Page 1

A

AP-41

Separate Amplifier Type

M5

M5

M5

(Male)

M5

ø6

ø4

M5

ø6

ø4

M5

Rc(PT)1/8

Pressure Sensor

96M0761

FEATURES

● Separate amplifier-type pressure sensor

Faster response is achieved by reducing the total capacity of piping.

● Two-color, LED digital display

High-intensity, two-color LED ensures high visibility. Four types of

display patterns are selectable.

AP-40(P) Series

Instruction Manual

PART NAMES AND FUNCTIONS

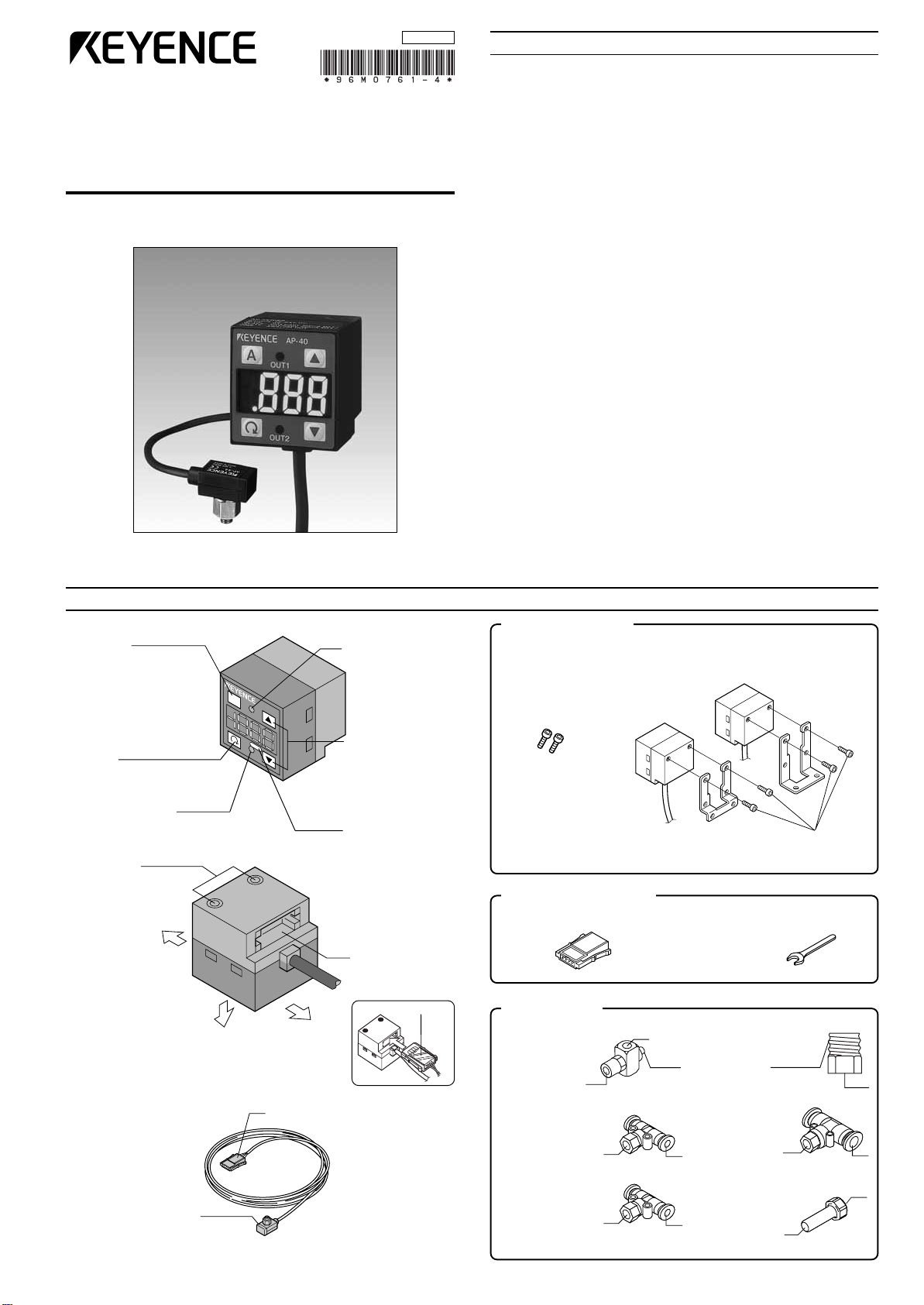

■ Amplifier

AUTO key

In auto-tuning mode, use

this key to detect pressure. In measurement

mode, press this key for 2

seconds or more to adjust

the zero-point.

SET key

Use this key to display or

change preset values.

Output indicator 2

(Green LED)

Screw hole

Use this hole

to bolt the

mounting

bracket with

a hexagonal

socket bolt.

Top side

Front side

Bottom side

Output indicator 1

(Red LED)

UP/DOWN key

Use these keys to

set output modes,

or to change preset

values or units.

Display unit label

Connector port

Insert the sensor

head connector.

Connector cover

● Chattering prevention function

The instantaneous drops in base pressure due to the activation of a

large-bore ejector or other devices can be canceled. This eliminates

the need for preparing a sequence program.

● Automatic sensor head recognition function

When the power is turned on, the amplifier checks the sensor head

connection automatically. A recognized sensor head type appears

green on the display for 0.5 seconds.

● Industry's smallest and lightest sensor head (AP-41M)

This sensor head with half the volume of conventional models

weighs only 4.8 g, enabling flexible mounting.

● Zero-shift function (AP-40Z)

The current pressure value can be reset to 0 at any time in order to

prevent measurements from being affected by fluctuations in base

pressure.

Amplifier accessories

• Instruction

manual: 1

• Hexagonal

socket bolt: 2

Reference:

DIN-rail mounting or panel

mounting is also available.

(Optional brackets are

required.)

Sensor head accessories

Spare connector: 1 Mini-wrench: 1

Piping options

OP-33155

Screw pipe joint

•Mounting

bracket A: 1

(for AP-41M only)

OP-35388

PT 1/8

conversion

joint

•Mounting

bracket B: 1

Hexagonal

socket bolts

■ Sensor head

Sensor head

AP-41(M)/43/44

Connector

OP-33156

T-shaped quickrelease joint (ø4)

OP-42220

T-shaped quick

release joint (M3)

M5

M3

OP-33157

T-shaped

quick-release

joint (ø6)

OP-33158

Reducer

1

Page 2

Orange

Brown

Blue

Gray

1

2

3

4

CAUTION

MOUNTING

Brown

Black or white

Blue

12 to 24 VDC

0 V

Load

Brown

Black or white

Blue

12 to 24 VDC

4.7 k Ω

0 V

Voltage output

Brown

Black

Blue

12 to 24 VDC

0 V

White

(Control output 1)

(Control output 2)

Load

Load

Pressure sensor main circuit

Over current

protection circuit

Blue

Pink

Pressure sensor

main circuit

12 to 24 VDC

3.3 k Ω

11 kΩ

Blue

Pink

Analog

output (+)

0 V

Protection

circuit

Pressure sensor

main circuit

CAUTION

CAUTION

Brown

Black or white

Blue

12 to 24 VDC

0 V

Load

Brown

Black or white

Blue

12 to 24 VDC

4.7 k Ω

0 V

Voltage output

Brown

Black

Blue

12 to 24 VDC

0 V

White

(Control output 1)

(Control output 2)

Load

Load

Over current

protection circuit

Pressure sensor main circuit

■ AP-40/40Z/40P

As shown in the figure with "Amplifier accessories" on page 1, attach

the mounting bracket to the amplifier with hexagonal socket bolts.

The mounting bracket can be attached laterally according to the

location.

To avoid breakage, limit the tightening torque

for the hexagonal socket bolt to 0.3 N•m.

■ AP-41(M)/43/44

Limit the tightening torque for the screw hole of

the sensor head to 0.3 N•m.

■ Zero-point adjustment

At normal atmospheric pressure (1 atm.), press A for at least 2

seconds in measurement mode. The display changes to “----”, then to

“0”. The zero adjustment function can be used when the pressure is

within ±5% of F.S.

CONNECTIONS AND INPUT/OUTPUT CIRCUIT

AP-40/40Z AP-40P

■ Connections

• Drive current load • Drive current load

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

BASIC OPERATION

Basic operation (See also "ADJUSTMENT" on page 4.)

<Example>

● Checking the suction condition

1. Select F-3 (2-independent mode) and return to the measurement

mode.

➮ Refer to the setting in "Operation Mode" on the left-hand side of page 4.

2. Enter the target pressure value (A) and return to the measurement

mode. (You can specify another target pressure value (b).)

➮ Refer to the setting in "Preset Value Input Mode" on the right-hand side of

page 4.

3. Start detection.

● Base pressure control

1. Select F-4 (Window mode) and return to the measurement mode.

➮ Refer to the setting in "Operation Mode" on the left-hand side of page 4.

2. Enter the upper (H) and lower (L) limit values of the allowable

pressure and return to the measurement mode.

➮ Refer to the setting in "Preset Value Input Mode" on the right-hand side of

page 4.

3. Start detection.

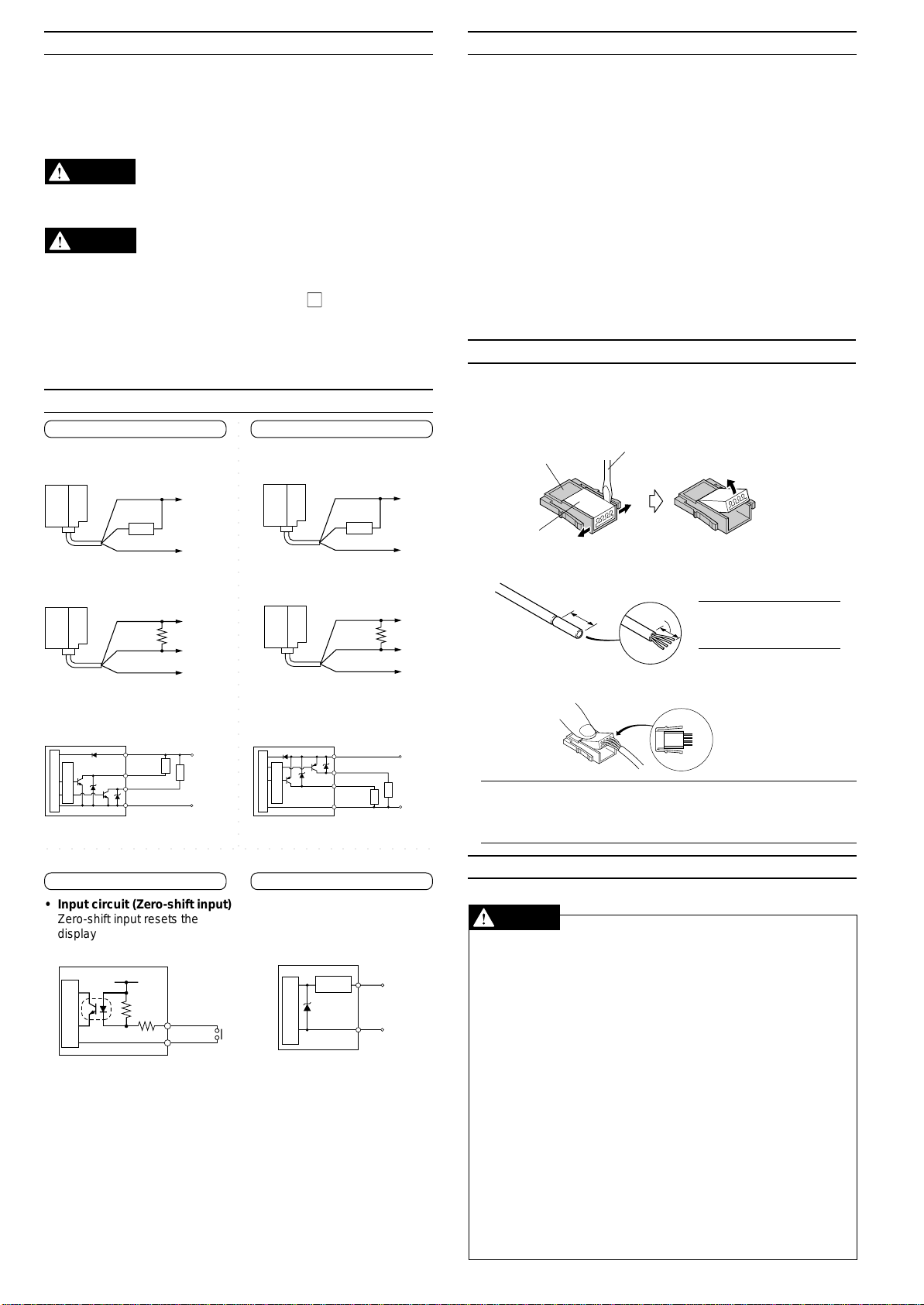

ATTACHING A SPARE CONNECTOR

Use the spare connector to change the length of the sensor head

cable. Cables as long as 10 m can be used.

1. If the connector cover is fitted into the connector body, open the

cover.

Connector body

Slotted screwdriver

2. Lift the end of the cover.

• Input to voltage input • Input to voltage input

equipment equipment

■ Input/output circuit

• Output circuit • Output circuit

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

AP-40Z (Z type only)

• Input circuit (Zero-shift input)

Zero-shift input resets the

display to “0” at the rising edge

of the signal.

AP-40/40P (40/40P type only)

• Analog output circuit

Connector cover

1. Widen the gap.

2. Cut a cable to the appropriate length and strip off the sheath for

approximately 25 mm from the end.

Approx.

25 mm

Approx.

25 mm

Note: It is not necessary

to remove the sheath of

the core wire.

3. Insert the cables into the proper holes as deep as possible. Then,

press the connector cover into the body with pliers.

Reference:

Note 1: Do not allow the cable to protrude from the other end of the

connector cover.

Note 2: Ensure that the cables are inserted as far as they will go. If

the inserted length is insufficient, the press-fitting fails.

SAFETY PRECAUTIONS

Be sure to follow the instructions below to avoid malfunctions.

■ Connection

• When using a commercially available switching regulator, be sure

to ground the frame ground terminals.

• Isolate the sensor’s wiring from power lines or high-voltage lines;

otherwise, the sensor may malfunction due to noise interference.

• The amplifier becomes hot or breaks down due to improper wiring.

• The press-fitting is available only once for each sensor head

connector.

■ Notice about CE marking

• Attach the ferrite core (OP-87505) if you extend a sensor head

cable/ amplifier power cable to 3 m or more to use.

(Attachment position: within 100 mm from the amplifier unit of a

power cable, Number of turns: 2)

■ Other

• Do not use the AP-40 Series for the detection of corrosive gases

or liquid.

• Do not insert any objects, such as wires, from the pressure port.

The pressure-sensing element may break, resulting in malfunctions.

• Do not press the front panel keys with a pointed object.

• The AP-40 Series does not have an explosion-proof structure.

Do not use it for the detection of flammable gases.

2

Page 3

noitacidnirorrEmelborPydemeR

sawtnemtsujdatniop-oreZ

foerusserpatadetucexe

± .S.Ffoeromro%5

tniop-orezmrofreP

lamrontatnemtsujda

.erusserpcirehpsomta

1TUOhguorhttnerrucrevO

2ro

tsujdadnafforewopnruT

tnerrucehttahtosdaoleht

.egnardetarehtnihtiwsi

sawerusserpdeilppA

.egnaryalpsidehtfoedistuo

(* FF ro FF- nehwsraeppa

siedomsucoftfihs-orezeht

).desu

nihtiwoterusserpehttsujdA

.egnardetareht

tonsidaehrosnesehT

gnitcennocehtrodetcennoc

.kaerbasahelbac

daehrosnesehttcennoC

.niagarewopehtnonrutdna

A

SH

Preset value C

SL

b

0

ON

OFF

ON

OFF

Control output 1

(OUT 1)

Control output 2

(OUT 2)

Pressure

Preset value H

H-h

0

ON

OFF

ON

OFF

Control output 2

(OUT 2)

h

Control output 1

(OUT 1)

Pressure

Preset value A

Preset value b

0

ON

OFF

ON

OFF

Control output 2

(OUT 2)

Control output 1

(OUT 1)

Pressure

Preset value H

SH

SL

Preset value L

0

ON

OFF

ON

OFF

Control output 1

(OUT 1)

Control output 2

(OUT 2)

Pressure

OTHER FUNCTIONS

▼

1 MPa

Atmospheric

pressure

Zero-shift input

Zero-shift input

-0.1 MPa is

acceptable.

-0.6 MPa is

not acceptable.

V1otV5

)M(14-PA 0otaPk3.101-

34-PA 0otaPM000.1+

44-PA 3.101+otaPk3.101–

■ Zero-shift function (AP-40Z type only)

The zero-shift function is used to reset the current pressure value to

“0” using an external signal input, in order to prevent measurements

from being affected by fluctuations in base pressure.

Example: Leakage test

Input a zero-shift value after

air supply is completed so

that air leakage after a

specified time is displayed

as a negative value. The

AP-40’s detection is

unaffected by fluctuations in air supply volume.

When the power is turned off, the value updated after the zero-shift

input (zero-shift value) is lost.

Note 1: The zero-shift function cannot be used in auto-tuning mode.

Note 2: The zero-shift input is effective when the current pressure is

between -3% of F.S. and 100% of F.S. for a shift of 0 (P = 0).

Note 3: If the applied pressure is outside the range of -15% to 110% of

the rated pressure, “-FFF” or “ FFF” appears.

Note 4: The display range for the zero-shift focus mode is ±19.9%.

When the pressure value is out of this range, “-FF” or “FF” is displayed.

■ Analog output function

(AP-40 only)

The voltage value according to the

pressure value is output.

■ Peak-hold/bottom-hold display function

The AP-40 Series internally updates the peak-hold and bottom-hold

values at all times.

● To display hold values

• While ▲ is held down in measurement mode, the peak-hold value

is displayed.

• While ▼ is held down in measurement mode, the bottom-hold

value is displayed.

● To reset the peak-hold and bottom-hold values

• Hold down ▲ and press ▼ in measurement mode.

● The peak-hold and bottom-hold values are also reset using the

following procedure.

• Turn the power off.

• Press for 3 seconds or more and change any settings.

Note: The hold values cannot be displayed when the front panel keys

are locked with the key protection function. Disable the function before

displaying the hold values.

■ Key protection

The key protection function is used to lock the front panel key in order

to prevent preset values from being accidentally changed.

To enable the key protection function, hold down A and press ▲.

“Loc” flashes for 2 seconds and the keys are locked.

To disable the key protection function, again hold down A and press

. “unL” flashes for 2 seconds and the keys are unlocked.

Using the EEPROM, the AP-40 Series can retain the preset values

even if the power is turned off.

■ Display color selection

You can set the color of the LED display either to the two-color mode

which displays the numerical value in green or red according to OUT1,

or to the single color mode which always shows the value in red or

green. The two-color display allows you to check the output condition

at a glance. (Refer to “ADJUSTMENT” on page 4 for the setting

procedure.)

In two-color mode (2-[) (Regardless of N.O./N.C. selection)

• When OUT1 is turned on: Red

• When OUT1 is turned off: Green

ERROR INDICATIONS AND REMEDIES

OPERATION MODE SELECTION

■ Auto-tuning mode (F-1)

Using the AUTO key, detect the upper limit value (A) and the lower

limit value (b). The detection level (C) is automatically set at the

midpoint between the two values. (You can finely adjust the preset

value C within the range between A and b.)

Control output 1: The sensor turns on when the pressure exceeds the

Control output 2: The sensor turns on when the pressure goes outside

■ Hysteresis mode (F-2)

Set desired detection level (H) and hysteresis (h) for the detection.

Control output 1: The sensor turns on when the pressure exceeds the

Control output 2: The sensor turns on when the pressure goes outside

■ 2-independent mode (F-3)

Set two desired detection points (A and B).

Control output 1: The sensor turns on when the pressure exceeds the

Control output 2: The sensor turns on when the pressure exceeds the

■ Window mode (F-4)

Set desired upper limit value (H) and lower limit value (L).

Control output 1: The sensor turns off when the pressure goes outside

Control output 2: The sensor turns off when the pressure goes outside

preset value C.

the stability levels.

* The stability levels are

automatically set as

shown in the following

calculations.

(A + C)

SH =

2

(C + b)

SL =

2

preset value H. When the pressure falls by the preset

value h, the sensor turns off.

the hysteresis width (H - h).

h: Hysteresis width of

OUT1

* When h is set to a

value close to 0, if

pressure fluctuates

around the detection

point, OUT1 will

chatter.

preset value A.

preset value b.

of the range between the upper limit value (H) and

lower limit value (L).

of the stability levels.

* The stability levels are

automatically set as

shown in the following

calculations.

Note 1: The above description shows the operation of control outputs

1 and 2 when the output selector switch is set to N.O.

SH = H –

SL = L +

(H - L)

4

(H - L)

4

When the output selector switch is set to N.C., the operation of control

outputs 1 and 2 is inverted.

Note 2: Except for OUT1 in hysteresis mode, each control output

includes an internal hysteresis of 0.5% of F.S.

3

Page 4

▼

▲

▲

ADJUSTMENT

dtS

,gHmm:44/)M(14-PA

mc/fgk:34-PA

2

AP

,aPk:44/)M(14-PA

aPM:34-PA

hcni

,gHhcni:44/)M(14-PA

:34-PAisP

RAb

rab:44/34/)M(14-PA

5.2

sm5.2

5

sm5

001

sm001

005

sm005

[-1

ylnoDELdeR

[-2

DELneerg/deR

tuptuonehwDER(

)NOsnrut1

❋ ❋ ❋ ❋

❋ ❋ ❋ ❋

❋ ❋ ❋ ❋

❋ ❋ ❋ ❋

❋ ❋ ❋ ❋

❋ ❋ ❋ ❋

• • •

• • •

• • •

• • •

A

A

(Measurement mode)

Current value

Flashes

alternately

Flashes

alternately

Flashes

alternately

Current upper

(lower) limit

value A

Current upper

(lower) limit

value b

The set value

C displays.

(C=

A + b

2

)

The updated value displays for 1 sec.

The updated value displays for 1 sec.

❋ ❋ ❋ ❋

❋ ❋ ❋ ❋

❋ ❋ ❋ ❋

• • •

• • •

1.

2.

3.

(Measurement mode)

Flashes

alternately

Current value

Flashes

alternately

Set the desired value

using

or

❋ ❋ ❋ ❋

Flashes

alternately

Set the desired value

using

or

• • •

1-F

edomgninut-otuA

3-F

tnednepedni-2

edomtuptuo

2-F

edomsiseretsyH

4-F

edomwodniW

Press the button

for 3 seconds or

more.

▲

Measurement mode

■ Unit Setting

Determine the desired units.

In measurement mode, press for at least 3 seconds. “- - - -”

appears first, and then the current units are displayed. Use ▲ or

to select the desired units. Pressing completes the unit

setting procedure and enters operation mode selection.

* When the units are changed, the preset values are automatically

converted to appropriate values for the updated units.

▲

Press the button once.

■ Operation Mode

Determine the desired operation mode.

(➮ Refer to “OPERATION MODE SELECTION” on page 3.)

The current operation mode is displayed. Use

the operation mode. Pressing completes the operation mode

setting procedure and enters N.O./N.C. selection.

or ▼ to select

Press the button

▲

▲

▲

once.

■ Preset Value Input Mode

Determine the preset values.

● Auto-tuning mode (F-1)

1. In measurement mode with the

current measured value displayed, press . The AP-40

enters the preset value input

mode.

2. “A” and the current preset value

flash alternately.

3. Position the target at the desired

upper (lower) limit.

4. Press A to register the value.

The updated value is displayed

for 1 second.

5. “b” and the current preset value

flash alternately.

6. Position the target at the desired

lower (upper) limit.

7. Press A to register the value. The updated value is displayed for 1

second.

8. “C” and the calculated preset value C flash alternately. (You can

change the C value to any value between A and b using ▲ or ▼.)

9. Press to register the C value. The setting procedure is completed and the unit returns to measurement mode.

* To confirm the preset value, press repeatedly.

▲

Press the button once.

■ N.O./N.C. Selection

Select N.O. (normally open) or N.C. (normally closed).

The current selection of “no” (normally open) or “nc” (normally

closed) is displayed. Use ▲ or ▼ to select the desired mode.

Pressing completes the N.O./N.C. selection procedure and

enters the chattering prevention setting.

▲

Press the button once.

■ Chattering Prevention

Determine the desired response time.

The current response time is displayed. Use ▲ or ▼ to select the

response time. Pressing completes the setting procedure and

enters the display color selection.

▲

Press the button once.

■ Display Color Selection

Determine the desired LED color for

numerical value display.

The current color is displayed. Use

or ▼ to select the color.

Pressing completes the setting

procedure and returns to the

measurement mode.

Press the button once.

* The setting is saved

in the EEPROM.

• Example of auto-tuning mode setting: Confirmation of work

piece pick-up.

Set the upper limit (A) to the position where the work piece is taken.

Set the lower limit (b) to the position where the nozzle becomes open

after releasing the work piece. Press A to register the upper and

lower limit values. The C value is automatically set to the midpoint

between the upper and lower limit values.

■ Hysteresis Mode (F-2), 2-independent Output

Mode (F-3), Window Mode (F-4)

1. In measurement mode with the

current measured value displayed,

press . The AP-40 enters the

preset value input mode.

2. “H” 1. and the current preset value

flash alternately.

3. Use ▲ or ▼ to change the value

to the desired value. Press to

register the updated H value.

4. “h” 2. and the current preset value

flash alternately.

5. Use ▲ or ▼ to change the value

to the desired value. Press to

register the updated h value.

6. “P” 3. and the shift value of the

zero-shift adjustment flash

alternately.

8. Press to complete the setting procedure and return to measurement mode.

* To confirm the preset value, press repeatedly.

[Example: In hysteresis mode]

1. “A” appears in the 2-independent

output mode.

2. “b” appears in the 2-independent

output mode.

“L” appears in the window mode.

3. Shown with Z type only.

Press the button once.

* The setting is saved

in the EEPROM.

Note 1: When the operation mode is changed, check the preset values

in the preset value input mode.

Note 2: Perform the zero-shift adjustment periodically.

Note 3: The initial output voltage may fluctuate by ±1.0% immediately

after the power is turned on. To measure minute differences in

pressure, let the sensor warm up for approximately 15 to 30 minutes.

Note 4: The amount of zero shift ("P") is displayed without multiplication even in the zero-shift focus mode.

4

Page 5

SPECIFICATIONS

ledoMM14/14-PA34-PA44-PA

erusserpdetaR

aPk3.101-ot0

)gHmm067-ot0(

aPM1ot0

mc/fgk01ot0(

2

)

otaPk3.101+

aPk3.101–

)gHmm067-ot067(

erusserpfoorP aPk005aPM5.1aPk005

sepytdiulF sesagevisorrocnonroriA

epyterusserP erusserpeguaG

ytilibataepeR

± .xam.S.Ffo%2.0

)reifilpmagnidulcni(

erutarepmeT

noitautculf

± .xam.S.Ffo%2

tropnoitcennoC

retemaid

wercselam5M

)ylnoM14-PAehtrofwercselam3M(

erutarepmettneibmA 05ot0 ° 221ot23(C ° gnizeerfoN,)F

ytidimuhevitaleR noitasnednocoN,%58ot53

noitarbiV

,Y,Xniedutilpmaelbuodmm5.1,zH55ot01

ylevitcepsersruoh4,snoitceridZdna

kcohS

s/m0001

2

ylevitcepsersemit01,snoitceridZdna,Y,Xni

)semit06:latoT(

lairetaM leetssselniatS:wercS,TBP:gnisuoH

thgieW

,)elbactuohtiw(g8.4:M14-PA

)elbacm3gnidulcni(g8.76

,)elbactuohtiw(g7:44/34/14-PA

)elbacm3gnidulcni(g07

ledoMP04/Z04/04-PA

ylppusrewoP CDV42ot21 ± .xam%01:)p-p(elppiR,%01

noitpmusnoctnerruC )daehrosnesgnidulcni()V42(Am55,)V21(Am501

yalpsiD

DELtnemges-7,roloc-2,tigid-2/13

.ces/semit5:elcycyalpsiD,)mm11:thgiehretcarahC(

egnarerusserpelbatceteD .S.Ffo%011+ot%51-

noituloseryalpsiD

,aPk1.0

,gHmm1

gHhcni1.0

rab100.0

aPM100.0

mc/fgk10.0

2

isP2.0

rab10.0

aPk2.0

gHmm2

gHhcni1.0

rab200.0

gnirettahc(emitesnopseR

)noitcnufnoitneverp

cesm005/001/5/5.2

tupnitfihs-oreZ

)ylnoepytZ(

eromrosm02:emittupnI

lortnoC

tuptuo

tuptuoNPN

,).xamV04(.xamAm001:rotcelloc-nepoNPN

.xamV1:egatlovlaudiseR

)elbatceles.C.N/.O.N(tuptuo-2

tuptuoPNP

,).xamV03(.xamAm001:rotcelloc-nepoPNP

.xamV1:egatlovlaudiseR

)elbatceles.C.N/.O.N(tuptuo-2

tuptuoegatlovgolanA

.1

V5ot1

rofnoitautculferutarepmeT

yalpsid

± .S.Ffo.xam%0.1

rofnoitautculferutarepmeT

tuptuogolana

.1

± .S.Ffo.xam%0.2

erutarepmettneibmA 05ot0 ° 221ot23(C ° gnizeerfoN,)F

ytidimuhevitaleR noitasnednocoN,%58ot53

noitarbiV

,Y,Xniedutilpmaelbuodmm5.1,zH55ot01

ylevitcepsersruoh2,snoitceridZdna

kcohS s/m001

2

ylevitcepsersemit3,snoitceridZdna,Y,Xni

lairetaM

,TEP:teehslenaptnorF,edimayloP:gnisuohtnorF

erytbacfoorp-liO:elbaC,enoflusyloP:gnisuohraeR

elbac

gnitnuoM

ro)sepyt2(tekcarbgnitnuomdeilppushtiW

tekcarbgnitnuomlenaplanoitpo

.2

thgieW )elbactuohtiwg82()elbacm2gnidulcni(g08

31

(4)

33

31

Cable length: 2 m

ø4 (5 x 0.18 mm

2

)

2 x M3 screw

20

26

40

t=1.5

2-ø4.5

mounting hole

25

6

16

22

31

45.5

t=1.5

2-ø4.5

4-ø3.5

45

14

20

30

25

16

22

35

19

20

t=1.5

2-ø4.5

4-ø3.5

14

20

20

13

30

45

8.6

19

20

t=1.5

31

20

45.5

13

31

M5 screw

Cable length: 3 m

(oil-resistant, flexible type)

ø3.6 (4 x 0.18 mm

2

core)

20 135.5

10

10

9

12

5

Cable length: 3 m

(oil-resistant, flexible type)

ø3.6 (4 x 0.18 mm

2

core)

19

9.8 9.2

0.9

617.3

10.3

M3 x 0.5

4

0.5

6.7

j

Copyright (c) 2001 KEYENCE CORPORATION. All rights reserved.

0761E 1022-4 96M0761 Printed in Japan

Sensor head

DIMENSIONS

AP-40/40Z

Unit: mm

Amplifier

When mounting

bracket A is attached

[Top view]

Mounting bracket A

(Accessory)

AP-41M

When mounting

bracket B is attached

[Side view]

Mounting bracket B

(Accessory)

1. Not provided with the AP-40Z.

2. Optional panel mounting brackets: OP-31357 (black), OP-32808 (gray) and OP-42192

(for a 5 mm-thick panel)

WARRANTIES AND DISCLAIMERS

KEYENCE, at its sole option, will refund, repair or replace at no charge any

defective Products within 1 year from the date of shipment. Unless stated

otherwise herein, the Products should not be used internally in humans, for

human transportation, as safety devices or fail-safe systems. EXCEPT FOR

THE FOREGOING, ALL EXPRESS, IMPLIED AND STATUTORY

WARRANTIES, INCLUDING WARRANTIES OF MERCHANTABILITY,

FITNESS FOR A PARTICULAR PURPOSE AND NONINFRINGEMENT OF

PROPRIETARY RIGHTS, ARE EXPRESSLY DISCLAIMED. KEYENCE

SHALL NOT BE LIABLE FOR ANY DIRECT, INDIRECT, INCIDENTAL,

CONSEQUENTIAL OR OTHER DAMAGES, EVEN IF DAMAGES RESULT

FROM THE USE OF THE PRODUCTS IN ACCORDANCE WITH ANY

SUGGESTIONS OR INFORMATION PROVIDED BY KEYENCE. In some

may not apply.

urisdictions, some of the foregoing warranty disclaimers or damage limitations

AP-41/43/44

E 1101-3

5

Loading...

Loading...