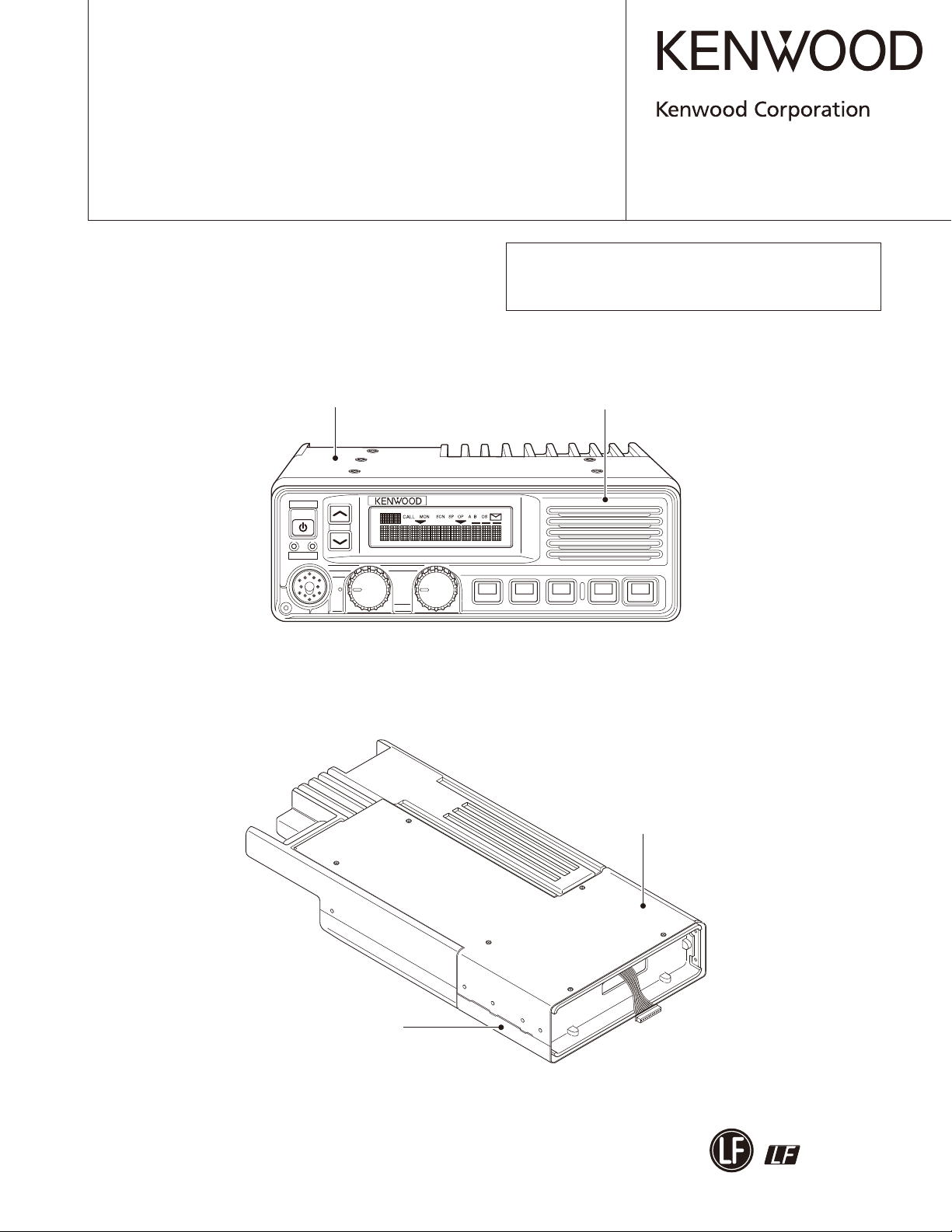

UHF P25 TRANSCEIVER

TK-5810(BG

TK-5810H(BG

SERVICE MANUAL

TK-5810(BG) with KCH-14

Metallic cabinet (Top)

(A01-2161-32)

POWER

GRP

)

)

© 2010-3 PRINTED IN JA PAN

B51-8913-00 (N

Use this service manual together with the KCH-14/15 service

manual (B51-8728-00) or KCH-16 service manual (B51-8834-00).

As for the hardware of this transceiver, version 3 is used.

The programming software must use KPG-95DG.

KCH-14

(Front panel kit)

)

TK-5810H(BG)

BUSY

TX

VOL

CH

Metallic cabinet (Top)

(A01-2163-21)

This product complies with the

Metallic cabinet (Bottom)

(A01-2164-31)

directive for the European market.

RoHS

This product uses Lead Free solder.

TK-5810(BG)/5810H(BG

)

CONTENTS

GENERAL ................................................................... 2

SYSTEM SET-UP ....................................................... 4

REALIGNMENT ......................................................... 5

INSTALLATION ........................................................ 12

DISASSEMBLY FOR REPAIR .................................. 20

CIRCUIT DESCRIPTION .......................................... 24

COMPONENTS DESCRIPTION ............................... 32

PARTS LIST ............................................................. 35

EXPLODED VIEW .................................................... 50

PACKING .................................................................. 52

TROUBLE SHOOTING ............................................ 54

ADJUSTMENT ........................................................ 56

Document Copyrights

Copyright 2010 by Kenwood Corporation. All rights re-

served.

No part of this manual may be reproduced, translated,

distributed, or transmitted in any form or by any means,

electronic, mechanical, photocopying, recording, or otherwise, for any purpose without the prior written permission

of Kenwood.

Disclaimer

While every precaution has been taken in the preparation

of this manual, Kenwood assumes no responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained

herein. Kenwood reserves the right to make changes to any

products herein at any time for improvement purposes.

TERMINAL FUNCTION ........................................... 75

PC BOARD

FINAL UNIT (X45-3790-XX): TK-5810(BG) ......... 80

FINAL UNIT (X45-3800-XX): TK-5810H(BG) ...... 82

CONTROL UNIT (X53-4400-10) .......................... 86

TX-RX UNIT (X57-7270-XX) ................................ 90

INTERCONNECTION DIAGRAM ............................ 94

SCHEMATIC DIAGRAM .......................................... 96

BLOCK DIAGRAM ................................................. 114

LEVEL DIAGRAM .................................................. 120

SPECIFICATIONS .................................................. 121

Firmware Copyrights

The title to and ownership of copyrights for firmware

embedded in Kenwood product memories are reserved for

Kenwood Corporation. Any modifying, reverse engineering, copy, reproducing or disclosing on an Internet website

of the firmware is strictly prohibited without prior written

consent of Kenwood Corporation. Furthermore, any reselling, assigning or transferring of the fi rmware is also strictly

prohibited without embedding the firmware in Kenwood

product memories.

Transceivers containing AMBE+2™ Vocoder:

The AMBE+2™ voice coding technology is embedded in

the fi rmware under the license of Digital Voice Systems, Inc.

INTRODUCTION

SCOPE OF THIS MANUAL

This manual is intended for use by experienced technicians familiar with similar types of commercial grade communications equipment. It contains all required service

information for the equipment and is current as of the publication date. Changes which may occur after publication

are covered by either Service Bulletins or Manual Revisions.

These are issued as required.

2

GENERAL

ORDERING REPLACEMENT PARTS

When ordering replacement parts or equipment information, the full part identifi cation number should be included.

This applies to all parts: components, kits, or chassis. If the

part number is not known, include the chassis or kit number

of which it is a part, and a suffi cient description of the required component for proper identifi cation.

GENERAL

TK-5810(BG)/5810H(BG

)

PERSONAL SAFETY

The following precautions are recommended for personal

safety:

• DO NOT transmit if someone is within two feet (0.6 meter) of the antenna.

• DO NOT transmit until all RF connectors are secure and

any open connectors are properly terminated.

• SHUT OFF this equipment when near electrical blasting

caps or while in an explosive atmosphere.

• All equipment should be properly grounded before power-up for safe operation.

• This equipment should be serviced by only qualified

technicians.

PRE-INSTALLATION CONSIDERATIONS

1. UNPACKING

Unpack the radio from its shipping container and check

for accessory items. If any item is missing, please contact

KENWOOD immediately.

2. LICENSING REQUIREMENTS

Federal regulations require a station license for each

radio installation (mobile or base) be obtained by the equipment owner. The licensee is responsible for ensuring transmitter power, frequency, and deviation are within the limits

permitted by the station license.

Transmitter adjustments may be performed only by a

licensed technician holding an FCC fi rst, second or general

class commercial radiotelephone operator’s license. There is

no license required to install or operate the radio.

3. PRE-INSTALLATION CHECKOUT

3-1. Introduction

Each radio is adjusted and tested before shipment. How-

ever, it is recommended that receiver and transmitter operation be checked for proper operation before installation.

3-2. Testing

The radio should be tested complete with all cabling and

accessories as they will be connected in the fi nal installation. Transmitter frequency, deviation, and power output

should be checked, as should receiver sensitivity, squelch

operation, and audio output. Signaling equipment operation

should be verifi ed.

4. PLANNING THE INSTALLATION

4-1. General

Inspect the vehicle and determine how and where the

radio antenna and accessories will be mounted.

Plan cable runs for protection against pinching or crush-

ing wiring, and radio installation to prevent overheating.

4-2. Antenna

The favored location for an antenna is in the center of a

large, flat conductive area, usually at the roof center. The

trunk lid is preferred, bond the trunk lid and vehicle chassis

using ground straps to ensure the lid is at chassis ground.

4-3. Radio

The universal mount bracket allows the radio to be

mounted in a variety of ways. Be sure the mounting surface

is adequate to support the radio’s weight. Allow suffi cient

space around the radio for air cooling. Position the radio

close enough to the vehicle operator to permit easy access

to the controls when driving.

4-4. DC Power and wiring

1. This radio may be installed in negative ground electrical

systems only. Reverse polarity will cause the cable fuse

to blow. Check the vehicle ground polarity before instal-

lation to prevent wasted time and effort.

2. Connect the positive power lead directly to the vehicle

battery positive terminal. Connecting the Positive lead

to any other positive voltage source in the vehicle is not

recommended.

3. Connect the ground lead directly to the battery negative

terminal.

4. The cable provided with the radio is suffi cient to handle

the maximum radio current demand. If the cable must be

extended, be sure the additional wire is suffi cient for the

current to be carried and length of the added lead.

5.

INSTALLATION PLANNING – CONTROL STATIONS

5-1. Antenna system

Control station. The antenna system selection depends

on many factors and is beyond the scope of this manual.

Your KENWOOD dealer can help you select an antenna system that will best serve your particular needs.

5-2. Radio location

Select a convenient location for your control station radio which is as close as practical to the antenna cable entry

point. Secondly, use your system’s power supply (which

supplies the voltage and current required for your system).

Make sure suffi cient air can fl ow around the radio and power supply to allow adequate cooling.

SERVICE

This radio is designed for easy servicing. Refer to the

schematic diagrams, printed circuit board views, and alignment procedures contained in this manual.

NOTE

You must use KPG-95DG version 6.10 or later for this

transceiver.

3

TK-5810(BG)/5810H(BG

)

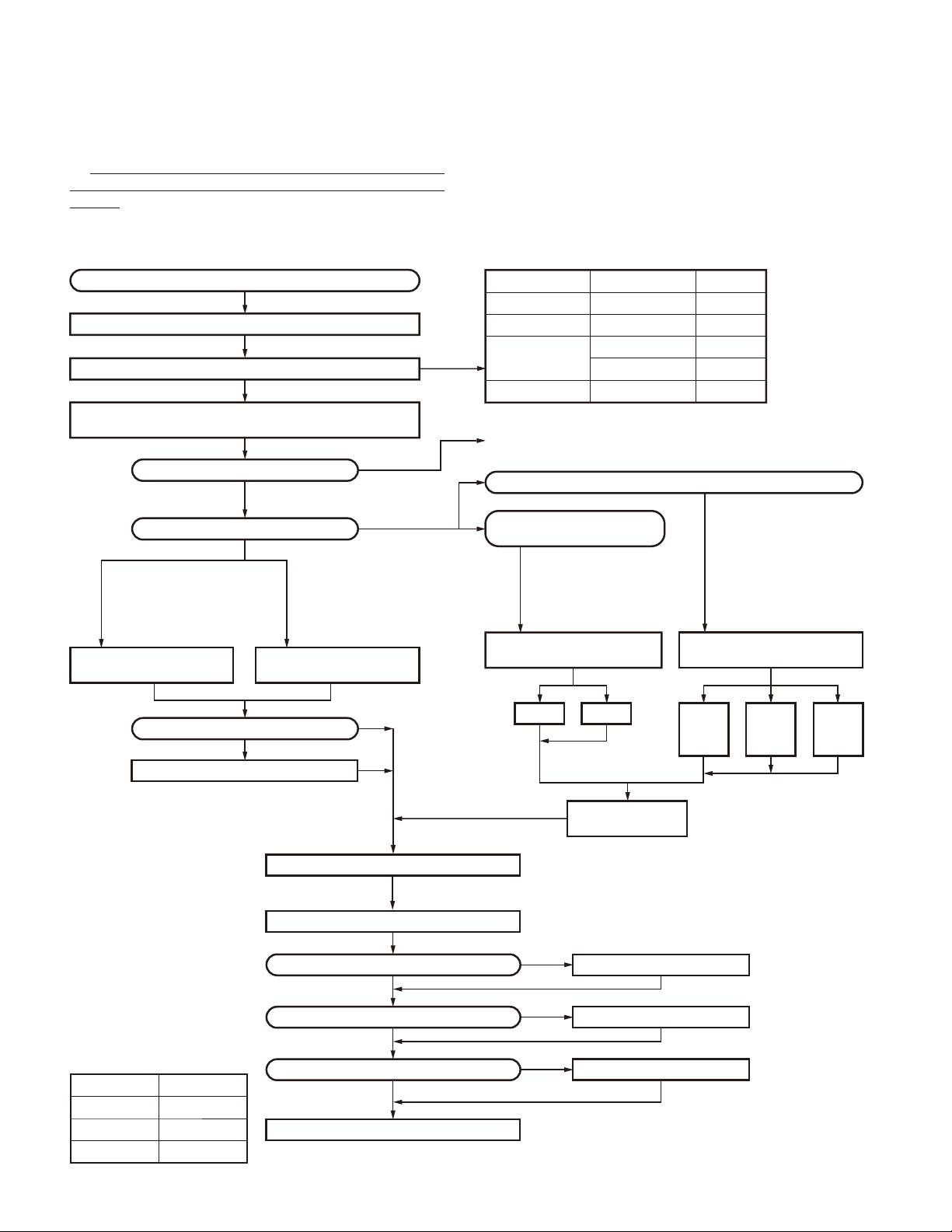

SYSTEM SET-UP

Before Reading About System Set-up

The TK-5810(BG)/5810H(BG) is a transceiver main unit

(without a panel or speaker) that you complete by adding

options.

The options are classifi ed into three types according to

operation and function.

Merchandise received

License and frequency allocated by FCC

Choose the type of transceiver

TK-5810(BG)/5810H(BG) is complete by combining options

with only the transceiver body (without panel)

Are you using the handheld control head?

NO

Are you using the remote kit?

NO

See page 12

Please refer to the

KCH-14/15 service manual

(B51-8728-00) for serving

information, such as circuit

diagram, parts list and etc.

KCH-14 (Basic model)

Front panel kit

Are you using the printed keytops?

See page 12

Supplied accessory keytops

YES

See page 12

Please refer to the

KCH-14/15 service manual

(B51-8728-00) for serving

information, such as circuit

diagram, parts list and etc.

KCH-15 (Full-featured

model) Front panel kit

YES

YES

NO

1. Install the front panel kit (controller) directly on a radio to

operate it. (Form: Radio + KCH-14/15)

2. Remotely control one radio with one controller. (Form:

Radio + KRK-5 + KCH-14/15 + KCT-22M/M2/M3)

3. Remotely control one radio with two controllers. (Form:

Radio + KRK-6DH + KCH-14/15 (two) + KCT-22M/M2/M3

(two))

Type

TK-5810H(BG) K

TK-5810H(BG) K2

Please refer to the KCH-16 service manual (B51-8834-00)

for serving information, such as circuit diagram,

installation, adjustment and etc.

Are you using one transceiver

with one controller?

See page 13

YES

Please refer to the

KRK-5/6DH service manual

(B51-8445-20) for serving

information, such as circuit

diagram, parts list and etc.

Single control head remote kit

KCH-14 KCH-15

Frequency range RF power

450~520MHz 45W~5WTK-5810(BG) K

400~470MHz 45W~5WTK-5810(BG) K2

450~500MHz 100W~50W

500~520MHz

400~470MHz

Are you using one radio with two controllers?

KRK-5

(Option) (Option)

60W~50W

100W~50W

YES

See page 15

Please refer to the

KRK-5/6DH service manual

(B51-8445-20) for serving

information, such as circuit

diagram, parts list and etc.

oror or

+

KRK-6DH

KCH-14

+

KCH-15

Dual control head remote kit

KCH-14

KCH-14

KCH-15

+

KCH-15

Service manual parts No. list

Model Parts No.

KRK-5/6DH B51-8445-20

KCH-14/15 B51-8728-00

KCH-16 B51-8834-00

4

Transceiver programming

KCT-23 DC cable

Are you using the voice guide & storage unit?

NO

Are you using the external speaker?

NO

Are you using the keypad microphone?

NO

Delivery

KCT-22M/M2/M3

Control cable

See page 5

A personal computer, programming interface (KPG-43/43A),

USB adapter (KCT-53U), and programming software

(KPG-95DG: ver. 6.10 or later) are required for programming.

(The frequency and signaling data are programmed for the transceiver.)

KCT-23 M,M3

YES

YES

YES

VGS-1

KES-5

KMC-28

See pages 14 and 15

See page 17

(Option)

See page 17

(Option)

(Option)

Desk top microphone KMC-9B

TK-5810(BG)/5810H(BG

REALIGNMENT

)

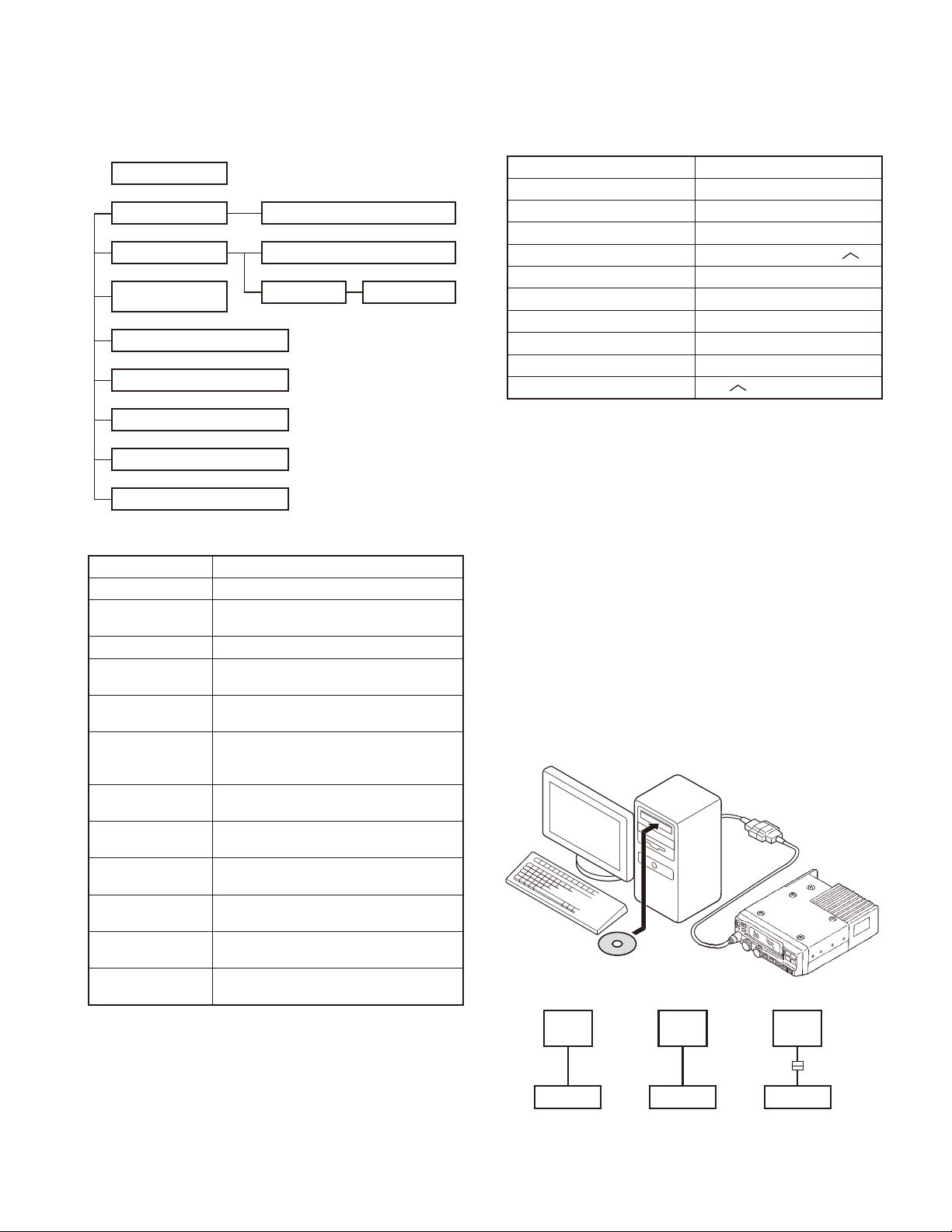

1. Modes

User mode

Panel test mode

PC mode

Firmware

programming mode

Firmware version information

Clock adjustment mode

Transceiver information mode

Clone mode

Self programming mode

Mode Function

User mode For normal use.

Panel test mode

Panel tuning mode Used by the dealer to tune the transceiver.

PC mode

Data programming

mode

PC test mode

Firmware

programming mode

Firmware version

information

Clock adjustment

mode

Transceiver

information mode

Clone mode

Self programming

mode

Used by the dealer to check the fundamental characteristics.

Used for communication between the

transceiver and PC.

Used to read and write frequency data and

other features to and from the transceiver.

Used to check the transceiver using the

PC. This feature is included in the FPU.

See panel tuning.

Used when changing the main program of

the fl ash memory.

Used to confi rm the internal fi rmware version.

Used by the dealer to adjust date and time.

Used to confi rm the transceiver fi rmware

version.

Used to transfer programming data from

one transceiver to another.

Frequency, signaling and features write to

the transceiver.

Panel tuning mode

Data programming mode

PC test mode

PC tuning mode

2. How to Enter Each Mode

Mode Operation

User mode Power ON

Panel test mode [PF1] + Power ON

PC mode Received commands from PC

Panel tuning mode [Panel test mode] + [GRP

Firmware programming mode [PF2] + Power ON

Firmware version information [PF3] + Power ON

Clock adjustment mode [PF4] + Power ON

Transceiver information mode [PF1] + [PF3] + Power ON

Clone mode [PF5] + Power ON

Self programming mode [GRP ] + Power ON

]

3. Panel Test Mode

Setting method refer to ADJUSTMENT.

4. Panel Tuning Mode

Setting method refer to ADJUSTMENT.

5. PC Mode

5-1. Preface

The transceiver is programmed by using a personal computer, programming interface (KPG-43/43A), USB adapter

(KCT-53U) and programming software (KPG-95DG: ver. 6.10

or later).

The programming software can be used with a PC. Figure 1 shows the setup of a PC for programming.

PC

KPG-43 or KPG-43A or

KPG-43A + KCT-53U

Illustration is KPG-43.

KPG-95DG

(Ver. 6.10 or later)

PC

D-SUB

(25-pin)

KPG-43

Transceiver

PC

D-SUB

(9-pin)

KPG-43A

Transceiver

PC

USB

KCT-53U

KPG-43A

Transceiver

Fig. 1

5

TK-5810(BG)/5810H(BG

)

REALIGNMENT

5-2. Connection procedure

1. Connect the transceiver to the computer using the interface cable and USB adapter (When the interface cable is

KPG-43A, the KCT-53U can be used.).

Note:

• You must install the KCT-53U driver in the computer to

use the USB adapter (KCT-53U).

• When using the USB adapter (KCT-53U) for the fi rst time,

plug the KCT-53U into a USB port on the computer with

the computer power ON.

2. When the POWER switch on, user mode can be entered

immediately. When PC sends command the transceiver

enter PC mode, and “PROGRAM” is displayed on the

LCD. When data transmitting from transceiver, the red

LED is lights. When data receiving to transceiver, the

green LED is lights.

Note:

The data stored in the computer must match the “Model

Name and Market Code” when it is written into the fl ash

memory.

5-3. KPG-43/KPG-43A description

(PC programming interface cable: Option)

The KPG-43/43A is required to interface the transceiver

to the computer. It has a circuit in its D-sub connector (KPG43: 25-pin, KPG-43A: 9-pin) case that converts the RS-232C

logic level to the CMOS level.

The KPG-43/43A connects the microphone jack of the

transceiver to the RS-232C serial port of the computer.

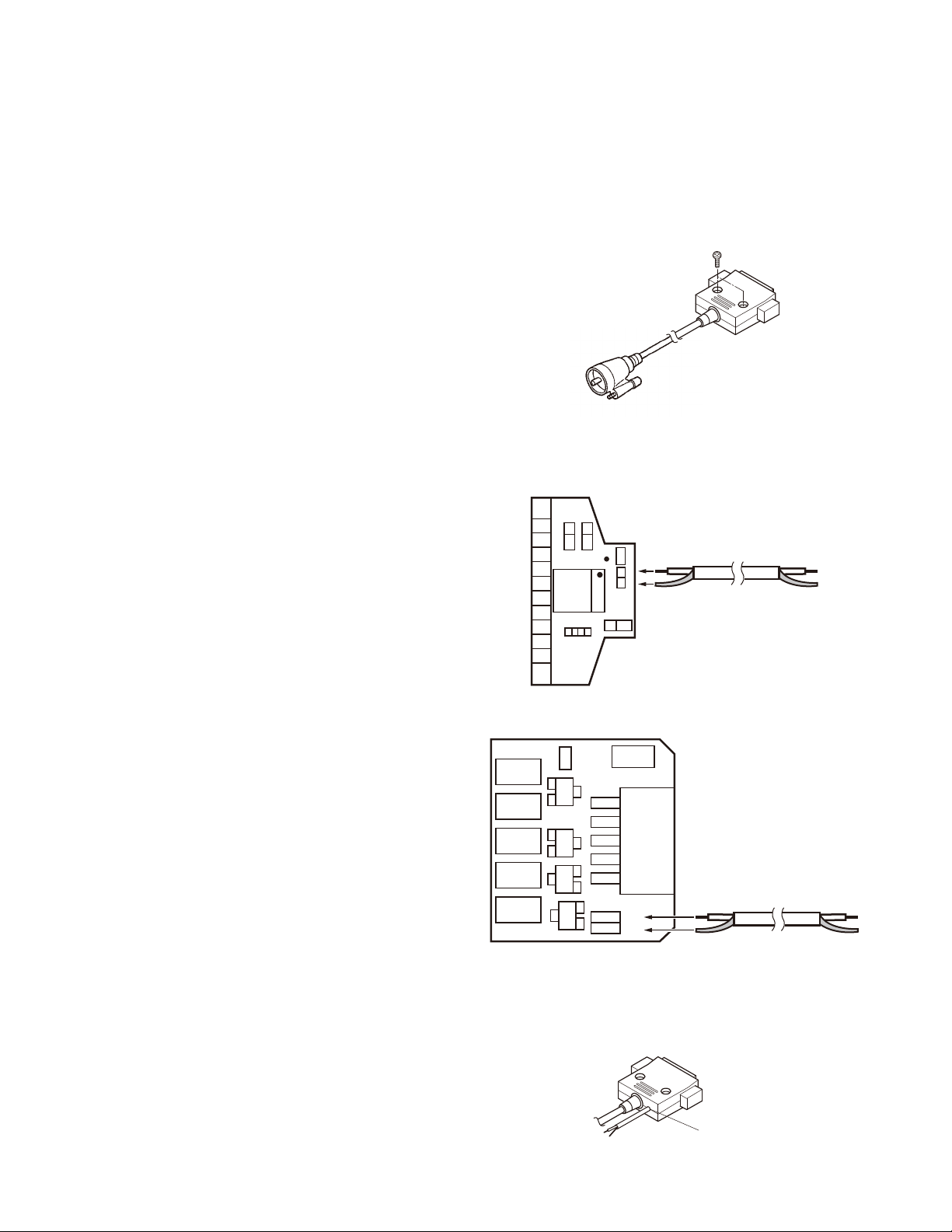

6. PC Tuning Mode

When making adjustment while in PC tuning mode,

modify the KPG-43/43A programming interface cable as described below.

1. Remove the two screws from the plug cover, then lift

the cover from the plug.

2. Solder the lead wire onto the MIC tab on the PCB, and

the ground wire onto the ME tab.

• KPG-43

++

C5

C4

Q1

MIC

MAX232C

ME

TRD

MAXIM

GND

SB

IC1

C7

+

5-4. KCT-53U description (USB adapter: Option)

The KCT-53U is a cable which connects the KPG-43A to

a USB port on a computer.

When using the KCT-53U, install the supplied CD-ROM

(with driver software) in the computer. The KCT-53U driver

runs under Windows 2000, XP or Vista (32-bit).

5-5. Programming software KPG-95DG description

The KPG-95DG (ver. 6.10 or later) is the programming

software for the transceiver supplied on a CD-ROM. This

software runs under Windows 98, ME, Windows NT4.0,

2000, XP or Vista (32-bit) on a PC.

The data can be input to or read from the transceiver and

edited on the screen. The programmed or edited data can

be printed out. It is also possible to tune the transceiver.

• KPG-43A

R3

Q1

D1

Q2

Q3

MIC

ME

C2

CN1

3.

• KPG-43

Create a hole in the casing (as shown in the illustration)

then fi t the cable into the hole. Replace the cover and

secure it using the two screws.

MIC

Cable

ME

Create a hole

6

TK-5810(BG)/5810H(BG

REALIGNMENT

)

• KPG-43A

Install the D-SUB socket into the cover after aligning the

lead wire as shown in the fi gure.

Replace the cover and secure it using the two screws.

D-SUB socket

Lead wire

MIC

ME

Cover

7. Firmware Programming Mode

7-1. Preface

Flash memory is mounted on the transceiver. This allows the transceiver to be upgraded when new features are

released in the future. (For details on how to obtain the fi rmware, contact Customer Service.)

• These transceivers use firmware versions G5.10 or

later. When using fi rmware versions earlier than version

G5.10, a “Check connection” error message will appear on the LCD. Firmware versions earlier than version

G5.10 will not write to the transceiver.

• While the firmware is being written, if the transceiver

resets due to a power supply interruption or other problem, the LCD may not display correctly (for example,

“PROGRAM FIRM” may not display).

Additionally, transceiver keys other than the power

switch cannot be operated.

To return to normal operation, click the “Cancel” but-

ton in the firmware programming software, then turn

the transceiver power OFF and back ON. “PROGRAM

FIRM” reappears on the display and the transceiver keys

can be operated. However, the previously written fi rmware data is lost; you must write the fi rmware using the

fi rmware programming software again.

8. Firmware Version Information

Press and hold the [PF3] key while turning the transceiv-

er power ON and then keep pressing and holding the [PF3]

key, the fi rmware version information appears on the LCD.

7-2. Connection procedure

Connect the transceiver to the personal computer (PC)

using the interface cable (KPG-43/43A) and USB adapter

(KCT-53U: When the interface cable is KPG-43A, the KCT53U can be used.). (Connection is the same as in the PC

Mode.)

7-3. Programming

1. Start up the fi rmware programming software (Fpro.exe).

2. Set the communications speed (normally, 115200 bps)

and communications port in the confi guration item.

3. Set the fi rmware to be updated by File name item.

4. Press and hold the [PF2] key while turning the transceiv-

er power ON. Then, the orange LED on the transceiver

lights and “PROGRAM FIRM” is displayed.

5. Check the connection between the transceiver and the

personal computer, and make sure that the transceiver is

in the Program mode.

6. Press “write” button in the window. When the trans-

ceiver starts to receive data, the [PG] display is blinking.

7. If writing ends successfully, the checksum is calculated

and a result is displayed.

8. If you want to continue programming other transceivers,

repeat steps 4 to 7.

Note:

• This mode cannot be entered if the Firmware Program-

ming mode is set to Disable in the Programming soft-

ware.

9. Clock Adjustment Mode

9-1. Flow chart of operation

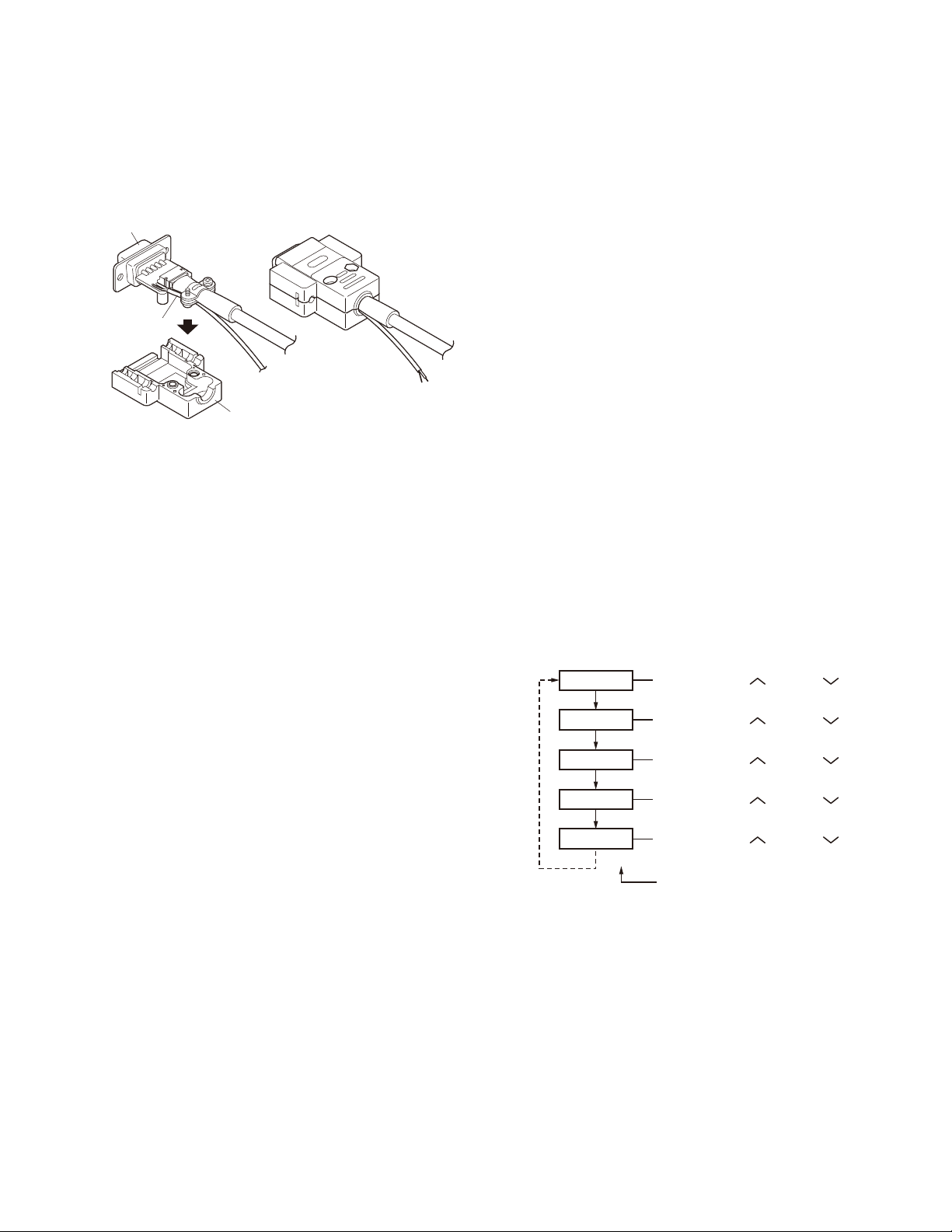

[PF4] + Power ON

YEAR

MONTH

DAY

HOUR

MINUTE

[Selector] or [GRP ] and [GRP ]

[PF2]

[Selector] or [GRP ] and [GRP ]

[PF2]

[Selector] or [GRP ] and [GRP ]

[PF2]

[Selector] or [GRP ] and [GRP ]

[PF2]

[Selector] or [GRP ] and [GRP ]

[PF2]

Completion

10. Transceiver Information Mode

Use this function to confirm the transceiver firmware

version.

1. Press and hold the [PF1] and [PF3] keys while turning the

transceiver power ON.

2. The transceiver fi rmware version appears on the LCD.

3. To exit the transceiver information mode, turn the transceiver power OFF.

7

TK-5810(BG)/5810H(BG

)

REALIGNMENT

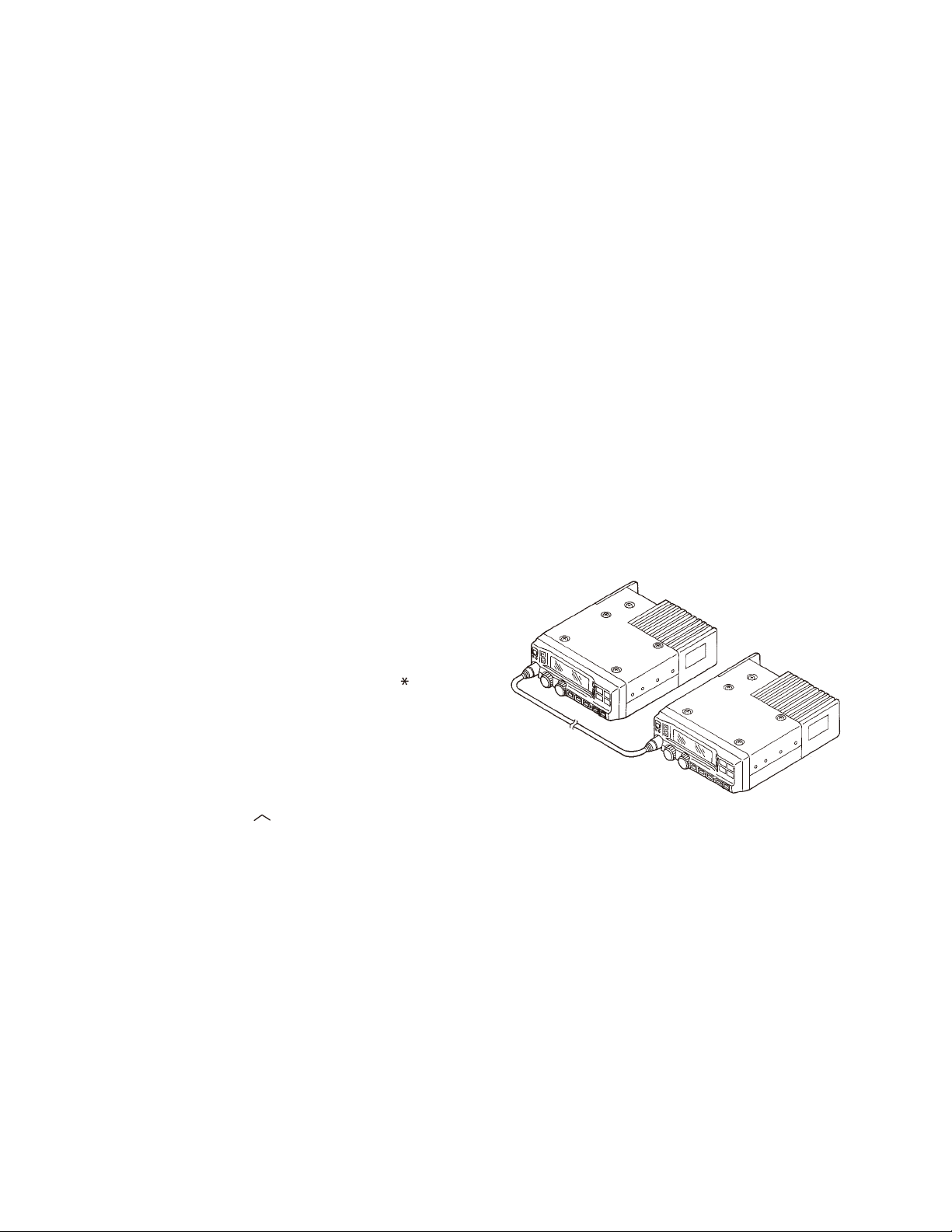

11. Clone Mode

Programming data can be transferred from one transceiver to another by connecting them via their microphone

jacks. The operation is as follows (the transmit transceiver

is the source and the receive transceiver is a target).

The following data cannot be cloned.

• Tuning data

• Embedded message with password

• Model name data

• ESN (Electronic Serial Number) data

• Network fi le data (P25)

Key guide on the “INPUT PASSWORD” display.

1. Press and hold the [PF5] key while turning the trans-

ceiver power ON. If the Read authorization password is

set to the transceiver, the transceiver displays “CLONE

LOCK”. If the password is not set, the transceiver dis-

plays “CLONE MODE”.

2. When you enter the correct password, and “CLONE

MODE” is displayed, the transceiver can be used as the

cloning source. The following describes how to enter

the read authorization password.

3.

• How to enter the read authorization password using

the microphone keypad;

If one of keys 0 to 9 is pressed while “CLONE LOCK” is

displayed, the pressed number is displayed on the LCD.

Each press of the key shifts the display in order to the

left.

If you press the [#] key, the least digit of the password is

deleted.

When you enter the password and press the [

“CLONE MODE” is displayed if the entered password is

correct. If the password is incorrect, “CLONE LOCK” is

redisplayed.

• How to enter the read authorization password using

the [Selector] knob;

If the [Selector] knob is rotated while “CLONE LOCK”

is displayed, the number (0 to 9) flashes on the LCD.

When you press the [GRP

number is determined. If you press the [PF3] key, the

least digit of the password is deleted. If you press the

[PF2] key after entering the password in this procedure,

“CLONE MODE” is displayed if the entered password is

correct. If the password is incorrect, “CLONE LOCK” is

redisplayed.

4. Power ON the target transceiver.

5. Connect the cloning cable (part No. E30-3370-05) to the

microphone jacks on the source and target.

6. Press the [PF2] key on the source while the source dis-

plays “CLONE MODE”. The data of the source is sent to

the target. While the target is receiving the data, “PRO-

GRAM” is displayed. When cloning of data is completed,

the source displays “END”, and the target automatically

operates in the User mode. The target can then be oper-

ated by the same program as the source.

] key, the currently selected

] key,

7. The other target can be continuously cloned. When

the [PF2] key on the source is pressed while the source

displays “END”, the source displays “CLONE MODE”.

Carry out the operation in step 4 to 6.

Note:

• You cannot clone transceivers using hardware versions

1.0 or 2.0.

Cloning is only possible when both transceivers are us-

ing hardware version 3.0.

• Cannot be cloned if the overwrite password is programmed to the target.

• “Model Name and Market Code”, “Head Confi guration”

and “Head Type” must be same to clone the transceiver.

However, it may be unable to clone the transceiver depending on the enhanced features settings.

(Refer to the FPU for the enhanced features details.)

• Under certain conditions, clone mode cannot be activated even if the clone mode of the source transceiver,

using Hardware Version 3.0, is set to enable. Refer to

the FPU for more details.

• Can not clone if the checksum in the Network File area

of the source transceiver and the target transceiver is different.

Cloning cable

(E30-3370-05)

8

TK-5810(BG)/5810H(BG

REALIGNMENT

)

12. Self Programming Mode

Write mode for frequency data and signaling etc. To be

used ONLY by the authorized service person maintaining the

user’s equipment. After programming, reset the FPU to the

“Self- Programming” disabled mode. Transceivers CANNOT

be delivered to the end-user in the self-programming mode.

The following setup items in the channels programmed

by the FPU can be changed using the self-programming

mode. The addition of new channel and the deletion of

channel that has already been programmed by the FPU cannot be performed using the self-programming mode.

• RX Frequency

• TX Frequency

• Channel Type (ANALOG or MIXED)

• TX Mode (When the channel type is selected “MIXED”.)

• Channel Spacing

• RX Signaling

• TX Signaling

• RX NAC

• TX NAC

• Talkgroup List No.

Note:

The personality will be also changed when the above-

mentioned items is changed. (Refer to the FPU for the

personality details.)

12-1. Enter to the self programming mode

Press and hold the [GRP ] key while turning the transceiver power ON. Ignoring whether the Read authorization

password is set or not, “PASSWORD” appears.

If the Read authorization password is not set to the transceiver, “SELF PG MODE” is displayed on the LCD when the

[PF2] key is pressed while “PASSWORD” is displayed.

If the password is set to the transceiver, “SELF PG

MODE” is displayed on the LCD when you enter the correct

password while “PASSWORD” is displayed.

For the password input method, see “11. Clone Mode”

step3 described on page 8.

Note:

This mode (self programming mode) cannot be set when

it has been disabled with the FPU.

12-2. Data writing

Before moving to the next Zone/Channel, “KEEP THIS

CHANGE?” appears on the LCD, if you select ”YES”, the

new data is written to memory. IF you select “NO”, the

new data will not be written; the new data will be erased.

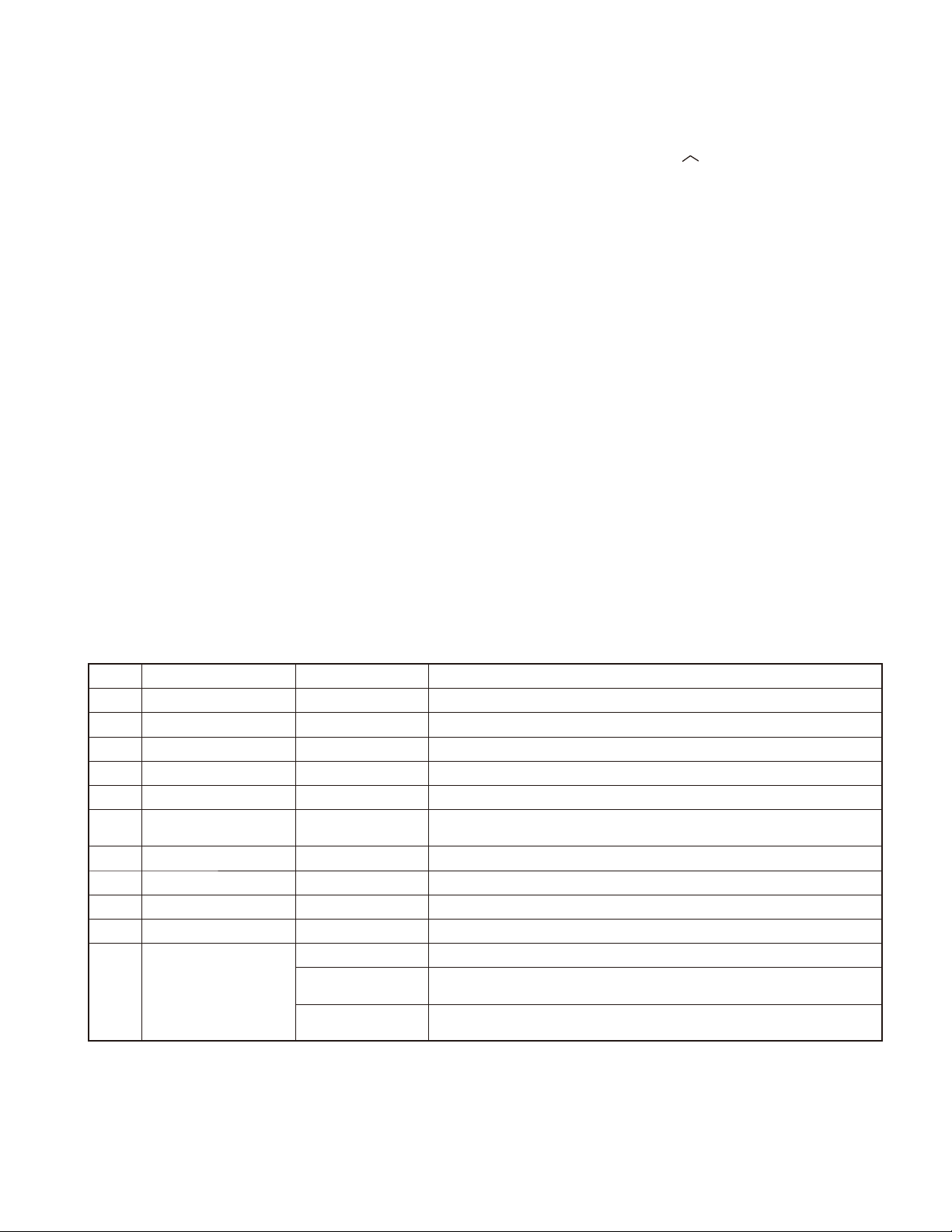

12-3. Setup items for self programming mode

No. Setup item Display Remarks

1 Select Zone/Channel

2 RX Frequency

3 TX Frequency

4 Channel Type TYPE ANALOG/P25/MIXED

5 TX Mode MODE ANALOG/P25

6 Channel Spacing SPACE

7 RX Signaling RX-SIG Receive QT/DQT

8 TX Signaling TX-SIG Transmit QT/DQT

9 RX NAC RX-NAC

10 TX NAC TX-NAC

11 Talkgroup List No.

-

∗∗∗

∗∗∗

∗∗∗.∗∗∗∗∗

∗∗∗.∗∗∗∗∗

None When you do not want to set the Talkgroup list number to the transceiver.

∗∗∗

∗∗∗∗∗∗∗∗∗∗∗∗

MHz Receive frequency

MHz Transmit frequency

∗∗∗

∗∗∗

Zone: 1~100, Channel: 1~512

25.0kHz/12.5kHz (When the Channel type is selected “ANALOG” or “MIXED”.)

“P25 12.5kHz”

000~FFF (Hexadecimal) Note: “F7F” cannot be set.

000~FFF (Hexadecimal) Note: “F7E” and “F7F” cannot be set.

Talkgroup list number (1~250)

(When the Talkgroup list name is not set to the transceiver.)

Talkgroup list name (12 digits)

(When the Talkgroup list name is set to the transceiver.)

9

TK-5810(BG)/5810H(BG

)

REALIGNMENT

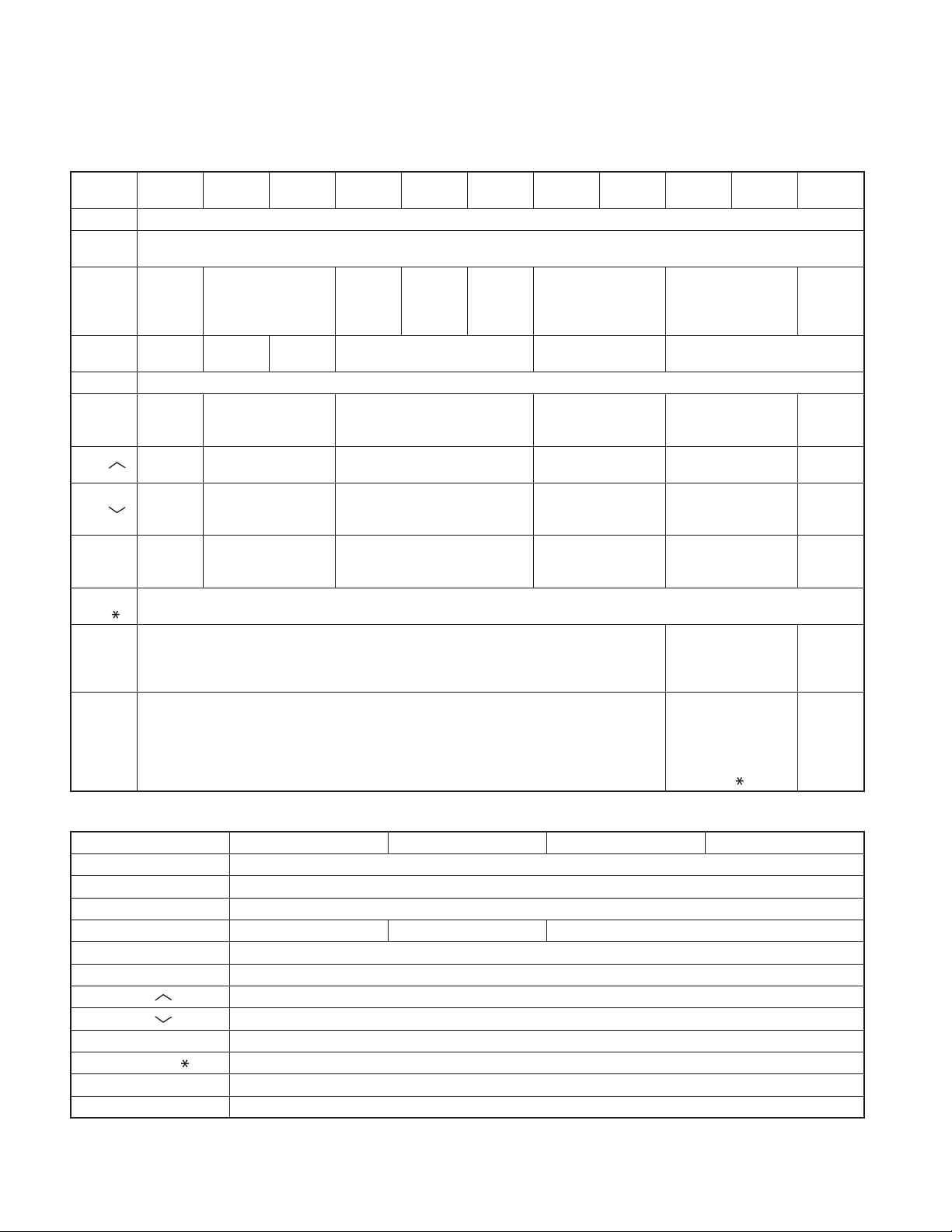

12-4. Key operation

• Normal mode

Key

[PF1] Unused

[PF2] Go to the next item

Zone-

Channel

RX

Frequency

TX

Frequency

Channel

Type

TX Mode

Channel

Spacing

RX

Signaling

TX

Signaling

RX NAC TX NAC

TG

List No.

Zone/

[PF3]

[PF4]

[PF5] Unused

[Selector]

[GRP

[GRP

MIC

keypad

([0] to [9])

MIC key-

pad ([

MIC key-

pad ([#])

MIC PTT Unused

Channel

switching

Data Writ-

Channel

up/ down

]

Channel up

]

Channel

Unused

])

ing

Zone/

Zone/

Zone/

down

5kHz/ 6.25kHz/ 1MHz

step switching

Unused

1step up/ down Unused Signaling up/ down

Go to the MIC keypad

ON/ OFF

switching

1step up Unused Signaling up

1step down Unused Signaling down Unused

input mode

ANALOG/

P25/

MIXED

switching

Unused

ANALOG/

P25

switching

Unused

Unused

Channel

Spacing

switching

Unused

1step/ Standard

switching

QT/ DQT(N)/ DQT(I)/

OFF switching

Go to the MIC keypad

input mode

Delete the least digit

from the current number (Press and hold to

delete all numbers.)

Unused

Increment/ Decrement

a number in the speci-

fi ed digit

Determine the least

digit

Add a digit to the cur-

rent number

Delete the least digit

from the current number (Press and hold to

delete all numbers.)

[PTT] + [2]: “A”

[PTT] + [5]: “B”

[PTT] + [8]: “C”

[PTT] + [0]: “D”

[PTT] + [#]: “E”

[PTT] + [

]: “F”

Unused

TG List

number

up/ down

TG List

number up

TG List

number

down

Unused

Unused

Unused

• MIC keypad input mode

Key RX Frequency TX Frequency RX Signaling TX Signaling

[PF1] Cancel the MIC keypad input mode (Return to the normal mode)

[PF2] Cancel the MIC keypad input mode (Return to the normal mode)

[PF3] Delete the least digit from the current number (Press and hold to delete all numbers.)

[PF4] Unused ON/ OFF switching QT/ DQT(N)/ DQT(I)/ OFF switching

[PF5] Unused

[Selector] Unused

[GRP

[GRP

MIC keypad ([0] to [9]) Add a digit to the current number (Return to the normal mode automatically if all digit are entered.)

MIC keypad ([

MIC keypad ([#]) Delete the least digit from the current number (Press and hold to delete all numbers.)

] Unused

] Unused

]) Cancel the MIC keypad input mode (Return to the normal mode)

MIC PTT Unused

10

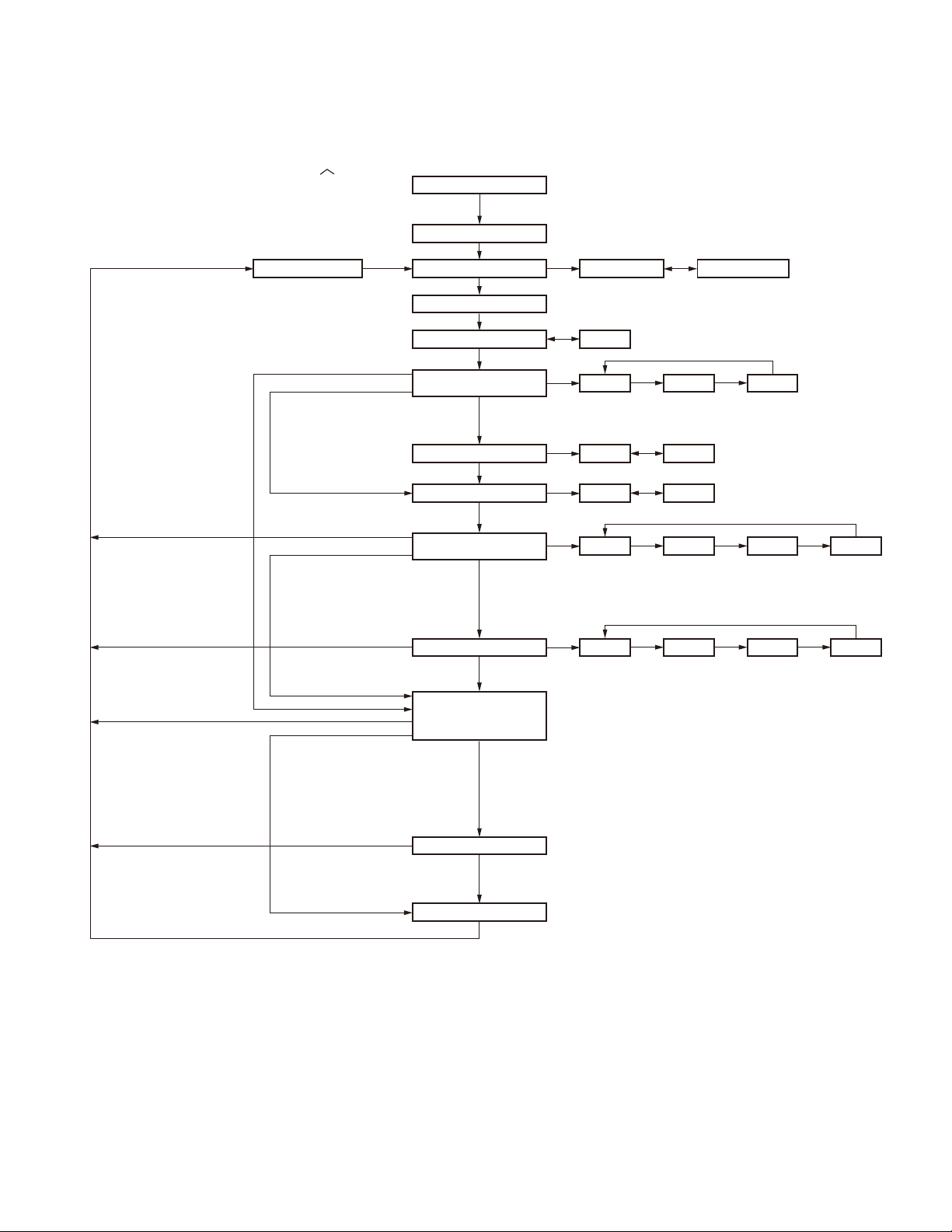

12-5. Self programming mode fl ow chart

TK-5810(BG)/5810H(BG

REALIGNMENT

)

[PF2]

[TX Frequency]: “OFF”

[Channel Type]: “ANALOG”

[PF2]

[Channel Type]: “ANALOG”

[GRP ] + Power ON

Self programming mode

KEEP THIS CHANGE

[PF2]: “YES” or

[PF1]: “NO”

[PF2]

[Channel Type]: “P25”

[PF2]

[TX Frequency]: “OFF”

or

[Channel Type]: “ANALOG” or “MIXED”

[PF2]

[TX Frequency]: “OFF”

[Channel Type]: “P25” or “MIXED”

or

[TX Frequency]: Other than “OFF”

[Channel Type]: “MIXED”

[TX Mode]: “P25”

Input Password

Read authorization password entry (6 digits)

[PF2]

[PF2]

Zone/Channel

[PF2]

RX Frequency

[PF2]

TX Frequency

[PF2]

Channel Type

[PF2]

[TX Frequency]: Other than “OFF”

[Channel Type]: “MIXED”

TX Mode

[PF2]

Channel Spacing

[PF2]

RX Signaling

[PF2]

[TX Frequency]: Other than “OFF”

[Channel Type]: “ANALOG” or “MIXED”

[TX Mode]: “ANALOG”

TX Signaling

[PF2]

[Channel Type]: “MIXED”

[PF4]

Zone selection

OFF

ANALOG

ANALOG

25.0kHz

[PF3]

[PF3]

[PF3]

[PF4] [PF4]

OFF

[PF4] [PF4]

OFF

[PF3]

Channel selection

[PF3]

[PF3]

P25 MIXED

P25

12.5kHz

[PF4]

QT DQT N

[PF4]

QT DQT N

[PF4]

[PF4]

DQT I

DQT I

[PF2]

[TX Frequency]: “OFF”

Squelch Type*

or

[TX Frequency]: Other than “OFF”

[Channel Type]: “MIXED”

[TX Mode]: “ANALOG”

Squelch Type*1: “NAC”

[PF2]

Talkgroup ID List Amount: 0

*1: The squelch type can not be set using the self-programming mode.

1

: “NAC”

[PF2]

[TX Frequency]: “OFF”

Talkgroup ID List Amount must not be 0.

or

[TX Frequency]: Other than “OFF”

[Channel Type]: “MIXED”

[TX Mode]: “ANALOG”

Talkgroup ID List Amount must not be 0.

Talkgroup List No.

RX NAC

[PF2]

[TX Frequency]: Other than “OFF”

[Channel Type]: “P25” or “MIXED”

If [Channel Type] is set to “MIXED”,

[TX Mode] must be set to “P25”.

TX NAC

[PF2]

[Channel Type]: “P25” or “MIXED”

Talkgroup ID List Amount must not be 0.

[PF2]

11

TK-5810(BG)/5810H(BG

)

INSTALLATION

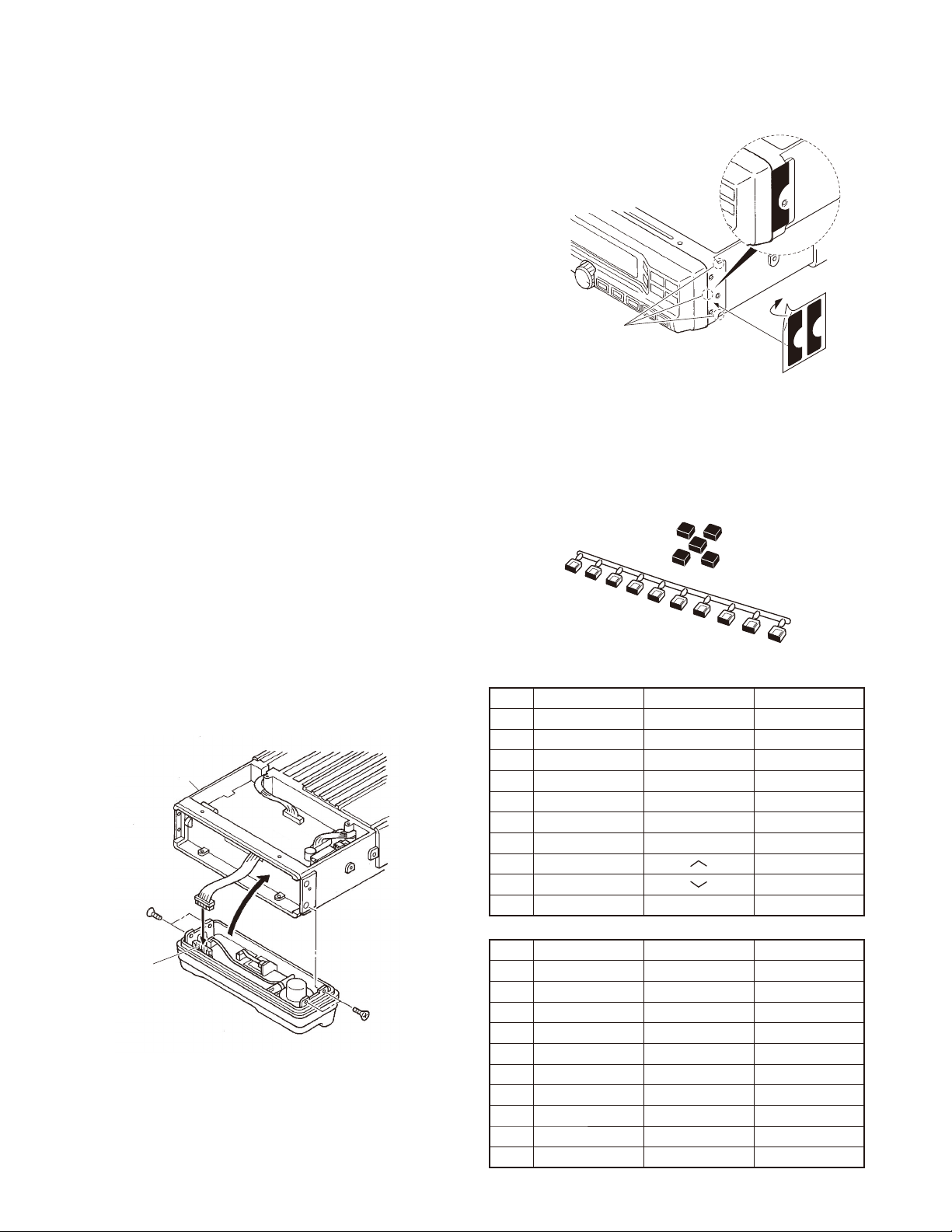

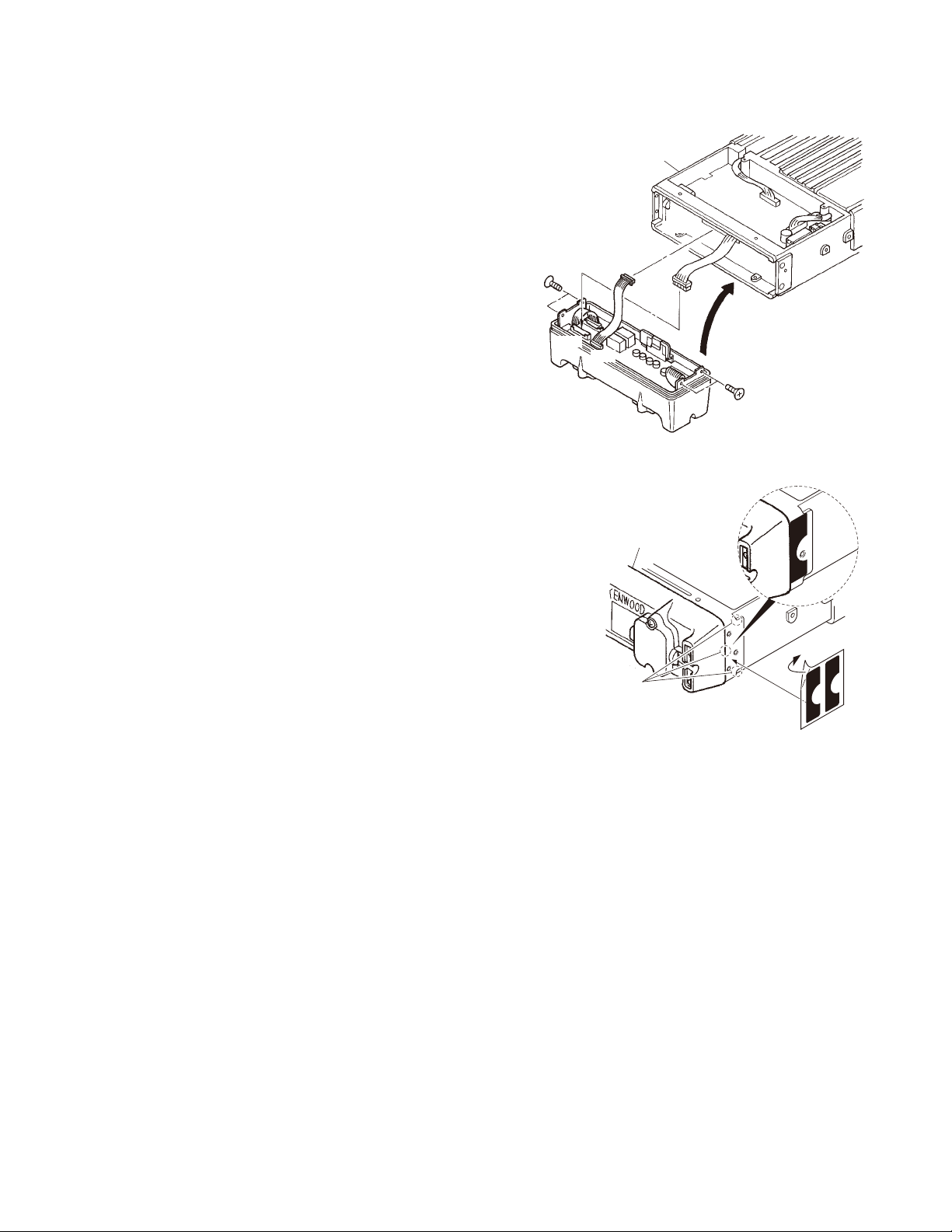

1. Front Panel Kit (KCH-14/15: Option)

1-1. Installing the KCH-14/15 front panel kit to the

transceiver

1. Remove the upper case and lower case of the transceiver.

2. Insert the lead wire with connector (W700) of the control

unit (X53-440) into the connector (CN1) of the KCH-14 or

KCH-15.

3. Install the KCH-14 or KCH-15 on the transceiver using

the four screws q supplied with the front panel kit.

Note:

Take care that the lead wire with connector (W700) is

not caught when fitting the KCH-14 or KCH-15 on the

transceiver. (You can install the panel upside down if necessary to install the transceiver.)

4. Affixing the sheet (G11-4379-04) for the waterproof

(Fig.1-1-2).

(1) Remove the covering paper of the sheet w.

(2) Affi x the sheet while taking note of the position of the

three parts as shown in Fig.1-1-2 e.

Firmly affi x the sheet to the chassis by pushing the

double-coated tape with your fi ngers.

(3) Repeat step (2) to affi x the sheet to the other side of

chassis.

Note:

The sheet cannot be reused. Affix a new sheet when

you removed the sheet.

5. Reassemble the upper case and lower case. (Refer to

page 18)

Note:

Take care that the sheet (G11-4379-04) is not peeled off

when installing the upper/lower case.

6. Connect the short plug to the accessory connector (9-pin)

on the rear of the transceiver.

Transceiver

W700

:

@

Affix the sheet while

taking note of the position

of the three parts.

.

Fig. 1-1-2

1-2. Installing the accessory keytops to the front

panel kit

When a function is set by the programming software

(KPG-95DG), the key legend can be changed by inserting

the accessory keytops into PF1 to PF9 of the KCH-15 (PF1

to PF5: KCH-14). The accessory contains 60 keytops as

shown the table below.

1

2

3

4

5

6

7

8

9

Fig. 1-2

No. K29-5276-03 K29-5277-03 K29-5305-03

1 AN RCL CH1

2 D/A RPT CH2

3 DIM SCN CH3

4 HA SP CH4

5 HC SPM CH5

6 IC SQ AUX A

7 MON TA AUX B

8 OPT

9 OST

10 PA No printing

10

AUX C

EMG

■

12

CN1

KCH-14 or

KCH-15

Fig. 1-1-1

No. K29-9353-13 K29-9354-13 K29-9356-03

1 2TN GPS PAG

2 AD STS SIT

:

3 AR TAC SRC

4 CLK TON No printing

5 FNC RES No printing

6 PBK IDV No printing

7 SCP KDL No printing

8 SEC TGR No printing

9 SEL RGP No printing

10 SES No printing No printing

TK-5810(BG)/5810H(BG

INSTALLATION

)

KCH-14

POWER

TX

BUSY

KCH-15

POWER

TX

BUSY

2. Remote kit (KRK-5: Option)

The KRK-5 remote kit is used to remotely operate the

GRP

VOL

GRP

VOL

CALL

CH

PF1 PF2 PF3 PF4 PF5

SCAN OPT OSTA B CMON

SP

CH

PF1 PF2 PF3 PF4 PF5

MON

PF7PF6

SCN

PF9PF8

Fig. 1-3

transceiver. The KRK-5 is connected to the KCH-14 or KCH15 with an optional KCT-22M (8 feet), KCT-22M2 (17 feet),

or KCT-22M3 (25 feet) control cable.

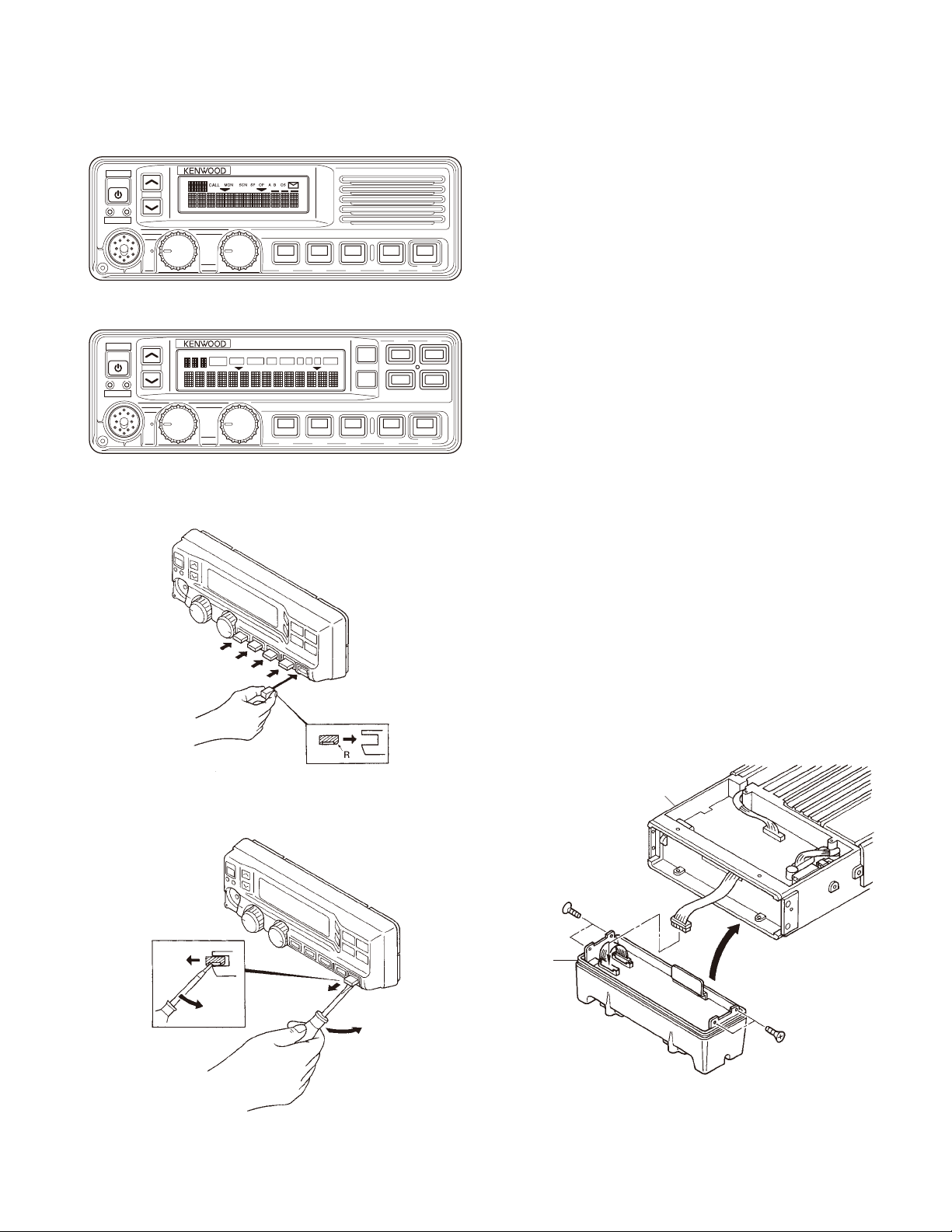

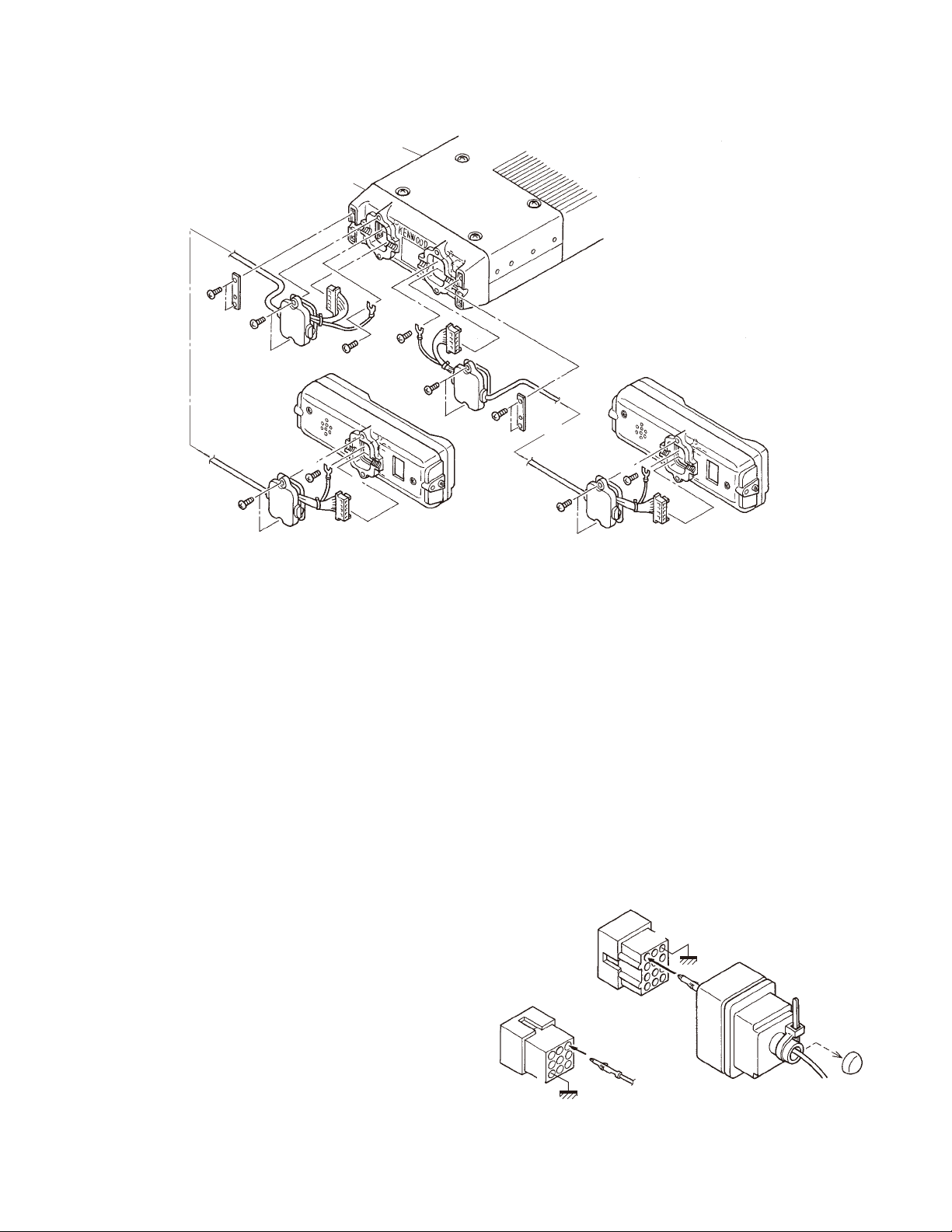

2-1. Installing the KRK-5 main panel onto the

transceiver

1. Remove the upper case and lower case of the transceiver.

2. Insert the lead wire with connector (W700) of the control

unit (X53-440) into the connector (CN4) of the KRK-5.

3. Install the KRK-5 main panel on the transceiver using

four screws q.

Note:

Take care that the lead wire with connector (W700) is not

caught when fi tting the KRK-5 main panel on the transceiver.

4. Affixing the sheet (G11-4379-04) for the waterproof

(Fig.2-1-2).

(1) Remove the covering paper of the sheet w.

(2) Affi x the sheet while taking note of the position of the

three parts as shown in Fig.2-1-2 e.

Firmly affi x the sheet to the chassis by pushing the

double-coated tape with your fi ngers.

(3) Repeat step (2) to affi x the sheet to the other side of

chassis.

Note:

The sheet cannot be reused. Affix a new sheet when

you removed the sheet.

5. Reassemble the upper case and lower case of the transceiver. (Refer to page 18)

Note:

Take care that the sheet (G11-4379-04) is not peeled off

when installing the upper/lower case.

Fig. 1-4 Keytop insertion

Fig. 1-5 Keytop removal

Packing

Transceiver

:

CN4

KRK-5 main panel

W700

:

Fig. 2-1-1

13

TK-5810(BG)/5810H(BG

)

INSTALLATION

KRK-5 main panel

@

Affix the sheet while

taking note of the position

of the three parts.

Fig. 2-1-2

.

2-3. Control cable (KCT-22) connection (Fig. 2-3)

1. Insert one connector of the control cable to the transceiver (with KRK-5) and the other to the display. Connect

the cable to the GND terminal with the screw q supplied with the control cable.

2. Secure the one connector of the control cable to the

KRK-5 main panel with two screws w according to the

installation condition of the transceiver. Secure the control cable to the KRK-5 main panel with the cable fi tting

(J21-4354-04) and two screws e supplied with the KRK-

5.

3. Secure the other connector of the control cable to the

display with two screws r in the same way.

2-2. Installing the KRK-5 rear panel onto the front

panel kit

The following steps apply to both the KCH-14 and KCH-15.

1. Remove three screws q on the KRK-5 rear panel, then

remove the KRK-5 sub panel.

2. Insert the lead wire with connector (W102) of the KRK-5

into the connector (CN1) of the front panel kit w.

3. Insert the lead wire with connector (W103) of the KRK-5

into the connector (CN3) of the front panel kit e.

4. Make a slight cut in the end of the rubber cap r.

5. Slide the lead wire of the connector wiring t through

the slit in the rubber cap y.

6. Insert the rubber cap into the hole of the KRK-5 rear

panel u.

7. Insert the connector i to the ACC connector o on the

KRK-5 sub panel as shown by the arrow !0.

8. Install the KRK-5 sub panel onto the sub panel of the

front panel kit !1.

9. Install the KRK-5 sub panel to the sub panel of the front

panel kit using four screws !2.

10. Reinstall the KRK-5 rear panel using three screws removed in step 1.

11. Use a wire band to secure the lead wire at the end of the

rubber cap !3.

Front panel kit

(Example : KCH-14)

Packing

Sub panel

Transceiver

KRK-5 main panel

.

Cable

fitting

@

:

Control cable

KCT-22

GND

Display

:

GND

;

Fig. 2-3

2-4. Display installation (Fig. 2-4)

1. Install the display with the angle bracket (J29-0648-03)

and two screws (N08-0526-04) w supplied with the

q

KRK-5.

14

Rubber

cap

CN1

CN3

.

W103

1

;

2

3

=

Make

a cut

@

W102

IGN,

GND etc.

8

B

Fig. 2-2

>

KRK-5 sub panel

KRK-5 rear panel

Lead wire

IGN,GND etc.

@

:

:

Angle

bracket

@

Fig. 2-4

TK-5810(BG)/5810H(BG

INSTALLATION

)

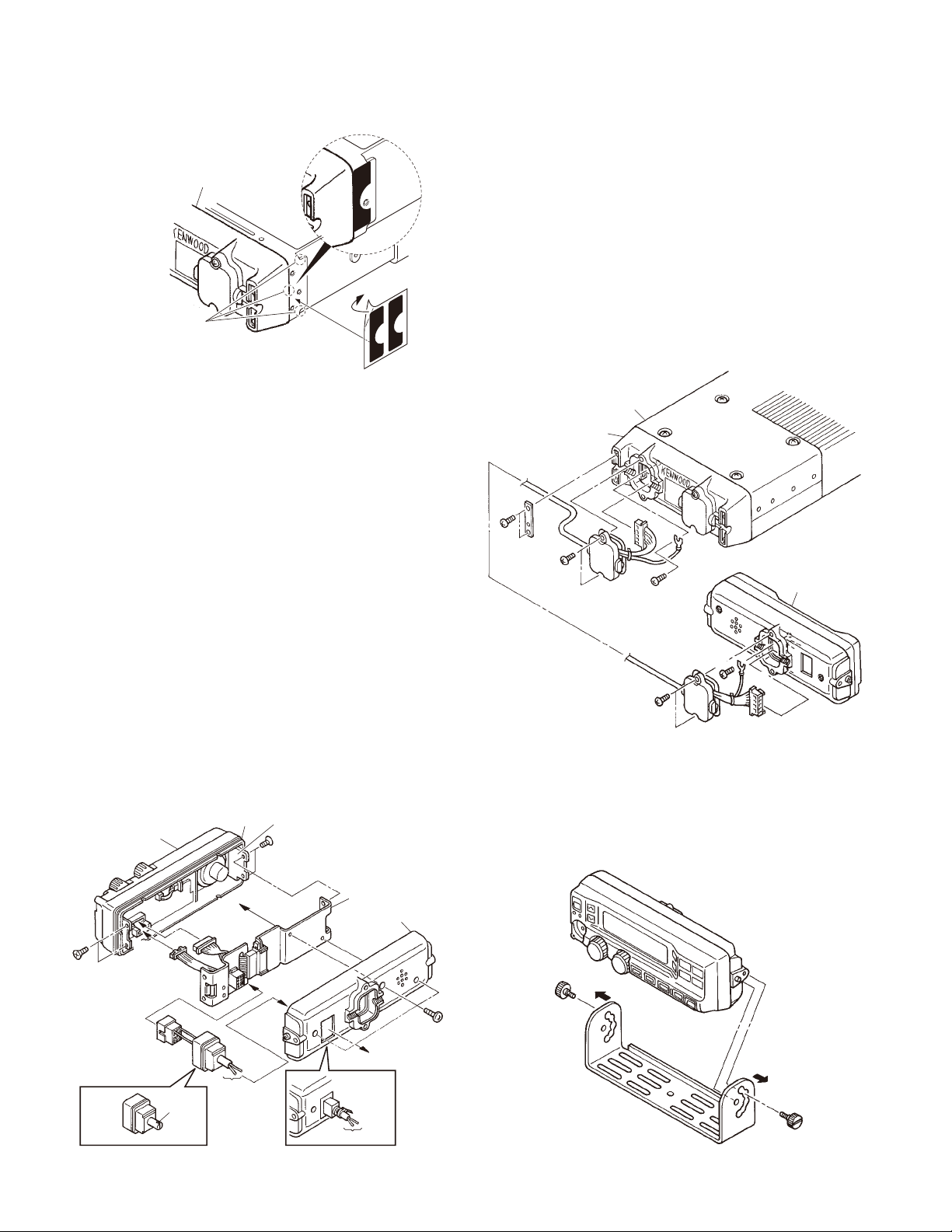

3. Dual Control Head Remote Kit

(KRK-6DH: Option)

The KRK-6DH remote kit connects two displays (two

KCH-14s or KCH-15s) to the transceiver. The KRK-6DH is

connected to the KCH-14s or KCH-15s with two optional

control cables. There are three version of the control cable:

KCT-22M (8 feet), KCT-22M2 (17 feet), and KCT-22M3 (25

feet).

3-1. Installing the KRK-6DH main panel onto the

transceiver

1. Remove the upper case and lower case of the transceiv-

er.

2. Insert the lead wire with connector (W700) of the control

unit (X53-440) into the connector (CN4) of the KRK-6DH.

Insert the lead wire with connector (W104) of the KRK-

6DH into the connector (CN503) of the transceiver.

3. Install the KRK-6DH main panel on the transceiver using

four screws q.

Note:

Take care that the lead wire with connector (W700) is

not caught when fi tting the KRK-6DH main panel on the

transceiver.

4. Affixing the sheet (G11-4379-04) for the waterproof

(Fig.3-1-2).

(1) Remove the covering paper of the sheet w.

(2) Affi x the sheet while taking note of the position of the

three parts as shown in Fig.3-1-2 e.

Firmly affi x the sheet to the chassis by pushing the

double-coated tape with your fi ngers.

(3) Repeat step (2) to affi x the sheet to the other side of

chassis.

Note:

The sheet cannot be reused. Affix a new sheet when

you removed the sheet.

5. Reassemble the upper case and lower case of the trans-

ceiver. (Refer to page 18)

Note:

Take care that the sheet (G11-4379-04) is not peeled off

when installing the upper/lower case.

Transceiver

CN503

:

W104

CN4

CN5

KRK-6DH

main panel

W700

:

Fig. 3-1-1

KRK-6DH main panel

@

Affix the sheet while

taking note of the position

of the three parts.

.

Fig. 3-1-2

3-2. Installing two KRK-6DH rear panels onto two

front panel kits

Install each KRK-6DH rear panel onto each front panel

kit as same as “2-2.Install the KRK-5 rear panel onto the

front panel kit” described on page 14.

3-3. Control cable (KCT-22) connection (Fig. 3-2)

1. Use two control cables. Insert one connector of the one

control cable to the transceiver (with KRK-6DH) and the

other to the display 1.

Insert one connector of the other control cable to the

transceiver (with KRK-6DH) and the other to the display 2.

Connect each cable to the GND terminal with the screws

supplied with each control cable.

q

2. Secure the one connector of each control cable to the

KRK-6DH main panel with two screws w according to

the installation condition of the transceiver. Pass the control cables through the grooves at both ends of the KRK6DH main panel and secure the control cables to the

KRK-6DH with the cable fitting (J21-4354-04) and two

screws e supplied with the KRK-6DH.

3. Secure the other connectors of the control cables to the

display 1 and display 2 with two screws r in the same

way.

15

TK-5810(BG)/5810H(BG

)

INSTALLATION

Transceiver

KRK-6DH

main panel

.

Cable

fitting

@

:

Display 1

GND

:

GND

@

.

Display 2

Cable

fitting

KCT-22

Control cable

:

GND

;

4. Ignition Sense Cable (KCT-18: Option)

The KCT-18 is an optional cable to use the following func-

tions:

• Ignition function

The ignition function allows you to turn the transceiver's

power on and off with the ignition key of your car. When

you are driving with the ignition key on, the horn alert function is disabled.

• Timed power-off function

The timed power-off function turns the transceiver's

power off the time specified with the programming software (KPG-95DG) after the ignition key is turned off. When

you are driving with the ignition key on, the horn alert function is disabled.

The ignition sense function and the timed power-off

function can be used at the same time.

KCT-22

Control cable

Fig. 3-2

:

GND

;

4-2. Connecting the KCT-18 cable to the

KRK-5/6DH remote kit

1. Remove the square plug from the accessory connector

(12-pin) on the rear of the control head.

2. Cut off the end of the rubber cap (accessory), insert the

KCT-18 lead terminal into the rubber cap, and insert it

into pin 1 (IGN) of the square plug.

3. Connect the square plug and rubber cap to the accessory

connector (12-pin) on the rear of the control head, then

clamp the bottom of the rubber cap with the supplied tie

wrap.

Note:

You must setup using the KPG-95DG.

Square plug

(12-pin)

3

1

Rubber cap

4-1.

Connecting the KCT-18 cable to the transceiver

1. Remove the short plug from the accessory connector (9pin) on the rear of the transceiver.

2. Insert the KCT-18 lead terminal into pin 1 (IGN) of the

short plug (9-pin).

3. Connect the short plug to the accessory connector (9-pin)

on the rear of the transceiver.

Note:

You must setup using the KPG-95DG.

16

12

Short plug

(9-pin)

7

9

1

3

10

KCT-18

Fig. 4-1 Fig. 4-2

Tie wrap

Cut

KCT-18

TK-5810(BG)/5810H(BG

INSTALLATION

)

5. Voice Guide & Storage Unit

(VGS-1: Option)

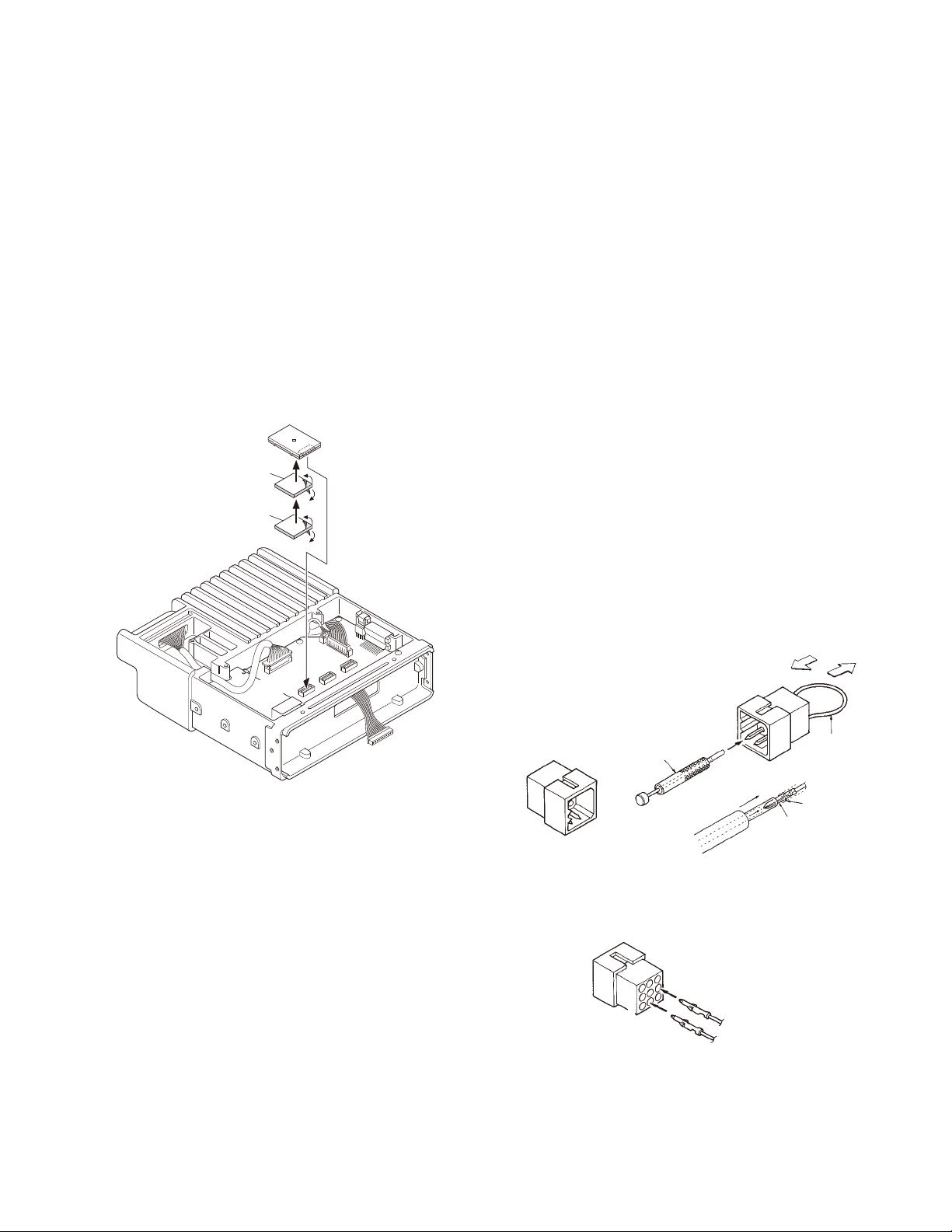

5-1. Installing the VGS-1 unit in the transceiver

1. Remove the upper case and upper packing of the transceiver.

2. Attach two cushions to the VGS-1 as shown in fi gure.

Note:

Be sure not to cover the VGS-1 connector (CN1) with the

cushion.

3. Insert the VGS-1 connector (CN1) into the control unit

connector (CN411).

Note:

You must setup using the KPG-95DG.

VGS-1

Cushion

(G13-1992-04)

21 x 21 x 2.5mm

Cushion

(G13-1974-04)

21 x 21 x 1.0mm

CN1

6-1. Connecting the KES-5 external speaker to the

transceiver

• When taking the AF output from the accessory connector (9-pin) on the rear of the transceiver

The following tools are required for changing the connec-

tor.

Extracting tool

The following extracting tool is recommended :

Molex Inc. Order No.: 11-03-0002

1. Remove the short plug from the accessory connector (9pin) on the rear of the transceiver (Fig. 6-1-1).

Note: Save the jumper, which is required when the trans-

ceiver is used without the external speaker.

2. Remove the terminals with the jumper from the connector housing holes number 3 and 6 using the extracting

tool.

Removing the jumper lead (Fig. 6-1-2)

1) Insert the extracting tool (11-03-0002) into the con-

nector while pushing the jumper lead in the direction

of (a).

2) Push the extracting tool into collapse the barbs of the

crimp terminal.

3) Pull out the lead while continuing to push the extract-

ing tool in the direction (b).

3. Reinsert the terminal with the black and white stripe lead

into hole number 2, and the terminal with the black lead

into hole number 6 (Fig. 6-1-3).

4. Connect the short plug to the accessory connector (9-pin)

on the rear of the transceiver.

(a)

CN411

Fig. 5

6. External Speaker (KES-5: Option)

The speaker output from the transceiver is as follows:

1. The KCH-14 has a built-in speaker (3W/8 ohms).

2. The KCH-15 does not have a built-in speaker.

3. The external speaker output from the accessory connector (9-pin) on the rear of the transceiver is 13W/4 ohms.

Use the KES-5.

4. The speaker output from the accessory connector (12pin) on the rear of the control head is 2W/4 ohms. If the

remote kit (KRK-5, KRK-6DH) is used, use the KES-5.

Note:

Since the transceiver uses a BTL audio amplifi er, do not

ground the speaker output pin.

Short plug

(E37-0733-05)

Extracting tool

(11-03-0002)

Crimp terminal

Fig. 6-1-1 Fig. 6-1-2

Short plug

(9-pin)

1

7

9

2

To KES-5

6

Black/White lead

Black lead

Fig. 6-1-3

(b)

Jumper lead

Barbs

17

TK-5810(BG)/5810H(BG

)

INSTALLATION

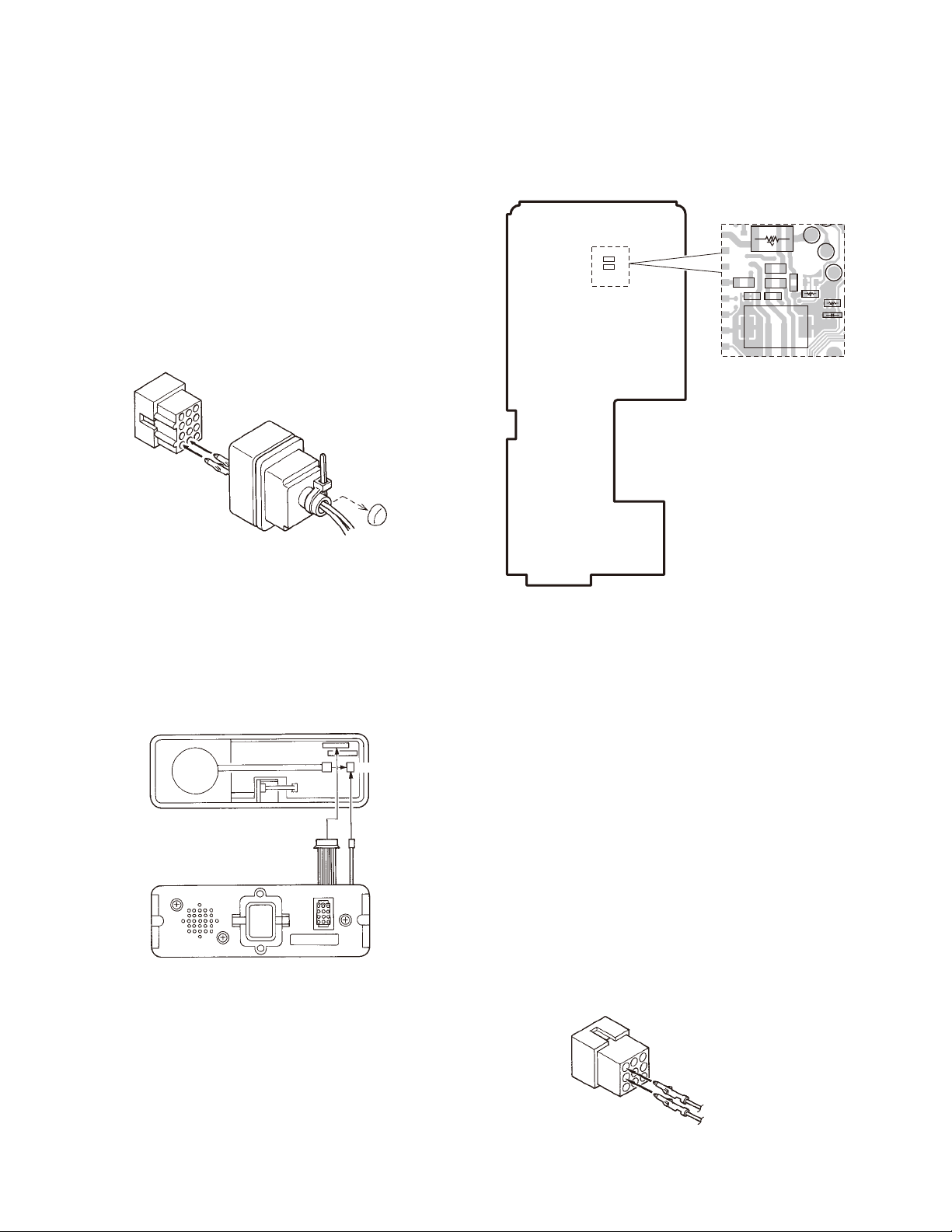

6-2. Connecting the KES-5 external speaker to the

KRK-5/6DH remote kit

• When taking the AF output from the 12-pin accessory connector on the rear of the control head

• Modifi cation of plug (12-pin)

1. Remove the square plug from the accessory connector

(12-pin) on the rear of the control head.

2. Cut off the end of the rubber cap, insert the KES-5

speaker cable into the cap, and insert it into pins 10 and

11 of the square plug.

3. Connect the square plug and rubber cap to the accessory

connector (12-pin) on the rear of the control head, then

clamp the bottom of the rubber cap with the supplied tie

wrap.

Square plug (12-pin)

11

10

Rubber cap

Tie wrap

Cut

Speaker cable

(To KES-5)

Fig. 6-2-1

Note:

Even if the KRK-6DH is modifi ed in this way, the audio

output of head 2 cannot be increased.

SB

ES2

$R73

R74

CN2

KCH-14

DISPLAY UNIT (X54-349 A/3)

Foil side view

NC

• If the KCH-14 is used

If the KES-5 is connected to the 12-pin accessory con-

nector, remove the internal speaker wire.

If the internal speaker is used, remove the wire connect-

ed to pins 10 and 11 of the 12-pin accessory connector.

KCH-14

CN3

SP

CN1

Rear of the control head

CN2

Fig. 6-2-2

6-3. Modifi cation to increase the audio output of

the control head

The speaker output can be increased to 13W by moving

jumper resistor (0 ohm) R74 to $R73 on the KCH-14 display

unit (X54-349 A/3). In this case, the KCH-14 internal speaker

cannot be used because the maximum input (3W) of the internal speaker is exceeded. Therefore, use the KES-5.

18

Fig. 6-3

6-4. Use as public address speaker

1. Remove the short plug from the 9-pin accessory connector on the rear of the transceiver. (Remove the jumper

lead as described in Section 6-1 on page 17.)

2. Insert the KES-5 speaker leads into pins 7 and 8 of the

short plug.

3. If you remove jumper shorting pins 3 and 6, the 20W PA

(public address) voice signal is output from pins 7 and 8.

(Only when the PA or SP switch is on.)

4. If you use the transceiver shorted with pins 3 and 6, the

internal speaker is available (when the KCH-14 is used).

The KCH-15 does not contain a speaker.

Note:

Relationship between accessory connector (9-pin) con-

nection and speaker output.

When pins 3 and 6 are shorted; The 3W internal speaker

is used (KCH-14 only).

When pins 3 and 6 are opened and is output from pins 7

and 8; The 20W external speaker is used.

Short plug (9-pin)

7

8

Crimp terminal

(E23-0613-05)

To KES-5

Black lead

Black/White lead

Fig. 6-4

TK-5810(BG)/5810H(BG

INSTALLATION

)

7. Horn Alert Function

The HR1 and HR2 pins of the accessory connector (9pin) on the rear of the transceiver are connected to the relay

(K500) and the maximum current is 1A.

1. Remove the upper case of the transceiver.

2. To make the HR2 pin, remove the jumper resistor (0

ohm) R634 on the control unit (X53-440) as shown in

Table 1.

3. Reassemble the PC board and the upper case.

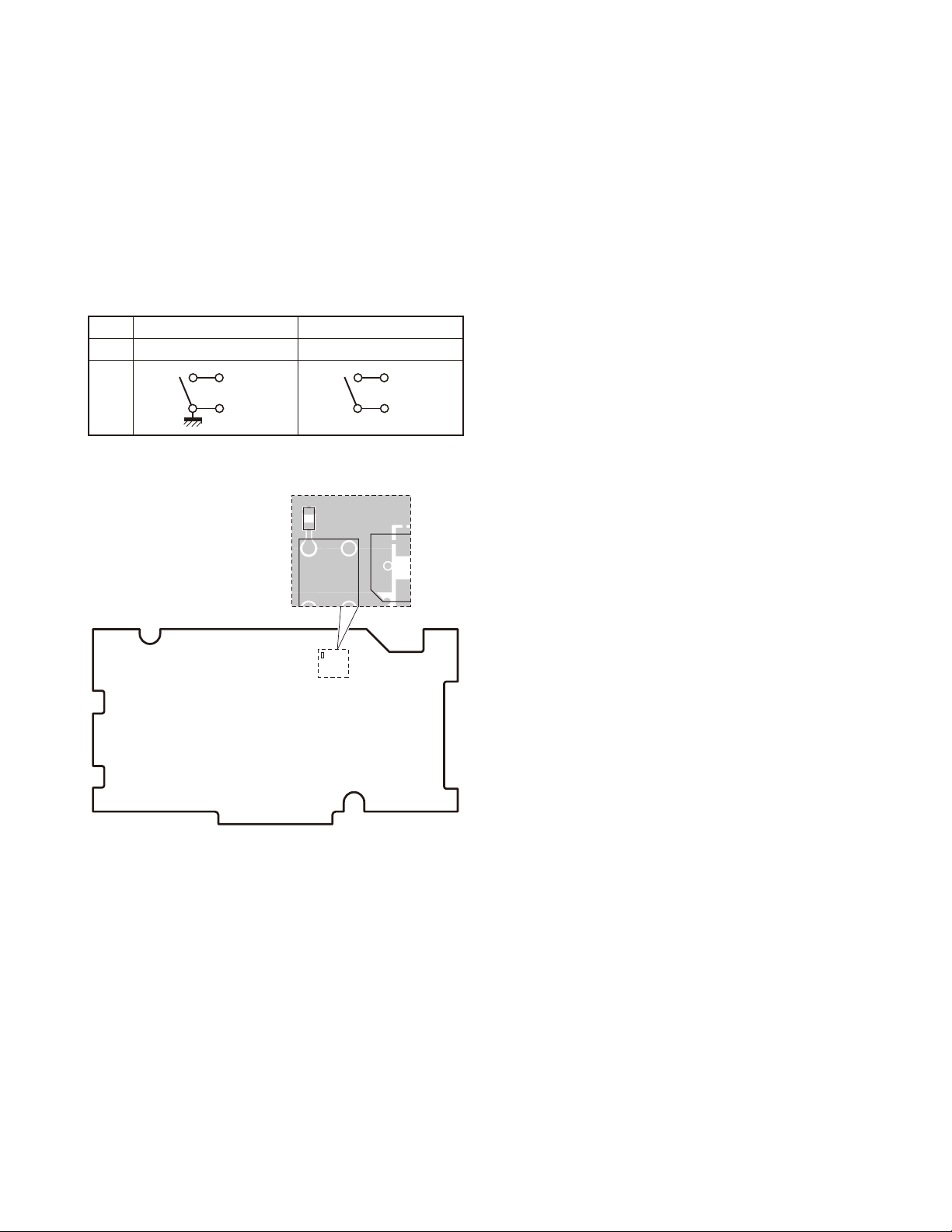

Default Modifi cation

R634 Present Absent

State

HR1

HR2

Table 1

R634

K500

HR1

HR2

C6

8. Handheld control head

(KCH-16: Option)

The KCH-16 Handheld control head is used to remotely

operate the transceiver.

See the service manual No. B51-8834-00

CONTROL UNIT (X53-440)

Component side view

Fig. 7

19

TK-5810(BG)/5810H(BG

)

DISASSEMBLY FOR REPAIR

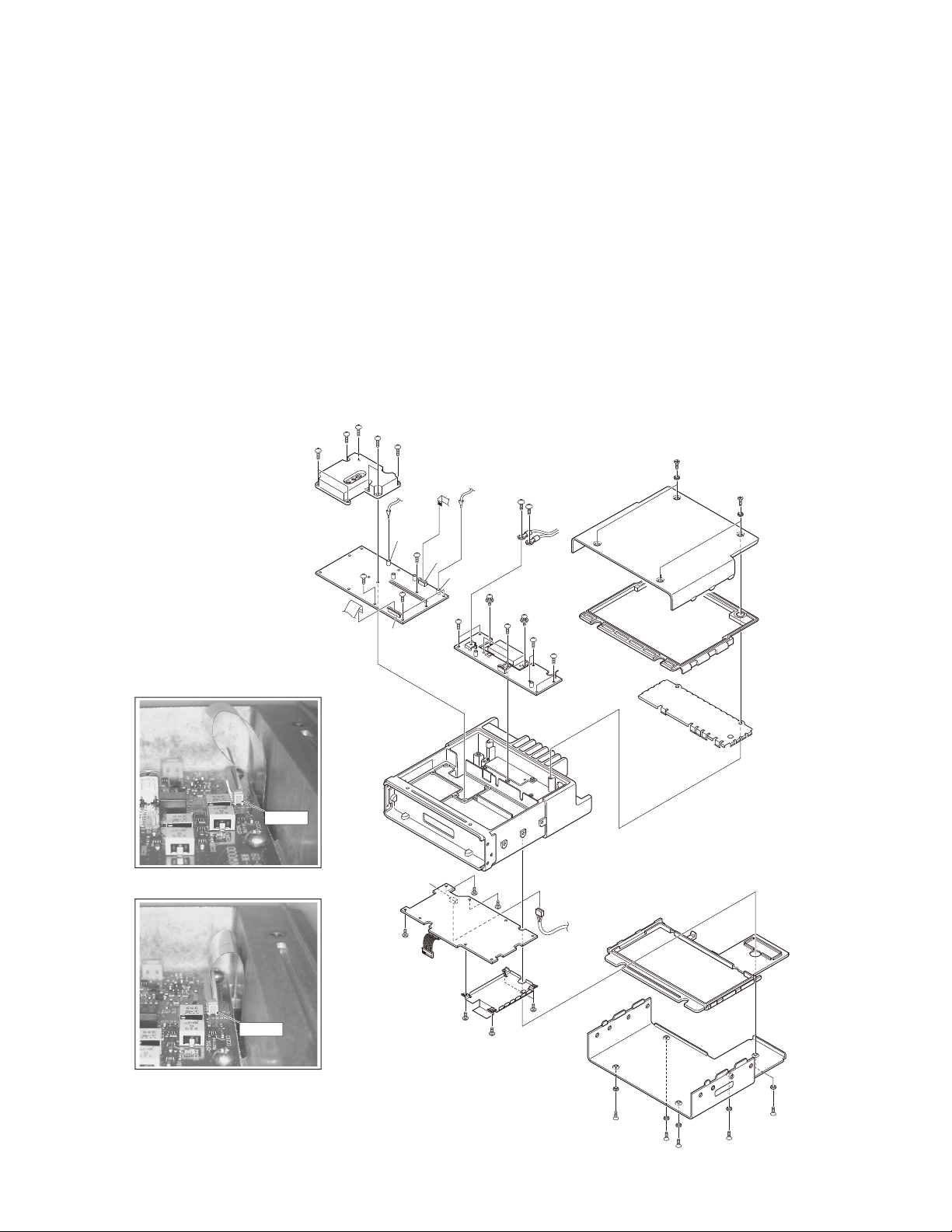

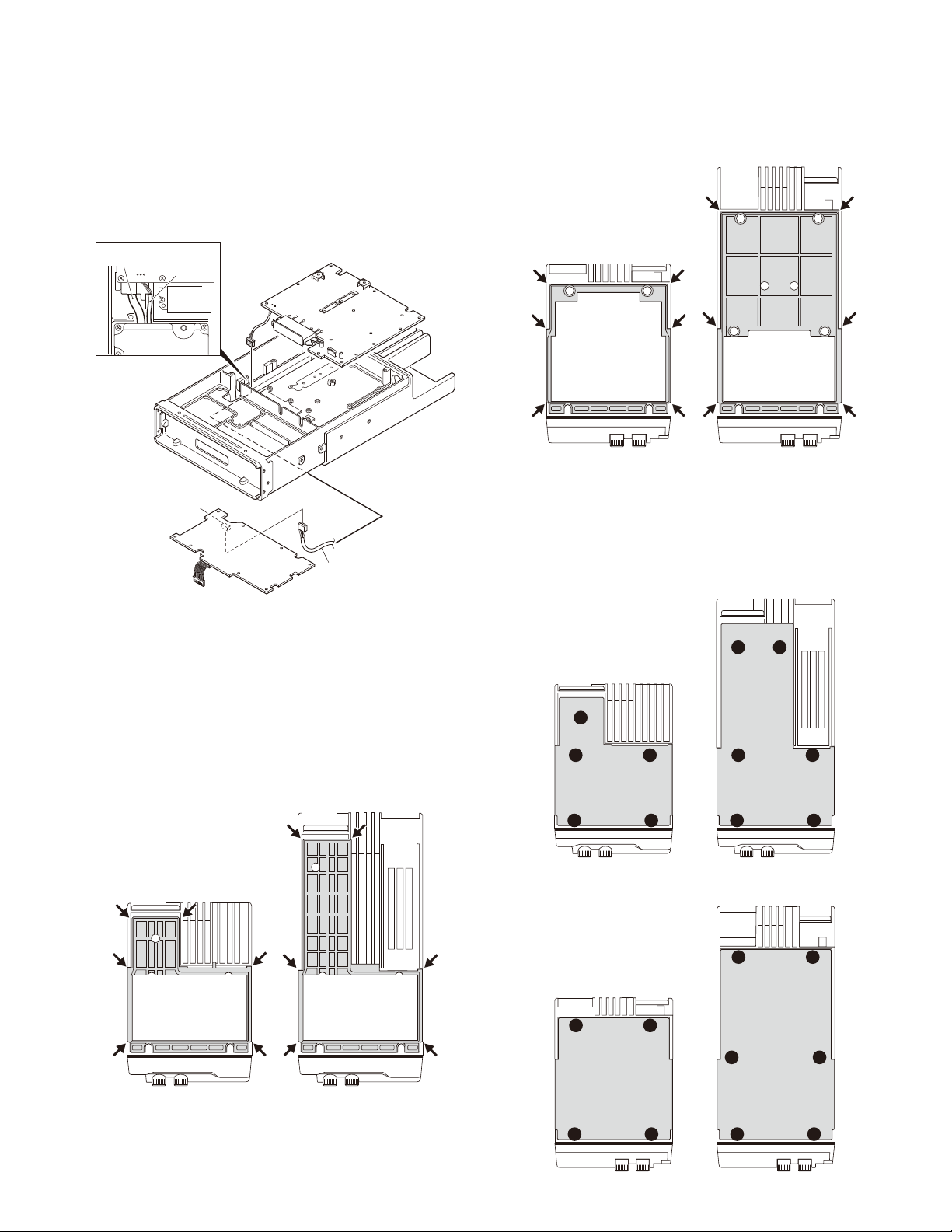

Disassembly Procedure (TK-5810(BG))

Removing the upper/lower case and shielding cover

■

1. Remove the 9 screws q and 9 spacers w.

2. Remove the upper case e and lower case r.

3. Remove the upper packing t and lower packing y.

4. Remove the shielding cover u.

Removing the TX-RX unit (X57-727)

■

1. Remove the 7 screws i holding the PLL shielding cover.

2. Remove the PLL shielding cover o.

3. Remove the coaxial cables from the two connectors

(CN151 and CN200) of the TX-RX unit !0.

4. Remove the fl at cables from the two connectors (CN600

and CN601) of the TX-RX unit !1.

2

2

2

2

TX-RX

unit

8

2

CN151

CN601

CN600

CN200

Note:

When re-installing the fl at cable to the connector on the

CN600 side, do not align the cable as shown in the fi gure

1, as there is a possibility of producing an effect on the

sensitivity of P25.

5. Remove the 5 screws !2.

Removing the Final unit (X45-379)

■

1. Remove the cables from the connector (CN1) of the control unit !3.

2. Remove the 2 screws !4 holding the power module.

3. Remove the solder of the power module with a solder

absorber.

4. Remove the 2 screws !5 holding the + (positive) terminal

and – (negative) terminal of the power supply cable.

5. Remove the 8 screws !6 holding the fi nal unit.

6. Remove the solder of the antenna receptacle with a solder absorber.

:

@

;

B

:

@

Wrong

Right

CN600

CN600

CN1

Control

unit

Final unit

>

=

.

@

@

2

:

@

:

:

:

@

@

:

20

TK-5810(BG)/5810H(BG

DISASSEMBLY FOR REPAIR

)

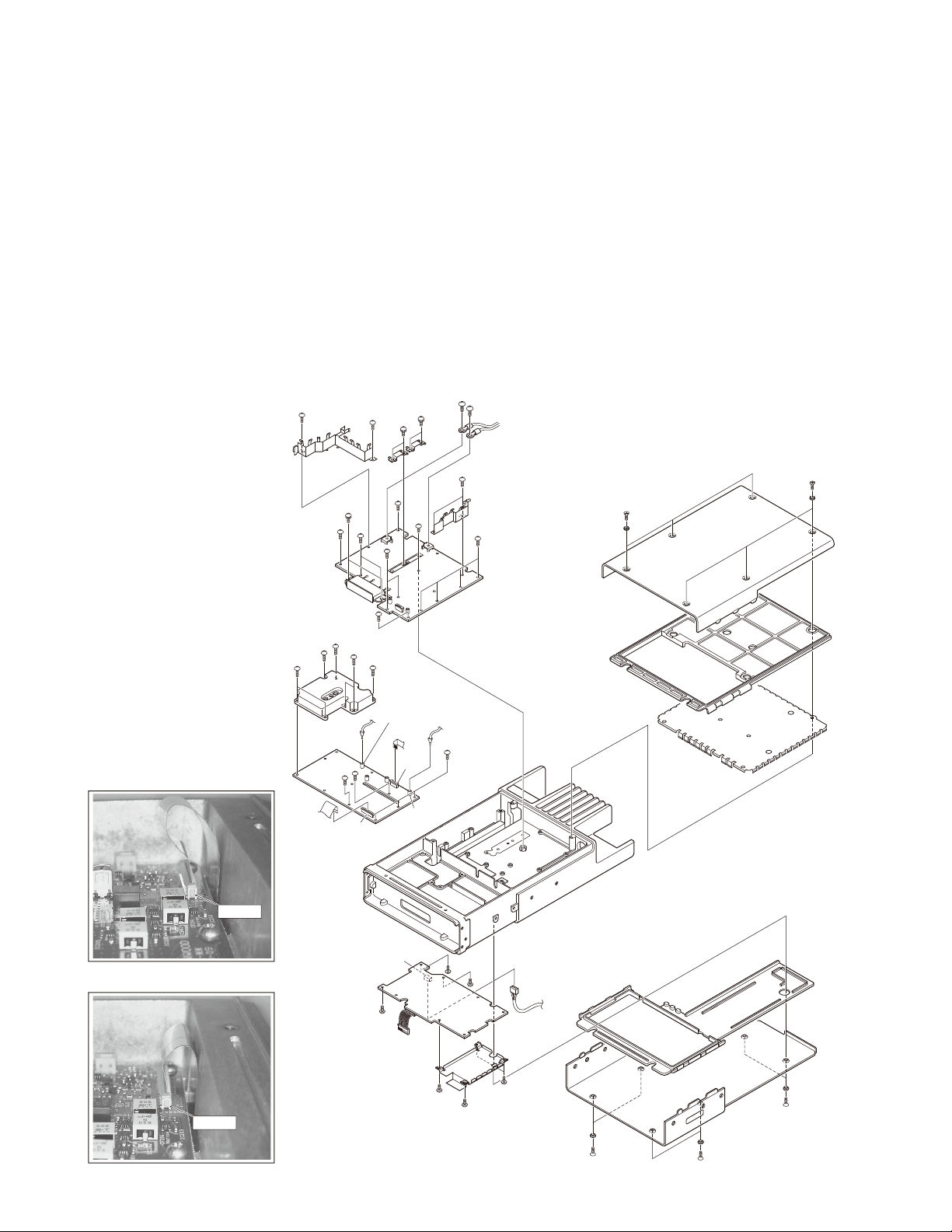

Disassembly Procedure (TK-5810H(BG))

Removing the upper/lower case and shielding cover

■

1. Remove the 12 screws q and 12 spacers w.

2. Remove the upper case e and lower case r.

3. Remove the upper packing t and lower packing y.

4. Remove the shielding cover u.

Removing the TX-RX unit (X57-727)

■

1. Remove the 7 screws i holding the PLL shielding cover.

2. Remove the PLL shielding cover o.

3. Remove the coaxial cables from the two connectors

(CN151 and CN200) of the TX-RX unit !0.

4. Remove the fl at cables from the two connectors (CN600

and CN601) of the TX-RX unit !1.

Note:

When re-installing the fl at cable to the connector on the

CN600 side, do not align the cable as shown in the fi gure

1, as there is a possibility of producing an effect on the

sensitivity of P25.

5. Remove the 5 screws !2.

Removing the Final unit (X45-380)

■

1. Remove the cables from the connector (CN1) of the control unit !3.

2. Remove the 2 screws !4 holding the power module.

3. Remove the solder of the power module with a solder

absorber.

4. Remove the 4 screws !5 holding the two final transistors.

5. Remove the 2 screws !6 holding the + (positive) terminal

and – (negative) terminal of the power supply cable.

6. Remove the 16 screws !7 holding the fi nal unit.

7. Remove the solder of the antenna receptacle with a sol-

der absorber.

:

@

;

:

@

Wrong

Right

CN600

2

2

8

TX-RX

unit

2

CN600

CN200

Final unit

Control

unit

B

>

=

2

2

CN151

CN601

CN1

CN600

.

@

:

@

:

@

:

21

TK-5810(BG)/5810H(BG

)

DISASSEMBLY FOR REPAIR

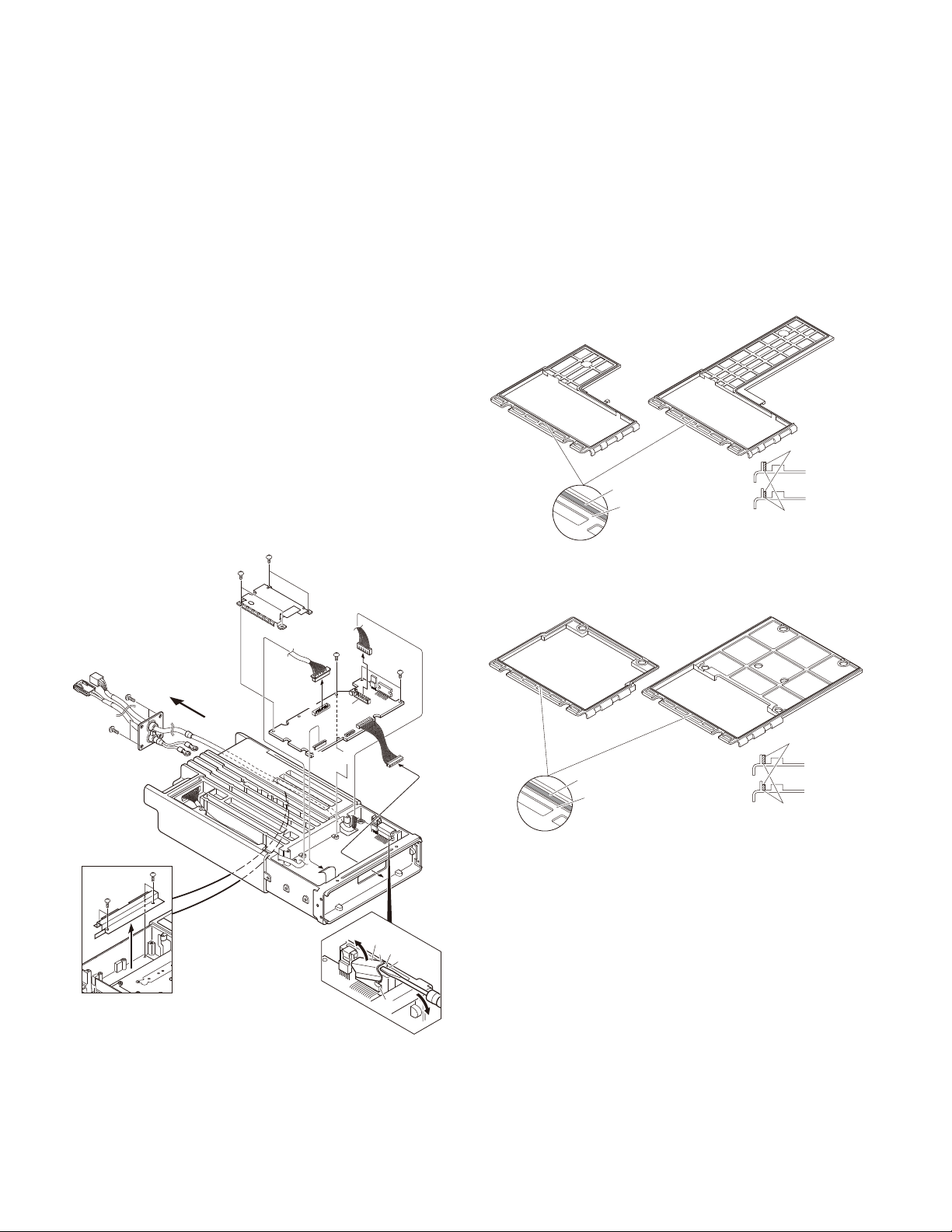

Disassembly Procedure (TK-5810(BG)/5810H(BG))

Removing the Control unit (X53-440)

■

1. Remove the 7 screws q.

2. Remove the shielding plate w.

3. With a fl at-head screwdriver, remove the 2 fl at springs

holding the ICs (IC5 and IC522) e.

4. Remove the fl at cable from the connector (CN501) r.

5. Remove the cables from the two connectors (CN459 and

CN502) t.

Removing the accessory cable and power sup-

■

Precautions for Reassembly

■

Paint the lubricant to the position as shown in fi gure af-

Note:

To assure waterproofing, paint the lubricant on the

• Case packing (Upper)

TK-5810 TK-5810H

ply cable on the rear of the transceiver

1. Confi rm the following contents.

• The screws holding the + (positive) terminal and –

(negative) terminal of the power supply cable is removed.

• The cable from the connector (CN502) of the Control

unit is removed.

2. Remove the 4 screws y holding the shielding plate,

and remove the shielding plate u from the chassis (TK5810H(BG) only).

3. Remove the 4 screws i on the rear of the transceiver.

4. Pull out the power supply cable and accessory cable.

:

:

• Case packing (Lower)

@

:

:

=

2

2

B

B

>

CN459

=

CN502

CN501

;

TK-5810 TK-5810H

Painting the lubricant (Part No.: 410-0019-05) on

the groove of the case packing

ter replacing or assembling the case packing.

groove of the case packing.

lubricant

lubricant

case packing

Paint the lubricant (Part No.410-0019-05)

on the groove of the case packing.

lubricant

case packing

Paint the lubricant (Part No.410-0019-05)

on the groove of the case packing.

OK

NG

OK

NG

groove of the

case packing

lubricant

groove of the

case packing

22

Flat

spring

IC

.

TK-5810(BG)/5810H(BG

DISASSEMBLY FOR REPAIR

)

Align the cable connecting the W2 terminal:

■

TK-5810H(BG) only

When you assemble the fi nal unit, align the cable con-

necting the W1 terminal as shown in fi gure, then insert it

into the connector (CN1) of the control unit.

Accessory

cable

W1 terminal

cable

CN1

W1

Control

unit

Final unit

W1 terminal

cable

• Case packing (Lower)

TK-5810H

TK-5810

Sequence of tightening the screws for the up-

■

per/lower case to the chassis

Install the upper/lower case to the chassis and tighten

the screws in the order shown in the fi gure below.

• Case case

TK-5810H

Procedures after installing the case packing to

■

the chassis

After installing the case packing to the chassis, confi rm

that all corners of the upper/lower packing are securely

fi tted to the chassis. Place are shown in the arrow in the

fi gure below.

• Case packing (Upper)

TK-5810H

TK-5810

TK-5810

3

1 2

•Lower case

TK-5810

3 4

5 6

5

4

3

1 2

TK-5810H

5 6

3 4

4

1 2

1 2

23

TK-5810(BG)/5810H(BG

)

CIRCUIT DESCRIPTION

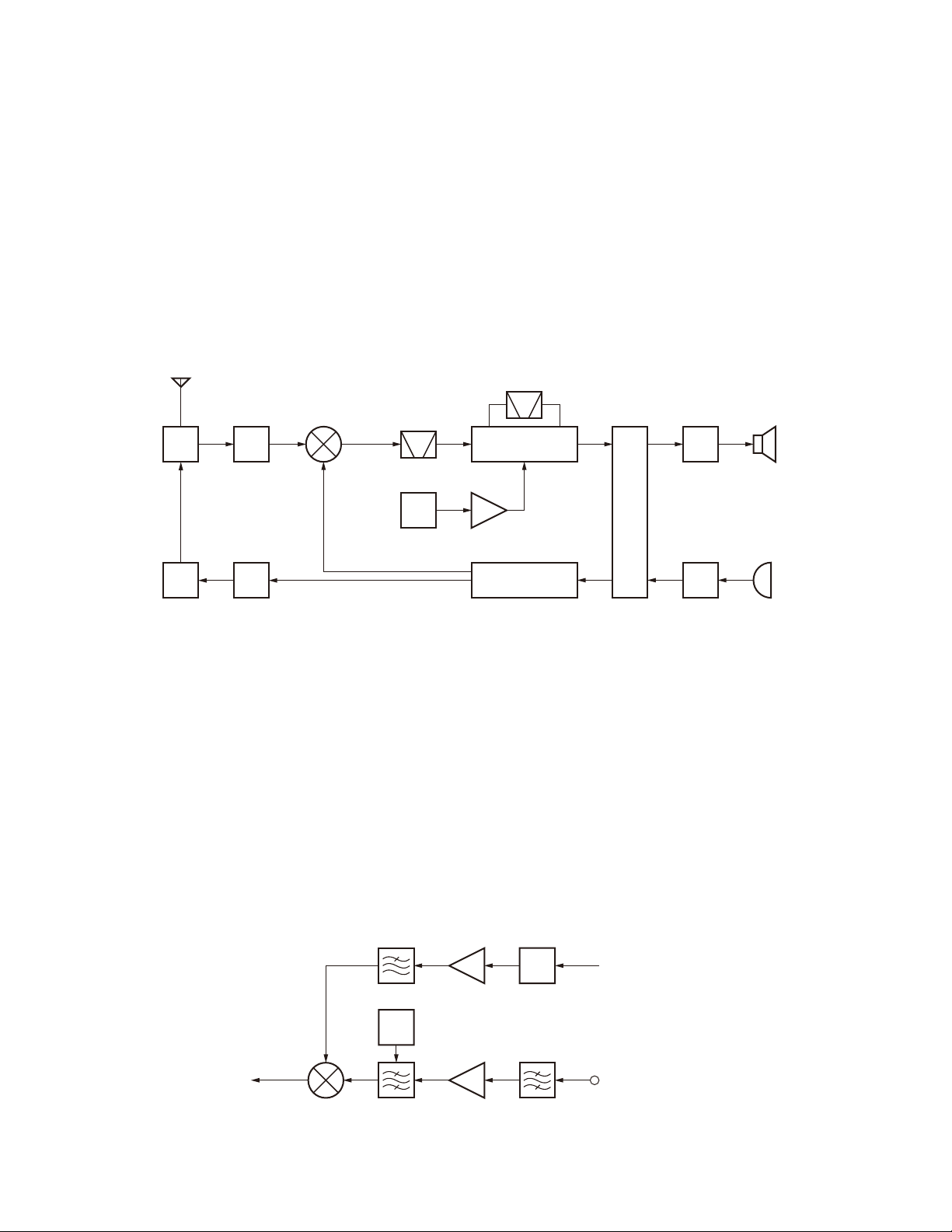

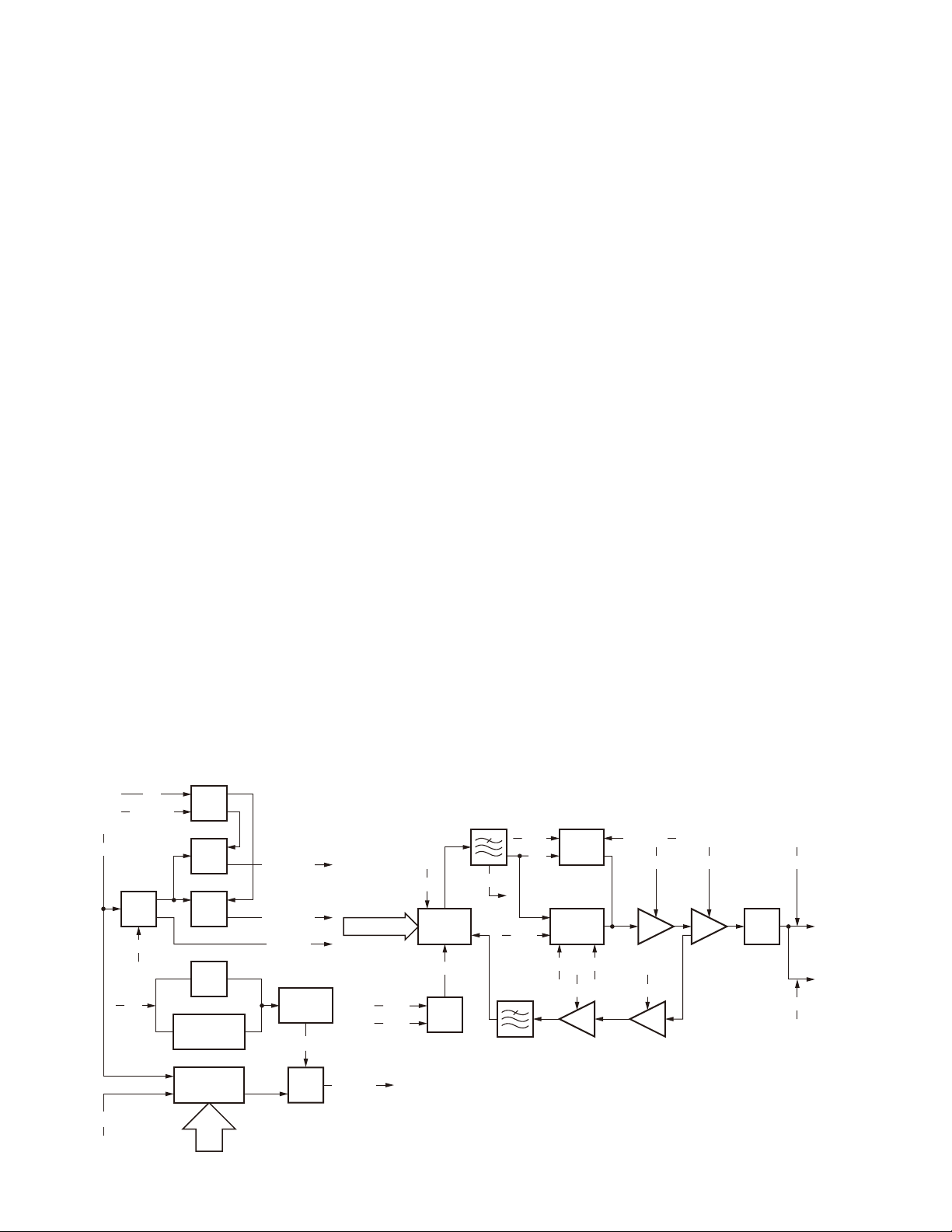

1. Overview

This transceiver is a UHF/FM/P25 transceiver designed

to operate in the frequency range of 450 to 520MHz (K) or

400 to 470MHz (K2).

The unit consists of receiver, transmitter, phase-locked

loop (PLL) frequency synthesizer, base band parts, power

supply, and control circuits.

ANT

TX/RX: 450~520MHz (K)

TX/RX: 400~470MHz (K2)

ANT

SW

PA

AMP

RF

AMP

TX

AMP

1st MIX

400.05~470.05MHz(K)

350.05~420.05MHz(K2)

450~520MHz (K)

400~470MHz (K2)

MCF

49.95MHz

16.8MHz

VCXO

2. Frequency Confi guration

The receiver is a double-conversion superheterodyne

using fi rst intermediate frequency (IF) of 49.95MHz and second IF of 450kHz. Incoming signals from the antenna are

mixed with the local signal from the PLL circuit to produce

the fi rst IF of 49.95MHz.

This is then mixed with the 50.4MHz second local oscillator output to produce the 450kHz second IF. This signal is

detected to give the demodulated signal in the DSP.

The transmit signal frequency is generated by the PLL

VCO, and modulated by the signal from the DSP. It is then

amplifi ed and fed to the antenna.

CF

450kHz

SP

MIX

IF AMP

x3

50.4MHz

PLL

VCO

ASIC

A/D

D/A

DSP

AF

AMP

MIC

MIC

AMP

Fig. 1 Frequency confi guration

3. Receiver System

3-1. Front-end RF Amplifi er

The receive signal from the RX terminal (CN200) of the

TX-RX unit (X57-727) is amplifi ed by a transistor (Q200) and

passes through the band-pass fi lter (L207, L208, L209 and

L210) to remove unwanted signal.

The signal passing through the band-pass fi lter goes into

the 1st mixer.

These band-pass fi lters are tuned to a desired frequency

by variable capacitance diode (D204, D205, D206 and D207).

Local AMP

LPF

D204,D205,D206,D207

VC

TUNE

1st MIXER

1st IF

49.95MHz

IC200

BPF

L207,L208,L209,L210

Q203

RF AMP

Q200

LNA

A tuning voltage corresponding to the desired signal is

applied to each variable capacitance diode to tune to the receive frequency.

3-2. 1st Local

The 1st mixer uses double balanced mixer (IC200).

The receive signal passing through the band-pass fi lter

(L207, L208, L209 and L210) and the 1st local signal generated by the VCO, are mixed by the 1st mixer (IC200) to produce a 1st IF signal (49.95MHz) (Lower heterodyne).

VCO

1st Local OSC

400.05~470.05MHz (K)

350.05~420.05MHz (K2

RX terminal (CN200)

450~520MHz (K)

400~470MHz (K2)

)

24

Fig. 2 Front-end RF amplifi er and 1st local

TK-5810(BG)/5810H(BG

CIRCUIT DESCRIPTION

)

3-3. 1st IF

The 1st IF signal passes through the MCF (Monolithic

Crystal Filter) to remove unwanted signal.

The MCF has two paths (Wide band: XF201, Narrow

band: XF200), and these are controlled with the IF filter

switch (D208, D209, D210, D211, D212, D213, D214 and

D215).

The signal passes through the MCF (XF201) when the

Wide band (D209, D211, D213 and D215 are ON) is selected. The signal passes through the MCF (XF200) when

the Narrow band (D208, D210, D212 and D214 are ON) is

selected.

2nd IF

450kHz

2nd Local

50.40MHz

IC209

FM IC

Tripler

Q207

Q205 Q204

VCXO

D214

D215

X200

16.8MHz

WIDE

XF201

NARROW

XF200

SW

Fig. 3 1st IF and 2nd local

The 1st IF signal passing through these MCFs is amplified by the IF amplifier (Q205) and goes into the FM IC

(IC209).

3-4. 2nd Local

The 1st IF signal (49.95MHz) amplifi ed by the IF amplifi er (Q205) and the 2nd local signal (50.4MHz) generated by

tripling the reference oscillator frequency (16.8MHz) of the

VCXO (X200) by Q207, are mixed in the FM IC (IC209) to

produce a 2nd IF signal (450kHz) (Upper heterodyne).

WIDE

XF201

D212

D213

SW

D210

D211

SW

NARROW

XF200

D208

D209

SW

1st IF

49.95MHz

3-5. 2nd IF

The 2nd IF signal passes through the ceramic fi lter to re-

move unwanted signal.

The ceramic fi lter has two paths (Wide band: CF201 and

CF202, Narrow/P25 band: CF200 and CF204), and these

are controlled with the multiplexers (IC201, IC202, IC203,

IC205, IC206 and IC207).

The control line is W/N1, W/N2 and VN.

WIDE

CF201

IC205

W/N2 W/N2

SW

IC206

SW

NARROW/P25

CF200

DET

L234

FM/P25 DET

DET

COIL

IC201

SW

IC202

SW

The signal passes through the ceramic fi lters (CF201 and

CF202) when the Wide band (W/N1: high level, W/N2: high

level, VN: high level) is selected. The signal passes through

the ceramic filters (CF200 and CF204) when the Narrow/

P25 band (W/N1: low level, W/N2: low level, VN: high level)

is selected.

After that, the signal is fed into ASIC (IC708) through ceramic fi lter (CF100), and then, the signal is demodulated in

ASIC and the AF signal is dealing with DSP (IC701).

WIDE

CF202

W/N1 W/N1

IC203

SW

NARROW

CF204

IC209

FM IC

IC207

SW

2nd Local OSC

2nd IF

450kHz

50.4MHz

1st IF

49.95MHz

Fig. 4 2nd IF

25

TK-5810(BG)/5810H(BG

)

CIRCUIT DESCRIPTION

3-6. Audio Amplifi er Circuit

Audio processing (high-pass filter, low-pass filter, deemphasized and so on) at FM mode and decoding at P25

mode are processed by DSP. Audio signal from IC708,

IC701 goes through Low-pass fi lter (IC503). The signal then

goes through mute switch (IC506), amplifier (IC510), and

switch (IC515), and electronic volume control (IC517), and

pre-amp (IC516), and audio mute switch (Q506), and audio

route switch (IC518), and audio power amp (IC522).

While busy, /SPK_MUTE becomes High, turn Mute

switch (Q506) off, and signal is fed to AF Power Amp (IC522).

While Non-busy, /SPK_MUTE is become Low, turn Mute

switch (Q506) on, then there is not AF output.

IC708

ASIC

DSP

IC701

IC503 IC506 IC510 IC515 IC517 IC516 Q506 IC518

LPF

SW

AMT /SCSW DBSW /SPK_MUTE PA

SW DAC SW SW

Fig. 5 Audio Amplifi er circuit

3-7. Squelch Circuit

It amplifies the demodulated noise signal from FM IC

(IC209) after fi ltering through BPF circuit. Then, the amplifi ed signal is converted to DC signal by the detection circuit.

The converted signal is fed to the ASIC (IC708).

IC209

FM IC

Q211

Noise Amp

D216

DET

IC708

ASIC

Fig. 6 Squelch circuit

IC522

Int/Ext

SP

PA

SPIC522

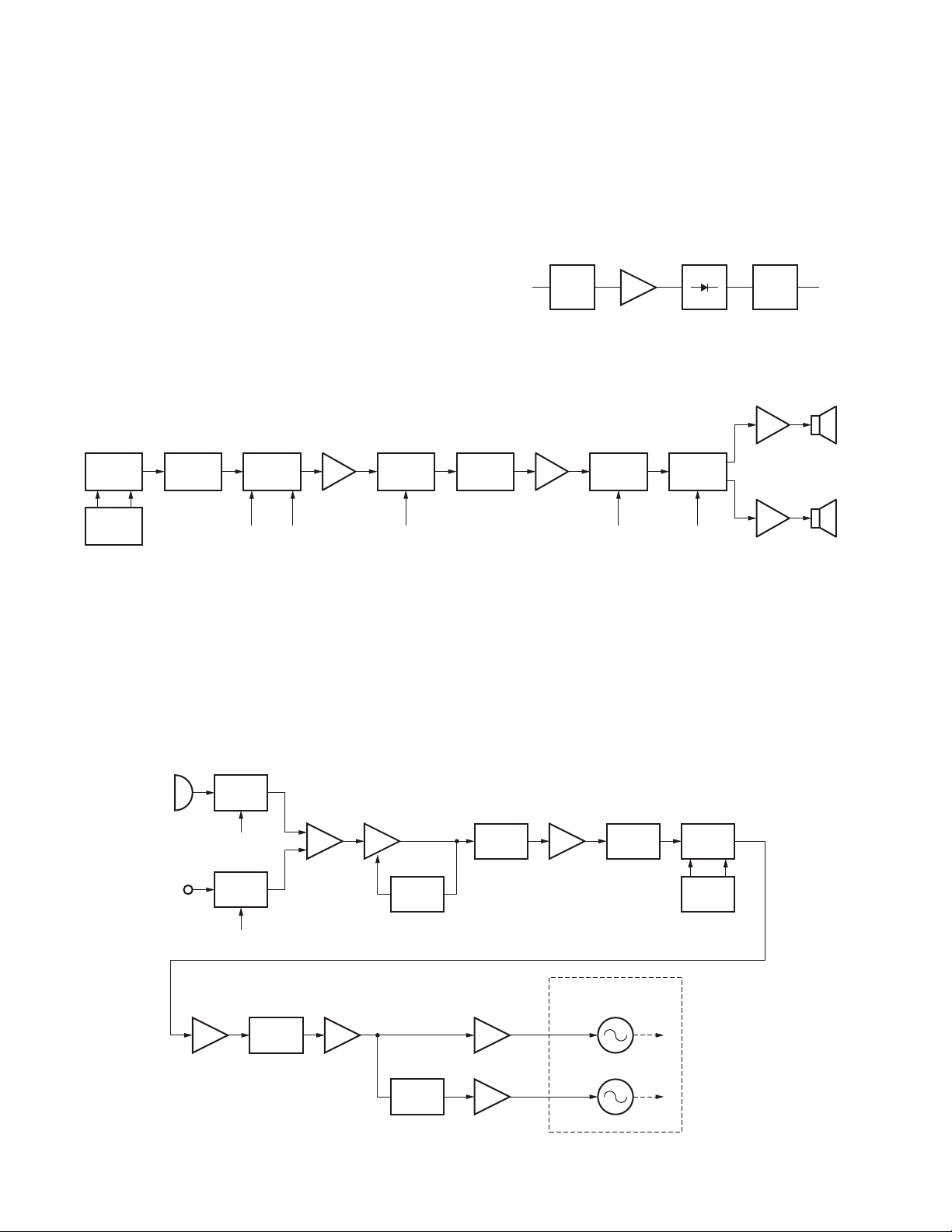

4. Transmitter System

4-1. Audio Band Circuit

The signal from the microphone goes through the mute

switch (Q503), the MIC-Mute signal (MM) becomes Low,

and then mute switch (Q503) is turned off. The signal

MIC

MI2

Q503

SW

IC512

MM

Q505

SW

MM2

IC502 IC514 IC519 VCXO

IC514

LPF

IC512

DET

D500,D501

Q501,Q502

IC517

DAC

from microphone goes through summing-Amp (IC512) and

MIC-AGC (IC512, Q501, Q502, D500 and D501), and goes

through audio route switch (IC509), and amplifi ed by MICAmp IC505. LPF IC501 works as anti-aliasing fi lter.

IC509

SW

IC524

IC505

IC501

LPF

TX-RX UNIT

VCO

IC708

ASIC

DSP

IC701

26

Fig. 7 Audio band and Base band circuit

TK-5810(BG)/5810H(BG

CIRCUIT DESCRIPTION

)

4-2. Base Band Circuit

The audio signal output from the base band circuit is

converted by ASIC (IC708) to digital data of a sampling frequency of 48 kHz. This digital data is sent to the DSP (IC701)

and voice signals of 300Hz or lower and frequencies of

3kHz or higher are cut off and an audio range 300Hz to 3kHz

is extracted. The audio signal is then pre-emphasized in

FM mode and synthesized with the signals, such as QT and

DQT, as required, and is then output from the ASIC (IC708).

In P25 mode, the audio signal is converted to the 4-Level

FSK base band signal and output from the ASIC (IC708).

The DTMF, 2tone and MSK base band signals are also generated by the DSP (IC701) and output by the ASIC (IC708).

LPF (IC514) works as smoothing fi lter. The DAC (IC517)

assigns the base band signal to the VCO and VCXO (X400).

At this time, the level output according to the transmit carrier is fi ne-adjusted according to each modulation method.

4-3. Drive Amplifier Circuit (From T/R switch to

Power module)

The transmit signal passing through the T/R switch (D420)

is amplifi ed by the two drive amplifi ers (Q150 and Q151).

The transmit signal from the drive amplifi er (Q151) passes

through a 3dB attenuator and is fed to the power module.

D420

T/R

SW

8T

Drive AMP

Q150

Drive AMP

Q151

3dB

Attenuator

POWER

MODULE

Fig. 8 Drive amplifi er circuit

4-4. Final Amplifi er Circuit (From Power module to

Antenna output): TK-5810(BG)

The transmit signal from the TX terminal (CN1) of the fi -

nal unit (X45-379) is amplifi ed by the power module (IC2).

The signal amplified by the power module passes

through the CM coupler, antenna switch (D1, D12, D3 and

D11) and low-pass fi lter, then it is fed to the antenna.

CM coupler is a line for detecting forward RF power and

refl ected RF power.

Forward RF power is detected by D5, and is converted

into DC voltage. The converted DC voltage is fed to the APC

comparator (IC1), and is compared with the PC voltage, then

is output from the OUT-B terminal (pin 7) of IC1 as an APC

voltage. The APC voltage controls the gate voltage of the

power module (IC2), and keeps transmission output stable.

If an abnormal antenna load is connected, refl ected RF

power is detected by D6, and output voltage (DC voltage) is

fed to the APC comparator (IC1). The transmission output

is reduced more as this DC voltage rises.

FINAL UNIT (X45-379)

TX

(CN1)

+B

IC2

POWER

MODULE

IC1

VR1

PC

D5

FWD

DET

8T

APC

Fig. 9 Final amplifi er circuit: TK-5810(BG)

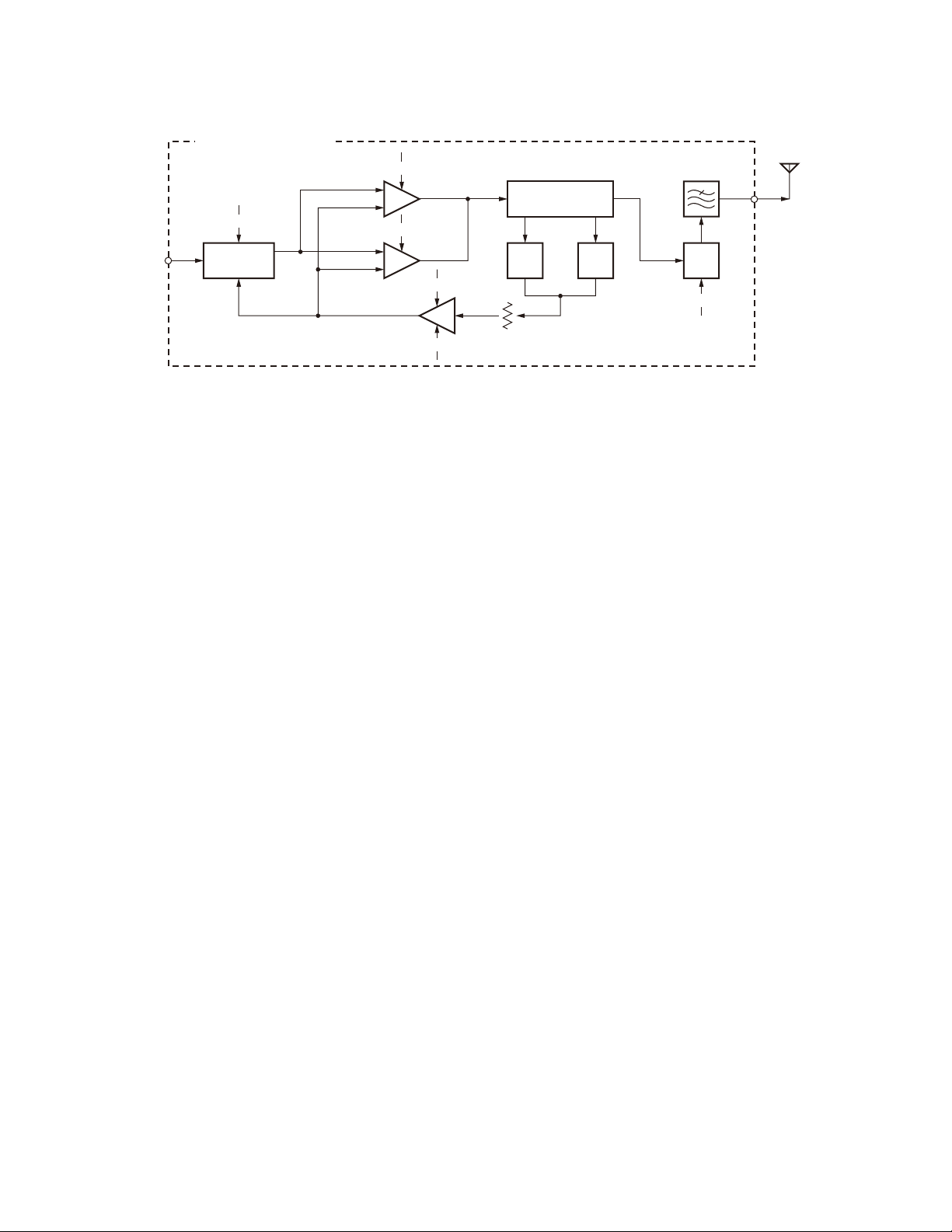

4-5. Final Amplifi er Circuit (From Power module to

Antenna output): TK-5810H(BG)

The transmit signal from the TX terminal (CN1) of the fi -

nal unit (X45-380) is amplifi ed by the power module (IC1).

The signal amplifi ed by the power module is divided into

two signal, and further is amplifi ed by the fi nal amplifi er (Q1

and Q2). The each signal from Q1 and Q2 is combined.

The combined signal passes through the antenna switch

(D5, D6, D7, D8, D15 and D16), CM coupler and low-pass

fi lter, then it is fed to the antenna.

CM coupler is a line for detecting forward wave and refl ected wave.

CM

COUPLER

D6

REFL

DET

D1,D3,D11,D12

ANT

SW

8T

Forward wave is detected by D2, and is converted into

DC voltage. The converted DC voltage is fed to the APC

comparator (IC2), and is compared with the PC voltage,

then is output from the OUT-B terminal (pin 7) of IC2 as an

APC voltage. The APC voltage controls the gate voltage of

the power module (IC1) and fi nal amplifi er (Q1 and Q2), and

keeps transmission output stable.

If an abnormal antenna load is connected, refl ected wave

is detected by D3, and output voltage (DC voltage) is fed to

the APC comparator (IC2). The transmission output is reduced more as this DC voltage rises.

LPF

ANT

27

TK-5810(BG)/5810H(BG

)

CIRCUIT DESCRIPTION

FINAL UNIT (X45-380)

+B

+B

8T

IC2

APC

PC

TX

(CN1)

+B

IC1

POWER

MODULE

Final AMP

Q1

Final AMP

Q2

Fig. 10 Final amplifi er circuit: TK-5810H(BG)

4-6. Automatic Power Control Circuit

The automatic power control (APC) circuit stabilizes the

transmitter output power at a predetermined level and consists of forward/refl ected power detector circuits.

The forward/refl ected power detector circuits detect forward RF power and refl ected RF power to DC voltage, and

consists of a CM coupling type detection circuit formed by a

CM coupler.

The voltage comparator compares the voltage obtained

by the above detected voltage with the PC voltage.

An APC voltage proportional to the difference between

the sensed voltage and the reference voltage appears at the

output of the comparator. This output voltage controls the

gate voltage to the fi nal amplifi er.

4-7. Temperature Protection Circuit: TK-5810(BG)

To prevent thermal destruction of the power module (IC2),

this circuit reduces APC voltage when temperature of the

power module (IC2) rises.

The ASIC (IC708) detects temperature with a thermistor

(TH1 and TH4) and controls reference voltage to the APC

circuit.

4-8. Temperature Protection Circuit: TK-5810H(BG)

To prevent thermal destruction of the power module (IC1)

and fi nal amplifi er (Q1 and Q2), this circuit reduces APC voltage when temperature of the power module (IC1) and fi nal

amplifi er (Q1 and Q2) rises.

The ASIC (IC708) detects temperature with the thermistor (TH1 and TH3) and controls reference voltage to the APC

circuit.

5. PLL Frequency Synthesizer

The PLL Frequency Synthesizer consists of the following

components:

• VCXO (X400)

• VCO (Q413, Q414 and Q415)

• Potentiometer IC (IC401)

• PLL IC (IC400)

• Local switch (D419 and D420)

ANT

LPF

CM

COUPLER

D2

FWD

DET

VR1

This PLL system is composed of a PLL IC (IC400), a crys-

tal oscillator (X400), VCO and a potentiometer IC (IC401).

VCO (Voltage Controlled Oscillator) is provided with 2

input terminals which are controlled by the potentiometer IC

and the PLL IC. The potentiometer IC brings the oscillation

frequency of VCO close to the target frequency, after the

PLL locks it up.

The operation frequency of PLL is from 450 to 520MHz