Kenmore 3851258180, 3851168291, 3851168280 Owner’s Manual

SEWING MACHINE

SEARS, ROEBUCK AND CO.

Dear Customer:

You have just invested in a very fine zigzag sewing machine. Before using your new Kenmore machine,

please pause for a moment and carefully read this booklet which contains instructions on how to operate

and care for your machine.

Specific instructions are given on threading, tension adjustments, cleaning, oiling, etc. This will help you

obtain the best sewing results and avoid unnecessary service expense for conditions beyond our control.

Advice on the operation and care of your machine is always available at your nearest Sears Retail Store.

Please remember, if you have questions about your machine or need parts and service, always mention

the model number and serial number when you inquire.

Kenmore Sewing Machine

Record in space provided below the model number and serial

number of this appliance. The model number and serial number

are located on the nomenclature plate, as identified on Page 3 of

this booklet.

Model No. 385. Serial No.

Retain these numbers for future reference.

THIS MODEL IS A CENTER NEEDLE, LOW BAR SEWING MACHINE.

IMPORTANT SAFETY

INSTRUCTIONS

Your sewing ma(_hineisdesignedand constructed only for HOUSEHOLD use.

Read all instruction before using this sewing machine.

DAN GER- Toreduce the risk of electric shock:

1. An appliance should never be left unattended when plugged in. Always

unplug this appliance from the electric outlet immediately after using

and before cleaning.

2. Always unplug before relamping. Replace bulb with same type rated

15 Watts.

3. Do not reach for the appliance that has fallen into water. Unplug

immediately.

4. Do not place or store appliance where it can fall or bepulled into a tub

or sink. Do not place in or drop into water or other liquid.

or injury to persons.

1, Do not allow to be usedas a toy. Closeattention is necessarywhen this

appliance is used by or near children.

2, Use this appliance only for its intended useas described in this manual.

Use only attachments recommended by the manufacturer ascontained in

this manual.

3. Never operate this appliance if it has a damaged cord or plug, if it is not

working properly, if it has been dropped or damaged, or dropped into

water. Return the appliance to the nearest authorized dealer or service

center for examination, repair, electrical or mechanical adjustment.

4. Never operate the appliance with any air opening blocked. Keep

ventilation openings of the sewing machine and foot controller free from

accumulation of lint, dust, and loose cloth.

5. Never drop or insert any object into any opening.

6. Do not useoutdoors.

7. Do not operate where aerosol (spray) products are being used or where

oxigen isbeing administered.

8. To disconnect, turn all controls to the off ("O") position, then remove

plug from outlet.

9. Do not unplug by pulling on cord. To unplug, graspthe plug, not the

cord.

10. Keept fingers away from all moving parts. Special care is required

around the sewing machine needle.

11. Always use the proper needle plate. The wrong plate can cause the

needle to break.

12. Do not use bent needles.

13. Do not poll or push fabric while stitching.

tt may deflect the needle causing it to break.

14. Switch the sewing machine off ("O") when making any adjustment in

:_,_ _ foot, and _ I_=ke;

15.

Always unplug the sewing machine from the electrical outlet when

removing covers, lubricating, or when marking any other user servicing

adjustments mentioned in the instruction manual.

SAVE THESE INSTRUCTIONS

OPERATING INSTRUCTIONS

"For appliances With a potariz_ plug (one blade wider t_an the other)_

To reduce the risk of electric shock, this plug is intended to fit in a

polarized outlet only one way. If the plug does not fit fully in the outlet,

reverse the plug. If it still does not fit, contact a qualified electrician to install

the proper outlet. Do not modify the plug in any way."

"Foot Controller Model YC-482P for use with Sewing Machine Models

385.1148x x x, 385.1158 x x x, 385.1168x x x, 385.1258x x x, 385.1268x x x,

385.12612x x x, 385.1278x x x, 385.11607x x x, 385.12710x x x, 385.12714x x x,

385.12712x x x, 385.17622x x x, 385.11608x x x, 385.12814x x x and 385.12014x x x.

xx x - represents humblers 000 through 999."

(For U.S.A. market only)

TABLE OF CONTENTS

SECTION

KNOW YOUR MACHINE

A Portable Caseor Cabinet is Available .............. 2

Locate and Identify the Parts .................. 2_3

Identify the Accessories ........................ 3

SECTION

2. PREPARE YOUR MACHINE FOR SEWING

Set Up the Machine ......................... 4_6

• Plug in the Machine and Switch on the Power ....... 4

• Foot Control Use .......................... 4

• Setting Spool Pin .......................... 5

• Adjust the Presser Foot Lever .................. 5

• Thread Cutter ............................ 5

• Free Arm Sewing: the Removable Extension Table .... 6

• Accessory Storage Box ...................... 6

• Change the Presser Foot ...................... 6

Choose Your Needle and Thread ................ 6_7

• To Change Your Needle ....................... 6

• Check Your Needle ......................... 7

• Fabric, Needle, Thread and Stitch Length Chart ...... 7

Prepare the Bobbin ......................... 8_9

• To Remove the Bobbin Case from the Machine ...... 8

• Wind the Bobbin ........................ 8_9

• Insert the Bobbin into the Bobbin Case ............ 9

Prepare Your Top Thread .................... 10_11

• Thread Your Needle ....................... 10

the Top T__ .; .... ] ........ ;: 11_}3

Stitch Selector ............................. 14

Stitch Length Control ........................ 14

Adjusting Stretch Stitch Balance ................. 15

Reverse Stitch Control ........................ 15

Starting To Sew ............................ 16

SECTION 3. LEARN THE STITCHES

Straight Stitches .......................... 17_18

• Straight Stitch ........................... 17

• Use the Seam Guides ....................... 17

• Turna Square Corner ...................... 17

• Use the Darning Plate ...................... 18

• Topstitching ............................ 18

• Left Needle Position ........................ 18

Darning ................................. 19

Straight Stretch ............................ 19

Zigzag Stitches ........................... 20_26

• Basic Zigzag ............................. 20

• Satin Stitch ............................. 21

• Applique ............................... 22

• Bar Tacking ............................. 22

• Sew a Button ............................ 23

• Overcasting Stitch ......................... 24

• Rick- Rack Stretch ........................ 24

• Overcast Stretch Stitching

(Models 12781, 12681 and 12581) ............. 25

• Serging or Pine Leaf Stretch Stitching

(Model 12781 and 12681) ................... 25

• Three-Step Zigzag ......................... 26

Lace Work (Models 12781, 12681 and 12581) ........ 26

Blind Hemming (Models 12781,12681 and 12581) ..... 27

Buttonholes ............................. 28_29

Sew in a Zipper .......................... 30_31

Shell Stitching (Model 12781 and 12681) ........... 32

Smocking ................................ 32

Elastic Stretch Stitch (Model 12781 only) ........... 33

Box Stitching (Model 12781 only) ................ 33

SECTION 4. PEL:iFQBMAJ_.CE PROBLEMS CHART

_tto _n ......................... 34,_35

SECTION 5.

PARTS LIST ........................................ 39

CARE FOR YOUR MACHINE

Replacing the Light Bulb ...................... 36

Cleaning the Machine ...................... 36_37

• Clean the Feed Dogs ....................... 36

• Clean the Shuttle Race ..................... 37

Oiling the Machine .......................... 38

• Oil behind the Face Cover Plate and under the

Arm Cover Plate .......................... 38

• Oil the Underside ......................... 38

INDEX ............................................ 40

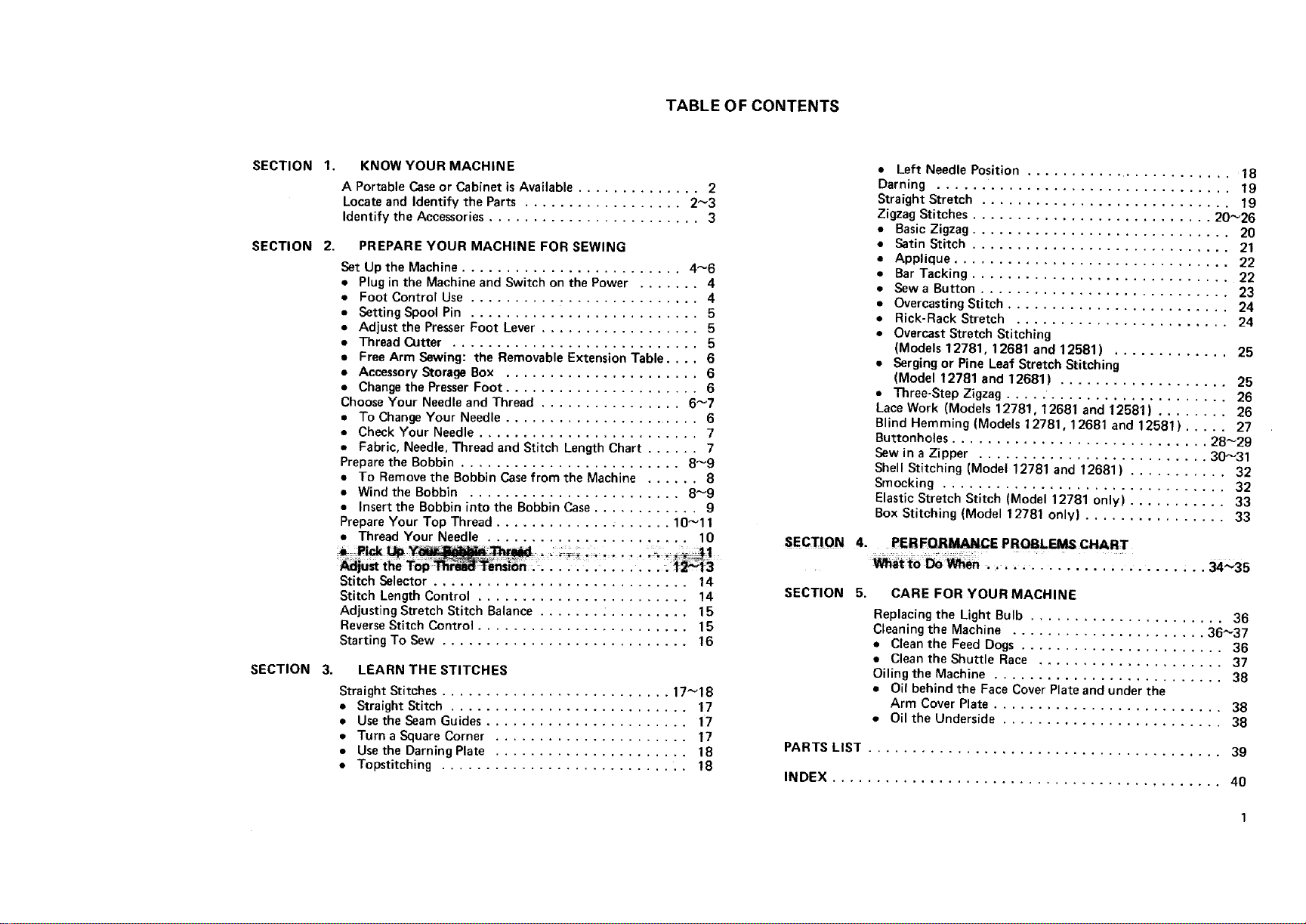

SECTION 1. KNOW YOUR MACHINE

A Portable Case or Cabinet is Available

A full line of sewing cabinets are available at your

nearest Sears retail store or through our general

catalog.

Another option . . . buy a Carrying Case... then

your Kenmore goes anywhere, can be stored any-

where.

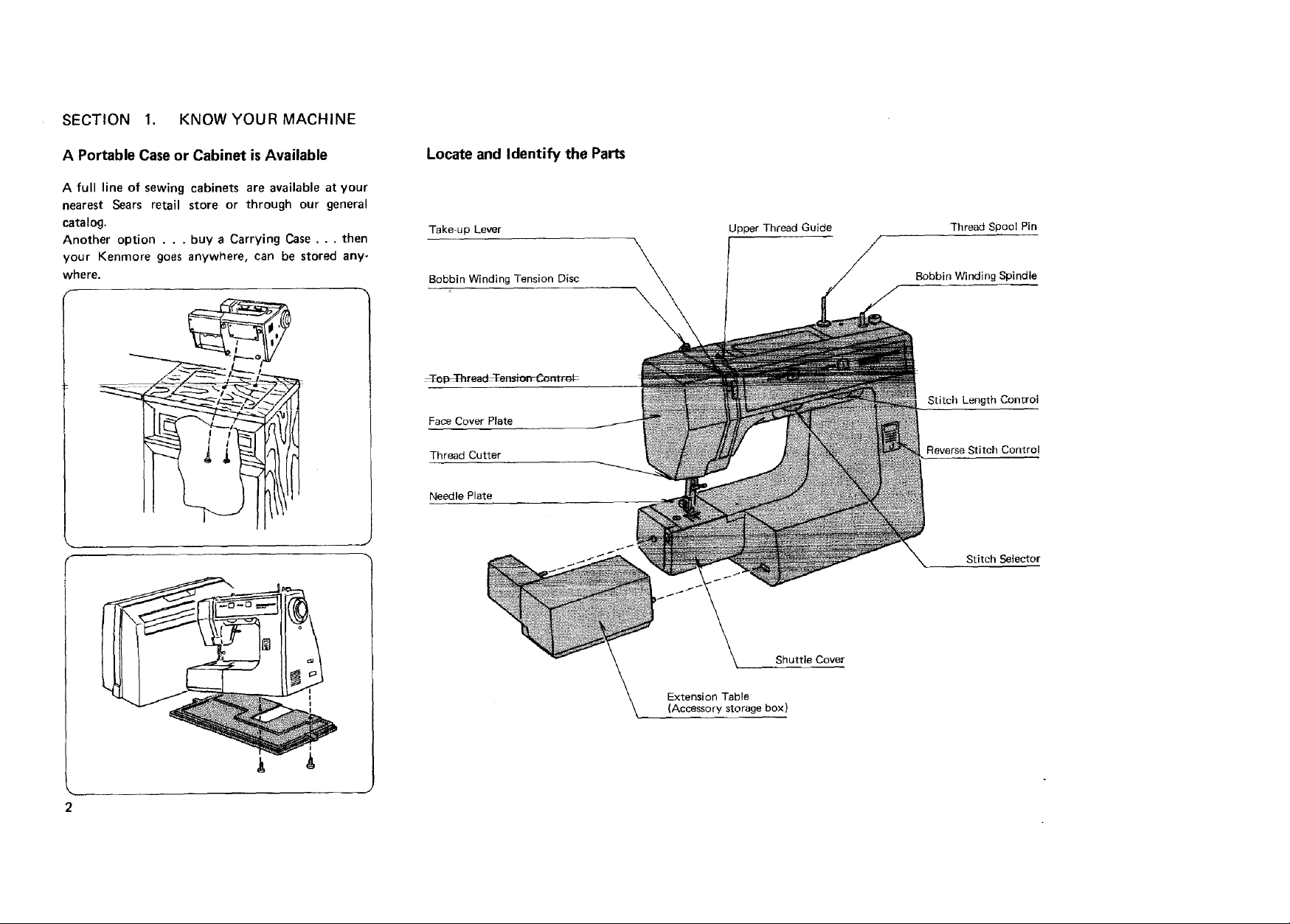

Locate and Identify the Parts

Take-up Lever

Bobbin Winding Tension Disc

_read T_er_orr ¢_m_

Face Cover Plate

Thread Cutter

Needle Plate

Upper Thread Guide

Thread Spool Pin

Bobbin Winding Spindle

\

Stitch Length Control

Reverse Stitch Control

Stitch Selector

Extension Table

(Accessory storage box)

Shuttle Cover

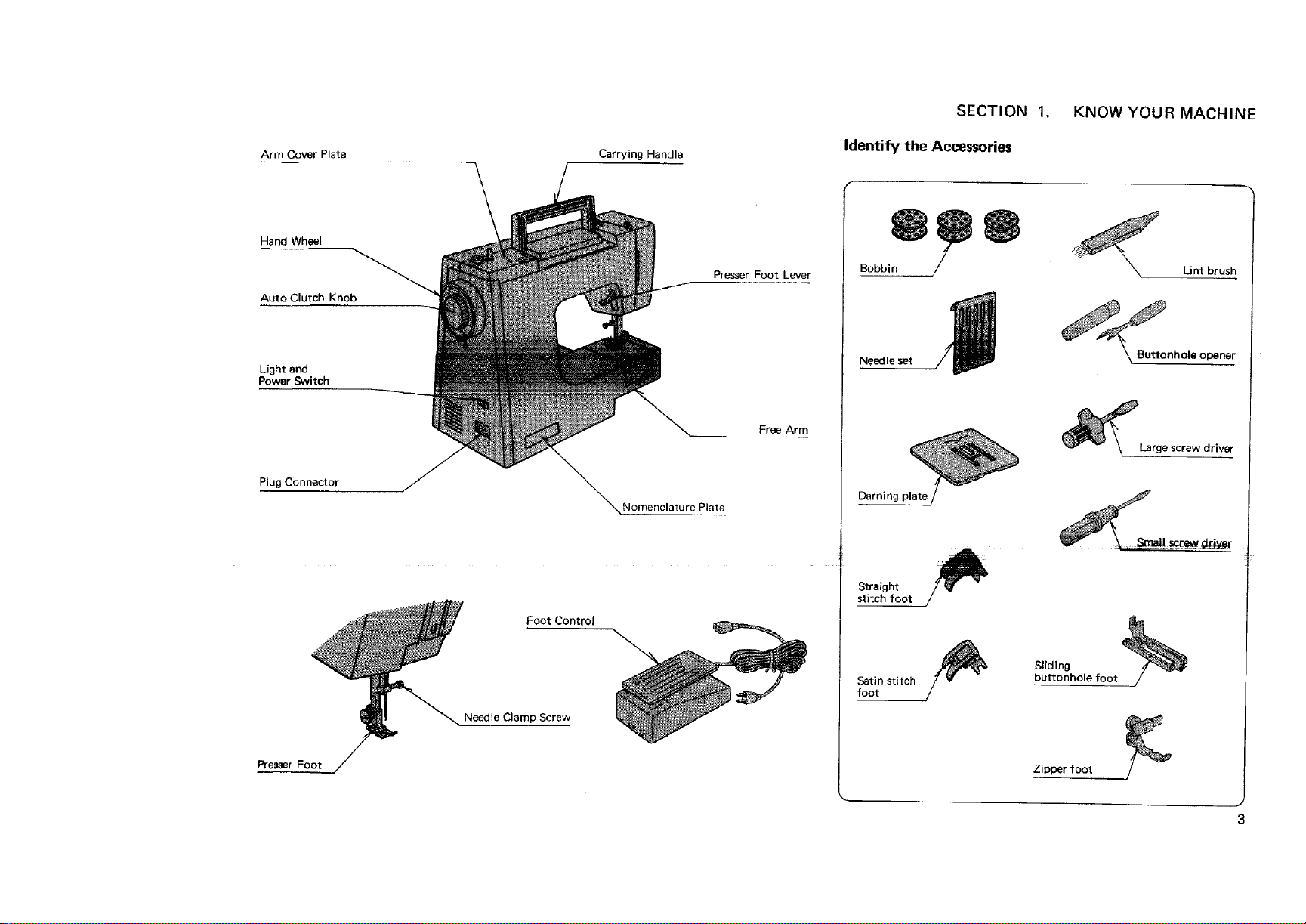

SECTION 1. KNOW YOUR MACHINE

ArmCoverPlate

HandWheel

AutoClutchKnob

Light and

Power Switch

Plug Connector

Foot Control

Carrying Handle

Nomenclature Plate

Presser Foot Lever

Free Arm

Identify the Accessories

Bobbin Lint brush

Needle set nhole opener

_Large screw driver

Darning plate

Straight

stitch foot

Presser Foot

Needle Clamp Screw

Satin stitch

foot

Sliding

buttonhole foot

Zipper foot

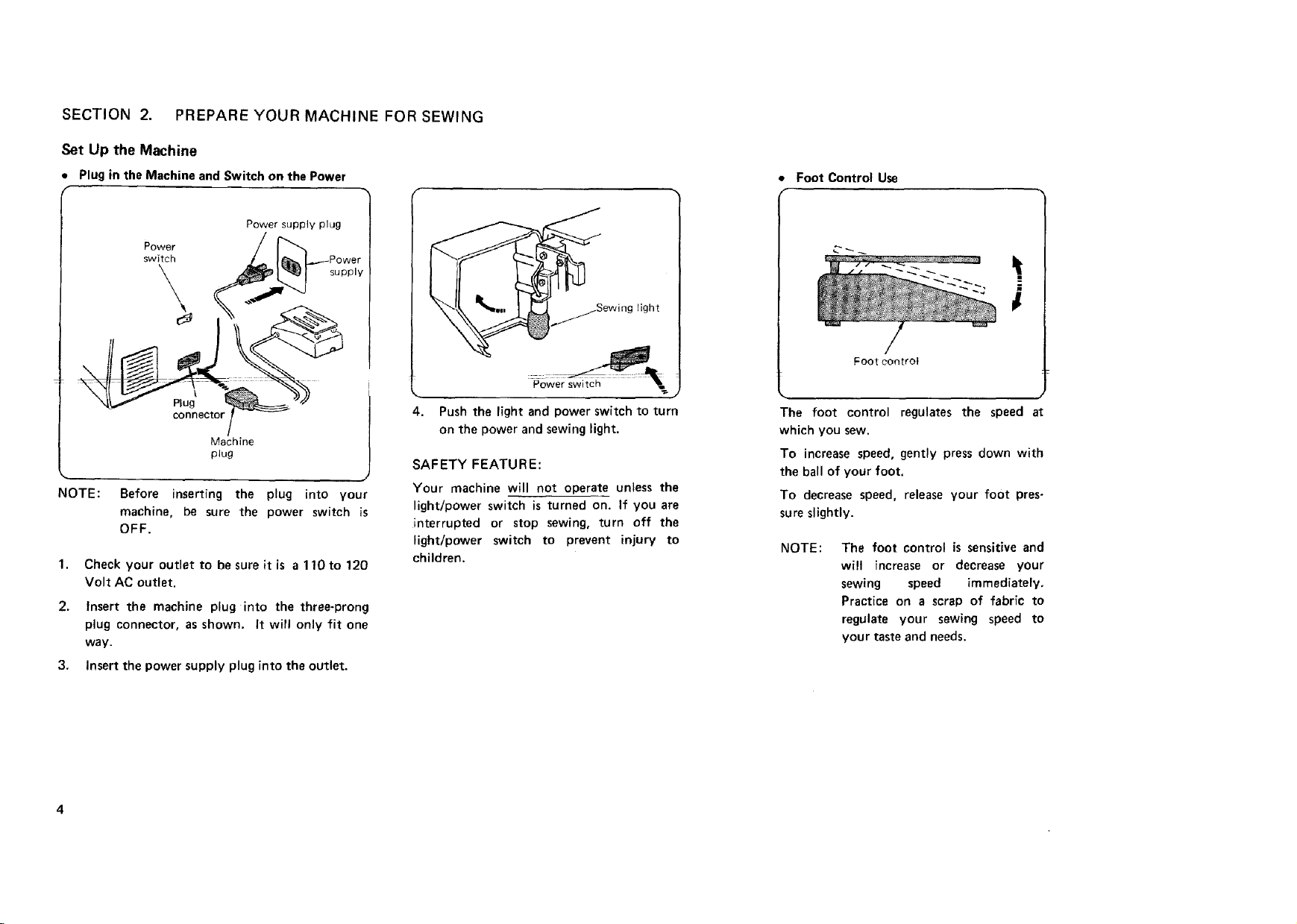

SECTION 2. PREPARE YOUR MACHINE FOR SEWING

Set Up the Machine

Plug in the Machine and Switch on the Power

Power supply plug

sPw°itwce_ Z _'_Power

• Foot Control Use

light

Foot control

Plu_l

connector

Machine

plug

NOTE:

Before inserting the plug into your

machine, be sure the power switch is

OFF.

Check your outlet to be sure it is a 110 to 120

Volt AC outlet.

2. Insert the machine plug into the three-prong

plug connector, as shown. It will only fit one

way.

3. Insert the power supply plug into the outlet.

4. Push the light and power switch to turn

on the power and sewing light.

SAFETY FEATURE:

J

Your machine will not operate unless the

light/power switch is turned on. If you are

interrupted or stop sewing, turn off the

light/power switch to prevent injury to

children.

The foot control regulates the speed at

which you sew.

To increase speed, gently press down with

the ball of your foot.

To decrease speed, release your foot pres-

sure slightly.

NOTE : The foot control is sensitive and

will increase or decrease your

sewing speed immediately.

Practice on a scrap of fabric to

regulate your sewing speed to

your taste and needs.

SECTION 2. PREPARE YOUR MACHINE FOR SEWING

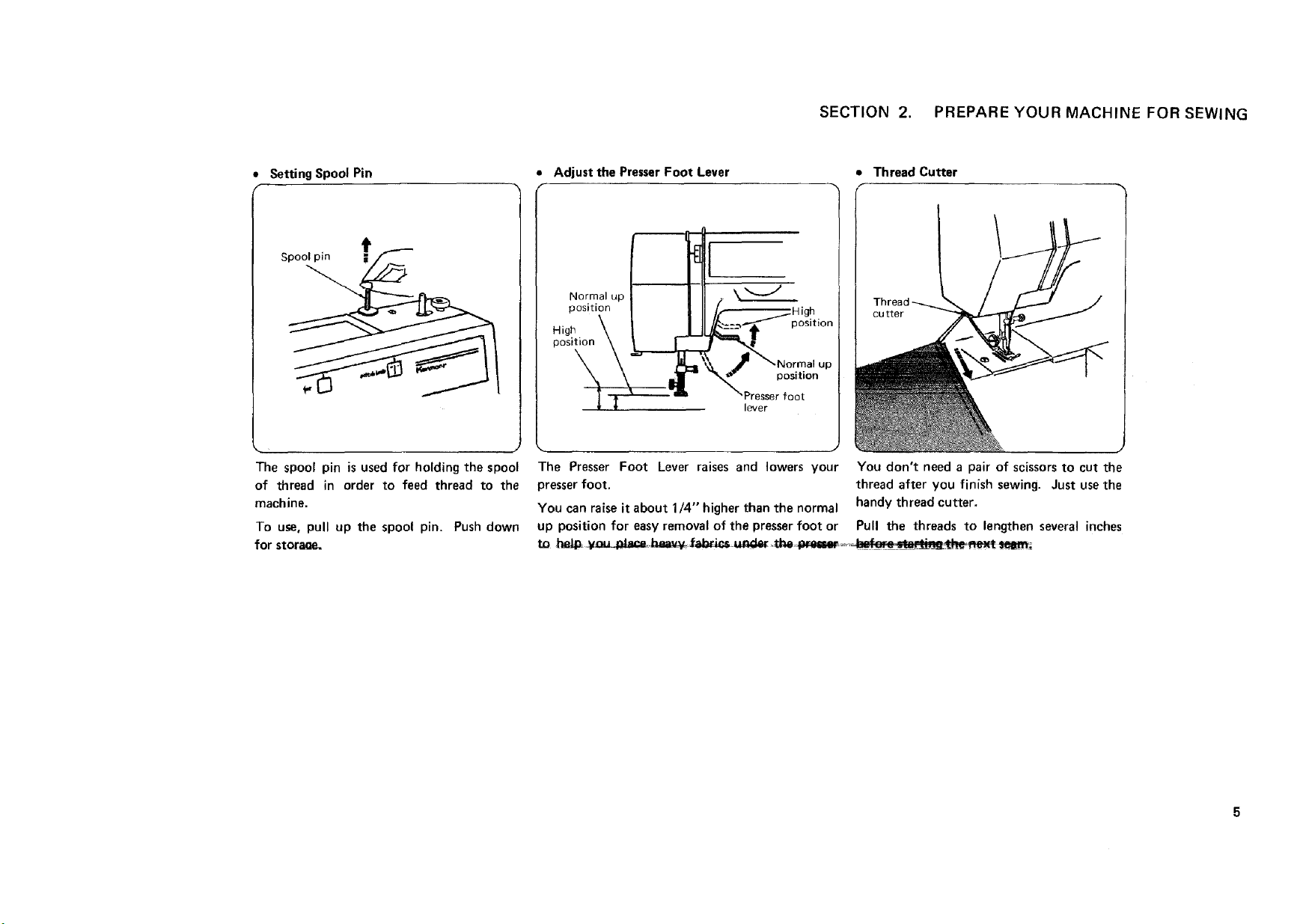

Setting Spool Pin

Spool pin =

t

The spool pin is used for holding the spool

of thread in order to feed thread to the

machine.

To use, pull up the spool pin. Push down

for storage.

• Adjust the Presser Foot Lever

Normal up

position

High

position

'Presser foot

lever

The Presser Foot Lever raises and lowers your You don't need a pair of scissors to cut the

presser foot. thread after you finish sewing. Just use the

You can raise it about 1/4" higher than the normal handy thread cutter,

up position for easy removal of the presser foot or Pull the threads to lengthen several inches

positior

position

• Thread Cutter

P

J

SECTION 2. PREPARE YOUR MACHINE FOR SEWING

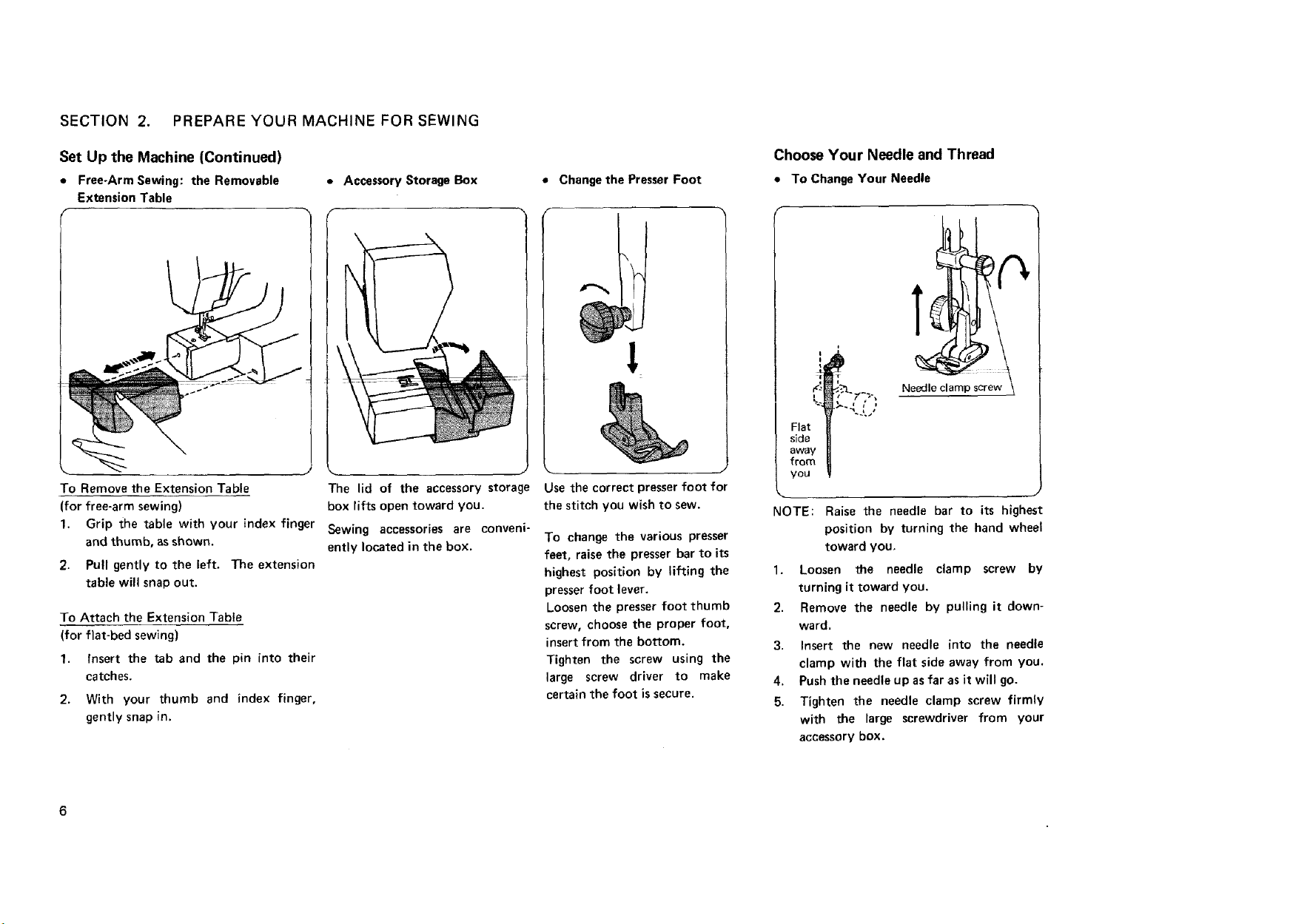

Set Up the Machine (Continued)

• Free-ArmSewing: the Removable = AccessoryStorageBox

ExtensionTable

To Remove the Extension Table

(for free-arm sewing)

1.

Grip the table with your index finger Sewing accessories are conveni-

and thumb, as shown, ently located in the box.

2,

Pull gently to the left. The extension

table will snap out.

To Attach the Extension Table

(for flat-bed sewing)

1. Insert the tab and the pin into their

catches.

2. With your thumb and index finger,

gently snap in.

The lid of the accessory storage

box lifts open toward you.

• Change the PresserFoot

!

Use the correct presser foot for

the stitch you wish to sew.

To change the various presser

feet, raisethe presser bar to its

highest position by lifting the

presserfoot lever.

Loosen the presser foot thumb

screw, choose the proper foot,

insert from the bottom.

Tighten the screw using the

large screw driver to make

certain the foot is secure.

Choose Your Needle and Thread

• To Change Your Needle

' _. _ Needle clamp screw

;/ I' 7"-_,

side _

away II

from

you

%. . J

NOTE: Raise the needle bar to its highest

1. Loosen the needle clamp screw by

turning it toward you.

2. Remove the needle by pulling it down-

ward.

3. Insert the new needle into the needle

clamp with the flat side away from you.

4. Push the needle up as far as it will go.

5. Tighten the needle clamp screw firmly

with the large screwdriver from your

accessory box.

'J J

position by turning the hand wheel

toward you.

SECTION 2. PREPARE YOUR MACHINE FOR SEWING

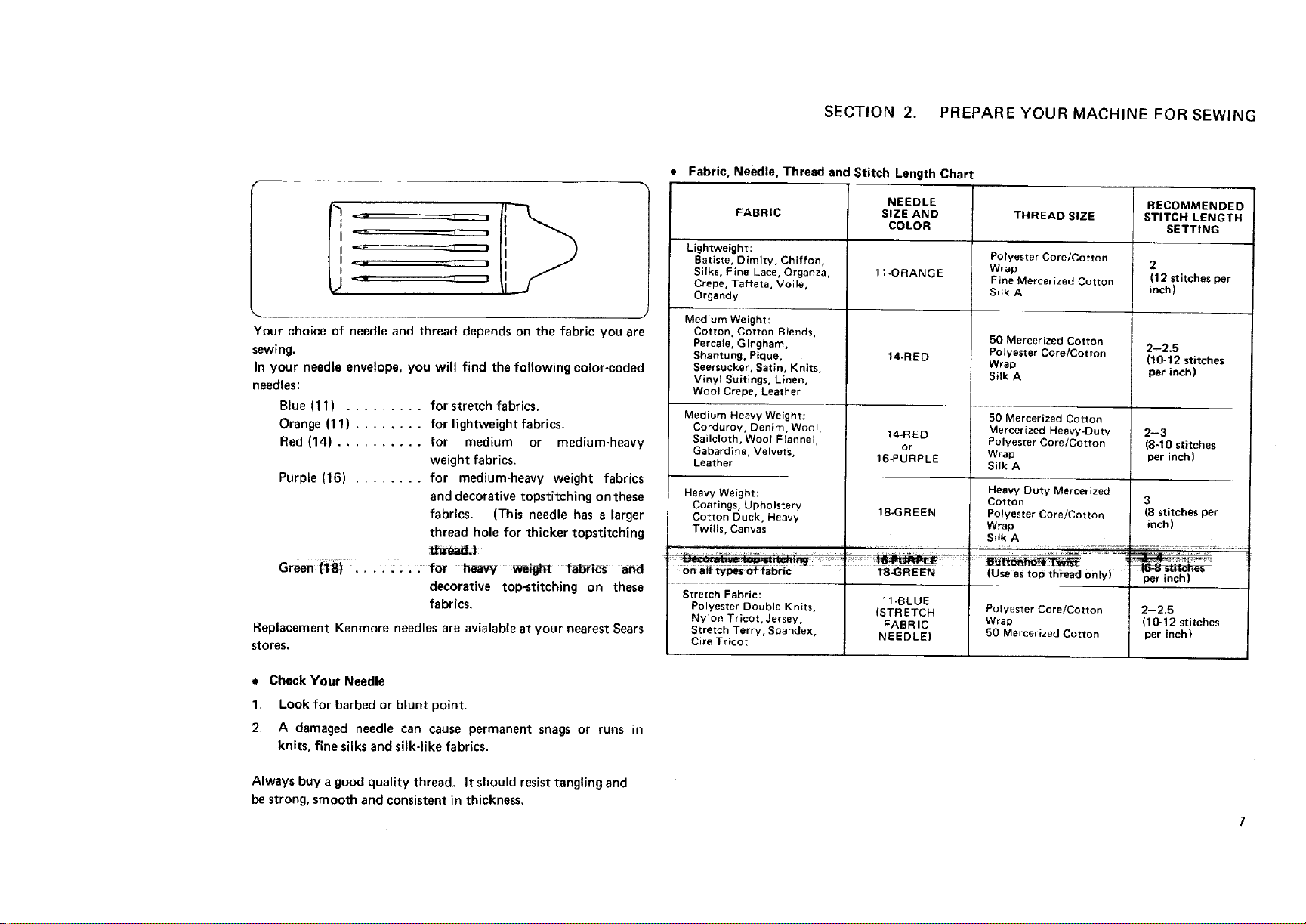

• Fabric, Needle, Thread and Stitch Length Chart

Your choice of needle and thread depends on the fabric you are

sewing.

In your needle envelope, you will find the following color-coded

needles:

Blue (11) ......... for stretch fabrics.

Orange (11 ) ........ for lightweight fabrics.

Red (14) .......... for medium or medium-heavy

weight fabrics.

Purple (16) ........ for medium-heavy weight fabrics

and decorative topstitching on these

fabrics. (This needle has a larger

thread hole for thicker topstitching

ttm_d._

Green|_ ...,:,.. for _ _ fa_r_

decorative top-stitching on these

fabrics.

Replacement Kenmore needles are avialable at your nearest Sears

stores.

Lightweight:

Batiste, Dimity, Chiffon,

Silks, Fine Lace, Organza,

Crepe, Taffeta, Voile,

Organdy

>

Medium Weight:

Cotton, Cotton Blends,

Percale, Gingham,

Shantung, Pique,

Seersucker, Satin, Knits,

Vinyl Suitings, Linen,

Wool Crepe, Leather

Medium Heavy Weight:

Corduroy, Denim, Wool,

Sailcloth, Wool Flannel,

Gabardine, Velvets,

Leather

Heavy Weight:

Coatings, Upholstery

Cotton Duck, Heavy

Twills, Canvas

on a½ttyp_of fabric

Stretch Fabric:

Polyester Double Knits,

Nylon Tricot, Jersey,

Stretch Terry, Spandex,

Cire Tricot

FABRIC

NEEDLE

SIZE AND

COLOR

11-ORANGE

14-RED

14-RED

or

16-PURPLE

1B-GREEN

r, ,

TS_GREEN

11-BLUE

(STRETCH

FABRIC

NEEDLE)

THREAD SIZE

Polyester Core/Cotton

Wrap

Fine Mercerized Cotton

Silk A

50 Mercerized Cotton

Polyester Core/Cotton

Wrap

Silk A

50 Mercerized Cotton

Mercerized Heavy-Duty

Polyester Core/Cotton

Wrap

Silk A

Heavy Duty Mercerized

Cotton

Polyester Core/Cotton

Wrap

Silk A

(_ aS top thread only) t°°per inch)_

Polyester Core/Cotton 2--2.5

Wrap (10-12 stitches

50 Mercerized Cotton per inch)

RECOMMENDED

STITCH LENGTH

SETTING

2

(12 stitches per

inch )

2--2.5

(10-12 stitches

per inch)

2--3

(8-I0 stitches

per inch)

3

(8 stitches per

inch )

• Check Your Needle

1. Look for barbed or blunt point.

2. A damaged needle can cause permanent snags or runs in

knits, fine silks and silk-like fabrics.

Always buy a good quality thread, It should resist tangling and

be strong, smooth and consistent in thickness,

SECTION 2. PREPARE YOUR MACHINE FOR SEWING

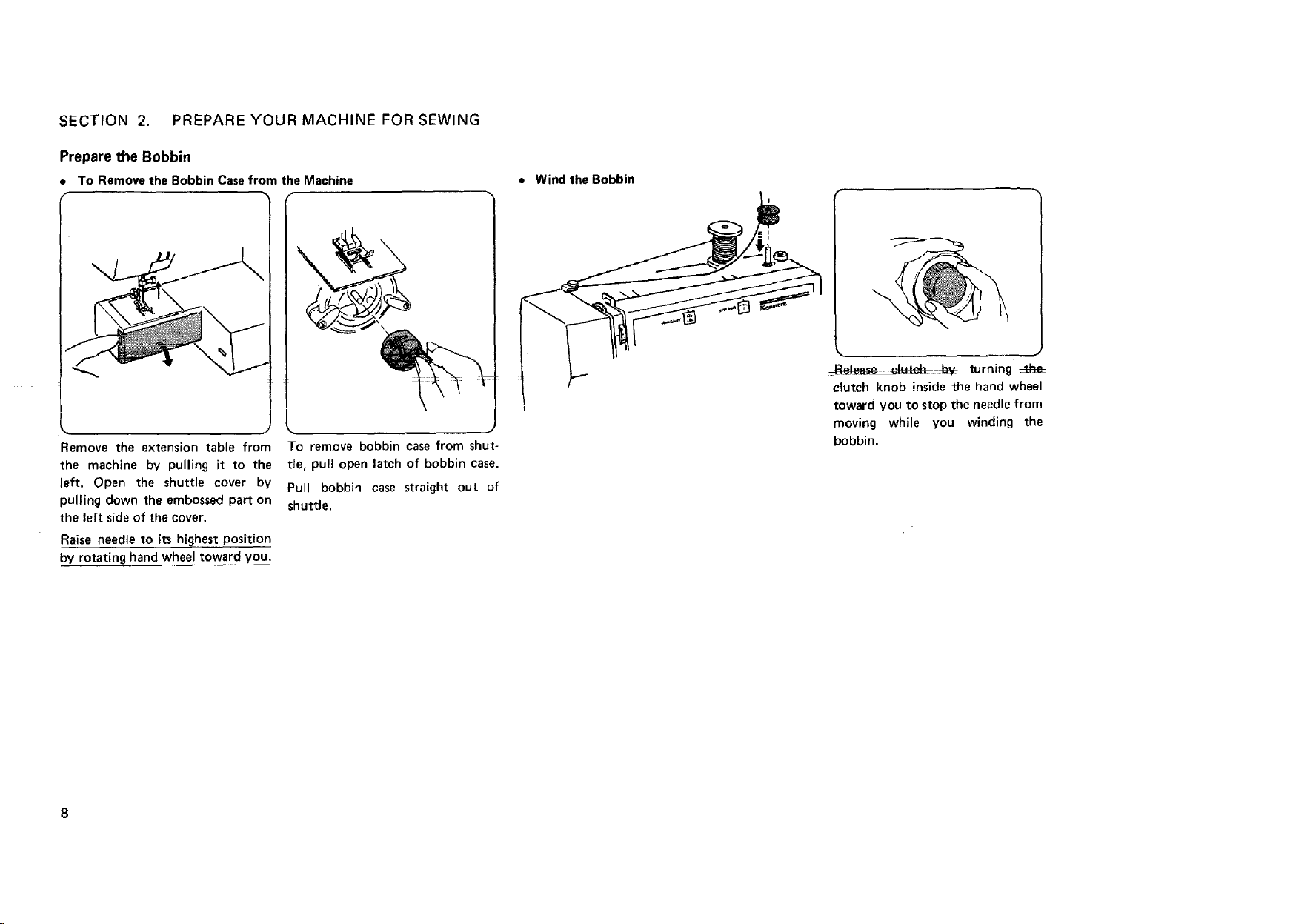

Prepare the Bobbin

• To Remove the Bobbin Casefrom the Machine • Wind the Bobbin

J

Remove the extension table from

the machine by pulling it to the

left. Open the shuttle cover by

pulling down the embossed part on

the left side of the cover.

Raise needle to its hi_ghest position

by rotating hand wheel toward you.

To remove bobbin case from shut-

tle, pul! open latch of bobbin case.

Pull bobbin case straight out of

shuttle.

J

clutch knob inside the hand wheel

toward you to stop the needle from

moving while you winding the

bobbin.

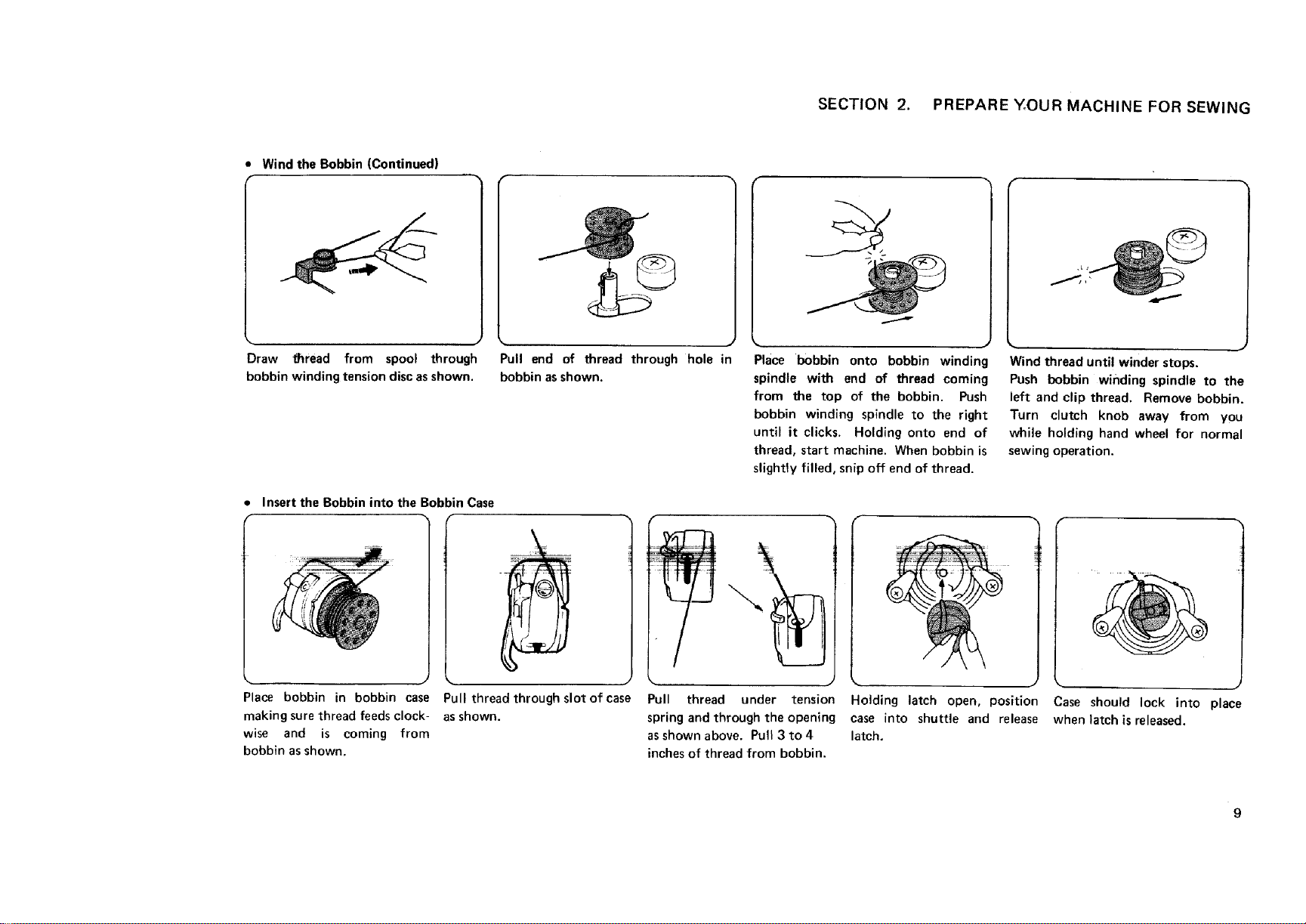

Wind the Bobbin (Continued)

SECTION 2. PREPARE Y_OUR MACHINE FOR SEWING

7

Draw thread from spool through

bobbin winding tension disc asshown.

Pull end of thread through hole in

bobbin asshown.

• Insert the Bobbin into the Bobbin Case

Place bobbin in bobbin case Pull thread through slot of case

making sure thread feeds clock- as shown.

wise and is coming from

bobbin asshown.

Place bobbin onto bobbin winding

spindle with end of thread coming

from the top of the bobbin. Push

bobbin winding spindle to the right

until it clicks. Holding onto end of

thread, start machine. When bobbin is

slightly filled, snip off end of thread.

Pull thread under tension

spring and through the opening

asshown above. Pull 3 to 4

inches of thread from bobbin.

Wind thread until winder stops.

Push bobbin winding spindle to the

left and clip thread. Remove bobbin.

Turn clutch knob away from you

while holding hand wheel for normal

sewing operation.

Holding latch open, position

case into shuttle and release

latch.

Case should lock into place

when latch is released.

9

SECTION 2. PREPARE YOUR MACHINE FOR SEWING

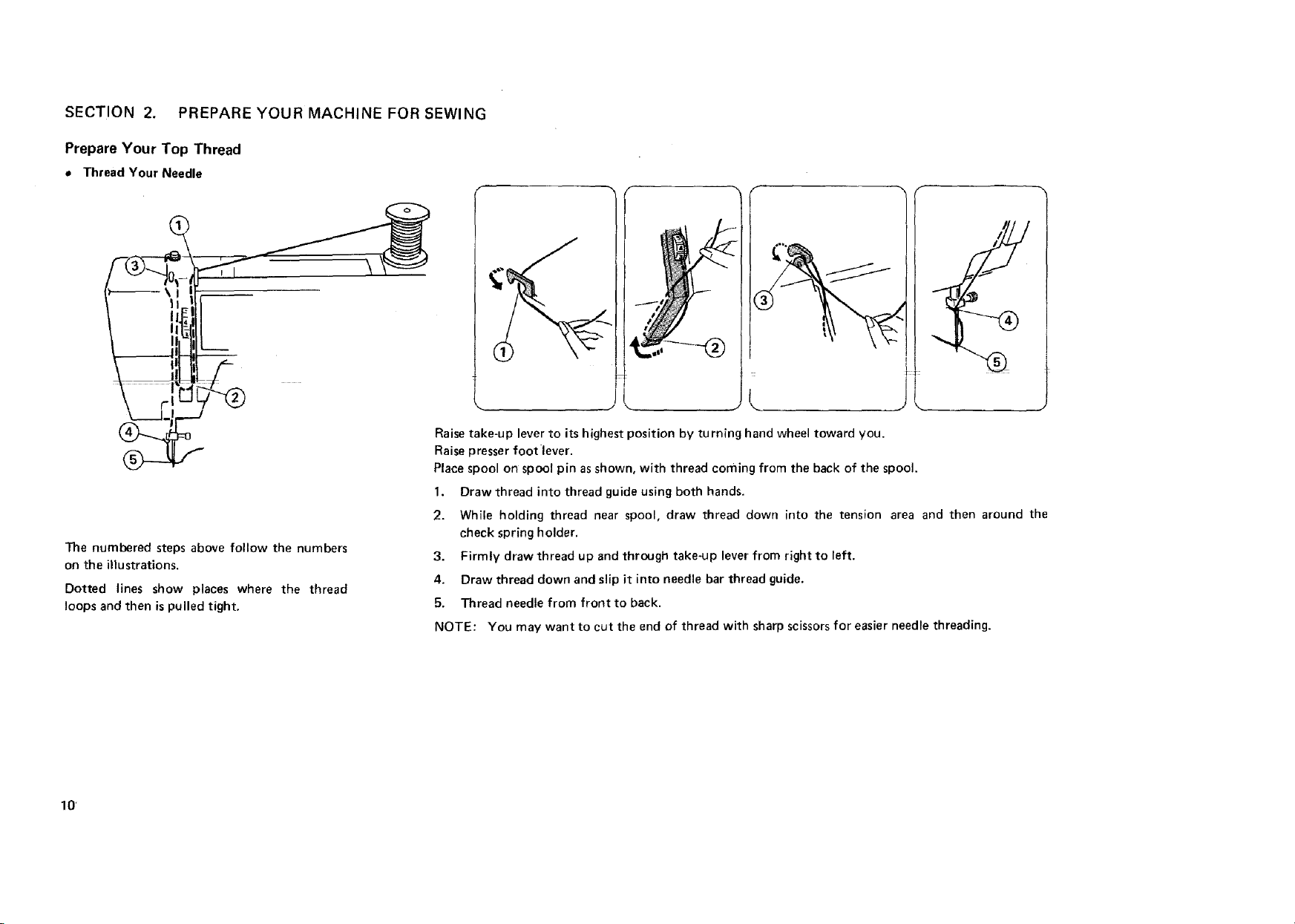

Prepare Your Top Thread

• Thread Your Needle

I

The numbered steps above follow the numbers

on the illustrations.

Dotted lines show places where the thread

loops and then is pulled tight.

10'

.... J _- J _ ,, _.. •

Raise take-up lever to its highest position by turning hand wheel toward you.

Raise presser foot]ever.

Place spool on spool pin as shown, with thread coming from the back of the spool.

1. Draw thread into thread guide using both hands.

2. While holding thread near spool, draw thread down into the tension area and then around the

check spring holder.

3. Firmly draw thread up and through take-up lever from right to left.

4. Draw thread down and slip it into needle bar thread guide.

5. Thread needle from front to back.

NOTE: You may want to cut the end of thread with sharp scissors for easier needle threading.

I i

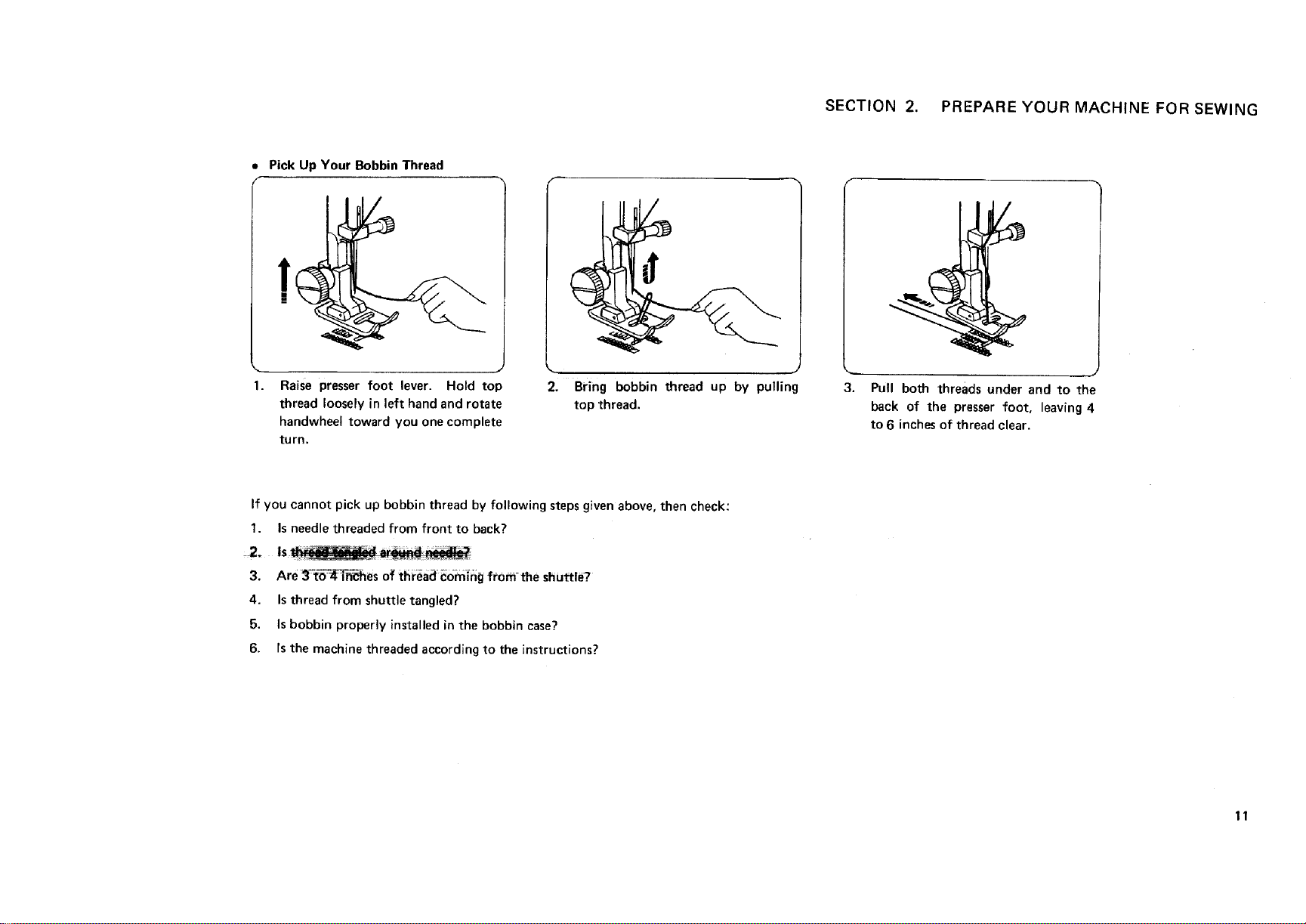

Pick Up Your Bobbin Thread

SECTION 2. PREPARE YOUR MACHINE FOR SEWING

Raise presser foot lever. Hold top

thread loosely in left hand and rotate

2. Bring bobbin thread up by pulling

top thread,

handwheel toward you one complete

turn.

If you cannot pick up bobbin thread by following stepsgiven above, then check:

1. Isneedle threaded from front to back?

3. Are 3 t-0-_'lTn-_nesof thread com;ng from the shuttle?

4. Is thread from shuttle tangled?

5. Isbobbin properly installed in the bobbin case?

6. Is the machine threaded according to the instructions?

3.

Pull both threads under and to the

back of the presser foot, leaving 4

to 6 inchesof thread clear.

F

11

Loading...

Loading...