Page 1

Instruction Manual

Model 191

Digital Multimeter

01979, Keithley Instruments, Inc.

Cleveland, Ohio, U.S.A.

Page 2

TABLE OF CONTENTS

6-1

6-l

6-1

h-l

6-l

6-l

6-2

6.2

ii

Page 3

MODEL 191 DMM

GENERAL INFORMATION

SECTION 1. GENERAL INFORMATION

l-l.

INTRODUCTION.

1-2.

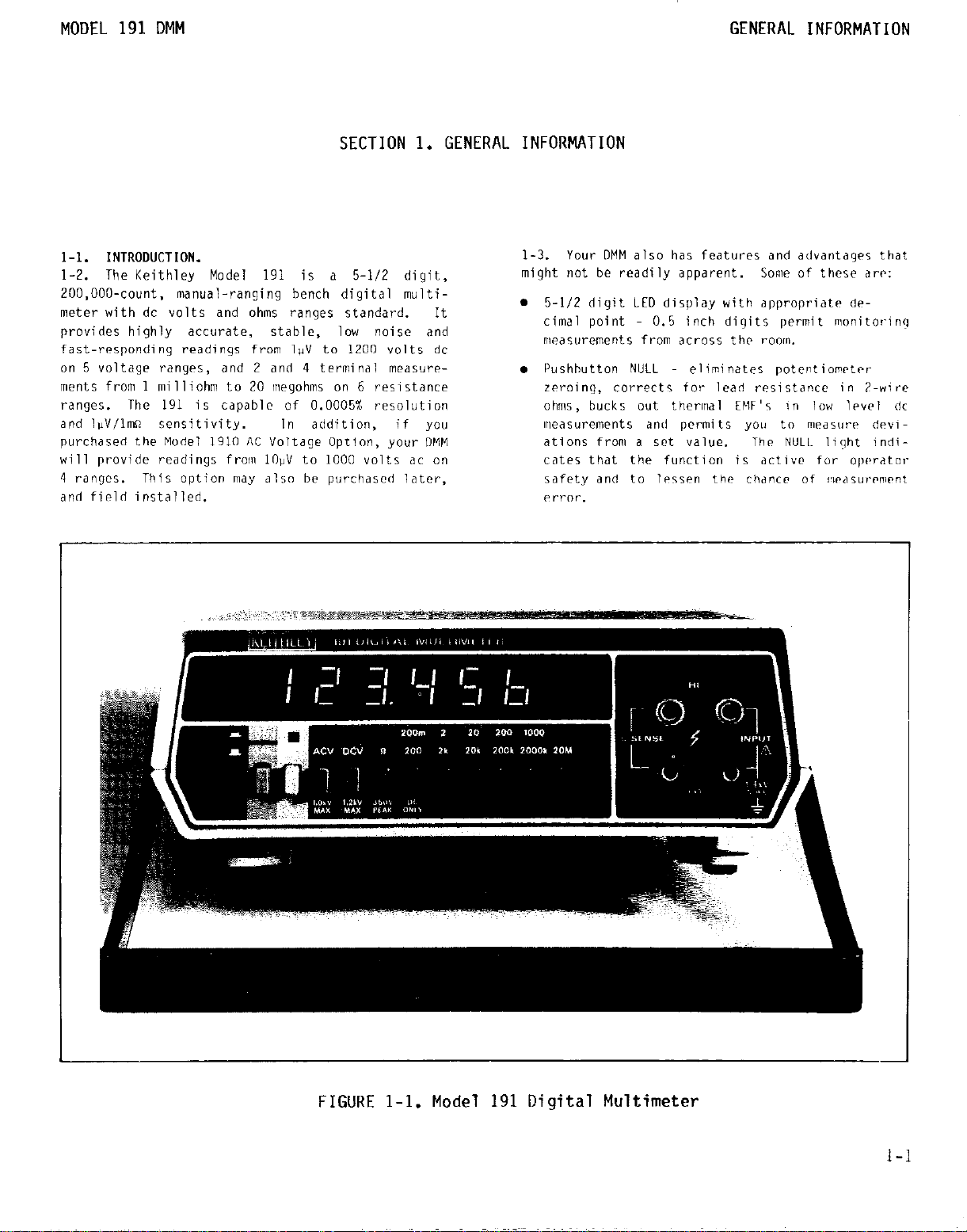

The Keithley Model 191 is a 5-l/2 digit,

200,000-count,

meter with dc volts and ohms ranges standard. It

provides highly accurate, stable, low noise and

fast-responding readings from 1uV to 1200 volts dc

on 5 voltage ranges,

ments from 1 milliohm to 20 lrlegohms on 6 resistance

ranges. The 191 is capable of 0.0005% resolution

and luVlln!G sensitivity. In addition, if you

purchased the Model

will provide readings from 1OuV to

4 ra"gES. This option may alsn be purchased later.

and field installed.

manual-ranging bench digital multi-

and 2 and 4 terminal measut-e-

1910 AC

Voltage Option, your "MM

lOO(1 volts ac on

1-3. Your OMM also has features and advantages that

might not be readily apparent. Soae of these aw:

. 5-l/2 digit LEO display with appropriate de-

cimal point - 0.5 inch digits permit monitorinq

nx?asurements fron1 across tllc r""!".

l

Pushbutton NULL eliminates potenti"mrtPr

zeroing, corrects for lead resistance in ?-wire

ohms, bucks out thermal EMF's in 1ow IPYPI dc

nleasurements 3°C permits you t" medsuv? deviations from a set value. The NULi~ light indicates that the function is dctivc for "p~rat"rsaietv and to lessen the? ChdrlCC Of I.IP‘3S,II'P,~IPnt

FIGURE

l-l.

Model

191

Digital Multimeter

I-1

Page 4

GENERAL INFORMATIOP

MODEL

191

DMM

Continued.

l-3.

A Micro-processor

provides:

A Combination of single slope and charge balance

AD conversion - for faster response and better

linearity.

Automatic non-linear digital filtering - for

faster response

display.

A reduction in the number of parts while maintaining high accuracy and speed of measurement simplifies high accuracy measurements and calibration of the instrument and provides higher

mean time between failures.

-1EEEEE error message indicates improper

uses of the instrument - prevents erroneous readings and reduces possibility of injury to the

user or damage to the instrument.

Each range has:

Automatic polarity operation minus sign displayed, positive implied.

Effective input overload protection.

Overrange indication - polarity and overrange

digit displayed.

Decimal point positioned by range pushbutton.

Automatic Z/4 wire ohms operation - saves

time and simplifies Z-wire or 4-wire ohms

measurements.

A full line of optional accessories that

exterd the measurement capability of your llcdel

191.

IGOO High voltage Probe allows your Dill1 to

measure fron 12OOV to 40kV dc.

1901 Plug-l" Current Adapter allows your D,,,, to

read dc current from lvA/digit to 2000mA.

the AC Voltage option, it reads from lOti/digit

to 2000nA ac.

1682 High Frequerxy (RF) Probe allows your Dills to

RedSUre fr0n 0.25v to 3ov t-lx ac wer a frequency

t-awe of 100kHr to 1OOMHr.

without the AC Voltage Option.

1685 Clamp-On AC Current Probe (when used with AC

Voltage Option) allws your Dllll to measure fron

zero to 200A rns ac.

Some of these accessory ncde1s are:

based design that

and reduced noise on

It can be used

the

Hi th

1651

50.Ampere Current shunt allows your D!IM to

measure fron O-50A dc, ard with AC Voltaqe Option

fron IOA to 50A ms ac.

NOTE

Refer to Section 4 for more detailed information

on these accessories.

l-4. WARRANTY INFORMATION.

1-5. The Warranty is given on the inside front cover

of this Instruction Manual. If there is a need to

exercise

Representative in your area to determine the proper

action to be taken. Keithley maintains service

facilities in the United Kingdom and West Germany,

as well as in the United States. Check the inside

front cover of this Manual for addresses.

l-6.

l-7.

which occur after printing of the Instruction Man-

ual will be explained on a Change Notice sheet

attached to the inside back cover.

1-8.

1-9. Safety symbols used in this manual are as

follows:

The b

this Manual.

CAUTION statements with regard to proper use and

handling of the instrument.

instrument may occur if these precautions are

ignored.

This\ ~

this Manual.

on the instrument which are potential shock

hazards.

statements with regard to proper use and handling

of the instrument.

result if these precautions are ignored.

l-10.

I-11.

given in Table 1-I.

the warranty, contact the Keithley

CHANGE NOTICES.

Improvements or changes to the instrument

SAFETY SYMBOLS.

IMPORTANT

symbol can be found in various places in

Carefully read the associated

Oamage to the

svmbol can be found in various places in

This symbol indicates those areas

Carefully read the associated WARNING

Serious personal injury may

SPECIFICATIONS

Detailed specifications for the Model 191 are

l-2

Page 5

MODEL

191

DMM

GENERAL INFORMATION

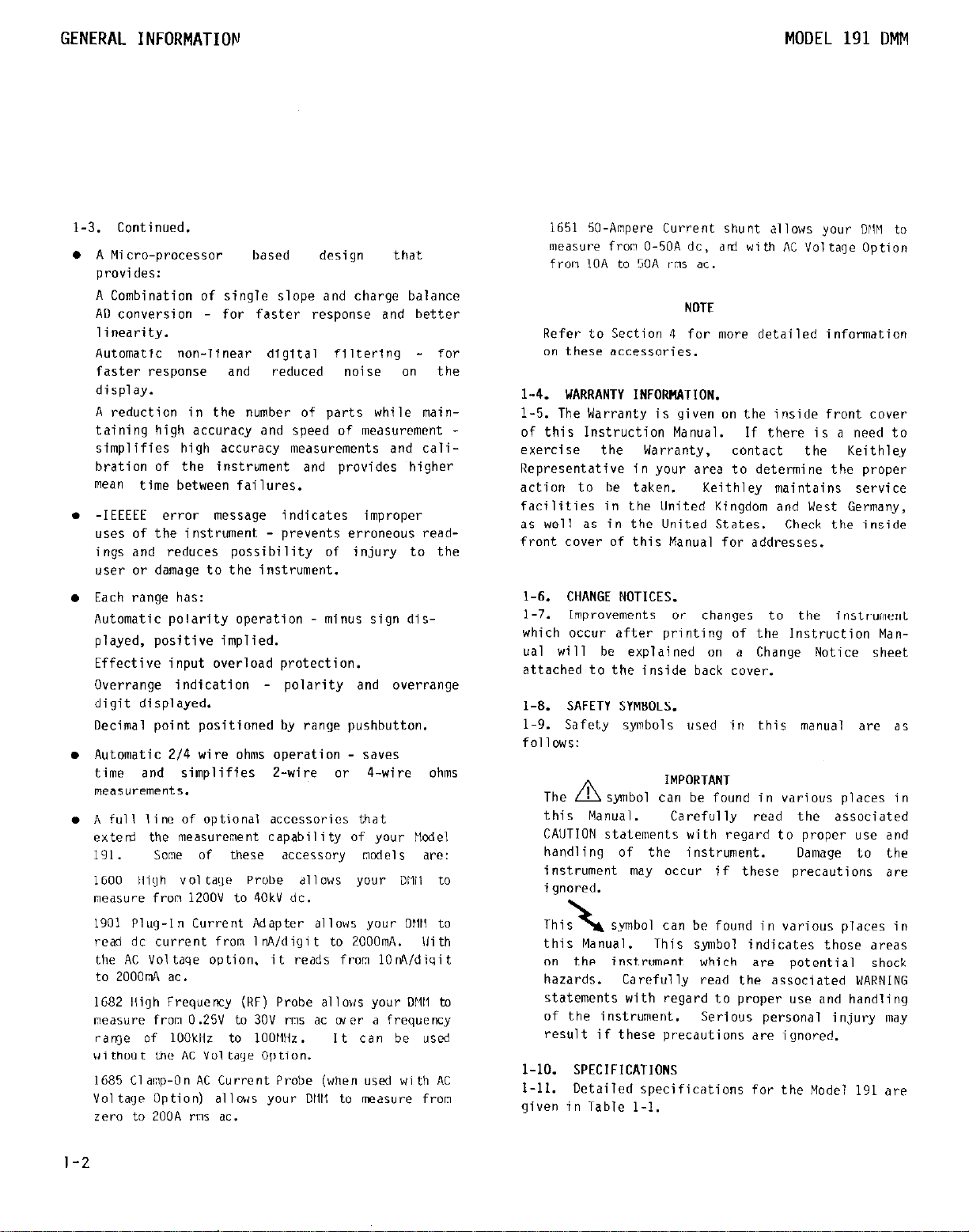

TABLE l-l

SPECIFICATIONS

Page 6

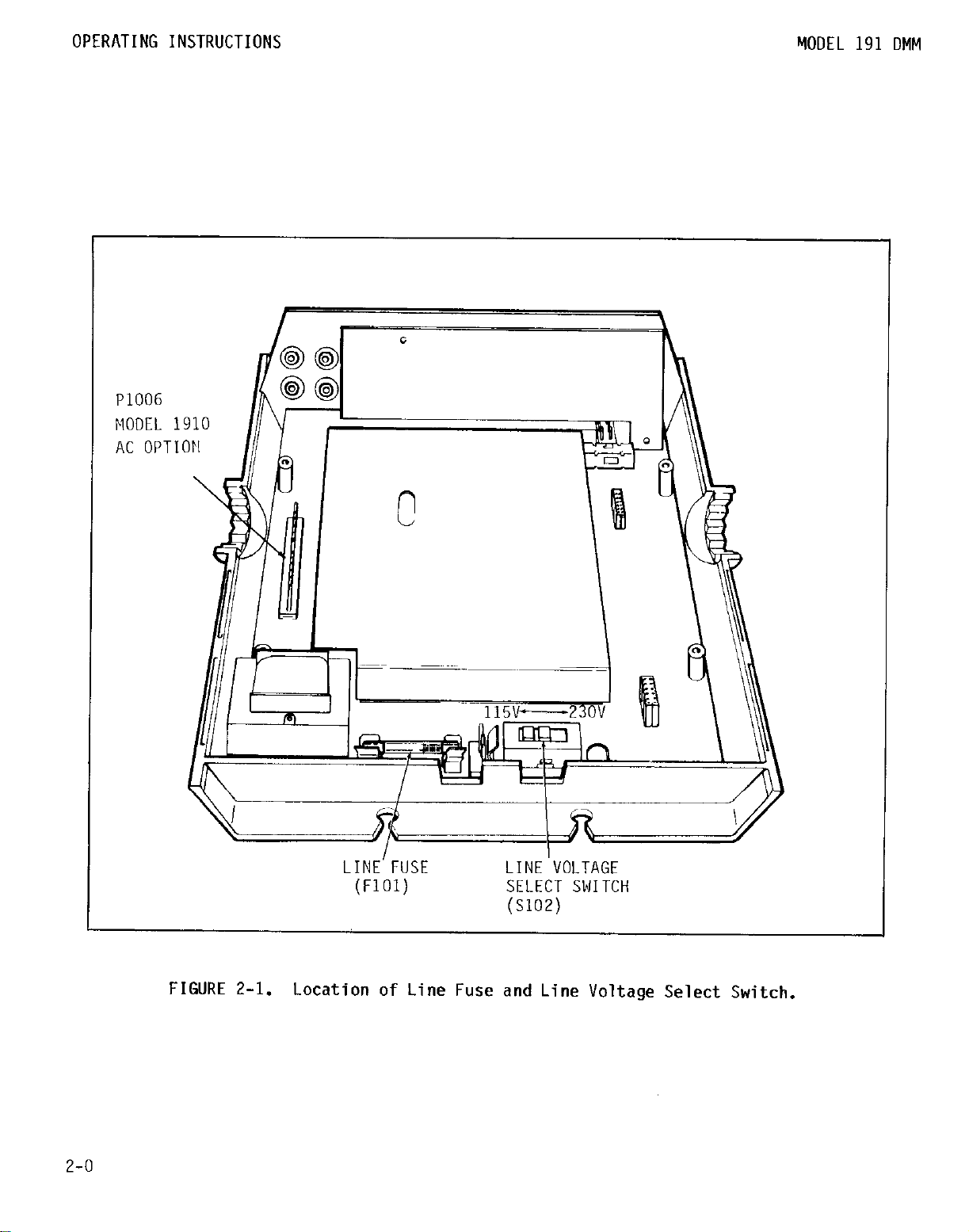

OPERATING INSTRUCTIONS

P1006

MODEL

AC OPl

YODEL

191

DMM

e

LINE/FUSE

(F101)

LINE'VOLTAGE

SELECT SWITCH

(S102)

2-o

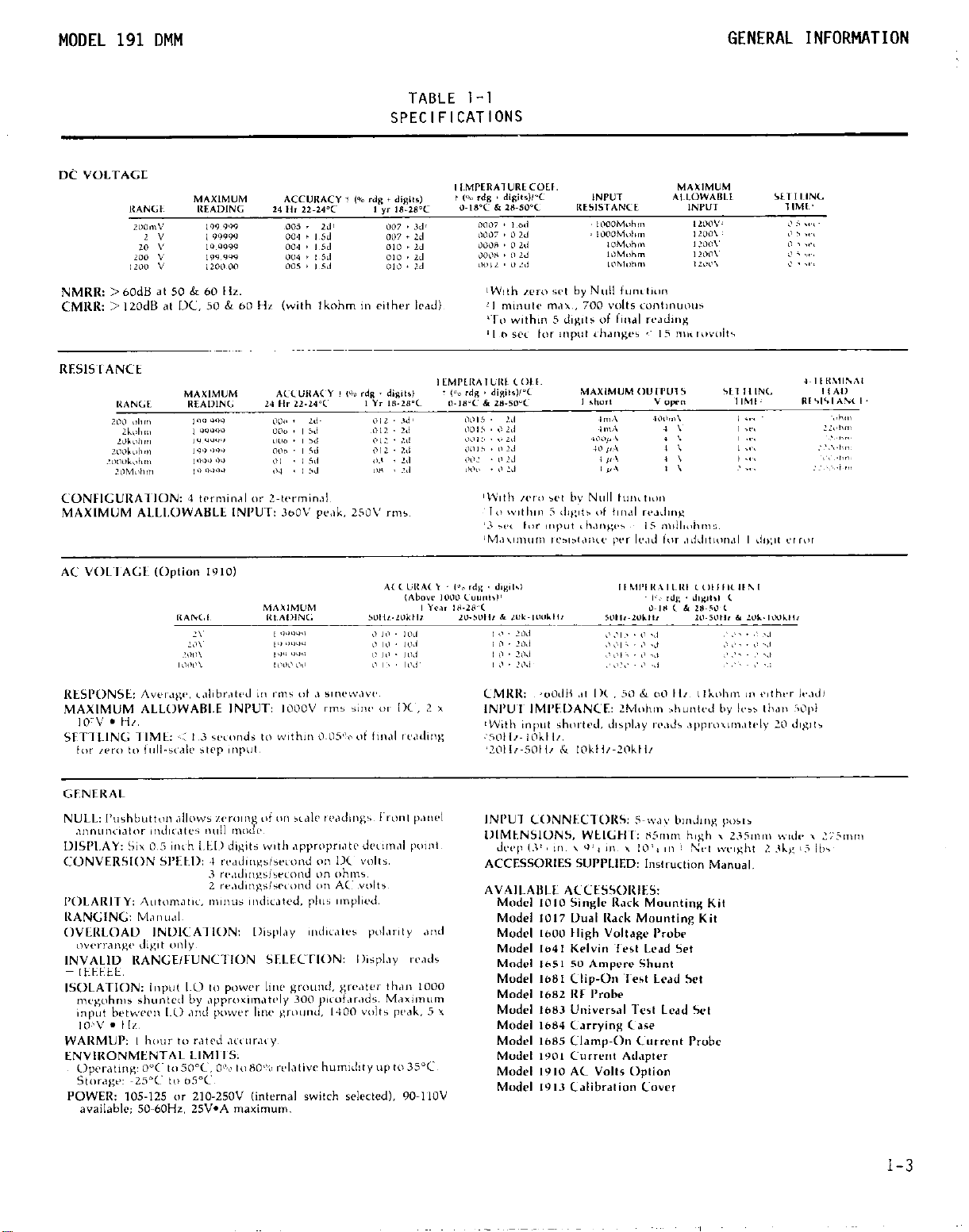

FIGURE 2-1.

Location of Line Fuse and Line Voltage Select Switch.

Page 7

MODEL 191 DMM

~OPERATING INSTRUCTIONS

SECTION 2. OPERATION.

INTRODUCTION.

Z-l.

2-2.

incoming

operation of the Model

2-3.

2-4.

mechanically and electrically before shipment. Upon

receiving the Model 191,

shipping container and check for any obvious damage

which may have occured during transit.

damages to the shipping agent.

original

required.

Model 191 orders:

2-5.

2-6.

on how to connect the Model 191 to your available ac

This section provides information needed for

inspection, preparation for use, and

191 and

UNPACKING AN0 INSPECTION,

The Model 191 was carefully inspected, both

packaging materials if reshipment is

The following items are shipped with all

a. Model 191 OMM.

b. A Copy of this Manual.

Installed or separate optional accessories, as

C.

ordered.

PREPARATION FOR USE.

The Model 191 is shipped ready-for-use on the

line voltage marked on its rear panel. Instructions

line power are contained in Paragraph Z-7 Line

Power.

its accessorieS.

unpack all items front the

Report any

Retain and use the

NOTE

The line voltage sct/tinq of the instrument

is marked on the &r panel. The following

procedure can be uqed to either confirm the

factory setting, or 40 set up the instrument for

operation on another ivoltage range.

voltage range is chdnged, the box next to the

selected line voltaTe should be appropriately

marked as an externalI reminder of the setting.

Use a water soluable barking pen.

Line Voltage Selec~tion.

2-9.

Z-10. Set up the Modejl 191 to operate on your

available ac line voltage as follows:

Turn the DMM botltom side up and loosen the

a.

four screws in the boqtom cover. These sci-ews are

held captive hy rubber O-rings.

Hold the top an?

h.

prevent their separatjon and turn the DMb1 over to

normal position. Rem+, the top cover.

Set switch

c.

line fuse, as indicated in Table 2-1. for your

available input line ~ voltage.

shown in Figure

d. Reinstall the top cover.

8102

2-l.

bottom cover

aind install the proper rated

if the line

together t"

These items are

2-7. LINE POWER

2-R.

cord which mates with a 3rd wire earth grounded

receptacle.

voltage ranges of 60 or 50 Hertz ac power.

voltage ranges are 105 to 125 volts and 210 to 250

volts.

positioning an internal slide switch and installing

the appropriate fuse for that range.

your available ac power inaccordance with the

The Model 191 is provided with a 3-wire line

The instrument will operate on 3

Standard

Either of these ranges may be selected by

An optional

line voltage range of 90 to 110 volts is available

by special order.

different transformer.

following procedures:

Instruments with this range use a

Connect the Model 191 to

TABLE 4-l.

Line Voltagq Selection

*Requires special~factory installed

transformer.

2-l

Page 8

OPERATING INSTRUCTIONS MODEL

191

DMM

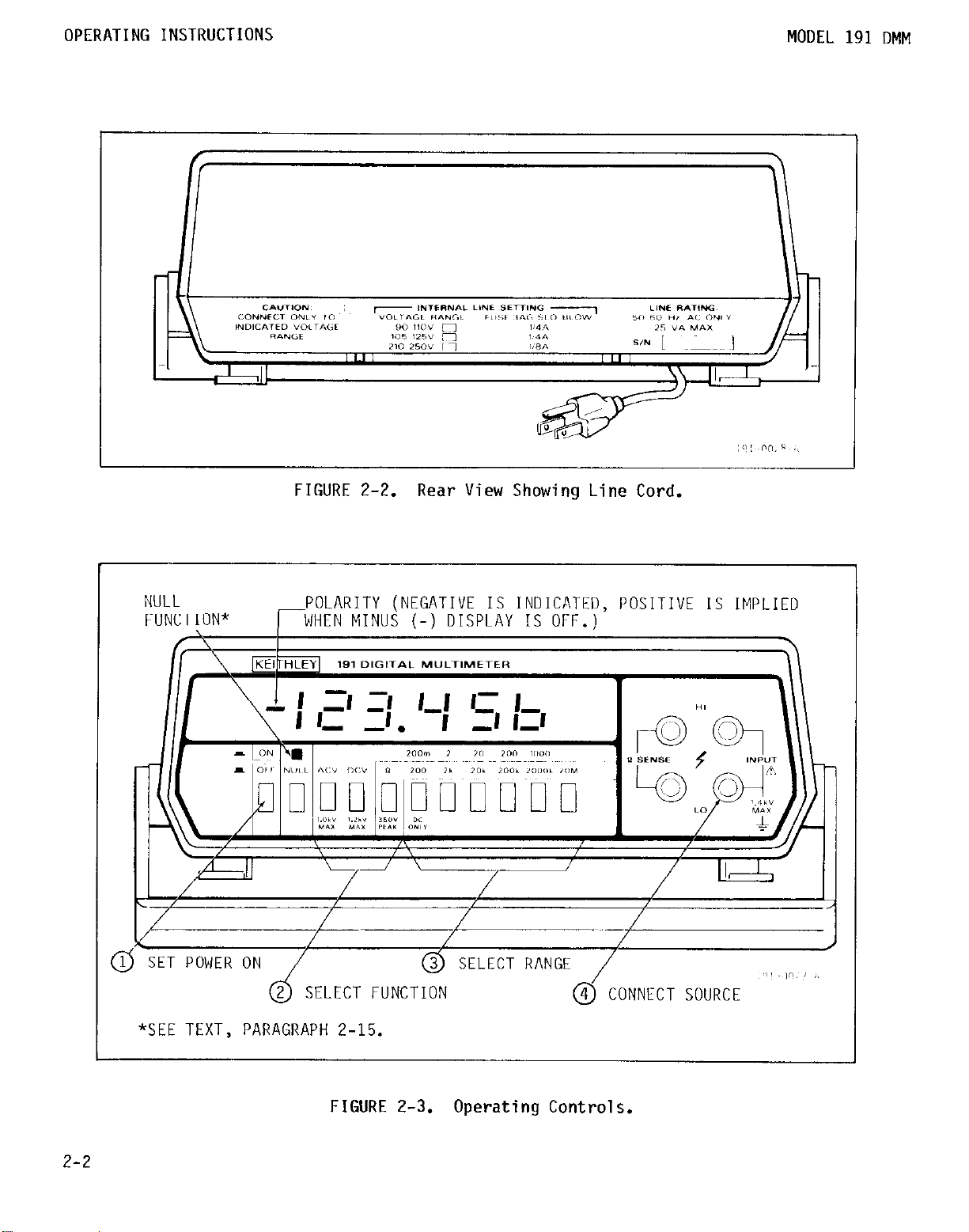

NULL

FUNCTION*

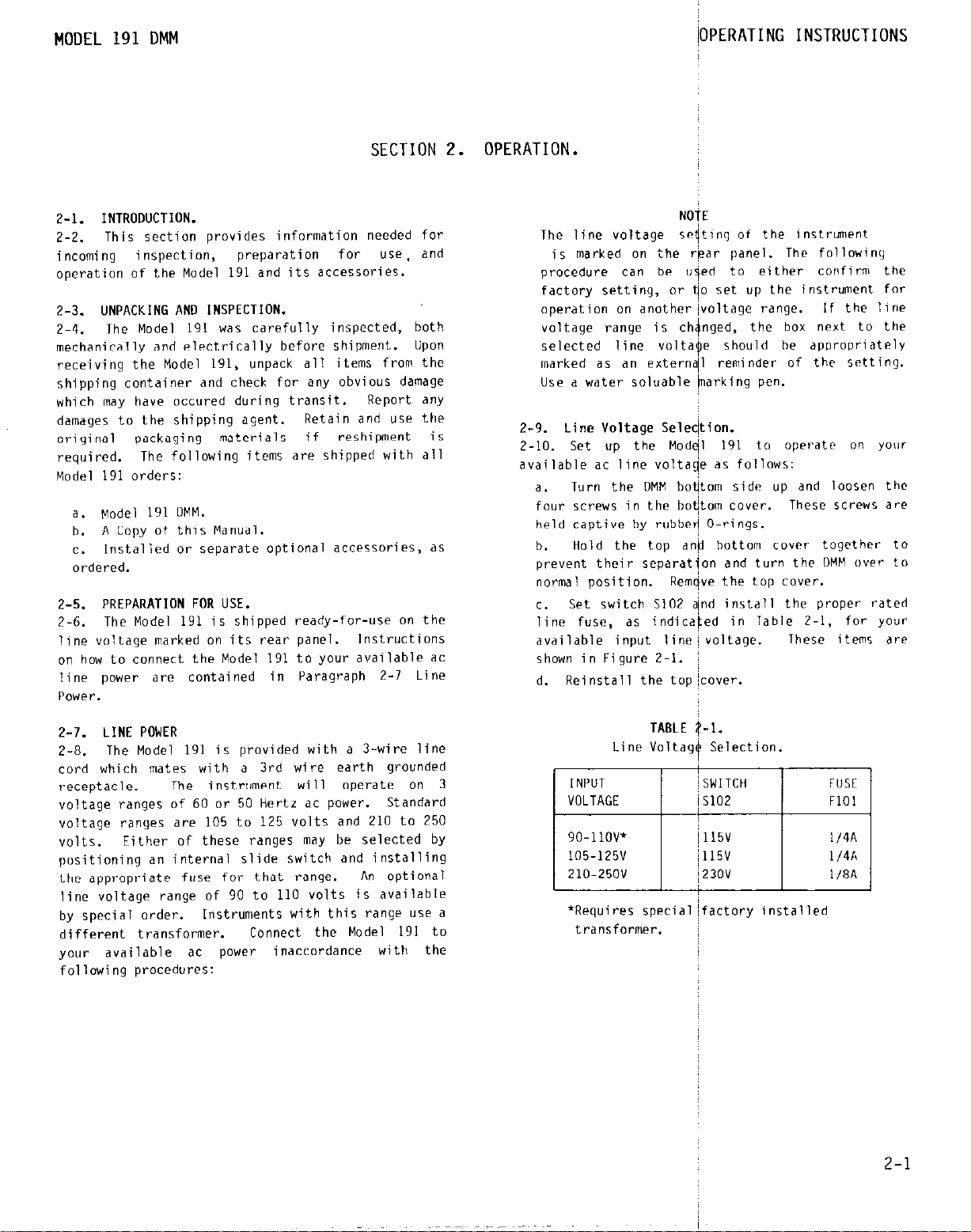

FIGURE 2-2.

POLARITY (NEGATIVE Is INDICATED, POSITIVE Is IMPLIED

rblHEN MINUS (-) DISPLAY IS OFF.)

Rear View Showing Line Cord.

/

2-2

1 SET POWER ON

(I.3

*SEE TEXT, PARAGRAPH 2-15.

I

@j SELECT RANGE

4 CONNECT SOURCE

0'

FIGURE 2-3. Operating Controls.

I", 3 ,.

Page 9

OPERATING INSTRUCTIONS MODEL

2-2

Z-11.

z-12. The Model 191 is provided with a 3-wire line

cord, shown in Figure 2-2, which mates with third-

wire grounded receptacles. Connect the instrument

to ac line power as follows:

2-13. OPERATING INSTRUCTIONS

2-14.

Model 191 [IMM are outlined below, and Condensed

Operating instructions are provided on the bottom

cover of the instrument. These instructions should

only be used after becoming completely familiar with

the operation of the Model

"SC?.

performance and safest operation will be obtained by

using the individual instructions provided in this

section which describe how t" make specific function

mea*"reme"ts.

OMM a5 f0110w5:

Connecting Line Power.

WARNING

\,

Ground the instrument through a properly earthgrounded receptacle before operation. Failure to

ground the instrument can result in sevet-e injury

or death in the event of short circuit or

malfunction. In addition, connect only t" the

line voltage selected. Application of incorrect

voltage can damage the instrument.

Plug the power c"rd into a properly grounded

a.

outlet of a source having the selected line

voltage.

Operate the Model

b.

Paragraph Z-13.

The basic operating instructions for the

Until this familiarity ha5 been achieved, best

Refer to Figure 2-3 and operate the

/&CAUTION

no not exceed the Maximum Inputs limits given in

Table 2-2.

Turn on the power by depressing the ON/OFF

a.

pushbutton.

it is useable immediately, but a 1 hour warmup is

required to obtain rated accuracy.

additional hour may be required from temperature

extrelne5.

Select the function with the ACV, IDCV or n

b.

pushbuttons.

Select the range by depressing the appropriate

c.

pushbutton,

Connect the source to the INPUT terminals and

d.

make the ,n,easurement.

Section 4 should he (used as required.

If the instrument is within 18-2R°C,

191

as described in

191

through day-to-day

up to 1

Accessories described in

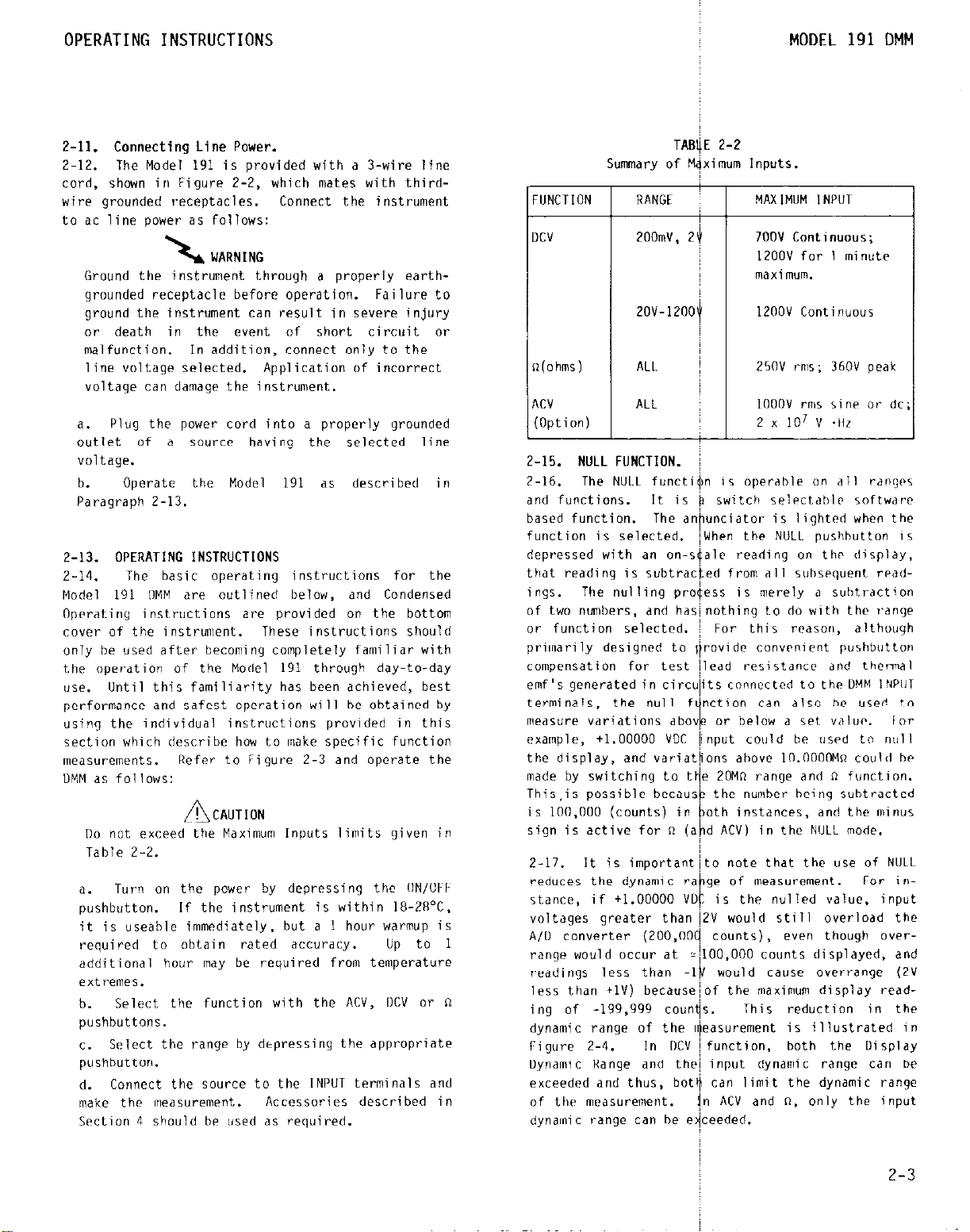

Summary of M

UNCTION

2-15. NULL FUNCTION.

Z-16.

and functions. It is

based function. The dr

function is selected.

depressed with an "n-5

that reading is subtrx

1ngs. The nulling pr"

of two numhers, and ha5

or function selected.

primarily designed to

compen*ation for te5t

emf's generated in circa

terminals,

measure variation5 db"'

example,

the display, and variat

made by switching to t

This,is possible hecaur

is 100,000 (counts) in

sign is active for n (a

2-17. it is important

reduce5 the dynamic re

stance, if

voltages greater than

A,0 c"nverter (200,OOI

range would occur at *

readings less than -1

less than +lV) because

ing of

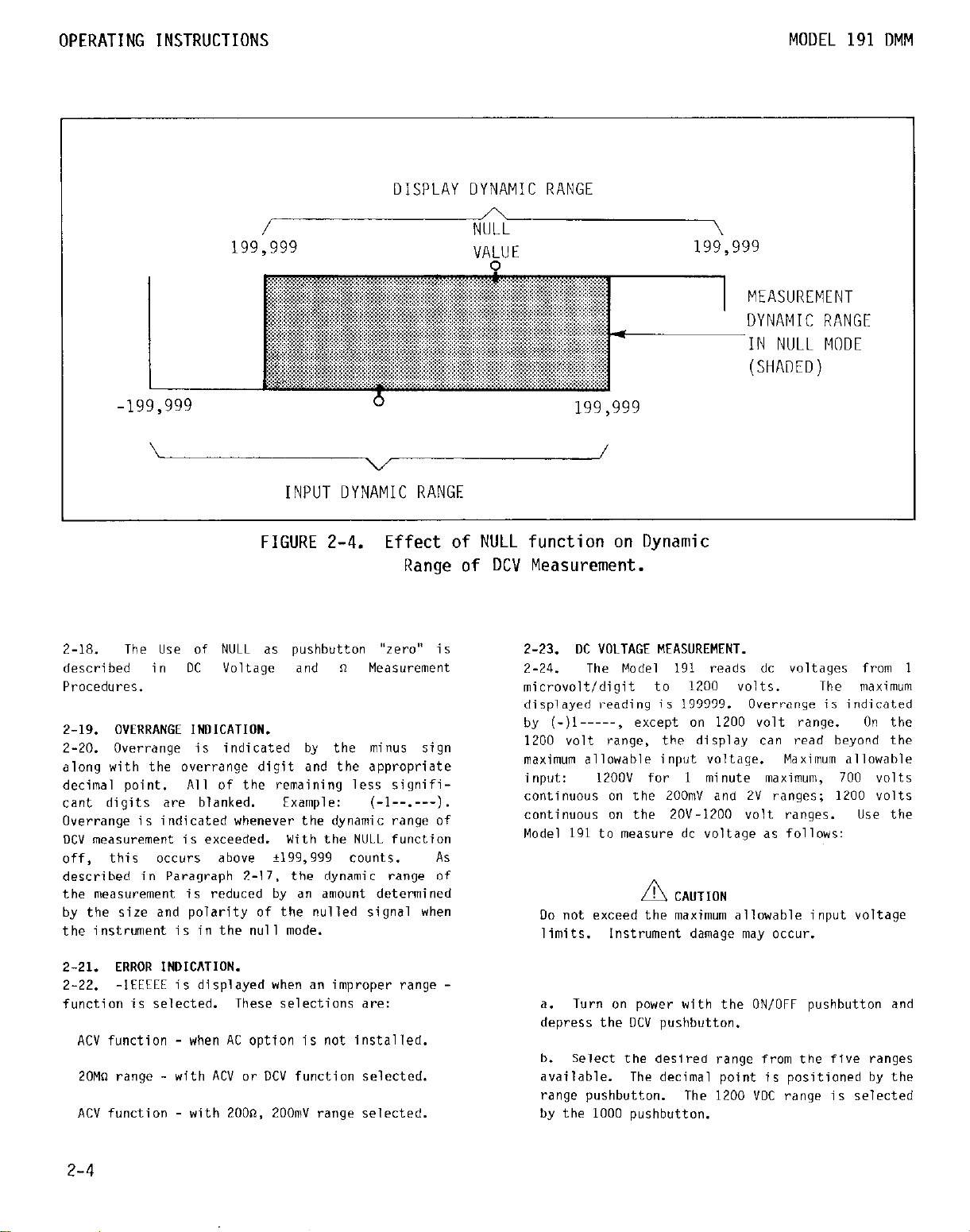

dynamic range of the

Figure 2-4.

Dynamic Range and the

exceeded and thus, bot

of the meaS"i-erne"t.

dynamic range can be e

The NULL functi

the null f

+1.00000 VDC

t1.00000

-199,999 coun

TAB

RANGE

ZOOmV, 2

zov-1200

ALL

ALL

VL

In ocv

imum Inputs.

MAXIMUM INPUT

7OOV Continuous;

12OOV for 1 minute

Rh3Xllll"lll.

IZOOV Continuous

25OV rms; 360V peak

IOOOV rnis sine or dc

2 x 107 v .Hz

is operable "n all ranger

switch selectdblr software

nciator is lighted when the

?en the NULL pushbutton is

1~ reading on tlw display,

d from all subsequent read55 is merely d subtraction

"thing to do with the range

For this wds"n, althouyh

,vide convenient pushbutton

lad re5istance dnd thermal

s connected to the DMO INPill

:tion cd" also be used t"

or below a 5et valur. 101.

put coutd be used to null

ns ahovc 1O.OOOWO could be

2OMn range and n function.

the numher heing subtracted

th instances, and the minus

ACV) in the NULL mode.

o note that the use of NULL

e of meas"rerne"t.

is the nullpd value. input

I would still overload the

counts), even though "ver-

10.000 counts displayed, and

would cause overrange (2V

f the maximum display read-

This reduction in the

~surement is illustrated in

unction, both the Display

nput dynamic range cd" he

:dn limit the dynamic range

ACV and n, only the input

!eded.

191

For in-

DMM

2-3

Page 10

OPERATING INSTRUCTIONS

199,999

DISPLAY DYNAMIC RANGE

A

/ NULL \

VA&UE

199,999

MODEL

191

MEASUREMENT

DYNAMIC RANGE

IN NULL MODE

(SHADED)

DMM

\

v

INPUT DYNAMIC RANGE

FIGURE 2-4.

Effect of NULL function on Dynamic

Range of DCV Measurement.

Z-18.

described in DC Voltage and n Measurement

Procedures.

2-19.

Z-20. Overrange is indicated by the minus sign

along with the over-range digit and the appropriate

decimal point. All of the remaining less significant digits are blanked. Example:

Overrange is indicated whenever the dynamic range of

DCV measurement is exceeded. With the NULL function

off,

described in Paragraph Z-17, the dynamic range of

the measurement is reduced by an amount determined

by the size and polarity of the nulled signal when

the instrument is in the null mode.

The Use of NULL as pushbutton 'zero" is

OVERRANGE INDICATION.

(-I--.---).

this occurs above

*199,999 CO”“tS. As

/

2-23. DC VOLTAGE MEASUREMENT.

2-24.

microvolt/digit to

displayed reading is 139999. Overrange is indicated

by (-)I-----, except on 1200 volt range. On the

1200 volt range,

maximum allowable input voltage. Maximum allowable

input: 12OOV for

continuous on the 200mV and 2V ranges; 1200 volts

continuous on the ZOV-1200 volt ranges. Use the

Model

The Model 191 reads dc voltages from I

1200 volts. The maximum

the display can read beyond the

I

minute maximum,

191

to measure dc voltage as follows:

CAUTION

A

Do not exceed the maximum allowable input voltage

limits. Instrument damage may occur.

700

volts

2-21.

2-22.

function is selected. These selections are:

2-4

ERROR INDICATION.

-1EEEEE is displayed when an improper range -

ACV function - when AC option is not installed.

20Mn range - with ACV or DCV function selected.

ACV function with 2000, 200mV range selected.

a.

Turn on power with the ON/OFF pushbutton and

depress the DCV pushbutton.

b. Select the desired range from the five ranges

available.

range pushbutton.

by the

The decimal point is positioned by the

The 1200 VDC range is selected

1000

pushbutton.

Page 11

MODEL

c.

off) unless measurements are to be made as

deviations from a preset value.

d.

INPUT HI and LO binding posts. The binding posts

accept wires, spade lugs or banana plugs for ease

of connecting the circuit to be measured. LOW

thermal cabling and connections are recommended

for measurements on the 200mV range.

e.

displayed digits, polarity sign and decimal point

locations.

in volts.

f.

NULL function to obtain rated accuracy. Zeroing

is necessary to compensate for thermal EMF's

generated by the connections to the circuit to be

measured.

microvolts or several tens of microvolts. set

zero as follows:

191

DMM

Ensure that the NULL pushbutton is out (light

Connect the signal to be measured between the

For the top four ranges, merely observe the

The top four ranges are direct-reading

For the 200mV range, ZERO must set with the

These voltages may be only a few

1) Set

2) Disconnect the test leads at the circuit to

be measured and short them.

3) Depress the NULL pushbutton.

4) Reconnect the test lead and make the

measurement by applying the signal and reading

millivolts on the display.

Model

191 to

200mV

range.

g. The optional Mode

be used with the Modt

up to 40 Kilovolts, a

Paragraph Z-30.

2-25.

Z-26.

millioha/diqit to 20

rarqes.

4.wire oh,:6 operation.

sense leads are conmec

natically dew 4-termi

not connected, the me

For 46terminal meax

digit) can be obtaine

log as the maximum 1~

2-3 are mt exceeded.

measurements on the 20

the NULL furrtion to o

RESISTANCE (n)

The Model

The Model 191

191 I

tlodcl 191 to measure 7

&CA"

MAXIMUM ALLOWABLE I

36OV peak, 25UV rms

voltage.

a. Turn on power and

h. Connect the circ

INPUT terminals and I

the six ranges avail

positioned by the ran

Instrument

IOPERATING INSTRUCTIONS

1600

High voltage Probe can

191 to measure

reduced accuracy. Refer to

JASUREMENT

IN ~nedsures resistdrre fron 1

eqohms.

prwides d~tondt>c 2-wit-e or

This nedns that if the ohms

ed, the rneasurcment IS autoIal if the sense leads are

iureiaent is done 2.terminal.

eme nts

on the top five rarqes as

ION

'UT VOLTAGE (all ranges):

Do not exceed maximum

amage may occur.

depress n pushbutton.

lit to be measured to the

,lect the desired range from

ble.

e pushhutton.

SEC Table 2-3 for

rated

The decimal point is

dc voltages

dCC"l'dCY (tl

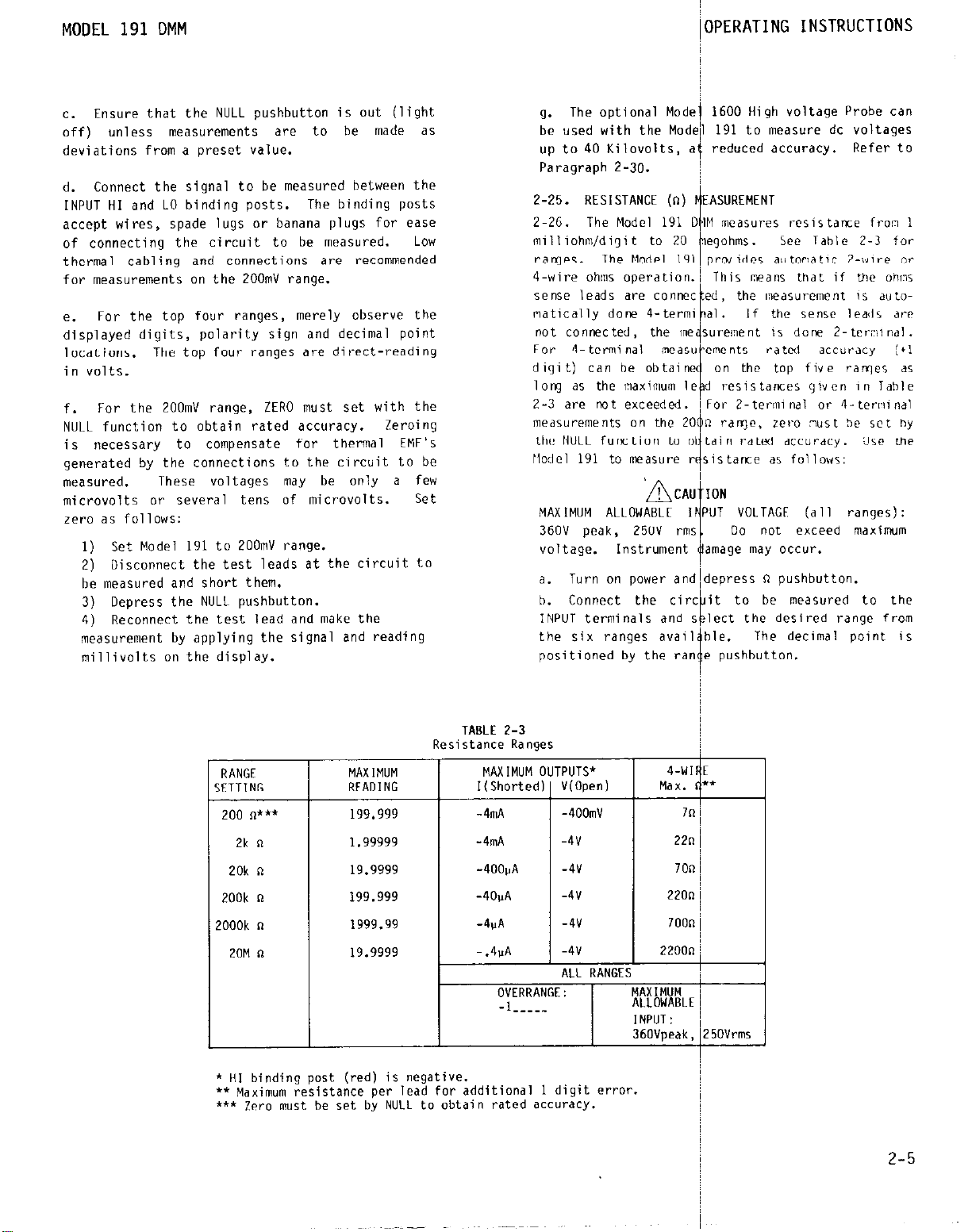

TABLE 2-3

Resistance Ranges

RANGE

SETTING

200 n***

2k n

20k n

200k n

2000k "

20M n

MAXIM""

READING

199.999

1.99999

19.9999

199.999

1999.99

MAXIMUM OUTPUTS'

I(Shorted) V(Openl

-4mA -4OOmV 7n

-4mA -4V 22"

-4OOuA

-4OuA

-4uA -4v 7000

1g.gggg t-““-

OVERRANGE: MAXIMUM

-l---_

* HI binding post (red) is negative.

** Maximum resistance per lead for additional

l

** Zero must be set by NULL to obtain rated accuracy.

1

digit en-or.

.,

-4v

-4v

-4v

ALL RANGES

-r

ALLOWABLE

360Vpeak,

MBX.

2200n

INPUT:

4-w,

700

22on

;*

250Vrms

2-5

Page 12

OPERATING INSTRUCTIONS

MODEL 191 DMM

For 4-terminal measurement c"nnect the sense

c.

leads t" the circuit t" be measured and to the n

SENSE terminals on the 191. This arrangement

eliminates the err"r due to the voltage drop

across the current-carrying leads.

d. Ensure that the NULL pushbutton is out (light

off) unless measurements are to be made as

deviations from a preset value.

c. For the top five ranges of Z-wire or 4-wire

measurements, merely observe the displayed digits

and decimal point to make the measurement.

f. For d Z-wire or 4-wire ohms imeasurement on the

200n ra"qE,

function to obtain rated accuracy.

necessary to colrlpfnsate for test Icad resistance

On Z-wire & Thermal Emfs on 2 & 4-wire.

as follows:

1) IDisconnect the test leads at the circuit to

be rmeasured, and short them.

2) ocpress NU,.L p"shb"tt"n.

3) iReconnect the test leads and <make the

IIIEaSIItm!x!"t.

g. "iodf Test.

diode testinq.

resistance Of J

approximately 190n. (Hiqh Terminal is Negative)

Z-27.

OPTION).

2-28.

reads ac voltages from 10 microvoltsldigit to 1000

lCK0 rmust be set with the NULL

Zeroing is

set LPr"

Thr 2Kn range is rccomxnded for

On this range the forward oil

silicon diode

Ac VOLTAGE MEASUREMENT (WITH 1910 AC

With the Model 1910 option, the Model 191

will read

volts. The instrument is avera9e responding and

displays the root !:ledo square

with a frequency of 50Hr t" 100kllr. Accuracy is

specified for 1000 counts and above. The maximum

reading is 199999. Overrange is indicated by (-)

i-----, except on 1000 volt range. On the 1000 volt

range,

allowable input voltage. Maximum allowable input:

IOOOV r‘ms or dc; 2 x lO'V.tir. "se the Model 19,

to "leasure dC voltage as follows:

a. Turn on power with ON/OFF pushbutton and

depress the ACV pushbutton.

h.

available. The decinlal point is positioned hy the

range pushbutton.

C.

off) ""less measurements are to

deviations front a preset value.

the display can read beyond the lmaximum

/!&CAUTION

Do not exceed maximunl allowable input voltage.

Instrument damage may occur.

Select the desired range from the 4 ranges

insure that the NULL pushbutton is out (light

NOTE

Do not use NULL to zero Lhe range.

residual zero reading is normal (approx. 20tiuV)

If NIJLI. is used to zero this offset. reailirlgs in

specified accuracy range wili be 1"~ by the

offset amount.

d. Connect the signal to be measured between the

INPUT Ill and LO binding posts.

accept wres,

of connecting the circuit to be measured. Observe

the displayed digits and decimal point.

e. The Model 1682 RF Probe can he used with the

Model 191 to measure 0.25V to 30V rms ac signals

with a frequency IOOkHr to IOOMHr (and above at

reduced accuracy). Refer to Paragraph 2-36.

spade lugs or banana plugs for ease

value Of a 51~ W~VC

he Imade as

A Sllldll

The hinding posts

2-6

Page 13

MODEL

191

DMM

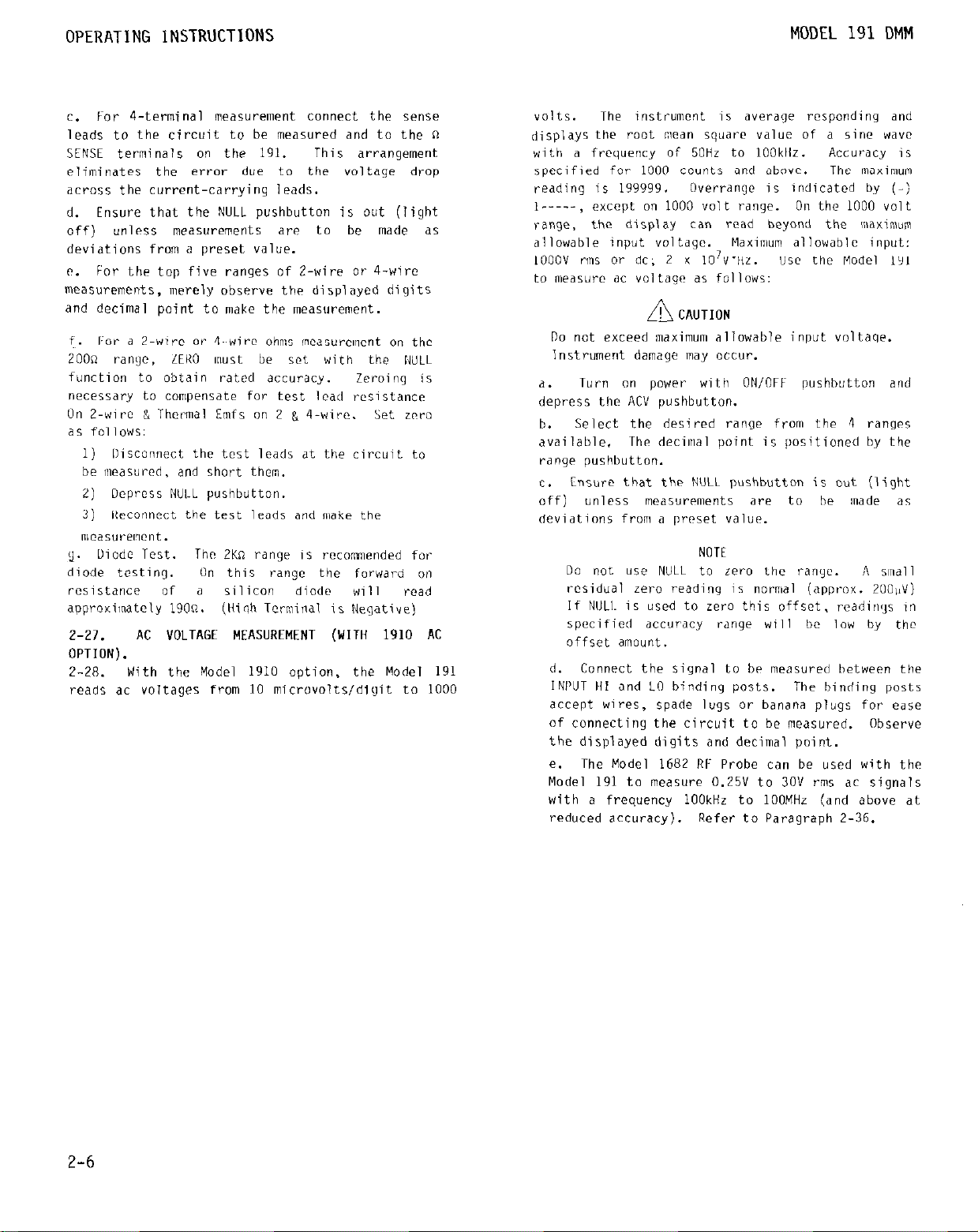

SECTION 3 PERFORMANCE VERIFICATION.

3-1.

GENERAL.

Performance verification may be performed upon

3-2.

receipt of the instrument to ensure that no damaqc

or nisadjustment has occurred during transit. Verification may also be performed whenever there is

question of the instrument's accuracy, and following

calibration, if desired.

NOTE

For instruments that are still under warranty

(LESS than 12 month5 since date of shipment),

if the instrument's performance falls outside

specifications at

Keithley rcpresentativc or the factory iomediate1y.

3-3. RECOMMENDED TEST EQUIPMENT.

3-4. Kecommended test equipment for performance

verification is listed in Table 3-1. Alternate test

equipment nay be used.

the alternate test equipment is not at least 3 tines

better than the instrument specifications, addition-

al allowance must be made in the readings obtained.

Some of the equipment listed in Table 3-l is not 3

times better than the 191 specifications because

such equipment is not readily available. In these

instances, the verification procedures indicate the

equipment manufacturer's specified uncertainty, and

include the uncertainty in determining the allowable

rcadiny for the Model 191.

any point,

However, if the dccuracy of

contact your

PERFORMANCE

VERIFICATION

3-5. ENVIRONMENTAL COND1TIONS.

All neasurenents slhouid be made dt a" dnbirnt

3-6.

tenpcraturc within the rpnge of 18' to 28°C (65" to

82Or). and a relative hu#idity of lcsr thdri 80%.

3-1. PERFORMANCE VERIFI$ATION PROCEDURE.

3-K.

basic accuracy of the Moidfl Ill DI,!M for dc voltnge.

resistance and dc voitagc (rrlth l.lodei 1910 AC

Voltage Option installdd) 1mcd5urcnwnts. it thP

instrument is out Of s~pecificdtion at Jny po,nt,

perfor,, a complete ca)ibration a5 d,xc,.ibv! in

Section 6,

wavva"ty, as noted above.

3-9.

Use the f"llowin(i procedures to verify the

~nlcss the :instrwwnt 15 still iindrr

NOTE

Performance verificbtion should bc pcrfonncd by

qualified pcrsonnel~ using accurdtc and rcliablr

test eq"lpncnt. ~

initial Conditions;

Recommended Test Equipment For Performance Vcrifica

T

ITEP

DESCRIPTION

-

A

DC Calibrator

8

AC Calibrator

C

High Voltage Amplifier

(Used with Model 745A)

"

IIccade Resistor

E

Kelvin-Varlcy Voltage

Uivider

(Used with Model 343A)

TABLE 3-l.

SPECIFICATION

190n, 1.9kn,19kil,

190k0,1.9Mn, lOMn,

t0.017,

.19v, 1.9v

with .2ppm Terminal

Linearity

tilot

1.

72OA

3-l

Page 14

PERFORMANCE

VERIFICATION

MODEL

191

DMM

b. Turn on the Model 191 and allow it to wdrrl up

for one hour.

WARNING

Sonc procedures require the USC of hi9h voltage. Take cat-c to prevent contact with live

circuits which could cause electrical shock resulting in injury or death.

3-11. DC Voltage Accuracy Check ('ZOV to 1ZOOV

R‘?"%? Applied Allowable Readings at 18O to 28'C

I I

I 4

I

3-12. DC Voltage Accuracy Check (200mV and 2V

Ranges).

4. Select dc voltaqe function.

h. Connect the DC calibrator (Item A, Table 3-l)

to the instrument.

c. Select the 2flV range, and apply positive 1OV

dc to the DMM. The readin &st be within the

limits specified in Table 3-2.

Select each rcnaining range and apply r-c-

!i.

quircd voltage specified in Table 3-2.

that the reading is rrithin specifications.

f. Repeat all checks with negative voltage.

DC Voltaqc Performance Check (2OV to 12OOV Ranoc).

Voltage

I

Ranges).

2. Sclcct DCV and 200mV range.

b. Disconnect test leads at the DC calibrator

(A) and short them.

Ibutton. Verify a display indication of OO.OOOmV

+O.OOlnV flashin9.

t

I

TABLE 3-2.

99.986 to 100.014

999.86 to 1000.14

9.9986 to 10.0014

Depress the Model 191 NULL

Verify

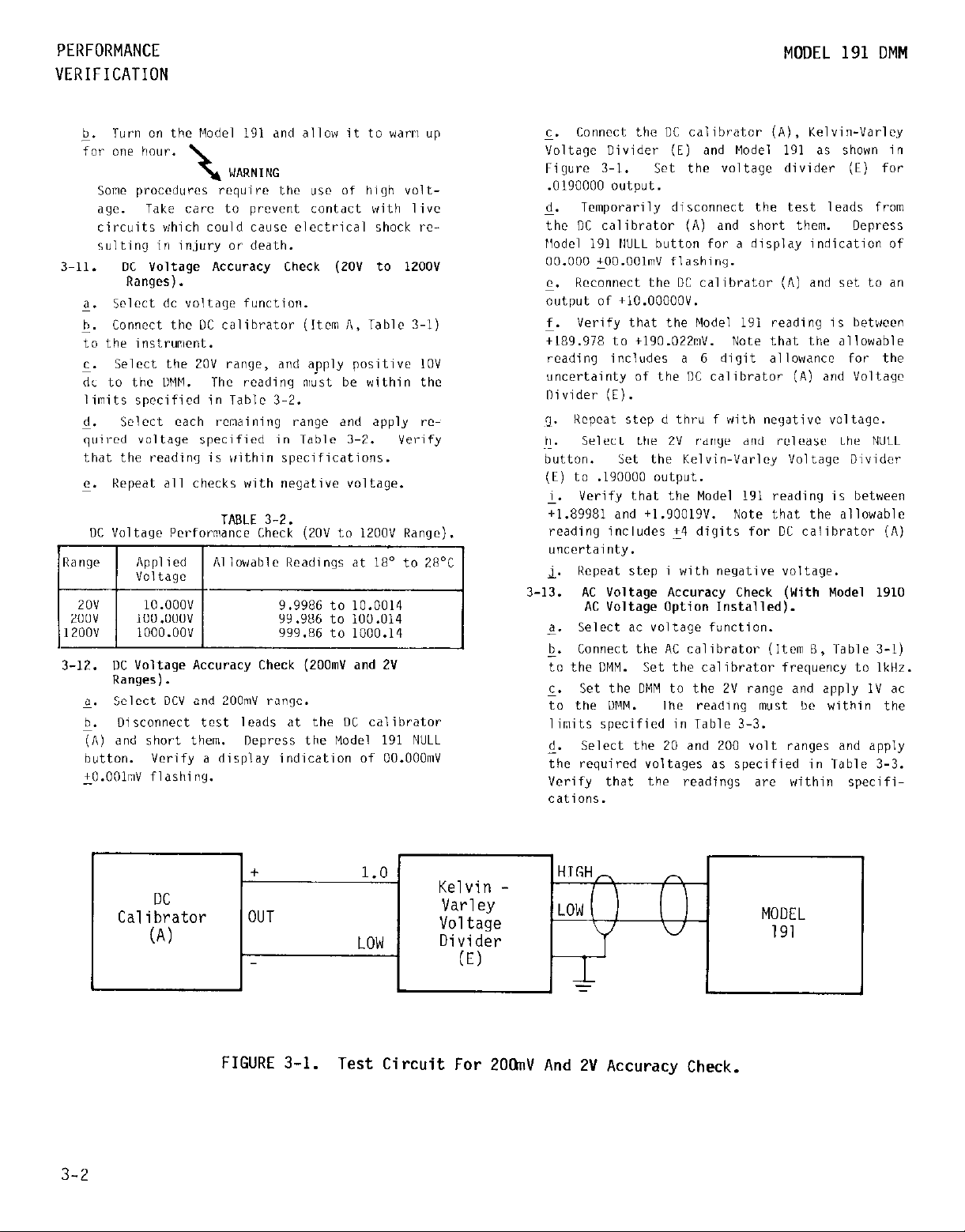

c. Connect the DC calibrator (A), Kelvin-Varley

Voltage Divider (E) and Model 191 as shown in

Fi9urc 3-1.

.0190000 output.

Temporarily disconnect the test leads from

i,

the DC calibrator (A) and short them.

Model 191 PlULL button for a display indication of

00.000 ~OO.OOLmV flashing.

c. Reconnect the DC calibrator (A) and set to an

output Of +10.00000V.

f. Verify that the Model 191 reading is between

t189.978 to t190.022nV. Note that the allowable

reading includes a 6 digit allowance for the

uncertainty of the DC calibrator (A) and Voltage

Divider (E).

~9~. Kopfat step d thru f with negative voltage.

h. Select the 2V range and rcleasc the NULL

button. Set the Kelvin-Varlcy Voltage Divider

(E) to .I90000 output.

1. Verify that the Model 191 reading is between

t1.89981 and t1.90019V. Note that the allowable

reading includes 24 digits for DC calibrator (A)

uncertainty.

i. llfpeat step i with negative voltage.

3-13. AC Voltage Accuracy Check (With Model 1910

I

1

AC Voltage Option Installed).

A. Select ac voltage function.

b. Connect the AC calibrator (Item R, Table 3-1)

to the DMM. Set the calibrator frequency to IkHr.

2. Set the DMM to the 2V range and apply IV ac

to the DMM. The reading must be within the

limits specified in Table 3-3.

Select the 20 and 200 volt ranges and apply

d.

the required voltages as specified in Table 3-3.

Verify that the readings are within specifi-

Set the voltage divider (E) for

DepESS

3-2

DC

Calibrator

(A)

+

OUT

FIGURE 3-l.

1.0

HIGH,

Kelvin -

Varley

LOW

Voltage

LOW

Divider

(El

Test Circuit For 2OCmV And 2V Accuracy Check.

MODEL

191

Page 15

MODEL

191

DMM

PERFORMANCE

VERIFICATION

To check the 1000 volt range, connect the

2.

High Voltage Amplifier (Item C, Table 3-l) to the

output of the AC calibrator per the manufacturer's instructions. Connect the amplifier

output to the Model 191 INPUT terminals. Set the

AC calibrator for amplifier output of 1000.00

volts at lktlz. Verify that the DMM reading is

within the specified limits in Table 3-3.

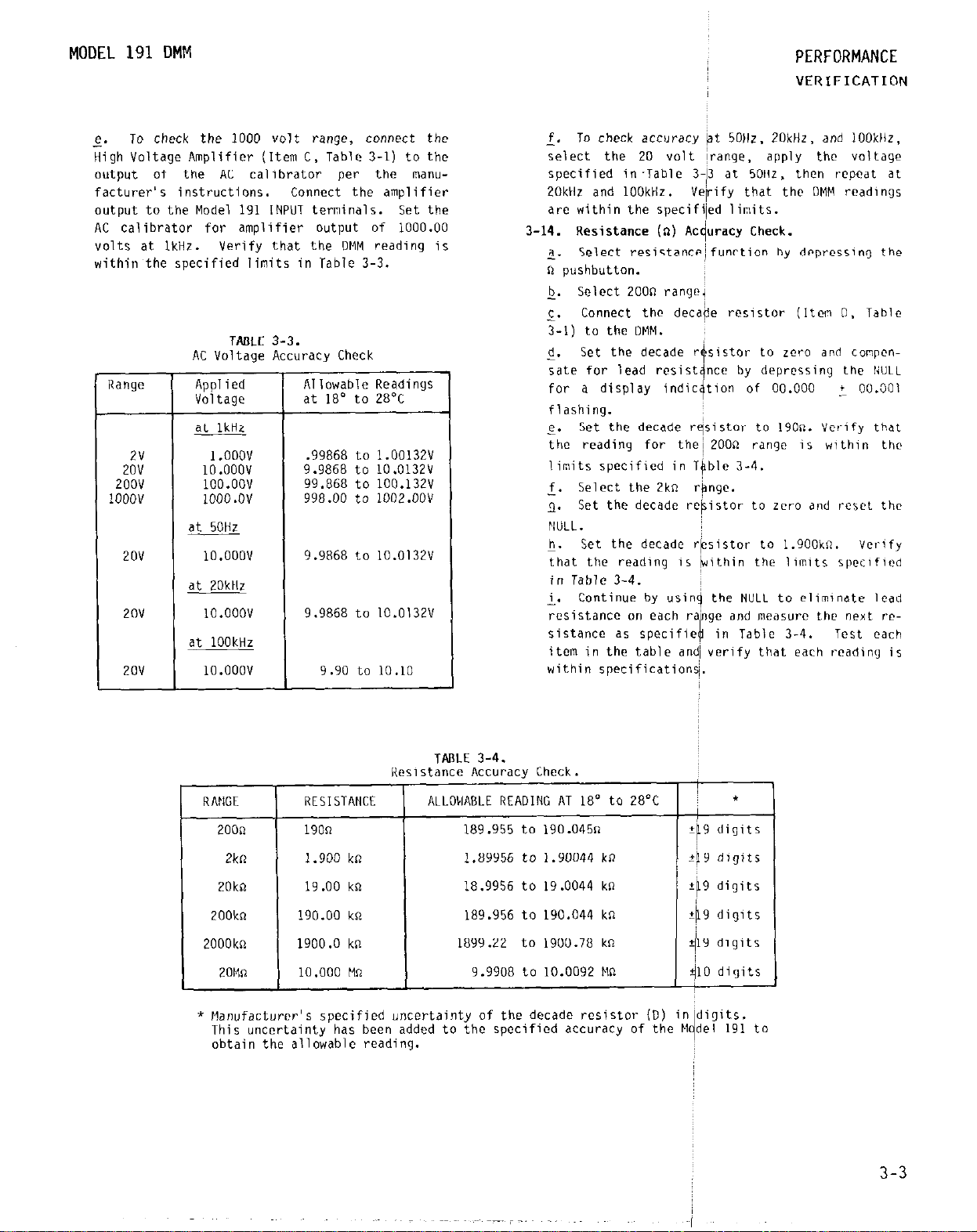

TABLE 3-3.

AC Voltage Accuracy Check

Range Applied

Voltage

Allowable Readings

at 18’= to 28’C

at

2:;

2oov 1oo.oov

1ooov

10 1 .ooov .ooov

1ooo.ov

9.9868 .99868 to to 10.0132V 1.00132V

99.068 to 100.132V

998.00 to 1002.00v

m

2ov 1o.ooov

at 20ktlz

2ov 1o.ooov

at 100kHr

9.9868 to 10.0132V

9.9868 to 10.0132V

2ov 1o.ooov 9.90 to 10.10

L

f. To check accuracy /at 5OHz. ZOktlz, and lOOkliz,

select the 20 volt ;ranqe, apply the voltage

specified in-Table 3-13 at 5011z, then repeat at

20kHz and 100kHz.

are within the specifiied limits.

3-14.

Resistance (n) Accjuracy Check.

5. Select resistancejfunction by depressing the

R pushbutton.

0. SeleCt

C.

3-I) to the DMM.

L!.

sate for lead resist+xe by depressing the IiuLL

for a display indicition of 00.000

flashing.

Set the decade rjsistar to 1900. Verify that

J2.

the reading for the! 200n range is within the

limits specified in Tbblc 3-4.

f. Select the Zkr! rpngc.

Set the decade rcpistor to LC~O and reset the

9.

NULL.

h. Set the decade rbsistor to 1.900kn.

that the reading is bithin the limits spc!clfiCd

in Table 3-4.

L. COntiNE by uSin the NULL to eliminate lead

resistance on each ra'ngc and measure the next rcsistance as specifiei in Table 3-4. Test each

item in the table andi verify that each wading is

within specificationsi.

200n rc3ngfi

Connect the decape resistor (Itw 0. Table

Set the decade rjsistor to zero and comp~n-

Veinfy that the DMkl readings

~

* 00.301

vwify

TABLE 3-4.

Resistance Accuracy Check.

RANGE RESISTANCE

zoon 190n

2kn

20kn 19.00 kn

200kn

2000kn

20Mn

* Manufacturer's specified uncertainty of the decade resistor (D)

This uncertainty has been added to the specified accuracy of the

obtain the allowable reading.

1.900 kn

190.00

1900.0

kn

kn

10.000 nn

ALLOUABLE READING AT 18' to 28'C

189.955 to 190.045ri

1.89956 to 1.90044 kn

18.9956 to 19.0044

189.956 to 190.044

1899.22 to 1900.78

kn -p

kn 219 diqits

kn

9.9908 to 10.0092 Mn

~ *

,

?I9 digits

219 digits

+ 9 digits

?(19

digits

410

digits

3-3

Page 16

Page 17

MODEL 191 DMM

ACCESSORIES

SECTION 4.

4-1. GENERAL.

This section describes the various accessories

4-2.

and options available for use with the Model 191

DMM.

4-3. LINE POWER OPTION.

The Model 191 can be powered by a line voltage

4-4.

of 90 llOV, 50 - 60Hz with the special factory

installed transformer option.

available by ordering a Model

- 60Hr).

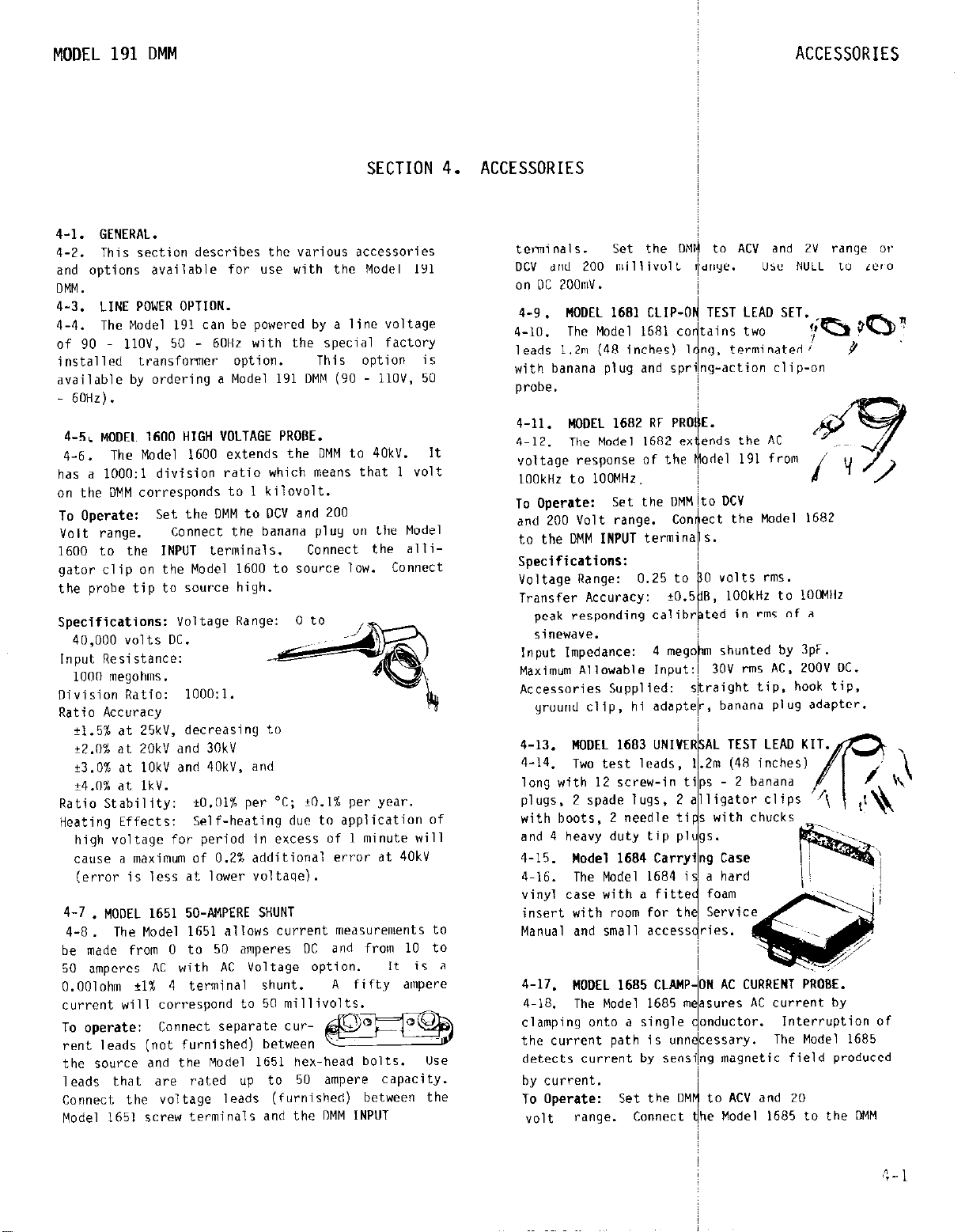

4-5~ MODEL

4-6.

has a

on the DMM corresponds to 1 kilovolt.

TO operate:

Volt range.

1600 to the INPUT terminals.

gator clip on the Model 1600 to source low. Connect

the probe tip to source high.

Specifications: Voltage Rang

40,000 volts DC.

Input Resistance:

1000

Division Ratio:

Ratio Accuracy

+1.5% at Z!ikV, decreasing to

fZ.fl% at 20kV and 30kV

f3.0% at 1OkV and 4OkV, and

+4.0% at 1kV.

Ratio Stability:

Heating Effects: Self-heating due to application of

high voltage for period in excess of 1 minute will

cause a maximum of 0.2% additional error at 40kV

(error is less at lower voltage).

4-7 . MODEL 1651 50-AMPERE SHUNT

4-8. The Model

be made from 0 to 50 amperes DC and from

50 amperes AC with AC Voltage option.

O.OOlohm

current will correspond to 50 millivolts.

To operate: Connect separate CUTrent leads (not furnished) between

the source and the Model 1651 hex-head bolts.

leads that are rated up to 50 ampere capacity.

Connect the voltage leads (furnished) between the

Model 1651 screw terminals and the DMM INPUT

1600

HIGH VOLTAGE PROBE.

The Model 1600 extends the DMM to 40kV. It

1OOO:I

division ratio which means that 1 volt

Set the DMM to OCV and 200

Connect the banana plug on the Model

imegohms.

1OOO:l.

tO.Ol%

1651

kl%

4 terminal shunt.

per "C;

allows current measurenlents to

This option is

191 DMM (90 IlOV, 50

Connect the alli-

eO.l%

per year.

10 t0

It is a

A fifty ampere

Use

ACCESSORIES

terminals.

DCV and 200 millivolt iange.

on DC 200mV.

4-9.

4-10.

leads 1.2~1 (48 inches) 1 ng, terminatedY p

with banana plug and spri,ng-action clip-on

probe.

4-11. MODEL 1682 RF

4.12. The Model 1682 ex

voltage response of the

lOOkliz to lOOMHz,

To Operate:

and 200 Volt range.

to the DMM INPUT termina

Specifications:

Voltage Range: 0.25 to

Transfer Accuracy:

peak responding calibr ted in rms of a

sinewave.

Input Impedance:

Maximum Allowable Input:1 30V pms AC. 2OOV UC.

Accessories Supplied: shraight tip. hook tip,

ground clip, hi adapt+, banana plug adapter.

4-13.

4-14.

long with 12 screw-in tips - 2 banana

plugs, 2 spade lugs. 2 alligator clips ,I\

with boots, 2 needle ti

and 4 heavy duty tip plugs.

4-15.

4-16.

vinyl case with a fitte

insert with room for the Servic

Manual and small access+ies.

4-17.

4.18.

clamping onto a single conductor.

the current path is unngessary.

detects current by sensilng magnetic field produced

by current.

To Operate: Set the OM

volt

Set the DMlj to ACV and 2V range or

MODEL

1681

CLIP-04 TEST LEA0 SET

The Model

NODEL 1683 UNIVERbAL TEST LEAD KIT.

Two test leads, 11.2m (48 inches)

Model 1684 Carrying Case

The Model 1684 is a hard

MODEL 1685 CLAMP-ON AC CURRENT PROBE.

The Model 1685 "edsure~ AC current by

range.

1681 CO tdins two

Set the DMM~to DCV

Connect t/he Model 1685 to the DMM

!

"SC NULL to zero

PRO

Con ect the Model 1682

5.

1

0 volts rms.

to.5 B, 1OOkHz to 1OoMtlZ

1

4 megop shunted by 3pF.

s with chucks

v

foam

1

Interruption of

The Model 1685

to ACV and 20

4

/I"

f! J

A

\

/

i

4-l

Page 18

ACCESSORIES

MODEL

191

DMM

INPUT terminals. The DMM will display 0.1

volts per ampere.

Specifications:

Range: 2, 20

and 200

amperes r-m.

Accuracy: i-4% of range at

60Hz. ST% of range at 50Hz.

Temperature Coefficient:

200 ampere range.

range.

Maximum Allowable Current: 300 amperes rms.

Maximum Conductor Voltage: 600 volts rms.

Conversion Ratio: 0.1 volt rms per ampere.

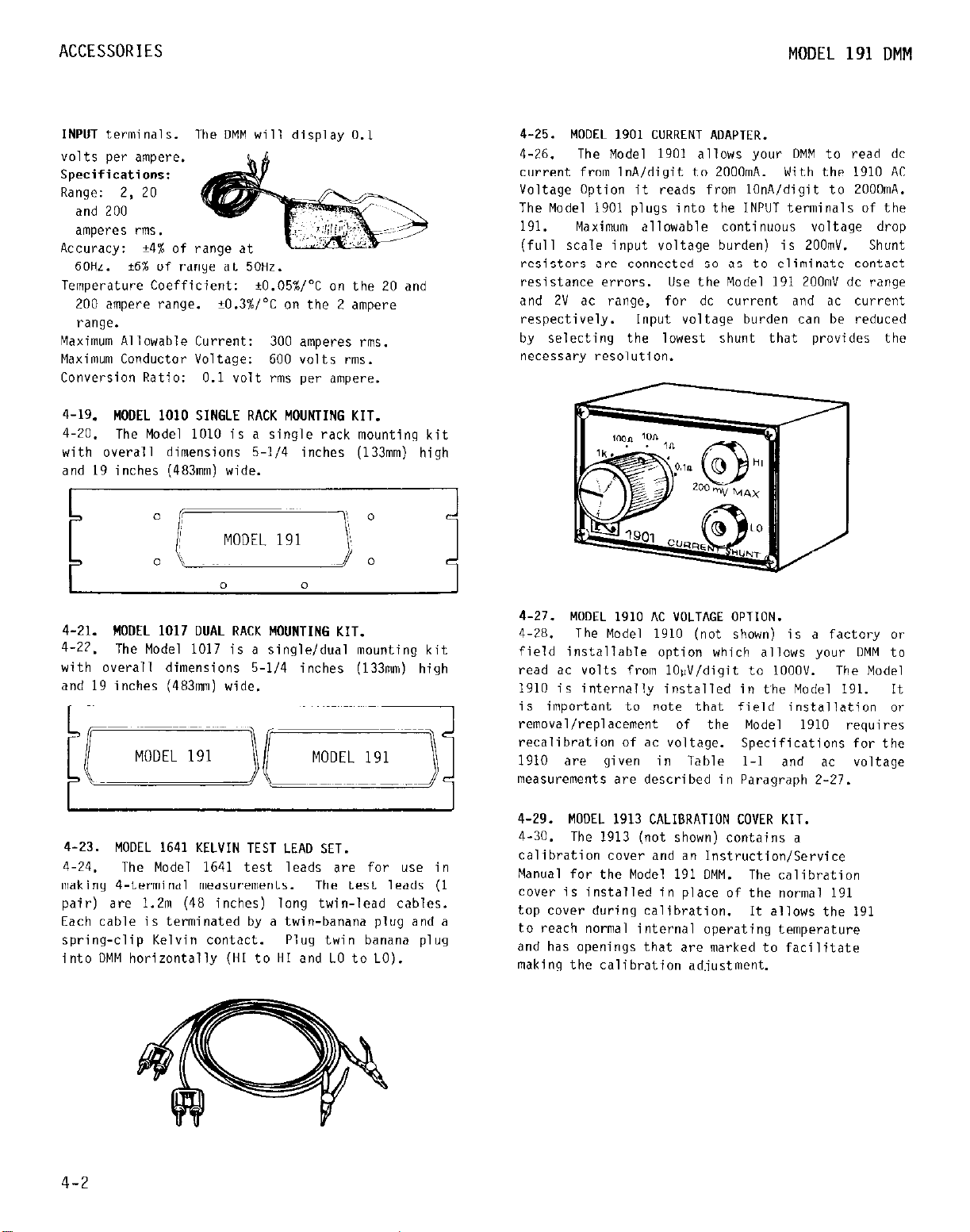

4-19.

4-20.

with overall dimensions 5-I/4 inches (133mm) high

and

MODEL

1010

SINGLE RACK MOUNTING KIT.

The Model

19

inches (4l33mm) wide.

1010

?O.O5%/"C an the 20 and

*0.3%/Y on the 2 ampere

is a single rack mounting kit

4-25.

4-26. The Model 1901 allows your DMM to read dc

current from 1nAldigit to 2000mA. With the

Voltage Option it reads from lOnA/digit to 2000mA.

The Model 1901 plugs into the INPUT terminals of the

191.

(full scale input voltage burden) is 200mV. Shunt

resistors are connected so as to eliminate contact

resistance errors. Use the Model 191 200mV dc range

and 2V ac range, for dc current and ac cut-rent

respectively. Input voltage burden can be reduced

by selecting the lowest shunt that provides the

necessary resolution.

MODEL

1901

CURRENT ADAPTER.

1910

Maximum allowable continuous voltage drop

AC

4-21. MODEL 1017 DUAL RACK MOUNTING KIT.

4-22.

with overall dimensions 5-l/4 inches (133mm) high

and

4-23. MODEL 1641 KELVIN TEST LEAD SET.

q-24.

making 4-terminal measurements. The test leads

pair) are 1.2m (48 inches) long twin-lead cables.

Each cable is terminated by a twin-banana plug and a

spring-clip Kelvin contact. Plug twin banana plug

into DMM horizontally (HI to HI and LO to LO).

The Model 1017 is a single/dual mounting kit

19

inches (483mm) wide.

The Model

1641

test leads are for use in

(1

4-27.

4.28. The Model 1910 (not shown) is a factory or

field installable option which allows your DMM to

read ac volts from IOuV/digit to 1OOOV.

1910 is internally installed in the Model

is important to note that field installation or

removal/replacement of the Model

recalibration of ac voltage.

1910 are given in Table 1-l and ac voltage

measurements are described in Paragraph 2-27.

4-29. MODEL

4-30.

calibration cover and an Instruction/Service

Manual for the Model 191 DMM. The calibration

cover is installed in place of the normal 191

top cover during calibration.

to reach normal internal operating temperature

and has openings that are marked to facilitate

making the calibration adjustment.

MODEL

The

1913

1910

AC VOLTAGE OPTION.

1913

CALIBRATION COVER KIT.

(not shown) contains a

The Model

191. It

1910

requires

Specifications for the

It

allows the 191

4-2

Page 19

MODEL 191 DMM

SECTION 5. THEORY OF OPERATION

GENERAL

5-l.

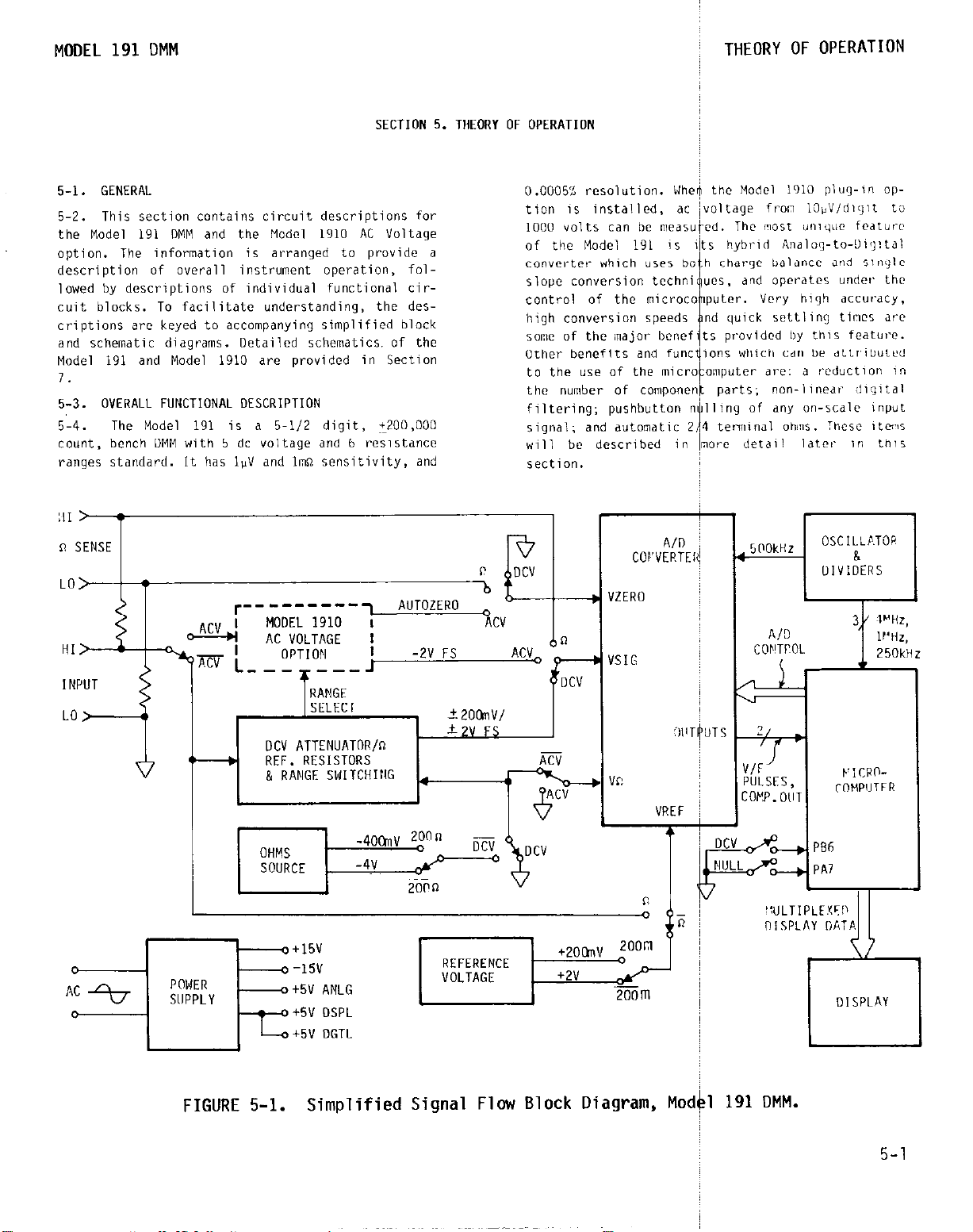

5-2. This section contains circuit descriptions for

the Model 191 DMM and the Model

option.

description of overall instrument operation, followed by descriptions of individual functional circuit blocks. To facilitate understanding, the descriptions arc keyed to accompanying simplified block

and schematic diagrams. Detailed schematics. of the

Model 191 and Model 1910 are provided in Section

1.

5-3.

5-4.

count, bench DMM with 5 dc voltage and 6 resistance

ranges standard. It has luV and Inn sensitivity, and

The information is arranged to provide d

OVERALL FUNCTIONAL DESCRIPTION

The Model 191 is a 5.112 digit, ~200,000

1910

AC Voltage

THEORY OF OPERATION

0.00052 resolution. Whe

tion is installed, ac

1000 volts can be "leas"

of the Model 191 is

converter which uses b"

slope conversion techni

control of the microcc

high conversion speeds

some of the Imajor bcnef

Other benefits and func

to the use of the micr(

the number of componer

filtering; pushbutton n

signal; and automatic 2

will bc described 1n

sectlo".

,.“, “.-..J

MODEL 1910

AC VOLTAGE

DCV ATTENUATOR/n

REF. RESISTORS

& RAFIGE SWITCHING q

ACV

O--I- n

ACV

ACV

f2

COE'VERTEI

VZERO

VSIG

A/D

VREF

57+

V/F

PULSES,

cnw.0111

PICRO-

COMPUTER

DISPLAY

FIGURE 5-l.

Simplified Signal Flow Block Diagram, Mod.

41

191

cl

DMM.

5-1

Page 20

THEORY OF OPERATION

MODEL

191

DMM

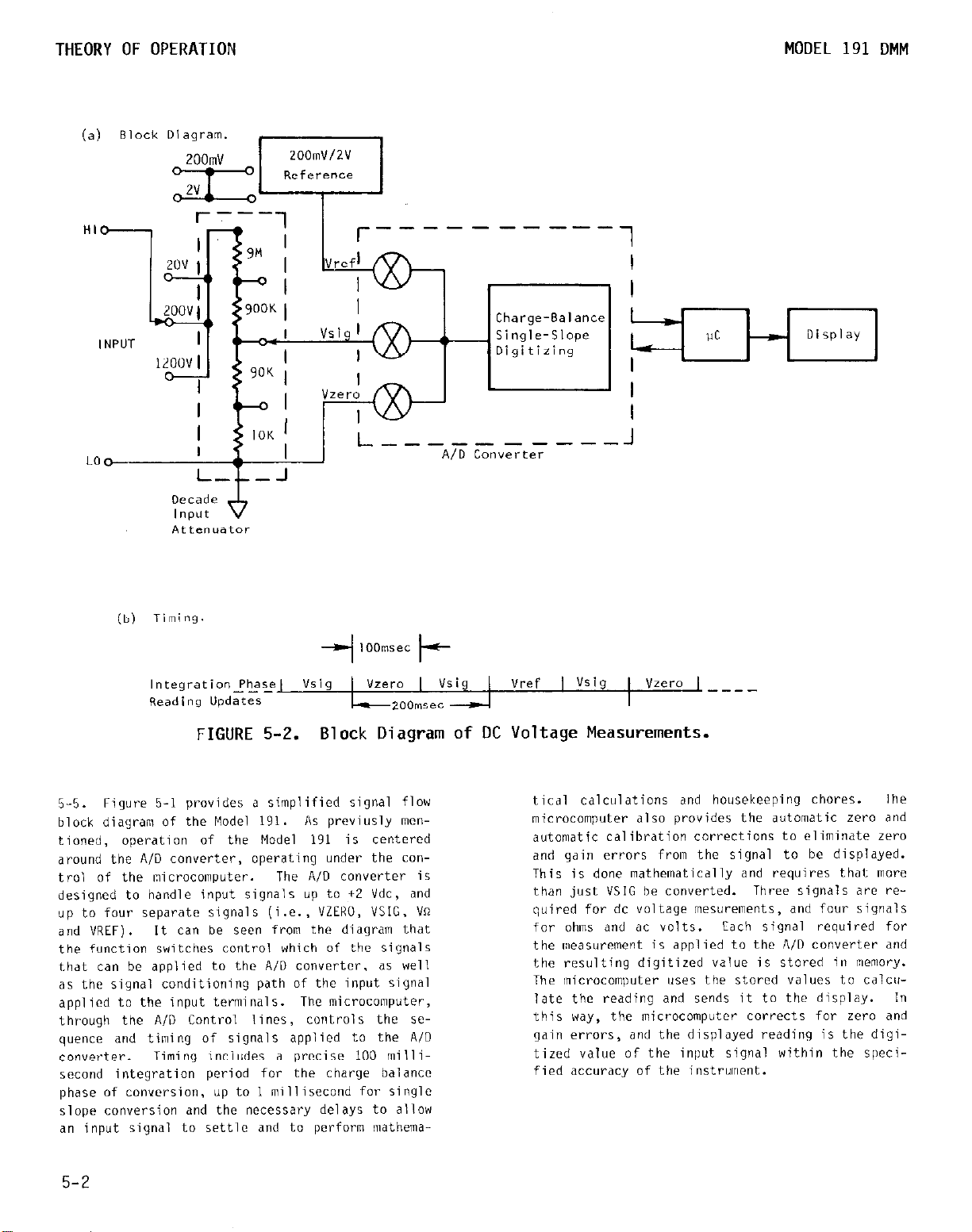

(b) Timing.

loome‘

--I t-

Inteqratian_Ph_asej Vsig 1 Vzero I Vsig

Reading Updates

FIGURE 5-2.

Block Diagram of DC Voltage Measurements.

200msec

Charge-Balance

I Vref I Vsig I

in

vrero ----

Figure 5-1 provides a simplified signal flow

5-5.

block diagram of the Model 191.

tioned,

around the A/D converter, operating under the control of the nicrocomputer.

designed to handle input signals up to t2 Vdc, and

up to four separate signals (i.e., VLEKO, VSIG, Vn

and VREF).

the function switches control which of the siqnals

that can be applied to the A/D convcrtcr, as well

as the signal conditioning path of the input signal

applied to the input terminals. The microcomputer,

through the A/D Control lines, controls the sfquence and timing of signals applied to the A/D

converter.

second integration period for the charge balance

phase of conucrsion, up to 1 millisecond for single

slope conversion and the necessary delays to allow

an input signal to Settle and to perform nathema-

5-2

operation of the Model 191 is centered

It can be seen from the diagram that

Timin includes a precise 100 milli-

As previusly men-

The A/D converter is

tical calculations and housekeeping chores.

microcomputer also provides the automatic zero and

automatic calibration corrections to eliminate zero

and gain errors frown the signal to be displayed.

This is done mathematically and requires that more

than just VSIG be converted. Three signals are required for dc voltage mesurements, and four signals

for ohms and JC volts. Lath signal required for

the wzas~~rement is applied to the A/D converter and

the resulting digitized value is stored in ~memory.

The microcomputer muses the stored values to calcu-

late the reading and sends it to the display. In

this way, the microcamputcr corrects for zero and

gain errors, arId the displayed reading is the digitized value of the input signal within the specified accuracy of the

instrument.

The

Page 21

MODEL

191

DMM : THEORY OF OPERATION

5-6.

DC Voltage Measurement.

5-7.

5-2, the input signal either goes directly to the

A/D or is connected across a decade attenuator with

a total resistance of 10 megohms. The attenuation

of the dc input signal is determined by the range

selected.

signals to the A/D converter arc rcquircd for dc

volts operation (i.e.,

signal is presented to the AID input and (measured

for 100 milliseconds (See A/D Converter discussion). Each digitized value is stored in memory and

then used to calculate a reading by the formula:

In dc volts operation, as shown in Figure

As previously mentioned, three input

"SIG, "ZERO and VREF). Each

(a) BLOCK DIAGRAM

-4oomv/-4V

Voltage

SO"rCe

r- --i

eference Resistor Decade

It can be seen that

tracted from both the

then the ratio is ti

needed because the r

milllivolts on the loti

5-R.

gram, VSIG is medsure

and VREF are alternati

This permits the disp

two integration (char!

ing that up to an addi

required (to complet

counting of the remail

tic.31 computations),

made approximately (

approximately 4 read'

As shown in th

the zero error is sub-

II and the reference, and

Multiplication by 2 is

nce is 2 volts (or 200

ic range).

ling portion of the dia'ry other time dnd VZtRO

in the other tine slots.

3 be updated after every

am?) phases. Consider11 70 milliseconds nay bc

Igle slope conversions.

in counters and mathcmaI display update cdn be

210 nilliseconds, or

;econd cd" be obtsined.

%

(b)

TIMING

9 IOOms /---

INTEGRATION PHASE 1 DELAY 1

READING UPDATE

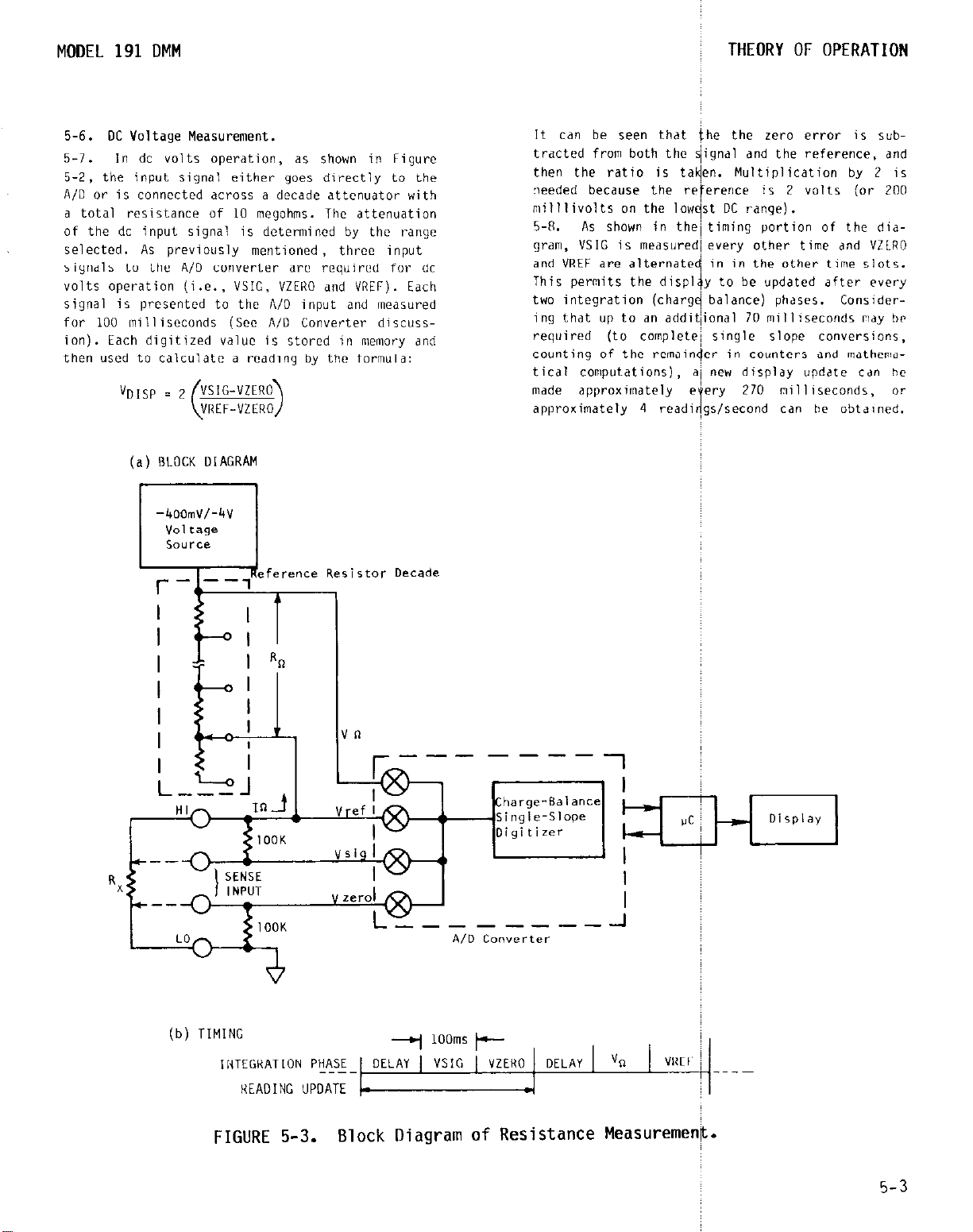

FIGURE 5-3.

Block Diagram of Resistance Measureme:

VSIG 1 VLEKO DELAY

cl

'0 VKEt

_.

4

n%.

5-3

Page 22

THEORY OF OPERATION

MODEL 191 DMM

5-9. Resistance Measurement.

5.10. In ohms operation, as shown in Figure 5-3,

the ohms voltage source is connected as an input to

the A,0 converter and to one end of the reference

resistor decade. The resistance reference resistors

are the same resistors that are use for dc volts

attenuation, but unlike dc volts, where only the

ratios affect accuracy, the absolute characteris-

tics of the resistors determine accuracy of the

ohms measurement. The value of the ohms reference

resistor (Itn) is determined by the range selected.

An ohms source voltage of -400 millivolts is used

on the 200~2 range, and -4V is used for all other n

ranges.

signals to the A/D converter are required. Each

signal is measured for 100 milliseconds and its

diyitirec value is stored in memory. The microcomputer then calculates a reading using the formula:

It can be seen that "$2 - VKEF is the voltage across

Kn (Ifi X rtn) and that "SIG VZEKO is the volt-

age acrossRX ('n X i(X). therefore:

For resistance measurements, four input

nD,SP = vslc - VZEKO

vn VREF

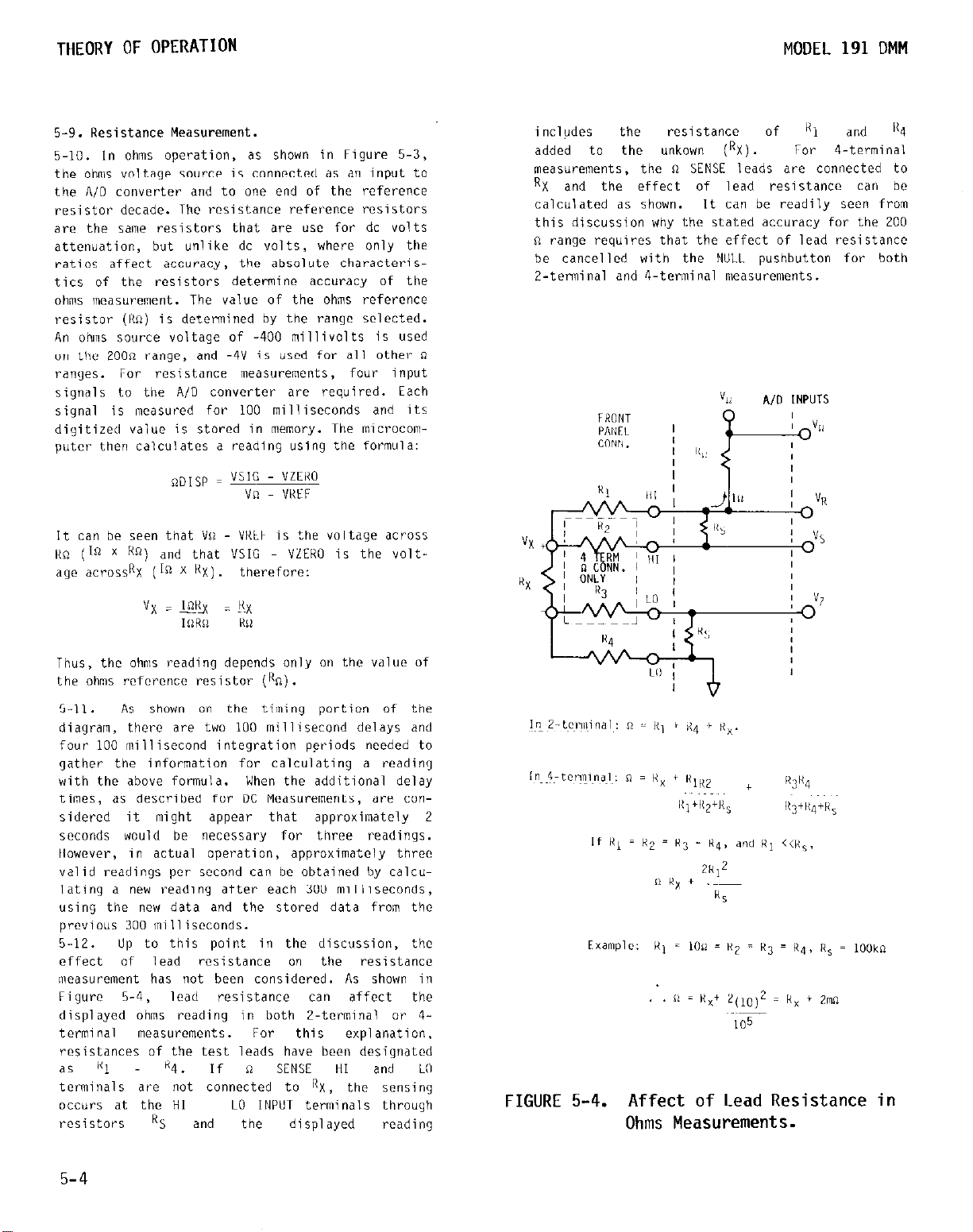

includes

added to

,"easurt3"ents,

RX and the effect of lead resistance can be

calculated as shown.

this discussion why the stated accuracy for the 200

n range requires that the effect of lead resistance

be cancelled with the NULL pushbutton for both

Z-terminal and &terminal measurements.

the rESlSta"Cf of RI

the unkown (RX). For &terminal

the n SENSE leads are connected to

It can be readily seen from

and 'I4

Thus, the ohms reading depends only an the value of

the ohms rcfcrfncf resistor ("n).

5-11.

diagram, there are two 100 millisecond delays and

four 100 millisecond integration p?riods needed to

gather the information for calculating a reading

with the above formula.

times, as described for DC Measurements, are considered it might appear that approxilnately 2

seconds would be necessary for three readings.

IloWeYfr, in actual operation, approximately three

valid readings per second can be obtained by calcu-

lating a new reading after each 300 milliseconds,

using the new data and the stored data from the

previous 300 milliseconds.

5-12. Up to this point in the discussion, the

Effect of lead

n~easurement has not been considered. As shown in

Figure

displayed ohms reading in both Z-terminal or 4terminal meas"rements.

resistances of the test leads have been designated

3s '31 @4. If n

terminals are not connected to Rx, the sensing

occurs at the HI

rfsistors

AS shown on the tilning portion of the

When the additional delay

resistance an the resistance

5-4,

lead resistance can

For this explanation,

SENSE HI

KS

LO INPUT terminals through

and

the displayed

affect the

and LO

reading

FIGURE 5-4. Affect of Lead Resistance in

Ohms Measurements.

5-4

Page 23

MODEL

191

DMM

THEORY OF OPERATION

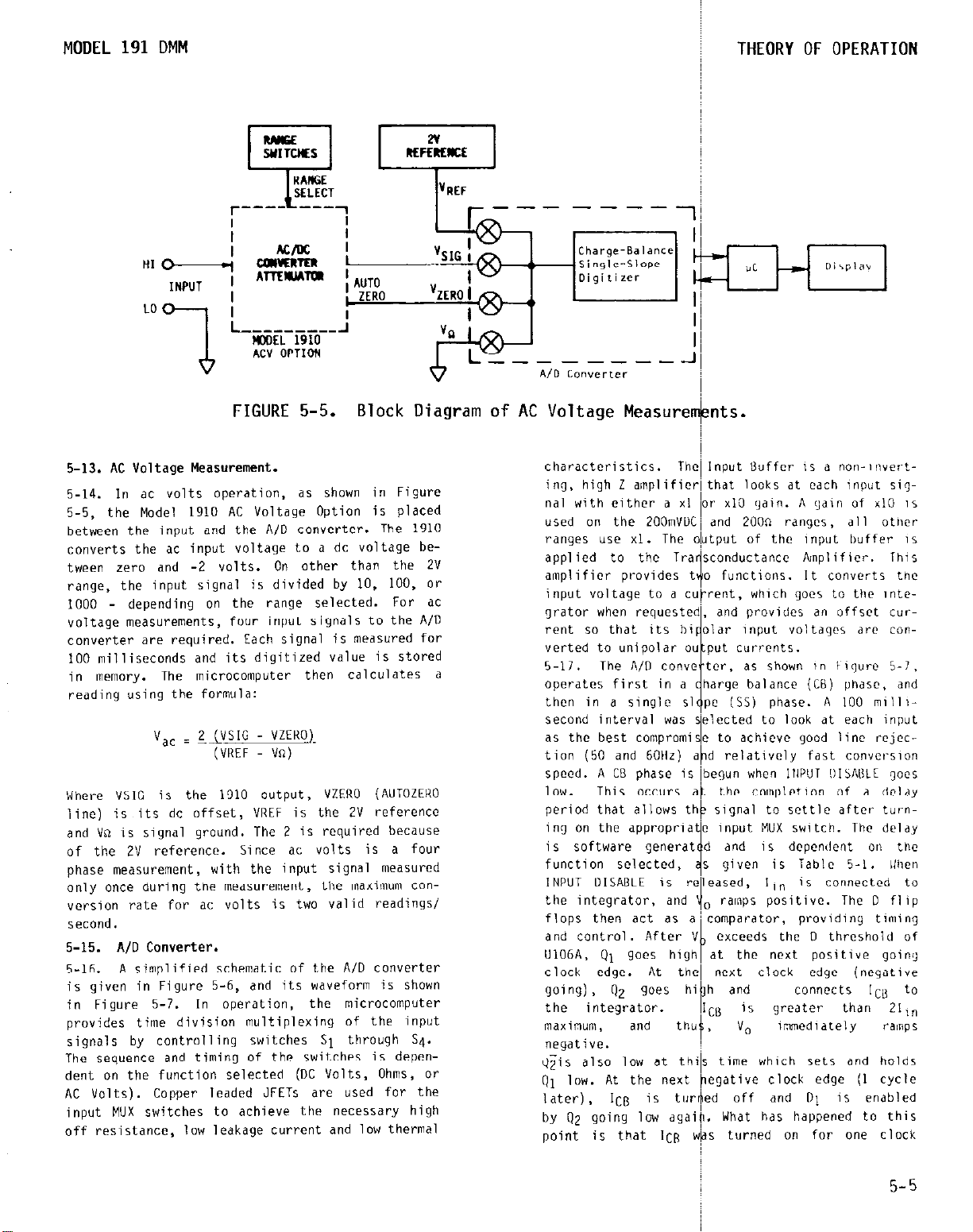

FIGURE 5-5. Block Diagram of AC Voltage Measure+nts.

5-13. AC Voltage Measurement.

5-14.

5-5, the Model

between the input and the A/D converter. The

converts the ac input voltage to a dc voltage between zero and -2 volts. On other than the 2V

range, the input signal is divided by 10,

1000 - depending on the range selected. For ac

voltage measurements, four input signals to the A/D

converter are required. Each signal is measured for

Where VSIG is the

line) is its dc offset, VREF is the 2V reference

and Vn is signal ground. The 2 is required because

of the 2V reference.

phase measurement, with the input signal measured

only once during the measurement, the maximum con-

version rate for ac volts is two valid readings/

second.

5-15.

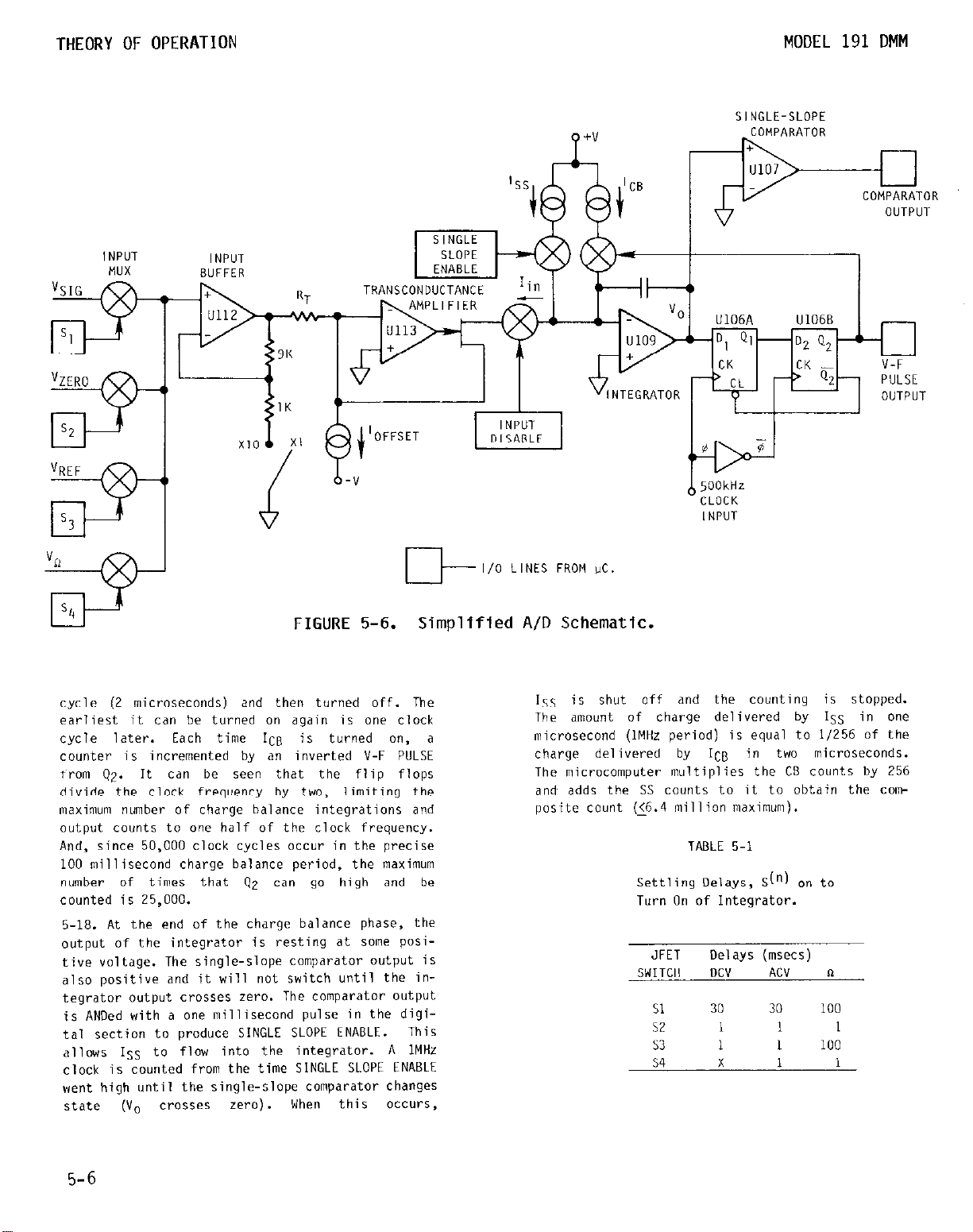

5-16.

is given in Figure 5-6, and its waveform is shown

in Figure 5-7. In operation, the microcomputer

provides time division multiplexing of the input

signals by controlling switches S1 through 54.

The sequence and timing of the switches is dependent on the function selected (DC Volts, Ohms, or

AC volts).

input MUX switches to achieve the necessary high

off resistance, low leakage current and low thermal

In ac volts operation, as shown in Figure

1910

AC Voltage Option is placed

1910

100, or

100 milliseconds and its digitized value is stored

,n memory.

reading using the formula:

The microcolnputer then calculates a

V,, = L?VSIG - VZEKO).

(VKEF

1910

A/D Converter.

A simplified schematic of the A/D converter

Copper leaded JFETs are used for the

vn)

output, VZERO (AUTOZEKO

Since ac volts is d four

characteristics.

ing, high Z alnplificrlthat looks dt each input siqnal with either a xi or. x10 gain. A gain of xi0 IS

used on the 200mVDC~ and 2000 ranges, all otner

ranges

applied to the Tra sconductance Ainpiifier. lhis

amplifier provides t o

input voltage to d cufrent, which goes to the antegrater when requested, and provides a" offset CUTrent so that its hi alar

verted to unipolar ou

5-17.

operates first in a

then in a single sl pc

second interval was selected to look dt each input

as the best compramis,e to achieve good line rcjcction (50 and 60tlr) dbd relatively fast convex-soon

speed. A CB phase is ibegun when INPUT !II>AKLC goes

1OW.

period that allows thb signal to settle after tur-nlng on the appropriate input MUX switch. The delay

is software generat d and is dcpendcnt on the

function selected,

INPUT DISABLE is released, Iin IS connected to

the integrator, and

flops then act as a!comparator, providing timing

and control. After V

U106A. 91 goes high at the next positive going

clock edge.

wing)

the ikt$raraPd)rqs "'bb ""fs gre~~~:cct:ha/C"21:~

maXlGl""\,

negative.

d$is also low at

(h low. At the next pegative clock edge

I ater) ,

by 42 going low agaio. What has happened to this

point is that lC8 wbs turned on for one clock

“SE xl.

The A/II conve ter, as shown in iigurc 5-I.

This occurs al the completion of d dcldy

and th"

1~0 is turted off and D] is enabled

TheI input Uuffcr is a non-~nveit-

The output of the input buffer IS

functions. It converts the

1

input

voltdqes

put cur-rents.

barge balance (CU) phase. and

(8s) phase. A 100 mills-

/

5 given is Table 5-1. llben

,"

o ramps positive. The D flip

d

exceeds the " threshold of

At theI next clock edge (negative

P

13 v.

s time which sets and holds

thil

imediately rmp5

are con-

(1 cycle

5-5

Page 24

THEORY OF OPERATION

MODEL 191 DMM

El--

l/O LINES FROM UC.

*

+v

~RATDR -

U106A

D,

CK

’ CL

50OkHZ

CLOCK

INPUT

QI

U106B

-02 Q2 CK -

QZ--

r’-

cl

1

V-F

&iSE

OUTPUT

SINGLE-SLOPE

FIGURE 5-6.

cycle (2 microseconds) and then turned off. The

earliest it can be turned on again is one clock

cycle later.

counter is incremented by an inverted V-F PULSE

from 92. It cdn be seen that the flip flops

divide the clock frequency by two, limiting the

maximum number of charge balance integrations and

output co"nts to one half of the clock frequency.

And, since 50,000 clock cycles occur in the precise

100

millisecond charge balance period, the maximum

number of times that (12 can go high and be

counted is 25,000.

5-18. At the end of the charge balance phase, the

output of the integrator is resting at some posi-

tive voltage. The single-slope comparator output is

also positive and it will not switch until the integrator output crosses zero. The comparator output

is ANDed with a one millisecond pulse in the digital section to produce SINGLE SLOPE ENABLE.

allows ISS to flaw into the integrator. A 1MHz

clock is counted from the time SINGLE SLOPE ENABLE

went high until the single-slope comparator changes

state (vo crosses zero). When this occurs,

Each time 1,"~ is turned on, a

Simplified A/D Schematic.

This

ISS is shut off and the counting is stopped.

The amount of charge delivered by ISS in one

microsecond (IMHz period) is equal to I/256 of the

charge delivered by ICB in two microseconds.

The microcomputer multiplies the CL3 counts by 256

and adds the SS counts. to it to obtain the corn-

posite count ((6.4 million maximum).

TABLE 5-I

Settling Delays, SC") on to

Turn On Of Integrator.

JFET Delays (msecs)

SWITCH DC"

81

30

52 1

53 1

s4 x

AC" n

30 100

1 1

1 100

1 1

5-6

Page 25

MODEL 191 DMM

-+1.5v

THEORY OF OPERATION

P

CHARGE BALANCE PHASE

IOOmsec

ELA:

*FOR

5-19.

5-20.

control and display circuitry is given in Figure

5-8. This diagram also shows location of the circuits by printed circuit board.

5-21. Microcomputer.

5-22.

circuitry provide timing and control of both the

display and the A/O converter. Additional functions

provided by the microcomputer include the NULL

function and digital filtering. The Null function

is described in Paragraph 2-15 and digital

filtering is described later in this section. Count

prescaling, and recovery Crow d transient or‘ lost

program are additional functions provided by the

logic circuitry.

5-23.

system, that is comprised of d 6802 microprocessor

DIGITAL CONTROL and DISPLAY CIRCUITS.

A functional block diagram of the digital

The microcomputer and its associated logic

The microcomputer is d MicroBus 8 based

READOUT OF UP PRE-SCALE COUNTER

FIGURE 5-7. 191 A/D Waveform.

*

c

I

I

SINGLE SLOPE

PHASE __L

I msec

-B

ELA'

INTEGRATOR INPUT l

DISABLED -

N302) I

U303), and 1024 x R b&es of read only mm~ory which

provides the control ;program dnd is contnined on

either U305 (ROM) 0,. U304 and "305 (PROMs). The

microprocessor contdil/S a set of 72 variable length

instructions,

llWlll0ry (RAM) for tem+OTdTy storage. The FiA coo-

tdins four bytes 01 memory and provides the

Input/Output (I/O) c ntrol

the Imicrocomputer to

The microcomputer u+s partial memory decoding.

When Al5 is a logic I'O", either the 128 bytes of

RAM or bytes 129 thro gh

ted.

logic "0" RAM. logic !'I" PIA). When A15 is d logic

“1”

(ROM/PROMS),

512

A9 is high, the upper!512 bytes are selected.

d 6821 peripyerdl interfdce dddptw (Pin,

and 1281 x 8 bytes of rdndon, access

he other circuits in the ill.

1

A7 then determi es which is selected (A7 =

(high), read ~only rmemory is selected

and Ag Vetermines whether th? lower

bytes or the upper 512 bytes di-e selected. When

i:

*MEASUREMENT--c

lines for intcrfaclng

132 in the PlA dw selec-

NEXT

PHASE

@Registered Trademark of Motorola, Inc

5-7

Page 26

L --------- --__---__----

------ --1L ---------- 1

’ 3

g

F

FIGURE 5-8. Functional Block Diagram of Digital Control and Display Circuit.

5

Page 27

MODEL

191

DMM

2.5kHz

CHARGE BALANCE

START/m

CLEAR

COUNTER

THEORY OF OPERATION

FIGURE 5-9.

5-24.

5-25.

5-0, a logic "0" on PA7 indicates that the NULL

function is selected and a logic "1" on PB7

indicates that the instrument is in DC volts. These

signals are from the front panel NULL and WV pushbuttons, respectively. If not in DC volts mode, the

processor determines whether AC volts or Ohms has

been selected by looking at the value of the

reference voltage after it has been digitized.

5-26. Refer to Figure 5-8 and the timing diagram in

Figure 5-9 for

Charge-Balance phase begins with the MASTER RESET

line pulsing low, clearing U309A and 8 flip flops.

As described in the A/D converter discussion, the

appropriate signal to its input amplifiers is then

enabled by Sl,

After the completion of the appropriate delay

period given in Table 5-1, the "D" input to U309A

is made a "1". This same signal is ANDed at this

time to clear the H-F PRescaling counter U307. The

next rising edge of the 2.5kHz clock sets the Q

A/D Converter Control.

Looking at the A/D Controls Lines on Figure

the fallowing discussion. A

S2, S3 or S4 going to a logic "1".

Charge Balance Timing.

output of U309A low, ~enabling the input signal to

the integrator of thelAID. The processor now counts

250 interrupts from the 25kHz clock, and then sets

the "D" input to U309A to d "0". The next rising

edge of the clock sets INPUT DISABLE high again,

disabling the input 40 the integrator, and ending

the exact 100 millise ond integration period.

5-27.

PULSES are fed into lcounter U307. Each time the

counter overflows (a ter 256 counts) an interrupt

is generated which bhe processor counts in an

internal register.

the 8 most significant bits of the result.

5-28. At the end ofi the charge-balance phase, 8

bits of data are left on counter U307. This data is

obtained by pulsing t e MASTER RESET line into the

counter, and waiting

The number left on

minus the the

data becomes the ml die

result.

5-29. At the completi$n of remainder counting, the

Single-Slope phase ij begun by the SINGLE SLOPE

During the integration period above, V-F

1

1

Tfese interrupt counts become

1

for the counter to overflow.

he counter is equal to 256

1

number 'of MASTER RESET pulses. This

8 bits of the 24 bit

.j

5-9

Page 28

THEORY OF OPERATION

MODEL

191

DMM

FIGURE 5-10.

START/STOP signal going high, setting the "D" input

of U3098 to a "1". On the next rising edge of the

IMHr clock, the SINGLE SLOPE BEGIN signal from Q of

U3095 goes high, and is ANDed with the COMPARATOR

OUTPUT signal to enable single-slope counting. The

IMtir clock is now fed to U307, and counted similar

to the charge balance phase.

phase ends when COMPARATOR OUTPUT goes low, and

gates off the IMHr clock to the counter. The

remainder left in the counter is again read, as in

the charge-balance phase. This result is added to

the charge-balance counts to generate the 24 bit

(22 bit maximum) result. Timing for the single-

slope phase is shown in Figure 5-10.

5-30.

5-31.

5-8, consist of the LEO digits, and the necex~ary

decoding and driver circuits. These operate under

the control of the microcomputer. The diagram shows

the possible location of the decimal points, but

they are controlled by the range switching which is

not shown.

5-32. Display information is fed out on lines PAg

through PA6 of the PIA I/O bus. It is updated at a

2.5ktlr rate. with each digit an for approximately

400 microseconds. Since the display is fully aulti-

plexed, 6 updates are required to turn each of the

six digits of the display on once. This means that

the entire display is updated 416 times a second.

An update begins by blanking the display and disab-

Display.

The display circuits, as shown in Figure

The single-slope

Single Slope Timing.

eLAwy

FIGURE 5-11.

k

I

?""ZC

I

IN Ill":

Display Timing.

5-10

Page 29

MODEL 191 OMM

THEORY OF OPERATION

1

9.76 -102mscc pfriod U308

FIGURE 5-12.

ling the latch of "202.

PA6 pulsing to a logic "0" for 20 microseconds, and

the latch is disabled by pulsinq PA4 and PA5 to a

"1" for 10 imicroseconds. New segment data is now

presented on lines PA@ through PA3, and this data

is latched into U202 when PA4 and PA5 return low

after the

of the 20 microsecond period, the display is

unblanked, while new digit information is on the

PIA bus.

latched segment data being turned on until the

beginning of the next update.

shown in Figure S-11.

5-33.

5-34.

shown below the PIA on Figure 5-8. it consists of

two NAND gates, an AN0 gate, a 68OOpF capacitor and

counter U308 which divides by 256. Its function is

to restart the system by resetting the Microproces-

sor and PlA whenever either the prograiri is lost or

d long duration transient "CCII~S.

5-35. Timing of this circuit is shown in Figure

5-12.

10

microsecond period. At the completion

This results in the correct digit for the

Reset and Transient Recovery Circuit.

The reset and transient recovery circuit is

The circuit has two input signals, the 2.5kIlr

The display is blanked by

Reset and Transient Recovery Circuit Tilming.

Oisplay timinq is

i

1

I

k

l(i2nsec

clock and ILATCH ENARLi

by

U308 and LATCII ENA LE

normal operation, LAT$H iNARLt pulses low for 10

nicroseconds every 40

as described in the Di

Cb!ARLL is low, the vqltage on the cd~acitof (Vc)

rises exponentially. 1 When LATCI, LNARLC wt!irns

high, and while Vc is; dhovc the thwshold of thtz

ANn gate, a clear lpul e

normally U308 accuwul~tes one count and is then

cleared. A transient icdn mask the LATCH INAIII.C

pulses or a lost prag 'an, cd" prevent their appesrdnce at all. If no

128

seconds,

accumulate in U3fl8 afld its output will go high.

This high is NANOed {vith +5 volts to clear the

nlicroprocessor and Pld. Coincidently, LATCH FNABLI:

is forced low and Vc

U308

continues to cou t

it overflows after Z$snts, its ""put returns

low. This removes the!RESET and allows the micropr"cess"i- to return t the proper location in the

control

pr"CeSS.

counts r,",, the 2.5kHz clock wi,,

pr"gra"l. completes the recovery

The 2.5kilz clock is counted

is used to clear 11308. In

16

microseconds (2.5kKz r&e),

play discussion. k!hilr i~ATCli

%

1s applied to "308. Thus.

{

ulses appear for 5, milli-

a

b 1 gins to rise to its naxiriw.

the 2.5kHr clock dnd when

5-11

Page 30

THEORY OF OPERATION

MODEL 191 OMM

1 FIUXFET

INPUT BUFFER

FIGURE 5-13.

5-36. Digital Filtering.

5-37. When the 200mV or 200 Ohm range is selected,

a logic "0" is applied to PB7 of the PIA, which

tells the microprocessor to filter by averaging the

last 8 readings. For this condition, the last 8

readings are averaged together and displayed, as

lonq as the latest conversion is within digits of

the prfvious diplay. If the new conversion is more

than + digits away from the previous wading, the

new reading is displayed. Thus, speed is attained

for large signal changes, but random noise is reduced by a factor of 8. For all other ranqes, the

microprocessor USES a threshold of +5 digits and

averaqes the last 4 readings. Thus, snallcr siqnal

changes arc responded to, while random noise is

reduced by a factor of 4.

5-38.

5-39.

fom in the lower riqht corner of Figure 5-8, and

the complete circuits are shown on page 2 Of

Schematic 301620. Basically, the 4MHz crystal

control oscillator is a Pierce type oscillator. Its

4MHr output is fed direct to the clock divider

before application to the microprocessor (U302).

11105 provides three outputs by dividing 4MHz by 4,

8 and 16.

inverters to provide zero to t4 volt square waves.

The 1MHz output is used for Single-Slope countinq,

5OOkllr is

Charge-Balance timing, and 25Oktlr is divided by 100

in U301 to produce the 2.5kHz clock.

Oscillator and Clock Divider.

These circuits are shown in block diaqranl

(U105),

and it is buffered by a CMOS inserter

Its outputs arc buffered by CMOS

used in

the A/D converter for

9k

Turning on JFET Switches.

5-40. A/D CONVERTER CIRCUITS

5-41. The A/D convfrtfr rust have a high input

impedance and be linear to within a few parts per

million over the + 2 volt operating range. To [meet

this critera, several innovative circuits had to bc

desiqned. These circuits are described in the

following paragraphs.

5-42. Input Buffer.

5-43. The input buffer is a non-inverting. hiqh

input impedance amplifier which looks at each input

with either x10 or xl lain. Its input signals are

multiplexed by switches Sl through 54 under the

control of the microcomputer. One of the first

problems encountered was the high transients that

appear as the multiplexing switches are turned on.

The effects of these transients were eliminated by

the use of software generated delays.

EYCP, necessary to drive the gate of the appropri-

ate JFET with the input siqnal voltage to turn 1t

on. This was accomplished with a bootstrap ampli-

fier (BSA) connected to the invertinq terminal of

the input buffer (SEE Figure 5-13). When switch 5

is opened, the gate of Q rises to the output of BSA

which

t"mS q on, which means that VI,, = V) = VG.

Note that this technique works regardless of input

buffer gain.

equals the

0

lk

It was, how-

input voltage (V[N). This

5-12

Page 31

MODEL 191 DMM

THEORY OF OPERATION

FIGURE 5-14. Power Supply Comon Bootstrapped to Input Voltage.

5-44. As previously mentioned, the A/D convcrtfr

was designed for linearity. This means that the

input buffer must be linear over the full ~mfasurement range of t2V to no more than a few parts per

million. Since it also must be non-inverting, with

very hiqh input impedance, its gain linearity would

normally be determined by common mode non-linearity.

Most amplifiers specify 80 dB CMKK, and since CM

non-linearity would typically be a factor of 10 or

better, one could expect 10 ppn non-linearity frolv

CM Effects.

error, it was required that the common mode ~frors

be reduced.

either by improving CMRK through critical sclcction

of devices, br by eliminating the colirnon mode (CM)

voltage. The latter method was chosen, as shown in

Figure 5-14.

inverting operational amplifiers, the common mode

voltage

(power supply common). Thus, it can be seen that if

"IN -

common mode errors would be zero because VCM =

0. To achieve this,

Since this would be far to" much

Common mode errors can bf "v~rcomf

First consider that, for non-

(VCM) is equal to VIN VCOM

VC-M could

be made equal to Zero,

it was necessary to bootstrap

the power supply con~ion for the input a,n,i,if~cr- i)t

the input voltage. This wds accomplished !)y d:ld)":;

2 zmers, 2 transistbrs, and d few resistors. :hr

power supply common :is seen to be thr junctlori of

VKIOS and VI1106 (the ;"utPut of INSA), which is eqiial

to

"IN.

0, and the common mbde error is elininatcd. !i"te

that this techniques also raises input inpcdancc

because:

And, since there is in" bias change on the input

FETs of the input1 amplifier,

Z[NW". With the &mm"n mode error elimnatcd,

the only gain error is "pen loop gain nonlinearity

divided by loop gainj For closed loop unity ~jain,

non-linearity is 0.5 :ppm since "pen loop gain non-

linearity is 10% and "pen loop gain is 200,000.

For x10 gain, nonlinebrity is 5 PF~I.

Thus. VC,, =

VIII

I,!{= J and

"UX.!;F

5-13

Page 32

THEORY OF OPERATION

IO = Ioff - Iin

MODEL

OUTPUT

191

DMM

Ioff

is made + Vin

Rin

Thus \,hen Vi" = Vin max, 10-0 (pcs. full scale)

Vin =O, IO 'Ioff (zero)

Vin = -Vjn max.

FIGURE 5-15.

5-45. Transconductance Amplifier.

5-46. This alnplifier performs two functions. It

converts the input voltage to an output current

that is sent to the integrator on request. It also

provides an offset current so that its bipolar

input voltages are converted to unipolar output

C"!-"?CTltS. BEcause of

operation, its linearity is cxccllent. Figure 5-15

shows how the circuit operates.

5-47. Integrator.

5-48. The integrator has been dfsigned to guard

against the !m"st common problems associated with

high speed integrator operation.

tors have two Imajor problems which limit their high

speed performance. One is the GAINBANDWIDTH of the

integrator amplifier, and the "th"r is the output

resistance of the same amplifier.

the current mode of

Io= Ioff + Vin max*z Ioff (minus f-s.)

Transconductance Amplifier Operation.

Active integra-

These effects

Flax.

Rin

can be seen by looking at the integrator rmodcl in

Figure 5-16. If a voltage step appears at Vi".

the amplifier will not respond immediately, and C

will initially be a short circuit. As shown in the

equation, the effect is that the wrong current will

be applied to the capacitor until the amplifier I‘"covc~s. It can also be seen that if a bipolar input

amplifier was used for the integrator, charge could

be conducted away from the capacitor and cause

significant ~rr"rs. To guard against these problems, the 191 uses an emitter follower on the integrator output to keep I?" small into the MHz region, and ail inputs to the integrator are current

sources. Also, FET input operational amplifier is

used, which would allow a few volts to appear on

the summing junction with no loss in charge.

5-14

Page 33

MODEL 191 DMM

THEORY OF OPERATION

For step voltage inputs:

FIGURE 5-16.

REFERENCE

DIVIDER

+2v

+.2v

Integrator Problems at High Speed,

e-e0 = Vin

2.74k

+

6.1

13

k

k

FIGURE 5-17.

6

Simplified Schematic of Reference

UPPlY.

5-15

Page 34

rHEORY OF OPERATION

MODEL

191

DMM

5-49.

5-50.

5-17.

was designed for linearity and low noise. This

means that stability and accuracy must be provided

by the reference.

cuit is a buried layer zener diode, with an "n-

board heater, which was selected because of its

stability, low noise,

and low dynamic resistance. It is driven by a con-

stant current (nominally ImA) developed by amplifier U102. Since the zener current is well regulated,

Far example: a 1 volt change In +V would only cause

a zener current change of about 150 nanoamperes.

And, since the dynamic resistance of the zfner is

0.5 ohms, the zen~r voltage would only change 7.5

nanovolts. Super stable tracking resistors are used

in the reference divider to provide very stable 2

volt and 0.2 volt reference voltages. The input

resistors of the divider are specially selected

nominal 100 microamperes of current to the divider.

For example: the values of resistance shown in the

diagram would be for a zener voltage of 6.95 volts.

5-51.

5-52.

tage regulators,

switching and full-wave rectifiers which make up

the power supply for the Model 191. There are three

component regulator used. The plus and minus 15

ment.

+ 5% dCC"raCy. Its input voltage is supplied from

REFERENCE SUPPLY.

The reference supply is shown in Figure

As previously mentioned, the A/D converter

The heart of the reference cir-

low temperature coefficient

it is imune to power supply variations.

(depending on the zener voltage) to provide a

POWER SUPPLY.

Page 4 of Schematic 301620 contains the vol-

line transformer, line voltage

integrated circuit

volts dc is provided by VRlOl and VR102, respectively. These are 3-terminal regulators with + 10%

accuracy.

volts dc from TlOl and

selected line voltage is supplied to the instru-

and input currents are limited by RI58 and R159.

Output voltages are filtered by

VR104 provides the t5 volts used in the analog

(ANLG) circuitry. It is a 3-terminal regulator with

TlOl and CRIOI,

(+0.5V) with minimum selected line voltage applied.

Input filtering is provided by

filtering by C116. 9126 and Q127 comprise a series

regulator which provides +5 volts for the Digital

and Display circuitry.

thus,

approximately 6.5 volts (+0.5V) from TlOl and CR103

when minmum selected line voltage is applied. Input

filtering is provided by C109, and CR106 prevents

thermal runaway in the event of a circuit fault.

They receive approximately +I8 and -18

lnput voltages are filtered by

has the same output accuracy.

regulators and one discrete

CR102

and is approximately 8 volts

It is slaved to VR104, and

when the minimum

Cl11

and Cl14

Cl10

and C113.

C115,

and output

It recei vcs

The allowable zener voltage is between 6.6 and 7.3

volts, with the resistors matched accordingly.

MODEL

1910

5-53.

5-54. The Model 1910 is basically a plug-in acldc

converter with variable gain that conditions the ac

input voltage for application to the A/D c""wrtfr.

The basic transfer function of the acldc converter