Page 1

AutoID System

Integrated Setup Software

AutoID Navigator

User's Manual

Page 2

Preface

This manual presents an outline of the AutoID System Integrated Setup Software AutoID Navigator,

and describes the functions and method of use of this software.

Read and thoroughly understand this manual before you start to use this software. Store this

manual in a safe place so that you can retrieve it whenever necessary.

■ Related Manuals

Read the following manuals when you use the AutoID Navigator.

If you require these manuals, contact your agent.

Type of Manual Description of Manual

RF-500

Installation Guide

RF-500

Installation/Connection Manual

RF-500

Operation Manual

AutoID Navigator

User's Manual

(PDF only)

N-410

User's Manual

BL-700 Series

BL-U1, BL-U2, N-42

User's Manual

BL-600 Series

User's Manual

BL-500 Series

User's Manual

BL-180 Series

User's Manual

SR-500 Series

User's Manual

This manual describes the functions and features of the RF-500 Series,

and presents installation examples.

This manual describes how to install and connect the RF-500 Series or

related devices, and how to operate these devices.

This manual describes operation of the various system component devices,

settings for operating these devices, and the commands

for performing

communications between the various devices.

This manual.

This manual describes how to operate and set up the AutoID system

integrated setup software AutoID Navigator.

This manual describes how to install and set up the RS-485 Master Unit

N-410, settings for operating the N-410, and how to operate devices.

This manual describes how to connect, install, and set the BL-700 Series

Long Range Laser Bar Code Reader and the BL-U1/BL-U2/N-42 Power

Supply Unit and includes precautions for usage.

This manual describes how to connect, install, and set the BL-600 Series

Super Compact Laser Bar Code Reader and includes precautions for

usage.

This manual describes how to connect, install, and set the BL-500 Series

Super Compact Laser Bar Code Reader and includes precautions for

usage.

This manual describes how to connect, install, and set the BL-180 Series

Super Compact CCD Bar Code Reader and includes precautions for

usage.

This manual describes how to connect, install, and set the SR-500 Series

Fixed 2D Code Reader and includes precautions for usage.

•Microsoft, Windows, Windows 2000, Windows XP are registered trademarks or trademarks

of Microsoft Corporation in the United States or other respective countries.

• CC-Link and MELSEC are registered trademarks of Mitsubishi Electric Corporation.

•DeviceNet is a registered trademark of ODVA (Open DeviceNet Vendor Association, Inc.).

• SYSMAC is a registered trademark of OMRON Corporation.

Page 3

For Safe Usage

This manual describes handling, operation, and safety information for AutoID Navigator.

Read this manual thoroughly in order to take full advantage of product performance, and use the

product only after fully understanding its contents.

Store this manual in a safe place so that you can retrieve it whenever necessary.

See to it that the manual reaches the last person who is going to use the product.

■ This manual's format

This manual uses the following symbols to alert you to important information.

Important

Note

Tip

DANGER

WARNING

CAUTION

Failure to follow these instructions may lead to death or serious injury.

Failure to follow these instructions may lead to injury.

Failure to follow these instructions may lead to physical damage (product

malfunction, etc.).

This heading is used to indicate precautions and restrictions that must be followed when operating the product.

This heading is used to indicate cautions relating to device operation where

operator error is likely.

Indicates useful information or information that aids understanding of text descriptions.

Indicates a reference item or page to be referred to in this manual and a separate manual.

1

Page 4

■ General Precautions

•Verify that this device is operating normally in terms of functionality and performance before the

start of work and when operating this device.

•We recommend that you take substantial safety measures to avoid any damage in the event

that a problem occurs.

•Proceed with care when modifying this product, or when using it in a manner that falls outside of

the ranges indicated in its specifications, since KEYENCE is unable to guarantee device functionality or performance in such situations.

•Use this product in combination with other devices only after careful consideration, since it may

fail to satisfy its functionality and performance capabilities as a result of the conditions and environment in which it is used.

•Do not use the product with the purpose of protecting human beings.

■ Requests

When using this device under the following conditions or operating environments, please consult

with your KEYENCE sales representative in addition to implementing safety measures such as

product operation that allows leeway with respect to features and use of failsafe provisions.

•Use of the product under conditions not described in this manual

•Use of the product in nuclear power generation control, railroad facilities, aviation facilities,

vehicles, combustion devices, medical equipment, entertainment machinery, safety equipment,

etc.

•Use of the product in applications that may have a significant impact on human life or property,

or that place a high priority on safety

2

Page 5

Software License Agreement

Before you use this software, be sure to read the terms of this agreement.

Once you have started to use this software, it is assumed that you have consented to these

terms, and an agreement is established between KEYENCE CORPORATION and the user.

Terms

1. Rights of Use

KEYENCE CORPORATION shall permit the user the non-exclusive rights to use this software

in accordance with the terms of this agreement.

2. Copyright

Copyright relating to this software and manual shall belong to KEYENCE CORPORATION,

and the user shall not have rights other than the rights of use.

3. Forbidden Items

The user shall not be able to copy this software, nor be able to sell or distribute it to a third

party. The user, however, shall be able to copy this software for the purpose of making backups

for the user's own use.

4. Exemption of Liabilities

KEYENCE CORPORATION shall not be subject to liability with respect to damage on the part

of the user or a third party as a result of having operated this software.

5. Cancellation of Agreement

Should the user have violated any terms of this agreement, KEYENCE CORPORATION shall

immediately be able to cancel this agreement, and the user shall destroy or return this software and copies to KEYENCE CORPORATION.

3

Page 6

Contents

Preface

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Conventions Used In This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Te r m i n o lo g y . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Chapter 1 BEFORE YOU START USING AutoID Navigator

1-1 Checking the Contents of the Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1-2 Operating Environment and System Configuration . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Operating Environment and System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Functions and Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

1-3 Installing AutoID Navigator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Before Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

Installing AutoID Navigator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

Uninstalling AutoID Navigator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

1-4 Data Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-11

Compatibility between Setup Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Chapter 2 OUTLINE OF AutoID Navigator

2-1 Starting Up and Quitting AutoID Navigator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

How to Startup AutoID Navigator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

How to Quit AutoID Navigator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Option Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

2-2 Names and Functions of Screen Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

About screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

2-3 Registerable Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Registerable Devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

2-4 List of Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Basic Project File Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

Setup File Management Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

Device Add/Delete Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

Chapter 3 MANAGING PROJECTS

3-1 Outline of Projects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

What Is a "Project"?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

3-2 Creating Projects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Procedure for Creating a Project . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

3-3 Registering Devices and Saving Projects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Signal Registration and Network Registration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Registering Devices by Single Registration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Registering Devices by Network Registration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-6

Saving Projects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-9

Opening Projects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-10

Creating a New Project . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-10

4

Page 7

3-4 Editing Setup Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-11

Type of and Brief Description of Setup Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

How to Set Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-13

Saving Setup Files. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-14

Opening Setup Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-14

Initializing Setup Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-14

Sending/Receiving Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-15

Chapter 4 SETTING DEVICE OPERATIONS

4-1 Setting IC Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Setting the Memory Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

Memo. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

Memory Dump. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

4-2 RF-500 Series Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Parameters to be Set. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

Act Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

RFID Communication Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

Output Data Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-9

RS-232C Port Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-10

4-3 BL Series Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

Parameters to be Set. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Act Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-12

Barcode Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-14

Port Setting (in case of BL-180 /500 /600 /700 ) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-15

Other Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-17

4-4 SR-500 Series Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

Parameters to be Set. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-18

Act Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-19

Code Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-20

Camera Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-21

Timing Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-22

Port Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-23

Other Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-24

4-5 RS-485 Controller (NX-50RS) Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-25

Parameters to be Set. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-25

RS-232C (modular) Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-26

Head Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-27

Te r m i n a l S e t t ing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-28

RS-485 Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-29

4-6 CC-Link Controller (NX-50CL) Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-30

Parameters to be Set. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-30

RS-232C (modular) Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-31

Head Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-32

Te r m i n a l S e t t ing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-33

CC-Link Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-34

5

Page 8

4-7 DeviceNet Controller (NX-50DN) Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-35

Parameters to be Set. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-35

RS-232C (modular) Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-36

Head Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-37

Te r m i n a l S e t t ing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-38

DeviceNet Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-39

4-8 RS-485 Master Unit (N-410) Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-40

Parameters to be Set. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-40

Main Setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-41

Slave Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-42

Protocol Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-43

RS-232C Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-45

RS-485 Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-46

Chapter 5 OTHER SETTINGS AND OPERATIONS

5-1 Settings Macros . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Macros and Active Macros . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

5-2 Setting Macro Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Setting Macro Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Act Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

Macro Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-5

5-3 Quick Calibration Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Code Specification Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-6

Code Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-7

Camera Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-8

5-4 Creating a Quick Setup Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Chapter 6 TEST FUNCTIONS

6-1 Terminal Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Te r m i n a l F u nc tion Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-2

6-2 Test Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Te s t Function Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-3

6-3 View Image Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

View image function screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-4

Chapter A APPENDIX

1 Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

6

Page 9

Conventions Used In This Manual

Terminology

This manual uses the following terminology excluding some instances.

Ter m Description

Head Refers to the RF Series, BL Series, or SR Series.

RF Series Refers to the RF Series RFID system.

BL Series Refers to the BL Series bar code readers.

SR Series Refers to the SR Series 2D code readers.

IC tag Generic name for the IC tags which are supported by the RF-500 Series.

Coin-shaped IC tag Refers to the RF-T5P10 (coin-shaped IC tag).

Small IC tag Refers to the RF-T5F20 (small IC tag).

Standard IC tag Refers to the RF-T5F30 (standard IC tag).

Network controller Generic name for the NX-50 Series which relays a head to/from a field network.

RS-485 controller Refers to the NX-50RS (a network controller supporting RS-485).

CC-Link controller Refers to the NX-50CL (a network controller supporting CC-Link).

DeviceNet controller Refers to the NX-50DN (a network controller supporting DeviceNet).

RS-485 master unit Refers to the N-410 (RS-485 master unit).

AutoID Navigator

Integrated program for controlling and configuring all devices used with the RF500 Series.

7

Page 10

MEMO

8

Page 11

1

BEFORE YOU START

USING AutoID Navigator

This chapter describes the contents of the package, basic functions and

operating environment of AutoID Navigator, and how to install AutoID

Navigator.

1-1 Checking the Contents of the Package . . . . . . . . . . 1-2

1-2 Operating Environment and System Configuration . 1-3

1-3 Installing AutoID Navigator. . . . . . . . . . . . . . . . . . . . 1-5

1-4 Data Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . .1-11

1-1

Page 12

1-1

Checking the Contents of the Package

1

The package contains the following disk.

BEFORE YOU START USING AutoID Navigator

Before you start using AutoID Navigator, make sure that the package contains this disk.

Master Disk (CD-ROM) ... 1 disk

■ Contents of CD-ROM

AutoID Navigator (Japanese, English)

PDF manual (Japanese, English)

AutoID Navigator User’s Manual

RF-500 Series Operation Manual

RF-500 Series Installation and Connection Manual

NX-50 Series Operation Manual

1-2

Page 13

1-2

Operating Environment and System Configuration

This section describes the operating environment, system configuration, features and functions of

AutoID Navigator.

Be sure to read this section before using AutoID Navigator.

Operating Environment and System Configuration

The following environment is required to run the AutoID System Integrated Setup Software

AutoID Navigator.

Make sure that the system you are using satisfies the following conditions and that all of the

required hardware is present.

Item Description

OS

CPU PentiumIII 600MHz or more

Memory 128MB or more

Hard disk 400MB or more

CD-ROM drive Required for installation

RS-232C port

Windows XP (SP1 or later)

Windows 2000 (SP2 or later)

D-Sub 9-pin RS-232C port

This is required to communicate with an NX Series (network controller),

N-410 (RS-485 master unit) and BL-U1/U2 (dedicated power supply unit).

1

BEFORE YOU START USING AutoID Navigator

1-3

Page 14

1-2 Operating Environment and System Configuration

1

Functions and Features

BEFORE YOU START USING AutoID Navigator

AutoID Navigator is integrated setup software for editing and setting up AutoID devices, such as

RFID systems, barcode readers, and 2D code readers on Windows. This software allows you to

batch-manage the complex settings of system component devices in an easy-to-understand manner.

■ Parameter setup function

Setup parameters for AutoID system devices can be set, sent to and read from devices so that they

can be loaded and managed as setup files.

AutoID Navigator allows you to set and manage the following Keyence AutoID devices:

•RFID system RF-500 Series

•Barcode reader BL Series

•2D code reader SR-500 Series

•Network controller NX-50 Series

•RS-485 master unit N-410

■ Terminal function

This function allows you to send commands so that you can simply check operation of connected

devices. Also, responses to commands can also be collected and saved as a log.

■ Test function

This function allows you to test the operation status or communications status of the connected

devices.

Var i o u s t e st modes are available according to the connecting device.

For details about the test mode, refer to the User’s Manual.

■ Print function, file output function

This function allows you to print the settings of each device configured with AutoID Navigator, or

output the history data collected with the terminal function or test function in the CSV format.

1-4

Page 15

1-3 Installing AutoID Navigator

This section describes how to install AutoID Navigator on your personal computer's hard disk.

Before Installation

Check the following before you start to install AutoID Navigator.

Note

We recommend making a backup of the master disk in the event of it becoming

damaged, for example.

■ Windows environment and installation media

AutoID Navigator is software that runs on Windows XP or Windows 2000.

Make sure that Windows XP or Windows 2000 is installed and running normally on the personal

computer you are using.

■ Free space on hard disk

AutoID Navigator can be installed on hard disk.

At least 400 Mbytes of free space is needed on the hard disk where AutoID Navigator is to be

installed.

1

BEFORE YOU START USING AutoID Navigator

1-5

Page 16

1-3 Installing AutoID Navigator

1

Installing AutoID Navigator

BEFORE YOU START USING AutoID Navigator

The following describes how to install AutoID Navigator to Windows XP at the following drive configuration:

C drive: hard disk drive

E drive: CD-ROM drive

1 Tur n y our personal computer ON and start up Windows.

Note

•When installing AutoID Navigator, log on as Administrator or a user having

rights such as a computer administrator who is permitted to change the system settings.

•Before starting installation, quit all other applications. Installation may take

longer if anti-virus software is running.

2 Insert the "AutoID Navigator master disk" into the CD-ROM drive of the personal computer.

3 Open the CD-ROM from Explorer, for example, and double-click "Setup_en.exe" in the root

folder.

4 Click the "Next" button.

The [Select Destination Folder] window is displayed.

Tip

To change the installation directory, click the "Browse" button and change the directory.

1-6

Page 17

1-3 Installing AutoID Navigator

5 Click the "Next" button.

The [Select Program Folder] window is displayed.

6 Click the "Next" button.

The [Create Shortcut] window is displayed.

1

BEFORE YOU START USING AutoID Navigator

7 Click the "Next" button.

The [Check the Installation information] window is displayed.

1-7

Page 18

1-3 Installing AutoID Navigator

1

8 Click the "Next" button.

BEFORE YOU START USING AutoID Navigator

9 If the message [The destination folder does not exist. Do you want to create it?] is dis-

played, click the "Yes" button.

The [Congratulations!] window is displayed.

10

Click the "Finish" button.

This completes installation of AutoID Navigator.

1-8

Page 19

1-3 Installing AutoID Navigator

Uninstalling AutoID Navigator

The following describes how to uninstall AutoID Navigator from a personal computer running WindowsXP.

1 Tur n y our personal computer ON and start up Windows.

Note

When uninstalling AutoID Navigator, log on as Administrator or a user having

rights such as a computer administrator who is permitted to change the system

settings.

2 Select {Start} - {Control Panel(C)} in that order.

The [Control Panel] window is displayed.

3 Double-click the "Add or Remove Programs" icon.

The [Add or Remove Programs] dialog box is displayed.

4 Select "AutoID Navigator" and click the "Remove" button.

1

BEFORE YOU START USING AutoID Navigator

5 The program delete confirmation screen is displayed. Click the "Next" button.

The [Uninstallation] window is displayed.

1-9

Page 20

1-3 Installing AutoID Navigator

1

6 Click the "Yes" button.

BEFORE YOU START USING AutoID Navigator

The [Finished Uninstallation] window is displayed.

7 Click the "Finish" button.

This completes uninstallation of AutoID Navigator.

1-10

Page 21

1-4 Data Compatibility

The following describes data compatibility.

Compatibility between Setup Files

AutoID Navigator does not support the reading of setup files made on the following setup software:

•Barcode Reader BL Series Setup Software

•Multi-drop Link Unit N-400 Setup Software

Also, setup files made on the AutoID Navigator are not compatible with setup files made on the

above setup software.

Note

•N-410 settings cannot be made on N-400 Setup Software.

•N-400 settings cannot be made on AutoID Navigator. When using N-400, use

the existing N-400 Setup Software.

•When changing the settings of a BL Series used on an existing system, set the

device settings again on AutoID Navigator for use.

1

BEFORE YOU START USING AutoID Navigator

1-11

Page 22

1-4 Data Compatibility

1

MEMO

BEFORE YOU START USING AutoID Navigator

1-12

Page 23

2

OUTLINE OF AutoID

Navigator

This chapter describes basic operations in AutoID Navigator, screens, devices

that can be registered, and how to create projects.

2-1 Starting Up and Quitting AutoID Navigator. . . . . . . . 2-2

2-2 Names and Functions of Screen Parts. . . . . . . . . . . 2-4

2-3 Registerable Devices . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2-4 List of Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

2-1

Page 24

2

2-1

This section describes how to start up and quit AutoID Navigator.

OUTLINE OF AutoID Navigator

How to Startup AutoID Navigator

Start up AutoID Navigator.

Starting Up and Quitting AutoID Navigator

1 Select {Programs(P)} → {KEYENCE Applications} → {AutoID Navigator} in that order from

the Start menu, or double-click on the desktop screen.

This starts up AutoID Navigator.

How to Quit AutoID Navigator

Quit AutoID Navigator.

1 Click the button on the right edge of the title bar.

This quits AutoID Navigator.

Different Procedure

2-2

Press the + keys.

Page 25

Option Settings

2-1 Starting Up and Quitting AutoID Navigator

The following describes the option settings on AutoID Navigator.

With the option settings, set the COM port and communications parameters that are used for

communicating between AutoID devices and the personal computer where AutoID Navigator is

installed.

1 Start up AutoID Navigator and click .

2 Select the COM port (RS-232C) on the personal computer and click the "OK" button.

2

OUTLINE OF AutoID Navigator

Note

•When "Manual" is selected as the connection method, select parameters

matched to the devices to be connected.

•When connecting the DV-90 Series using its USB port, select "DV-90 PC

Direct". Also, be sure to set the DV-90 Series to the direct communication

mode.

2-3

Page 26

2

2-2

The following describes the names and functions of parts in AutoID Navigator screens.

OUTLINE OF AutoID Navigator

About screens

The following screen is displayed when AutoID Navigator is started up.

Names and Functions of Screen Parts

(6) "Terminal" button

(1)Menu icons

(2) Display settings

tab

(3) Select configura-

tion menu

(4) Selection area

(5) Registration/setting area

Name Functions

(1) Menu icons

(2) Display settings tab This tab switches the display between "Project" or "Unit". 2-5

(3) Select configuration

menu

(4) Selection area This area displays details that can be set on tabs. 2-6

(5) Registration/setting

area

(6) "Terminal" button

(7) "Test mode" button

(8) "View image" button This button is used to obtain images with the SR-500 Series. 6-4

These icons are for managing (creating new, saving and reading) project

files, setting options, and updating the connection to devices.

This menu switches display of the project display area between "system

configuration" and "file constitution".

This area changes the selection of devices to register and the device

settings.

This button sends commands to the connected device, and displays the

terminal screen for verification of data that is read.

This button displays the test mode screen for testing the communication

status between the head and the IC tag, code reader reading status and

other information.

(8) "View image" button(7) "Test mode" button

See Page

2-9

2-6

2-7

6-2

6-3

2-4

Page 27

2-2 Names and Functions of Screen Parts

■ Project display and Unit display

AutoID Navigator is provided with two display modes for registered devices and setup files,

Project display and Unit display.

When Project display is selected, the device configuration registered to the project is displayed, and when Unit display is selected, information is displayed according to each

device type.

Switching between Project display and Unit display is performed by the [Project] and [Unit] tabs,

respectively.

Project display

2

OUTLINE OF AutoID Navigator

Click the tabs to switch between

display modes.

Display Tab Features

The device configuration registered to the project is displayed.

Project

Unit

Parameters can be set up and managed by each currently registered device.

When no devices are registered to the project, only the project name is

displayed.

Devices that can be registered by AutoID Navigator are displayed by device type.

This feature is useful to batch-set parameters for a particular device type.

However, the settings cannot be sent to or received from the devices connected

via the NX-50 Series or the N-410 Series.

Display by project configuration

Unit display

Display by device type

2-5

Page 28

2

2-2 Names and Functions of Screen Parts

■ System configuration and File constitution

["System configuration" and "File constitution" are indicated on the [Project] tab. "System configuration" hierarchically displays the devices registered to the project, and "File constitution" displays

device setup files divided into type groups.

OUTLINE OF AutoID Navigator

System configuration

Click to select the configuration

to be displayed from the list.

Display Configuration

The system configuration for the project is displayed hierarchically by individual

System configuration

File constitution

network.

This allows you to set devices while visually grasping the structure of the project.

The configuration of the project is displayed hierarchically by file type.

Files can be managed displayed by type (setup parameters, memory map and

macros).

The file name is indicated inside the brackets [ ], and files that are not yet saved

during editing or after a change are suffixed with "*".

Setup files whose checkbox is marked in the file constitution display can be printed

by the "Print" button at the bottom of the screen. Memory maps can be output as a

CSV format file by the "Save Tag Map" button.

Devices displayed hierarchically

by component device

File constitution

Setup files displayed hierarchically

by type group

Features

2-6

Page 29

2-3 Registerable Devices

This section describes the devices that can be registered to projects by AutoID Navigator.

Registerable Devices

The following devices can be registered and set on AutoID Navigator.

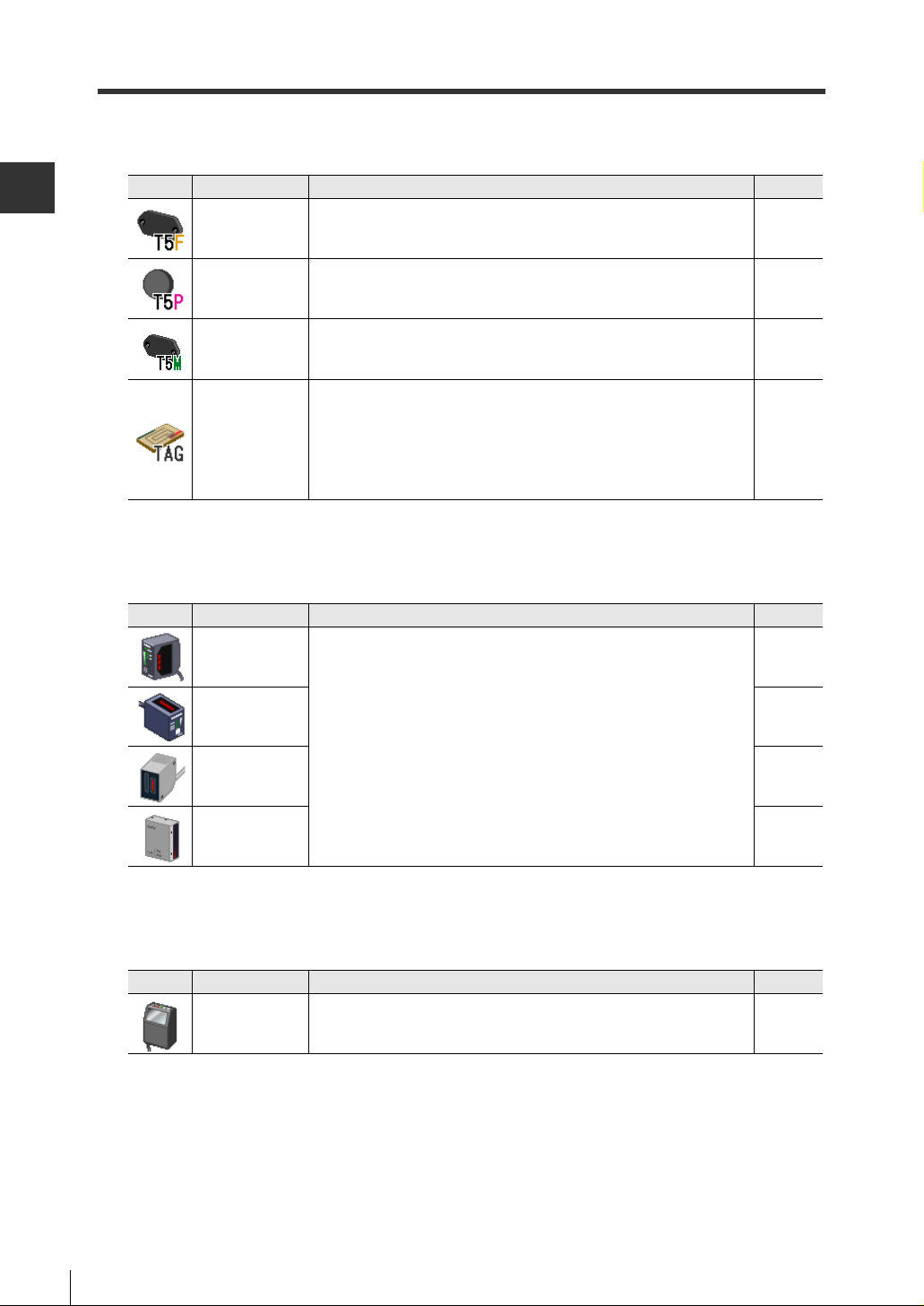

■ Masters

2

OUTLINE OF AutoID Navigator

Icon Device Description

N-410 Master unit made by Keyence for connecting by the RS-485 interface 4-33

Master unit This master unit supports CC-Link or DeviceNet. –

■ Controllers

Icon Device Description

NX-50RS This network controller supports the RS-485 link. 4-18

NX-50CL This network controller supports the CC-Link connection. 4-23

NX-50DN This network controller supports the DeviceNet connection. 4-28

■ RFID head

See Page

See Page

Icon Device Description

RF-500

This is the head of the RF-500 Series to which macros can be

registered.

See Page

4-5

2-7

Page 30

2-3 Registerable Devices

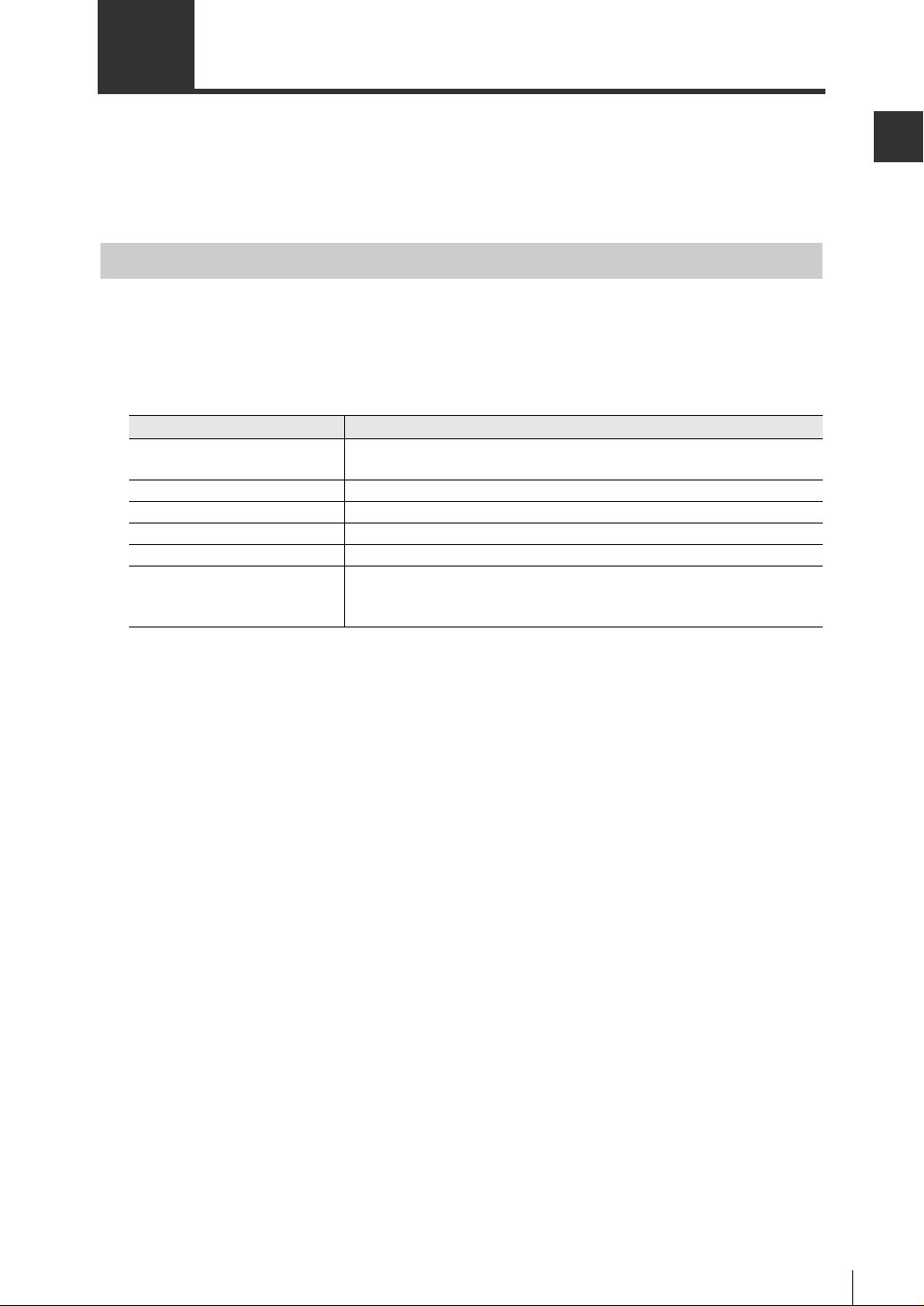

■ IC tags

2

Icon Device Description

OUTLINE OF AutoID Navigator

T5F** This IC tag is for FeRAM 2000 byte type RF-500 Series. 4-2

T5P10 This IC tag is for EEPROM 256 byte type RF-500 Series. 4-2

T5M** This IC tag is for EEPROM 992 byte type RF-500 Series. 4-2

Specify these tags when using the following standard IC tags that

General-purpose

tags

comply with ISO15693 other than Keyence IC tags:

• MB89R118

• I·CODE SLI

• Tag-it HF-I

• my-d

See Page

4-2

■ Barcode readers

Icon Device Description

BL-700

BL-600 4-11

BL-500 4-11

Standalone type compact barcode readers

See Page

4-11

BL-180 4-11

■ 2D code reader

Icon Device Description

SR-500 This is a small stationary 2D code reader. 4-18

2-8

See Page

Page 31

2-4 List of Functions

The following describes the functions of AutoID Navigator.

Basic Project File Functions

2

OUTLINE OF AutoID Navigator

Icon Name Functions

New project Creates a new project file. 3-10

Open project file Opens a saved project file. 3-10

Save project file Saves a created project file. 3-9

Option Settings

(communication

settings)

Update connection Establishes the connection with a selected device. 3-15

Sets the COM port (RS-232C port) on the

personal computer to communicate with.

The version of AutoID Navigator also be

confirmed.

Setup File Management Functions

Icon Name Functions

Open setup file Opens a saved setup file. 3-14

Save setup file

Write setting

Saves set parameters to a personal computer as a

setup file.

Writes (sends) the set parameters to a device.

See Page

2-3

See Page

3-14

3-16

Read setting

Edit parameter setup file Edits parameters on the currently selected device. 4-1

Edit macro setup file

Initialize setup

Te rminal function Sends commands to the target device. 6-2

Te st function

Reads (receives) set parameters from a device.

Edits macro setup files to be registered to the

currently selected head.

Clears set parameters and returns them to their

defaults.

Te sts the communications status between target

devices and IC tags, and the barcode reading

state.

3-17

5-1

3-14

6-3

2-9

Page 32

2

2-4 List of Functions

Device Add/Delete Functions

OUTLINE OF AutoID Navigator

Icon Name Functions

Rename

Add registered device Adds a device to a project. 3-8

Delete registered device

Applies the name of the project entered in the

[Name] field and the new name for a currently

registered device.

Delete a currently registered device from a

project.

See Page

3-8

3-8

2-10

Page 33

3

MANAGING PROJECTS

This chapter describes how projects are configured and setup files.

3-1 Outline of Projects . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3-2 Creating Projects . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3-3 Registering Devices and Saving Projects . . . . . . . . 3-4

3-4 Editing Setup Files . . . . . . . . . . . . . . . . . . . . . . . . . .3-11

3-1

Page 34

3-1 Outline of Projects

A "project file" is a file that integrates and manages all of the devices required for production processes.

Devices to be connected to production processes can be managed efficiently by individual field

network or master units.

3

MANAGING PROJECTS

What Is a "Project"?

On AutoID Navigator, the parameters of devices to be connected and memory map- or macrorelated setups are managed as "projects."

Projects are managed in individual folder, and each folder is called a "project folder." On AutoID

Navigator, the following files are created in project folders.

File names can be entered by the user.

Project file (project name).ain

Parameter setup

file

Memory map

file

Macro setup file macro (number).aim

Log file

File File Typ e Description

Project management system component information (device

information, tag information) that indicates an individual production

process (line) is saved to this file. These files save currently

registered devices and network configurations.

Setup parameters and other information of each device are saved

config (number).aic

tagmap (number).ait

Te rminalLogFile.log

Te stLogFile.csv The communication log of the test mode is saved to this file.

to this file. Files are saved for individual devices. Files can be

renamed.

The memory map information (memo) of IC tags is saved to this

file. Files are saved for individual IC tags. Files can be renamed.

The macro operations of heads are saved to this file.

Files are saved for individual macros. Files can be renamed.

A log of communications performed by the terminal function is

saved to this file.

■ Project save destination

Any folder for saving project data can be created when saving projects.

Folders can freely managed, for example, by saving data in separate folders by individual project.

3-2

Page 35

3-2 Creating Projects

The following describes how to create projects.

Procedure for Creating a Project

The following shows the basic flow of operations for creating a project.

Registering devices and saving projects

Register the devices that configure the system to the project, and save these devices as a project.

1

"Registering Devices and Saving Projects" (page 3-4)

Setting parameters

Set the parameters of the devices registered to the project.

2

"How to Set Parameters" (page 3-13)

3

MANAGING PROJECTS

Sending set parameters

Send the parameters you have set up to the devices.

3

"Sending/Receiving Parameters" (page 3-15)

3-3

Page 36

3-3

When AutoID Navigator is started up, a new project is already created for use.

Determine the devices to register and how to register the devices suited to your particular requirements.

3

MANAGING PROJECTS

Signal Registration and Network Registration

There are two ways of registering devices on AutoID Navigator, "single registration" and "network

registration." With single registration, devices are not assigned an ID and are registered as independently operating devices. With network registration, devices are assigned an ID and are registered as devices that operate on a network.

Select the registration method to suit your particular requirements.

■ Single registration

When registering devices by single registration, register the

device with a project selected.

Registering Devices and Saving Projects

■ Network registration

When registering devices by network registration, first register the master unit, and then connected subordinate devices.

Note

IC tags are registered by single registration as they are not linked to the network.

When registering IC tags, select the IC tag to register from the list that is displayed when a project is selected and then register the device.

3-4

Page 37

3-3 Registering Devices and Saving Projects

● Example: Registering devices

With network registration, register controllers or heads as slave devices hierarchically to a master

device.

Multiple slave devices can be connected to a master.

Master device

N-410

Slave device

NX-50RS

SR-500

NX-50RS

Registering Devices by Single Registration

1

Click the device to register with a project selected, and click the "Regist" button, or doubleclick on the selected device.

3

MANAGING PROJECTS

To c o nt i nue registering devices by single registration, make sure that the project is still selected,

then register devices.

3-5

Page 38

3-3 Registering Devices and Saving Projects

Registering Devices by Network Registration

When registering devices by network registration, follow the procedure below to register devices

to the project.

3

MANAGING PROJECTS

1 Select the master unit, and click the "Regist" button.

This registers the master unit.

Note

•Parameters cannot be set to master units to be used on CC-Link or DeviceNet

from AutoID Navigator. Set parameters referring to the manual for the master

unit to be used.

•When building an RS-485 network system, select N-410 as the master unit.

2 Click the registered master unit, select the controllers to be added to the project as slaves,

and click the "Regist" button.

Note

3-6

Select the type of controller to match the network you are building. Select an NX50CL or NX-50DN as the controller

if the master unit is registered.

Page 39

3-3 Registering Devices and Saving Projects

3 The [ID registration] dialog box is displayed. Enter the ID and click the "OK" button.

Note

•AutoID Navigator automatically enters a serial number as the ID to prevent IDs

from being duplicated. When manually changing IDs, take care to prevent the

ID from duplicating another ID.

•When registering the NX-50CL, set the number of occupied stations and cyclic

setting. The NX-50CL occupies two to four stations depending on its settings.

Click to select the number of

stations from the list.

•The ID set here can also be changed later on.

"Renaming devices and changing IDs" (page 3-8)

3

MANAGING PROJECTS

4 Click the registered controller, select the head or barcode reader to be added to the project

as slaves, and click the "Regist" button.

When connecting multiple controllers (slave devices) to a master device, click the slave device to

add to the master device, select the controller and click the "Regist" button.

The following controllers can be connected to the master:

•N-410

NX-50RS

•Master unit

NX-50CL or NX-50DN

Note

•Only one type of controller can be registered to a single master unit. An NX50DN cannot be registered to a master unit to which an NX-50CL is registered.

•When the exclusive communication unit (N-48) is used, the head is connected

directly under the N-410.

3-7

Page 40

3-3 Registering Devices and Saving Projects

■ Renaming devices and changing IDs

When renaming a device or changing its ID, enter in the [Name] and [ID] fields at the bottom left of

the screen, and click the "Edit" button. A currently selected device can also be deleted or a new

device added.

3

MANAGING PROJECTS

Also, the position where devices are registered can be changed in the selection area just as if you

are moving files or folders by Explorer in Windows.

Renaming devices

The current device name is displayed in the

[Name] field. Enter the new name, and click

the "Edit" button.

Deletes the selected device.

Adds a slave device to the selected device.

Changing the ID No.

The current ID is displayed in the [ID] field.

Enter the new name, and click the "Edit" button.

1 Selecting the device to move

Devices currently connected to the

selected device also move.

2 When you drop the device at the

desired move destination, the [ID registration] dialog box is displayed.

Enter the ID to match the network you are

moving to, and click the "OK" button.

3-8

Page 41

3-3 Registering Devices and Saving Projects

Saving Projects

To s a ve a registered device configuration, follow the procedure below to save the configuration as

a project.

1 Select the project.

2 Enter the project name in the [Name] field, and click the "Edit" button.

The project name you entered is reflected.

3

MANAGING PROJECTS

3 Click (save project file) to save the project.

This saves the project as an ain file.

When the project file is saved, the setup files of the registered devices also are saved. Click the

"Save" button to save the files currently registered to the project.

If you click the "Cancel" button here, those setup files will not be saved, and the state will return to

the initial setup state when the project file was opened.

3-9

Page 42

3-3 Registering Devices and Saving Projects

Opening Projects

To o pen a saved project, click (open project file) on the tool bar, and select the project file

(**.ain) to be opened.

3

MANAGING PROJECTS

Creating a New Project

To c r eate a new project, click (new project) on the tool bar.

When a new project is created, the project that is currently being edited is discarded. When creating a new project, be sure to save the required project files and setup files.

3-10

Page 43

3-4 Editing Setup Files

AutoID Navigator manages the settings (parameters) by each individual device as a setup file.

This section describes how to save setup files, and how to read and write setup files from and to

devices.

Type of and Brief Description of Setup Files

Setup files are files to which the parameters of devices currently registered to a project are saved

and managed. Network IDs and communication parameters, and trigger inputs and other setup

information are saved to setup files by individual device. There are three types of setup files as

follows:

•Parameter setup files

•Memory map files

•Macro setup files

■ Parameter setup files

To s e t the parameters of a registered device, click .

The parameter settings of the currently selected device are displayed.

3

MANAGING PROJECTS

1 Click the device whose

parameters are to be set

2 Click to set the

parameters.

For details on setting parameters, see

(page 4-1).

"Chapter 4 SETTING DEVICE OPERATIONS"

3-11

Page 44

3-4 Editing Setup Files

y

■ Memory map files

To e d it t he memory map of a registered IC tag, click the desired IC tag to display the memory map

edit screen.

3

MANAGING PROJECTS

1 Click to select the IC tag whose

2 Click to select the area to edit.

3 Click the [MEMO] tab to edit the

memory map is to be displayed.

memory map.

You c a n execute a memory dump

clicking the [Memory dump] tab.

b

For details on memory map settings, see

(page 4-1).

"Chapter 4 SETTING DEVICE OPERATIONS"

■ Macro setup files

To s e t the macros of a registered RF-500 Series device, click .

The macro settings currently registered to the selected RF-500 Series device are displayed.

1 Click the RF-500 Series device to

set a macro to.

2 Click to set macro

operation.

To s e t m a cro operation, select the

macro to be set, and set the macro

operation on the [Act setting] tab.

To t e st operation of a macro, click the

[Macro test] tab.

For details on macro settings, see "Chapter 5 OTHER SETTINGS AND OPERATIONS" (page

5-1).

3-12

Page 45

3-4 Editing Setup Files

How to Set Parameters

When you have finished registered the component devices of a project, set the parameters of the

devices as follows.

There are three ways of setting parameters:

•By setting parameters by individual device

•By batch-setting parameters for a specific device model

•By setting parameters by individual files of a registered device

For details on the settings of each device, see

(page 4-1).

■ Setting parameters by individual device

When setting parameters by individual device, you can set parameters by individual device by

clicking the [Project] tab.

"Chapter 4 SETTING DEVICE OPERATIONS"

3

MANAGING PROJECTS

■ Batch-setting parameters for a specific device model

When the settings are common for a specific device model, you can batch-set parameters for the

specific model by clicking the [Unit] tab.

3-13

Page 46

3-4 Editing Setup Files

■ Setting parameters by individual files of a registered device

Parameters that have been set are saved as a file.

To change or edit settings by each individual saved file, select [File constitution] on the [Project]

tab. The parameter setup files of the project component devices are displayed in tree format by

file type.

3

MANAGING PROJECTS

■ Printing settings

The settings of each of the selected parameter setup files, memory map files and macro setup

files can be printed. Tag maps can also be saved in CSV file format.

Prints settings.

Saves tag maps in CSV file format.

Displays a print preview of the settings.

Saving Setup Files

To s a ve a setup file currently being edited, click (save) at the top right of the screen.

Opening Setup Files

To open an edited setup file, click (open) at the top right of the screen, and select the setup

file to be opened.

Initializing Setup Files

To i n itialize a setup file during editing, click (default setting) at the top right

of the screen.

3-14

Page 47

3-4 Editing Setup Files

Sending/Receiving Parameters

Parameters set in AutoID Navigator are not reflected as they are in a device. They must be sent

to the device.

Follow the procedure below establish a communication connection and send the parameters.

Note

To upd a t e a c o nnection with a device, the personal computer installed with

AutoID Navigator must be connected to the controller by an RS-232C cable.

■ Establishing the connection with the controller

1 Click (connect) on the tool bar.

The communication in progress dialog box is displayed and communication with the device starts.

3

MANAGING PROJECTS

When the connection is established, an icon is displayed to the left of the device name and the

parameter send/receive buttons are enabled.

When the following screens are displayed, this indicates that the connection between the device

and personal computer, or between devices failed.

Make sure that cable connections are correct.

The personal computer is not

connected to the device

The connection between the

controller and head failed

3-15

Page 48

3-4 Editing Setup Files

■ Sending parameters

To s e t p a ra meters preset on AutoID Navigator to a device, following the procedure below to send

the parameters.

3

MANAGING PROJECTS

1 Click (write setting) at the top right of the screen.

2 The confirmation dialog box is displayed. Click the "OK" button.

The communication in progress dialog box is displayed and parameters start to be sent.

3 The write completion dialog box is displayed. Click the "OK" button.

This completes transmission of the parameters.

Note

3-16

When the RF-500 Series is used, the parameter settings file and the macro settings file are created as separate files. The parameter settings and the macro settings need to be sent separately.

Page 49

3-4 Editing Setup Files

■ Receiving parameters

To read parameters that are already set to a device to AutoID Navigator, follow the procedure

below to receive the parameters.

Received parameters can be saved as setup files on AutoID Navigator, and their settings re-used

on other devices.

1 Click (read setting) at the top right of the screen.

2 The confirmation dialog box is displayed. Click the "OK" button.

The communication in progress dialog box is displayed and parameters start to be received.

3

MANAGING PROJECTS

3 The read completion dialog box is displayed. Click the "OK" button.

This completes reception of the parameters.

3-17

Page 50

3-4 Editing Setup Files

3

MANAGING PROJECTS

MEMO

3-18

Page 51

4

SETTING DEVICE

OPERATIONS

This chapter describes the parameter setups of the devices registered to

a project.

4-1 Setting IC Tags. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4-2 RF-500 Series Settings . . . . . . . . . . . . . . . . . . . . . . 4-5

4-3 BL Series Settings . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

4-4 SR-500 Series Settings . . . . . . . . . . . . . . . . . . . . . 4-18

4-5 RS-485 Controller (NX-50RS) Settings . . . . . . . . . 4-25

4-6 CC-Link Controller (NX-50CL) Settings . . . . . . . . . 4-30

4-7 DeviceNet Controller (NX-50DN) Settings . . . . . . . 4-35

4-8 RS-485 Master Unit (N-410) Settings. . . . . . . . . . . 4-40

4-1

Page 52

4

SETTING DEVICE OPERATIONS

4-1 Setting IC Tags

Setting the Memory Map

AutoID Navigator allows you to partition IC tag memory area by individual application in advance

and append each area with a label (name) for management.

Each of the areas to which information is stored can be given a label (name) which can be made

use of when performing verification during design and when creating Specification Sheets.

The MEMO function allows you to color-code the display of changed addresses or write-protected

addresses so that you can intuitively grasp the memory map.

Edited memory map files can also be output as CSV format files.

Note

Memory maps that have been edited on AutoID Navigator cannot be written to IC

tags.

Use memory map information as materials for grasping the design and specifications of memory maps.

4-2

Page 53

Memo

The following describes the settings of the [MEMO] tab for IC tags.

(1) Section Memo (2) Details memo

4-1 Setting IC Tags

4

SETTING DEVICE OPERATIONS

(4) Specification of area

name

(5) Specification of area

color/protection

(6) Specification of area to be secured (7) "Add"/"Edit" button(3) Tag information

Item Description

(1) Section Memo

(2) Details memo

(3) Tag information

(4) Specification of area

name

(5) Specification of area

color/protection

(6) Specification of area to

be secured

(7) "Add"/"Edit" button

(8) "Delete" button Deletes the area currently being set (or changed).

Displays the details of IC tag memory divided up into section.

Details can be edit with a selection section appended with an area name.

Details can be edited when areas within a selected section are further divided

up into section.

Displays the type and memory size of the currently set IC tag.

* In the case of general-purpose IC tags, click the "Edit size" button to set the

size matched to the memory size of the IC tag you are using.

Enter the name of the area.

Select the display color of the area from the pulldown menu.

Color and protection can be specified only for Section Memo and cannot be

specified for Details memo.

* Protection cannot be specified to areas straddling blocks.

Protection can be specified to Section Memos at the boundary of blocks for an

IC tag currently being edited.

* IC tag memory is configured in 4-byte or 8-byte units called "blocks."

T5P10 and T5M** are configured in 4 bytes per block, and T5F** is configured

in 8 bytes per block. For details, refer to the "RF-500 Series Operation

Manual"

To secure area, specify the start of the address at [Start], and enter the end

address or the size of the area to be secured.

To specify the end address, click [End Address]. To specify by the size to be

secured, click [Size] and enter the size of the area to be secured.

The "Add" button is displayed when an area is newly set.

The "Edit" button is displayed when an already set area is selected.

(8) "Delete" button

4-3

Page 54

4

4-1 Setting IC Tags

Memory Dump

The details of IC tag memory can be read, and the start address and write details (ASCII text

strings) can be set and data written to IC tags.

SETTING DEVICE OPERATIONS

(1) Memory dump display

(9) Write Data

(4) Protect

indication

(3) Lock indication

(2) Head selection

(5) "Set write-protect" button

(8) Address

(7) "Write data" button

(6) "Read data" button

Item Description

(1) Memory dump display

(2) Head selection

(3) Lock indication

(4) Protection indication

"Set write-protect" button

(5)

(6) "Read data" button Performs communication with the IC tag to read memory details.

(7) "Write data" button Writes the details set at [Address] and [Write Data (ASCII)] to IC tag.

(8) Address Enter the start address to write data to.

(9) Write Data

Displays the memory dump result. Changes since the previous communication

are indicated in red.

Select the head to be used for communication with the IC tag currently being

edited from the pulldown menu.

When this checkbox is marked, write-locked areas are displayed color-coded in

the memory dump display.

When this checkbox is marked, write-protected areas are displayed colorcoded in the memory dump display.

Specifies the map range specified as write-protected (color-coded) as a

protected area.

Enter the data to be written. Enter data within 32 characters in ASCII code. To

enter in hexadecimal, mark the [Hex] checkbox.

■ Printing the Memory Map and Outputting a CSV File

The memory map created with AutoID Navigator can be printed or output as a CSV file. The

memory map output as a CSV file can also be managed using Excel or other applications as an

original form.

4-4

Page 55

4-2 RF-500 Series Settings

Parameters to be Set

There are four parameter items to be set up for the head. Switch to the desired setting item by

clicking the respective tab and set the parameters on that tab.

(1) Act setting

Setting Item Description See Page

(1) Act setting This tab is for setting the trigger mode and I/O terminals. 4-6

(2) RFID

communication

setting

(3) Output data setting This tab is for making the data output settings. 4-9

(4) RS-232 port setting

This tab is for making the settings for communication with an IC tag.

Write protection and UID authentication passwords are also set in this

item.

This tab is for setting devices connected to the head, and for setting

the communication speed, parity and other communication settings.

(2) RFID communi-

cation setting

(3) Output data

setting

(4) RS-232 port setting

4-7

4-10

4

SETTING DEVICE OPERATIONS

4-5

Page 56

4

4-2 RF-500 Series Settings

Act Setting

This section describes the [Act setting] tab for the head.

SETTING DEVICE OPERATIONS

■ Action mode

Item Description

Trigger setting

Access retry count

Auto trigger on delay

Select from Level trigger, One-shot trigger and Auto trigger as the trigger mode.

"RF-500 Series Operation Manual"

Set the access retry count when "One-shot trigger" or "Auto trigger" is set at

Trigger setting.

"RF-500 Series Operation Manual"

Set the time for preventing continuous action of the auto trigger when "Auto

trigger" is set at Trigger setting.

"RF-500 Series Operation Manual"

■ I/O setting

Item Description

Output duration

Input state Set Norm. open or Norm. close as the polarity of the input contact.

Set the ON time for when OUT1 to OUT4 terminals are used to transfer the

operation result to the host device.

4-6

Page 57

RFID Communication Setting

This section describes the [RFID communication setting] tab for the head.

4-2 RF-500 Series Settings

4

SETTING DEVICE OPERATIONS

■ Radio communication setting

Item Description

Select the IC tag to be registered to the head.

Tag 1/2/3

Active tag

Check read Set Disable/Enable for check read.

Write-protect Set Disable/Enable for Write-protect

"Optional tag" button

Set Tag 2 and Tag 3 by the "Optional tag" button.

"4-1 Setting IC Tags" (page 4-2)

Specify wh ich of Tag 1 to Tag 3 is to be used for the head.

Click this button to set types Tag 2 and Tag 3.

When registering a general tag, click General-tag and select the tag from

the pulldown menu.

■ Radio communication enable setting

Item Description

Communication enable

message

Count of communication

success

Set Send or Don’t send for Communication enable message.

Set the successful communication count within the range 1 to 255 times.

Set this when "Communication enable message" is set to send.

4-7

Page 58

4

SETTING DEVICE OPERATIONS

4-2 RF-500 Series Settings

■ Verification setting

Set the preset data when executing each of the "[VD] Verify data" and "[VB] Verify bit" commands.

Item Description

Preset data Set the preset data in ASCII code or Hexadecimal (HEX).

Preset bits Set the preset bit data.

Preset top address

Preset size (byte)

"

RF-500 Series Operation Manual"

Specify the top address and size when data read from an IC tag is to be taken

as the preset data.

■ Authentication setting

Set the password and authentication key for when the "[WK] Authentication key" command for

preventing forgery is executed.

These can be set when the "Authentication setting" key is clicked.

Item Description

Authentication key Set the authentication key.

New password Enter the new password.

Password Enter the current password.

RF-500 Series Operation Manual"

"

4-8

Page 59

Output Data Setting

This section describes the [Output data setting] tab for the head.

4-2 RF-500 Series Settings

4

SETTING DEVICE OPERATIONS

Item Description

Additional information

(processing time)

Additional information

(retry count)

Header

Delimiter

Checksum Select Don't add or Add for Checksum.

Send delay time Set the send delay time.

Set Disable/Enable for Additional information (processing time).

Set Disable/Enable for Additional information (retry count).

Select None, STX or ESC for Header.

Select CR, ETX or CR+LF for Delimiter.

4-9

Page 60

4

4-2 RF-500 Series Settings

RS-232C Port Setting

This section describes the [RS-232C port setting] tab for the head.

SETTING DEVICE OPERATIONS

Item Description

Baud rate Select the baud rate (bit/s) from the pulldown menu.

Parity Select None, Even or Odd for Parity.

Data bits Select 7 bits or 8 bits for Data bits.

Stop bit Select 1 bit or 2 bits for Stop bit.

Protocol

ID (1 to 31)

RTS/CTS protocol

Select None, PASS/RTRY, ACK/NAK or Multi-drop as the software-based

communication protocol.

Set the ID No. of the head.

This is set when "Multi-drop" is set at Protocol.

Select Disable or Enable for RTS/CTS protocol.

Set this when the Protocol setting is other than "Multi-drop".

4-10

Page 61

4-3 BL Series Settings

This section describes the settings of the KEYENCE Barcode Reader BL Series.

Parameters to be Set

There are four parameter items to be set up for the barcode reader. Switch to the desired setting

item by clicking the respective tab and set the parameters on that tab.

Note

Communication settings differ according to the barcode reader.

(1) Act setting (2) Barcode setting (3) Port setting (4) Other settings

4

SETTING DEVICE OPERATIONS

Setting Item Description See Page

(1) Act setting This tab is for making settings relating to reading of barcodes. 4-12

This tab is for making settings relating to the type of barcode to

(2) Barcode setting

(3) Port setting

(4) Other settings

be read, details of each individual barcode, and options and

special settings.

This tab is for making settings relating to communication

between the barcode reader and host or PLC.

This tab is for making settings relating to options (e.g. trigger

settings and reading of reversed barcodes).

4-14

4-15

4-17

4-11

Page 62

4

4-3 BL Series Settings

Act Setting

This section describes the [Act setting] tab for the barcode reader.

SETTING DEVICE OPERATIONS

Item Description

Select the read mode.

Read mode

Additional information

Decoding match count

Read error

Data-send timing This item must be set only when Read mode is set to "Single".

Repeat-reading interval

"Trigger setup" button The trigger input can be set up by clicking this button.

When "Single" is selected, set "Data-send timing".

When "Multi1" or "Multi2" is set, set "Repeat-reading interval".

Set the additional information.

"Scan count" can be set only when "Decoding count" is set.

"Symbology ID" and "PMI" can be set only on the BL-600.

When the "PMI" checkbox is marked, set each preventive maintenance

information (PMI) value within the range 0 to 100.

Enter any desired numerical value within the range 1 to 255 (times).

Normally, use the default (2 times).

Though a larger "Decoding match count" setting increases the reliability of

reading, the reading speed slows down. Alternatively, a smaller setting increases

the reading speed but lowers the reliability of reading.

On the BL Series, when the scan count (decoding counting) in which the barcode

was successfully decoded (read) becomes the value set at "Decoding match

count", the barcode is judged to have been read.

This item is for setting the error code that is sent to the personal computer by the

barcode reader when a barcode cannot be read.

Any error code up to eight characters in length can be set. However, normally,

use the default (ERROR). Leaving the text box blank disables sending of an error

code.

Set 1 to 255 (100 to 25500 ms) for Repeat-reading interval.

This item must be set only when Read mode is set to "Multi1" or "Multi2".

4-12

Page 63

■ Trigger setup

Item Description

Signal type

Input state

Input pulse width

Te st mode initiated with

trigger input ON

Te st mode initiated upon

power-up

Power-on trigger

Cmd for trigger ON

Cmd for trigger OFF

4-3 BL Series Settings

Select the "Signal type".

When "One-shot" is selected, One-shot input time is displayed. Set this time

within the range 1 to 255 (100 to 25500 ms).

Select Norm.open (to turn laser light emission ON with trigger input ON) or

Norm. close (to turn laser light emission ON with trigger input OFF).

This setting is to prevent a trigger input from being accepted unless it is ON

for the preset time or longer.

When "10 ms" is set, chattering of contacts can be ignored when an output

with a contact (e.g. relay) is connected for the trigger input.

Set this item only to initiate the test mode when trigger input turns ON or

when the power is turned ON. Normally, do not set this item.

* Trigger input does not function normally when "Test mode initiated with

trigger input ON".

Select this item to turn laser light emission ON at all times from the time that

power is turned ON. (On the BL Series, laser light emission is not turned ON

for five seconds after the power is turned ON )

Set the command characters for when reading operation is controlled (laser

light emission is turned ON/OFF) by sending a command.

Any command up to eight characters in length can be set. However, normally

use the defaults (LON for "Cmd for trigger ON" and LOFF for "Cmd for trigger

OFF").

4

SETTING DEVICE OPERATIONS

4-13

Page 64

4

4-3 BL Series Settings

Barcode Setting

This section describes the [Barcode setting] tab for the barcode reader.

On this tab, set the barcode type, the minimum and maximum code lengths, and other barcode

settings.

SETTING DEVICE OPERATIONS

Item Description

Code 1 to 4

Code length

"Detail" button

"Options" button

Select the type of barcodes from the pulldown menus.

* When completely different barcodes are set to "Code 1" to "Code 4", four

types of barcodes can be read without changing the respective settings.

Set the maximum and minimum number of digits for each barcode type at "Max"

and "Min", respectively.

When the "Edit" button is clicked, the [Code

length] dialog box is displayed. Enter the

desired numerical values, and click the

"OK" button.

* The code length that can be set differs

according to the type of barcode.

When the "Detail" button is clicked at "Code 1" to "Code 4", the [Barcode detail

setup] dialog box is displayed. Set each item in this dialog box.

* The details that can be set differ according to the type of barcode.