Page 1

Instruction Manual

Model 193

System DMM

01985, Keithley Instruments, Inc.

Instrument Division

Cleveland, Ohio, U.S.A.

Document Number 193-901-01

Page 2

Page 3

SAFETY PRECAUTIONS

The following safety precautions should be observed before operating the Model ‘I93

This instrument is intended for use by qualified personnel who recognize shock hazards ,Ind arc f~u~~ili.~t

with the safety precautions required to avoid possible injury. Read over the manual carefully bei~rc upcrating

this instrumen(.

Exercise extreme caution when a shock hazard is present at the instrument’s input. The American Nati,,nal

Standards Institute (ANSI) states that a shock hazards exists when voltage levels greater than XlV rms 01

42.4V peak are present. A good safety practice is to expect that a hazardous voltage is present in any unknown

circuit before measuring.

Inspect the test lends for possible wear, cracks or breaks before each use. If any defects are fl,und, wplxe

with test leads that have the same measure of safety as those supplied with the instrument.

For optimum safety do not touch the test leads or the instrument while power is applied to the circuit under

test. Turn the power off and discharge all capacitors, bcforc connecting or disconnecting the instrunwnt.

Always disconnect all unused test leads from the instrument.

Do not touch any object which could provide a current path to the common side of the circuit under test

or power line (earth) ground. Always make measurements with dry hands while standing on a dry, ill-

s&ted surface, capable of withstanding the voltage being measured.

Exercise extreme safety when testing high energy power circuits (AC line or mains, ctc). Refer tu the fligh

Energy Circuit Safety Precautions found in paragraph 2.6 (Basic Measurements).

Do not exceed the instrument’s maximum allowable input as defined in the specifications and operation

section.

Page 4

Page 5

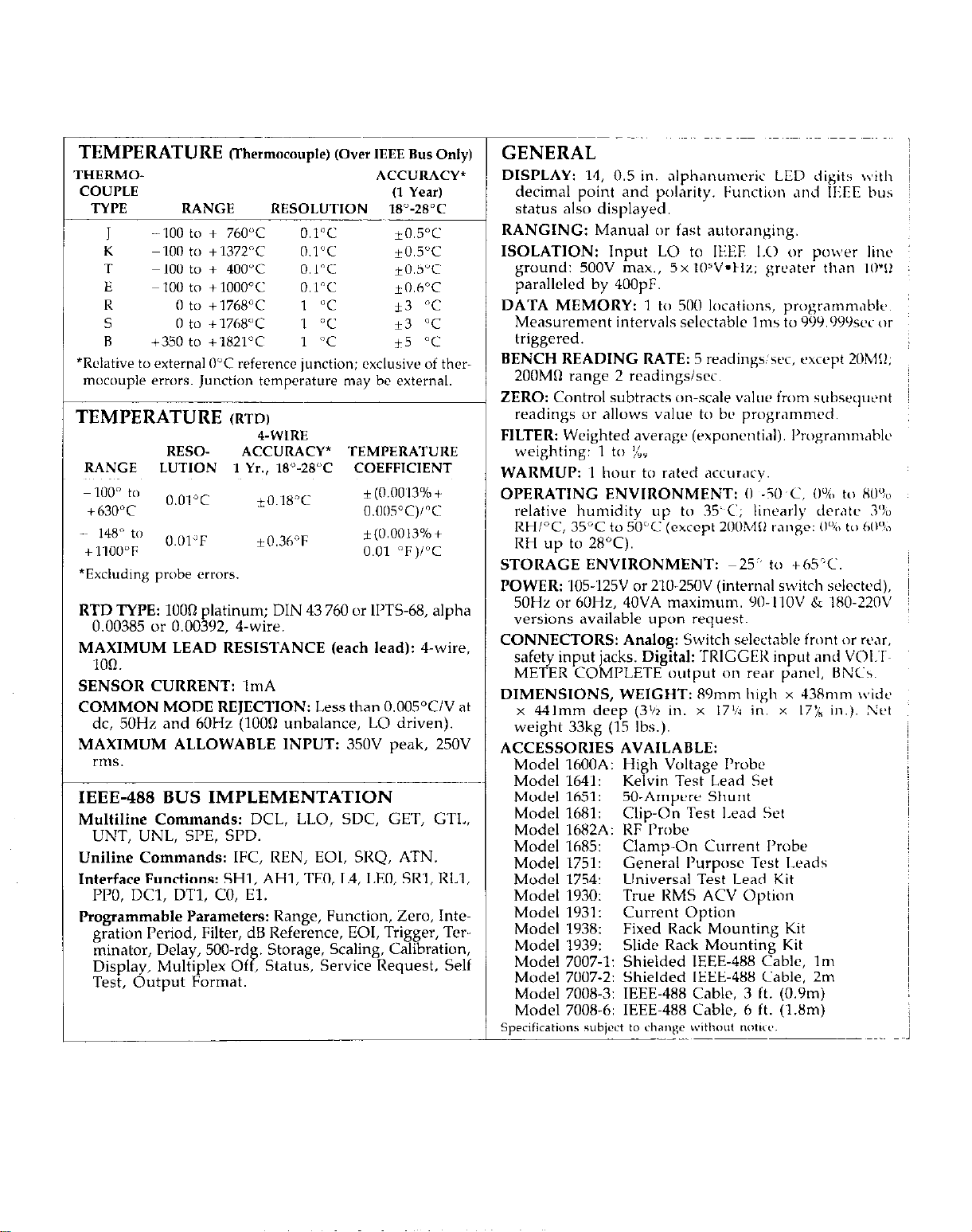

SPECIFICATIONS

1 DC VOLTS

MAXIMUM

READING RESO: ~~~ -

RANGE (5% Digits)

2 V 2:lY999 V ‘I pv ‘IO ,v >~IGO 0.002 + 1 O.UO5 + 2

20 v 2~1.9999 v

200 V 219.999 V ~100 @V ~ImV IOMR

1000 v 1000.00 v ~IlTlV ~lOl”V ~IOMR 0.004+ I 0.007+ I

*When properly zerued. **Multiply digit error by IO for h’i%digit accur~y.

NMRR: Crcater than 60dB at 50 or 60Hz.

CMRR: Greater than 120dB at dc and 50 or 60Hr

(with IkO in either lead).

MAXIMUM ALLOWABLE INPUT: ~IOOOV peak.

L”‘rI”N

6% 5% RESISTANCE 23°*10C 23:’ * 5°C 23”*5’;C 0”-18°C & 28 ‘-50 ‘C TIME”’

~10 pv ~100 pv 1OMR 0.003 + 1 0.007-1- ~1 0.009 + 3 0.0007+~,1, I < Ims

INPUT 24 Hr., 90 Days,

ACCURACY (5% Digits)**

+ (%rdg + counts)

L

0.005+2

0.003+ I

0.007+ I

MAXIMUM MEASUREMENT RATES (into internal

memory, filter and multiplex off):

3% Digit 4% Digit

1000 rdg:s 333 “dg; s 25 rdg,*

AC VOLTS (Option 1930)

MAXIMUM

READING

(5% Digits)

2v 2.1Y999V ‘I ,rV

2uv 2~1.9Y99V 10 pv I 00 ,rV

2OOV 2’19.999V ~lnn pv ImV

701lV 700.00 v ‘IlllV

*Above 2000 counts. **

Abow 2OOOt1 counts; 3%+500 lypicd b&w 2OOl10. “*Multiply digit crrlw 13~ Ill fur O’~di~it .xcur.x\

RESOLUTION

6% 5’,>

IO pv ~1 + 100 0.21 + IUU

I ~+ 1nu 0.25+ IUU l1~3i+300

~I + Ino 11.25 + ~IOU ,I.35 + 301,

IOmV 1 + ‘100 0.35+ 100 o., +3un

1 Yr.,

11.008+2’ o.onu3 in I

0.007 + 2

0.009 + 3 t1.ot107 4~ 0. I < 1111’

1).1109+5 t1.0007 +03 c 1111’

***To O.Ol’%> ot step chdng~

ACCURACY (5’:~ Digits)‘*’

I (%rdg ~+ counts,

50Hz-IOkHz’

0.35 +.m, I . SUli

TEMPERATURE

COEFFICIENT ANALOG

i (%rdg + counts), TIC SETTLING

< ?,,I> 200mV 219.99YmV IO0 nV 1 uV >lGG 0.003 + 2

o.ono3i~I1. I < I”,5

5’h Digit

6’h Digit

2.5 rds 5

I +~ i,ll,

I + ml

I i .iou

RESPONSE: True root mean square, ac or ac + dc.

CREST FACTOR: Rated accuracy to 3. Specified fat

pulse widths >lOPs, peak voltage 51.36 x full scale.

AC+DC: Add 60 counts to specified accuracy.

MAXIMUM INPUT: ‘IOOOV peak ac+dc, 2x’107V*Hz.

SETTLING TIME: 0.5s to within (1.~1% uf change in

reading.

INPUT IMPEDANCE: 1MIl shunted by less than 120pF.

TEMPERATURE COEFFICIENT CO”-18°C & 28”-50°C):

ILess than +(O.lxapplicable accuracy spccification)i”C

below 50kHz; (0.2x) for 5OkHz to 100kHz. ‘Typical

ACCURACY (1 Year)

(3% Digits)

e P/ad8 + counts)

RESOLUTION

..-

18”-28°C

2+3

2+3

2+3

2+3

21~3

3dB BANDWIDTH: .i00kl I% typic,d

CMRR: C;realer than htldll at 50 ,~nd hOtI/ (Ikl! ,,w

b&IlC~).

dBV (Ref. = 1V): ACCURACY idRV

44 tii t.i7dBV

(20llmV ti, 7OtiV rms) 0.2 (I,4

-34 to 14dBV

(2OmV tc 21UlmV)

RESPONSE: True rout mean squaw, ac -+ dc.

BANDWIDTH: 0.1 to 1011~.

1 Year, 18 -28 c

INPUT ZOHz-20kHz ZOkHz-lOOklIz RESOLUTION

Il.llldB\’

I.5

7’

0 lll‘lil\’

Page 6

OHMS

MAXIMUM

READING

RANGE

200 0

2 kO

20 k0

200 kl2

2MQ

2OMSl

200Mn

*When properly zeroed. **Nominal short circuit current.

***4-terminal accuracy 200R-20k range. Multiply digit error by 10 for 6%d accuracy

(5% Digits)

219.999 12

2.1Y99Y kl2

21.9999 kn

219.999 kR

2.19999MII

21.9999Mn

219.999M12

RESOLUTION

6% 5%

100 $2 lm0

lmll ~IOmR

1Omfl 1OOmn

~loomn 1 0

1 n 10 n

10 n 100 n

100 R 1 kn

CURRENT

THROUGH

UNKNOWN

‘ImA

ImA

100 PA

10 PA

1 PA

100 nA

100 n/t**

ACCURACY (5’h Digits)***

+ (%rdg + counts)

24 Hr., 90 Days, 1 Yr.,

23°+10c

0.0035+2* 0.007+2* 0.010+2*

0.0035+2 0.007+2 0.0’10+2

0.0035 + 2 0.007+2 0.010+2

u.o035+2

0.005 +2 0.010+2 0.010+2

0.040 +2 0.070+2 0.070+2

3.2 +2 3.2 +2 3.2 +2

23’+ 5°C

0.007+2 0.010+2

23”tST

TEMPERATURE

COEFFICIENT

*(%rdg+counts)l”C

O”lE°C & 28’-50°C

0.00’1 +0.7

0.001+0.1

0.001+11:1

0.001+0:1

0.001+0.1

0.010+0:1

0.230 + 0. ~1

CONFIGURATION: Automatic 2- or 4-terminal.

MAXIMUM ALLOWABLE INPUT: 350V peak or

250V rms.

DC AMPS (Option 1931)

ACCURACY

(5% Digits) TEMPERATURE

RESO-

LUTION *(%rdg+counts) #adg+counts)i”C

RANGE (5% Digits) 18~28°C

200 @A 1nA 0.09+10 0.01+0.5

2mA 1OnA 0.09+10 0.01+0.5

20mA IOOnA

200mA

2 A 1OpA

IpA

(1 Year)

0.09+10

0.09+10 O.Ol+ 0.5

0.09+ 10 0.01+0.5

COEFFICIENT

O’Q”C & 28c50T

0.0110.5

TRMS AC AMPS (Options 1930 and 1931)

ACCURACY*

45Hz to 1OkHz

(5% Digits)

RESO-

LUTION +Phrdg+counts) +(%rdg+counts)i”C

RANGE (5% Digits) 18%28T 00-18”C & 280-5OT

200 pA

2mA 1OnA 0.6+300 0.04+10

2OmA lOOnA 0.6+300 0.04 + 10

200mA

2 A IOpA 0.6+300

i *Above 2000 camts.

1nA

W

(1 Year)

0.6+300

0.6+300 0.04+10

TEMPERATURE

COEFFICIENT

0.04+10

0.04+10

MAXIMUM OPEN CIRCUIT VOLTAGE: - 7V.

OVERLOAD PROTECTION: 2A fuse (25OV), externally

accessible.

MAXIMUM VOLTAGE BURDEN: (1.25V on 2OOfiV

through 20mA ranges; 0.28V on 200mA range; 1V on

2A range.

RESPONSE: True root mean square, ac or ac + dc.

CREST FACTOR: Rated accuracy to 3. Specified for

pulse width > 1 ms, peak current 5 1.36 x full scale.

MAXIMUM VOLTAGE BURDEN: 0.25V on ZOO&V

through 2OmA ranges; 0.28V on 200mA range; 1V on

2A range.

OVERLOAD PROTECTION: 2A fuse (25OV), externally

accessible.

SETTLING TIME: 0.5s to within 0.1% of change in

reading.

dB (Ref. = ImA):

ACCURACY +dB

INPUT

-34 to +66dB

20pA to 2A

-54 to -34dB

2&A to 20fiA

1 Year, 18°-280c

45Hz-10kHr

0.3

2

RESOLUTION

O.OldB

O.OldB

Page 7

TEMPERATURE

THERMO-

COUPLE

TYPE RANGE

400 to + 760°C O.l”C

J

K

? -100 t” + 400°C

E

R

s 0 to + 1768°C

R +350 t” +1821”C 1 “C

*Relative to external 0°C reference junction; ~‘xcIusivc’ of ther-

mocouple errors. Junction temperature may be external.

ml to + 1372°C O.l”C +0.5”C

100 t” + 1ooov Kl”C

0 to +‘1768”C 1 “C +3 “C

TEMPERATURE

RESO-

RANGE LUTION 1 Yr., 18”-28°C COEFFICIENT

100” to

+630”C cl.llosT)/“c

-~ 148” to

+lloo”F 0.01 “F)PC

*Excluding probe errors.

RTD TYPE: 1000 platinum; DIN 43 760 or II’TS-68, alpha

0.00385 or 0.00392, 4.wire.

MAXIMUM LEAD RESISTANCE (each lead): 4-w&,

‘Ion.

SENSOR CURRENT: 1mA

COMMON MODE REJECTION: Less than 0.005”CIV at

dc, 50Hz and 60Hz (1000 unbalance, LO driven).

MAXIMUM ALLOWABLE INPUT: 350V peak, 250V

rms.

O.Ol”C *O.~l8”C

f..Ol”F

IThermocouple) (Over IEEE Bus Only)

ACCURACY’

(1 Year)

RESOLUTION 18”-28°C

*0.5”C

O.l”C YO.S”C

kO.hT

1 “C *3 “C

j5 “C

(RTD)

4-WIRE

ACCURACY* TEMPERATURE

*(fl.rm3%+

10.3h”F

~(0.0013%+

IEEE-488 BUS IMPLEMENTATION

Multiline Commands: DCL, LLO, SDC, GET, GTI.,

UNT, UNL, SPE, SPD.

Uniline Commands: IFC, REN, EOI, SRQ, ATN.

Interface Functions: SH1, AHl, TEO, L4, LEO, SRl, RLl,

PPO, DCl, DTl, CO, El.

kogrammable Parameters: Range, Function, Zero, Inte-

gration Period, Filter, dB Reference, EOI, Trigger, Tcrminator, Delay, 500.rd Storage, Scaling, Calibration,

Display, Multiplex Of, Status, Service Request, Self f

Test, Output Format.

GENERAL

DISPLAY: 14, 0.5.in. alphanumeric LED digits with

decimal point and polarity. Function and lf:EE bus

status also displayed.

RANGING: Manual or fast autoranging.

ISOLATION: Input LO to IEEE I.0 or power line

ground: 500V max., 5x l(l%‘*tlz; greater than IIPI!

paralleled by 400pF.

DATA MEMORY: ~1 to SO(l locations, pnrgr‘~r~~n~‘~hle.

Measurement intervals selcctablc ‘Ims to 999.999sec or

triggered.

BENCH READING RATE: 5 readings:wc, cuxpt 2Ohl!I;

200MR range 2 readingsisrc.

ZERO: Control subtracts w-scale valw from subseqwnt

readings or allows value to bc programmed.

FILTER: Weighted average (exponential). I’rogr.mm~~~hl~

weighting: 1 to li:.

WARMUP: ~1 hour to rated accur<rv.

OPERATING ENVIRONMENT: 0 -5iPC. (I%> to 80%

relative humidity up to 3PC; linearly dcr.lte 3%

RHPC. 35°C to 50°C (extent 2lIOM11 rr,nx: tl”,,, t,, 60%

RH up to 28°C). ’

STORAGE ENVIRONMENT: -25:’ to +hS’C.

POWER: ‘lO5-125V or ZlO-250V (internal switch selected),

50Hz or 60Hz, 40VA maximum 9(1-IlOV & 180.22OV

versions available upon request.

CONNECTORS: Analog: Switch s&ctabte front (>r rt’x,

safety input jacks. Digital: TRIGGEt< input and VOt.‘I~~

METER COMPLETE output on re.,r panel, HNCs.

DIMENSIONS, WEIGHT: 89mm high x 43Hmm wide

x 441mm deep (3’12 in. x 17’11 in, x l7:, in.). Net

weight 33kg (15 Ibs.).

ACCESSORIES AVAILABLE:

Model 160OA: High Voltage I’robc

Model 1641: Kelvin Test Lead Set

Model 1651:

Model 1681: Clip-On Test Lead Set

Model 1682A: RF Probe

Model 1685: Clamp-On Current Probe

Model 1751: Gener.71 I’urpw Test Leads

Model 1754: Universal Test Lead Kit

Model 1930: True RMS ACV Option

Model 1931: Current Option

Model 1938: Fixed Rack Mounting Kit

Model 1939: Slide Rack Mounting Kit

Model 7007-l: Shielded IEEE-488 Cable, lm

Model 7007-2: Shielded IEEE-488 Cable. 2m

Model 7008.3: IEEE-488 Cable, 3 ft. (0.9m)

Model 7008-6: IEEE-488 Cable, 6 ft. (l&m)

Specifications subject to change withut tnm~c,.

50.Ampere Shunt

,,

j

Page 8

Page 9

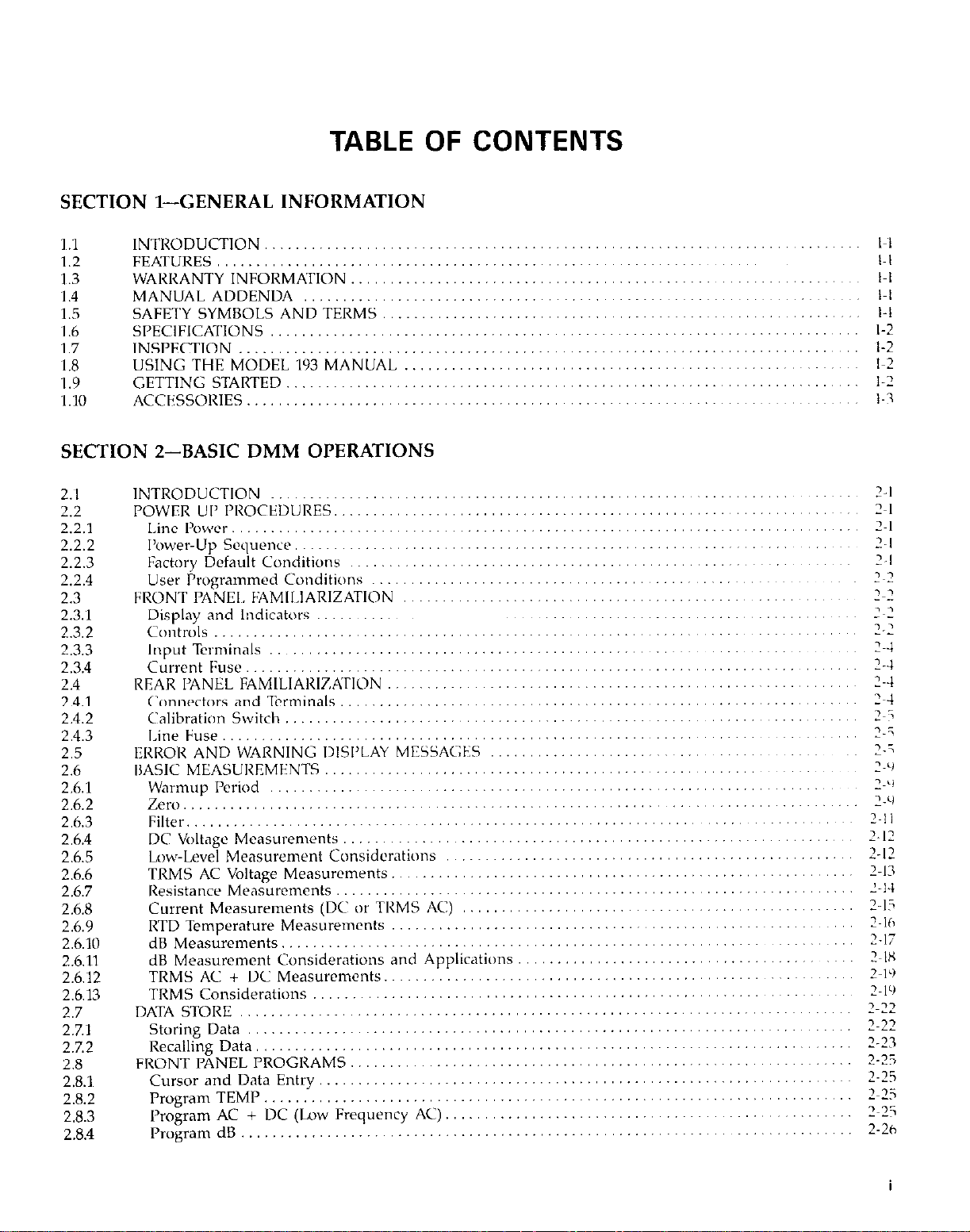

TABLE OF

CONTENTS

SECTION

1.1 INTRODUCTION

1.2

3.3

‘I .4

1.5 SAFETY SYMBOLS AND TERMS

‘I .6 SI’ECIFKATIONS

1.7

1.8

1.9

‘I.10

l-GENERAL INFORMATION

.........................

FEATURES.. .............................

WARRANTY INFORMATION ..............

MANUAL ADDENDA ....................

..........

.........................

INSPECTION .............................

USING THE MODEL ‘193 MANUAL ........

GETTING STARTED

ACCESSORIES ............................

.......................

SECTION 2-BASIC DMM OPERATIONS

2.1

2.2

2.2.1

2.2.2

2.2.3

2.2.4

2.3

2.3.1

2.3.2

2.3.3

2.3.4

2.4

2.4.1

2.4.2

2.4.3

2.5

2.6

2.6.1

2.6.2

2.6.3

2.6.4

2.6.5

2.6.6

2.6.7

2.6.8

2.6.9

2.6.10

2.6.11

2.6.12

2.6.13

2.7

2.7.1

2.7.2

2.8

28.1

2.8.2

2.8.3

2.8.4

INTRODUCTION ........................

POWER UI’ I’ROCEDIJRES

Line Power.

I’ower-Up Scquc”ce, ....................

Factory Default Conditions ..............

User Programmed Conditions ............

FRONT PANEL FAMII~.IARIZATION ........

Display and Indicators ...................

Co”tnlls

Input Terminals

C&rent Fuse

REAR PANEL FAMILIARIZATION

Connectors and Terminals ................

Calibration Switch ......................

Line Fuse..

ERR013 AND WARNING DISI’LAY MESSAGES

BASIC MEASUI~EMFN’I‘S.......................................................~~~~.~

Warmup Period ................................................................

...................................................................................

Zero

Filter...................................................~

DC V<,ltage Measurements

Lw+Level Measurement Considerations

TRMS AC Voltage

Resistance

Current Measurements (DC or TRMS AC)

RTD Temperature Measurements

dB Measurements

dB Measurement Considerations and Applications

TRMS AC + DC Measurcm~nts

TRMS Considerations

DATA STORE

Storing Data

Recalling Data ............................................................................

FRONT PANEL PROGRAMS ................................................................

Cursor and Data Entry

Program TEMP ...........................................................................

Program AC + DC (Low Frequency AC).

Program dB

............................

................................

........................

............................

.......

Measurements

Measurements

........................................................................

.........

.........

..,

...

................

..........

... ............

......... ..

....... ..

..................................................................

................................ ..................

..........................................................

................................................................

....................................................................

.............

..,

..............

....................................................................

... ... ...................................

... ...

... ... ...

........................ ........ ....

.................................

.............

................. ...............................

.........

......................................

..........................................

..................................................

..................................................

.............

... ., .........................

................................

.............................

.................. ...

..

........... .. .... ...

..

....................... ...........

.........

....

....

~,,~ ~.,,

.........

....

,,,

...

Page 10

2.8.5

2.8.6

2.8.7

2.88

2.8.9

28.10

2.8.11

2.8.12

2.8.13

2.8.14

2.8.15

2.9

2.10

2.lO10.1

2:11x2

2.10.3

Program ZERO..

Program FILTER

Program RESET

Program 4

Program 90 (Save)

Program 91 (IEEE Address)

Program 92 (Freq)

Program 93 (Diagnostics)

Program 94 (MX + B Status)

Program Y5 (Multiplexer)

Program 96 (CAL) ................................

FRONT PANEL TRIGGERING

EXTERNAL TRIGGERING

External Trigger

Voltmeter Complete

Triggering Example

.................................

..................................

..................................

.......................................

................................

........................

................................

..........................

......................

..........................

......................

..........................

..................................

..............................

..............................

SECTION 3-IEEE-488 PROGRAMMING

..........

..........

..........

..........

..........

..........

..........

..........

..........

..........

..........

..........

.........

.........

..........

..........

..........

..........

..........

..........

..........

..........

..........

..........

..........

..........

.........

.........

.........

.........

.........

.........

.........

.........

.........

2-26

2-26

2.27

2-27

2-28

2-28

2.29

2-29

2-29

2-30

2-30

2.30

2-30

2-30

2-31

2-w

3.7

3.2

3.3

3.3.1

3.3.2

3.3.3

3.4

3.4.1

3.4.2

3.4.3

3.4.4

3.4.5

3.5

3.6

3.6.1

3.6.2

3.6.3

3.7

3.7:1

3.7.2

3.7.3

3.R

38.1

3.8.2

3.8.3

3.8.4

3.9

3.9.1

3.Y.2

3.9.3

3.9.4

3.9.5

3.9.6

3.9.7

3.9.8

3.10

3.10.1

3.10.2

3.10.3

3.10.4

3.10.5

INTRODUCTION ..........................................................................

BUS DESCRIPTION ........................................................................

IEEE-488 BUS LINES .......................................................................

Data Lines..

Bus Management Lines ...................................................................

Handshake Lines

BUS COMMANDS .........................................................................

Uniline C~,mmands .......................................................................

Universal Commands ..: ..................................................................

Addressed Commands..

Unaddressed Commands ..................................................................

Device-Dependent Commands

COMMAND CODES..

COMMAND SEQUENCES.. ................................................................

Addressed Command Sequencr ............................................................

Universal Command Sequence

Device-Dependent Command Sequence

HARDWARE CONSIDERATIONS

Typical Controlled Systems

Bus Connections

Primary Address Programming. ...........................................................

SOFTWARE CONSIDERATIONS ............................................................

Controller Handler Software ..............................................................

Interface BASIC Programming Statements

Interface Function Codes .................................................................

IEEE Command Groups ..................................................................

GENERAL BUS COMMAND I’ROGIIAMMINC

REN (Remote Enable) ....................................................................

IFC(Interfacc Clear) ......................................................................

LLO (Local Lockout) .....................................................................

GTL (Go To Local) and Local .............................................................

DCL (Device Clear) ......................................................................

SDC (Send Device Clear) .................................................................

GET (Group Execute Trigger) .............................................................

Serial Polling (SI’E, SPD) .................................................................

DEVICE-DEPENDENT COMMAND PROGRAMMING, .......................................

Execute(X) ..............................................................................

Function(F) ..............................................................................

Range(R)

Zero (Z)

Filter(P)

.............................................................................

.........................................................................

..................................................................

.............................................................

.....................................................................

.............................................................

....................................................

............................................................

................................................................

.........................................................................

..................................................

..............................................

................................................................................

.................................................................................

.................................................................................

3-I

3-1

3-2

3-2

3-2

3-2

3-3

3-4

3-4

3-5

3-5

3-s

3-5

3-7

3-7

3-7

3-7

3-7

3-7

3-8

NO

s-10

i-10

3-K

s-11

1.12

3-12

3-13

3-13

3-14

3-14

3-14

3-15

3-15

3-16

3-17

3-20

3-20

3-21

3.22

3-22

ii

Page 11

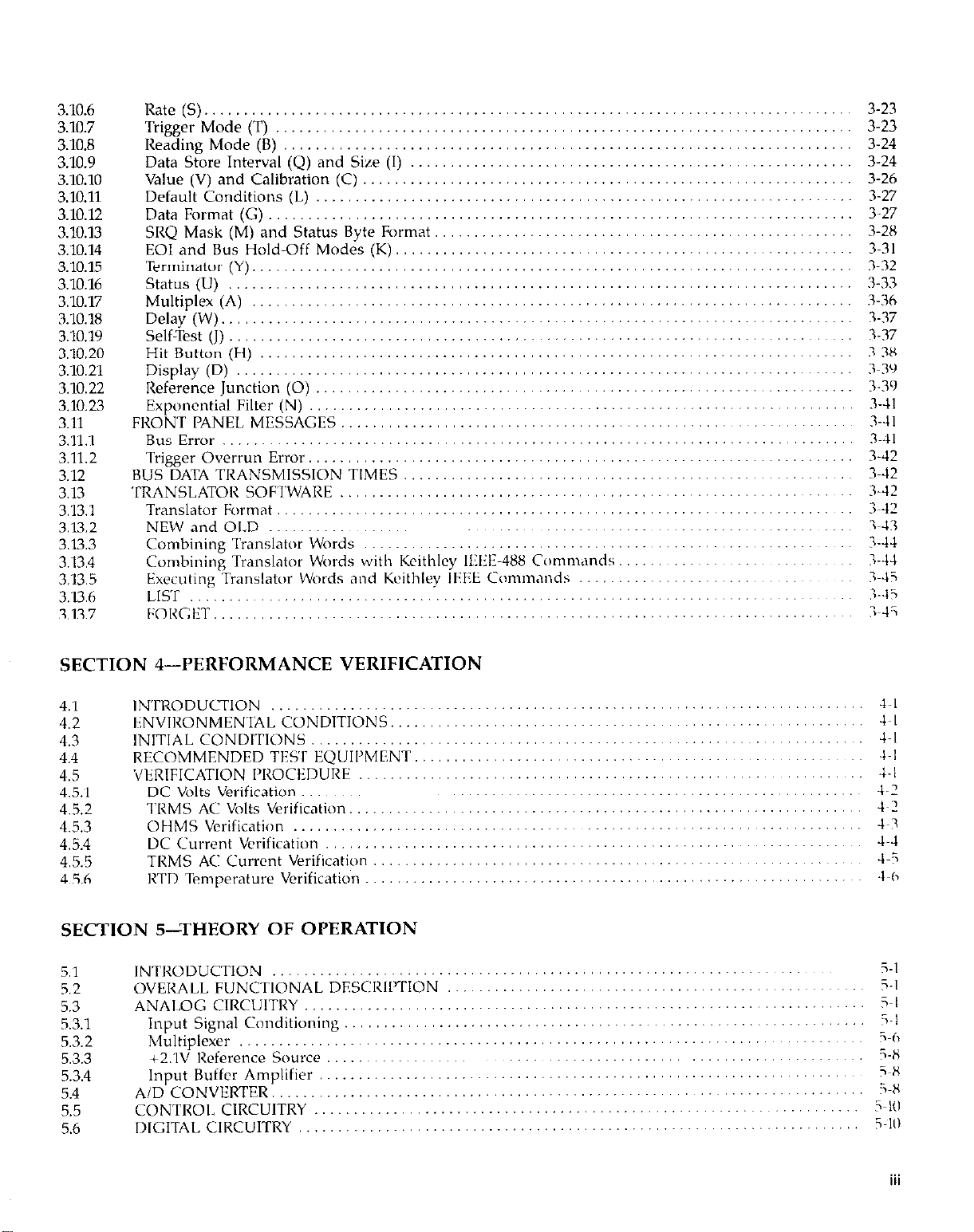

3.10.6

3.10.7

3.10.8

3.10.9

3.10.10

3.10.11

3.10.12

3.10.13

3.10.14

3.10.15

3.10.16

3.10.17

3.10.18

3.10.19

3.10.20

3.10.21

3.10.22

3.1023

3.11

3.11.1

3.11.2

3.12

3.13

3.13.1

3.U.2

3.13.3

3.13.4

3.13.5

3.13.6

3.13.7

Rate (S).

Trigger Mode (T)

Reading Mode (8) ........................................................................

Data Store Interval (Q) and Size (I)

Value (V) and Calibration (C)

Default Conditions (L) ....................................................................

Data Format (G)

SRQ Mask (M) and Status Byte Format.

EOIand Bus Hold-Off Modes ..........................................................

Terminator (Y) ............................................................................

status (LJ) ...............................................................................

Multiplex (A) ............................................................................

Delay (W) ................................................................................

Self-Test (J)

Hit Button (H) ...........................................................................

Display (D)

Reference Junction (0)

Exponential Filter (N)

FRONT PANEL M~SSAGTS...................................................~.~~ ..........

Bus Error

Trigger Overrun Error ..................................................................... 3-42

BUS DATA TRANSMISSION TIMES

TRANSLATOR SOFTWARE

Translator hlrmat

NEW and OLD

Combining Translator Words

Combining Translator Wurds with Kcithlcy ll%l~-488 Commands,

Executing Translator Words and Keithley IEEE Comnunds

LIST

F:ORGET ...............................................................................

.................................................................................

.........................................................................

........................................................ 3-24

.............................................................. 3-26

..........................................................................

.................................................... 3-2X

...............................................................................

.............................................................................. 3~39

....................................................................

......................................................... ..... .....

................................................................................

.........................................................

.................................................................

........................................................................

............................................................ ........

.................................... ...... .. ........

.......................... .. 3-14

......................

...........................................................................

~,

.,

....

.....

.......

3-23

3-23

3.24

3-27

3-27

3-31

3.32

3-33

3.36

3-37

3-37

3-3X

3-3’1

3-41

3-41

3.41

3-42

3-42

3-42

3-43

3-44

3-45

.%-.I?

iwli

SECTION 4--PERFORMANCE VERIFICATION

4.1

4.2

4.3

4.4

4~.5

4.5.~1

4.52

4.5.3

4.5.4

4.5.5

4.5.6

INTRODUCTION

ENVIRONMENTAL CONDITIONS

INITIAL CONDITIONS.......................................................~ ..............

RECOMMENDED TESf EQUIPMENT

VERIFICATION I~ROCEDURE

DC Volts Verification

TRMS AC Volts Verification.,

OHMS Verification

DC Current Verification

TRMS AC Current Verification

RTD Temperature Verification

... .... ...

... ...........

... ....

....................................................... ............ +I

........... . ...

......

................................................

...

........... .. ....... ..

...

...........

....................................... ...... .....

...

........ .. ..... .....

...

SECTION 5-THEORY OF OPERATION

5.1

5.2

5.3

53.1

53.2

5.3.3

5.3.4

5.4

5.5

5.6

INTRODUCTION

OVERALL FUNCTIONAL DESCRIPTION

ANALOG CIRCUITRY

Input Signal Conditioning

Multiplexer ..,

+2.1v Reference Source

Input Buffcr Amplifier

AID CONVERTER

CONTROI,ClRCUlTRY

DIGITAL CIRCUITRY ..,

........ . .......... . ..

.......................................................................

............................................................................ i-h

..

......................

....................................................................

..........................................................................

.....................................................................

.................................................................... 5~10

................

............. ..

................ ... ... ....

............. .. ..

.. ......

............

......................

............

.. ....

..........

...........

............

................ ......... .&(I

...............................

................................

,.,

...........

........ .....

......... &I

.. .. ... ..

.............. ......

............. ....

........ .............

......... ..... ..

......................

...........

4-I

&I

&I

-I-l

4.2

4~2

1~?

4-5

5-l

5-l

5-l

i-i

i-X

;~x

i-X

i-It1

...

111

Page 12

5.6.1

5.6.2

5.7

Microcomputer ...........................................................................

Display Circuitry ..........................................................................

POWER SUPPLIES

SECTION 6-MAINTENANCE

.........................................................................

5-10

S-10

5-K

6.1

6.2

6.3

6.3.1

6.3.2

6.4

6.5

6.6

b.b.‘l

6.6.2

6.6.3

6.6.4

6.6.5

6.6.6

6.6.7

6.6.8

b.b.9

h.b.10

6.6.11

6.6.12

6.7

6.8

6.9

6.9.1

6.9.2

b.Y.3

6.9.4

6.9.5

6.9.b

INTRODUCTION ...........................................................................

LINE VOLTAGE SELECTION

FUSE REPLACEMENT

Line Fuse

Current F~use

MODEL 1930 TRMS ACV OPTION INSTALLATION,,

MODEL 1931 CURRENT OPTION INSTALLATION

CALIBRATION ..............................................................................

Recommended Calibration Equipment

Environmental Conditions.,

Warm-Up Period ..........................................................................

Calibration Switch .........................................................................

Front Panel

IEEE-488 Bus Calibration

Calibration Sequence .......................................................................

DC Volts Calibration

Resistance Calibration

TRMS AC Volts Calibration

DC Current Calibration.

TRMS AC Current Calibration

DISASSEMBIdY INSTRUCTIONS

SPECIAL HANDLING OF STATIC-SENSITIVE DEVICES

TROUBLESHOOTING

Recommended Test Equipment

Power-Up Self Test .......................................................................

Program 93.Self Diagnostic Program.

Power Supplies ...........................................................................

Signal Conditioning Checks

Digital and Display Circuitry Checks

.................................................................................

..............................................................................

Callbratmn

.......................................................................

.......................................................................

................................................................. 6-l

..........................................

............................................ 6-3

....................................................... 6-3

................................................................ b-3

................................................................... b-b

....................................................................... 6-7

......................................................................

................................................................ h-10

................................................................... 6.13

............................................................. 6-14

.............................................................

...................................... b-21

...................................................................... 6-21

............................................................ 6.22

.......................................................

............................................................... 6-23

....................................................... 6-23

b-l

6-l

b-1

b-2

6-2

6-3

b-3

6-3

6-5

b-7

6-8

6.15

6.22

6-23

b-23

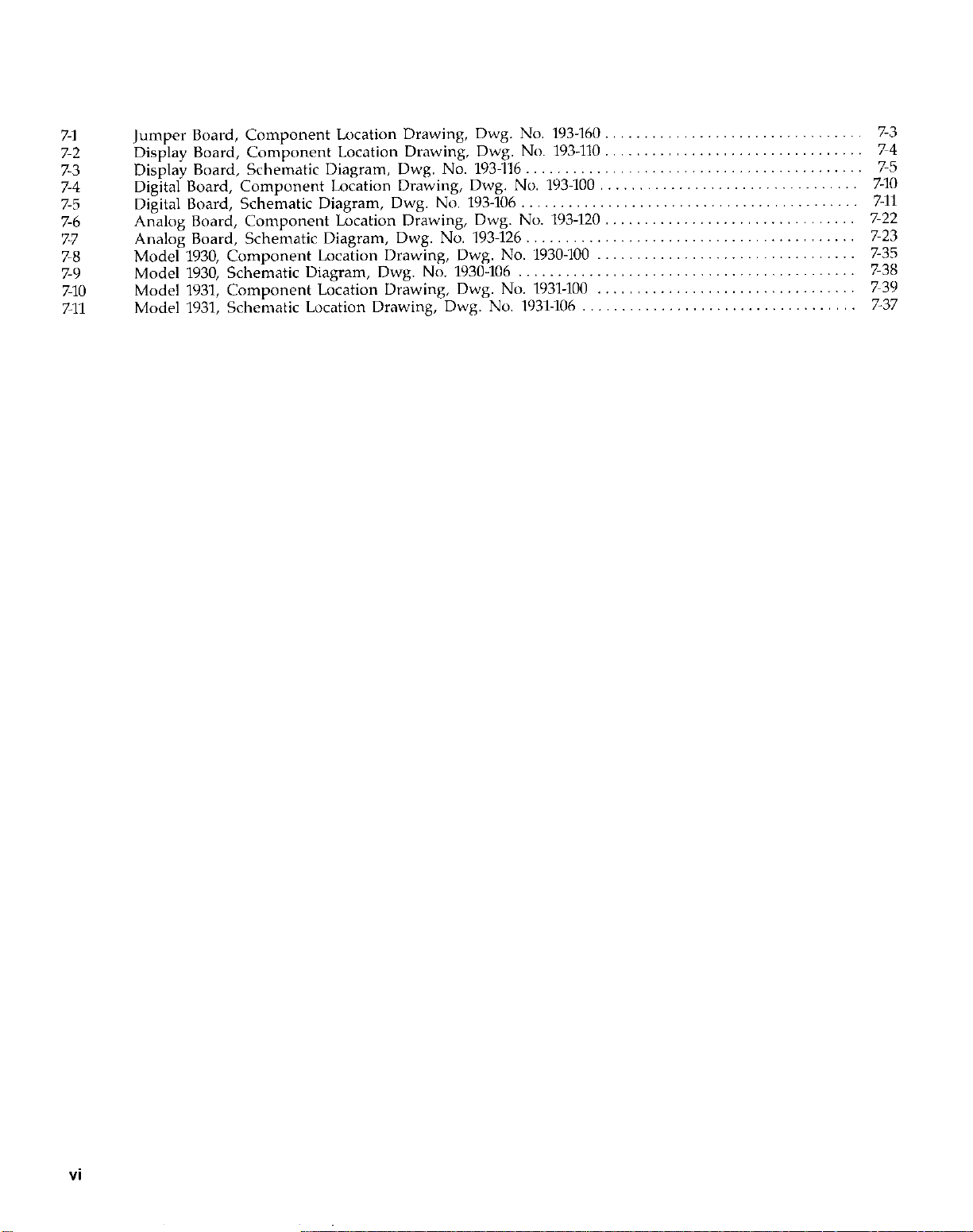

SECTION 7-REPLACEABLE PARTS

7.1

7.2

7.3

7.4

7.5 SCHEMATIC DIAGRAMS AND COMPONENT LOCATlON DRAWINGS

iv

INTRODUCTION.. .......................................................................... 7-l

I-ARTS LIST .................................................................................

ORDERING INFORMATION ................................................................. 7-l

FACTORY SERVICE .......................................................................... 7-l

7-l

......................... 7-l

Page 13

LIST OF ILLUSTRATIONS

2-l

2-2

2-3

2-4

2-5

2-6

2-7

2-8

2-9

2-10

2-u

3-l

3-2

3-3

3-4

3-5

3-6

3-7

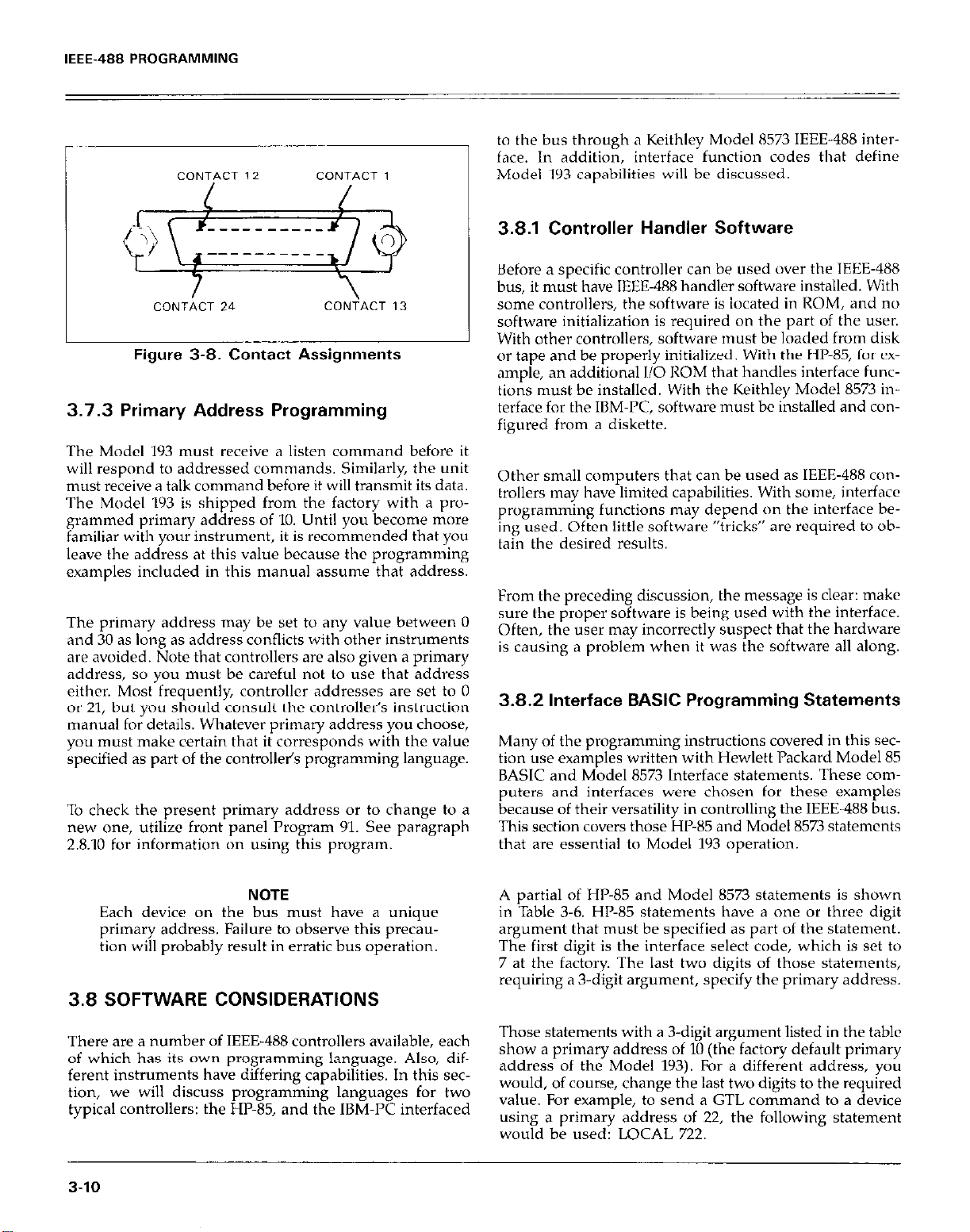

3-8

3-9

3-10

3-11

3-12

3-13

4-1

4-2

4-3

4-4

4-5

4-6

4-7

Model 193 Front Panel

Model 193 Rear l’anel

DC Voltage Measurements ...................................................................

TRMS AC Voltage Measurements

Two’Terminal Resistance Measurements

Four-Terminal Resistance Mrasuremcnts

Current Measurements..

RTD Temperature Measurements

External Pulse Specifications

Meter Complete Pulse Specifications

External Triggering

IEEE-488 Bus Configuration

lEEE-488 Handshake Sequence

Command Groups

System Types..

Typical Bus Connector,,

IEEE-488 Connections..................................................................~~~~

Model 193 IEEE-488 Connector

Contact Assignments.,

General Data Format

SRQ Mask and Status Byte Fomr,lt

UO Status Word and Default V.llues

Ul Error Status Word..

tHit Button Command Numbers

Connections for DC Vc,lts Verification

Connections for TRMS AC Volts Verification

Connections for Ohms Verification (200%20kR) Range

Connections for Ohms Verifications (2OOk%200Mn Ranga)

Connections for DC Current Verification.

Connections for TRMS AC Current Verification

Connections for RTD Temperature Verification.

.......................................................................

........................................................................

............................................................

.......................................................

......................................... .............

....................................................................

.......................................... ... ..

....................................................... ...

.................................... ....

Example

..........................................................................

........................................................

....................................... ......... .....

.....................................................

...............................................................

.....................................................................

..................................................

............................................ ..........

.................................................. .....

.................................................................

....

............................................. ............

................................................... ......

............................................................ 3-3’1

....................

..............

.....

.................

...........

...........

,,....

?i

2?

2-12

2-l-1

Z-15

2~15

Z-lh

......

........ ...

.... .. 1-2

...

................... 3-X

.....

~,

....... ..

...

;:;;

l~.?l

2~32

3~3

3-1,

3-P

3.‘)

..

3~‘)

..

?-Ill

.%?‘I

3~2’)

3~34

1-3;

5-l

5-2

5-3

5-4

5-5

5-6

5-7

6-l

6-2

6-3

6-4

6-5

h-6

6-7

6-8

6-9

6-10

6-11

6-12

Overall Block Diagram ..............................................

Input Configuration During 2 and 4Tcmminal Resistance Measurements

Ohms Source (2kn Range Shown)

Resistance Measuwment Simplified Circuitry

JFET Multiplexer

Multiplexer Phases

A/D Converter Simplified Schematic

Models 1930 and 1931 Installation

DC Volts Calibration Configuration (2OOmV and 2V Ranges)

DC Volts Calibration Configuration (2OV-IOOOV Ranges).

Four-Wire Resistance Configuration (200%20kll Ranges)

Two-Wire Resistance Calibration Configuration (200kR.2OOMR Ranges)

Flowchart of AC Volts Calibration Procedure

TRMS AC Volts Calibration Adjustments,

TRMS AC Volts Calibration Configuration,

DC Current Calibration Configuration

TRMS AC Current Calibration Configuration

Co”“ectors

Model 193 Exploded View

...................................................

................................................

.........

...........................................................................................................................................

.................................

.........................

.................................

.............................................................

.....................................

............................ ............

.........................................

..................................................

.....................................................

....................................................

................................................ .......

..................................................

............................

(,-.l

;I::

&‘I

h-‘1

h-II

&i;

h-l-l

h-15

66;

Page 14

7-l

7-2 Display Board, Component Location Drawing, Dwg. No 193.130

7-3

7-4

7%

7-6

7-7

7-8

79

7-10

7-11

Jumper Board, Component Location Drawing, Dwg. No. 193-160

Display Board, Schematic Diagram, Dwg. No. 193.116

Digital Board, Component Location Drawing, Dwg. No. 193.100

Digital Board, Schematic Diagram, Dwg. No. 193.106

Analog Board, Component Location Drawing, Dwg. No. 193.120

Analog Board, Schematic Diagram, Dwg. No. 193.126

Model 1930, Component Location Drawing, Dwg. No. 1930-100

Model 1930, Schematic Diagram, Dwg. No. 1930.106

Model 1931, Component Location Drawing, Dwg. No. 1931-100

Model 1931, Schematic Location Drawing, Dwg. No. 1931-106

...........................................

...........................................

..........................................

...........................................

................................... 7-37

.................................

................................. 7-4

.................................

................................

................................. 7-35

.................................

7-3

7-5

7.10

7-n

7.22

7-23

7-38

7-39

vi

Page 15

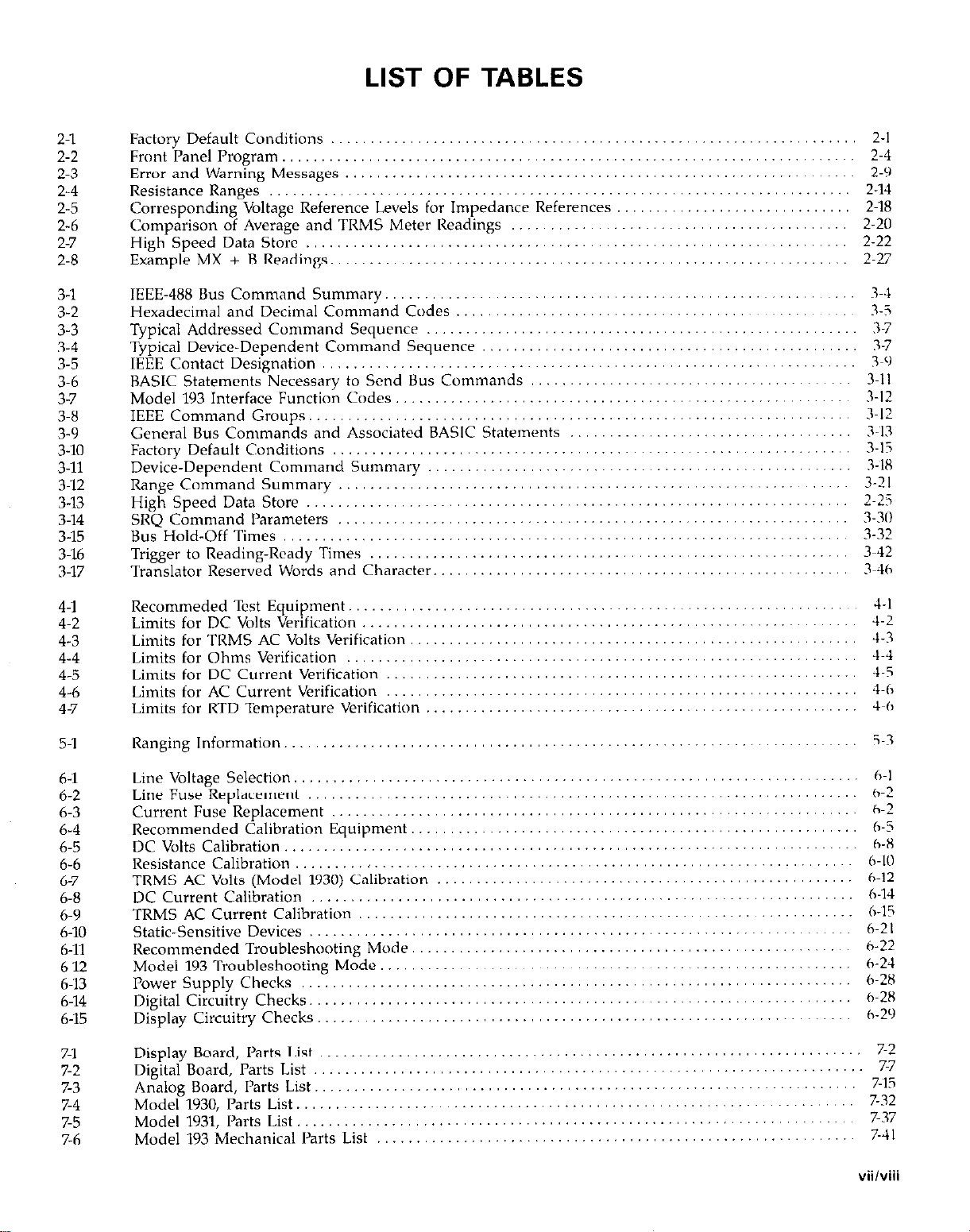

LIST OF TABLES

2-l

2-2

2-3

2-4

2-5

2-6

2-7

2-8

3-l

3-2

3-3

3-4

3-5

3-6

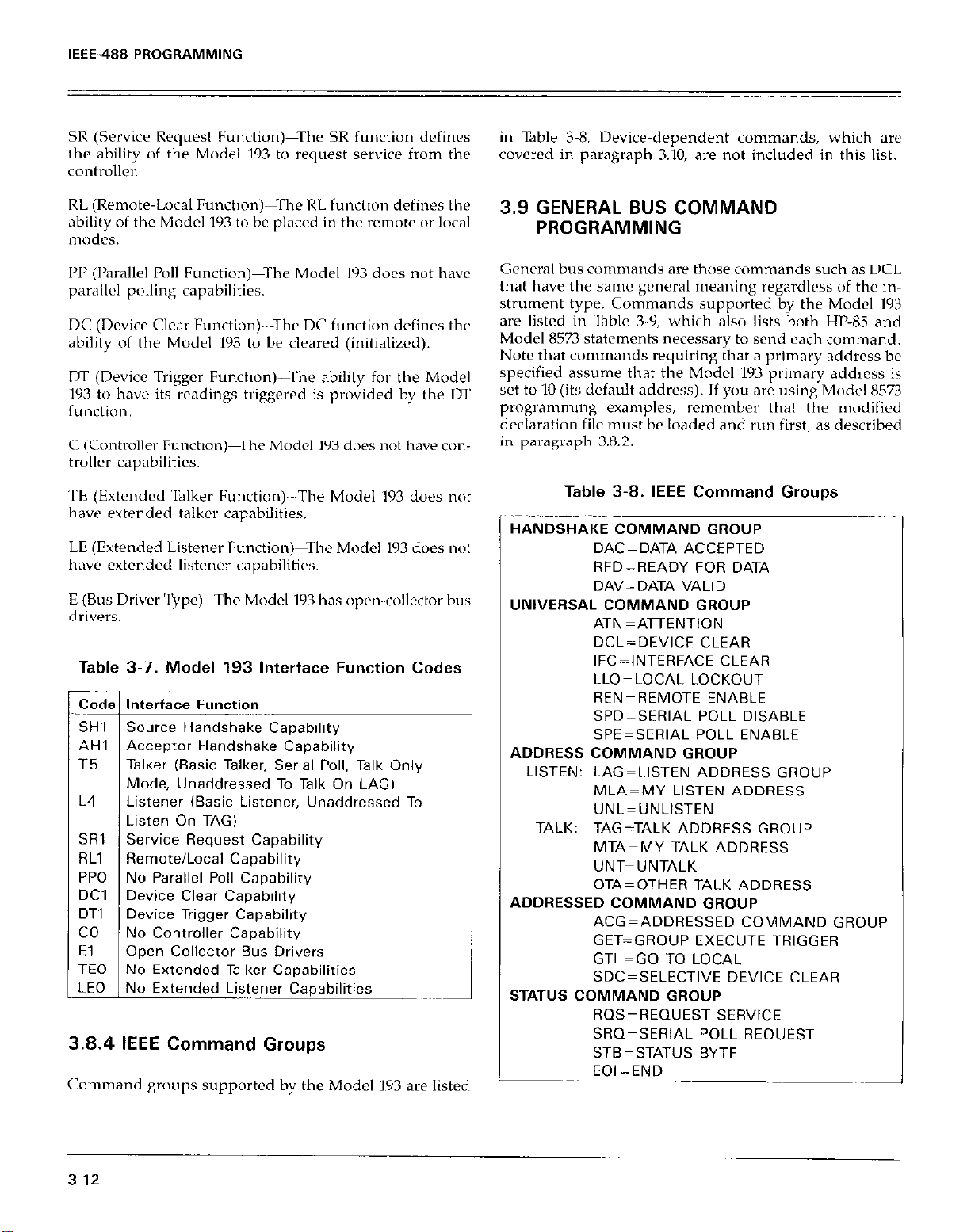

3-7

3-8

3-9

3-10

3.11

3-12

3-13

3-14

3-15

3-16

3-17

Factory Default Conditions

Front

Panel Program

Error and Warning Messages .................................................................

Resistance Ranges ..........................................................................

Corresponding Voltage Reference Levels for Impedance References

Comparison of Average and TRMS Meter Readings

High Speed Data Store

Example MX + BReadillgs ..................................................................

IEEE-488 Bus Command Summary

Hexadecimal and Decimal Command Codes

Typical Addressed Command Sequence

Typical Device-Dependent Command Sequence

IEEE Contact Designation

BASIC Statements Necessary to Send Bus Commands

Model 193 Interface Function Codes

IEEE Command Groups

General Bus Commands and Associated BASIC Statements

Factory Default Conditions

Device-Dependent Command Summary

Range Command Summary

High Speed Data Store .....................................................................

SRQ Command Parameters

Bus Hold-Off Times ........................................................................

Trigger to Reading-Ready Times

Translator Reserved Words and Character

.........................................................................

................................................................... 2-l

........................................... 2.20

..................................................................... 2.22

............................................................

...................................................

.......................................................

................................................ 3-7

....................................................................

......................................... 3-11

.......................................................... 7-12

.....................................................................

.................................... 3-U

.................................................................. 3-15

......................................................

................................................................. 3-21

.................................................................

.............................................................

..................................................... 3-46

2-4

2-9

2.14

.............................. 2-18

2.27

3-l

3-i

3-i

3-c)

3-12

R-18

2-Z

3-31)

3-32

3-42

4-l

4-2

4-3

4-4

4-5

4-6

4-7

5-l

h-l

6-2

6-3

6-4

6-5

b-b

6-7

6-8

6-9

6-10

6-11

6-12

6-13

6-14

6-15

7-l

7-2

7-3

7-4

7-5

7-6

Recommeded Test Equipment.

Limits for DC Volts Verification

Limits for TRMS AC Volts Verification

Limits for Ohms Verification

Limits for DC Current Verification

Limits for AC Current Verification

Limits for RTD Temperature Verification

Ranging Information

Line Voltage Selection

Line Fuse Replacement

Current Fuse Replacement

Recommended Calibration Equipment.

DC Volts Calibration

Resistance Calibration

TRMS AC Volts (Model 1930) Calibration

DC Current Calibration

TRMS AC $wnt Calibration

Static-Sensltwe Devices

Recommended Troubleshooting Mode.

Model 193 Troubleshooting Mode

Power Supply Checks

Digital Circuitry Checks ...........................................................................................................................................

Display Circuitry Checks

Display Board, Parts List

Digital Board, Parts List

Analog Board, I’arts List

Model 1930, Parts List

Model 1931, Parts List

Model 193 Mechanical Parts List

.........................................................................

.......

......................................................................

...................................................................... h-8

.........

.......................................................................

.......................................................................

...........

...........

.....

.............

........

........

...............

................

.......................................................... ..

,,

..........

..

.....................................................................

....................................................................

............

.....................................................................

.........................................................

.....

...................

.........................

.

.... ....... ..

....................

.....................

.....................

.....................

.....................

.....................

.....................

...

............................................. h-l

.

..................................................

........................................................

................................................... h-12

......................................................

.......................................................

........................................

.._

.

.................................................................................................

...........

............................... 7-41

.....

......

......

......

......

......

4-I

-1-2

4-3

4-4

4-5

4-h

4-h

5~3

h-2

h-2

h-5

6-K

::;:

1

h-2 I

h-22

h-24

f~:;;

h-29

;-;

7%

7-32

7-37

vii/viii

Page 16

Page 17

SECTION 1

GENERAL INFORMATION

1.1 INTRODUCTION

The Kcithlcy Model ~IYO System DMM, with thcTRMS AC

Volt ,Ind Current options installed, is ‘I six function

,tutora”ging digital multimeter. At 6% digit rcsc>lutio”, the

IID display cn” display +2,200,(100 counts. The rang? of

this anal[,g~to-digit,ll (ND) converter is gl-cater than the

nwmal +‘l,YYY,YYY count AID c”nwrtrr used in many 6%

digit DMMs. ‘l’hc built-in IEEE-48X interfax makes the instrument fully programmable ,,ver the IEEl:-4B8 bus. With

ihc ‘TRMS ACV option and the Current option installed,

the Model ~IY3 CJ” make the f~~llowing basic

measurements:

In addition to the above Imentioned mcaurcmcnt

capabilities, the Model ‘lY3 can “lake dB and TRMS AC

+ DC meaSu1’Cnw”tS.

1.2 FEATURES

Some important Model ‘lY3 features include:

l

14 Character Alphanumwic Display+‘asy t,, read 14

segment l.EDs used for readings and front panel

messages.

l

High Speed Measurement Ratc~‘lO00 readings per

second.

l

Zero-Used to cancel offsets or establish basclincs. A

zero value can be pmgrammcd from the front panel 01

over the IEEE-4X8 bus.

l

Filter-The weighted avcragc digital filter cd” bc set f”t

1 to YY readings from the front panel or <,ver the bus.

l

Data Store-An internal buffer that can store up t” 500

readings is accessible from either the front panel or <wt’r

the bus.

l

Digital Calibration-The instrument may bc digitally

calibrated from either the front panc’l or over the bus.

. User Programmable Default Qnditions-Any instru-

ment measurement configuration can be established as

1-l

Page 18

GENERAL INFORMATION

1.6 SPECIFICATIONS

Detailed Model 193 specifications may be found preceding

the Table of Contents of this manual.

l

Section 6 contains information for servicing the instrument. This section includes information on fuse replacement, line voltage selection, calibration and

troubleshooting.

l

Section 7 contains replaceable parts information.

1.7 INSPECTION

The Model 193 System DMM was carefully inspected, both

electrically and mechanically before shipment. After un-

packing all items from the shipping carton, check for any

obvious signs of physical damage that may have occurred

during transit. Report any damage to the shipping agent.

Retain and use the original packing materials in case

reshipment is necessary. The following items are shipped

with every Model 193 order:

Model 193 System DMM

Model 193 Instruction Manual

Safety Shrouded Test Leads

Additional accessories as ordered.

If an additional instruction manual is required, order the

manual package (Keithley Part Number 193-901-00). The

manual package includes an instruction manual and any

apphcable addenda.

1.8 USING THE MODEL 193 MANUAL

This manual contains information necessary for operating

and servicing the Model 193 System DMM, TRMS ACV

option and the Current option. The information is divided into the following sections:

l

Section 1 contains general information about the Model

193 including that necessary to inspect the instrument

and get it operating as quickly as possible,

l

Section 2 contains detailed operating information on using the front panel controls and programs, making connections and basic measuring techniques for each of the

available measuring functions.

l

Section 3 contains the information necessary to connect

the Model 193 to the IEEE-488 bus and program operating

modes and functions from a controller.

l

Section 4 contains performance verification procedures

for the instrument. This information will be helpful if

you wish to verify that the instrument is operating in

compliance with its stated specifications.

l

Section 5 contains a description of operating theory.

Analog, digital, power supply, and IEEE-488 interface

operation is included.

1.9 GETTING STARTED

The Model 193 System DMM is a highly sophisticated instrument with many capabilities. To get the instrument up

and running quickly use the following procedure. For com-

plete information on operating the Model 193 consult the

appropriate section of this manual.

POWW-Up

1. Plug the line cord into the rear panel power jack and

plug the other end of the cord into an appropriate,

grounded power source. See paragraph 22.1 for more

complete information.

2. Press in the POWER switch to apply power to the instrument. The instrument will power up to the XXIOVDC

range.

Making Measurements

1. Connect the supplied safety shrouded test leads to the

front panel VOLTS HI and LO input terminals. Make

sure the INPUT switch is in the out (FRONT) position.

2. To make a voltage measurement, simply connect the input leads to a DC voltage surge (up to 1OOOV) and take

the reading from the display.

3. To change to a different measuring function, simply

press the desired function button. For example, to

measure resistance, press the OHMS button.

Using

Storing Data:

1. Press the DATA STORE button. The DATA STORE in-

2. Select an interval, other than 000.000, using the 4 and

3. Press the ENTER button. The buffer sire will be

4. If a different buffer size is desired, enter the value us-

5. Press the ENTER button to start the storage process,

Data Store

dicator will turn on and a storage rate (in seconds) will

be displayed.

), and data buttons.

displayed. Size 000 indicates that data will overwrite

after 500 readings have been stored.

ing the number buttons (0 through 9).

l-2

Page 19

GENERAL INFORMATION

The data store mode can bc exited at any time before the

start of the storage process by pressing the RESET button.

Once storage has commenced, the storage process can be

stopped by pressing any function button. See paragraph

2.7.1 for complete information on storing data.

Recalling Data:

1. Press the RECALL button. The buffer location of last

stored reading will be displayed.

2. To read the data at a different memory location, enter

the value using the number buttons (O-9).

3. Press the ENTER button. The reading and the memory

location will be displayed.

4. The A and V buttons can be used to read the data in

all filled memory locations.

5. ‘To read the highest, lowest and average reading stored

in the buffer, press the number 1, 2 and 3 buttons

respectively. Note that the memory location of the

highest and lowest reading is also displayed. The

average reading is displayed along with the number of

readings averaged.

The recall mode can be exited by pressing the RESET button. See paragraph 2.7.2 for complete information on data

recall.

Using Front Panel Programs

I’mgram selection is accomplished by pressing the PRGM

button followed by the button(s) that corresponds to the

program number or name. For example, to select Program

93 (IEEE status), press the PRGM button and then 9 and

1 buttons. Table 2-2 lists and briefly describes the available

front panel programs. Once a program is selected the

following general rules will apply:

1. A displayed program condition can be entered by pressing the ENTER button.

2. Program conditions that prompt the user with a flashing

digit can be modified using the data buttons (0 through

9 and *) and the cursor control buttons (manual range

buttons).

3. Programs that contain alternate conditions can be

displayed by pressing one of the manual range buttons.

Each press of one of these buttons toggles the display

between the two available conditions.

4. A program will be executed when the pressed ENTER

button causes the instrument to exit the program mode.

5. A program can be exited at any time and thus not executed, by pressing the RESET button.

Paragraph 2.8 provides the dctailcd inform,ltion for “sing

the front paw1 programs.

1.10 ACCESSORIES

The following accessories are available to c~nhancr the

Model 193% capabilities.

ModcJ l6OOB High Voltage J’robc-The Model Jhl)l)l% CAtends DMM measurements to 4OkV.

Model 1641 Kelvin Test Lead Set-The Model 1641 has

special clip leads that allow 4.terminal measurements to

be made while making only tvw connections.

Model 1651 SO-Ampere Current Shunts-l‘hr h,Judcl I651 is

an external O.OOlR *l% 4-terminal shunt, \\hich pwmits

current measurements from 0 to SOA AC or DC.

Model ~1681 Clip-On Test Lead Set-l’hc Model I681 cow

tains two leads, 1.2m (48’) long terminated with banana

plugs and spring action clip probes.

Model 16R2A RF Probe-The Model 1682A permits voltage

measurements from ~IOOkIiz to 250MHz. AC to IX transfw

accuracy is -tldB from 1OOkHz to 25OMHz at IV, peak

responding, calibrated in I<MS of d sine \\‘ave.

Model ~1751 Safety Test JLcads-J’his test Icad SC~ is supplied

with every Model 193. Finger guards and shnrudcd banxu

plugs help minimize the chance of making contact with

live circuitry.

1-3

Page 20

GENERAL lNFORMAT,ON

is installed, AC + DC voltage measurements can bc made.

Field installation 01’ r~movallrcplacement of the Model 1930

will require recalibration of the Model 143 and the Model

lY30.

Model 193~1 Current Option--The Model 1931 is a plug-in

current option for the Model 793. This option allows the

instrument to measure DC current up to 2A. When both

Models lY30 and 1931 are installed, the instrument can

make TRMS AC current measurements and TRMS AC +

DC curi-ent meas”re”le”ts. Field installation requires

recalibration of the Model 193.

Model ~I938 Fixed Rack Mount-The Model ~1938 is a stationary mount kit that allows the Model 193 tube mounted

in a standard 19 inch rack.

Model 1939 Slide Rack Mount-l‘he Model 1939 is a sliding

mount kit that allows the Model 193 to be rack mounted

with the added feature of sliding the instrument forward

for cay access to the rear panel and top cover.

Model 7007 IEEE-488 Shielded Cables-The Model 7007

connects the Model 193 to the IEEE~488 bus using shielded cables to reduce electromagnetic interference (EMI). The

Model 7007-1 is one meter in length and has a EMI shirlded IEEE-488 wnnector at each end. The Model 7007.2 is

identical to the Model 7007-1, but is two meters in Icngth

Model 7008 IEEE-488 Cables-l’he Model 7008 connects the

Model 193 to the IEEE-488 bus. ‘The Model 7008-3 is 0.9m

(3 ft.) in length and has a standard IEEE-488 connector at

each end. ‘I‘hc Model 71108-6 cable is identical to the Model

7008.3, but is ~l.Hm (6 ft.) in length.

Model 8573 lEEE~488 Interface-~-rhr Model 8373 is an

IEEE-488 standard intcrfacc designed to interface the IBM

PC or X1‘ computers to Keithlcy instrumentation over the

IEEE-488 bus. The interface system contains two distinctive parts: an interfacr board containing logic to perform

the necessary hardware functions and the handler software (supplied on disk) to perform the rquircd control

functions. Thcsc twu important facets of the Model 8573

join together to give the IBM advanced capabilities over

IEEE-488 interfaceable instrumentation.

1-4

Page 21

SECTION 2

BASIC DMM OPERATION

2.1 INTRODUCTION

Operation of the Model 193 may be divided into two

general categories: front panel operation and IEEE-488 bus

operation. This section contains information necessary to

use the instrument from the front panel. These functions

can also be programmed over the IEEE-488 bus, as described in Section 3.

2.2 POWER UP PROCEDURE

2.2.1 Line Power

Use the following procedure to connect the Model 193 to

line power and power up the instrument.

1. Check that the instrument is set to correspond to the

available line power. When the instrument leaves the

factory, the internally selected line voltage is marked on

the rear panel near the AC power receptacle. Ranges are

105V.125V or ZlOV-250V 50160Hz AC. If the line voltage

setting of the instrument needs to be changed, refer to

Section 6, paragraph 6.2 for the procedure. If the line

frequency setting of the instrument needs to be checked

and/or changed, utilix front panel Program 92 (see

paragraph 2.8.11) after the instrument completes the

power-up sequence.

2. Connect the female end of the power cord to the AC

receptacle on the rear panel of the instrument. Connect

the other end of the cord to a grounded AC outlet.

WARNING

The Model 193 is equipped with a 3-wire power

cord that contains a separate ground

is designed to be used with grounded outlets.

When proper connections are made, instrument

chassis is connected to power line ground.

Failure to use a grounded outlet may result in personal injury or death because of electric shock.

wire

and

2.2.2 Power-Up Sequence

The instrument can bc turned on bv pressing i” the front

panel POWER switch The switch !$:ill bc at the inner most

position when the instrument is turned 01,. LJpcrn powerup, the instrument will dn a number of tests on itself. ‘rests

are performed on memory (ROM, RAM and NVRAM). If

RAM or ROM fails, the it~strument will lock up. If E’PROM

FAILS, the message “UNCALIBRATED” will be displayed.

See paragraph 6.9.2 for a complete description of the

power-up self test and recommendations to resolve

failures.

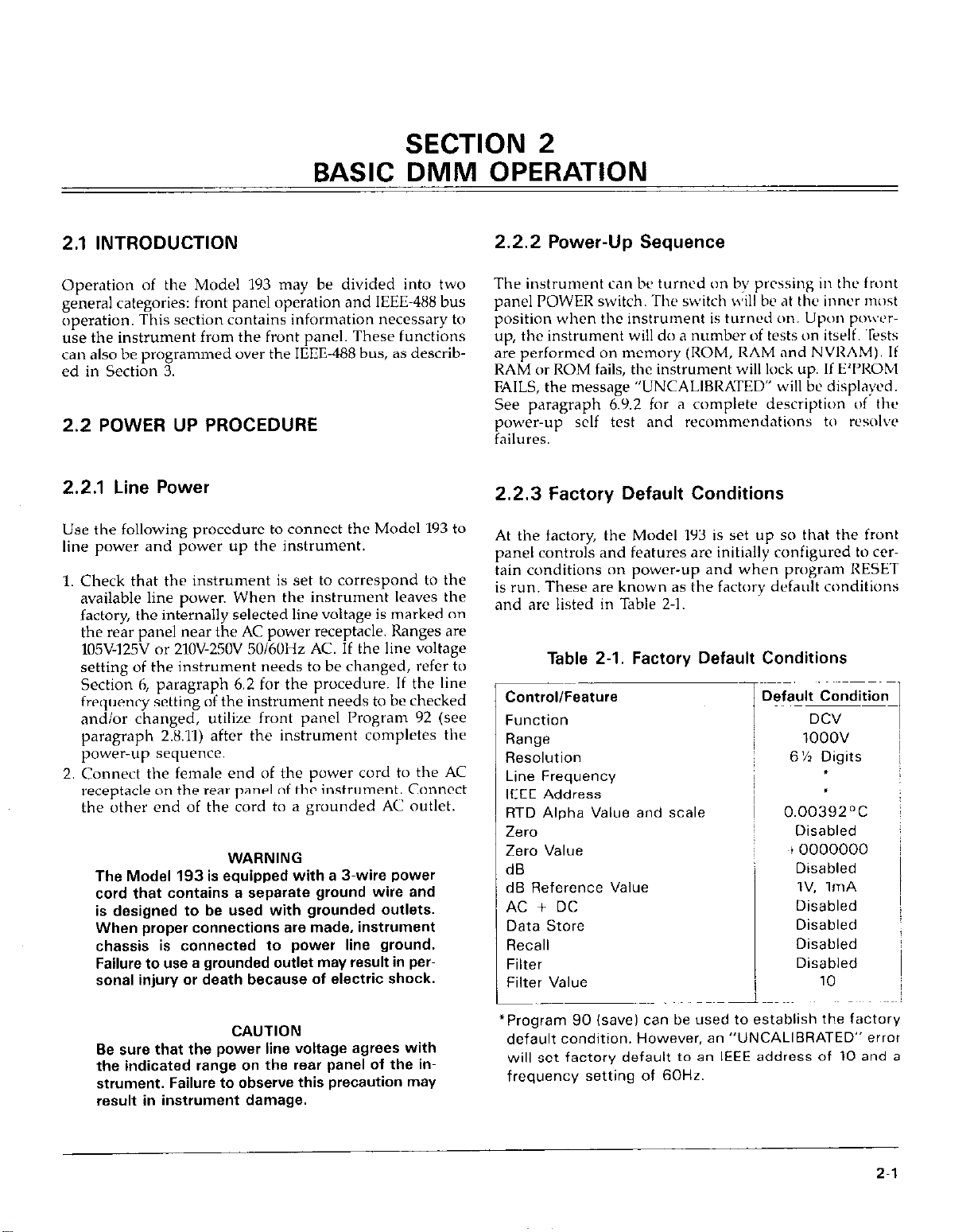

2.2.3 Factory Default Conditions

At the factory, the Model 193 is set up so that the front

panel controls and features are initially configured to cer-

tain conditions on power-up and when program RESET

is run. These are known as the factory default conditions

and are listed in Table 2-l.

Table 2-l. Factory Default Conditions

Control/Feature

Function

Range

Resolution

Line Frequency

IEEE Address

RTD Alpha Value and scale

Zero

Zero Value

dB

dB Reference Value

AC + DC

Data Store

Recall

Filter

Filter Value

Default Condition

DCV

1ooov

6% Digits

f

.

0.00392~C

Disabled

~l0000000

Disabled

IV, 1mA

Disabled

Disabled

Disabled

Disabled

10

CAUTION

Be s.ure that the power line voltage agrees with

the indicated range on the rear panel of the instrument. Failure to observe this precaution may

result in instrument damage.

*Program 90 (save) can be used to establish the factory

default condition. However, an “UNCALIBRATED” error

will set factory default to an IEEE address of 10 and a

frequency setting of 60Hr.

2-l

Page 22

OPERATION

2.2.4 User Programmed Conditions

A unique feature of the Model ~193 is that each function

“remembers” the last measurement configuration that it

was set up for (such as range, zc’ro value, filter value, ctc).

Switching back and forth betcveen functions will not alfeet the unique configuration of each function. Howcwr,

the instrument wili “forget” Ihc configurations on

pw”-dmvn.

Certain configurations can be saved by utilizing front panel

I’rugram 90. On power-up, thcsc user saved default c(,m

ditions will prevail over the factory default conditions.

Also, a DCI. (lr SDC asserted over the IEEE-4HH bus will

set the instrument to the user saved default conditions.

For more information, see paragraph 2.X.9 (I’rugram YO).

NOTE

Keep in mind that power-up deiault conditions

can br either factory default a,nditions or LISCI

saved default conditions.

2.3 FRONT PANEL FAMILIARIZATION

‘The front panel layout of the Model 1Y3 is shown in Figure

2~1. ‘The following paragraphs describe the various consponents of the front panel in detail.

POWER-The POWER switch cont~rols AC power to the instrument. Depressing and releasing the switch once turns

the power on. Depressing and releasing the switch a second time turns the power off. The correct positions for

on and off are marked on the front panel by the POWER

switch

INPUT~Thc INPUT switch connwts thcz instrument to

either the front panel input terminals (lr the war panel in-

put terminals. This witch oprrates in same manner as the

power switch. The front panel input tcmminals arc selected

when the switch is in the “out” position and the rear panel

input terminals art’ sclcctcd when the switch is in the “in”

pmition.

FUNCTlON GROUP-I’he FUNCI‘ION buttons are used

to s&cl the primary mcasurcment functions of the instru-

ment. Thcsc buttons rllsu have wwndwy functions.

DCV--The DCV button places the instrument in the DC

volts measurement Imodc. The secondary function of this

button is to enter the number 0. Set paragraph 2.h.4 iw

DCV measurements.

AC&With the ACV option installed, the ACV button

places the instrument in the AC volts measurcmcnt mode.

The secondary function of this button is to enter the

number I. See paragraph 2.66 for ACV mcasurcmcnts.

2.3.1 Display and Indicators

IXsplay-The 14 character, alphanumeric, LED display is

used to display numeric conversion data, range and function mnemonics (ix. mV) and messages.

Status Indicators-These three indicators apply to instrum

ment operation over the IEEE-488 bus. The REMOTE illdicator shows when the instrument is in the IEEE-488

remote state. ‘The TALK and LISTEN indicators show when

the instrument is in the talk and listen states respectively.

See Section 3 for detailed information on operation over

the bus.

2.3.2 Controls

All front panel controls, except the POWER and INPUT

switches, are momentary contact switches. Indicators are

located above certain feature buttons to show that they are

enabled. Included arc AUTO (autorange), ZERO, FILTER,

RECALI. and DATA STORE. Some buttons have secondary

functions that are associated with front panel program

operation. See paragraph 2-8 for detailed information on

front panel programs.

OHMS-The OfiMS button places the instrument in the

ohms measurement mode. The sccondnry function c)f this

button is to enter the number 2. See paragraph 2.6.7 fat

resistance measurements.

ACA-With the ACV option and current option installed,

the ACA button places the instrument in the AC amps

measurement mode. The secondary function of this button is to enter the number 3. See paragraph 2.6.8 for ACA

measurements.

DC-With the current option installed, the DCA button

places the instrument in the DC amps measurement mode.

The secondary function of this button is to enter the

number 4. See paragraph 2.6.8 for DCA mrasurcments.

TEMP--‘The TEMP button places the instrument in the RTD

temperature measurement mode. The secondary functions

of this button are to select the TEMI’ program (select alternate alpha value and thermometric scale) and to enter the

number 5. See paragraph 2.6.9 for RTD temperature

measureme”ts.

RANGE GROUPLl’he Aand vbuttons are used for

manual ranging and the AUTO button is used fat

autoranging. These buttons also have secondary iunctions.

2-2

Page 23

OPERATION

Manual-Each tinxe the A button is pressed, the instrument will mow up one range, while the r button will

move the instrument down one range each time it is

pressed. Pressing either of these buttons will cancel

autorange, if it was previous selcctcd. The secondary func-

tions of these buttons are associated with front panel pro-

gram operation.

AUTO-The AUTO button places the instrument in the

autorange mode and turns on the AUTO indicator. While

in this mode, the instrument will go to the best range to

measure the applied signal. Autoranging is available for

all functions and ranges. Autoranging may bc cancelled

by pressing the AUTO button or one of the manual range

buttons. The secondary function of this button is to enter

the + sign.

MODIFIER GROUP-The MODIFIER buttons activate

features that arc used to enhance the nwasurcment

capabilities of the Model 193. These features in effect

modify the selected function. In addition to their primary

tasks, these buttons have secondary functions.

ZERO-The ZERO button turns on the ZERO indicator

and causes the displayed reading to be subtracted from

subsequent readings. This feature allows for zer” correction or storage of baseline values. The secondary function

of this button is to select the ZERO program. Refer to

paragraph 2.6.2 for detailed information on the zero

feature.

dB-The dB button places the instrument in the dB

measurement mode and may be used with the ACV and

ACA functions. Under factory default conditions,

measurements are rcfcrenced to 1V or ImA. Howwer, the

dB program may be used to change the reference level.

The secondary function of this button is to select the dB

program. See paragraph 2.6.10 for dB measurements.

FILTER-The FILTER button turns on the FILTER in-

dicator and causes the instrument to start weighted

averaging a number (l-99) of readings. The factory default

value is 10, but may be changed using the FILTER pro-

gram (see paragraph 2.8.6). See paragraph 2.6.3 for filter

operation. Selecting the FlLTER program is one of the

secondary functions of this button. The other secondary

function is to enter the number 6.

AC + DC-With the appropriate options installed, the AC

+ DC button (with ACV selected) places the instrument

in the AC + DC measurement mode. With the ACV option installed, VAC + DC measurements can be made.

With both the ACV and current option installed, AAC iDC measurements can be made. See paragraph 2.6.12 for

AC + DC measurements. The secondary functions of this

button are to select the AC + DC program (low frequen-

cy TRMS measurements) and to enter the number 7.

CONTROL GROUP-The CONTROI~. buttons llr<’

features that allow for the control and m;tniplil.lti~~n i,i

various aspects of instrument “peraticrn. All of these but-

tons, except I’RGM, have II secondxy function

RESOl.N-The RES0I.N button ;tll~n\,s for the s&ctiiu~

of the number of digits of displdy rrsolutim~. Each pwss

of the RESOLN button incr11~~scs resolution by one digit.

Pressing the RESOLN button after the m<lkimum wsolw

tion is reached will revert the display back tu the I(,wcst

resolution. Display resolution of 3%. 4112, 5% (Ir 6% digits

can be selected for DCV and ACV. Display wwlution ot

4% or 5% digits can be selected for DCA and ACA On

OIIMS, 3’12, 4% 5% and 6% digit rtw,luti<~” is Ilvl~ill~bl~~

on the 20011 through 2OOkll ranges. 0” the 2h,ll! .l”d ?i)hl!!

ranges, 5% and 6% digits can bc sc~lc~cted. On the ?llOhl!!

range, only 5%d resoluti~,n is av~ilablc. .The RI~SOI..~ bul-

ton has “~, effect on I”\%, freqwwy ,\C i DC (I’rogrdnl

AC + DC), ‘TEMP or dB measurcnwnts. l’hc wcondx\

function of this button is to enter lhc dccinul puint (.i.

TRIGGER/ENTER-The TRIG(;ERiENTlill butti~n is used

as a terminator fur data entry when the instrumwt is i”

the front panel progrxn mode and 11s a front p.mel trig:

ger when the data stow is xtive.

STATUSIRESE-l

STATUS-lnstrumcnt status c.1” bc displwd \vhcrr th<,

instrument is in the normal measurclncnt &,dc or Iogging readings. When the STA’I’US button is first pressed

the following current instrument conditi~,ns ca” be

displayed with the use of the A and v buttons:

Software rcvisio” level

IEEE address

Line frequency setting

Multiplexer status (on/off)

MX+B status (on/off)

MX+B values

dB reference value

Filter value (OO=filter disabled)

Zen1 status (on!off)

Zero value

Pressing the STATUS button a scctmd time takes the ill-

strument out of the status mode.

RESET-The RESET button is used to reset the instrument

back to the previously entered paranwtcr. Keyed in

parameters are only entered after the ENTER button is

pressed. If RESET is pressed with the last p‘lramrter (It

a program displayed, the program will be exited and the

instrument will return to the previous clperating state. This

button aborts back to normal “pcr.ltion when it is i” 0111’

of the following modes:

2-3

Page 24

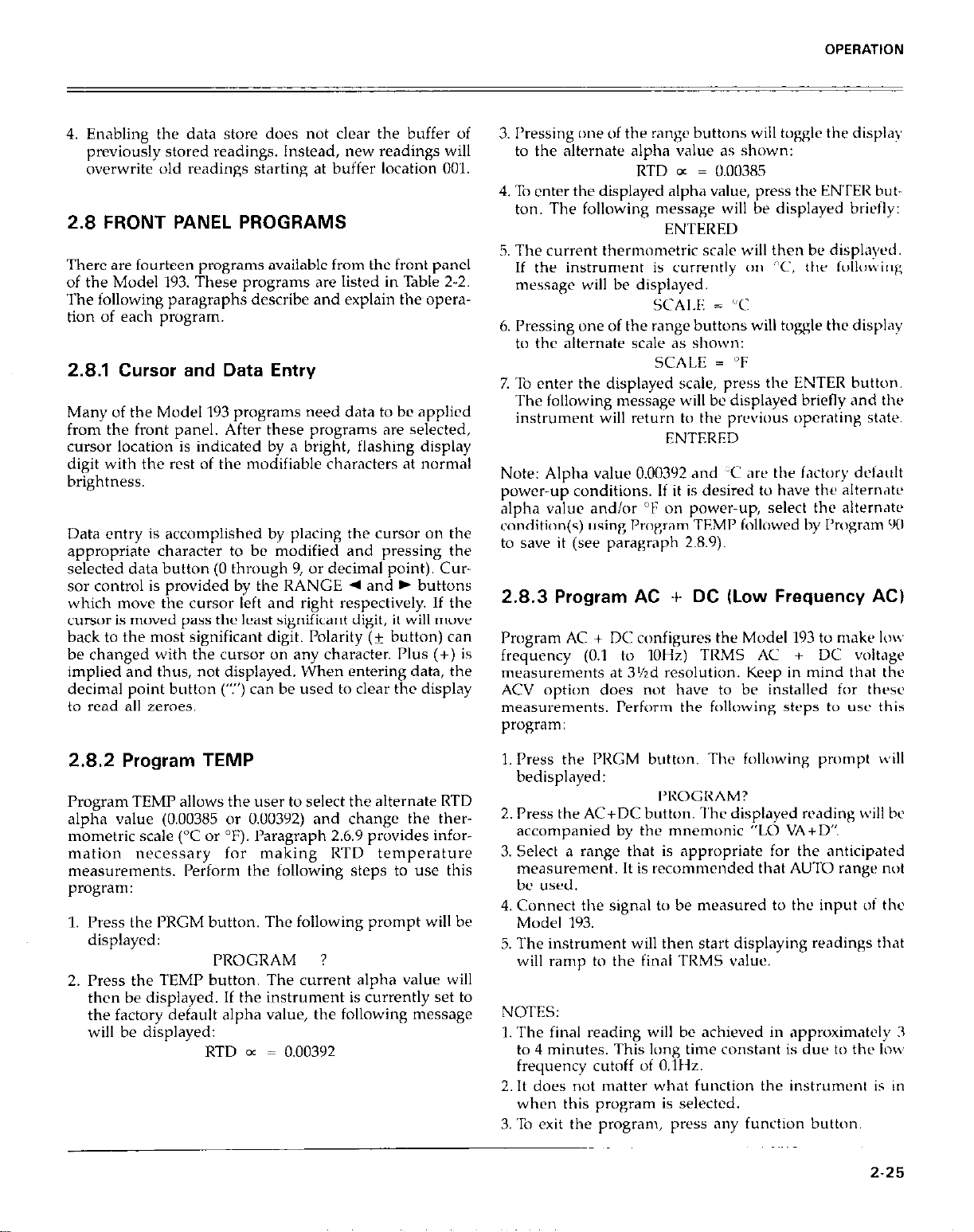

OPERATION

1. The data store is prompting for paramckrs (interval or

size).

2. The instrument is in the RECALL mode.

3. A front panel program has been selected (except Program AC+DC which is treated as a normal mcasure~

ment function (see STATUS).

Program RESET--Program RESET returns the instrument

to the factory default conditions. See paragraph 2.8.7 for

information on using this program.

DATA STORE-The DATA STORE button s&c& the 500

point data store mode of operation Paragraph 2.7 contains

a complete description of data store operation. The secondary function uf this button is to enter the number 9.

RECALLJhe RECALL button recalls and displays

readings stored in the data stow Paragraph 2.7.2 provides

a detailed procedure for recalling data. The secondary

function of this button is to enter the number 8.

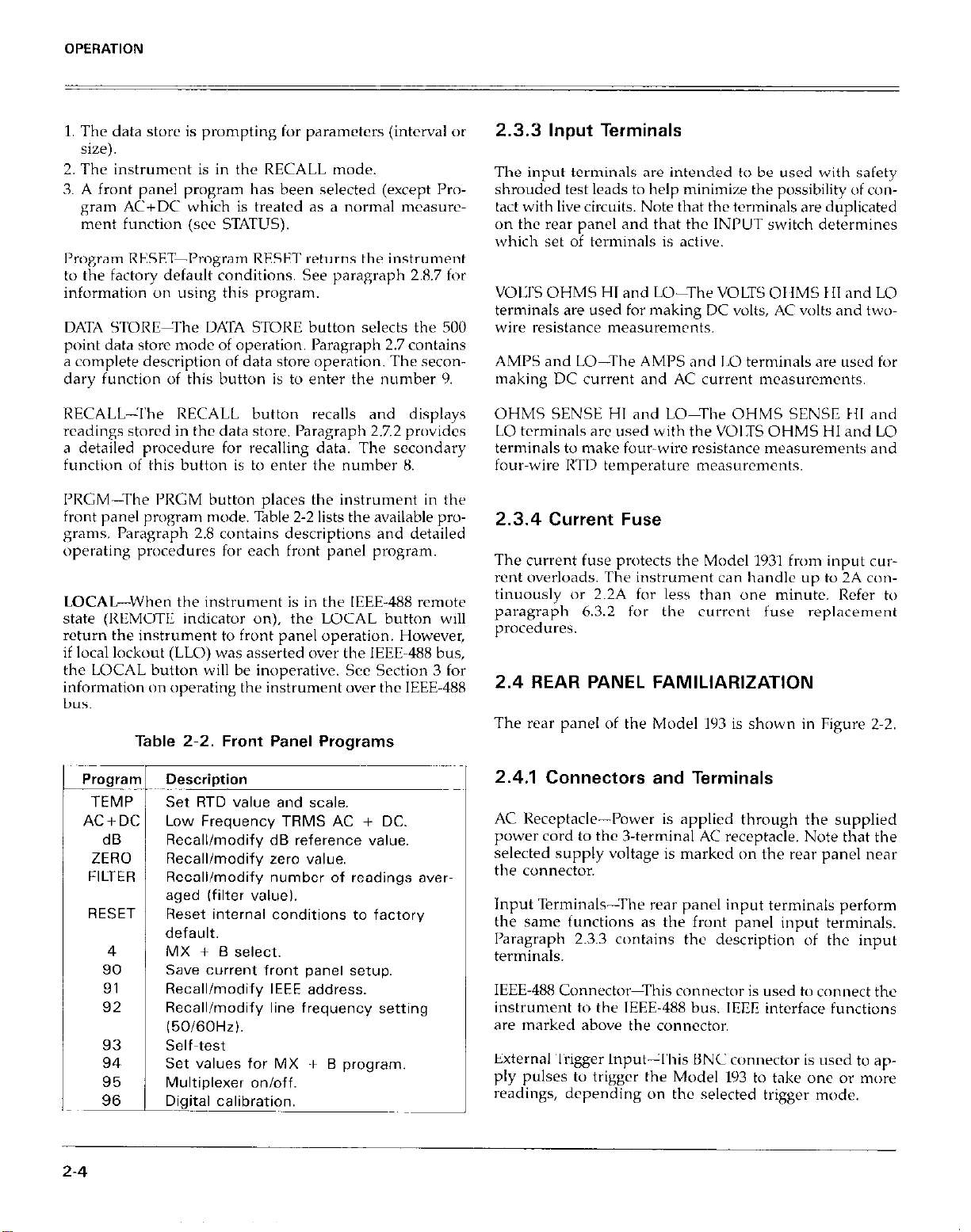

I’RCM-The PRGM button places the instrument in the

front panel program mode. Table 2-2 lists the available pro@xns. Paragraph 2.8 contains descriptions and detailed

operating pnwzdures for each front panel pn,gram.

LOCAL-When the instrument is in the IEEE-488 remote

state (REMOTII indicator on), the LOCAL button will

return the instrument to front panel operation. However,

if local lockout (LLO) was asserted over the IEEE-488 bus,

the LOCAL button will be inoperative. SW Section 3 for

information on uperating the instrument over the IEEE-488

bus.

Table 2-2. Front Panel Programs

2.3.3 Input Terminals

The input terminals are intended to be used with safety

shrouded test leads to help minimize the possibility of con-

tact with live circui&. Note that the twninals are duplicated

on the rear panel and that the INPUT switch determines

which set of terminals is active.

VOI:l’S OHMS HI and I>O-The VOLTS OHMS 111 and LO

terminals are used for making DC volts, AC volts and tww

wire resistance measurements.

AMPS and LO-The AMPS and 1.0 &rminals are used for

snaking DC current and AC current nwasurcmcnts.

OHMS SENSE HI and LO-The OHMS SENSE ktl and

LO terminals arc used with the VOIDS OHMS HI and LO

terminals to make four-wire resistance measurements and

four-wire liTI1 temperature measurcnwnts.

2.3.4 Current Fuse

The current fuse protects the Model lY31 from input current overloads. The instrument can handle up lo 2A cow

tinuously or 2.2A for less than one minute. Refer tu

paragraph 6.3.2 for the currcnl fuse replacement

procedures.

2.4 REAR PANEL FAMILIARIZATION

The rear panel of the Model 7Y3 is shown in Figure 2.2.

Progran

TEMP

AC+DC

ZERO

FILTER

RESET

2-4

dB

4

90

91

92

93

94

95

96

Description

Set RTD value and scale.

Low Frequency TRMS AC + DC.

Recall/modify dB reference value.

Recall/modify zero value.

Recall/modify number of readings averaged (filter value).

Reset internal conditions to factory

default.

MX + B select.

Save current front panel setup.

Recall/modify IEEE address.

Recall/modify line frequency setting

l50160Hz).

Self-test

Set values for MX + B program.

Multiplexer on/off.

Digital calibration.

2.4.1 Connectors and Terminals

AC Receptacle-Power is applied through the supplied

power cord to the 3.terminal AC receptacle. Note that the

selected supply voltage is marked on the rear panel “ear

the connector.

Input Terminals-The rear panel input terminals perform

the sane functions as the front panel input terminals.

Paragraph 2.3.3 contains the description of the input

terminals.

IEEE-488 Connector-This connector is used to connect the

instrument to the IEEE-488 bus. IEEE interface functions

are marked above the connector.

External Trigger Input-This BNC connector is used to apply pulses to trigger the Model 193 to take one or more

readings, depending on the selected trigger mode.

Page 25

OPERATION