Page 1

Page 2

WARRANTY

Keithley Instruments, Inc. warrants this product to be free from defects in material and workmanship for a period of 1 year

from date of shipment.

Keithley Instruments, Inc. warrants the following items for 90 days from the date of shipment: probes, cables, rechargeable

batteries, diskettes, and documentation.

During the warranty period, we will, at our option, either repair or replace any product that prows to be defective,

To exercise this wammty, write or call your local Keithley representative, or contact Keithley headquarters in Cleveland, Ohio.

You will be given prompt assistance and return instructions. Send the product, transportation prepaid, to the indicated service

facility. Repairs will be made and the product returned, transportation prepaid. Repaired or replaced products are warranted for

the balance of the original warranty period, OT at least 90 days.

LIMITATION OF WARRANTY

This warranty does not apply to defects resulting from product modification without Keithley’s express written consent, or

misuse of any product or part. This warranty also does not apply to fuses, software, non-rechargeable batteries, damage from

battery leakage, 01 problems arising from normal we.a~ or failure to follow instructions.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING ANY

IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR USE. THE REMEDIES PROVIDED HEREIN ARE BUYER’S SOLE AND EXCLUSIVE REMEDIES.

NEITHER KBITHLEY INSTRUMENTS, INC. NOR ANY OF ITS EMPLOYEES SHALL BE LIABLE FOR ANY DIRECT,

INDIRECT, SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES ARISING OUT OF THE USE OF ITS

INSTRUMENTS AND SOFTWARE EVEN IF KEITHLEY INSTRUMENTS, INC., HAS BEEN ADVISED IN ADVANCE

OF THE POSSIBILITY OF SUCH DAMAGES. SUCH EXCLUDED DAMAGES SHALL INCLUDE, BUT ARE NOT LIMITED TO: COSTS OF REMOVAL AND INSTALLATION, LOSSES SUSTAINED AS THE RESULT OF INJURY TO ANY

PERSON, OR DAMAGE TO PROPERTY.

Keithley Instruments, Inc. - 28775 Aurora R

Page 3

Model 486 Picoammeter

Model 487 Picoammeter/Vokage Source

Instruction Manual

01990, Keithley Instruments, Inc.

All rights reserved.

Cleveland, Ohio, U.S.A.

Fourth Printing, August 2000

Document Number: 486-901-01 Rev. D

Page 4

Manual Print History

The print history shown below lists the printing dates of all Revisions and Addenda created for this manual. The

Revision Level letter increases alphabetically as the manual undergoes subsequent updates. Addenda, which are

released between Revisions, contain important change information that the user should incorporate immediately into

the manual. Addenda are numbered sequentially. When a new Revision is created, all Addenda associated with the

previous Revision of the manual arc incorporated into the new Revision of the manual. Each new Revision includes

a revised copy of this print history page.

Revision C (Document Number 486-901-01)

Revision D (Document Number 486-901-01).

............................................. December

................................................. August 2000

1991

Page 5

BESCHEJNIGUNG DES HERSTELLERS/IMl’ORTEURS

Hiermitwirdbescheinigt,(daS)/dasMODEL 486 PICOAMMETER AND MODEL 487 PICOAMMETER/

VOLTAGE SOURCEinUbereinstimmungmitdenBestimmungenderVfg1046/1984funksntstortist.DerDeuk~en

Bundespost

Eiihmg der Bestimmungen eingeraumt.

Die Einhaltung der betreffenden Bestimmungen setzt vordus, dag, (da& geschirmte Mt$leitungen venvendet werden.

Fur die Beschaffung richtiger Me~leitungen ist der Betreiber verantwortlich.

DIESES GERAET WURDE SOWOHL ElNZELN ALS AUCH IN ElNERANLAGE, DIE EINEN NORMALW

ANWENDUNGSFALL NACHBILDET, AUF DIE EINHALTUNG DER FEN

GEPRUEFT. EST IS JEDOCH MOEGLICH, DASS DIE

UNGUENSTIGEN UMSTAENDEN BEI ANDEREN G ERAETEKOMBJNATIONEN NIGHT EINGEHALTEN

WERDEN. FUER DIE EINHALTIJNG DER FUNK-ENTSTOERBE GEN SEINER GESAMTEN ANLAGE,

IN DER DlESES GERAET BETRIEBEN WlRD, IST DER B?ZlXEZBER VERANTWORTLICH.

wurde

das Inverkehrbringen dieses Gerates angezeigt und die Berechtigmg ZUI Uberprufmg der Serie auf

FUNK-ENTSTOEXB -GEN IJNTFX

Keithley Instruments, Incorporated

CERTIFICATE BY MANUFACTURER/TMPORTER

ThisistocertlfythattheheMODEL

SOURCE isshielded againstadiointerferenceinaccordancewiththeprovisions ofVfglO46/1984. TheGermanPostal

Services have been advised that this device is being put on the market and that they have been given the right to inspect

the series for compliance with the regulations.

Compliance with applicable regulations depends on the use of shielded cables. It is the user who is responsible for prycuring the appropriate cables.

THIS EQUlFMENT HAS BEEN TFSTED CONCERNING COMPLIANCE WITH THE RELFVANT RFl PROTECTION REQUIREMENTS BOTH lNDMDUALLY AND ON SYSTEM LEVEL (TO

TION CONDlTIONS). HOWEVER, IT IS POSSIBLE THAT THESE RFI RBQCERTAIN UNFAV0RABL.E CONDlTIONS IN OTHER INSTALLATIONS. lT IS THE USER WHO IS RESPONSIBLE FOR COMX’LIAN

CE OF HIS PARTICULAR INSTALLATION.

SIMULATE NORMAL OPERA-

ARENOTMETUNJXR

Keithley Instruments, Incorporated

Page 6

Page 7

Safety Precautions

The following safety precautions should be observed before using

this product and soy associated instrumentation. Although some inmument~ and accessories would normally be used with non-hazardous voltages, there are situations where hazardous conditions

may he present.

This product is intended for use by qualified personnel who recognize shock hazards and am familiar with the safety precautions mquired to avoid possible injury. Read the operating information

carefully before using the product.

The types of product users are

Responsible body is the individual or group responsible for the use

and maintenance of equipment, for ensuring that the equipment is

operated within its specifications and operating limits, and for ensuring that operators are adequately trained.

Operators use the product for its intended function. They most be

trained in electrical safety procedures and proper use of the instmment. They most be protected from electric shock and contact with

hazardous live circuits.

Maintenance personnel perform routine procedures on the product

to keep it operating, for example, setting the line voltage or replacing consumable materials. Maintenance procedures are described in

the manual. The procedures explicitly state if the operator may perform them. Otherwise, they should be performed only by service

persomlel.

Service personnel are trained to work on live circuits, and perform

safe installations and repairs of products. Only properly trained service personnel may perform installation and service procedures.

Users of this product most be protected from electric shock at all

times. The responsible body must ensure that users are prevented

access and/or insulated from every connection point. Io some cases,

connections must be exposed to potential human contact. Product

users in these circumstances most be trained to protect themselves

from the risk of electric shock. If the circuit is capable of operating

at or above 1000 volts, no conductive part of the circuit may be

exposed.

As described in the International Electrotcchnical Commission

(IEC) Standard IEC 664, digital multimeter measuring circuits

(e.g., Keitbley Models I75A. 199, 2000,2001,2W2, and 2010) are

Installation Category II. All other instruments signal terminals are

Installation Category I and most not be connected to mains.

Do not connect switching cards directly to unlimited power circuits.

They are intended to be used with impedance limited sources.

NEVER connect switching cards directly to AC mains. When connecting sources to switching cards, install protective devices to lim-

it fault cwrent and voltage to the card.

Before operating an instrument, make sore the line cord is connectcd to a properly grounded power receptacle. Inspect the connecting

cables, test leads, and jumpers for possible wear, cracks, or breaks

before each we.

For maximom safety, do not touch the product, test cables, or any

other instruments while power is applied to tic circuit under test.

ALWAYS remove power from the entire test system and discharge

any capacitors before: connecting or disconnecting cables or jompen, installing or removing switching cards, or making internal

changes, such as installing or removing jumpers.

Exercise extreme caution when a shock hazard is present. Lethal

voltage may he present an cable connector jacks or test fixtures. The

American National Standards Institote (ANSI) states that a shock

hazard exists when voltage levels greater than 3OV RMS, 42.4V

peak, or 60VDC are present. A good safety practice is to expect

that hazardous voltage is present in any unknown circuit before

measuring.

Do not touch any object that could provide a cormot path to the

common side of the circuit under test or power line (earth) ground.

Always make measurements with dry hands while standing on a

dry, insulated surface capable of withstanding the voltage being

measured.

Page 8

The instrument and accessories must be used in accordance with its

specifications and operating instructions or the safety of the equip-

ment may be impaired.

The WARNING heading in a manual explains dangers that might

result in personal injury or death. Always read the associated information very carefully before performing the indicated procedure.

Do not exceed the maximum signal levels of the instruments and accessories, as defined in the specifications and operating infonna-

don, and es shown on the instrument or test fixture panels, or

switching card.

When fuses are used in a product, replace with same type and rating

for continued protection against tire hazard.

Chassis connections must only be used as shield connections for

measuring circuits, NOT as safety earth ground connections.

If you are using a test fixture, keep the lid closed while power is applied to the device under test. Safe operation requires the use of a

lid interlock.

Ifa@ screw is present, connect it to safety earth ground using the

wire recommended in the user documentation.

Then

fer to the operating instructions located in the manual.

-Ibe A

sure 1000 volts or more, including the combined effect of normal

and common mode voltages. Use standard safety precautions to

avoid personal contact with these voltages.

symbol on an instmment indicates that the user should E-

symbol on an instrument shows that it can source or mea-

The CAUTION heading in a manual explains hazards that could

damage the instrument. Such damage may invalidate the warranty.

Instrumentation and accessories shall not be connected to humans.

Before performing any maintenance, disconnect the line cord and

all test cables.

To maintain protection from electric shock end tire, replacement

components in mains circuits, including the power transformer, test

leads, and input jacks, must be purchased from Keithley Instnmenu. Standard fuses, with applicable national safety approvals,

may be used if the rating and type are the same. Other components

that are not safety related may be purchased from other suppliers as

long as they are equivalent to the original component. (Note that se-

lected parts should be purchased only through Keithley Insrmments

to maintain accuracy and functionality of the product.) If you are

unsure about the applicability of a replacement component, call a

Keithley Instruments office for information.

To clean an instrument, use a damp cloth or mild, water based

cleaner. Clean the exterior of the instmment only. Do not apply

cleaner directly to the instrument or allow liquids to enter or spill

on the instrument. Products that consist of a circuit board with no

case or chassis (e.g., data acquisition board for installation into a

computer) should never require cleaning if handled according to instructions. If the board becomes contaminated and operation is affected, the board should he returned to the factmy for proper

cleaning/servicing.

Rev. IO/99

Page 9

SAFETY WARNINGS

hstmnentation and accessories should not be connected

to humans.

The following prec.~tions should be observed before using Model 4&X/487. Refer to main manual for detailed

safety information and complete operating instructions.

The Model 486/487 is intended for use by qualified personnel who recognize shock hazards snd are familiar

with the safety precautions required to avoid possible injury. Read over the instruction manual carefully before

using the ins+nunent.

Before operating the instrument, make sore the line cord

is connected to a properly grounded power receptacle.

Exercise extreme caution when a shock hazard is present.

Lethal voltages may be present on the test fixture or the

Model 487 output jacks. The American National Standards Institute WNSI) states that a shock hazard exists

when voltage levels greater than 30V RMS or 424V peak

are present. A good safety practice is to expect that hazardo~voltageispresentinany~o~cirmitbefore

measuriug.

Inspect the connecting cables, test leads, and jumpers for

possible wear, cracks, or breaks before each use.

Maintenance should only be performed by qualified

service personnel. Before performing any maintenance,

disconnect the line cord and all test cables from the instrument.

CONTROL SUMMARY

DISPLAY INTENSl7Y: Selects normal/dim/off display.

LOCAL: Places unit in local and restores front panel key

opergion.

MENU: Use with the knob or cursor keys to configure the

following menu items; data store, data recall, I-limit

(Model487), integration, IEEE-488 bus Coos or talk-only),

defaults, self&t, debug, calibrate, and V-Source calibrate

(Model 487 only).

SHIFT EXIT:

ZERO CHECK Allows check of offsets, and must be disabled to obtain an input signal measurement.

SHIFT CORRECT: Performs automatic zero correction to

null insment offsets.

FILTER: Enables or disables the selected filter(s).

&ik MENLJ or trigger SETUP.

Formadmumsafety,donot touchtheModel487connections, teat fixture, test cables or connections to any other

instruments while power is applied to the circuit under

test. Turn off all power and discharge all capacitors before connecting or disconnecdng cables or jumpas. Also,

keep the test fixture lid dosed while power is applied to

the device under test. Safe operation requires the use of

the lid interlock.

Do not touch any object which could provide a current

path to the common side of the &cuit under test or

power line (earth) ground.

Do not exceed the maximum signal levels of the in&ument, as shown on the rear panel and as defined in the

specifications and operation section of the instnxtion

manual.

Connect the - screw of the test fixture to safety earth

ground using #I8 AWG or larger wire.

0

SHIFTFILTER SELECT: Use with knob or cursor to select

the f&r(s); digital, analog, or digital + analog.

REL Use to establish a baseline using the displayedreading.

V RANGE A: Use range keys to select a lower or higher

current range.

SHm AUTO RANGE: Use to enable/disable autorange.

SETLIP: Use with knob or cursor keys to con@ure the fol-

lowingtriggersetupitems;triggermode,triggerinterval,

trigger delay, and bigger source.

OPERATE: Places V-Source of Model 487 in operate or

standby.

TRIGGEE Press to trigger a reading or start the data

store.

PRESET: Toggles between two preset V-Source values

(Model 487 only).

SHIFT OHMS cV/Ij: Press to select V/I Ohms.

Page 10

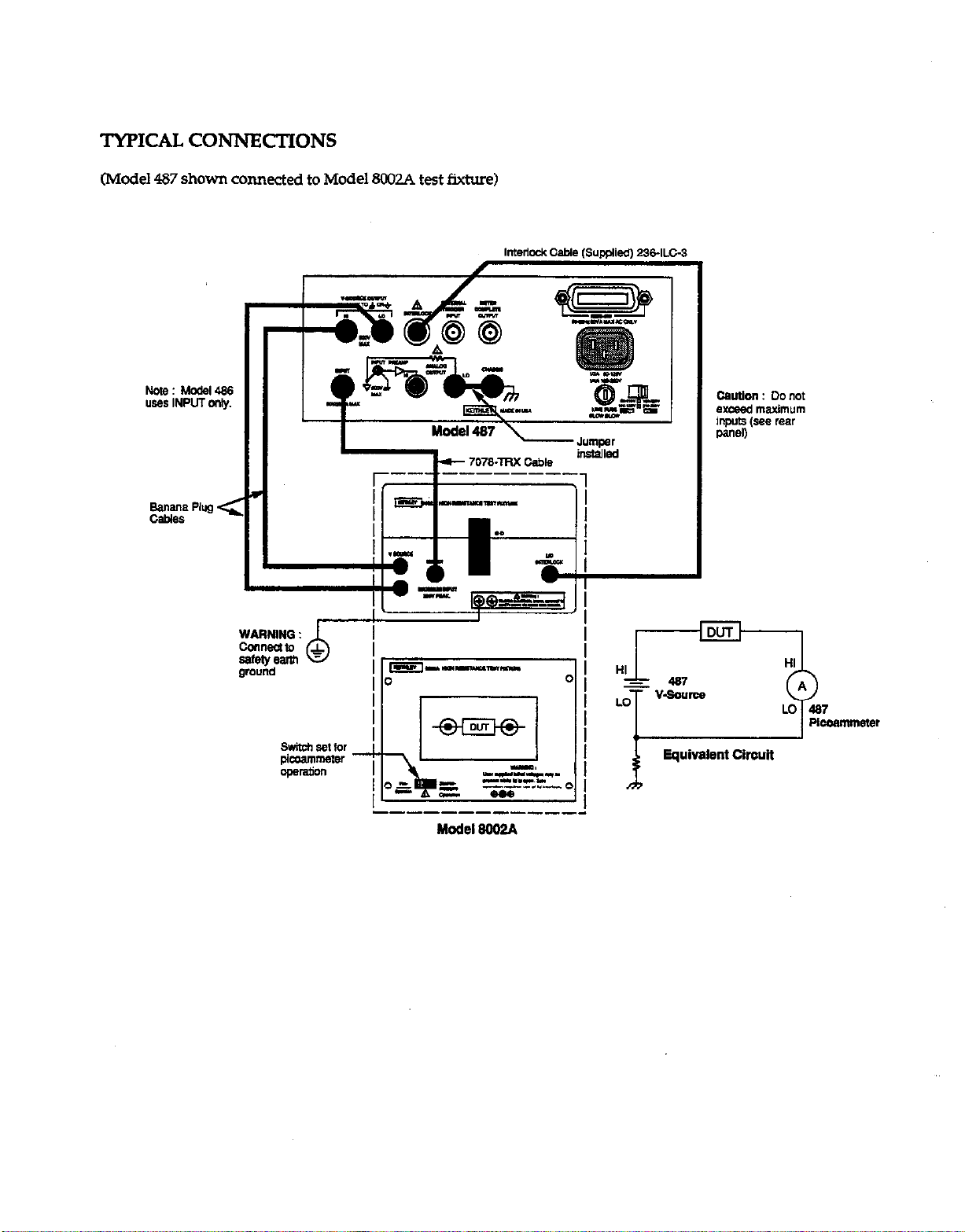

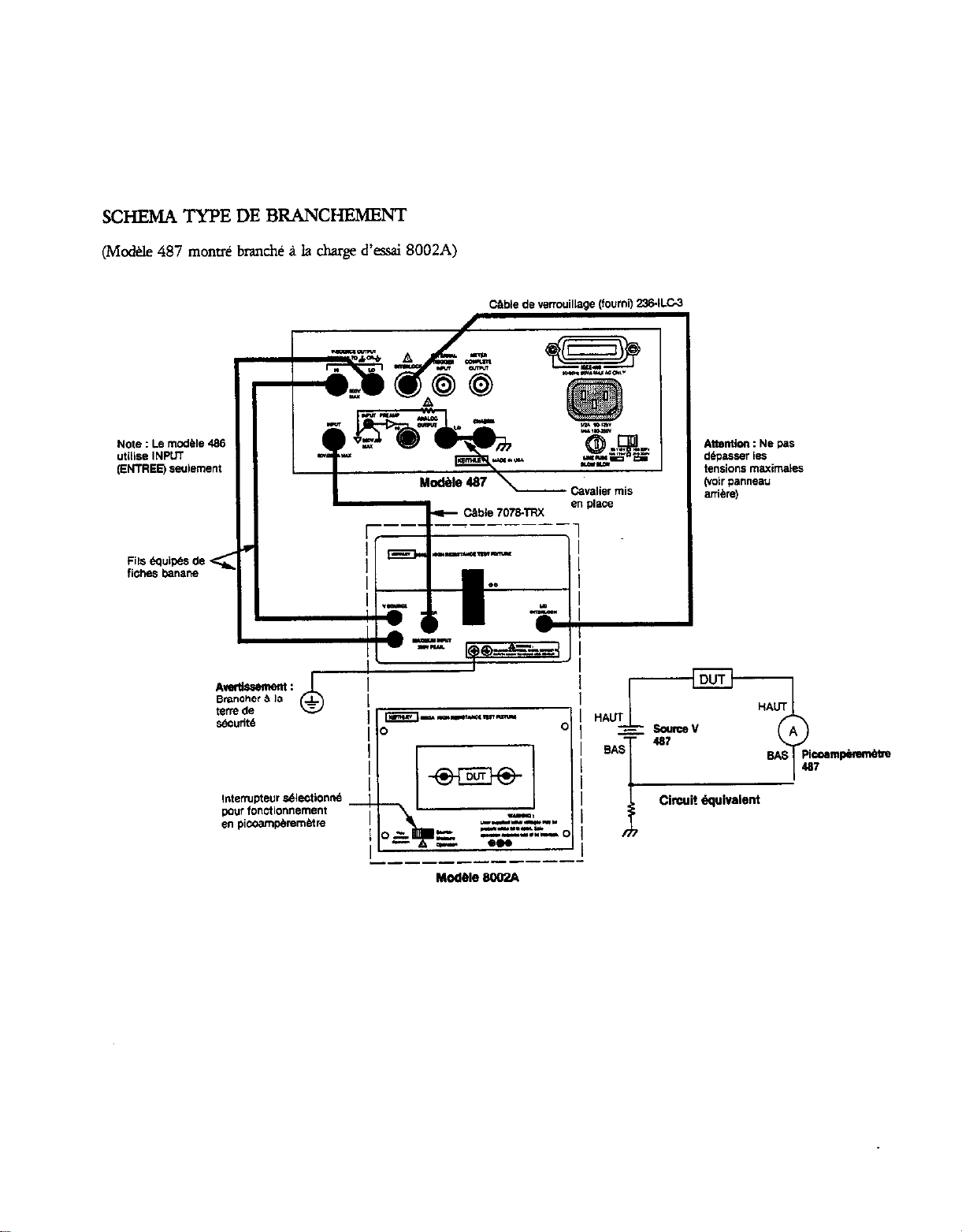

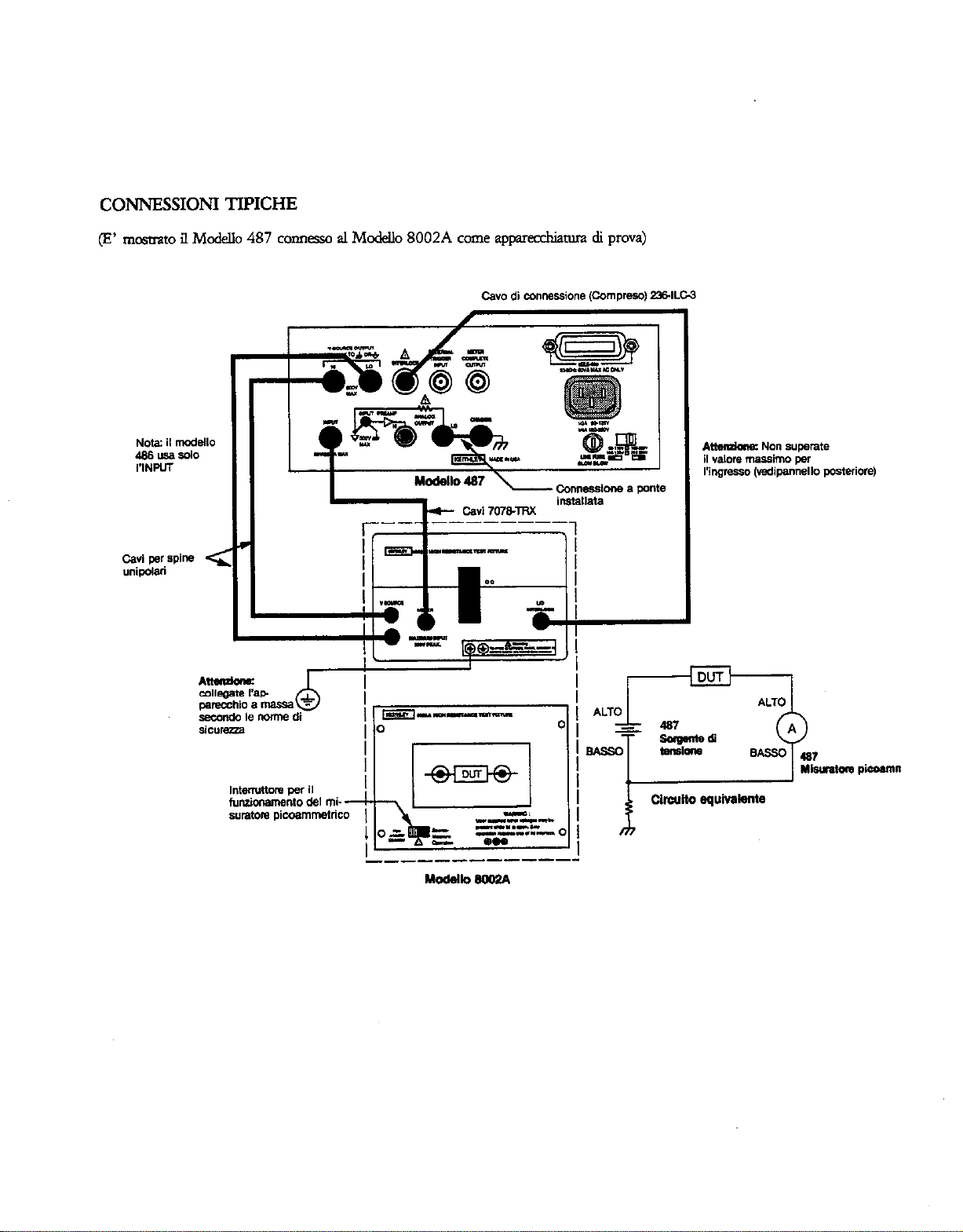

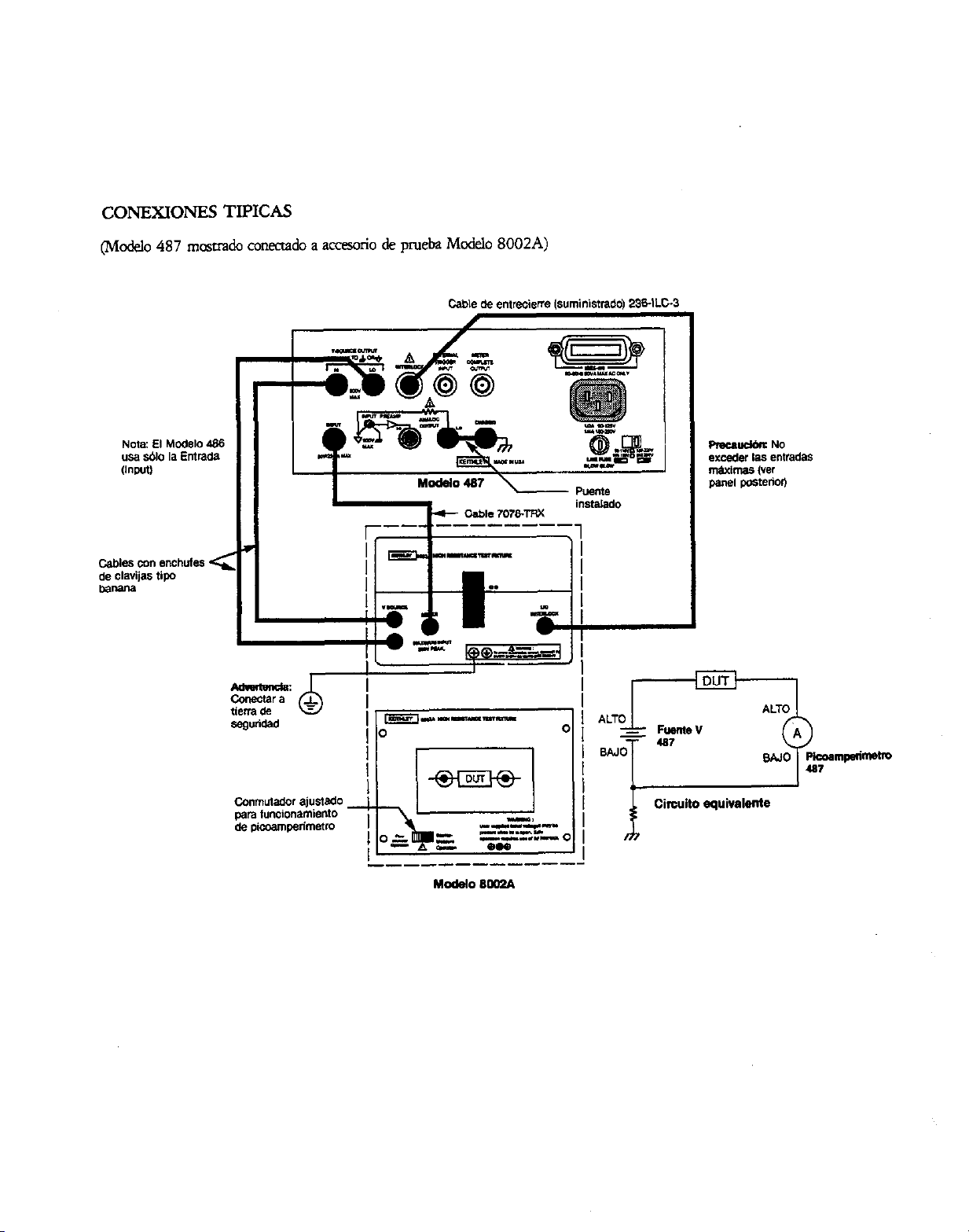

TYPICAL CONNECTIONS

(Model 487 shown connected to Model 8CKQA test fixture)

Model 8002A

TL

- 487

“-so”rcw

LO

T

Equivalent circuit

i

HI

A

LO 487

Plcoammeter

0

Page 11

CONSIGhTS DE SECURITF!

RESUME DES COMMANDES

n faut prendre les pr&autions suivames avant d’wiliw les me

d&les 4861487. Veuilk vow reporter au manuel principal qui

comiem tous les remeignemenu sur les consigns de skcuritt

ainsi qw les clirectiva d’utilisation.

LE mod&s 4861487 soot destiks a des spkialistes cotxcients

des dangers de secow &cuique et co-t les mesur-es de

prkntion g prendre pour eviter tout risque de blesnuex. Veuilez lire attentivemeot ce manxl avant d’utiliser l’insmtment.

V&&z., avant d’utiliser I’instmment, que le cordon soit branchC

SW une prise convenablement reli& B la term.

Redoublez de pr&autions lorsqu’il existe tm risque de secow

&cttique. Des tenkn.5 moxtelks risqueot d’&.e pksentes au

n&au du circuit d’essais ou des j&s de sortie du mcckle 487.

selon l’instintt amticain des normes (ANSI), il e&e ml risque

de secousse &cuique lorsque le nivem de la tension d+asse 30 V

efficaces ou 42,4 VC de tension c&e. If esf toujours prudent

de consid&r.er qu’une tension dangerewe est prknte dam

tout circuit incomm avant dkffectua une mesure.

Examinez l’itat da cslbles de cotmexion, des fils d’& et des

cavaliers pour s’asurer qu’ils ne prksentent ni &g&B d’usure, ni

aaqlxlures, ni fissures want chaqlle essai.

Pour un maximum de s&m-it& ne touchez pas les fik du mod&

487,

le circuit de mesure, les &les d’essais, ni les braochemenn

a attam mm inmument lotxque le circuit en mm-s d’essai est

at.5 tension. Coupe2 l’alimentation en comam et d&barge2 tous

les con~teun avant de braocher ou de &brancber d-es c5ble-s.

ll faut +akment veiller A ce que le couvercle du circuit de mesure

d’mais mte fermi pendant que l’appareil en cow-s d’essai est

sous tension. Le vermuillage du couvercle et nkssaire pour tm

foIutiomlemem en tome skmi~.

Ne touchez aucun objet susceptible de fomnir tm chemin conductem vers le c&k commun du tit en cows d’essai ou la terre (masse) &I circuit d’alimeotxion.

Ne .L+SS.Z pa 1s nivemx

malt 6gurant sur le pamleau an&e et d&is a” chapitre caratt&istiques et folxxionnement de la notice d’utilisatiotl.

Fiiezlavis Q dudrruitd’eyaisalaterregl’aided’un~de

jauge 18 AWG ou plus gms.

lnsrmmena et accgsoiTes

somles

lo ne faut faire edcuter la maintenance que par du penonnel Spe

cialisd. Dkbranchez le cordon d’alimentation et tous les Cgbler

d’esais de I’instmment avant d’effecmer tme quelconque o@ra

don de maintenance.

maximum de sigoaux de l’iosav

ne dokent pas be oxcord& g des per-

lNZBX!SIl?E D’AFHCHAGE (DISPLAY lNTEN.SITyI :

Pennet de s&ctiomw : normaL&.ible!pas d’affichage.

COMMANDE DIRECZZ (LOCAL) :

r-em l’appareil et remet en foxtionnement les touches du

panneau d’affichage.

MENU (MENU) : s’udise avec le bouton on les touches du NTsew pour configurer Ia &mems suivants du menu : mise en

m&mire de dam&, rappel de doonkes, limite I (tooMe 487),

int&mion, le bus EEE-488 (voie de tmmmksion ou communication seulement), v&m par d4fam, contrble automatique, mise

au point, balormage et &lomage de la source de tension V

(mod&

487 seulement).

TOUCHE MAJUSCUJX - SORllE (SHIFTEXI’IJ :

de soti du MENU oli de d&lencher I’INSTALLATION

@ETup).

lrwFCATIoN DU ZERO (ZERO CHECK) :

ficatim cles d4cdam et doit &re invalid& pour obtenir le signal

normal de sortie.

Permet de commander di-

Permet

Pet-met la v&i-

TOUCHI? MAJUSCULE - CORRECTION (SHlFT COR-

RECTJ : R&l&e la mix e z&o automatique pour am-&r les

c2kcalaga des instruments.

TOUCHF MAJUSCULE - SELECTION DU FLXRE

(SHIFT FILTER SELECT) : s’urilise avec le bouton ou le curseu pour selectiotmer le(s) filtfe(s); mm&iqtx, analogique 0”

numkique + analogique.

V RANGE A (RANGE) :

selectiomler lme gamme plus basse ou plus haute.

Utilkez les touches de gamme pcnu

TOUCHE MAJ(ISCULE - GAMME AUTOMAnQUE

(SHIFi- AUTO RANGE) : s’wilis pour valider ou irmlickr

mode gamme automatique.

IhSTALLATION (SETUP) : s’unlise avec un bouton ou les

touches c,mems pour configurer le ciichchmat des systemes

de cklenchemem suivaoa : mode &clenchement, intervalle de

Wenchement, retard de dklencbemem et source de dkclencbe

*em.

FONCli’ONNEMtWT (OPERA=) : Met la source

V du ma&k 487 en fonaioonement ou en veik.

DECLWCI.zW@h’T (TRIGGER) :

tme lecture ou d&arer la mix en memoire des doom&.

PREREGLAGE (PRESEV :

sources de t&on V (mod& 487 seulement).

Pa-met de ba.scuk entre V&LIE de

Appuyez pour d-klmcber

de tension

TOUCHE MAJUSCULE - OHMS (SHI3T OHMS V@ :

puyez pour sactiomler v/l ohms.

k

Ap

Page 12

SCHEMA TYPE DE BRANCHFNENT

(Mcd+.le 487 mom& branch& P Ia charge d’csai 8002A)

Cimit dquivalent

k

DUT

Page 13

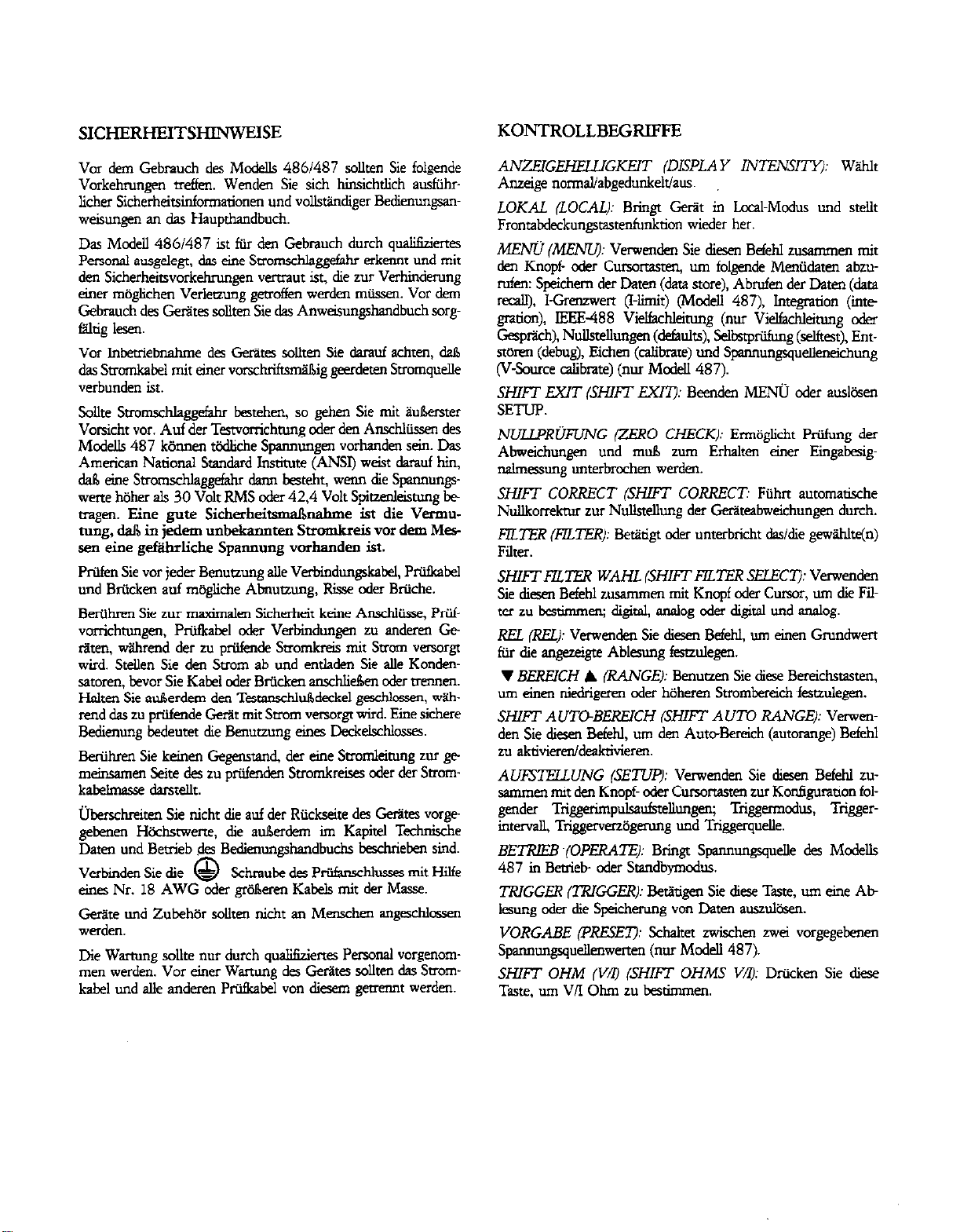

SICHERHEITSHINWEISE

KONTROLLBEGRIFF’E

Vor dem Gebrauch des M&ells 4861487 soIlten Sie folgende

Vorkehrungen &fen. Wenden Sie sich hinsichtlich ausfiihrlither Sicherheitsinformationen und vollst&~diger Bedienungsm

weisungen an das Haupthandbucb.

Dar M&U 4861487 is fiir den Gebrauch durch qu&izierts

Personal ausgelegt, das eine Stromwhkggefahr erkenm und mit

da Sicherheitworkehmngehrungen vertraut ist, die zur Verhinderung

einer mbglicben Verletzung pea&n we&n miisxn Vor den

G&much des G&&s sollten Sie da Anweisungshandbuch sorgfag lesen.

Vor Uxtriebnabme des G&es soilten Sic da-auf achten, da&

da Suomkabel mit einer vo~ig gee&ten Suomquelk

verbunden is.

S&e Suomvhlaggefabr best&n, so g&en Sie mit Xuiulsenter

Vosicbt var. Auf der Tatvonichtung c&r den Amcbliisxn des

Modells 487 kijnnen t&&he Sparmungen vorhanden sein. Das

American National Standard Institute (ANSQ weist damuf bin,

da& eine Suomschlagg~ dam besteht, wenn die SFannungswene h6her als 30 Volt RMS oder 42,4 Volt Spia&is@.mg be

uagen. Eine gute Sicherhei@nahme ist die Vermutnng, da& in jedem unbekannten Stromkreis vor dem MS

sen eine g&liche Spamung vorhanden is.

PrJfen Sie vor jeder

md

Briicken auf m&$icbe Abnutnmg, Rise cder Briiche.

Beriibren Sie LUT maxim&n Siiherheit keine Amcbiiisse, Priifvonichtungen, Priifkabel ode Verbindungen zu anderen Ge

men, w&rend der zu priifende S~omkreis mit Strom versorgt

wird. Sellen Sic den Strom ab und entladen Sic alle Kondensatmen, bevor Sic K&l c&r Briicken an&Ii&n oder trennen.

H&en Sic auBer&m den Testmscbl&deckel ggchlos~en, withrend das zu priifende G&t mit Strom versorgr wird. Eine sichere

Bedhung bedeutet die Benutzung e&s Deckeischlosses.

Baiihrm Sie keinen Gegastan& der eine Stmmleitung LUT ge

meinsamen site des zll priifendsI stmmkreises cder deI Stromkatebnaw dare&.

iiberschreiten Sic nicht die auf da Riickseite des G&&es verge

gebenen HlichstwMe, die auBer&m ix-n Kapitel Tech&&e

Dawn und Beuieb da Bediemmgshandbuchs bschrieba sind.

V&inda Sie die 0 = Scbraube des Pr&xchl- mit Hilfe

eims Nr. 18 AWG c&r gr&ren Kabels mit da Masse.

Geme und Zubehtir s&a nicbt an Mahen an&+scblassen

werden.

Die Wammg s&e nut durch qualifiziertes Penxnl vorgenommen werden. Vor einer Wammg des Get-&s solken das Stromk&l und alle anderen Priifkabel van diem geuennt werden.

BmuQung

alle Verbindungskabel, Priif?abel

AN.ZIGEHELLIGKEIT (DISPLAY Ihfl.ENSI~):

Anzeige normaUabgedunkeltiaus.

LOKAL (LOCAL):

Frontabdeckungstastenfunkdon wieder her.

Genii (MENlJ: Venvenden Sie diesen B&hl nsammen x-nit

den Knopf- c&r C~rtasten, um f&en& Meniidaten abzur&n: $&hem der Dawn (data store), Abmfen der Data (data

red), IGrenrwert (Rimit) (Mcddl 487), Integlatioxl (mtegradon), IEEE-488 VielfKhlenmg (nur Vielfachleitung a.&

Gqdch), Nullstellungen (~dts), Sehtpriifung (seXtest), Emstijren (debug), Eicben (calibrate) und Spannungs4u~~tichu,-,g

(V-Sowc~ calibrate) (nw MC&II 487).

SHIFT EXIT (SHIFT EXIZJ: Bender, ME& c&r auslijsen

SETUP.

NULL?‘RiiFUNG (ZERO Ch!ECK):

Abweicbungen und mui3 zum Erhaltm einer F.ingabesig-

nabnaung unterbrwhen we&a.

SHFi- CORRECT (SHLFT CORRECT Fiibrt automatische

Nullkorrektur ZUT Nulhllmg der Ger&abwichungen durcb.

FZLTER (RZERJ: Bet&&t oder unterbricht da?&& gewiihlte(n)

Filter.

Bringt Geriit in Local-Modus und stellt

Em@licbt Priifung der

Wtit

SHIFi-FLLTER WAHL (.SHL=TRLll?R SELECn: Venvenden

SiediesenBefeblr

ter zu bestimmm; digital, analog cder digital und analog.

REL (R.&C): Verwada Sie diezen Befehl, urn linen Gnmthvert

fiir die angezeigte Ablesung faulegen.

V BJZREICH A (RAh’GE):

urn e&n nkdrigeren oder h&eren Strombereicb festzulegen.

SHIFT AUTO-BEREICH (SHIFT AUTO RANGE):

den Sie diesen B&l, um den AutoBaeicb (autorange) Befehl

zu aktividd.

AUIT7ELLVNG (SEW): Verwenden Sie diesen Befehl zusammen mit den Knopf- odet Curscnasten zur Kon&uration folgender TrQeritnp~ufsteUun~; Trig&mndus, TriggerintervaIl, Tti~emerr6genmg und TriggerqueUe.

BETRlEE(OPERATE):

487 in Be&b c&r Standbymcdu.

TRIGGER (ZWGGER): Betitip Sic dige Taste, urn eine Ab

lesung cder die speichaung “on Lktm awdiisen.

usammen nit Kxpf c&r Cunor, urn die Fil-

Benutzen Sie diese Bereichsmsen,

Verwen-

Bringt Spannungsquelle de Mcdells

VORGABE (PREFl-: Schdtet zwischm zwti vor~e&enen

Spannm~uellenwerten (mu Modell487).

SHIFT OHM (V/I) (SHIFT OHMS V7Ij:

Taste, urn V/I Ohm zu betimmen.

Driicken Sie dies=

Page 14

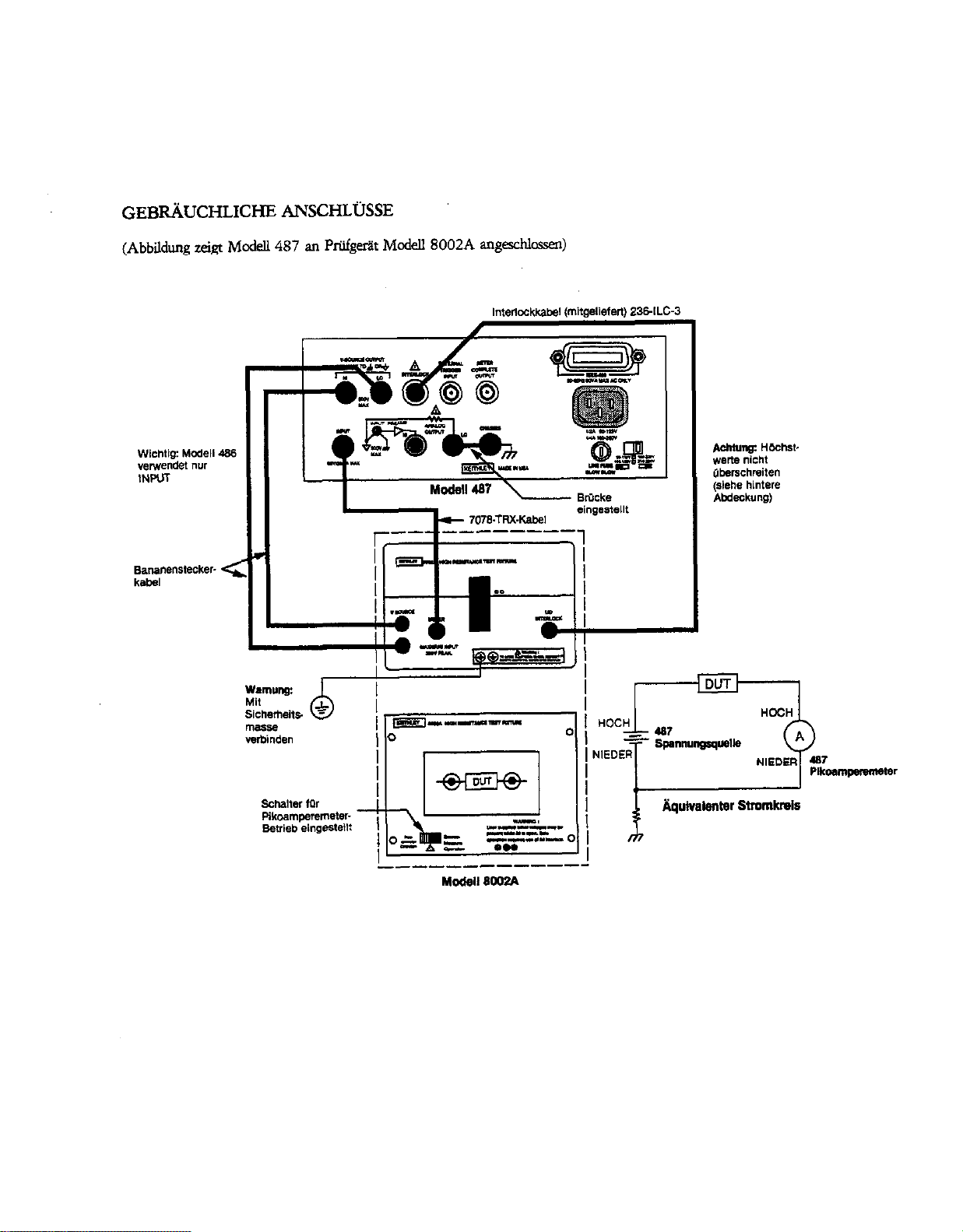

GEBRiiUCHLICHE ANSCHLijSSE

(Abbildq zeigt McdeU 487 an Priifgeriit Mcdell8002A “I@chlossen)

I

T

I

Page 15

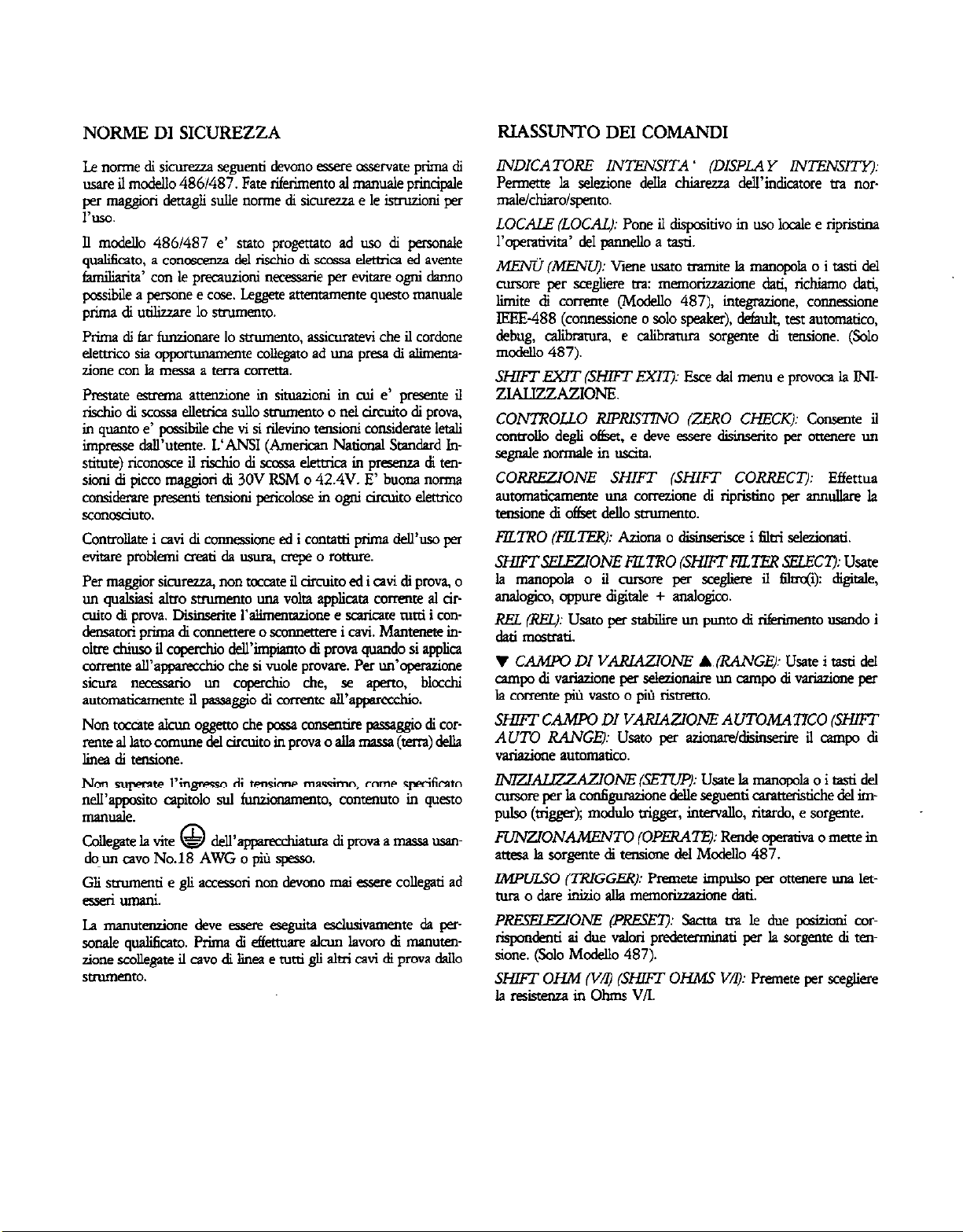

NORME DI SICUREZZA

IUASSUh’TO DJ3 COMANDI

Le name di sicurezza segwnd dew10 mere mervate prima di

ware U modello 4861487. Fate riftiento al rnmuaie principale

per “ngsioti demgu suue norme di sicurn e le is”lKio”i per

I’uro.

II modello 4861487 e’ stat0 progetrato ad uo di pe~nale

qlmlificato, a co”cscenza CM Ii&i0 di sccma elemica ed awnte

-ma’ co” le preca”z.ioti necemarie per evimre ogni da”“0

possibiie a persane e case. Leggem attentamente quest0 “ranwale

prima di udliuare lo sml”lento.

Prima di far fu”zionare lo sml”lento, &%sic”ratevi the il cordone

elemico sia appmmamente adlegato ad una press di alimentazione CO” la mesa a terra ccuretm.

Prrstate esn-ema atten7io”e in situazioni in cui e’ prwnte il

rischio di sccaa elletrica sulk3 -ento 0 “el cimdto di prow%

in qtmnto e’ p&bile the vi si rilevino tensioni considerate letah

imprerse dall’utente. L‘ANSI (American National Standard Insti~te)riconmceurischiodismssaelemicdinpresenraditensioni di picco ma&xi di 30V RSM o 42.4V. E’ buona “orma

coti* presenti tensio”i peric&se i” ogni circllito elemico

slxmxiuto.

Controllate i cavi di mnnesSone ed i conmti prima delYw per

witare problemi cwati da usurq crepe o romue.

Per maggior sicurezza, “on toccate il cirtito ed i cavi di prova, 0

II” qualsiasi ah smlme”t0 una volm applicam -te al cirait0 di prow. Diskwrite I’alimentazione e saricam tutti i condensatori prima di connette~e o sonmetwe i cati. Mante”ete inoh chi”so il cope&h dell’impianto di prow quando si applica

corrente au’apparecchio the ti vuole prowre. Per ““‘@Gne

sicwa necesrio un copxhio the, se apert”, bloxhi

aut0”laticame”te 1 parsaggio di ccrrelte dl’apparecchio.

Non tcccate alcun oggetto the possa ccmvmtire passaggio di COP

reme al km conlune dd circuit0 in prwa 0 aIla massa (tara) ala

linea d.i tensione.

Non superate l’ingreso di tensione nwsimo, come yxcifiato

nell’appmito capitol0 sul hnzio”a”wnto, conten”to in quest0

nmnuale.

collegatelavite 1 d.eu’apparecchiaturadiproMa-usan-

do~un avo No.18 AWG o pii~ spgso.

Gli -enti e gli accessori non devono mai - collegati ad

esxriumani.

IA “m”uterKio”e dew gsere equita esclusivame”te da perso”& q”alificato. Prima di efkmMre ahn lavoro di “m”“teD

ione scollegate u Lea”0 di hea e tuni gu alti cavi di prcwa daIl0

SO-lU”~rO.

0

INDICA TORE INZWSITA ’ (DISPLAY INllENSIITyI:

Peimette la selezione delh chiareua delhdicatore tra “or“mldchiarol~to.

LOCALE (LOCAL]:

l’opemivim’ del pannell a ati.

MENU (MJZNV): Wene usam aamite la mancpla 0

cursore per scegliere “a: menlorizzazicole dati, richianlo dati,

limite di corrente (Modello 487), integrazim, conngsione

IEEE-488 (connesione 0 solo speaker), dehllt, test autonmtico,

debug, calibratua. e calibrantra sorgente di tasione. (Solo

modello 487).

.sHlmExlT (Srnrn~: Exe ti menu e prowxa la IMzlALrzzAz10NE.

Pane il dis@tivo in wo locale e riprki”a

i tarti del

CONTROLLO RLPRIS7liVO (ZERO CHECK): Commte il

mnuoUo degli offset, e deve esere dkinwito per omenere un

seg”ale nornmle in lmcim.

CORREZIONE SHIFT (SHIFT CORRECT):

autGmaticar”ente una cotrezio”e di ripristi”0 per a”““llare la

telciione di &et dell0 smlme”to.

FEZ?0 (FUTER): Aziona 0 diskeke i flui sekio”ati.

sHIFT~oNEmmo (.s%TFILl-ERsElEc1): uwe

la rnmopola 0 U amore per scegliere il f&c(i): di&ale,

analo~co, oppure digimle + analogico.

REL @EL): Usato per stabike un punt0 di rihirnento uando i

dati “xsuati.

V CAMP0 DI VARlAZIONL? A, (FLANGE): Usate

campdivariadoneperseler&uncampodi-per

la corrente piti “as0 0 phi risueno.

Effenua

i tasti del

SHl?i- CAMP0 DI VARIAZIONE AUTOMAlTCO (SIfIFT

AUTO RANGE): Usato per aricmareldidnsaire il camp di

variazione autmnatico.

-ONE (SE’TW): Usate k nmnopch o i msti del

l2umn-e per la ccm6gurazione delle s.eguellti carattetistiche dd in?

pulw (nigger); mcdulo trig&a, il-lmrvaJlo, rimrda, e sorgente.

FUNZONAhfENTO (OPERATE):

mea la sorgente di taskme deI MakIlo 487.

IMPLLLSO (EQIGGER): Premete imp&o per ottenere ““a let-

ma 0 dare inizio alla mfznmimione dati.

Rmde operadva o mate in

PREsELEnONE (PRESEZJ: sama Isa k due pxizioni COT-

l-i!pnde”ti ai due vd0I-i predetaminati per la sorge”te di tar

&me. (Solo M&k 487).

SHIFT OHM (v/l) (Srn OHMS v7: Premete per scegliere

lami.uenzai”ohmsvn.

Page 16

c0NNEss10NI TIPICHE

(E’ n-,nstrato il Mod& 487 connesso al Mod& 8002A come aw&tura di prova)

i

.__---_-----

Mdek.8W2A

11-w-w

-I”....L

Page 17

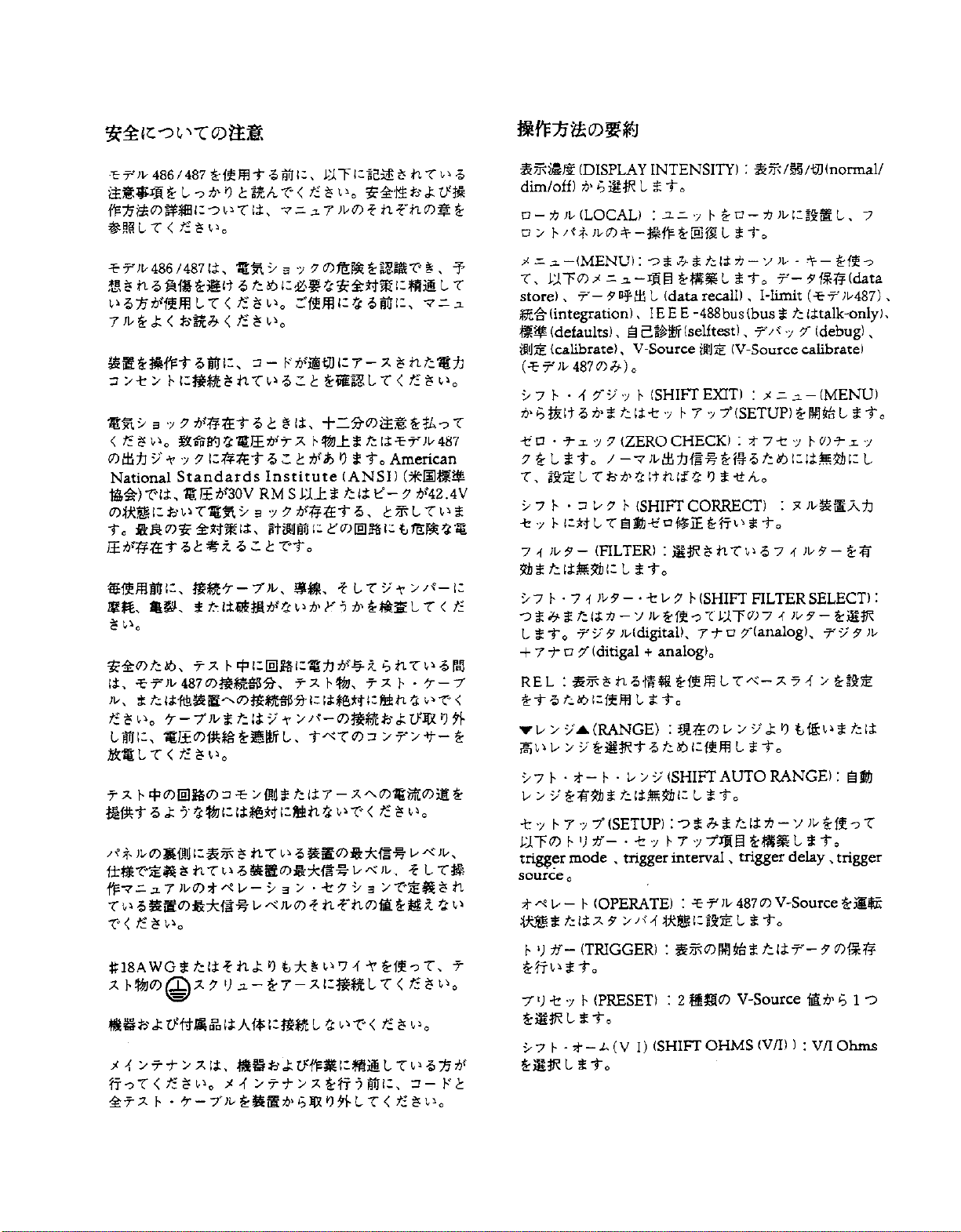

Page 18

___ _-------

M-m-

.o

.-

1

-"=-I

zz"

Z3ZZ!kZ

i3iL

_----B-e-----

E=JL 8oOP.A

Page 19

ADVERTENCIAS DE SEGURIDAD

SUMARIO DE CONTROL

Las precaucione siguientes deben ser observadas arms de war

los Modelm 4861487. Remitirse al manual principal para informa&n detdada de xgtuidad e instmccion~ completas de fundonamiento.

Tener cuidado extreme cuando hay la posibilidad de chque elktrim. F’wdem existi voltajes letaks en ks davijas de tida del

Mod& 487 6 en el accesorio de prueba. El Ins&to National

Ameicmo de Norms (ANSI) expose que e&e un peligro de

chcque cuando bay presents niveks de vohaje de mk de 30V

VCM (valor cuadrhtico media) 0 de 42,4V pica. Una buaa

pktica de seguridad es la de espemr que haya voltajes

peligmscs presentcs en cdquier circuito desconocido

antes de medirlo.

LNTENSIDAD DE PRESENTACION (DLWAY INllW

SIm): selffdonar

LOCAL (LOCAL):

OperadLin de la llave de] panel delantero.

MENU (MEh’U): Se usa con lar Uaves del cursor o perilla para

mdigum lo siguiente: alma- ‘elm de dates, recuperaci6Il

de dam, limite de coniam 0 (Mcdelo 487), integradn, bam

IEEE-488 (balm 0 tile voz), surdtuci6n, autqlmeh, ebminacibn de fallas, cezdilmtibn y calibraci6n de fuente de voltaje (V)

(sdo

Mod&

preentack% normal/amotigzuh/apa~da.

Pane a la unidad en acci6n local y restaura la

487).

CAMBIO SALWA (SHFi-m: S&b del MENU o activa-

citi de Prepara&n (SETUP).

COMPROBACION DE CERO (ZERO CHECK):

compmbacih de desplammientos y dek ser inhabilitado par-a ob

tenermamedici6nde~deenuada.

Permite la

CORFECION DE DEV’LAZAMZW TO (SHIFT COR-

RECT R& correcd6n autcm&ica de cero para balancear de

plazaodentos del instnunento.

Fm-Ro (EllTER): Habilita 0 inbabilita el 0 los iiltm s.2k.io

rlados.

No war nin@n objeto que pudka provea un camino a la cctieme al Iado comirn &I circuim bajo prueba o la tiena de la

line3 de energia.

~GAMAA~GE):UsalasUaverdegamapara~~onar

lmgamade conimte mis elm 0 mAs baja.

CAMBIO GAMA AUTOMATICA (SHIFT AUTO

RANGE)): Se wa pm bab la gama autodtica.

PREPARACION (SE77lP): Usado cm Uaves de tumor o periua

pal-a Nmiigurar la disposiciones sigulenm d-2 activti6n: moda-

lidad de activtibn, imervalo de activaci6n, demaa de activaci6n.

fuente de acdvacih.

OPERACION (OPERAlF): Siti k

en Funcionamiu~ta o Espwa.

Fueme V del Modelo 487

AC’i7XACION (TRIGGER): Se deprime para activar una kcturd 0 catlauar al almacenamulto de dam.

PREAJUSZE(P~: OS& emre cim v&n-es de la

preajustados (s5lo Mod& 487).

CAMBIOS OHMIOS v/c (SHIJT OHMS v7q se

sek@ilmal otios Voltaje coniente.

Fueme V

optime para

Page 20

CONEXIONES TIPICAS

(Mod.90 487 mcsuado conmado a arreylrio de pm& M&lo 8002A)

- .--------.

w-P--

Circuit0 equivatente

i

Page 21

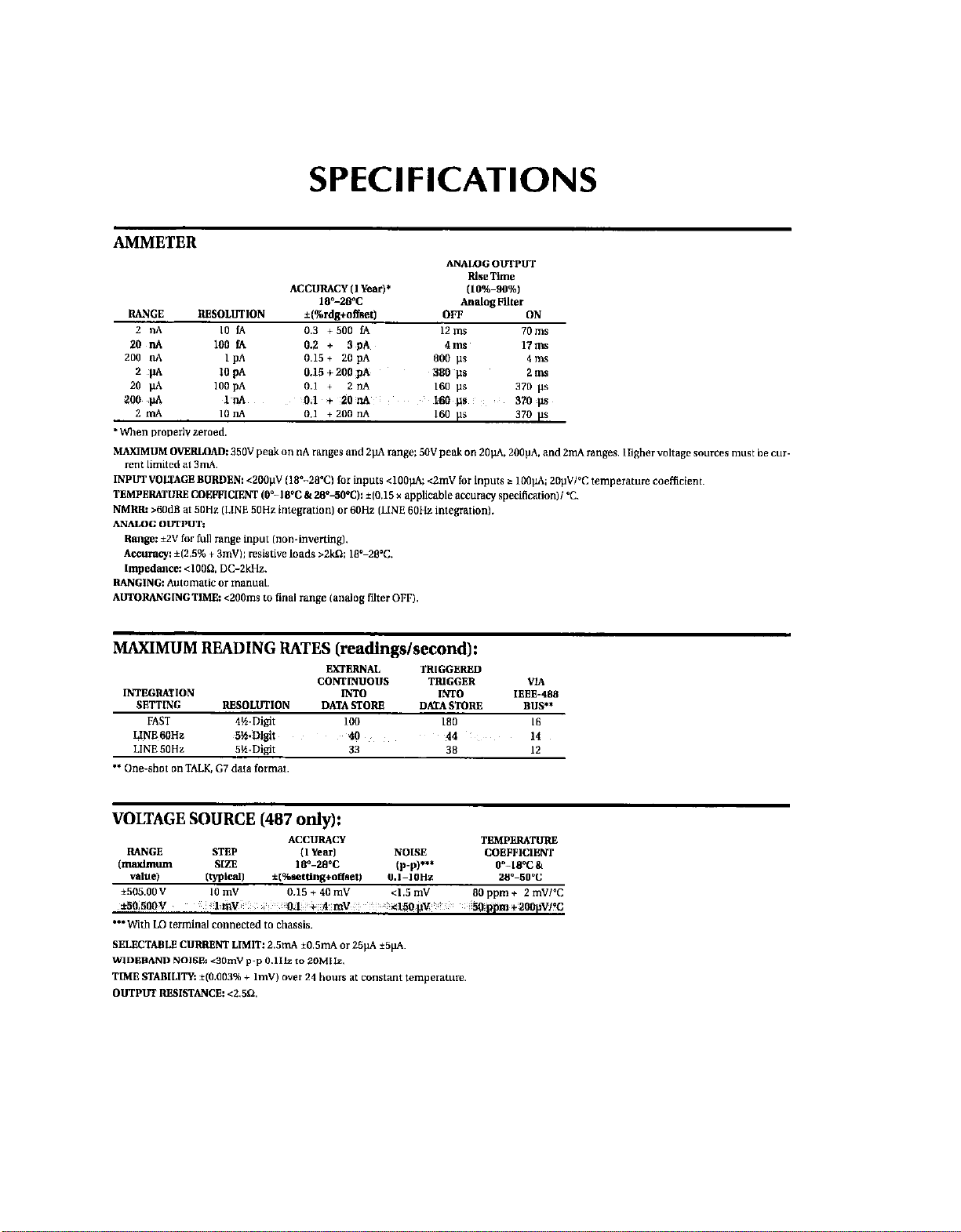

SPECIFICATIONS

MAXIMUM READING RATES (readings/second):

VOLTAGE SOURCE (487 only):

Page 22

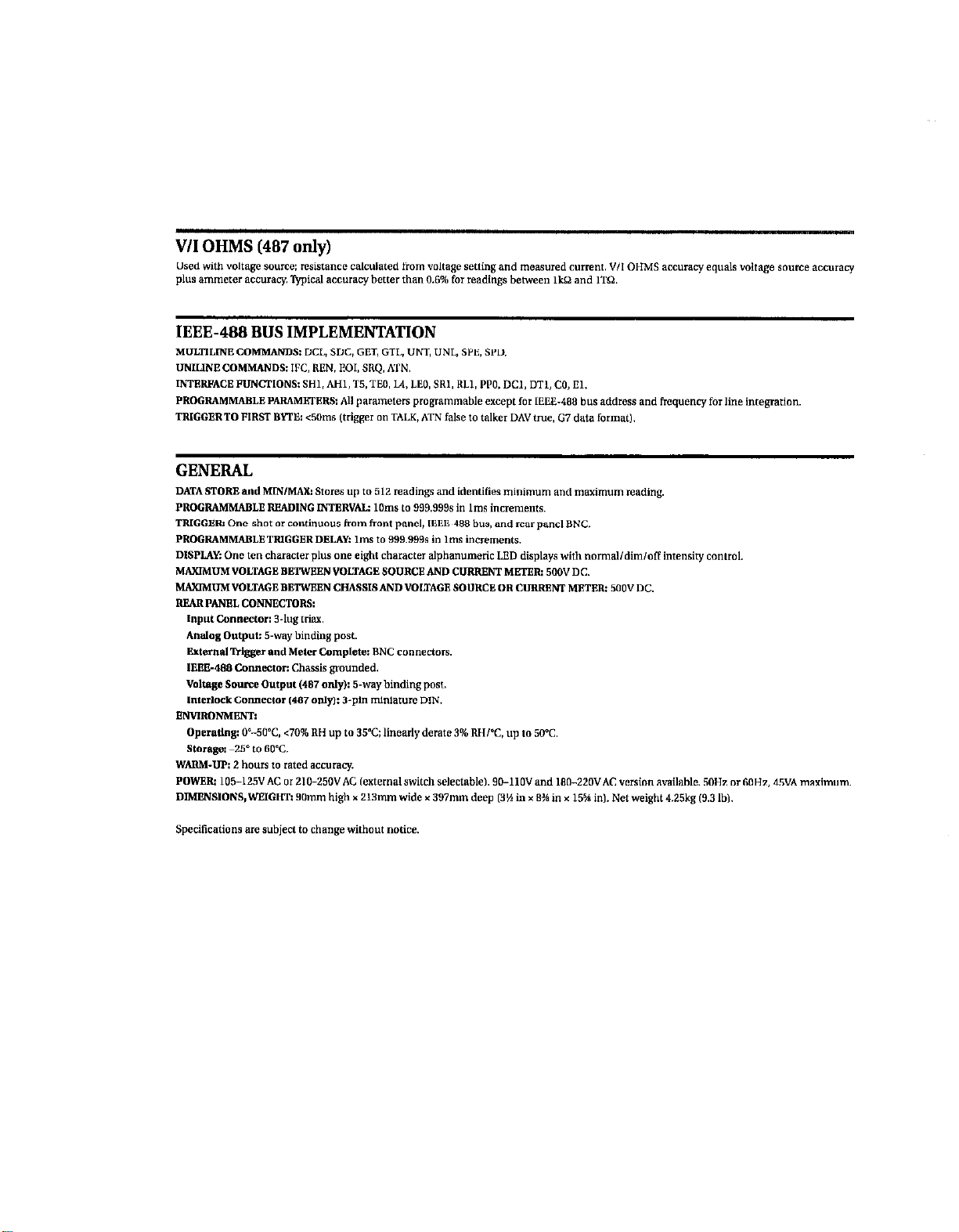

IEEE-488 BUS IMPLEMENTATION

Page 23

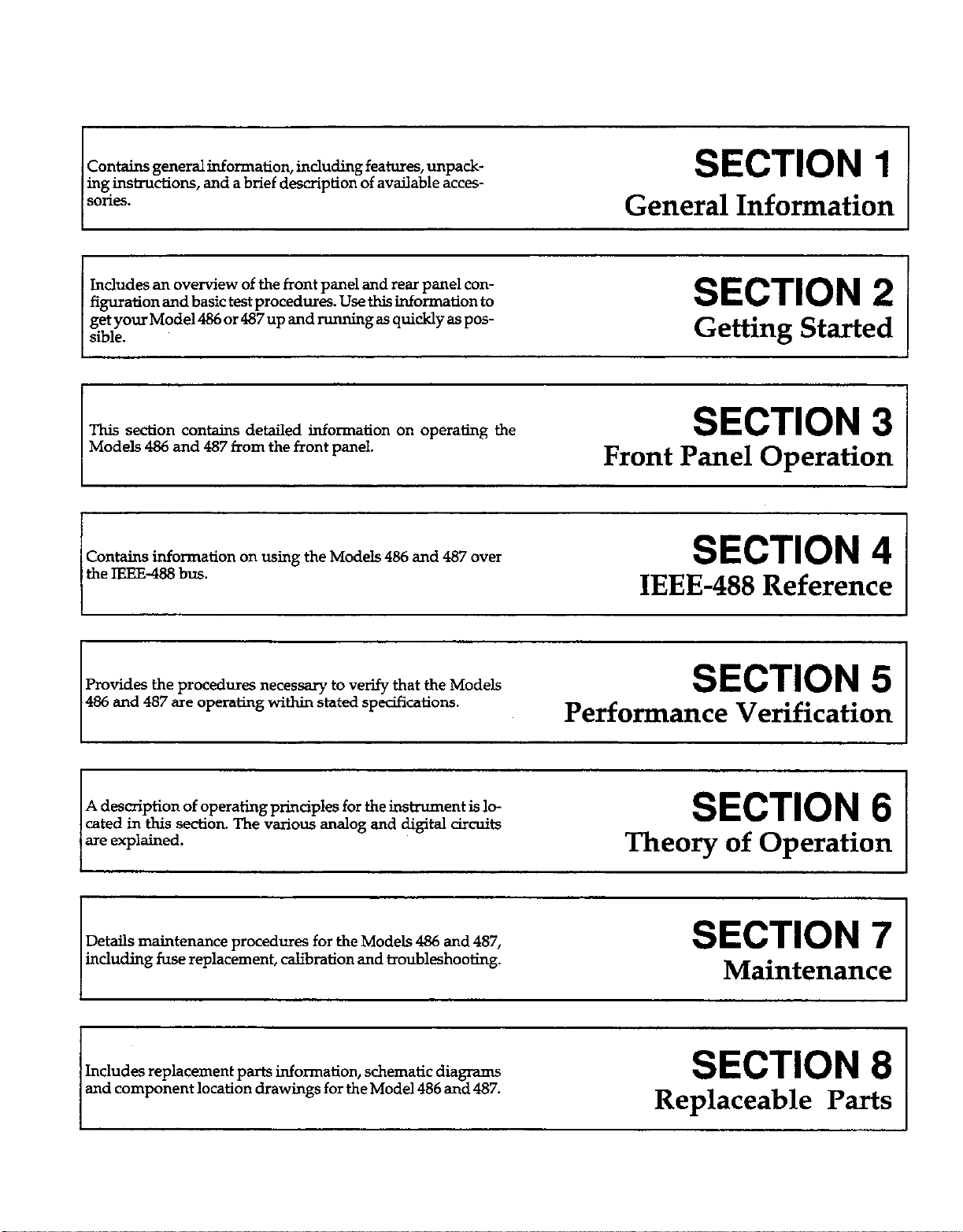

contains general information, inclding features, unpack-

ing insimxtions, and a brief description of available acces-

SO&S.

SECTION

General Information

1

Includes an overview of the front panel and rear panel configuration and basic test procedures. Use this information to

getyourMode1486or487up andmmingas quicklyaspossible.

This section contains detailed information on operating the

Models 486 and 487 from the front panel.

SECTION 2

Getting Started

SECTION 3

Front Panel Operation

Contains information on using the Models 466 and 487 over

the IEEE-488 bus.

SECTION 4

IEEE-488 Reference

Provides the procedures necessary to verify that the Models

486 and 487 are operating within stated specifications.

SECTION 5

Performance Verification

I 1

I

A description of operating principles for the instrument is located in this section. The various analog and digital circuits

are explained.

Details maintenance procedures for the Models 486 and 487,

including fuse replacement, calibration and troubleshooting.

Includes replacement parts information, schematic diagrams

and component location drawings for the Model 486 and 487.

I

SECTION 6

Theory of Operation

SECTION 7

Maintenance

SECTION 8

Replaceable Parts

Page 24

Page 25

Table of Contents

SECTION 1

1.1

1.2 FEATURES.

1.3 WARRANTY INFORMATION,

1.4

1.5

1.6

1.7

1.8

SECTION 2

2.1

2.2

2.3

2.3.1

2.3.2

2.4

2.4.1

2.4.2

SECTION

- General Information

INTRODUCTION.

MANUAL ADDENDA

SAFETY SYMBOLS and TERMS

SPECIFICATIONS

INSPECTION

OPTIONAL ACCESSORIES

- Getting Started

INTRODUCTION

FRONT AND REAR PANEL CONFIGURATION,

BASIC FRONT PANEL OPERATION.

Current Measurements

V/I Ohms Measurements (Model 487)

BASIC IEEE-488 OPERATION. .......................

Current Measurements Over the Bus

V/I Ohms Measurements Over the Bus (Model 487)

...................................

............................

3 - Front Panel Operation

.................

...............

................

.......

...

.................

.................

.................

.................

.................

.................

.................

.................

.........

.........

.........

.........

.........

.........

.........

.........

..............

..............

..............

..............

..............

..............

..............

..............

2-l

2-l

2-5

2-6

2-6

2-9

2-11

2-11

3.1

3.2

3.2.1

3.2.2

3.2.3

3.2.4

3.2.5

3.2.6

3.2.7

3.3

3.4

3.5

3.5.1

3.5.2

3.5.3

3.5.4

3.5.5

3.5.6

3.6

3.6.1

3.6.2

INTRODUCTION.

POWER-UP PROCEDURE

Line Voltage Setting

Fuse Replacement

Power Cord

Power up Sequence

Default Conditions

Line Cycle Integration

Warm up Period

ERROR MESSAGES

DATA ENTRY; BASIC RULES

CURRENT MEASUREMENTS.

Current Ranges.

Autorange

Zero Check and Correct.

Filters

Rel......................................

Current Measurements

USING THE VOLTAGE SOURCE (Model 487)

Test Fixture and Interlock

Adjusting V-Source Level

3-l

3-1

3-l

3-l

3-2

3-2

3-2

3-3

3-3

3-3

3-4

3-5

3-5

3-5

3-5

3-6

3-7

3-8

3-10

3-10

3-11

Page 26

3.6.3

3.6.4

3.6.5

3.6.6

3.7

3.8

3.8.1

3.82

3.8.3

3.8.4

3.8.5

3.8.6

3.8.7

3.8.8

3.8.9

3.8.10

3.9

3.9.1

3.9.2

3.9.3

3.9.4

3.9.5

3.10

3.10.1

3.102

3.11

3.11.1

3.112

3.11.3

3.12

3.13

3.14

3.14.1

3.14.2

3.15

3.15.1

3.15.2

3.16

3.16.1

3.16.2

3.16.3

3.16.4

3.16.5

3.16.6

3.16.7

3.16.8

Preset .............................................................................

I-Limit .............................................................................

Operate ............................................................................

Basic V-Source Operating Procedure.

V/I OHMS MEASUREMENTS (Model 487)

..................................................

..............................................

MENU ..............................................................................

DataStore .........................................................................

DataRecall .........................................................................

I-Limit(Model487) .................................................................

Integration .........................................................................

IEEE-488AddressorTalk.Only .......................................................

Defau~s ...........................................................................

Self-Test ...........................................................................

Debug .............................................................................

Calibrate ...........................................................................

CalVSRC(Mode1487) ..............................................................

FRONTPANELTRIGGERING .........................................................

TriggerMode .......................................................................

TriggerInterval...............................................................~

TriggerDelay .......................................................................

Trigger Sources

.....................................................................

Trigger Examples ...................................................................

EXTERNAL TRIGGERING.

............................................................

ExternalTrigger ....................................................................

Meter Complete ....................................................................

DATASTORE ........................................................................

Storing Data at Programmed Intervals, ................................................

Triggering One-shot Readings into Data Store

..........................................

RecallingData ......................................................................

ANALOGOUTPUT ...................................................................

TALK-ONLY .........................................................................

OPERATINGEXAMPLES .............................................................

Measuring Current Generated by an LED ..............................................

Resistivity Tests (Model 487) .........................................................

SOURCE VOLTAGE/MEASURE CURRENT (Model 487). .................................

Basic Source V/Measure I Configuration.

..............................................

Testing2-TerminalDevices ...........................................................

MEASUREMENT CONSIDERATIONS ..................................................

Source Resistance. ..................................................................

SourceCapacitance ..................................................................

Triboelectric and I’iezoelectric Effects. .................................................

Electrostatic Interference. ............................................................

ThermalEMFs ......................................................................

Electromagnetic Interference (EMI). ...................................................

GroundLoops ......................................................................

Floating Measurements

..............................................................

.....

3-12

3-13

3-13

3-13

3-14

3-16

3-16

3-17

3-18

3-18

3-19

3-19

3-19

3-20

3-20

3-20

3-20

3-20

3-21

3-21

3-21

3-22

3-22

3-23

3-23

3-23

3-23

3-24

3-25

3-25

3-27

3-27

3-27

3-29

3-31

3-31

3-32

3-33

3-33

3-33

3-34

3-35

3-35

3-35

3-35

3-36

Page 27

SECTION 4

- IEEE-488 Reference

4.1

4.2

4.2.1

4.2.2

4.2.3

4.2.4

4.2.5

4.2.6

4.2.7

4.2.8

4.2.9

4.2.10

4.2.11

4.2.12

4.2.13

4.2.14

4.2.15

4.2.16

4.2.17

4.2.18

4.2.19

4.2.20

4.2.21

4.2.22

4.2.23

4.2.24

4.3

4.3.1

4.3.2

4.3.3

4.3.4

4.3.5

4.3.6

4.3.7

4.3.8

4.4

4.5

4.6

4.7

4.7.1

4.7.2

4.7.3

4.8

INTRODUCTION

DEVICE-DEPENDENT COMMAND PROGRAMMING

A-Display Intensity

B-ReadingSource

C . Zero Check and Zero Correct. ....................................................

D-Display.

F-V/IOhms

G-DataFormat

H-HitControl

J-Self-Tests. ......................................................................

K . EOI and Bus Hold-Off. ..........................................................

L-Default Condlhons or Calibration. ................................................

M - SRQ Mask and Serial Poll Byte Format

N-DDataStore;ArmandSetSize..

0-Operate(Mode1487)

P-Filters

Q-Interval

R-Range .........................................................................

S~IntegrationPeriod

T-Trigger

u-status .........................................................................

V-VoltageSource

W~Delay .........................................................................

X-Execute

Y-Terminator

Z-Relative

GENERAL BUS COMMANDS. .........................................................

REN(RemoteEnable)

IFC (InterfaceClear) .................................................................

LLO(LocalLockout)

GTL (Go To Local) and Local .........................................................

DCL(DeviceClear)

SDC(SelectiveDeviceClear)

GET (Group Execute Trigger)

SPE, SPD (Serial Polling)

IEEE-488BUSCONNECTIONS

PRIMARY ADDRESS SELECTION

CONTROLLER PROGRAMMING

FRONT PANEL ASPECTS OF IEEE-488 OPERATION .....................................

Front PanelError Messages

IEEE-488 Status Indicators. ...........................................................

LOCALKey

BUS DATA TRANSMISSION TIMES ....................................................

.....................................................................

...................................

...............................................................

.................................................................

......................................................................

......................................................................

...................................................................

....................................................................

..

............................................

...................................................

............................................................

.........................................................................

.......................................................................

...............................................................

........................................................................

.................................................................

........................................................................

.....................................................................

.......................................................................

................................................................

.................................................................

..................................................................

.........................................................

.........................................................

.............................................................

.........................................................

......................................................

......................................................

...........................................................

........................................................................

4-l

4-1

4-6

4-7

4-8

4-9

4.10

4-11

4-15

4-16

4-17

4.19

4-21

4-24

4.26

4-27

4-28

4-29

4-30

4.31

4-32

4-38

4-39

4-40

4-41

4-42

4-44

4-44

4-44

4-45

4-45

4-45

4-45

4-45

4-46

4-46

4-47

4-48

4-48

4-48

4-50

4-51

4-51

Page 28

SECTION

5 - Performance Verification

5.1 INTRODUCTION

5.2 ENVIRONMENTALCONDITIONS

5.3 INITIALCONDITIONS

5.4 REQUIREDTESTEQUIPMENT

5.5 VERIFICATION PROCEDURES ........................................................

5.5.1 PicoammeterVeri~cation..

5.5.2 Voltage Source Verification (Model 487). ...............................................

SECTION 6

6.1

6.2 ANALOG CIRCUITS.

6.2.1 Input Amplifier.

6.2.2 Analog Filter

6.2.3 Multiplexer . ..__. .., ., ,., ._, ,_

6.2.4 +2.8V Reference

6.2.5 Analog Output

6.2.6 Voltage Source (Model 487).

6.3 ANALOG CONTROL CIRCUITRY.

6.4

6.5 DIGITAL CIRCUITS

6.5.1

6.5.2

6.5.3 Display/Keyboard.

6.5.4 IEEE-488 Interface .

6.6 POWER SUPPLIES

6.6.1 ACLineInput..........................

6.6.2

6.6.3

6.6.4

- Theory of Operation

INTRODUCTION

A/D CONVERTER

Digital Block Diagram.

Microcomputer

*15V Supplies

+5VA Supply. .

+6.5V Supply.

....................................................................

.....................................................

...............................................................

........................................................

..........................................................

.

.

.

. .

5-l

5-l

5-1

5-l

5-2

5-2

s-4

6-l

6-1

6-1

6-2

6-3

6-3

6-5

6-5

6-6

6-8

6-9

6-9

6-11

6-12

6-13

6-14

6-14

6-14

6-14

6-14

SECTION

7.1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . .._.

7.2 LINE FUSE REPLACEMENT.

7.3

7.3.1

7.3.2

7.3.3

7.3.4 Warm-Up Period.

7.3.5 Front Panel Calibration

7.3.6 IEEE-488 Bus Calibration . .

7.4 HANDLING AND CLEANING PRECAUTIONS

7.5 DISASSEMBLY................................

7.5.1 CoverRemoval..............................

7.5.2 Shield Removal.

7 - Maintenance

CALIBRATION.

Recommended Calibration Equipment.

Environmental Conditions

CAL LOCK Switch.

7-1

7-l

7-1

7-1

7-2

7-2

7-2

7-2

7-6

7-8

7-9

7-9

7-11

Page 29

7.5.3

7.5.4

7.6

7.7

7.7.1

7.7.2

7.7.3

7.7.4

7.7.5

7.7.6

7.7.7

Front Panel Removal

Circuit Board Removal.

................................

..............................

SPECIAL HANDLING OF STATIC SENSITIVE DEVICES

TROUBLESHOOTING

Recommended Troubleshooting Equipment

Self-Test

...........................................

Analog Control Lines.

A/D Test Mode

Troubleshooting Procedures

Input Offset Voltage Adjust.

Fusible Resistor Replacement,

................................

............

...............................

.....................................

..........................

..........................

........................

..........

..........

..........

..........

..........

..........

..........

..........

..........

..........

..........

7-11

7-11

7-11

7-12

7-12

7-12

7-12

7-13

7-13

7-19

7-19

SECTION

8.1

8.2

8.3

5.4

8.5

8 - Replaceable Parts

INTRODUCTION........................................................

PARTSLISTS............................................................

ORDERINGINFORMATION..............................................

FACTORYSERVICE......................................................

SCHEMATIC DIAGRAMS AND COMPONENT LOCATION DRAWINGS.

APPENDICES

A

B

C ASCII Character Codes and IEEE-488 Multiline Interface Command Messages.

D

E

Device-dependent Command Summary

Interface Function Codes.

Controllerrrograms.......................................................

IEEE-488BusOverview....................................................

8-l

8-l

8-l

8-l

8-l

A-l

B-l

C-l

D-l

E-l

Page 30

Page 31

List of Illustrations

SECTION 2 - Getting

Figure 2-l

Figure 2-2

Figure 2-3

Figure 2-4

Figure 2-5

Figure 2-6

SECTION 3

Figure 3-l

Figure 3-2

Figure 3-3

Figure 3-4

Figure 3-5

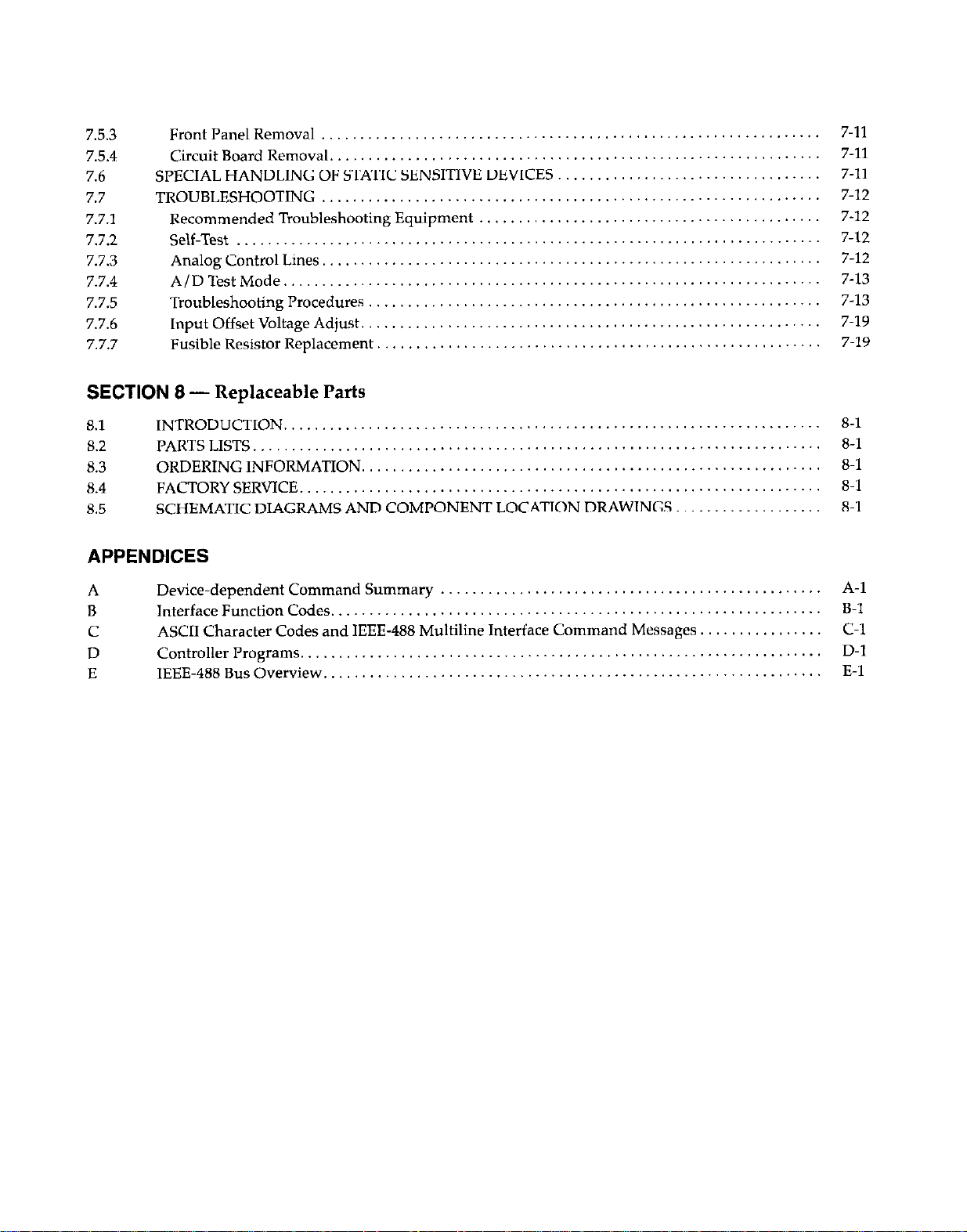

Figure 3-6

Figure 3-7

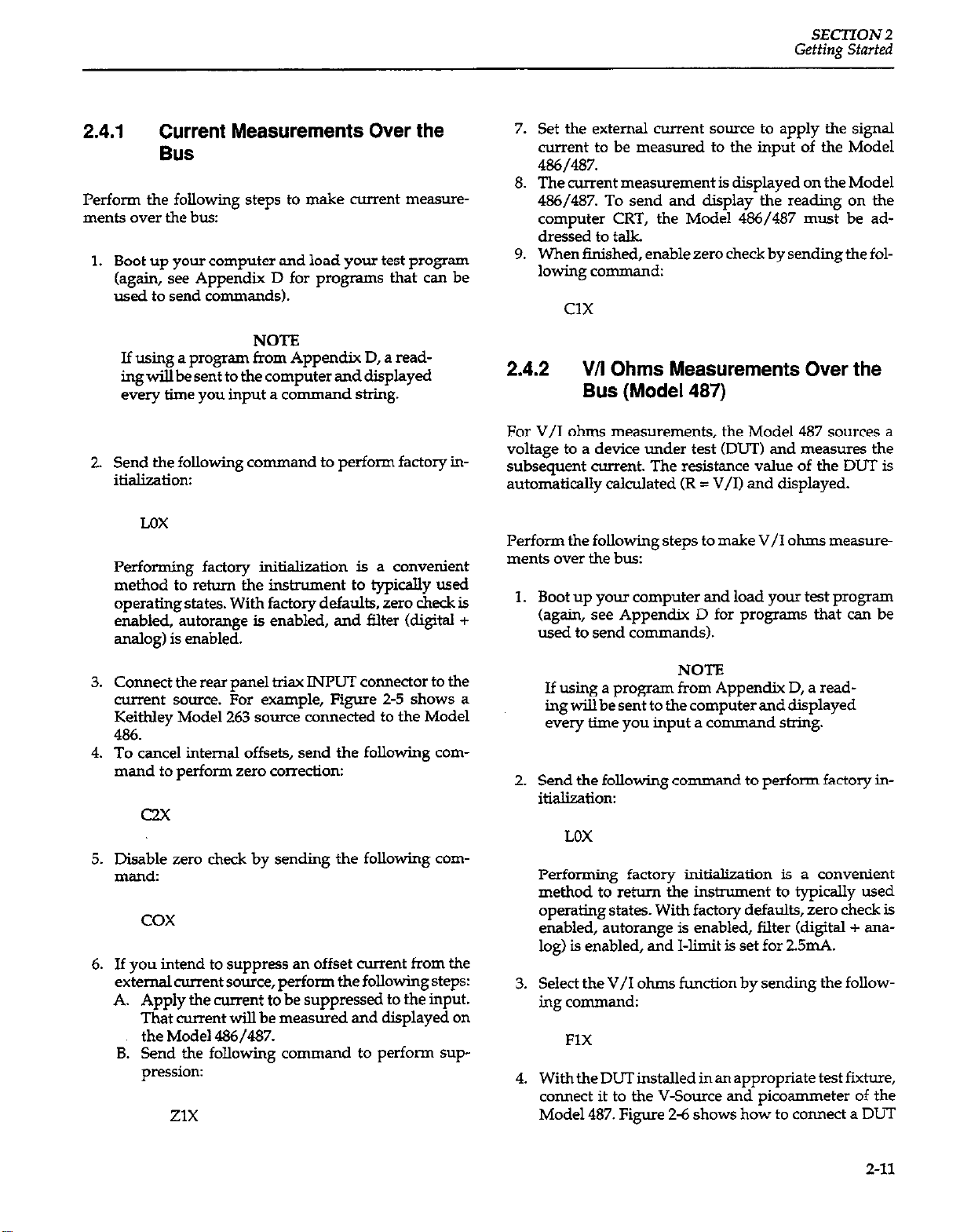

Figure 3-8

Figure 3-9

Figure 3-10

Figure 3-11

Figure 3-12

Figure 3-13 Meter Complete Specifications.

Figure 3-14

Figure 3-15

Figure 3-16

Figure 3-17

Figure 3-18

Figure 3-19

Figure 3-20

Figure 3-21

Figure 3-22

Figure 3-23

Figure 3-24

Model 486 Front Panel.

Model 487 Front Panel.

Model 486 Rear Panel.

Model 487 Rear Panel.

Connections to Measure Current.

Connections for V/I Ohms Measurements

- Front Panel Operation

Line Voltage Switch and Line Fuse

Data Entry.. .....................................................................

Trim Input Connector (3-Lug)

Picoammeter Connections.

Model 487 V-Source Output Terminals,

InterlockConnections.. ...........................................................

InterlockConnections .............................................................

V-SourceAdjust ..................................................................

Basic V-Source Connections

V/I Ohms Connections (Source V Measure I)

TriggerConnectors ................................................................

External Trigger Pulse Specifications.

Typical Analog Output Connections.

Setup for MeasureLED Current

Connections for Resistivity Test,

Configuration for Surface Resistivity

Configuration for Volume Resistivity

Simplified Model from Source Resistance and Source Capacitance Effects

TriboelectricEffect ................................................................

PiezoelectricEffect ................................................................

Multiple Ground Points Create a Ground Loop

Eliminating Ground Loop.

Improper Method to make Floating Measurements.

Started

.........................................................

........................................................

.........................................................

..................................................

......................................................

..............................................

.........................................

................................................

.....................................................

................................................

.....................................................

....................................................

................................................

................................................

.......................................

...................................

................

2-2

2-3

2-4

2-5

2-7

2-8

3-l

3-4

3-8

3-9

3-10

3-11

3-11

3-12

3-14

3-15

3-23

3-23

3-23

3-26

3-29

3-30

3-30

3-31

3-33

3-34

3-34

3-35

3-36

3-36

SECTION

Figure 4-1

Figure 4-2

Figure 4-3

Figure 4-4

Figure 4-5

Figure 4-6

Figure 4-7

4 - IEEE-488 Reference

ASCII Data Format (G2; Prefix and Suffix).

G6 and G7 Binary Data Formats (Counts/Exponent).

G4 and G5 Binary Data Formats (IEEE Std. 754).

Headers For Binary Formats.

SRQ Mask and Serial Poll Byte Format.

UO Machine Status Word (Factory Defaults Shown).

Ul Error Status Word.

4-11

4-12

4-12

4-13

4-21

4-33

4.34

Page 32

Figure 4-8

Figure 4-9

Figure 4-10

Figure 4-11

U9 Voltage Source Error Status Word

IEEE-488 Connector.

IEEE Connections.

.......................

IEEE-488 Connector Location.

Figure 4-12 Contact Assignments.

.....................

.............

....................

.......

.......

.......

.......

.......

.......

..........

..........

..........

..........

..........

. . . .

. . .

4-36

4-46

447

4-47

4-47

SECTION

5 -Performance Verification

Figure 5-l Setup for Picoammeter Verification. . .

Figure 5-2 Setup for Voltage Source Verification (Model 487)

SECTION 6

Figure 6-1

Figure 6-2

Figure 6-3

Figure 6-4

Figure 6-5

Figure 6-6

Figure 6-7

Figure 6-8

Figure 6-9

Figure 6-10

Figure 6-11

Figure 6-12

Figure 6-13

Figure 6-14

Figure 6-15

Figure 6-16

Figure 6-17

- Theory of Operation

Overall Block Diagram

Simplified Model of Input Amplifier

Zero Check Configuration

Offset Voltage Adjust Circuit

Analog Filter Circuitry

Multiplexer .............................

Multiplexer Phases.

Analog Output Circuit (Simplified) .

Simplified Model of V-Source (Model 487)

Analog Control Circuitry

Control Word

...........................

A/D Converter Simplified Schematic.

Digital Block Diagram.

Memory Map

...........................

Simplified Block Diagram of Serial Port.

Display Block Diagram.

Power Supply Block Diagram

...................

.......

................

..............

...................

......................

.................

...................

....

..................

.............

.......

.......

.......

.......

.......

.......

.......

.......

.......

.......

.......

.......

.......

.......

.......

.......

.......

.......

.......

.......

.......

.......

.......

.......

.......

.......

.......

.......

.......

.......

.......

.......

.......

.......

5-3

5-5

6-l

6-2

6-2

6-2

6-3

6-4

. 6-5

. . . ..I. . 6-5

6-5

6-7

6-8

6-9

6-10

6-11

. .

6-12

6-13

6-14

SECTION 7

Figure 7-l

- Maintenance

Cal Lock Switch

Figure 7-2 Setup for Picoammeter Calibration.

Figure 7-3

Setup for Voltage Source Calibration (Model 487)

Figure 7-4 ExplodedView..................................

Figure 7-5 Test Point, R198 and R203 Locations,

Figure 7-6 Integrator Output (Typical)

APPENDICES

Figure E-l

Figure E-2

Figure E-3

IEEE-488 Bus Configuration.

IEEE-488 Handshake Sequence

Command Codes

........................

..............

............

.......

.......

.......

. . .

. . .

7-2

7-4

7-5

7-10

7-14

7-17

E-2

E-3

E-6

.......

.......

.......

.......

.......

.......

.......

.

.......

.......

..........

..........

..........

..........

..........

..........

Page 33

List of Tables

SECTION

Table 2-l

2 - Getting Started

SECTION 3

Table 3-l

Table 3-2

Table 3-3

Table 3-4

Table 3-5

Table 3-6

Table 3-7

Table 3-8

Table 3-9

Table 3-10

Table 3-11

SECTION 4

Table 4-l

Table 4-2

Table 43

Table 4-4

Table 4-5

Table 46

Table 4-7

Abbreviated Command Summary.

- Front Panel Operation

Line

Voltage

LineFuseSelection

Factory Default Conditions (Front Panel).

Error Messages..

CurrentRanges

Analog Filter Effects.

Model 487 V-Source

MENU Items

Typical Analog Output Values

Minimum Recommended

Feedback Capacitor (CF) Values.

Selection (50.60~2)

................................................

.................................................

...................................................

....................................

- IEEE-488 Reference

Device-dependent Command Summary

Typical Bus Holdoff Times

Factory Default Conditions.

IEEE Contact Designations.

HP BASIC 4.0 IEEE-488 Statements.

IEEE-488 Error Messages.

Typical Trigger to First Byte Out Times.

............................

.....................

.....................

.....................

.....................

.....................

.....................

.............

.............

.............

.............

.............

.............

.............

,,....

.,....

,.....

,_....

,....,

2-10

3-l

3-2

3-3

3-4

3-5

3-6

3-10

3.17

3.26

3-33

3-33

4-2

4-18

4.19

444

4-48

4-49

4-51

SECTION

Table 5-1

Table 5-2

SECTION 6

Table 6-l

Table 6-2

SECTION

Table 7-l

Table 7-2

Table 7-3

Table 7-4 Recommended Troubleshooting Equipment

5 - Performance Verification

VerificationEquipment............................................................

Picoammeter Verification

- Theory of Operation

RangeRelays

Filter Relay Switching

.....................................................................

.............................................................

7 - Maintenance

LineFuseSelection

CalibrationEquipment

Picoammeter Calibration.

................................................................

............................................................

..........................................................

..........................................

5-l

5-3

6-2

6-4

7-l

7-2

7-3

7.12

Page 34

Table 7-5

PowerSupplyChecks

Table 7-6 Digital Circuitry Checks

................................................

..............................................

Table 7-7 Analog Circuitry Checks. .............................................

Table 7-8

V-Source Checks (Model 487 Only).

....................................

APPENDICES

...........

...........

...........

...........

7-14

7-15

7-16

7-18

Table A-l

Table B-l

Table D-l

Table E-l

Table E-2

Table E-3

Table E-4

Table E-5

Device-dependent Command Summary

Model 486/487 Interface Function Codes

........................

.......................

BASIC Statements Necessary to Send Bus Commands

IEEE-488 Bus Command Summary.

Hexadecimal and Decimal Command Codes

Typical Addressed Command Sequence

Typical Device-dependent Command Sequence.

IEEE Command Groups

......................................

............................

....................

........................

.................

............

...........

...........

...........

...........

...........

.

...........

...........

...........

A-l

B-l

D-3

E-4

E-7

E-7

E-7

E-8

Page 35

SECTION 1

General Information

1.1 INTRODUCTION

This section contains general information about the

Model 486 Picoammeter and the Model 487 Picoammeter/vo1tage S&we.

1.2 FEATURES

Some important Model 486/487 features include:

DualDisplays-Alocharacteralphanumericdisplay

used for current readings and front panel messages,

and a smaller 8 character alphanumeric display for

front panel messages and the voltage source setting of

the Model 487.

zero correct - used to cancel internal offsets.

Relative @EL) -Used to establish baselines.

DataStore-CCanstoreupto512readingsandisaccessible over the bus 01 from the front panel.

User Programmed Default Conditions - Establish

present operating setup conditions as power-up de

fault conditions.

Talk-Only - From the front panel, set instnmwnt to

send readings over the bus to a listen-only device,

such as a printer.

V/I ohms resistance measurements up to 5OPQ

(Model 487 only).

Preset (Model 487) toggles between preset V-source

values

1.4 MANUAL ADDENDA

Any improvements or changes concerning the instrument or manual will be explained in an addendum included with the manual. Be sure to note these changes

and incorporate them into the manual.

1.5

The following symbols and terms may be found on an instrument or used in this manual.

The A

should refer to the operating inskwiions located in the

instmction manual.

The WARNING heading used in this manual explains

dangers that might result in personal injmy or death. Always read the assodated information very carefully before performing the indicated procedure.

The CAUTION heading used in this manual explains

hazards that could damage theinstnunent. Such damage

may invalidate the warranty.

SAFETY SYMBOLS and TERMS

symbol on an insinunent indicates that the user

1.6 SPECIFICATIONS

Model 486/487 specifications may be found at the front

of this manual.

1.3 WARRANTY INFORMATION

Warranty information is located on the inside front cover

of this inskwtion manual. Should your Model 486/487

require warranty service, contact the Keithley represen-

tative or authorized repair facility in your area for further

information. when returning the instrument for repair,

be sure to fill out and include the service form at the back

of this manual in order to provide the repair facility with

the necessary information

1.7 INSPECTION

The Model 486/487 was carefully inspected, both electrically and mechanically before shipment. After unpacking all items from the shipping carton, check for any obvious signs of physical damage that may have occurred

during transit. Report any damage to the shipping agent

immediately. Save the original packing carton for possible future reshipment. The following items are included

with every Model 4%/487 order.

l-l

Page 36

SECTION 1

General Information

Model 486 Picoammeter or Model 487 Picoammeter/

Voltage Source.

Model 486/487 Instruction Manual.

Model 2.36~IX-3 Interlock Cable (Model 487 only)

Model 237-ALG-2 Triax to Alligator-clip Cable.

Quick Reference Guide

Additional Accessories as ordered.

If an additional instnxtion

manual

is required, order the

manual package, Keithley part number 486-901-00. The

manual package includes an instruction manual and any

pertinent addenda.

1.6 OPTIONAL ACCESSORIES

The following accessories are available

use with the Model 486/487.

Model 4.288-l SingleFixed RackMount Kif -Mounts a sin-

gle Model 486/487 in a standard 19 inch rack.

from

Keithley for

Model 61713~slot to.Z-lug Triax Adapter- Adapts INPUT

connector for 2slot triax cables.

Model 7007 Shielded IEEE-488 Cables - Connects the

Mode1486/487 to the IEEE-488 bus using shielded cables

to

reduce electromagnetic interference @Ml). The Model

7007-l is one meter in length and has an EMI shielded

IEEE-488 connector at each end. The Model 7007-2 is

identical to the Model 7007-1, but is two meters in length.

Model 7078-TRXTriaxiaJ Cables-Low noise cables terminated with 3&t male triaxial cormectors. The Model

7078~TRX-3 is

O.Qm

(3 ft.) in length, the Model

7078TRX-10 is 3m (10 ft.) in length, and the Model

7078-TRX-20 is 61x1(20 ft.) in length.

Model 8002A High Resistance Test Fixture -Use with the

Model 487 to make high resistance W/II measurements.

The Model 8002 is designed to minimize leakage currents

that could otherwise degrade the measurement. Connectors in&de one pair of 5-way binding posts, two 3-lug

biaxial connectors, and a standard interlock connector

for the safety interlock switch.

Model 4288-2 DwJ Fixed Rack Mount Kit - Mounts two

Model 486/487s in a standard 19 inch rack.

Model 61 OS Resistivity Chamber -Use with the Model487

to measure the volume and surface resistivity of test samples. Accommodates sheet samples 64 to 102mm (2.5 to 4

in.) in diameter and up to 6.4mm (0.25 in.) thick.

Model 8006 Component Test Fixture-Provides a convenient and practical way of making sensitive test measure-

ments

on a variety of standard packaged devices. Sockets

are provided for resistors, diodes, 4-, 8; IO-, and 12-lead

axial (TO) packages, and DIPS up to 28 pins. Connectors

include 16 3-lug triaxial, two BNC, five 5-way binding

posts, and a standard interlock connector for the safety

interlock switch.

1-z

Page 37

SECTION 2

Getting Started

2.1 INTRODUCTION

This section contains introductory information on using

the Model 486 Pico-eter and the Model 487 Picoammeter/Voltage Source. For detailed front panel and

IEEE-488 bus operation, refer to Sections 3 and 4 mpeclively.

2.2 FRONT AND REAR PANEL CONFIGURATION

Figure 2-1 and Figure 2-2 show the respective front panek of the Models 486 and 487, while Figure 2-3 and

Figure 2-4 show the respective rear panels. Each of these

figures includes important information that should be reviewed before operating the instrument.

2-l

Page 38

SECllON 2

Getting Started

l-lx-ml

Ygure 2-1. Model 486 Front Panel

2-2

Page 39

SECTION 2

Getting started

gure 2-2.

Model 487 Front Panel

2-3

Page 40

SECTION 2

Getting Started

I

3-lug Triax

Current input

Trigger Connections

An;og

Output Binding

Posts

Chassis

Ground

3inding Posts

IEEE-438 Connector

BNC

Calibration Switch

(sticker cows access hole)

In = Calibration enabled

Out = Calibration disabled

Note : Use shielded IEEE-488 cable

Line Fuse

CAUTION : Replac- .___

with one of same type ant

rating : WA, 90-125V

114

Line Power Input

WARNING : Connect to

grounded outlet using

3-wire power cord

& Line Voltage Switch

1 105W125V

21 O-250V

(Optional transformer

required for 90-l 1 OV,

1 SO-220V operation)

CAUTION : Operation

on improper line

voltage may damage

unit

A, 180.250V

‘igure 2-3.

Model 486

Rear

Panel

2-4

Page 41

Binding Post

Fipre 2-4.

Interlock

Cur& input r0s’s

Model 487 Rear Panel

IEEE-488 Connector

Note : Use shielded IEEE-488 cable

1 Out = Calibration disabled 1

Line Fuse

CAUTION : Replace fuse

with one of 8ame type and

rating : f/z?A. go-12Sv

l/4 A, 180-250v

SECTION 2

Getting Started

Line Power Input

WARNING : Connect to

grounded outlet using

%wirs power cord

- Line Voltage Switch

105v-125v

210-250”

,n^+;..“..l ‘-41rmer

~~l-.~--.-. -_ .lOV,

1 SO-22OV operation)

CAUTION : Ooeration

on Improper I&

Voltage may damage

““II

2.3 BASIC FRONT PANEL OPERATION

The following presents the basic information needed to

use the Model 486/487 to make current measurements.

For the Model 487, a procedure to use the voltage source

in conjunction with the picoammeter is provided to

demonstrate V/I Ohms resistance measurements.

NOTE

Make signal input low connections only to

II’UT LO. Do not use ANALOG OUTPUT

LO for input connections.

Before attempting to operate the instrument, verify that

the rear panel line voltage switch is in the correct position for the power line voltage in your area. Connect the

instrument to an appropriate power source using the

supplied line cord, then turn on the power by pressing

in the front panel POWER switch.

WARNING

Use only a grounded ac outlet to avoid a possible shock hazard.

CAUTION

Operating the instrument an an incorrect

line voltage may cause damage to the

instrument.

NOTE

If the front panel display should appear to be

inoperative,

try pressing the DISPLAY

INTENSITY key once or twice to restore the

display to normal intensity.

2-5

Page 42

SECTION 2

Getting Started

2.3.1

The steps below outline the basic procedure for using the

Mode1486/487 to make current measurements from the

front panel:

1.

2.

3.

4.

5.

6.

7.

8.

Current Measurements

Perform factory initialization as follows to return the

instnunent to factory default conditions:

Press and rele&e MFNIJ until the following

A.

message is displayed:

DEFAULTS

B.

Use the rotary knob, or the4 and b keys to display the following message:

DEFAULTS FACTORY

Press MENU. The instrument will return to the

C.

normal IneasuTement display state.

Note: Performing factory initialization is a convenient method to return the instrument to typi-

cally used operating states. Using factoiy defaults, zero check is enabled, autorange is enabled, and filter (digital + analog) is enabled.

Connect the rear panel triax INPUT connector to the

current source. For example, Figure 2-5 shows a

Keithley Model 263 source connected to the Model

486/4si

On the Model 486/487, press SHIFT and then COR-

RECT to perform zero cormztion. This will cancel

ally inted offsets.

On the Model 486/487, disable zero check by pressingZEROCHECK.The~OCHECKindicatorwill

turn off.

If you intend to suppress an offset current from the

external current source, perform the following steps:

A. Apply the current to be suppressed to the input.

That current will be measured and displayed on

the Model 4861487.

B. On the Model 486/487, press REL. The current

will be suppressed as indicated by the zeroed

display.

Apply the signal current to be measured to the input

of the Model 486/487.

Read the current measurement on the display of the

Model 486/487.

When the measurement is complete, enable zero

check to avoid accidental overloads to the instrument. In general, zero check should be left enabled

while the instrument is tuned on but not in use.

OK

2.3.2 V/I Ohms Measurements

(Model 487)

NOTE

The following procedure demonstrates how

to properly use the V-Source of the Model 487.

Keep in mind that the V-Source can be used as

an &dependent source for any appropriate

application.

For V/I Ohms resistance measurements, the Model 487

sources a voltage to a device under test (DUT) and measures the subsequent current. The resistance value of the

DLIT is automatically calculated (R = V/I) and displayed

in ohms.

The steps below outline the basic procedure for using the

Model 487 to make V/I Ohms measurements from the

front panel:

1. Performfactory initializationasfollows toretumthe

instroment to factors default conditions:

Press and relea;e MENU until the following

A.