Page 1

INSTRUCTION MANUAL

Model 244

High Voltage Supply

(and Model 2441 Overload Protection Option)

@COPYRIGHT 1976, KEITHLEY INSTRUMENTS, INC.

FOURTH PRINTING, DEC. 1977, CLEVELAND, OHIO, U.S.A.

Page 2

Page 3

MODEL 244

CONTENTS

CONTENTS

SWtiO”

SPECIFIC.4TIONS

....................................

1. GENERAL DESCRIPTION.

2.

OPERATION.

....................................

3. CIRCUIT DESCRIPTION.

4. ACCESSORIES

5. REPLACEABLE PARTS.

6. CALIBRATION

SCHEMATICS

....................................

................................

....................................

......................................

...............................

...............................

ILLUSTRATIONS

Page

iv

1

4

6

8

13

19

25

Figure NO.

1

2 FrOnL Panel Controls.

Title

Model 244 High Volt+ Supply

..........................

3 Rear Panel Controls ...........................

4 current Limiting. ............................

5 Simplified Circuit Diagram.

6

7

8 Top Cover Assembly.

9

10

11

Overload Protection Cmmectio,, Diagram.

Overload Protection Circuit Diagram

...........................

Bottom cover Assembly

..........................

Circuit for Laad BDX LB-1

Circuit for Divider ""-1.

......................

.......................

...................

........................

........................

Page

1

3

3

5

6

................. 10

11

15

15

22

22

1176

Page 4

SI?ECIFICATIONS

MODEL 244 HIGH VOLTAGE SUPPLY

SPECIFICATIONS

OUTPUT :

Voltage:

-200 to -2200 volts in ZO-volt steps

current: 10 milliamperes maximum

Polarity: Negative with respect Lo chassis

ACCWACY: il% of dial setting

RESOLUTION: A O-25 volt "Trim" porentiameter permits interpolation be-

tween steps with a resolution of better than 100 millivalts.

STABILITY: ~0.005% per hour after a two-hour warm-up; +o.Ol% the first

hour or in subsequent S-hour periods after a one-hour warm-up.

LINE KECULATION: +O.OOl% for a 10% change in line voltage.

LOh" REGULATION: ,O.OOl% for a 5-milliampere load change.

RIPPLE AN" NOISE: Less than 0.5 milli"olt rms above 5 Hz.

OVERLOAD: Electronic current limiting with automatic recovery.

METER:

Provides check on OUtpUt voltage.

CONNECTOKS: Output (on rear) MHV series (UC-931/U)

POWER :

105-125 or 210.250 volts (switch-selected); 50-60 Hz; 90 watts.

OIMENSlONS: b-114" high x S-718" wide x l&7/8" deep (158 x 225 x 378 mm)

WEIGHT: net weight, 13 pounds (6,O kg).

ACCESSORIES FURNISMED: Mating Connector (MHV series, UC-932A/U)

iv

1176

Page 5

MODEL 244 HIGH VOLTAGE SUPPLY

GENERAL DESCRIPTlON

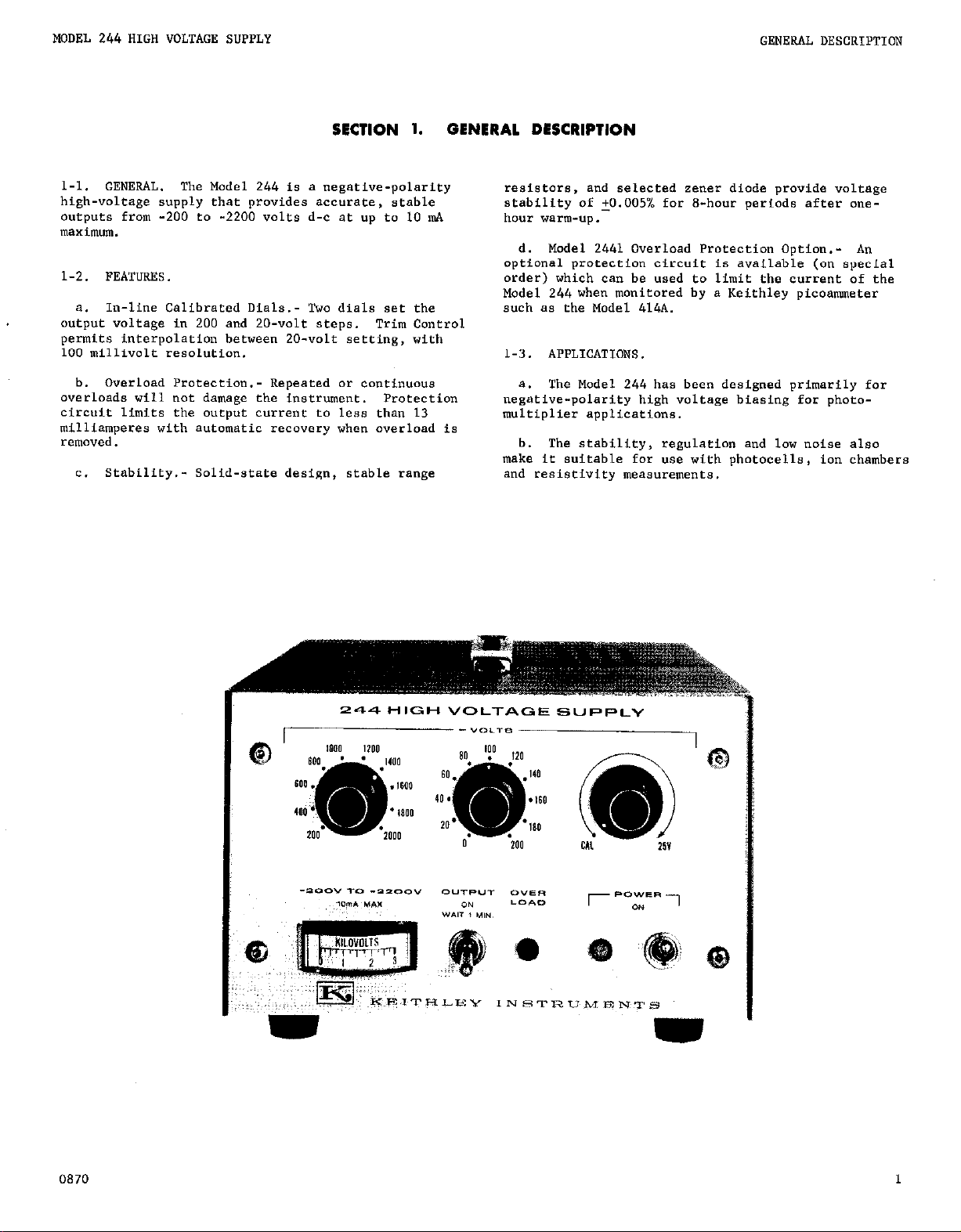

SECTION I.

l-l.

GENERAL.

high-voltage supply that provides accurate, stable

outpote from -200 to -2200 volts d-c at up to 10 ,,$.

"l~Xi"l"Ul.

1-2. FEATURES.

a. In-line Calibrated Dials.- Two dials set the

output voltage in 200 and ZO-volt steps. Trim Control

permits interpolation between ZO-volt setting, with

100 millivolt resolution.

b. Overload Protection.- Repeated or continuous

overloads will not damage the instr,m,ent.

circuit limits the oucput current to less than 13

milliamperes with automatic recovery when overload is

removed.

c. Stability.- Solid-state design, stable range

The Model 244 is a negative-polarity

Protection

GENERAL DESCRIPTION

resistors, and selected zener diode provide voltage

stability of +0.005% for B-hour periods after onehour warm-up.

d. Model 2441 Overload Protection Option.- A,,

optional protection circuit is available (on special

order) which can be used to limit the current of the

Model 244 when monitored by e Keithley picoammeter

such es the Model 414A.

1-3. APPLICATIONS.

a. The Model 244 has bee,, designed primarily for

negative-polarity high voltage biasing for photomultiplier applications.

b. The stability, regulation and low noise also

make it suitable for use with photocells, ion chambers

and resietiviey measurements.

0870

1

Page 6

GENERAL DESCRIPTION

MODEL 244 HIGH VOLTAGE SUPPLY

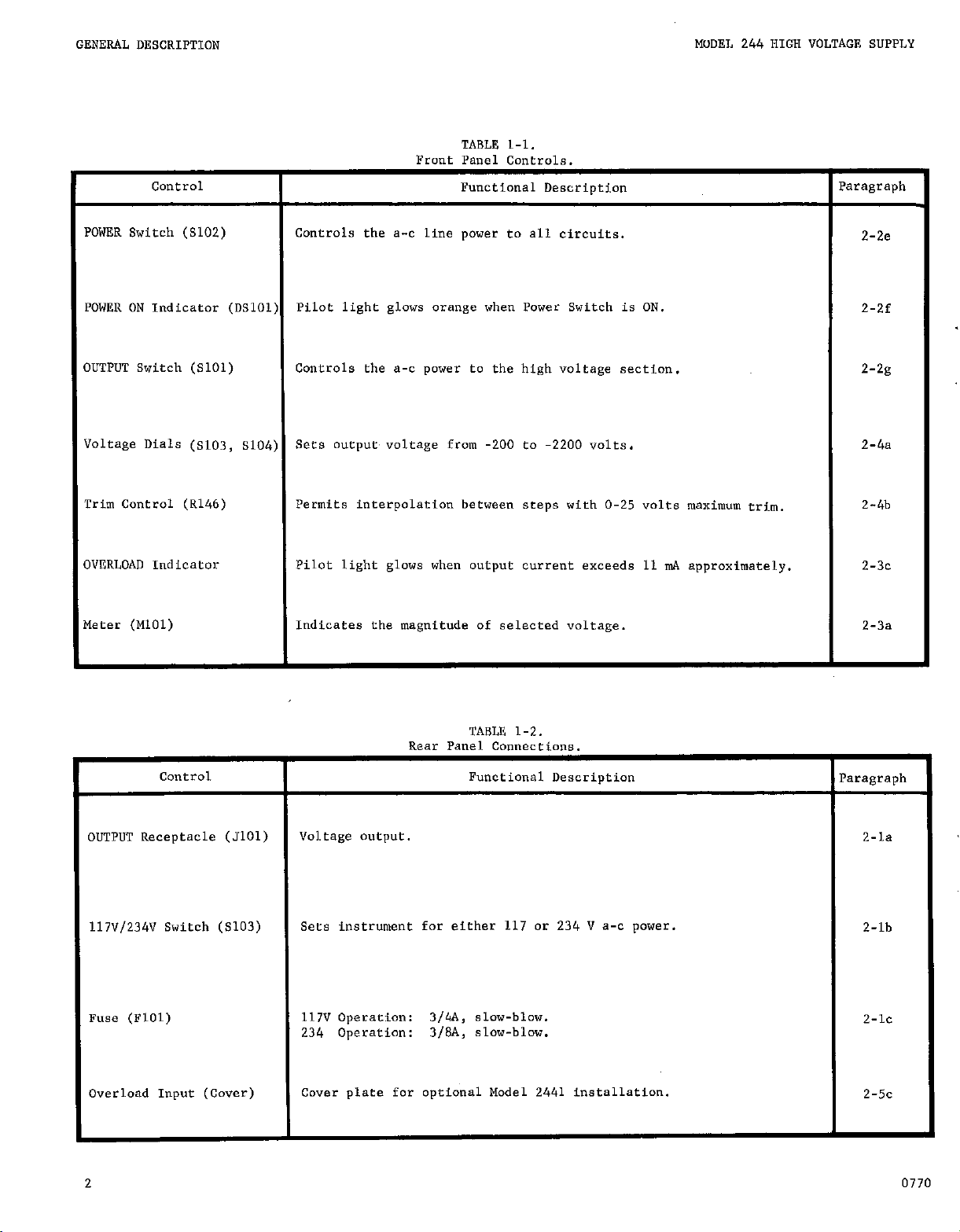

TABLE 1-l.

Front Panel Controls.

COntrOl

OWER Switch (S102)

Controls the a-c line power to all circuits.

Functional Description

OWER ON indicator (mlol) Pilot light glows orange when Power Switch is ON.

UTPUT Switch (5101)

oltwe Dials (s103, s104)

rim Control (R146)

Controls the a-c power to the high voltage section. 2-2g

sets oueput voltage from -200 to -2ml volts.

Permits interpolation between steps with O-25 volts maximum trim.

VBRLOAD Indicator Pilot light glows when output current exceeds 11 I&. approximately.

,eter (MlOl)

Indicates the magnitude of selected voltage.

Paragraph

2-2e

z-2f

2-b

2-a

2-3~

2-3a

Control

OUTPUT Receptacle

117V/234V

Switch (5103)

(5101)

Fuse (FlOl)

Overload Input (Cover)

2

Rear Panel

TABLE 1-2.

Connections.

Functional Description

VOl tage o"tp"t

Sets instrument far either 117 or 234 " a-c power.

117" operation: 3/4A, slow-blow.

234

Operatim: 3/&I, slow-blow.

Cover plate for optional Model 2441 installation.

Paragraph

2-la

Z-lb

2-k

2-k

0770

Page 7

0”tpllt

Selector

Switch

(SlO3)

output

Selector

switch

(X04)

(MlOl)

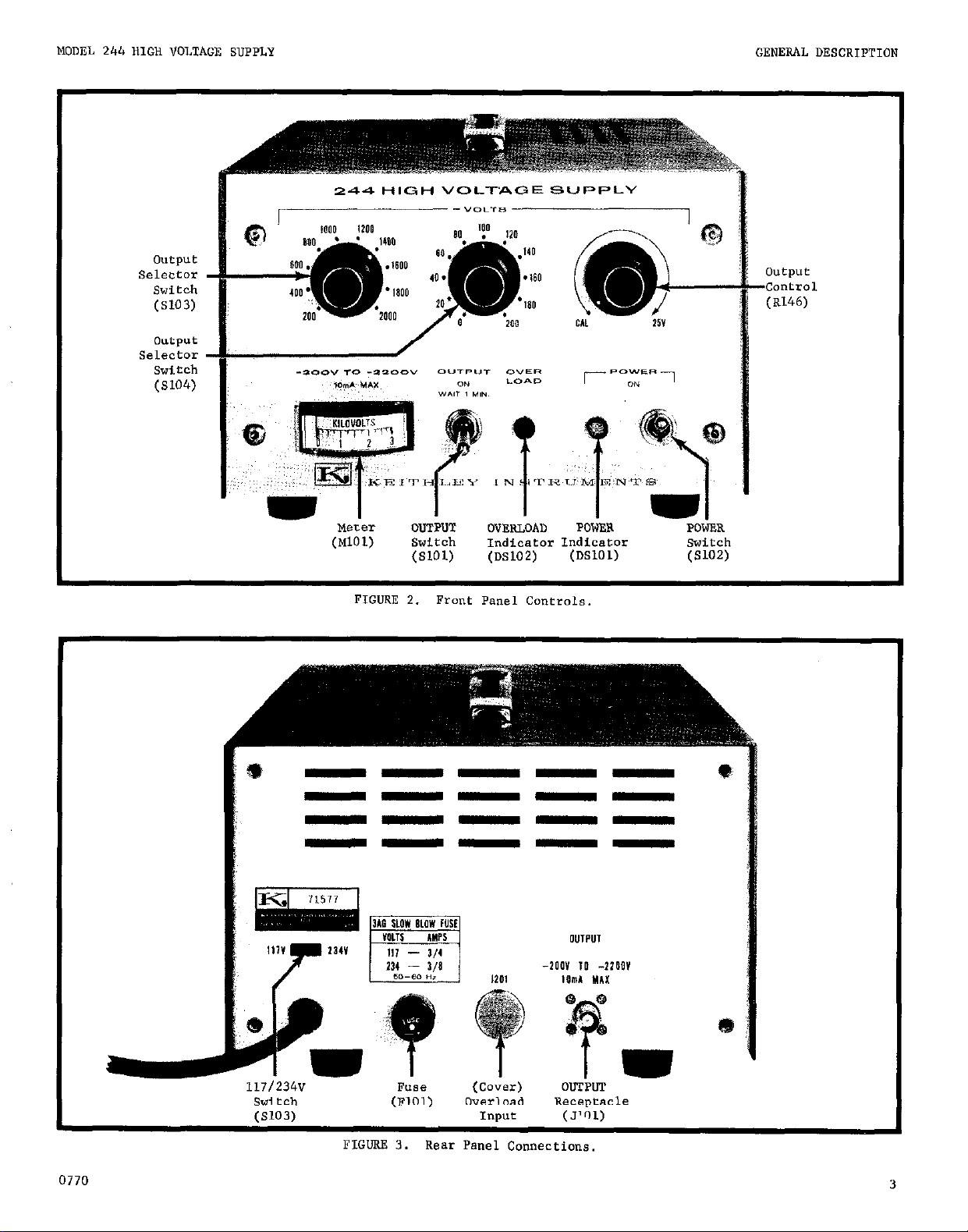

FIGURE 2. Front Panel Controls.

Switch indicator Indicator

(SlOl) (DS102)

(OSlOl)

Switch

(5102)

0770

117/234V

Switch

(5103)

F"LTC5

(FlOl)

z.rnrmm I) "_^_ n--.7 "~~~-.-_,~

(COWS)

Overload

Input

Receptacle

OUTPUT

(J")l)

3

Page 8

OPERATION

MODEL 244 HIGH VOLTAGE SUPPLY

SECTION 2.

2-1. CONNECTIONS.

a. Output Receptacle.- A rear panel mounted MHV

teflon-insulated receptacle provides connection to

the load circuit. The outer shell of the receptacle

is connected to chassis.

b. Coaxial Cables.- Use coaxial cables which are

rated for greater than 2200 volts for safe operation.

Coaxial cables provide best noise immunity for critical meaeurements.

C. Earth Ground.- For maximum operator safety use

the 3-wire power cord with third wire solidly connected to earth ground.

PRELIMINARY PROCEDURES.

2-2.

a. The instrument is shipped in operating condition

+ith all components installed for immediate use.

Set the 117-234 volt switch for operating line

b.

voltage.

C. Check the fuse for proper type and rating.

d. Provide adequate ventilation for the instrument.

Air flow should be maintained along the top and bottom

surfaces.

OPERATION

OPERATING CHECK-OUT.

2-3.

a. Meter Indication.- When the OUTPUT Switch is ON

the meter should indicate the dialed voltage.

b. Output Voltage.- Connect an accurate voltmeter

such as Keithley Model 153 to the output to verify

the power supply voltage accuracy. The Trim Control

should be set to CAL position.

output for dial settings of 200,,,500, and 1000 volts.

Accuracy should be 21% of dial setting.

c. Current Limit.- (Refer also to paragraph 2-5

for a more complete discussion of the overload current

operation.)

1. Connect an accurate ammeter such as a Keithley Model 153 in series with an adjustable resistance decade box.

Model 244 at -200 volts with the OUTPUT Switch

"OFF".

decade box set at 20 kilahms. The ammeter should

indicate 10 mA when the OUTPUT Switch is placed

nON"

Decrease the resistance load until the OVERLOAD Indicator is lighted.

between 11 mA and 12 n!A.

Apply the -200 volt output to the resistance

.

The OVERLOAD Indicator should not be lighted.

Set the dialed voltage on the

The annneter should indicate

measure the Model 244

NOTE

If air flow is constricted the internal

temperature will rise above normal design

limits causing degradation of critical

components.

e. Set the front panel controls as follows:

POWER Switch

Voltage Dials

OUTPUT Switch

f. Connect the line cord and set the POWER

Switch to ON. (The POWER indicator should

be lighted.)

NOTE

The meter should indicate 0 KILOVOLTS.

g. After a preliminary one minute warmup period,

p&ace the OUTPUT Switch to ON position. Allow another

warmup period (30 minutes) for the high voltage sec-

tion to stabilize.

imately one minor division or 200 volts.

The meter should indicate approx-

Off

2-o-o

Off

NOTE

Resistor load power dissipation is approx-

imately 2.2 Watts.

2. Connect an ammeter and 50 kilohm resistive

load to the output of the Model 244. Set the dialed voltage an the Model 244 at -200 volts with the

OUTPUT Switch "OFF".

"ON" position. Reduce the load to zero ohms (short

circuit) and measure the output current. The

ammeter should indicate less than 14 milliamperes

with the Model 244 OVERLOAD Indicator lighted.

SETTING OUTPUT VOLTAGE. The setting of the

2-4.

Voltage Dials and Trim Control determines the magni-

tude of the output.

a. The two Voltage Diala set the output from -200

to -2200 volts d-c in calibrated 200 and 20-volt

steps. With the Trim Control in CAL position the

output is set by the Voltage Dials within specified

kXC"K%Y.

b. The Trim Control interpolates between 20-volt

settings with 100 millivolt resolution. The Trim

Control range is 0 to 25 volts.

Place the OUTPUT Switch to

4

0770

Page 9

MODEL 244 HIGH VOLTAGE SUPPLY

OPERATION

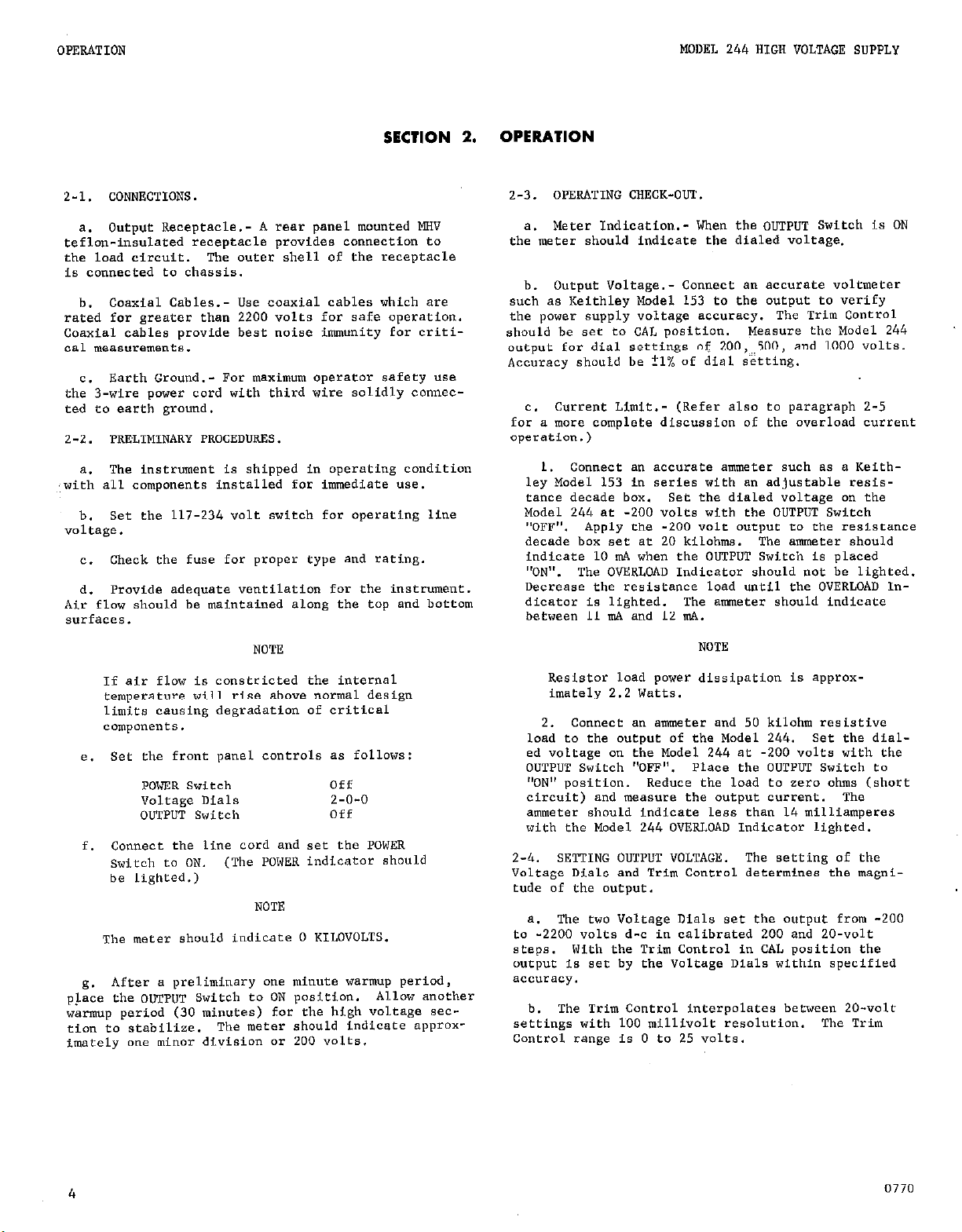

2-5. OVERLOAD PROTECTION.

a. The Model 244 has an overload current limiting

circuit which limits the output short-circuit current

to a maximum 14 milliamperes. The circuit is adjusted

so that the OVEKLOAD Indicator will be lighted when

the output current exceeds 11 milliamperes. When the

overload is removed the Model 244 will automatically

reset to normal operation and the OVERLOAD Indicator

will turn off.

b. Current Limiting Characteristic.- The Model 244

current limiting is shown graphically by the typical

V-I characteristic curves in Figure 4. The OVERLOAD

Indicator is factory-adjusted to turn on at approxi-

mately 11 milliamperes. However the output voltage

remains constant for current exceeding 11 milliamperes

as shown.

The current limiting occurs typically from

11.3 to 12.2 milliamperes depending on the dialed

voltage.

c. Model 2441 Overload Protection Option.- An

optional protection circuit is available which can

bz used to limit the current of the Model 244 when

w>nitored by a Keithley picoammeter such as the

I!zrdel 414A. Consult your Keithley representative or

t:,e Sales Service Department for further information

regarding the Model 2441 Option.

2-6.

CAPACITIVE La4ix.

a. When a capacitive load is connected to the output, Model 244 will deliver a charging current up to

14 milliamperes maximum until the dialed voltage is

developed across the load. During the charging time

the OVERLOAD Indicator will be lighted as long as the

output current exceeds 11 milliamperes. The OVERLOAD

Indicator will turn off automatically when the charging current is reduced to less than 11 milliamperes.

b.

Before reducing the dialed voltage with large

capacitive loads (exceeding 1 joule of energy), set

the OUTPUT Switch to “OFF”. Readjust the dialed

voltage and set the OUTPUT Switch to “ON”.

NOTE

A resonant condition (with increased output

noise) could result for large capacitive

loads.

If this should occur, change the

load capacitance slightly to remove the

resonant condition and reduce the output

noise.

2-7.

OUTPUT NOISE. The Model 244 output ripple and

noise is less than 0.5 millivolt rms above 5Hz with

maximum load. The output noise is typically 200 WV

rms ~with no load. Transient power line noise will

tend to increase the output noise.

2-8.

SHORT-TERM STABILITY. The Model 244 stability

is specified to be + 0.005% per hour worst-case after

0

10

12

f .

14 mA

I

a two-hour warm-up. After warm-up, the short-term

stability is typically 0.003% per hour for constant

line voltage, load, and ambient temperature.

2-9.

TEMPFJATURE

COEFFICIENT. The temperature co-

efficient is typically 30 PPM1 C (with a maximum

FIGURE 4. Current Limiting.

temperature coefficient not to exceed 60 ppml C).

1176

5

Page 10

CIRCUIT DESCRIPTION

MODEI: 244 HIGH VOLTAGE SUPPLY

SECTION 3. CIRCUIT DESCRIPTION

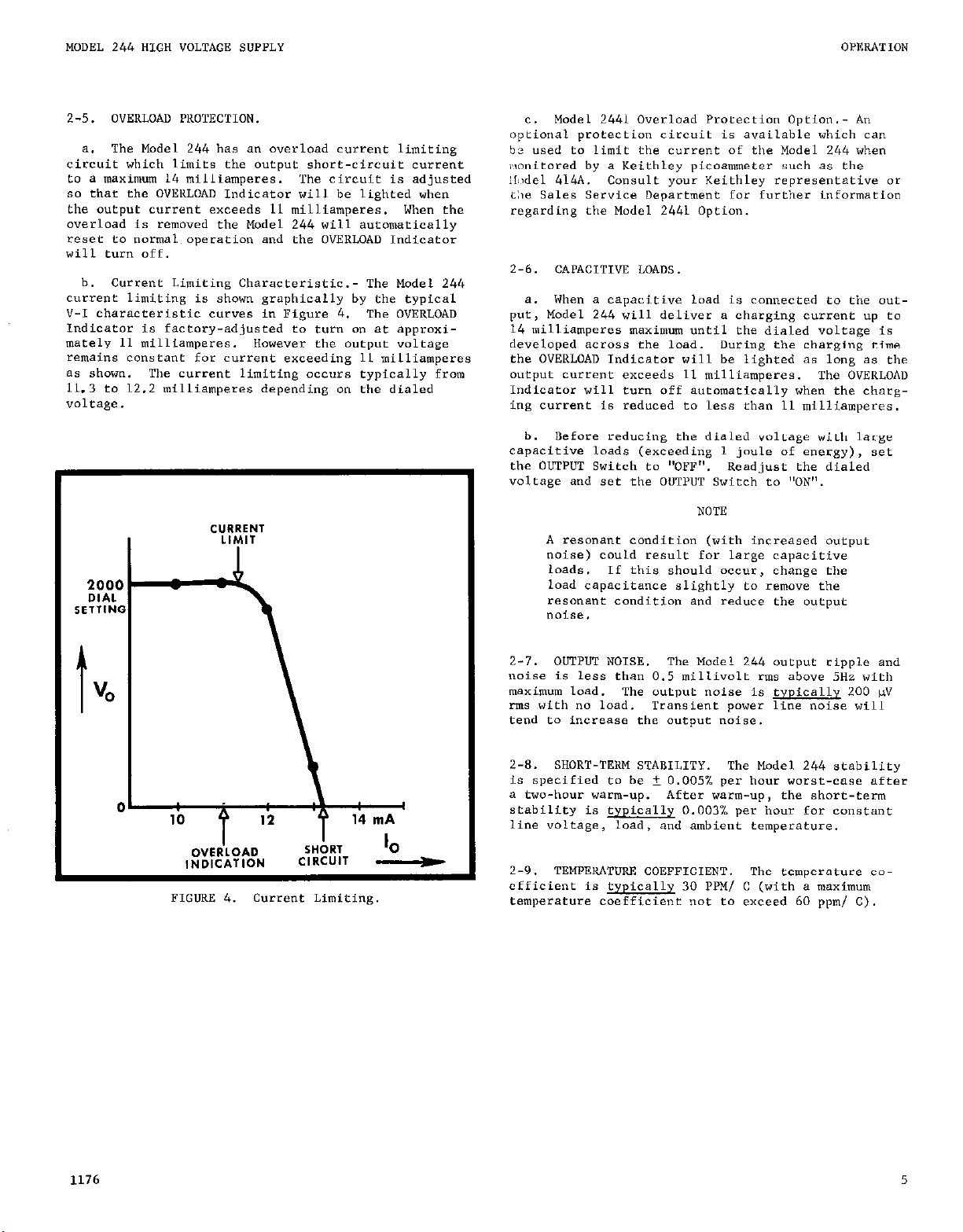

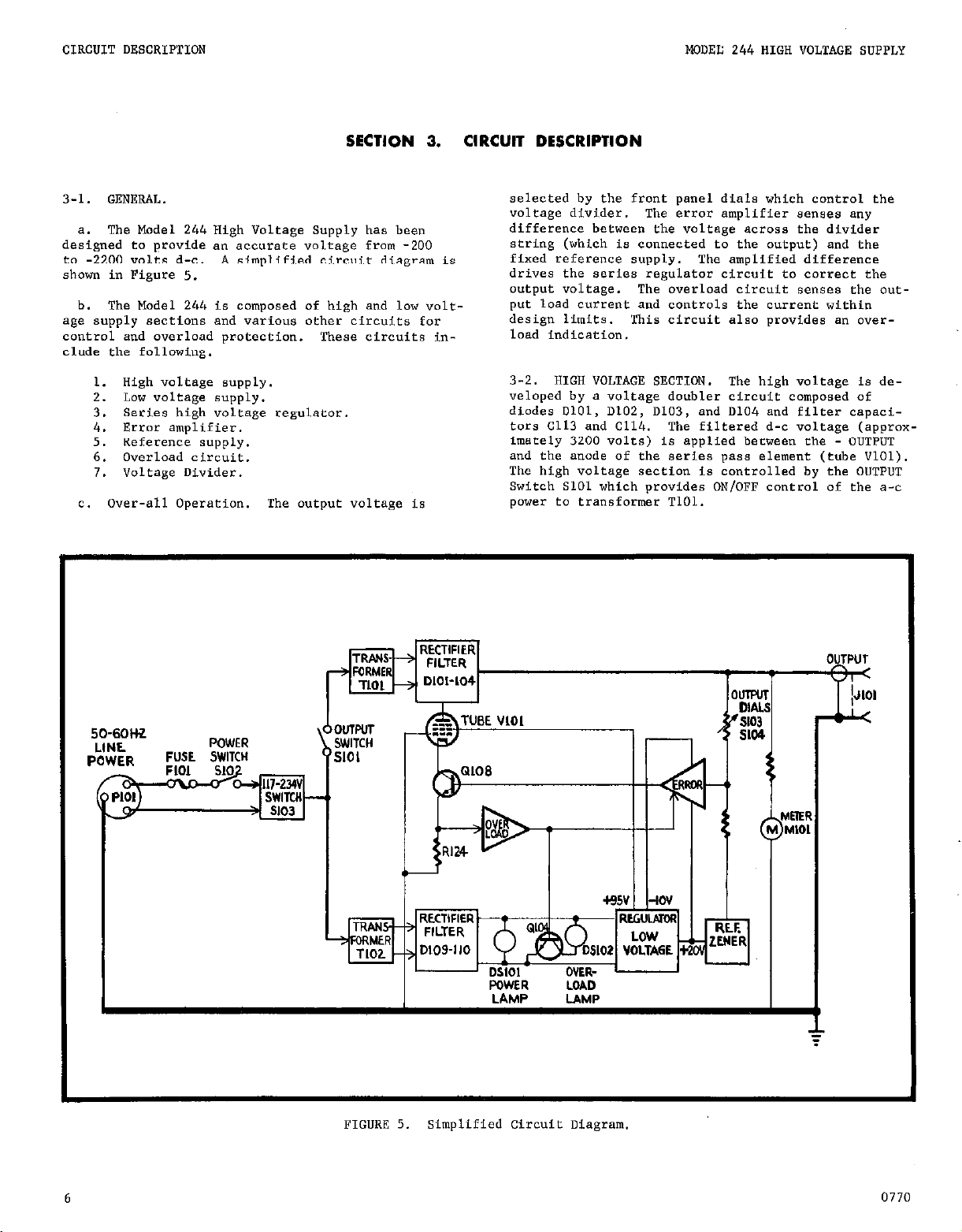

3-1. GENERAL.

a. The Model 244 High Voltage Supply haa been

designed to provide a,, accurate voltage from -200

to -2200 volts d-c.

A

simplified circuit diagram is

shown in Figure 5.

b. The Model 244 is composed of high and low voltage supply sections and various other circuits for

control and overload protection. These circuits include the following.

1. High voltage supply.

2. LOW voltage supply.

3. Series high voltage regulator.

4.

Error amplifier.

5. Reference supply.

6. Overload circuit.

7. Voltage Divider.

C. Over-all Operation.

The output voltage is

selected by the front panel dials which control the

voltage divider. The error amplifier senses any

difference between the voltage across the divider

string (which is connected to the output) and the

fixed reference supply.

The amplified difference

drives the series regulator circuit to correct the

output voltage.

The overload circuit senses the output load current and controls the current within

design limits.

This circuit also provides an over-

load indication.

3-2. HIGH VOLTAGE SECTION.

The high voltage is developed by a voltage doubler circuit composed of

diodes 0101, DlC2, DlC3, and 0104 and fileer capacitars Cl13 and C114.

The filtered d-c voltage (approxFmaeely 3200 volts) is applied between the - OUTPUT

and the anode of the series pass element (tube VlOl).

The high voltage section is controlled by the OUTPUT

Switch SlOl which provides

ON/OFF

control of the a-c

power to transformer TlOl.

R

H

WWER LDAD

LAMP UMP

I

FIGURE 5. Simplified Circuit Diagram.

6

0770

Page 11

MODEL 244 HIGH VOLTAGE SUPPLY

CIRCUIT DESCRIPTION

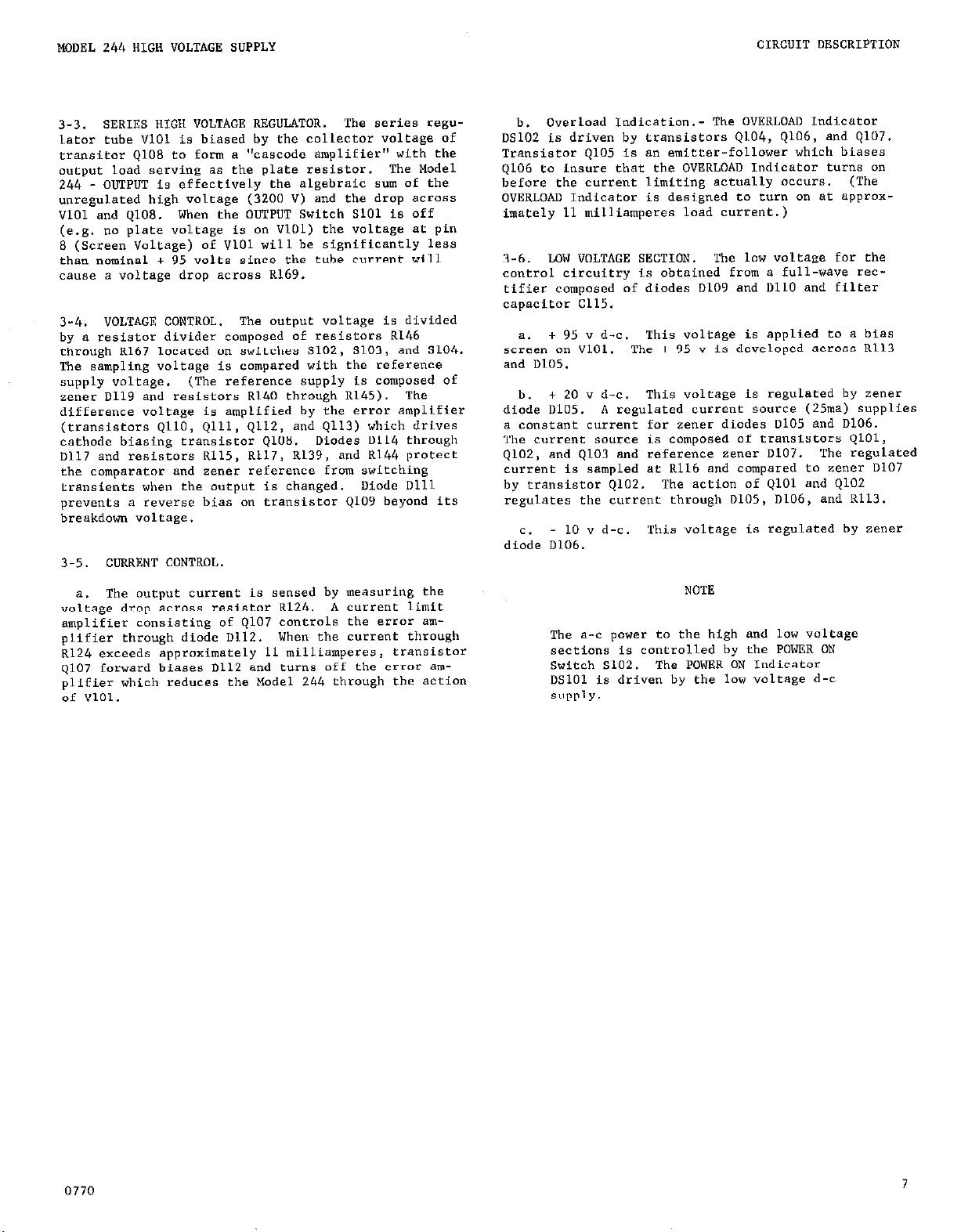

SERIES HIGH VOLTAGE REGULATOR. The series regu-

3-3.

lator tube VlOl is biased by the collector voltage of

transitor QlOE to form a “cascade amplifier” with the

output load serving as the plate resistor. The Model

244 - OUTPUT is effectively the algebraic sum of the

unregulated high voltage (3200 V) and the drop across

“101 and QlOE. When the OUTPUT Switch SlOl is off

(e.g. no plate voltage is on “101) the voltage at pin

8 (Screen Voltage) of VlOl will be significantly less

than nominal + 95 volts since the tube current will

cause a voltage drop across R169.

VOLTAGE CONTROL. The output voltage is divided

3-4.

by a resistor divider composed of resistors R146

through R167 located an switches S102, 5103, and S104.

The sampling voltage is compared with the reference

supply voltage. (The reference supply is composed of

zener D119 and resistors Rl40 through R145). The

difference voltage is amplified by the error amplifier

(transistors QllO, Qlll, Q112, and Q113) which drives

cathode biasing transistor ~108. Diodes 0114 through

Dl17 and resistors R115, R117, R139, and R144 protec?

the comparator and zener reference from switching

transients when the output is changed.

Diode Dill

prevents a reverse bias on transistor QlOV beyond its

breakdown voltage.

3-5. CURRENT CONTROL,

b. Overload Indication.- The OVERLOAD Indicator

05102 is driven by transistors 4104, Q106, and Q107.

Transistor QlO5 is an emitter-follower which biases

9106 to insure that the OVERLOAD Indicator turns on

before the current limiting actually occurs.

(The

OVERLOAD Indicator is designed to turn on at approx-

imately 11 milliamperes load current.)

LOW VOLTAGE SECTION. The low voltage for the

3-6.

control circuitry is obtained from a full-wave rec-

tifier composed of diodes D109 and I1110 and filter

capacitor c115.

+ 95 v d-c. This voltage is applied to a bias

a.

screen on “101. The + 95 v is developed across R113

and D105.

+ 20 v d-c. This voleage is regulaeed by zener

b.

diode D105. A regulated current sowce (25~) supplies

a constant current far zener diodes D105 and D106.

The current source is composed of transistors QlOl,

9102, and Q103 and reference zener D107. The regulated

current is sampled at R116 and compared to zener 0107

by transistor Q102. The action of QlOl and Q102

regulates the currene through 0105, D106, and R113.

- 10 v d-c. This voltage is regulated by zener

c.

diode 0106.

a. The output current is sensed by measuring the

voleage drop across resistor R124. A current limit

amplifier consisting of Q107 controls the error amplifier through diode D112. When the current through

R124 exceeds approximately 11 milliamperes, transistor

Q107 forward biases D112 and turns off the error amplifier which reduces the Model 244 through the action

of VlOl.

NOTE

The a-c power to the high and low voltage

sections is controlled by the POWER ON

Switch ~102. The POWER ON Indicator

ix101 is driven by the low voltage d-c

SUPPlY.

0770

7

Page 12

ACCESSORIES

SECTION 4. ACCESSORIES

4-l.

GENERAL.

be used with the Model 244 to provide additional co"venience and versatility.

The following Keithley accessories can 4-2.

Model 4003A Rack Mounting Kit

MODEL 244 HIGH VOLTAGE SUPPLY

OPERATING

INSTRUCTIONS. A separate Instruction

Manual is supplied with each accessory giving complete

operating information.

Description:

The Model 4003A is a rack mounting kit with overall

dimensions, 5-l/4 inches hFgh x 19 inches wide. Two

cop covers are provided for use with either 10 inch or

13 inch deep instruments.

Application:

The Model 4003A converts the instrument from bench

mounting to rack mounting. It is suitable for mount-

ing one instrument Fn one-half of a standard lY-inch

rack.

Parts Liar:

Item

NO.

1 Top cover, 10" 1 18554B

2

Panel

3 Angle Support 1 17476A

4 Screw, ii10 x 318" 4 ---

5 Connecting Place 1

6 Screw, #lo x 112" 4 -_-

Adapter Plate 1 17452B

Qty. ,Per

Assemblv Part No.

Keithley

7 Angle 1 14624B

8 Top Cover, 13" 1 20015B

191268

Page 13

MODEL 244 HIGH VOLTAGE SUPPLY

ACCESSORIES

Model 4004A Dual Rack Mounting Kit

Description:

The Model 4004A is a rack mounting kit with overall

dimensions, 5-l/4 inches high x 19 inches wide. Two

top covet-~ are provided for use with either 10 inch

or 13 inch deep instruments.

Application:

The Model 4004A converts the instrument from bench

mounting to rack mounting.

ing two inseruments in a standard 19-inch rack.

It is suitable for mount-

parts List:

Item

NO.

1

4 screw, #lO x l/2

5

6

7

8

9

10

Description

Top cover, 10"

Connecting Plate

screw, (110 x l/2

Angle

Top Cover, 13"

Zee Bracket

Plate (not shown)

Qty. Per

Assembly

Keithley

Part No.

185540

19126A

___

14624B

20015B

1914411

174548

Page 14

ACCESSORIES

MODEL 244 HIGH VOLTAGE SUPPLY

Model 2441 Overload Protection Option

Description:

The Model 2441 when factory installed on the Model

244 provides automatic current limiting of the Model

244 output.

Specifications:

OVERLOAD:

current limiting of the Model 244 when the overload input voltage to the Model 2441 exceeds

approximately +1.4 volts.

SENSITI"IT:T:

to +2.OV (+1.7 volts typically) will cause current limiting of the Model 244 output.

OVERLOAD INDICATIONS:

cate whenever rhe Model 244 is in a current

limiting mode.

NOISE IMMUNITY:

signal will not operate overload.

RESPONSE TIME:

"ate 2441 is typically 0.25 seconds (lo-go%).

Model 2441 circuitry provides automatic

An overload input voltage from +1.4V

The overload lamn will indi-

NOTE

The Model 244 will deliver a calibrated

voltage as long as the overload lamp is off

(or the overload input voltage does not

exceed +1.2 volts).

An 8V p-p at 60 Hz overload input

Time for a 2.5" Peak pulse to acti-

Typical Operation:

NOTE

The picaammeter (such as Model 414A) has a 1

volt output for full scale input on the range

selected.

Model 414A increases to approximately 170% of

full scale the Model 414A output,of the 1.7

volts will activate the Model 2441 circuit.

Any

further increase in the current monitored

by the picoammeter will ultimately be limited

to no more than 200% of the full scale range

of the picoammeter. However current limiting

of the Model 244 will occur whenever the Model

244 output exceeds 11 milliamperes s the Model

2441 is activated.

a. Connect the recorder output of a Keithley

picoammeter such as the Model 414A or equivalent to

the Overload Protection Input receptacle 5201.

Figure 1.

b. Select the full scale current range an the

picoammeter for desired operating range.

c. Recorder output of 414A should be in 1 volt

mode.

d. Operate the Model 244 as described in gecrion

2.

If the current monitored by the

see

10

MODEL 244-2441

MODEL 244-2441

I

I

T Ground

FIGURE 6.

System

PICOAMMETER

PICOAMMETER

r-l

Overload Protection Connection Diagram.

0976

Page 15

MODEL 244 HIGH VOLTAGE SUPPLY

ACCESSORIES

Theory of operation far Model

24640A.)

a. The Model

2441

Option provides current limiting

2441:

(See Schematic

control when used with a ,,icoammeter with a 1 volt

output. The Overload Protection Input 5201 requires

an input signal between 1.4 to 2.0 volts d-c.

Model

2441

circuit activates the Model 244 control

The

circuit by meant of transistor switch Q202. The

Model

2441

filter circuit prevents false overloads

due to 60 Hz noise while not affecting the response

which is approximately

0.25

seconds (10-W% rise

the).

b. 'rhe

fallower transistor

switch

2441

Circuit is composed of an emitter

Q201

Q202

which is paralleled wieh the Model 244

which drives a transistor

overload transistor switch 4107. A filter circuit

is composed of R203 and C2Ol.

Replaceable Parts for Model 2441:

C*l-C"it

Mfr. Mfr. Keithley

oesig. oescription Code oesig. Part NO.

5201 COll"eCtOr

--

Cable, 3 ft., k&es

APH so-PC2M

a-233

with 5201) K-I -- 3991

Q201

Q202

Transistor F-I

Transistor

F-l

2N3565

2N3565

'i-G-39

'K-39

R201 Resistor,lMn,l0%,1/2W A-B EB Rl-1M

R202 Resistar.3.9Kn.l0%.1/2W A-B EB Rl-3.9K

R203 ~~~~~~~~~ m,io%,i/2w ~-8 EB n-x

R204

R205

c201

-_

5107

Resistor,

10Kn,10%,1/2W

n-B EB

Resistor,100K~,10%,1/2W h-B EB

u-c

Capacitor, 22ufd,20"

K22JZOK

Stand off K-I -COll”eCt’X

K-I -- SpCXid

Rl-1OK

Rl-100K

CSO-2x4

ST-25

0976

FlClmE 7.

Overload Protection circuit Diagram.

Page 16

ACCESSORIES

MODEL 244 HXH VOLTAGE SUPPLY

MH” connector, cs-191

D~SCt-ipfiOll:

TL- mv ~..-..~~~nr o..nnli~A . ..lrh the instrument is a

------TOT. This part

Il.

Assembly Instructions:

Application:

The connector should be used with low noise coaxial

cables such as RG58A/U or RG59/U.

The cable size

used with this connector should not exceed .257in. 0.1)

12

Fold brald back over brald clnp and

3.

trim .I ,kwn. Cut dlelectrlc and center

conductor to 7/W’ dimension then

strip dlelsctrlc to .470 dimension.

4. Solder contact to center conductor.

Slide back end p.rts forward then

5.

thread assembly into connector and

lock securely.

split by brald clamp.

“ee qmket must be

0870

Page 17

MODEL 244 HIGH VOLTAGE SUPPLY

REPLACEABLE PARTS

SECTION 5.

REPLACEABLE PARTS LIST: This section contains t”rer’s Part Number, and ehe Keithley Part Number.

5-l.

REPLACEABLE PARTS

a list of camponen~s used in this instrument for user Also included is a Figure Reference Number where

reference. The Replaceable Parts List describes the applicable. The complete name and address af each

individual parts giving Circuit Designation, Descrip- Manufacturer is listed in the CODE-TO-NAME Listing

tion, Suggested Manufacturer (Code Number), Manufac- following the parts list.

TABLE 5-l.

Abbreviations and Symbols

A

i ampere

Cb”ar : Carbon Variable

cem : ceramic oisc

Cer Trimmer ; Ceramic

Chip

: composition

Trimmer

: Deposit

DCb : Deposited Carbon

Desig. : Designation

EAL i Electrolytic, Aluminum

ETB : Electrolytic, tubular

ETT

i Electrolytic, tantalum

F i farad

Fig :

GCb i

Fig”?-+

Glass enclosed Carbon

k kilo (10-3)

P

M

micro (10.6)

~~~ (106)

Manufacturer ” : valt Mfr. i

MtF : Metal Film

MY

NO.

Mylar W : watt

Number

; ohm

n

pica (10-'2)

i

P

PC

: Printed Circuit

POly

; Polystyrene

Ref.

: Reference

TC”

i Tinner Copperweld

ww

i Wirewound

ww”ar :

Wirewound Variable

5-2. ELECTRICAL SCHEMATICS AND DlAGRANS. Schemaeics

and diagrams are included to describe the electrical

Sales Service Department, Keithley lii~truments, Inc.

or your nearest Keirhley representative.

circuits as discussed in Section 3. Refer to Table

5-2 which identifies all schematic part numbers

b. When ordering parts, include the following in-

included. formation.

1. Instrument Model Number.

HOW TO “SE THE REPLACEABLE PARTS LIST. This

5-3.

Parts Lise is arranged such that the individual types

Of components are listed in alphabetical order. The

parts for the instrument’s Main Chassis are listed

2. Inserument Serial Number.

3. Pare Description.

4.. Schematic Circuit Designation

5. Keithley Part Number.

followed by printed circuit boards and other subassemblies.

c. All pares listed are maintained in Keithley

spare Parts Stock.

available upan request. Parts identified by the

HOW TO ORDER PARTS,

5-4.

Keithley Manufacturing Cade Number 80164 should be

ordered directly fram Keithley Instruments, Inc.

a.

Replaceable parts may be ordered through the

TABLE 5-2.

Circuit Designaeion

Power supply

PC-270

Any part not listed can be made

Schematic Part Number

243173

0870

13

Page 18

REPLACEABLE PARTS

TABLE 5-3.

Mechanical Parts List

MODEL 244 HIGH

VOLTAGE SUPPLY

Description

1) Chassis

11) Fro,e Panel

Top Cover Assembly

12) Cover, Sheet Metal

13) screws

Handle Assembly

14) Handle

15) Screws #6-32x3/8" R. H. Slotted

Bottom Cover Assembly

2) cover

3) Fastener

Feet Assembly

4) Feet

5) Ball

6) screws #8-32x3/8” Phillips, Pan Head

Tile Bail Assembly

Qll.%ltity

Per Assembly

1

1

___

1

4

___

1

2

__1

2

-_-

4

4

4

___

Keithley

Part NO.

24304C

24306C

19057

19055c

W-18

___

190628

FA-54

___

FE-5

FE-6

___

Fig.

7

637

6

6

7

7,

7

7)

Bail

8) Right Assembly

9) Left Assembly

10) Screws 1/6-32x1/4” Phillips, Pan Head

1

1

1

2

171470

19206B

192058

-__

14

1176

Page 19

MODEL 244 HIGH VOLTAGE SUPPLY

REPLACEABLE PARTS

I

FIGURE 8. To,, Cover Assembly.

-

1176

15

Page 20

REPLACEABLE PARTS

MODEL 244 HIGH VOLTAGE SUPPLY

Cl16

Cl17

5104

5105

5106

5107

5108

___

0.1 IIF

0.1 !JF

0.1 VF

0.1 !lF

.02 UP

0.1 UP

0.1 UF

22 PP

33 PF

.02 PF

100 PP

0.1 !lF

1.0 UP

1.0 UP

40 !lF

0.1 PP

0.1 "F

15”

15"

15"

15"

600"

250"

250"

600"

600"

600"

600"

4OOOV

2000"

2000"

350"

4ooov

250"

connector, ~lnl-P" (Solde

connector, Mini-P" (Solde

connector, mini-P" (S&de

Receptacle, female

Connecfor, male (mate far J108)

890159

890159 c93-.lM

c93-.lM

890159 c93-.l.M

890159

C93-.lM

SW.02 C22-.02M

CZJOAE Cl,&.lM

C28OAE C17G.l"

ED-47

c22-22P

ED-33 cx-3%

ED-.02

ED-100

C22-.02M

CL*-1OOP

LQ40104X c192-.lM

LQ20105X c191-lM

LQ20105X

TVA1611 C23-40M

C191-lM

LQ40104X c192-.lM

C178-.1M

CS-236 10

246588

10

BRG

Bps.

BRG

BRG

BRG

BRG

K-I

CiSOAE

20052 lx-237 3

47439 E-236 10

47439

47439 CS-236 10

47439 cs-236 10

47439 cs-236 10

APH UG93l/V cs-190 io

Am

"G-932AIU

cs-191 10

Mfr.

Code

S-T

S-T

S-T

S-T

Mfr.

Part NO.

3CFS25

3CFS25 RF-49 10

3CFS25

3CFS25

Keichley Fi.g .

Pare NO. Ref.

RF-49

RF-49 IO

RF-49

ITT Z"20 m-25

DIG 1N302OA m-39

DIG

T-I

MOT

MOT

T-I

lN713

18645

lN4006 RF-38

IN4006 RF-38

lA645 RF-14

T-I IN645

T-I

T-I

T-1

T-I

MOT

MOT

lN914

lN645

lN645

IN645 RF-14

IN4006

UT4006

MOT IN938

S-T

vR47

m-14

w-14

RF-14

RF-28 >

RF-14

w-14

RF-38

RF-38

Z-6

25725A

10

10

10

10

10

10

10

Page 21

MODEL 244 HIGH VOLTAGE SUPPLY

REPLACEABLE PARTS

MISCELLANEOUS

circuit

rlesig. Type Code

"SlOl

Pilot Lamp, Neon, White Lens

05102 Pilot Lamp, Neon, Red Lens

DS1,03 Pilot Lamp, Neon

PlOl Fuse, Slow-Blow, 0.75 A, 250V

Ml01 Meter

TlOl

Transformer

T102 Transformer

"101 Vacuum Tube

Mfr. Mfr. Keithley Fig!.

1-D

1-D

G-E

BUS

K-I

K-I

K-I

K-I

RESISTORS

circuit

rasig. Value Rating

RlOl

R102

RI03

R104

RI05

R106

R107

R108

R109

RllO

Rlll

R112

8113

R114

R115

100 n

IK 0

4.7M n

4.7M n

4.7M n

4.7M n

4.7M n

4.m 0

600K n

600K n

600K R

600K 0

2.5K 0

2K n

1K n

lO%, l/4 w

IO%, l/4 w

lO%, 1/2 w

lo%, l/2 w

lO%, l/2 w

lO%, l/2 w

lo%, l/2 w

lO%, l/2 w

l%, l/2 w

l%, l/2 w

1%. l/2 w

l%, l/2 w

5%, 10 w

1%, l/2 w

l%, l/8 W

TYPe

Mfr.

Code

OHM

OHM

A-B

A-B

A-B

A-B

A-B

A-B

DLE

DLE

DLE

DLE

OHM

IRC

IRC

Part No.

Pare NO. Ref.

2100 PL-49

2100

PL-50

NE-83 PL-41

MDL F"-19

___

__.

___

Mfr.

Part NO.

RC07

RC07

EB

B8

EB

EB

EB

ED

DCF-l/2

DCF-l/2

DCF-l/2

cm-l/2

D57F

CEC

CEA

m-87

TR-134

TR-131

W-8068

Keithley

Part No.

K76-100

R76-1K

RI-4.7M

Rl-4.7M

Rl-4.7M

RI-4.7M

Rl-4.7M

RI-4.7M

R12-600K

RlZ-600K

K12-600K

RlZ-600K

R5-2.5K

R94-2K

R88-1K

2

2

10

3

2

10

10

10

Fig.

Ref.

10

10

10

10

10

10

10

10

LO

10

10

10

10

1.0

10

R116

R117

RI18

RI19

RI20

RI21

R122

R123

R124

R125

R126

F.127

R128

R129

it130

RI31

R132

R133

RI34

R135

RI36

R137

R138

R139

R140

402 5,

1K n

33K n

220K n

4.02KR

47K n

4x n

47K n

*Selected R

4.7K n

4.7K n

14 R

15K n

30.lKn

45.3Kcl

47K n

33K n

18K n

120K n

1.5M n

475K R

1K R

1K R

1K R

604 n

1%. l/2 w

l%, l/8 w

lO%, l/2 w

lo%, l/2 w

l%, l/2 w

lO%, l/2 w

10%. 112 w

lO%, l/2 w

l%, l/2 w

IO%, l/2 w

lO%, l/2 w

l%, l/2 w

lO%, l/2 w

I%, l/2 w

l%, l/2 w

lo%, l/2 w

lO%, l/2 w

lO%, l/2 w

10%, l/2 w

l%, l/2 w

I%, l/2 w

l%, l/2 w

20%, 2w

lO%, l/2 w

I%, l/8 w

IRC

IRC

A-B

A-B

IRC

A-B

CEC

CEA

ES

ED

CEC

EB

A-B EB

A-B

IRC

A-P,

A-B

IRC

A-B

IRC

IRC

A-B

A-B

A-B

A-B

IRC

IRC

IRC

CTS

A-B

IRC

EB

CEC

EB

E"

CRC

EB

CEC

CEC

EB

EB

EB

EB

CEC

CEC

CRC

INS-115

EB

CBA

R94-402

R88-1K

Rl-33K

RI-220K

R94-4.02K

Rl-47K

RI-47K

Rl-47K

R94"

Rl-4.7K

Rl-4.7K

R94-14K

Rl-15K

K94-30.x

R94-45.3K

Rl-47K

Rl-33K

RI-18K

Rl-120K

R94-1.5M

R94-475K

R94-1K

RP50-1K

Rl-1K

R88-604

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

LO

1176

17

Page 22

CitX”it

twig.

Value

RESwrORS (Cont’d)

Mfr.

Raring Type Code

Mfr.

Keithley

Fig.

Pare NO. Pare NO. Ref.

MODEL 244

R141

R142

RI43

RI44

R145

RI46

RI47

RI48

R149

R150

R151

R152

R153

RI54

R155

RI56

R157

R158

R159

R160

F.161

R162

R163

R164

RI65

R166

R167

8.168

R169

R170

R171

R172

R173

RI74

604 n

604 0

16.W 0

100 n

1K fi

5OK 0

402K il

402K a

402K cl

4OZK n

402K n

402K n

402K n

402K 0

402K n

402K n

Not Used

40.2K n

40.2K n

40.2K n

40.x 0

40.2K n

40.2K 0

40.2K 0

40.z n

40.2K n

40.2K 0

Not USed

33K n

60OK Cl

47K n

100 n

100 R

10 Ml?

I%, l/8 w

l%, 1/g w

0.5%, l/2 w

lo%, 1 w

*o%, 2 w

E%, l/2 w

0.5%, l/2 w

0.5%, l/2 w

0.5%, l/2 w

0.5%, l/2 w

0.5%, l/2 w

0.5%, l/2 w

0.5%, l/2 w

0.5%, l/2 w

0.5%, l/2 w

0.5%, l/2 w

0.5%, l/2 w

0.5%, l/2 w

0.5%, l/2 w

0.5%, l/2 w

0.5%, l/2 w

0.5%, l/2 w

0.5%, l/2 w

0.5%, l/2 w

0.5%, l/2 w

lo%, l/2 w

1%, l/2 w

I%, l/2 w

10%. l/4 w

lo%, l/4 w

IO%, l/4 w

MW

MtF

MeF

camp

ww var

cermet var

Mt”

bit”

Me”

Mt”

MtP

MU

Mm

MU

Mm

MCF

MLF

MLF

WCF

Mm

Mm

Mm

MeF

MCF

Mm

MtF

camp

DCb

DCb

00Ulp

camp

camp

IRC

IRC

DLE

A-B

CTS

cm

DLE

DLE

DLE

DLE

DLE

DLE

DLE

DLE

DLE

DLE

DLE

DLE

DLE

DLE

DLE

DLE

DLE

DLE

DLE

DLE

A-B

DLE

DLE

OHM

OHM

CEA

CEA

mm/m9

GB

INS-115

550

MMF1/2T9

mm1,2T9

MMF1/2T9

W1,2T9

blMFll2T9

MMFl/ZW

MMFlf2T9

MMF1/2T9

mm/n9

m!m,2T9

MMFl/ZT2

MMF1/2T2

MMFlf2T2

m1,2T*

MNF1/2T2

mm/2T2

W1/2T2

MMm,2T2

lWF1,2TZ

wm1/2T2

EB

DCF-l/2

OCR-1,2

RCO7

RCO7

RCO7

Rgg-604

Rgg-604

8171-16.Z

RZ-100

RPSO-1K

RP87-50K

8171-402K

R171-402K

R171-402K

R171-4OZK

Rl,l-402K

R171-402K

Rl,l-402K

R171-40x

Rl,l-402K

?.,,I-40ZK

Rl-33K

RlZ-600K

RlZ-600K

R76-100

8.76-100

R76-10~

10

::

10

10

2

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

QlOl Silicon NPN, TO-92 case

Q102 Silicon NPN, TO-5 case

Q103

Q104

QlO5

Q106

9107

___

___

Silicon

Silicon - PNP

Silicon

Q108 --Q109

QllO

Qlll

Q112

Q113

Silicon

siticon

Silicon

Silicon

Differential Amp.

*Selected Parr E-44

CirC”it

msig.

SlOl

S102

5103

SlOl

5105

Description

Toggle type, OUTPUT

Toggle type, POWER

Rotary type, 200 " Steps

Rotary type. 20 v steps

Slide type, 117"/234"

18

Mfr.

MOT

P.c*

KCA

RCA

F-I

MOT

F-T

K-I

P-1

F-I

P-I:

F-1

F-I

SWITCHES

Mfr. Mfr. Keirhley Pig.

Code

an904

40346 2167&t* 10

E-47

40317 TG-43 10

40346 TG-44 10

*IT3565

MPSL51

2N3565

m-39

E-72

TG-39

21676A

283565

*Ii5139

2N5139

2N3565

IT122

Part NO. Part NO.

m-39

E-66

TG-66

TG-39

m-73

SW238

Am

20994L" SW4

SW321

K-1

___

SW323 2

24665A

10

10

10

10

10

10

10

10

10

10

Ref.

2

2

2

3

1277

Page 23

MODEL 244

CALIBRATION

SECTION 6.

TEST 6-1.

Test Equipment

Electrometer Keithley

Voltmeter, TRM

Voltmeter, Differential Keithley

O.VCillOSCOp~ Tektronix

Voltmeter DVM Keithley

Micra"oltmeter

Variable Transformer "ari.W

Line Voltage Monitor RCA

Voltage Divider (See Fig. 9) Keithley

Loading Box (See Fig. 8)

Nanovolt source Keithley

6-l. TEST PROCEDORES.

a. General.

1. Maintain caueion and always turn 244 OUTPUT

switch off before working inside chassis and after

each step in this procedure.

Ballafine

Keithley

Keithley

610B

323-01

662

561

160

155

lN-1

LB-l

260

CALIBRATION

2. Amplifier Operation.

a). Output switch on 244 must still be in the

OFF position.

b). Connect 155 Microvoltmeter HI to TP-J and LO

chassis and set range fo 1 volt. Reading On 155

should be .8 volts to 1 volt.

c). Place Nanovolt Source switch in the OFF

position and connect HI of source to TP-E of 244,

LO to chassis.

d). Set dials of Nanovalt Source to 40 mV. See

switch to (-) polarity turn dial up to 60 m".

Reading on 155 should now drop to zero somewhere

between 40 mV and 60 mV indicating amplifier is

operating correctly.

dropping to zero amplifier is not operating prop-

erly.

e). Place Nanovolt Source to the OFF position

and disconnect the Nanovolr Source and fhe 155

from the 244.

3. Zener Current Adjust. Connect DVM HI to TP-F

and LO to TP-G.

to +8.01 "OlfS.

If 1 volt is sluggish when

See Zener Adj. R138 for +7.99 voles

2. The 244 has a unipalar negative output in

which LO and the 244 chassis are the same.

3. Before calibrating the 244 visually inspect it

for incorrect wiring, interchanged parts, diodes in

backwards, bridged or broken tapes. Also mechanical-

ly inspect for smoothly operating controls.

4. Make certain that the 117-234 volt switch is

in Lhe 117 vol? position before calibrating the 244.

b. Preliminary Calibration.

1. Power Supplies.

a). Install one EV-8068 Power Tube (VlOl) and

clamp in place. Make certain tbae all controls

are full CCW and that the Power and output switches

are in the off position.

b). Plug the 244 into a variac and turn power

Connect DVM between TP-H and ground (chassis).

on.

D"M should read -9 volts to -11 volts. Ripple

should be no mare than 5 m" peak-to-peak.

c). Connect DVM beeween W-F and ground (chassis).

DVM should read +18 volts to +22 volts. Ripple

should be no more than 10 m" peak-to-peak.

4. Calibrate Adjust.

a). Place cap on plate of "101 power tube.

b). With 244 OUTPUT switch still off connect HI

of DVM to side of R113 power resistor closest to

side panel of 244 and LO to chassis. Reading

should

volts. Reading should not change more than 2OOm".

Return line voltage to 117 V ac.

volt cal control FULL CCW.

otherwise irreparable damage to range resistors

now rise 5 to 10 volts. Ripple should be more

than 50 m" peak-to-peak.

be

+76 volts eo +92 volts.

c). Vary line voltage from 105 "OlCS to 125

d). Set controls a,, 244 for -1000 volts. 25

CAUTION

If 244 meter swings full scale when OUTPUT

switch is turned oil turn switch OFF IMMEDIATELY,

can OCC"r.

e). Turn 244 OUTPUT switch on DVM reading ehould

0771 19

Page 24

CALIBRATION

MODEL 244

f). Turn the 244 OUTPUT switch off. Connect

the W-1 to the 244 output and the dc output on

the W-1 to the 662. See the 662 controls as

follows:

RANGE FULL SCALE

NULL FULL SCALE

-50 volts

-100 In"

DIALS -10.000

POLARITY

(-)

g). Turn the 244 OUTPUT switch on and set Cal.

Pot. R145 for -10 volts +lO m" reading on 662.

Cut jumpers BCP088 R140, R141 and R142 as necessary to set Cal. Pot.

5.

Overload Calibration

Turn 244

OUTPUT switch off.

a). Connect Loading Box LB-1 Fixture to output

of 244 and set for - and lk-3kV.

put for -2000 Volts.

Turn 244 OUTPUT

set Voltage Out-

8"ltch on.

b). Adjust load until 244 overload light comes

0". If meter on test fixture now reads 11.0 mA

to 11.9 nA resistor R124 is already optimum value.

If reading is not within this range replace R124

with one selected from table below. Turn OUTPUT

switch m before changing resistors.

current in "IA

10.2 - 11.0

12.9 - 13.9 52.3

13.9 - 15.0

R124 in OHMS

42.2

45.3

already installed

48.7

56.2

c). If overload current is less than 10.2 mA or

greater than 15.0 mA change Q107 as IoL dependent

on ",,,o of Q107. Turn 244 OUTPUT switch OFF.

d). Step

Decade Capacitor Box from zero to 1.0

MF in 0.1 MF steps while observing scope. No

oscillations should occur. Disregard line spikes

which may or may not appear.

e). Turn output switch OFF.

8.

234

Volt Operation.

a). Turn 244

Foyer Off and unplug from variac.

Set 117-234 volt switch on rear of 244 to the 234

volt position.

output.

Plug 244 into 234 volt line and turn

Set

244

controls for -200 volt

Power Switch on.

b). Set,ehe 661 controls as follows:

RANGE FULL SCALE

NULL FULL SCALE

DIALS

POLARITY

c). Connect the 662 and

Fixture

Co""ectar.

W-1 to Output of

Connect Scope

High Voltage Divider

244 thrbugh MH" TEE

to ac out conneCtor on

500

volts

10 volts

200.00

(-)

w-1.

d). Set scope controls as follows:

TIME BASE 1 MS/DIV

TRIGGER

VERTICAL

e).

Turn 244 output on.

il volt.

Set Short-Open Switch on W-1 to open.

SENSITIVITY

662

INTERNAL

1 Mv/DIV

should read -200

Noise observed on scope should be less than 200

microvolts.

Set Short-Open Switch on w-1 to

Short.

Short Circuit Output Current.

6.

a). Set 610B on 30 mA range (Multiplier -30

Range 10d3 Amperes Meter -) connect to output jack

on 244.

b). Set all controls on 244 fully CCW and turn

244 OOTPO'I

switch on.

610B should read 12.0 ,,,A

to 14.0 nA and over load light should come on. If

reading is higher change Q107. Turn 244 OUTPUT

switch OFF.

7.

Load Dependent Oscillations.

a). Connect Decade Capacitor Box to 244 output

through MH" TEE Connector.

b). Set oscilloscope as follows:

TIME BASE 1

MSIDIV

TRIGGER INTERNAL

VERTICAL SENSITIVITY 1 WIDIV

c). Connect oscilloscope to 244 output through

NH" TEE connector. Set

244

for -200 volts and

t"rn OUTPUT switch on.

f). Turn 244 output and power switches off.

Unplug 244 from 234 volt line. Set 117-234 volt

switch back to 117 position.

C. Final Calibration.

1. Re-check Zener Adjust and Calibrate.

2.

Load @gulstion.

a). Connect Loading Box LB-l Fixture to 244

output through MHV TEE Connector and set for and lk-3kV.

b). Connect

MVH TEE Connector and connect

662.

Set 244

W-1

controls for -2000,volts.

Divider to 244 output through

W-1 DC output to

20

0771

Page 25

MODEL 244

CALIBRATION

c). Set controls on 662 as follows:

RANGE FULL SCALE 50 volts

NULL FULL SCALE

DIALS

POLARITY

1 In"

20.000

(-)

d). Turn 244 OUTPUT on. 662 should now read

zero center scsle, if not set dials on 662 until

zero reading is obtained.

e). Adjust Load Box between 0 mA and 10 n-4.

Reading an 662 shall not change more than 14

major divisions.

f). Adjust Load Box for 0 mA. Load and vary

line voltage from 105 VAC to 125 VAC. Reading

on 662 shell not change more than +2 major divisions. Return line voltage to 117 "AC.

g). Turn 244 output off.

3. Accuracy.

a). Connect output of 244 to input of W-1 1OO:l

Divider. Connect output of W-1 to input of 662.

b). Set 244 to -200 volts. Set the 662 controls

as follows:

3.4000

3.6000

3.8000

4.0000

2.0000

4.0000

Change 662 to 50

6.000

8.000

10.000

Change 662 to 1

12.000

14.000

16.000

18.000

20.000

TABLE 6-2.

Accuracy Check.

220

240

260

280

300

320

340

360

380

2.178 - 2.222

2.376 - 2.424

2.574 - 2.626

2.772 - 2.828

2.970 - 3.030

3.168 - 3.232

3.366 - 3.434

3.564 - 3.636

3,762 - 3.838

400 3.960 200 1.980 400

3.960 -

volts Range Full Scale

600

800

1000

5.940

7.920 -

9.900 -

volt Null Full Scale

1200

1400

1600

1800

2000

11.880 -

13.860 -

15.840 -

17.820 -

19.800 -

4.040

2.020

4.040

6.060

8.080

10.100

12.120

14.140

16.160

18.180

20.200

RANGE FULL SCALE 5 Volts

NULL FULL SCALE

1 volt

DIALS 2.0000

POLARITY

C-1

c), Turn 244 oofput switch on. The 662 should

now read -2

volts. Turn 244 CAL-25" pot full CW.

The 662 should now read -2.2000 volts to -2.2500

volts.

Return CAL-25" pot full CCW. Turn 244

output switch off.

d). Set 661 control. as follows:

RANGE FULL SCALE

NULL FLlLL SCALE

5 Volts

100 In"

DIALS 2.2000

POLARITY

C-1

e). see 244 controls for -220 volts and turn

244 output s"itch on.

f). Step 662 and 244 thru settings listed in

Table 6-2 take reading shown. Reading must be

within range given. Turn output off when com-

pleted.

4. Output Noise.

a). Set 244 for -2000 volt output. Connect

244 output to input of W-1 and TRMS voltmeter

to ac out connector. Set TRM.9 voltmeter on 300

volt range.

b). Turn 244 output switch on.

Place short-

open switch on W-1 to open and step TRMS volt-

meter to 1 mV range. Meter should read no higher

than 500 microvolts.

1. Vary line voltage from 105 VAC to 125 VAC.

2. Return line voltage to 117 VAC.

c). Place open-short switch on W-1 to short

and turn 244 output and power switches off. Unplug 244 from "ariac.

0771

21

Page 26

--HV

Kn ADJUST FOR II mA LOAD.

TUBE: EV8068

TFtANSFORMER

INSULATION TO 5kV

‘-ym ‘-c MFR: STANCOR P-8190

TRIAD F-52X

-l-IV >

GND F

KEITHLW MOML 669lA

100: I DIVIDER .Ol%

_---

c51 5ocKw 1

I I I I

L “-.-_I pL-K)

< DC OUT

< GND

<AC OUT

Page 27

MODEL 244

CALIBRATION

TABLE 6-3.

Cross-Reference of Manufacturers

CODE

A-B

*WI

APH

APX ,

BIG

BUS

CTS

DIC

DLE

ERI

F-I

G-E

1-D

IRC

ITT

K-I

MOT

OHM

PC1

RCA

S-T

SPG

T-I

NAME AND ADDRESS

Allen-Bradley Corp.

Milwaukee, WI 53204

Arrowhart, Inc.

Hartford, CT 06106

Amphenol

Broadview, IL 60153

Amperex

Elkgrove Village, I,. 60007

Berg Electronics 1°C.

New Cumberland, PA 17070

B"*Sman Mfg. Di".

St. Louis, MO 63017

CTS corporation

Elkhart, IN 46514

Dickson Electronics Corp.

Scottsdale, AZ 85252

Dale Electronics Inc.

Columbus, NE 68601

Erie Technological Products, Inc.

Brie, PA 16512

Fairchild Instruments Corp.

Mountain Vie", CA 94043

General Electric Company

Syracuse, NY 13201

Industrial Devices, Inc.

Edgewater, NJ 07020

IRC Division

BurlinSton, IA 52601

ITT Semiconduceors

Lawrence, MA 01841

Keitbley Instruments, Inc.

Cleveland, OH 44139

Motorola Semiconductor Products, Inc.

Phoenix, AZ 85008

Ohmife Mfg. Co.

Skokie, IL 60076

Plastic Capacitors, Inc.

Chicago, IL 60614

RCA corporation

MOO~~O~, NJ 08050

Sarkes Tarsian, Inc.

Bloamington, IN 47401

Sprague Electric Company

VisaHa, CA 93278

Texas Instruments, Inc.

Dallas. TX 75231

1176

Page 28

Page 29

SWitchcraft, 1°C.

5527 N. Elsfo” he.

Chicago, III. 60630

“670

Page 30

I

I

Page 31

Cl0

RI04

RIO

RIO

Page 32

~RlOl-,

Cl04

r-7

D106.

J102

D105

Cl17 -

D116 ‘- E

D115

.(- ITo

$4

*C/-l

I

. D104

I

$2 g

gE6ge

. D114.-

----- RI03

, RI04

A RI05

/../--- RI06

- RI07

, RI00

u-l

(D

r.

co

a

\Rl69/

f--R113

rDlOh .

LR116J __

Cl07

v

m

N

g

co $

z Fi

JIOI

I

‘cl C&--$

.=

a

i;

W

J104

,-R140j 5 g u ,

mR141 -

‘R142J

s

E LR143JJ,05 -

g cl106

c. yD1081

1

I~,.-

9

yR144\

Cl06

Page 33

Q20 I

3 ro1c

+k

Page 34

I

I

I

4

8

I

I

I

I

; For repair or calibration,

I

I

I

I

I

I

I

I

Sales Service Department

Keithley Instruments, 1~.

28775 Aurora Road Do not write in this space.

Cleveland, Ohio 44139

: User’s Name

; company

REPAIR AND CALIBRATION FORM

please fill out this form and return it with your instrument to:

Telephone

Address

1 Division City

; Date

Model No.

R-

state

Serial No.

Ext.

Zip

j 1.

I

I

I

I

I

I

I

I

I

I

I

I

I

Reason for Return

2. Calibration Report Desired

0 Repair and Recalibration 0 Report of Calibration Certified

0 Recalibration only (No report, except

as specified in item 4 on reverse)*

*If repairs are necessary to meet speci-

fications,

they will be in addition to

Traceable to N.B.S.

0 Calibration Report

~7 Certificate of Compliance

a Norie

the calibration. (for details, see reverse side of this form)

3. To help repair the instrument, briefly describe the problem:

z

JJ ‘L.

I

&

iif

2

a

Is the problem - Constant

Under what conditions does the problem occur:

Control setting e) Line voltage

=)

- Intermittant

f) Other (such as line transients,

b) Approx. Temperature OF

2

u

Approx. Temperature variation * OF

C)

d) Approx. Humidity (high, medium, low)

5. Please draw a block diagram of the system using the Keithley.

nent data which can help in the repair. Include charts or other data if available.

Signal Source

Source Impedance

Readout Device:

~Recorder

m Oscilloscope

-Other

0 None

Lengths & Types of Connecting Cables

line variations, etc.)

List any other perti-

I

; 6. What repairs or modifications have been made on this instrument which are not on file

I

I

I

[ 7. Please

I

I

I

I

I

,

t

I

I

with the Keithley Repair Department?

enclose

any other pertinent data and charl;c jvhich you feel might help the

Repair and Calibration Department

Signature

Title

Page 35

CALIBRATIONS AVAILABLE AT KBITHLEY INSTRUMENTS.

Listed and defined below are the four types of calibrations and their associated report

formats which are presently available at Keithley Instruments. They fall into the following categories:

Report of Calibration Certified Traceable to the National Bureau of

1.

standards

Calibration Report

2.

Certificate of Compliance

3.

4. Recalibration

All calibration and certification performed by Keithley Instruments is in accord with

MIL-C-45662A.

Prices shown below are in addition to repair charges for any work necessary to place a

customer’s unit into first class condition prior to the calibration.

Page 36

KEITHLEY INSTRUMENTS, INC.

28775 AURORA ROAD

CLEVELAND, OHIO 44139

SERVICE FORM

MODEL NO. SERIAL NO. P.O. NO. DATE

NAME PHONE

COMPANY

ADDRESS

Describe problem and symptoms using quantitative data whenever possible (enclose

El

readings, chart recordings, e c

Show a block diagram of your measurement system including all instruments connected

El

El

El

(whether power is turned on or not). Also describe signal source.

List the positions of fl controls and switches on both front and rear panels of

the instrument.

4. Describe input signal source levels, frequencies, etc.

t .I

CITY

(Attach additional sheets as necessary).

STATE -

ZIP

List and describe all cables used in the experiment (length, shielding, etc.).

a

List and describe all other equipment used in the experiment. Give control settings

El

for each.

Environment:

El

q

Where is the measurement being performed?

out-of-doors, etc.)

What power line voltage is used?

Ambient temperature? "F. Variation? "F. Rel. Humidity?

Other

Additional Information.

please describe below.)

(If special modifications have been made by the user,

(Factory, controlled laboratory,

Variation? Frequency?

REV 0774

Loading...

Loading...