Page 1

Use & Care Guide

Model: 415.16139110

Kenmore Elite®

Liquid Propane Gas Grill

P/N G523-001-010801

Sears Brands Management Corporation

Hoffman Estates, IL 60179 U.S.A.

www.kenmore.com

www.sears.com

Model 464224211 • Nov-03-10

Page 2

DANGER

WARNING

If you smell gas:

1. Shut off gas to the appliance.

2. Extinguish any open flame.

3. Open lid.

4. If odor continues, keep away from the appliance

and immediately call your gas supplier or your

fire department.

WARNING

1. Do not store or use gasoline or other

flammable liquids or vapors in the vicinity of

this or any other appliance.

2. An LP Tank not connected for use shall not

be stored in the vicinity of this or any other

appliance.

Call the Grill Information Center for Help and Parts

Missing Parts? Assembly Questions?

Before returning grill to store, call 1-800-241-7548

Product Record

IMPORTANT: Fill out the product record information below.

Model Number

Serial Number

See rating label on grill for serial number.

Operation Problems?

CALIFORNIA PROPOSITION 65

1. Combustion by-products produced when using this

product contain chemicals known to the State of

California to cause cancer, birth defects, and other

reproductive harm.

2. This product contains chemicals, including lead

and lead compounds, known to the State of

California to cause cancer, birth defects or other

reproductive harm.

Wash your hands after handling this product.

Installation Safety Precautions

• Use grill, as purchased, only with LP (propane) gas and the

regulator/valve assembly supplied.

• Grill installation must conform with local codes, or in the

absence of local codes, with either the National Fuel Gas

Code, ANSI Z223.1/ NFPA 54, Natural Gas and Propane

Installation Code, CSA B149.1, or Propane Storage and

Handling Code, B149.2, or the Standard for Recreational

Vehicles, ANSI A 119.2/NFPA 1192, and CSA Z240 RV

Series, Recreational Vehicle Code, as applicable.

• All electrical accessories (such as a rotisserie) must be

electrically grounded in accordance with local codes, or

National Electrical Code, ANSI / NFPA 70 or Canadian

Electrical Code, CSA C22.1. Keep any electrical cords

and/or fuel supply hoses away from any hot surfaces.

• Grill is not for use in or on recreational vehicles and/or boats.

• This grill is safety certified for use in the United States

and/or Canada only. Do not modify for use in any other

location. Modification will result in a safety hazard.

Safety Symbols

The symbols and boxes shown below explain what each

heading means. Read and follow all of the messages found

throughout the manual.

Date Purchased

To Installer/Assembler: Leave these instructions with

consumer.

To Consumer: Keep this manual for future reference.

CAUTION

Some parts may contain sharp edges, especially

as noted in these instructions.

Wear protective gloves if necessary.

CAUTION

For residential use only. Do not use for commercial

cooking.

© 2010 Sears Brands Management Corporation

2 • 464224211

DANGER

DANGER: Indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

WARNING

WARNING: Be alert to the possibility of serious bodily injury

if the instructions are not followed. Be sure to read and

carefully follow all of the messages.

CAUTION

CAUTION: Indicates a potentially hazardous situation which,

if not avoided, may result in minor or moderate injury.

Printed in China

Page 3

Table of Contents WARRANTY

For Your Safety..............................................................2

Grill Information Center

.............................................2

Product Record Information........................................2

Safety Symbols.............................................................2

Installation Safety Precautions...................................2

Kenmore Grill Warranty.............................................3

Use and Care...........................................................4-12

Parts List........................................................................13

Parts Diagram.............................................................14

Assembly................................................................15-20

Troubleshooting.....................................................21-23

Repair Protection Agreements

Congratulations on making a smart purchase. Your new

Kenmore product is designed and manufactured for years of

dependable operation. But like all products, it may require

repair from time to time. That’s when having a Repair Protection

Agreement can save you money and aggravation.

Here’s what the Repair Protection Agreement* includes:

Expert service by our 10,000 professional repair specialists

Unlimited service and no charge for parts and labor on all

covered repairs

Product replacement up to $1500 if your covered product

can’t be fixed

Discount of 10% from regular price of service and related

installed parts not covered by the agreement; also, 10% off

regular price of preventive maintenance check

Fast help by phone – we call it Rapid Resolution –

phone support from a Sears representative. Think of us

as a “talking owner’s manual.”

Once you purchase the Repair Protection Agreement, a

simple phone call is all that it takes for you to schedule service.

You can call anytime day or night, or schedule a service

appointment online.

The Repair Protection Agreement is a risk-free purchase. If

you cancel for any reason during the product warranty period,

we will provide a full refund. Or, a prorated refund anytime after

the product warranty period expires. Purchase your Repair

Protection Agreement today!

Some limitations and exclusions apply. For prices and

additional information in the U.S.A. call 1-800-827-6655.

*Coverage in Canada varies on some items. For full details

call Sears Canada at 1-800-361-6665.

Sears Installation Service

For Sears professional installation of home appliances, garage

door openers, water heaters, and other major home items, in the

U.S.A. or Canada call 1-800-4-MY-HOME®.

KENMORE ELITE FULL WARRANTY

If this grill fails due to a defect in material or workmanship

within two years from the date of purchase, call 1-800-4-MY-

®

HOME to arrange for free repair (or replacement if repair

proves impossible).

Limited Warranty on Stainless Steel Burners

Any stainless steel burner that ever rusts through will be

replaced free of charge. After the second year from the date

of purchase you must pay to have it installed.

Limited Warranty on Selected Grill Parts

For two years from the date of purchase, any stainless or

painted steel part will be replaced free of charge if it rusts

through. After the second year from the date of purchase you

must pay to have it installed.

All warranty coverage excludes ignitor batteries and grill

part paint loss or rusting (except for rust-through as specified

above), which are either expendable parts that can wear out

from normal use in less than a year, or are conditions that

can be the result of normal use, accident or improper

maintenance.

All warranty coverage is void if this grill is ever used for

commercial or rental purposes.

All warranty coverage applies only if this grill is used in the

United States.

This warranty gives you specific legal rights, and you may

have other rights which vary from state to state.

Sears Brands Management Corporation

Hoffman Estates, IL 60179

WARNING

• Read and follow all Safety, Assembly, and

Use and Care Instructions in this Guide

before assembling and cooking with this

grill.

• Failure to follow all instructions in this Use

and Care Guide may lead to fire or

explosion, which could result in property

damage, personal injury or death.

This Grill is for Outdoor Use Only

Tools needed for assembly:

Adjustable wrench (not provided)

Screwdriver (not provided)

7/16" Combination wrench (not provided)

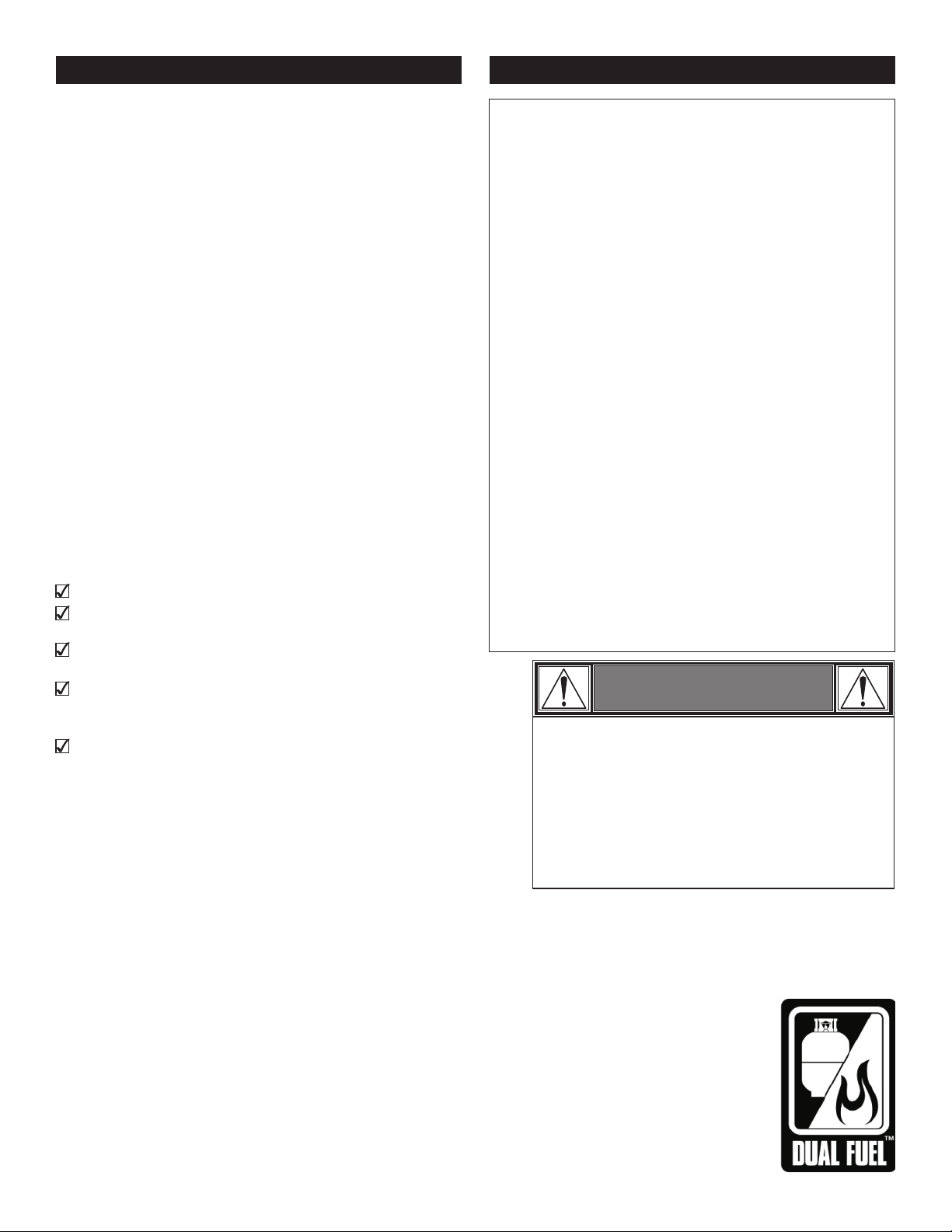

CONVERSION READY

This grill easily converts from LP liquid

propane to NG natural gas.

Contact 1-800-4-MY-HOME or

www.sears.com to purchase a natural gas

conversion kit, part number 415.7116572.

Dual Fuel™ is a registered trademarks of

the W. C. Bradley Company and used,

with permission, by Sears Holdings

Corporation. All rights reserved.

®

464224211 • 3

Page 4

USE AND CARE

DANGER

• NEVER store a spare LP cylinder under or near the

appliance or in an enclosed area.

• Never fill a cylinder beyond 80% full.

• If the information in the two points above is not

followed exactly, a fire causing death or serious

injury may occur.

• An overfilled or improperly stored cylinder is a

hazard due to possible gas release from the safety

relief valve. This could cause an intense fire with

risk of property damage, serious injury or death.

• If you see, smell or hear gas escaping, immediately

get away from the LP cylinder and appliance and

call your fire department.

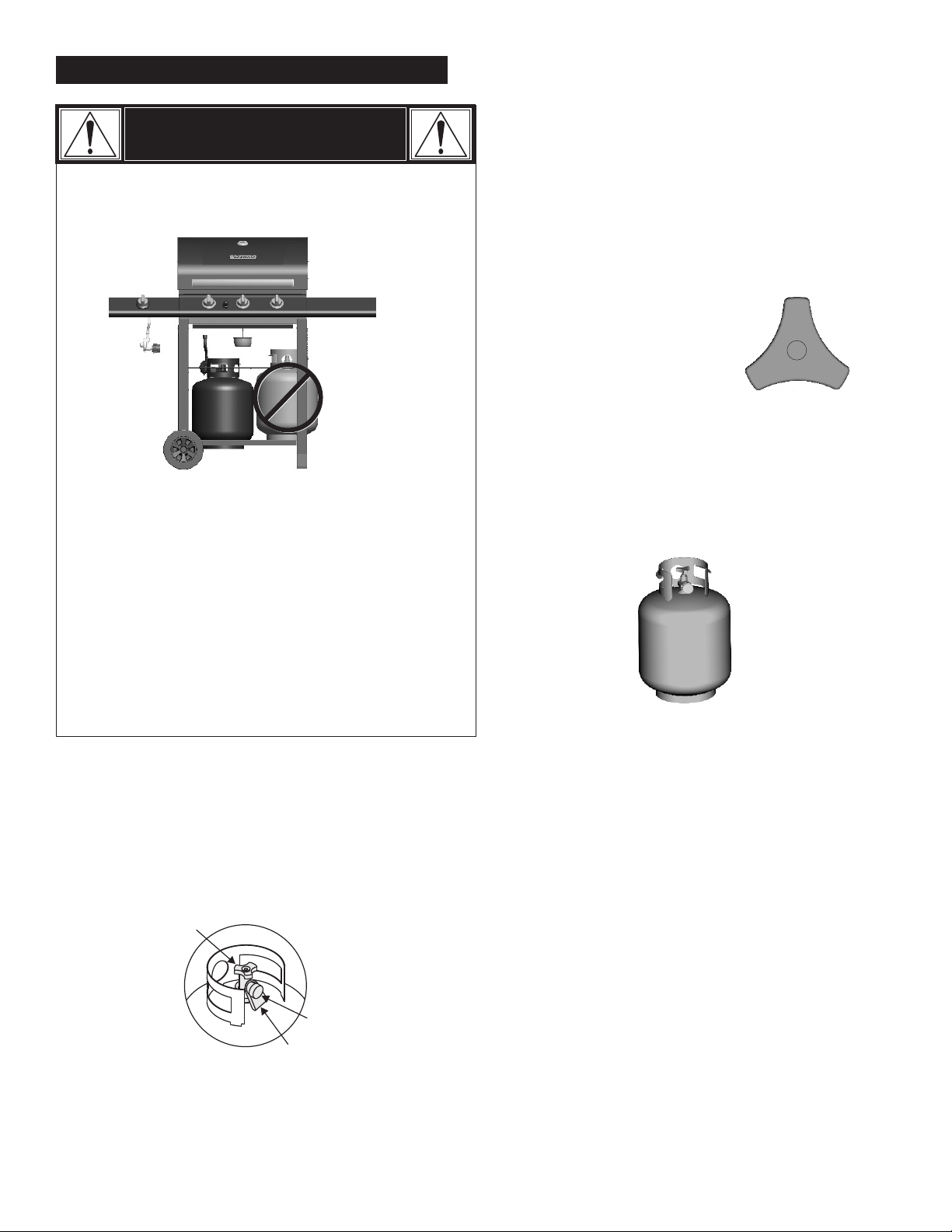

LP Tank

• The LP Tank used with your grill must meet the following

requirements:

• Use LP Tanks only with these required measurements: 12"

(30.5cm) (diameter) x 18" (45.7 cm) (tall) with 20 lb. (9 kg.)

capacity maximum.

• LP Tanks must be constructed and marked in accordance

with specifications for LP Tanks of the U.S. Department of

Transportation (DOT) or for Canada, CAN/CSA-B339, tanks,

spheres and tubes for transportation of dangerous goods.

Transport Canada (TC). See LP Tank collar for marking.

• LP Tank valve must have:

• Type 1 outlet compatible with

regulator or grill.

• Safety relief valve.

• UL listed Overfill Protection

Device (OPD). This OPD safety

feature is identified by a unique triangular hand wheel.

Use only LP Tanks equipped with this type of valve.

• LP Tank must be arranged for vapor withdrawal and include

collar to protect LP Tank valve. Always keep LP Tanks in

upright position during use, transit or storage.

LP Tank in upright position for vapor withdrawal

OPD Hand Wheel

LP Tank Removal, Transport And Storage

• Turn OFF all control knobs and LP tank valve. Turn coupling

nut counterclockwise by hand only - do not use tools to

disconnect. Lift LP tank wire upward off of LP tank collar,

then lift LP tank up and off of support bracket. Install

safety cap onto LP tank valve. Always use cap and strap

supplied with valve.

Failure to use safety cap as directed may result in serious

personal injury and/or property damage.

LP Tank Valve

Safety Cap

Retainer Strap

• A disconnected LP tank in storage or being transported must

have a safety cap installed (as shown). Do not store an LP

tank in enclosed spaces such as a carport, garage, porch,

covered patio or other building. Never leave an LP tank

inside a vehicle which may become overheated by the sun.

• Do not store an LP tank in an area where children play.

4 • 464224211

LP (Liquefied Petroleum Gas)

• LP gas is nontoxic, odorless and colorless when produced.

For Your Safety, LP gas has been given an odor (similar to

rotten cabbage) so that it can be smelled.

• LP gas is highly flammable and may ignite unexpectedly

when mixed with air.

LP Tank Filling

• Use only licensed and experienced dealers.

• LP dealer must purge new tank before filling.

• Dealer should NEVER fill LP Tank more than 80% of LP Tank

volume. Volume of propane in tank will vary by temperature.

• A frosty regulator indicates gas overfill. Immediately close

LP Tank valve and call local LP gas dealer for assistance.

• Do not release liquid propane (LP) gas into the atmosphere.

This is a hazardous practice.

• To remove gas from LP Tank, contact an LP dealer or call a

local fire department for assistance. Check the telephone

directory under “Gas Companies” for nearest certified LP

dealers.

Page 5

LP Tank Exchange

• Many retailers that sell grills offer you the option of

replacing your empty LP tank through an exchange service.

Use only those reputable exchange companies that inspect,

precision fill, test and certify their tanks. Exchange your

tank only for an OPD safety feature-equipped tank as

described in the "LP Tank" section of this manual.

• Always keep new and exchanged LP tanks in upright

position during use, transit or storage.

• Leak test new and exchanged LP tanks BEFORE

connecting to grill.

• Place dust cap on cylinder valve outlet whenever the

cylinder is not in use. Only install the type of dust cap on

the cylinder valve outlet that is provided with the cylinder

valve. Other types of caps or plugs may result in leakage

of propane.

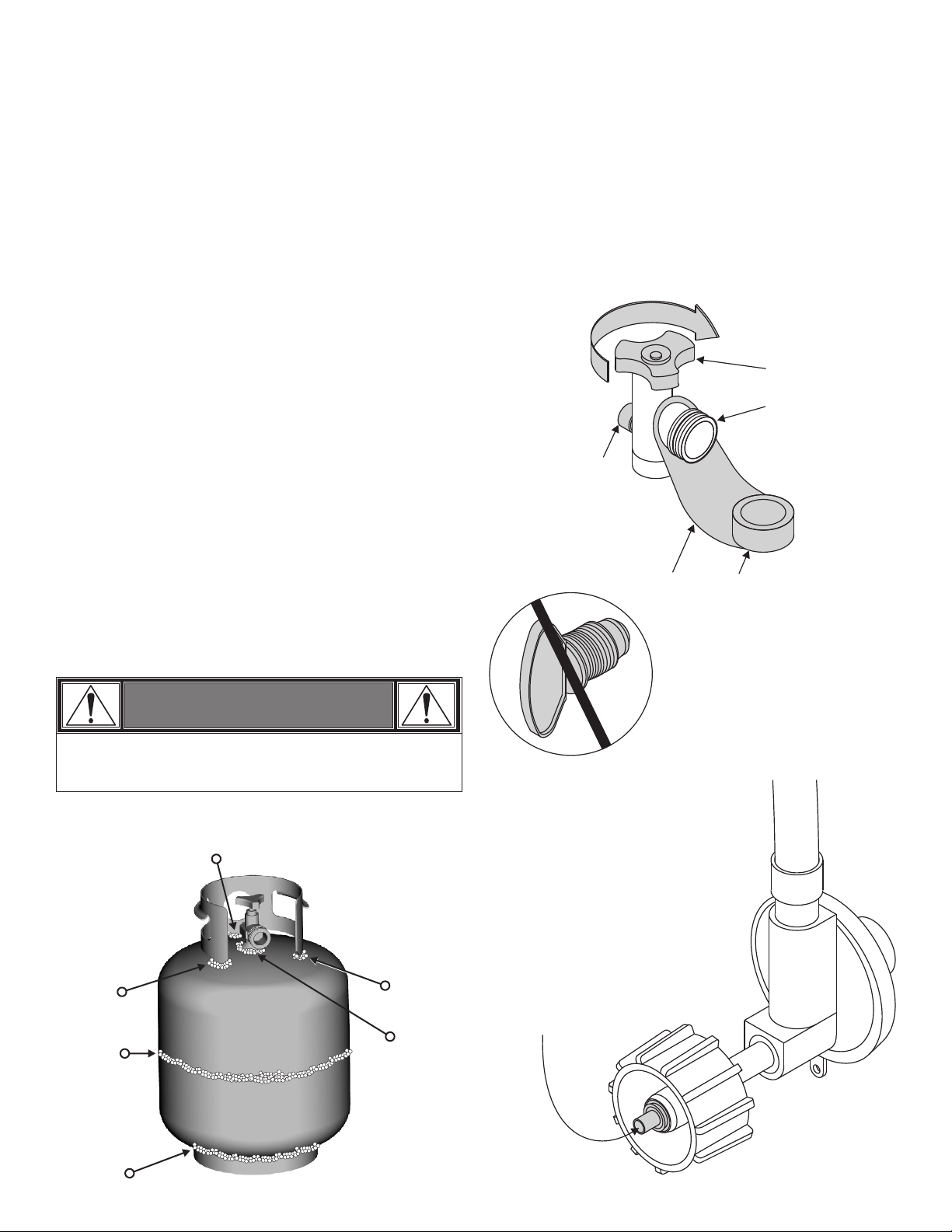

LP Tank Leak Test

For your safety

• Leak test must be repeated each time LP tank is exchanged

or refilled.

• Do not smoke during leak test.

• Do not use an open flame to check for gas leaks.

• Grill must be leak tested outdoors in a well-ventilated area,

away from ignition sources such as gas fired or electrical

appliances. During leak test, keep grill away from open

flames or sparks.

• Use a clean paintbrush and a 50/50 mild soap and water

solution. Brush soapy solution onto areas indicated by

arrows in figure below. Leaks are indicated by growing

bubbles.

WARNING

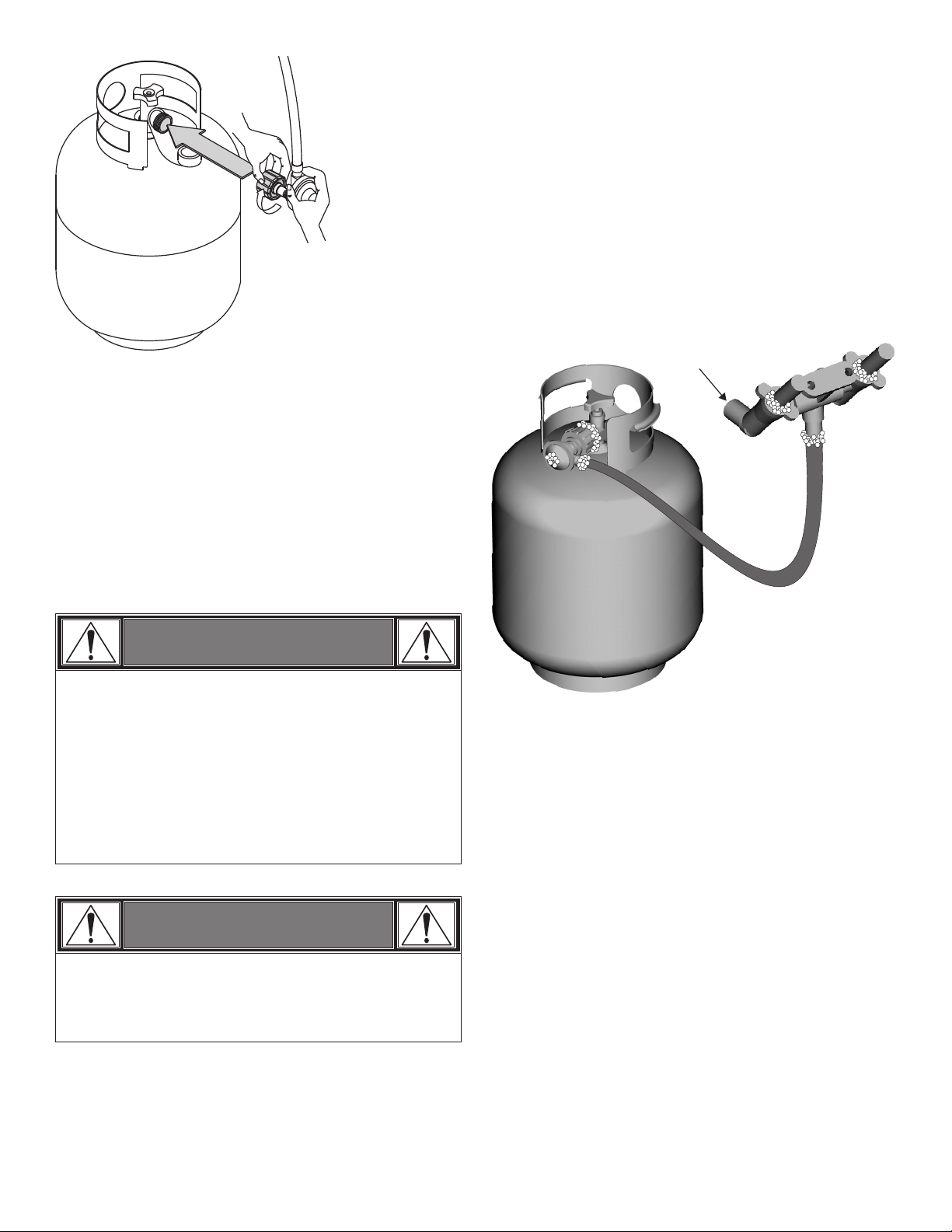

Connecting Regulator To The LP Tank

1. LP tank must be properly secured onto grill. (Refer to

assembly section.)

2. Turn all control knobs to the OFF position.

3. Turn LP tank OFF by turning OPD hand wheel clockwise to

a full stop.

4. Remove the protective cap from LP tank valve. Always use

cap and strap supplied with valve.

c

k

w

o

i

l

s

e

OPD Hand Wheel

Type 1 outlet with

thread on outside

Strap and Cap

Do not insert a POL transport plug

(plastic part with external threads)

into the Type 1 tank valve outlet.

It will defeat the Safety Relief

Valve feature.

Safety Relief Valve

C

f

f

O

If “growing” bubbles appear do not use or move the LP tank.

Contact an LP gas supplier or your fire department!

Do not use household cleaning agents. Damage to gas

valve/hose/regulator components can result.

5. Hold regulator and insert nipple into LP

tank valve. Hand-tighten the coupling

nut, holding regulator in a straight line

with LP tank valve so as not to crossthread the connection.

Nipple has to be centered

into the LP tank valve.

464224211 • 5

Page 6

Leak Testing Valves, Hose and Regulator

1. Turn all grill control knobs to OFF.

Straight

Hold coupling nut and regulator

as shown for proper connection

to LP tank valve.

6. Turn the coupling nut clockwise and tighten to a full stop. The

regulator will seal on the back-check feature in the LP tank

valve, resulting in some resistance. An additional one-half to

three-quarters turn is required to complete the

connection. Tighten by hand only – do not use tools.

NOTE:

If you cannot complete the connection, disconnect regulator

and repeat steps 5 and 6. If you are still unable to complete

the connection, do not use this regulator!

Call 1-800-4-MY-HOME for identical replacement parts.

®

2. Be sure regulator is tightly connected to LP tank.

3. Completely open LP tank valve by turning OPD hand wheel

counterclockwise. If you hear a rushing sound, turn gas off

immediately. There is a major leak at the connection.

Correct before proceeding by calling Sears for replacement

parts at 1-800-4-MY-HOME .

®

4. Brush soapy solution onto areas where bubbles are shown in

picture below:

Never remove threaded

orifice at end of valve.

DANGER

• Do not insert any tool or foreign objects into the valve

outlet or safety relief valve. You may damage the valve

and cause a leak. Leaking propane may result in

explosion, fire, severe personal injury, or death.

• If a leak is detected at any time, STOP and call the fire

department.

• If you cannot stop a gas leak, immediately close LP tank

valve and call LP gas supplier or your fire department!

WARNING

• Never attempt to attach this grill to the self-contained

LP gas system of a camper trailer or motor home.

• Do not use grill until leak-tested.

5. If “growing” bubbles appear, there is a leak. Close LP tank

valve immediately and retighten connections. If leaks

cannot be stopped do not try to repair. Call Sears for

replacement parts at 1-800-4-MY-HOME .

®

6. Always close LP tank valve after performing leak test by

turning hand wheel clockwise.

6 • 464224211

Page 7

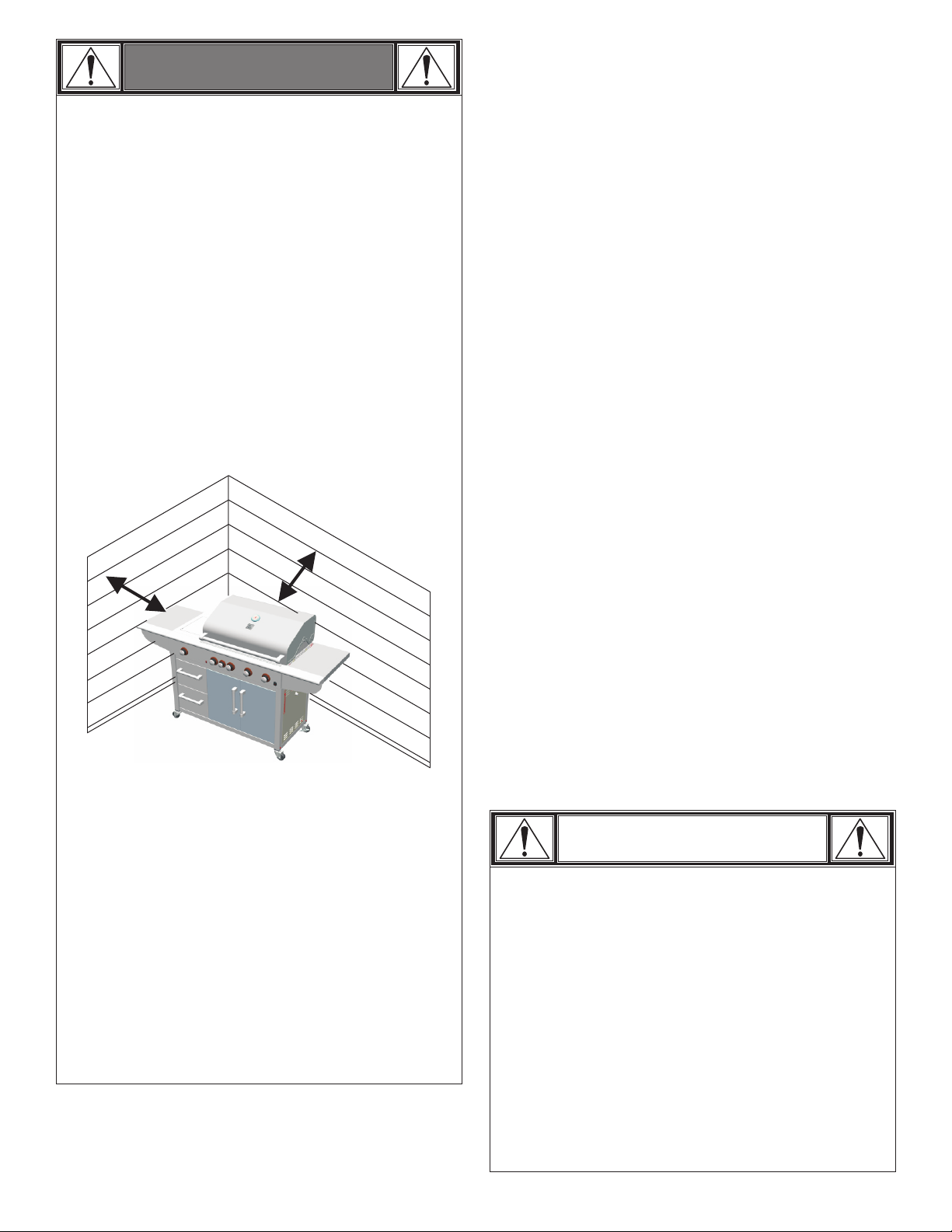

WARNING

For Safe Use of Your Grill and to Avoid Serious

Injury:

• Do not let children operate or play near grill.

• Keep grill area clear and free from materials that burn.

• Do not block holes in sides or back of grill.

• Check burner flames regularly.

• Use grill only in well-ventilated space. NEVER use in

enclosed space such as carport, garage, porch,

covered patio, or under an overhead structure of any

kind.

• Do not use charcoal or ceramic briquets in a gas grill.

(Unless briquets are supplied with your grill.)

• Use grill at least 3 ft. from any wall or surface.

Maintain 10 ft. clearance to objects that can catch fire

or sources of ignition such as pilot lights on water

heaters, live electrical appliances, etc.

• Apartment Dwellers:

Check with management to learn the requirements

and fire codes for using an LP gas grill in your

apartment complex. If allowed, use outside on the

ground floor with a three (3) foot clearance from

walls or rails. Do not use on or under balconies.

• NEVER attempt to light burner with lid closed. A

buildup of non-ignited gas inside a closed grill is

hazardous.

• Never operate grill with LP cylinder out of correct

position specified in assembly instructions.

• Always close LP cylinder valve and remove

coupling nut before moving LP cylinder from

specified operation position.

Safety Tips

Before opening LP cylinder valve, check the coupling nut for

•

tightness.

When grill is not in use, turn off all control knobs and LP

•

cylinder valve.

•

Never move grill while in operation or still hot.

•

Use long-handled barbecue utensils and oven mitts to avoid

burns and splatters.

Maximum load for sideburner and side shelf is 10 lbs.

•

•

The grease tray must be inserted into grill and emptied after

each use. Do not remove grease tray until grill has

completely cooled.

•

Clean grill often, preferably after each cookout. If a bristle

brush is used to clean any of the grill cooking surfaces,

ensure no loose bristles remain on cooking surfaces prior to

grilling. It is not recommended to clean cooking surfaces

while grill is hot.

•

If you notice grease or other hot material dripping from grill

onto valve, hose or regulator, turn off gas supply at once.

Determine the cause, correct it, then clean and inspect valve,

hose and regulator before continuing. Perform a leak test.

•

Keep ventilation openings in cylinder enclosure (grill cart) free

and clear of debris.

•

Do not store objects or materials inside the grill cart

enclosure that would block the flow of combustion air to the

underside of either the control panel or the firebox bowl.

•

The regulator may make a humming or whistling noise during

operation. This will not affect safety or use of grill.

•

If you have a grill problem see the "Troubleshooting Section".

•

If the regulator frosts, turn off grill and LP cylinder valve

immediately. This indicates a problem with the cylinder and it

should not be used on any product. Return to supplier!

Storing Your Grill

• Clean cooking grates.

• Store in dry location.

• When LP tank is connected to grill, store outdoors in wellventilated space and out of reach of children.

• Cover grill if stored outdoors.

• Store grill indoors ONLY if LP tank is turned off and

disconnected, removed from grill and stored outdoors.

• When removing grill from storage follow "Cleaning Burner

Assembly" instructions before starting grill.

CAUTION

• Do not preheat the grill on HIGH with the lid closed

for longer than 15 minutes. Preheating the grill

with the lid closed beyond this point can result in

excessive cooking temperatures, risk of injury.

• Putting out grease fires by closing the lid is not

possible. Grills are well ventilated for safety

reasons.

• Do not use water on a grease fire. Personal injury

may result. If a grease fire develops, turn knobs

and LP cylinder off.

• Do not leave grill unattended while preheating or

burning off food residue on HIGH. If grill has not

been regularly cleaned, a grease fire can occur

that may damage the product.

464224211 • 7

Page 8

Main Burner Ignitor Lighting

• Open grill lid during Lighting.

• Do not lean over grill while lighting.

1. Turn OFF all Gas Burner Control Valves.

2. Turn ON gas at LP cylinder.

3. To ignite any main burner, push in and turn the burner

control knob to the position.

4. Press and hold the ELECTRONIC IGNITOR button until

the burner ignites.

5. Once burner has ignited, turn knob to desired setting.

6. If Ignition does not occur in 5 seconds, turn the burner

control to OFF, wait 5 minutes for gas to clear away, and

repeat the lighting procedure.

7. Repeat steps 4 through 6 for the remaining main burners.

Sear Burner Ignitor Lighting

• Do not lean over grill while lighting.

• Open lid during lighting.

1. Turn on gas at LP cylinder.

2. To ignite the sear burner, push in and turn the sear burner

control knob to the position.

3. Press and hold the ELECTRONIC IGNITOR button until the

sear burner ignites.

4. Once sear burner has ignited, turn knob to desired

setting.

5. If Ignition does not occur in 5 seconds, turn the burner

control to OFF, wait 5 minutes for gas to clear away, and

repeat the lighting procedure.

Rotisserie Burner Ignitor Lighting

• Do not lean over grill while lighting.

1. Open grill lid during lighting. Turn on gas at LP cylinder.

2. To ignite the rotisserie burner, push in and turn the

rotisserie burner control knob to the position.

3. Press and hold the ELECTRONIC IGNITOR button until the

rotisserie burner ignites.

4. Once burner has ignited, turn knob to desired setting.

5. If ignition does NOT occur in 5 seconds, turn the burner

control OFF. Wait 5 minutes for gas to clear away, and

repeat the lighting procedure.

Match-Lighting

• Do not lean over grill while lighting.

• Open lid. Turn on gas at LP cylinder.

• Light Burners one at time.

Match Lighting the Main Burners

1. Place match into match holder (hanging from RH side or

LH side of the cart).

2. Strike the match and position lit match through cooking

grates as shown in Figure A.

3. Position lit match next to far left main burner.

4. Push in and turn far left control knob to position. Be

sure burner lights and stays lit.

5. If ignition does NOT occur in 5 seconds, turn the burner

control knob OFF, wait 5 minutes for gas to clear away

and repeat the lighting procedure.

6. Light other burners in sequence from left to right by

pushing main burner control knob in and turning to

position.

Figure A

Sear Burner

Figure A

Match-Lighting the Sear Burner

• Do not lean over grill while lighting.

• Open lid. Turn on gas at LP cylinder.

1. Place match into match holder (hanging from RH side of

the cart).

2. Strike the match and position lit match through cooking

grates as shown in Figure B.

3. Position lit match above the burner.

4. Push in and turn sear burner control knob to position.

Be sure burner lights and stays lit.

5. If ignition does NOT occur in 5 seconds, turn the burner

control knob OFF, wait 5 minutes for gas to clear away

and repeat the lighting procedure.

Main Burners

Main Burners

Figure B

Sear Burner

WARNING

Turn controls and gas source or tank OFF when not

in use.

CAUTION

If ignition does NOT occur in 5 seconds, turn the

burner controls OFF, wait 5 minutes and repeat the

lighting procedure. If the burner does not ignite with

the valve open, gas will continue to flow out of the

burner and could accidently ignite with risk of injury.

8 • 464224211

Match lighting the Rotisserie Burner - Figure C

1. Place match in match holder. Strike the Match. Position lit

match close to the front center of the rotisserie burner.

2. Push in and turn rotisserie burner control knob to .

3. If ignition does NOT occur in 5 seconds, turn the burner

control knob OFF, wait 5 minutes for gas to clear away,

and repeat the lighting procedure.

Match holder

Rotisserie Burner

Figure C

Match Lighting Instructions continued on next page.

Page 9

Sideburner Ignitor Lighting

Do not lean over grill while lighting.

1. Open sideburner lid. Turn ON gas at LP cylinder.

2. Turn sideburner knob to the HI position, push and hold

ELECTRONIC IGNITOR button.

3. If sideburner does NOT light within 5 seconds, turn knob

to repeat lighting procedure.OFF, wait 5 minutes, then

Match lighting the Side Burner - Figure D

1. Open the sideburner lid during lighting.

2. Place match in match holder. Strike the Match. Position

lit match close to the side burner.

3. Push in and turn side burner knob to position. Be sure

burner lights and stays lit.

4. If ignition does NOT occur in 5 seconds, turn the burner

control knob OFF, wait 5 minutes for gas to clear away,

and repeat the lighting procedure.

CAUTION

SPIDER ALERT!

SPIDER AND WEBS

INSIDE BURNER TUBE

If you notice that your grill is getting hard to light or that the

flame isn’t as strong as it should be, take the time to check and

clean the See section “Cleaning Burner burner tubes.

Assemblies” next page.

Figure D

Burner Flame Check

• Remove cooking grates and flame tamers. Light burners, rotate

knobs from HIGH to low. You should see a smaller flame in

low position than seen on HIGH Perform burner flame check on

sideburner, sear burner and rotisserie also. Always check flame

prior to each use. If only low flame is seen refer to "Sudden drop

or low flame" in the Troubleshooting Section.

HIGH

LOW

Turning Grill Off

• Turn all knobs to OFF position. Turn LP cylinder off by turning

hand-wheel clockwise to a full stop.

Ignitor Check

• Turn gas off at LP cylinder. Push and turn control knob to

and hold in. You will hear a clicking sound as the burner is being

ignited. Ignition should occur within 5 seconds, but continue to

hold the knob in for a full 10 seconds to maintain ignition.

Valve Check

• Important: Make sure gas is off at LP cylinder before

checking valves. Knobs lock in OFF position. To check

valves, first push in knobs and release, knobs should spring

back. If knobs do not spring back, replace valve assembly

before using grill. Turn knobs to LOW position then turn

back to OFF position. Valves should turn smoothly.

Hose Check

• Before each use, check to see if hoses are cut or worn.

Replace damaged hoses before using grill. Use only

valve/hose/regulator specified by manufacturer.

VALVE

CONTROL PANEL

Spiders or small insects have been known to create “flashback”

problems. The spiders spin webs, build nests and lay eggs in the

grill’s venturi tube(s) obstructing the flow of gas to the burner.

The backed-up gas can ignite in the burner tube behind the

control panel. This is known as a flashback and it can damage

your grill and even cause injury.

To prevent flashbacks and ensure good performance the burner and

burner tube assembly should be removed from the grill and cleaned

before use whenever the grill has been idle for an extended period.

SPIDER WEBS

INSIDE BURNER TUBE

BURNER

CAUTION

Do not remove glass for cleaning.

Glass is not dishwasher safe.

464224211 • 9

Page 10

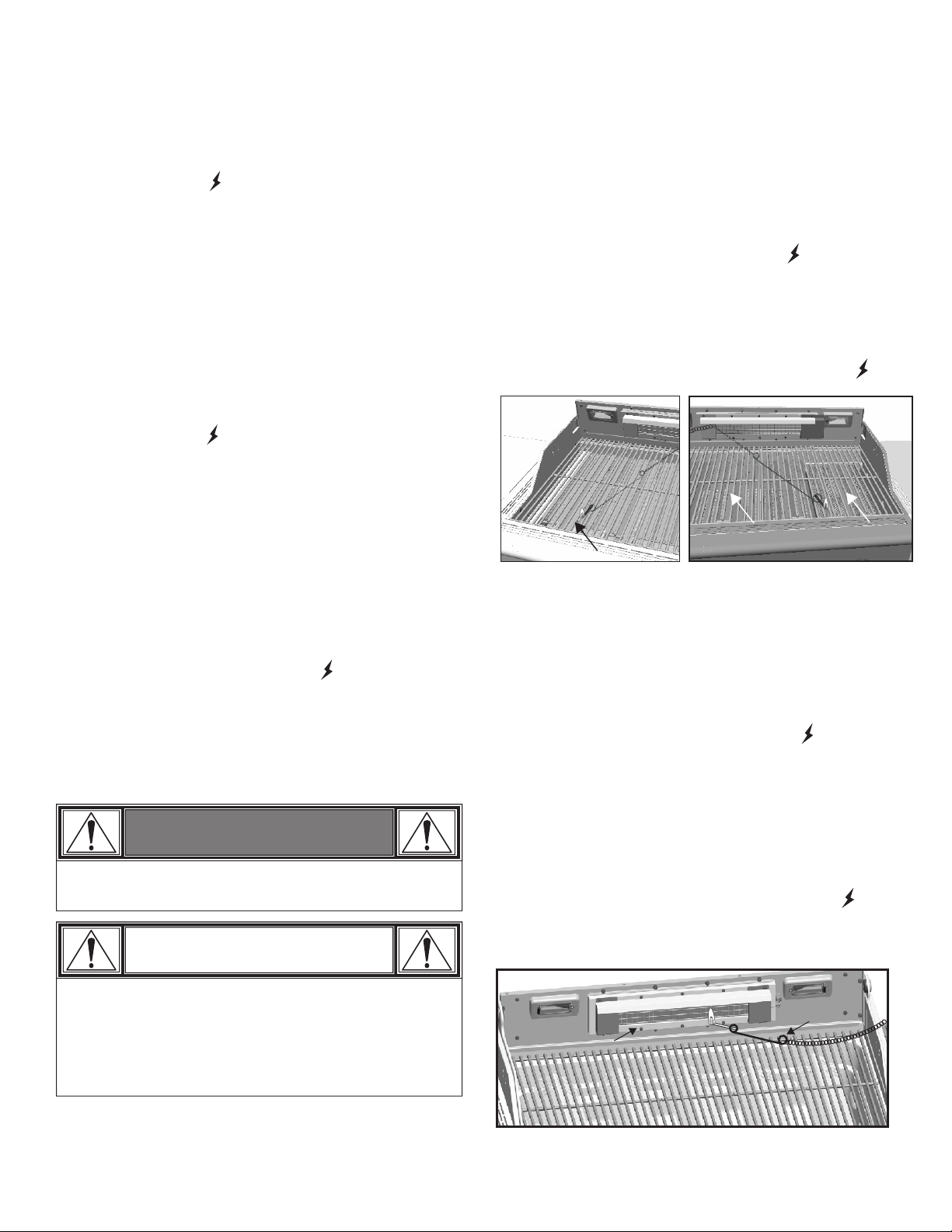

Cleaning the Main Burner Assembly

Follow these instructions to clean and/or replace parts of burner

assembly or if you have trouble igniting grill.

1. Turn gas off at control knobs and LP Tank.

2. Remove cooking grates and heat diffusers.

3. Remove electrode from burner by prying the clip away as

shown in Figure A. Electrode should remain in firebox.

4. Remove hitch pins and flame carryover tubes from front of

burners as shown in Figure B.

5. Remove remaining hitch pins from rear of burner

to disengage burner from bracket on firebox.

6. Carefully lift each burner up and away from valve openings.

We suggest three ways to clean the burner tubes. Use the one

easiest for you.

(A) Bend a stiff wire (a light weight coat hanger works well)

into a small hook. Run the hook through each burner

tube several times.

(B)

Use a narrow bottle brush with a flexible handle (do not

use a brass wire brush), run the brush through each

burner tube several times.

(C)

Wear eye protection: Use an air hose to force air into

the burner tube and out the burner ports. Check each

port to make sure air comes out each hole.

7.

Wire brush entire outer surface of burner to remove food

residue and dirt.

8.

Clean any blocked ports with a stiff wire such as an open

paper clip.

9.

Check burner for damage, due to normal wear and corrosion

some holes may become enlarged. If any large cracks or

holes are found replace burner.

VERY IMPORTANT: Burner tubes must re-engage valve

openings. See illustrations at right.

10.

Carefully replace burners.

11.

Attach electrode to burner.

12.

Attach burners to brackets on firebox.

13.

Reposition flame carryover tubes and

attach to burners. Replace heat tents

and cooking grates.

Figure A

Electrode

Figure B

Pry off electrode

with a flat blade

screwdriver

10 • 464224211

Carryo

bracket

Correct

burner-to-valve

engagement

Firebox

ver tube

Firebox burner

General Grill Cleaning

• Do not mistake brown or black accumulation of grease

and smoke for paint. Interiors of gas grills are not

painted at the factory (and should never be painted).

Apply a strong solution of detergent and water or use a

grill cleaner with scrub brush on insides of grill lid and

bottom. Rinse and allow to completely air dry. Do not

apply a caustic grill/oven cleaner to painted or glass

surfaces.

• Plastic parts: Wash with warm soapy water and wipe

dry.Do not use citrisol, abrasive cleaners, degreasers or

a concentrated grill cleaner on plastic parts. Damage

to and failure of parts can result.

• Porcelain surfaces: Because of glass-like composition,

most residue can be wiped away with baking

soda/water solution or specially formulated cleaner.

Use nonabrasive scouring powder for stubborn stains.

• Painted surfaces: Wash with mild detergent or

nonabrasive cleaner and warm soapy water. Wipe dry

with a soft nonabrasive cloth.

• Stainless steel surfaces: To maintain your grill’s high

quality appearance, wash with mild detergent and

warm soapy water and wipe dry with a soft cloth after

each use. Baked-on grease deposits may require the

use of an abrasive plastic cleaning pad. Use only in

direction of brushed finish to avoid damage. Do not use

abrasive pad on areas with graphics.

• Cooking surfaces: If a bristle brush is used to clean any

of the grill cooking surfaces, ensure no loose bristles

remain on cooking surfaces prior to grilling. It is not

recommended to clean cooking surfaces while grill is

hot.

Food Safety

Food safety is a very important part of enjoying the

outdoor cooking experience. To keep food safe from

harmful bacteria, follow these four basic steps:

Clean: Wash hands, utensils, and surfaces with hot soapy

water before and after handling raw meat and poultry.

Separate: Separate raw meats and poultry from readyto-eat foods to avoid cross contamination. Use a clean

platter and utensils when removing cooked foods.

Cook: Cook meat and poultry thoroughly to kill bacteria.

Use a food thermometer to ensure proper internal food

temperatures. Chill: Refrigerate prepared foods and

leftovers promptly. For more information call: USDA Meat

and Poultry Hotline at 1-800-535-4555 (In Washington,

DC (202) 720-3333, 10:00 am-4:00 pm EST).

How To Tell If Meat Is Grilled Thoroughly

• Meat and poultry cooked on a grill often browns very

fast on the outside. Use a meat thermometer to be sure

food has reached a safe internal temperature, and cut

into food to check for visual signs of doneness.

• Whole poultry should reach 165° F. Juices should run

clear and flesh should not be pink.

• Hamburgers made of any ground meat or poultry

should reach 160° F, and be brown in the middle with

no pink juices. Beef, veal and lamb steaks, roasts and

chops can be cooked to 145° F. All cuts of pork should

reach 160° F.

• NEVER partially grill meat or poultry and finish cooking

later. Cook food completely to destroy harmful

bacteria.

• When reheating takeout foods or fully cooked meats

like hot dogs, grill to 165° F, or until steaming hot.

Page 11

Grill Halogen Light

LIGHT OPERATION INSTRUCTIONS

1. Make sure light switch on the control panel is in the “OFF” position.

2. Connect light plug to an extension cord, then plug the extension

cord into the outlet on the wall.

3. Turn the light switch to “ON”.

WARNING

˙

Keep any electrical supply cord away from any

1.

ON

OFF

Light plug

2.

Extension cord,

for outdoor use

heated surface.

˙

Use the shortest length extension cord required.

Do not connect 2 or more extension cords together.

Bulb Replacement

▲

Make sure light switch on the control panel is in the “OFF” position and adapter plug is disconnected from outlet.

Step 1

Step 2

Step 3

3.

ON

OFF

Remove the screw securing the light

socket.

Step 4

Pull out the bulb and replace

with a new bulb.

Take out the socket and remove the lens.

Loosen the two screws which lock

the bulb in place.

Step 5

Reverse instructions from step 3

through step 1 to re-install socket.

CAUTION

Take care not to touch the bulb with your bare fingers.

Touching bulb with your skin can leave a film on the

bulb that causes it to burn out quickly.

Bulb Specification

Bulb Type: Halogen

Wattage: 10 W per bulb

Voltage: 12 V

Continued on next page

464224211 • 11

Page 12

Cleaning the Lens

1. Prior to cleaning, make sure the light switch is in the “OFF” position and the light plug is

disconnected from the power supply.

2. Do not clean the glass lens when warm. Allow to cool before cleaning. Sudden change in

temperature may cause cracking of the glass lens.

3. Use a damp towel to clean the surface of the glass lens.

4. Allow the lens to dry before reconnecting the light plug to the power supply and turning the

light switch to the “ON” position.

IMPORTANT

• Since 1971 the National Electric Code (NEC) has required Ground Fault Interrupter devices on all outdoor

circuits.

• If your residence was built before 1971, check with a qualified electrician to determine if a Ground Fault

Interrupter protector exists.

• Do not use this appliance if the circuit does not have GFI protection.

• Do not plug this appliance into an indoor circuit.

WARNING

1. To protect against electric shock, do not immerse cord or plugs in water or other liquid.

2. Unplug from the outlet when not in use and before cleaning. Allow to cool before putting on or taking off parts.

3. Do not operate grill with a damaged cord, plug, or after the appliance malfunctions or has been damaged in any

manner.

4. Do not let the cord hang over the edge of a table or touch hot surfaces.

5. Do not use an outdoor cooking gas appliance for purposes other than intended.

6. When connecting, first connect plug to the outdoor cooking gas appliance then plug appliance into the outlet.

7. Use only a Ground Fault Interrupter(GFI) protected circuit with this outdoor cooking gas appliance.

8. Never remove the grounding plug or use with an adapter of 2 prongs.

9. Use only extension cords with a 3 prong grounding plug, rated for the power of the equipment, and approved for

outdoor use with a W-A marking.

12 • 464224211

Page 13

PARTS LIST

Key Qty Description

Part #

1 1 LEFT SIDE SHELF G523-1100-W1

2 1 FASCIA, LEFT SHELF G523-0051-W1

3 1 RIGHT SIDE SHELF G523-1200-W1

4 1 FASCIA, RIGHT SHELF G523-0052-W1

5 1 TOP LID G523-0100-W1

6 1 INNER INSERT, F/ TOP LID G523-0001-W1

7 1 TEMPERATURE GAUGE G518-0075-W1

8 1 BEZEL, F/ TEMPERATURE GAUGE G503-0002-W1

9 1 LOGO PLATE G523-0002-W1

10 1 HANDLE, F/ TOP LID G523-0003-W1

11 2 BEZEL, F/ LID HANDLE G509-0003-W1

12 2

RUBBER BUMPER, RECTANGLE, F/

TOP LID

G413-0025-W1

13 2 LID BUMPER, ROUND G501-0066-W1

14 1 HARDWARE F/ TOP LID ASSEMBLY G515-0035-W1

15 1 FIREBOX G523-3100-W1

16 3 MAIN BURNER G517-7300-W1

17 2

ELECTRODE, F/MAIN BURNER,

900MM WIRE

G515-0014-W1

18 2 FLAME CARRYOVER TUBE G524-0036-W1

19 1 SEAR BURNER G523-3200-W1

20 1 ROTISSERIE BURNER G614-1900-W1

21 1

RIGHT WIND SHIELD, ROTISSERIE

BURNER

G614-0052-W1A

22 1

LEFT WIND SHIELD, ROTISSERIE

BURNER

G614-0053-W1

23 1

ELECTRODE, F/MAIN BURNER,

600MM WIRE

G515-0067-W1

24 1 ELECTRODE, F/ ROTISSERIE G614-0094-W1

25 1 ELECTRODE WIRE, F/ ROTISSERIE G614-0059-W1A

26 1 GROUND WIRE, F/ EI MODULE G614-0098-W1

27 1 BACK COVER, ROTISSERIE BURNER G523-0011-W1

28 1 LIGHT SWITCH G520-0013-W1

29 1 HALOGEN LIGHT ASSEMBLY G614-8200-W1

30 7 HOSE CLIP G608-0041-W1

31 1 SB EXTEND SHELF G523-3400-W1

32 1 SIDEBURNER PAN G523-0012-W1

33 1 ELECTRODE, F/ SIDEBURNER G430-2604-W1

34 1 LID, F/ SIDEBURNER G507-0011-W2

35 2 BUMPER, F/ SIDEBURNER LID G508-0033-W1

36 1 SIDEBURNER G523-0058-W1

37 1 SIDEBURNER GRATE G501-0077-W1

38 1 INNER PANEL, F/ CONTROL PANEL G523-0014-W1

39 1 HOSE VALVE REGULATOR G523-3700-W1

40 1 CONTROL PANEL G523-0020-W1

41 5 BEZEL, F/ CONTROL KNOB G614-0064-W1

Key Qty Description

Part #

48 1 BOTTOM SHELF G523-0025-W1

49 2 DOOR MAGNET ASSEMBLY G501-0016-W2

50 1 TANK SHELF ASSY G523-4100-W1

51 1 LEFT SIDE PANEL G523-0800-W1

52 1 RIGHT SIDE PANEL G523-0900-W1

53 2 LOCKING CASTER G523-0028-W1

54 2 FIXED CASTER G523-0029-W1

55 1 ELECTRONIC IGNITION MODULE G513-0021-W1

56 1 ELECTRODE WIRE, F/ SIDEBURNER G606-0068-W1

57 1 LOWER BACK PANEL G523-0030-W1

58 1 GROMMET G501-0039-W1

59 1 12 VOLT ADAPTER G518-0076-W1

60 1 RIGHT PANEL F/ DRAWER G523-0031-W1

61 1 HEAT SHIELD, F/ TANK G523-1000-W1

62 1 FRONT BRACE G523-5000-W1

63 2 DRAWER FRONT G523-0034-W1

64 2 DRAWER FRAME G523-0035-W1

65 4 HANDLE, F/ DOOR & DRAWER G523-0036-W1

66 8 HANDLE END, F/ DOOR & DRAWER G509-0011-W1

67 1

DOOR, LEFT, NO HANDLE

G523-0037-W1

68 1 BAG HOOK, F/ DOOR G523-0039-W1

69 1 CONDIMENT TRAY, LEFT DOOR G523-0040-W1

70 1 DOOR LINER, LEFT G523-0038-W1

71 1

DOOR, RIGHT, NO HANDLE

G523-0041-W1

72 1

CONDIMENT TRAY, RIGHT DOOR,

UPPER

G523-0043-W1

73 1

CONDIMENT TRAY, RIGHT DOOR,

LOWER

G523-0044-W1

74 1 PAPER TOWEL HOLDER, DOOR G523-6300-W1

75 1 DOOR LINER, RIGHT G523-0042-W1

76 2 HEAT DIFFUSER, LONG G523-0048-W1

77 1 HEAT DIFFUSER, SHORT G523-0053-W1

78 4 COOKING GRATE, MAIN G523-0049-W1

79 1 WARMING RACK G523-0050-W1

80 1 GREASE TRAY G516-4600-W1A

81 1

CAP, F/ ELECTRONIC IGNITION

MODULE

G513-0021-W2

Key Qty Description

Part #

… 1 HARDWARE PACK G523-B001-W1

… 1 ASSEMBLY MANUAL, ENGLISH G523-010801-W1

… 1 ASSEMBLY MANUAL, SPANISH G523-010802-W1

42 1 BEZEL, F/ ROTISSERIE KNOB G614-0065-W1

43 1 IGNITER SWITCH MODULE G518-0026-W1A

44 1 REAR UPPER PANEL, FIREBOX G523-0013-W1

45 5 CONTROL KNOB G523-3800-W1

46 1 CONTROL KNOB, F/ ROTISSERIE G523-3900-W1

47 2 MATCH HOLDER AND CHAIN G508-0039-W1

NOTE: Some grill parts shown in the assembly steps may differ slightly in appearance from

those on your particular grill model. However, the method of assembly remains the same.

Not Pictured

If you are missing hardware or have damaged parts after

unpacking grill, call 1-800-241-7548 for replacement.

To order replacement parts after using grill, call

1-800-4-MY-HOME

®

464224211 • 13

Page 14

PARTS DIAGRAM

14

79

6

5

10

27

80

11

9

7

19

21

24

20

3

25

4

55

12

76

78

32

31

77

34

37

16

36

35

1

2

13

15

47

44

23

17

18

33

46

41

45

30

59

56

45

42

41

45

28

40

43

57

8

47

38

39

22

29

58

68

14 • 464224211

64

48

51

49

62

64

72

74

73

69

60

53

63

70

54

66

65

61

66

66

65

66

67

75

50

26

49

81

63

66

71

52

65

66

66

65

66

Page 15

1

Insert flange on left side shelf into side shelf brackets, shown A.

Attach left side shelf rear using two 1/4-20x1/2” screws, 7mm lock washers and 7mm flat washers,

shown B.

Attach left side shelf front using three 1/4-20x1/2” screws, 7mm lock washers and 7mm flat washers,

shown C.

1/4-20x1/2” screw

Qty.5

A

7mm lock washer

Qty.5 Qty.5

7mm flat washer

Bracket

Flange into bracket

B

7mm lock

washer

1/4-20x1/2”

screw

7mm flat

washer

C

7mm lock

washer

1/4-20x1/2”

7mm flat

washer

screw

464224211 • 15

Page 16

Insert flange on right side shelf into side shelf brackets, shown A.

2

1/4-20x3/4” screw

Qty.3

Attach right side shelf top using two 1/4-20x3/4” screws, 7mm flat washers, 7mm lock washers and

1/4” nuts, shown B.

Attach right side shelf rear using one 1/4-20x3/4” screw, 7mm lock washer and 7mm flat washer,

shown C.

Attach right side shelf front using two 1/4-20x1/2” screws, 7mm lock washers and 7mm flat washers,

shown D.

A

Bracket

1/4-20x1/2” screw

Qty.2

7mm flat washer

Qty.5

7mm lock washer

Qty.5

1/4” nut

Qty.2

C

Flange into bracket

B

7mm lock

1/4-20x3/4”

screw

7mm flat

washer

washer

1/4” nut

D

7mm lock

washer

16 • 464224211

7mm lock

washer

7mm flat

washer

1/4-20x3/4”

screw

1/4-20x1/2”

screw

7mm flat

washer

Page 17

3

Install heat diffusers by sliding one end of each heat diffuser into slots at front of firebox and resting

opposite end on pins at back of firebox. Make sure to install the shorter heat diffuser in A position,

and install the two longer heat diffusers in B and C position.

Heat diffuser

Front of firebox

A

B

C

Pin

Rear of firebox

Place cooking grates onto the firebox as shown. Insert the three wire ends at rear of warming rack into

4

holes in back of firebox. Front wires of warming rack rest on sides of firebox.

Warming rack

Cooking grate

464224211 • 17

Page 18

5

Place sideburner grate into sideburner shelf, aligning grate legs with holes in shelf.

6

On back of grill, slide grease tray into opening in lower back panel.

CAUTION

Failure to install grease tray will

cause hot grease to drip from

bottom of grill with risk of fire or

property damage.

Grease tray

18 • 464224211

Page 19

7

Unscrew electronic ignition cap on cart right side panel. Insert AA battery into ignitor, negative(-) end

first. Replace the cap.

AA Battery

LP TANK IS SOLD SEPARATELY. Fill and leak check the tank before attaching to grill and regulator (see

8

Tank Screw at bottom of tank tray

Use & Care section).

Once tank has been filled and checked for leaks, slide tank tray in bottom shelf forward. Fully loosen tank

screw at bottom of tank tray. Insert tank into tray with tank valve facing to right side of cart. Secure tank

by tightening tank tray screw. Connect regulator to tank as described in Use and Care section. Slide tank

shelf back into place.

See Use & Care section of this manual to perform the "Burner Flame Check" and for important safety

instructions before using.

-

Always keep LP tank in upright position during use,

transport, and storage.

+

Electronic Ignition Cap

CAUTION

LP Tank valve must face to right side of

cart once tank is attached. Failure to

install cylinder correctly may cause gas

hose to be damaged in operation,

resulting in the risk of fire.

Tank

(not included)

Regulator

464224211 • 19

Page 20

9

Install door organizers

Back of left door:

Attach bag hook by inserting wire ends in the holes on the door, shown A.

Attach condiment tray by sliding it onto tabs on lower door back panel, shown A.

Back of right door:

Attach condiment trays by sliding them onto tabs on upper and lower door back panel, shown B.

Attach paper towel holder between condiment trays, shown B.

A

Bag hook

Condiment tray

B

Condiment tray

Paper towel

holder

Condiment tray

20 • 464224211

Tabs

Page 21

EMERGENCIES: If a gas leak cannot be stopped, or a fire occurs due to gas leakage, call the fire department.

Emergencies

Gas leaking from

cracked/cut/burned

hose.

Gas leaking from LP

cylinder.

Gas leaking from LP

cylinder valve.

Gas leaking between

LP cylinder and

regulator connection.

Fire coming through

control panel.

Grease fire or

continuous excessive

flames above cooking

surface.

Troubleshooting

Problem

Burner(s) will not light

using ignitor.

(See Electronic Ignition

Troubleshooting also)

Continued on next

page.

Possible Cause

• Damaged hose.

• Mechanical failure due to rusting or

mishandling.

• Failure of cylinder valve from

mishandling or mechanical failure.

• Improper installation, connection not

tight, failure of rubber seal.

• Fire in burner tube section of burner

due to blockage.

• Too much grease buildup in burner

area.

Possible Cause

GAS ISSUES:

• Trying to light wrong burner.

• Burner not engaged with control valve.

• Obstruction in burner.

• No gas flow.

Prevention/Solution

• Turn off gas at LP cylinder or at source on natural gas systems.

If the hose is cracked or cut but not burned, simply replace

valve/hose/ regulator. If the hose is burned, the cause could be

other than a faulty valve/hose/regulator. Discontinue use of

grill until a plumber or gas technician has investigated and

corrected the problem.

• Replace LP cylinder.

• Turn off LP cylinder valve. Return LP cylinder to gas supplier.

• Turn off LP cylinder valve. Remove regulator from cylinder and

visually inspect rubber seal for damage. See LP Cylinder Leak

Test and Connecting Regulator to the LP Cylinder.

• Turn off control knobs and LP cylinder valve. Leave lid open to

allow flames to die down. After fire is out and grill is cold,

remove burner and inspect for spider nests or rust.

Alert and Cleaning the Burner Assembly sections of this Use &

Care Guide.

• Turn off control knobs and LP cylinder valve. Leave lid open to

allow flames to die down. After cooling, clean food particles

and excess grease from inside firebox area, grease tray, and

other surfaces.

Prevention/Solution

• See instructions on control panel and in Use and Care section.

• Make sure valves are positioned inside of burner tubes.

• Ensure burner tubes are not obstructed with spider webs or other

matter. See cleaning section of Use and Care.

• Make sure LP cylinder is not empty. If LP cylinder is not empty,

refer to “Sudden drop in gas flow.”

See Spider

• Vapor lock at coupling nut to LP

cylinder.

• Coupling nut and LP cylinder valve not

fully connected.

ELECTRICAL ISSUES:

• Electrode cracked or broken; “sparks at

crack.”

• Electrode tip not in proper position.

• Wire and/or electrode covered with

cooking residue.

• Wires are loose or disconnected.

• Wires are shorting (sparking) between

ignitor and electrode.

• Dead battery.

• Turn off knobs and disconnect coupling nut from LP cylinder.

Reconnect and retry.

• Turn the coupling nut approximately one-half to three-quarters

additional turn until solid stop. Tighten by hand only - do not

use tools.

• Replace electrode(s).

Main Burners:

• Tip of electrode should be pointing toward gas port opening on

burner. The distance should be 1/8” to 1/4”. Adjust if necessary.

Sideburner:

• Tip of electrode should be pointing toward gas port opening on

burner. the distance should be 1/8” to 3/16”. Adjust if necessary.

• Clean wire and/or electrode with rubbing alcohol and clean

swab.

• Reconnect wires or replace electrode/wire assembly.

• Replace ignitor wire/electrode assembly.

• Replace with a new AA-size alkaline battery.

464224211 • 21

Page 22

Troubleshooting (continued)

Problem

Burner(s) will not light

using ignitor.

(See Electronic Ignition

Troubleshooting also)

Burner(s) will not

match light.

Sudden drop in gas

flow or low flame.

Flames blow out.

Possible Cause

ELECTRONIC IGNITION:

• No spark, no ignition noise.

• No spark, some ignition noise.

• Sparks, but not at electrode or at full

strength.

• See “GAS ISSUES:” on previous page.

• Match will not reach.

• Improper method of match-lighting.

• Out of gas.

• Excess flow valve tripped.

• Vapor lock at coupling nut/LP cylinder

connection.

• High or gusting winds.

• Low on LP gas.

Prevention/Solution

• See Section I of Electronic Ignition System.

• See Section II of Electronic Ignition System.

• See Section III of Electronic Ignition System.

• Use long-stem match (fireplace match).

• See “Match-Lighting” section of Use and Care.

• Check for gas in LP cylinder.

• Turn off knobs, wait 30 seconds and light grill. If flames are still

low, turn off knobs and LP cylinder valve. Disconnect regulator.

Reconnect regulator and leak-test. Turn on LP cylinder valve,

wait 30 seconds and then light grill.

• Turn off knobs and LP cylinder valve. Disconnect coupling nut

from cylinder. Reconnect and retry.

• Turn front of grill to face wind or increase flame height.

• Refill LP cylinder.

Flare-up.

Persistent grease fire.

Flashback...

(fire in burner tube(s)).

Unable to fill LP

cylinder.

One burner does not

light from other

burner(s).

• Excess flow valve tripped.

• Grease buildup.

• Excessive fat in meat.

• Excessive cooking temperature.

• Grease trapped by food buildup

around burner system.

• Burner and/or burner tubes are

blocked.

• Some dealers have older fill nozzles

with worn threads.

• Grease buildup or food particles in

end(s) of carryover tube(s).

• Refer to “Sudden drop in gas flow” above.

• Clean burners and inside of grill/firebox.

• Trim fat from meat before grilling.

• Adjust (lower) temperature accordingly.

• Turn knobs to OFF. Turn gas off at LP cylinder. Leave lid in

position

all parts.

• Turn knobs to OFF. Clean burner and/or burner tubes. See

burner cleaning section of Use and Care.

• The worn nozzles don’t have enough “bite” to engage the valve.

Try a second LP dealer.

• Clean carry-over tube(s) with wire brush.

and let fire burn out. After grill cools, remove and clean

22 • 464224211

Page 23

Troubleshooting - Electronic Ignition

Problem (Ignition)

SECTION I

No sparks appear at

any electrodes when

Electronic Ignition

Button is pressed; no

be heard noise can

from spark module.

SECTION II

No sparks appear at

any electrodes when

Electronic Ignition

Button is pressed; noise

be heard from can

spark module.

Possible Cause

• Battery not installed

properly.

• Dead battery.

• Button assembly not

installed properly.

• Faulty spark module.

• Output lead

connections not

connected.

Check Procedure

• Check battery orientation.

• Has battery been used

previously?

• Check to insure threads are

properly engaged. Button

should travel up and down

without binding.

• If no sparks are generated

with new battery and good

wire connections, module is

faulty.

• Are output connections on

and tight?

Prevention/Solution

• Install battery (make sure that “+” and “–”

connectors are oriented correctly, with “+” end up

and “–” end down.)

• Replace battery with new AA-size alkaline battery.

• Unscrew button cap assembly and reinstall,

making

fully.

• Replace spark module assembly.

• Remove and reconnect all output connections at

module and electrodes.

sure threads are aligned and engaged

SECTION III

Sparks are present

but not at all

electrodes and/or not

at full strength

• Output lead

connections not

connected.

• Arcing to grill away

from burner(s).

• Weak battery.

• Electrodes are wet.

• Electrodes cracked or

broken “sparks at

crack”.

• Are output connections on

and tight?

• If possible, observe grill in

dark location. Operate

ignition system and look for

arcing between output wires

and grill frame.

• All sparks present but weak

or at slow rate.

• Has moisture accumulated

on electrode and/or in

burner ports?

• Inspect electrodes for

cracks.

• Remove and reconnect all output connections at

module and electrodes.

• If sparks are observed other than from burner(s),

wire insulation may be damaged. Replace wires.

• Replace battery with a new AA-size alkaline

battery.

• Use paper towel to remove moisture.

• Replace cracked or broken electrodes.

464224211 • 23

Page 24

Loading...

Loading...