KitchenAid KESI901PBS, KESA907P, KESV908PSS, KESV908PMT, KESA907PWW Technical Education

...

KAC-38

TECHNICAL EDUCATION

SELF-CLEANING

SLIDE-IN/FREESTANDING

ELECTRIC RANGES

Freestanding Model: KERA807P

Slide-In Models: KESV808P, KESV908P,

KESA907P, & KESI901P

JOB AID 4317354

FORWARD

This KitchenAid Job Aid, “Self-Cleaning Slide-In/Freestanding Electric Ranges,” (Part #4317354),

provides the technician with information on the installation, operation, and service of Self-Cleaning

Slide-In/Freestanding Electric Ranges. It is to be used as a training Job Aid and Service Manual.

For specific information on the model being serviced, refer to the “Use and Care Guide,” or “Wiring

Diagram” provided with the electric range.

The Wiring Diagrams and Strip Circuits used in this Job Aid are typical and should be used for

training purposes only. Always use the Wiring Diagram supplied with the product when servicing

the unit.

GOALS AND OBJECTIVES

The goal of this Job Aid is to provide detailed information that will enable the service technician to

properly diagnose malfunctions and repair KitchenAid Self-Cleaning Slide-In/Freestanding Electric Ranges.

The objectives of this Job Aid are to:

• Understand and follow proper safety precautions.

• Successfully troubleshoot and diagnose malfunctions.

• Successfully perform necessary repairs.

• Successfully return the range to its proper operational status.

WHIRLPOOL CORPORATION assumes no responsibility for any repairs made

on our products by anyone other than Authorized Service Technicians.

Copyright © 2004, Whirlpool Corporation, Benton Harbor, MI 49022

- ii -

TABLE OF CONTENTS

Page

GENERAL............................................................................................................................... 1-1

Safety First......................................................................................................................... 1-1

Model & Serial Number Designations ................................................................................ 1-2

Model & Serial Number Label & Tech Sheet Locations..................................................... 1-3

Specifications..................................................................................................................... 1-4

KitchenAid Electric Range Warranty.................................................................................. 1-6

INSTALLATION INFORMATION ........................................................................................... 2-1

Installation Requirements .................................................................................................. 2-1

Tools And Parts ............................................................................................................. 2-1

Location Requirements .................................................................................................. 2-2

Product Dimensions....................................................................................................... 2-3

Installation Clearances .................................................................................................. 2-4

Electrical Requirements ................................................................................................. 2-5

Countertop Preparation (Slide-In Ranges Only) ............................................................ 2-7

Installation Instructions ...................................................................................................... 2-8

Electrical Connection ..................................................................................................... 2-8

THEORY OF OPERATION ..................................................................................................... 3-1

Convection Bowtie Baffle ................................................................................................... 3-1

COMPONENT ACCESS ......................................................................................................... 4-1

Component Locations ........................................................................................................ 4-1

Removing The EOC Assembly On Slide-In & Freestanding Models,

And The User Interface.................................................................................................. 4-2

Removing An LED Indicator And An Infinite Switch .......................................................... 4-4

Removing The Cooktop Glass ........................................................................................... 4-5

Removing The Control & Cooling Fan Thermal Switches And

The Door Latch Assembly ............................................................................................. 4-6

Removing The Control Power Supply And The Power Supply Transformer ..................... 4-7

Removing An Element & Limiter And The Hot Surface Indicator Assembly ...................... 4-8

Removing The Rear Panel ................................................................................................ 4-9

Removing An Oven Light Socket Assembly .................................................................... 4-10

Removing The Dual Broil Element................................................................................... 4-11

Removing The Oven Temperature Sensor ...................................................................... 4-12

Removing The Convection Element & Fan Motor ........................................................... 4-13

Removing The Cooling Fan ............................................................................................. 4-15

Removing The Oven TOD ............................................................................................... 4-16

Removing The Hidden Bake Element.............................................................................. 4-17

Removing The Warming Drawer Temperature Sensor And Element .............................. 4-19

Removing A Side Panel ................................................................................................... 4-21

Removing & Reinstalling The Oven Door ........................................................................ 4-22

Removing The Oven Door Gasket................................................................................... 4-23

Removing The Decorative Glass And Oven Door Handle,

The Hinges, And The Oven Door Glass ...................................................................... 4-24

- iii -

Page

COMPONENT TESTING ........................................................................................................ 5-1

Infinite (Smart) Switch........................................................................................................ 5-1

Dual & Single Infinite & Warming Drawer Switches

Models: KESV808, KESV908, & KESI901 .................................................................... 5-1

Control & Cooling Fan Thermal Switches .......................................................................... 5-2

Door Latch Assembly......................................................................................................... 5-2

Power Supply Transformer ................................................................................................ 5-3

Oven & Warming Drawer Temperature Sensors ............................................................... 5-3

Elements & Limiters ........................................................................................................... 5-4

Dual Broil Element ............................................................................................................. 5-5

Convection Element........................................................................................................... 5-5

Convection Fan Motor ....................................................................................................... 5-6

Cooling Fan Motor ............................................................................................................. 5-6

Oven TOD.......................................................................................................................... 5-7

Hidden Bake Element ........................................................................................................ 5-7

Warming Drawer Element.................................................................................................. 5-8

DIAGNOSTICS & TROUBLESHOOTING .............................................................................. 6-1

Diagnostics ........................................................................................................................ 6-1

Troubleshooting ................................................................................................................. 6-6

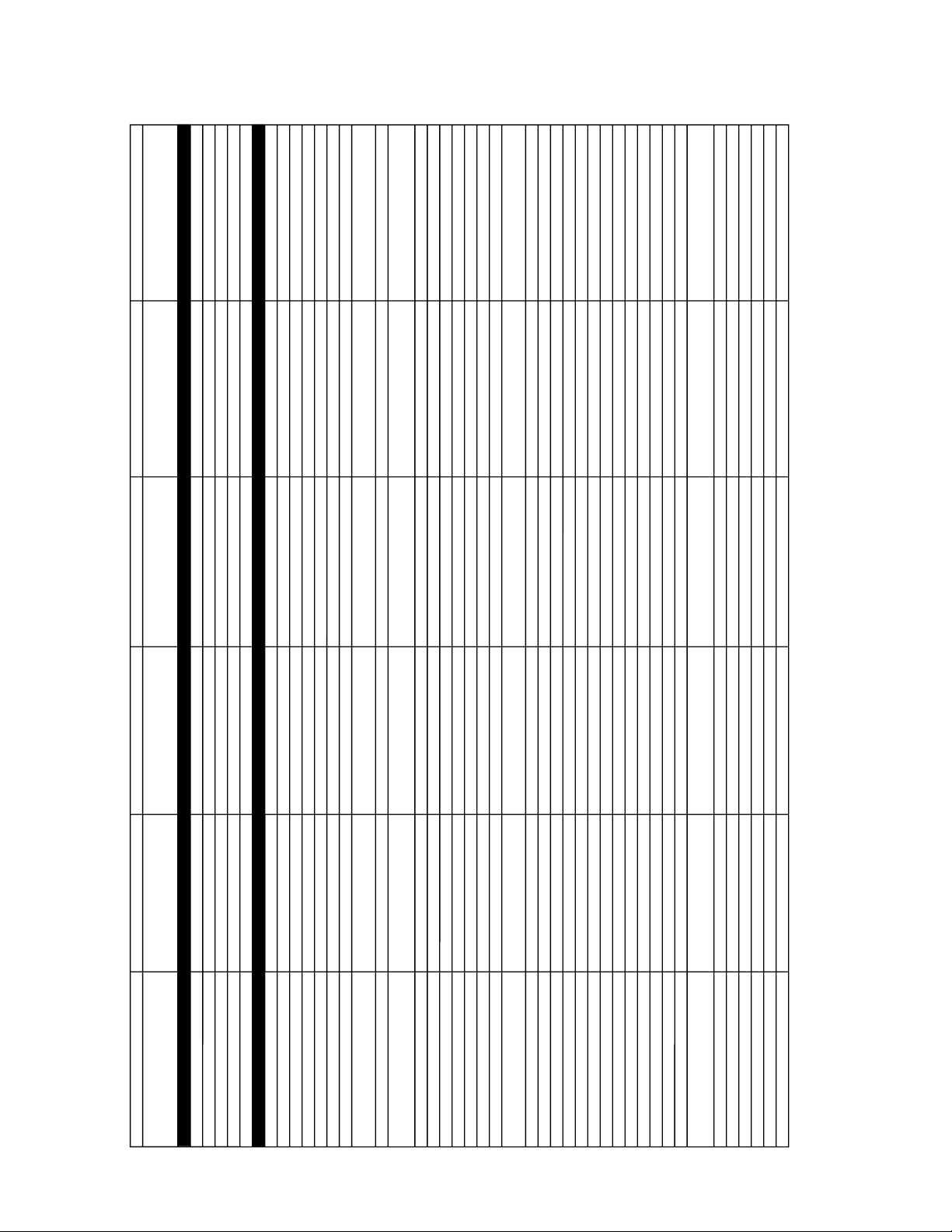

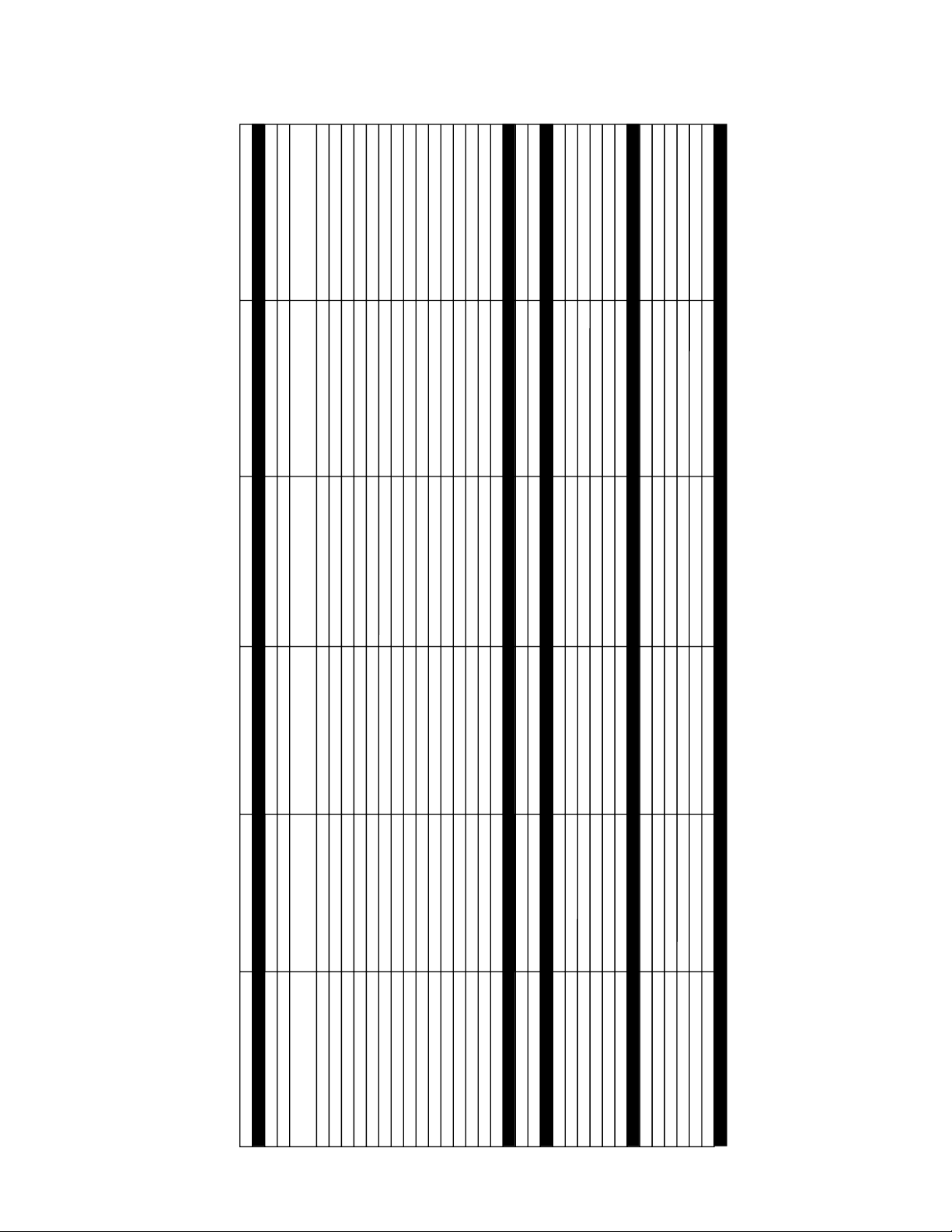

WIRING DIAGRAMS & STRIP CIRCUITS ............................................................................. 7-1

Wiring Diagrams ................................................................................................................ 7-1

Strip Circuits ...................................................................................................................... 7-3

- iv -

GENERAL

SAFETY FIRST

Your safety and the safety of others is very important.

We have provided many important safety messages in this Job Aid and on the appliance. Always

read and obey all safety messages.

This is the safety alert symbol.

This symbol alerts you to hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word

“DANGER” or “WARNING.” These words mean:

You can be killed or seriously injured if you don’t

DANGER

WARNING

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance

of injury, and tell you what can happen if the instructions are not followed.

immediately follow instructions.

You can be killed or seriously injured if you don’t

follow instructions.

1-1

MODEL & SERIAL NUMBER DESIGNATIONS

MODEL NUMBER

MODEL NUMBER K ES V 90 8 P MT 0

PRODUCT GROUP

K = KITCHENAID

PRODUCT IDENTIFICATION

DR = DUAL FUEL RANGE

DS = DUAL FUEL SLIDE-IN RANGE

ER = ELECTRIC STANDARD RANGE

ES = ELECTRIC SLIDE-IN RANGE

GR = GAS STANDARD RANGE

GS = GAS SLIDE-IN RANGE

MERCHANDISING SCHEME

A = ARCHITECT

C = CONTRACT / ADVERTISING

I = STANDARD

K/L = SEARS MODELS

P = COMMERCIAL STYLE

V = VBL PRO LINE STYLE

CAPACITY / SIZE / SERIES / CONFIGURATION

1ST POSITION 2ND POSITION

2 = FS RANGE BACK CONTROL 0 = 30″ WIDE

4 = COMMERCIAL 6 = 36″ WIDE

8 = FS RANGE FRONT CONTROL 8 = 48″ WIDE

9 = SLIDE-IN

FEATURES

0 = CONVENTIONAL OVEN, COIL COOKTOP

1 = CONVENTIONAL OVEN, CERAN OR GAS COOKTOP

2 = CONVENTIONAL OVEN, WARMING DRAWER, GAS COOKTOP

3 = CONVENTIONAL OVEN, AUTO CONVECT, CERAN

OR GAS COOKTOP

4 = CONVECTION OVEN, COIL COOKTOP

5 = CONVECTION OVEN, CERAN COOKTOP

6 = CONVECTION OVEN, GAS COOKTOP W / TRIPLE TIER

7 = CONVECTION OVEN, WARMING DRAWER, CERAN COOKTOP

W / ELECTRONIC KNOB COOKTOP, OR GAS COOKTOP

W / TRIPLE TIER

8 = CONVECTION OVEN, WARMING DRAWER, CERAN COOKTOP

W / ELECTRONIC COOKTOP

YEAR OF INTRODUCTION

P - 2004, R = 2005

COLOR CODE

BL = BLACK, WH = WHITE, BT = BISCUIT, MT = METEORITE

BS = BLACK ON STAINLESS, SS = BRUSHED STAINLESS STEEL

ENGINEERING CHANGE (NUMERIC)

SERIAL NUMBER

SERIAL NUMBER X R 31 73981

MANUFACTURING SITE

X = OXFORD, MS

YEAR OF PRODUCTION

R = 2004

WEEK OF PRODUCTION

31 = 31ST WEEK

PRODUCT SEQUENCE NUMBER

1-2

MODEL & SERIAL NUMBER LABEL

& TECH SHEET LOCATIONS

The Model/Serial Number label and Tech Sheet locations are shown below.

Model/Serial

Number Location

(On Chassis Frame)

Tech Sheet Location

Warming Drawer Models Only

(On Chassis Under Drawer)

Model/Serial

Number Location

(On Chassis Frame)

Tech Sheet Location

Storage Drawer Models Only

(On Underside Of Drawer)

1-3

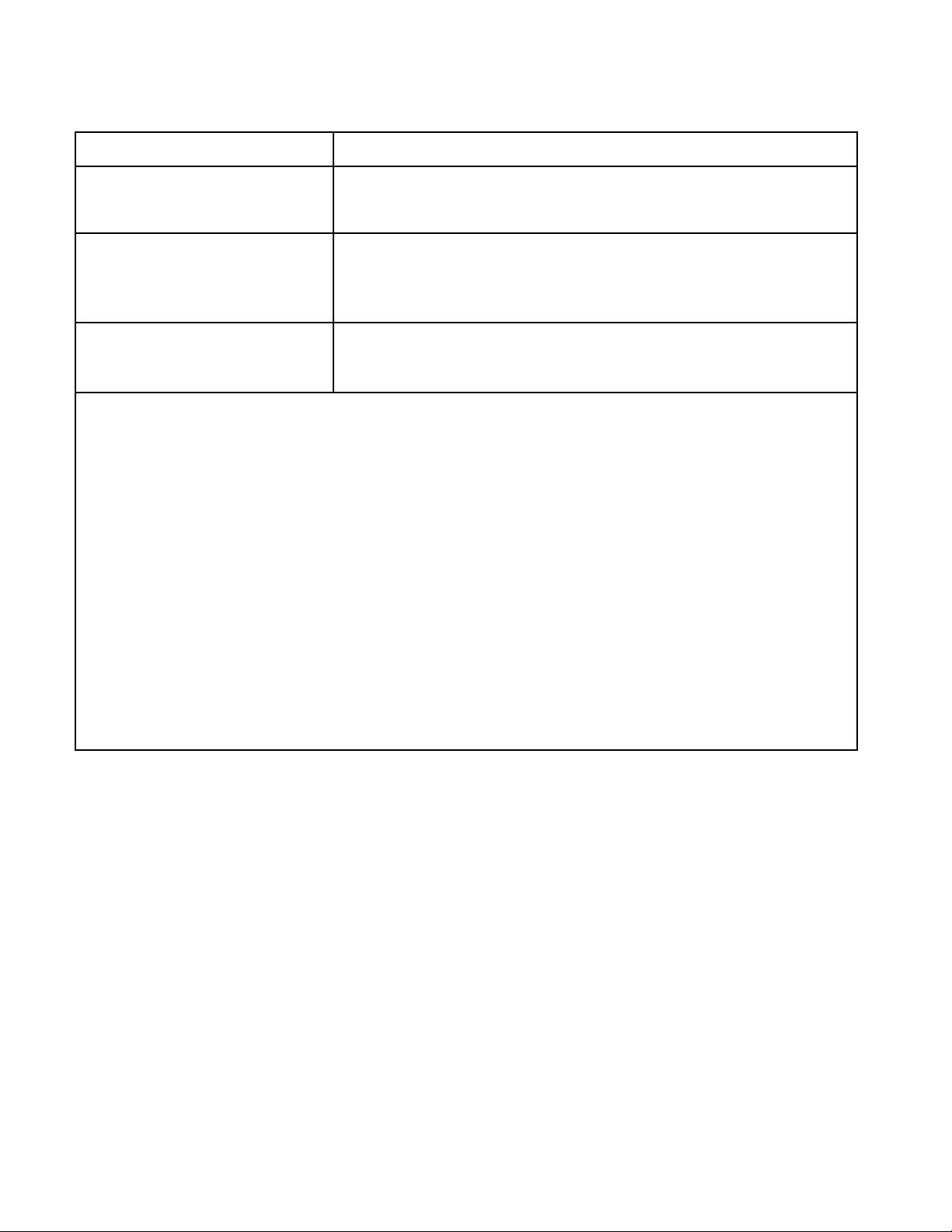

SPECIFICATIONS

Model Number

KESI901P BL, BS, WH KERA807P BB, BL, SS,WW KERK807P BB, BL, SS, WW KESA907P BB, BL, SS, WW KESV908P MT, SS

Model Description

Slide-In

True Convection with Easy Convect

Conversion; Waming Drawer

Freestanding

Slide-In; True Convection with Easy

Convect Conversion; Warming Drawer

Dimensions/Specifications

Exterior Dimensions

Shipping Weight (lbs)

160 180 180 160 160

240 Volts

13.5 14.4 14.4 14.4 13.3

208 Volts

10.1 10.9 10.9 10.9 10

Circuit Amps

40 40 40 40 40

Exterior

Broiler Stop

No No No No No

Cooktop Control Type

Electromechanical Electronic Knobs Electronic Knobs Electronic Knobs Touch Activated Electronics

Cooktop Control #

Knobs - 4, Buttons - 2 Knobs - 4 Knobs - 4 Knobs - 4

Simmer Specialty Switch

Yes - 1 No No No No

Keep Warm Switch

Yes - 1 No No No No

Top Light and Switch

No Yes Yes Yes Yes

Cooktop Lock Out

No No No No Yes

Cooktop Features

Melt & Hold, Keep Warm, & 3

Simmer Levels

Melt & Hold, Keep Warm, & 3

Simmer Levels

Cooktop Material

Ceramic Glass Ceramic Glass Ceramic Glass Ceramic Glass Ceramic Glass

Cooktop Indicator Light

Yes - Red Yes - Red, Yes - Red, Single & Dual Yes - Red, Yes - Red, Single & Dual Yes - Red, Yes - Red, Single & Dual

Yes - Red, Yes - Red, Single, Dual,

Triple

Electric Element Configuration

6", 7", 8", 9.5" 6"/10", 7", 9"/5", 9"/5" 6"/10", 7", 9"/5", 9"/5" 6"/10", 7", 9"/5", 9"/5" 6"/10", 6", 9"/5", 9"/7"/5"

Electric Element Type

Radiant Radiant Radiant Radiant Radiant

Electric RF Output (w@240/208v)

7" 1800W @ 240V 7" 1800W @ 240V 7" 1800W @ 240V 7" 1800W @ 240V 6" 1500W @ 240W

Electric LF Output (w@240/208v)

9"/5" 2500W/1200W @ 240V 9"/5" 2500W/1200W @ 240V 9"/5" 2500W/1200W @ 240V 9"/5" 2500W/1200W @ 240V 9"/7"/5" 2500W/1600W/800W

Electric RR Output (w@240/208v)

8" 2200 W @ 240W 9"/5" 2500W/1200W @ 240V 9"/5" 2500W/1200W @ 240V 9"/5" 2500W/1200W @ 240V 9"/5" 2500W/1000W

Electric LR Output (w@240/208v)

6" 1500W @ 240W 6"/10" 1000W/1800W @ 240W 6"/10" 1000W/1800W @ 240W 6"/10" 1000W/1800W @ 240W 6"/10" 1000W/1800W @ 240W

Electric Keep Warm Burner

6" - 100W All Elements All Elements All Elements All Elements

Electric Simmer Burner Type

Low Simmer Right Front - 450W

All Elements: 3 Simmer Settings,

1 Melt & Hold Setting

All Elements: 3 Simmer Settings,

1 Melt & Hold Setting

Electrtic Simmer Burner-Number

1

208 V Compensation

Yes Yes Yes Yes

Oven Controls

Jabil GOC KitchenAid Premium Jabil GOC KitchenAid Premium Jabil GOC KitchenAid Premium Jabil GOC KitchenAid Premium Jabil GOC KitchenAid Premium

Bake

Yes Yes Yes Yes Yes

Bread Proofing

Yes Yes Yes Yes Yes

Oven Broil

Yes Yes Yes Yes

Closed Door Broil

Yes Yes Yes Yes Yes

Maxi Broil

Yes Yes Yes Yes Yes

Econo Broil

Yes Yes Yes Yes Yes

Convection

True Convection, 3rd Element True Convection, 3rd Element True Convection, 3rd Element True Convection, 3rd Element

Convection Bake

Yes Yes Yes Yes

Convection Broil

Yes Yes Yes Yes

Convection Roast

Yes Yes Yes Yes

Easy Convection Baked Goods

Yes Yes Yes Yes

Easy Convection Meats

Yes Yes Yes Yes

Easy Convection Other Foods

Yes Yes Yes Yes

Sabbath Mode

Yes Yes Yes Yes Yes

Sales Demo

Yes Yes Yes Yes Yes

Temperature Probe

Yes Yes Yes Yes

208 Volt Compensation

Yes Yes Yes Yes Yes

1-4

Model Number

KESI901P BL, BS, WH KERA807P BB, BL, SS,WW KERK807P BB, BL, SS, WW KESA907P BB, BL, SS, WW KESV908P MT, SS

Interior

Main Oven

Cooking System

Standard True Convection True Convection True Convection True Convection

Cleaning System

Self Cleaning - Timed Self Cleaning - Soil Level & Timed Self Cleaning - Soil Level & Timed Self Cleaning - Soil Level & Timed Self Cleaning - Soil Level & Timed

Auto Self Clean Latch

Yes - Motorized Yes - Motorized Yes - Motorized Yes - Motorized Yes - Motorized

Oven Dimensions

Oven Volume (cu ft)

Overall Capacity: 4.2; AHAM Overall Capacity: 3.9; AHAM Overall Capacity: 3.9; AHAM Overall Capacity: 3.9; AHAM Overall Capacity: 3.9; AHAM

Oven Light Number

2 Incandescent 2 Incandescent 2 Incandescent 2 Incandescent 2 Incandescent

Main Electric Oven

Yes Yes Yes Yes Yes

Hidden Bake Element

Yes Yes Yes Yes Yes

Electric Element Output

Bake (W@240/208v)

2000 W 2000 W 2000 W 2000 W 2000 W

Broil (W@240/208v)

Broil Inner Elem (W@240/208v)

1790W 1790W 1790W 1790W 1790W

Broil Outer Elem (W@240/208v)

1450W 1450W 1450W 1450W 1450W

Convection (W@240/208v)

1600W 1600W 1600W 1600W

Oven Lower Panel/ Door

Yes Yes Yes Yes Yes

Warming Drawer

Yes Yes Yes Yes

Warming Drawer Element Wattage

850 W 850 W 850 W 850 W

Accessories

Griddle

Yes - Optional Yes - Optional Yes - Included Yes - Optional Yes - Optional

Griddle Part/Comment

4396096 4396096 9755634 4396096 4396096

Miscellaneous

Installation Instructions Part/Comme

9757446 9757446 9757446 9757446 9757446

Tech Sheet Part/Comment 9757663 9757662 9757662 9757662 9757662

Job Aid Part/Comment 4317354 4317354 4317354 4317354 4317354

Use & Care Guide Part/Comment

9757451 9757451 9757451 9757451 9757451

Agency Approvals

UL UL UL UL UL

Anti-tip Device With Unit

Floor Floor Floor Floor Floor

Warranty

Full

11 months 12 months 12 months 12 months 12 months

Extended

Ceramic Glass Cooking Surface

2nd through 5th year, parts 2nd through 5th year, parts 2nd through 5th year, parts 2nd through 5th year, parts 2nd through 5th year, parts

Electronic Controls

2nd through 5th year, parts 2nd through 5th year, parts 2nd through 5th year, parts 2nd through 5th year, parts 2nd through 5th year, parts

Electrical Elements

2nd through 5th year, parts 2nd through 5th year, parts 2nd through 5th year, parts 2nd through 5th year, parts 2nd through 5th year, parts

Porcelain Liner/Door

1st through 10th year, parts 2nd through 10th year, parts 2nd through 10th year, parts 2nd through 10th year, parts 2nd through 10th year, parts

1-5

KITCHENAID ELECTRIC RANGE WARRANTY

LENGTH OF WARRANTY

FULL ONE YEAR WARRANTY

From Date of Purchase.

SECOND THROUGH FIFTH

YEAR LIMITED WARRANTY

From Date of Purchase.

SECOND THROUGH TENTH

YEAR LIMITED WARRANTY

From Date of Purchase.

KITCHENAID WILL NOT PAY FOR:

A. Service calls to:

1. Correct the installation of the range.

2. Instruct you how to use the range.

3. Replace house fuses or correct house wiring.

B. Repairs when range is used in other than normal, single family household use.

C. Damage resulting from accident, alteration, misuse, abuse, fire, flood, acts of God, improper installation, or

installation not in accordance with local electrical codes.

D. Any labor costs during the limited warranties.

E. Replacement parts or repair labor costs for units operated outside the United States and Canada.

F. Pickup and delivery. Your range is designed to be repaired in the home.

G. Repairs to ceramic glass cooktop if it has not been cared for as recommended in the Use and Care Guide.

H. Repairs to parts or systems resulting from unauthorized modifications made to the appliance.

I. In Canada, travel or transportation expenses to customers who reside in remote areas.

KITCHENAID WILL PAY FOR:

Replacement parts and repair labor costs to correct defects in materials

or workmanship. Service must be provided by a KitchenAid designated

servicing outlet.

Replacement parts for any electric element to correct defects in materials or workmanship. Replacement ceramic glass if breakage is due to

defects in materials or workmanship. Replacement parts for solid state

touch control system to correct defects in materials or workmanship.

Replacement parts for the porcelain oven cavity / inner door if the part

rusts through due to defects in materials or workmanship.

KITCHENAID OR KITCHENAID CANADA DO NOT ASSUME ANY RESPONSIBILITY FOR INCIDENTAL OR

CONSEQUENTIAL DAMAGES. Some states or provinces do not allow the exclusion or limitation of incidental or

consequential damages, so this exclusion or limitation may not apply to you. This warranty gives you specific legal

rights, and you may also have other rights which vary from state-to-state or province-to-province.

Outside the United States and Canada, a different warranty may apply. For details, please contact your

authorized KitchenAid dealer.

If you need service first see the “Troubleshooting” section of the Use and Care Guide. After checking “Troubleshooting,” additional help can be found by checking the “Requesting Assistance or Service” section, or by calling

our Customer Interaction Center telephone numbers, listed below, from anywhere in the U.S.A. or Canada.

KitchenAid: 1-800-422-1230

Canadian Residents call: 1-800-807-6777

1-6

INSTALLATION INFORMATION

INSTALLATION REQUIREMENTS

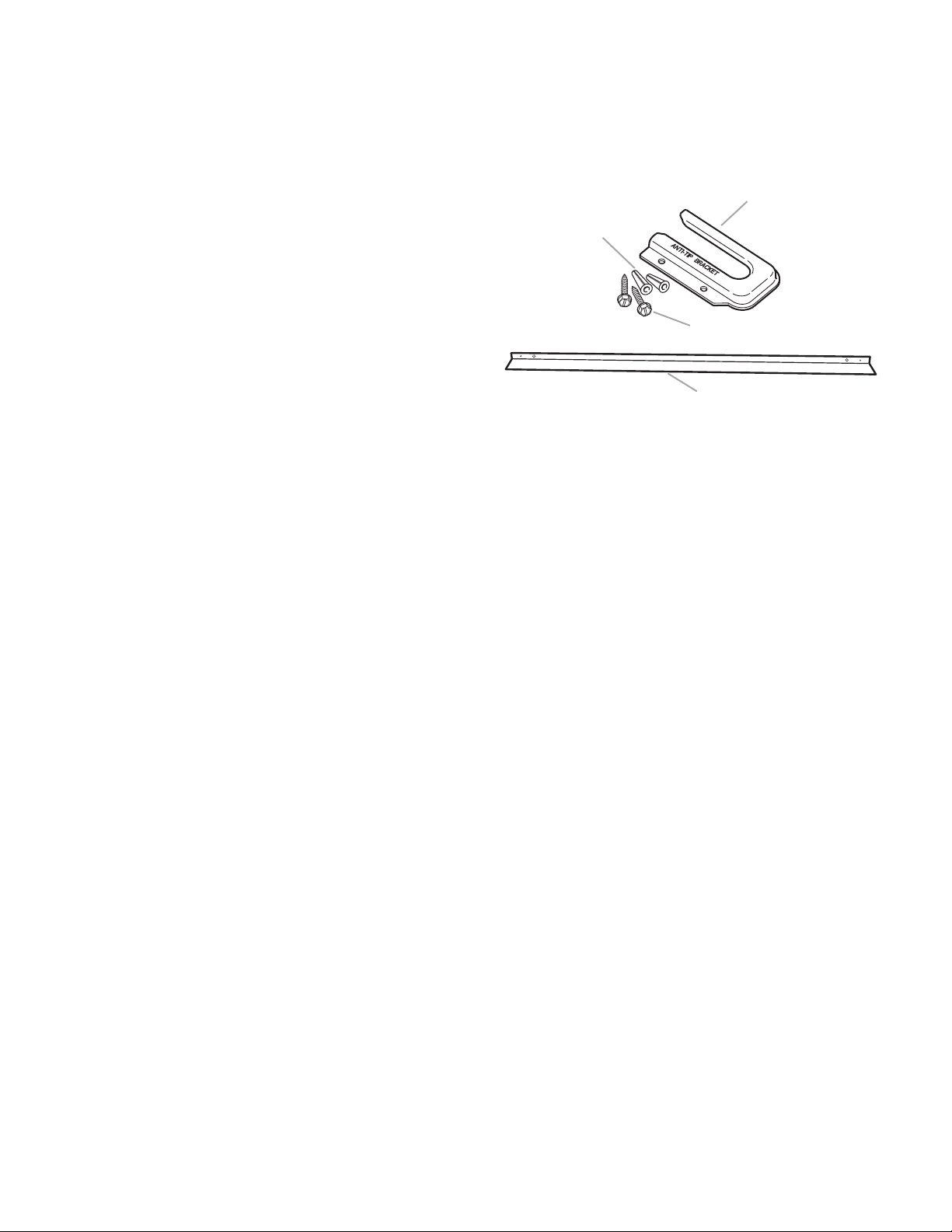

TOOLS AND PARTS

Assemble the required tools and parts before

starting installation. Read and follow the safety

instructions provided with any tools listed here.

Tools Needed

• Tape measure

• Flat-blade screwdriver

• Level

• Hammer

• Hand or electric drill

• Channel lock pliers

• Marker or pencil

• Masking tape

• 3/8″ drive rachet

• 1/4″ nut driver

• 5/16″ nut driver

• 1/8″ (3.2 mm) drill bit (for wood floors)

• 3/16″ (4.8 mm) carbide-tipped masonry drill

bit (for concrete/ceramic floors)

Parts Supplied

B

C

D

A. Anti-tip bracket

B. Plastic anchors (2)

C. #10 x 1/2″ screws (2)

D. Rear spacer cover for slide-in models

(supplied on some models)*

* To order, contact your dealer or refer to the “Assis-

tance or Service” section of the Use and Care Guide.

Request Part #9757784WH (White), #9757784BT

(Biscuit), #9757784BL (Black), #9757784MT (Mete-

orite), or #9757784SS (Stainless Steel).

A

Check that all parts are included.

• Brackets must be securely mounted to

subfloor. Thickness of flooring may require

longer screws to anchor bracket to subfloor.

Longer screws are available from your local

hardware store.

Parts Needed

Check local codes. Check existing electrical

supply (see “Electrical Requirements” on page

2-5).

All electrical connections should be made by a

licensed, qualified electrical installer.

2-1

LOCATION REQUIREMENTS

IMPORTANT: Observe all governing codes

and ordinances. Failure to meet codes and

ordinances could lead to fire or electrical shock.

• It is the installer’s responsibility to comply

with installation clearances specified on the

model/serial rating plate. The model/serial

rating plate is located on the oven frame

behind the storage drawer panel.

• The range should be located for convenient

use in the kitchen.

• To eliminate the risk of burns or fire by

reaching over heated surface units, cabinet

storage space located above the surface

units should be avoided. If cabinet storage is

to be provided, the risk can be reduced by

installing a range hood that projects horizontally a minimum of 5″ (12.7 cm) beyond the

bottom of the cabinets.

• Cabinet opening dimensions that are shown

must be used. Given dimensions are minimum clearances.

• The floor anti-tip bracket must be installed.

To install the anti-tip bracket shipped with

the range, see the Installation Instructions

provided with the range.

Mobile Home - Additional Installation Requirements

The installation of this range must conform to

the Manufactured Home Construction and

Safety Standard, Title 24 CFR, Part 3280 (formerly the Federal Standard for Mobile Home

Construction and Safety, Title 24, HUD Part

280). When such standard is not applicable,

use the Standard for Manufactured Home Installations, ANSI A225.1/NFPA 501A or with

local codes.

In Canada, the installation of this range must

conform with the current standards CAN/CSAA240-latest edition, or local codes.

Mobile home installations require:

• When this range is installed in a mobile

home, it must be secured to the floor during

transit. Any method of securing the range is

adequate as long as it conforms to the standards listed above.

• Four-wire power supply cord or cable must

be used in a mobile home installation. The

appliance wiring will need to be revised (see

“Electrical Connection” on page 2-5)

• A grounded electrical supply is required (see

“Electrical Requirements” on page 2-5).

2-2

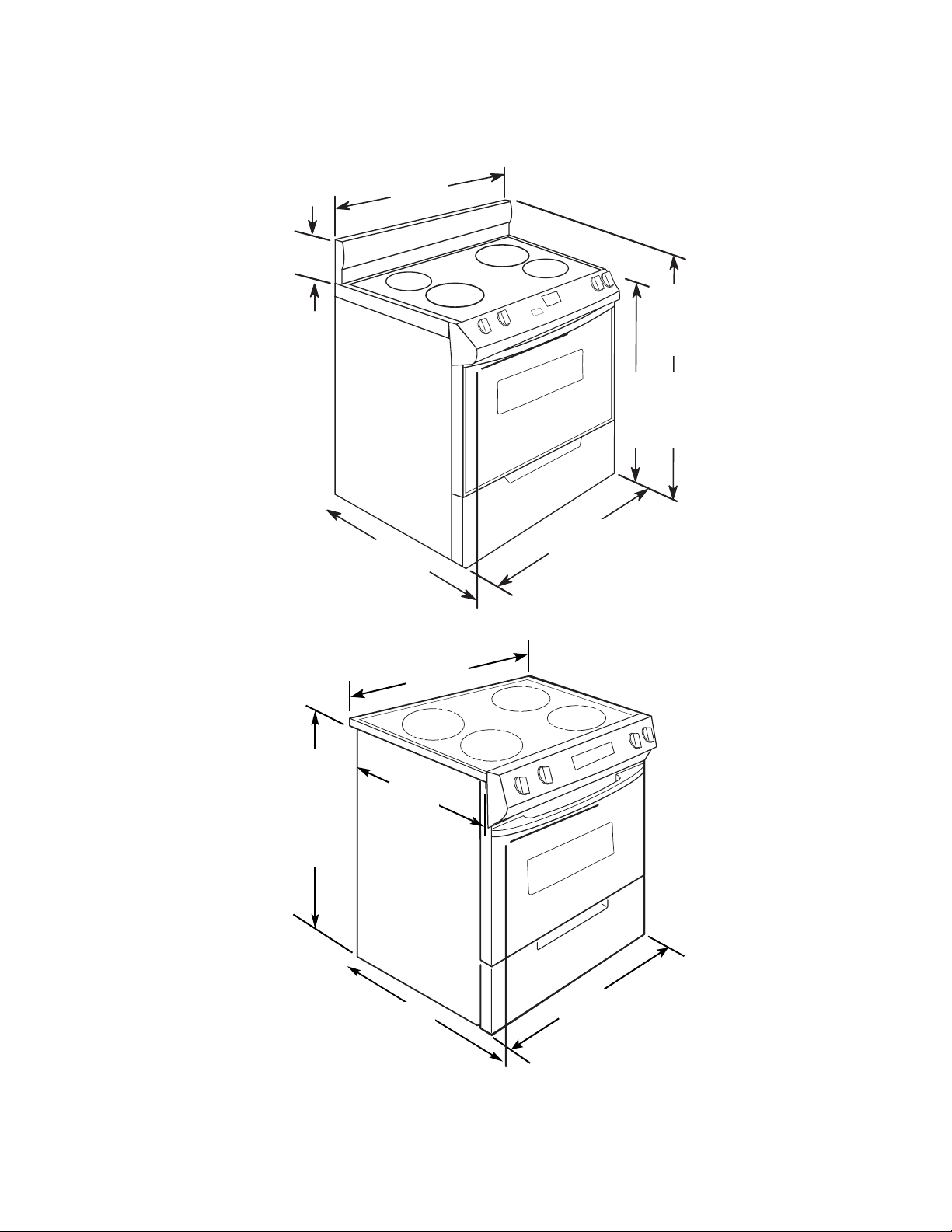

PRODUCT DIMENSIONS

Freestanding Range

7-7/8"

(20 cm)

30"

(76.2 cm)

*27"

(68.6 cm)

to handle

43-7/8"

(111.4 cm)

overall

height

36" (91.4 cm)

cooktop height

with leveling

legs lowered

1-1/2 turns

30"

(76.2 cm)

Slide-In Range

35-5/8"

(90.5 cm)

cooktop height

with leveling

legs lowered

1-1/2

turns

30-11/16"

(77.9 cm)

23-1/2"

(59.8 cm)

* 27"

(68.6 cm)

to handle

30"

(76.2 cm)

* When installed in a 24″ (61 cm) base cabinet with 25″ (63.5 cm) countertop; front of oven door protrudes 1-7/8″

(4.8 cm) beyond 24″ (61 cm) base cabinet.

2-3

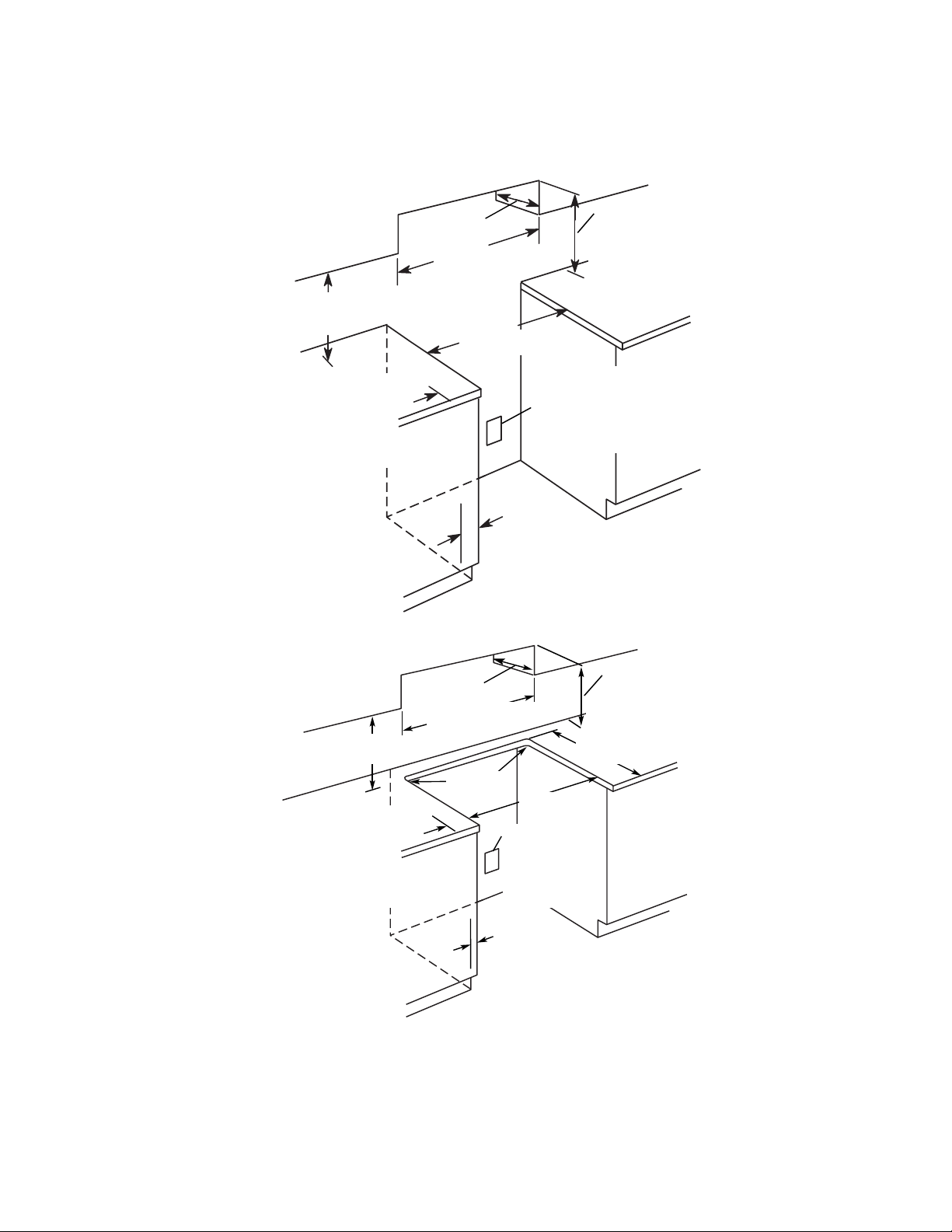

INSTALLATION CLEARANCES

Cabinet opening dimensions shown are for

25,″ (64 cm) countertop depth, 24″ (61 cm)

Freestanding Range

13" (33 cm) max.

upper cabinet depth

18" (45.7 cm)

upper cabinet

to countertop

4" (10.2 cm)

min. clearance

from both sides

of range to side

wall or other

combustible

material.

base cabinet depth and 36″ (91.4 cm)

countertop height.

For minimum

clearance to

the top of the

30" (76.2 cm) min.

opening width

30" (76.2 cm) min.

opening width

Junction box 8" (20.3 cm) to

22" (55.9 cm) from

either cabinet,

7" (17.8 cm) max.

from door.

7/8" (2.2 cm)

min. required

between cutout

and cabinet

door or hinge.

cooktop, see

NOTE.

13" (33 cm)

Slide-In Range

18" (45.7 cm)

upper cabinet to

countertop

4" (10.2 cm) min.

clearance from

both sides of

range to side wall

or other combustible

material between

upper cabinet and

countertop.

upper cabinet depth

30" (76.2 cm)

opening width

NOTE: 24″ (61 cm) minimum when bottom of

wood or metal cabinet is protected by not less

than 1/4″ (0.64 cm) flame retardant millboard

covered with not less than No. 28 MSG sheet

steel, 0.015″ (0.4 mm) stainless steel, 0.024″

For minimum

clearance to

the top of the

cooktop, see

NOTE.

" (57.8 cm)

22-3/4

opening depth

1/4" (6.2 cm)

radius both

corners

30" (76.2 cm)

opening width

Junction box 8" (20.3 cm) to

22" (55.9 cm) from

either cabinet,

7" (17.8 cm) max.

from floor.

7/8" (2.2 cm) min.

required between

cutout and cabinet

door or hinge.

(0.6 mm) aluminum, or 0.020″ (0.5 mm) copper.

30″ (76.2 cm) minimum clearance between the

top of the cooking platform and the bottom of an

unprotected wood or metal cabinet.

2-4

ELECTRICAL REQUIREMENTS

If codes permit and a separate ground wire is

used, it is recommended that a qualified electrical installer determine that the ground path

and wire gauge are in accordance with local

codes.

If codes permit and a separate ground wire is

used, it is recommended that a qualified electrician determine that the ground path is adequate.

Do not use an extension cord.

Be sure that the electrical connection and wire

size are adequate and in conformance with the

National Electrical Code, ANSI/NFPA 70-latest edition and all local codes and ordinances.

A copy of the above code standards can be

obtained from: National Fire Protection Association, One Batterymarch Park, Quincy, MA

02269.

ELECTRICAL CONNECTION

To properly install your range, you must determine the type of electrical connection you will

be using and follow the instructions provided

for it here.

• Range must be connected to the proper

electrical voltage and frequency as specified

on the model/serial number rating plate.

(The model/serial number rating plate is

located on the oven frame behind the storage drawer panel.)

• When a 4-wire or 3-wire, single phase 120/

240-volt, 60 Hz, AC-only electrical supply is

available, a 50 amp maximum circuit protection is required (or, if specified on the model/

serial rating plate, when a 4-wire or 3-wire

single phase 120/208-volt 60 Hz, AC-only

electrical supply is available, a 40 amp maximum circuit protection is required), fused on

both sides of the line.

• The range can be connected directly to the

fused disconnect (or circuit breaker box)

through flexible, armored or nonmetallic

sheathed, copper or aluminum cable.

• Allow 2 to 3 ft. of slack in the line so that the

range can be moved if servicing is ever

necessary.

• A UL listed conduit connector must be provided at each end of the power supply cable

(at the range and at the junction box).

• Wire sizes and connections must conform

with the rating of the range (40 amps).

• The wiring diagram is located on the underside of the storage drawer or below the

warming drawer in a clear plastic bag.

If connecting to a 4-wire system:

This range is manufactured with the ground

connected to the cabinet. The ground must be

revised so the green grounding wire of the 4wire power supply cord is connected to the

cabinet.

Grounding through the neutral conductor is

prohibited for new branch-circuit installations

(1996 NEC); mobile homes; and recreational

vehicles, or an area where local codes prohibit

grounding through the neutral conductor.

When a 4-wire receptacle of NEMA Type 1450R is used, a matching UL listed, 4-wire, 250volt, 40 amp, range power supply cord (pigtail)

must be used. This cord contains 4 copper

conductors with ring terminals or open-end

spade terminals with upturned ends, terminating in a NEMA Type 14-50P plug on the supply

end.

The fourth (grounding) conductor must be identified by a green or green/yellow cover and the

neutral conductor by a white cover.

• A time-delay fuse or circuit breaker is recommended.

2-5

The cord should be Type SRD or SRDT with a

UL listed strain relief and be at least 4 ft.

(1.22m) long.

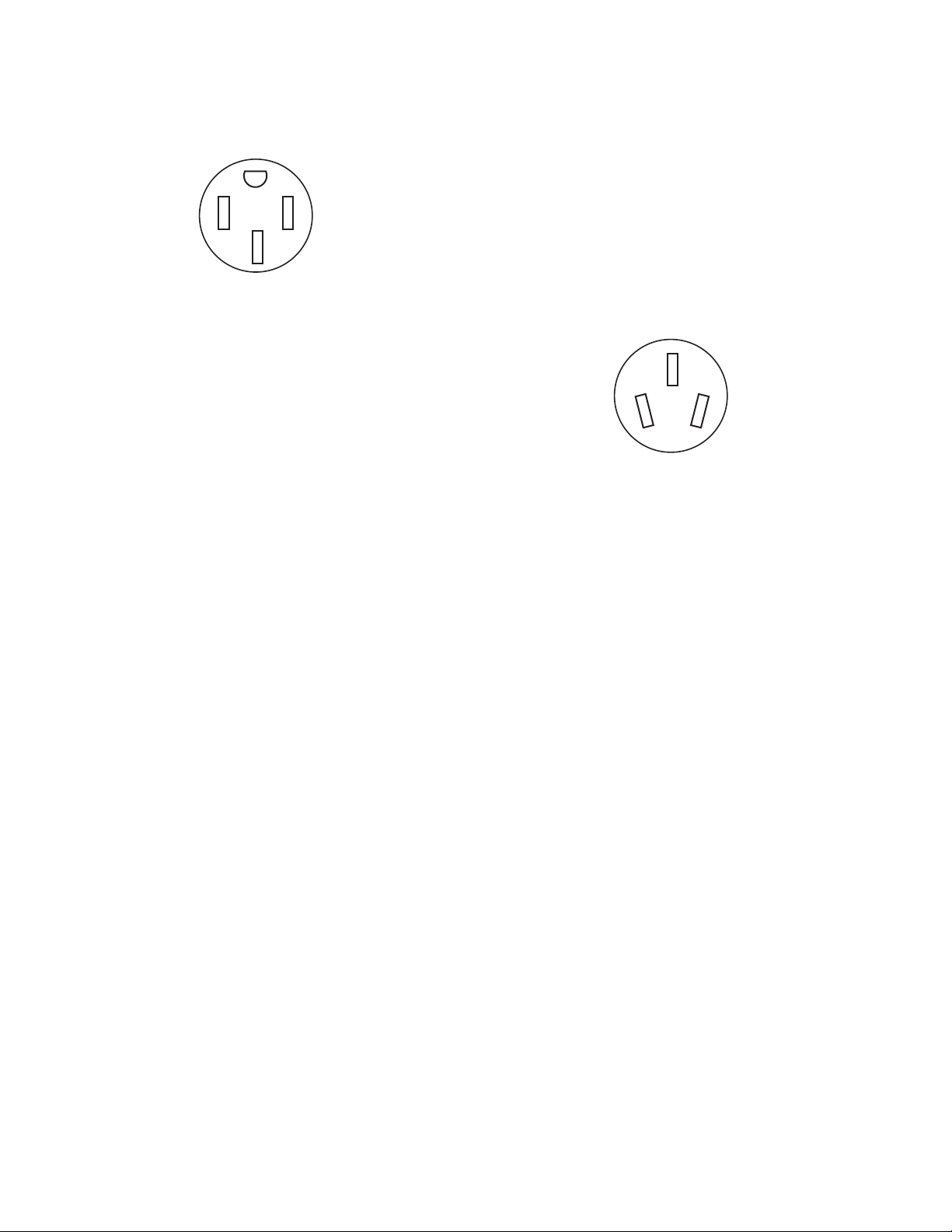

4-Wire Receptacle (14-50R)

The minimum conductor sizes for the copper

4-wire power cord are:

40 amp circuit

2 No.-8 conductors

1 No.-10 white neutral

1 No.-8 green grounding

If connecting to a 3-wire system:

Local codes may permit the use of a UL listed,

3-wire, 250-volt, 40 amp range power supply

cord (pigtail). This cord contains 3 copper

conductors with ring terminals or open-end

spade terminals with upturned ends, terminating in a NEMA Type 10-50P plug on the supply

end. Connectors on the appliance end must be

provided at the point the power supply cord

enters the appliance. This uses a 3-wire receptacle of NEMA Type 10-50R.

3-Wire Receptacle (10-50R)

2-6

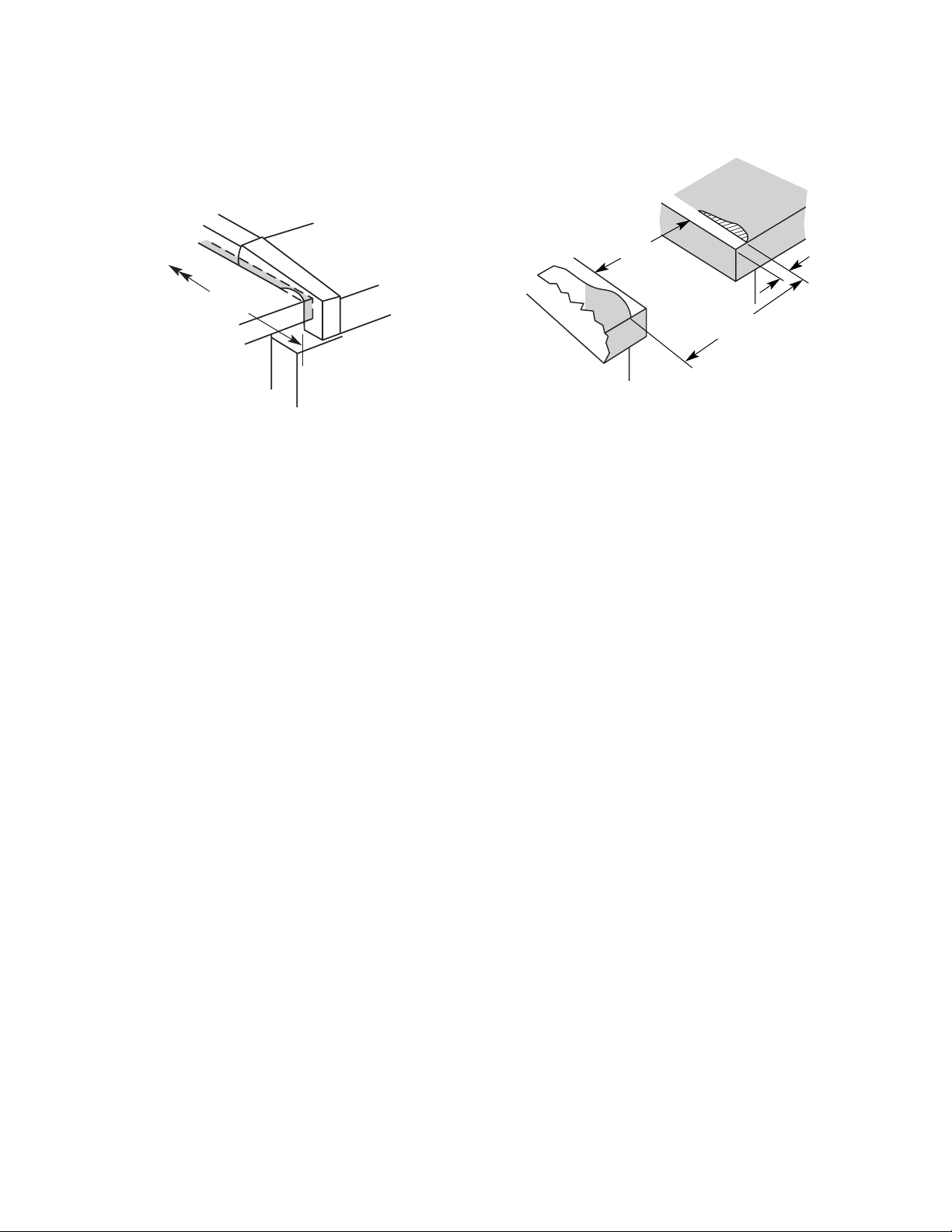

COUNTERTOP PREPARATION

(SLIDE-IN RANGES ONLY)

The cooktop sides of the slide-in range fit over

the cutout edge of the countertop.

Tile countertops may need the trim cut back

3/8″ (1.0 cm) from each front corner, and/or

have the rounded edge flattened.

30"

(76.2 cm)

3/8"

(1.0 cm)

22-3/4"

(57.8 cm)

If you have a square finish (flat) countertop,

and the opening width is 30″ (76.2 cm), no

countertop preparation is required.

Formed front-edged countertops must have

the molded edge shaved flat 3/8″ (1.0 cm) from

each front corner of the opening.

30-3/4"

(78.1 cm)

If the countertop opening width is greater than

30″ (76.2 cm), adjust the 3/8″ (1.0 cm) dimension.

The countertop must be level. Place a level on

the countertop, first side-to-side; then front-toback. If the countertop is not level, the range

will not be level. The oven must be level for

satisfactory baking performance.

2-7

INSTALLATION INSTRUCTIONS

If your home has: And you will be

connecting to:

Go to Section:

4-wire receptacle

(NEMA type 14-50R)

A UL listed,

250-volt

minimum,

40 amp, range

power supply

cord

4-wire connection:

Power supply cord

4-wire direct A fused

disconnect or

circuit breaker

box

4-wire connection:

Direct wire

3-wire receptacle

(NEMA type 10-50R)

A UL listed,

250-volt

minimum,

40 amp, range

power supply

cord

3-wire connection:

3-wire connection:

Power supply cord

3-wire direct A fused

disconnect or

circuit breaker

box

Direct wire

5"

(12.7 cm)

3"

(7.6 cm)

1"

(2.5 cm)

ELECTRICAL CONNECTION

Power Supply Cord

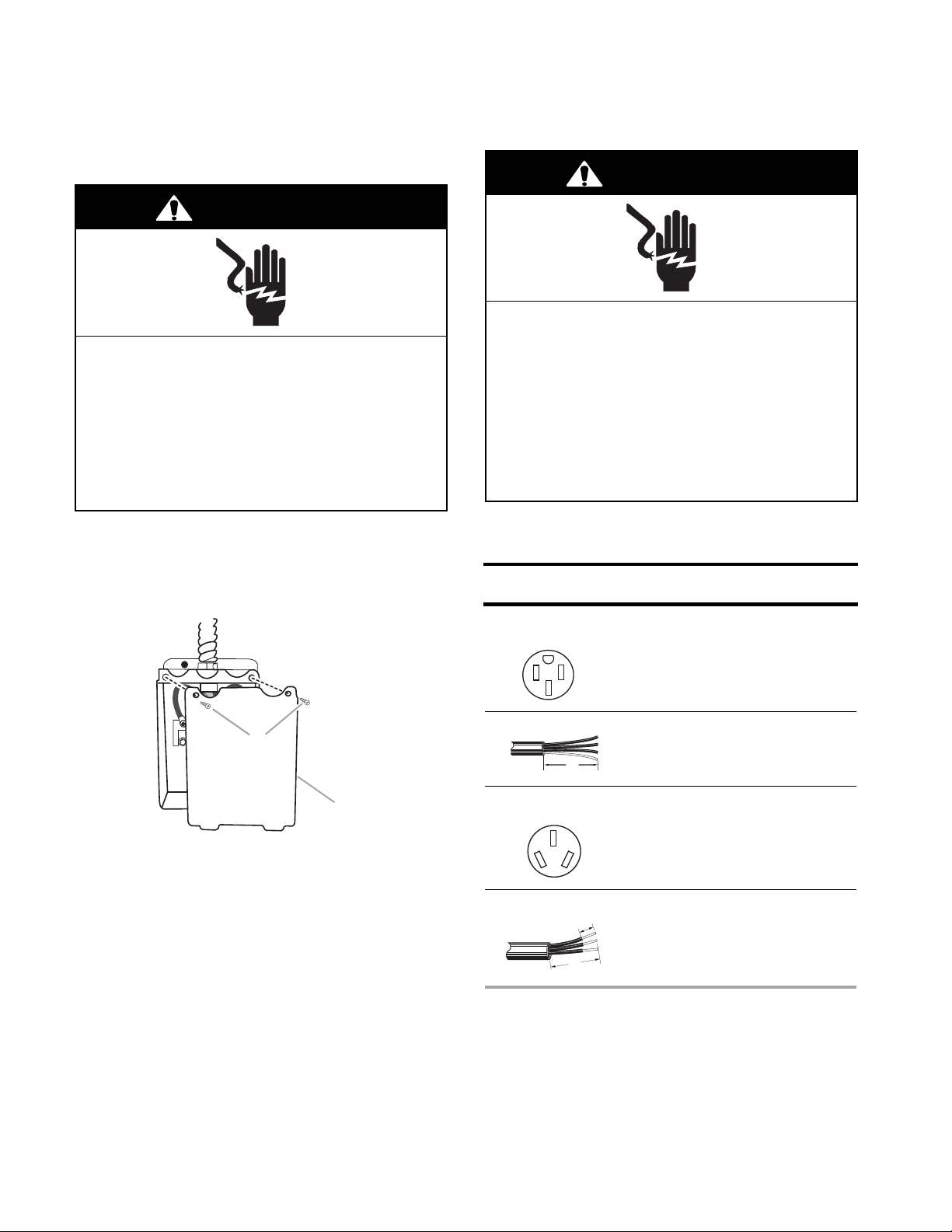

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Use a new 40 amp power supply cord.

Plug into a grounded outlet.

Failure to follow these instructions can

result in death, fire, or electrical shock.

1. Disconnect power.

2. Remove the hold-down screws and terminal block cover from the back of the range.

Direct Wire

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Use 8 gauge copper or 6 gauge

aluminum wire.

Electrically ground range.

Failure to follow these instructions can

result in death, fire, or electrical shock.

Electrical Connection Options

3. Complete installation following instructions

A. Hold-down screws

B. Terminal block cover

for your type of electrical connection:

4-wire (recommended)

3-wire (if 4-wire is not available)

A

B

2-8

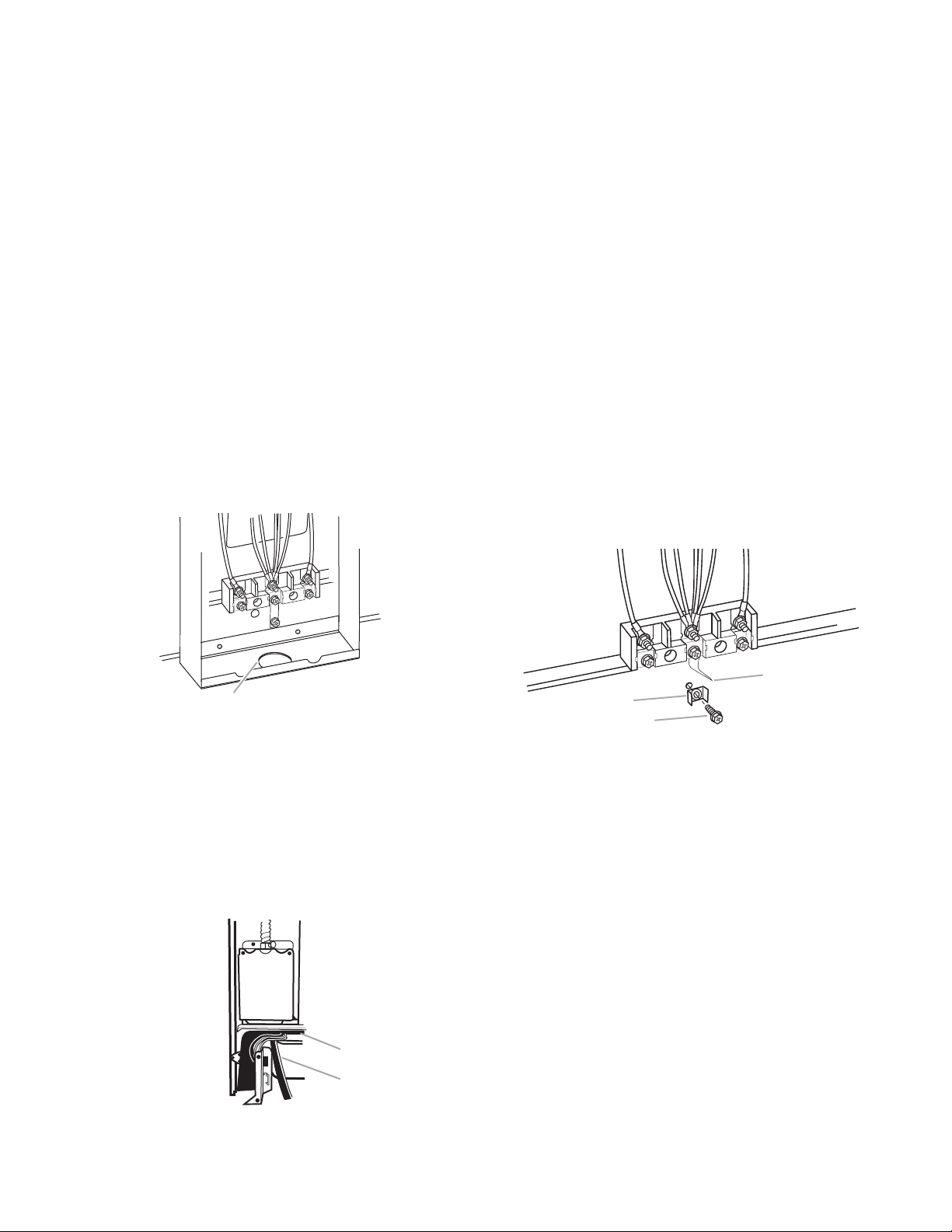

Power Supply Cord Installation

A. Ground-link screw

B. Cup washer

C. Ground-link bent away from range

A

C

B

WARNING: Improper connection of the equipment-grounding conductor can result in a risk

of electric shock. Check with a qualified electrician or service technician if you are in doubt as

to whether the appliance is properly grounded.

Do not modify the power supply cord plug. If it

will not fit the outlet, have a proper outlet

installed by a qualified electrician.

This range is manufactured with the neutral

terminal connected to the cabinet. Use a 3wire, UL listed, 40 amp power supply cord

(pigtail); or if local codes do not permit ground

through the neutral, use a 4-wire power supply

cord rated at 250-volts, 40 amps and investigated for use with ranges.

1. Remove the knockout for the 40 amp

power supply cord.

4. Connect the terminals (ring-type or spade

with upturned ends) on the end of the

power cord to the power supply.

5. Complete electrical connection according

to your type electrical supply (4-wire or

3-wire electrical connection).

4-wire connection: Power supply cord

Use this method for:

• New branch-circuit installations (1996 NEC)

• Mobile homes

• Recreational vehicles

• In an area where local codes prohibit ground-

ing through the neutral

1. Remove the ground-link screw from the

range frame. Save the ground link screw

and cup washer. Bend the ground-link

away from the range so that it does not

contact the range.

A

A. Remove knockout for 40 amp power cord

and UL listed strain relief

2. Assemble a UL listed strain relief in the

opening.

3. Feed the power supply cord behind the

black horizontal crossbrace and through

the strain relief, allowing enough slack to

easily attach the wiring to the terminal

block.

A

B

A. Black horizontal cross brace

B. Power supply cord

2. Connect the green ground wire from the

power supply cord to the range using the

ground-link screw and cup washer. The

ground wire must be attached first and

must not contact any other terminal.

2-9

3. Use a 1/4″ nut driver and remove the hex

washer head screws from the terminal

blocks.

4. Connect the neutral (center) wire to the

center terminal connector using one of the

hex washer head screws. Securely tighten

screw for proper electrical connection.

E

D

3-wire connection: Power supply cord

Use this method only if local codes permit

connecting cabinet-ground conductor to neutral wire of power supply cord.

1. Use a 1/4″ nut driver and remove the hex

washer head screws from the aluminum

terminal blocks.

2. Connect the neutral (center) wire to the

center terminal connector using one of the

hex washer head screws. Securely tighten

screw for proper electrical connection.

C

B

A

A. Line 1

B. Green ground wire

C. Ground-link screw

D. Hex washer head screw

E.Silver-colored terminal

block screw

I

F. Ground-link

G. Neutral (center) wire

H. Line 2

I. UL listed strain relief and

40 amp range power

supply cord

F

G

H

5. Connect the other 2 wires (lines 1 and 2)

to the outer aluminum terminal blocks.

6. Securely tighten screws for proper electrical connection.

7. Tighten strain relief screws.

8. Replace terminal block cover.

9. Plug in range or reconnect power.

D

C

E

B

F

A

G

A. Line 1

B. Ground-link

C. Hex washer head screw

D. Silver-colored terminal

block screw

E. Neutral (center) wire

F. Line 2

G. UL listed strain relief

and 40 amp range power

supply cord

3. Connect the other 2 wires (lines 1 and 2)

to the outer terminal screws on the terminal block.

4. Tighten strain relief screws.

5. Replace terminal block cover.

6. Plug in range or reconnect power.

2-10

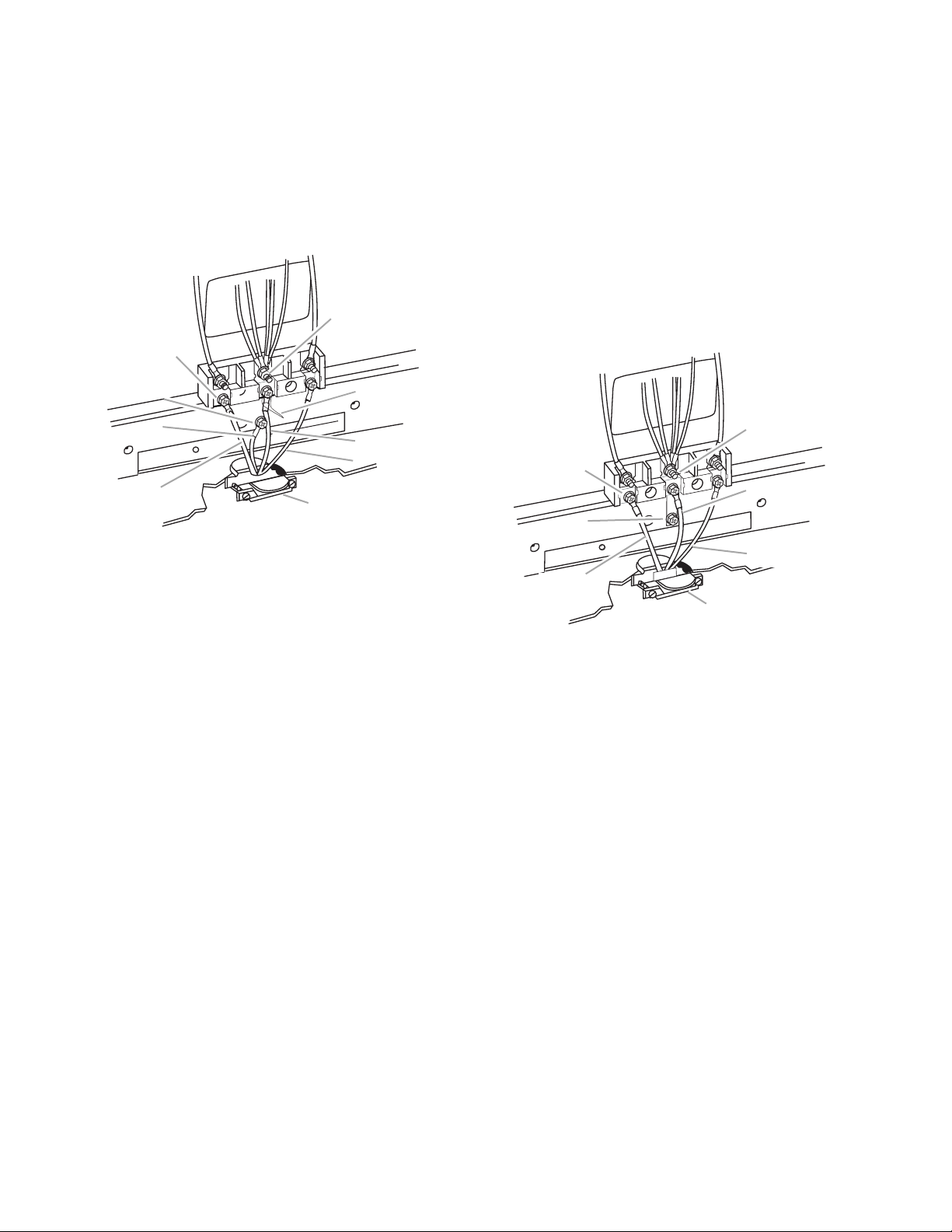

Direct Wire Installation: Copper or Aluminum Wire

This range may be connected directly to the

fuse disconnect or circuit breaker box. Depending on your electrical supply, make the

required 3-wire or 4-wire connection.

1. Remove the knockout as needed for the

conduit connection.

2. Assemble a UL listed conduit connector in

the opening.

A

A. UL listed conduit connector

3. Strip outer covering back 3″ (7.6 cm) to

expose wires. Strip the insulation back 1″

(2.5 cm) from the end of each wire.

1"

(2.5 cm)

3"

(7.6 cm)

1. Remove the ground-link screw from the

range frame. Save the ground-link screw

and cup washer. Bend the ground-link

away from the range so that it does not

contact the range.

C

B

A

A. Ground-link screw

B. Cup washer

C. Ground-link bent away from range

2. Connect the bare ground wire to the range

using the ground-link screw and cup

washer. The ground wire must be attached

first and must not contact any other terminal.

D

C

E

F

B

A

G

4. Allow enough slack in the wire to easily

attach the wiring terminal block.

5. Complete electrical connection according

to your type electrical supply (4-wire or 3wire electrical connection).

4-wire connection: Direct wire

Use this method for:

• New branch-circuit installations (1996 NEC)

• Mobile homes

• Recreational vehicles

• In an area where local codes prohibit ground-

ing through the neutral

A. Bare wire from power

supply cable

B. Line 1

C. Hex washer head screw

D. Silver-colored terminal

block screw

E.Line 2

F. Neutral (white) wire

G. UL listed conduit

connector and power

supply cable

3. Loosen (do not remove) the hex washer

head screw and insert the neutral (white)

wire under the screw clamp at the bottom

of the center position terminal connector.

2-11

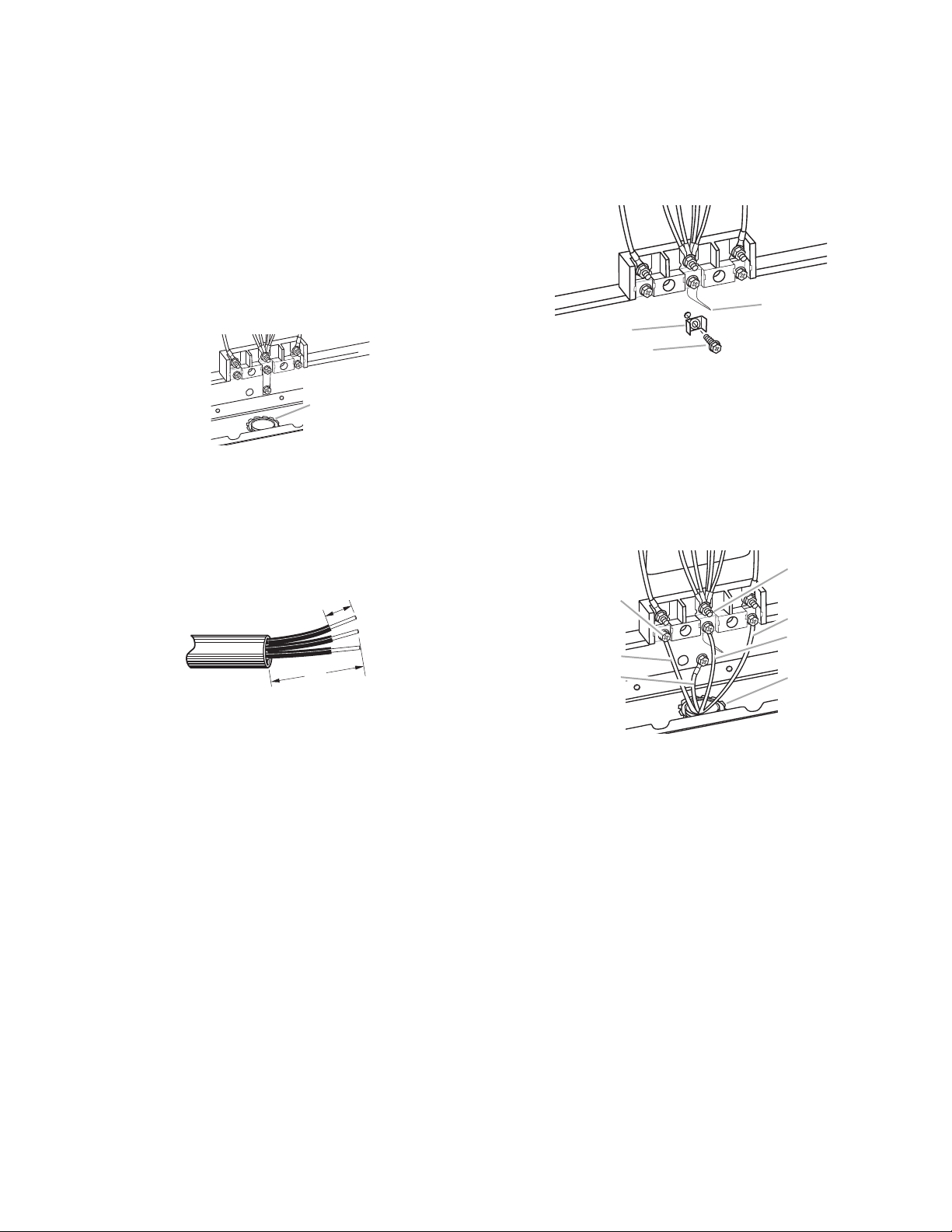

4. Insert the other 2 wires (lines 1 and 2)

under the other 2 screw clamps.

B

A

A. Insert wire under screw clamp

B. Hex washer head screw

3-wire connection: Direct wire

Use this method only if local codes permit

connecting ground conductor to neutral supply

wire.

1. Loosen (do not remove) the hex washer

head screws and insert the neutral (white)

wire under the screw clamp at the bottom

of the center position terminal connector.

D

5. Securely tighten the hex washer head

screws to 90 in.2/lbs minimum torque to

make proper electrical connection.

6. Tighten the locking ring of the conduit

connector.

7. Replace the terminal block cover.

C

E

F

B

A

A. Line 1

B. Ground-link

C. Hex washer head screw

D. Silver-colored terminal

block screw

E. Neutral (white) wire

F. Line 2

G. UL listed conduit

connector and power

supply cable

G

2. Insert the other 2 wires (lines 1 and 2)

under the other 2 screw clamps.

B

A

A. Insert wire under screw clamp

B. Hex washer head screw

3. Securely tighten the hex washer head

screws to 90 in.2/lbs minimum torque to

make a proper electrical connection.

4. Tighten the locking ring of the conduit

connector.

5. Replace the terminal block cover.

2-12

THEORY OF OPERATION

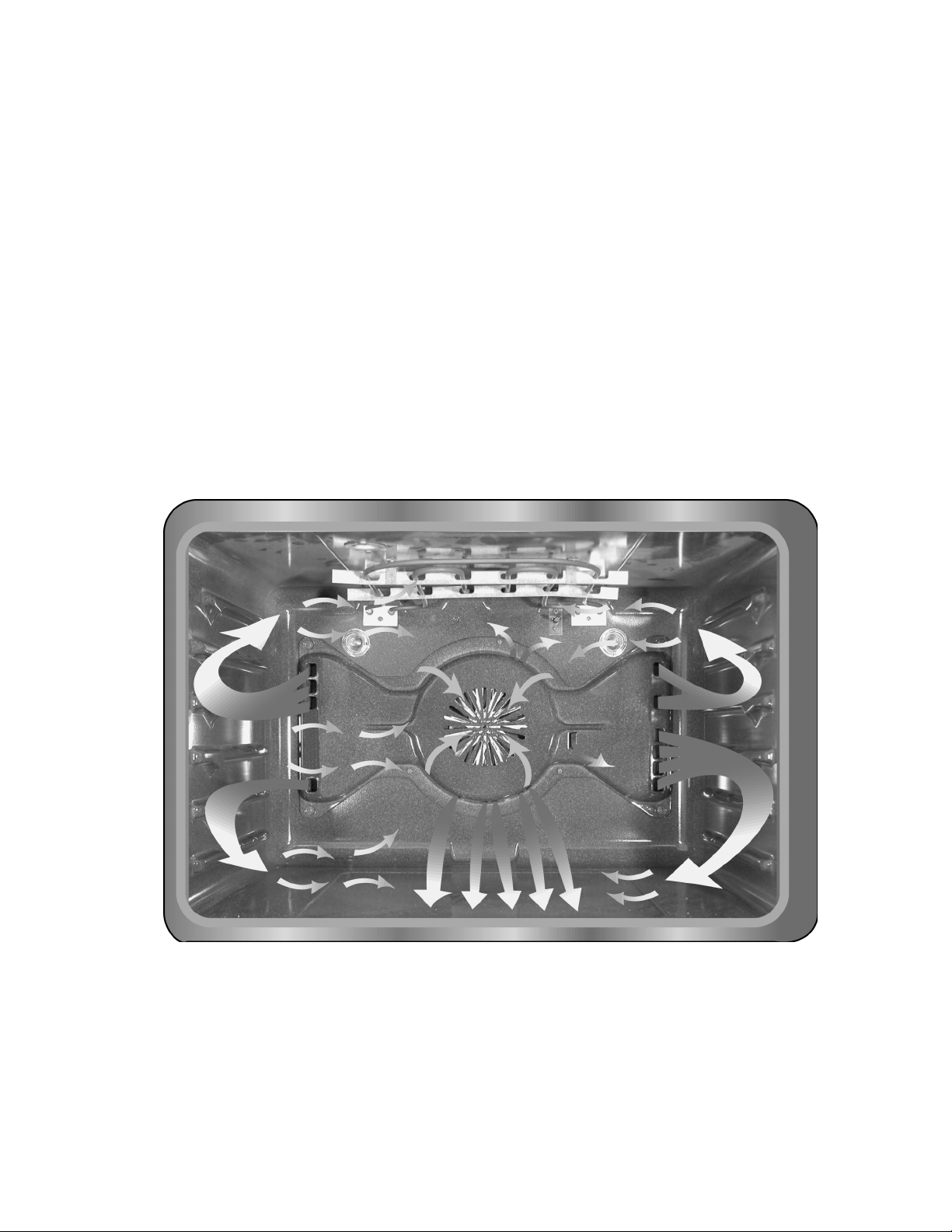

CONVECTION BOWTIE BAFFLE

AIRFLOW

The bowtie baffle provides a wider air flow

throughout the oven when using the convection cooking modes. The baffle, shown below,

is for an electric, Oxford-built oven. The gas

version of the Oxford oven has fewer air outlets, which eliminates too much air movement

during cooking (safety).

The correct baffle must always be used when

servicing a gas or electric oven. The oven cavity for Tulsa-built ranges is larger, (4.65 cu. ft.

as compared to 3.93 cu. ft.), and requires a

different baffle.

In a gas range, the convection fan will not turn

on for the first four minutes of operation. This

is to assure that a proper gas flame is present

before the convection fan starts to circulate air

in the oven cavity.

The fan blows hot air out the baffle along the

outer edges of the oven cavity, toward the front,

over the food, and back into the fan inlet. There

are air slots at the top and bottom of the center circle, which adds to the overall air flow

system.

Electric Oxford-Built Oven Convection Bowtie Baffle System

3-1

Loading...

Loading...