Page 1

Ultra-compact Digital

CAUTION

Pressure Sensor

AP-C30W (P) Series

Instruction Manual

1. Safety Precautions

WARNING

●

Do not use this product in safety circuits such as those designed to

protect human workers.

●

This product does not employ an explosion-proof construction. Do not

use it in the presence of flammable gasses, liquids, or powders.

●

This is a direct current power supply type sensor. Application of an

alternating current may result in explosion or fire.

???

96M1192

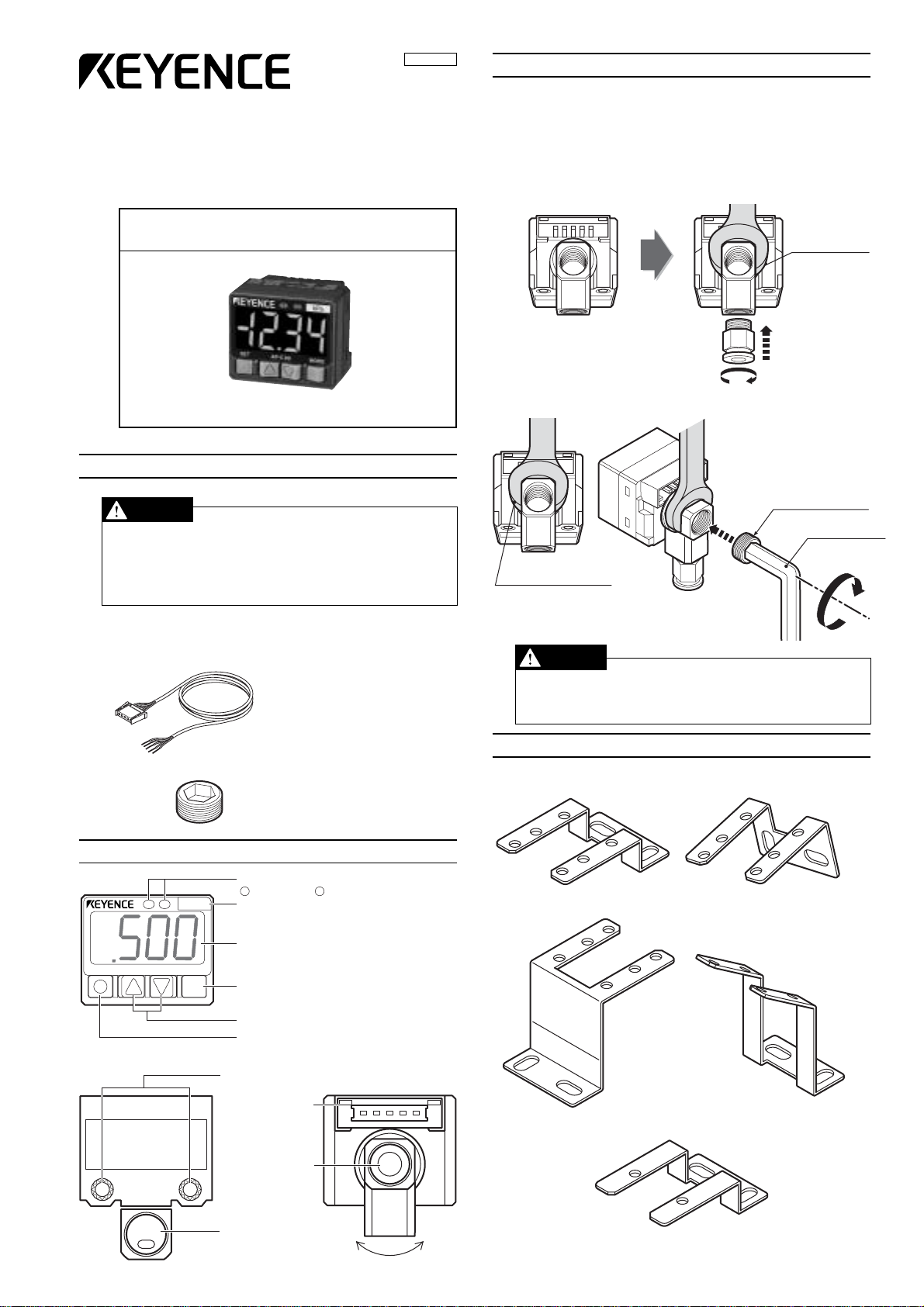

3. Pipe Connections

You can select from one of two pressure ports: one on the back of the

sensor that can accommodate a pipe leading directly away from the back

of the sensor, and one on the side of the sensor to accommodate a pipe

leading away from the sensor at a right angle.

1) The pressure port is 1/8 of Rc (PT). Commercially available air pressure

joints and nipples can be used with the port.

When attaching the joint, use a wrench to hold the pressure port in

place as illustrated below.

Hold in place

with wrench

(12mm).

2) Attach the included valve plug to the pressure port not being used.

Valve plug with

hexagonal hole

Hexagonal

wrench (5mm)

Hold in place with

wrench (12 mm).

■ Accessories

●

1 connector cable (2 m)

●

1 valve plug with hexagonal hole

2. Part Names

21

SET AP-C33W MODE

MPa

Operational indicator

1 2

Output 1 Output 2

Pressure display unit

*Apply the units sticker here.

Pressure display

Mode button

Manual adjustment button

Set button

Mounting screws

(M3 x 2)

Wiring

connector

●

1 unit scale label

●

1 instruction

manual

• Do not use a torque in excess of 10 Nm when tightening the joint.

Doing so may damage the joint.

• Apply sealing tape when attaching the joint in order to prevent air leaks.

4. Mounting Brackets (option)

Dedicated mounting hardware is available for the sensor, allowing it to be

installed in a range of locations.

Horizontal mounting bracket Wall mounting bracket

(AP-BO1) (AP-BO2)

Faceplate/ceiling mounting bracket Tilted mounting bracket

(AP-BO3) (AP-BO4)

Pressure

port (rear)

Pressure port

(side)

Approx. ± 90°

Substitution bracket (AP-BO5)

1

* Distance between arms is same as the AP-30/40 Series brackets.

Page 2

AP-AO1 Panel mounting bracket

S

E

T

A

P

-C

4

0

M

O

D

E

M

P

a

Panel-mounted sample

<Output 1>

P1

0

Output 1

OFF ON OFF

Hi

Lo

Output1/Output2

OFF ON ONOFF OFF

<Output 1/Output 2>

0

<Output 1>

P1

Output 1

OFF ON OFF

0

<Output 1>

P1

Output1

Zero shift input

OFF ON

OFF ON

0

Panel mounting ring

M

P

a

P

-C

3

3

M

O

D

E

Panel-mounted sample

Panel-mounted sample

Front protective

cover

S

E

TA

5. Connection Method and Diagrams

Insert the included connector-tipped cable into the sensor’s connector.

Position the connector so that the side of the connector where the metallic

contacts are visible is facing up.

Side where the metallic

contacts are visible faces up.

Connector cable

7. Detection Mode Operation

■ General-purpose mode (F-1)

This mode allows the user to configure 2 detection points.

Control output 1: Turns ON when pressure exceeds setting P1.

Control output 2: Turns ON when pressure exceeds setting P2.

*Hysteresis is a standard 0.5% of F.S. when operating in general-pur-

pose mode and application modes 1 and 2. During focus mode operation, it is 0.2% of F.S.

■ Variable hysteresis mode (F-2)

Two detection points may be user-configured, and hysteresis for both

may also be set.

Control output 1

: Turns ON when pressure exceeds setting P1. Turns OFF

when pressure drops the selected hysteresis amount

below P1.

Control output 2:

Turns ON when pressure exceeds setting P2. Turns OFF

when pressure drops the selected hysteresis amount

below P2.

<Output 1>

P1

0

Output 1

OFF ON OFF

H1

■ Window mode (F-3)

The user may select a pair of upper (Hi) and lower (Lo) thresholds, and

the sensor turns OFF when the pressure falls outside of the resulting

range.

*Control output 1 is a standard 0.5% of F .S. During focus mode opera-

tion, it has a hysteresis of 0.2% of F.S., and control output 2 has a

hysteresis of 0.

Output 2

P2

Output 2

<Output 2>

P2

0

<Output 2>

0

OFF ON OFF

OFF ON OFF

H2

Input/output circuit Input/output circuit

(AP-C30W/C31W/C33W) (AP-C30WP/C31WP/C33WP)

Brown

Black

Load

White

Load

Blue

Analog output/

zero shift input: switchable

Pink

12 to 24 VDC

5 to 40 VDC

5 to 40 VDC

0V

protection circuit

Main circuit

Overcurrent

Input/output

circuit

protection circuit

Main circuit

Overcurrent

Input/output

circuit

Analog output circuit

Pink

Blue

Analog

output (1 to 5 V)

0 V

circuit

Main

Zero shift input circuit Zero shift input circuit

(AP-C30W/C31W/C33W) (AP-C30WP/C31WP/C33WP)

circuit

Main

circuit

Main

(Short-circuit current 5 mA max.)

Pink

Blue

(Short-circuit current 5 mA max.)

Use non-contact input device such as open-collector.

6. Precautions for Safe Use

Follow these guidelines. Failure to do so may result in product damage.

CAUTION

■

Connections

Input/output circuit

●

Always ground the frame ground terminal when using an off-the-shelf

switching regulator.

●

Use separate conduits for power line and high voltage lines, since use

of a common conduit may result in device malfunction.

●

Improper wiring may result in the device becoming excessively hot or

in device damage.

■

Other

●

Do not use this sensor with corrosive gasses or liquids.

●

Do not insert objects such as wire into the pressure insertion area.

Doing so may result in the device failing to operate properly due to

damage to the pressure-sensitive elements.

●

Do not use sharp-tipped objects to press the setting keys.

Brown

Black

White

Load

Load

Blue

Analog output/

zero shift input: switchable

Pink

12 to 24 VDC

Brown

Pink

12 to 24 VDC

0V

■ Application mode 1 (A-1)

This detection mode is optimum for use in suction detection applications.

Recommended sensor heads: AP-C30W/C30WP/C31W/C31WP

Control output 1:

Control output 2:

Zero shift: The zero point is shifted immediately after the zero

P1: Pressure setting for control output 1.

T1: Zero shift timer setting (ms) < Variable between 0 and 1,999 ms>

P2: Pressure setting for control output 2.

*P2 is unrelated to zero shift and is always based on the current ambi-

ent pressure.

■ Application mode 2 (A-2)

This mode is optimum for use in leak test applications.

Recommended sensor head: AP-C33W/C33WP

Control output 1

Control output 2:

P1: Pressure setting for control output 1.

Hi: Upper threshold setting for control output 2.

Lo: Lower threshold setting for control output 2.

*The Hi and Lo values are unrelated to zero shift and are always based

on the current ambient pressure.

2

Suction pressure detection.

Turns ON when pressure exceeds setting P1.

Detection and confirmation of vacuum burst pressure

detection (or vacuum ultimate pressure).

Turns ON when the pressure falls below setting P2.

*Cannot be used to detect vacuum burst pressure with

the AP-C31W/C31WP when operating in focus mode.

Standard mode operation only.

shift timer is set following the activation of zero shift

input.

<Output 2>

0

P2

OFF ON OFF

Output 2

Shift

<Zero shift>

0

0

Zero shift input

T1

:Leak pressure detection.

Turns ON when pressure falls below setting P1.

*Output only when receiving zero shift input.

Window comparator output for detection of fill pressure.

Turns OFF when pressure falls outside the range determined by upper (Hi) and lower (Lo) thresholds.

*Fill pressure values are displayed with the center pres-

sure as 0 during focus mode operation.

<Output 2>

Hi

Lo

OFFONOFF OFF

Output 2

ON

Page 3

8. Sensor Configuration

■ Toggling the

display

Current value

+

+

Reference value*

After 4 sec

of no key

■ Manual configuration

Settings are

manually

configured. The

display changes

for each mode.

*Toggling the

display of

settings (see the

diagram below).

*Manual

configuration

only during F-3/A2 mode operation.

■ Toggling the display of settings

●

General-purpose mode/F1

●

Variable hysteresis mode/F-2

●

Window mode/F-3

●

Application mode 1/A-1

●

Application mode 2/A-2

■ Two-point tuning (F-1/F-2)

The sensor is made to detect the pressures when the target object is

present and then absent for confirmation of target suction pick-up, and

the intermediate value is used.

Control output 1 configuration: When P1 (H1) is selected on the settings

display.

Control output 2 configuration: When P2 (H2) is selected on the settings

display.

Target object

present

■ Active tuning (A-1)

See Section 10.

Note:• Press and hold the MODE button ( ) for at least 3 seconds to return to the current

value/reference value/hold value display from each of the mode setting screens.

• Press the left side on the manual adjustment button ( ) while holding down the

mode button ( ) to return to the previous display.

• The current value will be displayed based on the ambient pressure conditions prevalent

at that time without regard to zero shift input when the P2 setting display is selected for

A-1 mode or when the Hi and Lo setting displays are selected for A-2 mode.

• The sensor must be configured manually when operating in the F-3/A-2 modes. The

SET button ( ) will not function.

operation.

Target object

absent

Increase the

setting.

Decrease the

setting.

Setting

Flashes

for 3 sec.

•Two-point tuning

• Active tuning

3

Peak hold

Bottom hold

■ Mode

Press for 3 sec or more.

configuration

AP-C31W(P)/

C33W(P)

AP-

C30W(P)

only

When

operating

mode is

When

A-1/A-2 is

selected

during

fixed mode

()

operation

Current value

Reference value

Hold value

Detection range (AP-C30W(P) only)

Units

Detection mode

Operating mode

Focus center pressure

* See the Focus Mode section of

Part 9 for the center pressures

that can be selected.

N.O./N.C.

• N.O. = normal open.

• N.C. = normal close.

Analog/zero shift

Chatter prevention

Sets response time.

Display color (7-segment)

*

* F-1 and F-2 mode only

Values that fall between the P1

and P2 settings will be displayed

in green, while values outside

that range will be displayed in

red.

Power-save

*The reference value is

the pressure value when

zero shift input is

received and is replaced

only when zero shift

input is selected.

Compound pressure range

Positive pressure range

Negative pressure range

Pa

kgf/cm2 (AP-C30/C33 only)

mmHg (AP-C30/C31only)

inHg (AP-C30/C31only)

psi

bar

General-purpose mode

Variable hysteresis mode

Window mode

Application mode 1

Application mode 2

Standard

Focus mode

Control

output 1

N.O.

N.O.

N.C.

N.C.

Zero shift input

Analog output

2.5 msec

5 msec

100 msec

500 msec

ON: Red, OFF: Green

ON: Green, OFF: Red

Normally red

Normally green

Within set value: Green

Outside set value: Red

Standard

Eco mode

Control

output 2

N.O.

N.C.

N.O.

N.C.

Page 4

9. Explanation of Features

Active 2 point tuning

Active 1 point tuning

Suction

Vacuum burst

P1 P2 T1

Automatic

configuration

_

_

Automatic

configuration

Manual

configuration

_

ApplicationType

■ Switching the detection range (AP-C30W(P) only)

The AP-C30WP allows you to select a detection range. (When using Pa units)

DisplayPressure type

Negative pressure

Positive pressure

Compound pressure

■ Focus mode (AP-C31W/C31WP/C33W/C33WP)

Focus mode increases all display resolutions by a factor of 10.

Normal mode Focus mode

The following focus center pressures can be selected for the models

noted in the table below.

AP-C31W(P)

AP-C33W(P)

AP-C31W(P)

AP-C33W(P)

AP-C31W(P)

AP-C33W(P)

AP-C31W(P)

AP-C33W(P)

AP-C31W(P)

AP-C33W(P)

AP-C31W(P)

AP-C33W(P)

kPa

kgf/cm

mmHg

inHg

psi

mbar

bar

-20.0/-30.0/-40.0/-50.0/-60.0/-70.0/-80.0

2

-2.90/-4.35/-5.80/-7.25/-8.70/-10.15/-11.60

The current value is displayed in a range of ±20% of F .S. using the focus

center pressure as the reference value (0).

■ Zero shift

Zero shift input forces the pressure at that time to be defined as zero.

This feature is useful in applications that require the detection of a certain amount of pressure fluctuation without being influenced by changes

in the original pressure.

1MPa

Zero shift input

Range

0 to -101.3 kPa

0 to 100.0 kPa

101.3 to -101.3 kPa

200/300/400/500/600/700/800

-

2.04/3.06/4.08/5.10/6.12/7.14/8.16

-150/-225/-300/-375/-450/-525/-600

-

-5.9/-8.9/-11.8/-14.8/-17.7/-20.7/-23.6

-

29.0/43.5/58.0/72.5/87.0/101.5/116.0

-200/-300/-400/-500/-600/-700/-800

2.00/3.00/4.00/5.00/6.00/7.00/8.00

Zero shift input

-0.5MPa

-0.1MPa

O.K.

N.G.

Resetting the peak/bottom hold values/

Pressing for 3 seconds or more while the peak and bottom hold

values are being displayed will reset the values.

*The values will also be reset when power to the sensor is turned off,

and when the device's detection mode or operating mode is changed.

●

During A-1 mode operation (active hold display)

The hold values are reset each time the pressure value exceeds (or falls

below) the setting, and the peak hold (bottom hold) will then vary from

this point.

Peak hold value: The peak hold value will be reset once a value is

encountered that exceeds setting P1, and new peak

values will be held from that point.

Bottom hold value: The bottom hold value will be reset once a value is

encountered that falls below setting P2, and new

bottom values will be held from that point.

■ Power-save

The value display will be turned off during power-save operation to reduce the amount of power consumed.

●

Use of any keys during eco mode operation will revert the sensor to

its normal display. The sensor will return to the eco display when

there is no key input for a period of 3 minutes.

■ Switching the display color

Corresponds to either output 1 or output 2 based on which setting display has been selected.

* rGr can only be set when either the F-1 or F-2 mode is selected.

Values that fall between the P1 and P2 settings will be displayed in

green, while values outside that range will be displayed in red.

10

.Active T uning

Vacuum

P1

■ Analog output

■ Peak/bottom hold display

0

(Example: leak testing)

Zero shift input received when a container is filled with air will allow the

amount of leak after a certain time to be displayed as negative pressure.

This approach eliminates the influence of small variations in the final fill

pressure of the container.

The pressure value (reference value) when zero shift input is received

can be verified from the current value display by pressing the button

to switch to the reference value display.

( ⇔ )

Press the button once more to return to the current value display.

A voltage corresponding to the pressure value is output. (When using Pa units)

AP-C30W/C30WP

Negative pressure range

Positive pressure range

Compound pressure range

Model

AP-C31W/C31WP

Normal mode

Focus mode

AP-C33W/C33WP

Normal mode

Focus mode

1 to 5V

-101.3to 0 kPa

0to100.0 kPa

-101.3to 101.3 kPa

0to-101.3 kPa

20.0 to -20.0 kPa

0to1.000 MPa

-200 to 200 kPa

* The pressure value of the focus mode is based on the selected

center pressure.

The maximum (minimum) values are displayed continuously after power to

the sensor is turned on.

The active hold display indicated below is used when the A-1 mode is selected.

How to display hold values/

From current value/reference value display

+ / Activates peak hold display.

+ /Activates bottom hold display.

The minimum value during zero shift input is displayed for the bottom

hold during A-2 mode operation.

4

Time

T1

Zero shift input

P2

■ Perform these steps first

• Select the setting display as indicated below before performing the

tuning procedures.

Active 2 point tuning:Select either P1 or T1 for the setting display.

Active 1 point tuning:Select P2 from the settings display.

• Connect the external signal to the zero shift input.

■ Active 2 point tuning / a tuning method suited for automatically configuring suction pick-up detection pressures

The zero shift timer setting is manually configured, and the sensor automatically selects the best pressure setting (P1) for this value.

Step 1)

Step 2)

Device operation

with no target

object present

Device operation

with target

object present

Start

Start

Sampling

Sampling

Operation

for several

cycles

Finish

Operation

for several

cycles

Finish

Sensitivity

difference

display

■ Active 1 point tuning / tuning optimized for vacuum burst

detection

The sensor automatically selects the best pressure setting (P2) for

vacuum burst detection.

Setting

display

Target object

present

Start Finish

Sampling

* Cannot be used to detect vacuum burst pressure when operating in

focus mode (AP-C31W/C31WP).

Page 5

AP-C30W AP-C30W

AP-C31W(P)/

C33W(P)

AP-C31W(P)/

C33W(P)

Detection

range

Units

Detection

mode

Operating

mode

N.O./N.C.

switching

Analog/

zero shift

Chatter prevention

Display

color

Powersave

11

.Ambient Pressure Compensation

Open the applied pressure to the surrounding air so that it equals the

ambient pressure and press the button for 3 seconds or more

while the current value or reference value is being displayed.

The ambient pressure point will be corrected.

*1 Ambient pressure can be corrected within a range of ±5 % of F.S.

When atmospheric pressure compensation has been performed, the

settings will be saved even when power to the sensor is turned off.

*2 AP-C31W/C31WP/C33W/C33WP: Can be used during focus mode op-

eration as well. Values will be compensated based on the center pressure.

12

.Key Lock

Disables operations that would modify the sensor's configuration. Display

content can be toggled.

Pressing and holding either or for at least 3 seconds while pressing

button will lock the keypad and cause the display to flash.

*The same key combination will deactivate the key lock feature.

13

.Specifications

Type

Model

Rated pressure range

Unit

kPa

kgf/cm

mmHg

inHg

psi

bar

Pressure resistance

Adaptive fluids

Pressure type

Power supply voltage

Rating

Current

consumption

Display method

Configuration/display range *

Operating status indicators

Unit

kPa

Multi-range Standard mode Focus mode

kgf/cm

mmHg

inHg

psi

bar

kPa

Resolution

kgf/cm

mmHg

inHg

psi

bar

kPa

kgf/cm

mmHg

inHg

psi

bar

Repeatability

Hysteresis *

Display temperature characteristics

Response (chatter prevention feature)

Zero shift input

Control output *

Analog output

Environmental

resistance

Ambient temperature

Relative humidity

Vibration

Pressure port

Housing material

Weight

Accessories

*1 During focus mode operation, restricted to focus range.

*2 During focus mode operation, standard 0.2% of F.S.

*3 The AP-C30W(P), C31W(P), and C33W(P) use PNP output.

Negative pressure

0 to -101.3

2

0 to -1.033

0 to -760

0 to -29.9

0 to -14.69

0 to -1.013

Normal

Eco mode

1

Negative pressure

2

2

2

2

3

1to 5 V Output impedance 1 kΩ max. (Switchable with zero shift input.)

10 to 55 Hz, compound amplitude 1.5 mm, 2 hours for each of XYZ axes

Multi-range

AP-C30W/C30WP

Positive pressure

0 to 100.0

0 to 1.020

0 to 750

0 to 29.5

0 to 14.50

0 to 1.000

12 to 24 VDC±10% Ripple (P-P) 10% max.

12 V operation(NPN/PNP) 24 V operation(NPN/PNP)

720 mW(60 mA)/900 mW(75 mA) max.

480 mW(40 mA)/600 mW(50 mA) max. 720 mW(30 mA)/960 mW(40 mA) max.

(11 mm character height) Display cycle: 10 times/second

-10 to +110 % of F.S. -15 to +110 % of F.S.

Red LED x 2 (supports control output 1 / control output 2)

Positive pressure

0.1

0.001

1

0.1

0.02

0.001

Input time 2 ms or greater (Switchable with analog output.)

NPN open collector max. 100 mA (40 V max.)

residual voltage 1 V max., 2 outputs (NO/NC switchable)

PNP open collector Max. 100 mA (30 V max.)

residual voltage 1 V max., 2 outputs (NO/NC switchable)

Rc(PT)1/8 Bidirectional rotating type

Front case: polysarfun; Rear case: PBT;

Front sheet: polycarbonate; Pressure port: die-cast zinc

30 g (not including cables) / 78 g (including 2-m cable)

Power cord (2-m, connector type) Units sticker

Compound pressure

101.3 to -101.3

1.033 to -1.033

760 to -760

29.9 to -29.9

14.69 to -14.69

1.013 to -1.013

500kPa 500kPa

Air, non-corrosive gasses

Gauge pressure

3.5 digit two-color 7 segment LED

Compound pressure

0.1

0.001

1

0.1

0.02

0.001

± 0.2 % of F.S.

Variable (standard 0.5% of F.S.)

± 1 % of F.S. max.

Selectable from 2.5, 5, 100, 500 ms

No-voltage input (without contacts)

0 to +50 °C (No freezing)

35 to 85 % RH (No condensation)

Negative pressure

AP-C31W/C31WP AP-C33W/C33WP

Negative pressure

0 to -101.3

0 to -760

0 to -29.9

0 to -14.69

0 to -1.013

960 mW(40 mA)/1320 mW(55 mA) max.

0.2

0.002

2

0.1

0.04

0.002

0.1mbar

0.1

1

0.1

0.02

0.001

0.01

0.1

0.01

0.002

Positive pressure

Positive pressure

1.000MPa

0 to

0 to 10.20

0 to 145.0

0 to 10.00

1.5MPa

0.001MPa

0.01

0.2

0.01

0.1

0.001

0.02

0.001

14

.Error Displays and Corrective Actions

■ Error displays during normal operation

Display Cause Solution

• No difference in sensitivity

(during 2 point tuning/active

tuning).

• There is an applied pressure

of ±5 % of F.S. during ambient

pressure compensation.

• An excess current is flowing to the

control output.

• Reading is falling below

(exceeding) configuration/display

pressure range.

• Reading is exceeding (falling

below) configuration/display

pressure range.

•When there were not at least 2

shift inputs during active 2 point

tuning.

Adjust the air pressure device so that

there will be a difference in sensitivity.

(Return to atmospheric pressure.)

Repeat atmospheric compensation.

Check the load and return it to the

rated range.

Return the pressure to the rated

pressure range.

Return the pressure to the rated

pressure range.

Repeat the active tuning procedure

so that there are at least 2 shift inputs.

* Contact KEYENCE for information about error displays other than those

described above.

15

.Default Mode Settings (Initialization)

The sensor ships with the following configuration.

*Press button 5 times while holding down the button to return the

sensor to its default configuration.

WARRANTIES AND DISCLAIMERS

(1) KEYENCE warrants the Products to be free of defects in materials and workmanship for a period

of one (1) year from the date of shipment. If any models or samples were shown to Buyer, such models

or samples were used merely to illustrate the general type and quality of the Products and not to

represent that the Products would necessarily conform to said models or samples. Any Products found

to be defective must be shipped to KEYENCE with all shipping costs paid by Buyer or offered to KEYENCE

for inspection and examination. Upon examination by KEYENCE, KEYENCE, at its sole option, will

refund the purchase price of, or repair or replace at no charge any Products found to be defective. This

warranty does not apply to any defects resulting from any action of Buyer, including but not limited to

improper installation, improper interfacing, improper repair, unauthorized modification, misapplication

and mishandling, such as exposure to excessive current, heat, coldness, moisture, vibration or outdoors

air. Components which wear are not warranted.

(2) KEYENCE is pleased to offer suggestions on the use of its various Products. They are only

suggestions, and it is Buyer’s responsibility to ascertain the fitness of the Products for Buyer’ s intended

use. KEYENCE will not be responsible for any damages that may result from the use of the Products.

(3) The Products and any samples (“Products/Samples”) supplied to Buyer are not to be used

internally in humans, for human transportation, as safety devices or fail-safe systems, unless their

written specifications state otherwise. Should any Products/Samples be used in such a manner or

misused in any way, KEYENCE assumes no responsibility , and additionally Buyer will indemnify KEYENCE

and hold KEYENCE harmless from any liability or damage whatsoever arising out of any misuse of the

Products/Samples.

(4) OTHER THAN AS STATED HEREIN, THE PRODUCTS/SAMPLES ARE PROVIDED WITH NO OTHER

WARRANTIES WHATSOEVER. ALL EXPRESS, IMPLIED, AND ST A TUTORY WARRANTIES, INCLUDING,

WITHOUT LIMITATION, THE WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR

PURPOSE, AND NON-INFRINGEMENT OF PROPRIETARY RIGHTS, ARE EXPRESSLY DISCLAIMED. IN

NO EVENT SHALL KEYENCE AND ITS AFFILIATED ENTITIES BE LIABLE TO ANY PERSON OR ENTITY

FOR ANY DIRECT, INDIRECT, INCIDENTAL, PUNITIVE, SPECIAL OR CONSEQUENTIAL DAMAGES

(INCLUDING, WITHOUT LIMITATION, ANY DAMAGES RESULTING FROM LOSS OF USE, BUSINESS

INTERRUPTION, LOSS OF INFORMATION, LOSS OR INACCURACY OF DA T A, LOSS OF PROFITS, LOSS

OF SAVINGS, THE COST OF PROCUREMENT OF SUBSTITUTED GOODS, SERVICES OR TECHNOLOGIES,

OR FOR ANY MATTER ARISING OUT OF OR IN CONNECTION WITH THE USE OR INABILITY TO USE

THE PRODUCTS, EVEN IF KEYENCE OR ONE OF ITS AFFILIATED ENTITIES WAS ADVISED OF A POSSIBLE

THIRD PARTY’S CLAIM FOR DAMAGES OR ANY OTHER CLAIM AGAINST BUYER. In some jurisdictions,

some of the foregoing warranty disclaimers or damage limitations may not apply.

KEYENCE CORPORATION

1-3-14, Higashi-Nakajima, Higashi-Yodogawa-ku,

Osaka, 533-8555, Japan

PHONE: +81-6-6379-2211 FAX: +81-6-6379-2131

KEYENCE CORPORATION OF AMERICA

PHONE: 201-930-0100

FAX: 201-930-0099

KEYENCE DEUTSCHLAND GmbH

PHONE: 06102-36 89-0

FAX: 06102-36 89-100

KEYENCE (UK) LIMITED

PHONE: 01908-696900

FAX: 01908-696777

KEYENCE FRANCE S.A.

PHONE: 01 56 37 78 00

FAX: 01 56 37 78 01

KEYENCE ITALIA S.p.A.

PHONE: 02-668-8220

FAX: 02-668-25099

KEYENCE SINGAPORE PTE LTD.

PHONE: 6392-1011

FAX: 6392-5055

5

AFFILIATED COMPANIES

KEYENCE (MALAYSIA) SDN BHD

PHONE: 03-2092-2211

FAX: 03-2092-2131

KEYENCE (THAILAND) CO., LTD.

PHONE: 02-369-2777

FAX: 02-369-2775

KEYENCE TAIWAN CO., LTD.

PHONE: 02-2627-3100

FAX: 02-2798-8925

KEYENCE (HONG KONG) CO., LTD.

PHONE: 3104-1010 FAX: 3104-1080

KEYENCE INTERNATIONAL TRADING

(SHANGHAI) CO., LTD.

PHONE: 021-68757500

FAX: 021-68757550

KEYENCE KOREA CORPORATION

PHONE: 02-563-1270

FAX: 02-563-1271

© KEYENCE CORPORATION, 2003

0044-1 96M1192

Printed in Japan

Loading...

Loading...