Page 1

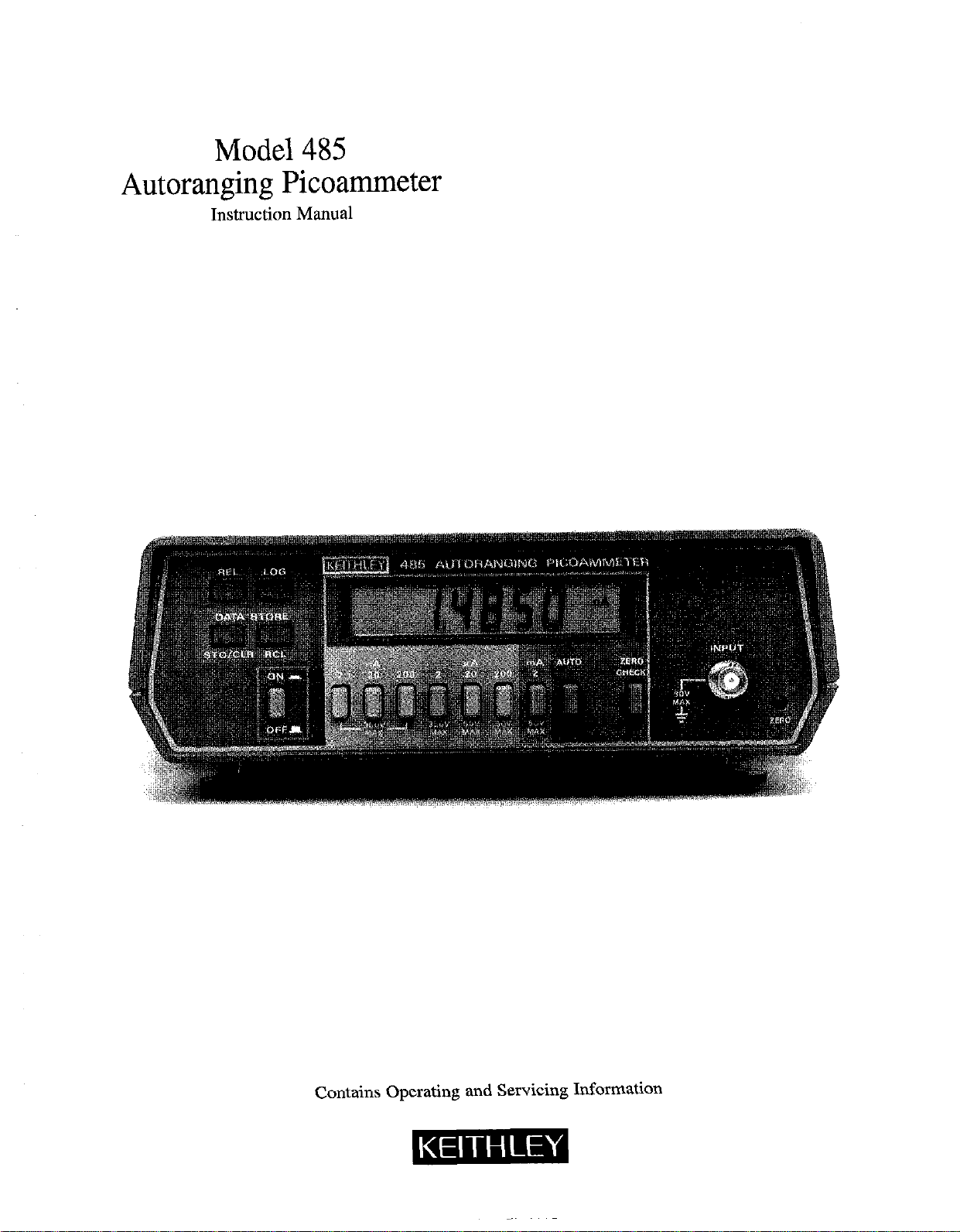

Model 485

Autoranging Picoammeter

Instruction Manual

Contains Operating and Servicing Information

Page 2

WARRANTY

Keithley Instruments, Inc. warrants this product to be free from defects in material and workmanship for a period of 1 year from date of

shipment.

Keithley Instruments, Inc. warrants the following items for 90 days from the date of shipment: probes, cables, rechargeable batteries,

diskettes, and documentation.

During the warranty period, we will, at our option, either repair or replace any product that proves to be defective.

To exercise this warranty, write or call your local Keithley representative, or contact Keithley headquarters in Cleveland, Ohio. You will

be given prompt assistance and return instructions. Send the product, transportation prepaid, to the indicated service facility. Repairs

will be made and the product returned, transportation prepaid. Repaired or replaced products are warranted for the balance of the original warranty period, or at least 90 days.

LIMITATION OF WARRAN-IY

This warranty does not apply to defects resulting from product modification without Keithley’s express written consent, or misuse of

any product or pwt. This warranty also does not apply to fuses, software, non-rechargeable batteries, damage from battery leakage, or

problems arising from normal wear or failure to follow instructions.

THIS WARRANTY IS IN LlBU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING ANY IMPLIED

WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR USE. THE REMEDIES PROVIDED HEREIN ARE

BUYER’S SOLE AND EXCLUSIVE REMEDIES.

NEITHER KBITHLEY INSTRUMENTS, INC. NOR ANY OF ITS EMPLOYEES SHALL BE LIABLE FOR ANY DIRECT, INDIRECT, SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES ARISING OUT OF THE USE OF ITS INSTRUMENTS AND

SOFTWARE EVEN IF KEITHLEY INSTRUMENTS, INC., HAS BEEN ADVISED IN ADVANCE OF THE POSSIBILITY OF

SUCH DAMAGES. SUCH EXCLUDED DAMAGES SHALL INCLUDE, BUT ARE NOT LIMITED TO: COSTS OF REMOVAL

AND INSTALLATION, LOSSES SUSTAINED AS THE RESULT OF INJURY TO ANY PERSON, OR DAMAGE TO PROPERTY

Keithley Instruments, Inc. - 28775 Aurora Road *Cleveland, OH 44139~216-248-0400 -Fax: 216-248-6168 * http://www.keithley.com

Page 3

Model 485 Autoranging Picoammeter

Instruction Manual

0 1984, Keithley Instruments, Inc.

Test Instrumentation Group

All rights reserved.

Cleveland, Ohio, U.S.A.

January 1990, Sixth Printing

Document Number: 485-901-01 Rev. F

Page 4

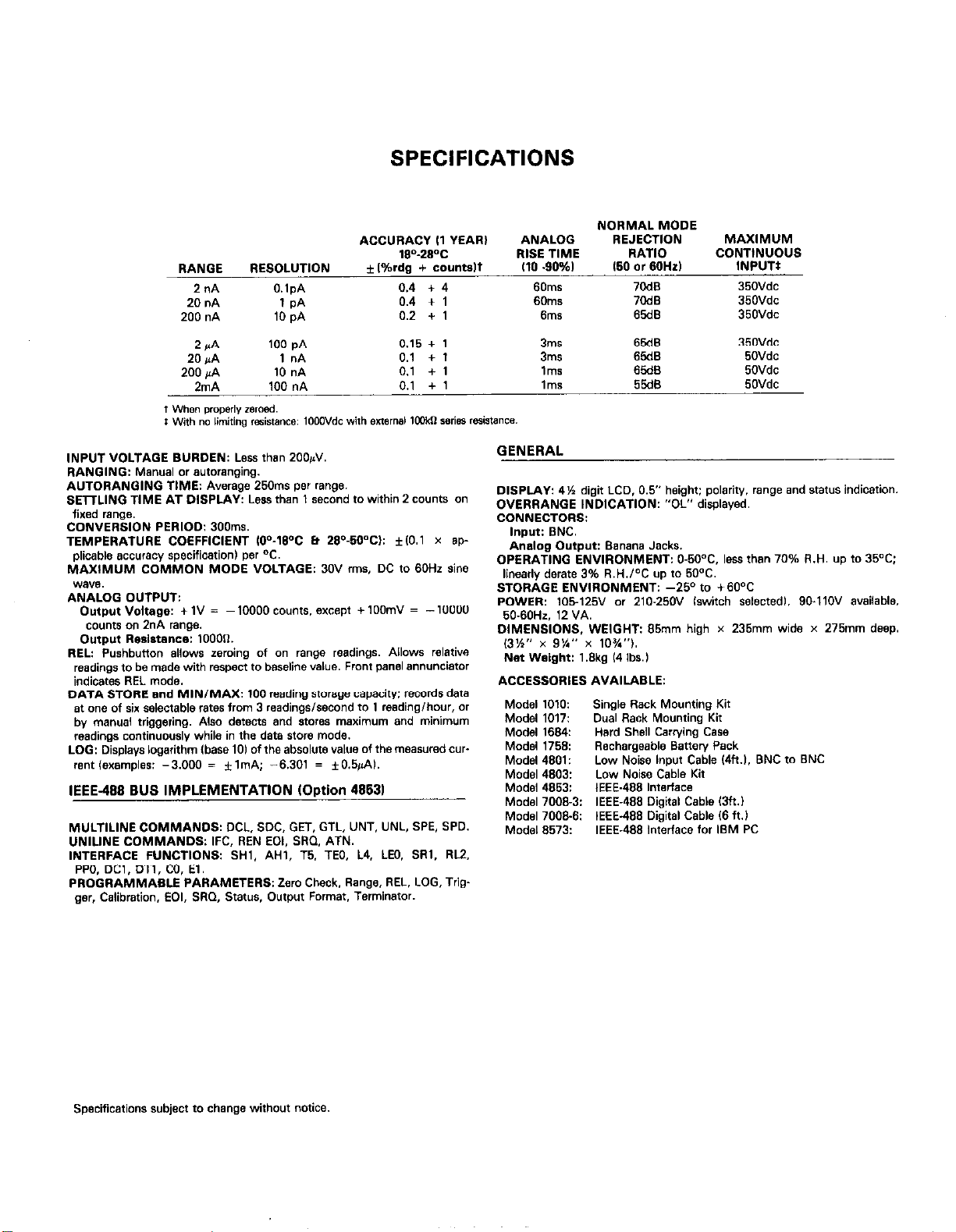

SPECIFICATIONS

ACCURACY I1 YEAR,

lW28~C

RANGE

2nA

20

200

RESOLUTION

“A 1 PA

“A 10 pA

O.lpA

2 PA 100 PA

20

!A 1 nA

200

,‘A 10 “A

2mA

,NP”T VOLTAGE BURDEN: Less than 200&V.

RANQING: Manual or autoranging.

AUTORANGING TIME: Average 250ms per range.

SmLlNG TIME AT DISPLAY: Less than 1 second to within 2 co”nts on

fixed range.

CONVERSION PERIOD: 300,“s.

TEMPERATURE COEFFICIENT 10°-160C B 26°-50”C,: f10.1 x BP-

plicable sccuracy specification) per OC.

MAwMUM COMMON MODE VOLTAGE: 30V rms. DC to 60Hz sine

100 “A

* l%rdg + countslt

0.4 + 4

0.4 + 1

0.2 + 1

0.15 + 1

0.1 + 1

0.1 +1

0.1 +1

WWB.

ANALOG OUTPUT:

Output Voltage: + IV = - 10000 co”ntf.. mept + 1OOmV = - 10000

mints 0” 2nn range.

OUtput tIea,*tance: 10000.

REL: Pushbutton allows zeroing of an range readings. Allows relative

readings to be made with respect to baseline value. Front panel ~nnuncistor

indicates REL mode.

DATA STORE and MINIMAX: 100 reading storage capacity: records data

at one of six selectable rates from 3 readings/second to 1 reading/hour, or

by manual triggering. Also detects and stores maximum and minimum

readings comin”““sIY while in the data store mode.

LOG: Displays logarithm (base 101 of the absolute value of the measured C”F

rent Iexamples: -3.000 = *ImA; -6.301 = +O.$Al.

IEEE-488 BUS IMPLEMENTATION (Option 48631

MULTILINE COMMANDS: DCL, SDC, GET, GTL, “NT. UNL. SPE. SPD.

UNILINE COMMANDS: IFC, REN EO,. SRC. ATN.

INTERFACE FUNCTIONS: SHl. AH,, T5. TEO. L4, LEO. SRI, RL2,

PPO. DCl, DTI, CO, El.

PROGRAMMABLE PARAMETERS: Zero Check. Range, REL. LOG, Trig-

ger, Calibration. EO,, SRO, Status. 0”tp”t Format. Terminator.

ANALOG REJECTION

RISE TIME RATIO

I10 .SO%, IS0 or EOHz, INPUTt

60ms

60iTlS

6rnS

3ms

3ms

lms

lms

GENERAL

DISPLAY: 4% digit LCD, 0.5” height: polarity. range and staf”s indication.

OVERRANGE INDICATION: “OL” displayed.

CONNECTORS:

Input: ENC.

Analog Output: Banana Jacks.

OPERATING ENVIRONMENT: 0-50.X. less than 70% R.H. up to 35’C:

linearly derate 3% R.H./OC up to 5OOC.

STORAGE ENVIRONMENT: -25O to +BO”C

POWER: lOF,-125V or 210.250V (switch selected,. go-llOV available.

SO-6OHr. 12 VA.

DIMENSIONS, WEIGHT: 65mm high Y 235mm wide x 275mm deep.

(3%” x 9%” x lO%“,.

Net Weight: 1 .Skg I4 Ibs.)

ACCESSORIES AVAILABLE:

Model 1010:

Model ,017:

Model 1664:

Mods, 1758:

Model 4801:

Model 4603:

Model 4653:

Model 7006-3:

Model 7006-6:

Model 6573:

NORMAL MODE

7OdB

7OdB 350Vdc

65dB 350Vdc

6FdB 350Vdc

65dB 5O”dc

65dB 5OVdc

55dB

Single Rack Mounting Kit

Dual Rack Mounting Kit

Hard Shell Carrying Case

Rechargesble Battery Pack

Low Noise Input Cable (4ft.l. BNC to ONC

Low Noise Cable Kit

IEEE-486 Interface

IEEE-466 Digital Cable 13ft.b

IEEE-468 Digital Cable 16 ft.1

IEEE-488 Interface for IBM PC

MAXIMUM

CONTINUOUS

350”dC

5OVdc

Specifications subject to change without notice.

Page 5

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

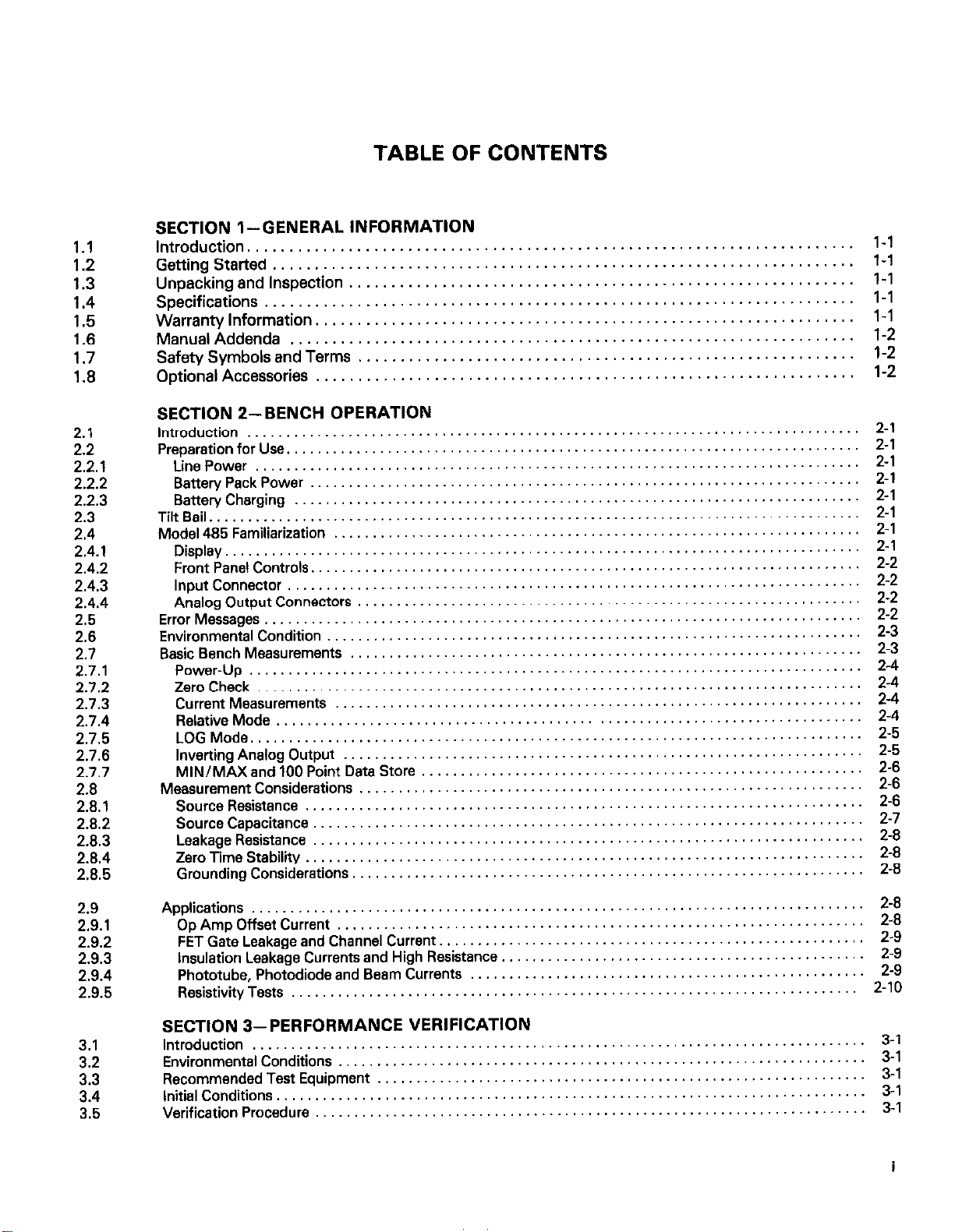

TABLE OF CONTENTS

SECTION l-GENERAL INFORMATION

Introduction.

Getting Started

Unpacking and Inspection

Specifications

Warranty Information.

Manual Addenda

Safety Symbols and Terms

Optional Accessories

........................... ...... ......

.........................

................

..........................

...................

.......................

...............

....................

...... ......

...... ......

......

...... ......

...... ......

...... ......

...... ......

......

......

......

......

......

......

. ......

......

......

......

......

......

......

......

......

......

......

l-1

1-l

l-l

l-l

l-l

1-2

1-2

l-2

2.1

2.2

2.2.1

2.2.2

2.2.3

2.3

2.4

2.4.1

2.4.2

2.4.3

2.4.4

2.5

2.6

2.7

2.7.1

2.7.2

2.7.3

2.7.4

2.75

2.7.6

2.7.7

2.8

2.8.1

2.8.2

2.8.3

2.8.4

2.8.5

SECTION Z-BENCH OPERATION

introduction ...............................................................................

PreparationforUse

Line Power ..............................................................................

Battery Pack Power .......................................................................

BatteryCharging

TntBail ....................................................................................

Model 485 Familiarization

Display

FrontPanelControls

InputConnector ..........................................................................

AnalogOutputConnectors

Error Messages

EnvironmentalCondition .....................................................................

BasicBenchMeasurements

Power-Up ...............................................................................

Zero Check ..............................................................................

Current Measurements ....................................................................

RelativeMode

LOGMode ...............................................................................

Inverting Analog Output ...................................................................

MIN/MAXand 100 Point Data Store

MeasurementConsiderations

SourceResistance ........................................................................

SourceCapacitance

LeakageResistance .......................................................................

ZeroTimeStability

Groundingconsiderations

..................................................................................

..........................................................................

.........................................................................

....................................................................

.......................................................................

.................................................................

.............................................................................

..................................................................

...........................................................................

.........................................................

.................................................................

.......................................................................

........................................................................

..................................................................

2-l

2-l

2-l

2-l

2-l

2-1

2-l

2-l

2-2

2-2

2-2

2-2

2-3

2-3

2-4

2-4

2-4

2-4

2-5

2-5

2-6

2-6

2-6

2-7

2-8

2-8

2-8

2.9

2.9.1

2.9.2

2.9.3

2.9.4

2.9.5

3.1

3.2

i::

3.5

Applications

Op Amp Offset Current

FET Gate Leakage and Channel Current.

Insulation Leakage Currents and High Resistance.

Phototube, Photodiode and Beam Currents

Resistivity Tests

SECTION 3-PERFORMANCE VERIFICATION

Introduction ......................................

Environmental Conditions

Recommendrsd Test Equipment

Initial Conditrons

Verification Procedure

................................................. .........................

......................................

.......................

.....................

............................................

...........................

......................

...................................

..............................

................

.........................

.........................

.........................

.........................

.........................

..................

,,....

,,....

..................

..................

..................

..................

3-l

3-l

,. 3-l

3-1

3-l

i

Page 6

4.1

4.2

4.3

4.3.1

4.3.2

4.3.3

4.3.4

4.3.5

4.4

4.4.1

4.4.2

4.4.3

4.4.4

4.5

4.6

4.7

5.1

5.2

5.3

5.4

5.4.1

5.4.2

5.4.3

5.4.4

5.4.5

5.5

5.6

5.6.1

5.62

5.63

5.6.4

5.6.5

5.7

5.8

5.9

TABLE OF CONTENTS (CONT.)

SECTION 4-THEORY OF OPERATION

Introduction ...............................................................................

Overall Functional Description. ................................................................

AnalogCircuitry ............................................................................

Current-to-Voltage Converter ...............................................................

Multiplexer ............................................................................

InputBufferAmplifier .....................................................................

-2VReferenceSource .....................................................................

AIDConverter.. ......................................................................... 4-3

Digital Circuitry .............................................................................

Microcomputer ...........................................................................

Address Decoding ........................................................................

PIA .....................................................................................

DisplayBoard.. ..........................................................................

Digital Calibration ...........................................................................

PowerSupply ..............................................................................

Model 1758 Battery Option ...................................................................

SECTION 5-MAINTENANCE

Introduction ...............................................................................

Top Cover Removal/Installation ...............................................................

Battery Pack (Model 1758) Installation

Front Panel Calibration ......................................................................

Recommended Calibration Equipment.

CalibrationJumper ........................................................................

Environmental Conditions ..................................................................

Calibration Procedure. .....................................................................

CalibrationStorage ........................................................................

Calibration Over IEEE-488 Bus .................................................................

Troubleshooting ............................................................................

Recommended Test Equipment .............................................................

Self Diagnostic Program ...................................................................

Power Supply and Battery Pack (Model 1758) Checks

A/D Converter and Display .................................................................

SignalConditioning .......................................................................

Input Amplifier NJ105) Balancing ..............................................................

LineFuseReplacement ......................................................................

Special Handling of Static Sensitive Devices.,

.........................................................

.......................................................

...................................................

4-2

...........................................

4-l

4-l

4-l

4-1

4-2

4-3

4-4

4-4

4-4

4-4

4-4

4-4

4-4

4-4

5-I

5-l

5-l

5-l

5-1

5-2

6-2

5-2

5-2

5-3

5-3

5-3

5-3

5-6

5-6

5-7

5-7

5-7

5-8

6.1

if

6.4

6.5

SECTION B-REPLACEMENT PARTS

Introduction ...............................................................................

ReplaceableParts ...........................................................................

Ordering Information ........................................................................

FactorySen/ice .............................................................................

Component Location Drawings and Schematic Diagrams

ii

..........................................

6-l

6-l

6-l

6-l

6-l

Page 7

LIST OF ILLUSTRATIONS

2-1

2-2

2-3

2-4

2-5

2-6

2-7

Z-8

2-9

2-10

3-l

4-l

4-2

4-3

4-4

4-5

5-I

5-2

6-l

6-2

6-3

6-4

6-5

6-6

6-7

6-8

Model485FrontPanel ....................................................................... 2-2

Model 465 Inverting Analog Output

Simplified Model for Input Signal Conditioning

Test Fixture Guarding ....................................................................... 2-8

LeakageTestSetUpUsingModel6104 ........................................................ 2-8

Op Amp Input Offset Currents Measurement

F5T Gate Leakageand Channel Currents Measurement.

Insulation Leakage Currents end High Resistances Measurement .................................... 2-9

Set Up to Measure Photomultiplier, Photodiode end Beam Currents .............................. ,, 2-9

ResistivityTestSetUp

Shielded Test Fixture ........................................................................ 3-2

Simplified Block Diagram ..................................................................... 4-l

Current-to-Voltage Converter

Simplified Schematic of the Multiplexer

Simplified Schematic of the Input Buffer Amplifier

AIDConverter

Segmentldentification

JumperLocations ...........................................................................

Model485MiscelianeousParts

Display Assembly

Mother Board, Component Location Drawing. Dwg. No. 485-100

Mother Board, Schematic Diagram, Dwg. No. 485-106., .......................................... 6-9

Display Board, Component Location Drawing, Dwg. No. 485.110 ................................... E-13

Display Board, Schematic Diagram, Dwg. No. 485-116

Model 1758 Battery Peck, Component Location Drawing, Dwg. No. 1758-100 ......................... 615

Model 1758 Battery Peck, Schematic Diagram, Dwg. No. 1768-106 ................................. 6.16

.............................................................................

......................................................................

.......................................................................

...........................................................................

........................................................... 2-6

..................................................

....................................................

...........................................

.................................................................

.........................................................

................................................

...............................................................

...................................

............................................

2-7

2-8

2-9

Z-IO

4-2

4-2

4-2

4-3

5-4

5-7

6-2

6-3

6-7

6-14

iii

Page 8

LIST OF TABLES

2-1

2-2

2-3

3-1

3-2

5-1

5-2

5-3

5-4

5-5

5-6

5-7

5-8

6-1

6-2

83

8-4

Error Messages.. ..........................................

Range, Accuracy and hlaximum Allowable Inputs

Equivalent Input Resistance With Zero Check Enabled

Recommended Test Equipment ..............................

RangeAccuracy ...........................................

Range Calibration ..........................................

Recommended Troubleshooting Equipment

TroubleshootingModes .....................................

Power Supply Checks and Battery Pack (Model 1758) Checks

A/DConverterChecks ......................................

DisplayBoardChecks ......................................

OffsetJumparSetUp ......................................

Static Sensitive Devices ....................................

Mother Boerd, Parts List ....................................

Display Board, Parts List ....................................

Model 1758 Battery Pack, Parts List ...........................

Model485SperePartsList ..................................

...............

............

....................

.....

.......

.......

.......

.......

2-3

2-3

2-4

3-l

3-2

5-3

5-3

5-5

6-6

6-6

5-7

5-7

5-8

6-4

6-13

6-15

6-17

iv

Page 9

SAFETY PRECAUTIONS

The following safety precautions should be observed before operating the Model 485.

This instrument is intended for use by qualified personnel who recognize shock hazards and are familiar

with the safety precautions required to avoid possible injury. Read over the manual carefully before

operating this instrument.

Exercise extreme caution when a shock hazard is present at the instrument’s input. The American

National Standards Institute (ANSI) states that a shock hazard exists when voltage levels greater than

30V rms or 42.4V peak are present. A good safety practice is to expect that a hazardous voltage

is present in any unknown circuit before measuring.

Do not exceed 30V rms between the input connector shell and earth ground.

Inspect the test leads for possible weer, cracks or breaks before each use. If any defects are found,

replace with test leads that have the same measure of safety as those supplied with the instrument.

For optimum safety do not touch the test leads or the instrument while power is applied to the circuit

under test. Turn the power off and discharge all capacitors, before connecting or disconnecting the instrument.

Do not touch any object which could provide a current path to the common side of the circuit under

test or power line (earth) ground. Always make measurements with dry hands while standing on a dry,

insulated surface, capable of withstanding the voltage being measured.

Do not exceed the instrument’s maximum allowable input as defined in the specifications and operation

section.

Safe operation and good measurement practice dictates use of an external resistor when necessary to

limit input currents to less than 3mA.

Page 10

Model 485 Addendum

me following idormation is supplied as a supplement to tfi manual k order to prmide the user

with the latest tiprovements. It is recommended that vefication tio~tion k added to Section 3

of the Model 485 Instiction Manual and c&bration tifomatimr be added to Section 5.

~is addendum contatis complete procedures for vefi@g and cahhatig the Model 485 ustig the

WltMq Model 2& Cdibmtor/Somce. Complete sepmate pmcedmes a pmtided for @otig di@ti

calibration horn either the hont panel or over the IEEE+8 bus. Dgitd ctibration over the bus is

automated ustig a BASIC pro~am mn @ the W 85 computer.

PA-2w Rev. A / 149

Page 11

PERFORMANCE VERIFICATION USING

MODEL 263 ~LIBRATOR/SOURCE

Use of the Model 263 to verify ac~aq specifications of

the Model 485 stip~ies the prored~ by etiating the

need for user desi~ed _nt somces. The quipment

fisted h Table >1 of the manual is not needed.

Idetiy performance verification shotid be perfomed

when the tis~ent k first received to emm that no

daage or chmge h calibration has ocmed dtig ship

ment. It may&O be perfomed when fi~ent acwa~

is swpe~ Orfo~w~ c~bration. E perfmrnance on any

of the rmges ia outside the specified tits, ctibrate the

titiment.

NOTE

Mthe

~ent does not meti spedicatiom md

is stfl under warrmty ~ess thm Q months stice

date of shipment), con~d your ~lMey mpmsentative Orthe factory b detetie the atimr to &

t&en.

2. Tm on the Models 485 and 263, and allow them to

wm up for one hour. The Model ~ may be operated

from either ~ie power or battery pack power, as long

as the batteq pack has been fu~y charged..

Veficatirur Prncedw

Weed as fo~ows to verify the accuraq of the Model 485:

1. On the Model 485, press ZERO CHECK and select the

M rmge.

2. With an open input, adjust the ZERO pot for .0000 *1

cmrnt on the display.

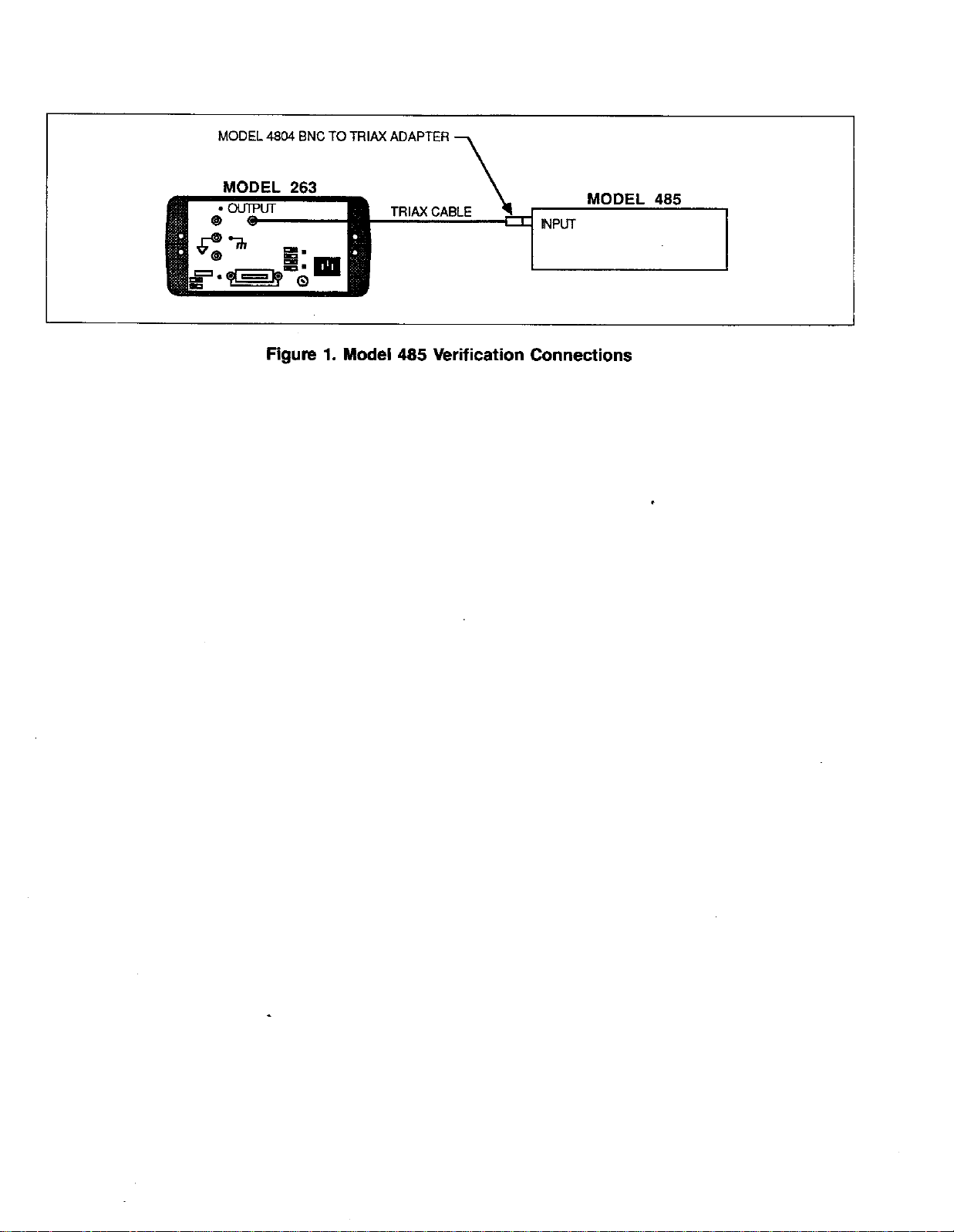

3. Comect the Model 263 to the Model 485 as shown in

Fi~e 1. Make sue the cdlbrator is in standby.

4. Relesae ZERO CHECK on the Model 485.

5. Using the AMPS (adive) c~nt source, program the

Model 263 to output 1.90~nA and verify that the

reading is within the Itits h Table 1,

6. Using Table 1 as a guide, check the rest of the current

ranges by applying the a~ropriate current and verifying that the reatig is within the allowable limits.

Etimenti Condltiom

M measurements shodd be made at m mbient

temperature b~een M“ md 28°C (&” to 82°~ with a

relatiw humidity less thm 70°h.

Irritid

Conditimra

Before perfofig the verification procedure, m&e sure

the Models 485 md 263 meet the fo~owtig conditiom:

1 E the tis~ents have been subjed b tempmams

blow M°C (&°F) Orabom 28°C (82°F), dow sufficient

tie for the titruments to reach temperahs tithti

the rmge. GenerWy, it tskes one hour to stabtie m

irrs~ent that is M“C (MOF)outside of the specfied

range.

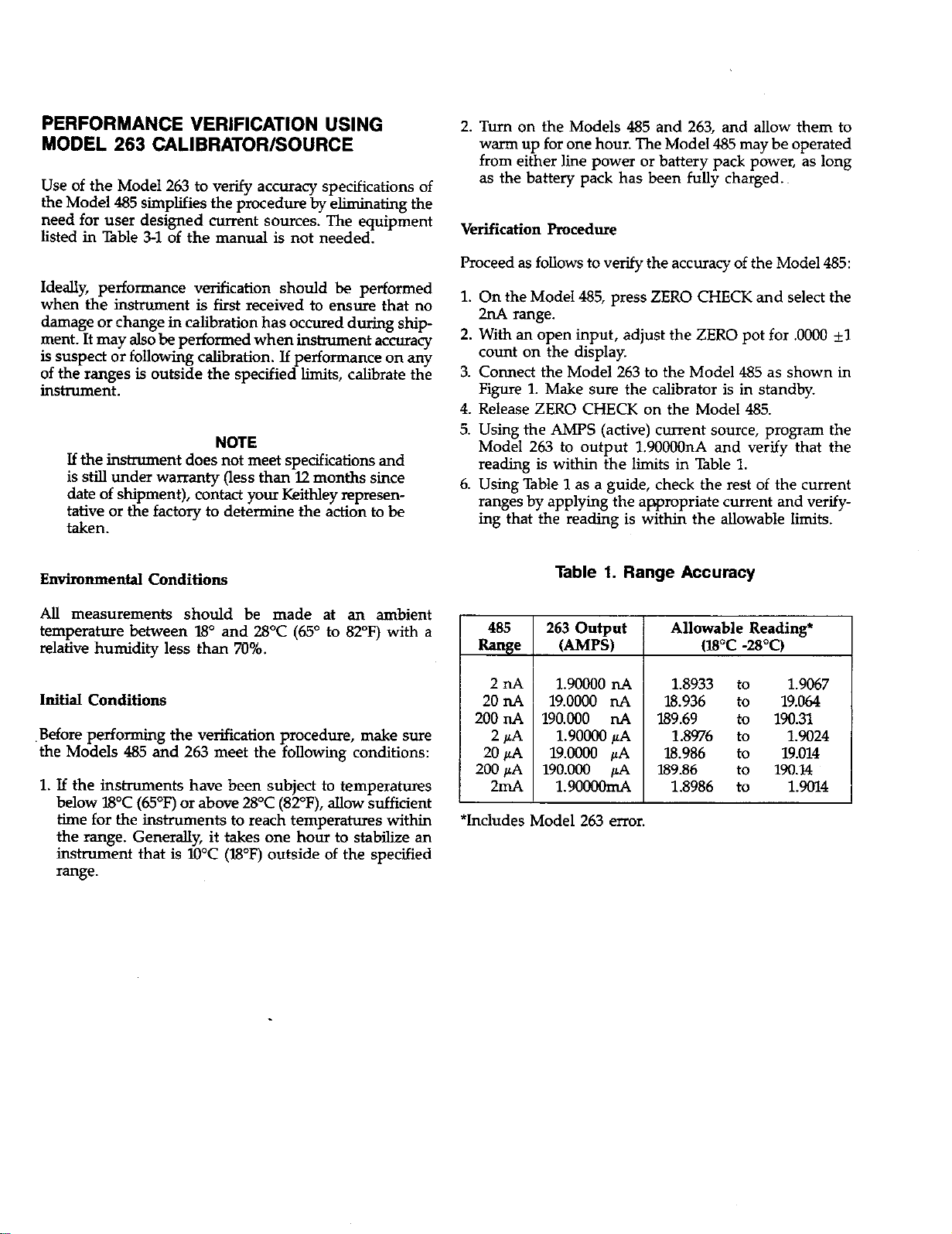

Table 1. Range Accumcy

263 Output

(AMPS)

1.90M0 A

19.0000 M

190.WO A

1.90000 PA

19.0000 ~A

190.000 @

1.9oooofl

*Includes Model 263 error.

Allowable Reading*

(M”C -28°C)

1.8933 to

B.936 to

M9.69 to

1.8976

28.986

to

to

E9.86 to

1.8986 to

1.9067

19.064

190.31

1.9024

19.014

lW.14

1.9014

Page 12

MODEL 4W BNC TO TRIW ADAPTER

MODEL 263

Rgum 1. Model 485 Verification Connections

\

MODEL 485

.

Page 13

CALIBRATION USING MODEL 263

CALIBRATOWSOURCE

me fo~oting pua~aphs ptide detded pmcedwes for

c~bratig the Model 485 Picommeter using the Model

263 Wbrator/Some. M but one of the cfibratimr adjmtienta ~e digiti md ~ & done km the ~nt pmel

m over the ~EE~ bus.

TOc~brate the tis~ent bm the tint pmel, pefiom

the fo~otig pmedures, muitig pma~aph ‘TEEE=

BW Cfibration”. TO ctibate the Model 485 over the

=4 bus, pdom the foflwtig pmedmes, ornitig

pmagaph ‘Tmnt ~el Mbration”.

Environmental Conditions

C~bration shmdd be pefiomed under labrato~ ccm&tiom hatig m -bient tempera~ of 23 +l°C md a

relative hufidity of less tha 70%. With both the Model

485 and 263 on, dow them to wam up for one hem. K

either ina~ent has ken subjected to mtieme temperatim or hufidity, dow at least one ad~tiond how for

the titiment to stabike before be@tig the ctibration procedw.

NWE

Cfibration can be stopped at ay tie md ody

those ranges out of spwificatimr need be cdbra~d.

Calibmtion Stomge Enable

The Model 485 mmt be in cfibratimr storage enable to

stem cfihation comtita h NVRAM. E the instiment

k not placed h ti mode, subsequent ctibration W be

lost when the ~

~g steps tO enable cab~mtiOn stOrage.

1. Mthe Model 485 is presently rm, * it off.

2. We holtig k the S~/CLR button, - the ina~ment back on.

3. When the “CA~ message is displayed, mle=e the

~/CLR button. The ina~ent ti ~ to the rmrmd diapl~ mode md the stotig of cdibratimr cons~ts is now enabled.

at k bd off. @fiOm the fOflw-

Required Equipment

The fo~-g item (one of each) me necess~ ti ctihate

the Model ~:

1. WitMq Model 263 Cti&ator/Some.

2. Trim to Tri= Cable (suppfied with 263)

3. kiW~ Model W Mde BNC to Pemde Tfi Adapter.

N~: The fo~owtig ad~tiond item@ be nwces~

if c~bration is to be petioned over the ~E4 bus.

4. KiMey Model 4853 EEE48 Intetiace tisti~ed h the

Model 485.

5. ~ 85 Computer eqtipped tik ~ 82937 GP~ kterface md 1/0 ROM.

6. KltMey Model 7008 ~E cable.

Front Panel Calibmtion

Petiom the foE- steps to dbrate the Model& tim

the front pmek .

1. On the Model 485, depress ZERO C~CK and select

the M rmge.

2. With m open tiput, adjust the Z~O pot for.~ AI

count on the display.

N~E

H

Q104, U105, RIU, Rl14 or RIB hwe been replaced, the pico-der may not zero. See paa&aph 5.7 h the Model& btition Manual fur

the pmcedti to bdmce the tiput amp~er.

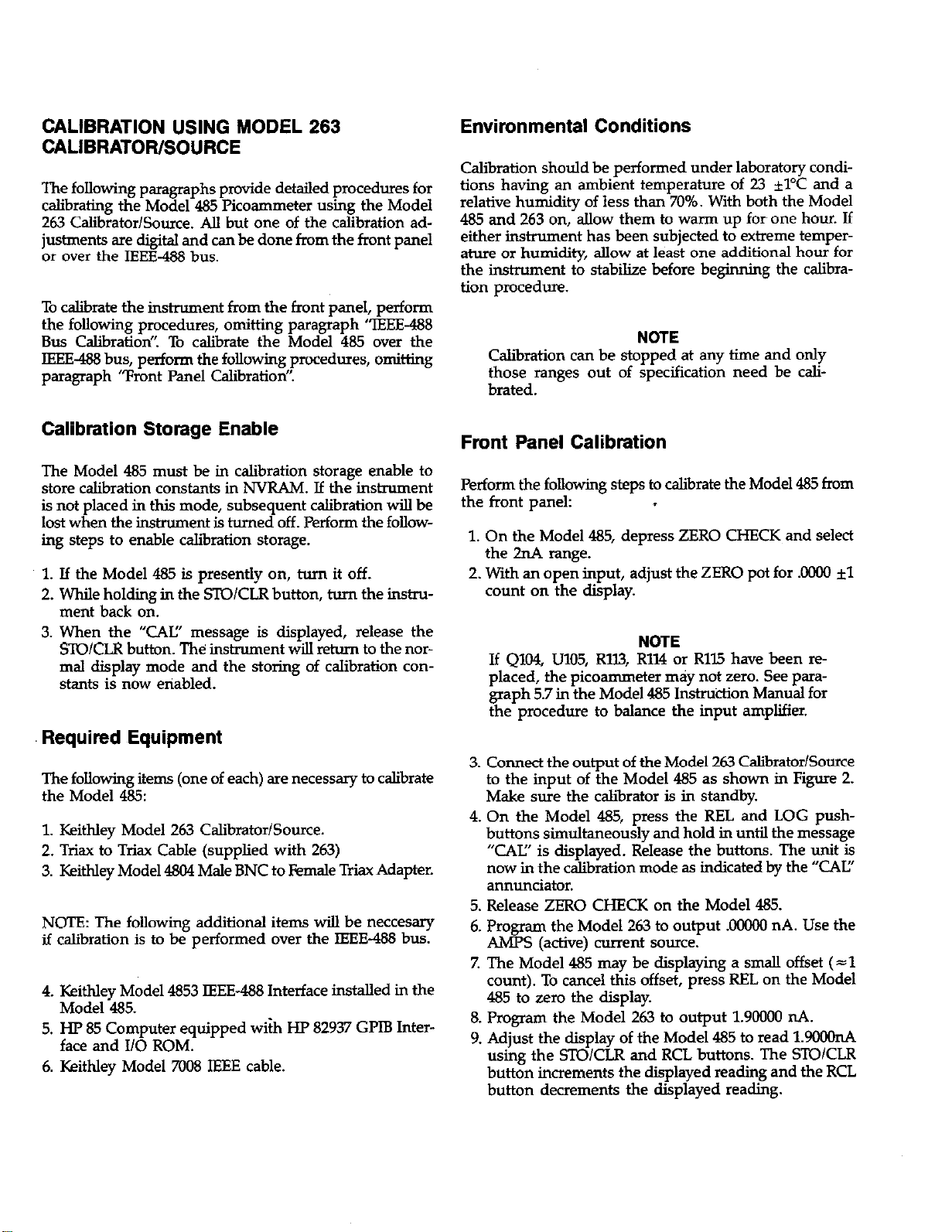

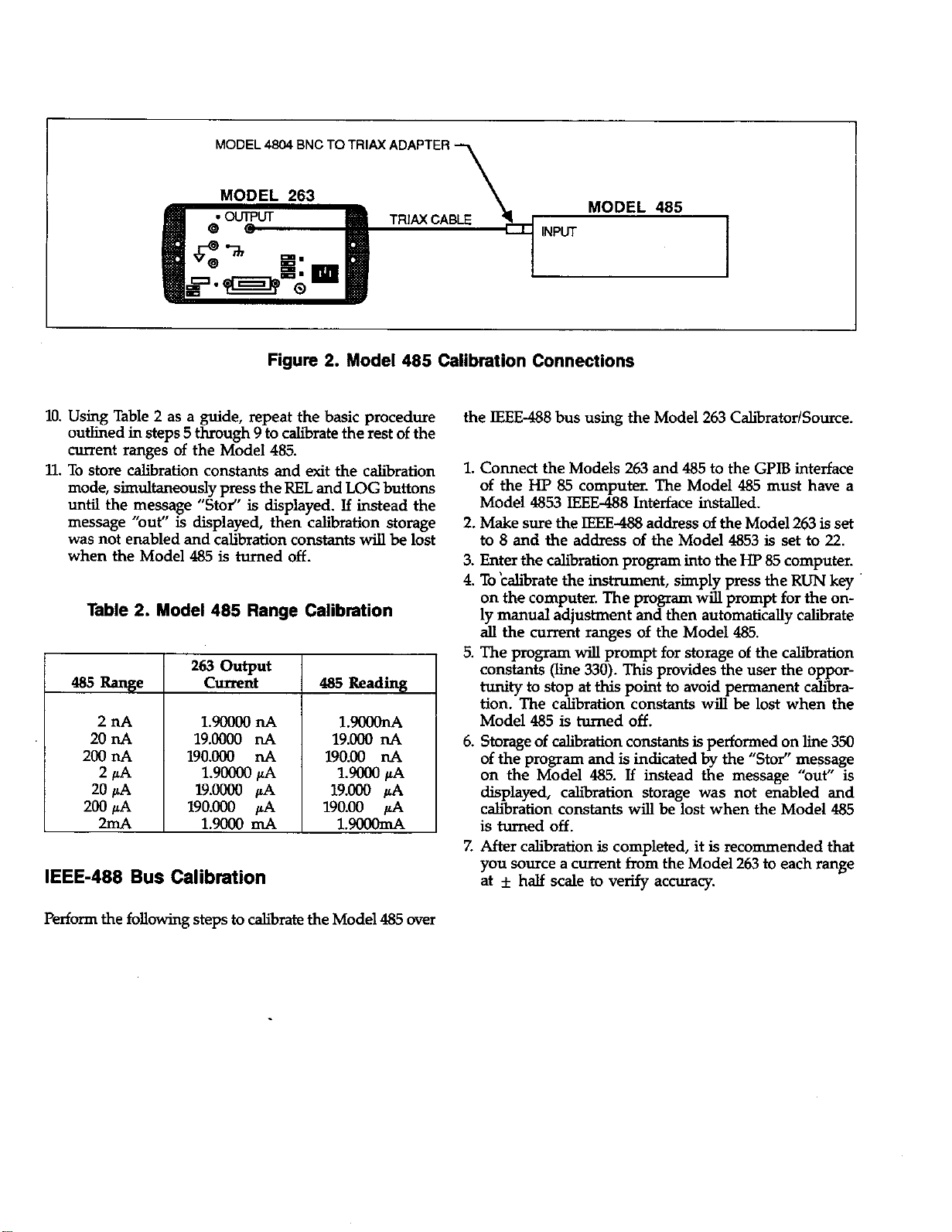

3. Comect the output of the Model 263 ~hatur/Sowe

to the tiput of the Model 485 as show h Fi~ 2.

M*e sue the ctibrator is h standby.

4. On the Model 485, press the R~ arrd ~G pwhbuttmrs stidtanemrsly md hold k unti the message

“CAH is &played. Release the buttons. The tit is

now h the c~bration mode m kdicated by the “~~

annunciator.

5. Release Z~O HCK on the Model 485.

6. Pro&mn the Model 263 to output .m nA. Use the

AMPS (active) -ent some.

7. The Model& maybe displaying a smfl offset (=1

count). TOcmcel this offset, press ML rm the Model

485 to zem the display.

8. Pro~a the Model 263 to output 1.900W nA.

9. Adjust the display of the Model 485 to read l.~

uatig the S~/CLR md RCL httons. The STO/CLR

button hcrements the displayed reading and the R~

button demments the displayed reatig.

Page 14

MODEL 4W BNC TO TRl~ ADAPTER ~

MODEL 263

MODEL 485

Rgum 2. Model 485 Catibmtion Connections

10. Ustig Table 2 as a guide, repeat the basic pmcedme the ~E48 bus ustig the Model 263 C~brator/Sowe.

oufltied h steps 5 thmuxh 9 to ctibrate the rest of the

-ent range; of the M;del 485.

11. TOatom A:bration comtmta md ~t the ctibration

mode, simti~eously press the ~ md LOG buttom

UM the message “Stofl is &played. E titead the

message “ouf’ is displayed, then ctihation storage 2. Make sue the =488 adtiess of the Model 2@ is set

was not embled md cahbatimr crmstits W be lost

when the Model N is tied off.

Table 2. Model 485 Range Calibtion

263 titput

Cumnt

1.90000 d

485 Readtig

19.0000A

190.000 A

Lm &

19.0000@

190.000 @

1.9W d

IEEE-488 Bus Calibmtion

1. Comect the Models 263 md 485 to the GP~ titefiace

of the HP 85 computm. The Model 485 mti have a

Modd &53 ~488 htefiace tistied.

to 8 md the adhss of the Model 4853 is set to 22.

3. Enter the c~iration pm~m tito the HP 85 computer.

4. TO‘dbmte the titiment, stiply press the R~ key

on the computi. The -m wfl prompt for the Only marmd adjustimt md then automatically cdbrate

d the mmnt rmges of the Model 485.

5. The pm-@ prompt for storage of the c~tiation

constita me 330). ~ ptides the user the opportity to stop at this petit to avoid pemment cAha-

tiOn. me Ctibation con~ts WM ~ lost when the

Model 485 is tied off.

6. Stomge of c~bmtion comtits is pefimed mrhe 350

of the pmga md is tidcated by the “Stofl message

on the Model 485. H btead the message “out” k

displayed, c~iratiorr storage was not enabled md

c~bmtion com~ts w~ be lost when the Model &

is ~ed off,

Z After c~bration is completed, it is mcomended that

you somce a mnt fmm the Model 263 to each rmge

at k h~ scale b verify acwacy.

Pdom the fofltig steps to dbrate the Model 485 mr

Page 15

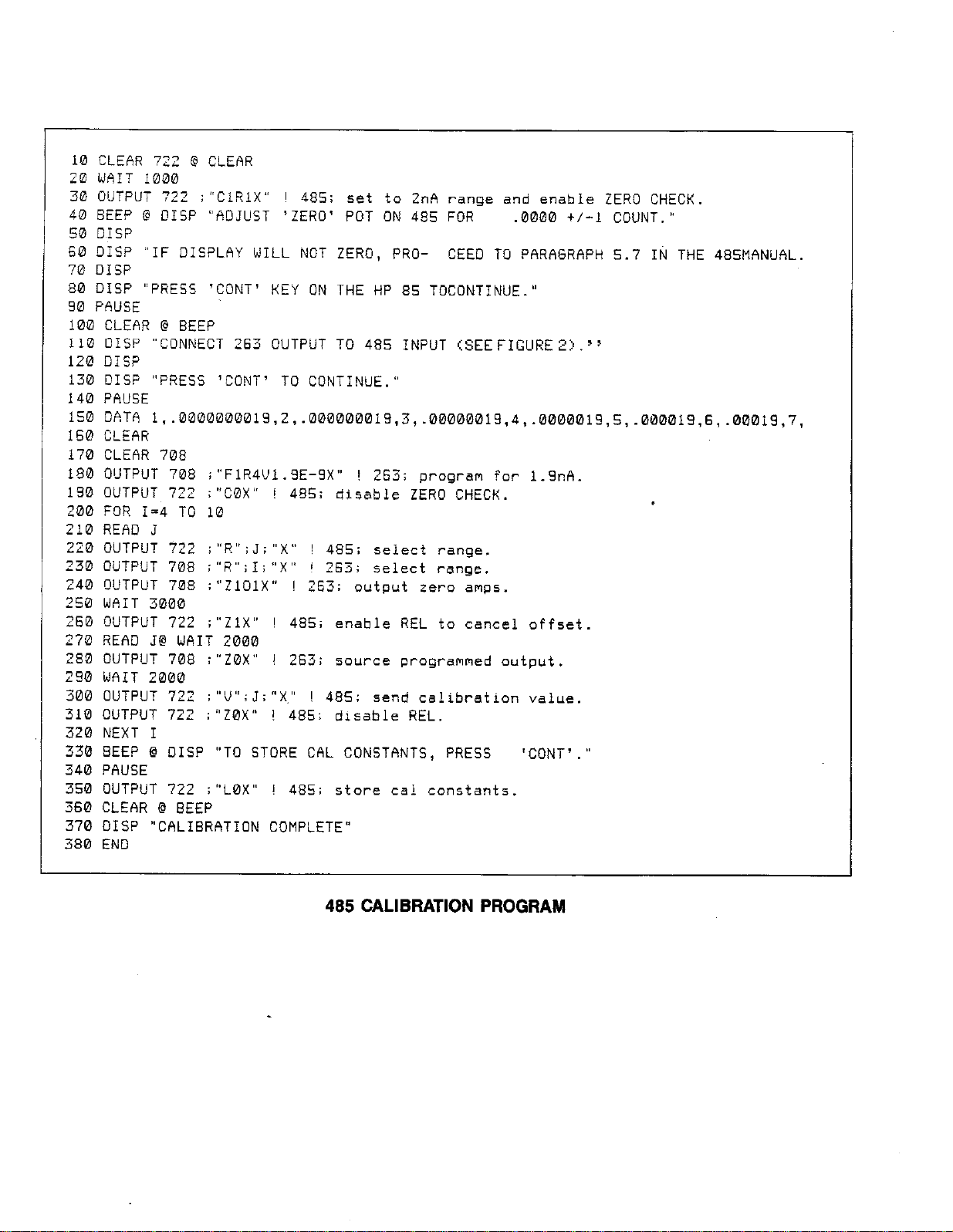

10 CLEAR 722 @ CLEfiR

NAIT 1020

22

32

OUTPUT 722 ; “CIRIX”

42 BEEP @ DISP

50 DIsP

S0 DISP “IF DISPLAY WILL NOT ZERO, PRO- CEEO TO P6RAGRAPH 5.7 IN THE 48 SMANUAL.

70 OISP

80 DISP ,’PRESS ‘CONT’ KEY ON THE HP 85 TOCONTINUE. “

90 P6USE

100 CLEAR @ BEEP

110 DISP “CONNECT ?G3 OIJTPUT TO 485 INPUT (SEE FICURE 2) ~ ~

120 DIS?

130 OISP “PRESS ‘CONT’ TO CONTINUE. “

140 PAUSE

152 06Th 1, .0000000019,2,.000000019,3, .00000019,4, .0000019,5,.000019,6, .00019,7,

160 CLEAR

170 CLEAR 708

180 OUTPUT 708 ; “F1R4UI . gE-gx,

190 OUTPUT 722 ; “COX,,

200 FOR 1=4 TO 10

210 REAO J

~ZO OUTPUT 722 ~ ,,R,, ;J; ,,x, ! 485; ~e~ect ~ange,

230 OUTPUT 708 ; R; I; ,X< ! 265; select range.

240 OUTPUT 708 ; “Z101X” ! 263; output zero amp5.

2S0 WAIT 3000

260 OUTPUT 722 ; “ZIXS’ ! 485; enable REL to

270 REAO J@ WAIT 2000

~sO OUTp UT 708 ; ,,zOx,, ! ~E~;

290 Wfl IT 2000

300 OUTPUT 722 ; “V’’; J; “X,” ! 485; send calibration value.

310 OUTPUT 722 ; “ZOX” ! 485; disable REL.

320 NEXT I

330 BEEP @ OISP “TO STORE C6L CONSTANTS, PRESS ‘CONT’ . “

340 PAUSE

‘AOJUST ‘ZERO’ POT ON 495 FOR

! 485; set to 2nA range and enable ZERO CHECK.

.0000 +/-1 COUNT. “

! 263; program for 1.9nA.

! 4S5; disable ZERO CHECK.

cancel Of

source programmed outpu

5et .

350 OUTPUT 722 ; ‘“LOX,’ ! 485; store cal constants.

560 CLEhR @ BEEP

370 DISP “CfiLIBRATION COMPLETE”

380 END

485 CALIBRATION PROGRAM

Page 16

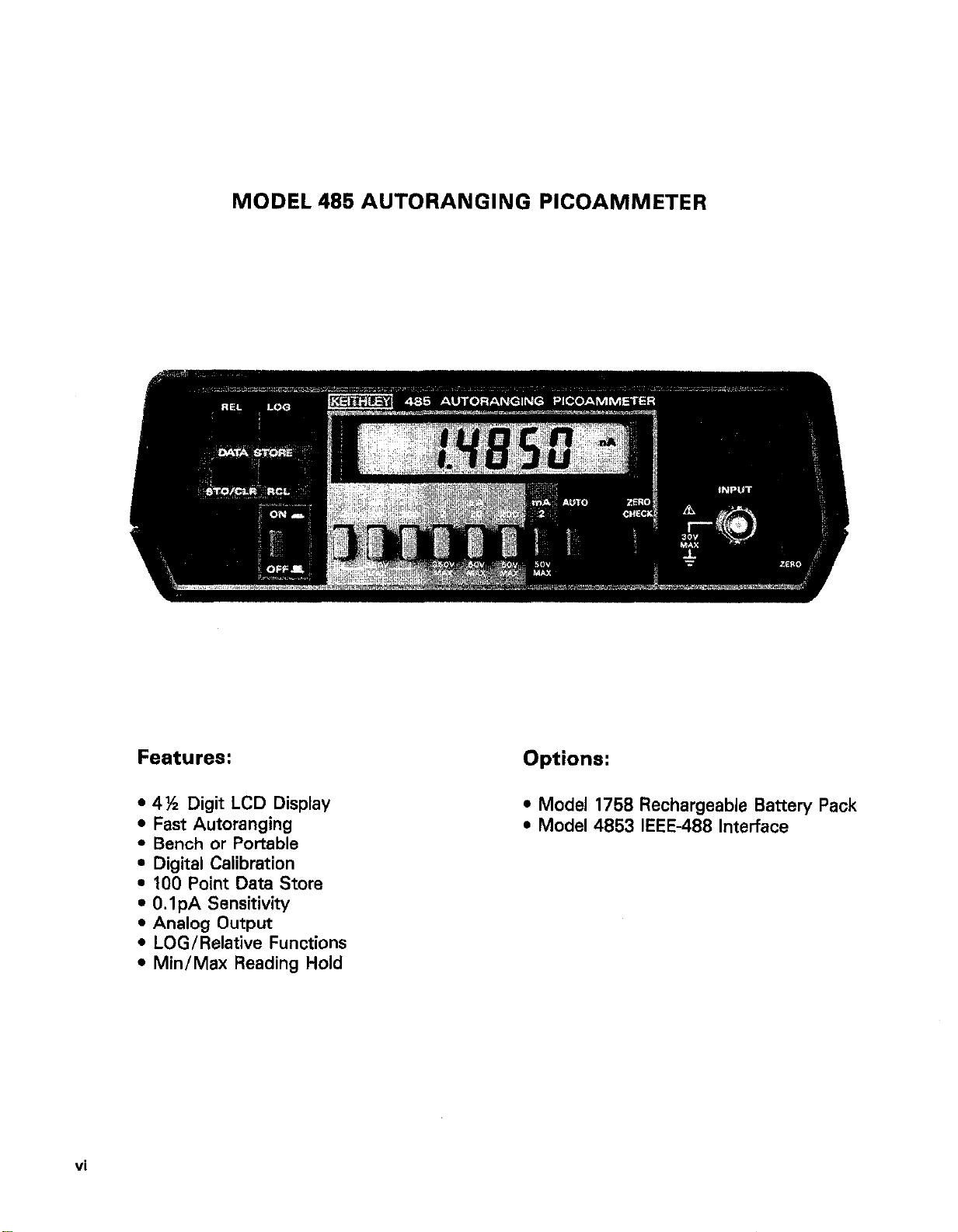

MODEL 485 AUTORANGING PICOAMMETER

vi

Features:

l 4% Digit LCD Display

l Fast Autoranging

l Bench or Portable

l Digital Calibration

l 100 Point Data Store

l O.lpA Sensitivity

l Analog Output

l LOG/Relative Functions

l Min/Max Reading Hold

Options:

l Model 1758 Rechargeable Battery Pack

l Model 4853 IEEE-488 Interface

Page 17

SECTION 1

GENERAL INFORMATION

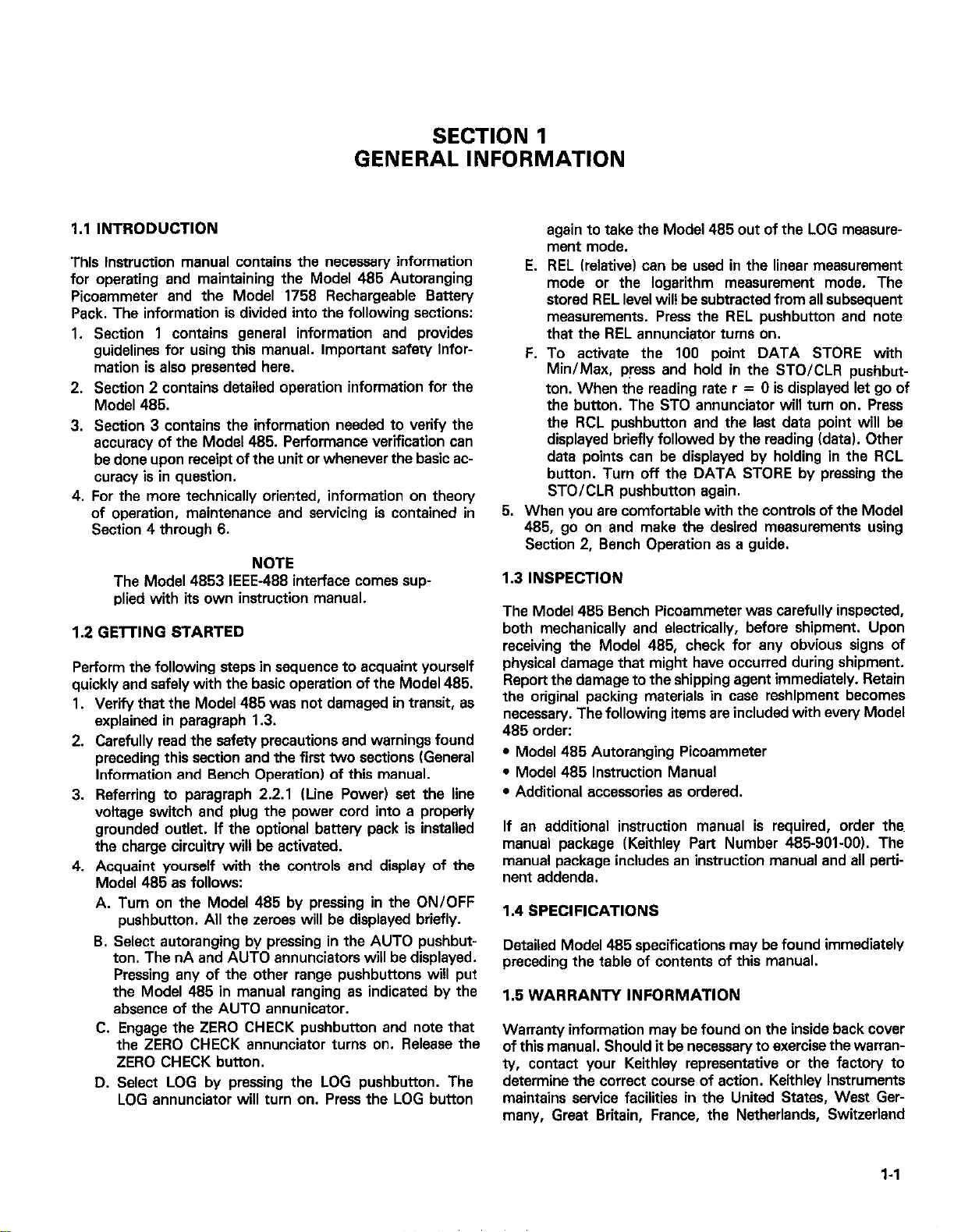

1.1 INTRODUCTION

This instruction manual contains the necessary information

for operating and maintaining the Model 485 Autoranging

Picoammeter and the Model 1758 Rechargeable Battery

Pack. The information is divided into the following sections:

1. Section 1 contains general information and provides

guidelines for using this manual. Important safety information is also presented here.

2. Section 2 contains detailed operation information for the

Model 485.

3. Section 3 contains the information needed to verify the

accuracy of the Model 485. Performance verification can

be done upon receipt of the unit or whenever the basic accuracy is in question.

4. For the more technically oriented, information on theory

of operation, maintenance and servicing is contained in

Section 4 through 6.

NOTE

The Model 4853 IEEE-488 interface comes supplied with its own instruction manual.

1.2 GElTlNG STARTED

Perform the following steps in sequence to acquaint yourself

quickly and safely with the basic operation of the Model 485.

1.

Verify that the Model 485 was not damaged in transit, as

explained in paragraph 1.3.

2.

Carefully read the safety precautions and warnings found

preceding this section and the first two sections (General

Information and Bench Operation) of this manual.

Referring to paragraph 2.2.1 (Line Power) set the line

3.

voltage switch and plug the power cord into a properly

grounded cutlet. If the optional battery pack is installed

the charge circuitry will be activated.

4.

Acquaint yourself with the controls and display of the

Model 485 as follows:

A. Turn on the Model 485 by pressing in the ON/OFF

pushbutton. All the zeroes will be displayed briefly.

B. Select autoranging by pressing in the AUTO pushbut-

ton. The nA and AUTO annunciators will be displayed.

Pressing any of the other range pushbuttons will put

the Model 485 in manual ranging as indicated by the

absence of the AUTO annunicator.

C. Engage the ZERO CHECK pushbutton and note that

the ZERO CHECK annunciator turns on. Release the

ZERO CHECK button.

D. Select LOG by pressing the LOG pushbutton. The

LOG annunciator will turn on. Press the LOG button

again to take the Model 485 cut of the LOG measurement mode.

E. REL (relative) can be used in the linear measurement

mode or the logarithm measurement mode. The

stored REL level will be subtracted from all subsequent

measurements. Press the REL pushbutton and note

that the REL annunciator turns on.

F. To activate the 100 point DATA STORE with

MinIMax, press end hold in the STO/CLR pushbut-

ton. When the reading rate r = 0 is displayed let go of

the button. The ST0 annunciator will turn on. Press

the RCL pushbutton and the last data point will be

displayed briefly followed by the reading (data). Other

date points can be displayed by holding in the RCL

button. Turn off the DATA STORE by pressing the

STO/CLR pushbutton again.

5. When you are comfortable with the controls of the Model

485, go on and make the desired measurements using

Section 2, Bench Operation as a guide.

1.3 INSPECTION

The Model 485 Bench Picoammeter was carefully inspected,

both mechanically and electrically, before shipment. Upon

receiving the Model 485, check for any obvious signs of

physical damage that might have occurred during shipment.

Report the damage to the shipping agent immediately. Retain

the original packing materials in case reshipment becomes

necessary. The following items are included with every Model

485 order:

l Model 485 Autoranging Picoammeter

l Model 485 Instruction Manual

l Additional accessories as ordered.

If an additional instruction manual is required, order then

manual package (Keithley Part Number 486-901-00). The

manual package includes an instruction manual and all pertinent addenda.

1.4 SPECIFICATIONS

Detailed Model 485 specifications may be found immediately

preceding the table of contents of this manual.

1.5 WARRANTY INFORMATION

Warranty information may be found on the inside back cover

of this manual. Should it be necessary to exercise the warran-

ty, contact your Keithley representative or the factory to

determine the correct course of action. Keithley Instruments

maintains service facilities in the United States, West Germany, Great Britain, France, the Netherlands, Switzerland

1-l

Page 18

and Austria. Information concerning the application, cperaticn or service of your instrument may be directed fc the ap-

plications engineer at any of these locations. Check the inside

front cover of this manual for addresses.

Model 1684 Hard Shell Carrying Case-Hard vinyl case,

IOOmm x 300mm x 350mm (4 x 13 x 14 inches) has a fit-

ted foam insert with room for the Model 485, instruction

manual end small accessories.

1.6 MANUAL ADDENDA

Information concerning improvements or changes to the in-

strument which occur after the printing of this manual will be

found on an addendum sheet included with this manual. Be

sure to review these changes before attempting to operate or

service the instrument.

1.7 SAFETY SYMBOLS AND TERMS

The following safety symbols and terms are used in this

manual or found on the Model 485.

The symbol

should refer to the operating instructions in this manual.

The WARNING heading in this manuel explains dangers that

could result in personal injury or death.

The CAUTION heading in this manual explains hazards that

could damage the instrument.

1.8 OPTIONAL ACCESSORIES

The following accessories can be used with the Model 485.

Model 1010 Single Reck Mounting Kit-Use to mount

one Model 485 in e standard 5% x 19” rack.

on the instrument indicates that the user

A

Model 1768 Rechargaable Battery Pack-Provides six

hours minimum operation from full charge, recharges within

10 hours end is field installable.

Model 4801 Input Cable-A low noise coaxial cable four

feet (1.2m) in length with a male BNC connector on each

end.

Model 4803 Low Noise Cable Kit-Consists of 50 feet

(15.2m) of low noise coaxial cable, 10 male BNC connectors,

and five female chassis mount BNC connectors.

Model 4863 IEEE-486 Interface-Field installable prcgram-

mable option provides isolated data output. Switchselectable talk only or addressable modes. Mounts within and

powered by the Model 485.

Model 7008 IEEE-488 Digital Cable-Useful for ccnnecting the Model 4853 to the IEEE-488 bus. The Model 7008-3 is

0.9m 13 ft) in length and has a standard IEEE-488 connector

at each end. The Model 7008-6 is 1.8m (6 ft) in length.

Modal 8673 IEEE-486 Interface for IBM PC-Field in-

stallable programmable option provides data output for the

IBM PC. Mounts within and powered by the IBM PC.

Model 1017 Dual Reck Mounting Kit-Use to mount two

Model 486’s in a standard 5% x 18” rack.

l-2

Page 19

SECTION 2

BENCH OPERATION

2.1 INTRODUCTION

This section contains the information needed to prepare and

operate the Model 485 as a bench picoammeter. Bench

operation consists of using the Model 485 to perform basic

current measurements. Data store operation is also covered.

The capabilities of the Model 485 can be enhanced with the

addition of the Model 4853 IEEE-488 interface. IEEE operstion is covered in the Model 4853 Instruction Manual.

2.2 PREPARATION FOR USE

2.2.1 Line Power

The Model 485 is provided with a three-wire line cord which

mates with third-wire grounded receptacles. Connect the in-

strument to AC line power as follows:

1. Set the LINE VOLTAGE switch on the back of the instrument to correspond to line voltage available. Ranges are

105-125V or 210-250V 50/60Hz AC.

CAUTION

Connect only to the line voltage selected.

Application of incorrect voltage can

damage the instrument.

2. Plug the power cord into a properly grounded outlet.

WARNING

Ground the instrument through a properly

grounded receptacle before operation.

Failure to ground the instrument can result

in severe injury or death in the event of

short circuit or malfunction.

NOTE

Although the Model 485 is specified at 50Hz and

60Hz the instrument may be operated at 400Hz

and 440Hz. Add one count to instrument

specifications under this condition.

2.2.3 Battery Charging

After the Model 1758 Banery Pack is installed in the Model

485 it can be charged and recharged as follows:

1. Connect the instrument to line power as described in

paragraph 2.2.1.

2. With the power switch off, the battery charge circuitry is

automatically energized to charge the battery at the maximum rate. When the battery pack is first installed, or if it is

completely discharged, allow it to charge for ten hours.

NOTE

For maximum battery efficiency only charge the

battery pack after it has become discharged and

only charge until it is fully charged I,10 hours).

Continuous charging over long periods of time

will not damage the batteries but, useful life will

gradually decrease. This loss is not permanent

and may be restored by cycling the battery pack

through several complete charge/discharge

cycles. The battery pack is capable of 500 to

1000 charge/discharge cycles before replace-

ment is needed.

Do not make measurements with the BAT annunciator on as

the readings may be erroneous.

3. When the Model 485 is in use on line power, the banely

charger maintains a trickle charge on the battery pack.

2.3 TILT BAIL

The Model 485 is equipped with a tilt bail which makes it

possible to elevate the instrument to a convenient viewing

position. To change the bail position, pull out the bail handle

from each side of the case until it rotates freely; rotate the bail

to the desired position and release the bail to allow it to lock

into place.

2.4 MODEL 485 FAMILIARIZATION

2.2.2 Battery Pack Power

The Model 485 may also be operated from rechargeable

sealed nickel-cadmium batteries contained in the optional

Model 1758 Rechargeable Battery Pack. The battery pack will

operate the Model 485 for up to six hours. The BAT ennunciator will turn on when the banely charge is insufficient to

maintain eccurate readings. Refer to Section 5, paragraph 5.3

for installation procedures.

The following paragraphs and Figure 2-l provides a brief

description of the display, front panel controls and connec-

tors.

2.4.1 Display

The Model 485 has a 4% digit liquid crystal display (LCD).

The minus sign is displayed. The plus sign is implied by the

absence of the minus sign. The following annunciators are

displayed on the LCD.

2-l

Page 20

BAT-Low battery indicator for the Model 1758.

nA. uA or mA-Nanoamos. Microamos or Milliamos

selected.

RMT IRemote)-Model 485 being controlled over the

IEEE-488 bus (Model 4853 installed).

CAL-Model 485 in calibration mode.

AUTO-Autorange selected.

REL-Relative selected.

LOG-Logarithm selected.

ZERO CHECK-Zero Check selected.

BTO- Data being stored.

RCL-Data being recalled. RCL flashes when buffer is full

during store cycle.

1. STO/CLR-Pressing this button initiates the storage sequence. Pressing the button a second time shuts off the

data store when in r=Othrough r=5. When in r=6, pressing this button stores one reading.

2. RCL-Pressing and holding this button in scrolls the data

pointer. To read the data at a particular point, simply

release the button.

Range Pushbuttons

1. Auto-This pushbutton selects autoranging.

2. Manual ranging is accomplished by depressing the appropriate range button.

2.4.2 Front Panel Controls

ON/OFF-Pressing in this pushbutton turns the Model 485

on. Releasing (out) this pushbutton turns the instrument off.

ZERO CHECK and ZERO-This pushbutton and trimpot are

used to zero the instrument’s internal offsets.

REL (Relative)-This pushbutton is used to cancel measurement offsets or store the input signal as a reference level.

Pressing this button again shuts REL off.

LOG-This pushbutton selects the logarithm function. The

displayed current measurement is expressed as the logarithm

(base IO) of the measured current referenced to one ampere.

Pressing this button again shuts LOG off.

DATA STORE-Has MlNlMAX and 100 point reading

storage capachY; records data at one of seven selectable

rates. Records minimum and maximum conversion during

the period the data store is active at the rate of 3/set.

ITHLEY 485 AUTORANGING PICOAMMETER

i_J

2.4.3 Input Connector

The input connector is a standard BNC type.

2.4.4 Analog Output Connectors

A voltage level that is proportional to the incoming current

can be monitored using the analog output banana jacks

located on the rear panel.

2.5 ERROR MESSAGES

Table 2-1 lists the error messages associated with basic front

panel operation. Note that the instrument has a number of

other messages that are discussed in the appropriate sections

of this manual.

4 \

2-2

Figure 2-l. Model 485 Front Panel

Page 21

Table 2-l. Error Messages

Display Message Comments

im RAM Error

IpEz

kiir-

2.6 ENVIRONMENTAL CONDITIONS

All measurements should be made at an ambient temperature

within the range of O°C to 50°C, and with a relative humidity

of 0% to 70% up to 35OC. For instruments above 35OC

derate humidity 3% per OC up to 50°C. If the instrument has

been subjected to extremes of temperature, allow sufficient

time for internal temperatures to reach environmental condi-

tions. Typically, it takes one hour to stabilize a unit that is

10°C IlEaF) out of specified temperature range.

2.7 BASIC BENCH MEASUREMENTS

Basic measurement techniques for using the Model 485 to

measure DC current are covered in the following paragraphs.

Also included is the operation of the MinIMax and 100 point

data store. A summary of range, accuracy and maximum

allowable input information is given in Table 2-2.

Calibration Error Model 485 locks up, but operation can be restored by pressing

INVRAM Failure) any one of the four momentary pushbuttons. If restored, calibration

Overrange Overrange input applied to the Model 485. Leading minus sign

Model 485 locks up. See Section 5 for troubleshooting information.

is invalid as indicated by the flashing “CAL” annunciator. See Sec-

tion 5 for troubleshooting information.

indicates that input signal has a negative value.

WARNING

Before operating the Model 485, observe

the safety precautions found preceding

Section 1. Failure to observe these and

other safety precautions found in this

manual could result in severe injury or

death.

WARNING

Do not exceed 30V RMS between input low

and power line ground or a shock hazard

will result. Also, current inputs that exceed

3mA may be erroneously displayed as a”

on-scale reading.

CAUTION

Do not exceed the maximum input limits

shown in Table 2-2.

Table 2-2. Range, Accuracy and Maximum Allowable Inputs

r

Maximum Accuracy Source

Flli;lry i *l%Reading + Counts1

Range

2mA

1.9999 nA

19.999 nA

199.99 nA

1.9999 pA

19.999 pA 0.1 + 1

199.99 pA 0.1 +1

1.9998mA

2 nA

20 nA

200 nA

22$

200 PA

IOTE:

Current above maximum will result in an “OL” display.

,. Source resistances lower than these may result in higher instrument noise and drift.

i. Maximum Transient Overload Voltage: IOOOV with a series 1OOkB resistor. Safe

operation and good measurement practice dictates use of an external resistor when

necessary to limit input currents to less than 3mA.

Maximum volts-hertz product (common mode): 108V.H~

lB°C -28OC (Note 2) (Note 3)

0.4 + 4

0.4 + 1

0.2 + 1

0.15 + 1

0.1 +1

Minimum

Recommended Maximun

Allowablt

Resistance

1OOMB 350v

1OOMB 350v

10MB 350v

1MB 350v

100 kC 5ov

10 kB 5ov

1 kKl 5ov

Input

1

1

2-3

Page 22

2.7.1 Power-Up

NOTE

The software revision level of the Model 485 can

be disolaved uoon oower-uo bv runnino the

diagnostic program. See .Section 5,

Maintenance, for more information.

Turn on the Model 485 by pressing in the ON/OFF switch.

The following will occur automatically:

1. Reset- All zeroes will be briefly displayed before going into

the measurement mode.

2. RAM Test-If this test fails the Model 485 will lock up with

zeroes displayed.

3. NVRAM Test-This test determines if the calibration constants are properly read from NVRAM. If this test fails the

display will show the error message “cErr”.

Refer to Table 2-1 for more information pertaining to error

messages.

CAUTION

During power up and power down, using

AC line or battery pack, a current surge

15mA, 5V maximum) can appear at the INPUT of the Modal 455. Protect any circuitry

that would be damaged by these levels by

making circuit connections only after turning on the Model 485. Disconnect these circuits before turning off the Model 485.

2.7.2 Zero Check

The instrument should be properly zeroed (after one hour

warm-up) before making any current measurements. Only

the 2nA current range needs to be zeroed. To check or adjust

zero, proceed as follows:

1. Select the 2nA range.

2. Turn off REL and LOG if they are on.

3. Depress the ZERO CHECK pushbutton. Momentary or

locking action can be achieved depending on how far the

button is depressed. To adjust zero, place the pushbutton

in to the lock position.

4. Adjust zero level trimpot via access hole on front panel for

a zero indication on the digital display.

5. Release the ZERO CHECK button.

In normal operation, the equivalent input resistance of the

485 picoammeter is equal to or less than the maximum

burden voltage (2OOfiV) divided by the maximum range current. This does not hold while in zero check or overload con-

ditions because the feedback to the input node is broken.

Values of input impedance for normal operation and zero

check/overload are shown in Table 23.

NOTES

1. When zero is properly adjusted, the input voltage burden

for an on-range reading will be less than or equal to 2OOpV.

2. The REL feature can be used instead of the ZERO pot to

zero the display. However, REL then cannot be used to

cancel a measurement offset or establish a reference level.

Table 2-3. Equivalent Input Resistance With Zero

Check Enabled

:urrent Maximum Effective Impedance In

Range

2 nA 1OOkD 9MGll230pF

20 nA

200 nA

2::: 100 10 D a 900k08230pF 100kGll0.01~F

200 pA lOkDUO.OlpF

2mA 0.: IY Ik9ljO.Ol~F

2.7.3 Current Measurements

1. Zero the instrument as described in paragraph 2.7.2.

2. Select a current range that is appropriate for the expected

input level or select autorange.

3. Connect the source to the INPUT connector on the front

panel. Low-noise cable and connector accessories de-~

scribed in Section 1 should be used as required. Measurement considerations are discussed in paragraph 2.8. A

summary of range, accuracy and input overload information is given in Table 2-2.

4. Read the input current on the digital display. Overrange is

indicated by an “OL” message.

2.7.4 Relative Mode

When the relative mode is selected with an on-scale reading

on the display the following occurs:

1. The REL annunciator is displayed.

2. The next reading is stored.

3. The stored reading is then algebraically subtracted from all

subsequent readings and displayed.

A REL level can be established for the linear measurement

mode or the logarithm measurement mode and is effective

only in that mode. Changing modes will not affect a REL level

already established. However, if another REL level is set fin

the other measurement mode) the previous REL level will be

cancelled. For example, place the Model 485 in the logarithm

mode (LOG annunciator on) and select the 2pA range. With

an open input, note the approximate -10.0 reading on the

display. Press the REL button and note that the REL annunciator is on and that display is zeroed. Select the linear

measurement mode by pressing the LOG button (LOG annunciator off). Note that the REL annunciator is off, indicating that there is not a REL level established for the linear

measurement mode. Switch back to the LOG mode and note

Input Resistance Zero Check/Overload

IOkD 9MDjj230pF

IkD 5MCll230pF

2-4

Page 23

that the REL level is still there. Again, go back to the linear

measurement mode (LOG off) and set a REL level of lfi. the

REL annunciator will turn on. Switch back to the LOG mode

and note that the REL annunciator is off, indicating that the

REL level for the LOG mode is cancelled.

Once a REL level is established for a measurement mode, that

stored level will be the same regardless of what range the

Model 485 is on. For example, if + IMA is established es the

AEL level on the 20/~A range, + IpA will also be the REL level

on the 2mA range.

It is important to note that the use of REL reduces the

dynamic range of measurements by that level. For instance,

assume that the REL level is + IpA and the Model 485 is

manually set to the 26 range. The maximum positive

displayed reading (before overranging), would be

+0.9999& This is because the A/D converter would be

seeing 1.9999fl (maximum) from the input. Thus, the

dynamic range of measurement is -1.9999fi to +0.9999fi

(2.9998fi) as compared to the normal -1.9999fi to

+ I .9999/rA (3.9998$1. The dynamic range of measurement

has been reduced by l& The effects on dynamic range can

be reduced by selecting a higher range or using autorange.

2.7.6 LOG Mode

The Model 485 can make logarithm measurements refer-

enced to a 1A current level or to other current levels with the

use of the REL feature.

The following examples compute the expected LOG

readings for various current levels applied to the Model

485:

A. InA

LOG reading = LDG +$LOG reading = -9.000

B. 0.5&A

LOG reading = LOG LOG reading = -6.301

C. -1mA

LOG reading = LOG I+1

LOG reading = -3.000

To make LOG measurements reference to lA, proceed as

follows:

A. Zero the instrument, if required, as described in

paragraph 2.7.2.

B. Select auto range on the Model 486.

C. Connect the source to the Model 485.

D. Press the LOG button.

E. Take the LOG reading from the display.

2. Log measurements using other reference currents:

LOG measurements, referenced to other current levels,

can be read directly from the display of the Model 485 by

utilizing the REL feature and an accurate current source.

I I

0.5fi

I I

The basic procedure for using the LOG mode is to select auto

range and press the LOG button (LOG annunciator on). To

get out of the LOG mode, press the LOG button again. The

LOG annunciator will turn off.

Because the logarithm of a negative number is undefined, the

logarithm is taken with the absolute value of the measured

current.

NOTE

LOG measurements must always be made on

the lowest Dossible ranae (without overranging).

Readings dn high ranges will not allow Optimum

calculations of the logarithm. When in doubt,

use Auto Range.

1. Log Measurements with IA reference currant: The

LOG measurement mode displays the absolute value of

the logarithm (base 101 of the input current referenced to

IA. The following equation illustrates this relationship:

LOG Reading = Log

Using this reference &rent, the LOG riading span is from

-13.0 (fO.lpA) to -2.699 (1tI.9999mAl.

Applied Current

I

IA

To make LOG measurements referenced to another cur-

rent level, proceed as follows:

A. Z.&o the instrument, if required, as described in

paragraph 2.7.2.

B. Set the Model 485 to auto range.

C. Input the reference current to the Model 485.

D. With the Model 485 in the LOG mode, press the REL

button. The REL annunciator will turn on and the

display will zero.

E. Remove the reference current source from the Model

485.

F. The Model 485 is now set up to make LOG

measurements referenced to that current level. Simply

input the current to be measured and take the reading

from the display.

2.7.6 Inverting Analog Output

Two banana jacks, accessible from the rear panel, permit

monitoring or recording of the output from the current-to-

voltage converter within the Model 485. Since the Model 465

is a feedback picoammeter, as shown in Figure 2-2, the input

current is forced through the feedback resistor and an in-

2-5

Page 24

verted analog output voltage is developed by the operational

amplifier. The feedback (Rangel resistors are selected such

that voltage for an on-scale reading on the 2nA range will be

between zero and k200mV. The output voltage for the rest

of the ranges will be between zero and f2V. The relationship

between the analog output signal and the digital display is as

follows:

2nA Range: 10000 counts = -1OOmV. or -1OFVIcount

20nA-2mA Ranges: 10000 counts = -IV or -lOO~V/count

The analog ouput is input protected up to 20V RMS and during an input current overload the analog output is clamped to

a maximum voltage swing of approximately *4V. Although

protected up to 20V to prevent instrument damage, a voltage

applied to the analog output could cause an erroneous

display, rather than the “OL” message.

Since the output of the current-to-voltage converter is

bipolar, the inverting analog output can also be used to

measure low frequency AC current which falls within the

specified analog rise time. The inverting analog output

resistance is 1 .Ol kD; 9lOD in series with the signal leads and

1OOD in series with the ground lead.

Typical Analog Output Accuracy:

Linearity: < 0.1% full scsle

Gain Accuracy: k 1%

Output Resistance: +5%

Ff+ ‘Efif

Figure 2-2. Model 485 Inverting Analog Output

2.7.7 Mm/Max and 100 Point Data Store

The data store can save up to 100 readings and store the

minimum and maximum readings recorded during the period

that the data store is active. The 100 points of data are stored

at one of six selectable rates. Manuel data entry (r = 6) is also

available. Readings for minimum and maximum are sampled

at the rate of three per second regardless of the selected rate.

The minimum and maximum readings are continuously updated while in the data store mode. The procedure for

operating the data store is as follows:

1. Connect the desired measurement configuration to the

Model 465. Make sure that the controls of the Model 485

are set appropriately.

2. Storing Data:

A. Press and hold the STO/CLR pushbutton. The follow-

ing reading rates will scroll on the display:

r = 0 I3 rds/sec)

r = 1 (1 rdglsecl

r = 2 (1 rdg/lO secj

r = 3 II rdglmin)

r = 4 (I rdg/lO mini

r = 5 (I rdglhr)

r = 6 (I rdg every time ST0 button is pressed)

NOTE

There is no need to select a rate if just

minimum/maximum readings are desired.

Momentarily press the STO/CLR button to start

the store.

6. Release the STO/CLR pushbutton when the desired

reading rate is displayed. The ST0 annunciator will

turn on and data will be stored at the selected rate.

NOTE

The date store cycle can be terminated at any

time by doing the following:

A. If in r=6 mode, press the RCL button and

the STO/CLR button.

6. If in any other r mode, only press the STO/

CLR button.

With the data store off, data is retained and can be recalled at

any time as long as the instrument remains on.

3. Data Retrieval: Data can be retrieved at any time, but a

flashing RCL annunciator indicates that the maximum

number of readings (100) have been stored.

A. Press and hold in the RCL pushbutton. The display will

scroll through the date points and MlNlMAX (LO/HI).

The first data point displayed will be the last stored

reading. The next two data points will be the HI and LO

readings made during that store cycle. Notice that the

longer the RCL pushbutton is held in the faster the data

points will scroll on the display.

B. Release the RCL pushbutton at the desired data point

and note the reading (data) on the display. The data

pointer can be incremented by steps of one by momentarily holding in the RCL pushbutton.

4. Shut off the data store by pressing the STO/CLR

pushbutton. All stored data will be retained until a new

store cycle has commenced.

2.6 MEASUREMENT CONSIDERATIONS

This section describes the effects of source resistance,

capacitance, noise and leakage resistance on the measurement. Other measurement considerations are also discussed.

Minimum and maximum values of these source parameters

are defined, at which point a significant degradation of the

measurement can begin to occur. Compensation methods

are described to minimize these effects. Refer to Figure 2-3

for the following discussion.

2-6

Page 25

2.8.1 Source Resistance

Increasing capacitance beyond this level may increase noise

and induce instrument instability. The noise gain of the

As shown in Table 2-2, a minimum value of source resistance

is recommended for each range. The reason for this can be

understood by examining Figure 2-3. Considering effects on

low frequency noise and drift, CS and CFB can momentarily

measurement circuit can be found from:

Equation 2.

Output en = Input en x(1 +

be ignored. where ZF =

Input amplifier noise and drift appearing at the output can be

calculated as follows:

Equation 1.

Output enOiSe = IflpUt enOjSe

x(1+ -@)

Thus it is clear than as long as RS>>RFB, Output enoNe fz

Input enoNe. When RFB = RS, Output enojse = 2 x input

enoise,

The same applies for eos.

, , cFB

CS

II

I I

RFB

(1 Es

RS

Slrm

WVV

lOon

T--

ANALOG 10,OOOpF is leakage measurement of capacitors. In this case

OUTPUT

.

TO A/D

CONVERTER

v

6

Figure 2-3. Simplified Model for Input Signal

Conditioning

RFB

\j

and ZS =

RS

42a fRSCSP+ 1 j

Clearly ss f -0

equation (2) reduces to equation (I).

The frequency range in interest is O.lHz to IOHz which is the

noise bandwidth of the AID convener. The value of CF is

22OpF for nA ranges and O.OlpF otherwise.

In general, as CS becomes larger, the noise gain becomes

larger. An application where CS may be greater than

Input en must include the effects of the voltage source (ES)

used to bias the capacitor. The Keithley Model 230 is recommended for this application.

When measuring leakage currents on capacitors larger than

10,OOOpF. stability and noise performance can be maintained

by adding a resistor in series with the capacitor under test.

The value of this resistor shoulde be around 1 MB. For large

capacitor values (z lrFj, the value of the series limiting

resistor can be made lower in order to improve settling times:

however, values below 1OkD are not generally recommended.

Model 485 will typically show insignificant degradation in

displayed performance with the noise gain of 2 resulting from

allowing RS = RFB. Typical amplifier input enOjSe is about

5@ p-p in a bandwidth of 0.1.IOHz. Amplifier ECS can be

nulled with front panel ZERO adjustment, but available

resolution limits this adjustment to about 5V. The

temperature coefficient of ECS is < 2OpV/“C. These

numbers can be used with Equation 111 to determine ex-

pected displayed noise/drift given any source resistance.

Remember that 1 displayed count = lOO$/ except on 2nA

range where 1 displayed count = lO@V. Note also that the

values given in Table 2-2 for minimum source resistance also

represent the value of RFB on that range.

2.8.2 Source Capacitance

The Model 485 is designed to accomodate up to 10,OOOpF in-

put capacitance ICS). This limit will preclude problems in

most test setups and allow extremely long input cable lengths

without inducing instabiliw or oscillations.

This resistor is not critical in terms of tolerance or stability.

Any carbon composition resistor will prove adequate.

A second-order advantage to using this limiting resistor is sdded protection to Model 485 in the event of capacitor failure.

2.8.3 Leakage Resistance

The effect of leakage currents should be considered when

making small current measurements with high impedance

sources. Leakage current and its effects can be minimized by

using high resistance insulation in the test circuits and guerding. Since the Model 485 is a feedback picoammeter, it is ef-

fectively guarded at the input. The effect of leakage paths on

the measurement can be further minimized by using a gusrd-

ed text fixture as shown in Figure 2-4. In the configuration

shown, the current through the component under test will

not be shunted significantly by either leakage resistance path.

If a high voltage supply is used to make high resistance

leakage measurements, it is suggested that a series current

2-7

Page 26

limiting resistor be used to prevent exceeding the maximum

overload input limit of the Model 455 in the event the item

under test is shorted.

2.5.4 Zero Time Stability

The typical zero time stability of the Model 455 is less than

one count per week, exclusive of temperature effects.

SHORT

CIRCUIT

CURRENT -

LIMITER

TEFLON

INSULATOR

VVV’I

Figure 2-4. Test Fixture Guarding

2.5.5 Grounding Considerations

Input LO (outer ring of input connector) should be connected

to a potential at the source which is within 30V RMS of

power line ground of the Model 455 or the equipment near it.

Connection to power line ground is not made internally in

order to avoid possible ground loops.

MODEL 485

2.5 APPLICATIONS

The following applications can be automated to various

degrees with the use of programmable equipment over the

IEEE-455 bus. The Model 455 becomes fully programmable

with the addition of the Model 4553 interface. Programmable

sources are available from Keithley and other manufacturers.

The documentation that is provided with the Model 4553 includes example programs using various controllers.

The Model 455 may be used in conjunction with the Model

6104. The Model 6104 is a guarded and shielded test box for

2-terminal or 3-terminal connections. The Model 6104 pro-

vides excellent electrostatic shielding and high isolation

resistance for the component under test. Clips plug into

banana jacks allowing the user to fashion modified connec-

tions to suit the component to be tested.

The Model 6104 is useable with the Model 455 picoammeter

and Keithley voltage supplies, such as the Model 230. When

connected together as a system, using the cable and connector options, they form a complete test facility for measuring

leakage current and other low current parameters for various

test applications. A possible test set up is hewn in Figure 2-5.

The measurement sample would be connected between Jl

and J7 or J6.

EXT. SOURCE

MODEL

BLhK [ j4 45 j

CASE

Figure 2-5. Leakage Test Sat Up Using Modal 6104

2.9.1 Op Amp Input Offset Currents

As the parameters of new BIFET, BIMOS, and FET op amps

approach the parameters of the ideal op amp, such

characteristics as the input offset current are breaking

through the 1pA level. Use the Model 455 to measure these

low level currents as shown in Figure 2-6. Note the connection of Model 455 input low.

2-5

Figure 2-6. OP Amp Input Offset Currents

Measurement

Page 27

2.9.2 FET Gate Leakage and Channel Currants

Analog switches, multiplexer circuits, sample and hold circuits, integrators, LED drives, and many other circuits have

errors generated by either gate leakage or channel leakage in

FET-based components. For understanding the design limita-

tions of a component or for tight component selection use

the Model 485 as shown in Figure 2-7.

Figure 2-7. FET Gate Leakage and Channel Currents

Measurement

2.9.3 Insulation Leakage Currents and High Resistance

In precise low power, low current circuitry, stray leakage cur-

rents can adversely affect circuit performance. Since leakage

current is a non-linear function of voltage, the expected

voltage level must be applied.

Leakage resistance of 10% can be determined with the

Model 485 and a voltage source of 1OOV. Using this tech-

nique, you can evaluate high resistance materials or insulation leakage of capacitors, PC boards, switches, or connectors under normal environmental conditions and under

elevated temperature and humidity conditions. (see Figure

Z-8).

Figure 2-S. Insulation Leakage Currents and High Resis-

tances Measurements

2.9.4 Phototube. Photodiode and Beam Currents

Photomultiplier tubes and other light detection devices require precise measurement of a wide range of currents (see

Figure 2-9). Beam currents used for ion implantation, surface

phenomena studies, and atomic structure analysis using

scanning electron microscopy are in the picoamp to nanoamp

range. The Model 485 has the accuracy and sensitivity to

make these measurements with routine ease. In addition, for

these applications it is convenient to cancel out dark currents,

using the Model 485’s “REL” feature. To present data in a

logarithm format, simply touch the “LOG” button. Use the

AUTO ranging feature to cover a broad dynamic range.

SCANNING

ELECTRON

MICROSCOPE

Figure 2-9. Setup to Measure Photomultiplier, Photodiode and Beam Currents

2-9

Page 28

2.9.5 Resistivity Tests

The Model 485 may be used along with the Model 6105 to

perform resistivity tests. The Model 6105 is a guarded test fix-

ture for measurement of surface and volume resistivities. The

chamber is designed in accordance with ASTM Standard

Method of Test Electrical Resistance of Insulating Materials,

D257-66. The Model 6105 can be used in conjunction with

the Model 485 and a high voltage power supply, such as the

Modal 247.

MODEL* MODEL

32418 4801

CABLE

m M~uHF~+C[~

NOT TO

EXCEED IOOOV

*Supplied with Model 247

Figure 2-10. Resistivity Test Set Up

Resistivity can be determined by measuring the current

through a sample with a known voltage impressed. The

Model 6105 can accomodate non-rigid sheet samples 2%

inches (63mm) to four inches (102mm) in diameter and %

inch (6mml thick with excitation voltages up to IOOOV. The

Model 6105 has a UHF connector for the bias supply and a

BNC output to the Model 485. A test hook up using the

Model 247 power supply is shown in Figure 2-10.

CABLE

2-10

Page 29

SECTION 3

PERFORMANCE VERIFICATION

3.1 INTRODUCTION

This section contains information necessary to verify that the

Model 485 performance is within specified accuracy Model

485 specifications may be found at the front of this manual.

Ideally, performance verification should be performed when

the instrument is first received to ensure that no damage or

change in calibration has occurred during shipment. The

verification procedure may also be performed whenever instrument accuracy is suspect or following calibration. If performance on any of the ranges is outside specified limits,

calibration can be performed as described in Section 5.

NOTE

If the instrument does not meet specifications

and it is still under warranty (less than 12 months

since date of shipment), contact your Keithley

representative or the factory to determine the

action to be taken.

3.2 ENVIRONMENTAL CONDITIONS

All measurements should be made at an ambient temperature

between 18e and 28OC (65” to 82OFl with a relative humidity

less than 70%.

3.3 RECOMMENDED TEST EQUIPMENT

Equipment for verifying the performance of the Model 485 is

listed in Table 3-I. Alternate equipment may be used as long

as the equipment accuracy is at least as good as the

specifications listed in Table 3-1. Information needed to build

the test fixture can be found in Figure 3-1.

3.4 INITIAL CONDITIONS

Before performing the verification procedures, make sure the

Model 485 meets the following conditions:

1. If the instrument has been subject to temperatures below

18eC (65OF) or above 28°C (82eFj. allow sufficient time for

the instrument to reach temperatures within the range.

Generally, it takes one hour to stabilize an instrument that

is 10°C (18°F) outside of this range.

2. Turn on the Model 485 and allow it to warm up one hour.

The instrument may be operated from either line power or

battery pack power, as long as the battery pack has been

fully charged as described in paragraph 2.2.3.

3.5 VERIFICATION PROCEDURE

The following paragraphs give the basic verification procedure for checking accuracy.