Page 1

Brown

Black or white

Blue

12 to 24 VDC

0 V

Load

SPECIFICATIONS

Two-color Digital Display

Pressure Sensor

AP-30 Series

Instruction Manual

epyT

.1

ledoM

erusserpdetaR

erusserpfoorP

epyterusserP erusserpeguaG

sepytdiulF sesagevisorrocnonroriA

yalpsiD )mm11:thgiehretcarahC(DELtnemges-7,roloc-2,tigid-2/13

noituloseryalpsiD

ytilibataepeR ± )eromrosm5(.S.Ffo%2.0

tupnitfihs-oreZ

tuptuolortnoC

tuptuogolanA

yalpsidrof

ylppusrewoP CDV42ot21 ± .xam%01:)p-p(elppiR,%01

noitarbiV

lairetaM

thgieW

egnarerusserpelbatceteD .S.Ffo%011+ot%51-

gnirettahc(emitesnopseR

)noitcnufnoitneverp

.2

.3

noitautculferutarepmeT

tuptuogolanarof

noitautculferutarepmeT

noitpmusnoctnerruC )V21ta(Am09,)V42ta(Am05

erutarepmettneibmA 05ot0 °C

ytidimuhevitaleR %58ot53

)elbacm2gnidulcni(

evitageN

erusserp

)Z(13-PA)Z(23-PA)Z(33-PA)Z(43-PA

aPk3.101-ot0

067-ot0(

)gHmm

aPk094

2

mc/fgk5(

)

,aPk1.0

,gHmm1

isP20.0

± 52taerusserpgnitcetedfo).S.Ffo(.xam%2 ° 05ot0(C ° )C

± 52taerusserpgnitcetedfo).S.Ffo(.xam%1 ° 05ot0(C ° )C

1ot0(

2

mc/fgk

)

aPk094

2

mc/fgk5(

)

,aPk1.0

mc/fgk100.0

isP20.0

erusserpevitisoP

aPk0.001ot0

2

,

aPM000.1ot0

01ot0(

mc/fgk2)

aPM74.1

2

mc/fgk51(

)

,apM100.0

2

mc/fgk10.0

,

isP2.0

)elbatceles(sm005/001/5/5.2

eromrosm02:emittupnI

k74:ecnadepmidaoL(V5ot1 Ω ).nim

elbacerytbacfoorp-liO:elbaC

g021.xorppA

1. The zero-shift type sensor is suffixed with Z after the model name.

2. Z type only. 3. Not provided with Z type

dnuopmoC

erusserp

ot3.101+

aPk3.101–

gHmm067+(

)gHmm067-ot

aPk094

2

mc/fgk5(

)

,aPk2.0

,gHmm2

isP40.0

,)etats-dilos,tcatnoc(tupniegatlov-noN

laudiseR,).xamV04(.xamAm001:rotcelloc-nepoNPN

)elbatceles.C.N/.O.N(tuptuo-2.xamV1:egatlov

,Y,Xniedutilpmaelbuodmm5.1,zH55ot01

ylevitcepsersruoh2,snoitceridZdna

,TEP:teehslenaptnorF,edimayloP:gnisuohtnorF

,cniztsac-eiD:troperusserP,enoflusyloP:gnisuohraeR

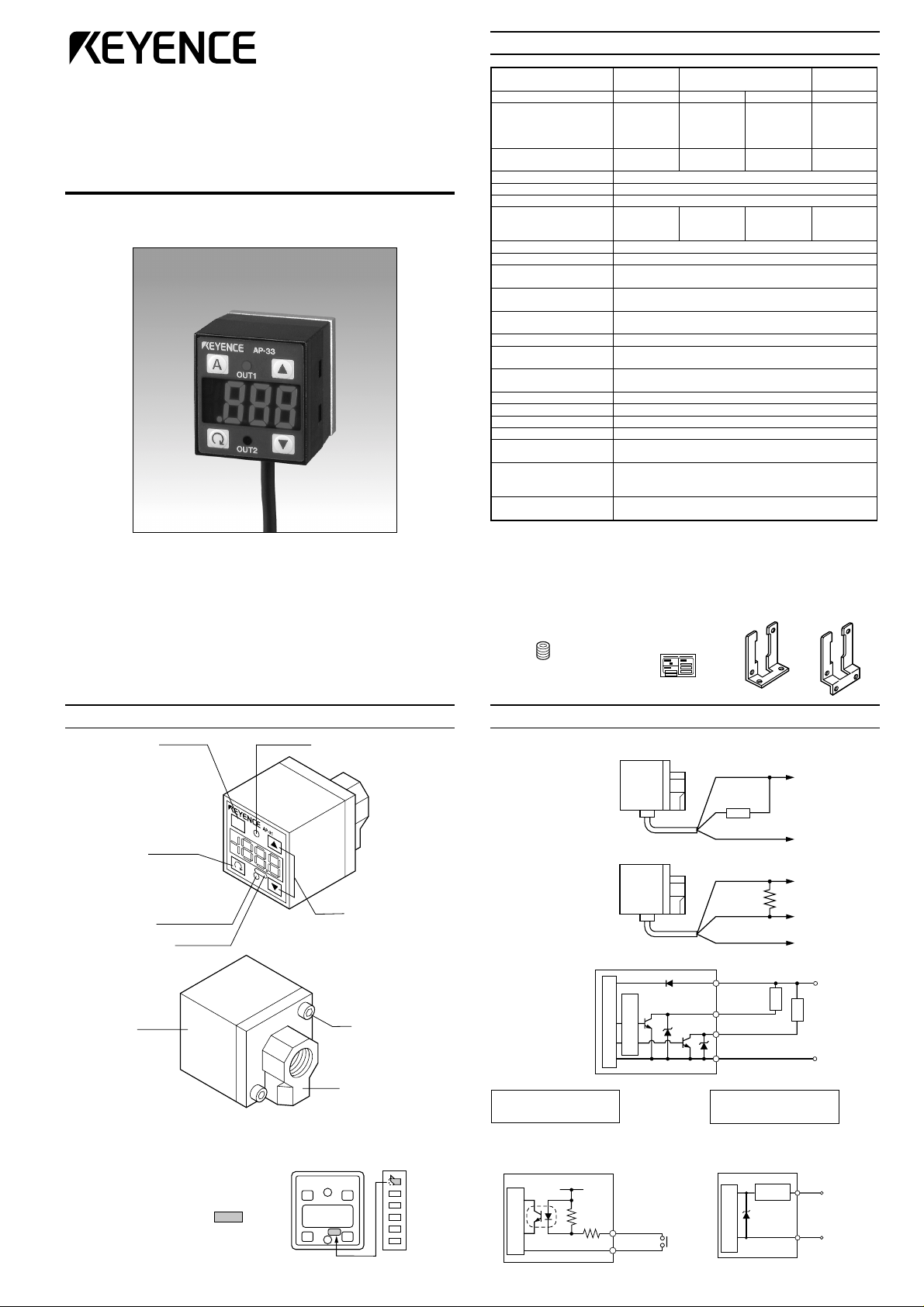

PART NAMES AND FUNCTIONS

AUTO key

In auto-tuning mode, use

this key to detect pressure. In measurement

mode, press this key for 2

seconds or more to adjust

the zero-point.

SET key

Use this key to display or

change preset values.

Output indicator 2

(Green LED)

Display unit label

Housing

■Display unit label

The AP-30 series enables you to

select the display units for pressure.

Attach the included display unit label

for the desired units at the

position in the figure.

A

Output indicator 1

(Red LED)

UP/DOWN key

Use these keys to

set output modes,

or to change preset

values or units.

Hexagonal

socket bolt

Rear metal casing

(Die-cast zinc)

■ACCESSORIES

• Instruction manual: 1

• Hexagonal-socket

port stopper: 1

• Display unit

label sheet: 1

• Quick reference

sheet: 1

Mounting

bracket A: 1

Mounting

bracket B: 1

CONNECTIONS AND INPUT/OUTPUT CIRCUIT

■Connections

• Drive current load

• Input to voltage input equipment

■Input/output circuit

• Output circuit

Over current

protection circuit

Pressure sensor main circuit

AP-31Z/32Z/33Z/34Z

(Z type only)

Input circuit (Zero-shift input)

Zero-shift input resets the display to

“0” at the rising edge of the signal.

12 to 24 VDC

3.3 k Ω

Pink

Blue

Pressure sensor

main circuit

11 kΩ

Brown

Black or white

Blue

Brown

Black

(Control output 1)

White

(Control output 2)

Blue

AP-31/32/33/34

(Except for Z type)

Analog output circuit

Pressure sensor

main circuit

Protection

circuit

12 to 24 VDC

4.7 k Ω

Load

Voltage output

0 V

12 to 24 VDC

Load

0 V

Pink

Analog

output (+)

Blue

0 V

Page 2

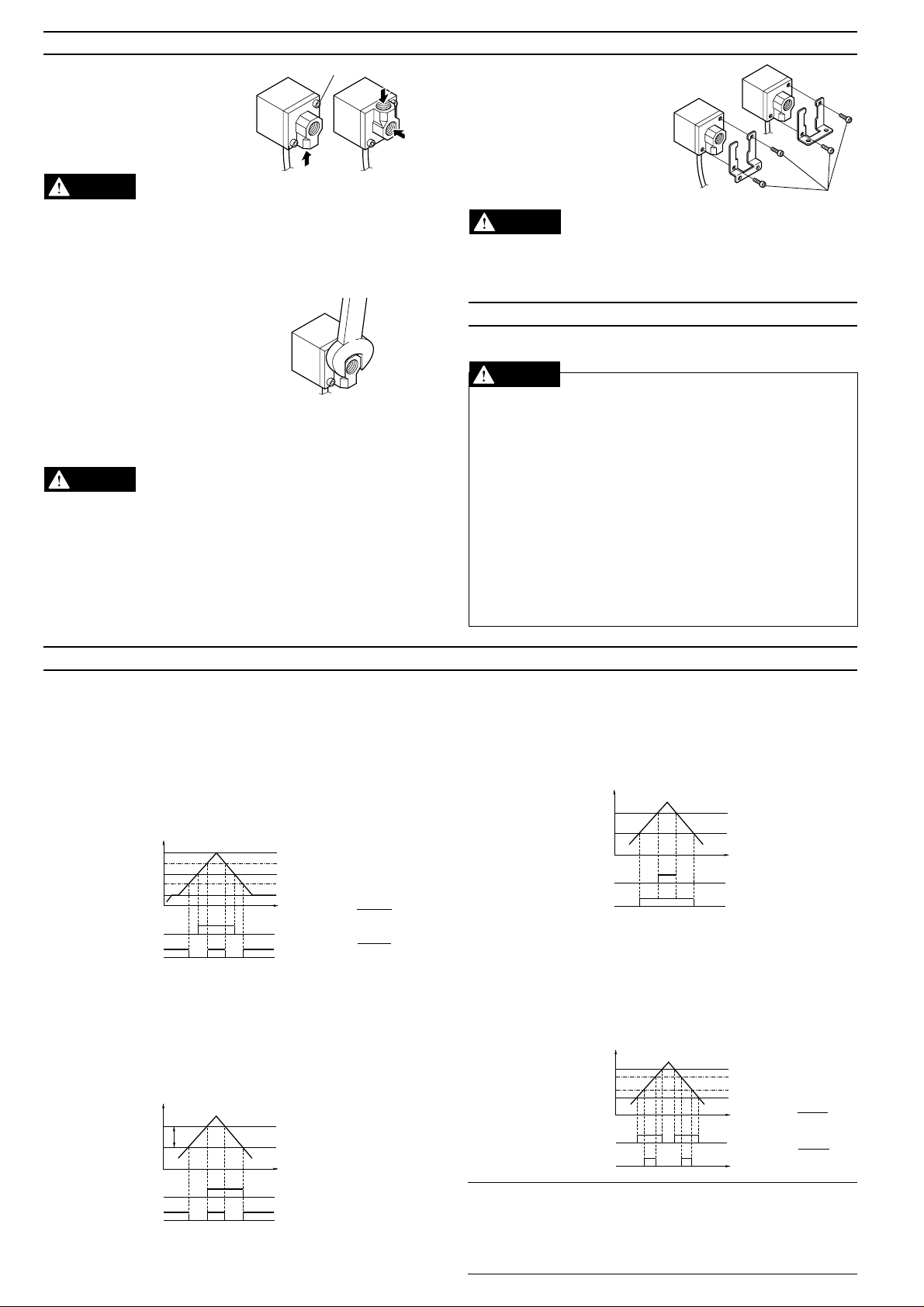

PIPING/MOUNTING

CAUTION

CAUTION

Preset value A

Preset value b

0

ON

OFF

ON

OFF

Control output 2

(OUT 2)

Control output 1

(OUT 1)

Pressure

Preset value H

SH

SL

Preset value L

0

ON

OFF

ON

OFF

Control output 1

(OUT 1)

Control output 2

(OUT 2)

Pressure

• You can select from three

pressure port positions by

selecting or replacing the

pressure ports. Select the

optimal position based on

your location.

CAUTION

* The arrow shows the pressure port

positions that can be selected.

The maximum tightening torque for the hexagonal socket bolt is

0.3 Nm (Approx. 3 kgf•cm). To avoid breakage, do not exceed the

specified value.

• An Rc (PT) 1/8 internal thread is provided on the pressure port of

the AP-30 series. Commercially available air-pressure pipe joints or

nipples can be used.

• When connecting a joint or a plug,

use a wrench (14 mm) to hold the

metallic part as shown in the figure to

avoid a large force being applied to

the sensor housing (resin part).

• Be sure to block an unused pressure port with the hexagonal-socket

port stopper provided.

CAUTION

The maximum tightening torque for the hexagonal-socket port

stopper is 10 Nm (Approx. 100 kgf•cm). To avoid breakage, do not

exceed the specified value.

• To prevent air leaks, wrap the male screw with sealing tape.

• To mount the AP-30 series to a panel using the panel mounting

holder set (OP-31357), use a panel with 1 to 3.5 mm thickness.

Hexagonal socket bolt

Hold this part with a

wrench (14 mm).

• Special mounting brackets are

included with the AP-30 series.

Use the type of mounting bracket

appropriate for the location

where the sensor is mounted. To

mount the sensor, remove the

hexagonal socket bolts and then

retighten them through the

mounting bracket.

Hexagonal

socket bolts

The maximum tightening torque for the hexagonal socket bolt is

0.3 Nm (Approx. 3 kgf•cm). To avoid breakage, do not exceed the

specified value.

SAFETY PRECAUTIONS

Be sure to follow the instructions below to avoid malfunctions.

■Connection

• When using a commercially available switching regulator, be sure

to ground the frame ground terminals.

• Isolate the sensor’s wiring from power lines or high-voltage lines;

otherwise, the sensor may malfunction due to noise interference.

■Other

• Do not use the AP-30 series for the detection of corrosive gases

or liquid.

• Do not insert any objects, such as wires, from the pressure port.

The pressure-sensing element may break, resulting in malfunctions.

• Do not press the front panel keys with a pointed object.

• The AP-30 series does not have an explosion-proof structure.

Do not use it for the detection of flammable gases.

OPERATION MODE SELECTION

■Auto-tuning mode (F-1)

Using the AUTO key, detect the upper limit value (A) and the lower

limit value (b). The detection level (C) is automatically set at the

midpoint between the two values. (You can finely adjust the preset

value C within the range between A and b.)

Control output 1: The sensor turns on when the pressure exceeds the

Control output 2: The sensor turns on when the pressure goes outside

Control output 1

Control output 2

■Hysteresis mode (F-2)

Set desired detection level (H) and hysteresis (h) for the detection.

Control output 1: The sensor turns on when the pressure exceeds the

Control output 2: The sensor turns on when the pressure goes outside

Control output 1

Control output 2

preset value C.

the stability levels.

Pressure

Preset value C

(OUT 1)

OFF

(OUT 2)

OFF

SH

ON

ON

A

SL

b

0

* The stability levels are

automatically set as

shown in the following

calculations.

SH =

SL =

preset value H. When the pressure falls by the preset

value h, the sensor turns off.

the hysteresis width (H - h).

Pressure

Preset value H

H-h

ON

(OUT 1)

OFF

ON

(OUT 2)

OFF

h

0

h: Hysteresis width of

OUT1

* When h is set to a

value close to 0, if

pressure fluctuates

around the detection

point, OUT1 will

chatter.

(A + C)

2

(C + b)

2

■2-independent mode (F-3)

Set two desired detection points (A and B).

Control output 1: The sensor turns on when the pressure exceeds the

preset value A.

Control output 2: The sensor turns on when the pressure exceeds the

preset value b.

■Window mode (F-4)

Set desired upper limit value (H) and lower limit value (L).

Control output 1: The sensor turns off when the pressure goes outside

Control output 2: The sensor turns off when the pressure goes outside

Note 1: The above description shows the operation of control outputs

1 and 2 when the output selector switch is set to N.O.

When the output selector switch is set to N.C., the operation of control

outputs 1 and 2 is inverted.

Note 2: Except for OUT1 in hysteresis mode, each control output

includes an internal hysteresis of 0.5% of F.S.

of the range between the upper limit value (H) and

lower limit value (L).

of the stability levels.

* The stability levels are

automatically set as

shown in the following

calculations.

SH = H –

SL = L +

(H - L)

4

(H - L)

4

Page 3

ADJUSTMENT

Press the button

for 3 seconds or

more.

■Unit Setting

Determine the desired units.

In measurement mode, press

appears first, and then the current units are displayed. Use ▲ or

to select the desired units. Pressing completes the unit

▼

setting procedure and enters operation mode selection.

dtS

isp

■Operation Mode

Determine the desired operation mode.

(➮ Refer to “OPERATION MODE SELECTION” on page 2.)

The current operation mode is displayed. Use ▲ or ▼ to select

the operation mode. Pressing completes the operation mode

setting procedure and enters N.O./N.C. selection.

1-F

3-F

■N.O./N.C. Selection

Select N.O. (normally open) or N.C. (normally closed).

The current selection of “no” (normally open) or “nc” (normally

closed) is displayed. Use ▲ or ▼ to select the desired mode.

Pressing completes the N.O./N.C. selection procedure and

enters the chattering prevention setting.

■Chattering Prevention

Determine the desired response time.

The current response time is

displayed. Use ▲ or ▼ to select

the response time. Pressing

completes the setting procedure and

enters the display color selection.

■Display Color Selection

Determine the desired LED color for numerical value display.

The current color is displayed. Use ▲ or ▼ to select the color.

Pressing completes the setting procedure and returns to the

measurement mode.

[-1

[-2

edomtuptuo

ylnoDELdeR

DELneerg/deR

▲

for at least 3 seconds. “- - - -“

,gHmm:43/13-PA

AP

2

mc/fgk:33/23-PA

* When the units are changed, the preset

values are automatically converted to

appropriate values for the updated units.

Press the button once.

▲

edomgninut-otuA

2-F

tnednepedni-2

4-F

Press the button once.

▲

Press the button once.

▲

Press the button once.

▲

5.2

5

001

005

,aPk:43/23/13-PA

aPM:33-PA

edomsiseretsyH

edomwodniW

sm5.2

sm5

sm001

sm005

Measurement mode

▲

▲

■Preset Value Input Mode

Determine the preset values.

● Auto-tuning mode (F-1)

1. In measurement mode with the

current measured value displayed, press . The AP-30

enters the preset value input

mode.

2. “A” and the current preset value

flash alternately.

3. Position the target at the desired

upper (lower) limit.

4. Press A to register the value.

The updated value is displayed

for 1 second.

5. “b” and the current preset value

flash alternately.

6. Position the target at the desired

lower (upper) limit.

7. Press A to register the value. The updated value is displayed for 1

second.

8. “C” and the calculated preset value C flash alternately. (You can

change the C value to any value between A and b using ▲ or ▼.)

9. Press to register the C value. The setting procedure is completed

and the unit returns to measurement mode.

* To confirm the preset value, press repeatedly.

• Example of auto-tuning mode setting: Confirmation of work

piece pick-up.

Set the upper limit (A) to the position where the work piece is taken.

Set the lower limit (b) to the position where the nozzle becomes open

after releasing the work piece. Press A to register the upper and

lower limit values. The C value is automatically set to the midpoint

between the upper and lower limit values.

■Hysteresis Mode (F-2), 2-independent Output

Mode (F-3), Window Mode (F-4)

1. In measurement mode with the

current measured value displayed,

press . The AP-30 enters the

preset value input mode.

2. “H” 1. and the current preset value

flash alternately.

3. Use ▲ or ▼ to change the value

to the desired value. Press to

register the updated H value.

4. “h” 2. and the current preset value

flash alternately.

5. Use ▲ or ▼ to change the value

to the desired value. Press to

register the updated h value.

6. “P” 3. and the shift value of the

zero-shift adjustment flash

alternately.

8. Press to complete the setting procedure and return to measure-

ment mode.

* To confirm the preset value, press repeatedly.

Note 1: In hysteresis mode, (h - F.S.) cannot be set to a value greater

than H.

Note 2: In window mode, (L + 1% of F.S.) cannot be set to a value

greater than H.

Press the button

once.

▲

(Measurement mode)

❋ ❋ ❋ ❋

Current value

• • •

❋ ❋ ❋ ❋

Current upper

(lower) limit

value A

❋ ❋ ❋ ❋

Current upper

(lower) limit

value b

❋ ❋ ❋ ❋

The set value

C displays.

A + b

(C=

2

A

A

• • •

❋ ❋ ❋ ❋

The updated value displays for 1 sec.

• • •

❋ ❋ ❋ ❋

The updated value displays for 1 sec.

• • •

Flashes

alternately

Flashes

alternately

Flashes

alternately

[Example: In hysteresis mode]

(Measurement mode)

❋ ❋ ❋ ❋

Current value

• • •

• • •

• • •

1. “A” appears in the 2-independent

output mode.

2. “b” appears in the 2-independent

output mode.

“L” appears in the window mode.

3. Shown with Z type only.

* The setting is saved

in the EEPROM.

Flashes

1.

alternately

❋ ❋ ❋ ❋

Set the desired value

using

or

Flashes

2.

alternately

❋ ❋ ❋ ❋

Set the desired value

using

or

Flashes

3.

alternately

❋ ❋ ❋ ❋

)

* The setting is saved

in the EEPROM.

●Zero-point adjustment

At normal atmospheric pressure (1 atm.), press A for at least 2

seconds in measurement mode. The display changes to “----“, then

to “0”. The zero adjustment function can be used when the

pressure is within ±5% of F.S.

Note 1: When the operation mode is changed, check the preset values in the

preset value input mode.

Note 2: When units of psi are selected with the AP-34Z, the display range

becomes 19.99 to 19.99.

Note 3: Perform the zero-shift adjustment periodically.

Note 4: The initial output voltage may fluctuate by ±1.0% immediately after the

power is turned on. To measure minute differences in pressure, let the sensor

warm up for approximately 15 to 30 minutes.

Page 4

OTHER FUNCTIONS AND ERROR INDICATION

6

■Zero-shift function (Z type only)

The zero-shift function is used to reset the current pressure value to

“0” using an external signal input, in order to prevent measurements

from being affected by fluctuations in base pressure.

Example: Leakage test

Input a zero-shift value after air supply is completed so that air leakage

after a specified time is displayed as a negative value. The AP-30’s

detection is unaffected by fluctuations in air supply volume.

Zero-shift input

1 MPa

Atmospheric

pressure

When the power is turned off, the value updated after the zero-shift

input (zero-shift value) is lost.

Note 1: The zero-shift function cannot be used in auto-tuning mode.

Note 2: The zero-shift input is effective when the current pressure is

between -3% of F.S. and F.S. for a shift of 0 (P = 0).

Note 3: If the applied pressure is outside the range of -15% to 110% of

the rated pressure, “-FFF” or “ FFF” appears.

■Key protection function

The key protection function is used to lock the front panel key in order

to prevent preset values from being accidentally changed.

To enable the key protection function, hold down A and press ▲.

“Loc” flashes for 2 seconds and the keys are locked.

To disable the key protection function, again hold down A and press

. “unL” flashes for 2 seconds and the keys are unlocked.

▼

Using the EEPROM, the AP-30 series can retain the preset values

even if the power is turned off.

■Display color selection

You can set the color of the LED display either to the two-color mode

which displays the numerical value in green or red according to OUT1,

or to the single color mode which always shows the value in red. The

two-color display allows you to check the output condition at a glance.

(Refer to “ADJUSTMENT” on page 3 for the setting procedure.)

In two-color mode (Regardless of N.O./N.C. selection)

• When OUT1 is turned on: Red

• When OUT1 is turned off: Green

Zero-shift input

-0.1 MPa is

acceptable.

-0.6 MPa is

not acceptable.

■Peak-hold/bottom-hold display function

The AP-30 series internally updates the peak-hold and bottom-hold

values at all times.

● To display hold values

• While ▲ is held down in measurement mode, the peak-hold value

is displayed.

• While

is held down in measurement mode, the bottom-hold value

▼

is displayed.

● To reset the peak-hold and bottom-hold values

• Hold down

and press ▼ in measurement mode.

▲

● The peak-hold and bottom-hold values are also reset using the

following procedure.

• Turn the power off.

• Press for 3 seconds or more and change any settings.

Note: The hold values cannot be displayed when the front panel keys

are locked with the key protection function. Disable the function before

displaying the hold values.

■Analog output function (Except for Z type)

The voltage value according to the pressure value is output.

ledoM V5otV1

13-PA aPk3.101-ot0

23-PA aPk0.001+ot0

33-PA aPM000.1+ot0

43-PA aPk3.101-ot3.101+

■Error indications and remedies

Error indication Problem Remedy

E

Ec

Zero-point adjustment was

executed at a pressure of

±5% or more of F.S.

Overcurrent through OUT1

or 2

Perform zero-point adjustment

at normal atmospheric

pressure.

Turn power off and adjust the

load so that the current is

within the rated range.

-FFF, FFF

Applied pressure was

outside of the display

Adjust the pressure to within

the rated range.

range.

■N.O./N.C. selection

The N.O. or N.C. output can be selected according to the device’s

control method. When the output status is changed, the color of the

numerical value display LED is inverted.

■Chattering prevention function

The chattering prevention function is used to prevent outputs from

chattering by changing the response time. The response time can be

selected from 4 settings. When the detection (non-detection) state

continues for more than a preset response time, the output is produced.

DIMENSIONS

AP-30 (Sensor unit)

31

33

(4)

Mounting bracket A

(Accessory)

16

22

20

19

Cable length: 2 m

ø4, 5 x 0.18 mm

25

35

30

20

2-ø3.5

14

2-ø4.5

t=1.5

2

core

8.5

31

24.5

6.5

Mounting bracket B

(Accessory)

20

19

45

Pressure port:

Rc (PT) 1/8

8.6

20

2 x M3 screw

14

20

6.5

30

20

2-ø3.5

14

20

2-ø4.5

13

45

t=1.5

When mounting bracket A is

attached

[Top view]

25

16.5

6

16

When mounting bracket B is

attached

31

45.5

20

2-ø4.5

mounting hole

31

[Side view]

31

22

t=1.6

13

t=1.

Worldwide Headquarters

KEYENCE CORPORATION

1-3-14, Higashi-Nakajima, Higashi-Yodogawa-ku,

Osaka, 533-8555, Japan

PHONE: 81-6-379-2211 FAX: 81-6-379-2131

KEYENCE CORPORATION OF AMERICA

PHONE: 201-930-0100 FAX: 201-930-0099

45

KEYENCE (UK) LIMITED

PHONE: 01908-696900 FAX: 01908-696777

KEYENCE DEUTSCHLAND GmbH

PHONE: 0711-7973710 FAX: 0711-7977799

KEYENCE FRANCE S.A.

PHONE: 01 47 92 76 76 FAX: 01 47 92 76 77

KEYENCE SINGAPORE PTE LTD

PHONE: 392-1011 FAX: 392-5055

KEYENCE SENSORS & MEASURING SDN BHD

PHONE: 03-252-2211 FAX: 03-252-2131

KEYENCE (THAILAND) CO., LTD

PHONE: 02-934-6772~4 FAX: 02-934-6775

KEYENCE KOREA CORPORATION

PHONE: 02-563-1270 FAX: 02-563-1271

© KEYENCE CORPORATION, 1998

Specifications are subject to change without notice.

AP3-IM-1-0398 Printed in Japan

Loading...

Loading...