Page 1

INSTKUCTIW MANUAL

IlUUEL 1YZU

TKWS UPTIUII

Copyright 1981 Keithley Instruments, Inc.

First Printing, July, 1981, Cleveland, Ohio, U.S.A.

Document No. 32000, Kev. A

Page 2

Page 3

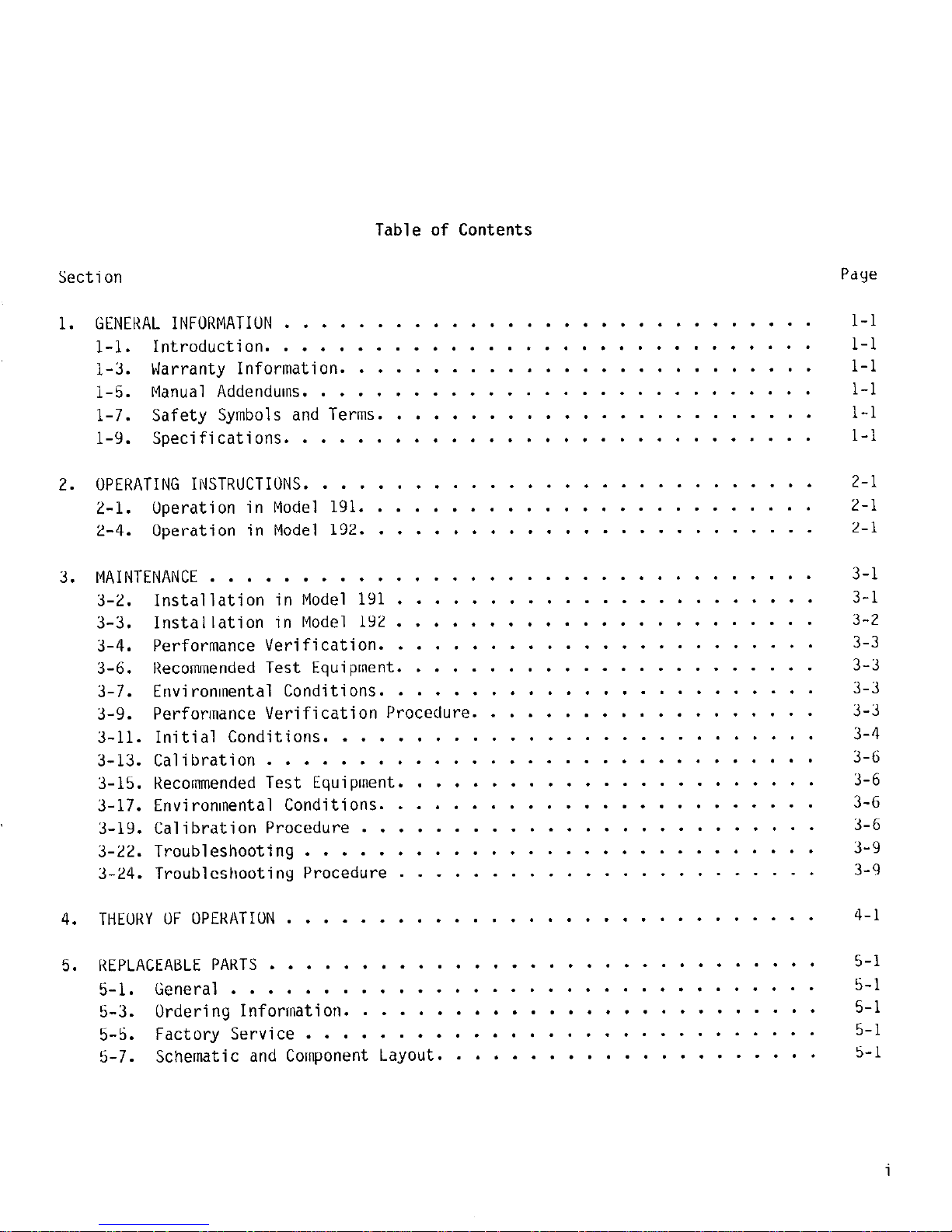

Table of Contents

Section

1.

2.

3.

4.

5.

ClENEKAL INFORMATION

.............................

l-l.

Introduction.

.............................

l-3. Warranty Information.

.........................

1-5.

Manual Addendums.

...........................

l-7. Safety Symbols and Terms.

.......................

l-9. Specifications.

............................

OPERATING INSTRUCTIONS.

...........................

2-l.

Operation in Model 191.

........................

2-4. Operation in Model 192.

........................

MAINTENANCE .................................

3-2. Installation in Model 191

.......................

3-3. Installation in Model 192

.......................

3-4.

Performance Verification.

.......................

3-6. Kecommended Test Equipment.

......................

3-7.

Environmental Conditions.

.......................

3-9.

Performance Verification Procedure.

..................

3-11.

Initial Conditions.

..........................

3-13. Calibration

..............................

3-15. Kecommended Test Equipment.

......................

3-17. Environmental Conditions.

.......................

X-19.

Calibration Procedure

.........................

3-22. Troubleshooting

............................

3-24. Troubleshootiny Procedure

.......................

TtiEURY OF UPEKATIUN

.............................

REPLACEABLE PAKTS

..............................

5-l.

General

................................

5-3. Ordering Information.

.........................

5-5.

Factory Service

............................

5-7.

Schematic and Component Layout.

....................

Page

l-l

l-l

l-l

l-l

l-l

l-l

2-1

2-l

2-1

3-l

3-l

3-2

3-3

3-3

3-3

3-3

3-4

3-6

3-6

3-G

3-6

3-9

3-9

4-l

5-l

5-l

5-l

5-i

5-l

Page 4

Page 5

Model 1920

General Information

SECTION 1. GENERAL INFORMATION

l-l. INTRODUCTION

l-2.

The Keithley Model

1920

is a True Root Mean Square (TKMS) AC plug-in option for the

Models

192

and

191.

The 1920 enables the 191 or 192 to measure the TKMS value of an AC

siynal.

When the 1920 is installed in the Model

192

an ACtUC function is available. The

Model

1920

has four ranges on which an AC siynal can be measured.

It

is field

installable.

1-3.

Warranty Information

l-4.

The warranty is yiven on the inside front cover of this manual. If there is a need

to exercise the Warranty,

contact the Keithley Representative in your area to determine

the proper action to be taken.

Keithley maintains complete repair and calibration

facilities in the United States, West tiermany,

tireat Britain, France, the Netherlands,

Switzerland and Austria.

Information concerning the application, operation or service of

your instrument may be directed to the applications engineer at any of the above

locations.

Check the inside front cover of this manual for addresses.

l-5. Manual Addendums

1-G.

Improvements or changes to the instrument that occur after printing of the [manual

will be explained on an addendum which will be attached to the inside back cover.

1-7.

Safety Symbols and Terms

l-8. The symbol

A

on the instrument denotes that the user should refer to the operating

instructions.

t

The symbol

on the instrument denotes that up to 5UllV may be present on the terminals.

The WARNING used in this manual explains dangers that could result in personal injury

or death.

The CAUTION used in this manual explains hazards that could damage the instrument.

l-9.

Specifications

l-10.

Uetailed specifications for the Model 1920 are given in Table

l-l.

l-l

Page 6

General Information

Model 1920

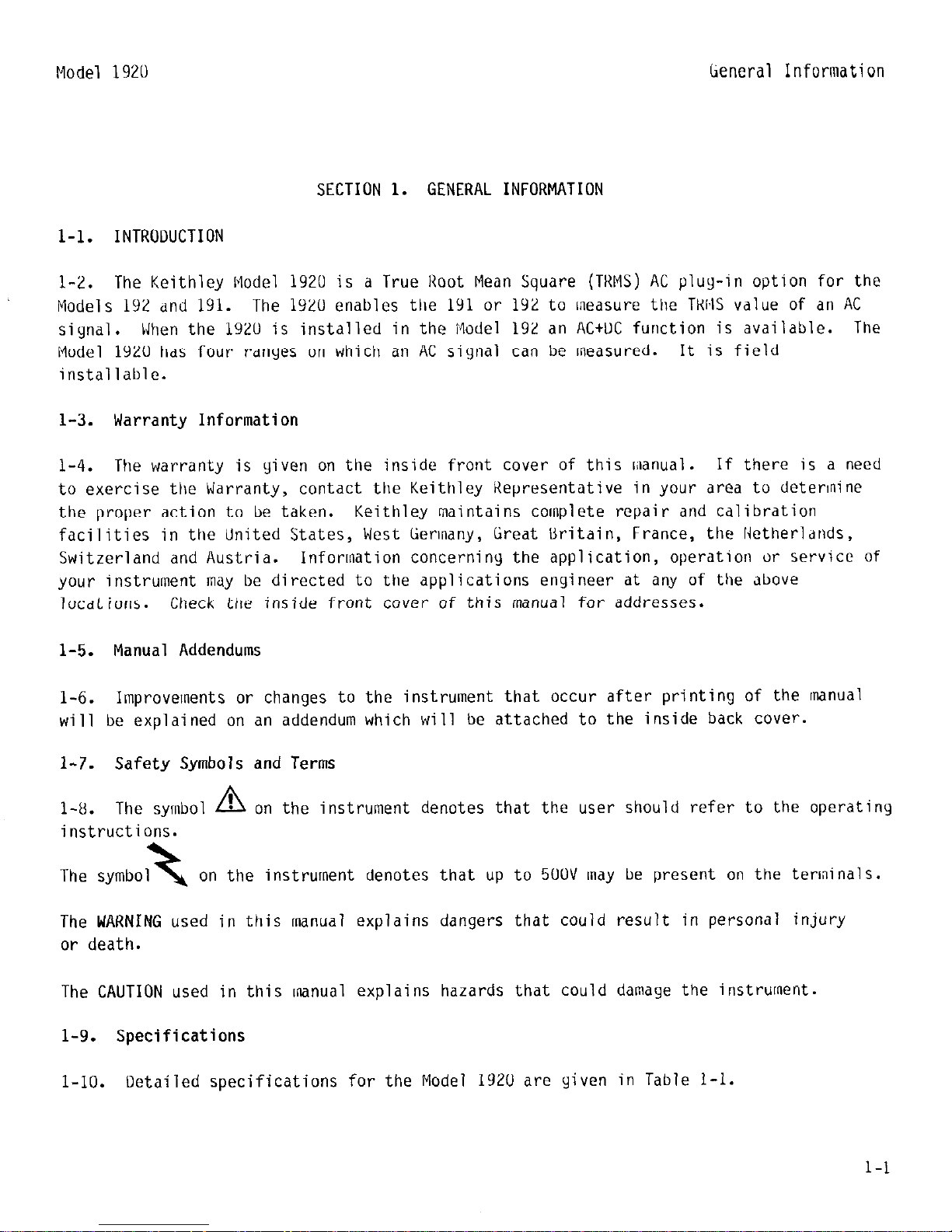

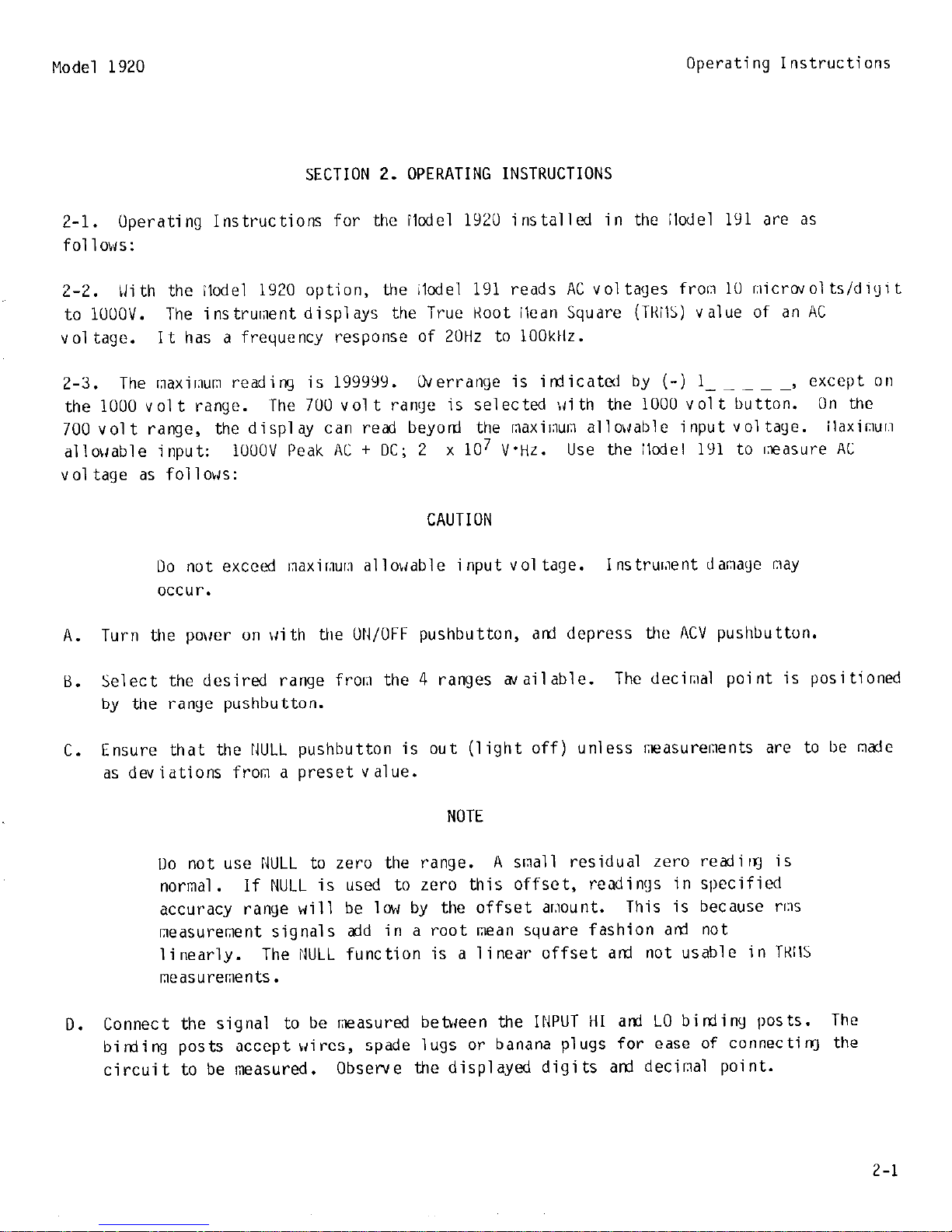

TABLE 1-l

1920 Specifications

5-l/2 Digit Accuracy, +(% Rdg + Counts),

1

yr 18-28'C

5-l/2 Digit

20-50Hz"

DC, 50Hz-lOkHz* lOK-20kHz"

20kHz-lOOkHz**

Range

RESOLUTION

2v 1OPV 1% t

100

0.25% t 100 0.35% + 300

1% t 500

2ov lOOld

1% t 100

0.25% t 100 0.35% + 300

1% t 500

2oov 1mV 1% t

100

0.25% + 100 0.35% + 300 1% t 500

7oov 1OmV

1% t 100

0.354: t 100 0.5% + 300

1% t 500

RESPONSE:

CREST FACTOR

AC + DC MODE:

riAxIriuri INPUT:

SETTLING TIME:

INPUT IMPEDANCE:

TEMP. COEFFICIENT:

3dB BANTMIDTH:

CFIRR:

TRUE RFlS

Add 60 counts to specified accuracy (not wailable in We1

191)

1OOOV Peak AC + DC, 2 x lo7 V* Hz

0.5 set to within 0.1% of change in reading

211 ohm shunted by less than 5OpF.

(O"-18OC and 28"-5O'C): Less than

0.1

x applicable accuracy

specification per "C below 50kHz; 0.2 x for 50kHz to 1OOkHz

500kHz Typical

Greater than 60dB at 50 and 60Hz

(lk

ohm unbalanced)

* Above 2000 counts

** Above 20000 counts; 3% + 500 typical below 20000

l-2

Page 7

Model 1920

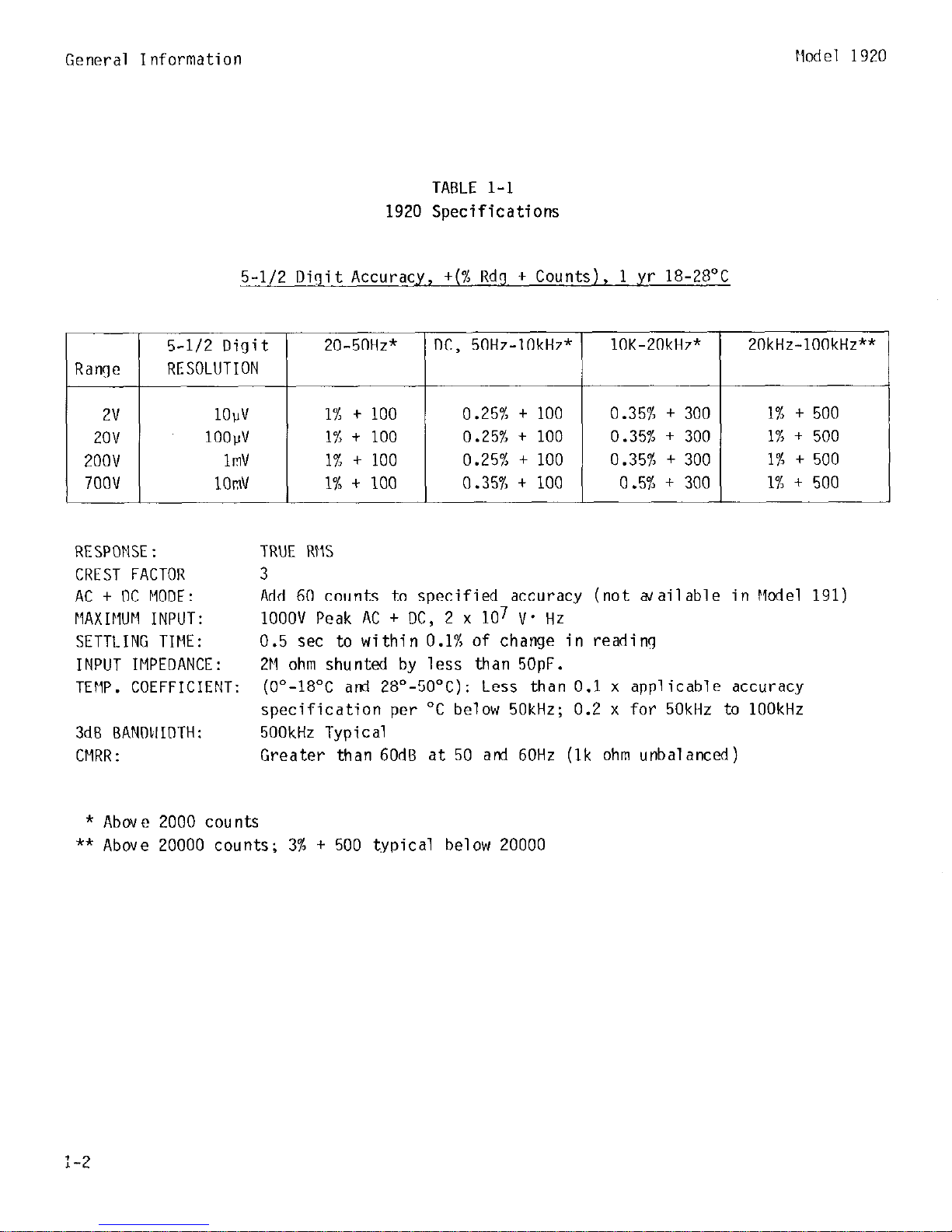

SECTION 2. OPERATING INSTRUCTIONS

Operating Instructions

Z-l. Operating Instructions for the rlcdel 1920 installed in the ilodel 191 are as

follows:

2-2.

Ilith the ilodel 1920 option, the ilcdel 191

reads AC voltages froln 10 r;licrovolts/digit

to 1000v.

The instrument displays the True Koot llean Square (TKilS) value of an AC

voltage.

It has a frequency response of 20Hz to 100ktlz.

2-3.

The rnaximm reading is 199YYY. Werrange is irdicatcd by (-) l-----, except on

the 1000 volt range.

The 700 volt range is selected idith the 1000 volt button. On the

700 volt range, the display can read beyond the rnaxiinuln allobiable input voltage. ilaximun

allobcable input: 1OOOV Peak AC + DC; 2 x lo7 V'Hz. Use the ilodel 191 to lneasure AC

voltage as follobis:

CAUTION

Do not exceed maximum allohcable input voltage. Instrument damage may

occur.

A. Turn the pokier on IJith the UN/OFF pushbutton,

ati depress the ACV pushbutton.

8.

Select the desired range from the 4 ranges available.

The decimal point is positioned

by the range pushbutton.

C.

Ensure that the I0JLL pushbutton is out (light off) unless measurements are to be made

as deviations from a preset value.

NOTE

Do not use NULL to zero the range.

A small residual zero readirq is

normal. If NULL is used to zero this offset, readings in specified

accuracy range will be low by the offset amount.

This is because rms

measurement signals add in a root mean square fashion arrl not

linearly.

The NULL function is a linear offset axl not usable in TKllS

measurements.

0.

Connect the signal to be measured between the INPUT HI ati LO binjiny posts. The

birding posts accept wires, spade lugs or banana plugs for ease of connectiq the

circuit to be measured.

Observe the displayed digits ard decimal point.

2-1

Page 8

Operating Instructions

Model 1920

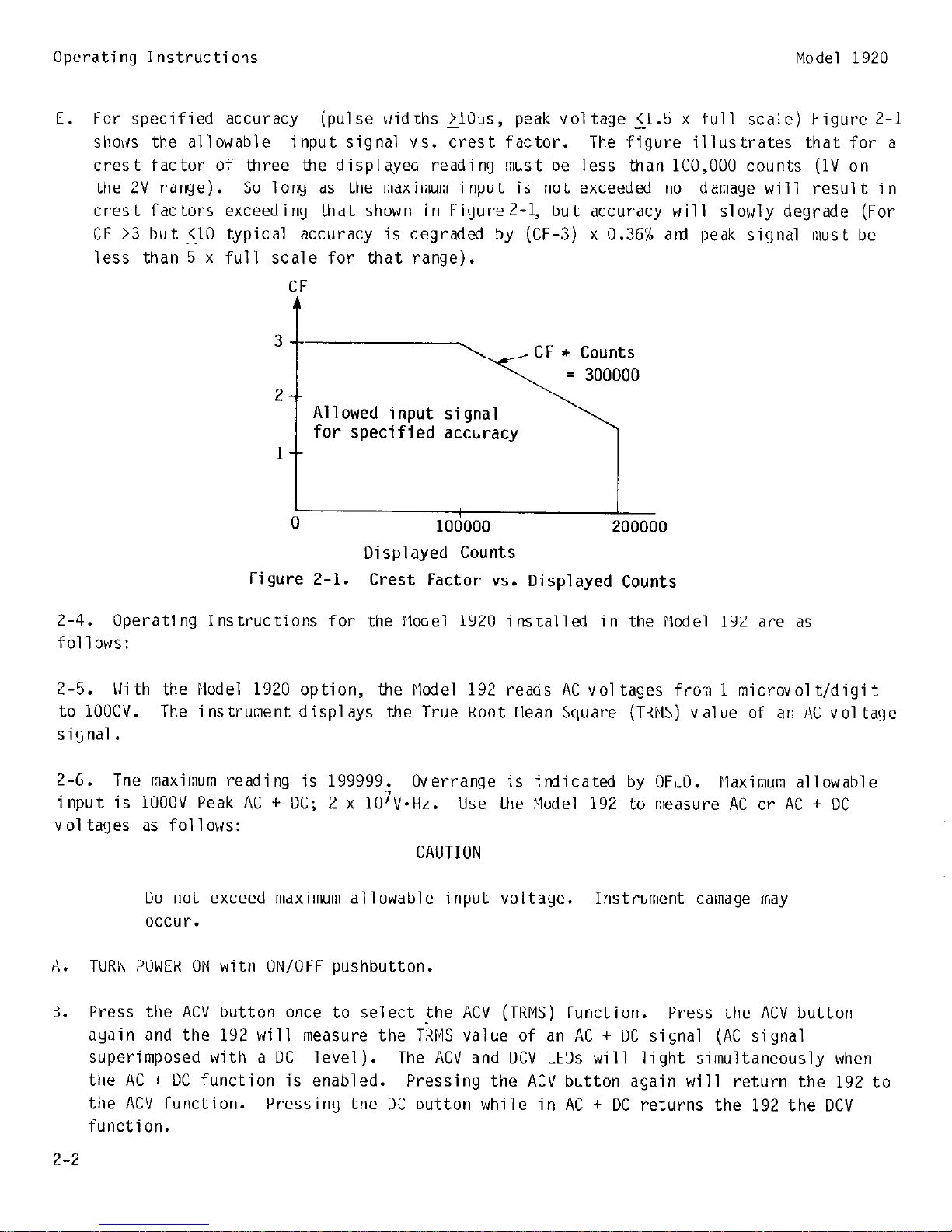

E.

For specified accuracy (pulse widths ,lOns, peak voltage (1.5 x full scale) Figure 2-1

shows the allowable input signal vs. crest factor.

The figure illustrates that for a

crest factor of three the displayed reading must be less than 100,000 counts (1V on

the 2V range).

So long as the maximum input is not exceeded no damage will result in

crest factors exceeding that shown in Figure2-I, but accuracy will slowly degrade (For

CF >3 but<10 typical accuracy is degraded by (CF-3) x 0.36% arti peak signal must be

less than 5 x full scale for that range).

CF

I

I

0

100000

200000

Displayed Counts

Figure 2-l.

Crest Factor VS. Displayed Counts

2-4. Operating Instructions for the Model lY20 installed in the Model 192 are as

follows:

2-5.

With the Model 1920 option, the Model

192

reads AC voltages from 1 microvolt/digit

to 1ooov.

The instrument displays the True Koot Mean Square (TKMS) value of an AC voltage

signal.

2-G.

The maximum reading is 199999.

Overrange is indicated by OFLO. Maximum allowable

input is 1OOOV Peak AC f DC; 2 x 107V.Hz. Use the Model

192

to measure AC or AC + DC

voltages as follows:

CAUTION

Do not exceed maximum allowable input voltage. Instrument darnage may

occur.

A. TURN POWER UN with UN/OFF pushbutton.

B.

Press the ACV button once to select the ACV (TKMS) function. Press the ACV button

ayain and the 192 will measure the T'KMS value of an AC + UC signal (AC signal

superimposed with a DC level). The ACV and DCV LEDs will light simultaneously when

the AC + UC function is enabled.

Pressing the ACV button again will return the 192 to

the ACV function. Pressiny the DC button while in AC t DC returns the

192

the DCV

function.

2-2

Page 9

UPEKATINti INSTKUCTIUNS

NOTE

IWDEL 1YZU

The 14odel 192 will display "NO AC" if ACV is selected without the 1920

or 1910 ACV option.

The AC + UC function is available only with C-4

and dbove software and Kev U and above Analoy Board.

C. SELECT KANtiE from the four ranyes available. The decimal point is positioned by the

ranye pushbutton. The 1UOUV ranye is selected with the 2000 button. If the ZUIQ

button is inadvertently pressed when in ACV function,

the 192 will set the ranye to

1uuo.

Il. ZEKU OFF unless [measurements are to be made as deviations frown a preset value.

NOTE

Uo not use ZEKU to zero the ranye. A small residual zero readiny is

normal. If LEKU is used, the residual voltaye readiny in specified

accuracy ranye will be low by the amplitude of the zeroed residual

voltaye.

This is because rms measurement signals add in a root mean

square fashion and NUT linearly. THe LEKU function is a linear offset

and not usable in TKMS measurelnents.

E.

CONNECT IllPUT to be measured between the HI HCV and LO bindiny posts.

F.

TAKE KEAUING.

ti. For specified accuracy (pulse widths LlUus, peak voltage (1.5 x full scale) Figure Z-l

shows the allowable input siynal vs. crest factor.

The figure illustrates that for d

crest factor of three the displayed readiny (must be less than lUU,UUU counts (1V on

the ZV ranye).

So long as the maximum input is not exceeded no damage will result in

crest factors exceediny that shown in Fiyure 2-1,

but accuracy will slowly degrade

(For CF >3 but 510 typical accuracy is degraded by (CF-3) x U.3GX and peak signal must

be less than 5 x full scale for that range).

Page 10

Page 11

Model 1920

SECTION 3. MAINTENANCE

Maintenance

3-l. The Model 1920 is a plug-in option that can be installed in your Model 191 or 192

Instdllation of the 1920 into your instrument is as follows.

WARNING

All service information is intended for qualified electronic maintenance

personnel only.

3-2. INSTALLATION: (For use with Model

191)

A. Disconnect the line power cord of the Model

191

and remove all test leads from its

input terminals for safety.

B. Turn the DMM bottom side up and loosen the four screws in the bottom cover.

C.

Hold the top and bottom cover together to prevent their separation and turn the DMM

over to the normal position. Remove the top cover.

D. Remove the RF shield by grasping it and FIRMLY lifting it away from the motherboard.

E. Carefully insert the connector of the

1920

into its mating receptacle on the 191

motherboard. Take note of the orientation of the

1920

into the 191 motherboard as

shown in the figure below. Connect the brown wire of the

1920

to Pin 7 of the DCV

switch, and connect the blue wire to Pin 9 of the ACV switch.

F. Replace the RF shield being careful not to pinch any wires.

G. Calibrate the

1920

per the procedure located on Table 3-5.

H.

Replace the top cover.

3-l

Page 12

Maintenance

Model 1920

NOTE

Pin locations for the switches are shown on the decal on top of the RF

shield.

WARNING

All service information is intended for qualified electronic

maintenance personnel only.

3-3.

INSTALLATION: (For use with Model 192)

A. Uisconnect the line power cord of the Model 192 and remove all test leads from its

input terminals for safety.

B.

Remove two screws that hold the top cover to the rear panel and remove the cover.

C.

Remove the top shield from the Analog Board by grasping it and FIRMLY lifting it off,

with a prying motion of the four retaining clips.

u. Carefully insert the connector of the 1920 into its mating receptacle on the Analog

Uoard.

Take note of the orientation of the 1920 onto the 192 Analog Hoard as shown in

the figure below.

3-2

Page 13

Model 1920

Maintenance

E.

Connect the brown wire of the 1920 to P1014 on the Analog Board as shown in the figure

below.

Connect the blue wire to PlOlG which is located on the ACV HI input terminal.

This is also shown in the figure below.

F.

Replace the shield to the Analoy Board beiny careful not to pinch any wires when

engaying the shield into the retaining clips.

ti.

Calibrate the lY20 per the procedure located on Table 3-4.

3-3

Page 14

Maintenance

Model

1920

3-4. PERFORMANCE VERIFICATION

3-5.

Performance verification may be performed upon receipt of the instrument to ensure

that no damaye or misadjustment has occurred duriny transit.

NOTE

For instruments that are still under warranty (less than 12 months

since date of shipment), if the instrument's performance falls outside

specifications at any point, contact your Keithley representative or

the factory immediately.

3-6. RECOMMENDED TEST EQUIPMENT

3-7. Kecommended test equipment for performance verification is listed in Table 3-l.

Alternate test equipment may be used.

However, if the accuracy of the alternate test

equipment is not at least 4 times better than the instrument specifications, additional

allowance must be made in the readinys obtained.

ITEM

TABLE 3-l

Recommended Test Equipment For Performance Verification

UESCKIPTIUN

SPECIFICATION

MFK,

I

O.lV, lV,

lOV, 1oov

H-P

+O.WzX

1OOOV

H-P

+0.04%

AC Calibrator

High Voltage Amplifier

(Used with Model 745A)

UC Calibrator

I

1v +0.002x

Flukl

746A

343A

3-7.

ENVIRONMENTAL CONDITIONS

3-8.

All measurements should be made at an ambient temperature within the range of 18" to

28'C (GS" to 82'F), and a relative humidity of less than 8o'k.

3-9. PERFORMANCE VERIFICATION PROCEDURE

3-10.

Use the following procedure to verify the basic accuracy for AC voltage in the

Model

191

or the Model 192.

3-4

Page 15

Model 1920

Maintenance

WARNING

Performance verification should be performed by qualified personnel

using accurate and reliable test equipment.

3-11. INITIAL CONDITIONS

3-12. Before beginning the verification procedure,

the instrument must meet the following

conditions:

A. If the instrument has been subject to extremes of temperature, allow sufficient time

for internal temperatures to reach environmental conditions specified (1X0-28'C).

Typically, it takes one hour to stabilize a unit that is 10°C (1U'F) out of the

specified temperature range.

B. Turn on the instrument and allow it to warm up for two hours before using it with the

Model 192 and one hour before using it with the Model 1Yl.

WARNING

Some procedures require the use of high voltage. Take care to

prevent contact with live circuits which could cause electrical shock

resulting in injury or death.

3-5

Page 16

Maintenance

Model 1920

Performance Verification

2V

2UV

zoov

7oov

2V

ZUV

zoov

2V

NV

2UUV

7oov

ZUV

zov

ZV

2V

APPLIED INPUT

AT

1kHz

l.UUUOUV

1o.ouoov

lUO.UUUV

7oo.oov

AT ZUkHz

l.UUUUOV

lU.UUUUV

lUU.UUUV

AT 1UUkHz

l.UUUUUV

lU.UUUUV

lUU.UOUV

AT 3UkHz

700. oov

AT ZOHz

1o.uuuuv

AT 50Hz

10. ououv

AC + UC Mode

+1.uuouov UC

-1.uuuuuv UC

T

ALLUWAfJLf

For 191

.9965UV to 1.0035UV

9.965OV to 10.035UV

99.65UV to 100.35UV

696.55V to 703.45V

.9935UV to l.UU65OV

9.Y35UV to lU.UG5UV

99.35UV to 100.65UV

.985UUV to 1.01500v

9.x5uuv to 10.1500v

Y8.5UOV to 101.5uuv

688.UOV to 712.oov

9.89UUV to 10.1100v

9.89UUV to 10.1100v

L

:EAUIIVGS

For

192

.Y9G5UV to 1.0035OV

9.965OV to 10.035UV

99.GWV to lOU.35OV

696.55V to 703.45V

.9935OV to l.UU65UV

9.935011 to lU.UG5OV

99.35UV to lUU.65OV

.985UUV to 1.015uuv

9.85OUV to lU.15OOV

9x.5uuv to lU1.5OOV

688.OOV to 712.OOV

Y.89OUV to 10.1100v

9.89UOV to 10.1100v

.995YUV to 1.ou41uv

-.9959uv to -1.uu410

3-6

Page 17

Model 1920

Maintenance

3-13.

CALIBRATION

3-14.

This section contains information necessary to calibrate the Model 1920 in your

instrument (191 or lY2). Calibration should be performed when any of the followiny

conditions occur:

A. Annually

B. Installation of the 1920

C. Performance Verification indicates 1920 as out of specification

3-15. RECOMMENDED TEST EQUIPMENT

3-16. Recommended test equipment for calibration is listed in the following table.

Alternate equipment may be used. However, the accuracy of the alternate equipment must be

at least 4 times better than the Model 1920 specifications,

or equal to the specifications

listed in the Table below.

TABLE 3-3

Recommended Test Equipment For Calibration

ITEM

UESCRIPTION

SPECIFICATION MFK. MOUEL

-

A DC Calibrator

+1v

Fluke

343A

r.uw'/

B

AC Calibrator

U.lV,

lV, lOV, 1uuv

H-P 745A

Hl.U22%

C High Voltage Amplifier

IUOUV H-P 746A

(Used with Model 74SA)

+0.04x

II

Calibration Cover

--

Keithley 1913 (191)

3-17. ENVIRONMENTAL CONDITIONS

3-18. Calibration should be performed under laboratory conditions having an ambient

temperature of 23

_+l”C,

and a relative humidity of less than 70%. If the instrument has

been subjected to temperatures outside of this range, or the higher humidity, allow two

hours minimum for the instrument to stabilize at the specified environmental conditions

before beginning the calibration procedure.

3-19. CALIBRATION PROCEDURE

3-20.

Remove the top cover of your instrument and replace it with the appropriate

calibration cover.

With the calibration cover in place allow the internal temperature of

the instrument to stabilize for two hours before performing the calibration.

3-7

Page 18

Maintenance

WARNING

Model 1920

3-8

STEP

1

2

*AUJU

3

4

5

6

Some procedures require the use of high voltage. Take care to prevent

contact with live circuits which could cause electrical shock

resulting in injury or death.

R42G

R406 C412

Model 1920 Calibration Adjustments

TABLE 3-4

Model 1920 Installed in the 192

Calibration Procedure

KANtiE

FWCTIUN

APPLIEU INPUT

AUJIJSTMENT

KEAUINti

2

ACV + KY

1.lllllloov UC

*Calibrator

I.UOOOO ?lO counts

2

ACV + UCV

-1.UOUUUV UC

*K411

l.UOOUU QO counts

I

I

KNT: Adjust the UC calibrlator until the display reads 1.00000 +I0 digits.

leads and take note of the reading.

Keverse th

Adjust K411 to l/Z the difference (Example:

Keadiny is l.U04lJU, adjust K411 to read 1.00200).

?peat Steps and 2 until there is < 10 digits

change in reading from + to -.

ACV

l.UlxlUUV AC

at SUUtir

ACV

.llJlJUlJV AC

INepeat Steps 4 and 5 until they

K407

1.00000 ?lO counts

K4Z6

.lOOOlJ i-10 collnts

are within tolerance.

Page 19

Wodel

1920

Maintenance

c

I;iP

7

20

c, mu

Y I 2lJlJu

( 700V AC Max)

10 2UU

11

2

12

20

ACV

ACV

5UU.UUV AC

IUU.UUUV AC

at

1Wktiz

/\cv

ACV

l.UUUUUV AC

at 1UUkHr

lU.UUUUV AC

I

I

I

at 1UUktir

13

Kepeat Steps lU-12 until no chanye.

14

Kepeat Steps l-l:! to verify the readings.

NOTE

T

TABLE 3-4

Model 1920 Installed in the 192

Calibration Procedure (cont.)

FUNCTION APPLIED INPUl AUJUSTMENl

ACV

ACV

1o.oLwLlv HC

at SUUtir

lUU.UUUV AC

at 5UUtlr

K4U0

K405

K404

C413

Caution: Use

an insulated

aliynlnent tool

c4u2

C4U7

KEAUINti

5LlO.UU r10 counts

lOO.llU +25u counts

l.OUOU *50 counts

lU.ULlUU ~100 counts

tliyh frequency (100kHr) measurements are sensitive to component location.

Uo nut move or bend the components in the input area (C401, iKWJ, etc.)

Kecalibration is necessary if these components are moved.

If the 1uuv

1UUkHr cannot be brouytit into specification,

refer to the troubleshootiny

section.

WARNING

Some procedures require the use of high voltage. Use an insulated alignment

tool.

Take care to prevent contact with live circuits which could cause

electrical shock resulting in injury or death.

3-9

Page 20

Maintenance

Model 1920

TABLE 3-5

Model 1920 Installed in the 191

Calibration Procedure

STEP

KANtiE

FWCTIUI~

I\PPLIEU INPUT

AUJUSTMENT

KEAUING

1

2 ACV

1UUmV AC

K411 Minimum Reading

at 50011r

2 2 ACV

1UmV AC

K411

Minimum Reading

at SUUHr

3 2 ACV

l.UUUUUV AC

K4U7 l.UUOUU *lo counts

at SUUHZ

4 2 ACV .lUUUUV AC 11426

.lUUUU *lo counts

at 5UUHr

:, IRepeat Steps 3 dnd 4 until they are within specification.

ti

20

ACV

11).uouuv AC

K4UG

10.0000 *lo counts

at 5UUHz

7 2uu ACV

IUU.UUUV AC

I<405

100.000 ?lO counts

at SUUHZ

8

zuuu

ACV

suu.ouv AC

11404 5u0.00 +10 counts

( 7UOb AC Max)

9,

LOU

ACV

lUU.UUUV AC

c413

100.00 i25ll counts

at 1lJUkHr

Caution: Use an

insulated alignment tool.

10

ii

ACV

l.UUUUUV AC

c4uil 1.0000 +50 counts

at 1UUkHz

11 20 ACV lU.UUUUV AC c4u7

10.0000 *loo counts

at 1OUkHr

12 Hepeat Steps 9 thru 11 until no change.

13 Kepeat Steps 1 thru 11 to verify the readings.

NOTE

Hiyh frequency (100kHz) measurements are sensitive to component location.

Do not move or bend the components in the input area (C401, K403, etc.)

Recalibration is necessary if these components are inoved.

If the 1OUV

1UUkHz cannot be bt-ouyht into specification,

refer to the troubleshooting

section.

3-22.

Troubleshooting

3-23. The troubleshootiny instructions contained in this section are intended for

qualified personnel having a basic understanding of analog and digital electronic

principles and components used in precision electronic test equipment. Instructions have

been written to assist in isolating the defective circuit or subcircuit.

Isolation of the

specific defective component has been left to the technician.

3-10

Page 21

Model 1920

Maintenance

NOTE

For 1920's that are still under warranty (less than 12 months

since date of shipment), if the 1920's performance is outside

of specifications at any point,

contact your Keithley representative

or the factory before attempting troubleshootiny or repair.

3-24. Troubleshooting Procedure

3-25. Table lists step by step checks of the lnajor circuit blocks of the 1920. Follow

Table 3-G to locate the trouble.

NOTE

Performance Verification of the Model 1920 is necessary if any of

the following occurs.

1)

Kemoval /rep1 acement of 1920

2) Removal/replacement of shields on the 1920

WARNING

Some procedures require the use of High Voltage. Take care to prevent

contact with live circuits which could cause electrical shock resulting in

injury or death.

TABLE 3-6

Model 1920 Troubleshooting (cont.)

STEP

1

7

8

9

ITEWCOf1PONENT

REQUIKEO CONDITIOll KEHAKKS

J1006,

Pin 1

U401, Pin 7

U401, Pin 4

U403, Pin 8

(Brown wire 51008)

U401, Pin G

Q408, Pins 2

anJ. 5

Q408, Pin 3

Turn on Power. Select the

AC function ard 2V range.

t5V <lOOnV AC noise

t15V *lV DC <lOOnV AC noise

-15V +lV DC <lOOnV AC noise

Apply 1 volt at 1ktlZ

1 volt DC

+5v supply

t15v supply

-15v supply

1920 output

1 Volt AC at IkHZ, no DC Offset

u401 output

+3V to t8V DC, within

1OmV

Differential Output

of each other

of Q408

UV t 25mV

Input summifq junction

Page 22

Maintenance

Model 1920

-

TABLE 3-6

Model 1920 Troubleshooting (cont.)

STEP

10

11

12

13

14

ITEM/COMPONENT

REQUIRED CONDITION

Select 2ov range

a,j apply 1OV AC at 1kHZ

Select 2oov ranye ard

apply 100 V AC at 1kHZ

Select 700V range ard

apply 350V AC at 1kHZ

Select AC + DC function

ard the 2V rarqe. Apply

1v DC

Select AC apply IV DC

KEIlAKKS

(virtual ground)

If display overranges

check (1406 an3 Q407

for gate drive ard

signal

If

display met-ranges

check Q404 ard Q405

for gate drive anl

signal

If display wet-ranges

check Q402 arrl Q403

for gate drive drd

signal

Check display for 1V

if not, check (1401 an3

K401

Oisplay approx. OV

if not, check Q401

K401, c401

NOTE

If the 1OOV 1OUkHz adjustment cannot be brought into specification,

check the spaciny between C4Ul and K403. If these components have

been bent toward or away from each other, C413 may not have adequate

calibration ranye.

Moviny C401 and K403 closer toyether increases the

1OOkHz response on all ranges.

Check and adjust, if necessary.

3-12

Page 23

Model 1920

Theory of Operation

SECTION 4. MODEL 1920 THEORY OF OPERATION

4-l. The Model 1920 is a plug in AC(+UC) to RMS converter with variable yain. The gain

factor conditions the AC input voltaye for application to the A/U converter.

4-2. The input siynal is applied through GIN (0.05uF) and KIN (2Mrl) to 4408. For

AC+UC operation GIN is shorted by Relay K4Ul.

The two stage amplifier (op amp) is a

variable yain inverting type with gain from-U.001 to-l (see table below). The gain is

selected accordingly by the double FET switches Q402-Q407. Two FETs are used for each

range.

They are configured in a T-type attenuator with the 1Uk resistors K413, K414 and

K41G to effectively attenuate high frequency (1UUkHz) signals.

4-3.

The op amp is a two stage amplifier. The first stage is confiyured around dual FET

Q408. 4408 allows the reduction of input bias current.

This reduction is necessary

because an auto zero cycle is not possible on the AC or AC+UC functions. Any input bias

current will show up as an input offset voltage.

The second stage is configured around

u401. The output of U4Ul is applied to the KMS converter U403. C409, C41U and K42U make

up the two pole filter that is located at the output of U403. The output of U403 is a UC

signal which is applied to the A/U converter.

A small UC offset may be applied to the

auto zero A/D input by adjusting R426.

This allows compensation for the KMS converter's

output offset.

TABLE 4-l

Ranging Information

Ranye tiain

UP Amp Feedback Resistance Engergized FETs

2v 1

None

2ov

l/10 (217k f"K4U6) 11 2M

Q406, q4u7

2ouv

l/100 (19.6k + K405)1) 2M

Q404, Q405

7UOV

l/lOUU

(2.12k + K404)I)

Q402, Q403,

(19.GK + R405)1/ 2M

Q404, Q4U5

.I

4-1

Page 24

Model 1920 Biock Diagram

FET

Orive

-

-

Range

Select

Page 25

Model 1920

Repldieabl

e Parts

SECTION 5.

REPLACEABLE PARTS

5-l.

General

5-2. This section contains information for ordering replacement parts. The replaceable

parts list is arranged in alphabetical order of the circuit designations of the

components.

A crass reference list of manufacturers containing their addresses is

given in Table 5-1.

5-3.

Ordering Information

5-4.

To place an order or to obtain information concerning replacement parts contact your

Keithley representative or the factory.

See the inside front cover for addresses.

When ordering,

include the following information:

a. Instrument Model Number

b.

Instrument Serial Number

c. Part Uescription

d.

Circuit Designation (if applicable)

e. Keithley Part Number

5-5. Factory Service

5-6. If the instrument is to be returned to the factory for service, please complete the

Service Form which follows this section and return it with the instrument.

5-7. Schematic and Component Layout

5-B. The Schematic and Component Layout follow this section.

TABLE 5-l

Cross Reference of Manufacturers

MFti Code

A-U

NAME AND AUURESS

Analog Uevices, Inc.

Norwood, MA 02026

FEUEKAL SUPPLY COUE

01121

BKN

Bourns, Inc.

Kiverside, CA 92507

80294

5-l

Page 26

Replaceable Parts

Model 1920

MFti Code

c-u

CLU

CLK

ULE

EC1

EFJ

EKI

INT

K-I

NAT

N I c

NYT

MEP

TABLE 5-l

Cross Reference of Manufacturers (cont.)

INAME ANU AUUKESS

Cornell-Uubilier

Newark, NJ 07101

Centralab Uivision

Milwaukee, WI 532021

Clarostat Manufacturing Co.

Uover, NH 03820

Uale Electronics

Columbus, NE 68601

Electra-Cube, Inc.

San Gabriel, CA

91776

E. F. Johnson Co.

Waseca, MN 56093

Erie Technological Products

Erie, PA

16512

Intersil,

Inc.

Cupertino, CA

95014

Keithley Instruments, Inc.

Cleveland, Ohio 44139

National Semi Corp.

Santa Clara, CA 95051

Nichicon Corp.

Chicago, IL 60645

Nytronics Components Group

Darlington, SC 29532

Mepco, Inc.

Morristown,

NJ 07960

FEUERAL SUPPLY CODE

-

1

14655

71590

12697

91637

14752

74979

72982

32294

80164

27014

83125

80031

5-2

Page 27

Model 1920 Replaceable Parts

TABLE 5-1

Cross Reference of Manufacturers (cont.)

MFG Code

PKP

NAME ANU AUUKESS

Precision Kesistive Products

Mediapolis, IA 53237

FEUERAL SUPPLY COUE

SIL

Siliconix, Inc.

Santa Clara, CA 95054

17856

STD

Standard Condenser

Chicago, IL

Texas Instruments,

Inc.

Uallas, TX 75231

97419

T-I

01295

5-3

Page 28

Replaceable Parts

Model 1920

TABLE 5-2

Replaceable Parts List (cont.)

Circuit Schematic PC-Board Mfr. Mfr.

Keithley

Lksig. Description

Location Item No./Location Code Lksig.

Part No.

c401 .05,#, lUUUV, Metal Poly A4 5/EZ STU CAPACPLYEEOX

C-285-.05

c402 .25pF to 1.5pF, ZOOUV Trimmer 23 6/E2

EFJ 273-0001-002 31863A

c403

IpF, XV, Alum Elect tI3 7/u

NIC SOVKBID c-325-1.0

c404 luF, 16V, Alum Elect 04 8/E2

NIC SIJVKBIU c-325-1.0

c4u5 33OpF, 5OUV, Poly

Cl Y/D2 CLtJ CPK330J C-138-33UpF

C406 3llpF. 5OUV, Mica

c2 IO/D2 C-O

UClOEUUOJ3 C-236-30pF

c407 .25pF to 1.5pF, 2UUUV,

c3

11/w

K-l 273-0001-002 3186311

Trimmer

c4w luF, 5UV, Metal Poly F4 12/c3

EC1 625U

c-335-1.0

C4OY

l,,F, SUV, Metal Poly FS 13/c3

EC1 6258 c-335-1.0

c41u

l"F, 5UV, Metal Poly F5

14/C3 EC1 62513

c-335-1.0

c411 33pF, 5UlJV, Mica 04

15/w C-D

UClUEU3OUJ3 C236-33pF

c412 G.BpF, SOV, Tube Cer

lUU/W ERI

301.oooco c-282-6.8pF

HO15

c413 .25pF tu l.SpF, XJOOV, u4

101/u K-I 273.OOUl-002

3186311

Trimmer

102/E2

CKL KlCC2U

C-77-0.75pF

IN914

RF-28

IN914

RF-28

IN914

RF-28

KL-69

5-4

Page 29

Model 1920

Replaceable Parts

Circuit

lksig.

L401

L4U2

q401

q402

q403

4404

q405

4406

4407

441)s

R401

R4O2

R403

R404

R405

R406

R407

R408

R409

K410

R411

Description

lUU,,H Choke

lOU$l Choke

Transistor, PNP

N-Channel JFET (selected)

N-Channel JFET

N-Channel JFET (selected)

N-Channel JFET

N-Channel JFET (selected)

N-Channel JFET

Uual N-Channel JFET

lk, 1%. 1/2W, rntf

lk, I%, i/ZW, lntf

2M,

.5x,

lW, mtf

Pot, lUUl1, lor, 3/4w

Pot, lk,

lo’b,

J/4W

Pot, 1Uk. lOY, 3/4W

Pot, lk, lo%, 3/4W

2.12k,

.Yb,

1/8W, intf

19.6k, .a, l/IIW, mtf

217k,

.5x,

1/8W,

mtf

Pot, lOk, lo'b, 3/4W

TABLE 5-2

laceable Parts List (cont.)

thematic

ocati on

A3

A3

nz

lx

E2

u2

E2

II3

E3

c4

84

04

B4

CZ

C2

C3

F5

c2

CZ

C3

05

17/w

l&l/U3

34lE3

35/U2

36102

37/w

38/U2

39/w

4U/U2

41/E2

57/F2

58!FZ

5Y/E2

(IU/UZ

61/02

62/W

63/1)2

64102

65lU2

a/u2

67lE2

I

PC-Board

,tem No./Location

Mfr.

Code

NYT

NYT

A-U

K-I

INT

K-l

INT

K-l

INT

SIL

ULE

ULE

ULE

BRN

BRN

BRN

BHN

ULE

ULE

OLE

URN

Mfr.

Desig.

swu-100

swu-1uu

AU-820

lTE43Y2

lTE4392

ITE4392

E411

MFF-l/2

MFF-l/2

MFF-l/2-31

36UU, IiPlUU

3600, GPlOUU

36OO, GPlOUUU

3600,

tiPlOO

MFF

l/U

MFF-l/8

MFF-l/8

3600, GPlOUOO

T

Keithley

Part No.

CH-14

CM-14

Tti-84

TG-128

Tti-77

Tti-128

Tti-77

FIG-12X

TG-77

Tti-118

K-94-lk

K-Y4-lk

K-303-21.1

IRP-XY-100

KP-XY-lk

RP-&l9-1Ok

KP-89-lk

R-246-2.12k

R-246-19.6k

K-246-217k

RP-89-1Ok

5-5

Page 30

Reolaceable Parts

Model 19'20

TABLE 5-2

Replaceable Parts List (cant

Circuit

Desig.

R412

R413

R414

11415

K416

K417

K418

11419

R420

K421

R422

11423

K424

R425

K426

K427

K428

R42Y

lK430

K431

H432

K433

K434

Iescription

LM, 5X, 1/4W, Carb

LUk, 5'h, 1/4W, Carb

IOk, 5%, 1/4W, Carb

LM, 5%. 1/4W, Carb

lOk, Y/S, 1/4W, Garb

lM, 5X, 1/4W Carb

ZM, .b%, 1/8W, i&f

j.65k, lY, l/ilW, mtf

24k, 5X, 1/4W, Carb

IOk, I%, 1/8W, mtf

2.20, 5X, 1/4W, Carb

Z.Zk, 5%. 1/4W, Carb

J.3k, 5X, 1/4W, Carb

2.2k,

5y,

1/4W, Cat-b

Pot, lOk, lo%, 1/2W.

2.2k, 5$, 1/4W. Garb

49912, la, l/&l, mtf

SG.Zk, .5x,

1/8W,

mtf

56.2k, .5%, l/SW, mtf

44.2k, I%, 1/8W, mtf

lOk, 5X, 1/4W, Carb

16.9n, 1X, l/&J, mtf

33k, 5X, 1/4W, Carb

ichematic

.ocation

U2

UZ

II3

U3

u3

U3

c4

04

F5

F2

GZ

F4

G4

A2

F2

F5

E5

c4

C4

c5

c5

c5

u4

t-

PC-Board

tern No./Location

68/C2

69/U

7o/c3

7l/C3

72ic3

73/a

74/E2

75/U2

76JC3

77/u

78/C?!

7Y/CZ

UUICZ

Xl/E2

82/C2

83/U3

84/w

85/E2

86/U2

87/E2

@S/E2

89/U

YO/OZ

Mfr.

Code

MEP

MEP

MEP

MEP

MEP

MEP

ULE

PRP

MEP

PRP

MEP

MEP

MCP

MEP

URN

MEP

PRP

ULE

ULE

PKP

MEP

PKP

MEP

Yfr.

Jesig.

X25*

CK25*

CK25*

CK25*

CK25*

CR25*

YFF-l/II

**

CR25*

**

CK25*

CR25*

CR25*

CRZS*

3386H-1-103

UK25*

**

MFF-l/8

MFF-l/8

**

cn25*

**

CR25*

Keithley

Part No.

R-76.1M

IK-76-1Ok

IK-76-10k

K-76.1M

H-76-1UK

K-76-1M

IR-246-2M

K-88-3.65k

IR-76.24k

IK-88.1Ok

R-76-2.2

R-76.2.2k

IK-76-3.3k

R-76-2.2k

KP-111.1Ok

K-76-2.2k

R-88-499

K-246-56.2k

K-246-56.2k

R-88-44.2k

R-76-10k

K-88-16.9

R-76-33k

CK25* Manufacturers Uesignation includes parts description e.g. CK25 33k, 5'6, 1/4W, Carb for 11434

**

Manufacturers &sign&ion is GP1/4, 1X, 7100, Kesistance value

5-6

Page 31

Model 1920

Replaceable Parts

I

Circuit

Uesiq.

u401

u4w

u4u3

2P

RI

VOI tage Quad comparator

1

t

TABLE 5-2

laceable Parts List (cont.)

khematic

aation

u4

I73,4

E5

41/u

1:

4Y/U3

49/u3

Mfr.

Code

NAT

Mfr.

Desig.

LF356H

LM339

AUS36AK

5-7

Page 32

Page 33

Page 34

KEITHLEY INSTRUMENTS, INC.

28775 AURORA ROAD

CLE'.'ELAND, OHIO 44139

SERViCE FORWl

MODEL NO. SERIAL ?lO,~

P.O. NO. DATE R-

_. ,--- _..~___

1

NAME

PHONE

COMPANY

ADDRESS

CITY

STATE

ZIP

I3 :

Describe problem and symptoms using quantitative data whenever possible (enclose

readings, chart recordings, etc.)

(Attach additional sheets as necessary).

El

Show a block diagram of your measurement system including all instruments connected

(whether power is turned on or not). Also describe signal source.

q

the instrument.

List the positions of alJ controls and switches on both front and rear panels of

El

Describe input signal source levels, frequencies, etc.

q .

List and describe all cables used in the experiment (length, shielding, etc.).

q

for each.

List and describe all other equipment used in the experiment. Give control settings

El

Environment:

Where is the measurement being performed?

(Factory, controlled laboratory,

out-of-doors, etc.)

What power line volt=is used?

Variation? Frequency?

Ambient temperature?

"F. Variation?

"F. Rel. Humidity?

Other

lxl

Additional Information. (If special modifications have been made by the user,

please describe below.)

REV 0774

Page 35

Loading...

Loading...