Page 1

Technical Reference

Model 5312B

Technical Reference

64970 Rev. F / 7-98

Page 2

WARRANTY

Hardware

Keithley Instruments, Inc. warrants that, for a period of one (1) year from the date of shipment (3 years for Models 2000, 2001, 2002, and 2010), the Keithley

Hardware product will be free from defects in materials or workmanship. This warranty will be honored provided the defect has not been caused by use of the

Keithley Hardware not in accordance with the instructions for the product. This warranty shall be null and void upon: (1) any modification of Keithley Hardware that is made by other than Keithley and not approved in writing by Keithley or (2) operation of the Keithley Hardware outside of the environmental specifications therefore.

Upon receiving notification of a defect in the Keithley Hardware during the warranty period, Keithley will, at its option, either repair or replace such Keithley

Hardware. During the first ninety days of the warranty period, Keithley will, at its option, supply the necessary on site labor to return the product to the condition prior to the notification of a defect. Failure to notify Keithley of a defect during the warranty shall relieve Keithley of its obligations and liabilities under

this warranty.

Other Hardware

The portion of the product that is not manufactured by Keithley (Other Hardware) shall not be covered by this w arranty, and Keithley shall hav e no duty of obligation to enforce any manufacturers' warranties on behalf of the customer. On those other manufacturers’ products that Keithley purchases for resale, Keithley

shall have no duty of obligation to enforce any manufacturers’ warranties on behalf of the customer.

Software

Keithley warrants that for a period of one (1) year from date of shipment, the Keithle y produced portion of the software or firmw are (Keithley Software) will conform in all material respects with the published specifications provided such Keithley Software is used on the product for which it is intended and otherwise in

accordance with the instructions therefore. Keithley does not warrant that operation of the Keithley Softw are will be uninterrupted or error-free and/or that the

Keithley Software will be adequate for the customer's intended application and/or use. This warranty shall be null and v oid upon an y modification of the K eithle y

Software that is made by other than Keithley and not approved in writing by Keithley.

If Keithley receiv es notification of a K eithle y Software nonconformity that is co v ered by this warranty during the w arranty period, K eithle y will review the conditions described in such notice. Such notice must state the published specification(s) to which the Keithley Software fails to conform and the manner in which

the Keithley Software fails to conform to such published specification(s) with sufficient specificity to permit K eithle y to correct such nonconformity. If Keithley

determines that the Keithley Software does not conform with the published specifications, Keithley will, at its option, provide either the programming services

necessary to correct such nonconformity or develop a program change to bypass such nonconformity in the Keithley Software. Failure to notify Keithley of a

nonconformity during the warranty shall relieve Keithley of its obligations and liabilities under this warranty.

Other Software

OEM software that is not produced by Keithley (Other Software) shall not be covered by this w arranty, and Keithley shall hav e no duty or obligation to enforce

any OEM's warranties on behalf of the customer.

Other Items

Keithley warrants the following items for 90 days from the date of shipment: probes, cables, rechar geable batteries, diskettes, and documentation.

Items not Covered under Warranty

This warranty does not apply to fuses, non-rechargeable batteries, damage from battery leakage, or problems arising from normal wear or failure to follow

instructions.

Limitation of Warranty

This warranty does not apply to defects resulting from product modification made by Purchaser without Keithley's express written consent, or by misuse of any

product or part.

Disclaimer of Warranties

EXCEPT FOR THE EXPRESS WARRANTIES ABOVE KEITHLEY DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING

WITHOUT LIMIT ATION, ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A P ARTICULAR PURPOSE. KEITHLEY DISCLAIMS ALL WARRANTIES WITH RESPECT TO THE OTHER HARDWARE AND OTHER SOFTWARE.

Limitation of Liability

KEITHLEY INSTRUMENTS SHALL IN NO EVENT, REGARDLESS OF CAUSE, ASSUME RESPONSIBILITY FOR OR BE LIABLE FOR: (1) ECONOMICAL, INCIDENTAL, CONSEQUENTIAL, INDIRECT, SPECIAL, PUNITIVE OR EXEMPLARY DAMAGES, WHETHER CLAIMED UNDER

CONTRACT, TORT OR ANY OTHER LEGAL THEORY, (2) LOSS OF OR DAMAGE TO THE CUSTOMER'S DATA OR PROGRAMMING, OR (3) PENAL TIES OR PENALTY CLAUSES OF ANY DESCRIPTION OR INDEMNIFICATION OF THE CUST OMER OR O THERS FOR COSTS, DAMAGES, OR

EXPENSES RELATED TO THE GOODS OR SERVICES PROVIDED UNDER THIS WARRANTY.

Keithley Instruments, Inc. • 28775 Aurora Road • Cleveland, OH 44139 • 440-248-0400 • Fax: 440-248-6168 • http://www.keithley.com

CHINA: Keithley Instruments China • Yuan Chen Xin Building, Room 705 • 12 Yumin Road, Dewai, Madian • Beijing 100029 • 8610-62022886 • Fax: 8610-62022892

FRANCE: Keithley Instruments SARL • BP 60 • 3 Allée des Garays • 91122 Palaiseau Cédex • 33-1-60-11-51-55 • Fax: 33-1-60-11-77-26

GERMANY: Keithley Instruments GmbH • Landsberger Strasse 65 • D-82110 Germering, Munich • 49-89-8493070 • Fax: 49-89-84930759

GREAT BRITAIN: Keithley Instruments, Ltd. • The Minster • 58 Portman Road • Reading, Berkshire RG30 1EA • 44-1189-596469 • Fax: 44-1189-575666

ITALY: Keithley Instruments SRL • Viale S. Gimignano 38 • 20146 Milano • 39-2-48303008 • Fax: 39-2-48302274

NETHERLANDS: Keithley Instruments BV • Avelingen West 49 • 4202 MS Gorinchem • 31-(0)183-635333 • Fax: 31-(0)183-630821

SWITZERLAND: Keithley Instruments SA • Kriesbachstrasse 4 • 8600 Dübendorf • 41-1-8219444 • Fax: 41-1-8203081

TAIWAN: Keithley Instruments Taiwan • 1FL., 85 Po Ai Street • Hsinchu, Taiwan • 886-3-572-9077 • Fax: 886-3-572-9031

Page 3

Model 5312B

Technical Reference

©1995, Keithley Instruments, Inc.

All rights reserved.

Cleveland, Ohio, U.S.A.

Second Printing, July 1998

Document Number: 64970 Rev. F

Page 4

Manual Print History

The print history shown below lists the printing dates of all Revisions and Addenda created for this manual. The Revision

Level letter increases alphabetically as the manual undergoes subsequent updates. Addenda, which are released between Revisions, contain important change information that the user should incorporate immediately into the manual. Addenda are numbered sequentially. When a new Revision is created, all Addenda associated with the previous Revision of the manual are

incorporated into the new Revision of the manual. Each new Revision includes a revised copy of this print history page.

Revision E (Document Number 64970) ............................................................................................. January 1996

Revision F (Document Number 64970) ................................................................................................... July 1998

All Keithley product names are trademarks or registered trademarks of Keithley Instruments, Inc.

Other brand and product names are trademarks or registered trademarks of their respective holders.

Page 5

Safety Precautions

The following safety precautions should be observed before using

this product and any associated instrumentation. Although some instruments and accessories would normally be used with non-hazardous voltages, there are situations where hazardous conditions

may be present.

This product is intended for use by qualified personnel who recognize shock hazards and are familiar with the safety precautions required to avoid possible injury. Read the operating information

carefully before using the product.

The types of product users are:

Responsible body is the individual or group responsible for the use

and maintenance of equipment, and for ensuring that operators are

adequately trained.

Operators use the product for its intended function. They must be

trained in electrical safety procedures and proper use of the instrument. They must be protected from electric shock and contact with

hazardous live circuits.

Maintenance personnel perform routine procedures on the product

to keep it operating, for example, setting the line voltage or replacing consumable materials. Maintenance procedures are described in

the manual. The procedures explicitly state if the operator may perform them. Otherwise, they should be performed only by service

personnel.

Service personnel are trained to work on live circuits, and perform

safe installations and repairs of products. Only properly trained service personnel may perform installation and service procedures.

Exercise extreme caution when a shock hazard is present. Lethal

voltage may be present on cable connector jacks or test fixtures. The

American National Standards Institute (ANSI) states that a shock

hazard exists when voltage levels greater than 30V RMS, 42.4V

peak, or 60VDC are present. A good safety practice is to expect

that hazardous voltage is present in any unknown circuit bef ore

measuring.

Users of this product must be protected from electric shock at all

times. The responsible body must ensure that users are prevented

access and/or insulated from every connection point. In some cases,

connections must be exposed to potential human contact. Product

users in these circumstances must be trained to protect themselves

from the risk of electric shock. If the circuit is capable of operating

at or above 1000 volts, no conductive part of the circuit may be

exposed.

As described in the International Electrotechnical Commission

(IEC) Standard IEC 664, digital multimeter measuring circuits

(e.g., Keithley Models 175A, 199, 2000, 2001, 2002, and 2010) are

Installation Category II. All other instruments’ signal terminals are

Installation Category I and must not be connected to mains.

Do not connect switching cards directly to unlimited power circuits.

They are intended to be used with impedance limited sources.

NEVER connect switching cards directly to AC mains. When connecting sources to switching cards, install protective devices to limit fault current and voltage to the card.

Before operating an instrument, make sure the line cord is connected to a properly grounded power receptacle. Inspect the connecting

cables, test leads, and jumpers for possible wear, cracks, or breaks

before each use.

For maximum safety, do not touch the product, test cables, or any

other instruments while power is applied to the circuit under test.

ALWAYS remove power from the entire test system and discharge

any capacitors before: connecting or disconnecting cables or jumpers, installing or removing switching cards, or making internal

changes, such as installing or removing jumpers.

Do not touch any object that could provide a current path to the

common side of the circuit under test or power line (earth) ground.

Always make measurements with dry hands while standing on a

dry, insulated surface capable of withstanding the voltage being

measured.

Page 6

Do not exceed the maximum signal levels of the instruments and accessories, as defined in the specifications and operating information, and as shown on the instrument or test fixture panels, or

switching card.

When fuses are used in a product, replace with same type and rating

for continued protection against fire hazard.

Chassis connections must only be used as shield connections for

measuring circuits, NOT as safety earth ground connections.

If you are using a test fixture, keep the lid closed while power is applied to the device under test. Safe operation requires the use of a

lid interlock.

If a screw is present, connect it to safety earth ground using the

wire recommended in the user documentation.

!

The symbol on an instrument indicates that the user should refer to the operating instructions located in the manual.

The symbol on an instrument shows that it can source or measure 1000 volts or more, including the combined effect of normal

and common mode voltages. Use standard safety precautions to

avoid personal contact with these voltages.

The WARNING heading in a manual explains dangers that might

result in personal injury or death. Alw ays read the associated infor mation very carefully before performing the indicated procedure.

Instrumentation and accessories shall not be connected to humans.

Before performing any maintenance, disconnect the line cord and

all test cables.

To maintain protection from electric shock and fire, replacement

components in mains circuits, including the power transformer, test

leads, and input jacks, must be purchased from Keithley Instruments. Standard fuses, with applicable national safety approvals,

may be used if the rating and type are the same. Other components

that are not safety related may be purchased from other suppliers as

long as they are equivalent to the original component. (Note that selected parts should be purchased only through Keithley Instruments

to maintain accuracy and functionality of the product.) If you are

unsure about the applicability of a replacement component, call

technical support for information.

To clean the instrument, use a damp cloth or mild, water based

cleaner. Clean the exterior of the instrument only. Do not apply

cleaner directly to the instrument or allow liquids to enter or spill

on the instrument.

The CAUTION heading in a manual explains hazards that could

damage the instrument. Such damage may invalidate the warranty.

Page 7

About this manual

Quality control

Keithley Instruments manufactures quality and versatile products, and we want our documentation to reflect that same quality. We take great pains to publish manuals that are informative and

well organized. We also strive to make our documentation easy to understand for the novice as

well as the expert.

If you have comments or suggestions about how to mak e this (or other) manuals easier to understand, or if you find an error or an omission, please fill out and mail the reader response card at

the end of this manual (postage is prepaid).

Conventions

Procedural

Keithley Instruments uses various conventions throughout this manual. You should become

familiar with these conventions as they are used to draw attention to items of importance and

items that will generally assist you in understanding a particular area.

WARNING

CAUTION

NOTE

When referring to pin numbering, pin 1 is always associated with a square solder pad on the

actual component footprint.

A warning is used to indicate that an action must be done with great

care. Otherwise, personal injury may result.

A caution is used to indicate that an action may cause minor equipment damage or the loss of data if not performed carefully.

A note is used to indicate important information needed to perform an

action or information that is nice-to-know.

Notational

A forward slash (/) preceding a signal name denotes an active LOW signal. This is a standard

Intel convention.

Caret brackets (<>) denote keystrokes. For instance <Enter> represents carriage-return-withline-feed keystroke, and <Esc> represents an escape keystroke.

Driver routine declarations are shown for C and BASIC (where applicable).

Hungarian notation is used for software parameters. In other words, the parameter type is

denoted by a one or two letter lower case prefix:

c character, signed or unsigned

s short integer, signed

w short integer, unsigned

l long integer, signed

dw long integer, unsigned

For example, wBoardAddr would be an unsigned short integer parameter.

Page 8

An additional p prefix before the type prefix indicates that the parameter is being passed by reference instead of by value. (A pointer to the variable is being passed instead of the variable

itself).

For example, pwErr would be an unsigned short integer parameter passed by reference.

This notation is also used in BASIC although no distinction between signed and unsigned vari-

ables exists.

In BASIC, all parameters also have a type suffix:

$ character, signed or unsigned

% integer, signed or unsigned

& long integer, signed or unsigned

Routine names are printed in bold font when they appear outside of function declarations, e.g.,

ReadStatus.

Parameter names are printed in italics when they appear outside of function declarations, e.g.

sControls.

Constants are defined with all caps, e.g., ALL_AXES. Underscores {_} must be replaced by

periods {.} for use with BASIC.

Combinational logic and hexadecimal notation is in C convention in many cases. For example,

the hexadecimal number 7Ch is shown as 0x7C.

C relational operators for OR and AND functions — “| |” and “&&” — are used to minimize the

confusion associated with grammar.

Page 9

Table of Contents

1 Introduction and Installation

Description ......................................................................................................................................................... 1-2

Technical Specifications .................................................................................................................................... 1-3

Setting the jumpers ............................................................................................................................................. 1-3

Base adddressing ........................................................................................................................................ 1-4

Indirect addressing ..................................................................................................................................... 1-5

Termination resistors .................................................................................................................................. 1-6

Selecting an index option ........................................................................................................................... 1-8

Selecting the card configuration ................................................................................................................. 1-9

Interrupt selection .................................................................................................................................... 1-10

Wait states ................................................................................................................................................ 1-11

Installation ........................................................................................................................................................ 1-11

Power considerations ............................................................................................................................... 1-12

Connector pinouts .................................................................................................................................... 1-13

2 Operation and Programming

Theory of operation ............................................................................................................................................ 2-2

Programming ...................................................................................................................................................... 2-2

Writing the Preset Register (PR) ................................................................................................................ 2-2

Reading the Output Latch register (OL) .................................................................................................... 2-3

Writing the Command Register (CR) ........................................................................................................ 2-3

Master Control Register (MCR) ................................................................................................................ 2-3

Input Control Register (ICR) ..................................................................................................................... 2-4

Output/Counter Control Register (OCCR) ................................................................................................. 2-4

Quadrature Register (QR) .......................................................................................................................... 2-5

Output Status Register (OSR) .................................................................................................................... 2-6

Typical programming examples ................................................................................................................. 2-6

Selecting a sample clock frequency ........................................................................................................... 2-8

i

Page 10

3 Interrupt Control

Description of interrupt control ......................................................................................................................... 3-2

Interrupt Request Rgtr (IRR), In Service Rgtr (ISR) ................................................................................. 3-2

Priority Resolver (PR) ................................................................................................................................ 3-3

Interrupt Mask Register (IMR) ................................................................................................................... 3-3

Interrupt output (INT) ................................................................................................................................. 3-3

PIC operation ...................................................................................................................................................... 3-3

Interrupt sequence, 80x86/80x88 mode ..................................................................................................... 3-3

End-of-interrupt command ......................................................................................................................... 3-4

Completing an interrupt .............................................................................................................................. 3-4

Operating modes ................................................................................................................................................. 3-4

Fully nested mode ....................................................................................................................................... 3-4

Special mask mode ..................................................................................................................................... 3-5

Specific rotation (specific priority) ............................................................................................................ 3-5

Automatic rotation (equal priority) ............................................................................................................ 3-5

Non-vectored mode (poll command) .......................................................................................................... 3-5

PIC programming ............................................................................................................................................... 3-5

Initialization Command Words (ICW) ....................................................................................................... 3-5

ICW1 format and description ..................................................................................................................... 3-6

ICW4 format and description ..................................................................................................................... 3-7

Operation Command Words (OCW) .......................................................................................................... 3-7

OCW1 format and description .................................................................................................................... 3-8

OCW2 format and description .................................................................................................................... 3-9

OCW2 commands ...................................................................................................................................... 3-9

OCW3 format and description .................................................................................................................... 3-9

A PC I/O and Interrupt Mapping

PC I/O map ........................................................................................................................................................ A-2

B T ech Bulletins and Application Notes

Timer application in velocity mode ................................................................................................................... B-2

Setting up axis 3 as an interval timer ................................................................................................................. B-2

C Circuit Diagrams

ii

Page 11

List of Illustrations

1 Introduction and Installation

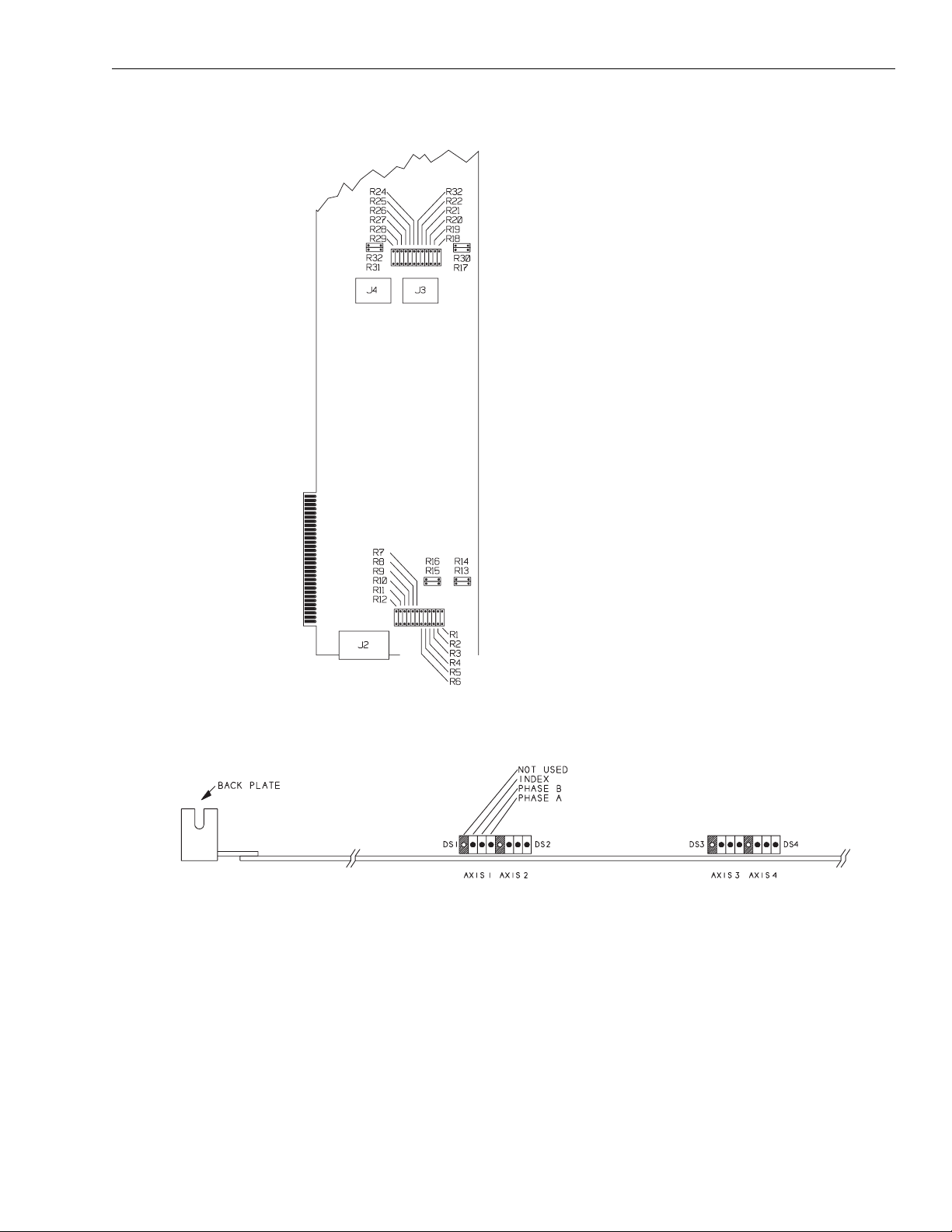

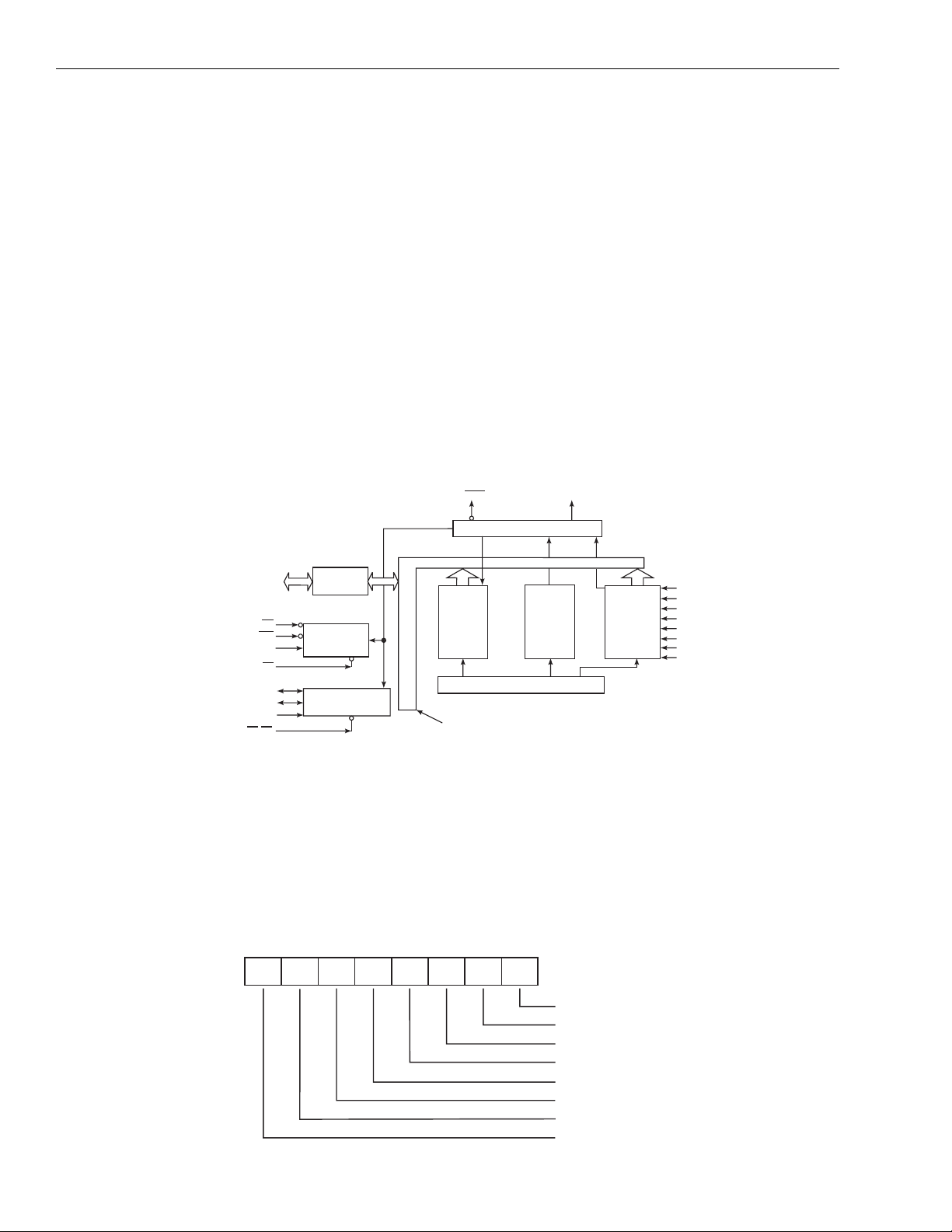

Figure 1-1 Functional block diagram for the 5312 ...................................................................................................... 1-2

Figure 1-2 Jumper locations for the 5312 .................................................................................................................... 1-4

Figure 1-3 Encoder termination resistor locations ....................................................................................................... 1-7

Figure 1-4 LED locations on the card edge ................................................................................................................. 1-7

Figure 1-5 Connector locations on the board ............................................................................................................. 1-12

2 Operation and Programming

Figure 2-1 Example of a 4-stage signal conditioning filter ......................................................................................... 2-8

3 Interrupt Control

Figure 3-1 PIC block level diagram ............................................................................................................................. 3-2

Figure 3-2 PIC initialization sequence ......................................................................................................................... 3-5

Figure 3-3 PIC ICW format ......................................................................................................................................... 3-6

Figure 3-4 PIC OCW format ....................................................................................................................................... 3-8

iii

Page 12

List of Tables

1 Introduction and Installation

Table 1-1 W19, base address select (upper nibble) .................................................................................................... 1-4

Table 1-2 5312 I/O map ............................................................................................................................................. 1-5

Table 1-3 Termination resistors in differential mode.................................................................................................. 1-6

Table 1-4 Terminal resistors in single-ended mode ................................................................................................... 1-6

Table 1-5 Index option selections ............................................................................................................................... 1-8

Table 1-6 Jumper selection for differential/single-ended operation ........................................................................... 1-9

Table 1-7 Sample clock frequency jumper settings .................................................................................................... 1-9

Table 1-8 Cascading the counters ............................................................................................................................. 1-10

Table 1-9 Jumpering for disabling/enabling borrow interrupts ................................................................................ 1-10

Table 1-10 Selecting an interrupt ............................................................................................................................... 1-10

Table 1-11 Generating wait states .............................................................................................................................. 1-11

Table 1-12 Connector J1-J4 pin assignments ............................................................................................................. 1-13

Table 1-13 Default jumper settings for all board versions ......................................................................................... 1-14

2 Operation and Programming

Table 2-1 Register select ............................................................................................................................................ 2-3

Table 2-2 Output/counter control modes .................................................................................................................... 2-5

Table 2-3 Quadrature register modes ......................................................................................................................... 2-5

3 Interrupt Control

Table 3-1 Interrupt code ............................................................................................................................................. 3-4

A PC I/O Map

Table A-1 PC I/O map ................................................................................................................................................ A-2

Table A-2 PC interrupt map ....................................................................................................................................... A-3

v

Page 13

1

Introduction and Installation

Page 14

1-2 Introduction and Installation Model 5312B Technical Reference

Description

NOTE

The 5312 Quadrature Encoder card is PC bus compatible. It provides inputs and decoding for

up to four incremental quadrature encoders depending on the model purchased. You may also

use the card as a high-speed pulse counter (up/down and pulse/direction) for general counting

applications. Figure 1-1 shows a functional block diagram.

Figure 1-1

Functional block diagram for the 5312

This manual is model dependent. For models not using all encoder

ports, disregard the appropriate upper axis.

For each encoder circuit, Phase A (Phase 0), Phase B (Phase 90), and Inde x pulse inputs are provided. Jumper options on board allow you to configure the inputs as single-ended TTL or dif fer ential (the recommended connection method). Individual connectors for each encoder provide

power (+5V) and ground for the encoder if needed.

You can also use the 5312 as pulse counter for up to 4 independent events, or you can cascade

the counters to provide high speed pulse counting over an extended count range.

Inputs are conditioned by a 4-stage digital filter. The filter clock is one of five jumper -selectable

sampling frequencies ranging up to 10 MHz. Selecting the lowest frequency compatible with

the highest expected input rate will maximize noise immunity. The maximum input rate per

phase in quadrature decode mode is approximately 333 kHz. The maximum input rate in count

mode is approximately 1.25 MHz. Sample clock frequency selection is described in detail in

Section 2.

The conditioned inputs are applied to a 24-bit counter provided for each encoder. You can use

the counters for quadrature decoding, pulse and direction input counting, or as a pulse input up/

down counter. Count output is available for the PC bus in binary or binary coded decimal

(BCD) form. The count value may be latched on command, latched on an index pulse, or

latched with a new count value when an index pulse occurs.

Page 15

Model 5312B Technical Reference Introduction and Installation 1-3

The 5312 is capable of generating interrupts. Maskable interrupts may come from a valid index

pulse, counter overflow/underflow, or on count value match with a preset compare value.

T echnical specifications

Voltage Requirements: 4-axis: 1.5A (typical), 2.0A (maximum)

3-axis: 1.25A (typical), 1.75A (maximum)

2-axis: 1.0A (typical), 1.5A (maximum)

1-axis: 0.9A (typical), 1.25A (maximum)

Compatibility : PC/XT/AT

Single-ended or Differential

Incremental Encoders

TTL or CMOS Signal Sources

Operating Range: 0 to 70 degrees Celsius

Mating Connectors:

Card Dimensions: 13.3 x 4.2 x 0.5 inches

Setting the jumpers

CAUTION Always remove power from the PC and any external system

Jumper options on the 5312 offer a great deal of flexibility in system operation. These options

are grouped into 4 areas according to functions — encoder inputs, card functions, interrupt

action, and card addressing.

All cards are shipped with most jumpers installed for a given configuration. All factory default

jumpers are indicated throughout this manual in the appropriate tables with a † symbol. However, due to possible rough handling during shipment, there is no assurance that all jumpers will

be in the indicated position.

NOTE

9-pin Dsub:

devices before removing any connection on the 5312. Failure to do

so may result in permanent damage to the card and will void any

warranty.

Default jumper settings shown are those for the 4-axis version of the

M5312. For default settings on other versions, see Table 1-13 at the

end of Section 1.

Ansley 609-9p

Amphenol

841-17-DEFR-B09P

Check and properly configure all boards before installing.

Jumper locations are shown in Figure 1-2. We strongly recommend, however, that once you

determine the proper jumper settings, replace all jumpers with more reliable wire-wrapped connections. This is particularly important when exposing the card to an industrial environment

where vibration, dust, oil, or other contaminants may be present.

Page 16

1-4 Introduction and Installation Model 5312B Technical Reference

Base addressing

Jumper W19 determines the upper nibble (4 bits) of the card base address according to Table 1-1.

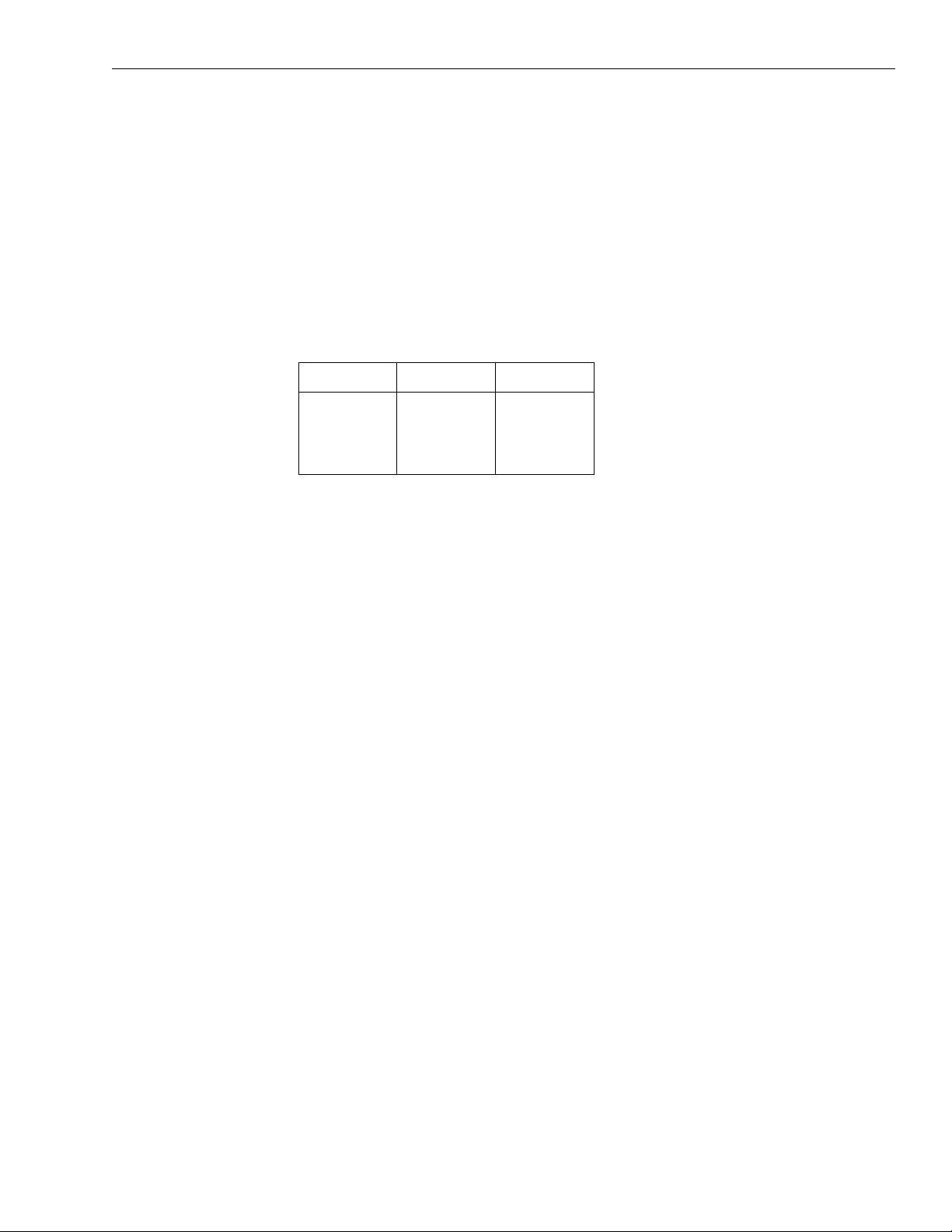

Table 1-1

W19, base address select (upper nibble)

W19 Base Address

(1-2)†

(2-3)

† Default jumper setting

Set hex switches SW1 and SW2 to determine the lower 8 bits of the address. Switch SW2 represents the most significant nibble (MSN), and SW1 represents the least significant nibble (LSN).

Since the 5312 occupies two adjacent I/O ports, only the even settings of the LSN switch are

used.

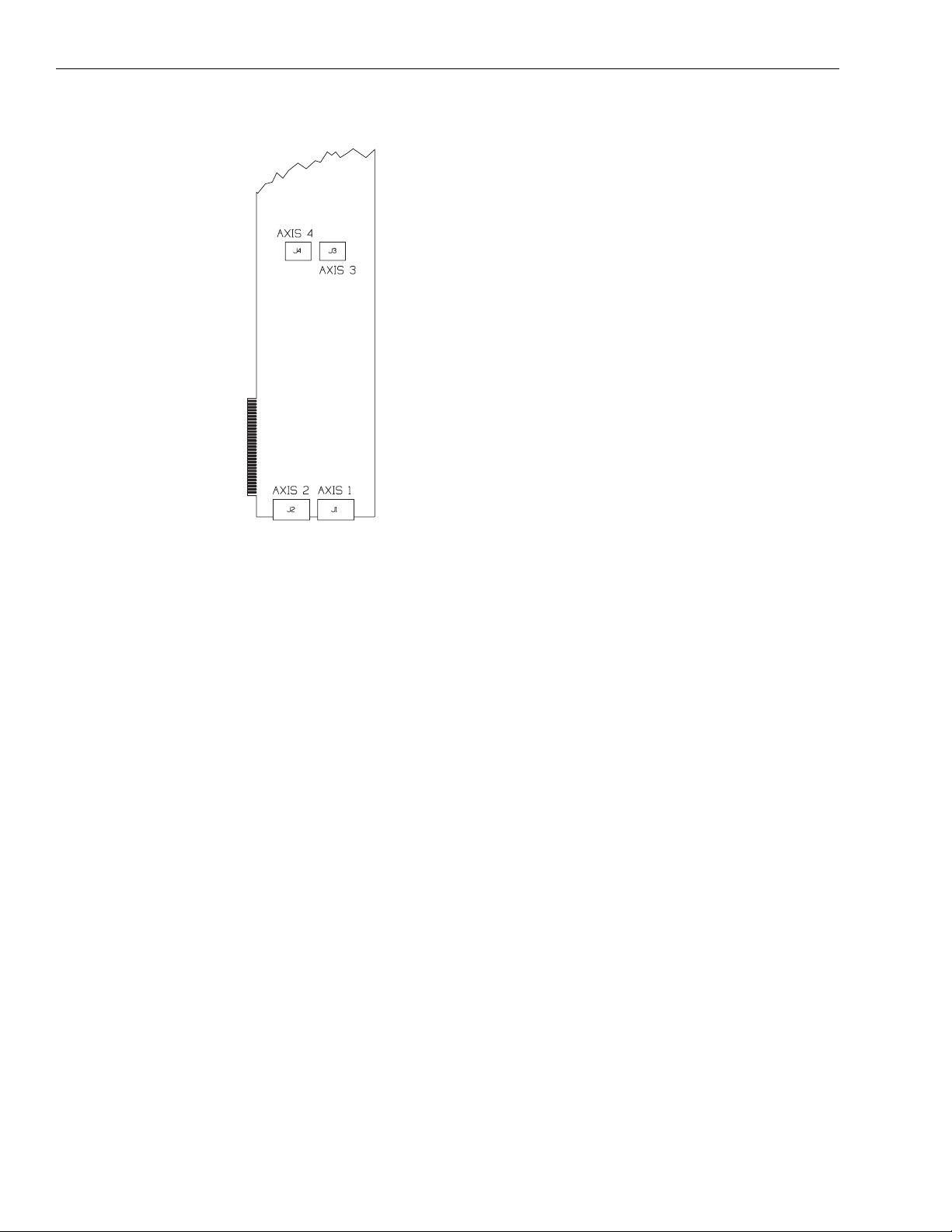

Figure 1-2

Jumper locations for the 5312

2 xx h

3 xx h

1

W5

1

W5

1

W4

W4

W4

W4

W4

W3

W3

1

W3

1

W3

1

W2

1

W2

1

W2

W2

W2

1

2

W1

9

10

W

W

W2

W3

W3

W3

W3

W2

W2

1

W2

1

W1

1

1

1

SW

SW

W

W

W

1

W1

W1

W

1

9

W2

11111

WW4W1W4W

WW4W

WW3W

1

W4

W4

W3

2

10

W

W

Page 17

Model 5312B Technical Reference Introduction and Installation 1-5

Indirect addressing

To conserve I/O space on the PC bus, the 5312 is indirectly addressed (see Table 1-2). This

allows the card to occupy only two direct I/O ports by using one for indirect addressing (e v en or

lower) and the other for data (the odd or greater of the two ports). The sequence for writing to

any indirect port is to first write the indirect port address to the address port. The desired data

can then be written to the data port. This indirect port will remain addressed until the indirect

address port is again written. For example, to write the initialization bytes MCR, ICR, OCCR,

and QR to the command port of axis 1 assuming the card is strapped to 300h as the base address:

1. Write the indirect address for the axis A command port (01h) to the indirect address port

(300h).

2. Write the first byte (Master Control Register) to the data port (301h).

3. Write the second byte (Input Control Register) to the data port (301h).

4. Write the third byte (Output/Counter Control Register) to the data port (301h).

5. Write the last byte (Quadrature Encoder) to the data port (301h).

NOTE

The C function libraries on the software diskette make this sequence

transparent to the user.

Table 1-2

5312 I/O map

Axis Address When Written When Read

1 00 Write to preset register (PR) and

increment register address

counter.

01 Write to command register. Read OSR (output status

2 02 Write to PR and increment

register address counter.

03 Write to command register. Read OSR.

3 04 Write to PR and increment

register address counter.

05 Write to command register. Read OSR.

4 06 Write to PR and increment

register address counter.

07 Write to command register. Read OSR.

Global 08 Global write to all four PRs. Invalid

09 Global write to all four command

registers.

PIC 0A Low Port Low Port

0B High Port High Port

Read OL (output latch) and

increment register address

counter.

register).

Read OL and increment

register address counter.

Read OL and increment

register address counter.

Read OL and increment

register address counter.

Invalid

Page 18

1-6 Introduction and Installation Model 5312B Technical Reference

T ermination resistors

If differential input is used, give consideration to terminating the cable lines connecting the signal to the card. Cable length and signal frequency determine how critical the termination factor

is. Since the needed termination resistor value is determined by cable type, sockets are provided

for easy insertion and removal of termination resistors. Unless otherwise specified by the

encoder manufacturer, one-quarter watt carbon film resistors of a standard EIA value closest to

one half the characteristic impedance of the cable are adequate (see cable manufacturers specification for values). Termination resistors apply a load to the signal source, so make sure that the

source can supply enough drive capability to compensate for this condition.

Figure 1-3 shows the termination resistor locations for both single-ended and differential. Table

1-3 shows the termination resistor assignments for each signal in differential mode. The inputs

should be terminated in the characteristic impedance of the input line.

Table 1-3

Termination resistors in differential mode

Signal Axis 1 Axis 2 Axis 3 Axis 4

Phase A

Phase B

Index

R1, R2

R3, R4

R5, R6

R7, R8

R9, R10

R11, R12

R18, R19

R20, R21

R22, R23

R24, R25

R26, R27

R28, R29

When single-ended encoder inputs are used, the logic level of the input signal is determined by

comparison with a reference voltage on the card. This reference is set by a pair of resistors

selected and inserted by the user, and they form a voltage divider network that establishes the

center point for the input Hysteresis band.

Resistor assignments in a single-ended mode are shown in Table 1-4.

Table 1-4

Termination resistors in single-ended mode

Typical Value Axis 1 Axis 2 Axis 3 Axis 4

220 Ohms

150 Ohms

The 5312 features encoder input indicators that are useful when determining proper encoder

operation and connection. Only three of the four LEDs in each package are used. Figure 1-4

shows the location of LEDs on the outboard edge of the card as you view do wn from the top. An

LED is on when its corresponding input signal is LOW.

R14

R14

R15

R16

R17

R30

R31

R32

Page 19

Model 5312B Technical Reference Introduction and Installation 1-7

Figure 1-3

Encoder termination resistor locations

Figure 1-4

LED

locations on the card edge

Page 20

•

•

•

•

1-8 Introduction and Installation Model 5312B Technical Reference

Selecting an index option

The following are the available jumper options that direct the function of the encoder index

pulse. The first two options work in conjunction with bits D4 and D5 respectively of the Input

Control Register (ICR). Table 1-5 shows the jumper configuration for selecting an index option.

Index Action to /ABGT (ABGaTe) or /RCTR (Reset CounTeR):

ICRB4 = 0:A valid index level will reset the counter.

ICRB4 = 1:A valid index level will gate phase A and B inputs to the counter.

Index Action to /LCTR (Load CounTer) or /LLTC (Load output LaTCh).

ICRB5 = 0:A valid index level will load the contents of the preset register into the counter.

ICRB5 = 1:A valid index level will load the contents of the counter into the Output Latch.

Active Low Index Polarity.

Select this option if the encoder provides an active LOW index pulse.

Active High Index Polarity.

Select this option if the encoder provides an active HIGH index pulse.

Correct strapping for each axis is detailed in Table 1-6 below. The following tables also provide

the necessary jumpering information for operating the encoder.

If the index is not used, remove jumpers W17, W22, and W29. Failure to do so will result in

incorrect encoder operation. If index is used, we recommend that you check for correct encoder

operation with the jumpers removed, then with the jumpers installed.

Table 1-5

Index option selections

Operation Axis 1 Axis 2

Index Action

W24(2-3) W17(2-3) W22(2-3) W29(2-3)

Axis 3

Axis 4

/ABGT-/RCTR† (AB GateReset Counter)

Index Action

W24(1-2)† W17(1-2)† W22(1-2)† W29(1-2)†

/LCTR-/LL TC†

(Load Counter-Load Latch)

Active LOW Index Polarity W13(2-3)† W16(2-3)‡ W51(2-3)† W50(2-3)†

Active HIGH Index Polarity W13(1-2) W16(1-2)†‡ W51(1-2) W50(1-2)

† Default jumper setting

‡

For axis 2, strap (1-2) for active LOW, (2-3) for active HIGH

Note: A forward slash preceding a signal name denotes an active LOW signal.

Page 21

Model 5312B Technical Reference Introduction and Installation 1-9

Table 1-6

Jumper selection for differential/single-ended operation

Axis Operating Mode Jumpers Strapping

1 Differential

Single-Ended

2 Differential

Single-Ended

3 Differential

Single-Ended

4 Differential

Single-Ended

†

Default jumper setting

W1, W3, W5

W2, W4, W6

W1, W3, W5

W2, W4, W6

W7, W9, W11

W8, W10, W12

W7, W9, W11

W8, W10, W12

W38, W40, W42

W39, W41, W43

W38, W40, W42

W39, W41, W43

W44, W46, W48

W45, W47, W49

W44, W46, W48

W45, W47, W49

none

(1-2)

(1-2)†

(2-3)†

none

(1-2)

(1-2)†

(2-3)†

none

(1-2)

(1-2)†

(2-3)†

none

(1-2)

(1-2)†

(2-3)†

Selecting the card configuration

The following tables provide the necessary jumpering information for selecting card function.

Sample clock frequency jumpering

Jumper W23 (Table 1-7) is used to select the sample clock frequency used by the digital filters.

For more information, see Section 2.

Table 1-7

Sample clock frequency jumper settings

Sample Clock Frequency (MHz) W23

0.625

1.250

2.500

5.000

10.00

†Default jumper setting

(9-10)†

(7-8)

(5-6)

(3-4)

(1-2)

Page 22

1-10 Introduction and Installation Model 5312B Technical Reference

Counter cascading

If you need to extend the counting range of the 5312, you can cascade the counters according to

Table 1-8.

Table 1-8

Cascading the counters

Operation Jumper Strapping

Cascade Axis 1 to Axis 2

No Cascading Axis 1 to Axis 2

Cascade Axis 2 to Axis 3

No Cascading Axis 2 to Axis 3

Cascade Axis 3 to Axis 4

No Cascading Axis 3 to Axis 4

† Default jumper setting

W28, W25

W28, W25

W27, W31

W27, W31

W33, W37

W33, W37

(2-3)†

(1-2)†

(2-3)†

(1-2)†

(2-3)†

(1-2)†

Interrupt selection

Enabling and disabling PIC interrupts

T able 1-9 provides the necessary information for enabling and disabling Programmable Interrupt

Control (PIC) interrupts. For further information on interrupt selection, refer to Section 2.

Table 1-9

Jumpering for disabling/enabling borrow interrupts

Operation Axis 1 Axis 2 Axis 3 Axis 4 Strapping

Disable‡

/BW† (borrow) output to the PIC

Enable

/BW† output to the PIC

† Default jumper setting

‡ Disable /BW to use comparator mode

Note: A forward slash (/) preceding a signal name denotes an active LOW signal.

PC bus interrupts

W18 selects the PC bus interrupt request line used for interrupt operation as shown in Table 1-10.

Table 1-10

Selecting an interrupt

W26

W26

W32

W32

W35

W35

W36

W36

(1-2)

(2-3)†

Interrupt

W18

(1-2)

(3-4)†

(5-6)

(7-8)

(9-10)

(11-12)

† Default jumper setting

‡ Unused on XT only, not available on AT

Request Line Hardware Interrupt

IRQ2

IRQ3

IRQ4

IRQ5

IRQ6

IRQ7

Unused‡

Unused

Serial Port

Unused

Diskette Port

Parallel Printer Port

Interrupt

Number

0Ah

0Bh

0Ch

0Dh

0Eh

0Fh

Page 23

Model 5312B Technical Reference Introduction and Installation 1-11

W ait states

A wait state is a period of time requested by a peripheral device to pause the host computer during a read or write operation. A de vice pauses the host to ensure that v alid data are passed. Each

wait state is equal to 1 clock cycle. Without wait states on the host, faster PCs will terminate an

operation before the peripheral card can fully and reliably gate the data in from or out to the PC

bus. As shipped, the card is jumpered for 2 wait states, although some slower PCs may be able

to use the card with less than 2. Jumpers W34 and W30 determine the number of wait states as

shown in Table 1-11.

Table 1-11

Generating wait states

Wait State W34 W30

none

1

2

Invalid

† Default jumper setting

none

none

installed†

installed

none

installed

none†

installed

Installation

The 5312 is designed to operate in a PC backplane or on a motherboard. You may install the

board into any 8-bit slot in the PC according to the PC manufacturer's instructions. If you use

more than 2 of the 4 available axes, an additional expansion slot is required. Connect ribbon

cables as required from J3 and J4 to the additional back plate.

Give consideration to power and ground connections to ensure reliable system operation.

Encoder connections are made to the card through up to 4 9-pin, Dsub connectors. Board connections are located according to Figure 1-5.

The pin assignments for these connectors are shown in section Connector pinouts.

Properly phase the encoder according to manufacturer's instructions.

Page 24

1-12 Introduction and Installation Model 5312B Technical Reference

Figure 1-5

Connector locations on the board

Power considerations

The Model 5312 requires +5V from the PC bus. The typical current load is 1A with a maximum

of 1.5A depending on the number of axes used. In addition, +5V is available at J1, J2, J3, and J4

for any external devices that need +5V. The total current load must be considered when determining how much power is required for the system.

Page 25

Model 5312B Technical Reference Introduction and Installation 1-13

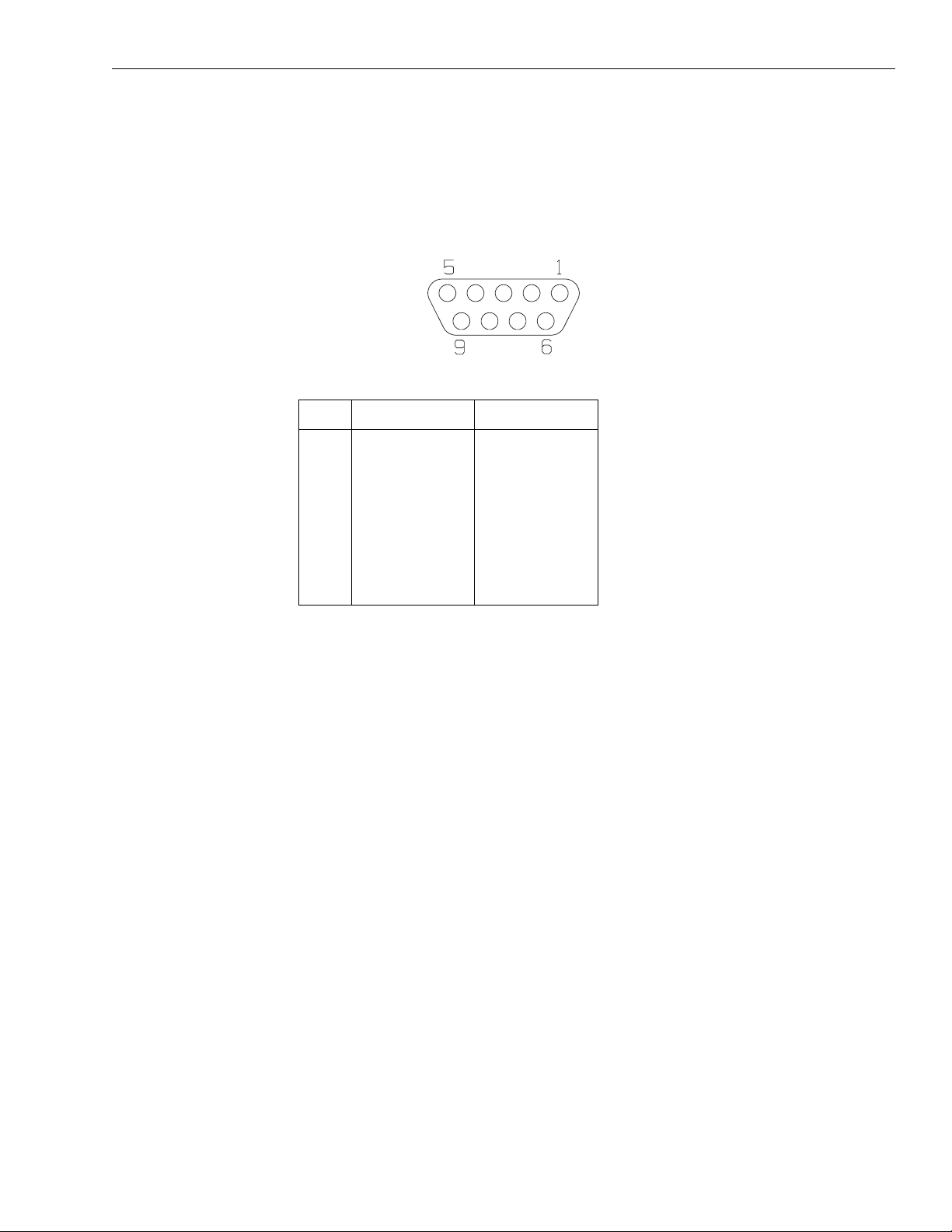

Connector pinouts

Table 1-12 lists the pin assignments for J1 to J4 . The view shown of the connector is looking

into the board from the backpanel. Figure 1-5 shows the connector locations on the board. Ribbon cables connect axes 3 and 4 from the 10–pin unshrouded headers to chassis I/O slots on the

backpanel. The pinout on the backpanel connectors is the same as for axes 1 and 2.

Table 1-12

Connector J1-J4 pin assignments

Pin Single-Ended Differential

1

Ground

2

+5V

3

Ground

4

+5V

5

Ground

6

Phase A

7

Phase B

8

Ground

9

Index

† A forward slash (/) preceding a signal name denotes an

active LOW signal.

/Phase A†

+5V

/Phase B†

+5V

/Index†

Phase A

Phase B

Ground

Index

Page 26

1-14 Introduction and Installation Model 5312B Technical Reference

Table 1-13

Default jumper settings for all board versions

Jumper

W1

W2

W3

W4

W5

W6

W7

W8

W9

W10

W11

W12

W13

W16

W17

W18

W19

W22

W23

W24

W25

W26

W27

W28

W29

W30

W31

W32

W33

W34

W35

W36

W37

W38

W39

W40

W41

W42

W43

W44

W45

W46

W47

W48

W49

W50

W51

4-Axis

(1-2)

(2-3)

(1-2)

(2-3)

(1-2)

(2-3)

(1-2)

(2-3)

(1-2)

(2-3)

(1-2)

(2-3)

(2-3)

(1-2)

(1-2)

(3-4)

(1-2)

(1-2)

(9-10)

(1-2)

(1-2)

(2-3)

(1-2)

(1-2)

(1-2)

none

(1-2)

(2-3)

(1-2)

(1-2)

(2-3)

(2-3)

(1-2)

(1-2)

(2-3)

(1-2)

(2-3)

(1-2)

(2-3)

(1-2)

(2-3)

(1-2)

(2-3)

(1-2)

(2-3)

(2-3)

(2-3)

3-Axis

(1-2)

(2-3)

(1-2)

(2-3)

(1-2)

(2-3)

(1-2)

(2-3)

(1-2)

(2-3)

(1-2)

(2-3)

(2-3)

(1-2)

(1-2)

(3-4)

(1-2)

(1-2)

(9-10)

(1-2)

(1-2)

(2-3)

(1-2)

(1-2)

none

none

(1-2)

(2-3)

none

(1-2)

(2-3)

none

none

(1-2)

(2-3)

(1-2)

(2-3)

(1-2)

(2-3)

none

none

none

none

none

none

none

(2-3)

2-Axis

(1-2)

(2-3)

(1-2)

(2-3)

(1-2)

(2-3)

(1-2)

(2-3)

(1-2)

(2-3)

(1-2)

(2-3)

(2-3)

(1-2)

(1-2)

(3-4)

(1-2)

none

(9-10)

(1-2)

(1-2)

(2-3)

none

(1-2)

none

none

none

(2-3)

none

(1-2)

none

none

none

none

none

none

none

none

none

none

none

none

none

none

none

none

none

1-Axis

(1-2)

(2-3)

(1-2)

(2-3)

(1-2)

(2-3)

none

none

none

none

none

none

(2-3)

none

none

(3-4)

(1-2)

none

(9-10)

(1-2)

none

(2-3)

none

none

none

none

none

none

none

(1-2)

none

none

none

none

none

none

none

none

none

none

none

none

none

none

none

none

none

Page 27

2

Operation

and Programming

Page 28

•

•

•

•

2-2 Operation and Programming Model 5312B Technical Reference

•

•

•

Theory of operation

The Model 5312 can be configured for up to 4 independent 24-bit multimode counters depending on the model purchased. All models are PC/XT/AT compatible. For applications requiring

more than 24 bits of count range, the counters can be cascaded together to form various 24-bit

counter configurations. For example, you can cascade counters to obtain one 48-bit counter, a

24-bit counter and a 72-bit counter, or even one 96-bit counter.

Each counter is capable of numerous modes. Examples include:

A/B quadrature with a maximum input frequency of .333 MHz

Up/down count with a maximum input frequency of 1.25 MHz

Count/direction with a maximum input frequency of 1.25 MHz

Divide by n mode with a maximum input frequency of 1.25 MHz

All three inputs to each counter — Phase A, Phase B, and Index — can be connected singleended TTL or differential for greater noise immunity. The 5312 provides sockets in differential

mode to allow easy insertion of termination resistors. The input lines do not need to be terminated, but for best noise immunity terminate them at the characteristic impedance of the input

line. Each input is tied through a buffer to an LED which is turned on when the respective input

is LOW.

Programming

Writing the Preset Register (PR)

Each input is digitally filtered (see section Selecting a sample clock frequency) using a sample

clock rate that can be optimized for your signal input rate. The index input can be used to generate an interrupt or any one of the following:

Resetting the counter

Enabling the gate for phase A and B inputs

Transferring the 24-bit count value to the count latch

The counter can generate an interrupt on an overflow/underflow or on a compare match condition between the counter and the preset register.

An 8259 Programmable Interrupt Controller (PIC) handles interrupts, and the PIC can be polled

to determine the cause of the interrupt.

The PC bus interface to each counter is handled by multiple 8-bit reads and writes. The 24-bit

value is read or written, LSB first (little endian).

Programming the 5312 requires that you read and write the board multimode counter. By under standing the functions of all registers and knowing how to access them, you will be able to issue

commands to the board. The following is a discussion of each register.

To load the PR:

1. Reset the PR and the Output Latch address counter by writing 01h to the Command Register

(see below).

2. Write the three bytes that will comprise the 24-bit value of the PR by writing the LSB first

and the MSB last.

Page 29

B6 B2B4 B0B7 B3B5 B1

1: ADDRESS COUNTER

1: LOADS OUTPUT LATCH WITH 24-BIT COUNTER VALUE

1: RESETS BORROW TOGGLE F/F

1: LOADS 24-BIT COUNTER WITH PRESET REGISTER VALUE

1: RESETS COMPARE TOGGLE F/F

1: MASTER RESET

PRESETS ALL PRESET REGISTERS TO 1

RESETS 24-BIT COUNTER

OUTPUT LATCH

OUTPUT STATUS REGISTER

ALL CONTROL REGISTERS EXCEPT MCR

00: SEE TABLE 2-1

CARRY TOGGLE F/F

SIGN REGISTER

Model 5312B Technical Reference Operation and Programming 2-3

Reading the Output Latch register (OL)

To read the OL:

1. Reset the PR and OL address counter by writing 01h to the Command Register (see below).

2. Read the three bytes that comprise the 24-bit value in the OL by reading the LSB first and the

MSB last.

Writing the Command Register (CR)

The CR is used to configure the counter for its various modes of operation. The follo wing format

is used for the command byte:

B6 B2B4 B0B7 B3B5 B1

MODE

REGISTER SELECT (TABLE 2-1)

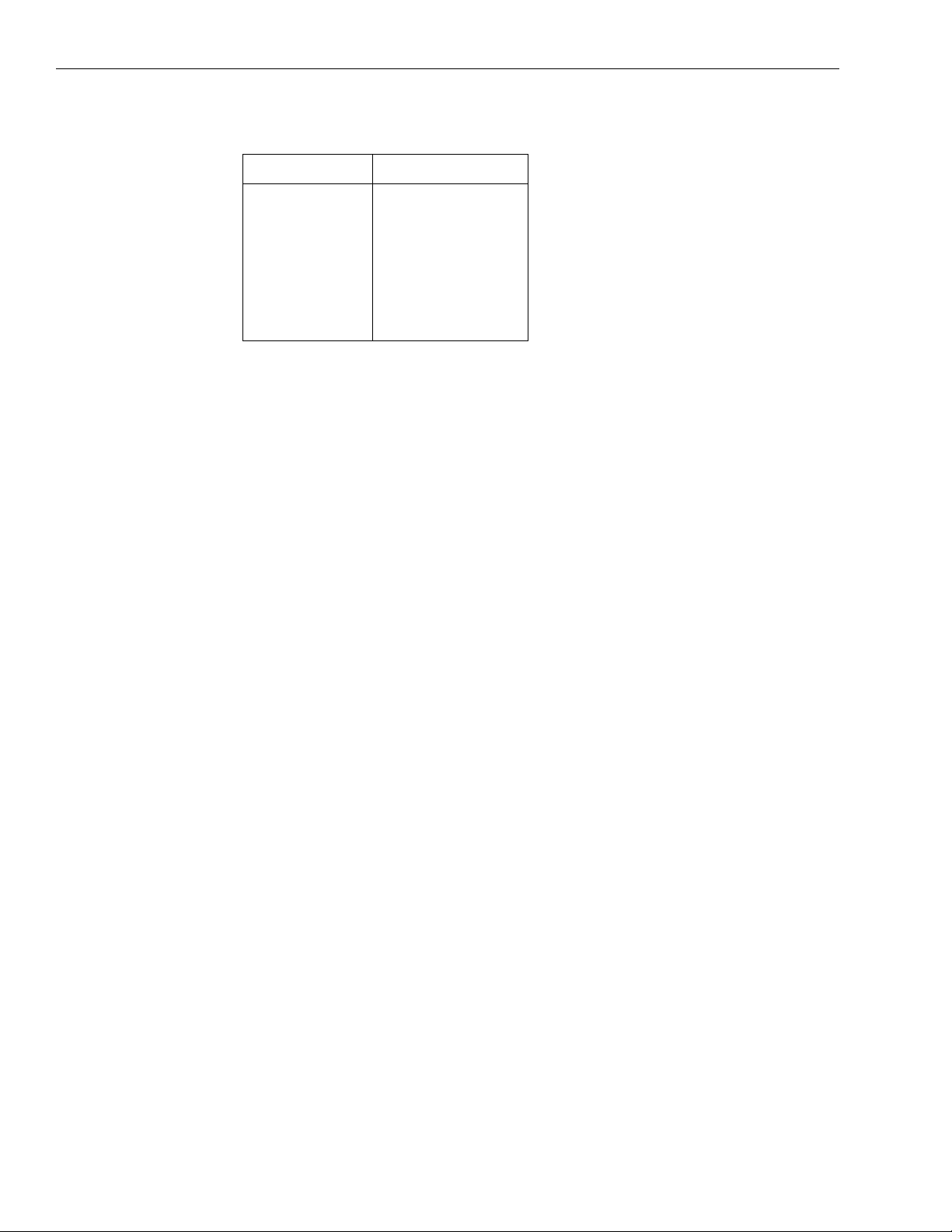

Table 2-1

Register select

B7 B6 Register

0 0

0 1

1 0

1 1

Master Control Register (MCR)

Input Control Register (ICR)

Output/Counter Control Register (OCCR)

Quadrature Register (QR)

Mode bit selection for each control register is explained below.

Master Control Register (MCR)

Page 30

2-4 Operation and Programming Model 5312B Technical Reference

When enabling a value transfer from the PR to the counter (B3), the borrow toggle, the carry

toggle, and the compare toggle flip-flops may be altered. You should read these values immediately after transfer and watch for a change in the desired status bit.

Note that a master reset overrides B1 and B3.

Input Control Register (ICR)

B6 B2B4 B0B7 B3B5 B1

0: SETS PHASE A AS UP-COUNT. PHASE B AS DOWN-COUNT

1: SETS PHASE A AS COUNT. PHASE B AS DIRECTION

1: INCREMENTS 24-BIT COUNTER

1: DECREMENTS 24-BIT COUNTER

0: DISABLES PHASE A/B

1: ENABLES PHASE A/B

0: SETS ABGT/RCTR AS COUNTER RESET INPUT

1: SETS ABGT/RCTR AS PHASE A/B ENABLE/DIABLE GATE

0: SETS LLTC/LCTR AS EXTERNAL LOAD COMMAND FOR 24-BIT COUNTER

1: SETS LLTC/LCTR AS EXTERNAL LOAD COMMAND FOR OUTPUT LATCH

01: SEE TABLE 2-1

When configured as up/down count mode (B0=0), the state of the unused input must be HIGH.

In other words, Phase A must be HIGH when Phase B is clocked LOW for input count, and

Phase B must be HIGH when Phase A is clocked LOW for input count. Both phases are HIGH

when no counts are input. It is illegal for both phases to be LOW at the same time.

In order to increment or decrement (by 1) the 24-bit counter by writing to the ICR, Phase A and

Phase B signals must be HIGH at the same time.

Output/Counter Control Register (OCCR)

B6 B2B4 B0B7 B3B5 B1

0: SETS COUNTER TO BINARY CODE

1: SETS COUNTER TO BCD CODE

1: SETS 24-BIT COUNTER TO ON-RECYLCLE MODE

1: SETS 24-BIT COUNTER TO DIVIDE-BY-n MODE

1: SETS 24-BIT COUNTER TO 24-HOUR CLOCK MODE

SEE TABLE 2-2

10: SEE TABLE 2-1

Page 31

Model 5312B Technical Reference Operation and Programming 2-5

Table 2-2

Output/counter control modes

B5 B4 Mode

0 0

Enable active LOW carry pulse, active LOW borrow on /CY

and /BW, respectively

0 1

Enable carry toggle fip-flop, borrow toggle flip-flop on /CY

and /BW, respectively

1 0

Enable active HIGH carry and borrow pulse on /CY and /BW,

respectively

1 1

Note: A forward slash (/) preceding a signal name denotes an active LOW signal.

Enable comparator output on flip-flop and pulse on /BW

On-recycle mode (B1) counts for only one cycle beginning with a counter reset or load command. It ends with the generation of a carry or a borrow. The counter is then inhibited until a

new reset or load command is issued.

In divide-by- n mode (B2), the counter is reloaded with the Preset Register value every time the

counter overflows or underflows.

The 24-hour clock mode overrides both binary and BCD modes.

Quadrature Register (QR)

B6 B2B4 B0B7 B3B5 B1

SEE TABLE 2-3

Table 2-3

Quadrature register modes

B1 B0 Mode

0 0

0 1

1 0

1 1

Disables Quadrature Mode

1x Quadrature Mode

2x Quadrature Mode

4x Quadrature Mode

DON’T CARE

11: SEE TABLE 2-1

Page 32

2-6 Operation and Programming Model 5312B Technical Reference

Output Status Register (OSR)

B6 B2B4 B0B7 B3B5 B1

BORROW TOGGLE F/F (BWT)

CARRY TOGGLE F/F (CYT)

COMPARE TOGGLE F/F (COMPT)

SIGN REGISTER

UP/DOWN INDICATOR

DON’T CARE

B0:

B1:

B2:

B3:

B4:

B5-B7: Don't care.

BWT — This flip-flop changes state when the 24-bit counter underflows.

CYT — This flip-flop changes state when the 24-bit counter overflows.

COMPT — This flip-flop changes state when the 24-bit counter matches PR bits (0-2).

Sign Register — This register bit is set when the 24-bit counter underflows indicating

that a borrow has taken place. It is cleared when the 24-bit counter overflows indicating

a carry. It is also reset whenever the 24-bit counter is reset.

Up/Down — This bit set in quadrature mode indicates that the counter is operating in

up-count mode. When clear, this bit indicates that the counter is in down-count

mode. When not in quadrature mode, this bit is always set.

T ypical programming examples

Example 1

Parameters

Steps

Quadrature mode.

Index latches count in OL.

BCD output.

1. Initialize the counter

Write the following bytes to the CR:

Byte Register Description

35h MCR Reset

68h ICR Sets the /LCTR - LLTC input to latch the 24-

81h OCCR Enables active LOW /CY and /BW and

C3h QR Enables quadrature decode mode.

bit counter value at the index and enables

Phases A and B.

sets the counter to BCD mode.

Page 33

Model 5312B Technical Reference Operation and Programming 2-7

2. Read the counter.

Write the following byte to the CR:

Byte Register Description

03h MCR Resets the PR and OL address counter and

loads the OL with the 24-bit counter value

3. Read the three bytes of data in the OL register (reading the LSB first and the

MSBlast) to obtain the 24-bit counter value.

Example 2

Parameters

Steps

Example 3

Count and direction mode.

Reset counter on index.

Binary output.

1. Initialize the counter.

Write the following bytes to the CR:

Byte Registers Description

35h MCR Reset

49h ICR Sets Phase A as count input and Phase B as

direction input, enables Phases A and B, and

sets /ABGT and /RCTR as the counter reset.

80h OCC Enables active LOW /CY /and /BW and sets

the counter to BC mode.

C0h QR Disables quadrature decode mode.

2. Read the Counter.

Write the following bytes to the CR:

Byte Register Description

03h MCR Resets the PR and OL address counter and

loads the OL with the 24-bit counter value.

3. Read the three bytes of data in the OL register (reading the LSB first and the

MSB last) to obtain the 24-bit counter value.

Parameters

Steps

Value to be loaded in counter: 654321h.

1. Reset the PR address.

Byte Register Description

01h MCR Reset PR address.

2. Write the value to the PR.

Byte Register Description

21h Data LSB

43h Data LSB + 1

65h Data MSB

3. Transfer PR to counter.

Byte Register Description

08h MCR Transfer PR to counter.

Page 34

2-8 Operation and Programming Model 5312B Technical Reference

Selecting a sample clock frequency

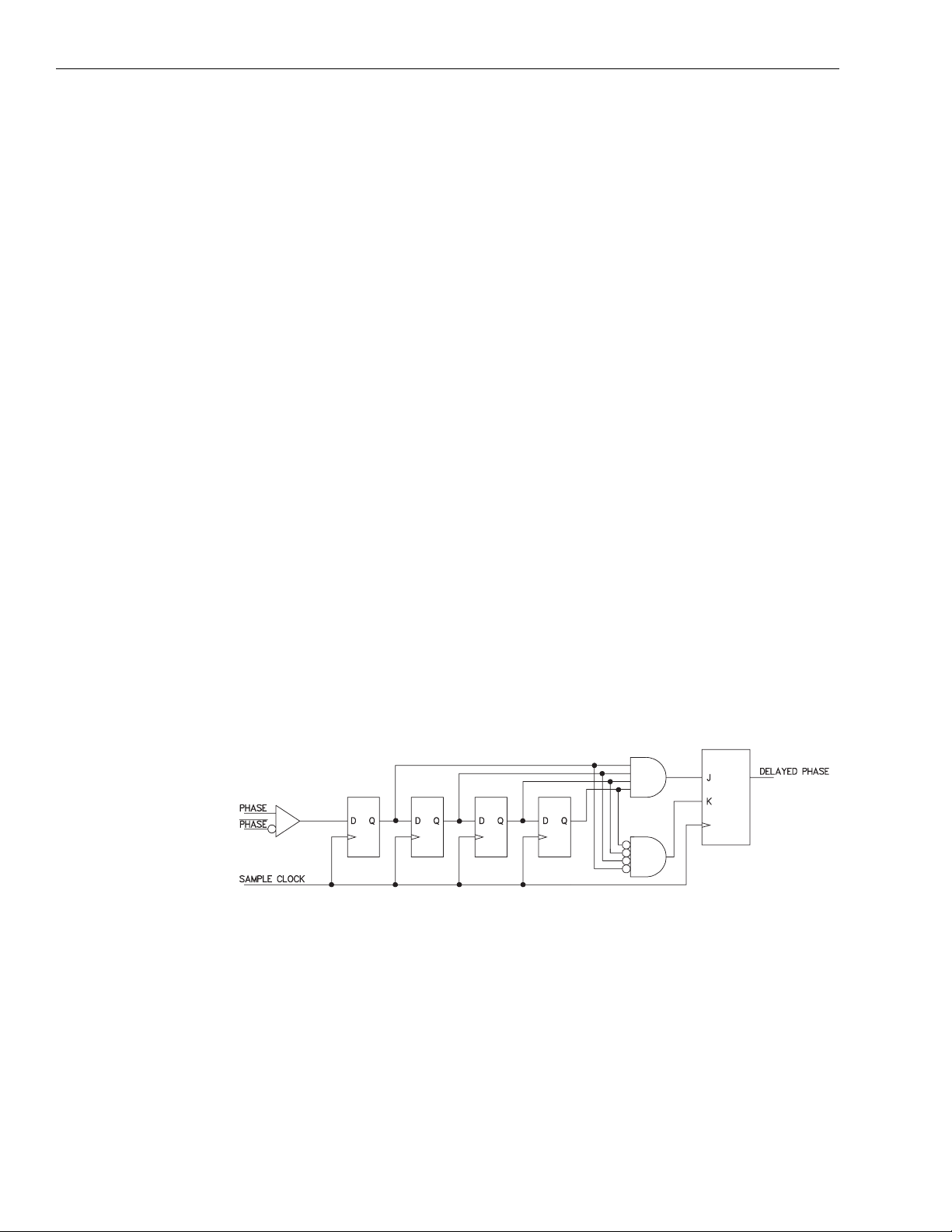

Each input line on the 5312 consists of a differential receiver pair followed by a 4-stage digital

filter. This digital filter is shown in simplified form in Figure 2-1. An input signal level must be

a valid HIGH for four sample clock cycles or a valid LOW for four sample clock cycles before

the filter output will change to the level of the input. This action prevents noise pulses of a duration shorter than (sample clock period)/4 from affecting the filter output signal.

To ensure that all valid input signals are transferred to the filter output, the sample clock period

should be approximately one eighth the width of the narrowest positive or negative input pulse.

In other words, the sample clock frequency should be eight times the input frequency assuming

a 50 percent duty cycle input signal.

One side effect of the digital filter is a 4-sample period delay from the time a signal arrives at the

input of the filter to the time it exits. For example, at the lowest sample clock frequency

(625 KHz) the filter delay is approximately 8 microseconds. At the maximum recommended

input pulse rate for this sample clock frequency, this is approximately 13 microseconds (assuming a 50 percent duty cycle). Thus, the filter delay is approximately 60 percent of the minimum

period input signal.

If delays of this length are unacceptable, a higher frequency sample clock may be used with the

loss of some noise immunity.

For example, if you select a sample clock rate of 1.25 MHz, the filter delay is approximately 4

microseconds or one third of the input signal period. However, the noise immunity of the filter is

degraded when compared with that obtained at a clock frequency of 625 KHz. When using a

clock period of 1.6 microseconds (1/0.625 MHz), intermittent noise pulses of greater than

6.4 microseconds will pass through the filter. Using a clock period of 0.8 microseconds

(1/2.5 MHz), intermittent noise pulses of greater than 3.2 microseconds will pass through the

filter.

Sample clock frequency selection is a trade-off between noise immunity and delay. For jumper

options, see Section 1.

Figure 2-1

Example of a 4-stage signal conditioning filter

Note: A side effect of using a digital filter is a 4-sample propagation delay.

Page 35

3

Interrupt Control

Page 36

3-2 Interrupt Control Model 5312B Technical Reference

Description of interrupt control

The 5312 uses an 8259A Programmable Interrupt Controller (PIC) to handle the interrupt

sources on the board, and must be programmed prior to operation. Each axis can generate two

interrupts: the first is a carry/borrow, signaling that an overflow or underflow has occurred, and

the second interrupt is caused when a valid index pulse has occurred.

The PIC may only be used in a nonvectored mode (polled). When a board-level interrupt is generated, the PIC must be polled to determine which interrupt was triggered. The PIC may be disabled by removing jumper W8.

Only the features of the 8259A PIC that are used by 5312 are discussed below. For complete

information on the 8259A PIC refer to the Peripheral Components Manual or the Microsystem

Components Handbook, Vol 1, published by Intel.

Figure 3-1 shows a functional block diagram of the 8259A PIC. On the 5312, the PIC is connected directly to the PC bus through jumper W14.

Figure 3-1

PIC block level diagram

INTA INT

CONTROL LOGIC

D7-D0

WR

AO

CAS0

CAS1

CAS2

SP/EN

RD

CS

DATA BUS

BUFFER

READ/WRITE

LOGIC

CASCADE BUFFER/

COMPARITOR

IN

SERVICE

REGISTER

(ISR)

INTERRUPT MASK REGISTER (1MR)

INTERNAL BUS

PRIORITY

RESOLVER

The 5312 uses an Intel 8259A and is directly connected to the PC bus through jumper W14.

Interrupt Request Rgtr (IRR), In-Service Rgtr (ISR)

The interrupts at the interrupt request input lines (IR0-IR5) are handled by the IRR and the ISR.

The IRR is used to store the interrupts requesting service, and the ISR is used to store the interrupts being serviced. Interrupts and IRR/ISR bits correspond to the format below.

Interrupt Request Register

INTERRUPT

REQUEST

REGISTER

(1RR)

AXIS A EOM

AXIS A EXT

AXIS B EOM

AXIS B EXT

AXIS C EOM

AXIS C EXT

NOT

NOT

IR6 IR2IR4 IR0IR7

IR3IR5 IR1

AXIS 1 CARRY/BORROW

AXIS 2 CARRY/BORROW

AXIS 3 CARRY/BORROW

AXIS 4 CARRY/BORROW

AXIS 1 INDEX

AXIS 2 INDEX

AXIS 3 INDEX

AXIS 4 INDEX

Page 37

D6 D2D4

Operating Mode

D0D7 D3D5 D1

INTERRUPT CODE

(SEE TABLE 3-1)

1: INTERRUPT HAS OCCOURED

Model 5312B Technical Reference Interrupt Control 3-3

Priority Resolver (PR)

The Priority Resolver (PR) block determines the priority of the bits set in the IRR. The highest

priority bit is selected and strobed into the corresponding ISR bit at the time of the poll

command.

Interrupt Mask Register (IMR)

The Interrupt Mask Register stores the bits that determine the interrupt lines to be masked. The

IMR operates on the IRR. Masking a higher priority input will not affect the interrupt request

lines of lower priority. Masking disables the interrupt for the masked input.

Interrupt output (INT)

The Interrupt Output (INT) signal indicates that the PIC has an interrupt request pending. This

signal can be routed to PC bus interrupt IRQ2 through IRQ7 (IRQ2 default) via W8. The poll

command causes interrupt status to be placed on the bus during the next read of the PIC.

PIC operation

Interrupt sequence, 80

x

86/80

The sequence of events during an interrupt when using an 80 x 86/80 x 88 CPU is as follows:

1. One or more of the interrupt request lines (IR0-IR7) are raised high setting the corresponding

IRR bit(s).

2. The PIC evaluates these requests and sends an interrupt request to the CPU provided that

jumper W8 is installed.

3. The interrupt is acknowledged by your program interrupt service routine by writing a poll

command (OCW3) to the PIC.

4. The CPU reads the PIC to obtain the priority level as shown below. After the read, the high

ISR bit is set, and the corresponding IRR bit is reset.

x

88 mode

Page 38

3-4 Interrupt Control Model 5312B Technical Reference

Table 3-1

Interrupt code

D2 D1 D0 Interrupt Request

0 0 0

0 0 1

0 1 0

0 1 1

1 0 0

1 0 1

1 1 0

1 1 1

The interrupt code returns the highest priority interrupt and sets the corresponding ISR bit.

5. The previous step completes the interrupt cycle. In the Automatic End-Of-Interrupt (AEOI)

mode, the ISR bit is reset on the read following the poll command. Otherwise, the ISR bit

remains set until an appropriate End-Of-Interrupt (EOI) command is issued.

IRQ0

IRQ1

IRQ2

IRQ3

IRQ4

IRQ5

IRQ6

IRQ7

End-of-interrupt command

Completing an interrupt

Operating modes

NOTE

After the priority level is read, the ISR bit must be reset. This is done with EOI command from

the host PC, or it can be done automatically in the AEOI mode. There are two forms of the EOI

command — Specific and Non-Specific. A Non-Specific EOI command resets the highest ISR

bit of those that were set, and a Specific EOI command can be issued to reset a specified ISR bit.

You have to provide an interrupt routine to trap IR7 interrupt glitches that appear as interrupt 7

requests. In the AEOI mode, the ISR bit for the interrupt being serviced is reset automatically at

the interrupt return in your interrupt routine.

If no IR lines are HIGH at step 4 of the sequence (i.e., the IR line went

HIGH to generate an interrupt request but then went away before it

was acknowledge), the PIC will issue an interrupt level 7. This causes

the call address or the vector byte to look as if IR7 generated an interrupt request. This is useful in determining whether an actual interrupt

request occurred or a noise spike tripped the request line.

Fully nested mode

This is the default mode entered after initialization unless another mode is programmed. In this

mode, interrupt requests are ordered in priority from 0 through 7 with 0 being the highest priority.

When a poll command is received and the priority level is read, the highest priority request is

placed on the data bus. The corresponding bit in the ISR is also set. It stays set until the CPU

issues an EOI command, or, if in AEOI mode, until the priority level is read. While the ISR bit is

set, all further interrupts of equal or lower priority are inhibited. Interrupts of higher priority will

issue an interrupt request (which will be acknowledged only if the PC has unmasked the interrupt).

Page 39

Model 5312B Technical Reference Interrupt Control 3-5

Special mask mode

This mode is similar to the fully nested mode except that when a bit in the ISR is set, it only

inhibits interrupt requests at that level. All other unmasked interrupt requests (lower as well as

higher) are enabled.

Specific rotation (specific priority)

The default priority of interrupts is IR0 (highest) through IR7 (lowest). This can be changed

using the set priority command. This command specifies one input as having the lowest priority

and fixing all other priorities. For example, if IR2 is specified as having the lowest priority, the

priority of interrupts will be: IR3 (highest), IR4, IR5, IR6, IR7, IR0, IR1, IR2 (lowest).

Automatic rotation (equal priority)

In this mode, a device, after being serviced, receives the lowest priority. Such a device requesting an interrupt would have to wait until all other devices have been serviced.

Non-vectored mode (poll command)

PIC programming

Initialization Command W ords (ICW)

The PIC must be polled for interrupt status. To do this, the poll command is written to the PIC,

and then the status is read. The PIC treats the read pulse as an INTA pulse. The interrupt is frozen from the write to the read.

The PIC accepts two types of command words from the CPU: Initialization Command Words

(ICW) and Operational Command Words (OCW).

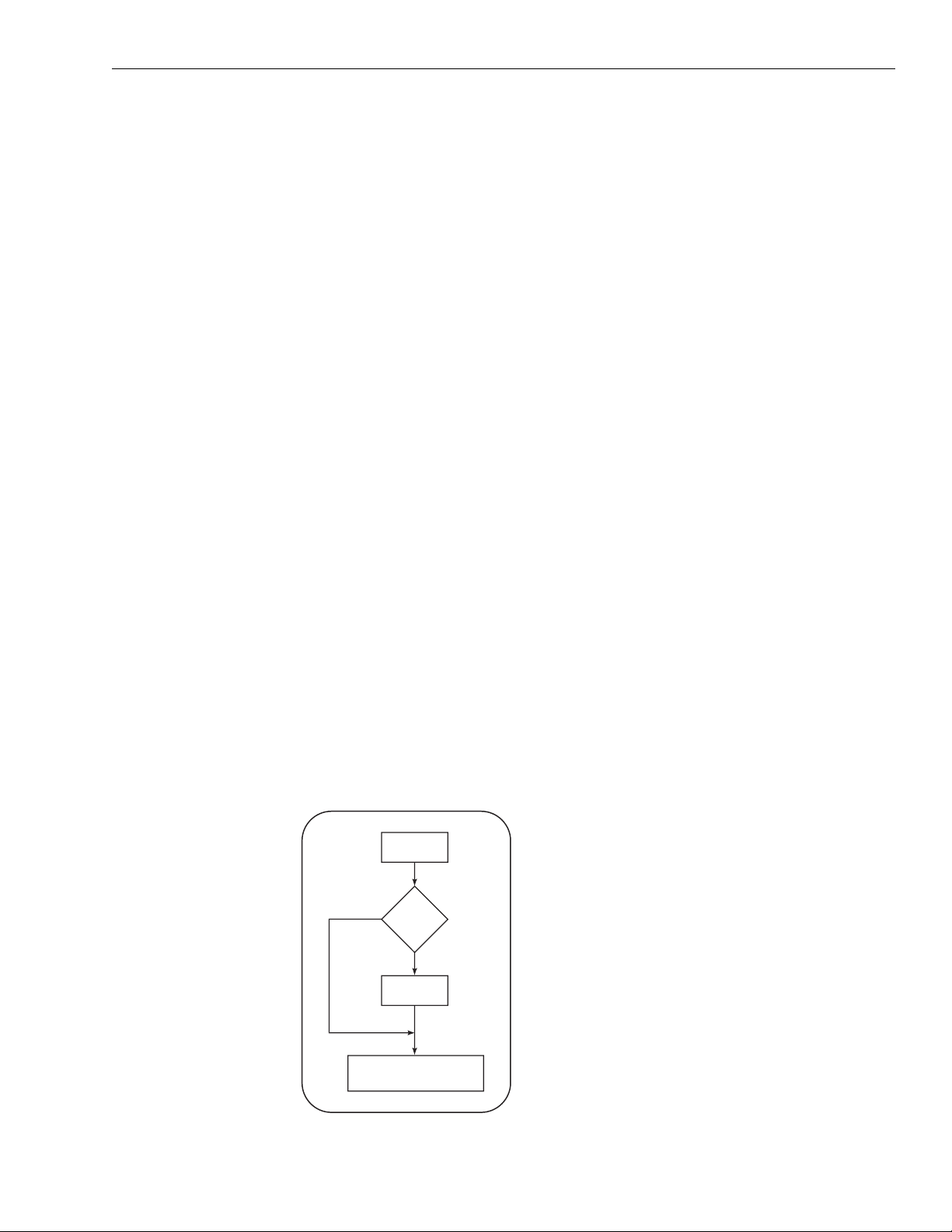

Figure 3-2

PIC initialization sequence

ICW1

NO

(CIC4-0)

NEED

ICW4

YES

(CIC4-1)

ICW1

READY TO ACCEPT

INTERRUPT REQUESTS

Note: Bit D4 set assumes the next word issued will be ICW4.

Page 40

3-6 Interrupt Control Model 5312B Technical Reference

Before normal operation can begin, the PIC must be brought to a starting point by a sequence of

three bytes. Figure 3-2 shows the initialization sequence. Whene v er a command is written to the

PIC low port with bit D4 = 1, it is interpreted as ICW1. Register ICW1 starts the initialization

sequence during which the following automatically occur:

1. The IMR is cleared.

2. IR7 is assigned the lowest priority.

3. The slave mode address is set to 7.

4. Special Mask Mode is cleared.

5. Status Read is set to IRR.

6. If IC4 = 0, then all functions selected in ICW4 are set.

ICW2 is not used by the 5312. However, a value must be written to it to properly initialize the

PIC. Any value may be written since the value will have no effect on PIC operation.

ICW3 is not used by the 5312.

Writing to the ICW4 completes the initialization sequence.

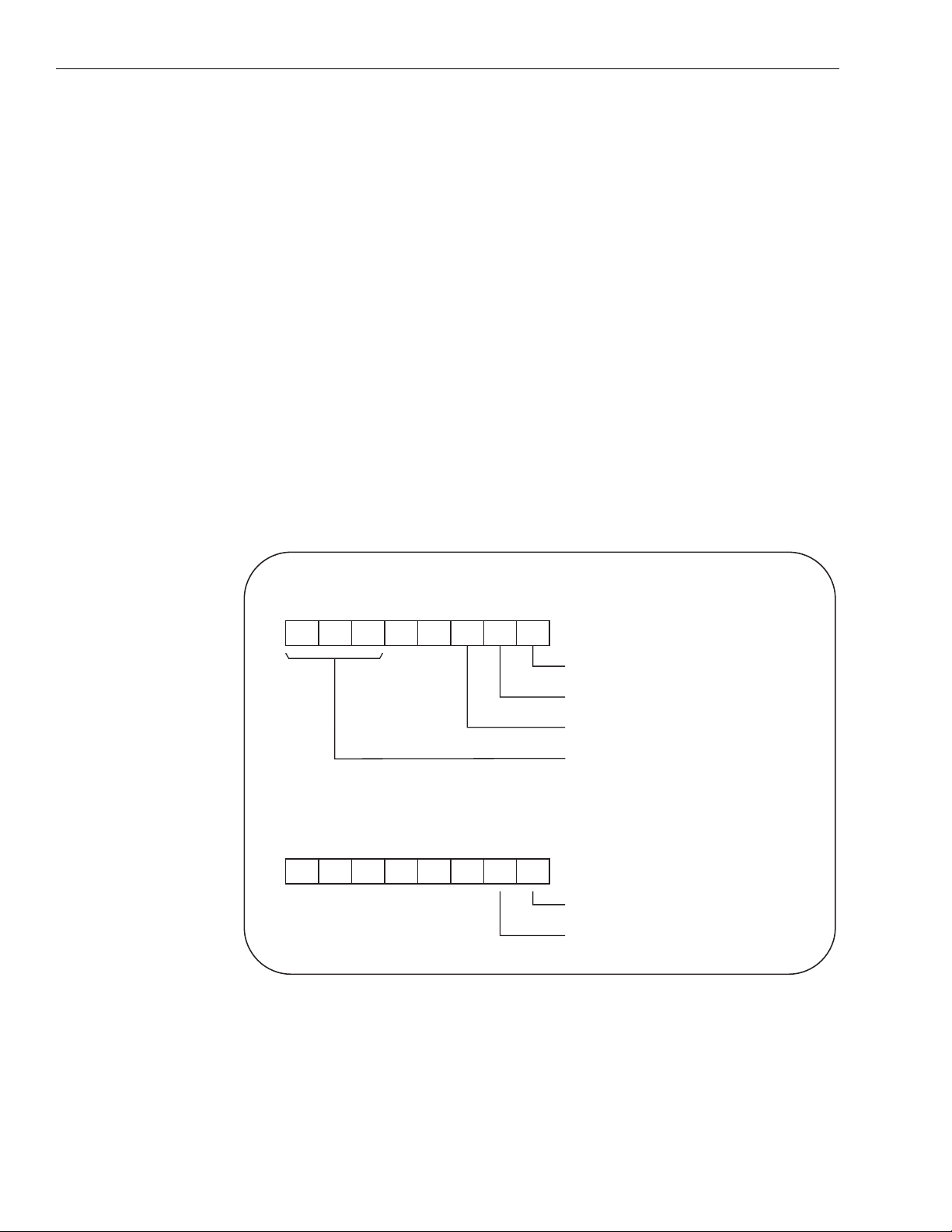

ICW1 format and description

Figure 3-3

PIC ICW format

ICWI

ICWI

(WRITTEN TO THE PIC LOW PORT)

D6

D7

A7

D7

0

D5

A6

A5

(WRITTEN TO THE PIC HIGH PORT)

D6

D5

0

0

D4

I

D4

0

D3

D3

D2

0

ADI

D2

0

0

D1

SGL

D1

AE0I

D0

IC4

D0

UPM

I : ICW4 NEEDED

0 : ICW4 NOT NEEDED

I : SINGLE

0 : CASCADE MODE

I : CALL ADDRESS INTERVAL 4

0 : CALL ADDRESS INTERVAL 8

I : A7-A5 OF INTERRUPT VECTOR

0 : ADDRESS (8080/8085 MODE ONLY)

I : I8086/8088 MODE

0 : 8080/8085 MODE

I : AUTO E0I

0 : NORMAL E0I

Note: Write ICW1 to the PIC low port and ICW4 to the PIC high port depending on how you initialize.

Figure 3-3 shows the format for ICW1 and ICW4. Set the bits for the 5312 to the PIC low port in

the following manner:

D5-D7 (A7-A5): May be set or cleared. This bit has no impact on the operation of the 5312.

D2 (ADI): May be set or cleared. This bit has no impact on the operation of the 5312.

D1 (SNGL): Set this bit.

Page 41

Model 5312B Technical Reference Interrupt Control 3-7