Page 1

Safety Interlocking

Important

Point

Reference

Important

DANGER

NOTICE

DANGER

96M15311

DANGER

DANGER

DANGER

DANGER

Switch

GS

(Non-contact)

Instruction Manual

• The GS (Non-contact) is designed with the assumption that

it would be correctly installed in accordance with the

installation procedures described in this manual and

correctly operated according to the instructions in this

manual. You must perform an appropriate installation of the

GS (Non-contact) after performing a sufficient risk

assessment for the target machine.

• Be sure to absolutely confirm that there is nobody in the

hazardous zone, before you remove the GS (Non-contact)

from the machine for replacement or disposal.

• When disposing the GS (Non-contact), always follow the

applicable requirements of the laws, rules, regulations and

standards in the country or region where the GS (Noncontact) is used.

• Dispose of this product as industrial waste.

Detailed information and use of the GS (Non-contact) is also described in

the "GS (Non-contact) User's manual". In order to acquire the "GS (Noncontact) User's manual", download it from the KEYENCE website or call the

nearest KEYENCE office.

<KEYENCE website> www.keyence.com/global.jsp

This manual explains items such as the handling, operation, and precautions

for the Safety Interlocking Switch GS (Non-contact). Read this manual

carefully and thoroughly understand its contents to use the GS (Non-contact)

to the full extent of its capabilities.

Also, keep this manual in a safe place for future reference.

Ensure that the end user of this product receives this manual.

This manual is the original instruction manual.

Symbols

It indicates a hazardous situation which, if not avoided, will

result in death or serious injury.

It indicates a situation which, if not avoided, could result in

product damage as well as property damage.

It indicates cautions and limitations that must be followed

during operation.

It indicates additional information on proper operation.

It indicates tips for better understanding or useful information.

Safety Precautions

General precautions

• KEYENCE does not guarantee the function or performance

of the GS (Non-contact) if it is used in a manner that differs

from the GS (Non-contact) specifications contained in this

manual or if the GS (Non-contact) is modified by the

customer.

• The GS (Non-contact) can only be used in combination with

dedicated actuators. It cannot be used in combination with

other actuators or similar devices.

• Do not bypass the GS (Non-contact), remove it or change its

installation orientation after installation.

• Do not use a replacement actuator to bypass the GS (Noncontact). Store replacement actuators strictly to prevent

their easy access.

• When using the GS (Non-contact) to protect machine

operators against a hazard or hazardous zone or when

using the GS (Non-contact) as a safety component for any

purpose, always follow the applicable requirements of the

laws, rules, regulations and standards in the country or

region where the GS (Non-contact) is used. For such

regulations, you should directly contact the regulatory

agency responsible for occupational safety and health in

your country or region.

• Depending on the type of machine on which the GS (Noncontact) is installed, there may be special safety regulations

related to the use, installation, maintenance, and operation

of the safety component. In such a case, you must fulfill

such safety regulations. The responsible personnel must

install the GS (Non-contact) in strict compliance with such

safety regulations.

• The responsible personnel must do the training to the

assigned personnel for the correct use, installation,

maintenance, and operation of the GS (Non-contact).

• The user of the machine must receive specialized training

related to the GS (Non-contact), and must then understand

and adhere to the safety restrictions, laws, and regulations

in the country or area in which the GS (Non-contact) is

being used.

• If the GS (Non-contact) does not operate correctly, the user

of the machine must report this information to the party

responsible for the use of the GS (Non-contact) and

immediately stop the machine.

Environment of use

• Do not use the GS (Non-contact) in an environment

(temperature, humidity, interfering light, etc.) that does not

conform to the specifications contained in this manual.

• Do not use a device that emits strong electromagnetic

waves near the GS (Non-contact).

• This product is not intended for use as an explosion-proof

product. Do not use this product in a hazardous location

and/or potentially explosive atmosphere.

• Do not use the GS (Non-contact) in the presence of

substances, such as heavy smoke, particulate matter, or

corrosive chemical agents, that may induce deterioration in

product quality.

• Be sure to absolutely confirm that there is nobody in the

hazardous zone, before the interlock is released (i.e. the

machine system restarts) by the interlock reset mechanism.

• Indoor use only.

Target machines for installation

• It must be possible to perform an emergency stop on the

machine to which the GS (Non-contact) is installed at any

and all operation points during the operation cycle. Also, do

not use the GS (Non-contact) on machines that have

irregular stop times.

• Do not use the GS (Non-contact) to control (stop forward

motion, etc.) trains, cars and other transportation vehicles,

aircraft, equipment for use in space, medical devices, or

nuclear power generation systems.

Circuit design and wiring

• Be sure to turn the power supply off before performing

electrical wiring.

• Perform electrical wiring according to the electrical

conventions, restrictions, standards, and laws in the

country or area in which the GS (Non-contact) will be used.

• Use cables with length less than or equal to the

specification in this manual. Usage of cables longer than

the specified value may cause the improper operation of

safety functions and may cause a dangerous situation.

Precautions on Regulations and Standards

CE Marking

KEYENCE Corporation has confirmed that this product complies with the

essential requirements of the applicable EU Directive(s), based on the

following specifications. Be sure to consider the following specifications when

using this product in the Member States of European Union.

• Machinery Directive

• RE Directive

The GS (Non-contact) is a safety component defined in the EU Machinery

Directive Annex V and has been certified by TÜV SÜD Product Service

GmbH. The GS (Non-contact) complies with the following EN Standards.

• EN 61508

• EN 62061

• EN ISO13849-1

• EN ISO14119

• EN 60947-5-3

• EN300 330

The full text of the EU declaration of conformity is available at the following

internet address: http://www.keyence.com/cedoc

• Frequency band of operation 123kHz

• Maximum radio-frequency power 60 dBμV/m

These specifications do not give any guarantee that the end-product with this

product incorporated complies with the essential requirements of RE and

Machinery Directive. The manufacturer of the end-product is solely

responsible for the compliance on the end-product itself according to these

Directives.

CSA Certificate and North American Regulations

The GS (Non-contact) complies with the following UL and CSA standards and

regulations, and has received CSA certification.

1

E GS (Non-contact) IM

Page 2

Applicable standards:

Reference

Highly visible

indicator

Detailed indicator

Main unit

Actuator

• CAN/CSA C22.2 No. 61010-1

• UL61010-1

Be sure to consider the following specifications when using this product as a

product certified by CSA.

• Overvoltage category II

• Pollution degree 3.

• Install this product at the altitude of 2000 m or less.

• Indoor use only.

• When using this product, use the following power supply. CSA or UL

certified power supply that provides Class 2 output as defined in the CEC

(Canadian Electrical Code) and NEC (National Electrical Code)

Applicable standard:

• FCC Part15 Subpart B, Class A Digital Device

• FCC Part15 Subpart C

• ICES-003, Class A Digital Apparatus

• RSS-210

This device complies with part 15 of FCC Rules and Innovation, Science and

Economic Development Canada's licence-exempt RSSs. Operation is subject

to the following two conditions: (1) this device may not cause harmful

interference, and (2) this device must accept any interference received,

including interference that may cause undesired operation.

Le présent appareil est conforme à la partie 15 des règles de la FCC et aux

normes des CNR d’Innovation, Sciences et Développement économique

Canada applicables aux appareils radio exempts de licence. L’exploitation

est autorisée aux deux conditions suivantes : (1)l’appareil ne doit pas

produire de brouillage, et (2) l’appareil doit accepter tout brouillage subi,

même si le brouillage est susceptible d’en compromettre le fonctionnement.

FCC CAUTION

Changes or modifications not expressly approved by the party responsible

for compliance could void the user’s authority to operate the equipment.

Note: This equipment has been tested and found to comply with the limits for

a Class A digital device, pursuant to part 15 of the FCC Rules. These limits

are designed to provide reasonable protection against harmful interference

when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if

not installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this equipment in

a residential area is likely to cause harmful interference in which case the user

will be required to correct the interference at his own expense.

Chapter 1 Before Operation

1-2 Product List

Main unit

For details on the main unit models, see “5-1 Model Number Description”

(page 7).

M12 connector type cables

z Standard cables

Use this cable in combination with a main unit (connector type), Y-shaped

connector, or extension cable.

Typ e Model Number of pins Length

GS-P5C5

Simple

function

Standard

Advanced

function

GS-P5C10 10 m

GS-P8C5

GS-P8C10 10 m

GS-P12C5

GS-P12C10 10 m

GS-P12C20 20 m

5

8

12

z Extension cables

Typ e Model Number of pins Length

GS-P5CC5

Simple

function

Standard

GS-P5CC10 10 m

GS-P8CC1

GS-P8CC5 5 m

GS-P8CC10 10 m

5

8

Mounting brackets

• GS-B01

• GS-B11

Optional parts

z Y-shaped connector

GS-Y01

z End connector

GS-Y02

z Replacement actuator

GS-A01

5 m

5 m

5 m

5 m

1 m

1-1 Overview and Configuration

The GS (Non-contact) is a Type4 Interlocking Device without guard lock

based on ISO14119.

Coding level: Low or high (switchable)

“4-6 Coding Level” (page 6)

By combining the GS (Non-contact) with a door or similar movable safety

guard and with a safety-related control system, it is possible to stop

hazardous machine operations if the door or similar part opens during

hazardous machine operations.

The GS (Non-contact) can also be used for other purposes such

as protecting manufacturing processes.

1-3 Package Contents

Main unit

• Sensor (main unit)

• Actuator

• Instruction Manual

E GS (Non-contact) IM

2

Page 3

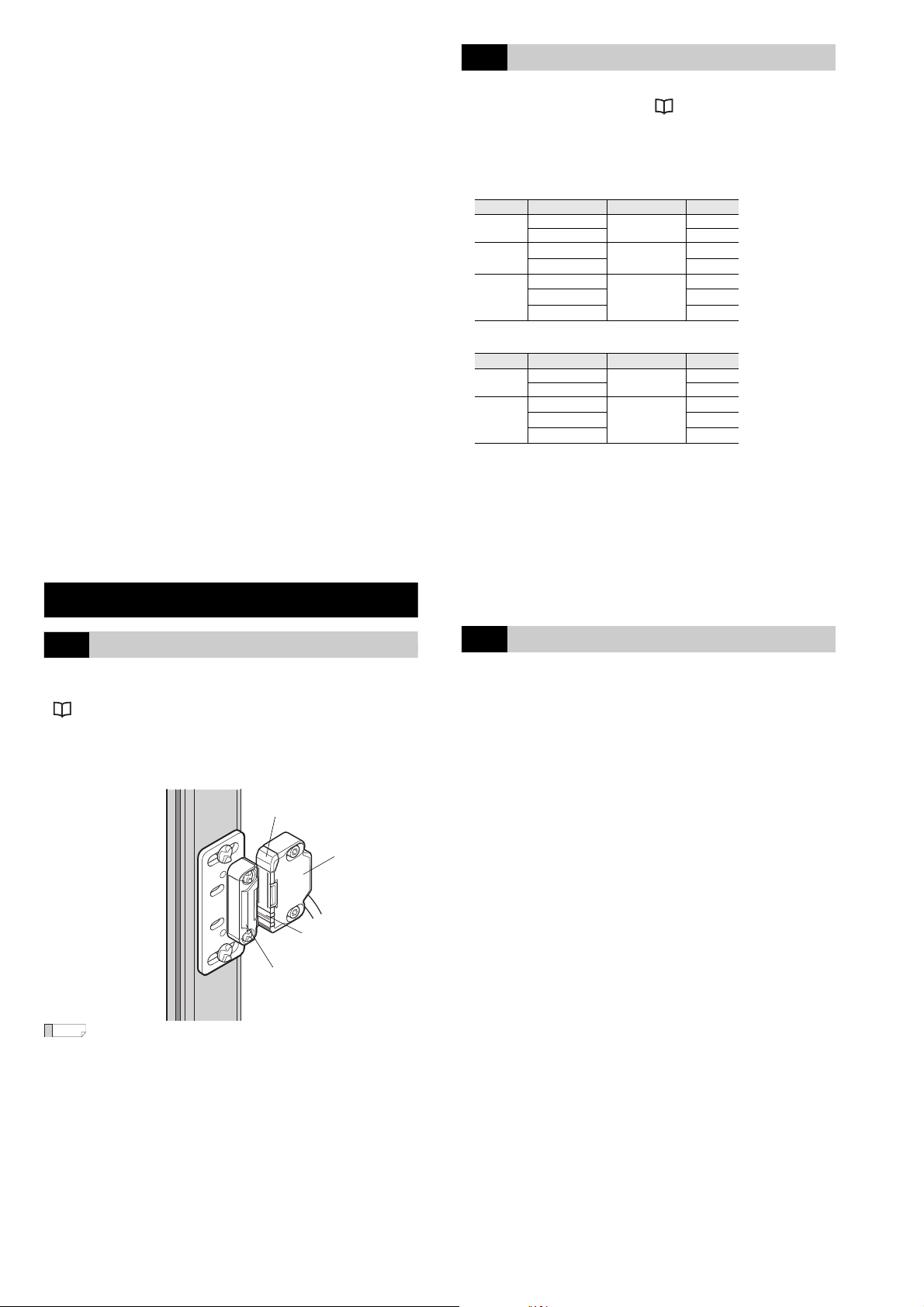

Chapter 2 Installation

DANGER

DANGER

From the front From the side

Reverse orientation

Y

Z

X

Y

X

Y

Z

Y

Z

0

4

8

12

16

10-10-20-30 20 30

Y

X

0

16

4

8

12

-25

-20 -15 -10 -5 255 10 15 20

4

0

-4

-8

-12

-16

-20

-24

-28

8

12

16

20

24

28

4 8 1216

4812

-30

-27

-24

-21

-18

-15

-12

-9

-6

-3

0

3

6

9

12

15

Y

Z

X

ON area

Front installation

Side installation

60 mm or more

50 mm or more

60 mm or more

2-1 Installation Conditions

Note the following items before installation.

The effect of surrounding metal

The sensor’s operating distance may be affected by the

presence of metal in the surrounding area. After installation,

check that an appropriate safety distance based on the

detecting distance is used.

Sensor and actuator orientation

Correct installation orientations

Incorrect installation orientations

Mutual interference

When using multiple GS (Non-contact) units in close proximity, they may

malfunction due to mutual interference. To prevent mutual interference, install

the GS (Non-contact) units as shown below.

Distance between sensors

Distance between actuators

Operating area

• The above values indicate the recommended distance.

Check whether there are issues in the actual installation

environment.

• When installing the unit on a sliding door, do so at a distance

of 6 mm or more to prevent the effect of the side lobe.

3

E GS (Non-contact) IM

Page 4

2-2 Installation Method

Reference

Important

DANGER

M4 screw

Tightening torque: 1.0 N⋅m

M4 screw

Tightening torque: 1.0 N⋅m

1

2

3

5

4

2

3

4

8

5

6

7

1

10

6

1

93

4

5

7

8

12

11

2

Installing the unit to a hinged door

1

Chapter 3 Wiring

3-1 Power Supply

If the power supply for the GS (Non-contact) is the converting type, the power

supply for the GS (Non-contact) must meet the conditions listed below in

order to meet the requirements specified in ISO 14119, IEC 60947-5-3, UL

61010-1, and CAN/CSA-C22.2 No. 61010-1.

(a) The rated output voltage is within 24 V DC ±20 % (Ripple P-P 10 % or

less, Class2, SELV, Overvoltage category II).

(b) The insulation between the primary and secondary circuits is reinforced or

double insulation.

(c) The power supply complies with the laws, regulations, and standards

related to items such as electrical safety and electromagnetic

compatibility (EMC) in the country or area in which the GS (Non-contact)

will be used.

When the power supply used with the GS (Non-contact) is

shared with other machines or electrical products, the voltage

supplied to the GS (Non-contact) may drop due to temporary

increases in the current consumption of these other machines

and the GS (Non-contact) may also be affected by the noise

generated by these other machines. Errors or other such

problems may occur with the GS (Non-contact) in this

situation, so it is strongly recommended to avoid sharing the

power supply of the GS (Non-contact) with other machines or

electrical products.

2

3-2 Cable Wire Colors and Functions

Simple function type (M12 connector, 5 pins)

Pin number Wire color Function

1 Brown +24 V

2 White OSSD2

3Blue 0 V

4 Black OSSD1

5 Gray AUX output1

Standard type (loose wires or M12 connector, 8 pins)

Pin number Wire color Function

1 Gray AUX output1

2 Brown +24 V

3 Light blue Not used

4 Red/white Safety input 2

5 Black OSSD1

6 White OSSD2

7Blue 0 V

8 Red/black Safety input 1

Advanced function type (loose wires or M12 connector, 12 pins)

• To minimize defeat possibilities, GS (Non-contact) should

be installed in a position where the accessibility to GS

(Non-contact) is prevented (e.g. mounting out of reach,

physical obstruction or shielding or mounting in hidden

position), otherwise use non-detachable fixing to prevent

dismantling or de-positioning of GS (Non-contact) (e.g.

Using a flat head screw and plugging the slot on the screw

head with a high-strength threadlocker after tightening the

screw or other equivalent fixing system).

Refer ISO 14119 for more information to minimize defeat

possibilities.

• Securely tighten the screws for the sensor, actuator, and

mounting brackets according to the specified tightening

torque.

• To prevent self-loosening, use screw locker on the screws

fixing the GS (Non-contact).

• When replacing the sensor or actuator, do so by following the

same procedure.

• The appropriate screws must be purchased separately.

Pin number Wire color Function

1 Brown +24 V

2 Red/black Safety input 1

3Blue 0 V

4 Black OSSD1

5 Gray AUX output 1

6 Red/white Safety input 2

7 White OSSD2

8 Pink Interlock/EDM selection input

9 Gray/black

10 Light blue

11 Yellow Reset/EDM input

12 Light blue/black

*1 This is not present on loose wire types.

*1

*1

*1

Not used

Not used

Not used

Pin layout (sensor main unit, M12 connector type)

Simple function

(M12, 5 pins, male)

Standard type

(M12, 8 pins, male)

Advanced function type

(M12, 12 pins, male)

2-3 Cascade Connection Between Units

Multiple GS (Non-contact) and GS (Lock) units can be connected in series (in

a cascade connection).

This makes it possible to monitor the opening and closing of multiple doors or

similar items on the same machine.

For the wiring method, see “Cascade connection wiring example” (page

5).

E GS (Non-contact) IM

4

Page 5

3-3 Wiring Example

4: Black (OSSD1)

7: White (OSSD2)

11: Yellow (reset/EDM input)

8: Pink (interlock/EDM selection input)

1: Brown (+24 V)

3: Blue (0 V)

5: Gray (AUX output 1)

2: Red/black (safety input 1)

6: Red/white (safety input 2)

4: Black (OSSD1)

7: White (OSSD2)

11: Yellow (reset/EDM input)

8: Pink (interlock/EDM selection input)

1: Brown (+24 V)

3: Blue (0 V)

5: Gray (AUX output 1)

2: Red/black (safety input 1)

6: Red/white (safety input 2)

K1 K2

K2

K1

S1-1

General-purpose PLC

K1 K2

K1, K2: External device (force guided relay, magnet

connector, etc.)

S1-1: Reset switch (N.O.)

1st unit

GS (Non-contact)

PNP output

Advanced function type

Interlock: Manual

EDM: Use

Cascade connection: Yes

2nd unit

GS (Non-contact)

PNP output

Advanced function type

Interlock: Automatic

EDM: Do not use

Cascade connection: No

Black or white

Blue

+24V

0 V

External device

Main

circuit

Brown

Brown

Black or white

Blue

+24 V

0 V

External device

Main

circuit

Brown

(Input wire)

Blue

+24 V

Main

circuit

0 V

Brown

(Input wire)

Blue

+24 V

0 V

Main

circuit

DANGER

Brown

(Output

wire)

Blue

+24 V

0 V

Input

device

Main

circuit

Cascade connection wiring example

Wire the safety inputs of a GS (Non-contact) to the OSSDs of the next GS

(Non-contact) or GS (Non-contact) to implement a cascade connection.

• “4-1 OSSD” (page 5)

• “4-2 Safety Input” (page 6)

Cable length and number of connected units (Standard)

B: Maximum number of connected units 30

Contact KEYENCE for the maximum number of connected units when using a

cascade connection that also includes GS (Lock) units.

3-4 I/O Circuit Diagrams

Output circuit (PNP type) Output circuit (NPN type)

Input circuit (PNP type) Input circuit (NPN type)

A: Maximum cable length 30.3 m

AUX output circuit (PNP/NPN common)

Chapter 4 Functions

The functions that can be used with the GS (Non-contact) vary depending on

the model of the main unit (simple function type/standard type/advanced

function type).

Simple function

type

Standard type

Number of pins 5 8 12 (*1)

OSSD

Safety input

Interlock function

EDM function

333

− 33

− −

− −

Number of AUX outputs 1 1 1

Coding level switching

333

*1 The loose wire type has nine cores.

4-1 OSSD

An OSSD output is a safety output for the safety-related part of a machine

control system.

OSSD 1/2 is a pair of safety outputs that are redundant.

The GS (Non-contact) generates self-diagnosis signals on its internal control

circuit to perform diagnostics on the OSSD. These signals periodically force the

OSSD into a temporary OFF-state when the OSSD is in the ON-state.

If the internal control circuit receives a feed-back signal (OFF-signal) based on

the self-diagnosis, the GS (Non-contact) determines that its OSSD is operating

normally. If the OFF-signal is not returned to the internal control circuit, the GS

(Non-contact) determines that there is a problem with the OSSD or wiring and

goes to an error state.

OSSD operation

The OSSDs go to OFF state:

• During startup, in the error state, when switching the coding level

When all the conditions shown below are met during normal operation, the

OSSDs go to ON state. (*1)

• The sensor has detected an actuator.

• Safety inputs are ON.

*1: The OSSDs go to OFF state in the interlock reset ready state.

• For the wiring to a safety-related machine control system,

the output of both OSSD 1 and OSSD 2 must be used by the

safety-related machine control system in order to create a

safety system.

• If only one OSSD output is used to construct the machine’s

control system, an OSSD malfunction will make it

impossible to stop the machine, which may lead to

extremely dangerous situations including serious injury to

or death of the machine’s user.

• When using a PNP sensor, do not cause a short-circuit

between the OSSD and +24V. Otherwise, the OSSDs will

stay in the ON-state and it will cause a dangerous situation.

• When using a PNP sensor, be sure to connect the load

between the OSSD and 0 V. Connecting this between the

OSSD and +24 V by mistake will invert the OSSD operation

from its normal behavior, which is extremely dangerous.

• When using an NPN sensor, do not cause a short-circuit

between the OSSDs and 0V. Otherwise, the OSSDs stay in

the ON-state and it will cause a dangerous situation.

• When using an NPN sensor, be sure to connect the load

between the OSSD and +24 V. Connecting this between the

OSSD and 0 V by mistake will invert the OSSD operation

from its normal behavior, which is extremely dangerous.

• To prevent malfunctions caused by ground faults on the

OSSD output wire, perform wiring in a manner such that the

requirements specified in paragraph 9.4.3 of IEC 60204-1

are met.

Advanced

function type

3

3

5

E GS (Non-contact) IM

Page 6

4-2 Safety Input

Point

Reference

Point

DANGER

Standard type

Advanced function type

Advanced function type

DANGER

DANGER

Advanced function type

This function controls the OSSDs of the GS (Non-contact) with input signals

from sensors or similar devices connected to the safety inputs.

Safety input 1 and safety input 2 form a safety input pair. If safety input 1 or

safety input 2 turns OFF, the OSSDs turn OFF.

Multiple GS units can be connected and used in an expanded system (with a

cascade connection) by connecting the OSSDs of a different GS (Noncontact) or GS (Lock) to the safety inputs. The system can be expanded to

include up to thirty units in the case of the GS (Non-contact).

The simple function type has no safety input.

• Wire the safety inputs as shown below when they are not in use.

PNP type: Short circuit to 24 V.

NPN type: Short circuit to 0 V.

• If safety input 1 and safety input 2 are mismatched for 3

seconds or more a Safety Input Error will occur.

Emergency stop switch/button wiring

Wiring an emergency stop switch/button to the safety inputs makes it

possible to perform an emergency stop on the machine by pressing the

emergency stop switch/button.

• Use an emergency stop switch/button that has two or more

independent, NC (normally closed) contacts. For the

requirements related to emergency stop switches, see IEC

60204-1, ISO 13850, and all other requirements, regulations,

standards, and laws related to occupational safety and

health in the country or area where the GS (Non-contact)

will be used. For such regulations, you should directly

contact the regulatory agency responsible for occupational

safety and health in your country or region.

• Ensure that the device does not start or restart automatically

when the emergency stop switch/button is reset.

• Only the devices shown below can be connected to the

safety inputs. Do not connect any other devices.

• GS (Non-contact) OSSDs, GS (Non-contact) OSSDs, and

emergency stop switch/button

• When using a PNP sensor, please connect the OSSDs of the

PNP type GS (Lock) or GS (Non-contact) to the safety

inputs.

• When using a NPN sensor, plesae connect the OSSDs of the

NPN type GS (Lock) or GS (Non-contact) to the safety

inputs.

4-3 Interlock Function

Interlock is a function that prevents the OSSDs from automatically going into

the ON-state from the OFF-state. This prevents the unintended start-up and/or

the unintended restart of the machine if the interlock is applied to the GS

(Non-contact). It is necessary to perform the reset operation in order for the

GS (Non-contact) to go back to normal operation from the interlock condition.

• Be sure to absolutely confirm that there is nobody in the

hazardous zone before the interlock condition is terminated

(i.e. the machine system restarts) by the interlock reset

mechanism.

• Install the switch, etc. for releasing the interlock state in a

position where it is possible to check the entirety of the

hazardous zone and where the switch, etc. cannot be

operated from within the hazardous zone.

• When the interlock function is set to Automatic, it is

necessary to ensure the safety of the entire control system in

order to prevent unexpected starts from occurring.

• Exercise caution to prevent the reset/EDM input from

forming a short circuit with other inputs or outputs.

4-4 EDM Function

The GS (Non-contact) can monitor the state of external devices, such as a

safety relay or contactors that are connected to the OSSDs, in order to detect

the failure of the external device. This monitoring function is called the EDM

function.

EDM function settings

Use the wiring to configure the settings. The wiring varies depending on

whether the interlock function is used. For details, see “4-3 Interlock

Function” (page 6).

4-5 AUX Output

This is an informational output used to check the operating status of the GS

(Non-contact).

The AUX outputs cannot be used as the safety outputs to a

safety-related control system.

4-6 Coding Level

The GS (Non-contact) has two coding levels.

Coding level: Low

(multi operation)

Coding level: High

(unique operation)

Any actuator is detected when it enters the range of

the operating distance from the sensor. (Initial setting)

Only the specific actuator that the sensor has been

taught to detect is detected when it enters the range of

the operating distance from the sensor. The sensor

does not respond if an actuator other than the actuator

that it has been taught to detect is within the range of

the operating distance.

The interlock function cannot be set on the simple function

type and standard type. The interlock function is fixed to

Automatic.

On the advanced function type, the interlock function setting can be selected

from two types: Automatic and Manual.

Automatic and Manual indicate the following operations.

Automatic:

The OSSDs immediately switches to the ON state when the conditions for

doing so—such as the door closed—are met.

Manual:

Even if the conditions for switching the OSSDs to the ON state are met, the

OSSDs maintain the OFF state (interlock state).

<Terminating the interlock state>

To set the OSSDs to the ON state and to start the machine, close the door to

which the GS (Non-contact) has been installed and perform the reset

operation after the preparations for starting the machine are complete. This

sets the OSSDs to the ON state and terminates the interlock state.

Interlock function settings

Use the wiring to configure the settings. The wiring method varies depending

on whether the “4-4 EDM Function” (page 6) is used.

Interlock

function

Automatic Do not use 0 V 0 V

Automatic Use

Manual Do not use

Manual Use

EDM

function

Reset/EDM input

Connected to 24 V via a relay

NC contact

Connected to 24 V via an NO

reset switch

Connected to 24 V via an NO

reset switch and a relay NC

contact

Interlock/

EDM function selection input

Open

Connected to 24 V

Connected to 24 V

E GS (Non-contact) IM

6

Page 7

Chapter 5 Specifications

GS - 1 1 P * 5

Cable length

C: M12 connector,

Blank: Loose wires

P: PNP, N: NPN

0: Simple function, 1: Standard, 3: Advanced function

1: Non-contact

* only necessary when using

loose wire connection

GS - P 5 C 5

Cable length

C: Standard cable

CC: Extension cable

5: 5 pins (simple function)

8: 8 pins (standard)

12: 12 pins (advanced function)

5-1 Model Number Description

Main unit

Cable

5-2 Specifications

Specifications

GS-

GS-

GS-

GS-

GS-

GS-

Model

Typ e

Output type PNP PNP NPN PNP NPN PNP PNP PNP

Operating

distance

Response

*1

time (ms)

Door

operation

Cascading

Control

output

(OSSD

output)

AUX

(Nonsafetyrelated

output)

External

input

(Shortcircuit

current)

Power

supply

Protection circuit

Environment

al resistance

Material

Weight

*1 Risk time according to IEC60947-5-3 is 150 ms + 2 ms × (number of cascaded units - 1).

*2 When AUX outputs of each unit are not used, it is possible to cascade up to 10 units.

*3 When stored for a long period of time, please store it at temperature of 55°C or lower.

Sao (OFF

→ ON)

Front

Sar (ON →

OFF)

Sao (OFF

→ ON)

Side

Sar (ON →

OFF)

Detect →

Not detect

Detection

Not detect

→ Detect

Acceptable operation

frequency

Standard - Max. 30 units

Using Y-shaped

connector

Output Transistor outputs × 2

Max. load current PNP: Max. 150 mA, NPN: Max. 100 mA

Residual voltage

(during ON)

OFF state voltage Max 2.0 V (with a cable length of 5 m)

Leakage current Max. 500 μA

Max. capacitive load 2 .2 μF

Load wiring resistance Max. 2.5 Ω

Output Transistor output

Number of output 1

Max. load current 50 mA

Residual voltage

(during ON)

Safety input - Approx. 1.5 mA × 2

Reset/EDM input -

Power voltage 24 V DC ±20 % (Ripple P-P 10 % or less, Class2)

Power consumption 0.8 W

Enclosure rating

Operating ambient

temperature

Storage temperature -25°C to +70°C (No freezing)

Operating relative

humidity

Storage relative

humidity

Vibration resistance

Shock resistance 30 G in X, Y, Z directions 6 times each axis (IEC 60947-5-3)

Case Zinc die cast (Nickel chrome plating), PBT, PAR

Sensor

main unit

Cable PVC

Actuator Case SUS430, SUS304, PBT

10PC

11P5

11N5

11P10

Simple

function

type

20 ms + 2 ms × (number of cascaded unit - 1)

30 ms + 25 ms × (number of cascaded unit - 1)

-

Max 2.5 V (with a cable length of 5 m)

Max 2.5 V (with a cable length of 5 m)

Reverse current protection, short-circuit protection and surge

IP65/67(IEC60529), IP69K(ISO20653) (TÜV SÜD certified)

5 minutes in each of the X, Y, and Z directions (IEC 60947-5-3)

Approx.

80 g

protection for each output

Enclosure Type 3/4X/12/13 (NEMA250)

-20°C to +55°C (No freezing)

10 to 55 Hz, Double amplitude 3.0 mm,

Approx. 270 g Approx. 480 g

11N10

Standard type

10 mm

18 mm

6 mm

14 mm

3 Hz

5% to 95%RH

5% to 95%RH

Safety-related parameters

Mission time 20 years

Hardware fault tolerance 1

Type of element B

Performance level e

Category 4

SIL 3

11PC

Max. 4

units

*3

Approx.

80 g

GS-

13P5

Advanced

function type

*2

Approx. 5.0 mA

Approx.

280 g

13PC

-

× 1

Approx.

GS-

80 g

PFH (IEC 61508)

Interlocking function 4.78×10

7

-10

E GS (Non-contact) IM

Page 8

Chapter 6 Appendix

OSSD

INPUT

READY

GS-11P5

(1) Highly visible indicator

(2) OSSD indicator

(3) INPUT READY indicator

3 (detection center)

5 38

15

5

30

ø5.2

2-4.2x9.2 through hole

7.4x12.4 depth of counterbore:

4.2 (both surfaces)

GS-13P5

Black, gray, red/white, red/black,

5.9

(detection center)

11.8

48

24

(detection center)

Unit: mm

38

5

7

2-ø4.2 through hole

ø8 depth of

counterbore: 4.2

12.5

5.9 (detection center)

11.8

48

Unit: mm

6-1 Indicator Descriptions

6-2 Dimensions

Direct mounting

Sensor main unit

(1) Highly visible indicator

Light

Status Details

color

Green ON During normal operation. ON Detected

Blinking

(fast)

Orange

Blinking

ON Door, etc. is open. OFF Not detected

Red

Blinking

OFF

-

During operation with the “High”

coding level, an actuator different

from the one that was taught was

detected.

Error during coding level switching Uncertain

Switching coding level or teaching

for an actuator

Error state. The GS (Non-contact)

has detected an error.

Power OFF. OFF Uncertain

(2) OSSD indicator

Light

Status Details

color

ON The OSSD is ON. ON Detected

Green

Blinking

Red ON The OSSD is OFF. OFF Uncertain

The OSSD is ON but the state is

unstable such as the door starting

to open.

(3) INPUT READY indicator

Light

Status Details

color

ON

Yellow

Blinking Safety inputs are OFF. OFF Uncertain

OFF

-

E GS (Non-contact) IM

Interlock release wait state (waiting

for reset input).

Other state.

OSSD

status

OFF

OFF Uncertain

OFF Uncertain

OSSD

status

ON Detected

OSSD

status

OFF Detected

Uncertain

detection status

Incorrect

actuator

detected

detection status

Uncertain

Actuator

Actuator

Actuator

detection status

9 cores × blue/brown: 0.22 mm

white, pink, yellow:0.14 mm

GS-11P5/GS-11N5/GS-11P10/GS-11N10

8 cores × blue/brown: 0.22 mm

Black, gray, red/white, red/black,

white, light blue:0.14 mm

2

2

2

2

Actuator

6-3 Troubleshooting

If the operation of the GS (Non-contact) is abnormal, identify the cause of the

error and carry out the countermeasures according to the following tables.

[A] The OSSD does not turn ON (or turns OFF unexpectedly).

Possible cause

The GS (Non-contact) is in the

error state.

The actuator is not detect ed

correctly.

The actuator is broken. Replace the actuator.

During operation with the

“High” encoding level, an

actuator different from the one

that was taught was detected.

Safety input is not ON.

The unit is in the interlock

reset ready state.

The sensor and actuator a re

at a greater distance than the

specified operating distance

Sao (OFF→ON).

The unit is affected by the

surrounding metal.

The unit is affected by

interference from other

sensors.

Confirmation

method

The highly visible

indicator is blinking

in red.

The highly visible

indicator is ON in

red.

The highly visible

indicator is blinking

in orange.

The INPUT READY

indicator is blinking

in yellow.

The INPUT READY

indicator is ON in

yellow.

— Check the installation.

— Check the installation.

— Check the installation.

Identify the cause of the error and

implement countermeasures

according to “Display details when

an error occurs.”

Bring the actuator within the

detection range.

Use the actuator that was taught to

the unit.

Turn ON the safety input.

Release the interlock state by

turning the RESET/EDM input ON.

Countermeasure

8

Page 9

[B] The OSSD does not turn OFF (or turns ON unexpectedly).

DANGER

Possible cause

The sensor and actuator are

at a shorter distance than the

specified operating distance

Sar (ON→OFF).

The unit is affected by the

surrounding metal.

The unit is affected by

interference from other

sensors.

The cascade connection

wiring is incorrect.

Confirmation

method

— Check the installation.

— Check the installation.

— Check the installation.

The INPUT READY

indicator is off.

Check the safety input wiring.

Countermeasure

[C] The OSSD sometimes turns ON and OFF.

Possible cause

The sensor is subject to noise. —

The unit is affected by the

surrounding metal.

The unit is affected by

interference from other

sensors.

The sensor and actuator are

at a distance between the

specified operating distance

Sao (OFF→ON) and Sar (ON

→OFF).

Confirmation

method

— Check the installation.

— Check the installation.

— Check the installation.

Check the noise environment

around the wiring.

Countermeasure

[D] The connected device repeatedly turns the OSSD ON/OFF

at high speed (chattering).

Possible cause

The OSSDs turn OFF

periodically by the selfdiagnosis function, but the

connected device may be

recognizing this short OFF

signal.

Confirmation

method

—

Countermeasure

Select a device that does not detect

the OSSD’s periodic OFF signal for

the connected device.

[E] No indicators light.

Possible cause

The power is off or the power

supply voltage is insufficient.

An extension cable or other

such connector cable is not

connected correctly.

Confirmation

method

Power supply

voltage or power

supply wiring

Connection status

of connector cables

Countermeasure

Ensure that the power supply

voltage is within the range in the

specifications.

Wire the power supply correctly.

If necessary, connect the parts

again.

6-4 Inspection and Maintenance

Inspect the safety function of the GS (Non-contact) on the basis of the results

of a risk assessment of the target machine. It is strongly recommended that,

at minimum, the following items and periods be met.

• To prevent danger due to the machine starting, thoroughly

ensure that no one is present in the hazardous zone during

inspection.

• If some error is found on the GS (Non-contact) as a result of

the inspection, do not operate the machine.

• Initial inspection

Items

The sensor and actuator are installed on the basis of the installation

conditions, installation methods, and wiring specifications specified in this

manual.

The safety functions being used (“4-1 OSSD” (page 5), “4-2 Safety Input”

(page 6), “4-3 Interlock Function” (page 6), or “4-4 EDM Function” (page

6)) operate as intended.

• Periodic inspection

Periods

SIL3/PLe: Once/month or more, SIL2/PLd: Once/year or more (ISO 14119)

Items

If an emergency stop switch is connected to the safety input, the safety

function acts correctly when the emergency stop switch is pressed.

There are no changes in the mounting conditions of the sensor and

actuator or in the doors, etc. to which these devices are installed.

The door, etc. is not deformed.

There are no changes to the installation status that will affect the results of

the risk assessment carried out at the start of the installation.

The mounting screws and seals (in the case that seals have been applied

to the manual release) have been applied correctly.

No excessive damage or dirt is present.

Especially in the following cases, check the same details as the initial

inspection.

• When a change is made to the installation, wiring, or functions

• When the sensor or actuator is replaced

• When the equipment is not used for a long period of time

• When a defect occurs

Store the inspection results together with the machine’s records.

Errors found on the sensor or actuator cannot be repaired by the customer.

Replace the product with a new one or contact the nearest KEYENCE office.

9

E GS (Non-contact) IM

Page 10

WARRANTIES AND DISCLAIMERS

Copyright (c) 2018 KEYENCE CORPORATION. All rights reserved.

15311E 1098-1 96M15311 Printed in Japan

(1) KEYENCE warrants the Products to be free of defects in materials and

workmanship for a period of one (1) year from the date of shipment. If any

models or samples were shown to Buyer, such models or samples were

used merely to illustrate the general type and quality of the Products and

not to represent that the Products would necessarily conform to said

models or samples. Any Products found to be defective must be shipped to

KEYENCE with all shipping costs paid by Buyer or offered to KEYENCE

for inspection and examination. Upon examination by KEYENCE,

KEYENCE, at its sole option, will refund the purchase price of, or repair or

replace at no charge any Products found to be defective. This warranty

does not apply to any defects resulting from any action of Buyer, including

but not limited to improper installation, improper interfacing, improper

repair, unauthorized modification, misapplication and mishandling, such as

exposure to excessive current, heat, coldness, moisture, vibration or

outdoors air. Components which wear are not warranted.

(2) KEYENCE is pleased to offer suggestions on the use of its various

Products. They are only suggestions, and it is Buyer’s responsibility to

ascertain the fitness of the Products for Buyer’s intended use. KEYENCE

will not be responsible for any damages that may result from the use of the

Products.

(3) The Products and any samples ("Products/Samples") supplied to Buyer are

not to be used internally in humans, for human transportation, as safety

devices or fail-safe systems, unless their written specifications state

otherwise. Should any Products/Samples be used in such a manner or

misused in any way, KEYENCE assumes no responsibility, and additionally

Buyer will indemnify KEYENCE and hold KEYENCE harmless from any

liability or damage whatsoever arising out of any misuse of the Products/

Samples.

(4) OTHER THAN AS STATED HEREIN, THE PRODUCTS/SAMPLES ARE

PROVIDED WITH NO OTHER WARRANTIES WHATSOEVER. ALL

EXPRESS, IMPLIED, AND STATUTORY WARRANTIES, INCLUDING,

WITHOUT LIMITATION, THE WARRANTIES OF MERCHANTABILITY,

FITNESS FOR A PARTICULAR PURPOSE, AND NON-INFRINGEMENT

OF PROPRIETARY RIGHTS, ARE EXPRESSLY DISCLAIMED.

IN NO EVENT SHALL KEYENCE AND ITS AFFILIATED ENTITIES BE

LIABLE TO ANY PERSON OR ENTITY FOR ANY DIRECT, INDIRECT,

INCIDENTAL, PUNITIVE, SPECIAL OR CONSEQUENTIAL DAMAGES

(INCLUDING, WITHOUT LIMITATION, ANY DAMAGES RESULTING

FROM LOSS OF USE, BUSINESS INTERRUPTION, LOSS OF

INFORMATION, LOSS OR INACCURACY OF DATA, LOSS OF

PROFITS, LOSS OF SAVINGS, THE COST OF PROCUREMENT OF

SUBSTITUTED GOODS, SERVICES OR TECHNOLOGIES, OR FOR

ANY MATTER ARISING OUT OF OR IN CONNECTION WITH THE USE

OR INABILITY TO USE THE PRODUCTS, EVEN IF KEYENCE OR ONE

OF ITS AFFILIATED ENTITIES WAS ADVISED OF A POSSIBLE THIRD

PARTY’S CLAIM FOR DAMAGES OR ANY OTHER CLAIM AGAINST

BUYER. In some jurisdictions, some of the foregoing warranty disclaimers

or damage limitations may not apply.

BUYER’S TRANSFER OBLIGATIONS:

If the Products/Samples purchased by Buyer are to be resold or delivered

to a third party, Buyer must provide such third party with a copy of this

document, all specifications, manuals, catalogs, leaflets and written

information provided to Buyer pertaining to the Products/Samples.

E 1101-3

Document Control No. 1477BAE201

E GS (Non-contact) IM

10

Loading...

Loading...