Kenwood KDC-BT92SD Service manual

SERVICE MANUAL

COPYRIGHT © 2012 JVC KENWOOD Corporation

No.WA020<Rev.001>

2012/4

B53-0929-00

CD RECEIVER

WA020<Rev.001>20124SERVICE MANUALB53-0929-00

KDC-BT92SD, KDC-X8019BT,

KDC-X8019BTL

COPYRIGHT © 2012 JVC KENWOOD Corporation

TDF SPARE-PANEL

KDC-BT92SD

KDC-X8019BT

KDC-X8019BTL

Y33-3612-71

Y33-3610-21

Y33-3610-22

TDF-BT92SD

TDF-X8019BT

TDF-X8019BTL

PbF

This product uses Lead Free solder.

This product complies with the RoHS directive for the European market.

Lever

Mounting hardware assy

DC cord

(J22-0789-03)

(E30-6939-05)

DC cord

(E30-6940-05)

Remote controller assy (RC-405)

Compact disc

(A70-2104-05)

(W01-2028-05)

Carrying case

(W01-1710-05)

Escutcheon

(D10-7106-04) x2

(B07-3235-03)

Microphone (3m)

(W01-1768-15)

Plastic cabinet assy

(A02-2763-03)

Screw set

(N99-1757-15)

Screw set

(N99-1730-35)

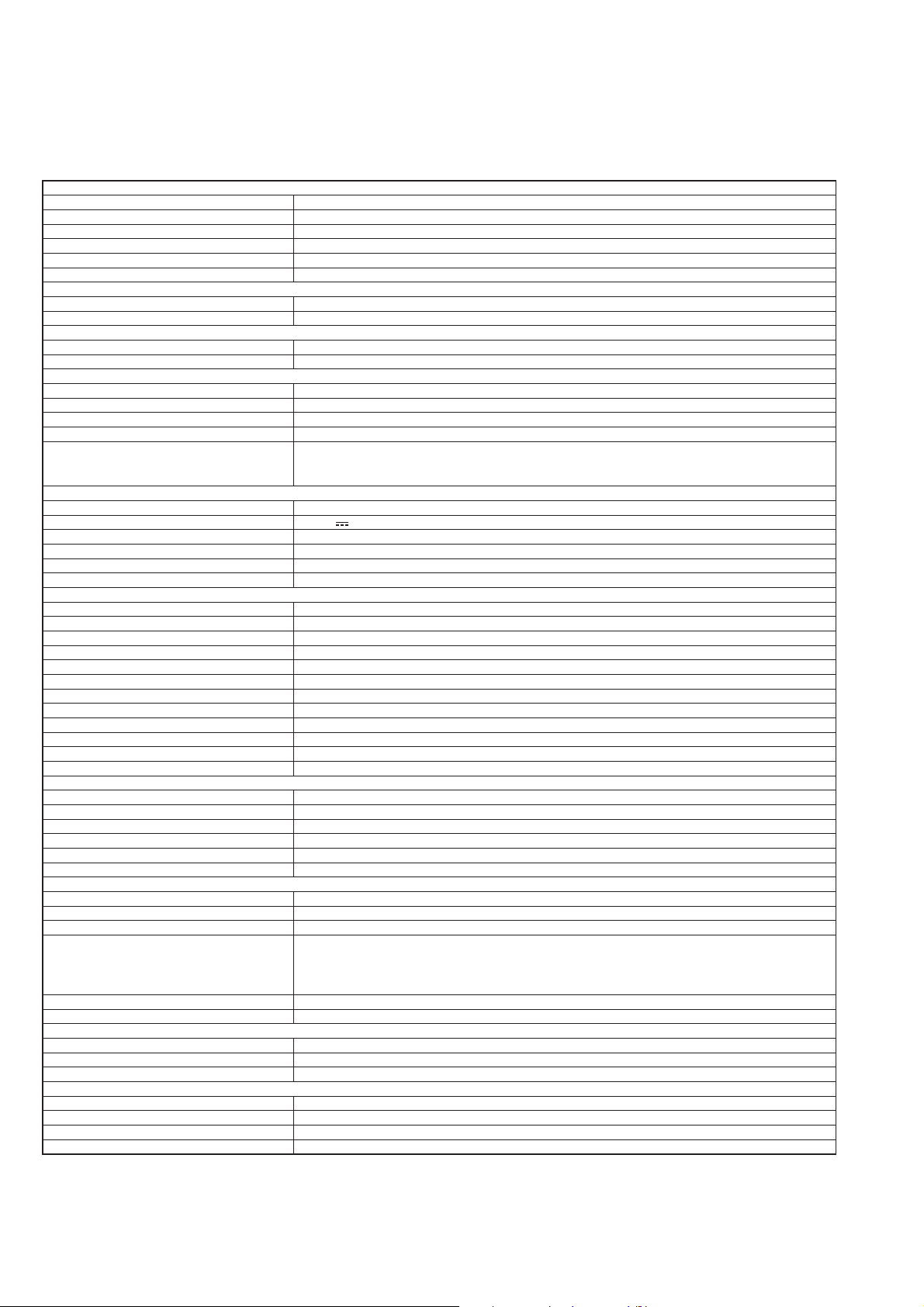

MAIN UNIT NAME TDF PARTS No. TDF NAME

SPECIFICATION

Model for destination "E" (KDC-BT92SD)

FM tuner section

Frequency range (50 kHz space) 87.5 MHz - 108.0 MHz

Usable sensitivity (S/N= 26 dB) 1 µV/75 Ω

Quieting sensitivity (DIN S/N = 46 dB) 2.5 µV/75 Ω

Frequency response (± 3.0 dB) 30 Hz - 15 kHz

Signal to Noise ratio (MONO) 63 dB

Stereo separation (1 kHz) 40 dB

MW tuner section

Frequency range (9 kHz space) 531 kHz - 1611 kHz

Usable sensitivity (S/N= 20 dB) 36 µV

LW tuner section

Frequency range 153 kHz - 279 kHz

Usable sensitivity (S/N= 20 dB) 57 µV

Bluetooth section

Version Bluetooth Ver.3.0 Certified

Frequency range 2.402 GHz - 2.480 GHz

Output Power +4 dBm (MAX), 0 dBm (AVE) Power Class 2

Maximum Communication range Line of sight approx. 10m (32.8 ft)

Profile HFP (Hands Free Profile), HSP (Headset Profile), SPP (Serial Port Profile), PBAP (Phone Book Ac-

USB interface

USB standard USB1.1/ 2.0 (Full speed)

Maximum supply current DC 5 V 1 A

File system FAT16/ 32

MP3 decode Compliant with MPEG-1/2 Audio Layer-3

WMA decode Compliant with Windows Media Audio

AAC decode AAC-LC ".m4a" files

CD player section

Laser diode GaAIAs

Digital filter (D/A) 8 Times Over Sampling

D/A converter 24 Bit

Spindle speed 500 - 200 rpm (CLV)

Wow & Flutter Below Measurable Limit

Frequency response (± 1 dB) 10 Hz - 20 kHz

Total harmonic distortion (1 kHz) 0.008 %

Signal to Noise ratio (1 kHz) 110 dB

Dynamic range 93 dB

MP3 decode Compliant with MPEG-1/2 Audio Layer-3

WMA decode Compliant with Windows Media Audio

AAC decode AAC-LC ".m4a" files

SD card section

Compatible physical format Version 2.00

Maximum memory capacity 32 GB

File system FAT16/ 32

MP3 decode Compliant with MPEG-1/2 Audio Layer-3

WMA decode Compliant with Windows Media Audio

AAC decode AAC-LC ".m4a" files

Audio section

Maximum output power 50 W × 4

Output power (DIN 45324, +B=14.4V) 30 W × 4

Speaker impedance 4 - 8 Ω

Tone action BAND1 (62.5 Hz): ±9 dB, BAND2 (100 Hz): ±9 dB, BAND3 (160 Hz): ±9 dB, BAND4 (250 Hz): ±9 dB,

Preout level / load (CD) 4000 mV/10 kΩ

Preout impedance ≤ 600 Ω

Auxiliary input

Frequency response (± 3 dB)

Input maximum voltage 1200 mV

Input impedance 10 kΩ

General

Operating voltage (10.5 V - 16 V allowable) 14.4 V

Maximum current consumption 10 A

Installation size (W × H × D) 182 × 53 × 157 mm

Weight 1.3 kg

Subject to change without notice.

cess Profile), OPP (Object Push Profile), A2DP (Advanced Audio Distribution Profile), AVRCP (Audio/

Video Remote Control Profile)

BAND5 (400 Hz): ±9 dB, BAND6 (630 Hz): ±9 dB, BAND7 (1 kH): ±9 dB, BAND8 (1.6 kH): ±9 dB,

BAND9 (2.5 kH): ±9 dB, BAND10 (4 kH): ±9 dB, BAND11 (6.3 kHz): ±9 dB, BAND12 (10 kHz): ±9 dB,

BAND13 (16 kHz): ±9 dB

20 Hz - 20 kHz

(No.WA020<Rev.001>)2/24

SPECIFICATION

Models for destination "M" (KDC-X8019BT, KDC-X8019BTL)

FM tuner section

Frequency range (200 kHz space) 87.9 MHz - 107.9 MHz

Frequency range (50 kHz space) 87.5 MHz - 108.0 MHz

Usable sensitivity (S/N= 26 dB) 11.2 dBf (1.0 µV/75 Ω)

Quieting sensitivity (DIN S/N = 46 dB) 19.2 dBf (2.5 µV/75 Ω)

Frequency response (± 3 dB) 30 Hz - 15 kHz

Signal to Noise ratio (MONO) 63 dB

Stereo separation (1 kHz) 40 dB

AM tuner section

Frequency range 530 kHz - 1 700 kHz (10 kHz space)

Usable sensitivity (S/N= 20 dB) 31 dBµ (36 µV)

Bluetooth section

Version Bluetooth Ver.3.0 Certified

Frequency range 2.402 GHz - 2.480 GHz

Output Power +4 dBm (MAX), 0 dBm (AVE) Power Class 2

Maximum Communication range Line of sight approx. 10m (32.8 ft)

Profile HFP (Hands Free Profile), HSP (Headset Profile), SPP (Serial Port Profile), PBAP (Phone Book Ac-

USB interface

USB standard USB1.1/ 2.0 (Full speed)

Maximum supply current DC 5 V 1 A

File system FAT16/ 32

MP3 decode Compliant with MPEG-1/2 Audio Layer-3

WMA decode Compliant with Windows Media Audio

AAC decode AAC-LC ".m4a" files

CD player section

Laser diode GaAIAs

Digital filter (D/A) 8 Times Over Sampling

D/A converter 24 Bit

Spindle speed 500 - 200 rpm (CLV)

Wow & Flutter Below Measurable Limit

Frequency response (± 1 dB) 10 Hz - 20 kHz

Total harmonic distortion (1 kHz) 0.008%

Signal to Noise ratio (1 kHz) 110 dB

Dynamic range 93 dB

MP3 decode Compliant with MPEG-1/2 Audio Layer-3

WMA decode Compliant with Windows Media Audio

AAC decode AAC-LC ".m4a" files

SD card section

Compatible physical format Version 2.00

Maximum memory capacity 32 GB

File system FAT16/ 32

MP3 decode Compliant with MPEG-1/2 Audio Layer-3

WMA decode Compliant with Windows Media Audio

AAC decode AAC-LC ".m4a" files

Audio section

Maximum output power 50 W × 4

Full Bandwidth Power (at less than 1% THD) 22 W × 4

Speaker impedance 4 - 8 Ω

Tone action BAND1 (62.5 Hz): ±9 dB, BAND2 (100 Hz): ±9 dB, BAND3 (160 Hz): ±9 dB, BAND4 (250 Hz): ±9 dB,

Preout level / load (CD) 4000 mV/10 kΩ

Preout impedance ≤ 600 Ω

Auxiliary input

Frequency response (± 3 dB)

Input maximum voltage 1200 mV

Input impedance 10 kΩ

General

Operating voltage (10.5 V - 16 V allowable) 14.4 V

Maximum current consumption 10 A

Installation size (W × H × D) 182 × 53 × 157 mm

Weight 1.30 kg

Subject to change without notice.

531 kHz - 1 611 kHz (9 kHz space)

cess Profile), OPP (Object Push Profile), A2DP (Advanced Audio Distribution Profile), AVRCP (Audio/

Video Remote Control Profile)

BAND5 (400 Hz): ±9 dB, BAND6 (630 Hz): ±9 dB, BAND7 (1 kH): ±9 dB, BAND8 (1.6 kH): ±9 dB,

BAND9 (2.5 kH): ±9 dB, BAND10 (4 kH): ±9 dB, BAND11 (6.3 kHz): ±9 dB, BAND12 (10 kHz): ±9 dB,

BAND13 (16 kHz): ±9 dB

20 Hz - 20 kHz

(No.WA020<Rev.001>)3/24

SECTION 1

Good earth ground

Place this

probe on

each exposed

metal part.

AC VOLTMETER

(Having 1000

ohms/volts,

or more sensitivity)

1500 10W

0.15 F AC TYPE

PRECAUTION

1.1 Safety Precautions

(1) This design of this product contains special hardware and

many circuits and components specially for safety purposes. For continued protection, no changes should be made

to the original design unless authorized in writing by the

manufacturer. Replacement parts must be identical to

those used in the original circuits. Services should be performed by qualified personnel only.

(2) Alterations of the design or circuitry of the product should

not be made. Any design alterations of the product should

not be made. Any design alterations or additions will void

the manufacturers warranty and will further relieve the

manufacture of responsibility for personal injury or property

damage resulting therefrom.

(3) Many electrical and mechanical parts in the products have

special safety-related characteristics. These characteristics are often not evident from visual inspection nor can the

protection afforded by them necessarily be obtained by using replacement components rated for higher voltage, wattage, etc. Replacement parts which have these special

safety characteristics are identified in the Parts List of Service Manual. Electrical components having such features

are identified by shading on the schematics and by ( ) on

the Parts List in the Service Manual. The use of a substitute

replacement which does not have the same safety characteristics as the recommended replacement parts shown in

the Parts List of Service Manual may create shock, fire, or

other hazards.

(4) The leads in the products are routed and dressed with ties,

clamps, tubings, barriers and the like to be separated from

live parts, high temperature parts, moving parts and/or

sharp edges for the prevention of electric shock and fire

hazard. When service is required, the original lead routing

and dress should be observed, and it should be confirmed

that they have been returned to normal, after reassembling.

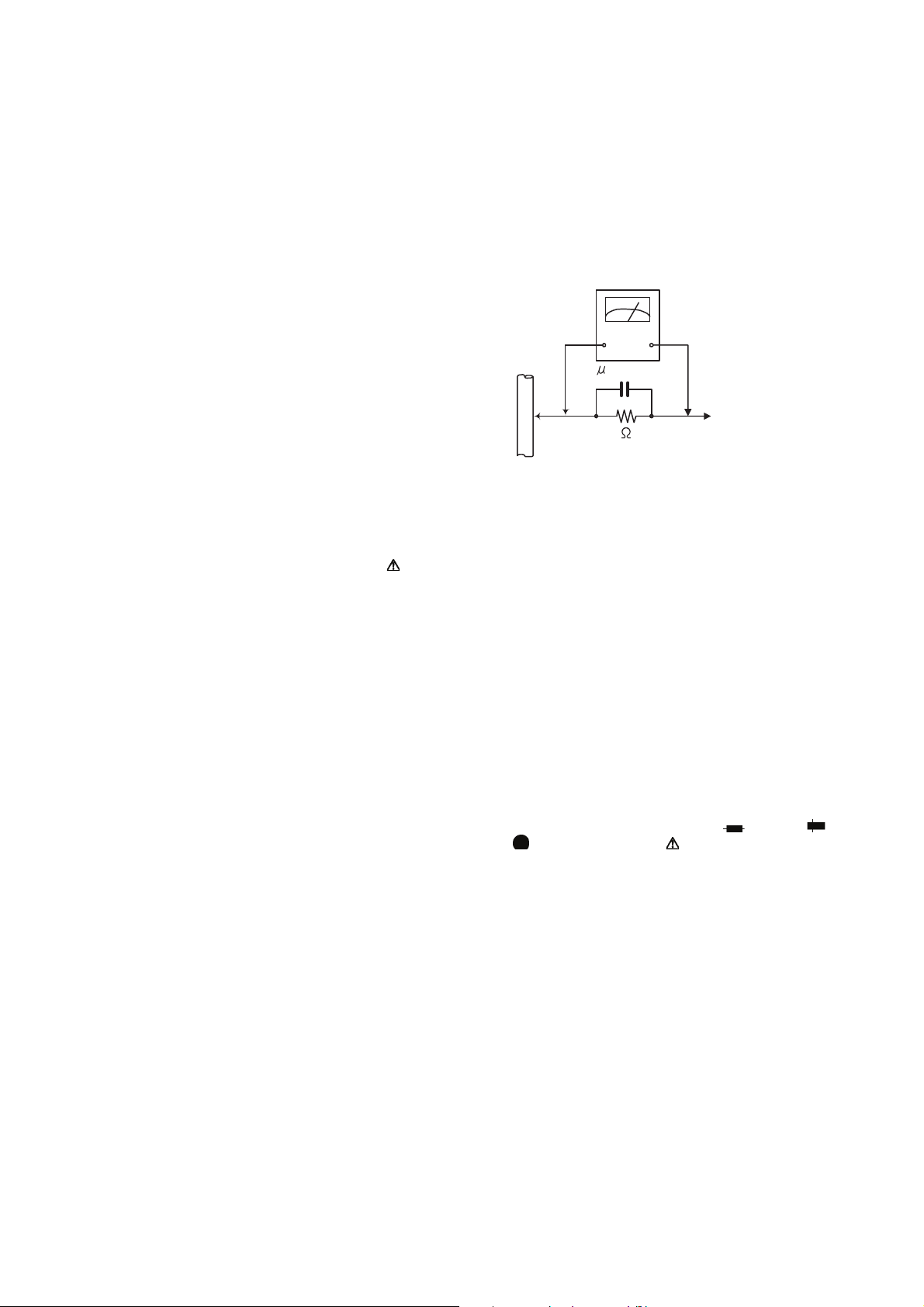

(5) Leakage shock hazard testing

After reassembling the product, always perform an isolation check on the exposed metal parts of the product (antenna terminals, knobs, metal cabinet, screw heads,

headphone jack, control shafts, etc.) to be sure the product

is safe to operate without danger of electrical shock.Do not

use a line isolation transformer during this check.

• Plug the AC line cord directly into the AC outlet. Using a

"Leakage Current Tester", measure the leakage current

from each exposed metal parts of the cabinet, particularly any exposed metal part having a return path to the

chassis, to a known good earth ground. Any leakage current must not exceed 0.5mA AC (r.m.s.).

• Alternate check method

Plug the AC line cord directly into the AC outlet. Use an

AC voltmeter having, 1,000Ω per volt or more sensitivity

in the following manner. Connect a 1,500Ω 10W resistor

paralleled by a 0.15µF AC-type capacitor between an exposed metal part and a known good earth ground.

Measure the AC voltage across the resistor with the AC

voltmeter.

Move the resistor connection to each exposed metal

part, particularly any exposed metal part having a return

path to the chassis, and measure the AC voltage across

the resistor. Now, reverse the plug in the AC outlet and

repeat each measurement. Voltage measured any must

not exceed 0.75 V AC (r.m.s.). This corresponds to 0.5

mA AC (r.m.s.).

1.2 Warning

(1) This equipment has been designed and manufactured to

meet international safety standards.

(2) It is the legal responsibility of the repairer to ensure that

these safety standards are maintained.

(3) Repairs must be made in accordance with the relevant

safety standards.

(4) It is essential that safety critical components are replaced

by approved parts.

(5) If mains voltage selector is provided, check setting for local

voltage.

1.3 Caution

Burrs formed during molding may be left over on some parts

of the chassis.

Therefore, pay attention to such burrs in the case of preforming repair of this system.

1.4 Critical parts for safety

In regard with component parts appearing on the silk-screen

printed side (parts side) of the PWB diagrams, the parts that are

printed over with black such as the resistor ( ), diode ( )

and ICP ( ) or identified by the " " mark nearby are critical

for safety. When replacing them, be sure to use the parts of the

same type and rating as specified by the manufacturer.

(This regulation dose not Except the J and C version)

(No.WA020<Rev.001>)4/24

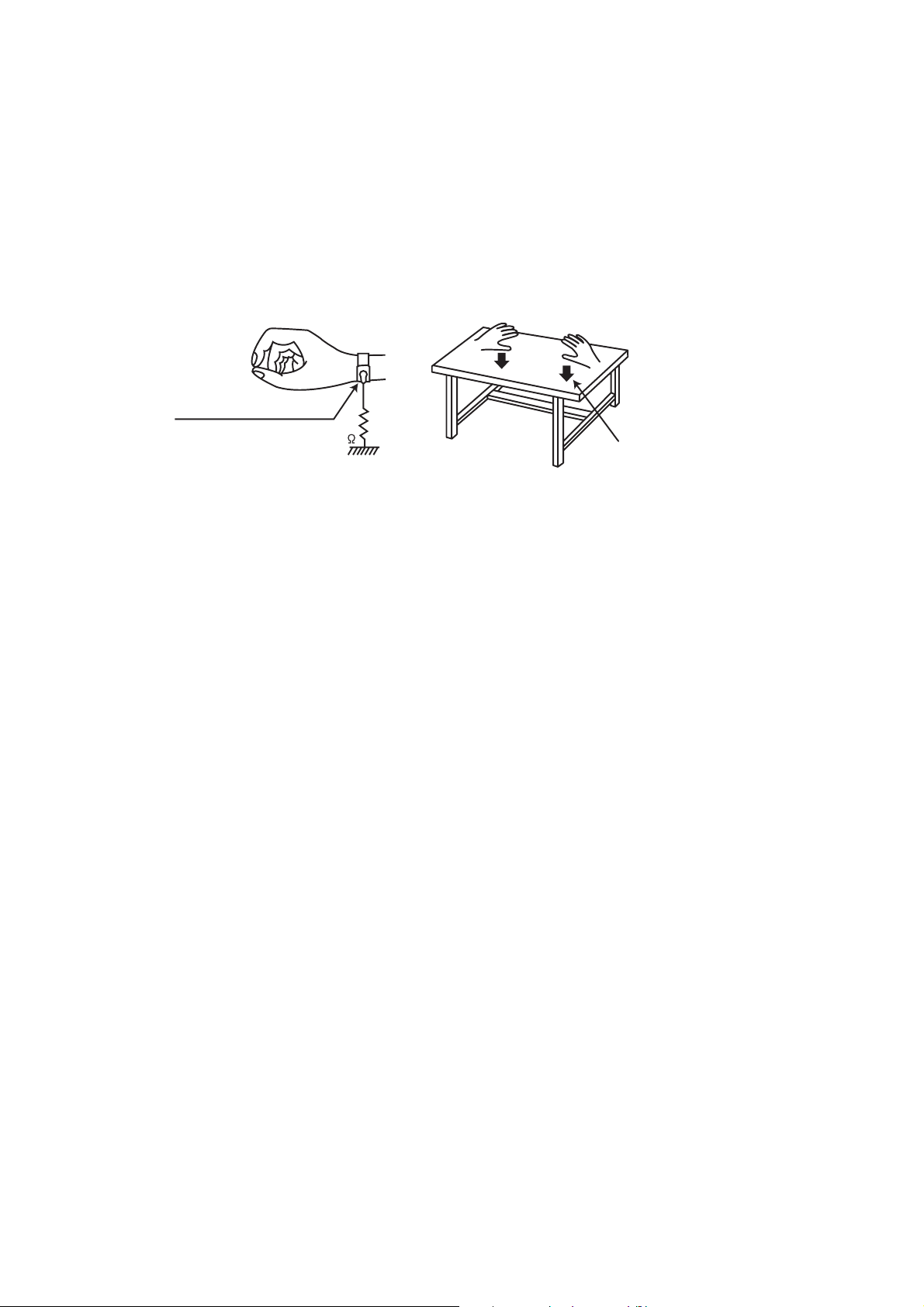

1.5 Preventing static electricity

1M

Conductive material

(conductive sheet) or iron palate

(caption)

Anti-static wrist strap

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged, can destroy the laser

diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

1.5.1 Grounding to prevent damage by static electricity

Static electricity in the work area can destroy the optical pickup (laser diode) in devices such as laser products.

Be careful to use proper grounding in the area where repairs are being performed.

(1) Ground the workbench

Ground the workbench by laying conductive material (such as a conductive sheet) or an iron plate over it before placing the

traverse unit (optical pickup) on it.

(2) Ground yourself

Use an anti-static wrist strap to release any static electricity built up in your body.

(3) Handling the optical pickup

• In order to maintain quality during transport and before installation, both sides of the laser diode on the replacement optical

pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

• Do not use a tester to check the condition of the laser diode in the optical pickup. The tester's internal power source can easily

destroy the laser diode.

1.6 Handling the traverse unit (optical pickup)

(1) Do not subject the traverse unit (optical pickup) to strong shocks, as it is a sensitive, complex unit.

(2) Cut off the shorted part of the flexible cable using nippers, etc. after replacing the optical pickup. For specific details, refer to the

replacement procedure in the text. Remove the anti-static pin when replacing the traverse unit. Be careful not to take too long a

time when attaching it to the connector.

(3) Handle the flexible cable carefully as it may break when subjected to strong force.

(4) I t is not possible to adjust the semi-fixed resistor that adjusts the laser power. Do not turn it.

(No.WA020<Rev.001>)5/24

1.7 Important for laser products

!

Please use enough caution not to

see the beam directly or touch it

in case of an adjustment or operation

check.

1.CLASS 1 LASER PRODUCT

2.CAUTION :

(For U.S.A.) Visible and/or invisible class II laser radiation

when open. Do not stare into beam.

(Others) Visible and/or invisible class 1M laser radiation

when open. Do not view directly with optical instruments.

3.CAUTION : Visible and/or invisible laser radiation when

open and inter lock failed or defeated. Avoid direct

exposure to beam.

4.CAUTION : This laser product uses visible and/or invisible

laser radiation and is equipped with safety switches which

prevent emission of radiation when the drawer is open and

the safety interlocks have failed or are defeated. It is

dangerous to defeat the safety switches.

5.CAUTION : If safety switches malfunction, the laser is able

to function.

6.CAUTION : Use of controls, adjustments or performance of

procedures other than those specified here in may result in

hazardous radiation exposure.

(No.WA020<Rev.001>)6/24

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

2.1 COMPONENTS DESCRIPTION

2.1.1 ELECTRIC UNIT (X34-721x-xx)

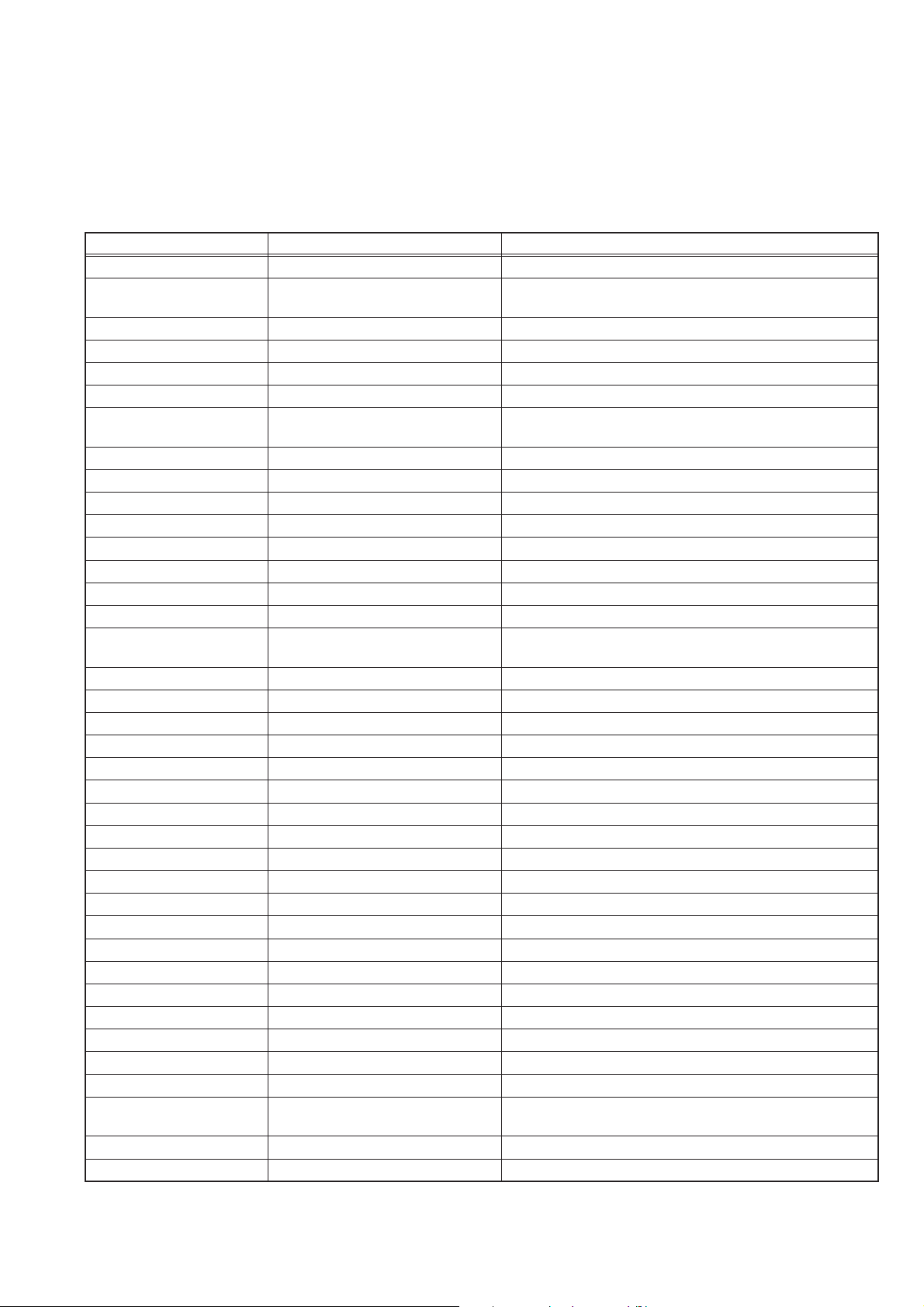

Ref. No. Application / Function Operation / Condition / Compatibility

IC40 Regulator Power supply for BU3.3V (to System u-com)

IC70 Switching Regulator Power supply for D5V (to HiSide-SW, BT3.3V, SD3.3V,

Pan3.3V)

IC90 Regulator Power supply for BT3.3V (to BT Module, BT1.8V)

IC95 Regulator Power supply for BT1.8V (to BT Module)

IC100 Regulator Power supply for SD3.3V (to X15 SD unit)

IC105 Regulator Power supply for Panel3.3V (to X16)

IC165 Hi-Side SW Power supply for USB port with thermal shut down & Over cur-

rent detection

IC220 Logic IC Level shift (3.3V → 5V)

IC250 Power IC Amplifies the front L/R and the rear L/R to 50W maximum

IC251 Logic IC Level shift (3.3V → 5V)

IC270 Electrical Volume & Source Selector Controls the source, volume

IC300 Regulator Power supply for DSP5V (to DSP)

IC310 DSP IC Digital Signal Processor

IC350 OP Amp Bluetooth isolation

IC400 System u-com Controls USB/CD mechanism, Panel, volume and tone

IC401 Reset IC Output "L" (System u-com Reset), when detection voltage

goes below 2.8V or less

IC402 EEP ROM For iTunes Tagging and BT memory etc

IC403 Muting logic IC Controls logic for muting

IC600 Logic IC Level Shift (3.3V → 5V)

IC601 Logic IC Level Shift (5V → 3.3V)

IC700 Sub u-com Controls FM/AM/HD Tuner, SXM I/F

IC730 Op AMP Tuner isolation

IC750 Regulator Power supply for HD3.3V (to X86)

IC755 Regulator Power supply for HD1.2V (to X86)

IC760 Regulator Power supply for RF5V (to X86)

IC771 Regulator Power supply for HD3.3V (to HD1.2V)

IC780 iPod Authentication Coprocessor For APPLE certification

IC850 Tuner IC AM/FM radio receiver

Q20, 21, 22, 23, 24, 25 Audio 8V AVR When Q25 goes ON, A8V AVR outputs 8.36V

Q31 Thermal protection SW When Q31 goes ON, Thermal protection goes on

Q32, 33 B.U.5V AVR While BU is applied, BU5V AVR outputs 5V

Q40 SW3.3V SW When Q40 goes ON, SW3.3V is output

Q50, 51, 52, 53, 54, 55, 56 Servo+B AVR When Q56 goes ON, Servo+B outputs 7.5V

Q60, 61, 62, 63 ILL+B AVR When Q63 goes ON, AVR outputs 10.5V

Q70, 71 Frequency SW Switch for SW Regulator frequency

Q110, 111, 112, 113, 114,

115

Q120 B.U. Detect SW When Q120 goes ON, BU voltage is detected

Q121 Surge Detect SW When Q121 goes ON, Surge voltage is detected

4V Pre+B AVR When Q115 goes ON, 4VPre+B output 12V

(No.WA020<Rev.001>)7/24

Ref. No. Application / Function Operation / Condition / Compatibility

Q122 ACC Detect SW When Q122 goes ON, ACC voltage is detected

Q140, 141, 142, 143 P.CON AVR When Q110 goes ON, AVR outputs 14V

Q144, 145 Power Antenna SW When Q145 goes ON, Power antenna switch outputs 14V

Q160 Small lamp Detect SW When Q160 goes ON, Small lamp is detected

Q350, 351 ISO Ref. Buffer The reference voltage of BT ISO AMP is made

Q650, 652, 660, 661, 670,

Preout mute SW When they go ON, Preout is muted

672

Q651, 671 Preout mute driver When they go ON, mute driver is turned on

Q730, 731 ISO Ref. Buffer The reference voltage of Tuner ISO AMP is made

Q800, 801 X15 DSI SW When Q801 goes ON, DSI in X15 is ON

2.1.2 SWITCH UNIT (X16-7170-xx)

Ref. No. Application / Function Operation / Condition / Compatibility

IC1 Panel u-com LCD Encoder Key LED SW (ON/OFF) is controlled by IC1.

IC3 Remote Control IC Remote control receiver.

IC6 3.2V Regulator The power supply for 3.2V.

Q1 Red Driver D1: It is controlled by IC1

Q3 Left / Right Red LED Driver D3, D4, D5: It is controlled by IC1

Q4 Left / Right Green LED Driver D3, D4, D5: It is controlled by IC1

Q5 Left / Right Blue LED Driver D3, D4, D5: It is controlled by IC1

Q6 Seesaw Red LED Driver D6: It is controlled by IC1

Q7 Seesaw Green LED Driver D6: It is controlled by IC1

Q8 Seesaw Blue LED Driver D6: It is controlled by IC1

Q21 LCD Back Light Green LED Driver D21, D22: It is controlled by IC1

Q22 LCD Back Light Red LED Driver D21, D22: It is controlled by IC1

Q23 LCD Back Light Blue LED Driver D21, D22: It is controlled by IC1

2.1.3 CD PLAYER UNIT (X32-6250-02)

Ref. No. Application / Function Operation / Condition / Compatibility

IC3 4ch BTL Driver Driver for focusing & tracking coil, driver for sled & spindle motor, and operation

for disc loading & ejection

IC4 Servo DSP with built-in Audio DAC With built-in MP3/WMA/ACC decoder and 1M-bit-SRAM.

IC5 BU1.5V/D3.3V REG. Power supply for BU1.5V.

Power supply for digital/analogue/audio 3.3V.

Q1 APC (Auto Power Control) Drives LD (Laser Diode).

Q14 D1.5V Output Switches ON/OFF at one end of BU1.5V line which is separated into 2 directions.

Uses output voltage as D1.5V.

D2 Laser Diode Protection Prevents reverse bias which is applied to laser.

Laser destruction prevention.

D3,4 Static Electricity Countermeasure Prevents malfunction by static electricity.

(No.WA020<Rev.001>)8/24

SECTION 3

hook

a

hook

a

A

hook

b

B

C

D

E

F

DISASSEMBLY

3.1 Main body

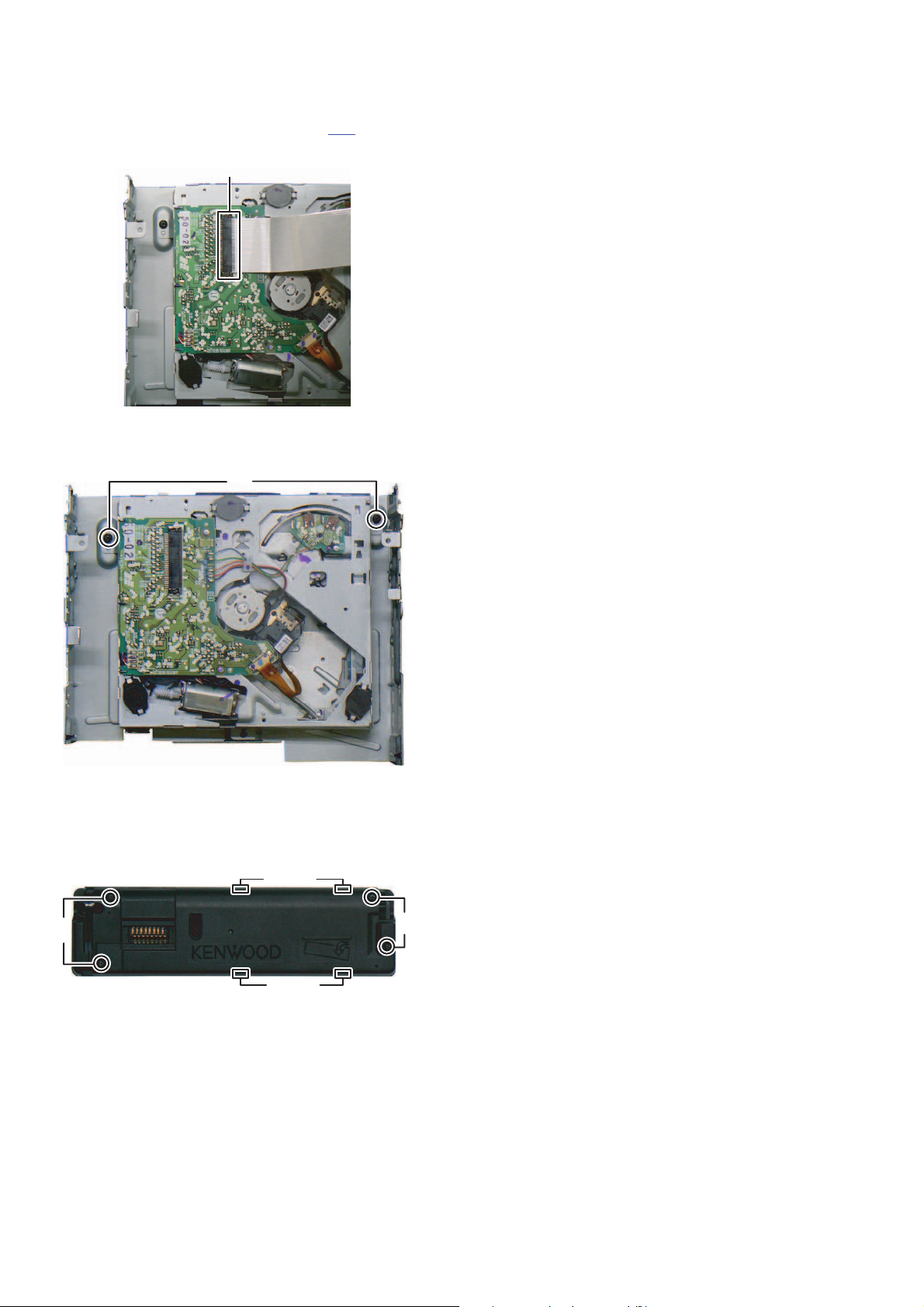

3.1.1 Removing the Bottom chassis (See Fig.1)

(1) Disengage the 4 hooks a engaging the Bottom chassis.

(See Fig.1)

Fig.1

(2) Slide the Bottom chassis backward to remove it.

3.1.2 Removing the Front chassis, Display unit (See Fig.2

and 3)

(1) Remove the 2 screws A attaching the Front chassis.(See

Fig.2)

3.1.3 Removing the Electric unit (See Fig.4, 5, 6 and 7)

(1) Remove the 4 screws B attaching the Heat sink. (See

Fig.4)

(2) Remove the 1 screw C attaching both sides of the Top

chassis. (See Fig.4)

Fig.4

(3) Remove the 1 screws D attaching the Rear bracket. (See

Fig.5)

Fig.2

(2) Disengage the 4 hooks b engaging both sides of the Front

chassis.(See Fig.3)

(3) Remove the Bracket & Display unit.

Fig.3

Fig.5

(4) Remove the 1 screw E and 1 screw F attaching the Electric

unit. (See Fig.6)

Fig.6

(No.WA020<Rev.001>)9/24

(5) Disconnect the board to board connector

CN2

G

hook

c

H

H

hook

c

the Electric unit and the CD mechanism. (See Fig.7)

Fig.7

3.1.4 Removing the CD mechanism (See Fig.8)

(1) Remove the 2 screws G attaching the CD mechanism.

CN2

connecting

Fig.8

3.1.5 Removing the Switch unit (See Fig.9)

(1) Remove the Volume knob.

(2) Remove the 4 screws H attaching the Rear cover.

(3) Disengage the 4 hooks c engaging the Rear cover.

Fig.9

(No.WA020<Rev.001>)10/24

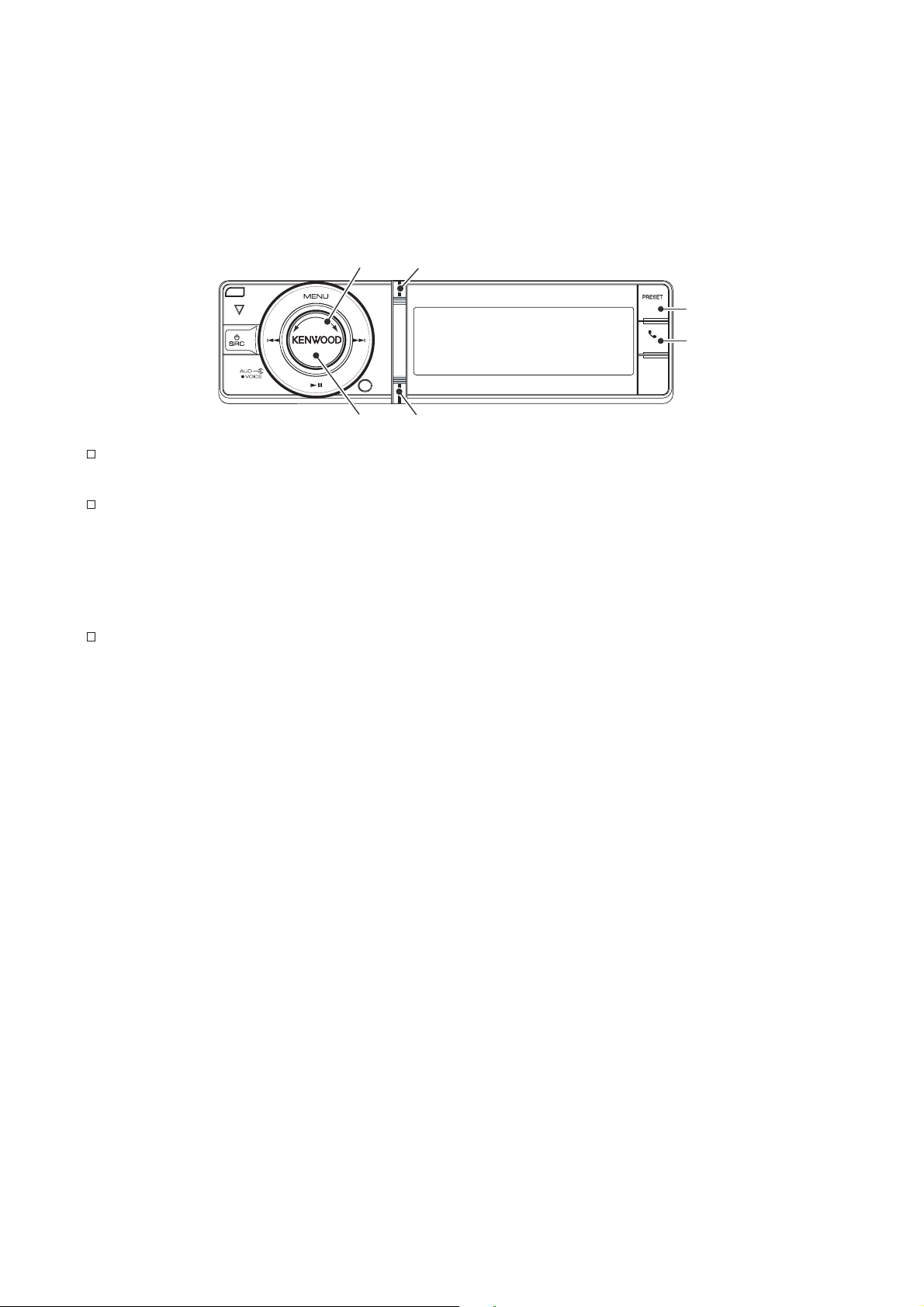

4.1 TEST MODE

Rotary

TEL

DISP

iPod

PRESET

Audio

4.1.1 Panel

*[RESET] button is mounted on the sub panel section.

SECTION 4

ADJUSTMENT

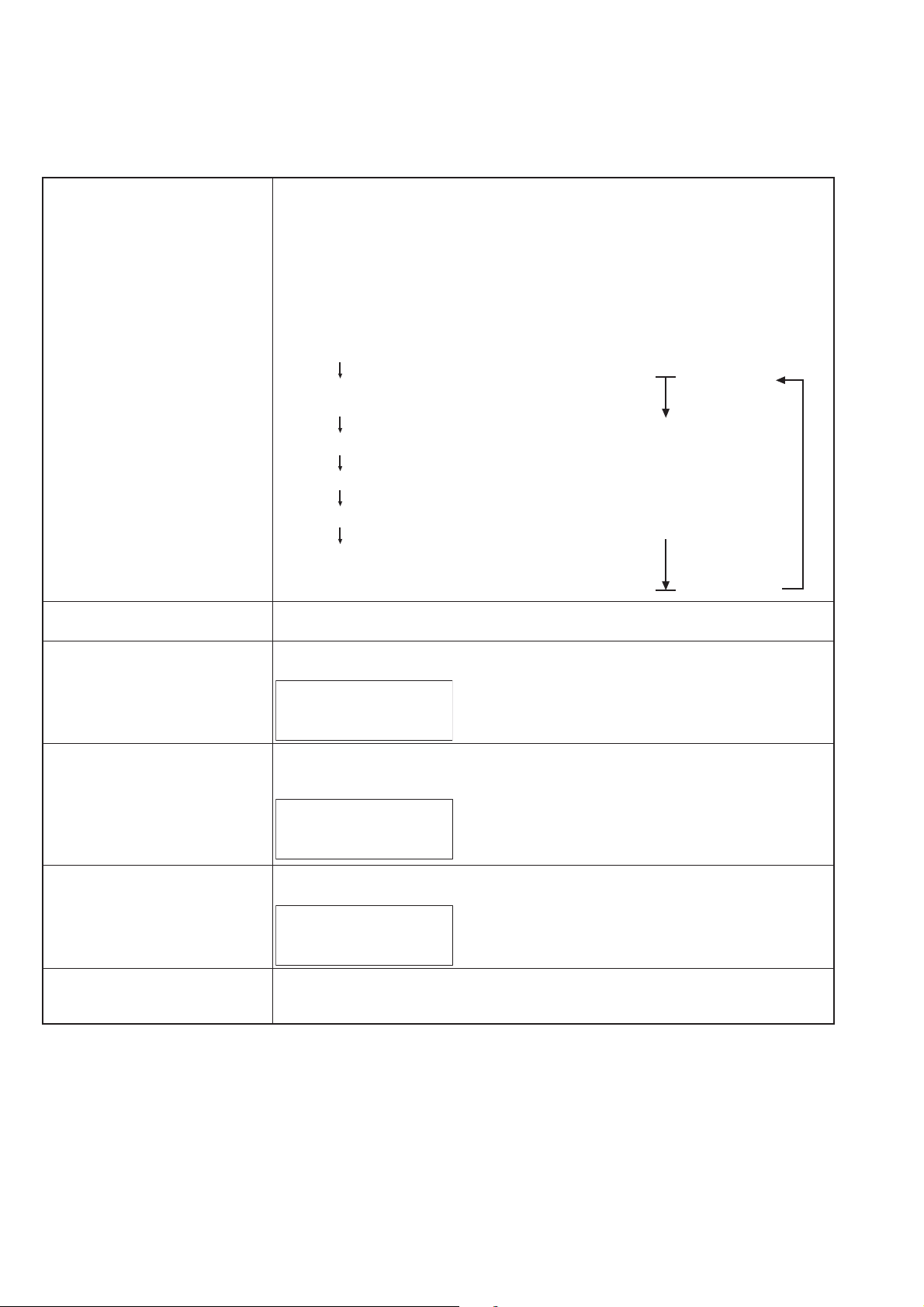

How to transfer into the test mode

!

Reset operation by pressing [iPod] key and [TEL] key simultaneously.

*Reset can be made also by turning on the head unit power supply.

How to clear the test mode

!

It is required to clear the test mode under any of the following conditions:

• Reset

• Momentary power down detection

• ACC OFF operation

• POWER OFF operation

• Panel detach operation

!

Initial setting

• The source when making the transfer shall be STANDBY source.

• Set SRC Select to Setting 1. (Same as normal)

• All the LCDs shall be turned on.

• VOLUME setting shall be 33.

• KEY ON BEEP setting shall be ON regardless of destination. (Enable STANDBY source too)

• Build-in AUX shall be ON.

• DISPLAY setting shall be 5-line display mode, STATUS setting shall be OFF, and SIDE setting shall be TAG.

• DISPLAY TEXT setting in TUNER source shall be as follows:

M type 1st row: Frequency

• DISPLAY TEXT setting in CD/USB source shall be as follows:

1st row: P-TIME

• In every source, DISPLAY TEXT setting in 4th and 5th row shall be as follows:

4th row: Date

5th row: Spectrum analyzer/ Clock (In some sources, setting shall be Clock only)

• The illumi settings shall be R255, G255, and B255 (white).

• Stop the motor of mechanism without rotating when it goes into the test mode without a DISC inserted.

(No.WA020<Rev.001>)11/24

4.1.2 Information display while all the lights are turned on

A U D I O _ I N I T

P O F F _ - - -

PNL

(No Forced POWER OFF)

(Forced POWER OFF because of communication

error between system m-com and panel)

i P o d _ OK _

NG

(Installation condition OK)

(Installation condition NG)

The following information shall be displayed when the key listed in the next table is pressed while all the lights are turned on in STANDBY source.

Press this key briefly: To transfer to Software version & various service information display

mode.

When [DISP] key is pressed briefly, the following items are displayed alternately (toggled) as

shown hereunder.

*Switch between "Version display" → ... → "PANEL open/close times display" → "All lights ON

display" → "Version display" by briefly pressing [DISP] key.

*When the one of remote controller [1] to [6] key is pressed briefly, the display can be switched

directly to the item for that key.

[DISP]

*Press this key briefly

or

[1] to [6]

(Remote controller)

[Item]

Display of System -com/ Panel software version and Serial number

Display of Development code, Destination setting,

and Panel ROM correction version

POWER ON time display

CD operation time display

CD EJECT times display

PANEL open/close times display

[DISP]

* Press this key

briefly to toggle

the display item

* All lights ON

display is also

included

[1]

[2]

[3]

[4]

[5]

[MENU]

*Press this key briefly

[!]

*Press this key briefly

["]

[iPod]

*Press this key briefly

[PRESET]

*Press this key briefly

* Refer to "Attached table 1" for details

Press this key briefly: To call MENU LIST (same as normal operation [product specification])

Press this key briefly: To initialize AUDIO data

[Image of display]

Press this key briefly: To display Forced POWER OFF information

Press and hold this key: To clear Forced POWER OFF information

[Image of display]

Press this key briefly: To display iPod authentication IC installation condition.

[Image of display]

Press this key briefly: To change illumination color

The color is switched in the next sequence: White (R255/G255/B255) → Red (R255/G0/B0)

→ Green (R0/G255/B0)→ Blue (R0/G0/B255) → ...

[6]

(No.WA020<Rev.001>)12/24

4.1.2.1 Attached table 1: Version & service information display mode

B T _ V E R : HW x x

: SW x . x x . x x

A D D R : x x x x x x x x x x x x

P I N : x x x x x x x x

Software version & serial number display

• Description

Display the software version and serial No. of the system u-com/ panel.

• Software version display

Display the software version and serial No. of the system u-com/ panel u-com.

In addition, attach the following figure in front of every code of system u-com and panel, and

display the code together with the attached figure.

- System u-com

Ex. SYS02_*.**

- Panel

E type: Ex. PAN01_*.**

M type: Ex. PAN02_*.**

M3 type: Ex. PAN03_*.**

[Layout of display]

1st line: System u-com software version display

2nd line: Panel software version display

3rd line: Blank (No display)

4th line: Blank (No display)

5th line: Serial number display

[Image of display]

S Y S 0 1 - 1 . 2 3

P A N 0 1 - 1 . 1 1

[Rotary]

(Counter clockwise)

↑

[1]

(Remote

controller)

S N o _ x x x x x x x x

↓

[Rotary]

(Clockwise)

or

[DISP]

*Press this key

briefly to switch

the display

↓ ↑ Remote controller [1] key or ["]/[!] can be used to switch

• Display of version of BT-related information

[Layout of display]

1st line: BT module H/W Version

2nd line: BT module S/W Version

3rd line: BT module Device Address

4th line: BT module PIN Code

[Image of display]

[2]

(Remote

controller)

Display of Development code & Mechanism u-com version & System u-com/ Panel ROM correction

• Description

Display the development code, destination setting (destination resistance setting), ROM

correction version of the panel.

• Display of Panel ROM correction version

[Display specification]

When ROM correction data is written in:

PAN_ROM_R1234

When ROM correction data is not yet written in:

PAN_ROM_R_ _ _ _

When inconsistency is found in ROM correction data:

*When the data cannot be applicable (cannot be used) because the source code and ROM

correction data are inconsistent:

PAN_ROM_R****

When E2PROM is not yet installed:

PAN_ROM_ERR_ _

(No.WA020<Rev.001>)13/24

[2]

C 1 0 3 0 W K

S T Y P E : x x P T Y P E : K

P A N _ R O M _ R 1 2 3 4

S o C : _ X. X X

P o n T i m _ 0 H x x _

x x x x x

C D T i m_ 0 H x x _

x x x x x

E j e Cn t _ x x x x x

P n C n t _ x x x x x

(Remote

controller)

[SoC version display]

Display the latest SoC version for designs.

SoC:_X.XX

[Layout of display]

1st line: Development code

2nd line: Destination setting of system u-com/ panel

*This setting should be used in [software] and [schematic] to check if the proper resistance for

that destination is used or not.

3rd line: Display of panel ROM correction version

[Image of display]

POWER ON time display

[Image of display]

[Rotary]

(Counter clockwise)

↑

↓

[Rotary]

(Clockwise)

or

[DISP]

*Press this key

briefly to switch

the display

[3]

(Remote

controller)

[4]

(Remote

controller)

[5]

(Remote

controller)

[6]

(Remote

controller)

(In the "xx", the figure between 00 and 50 (00~50) shall be displayed. When it is less than 1

hour, it shall be displayed rounded up/down to 10 minutes.)

When the unit is normally turned on even only 1 time, the value “0H10” is memorized.

(In the "xxxxxx", the figure between 00001 and 10922 (00001~10922) shall be displayed. The

figure is shown in h [hour])

CD operation time display

[Image of display]

(In the "xx", the figure between 00 and 50 (00~50) shall be displayed. When it is less than 1

hour, it shall be displayed rounded up/down to 10 minutes.)

(In the "xxxxxx", the figure between 00001 and 10922 (00001~10922) shall be displayed. The

figure is shown in h [hour])

CD EJECT times display

[Image of display]

(The maximum value is 65535 and it indicates the number of ejections)

PANEL open/close times display

[Image of display]

(The maximum value is 65535 and it indicates the number of panel open/close)

(No.WA020<Rev.001>)14/24

4.1.2.2 Attached table 2: CD information display mode

I2C_

_ _ _ _ _ _ _ _ _ _ _ _

ERR_1- , 2- , 3-

L o a d _ E r r o r _ _ _ _

_ _(1) x x_ _(2) x x

E j e c t _ E r r o r _ _ _ _

_ _(1) x x_ _(2) x x

_ _(3) x x_ _(4) x x

C o u n t _ L o s e

_ _CDDA _ : x x

_ _CDROM : x x

C o u n t _ S t a y

_ _CDDA _ : x x

_ _CDROM : x x

[#$]

*Press this

key briefly

Press this key briefly: Transition to CD information display mode

I2C communication condition & CD mechanism error log display

[Image of display]

[Rotary]

(Counter

clockwise)

↑

↓

[Rotary]

(Clockwise)

(In the " ", "OK" or "NG" shall be displayed. “ " shall display "- -" or "error code".)

CD load error information display

[Image of display]

(In the "xx", the number of Load Error shall be displayed. The maximum value is 99 and it indicates the number of

Load Error)

CD Eject error information display

[Image of display]

(In the "xx", the number of Eject Error shall be displayed. The maximum value is 99 and it indicates the number of

Eject Error)

CD time code false count information display (Count skipping)

[Image of display]

(In the "xx", the number of Count Lose shall be displayed. The maximum value is 99 and it indicates the number of

Count Lose)

CD time code false count information display (Count not updated)

[Image of display]

(In the "xx", the number of Count Stay shall be displayed. The maximum value is 99 and it indicates the number of

Count Stay)

[#$] When this key is pressed briefly: CD information display mode is turned OFF (Recover).

[Audio]

4.1.2.3 Initialization of settings related to AUDIO setup

• When [!] key is pressed briefly in STANDBY source, AUDIO settings are reset to their default values in the test mode.

4.1.2.4 Others

• In turning on this unit in the test mode, change LINE MUTE inhibit period of time from 10s to 1s.

• In the test mode, do not write the DC offset error detection information in E2PROM even if the error is detected.

• In the test mode, do not record contents of the backup memory in E2PROM even if the prescribed period of time is elapsed.

• Do not run DEMO mode in the following modes: Test mode, Backup/Installer memory & CD mechanism information & service information & DC offset error detection information & BT memory information clear mode, or DC offset error detection information clear

mode.

Also, in the above mode, do not display DEMO ON/OFF switching items in the Menu list.

When this key is pressed briefly: Invalid (It does not cause any operation)

When this key is pressed and held: All of CD information is cleared. (Press and hold this key for 2 seconds while the

service information is being displayed)

(No.WA020<Rev.001>)15/24

4.1.3 Tuner source test mode

T U N _ C O N _ N G

F M - 3 c h A 9 7 . 9

E R R A 9 7 . 9

[PRESET]

*Press this

key briefly

BAND switching

[Description]

You can switch the band.

M/M3 Type: FM→AM→FM...

E Type: FM→MW or LW→FM...

[PRESET]

*Press and hold this

key

Preset Mode

[Description]

You can call up the preset list to perform a preset call.

[Audio]

*Press and hold this

key

Tuner IC version display

[Description]

Displays the IC version of the tuner.

IC_Ver : xx.xx

[Image of display]

I C _ V e r : x x . x x

4.1.3.1 Display during tuner error

Display the following in the event of a tuner error.

Atomic Error

[Description]

Appears when an error occurs with atomic.

[Image of display]

Level offset adjustment error display

[Description]

Display an error when level offset is not adjusted. In addition to the test mode, show *ERR* as blinking too during

normal operation.

Show error display in only 1 line during normal operation, and show all 5 lines of error display in the test mode.

[Image of usual display]

[Image of during error display]

*If the level offset value is not adjusted (0xFF or 0x00), show error display. (Blinking

at 500ms cycle)

4.1.3.2 Tuner control during normal operation

(No.WA020<Rev.001>)16/24