Page 1

CNC Series

KND—1000 TⅠ/1000 TⅡ CNC system for Lathe

USER’S MANUAL

Beijing KND CNC Technique Co. Ltd.

B12B-T00N-0101

KND LTD,2006

C

Page 2

CONTENTS

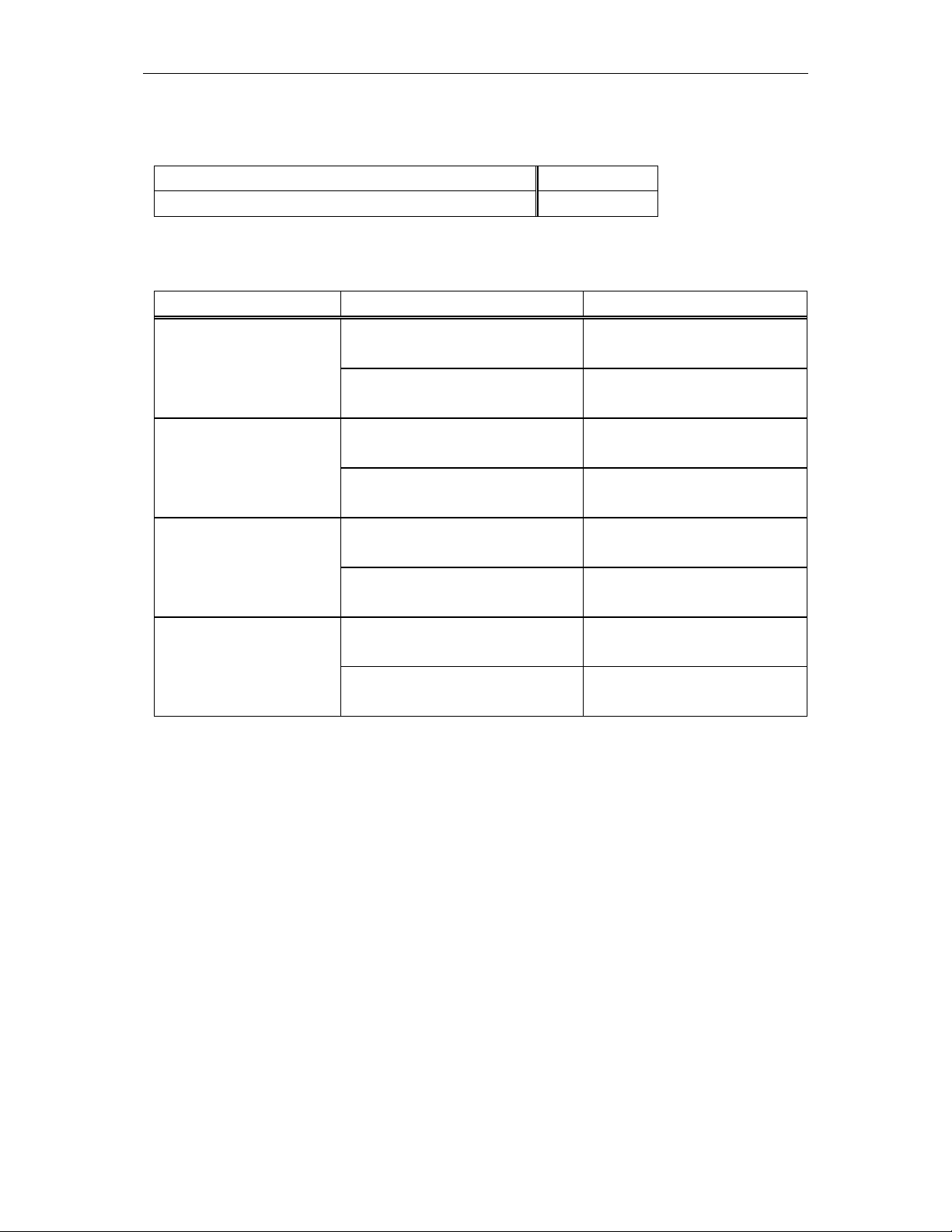

I GENERAL

1. GENERAL

1.1 GENERAL FLOW OF OPERATION OF CNC MACHINE TOOL

1.2 NOTES ON READING THIS MANUA

II PROGRAMMING

1. GENERAL

1.1 TOOL MOVEMENT ALONG WORKPIECE PARTS FIGURE-INTERPOLATION

1.2 FEED-FEED FUNCTION

1.3 PART DRAWING AND TOOL MOVEMENT

1.4 CUTTING FEED─SPINDLE SPEED FUNCTION

1.5 SELECTION OF TOOL USED FOR VARIOUS MACHINING-TOOL FUNCTION

1.6 COMMAND FOR MACHINE OPERATIONS MISCELLANEOUS FUNCTION

1.7 PROGRAM CONFIGURATION

1.8 TOOL COMPENSATION FUNCTION

1.9 TOOL MOVEMENT RANGE –STROKE

2. CONTROLLED AXES

2.1 CONTROLLED AXES

2.2 SETTING UNIT

2.3 MAXIMUM STROKES

3. PREPARATORY FUNCTION (G FUNCTION)

4. INTERPOLATION FUNCTIONS

4.1 POSITIONING (G00)

4.2 LINEAR INTERPOLATION (G01)

4.3 CIRCULAR INTERPOLATION (G02,G03)

5. THREAD CUTTING

5.1 THREAD CUTTING(G32)

5.2 unequal lead thread cuttingG34

6. FEED FUNCTION

6.1 RAPID TRAVERS

6.2 CUTTING FEEDRATE

6.3 AUTOMATIC ACCELERATION/DECELERATION

6.4 SPEED CONTROL AT COMERS OF BLOCKS

6.5 DWELL(G04)

7. REFERENCE POSITON

7.1 AUTOMATIC REFERENCE POINT TETURN(G28)

8. COORDINATE SYSTEM SETTING(G50)

……………………………………………………………………………………

……………………………………………………………………………………

……………………

L…………………………………………………

………………………………………………………………………

……………………………………………………………………………………

…………………………………………………………………

…………………………………………

……………………………………

…………………………………………………………

…………………………………………………

………………………………………………

……………………………………………………………………

……………………………………………………………………

……………………………………………………………………………

……………………………………………………………………

………………………………………

…………………………………………………………

……………………………………………………………………

………………………………………………………

……………………………………………

………………………………………………………………………

………………………………………………………………

……………………………………………………

………………………………………………………………………

………………………………………………………………………

…………………………………………………………………

…………………………………

……………………………………

……………………………………………………………………………

…………………………………………………………………

…………………………………

……………………………………………

…

…

……

1 - 0

1 - 1

1 - 1

1 - 2

1 - 0

1 - 1

1 - 2

1 - 4

1 - 3

1 - 9

1 - 10

1 - 10

1 - 11

1 - 13

1 - 13

2 - 1

2 - 1

2 - 1

2 - 1

3 - 1

4 - 1

4 - 1

4 - 2

4 - 2

5 - 1

5 - 1

5 - 6

6 - 1

6 – 1

6 - 1

6 - 3

6 - 4

6 - 5

7 - 1

7 - 1

8 - 1

Page 3

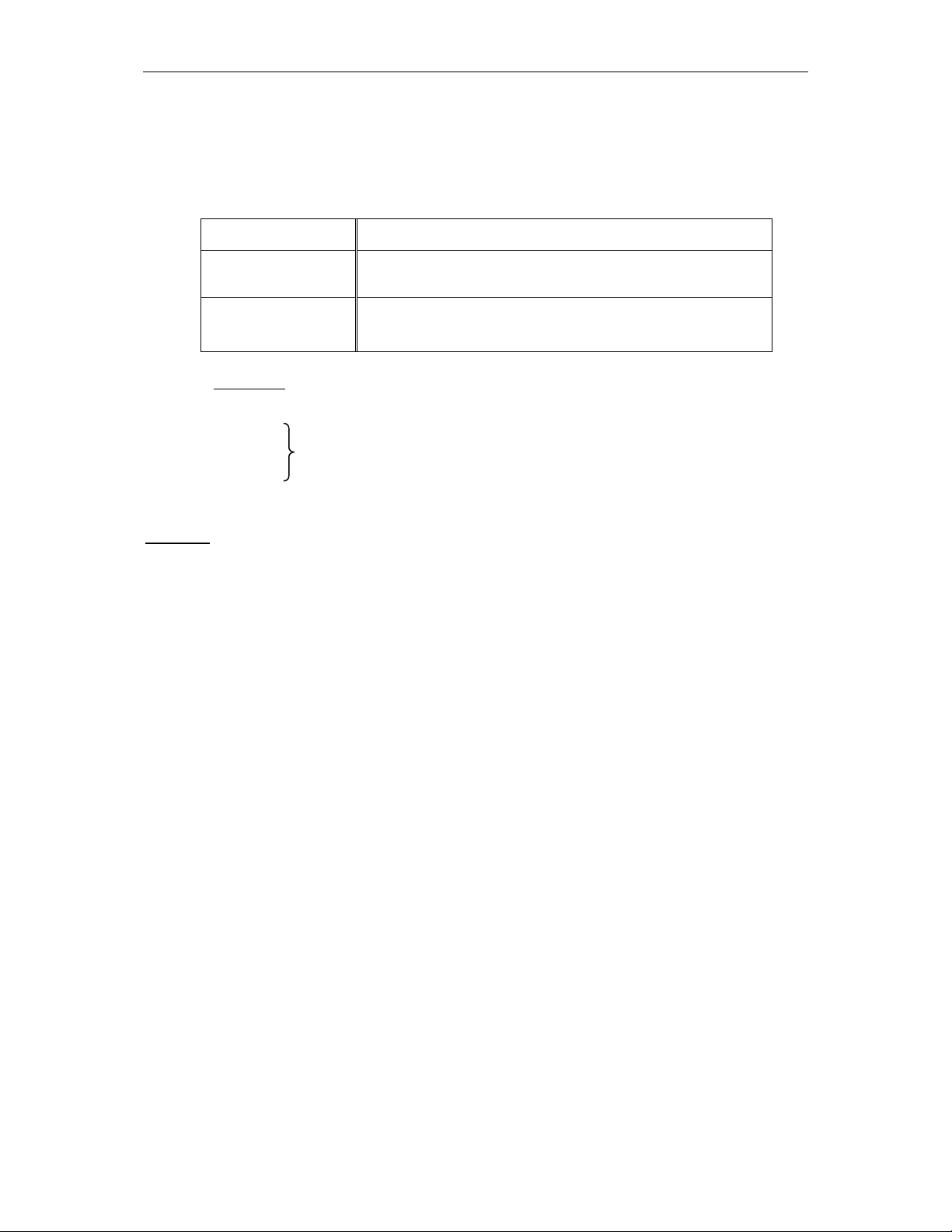

8.1 COORDINATE SYSTEM SETTING

8.2 COORDINATE SYSTEM SHIET

8.3 AUTOMATIC COORDINATE SYSTEM SETTING

8.4 WORK COORDINATE SYSTEM SHIFT

8.5 DIRECT MEASURED VALUE INPUT FOR WORK COORDINATE SYSTEM

SHIFT

………………………………………………………………………………………

9.COORDINATE VALUE AND DIMENSION

9.1 ABSOLUTE AND INCTEMENTAL PROGRAMMING

9.2 INCH/METRIC CONVERSION(G20,G21)

9.3 DECIMAL POINT PROGRAMMING/POCKET CALCULATOR TYPE DECIMAL

POINT PROGRAMMING

9.4 DIAMETER AND RADIUS PROGRAMMING

…………………………………………………………………

10. SPINDLE FUCTION(S FUCTION)

10.1 SPINDLE SPEED COMMAND

10.2 SIMULATING SPINDLE GEAR SHIFTING

10.3 CONSTANT SUREACE SPEED CONTROL(G96,G97)

10.4 CONTROLLING SPINDLE CHUCK

10.5 CONTROLLING TALSTOCK

10.6 SPINDLE ROTATION DWELL FUNCTION

11.TOOL FUNCTION (T FUNCTION)

11.1 TOOL-CHANGING PROCEDURE

11.2 FUNCTION FOR CHECKING INPUT SIGNAL OF TOOL CARRIER

11.3 SELECTING REAR TOOL CARRIER

11.4 PARAMETERS RELATIVE WITH TOOL CHANGING

12. MISCELLANEOUS FUNCTION

12.1 MISCELLANEOUS FUNCTION(M FUNCTION

12.2 USER INTERFACE GO TO FUNCTIONM CODE:M91/M92,M93/M94

12.3 SPECIAL M CODE:M21/M22,M23/M24

12.4 PARAMETERS OF MISCELLANE:M21/M22,M23/M24

13. PROGRAM CONFIGURATION

13.1 PROGRAMR

13.2 PROGRAM END

13.3 TABE END

……………………………………………………………………………

…………………………………………………………………………

………………………………………………………………………………

14. FUNCTIONS TO SIMPLIFY PROGRAMMING

14.1 CANNED CYCLE (G90,G92,G94.G93)

14.2 MULTIPLE REPETITIVE CYCLE(G70~G76)

14.3 CHAMFERING AND CORNER

15. COMPENSATION FUNCTION

……………………………………………………

………………………………………………………

……………………………………

………………………………………………

……………………………………………

…………………………………

……………………………………………

…………………………………………

……………………………………………………

………………………………………………………

…………………………………………

……………………………

……………………………………………………

…………………………………………………………

…………………………………………

……………………………………………………

……………………………………………………

…………………………………………………

………………………………

………………………………………………………

………………………………………

………………………………………………

……………………………

………………………………………………………

……………………………………

………………………………………………

…………………………………………

………………………………………………………

…………………………………………………………

……………

…………

8 - 1

8 - 1

8 - 2

8 - 3

8 - 4

9 - 1

9 - 1

9 - 3

9 - 3

9 - 5

10- 1

10- 1

10- 2

10- 4

10- 8

10- 8

10- 9

11- 1

11- 1

11- 2

11- 3

11- 3

12- 1

12- 1

12- 3

12- 4

12- 4

13- 1

13- 1

13- 7

13- 8

14- 1

14- 1

14-09

14-21

15- 1

Page 4

15.1 TOOLOFFSET

15.2 TOOL NOSE RADIUS COMPENSATION(G40 TO G42)

15.3 CHANGING OF TOOL OFFSET AMOUNT(PROGRAMMABLE DATE

INPUT)(G10)

……………………………………………………………………………………

…………………………………………………………………………

……………………………

16. MANUAL MEASURE INPUT OF TOOL COMPENSATION

16.1 OFFSET INPUT BY COUNTING

16.2 MEASURE INPUT

16.3 THE 2 WAYOF OFFSET INPUT

17. MEASURE FUNCTION

17.1 SKIP FUNCTION (G31)

17.2 ZUTOMATIC TOOL OFFSET(G36,G37)

………………………………………………………………………

…………………………………………………………………

…………………………………………………………………

18. WORKPIECE COORDINATE SYSTEM (G54~G59)

18.1 WORKPIECE COORDINATE SYSTEM

18.2 SHIFT OR CHANGE WORKPIECE COORDINATE SYSTEM(G10)

18.3 AUTOMATIC COOTDINATE SYSTEM SETTING

19. CUSTOM MACRO COMMAND

19.1 CUSTOM MACRO COMMAND

19.2 CUSTOME MACRO BODY

13.3 APPLICATION OF CUSTOM MACTOM MACRO

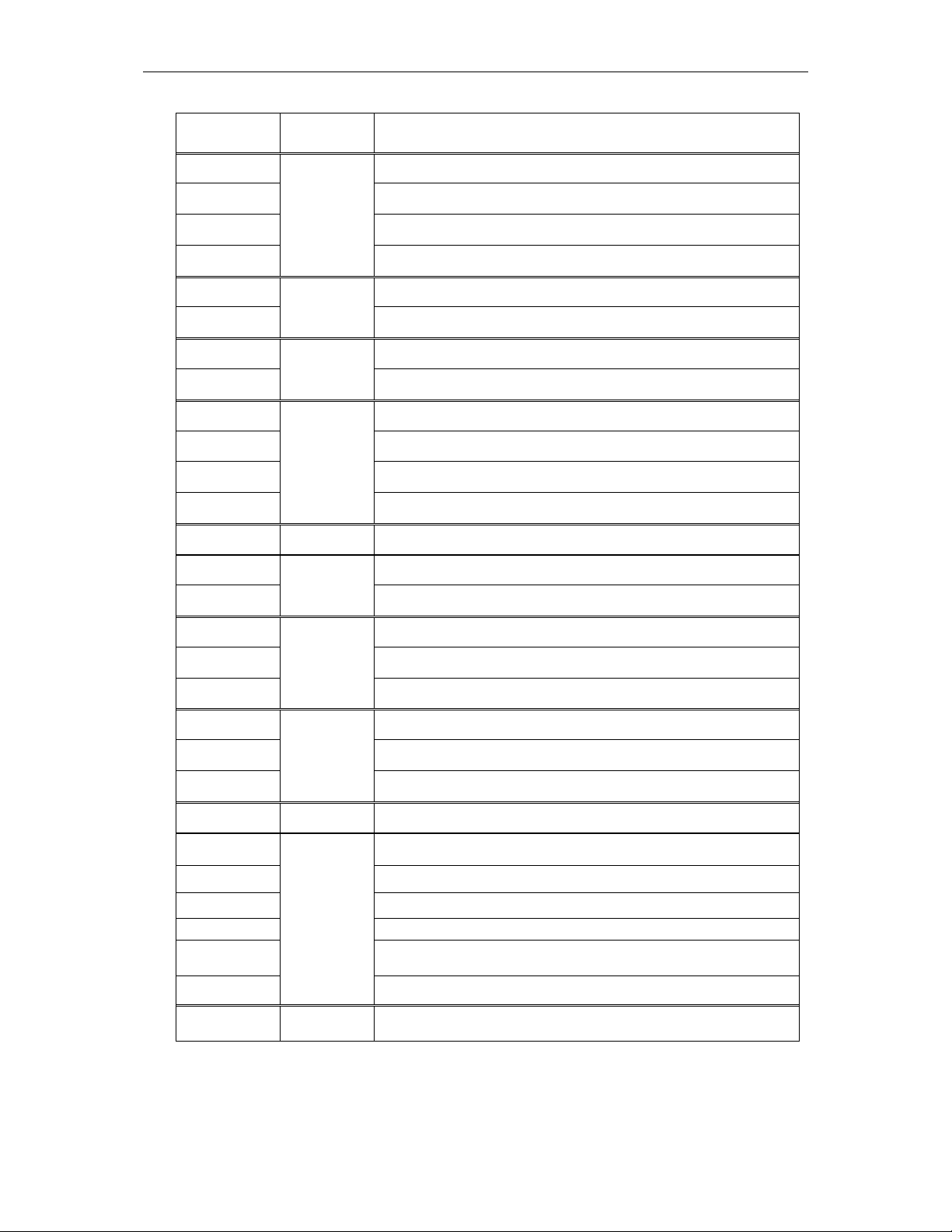

III OPERATION

1. GENERAL

1.1 MANUAL OPERATION

1.2 TOOL MOVEMENT BY PROGRAMING-AUTOMATIC OPERATION

1.3 AUTOMATIC OPERATION

1.4 TESTING A PROGRAM

1.5 EDITING A PART PROGRAM

1.6 DISPLAYING AND SETTING DATA

1.7 DISPLAY

1.8 DATA INPUT/OUTPUT

2. OPERATIONAL DEVICES

2.1 LCD/MDI PANEL

2.2 MACHINE TOOL OPERATIR’S PABEL

3. POWER ON / OFF

3.1 TUMING ON THE POWER

3.2 TURING OFF THE POWER

4. MANUAL OPERATION

4.1 MANUAL REFERENCE POSITION RETURN

4.2 JOG FEE

………………………………………………………………………………

………………………………………………………………………………………

…………………………………………………………………

………………………………………………………………

…………………………………………………………………

…………………………………………………………………………………

…………………………………………………………………

………………………………………………………………

………………………………………………………………………

……………………………………………………………………………

………………………………………………………………

……………………………………………………………………

…………………………………………………………………………………

………………………………………………………

……………………………………………………

……………………………………………

……………………………

………………………………………………

…………………………………

………………………………………………………

………………………………………………………

……………………………………………………………

……………………………………

…………………………………………………………

…………………………………………………

………………………………………………

……………………………………………………………

…………………………………………

……………………

……………

………………

15- 1

15- 4

15-40

16- 1

16- 1

16- 1

16- 2

17- 1

17- 1

17- 2

18- 1

18- 1

18- 2

18- 3

19- 1

19- 1

19- 1

19-10

1 - 0

1 - 1

1 - 1

1 - 2

1 - 3

1 - 4

1 - 7

1 - 8

1 -11

1 - 13

2 - 1

2 - 1

2 - 6

3 - 1

3 - 1

3 - 1

4 - 1

4 - 1

4 - 2

Page 5

4.3 STEP FEED

……………………………………

4.4 MANUAL HANDLE FEED (OPTIONAL FUNCTION)

4.5 MANUAL PROGRAM ZERO RETURN ZERO MODF

4.6 MANUAL ABSOLUTE ON/OFF

4.7 MANUAL AUXILIARY FUNCTION OPERATION

5. AUTOMATIC OPERATION

5.1 OPERATION MODE

5.2 AUTOMATIC OPERATION EXECUTION

5.3 AUTO OPERATION EXECUTION

5.4 STOPING AND TERMINATING AUROMATIC OPERATION

6. DRY RUN

6.1 ALL-AXIS MACHINE LOCK

6.2 AUXILIARY FUCTION LOCK

6.3 FEEDRATE OVERRIDE

6.4 RAPID TRAVERSE OVERRIDE

6.5 DRY RUN

6.6 SINGLE BLOCK

6.7 RESTART

6.8 OPTIONAL BLOCK SKIP

………………………………………………………………………………………

7. SAFTY OPERATION

7.1 EMERGENCY STOP

7.2 OVERTRAVEL

8. ALARM FUNCTION

9. PROGRAM STORAGE AND EDITING

9.1 PREPARATION

9.2 PROGRAM STORAGETO MEMORY

9.3 FILE INCLUDING MANY PROGRAMS STORED INTO MEMORY

9.4 PROGRAM SEARCH

9.5 DELETING PROGRAM

9.6 ALL PROGRAMS DELETING

9.7 PROGRAM OUTPUT

9.8 ALL PROGRAMS OUTPUT

9.9 SEQUENCE NUMBER SEARCH

9.10 PROGRAM COMPARATION BETWEEN IN MEMORY AND IN

PROGRAMMER

9.11 INSERTING, ALTERING AND DELETING A WORD

9.12 SEQUENCE NUMBER TO BE INSERTED AUTOMATICALLY

9.13 NUMBER OF REGISTERED PROGRAMS

………………………………………………………………………………

…………………………………

………………………………

…………………………………………………………

……………………………………

………………………………………………………………

………………………………………………………………………

………………………………………………

………………………………………………………

……………………………………………………………

……………………………………………………………

…………………………………………………………………

………………………………………………………

…………………………………………………………………………………

…………………………………………………………………………

……………………………………………

………………………………………………………………

………………………………………………………………………

……………………………………………………………………

……………………………………………………………………………

………………………………………………………………………

………………………………………………

……………………………………………………………………………

…………………………………………………

……………………………………………………………………

…………………………………………………………………

……………………………………………………………

……………………………………………………………………

……………………………………………………………

………………………………………………………

…………………………………………………………………………

………………………………

…………………………………………

………………………

………………

……………………

4 - 4

4 - 5

4 - 6

4 - 6

4 - 10

5 - 1

5 - 1

5 - 3

5 - 3

5 - 3

6 - 1

6 - 1

6 - 1

6 - 1

6 - 2

6 - 3

6 - 3

6 - 5

6 - 5

7 - 1

7 - 1

7 - 1

8 - 1

9 - 1

9 - 1

9 - 1

9 - 2

9 - 2

9 - 3

9 - 3

9 - 3

9 - 4

9 - 4

9 - 5

9 - 5

9 - 10

9 - 11

Page 6

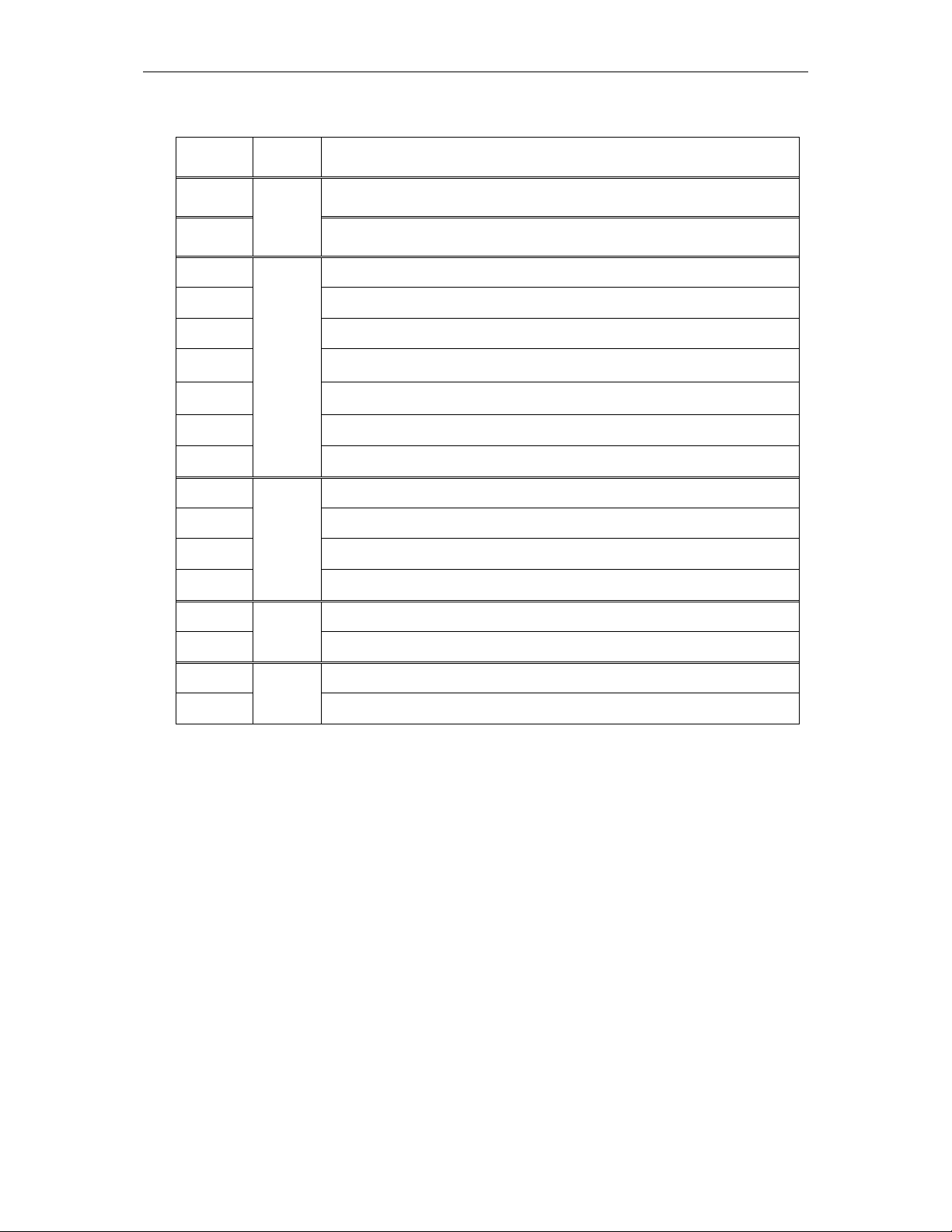

9.14 STORAGE CAPACITY

10. DATA DISPLAY AND SET

10.1 OFFSET

10.2 SETTING THE SET PARAMETER

10.3 CUSTOM MACRO VARIABLES DISPLAY AND SETTING

10.4 PARAMETER

10.5 PITCH ERROR COMPENSATION DATA

10.6 DIAGNOSE AND PLC PARAMET

10.7 DISPLAY AND SET MACHINE SOFTWARE OPERATOR’S PANEL

11. DISPLAY

11.1 STATUS INDICATION

11.2 DATA KEYED IN DISPLAYING

11.3 SEQUENCE NUMBER AND PROGRAM NUMBER DISPLAY

11.4 PROGRAM MEMORY USAGE DISPLAY

11.5 COMMAND VALUE DISPLAY

11.6 CURRENT POSITION DISPLAY

11.7 RUNTIME AND PARTS COUNT DISPLAY

11.8 ALARM DISPLAY

11.9 INDEX DISPLAY

…………………………………………………………………………………

……………………………………………………………………………

……………………………………………………………………………………

12. DATA OUTPUT AND FLASH MEMORY

12.1 TOOL COMPENSATION

12.2 PARAMETER

12.3 FLASH MEMORY

……………………………………………………………………………

13. GRAPH FUNCTION

13.1 SET GRAPH PARAMETER

13.2 DESCRIPTIONPARAMETER

13.3 DESCRIPTION OF TOOL PATH

13.4 EXAMPLE

………………………………………………………………………………

14. UPPER LIMIT FEED

14.1 UPPER LIMIT FEED

14.2 SETTING RAPID TRAVERSE

14.3 SETTING ELECTRIC GEAR RATE N

14.4 SETTING ACCELERATION/DECELERATION TIME CONCTANT

14.5 PARAMETER SETTING

14.6 DRIVER ALARM

15. DESCRIPTION

15.1 STANDARD PARAMETER SETTING AND MEMORY CLEARING

15.2 NOT CHECK SOFT OVER TRAVEL

…………………………………………………………………………

……………………………………………………………………………

…………………………………………………………………

……………………………………………………………

……………………………………………………

……………………………………………

……………………………………………………

…………………………………………………………………

………………………………………………………

……………………………………………

…………………………………………………………

………………………………………………………

…………………………………………

………………………………………………………………………

………………………………………………………………………

……………………………………………

………………………………………………………………

………………………………………………………………………

………………………………………………………………………

……………………………………………………………

…………………………………………………………

………………………………………………………

………………………………………………………………………

……………………………………………………………………

…………………………………………………………

………………………………………………

………………………………………………………………

…………………………………………………

………………………

……………

……………………

………………

………………

9 - 11

10- 1

10 - 1

10 - 3

10 - 5

10 - 6

10 - 9

10 - 9

10 -10

11- 1

11 - 1

11 - 1

11 - 1

11 - 2

11 - 2

11 - 4

11 - 6

11 - 7

11 - 7

12 - 1

12 - 1

12 - 1

12 - 1

13 - 1

13 - 2

13 - 3

13 - 4

13 - 5

14 - 1

14 - 1

14 - 1

14 - 1

14 - 2

14 - 2

14 - 5

15 - 1

15 - 1

15 - 1

Page 7

15.3 BACKLASH COMPENSATION DESTIPTION

15.4 KEYBOARD AND INPUT SIGNAL FILTER

15.5 TURN ON THE POWER NOT TO ENTER NORMAL SCREEN

15.6 ROM PARITY ALARM,CMOSDATA LOSE, RAM CHECK

16. ILLUSTRATION OF USING U DISK (ⅡTYEP SYSTEM)

16.1 U DISK AND FILE SYSTEM

16.2 SYSTEMFUNCTION

IV CONNECTION

1. SYSTEM STRUCTURE

1.1 SYSTEM CONFIGURATION

1.2 INSTALLATION DIMENSION OF CNC CONTROL UNIT

1.3 ADDITIONAL OPERATOR’S PANEL DIMENSION

…………………………………………………………………………

……………………………………………………………………

2. INTERNAL CONNECTION

2.1 SYSTEM INTERNALCONNECTION DIAGRAM

2.2 POWER SOCKET SIGNAL ARRANGEMENT

2.3 CNC MAINBOARD SWITCH DESCRIPTION

3. EXTERNAL CONNECTION

3.1 SYSTEM EXTERNAL CONNECTION DIAGRAM

3.2 INTERFACE SIGNAL FROM CNC TO DRIVER

3.3 RS232-C STANDARD SERIES PORT

3.4 ANALOGUE SPINDLE INTERFACE CONNECTION

3.5 CONNECTION OF ADDITIONAL OPERATOR’S PANEL

3.6 OPTIONAL OPERATOR’S PANEL

3.7 Spindle coder CONNECTION …………………………………………………………

3.8 Connection of the Can bus interface …………………………………………………

…………………………………………………………

………………………………………………………………

……………………………………………………………

………………………………………………………………

……………………………………………………………

…………………………………………………

……………………………………………………

………………………………………

…………………………………………

…………………

…………………………

……………………

……………………………

…………………………………

………………………………………

…………………………………………

…………………………………………

……………………………………

………………………………………

…………………………………

…………………………

15 - 1

15 - 1

15 - 2

15 - 2

16 - 1

16-1

16-1

1 - 0

1 - 1

1 - 1

1 - 3

1 - 4

2 - 1

2 - 1

2 - 3

2 - 3

3 - 1

3 - 1

3 - 3

3 - 10

3 - 10

3 - 11

3 - 13

3 - 13

3 - 15

4. MACHINE TOOL INTERFACE

4.1 DESCRIPTION OF INPUT SIGNAL INTERFACE

4.2 DESCRIPTION OF OUTPUT SIGNAL INTERFACE

4.3 THE TABLE OF INPUT AND OUTPUT SIGNAL

4.4 DESCRIPTION OF INPUT AND OUTPUT SIGNAL

V APPENDIXES

APPENDIX 1 STORED PITCH ERROR COMPENSATON FUNCTION

APPENDIX2 G FUNCTION TABLE

APPENDIX3 TABLE OF RANGE OF COMMAND VALUE

APPENDIX4 BINARY AND DECIMAL CONVERSION

APPENDIX5 ALARM LIST

APPENDIX6 STATUS OF POWER ON, AT RESET

APPENDIX7 SPECIFION TABLE

……………………………………………………………………………

………………………………………………………………………

………………………………………………………

……………………………………

…………………………………

……………………………………

…………………………………

……………………………………………………………

…………………………………

………………………………………

…………………………………………

………………………………………………………………

……………………

4 - 1

4 - 1

4 - 3

4 - 5

4 -10

1 – 0

1 - 1

2 - 1

3 - 1

4 - 1

5 - 1

6 - 1

7 - 1

Page 8

APPENDIX8 PLC PARAMETER AND DIAGNOSE MESSAGE

1. DIAGNOSE DATA

2. PLC PARAMETER

APPENDIX9 PARAMETERS

APPENDIX10 OPERATION LIST

APPENDIX11 CNC STATUS DIAGNOSE MESSAGE

APPENDIX12 MACHINE DEBUG

12.1 TOOL SETTING

12.2 FUNCTION FOR STARTING AT ANY POINT

12.3 AKKITIONAL OPERATOT PANEL FOR MACHINE

12.4 FUNCTION OF SPINDLE PAUSE

12.5 FUNCTION FOR CHECKING INPUT SIGNAL OF TOOL HOLDER

APPENDIX13 INSTRUCTIONS OM KND COMMUNICATION SOFTWARE

………………………………………………………………………

…………………………………………………………………………

……………………………………………………………………

………………………………………………………………

…………………………………………

………………………………………………………………

…………………………………………………………………………

………………………………………

……………………………………………………

……………………………

…………………………………

………………

………………

8 - 1

8 - 5

8 - 5

9 - 1

10- 1

11- 1

12- 1

12- 1

12- 7

12-11

12-11

12-11

13- 1

Page 9

Overview Ⅰ -1(General) 1 - 0

I. OVERVIEW

Page 10

Overview Ⅰ -1(General) 1 - 1

SECTION I.OVERVIWE

1. GENERAL

K1000T achieves hi-speed and hi-accuracy control by using a 32-bit processor.

The screen is a monochrome 7.5″ LCD with resolution 640×480.

The main board is a 6-layer circuit board, with surface-mounted elements, and

customized FPGA, so that it is highly integrated, the whole unit has a reasonable

process structure, high interference immunity and reliability.

Full-Chinese operation interface, complete Help info, easy to operate.

Using G commands from international standard, compatible with FANUC system.

Completely new molded panel in internationally popular color, with elegant

appearance.

Super-strong program command processing capability, up to 10000 pieces/18sec,

can achieve hi-speed mini-line cutting.

With function for lead screw error compensation.

Hi-speed thread machining, rapid retreat.

Employing electronic disk, data will be saved in several positions, can restore

rapidly at an error.

Program memory with high capacity (640k byte).

DI/DO can be expanded freely by CAN bus. (Under development)

Type Ⅱ system has a interface for disk U, through which realizes saving

procedures between system and U disk mutually.

Type Ⅱ system panel does not contain the keys of machine tool, the user can

assemble by oneself or match the standard machine tool operator's panel.

This manual introduces the programming, operation and connection of KND 1000T

CNC system for drilling, boring, milling machines and machining centers.

This manual describes all optional functions of KND 1000T, in “specification list”

under appendices it has also introduced varied functions of the CNC system. Look up

the options incorporated into your system in the manual written by the machine tool

builder. Also look up the manual written by the machine tool builder for the specification,

operation for the operator’s panel.

K1000T system has following variety:

●K1000TA

monochrome LCD.

●K1000TB

color LCD.

: typeⅠ structure , panel dimension:400×306 , Using 7.4″

Ⅰ

: typeⅠ structure , panel dimension:400×306 , Using 7.5″

Ⅰ

Page 11

Overview Ⅰ -1(General) 1 - 2

●K1000TA

: typeⅡ structure , panel dimension:400×200 ,Using 7.4″

Ⅱ

monochrome LCD.

●K1000TD

: type

Ⅱ

structure , panel dimension:400×200 ,Using 8.4″

Ⅱ

TFT color LCD.

May select and match Machine tool Operator’s panel regarding K1000T system,

this panel apart two parts. the left part install the manual handle, the range selector,

emergency stop switch, the three-position switch, the circulation starting switch, the

power switch and so on; the right part is the machine tool keys, including 50 keys and

50 indicating lamps, when under the open style PLC system software, the key and the

lamp function may from the definition.

The difference between type

1. Panel dimension is different. type

2. type

without machine tool keys, may match independence machine tool

Ⅱ

and type Ⅱ structure is as follow :

Ⅰ

400×306

:

Ⅰ

type Ⅱ:400×200

,

operator’s panel .

3. type

system panel has USB and RS232

Ⅱ

interfaces.

The supplementary material of KND-1000T is as follows:

KND1000T USER’S MANUAL

Contain system programming, operation, connection and routine maintenance.

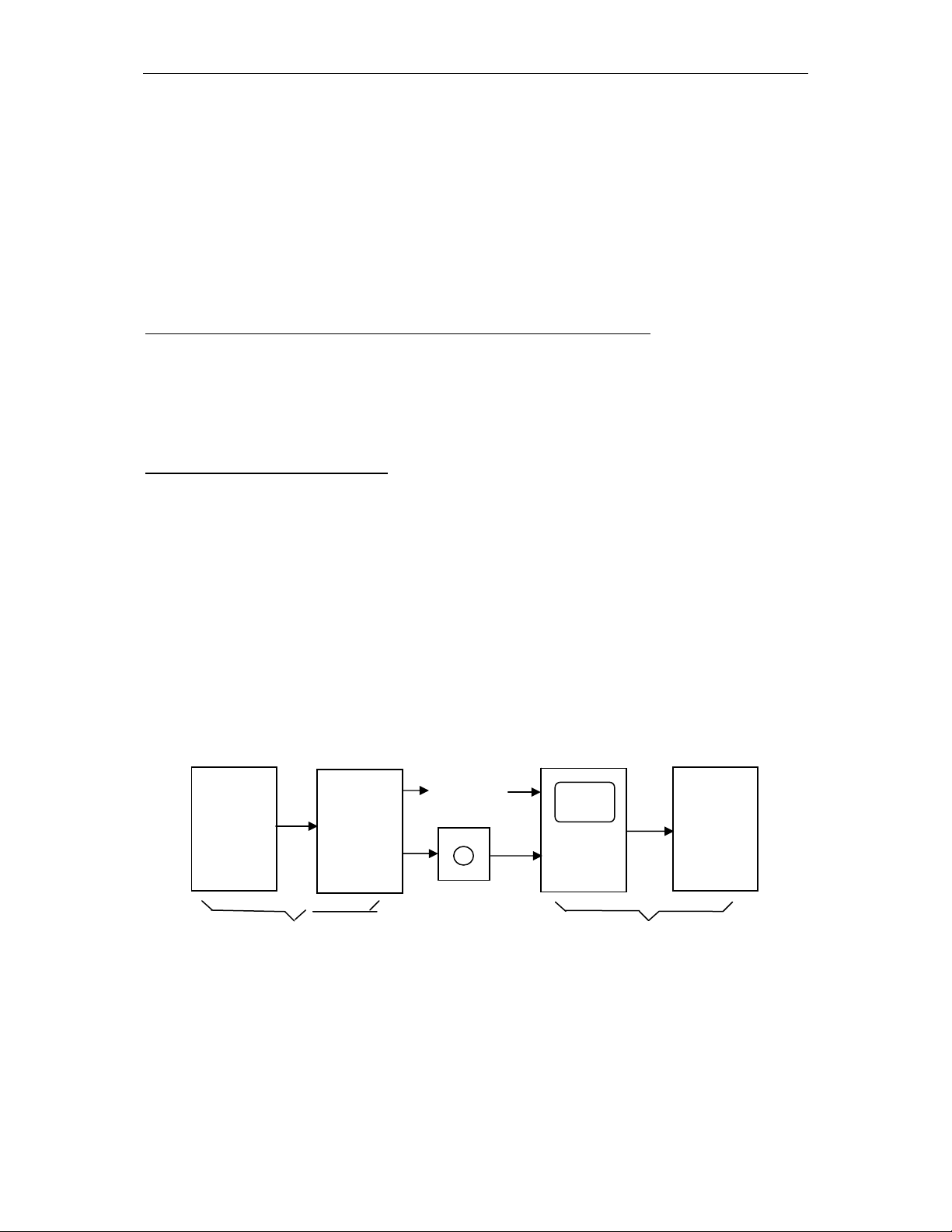

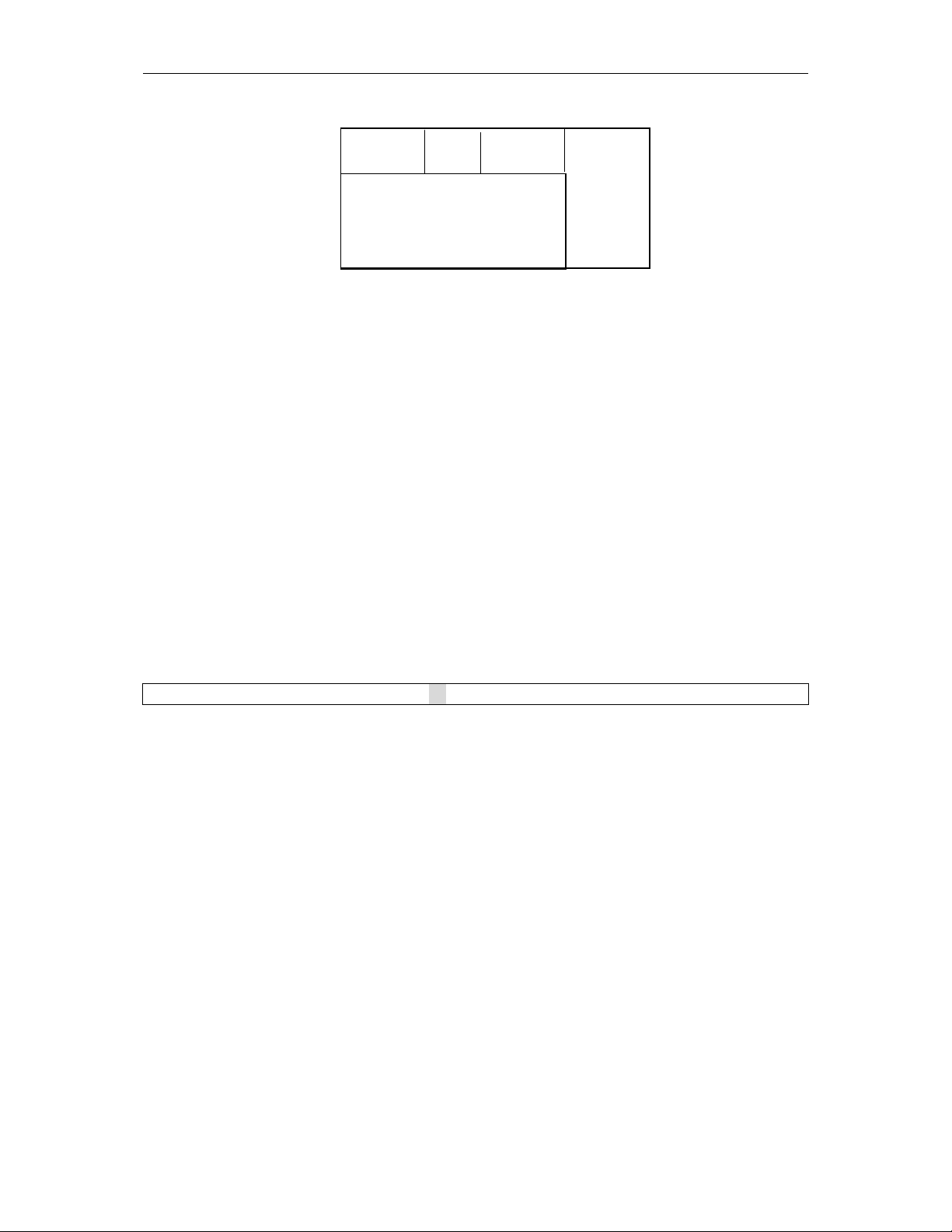

1.1 GENRAL FLOW OF OPERATION OF OPERATION OF CNC

MACHINE TOOL

When machining a part using the CNC machine tool, first prepares the program, and

then operates the CNC machine by using the program.

(1) First, prepare the program from a part drawing for cutting. How to prepare the

program is described in “II. PROGRAMMING”.

(2) The program is to be read into the CNC system. Then, mount the workpieces

and tools on the machine, and operate the tools according to the programming. Finally,

execute the machining actually.

How to operate the CNC system is described in “III. OPERATION”.

Part

drawing

Cutting

program

MDI/LCD

Machine

CNC

system

Disk

Refer to‘Programming’

Refer to‘Operation’

1.2 NOTES ON READING THIS MANUAL

The function of a CNC machine tool system depends not only on the CNC, but on

the combination of the machine tool, its magnetic cabinet, and driving system, etc. And

details about the function, programming, and operation relating to all combinations can

Page 12

Overview Ⅰ -1(General) 1 - 3

be determined only based on a concrete machine.

Option

function 1

. . .

Option

function N

CNC basic function

Interface

CNC system

From figure above one can see, a CNC system consists of basic function, optional

functions and interfaces, etc., different machines will have different optional functions

and interface designs. Please look up the manual from the machine builder.

(2) As mentioned above, KND 1000 CNC system is a universal system. This

manual provides a general description about various functions of the CNC system. For

a machine designer, in addition to read this manual, he shall also read the connection

manual, only in this way can he understand in an all-sided way the functions of the

system. And only based on above, can he give play to these functions optimally so that

the machine tool can reach its optimal performance. In addition, this manual is only a

description about functions, for a certain function, it is different on different machines,

and it’s impossible to present all examples for concrete use, so please do refer to the

manual from the machine builder.

(3) This manual is prepared based on system main board version 0012I-0000-

W01Z-0108, and system software version K1000TA

A01_060817.

Ⅰ

(4) As for the differences of systems with other software versions, please refer to

“Additional Description”.

(5)

If program the PLC procedure by yourself, please read 《PLC USERS

MANUAL》carefully.

★

Important:

K1000T system is of electronic disk function. After commissioning the machine,

please save current data of the system into the electronic disk. In this way, it is

possible to restore the system rapidly when current data of system is lost and becomes

disorder hence can’t work. As for the operating way please refer to “Operation 12-2”.

Page 13

Ⅱ PROGRAMMING -1(GENERAL) 1-0

Ⅱ PROGRAMMING

Page 14

Ⅱ PROGRAMMING -1(GENERAL) 1-1

1. GENERAL

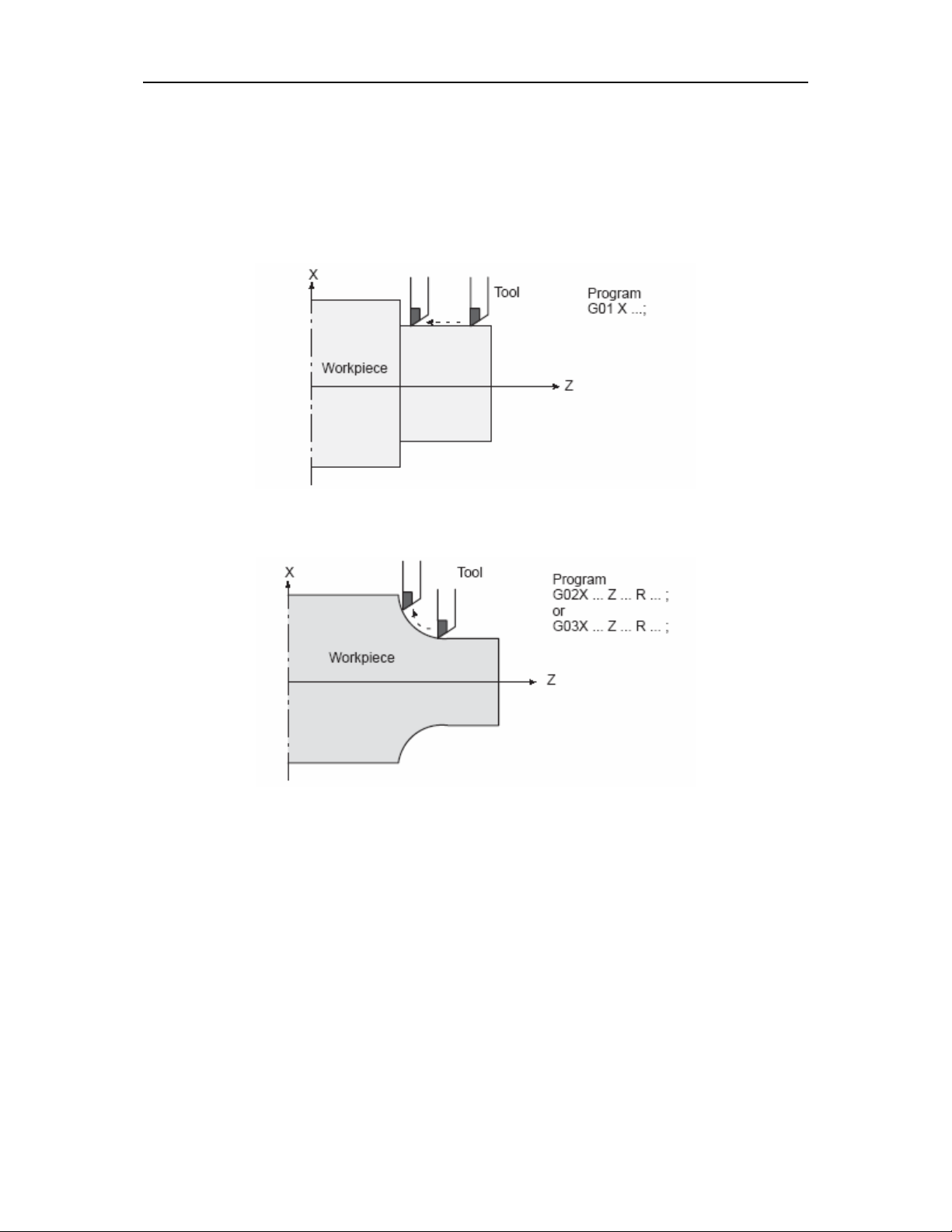

1.1 TOOLMOVEMENT ALONG WORKPIECE PARTS

FIGURE——INTERPOLATION

The tool moves along straight lines and arcs constituting the workpiece parts figure

(See II-4).

1.1.1 Tool movement along a straight line

Fig. 1.1.1 Tool movement along the straight line which is parallel to Z–axis

1.1.2 Tool movement along an arc

Fig. 1.1.2 Tool movement along an arc

1.1.3 Thread cutting

Threads can be cut by moving the tool in synchronization with spindle rotation.

(1) Straight thread cutting

Page 15

Ⅱ PROGRAMMING -1(GENERAL) 1-2

(2)Taper thread cutting

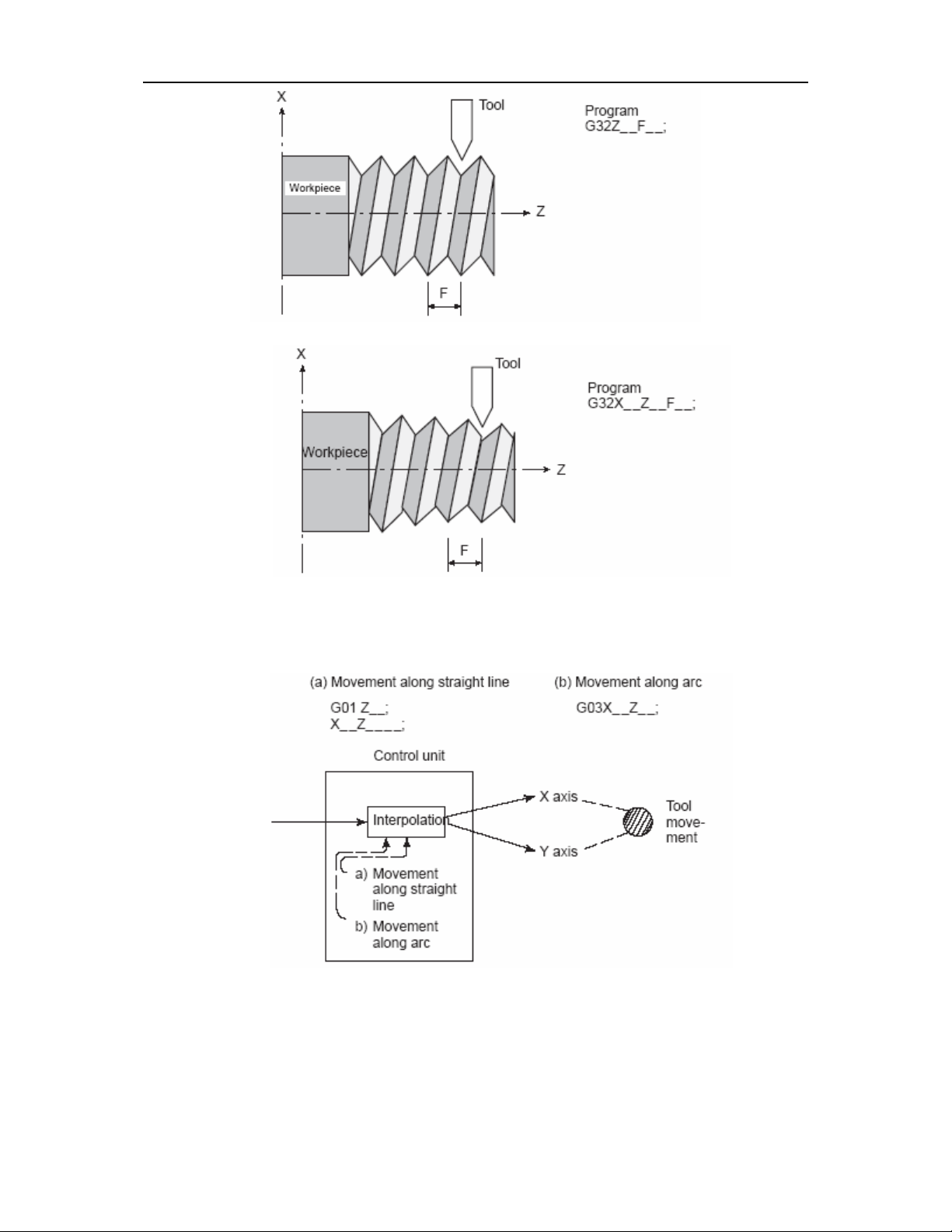

The term interpolation refers to an operation in which the tool moves along a

straight line or arc in the way described above.

Symbols of the programmed commands G01, G02, ... are called the preparatory

function and specify the type of interpolation conducted in the control unit.

Page 16

Ⅱ PROGRAMMING -1(GENERAL) 1-3

1.2 FEED–FEED FUNCTION

Movement of the tool at a specified speed for cutting a workpiece is called the

feed.

Feedrates can be specified by using actual numerics. For example, the following

command can be used to feed the tool 150 mm/s——F150.

The function of deciding the feed rate is called the feed function(SeeII–6).

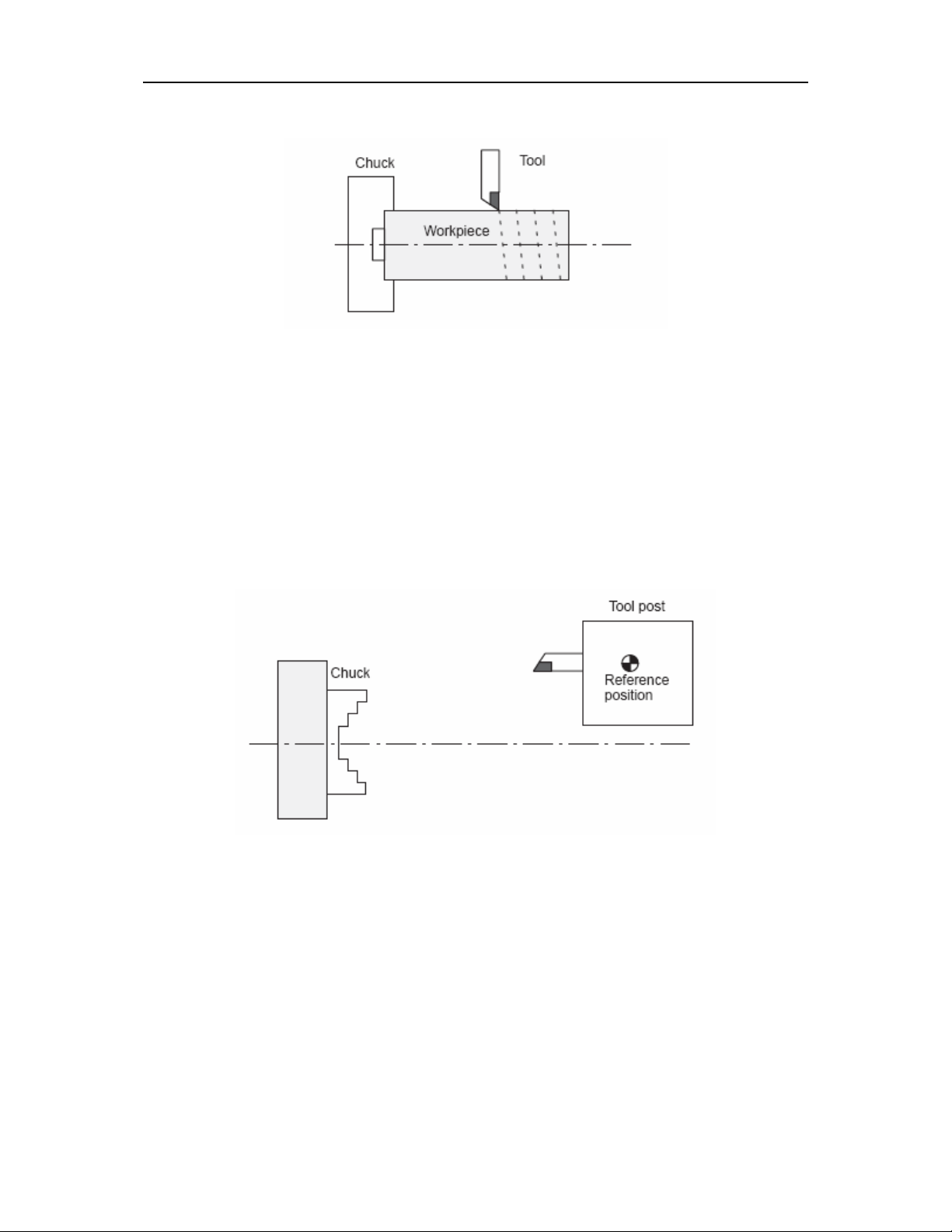

1.3 PART DRAWING AND TOOL MOVEMENT

1.3.1 Reference position (Machine–Specific Position)

A CNC machine tool is provided with a fixed position. Normally, tool change and

programming of absolute zero point as described later are performed at this position.

This position is called the reference position.

The tool can be moved to the reference position in two ways:

(Ⅰ)Manual reference position return

(Ⅱ)Automatic reference position return

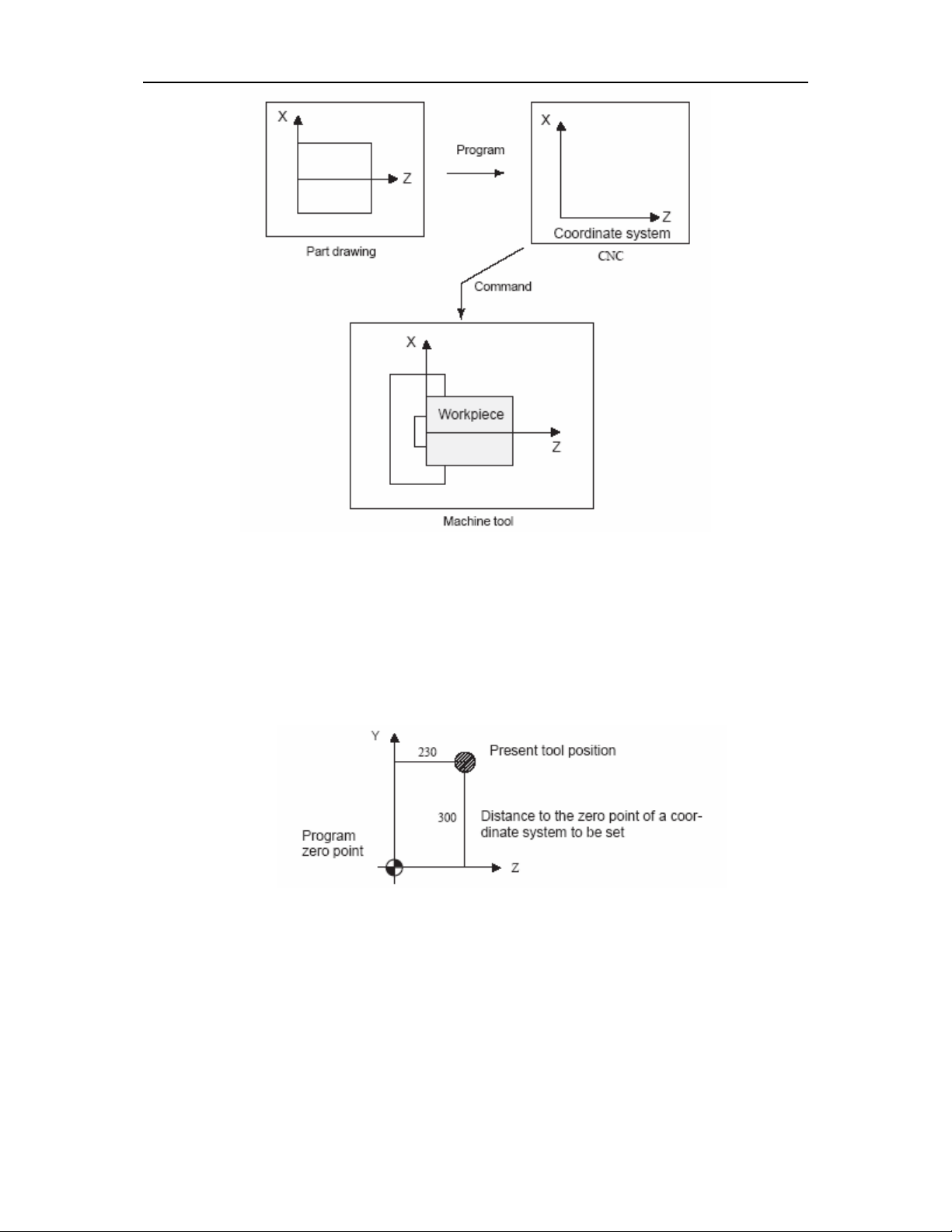

1.3.2 Coordinate system on part drawing and coordinate system

specified by CNC coordinate system

Page 17

Ⅱ PROGRAMMING -1(GENERAL) 1-4

The following two coordinate systems are specified at different locations:

ⅠCoordinate system on part drawing

The coordinate system is written on the part drawing. As the program data, the

coordinate values on this coordinate system are used.

Ⅱ Coordinate system specified by the CNC

The coordinate system is prepared on the actual machine tool. This can be

achieved by programming the distance from the current position of the tool to the zero

point of the coordinate system to be set.

The tool moves on the coordinate system specified by the CNC in accordance with

the command program generated with respect to the coordinate system on the part

drawing, and cuts a workpiece into a shape on the drawing.

Therefore, in order to correctly cut the workpiece as specified on the drawing, the

two coordinate systems must be set at the same position.

Page 18

Ⅱ PROGRAMMING -1(GENERAL) 1-5

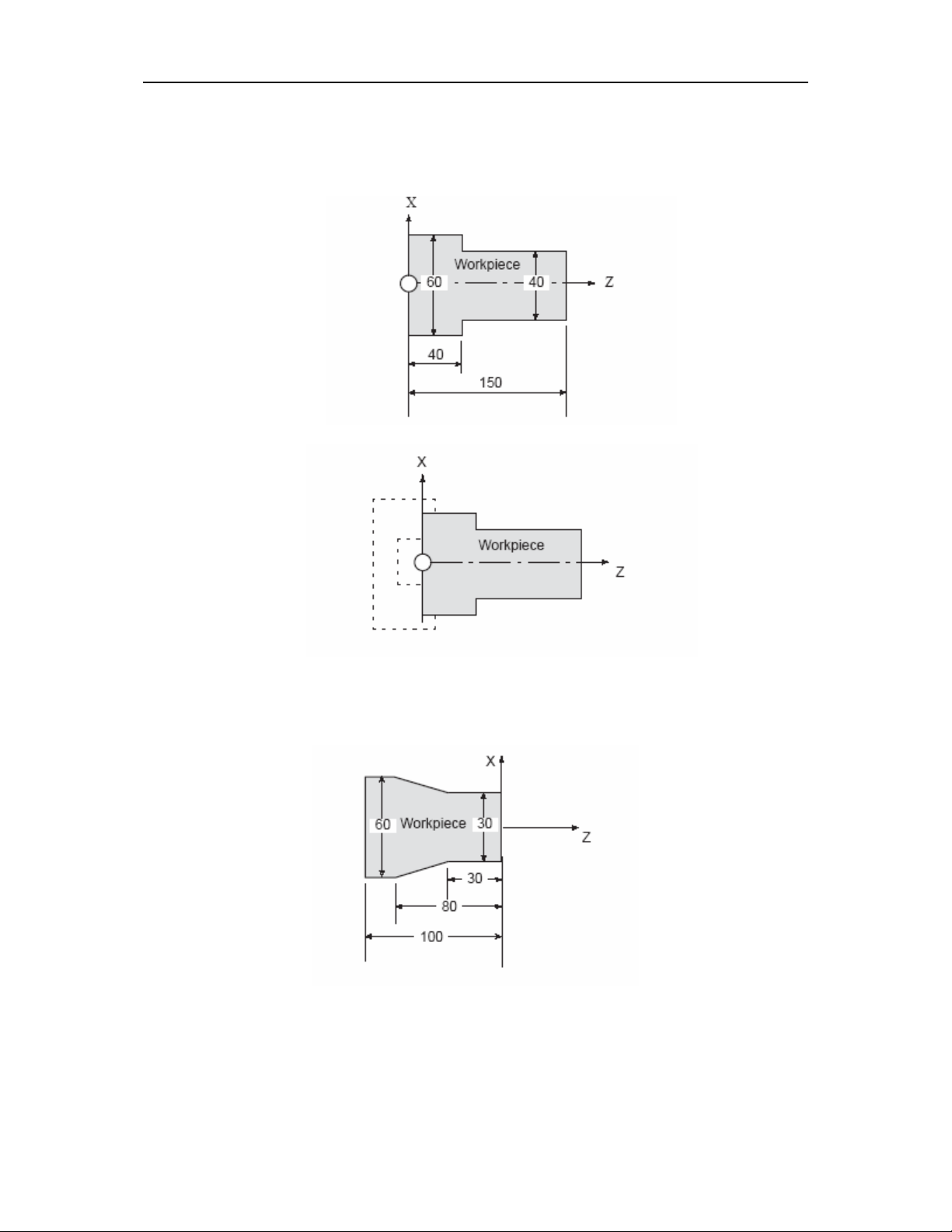

Methods of setting the two coordinate systems in the same position

The following method is usually used to define two coordinate systems at the same

location.

1. When coordinate zero point is set at chuck face

Fig. Coordinates and dimensions on part drawing

Fig. Coordinate system on lathe as specified by CNC

(made to coincide with the coordinate system on part drawing)

2. When coordinate zero point is set at work end face.

Fig. Coordinates and dimensions on part drawing

Page 19

Ⅱ PROGRAMMING -1(GENERAL) 1-6

Fig. Coordinate system on lathe as specified by CNC

(made to coincide with the coordinate system on part drawing)

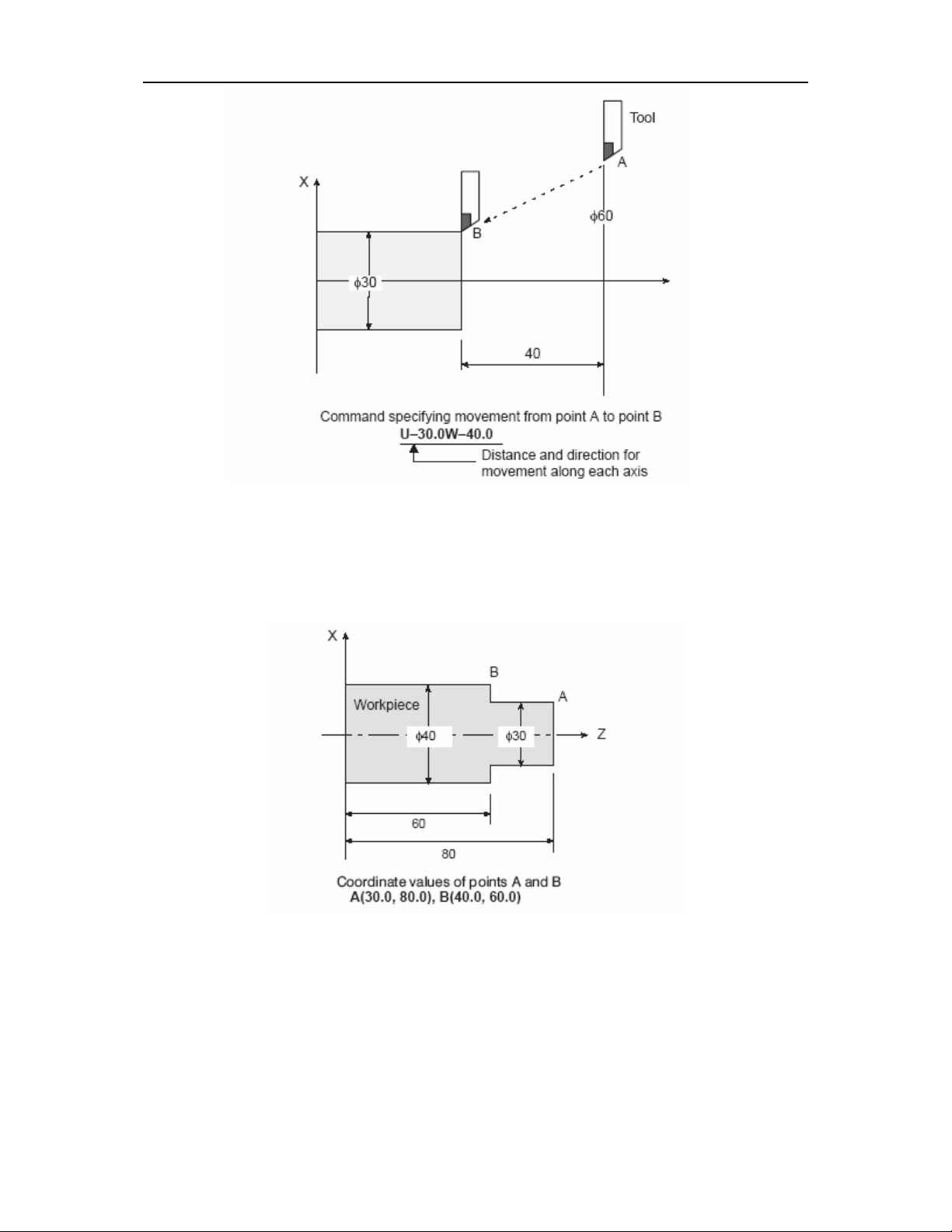

1.3.3 How to indicate command dimensions for moving the tool

absolute, incremental commands

Coordinate values of command for moving the tool can be indicated by absolute or

incremental designation (See II–9).

(Ⅰ)Absolute commands

The tool moves to a point at ”the distance from zero point of the coordinate

system” that is to the position of the coordinate values.

() Ⅱ Incremental comands

Specify the distance from the previous tool position to the next tool position.

Page 20

Ⅱ PROGRAMMING -1(GENERAL) 1-7

1.3.4 Diameter programming /radius programming

Dimensions of the X axis can be set in diameter or in radius. Diameter

programming or radius programming is employed independently in each machine.

1. Diameter programming

In diameter programming, specify the diameter value indicated on the drawing as

the value of the X axis.

2. Radius programming

In radius programming, specify the distance from the center of the workpiece, i.e.

the radius value as the value of the X axis.

Page 21

Ⅱ PROGRAMMING -1(GENERAL) 1-8

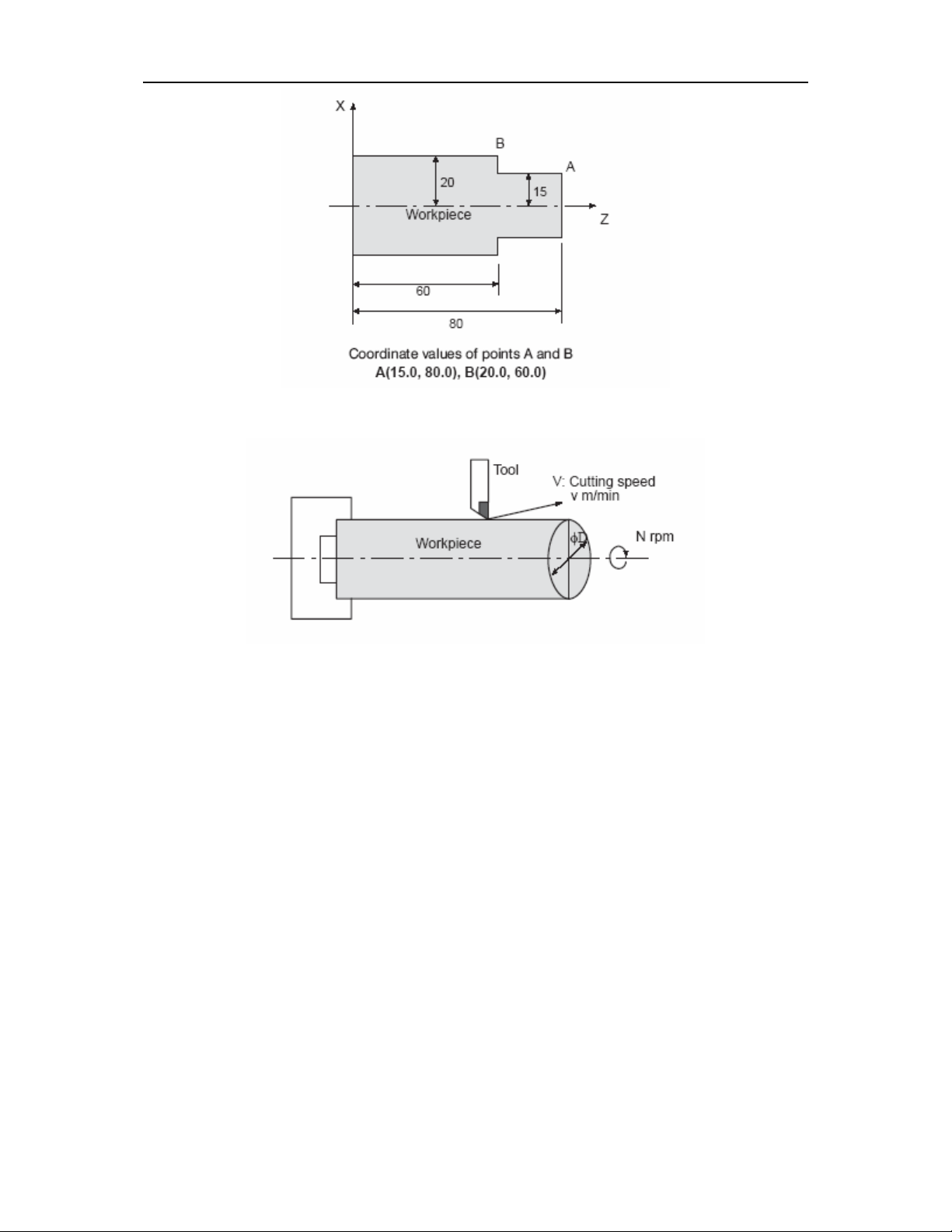

1.4 CUTTING SPEED –SPINDLE SPEED FUNCTION

The speed of the tool with respect to the workpiece when the workpiece is cut is

called the cutting speed. As for the CNC, the cutting speed can be specified by the

spindle speed in rpm unit.

EXAMPLE:

<When a workpiece 100 mm in diameter should be machined at a cutting speed of

80 mm/min. >

The spindle speed is approximately 250 rpm, which is obtained from N=1000v/_D.

Hence the following command is required:S250

Commands related to the spindle speed are called the spindle speed function (See

II–10)

The cutting speed v (m/min) can also be specified directly by the speed value.

Even when the workpiece diameter is changed, the CNC changes the spindle speed so

that the cutting speed remains constant.

This function is called the constant surface speed control function.

Page 22

Ⅱ PROGRAMMING -1(GENERAL) 1-9

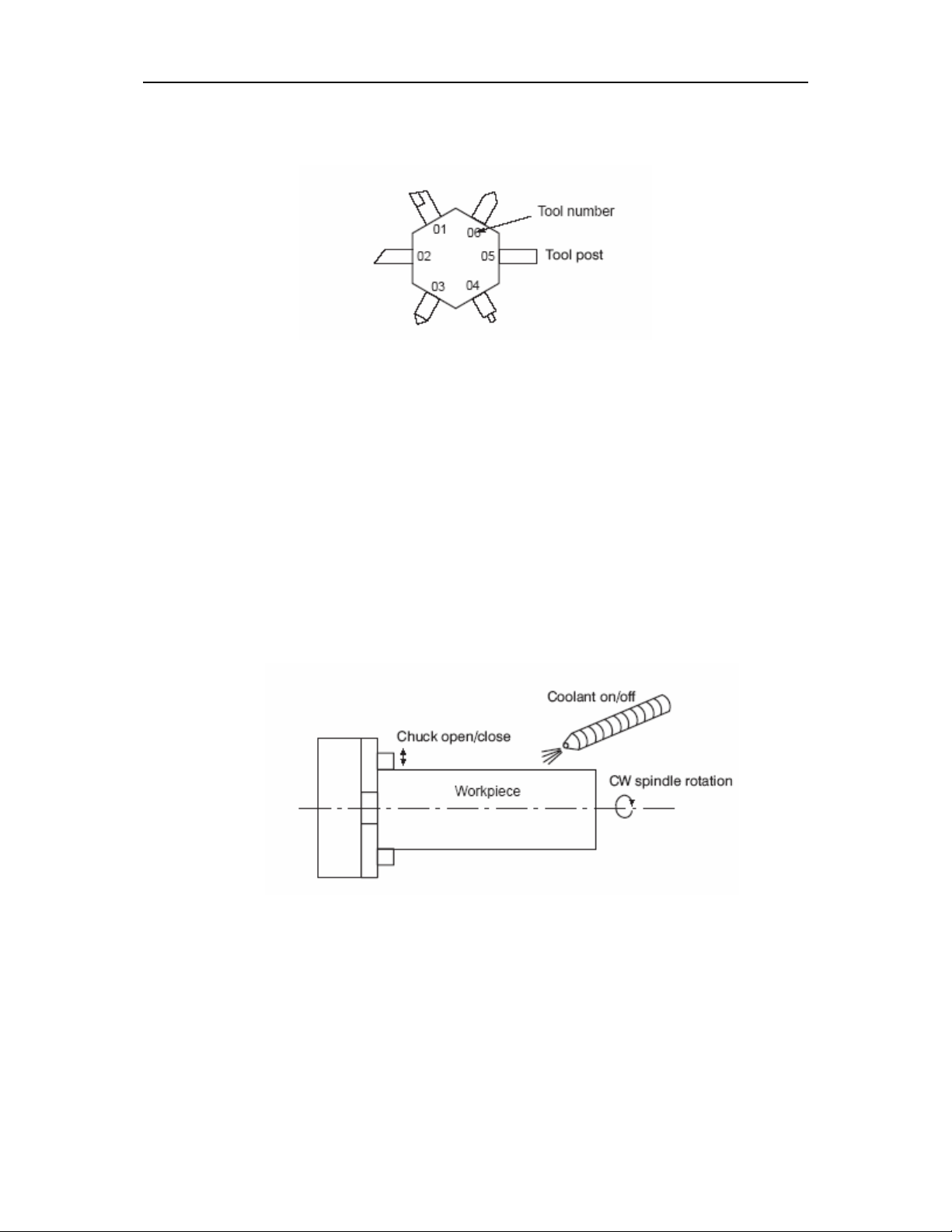

1.5 SELECTION OF TOOL USED FOR VARIOUS MACHINING –

TOOL

FUNCTION

When drilling, tapping, boring, milling or the like, is performed, it is necessary to

select a suitable tool. When a number is assigned to each tool and the number is

specified in the program, the corresponding tool is selected.

EXAMPLE:

<When No.01 is assigned to a roughing tool>

When the tool is stored at location 01 of the tool post, the tool can be selected by

specifying T0101.

This is called the tool function.

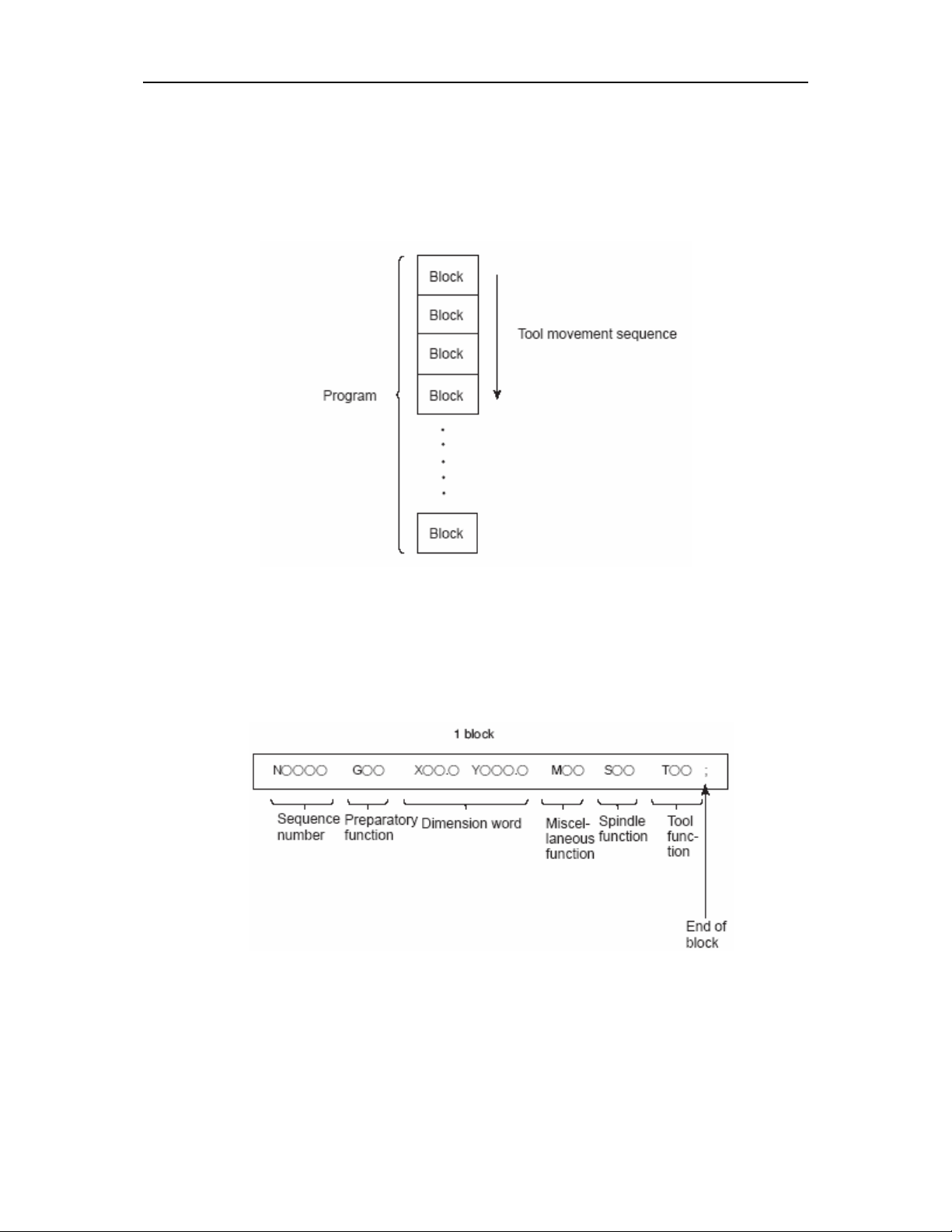

1.6 COMMAND FOR MACHINE OPERATIONS MISCELLANEOUS

FUNCTION

When machining is actually started, it is necessary to rotate the spindle, and feed

coolant. For this purpose, on–off operations of spindle motor and coolant valve should

be controlled.

The function of specifying the on–off operations of the components of the machine

is called the miscellaneous function. In general, the function is specified by an M code.

(See II–11)

For example, when M03 is specified, the spindle is rotated clockwise at the

specified spindle speed.

Page 23

Ⅱ PROGRAMMING -1(GENERAL) 1-10

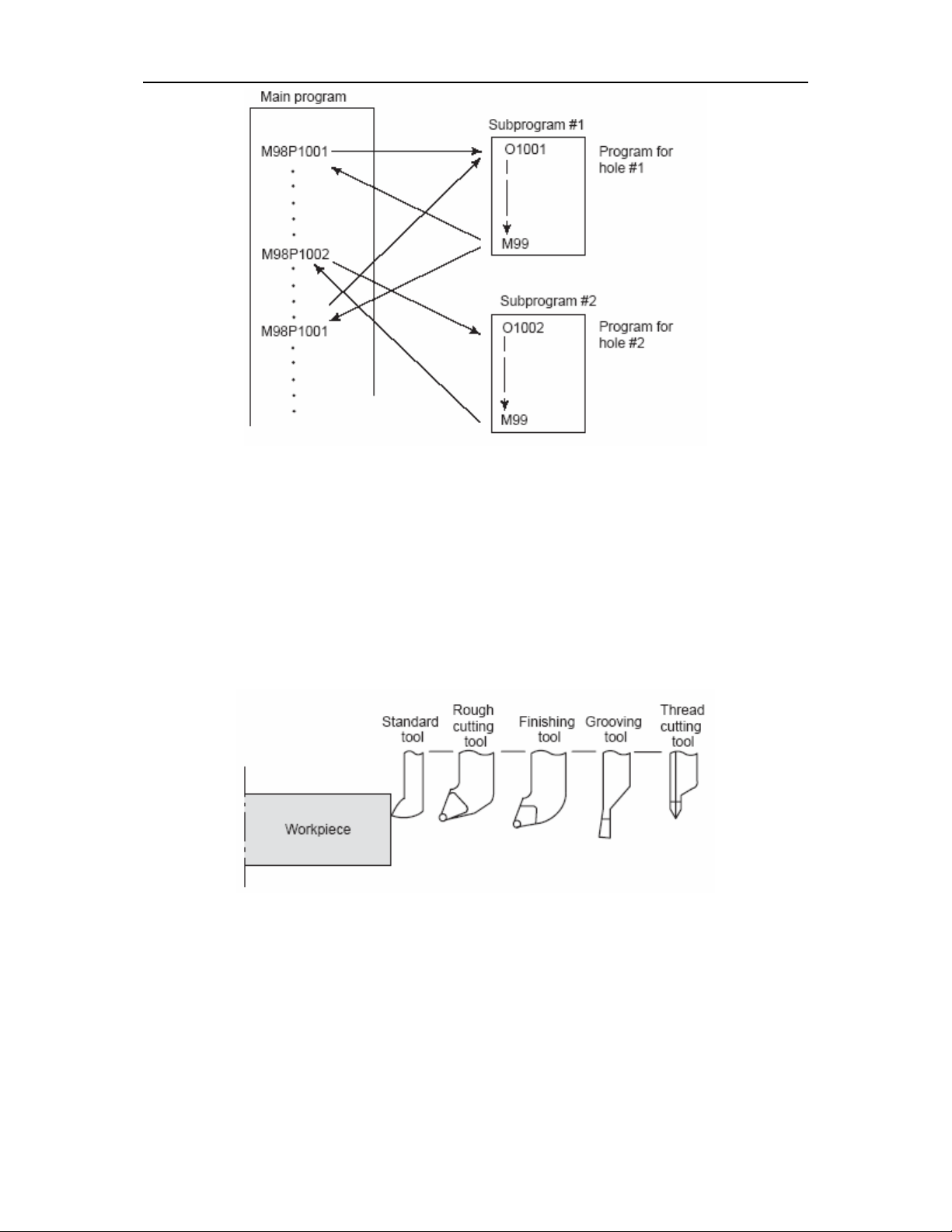

1.7 PROGRAM CONFIGURATION

A group of commands given to the CNC for operating the machine is called the

program. By specifying the commands, the tool is moved along a straight line or an arc,

or the spindle motor is turned on and off. In the program, specify the commands in the

sequence of actual tool movements.

A group of commands at each step of the sequence is called the block.

The program consists of a group of blocks for a series of machining. The number

for discriminating each block is called the sequence number, and the number for

discriminating each program is called the program

number (See II–13.)

1.7.1Block

The block and the program have the following configurations.

Each block starts with a sequence number which identifies the block, and ends

with an end–of–block code which indicates the end of the block.

This manual indicates the end–of–block code by ;

Page 24

Ⅱ PROGRAMMING -1(GENERAL) 1-11

1.7.2 Program

Normally, a program number is specified after the end–of–block (;) code at the

beginning of the program, and a program end code M30 is specified at the end of the

program.

1.7.3 Main program and subprogram

When machining of the same pattern appears at many portions of a program, a

program for the pattern is created. This is called the subprogram. On the other hand,

the original program is called the main program. When a subprogram execution

command appears during execution of the main program, commands of the

subprogram are executed. When execution of the subprogram is finished, the

sequence returns to the main program.

Page 25

Ⅱ PROGRAMMING -1(GENERAL) 1-12

1.8 TOOL COMPENSATION FUNCTION

1.8.1 Tool offset

Usually, several tools are used for machining one workpiece. The tools have

different tool length. It is very troublesome to change the program in accordance with

the tools.

Therefore, the length of each tool used should be measured in advance.

By setting the difference between the length of the standard tool and the length of

each tool in the CNC (data display and setting : see III–15), machining can be

performed without altering the program even when the tool is changed. This function is

called tool length compensation.

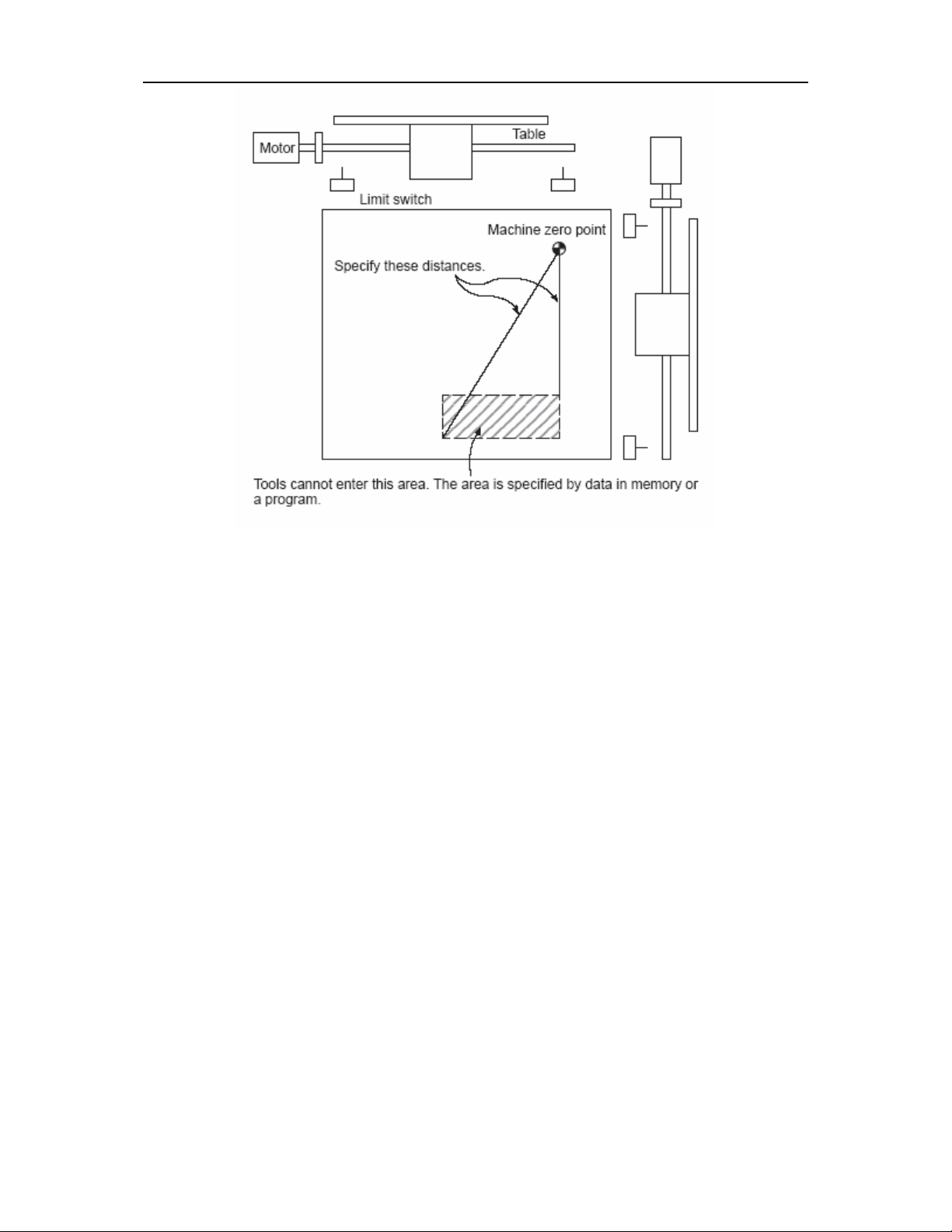

1.9 TOOL MOVEMENT RANGE—— STROKE

Limit switches are installed at the ends of each axis on the machine to prevent

tools from moving beyond the ends. The range in which tools can move is called the

stroke.

Page 26

Ⅱ PROGRAMMING -1(GENERAL) 1-13

Page 27

Ⅱ PROGRAMNING -2(CONTROLLED AXES) 2-1

2. CONTROLLED AXES

2.1 CONTROLLED AXES

Number of controlled basic axes

Number of simultaneously controlled basic axes

2.2 SETTING UNIT

INPUT/OUTPUT Least input increment Least command increment

X:0.001 mm (Diameter)

Z:0.001 mm

Mm output

Inch input

Mm output X:0.0001inch (Radius)

Mm input

inch output X:0.001 mm (Radius)

inch input

inch output X:0.0001inch (Radius)

NOTE:

X:0.001 mm (Radius)

Z:0.001 mm

X:0.0001inch (Diameter)

Z:0.0001inch

Z:0.0001inch

X:0.001 mm (Diameter)

Z:0.001 mm

Z:0.001 mm

X:0.0001inch (Diameter)

Z:0.0001inch

Z:0.0001inch

1、 The unit in the table is a diameter value with diameter programming and a

radius value in radius programming.

2、 Least command increment is consisting of metric and inch input, and it is

depending on the machine. The bit SCW of parameter №004 can select mm or

inch. Mm and inch can not occur in the same program.

3、 Setting unit refer to the machine tool’s description.

2.3 MAXIMUM STROKES

Maximum stroke=Least command increment×99999999

2(X,Z)

2(X,Z)

X:0.0005 mm

Z:0.001 mm Mm input

X:0.001 mm

Z:0.001 mm

X:0.0005 mm

Z:0.001 mm

X:0.001 mm

Z:0.001 mm

X:0.00005inch

Z:0.0001 inch

X:0.0001 inch

Z:0.0001 inch

X:0.00005inch

Z:0.0001 inch

X:0.0001 inch

Z:0.0001 inch

Page 28

Ⅱ PROGRAMMING-3 (PREPARATORY FUNCTION) 3-1

3. PREPARATORY FUNCTION(G FUNCTION)

A number following address G determines the meaning of the command for the

concerned block. G codes are divided into the following two types.

Type Meaning

One-shot G code

Modal G code

NOTE:

or the system is reset to the clear state.

whose options are not supported is specified, alarm No. 010 is displayed.

multiple G codes of one group are specified in a block, the G code specified last is

effective.

Example:

G01 and G00 are modal G codes in group 01.

G01X _;

Z _; G01 is effective in this range.

X _;

G00 Z_;

1. Modal G codes have the following initial conditions when the power is turned on

1) Those G codes marked* in Table 3 are specified automatically.

2) G20 and G21 retain their original conditions.

3) G00 or G01 is automatically selected according to parameter setting.

2. The G codes of group 00 are one-shot G codes.

3. If a G code that does not appear in the G code list is specified, or a G code

4. Multiple G codes of different groups can be specified in a single block. When

5. G code can set the max speed of spindle in constant surface speed control.

6. A G code is displayed from each group.

The G code is effective only in the block in which it

is specified.

The G code is effective until another G code of the

same group is specified.

Page 29

Ⅱ PROGRAMMING-3 (PREPARATORY FUNCTION) 3-2

Table 3 G code list (1/2)

G code

G00

*G01

Group Function

Positioning

Linear interpolation

01

G02

G03

Circular interpolation CW

Circular interpolation CCW

G04 Dwell, Exact stop

00

G10

Offset value setting

G20 Input in inch

04

G21

G27

Input in mm

Reference position return check

G28 Return to reference position

00

G29 Return from reference position

G31

G32 01

Skip function

Thread cutting

G36 Automatic tool compensation X

00

G37

Automatic tool compensation Z

*G40

G41 Tool nose radius compensation left

07

G42

G43

G44

08

*G49

G50 00

*G54

G55

G56

G57 Workpiece coordinate system 4 selection

03

G58

G59

Tool nose radius compensation cancel

Tool nose radius compensation right

Tool length compensation + direction

Tool length compensation - direction

Tool length compensation cancel

coordinate system setting

Workpiece coordinate system 1 selection

Workpiece coordinate system 2 selection

Workpiece coordinate system 3 selection

Workpiece coordinate system 5 selection

Workpiece coordinate system 6 selection

G65 00 Macro calling

Page 30

Ⅱ PROGRAMMING-3 (PREPARATORY FUNCTION) 3-3

Table 3 G code list(2/2)

G code

G68

Group Function

Mirror image for X-axes ON

06

*G69

G70

G71

Mirror image for X-axes OFF

Finishing cycle

Stock removal in turning

G72 Stock removal in facing

G73

00

G74

G75

G76

G90

G92

Pattern repeating

Peck drilling on Z axis

Grooving on X axis

Multiple threading cycle

Outer diameter/internal diameter cutting cycle

Thread cutting cycle

01

G93

G94

Tapping cycle

End face turning cycle

G96

Constant surface speed control ON

02

*G97

G98

Constant surface speed control OFF

Per minute feed

03

G99

Per revolution feed

Page 31

PROGRAMMINGⅡ -4 (INTERPOLATION FUNCYION) 4- 1

(

4. INTERPOLATION FUNCTIONS

4.1 POSITIONING(G00)

The G00 command moves a tool to the position in the workpiece system specified

with an absolute or an incremental command at a rapid traverse rate. In the absolute

command, coordinate value of the end point is programmed. In the incremental

command the distance the tool moves is programmed.

Format

G00 IP _;

IP _: For an absolute command, the coordinates of an end position, and for an

incremental command, the distance of the tool moves.

Tool path generally does not become a straight line.

EXAMPLE

NOTE:

The rapid traverse rate in the G00 command is set by the parameter No. 038 to

040 for each axis independently by the machine tool builder. The rapid traverse rate

cannot be specified in the address F. Feed rate specified by address F is valid.

X

Z

X

(diameter)

Z

Non liner positioning.

36.0

56.0

30.0

diameter)

G00 X40.0 Z56.0 ;or

40.0

Z

G00 U60.0 W-36.0 ;

Page 32

PROGRAMMINGⅡ -4 (INTERPOLATION FUNCYION) 4- 2

4.2 LINEAR INTERPOLATION (G01)

Format

G01 IP _F_;

IP _: For an absolute command, the coordinates of an end position, and for an

incremental command, the distance of the tool moves.

F_; Speed of tool feed (Feedrate)

A tools move along a line to the specified position at the feedrate specified in F.

The feedrate specified in F is effective until a new value is specified. It need not be

specified for each block. The command X and Z is absolute command and U and W is

incremental command.

G01 Xα Zβ F f

α

Feed rate of X-axis direction:

Feed rate of Z-axis direction: f

L =

22

βα

+

F

x

F ×=

z

f=×

L

β

L

4.3 CIRCULAR INTERPOLATION(G02, G03)

The command below will move a tool along a circular arc.

G02 R_

X_ Z_

G03 I_ K_

F_;

Page 33

PROGRAMMINGⅡ -4 (INTERPOLATION FUNCYION) 4- 3

Date to be given command meaning

1 Rotation direction

G02 Clockwise direction CW

G03 Counterclockwise direction CCW

X、Z

U、W

End point position in the work

coordinate system

Distance from start point to

2

absolute

End point

incremental

end point

Distance from start

3

point to center

Radius of arc R

I、K

Distance with direction from

start point to arc center.(radius

command)

4 feedrate F Federate along the arc

The clockwise or counterclockwise direction varies in right or left hand coordinate

systems.

X

Z

G03

G02

G02

G03

Z

Right hand

X

Left hand

The end point an arc is specified by address X, Z or U, W, and is expressed as an

absolute or incremental value. For the incremental value, the coordinate of the end

point which is views from the start point of the arc is specified. The arc center is

Page 34

PROGRAMMINGⅡ -4 (INTERPOLATION FUNCYION) 4- 4

specified by address I and K for the X and Z axis, respectively. The numerical value

following I, K, however, is a vector component in which the arc center is seen from the

start point, and is always specified as an incremental value as shown in the figure.

End point(Z,X)

center

K

Start point

I

I and K must be as signed according to the direction. The radius can be specified

with address R instead of specifying the center by I or K. the command format is as

follows:

G02

G03

In this case, two types of arcs (one arc is less than 180°; the other is more than

180°) are considered, as shown in the figure below.

X_ Z_ R_ F_ ;

Page 35

PROGRAMMINGⅡ -4 (INTERPOLATION FUNCYION) 4- 5

EXAMPLE

X

15.0

R25.0

Φ50.0

Φ30.0

Z

30.0

50.0

G02 X50.0 Z30.0 I35.0 F30; or

G02 U20.0 W-20.0 I35.0 F30; or

G02 X50.0 Z30.0 R25.0 F30; or

G02 U20.0 W-20.0 R25.0 F30;

The feed speed of the circular interpolation is specified by F, and it is the speed of tool

along circular tangent.

NOTE:

1、 I0 and K0 can be omitted.

2、 If X and Z are both omitted or if the end point is located at the same position

as the start point, and when the center is commanded by I and K, an arc of

360° (a complete circle) is assumed.

G02 I_ ; (a completer circle)

When R is used, an arc of 0° is programmed:

G02 R_ ; (the cutter does not move)

3、 The error between the specified federate and the actual tool federate is ±2%

or less. However , this federate is measured along the arc after the tool

mose R compensation is applied.

4、 If I ,K and R addressed are specified simultaneously, the arc specified by

address R takes precedence and the others are ignored.

5、 If I or K is used, the difference in the radius values at the start and end

points of an arc does not cause an alarm.

Page 36

Ⅱ PROGRAMMING -5(THREAD CUTTING) 5-1

5. THREAD CUTTING(G32,G34)

5.1 THREAD CUTTING (G32)

Tapered screws and scroll threads in addition to equal lead straight threads can

be cut by using a G32 command.

FORMAT

G32IP_F_;

IP_: End point

F_: Lead of the long axis (always radius programming)

EXAMPLE

G32 X__ Z__ F__ ;

L

L

In general, thread cutting is repeated along the same tool path from rough cutting

to finish cutting for a screw. Since thread cutting starts when the position coder

mounted on the spindle outputs a 1–turn signal, threading is started at a fixed point and

the tool path on the workpiece is unchanged for repeated thread cutting. Note that the

spindle speed must remain constant from rough cutting to finish cutting. If not, incorrect

thread lead will occur.

Page 37

Ⅱ PROGRAMMING -5(THREAD CUTTING) 5-2

X

The thread lead must be specified as a radius value.

In general, the lag of the servo system, etc. will produce somewhat incorrect leads

at the starting and ending points of a thread cut. To compensate for this, a threading

length somewhat longer than required should be specified.

Lead command range

Metric input

Inch input

0.0001~500.0000 MM

0.000001~50.000000 INCH

EXAMPLE

δ2

30mm

δ1

Z

70mm

The following values are used in programming :

Thread lead: 4mm

δ1=3mm

δ2=1.5mm

Depth of cut : 1mm (cut twice)

(Metric input, Diameter programming)

G00 U– 62.0;

G32 W–74.5 F 4.0;

G00 U 62.0;

W 74.5;

U–64.0;

(For the second cut, cut 1mm more)

Page 38

Ⅱ PROGRAMMING -5(THREAD CUTTING) 5-3

X

G32 W–74.5;

G00 U64.0;

W74.5;

Φ50.0

Φ43.0

δ2

30mm

40mm

The following values are used in programming:

Thread lead: 3.5mm in the direction of the Z axis

δ1=2mm

δ2=1mm

Cutting depth in the X axis direction is 1mm

(Cut twice)

(Metric input, Diameter programming)

G00 X12.0 Z72.0;

G32 X41.0 Z29.0 F3.5;

G00 X50.0 Z72.0;

X10.0; (For the second cut, cut 1mm more M)

G32 X39.0 Z29.0;

G00 X50.0 Z72.0;

NOTE:

1、 Feed rate override is effective (fixed at 100%) during thread cutting.

2、 It is very dangerous to stop feeding the thread cutter. This will suddenly

increase the cutting depth. Thus, the feed hold function is ineffective while

thread cutting. If the feed hold button is pressed during thread cutting, the

tool will stop after a block not specifying thread cutting is executed as if the

SINGLE BLOCK button were pushed. However, the feed hold lamp (SPL

lamp) lights when the FEED HOLD button on the machine control panel is

pushed. Then, when the tool stops, the lamp is turned off (Single Block stop

status).

δ1

Z

Φ14.0

Page 39

Ⅱ PROGRAMMING -5(THREAD CUTTING) 5-4

3、 When the FEED HOLD button is again pushed during the first block not

specifying thread cutting just after thread cutting block or when it has been

continuously pushed, the tool stops at the block not specifying thread cutting.

4 、When thread cutting is executed in the single block status, the tool stops after

execution of the first block not specifying thread cutting.

5、 When the mode was changed from automatic operation to manual operation

during thread cutting, the tool stops at the first block not specifying thread

cutting as when the feed hold button is pushed as mentioned in Note 3.

However, when the mode is changed from automatic mode to another, the tool

as a single block mode will stop after execution of the block not specifying

thread cutting like in Note 4.

6 、 When the previous block was a thread cutting block, cutting will start

immediately without waiting for detection of the 1–turn signal even if the

present block is a thread cutting block. However, the lead at the point where

the blocks join is incorrect. To obtain the correct lead, the continuous

threading option is required.

G32Z _ F_;

Z _; (A 1–turn signal is not detected before this block.)

G32; (Regarded as threading block.)

Z_ F_; (One turn signal is also not detected.)

7、 Because the constant surface speed control is effective during scroll thread or

tapered screw cutting and the spindle speed changes, the correct thread lead

may not be cut. Therefore, do not use the constant surface speed control

during thread cutting.

8 、 A movement block preceding the thread cutting block must not specify

chamfering or corner R.

9、 A thread cutting block must not specifying chamfering or corner R.

10、The spindle speed override is effective in thread cutting mode.

11、Spindle override is valid in thread cutting. If the override is changed, incorrect

thread will generate due to acc./dec. rate.

5.1.1 INCH THREAD CUTTING FUNCTION

Page 40

Ⅱ PROGRAMMING -5(THREAD CUTTING) 5-5

Thread lead is specified by F code in thread cutting G32 and G92. If address I is

specified instead of F, the unit of I is lead per inch.

Command range : 0.060~254000.000 lead/inch.

NOTE:

1、 If I and F are both specified at the same program, F is valid.

2、 Decimal point is allowed in program, the unit of address I is 0.001lead/inch,

eg. I16=0.016lead/inch

I16=16lead/inch

3、 F is calculated automatically when I is commanded

F = 25.4×1000/I (unit: 0.0001 mm/rev)

4 bits behind the decimal is valid.

eg. When F = 2.86764, F = 2.8676 is valid.

When F = 2.86765, F = 2.8677 is valid

1

(1) Cutting thread is

(2) Cutting thread

50

lead/inch, I2.125 (or I2125) is specified.

2

8

4

lead/inch, I50.8 (or I50800) is specified.

5

(3) Cutting thread 6 lead/inch, I = 6 (or I6000) is specified.

5.1.2 START ANGLE OFFSET IN THREAD CUTTING

FORMAT

G32 X_ Z_ F_ Q_;

Q: offset angle, 0~360

Multi-lead thread will be cut after the offset Q angle is specified in Multi-lead

thread cutting.

NOTE

:

1、Q is only valid in specified block.

2、It is invalid if it exceeds 360, zero will be set to Q.

3、Q is only valid in the first G32 block when many G32 commands are

specified.

5.2 unequal lead thread cutting—G34

The increase or the decrease can be set in every thread cutting, in this way

Page 41

Ⅱ PROGRAMMING -5(THREAD CUTTING) 5-6

unequal lead thread cutting is finished.

Format: G34 IP_ F_ K_;

IP_ : End point

F_ : Thread lead of long axis at jumping-off point

K _ : Increase or the decrease in every thread cutting of spindle

Explanation:

The addresses except K are the same as straight thread and tapered screws in G32.

The range of K:

metric input: ±0.0001~±500.0000mm/turn

Inch input : ±0.000001~±9.999999inch/turn

When K exceeds this range, and thread lead exceeds permission or thread lead

becomes minus due to the increase or decrease of K, P/S alarm No.1

4 will generate.

5.2.1 multi- pitch unequal lead thread cutting

The following command can machining multi-pitch unequal lead thread. Q is the

same with the one in G32.

Format: G34 IP_ F_ K_ Q_

Warning:

The escaping function of thread cutting is invalid in G34.

If thread lead is too much larger, the rotate speed should be set smaller. Or the

calculated feed speed may exceed the upper limit of the feed speed (parameter No.45);

here system will automatically move at the rate of the upper limit, which will result in

machining incorrect thread lead.

Example:

The thread lead at jumping-off point: 8.0mm

The increase of the thread lead: 0.5mm/ turn

G34 Z-36.0 F8.0 K0.5;

Page 42

Ⅱ PROGRAMMING-6 (FEED FUNCTION) 6 - 1

A

6. FEED FUNCTION

6.1 RAPID TRAVERSE

The positioning command (G00) positions the tool by rapid traverse. A rapid

traverse rate is set for each axis by parameter No. 038to 040, so no rapid traverse

feedrate need be programmed.

The following overrides can be applied to a rapid traverse rate with the switch on

the machine operator’s panel:

F0, 25, 50, 100%

F0: Allows a fixed feedrate to be set for each axis by parameter No. 051

For detailed information, refer to the appropriate manual of the machine tool

builder.

6.2 CUTTING FEEDRATE

Feedrate of linear interpolation (G01), circular interpolation (G02, G03), and etc. re

commanded with numbers after the F code.

The unit of F code is mm/min or inch/min.

6.2.1 Tangential speed constant control

Cutting feed is controlled so that the tangential feedrate is always set at a specified

feedrate.

Cutting feed usually controls the speed of tangential direction and makes it come

to the instruction speed.

X

F

F

Start poing

X

F

Z

F: tangential feedrate

FX: X-axis feedrate

FZ: Z-axis feedrate

6.2.2 Cutting feedrate clamp

End point

Z

2

X FFF +=

Z

2

X

Start poing

rc interpolation

F

Z

F

X

F

End point

Z

Page 43

Ⅱ PROGRAMMING-6 (FEED FUNCTION) 6 - 2

Cutting feedrate upper limit can be set as parameter №.045. if the actual cutting

feedrate (feed rate with override) is commanded exceeding the upper limit it is clamped

to a speed not exceeding the upper limit value.

The clamped values are set in mm/min or inch/min.

Except during acceleration or deceleration, the CNC arithmetic error for the

command value of the feed rate is within ±2%. This error is applied to the time

measured for the tool to move a distance of 500mm or more under stationary

conditions.

6.2.3 Feed rate override

Feedrate can be overridden by a switch located on operator’s panel, from 0 to

150% (step 10%).

6.2.4 Feed per minute(G98)

With the feed per minute mode G98, tool feed rate per minute is directly

commanded by numerical value after F code.

G98 is model. Once commanded, it is effective until G99(per revolution feed) is

commanded.

6.2.5 Feed per revolution(G99)

Specify feed per revolution mode by G99. following F, directly specify the feed of

tool per spindle revolution. It is necessary to mount a position coder on the spindle.

G99 is modal. After G99 is specified, it is effective until G98per minute feed) is

commanded.

Table 6.2.5 feed per minute and revolution

Feed per minute Feed per revolution

Designated address F F

Designated G code G98 G99

Range of

designation

Clamping value

Override

Mm input

Inch

input

1~15000mm/min

(F1~F15000)

0.01~600.00inch/min

(F1~F60000)

Clamping takes place at a certain specific speed for both

feed per minute and feed per revolution.

The clamping value is set by the machine tool builder.

(override is applied to implement clamping of speed.)

For both feed per minute and feed per revolution, 0 to

150% override can be applied (in increments of 10%)

0.0001~500.0000mm/rev

(F1~F5000000)

0.000001~50.000000inch/rev

(F1~F9999999)

Page 44

Ⅱ PROGRAMMING-6 (FEED FUNCTION) 6 - 3

NOTE:

1、 when the rotation speed of the position coder is 1 rpm or less, the feed rate

becomes no uniform. In cases where machining is not adversely affected by

feed rate no uniformity , the position coder can be used at 1 rpm or less.

Though the degree of no uniformity differs according to the case, the degree

becomes large as the rotation speed becomes low less than 1 rpm.

2、 G98 and G99 are modal; once they are commanded, they are effective until

another code appears.

3、 The error from the standpoint of the CNC operation with respect to the

command value of the federate is ±2%. After the feed rate has attained its

rated value, the time required to move over a distance exceeding 500mm is

measured and the error is calculated.

4、 Input of F code is possible up to a maximum of seven digits. However, even

when a value exceeding the clamping value of the feed rate is input, it is

clamped at that value while the movement is taking place.

5、 When using the feed per revolution mode, it is necessary to affix a position

coder to the spindle.

6.3 AUTUTOMATIC ACCELERATION/DECELERATION

Acceleration and deceleration is performed when starting and ending movement,

resulting in smooth start and stop. Automatic acceleration and deceleration is also

performed when feed rate changes, so changes in speed are also smoothly done.

It is not necessary to take acceleration and deceleration into consideration when

programming.

Rapid traverse: Linear acceleration/deceleration (constant acceleration) (№.041~

042)

Cutting feed: Exponential acceleration/deceleration (constant time constant)

(№.047)

Jogging feed :Exponential acceleration/deceleration (constant time constant )

(№.047)

Page 45

Ⅱ PROGRAMMING-6 (FEED FUNCTION) 6 - 4

CNC

command

feedrate after interpolation feedrate after acceleration/deceleration

Pulse distribution

(interpolation)

acceleration/

deceleration

acceleration/

deceleration

driver control

stepper motor

driver control

6.4 The speed control in program block corner

Automatic acceleration/deceleration for linear acceleration and deceleration after

interpolation, the acceleration or deceleration is applied in feed start and feed stop,

automatically with a time constant so that the machine tool system is not jarred.

Therefore, this need not be considered when programming. Because of automatic

Page 46

Ⅱ PROGRAMMING-6 (FEED FUNCTION) 6 - 5

acceleration and deceleration, corners are not cut sharply. In this case, deceleration

command(G04) must be commanded at the corner to cut sharp.

For example, if the tool moves along the X axis only in one block and along the Z axis

in the next block, the feed rate for the X axis decelerates while motion along the Z axis

accelerates and the actual tool path is as follows.

At the point, insert the dwell command

X

Programmed path

Too l pa th

Z

If the dwell command is inserted, the actual tool path matches the programmed

path. The faster the feed rate and the larger the acceleration/deceleration time

constant, the larger the error at the corner. In circular interpolation, the actual arc

radius is smaller than that of the programmed arc. This error can be minimized by

making the acceleration/deceleration time constant of feed rate small.

The following chart shows feed rate changes between blocks of information

specifying different types of movement

.

previous block

Next block

Positioning

Feed

Not moving

×: The next block is executed after commanded rate has decreased to zero.

○: The next block is executed sequentially so that the feedrate is not changed by

very much.

Positioning Feed Not moving

× × ×

× ○ ×

× × ×

6.5 DWELL(G04)

FORMAT

Dwell G04 X/U_ ; or G04 P_ ;

X/U_ : Specify a time (decimal point permitted)

P_ : Specify a time (decimal point not permitted)

EXPLANATIONS

By specifying a dwell, the execution of the next block is delayed by the specified

time. When neither P nor X is specified, exact stop is performed.

Page 47

PROGRAMMING-7(REFERANCE POSITION)

Ⅱ

7-1

7. Reference position

The reference position is a fixed position on a machine tool to which the tool can

easily be moved by the reference position return function.

7.1 AUTOMATIC REFERENCE POINT TETURN(G28)

G28 IP__ ;

This command specifies automatic return to the reference point for the specified

axes. IP_ ; is an intermediate coordinate and is commanded by absolute or

incremental value.

(1) The G28 block is used to position the tool at the intermediate point of all

specified axes at the rapid traverse speed (A→B)。

(2) Then move to the reference point at the rapid traverse rate. (B→R)。

(3) If the machine lock has not been set ,the Reference Return lamp goes on 。

7.1.1 return to the refernce point

Page 48

PROGRAMMING-7(REFERANCE POSITION)

Ⅱ

7-2

NOTE:

When the G28 command is specified when manual return to the reference point

has not been performed after the power has been turned on,the movement from the

intermediate point is the same as in manual return to the reference point .In this case,

the direction from the intermediate point is equal to that for reference point selected by

parameter(№.006 ZMX,ZMZ).

Page 49

Ⅱ PROGRAMNING -8COORDINATE SYSTEM SETTING 8-1

X

8. COORDINATE SYSTEM SETTING (G50)

8.1 COORDONATE SYSTEM SETTING

The next command can set the coordinate system:

G50 X(x) Z(z) ;

By means of this command, a certain point of the tool for example, a coordinate

system whereby the tip of the cutting edge becomes (x, z) of the coordinate system.

This coordinate system is referred to as the work coordinate system. Once a

coordinate system has been set, all subsequent absolute commands that are

commanded become at the position of this work coordinate system.

The value of x is the value of the diameter when diameter designation has been

effected and the value of the radius when radius designation has been effected.

(Example) Coordinate system setting with diameter designation.

G50 X1200.0 Z700.0 ;

As show in the illustration above, the reference point on the turret is aligned with

the start point, and the coordinate system is set at the head of the program by means

of G50.When an absolute command is carried out as is, the reference point will move

to the position commanded. In order to move the tip of the cutting edge to the position

commanded, the difference between the reference point and the tip of the cutting edge

is compensated for by tool offset.

(Note) If the coordinate system setting is carried out by G50 in the offset mode, a

coordinate system in which position prior to the effecting of the offset becomes the

designated position is set.

8.2 COORDINATE SYSTEM SHIFT

G50 U(u) W(w) ;

This command creates a new coordinate system in which the coordinates (x, z) of

700.0

Start point=Standard point

Z

1200.0 mm

Page 50

Ⅱ PROGRAMNING -8COORDINATE SYSTEM SETTING 8-2

a point on the tool (e.g. n tool nose) on the current coordinate system correspond to

(X+u, Z+W)

The x and u values are in diameter in the case of diameter designation and in

radius in the case of radius designation.

(Example) Coordinate system shift when changing from tool A to B

G50 U20.4 W30.56 ; (Diameter designation)

X

A

30.56

B

10.2

Z

8.3 AUTOMATIC COORDINATE SYSTEM SETTING

When parameter APRS (№012) for automatic coordinate system setting is set in

advance, the coordinate system is determined automatically at the time of manual

reference point return. If αis set at parameter number 0709, a work coordinate system

is set so that standard point on the turret or the nose of the standard toll (any specific

standard point) is at (X=α, Z=β).

This is the same as when the following command is designated at the reference

point.

G50 Xα Zβ ;

Page 51

Ⅱ PROGRAMNING -8COORDINATE SYSTEM SETTING 8-3

β

α

Z

8.4 WORK COORDINATE SYSTEM SHIFT

When the coordinate system actually set by the G50 command or the automatic

coordinate system setting deviates from the programmed work coordinate system, the

set coordinate system can be shifted.

Set the desired shift amount in the work coordinate system shift memory.

Set the shift amount from 0’ to 0 in the work coordinate system shift memory.

XZ-O: programming coordinate system

X1Z1-O1: current set work coordinate system

When the command below is carried

G50 X120.0 Z70.0 ;

X1

O1

Z1

Z

O

Page 52

Ⅱ PROGRAMNING -8COORDINATE SYSTEM SETTING 8-4

The coordinate system (shift amount: 0) has been set so that the standard point is

X=120.0mm (diameter), Z=70.0mm (diameter) with reference to the work zero point.

However, the actually measured distance from the zero point is X=121.0mm(diameter),

Z=69.0mm(diameter).In this case, the desired coordinate system can be set by setting

the following shift amount.

X=1.0mm

Z=-1.0mm

Start point=standard point

NOTE:

1. Shift of the work coordinate system becomes valid immediately when the shift

amount is set.

2. When the coordinate system is set with G50 after the shift amount was set, the

shift amount is invalid.

For example, when G50 X100.0 Z80.0; is set, the coordinate system is set so that

the standard point of the current tool is X100.1, Z=80.0 regardless of the shift amount.

3. When the automatic coordinate system setting is conducted by manual

reference point return after setting the shift amount, the shift amount is activated and

the set coordinate system is shifted immediately.

4. Work coordinate system shift is valid when the parameter WSFT (parameter

number 12) is 1.

5. Whether the shift amount on the X axis is diameter or radius value depends on

the diameter/radius designation in the program.

8.5 DIRECT MEASURED VALUE INPUT FOR WORK

COORDINATE SYSTEM SHIFT

When the work coordinate system set with a G50 command or the automatic

Page 53

Ⅱ PROGRAMNING -8COORDINATE SYSTEM SETTING 8-5

coordinate system setting function is different from the coordinate system used in

programming, the coordinate system can be shifted by storing the measured distance

directly as follows:

(1) Cut the workpiece along surface A using the standard tool in manual

operation.

(2) Retract the tool only in the X direction without Z axis movement and stop

the spindle.

(3) Measure distance “β”from the zero point in programming to surface A. Set

the measured value as the Z value in the measured value (number: 100) memory for

the work coordinate system shift.

(4) Cut the workpiece along surface B by manual operation.

(5) Retract the tool only in the Z direction without X axis movement and stop

the spindle.

(6) Measure the diameterα at surface B, and set the measured value as the X

value in the measured value memory for the work coordinate system shift.

The shift amount , 0~0', is automatically set in the work coordinate system shift

memory 00. At the same time, the actual set coordinate system is shifted to coincide

with the coordinate system used in programming.

NOTE: The αvalue should be set in a diameter value.

Page 54

Ⅱ PROGRAMNING -9(COORDINATE VALUE AND DIMENSION) 9-1

9.COORDINATE VALUE AND DIMENSION

9.1 ABSOLUTE AND INCREMENTAL PROGRAMMING

There are two ways to command travels of the axes; the absolute command, and

the incremental command. In the absolute command, coordinate value of the end point

is programmed; in the incremental command, move distance of the axis itself is

programmed.

For the above figure, incremental command programming results in:

U40.0W_60.0;

While absolute command programming results in:

X70.0 Z40.0;

The absolute/incremental commands are distinguished by address words.

Absolute

command

Incremental

command

Notes

X U

Z W

(Example): X_ W_ ;

Incremental command (Z axis move command)

Absolute command (X axis move command)

NOTE:

For special G code, either absolute command or incremental command is

commanded in G90/G91. And use X/Z for the address.

G90: Absolute command

G91: Incremental command

X axis move

command

Z axis move

Command

Page 55

Ⅱ PROGRAMNING -9(COORDINATE VALUE AND DIMENSION) 9-2

For the above figure, programming is as follows.

Incremental programming

G91 X40.0 Z-60.0;

Absolute programming

G90 X70.0 Z40.0;

(Example):

Command methods Address

Absolute

programming

Incremental

programming

Specifies an end

point in the work

coordinate

Specifies a

distance from start

point to end point

X (Coordinate value

on the X axis)

Z (Coordinate value

on the Z axis)

U (Distance along the

Z (Distance along

the Z axis)

X axis)

Command specifying

Movement from B to A above

X400.0 Z50.0;

U200.0 W-400.0;

NOTE:

1. Absolute and incremental commands can be used together in a block. In the

above example, the following command can be specified:

X400.0 W-400.0;

2. When both X and U or W and Z are used together in a block, the one specified

later is effective.

Page 56

Ⅱ PROGRAMNING -9(COORDINATE VALUE AND DIMENSION) 9-3

9.2 INCH/METRIC CONVERSION (G20, G21)

Either inch or metric input can be selected by G code.

Unit system G Code Least input increment

Inch G20 0.0001inch

Millimeter G21 0.001mm

This G code must be specified in an independent block before setting the

coordinate at the beginning of the program.

The unit systems of the following items can be changed with G codes:

(1) Feedrate commanded by F code

(2) Positional command

(3) Offset value

(4) Unit of scale for manual pulse generator

(5) Movement distance in step feed

(6) Some parameters

NOTE:

1. When the power is turned on, the NC status is the same as that held before

the power was turn off.

2. G20 and G21 must not be switched during a program.

3. When the machine unit and the input unit systems are different, the maximum

error is half of the least command increment. This error is not accumulated.

4. When switching inch input (G20) to metric input (G21) and vice versa, the

offset value must be reset according to the input unit.

9.3 DECIMAL POINT PROGRAMMING /POCKET CALCULATOR

TYPE DECIMAL POINT PROGRAMMING

This control can input numerical values with a decimal point. However, some

addresses cannot use a decimal point. A decimal point may be used with mm, inches

or second values. The location of decimal point is mm, inch or second.

Z15.0 Z15mm or Z15 inch

F10.0 10mm/r,10mm/min,10inch/r,10inch/min

The following addresses can be used with a decimal point:

X, Z, U, W, R, A, K, I, F

NOTE:

1. In the dwell command, decimal point can be used with address X but not

with address P. (This is because P is also used for a sequence number.)

2. The appropriate G code should be specified before the numerical values are

specified in one block.

(1) G20; (inch dimension)

X1.0 G04;

Page 57

Ⅱ PROGRAMNING -9(COORDINATE VALUE AND DIMENSION) 9-4

The value X1.0 is regarded as the distance of motion (in inches),

X10000G04 is assumed resulting in dwelling for 10 seconds.

G04X1.0

This is regarded as G04X1000 and dwell is performed for a second.

(2) G98 (mm/min)

F1. G99; This is regarded as F1 G99, 0.01mm/r (specified G99

mm/r)

G98 (specified mm/min)

G99 F1; Regarded as G99 F100, 1mm/r (specified G99 mm/r)

3. This is great difference in values with and without the decimal point, when

programmed conventional decimal point programming.

G21; (millimeter dimensions)

X1. …… X1 mm

X1 …… X0.001 mm

G20; (Inch dimension)

X1. …… X1 inch

X1 …… X0.0001inch

4. Values with and without a decimal point can be specified together.

X1000Z23.7;

X10.Y22359;

5. Values less than the least input increment are rounded off.

When X1.23456 is specified, X1.234 is assumed in millimeter input and

X1.2345 is assumed in inch input.

6. When a number with a decimal point has been input, the number is converted

into an integer of the least input increment.

Example:

X12.34 → X12340(input in millimeter)

This converted integer is checked for its number of digits.

Example:

X123456.7 → X123456700(input in millimeter)

An alarm occurs because the converted integer exceeds 7 digits.

7. Parameter P013 PODI specified default decimal point or not.

PODI : When the addresses that decimal points can be specified in a

program haven’t decimal point, a decimal point is conformed to exit.

Eg:X100=X100. (X100mm)

8. A decimal point is necessary or not by using parameter P013 PODI, in order

to prevent a decimal point omitting in absolute programming.

POD 0: a decimal point is optional

1: a decimal point is necessary, or an alarm occurs (No.007).

SPECIAL EXAMPLE:

1 Though F100. =F100, when parameter POD=1, a decimal point is necessary.

(F100.)

Page 58

Ⅱ PROGRAMNING -9(COORDINATE VALUE AND DIMENSION) 9-5

2 Address Q can specify with the decimal point, when macro variables DO=1, 1. Or

0.01 must be specified in address Q. If the low eight-bit of macro variables #1132

are 1: G65 H01 #1132 Q0.255

9.4 DIAMETER AND RADIUS PROGRAMMING

Since the work cross sections usually circular in CNC lathe control programming,

its dimension can be specified in to two ways: diameter and radius.。

When the diameter is specified, it is called diameter programming and when the

radius specified, it is called radius programming.

When using diameter programming on the X axis, note the conditions listed in the

following table.

Item Notes

Z axis command

X axis command Specified with a diameter value.

Incremental command with address

U

Coordinate system setting(G50)

X component of tool offset value

Parameters in G90, G92, G94, such

as cutting depth along X axis.

Radius designation in circular

interpolation (R,I,K)

Feedrate along X axis

Display of X-axis position Displayed as diameter value.

Specified independently of diameter or

radius value.

Specified with a diameter value.

In the above figure, specifies from D2 to

D1 for tool path B to A.

Specified an X axis coordinate value with

a diameter.

Parameter setting (NO.004, ORC)

determines either diameter or radius

value.

Specified a radius value.

Specified a radius value.

Change of radius/rev.

Change of radius/min.

Page 59

Ⅱ PROGRAMNING -9(COORDINATE VALUE AND DIMENSION) 9-6

NOTE:

1. In the following explanations, although the type of programming (diameter or

radius) is not specified, X axis graduation indicates diameter value in radius

programming.

2. When a diameter value is specified for the tool offset it indicates that when the

outer diameter is cut with a new tool offset value the outer diameter is

changed by the offset value.

For example, when the offset value changes by 10 mm while the tool remains

unchanged, the outer diameter changes by a diameter value of 10 mm.

3. When using a radius value for the tool offset value, the tool length itself can be

set.

Page 60

Ⅱ PROGRAMMING -10(SPINDLE FUNCTION) 10-1

10. SPINDLE FUCTION(S FUCTION)

10.1 SPINDLE SPEED COMMAND

By specifying a numerical value following address S, a code signal and a strobe

signal are transmitted to the machine tool. This is mainly used to control the spindle

speed. An S code can be commanded in a block.

Refer to the machine tool builder’s manual for the number of digits commandable