Page 1

Model 2520INT

Quick Start Guide

Integrating Sphere

A GREATER MEASURE OF CONFIDENCE

Page 2

WARRANTY

Keithley Instruments, Inc. warrants this product to be free from defects in material and workmanship for a

period of 1 year from date of shipment.

Keithley Instruments, Inc. warrants the following items for 90 days from the date of shipment: probes, cables,

rechargeable batteries, diskettes, and documentation.

During the warranty period, we will, at our option, either repair or replace any product that proves to be defective.

To exercise this warranty, write or call your local Keithley representative, or contact Keithley headquarters in

Cleveland, Ohio. You will be given prompt assistance and return instructions. Send the product, transportation

prepaid, to the indicated service facility. Repairs will be made and the product returned, transportation prepaid.

Repaired or replaced products are warranted for the balance of the original warranty period, or at least 90 days.

LIMITATION OF WARRANTY

This warranty does not apply to defects resulting from product modification without Keithley’s express written

consent, or misuse of any product or part. This warranty also does not apply to fuses, software, non-rechargeable

batteries, damage from battery leakage, or problems arising from normal wear or failure to follow instructions.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR USE.

THE REMEDIES PROVIDED HEREIN ARE BUYER’S SOLE AND EXCLUSIVE REMEDIES.

NEITHER KEITHLEY INSTRUMENTS, INC. NOR ANY OF ITS EMPLOYEES SHALL BE LIABLE FOR

ANY DIRECT, INDIRECT, SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES ARISING OUT OF

THE USE OF ITS INSTRUMENTS AND SOFTWARE EVEN IF KEITHLEY INSTRUMENTS, INC., HAS

BEEN ADVISED IN ADVANCE OF THE POSSIBILITY OF SUCH DAMAGES. SUCH EXCLUDED DAMAGES SHALL INCLUDE, BUT ARE NOT LIMITED TO: COSTS OF REMOVAL AND INSTALLATION,

LOSSES SUSTAINED AS THE RESULT OF INJURY TO ANY PERSON, OR DAMAGE TO PROPERTY.

Keithley Instruments, Inc.

Sales Offices: BELGIUM: Bergensesteenweg 709 • B-1600 Sint-Pieters-Leeuw • 02-363 00 40 • Fax: 02/363 00 64

CHINA: Yuan Chen Xin Building, Room 705 • 12 Yumin Road, Dewai, Madian • Beijing 100029 • 8610-6202-2886 • Fax: 8610-6202-2892

FINLAND: Tietäjäntie 2 • 02130 Espoo • Phone: 09-54 75 08 10 • Fax: 09-25 10 51 00

FRANCE: 3, allée des Garays • 91127 Palaiseau Cédex • 01-64 53 20 20 • Fax: 01-60 11 77 26

GERMANY: Landsberger Strasse 65 • 82110 Germering • 089/84 93 07-40 • Fax: 089/84 93 07-34

GREAT BRITAIN: Unit 2 Commerce Park, Brunel Road • Theale • Berkshire RG7 4AB • 0118 929 7500 • Fax: 0118 929 7519

INDIA: Flat 2B, Willocrissa • 14, Rest House Crescent • Bangalore 560 001 • 91-80-509-1320/21 • Fax: 91-80-509-1322

ITALY: Viale San Gimignano, 38 • 20146 Milano • 02-48 39 16 01 • Fax: 02-48 30 22 74

JAPAN: New Pier Takeshiba North Tower 13F • 11-1, Kaigan 1-chome • Minato-ku, Tokyo 105-0022 • 81-3-5733-7555 • Fax: 81-3-5733-7556

KOREA: 2FL., URI Building • 2-14 Yangjae-Dong • Seocho-Gu, Seoul 137-888 • 82-2-574-7778 • Fax: 82-2-574-7838

NETHERLANDS: Postbus 559 • 4200 AN Gorinchem • 0183-635333 • Fax: 0183-630821

SWEDEN: c/o Regus Business Centre • Frosundaviks Allé 15, 4tr • 169 70 Solna • 08-509 04 679 • Fax: 08-655 26 10

SWITZERLAND: Kriesbachstrasse 4 • 8600 Dübendorf • 01-821 94 44 • Fax: 01-820 30 81

TAIWAN: 1FL., 85 Po Ai Street • Hsinchu, Taiwan, R.O.C. • 886-3-572-9077• Fax: 886-3-572-9031

28775 Aurora Road • Cleveland, Ohio 44139 • 440-248-0400 • Fax: 440-248-6168

1-888-KEITHLEY (534-8453) • www.keithley.com

4/02

Page 3

Model 2520INT Integrating Sphere

Quick Start Guide

©2002, Keithley Instruments, Inc.

All rights reserved.

Cleveland, Ohio, U.S.A.

First Printing, April 2002

Document Number: 2520INT-903-01 Rev. A

Page 4

Manual Print History

The print history shown below lists the printing dates of all Revisions and Addenda created

for this manual. The Revision Level letter increases alphabetically as the manual undergoes subsequent updates. Addenda, which are released between Revisions, contain important change information that the user should incorporate immediately into the manual. Addenda are numbered

sequentially. When a new Revision is created, all Addenda associated with the previous Revision

of the manual are incorporated into the new Revision of the manual. Each new Revision includes

a revised copy of this print history page.

Revision A (Document Number 2520INT-903-01) .......................................................... April 2002

All Keithley product names are trademarks or registered trademarks of Keithley Instruments, Inc.

Other brand names are trademarks or registered trademarks of their respective holders.

Page 5

S

afety Precautions

The following safety precautions should be observed before using this product and any associated instrumentation. Although

some instruments and accessories would normally be used with non-hazardous voltages, there are situations where hazardous

conditions may be present.

This product is intended for use by qualified personnel who recognize shock hazards and are familiar with the safety precautions

required to avoid possible injury. Read and follow all installation, operation, and maintenance information carefully before using the product. Refer to the manual for complete product specifications.

If the product is used in a manner not specified, the protection provided by the product may be impaired.

The types of product users are:

Responsible body

ment is operated within its specifications and operating limits, and for ensuring that operators are adequately trained.

Operators

instrument. They must be protected from electric shock and contact with hazardous live circuits.

Maintenance personnel

voltage or replacing consumable materials. Maintenance procedures are described in the manual. The procedures explicitly state

if the operator may perform them. Otherwise, they should be performed only by service personnel.

Service personnel

trained service personnel may perform installation and service procedures.

Keithley products are designed for use with electrical signals that are rated Installation Category I and Installation Category II,

as described in the International Electrotechnical Commission (IEC) Standard IEC 60664. Most measurement, control, and data

I/O signals are Installation Category I and must not be directly connected to mains voltage or to voltage sources with high transient over-voltages. Installation Category II connections require protection for high transient over-voltages often associated with

local AC mains connections. Assume all measurement, control, and data I/O connections are for connection to Category I sources unless otherwise marked or described in the Manual.

Exercise extreme caution when a shock hazard is present. Lethal voltage may be present on cable connector jacks or test fixtures.

The American National Standards Institute (ANSI) states that a shock hazard exists when voltage levels greater than 30V RMS,

42.4V peak, or 60VDC are present.

circuit before measuring.

Operators of this product must be protected from electric shock at all times. The responsible body must ensure that operators

are prevented access and/or insulated from every connection point. In some cases, connections must be exposed to potential

human contact. Product operators in these circumstances must be trained to protect themselves from the risk of electric shock.

If the circuit is capable of operating at or above 1000 volts,

Do not connect switching cards directly to unlimited power circuits. They are intended to be used with impedance limited sources. NEVER connect switching cards directly to AC mains. When connecting sources to switching cards, install protective devices to limit fault current and voltage to the card.

Before operating an instrument, make sure the line cord is connected to a properly grounded power receptacle. Inspect the connecting cables, test leads, and jumpers for possible wear, cracks, or breaks before each use.

When installing equipment where access to the main power cord is restricted, such as rack mounting, a separate main input power disconnect device must be provided, in close proximity to the equipment and within easy reach of the operator.

For maximum safety, do not touch the product, test cables, or any other instruments while power is applied to the circuit under

test. ALWAYS remove power from the entire test system and discharge any capacitors before: connecting or disconnecting ca-

is the individual or group responsible for the use and maintenance of equipment, for ensuring that the equip-

use the product for its intended function. They must be trained in electrical safety procedures and proper use of the

perform routine procedures on the product to keep it operating properly, for example, setting the line

are trained to work on live circuits, and perform safe installations and repairs of products. Only properly

A good safety practice is to expect that hazardous voltage is present in any unknown

no conductive part of the circuit may be exposed.

5/02

Page 6

bles or jumpers, installing or removing switching cards, or making internal changes, such as installing or removing jumpers.

Do not touch any object that could provide a current path to the common side of the circuit under test or power line (earth) ground. Always make measurements with dry hands while standing on a dry, insulated surface capable of withstanding the voltage being measured.

The instrument and accessories must be used in accordance with its specifications and operating instructions or the safety of the

equipment may be impaired.

Do not exceed the maximum signal levels of the instruments and accessories, as defined in the specifications and operating information, and as shown on the instrument or test fixture panels, or switching card.

When fuses are used in a product, replace with same type and rating for continued protection against fire hazard.

Chassis connections must only be used as shield connections for measuring circuits, NOT as safety earth ground connections.

If you are using a test fixture, keep the lid closed while power is applied to the device under test. Safe operation requires the use

of a lid interlock.

If or is present, connect it to safety earth ground using the wire recommended in the user documentation.

!

The symbol on an instrument indicates that the user should refer to the operating instructions located in the manual.

The symbol on an instrument shows that it can source or measure 1000 volts or more, including the combined effect of

normal and common mode voltages. Use standard safety precautions to avoid personal contact with these voltages.

The

WARNING

information very carefully before performing the indicated procedure.

The

CAUTION

ranty.

Instrumentation and accessories shall not be connected to humans.

Before performing any maintenance, disconnect the line cord and all test cables.

To maintain protection from electric shock and fire, replacement components in mains circuits, including the power transformer,

test leads, and input jacks, must be purchased from Keithley Instruments. Standard fuses, with applicable national safety approvals, may be used if the rating and type are the same. Other components that are not safety related may be purchased from

other suppliers as long as they are equivalent to the original component. (Note that selected parts should be purchased only

through Keithley Instruments to maintain accuracy and functionality of the product.) If you are unsure about the applicability

of a replacement component, call a Keithley Instruments office for information.

To clean an instrument, use a damp cloth or mild, water based cleaner. Clean the exterior of the instrument only. Do not apply

cleaner directly to the instrument or allow liquids to enter or spill on the instrument. Products that consist of a circuit board with

no case or chassis (e.g., data acquisition board for installation into a computer) should never require cleaning if handled according to instructions. If the board becomes contaminated and operation is affected, the board should be returned to the factory for

proper cleaning/servicing.

heading in a manual explains dangers that might result in personal injury or death. Always read the associated

heading in a manual explains hazards that could damage the instrument. Such damage may invalidate the war-

Page 7

A

2520INT Series Specifications

This series covers the offering of Integrating Spheres for use with the Model 2520 Pulser Test System.

Products

The following lists the current products in the 2520INT Series. Each product has bundled a CD Manual, Calibration report, and

¼-20 post and base.

• 2520INT-1-GE 1in Integrating Sphere with a Germanium Detector

Accessories

Model 2520 Pulsed Laser Diode Test System

•

Model 7078-TRX Triax Cables

•

Specifications

Full Acceptance Angle1

90° vertical, 50° horizontal (max.)

Frontal View of Integrating Sphere showing Full Acceptance Angle Indicators:

Operating Wavelength Range

800 – 1700nm

Continuous Wave (CW) Calibration Wavelength Range2

950-1010nm and 1280-1620nm

HW 6/06/02

Rev.

Page 8

A

Wavelength (nm)

Measurable Optical Power Range 3

Typical Responsivity 4 (mA/W)

Resolution 5 (mW)

980 1310 1480 1550

29mW – 7W 17mW – 4W 14.5mW – 3.5W 13.5mW – 3W

3.5 6.0 7.0 7.5

0.2 0.1 0.1 0.1

Maximum Reverse Bias

5V (recommended)

Dark Current at Max Reverse Bias

4µA (typ.); 10µA (max.)

Photodiode Electrical Connections on 3 Lug Triax 6

Center Conductor

Inner Shield

Photodiode

• Center to Cathode

• Center Shield to Anode

• Outer Shield – Not Connect (Isolated from

chassis)

Outer-most Shield (NC)

Pulsed Operation

The 2520INT supports the pulse capabilities of the 2520 Pulsed Laser Diode Test System.

Fiber Tap Port

Connector Type: SMA

Numerical Aperature (NA): 0.22 (typ.)

Multi-Mode Patch Cord Core Diameter

Typical Attenuation (dB)

7

(µµµµm)

400 100 62.5 50

39.5 53 58.2 63

2

HW 6/06/02

Rev.

Page 9

A

General

Description Min Max

Temperature

Operating

Storage

0°C

-25°C

50°C

65°C

Weight 8 0.33 lbs (0.15 kg)

Dimension 8: LxDxH 2.36 in x 1.80 in x 3.40 in

(60.0 mm x 45.7 mm x 86.4 mm)

Input Port Diameter

0.25 in (6.35 mm)

Recommended Calibration Cycle 1 year

Notes

1

Maximum distance from input port to accept at full maximum acceptance angle: 3.1mm (0.12 in).

2

Calibration performed at 10nm wavelength intervals.

3

Based on detector being linear to up to 25mA photocurrent and on a Signal to Noise Ratio (SNR) ≥ 100.

4

Calibration of the 2520INT is performed with an open fiber tap port. The power measurement will increase by approximately 1% with an SMA

patch cord attached to the port.

5

Based on resolution of Model 2520 at 10mA (lowest) I

6

This configuration MUST have a NEGATIVE (Reverse) Bias Voltage applied. If a Positive (Forward) Bias is applied, the detector

(photodiode) will become damaged.

7

Use of Single Mode Fiber is Not Recommended.

8

Only for integrating head, does not include post and base.

meas

range.

HW 6/06/02

Rev.

Page 10

Table of Contents

1 General Overview

General Information ................................................................... 1-2

Warranty information .......................................................... 1-2

Contact information ............................................................ 1-2

Specifications ...................................................................... 1-2

Safety symbols and terms ................................................... 1-2

Laser safety precautions ...................................................... 1-3

Inspection ............................................................................ 1-4

Optional accessories ............................................................ 1-4

Product overview ........................................................................ 1-5

Available models ................................................................. 1-5

Configuration ...................................................................... 1-5

2 Getting Started

Electrical connections ................................................................ 2-2

Detector output terminals .................................................... 2-2

Connections to Model 2520 ................................................ 2-2

Connections to DUT .................................................................. 2-3

Free space operation and alignment considerations ............ 2-3

Instrument setup ......................................................................... 2-6

Detector voltage bias, current measurement polarity,

and range ............................................................................. 2-6

Configuring the Model 2520 voltage bias for

Model 2520INT .................................................................. 2-6

Configuring the Model 2520 detector polarity for the

Model 2520INT .................................................................. 2-6

Configuring the Model 2520 detector current

measurement range for the Model 2520INT ....................... 2-6

Remote instrument setup ..................................................... 2-6

Detector dark current measurements .......................................... 2-7

Description .......................................................................... 2-7

Optical power measurements .............................................. 2-8

Remote instrument setup ..................................................... 2-9

Saving and restoring user setups .............................................. 2-10

Page 11

3 Maintenance

Handling and cleaning precautions ............................................ 3-2

Dust ..................................................................................... 3-2

Cleaning .............................................................................. 3-2

Calibration .................................................................................. 3-2

Page 12

List of Illustrations

1 General Overview

Figure 1-1 Model 2520INT configuration ................................................ 1-5

2 Getting Started

Figure 2-1 Detector terminals ................................................................... 2-2

Figure 2-2 Electrical connections ............................................................. 2-3

Figure 2-3 Divergent beams ...................................................................... 2-4

Figure 2-4 Collimated beams .................................................................... 2-4

Figure 2-5 Horizontal and vertical acceptance angle ................................ 2-5

3 Maintenance

Page 13

List of Tables

1 General Overview

2 Getting Started

Table 2-2 Command summary for 2520INT connected to Detector 1 ... 2-7

Table 2-1 Remote voltage bias and detector polarity measurement

commands to bias 2520INT ................................................... 2-7

Table 2-3 Typical sphere responsivity .................................................... 2-8

Table 2-5 Programming example using MX + B math for optical

power with a reverse bias ..................................................... 2-10

Table 2-4 Remote MX+B commands used to calculate optical power.. 2-10

3 Maintenance

Page 14

1

General Overview

Page 15

1-2 General Overview Model 2520INT Quick Start Guide

General Information

Warranty information

Warranty information is lcoated at the front of this guide. Should your Model 2520INT

require warranty service, contact te Keithley representative or authorized repair facility in

your area for further information. When returning the unit for repair, be sure to fill out and

include the service form at the back of this guide to provide the repair facility with the

necessary information.

Contact information

Worldwide phone numbers are listed at the back of this guide. if you have any questions,

please contact your local Keithley representative or call one of our application engineers at

1-800-348-3735 (U.S. and Canada only). Additional information may be obtained at

www.keithley.com.

Specifications

Model 2520INT specifications shown at the front of this guide were current at the time of

duplication, but they are subject to change without notice. For the most recent specifications, refer to the web site at www.keithley.com.

Safety symbols and terms

The following symbols and terms may be found on an instrument or used in this guide.

!

The symbol on an instrument indicates that the user should refer to the operating

instructions located in the guide.

The symbol on the instrument shows that high voltage may be present on the terminal(s). Use standard safety precautions to avoid personal contact with these voltages.

The

WARNING

injury or death. Always read the associated information very carefully before performing

the indicated procedure.

The

CAUTION

ment. Such damage may invalidate the warranty.

heading used in this guide explains dangers that might result in personal

heading used in this guide explains hazards that could damage the instru-

Page 16

Model 2520INT Quick Start Guide General Overview 1-3

Laser safety precautions

WARNING

WARNING

While the Model 2520INT does not incorporate a laser, it is designed to

be used with laser diode devices. The following safety practices must be

used to protect operators and other users of this product from potential

exposure to laser radiation:

•

Operators must be protected from radiation and electrical hazards

at all times.

•

The installer must comply with all applicable laws and regulation

on laser safety. This requirement includes warning signs and operator training.

•

Where an interlock is required for safe operation, the test fixtures

must ensure that the interlock circuit is disabled (source outputs

inhibited) when the operator can be exposed to radiation. The

test fixture interlock must not be defeated under any operating

conditions.

•

When servicing the test system, any required personnel protection

equipment (e.g. laser safety goggles) must be provided by the customer's responsible body.

•

The customer's laser safety officer (LSO) must review and approve

all installations before being put into operation. Any safety concerns must be immediately reported to the customer's LSO.

•

When making connections, do not leave any exposed connections.

Be sure that all external circuits are properly insulated.

It is the responsibility of the customer to operate instruments in a safe

manner. Follow all applicable safety regulations for installing, configuring, and using the Model 2520. The Model 2520, as installed, should

be approved by the appropriate safety personnel, such as the responsible Laser Safety Officer or equivalent.

Suggested starting points for workplace regulations and standards:

ANSI Z136.1, IEC 825, OSHA 29 CFR 1910.

In short, always be aware of workplace hazards, strive to minimize

them, and work safely.

Page 17

1-4 General Overview Model 2520INT Quick Start Guide

Inspection

The Model 2520INT was carefully inspected before shipment. After unpacking all items

from the shipping carton, check for any obvious signs of physical damage that may have

occurred during transit. Report any damage to the shipping agent immediately. Save the

original packing carton for possible future shipment. The following items are included

with every Model 2520INT order:

• Model 2520INT Integrating Sphere.

• Optoelectronics CD-ROM that contains a PDF of this Quick Start Guide.

•¼ × 20 post and base.

• Calibration report.

Optional accessories

The following accessory is available to make connections to the Model 2520INT.

Triax cable

The following cable is required to connect the Model 2520INT detector output to the input

of the Model 2520 Pulsed Laser Diode Test System:

• Model 7078-TRX Series Cable: Low-noise triax cable to connect the Model

2520INT to the Model 2520 Pulsed Laser Diode Test System.

Page 18

Model 2520INT Quick Start Guide General Overview 1-5

Product overview

The 2520INT series of integrating sphere-based detectors are specifically designed to provide highly accurate light intensity measurements. The integrating sphere simplifies production testing of optical components by eliminating common measurement problems

related to detector alignment, beam profile, polarization, and back reflection.

Available models

See the Model 2520INT specifications for product list and key characteristics.

Configuration

As shown in Figure 1-1, the 2520INT consists of a sphere housing, detector, and mounting

holes.

Key components include:

• Detector output: 3-lug female triax connector to connect the unit to the Model 2520

Pulsed Laser Diode Test System.

• Optical input port: accepts light from optical source.

• Fiber tap port: may be used to tap off light into a 0.22 NA SMA fiber (customer

provided).

• Mounting holes: allows standard mounting in M6 or ¼ × 20.

NOTE

Specifications are subject to change without notice.

Figure 1-1

Model 2520INT configuration

Detector

Output

Mounting

Hole

90˚ Full Angle (FA)

Indicator

Detector

Output

50˚ FA

Indicator

SMA

Connector

Page 19

2

Getting Started

Page 20

2-2 Getting Started Model 2520INT Quick Start Guide

Electrical connections

Detector output terminals

Figure 2-1 shows the configuration of the detector output terminals. Note that center con-

ductor is the cathode, while the inner shield is connected to the anode.

Figure 2-1

Detector terminals

Internal

Photodiode

Detector

Detector Output Jack

Model 2520INT

Connections to Model 2520

Using Figure 2-2 as a guide, make electrical connections to the desired Model 2520

channel as follows:

1. Connect one end of the Model 7078-TRX triax cable to the Model 2520INT

detector output connector.

2. Connect the other end of the Model 7078-TRX triax cable to the desired Model

2520 DETECTOR jack.

CAUTION

Do not attempt to connect BNC connectors to the Model 2520INT

triax detector output jack. Attempting to do so may damage the

connector, voiding the warranty.

Cathode

(Center

Conductor)

Anode

(Inner Shield)

Outer Shield

Page 21

Model 2520INT Quick Start Guide Getting Started 2-3

Figure 2-2

Electrical connections

7078-TRX

Detector

BIAS

DETECTOR 1 DETECTOR 2

ISOLATION FROM EARTH: 10V MAX.

LO

HI

CURRENT

CURRENT

INPUT

!

OUTPUT

!

CAT I

VOLTAGE

SENSE

LO

HI

Triax Cable

Detector

Model 2520INT

Integrating Sphere

Model 2520

Testhead

Connections to DUT

Free space operation and alignment considerations

For free space operation, position the Model 2520INT as close as possible to the DUT.

Proper alignment of the Model 2520INT to the light source under test is important for

optimum optical power measurement. Key considerations include divergent beams, collimated beams, and full beam collection.

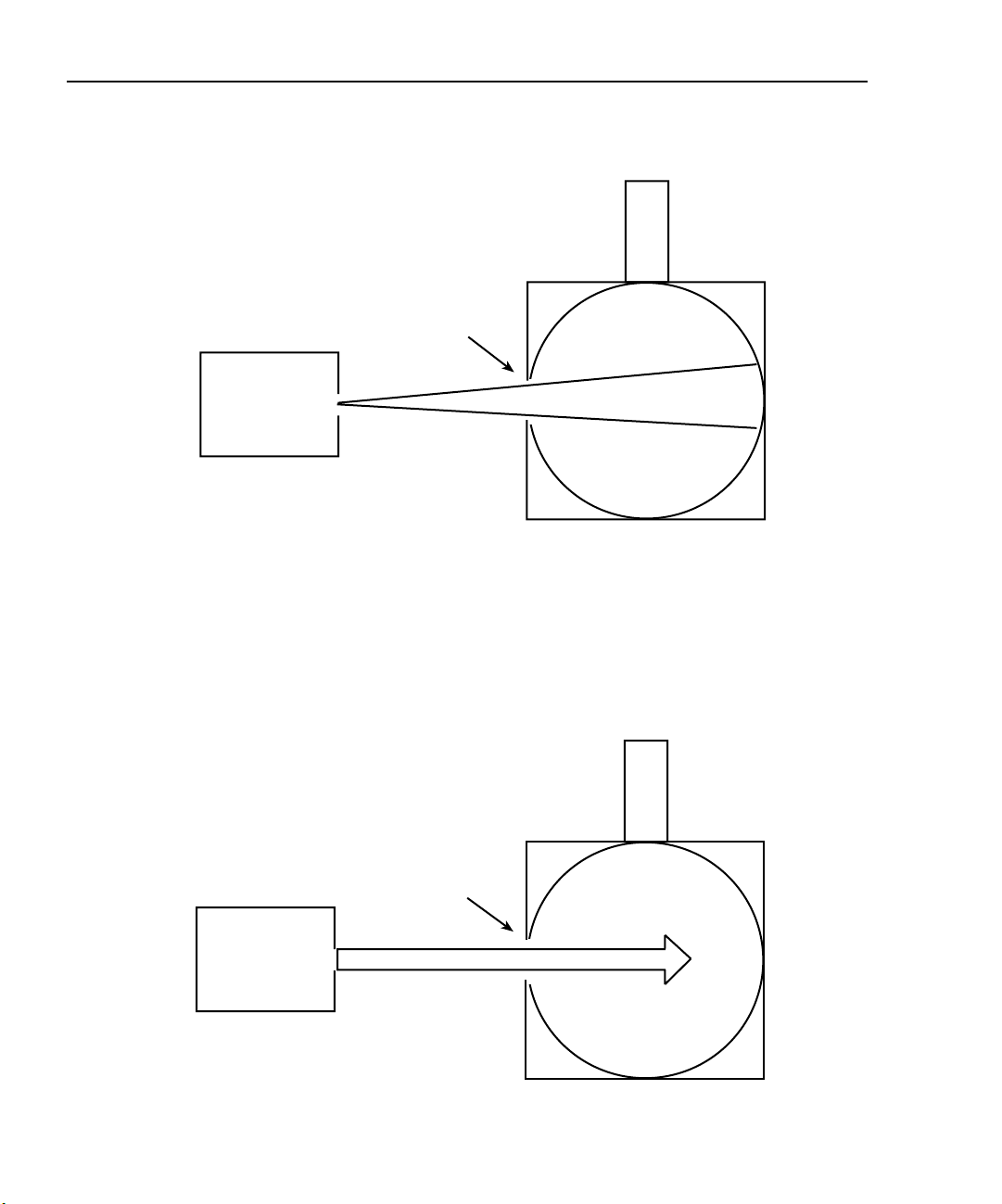

Divergent beams

Devices such as diode chips and bars have divergent beams. As shown in Figure 2-3, the

beam diameter increases as distance from the source increases. If improperly placed, the

port could block some of the entrance beam and lead to inaccurate power measurement.

To avoid inaccurate measurements, the large and small divergence angles of a diode laser

source should be aligned as indicated by the markings at the sphere entrance port.

Page 22

2-4 Getting Started Model 2520INT Quick Start Guide

Figure 2-3

Divergent beams

Detector

Entrance

Port

Light

Source

Collimated beams

Collimated beams differ from divergent beams in that the edges of the beam are parallel.

As shown in Figure 2-4, the beam diameter stays constant even as the distance from the

source increases.

Figure 2-4

Collimated beams

Detector

Entrance

Port

Light

Source

Page 23

Model 2520INT Quick Start Guide Getting Started 2-5

Full beam collection

Full beam collection is important for optimum optical power measurement (Figure 2-5).

The maximum acceptance angle of the sphere in the vertical direction is 45˚ half angle

(divergence) from the entrance port. The maximum acceptance angle of the sphere in the

horizontal direction is 25° half angle from the entrance port.

NOTE

Information provided is based on the sphere orientation shown in Figure 2-5.

Figure 2-5

Horizontal and vertical acceptance angle

Sphere

Input Port

DUT

NOTE

Distance for full acceptance at the maximum acceptance angles should not

exceed 3.1mm from input port.

Page 24

2-6 Getting Started Model 2520INT Quick Start Guide

Instrument setup

Detector voltage bias, current measurement polarity, and range

Using a reverse bias on the 2520INT is critical for good pulse measurement performance.

The reverse bias reduces the capacitance of the detector in the 2520INT, which greatly

speeds up the reaction time, permitting the 2520INT to respond to the 100 ns (or less) rise

time of the Model 2520’s pulses. The recommended bias is -5V. The necessary trade off

for using the bias is an increase in the dark current. See the following information for dark

current measurement and compensation.

The 2520INT is configured to output positive current to the 2520. Since the Model 2520

detector channels are unipolar, the channel utilized for the 2520INT must have its polarity

set to positive. For most applications, the 2520INT will output <10mA, so the current

measure range on the Model 2520 should be set to 10 mA.

Configuring the Model 2520 voltage bias for Model 2520INT

1. Press VB for the detector channel connected to the 2520INT.

2. Use the and keys to move the blinking value to the desired position.

3. Use the and keys to set the voltage to –05.00V.

4. Press ENTER when correct value is displayed.Voltage is applied to detector channel only when the Model 2520 output is on.

Configuring the Model 2520 detector polarity for the Model 2520INT

1. Press CONFIG then VB for the desired channel (DETECTOR 1 or DETECTOR 2).

2. Use the and keys to make POSITIVE the blinking value.

3. Press ENTER.

Configuring the Model 2520 detector current measurement range for

the Model 2520INT

1. Press IPD for the detector channel connected to the 2520INT.

2. Press the RANGE key until the 10mA range is reached.

Remote instrument setup

The Model 2520 can be set up for remote detector bias and detector current measure polarity by using the commands summarized in the Table 2-1.

Page 25

Model 2520INT Quick Start Guide Getting Started 2-7

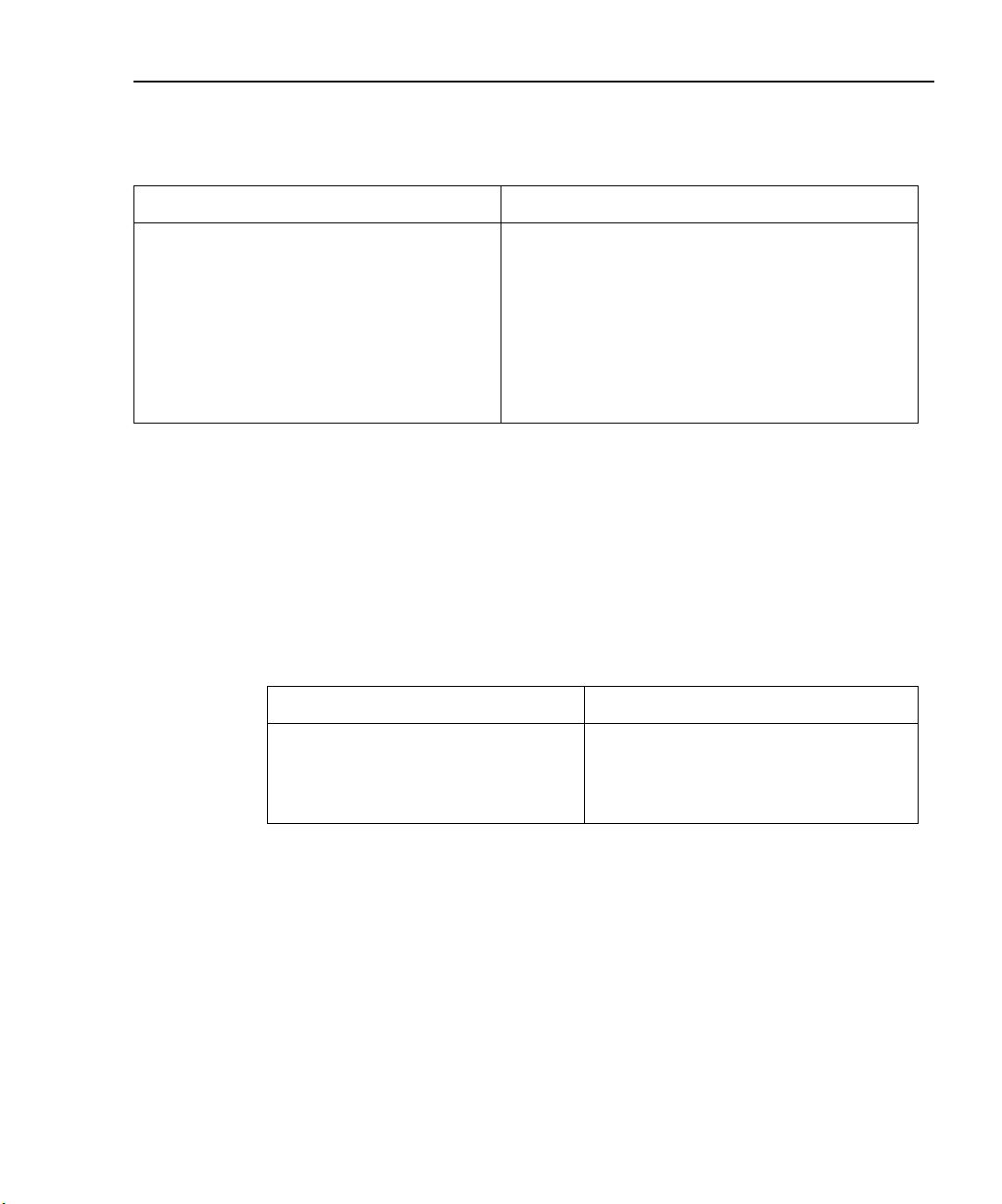

Table 2-1

Remote voltage bias and detector polarity measurement commands to bias 2520INT

Command Description

:SOURce2:VOLTage <voltage> Set detector #1 source voltage (0 to ±20).

:SOURce3:VOLTage <voltage> Set detector #2 source voltage (0 to ±20).

:SENSe2:CURRent:RANGe <range> Set detector #1 measure range (0.01, 0.02, 0.05, 0.1).

:SENSe2:CURRent:POLarity <polarity> Set detector #1 measure polarity.

:SENSe3:CURRent:RANGe <range> Set detector #2 measure range (0.01, 0.02, 0.05, 0.1).

:SENSe3:CURRent:POLarity <polarity> Set detector #2 measure polarity.

Programming example

Table 2-2 summarizes the commands for the 2520INT connected to Detector 1. These

commands set up the Model 2520 as follows:

• Measurement range: 10mA

• Bias Voltage: -5V

• Measurement polarity: Positive

Table 2-2

Command summary for 2520INT connected to Detector 1

Command Description

:SENS2:CURR:RANG 0.01 Detector 1 measurement range at 10mA

:SENS2:CURR:POL POS Detector 1 measurement polarity positive

:SOUR2:VOLT –5 Detector 1 bias = -5V

CAUTION

Applying voltage greater than -5V or .5V can damage the

Model 2520INT.

Detector dark current measurements

Description

The dark current is a current offset produced by the detector in the absence of light. Its

value is based on many factors including the reverse bias voltage on the detector, temperature, semiconductor architecture, and even the quality of the semiconductor material itself.

Proper measurement of and compensation for the dark current will ensure accurate optical

power measurements.

Page 26

2-8 Getting Started Model 2520INT Quick Start Guide

Typical responsivity values are summarized in Table 2-3.

Table 2-3

Typical sphere responsivity

Typical Responsivity

(mA/W)

Sphere

980nm 1550nm

Germanium 3.5 7.5

Measuring dark current

1. Connect the Model 2520INT to the desired Model 2520 detector channel.

2. Cover the optical input port of the Model 2520INT with a dust-free, lightproof

cover. Light leakage will result in erroneous dark current measurements and will

effect the overall accuracy of absolute power measurements.

3. From the Model 2520 front panel, press the CONFIG FILTER key.

4. Enter the number of readings to average (1-100).

5. Turn on the outputs, then press TRIG.

6. Note the detector current reading.

Optical power measurements

Optical power calculation

Optical power is calculated as follows:

Optical power = (I

Where: I

measured

I

dark current

Responsivity = amps/watt (see supplied Model 2520INT calibration constants)

= measured photodiode current (amps)

- I

measured

dark current

= photodiode dark current in amps (see above)

)/Responsivity

Page 27

Model 2520INT Quick Start Guide Getting Started 2-9

Configuring optical power measurements

1. Press CONFIG then MATH.

2. Select channel to configure.

• CHANNEL 2 = Detector Channel 1

• CHANNEL 3 = Detector Channel 2

NOTE

3. Enter 1/Responsivity (W/A) of sphere for device wavelength as M. Responsivity

4. Enter sphere dark current as B.

5. Select units as W for Watts.

6. Configure other channel as above if needed.

CHANNEL 1 = Voltage Sense Measurement Channel and is therefore not used

for Optical Power Measurements.

values are supplied with your 2520INT. Reference values are also given in Table 2-1.

Initiating optical power measurements

1. Select channel to initiate by pressing Ipd for the desired detector channel. The

selected channel is denoted by an asterisk (*) on the second display line of the

Model 2520 mainframe.

2. Press the MATH button.

3. Initiate the MATH function for the other channel if needed.

Remote instrument setup

Basic optical power commands

The Model 2520 can be set up for remote optical power measurements by using the

MX+B commands summarized in Table 2-5. See Sections 4 and 14 of the Model 2520

User’s Manual for details on using these and other commands necessary for complete

measurements.

Page 28

2-10 Getting Started Model 2520INT Quick Start Guide

Table 2-4

Remote MX+B commands used to calculate optical power

Command Description

:CALC2:KMAT:MBF <B_value>

:CALC2:KMAT:MMF<M_value>

:CALC2:STAT ON

:CALC2:DATA?

:CALC3:KMAT:MBF <B_value>

:CALC3:KMAT:MMF <M_value>

:CALC3:STAT ON

:CALC3:DATA?

Set detector 1 B value for MX + B math.

Setdetector 1 M value for MX + B math.

Enable detector 1 math.

Query detector 1 math data.

Set detector 2 B value for MX + B math.

Set detector 2 M value for MX + B math.

Enable channel 2 math.

Query channel 2 math data.

Programming example

Table 2-5 summarizes the basic command sequence for optical power measurements using

MX+B with detector 1. These commands set up the Model 2520 as follows:

• Measurement range: 10mA

• Math function: MX+B enabled

• Responsivity: M: 2

• Dark current: B: 0.5

• Bias voltage: -5V

Table 2-5

Programming example using MX + B math for optical power with a reverse bias

Command* Description

*RST

:SENS2:CURR:RANG 0.01

:CALC2:KMAT:MMF 2

:CALC2:KMAT:MBF 0.5

:CALC2:STAT ON

:SOUR2:VOLT -5

:OUTP1 ON

:INIT

:CALC2:DATA?

:OUTP1:OFF

Restore GPIB defaults.

10mA range.

M = 2.

B = 0.5.

Enable detector 1 math.

Detector 1 bias voltage = -5V.

Turn on outputs.

Trigger reading.

Request detector 1 reading.

Turn off outputs.

* Unit must be addressed to talk after :CALC2:DATA?

Saving and restoring user setups

See the Model 2520 User’s Manual Section 1 for details on how to save and recall up to 5

commonly used configurations.

Page 29

3

Maintenance

Page 30

3-2 Maintenance Model 2520INT Quick Start Guide

Handling and cleaning precautions

Dust

Cover the optical port opening when not in use to prevent internal contamination of the

Model 2520INT. Inconsistencies on the internal surface of the sphere will cause inaccuracies in measurements.

Cleaning

• Clean any exposed connector using a cleaning kit supplied by the connector manufacturer or high-grade isopropyl alcohol and a cotton swab.

• To clean with alcohol and a swab, dab the tip of a cotton swab in alcohol and then

shake off any excess alcohol. The tip should be moist, not dripping wet. Stroke the

swab tip gently across the surface of the connector and around the connector ferrule.

• Either allow the connector a minute to dry or blow dry the connector using clean

compressed air. Be careful when using compressed air because improper use may

deposit a spray residue.

Calibration

The Model 2520INT should be calibrated once a year. Contact your Keithley representative or call the factory directly to inquire about these services.

Page 31

Index

A

accessories 1-4

alignment considerations 2-3

C

Calibration 3-2

Collimated beams 2-4

Configuration 1-5

connections 2-2

Connections to Model 2520 2-2

Contact information 1-2

current measurement polarity 2-6

R

range 2-6

Remote instrument setup 2-6

S

Safety symbols and terms 1-2

Saving and restoring user setups 2-10

Specifications 1-2

T

Triax cable 1-4

V

voltage bias 2-6

D

detector current measurement range 2-6

Detector dark current measurements 2-7

Detector output terminals 2-2

detector polarity 2-6

Detector voltage bias 2-6

Divergent beams 2-3

F

Free space operation 2-3

Full beam collection 2-5

G

General Overview 1-1

Getting Started 2-1

H

Handling and cleaning precautions 3-2

I

Inspection 1-4

Instrument setup 2-6

L

Laser safety precautions 1-3

W

Warranty information 1-2

M

Maintenance 3-1

O

Optical power measurements 2-8

Page 32

Service Form

Model No. _______________ Serial No. __________________ Date _________________

Name and Telephone No. ____________________________________________________

Company _______________________________________________________________________

List all control settings, describe problem and check boxes that apply to problem. _________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

❑ Intermittent ❑ Analog output follows display ❑ Particular range or function bad; specify

_______________________________

❑ IEEE failure ❑ Obvious problem on power-up ❑ Batteries and fuses are OK

❑ Front panel operational ❑ All ranges or functions are bad ❑ Checked all cables

Display or output (check one)

❑ Drifts ❑ Unable to zero ❑ Unstable

❑ Overload ❑ Will not read applied input

❑ Calibration only ❑ Certificate of calibration required ❑ Data required

(attach any additional sheets as necessary)

Show a block diagram of your measurement including all instruments connected (whether power is turned on or

not). Also, describe signal source.

Where is the measurement being performed? (factory, controlled laboratory, out-of-doors, etc.)_______________

__________________________________________________________________________________________

What power line voltage is used?___________________ Ambient temperature? ________________________ °F

Relative humidity? ___________________________________________Other? __________________________

Any additional information. (If special modifications have been made by the user, please describe.)

__________________________________________________________________________________________

__________________________________________________________________________________________

Be sure to include your name and phone number on this service form.

Page 33

Specifications are subject to change without notice.

All Keithley trademarks and trade names are the property of Keithley Instruments, Inc. All other trademarks and

trade names are the property of their respective companies.

Keithley Instruments, Inc. 28775 Aurora Road • Cleveland, Ohio 44139 • 440-248-0400 • Fax: 440-248-6168

1-888-KEITHLEY (534-8453) • www.keithley.com

Sales Offices: BELGIUM: Bergensesteenweg 709 • B-1600 Sint-Pieters-Leeuw • 02-363 00 40 • Fax: 02/363 00 64

CHINA:

Yuan Chen Xin Building, Room 705 • 12 Yumin Road, Dewai, Madian • Beijing 100029 • 8610-6202-2886 • Fax: 8610-6202-2892

FINLAND: Tietäjäntie 2 • 02130 Espoo • Phone: 09-54 75 08 10 • Fax: 09-25 10 51 00

FRANCE: 3, allée des Garays • 91127 Palaiseau Cédex • 01-64 53 20 20 • Fax: 01-60 11 77 26

GERMANY: Landsberger Strasse 65 • 82110 Germering • 089/84 93 07-40 • Fax: 089/84 93 07-34

GREAT BRITAIN: Unit 2 Commerce Park, Brunel Road • Theale • Berkshire RG7 4AB • 0118 929 7500 • Fax: 0118 929 7519

INDIA: Flat 2B, Willocrissa • 14, Rest House Crescent • Bangalore 560 001 • 91-80-509-1320/21 • Fax: 91-80-509-1322

ITALY: Viale San Gimignano, 38 • 20146 Milano • 02-48 39 16 01 • Fax: 02-48 30 22 74

JAPAN:

New Pier Takeshiba North Tower 13F • 11-1, Kaigan 1-chome • Minato-ku, Tokyo 105-0022 • 81-3-5733-7555 • Fax: 81-3-5733-7556

KOREA: 2FL., URI Building • 2-14 Yangjae-Dong • Seocho-Gu, Seoul 137-888 • 82-2-574-7778 • Fax: 82-2-574-7838

NETHERLANDS: Postbus 559 • 4200 AN Gorinchem • 0183-635333 • Fax: 0183-630821

SWEDEN: c/o Regus Business Centre • Frosundaviks Allé 15, 4tr • 169 70 Solna • 08-509 04 679 • Fax: 08-655 26 10

SWITZERLAND: Kriesbachstrasse 4 • 8600 Dübendorf • 01-821 94 44 • Fax: 01-820 30 81

TAIWAN: 1FL., 85 Po Ai Street • Hsinchu, Taiwan, R.O.C. • 886-3-572-9077• Fax: 886-3-572-9031

© Copyright 2001 Keithley Instruments, Inc.

Printed in the U.S.A.

4/02

Loading...

Loading...