Page 1

INSTALLATION INSTRUCTIONS FOR FREESTANDING DUAL FUEL

INSTALLATION AND SERVICE MUST BE PERFORMED BY A QUALIFIED INSTALLER.

IMPORTANT: SAVE FOR LOCAL ELECTRICAL INSPECTOR’S USE.

READ AND SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE.

If the information in this manual is

not followed exactly, a fi re or explosion may

result causing property damage, personal

injury or death.

FOR YOUR SAFETY:

— Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

— WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch; do not

use any phone in your building.

• Immediately call your gas supplier from

a neighbor’s phone. Follow the gas

supplier’s instructions.

• If you cannot reach your gas supplier, call

the fi re department.

— Installation and service must be performed

by a qualifi ed installer, service agency or

the gas supplier.

Refer to your serial plate for

applicable agency certifi cations

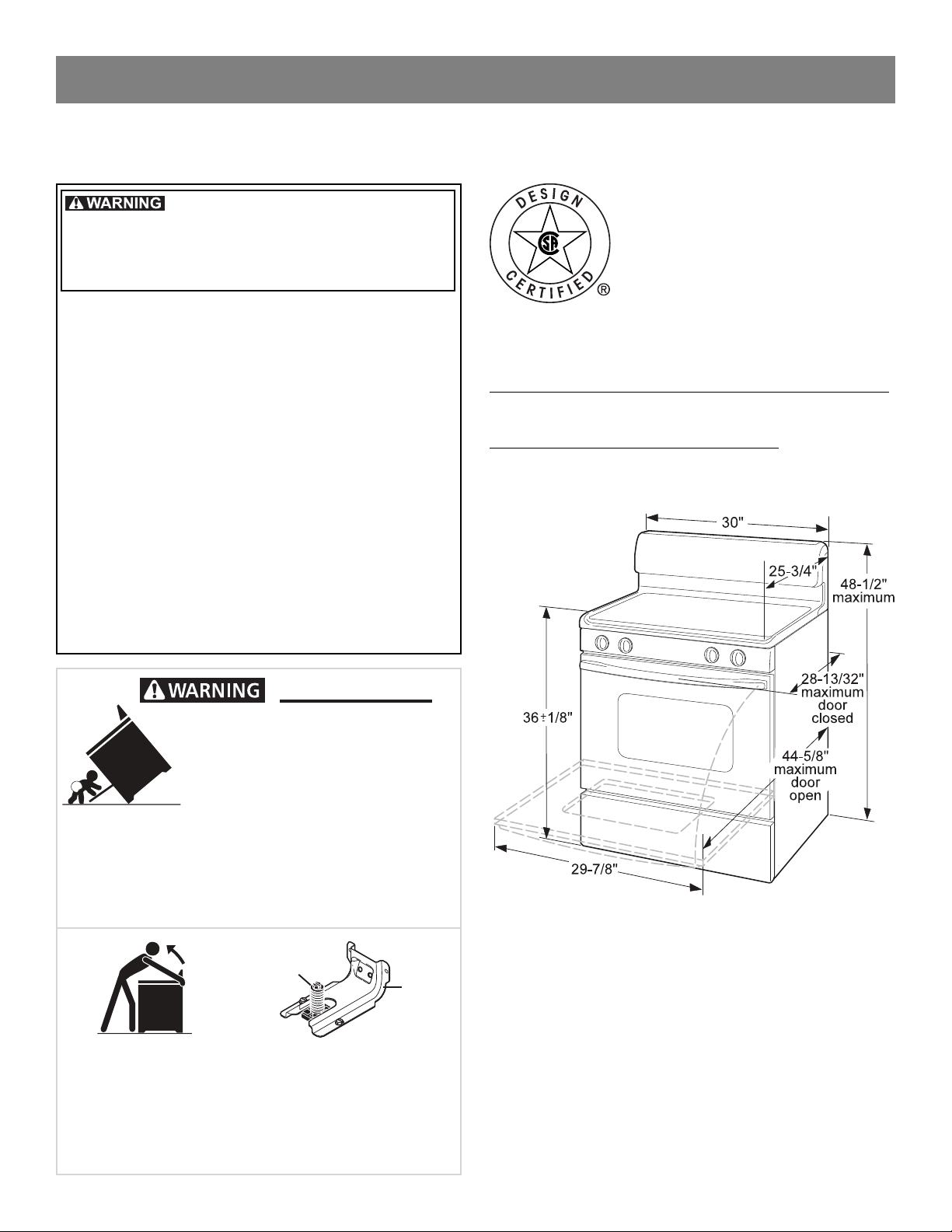

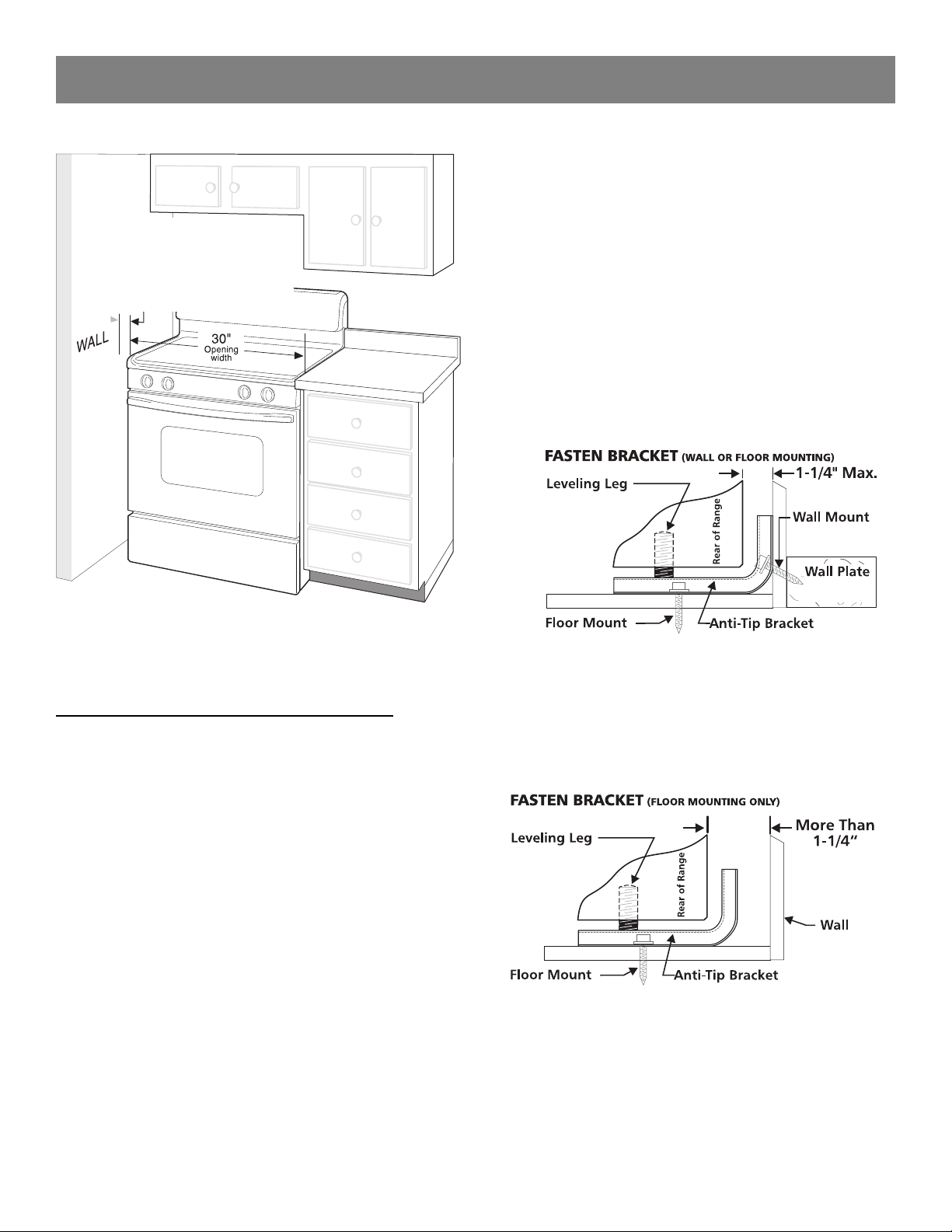

Clearances and Dimensions

Location: Check location where the range will be installed.

Check for proper electrical and gas supply, and the stability

of the fl oor.

Dimensions that are shown must be used. Given

dimensions provide minimum clearance. Contact surface

must be solid and level.

Tip Over Hazard

• A child or adult can tip the

range and be killed.

• Verify the anti-tip device has

been installed to floor or wall.

• Ensure the anti-tip device is re-engaged to floor

or wall when the range is moved.

• Do not operate the range without the anti-tip

device in place and engaged.

• Failure to follow these instructions can result in

death or serious burns to children and adults.

Range

leveling leg

Anti-tip

bracket

To check if the anti-tip bracket is installed properly, use

both arms to grasp the rear edge of the range back.

Carefully attempt to tilt range forward. When properly

installed, the range should not tilt forward.

Provide Proper Fuel Type

Before proceeding: Your range is factory preset to operate on

natural gas. If L.P. conversion is needed, contact your local

L.P. Gas provider for assistance.

The L.P. conversion kit may be located on the lower rear

back panel of the range. If no L.P. kit is provided, contact

your product dealer to obtain the correct L.P. conversion kit.

Refer to the anti-tip bracket installation instructions

supplied with your range for proper installation.

1

PN 316454928 Rev A (1206)

Page 2

INSTALLATION INSTRUCTIONS FOR FREESTANDING DUAL FUEL

INSTALLATION INSTRUCTIONS FOR FREESTANDING DUAL FUEL

IMPORTANT NOTE TO THE CONSUMER

• Keep these instructions with your Use & Care Guide

for future reference.

• As when using any appliance generating heat, there

are certain safety precautions you should follow. These

are listed in the Use & Care Guide, read it carefully.

• Be sure your range is installed and grounded properly

by a qualifi ed installer or service technician.

• Make sure the wall coverings around the range can

withstand the heat generated by the range.

• To eliminate the need to reach over the surface

elements or burners, cabinet storage space directly

above the range should be avoided.

IMPORTANT NOTES TO THE INSTALLER

• Read all instructions contained in these installation

instructions before installing range.

• Remove all packing material from the oven

compartments before connecting the gas and electrical

supply to the range.

• Observe all governing codes and ordinances.

• Be sure to leave these instructions with the consumer.

IMPORTANT SAFETY INSTRUCTIONS

• Installation of this range must conform with local codes

or, in the absence of local codes, with the National

Fuel Gas Code ANSI Z223.1—latest edition when

installed in the United States.

• When installed in a manufactured (mobile) home,

installation must conform with the Manufactured Home

Construction and Safety Standard, Title 24 CFR, Part

3280 [formerly the Federal Standard for Mobile Home

Construction and Safety, Title 24, HUD (Part 280)] or,

when such standard is not applicable, the Standard

for Manufactured Home Installations, ANSI/NCSBCS

A225.1, or with local codes.

• Proper Installation—Be sure your appliance is properly

installed and grounded by a qualifi ed technician in

accordance with the National Fuel Gas Code ANSI

Z223- latest edition, or in Canada CAN/CGA B149.1

and CAN/GGA B149.2, and the National Electrical

Code ANSI/NFPA No.70-latest edition, or in Canada

CSA Standard C22.1, Canadian Electrical Code,

Part 1, and local code requirements. Install only

per installation instructions provided in the literature

package for this range.

• This range has been design certifi ed by CSA

International. As with any appliance using gas and

generating heat, there are certain safety precautions

you should follow. You will fi nd them in the Use & Care

Guide, read it carefully.

• Special instructions for appliances installed in the

State of Massachusetts: This appliance can only be

installed in the State of Massachusetts by a Massachusetts licensed plumber or gas fi tter. When using

a fl exible gas connector, it must not exceed 3 feet

(36 inches) in length. A “T” handle type manual gas

valve must be installed in the gas supply line to this

appliance.

• Be sure your range is installed and grounded properly

by a qualifi ed installer or service technician.

• This range must be electrically grounded in

accordance with local codes or, in their absence, with

the National Electrical Code ANSI/NFPA No. 70 —

latest edition when installed in the United States. See

“Grounding Instructions” on page 7-9 in the Installation

Steps.

• Before installing the range in an area covered with

linoleum or any other synthetic fl oor covering, make

sure the fl oor covering can withstand heat at least

90°F above room temperature without shrinking,

warping or discoloring. Do not install the range over

carpeting unless you place an insulating pad or sheet

of 1/4-inch thick plywood between the range and

carpeting.

• Make sure the wall coverings around the range can

withstand the heat generated by the range.

• Do not obstruct the fl ow of combustion air at the oven

vent nor around the base or beneath the lower front

panel of the range. Avoid touching the vent openings

or nearby surfaces as they may become hot while the

oven is in operation. This range requires fresh air for

proper burner combustion.

• Do not store items of interest to children in the

cabinets above the range. Children could be seriously

burned climbing on the range to reach items.

• To eliminate the need to reach over the surface

burners, cabinet storage space above the burners

should be avoided.

• Adjust surface burner fl ame size so it does not extend

beyond the edge of the cooking utensil. Excessive

fl ame is hazardous.

• Do not use the oven as a storage space. This creates

a potentially hazardous situation.

• Never use your range for warming or heating the room.

Prolonged use of the range without adequate ventilation

can be dangerous.

• Do not store or use gasoline or other fl ammable vapors

and liquids near this or any other appliance. Explosions

or fi res could result.

• Reset all controls to the “off” position after using a

programmable timing operation.

FOR MODELS WITH SELF-CLEAN FEATURE:

• Remove broiler pan, food and other utensils before selfcleaning the oven. Wipe up excess spillage. Follow the

cleaning instructions in the Use & Care Guide.

• Unlike the standard gas range, THIS COOKTOP IS NOT

REMOVABLE. Do not attempt to remove the cooktop.

2

Page 3

INSTALLATION INSTRUCTIONS FOR FREESTANDING DUAL FUEL

INSTALLATION INSTRUCTIONS FOR FREESTANDING DUAL FUEL

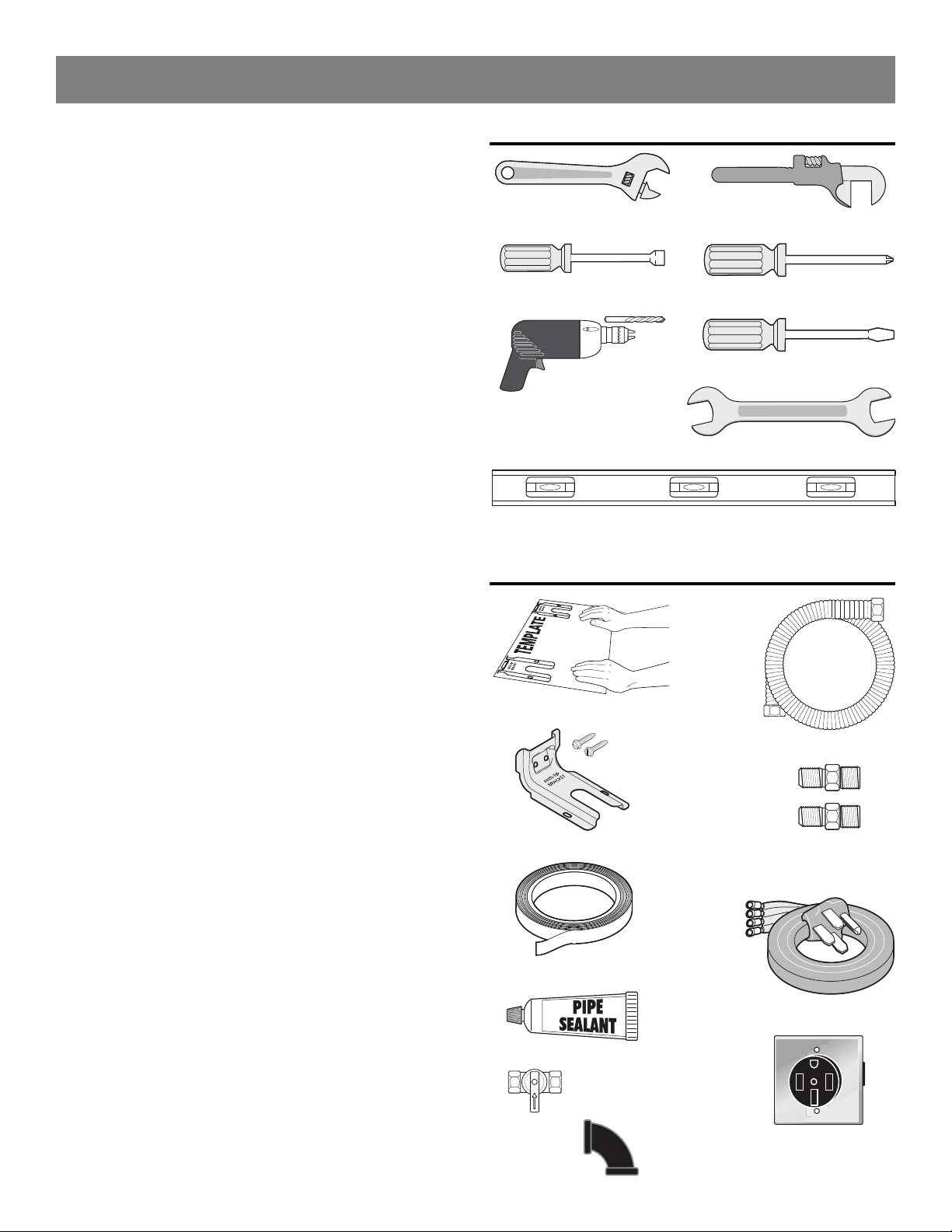

Tools you will need

(Wear safety glasses when using tools):

For leveling legs and Anti-Tip Bracket:

• Adjustable wrench or channel lock pliers (Fig. 1).

• 1/4” & 5/16” Nutdriver or fl at head screwdriver (Fig. 2).

• Electric drill & 1/8” dia. bit (5/32” Masonry drill bit if

installing in concrete (Fig. 3).

• Level (Fig. 4).

For gas supply connection:

• Pipe wrench (Fig. 5).

For burner fl ame adjustment:

• Phillips head and small blade-type screwdrivers (Fig. 6

and Fig. 7).

For gas conversion (LP/Propane or Natural):

• Open end wrench - 1/2” (Fig. 8).

Additional materials you may need:

• Anti-Tip Template (Fig. 9), Anti-Tip bracket, 2 mounting

screws (bracket and screws are supplied with range Fig. 10) and masking tape (Fig. 11).

• Pipe joint sealant that resists action of LP/Propane gas

(Fig. 12).

• Gas line manual shut-off valve (Fig. 13).

• 1/2” NPT 90° black pipe elbow (Fig. 14).

• A new fl exible metal appliance conduit (1/2” NPT

x 3/4” or 1/2” I.D.) must be design certifi ed by CSA

International (Fig. 15). Because solid pipe restricts

moving the range we recommend using a new fl exible

conduit (48” MAXIMUM LENGTH)for each new

installation and additional reinstallations.

• Always use the (2) new fl are adapters (1/2” NPT x 3/4”

or 1/2” I.D.) supplied with the new fl exible appliance

conduit for connection of the range (Fig. 16).

• Power cord (40/50 ampere rated Cord Kit - 48”

MAXIMUM LENGTH - Fig. 17).

• 4 or 3 wire, 40/50 ampere rated wall receptacle and

mounting plate (Fig. 18).

• Copper electrical wiring and metal conduit (for hard

wiring installation only).

Tools

Fig. 1

Fig. 2

Fig. 3

Fig. 4

Materials

Fig. 9

Fig. 10

Fig. 11

Fig. 5

Fig. 6

Fig. 7

Fig. 8

48”MAXIMUM

LENGTH

Fig. 15

Fig. 16

4 or 3 Wire Cord Kit

48”MAXIMUM LENGTH

Fig. 17

3

Fig. 12

Fig. 13

Fig. 18

Fig. 14

Page 4

INSTALLATION INSTRUCTIONS FOR FREESTANDING DUAL FUEL

INSTALLATION INSTRUCTIONS FOR FREESTANDING DUAL FUEL

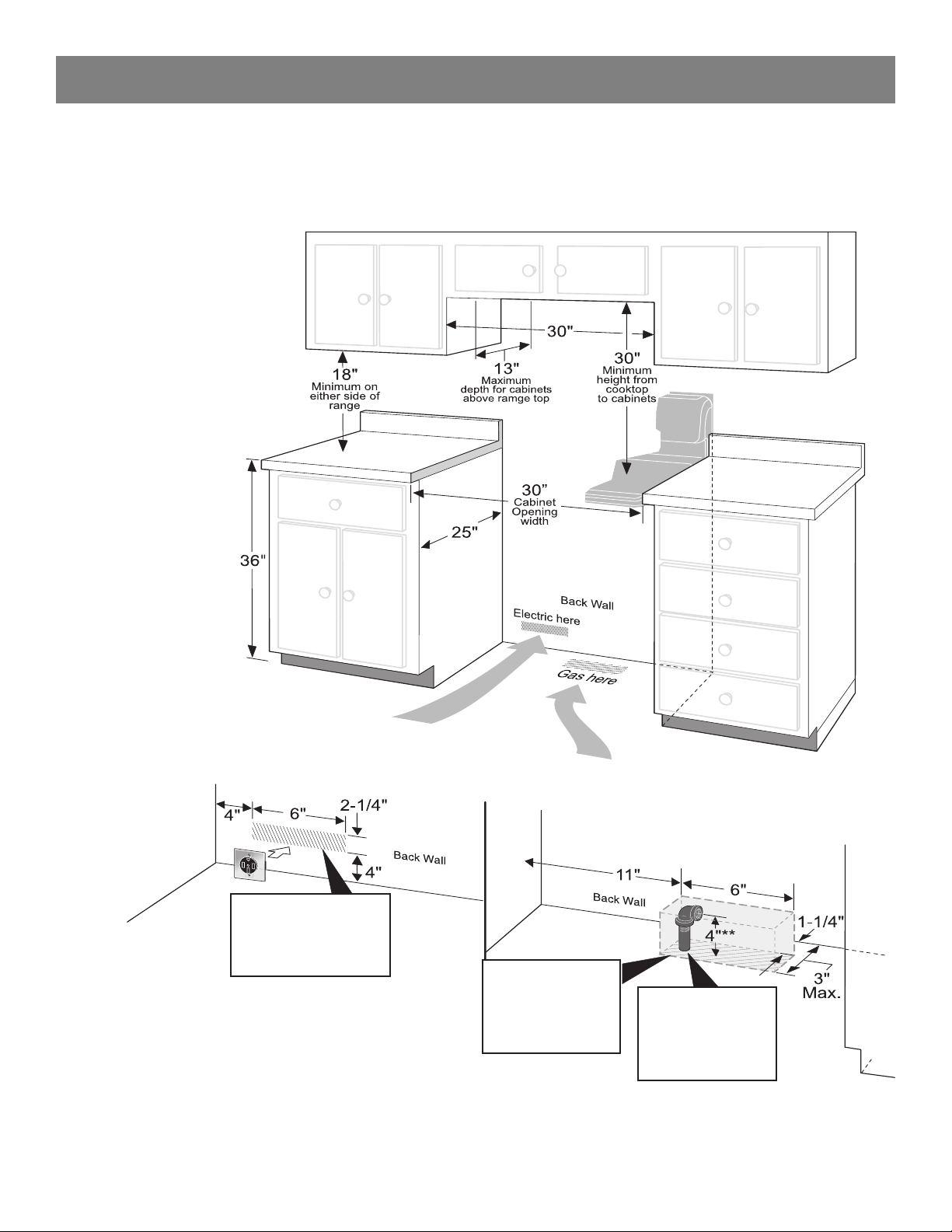

To eliminate the risk of burns

or fi re by reaching over

heated surface units, cabinet

storage space located above

the surface units should be

avoided. If cabinet storage

is to be provided, the risk

can be reduced by installing

a range hood that projects

horizontally a minimum of

5” beyond the bottom of the

cabinets.

Cabinet and countertop dimensions

• Check for wall and cabinet clearances where the range will be installed.

• Check the stability of the fl oor where the range will be installed.

• Check for proper electrical and gas supply.

Note: All dimensions provided are minimal unless otherwise stated.

Fig. A

Install a flush mount

240V 40/50 ampere

electrical wall outlet

Fig. B

• Do not seal the range to side cabinets.

• Do not pinch the power supply cord between the range

and the wall.

• If cabinet depth is greater than 25”, the oven front

frame must extend beyond cabinet front by 1/2”

minimum.

All openings in the wall or fl oor where the range is

to be installed must be sealed.

in the shaded area.

This shaded floor

area is for thru the

floor connection of

gas pipe stub and

shut-off valve.

Fig. C

Note: The gas supply pipe stube and elbow assembly

centerline should not exceed 4” height form the fl oor.

4

Add 1/2” NPT 90°

black pipe elbow to

the gas supply pipe

stub and orient the

elbow as shown.

Page 5

INSTALLATION INSTRUCTIONS FOR FREESTANDING DUAL FUEL

INSTALLATION INSTRUCTIONS FOR FREESTANDING DUAL FUEL

Installation with cabinets and wall

Minimum clearance to

side wall on either side of

range is 5”

Anti-tip bracket installation

1. Place the Bracket Using the Template - Bracket

may be positioned on either the left or right side of the

range. Refer to Fig. 19, Fig. 20, and Fig. 22 to position

the bracket if template is not available.

2. Mark the fl oor or wall where left or right side of the

range will be located.

• If rear of range is against wall or no further than 1-1/4”

from wall when installed, you may use the wall or fl oor

mount method (Fig 19).

• For wall mount (Fig. 19), locate the bracket by placing

the back edge of the template against rear wall

and the side edge of template on the mark made

referencing the side of the range. Place bracket on

top of template and mark location of the screw holes

in wall. If rear of range is further than 1-1/4” from wall

when installed, attach bracket to the fl oor.

Fig. D

Anti-tip installation

IMPORTANT SAFETY WARNING!

To reduce the risk of tipping of the range, the range must

be secured to the fl oor by properly installed anti-tip bracket

and screws packed with the range. Failure to install the

anti-tip bracket will allow the range to tip over if excessive

weight is placed on an open door or if a child climbs upon

it. Serious injury might result from spilled hot liquids or

from the range itself.

If range is ever moved to a different location, the anti-tip

brackets must also be moved and installed with the range.

Instructions are provided for installation in wood or cement

fastened to either the fl oor or wall. When installed to the

wall, make sure that screws completely penetrate dry wall

and are secured in wood or metal. When fastening to the

fl oor or wall, be sure that screws do not penetrate electrical

wiring or plumbing.

Fig 19

• For fl oor mount (Fig. 20), locate

the bracket by placing back edge of the template

where the rear of the range will be located. Mark the

location of the screw holes shown in template.

• If molding is installed and does not allow the bracket to

fi t fl ush against wall, remove molding or mount bracket

to fl oor (Fig. 20).

Fig 20

5

Page 6

INSTALLATION INSTRUCTIONS FOR FREESTANDING DUAL FUEL

INSTALLATION INSTRUCTIONS FOR FREESTANDING DUAL FUEL

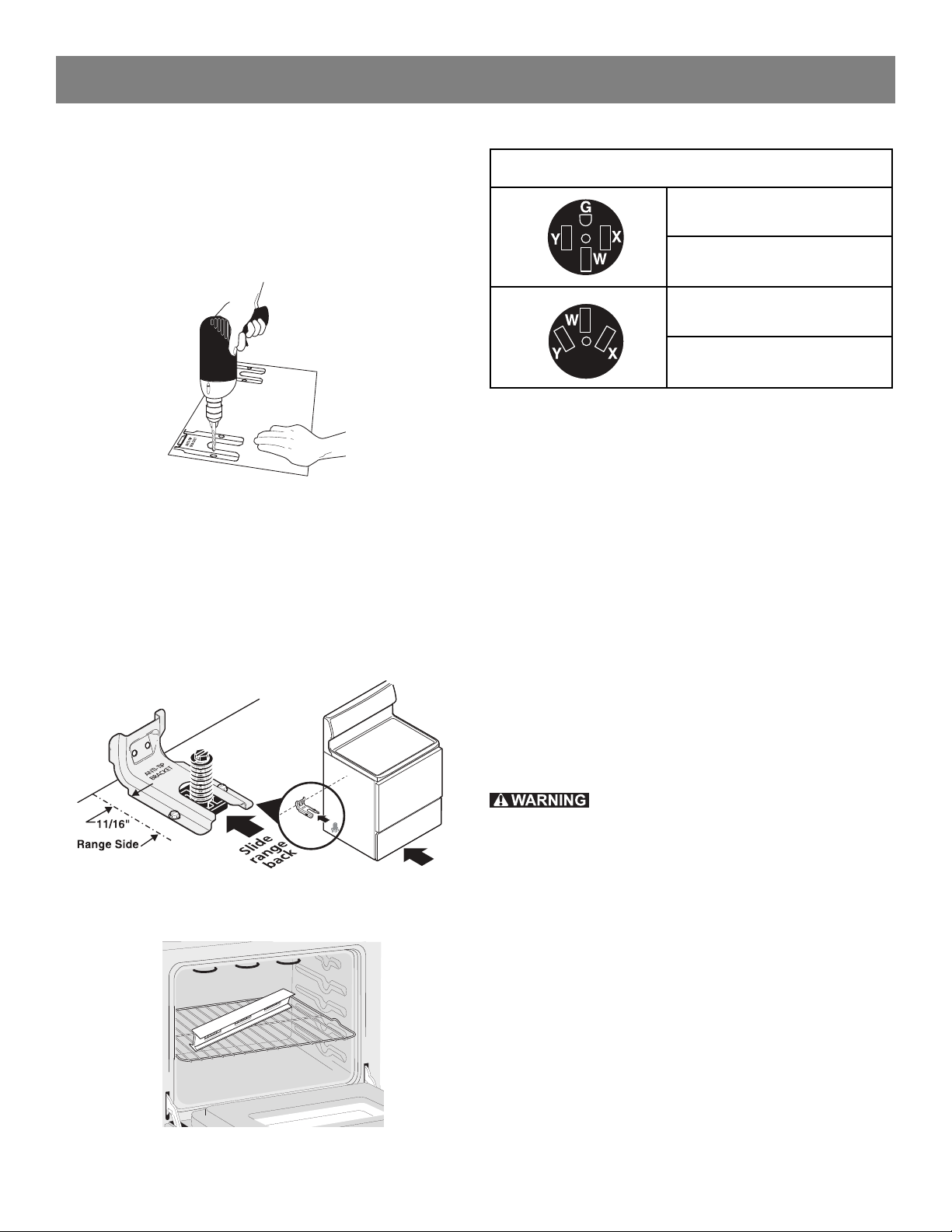

3. Drill Pilot Holes & Fasten Bracket - Drill 1/8” pilot

hole where screws are to be located (Fig. 21). If

bracket is to be mounted to the wall, drill pilot hole at

an approximate 20° downward angle. If bracket is to

be mounted to masonry or ceramic fl oors, drill 3/16”

pilot hole 1-3/4” deep. The screws provided may be

used in wood or concrete material. Use 5/16” nutdriver or fl at head screwdriver to secure the bracket in

place.

Fig 21

4. Level & Position Range - Level range by adjusting

the (4) leveling legs with a wrench. Note: A minimum

clearance of 1/8” is required between bottom of range

and leveling legs to allow room for bracket. Slide range

back into position (Fig. 22). Remove lower panel or

storage drawer to visually check that rear leveling leg

is inserted into and fully secured by the bracket. For

models with a warmer drawer or broiler compartment,

grasp the top rear edge of the range and carefully

attempt to tilt it forward.

Electrical connection requirements

3 and 4 - Wire electrical wall receptacle types and

recommended mounting orientation on wall

Required for new and remodeled

installations

4-Wire Wall receptacle (14-50R)

Allowed for existing installations

3 Wire Wall

receptacle (10-50R)

Fig. 24

This appliance must be properly installed and grounded

by a qualifi ed technician in accordance with the National

Electrical Code ANSI/NFPA No. 70 -- latest edition -- and

local electrical code requirements.

This appliance may be connected by means of permanent

“Hard Wiring” or “Power Supply Cord Kit.”

When hard wiring, do not leave excess wire in range

compartment. Excess wire in the range compartment may

not allow the access cover to be replaced properly, and

could create a potential electrical hazard if wires become

pinched. Connect only as instructed under “WIRING

INSTRUCTIONS” in Step B of the Installation Steps. When

using fl exible conduit or range cable use fl ex connector or

range cable strain relief (See Fig. 27 on page 7).

Fig 22

5. Use a level to check your adjustments (Fig. 23).

Fig 23

NOTE: Only use copper wire in connection to terminal

block.

MODELS REQUIRING POWER SUPPLY CORD KIT

RISK OF FIRE OR ELECTRICAL SHOCK MAY OCCUR IF

AN INCORRECT SIZE RANGE CORD KIT IS USED, THE

INSTALLATION INSTRUCTIONS ARE NOT FOLLOWED

OR STRAIN RELIEF BRACKET IS DISCARDED.

This appliance may be connected by means of a power

supply cord. Only a power supply cord kit rated at 125/250

volts minimum, and marked for use with ranges shall

be used. See chart (Fig. 28) for cord kit ampere rating

information. Cord must have either four (4) or three (3)

conductors (See Fig. 24). Terminals on end of wires

must be either closed loop or open-end spade lugs with

upturned ends. Cord must have strain relief clamp. See

Step B in Installation Steps for 4 or 3 - Wire connections.

6

Page 7

INSTALLATION INSTRUCTIONS FOR FREESTANDING DUAL FUEL

DO NOT MAKE ANY ATTEMPT TO

OPERATE THE ELECTRIC IGNITION OVEN DURING

AN ELECTRICAL POWER FAILURE. RESET ALL OVEN

CONTROLS TO “OFF” IN THE EVENT OF A POWER

FAILURE.

The electric ignitor will automatically re-ignite the oven

burner when power resumes if the oven thermostat control

was left in the “ON” position.

When an electrical power failure occurs during use, the

surface burners will continue to operate.

During a power outage, the surface burners can be lit

with a match. Hold a lighted match to the burner, then

Fig. 26

slowly turn the knob to the

(lite) position. Use extreme

caution when lighting burners this way.

RANGE INSTALLATIONS STEPS

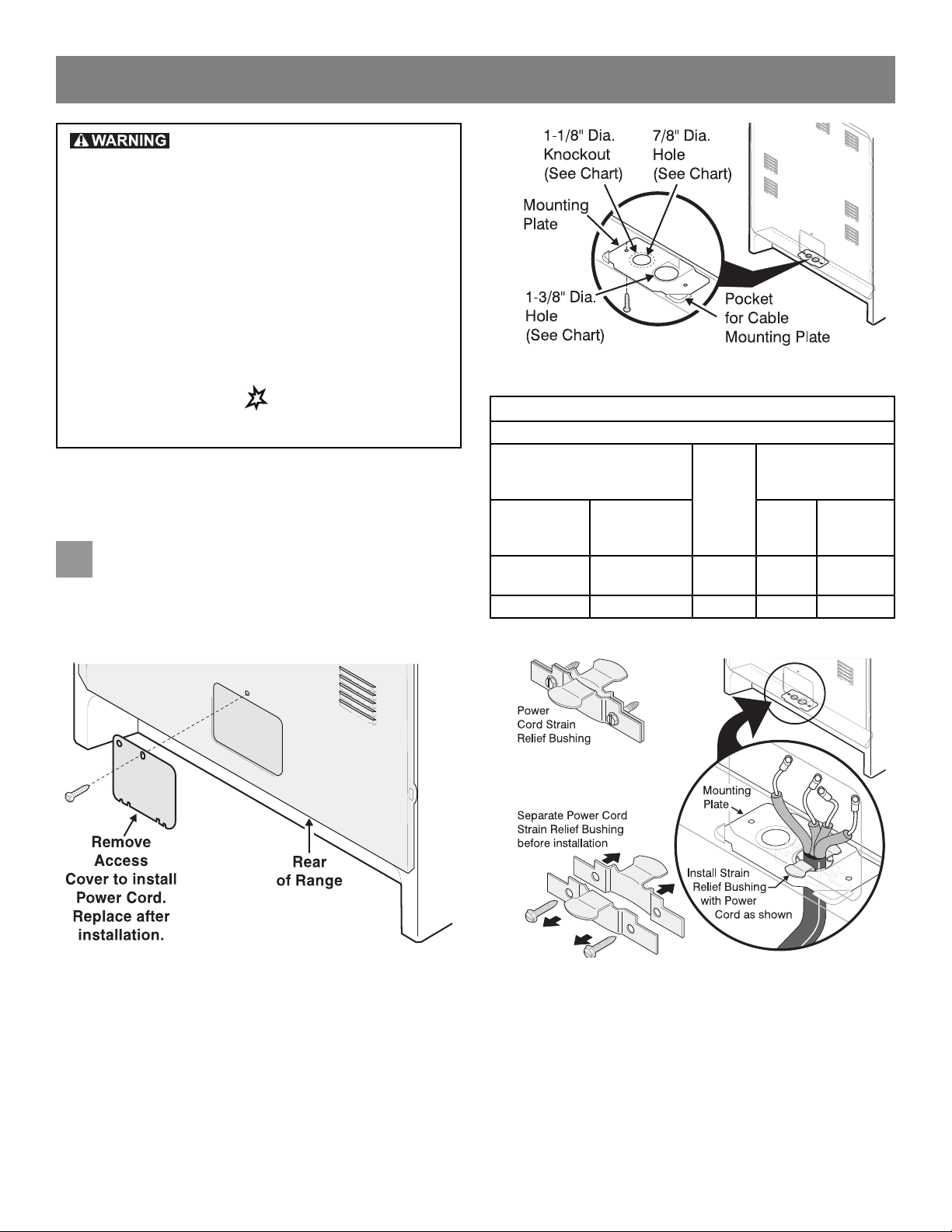

Access the terminal block

A

The rear access cover must be removed. To remove, loosen

center screw (one screw) and remove access cover. The

terminal block will then be accessible (See Fig. 25).

Range Connection Opening Size Chart

Supply cord kit ampere rating information.

See serial plate on range for

kilowatt (kw) rating

120/240 Volts 120/208 Volts Cord kit Perma-

8.8-16.5 kw 7.9-12.5 kw 40/50

16.6-22.5 kw 12.6-18.5 kw 50 Amp 1-3/8 in 1-3/8 in

Fig. 27

Cord Kit

Ampere

Rating

Amp

Diameter (inches)

of range conenction

opening

nent

wiring

1-3/8 in 1-1/8 in

Fig. 25

Fig. 28

7

Page 8

INSTALLATION INSTRUCTIONS FOR FREESTANDING DUAL FUEL

INSTALLATION INSTRUCTIONS FOR FREESTANDING DUAL FUEL

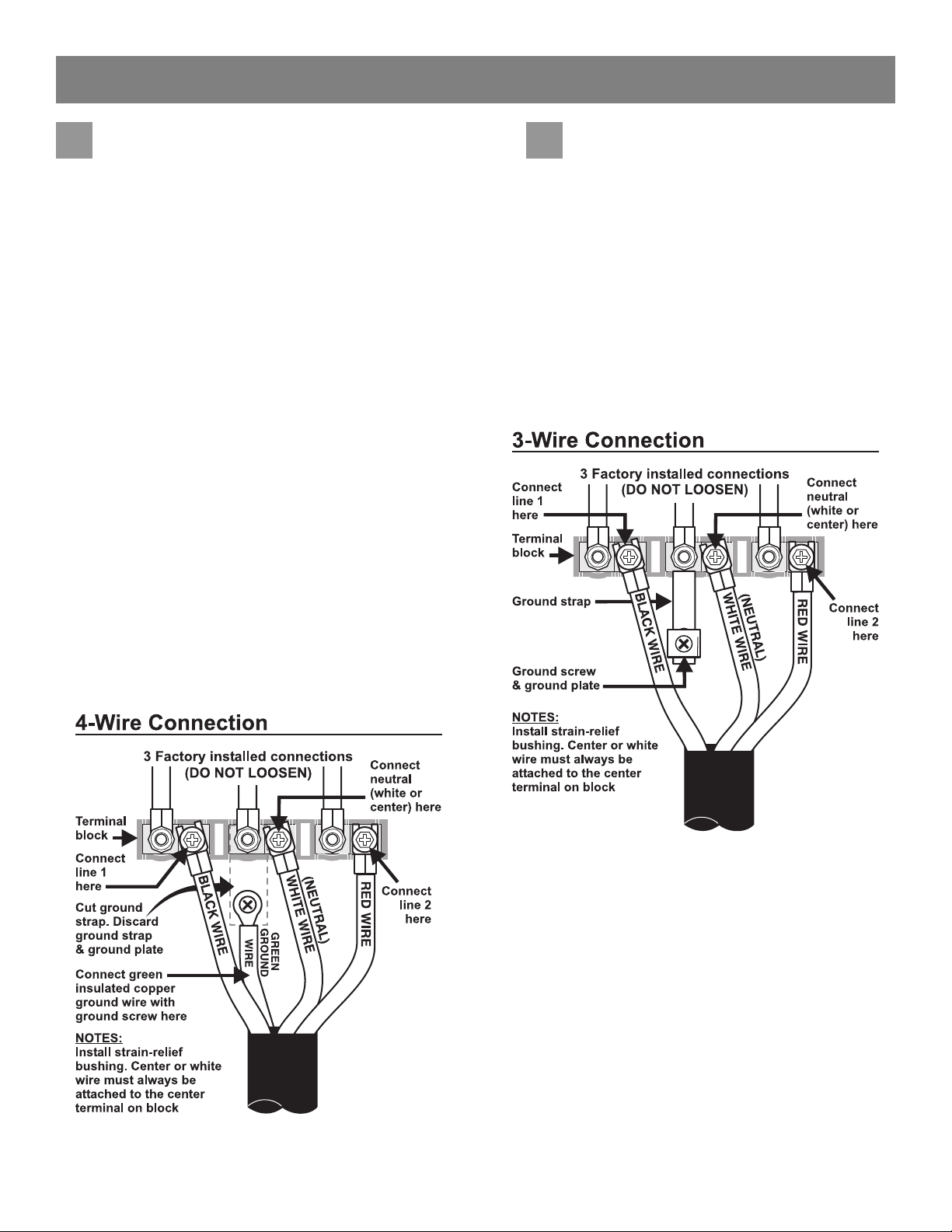

4-wire connection instructions

B

Before wiring the range review the suggested power

source location drawing in Fig. B. If connecting to a 4-Wire

electrical system (new branch-circuit or mobile home

requires 4-Wire connection):

Power cord instructions

1. Follow the manufacturer’s installation instructions

supplied with the strain relief and install (See Fig. 28).

2. Insert the end connectors for Line 1, Line 2 and

Neutral and tighten securely to the terminal block.

IMPORTANT NOTE: DO NOT LOOSEN the factory

installed nut connections which secure the range

wiring to the terminal block. Electrical failure or loss

of electrical connection may occur if these 3 nuts are

loosened or removed.

3. You must disconnect the ground strap. Remove the

factory installed ground screw and plate to release the

copper ground strap from the frame of the appliance.

Cut and discard the copper ground strap and plate.

KEEP the ground screw.

4. Connect the ground wire (Green) lead with the eyelet

to the frame of the appliance with the ground screw

using the same hole in the frame where the ground

screw was originally installed (See Fig. 29).

5. Make sure all screws are tightened securely and

replace the rear access cover (See Fig. 25).

OR 3-wire connection instructions

B

(for existing installations ONLY)

Power Cord Instructions

1. Follow the manufacturer’s installation instructions

supplied with the strain relief and install (See Fig. 28).

2. Insert the end connectors for Line 1, Line 2 and

Neutral and tighten securely to the terminal block (See

Fig. 30).

IMPORTANT NOTE: DO NOT LOOSEN the factory

installed nut connections which secure the range

wiring to the terminal block. Electrical failure or loss

of electrical connection may occur if these 3 nuts are

loosened or removed.

3. Make sure all connections are tightened securely and

replace the rear access cover (See Fig. 25).

Fig. 29

Fig. 30

3-Wire Connections ONLY - Grounding

Instructions

A ground strap is installed on this range which connects

the center terminal of the terminal block (neutral) to the

range chassis. The ground strap is connected to the range

by the center, lowest screw (

strap must not be removed unless national or local codes

do not permit use of ground strap.

NOTE: If the ground strap is removed for any reason, a

separate ground wire must be connected to the separate

ground screw attached to the range chassis and to an

adequate ground source.

8

See Fig. 30). The ground

Page 9

INSTALLATION INSTRUCTIONS FOR FREESTANDING DUAL FUEL

INSTALLATION INSTRUCTIONS FOR FREESTANDING DUAL FUEL

3 & 4-Wire permanent connections ONLY

IMPORTANT: 3 - Wire permanent connection - follow

Steps 1, 2 and 5 below.

IMPORTANT: 4 - Wire permanent connection - follow

Steps 1 thru 5 below.

Before wiring the range, review the suggested power

source location drawings in Fig. A and B on page 4. If

connecting to a 4-Wire electrical system (new branchcircuit or mobile home requires 4-Wire connection):

1. 3 and 4 - Wire Permanent Connections - Follow the

manufacturer’s installation instructions supplied with

the strain relief and install (See Figre 28).

2. 3 and 4 - Wire Permanent Connections - Strip

insulation away from the ends of the permanent wiring

for Line 1, Line 2, Neutral (also strip ground wire on

4-Wire Connections). Tighten all 3 wire leads to the

terminal block (follow wire locations shown in Fig. 31).

3. 4-Wire Permanent Connection ONLY - Disconnect

the ground strap. Remove the factory installed ground

screw & plate to release the factory installed copper

ground strap from frame of the appliance. Cut and

discard the copper strap from the terminal block. KEEP

the ground screw, ground plate and go to Step 4.

Fig. 32

4. 4-Wire Permanent Connection ONLY - Connect the

ground wire lead (Green) to the frame of the appliance

using the ground screw & plate as shown in Fig. 32.

Be sure to install using the same hole in the frame

where the ground screw was originally installed.

5. 3 and 4 - Wire Permanent Connections - Make sure

all connections are tightened securely and replace the

rear access cover (See Fig. 25).

Fig. 31

NOTE: Non-terminated fi eld wire compression

connections must be set at approximately 22in./lbs.

Always use 10 ga. wire or larger.

IMPORTANT NOTE: DO NOT LOOSEN the factory

installed nut connections which secure the range

wiring to the terminal block. Electrical failure or loss

of electrical connection may occur if these 3 nuts are

loosened or removed.

NOTE: For 3-Wire Permanent Connections skip Steps

3 and 4 and continue with Step 5.

Provide an adequate gas supply.

C

This range is pre-set to operate on 4” natural gas manifold

pressure. The Pressure Regulator is connected to the

manifold and MUST be connected in series with the gas

supply line (See Fig. 33 on page 10).

Care must be taken during installation of range not to

obstruct the fl ow of combustion and ventilation air. The gas

supply line should be 1/2” or 3/4” I.D.

For proper operation, the maximum inlet pressure to the

regulator should be no more than 14 inches of water

column pressure. The inlet pressure to the regulator must

be at least 1 inch greater than regulator manifold pressure.

Examples: If regulator is set for natural gas 4 inch manifold

pressure, inlet pressure must be at least 5 inches;

if regulator has been converted for LP/Propane gas

10 inch manifold pressure, inlet pressure must be at least

11 inches. Leak testing of the appliance shall be conducted

according to the instructions in Step E.

9

Page 10

INSTALLATION INSTRUCTIONS FOR FREESTANDING DUAL FUEL

INSTALLATION INSTRUCTIONS FOR FREESTANDING DUAL FUEL

Seal the wall and fl oor openings

D

Seal any openings in the wall behind the range and in the

fl oor under the range after gas supply line is installed. See

Figures A, B, C and D on pages 4 and 5.

Connect the range to the gas supply

E

Before connecting gas supply to range, review the

suggested power source location drawings (See Figures

A, B, and C on page 4). To prevent leaks apply pipe joint

sealant on all male (outside) pipe threading. The Pressure

Regulator can be found mounted to the lower left rear of

range (See Fig 32). To install the gas supply:

1.) Install 1/2” NPT 90° Black Pipe Elbow to the gas supply

pipe stub (See Fig 33)

2.) Install an external gas Shut-Off Valve (manual) to gas

supply line in an easily-accessible location outside of the

range. Be sure you know how and where to shut-off the

gas supply to the range (See Fig 33).

3.) Install Flare Adapter* to gas Pressure Regulator

(See Fig. 33).

*NOTE: Be sure to use the 2 Flare Adapters supplied with

the Flexible Conduit Kit.

Do not use a fl ame to check for gas leaks.

Checking Manifold Gas Pressure:

Disconnect the range and its individual shut-off valve from

the gas supply piping system during any pressure testing

of that system at test pressures greater than 14” of water

column pressure (approximately 1/2” psig). The appliance

must be isolated from the gas supply piping system by

closing its individual manual shut-off valve during any

pressure testing of the gas supply piping system at test

pressures equal to or less than 14” of water column

pressure (approximately 1/2” psig).

If it should be necessary to check the manifold gas

pressure, connect manometer (water gauge) or other

pressure device to the top burner right rear orifi ce. Using

a rubber hose with inside diameter of approximately 1/4,”

hold tubing down tight over orifi ce. Turn burner valve

on. For an accurate pressure check have at least two

(2) other top burners burning. Be sure the gas supply

(inlet) pressure is at least one inch above specifi ed range

manifold pressure. The gas supply pressure should never

be over 14” water column. When properly adjusted for

Natural Gas the manifold pressure is 4” (For LP/Propane

Gas the manifold pressure is 10”).

Fig. 33

Do not allow the Pressure Regulator to turn

on pipe when tightening fi ttings.

4.) Attach fl exible Appliance Conduit to Flare Adapter on

Pressure Regulator (See Fig 33).

5.) Install 2nd Flare Adapter* to external manual Shut-Off

Valve (See Fig 33).

6.) Attach fl exible Appliance Conduit to Flare Adapter on

Shut-Off Valve (See Fig 33).

7.) After making these connections, check for gas leaks.

Turn the gas supply on to the range and use a liquid leak

detector at all joints and conduits to check for leaks in

the system.

Read the electrical connection

F

details below. Plug the range into the

wall receptacle.

Before servicing, disconnect electrical

supply at circuit breaker, fuse or Power Cord.

PLEASE READ CAREFULLY! For

personal safety, this product must be properly grounded.

10

Page 11

INSTALLATION INSTRUCTIONS FOR FREESTANDING DUAL FUEL

INSTALLATION INSTRUCTIONS FOR FREESTANDING DUAL FUEL

Carefully slide range into cabinet opening while inserting

rear leveling leg into and FULLY ENGAGING THE ANTITIP BRACKET (See Fig. 22 on page 6). Make sure that

the fl exible appliance conduit and the power cord folds into

the remaining open fl oor area behind the range warmer

or storage drawer. Make sure that the fl exible appliance

conduit does not become pinched or kinked. Pre-shape the

fl exible appliance conduit and power cord if necessary to

insure that the range slides into cabinet opening properly.

Be sure to check level of the range by placing a level

horizontally on an oven rack (See Fig. 23 on page 6).

Surface burner heads, cap & grates

It is very important to make sure that all of the surface

burner heads, surface burner caps and surface burner

grates are installed correctly.

Your appliance was shipped with the burner heads and

burner caps assembled in the correct locations (See

Fig. 34).

Should you need to re-install the burner caps please refer

to the Use & Care guide for more information.

REMEMBER — DO NOT ALLOW SPILLS, FOOD, CLEANING

AGENTS OR ANY OTHER MATERIAL TO ENTER THE GAS

ORIFICE HOLDER OPENING.

Carefully slide range into cabinet

G

opening.

H

Check electric ignition of surface burners

I

Operation of electric igniters should be checked after range

and supply line connectors have been carefully checked for

leaks and range has been connected to electric power.

a. To check for proper ignition, push in and turn a surface

burner knob counterclockwise to the LITE position

(see Fig. 35). You will hear the igniter sparking.

b. The surface burner should ignite when gas is available

to the burner. Purge air from supply lines by leaving

knob in the LITE position until burner ignites. Each

burner should light within four (4) seconds in normal

operation after air has been purged from supply lines.

c. Visually check that burner has a fl ame. Once the

burner ignites, the control knob should be turned out of

the LITE position.

d. Try each surface control knob separately until all

surface burners have been checked. Each burner

location is equipped with a separate electrode.

Always keep the Burner Caps and Burner Heads in place

whenever the surface burners are in use.

Fig. 34

4

2

3

1. 5,000 BTU Simmer Burner.

2. 10,000 BTU Bridge Burner.

3. 9,500 BTU Power Burner.

4. 12,000 or 14,200 BTU Power Burner.

5. 18,000 BTU Double Burner (some models).

1

5

Fig. 35

11

Page 12

INSTALLATION INSTRUCTIONS FOR FREESTANDING DUAL FUEL

INSTALLATION INSTRUCTIONS FOR FREESTANDING DUAL FUEL

Adjust the “LOW” setting of surface

J

burner valve (for linear fl ow valves only)

1. Push in and turn knob to (lite) until burner ignites.

2. Push in and quickly turn knob to LOWEST

POSITION.

3. If burner goes out, reset control to OFF and set to

low fl ame again.

4. Remove the burner control knob.

5. Insert a thin-bladed screwdriver into the hollow

valve stem and engage the slotted screw inside

(See Fig. 36). Flame size can be increased or

decreased with the turn of the screw. Turn counterclockwise to increase fl ame size. Turn clockwise

to decrease fl ame size.

Care, cleaning and maintenance

Refer to the Use & Care Guide for cleaning instructions.

If removing the range is necessary for cleaning or

maintenance, shut off the gas supply. Disconnect the

gas and electrical supply. If the gas or electrical supply

is inaccessible, lift the range slightly at the front and pull

out away from the wall. Pull only as far as necessary to

disconnect the gas and electrical supply. Finish removing

the range for servicing and cleaning. Reinstall in reverse

order making sure to level the range and check gas

connections for leaks. See anti-tip instructions for proper

anti-tip anchoring instructions.

Before you call for service

Refer to the Use & Care Guide for cleaning instructions.

If removing the range is necessary for cleaning or

maintenance, shut off the gas supply. Disconnect the

gas and electrical supply. If the gas or electrical supply

is inaccessible, lift the range slightly at the front and pull

out away from the wall. Pull only as far as necessary to

disconnect the gas and electrical supply. Finish removing

the range for servicing and cleaning. Reinstall in reverse

order making sure to level the range and check gas

connections for leaks. See page 5 and 6 of this document

for proper anti-tip anchoring instructions.

Fig. 36

K

Model and serial number location

The Serial Plate is located on the right-hand surface of the

oven front frame at the storage or warmer drawer; or the

lower panel area (See Fig. 37).

After installation is complete, make all

controls are left in the OFF position.

Fig. 37

When ordering parts for or making inquires about your

range, always be sure to include the model and serial

numbers and a lot number or letter from the Serial Plate

on your range. The Serial Plate will also inform you of the

rating of the burners, the type of fuel and the pressure the

range was adjusted for when it left the factory.

12

Page 13

INSTUCCIONES PARA LA INSTALACIÓN DEL GAS DUAL

LA INSTALACION Y EL SERVICIO DEBEN SER EFECTUADOS POR UN INSTALADOR CALIFICADO.

IMPORTANTE: CONSERVE ESTAS INSTRUCCIONES PARA USO DEL INSPECTOR LOCAL DE ELECTRICIDAD.

LEA Y CONSERVE ESTAS INSTRUCCIONES PARA REFERENCIA FUTURA.

WARNING:

Consulte la placa de serie

para las certifi caciones de las

agencias correspondientes

WARNING:

Si no se sigue estrictamente

la información de este manual, se puede

producir un incendio o una explosión

causando daños materiales, lesiones

corporales o fatales.

PARA SU SEGURIDAD:

— No almacene ni use gasolina u

otros líquidos o vapores infl am-

ables cerca de este o cualquier

otro artefacto.

— SI SIENTE OLOR A GAS:

• No trate de encender el artefacto.

• No toque ningún interruptor eléctrico; no use ningún teléfono en

su edifi cio.

• Llame inmediatamente a su proveedor de gas desde un teléfono

vecino. Siga las instrucciones del

proveedor de gas.

• Si no puede comunicarse con su

proveedor de gas, llame al departamento de bomberos.

— La instalación y el servicio deben

ser efectuados por un instalador o

técnico califi cado o por el provee-

dor de gas.

• Asegúrese de que el dispositivo antivuelco se haya reacoplado

cuando mueva la estufa sobre el piso o a la pared.

• No utilice la estufa sin el dispositivo antivuelco instalado y

acoplado.

• Si no se siguen estas instrucciones, se puede provocar la muerte

o quemaduras graves en niños y adultos.

Para verificar si el soporte antivuelco está instalado

correctamente, sostenga el borde trasero de la parte

trasera de la estufa usando ambos brazos. Intente inclinar

la estufa hacia adelante con cuidado. Si está instalada

correctamente, la estufa no debería inclinarse hacia

adelante.

Consulte las instrucciones de instalación del soporte

antivuelco proporcionadas con la estufa para instalarlo

adecuadamente.

Espacios Libres y Dimensiones

Ubicación – Revise el lugar donde será instalada la estufa.

Verifi que el suministro de energía eléctrica y la estabilidad

del piso.

Es esencial que se usen las dimensiones que se

muestran. Las dimensiones indicadas proveen los

espacios libres mínimos. La superfi cie de contacto debe

ser fi rme y nivelada.

Riesgo de volcamiento

• Un niño o adulto puede volcar la estufa y

acabar muerto.

• Verifique que se haya instalado el

dispositivo antivuelco en el piso o en la

pared.

Tornillo

nivelador de

la estufa

Soporte

antivuelco

Proporcione el tipo de combustible adecuado

Antes de proceder: Su estufa fue ajustada en la fábrica para

utilizar gas natural. Si necesita realizar una conversión a

gas LP, llame a su distribuidor local de gas LP para obtener

asistencia.

Es posible que el kit de conversión a gas LP se encuentre

en el panel inferior trasero de la estufa. Si no se incluye un

kit de gas LP, póngase en contacto con su distribuidor de

electrodomésticos para obtener el kit de conversión a gas

LP adecuado.

PN 316454928 Rev A (1206)

1

Page 14

INSTUCCIONES PARA LA INSTALACIÓN DEL GAS DUAL

AVISO IMPORTANTE AL CONSUMIDOR

• Mantenga estas instrucciones con su Guía de Uso y

Cuidado para referencia futura.

• Al igual que con cualquier electrodoméstico que

genere calor, existen ciertas precauciones de

seguridad que usted debe seguir. Tales precauciones

se encuentran en la Guía de Uso y Cuidado, léala

atentamente.

• Asegúrese de que la estufa esté bien instalada y

puesta a tierra en forma debida por un instalador

califi cado o un técnico de servicio.

• Asegúrese de que el revestimiento de la pared

alrededor de la estufa puede resistir el calor generado

por la estufa.

• Para eliminar la necesidad de tener que pasar

sobre los elementos o quemadores superiores, se

recomienda no instalar armarios directamente arriba

de la cubierta de la estufa.

NOTAS IMPORTANTES PARA EL

INSTALADOR

• Lea todas las instrucciones indicadas en estas

instrucciones de instalación antes de instalar la estufa.

• Saque todo el material de empaque del

compartimiento del horno antes de conectar el

suministro de gas y de electricidad a la estufa.

• Observe todos los códigos y reglamentos pertinentes.

• Asegúrese de dejar estas instrucciones con el usuario.

INSTRUCCIONES IMPORTANTES DE

SEGURIDAD

• La instalación de esta estufa debe ser de acuerdo con

los códigos locales o, en ausencia de códigos locales,

con el Código Nacional de Gas Combustible ANSI

Z223.1 - última edición cuando sea instalado en los

Estados Unidos.

• Cuando la estufa sea instalada en una casa móvil

(prefabricada), la instalación debe cumplir con las normas

vigentes de Manufactured Home Construction and Safety

Standard (Normas de Construcción y Seguridad de Casas

Prefabricadas, Título 24 CFR, Parte 3280 (anteriormente

denominada Normas Federales para la Construcción y

Seguridad de Viviendas Móviles, Título 24, HUD (Parte

280) o, cuando tales normas no corresponden, se

deben cumplir las Normas para Instalaciones en Casas

Prefabricadas, ANSI/NCSBCS A225.1 o los códigos

locales.

• El diseño de esta estufa ha sido certifi cado por la CSA

International. Al igual que con cualquier artefacto que use

gas y genere calor, se deben seguir ciertas precauciones

de seguridad. Las encontrará en la Guía de Uso y

Cuidado, léala atentamente.

• Asegúrese de que su estufa sea instalada y puesta a

tierra en forma debida por un instalador califi cado o un

técnico de servicio.

• Esta estufa debe ser puesta a tierra eléctricamente

de acuerdo con los códigos locales o, en ausencia de

ellos, con el Código Eléctrico Nacional ANSI/NFPA No.

70 - última edición cuando es instalada en los Estados

Unidos. Vea las “Instrucciones para la Puesta a Tierra”

en la página 20 y 21 de los Pasos de la Instalación de

la Estufa.

• Antes de instalar la estufa en un área que esté cubierta

con linóleo o con cualquier otro revestimiento sintético de

piso, asegúrese de que el revestimiento del piso pueda

soportar calor de por lo menos 90°F sobre la temperatura

ambiente sin encogerse, combarse o descolorarse.

No instale la estufa sobre una alfombra a menos que

usted coloque un cojín aislante o una hoja de madera

contrachapada de 1/4” de grosor entre la estufa y la

alfombra.

• Asegúrese de que los revestimientos de la pared alrededor

de la estufa puedan soportar el calor generado por la

estufa.

• No obstruya el fl ujo del aire de combustión en la ventilación

del horno ni alrededor de la base ni debajo del panel

delantero inferior de la estufa. Evite tocar las aberturas

de ventilación o las superfi cies cercanas pues pueden

calentarse cuando el horno está en funcionamiento.

Esta estufa necesita aire fresco para una combustión

adecuada de los quemadores.

• No guarde artículos que interesen a los niños en los

armarios que estén arriba de la estufa. Los niños pueden

quemarse seriamente si se trepan a la estufa para

alcanzar artículos.

• Para eliminar la necesidad de alcanzar artículos pasando

sobre los quemadores, se debe evitar colocar armarios

de almacenamiento sobre los quemadores.

• Ajuste el tamaño de la llama del quemador superior

de manera que no se extienda más allá del borde del

utensilio de cocina. Una llama excesiva es peligrosa.

• No use el horno como espacio para almacenamiento.

Esto crea una situación potencialmente peligrosa.

• Nunca use este artefacto para calentar o calefaccionar la

habitación. El uso prolongado de la estufa sin ventilación

adecuada puede ser peligroso.

• No almacene ni use gasolina ni otros vapores o líquidos

infl amables cerca de este o de cualquier otro artefacto.

Se pueden producir explosiones o incendios.

• Vuelva a colocar todos los controles en la posición

“OFF” después de usar una operación programable con

temporizador.

PARA LOS MODELOS CON LA

CARACTERISTICA DE AUTOLIMPIEZA:

• Saque la asadera, los alimentos y otros utensilios

antes de efectuar la autolimpieza del horno. Limpie

los derrames. Siga las instrucciones de limpieza

indicadas en la Guía de Uso y Cuidado.

• A diferencia de una estufa a gas convencional, ESTA

CUBIERTA NO SE PUEDE SACAR. No trate de sacar

la cubierta.

2

Page 15

INSTUCCIONES PARA LA INSTALACIÓN DEL GAS DUAL

SELLANTE

DE TUBERÍAS

Herramientas y Materiales Necesarios

(Cuando trabaje con herramientas use lentes protectores):

Para los tornillos niveladores y soporte antivuelco:

Llave ajustable o pinzas ajustables (Fig. 1).

• Llave de tuerca de 1/4” y 5/16” o destornillador de

punta plana (Fig. 2).

• Taladro eléctrico y broca de 1/8” de diám. (broca para

taladro de mampostería de 5/32” si está instalando

en concreto) (Fig. 3).

• Nivel (Fig. 4)

Para la conexión al suministro del gas:

• Llave de tubo (Fig. 5).

Para ajustar la llama del quemador:

• Destornillador Phillips y destornilladores de punta

plana (Figs. 6 y 7).

Para conversión del gas (Gas propano/G.L.P.):

• Llave de boca abierta – 1/2” (Fig. 8).

Materiales adicionales que usted necesitará:

• Plantilla del soporte antivuelco (Fig. 9), 2 tornillos de

montaje (el soporte y los tornillos son suministrados

con la estufa - Fig. 10) y cinta adhesiva (Fig. 11).

• Compuesto sellador de juntas resistente al gas G.L.P./

Propano (Fig. 12).

• Llave de cierre de la tubería del gas (Fig. 13).

• Codo de tubería negro de ½” NPT 90° (Fig. 14).

• Un conducto nuevo para artefacto de metal fl exible

(1/2” NPT x 3/4” o 1/2” de D.I.) certifi cado por CSA

International. Debido a que la tubería sólida restringe

la movilidad de la estufa, recomendamos que use un

conducto nuevo fl exible (LARGO MAXIMO: 48”) para

cada nueva instalación y reinstalaciones adicionales.

• Siempre use los (2) adaptadores de unión abocinados

nuevos (1/2” NPT x 3/4” o 1/2” de D.I.) suministrados

con el nuevo conducto fl exible de artefacto para con-

exión de la estufa (Fig. 16).

• Cable eléctrico (Juego de Cable para 40/50 amperios LARGO MAXIMO: 48” - Fig. 17).

• Tomacorriente mural y placa de montaje, tetra o trifi lar,

para 40/50 amperios (Fig. 18).

• Alambre eléctrico de cobre y tubo de metal (para instalación con cables permanentes solamente).

Herramientas

Fig. 1

Fig. 2

Fig. 3

Fig. 4

Materiales

SOPORTE

ANTIVUELCO

PLANTILLA

SOPORTE

ANTIVUELCO

Fig. 9

SOPORTE

ANTIVUELCO

Fig. 10

Fig. 11

Fig. 5

Fig. 6

Fig. 7

Fig. 8

LARGO

MAXIMO:

48”

Fig. 15

Fig. 16

LARGO MAXIMO: 48”

Fig. 17

3

Fig. 12

Fig. 13

Fig. 18

Fig. 14

Page 16

INSTUCCIONES PARA LA INSTALACIÓN DEL GAS DUAL

A fi n de eliminar el riesgo de

quemaduras o incendio cuando

se pasa sobre los elementos

superiors calientes para

alcanzar los armarios, se debe

evitar instalar armarios arriba

de la cubierta. Si se provee

espacio para almacenamiento

en tal lugar, se puede reducer

el riesgo instalando una

campana extractora que

proteja horizontalmente un

minimo de 5” mas alla de la

parte inferior de los armarios.

Dimensiones del gabinete y de la cubierta:

• Verifi que el espacio libre entre las paredes y el gabinete del lugar donde se

instalará la estufa.

• Verifi que la estabilidad del piso donde se instalará la estufa.

• Verifi que el suministro electrico y de gas.

Nota: Todas las dimensiones están en la mínima longitud, esto si no se

menciona alguna excepción.

Fig. A

Ubicaciones sugeridas para la

alimentación eléctrica

En esta area rayaka

instale un

tomacorriente elétrico

mural embutido de

Fig. B

• No selle la estufa a los armarios laterals.

• No apriete el cable el éctrico entre la estufa y la pared.

• Si la profundidad del gabinete es superior a 25”,

el marco delantero del horo debe extenderse por

lo menos ½” m ás all á de la parte delantera del

gabinete.

Se deben sellar todas las aberturas de la pared o del

piso donde se instale la estufa.

240V 40/50 amperios.

En esta area rayada

en el piso es para la

instalaci ón a trav és

del piso del tubo

corto del gas de la b

álvula de cierre.

Agregue un codo de

tubería negro de ½”

NPT 90 al tubo corto

del suministro del gas

y dirija el codo como

se muestra.

Fig. C

Nota: La línea central del conjunto del tubo corto del

gas y del codo no dibe estar a m ás de 4: de altura

desde el suelo.

4

Page 17

INSTUCCIONES PARA LA INSTALACIÓN DEL GAS DUAL

Instalación con armarios y pared

Distancia mínima a la

pared lateral a ambos

lados de la estufa: 5”.

Fig. D

Instrucciones de Instalación para el

Soporte Antivuelco

1. Ubique el soporte utilizando la plantilla - El soporte

puede ser instalado ya sea en el lado izquierdo o

derecho de la estufa. Consulte desde la Fig. 19, 20,

y 22 para colocar el soporte si no se dispone de la

plantilla.

2. Marque el piso o la pared donde se colocará el

lado izquierdo o derecho de la estufa.

• Si la parte trasera de la estufa será colocada contra la

pared o a no más de 1-1/4”de la pared cuando ya esté

instalada, usted puede usar el método de instalación

en el piso o en la pared (Fig. 19).

• Para montaje en la pared (Fig. 19), ubique la plantilla

colocando el borde trasero de la plantilla contra la

pared trasera y el borde lateral de la plantilla en la

marca hecha indicando el lado de la estufa. Coloque

el soporte sobre la plantilla y marque la ubicación de

los agujeros de los tornillos en la pared. Si la parte

trasera de la estufa está a más de 1-1/4” de la pared

cuando ya está instalada, instale el soporte en el piso.

SOPORTE DE FIJACIÓN

(INSTALACIÓN EN LA PARED O EL PISO)

Pata

niveladora

1 1/4" (3 cm)

máx.

Instalación

en la pared

Instalación del Soporte Antivuelco

¡ADVERTENCIA DE SEGURIDAD

IMPORTANTE!

Para reducir el riesgo de que la estufa se vuelque,

es necesario asegurarla al piso instalando el soporte

antivuelco y los tornillos suministrados con la estufa. Si no

se instala el soporte antivuelco, la estufa se puede volcar

si un niño se sube a ella. Se pueden ocasionar lesiones

graves causadas por los líquidos calientes derramados o

por la estufa misma.

Si la estufa es movida a otro lugar, el soporte antivuelco

debe también ser movido e instalado en la estufa.

Las instrucciones son adecuadas para instalación en

pisos de madera o cemento sujeto ya sea al piso o la

pared. Cuando se instala en la pared, asegúrese de

que los tornillos penetren completamente en el drywall

y que estén asegurados en madera o metal. Cuando

se asegura al piso o en la pared, asegúrese de que los

tornillos no penetren ningún cableado eléctrico o plomería.

Parte

posterior

de la estufa

Larguero

Instalación

en el piso

Fig 19

Soporte antivuelco

• Para montaje en el piso (Fig. 20), ubique el soporte

colocando el borde trasero de la plantilla donde

quedará ubicada la parte trasera de la estufa. Marque

la ubicación de los agujeros de los tornillos mostrados

en la plantilla.

• Si tiene moldura instalada y ésta no permite que el

soporte quede a ras contra la pared, retire la moldura

o instale el soporte en el piso (Fig 20).

SOPORTE DE FIJACIÓN

(ÚNICAMENTE PARA INSTALACIÓN EN EL PISO)

Más

de 1 1/4"

(3 cm)

Pared

Fig 20

Pata

niveladora

Instalación

en el piso

posterior

Parte

de la estufa

Soporte antivuelco

5

Page 18

INSTUCCIONES PARA LA INSTALACIÓN DEL GAS DUAL

3. Taladre agujeros pilotos e instale el soporte -

Taladre un agujero piloto de 1/8” donde se van a

instalar los tornillos (Fig. 21). Si el soporte va a ser

instalado en la pared, taladre un agujero piloto en

un ángulo descente de aproximadamente 20°. Si el

soporte va a ser instalado en pisos de mampostería

o de cerámica, taladre un agujero piloto de 3/16” y

1-3/4” de profundidad. Los tornillos provistos pueden

ser usados en materiales de madera o concreto. Use

una llave de tuerca de 5/16” o un destornillador de

punta plana para asegurar el soporte en su lugar.

Fig 21

4. Nivele y ubique la estufa – Nivele la estufa ajustando

los cuatro (4) tornillos niveladores con una llave. Nota:

Se debe dejar un espacio libre mínimo de 1/8” entre

la parte inferior de la estufa y los tornillos niveladores

a fi n de dejar espacio para instalar el soporte (Fig.

22). Deslice la estufa de nuevo a su lugar. Retire el

panel inferior o la gaveta de almacenamiento para

verifi car visualmente si el tornillo nivelador trasero

está insertado y fi rmemente asegurado por el soporte.

Para los modelos con un compartimiento calefactor

o compartimiento de asador, sujete la estufa desde

el borde superior trasero y trate de inclinarla hacia

adelante cuidadosamente.

Fig 22

5. Use un nivel para verifi car sus ajustes (Fig. 23).

Requerimientos Eléctricos

Tipos de tomacorrientes murales eléctricos trifi lares o

tetrafi lares y orientación recomendada de montaje en la pared

Requerido para instalaciones

nuevas y remodeladas

Tomacorriente Mural Tetrafi lar

Permitido para instalaciones

Tomacorriente Mural Tetrafi lar

Fig. 24

Este artefacto debe ser instalado y puesto a tierra en

forma correcta por un técnico califi cado de acuerdo con

el Código Nacional de Electricidad ANSI/NFPA No. 70 —

última edición — y los requerimientos del código local de

electricidad.

Este artefacto debe ser conectado mediante “cableado

permanente” o el “Juego de Cable de Alimentación

Eléctrica.”

Cuando use cable, no deje el exceso de cable en el

compartimiento de la estufa. El exceso de alambre en el

compartimiento de la estufa puede impedir que la tapa de

acceso sea reinstalada en forma debida y podría crear un

riesgo eléctrico potencial si los alambres son apretados.

Conecte solamente como se indica en la sección

“INSTRUCCIONES PARA EL CABLEADO” en el Paso B

de los Pasos de la Instalación. Cuando use tubo fl exible

o cable de estufa, use sujetacable de estufa o conector

fl exible (Ver Fig. 27 en la página 7).

NOTA: Use solamente alambre de cobre en la conexión al

tablero de bornes.

WARNING:

Modelos que requieren el Juego de Cable

de Alimentación Eléctrica

PUEDE OCURRIR RIESGO DE INCENDIO O CHOQUE

ELECTRICO SI SE USA UN JUEGO DE CABLE DE

ESTUFA DE CALIBRE INCORRECTO, SI NO SE SIGUEN

LAS INSTRUCCIONES DE INSTALACION O SI NO SE

USA EL SOPORTE DEL SUJETACABLES.

Este artefacto puede ser conectado mediante un cable de

alimentación eléctrica. Se debe usar solamente un juego

de cable de alimentación eléctrica para 125/250 voltios

mínimo y marcado para uso con estufas. Vea la tabla

(Figura 29) para la información sobre la intensidad nominal

del juego de cable. El cable debe tener ya sea cuatro (4)

o tres (3) conductores (Ver Fig. 28). Los bornes en los

extremos de los cables deben ser ya sea en bucle cerrado

o terminales de horquilla con los extremos girados hacia

arriba. El cable debe tener abrazadera para sujetacable.

Ver Paso B en los Pasos de la Instalación para conexiones

con cables tetrafi lares o trifi lares.

(14-50R)

existentes

(10-50R)

Fig 23

6

Page 19

INSTUCCIONES PARA LA INSTALACIÓN DEL GAS DUAL

WARNING:

NO INTENTE USAR EL HORNO

DE ENCENDIDO ELECTRICO DURANTE UNA

INTERRUPCION DE LA CORRIENTE ELECTRICA.

COLOQUE TODOS LOS CONTROLES EN LA

POSICION “OFF” (APAGADO) EN CASO DE UNA

INTERRUPCION DE LA CORRIENTE ELECTRICA.

El encendedor eléctrico volverá a encender

automáticamente el quemador del horno cuando se

restaure la corriente eléctrica si es que el control del

termostato del horno se dejó en la posición “ON”

(ENCENDIDO).

Cuando ocurre una interrupción de la corriente

eléctrica durante el uso, los querradores superiores

continúan funcionando.

Durante una interrupción de la corriente eléctrica,

los quemadores superiores pueden ser encendidos

con un fósforo. Sujete un fósforo encendido cerca

del quemador, luego gire lentamente la perilla a

la posición “LITE”. Tenga mucho cuidado cuando

encienda los quemadores de esta manera.

PASOS DE INSTALACIÓN DE LA

ESTUFA

Como accesar al bloque de terminales

A

Se debe retirar la cubierta de acceso trasera. Para retirar,

afl oje el tornillo central (un tornillo) y retire la cubierta de

acceso. De este modo tendrá acceso al tablero de bornes.

(Ver Fig. 25).

Fig. 26

Tabla del Tamaña de la Abertura de la

Conexión de la Estufa

Información sobre la intensidad nominal del Juego de Cable de

Alimentación.

Ver la placa de serie en la estufa para la potencia nominal

el kilovatios.

120/240

Voltios

8,8-16,5 kw 7,9-12,5 kw 40/50

16,6-22,5 kw 12,6-18,5 kw 50 Amp 1-3/8

Fig. 27

120/208

Voltios

Inten-

sidad

Nomi-

nal del

Juego

de

cable

Amp

Diámetra (pulgadas) de la abertura

de conexión de la

estufa.

Juego

cable

1-3/8

pulg.

pulg.

de

Alambrado Permanente

1-1/8

pulg.

1-3/8

pulg.

Fig. 25

Sujetacable

Separe el

sujetacable antes

de la instalación

Fig. 28

Placa de

montaje

Instale

aquí el

sujetacable

7

Page 20

INSTUCCIONES PARA LA INSTALACIÓN DEL GAS DUAL

í

Instrucciones para conexión tetrafi lar

B

Antes del cableado de la estufa, revise los dibujos de las

ubicaciones sugeridas para la fuente de alimentación en la

Fig. 2. Si se va a conectar a un sistema eléctrico tetrafi lar

(los circuitos de derivación nuevos o las casas rodantes

requieren conexión tetrafi lar):

Instrucciones para el Cableado

1. Siga las instrucciones de instalación del fabricante

suministradas con el sujetacable e instale (Además

vea las Fig. 28).

2. Inserte los conectores de extremo para la Línea 1,

Línea 2 y Neutro y apriete fi rmemente en el tablero de

bornes.

NOTA IMPORTANTE: NO AFLOJE las conexiones

de tuerca instaladas en la fábrica que aseguran el

cableado de la estufa en el tablero de bornes. Se

puede producir una falla eléctrica o pérdida de la

conexión eléctrica si estas 3 tuercas son afl ojadas o

retiradas.

3. Usted debe desconectar la cinta de conexión a

tierra. Retire el tornillo y placa de tierra instalada en

la fábrica para soltar la cinta de conexión a tierra de

cobre del marco del electrodoméstico. CONSERVE el

tornillo de tierra.

4. Conecte el alambre de puesta a tierra (Verde) con el

ojal en el marco del electrodoméstico con el tornillo

de tierra usando el mismo agujero del marco donde

estaba originalmente instalado el tornillo de tierra (Ver

Fig. 29).

5. Asegúrese de que todas las tuercas estén fi rmemente

apretadas y vuelva a colocar la cubierta de acceso

trasera (Ver Fig. 25).

O Instrucciones para conexión trifi lar

B

(para instalaciones existentes

SOLAMENTE)

Instrucciones para el Cableado

1. Siga las instrucciones de instalación del fabricante

suministradas con el sujetacable e instale (Ver Fig.

28).

2. Inserte los conectores de extremo para la Línea 1,

Línea 2 y Neutro y apriete fi rmemente en el tablero de

bornes (Ver Fig.

NOTA IMPORTANTE: NO AFLOJE las conexiones

de tuerca instaladas en la fábrica que aseguran el

cableado de la estufa en el tablero de bornes. Se

puede producir una falla eléctrica o pérdida de la

conexión eléctrica si estas 3 tuercas son afl ojadas o

retiradas.

3. Asegúrese de que todas las conexiones estén

fi rmemente apretadas y vuelva a colocar la cubierta de

acceso trasera (Ver Fig. 25).

Conexión Trifilar

Conecte

Línea 1

aquí

Tablero de

bornes

CINTA DE

CONEXION

A TIERRA

TORNILLO Y

PLACA DE TIERRA

30).

Conexiones instaladas en la fábrica

(NO AFLOJAR)

ALAMBRE

NEGRO

ALAMBRE

(NEUTRO)

Conecte el

alambre

neutro (blanco

o central)

ALAMBRE

Conecte

Línea 2 aqu

ROJO

Conexión Tetrafilar

Tablero de

bornes

Conecte

Línea 1

aquí

Corte la cinta de conexión

a tierra. Descarte la cinta y

la placa de conexión a

tierra

Conecte aquí

el alambre de cobre verde

aislado de puesta a tierra con

el tornillo de tierra

NOTAS:

Instale el buje sujetacable. El

alambre central o blanco debe

estar siempre instalado en el

borne central del tablero de

bornes.

Fig. 29

Conexiones instaladas en la fábrica

(NO AFLOJAR)

ALAMBRE

NEGRO

ALAMBRE

(NEUTRO)

BLANCO

Conecte aquí el

alambre neutro

(blanco o central)

ALAMBRE

Conecte

Línea 2

aquí

ROJO

NOTAS:

Instale el buje sujetacable. El

alambre central o blanco debe

estar siempre instalado en el

borne central del tablero de

bornes.

Fig. 30

Conexiones Trifi lares SOLAMENTE -

Instrucciones para la Puesta a Tierra

Esta estufa tiene instalada una cinta de conexión a tierra

que conecta el borne central del tablero de bornes (neutro)

al chasis de la estufa. La cinta de conexión a tierra está

conectada a la estufa mediante el tornillo central más

inferior (Ver Fig. 30). La cinta de conexión de tierra no

debe retirarse a menos que el código nacional, estatal o

local no permitan el uso de una cinta de conexión a tierra.

NOTA: Si por cualquier motivo se retira la cinta de

conexión a tierra, se debe conectar un alambre de tierra

separado al tornillo de tierra instalado en el chasis de la

estufa y a una tierra adecuada.

8

Page 21

INSTUCCIONES PARA LA INSTALACIÓN DEL GAS DUAL

Conexión permanente tetrafilar SOLAMENTE

PLACA DE

CONEXION

A TIERRA

TORNILLO DE

CONEXION A

TIERRA

CABLE

TERMINAL DE

CONEXION

A TIERRA

TIERRA

APROPIADA

PARA

CONEXION

PERMANENTE

TETRAFILAR

TIERRA

CONEXIONES DEL CABLEADO PERMANENTE

TRIFILAR Y TETRAFILAR:

3 - Conexión trifi lar permanente - siga los pasos 1, 2 y 5

incluidos a continuación.

4 - Conexión tetrafi lar permanente - siga los pasos 1 al 5

que se encuentran más abajo.

Antes del cableado de la estufa, examine los dibujos de

la ubicación sugerida para la fuente de alimentación en la

Fig A y B.

1. (Conexiones permanentes trifi lares y tetrafi lares)

Siga las instrucciones de instalación del fabricante

suministradas con el sujetacable e instale (Fig. 28).

2. (Conexiones permanentes trifi lares y tetrafi lares)

Desforre el aislamiento de los extremos del cableado

permanente para la Línea 1, Línea 2, Neutro (además

desforre el alambre de conexión a tierra en las

conexiones tetrafi lares). Apriete los 3 conductores

hacia el tablero de bornes (Siga las ubicaciones de los

alambres que se muestran en la Fig. 31).

Conexión permanente tetrafilar SOLAMENTE

Fig. 31

APRIETE LOS 3 CABLES TERMINALES

Línea 1

Neutro

Tablero de bornes

PLACA DE CONEXION A TIERRA

TORNILLO DE CONEXION A TIERRA

CINTA DE CONEXION

DE TIERRA

NOTA: Las conexiones de compresión no terminadas

del cableado de campo deben ser ajustadas a

aproximadamente 22 pulg./lbs. Siempre use un alambre

galga 10 o mas grande.

NOTA IMPORTANTE: NO AFLOJE las conexiones

de tuerca instaladas en la fábrica que aseguran el

cableado de la estufa en el tablero de bornes. Se

puede producir una falla eléctrica o pérdida de la

conexión eléctrica si estas 3 tuercas son afl ojadas o

retiradas.

NOTA: Para las conexiones permanentes trifi lares

omita los Pasos 3 y 4 y continúe con el Paso 5.

3. (Conexión permanente tetrafi lar SOLAMENTE)

Desconecte la cinta de conexión a tierra. Retire el

tornillo y placa de tierra instalada en la fábrica para

soltar la cinta de conexión a tierra de cobre del marco

del electrodoméstico. CONSERVE el tornillo de tierra,

la placa de tierra y siga con el Paso 4.

Línea 2

Fig. 32

4. (Conexión permanente tetrafi lar SOLAMENTE)

Conecte el alambre terminal de puesta a tierra (Verde)

al marco del electrodoméstico usando el tornillo y

la placa de conexión a tierra, como se muestra en

la Fig. 32. Asegúrese de instalarlo usando el mismo

agujero del marco donde estaba originalmente

instalado el tornillo de tierra.

5. (Conexiones permanentes trifi lares y tetrafi lares)

Asegúrese de que todas las tuercas estén fi rmemente

apretadas y vuelva a colocar la cubierta de acceso

trasera (Ver Fig. 25).

Use un suministro de gas adecuado.

C

Esta estufa ha sido ajustada para funcionar a una presión

de 4” (columna de agua) del gas natural en el colector.

Un regulador de presión ha sido conectado al colector y

DEBE ser conectado en serie con la tubería de suministro

de gas (Consulte la Fig. 33).

Se debe tener cuidado durante la instalación de la estufa

de no obstruir el fl ujo de la combustión y el aire de

ventilación. La tubería de suministro del gas debe tener un

diámetro interior de 1/2” o 3/4”.

Para funcionamiento adecuado, la presión máxima de

entrada al regulador no debe ser de más de 14 pulgadas

de columna de agua. La presión de entrada al regulador

debe de ser de por lo menos 1 pulgada mayor que la

presión del regulador/colector. Ejemplos: Si la presión

del gas natural en el colector es de 4 pulgadas, la presión

de entrada debe ser de por lo menos 5 pulgadas; si el

regulador ha sido convertido a gas licuado de petróleo/

gas propano a una presión de 10 pulgadas de columna de

agua en el colector, la presión de entrada debe ser de por

lo menos 11 pulgadas (columna de agua). La prueba de

escapes del electrodoméstico será efectuada de acuerdo

con las instrucciones en el Paso E.

9

Page 22

INSTUCCIONES PARA LA INSTALACIÓN DEL GAS DUAL

Selle la abertura de la pared y del piso

D

Selle cualquier abertura que pueda haber en la pared detrás

de la estufa y en el piso debajo de la estufa después de que

se instale la tubería de suministro de gas. Consulte las Figs

A, B, y C.

Conexión del suministro del gas

E

a la estufa

Antes de conectar el gas a la estufa, revise los dibujos de

las ubicaciones sugeridas para la fuente de alimentación

(Figs. A, B y D). Para evitar fugas, aplique compuesto

sellador para juntas en todas las roscas machos

(exteriores) de la tubería. El regulador de presión se

encuentra en la parte trasera inferior izquierda de la estufa

(Ver Fig. 32). Para instalar el suministro de gas proceda

de la manera siguiente:

1.) Instale un codo de tubo negro de ½” NPT 90° al tubo

corto de suministro del gas (Ver Fig. 33)

2.) Instale una válvula externa de cierre del gas (manual)

en la tubería de suministro del gas en una ubicación

de fácil acceso, fuera de la estufa. Asegúrese de estar

informado como y donde se cierre el suministro de gas

a la estufa (Fig 33).

3.) Instale un adaptador abocinado* en el regulador de

presión del gas (Fig. 33).

Figura 37

7.) Después de hacer estas conexiones, verifi que si hay

fugas de gas. Abra el suministro de gas hacia la estufa

y use un detector de fugas líquido en todas las juntas.

*NOTA: Asegúrese de usar los 2 adaptadores abocinados

suministrados con el Juego de Conducto Flexible.

WARNING:

fugas de gas.

Verifi cación de la Presión del Gas en el Colector

Desconecte la estufa y su válvula de cierre individual del

sistema de tubería del suministro de gas cuando efectúe

cualquier prueba de presión de ese sistema a presiones

de prueba superiores a 14” de la presión en la columna

de agua (aproximadamente ½ lb/pulg.2). La estufa debe

aislarse del sistema de tubería del suministro de gas

cerrando su válvula de cierre manual individual durante

cualquier prueba de presión del sistema de tubería

del suministro de gas a presiones de prueba iguales

o inferiores a 14”de la presión en la columna de agua

(aproximadamente 1/2 lb/pulg.2).

Si fuera necesario verifi car la presión del gas en el

colector, conecte un manómetro (columna de agua) u

otro dispositivo para medir la presión en la tobera del

quemador superior derecho trasero. Use una manguera

de goma con un diámetro interior de aproximadamente

1/4” (0,63 cm) y mantenga la manguera bien apretada

sobre la tobera. Abra la válvula del quemador. Para una

verifi cación exacta de la presión, tenga por lo menos dos

(2) de los quemadores superiores encendidos. Asegúrese

de que la presión de suministro del gas (de admisión)

sea por lo menos una (1) pulgada más alta que la presión

especifi cada para el colector de la estufa. La presión del

suministro de gas no debe ser superior a 14 pulgadas

(columna de agua). Cuando está debidamente ajustada

para gas natural, la presión en el colector es de 4”. (Para

G.L.P./gas propano, la presión en el colector es de 10”.)

No use una llama para verifi car si hay

Fig. 33

WARNING:

la tubería cuando esté apretando los accesorios.

4.) Instale el conducto fl exible del artefacto en el adaptador

abocinado en el regulador de presión (Fig 33).

5.) Instale un segundo adaptador abocinado* en la válvula

de cierre externa manual (Fig 33).

6.) Instale el conducto fl exible del artefacto en el adaptador

abocinado en la válvula de cierre (Fig 33).

No permita que el regulador de presión gire en

Lea los detalles de la conexión léctrica

F

indicados a continuación. Enchufe la

estufa en el tomacorriente mural.

WARNING:

eléctrico en el disyuntor, fusible o cordón eléctrico.

WARNING:

seguridad personal, esta estufa debe ser puesta a tierra

de manera correcta.

10

Antes de reparar, desconecte el suministro

¡POR FAVOR LEA ATENTAMENTE! Para

Page 23

INSTUCCIONES PARA LA INSTALACIÓN DEL GAS DUAL

Oprimir

hacia dentro

G

i

r

a

r

h

a

c

i

a

l

a

i

z

q

u

i

e

r

d

a

Deslice cuidadosamente la estufa hacia

G

la abertura del gabinete

Deslice cuidadosamente la estufa hacia la abertura del

gabinete a la vez que inserta el tornillo nivelador trasero

en el SOPORTE ANTIVUELCO VERFICIANDO QUE

QUEDE BIEN ENGANCHADO (Ver Fig. 22). Asegúrese

de que el conducto fl exible del artefacto y el cordón de

alimentación quede plegado en el resto del área abierta

del piso detrás de la gaveta de almacenamiento o gaveta

calentadora de la estufa. ¡Asegúrese de que el conducto

fl exible de la estufa no quede aplastado o doblado! Arregle

de antemano la forma del conducto fl exible del artefacto

y el cordón de alimentación si es necesario para asegurar

de que la estufa se deslice en forma debida hacia la

abertura del gabinete. Asegúrese de verifi car la nivelación

de la estufa colocando un nivel horizontalmente en una de

las parrillas del horno (Fig. 23).

Instalación de las cabezas y tapas de

H

los quemadores

Su estufa fué enviada con los cabezales y tapas de los

quemadores ensamblados en el lugar correcto (Fig. 34).

Si necesita instalar de nuevo las tapas de los quemadores

por favor refi erase a la Guia de Uso y Cuidado para may

or información.

Verifi que el encendido eléctrico de los

I

quemadores superiores.

Se debe revisar el funcionamiento de los encendedores

eléctricos después de que la estufa y los conectores de la

tubería de suministro han sido cuidadosamente revisados

para verifi car fugas y la estufa ha sido conectada a la energía

eléctrica.

a. Para verifi car el encendido adecuado, oprima y gire

la perilla de un quemador superior a la izquierda a la

posición ‘LITE’. Usted oirá el ruido de las chispas del

encendedor (Ver Fig. 35)

b. El quemador superior debe encenderse cuando llega

gas al quemador superior. Purgue el aire de las

tuberías de suministro dejando la perilla en la posición

“LITE” hasta que el quemador se encienda. Todos los

quemadores deben encenderse dentro de cuatro (4)

segundos en funcionamiento normal después de que

el aire ha sido purgado de la tubería de suministro.

c. Verifi que visualmente si se encendió el quemador.

Una vez que el quemador se enciende, la perilla de

control debe ser girada para sacarla de la posición

“LITE”.

d. La estufa tiene electrodos (encendedores)

separados para cada quemador. Pruebe cada perilla

separadamente hasta que todas las válvulas de los

quemadores hayan sido revisadas.

RECUERDE — NO PERMITA QUE ENTREN

DERRAMES, ALIMENTO, AGENTES DE LIMPIEZA NI

NINGUN OTRO MATERIAL EN LA ABERTURA DEL

PORTATOBERA.

Siempre mantenga las tapas de los quemadores y las

cabezas de los quemadores en sus lugares cuando se

usen los quemadores superiores.

4

1

2

3

5

1. Quemador de fuego lento perfecto™- 5,000 BTU.

2. Quemador puente de 10,000 BTU.

3. Quemadores estandar - 9,500 BTU.

4. Quemador grande- 12,000 o 14,200 BTU.

5. Quemador doble - 18,000 BTU.

Fig. 34

Fig. 35

11

Page 24

INSTUCCIONES PARA LA INSTALACIÓN DEL GAS DUAL

Regule el ajuste “LO” (BAJO) de la

J

válvula del quemador superior (para

válvulas de fl ujo lineal solamente)

Prueba para verifi car si los ajustes de “LO or LOW” deben

ser ajustados (posicion frontal derecha SOLAMENTE):

1. Empuje hacia adentro y dele vuelta a la perilla hacia

(lite) hasta que el quemador encienda.

2. Empuje hacia adentro rapidamente dele vueltas a la

perilla a la POSICION MAS BAJA.

3. Si el quemador se apaga, ponga el control en OFF o

apagado y empiece a girar otra vez hasta ponerlo en

fl ama baja.

4. Remueva la perilla de control del quemador.

5. Utilice un desatornillador de hoja delgada y ajuste el

tamaño de la llama intern con los tornillos derechos

(Vea la Fig. 36). Ajuste el tamaño de la llama externa

con el juego de tornillos bajos (Vea la Fig. 36). Dele

vueltas en direccion contraria a las manijas del reloj

para incrementar el tamaño de la llama. Dele vueltas

en direccion a las manecillas de reloj para decrecer el

tamaño de la llama.

Cuidado, Limpieza y Mantenimiento

Consulte la Guía de Uso y Cuidado para las instrucciones

de limpieza. Si es necesario sacar la estufa para limpieza

o mantenimiento, cierre el suministro del gas. Desconecte

el gas y el suministro eléctrico. Si el suministro del gas o el

suministro eléctrico no son accesibles, levante ligeramente

la estufa del frente y retírela de la pared. Retírela

solamente hasta donde sea necesario para desconectar

el gas y la electricidad. Termine de retirar la estufa para

reparación y limpieza. Vuelva a instalar en el orden

inverso asegurándose de nivelar la estufa y revisar las

conexiones del gas para verifi car si hay fugas. Ver en la

página 3 de este documento las instrucciones para anclaje

correcto del soporte antivuelco.

Antes de Hacer una Llamada de Servicio

Lea la sección “Antes de Solicitar Servicio” en su Guía

de Uso y Cuidado. Puede ahorrarle tiempo y dinero. La

lista incluye los incidentes más comunes que no son

originados por la fabricación o materiales defectuosos en

este artefacto. Consulte la garantía en su Guía de Uso y

Cuidado para obtener nuestro número gratis de servicio

y dirección. Por favor llame o escriba si usted tiene

preguntas sobre su estufa y/o necesidad de hacer pedidos

de piezas.

Fig. 36

K

Después de haberse completado la

instalación, asegúrese de que todos

los controles fueron dejados en la

posición “OFF” (APAGADO).

Ubicación del Número de Modelo y Número de Serie