KEYENCE AP-V42AWP User Manual

96M1374

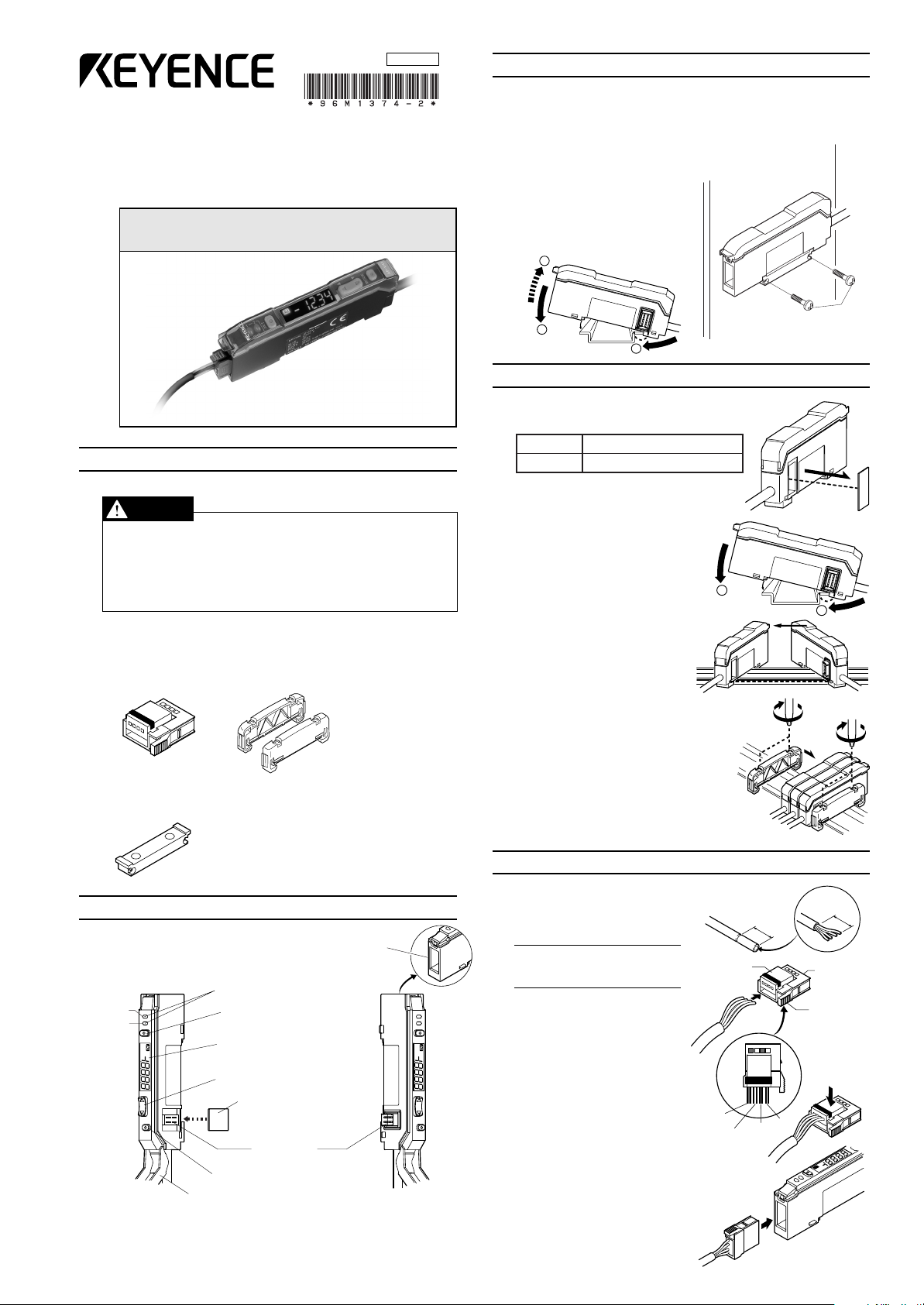

Up to 8 units AP-V42AW/LV-22A/12SA

Up to 16 units FS-T2/M2/V12/V22/PS-T2/ES-M2

Operating status indicators

Set button

Display

Manual adjustment button

Expansion

protective cover

Mode button

Dust cover

Expansion

connector

Sensor head connector

Output 1

Output 2

AP-V41AW(P) AP-V42AW(P)

2

1

AI

Insert until it

clicks into place.

3

2

1

M3 screws

About

25 mm

About

25 mm

Connector

body

Connector

cover

Connector

lock

Orange

Brown

Blue

Gray

Pressure

connection

WARNING

Wire-saving Digital

Pressure Sensor

AP-V41AW(P)/V42AW(P)

Instruction Manual

1. Safety Precautions

●

Do not use this product in safety circuits such as those designed to

protect human workers.

●

This product does not employ an explosion-proof construction. Do not

use it in the presence of flammable gasses, liquids, or powders.

●

This is a direct current power supply type sensor. Application of an

alternating current may result in explosion or fire.

3. Sensor Installation

●

●

Installation on a DIN track

1) Align the hook on the bottom

Installation using the included

mounting bracket

of the sensor to the DIN track

as shown below. Lower the sensor in the direction indicated by

➁while pressing on the sensor

in the direction indicated by ➀.

2) When removing the sensor, lift

the sensor as shown in ➂ while

pushing on the sensor in the direction indicated by ➀.

4. Additional Amplifier installation

A single AP-V41AW(P) sensor can be expanded

with the following number of slave units:

* The same applies to the PNP type of

the respective models.

1) Remove the AP-V41AW(P)

expansion protective cover.

2)Install the amps onto the DIN

track one at a time.

(AP-V41AW(P))

.

■ Accessories

●

1 sensor head

connector

●

1 mounting bracket

●

2 end units (included

with AP-V42AW(P))

●

Units sticker

(included with APV41AW(P))

2. Part Names

●

1 expansion seal

(included with

AP-V42AW(P))

●

1 instruction

manual

3) Insert the 2 hooks on each slave

unit into the groove on the APV41AW(P) until they click into

place.

4) Attach an end unit to each side

of the chain of amp units.

Sandwich the amps securely

between the end units and use

a Phillips head screwdriver to

tighten the screws on the top of

the end units (2 screws for each

unit).

5. Sensor Head Installation

1) Cut the cable to an appropriate

length and strip away about 25

mm of the outermost insulation.

Note: It is not necessary to

remove insulation from the

core wires.

2) Insert the cables after aligning

them with the colors on the seal

on top of the connector body.

3) Press together the body and the

connector cover into which the

cables were inserted to make a

connection (use a pair of pliers

or similar tool to press them together).

4) Insert the sensor head connector into the hole on the front of

the amp unit.

To remove the connector, depress the connector lock and

pull it out.

1

CAUTION

<Output 1>

P1

0

Output 1

OFF ON OFF

P2

0

OFF ON OFF

<Output 2>

Output 2

Hi

Lo

Output1/Output2

OFF ON ONOFF OFF

<Output 1/Output 2>

0

<Output 1>

P1

Output 1

OFF ON OFF

0

<Output 2>

0

Output 2

OFF ON OFF

P2

0

0

Shift

Zero shift input

T1

<Zero shift>

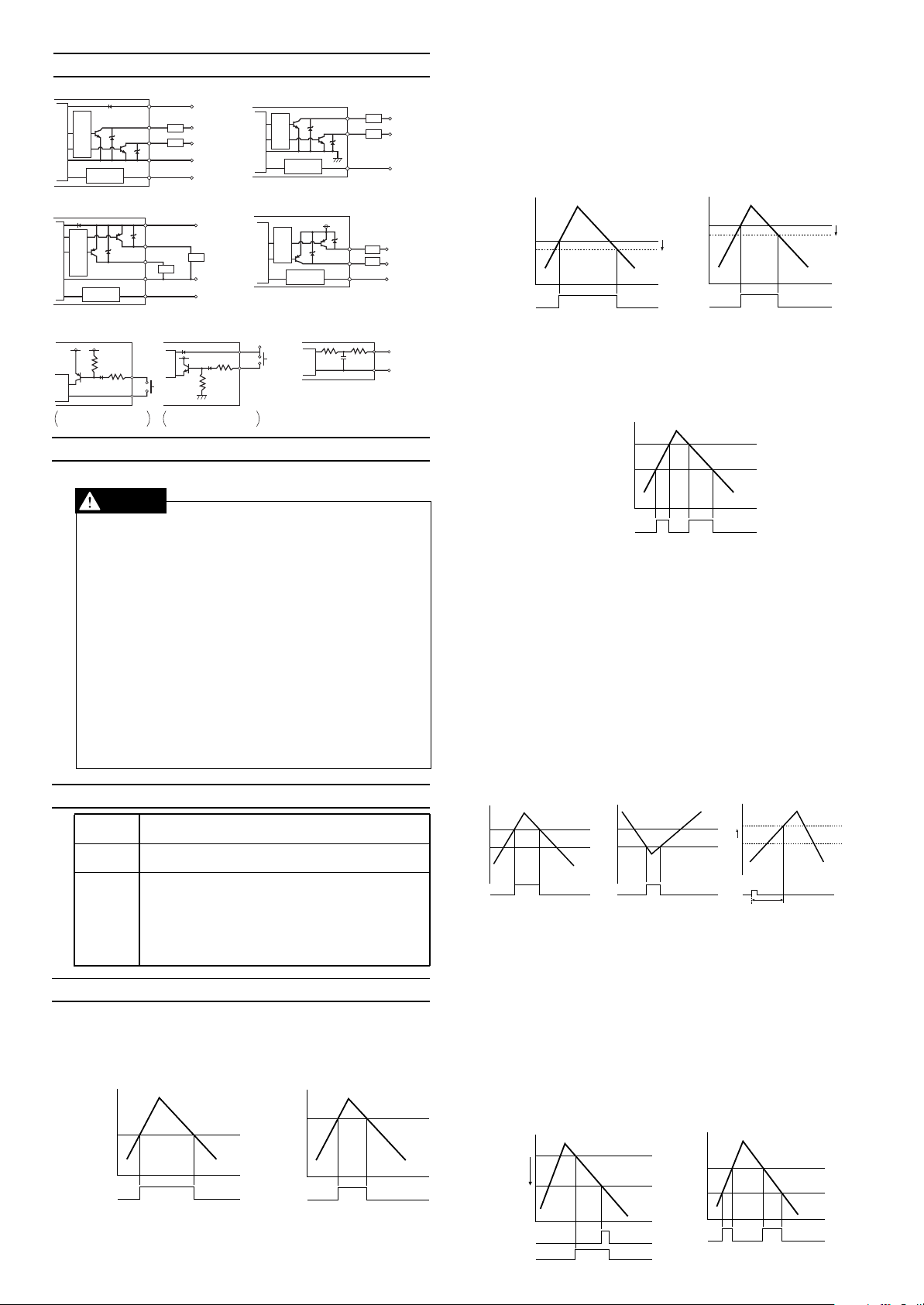

6. Connection Diagram

12 to 24 VDC

5 to 40 VDC

5 to 40 VDC

0V

Main circuit

Overcurrent

protection circuit

Load

Load

Input/output

circuit

Analog output/

zero shift input: switchable

Brown

Blue

Black

Control

output 1

Control

output 2

White

Pink

0 V

Load

Load

Zero shift input

5 to 40 VDC

Main circuit

Overcurrent

protection circuit

Input circuit

Black

White

Pink

5 to 40 VDC

Control

output 1

Control

output 2

12 to 24 VDC

0V

Main circuit

Overcurrent

protection circuit

Input/output

circuit

Analog output/

zero shift input: switchable

Brown

Blue

Black

White

Pink

Load

Load

Control

output 1

Control

output 2

12 to 24 VDC

0V 20mA max.

0V 20mA max.

Load

Load

Zero shift input

Main circuit

Overcurrent

protection circuit

Input circuit

Black

White

Pink

Control

output 1

Control

output 2

Short-circuit current AP-V41AW 5 mA max.

AP-V42AW 1 mA max.

Main

circuit

Blue

Pink

12 to 24 VDC

Main

circuit

Pink

Brown

Short-circuit current AP-V41AWP 5 mA max.

AP-V42AWP 1 mA max.

Analog

output (1 to 5 V)

0 V

Main

circuit

Blue

Pink

<Output 1>

P1

H1

Output 1

OFF ON OFF

0

P2

OFF ON OFF

H2

0

<Output 2>

Output 2

<Output 2>

Hi

Lo

Output 2

OFFONOFF OFF

ON

<Output 1>

P1

Output1

Zero shift input

OFF ON

OFF ON

0

Input/output circuit (AP-V41AW) Input/output circuit (AP-V42AW)

Input/output circuit (AP-V41AWP) Input/output circuit (AP-V42AWP)

■ Variable hysteresis mode (F-2)

Two detection points may be user-configured, and hysteresis for both

may also be set.

Control output 1

: Turns ON when pressure exceeds setting P1. Turns OFF

when pressure drops the selected hysteresis amount

below P1.

Control output 2:

Turns ON when pressure exceeds setting P2. Turns OFF

when pressure drops the selected hysteresis amount

below P2.

Zero shift input circuit

(AP-V41AW•V42AW)

Zero shift input circuit

(AP-V41AWP•V42AWP)

Analog output circuit

(AP-V41AW(P) only)

7. Precautions for Safe Use

Follow these guidelines. Failure to do so may result in product damage.

■

Connections

●

Always ground the frame ground terminal when using an off-the-shelf

switching regulator.

●

Use separate conduits for power line and high voltage lines, since use

of a common conduit may result in device malfunction.

●

Improper wiring may result in the device becoming excessively hot or

in device damage.

●

Sensor head connectors that have been pressure-connected once cannot be used again.

■

Notice about CE marking

●

Attach the ferrite core (OP-87505) if you extend a sensor head cable/

amplifier power cable to 3 m or more to use.

(Attachment position: within 100 mm from the amplifier unit of a

power cable, Number of turns: 2)

■

Other

●

Do not use this sensor with corrosive gasses or liquids.

●

Do not insert objects such as wire into the pressure insertion area.

Doing so may result in the device failing to operate properly due to

damage to the pressure-sensitive elements.

●

Do not use sharp-tipped objects to press the setting keys.

8. About Sensor Head Installation

Common Do not subject the case to pressure sufficient to deform

AP-41(M) • Use a torque of 0.3 N

43 • 44 for the sensor head conduits.

AP-48 Use a torque of 5 N

its shape during installation.

•

m or lower to tighten the screws

•

m or lower to tighten the screws for

the sensor head conduits.

Take care that no foreign objects enter the sensor when

opening one of the pressure ports to atmospheric air.

Take care not to bend the pressure ports.

Connect the “High” port to the high-pressure side of the

system and the “Low” port to the low-pressure side.

9. Detection Mode Operation

■ General-purpose mode (F-1)

This mode allows the user to configure 2 detection points.

Control output 1: Turns ON when pressure exceeds setting P1.

Control output 2: Turns ON when pressure exceeds setting P2.

■ Window mode (F-3)

The user may select a pair of upper (Hi) and lower (Lo) thresholds, and

the sensor turns OFF when the pressure falls outside of the resulting

range.

*Control output 1 uses a hysteresis of 0.5% of F.S., while control out-

put 2 uses a hysteresis of 0.

■ Application mode 1 (A-1)

This detection mode is optimum for use in suction detection applications.

Recommended heads: AP-41/41M/44

Control output 1:

Suction pressure detection.

Turns ON when pressure exceeds setting P1.

Control output 2:

Detection and confirmation of vacuum burst pressure

detection (or vacuum ultimate pressure).

Turns ON when the pressure falls below setting P2.

Zero shift: Shifts the zero point immediately after setting the zero

shift timer once zero shift input is received.

P1: Pressure setting for control output 1.

T1: Zero shift timer setting (ms)

P2: Pressure setting for control output 2.

*P2 is unrelated to zero shift and is always based on the current ambi-

ent pressure.

■ Application mode 2 (A-2)

This mode is optimum for use in leak test applications.

Recommended head: AP-43

Control output 1

: Leak pressure detection.

Turns ON when pressure falls below setting P1.

*Output only when zero shift input is ON.

Control output 2:

Window comparator output for detection of fill pressure.

Turns OFF when pressure falls outside the range deter-

mined by upper (HI) and lower (Lo) thresholds.

P1: Pressure setting for control output 1.

Hi: Upper threshold setting for control output 2.

Lo: Lower threshold setting for control output 2.

*The HI and Lo values are unrelated to zero shift and are always based

on the current ambient pressure.

*Hysteresis during general-purpose mode and application mode 1/2

operation is 0.5% of F.S. during standard and high-speed mode operation, and is 0.1% of F.S. during high-resolution mode operation.

2

Loading...

Loading...