Page 1

Model 2308 Portable Device

Battery/Charger Simulator

User’s Manual

2308-900-01 Rev. A / July 2008

www.keithley.com

A GREATER MEASURE OF CONFIDENCE

Page 2

.

Page 3

WARRANTY

Keithley Instruments, Inc. warrants this product to be free from defects in material and workmanship for a period of

one (1) year from date of shipment.

Keithley Instruments, Inc. warrants the following items for 90 days from the date of shipment: probes, cables,

software, rechargeable batteries, diskettes, and documentation.

During the warranty period, Keithley Instruments will, at its option, either repair or replace any product that proves

to be defective.

To exercise this warranty, write or call your local Keithley Instruments representative, or contact

Keithley Instruments headquarters in Cleveland, Ohio. You will be given prompt assistance and return instructions.

Send the product, transportation prepaid, to the indicated service facility. Repairs will be made and the product

returned, transportation prepaid. Repaired or replaced products are warranted for the balance of the original

warranty period, or at least 90 days.

LIMITATION OF WARRANTY

This warranty does not apply to defects resulting from product modification without Keithley Instruments’ express

written consent, or misuse of any product or part. This warranty also does not apply to fuses, software,

non-rechargeable batteries, damage from battery leakage, or problems arising from normal wear or failure to follow

instructions.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING ANY

IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR USE. THE REMEDIES

PROVIDED HEREIN ARE BUYER’S SOLE AND EXCLUSIVE REMEDIES.

NEITHER KEITHLEY INSTRUMENTS, INC. NOR ANY OF ITS EMPLOYEES SHALL BE LIABLE FOR ANY

DIRECT, INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES ARISING OUT OF THE USE

OF ITS INSTRUMENTS AND SOFTWARE, EVEN IF KEITHLEY INSTRUMENTS, INC. HAS BEEN ADVISED IN

ADVANCE OF THE POSSIBILITY OF SUCH DAMAGES. SUCH EXCLUDED DAMAGES SHALL INCLUDE, BUT

ARE NOT LIMITED TO: COST OF REMOVAL AND INSTALLATION, LOSSES SUSTAINED AS THE RESULT OF

INJURY TO ANY PERSON, OR DAMAGE TO PROPERTY.

A G R E A T E R M E A S U R E O F C O N F I D E N C E

Keithley Instruments, Inc.

Corporate Headquarters • 28775 Aurora Road • Cleveland, Ohio 44139

440-248-0400 • Fax: 440-248-6168 • 1-888-KEITHLEY (1-888-534-8453) • www.keithley.com

3/07

Page 4

Model 2308 Portable Device

Battery/Charger Simulator

User’s Manual

©2008, Keithley Instruments, Inc.

All rights reserved.

Any unauthorized reproduction, photocopy, or use the information herein, in whole or in part, without the prior written

approval of Keithley Instruments, Inc. is strictly prohibited.

TSP, TSP-Link, and TSP-Net are trademarks of Keithley Instruments, Inc. All other brand names are trademarks or

registered trademarks of their respective holders.

Cleveland, Ohio, U.S.A.

Document Number:

2308-900-01 Rev. A / July 2008

Page 5

The following safety precautions should be observed before using this product and any associated instrumentation. Although some

instruments and accessories would normally be used with non-hazardous voltages, there are situations where hazardous conditions may

be present.

This product is intended for use by qualified personnel who recognize shock hazards and are familiar with the safety precautions required

to avoid possible injury. Read and follow all installation, operation, and maintenance information carefully before using the product. Refer

to the user documentation for complete product specifications.

If the product is used in a manner not specified, the protection provided by the product warranty may be impaired.

The types of product users are:

Responsible body is the individual or group responsible for the use and maintenance of equipment, for ensuring that the equipment is

operated within its specifications and operating limits, and for ensuring that operators are adequately trained.

Operators use the product for its intended function. They must be trained in electrical safety procedures and proper use of the instrument.

They must be protected from electric shock and contact with hazardous live circuits.

Maintenance personnel perform routine procedures on the product to keep it operating properly, for example, setting the line voltage or

replacing consumable materials. Maintenance procedures are described in the user documentation. The procedures explicitly state if the

operator may perform them. Otherwise, they should be performed only by service personnel.

Safety Precautions

Service personnel are trained to work on live circuits, perform safe installations, and repair products. Only properly trained service

personnel may perform installation and service procedures.

Keithley Instruments products are designed for use with electrical signals that are rated Measurement Category I and Measurement

Category II, as described in the International Electrotechnical Commission (IEC) Standard IEC 60664. Most measurement, control, and

data I/O signals are Measurement Category I and must not be directly connected to mains voltage or to voltage sources with high transient

over-voltages. Measurement Category II connections require protection for high transient over-voltages often associated with local AC

mains connections. Assume all measurement, control, and data I/O connections are for connection to Category I sources unless otherwise

marked or described in the user documentation.

Exercise extreme caution when a shock hazard is present. Lethal voltage may be present on cable connector jacks or test fixtures. The

American National Standards Institute (ANSI) states that a shock hazard exists when voltage levels greater than 30V RMS, 42.4V peak,

or 60VDC are present. A good safety practice is to expect that hazardous voltage is present in any unknown circuit before measuring.

Operators of this product must be protected from electric shock at all times. The responsible body must ensure that operators are

prevented access and/or insulated from every connection point. In some cases, connections must be exposed to potential human contact.

Product operators in these circumstances must be trained to protect themselves from the risk of electric shock. If the circuit is capable of

operating at or above 1000V, no conductive part of the circuit may be exposed.

Do not connect switching cards directly to unlimited power circuits. They are intended to be used with impedance-limited sources. NEVER

connect switching cards directly to AC mains. When connecting sources to switching cards, install protective devices to limit fault current

and voltage to the card.

Before operating an instrument, ensure that the line cord is connected to a properly-grounded power receptacle. Inspect the connecting

cables, test leads, and jumpers for possible wear, cracks, or breaks before each use.

11/ 07

Page 6

When installing equipment where access to the main power cord is restricted, such as rack mounting, a separate main input power

!

disconnect device must be provided in close proximity to the equipment and within easy reach of the operator.

For maximum safety, do not touch the product, test cables, or any other instruments while power is applied to the circuit under test.

ALWAYS remove power from the entire test system and discharge any capacitors before: connecting or disconnecting cables or jumpers,

installing or removing switching cards, or making internal changes, such as installing or removing jumpers.

Do not touch any object that could provide a current path to the common side of the circuit under test or power line (earth) ground. Always

make measurements with dry hands while standing on a dry, insulated surface capable of withstanding the voltage being measured.

The instrument and accessories must be used in accordance with its specifications and operating instructions, or the safety of the

equipment may be impaired.

Do not exceed the maximum signal levels of the instruments and accessories, as defined in the specifications and operating information,

and as shown on the instrument or test fixture panels, or switching card.

When fuses are used in a product, replace with the same type and rating for continued protection against fire hazard.

Chassis connections must only be used as shield connections for measuring circuits, NOT as safety earth ground connections.

If you are using a test fixture, keep the lid closed while power is applied to the device under test. Safe operation requires the use of a lid

interlock.

If a screw is present, connect it to safety earth ground using the wire recommended in the user documentation.

The symbol on an instrument indicates that the user should refer to the operating instructions located in the user documentation.

The symbol on an instrument shows that it can source or measure 1000V or more, including the combined effect of normal and

common mode voltages. Use standard safety precautions to avoid personal contact with these voltages.

The symbol on an instrument shows that the surface may be hot. Avoid personal contact to prevent burns.

The symbol indicates a connection terminal to the equipment frame.

If this symbol is on a product, it indicates that mercury is present in the display lamp. Please note that the lamp must be properly

disposed of according to federal, state, and local laws.

The WARNING heading in the user documentation explains dangers that might result in personal injury or death. Always read the

associated information very carefully before performing the indicated procedure.

The CAUTION heading in the user documentation explains hazards that could damage the instrument. Such damage may invalidate the

warranty.

Instrumentation and accessories shall not be connected to humans.

Before performing any maintenance, disconnect the line cord and all test cables.

To maintain protection from electric shock and fire, replacement components in mains circuits - including the power transformer, test leads,

and input jacks - must be purchased from Keithley Instruments. Standard fuses with applicable national safety approvals may be used if

the rating and type are the same. Other components that are not safety-related may be purchased from other suppliers as long as they

are equivalent to the original component (note that selected parts should be purchased only through Keithley Instruments to maintain

accuracy and functionality of the product). If you are unsure about the applicability of a replacement component, call a Keithley Instruments

office for information.

To clean an instrument, use a damp cloth or mild, water-based cleaner. Clean the exterior of the instrument only. Do not apply cleaner

directly to the instrument or allow liquids to enter or spill on the instrument. Products that consist of a circuit board with no case or chassis

(e.g., a data acquisition board for installation into a computer) should never require cleaning if handled according to instructions. If the

board becomes contaminated and operation is affected, the board should be returned to the factory for proper cleaning/servicing.

Page 7

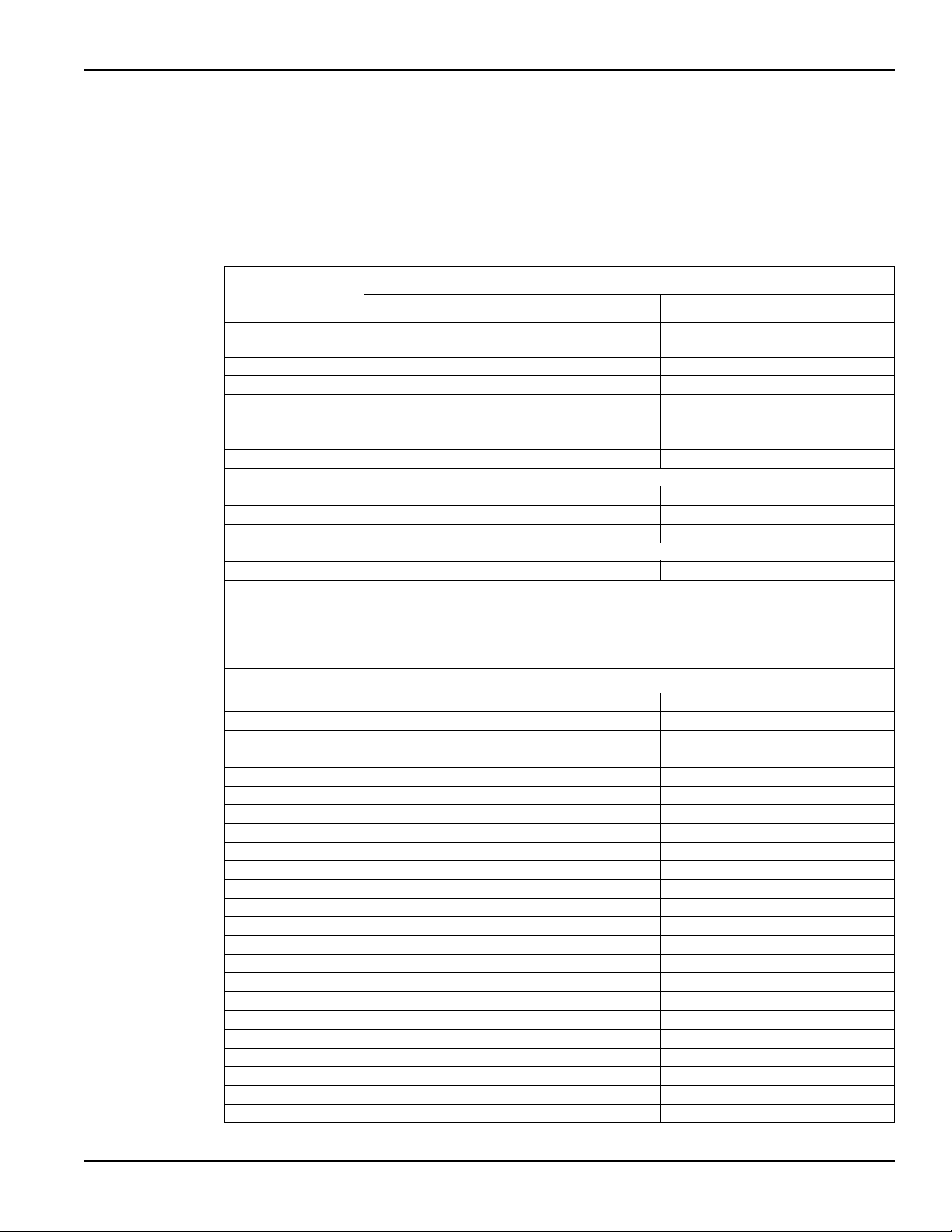

Table of Contents

Section Topic Page

1 Getting Started ....................................................................................... 1-1

Overview..................................................................................................... 1-2

Applications ................................................................................................ 1-2

Performance features ................................................................................. 1-2

Warranty information .................................................................................. 1-2

Contact information..................................................................................... 1-2

Specifications.............................................................................................. 1-3

Inspection ................................................................................................... 1-3

Options and accessories ............................................................................ 1-3

Power supply overview............................................................................... 1-3

Remote display option ................................................................................ 1-5

Power-up .................................................................................................... 1-7

Line power connection ......................................................................... 1-7

Power-up sequence ............................................................................. 1-7

Fuse replacement ................................................................................ 1-8

Display modes ............................................................................................ 1-8

Default settings ......................................................................................... 1-11

Setups - Save, Power-on, and Recall ................................................ 1-12

Menu......................................................................................................... 1-12

Getting around the MENU ........................................................................ 1-14

SCPI programming ................................................................................... 1-15

2 Basic Power Supply Operation .......................................................... 2-1

Test connections ........................................................................................ 2-2

Remote sense ...................................................................................... 2-5

Local sense .......................................................................................... 2-5

RFI considerations ............................................................................... 2-6

Outputting voltage and current ................................................................... 2-6

Setting voltage protection value ........................................................... 2-6

Selecting proper current range............................................................. 2-8

Selecting current limit mode................................................................. 2-8

Editing output voltage and current limit values..................................... 2-9

Using the OPERATE key.................................................................... 2-11

Output bandwidth...................................................................................... 2-11

Output impedance .................................................................................... 2-12

Changing the battery channel’s output impedance ............................ 2-12

SCPI programming - outputting voltage and current ................................ 2-13

Command notes (outputting voltage and current).............................. 2-14

Reading back V and I ............................................................................... 2-16

V and I display modes (Single or Dual)............................................. 2-16

Measurement configuration................................................................ 2-16

SCPI programming — measure V and I, and DVM input ......................... 2-17

Command notes (measure V and I, and DVM input) ......................... 2-18

Independent voltage measurements (DVM) ............................................. 2-18

DVM input display mode .................................................................... 2-18

Measurement configuration................................................................ 2-19

SCPI programming - DVM........................................................................ 2-19

Sink operation........................................................................................... 2-19

Page 8

Table of Contents Model 2308 Portable Device Battery/Charger Simulator User’s Manual

Section Topic Page

Programming examples ............................................................................ 2-21

Outputting and reading back V and I .................................................. 2-21

DVM measurements ........................................................................... 2-21

Analog output............................................................................................ 2-22

3 Pulse Current Measurements.............................................................. 3-1

Overview ..................................................................................................... 3-2

Trigger level.......................................................................................... 3-2

Trigger delay......................................................................................... 3-3

Integration times ................................................................................... 3-3

Average readings count........................................................................ 3-4

Measurement configuration......................................................................... 3-4

Current range ....................................................................................... 3-5

Integration times ................................................................................... 3-5

Average readings count........................................................................ 3-5

Trigger delay and trigger level .............................................................. 3-6

Pulse current display mode .................................................................. 3-7

Pulse current measurement procedure....................................................... 3-7

No pulses detected ............................................................................... 3-8

Determining correct trigger level (pulse current)................................... 3-9

TRIG NOT DETECTED message....................................................... 3-11

SCPI programming - pulse current measurements................................... 3-12

Command notes (pulse current measurements) ................................ 3-14

Using FAST, SEARch, and DETect..................................................... 3-16

Pulse current digitization ........................................................................... 3-19

Pulse current step method ........................................................................ 3-20

TLEV steps ......................................................................................... 3-21

Timeout setting ................................................................................... 3-25

Integration time ................................................................................... 3-25

Range with pulse current step ............................................................ 3-26

Programming examples ............................................................................ 3-26

Pulse current measurements.............................................................. 3-26

Pulse current digitization .................................................................... 3-27

Pulse current STEP method (battery channel only)............................ 3-27

4 Long Integration Measurements ........................................................ 4-1

Overview ..................................................................................................... 4-2

Integration time ..................................................................................... 4-3

Trigger edge ......................................................................................... 4-3

Trigger level.......................................................................................... 4-3

Pulse timeout........................................................................................ 4-4

Measurement configuration......................................................................... 4-6

Current range ....................................................................................... 4-6

Integration time ..................................................................................... 4-6

Pulse timeout........................................................................................ 4-7

Trigger edge and trigger level............................................................... 4-7

Long integration display mode.............................................................. 4-8

Long integration measurement procedure.................................................. 4-8

General notes ....................................................................................... 4-9

Determining correct trigger level (long integration)............................... 4-9

SCPI programming.................................................................................... 4-11

Command notes (long integration measurements)............................. 4-12

Using FAST, SEARch, and DETect..................................................... 4-12

Programming examples ............................................................................ 4-16

5 Relay Control .......................................................................................... 5-1

Overview ..................................................................................................... 5-2

Connections ................................................................................................ 5-3

Controlling relays ........................................................................................ 5-4

SCPI programming...................................................................................... 5-5

ii 2308-900-01 Rev. A / July 2008

Page 9

Model 2308 Portable Device Battery/Charger Simulator User’s Manual Table of Contents

Section Topic Page

6 GPIB Operation....................................................................................... 6-1

Introduction ................................................................................................. 6-2

GPIB bus connections................................................................................. 6-2

Primary address .......................................................................................... 6-3

Setting the GPIB timeout for responses...................................................... 6-4

Long integration readings ..................................................................... 6-4

Pulse current readings.......................................................................... 6-4

MAV (Message Available Bit) ............................................................... 6-4

General bus commands .............................................................................. 6-5

REN (remote enable)............................................................................ 6-5

IFC (interface clear).............................................................................. 6-6

LLO (local lockout)................................................................................ 6-6

GTL (go to local) ................................................................................... 6-6

DCL (device clear) ................................................................................ 6-6

SDC (selective device clear)................................................................. 6-6

GET (group execute trigger)................................................................. 6-6

SPE, SPD (serial polling)...................................................................... 6-6

Front panel aspects of GPIB operation ....................................................... 6-6

Remote indicator and LOCAL key ........................................................ 6-7

Error and status messages................................................................... 6-7

Programming syntax ................................................................................... 6-7

Command words................................................................................... 6-7

Program messages............................................................................... 6-9

Response messages .......................................................................... 6-11

Message exchange protocol............................................................... 6-12

7 Status Structure...................................................................................... 7-1

Overview ..................................................................................................... 7-2

Status byte and SRQ ............................................................................ 7-2

Status register sets ............................................................................... 7-2

Queues ................................................................................................. 7-2

Clearing registers and queues .................................................................... 7-3

Programming and reading registers............................................................ 7-4

Programming enable registers.............................................................. 7-4

Reading registers.................................................................................. 7-5

Status byte and service request (SRQ)....................................................... 7-5

Status byte register ............................................................................... 7-6

Service request enable register............................................................ 7-7

Serial polling and SRQ ......................................................................... 7-7

Status byte and service request commands ......................................... 7-8

Status register sets...................................................................................... 7-8

Register bit descriptions ....................................................................... 7-8

Condition registers .................................................................................... 7-12

Event registers.................................................................................... 7-12

Event enable registers........................................................................ 7-13

Queues...................................................................................................... 7-14

Output queue...................................................................................... 7-15

Error queue......................................................................................... 7-15

Programming example - read error queue.......................................... 7-16

8 Common Commands ............................................................................ 8-1

Overview ..................................................................................................... 8-2

IEEE-488.2 common commands and queries............................................. 8-2

*IDN? .................................................................................................... 8-2

*OPC..................................................................................................... 8-3

*SAV <NRf> and RCL <NRf> ............................................................... 8-3

*RST ..................................................................................................... 8-4

*TRG..................................................................................................... 8-4

*TST?.................................................................................................... 8-4

*WAI...................................................................................................... 8-4

2308-900-01 Rev. A / July 2008 iii

Page 10

Table of Contents Model 2308 Portable Device Battery/Charger Simulator User’s Manual

Section Topic Page

9 Measurement Commands and

Optimizing Measurement Speed ........................................................ 9-1

Overview ..................................................................................................... 9-2

Command notes: Signal-oriented measurement commands

and queries........................................................................................... 9-3

Optimizing measurement speed ................................................................. 9-5

Auto Zero State..................................................................................... 9-5

Programming examples........................................................................ 9-6

GPIB 488.1 protocol.................................................................................... 9-7

Selecting the 488.1 protocol ................................................................. 9-7

Protocol differences.............................................................................. 9-8

Trigger on talk both channels ...................................................................... 9-9

Bus commands................................................................................... 9-10

Command notes ................................................................................. 9-10

Trigger continuous mode........................................................................... 9-10

Bus commands................................................................................... 9-10

Command notes ................................................................................. 9-11

Using trigger continuous mode........................................................... 9-11

Programming sequence example....................................................... 9-11

10 DISPlay and FORMat ........................................................................... 10-1

DISPlay subsystem ................................................................................... 10-2

Command notes (SCPI commands - display)..................................... 10-2

FORMat subsystem .................................................................................. 10-4

Command notes (SCPI commands - data format).............................. 10-5

11 SCPI Tables............................................................................................ 11 -1

SCPI command subsystems reference tables .......................................... 11-2

General notes ..................................................................................... 11-2

DISPlay command summary .............................................................. 11-3

FORMat command summary.............................................................. 11 -4

OUTPut command summary .............................................................. 11-5

SENSe command summary .............................................................. 11-6

SOURce command summary........................................................... 11 -13

STATus command summary............................................................. 11- 14

SYSTem command summary ........................................................... 11-15

12 Performance Verification.................................................................... 12-1

Introduction ............................................................................................... 12-2

Verification test requirements.................................................................... 12-2

Environmental conditions.................................................................... 12-2

Warm-up period .................................................................................. 12-2

Line power .......................................................................................... 12-3

Recommended test equipment ................................................................. 12-3

Resistor connections .......................................................................... 12-3

Resistor considerations ...................................................................... 12-4

Verification limits ....................................................................................... 12-4

Example limits calculation................................................................... 12-4

Performing the verification test procedures............................................... 12-4

Test summary ..................................................................................... 12-4

Test considerations ............................................................................. 12-5

Output voltage accuracy ........................................................................... 12-5

Voltage readback accuracy ....................................................................... 12-7

Compliance current accuracy.................................................................... 12-8

Current readback accuracy ....................................................................... 12-9

5 A range readback accuracy ............................................................. 12-9

500 mA range readback accuracy.................................................... 12-10

50 mA range readback accuracy...................................................... 12-12

5 mA range readback accuracy........................................................ 12-13

Digital voltmeter input accuracy .............................................................. 12-15

iv 2308-900-01 Rev. A / July 2008

Page 11

Model 2308 Portable Device Battery/Charger Simulator User’s Manual Table of Contents

Section Topic Page

13 Calibration.............................................................................................. 13-1

Introduction ............................................................................................... 13-2

Environmental conditions.......................................................................... 13-2

Temperature and relative humidity...................................................... 13-2

Warm-up period .................................................................................. 13-2

Line power .......................................................................................... 13-2

Calibration considerations......................................................................... 13-2

Calibration cycle ................................................................................. 13-3

Recommended calibration equipment....................................................... 13-3

Resistor connections .......................................................................... 13-3

Resistor considerations ...................................................................... 13-3

Front panel calibration............................................................................... 13-4

Step 1: Prepare the Model 2308 for calibration .................................. 13-4

Step 2: Perform battery channel calibration steps .............................. 13-5

Step 3: Perform charger channel calibration steps............................. 13-9

Step 4: Enter calibration dates, and save calibration........................ 13-10

Remote calibration .................................................................................. 13-11

Remote calibration display................................................................ 13-11

Remote calibration procedure........................................................... 13-11

Step 1: Prepare the Model 2308 for calibration ................................ 13-11

Step 2: Perform battery channel calibration steps ............................ 13-12

Step 3: Perform charger channel calibration steps........................... 13-13

Step 4: Program calibration date ...................................................... 13-14

Step 5: Save calibration constants and lock out calibration.............. 13-14

Changing the calibration code................................................................. 13-15

Changing the code from the front panel ........................................... 13-16

Changing the code by remote........................................................... 13-16

Resetting the calibration code .......................................................... 13-16

Viewing calibration date and count ......................................................... 13-17

Viewing date and count from the front panel .................................... 13-17

Acquiring date and count by remote................................................. 13-17

Appendix Topic Page

A Error and Status Messages ................................................................ A-1

Error and status message definitions......................................................... A-2

B Calibration Reference .......................................................................... B-1

Introduction ................................................................................................ B-2

Command summary ............................................................................ B-2

Miscellaneous commands.......................................................................... B-2

Detecting calibration errors ........................................................................ B-5

Reading the error queue...................................................................... B-5

Error summary..................................................................................... B-5

Status byte EAV (Error Available) bit ................................................... B-6

Generating an SRQ on error................................................................ B-6

Detecting calibration step completion ........................................................ B-6

Using the *OPC command................................................................... B-7

Using the *OPC? query ....................................................................... B-7

Generating an SRQ on calibration complete ....................................... B-7

2308-900-01 Rev. A / July 2008 v

Page 12

This page left blank intentionally .

Page 13

List of Figures

Section Figure Title Page

1 Figure 1-1 Model 2308 front panel ................................................................. 1-4

1 Figure 1-2 Model 2308 rear panel................................................................... 1-4

1 Figure 1-3 Simplified power supply diagram .................................................. 1-5

1 Figure 1-4 Model 2306-DISP Remote display option...................................... 1-6

1 Figure 1-5 Fuse drawer location .................................................................... 1-8

2 Figure 2-1 Battery channel preferred connection (maximum stability) ............ 2-3

2 Figure 2-2 Battery channel fastest transient response connection ................. 2-4

2 Figure 2-3 Charger channel 4-wire remote sense connection

from the DUT to the ouput ............................................................. 2-5

2 Figure 2-4 Local Sense Connections (battery channel and

charger channel)............................................................................ 2-6

2 Figure 2-5 Charger Control Circuit Testing.................................................... 2-19

2 Figure 2-6 Sink operation.............................................................................. 2-20

2 Figure 2-7 Preferred method ........................................................................ 2-20

2 Figure 2-8 Analog output Connections.......................................................... 2-22

3 Figure 3-1 Pulse current measurement........................................................... 3-2

3 Figure 3-2 Trigger delay for high pulse current measurement ........................ 3-3

3 Figure 3-3 Determining voltage and current characteristics for

battery channel .............................................................................. 3-9

3 Figure 3-4 Determining voltage and current characteristics for

charger channel .......................................................................... 3-10

3 Figure 3-5 PCURrent and SEARch time for pulse high measurement ......... 3-17

3 Figure 3-6 Sample pulse forms for step method........................................... 3-22

3 Figure 3-7 Sample one-shot only pulses for step method............................. 3-22

3 Figure 3-8 Sample :STEP Pulse measurement ............................................ 3-23

3 Figure 3-9 Pulse form with rise and fall steps ............................................... 3-23

3 Figure 3-10 Pulse form with down steps first (600msec step duration) .......... 3-24

4 Figure 4-1 Steady state for waveforms based on low pulse times .................. 4-3

4 Figure 4-2 Long integration, search, and reading time comparison ................ 4-5

4 Figure 4-3 TOUT and search time ................................................................ 4-13

5 Figure 5-1 External source relay control ......................................................... 5-3

5 Figure 5-2 Internal source relay control .......................................................... 5-3

5 Figure 5-3 Relay connector (9-pin D-sub)....................................................... 5-4

6 Figure 6-1 IEEE-488 connector....................................................................... 6-2

6 Figure 6-2 Daisy chaining ............................................................................... 6-3

7 Figure 7-1 Status model structure................................................................... 7-3

7 Figure 7-2 Status byte and service request..................................................... 7-6

7 Figure 7-3 Standard event status .................................................................... 7-9

7 Figure 7-4 Operation event status................................................................. 7-10

7 Figure 7-5 Measurement event status .......................................................... 7-11

7 Figure 7-6 Questionable event status ........................................................... 7-12

10 Figure 10-1 IEEE-754 single precision data format ........................................ 10-5

10 Figure 10-2 IEEE-754 double precision data format ....................................... 10-6

12 Figure 12-1 Connections for voltage verification tests .................................... 12-6

Page 14

List of Figures Model 2308 Portable Device Battery/Charger Simulator User’s Manual

Section Figure Title Page

12 Figure 12-2 Connections for output current and 5 A range current

verification tests ........................................................................... 12-8

12 Figure 12-3 Battery channel connections for 500 mA current

verification tests ......................................................................... 12-11

12 Figure 12-4 Battery channel connections for 50 mA current

verification tests ......................................................................... 12-12

12 Figure 12-5 Connections for 5 mA current verification tests.......................... 12-14

12 Figure 12-6 Charger channel connections for DVM accuracy verification..... 12-15

13 Figure 13-1 Battery channel connections for voltage calibration ................... 13-6

13 Figure 13-2 Connections for 5 A, 500 mA, and 50 mA current calibration ...... 13-7

13 Figure 13-3 Connections for 5 mA range calibration....................................... 13-8

13 Figure 13-4 Charger channel connections for voltage calibration ................... 13-9

vii 2308-900-01 Rev. A / July 2008

Page 15

List of Tables

Section Table Title Page

1 Table 1-1 Display Modes ............................................................................... 1-9

1 Table 1-2 Display mode examples............................................................... 1-10

1 Table 1-3 Factory defaults (RST)................................................................. 1-11

1 Table 1-4 Main MENU structure .................................................................. 1-13

2 Table 2-1 Current ranges............................................................................... 2-8

2 Table 2-2 Output bandwidth channel setting ............................................... 2-11

2 Table 2-3 SCPI command summary - outputting voltage and current......... 2-13

2 Table 2-4 SCPI commands: Measure V and I, and DVM input.................... 2-17

3 Table 3-1 Current range and trigger level settings......................................... 3-6

3 Table 3-2 TRIG NOT DETECTED message................................................ 3-11

3 Table 3-3 SCPI commands - pulse current measurements ......................... 3-12

3 Table 3-4 PCURrent FAST, SEARch, and DETect commands .................... 3-18

3 Table 3-5 Setting UP and DOWN commands.............................................. 3-21

3 Table 3-6 Trigger Level Setting.................................................................... 3-22

3 Table 3-7 Sample TLEV values ................................................................... 3-23

3 Table 3-8 Sample integration times ............................................................. 3-25

4 Table 4-1 TRIG NOT DETECTED message................................................ 4-10

4 Table 4-2 SCPI commands - long integration measurements ..................... 4-11

4 Table 4-3 FAST, SEARch, and DETect command reference ....................... 4-14

5 Table 5-1 Relay pinouts ................................................................................. 5-4

5 Table 5-2 SCPI command - output relay control............................................ 5-5

6 Table 6-1 General bus commands................................................................. 6-5

7 Table 7-1 Common and SCPI commands - reset registers and

clear queues .................................................................................. 7-4

7 Table 7-2 16-bit status register ...................................................................... 7-5

7 Table 7-3 Common and SCPI Commands - status byte and

service request enable registers.................................................... 7-8

7 Table 7-4 Common and SCPI commands - condition registers................... 7-12

7 Table 7-5 Common and SCPI commands - event registers ........................ 7-13

7 Table 7-6 Common and SCPI commands - event enable registers............. 7-13

7 Table 7-7 SCPI Commands - error queue ................................................... 7-16

8 Table 8-1 IEEE-488.2 common commands and queries ............................... 8-2

8 Table 8-2 *OPC and *OPC? commands........................................................ 8-3

9 Table 9-1 Signal-oriented measurement command summary ....................... 9-2

9 Table 9-2 Trigger on talk bus commands..................................................... 9-10

9 Table 9-3 Trigger continuous bus commands.............................................. 9-10

9 Table 9-4 Trigger continuous mode programming example ........................ 9-11

10 Table 10-1 SCPI commands - display ........................................................... 10-2

10 Table 10-2 SCPI commands - data format .................................................... 10-4

11 Table 11-1 DISPlay command summary ....................................................... 11-3

11 Table 11-2 FORMat command summary....................................................... 11-4

11 Table 11-3 OUTPut command summary ....................................................... 11-5

11 Table 11-4 SENSe command summary ........................................................ 11 -6

11 Table 11-5 SOURce command summary .................................................... 11-13

Page 16

List of Tables Model 2308 Portable Device Battery/Charger Simulator User’s Manual

Section Table Title Page

11 Table 11-6 STATus command summary ...................................................... 11 -14

11 Table 11-7 SYSTem command summary..................................................... 11-15

12 Table 12-1 Recommended verification equipment ......................................... 12-3

12 Table 12-2 Output voltage accuracy limits ..................................................... 12-6

12 Table 12-3 Voltage readback accuracy limits................................................. 12-7

12 Table 12-4 Compliance current accuracy limits ............................................. 12-9

12 Table 12-5 5 A range current readback accuracy limits ............................... 12-10

12 Table 12-6 500 mA range current readback accuracy limits ........................ 12-11

12 Table 12-7 50 mA range current readback accuracy limits .......................... 12-13

12 Table 12-8 5 mA range current readback accuracy limits ............................ 12-14

12 Table 12-9 Digital voltmeter input accuracy limits ........................................ 12-16

13 Table 13-1 Recommended calibration equipment.......................................... 13-3

13 Table 13-2 Model 2308 front panel calibration summary ............................... 13-4

13 Table 13-3 Remote calibration summary ..................................................... 13-14

Appendix Table Title Page

A Table A-1 Error and status messages (all models)........................................ A-2

B Table B-1 Remote calibration command summary........................................ B-2

B Table B-2 Calibration errors........................................................................... B-6

ix 2308-900-01 Rev. A / July 2008

Page 17

In this section:

Section 1

Getting Started

Topi c Page

Overview ..................................................................................................... 1-2

Applications................................................................................................. 1-2

Performance features ................................................................................. 1-2

Warranty information................................................................................... 1-2

Contact information..................................................................................... 1-2

Specifications.............................................................................................. 1-3

Inspection.................................................................................................... 1-3

Options and accessories............................................................................. 1-3

Power supply overview ............................................................................... 1-3

Remote display option ................................................................................ 1-5

Power-up..................................................................................................... 1-7

Line power connection ......................................................................... 1-7

Power-up sequence ............................................................................. 1-7

Fuse replacement................................................................................. 1-8

Display modes ............................................................................................ 1-8

Default settings ......................................................................................... 1-11

Setups - Save, Power-on, and Recall................................................. 1-12

Menu ......................................................................................................... 1-12

Getting around the MENU......................................................................... 1-14

SCPI programming ................................................................................... 1-15

Page 18

Section 1: Getting Started Model 2308 Portable Device Battery/Charger Simulator User’s Manual

Overview

This manual describes Keithley Instruments Model 2308 Portable Device Battery/Charger

Simulator, which is designed specifically for development and high-speed production testing of DC

battery-operated products.

Applications

Development and high speed testing of DC battery-operated products, such as:

• Cellular handsets

• Cellular components like RFIC power amplifiers

• Other high-volume precision electrical components.

Performance features

Key features and benefits include:

• The Model 2308 is a specialized power supply that has a very fast recovery to large, near

instantaneous load current transitions. Conventional power supplies do not have this

capability. The Model 2308 is designed specifically to respond to large load changes and

very short pulsed loads with small transient voltage drop and a very fast recovery time.

Typical devices that have these types of characteristic loads are mobile phones, wireless

communication modules, and other portable, battery operated devices. The Model 2308 can

maintain a near-constant output, even under quickly-changing load conditions.

• The power supply can measure a wide range of load currents. It can resolve down to 0.1 μA

and measure up to 5 A. It has fast measurement capability as well and can measure load

current pulses as narrow as 50

• The Model 2308 can simulate the output of a battery. Its programmable output resistance

can simulate a battery’s internal resistance so that the voltage output looks exactly like that

of a battery’s output.

• The two channels can also sink current so that one channel (the battery channel) simulates

a discharged battery, while the other channel (the charger channel) can be used to simulate

a charger.

μsec.

NOTE Information contained in this section applies to all power supply channels

(unless otherwise noted). In this manual, Channel 1 refers to the battery

channel, Channel 2 refers to the charger channel.

Warranty information

Warranty information is located at the front of this manual. Should your power supply require

warranty service, contact the Keithley Instruments representative or authorized repair facility in

your area for further information. When returning the instrument for repair, be sure to fill out and

include the service form at the back of this manual to provide the repair facility with the necessary

information.

Contact information

If you have any questions after reviewing this information, please contact your local Keithley

representative or call one of our Applications Engineers at 1-800-348-3735 (U.S. and Canada

1-2 Return to Section Topics 2308-900-01 Rev. A / July 2008

Page 19

Model 2308 Portable Device Battery/Charger Simulator User’s Manual Section 1: Getting Started

only). A complete list of worldwide phone numbers are available on the Keithley Instruments

website at

www.keithley.com.

Specifications

Full Model 2308 specifications are included on the Model 2308 Portable Device Battery/Charger

Simulator Product Information CD-ROM. Check the Keithley Instruments website at

www.keithley.com for the latest updates to the specifications.

Inspection

The power supply was carefully inspected electrically and mechanically before shipment. After

unpacking all items from the shipping carton, check for any obvious signs of physical damage that

may have occurred during transit

NOTE There may be a protective film over the display lens, which can be removed.

Report any damage to the shipping agent immediately. Save the original packing carton for

possible future shipment. The following items are included with every order:

.

• Model 2308 Portable Device Battery/Charger Simulator with line cord

• Quick Disconnect Connector (2)

• Accessories as ordered

• Certificate of calibration

• Product Information CD-ROM that contains PDFs of Model 2308 User’s Manual and Model

2308 Quick Start Guide

Any improvements or changes concerning the instrument or manual will be explained in an

addendum included with the manual. Be sure to note these changes and incorporate them into the

manual.

Options and accessories

The following options and accessories are available for the power supply.

• 2306-DISP remote display unit

• Low inductance coaxial cable (SC-182)

• Single fixed rack mount kit (P/N 4288-1)

• Dual fixed rack mount kit (P/N 4288-2)

• IEEE-488 Interface for PCI bus (P/N KPCI-488LP)

• USB to GPIB adapter interface (P/N KUSB-488A)

• Double shielded premium GPIB cable, 0.5 m (1.6 ft) (P/N 7007-05)

• Double shielded premium GPIB cable, 1 m (3.2 ft) (P/N 7007-1)

• Double shielded premium GPIB cable, 2 m (6.5 ft) (P/N 7007-2)

• Double shielded premium GPIB cable, 3 m (10 ft) (P/N 7007-3)

• Double shielded premium GPIB cable, 4 m (13 ft) (P/N 7007-4)

Power supply overview

The Model 2308 power supply (see Figure 1-1) can simulate a battery channel (#1) or a charger

channel (#2). Figure 1-1 and Figure 1-2 show the Model 2308 front and rear panels.

2308-900-01 Rev. A / July 2008 Return to Section Topics 1-3

Page 20

Section 1: Getting Started Model 2308 Portable Device Battery/Charger Simulator User’s Manual

POWER

DISPLAY

OPERATE

ENTER

SET

MENU

LOCAL

2308 Portable Device Battery/Charger Simulator

WARNING:

NO INTERNAL OPERATOR SERVICABLE PARTS,SERVICE BY QUALIFIED PERSONNEL ONLY.

CAUTION:

FOR CONTINUED PROTECTION AGAINST FIRE HAZARD,REPLACE FUSE WITH SAME TYPE AND RATING.

MADE IN

U.S.A.

LINE RATING

100-120VAC, 200-240VAC

50, 60 HZ 165VA MAX

LINE FUSE

SLOWBLOW

2.0A, 250V

IEEE-488

(ENTER IEEE ADDRESS

FROM FRONT PANEL MENU)

REMOTE

DISPLAY

OPTION

+++

___

SOURCE SENSE

SOURCE

OUTPUT #1

ISOLATION FROM EARTH: 22 VOLTS MAX MAX.

RELAY

CONTROL

24VDC MAX

DVM IN

-30 VDC MAX

ANALOG

OUT

mA

(5/50)A(0.5/5)

+++

____

+

SOURCE SENSE

DVM IN

SOURCE

OUTPUT #2

Figure 1-1

Model 2308 front panel

Figure 1-2

Model 2308 rear panel

NOTE The output from each channel is isolated from the other channel.

CAUTION Allow for adequate ventilation around the front and rear-panel openings to

prevent the unit from overheating which may degrade performance.

Make sure that the maximum combined channel output is not exceeded (see complete

Specifications at

sink. For output voltages exceeding 5 V, the maximum sink current is less than 3 A (derate the

maximum sink current 0.2 A for each volt over 5 V).

NOTE When using the power supply as a sink (negative polarity), the power supply is

1-4 Return to Section Topics 2308-900-01 Rev. A / July 2008

www.keithley.com). Also, do not exceed 3 A when using the power supply as a

dissipating rather than sourcing power (see

Sink operation).

Page 21

Model 2308 Portable Device Battery/Charger Simulator User’s Manual Section 1: Getting Started

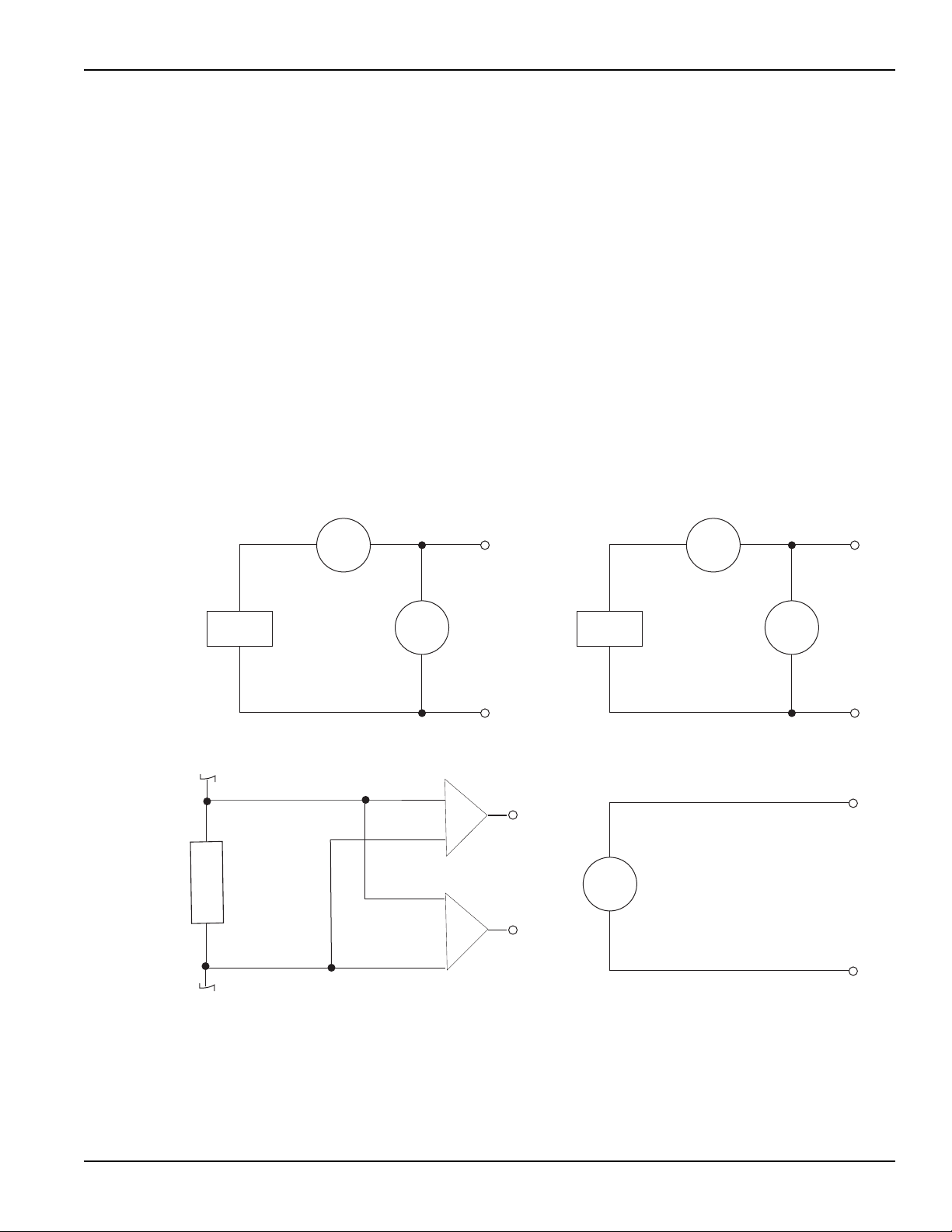

Battery Channel

(Channel #1)

Source

+

_

V-Source

with I-Limit

I meter

V meter

Charger Channel

(Channel #2)

Source

+

_

V-Source

with I-Limit

I meter

V meter

+

_

Digital

Voltmeter

DVM

Shunt

Current

Monitors

5/50mA

0.5/5A

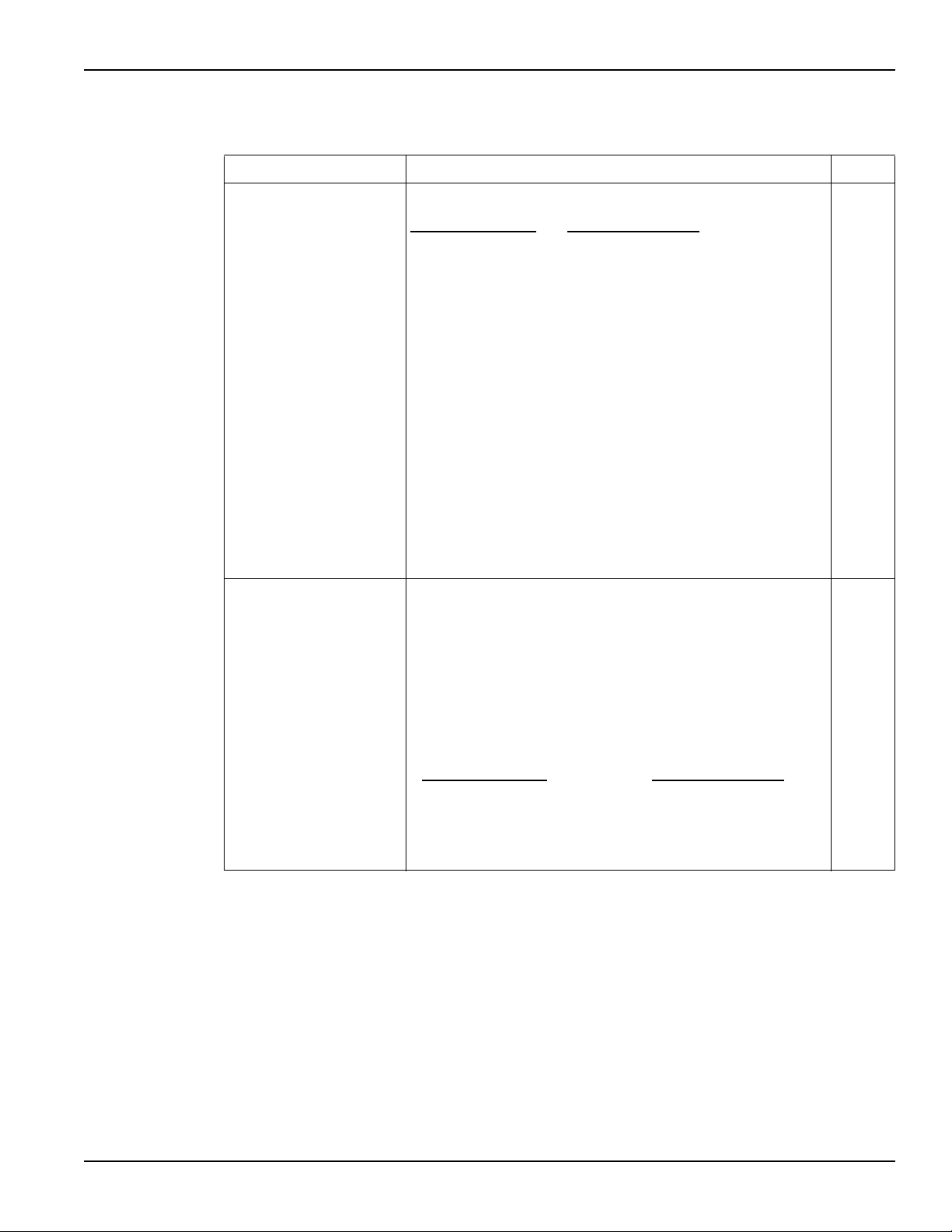

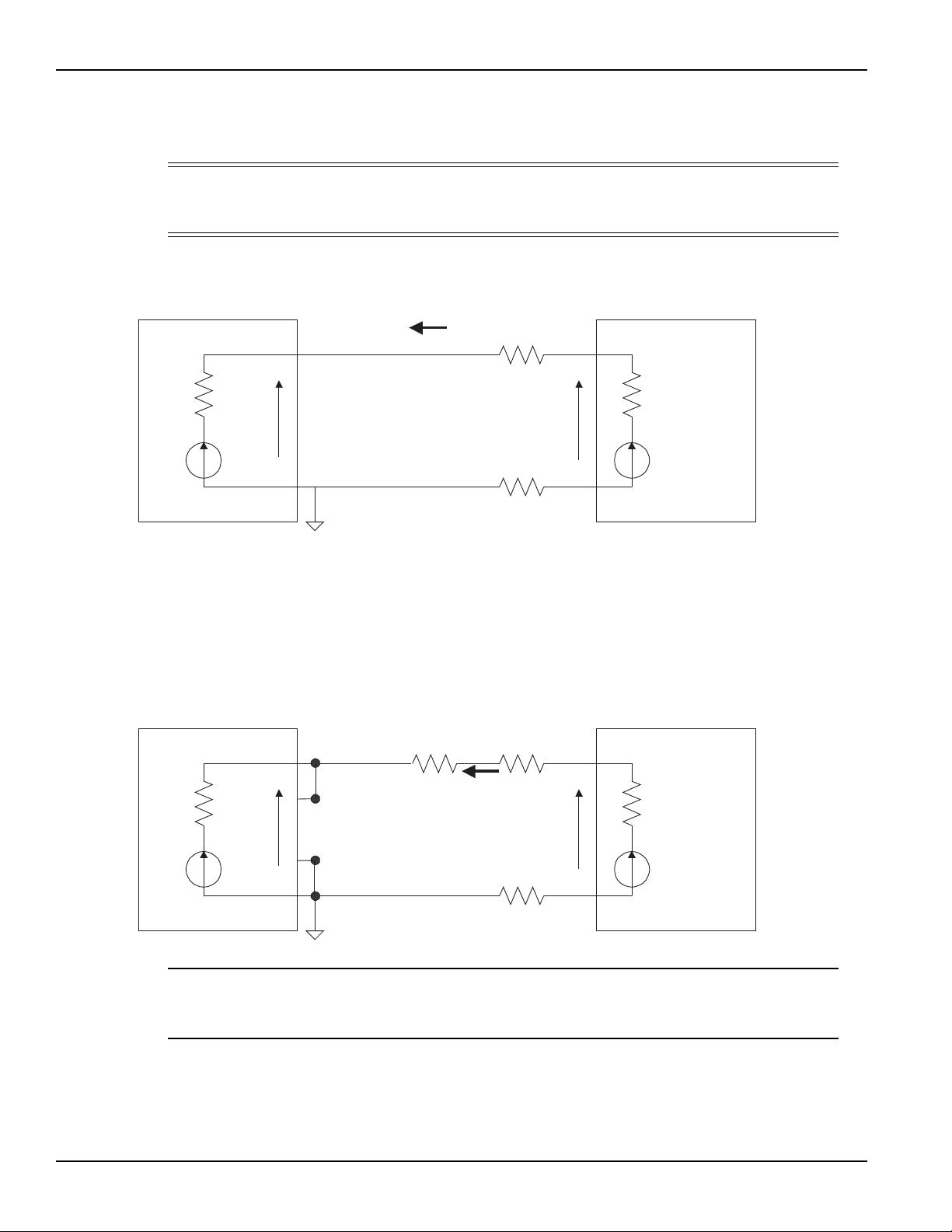

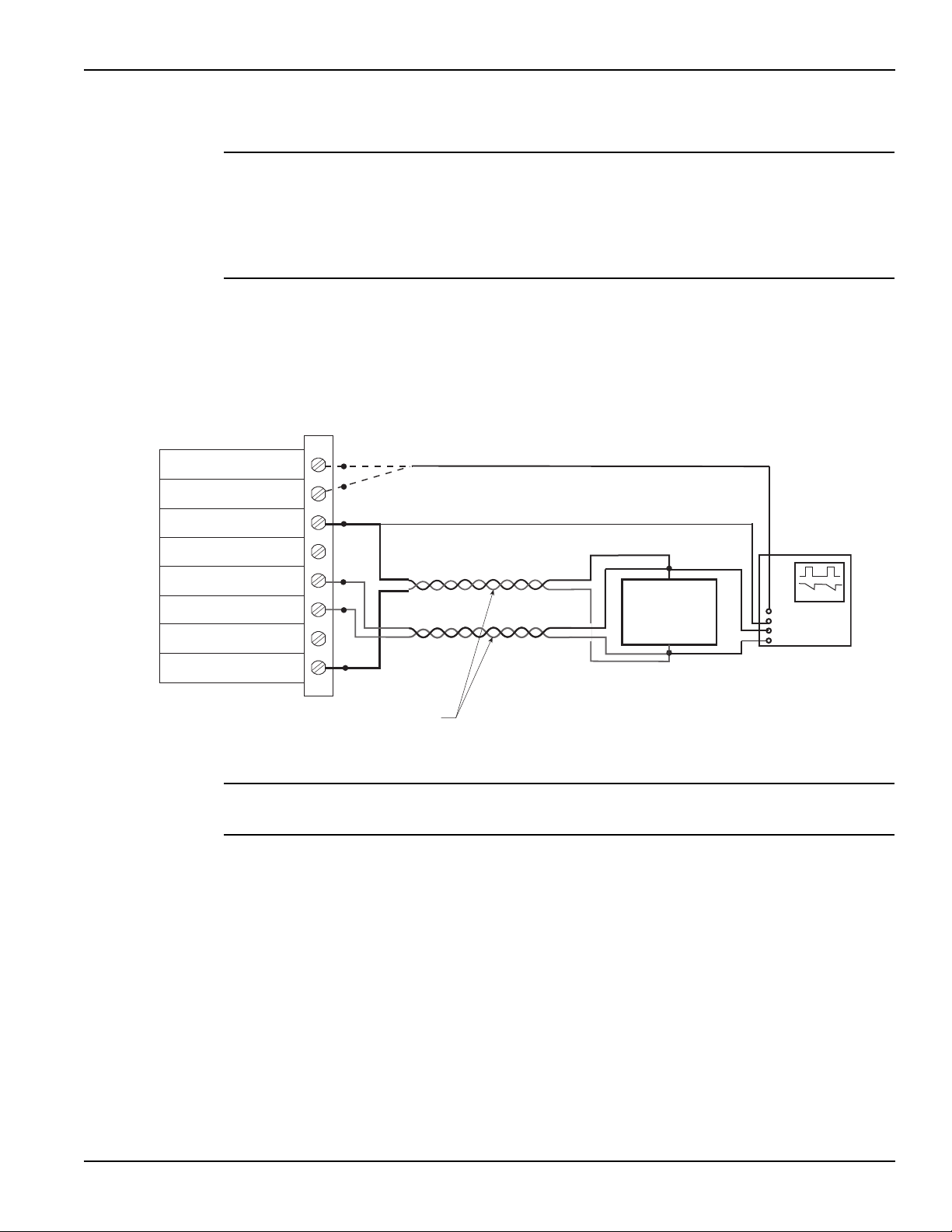

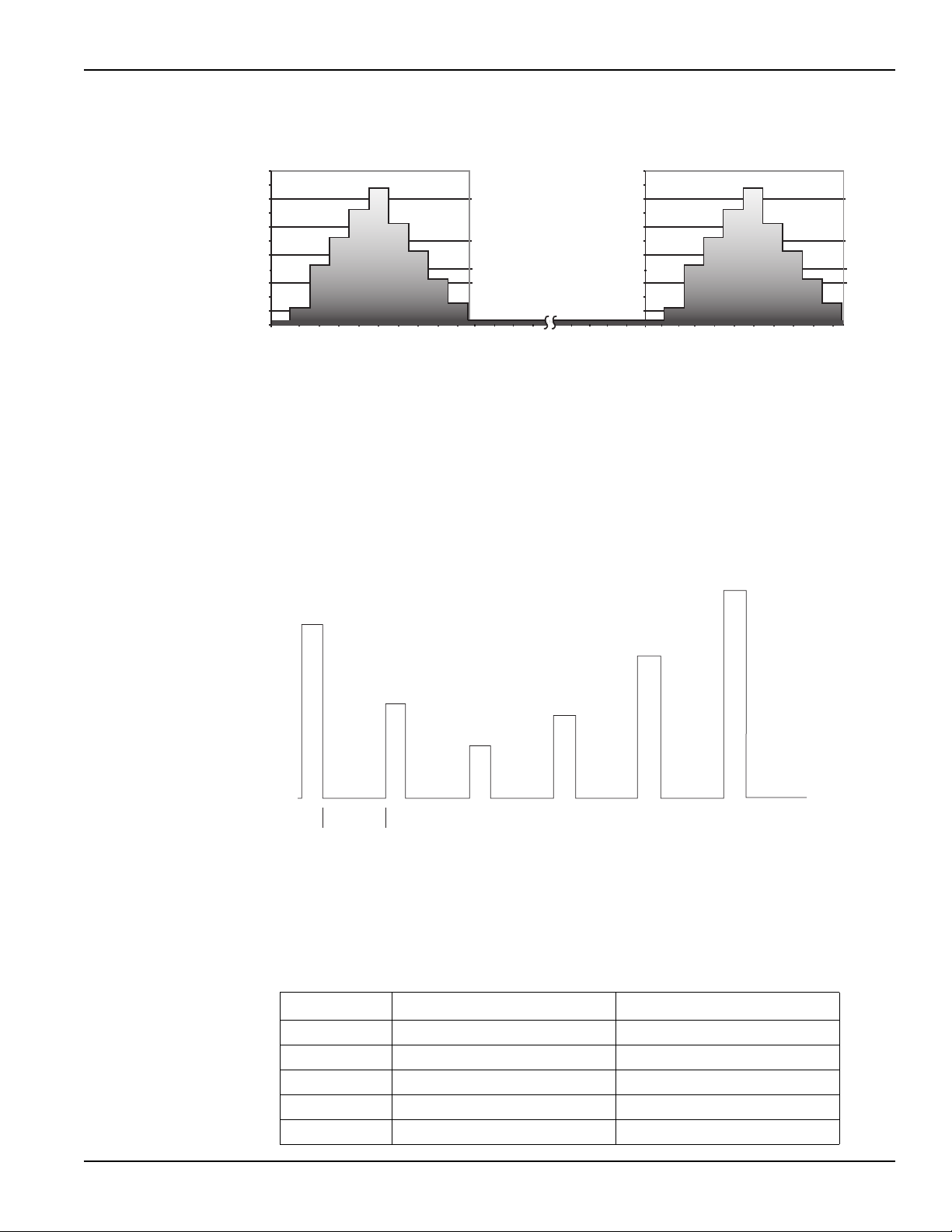

A simplified diagram of the power supply is shown in Figure 1-3. Note that it can read back the

output voltage (V

) and current (I

meter

). Display resolution for voltage readback is 1mV.

meter

The battery channel (#1) has four current ranges: 5 A, 500 mA, 50 mA and 5 mA. The charger has

5 A and 5 mA. The resolution on 5 A is 100 μA, and on 5 mA is 0.1 μA. The 500 mA is 10 μΑ and

50 mA is 1μΑ.

The power supply also has a digital voltmeter (DVM - on the charger channel only) that is

independent of the power supply circuit. The DVM can measure up to +30 V (1 mV resolution).

The power supply has analog output pins that allow acquisition of the load current waveform for indepth analysis on the battery channel only (see

Analog output for more information).

When used with a pulsed load, the power supply can read back peak current, idle current, and

average current (see

Section 3 for details). A long integration (up to 60 seconds) function is

provided to measure average current of a low frequency pulse (long period) or a series of pulses

(see

Section 4 for details).

Figure 1-3

Simplified power supply diagram

Remote display option

If you are mounting the power supply in a location where the display cannot be seen or the

controls are not easily accessible, use this option (see

Figure 1-4). This remote display module

2308-900-01 Rev. A / July 2008 Return to Section Topics 1-5

Page 22

Section 1: Getting Started Model 2308 Portable Device Battery/Charger Simulator User’s Manual

ET

A

R

EP

O

R

E

TNE

T

E

S

Y

AL

P

SID

U

N

EM

LACOL

YALPS

I

D

E

TOMER

PSID-603

2

includes all front-panel instrument controls/features (with the exception of power). All features and

menus work as described for the Model 2308. A 9-foot cable attaches the remote display to the

rear-panel of the power supply, allowing the unit to be operated remotely.

Figure 1-4

Model 2306-DISP Remote display option

Plug the remote display module into the rear-panel connector labeled REMOTE DISPLAY

OPTION (see rear panel in

Figure 1-2). When plugged in, the main display module is disabled with

the following message displayed:

REMOTE PANEL

ENABLED

When the remote display module is unplugged, control returns to the main display module.

NOTE When using the remote display, VFD BRIGHTNESS may not appear in the main

menu (dependent on the firmware revision in the unit).

When connecting or disconnecting the remote display, allow a few seconds for

the power supply to recognize the action. Fast, repeated connects/disconnects

of the remote display may cause the power supply to hang or appear to hang.

Disconnecting the remote display and waiting a few seconds to reconnect it may

clear the problem. If not, cycling power on the power supply clears the condition.

1-6 Return to Section Topics 2308-900-01 Rev. A / July 2008

Page 23

Model 2308 Portable Device Battery/Charger Simulator User’s Manual Section 1: Getting Started

Power-up

Line power connection

The power supply operates from a line voltage in the range of 100-120VAC/200-240VAC at a

frequency of 50 or 60 Hz, 165 V AC. Line voltage and frequency are automatically sensed,

therefore there are no switches to set. Check to see that the line power in your area is compatible.

Use the

NOTE See complete Specifications at www.keithley.com for the operating environment

Perform the following steps to connect the power supply to the line power and turn it on:

WARNING The power cord supplied with the Model 2308 contains a separate ground

:SYSTem::LFRequency? query (see Section 10) to read the line frequency.

requirements of the equipment before power-up.

for use with grounded outlets. When proper connections are made,

instrument chassis is connected to power line ground through the ground

wire in the power cord. Failure to use a grounded outlet may result in

personal injury or death due to electric shock.

1. Before plugging in the power cord, make sure the front-panel power switch is in the off (0)

position.

2. Connect the female end of the supplied power cord to the AC receptacle on the rear panel.

3. Turn on the power supply by pressing the front-panel power switch to the on (1) position.

Power-up sequence

On power-up, the power supply performs self-tests on its RAM and EPROM. After a blinking cursor

appears on line one, RAM tests are completed. After a blinking cursor appears on line two,

EPROM self tests are completed.

NOTE If a problem develops while the instrument is under warranty, return it to Keithley

Instruments for repair.

If the instrument passes the self tests, the following information is briefly

displayed:

• Top Line - The model number and the IEEE-488 address are displayed

(The factory default GPIB address is 16).

• Bottom Line - Firmware revision levels are displayed for the main board

and the display board. Also displayed is the detected line frequency.

After displaying the above information, any errors that occurred during the startup sequence will be

displayed. Then, the instrument goes to the default settings (*RST) or saved power-up settings

(SAV0-3) with the output off (see

over the bus using the :SYST:ERR? command (see Error queue).

Default settings). Any missed error messages may be viewed

2308-900-01 Rev. A / July 2008 Return to Section Topics 1-7

Page 24

Section 1: Getting Started Model 2308 Portable Device Battery/Charger Simulator User’s Manual

LINE RATING

100-120VAC, 200-240VAC

50, 60 HZ 165VA MAX

LINE FUSE

SLOWBLOW

2.0A, 250V

REMOTE

DISPLAY

OPTION

DVM IN

-30 VDC MAX

+++

____

+

SOURCE SENSE

DVM IN

SOURCE

OUTPUT #2

Fuse drawer

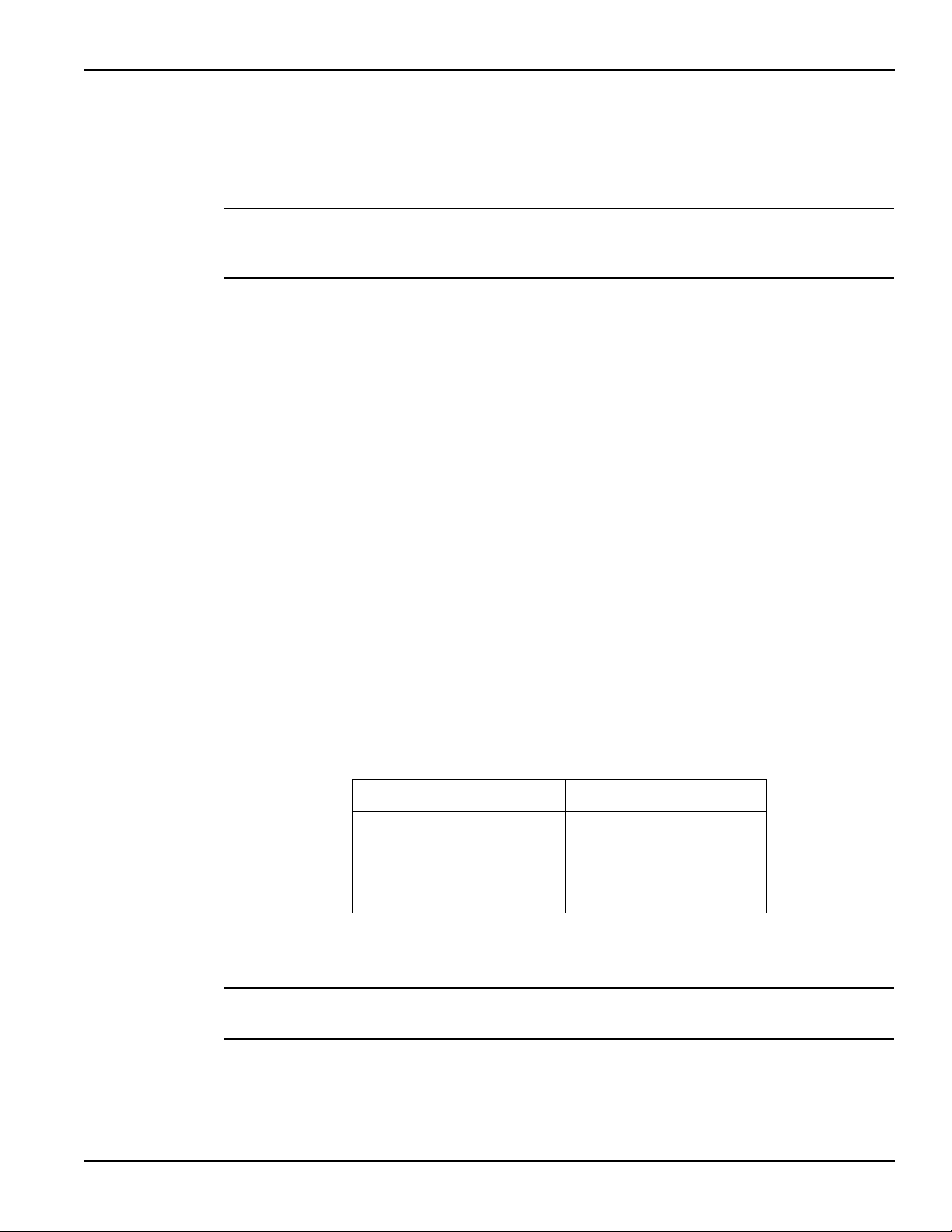

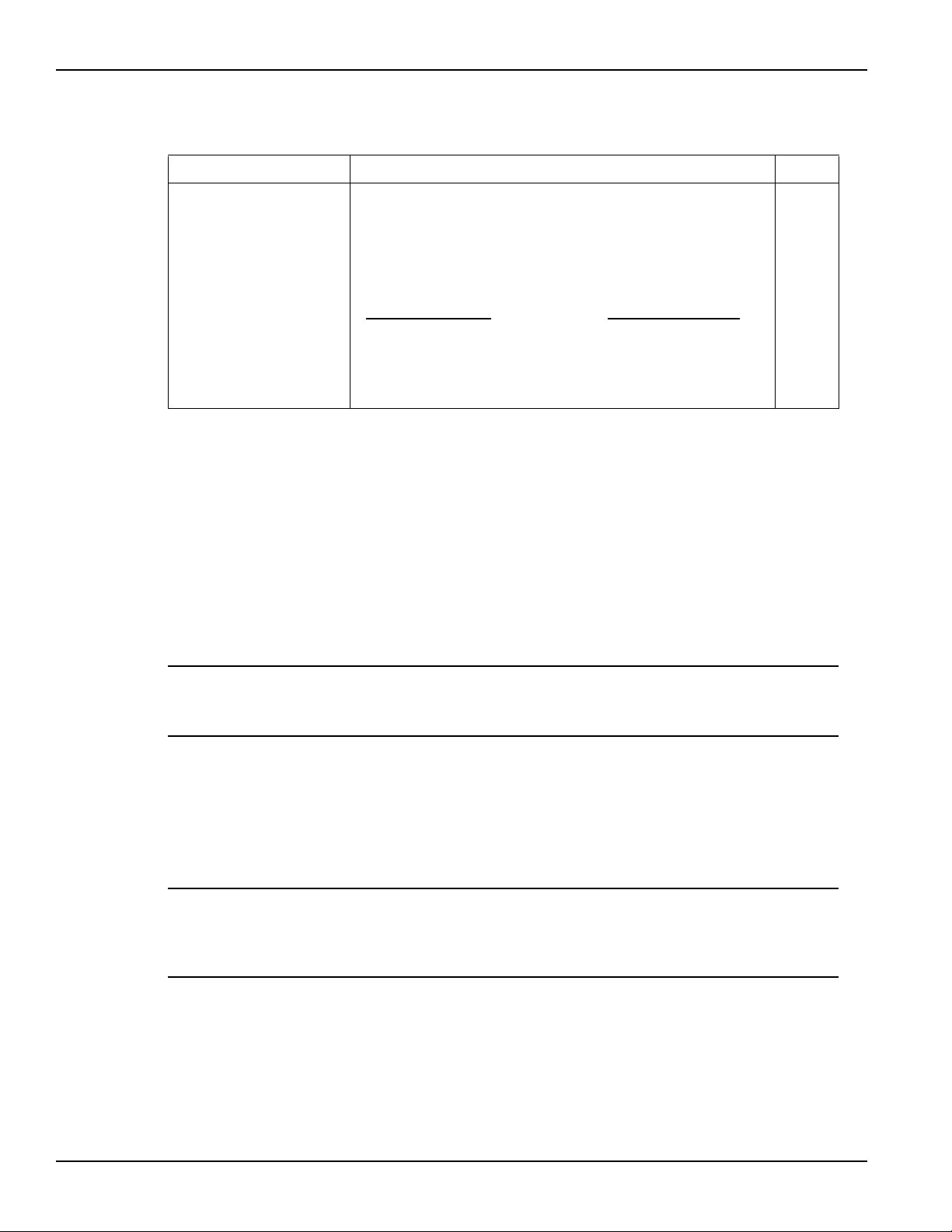

Fuse replacement

A rear-panel fuse protects the power line input of the power supply.

To replace the line fuse:

1. Power off the unit and remove line cord.

2. The fuse drawer is located on the left side of the AC receptacle (see Figure 1-5). On the

right side of the fuse drawer is a small tab. At this location, use a screwdriver to pry the fuse

drawer open.

3. Slide the fuse drawer out to gain access to the fuse. Note that the fuse drawer does not pull

all the way out of the power module.

4. Snap the fuse out of the drawer and replace it with the same type (250 V, 2.0 A, 5 × 20 mm

time lag). The Keithley Instruments part number is FU-81.

CAUTION For continued protection against fire or instrument damage, only replace the

fuse with the type and rating listed. If the instrument repeatedly blows fuses,

locate and correct the cause of the problem before replacing the fuse.

5. Push the fuse drawer back into the power module.

Display modes

1-8 Return to Section Topics 2308-900-01 Rev. A / July 2008

Figure 1-5

Fuse drawer location

For voltage and current readings, there are five display modes described as follows:

• SINGLE V AND I DISPLAY - This display mode is used to read back the actual output

voltage and current on a single channel. The active channel dictates if the single channel

being displayed is for the battery or charger channel. This display mode is the RST default

(see

Section 2 for details).

• DUAL V AND I DISPLAY - This display mode is used to read back the actual output voltage

and current for both channels simultaneously. The top display line shows the voltage and

current readings for the battery channel while the bottom line shows the charger channel

Page 25

Model 2308 Portable Device Battery/Charger Simulator User’s Manual Section 1: Getting Started

▲

▲

readings. The # symbol indicates the active channel (see Section 2 for details). For both

channels, the output state is indicated by:

• 0 (zero) if the output is OFF for that channel.

• l (lowercase L) if the output is ON for that channel..

NOTE With DUAL V AND I DISPLAY mode enabled, there is no indicator on the front

panel about voltage protection or current limit state. See

Section 2 for more

information on voltage protection and current limit.

• PULSE CURRENT - This mode is used to display high, low, or average pulse-current

measurements (see

Section 3 for details)

• LONG INTEGRATION - This mode is used to display average current measurements of a

pulse or pulses measuring periods between 850 msec to 60 sec (60 Hz line frequency) and

840 msec to 60 sec (50 Hz line frequency) (see

Section 4 for details).

• DVM INPUT (charger channel only) - This mode is used to display the DC voltage applied to

the DVM input of the power supply (see

Section 2 for details).

Use the SAVE SETUP item of the MENU to save the selected display mode in memory, and use

the POWER ON SETUP item to specify the power-on setup (

Setups - Save, Power-on, and Recall

for details). The Dual V and I display cannot be saved. A reset will not change this setting.

Recalling a setup may change the setting. If setup recalling has a channel function set to

something other than voltage or current then this setting is disabled otherwise the setting is left

unchanged.

Selecting (enabling) Dual V and I will switch the function to voltage for each channel unless the

function is already voltage or current. Dual V and I will be disabled if you change the display mode

on either channel to be Pulse Current, Long Integration, or DVM Input (Channel #2 only).

To select a display mode:

1. Press the DISPLAY key.

2. Press the

▲ or ▼ keys to scroll to the desired display mode.

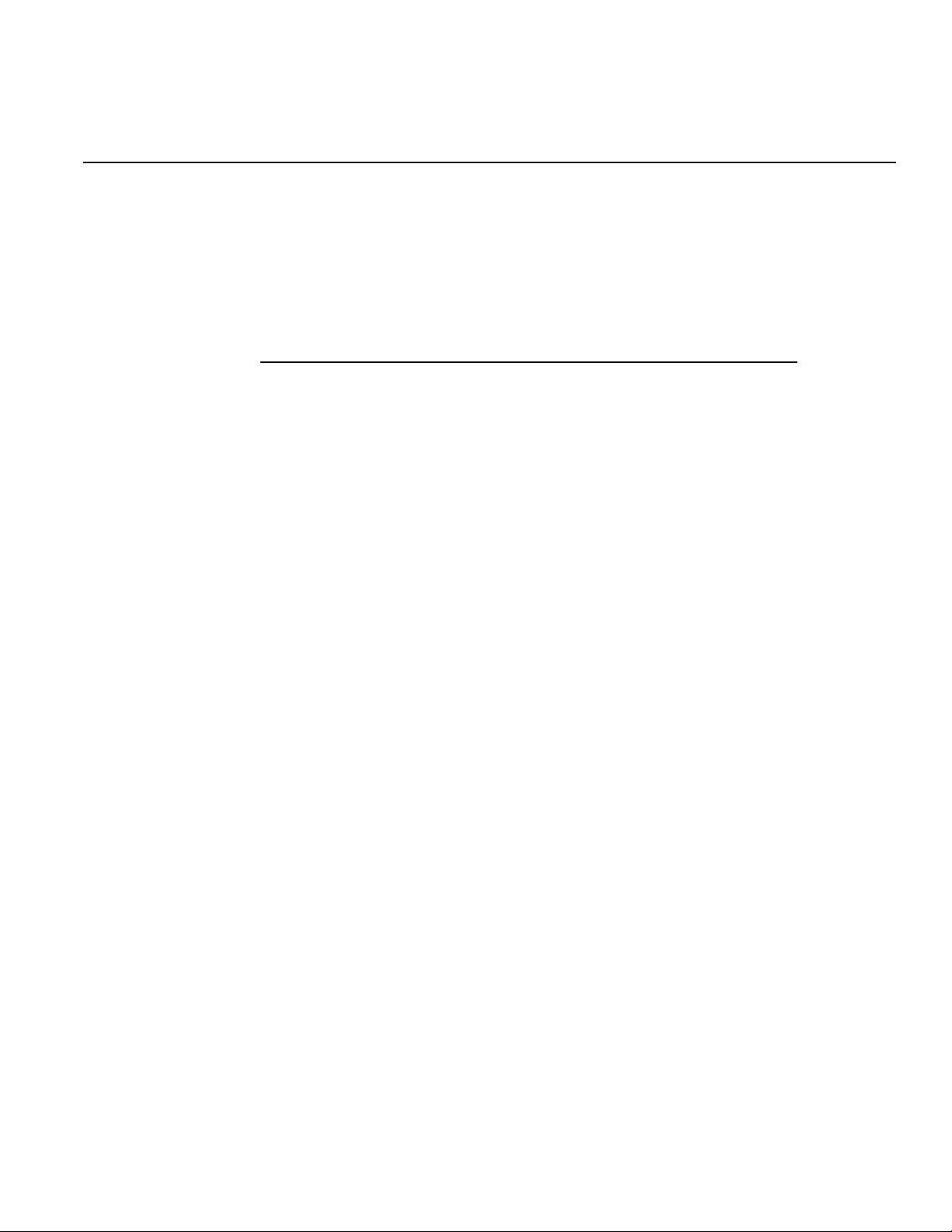

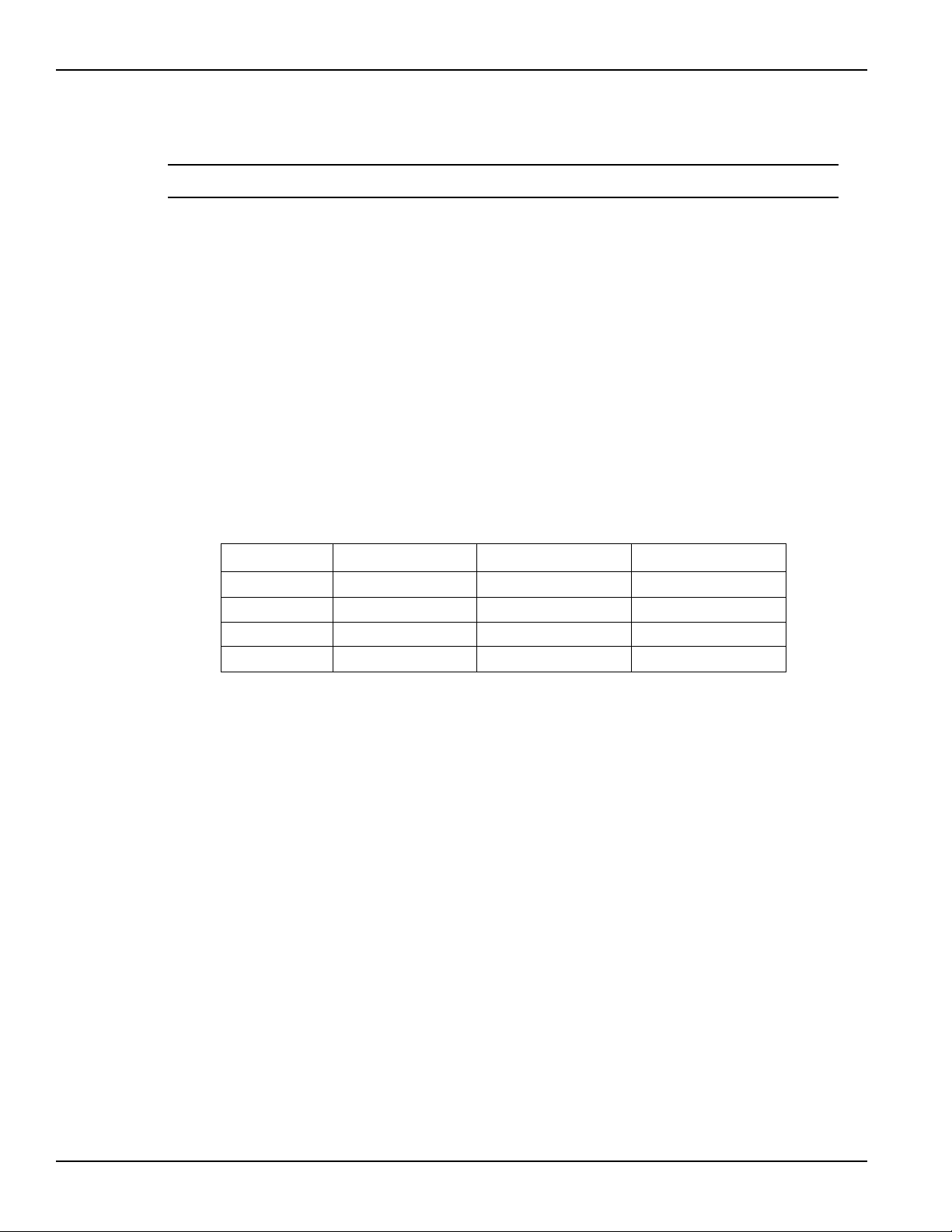

Table 1-1

Display Modes

Battery channel (#1) Charger channel (#2)

• SINGLE V AND I

• DUAL V AND I

• LONG INTEGRATION

• PULSE CURRENT

3. Press the

NOTE Switching back to the original active channel will display the initial setting for that

or keys to select Channel #1 or #2.

channel.

• SINGLE V AND I

• DUAL V AND I

• LONG INTEGRATION

• PULSE CURRENT

• DVM INPUT

4. With the desired mode and active channel displayed, press ENTER.

2308-900-01 Rev. A / July 2008 Return to Section Topics 1-9

Page 26

Section 1: Getting Started Model 2308 Portable Device Battery/Charger Simulator User’s Manual

Examples of the display modes are shown in Table 1-2.

NOTE To select PULSE CURRENT high (HI), low (LO) or average (AVG) readings,

use the

▲ or ▼ keys to select the desired pulse measurement after selecting

pulse current as the display mode.

Table 1-2

Display mode examples

Samples for battery

Display mode

SINGLE V AND I: 6.116V #1 ON 6.116 V #2 ON Section 2

DUAL V AND I: 2.97V 25.7m 1# 2.97V 25.7m 1

DVM input: N/A

Pulse current: PULSE HI #1 ON PULSE HI #2 ON Section 3

Long integration: LONG INT #1 ON LONG INT #2 ON Section 4

channel (#1)

1.2058 A 1.2058 A

0.00V 0.00A 0 1.00V 0.17A 1#

(charger channel only)

2.1947 A 2.1947 A

PULSE LO #1 ON PULSE LO #2 ON

0.2147 A 0.2147 A

PULSE AVG #1 ON PULSE AVG #2 ON

1.1495 A 1.1495 A

1.0236 A 1.0236 A

Samples for charger

channel (#2) Reference

Section 2

DVM INPUT #2 OFF

5.321 V

Section 2

NOTE #1 or #2 indicates the active channel. ON indicates that the output is turned on.

With the output turned off, OFF is displayed (see

Section 2 for details on

outputting current and voltage).

NO PULSE is displayed if the output is OFF or pulses are not detected (output

ON) for pulse current and long integration display modes only.

When a change is made that affects the readings being taken, dashes are

displayed instead of readings. The dashes remain until a valid reading for the

new condition is taken.

1-10 Return to Section Topics 2308-900-01 Rev. A / July 2008

Page 27

Model 2308 Portable Device Battery/Charger Simulator User’s Manual Section 1: Getting Started

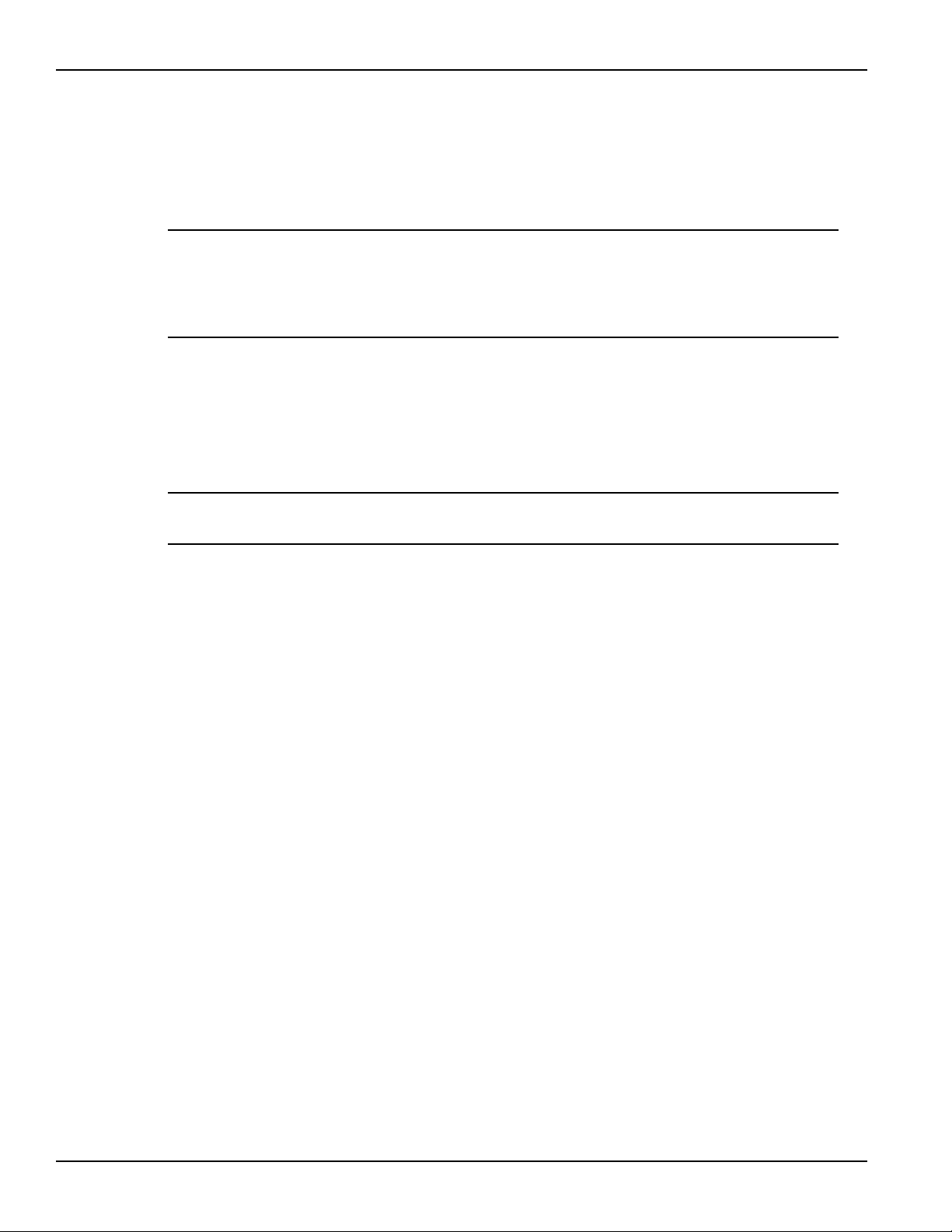

Default settings

The power supply can be set to power-on with the factory default conditions (RST defaults) or to

one of four user-saved setup conditions (SAV0 to SAV3). The factory default conditions are listed

in

Table 1-3.

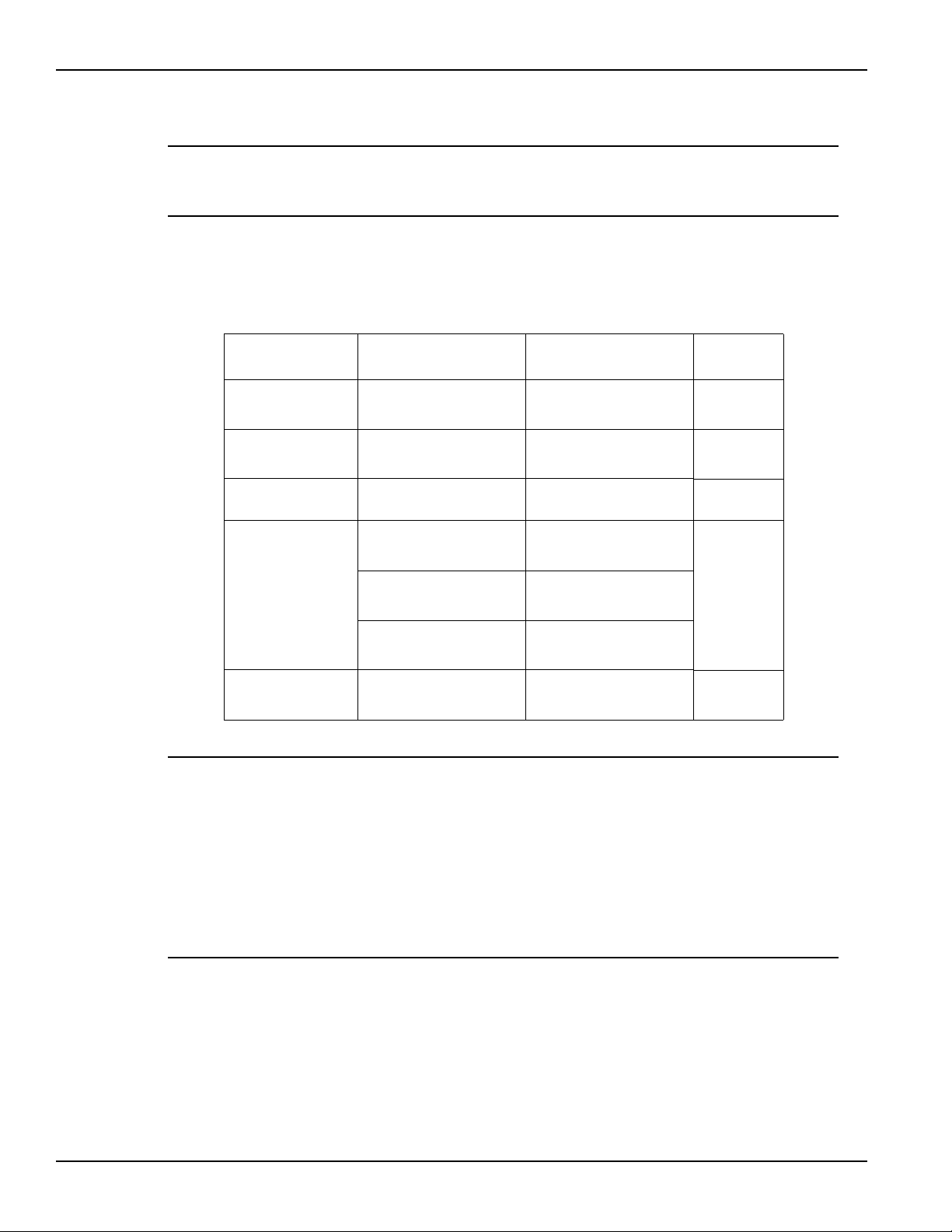

Table 1-3

Factory defaults (RST)

Reset (RST) default

Setting Battery channel (#1) Charger channel (#2)

Output value

settings:

Voltage (V) 0.000V 0.000V

Current (A) 0.2500A 0.2500A

Output state

(operate)

Voltage protection 8 V, clamp off 8 V, clamp off

Display type Single V and I Single V and I

GPIB address* No effect (factory set to 16)

Current range 5 A (Auto Range OFF) 5 A (Auto Range OFF)

Integration rate 1.00 PLC 1.00 PLC

Average readings 1 1

Power on setup* No effect (factory set to RST)

Current limit mode LIM LIM

Auto Zero State ON (applies to both channels)

Output relay one*

Output relay two*

Output relay three*

Output relay four*

VFD brightness*

Output bandwidth LOW LOW

Output impedance 0.00 Ω Not Applicable

Pulse current:

High time 33 µsec 33 µsec

Low time 33 µsec 33 µsec

Average time 33 µsec 33 µsec

Digitize time 33 µsec 33 µsec

Timeout 1.000 sec 1.000 sec

Average readings 1 1

Trigger delay 0.00000 sec 0.00000 sec

Trigger level: 0 0

Step Off

Step Initial 2 sec

Step Sequence 0

Step Length 0

Step Skip 0

Step up 1

Step down 1

Step time 200µs

Step timeout 2ms

Step delay 0

Long integration:

Integration time 1 second 1 second

**Global settings (not channel-specific).

OFF OFF

No effect (after power

cycle, set to zero)

Over bus: 1 From display: FULL BRIGHTNESS

2308-900-01 Rev. A / July 2008 Return to Section Topics 1-11

Page 28

Section 1: Getting Started Model 2308 Portable Device Battery/Charger Simulator User’s Manual

Table 1-3

Factory defaults (RST)

Reset (RST) default

Setting Battery channel (#1) Charger channel (#2)

Pulse timeout 16 seconds 16 seconds

Trigger edge RISING RISING

Trigger level Same as “Trigger level” under Pulse Current

(above)

**Global settings (not channel-specific).

Same as “Trigger level” under

Pulse Current (above)

Setups - Save, Power-on, and Recall

Setups are configured by SAVE SETUP, POWER ON SETUP and RECALL SETUP items of the

MENU (which is accessed by pressing the MENU key). When a setup is saved, all settings that are

channel-specific settings will be saved to that setup. Saving/recalling a setup has no effect on

Global Settings (see Global settings in

channel-specific parameters from that setup.

NOTE Table 1-4 shows the menu structure. Rules to navigate the menu follow the

table.

Table 1-3). Similarly, recalling a setup loads only the

Menu

The setup MENU items are explained as follows:

• SAVE SETUP - Save the present power supply setup to a memory location;

SAV0-SAV3.

• RECALL SETUP - Return the power supply to the RST defaults (Table 1-3), or to one of

four user-saved setups; RST, SAV0-SAV3.

• POWER-ON SETUP - Select the setup to use at power-up; RST, SAV0-SAV3.

When powering up or recalling the SAV0, SAV1, SAV2, or SAV3 setup, the output will be OFF

regardless of the operate state when the setup was saved. For example, if the output is ON when