Page 1

SelectSpray™ 1500E

Instructions for use and parts list

Mode d’ emploi et liste de pièces

Kent MODEL 56011781

English

Français

Nilfisk-Advance Select Spray 1500E Operator's Manual 1

5/00 Form Number 56041501

Page 2

TABLE OF CONTENTS

INTRODUCTION ............................................................................................................................. 3

IMPORTANT SAFETY WARNINGS ................................................................................................ 4-7

ELECTRICAL PRECAUTIONS ............................................................................................ 4

SPRAY PRECAUTIONS ...................................................................................................... 5

DETERGENT CLEANING PRECAUTIONS .......................................................................... 6

MISCELLANEOUS SAFETY PRECAUTIONS ...................................................................... 6

ADJUSTMENT PRECAUTIONS ........................................................................................... 7

SPECIFICATIONS ........................................................................................................................... 7

FEATURES ..................................................................................................................................... 8

SAFETY DECALS ........................................................................................................................... 9

INSTALLATION & PREPARATION ................................................................................................. 10-12

ATTIRE ............................................................................................................................... 10

SET-UP ............................................................................................................................... 10

NOZZLE REVIEW ............................................................................................................... 10

NOZZLE CONNECTION ....................................................................................................... 11

WATER SUPPLY ................................................................................................................ 11

POWER CORD CONNECTION ........................................................................................... 12

HEAT DUMP VALVE ........................................................................................................... 12

PRE-START INSPECTION PROCEDURES ......................................................................... 12

OPERATING INSTRUCTIONS ........................................................................................................ 14-15

PRIMING THE PUMP .......................................................................................................... 14

START-UP .......................................................................................................................... 14

CLEANING WITH DETERGENTS ........................................................................................ 15

SHUTDOWN ....................................................................................................................... 15

STORAGE & MAINTENANCE ......................................................................................................... 16-17

PUMP & NOZZLE MAINTENANCE ...................................................................................... 16

WINTERIZING ..................................................................................................................... 17

START UP AFTER EXTENDED STORAGE ......................................................................... 17

TROUBLESHOOTING .................................................................................................................... 18

NOTES ............................................................................................................................................ 19

PARTS LISTING .............................................................................................................................. 20-29

FRAME ASSEMBLY ........................................................................................................... 20

MOTOR ASSEMBLY ........................................................................................................... 22

PUMP ASSEMBLY .............................................................................................................. 24

GUN AND WAND ASSEMBLY ............................................................................................ 26

DETERGENT INJECTOR .................................................................................................... 28

WIRING DIAGRAM/ WIRING SCHEMATIC ......................................................................... 29

FRENCH ......................................................................................................................................... 30-51

STATEMENT OF WARRANTY ........................................................................................................ 52

2 Nilfisk-Advance Select Spray 1500E Operator's Manual

Page 3

INTRODUCTION

Congratulations on the purchase of your new Nilfisk-Advance pressure washer! You can be assured your pressure washer

was constructed and designed with quality and performance in mind. Each component has been rigorously tested to ensure

the highest level of acceptance.

This operator's manual was compiled for your benefit. By reading and following the simple safety, installation, operation,

maintenance and troubleshooting steps described in this manual, you will receive years of trouble free operation from your

new Nilfisk-Advance pressure washer. The contents of this manual are based on the latest product information available at

the time of publication. Nilfisk-Advance reserves the right to make changes in price, color, materials, equipment, specifications

or models at any time without notice.

! IMPORTANT !

These paragraphs are surrounded by a "SAFETY ALERT BOX". This box is used to designate

and emphasize Safety Warnings that must be followed when operating this pressure washer.

Accompanying the Safety Warnings are "signal words" which designate the degree or level

of hazard seriousness. The "signal words" used in this manual are as follows:

DANGER

WARNING

CAUTION

The symbols set to the left of this paragraph are "Safety Alert Symbols". These symbols are

used to call attention to items or procedures that could be dangerous to you or other persons

using this equipment.

ALWAYS PROVIDE A COPY OF THIS MANUAL TO ANYONE USING THIS EQUIPMENT. READ ALL

INSTRUCTIONS BEFORE OPERATING THIS PRESSURE WASHER AND ESPECIALLY POINT OUT

THE "SAFETY WARNINGS" TO PREVENT THE POSSIBILITY OF PERSONAL INJURY TO THE

OPERATOR.

Once the unit has been uncrated, immediately write in the serial number of your unit in the space provided below.

: Indicates an imminently hazardous situation which, if not avoided, WILL

result in death or serious injury.

: Indicates a potentially hazardous situation which, if not avoided, COULD

result in death or serious injury.

: Indicates a potentially hazardous situation which, if not avoided MAY

result in minor or moderate injury.

SERIAL NUMBER_________________________________

Inspect for signs of obvious or concealed freight damage. If damage does exist, file a claim with the transportation company

immediately. Be sure that all damaged parts are replaced and that the mechanical problems are corrected prior to operation

of the unit. If you require service, contact Nilfisk-Advance Customer Service at our toll-free number for the Sales or Service

Center nearest you:

800-989-2235

Please have the following information available for all service calls:

1. Model Number

2. Serial Number

3. Date and Place of Purchase

Nilfisk-Advance Select Spray 1500E Operator's Manual 3

Page 4

IMPORTANT SAFETY WARNINGS

ELECTRICAL PRECAUTIONS:

1. GROUNDING INSTRUCTIONS:

This product must be grounded. If it should malfunction or breakdown,

grounding provides a path of least resistance for electric current to reduce the

risk of electric shock. This product is equipped with a cord having an

equipment-grounding conductor and a grounding plug. The plug must be

plugged into an appropriate outlet that is properly installed and grounded in

accordance with all local codes and ordinances.

2. DANGER:

Improper connection of the equipment-grounding conductor can result in a

risk of electrocution. Check with a qualified electrician or service personnel

if you are in doubt as to whether the outlet is properly grounded. Do not modify

the plug provided with the product - if it will not fit the outlet, have a proper outlet

installed by a qualified electrician. Do not use any type of adaptor with this

product.

3. GROUND FAULT INTERRUPTER PROTECTION:

This pressure washer is provided with a Ground Fault Circuit Interrupter

(GFCI) built into the plug or the power supply cord. This device provides

additional protection from the risk of electric shock. Should replacement of the

cord become necessary, use only identical replacement parts that include

GFCI protection.

4. EXTENSION CORDS:

Nilfisk-Advance DOES NOT RECOMMEND THE USE OF EXTENSION

CORDS! If use of an extension cord is unavoidable, it must be plugged into a

GFCI found in circuit boxes or protected receptacles. When using an

extension cord, observe the following:

Cable Length Wire Gauge

Up to 50 feet 12 AWG

50 to 100 feet 10 AWG

WARNING

Use only 3-wire extension cords that have 3-prong grounding-type plugs and

3-pole cord connectors that accept the plug from the product. Use only

extension cords that are intended for outdoor use. These extension cords are

identified by a marking "Acceptable for use with outdoor appliances; store

indoors while not in use." Use only extension cords having an electrical rating

not less than the rating of the product. Do not use damaged extension cords.

Examine extension cord before using and replace if damaged. Do not abuse

extension cord and do not yank on any cord to disconnect. Keep cord away

from heat and sharp edges. Always disconnect the extension cord from the

receptacle before disconnecting the product from the extension cord.

To reduce the risk of electrocution, keep all connections dry and off the

ground. Do not allow electrical cords to lay in water or in such a position

where water could come in contact with them. Do not touch plug with wet

hands!

5. DO NOT drop the GFCI as damage could result. If the GFCI is accidentally

dropped, be certain to test the GFCI before using to ensure it is working

properly. (Follow instructions on GFCI for test procedures)

6. DO NOT pull on the electrical cord to disconnect from the outlet, OR carry the

unit by the cord.

7. Check power cord for damage before using. There is a hazard of electrical

shock from crushing, cutting or heat damage.

8. Always be certain the unit is receiving proper voltage. Before plugging the

unit into a compatible power source, be certain the switch is in the "OFF"

position. Disconnect when not in use.

9. DO NOT use the unit in an area where flammable gas vapors may be present.

An electric spark could cause an explosion or fire.

10. DO NOT direct water spray on or into electrical installations of any kind. This

includes electrical outlets, light bulbs, fuse boxes, transformers, the unit itself

etc. Severe electrical shock may occur.

11. Nilfisk-Advance does not recommend the owner attempt any electrical repairs to

this unit.

WARNING

4 Nilfisk-Advance Select Spray 1500E Operator's Manual

Page 5

IMPORTANT SAFETY WARNINGS

SPRAY PRECAUTIONS:

WARNING

RISK OF INJECTION OR SEVERE CUTTING INJURY

KEEP CLEAR OF NOZZLE

DO NOT DIRECT DISCHARGE STREAM AT PERSONS OR PETS

WHEN USING THIS PRODUCT, BASIC PRECAUTIONS SHOULD

ALWAYS BE OBSERVED, INCLUDING THE FOLLOWING:

1. KEEP AWAY FROM THE SPRAY:

-Because of the high pressure and velocity of the spray, fluids can

penetrate the skin, causing serious injury.

-Never point the gun at yourself or anyone else. Never put your hand,

fingers or body directly over the spray nozzle. Always keep operating area

clear of all persons. Use extreme caution when operating near children.

-If an accident does occur and the spray appears to have penetrated the

skin, SEEK EMERGENCY MEDICAL CARE. DO NOT TREAT AS A

SIMPLE CUT. If you are using cleaning agents, be prepared to tell a

physician exactly what kind.

2. When using hot inlet water, do not touch or direct dishcarge stream at

persons. Pump surface temperature is the same as inlet water temperature.

3. ALWAYS wear protective goggles when operating the unit to shield the eyes

from flying debris and detergents. Other protective equipment such as

rubber suits, gloves and respirators are advisable, especially when using

cleaning detergents. Use extreme caution when operating near children.

4. Stay alert-watch what you are doing. Do not operate the unit when fatigued

or under the influence of alcohol or drugs.

5. NEVER squeeze the trigger unless securely braced. The thrust from the

water traveling through the nozzle may be powerful enough to cause the

operator to lose balance if unprepared. DO NOT overreach or stand on

unstable support. Wet surfaces can be slippery, wear protective foot gear

and keep good footing and balance at all times. NEVER trigger the gun while

on a ladder or roof.

6. Caution should be used when directing spray toward fragile materials such

as glass. Shattering could result in serious injury.

7. ALWAYS hold on firmly to the gun/wand assembly when starting and

operating the unit. Failure to do so can cause the wand to fall and whip

dangerously. NEVER operate the gun with the trigger wired in the open

position. To prevent accidental discharge, the trigger gun should be

securely locked when not in use.

8. Even after you shut off the unit, there is high pressure water left in the pump,

hose and gun until you release it by triggering the gun. Before removing

the spray nozzle or servicing the unit, ALWAYS shut off the unit and trigger

the gun to release trapped pressure.

Nilfisk-Advance Select Spray 1500E Operator's Manual 5

Page 6

IMPORTANT SAFETY WARNINGS

DETERGENT CLEANING PRECAUTIONS:

1. DO NOT use solvents or highly corrosive detergents or acid type cleaners with

this pressure washer. Use only mild detergents.

2. KNOW YOUR DETERGENTS! Be prepared to tell a physician exactly what

you are using in the event of an emergency. Read the Material Safety Data

Sheet (MSDS) provided with your detergent and all detergent labels. Follow all

appropriate instructions regarding preparation use, safety and transportation.

Keep ALL detergents out of the reach of children.

3. DO NOT use this pressure washer to dispense hazardous detergents.

4. DO NOT alter the detergent injection feature in any manner not prescribed in

this manual. Use only genuine Nilfisk-Advance replacement parts for necessary

repairs.

MISCELLANEOUS SAFETY PRECAUTIONS:

1. NEVER ALLOW CHILDREN OR ADOLESCENTS TO OPERATE THIS UNIT!

2. Read and follow all handling, operations, maintenance and safety instructions

listed in this manual and provide such information to ANYONE who will be

operating this unit.

3. This pressure washer is provided with a Ground Fault Circuit Interrupter (GFCI)

built into the plug or the power supply cord. Should replacement of the cord

or plug become necessary, use only identical replacement parts that include

GFCI protection.

4. In freezing temperatures, the unit must always be warm enough to ensure there

is no ice formation in the pump. DO NOT start this unit if it has been transported

in an open or underheated vehicle without first allowing the pump to thaw.

5. When connecting the water inlet to the water supply mains, local regulations

of your water company must be observed. In some areas the unit must not

be connected directly to the public drinking water supply. This is to ensure

that there is no feedback of the detergents into the water supply. (Direct

connection is permitted if a back flow preventer is installed)

6. High pressure hoses should be inspected daily for signs of wear. If evidence

of failure exists, promptly replace all suspect hoses to prevent the possibility

of injury from the high pressure spray. If a hose or fitting is leaking, NEVER

place your hand directly on the leak.

7. DO NOT operate the unit if you see any pump oil or water leaks from the

machine. DO NOT resume operation until the unit has been inspected and

repaired by a qualified service person.

8. DO NOT operate the unit without all protective covers in place.

9. To reduce the risk of injury, maintain a safe distance from persons while

operating this unit. Close supervision is necessary when operating the unit

near children.

10. DO NOT leave pressurized unit unattended. Shut off the unit and release

trapped pressure before leaving.

11. DO NOT move the unit by pulling on the hose.

6 Nilfisk-Advance Select Spray 1500E Operator's Manual

Page 7

IMPORTANT SAFETY WARNINGS

ADJUSTMENT PRECAUTIONS:

1. NEVER alter or modify the equipment, be sure any accessory items and

system components being used will withstand the pressure developed.

Use ONLY genuine Nilfisk-Advance parts for repair of your pressure washer.

Failure to do so can cause hazardous operating conditions and will void

warranty.

2. NEVER make adjustments to the machinery while it is connected to the

power source.

3. Know how to stop the pressure washer and bleed pressures quickly. Be

thoroughly familiar with controls.

4. Before servicing the unit: turn the unit off, disconnect from the power source,

relieve the water pressure and allow the unit to cool down. Service in a

clean, dry, flat area.

5. Follow the maintenance instructions specified in this manual.

SAVE THESE INSTRUCTIONS

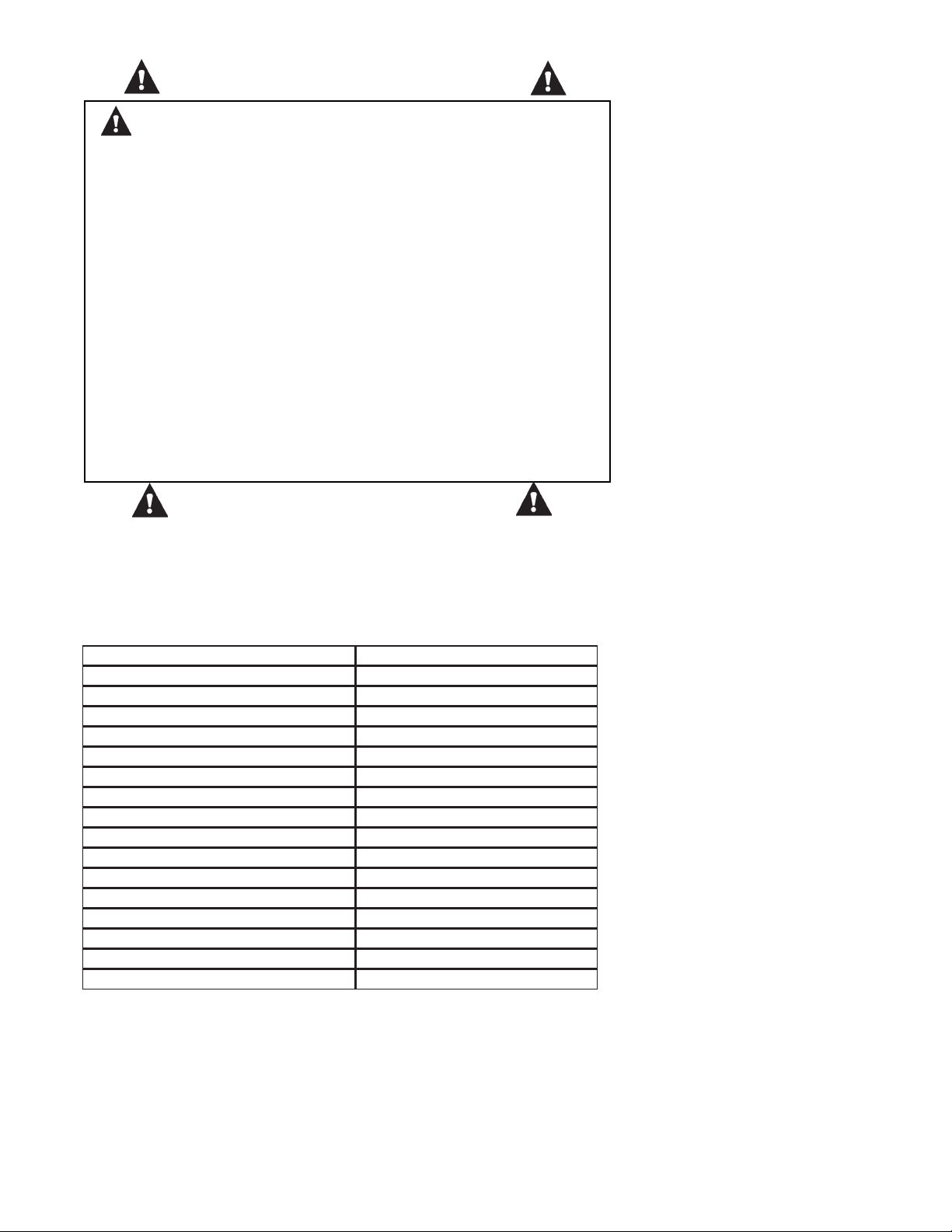

SPECIFICATIONS

rebmuNledoME0051YARPSTCELES

rewopesroHrotoM0.2

zH/esahP/egatloVgnitarepO06/1/021

egarepmA71

MPRrotoM0543

htgneLdroCrewoPICFG/wtf53

elytSpmuPnotsiPxelpirT

erusserP0051

)mpl/mpg(etaRwolF8/2

)C/F(erutarepmeTretaWtelnImumixaM°88/°091

epyTliOpmuPtnegretéD-noN03EAS

htgneLesoHerusserPteef52

)mc/ni(htgneLecnaL19/63

elgnAelzzoN °51

)mc/ni(HxWxLtinU 5.69x2.34x3.18/83x71x23

)sbl(thgieWtinU98

)sbl(thgieWgnippihS99

Nilfisk-Advance Select Spray 1500E Operator's Manual 7

Page 8

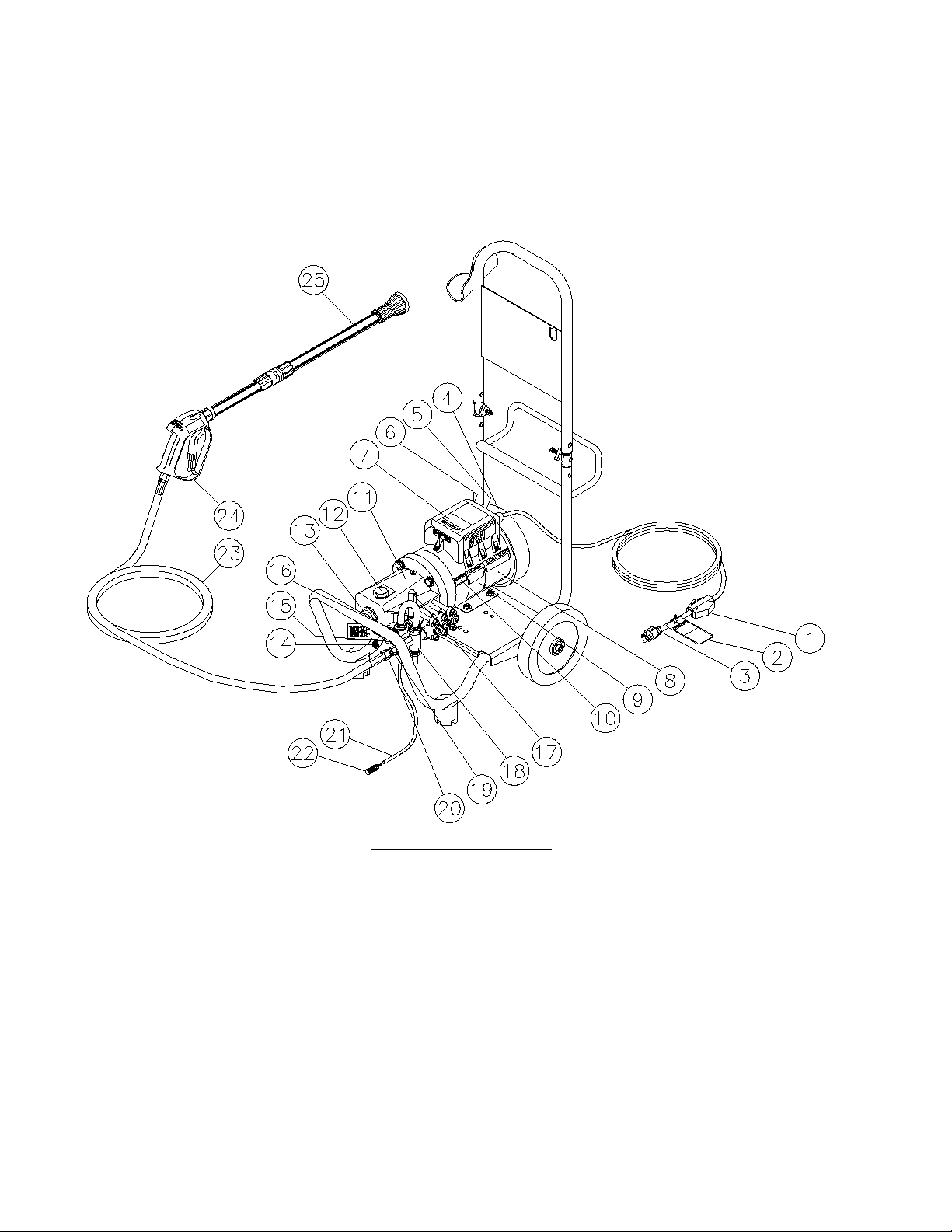

SELECT SPRAY 1500E FEATURES

NOTE: This drawing is referenced throughout the manual. Locations of

specific items will be noted by listing the REFERENCE # in parenthesis.

Example: Water Inlet (15)

OMCWU188-102998-RD

1. GFCI

2. Hang Tag-Warning: Risk of Electrocution

3. Power Cord

4. Electric Motor

5. On/Off Switch

6. Decal-Warning: Risk of Injection/Explosion

7. Decal-Warning: Risk of Electrocution

8. Decal-Caution Statements

9. Decal-Caution: Hot Water

10. Decal-Warning: Backflow

11. Pump

12. Oil Fill

8 Nilfisk-Advance Select Spray 1500E Operator's Manual

FEATURES LISTING

13. Oil Sight Glass

14. Water Inlet Strainer

15. Water Inlet

16. Decal-Temperature Indicator

17. Heat Dump Valve

18. Unloader

19. Detergent Injector

20. Water Outlet

21. Detergent Hose

22. Detergent Strainer

23. High Pressure Hose

24. Gun Assembly

25. Nozzzle Assembly

Page 9

SAFETY DECALS & PLACEMENT

FOR SELECT SPRAY 1500E

DO NOT REMOVE SAFETY DECALS FROM UNIT UNLESS REPLACING WITH MOST CURRENT SAFETY DECAL!!

Reference #7: Decal-

Warning-Risk of Electrocution (Part #56623229)

Reference #8: Decal-Caution Statements (Part #56623228)

Ref. #2: Tag-Warning-Risk of Electrocution

(Part #56623223)

Reference #9: Decal-Caution-Hot Water

(Part #56623230)

Reference #6: Decal-Warning-Risk of Injection/Explosion

(Part #56623227)

Nilfisk-Advance Select Spray 1500E Operator's Manual 9

Page 10

WARNING

RISK OF EXPLOSION!

DO NOT OPERATE UNIT IN AN

AREA WHERE FLAMMABLE GAS

VAPORS MAY BE PRESENT. AN

ELECTRIC SPARK MAY CAUSE

AN EXPLOSION.

RISK OF BURSTING!

DO NOT STORE / OPERATE UNIT

IN A FREEZING ENVIRONMENT.

WARNING

RISK OF INJECTION CAUSING

SEVERE INJURY!

NEVER LOOK DIRECTLY AT THE

NOZZLE ORIFICE UNLESS IT IS

DISCONNECTED FROM THE

GUN/WAND ASSEMBLY!

WHEN USING THE ADJUSTABLE

NOZZLE, NEVER ADJUST THE

SPRAY PATTERN WHILE THE

TRIGGER GUN IS OPEN!

INSTALLATION & PREPARATION

ATTIRE:

1. Proper attire is essential to your safety. It is advised to utilize whatever

means necessary to protect eyes, ears, and skin. Additional safety attire

(such as respiratory mask) may be required when using detergent cleaning

agents with this washer.

SET-UP:

1. This unit should only be placed on a level surface to ensure proper lubrication

for the water pump while operating. NEVER spray water directly on the unit!

2. Do not place unit in an area:

-where there is evidence of oil or gas leaks.

-where flammable gas vapors may be present.

3. Do not allow the unit to be exposed to rain, snow or freezing temperatures. If

any part of the unit becomes frozen: excessive pressure may build up in the

unit which could cause it to burst, resulting in possible serious injury to the

operator or bystanders.

4. Make sure the oil level is in the center of the sight glass. Pump oil level should

be checked before each use. If low, fill with SAE 30W Non-detergent oil. DO

NOT OVERFILL!

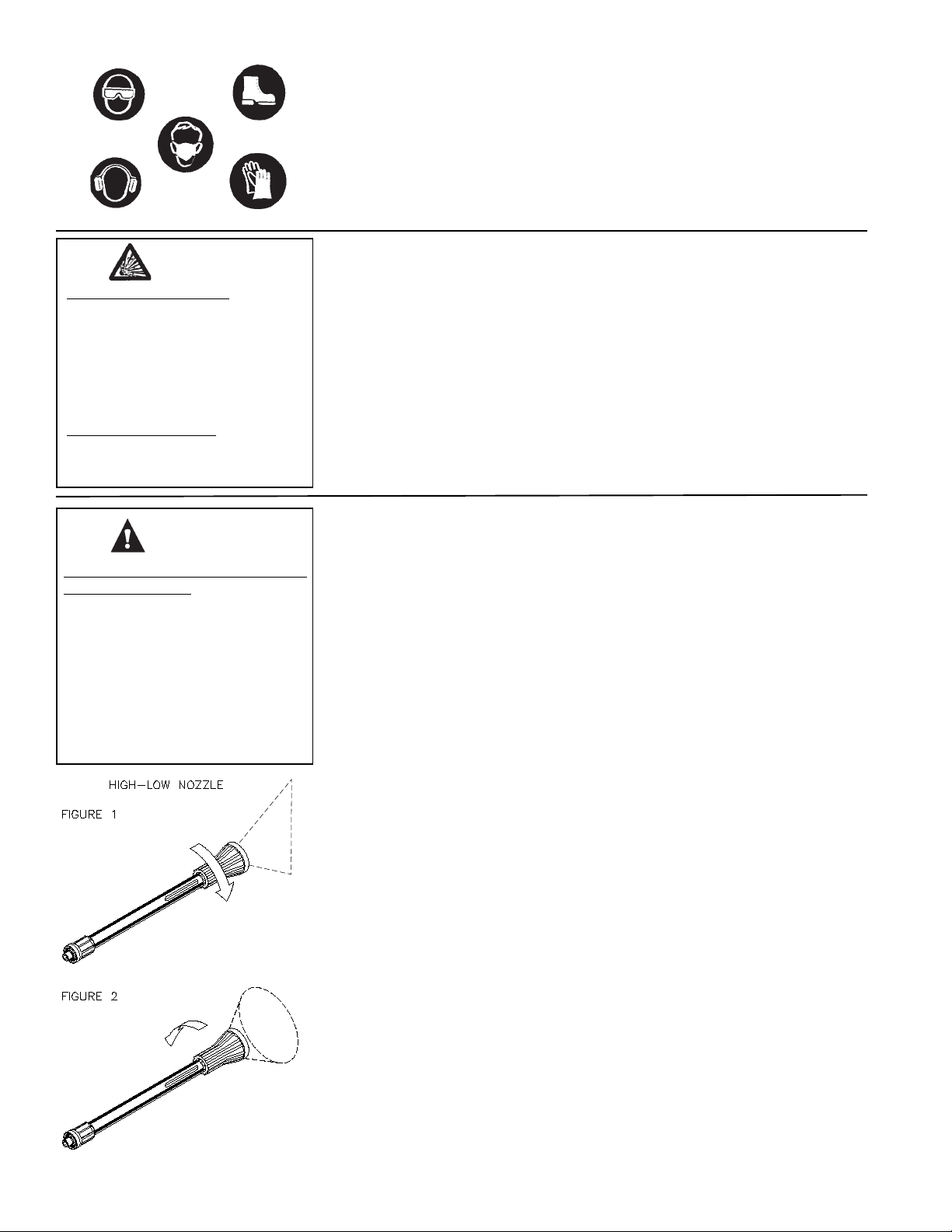

NOZZLE REVIEW:

NOTE: Nozzle assembly should NOT be connected to the gun assembly at this

time.

1. Selection of high pressure can be achieved by turning the protective collar

clockwise as shown in Figure 1, left. While in the high pressure mode, water

is directed solely through the 15° spray nozzle creating a concentrated high

pressure "fan" spray.

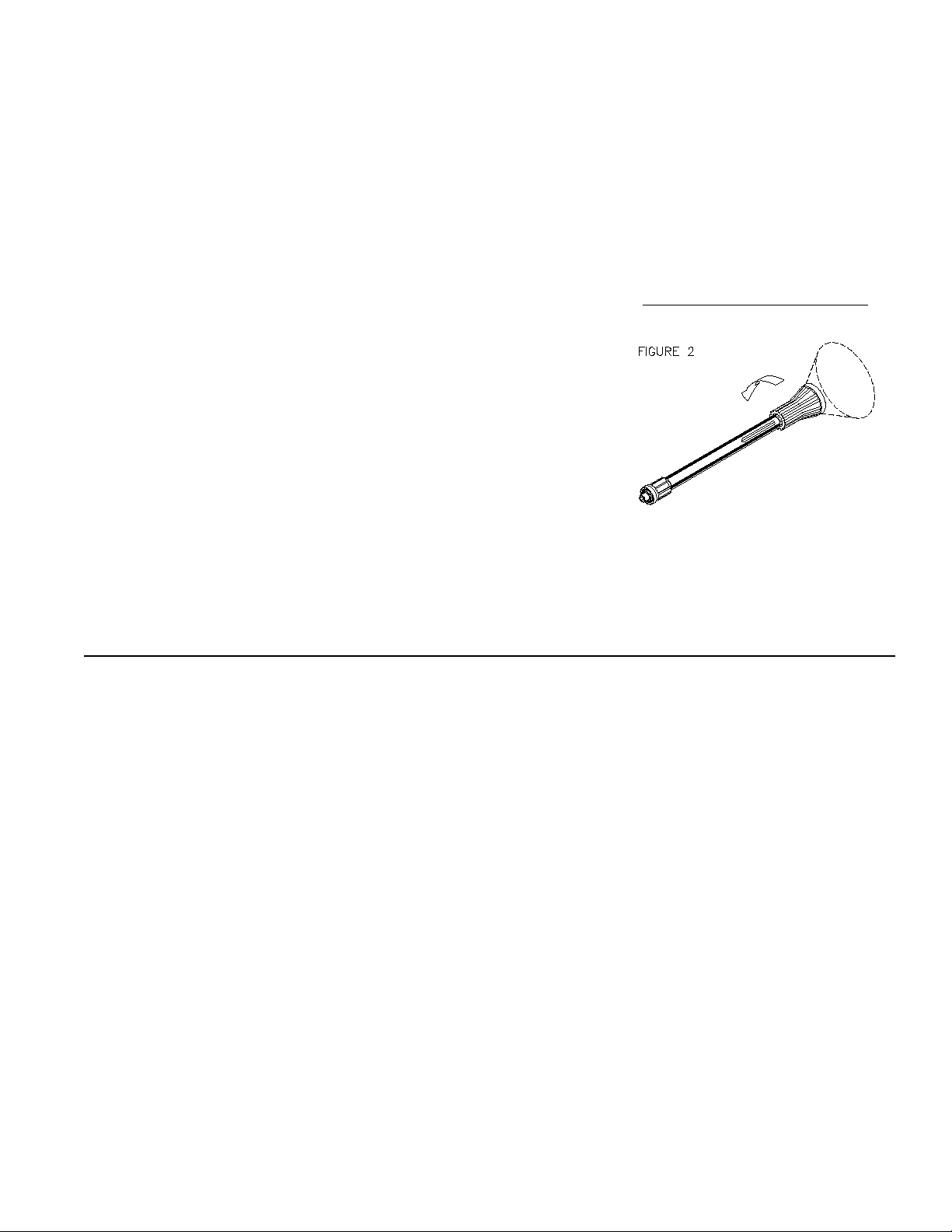

2. Selection of low pressure detergent application can be achieved by turning the

collar counterclockwise as shown in Figure 2, left. Once the pressure is low

enough, the detergent injector on the pressure washer will draw detergent into

the system. As the collar is turned, a water/detergent mixture exits not only from

the spray nozzle, but also around the nozzle. This creates a "fan/cone"

combination spray pattern.

OMGEN224/021696/DCE

10 Nilfisk-Advance Select Spray 1500E Operator's Manual

Page 11

INSTALLATION & PREPARATION

WARNING

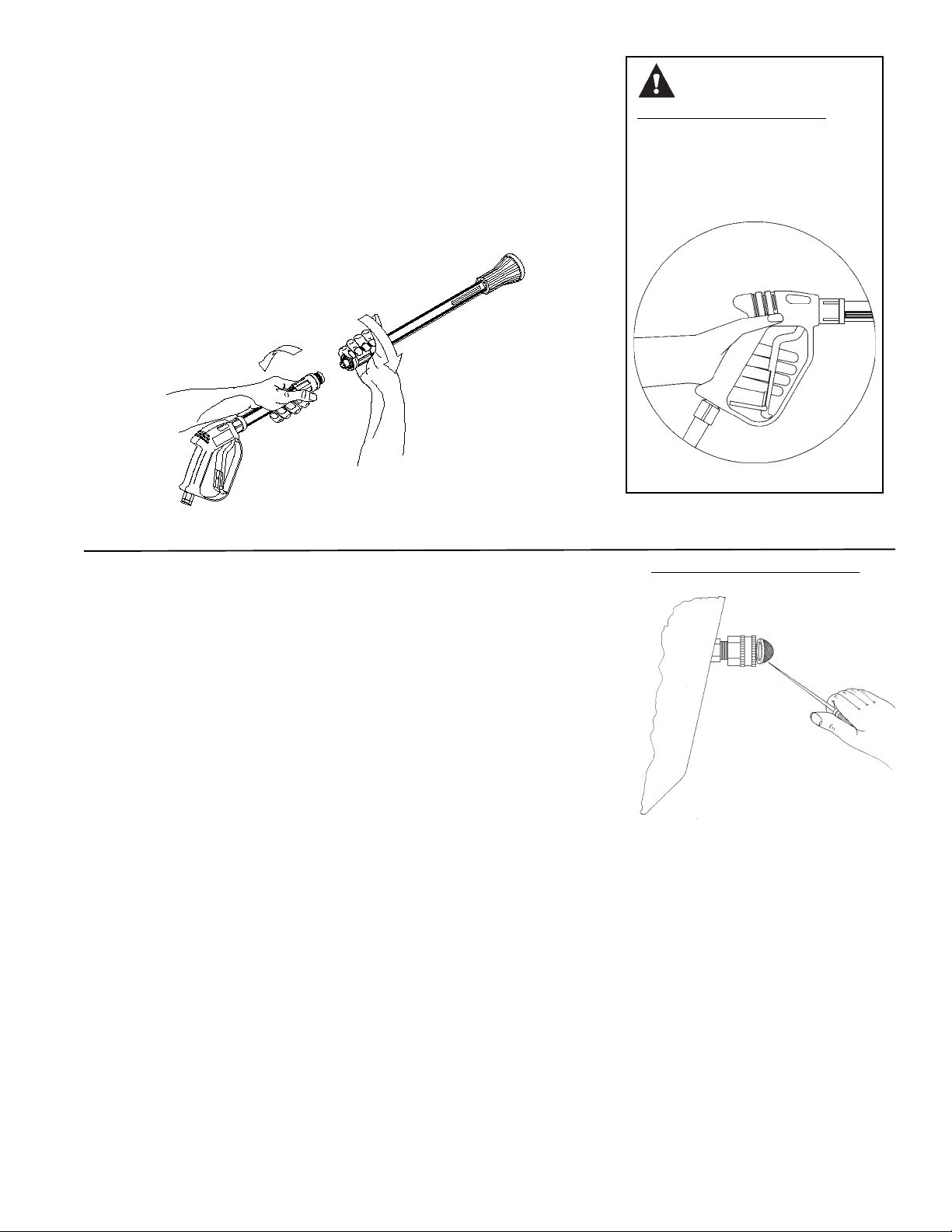

NOZZLE CONNECTION:

Be certain the trigger gun is locked in the "OFF" position. See

1.

WARNING

right.

2. The nozzle assembly should be disconnected from the gun assembly at

this time by unscrewing the nozzle/lance assembly from the gun/lance

assembly.

OMGEN228/031896/JTR

RISK OF SEVERE INJURY!

,

THE TRIGGER GUN SHOULD

ALWAYS BE LOCKED IN THE OFF

POSITION WHEN NOT IN USE!

GUN-LOCK.TIF/D1

WATER SUPPLY:

1. Select a water supply hose which is a quality grade of garden hose

measuring at least 3/4" ID and no longer than 50 feet.

2 Check the water inlet strainer (14) to ensure it is clean and free of any

obstructions. Periodic cleaning of the water strainer will help prevent pump

problems. As a strainer becomes obstructed, it restricts proper flow of

water to the pump. This can result in cavitations which will cause premature

failure of pump packings and valves. Using a screw driver, remove the

screen, clean or replace with Nilfisk-Advance #56632999 if necessary.

3. Connect the hoses:

a. Connect one end of the water supply hose to the water inlet (15) of the

unit.

b. Connect the other end of the hose to your pressurized water supply.

c. Connect the high pressure discharge hose (23) to the water outlet (20)

of the unit.

4. Follow the incoming water requirements listed below:

a. Water pressure must be a minimum of 20 pounds per square

inch (PSI) and a maximum of 125 PSI. (A typical outdoor faucet

will generally supply this PSI if turned completely "ON")

b. Incoming GPM must be approximately one gallon more than the

outgoing GPM stated on the pressure washer nameplate. (You

can check GPM by timing how long it takes to fill a 5 gallon

container)

c. Incoming water temperature must not exceed 190 °F/ 88°C. Excessive

pump damage may result if the water temperature exceeds this

acceptable level.

CHECK WATER INLET STRAINER

IN-STRN.TIF/D1

5. Never allow the unit to operate without the incoming water line attached and

the water supply turned all the way on.

Nilfisk-Advance Select Spray 1500E Operator's Manual 11

Page 12

INSTALLATION & PREPARATION

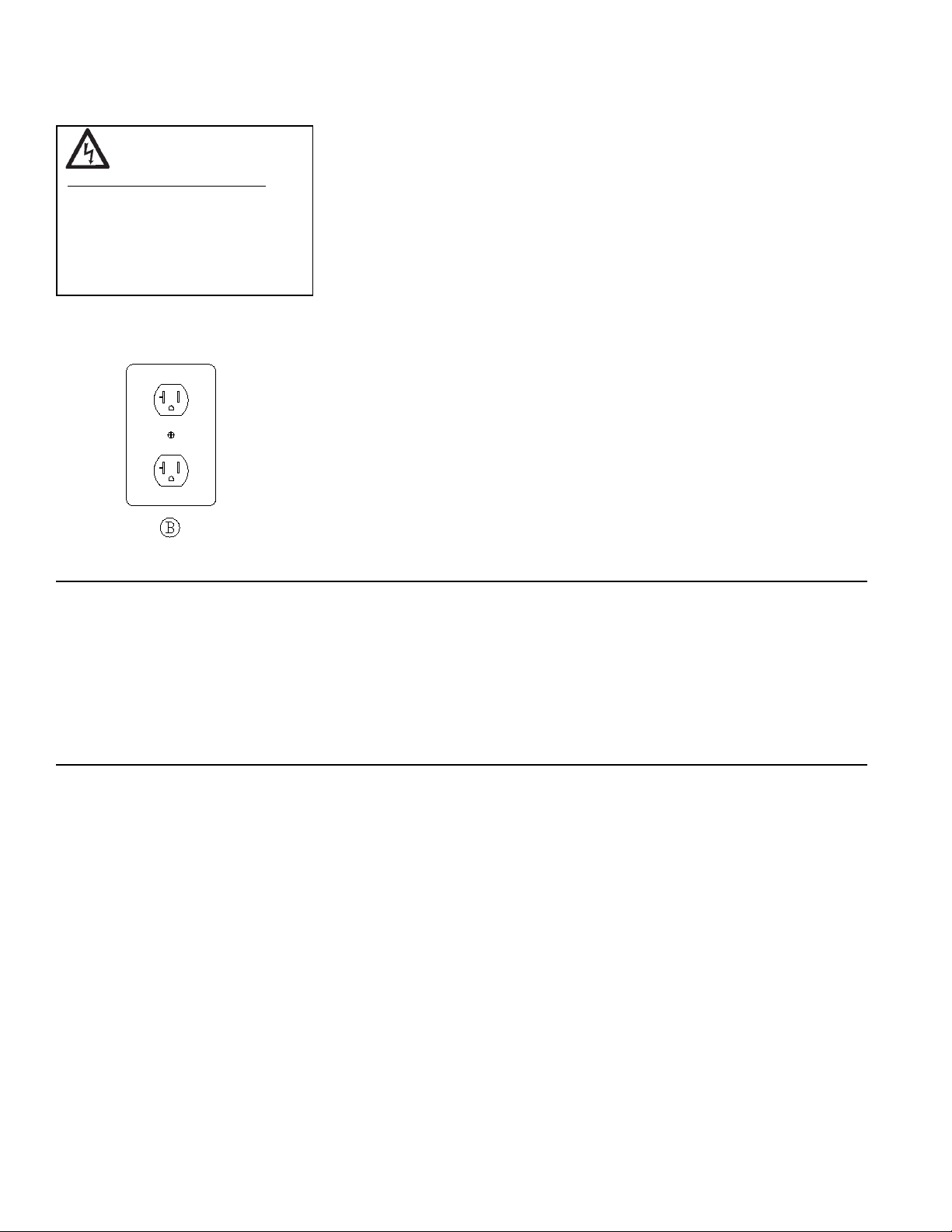

WARNING

RISK OF ELECTROCUTION!

This unit must be connected

to a properly grounded outlet.

DO NOT use an adapter OR

remove the third grounding

prong.

FIGURE A FIGURE B

OMGEN228/031296/JTR

POWER CORD CONNECTION:

1. Make certain the motor switch is in the "OFF" position.

2. Ensure electrical supply is 120Volt / 20 Amp / 60 Hertz. (See Figure B, Left)

3. Each time the GFCI is plugged into an outlet, test the GFCI according to the

instructions on the GFCI. Do not use the unit if the test fails!

4. Ensure the area between the pressure washer cord and the outlet is kept dry.

5. Insert the male plug into a grounded AC outlet. DO NOT use an adapter

OR remove the grounding plug!!

HEAT DUMP VALVE:

To ensure the water temperaure does not exceed acceptable levels, never allow

the pressure washer to operate in the bypass mode (with the unit running and the

trigger gun closed) for more than three minutes.

A "heat dump valve" has been added to this unit to protect the pump. It may begin

to open and release water if the water temperature in the pump has exceeded 180°F.

This will allow fresh, cool water to enter the system.

PRE-START INSPECTION PROCEDURES:

1. Before starting the unit, perform the following procedures:

a. Check the oil level in the pump.

b. Inspect the inlet water strainer. Clean or replace if necessary.

See "Water Supply", #2, pg. 11.

c. Check all hose connections to ensure they are securely tightened.

See "Water Supply", #3, pg. 11.

d. Inspect for system water leaks and oil leaks.

Be sure that all damaged parts are replaced and that the

mechanical problems are corrected prior to operation of the unit.

If service is needed, contact a Nilfisk-Advance Authorized Service

Center.

e. Inspect high pressure hose for kinking, cuts or leaks.

If a cut or leak is found, DO NOT USE HOSE!

Replace hose before starting unit.

See "Miscellaneous Safety Precautions" #6, pg. 6.

Be sure that all damaged parts are replaced and that the

mechanical problems are corrected prior to operation of the unit.

f. Inspect electrical cord for cuts.

If a cut is found, DO NOT TOUCH OR USE ELECTRICAL CORD!

Replace cord before starting the unit.

12 Nilfisk-Advance Select Spray 1500E Operator's Manual

Page 13

WARNING

THE FOLLOWING PAGES CONTAIN

OPERATING AND MAINTENANCE

INSTRUCTIONS

DO NOT ATTEMPT TO OPERATE THIS

PRESSURE WASHER

UNTIL YOU HAVE READ AND UNDERSTOOD

ALL SAFETY PRECAUTIONS AND

INSTRUCTIONS LISTED IN THIS MANUAL.

INCORRECT OPERATION OF THIS UNIT CAN

CAUSE SERIOUS INJURY!!

DO NOT ALTER OR MODIFY THIS

EQUIPMENT IN ANY MANNER!

Nilfisk-Advance Select Spray 1500E Operator's Manual 13

Page 14

WARNING

RISK OF INJECTION CAUSING

SEVERE INJURY!

KEEP CLEAR OF NOZZLE! NEVER

PLACE HAND OR FINGERS IN

FRONT OF NOZZLE!

DO NOT DIRECT DISCHARGE

STREAM AT PEOPLE OR PETS!

BE CERTAIN THE ADJUSTABLE

NOZZLE ASSY. IS SECURELY

CONNECTED TO THE WAND TO

PREVENT AN ACCIDENTAL

DISCHARGE!

CAUTION

RISK OF DAMAGE.

DO NOT ALLOW SPRAY

PATTERN TO REMAIN ON A FIXED

AREA FOR AN EXTENDED PERIOD

OF TIME. POSSIBLE DAMAGE

MAY OCCUR TO THE AREA.

OPERATING INSTRUCTIONS

PRIMING THE PUMP:

1. It is essential to prime the pump on initial start-up and each time the water

supply is disconnected from the unit after initial use.

2. Lay the high pressure hose out to remove any loops. Water flow will constrict

the hose, creating tight loops if the hose is not straight.

3. Securely connect the gun assembly to the high pressure hose.

NOTE: The nozzle assembly should NOT be connected to the gun assembly at

this time. (See Nozzle Connection" pg. 11)

4. With the trigger gun locked in the "OFF" position, turn the water supply

completely on. Pointing the gun in a safe direction, unlock the trigger gun and

squeeze the trigger.

5. Low pressure water will begin flowing from the hose/gun assembly. This allows

the unit to prime and purge any air from the system. The unit is primed when

water flow is uninterrupted by air.

6. Once the unit is primed, release the trigger and lock the gun in the "OFF"

position. Securely connect the nozzle assy. (See "Nozzle Connection"

pg. 11)

START-UP:

1. Refer to the "Safety Precautions" pgs. 4-7 before starting the unit.

2. Locate the Safety Decals on your unit and heed their warnings. (2,6,7,8,9)

3. With the gun locked in the "OFF" position, point the trigger gun away from

yourself or anyone else. Ensure water supply is turned completely on.

4. Disengage the safety lock-off on the gun and squeeze the trigger. Low

pressure water will begin flowing from the nozzle. Before starting the unit, brace

yourself as the gun will kick-back from the high pressure created by the pump

once the unit has started.

5. Move the On/Off Switch to the "ON" position. This switch includes a circuit

breaker for protection of the motor. In case of excess load, the circuit breaker

will automatically move the switch to the "OFF" position. To restart, move the

On/Off Switch to the "ON" position again.

6. Once the unit is turned on, perform the following procedures with the gun open:

a. Inspect for system water leaks and oil leaks.

If an oil leak is found, TURN UNIT OFF IMMEDIATELY!

Be sure that all damaged parts are replaced and that the

mechanical problems are corrected prior to operation of the unit.

If you require service, contact Nilfisk-Advance Customer Service.

b. Inspect high pressure hose for kinking cuts and leaks.

If a cut or leak is found, DO NOT TOUCH HOSE AT CUT OR

LEAK!!! TURN UNIT OFF IMMEDIATELY!

Replace hose before re-starting the unit. See "Miscellaneous

Safety Precautions #6, pg. 6. Be sure that all damaged parts are

replaced and that the mechanical problems are corrected prior to

operation of the unit. If you require service, contact Nilfisk-Advance Service.

c. Inspect electrical cord for cuts.

If a cut is found, DO NOT TOUCH OR USE ELECTRICAL CORD!

Replace cord before starting the unit.

7. Trigger the gun several times and try adjusting the spray pattern. Be certain

to LOCK the trigger gun in the "OFF" position whenever moving the adjustable

nozzle. NEVER look directly into the nozzle! High pressure water creates a

risk of severe injury!

8. Because your pressure washer delivers a high pressure spray and a variety

of spray patterns, there are many cleaning jobs that can be done without the

use of detergents. If a cleaning agent is required, see "Cleaning With

Detergents" pg. 15 for the correct procedures.

14 Nilfisk-Advance Select Spray 1500E Operator's Manual

Page 15

OPERATING INSTRUCTIONS

CLEANING WITH DETERGENTS:

1. Refer to "Detergent Cleaning Precautions" pg. 6 before working with

detergents. Be certain to wear protective safety attire as stated on pg. 10.

2. Prepare detergent solution according to label directions. Never pump

acids, alkaline, abrasive fluids or solvents through the unit.

3. Connect the detergent hose (21) to the unit as shown on page 8.

4. Immerse the strainer into the detergent solution to allow detergent to

siphon.

5. Be certain the water supply is completely turned "ON".

6. With the trigger gun locked in the "OFF" position, turn the collar at the end

of the wand counterclockwise for low pressure as shown in figure 2, right.

7. To apply solution, unlock the trigger gun and squeeze the trigger. In a few

moments a detergent/water mixture will exit the low pressure nozzle. Start

spraying the lower portion of the surface being cleaned and move up, using

long overlapping strokes. Applying from the bottom up helps avoid

streaking. Allow to soak briefly. (Avoid working on hot surfaces or in direct

sunlight to minimize the chances of the detergent drying, which may result

in damaging surfaces) Be certain to rinse a small section at a time.

ADJUSTABLE NOZZLE DETERGENT

OMGEN224/021696/DCE

8. To rinse: lock the trigger gun in the "OFF" position, turn the collar at the

end of the wand clockwise. Unlock the trigger gun and spray. It will take

about 30 seconds to purge all detergent from the line. For best rinsing

results, start at the top and work down.

9. Siphon a gallon of water through the low pressure detergent injection

system after each use. This prevents the possibility of corrosion or

detergent residue causing mechanical problems during the next use.

SHUT-DOWN:

1. Move the On/Off switch to the "OFF" position to turn unit off.

2. Turn the water supply "OFF".

3. Pointing the gun in a safe direction, trigger gun momentarily to relieve

any trapped pressure.

4. Once pressure is relieved, disconnect the nozzle assembly.

5. Disconnect the unit from the power source.

6. Disconnect and drain gun, wand and hoses.

7. Wipe unit clean and store with gun, wand and hoses in a safe, non-freezing

area.

Nilfisk-Advance Select Spray 1500E Operator's Manual 15

Page 16

STORAGE & MAINTENANCE

PUMP MAINTENANCE:

The pump oil must be changed after the first 25 hours of operation. Once the initial

oil change has been completed, it is recommended the oil be changed every 3

months or 250 hour intervals. If oil appears dirty or milky, changes may be required

at a greater frequency. Use SAE 30W Non-Detergent oil and fill only to the center

of the oil sight glass. DO NOT OVERFILL!

NOZZLE MAINTENANCE:

Water flow through the spray nozzle will erode the orifice, making it larger, resulting

in a pressure loss. Nozzles should be replaced whenever pressure is less than

85% of the maximulm. The frequency of replacement will depend upon such

variables as mineral content in the water and number of hours the nozzle is used.

16 Nilfisk-Advance Select Spray 1500E Operator's Manual

Page 17

WINTERIZING:

STORAGE & MAINTENANCE

1. For storage and transportation purposes in subfreezing ambient temperatures,

it will be necessary to winterize this unit. This unit must be protected to the

lowest incurred temperature for the following reasons:

a. If any part of the pumping system becomes frozen: excessive

pressure may build up in the unit which could cause the unit to burst

resulting in possible serious injury to the operator or bystanders.

b. The pumping system in this unit may be permanently damaged if

frozen. FREEZE DAMAGE IS NOT COVERED BY WARRANTY.

If you must store your unit in an area where the temperature may fall below

32°F, you can protect your unit by following the procedure outlined below.

1. Gather the following items:

a. Two 5 gallon containers.

b. One gallon of antifreeze.(Nilfisk-Advance recommends and

environmentally safe antifreeze)

c. Water supply.

d. Three foot hose, 1/2-3/4 I.D. with a 3/4 inch male garden

hose fitting.

2. Procedure:

a. Shut off the unit and water supply.

b. Relieve system pressure by pointing the trigger gun in a safe

direction and squeezing the trigger until water flow ceases

to exit the nozzle.

c. Lock the trigger gun in an OFF position and remove the

nozzle.

d. In a 5 gallon container, mix the antifreeze and water according

to manufacturer's recommendations for the temperature

you are winterizing to.

NOTE: Proper winterizing is based on the recommended manufacture's instructions

listed on the "Protection Chart" shown on the back label of most antifreeze

containers.

WARNING

RISK OF UNIT BURSTING!

DO NOT STORE OR OPERATE

UNIT IN A FREEZING ENVIRONMENT!

e. Remove the water supply hose from the unit and attach the

3 foot hose securely to the inlet connection. Submerge the

opposite end into the antifreeze solution.

f. Point the wand into the empty container and start the unit.

g. Trigger the gun until the antifreeze begins to exit the wand.

Release the trigger for 3 seconds, then trigger the gun for 3

seconds. Continue cycling the gun several times until all the

antifreeze mixture is siphoned from the container.

h. Detach the 3 foot hose from the unit and drain any excess

antifreeze back into the 5 gallon container.

i. Disconnect the hose/gun/wand assembly from the unit and

drain any excess antifreeze back into the 5 gallon container.

j. Store the hose, gun and wand with the unit in a safe area.

k. Store antifreeze solution for next use or dispose of according

to state EPA laws.

3. Optional Procedure:

a. Shut the unit off.

b. Relieve system pressure by pointing the trigger gun in a safe

direction and squeezing the trigger until water flow ceases

to exit the nozzle.

c. Disconnect and drain the hose, gun and wand.

d. Start the unit and allow it to run until all the water exits the

unit. Once the water has stopped flowing from the unit, turn

the unit off.

NOTE: When using this procedure, caution should be used as ice

STARTING UNIT AFTER EXTENDED STORAGE:

1. BE CERTAIN the unit is NOT plugged into the power source.

chips can form from drops of water which could cause the

unit to burst if starting before completely thawed.

2. Prior to restarting the unit, thaw out any possible ice from the wand, gun, hose

and unit.

3. After following all "PREPARATION" instructions, start the unit momentarily

and immediately turn "OFF" to ensure all parts are lubricated before operation.

Nilfisk-Advance Select Spray 1500E Operator's Manual 17

Page 18

TROUBLESHOOTING

SYMPTOM PROBABLE CAUSE REMEDY

Pump motor will not start, or stops GFCI tripped. Turn unit "OFF". Test GFCI by

while operating. pressing reset button.

Tripped circuit breaker or fuse Disconnect all other plugs on the

blown in circuit fuse box. circuit being used and reset circuit

Loose or disconnected plug. Reconnect plug.

Tripped circuit breaker in unit. Allow to cool and restart unit.

Unit is frozen. Allow to thaw. If any part of the unit

breaker OR check and replace fuse.

becomes frozen: excessive

pressure may build up in the unit

which could cause the unit to burst

resulting in possible serious injury to

the operator or bystanders.

Circuit breaker trips or fuse blows Circuit overload. Check that the circuit is rated

Extension cord is too long or wire Use correct electrical requirements

is too small. as listed on pg. 4.

GFCI trips. Incorrect voltage. Ensure electrical supply is

Electrical short to ground. Contact Nilfisk-Advance Service

Motor runs but there is no discharge Inadequate water supply. Ensure hose is 3/4" diameter and

at nozzle when trigger mechanism is incoming water supply is turned on.

squeezed. Kink in water inlet hose. Remove kink.

Kink in high pressure discharge hose. Replace hose.

Low or fluctuating pressure.

Water inlet screen obstructed. Remove screen, clean or replace.

Pump sucking air. (Prime lost) Tighten all water intake connections

Not in high pressure mode. Turn the collar clockwise to engage

Obstructed or worn orifice. Remove and clean, or Replace.

Bypass valve not operating correctly. Repair or replace.

Oil appears milky or foamy. Water in oil. Change pump oil. Fill to proper

1500 PSI/ 20A. Disconnect all plugs

on the circuit. When connecting to

a circuit protected by fuses, use time

delay fuses only.

120 V/ 20 A/ 60 Hz.

Center.

Eliminate leaks in intake line.

in the high pressure mode.

level.

Oil leaking from unit. DO NOT USE!!!!! Contact Nilfisk-Advance Service

Center.

Detergent will not siphon into Detergent strainer is not completely Check; submerge if necessary.

Low Pressure Detergent mode. submerged in detergent solution

Detergent strainer is obstructed. Inspect, clean or replace.

Detergent hose is obstructed, cut Inspect, clean or replace.

or kinked.

Not in Low Pressure mode. Turn collar counter-clockwise.

Nozzle assembly is plugged. Clean or replace.

Too many high pressure hose Use one extension maximum.

extensions attached to the water outlet.

Ball & Spring in Venturi stuck. Remove, clean or replace.

Water flows back into detergent Ball & Spring in Venturi reversed, Remove, clean or replace.

container. missing or corroded.

Water flows from the nozzle when the Gun is malfunctioning. Repair or replace.

trigger gun is in the "OFF" position.

18 Nilfisk-Advance Select Spray 1500E Operator's Manual

Page 19

NOTES

Nilfisk-Advance Select Spray 1500E Operator's Manual 19

Page 20

FRAME ASSEMBLY FOR 1500E

cd-1502-1KUC/CC-070299

20 Nilfisk-Advance Select Spray 1500E Operator's Manual

Page 21

CD-1502-1KCC-040400

FRAME ASSEMBLY FOR 1500E

Ref. # Description Pa rt # Qty.

1 Handle 56648286 1

2 Locknut 56623206 4

3 Bolt 56623177 4

4 Locknut 56633248 2

5 Knob 56623332 1

6 Upper Joint (Adjustable) 56633312 2

7 Lower Joint (Adjustable) 56633311 2

8 Bolt 56623178 2

9 Frame 56648287 1

10 Was her 56633218 2

11 Wheel 56632893 2

12 Hubcap 56633288 2

13 Isolator 56632895 2

14 Was her 56633221 2

15 Screw 56633179 2

16 Bolt 56623179 4

17 Was her 56623194 4

18 Locknut 56623207 4

19 Decal-W arning: Bac kflow (English/French) 56648288 1

20 Decal-Warning: Hot Water (English) 56623230 1

- Decal-Warning: Hot Water (English/Frenc h) 56648289 1

21 Decal-Caution: Important (English) 56623228 1

- Decal-Caution: Important (English/French) 56648290 1

22 Hang Tag-U/L Warning (English) 56623223 1

- Hang Tag-U/L W arning (English/Frenc h) 56648291 1

23 Cable Tie 56623217 1

24 Motor Assemby (USA) 56648265 1

- Motor As semby (Canada) 56648283 1

25 Decal-On/Off 56623226 1

26 Decal-Selec t Spray 1500E 56623231 2

27 Decal-Warning Statements (English) 56623229 1

- Decal-Warning Statements (English/ French) 56648292 1

28 Decal-Warning: Risk of Injection/Explosion (English) 56623227 1

- Decal-Warning: Risk of Injection/Ex plosion (English/Frenc h) 56648293 1

29 Decal-Serial Number N/A 1

30 Decal-U/ L Specs N/A 1

31 Decal-U/ L Date Code N/A 1

32 Pump 56623202 1

33 Plug 56623155 1

34 Detergent Strainer 56633001 1

35 Detergent Hose 56632898 1

36 Locknut 56623293 1

37 Detergent Injector 56633519 1

38 Quick-Connect Socket 56662972 1

39 O-ring 56633106 1

40 Heat Tape 56623218 1

41 Inlet Filter 56632999 1

42 Inlet Fitting 56648250 1

43 Heat Dump Valve 56648264 1

44 Quick-Connect Plug 56632974 1

45 High Pressure Hose 56632907 1

46 Foam Covering 56633534 1

47 Gun with Screw Lance 56632915 1

48 Nozzle Assembly 56633655 1

49 Lance 56632967 1

50 High-Low Adjusting Noz zle 56632966 1

51 Spray Nozzle 56632980 1

Nilfisk-Advance Select Spray 1500E Operator's Manual 21

Page 22

MOTOR ASSEMBLY (56648265 & 56648283) FOR 1500E

8510247-091399

22 Nilfisk-Advance Select Spray 1500E Operator's Manual

Page 23

PD851247N-091399

MOTOR ASSEMBLY (56648265 & 56648283)

REF. # DESCRIPTION PART # QTY.

1 Screw-hex N/A 8

2 Motor Box N/A 1

3 O-ring N/A 1

4 Terminal N/A 1

5 Switch 56633270 1

6Crimp Splice N/A1

7 Starting Capacitor 56623213 1

8 Running Capacitor 56623214 1

9 Terminal N/A 1

10 Strain Relief (USA) 56633284 1

Strain Relief (Canada) 56648284 1

11 GFCI Cord (USA) 56633262 1

GFCI Cord (Canada) 56648285 1

12 Strap for Motor Box N/A 1

13 Motor N/A 1

Nilfisk-Advance Select Spray 1500E Operator's Manual 23

Page 24

PUMP ASSEMBLY (56623202) FOR 1500E

3-0137

56648316

24 Nilfisk-Advance Select Spray 1500E Operator's Manual

Page 25

3-0137

REF # DESCRIPTI ON PART # QTY REF # DESCRIP TI ON PART # QTY

1 B olt 56623269 3 36 Disc harge Valve (See Kit 56633590) N/A Sep. 3

2 Flatwasher 56623172 3 37 V alve Spring (S ee Kit 56633590) N/A Sep. 3

3 Cover-Rear 56623256 1 38 Valve Spring Retainer (See Kit 56633590) N/A Sep. 3

4 O-ring 56623162 1 39 Manifold Outlet 56623264 1

5 Oil Seal 56623171 3 40 Bolt 56623266 6

6 B earing-Inner 56623311 1 41 Hose B arb 56623157 1

7 Connecting Rod 56623257 3 42 By-pass Hose 56633459 1

8 Crankshaft 56623294 1 43 Hose Clamp 56633441 1

9 S nap Ring 56623258 1 44 Hos e B arb 56633458 1

10 B earing-Outer 56623312 1 45 O-ring 56633128 3

11 Flatwasher (See 56623338) N/A Sep. 4 46 O-ring 56623160 1

12 Lock washer (See 56623338) N/A Sep. 4 47 Valve Seat 56633404 1

13 B olt (See 56623338) N/A Sep. 4 48 Valve & Ball As sembly 56633405 1

14 P lug 56633338 2 49 Unloader Body N/A 1

15 O-ring 56633127 2 50 Flow Balancer 56633409 1

16 Crankc ase 56623259 1 51 Spring 56633440 1

17 Oil Level Gauge 56633041 1 52 Disc harge Fitting 56633410 1

18 Gask et 56623170 1 53 Back-up Ring (See 56623341) N/A Sep. 1

19 Piston Rod Pin 56623243 3 54 O-ring (See 56623341) N/A Sep. 1

20 Piston Rod 56623260 3 55 Piston Retainer 56633406 1

21 W as her 56623265 3 56 O-ring (See 56623341) N/A Sep. 1

22 Oil S eal 56633165 3 57 B ack-up Ring (See 56623341) N/A Sep. 1

23 S eal Retainer 56633401 3 58 Piston Stem 56633408 1

24 Low Pres sure Seal (See K it 56633592) N/A Sep. 3 59 Spring Retainer 56633407 1

25 Manifold Inlet 56623261 1 60 Unloader Spring 56633498 1

26 P lunger 56633402 3 61 Loc knut 56623293 1

27 Valve Inlet 56648282 3 62 Hex Adjusting Cap 56633457 1

28 S pac er 56623262 3 63 Disc harge Valve Assembly 56648314 3

29 S pring 56623316 3 64 Valve Seat 56648315 3

30 W as her 56623267 3 Bolt Mount Kit ( 4 each 11-13) 56623338

31 Nut 56623268 3 Seal Kit (3 each 24, 32, 33) 56633592

32 Seal-High Pressure (See Kit 56633592) N/A Sep. 3 Valve Kit (3 each 33, 34, 36-38) 56633590

33 O-ring (See Kit 56633592) N/A Sep. 6 Optional Valve Kit (33, 35, 63, 64) 56648316

34 Disc harge Valve Seat 56623263 3 Unloader O-ring Kit (45, 53, 54, 56, 57) 56623341

35 Valve Assembly (36-38) (See Kit 56633590) N/A Sep. 3 Unloader Assembly (44-62) 56633625

PUMP ASS EMBLY (56623202)

Nilfisk-Advance Select Spray 1500E Operator's Manual 25

Page 26

GUN (56632915) AND WAND (56632967 & 56632966) ASSEMBLY FOR 1500E

0MGEN206-071596-DCE

26 Nilfisk-Advance Select Spray 1500E Operator's Manual

Page 27

OMGEN206N-071596-DCE

GUN (56632915) & WAND (56632967 & 56632966) ASSEMBLY

REF. # DESCRIPTION PART # QTY.

1 Screw 56623187 7

2 Plastic Housing (Left side) 56623135 1

3 Housing-Brass 56623153 1

4 Pipe 56633034 1

5 Coupler 56633069 1

6 Trigger Safety Lock 56632921 1

7 Trigger Rest 56623133 1

8 Trigger 56623134 1

9 Trigger Pin 56623244 1

10 Plastic Housing with Warning (Right Side) 56623132 1

11 Plug (See Kit 56633560) N/A Sep. 1

12 O-ring (See Kit 56633560) N/A Sep. 1

13 Spring (See Kit 56633560) N/A Sep. 1

14 Ball (See Kit 56633560) N/A Sep. 1

15 Seat (See Kit 56633560) N/A Sep. 1

16 O-ring (See Kit 56633560) N/A Sep. 1

17 Pin (See Kit 56633560) N/A Sep. 1

18 Washer (See Kit 56633560) N/A Sep. 1

19 O-ring (See Kit 56633560) N/A Sep. 1

20 Back-up Ring (See Kit 56633560) N/A Sep. 1

21 Gun/Wand Connector 56632920 1

22 Pipe 56633033 1

23 Wand Protector 56633530 1

24 Plastic Screw Connector-Male 56632919 1

25 Quick Connect-Female 56632976 1

26 O-ring 56633137 1

27 Quick Connect-Male 56632977 1

28 Plastic Screw Connector-Female 56623131 1

29 Pipe 56632970 1

30 Wand Protector 56623144 1

31 Body N/A 1

32 O-ring 56633152 1

33 Nozzle Cover N/A 1

34 O-ring 56633153 1

35 Nozzle Holder N/A 1

Gun w/Sc rew Lance (Includes items 1-25) 56632915

Gun Repair Kit (Includes items 11-20) 56633560

Lance Assembly Complete (Inc. 26-30) 56632967

High/Low Adj. Nozzle (Includes 31-35) 56632966

Lance/Nozzle Assembly (Includes 26-35) 56633655

Must order 56632915 & 56633655 for complete Gun & Wand Assembly

Nilfisk-Advance Select Spray 1500E Operator's Manual 27

Page 28

DETERGENT INJECTOR (56633519) FOR 1500E

OMGEN199-071596-JTR

0MGEN199N-032295

DETERGENT INJECTOR (56633519)

REF. # DESCRIPTION PART # QTY.

1 O-ring 56633128 1

2 Orifice 56648266 1

3 Injector Body N/A 1

4 Valve Spring (See 56648267) N/A Sep. 1

5 Ball-Stainless Steel (See 56648267) N/A Sep. 1

6 O-ring (See 56648267) N/A Sep. 1

7 Injector Barb 56648268 1

Injector Repair Kit (Includes 4-6) 56648267

28 Nilfisk-Advance Select Spray 1500E Operator's Manual

Page 29

WIRING SCHEMATIC FOR 1500E

OMCWU189S-061295-DCEOMCWU189W-061295-DCE

WIRING DIAGRAM FOR 1500E

Nilfisk-Advance Select Spray 1500E Operator's Manual 29

Page 30

TABLE DES MATIÈRES

INTRODUCTION .......................................................................................................................................... 31

IMPORTANTES CONSIGNES DE SÉCURITE ............................................................................................. 32-35

MESURES DE PRÉCAUTION -- ÉLECTRICITÉ ........................................................................ 32-33

MESURES DE PRÉCAUTION -- PULVÉRISATION ................................................................... 33-34

MESURES DE PRÉCAUTION -- NETTOYAGE À L’AIDE DE DÉTERSIF .................................. 34

MESURES DE PRÉCAUTION -- DIVERSES ............................................................................. 34-35

MESURES DE PRÉCAUTION -- RÉGLAGE .............................................................................. 35

CARACTÉRISTIQUES ................................................................................................................................. 35

COMPOSANTS ............................................................................................................................................ 36

AUTOCOLLANTS DE SÉCURITÉ ............................................................................................................... 37

INSTALLATION ET PRÉPARATION .................................................................................................... ........ 38-40

TENUE VESTIMENTAIRE .......................................................................................................... 38

MISE EN OEUVRE .................................................................................................................... 38

TÊTE DE LANCE À BUSE RÉGLABLE ..................................................................................... 38

PISTOLET ................................................................................................................................. 39

ALIMENTATION EN EAU ........................................................................................................... 39

BRANCHEMENT DU CORDON D’ALIMENTATION .................................................................... 40

VALVE D'EVACUATION DE CHALEUR ..................................................................................... 40

INSPECTION AVANT MISE EN MARCHE ................................................................................. 40

DIRECTIVES D’UTILISATION ...................................................................................................................... 42-43

AMORÇAGE DE LA POMPE ..................................................................................................... 42

MISE EN MARCHE DE L’APPAREIL ......................................................................................... 42

NETTOYAGE À L’AIDE DE DÉTERSIF ..................................................................................... 43

ARRÊT DE L’APPAREIL ........................................................................................................... 43

ENTREPOSAGE ET ENTRETIEN................................................................................................................ 44-46

ENTRETIEN DE LA POMPE/ LA BUSE ..................................................................................... 44

HIVERNISATION ....................................................................................................................... 45

MISE EN MARCHE APRÈS ENTREPOSAGE PROLONGÉ ........................................................ 46

DÉPANNAGE ............................................................................................................................................... 47-48

NOTE ........................................................................................................................................................... 49-51

GARANTIE ................................................................................................................................................... 52

30 Nilfisk-Advance Select Spray 1500E Operator's Manual

Page 31

INTRODUCTION

Toutes nos félicitations pour l’achat d’un appareil de lavage Nilfisk-Advance sous pression. Cet appareil a été conçu et

construit dans une optique de qualité et de rendement. Chacun de ses composants a fait l’objet de contrôles de qualité

rigoureux.

Le présent guide d’utilisation est rédigé à votre intention. Si vous suivez les directives simples relatives à la sécurité, à

l’installation, à l’utilisation, à l’entretien et au dépannage qui y sont exposées, votre appareil de lavage sous pression

Nilfisk-Advance vous assurera des années de bons et loyaux services. Le contenu du guide est établi en fonction des

toutes dernières informations sur le produit disponibles au moment de la publication. Nilfisk-Advance se réserve le droit

de modifier sans préavis les prix, couleur, matériaux, équipements, spécifications et modèles.

! IMPORTANT !

Dans le guide, certains paragraphes qui traitent de sécurité sont encadrés. L’encadrement

est destiné à mettre en évidence les consignes de sécurité qui doivent être suivies lors de

l’utilisation de l’appareil de lavage sous pression. Ces consignes sont précédées d’un «mot

d’alerte» qui indique le degré ou le niveau de gravité du danger. Les mots d’alerte utilisés

dans ce manuel sont les suivants :

DANGER :

MISE EN GARDE :

AVERTISSEMENT :

À gauche de certains paragraphes figure un «symbole d’alerte de sécurité» destiné à

attirer l’attention sur les pratiques ou les méthodes dangereuses pour les utilisateurs de

l’appareil.

REMETTRE UNE COPIE DE CE MANUEL À QUICONQUE UTILISE L’APPAREIL. LIRE TOUTES

LES DIRECTIVES AVANT D’UTILISER L’APPAREIL DE LAVAGE SOUS PRESSION ET

ATTIRER TOUT PARTICULIÈREMENT L’ATTENTION SUR LES «CONSIGNES DE SÉCURITÉ»

DESTINÉES À ÉVITER DE SE BLESSER EN UTILISANT L’APPAREIL.

Après avoir déballé l’appareil, en inscrire immédiatement le numéro de série ci-dessous.

NUMÉRO DE SÉRIE : _________________

Veuillez inspecter soigneusement l’appareil pour vous assurer qu’il est intact. En cas d’avarie, adressez immédiatement

une réclamation au transporteur. N’utilisez l’appareil qu’après avoir fait remplacer toute pièce endommagée et fait régler

tous les problèmes d’ordre mécanique. Pour cela, veuillez vous adresser au détaillant qui vous a vendu l’appareil ou au

centre d’entretien Nilfisk-Advance agréé de votre localité.

Signale un risque certain de blessures graves voire mortelles.

Signale un risque de blessures graves voire mortelles.

Signale un risque de blessures légères ou de dommages de

gravité moyenne.

800-989-2235

Avant d’appeler, veuillez disposer des renseignements suivants :

1. Numéro de modèle

2. Numéro de série

3. Date et lieu d’achat

Nilfisk-Advance Select Spray 1500E Operator's Manual 31

Page 32

IMPORTANTES CONSIGNES DE SÉCURITÉ

MESURES DE PRÉCAUTION -- ÉLECTRICITÉ:

1. DIRECTIVES DE MISE À LA TERRE:

Cet appareil doit être mis à la terre. En cas de défectuosité ou de panne,

le conducteur de mise à la terre offre un trajet de moindre résistance au

courant, ce qui réduit le risque de secousses électriques. L’appareil

comporte un cordon à conducteur et fiche de mise à la terre. Cette fiche

doit être branchée à une prise adéquate, installée et mise à la terre

conformément à tous les codes et règlements locaux.

2. DANGER:

S’il est mal connecté, le conducteur de mise à la terre présente un risque

d’électrocution. En cas de doute quant à la mise à la terre de la prise,

consulter un électricien agréé ou un spécialiste de l’entretien. Ne pas

modifier la fiche de l’appareil; si elle ne s’insère pas dans la prise, faire

poser une prise adéquate par un électricien agréé. N’utiliser aucun

adaptateur pour enficher l’appareil.

3. PROTECTION PAR DISJONCTEUR DE FUITE À LA TERRE:

Cet appareil de lavage sous pression comporte un disjoncteur de fuite à la

terre intégré à la fiche du cordon d’alimentation électrique. Ce dispositif

assure une protection supplémentaire contre le risque de secousses

électriques. Si on doit remplacer le cordon, n’utiliser que des pièces de

rechange identiques protégées par un disjoncteur de fuite à la terre.

4. CORDONS PROLONGATEURS:

MISE EN GARDE

Nilfisk-Advance

Si on doit employer un cordon prolongateur, le brancher à un disjoncteur

de fuite à la terre comme en comportent les boîtes de raccordement ou les

prises protégées. Ce cordon prolongateur doit avoir les caractéristiques

suivantes:

Longueur du cordon Diamètre du fil

Jusqu’à 15 m (50 pi) 14 AWG

De 15 à 30 m (50 à 100 pi) 12 AWG

DÉCONSEILLE L’EMPLOI DE CORDONS

PROLONGATEURS.

N’employer que des cordons prolongateurs trifilaires à fiches de mise à la

terre à trois broches et à connecteurs tripolaires adaptés à la prise de

l’appareil. N’employer que des cordons prolongateurs destinés à l’usage à

l’extérieur. Les cordons de ce type portent la mention «Acceptable for use

with outdoor appliances; store en salle while not in use» (Pour emploi à

l’extérieur; à entreposer à l’intérieur) N’employer que des cordons

prolongateurs dont les caractéristiques électriques sont au moins

équivalentes à celles de l’appareil. Ne pas employer de cordon

prolongateur endommagé. Examiner le cordon avant de s’en servir, et le

remplacer s’il est endommagé. Manipuler délicatement les cordons

prolongateurs et ne pas les tirer d’un coup sec pour les débrancher. Leur

éviter tout contact avec les sources de chaleur et les objets tranchants.

Toujours les débrancher de la prise avant de les débrancher de l’appareil.

MISE EN GARDE

Pour réduire le risque d’électrocution, veiller à ce que tous les

branchements restent secs et leur éviter tout contact avec le sol. NE PAS

laisser les cordons électriques et leurs branchements traîner dans l’eau ni

entrer en contact avec de l’eau. Ne pas toucher à la prise lorsqu’on a les

mains mouillées.

5. NE PAS faire tomber le disjoncteur de fuite à la terre, sous peine de

l’endommager.

6. NE PAS tirer sur le cordon électrique pour le débrancher de la prise, et NE

PAS transporter l’appareil en le tenant par son cordon.

32 Nilfisk-Advance Select Spray 1500E Operator's Manual

Page 33

IMPORTANTES CONSIGNES DE SÉCURITÉ

7. S’assurer que le cordon d’alimentation est intact avant de s’en servir. S’il

est écrasé, coupé ou endommagé par la chaleur, il présente un risque de

secousses électriques.

8. TOUJOURS s’assurer l’appareil est alimenté en courant de la tension

voulue. Avant de brancher l’appareil à une source d’alimentation adéquate,

s’assurer que son interrupteur est à ARRÊT. Débrancher l’appareil lorsqu’il

n’est pas en service.

9. NE PAS utiliser l’appareil à un endroit susceptible de contenir des vapeurs

inflammables, car une étincelle électrique peut y provoquer une explosion

ou un incendie.

10. Ne JAMAIS diriger le jet d’eau sur ou dans des installations électriques de

quelque type que ce soit, y compris les prises, les ampoules, les boîtes

de fusibles, les transformateurs, l’appareil lui-même, etc. Cela peut

occasionner de graves secousses électriques.

11. Nilfisk-Advance

réparation électrique de son appareil.

MESURES DE PRÉCAUTION -- PULVÉRISATION:

déconseille au propriétaire de procéder lui-même à toute

MISE EN GARDE

RISQUE D’INJECTION OU DE COUPURE GRAVE

NE PAS SE PLACER EN FACE DE LA BUSE.

NE DIRIGER LE JET NI SUR DES PERSONNES NI SUR DES ANIMAUX

DOMESTIQUES.

APPLIQUER SYSTÉMATIQUEMENT LES MESURES DE PRÉCAUTION

ÉLÉMENTAIRES, COMME:

1. SE TENIR À L ’ÉCART DU JET:

- À cause de la pression et de la vitesse élevées du jet, les liquides

peuvent pénétrer sous la peau, et blesser gravement.

- Ne JAMAIS diriger le pistolet ni vers soi ni vers quiconque. Ne JAMAIS

mettre la main, les doigts ou une partie du corps directement sur la

buse de pulvérisation. Éloigner toute personne de la zone d’utilisation

de l’appareil. Prendre des précautions toutes particulières lorsqu’on

utilise l’appareil à proximité d’enfants.

- En cas d’accident, si le jet semble avoir pénétré sous la peau,

OBTENIR DES SOINS MÉDICAUX D’URGENCE. NE PAS TRAITER

LA BLESSURE COMME UNE COUPURE ORDINAIRE. Si on utilise

des agents nettoyants, être en mesure d’en indiquer le type exact au

médecin.

2. Lorsqu' on utrilse de l'eau chaude, prendre garde aux brûlures et ne jamias

diriger le jet vers qui que ce soit. La pmpe est à la même température que

l'eau.

3. TOUJOURS porter des lunettes de protection lorsqu’on utilise l’appareil,

pour s’abriter des projections de débris et de détersif. En outre, il est

conseillé de porter des vêtements de caoutchouc, des gants et un masque

filtrant, en particulier lorsqu’on emploie du détersif. Prendre des

précautions toutes particulières lorsqu’on utilise l’appareil à proximité

d’enfants.

4. Rester vigilant et conscient de chacun de ses gestes. Ne pas utiliser

l’appareil lorsqu’on est fatigué ou qu’on a pris de l’alcool ou des

médicaments.

Nilfisk-Advance Select Spray 1500E Operator's Manual 33

Page 34

IMPORTANTES CONSIGNES DE SÉCURITÉ

5. Ne JAMAIS actionner la détente sans s’arc-bouter solidement. À la sortie

de la buse, le jet a une force suffisante pour faire perdre l’équilibre si on ne

s’est pas préparé. Se tenir bien d’aplomb, sur une surface stable. Comme

les surfaces mouillées peuvent être glissantes, porter des bottes de

protection et veiller à ne jamais perdre l’équilibre. Ne JAMAIS actionner la

détente lorsqu’on est sur une échelle ou sur un toit.

6. Éviter de diriger le jet sur des substances comme le verre qui, si elles se

brisent, peuvent blesser gravement.

7. TOUJOURS tenir fermement l’ensemble pistolet/lance lors de la mise en

marche et pendant l’utilisation de l’appareil. Sinon, la lance peut

s’échapper et fouetter dangereusement. Ne JAMAIS utiliser le pistolet en

bloquant la détente en position d’ouverture à l’aide d’un fil. Pour éviter toute

décharge accidentelle, verrouiller la détente du pistolet lorsque ce dernier

n’est pas utilisé.

8. Même après arrêt de l’appareil, la pompe, le flexible et le pistolet

contiennent toujours de l’eau sous pression qui n’est libérée que lorsqu’on

appuie sur la détente du pistolet. Avant de déposer la buse de pulvérisation

ou d’entretenir l’appareil, TOUJOURS arrêter l’appareil et actionner la

détente pour libérer la pression.

MESURES DE PRÉCAUTION -- NETTOYAGE AU DÉTERSIF:

1. NE PAS utiliser de solvants, de détersifs hautement corrosifs ou de

produits de nettoyage de type acide avec cet appareil de lavage sous

pression. N’utiliser que des détersifs Nilfisk-Advance.

2. BIEN CONNAÎTRE LES DÉTERSIFS EMPLOYÉS. Être en mesure d’en

indiquer le type exact au médecin consulté en cas d’urgence. Lire la fiche

technique santé-sécurité (FTSS) qui figure sur l’étiquette de tous les

détersifs. Appliquer toutes les directives relatives à la préparation, à

l’utilisation, à la sécurité et au transport. Entreposer les détersifs hors de

portée des enfants.

3. NE PAS utiliser cet appareil de lavage sous pression pour distribuer des

détersifs dangereux.

4. NE PAS modifier le dispositif d’injection de détersif de quelque manière

que ce soit non spécifiée dans ce manuel. N’utiliser que des pièces

d’origine Nilfisk-Advance pour exécuter les réparations nécessaires.

MESURES DE PRÉCAUTION -- DIVERSES:

1. NE JAMAIS LAISSER LES ENFANTS OU LES ADOLESCENTS FAIRE

FONCTIONNER CET APPAREIL.

2. Lire et appliquer toutes les directives de manutention, d’utilisation,

d’entretien et de sécurité énoncées dans ce manuel et les communiquer à

TOUS les utilisateurs de l’appareil.

3. Cet appareil de lavage sous pression comporte un disjoncteur de fuite à la

terre intégré à la fiche du cordon d’alimentation électrique. Si on doit

remplacer le cordon, n’utiliser que des pièces de rechange identiques

protégées par un disjoncteur de fuite à la terre.

4. Si la température ambiante est inférieure au point de congélation,

l’appareil doit toujours être assez chaud pour empêcher la formation de

glace dans la pompe. NE PAS mettre l’appareil en marche s’il a été

transporté dans un véhicule découvert ou dépourvu de chauffage sans

faire dégeler la pompe.

34 Nilfisk-Advance Select Spray 1500E Operator's Manual

Page 35

IMPORTANTES CONSIGNES DE SÉCURITÉ

5. Pour raccorder l’admission d’eau au réseau public d’alimentation en eau,

se conformer à la réglementation du service des eaux de la localité. Dans

certaines régions, on ne doit pas raccorder directement l’appareil au

réseau public d’alimentation en eau potable. Cela pour éviter d’éviter les

rejets de détersif dans le réseau d’alimentation. (Le raccordement direct

est autorisé si on a installé un clapet antiretour.)

6. Inspecter tous les jours les flexibles haute pression pour y déceler tout

signe d’usure. Remplacer sans délai tous les flexibles suspects pour éviter

toute blessure éventuelle sous l’effet de la pression élevée du jet. Si un

flexible ou un raccord fuit, ne JAMAIS mettre la main directement sur la

fuite.

7. NE PAS utiliser l’appareil si on constate une fuite d’huile ou d’eau en

provenance de la pompe. NE PAS remettre l’appareil en service avant qu’il

ait été inspecté ou réparé par un spécialiste de l’entretien.

8. Ne pas faire fonctionner l' appareil sans que les couvercles de protection

ne soient en place.

9. Pour réduire le risque de blessures, utiliser l’appareil à une distance

sécuritaire des personnes présentes. Exercer une surveillance étroite

lorsqu’on utilise l’appareil à proximité d’enfants.

10. Ne JAMAIS laisser l’appareil sans surveillance lorsqu’il est sous pression.

L’arrêter et libérer la pression avant de s’éloigner.

11. NE PAS déplacer l’appareil en le tirant par son flexible.

MESURES DE PRÉCAUTION -- RÉGLAGE:

1. Ne JAMAIS transformer ou modifier l’appareil, n’utiliser que des

accessoires et des composants aptes à supporter la pression de la

pompe. N’utiliser que des pièces d’origine Nilfisk-Advance pour réparer

l’appareil de lavage sous pression, sinon l’appareil deviendrait dangereux et

la garantie serait annulée.

2. Ne JAMAIS régler l’appareil lorsqu’il est sous tension.

3. Il importe de savoir comment arrêter rapidement l’appareil de lavage sous

pression et en évacuer la pression, et de bien connaître les commandes.

4. Avant d’entretenir l’appareil, l’arrêter, débrancher de la source d'

alimentation, en évacuer l’eau sous pression, et le laisser refroidir.

L’entretenir sur une surface propre, sèche et plane.

5. Appliquer les directives d’entretien énoncées dans ce manuel.

CONSERVER CES DIRECTIVES

CARACTÉRISTIQUES

elédoMedorémuNE0051YARPSTCELES

ruetoMudecnassiuP0,2

zH/esahP/lennoitarepOegatloV06/1/021

erépmA71

ruetoMudMPR0543

euqirtcelÉnodroCudrueugnoL

epmoPedetroSxelpirTnotsiP

noisserP0051

)mpl/mpg(noitalucriCedxuaT812

uae'dmumixaMerutarépmeT

C/Feévirra

epmoPalruoPeliuh'DetroStnegretéD-noN03EAS

noisserPáehcnaMaledrueugnoLsdeiP52

)mc/ni(zttecnaLaledrueugnoL19/63

teJudelgnAsérgeD51

ruetuahxruegralxrueugnolneétinu'L

)mc/ni(

)sbl(étinu'LedsdioPsbl98

)sbl(tnemegrahCedsdioPsbl99

Nilfisk-Advance Select Spray 1500E Operator's Manual 35

edesirPruetpurretnIcevAsdeiP53

tiucriCruoPerreT

sérged88/sérged091

5,69x2,34x3,18/83x71x23

Page 36

COMPOSANTS

REMARQUE : Des références sont faites à ce dessin tout au long du manuel.

L’emplacement des divers composants est indiqué avec le nº du composant entre

parenthèses (15).

OMCWU188-021497-JTR

LISTE DES COMPOSANTS

1. Disjoncteur de fruite á la terre

2. Étiquette de mise en garde : Risque d’électrocution

3. Cordon d'alimentation

4. Électrique Moteur

5. Interrupteur marche/arrêt

6. Autocollant de mise en garde: Risque d’injection/

Explosion

7. Autocollant de mise en garde: Risque d’électrocution

8. Autocollant d’avertissement

9. Autocollant: Avertissement-Eua chaude

10. Autocollant de mise en garde

11. Pompe

12. Remplissage d'huile

36 Nilfisk-Advance Select Spray 1500E Operator's Manual

13. Voyant d’huile

14. Filtre à tamis de l’admission d’eau

15. Admission d’eau

16. Autocollant de température indicateur

17. Valve d'evacuation de chaleur

18. Clapet de décharge

19. Injecteur de détersif

20. Sortie d'eau

21. Flexible du détersif

22. Filtre à tamis du détersif

23. Flexible de décharge à haute pression

24. Pistolet

25. Tête de lance à buse réglable

Page 37

AUTOCOLLANTS DE SÉCURITÉ ET EMPLACEMENT

N'ENLEVEZ LES AUTO-COLLANTS DE L'UNITÉ SEULEMENT QUE POUR LES

REMPLACER PAR DES PLUS RÉCENTS

Référence nº 17: Autocollant- Avertissement-

Risque d’électrocution (Pièce nº 56648292)

Référence nº 2: Étiquette-Avertissement-

Risque d’électrocution (Pièce nº 56648291)

Référence nº 8: Autocollant-Attention-

Risque De Blessures (Pièce nº 56648290)

Référence nº6: Autocollant-Avertissement-

Riesque d'injection/ Explosion (Pièce nº 56648293)

Référence nº 9: Autocollant-Attention-

Eua chaude (Pièce nº 56648289)

Référence nº 10: Autocollant-Avertissement-

(Pièce nº 56648288)

Nilfisk-Advance Select Spray 1500E Operator's Manual 37

Page 38

INSTALLATION ET PRÉPARATION

TENUE VESTIMENTAIRE:

1. Le port d’une tenue vestimentaire appropriée est essentiel à la sécurité

des utilisateurs. Il est conseillé d’employer tous les moyens voulus pour

se protéger les yeux, les oreilles et la peau. Le port d’un équipement de

protection supplémentaire (comme un masque respiratoire) peut être

nécessaire lors de l’emploi d’agents nettoyants détergents dans l’appareil.

MISE EN GARDE

RISQUE D’EXPLOSION OU

D'INCENDIE

NE PAS PLACER L'APPAREIL

À UN ENDROIT SUSCEPTIBLE

DE CONTENIR DES VAPEURS

INFLAMMABLES, CAR UNE

ÉTINCELLE POURRAIT Y

PROVOQUER UNE

EXPLOSION OU UN INCENDIE.

RISQUE D'EXPLOSION DE

L'APPARIEL

NE PAS ENTREPOSER OU

FAIRE FONCTIONNER

L'APPAREIL À TEMPERATURE

INFERIEURE AU POINT DE

CONGELATION DE L'EAU.

MISE EN GARDE

RISQUE D’INJECTION CAUSE

DE BLESSURES GRAVES

NE JAMAIS REGARDER

DIRECTEMENT DANS

L’ORIFICE DE LA BUSE, SAUF

SI ELLE EST DÉMONTÉE DE

L’ENSEMBLE PISTOLET/

LANCE.

LORSQU’ON UTILISE LA

BUSE RÉGLABLE, NE JAMAIS

RÉGLER LA FORME DU JET

LORSQUE LA DÉTENTE DU

PISTOLET EST EN POSITION

D’OUVERTURE.

La buse de la tête de

lance a deux fonctions

MISE EN OEUVRE:

1. N’installer cet appareil qu’à l’horizontale et sur une surface plane, pour

permettre une bonne lubrification de la pompe à eau pendant le

fonctionnement. Ne pas exposer l’appareil à la pluie, à la neige ou au gel.

Ne JAMAIS pulvériser d’eau directement sur l’appareil.

2. Ne pas placer l'appareil à un endriot:

-oú on a décelé des fuites d'essence ou de gaz.

-susceptible de contenir des vapeurs inflammables.

3. Ne pas exposer l'appariel à la pluie, à la neige ou au gel. Si l'une de ses

pièces gèle, la pression peut devenir excessive et faire exploser l'appareil,

en blessant gravement son utilisateur ou les personnes que se trouvent à

proximité.

4. Avant la première utilisation, remplacer le bouchon de transport par le

bouchon à évent livré avec l’appareil. S’assurer que le niveau d’huile est au

centre du voyant. Vérifier le niveau d’huile de la pompe avant chaque

utilisation. Si le niveau est bas, le compléter avec de l’huile pour pompes

(SAE30 Non-Détergent). NE PAS REMPLIR EXCESSIVEMENT.

TÊTE DE LANCE À BUSE RÉGLABLE:

NOTA: Pour le moment, NE PAS vissser la tête de lance au pistolet.

1. Pour régler en mode haute pression, faire pivoter le manchon protecteur

dans le sens horaire voir figure 1, à gauche. En mode haute pression,

l'eau ne sort que par la buse de pulvérisation 15°, sous forme de jet en

évential.

2. Pour régler en mode basse pression/détersif, faire pivoter le manchon

dans le sens antihoraire voir figure 2, à gauche. Dès que la pression est

assez basse, l'injecteur de détersif débite dans le circuit de l'appariel.

Lorsqu' on fait pivoter le manchon, le mélange d'eau et de détersif sort non

seulement par la buse de pulvérisation, mais aussi autour d'elle, ce qui

donne aujet une forme d'éventail/de cône.

OMGEN224/021696/DCE

38 Nilfisk-Advance Select Spray 1500E Operator's Manual

Page 39

PISTOLET:

INSTALLATION ET PRÉPARATION

MISE EN GARDE