Page 1

Model 192

Instruction Manual

Contains Operating and Servicing Information for

Model 192 Programmable DMM and Model 1910 AC Option

Publication Date: June 1984

Document Number: 30983 Rev. C

Page 2

WARRANTY

Keithley instruments, Inc. warrants this product to be free from defects

in

material and workmanship for a period of 1 year from date of shipment. During the warranty period, we will, at our option, either repair

or replace any product that proves to be defective.

To exercise this warranty, write or call your local Keithley represent-

ative, or contact Keithley headquarters in Cleveland, Ohio. You will be

given prompt assistance and return instructions. Send the instrument,

transportation prepaid, to the indicated service facility. Repairs will be

made and the instrument returned, transportation prepaid. Repaired

products are warranted for the balance of the original warranty period,

or at least 90 days.

LIMITATION OF WARRANTY

This warranty does not apply to defects resulting from unauthorized

modification or misuse of any product or part. This warranty also does

not apply to fuses, batteries, or damage from battery leakage.

This warranty is in lieu of all other warranties, expressed or implied, including any implied warranty of merchantability or fitness for a particular use. Keithley Instruments, Inc. shall not be liable for any indirect,

special or consequential damages.

STATEMENT OF CALIBRATION

This instrument has been inspected and tested in accordance with

specifications published by Keithley Instruments, Inc.

The accuracy and calibration of this instrument are traceable to the

National Bureau of Standards through equipment which is calibrated at

planned intervals by comparison to certified standards maintained in

the Laboratories of Keithlev Instruments, Inc.

Keithley Instruments, Inc. I instruments Division

28775 Aurora Road i Cleveland, Ohio 44139 , “.‘%A

Phone: (216) 248-0400 / Telex: 98.5469

Page 3

Instruction Manual

Model 192

Programmable DMM

01982, Keithley Instruments, Inc.

Cleveland, Ohio, U.S.A.

Document Number: 30983

Page 4

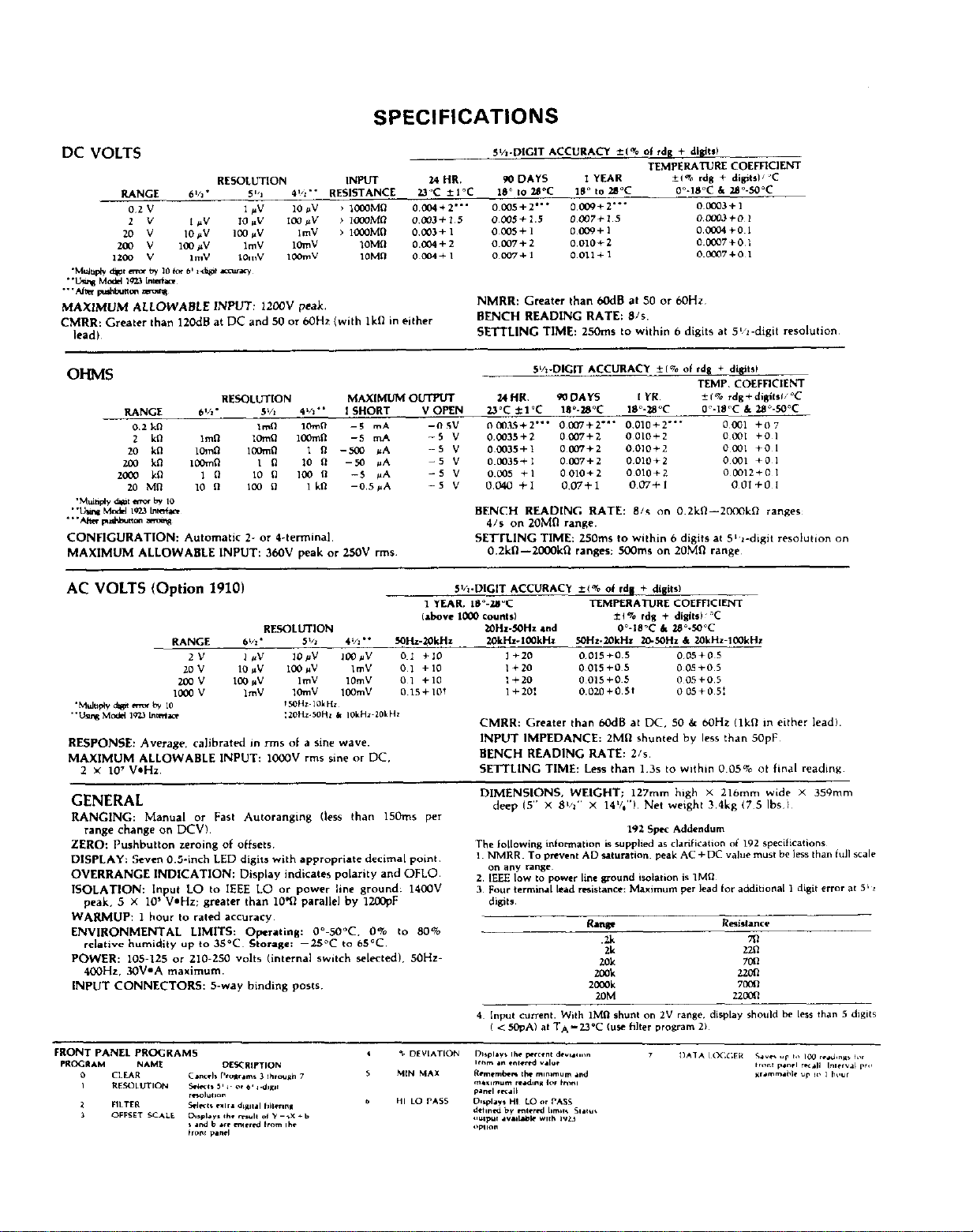

DC

SPECIFICATIONS

VOLTS

Page 5

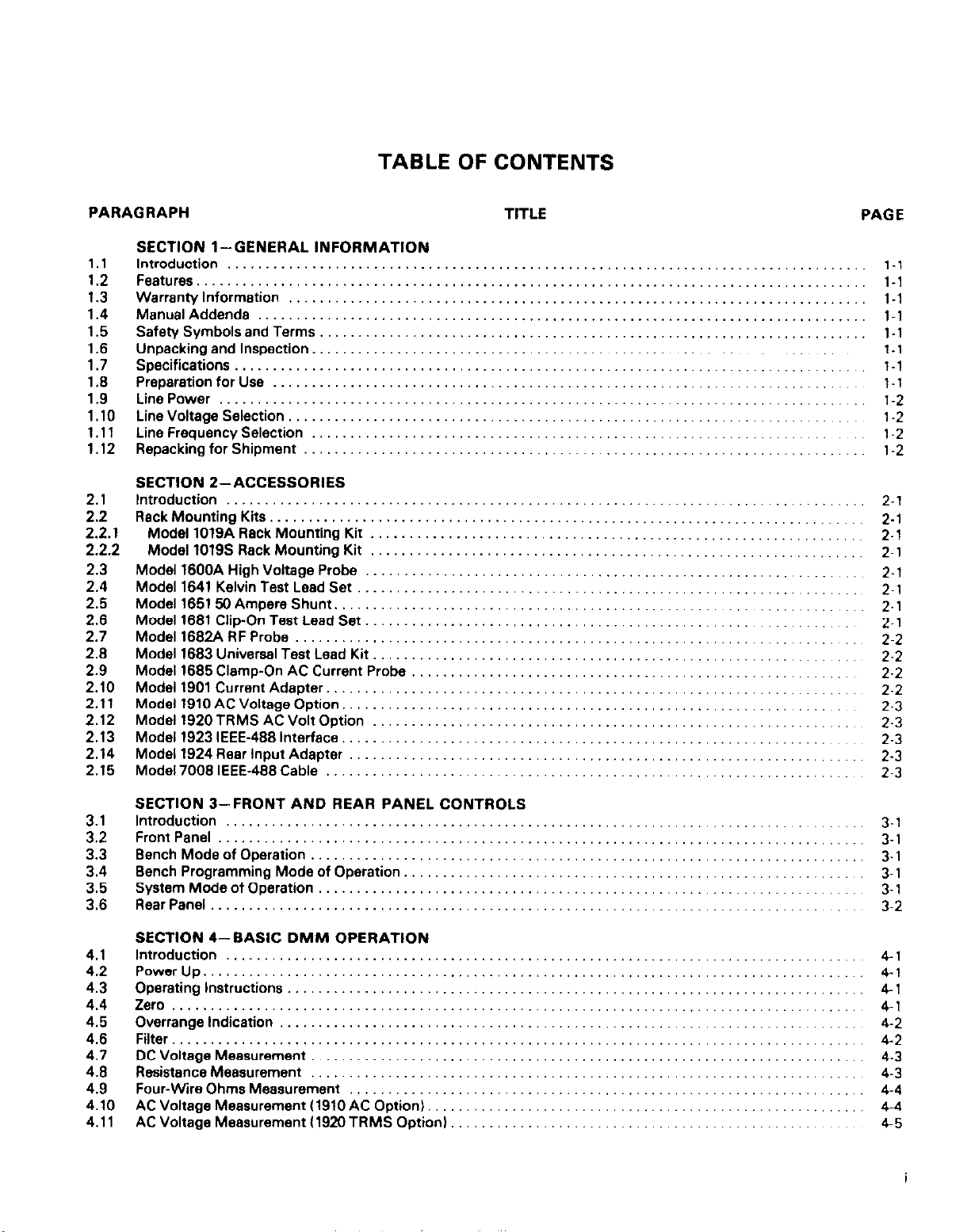

TABLE OF CONTENTS

PARAGRAPH TITLE PAGE

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

1.9

1.10

1.11

1.12

2.1

2.2

2.2.1

2.2.2

2.3

2.4

2.5

2.6

2.7

2.8

2.9

2.10

2.11

2.12

2.13

2.14

2.15

SECTION l-GENERAL INFORMATION

Introduction ...................................................................................

Features .......................................................................................

WarrantyInformation

ManualAddenda

SafetySymbolsandTerms

Unpackingandlnspection

Specifications.

Preparation for Use

Line Power

Line Voltage Selection

LineFrequencySelection

Repackingforshipment

SECTION Z-ACCESSORIES

Introduction

RackMountingKits

Model1019ARackMountingKit

Model1019SRackMountingKit

Model1600AHighVoltageProbe

Model1641KelvinTestLeadSet..............................................................~~

Model165150AmpereShunt................................................................~

Model1681Clip-OnTestLeadSet.............................................................~

Model1682ARFProbe......................................................................~

Model 1683 Universal Test Lead Kit. ..........................................................

Model 1685 Clamp-On AC Current Probe

Model1901CurrentAdapter ......................................................................

Model1910ACVoltageOption...............................................................~

Model1920TRMSACVoltOption

Model19231EEE-488lnterface...............................................................~~~~

Modal1924RearlnputAdapter..............................................................~.~~

Model7008IEEE.488Cable..

....................................................................................

...................................................................................

...........................................................................

...............................................................................

.......................................................................

........................................................................

................................................................................

............................................................................

..........................................................................

...................................................................

.........................................................................

.............................................................................

................................................................

................................................................

.................................................................

........................................................

................................................................

..................................................................

.~,~

...

...

..

..

1-l

l-l

l-l

1-l

l-l

l-l

l-l

l-l

1-2

l-2

1.2

1-2

2-l

2-1

2-l

2-1

2-l

2-1

2-l

2-l

2-2

2-2

2-2

2-2

2~3

2-3

2-3

2-3

2-3

3.1

3.2

4.1

4.2

4.3

4.4

4.5

4.6

4.7

4.8

4.9

4.10

4.11

SECTION 3-FRONT AND REAR PANEL CONTROLS

Introduction

Front Panel

BenchModeofOperation

Bench Programming Mode of Operation.

SystemModeofOperation

RearPanel

SECTION 4-BASIC DMM OPERATION

Introduction

Powerup....................................................................................~

Operating Instructions

zero .........................................................................................

Overrangelndication

Filter .........................................................................................

DCVoltageMeasurement

ResistanceMeasurement

Four-Wire Ohms Measurement ...................................................................

AC Voltage Measurement (1910AC Option).

AC Voltage Measurement l192OTRMS Optionl,

...................................................................................

....................................................................................

........................................................................

.........................................................

.......................................................................

.....................................................................................

...................................................................................

...........................................................................

............................................................................

........................................................................

......................................................................

........................................................

....................................................

3-1

3-l

3-l

3-l

3-l

3-2

4-l

4-1

4-l

4-l

4-2

4-2

4-3

.,

4-3

4-4

4-4

45

Page 6

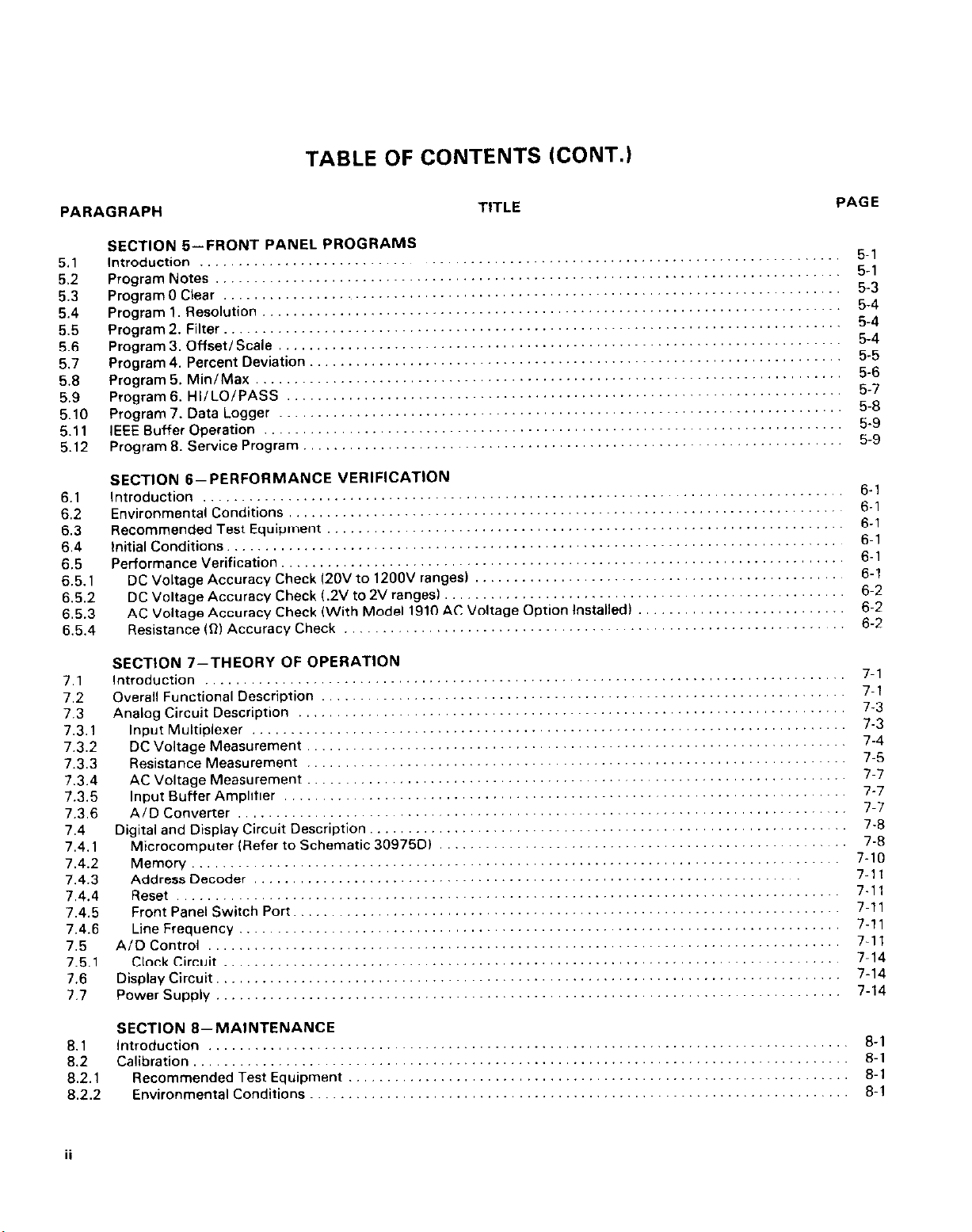

TABLE OF CONTENTS (CONT.1

PARAGRAPH

SECTION ‘&FRONT PANEL PROGRAMS

5.1

5.2

5.3

5.4

5.5

5.6

5.7

5.8

Introduction

.................................................................................................................................................................... Program Notes

P,og,a,“OC,~~, ................................................................................

Programl.Resolution

ProgramZ.Filter

Program3.Dffset/Scale

Program4. Percent Deviation.. ...................................................................

Program5,Min/Max

5.9

;:;(: Program7.DataLogger

5.12 ProgramB.ServiceProgram

6.1

6.2

Program&HI/LO/PASS

lEEEBufferOpmt,on

SECTION 6-PERFORMANCE VERIFICATION

Introduction ...................................................................................

Environmental Conditions ........................................................................

6.3

6.4

6.5

6.5.1

6.5.2

6.5.3

6.5.4

7.1

7.2

7.3

7.3.1

7.3.2

7.3.3

RecommendedTestEquipment

InitialConditions

Performanceverification

DC Voltage Accuracy Check 12OV to 12OOV ranges)

DC Voltage Accuracy Check (.2V to2V ranges1

AC Voltage Accuracy Check (With Model 1910 AC Voltage Option Installed)

Resistance(R)AccuracyCheck

SECTION 7-THEORY OF OPERATION

Introduction

Overall Functional Description

Analog Circuit Description

InputMultiplexer .............................................................................

...................................................................................

DCVoltage Measurement

ResistanceMeasurement

7.3.4 ACVoltageMeasurement

7.3.5

7.3.6

7.4

7.4.1

7.4.2

7.4.3

7.4.4

7.4.5

7.4.6

7.5 AIDControl ..................................................................................

7.5.1 ClockCircuit

7.6 DisplayCircuit

7.7

InputBufferAmplifier

AIDConverter ...............................................................................

Digital and Display Circuit Description

Microcomputer (Refer to Schematic 309750)

Memon/

AddressDecoder..

Reset ......................................................................................

FrontPanelSwitchPort

LineFrequency

PowerSupply

..............................................................................................................................................................

...........................................................................

.........................................................................................................................................................

............................................................................

.................................................................................................................................................

...........................................................................

......................................................................

...................................................................................................................................................

.........................................................................

.................................................................

....................................................................

.......................................................................

............................................................................................................................................

...............................................................................................................................................

..............................................................

.......................................................................

..............................................................................

.................................................................................................................................................................

.................................................................................

TITLE

.............................................

.................................................

.....................................................

...........................

PAGE

5-1

5.,

;I;

5-4

5-4

z:E

5-J

5-B

;I;

E:;

E:i

..

;:;;

;:;;

7.11

7.11

;I;:

7.14

6-l

6-l

;I:

6-2

7-l

7~1

7-3

7-3

;:;

;I:

7-7

;:;

SECTION E-MAINTENANCE

6.1 Introduction ...................................................................................

6.2 Calibration

6.2.1 RecommendedTestEquipment

8.2.2 Environmental Conditions

ii

.....................................................................................

.................................................................

...................................................................... B-1

B-l

8.1

B-l

Page 7

TABLE OF CONTENTS (CONT.)

PARAGRAPH

8.2.3

8.2.4

8.3

8.3.1

8.3.2

8.3.3

8.3.4

8.4

8.4.1

8.4.2

8.4.3

8.4.4

8.4.5

9.1

9.2

9.3

9.4

9.5

Warmup ................................................

Calibration Adjustments ...................................

Troubleshooting Set-Up Procedures

Line Power Fuse iFlO1) Replacement

Line Voltage Selection .....................................

Disassembly .............................................

Special Handling of Static Sensitive Devices

Troubleshooting Procedure ...................................

Line Power ..............................................

A/D Converter and Display .................................

ACConverter ............................................

DC Attenuator and Ohms Sources and Resistors.

DigitalBoard

SECTION B-REPLACEABLE PARTS

lntrodution ................................................

Parts List ..................................................

Ordering Information ........................................

Factory Service

Schematic Diagrams and Component Location Drawings

...........................

........................

.............................................

.............................................

TITLE

..................

..............

.........

.....................

......................

......................

......................

.... .... ..... ......

......

......

......

......

......

......

......

PAGE

8-l

ai

8-2

8-2

8-4

8.4

8-5

8-5

8-6

8-6

86

86

86

9-1

9-1

9-1

9-l

9- 1

iii

Page 8

LIST OF ILLUSTRATIONS

FIGURE

l-l

2-1

2-2

2-3

2-4

2-5

2-6

2-7

2-8

2-9

2-10

2.11

2-12

2-13

2.14

3-l

3-2

4-1

4-2

4-3

4-4

4-5

4-6

5-1

6-l

7~1

7-2

7-3

J-4

7-5

7-6

J-7

J-8

7-9

7-10

7-11

7-12

7.13

7-14

7.15

7-16

7.Ii

J-18

7-19

7-20

8-l

9-1

9-2

9-3

9-4

9-5

TITLE

Instrument Packaging

Model1019RackMountingKit ....................................................................

Model1600AHighVoltageProbe

Model 1641 Kelvin Test Lead Set

Model165150AmpereShunt

Model1681Clip-OnTestLeadSet

Model1682ARFProbe..........................................................~......~ ........

Model 1683 Universal Test Lead Kit

Clamp-OnACCurrentProbe ......................................................................

Model1901CurrentAdapter.............................................................~ ........

Model1910ACVoltageOption ....................................................................

Model 1920 TRMS AC Voltage Option

Model 1923 IEEE-488 Interface

IEEE-488Connector....................................................................~..~ .....

Model1924RearlnputAdapter

Modell92FrontPanel.............................~.............................~.~ .............

Model192RearPanel

Effect of Zero Function on Dynamic Range of Measurements

InputFilterFiesponseGraph

DCVoltageMeasurements

ResistanceMsasurements................~..........................~............~......~...~

Four-Wire Resistance Measurement

ACVoltage Measurements

Front Panel Program Buttons

TestCircuit,2mVand2V............~

Basic Block Diagram

Simplified Multiplexer Schematic.

DCVoltage Measurement

FET Switching Sequence for DC Voltage Measurement (Bench Mode of Operation)

DC Voltage Measurement FET Switching Sequence (System Mode of Operation1

Resistance Measurement Simplified Circuit

FETSwitchingSequenceforOhmsMeasurement

Affect of Lead Resistance in 2.Terminal Ohms Measurements.

Affect of Lead Resistance in 4.Terminal Ohms Measurements.

Block Diagram AC Volts Operation

ACVoltsOperationFlowChart..~ ....................................

Simplified Input Buffer Schematic

Simplified A/D Converter Schematic

AID Converter Integrator Output Waveform

Microcomputer Block Diagram

ChargeBalanceTimming

SingleSlopePhase.........~.........................................................~ ........

Simplified Schematic of Latch

Simplified Oscillator/Divider Diagram

Display Schematic

Adjustment Locations

Exploded View With Mechanical Parts

AC Converter, Component Location Drawing

MotherBoard,ComponentLocationDrawing

Analog Board, Component Location Drawing

Display Board, Component Location Drawing

...........................................................................

.................................................................

..................................................................

....................................................................

.................................................................

................................................................

.............................................................

..................................................... .....

.................................................................

..........................................................................

......................................................................

.....................................................................

.............................................. ..

........................................................... ~, ...

.................

.........................................................

.................................................................... ,.,

.................................. ...........

....................................................

......

..............

.............

..................................................................

.....................................................................

.............................................................. ....

..................................

.................................................................

..............................................

.............................................................

.................... ....... ..

....... ~,

................................

............... ...

.....

.....................

.......

......................................................

......................................................

......................................................

......................................................

....................... ................

.. ...... .. ..

.....

..................

................ ..

.......................... .... .. ....

...................... ...

....................................

...... ....

..........

~,.,~

......

..........................

.................

..

.....

., ., .....

.. .. .. .. ..

~.~.~,,

.. .... ..... ....

.....

.....

... ..

...........

..........

...

..

PAGE

l-2

2-1

2-l

2-1

2-1

2-2

2-2

2-2

2~2

2-3

2-3

2~3

2-3

2~3

2-J

3~:~

3-2

4~’

4~2

4~3

44

4~i

4~4

52

6-2

7~1

7~2

7~3

7-4

7~4

7~5

‘~6

M

7Yz

J-7

7~8

7-9

7-9

7.10

7~12

7~:3

7-14

7-15

7-15

7-16

8-3

9-2

9.11

9-13

9-17

9-21

iv

Page 9

LIST OF ILLUSTRATIONS (CONT.)

FIGURE

9-6

9-7 MotharBoard.SchematicDiagram............................................................... 9.25

9-a

9-9

AC Converter, Schematic Diagram g-23

Analog Board, Schematic Diagram

Display Board, Schematic Diagram

TITLE

PAGE

g-29

g-33

LIST OF TABLES

TABLE

4-l

4-2

4-3

4-4

5-l

52

6-l

6-Z

6-3

6-4

6-5

7-1

7-2

7-3

7-4

6-l

6-2

8-3

9-4

86

6-5

a-7

a8

a-9

a10

6-11

6-12

El3

6-14

9-1

9-2

9-3

9-4

9-5

TITLE

LineVoltagaSalection

MaximumInput

ResistanceRanges .............................................................................

Maximum Four-Wire Test Lead Resistance.

FrontPanalProgramSummary

Data Point Times

Recommended Test Equipment for Performance Verification

DC Voltage Performance Check (2OV to 12OOV Rangel

ACVoltageAccuracyChack

ZeroReading ..................................................................................

ResistanceAccuracyChack .....................................................................

SenlingDelays.SNontoTurnonoflntegrator..

MamoryByteLocations...............................................................~..~

FunctionsofLatchOutputs ....................................................................

Power Supply Component Identification.

Recommended Test Equipment for Calibration

CalibrationProcaduras.................................................................~~~

Fuse Replacement .............................................................................

LineVoltagaSalaction................................................................~~~~

TestNumberSummarization .....................................................................

Static Sensitive Devices .........................................................................

Program 8 A/D Test-FET Switching Sequence

LinePowarChecks................................................................~...~

AIDConvarterChacks .....................................................................

Display Checks..

ACConvartarCheckslModel1910) ................................................................

DCAnanuatorChacks.....................................................................~

Ohms Source and Resistors Checks. ..............................................................

DigitalBoardChecks....................................................................~..~.~

Modal192DrawingPackage..............................................................~..~..~

AC Converter PC-496, Parts List

MotharBoardPC-559,PartsList........................................................~~

Analog Board PC-560. PartsList

Display Board PC-530, Parts List

...........................................................................

...............................................................................

............................................ .....

...................................................................

..................................................................

...................................... ..

......................................... ..

..................................................................... 62

.........................................

.............................................. .....

....................................................

......................................... .......

.............................................................................

............................................................

............................................................

................................................................

....... 5-9

........

.......

......

PAGE

....

......

.....

...

.~~ 6.6

.... 6.10

.....

..

4-l

4-1

4-3

4-4

5-l

6-l

6-2

6-3

6-3

7-8

7-10

7-13

7-15

6-l

a-2

6-4

6-4

6-6

8-5

6.7

a-a

6.9

6.9

9-l 1

6-11

9-1

9-3

9.4

9.6

9-9

v/vi

Page 10

Page 11

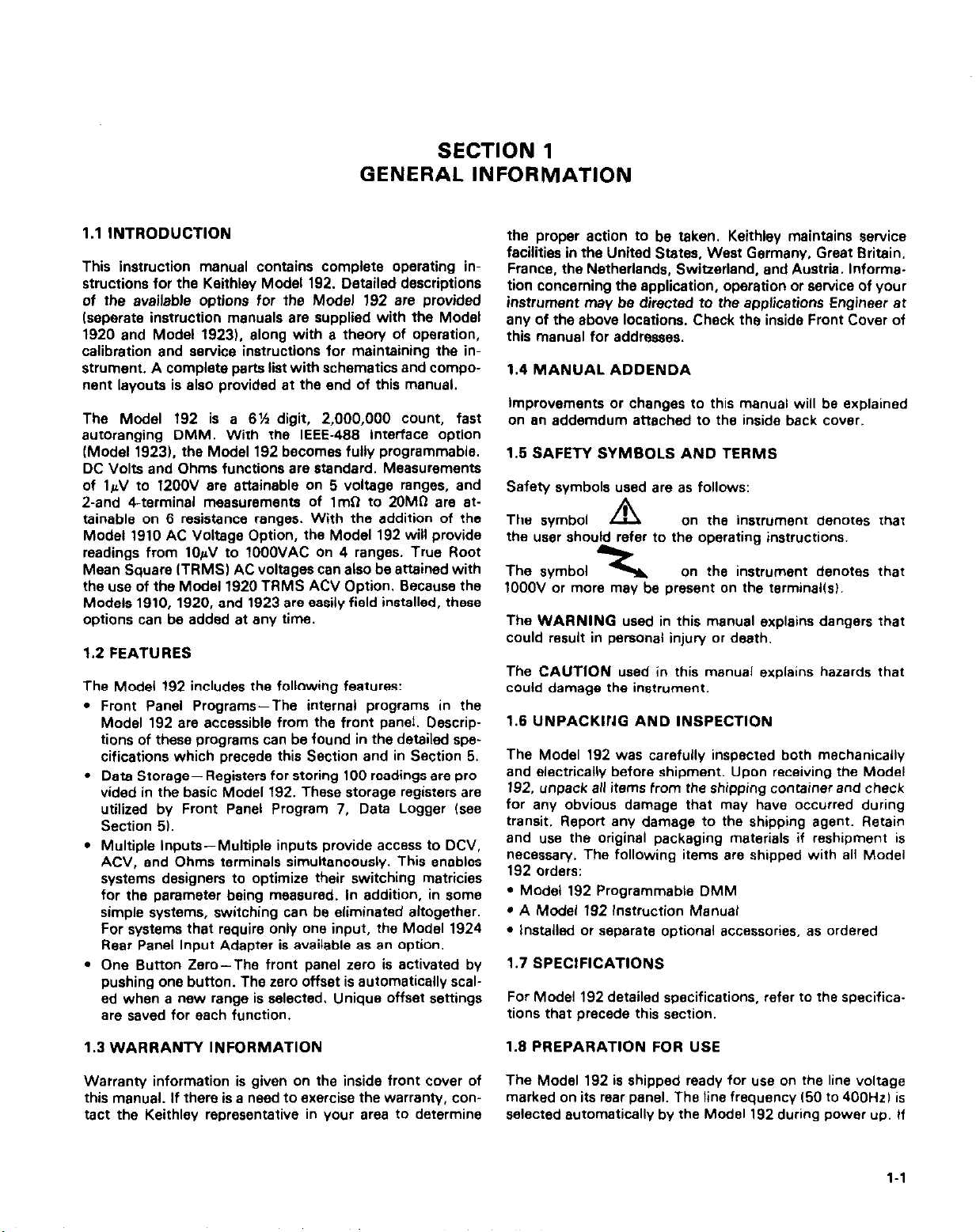

SECTION 1

GENERAL INFORMATION

1.1 INTRODUCTION

This instruction manual contains complete operating in-

structions for the Keithley Model 192. Detailed descriptions

of the available options for the Model 192 are provided

lseperate instruction manuals are supplied with the Model

1920 and Model 19231, along with a theory of operation,

calibration and service instructions for maintaining the instrument. A complete parts list with schematics and component layouts is also provided at the end of this manual.

The Model 192 is a 6’h digit, 2,000,OOO count, fast

autoranging DMM. With the IEEE-468 interface option

(Model 1923). the Model 192 becomes fully programmable.

DC Volts and Ohms functions are standard. Measurements

of l&V to 12OOV are attainable on 5 voltage ranges, and

Z-and 4-terminal messurements of 1mD to ZOMR are attainable on 6 resistance ranges. With the addition of the

Model 1910 AC Voltage Option, the Model 192 will provide

readings from 1OrV to 1OOOVAC on 4 ranges. True Root

Mean Square ITRMS) AC voltages can also be attained with

the use of the Model 1920 TRMS ACV Option. Because the

Models 1910, 1920, and 1923 are easily field installed, these

options can be added at any time.

1.2 FEATURES

The Model 192 includes the following features:

Front Panel Programs-The internal programs in the

Model 192 are accessible from the front panel. Descriptions of these programs can be found in the detailed specifications which precede this Section and in Section 5.

Data Storage- Registers for storing 100 readings are provided in the basic Model 192. These storage registers are

utilized by Front Panel Program 7. Data Logger (see

Section 51.

Multiple Inputs-Multiple inputs provide access to DCV.

ACV, and Ohms terminals simultaneously. This enables

systems designers to optimize their switching matricies

for the parameter being measured. In addition, in some

simple systems, switching can be eliminated altogether.

For systems that require only one input, the Model 1924

Rear Panel Input Adapter is available as an option.

One Button Zero-The front panel zero is activated by

pushing one button. The zero offset is automatically scaled when a new range is selected. Unique offset settings

are saved for each function.

the proper action to be taken. Keithley maintains service

facilities in the United States, West Germany, Greet Britain,

France, the Netherlands, Switzerland, and Austria. Information concerning the application, operation or service of your

instrument may be directed to the applications Engineer at

any of the above locations. Check the inside Front Cover of

this manual for addresses.

1.4 MANUAL ADDENDA

Improvements or changes to this manual will be explained

on an addemdum attached to the inside back cover.

1.5 SAFEN SYMBOLS AND TERMS

Safety symbols used are as follows:

The symbol

A

on the instrument denotes that

the user should refer to the operating instructions.

The symbol

i,

on the instrument denotes that

1OOOV or more may be present on the terminal(sl.

The WARNING used in this manual explains dangers that

could result in personal injuy or death.

The CAUTION used in this manual explains hazards that

could damage the instrument.

1.6 UNPACKIrdG AND INSPECTION

The Model 192 was carefully inspected both mechanically

and electrically before shipment. Upon receiving the Model

192, unpack all items from the shipping container and check

for any obvious damage that may have occurred during

transit. Report any damage to the shipping agent. Retain

and use the original packaging materials if reshipment is

necessan/. The following items are shipped with all Model

192 orders:

l

Model 192 Programmable DMM

l

A Model 192 instruction Manual

l

Installed or separate optional accessories, as ordered

1.7 SPECIFICATIONS

For Model 192 detailed specifications, refer to the specifications that precede this section.

1.3 WARRANTY INFORMATION

Warranty information is given on the inside front cover of

this manual. If there is a need to exercise the warranty, contact the Keithley representative in your area to determine

1.8 PREPARATION FOR USE

The Model 192 is shipped ready for use on the line voltage

marked on its rear panel. The line frequency 150 to 400Hzl is

selected automatically by the Model 192 during power up. If

l-l

Page 12

the Model 1923 IEEE Interface is installed it will be set to the

Addressable mode and et Address 8.

1.9 LINE POWER

The Model 192 is provided with a J-wire line cord which

mates with a third wire earth grounded receptacle. The instrument will operate on two of four voltage ranges listed in

Table B-4. These ranges may be selected by positioning an

internal slide switch and installing the appropriate fuse for

that range. An optional line voltage range of SO to 110 volts

is available by special order. Instruments with this range use

a different transformer.

1.10 LINE VOLTAGE SELECTION

Refer to Section 6 Maintenance to select the proper line

voltage settings.

CARDBOARD STRIP

NSTRUCTION MANUAL

1.11 LINE FREQUENCY SELECTION

Line frequency is sensed automatically by the Model 192

during power up. The instrument will operate at 50 to 400Hz

end will display F60 at 60Hz or F50 at either 50Hz or 400Hz.

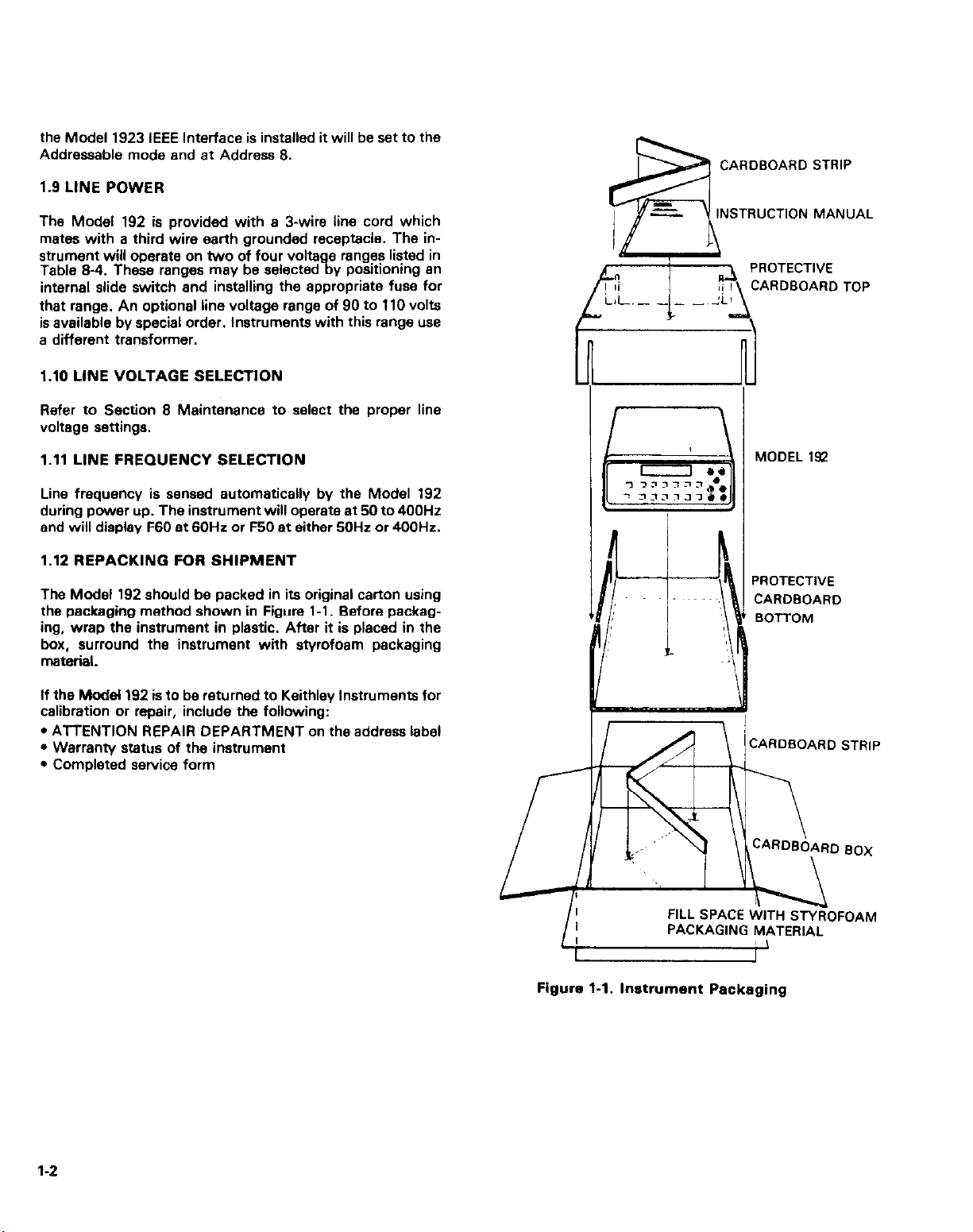

1.12 REPACKING FOR SHIPMENT

The Model 192 should be packed in its original carton using

the packaging method shown in Figure l-l. Before packag-

ing, wrap the instrument in plastic. After it is placed in the

box, surround the instrument with styrofoam packaging

material.

If the Modal 192 is to be returned to Keithley Instruments for

calibration or rapair, include the following:

l

AlTENTION REPAIR DEPARTMENT on the address label

l

Warranty status of the instrument

l

Completed service form

MODEL 192

PROTECTIVE

CARDBOARD

BOTTOM

ARDBOARD STRlP

1-2

PACKAGING MATERIAL

L

1

Figure l-l. Instrument Packaging

Page 13

SECTION 2

ACCESSORIES

2.1 INTRODUCTION

This section describes the various accessories and options

available for use with the Model 192 OMM.

2.2 RACK MOUNTING KITS

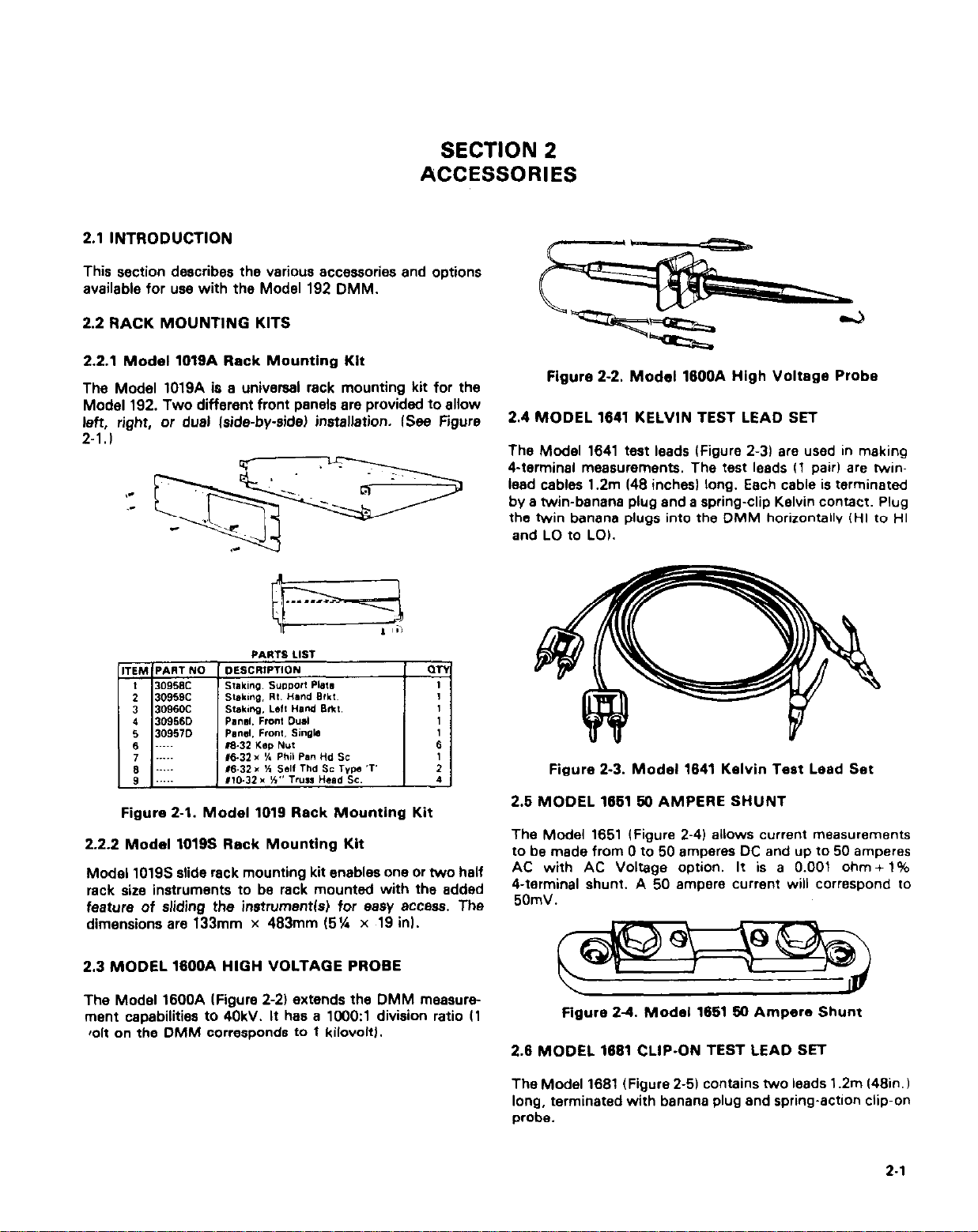

2.2.1 Model 1019A Rack Mounting Kit

The Model 1019A is a universal rack mounting kit for the

Model 192. Two different front panels &we provided to allow

left, right, or dual Iside-by-side) installation. ISee Figure

2-1.1

Figure 2-2. Model 16OOA High Voltage Probe

2.4 MODEL 1641 KELVIN TEST LEAD SR

The Model 1641 test leads (Figure 2.3) are used in making

4-terminal measurements. The test leads I1 pair1 are twin-

lead cables 1.2m 146 inches1 long. Each cable is terminated

by a twin-banana plug and a spring-clip Kelvin contact. Plug

the twin banana plugs into the DMM horizontallv (HI to HI

and LO to LO).

Figure 2-1. Model 1019 Rack Mounting Kit

2.2.2 Model 1019s Rack Mounting Kit

Model 1019s slide rack mounting kit enables one or two half

rack size instruments to be rack mounted with the added

feature of sliding the instrumentls) for easy access. The

dimensions are 133mm x 463mm (5% x 19 inl.

2.3 MODEL WOOA HIGH VOLTAGE PROBE

The Model 1600A (Figure 2-2) extends the DMM measure-

ment capabilities to 40kV. It has a 1M)O:l division ratio I1

lolt on the DMM corresponds to 1 kilovolt).

Figure 2-3. Model 1641 Kelvin Test Lead Set

2.6 MODEL 1661 66 AMPERE SHUNT

The Model 1651 (Figure 2-4) allows current measurements

to be made from 0 to 50 amperes DC and up to 50 amperes

AC with AC Voltage option. It is a 0.001 ohm + 1%

4-terminal shunt. A 50 ampere current will correspond to

50mV.

Figure 24. Model 1661 M Ampere Shunt

2.6 MODEL 1681 CLIP-ON TEST LEA0 SET

The Model 1661 (Figure 2-6) contains two leads 1.2117 146in. I

long, terminated with banana plug and spring-action clip-on

probe.

2-l

Page 14

Figure 2-7. Model 1663 Universal Test Lead Kit

Figure 2-6. Model 1661 Clip-On Test Lead Set

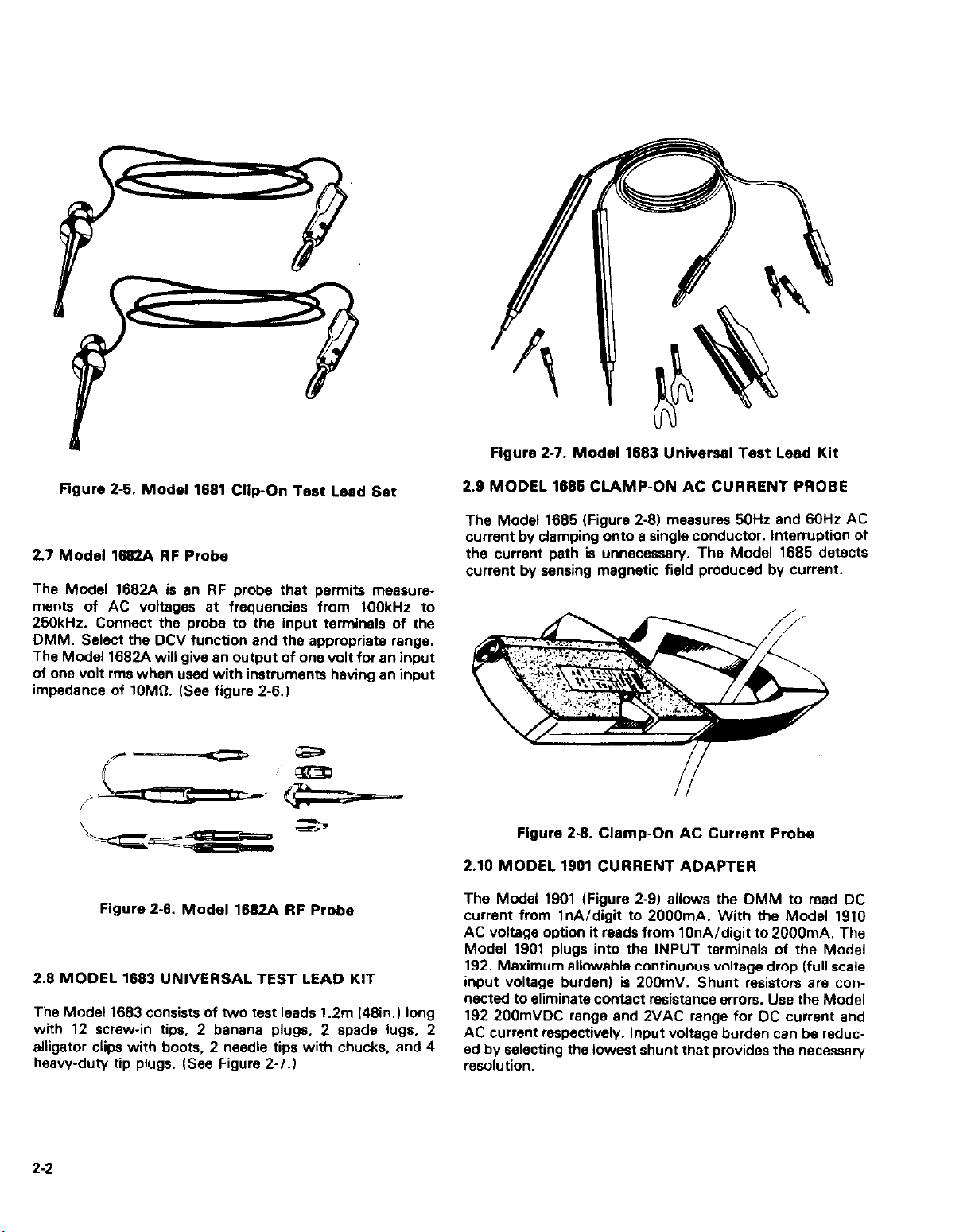

2.7 Model 1682A RF Probe

The Model 1662A is en RF probe that permits measure-

ments of AC voltages at frequencies from 1OOkHz to

250kHz. Connect the probe to the input terminals of the

DMM. Select the DCV function and the appropriate range.

The Model 1662A will give en output of one volt for an input

of one volt rms when usad with instruments having an input

impedance of 10MlI. ISee figure 2-6.)

Figure 2-6. Model 1662A RF Probe

2.6 MODEL 1663 UNIVERSAL TEST LEA0 KIT

The Model 1663 consists of two test leads 1.2m (48in. l long

with 12 screw-in tips, 2 banana plugs, 2 spade lugs, 2

alligator clips with boots, 2 needle tips with chucks, and 4

heavy-duty tip plugs. (See Figure 2-7.)

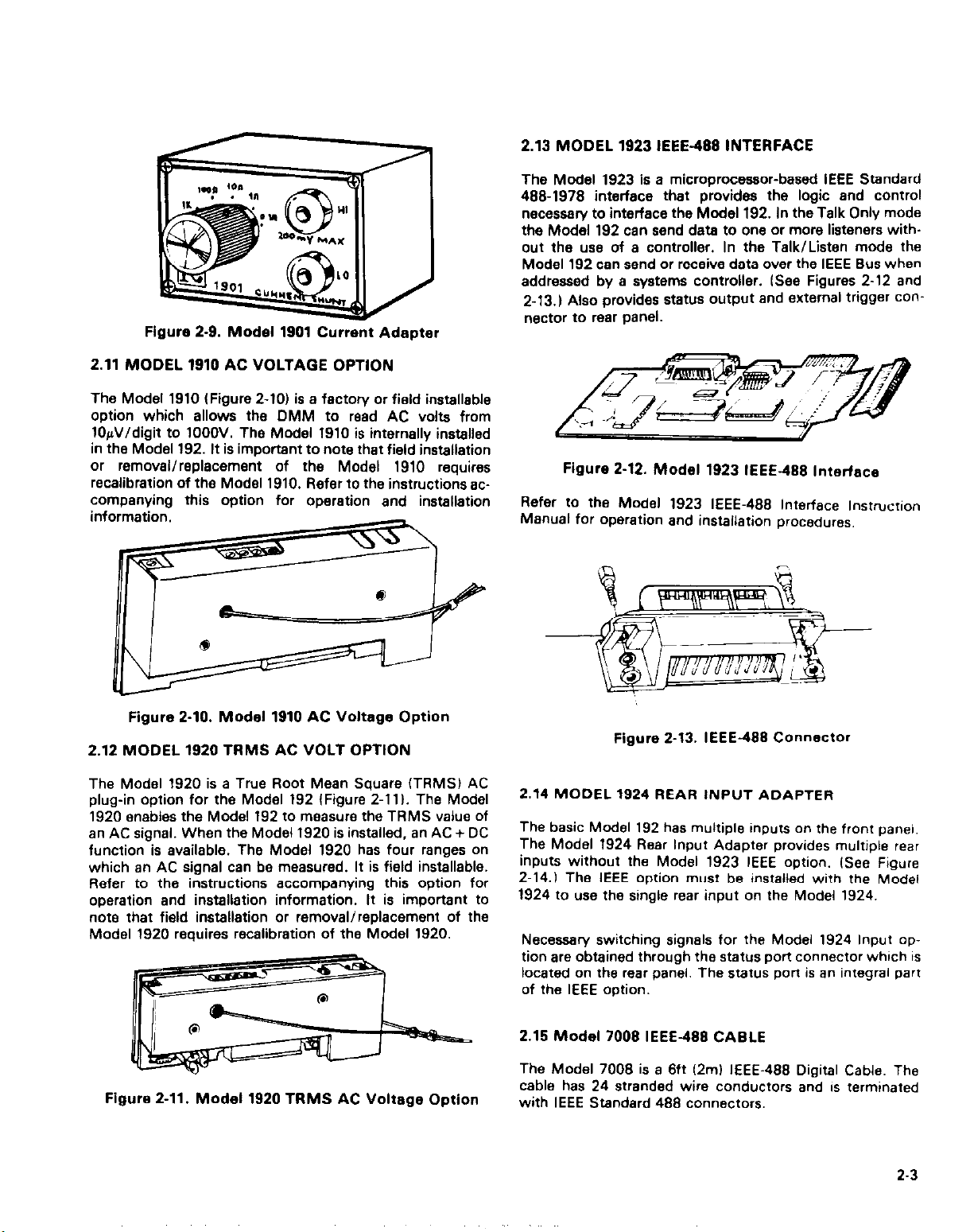

2.9 MODEL 1666 CLAMP-ON AC CURRENT PROBE

The Model 1666 (Figure 2-8) measures 60Hz and 60Hz AC

current by clamping onto a single conductor. Interruption of

the current path is unnecessary. The Model 1685 detects

current by sensing magnetic field produced by current.

Figure 24. Clamp-On AC Current Probe

2.10 MODEL 1901 CURRENT ADAPTER

The Model 1901 (Figure 2-91 allows the DMM to read DC

current from lnA/digit to 2000mA. With the Modal 1910

AC voltage option it reads from lOnA/digit to 2000mA. The

Model 1901 plugs into the INPUT terminals of the Model

192. Maximum allowable continuous voltage drop (full scale

input voltage burden) is 200mV. Shunt resistors are connected to eliminate contact resistance errors. Use the Model

192 200mVDC range and 2VAC range for DC current and

AC current respectively. Input voltage burden can be reduc-

ed by selecting the lowest shunt that provides the necessary

resolution.

2-2

Page 15

2.11 MODEL 1910 AC VOLTAGE OPTION

The Model 1910 (Figure 2-10) is a factory or field installable

option which allows the DMM to read AC volts from

lO@/digit to 1OOOV. The Model 1910 is internally installed

in the Modal 192. It is important to note that field installation

or removal/replacement of the Modal 1910 requires

recalibration of the Model 1910. Refer to the instructions ac-

information.

2.13 MODEL 1923 IEEE-466 INTERFACE

The Model 1923 is a microprocessor-based IEEE Standard

466-1976 interface that provides the logic and control

necessary to interface the Model 192. In the Talk Only mode

the Model 192 can send data to one or more listeners with-

out the use of a controller. In the Talk/Listen mode the

Model 192 can send or receive data over the IEEE Bus when

addressed by a systems controller. (See Figures 2-12 and

2-13.) Also provides status output and external trigger con

nector to rear panel.

Figure 2-12. Model 1923 IEEE-466 lnterfsce

Refer to the Model 1923 IEEE-468 Interface Instruction

Manual for operation and installation procedures.

Figure 2-10. Model 1910 AC Voltage Option

2.12 MODEL 1920 TRMS AC VOLT OPTION

The Model 1920 is a True Root Mean Square ITRMSI AC

plug-in option for the Model 192 (Figure Z-11). The Model

1920 enables the Model 192 to measure the TRMS value of

an AC signal. When the Model 1920 is installed, an AC + DC

function is available. The Model 1920 has four ranges on

which an AC signal can be measured. It is field installable.

Refer to the instructions accompanying this option for

operation and installation information. It is important to

note that field installation or removal/replacement of the

Model 1920 requires recalibration of the Model 1920.

Figure 2-11. Model 1920 TRMS AC Voltage Option

Figure 2-13. IEEE-466 Connector

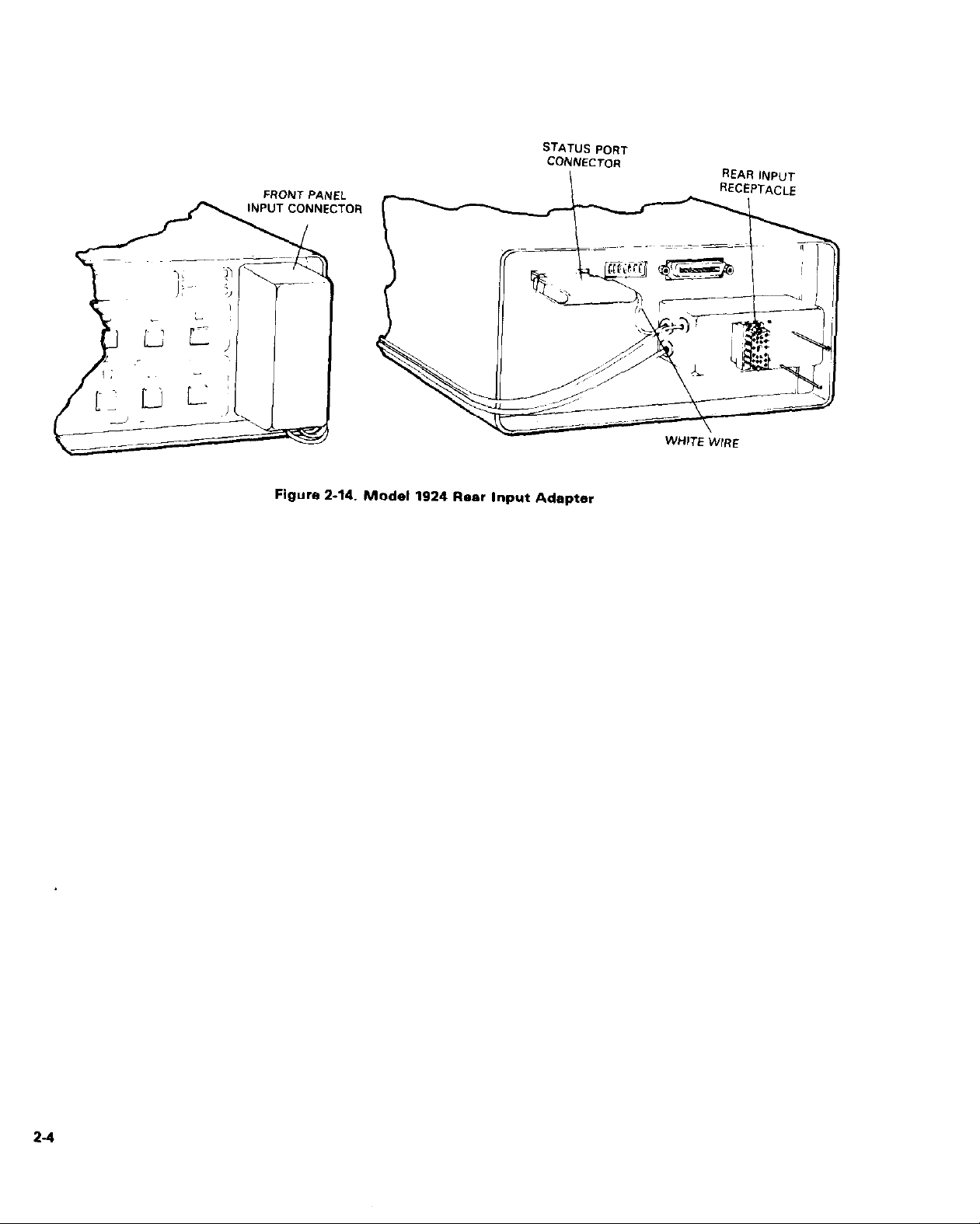

2.14 MODEL 1924 REAR INPUT ADAPTER

The basic Model 192 has multiple inputs on the front panel.

The Model 1924 Rear Input Adapter provides multiple rear

inputs without the Model 1923 IEEE option. (See Figure

2-14.1 The IEEE option must be installed with the Model

1924 to use the single rear input on the Model 1924.

Necessav switching signals for the Model 1924 Input op-

tion are obtained through the status port connector which is

located on the rear panel. The status port is an integral part

of the IEEE ootion.

2.15 Model 7008 IEEE-466 CABLE

The Model 7008 is a 6ft l2m) IEEE-488 Digits Cable. The

cable has 24 stranded wire conductors and is terminated

with IEEE Standard 488 connectors.

2-3

Page 16

FRONT PANEL

INPUT CONNECTOR

Figure Z-14. Model 1924 Rear Input Adapter

STATUSPORT

CONNECTOR

WHITE W,RE

2-4

Page 17

SECTION 3

FRONT AND REAR PANEL CONTROLS

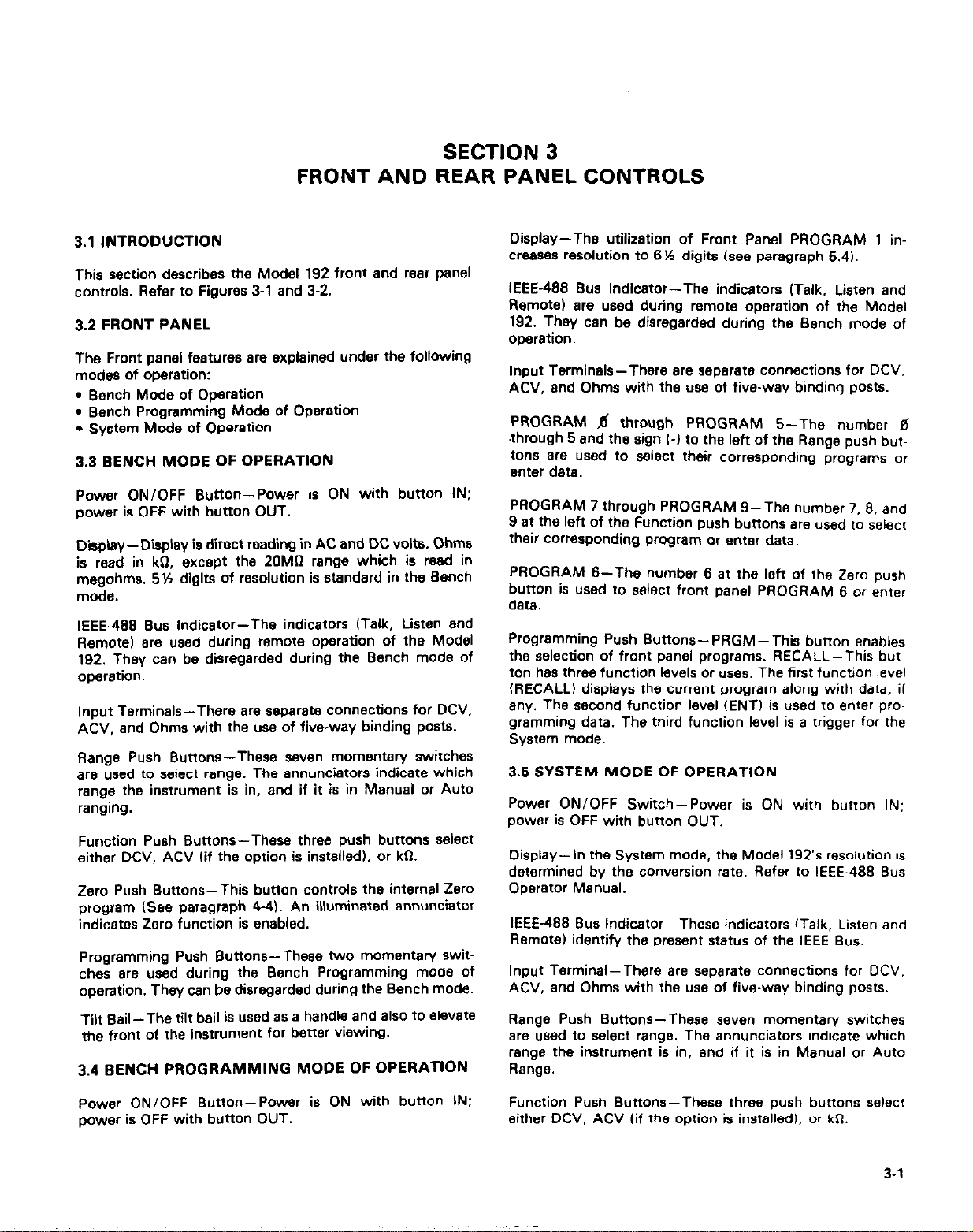

3.1 INTRODUCTION

This section describes the Model 192 front and rear panel

controls. Refer to Figures 3-1 and 3-2.

3.2 FRONT PANEL

The Front panel features are explained under the following

modes of operation:

l

Bench Mode of Operation

l

Bench Programming Mode of Operation

l

System Mode of Operation

3.3 BENCH MODE OF OPERATION

Power ON/OFF Button-Power is ON with button IN;

power is OFF with button OUT.

Display-Display is direct reading in AC and DC volts. Ohms

is read in kfl, except the 20MR range which is read in

megohms. 5’h digits of resolution is standard in the Bench

mode.

IEEE-488 Bus Indicator-The indicators (Talk, Listen and

Remote1 are used during remote operation of the Model

192. They can be disregarded during the Bench mode of

operation.

Input Terminals-There are separate connections for DCV,

ACV, and Ohms with the use of five-way binding posts.

Range Push Buttons-These seven momentary switches

are used to select range. The annunciators indicate which

range the instrument is in, and if it is in Manual or Auto

ranging.

Function Push Buttons-These three push buttons select

either DCV, ACV lif the option is installed), or kR.

Zero Push Buttons-This button controls the internal Zero

program (See paragraph 4-41. An illuminated annunciator

indicates Zero function is enabled.

Programming Push Buttons-These two momentary switches are used during tha Bench Programming mode of

operation. They can be disregarded during the Bench mode.

Tilt Bail-The tilt bail is used as a handle and also to elevate

the front of the instrument for better Viewing.

3.4 BENCH PROGRAMMING MODE OF OPERATION

Display-The utilization of Front Panel PROGRAM 1 increases resolution to 6% digits (see paragraph 5.41.

IEEE-466 Bus Indicator-The indicators (Talk, Listen and

Remote) are used during remote operation of the Model

192. They can be disregarded during the Bench mode of

operation.

Input Terminals-There are separate connections for DCV.

ACV, and Ohms with the use of five-way bindinq posts.

PROGRAM $ through PROGRAM 5-The number 0

.through 5 and the sign I-l to the left of the Range push buttons are used to select their corresponding programs or

enter data.

PROGRAM 7 through PROGRAM g--The number 7,8. and

9 at the left of the Function push buttons are “sed to select

their corresponding program or enter data,

PROGRAM 6-The number 6 at the left of the Zero push

button is used to select front panel PROGRAM 6 or enter

data.

Programming Push Buttons-PRGM-This button enables

the selection of front panel programs. RECALL-This butt

ton has three function levels or uses. The first function level

(RECALL) displays the currant program along with data, if

any. The second function level (ENTI is used to enter programming data. The third function level is a trigger for the

System mode.

3.5 SYSTEM MODE OF OPERATION

Power ON/OFF Switch-Power is ON with button IN;

power is OFF with button OUT.

Display-In the System mode, the Model 192’s resolution is

determined by the conversion rata. Refer to IEEE-469 Bus

Operator Manual.

IEEE-466 Bus Indicator-These indicators (Talk. Listen and

Remote) identify the present status of the IEEE Bus.

Input Terminal-There are separate connections for DCV.

ACV, and Ohms with the use of five-way binding posts.

Range Push Buttons-These seven momentary switches

are used to select range. The annunciators indicate which

range the instrument is in, and if it is in Manual or Auto

Range.

Power ON/OFF Button-Power is ON with button IN:

power is OFF with button OUT.

Function Push Buttons-These three push buttons select

either DCV, ACV lif the option is installed), or k0.

3-1

Page 18

Zero Push Buttons-This button controls the internal Zero

program ISee paragraph 4.4). An illuminated annunciator

indicates Zero function is enabled.

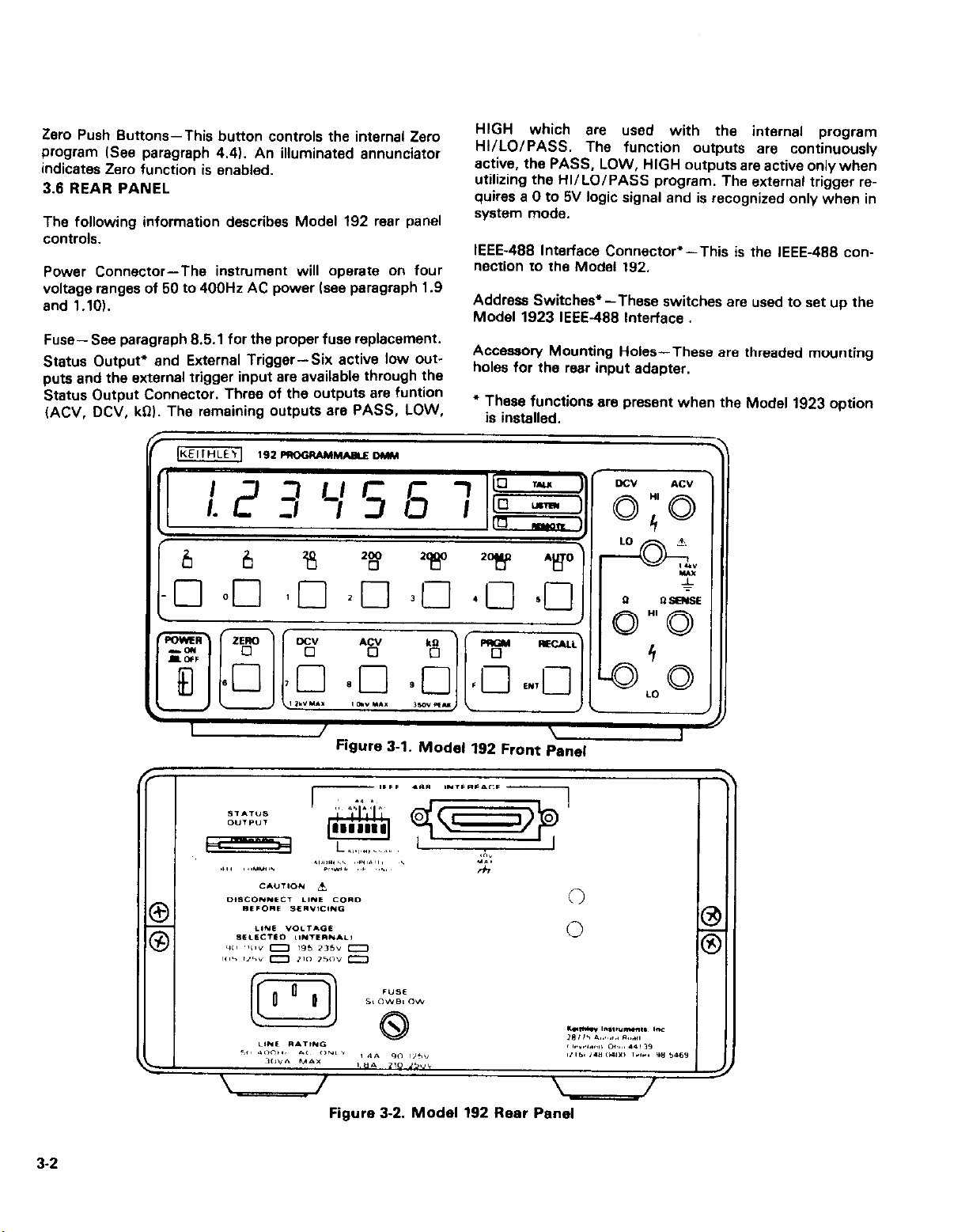

3.6 REAR PANEL

The following information describes Model 192 rear panel

controls.

Power Connector-The instrument will operate on four

voltage ranges of 50 to 400Hz AC power Isee paragraph 1.9

and 1.10).

Fuse-See paragraph 8.5.1 for the proper fuse replacement.

Status Output’ and External Trigger-Six active low out-

puts and the external trigger input are available through the

Status Output Connector. Three of the outputs are funtion

(ACV, DCV, kR). The remaining outputs are PASS, LOW,

HIGH which are used with the internal program

HI/LO/PASS. The function outputs are continuously

active, the PASS, LOW, HIGH outputs are active only when

utilizing the HI/LO/PASS program. The external trigger requires a 0 to 5V logic signal and is recognized only when in

system mode.

IEEE-488 Interface Connector’-This is the IEEE-488 con“action to the Modal 192.

Address Switches*-These switches are used to set up the

Model 1923 IEEE-488 interface.

Accessory Mounting Holes-These are threaded mounting

holes for the rear input adapter,

l

These functions are present when the Model 1923 option

is installed.

\ - \‘IWU. 1m1*..

.

1 /

Figure 3-1. Model 192 Front panel

Figure 3-2. Model 192 Rear Panel

I”“*Y) i-

,i

\

1

3-2

Page 19

SECTION 4

BASIC DMM OPERATION

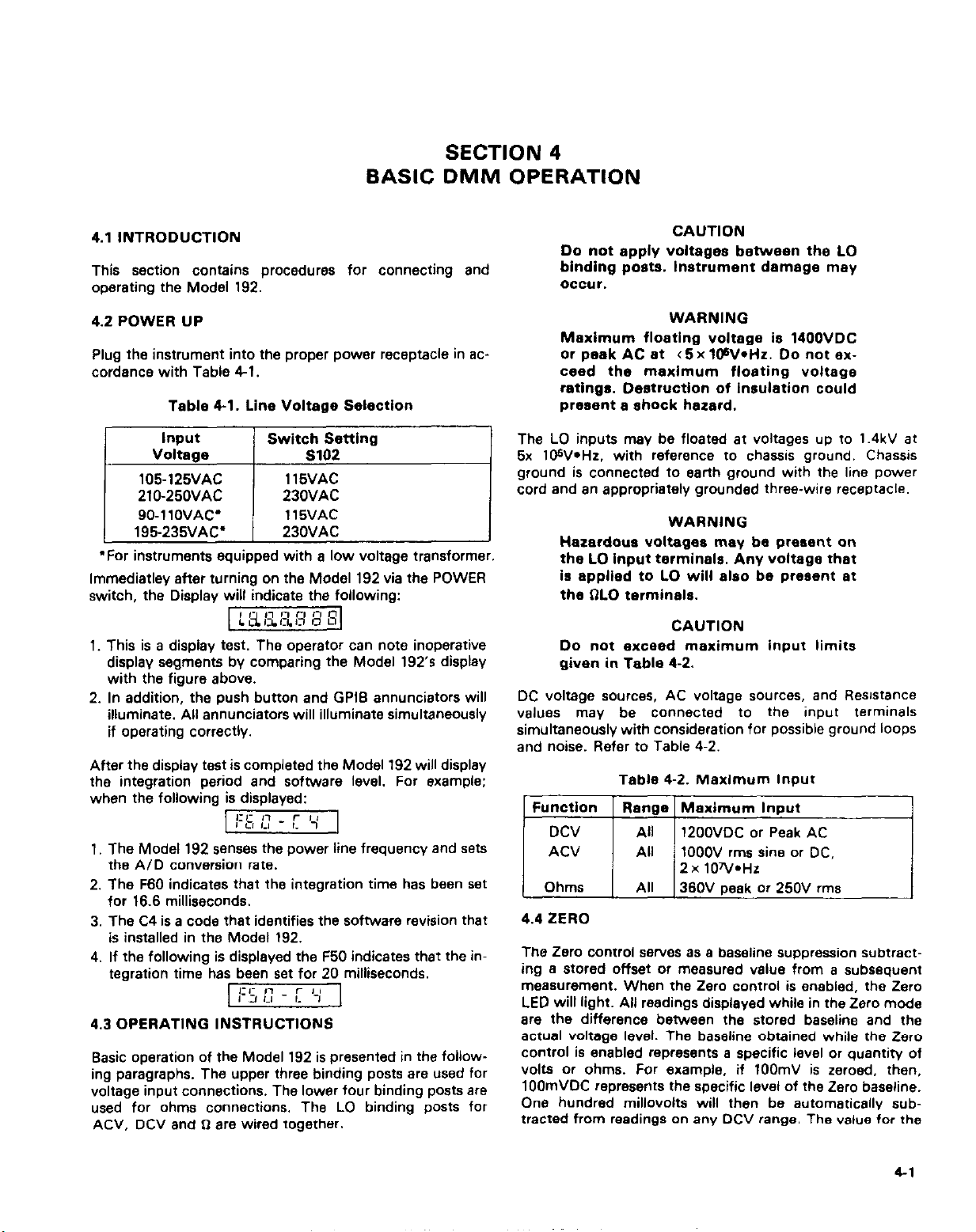

4.1 INTRODUCTION

This section contains procedures for connecting and

operating the Model 192.

4.2 POWER UP

Plug the instrument into the proper power receptacle in ac-

cordance with Table 4-l.

Table 4-l. Line Voltage Selection

Input

Voltage

105-125VAC

210-250VAC 230VAC

90-IlOVAC’ 115VAC

195235VAC’ 230VAC

‘For instruments equipped with a low voltage transformer,

lmmediatley after turning on the Model 192 via the POWER

switch, the Display will indicate the following:

1. This is a display test. The operator can note inoperative

display segments by comparing the Model 192’s display

with the figure above.

2. In addition, the push button and GPIB annunciators will

illuminate. All annunciators will illuminate simultaneously

if operating correctly.

After the display test is completed the Model 192 will display

the integration period and software level. For example;

when the following is displayed:

1. The Model 192 senses the power line frequency and sets

the A/D conversion rate.

2. The F60 indicates that the integration time has been set

for 16.6 milliseconds.

3. The C4 is a code that identifies the software revision that

is installed in the Model 192.

4. If the following is displayed the F50 indicates that the integration time has been set for 20 milliseconds.

4.3 OPERATING INSTRUCTIONS

Basic operation of the Modal 192 is presented in the following paragraphs. The upper three binding posts are used for

voltage input connections. The lower four binding posts are

used for ohms connections. The LO binding posts for

ACV, DCV and 0 are wired together.

Switch Setting

s102

115VAC

rlzKm?q

-1-6

-1-5

CAUTION

Do not apply voltages between the LO

binding posts. Instrument damage may

OCC”r.

WARNING

Maximum floating voltage is 1400VDC

or peak AC at < 5 x 106V.H~. Do not exceed the maximum floating voltage

ratings. Destruction of insulation could

present e shock hazard.

The LO inputs may be floated at voltages up to 1.4kV at

5x 106V*Hz. with reference to chassis ground. Chassis

ground is connected to earth ground with the line power

cord and an appropriately grounded three-wire receptacle.

WARNING

Hazardous voltages may be present on

the LO input terminals. Any voltage that

is applied to LO will also be present at

the DLO terminals.

CAUTION

Do not exceed maximum input limits

given in Table 4-2.

DC voltage sources. AC voltage sources, and Resistance

values may be connected to the input termtnals

simultaneously with consideration for possible ground loops

and noise. Refer to Table 4-2.

Table 4-2. Maximum Input

Function

4.4 ZERO

The Zero control serves as a baseline suppression subtract-

ing a stored offset or measured value from a subsequent

measurement. When the Zero control is enabled, the Zero

LED will light. All readings displayed while in the Zero mode

are the difference between the stored baseline and the

actual voltage level. The baseline obtained while the Zero

control is enabled represents a specific level or quantity of

volts or ohms. For example, if 1OOmV is zeroed. then,

1OOmVDC represents the specific level of the Zero baseline.

One hundred millovolts will then be automatically sub-

tracted from readings on any DCV range. The value for the

[ Ranga

Maximum Input

1200VDC or Peak AC

1OOOV rms sins or DC,

2x 10’V’Hz

360V peak or 250V rms

4-l

Page 20

baseline can be as little as a few microvolts or as large as

999 volts. This capacity enables the user to zero a wide

range of voltages. For example:

4.6 OVERRANGE INDICATION

Overrange is indicated by the following display:

Displayed Push

offset Zero Input Result

Example #l 1.23000 .ooooo

Example #2 .23000 .ooooo

Note

Setting range lower than the zero baseline

value, will overrange display.

WARNING

The voltage present on the input may be

greater than the displayed reading when

the instrument is Zeroed.

Example: 1OOV = stored baseline

lSOV=actual voltage to be

measured

SOV = displayed reading

One baseline can be stored for each of the functions (DC

Volts, AC Volts, and Ohms). For example, 20mVDC can be

stored for DC volts, 1OVAC volts and 50 can be stored for

ohms. Proceed as follows:

1. To store a zero value for DC volts, select the DC Volts

function. Press the ZERO Button. The reading on the

Model 192 display will be stored as the zero value. The

zero control can be disabled by pressing the ZERO button

again.

2. To store a zero value for AC volts, select the AC volts

function. Press the Zero button. The reading on the

Model 192 display will be stored as the zaro value. The

zero control can be disabled by pressing the ZERO button

again.

3. To store a zero value for Ohms, select the Ohms function. Press the ZERO button. The readina on the Model

192 display will be stored as the zero value. The zero con-

trol can be disabled by pressing the ZERO button again.

4. The Model 192 will retain these zero values. If the func-

tion is changed the Model 192 will recall the value of zero

that was set for that function. To replace an earlier stored

zero value, simply press the ZERO button twice. The

reading that was on the Model 192 will be stored as the

new zero value.

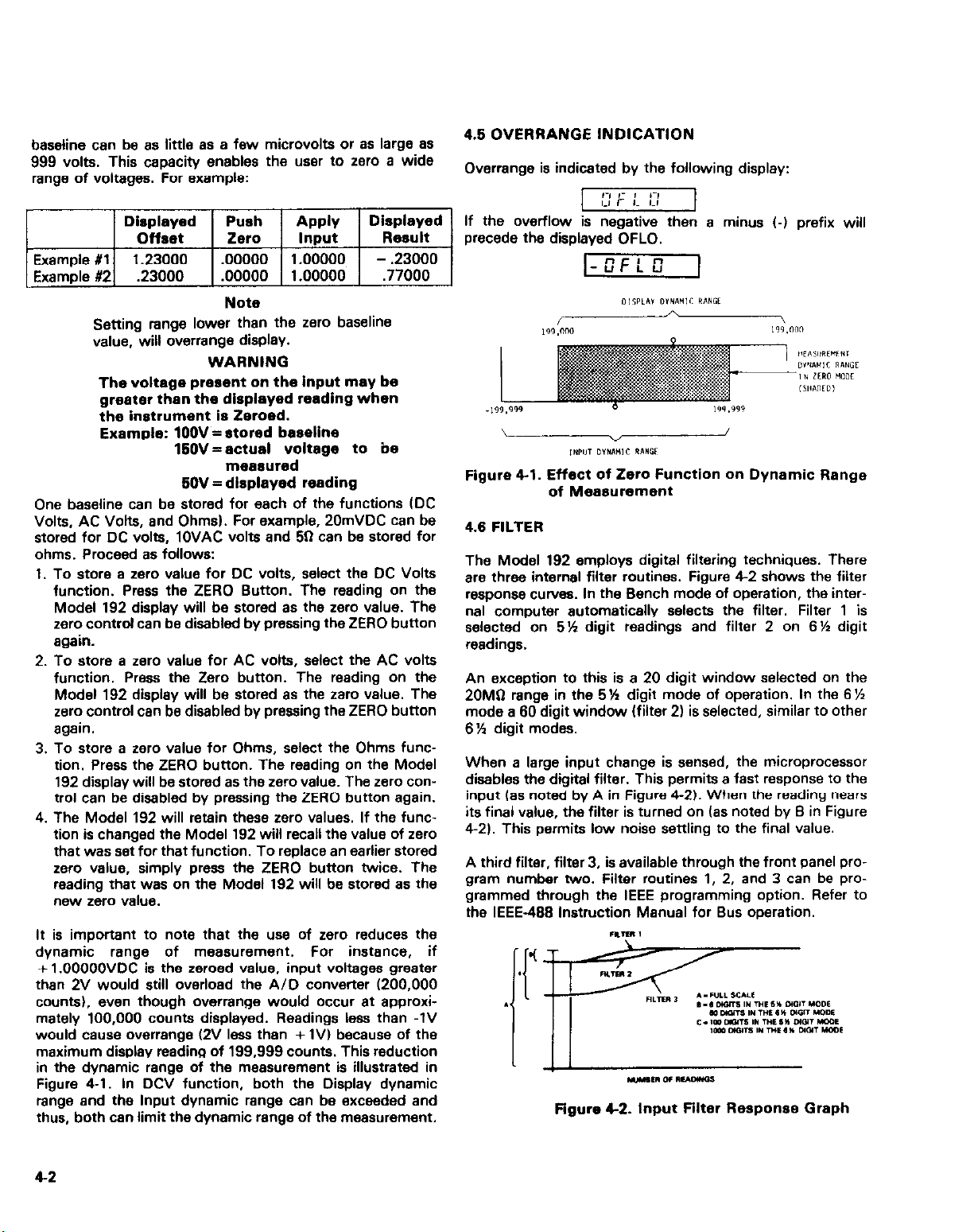

It is important to note that the use of zero reduces the

dynamic range of measurement. For instance, if

+ l.OOOOOVDC is the zeroed value, input voltages greater

than 2V would still overload the AID converter (200,000

counts). even though overrange would occur at approximately 100,000 counts displayed. Readings less than -lV

would cause overrange (2V less than + 1Vl because of the

maximum display reading of 199,999 counts. This reduction

in the dynamic range of the measurement is illustrated in

Figure 4-1. In DCV function, both the Displav dvnamic

range and the Input dynamic range can be &wed& and

thus, both can limit the dynamic range of the measurement.

Apply

1 .ooooo - .23000

1 .ooooo .77000

Displayed

If the overflow is negative then a minus I-) prefix will

precede the displayed OFLO.

\

Figure 4-l. Effect Of Zero Function on Dynamic Range

of Measurement

4.6 FILTER

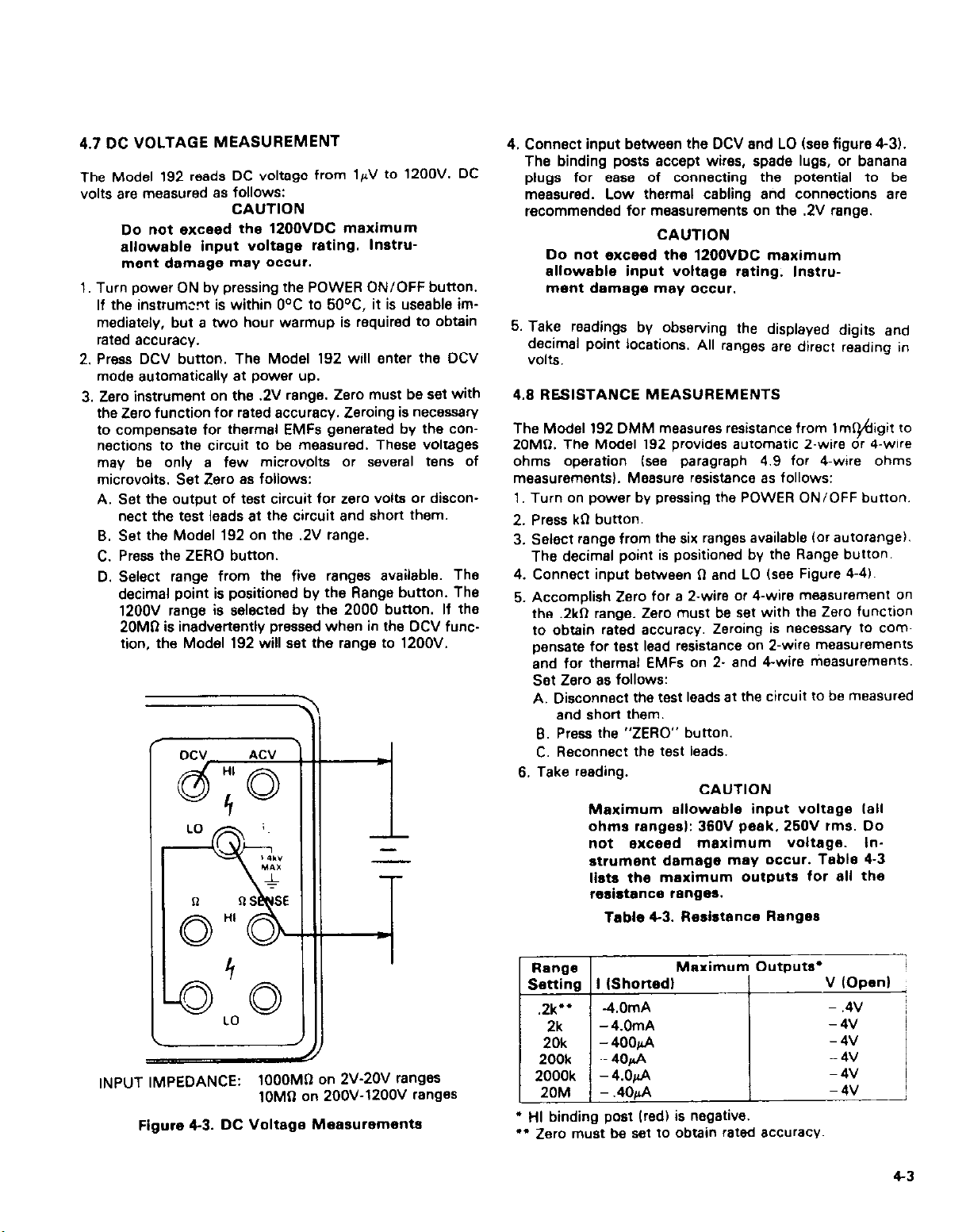

The Model 192 employs digital filtering techniques. There

are three internal filter routines. Figure 42 shows the filter

response curves. In the Bench mode of operation, the internal computer automatically selects the filter. Filter 1 is

selected on 5’S digit readings and filter 2 on 6% digit

readings.

An exception to this is a 20 digit window selected on the

20MIl range in the 5H digit mode of operation. In the 6%

mode a 60 digit window (filter 2) is selected, similar to other

6% digit modes.

When a large input change is sensed, the microprocessor

disables the digital filter. This permits a fast response to the

input (as noted by A in Figure 4-2). When the reading nears

its final value, the filter is turned on (as noted by 6 in Figure

4.2). This permits low noise senling to the final value.

A third filter, filter 3, is available through the front panel pro-

gram number two. Filter routines 1, 2, and 3 can be programmed through the IEEE programming option. Refer to

the IEEE-466 Instruction Manual for Bus operation.

Figure 4-2. Input Filter Response Graph

9

,HPllT O”~lWC PAHW

/

4-2

Page 21

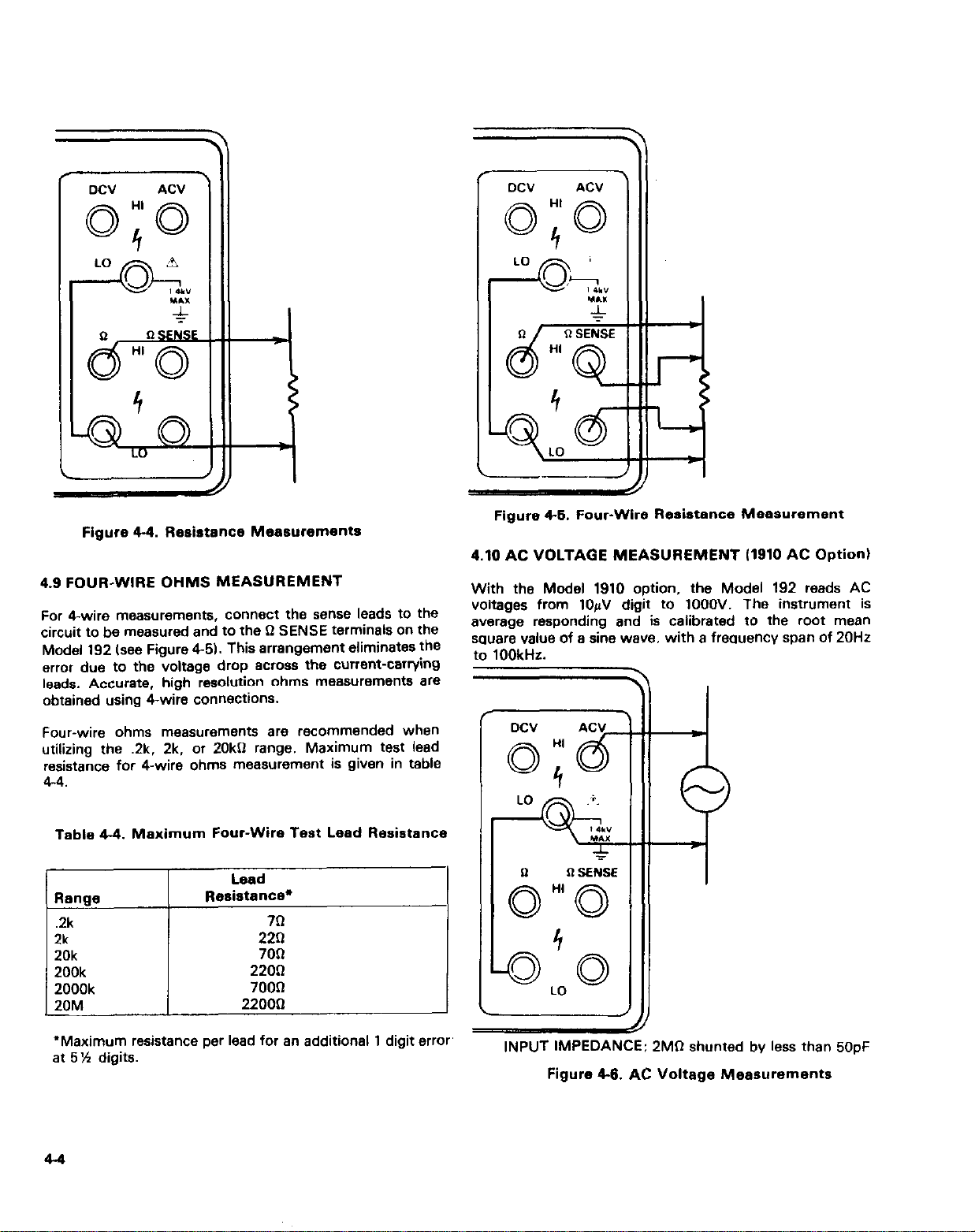

4.7 DC VOLTAGE MEASUREMENT

The Model 192 reads DC voltage from 1aV to 1200V. DC

volts are measured as follows:

CAUTION

Do not exceed the 1ZOOVDC maximum

allowable input voltage rating. Instru-

ment damage may occur.

1. Turn power ON by pressing the POWER ON/OFF button.

If the instrumc?t is within 0°C to 50°C. it is useable immediately, but a two hour warmup is required to obtain

rated accuracy.

2. Press DCV button. The Model 192 will enter the DCV

mode automatically at power up.

3. Zero instrument on the .2V range. Zero must be set with

the Zero function for rated accuracy. Zeroing is necessary

to compensate for thermal EMFs generated by the connections to the circuit to be measured. These voltages

may be only a few microwIts or several tens of

microvolts. Set Zero as follows:

A. Set the output of test circuit for zero volts or discon-

nect the test leads at the circuit and short them.

B. Set the Model 192 on the .2V range.

C. Press the ZERO button.

D. Select range from the five ranges available. The

decimal point is positioned by the Range button. The

1200V range is selected by the 2000 button. If the

20MR is inadvertently pressed when in the DCV function, the Model 192 will set the range to 1200V.

4. Connect input between the DCV and LO (see figure 43).

The binding posts accept wires, spade lugs, or banana

plugs for ease of connecting the potential to be

measured. Low thermal cabling atid connections are

recommended for measurements on the .2V range.

CAUTION

Do not exceed the 1200VDC maximum

allowable input voltage rating; Instrument damage may occur.

5. Take readings by observing the displayed digits and

decimal Point locations. All ranges are direct reading in

volts.

4.6 RESISTANCE MEASUREMENTS

The Model 192 DMM measures resistance from lm$figit to

20Mn. The Model 192 provides automatic 2.wire or 4.wire

ohms operation (see paragraph 4.9 for d-wire ohms

measurements). Measure resistance as follows:

1. Turn on power by pressing the POWER ON/OFF button.

2. Press kR button.

3. Select range from the six ranges available lor autorangei.

The decimal point is positioned by the Range button.

4. Connect input between n and LO Isee Figure 4-4).

5. Accomplish Zero for a 2.wire or 4.wire measurement on

the .2kQ range. Zero must be set with the Zero function

to obtain rated accuracy. Zeroing is necessav to cornpensate for test lead resistance on 2.wire measurements

and for thermal EMFs on 2. and 4.wire measurementS.

set zero as follows:

A. Disconnect the test leadsat the circuit to be measured

and short them.

B. Press the “ZERO” button.

C. Reconnect the test leads.

6. Take reading.

CAUTION

Maximum allowable input voltage lall

ohms rangesl: 38OV peek, 250V rms. Do

not exceed maximum voltage. Instrument damage may occur. Table 4-3

lists the maximum outputs for all the

resistance ranges.

Table 4-3. Resistance Ranges

INPUT IMPEDANCE:

Figure 4-3. DC

1OOOMD on 2V-20V ranges

1OMn on 2OOV-1200V ranges

Voltage Measurements

Range

Setting I (Shorted1

* HI binding post Ired) is negative.

** Zero must be set to obtain rated accuracy~

Maximum Outputs*

!

i

v IOpen) ~

4-3

Page 22

Figure 4-4. Resistance Measurements

Figure 4-5. Four-Wire Resistance Measurement

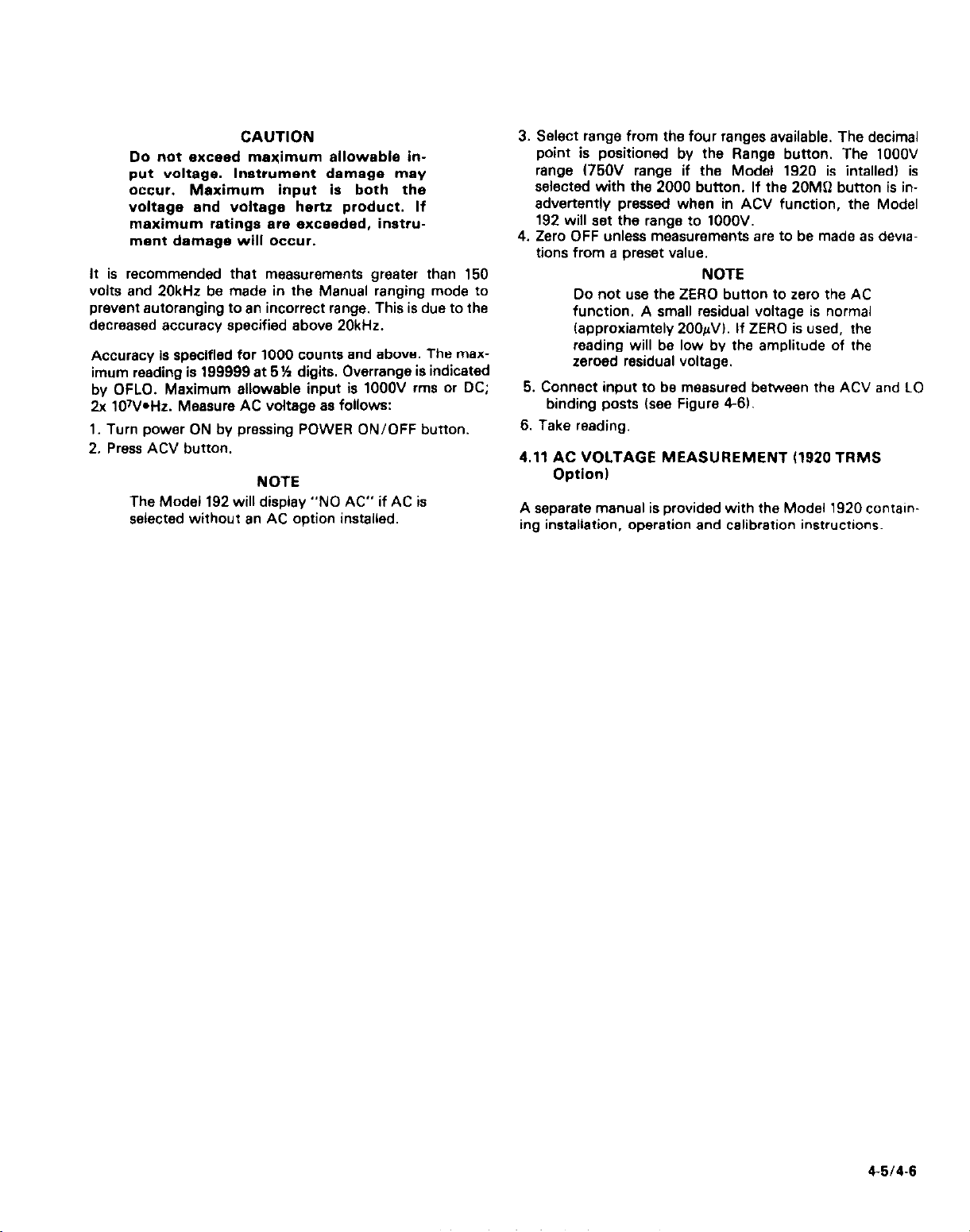

4.10 AC VOLTAGE MEASUREMENT II910 AC Option)

4.9 FOUR-WIRE OHMS MEASUREMENT

For 4-wire measurements. connect the sense leads to the

circuit to be measured and to the fi SENSE terminals on the

Model 192 (see Figure 4-5). This arrangement eliminates the

error due to the voltage drop ecross the current-carrying

leads. Accurate, high resolution ohms measurements are

obtained using 4wire connections.

Four-wire ohms measurements are recommended when

utilizing the .2k. 2k. or 20k0 range. Maximum test lead

resistance for 4-wire ohms measurement is given in table

4-4.

Table 4-4. Maximum Four-Wire Test Lead Resistance

Lead

Range

.2k

2k

20k

200k

2000k

20M

Resistance+

70

220

700

2200

7oon

22000

“Maximum resistance per lead for en additional 1 digit error

et 6K digits.

With the Model 1910 option, the Model 192 reads AC

volteges from 1OpV digit to 1OOOV. The instrument is

average responding and is calibrated to the root mean

sauare value of e sine weve. with a freauencv span of 20Hz

to 100kHz.

INPUT IMPEDANCE: 2MR shunted

by less than

5OpF

Figure 4-6. AC Voltage Measurements

Page 23

CAUTION

Do not exceed maximum allowable input voltage. Instrument damage may

occur. Maximum input is both the

voltage and voltage hertz product. If

maximum ratings ara exceeded, instrument damage will occur.

It is recommended that measurements greater than 150

volts and 2OkHz be made in the Manual ranging mode to

pravant autoranging to an incorrect range. This is due to the

decreased accuracy specified above 20kHz.

Accuracy is specified for 1000 counts and above. The maximum reading is 199999 at 5’h digits. Overrange is indicated

by OFLO. Maximum allowable input is 1OOOV rms or DC;

2x lOW*Hz. Measure AC voltage as follows:

1. Turn power ON by pressing POWER ON/OFF button.

2. Press ACV button.

NOTE

The Model 192 will display “NO AC” if AC is

selected without an AC option installed.

3. Select range from the four ranges available. The decimal

point is positioned by the Range button. The 1OOOV

range l75OV range if the Model 1920 is intalledj is

selected with the 2000 button. If the 20MQ button is inadvertently pressed when in ACV function, the Model

192 will set the range to 1OOOV.

4. Zero OFF unless measurements are to be made as deviations from a preset value.

NOTE

Do not use the ZERO button to zero the AC

function. A small residual voltage is normal

lapproxiamtely 200rV). If ZERO is used, the

reading will be low by the amplitude of the

zeroed residual voltage.

5. Connect input to be measured between the ACV and LO

binding posts (see Figure 4-61.

6. Take reading.

4.11 AC VOLTAGE MEASUREMENT (1920 TRMS

Option)

A separate manual is provided with the Model 1920 containing installation, operation and calibration instructions.

6514.6

Page 24

Page 25

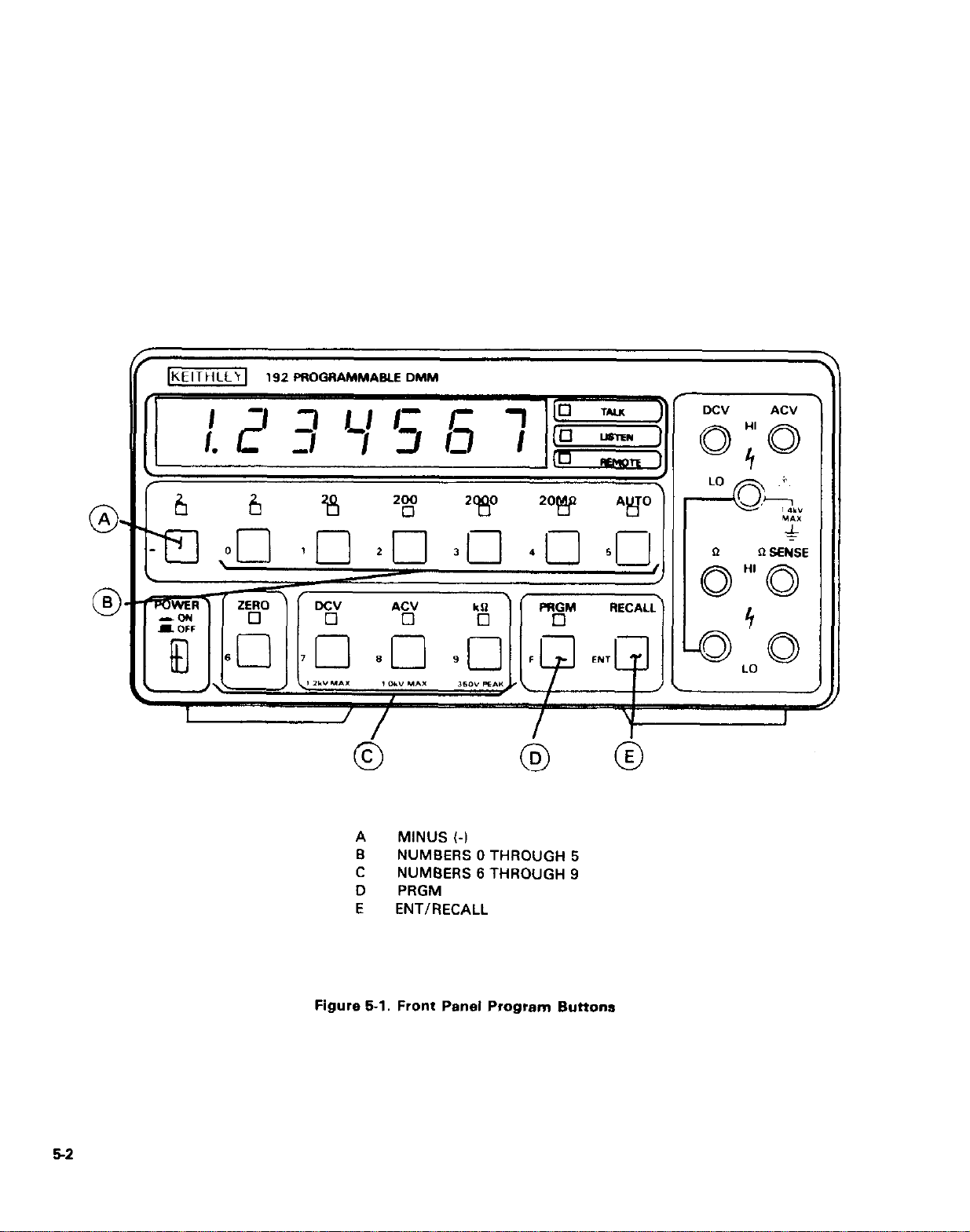

SECTION 5

FRONT PANEL PROGRAMS

5.1 INTRODUCTION

This section contains information and instructions

necessary for operating the nine internal programs of the

Model 192. These programs are run by depressing the front

panel PRGM button, along with the button representing the

appropriate program number. Some of the programs require

numerical constants that must be entered from the front

panel by using the numbered buttons. Other programs will

display appropriate messages. Program examples are provided when necessary to instruct the operator in practical

applications. For basic operation of the front panel buttons,

refer to Section 4. The programs, which are summarized in

Table 5-l. are explained in detail in the following paragraphs. Refer to Figure 5-1 for front panel details.

5.2 PROGRAM NOTES

1. Most of the front panel buttons serve a dual purpose.

The Range, Function, end Zero buttons are numbered in

sequence. These numbered buttons are used when a

program number or numerical constant is to be entered.

2. Each program is entered by depressing the PRGM but-

ton followed by the desired program number.

3. PROGRAM$is used to cancel all other programs except

PROGRAMS 1 end 2. An appropriate clear message is

displayed when this program is entered.

4. PROGRAM 1, which controls the display resolution, and

PROGRAM 2, which controls the internal filter, may

both be used with any other program.

5. PROGRAMS 3 through 7 are mutually exclusive; only

one of these programs may be used at any one time.

6. New programs may be entered without clearing a program that is presently running. To do so, depress the

PRGM button, followed by the desired program

number.

7. Anempting to enter an invalid program number will

result in the following error message:

B. The numerical constants used for each program are

stored separately and will not change unless entered at

the appropriate point in each program. Constant values

will be lost if the power is turned off.

9. Constants are to be entered when the operator is

prompted to do so by the instrument. When entering a

numerical constant:

A. The constant is entered by depressing the numoereo

buttons in the desired sequence.

B. The decimal point is automatically placed in accor-

dance with the allowable range of the constant.

C. Data is entered into the digit whose “c” segment is

fleshing by pressing the desired numbered button.

The “c” segment of a display digit is shown below:

E-8, ,,

c segment

As each digit is entered, the blinking segment will

move one place to the right until all the necessary

digits have been entered.

D. Only a 0 or 1 may be entered as the first digit for any

of the constants.

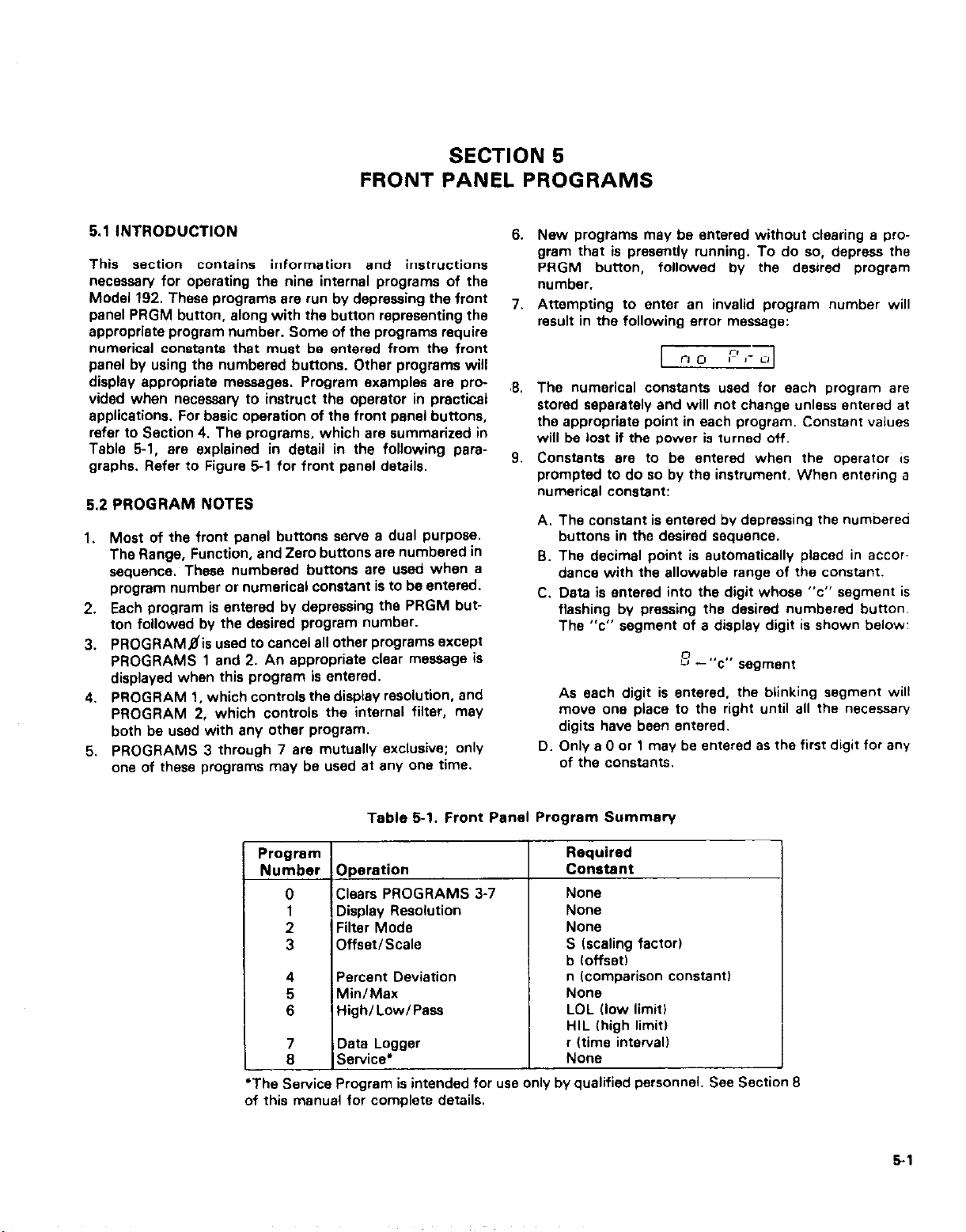

Table 6-l. Front Panel Program Summary

Program

Number Operation

0

1

2

3

4

:

7

B

‘The Service Program is intended for use only by qualified personnel. See Section 8

of this manual for complete details.

Clears PROGRAMS 3-7

Display Resolution

Filter Mode

Offset/Scale

Percent Deviation

Min/Max

High/Low/Pass

Data Logger

Service’

Required

Constant

None

None

None

S (scaling factor)

b (offset)

n (comparison constant1

None

LOL (low limit)

HIL (high limit)

r (time interval1

None

6-l

Page 26

192 PROGRAMMABLE DMM

Y--c71 n n 17 17

DCV AC”

qo

6-2

A

MINUS 1-l

B

NUMBERS 0 THROUGH 5

C

NUMBERS 6 THROUGH 9

D

PRGM

E ENT/RECALL

Figure 6-l. Front Panel Program Buttons

Page 27

E. Only es many significant digits es necessary need to

be entered. The Model 192 will complete the constant with trailing zeroes where necessary.

F. Invalid keys will be ignored. If an invalid key is

depressed, the blinking “c” segment will remain at

the current digit.

G. If an incorrect digit is entered, the complete constant

must be reentered. The new value may be entered by

cycling the display around to the beginning by

repeatedly depressing one of the number buttons.

H. A neoative constant mev be entered bv deoressina

I~ I

the front panel minus (-I button. The display will the;

show a negative number. This mey be done at any

point in the numeric input sequence. Depressing the

minus button a second time will restore the constant

to s positive value.

If too many digits are entered, the display will begin

again et the first digit on the left. All the digits in the

constant must then be entered again.

Once all the digits of the desired constant are shown

on the display, the constant is entered into the program by depressing the front panel ENT button.

The number of significant digits to be entered for s

constant will depend on the display resolution mode

in use. In the 5 H digit mode, only five digits after the

leadingfi or 1 may be entered. In the 6 !4 mode, up to

six digits in addition to the leading 0 or 1 may be

entered.

10. PROGRAMS 3 through 7 will be terminated if the Model

192 receives a Remote Enable command over the

IEEE-488 bus. PROGRAM&through 2 are not affected

by the Remote Enable command.

Note

If it becomes necessary to exit a program in

progress (for example, to change resolution

with PROGRAM 1, or change the filter mode

with PROGRAM 21, readings will be missed

while the instrument waits for the operator

to enter the desired program number.

11. When the front panel PRGM button is pressed, the

instrument will prompt the operator to enter the desired

program number by displaying the following message:

Note that the question mark on the display will blink

until a program number is entered. Depressing en invalid

button at this point will result in the following message,

which will be displayed for K second:

[no]

gram, the following message will be displayed for H

second:

j-z-T-q

13. While PROGRAMS 3 through 7 era being run, the front

panel PRGM indicator light will be on. This light will go

off if the program is cancelled. either by using PROGRAM 8: or if the Remote Enable command is received

over the IEEE-488 bus.

14. The front panel PRGM button will be inoperative if the

IEEE REMOTE indicator light is on. Once the instrument

is in the Remote mode, the following IEEE command

sequence must be sent to restore front panel program-

ming operation: GTL (Go to Local); DCL (Device Clear).

For more information on IEEE commands. refer to the

Model 1923 Instruction Manual. Alternately. the instrument may be turned off and then powered-up again to

restore programming operation. Of course. any con-

stants previously stored will be lost, and the instrument

will return to the power-on default conditions.

15. When PROGRAMS 3 through 7 are entered, the AUTO

range will be cancelled. The instrument will stay on the

present range when one of these programs is entered

6.3 PROGRAM 0. CLEAR

PROGRAMtimey be used to cancel PROGRAMS 3 through

7. This program is entered by depressing the PRGM switch

followed by the 0 button es follows:

1. Press PRGM. The instrument will display the following,

indicating it is waiting for s program number:

r-Fzi-71

2. Press 0. The following message will be displayed for approximately % second:

[ml

3. Immediately following the program number indication.

the following message will be displayed for Ih second:

4. PROGRAMS 3 through 7 will be cancelled. and the

Model 192 will return to the normal operating mode by

displaying readings. The operation of the Function.

Range, and Zero buttons will be restored after PRO-

GRAM 0 is entered.

5. Depressing the RECALL button after PROGRAM fi has

been run will cuese the following message to be dis-

played for H second:

12. The Range, Function, and Zero buttons are locked out

while PROGRAMS 3 through 7 sre in progress. The operator must exit the program if these parameters are to

be changed. If en invalid key is pressed durinp a pro-

6-3

Page 28

5.4 PROGRAM 1. RESOLUTION

The display resolution of the Model 192 may be changed to

5’h or 8% digits by running PROGRAM 1. If has no effect

on the date transmitted over the IEEE-488 bus, and may be

used with PROGRAMS 3 through 7. Each time PROGRAM

1 is entered. the instrument will change display resolution

modes. Upon power-up, the instrument is in the 5H digit

display mode. To change the resolution. PROGRAM 1 may

be entered as follows:

1, Press PRGM. The Model 192 will respond with the usual

prompt for a program number as follows:

-1

normally enabled for the 6H digit mode. For a more complete description of these routines, refer to paragraph 4.6.

PROGRAM 2 controls operation of a third available filter,

filter 3. Each time PROGRAM 2 is entered, the state of filter

3 is changed. If filter 3 was previously enabled, entering

PROGRAM 2 will turn filter 3 off, If the filter was previously

disabled, PROGRAM 2 will turn the filter on. Upon power-

up, filter 3 is disabled. The mode of filter~3 may be changed

by entering PROGRAM 2 as follows:

1. Press PRGM. The instrument will respond with the usual

prompt for a program number:

r-?z-7-\

2. Press 1. The unit will indicate it has entered PROGRAM 1

by displaying the following message for H second:

3. If the instrument was previously in the 5!4 digit mode, it

will change to the 6H digit mode as indicated by the

following message, which will be displayed for approx-

imately W second:

[s.;

Readings made in the 6H digit mode are made at a

slower rata, es indicated by the flashing rate of the

decimal point.

4. If the instrument was previously in the 6H digit mode, it

will change to the 5% digit mode and display the follow-

ing message for ‘h second:

[s.s

5. After PROGRAM 1 has been run, the Model 192 will continue to display normal readings. PROGRAMS 3 through

7 may be entered et this time without effecting display

resolution.

6. Example: Assume the Model 192 is connected to a DC

voltage source and is in the 5K digit mode on the 20V

range. A tYpical 5H digit display reading might be:

r-i-Gmq

After entering PROGRAM 1, the display reading might

change to:

Note that the lest digit was roundedoff when the instrument was in the 5% digit display mode.

5.5 PROGRAM 2. FILTER

The Model 192 has a digital filter that is useful for minimiz-

ing the effects of noise on the readings. Normally, filter 1 is

enabled for the 5’h digit resolution mode, while filter 2 is

2. Press 2. The program will be entered es indicated by the

following message which will be displayed for % second:

p.YG-iq

3. If the filter was previously turned off, the filter will be

enabled, and the following message will be displayed for

H second:

4. If the filter was on, it will be disabled. end the following

message will be displayed for approximately ‘/2 second:

NOTE

If the filter is not in the desired mode, it may

be chenged by running PROGRAM 2 again.

To do this, simply depress the PRGM end 2

buttons in sequence a second time. Each

time PROGRAM 2 is entered, the filter mode

changes to the alternate state.

5. Once PROGRAM 2 has been entered, the Model 192 continues normal operation by displaying readings. Other

programs may then be entered as desired.

6. As an example of PROGRAM 2 operation, assume that

readings on the 0.2VDC range are being made. If the

displayed readings continuously or intermittently hop

around, the filter should be turned on to minimize these

effects. Note that operating the Model 192 with the filter

on will increase the response time to sudden changes in

input level: if short settling times are required, the

operator should use PROGRAM 2 to disable the filter.

See figure 4-2 for the response graph of filter 3.

5.6 PROGRAM 3. OFFSET/SCALE

PROGRAM 3 allows the operator to automatically multiply

normal display readings IX) by a constant (St and add an

offset (b). The result (YI will be displayed in accordance

with the formula, Y = SX + b. Upon power up, S = 1, and

Page 29

b=O, but these constants may be changed at the appropriate point in the program. Note that Range, Function, end

Zero buttons are inoperative during the course of the program. If one of these buttons is depressed while PROGRAM

3 is running, an “in Pro” message will be displayed. PRO-

GRAM 3 is useful when slope calculations are required for a

series of measurements. Operating instructions for PRO-

GRAM 3 are as follows:

1. Select the Function and Range, and enable the Zero, if

desired, before PROGRAM 3 is entered. These operating

controls cannot be used once the program is run.

2. Press PRGM. The Model 192 will respond with the program prompt message 8s follows:

3. Press 3. The program number will be displayed for K

second es follows:

The instrument will now prompt the operator to enter the

4

S constant by displaying the following message for ‘h

second:

[]

The old value of S will then be displayed: the most signifi-

5

cant digit will show a blinking “c” segment to indicate

that en operator entry is required. If no changes in the

displayed value are desired. the constant may be entered

by depressing the ENT button.

6.

A new value for S may be entered by depressing the

numbered buttons in the desired sequence. Note that S

must be in the range -1.999999 L S L +1.999999.

After the desired value of S is shown on the display, the

constant must be entered into the program by depressing the front panel ENT button.

7

After the S constant is entered, the Modal 192 will

prompt the operator to enter the b constant by displaying the following message for % second:

8.

The display will then show the presently stored value of

b. In addition, the first digit “c” segment will blink, indicating the instrument is waiting for an input. At this

point, the old value of b may be entered simply by

depressing the ENT button.

9

A new value for b may be entered by depressing the

numbered buttons in the desired sequence. Note that

the b must be in the range of -1999999 (b ( + 1999999

with the decimal point automatically placed according

to range. For a given range, the value of b cannot

exceed the maximum that can be measured on that particular range. For example, the maximum value of b on

the 20VDC range is f 19.99989. Once the desired constant is shown on the display, it may be entered into the

program with the ENT button.

10. Once the ENT button has been depressed, the Model

192 will show the value of Y. If the value of Y is larger

then can be handled by the particular range, an “DFLO”

message will be displayed, indicating the instrument

must be switched to a higher range. Note that PROGRAM 3 must be cancelled with PROGRAM 6 before

the range can be changed.

11. While still in PROGRAM 3, new values for S and b may

be entered by using the RECALL button. The following

message will be displeyed.for X second:

? r ,I, 3

The Model 192 will then prompt for new values of S and

b es previously described. To enter new values. follow

the procedure in steps 5 through 9 of paragraph 5.6.

12. The values for S end b will be stored within the Model

192 until the power is turned off. These constants may

be used in future runs of PROGRAM 3. Note, however,

that the value of b is scaled according to the range in

use. If, for example, s value of 19.00000 was entered for

b with the instrument on the 20V range. the value of b

will be changed to 190.0000 if the program is entered

with the instrument on the 200V range.

13. An example of readings that will be obtained when PRO.

GRAM 3 is run is shown in the following. Each of the

obtained values for Y assumes the following constants:

S = + 1.5; b= +5. Also, the instrument is on the 20

IDCV, ACV. kfll range.

Normal Reading

+8 VDC

-5 VDC

PROGRAM 3 Reading IY = SX + bl

+ 17 VDC

-2.5 VDC

6.3 VAC’ 14.45 VAC

AkR

11 kR

‘Requires AC Option

NOTE