the machine tool builder. The rapid traverse

rate cannot be specified in the address F. Feed rate specified by address F is

valid.

2 The above parameter is in 3-axis NC system. When 4-axis is selected, parameter

number is in APPENDIX 7 note2 and 3. Parameter number without special

description in this manual is in 3-axis CNC system.

Start position

4.2 LINEAR INTERPOLATION (G01)

Format

G01 IP _F_;

IP _: For an absolute command, the coordinates of an end position, and

for an incremental command, the distance of the tool moves.

F_; Speed of tool feed (Feedrate)

Explanations

A tools move along a line to the specified position at the feedrate specified in F. The

feedrate specified in F is effective until a new value is specified. It need not be

specified for each block. It is set by the parameter of No.65. The feedrate

commanded by the F code is measured along the tool path. If the F code is not

commanded, the feedrate is regarded as zero. The feedrate of each axis direction is

as follows.

G01 Xα Yβ Zγ F f

α

Feed rate of X-axis direction :

Feed rate of Y-axis direction :

Feed rate of Z-axis direction :

F

x

F

Y

F

z

=×

f=×

L

β

f

L

γ

f=×

L

Page 31

ⅡPROGRAMMING-4(INTERPOLATION FUNCTIONS)

4-2

L =

Examples:

• Linear interpolation

22

αβγ

++

G91 G01 X200.0 Y100.0 F200.0

Y

100.0

0

start position

2

End position

200.0

X

4.3 CIRCULAR INTERPOLATION (G02,G03)

The command below will move a tool along a circular arc.

arc in the X Y plane

G17

arc in the Z X plane

arc in the Y Z plane

G02 R_

X_ Y_

G03 I_ J_

G02 R_

G18

G19

Command Description

X_ Z_

G03 I_ K_

G02 R_

Y_ Z_

G03 J_ K_

F_ ;

F_ ;

F_ ;

G17 Specification of arc on XY plane

G18 Specification of arc on ZX plane

G19 Specification of arc on ZY plane

G02 Circular Interpolation Clockwise direction (CW)

G03 Circular Interpolation Counterclockwise direction (CCW)

X _ Command values of X axis or its parallel axis

Y _ Command values of Y axis or its parallel axis

Z _ Command values of Z axis or its parallel axis

I_ X axis distance from the start point to the center of an arc with sign

J_ Y axis distance from the start point to the center of an arc with sign

K_ Z axis distance from the start point to the center of an arc with sign

R_ Arc radius with sign fixed to radius designation.

F_ Feedrate along the arc

Page 32

ⅡPROGRAMMING-4(INTERPOLATION FUNCTIONS)

Explanations

Direction of the circular interpolation

•

“Clockwise”(G02) and “counter clockwise”(G03) on the XY plane (ZX plane or

YZ plane) are defined when the XY plane is viewed in the positive-to-negative

direction of the Z-axis (Y axis or X axis, respectively) in the Cartesian coordinate

system. See the figure below.

Y

G03

X

G03

Z

G03

4-3

G02

X

G17

•Distance moved on an arc

The end point of an arc is specified by address X, Y or Z, and is expressed as

an absolute or incremental value according to G90 or G91. For the incremental

value, the distance of the end point which is viewed from the start point of the

arc is specified.

•Distance from the start point to the center of arc

The arc center is specified by addresses I, J and K for the X, Y, and Z axes,

respectively. The numerical value following I, J, or K, however, is a vector

component in which the arc center is seen from the start point, and is always

specified as an incremental value irrespective of G90 and G91, as shown below.

I, J and K must be signed according to the direction.

End point(X,Y)

Start point

G02

G18

End point(Z,X)

Start point

Z

End point(Y,Z)

G02

G19

Start point

Y

center

I

I0, J0, and K0 can be omitted. When X, Y, and Z are omitted (the end point is

the same as the start point) and the center is specified with I, J and K, a 360

(circle) is specified. G02I; Command for a circle

J

center

I

center

K

J

K

•Arc radius

The distance between an arc and the center of a circle that contains the arc can

be specified using the radius, R, of the circle instead of I, J, and K. In this case,

one arc is less than 180

When an arc exceeding 180

a negative value. If X, Y, and Z are all omitted, if the end point is located at the

°, and the other is more than 180°are considered.

°is commanded, the radius must be specified with

°arc

Page 33

ⅡPROGRAMMING-4(INTERPOLATION FUNCTIONS)

t

same position as the start point and when R is used, an arc of 0 ° is

programmed G02R ; (The cutter does not move.)

EXAMPLE:

For arc (1) (less than 180°)

G91 G02 XP60.0 YP20.0 R50.0 F300.0 ;

For arc (2) (greater than 180°

G91 G02 XP60.0 YP20.0 R-50.0 F300.0 ;

R=50

End poin

1

2

4-4

Start point

R=50

•Feedrate

The feedrate in circular interpolation is equal to the feed rate specified by the F

code, and the feedrate along the arc (the tangential feedrate of the arc) is

controlled to be the specified feedrate. The error between the specified feedrate

and the actual tool feedrate is ± 2% or less. However, this feed rate is

measured along the arc after the cutter compensation is applied.

•Restrictions

If I, J, K and R addresses are specified simultaneously, the arc specified by

address R takes precedence and the other are ignored. If an axis not comprising

the specified plane is commanded, an alarm is displayed. When an arc having a

center angle close to 180° is specified using its radius R, the system may fail to

calculate the center of the arc correctly. Therefore, specify the arc with I, J and

K.

EXAMPLES:

Y

100

R50

60

40

90 120

140

R60

200

X

Page 34

ⅡPROGRAMMING-4(INTERPOLATION FUNCTIONS)

The above tool path can be programmed as follows:

(1) in absolute programming

G92 X200.0 Y40.0 Z0 ;

G90 G03 X140.0 Y100.0 I-60.0 F300.0 ;

G02 X120.0 Y60.0 I-50.0 ;

or

G92 X200.0 Y40.0 Z0

;

G90 G03 X140.0 Y100.0 R60.0 F300.0 ;

G02 X120.0 Y60.0 R50.0 ;

(2) in incremental programming

G91 G03 X-60.0 Y60.0 I-60.0 F300.0 ;

G02 X-20.0 Y-40.0 I-50.0

;

or

G91 G03 X-60.0 Y60.0 R60.0 F300.0 ;

G02 X-20.0 Y-40.0 R50.0 ;

4-5

Page 35

5

PROGRAMMING-5(FEED FUNCTION)

Ⅱ

5-0

5.1

GENERAL

Page 36

PROGRAMMING-5(FEED FUNCTION)

Ⅱ

The feed functions control the feedrate of the tool. The following two feed functions are

available:

•

Feed functions

1. Rapid traverse

When the positioning command (G00) is specified, the tool moves at a rapid traverse

feedrate set in the CNC (parameter No. 038 to 040).

2. Cutting feed

The tool moves at a programmed cutting feedrate.

•Override

Override can be applied to a rapid traverse rate or cutting feedrate using the switch on the

machine operator’s panel.

•

Automatic acceleration/ deceleration

To prevent a mechanical shock, acceleration/deceleration is automatically applied when the

tool starts and ends its movement.

Rapid traverse: Linear acceleration/deceleration (constant acceleration) (№.041~043)

Cutting feed: Exponential acceleration/deceleration (constant time constant) (№.047)

Jog feed : Exponential acceleration/deceleration (constant time constant)(№.047)

f

eedrate after interpolation

feedrate after acceleration/deceleration

5-1

CNC

command

feedrate

Pulse distri bution

interpolation)

(

Rapid traverse rate

acceleration/

deceleration

acceleration/

deceleration

driver control

driver control

steppe r motor

interpolation

acceleration/deceleration

time

TR:: Acceleration/deceleration timeconstant for rapid

(parameterNo.041, No.042, No.043)

T

R

T

R

time

Page 37

PROGRAMMING-5(FEED FUNCTION)

T

C

A

Ⅱ

cutting feed, jog feed

:Acceleration/deceleration time constant for

feedrate. (parameter047)

time

C

•Tool path in a cutting feed

If the direction of movement changes between specified blocks during cutting feed, a

rounded-corner path may result. Because of automatic acceleration and deceleration,

corners are not cut sharply. The dwell command (G04) must be inserted between the two

blocks to cut a sharp corner.

t the point, insert the dwell command

5-2

X

Z

If the dwell command is inserted, the actual tool path matches the programmed path. The

faster the feedrate and the larger the acceleration/deceleration time constant, the larger the

error at the corner. In circular interpolation, the actual arc radius is smaller than that of the

programmed arc. This error can be minimized by making the acceleration/deceleration time

constant of feedrate small.

NOTE:

The following chart shows feedrate changes between blocks of information specifying

different types of movement.

previous block

Next block

Positioning

Feed

Not moving

×: The next block is executed after commanded rate has decreased to zero.

○: The next block is executed sequentially so that the feedrate is not changed by very much.

Positioning Feed Not moving

× × ×

× ○ ×

× × ×

Programmed path

Tool path

5.2 RAPID TRAVERSE

Format

G00 IP_ ;

G00 : G code (group 01) for positioning (rapid traverse)

IP_ ; Dimension word for the end point

Explanations

The positioning command (G00) positions the tool by rapid traverse. In rapid traverse, the

Page 38

PROGRAMMING-5(FEED FUNCTION)

A

Ⅱ

next block is executed after the specified feedrate becomes 0 and the servo motor reaches

a certain range set by the machine tool builder (in-position check). (In-position check can be

disabled for each block by setting bit 5 of parameter No. 020 to 1.) A rapid traverse rate is

set for each axis by parameter No. 038to 040, so no rapid traverse feedrate need be

programmed.

The following overrides can be applied to a rapid traverse rate with the switch on the

machine operator’s panel:

F0, 25, 50, 100%

F0: Allows a fixed feedrate to be set for each axis by parameter No. 051

For detailed information, refer to the appropriate manual of the machine tool builder.

5.3 CUTTING FEED

Feedrate of linear interpolation (G01), circular interpolation (G02, G03), etc. re commanded

with numbers after the F code. In cutting feed, the next block is executed so that the

feedrate change from the previous block is minimized.

EXPLANATIONS

•Tangential speed constant control

Cutting feed is controlled so that the tangential feedrate is always set at a specified feedrate.

X

F

End point

X

Start point

F

X

F

Z

F

5-3

F

X

Start point

F

Z

Linear interpolation

Z

rc interpolation

End point

Z

Tangential feedrate (F)

F: tangential feedrate

2

X FFF +=

2

Z

FX: X-axis feedrate

FZ: Z-axis feedrate

• Cutting feedrate clamp

A common upper limit can be set on the cutting feedrate along each axis with parameter No.

045. If an actual cutting feedrate (with an override applied) exceeds a specified upper limit, it

is clamped to the upper limit. An upper limit is set in mm/min or inch/min. CNC calculation

may involve a feedrate error of ±2% with respect to a specified value. However, this is not

true for acceleration/deceleration. To be more specific, this error is calculated with respect to

a measurement on the time the tool takes to move 500 mm or more during the steady state.

• Feedrate override

Feedrate can be overridden by a switch located on operator’s panel, from 0 to 150% (step

10%).

5.4 DWELL (G04)

FORMAT

Dwell G04 X_ ; or G04 P_

X_ : Specify a time (decimal point permitted)

;

Page 39

PROGRAMMING-5(FEED FUNCTION)

Ⅱ

P_ : Specify a time (decimal point not permitted)

EXPLANATIONS

By specifying a dwell, the execution of the next block is delayed by the specified time.

When neither P nor X is specified, exact stop is performed.

Command value range of the dwell time (Command by X)

Command value range Dwell time unit

0.001 to 99999.999s s

Command value range of the dwell time (Command by p)

Command value range Dwell time unit

1 to 99999999 0.001s

5-4

Page 40

REFERENCE POSITION

6

PROGRAMMING-6(REFERANCE POSITION)

Ⅱ

6-0

Page 41

6.General

PROGRAMMING-6(REFERANCE POSITION)

Ⅱ

6-1

•

REFERENCE POSITION

The reference position is a fixed position on a machine tool to which the tool can easily be

moved by the reference position return function. For example, the reference position is used

as a position at which tools are automatically changed. Up to two reference positions can be

specified by setting coordinates in the machine coordinate system in parameters. The first

reference position must be the machine zero point.

Reference position

workpiece

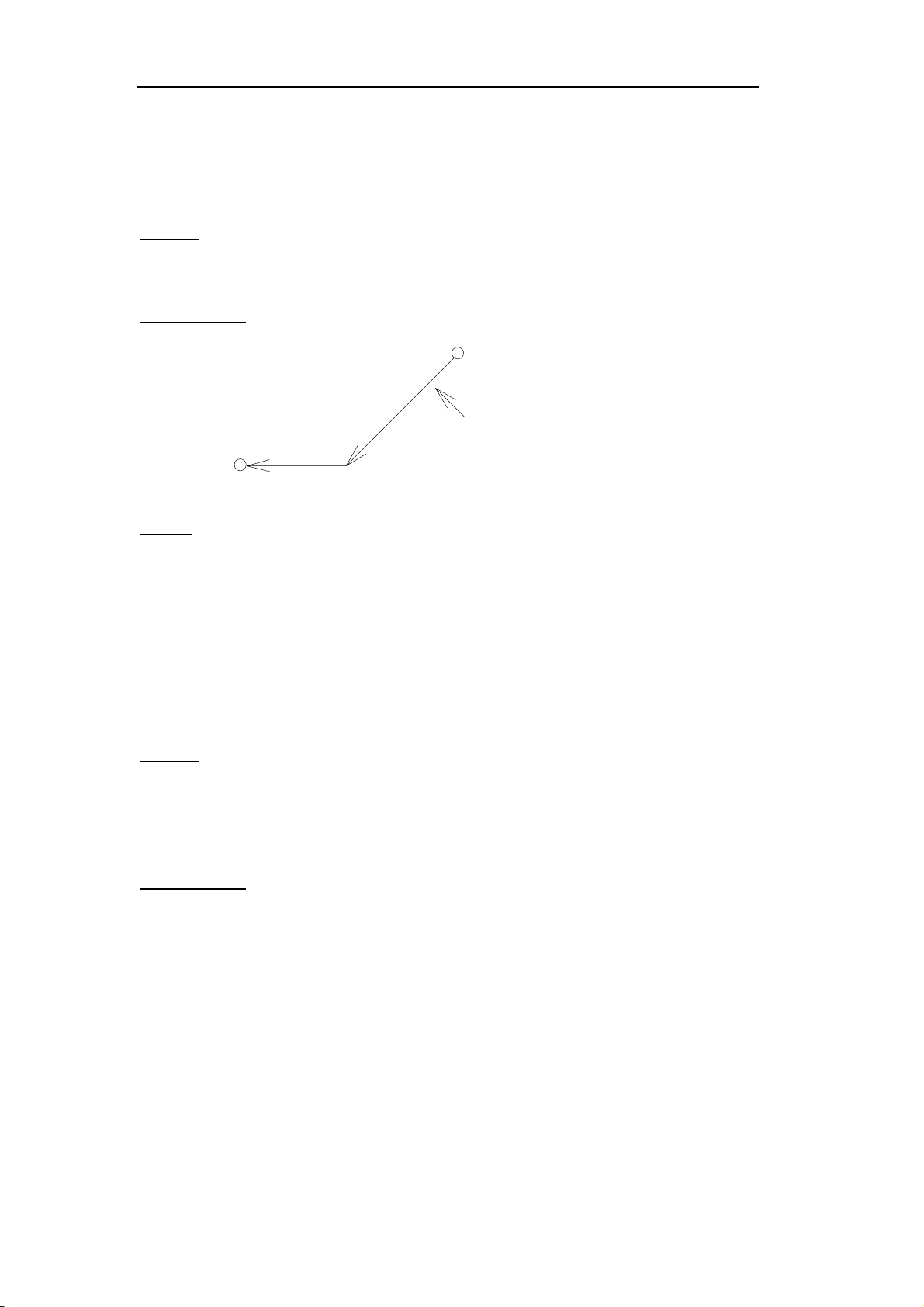

• Reference position return and movement from the reference position

Tools are automatically moved to the reference position via an intermediate position along a

specified axis. Or, tools are automatically moved from the reference position to a specified

position via an intermediate position along a specified axis. When reference position return

is completed, the lamp for indicating the completion of return goes on.

Reference position return A→B→R R (Reference position)

Return from the reference position R→B→C

B intermediate

A (Start position for reference position return)

Reference position return and return form the reference position

C (Destination of return from the reference position)

•Reference position return check

The reference position return check (G27) is the function which checks whether the tool has

correctly returned to the reference position as specified in the program. If the tool has

correctly returned to the reference position along a specified axis, the lamp for the axis goes

on.

Page 42

PROGRAMMING-6(REFERANCE POSITION)

Ⅱ

• Reference position return

G28 IP_; Reference position return

IP: Command specifying the intermediate position (Absolute/incremental command)

6-2

•

Return from reference position

G29 IP_;

IP: Command specifying the destination of return from reference position

(Absolute/incremental command)

•Reference position return check

G27 IP_;

IP: Command specifying the reference position (Absolute/incremental command)

EXPLANATION

•

Reference position return (G28)

Positioning to the intermediate or reference positions are performed at the rapid traverse

rate of each axis. Therefore, for safety, the cutter compensation, and tool length

compensation should be cancelled before executing this command. The coordinates for the

intermediate position are stored in the CNC only for the axes for which a value is specified

in a G28 block. For the other axes, the previously specified coordinates are used.

EXAMPLE:

N1 G28 X40.0 ; Intermediate position (X40.0)

N2 G28 Y60.0 ; Intermediate position (X40.0, Y60.0)

•

Return from reference position(G29)

In general, it is commanded immediately following the G28 command or G30. For

incremental programming, the command value specifies the incremental value from the

intermediate point. Positioning to the intermediate or reference points are performed at the

rapid traverse rate of each axis. When the workpiece coordinate system is changed after

the tool reaches the reference position through the intermediate point by the G28 command,

the intermediate point also shifts to a new coordinate system. If G29 is then commanded,

the tool moves to the commanded position through the intermediate point which has been

shifted to the new coordinate system.

•Reference position return check(G27)

G27 command positions the tool at rapid traverse rate. If the tool reaches the reference

position, the reference position return lamp lights up. However, if the position reached by

the tool is not the reference position, an alarm is displayed.

RESTRICTIONS

•Status the machine lock being turned on

The lamp for indicating the completion of return does not go on when the machine lock is

turned on, even when the tool has automatically returned to the reference position. In this

case, it is not checked whether the tool has returned to the reference position even when a

G27 command is specified.

First return to the reference position after power on (without an absolute position detector)

•

When the G28 command is specified when manual return to the reference position has not

Page 43

PROGRAMMING-6(REFERANCE POSITION)

A

Ⅱ

been performed after the power has been turned on, the movement from the intermediate

point is the same as in manual return to the reference position. In this case, the tool moves

in the direction for reference position return specified in parameter ( No. 006 ZMX ZMY

ZMZ). Therefore the specified intermediate position must be a position to which reference

position return is possible.

EXAMPLES

G28G90X1000.0Y500.0 ; (Programs movement from A to B)

T1111 ; (Changing the tool at the reference position)

G29X1300.0Y200.0 ; (Programs movement from B to C)

The tool is c hanged at t he reference positi on

Y

R

Reference position

6-3

700

B

Intermediate position

500

300

300

1300

1800

C

X(mm

)

Page 44

PROGRAMMING-7(COORDINATE SYSTEM) 7 - 1

Ⅱ

7. COORDINATE SYSTEM

By teaching the CNC a desired tool position, the tool can be moved to the position. Such a

tool position is represented by coordinates in a coordinate system. Coordinates are specified

using program axes.

When three program axes, the X-axis, Y-axis, and Z-axis, are used, coordinates are

specified as follows:

X_Y_Z__

This command is referred to as a dimension word

Z

20.0

30.0

40.0

.

Coordinates are specified in one of following three coordinate systems:

(1)Machine coordinate system

(2)Workpiece coordinate system

(3)Local coordinate system

The number of the axes of a coordinate system varies from one machine to another. So, in

this manual, a dimension word is represented as IP_.

X

Tool Position Specified by X40.0Y50.0Z25.0

Y

7.1 WORKPIECE COORDINATE SYSTEM

A coordinate system used for machining a workpiece is referred to as a workpiece

coordinate system. A workpiece coordinate system is to be set with the NC beforehand

(setting a workpiece coordinate system). A machining program sets a workpiece coordinate

system (selecting a workpiece coordinate system). A set workpiece coordinate system can

be changed by shifting its origin (changing a workpiece coordinate system).

7.2.1 Setting a Workpiece Coordinate System

A workpiece coordinate system can be set using one of three methods:

(1)

Method using G92

A workpiece coordinate system is set by specifying a value after G92 in the program.

(2)

Automatic setting

If bit APRS of parameter No. 012 is set beforehand, a workpiece coordinate system is

automatically set when manual reference position return is performed.

(3)

Input using the CRT/MDI panel

Six workpiece coordinate systems can be set beforehand using the CRT/MDI panel.

To use absolute programming, establish a workpiece coordinate system by applying one of

the methods described above.

FORMAT

•

Page 45

PROGRAMMING-7(COORDINATE SYSTEM) 7 - 2

Ⅱ

Setting a workpiece coordinate system by G92

G92 _ IP;

EXPLANATIONS

A workpiece coordinate system is set so that a point on the tool, such as the tool tip, is at

specified coordinates. If a coordinate system is set using G92 during tool length offset, a

coordinate system in which the position before offset matches the position specified in G92

is set. Cutter compensation is cancelled temporarily with G92.

Z

tool

Setting the coordinate system by the

23.0

G92X25.2Z23.0; comm and

(The tool tip is the start point f or the

program.)

X

25.3

G92 X25.3 Z23.0

Z

Base point

1200

600

*

Setting the coordinate system by the G92

command (The base point on the tool holder is

the start point for the program.) If an absolute

command is issued, the base point moves to the

commanded position. In order to move the tool

tip to the commanded position, the difference

from the tool tip to the base point is

compensated by tool length offset.

X

G92X600.0Z1200.0;

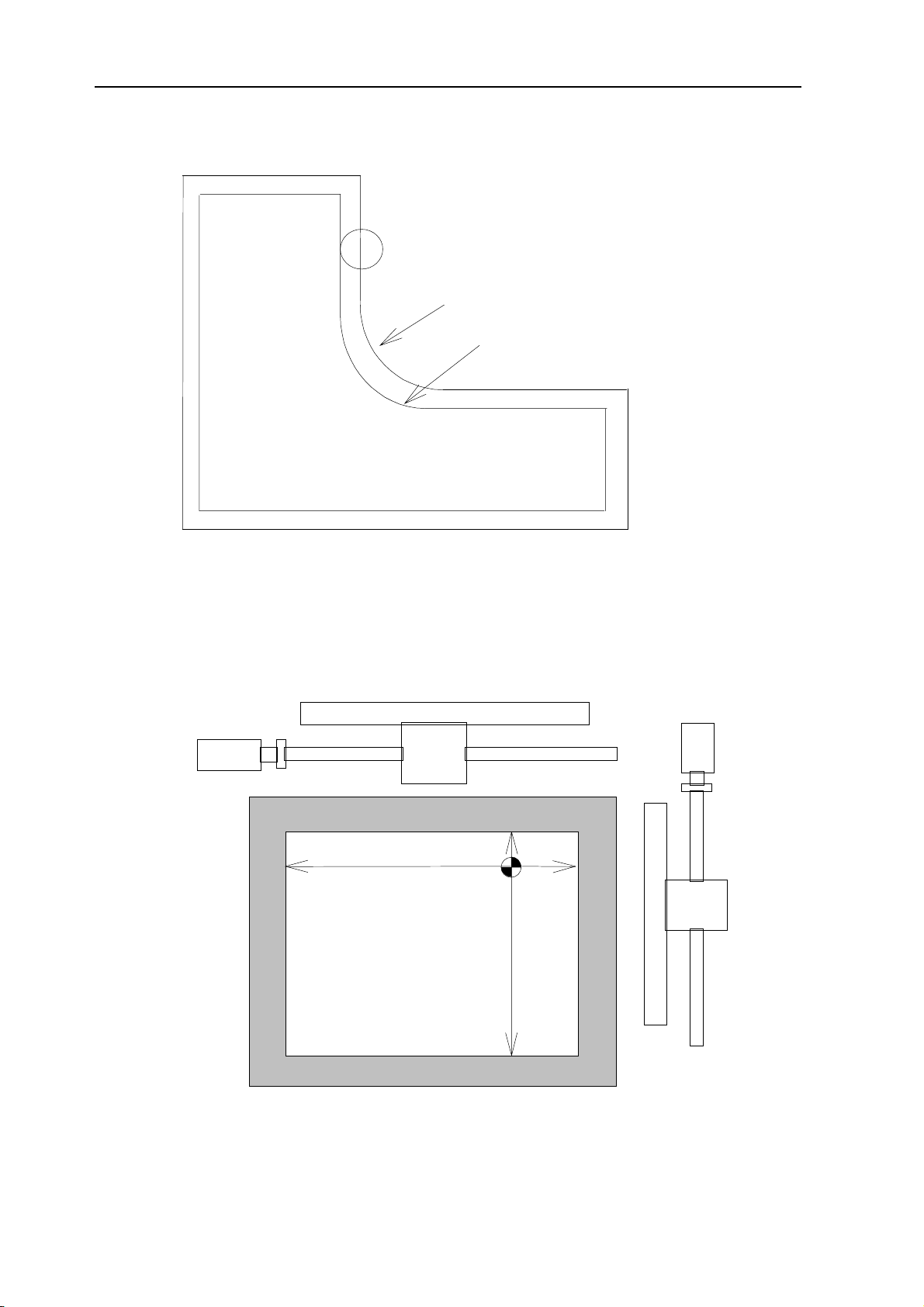

7.2 PLANE SELECTION

Select the planes for circular interpolation, cutter compensation, and drilling by G-code. The

following table lists G-codes and the planes selected by them.

EXPLANATIONS

Plane selected by G code

G code Selected plane X Y Z

G17 X Y plane

G18 Z X plane

G19 Y Z plane

X, Y, Z are determined by the axis address appeared in the block in which G17, G18 or G19

X-axis or an axis

parallel to it

y-axis or an axis

parallel to it

z-axis or an axis

parallel to it

Page 46

PROGRAMMING-7(COORDINATE SYSTEM) 7 - 3

Ⅱ

is commanded. When an axis address is omitted in G17, G18 or G19 block, it is assumed

that the addresses of basic three axes are omitted.The plane is unchanged in the block in

which G17, G18 or G19 is not commanded.

EXAMPLES

G17 X_Y_; XY plane,

G18 X_Z_ ; ZX plane

X_Y_; Plane is unchanged (ZX plane)

G17 XY plane

G18 ZX plane

G18 Y_ ; ZX plane, Y axis moves regardless without any relation to the plane.

NOTE:

When the system is turned on or placed in the clear state by a reset, G17, G18 or G19 is

selected according to the setting parameter.

Page 47

PROGRAMMING-8(COORDINATE AND DIMENSION

Ⅱ

8. COORDINATE VALUE AND DIMENSION

) 8 - 1

8.1

ABSOLUTE AND INCREMENTAL PROGRAMMING (G90, G91)

There are two ways to command travels of the tool; the absolute command, and the

incremental command. In the absolute command, coordinate value of the end position is

programmed; in the incremental command, move distance of the position itself is

programmed. G90 and G91 are used to command absolute or incremental command,

respectively.

FORMAT

G90 IP _ ; Absolute command

G91 IP_ ; Incremental command

EXAMPLES

Y

End point

70.0

30.0

Start point

40.0

G90 X40.0 Y70.0 ; Absolute command

G91 X-60.0 Y40.0 ; Incremental command

8.2 INCH/METRIC CONVERSION(G20,G21)

Either inch or metric input can be selected by G code.

unit G code Least command increment

inch G20 0.0001inch

metric G21 0.001 mm

This G code must be specified in an independent block before setting the coordinate

system at the beginning of the program. After the G code for inch/metric conversion is

specified, the unit of input data is switched to the least inch or metric input increment of

increment system. The unit of data input for degrees remains unchanged. The unit

systems for the following values are changed after inch/metric conversion:

(1) Feedrate commanded by F code

(2) Positional command

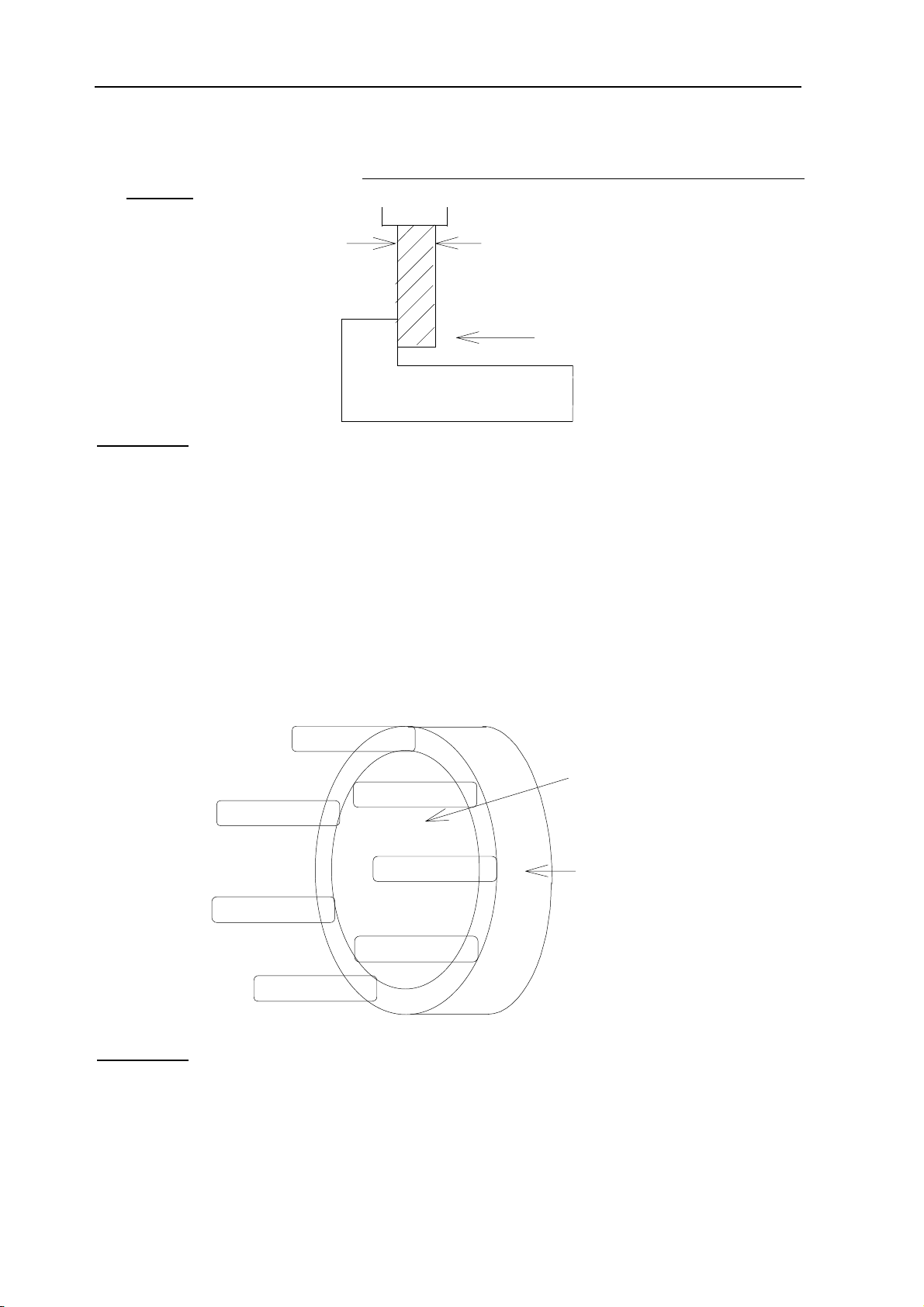

(3) Work zero point offset value

(4) Unit of scale for manual pulse generator

(5) Movement distance in incremental feed

(6) Some parameters

When the power is turned on, the G code is the same as that held before the power was

turn off.

100.0

X

Page 48

PROGRAMMING-8(COORDINATE AND DIMENSION

Ⅱ

WARNING

1 G20 and G21 must not be switched during a program.

2 When switching inch input (G20) to metric input (G21) and vice versa, the tool

compensation value must be reset according to the least input increment.

NOTE

1 When the least input increment and the least command increment systems are

different, the maximum error is half of the least command increment. This error is not

accumulated.

2 The inch and metric input can also be switched using settings.

8.3 DECIMAL POINT PROGRAMMING

Numerical values can be entered with a decimal point. A decimal point can be used

when entering a distance, time, or speed. Decimal points can be specified with the

following addresses: X, Y, Z, I, J, K, Q, R, and F

EXAMPLES:

Program command

Pocket calculator type

decimal point programming

) 8 - 2

Standard type decimal

point programming

X1000

Command value without decimal

point

X1000.0

Command value with decimal point

NOTE

1000mm

Unit : mm

1000mm

Unit : mm

1mm

Unit : Least input

increment (0.001 mm)

1000mm

Unit : mm

1 In the dwell command, decimal point can be used with address X but not with address

P.(This is because P is also used for a sequence number.)

2 In a single block, specify a G code before entering a value. The position of decimal point

may depend on the command.

Examples:

G20; Input in inches

X1.0 G04; X1.0 is considered to be a distance and processed as X10000.

This command is equivalent to G04 X10000. The tool dwells for 10 seconds.

G04 X1.0;

Equivalent to G04 X1000. The tool dwells for one second.

3 There is great difference in values with and without the decimal point.

G21; (millimeter dimensions)

X1. X 1mm

X1 X 0.001mm

G20; (inch dimensions)

X1. X 1inch

X1 X 0.0001inch

4 Values with and without a decimal point can be specified together.

X1000 Z23.7;

X10. Z22359;

5 Fractions less than the least input increment are truncated.

Page 49

PROGRAMMING-8(COORDINATE AND DIMENSION

Ⅱ

) 8 - 3

Examples:

X1.2345; Truncated to X1.234 when the least input increment is 0.001 mm. Processed as

X1.2345 when the least input increment is 0.0001 inch.

6 When more than eight digits are specified, an alarm occurs. If a value is entered with a

decimal point, the number of digits is also checked after the value is converted to an

integer according to the least input increment.

Examples:

X1.23456789; Alarm 003 occurs because more than eight digits are specified.

X123456.7; If the least input increment is 0.001 mm, the value is converted to integer

123456700. Because the integer has more than eight digits, an alarm

occurs.

7 A decimal point is default setting or not by using parameter P013 PODI.

PODI: When the addresses that decimal points can be specified in a program haven’t

decimal point, a decimal point is conformed to exit.

X100=X100. (X100mm)

8 A decimal point is necessary or not by using parameter P014 PODI, in order to prevent a

decimal point omitting in absolute programming.

POD 0: a decimal point is optional

1: a decimal point is necessary, or an alarm occurs (No.007).

SPECIAL EXAMPLE:

1 Though F100.=F100, when parameter POD=1, a decimal point is necessary.(F100.)

2 Address Q can specify with the decimal point, when macro variables DO=1, 1. or 0.01

must be specified in address Q. If the low eight-bit of macro variables #1132 are 1, G65

H01 #1132 Q0.255

Page 50

SPINDLE SPEED FUNCTION (S FUNCTION)

9

PROGRAMMING-9(SPINDLE SPEED FUNCTION)

Ⅱ

The spindle speed can be controlled by specifying a value

following

address S.

This chapter contains the following topics.

9.1 SPECIFYING THE SPINDLE SPEED WITH A CODE

9.2 SPECIFYING THE SPINDLE SPEED VALUE DIRECTLY

(S4-DIGIT COMMAND)

9 - 0

Page 51

PROGRAMMING-9(SPINDLE SPEED FUNCTION)

Ⅱ

9.1 SPECIFYING THE SPINDLE SPEED WITH A BINARY CODE

A 2-digit S code can be specified in a block. We can provide eight-level spindle speed

function. For a description of the use of S codes, such as their execution sequence in a

block in which a spindle speed, move command, and S code are specified, see the manual

provided by the machine tool builder.

S1~S8

S code’s execution time is set by the donors No.209.

Setting value: 0~255 (128ms~32.640ms)

Setting time=setting value x 128ms

Setting time

9 - 1

S code execution start

Execute the next block

Note:

When more than S code is specified, an alarm occurs and execution stops.

02:S code error

A 2-digit S code is effective, if a 4-digit S code is specified, the last 2-digit is effective.

S code setting time’s parameter (see 11.2)

9.2 SPECIFYING THE SPINDLE SPEED VALUE DIRECTLY

(S4-DIGIT COMMAND)

The spindle speed can be specified directly by address S followed by a four-digit value

(rpm). The unit for specifying the spindle speed may vary depending on the machine tool

builder. Refer to the appropriate manual provided by the machine tool builder for details.

9.2.1 JOG MODE

1 JOGS=1, S code specifies analogue spindle speed.

2 JOGS=0, Analogue spindle speed is set by the following parameter in JOG mode.

P61/71(4-axis):power-on initial value of analogue spindle speed in JOG mode.

unit:rpm

P62/72(4-axis):incremental value or decrement of analogue spindle speed.

P56/66 is upper limit in increment.

Spindle rotates at the speed to be set by parameter after spindle start-up in Jog mode. When

pressing the spindle override key + or -, each incremental value or decrement of spindle

speed is the increment set by parameter P62/72. Manual spindle rotational speed is displayed

on the address S of POS screen in JOG mode. In other mode, spindle rotates at the speed

specified by S code.

NOTE:

1 Rotational speed specified by parameter is not spindle motor rotational speed but spindle

speed. Spindle analogue voltage is determined by spindle shift inside CNC.

2 If mode shifts between manual and non- manual, spindle speed will change during rotation.

3 Standard parameter setting: P061=100 P062=50

4 JOG mode includes jog feed, handle/step or zero return mode(machine or program zero

return).

Page 52

10

PROGRAMMING-10(TOOL FUNCTION

Ⅱ

TOOL FUNCTION (T FUNCTION)

Tool Selection function (tool exchange) is unavailable in K100M.

) 10 - 1

Page 53

AUXILIARY FUNCTION

11

PROGRAMMING-11(AUXILIARY FUNCTION)

Ⅱ

11 - 0

Page 54

11. AUXILIARY FUNCTION

The auxiliary function: miscellaneous function (M code) for specifying spindle start,

spindle stop program end, and so on, When a move command and miscellaneous

function are specified in the same block, the commands are executed in one of the

following two ways:

i) Simultaneous execution of the move command and miscellaneous function

commands.

ii) Executing miscellaneous function commands upon completion of move command

execution.

The selection of either sequence depends on the machine tool builder’s specification.

Refer to the manual issued by the machine tool builder for details.

EXAMPLES:

N1 G91 G01 X50.0 Y-50.0 M05 ;(spindle stop)

Y

50

The commands of motion and

spindle stop execute simultaneously.

PROGRAMMING-11(AUXILIARY FUNCTION)

Ⅱ

11 - 1

50

X

11.1 AUXILIARY FUNCTION (M FUNCTION)

When a two-digit numeral is specified following address M, code signal and a strobe

signal are sent to the machine. The machine uses these signals to turn on or off its

functions. Usually, only one M code can be specified in one block. Which M code

corresponds to which machine function is determined by the machine tool builder.

M code:

M03 :spindle CW

M04 :spindle CCW

M05 :spindle stop

M08 :coolant on

M09 :coolant off

M10 :clamp

M11 :unclamp

M32 :lubricant on

M33 :lubricant off

M00 :program stop

M30 :end of program

M code’s execution time can be set by diagnose №208 except M00 and M30.

Setting value: 0~255 (128ms~32.640ms)

Setting time=setting value×128 ms

Setting time

M code execution start

ext block execution start

N

Page 55

PROGRAMMING-11(AUXILIARY FUNCTION)

Ⅱ

11 - 2

Sequence diagram and setting time

Spindle CW/CCW

Stop command

T1

Interlock signal

Spindle stop

T2

Spindle brake

T3

T1: When spindle stop command (automatic or jog) sends as it is rotating, axes interlock

signal is effective at first, spindle stop signal is sent after delaying T1. (see diagnose №

214.)

T2: the delay time from sending spindle stop signal to spindle brake signal is set by

diagnose №215/216.

T3: spindle brake time is set by diagnose №217/218.

NOTE:

1. Other M code expect mentioned is specified in program, an alarm occurs and execution

stops.

01: M code error.

2. M code will be held from beginning, even if mode changed, it can’t be cancelled in

jog mode. “RESET’ is on, M code will be disabled.

EXPLANATIONS

The following M codes have special meaning.

(1) M30

① This indicates the end of the main program.

② Automatic operation is stopped and the CNC unit is reset.

③ After a block specifying the end of the program is executed, control returns to the

start of the program.

④ The number of workpiece will increase one.

(2) M00

① Automatic operation is stopped after a block containing M00 is executed.

② When the program is stopped, all existing modal information remains unchanged

as in single block operation.

③ The automatic operation can be restarted by actuating the cycle operation.

(3) M98

① This code is used to call a subprogram.

② See the subprogram section Ⅱ-12 for details .

NOTE:

1 The block following M00 and M30, is not read into the input buffer register,

2 The code and strobe signals are not sent when M98 and M99 is actuating.

External buzzer output signal:

Page 56

PROGRAMMING-11(AUXILIARY FUNCTION)

Ⅱ

11 - 3

1 When gear shift or tool exchange in manual mode is set by parameter, a block

including S code or T code actuates in automatic mode, external buzzer output signal

will be sent automatically.

T

T

4T

after advance command finishing, press “CAN” key, external buzzer output signal

stop. If “cycle start” is pressed, the next block will be executed continuously.

Parameter 012.5 = 0/1 :S code auto/manual execution.

Parameter 012.6 = 0/1 :T code auto/manual execution

.

2 External buzzer output signal will be sent automatically when an alarm occurs.

T

T

T

Canceling the alarm or pressing “CAN” key external buzzer output stops. T is set by

diagnose №219.

11.2 AUXILIARY FUNCTIONS PARAMETER

Diagnose №160~223 is memorable (using battery) PLC parameter. The user can define

them using the BCD codes under concrete conditions.

SETTING METHOD

(1)

Setting

(A) Open program protection

(B) Select the MDI mode.

(C) Press the function button [DGNOS] to display the diagnose parameter screen.

(D) Move the cursor to the item to be changed.

(E) Input a binary data and press the key INPUT, the data will be changed .

(2)

Method of cursor moving

(A) Press PAGE or CURSOR key.

(B) Using index:

P→the desired diagnostic number→INPUT.

№208: M code process time

setting unit: 128ms

setting code: 0~255

setting value: (№208+1) x 128ms

setting field: 128ms~32.768ms

№209: S code process time

setting unit: 128ms

Page 57

PROGRAMMING-11(AUXILIARY FUNCTION)

Ⅱ

11 - 4

setting code: 0~255

setting value: (№209+1) x 128ms

setting field: 128ms~32.768ms

№214: Delay time T1 from spindle stop command sending to spindle stop signal sending

setting unit: 16ms

setting code: 0~255

setting value: №214 x 16ms

setting field: 0~4.096s

№215,216: Delay time from spindle stop signal sending to spindle brake signal sending

setting unit: 16ms

setting code: 0~65535

setting value: (№216x256+№215) x 16ms

setting field: 0~1048.560s

№217,218: Spindle brake time

setting unit: 16ms

setting code: 0~65535