Page 1

moc.yelhtiek.www

Series 2400 SourceMeter

User’s Manual

2400S-900-01 Rev. K / September 2011

®

ECNEDIFNOC FO ERUSAEM RETAERG A

Page 2

2400 Series SourceMeter

User’s Manual

®

©2011, Keithley Instruments, Inc.

All rights reserved.

Cleveland, Ohio, U.S.A.

Document Number: 2400S-900-01 Rev. K / September 2011

Page 3

The following safety precautions should be observed before using this product and any associated instrumentation.

Although some instruments and accessories would normally be used with non-hazardous voltages, there are

situations where hazardous conditions may be present.

This product is intended for use by qualified personnel who recognize shock hazards and are familiar with the safety

precautions required to avoid possible injury. Read and follow all installation, operation, and maintenance

information carefully before using the product. Refer to the user documentation for complete product specifications.

If the product is used in a manner not specified, the protection provided by the product warranty may be impaired.

The types of product users are:

Responsible body is the individual or group responsible for the use and maintenance of equipment, for ensuring

that the equipment is operated within its specifications and operating limits, and for ensuring that operators are

adequately trained.

Operators use the product for its intended function. They must be trained in electrical safety procedures and proper

use of the instrument. They must be protected from electric shock and contact with hazardous live circuits.

Maintenance personnel perform routine procedures on the product to keep it operating properly, for example,

setting the line voltage or replacing consumable materials. Maintenance procedures are described in the user

documentation. The procedures explicitly state if the operator may perform them. Otherwise, they should be

performed only by service personnel.

Safety Precautions

04/09

Service personnel are trained to work on live circuits, perform safe installations, and repair products. Only properly

trained service personnel may perform installation and service procedures.

Keithley Instruments products are designed for use with electrical signals that are rated Measurement Category I

and Measurement Category II, as described in the International Electrotechnical Commission (IEC) Standard IEC

60664. Most measurement, control, and data I/O signals are Measurement Category I and must not be directly

connected to mains voltage or to voltage sources with high transient over-voltages. Measurement Category II

connections require protection for high transient over-voltages often associated with local AC mains connections.

Assume all measurement, control, and data I/O connections are for connection to Category I sources unless

otherwise marked or described in the user documentation.

Exercise extreme caution when a shock hazard is present. Lethal voltage may be present on cable connector jacks

or test fixtures. The American National Standards Institute (ANSI) states that a shock hazard exists when voltage

levels greater than 30V RMS, 42.4V peak, or 60VDC are present. A good safety practice is to expect that hazardous

voltage is present in any unknown circuit before measuring.

Operators of this product must be protected from electric shock at all times. The responsible body must ensure that

operators are prevented access and/or insulated from every connection point. In some cases, connections must be

exposed to potential human contact. Product operators in these circumstances must be trained to protect

Page 4

themselves from the risk of electric shock. If the circuit is capable of operating at or above 1000V, no conductive part

!

of the circuit may be exposed.

Do not connect switching cards directly to unlimited power circuits. They are intended to be used with impedancelimited sources. NEVER connect switching cards directly to AC mains. When connecting sources to switching cards,

install protective devices to limit fault current and voltage to the card.

Before operating an instrument, ensure that the line cord is connected to a properly-grounded power receptacle.

Inspect the connecting cables, test leads, and jumpers for possible wear, cracks, or breaks before each use.

When installing equipment where access to the main power cord is restricted, such as rack mounting, a separate

main input power disconnect device must be provided in close proximity to the equipment and within easy reach of

the operator.

For maximum safety, do not touch the product, test cables, or any other instruments while power is applied to the

circuit under test. ALWAYS remove power from the entire test system and discharge any capacitors before:

connecting or disconnecting cables or jumpers, installing or removing switching cards, or making internal changes,

such as installing or removing jumpers.

Do not touch any object that could provide a current path to the common side of the circuit under test or power line

(earth) ground. Always make measurements with dry hands while standing on a dry, insulated surface capable of

withstanding the voltage being measured.

The instrument and accessories must be used in accordance with its specifications and operating instructions, or

the safety of the equipment may be impaired.

Do not exceed the maximum signal levels of the instruments and accessories, as defined in the specifications and

operating information, and as shown on the instrument or test fixture panels, or switching card.

When fuses are used in a product, replace with the same type and rating for continued protection against fire hazard.

Chassis connections must only be used as shield connections for measuring circuits, NOT as safety earth ground

connections.

If you are using a test fixture, keep the lid closed while power is applied to the device under test. Safe operation

requires the use of a lid interlock.

If a screw is present, connect it to safety earth ground using the wire recommended in the user documentation.

The symbol on an instrument means caution, risk of danger. The user should refer to the operating instructions

located in the user documentation in all cases where the symbol is marked on the instrument.

The symbol on an instrument means caution, risk of danger. Use standard safety precautions to avoid personal

contact with these voltages.

The symbol on an instrument shows that the surface may be hot. Avoid personal contact to prevent burns.

The symbol indicates a connection terminal to the equipment frame.

If this symbol is on a product, it indicates that mercury is present in the display lamp. Please note that the lamp

must be properly disposed of according to federal, state, and local laws.

Page 5

The WARNING heading in the user documentation explains dangers that might result in personal injury or death.

Always read the associated information very carefully before performing the indicated procedure.

The CAUTION heading in the user documentation explains hazards that could damage the instrument. Such

damage may invalidate the warranty.

Instrumentation and accessories shall not be connected to humans.

Before performing any maintenance, disconnect the line cord and all test cables.

To maintain protection from electric shock and fire, replacement components in mains circuits - including the power

transformer, test leads, and input jacks - must be purchased from Keithley Instruments. Standard fuses with

applicable national safety approvals may be used if the rating and type are the same. Other components that are

not safety-related may be purchased from other suppliers as long as they are equivalent to the original component

(note that selected parts should be purchased only through Keithley Instruments to maintain accuracy and

functionality of the product). If you are unsure about the applicability of a replacement component, call a Keithley

Instruments office for information.

To clean an instrument, use a damp cloth or mild, water-based cleaner. Clean the exterior of the instrument only.

Do not apply cleaner directly to the instrument or allow liquids to enter or spill on the instrument. Products that consist

of a circuit board with no case or chassis (e.g., a data acquisition board for installation into a computer) should never

require cleaning if handled according to instructions. If the board becomes contaminated and operation is affected,

the board should be returned to the factory for proper cleaning/servicing.

Page 6

Table of contents

Section Title Page

1 Getting Started

General information ....................................................................... 1-2

Contact information ................................................................. 1-2

Manual addenda ..................................................................... 1-2

Safety symbols and terms ...................................................... 1-2

Inspection ............................................................................... 1-3

Options and accessories ........................................................ 1-3

Product overview ........................................................................... 1-5

Front and rear panel familiarization ............................................... 1-6

Front panel summary .............................................................. 1-6

Rear panel summary .............................................................. 1-7

Power-up ....................................................................................... 1-9

Line power connection ............................................................ 1-9

Power-up sequence .............................................................. 1-10

Line frequency setting ........................................................... 1-11

Fuse replacement ................................................................. 1-11

Cooling fan .................................................................................. 1-12

Display ........................................................................................ 1-13

Display format ....................................................................... 1-13

EDIT key ............................................................................... 1-13

TOGGLE key ........................................................................ 1-13

Status and error messages ................................................... 1-14

Remote display programming ............................................... 1-14

Front panel tests ................................................................... 1-14

Default settings ........................................................................... 1-15

Saving and restoring user setups ......................................... 1-15

Factory default settings ......................................................... 1-16

Remote setups ...................................................................... 1-18

Menus ......................................................................................... 1-19

Page 7

Table of Contents 2400 Series SourceMeter® User’s Manual

Main menu ............................................................................ 1-19

Rules to navigate menus ...................................................... 1-22

Editing source and compliance values ................................. 1-23

Toggling the source and measure display fields ................... 1-23

Disabling front panel display ................................................. 1-24

Configuration menus ............................................................ 1-24

2 Connections

Connection overview ..................................................................... 2-2

Front/rear terminals selection ................................................. 2-2

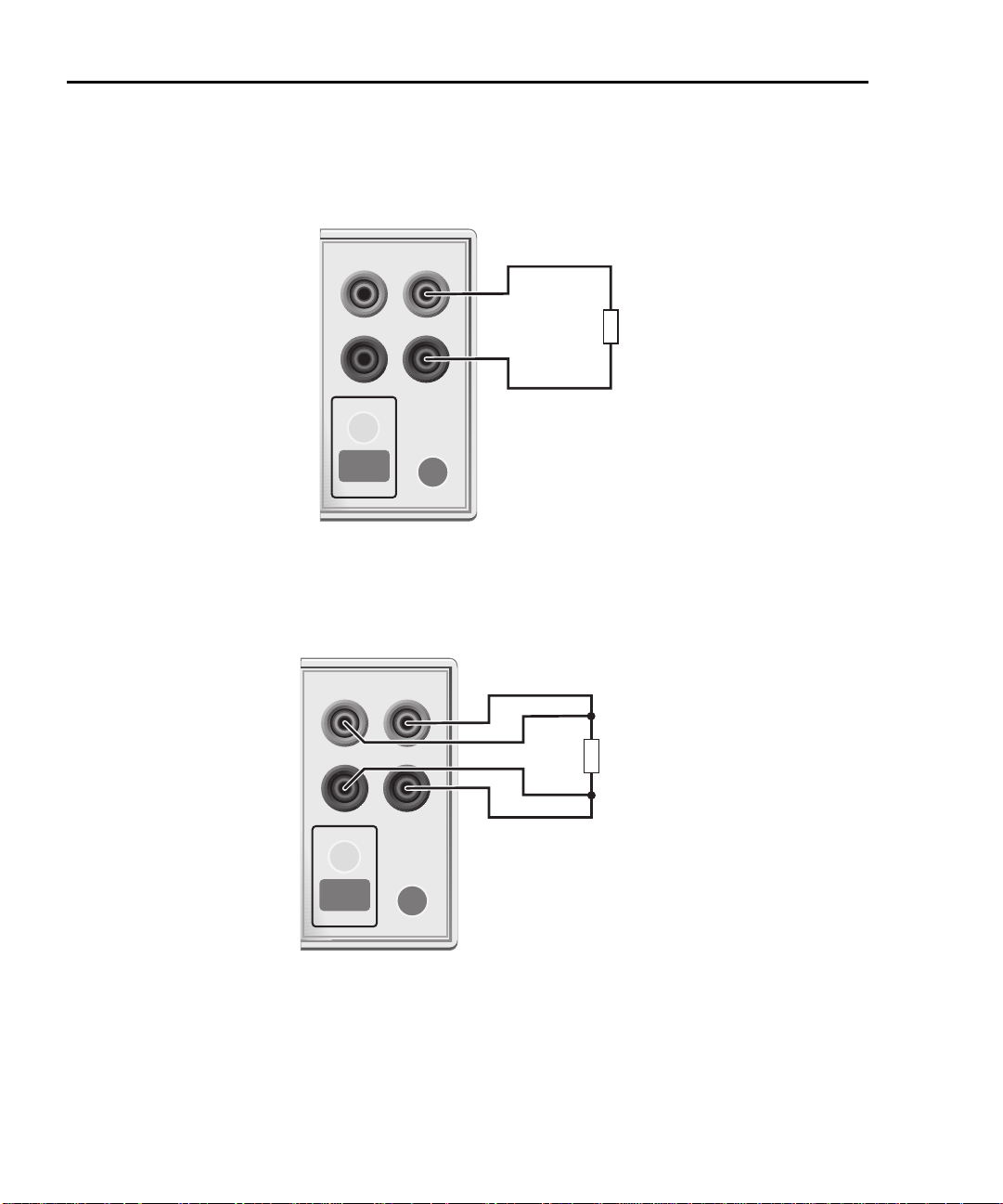

Connections to DUT ...................................................................... 2-3

Sensing methods .................................................................... 2-5

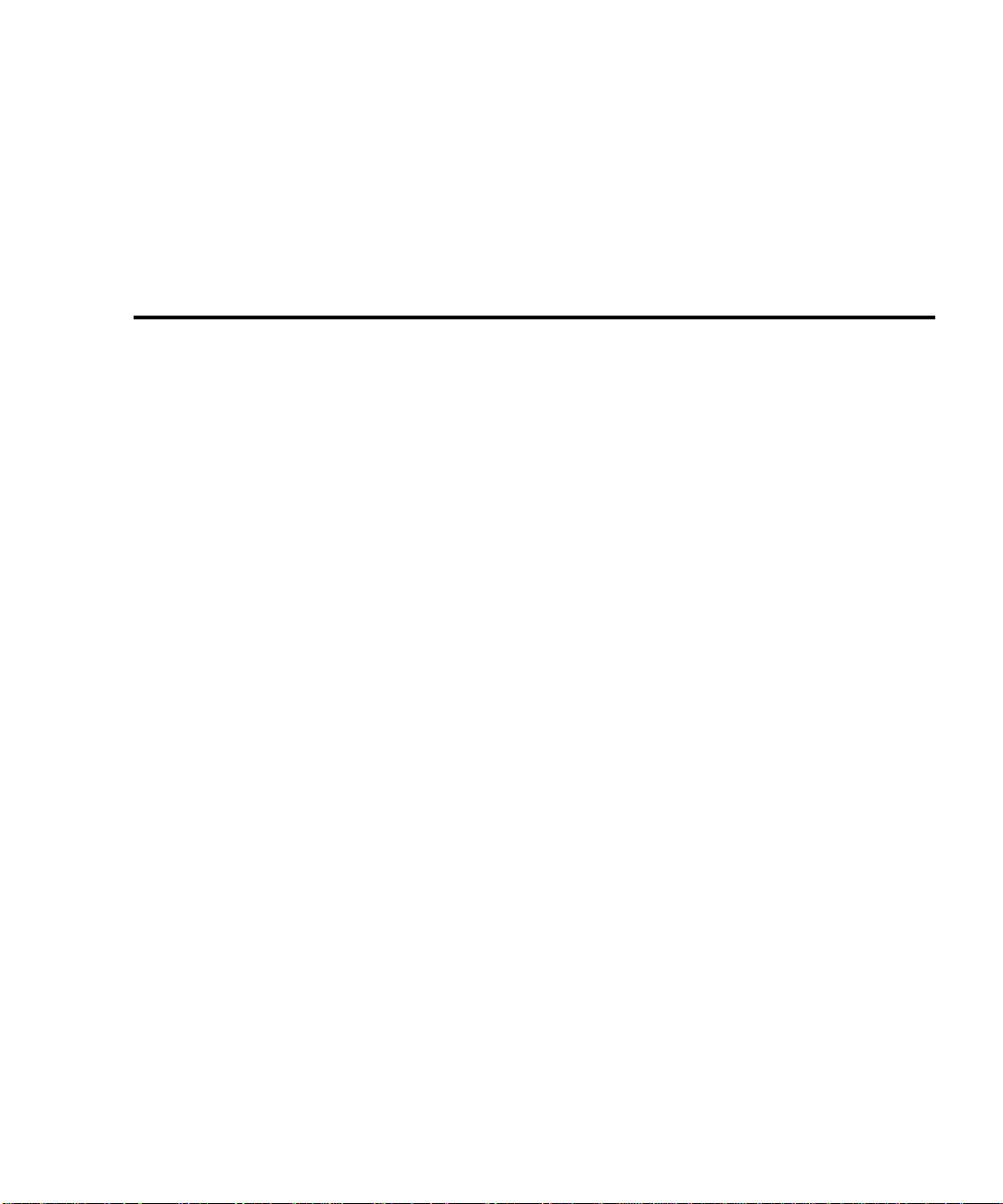

Guarding methods .................................................................. 2-8

3 Basic Source-Measure Operation

WARNING - CAUTION .................................................................. 3-2

Operation overview ....................................................................... 3-4

Source-measure capabilities .................................................. 3-4

Compliance limit ..................................................................... 3-6

Setting the compliance limit .................................................... 3-8

Basic circuit configurations ..................................................... 3-9

Operation considerations ............................................................ 3-10

Warm-up ............................................................................... 3-10

Auto zero .............................................................................. 3-10

NPLC caching ....................................................................... 3-11

V-source protection ............................................................... 3-12

Source delay ......................................................................... 3-13

Basic source-measure procedure ............................................... 3-15

Front panel source-measure procedure ............................... 3-15

Remote command source-measure procedure .................... 3-18

Measure only ............................................................................... 3-20

Front panel measure only ..................................................... 3-20

Remote command measure only .......................................... 3-21

Sink operation ............................................................................. 3-22

Battery charging/discharging ................................................ 3-22

Sink programming example .................................................. 3-24

4 Ohms Measurements

Ohms configuration menu ............................................................. 4-2

Ohms measurement methods ....................................................... 4-3

Selecting ohms measurement method ................................... 4-4

Ohms measurement procedure .............................................. 4-4

Ohms sensing ............................................................................... 4-6

Page 8

2400 Series SourceMeter® User’s Manual Table of Contents

Sense selection ...................................................................... 4-7

Offset-compensated ohms ............................................................ 4-8

Enabling/disabling offset-compensated ohms ........................ 4-8

Ohms accuracy calculations ................................................... 4-9

Ohms source readback ............................................................... 4-11

Ohms source readback selection ......................................... 4-11

6-wire ohms measurements ........................................................ 4-12

Remote ohms programming ........................................................ 4-13

Remote ohms commands ..................................................... 4-13

Ohms programming example ............................................... 4-14

5 Pulse Mode Operation (Model 2430 only)

Overview ....................................................................................... 5-2

Pulse characteristics ..................................................................... 5-3

Pulse width ............................................................................. 5-4

Output off-time ........................................................................ 5-6

Pulse duty cycle ...................................................................... 5-6

Fast pulse output .................................................................... 5-7

Pulse jitter ............................................................................... 5-8

Pulse energy limitations (10A range) ............................................ 5-9

Pulse Mode configuration ............................................................ 5-10

Front panel Pulse Mode configuration .................................. 5-10

Remote command Pulse Mode configuration ....................... 5-11

Pulse-measure considerations .................................................... 5-12

Measurement speed ............................................................. 5-12

Filter ...................................................................................... 5-12

Auto range ............................................................................ 5-12

Concurrent measurements ................................................... 5-12

Ohms source readback ......................................................... 5-12

Toggle key ............................................................................. 5-13

Offset-compensated ohms .................................................... 5-13

Source delay ......................................................................... 5-13

Trigger delay ......................................................................... 5-14

Input triggers ......................................................................... 5-14

Output triggers ...................................................................... 5-14

Auto output-off ...................................................................... 5-14

Output-off state ..................................................................... 5-15

Turning source on ................................................................. 5-15

SCPI signal oriented measurement commands ................... 5-15

6 Source-Measure Concepts

Compliance limit ............................................................................ 6-2

Types of compliance ............................................................... 6-2

Maximum compliance values .................................................. 6-3

Page 9

Table of Contents 2400 Series SourceMeter® User’s Manual

Compliance examples ............................................................ 6-4

Determining compliance limit .................................................. 6-4

Overheating protection .................................................................. 6-6

Overheating conditions ........................................................... 6-6

Source-delay-measure cycle ......................................................... 6-7

Sweep waveforms .................................................................. 6-9

Operating boundaries .................................................................. 6-10

Source or sink ....................................................................... 6-10

Duty cycle ............................................................................. 6-10

I-Source operating boundaries ............................................. 6-15

V-Source operating boundaries ............................................ 6-19

Source I measure I and source V measure V ....................... 6-22

Basic circuit configurations .......................................................... 6-23

Source I ................................................................................ 6-23

Source V ............................................................................... 6-24

Measure only (V or I) ............................................................ 6-25

Guard .......................................................................................... 6-27

Cable guard .......................................................................... 6-27

Ohms guard .......................................................................... 6-28

Guard sense ......................................................................... 6-32

Data flow ..................................................................................... 6-34

Buffer considerations ............................................................ 6-36

7 Range, Digits, Speed, and Filters

Range and digits ........................................................................... 7-2

Range ..................................................................................... 7-2

Digits ....................................................................................... 7-5

Remote range and digits programming .................................. 7-5

Speed ............................................................................................ 7-7

Setting speed .......................................................................... 7-7

Remote speed programming .................................................. 7-8

Filters ............................................................................................ 7-9

Front panel filter control ........................................................ 7-10

Remote filter programming ................................................... 7-12

8 Relative and Math

Relative ......................................................................................... 8-2

Front panel rel ......................................................................... 8-2

Remote rel programming ........................................................ 8-3

Math operations ............................................................................ 8-4

Built-in math functions ............................................................ 8-4

Front panel math operations ................................................... 8-6

Remote math operations ........................................................ 8-7

User-defined math functions ................................................... 8-7

Page 10

2400 Series SourceMeter® User’s Manual Table of Contents

9 Data Store

Data store overview ...................................................................... 9-2

Front panel data store ................................................................... 9-2

Storing readings ...................................................................... 9-2

Recalling readings .................................................................. 9-2

Buffer statistics ....................................................................... 9-3

Timestamp format ................................................................... 9-4

Buffer considerations .............................................................. 9-5

Remote command data store ........................................................ 9-5

Data store commands ............................................................. 9-5

Data store programming example .......................................... 9-5

10 Sweep Operation

Sweep types ................................................................................ 10-2

Linear staircase sweep ......................................................... 10-2

Logarithmic staircase sweep ................................................ 10-4

Abort on compliance ............................................................. 10-5

Custom sweep ...................................................................... 10-6

Source memory sweep ......................................................... 10-6

Configuring and running a sweep ............................................. 10-12

Front panel sweep operation .............................................. 10-12

Remote sweep operation .................................................... 10-19

Pulse Mode sweeps (Model 2430 only) .................................... 10-24

Front panel Pulse Mode sweep procedure ......................... 10-25

Remote Pulse Mode sweep operation ................................ 10-26

11 Triggering

Front panel trigger operation ....................................................... 11- 2

Front panel trigger model ...................................................... 11-2

Configuring triggering ........................................................... 11 - 7

Remote trigger operation .......................................................... 11-10

Remote trigger model ......................................................... 11-10

Remote trigger commands ................................................. 11-18

Trigger link ................................................................................. 11-19

Input trigger requirements ................................................... 11- 19

Output trigger specifications ............................................... 11-20

Pulse Mode triggering (Model 2430) ......................................... 11-20

Trigger models .................................................................... 11-20

Invalid trigger settings ......................................................... 11- 2 4

12 Limit Testing

Types of limits ............................................................................. 12-2

Pass/fail information ............................................................. 12-2

Page 11

Table of Contents 2400 Series SourceMeter® User’s Manual

Data flow ............................................................................... 12-3

Limit 1 test (compliance) ....................................................... 12-3

Limit 2, limit 3, and limit 5-12 tests ........................................ 12-3

Limit 4 ................................................................................... 12-3

Limit test modes ................................................................... 12-3

Binning .................................................................................. 12-4

Operation overview ..................................................................... 12-4

Grading mode ....................................................................... 12-4

Sorting mode ........................................................................ 12-7

Binning systems ........................................................................ 12-10

Handler interface ................................................................ 12-10

Handler types ..................................................................... 12-12

Basic binning systems ........................................................ 12-13

Digital output clear pattern .................................................. 12-14

Configuring and performing limit tests ....................................... 12-16

Configuring limit tests ......................................................... 12-16

Performing front panel limit tests ........................................ 12-19

Remote limit testing ................................................................... 12-20

Limit commands ................................................................. 12-20

13 Digital I/O Port, Output Enable, & Output Configuration

Digital I/O port ............................................................................. 13-2

Port configuration ................................................................. 13-2

Digital output configuration ................................................... 13-3

Controlling digital output lines ............................................... 13-4

Output enable line ....................................................................... 13-6

Front panel output configuration ................................................. 13-7

Configure OUTPUT menu .................................................... 13-8

Output-off states ................................................................... 13-9

Output-off states and inductive loads ................................. 13-11

Remote output configuration ..................................................... 13-12

Output configuration commands ......................................... 13-12

14 Remote Operations

Differences: remote vs. local operation ....................................... 14-2

Operation enhancements (remote operation) ....................... 14-2

Local-to-remote transition ..................................................... 14-2

Remote-to-local transition ..................................................... 14-3

Selecting an interface .................................................................. 14-3

GPIB operation ............................................................................ 14-4

GPIB standards .................................................................... 14-4

GPIB connections ................................................................. 14-4

Primary address ................................................................... 14-4

General bus commands .............................................................. 14-5

Page 12

2400 Series SourceMeter® User’s Manual Table of Contents

Front panel GPIB operation ........................................................ 14-5

Error and status messages ................................................... 14-5

GPIB status indicators .......................................................... 14-5

LOCAL key ........................................................................... 14-6

Programming syntax ................................................................... 14-6

Command words ................................................................... 14-6

Query commands ................................................................. 14-9

Case sensitivity ..................................................................... 14-9

Long-form and short-form versions ....................................... 14-9

Short-form rules .................................................................. 14-10

Response messages .......................................................... 14-12

Message exchange protocol ............................................... 14-13

RS-232 interface operation ....................................................... 14-13

Sending and receiving data ................................................ 14-13

Baud rate ............................................................................ 14-14

Data bits and parity ............................................................. 14-14

Terminator ........................................................................... 14-14

Flow control (signal handshaking) ...................................... 14-15

RS-232 connections ........................................................... 14-15

Error messages .................................................................. 14-17

15 Status Structure

Overview ..................................................................................... 15-2

Status byte and SRQ ............................................................ 15-2

Status register sets ............................................................... 15-2

Queues ................................................................................. 15-2

Clearing registers and queues .................................................... 15-4

Programming and reading registers ............................................ 15-5

Programming enable registers .............................................. 15-5

Reading registers .................................................................. 15-6

Status byte and service request (SRQ) ....................................... 15-7

Status byte register ............................................................... 15-8

Service request enable register ............................................ 15-9

Serial polling and SRQ ......................................................... 15-9

Status byte and service request commands ....................... 15-10

Status register sets .................................................................... 15-11

Register bit descriptions ..................................................... 15-11

Condition registers .............................................................. 15-16

Event registers .................................................................... 15-16

Event enable registers ........................................................ 15-17

Queues ...................................................................................... 15-18

Output queue ...................................................................... 15-18

Error queue ......................................................................... 15-19

Page 13

Table of Contents 2400 Series SourceMeter® User’s Manual

16 Common Commands

Command summary .................................................................... 16-2

Command reference ................................................................... 16-3

*IDN? — identification query ................................................ 16-3

*OPC — operation complete ................................................ 16-3

*OPC? — operation complete query .................................... 16-3

*SAV <NRf> — save ............................................................. 16-3

*RCL <NRf> — recall ........................................................... 16-3

**RST — reset ...................................................................... 16-4

*TRG — trigger ..................................................................... 16-4

**TST? — self-test query ...................................................... 16-4

*WAI — wait-to-continue ....................................................... 16-5

17 SCPI Signal Oriented Measurement Commands

Command summary .................................................................... 17-2

Configuring measurement function ............................................. 17-2

:CONFigure:<function> ......................................................... 17-2

Acquiring readings ...................................................................... 17-3

:FETCh? ............................................................................... 17-3

[:SENSe[1]]:DATA[:LATest]? ................................................. 17-4

:READ? ................................................................................. 17-4

:MEASure[:<function>]? ....................................................... 17-5

18 SCPI Command Reference

Reference tables ......................................................................... 18-2

Calculate subsystems ............................................................... 18-26

CALCulate[1] ............................................................................. 18-26

Select (create) math expression name ............................... 18-26

Assign unit suffix ................................................................. 18-28

Define math expression ...................................................... 18-29

Enable and read math expression result ............................ 18-32

CALCulate2 ............................................................................... 18-33

Select input path ................................................................. 18-33

Null feed reading ................................................................ 18-34

Read CALC2 ...................................................................... 18-34

Configure and control limit tests ......................................... 18-35

Composite testing ............................................................... 18-39

Clear test results ................................................................. 18-42

CALCulate3 ............................................................................... 18-43

Select statistic ..................................................................... 18-43

Acquire statistic ................................................................... 18-43

DISPlay subsystem ................................................................... 18-44

Control display .................................................................... 18-44

Page 14

2400 Series SourceMeter® User’s Manual Table of Contents

Read display ....................................................................... 18-46

Define :TEXT messages ..................................................... 18-46

FORMat subsystem .................................................................. 18-47

Data format ......................................................................... 18-47

Data elements ..................................................................... 18-49

CALC data elements ........................................................... 18-53

Byte order ........................................................................... 18-54

Status register format .......................................................... 18-54

OUTPut subsystem ................................................................... 18-55

Turn source on or off ........................................................... 18-55

Output enable line ............................................................... 18-56

Output-off states ................................................................. 18-56

ROUTe subsystem .................................................................... 18-57

Select input jacks ................................................................ 18-57

SENSe1 subsystem .................................................................. 18-58

Select measurement functions ........................................... 18-58

Select measurement range ................................................. 18-62

Select auto range ................................................................ 18-65

Current range holdoff .......................................................... 18-66

Set compliance parameters ................................................ 18-67

Set measurement speed ..................................................... 18-69

Configure and control filter .................................................. 18-70

SOURce subsystem .................................................................. 18-71

SOURce[1] .......................................................................... 18-71

Control source output-off .................................................... 18-71

Select function modes ........................................................ 18-72

Select sourcing mode ......................................................... 18-73

Select range ........................................................................ 18-74

Set amplitude for fixed source ............................................ 18-77

Set voltage limit .................................................................. 18-79

Set delay ............................................................................. 18-82

Configure voltage and current sweeps ............................... 18-83

Abort on compliance ........................................................... 18-90

Configure list ....................................................................... 18-91

Configure memory sweep ................................................... 18-93

Set scaling factor ................................................................ 18-95

Soak time ............................................................................ 18-96

Pulse Mode delays (Model 2430 only) ................................ 18-97

SOURce2 ............................................................................ 18-98

Setting digital output ........................................................... 18-98

Clearing digital output ......................................................... 18-99

STATus subsystem .................................................................. 18-101

Read event registers ......................................................... 18-101

Program event enable registers ........................................ 18-101

Read condition registers ................................................... 18-101

Page 15

Table of Contents 2400 Series SourceMeter® User’s Manual

Select default conditions ................................................... 18-102

Error queue ....................................................................... 18-102

SYSTem subsystem ................................................................ 18-103

Default conditions ............................................................. 18-103

Control remote sensing .................................................... 18-104

Select guard mode ........................................................... 18-105

Initialize memory ............................................................... 18-106

Control beeper .................................................................. 18-106

Control auto zero .............................................................. 18-107

Control NPLC caching ...................................................... 18-107

Select power line frequency setting .................................. 18-108

Error queue ....................................................................... 18-109

Simulate key presses ....................................................... 18-110

Read version of SCPI standard ........................................ 18-112

RS-232 interface ............................................................... 18-112

Query timestamp .............................................................. 18-112

Reset timestamp ............................................................... 18-113

Auto reset timestamp ........................................................ 18-113

Auto range change mode ................................................. 18-113

TRACe subsystem .................................................................. 18-114

Read and clear buffer ....................................................... 18-114

Configure and control buffer ............................................. 18-114

Select timestamp format ................................................... 18-116

TRIGger subsystem ................................................................ 18-116

Clear input triggers ........................................................... 18-116

Initiate source/measure cycle ........................................... 18-117

Abort source/measure cycle ............................................. 18-117

Program trigger model ...................................................... 18-117

Accuracy calculations ................................................................... A-2

Measure accuracy ................................................................. A-2

Source accuracy .................................................................... A-2

Source-Delay-Measure (SDM) cycle timing ................................. A-3

Definitions .............................................................................. A-3

Timing diagrams .................................................................... A-4

Introduction .................................................................................. B-2

Status and error messages .......................................................... B-2

Eliminating common SCPI errors ................................................. B-8

Introduction .................................................................................. C-2

FETCh? ................................................................................. C-3

CALCulate[1]:DATA? ............................................................. C-4

CALCulate2:DATA? ............................................................... C-4

TRACe:DATA? ....................................................................... C-4

CALCulate3:DATA? ............................................................... C-4

Introduction .................................................................................. D-2

Bus description ............................................................................. D-3

Page 16

2400 Series SourceMeter® User’s Manual Table of Contents

Bus lines ....................................................................................... D-5

Data lines ............................................................................... D-5

Bus management lines .......................................................... D-5

Handshake lines .................................................................... D-5

Bus commands ............................................................................ D-6

Addressed multiline commands ............................................. D-8

Address commands ............................................................... D-8

Unaddress commands ........................................................... D-8

Common commands .............................................................. D-8

SCPI commands .................................................................... D-8

Command codes .................................................................... D-9

IEEE command groups ........................................................ D-11

Interface function codes ............................................................. D-12

Introduction .................................................................................. E-2

Introduction ................................................................................... F-2

Overview ....................................................................................... F-2

Description .............................................................................. F-2

Operation ...................................................................................... F-3

DUT connections .................................................................... F-3

Contact check threshold resistances ...................................... F-4

Contact check failure indications ............................................ F-5

Auto and manual ohms ........................................................... F-5

Trigger model operation .......................................................... F-6

Sweep and binning considerations ............................................... F-6

Sweep limitations .................................................................... F-6

Limit test sequence ................................................................. F-7

Binning failure indications (grading mode) ............................ F-10

Front panel contact check operation ........................................... F-11

Menu selections .................................................................... F-11

Using contact check .............................................................. F-12

Remote contact check operation ................................................. F-14

Contact check remote commands ........................................ F-14

Contact check programming example .................................. F-15

Contact check command reference ............................................ F-17

Configure and control contact check .................................... F-17

Configure and control contact check limit test ...................... F-17

Configure and control contact check event detection ........... F-19

Contact check defaults ................................................................ F-20

Introduction .................................................................................. G-2

Selecting the 488.1 protocol ......................................................... G-2

Protocol differences ..................................................................... G-3

Message exchange protocol (MEP) ....................................... G-3

Using SCPI-based programs ................................................. G-4

NRFD hold-off ........................................................................ G-4

NDAC hold-off ........................................................................ G-4

Page 17

Table of Contents 2400 Series SourceMeter® User’s Manual

Trigger-on-talk ....................................................................... G-5

Message available ................................................................. G-5

General operation notes ........................................................ G-5

Page 18

1

Getting Started

• General information — Covers general information that includes contact

information, safety symbols and terms, inspection, and available options

and accessories.

• Product overview — Summarizes the features of the SourceMeter.

• Front and rear panel familiarization — Summarizes the controls and con-

nectors of the instrument.

• Power-up — Covers line power connection, line voltage settings, fuse

replacement, and the power-up sequence.

• Cooling fan — Covers the cooling fan in the Models 2410, 2420, 2425,

2430, and 2440.

• Display — Provides information about the SourceMeter display.

• Default settings — Covers factory default setups and saving and recalling

user setups.

• Menus — Covers the main and configuration menus as well as rules to

navigate menus.

Page 19

1-2 Getting Started 2400 Series SourceMeter® User’s Manual

!

General information

Contact information

Worldwide phone numbers are listed at the front of this manual. If you have any

questions, please contact your local Keithley representative or call one of our

Application Engineers at 1-800-348-3735 (U.S. and Canada only).

Manual addenda

Any improvements or changes concerning the instrument or manual will be

explained in an addendum included with the manual. Be sure to note these

changes and incorporate them into the manual.

Safety symbols and terms

The following symbols and terms may be found on the instrument or used in this

manual.

The symbol on an instrument indicates that the user should refer to the operating instructions located in the manual.

The symbol on the instrument shows that high voltage may be present on

the terminal(s). Use standard safety precautions to avoid personal contact with

these voltages.

The WARNING heading used in this manual explains dangers that might result in

personal injury or death. Always read the associated information very carefully

before performing the indicated procedure.

The CAUTION heading used in this manual explains hazards that could damage

the instrument. Such damage may invalidate the warranty.

Page 20

2400 Series SourceMeter® User’s Manual Getting Started 1-3

Inspection

The SourceMeter was carefully inspected electrically and mechanically before

shipment. After unpacking all items from the shipping carton, check for any obvious signs of physical damage that may have occurred during transit. (There may

be a protective film over the display lens, which can be removed.) Report any

damage to the shipping agent immediately. Save the original packing carton for

possible future shipment. The following items are included with every SourceMeter order:

• SourceMeter with line cord.

• Test leads (Model 8605 for 2400, 2400-C; Model 1754 for all other series

2400 units).

• Accessories as ordered.

• Certificate of calibration.

• User’s Manual.

• Service Manual.

• Support Software Disk including TestPoint instrument library for GPIB and

LabVIEW for Windows driver.

• Manual addenda containing any improvements or changes to the instrument or manual.

If an additional manual is required, order the appropriate manual package (for

example, 2400-901-00). The manual packages include a manual and any pertinent addenda.

Options and accessories

The following options and accessories are available from Keithley for use with the

SourceMeter.

Cables and adapters

Model 2499-DIGIO adapter — Lets you expand the Digital I/O port to 16 bits

instead of 4 bits.

Models 7007-1 and 7007-2 shielded GPIB cables — Connect the SourceMeter to

the GPIB bus using shielded cables and connectors to reduce electromagnetic

interference (EMI). The Model 7007-1 is 1m long; the Model 7007-2 is 2m long.

Models 8501-1 and 8501-2 trigger link cables — Connect the SourceMeter to

other instruments with Trigger Link connectors (e.g., Model 7001 Switch System).

The Model 8501-1 is 1m long; the Model 8501-2 is 2m long.

Model 8502 trigger link adapter — Lets you connect any of the six Trigger Link

lines of the SourceMeter to instruments that use the standard BNC trigger connectors.

Page 21

1-4 Getting Started 2400 Series SourceMeter® User’s Manual

Model 8503 DIN to BNC trigger cable — Lets you connect Trigger Link lines one

(Voltmeter Complete) and two (External Trigger) of the SourceMeter to instruments that use BNC trigger connectors. The Model 8503 is 1m long.

Model 8505 trigger link cable — The Model 8505 is a male to dual-female trigger

link cable.

Rack mount kits

Model 4288-1 single fixed rack mount kit — Mounts a single SourceMeter in a

standard 19-inch rack.

Model 4288-2 side-by-side rack mount kit — Mounts two instruments (Models

182, 428, 486, 487, 2000, 2001, 2002, 2010, 2015, 2400, 2410, 2420, 2425,

2430, 2440, 6430, 6517, 7001) side-by-side in a standard 19-inch rack.

Model 4288-3 side-by-side rack mount kit — Mounts a SourceMeter and a Model

199 side-by-side in a standard 19-inch rack.

Model 4288-4 side-by-side rack mount kit — Mounts a SourceMeter and a 5.25-

inch instrument (Models 195A, 196, 220, 224, 230, 263, 595, 614, 617, 705, 740,

775, etc.) side-by-side in a standard 19-inch rack.

Model 4288-5 dual fixed rack mounting kit — Mounts a SourceMeter and another

3H-inch high instrument (Model 182, 428, 486, 487, 2000, 2010, 2400, 2410,

2420, 2425, 2430, 6430, or 7001), side-by-side in a standard 19-inch rack.

Carrying case

Model 1050 padded carrying case — A carrying case for a SourceMeter. Includes

handles and a shoulder strap.

Page 22

2400 Series SourceMeter® User’s Manual Getting Started 1-5

Product overview

The SourceMeter combines a precise, low-noise, highly stable DC power supply

with a low-noise, highly repeatable, high-impedance multimeter. It has 0.012%

basic accuracy with 5H-digit resolution. At 5H digits, the SourceMeter delivers 520

readings/second over the IEEE-488 bus. At 4H digits, it can read up to 2000 read-

ings/second into its internal buffer. See Appendix A for specifications.

Some additional capabilities of the SourceMeter include:

• Concurrent measurements of all three functions over the remote interface.

• Source-measure sweep capabilities (linear and logarithmic staircase

sweeps, source sweep list of up to 2500 points, memory sweep of up to 100

instrument setups).

• 6-wire Ω measurement with programmable I-source or V-source with V or I

clamp.

• 4-quadrant source and sink operation.

• Up to 12 stages of limit testing with a built-in comparator for pass/fail testing.

• Digital I/O for stand-alone binning operations or interface to component

handler.

• Programming language and remote interfaces — The SourceMeter uses

the SCPI programming language and two remote interface ports (IEEE488/GPIB and RS-232C).

• Trigger-Link interface to Keithley Series 7000 switching hardware.

• Math expressions — Five built-in, up to five user-defined (bus only).

• Reading and setup storage — Up to 2500 readings and seven setups (five

user defaults, factory default, *RST default) can be stored and recalled.

• Closed-cover calibration — The instrument can be calibrated either from

the front panel or remote interface.

Page 23

1-6 Getting Started 2400 Series SourceMeter® User’s Manual

SourceMeter

250V

PEAK

5V

PEAK

HI

LO

OUTPUT

250V

PEAK

250V

PEAK

EDIT

TOGGLE

POWER

RANGE

INPUT/

OUTPUT

4-WIRE

SENSE

DISPLAY

ON/OFF

TERMINALS

FRONT/

REAR

AUTO

RANGE

EXIT ENTER

CONFIG MENU

SWEEP

TRIG

REL

LOCAL

FILTER

LIMIT

DIGITS SPEED

V

Ω

MEAS

I

FCTN

V

I

SOURCE

230

1

67

89

4

+/-

5

STORE

RECALL

EDIT

Front and rear panel familiarization

NOTE The SourceMeter models covered in this manual are very similar in

appearance. Therefore, to avoid redundancy, a generic Model 2400 is

used for illustration purposes.

Front panel summary

The front panel of the SourceMeter is shown in Figure 1-1. The following abbrevi-

ated information should be reviewed before operating the instrument.

Figure 1-1

SourceMeter front panel

Measurement (MEAS) function keys:

V Measure volts.

I Measure amps.

Ω Measure ohms.

FCTN Perform math functions.

SOURCE function keys:

V Source voltage (V-Source).

I Source current (I-Source).

∆ and ∇ Increase/decrease source or compliance value.

Operation keys:

EDIT Select source or compliance reading for editing.

TOGGLE Toggle display positions of source and measure readings, or display V and I

LOCAL Cancel remote operation.

REL Enable/disable relative reading on present function.

FILTER Display digital filter status for present function and toggle filter on/off.

LIMIT Perform configured limit tests.

TRIG Trigger a measurement from the front panel.

measurements.

Page 24

2400 Series SourceMeter® User’s Manual Getting Started 1-7

SWEEP Start configured sweep.

left/right arrows Move through parameter values or selections within functions and operations.

DIGITS Change number of digits of display resolution.

SPEED Change measurement speed by selecting accuracy or specifying NPLC.

STORE Set buffer size and enable reading storage.

RECALL Display stored readings and timestamp.

CONFIG Press CONFIG and then appropriate key to configure function or operation.

MENU Access and configure Main Menu selections. When entering numeric data, use to

EXIT Cancels selection. Use to back out of menu structures.

ENTER Accepts selection.

clear reading to minimum absolute value.

RANGE keys:

∆ Moves to next higher range, increments digit, moves to next selection.

∇ Moves to next lower range, decrements digit, moves to previous selection.

AUTO Enables or disables measurement auto range.

Annunciators:

EDIT Instrument in edit mode.

ERR Questionable reading, invalid cal step.

REM Instrument in GPIB remote mode.

TALK Instrument addressed to talk over GPIB.

LSTN Instrument addressed to listen over GPIB.

SRQ Service request over GPIB.

REAR Rear input/output connectors selected.

REL Relative measure reading displayed.

FILT Digital filter enabled.

MATH Math function enabled.

4W Remote sensing enabled.

AUTO Autoranging enabled.

ARM Source-measure operations being performed.

TRIG External trigger source selected.

* Reading being stored.

Input/output connectors:

INPUT/OUTPUT HI and LOUse to source-measure volts, amps, and ohms.

4-WIRE SENSE HI and LOUse for 4-wire remote sensing.

Input/output controls:

ON/OFF Turns the source on or off.

FRONT/REAR Selects front or rear panel input/output connections.

Handle:

Pull out and rotate to desired position.

Rear panel summary

The rear panel of the Model 2400 SourceMeter is shown in Figure 1-2. (The Mod-

els 2410, 2420, 2425, 2430, and 2440 are similar.) The following abbreviated

information should be reviewed before operating the instrument.

NOTE Models 2420, 2425, 2430, and 2440 are not UL listed.

Page 25

1-8 Getting Started 2400 Series SourceMeter® User’s Manual

WARNING: NO INTERNAL OPERATOR SERVICABLE PARTS, SERVICE BY QUALIFIED PERSONNEL ONLY.

CAUTION: FOR CONTINUED PROTECTION AGAINST FIRE HAZARD, REPLACE FUSE WITH SAME TYPE AND RATING.

MADE IN

U.S.A.

INPUT/

OUTPUT

250V

PEAK

250V

PEAK

TRIGGER

LINK

4-WIRE

SENSE

HI

LO

LINE RATING

100-240VAC

50, 60, Hz

190VA MAX.

RS-232

IEEE-488

(ENTER IEEE ADDRESS

WITH FRONT PANEL MENU)

250V

PEAK

5V

PEAK

5V

PEAK

5V

PK

V, Ω,

GUARD

GUARD

SENSE

LINE FUSE

SLOWBLOW

2.5A, 250V

OUTPUT

ENABLE

FUSE DRAWER

L

U

CUS

LISTED

SourceMeter

4ZA4

CAT I

!

Figure 1-2

SourceMeter rear panel

Input/output connectors:

INPUT/OUTPUT HI and LOUse to source-measure volts, amps, and ohms.

4-WIRE SENSE HI and LOUse for 4-wire remote sensing.

V, Ω GUARD Driven guard for guarded measurements.

GUARD SENSE Use to correct for IR drops in Guard Output lead.

Earth (chassis) ground screw.

WARNING INPUT/OUTPUT LO is not internally connected to the chassis and

cannot be allowed to float more than the values shown in

Section 2 above chassis ground.

Output enable and digital input/output port:

OUTPUT ENABLEConnector for digital output lines, output enable, and component handler signals.

Power module:

Contains the AC line receptacle and the power line fuse.

Trigger link connector:

TRIGGER LINK 8-pin micro-DIN connector for sending and receiving trigger pulses. Use a trigger

link cable or adapter, such as Models 8501-1, 8501-2, 8502, 8504.

RS-232 connector:

RS-232 Connector for RS-232 remote operation. Use a straight through (not null modem)

GPIB connector:

DB-9 cable.

IEEE-488 Connector for GPIB remote operation. Use a shielded cable (Model

INTERFACE 7007-1 or 7007-2).

Figure 2-1 in

Page 26

2400 Series SourceMeter® User’s Manual Getting Started 1-9

Power-up

During the power-up, voltage spik es may appear on the terminals of

the SourceMeter. These voltage spikes could be at hazardous levels

(42.4V peak) and could damage sensitive DUTs. Never touch external

circuitry or the test leads when powering up the SourceMeter. It is good

practice to always disconnect DUTs from the SourceMeter before pow

ering up the unit.

To prevent electric shock, test connections must be configured such

that the user cannot come in contact with conductors or any DUT that

is in contact with the conductors. Safe installation requires proper

shields, barriers, and grounding to prevent contact with conductors.

Operator protection and safety are the responsibility of the person

installing the product.

When handling the SourceMeter, NEVER touch the heat sink located

on the left side of the case. This heat sink could be hot enough to cause

burns.

-

Line power connection

The SourceMeter operates from a line voltage in the range of 100 to 240V at a frequency of 50 or 60Hz. Line voltage and line frequency are automatically sensed.

Therefore, there are no switches to set. Check to be sure the operating voltage in

your area is compatible.

CAUTION Operating the instrument on an incorrect line voltage may cause

damage, possibly voiding the warranty.

Perform the following steps to connect the SourceMeter to line power and turn it

on:

1. Before plugging in the power cord, make sure the front panel power switch

is in the off (0) position.

2. Connect the female end of the supplied power cord to the AC receptacle on

the rear panel.

Page 27

1-10 Getting Started 2400 Series SourceMeter® User’s Manual

The power cord supplied with the SourceMeter contains a separate

ground for use with grounded outlets. When proper connections are

made, instrument chassis is connected to power line ground through

the ground wire in the power cord. Failure to use a grounded outlet

may result in personal injury or death due to electric shock.

3. Turn on the instrument by pressing the front panel power switch to the on

(1) position.

Power-up sequence

On power-up, the SourceMeter performs self-tests on its EPROM and RAM and

momentarily lights all segments and annunciators. If a failure is detected, the

instrument momentarily displays an error message, and the ERR annunciator

turns on (error messages are listed in Appendix B).

NOTE For the Model 2430, there is an internal bank of capacitors that need to

charge. While charging, the message “Charging capacitor bank, please

wait” message will be displayed for approximately 10 seconds.

If a problem develops while the instrument is under warranty, return it to

Keithley Instruments, Inc., for repair.

If the instrument passes the self-tests, the model number and the firmware revision levels are displayed. For example:

REV A01 A02

where: A01 is the main board ROM revision.

A02 is the display board ROM revision.

Also displayed is the line frequency. (If the wrong frequency is displayed, it can be

set manually as covered below). The communication interface status is briefly displayed. If the IEEE-488 bus is the presently selected interface, the identification

message will include the primary address. For example, if the primary address is

24 (factory default), the “IEEE Addr=24” message is displayed. If the RS-232

interface is selected, the “RS-232” message is displayed.

After the power-up sequence, the instrument goes to its normal display state with

the output off (OUTPUT indicator light off). With the output off, the “OFF” message

is displayed, and dashes replace the reading.

Page 28

2400 Series SourceMeter® User’s Manual Getting Started 1-11

Line frequency setting

At the factory, the SourceMeter is configured to sense the power line frequency

and automatically select the frequency setting. If, however, the line power source

is noisy, the SourceMeter may select the wrong setting on power-up. If this situation occurs, noisy measurement readings will result, and accuracy may be

affected. You can manually set the line frequency from the front panel MENU/ADCTRL/LINE-FREQ selection, or SYST:LFR by remote.

Fuse replacement

A rear panel fuse protects the power line input of the SourceMeter. If the line fuse

needs to be replaced, perform the following steps:

CAUTION For continued protection against fire or instrument damage, replace

the fuse only with the type and rating listed. If the instrument repeat

edly blows fuses, locate and correct the cause of the problem

before replacing the fuse.

1. The fuse is located in a drawer above the AC receptacle (Figure 1-2). At the

bottom of the fuse drawer is a small tab. At this location, use a small bladed

screwdriver to pry the fuse drawer open.

2. Slide the fuse drawer out to gain access to the fuse. Note that the fuse

drawer does not pull all the way out of the power module.

3. Snap the fuse out of the drawer and replace it with the same type

(

Appendix Table 1-1).

4. Push the fuse drawer back into the power module.

-

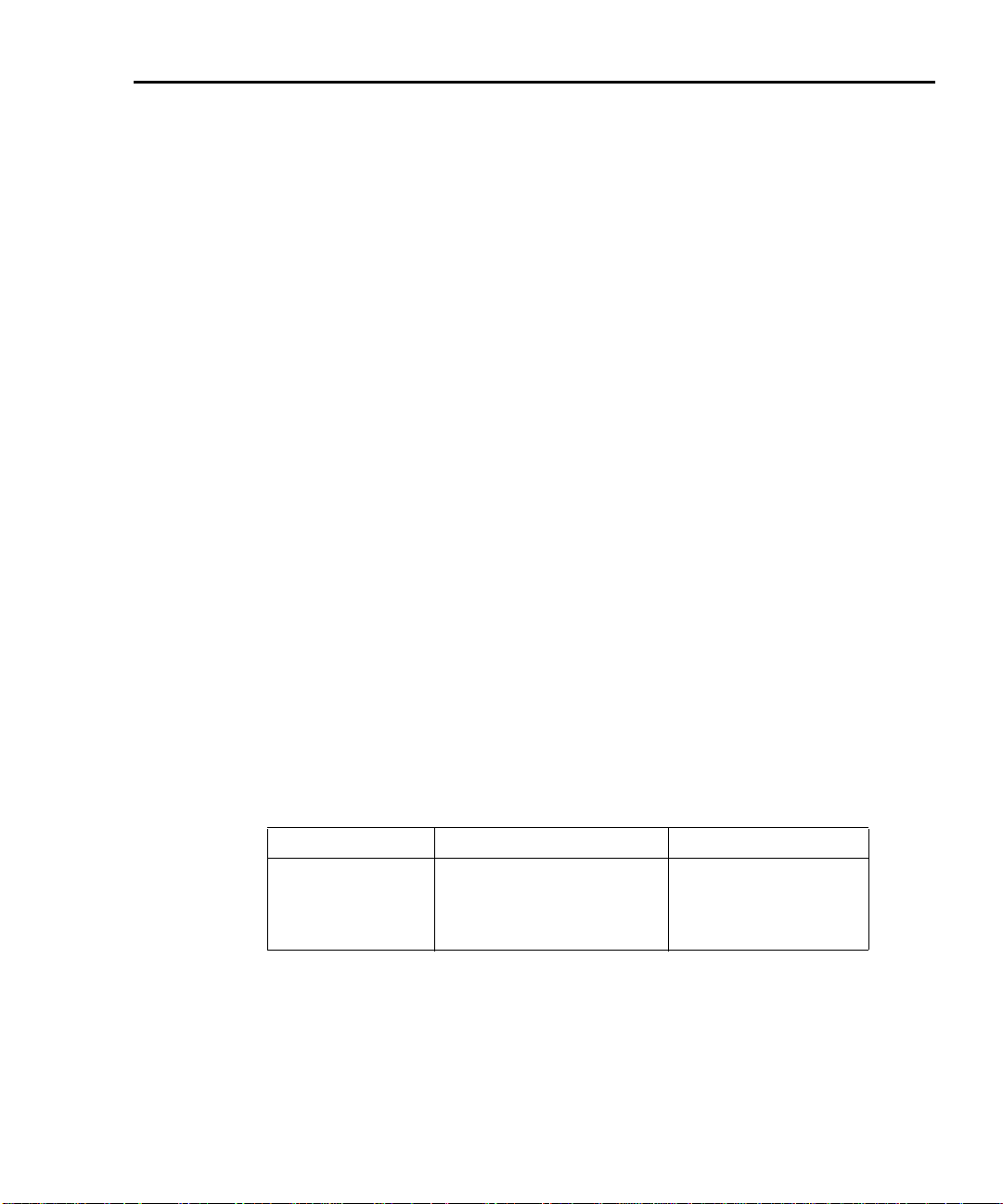

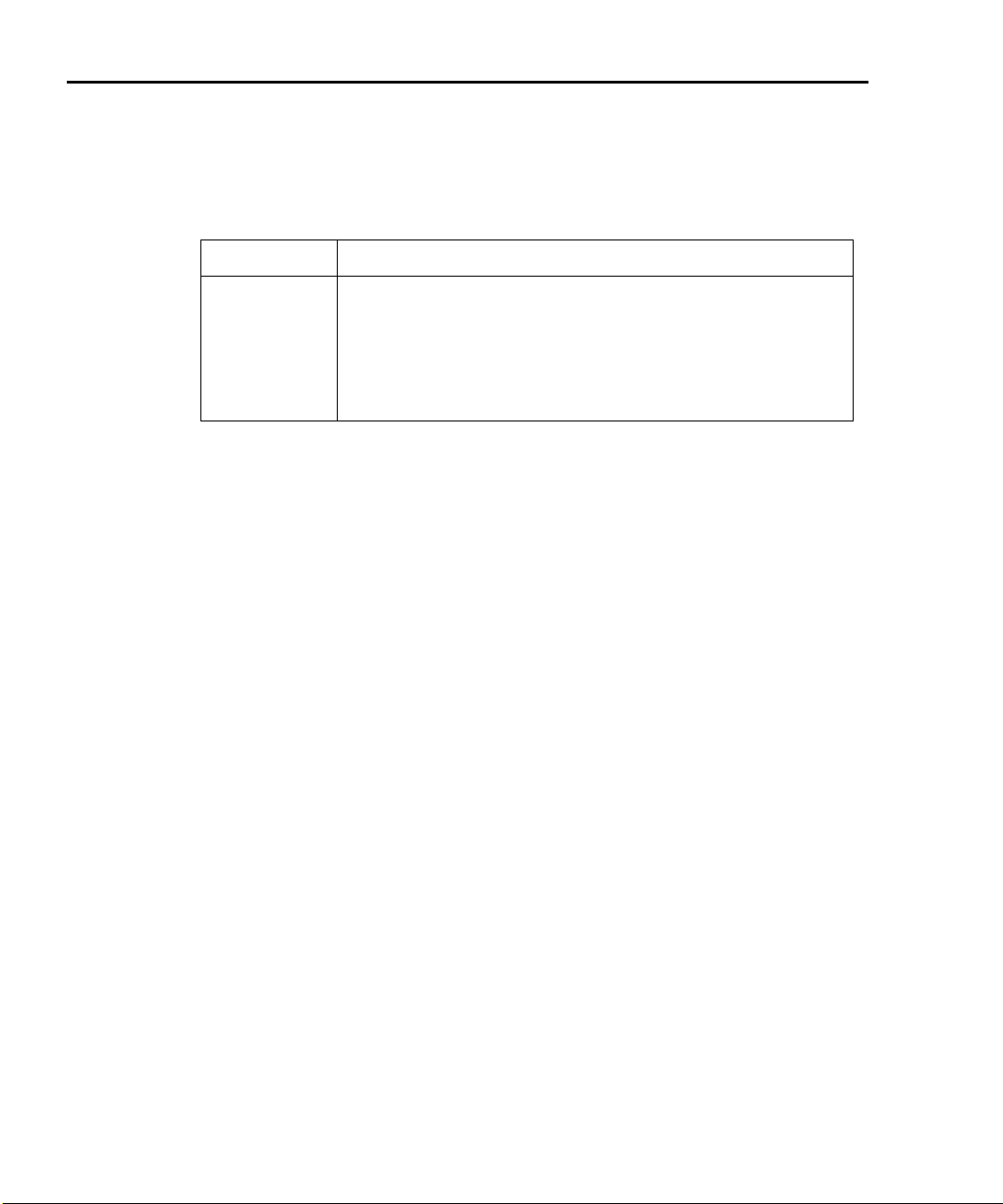

Table 1-1

Power line fuse

SourceMeter Fuse description Keithley part number

2400, 2400-LV,

2401, and 2410

2420, 2425, 2430,

and 2440

250V, 2.5A, 5 × 20mm FU-72

250V, 3.15A, 5 × 20mm FU-106-3.15

Page 29

1-12 Getting Started 2400 Series SourceMeter® User’s Manual

Cooling fan

The Models 2410, 2420, 2425, 2430, and 2440 use a cooling fan to help keep

them from overheating. The Models 2400 and 2401 do not have a cooling fan. In

either case (fan or no fan), proper ventilation must be maintained to prevent

overheating. Refer to the “WARNING - CAUTION” located at the beginning of

Section 3 for details on maintaining proper ventilation.

Model 2410 — Uses a constant-speed fan that runs continuously while the power

is on.

Models 2420, 2425, 2430, and 2440 — Uses a 3-speed fan. With the OUTPUT

ON, the fan speed setting is determined by the present current range (source or

measure).

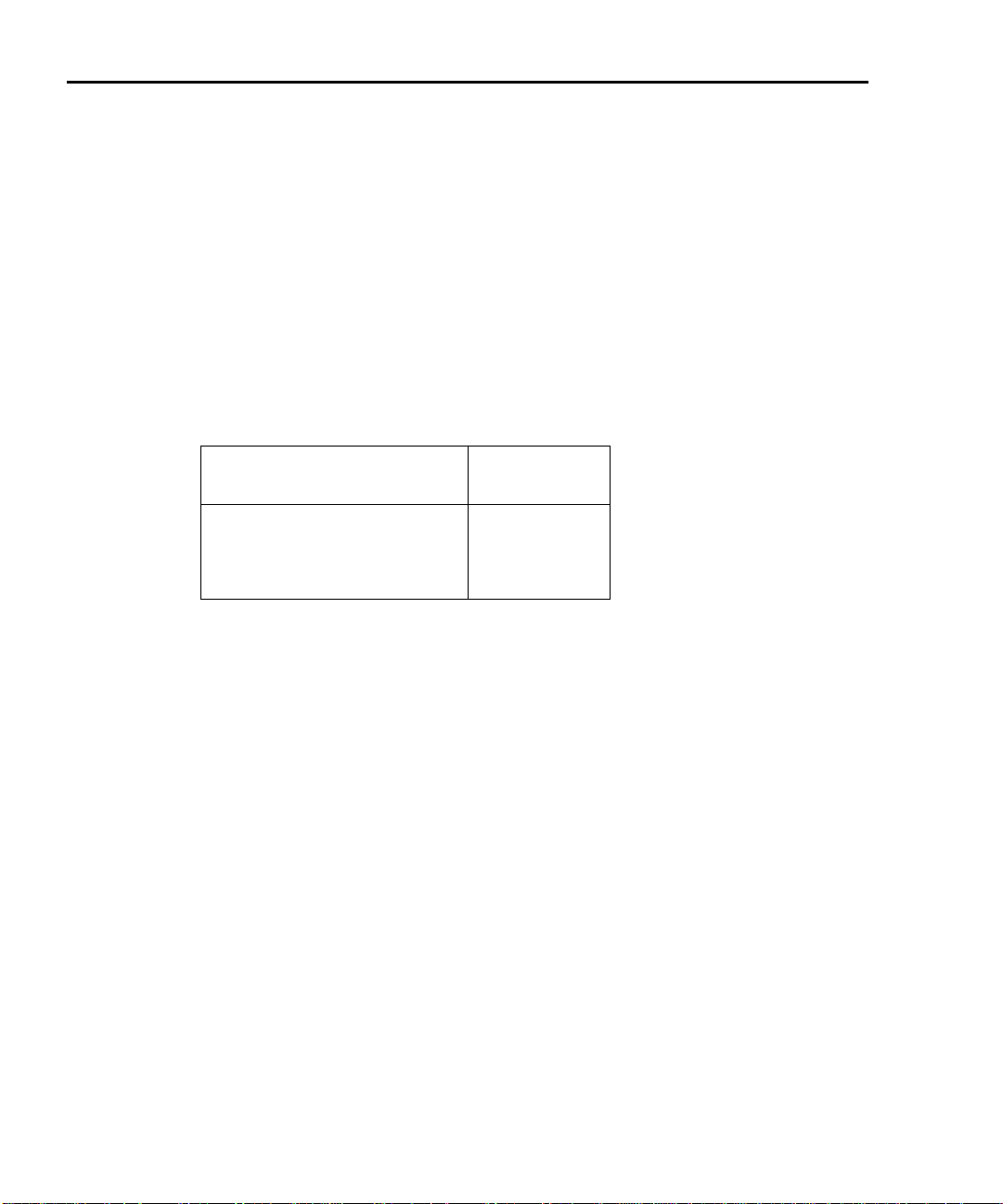

2420, 2425, 2430, and 2440

range

10uA, 100uA, 1mA Low (50%)

10mA, 100mA Medium (75%)

1A, 3A, 3A/10A (2430) High (100%)

1A, 5A (2440) High (100%)

Fan speed

When the OUTPUT is turned OFF, the fan will either run at the low speed or stay

at the speed it was at when the output was on (current range dependent). This

speed option is set from the FAN selection of the GENERAL MENU. (See “Main

menu” in this section.)

NOTE If the Model 2420, 2425, 2430, or 2440 overheats, the output will trip and

the cooling fan will run at high speed (regardless of the speed option set

ting). See Section 6, “Overheating protection,” for details.

-

Page 30

2400 Series SourceMeter® User’s Manual Getting Started 1-13

Display

Display format

The SourceMeter display is used primarily to program source and compliance values and display measured readings. Annunciators, which are located along the

top of the reading/message display, indicate various states of operation, as covered previously in “Front panel summary.”

On power-up, the top (primary) display is used for measurements when the output

is on (with the output off, “OFF” is displayed). The bottom-left display is used for

the programmed source value (Vsrc or Isrc), and the bottom-right display is used

for the programmed compliance (Cmpl) limit.

Reading information can be displayed using either engineering units or scientific

notation in either fixed- or floating-point format. Use the GENERAL/NUMBERS

selection of the main MENU to select the display format, as discussed in “Menus”

later in this section.

Engineering units example: 1.23456µA

Scientific notation example: 1.23456e -6

NOTE The display may be disabled for faster operation. See “Disabling front

EDIT key

The SourceMeter must be in the edit mode to set source and compliance values.

The edit mode is selected by pressing the EDIT key (EDIT annunciator on). The

editing cursor (flashing digit) appears for the source or compliance reading. If a

value is not edited within six seconds, the edit mode is cancelled. While in the edit

mode, the EDIT key toggles between the source value and compliance value. See

Section 3 for details on setting source and compliance values.

TOGGLE key

NOTE For the Model 2430 Pulse Mode, the TOGGLE key is disabled.

With the output on, the TOGGLE key manipulates readings on the top display and

on the bottom-left display. It has no effect on the compliance reading (Cmpl),

which is located on the bottom right. Each press of the TOGGLE key sequences

through the display options.

panel display,” page 1-24.

Page 31

1-14 Getting Started 2400 Series SourceMeter® User’s Manual

With the voltage (V) or current (I) measurement function selected, the TOGGLE

key lets you display both the current and voltage measurements at the same time.

It also allows you to toggle display positions of the source and measure readings.

With the ohms (Ω) measurement function selected, the ohms measurement is

always displayed on the top display. The TOGGLE key lets you display either the

programmed source value, the current measurement, or the voltage

measurement on the bottom-left display.

The TOGGLE key is also used to display statistical data on readings stored in the

data store. This function is performed from the data store RECALL mode.

NOTE If FCTN, REL, or Limits is enabled, the TOGGLE key is disabled.

Status and error messages

Status and error messages are displayed momentarily. During SourceMeter operation and programming, you will encounter a number of front panel messages.

Typical messages are either status or error in nature and are listed in Appendix B.

Remote display programming

The display can also be controlled by various SCPI :DISPlay subsystem commands. See Section 18, “DISPlay subsystem,” for more information on using

these commands. See also “Disabling front panel display,” page 1-24.

Front panel tests

Use the TEST/FRONT-PANEL-TESTS selection of the main MENU to test various

aspects of the front panel. See “Menus,” page 1-19, for more information.

Page 32

2400 Series SourceMeter® User’s Manual Getting Started 1-15

Default settings

By using appropriate menu selections, you can save and recall various instrument

setups, define the power-on configuration, or restore factory defaults as outlined

below.

Saving and restoring user setups

You can save and restore up to five of your own user setups as covered below.

This feature provides a convenient way to save specific instrument configurations

and then recall them as needed. Note that you can also set up the SourceMeter to

restore a specific user setup at power-on. See “Power-on configuration,”

page 1-15.

NOTE There are two types of setups. Instrument configuration (user) setups

(covered here) and source memory sweep setups (

Saving setups

1. Select the various instrument operating modes you wish to save.

2. Press the MENU key, select SAVESETUP, then press ENTER.

3. From the SAVESETUP menu, select GLOBAL, then press ENTER.

4. From the GLOBAL SETUP MENU, select SAVE, then press ENTER.

5. Select the setup position (0-4) to save, then press ENTER to complete the

process.

Section 10).

Restoring setups

1. Press the MENU key, select SAVESETUP, then press ENTER.

2. From the SAVESETUP menu, select GLOBAL, then press ENTER.

3. From the GLOBAL SETUP MENU, select RESTORE, then press ENTER.

4. Select the setup position (0-4) to restore, then press ENTER to complete

the process.

Power-on configuration

You can also define which of the stored setups (factory default or user) the instrument assumes as the power-on configuration as follows:

1. Press the MENU key, select SAVESETUP, then press ENTER.

2. From the SAVESETUP menu, select GLOBAL, then press ENTER.

3. From the GLOBAL SETUP MENU, select POWERON, then press ENTER.

4. From the SET POWER-ON DEFAULT menu, choose the power-on configuration: BENCH or GPIB (see below), or USER-SETUP-NUMBER.

Page 33

1-16 Getting Started 2400 Series SourceMeter® User’s Manual

5. If you chose to use a user setup as the power-on configuration, select the

user setup number, then press ENTER.

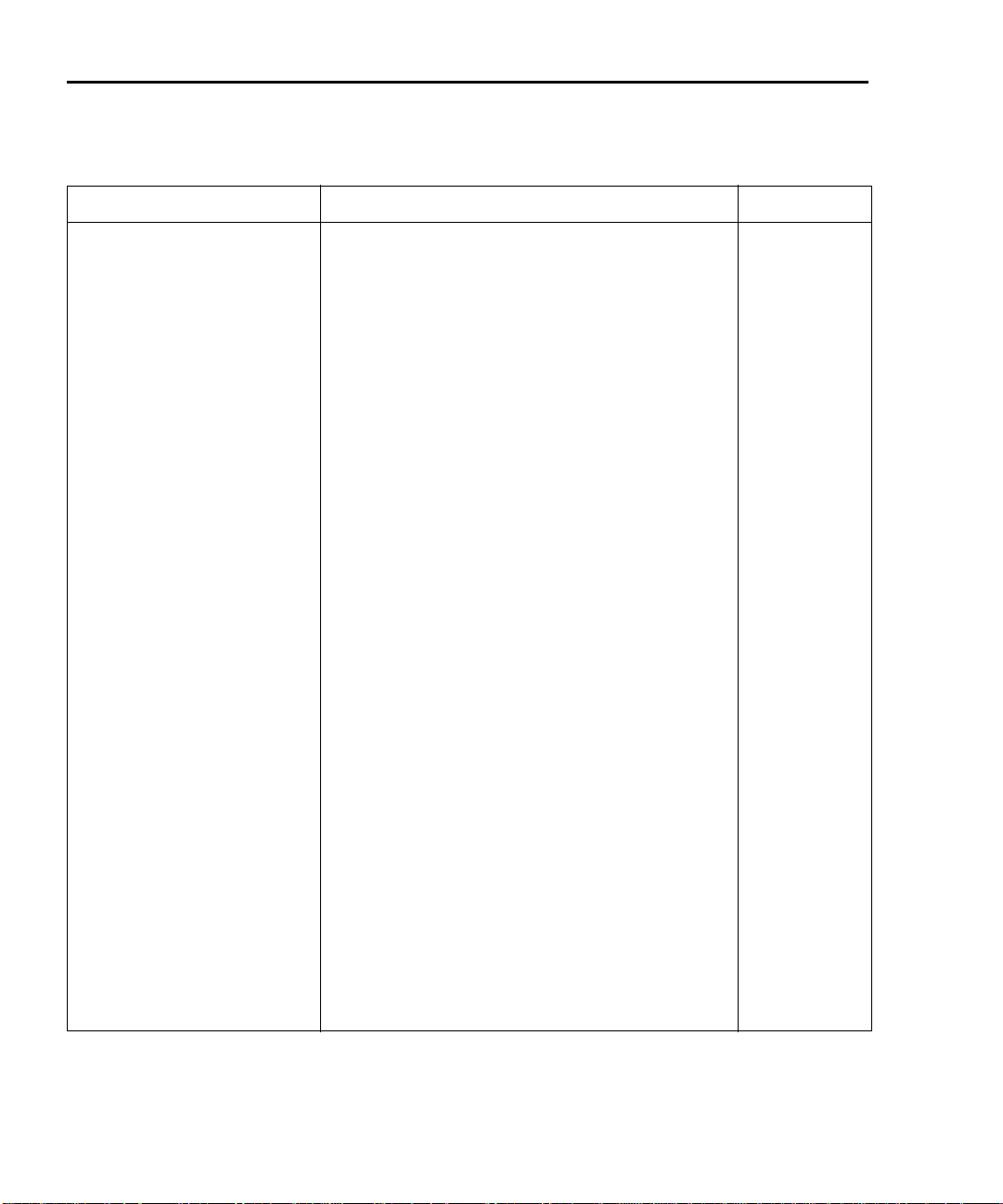

Factory default settings

As summarized in Table 1-2, there are two sets of factory defaults, BENCH (front

panel) and GPIB (remote). You can restore either of these default conditions as

follows:

1. Press the MENU key, select SAVESETUP, then press ENTER.

2. From the SAVESETUP menu, select GLOBAL, then press ENTER.

3. From the GLOBAL SETUP MENU, select RESET, then press ENTER.

4. Select BENCH or GPIB defaults as desired, then press ENTER to complete

the process.

Table 1-2

Factory default settings

BENCH or GPIB

Setting

A/D Controls:

Auto-zero

Line frequency No effect

Beeper On

Contact check mode