Page 1

96M11226

Digital Calibration Fiberoptic Sensors

Warning

• This product is just intended to detect the object(s). Do

not use this product for the purpose to protect a human

body or a part of human body.

• This product is not intended for use as explosion-proof

product. Do not use this product in a hazardous

location and/or potentially explosive atmosphere.

FS-V1(P)

Instruction Manual

Read this manual before using the product in order to achieve maximum performance.

Keep this manual in a safe place after reading it so that it can be used at any time.

Warning

NOTICE

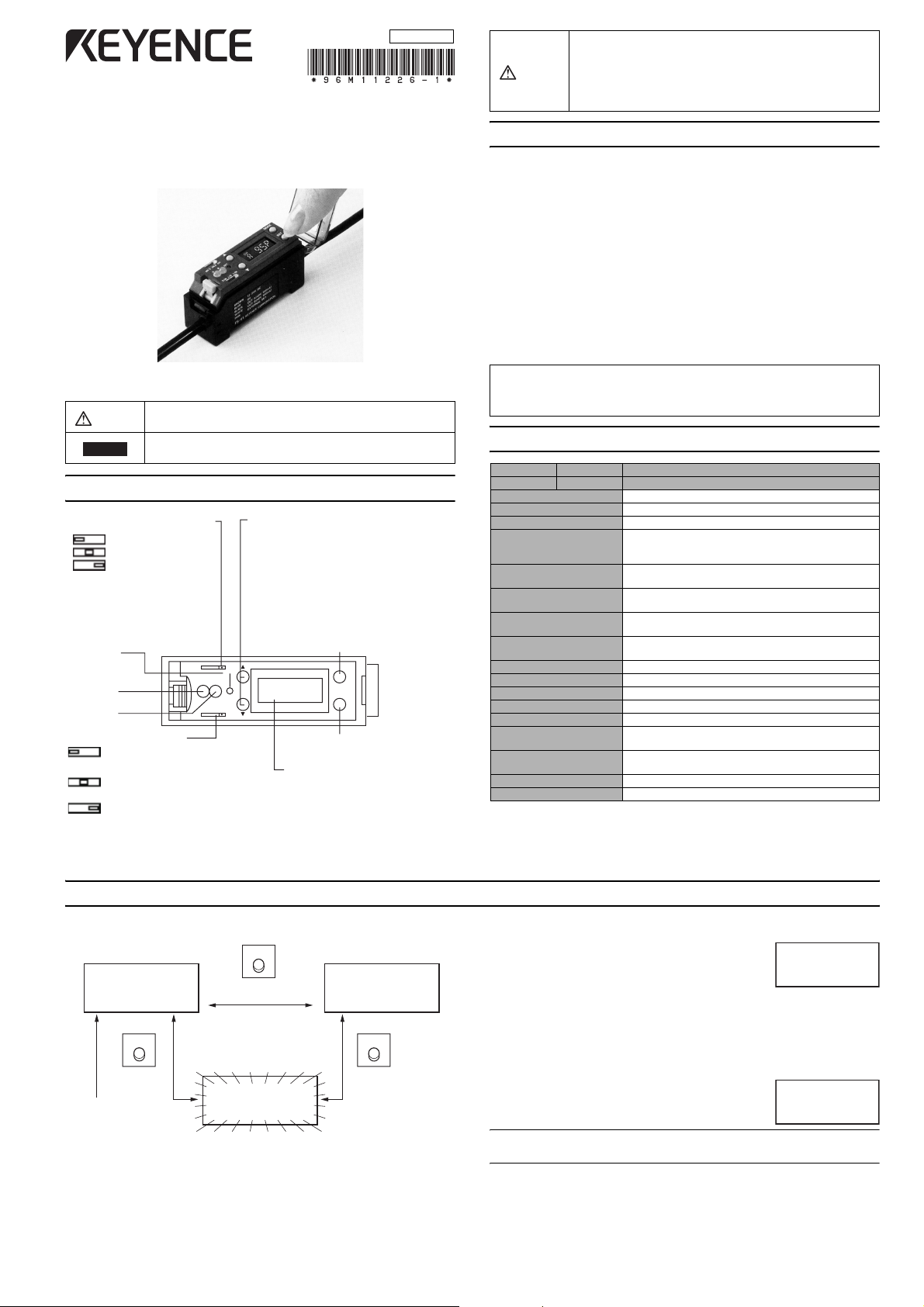

PART NAMES AND FUNCTIONS

Output timer selector switch UP/DOWN key

Note: Outputs of both A and B

are set to the same mode.

Calibration

indicator

Output A

indicator

Output B

indicator

Output selector switch

*Use the UP/DOWN key together with the MODE selector button.

It indicates a hazardous situation which, if not avoided,

could result in death or serious injury.

It indicates a situation which, if not avoided, could result in

product damage as well as property damage.

OFF-delay 40 ms

ON-delay 40 ms

Timer OFF

AB

DARK-ON for both outputs

A and B

LIGHT-ON for output A and

DARK-ON for output B

LIGHT-ON for both outputs

A and B

• Changes sensitivity setting value.

• Selects channel (expansion unit).

MODE selector button

• Selects displayed data.

• Excess gain

• Light intensity

• Setting value

• Selects channel (expansion unit). *

• Enables/disables key protect. *

MODE

CH

2

#

SET

SET button

Sets sensitivity.

LCD display monitor

Turns display red when the

selected channel is ON.

Turns display green when the

selected channel is OFF.

PRECAUTIONS ON REGULATIONS AND STANDARDS

UL Certificate

This product is an UL/C-UL Listed product.

• UL File No. E301717

• Category NRKH,NRKH7

• Enclosure Type 1 (Based on UL50)

Be sure to consider the following specifications when using this product

as an UL/C-UL Listed Product.

• Use the power supply with Class 2 output defined in NFPA70 (NEC:

National Electrical Code).

• Power supply/ Control input/ Control output circuits shall be connected to a single Class 2 source only.

• Use with the over current protection device which is rated 24 V or

more and not more than 2 A.

Accessories

• Instruction manual (x 1)

• Mounting bracket (x 1)

SPECIFICATIONS

Model NPN output

Light source Red LED

Response time 250 μs

Operation mode LIGHT-ON/DARK-ON (switch-selectable)

Indicators

Timer function ON-delay: 40 ms, OFF-delay: 40 ms,

External calibration

input signal

Control output

(2 outputs)

Protection circuit Reverse polarity protection, Over-current protection,

Power supply voltage 12 to 24 VDC ±10%, Ripple (P-P) 10% max., Class 2

Current consumption 50 mA max.

Ambient illumination Candescent lamp: 10,000 lx max., Sunlight: 20,000 lx max.

Ambient temperature -10 to +55°C (14 to 131°F), No freezing

Relative humidity 35 to 85%, No condensation

Vibration 10 to 55 Hz, 1.5 mm double amplitude in X, Y and

Shock immunity 500 m/s2 in X, Y and Z directions,

Housing material Body/Cover: Polycarbonate

Weight Approx. 80 g (including 2 m cable)

1 A "P" following the model number indicates PNP-output type.

2 When several units are connected, the allowable ambient temperature changes depending

on the following conditions. To connect several units, be sure to mount them to a DIN rail

(metal DIN rail). Make sure that the output current is 20 mA. max.

• When 3 to 10 units are connected: -10 to +50 °C

• When 11 to 16 units are connected: -10 to +45 °C

PNP output

Output indicators: 2 Red LED’s,

Received light intensity display: LCD (Red/Green LED back-lit)

Calibration indicator: Yellow LED,

Timer OFF (switch selectable)

NPN or PNP open-collector 24 V 100 mA max.,

Residual voltage : 1 V max.

FS-V1

FS-V1P

contact, solid state

Surge protection

Z directions for two hours

three times each

SELECTING DISPLAYED DATA

Excess gain (%)

CH

#

2

MODE

Press this

button once.

Channel display:

Indicates the

channel of the

expansion unit

currently being

monitored.

* The setting value flashes on and off.

(Factory-setting is Excess gain.)

MODE

Hold down this button

for longer than 3 seconds.

Setting value (4 digits)

CH

#

Received light intensity

(4 digits)

CH

#

MODE

Press this

button once.

Displaying excess gain

Received light intensity is converted by defining

the setting value as 100 P (%).

• Stable LIGHT status is obtained with 110 P (%) or more.

• Stable DARK status is obtained with 90 P (%) or less.

You can adjust the sensitivity in increments of 1%.

CH

# 2

¨ Refer to P.2.

Displaying received light intensity

Received light intensity is displayed approximately 4000 is the maximum setting.

Note: The MAX and MIN values vary depending on the fiber unit connected.

CH

#

Displaying a setting value

The current setting value is displayed. You can adjust the setting value

in increments of 1 .

¨ Refer to P.2.

1

Page 2

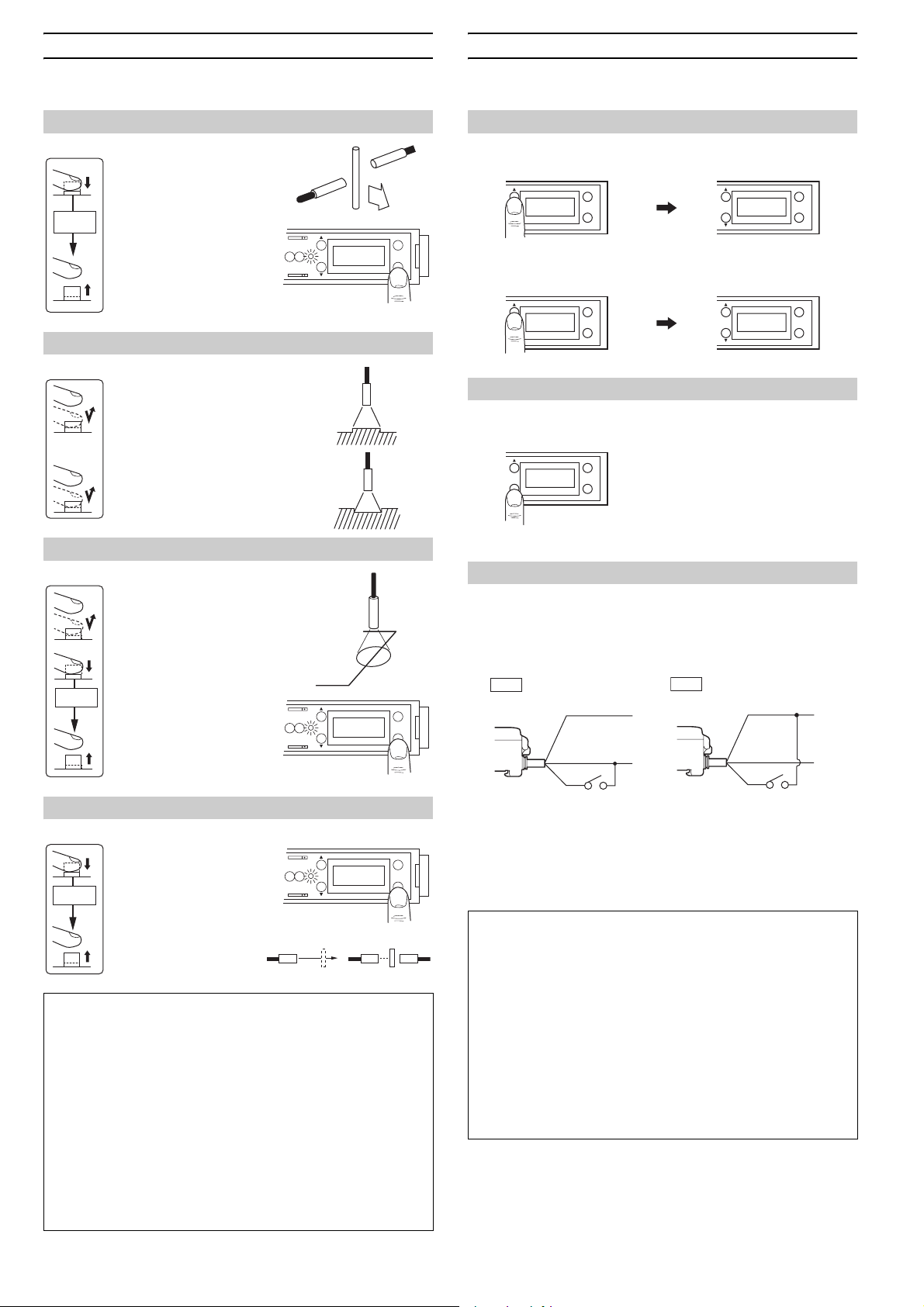

SETTING SENSITIVITY

Select the sensitivity setting procedure according to the target condition.

CHANGE THE SETTING VALUE

You can change the setting value in “excess gain display” mode or “setting value display” mode.

For sensitivity adjustment using a moving target

z Fully-automatic Calibration

1. Pass a target through the

optical axis while pressing the SET button.

At least

3 seconds

2. Confirm that the calibration indicator (yellow LED)

flashes.

3. Release the SET button.

AB

CH

# 2

MODE

SET

The calibration indicator

(yellow LED) goes off.

To detect a minute difference

z Two-point Calibration

1. With a target in place, press

the SET button and release it.

The calibration indicator (yellow LED) lights.

2. With the target removed,

press the SET button and

release it. The calibration

indicator (yellow LED) goes

off.

For target positioning

z Positioning Calibration

1. With no target, press the

SET button and release it.

The calibration indicator

(yellow LED) lights.

2. Place a target in the position where it is to be

At least

3 seconds

stopped.

3. Press the SET button until

the calibration indicator

flashes.

AB

CH

# 2

MODE

SET

4. Release the SET button.

For stable detection unaffected by dust

z Maximum Sensitivity Setting

1. Under the following con-

At least

3 seconds

ditions press the SET

button until the calibration

indicator (yellow LED)

flashes.

2. Release the SET button.

The calibration indicator

(yellow LED) goes off.

AB

Reflective type Thrubeam type

With no target With target

CH

# 2

CUE: When the sensitivity difference is insufficient

If sensitivity has no allowance after calibration, “------” flashes for 3

seconds on the LCD display monitor.

Note: Sensitivity is set and registered even when the sensitivity difference is insufficient. Be sure to confirm that detection is properly performed.

CUE: Locking the operation button (Key protect)

Hold down [MODE] and [UP] simultaneously for 3 seconds to lock the

operation button. When the operation button is locked, “Loc” is displayed in flashing letters.

To unlock the operation button, repeat the procedure above. “vnL”

(unlocked) is displayed in flashing letters.

Even when the operation button is locked, display data and channel

can be changed.

MODE

SET

Increase sensitivity (=Decrease the setting value)

z In excess gain display mode

The sensitivity increases by 1% each time you press [UP].

CH

# 2

MODE

SET

CH

# 2

MODE

SET

z In setting value display mode

The setting value decreases by 1 each time you press [DOWN].

CH

#

MODE

SET

CH

#

MODE

SET

Decrease sensitivity (=Increase the setting value)

The method for decreasing the sensitivity is the same as for increasing

the sensitivity, except you must press [DOWN] instead.

CH

# 2

MODE

SET

CUE: Holding down [UP] or [DOWN] changes the setting value rapidly.

For sensitivity adjustment using an external signal

z External Calibration Function

1. Hold down [MODE] and [UP] simultaneously for 3 seconds to display

“Loc”. (If “vnL” appears, repeat the same procedure.)

2. Connect the pink cable to a switch or PLC.

NPN

Brown

Blue

Pink

Contact or

solid-state input

The minimum input time is 20 ms.

3. The external calibration procedure is the same as using the SET button. Turn the input device on instead of pressing the SET button.

Also, turn the input device off instead of releasing the SET button.

(You can perform all the setting procedures described on the left.)

CUE: Calibration input during detection

You can re-adjust sensitivity during detection without stopping the

operation.

The sensor continues operation with the previous sensitivity setting

until sensitivity readjustment is completed.

CUE: External calibration with several units

When several units are connected, the sensitivity of all the FS-T2(P)

expansion units can be simultaneously set using the external calibration input through the FS-V1(P).

You can select a unit to be externally calibrated by setting its key protection switch to the LOCK position.

External calibration is effective for all the units which are locked. Set

the key protection switch to LOCK on the FS-T2(P) expansion unit to

be externally calibrated.

PNP

+V

0V

Brown

Blue

Pink

Contact or solid state input

+V

0V

2

Page 3

CONTROL AN EXPANSION UNIT [FS-T2(P)]

1. To change the channel, press

[UP] (or [DOWN]) while holding

[MODE].

Select the channel for the

expansion unit [FS-T2(P)] to be

controlled.

2. You can monitor the expansion

unit [FS-T2(P)] or change its

sensitivity setting value using

the same procedures as for the

FS-V1(P).

Channel

display

AB

CH

# 2

SET

MODE

CH2 CH17CH4CH3

Expansion units

CONNECTING FIBER UNIT

Lower the quick-release lever, insert the fiber unit about 14 mm until it

reaches the end, and then lift the quick-release lever.

12

• To connect a fiber unit with a small diameter, use the adaptor

included with the FU series.

1. Attach the adaptor to the fiber

unit.

2. Fully insert the adaptor into the

mounting holes of the amplifier,

and then lift the quick-release

lever.

1

2

• You cannot use the FS-V1(P)’s SET button to set the sensitivity of the

expansion unit.

• The red LED and green LED turn ON and OFF in response to the

expansion unit [FS-T2(P)] turning ON and OFF.

Note 1: You cannot control the [FS-M2(P)] (Manual calibration model).

Note 2: The channel for the [FS-M2(P)] is displayed as “------”. The

red LED and green LED turn ON and OFF in response to the [FSM2(P)] turning ON and OFF.

Note 3: If you add an FS-V20 Series expansion unit, you may not be

able to control the FS-V20 Series and any expansion units added after

the FS-V20 Series .

Note: If the fiber unit is improperly connected, the sensor cannot meet

the specifications.

• The required adaptor is included in each model of the FU series. If an

inadequate adaptor is used, the fiber unit cannot be properly installed.

Cable outer dia. Type Shape

φ1.3

φ1.0

Adaptor A

(OP-26500)

Adaptor B

(OP-26501)

• To connect the coaxial reflective type fiber unit to the amplifier, connect the single-core fiber to the transmitter side, and connect the

multiple-core fiber to the receiver side.

(Connect the fibers according to the marking on the amplifier lateral side.)

Transmitter

Multiple-core

Single-core

Receiver

MOUNTING MAIN UNIT

Mounting/Detaching the unit to/from a DIN rail or the

mounting bracket.

Hook the claw located at the unit cable side onto the DIN rail, and then hook the

front side claw to the rail while pressing the amplifier forward. To detach the

unit, unhook the front claw by lifting the unit front side while pressing it forward.

Mounting Detaching

MUTUAL INTERFERENCE SUPPRESSION FUNCTION

When using several fiber units, each fiber unit is free from light

interference from up to 4 adjacent fiber units.

When the fiber units are mounted closely, each fiber unit and its 4 adjacent units are designed to receive light at different pulse frequencies to

avoid interference.

MOUNTING EXPANSION UNITS

Mounting EXPANSION units

1. Detach the protective cover from the

unit’s side panel.

2. Mount units to a DIN rail one by one.

3. Slide one expansion unit toward

another. Align the front claws of the

units and push the unit together until

they click.

4. Fix the units together by pushing an

end unit onto each end. (The end units

are included in the expansion unit)

Detaching units from DIN rail

1. Remove the end units.

2. Slide the expansion units apart, and

detach them individually.

(Do not detach multiple units connected together with end units.)

• When several units are connected, confirm the ambient temperature. (See "Specifications" on P. 1.)

NOTICE

• To connect several units, be sure to use a DIN rail and end units.

• To mount or detach several units, be sure to turn the power off.

• Do not remove the protective cover of the expansion connector

on the outmost unit.

Mounting a unit laterally

Secure the screws through the mounting bracket’s side hole (accessory)

M3 screw

You can mount the FS-T(P) series and

the FS-M(P) series together within the

same system.

Note: If you do not use the expansionunits, the mutual interference suppress

function is not available.

Align the claw.

Expansion

Main unit

1.

Remove the protective cover.

2.

unit

Up to 16 expansion units

can be connected.

1. The FS-T1(P)/M1(P) can be used as the

same unit as well as the FS-V1(P).

2. FS-M2(P) can be used as the expansion unit

as well as the FS-T2(P).

The sticker shown on the right is

included in the expansion unit. Apply

this sticker near the sensor.

End unit

(Included

with FS-T2)

Slide the unit to the

right to remove it.

3

Page 4

SETTING 2 INDEPENDENT OUTPUTS

V

The FS-V1(P) allows you to set two types of sensitivity (tolerance individually.

To change the channel, press [UP] or [DOWN] while holding [MODE].

Output lines for channels A and B

CH

#

CH

Black

White

Channel A output

Channel B output

D

HINTS ON CORRECT USE

• To extend the cable length, use a cable with at least a 0.3 mm2

cross-section area. Limit the length of cable extension to no more

than 100 m. (To connect several units, contact Keyence for further

information.)

• If the amplifier cable is placed together with power lines or high voltage lines in the same conduit, detection error may occur due to noise

interference, or the sensor may be damaged. Isolate the amplifier

cable from these lines.

• When using a commercially available switching regulator, ground the

frame ground terminal and ground terminal.

• Do not use the FS series outdoors, or in a place where extraneous

light can enter the light receiving surface directly.

• During maximum sensitivity setting, the detecting distance may vary

due to the difference in characteristics of each unit.

• When the stability output is not used, cut the orange cable at the root

or connect it to the 0 V (“+” for PNP output model) terminal of the

power supply, in order to avoid contact with other cables.

• When the external calibration is not used, cut the pink cable at the

root or connect it to the “+” (“0 V” for PNP output model) terminal of

the power supply, in order to avoid contact with other cables.

DIMENSIONS

FS-V1(P)

18

(Maximum

when the

cover is

opened)

78

4

2.1

6.7

When the mounting bracket

[included in FS-V1(P)] is attached:

1.1

36.5

5

11.3

15

18.5

When several units are connected:

End unit

1.

618 6L

1. The FS-V1(P) is mounted in .

2. When using expansion units, be sure to use the end unit

(accessory to the expansions unit.)

DIN-rail mounting

1,1 6

(33)

28.5

12

min.

2 x φ3.4

8

φ3.9 5-core x

35.48.4

53.5

16

Brown/Blue: 0.34 mm

Black/White/Pink: 0.18 mm

Cable length: 2 m

135

max.

(12.5)

12

min.

Rear view of mounting

bracket

151815

29.4

2.

End unit

Unit: mm

2

2

2 x (4.4 x 3.4)

No. of units L

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

108

117

126

135

144

9

18

27

36

45

54

63

72

81

90

99

I/O CIRCUIT

FS-V1

Overcurrent

protection circuit

main circuit

Photoelectric sensor

Input circuit

(External calibration input circuit)

12 to 24 VDC

3.3 kΩ

11 kΩ

FS-V1P

Overcurrent

protection circuit

main circuit

Photoelectric sensor

Input circuit

(External calibration input circuit)

3.3 kΩ

11 kΩ

Brown

Black

(Control output)

White

(Control output)

Blue

Pink (External calibration input)

Pink

Contact or solid

state input

Brown

Black

White

Blue

Pink (External calibration input)

Pink

Contact or solid

state input

0 V

100mA max.

Load

100mA max.

Load

100mA max.

Load

100mA max.

Load

12 to 24 VDC

0

12 to 24 VDC

12 to 24 VDC

WARRANTY

KEYENCE products are strictly factory-inspected. However, in the event of a failure,

contact your nearest KEYENCE office with details of the failure.

1. WARRANTY PERIOD

The warranty period shall be for one year from the date that the product has been

delivered to the location specified by the purchaser.

2. WARRANTY SCOPE

(1) If a failure attributable to KEYENCE occurs within the above mentioned warranty

period, we will repair the product, free of charge. However, the following cases shall

be excluded from the warranty scope.

• Any failure resulting from improper conditions, improper environments, improper

handling, or improper usage other than described in the instruction manual, the

user’s manual, or the specifications specifically arranged between the purchaser

and KEYENCE.

• Any failure resulting from factors other than a defect of our product, such as the

purchaser’s equipment or the design of the purchaser’s software.

• Any failure resulting from modifications or repairs carried out by any person other

than KEYENCE staff.

• Any failure that can certainly be prevented when the expendable part(s) is

maintained or replaced correctly as described in the instruction manual, the

user’s manual, etc.

• Any failure caused by a factor that cannot be foreseen at a scientific/technical

level at the time when the product has been shipped from KEYENCE.

• Any disaster such as fire, earthquake, and flood, or any other external factor, such

as abnormal voltage, for which we are not liable.

(2) The warranty scope is limited to the extent set forth in item (1), and KEYENCE

assumes no liability for any purchaser’s secondary damage (damage of equipment,

loss of opportunities, loss of profits, etc.) or any other damage resulting from a

failure of our product.

3. PRODUCT APPLICABILITY

KEYENCE products are designed and manufactured as general-purpose products

for general industries.

Therefore, our products are not intended for the applications below and are not

applicable to them. If, however, the purchaser consults with us in advance regarding

the employment of our product, understands the specifications, ratings, and

performance of the product on their own responsibility, and takes necessary safety

measures, the product may be applied. In this case, the warranty scope shall be the

same as above.

• Facilities where the product may greatly affect human life or property, such as

nuclear power plants, aviation, railroads, ships, motor vehicles, or medical

equipment

• Public utilities such as electricity, gas, or water services

• Usage outdoors, under similar conditions or in similar environments

2010

11226E 1080-1 96M11226

4

Loading...

Loading...