Page 1

Service Manual

Model 181

Digital Nanovoltmeter

01981, Keithley Instruments, Inc.

October 1981, Cleveland, Ohio, U.S.A.

Document Number 30816

Page 2

Model 181 Service Manual Addendum

INTRODUCTION

This addendum to the Model 181 Service Manual is being provided in order to supply you with

the latest information in the least possible time. Please incorporate these changes into the manual

before servicing the Model 181.

Model 262 Low Thermal Voltage Divider

This addendum concerns availability of the Keithley Model 262 Low Thermal Voltage Divider,

which is recommended for verifying accuracy and calibrating the Model 181 mV

Model 262 is a precision low thermal divider with divider ratios of 101:1, lO?l, lO”:l, and lO?l. A

low thermal male-to-male output cable is included with the Model 262. Note that Model 181 verification and calibration procedures that use the Model 262 are included in the Model 262 Instruction Manual.

Section 2, page 2-2:

Include the Model 262 Low Thermal Voltage Divider in the list of available accessories.

ranges.

The

Table 3-1, page 3-1:

Replace Item B in the table with the Model 262

Table 5-1, page 5-l:

Replace Items B and F with the Model 262

I

Page 3

Page 4

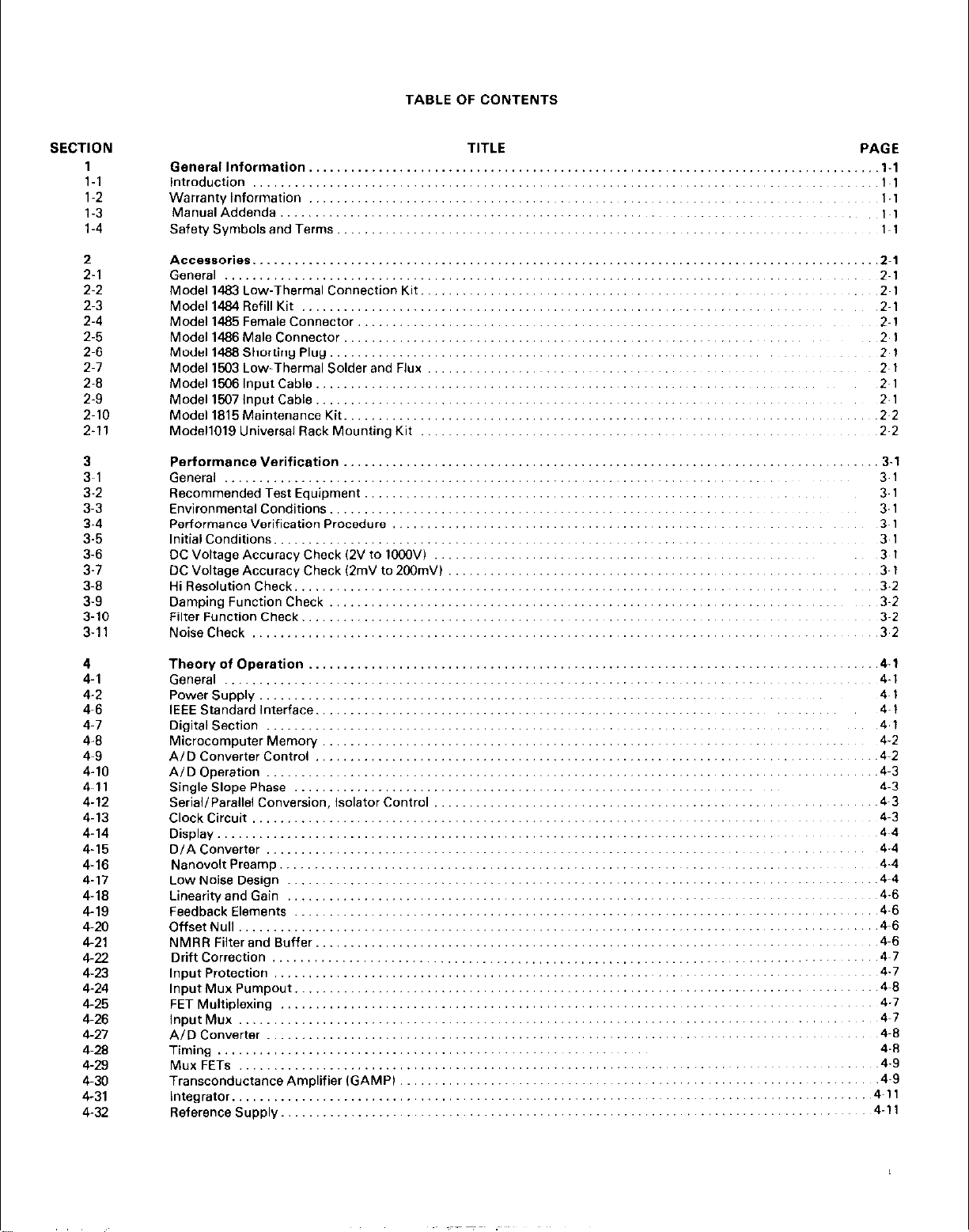

TABLE OF CONTENTS

SECTION

1

l-l

l-2

1-3

1-4

2

2-l

2-2

2-3

2-4

2-5

2-6

2-7

2-6

2-9

z-10

2-11

3

3-l

3-2

3-3

3-4

3-5

3-6

3-7

3-6

3-9

3-10

3.11

TITLE

Generallnformation ....................................

Introduction ............................................

Warranty Information ....................................

ManualAddenda

Safety Symbols and Terms. ...............................

Accessories ............................................

General ................................................

Model 1463 Low-Thermal Connection Kit

Model 1484 Refill Kit .....................................

Model 1485 Female Connector .............................

Model1486MaleConnector ...............................

Model 1488Shorting Plug .................................

Model 1503 Low-Thermal Solder and Flux

Model1506lnputCable ...................................

Model1507lnputCable ...................................

Model 1615Maintenance Kit ...............................

Model1019 Universal Rack Mounting Kit

Performance Verification ...............................

General ...........................................

Recommended Test Equipment ............................

Environmental Conditions .................................

Performance Verification Procedure ........................

Initial Conditions .........................................

DC Voltage Accuracy Check 12V to lO@S/)

DC Voltage Accuracy Check (2mV to 2OOmV)

HiResolutionCheck ......................................

Damping Function Check ....................

Filter Function Check ........................

NoiseCheck ...............................

........................................

....................

...................

....................

..................

................

PAGE

.......

.........

....

4

4-l

4-2

4-6

4-7

4-8

4-9

4-10

4-11

4-12

4-13

4-14

4-15

4.16

4-17

4-16

4-19

4-20

4-21

4-22

4-23

4-24

4-25

4-26

4-27

4-28

4-29

4-30

4-31

4-32

Theory of Operation ........ ..............

General .... ............................

Power Supply ..............................

IEEE Standard Interface ......................

Digital Section .............................

Microcomputer Memory .....................

AID Converter Control ......................

AID Operation .............................

Single Slope Phase .........................

Serial/Parallel Conversion, Isolator Control

Clock Circuit .. ... .....................

Display ....................................

D/A Converter .............................

Nanovolt Preamp ...........................

Low Noise Design ..........................

Linearity and Gain ..........................

Feedback Elements .........................

Offs&Null .................................

NMRR Filter and Suffer ......................

Drift Correction .................

Input Protection .. ......................

,nputMuxPumpout .........................

FET Multiplexing ...........................

InputMux

AID Converter .............................

Timing ....................................

MuxFETs

Transconductance Amplifier lGAMPl

integrator ..................................

Reference Supply ...........................

.................................

.................................

.. ....

..........

.....

.,.,4-l

~~~ 4-l

.........

.........

.........

.........

.........

...........

...........

...........

Page 5

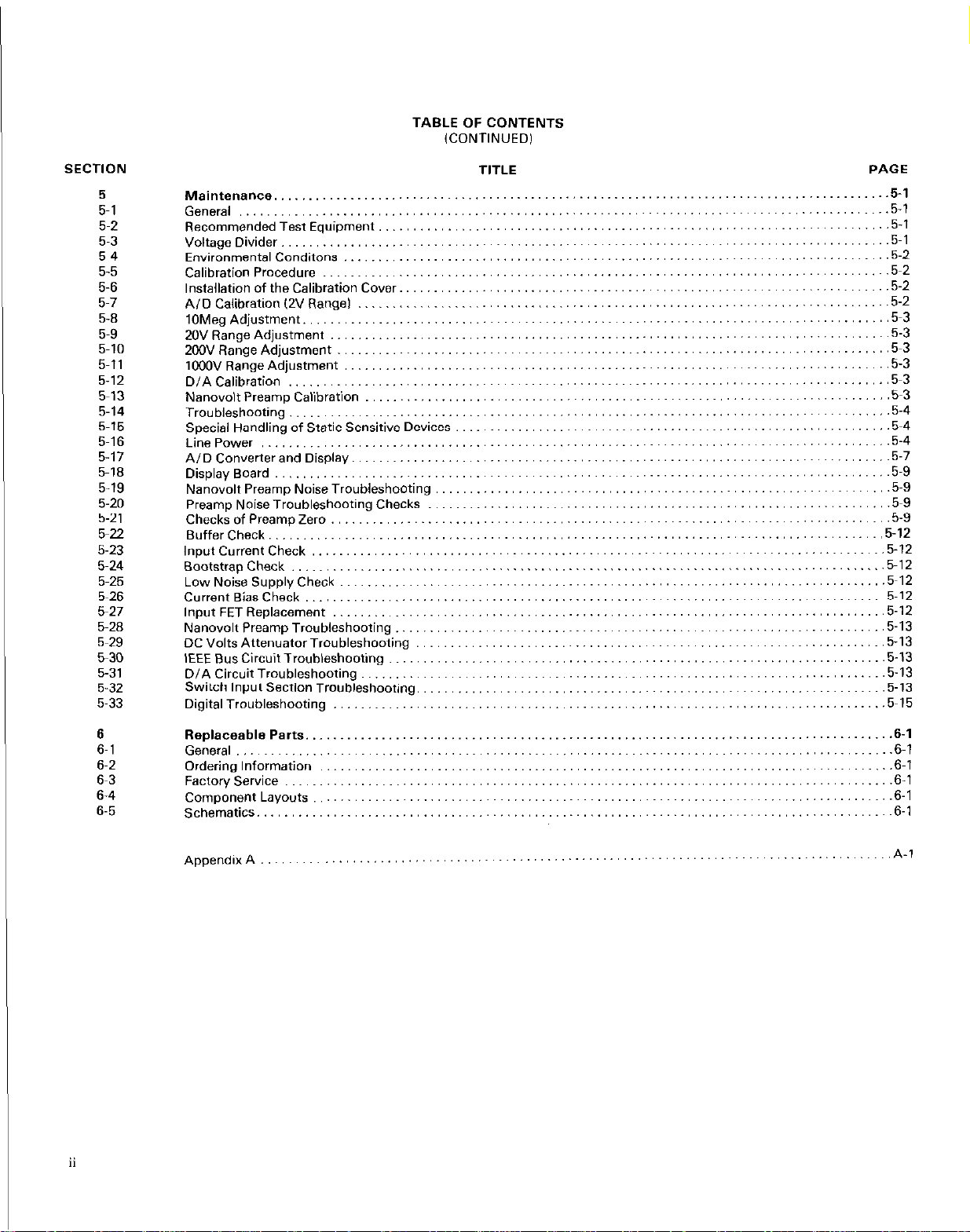

TABLE OF CONTENTS

(CONTINUEDI

SECTION

5

5-l

5-2

5~3

5-4

5-5

5-6

5-7

5-6

5-9

5-10

5-11

5-12

5-13

5-14

5.15

5-16

5-17

5-18

5.19

5-20

5-21

5-22

5-23

5-24

5-25

5~26

5-27

5-26

5-29

5-30

5-31

5-32

5-33

TITLE

Maintenance .........................................................................................

General ...........................................................................................

RecommendedTestEquipment..........................................................................5- 1

VoltageDivider........................................................................................6 -1

EnvironmentalConditons

CalibrationProcedure ................................................................................

Installation of the Calibration Cover

AIDCalibration(ZVRangel ..........................................................................

lOMegAdjustment.....................................................................................5~ 3

20VRangeAdjustment.................................................................................5 -3

200VRangeAdjustment................................................................................5~ 3

lOOOVRangeAdjustmant...............................................................................5- 3

DIACalibration

.....................................................................................

NanovolrPreampCalibration

Troubleshooting.......................................................................................5- 4

Special Handling of Static Sensitive Devices

Line Power

AIDConverterandDisplay..............................................................................5 -7

DisplayBoard

Nanovolt Preamp Noise Troubleshooting

Preamp NoiseTroubleshooting Checks

ChecksofPreampZero.................................................................................5- 9

BufferCheck.........................................................................................5-1 2

InputCurrentCheck

BootstrapCheck..

LowNoiseSupplyCheck...............................................................................5~1 2

CurrentBiasCheck..

InputFETReplacemenr

NanovoltPreampTroubleshooting.......................................................................5-1 3

DC Volts Attenuator Troubleshooting

lEEEBusCircuitTroubleshooting........................................................................5-1 3

DIACircuitTroubleshooting............................................................................5-1 3

SwitchlnputSectionTroubleshooting....................................................................5-1 3

DigitalTroubleshooting

...........................................................................................

......................................................................................

.............................................................................

......................................................................

..........................................................................

.............................................................. .5-4

................................................................. .5-9

..................................................................

................................................................................

..................................................................................

................................................................................

............................................................................

...................................................................

..............................................................................

PAGE

5-l

...5- 1

..5 -2

..5~ 2

.5-2

...5 -2

..5~ 3

..5~ 3

5-4

...5 -9

.5-9

...5-1 2

..5~12

..5~12

,.,.5-l 2

,513

..5~15

6

6-1

6-2

6-3

6-4

6-5

Replaceable Parts. .......

General ..................

Ordering Information ......

Factory Service ...........

Component Layouts .......

Schematics ...............

AppendixA............,,..,..,,.,....................,...............................................A-l

.........

.........

.........

.........

.......

.......

.......

.........

.........

.........

.........

.6-l

..6-1

,.6-l

,.6-l

..6-1

..6-1

ii

Page 6

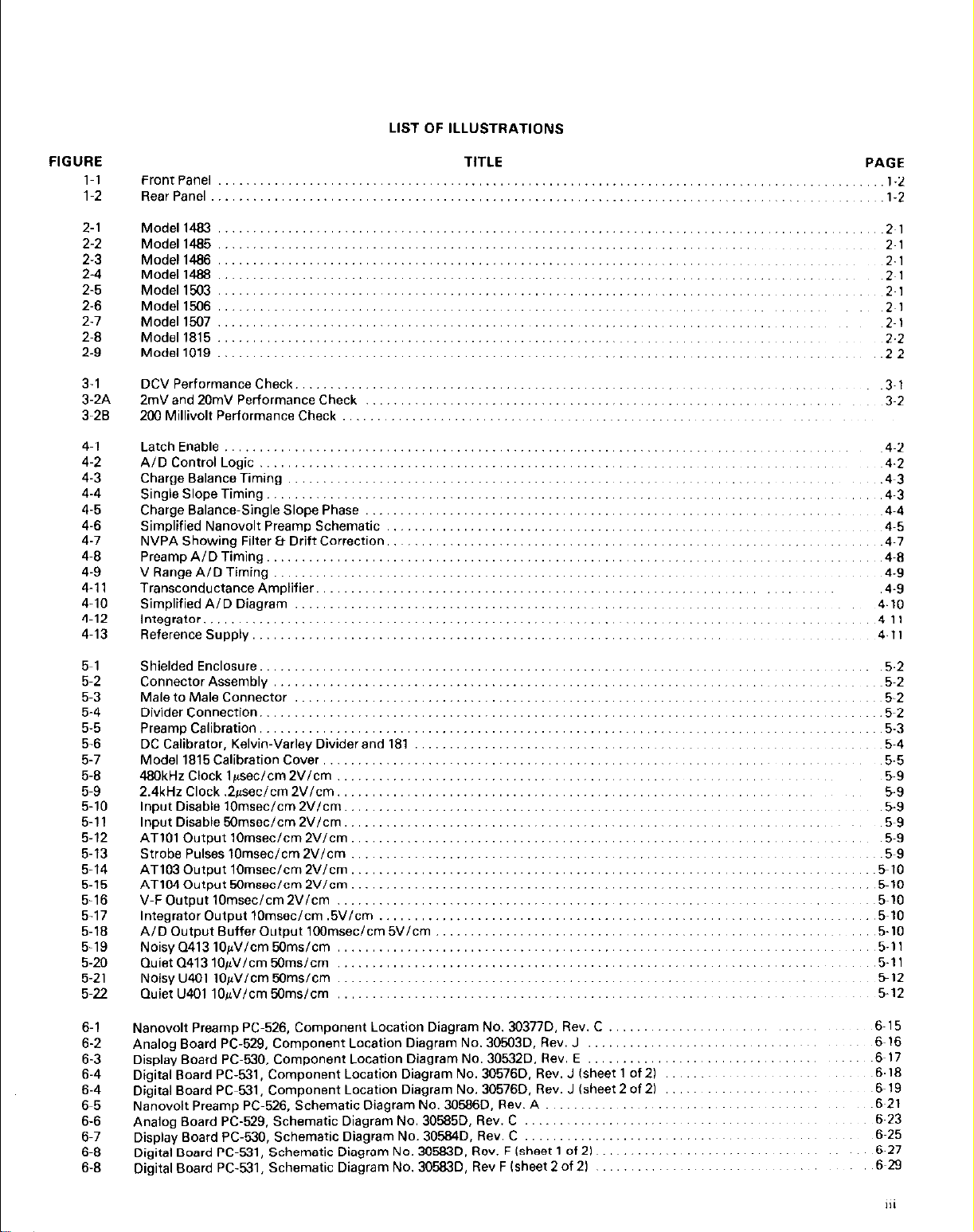

LIST OF ILLUSTRATIONS

FIGURE

1-l

1-2

2-l

2-2

2-3

2-4

2-5

2-6

2-7

2-8

2-9

3-l

3-2A

3-28

4-l

4-2

4-3

4-4

4-5

4-6

4-7

4-8

4-9

4-11

4-10

4-12

4.13

TITLE

Front Panel

Rear Panel

Model 1483

Model 1485

Model 1486 2-l

Model 1488

Model 1503 2~1

Model 1506

Model 1597

Model 1815

Model 1019

DCVPerformanceCheck.........................................,............~~.~~,~~..~..~~,~..,~

2mVand20mVPerformanceCheck ..~..~...............~......

200 Millivolt Performance Check ~. ~.

Latch Enable ............................ ~4~2

AID Control Logic .......................

Charge Balance Timing ...................

Single Slope Timing. .....................

Charge Balance-Single Slope Phase

Simplified Nanovolr Preamp Schematic

NVPA Showing Filter Et Drift Correction.

Preamp AID Timing.

V Range A/D Timing

Transconductance Amplifier. ..............

Simplified A/D Diagram .................. 4-10

Integrator ............................... 4~11

Reference Supply ........................

.........

.........

.........

.........

.........

......

.....

......................

......................

PAGE

. . ..l-2

..~.1.2

~2~1

2~1

2~1

2~1

2~1

2-2

~2~2

~3.1

3~2

~4-2

.4~3

~, ,4-3

~4~4

4~5

~4.7

4~8

4-9

,4-9

4-11

5-l

5-2

5-3

5-4

5-5

5-6

5-7

5-8

5-9

5-10

5-11

5-12

5-13

5-14

5-15

5-16

5-17

5-18

5-19

5-20

5-21

5-22

6-l

6-2

6-3

6-4

6-4

6-5

6-6

6-7

6-8

6-8

ShieldedEnclosure..................................................~....~~~

ConnectorAssembly......................................................................~......~.~.~

MaletoMaleConnector

DividerConnection...............................................................................~..~~~~~~.5~ 2

PreampCalibration....................................................~......~.~....~....~~~~~~.~~~~~~~.~ 5.3

DCCalibrator,Kelvin-VarleyDividerandW.. ............... .............

Model1815CalibrationCover..................................................~

480kHzClockl~sec/cm2V/cm..............................~

2.4kHzClock.2~eclcm2Vicm

lnputDisablelOmseclcm2V/cm...................................................................~

lnputDisable50mseclcm2V/cm

ATlOlOutputl0msec/cm2Vlcm..............................................................~

StrobePulsesl0mseclcm2Vlcm..................................................~.......~~~

AT103OutputlOmseclcm2Vlcm...........................................................~..~..~..~~

AT1040utput50msec/cm2Vlcm....................................................................~......5~1 0

V-FOutputl0msec/cm2Vlcm..

lntegratorOutput10mseclcm.5Vlcm.......................................................~........~~..~..5~l 0

AID Output Buffer Output lOOmsec/cm5V/cm

NoisyQ41310pVlcm50ms/cm

Quiet041310~VV/cmWms/cm ......................

NoisyU4O1lOpV/cmWms/cm..

0uietlJ40110~V/cm50ms/cm ...................................................................

Nanwolt Preamp PC-526, Component Location Diagram No. 30377D. Rev. C

Analog Board PC-529, Component Location Diagram No. 30503D. Rev. J

Display Board PC-530, Component Location Diagram No. 30532D, Rev. E

Digital Board PC-531, Component Location Diagram No. 30576D. Rev. J (sheet 1 of 21

Digital Board PC-531, Component Location Diagram No. 30676D. Rev. J (sheet 2 of 21

NanovoltPreampPC-526,SchematicDiagramNo.30586D,Rev.A..

Analog Board PC-529, Schematic Diagram No. 30685D. Rev. C

DisplayBoardPC-530.SchematicDiagramNo.30584D.Rev.C.. ..................

Digital Board PC-531, Schematic Diagram No. 30583D. Rev. F (sheet 1 of 21..

Digital Board PC-531, Schematic Diagram NO. 30583D. Rev F (sheet 2 of 21

............................................................................

..............................................................

......................................................................

..........................

........................... ............. .. .. ..... ..

..............................

..... .......... ....... ..................

...............................

........................... .. .. .......

.............................. ,~, 59

.. ... .. ......

.... ................

.............

... .. ........... .....

................ .. ..... ....

.......................

.......... .. ..

............... ..... ........

.......

............ ~.~,~~~~~ ......... ~5~4

............. ,.,,.~,,~ 5.5

....................... 512

.......... .. .....

.....................

.........

..............

~~,~~

................. ~~~5~10

............... ,.,,5-11

~~,.~

.........

......

.,,,

... ,.~ ,, 5~9

........ ~~~.5~9

....

.... ....

.....

~~,.~ ~,

~~~5~2

..~..~~~5- 2

.. ,5-9

~,

~~~5~10

,5-10

,5-11

5-12

6~15

6~16

...

~6~17

~6.18

~6~19

~6~21

6~23

,6~25

6-27

~6~29

5.2

5-9

5~9

iii

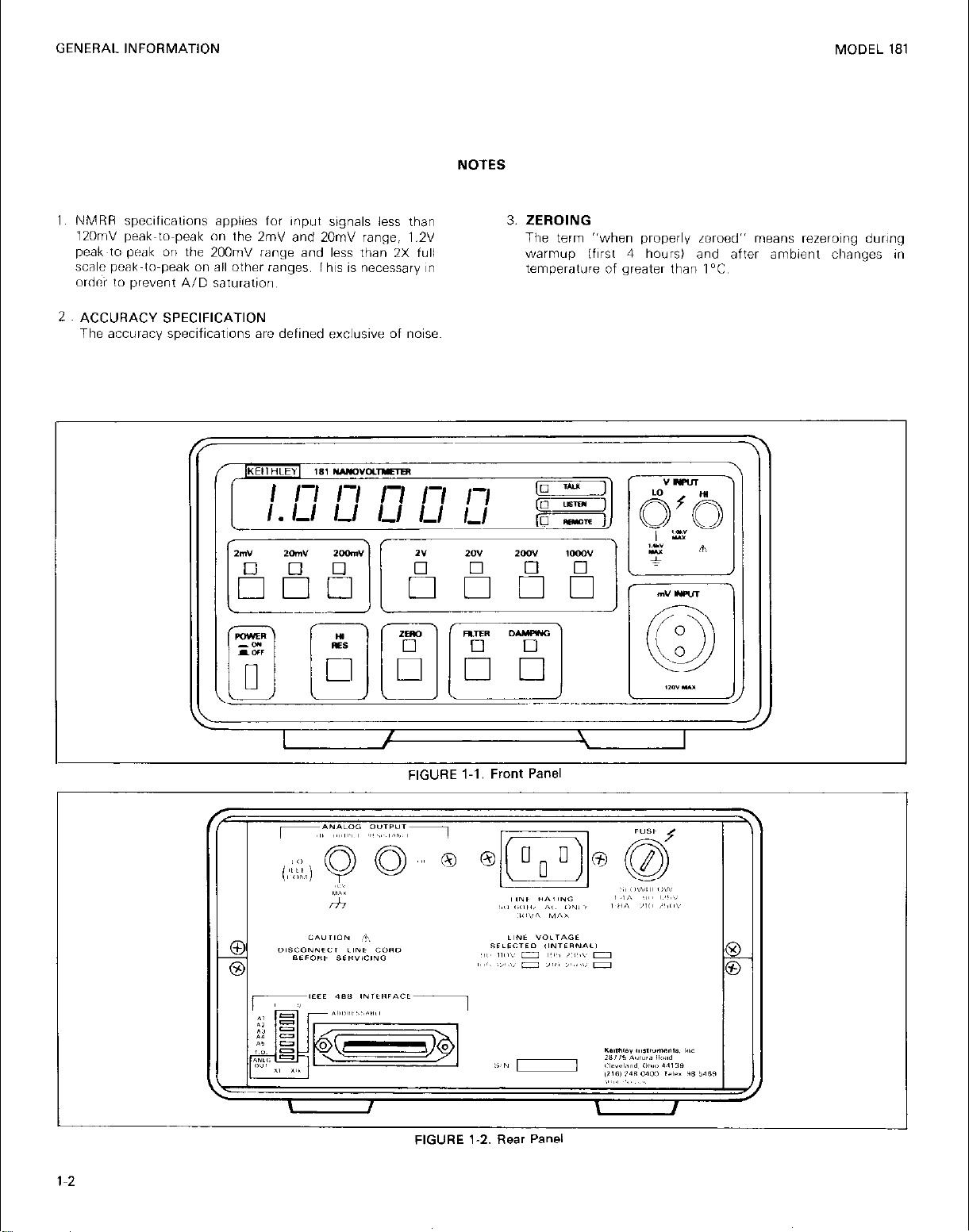

Page 7

I

TABLE

LIST OF TABLES

TITLE

PAGE

Recommended Test Equipment for Performance Verification

3~1

DC Voltage Performance Check (2V to 1OOOVl..

3-2

DC Voltage Performance Check (2mV to 200mVl

3-3

Microcomputer Memory Map ..............................

4~1

Gain Resistors

4~2

Gain Resistors for Volts

4~3

MuxFETs ..................................................

4-4

Recommended Test Equipment ...............................

5~1

Voltage Divider Parts List ................................

5~2

Power Supply Checks .................................

5~3

AIDConverter .....

5-4

Display..

5~5

Preamp Troubleshooting ....................

5-6

DCV Attenuator Troubleshooting

5~7

Replaceable Parts List PC-531 Schematic30593D

Replaceable Parts List PC-529 Schematic30585D

Replaceable Parts List PC-526 Schematic 30586D .........

Replaceable Mechanical Parts ...................

Cross Reference of Manufacturers.

.... ..................

.............. ..

.......................................

.........................................

...........................

~, .. .................

..........................

......

.............. ..

................

..................

.......

~, ...............

........ ......

... .........

.............

...

...

..

.........................

..........................

3-1

.3~1

.3~2

. ...4-2

.4~6

.4~6

. ...4-9

.,.,5-l

. ...5-1

.5-6

.5-7

.5-a

.5~13

.5~13

.6~1

.6~6

.6-10

.6-12

,613

Page 8

I

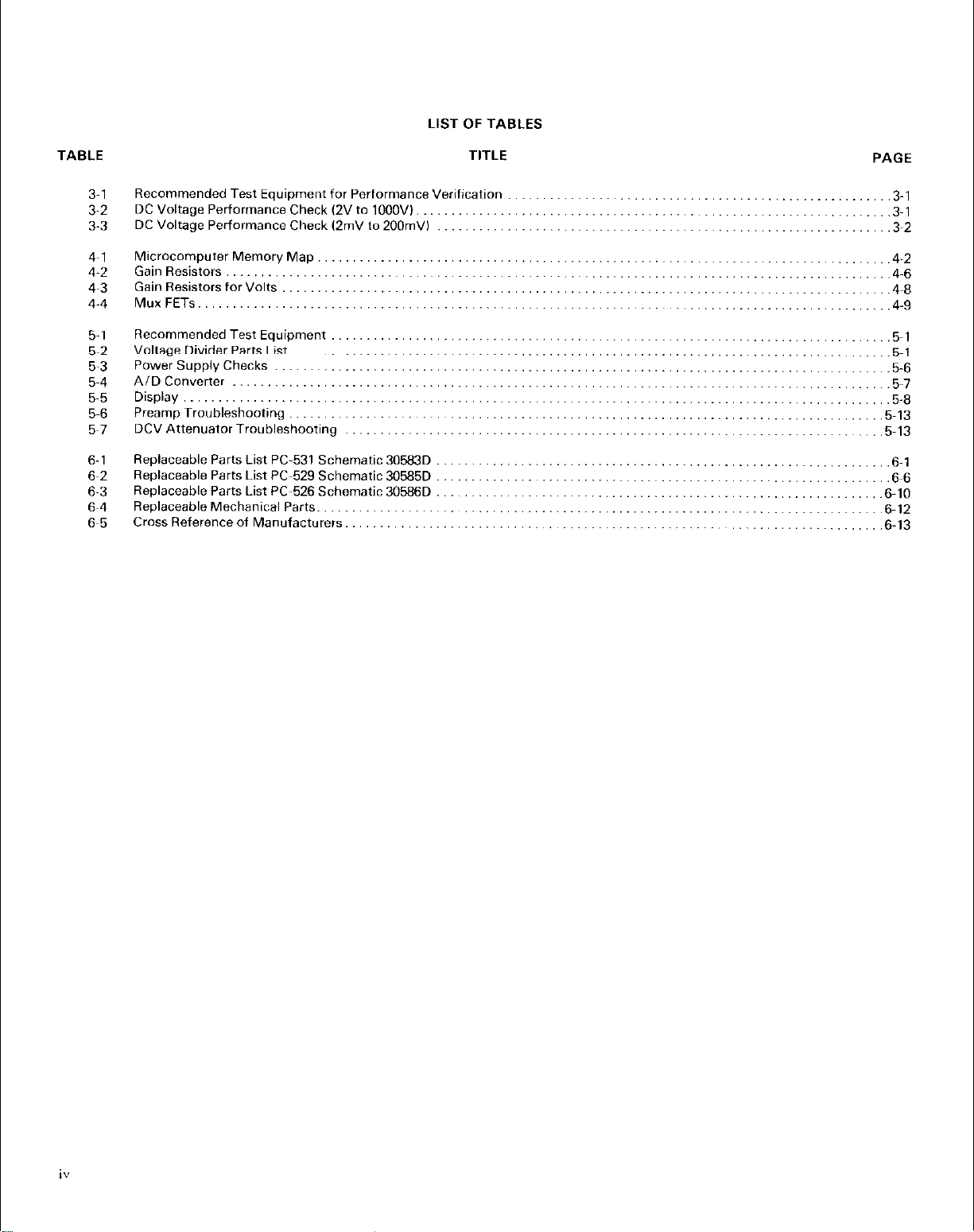

MODEL 181

Section 1. General Information

l-l. INTRODUCTION,

The Keithley Model 181 is a 5% and 6% digit DC voltmeter

with resolution to lOnV, The Model 181 is a unique DC

voltmeter in the respect that it combines microprocessor

technology for full programmability with a new concept in

nanovolt front ends, It provides highly accurate, stable and

low noise readings from 1OnV to 1CCQVDC on 7 voltage

ranges. The 2V through the 1CCOV ranges utilize the 5.way

binding posts. The 2mV through the 2CQmV ranges utilize the

special low thermal input connector.

The service manual contains the necessary information for

calibrating and maintaining the Model 181. This information is

provided in various sections throughout the manual. These

sections are listed as Performance Verification, Theory of

Operation and Maintenance/Calibration. Along with this

section, General Information, this manual also includes the

Accessories, a Parts List, and the Schematic Diagrams,

GENERAL INFORMATION

CMRR: 16OdS on mV ranqes. 140dS an V ranges; at DC and line fre

quency 60 or 60Hrl. ,lkR unbalance)

IEEE-488 BUS IMPLEMENTATION:

Multiline Commands: LXX. LLO. SDC. GET.

Unlline Commands: IFC, REN, EOI, SRD. ATN.

PROGRAMMASLE PARAMETERS:

Front Panel Controls: Range. Filter. Zero, Dampin% Hi Resolution.

Internal Parsmeters: SRCI Resoonse. Triswsr Modes. oats

Tetminators.

ADDRESS MODES: Talk-Only and Addressable.

TRIGGER MODES:

one Shot: Updates OUtpUt buffer once at first valid c”““ersi”” after

tdocler on TALK and/or GET.

GENERAL

NOISE: Less than 30nV pip on lowest range with Filter on.

INPVT CAPACITANCE: 5OOOpF on mV ranges.

SETTLING TIME: 0.5s to within 25 digits 01 final reading with Filter on,

Damping off

FILTER: 3~pole diSital: RC = 0.5, 1 or 2 seconds depending 0” range.

CONVERSION SPEED: 4 readings/second.

DISPLAY: Seven 13mm (0.6 in.1 LEO digitswith appropriatedecimal point

and polarity.

OVERLOAD INDICATION: Display indicates polarity and OFLO.

ANALOG OUTPUT:

--

Accuracy: f 10.15% of displayed reading + lm”i~

The Constent: 400ms.

Level: t 2V full scale on all ranges: x1 or x,000 gain

ISOLATION: Input LO 10 Outpur LO or power line ground’ ,400” peak. 5

x lOW.Hz. greater than ,090 paralleled by ,soJ”F

WARMUP: 1 hour IO rated SCCUE.CY when propedy zeroed,

ENWRONMENTAL LIMITS: OperatinS: WC 10 35°C. 0% la 80%

re,atiw hwnidirf .storags: 2vc to 65°C~

POWER: 105~125V or 210-250” lintelm SWlWh selected,. 50~60HZ.

30V.A maxim”m.

INPUT CONNECTORS: Special low thermal to, 20OmV and lower ,ilnges

Binding posts f”,2V to tooov rangss.

DIMENSIONS. WEIGHT: 127mm high x 216mm wde I 359mm deep

15” x BK” x 14W’,. Net weight 3.85kg ,8K lb*.,,

ACCESSORY SVPPLIED: Model ,606 Low Thermal Input Cable

ACCESSORIES AVAILABLE:

Model 1019 Rack Mounting Kit

Model ,483 LOW Thermal Connectlo” Kl,

Model 1484 Refill Kit for 1483 Kit

Model 1485 Female LOW Thermal Input Conneclor

Model ,486 Male LOW Thermal Input Connector

MO& 1488 LOW Thermal Shorting Plug

Model 1503 LOW Thermal Solder and Flux

Model ,506 LOW Thermal Input Cable 14 1tL alps,

Model ,507 LOW Thermal Input Cable 14 11.. Lugs1

Model ,815 Maintenance Kit

Page 9

I

I

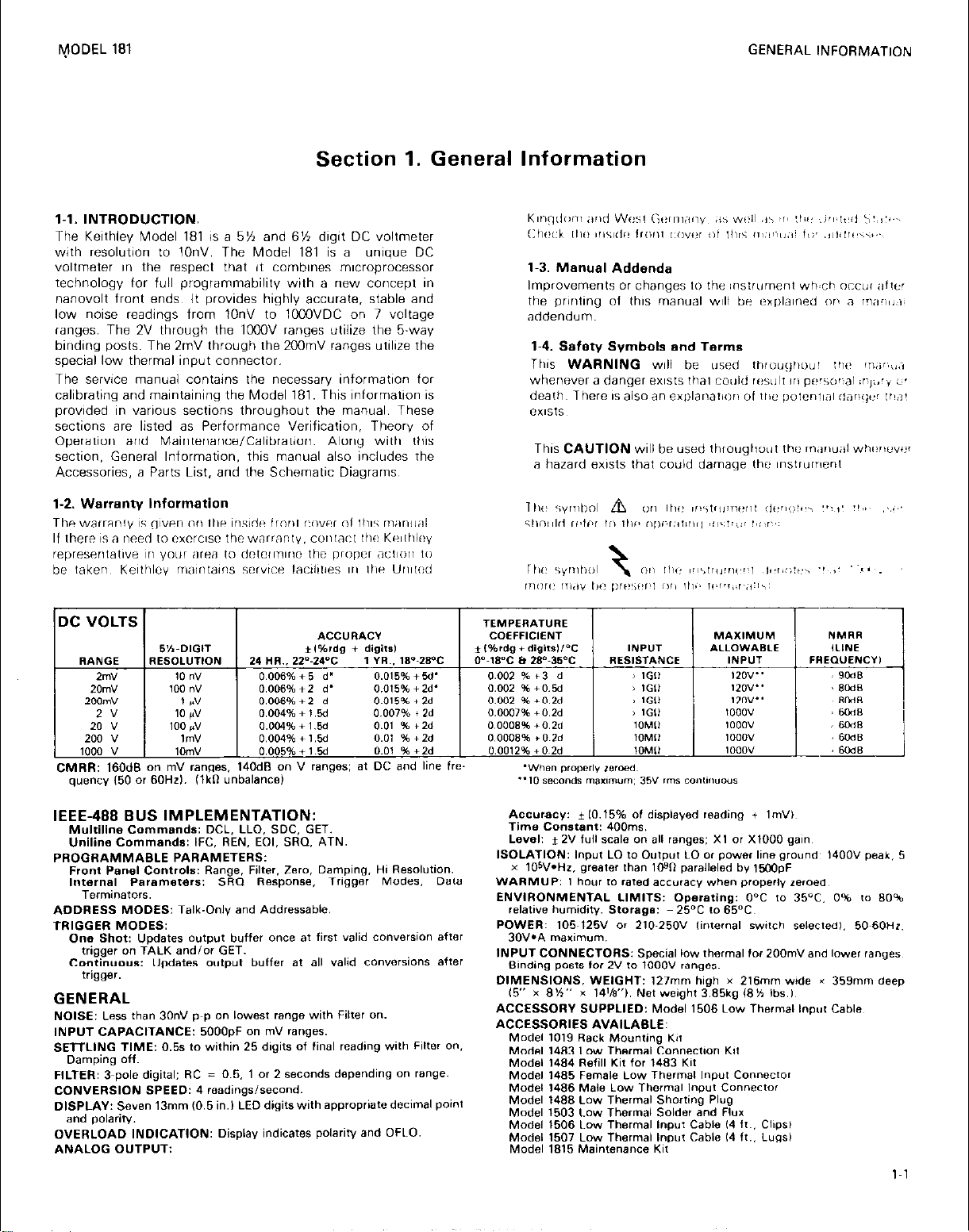

GENERAL INFORMATION

NOTES

1~ NMRA spocilicalions applies for input signals less than 3. ZEROING

12OmV peak~to~peak on the 2mV and 20mV range, ,.2V

poak~to peak on the 200mV range and less than 2X fuli

scale peak~lo-peak on all other ranges. This is necessary in

ordci 10 prevent AID sauration

2 ACCURACY SPECIFICATION

The accuracy specifications arc defined exclusive of noise

The term “when properly roroed” means rereroing during

warmup ifIrs 4 hoursi and after ambient changes in

temperalure of greater than 1’C

MODEL 181

l-2

F,G”RE l-l Front Panel

FIGURE 1-2. Rear Panel

Page 10

MODEL 181

Section 2. Accessories

2-l. GENERAL

This section describes rhr? va,ious xcesso,~~~s and options

available lor us” with the Model 181.

2.2. Model 1483 Low-Thermal Connection Kit. 1 he Model

1483 Kit Conlains a crimp tool, shielded cable, an assortment

01 copper lugs, copper wire, cadm,um solde, and nylriri brrlts

and nuts, i, is a com,,le,e kit lo, nrnk,ng v”,y low thcrmnl

measuring arcuifs, ihe kit enables th,! use, of ,118 Mode1 181

10 maintain ho i~iqh therma stability 01 the ,~anov,~ll,,m~l,?~ II!

t11s own appllcatiorl,

Figure 2-l. Model 1487

Figure 2-2. Model 1485

Figure 2-5. Model 1503

Figure 2-6. Model 1506

Figure 2-3. Model 1486

2.5. Model 1488 Shorting Plug. ~T~hr! Model 1488 is ~,sef~il for

checking proper operation and Ior cnlihratinq the Model 181~

Its electrical and thermal ~0,1stri~l10,1 mrlimms “,,“,s caused

by thr!,mn, EMFs, The Mode, 1488 is ““,y useful fm checkirii?

the Model 181’s offset and drtfl~

Figure 2~7. Model 1507

4

Page 11

ACCESSORIES

‘\

.-.

,.

‘:. 3.

MODEL 181

7

;:‘r

Figure 2.8. Model 1815

Figure 2-9. Model 1019

2-2

Page 12

MODEL 181

PERFORMANCE VERIFICATION

Section 3. Performance Verification

3-6. DC Voltage Accuracy Check i2V to 1wOV Range1

3-4. Performance Verification Procedure

Use the following procedure 10 verify fhe basic accuraw of the

Model 181 ior DC voltage. /I the instrumwIl IS out of

speciflcallon ar any point. perform a complete caIib,atiori iis

CAUTION

The performance verification and all service inform

mation is intended for quaIlfled personnel using

accurate and reliable test eqwment.

WARNING

Some procedures require the use of high voltage.

Take care to prevent contact with live circuits

which could cause electrical shock resulting in

injury or death.

3.5. Initial Conditions

Before beginning thu ver,f,ca,ion procedure. the ,i,slrument

must meer the followng conditiorls:

l, the instrument has beer, subjected 1” extremes

ol temperature, allow sufficient fime for interrlal

kmperatures 10 reach wwronmental conditions

1 ‘. : :

(I

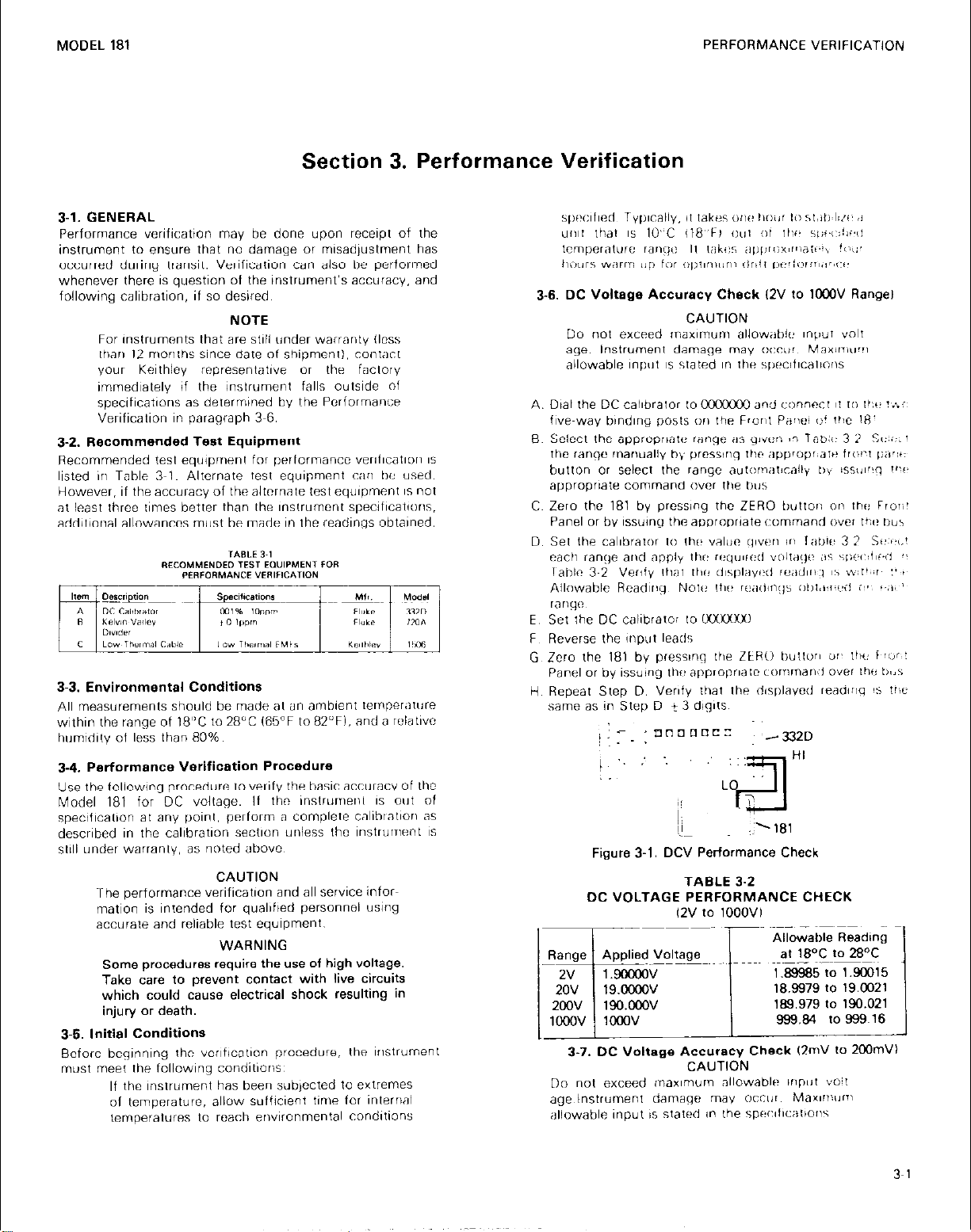

Figure 3-l. DCV Performance Check

DC VOLTAGE PERFORMANCE CHECK

I

I

3-7. DC Voltage Accuracy Check l2mV to 200mVl

TABLE 3-2

12v to 1OOOVl

CAUTION

.,‘181

1.89985 to 1.90015

,6.9978 to 19.0021

,E!xs,s 10 190.021

999.84 to999.16

Page 13

I

PERFORMANCE VERIFICATION

MODEL 181

A. Dbtnin a low thermal cable and divider box as described in

Section 5.

B. connect the low thermal cable between the 181 and the

divider box.

c. Connect the DC calibrator as shown ill Figure 3~2A. For the

ZmV md 20mV rangm Allow n few nlinUk?S for fhc!rrnal

FMF’S to settle OUL~ Use Figure 3~38 for the 200mV range.

Do Set the DC calibrator for OOWOOO output

E. Sclnct the appropriate range as given in Table 3-3 Select

the range manually by pressing the appropriate Front Panel

button 01~ select the range automat~caily by issuing the apt

propriate command over the bus.

F, Zero the 181 by pressir,g the ZERO button on the Front

Panel or by issuing the appropriate command over the bus.

G Apply lhe riiquired voltage as specified in Table 3~3. Verity

that the displayed reading IS wllllin speclficalions~ Note the

X!X,lM]~

Hi Repeat steps D through G on ,he remaining mV ranges,

I, Reverse the polarity of the source and set i, t” 0000000 a,,~

p”l~

Rerero the 181 by pressing the ZERO button twice.

K. Apply the input as in step G. Verify rhr displayed rcadfng

iwIth opposite polarityi is the same as in step G +3 digits

no

,Y n

Made, 181

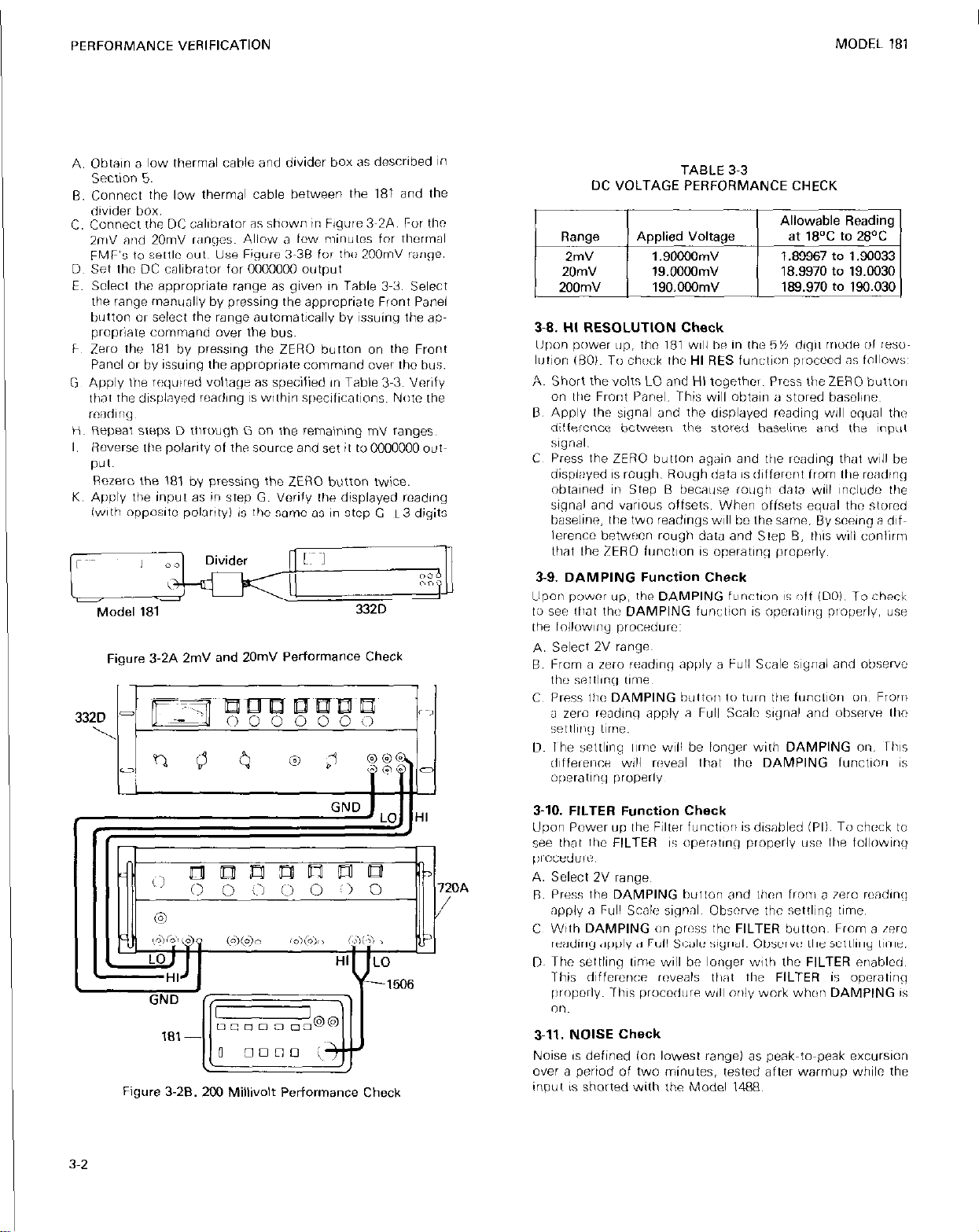

Figure 3.2A 2mV and 20mV Performance Check

TABLE 3-3

DC VOLTAGE PERFORMANCE CHECK

3.8. HI RESOLUTION Check

LJpon power [up, ftlc 181 WIII ba in the 5% dlgiI mode ol l~eso~

lllfion iROl~ To cheek fho HI RES funcl~on prncood as follows,

A~ Short thevolts IL0 2nd HI togrthcr~ Press the ZERO butlor~,

on the Front Panel. ~lhis will obtain a stored bascline~

I3 Apply the signal and the displayed reading will cqual thn

dilfr.rence between the stored baseline and the ,npu,

SIgnal.

3-9. DAMPING Function Check

Upor power up, the DAMPING fur,i:t,r,n IS r,,f iDO,, To check

10 see Ihat thi! DAMPING function IS operal~n!] properly, use

me l”llnwlilg procrd”,~e:

A. Select 2v ranq3

8. From a zero reading ;rprily a Fuil Scale signal and obserw

the serrling time,

3-2

I I I I

Figure 3-28. 203 Millivolt Petiormance Check

3-10. FILTER Function Check

Upon Power up the Filter functfon is dfsabled IPlI To chock to

see Li?at the FILTER IS operatfrq properly ust? Ihe following

procedure

A. Select 2V range.

/

H. Press the DAMPING burtor, and ti,w from a 7810 roedln~~

apply R Full Scale signnl Dbscrve fhc settling time,

C With DAMPING on press Ihc FILTER button Frorr a irro

rradli,rg apply a Full Scalii signsl~ Obswvc tl,e sctllmg l,mr.

Do The settling Lyme will be lorrger with thr FILTER enablcti

1 IliS dlffercnce ic”Cals ,ili,l the FILTER is operating

properly. Ths proccdur~ will wily work whcr DAMPING is

“11~

3.1,. NOISE Check

Noise is detined Ion lowest range, as peak-wpeak excursion

over a period of two minutes, tested after warmup while the

inpul is shorted with the Model 1488

Page 14

I

MODEL 181

Procedure for checking notse:

A. Short the mv ,npu, w,,h a Model ,488 Low Thermiil Short

B. Select the 2mV range,

C. Turn on HI RES so that 6’% digits arc displayed.

PERFORMANCE VERIFICATION

Page 15

Page 16

MODEL 181

Section 4. Theory of Operation

4-l. GENERAL

This section contains ln~depth discussions of the maj”r circuit

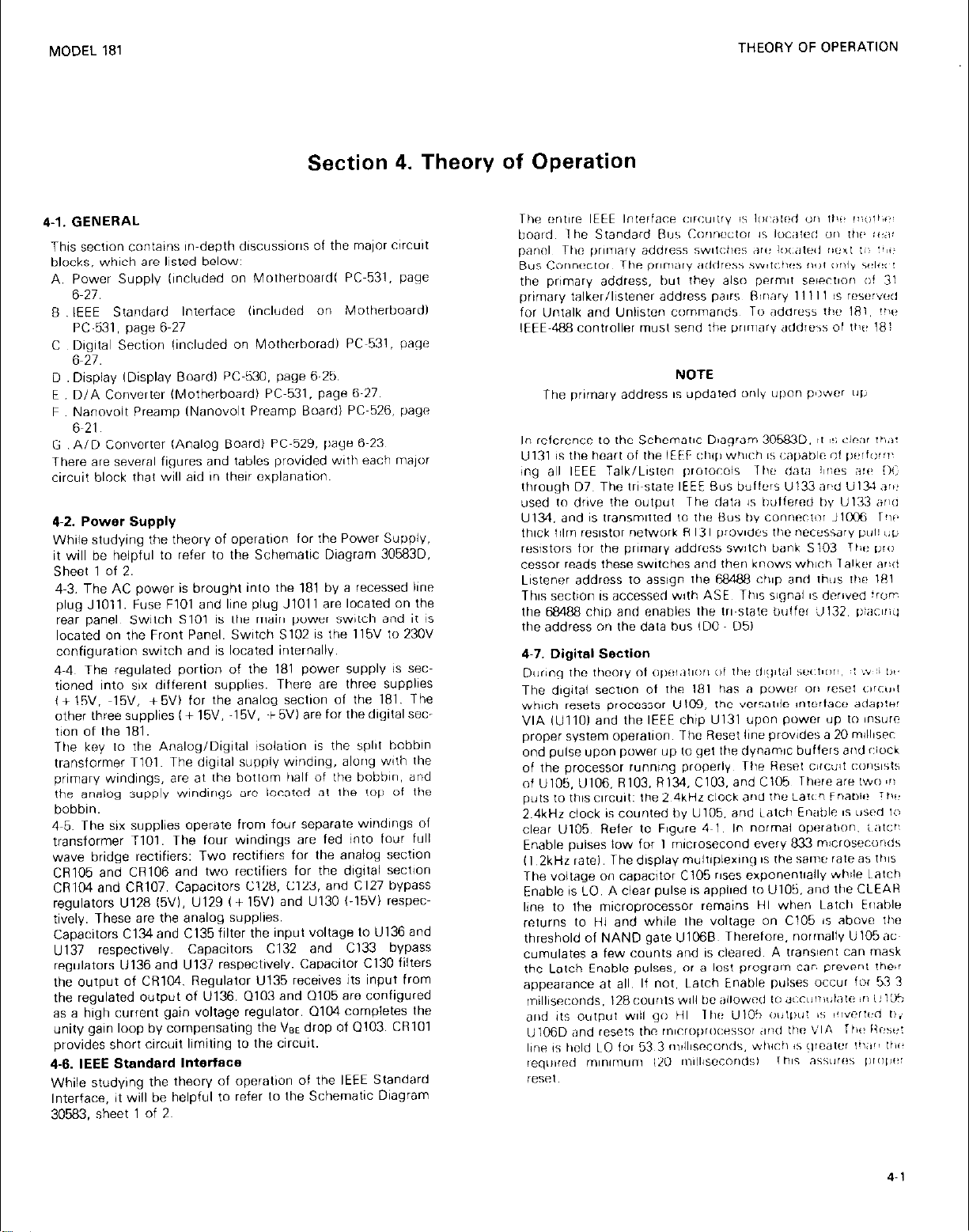

blocks, which are listed below:

A. Power Supply (included on MotherboardI PC~531. page

B IEEE Standard lnrerface iinr:ludcd on MotherboardI

PC ~531, page 6~27

C DigItal Section (included on Mofhcrboradi PC~531. page

D Dispiay [Display Board1 PC~530, page 6,25.

E D/A Converter iMotherboard PC~531. page

F Nanovolt Preamp lNanovol~ Preamp Board1 PC~526. page

G A/D Corrvcrter (Analog Board) PC~529, page 6~23,

There are several figures and tables [provided wilt1 each major

circuit block that will aid in their oxplanation~

6~27,

THEORY OF OPERATION

4-z. Power supply

While studying the theory of operation for the Power Supply.

it will be helpful 1” refer t” the Schematic Diagram 30583D.

Sheet 1 of 2.

4-3.

The AC power is brought int” the 161 by a recessed line

plug JlOll. Fuse FlOl and line plug J,O,l are located on the

rear panels Switch SlOl is the main power swtch and ii is

located on the Front Panel. Switch S102 is the 115V 1” 230V

configuration switch and is located internally.

4~4

The regulated portion of the 181 power supply is sect

tioned into six different supplies. There are three supplies

(+15V, -15V, +5V) ior the analog section of the 181. The

other three supplies (+ 1%‘. -15V. -+ 5VI are for the digital section of the 181.

The key to the Analog/Digital isolation is the split bobbin

transformer TlOl. The digital supply winding, along with tbe

primary windings, are at the bottom haIf of th~ bobbin, and

the analog supply windings am located al the lw of the

bobbin.

4~5. The six supplies “perate from four separate windings 01

transformer TlOl. The four windings are fed info four full

wave bridae rectifiers: Two recfifiers for the analog section

CR105 ani CR106 and two rectifiers for the digital sect~“n

CR104 and CR107. Capacitors C128, C123. and Cl27 bypass

regulators U12B l5VI, U129 (+ 15Vl and U130 I-15Vl respectively. These are the analog supplies.

Capacitors Cl34 and Cl35 filter the input voltage to U136 and

U137 respectively. Capacitors Cl32 and Cl33 bypass

regulators U136 and Ul37 respectively. Capacitor Cl30 filters

the “utput of CRlC4 Regulator U135 receives its input from

the regulated “utput of Ul36. Q103 and Q105 are configured

as a high current gain voltage regulator. 0104 completes the

unify gain loop by compensating the VeE drop of Q103. CR101

provides short circuit limiting t” the circuit.

4-6. IEEE Standard Interface

While studying the theory of operation oi the IEEE Standard

Interface, it will be helpful 1” refer to the Schematic Diagram

30583,

sheet 1 of 2.

Page 17

I

THEORY OF OPERATION

X5B30, Sheet 2 of 2 and 305&D, The digital cont~9 civails

of the 181 AID are located on Schematic 30583D. Sheet 2 of 2

while the circuits that they control are located on Schematic

30585D.

The conversion from analog data 10 digital data begins with

the integration cycle. Refer to Figures 4~3 and 4~4. An integration cycle begins with the appropriate signals to the input

amplifier and preamplifier enabled by one 01 more of the Sl

thru S12 lines going to a logic “1”. The charge balance line will

go to a logic “1” after the microprocessor waits for the input

to settle. The “D” Input of U122A also goes to a logic “1” and

is gated 10 U123B through U127B. This clears the 16 bit

counter U123B. The Q output of U122A will enable the input

signal to the integrator on the next rising edge of the 2.5kHr

clock. The microprocessor waits 16.66 milliseconds (the in&

gralion period lor 60Hr. 20~00 miillseconds for 60HrI then the

charge balance start line goes 10 logic “0”. At the next rising

edge of the clock, the Q output goes to a logic “1” again. This

WIII disable thn Input to the integrator and ends the exact 16,66

millisecond integration period.

Charge Balance Flip-Flop

MODEL 181

4-2

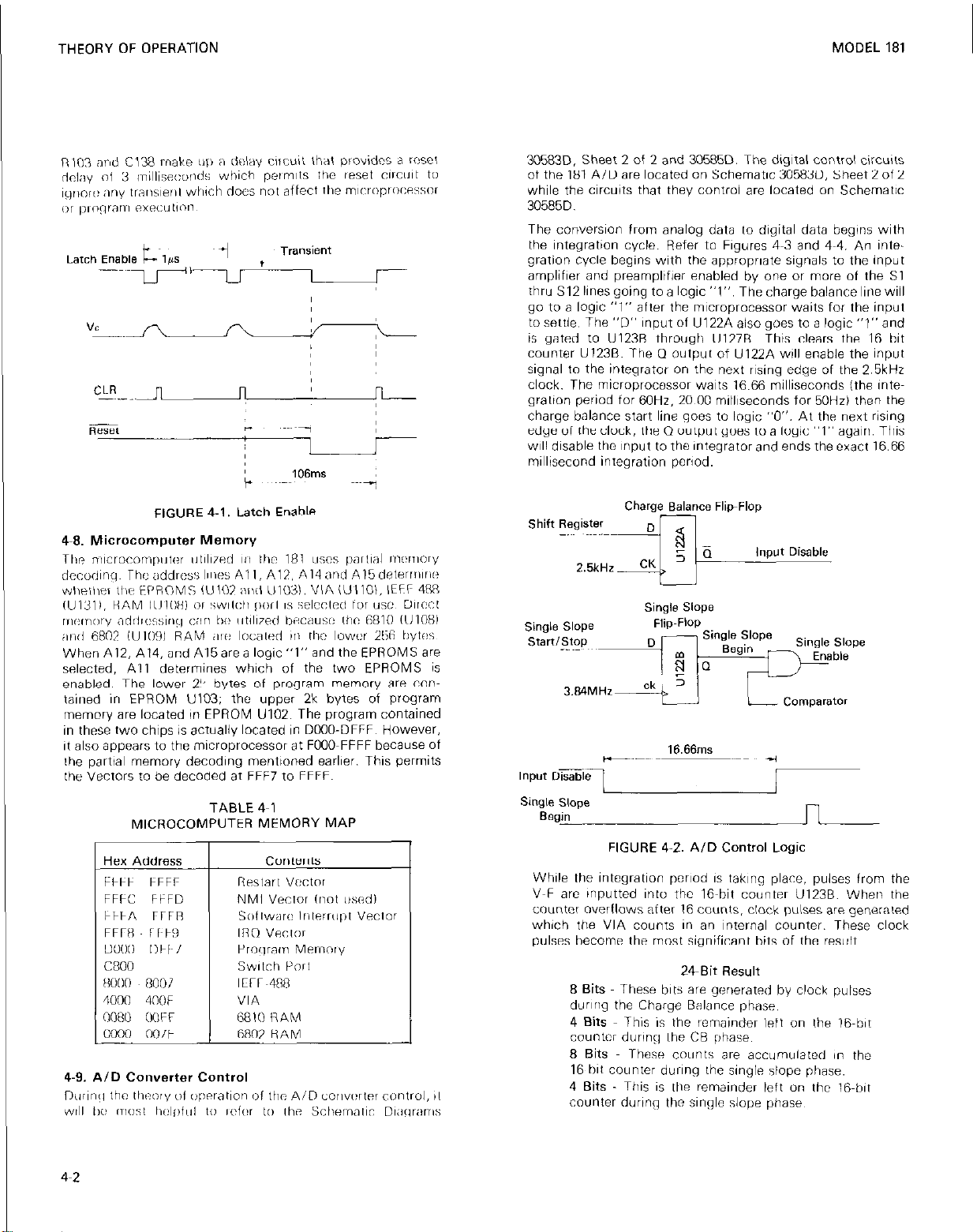

TABLE 4-l

MICROCOMPUTER MEMORY MAP

FIGURE 4.2. AID Control Logic

While the integration pcrlod is taking place, pulses from the

V~F arc inputted into the l&bit counter U123B. When the

co”“tcr overflows after 16 cowts, clock pulses are genoiared

which the VIA counts in an internal counter. These clock

pulses become the most significant bits of the result.

24-Bit Result

8 Bits These bits are generated by clock puises

during the Charge Balance phase.

4 Bits This is llhe remainder left on Ihn l&bit

cou”lcr durinij ,he CB phase.

8 Bits These counts are accumulated in the

16 bii counter during the single slope phase.

4 Bits This is Ihe remainder left on the 16~bir

counter during the sin(~lc slope phase,

Page 18

MODEL 181

Strobt- /

u

j --mllJlJr

E”df”z ~ /y Remainder Strobe P”‘ses

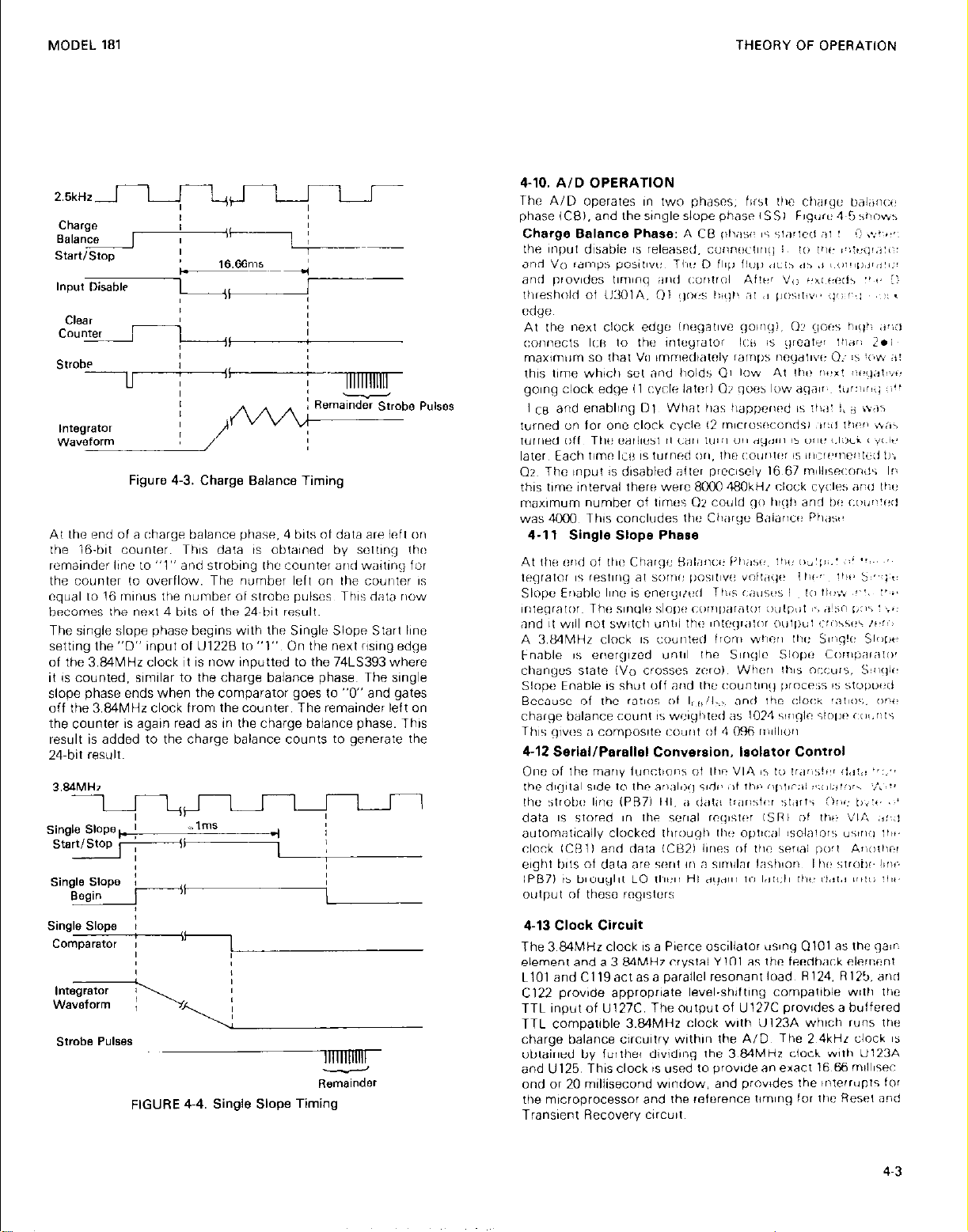

Figure 4-3. Charge Balance Timing

THEORY OF OPERATION

The single slope phase begins uwth the Single Slope Start l~“e

setting the “D” input of U122B 10 “l”, 0” the next risirlg edge

of the 3.84MHr clock it is “OW inputted fo the 74LS393 where

if is counted, similar to the charge balance phases The single

slope phase ends when the comparator goes to “0” and gates

off the 3.84MHr clock from the confer. The remainder left on

the counfer is again read as in the charge balance phase. This

result is added to the charge balance cwnfs fo generate the

24~bit result.

Single Slope, !

start/stop

Single slops ,

Begi”

,,-lrnS-

r

I

FIGURE 4-4. Single Slope Timing

Page 19

I

THEORY OF OPERATION

Input Disable

TO countet

0

MODEL 181

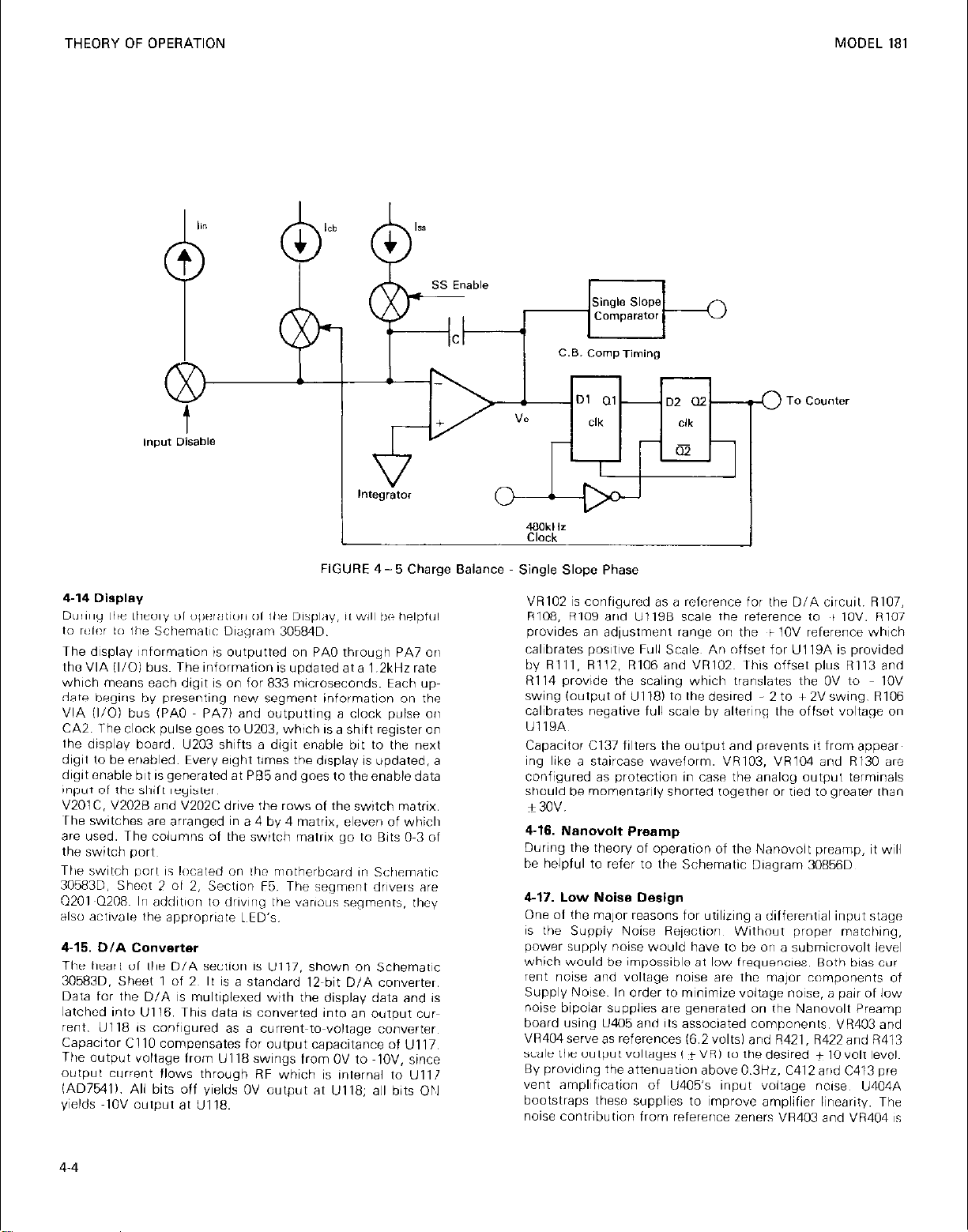

FIGURE 4-5 Charge Balance Single Slope Phase

4-14 Display

The display lr,formation is outputted on PA0 through PA7 on

the VIA II/O1 bus. The information is updated at a 1.2kHr rate

which means each digit is on for 833 microseconds. Each update begins by presenting new segment information on the

VIA II/O1 bus (PA0 PA71 and outputting a clock pulse oil

CAZ. The clock pulse goes to U203, which is a shift register on

the display board. U203 shifts a digit enable bit 10 the next

digit to be enabled. Ever” eiqht times the displav is updated. a

digitenable bit isgeneratedat P85andgoesto theenabledata

input of the shift register,

V201 C. V2028 and V202C drive the rows of the switch matrix.

~The switches are arranged in a 4 by 4 matrix, eleven of which

are used. The columns of the switch matrix go to Bits O-3 of

the switch ports

The switch port IS located on the motherboard fn Schematic

30583D. Sheet 2 01 2, Sectlo” F5. The segment dwers are

0201 0208~ 111 additlor to driwng the various segments, they

also artivak Ihe appropriale LCD’s,

4-15. DIA Converter

The heart of the D/A section is U117, shown on Schematic

30583D. Sheet 1 of 2~ It is a standard 12~bit D/A converter.

Data for the D/A IS multiplexed with the display data and is

latched info U116. This data is converted into an output current. Ul18 IS configured as a current-to~voltage converter.

Capacitor Cl10 compensates for output capacitance of Ull7.

The output voltage from U118 swings from OV to -1OV. since

ouiput current flows through RF which is internai to Ulll

lAD75411. All bits off yields OV output at Ull8; all bits ON

yields ~IOV output at Ul18.

VR102 is configured as a rcfcrence for Ihe D/A circuil. RIO/,

R108, RI09 arrd U119B scale the reference to ! 1OV. R107

provides an adjustment range on the + 1OV reference which

calibrates positive Full Scale An offset for U119A is provided

by Rlll, R112, R106 and VR102. This offset plus R113 and

R114 provide the scaling which translates the OV to 1OV

swing loutput of U1181 to Ihe desired 2 to +~ 2V swing. R106

calibrates negative full scale by altering the offset voltage on

UllSA,

Capacitor Cl37 filters the output and prevents it from appear

ing like a staircase waveform. VRlO3, VRIO4 and RI30 arc

configured as protection in case the analog output terminals

should be momentarily shorted together or tied to groater lhan

+3ov.

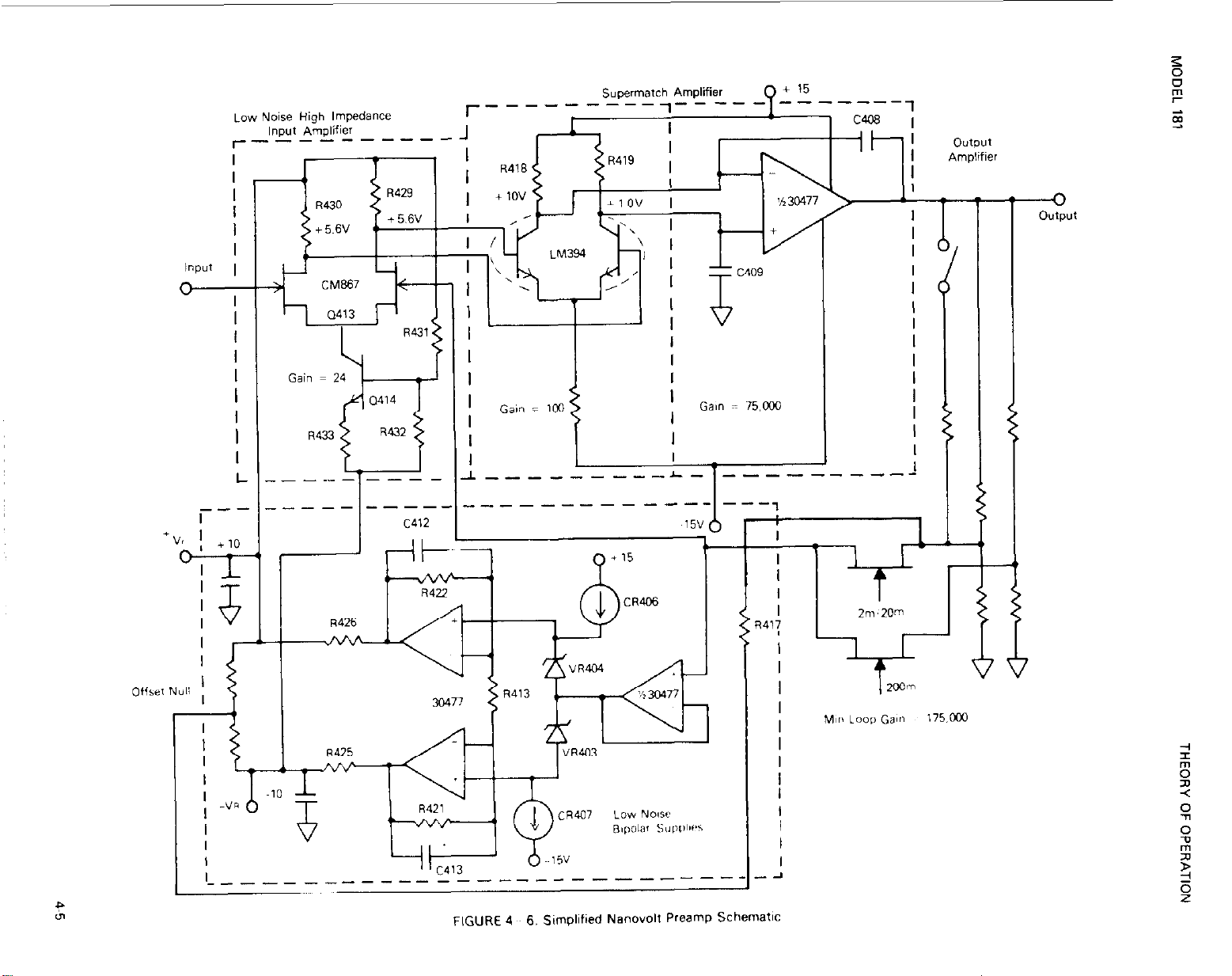

4-16. Nanovolt Presmp

During the theory of operation of the Nanovolt preamp, it will

be helpful to refer to the Schematic Diagram 30856D

4.17. Low Noise Design

One of the major reasons for utilizing a differential input stage

is the Supply Noise Reiec~ion Without proper matching,

power supply noise would have to be or a submicrovolt level

which would be impossible at low frequencies, Both bias cur

rent nom and voltage noise arc the major components of

Supply Noise. In order to minimize voltage noise, a pair of low

noise bipolar supplies are generated on the Nanovolt Preamp

board using U405 and IIS associated componen& VR403 and

VR404 serve as references (6.2 volts1 and R421, R422 and R413

scale the outpur voltages / ~+VRI 10 the desired f lOvolt Ievcl~

By providing the attenuation above 0.3Hr. C412 and C413 pre

vent ampllficafion of U405’s input voltage news U404A

bootstraps these supplies to improve amplifier linearity. The

noise conirlbution from reference zeners VR403 and VA404 IS

4-4

Page 20

I I

+vr ’

0

N”li

, +I0

/;5

I

I

I

I

I

I

I

I

-va

I

I

I

I

--

~10

b ‘s

---

----

_----

--------

)

-

-----

Page 21

THEORY OF OPERATION

MODEL 181

rnugl~yiblo, The bootstrap supply is decoupled from the input

via C414. C415, R425and R426. Rejection from the + 15V sups

plies is critic;iil as well. Therefore. current regulators CR406

and CR407 are a necessity iRp> 1M ohm) since Rs of VR403

and VR404 is approximately 100 ohms,

The key to maintaimng low current noise in the drain circuit of

Cl413 IS the selection of a low noise, high gain device for Q414

and maintaining low emitter and base impedances over the

bandwidth, R431, R432 and R433 provide bias for Q414 and

are referer~:ed 10 _t VR for low noise contribution

Noise contribution from the second stage depends upon drain

loads of Q413, gain of the lirst stage and input noise of the second

srage~ Q412 is a precisely matched low noise amplifier Wan

sister piiir which act as the second stage for the 181 preamp,

III addilior 10 low now, Ihls fransislor pa~r IQ4121 is required

because of 1,s hlgtl CMRR performance.

4.18. Linearity and Gain

,r a diifarential DC amplifier. nonlinearities irI the input stage

provide Ihe Iirnifal,on 10 gain linearity under the closed loop

condluon. In fact, no amount of loop gain car cailcol these

nonIinearities. The input FETS are square law devices which

means the output current varies as the square of the VGS. In

order fo r:anr:o, this nonlinearity. a second FET is used as a

load 10 the Hurst FET idifierer,lIaI pair). The degree of linearity

depends upon the match,ng between the two devlces~

The lolaI amplifier loop gain must be kept high so that closed

Ioop gain is independent of open loop gain. This eliminates

problems with gain drifts due to time/temperature var~atlons

inside Ihe loop. To maintain stable closed loop gains of 1000

i2mV rangel. 100 IZOmV range1 and 10 (200mV range) apt

propriate film or wirewound resistors are chosen as feedback

elements. Refer to Table 4~2~

TABLE 4-2

GAIN RESlSTORS

Range

2mv R40S. R414. R435 1000

ZOnl” R410, R415, R435 10” R410

zoomv R411, R416. R434

Thermal drifts in the input amplifier are relatively unimporfant

since they are autozeroed our. Slowly varying drill come

ponents isuch as solder joints, reed relay contacts) are of little

significance. ‘Therefore, no special lowthermal term~naIs are

necessary irl the feedback ,oop

However, for the nanovolt ranges (2mV. ZOmVl, it IS

necessary Lo use wirewound resistors wherever low voltage

signals are present, This is why R435 is a wirewound element,

whereas R434, R409-R416 are film resistors. Film resistors

display much higher voltage noise whereas wirewounds are

avaiInb,e whose noise approaches theoretical limifs. R435 is

s&x&d as 200 ohms since the Johnson noise of this value is

negligible compared to amplifier noise.

Gain Resistors Gain Adjustment

R40S

10 R411

4.20. Offset Null

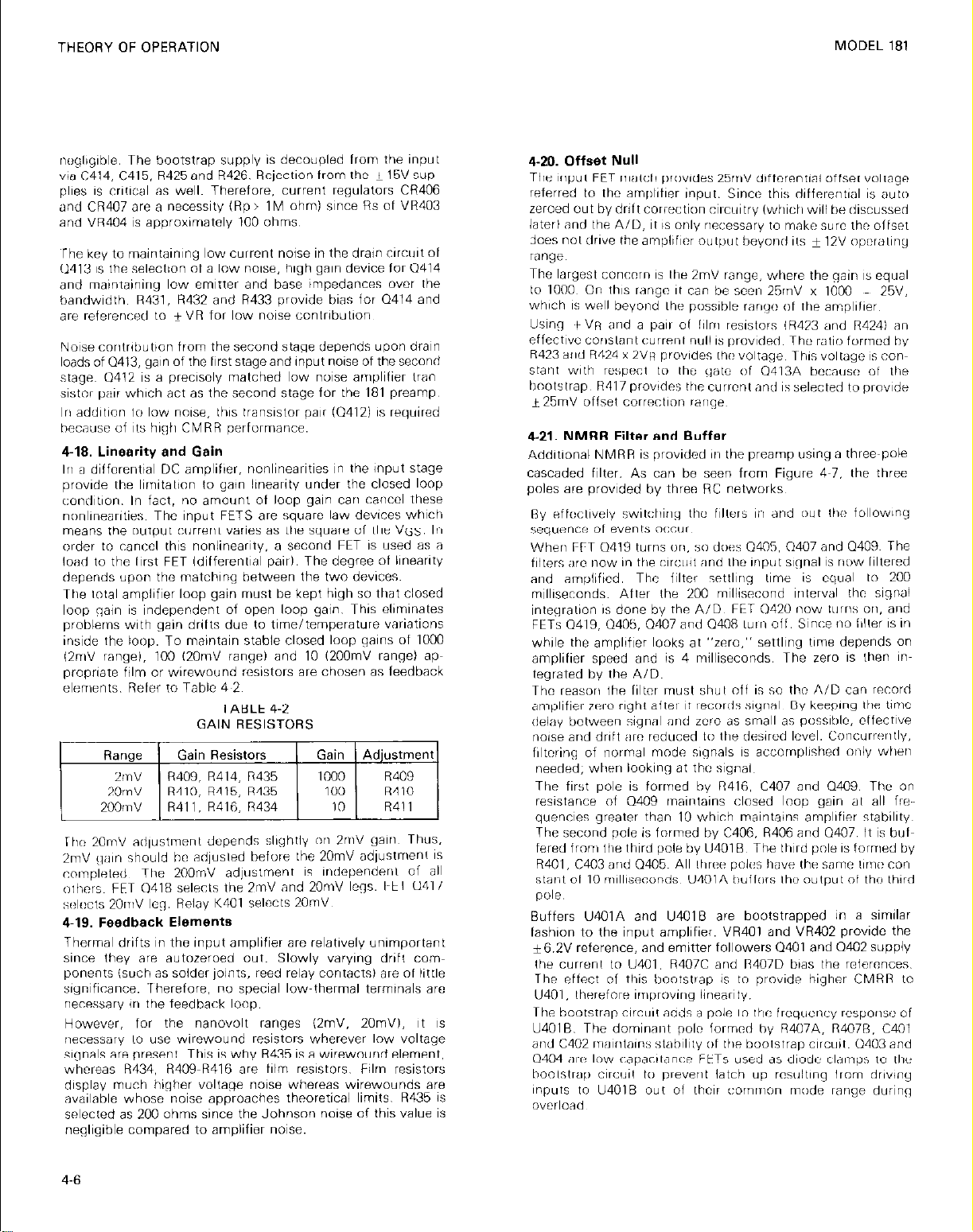

4.21. NMRR Filter and Buffer

Additional NMRR is provided 111 the preamp using a threepole

cascaded filter. As can be seen from Figure 4~7. the three

poles are provided by three RC networks~

Wher, FFT Q4,S turns o,. sii drw 0405. 0407 and Q4OS~ The

fliters arc mow in tile nrw11 arrd Ihe input signal is now liltered

and amplliicd, The filter settling I~me is equal 10 200

mi,Iiseconds. After lhe 200 millisecond ~rlferval the signa

integration 1s done by the A/D~ FET 0420 (now lums 011, and

FETs Q419. Q405, Q407 arid 0408 lurn off, Since 110 liller IS !n

while the amplifier looks at “zero,” settling time depends on

amplifier speed and is 4 milliseconds. The zero is lhen Inn

tegrated by the A/D.

The reasorl the filter must shut off is so fhc A/D can record

amplifier xxo rlghl after if records sign;lI By keeping the tlrll~

delay bctween signal anti iclo as small as pilss~t~lo, effective

,,o,se ar,d dr,f, iire reduced tc lI,e desired lkwel. Co~lcurrerltly,

filtering of ~nrxmal mode signals IS accomplished only whet1

needed; wl,an looking at the signn,~

T11e first pole is formed by “416, C407 and Q4oS. The on

resistance of Q409 rnair~lains i:,osed loop gain aI all ire

qurncies greater than 10 which maintains ampI,firr stability~

The second pole is formed by C406. R406 and Q407. It is butt

fered from tile third pole by U401 5, The third pale is formed by

R401, C403 arid Q405~ AI, 11,rw ,x>Ies ,havr Ihr same 1,mc con

slant 01 10 miI,lseconds~ U401A builcrs Ihr: oulput 01 thn third

p0le.

Buffers U4OlA and U4OlB are boo&trapped in a similar

fashion to the input amplifier. VR401 and VR402 provide the

+6.2V reference, and emitter followers WI1 and Q402 supply

Ihe currenl 10 ,,4Ol, R40,C and R407D b,as Ihi! r~iemnces.

The effect oi This boofstrap is fo provide higher CMRR 10

“401, Ihnrefore imprrivirng linearity.

The baotstia,, CllClllt aoiis a pole I” 11k ir”qlicrrcy rcsp”“sa 0,

U4016. The dominant pole formed by R407A. R407R. C401

arid C402 m~intnins stability rif the bootsrrap c~rcoif. Q403 and

Q404 illIi ,ciw capai:ilarK:~

boolslraji c~rcuil to preve~lf latch up rcsult,ng lrom driviing

inputs to U4OlB out 01 lhoir common mode range durincj

overload

FtTs used as d,odc clamps 10 Ihii

4-6

Page 22

I

MODEL 181

FIGURE 4-7. NVPA Showing Filter and Drift Correction

THEORY OF OPERATION

4-22 Drift Correction

The offset resistors A423 and R424 bring the amplifier ~ni” the!

operating rang”. The “f&et can only be nulled 1” 2m” referred

to the input. At the output on X1000. 2V can be presents The

AID would be overloaded by i:2,4V which means the 2V

component must be offset t” 0” for OV,“,

This offset c”rrec,,“n IS pr”v,ded by C404. 0406 and low

leakage buffer U4OlE. When Q420 IS on and when th” A/D IS

not lookIng at preamp zer” (during the A/D zero cycle1 Cl406

turns on and stores the offset voltage present on the DC

amplifier output “n C404. Then this capacitor holds this value

during the next two conversions 1.5 secj until it 1s updated.

This correction occurs two hmes a second. Leakage off this

capac~toi will yield offsets on the 200 m,lliv”l, range wiih ,nput

shorted. The major swrce of leakage is U4OlB and 0406.

These two devices are selected for leakage to mantain less

than 15 microvolls of drift over a conversion cycle of 50

millisecond. This is the time it takes 1” do a full preamp

signal/zero conversion. C405 prevents preamp slewing ibet~

ween signal and zero FET switching) from affecting the charge

on c404

4-23 Input Protection

CR402 and CR403 prevent input stage foldover which would

severely drop input impedance during overload. This also

prevents long recovery time caused by unbalancing power

dissipation between Q413A and 04138. 0410 and Q411 prevent the amplifier from getting lost during a range change or

severe overload by clamping the summing junction at * 1V.

CR&J, CR405, R427 and R428 provide a ground referenced

f0.7V threshold for the protection circuitry. High impedance

( ) 10Q ohm1 is not affected by the protection circuit for input

voltages less than 1 volt because of low leakage FET pair Q415

and 0416. However, for inputs greater than 1 volt. the input

““Itage is clamped and current limit is provided through R436.

Page 23

THEORY OF OPERATION

GAIN RESISTORS FOR VOLTS

MODEL 181

TABLE 4-3

4-E

1

LrKLr

FIGURE 4-8. Preamp A/D Timing

Page 24

I

MODEL 181

ON

Signal

S-line

OFF

Input Disable

WE_

mnsec

.4

1

THEORY OF OPERATION

OurrIm”

ON

ON

OFF s3

ON

OFF s4

,ntegrate

Rd FET

AID Zero

FET

16.66rnsec

.,, - -4rnSBC

A” I

FIGURE 4-9. V ran@ A/D TimIn

TABLE 4-4

MUX FETs

l-l-rLr

I--.-~-

~C e 4msec

4-B. MUX FETs

h

F~GVRE 4 - Il. Transconductance Amplifier

Page 25

Input Buffer

Single Slope

Comparator

Comparata

Output

+

4.7K

a

&kHz

Clock

IllpUt

ml/O Lines From pC.

FIGURE 4- 10. Simplified A/D Diagram

Page 26

MODEL 181

4.31. Integrator

The integrator has been designed to guard against the most

common problems associated witil tligh speed ~nlagrator

operation. Active integrators have two major problems which

limit their high speed performance: the cro~~ovei dtstortion

and the gain bandwidth of the integrator amplifier, These effects can be seen by looking at the integrator model in Figure

4-12. When a voltage step appears at Vin, the amplifier will not

respond immediately and C will initially be a short circuit

Then:

as shown in the nquat~on, the effect is that the wrong current

will be applied to the capacitor until the amplilier recovers~ /I

can also be seen that I/ a hipolar input amplifier was used for

the integrator, charge could be conducted away from Ihe

capacitor and cause significant erron To guard against these

problems, the 181 uses a bias resistor on the integrator output

to 15V to keep Ro small into the MHz region, and ail inputs

to the integrator are current sources. A FET input op amp IS

used which allows a few volts to appear on the summing junc~

tion with no loss in charge.

c

Ri”

-

THEORY OF OPERATION

R3x + R332

6-

FIGURE 4-13. Reference Supply

FIGURE 4- 12. Integrator

Page 27

Page 28

I

MODEL 181

MAINTENANCE

Section 5. Maintenance

5-l. GENERAL

This section contains information necessary to maintain the

Model 181. Adjustment/Calibration, troubleshooting and fuse

replacement procedures are provided. Calibration should be

performed yearly (every 12 months) or whenever 24 hour

specifications are desired or whenever performance verifi~

cation isee Section 3) indicates that lhe Model 181 is out of

specifications. If any step in the calibration procedure cannot

be performed properly, refer to the troubleshooting inform

mation in this section or contact your Keithley representative.

or the factory.

NOTE

Because of special handling, expertise, and

equipment that is required. it is strongly recom

mended that the 181 be sent back to the factory

for service andlor calibration.

WARNING

All service information is intended for qualified electronic maintenance

5-2. Recommended Test Equipment

Recommended test equipment for calibration is listed in Table

5-l. Alternate test equipment may be used. However, the

accuracy of the alternate test equipment must be at least three

times better than the Model 181 specifications, or equal to

Table 5-l specifications.

5-3. Voltage Divider

The Voltage Divider IBI recommended is not readily available

on the commercial market. The following information IS prop

vided in order that this divider may be constructed.

persOnnel

only.

VOLTAGE DIVIDER PARTS LIST

Keithley

Part Number

BP-l,-0

BP~ll-1

Model 1485

N/A

N/A

Model 1483

C. 2WA-29 Washer

D, 1 19166 Strain relief

I Black Blndlnq PO51

Red B,nd,ng Post

LowThermal Female Input

lIXlk0. 01%. 10ppmi”C. Wirewounil

Low Thermal Construction

lC0R. .Ol%, 10ppml°C. W~rewourrd

Low Thermal Construction

Low Thermal Construction KI,

TABLE 5-2

Description

Connecter

Item A Description

DC Calibrator

Voltage Divider

Oscilloscope

DMM

Maintenance Kit

Kelvin Varley Divider

Law Thermal input

Cable

Low Noise

Preamplifier

RECOMMENDED TEST EQUIPMENT

TABLE 5-l

Specifications

1.9v. ISV, 19ov. loco/

+ .ool% ,10ppmi

+ .Ol% IlOppml

2mClcm

.003% + Id

Mfr. Model

Fluke

332D

7603

5903

1815

720A

1481

Page 29

MAINTENANCE

FIGURE 5-l. Shielded Enclosure

MODEL 181

Pin El

Pin A

To prepare a low noise triaxlal cable for either d~recl cow

nr~tioris to a source or lor connector assembly Ihc stops

outl~nrd below should bc followed,

A. Gently c”t through the o”ter insulation without

cutting the oukr shield

B, Using a sharp point, unravel the braided shield,

C Twist Ihe bt~aid /o”tcr shield) and thoroughly clear off

traces of graphtte.

Do Gently cuI through the inner insulation without

cutting the inner shleld~

t. Using a sharp point, ~“nraw? Ihn braided shield.

F, Twist the braid

iinner

shield) and thoroughly clean off illI

traces of graphite.

Go Cut the center conductor to the proper length and strip

the insulation off of the center conductor,

H. Refer to Ftyure 5-2 and crimp the center conductor to Pin

A Crimp the inner shield 10 Pin B. Place the outer shfcld

braid between the two washers and secure the back of

the coni,ector as showrn

FIGURE 5-3. Male to Male Connectol

Heier 10 Figure 54 for a cornplate picture of lhe Calibrator to

Voltage Diwder lo 181 Connection.

5-2

3 Dial file DC calibrator fo ZERO Select the 2V range, Press

the Zero button, Check the Fro,,, Panel fo set that the Lern

Page 30

MODEL 181

LED is lit. Dial an output of + l.SCOOOV “n the calibrators

Adjust R316 on the Analog Board until the display reads

1.9OOCW + 1 digit. Take n”fe 01 the reading.

4. Press the ZERO button on the 181 twice to rezero the

instrument. Reverse the polarity of the ,nput~ D,al an ““1~

Put “f1.9ooOOV “” the calibrator IAl. Make sure the 18,

reads the same as in Step 3 t 3 digits. I1 the reversal err”r is

out of specification, then Model 181s wifh Potentrometer

R34 can be adjusted as in Step 5, For 181s without R344

and auf of reversal error specification, refer 1” the

troubleshooting section.

5. Adjust Rw until the reading is the same as in Step 3

f? digits.

5-S. lOMeg Adjustment B

Adjust R314 for the center of ifs span. When a problem is ens

countered iadjusfment runs t” the limit of its span, during

adjustment of step 3, 4 or 5, use R314 10 bring the adjustment

on range. Then go back and recalibrate the 2OV. 2OOV. and

1oow ranges.

5.9. ZOV Range Adjustment

Repeat Step 3 of A/D Calibration but use the 20V range. input

19,OOOOV and adjust R315 1” obtain a reading of 19,oooOV ? 1

digits I/ the rwersal in 5ltip 5 (Paragraph 5~71 is greater than

+3 diglts, refer to the troubleshooting section

m

99 r lC0~02K = .MK198RH

MAINTENANCE

H.i!l‘l

5.10. 25UV Range Adjustment

Repeat Step 3 of AID Calibration but use the 2COV range. ins

put 19O.oOOV and adjust R309 f” obtain a reading of 19O.ooOV

+ 1 digit. If the reversal in Step 5 iparagraph 5~71 is greater

lhan +3 digits, refer to the troubleshooting section,

5-11. 1OOOV Range Adjustment

Repeat Step 3 oi A/D Calibration but use the 1wOV range, ins

put lOOO.OOV and adjust R310 to obtain a reading of looO.03

i- 1 digit. If the reversal in Step 5 Iparagraph 5-71 is greater

than +2 digits, refer 1” the troubleshooting section.

5-12. D/A Calibration

1, Select Xl. on the analog output switch located on ihc rear

panel. Connecl the Model 1” anal”0 “uI”ut.

2. Select the 2V range and input %.looOOV, Verify thal ihc 181

display reads OFLO,

3, Adjust Rl06 for an output voltage of ~2,oOOV +~05%

It 1 mVi read on the display,

4, Input ~+2,lOOOOV into the 181 and wirily ihat the IHI

display reads OFLO,

5. Adjust R107 for an output voltage of +2.OOOV i ,05%

I + 1mVl read on the display.

5-13. Nanovolt Preamp Calibration @

ICannot be done until 2V range is calIbratedi,

1, Pumpout

A. Connect a 1OMn probe 10 the 181 Preamp Input ImV

inputi. Connect the other end of the probe to the input

of the lthaco Low Noise Preamp. Connect the output of

the Prevmp 1” ihe oscilloscope. A low thermal connect

lion is not necessary here,

q q

q

q

Model 181

FIGURE 5-5. Preamp Calibration

C Selnc~ the 2mV range DI;II I~C DC cai~brawr I:) o nxax

and press the ZERO on ,hc front panel 01 ,he 18,

D Apply 1~9033oV 10 the dwdei box Allow thr iii, to ,o,,ic

Now take the ratio just calculated and mulupiy 11 by FuiI

Scale which will be applied by the cal~biaror For example

.ooO9888 x 1~900000V = 1.87872mV

iRZ3,i”l

iApplied = (Expected

Inpurl

= Readlngl

Page 31

I

MAINTENANCE

A, SP/f!C, ,hP 20mV rarqn illlll rrlel” the 18,

B. Repeat step 3D except for a caiibrator OUtpUt of ,S.OoOOO”

and adjust R410 for the reading calculated + 10 digits.

5, 200 Millivolt Lange

A. Si!lr!i:l tile 200rn” range

R Connect the DC calibrator, Kelvin~Varlry Voltage divider

and IS1 as shown in Figure 5~6

C, DK, the DC calibrator to OOOOOCO and press the ?cr”

button “11 the front palld

Do Dial the Kelvin-Varley Voltage Divider lo OlWOCO and the

DC caIibrator to 1.SooOOOV. Adjust R411 for a displayed

readlng of 190~0000 f 10 digits.

El

MODEL 181

720A

Keithley Part No.

IC-250

IC-251

IC-247

PRO-106-00 127161

PRO-107-00 12716)

LSl~6

LSI-18

LSI-28

LSl-14

IC-229

IC-229

Reference

Designation

u104

UlZO. u121

u117

u102

u103

U108

UlOS

UllO

u131

u133

U134

5-4

Page 32

I

MODEL 181

MAINTENANCE

lub--

1815 CALIBRATION COVER

FIGURE 5-7. Model 1815 Calibration Cover

Page 33

I

MAINTENANCE

MODEL 181

TABLE 5-3

POWER SUPPLY CHECKS

Remarks

I

cuit diagram of the A/D converter is located on two

Schematics, 30585D and 30583D Sheet 2 of 2. Reading the

Theory of Operation for the AID converter is strongly recomb

mended before troubleshootlng the AID. There are several

WaVefOrms provided to help isolate the ~~rohlcm.

5-6

Page 34

I

MODEL 181

2

Display

3

Check main power suppIles

4

u301

5

u301 Pi” 4

6

7

U305 Pin 6

Source of Q309

MAINTENANCE

TABLE 5-4

A/D CONVERTER

O~MXK) ? 5 digits

O.woO Hi Res Engaged

Refer to Table 5 2

t5,6V

-5,6V

1ov t 10%

2v Cal

8

Anode of VR302

3

10

11

12 U307 Pin 14

3

13

14

15

16

17

18

19

20

21

22

U127C Pin 8

“123A Pin 5

U309A Pin 3

R324 Pin 5

Emitter Q313

U302 Pin 2

U127B Pin 5, U122A Pin 6

032OC Pin 6, U309B Pin 5

U126 Pin 13, PlOlO Pin 3

U309 Pin 10

u303 PI? 2

UllO Pin 16, AT101 Pin 4

AT102 Pin 4, U126 Pin 2

U120 Pin 1, U121 Pin 1

AT103 Pin 4, U120 Pin 2

AT104 Pin 4, U120 Pin 3 I

U121 Pin 3

-6.4V. +5%

TTL level square wav”

at 3,84MHr Rate

TTL level square wave

at 48OkHz rate

Refer to Flgure 5 8

TTL level pulses

at 2~4kHr rate

Refer to Figure 5~9

15v

*see Waveform Of

Figure 5 18

‘-2.49v. f-7% i+,lSmV~

‘See Waveform of

Figure5-17

‘TTL level pulses

Refer to Figure 5~~ 10

‘TTL level pulses

Refer to Flgure 5 16

I

‘5V. +7% (35QmVl

‘TTL ieve, pulses

Refer to Flgure 5- 12

‘TTL level pulses

Refer to Figure 5 13

“TTL level pulses

Refer 1” Figure 5- 14

‘TTL level pulses

Refer to Figure 5 15

3,64MHz Clock

2 4kHz Cioi:k

A/D Bulter Ouipu~

wl,h ,OmV iippi,cd

Transconduc,;incc

Amp IGAMPI hlas

lnlegrator outpiit

Wavelorm

Input Disable

v F plllscs 1”

C”“nler

Charge Dispenser Bias

Charge Balanco/S,n~~lr?

Slope Waveform iit At101

Reference to Analog out LC

Strobe puisos

of AT102

Data to U120

I

1

“Referenced t” the emitter of 0313

5-7

Page 35

MAINTENANCE

Figure 5~18 is the A/D Buffer Output Wavefom The 181 is on

the 2OmV range with 1OmV applied to the inputs Thts

waveform begins with a 200msec delay and then a signal ins

tegratc takes place. After thesignal integrate, the preamp zero

takes place, Then a 2V cal is performed. When the 2V cal IS

compleio, another 200msec delay occurs. The 2OOmscc delays

are 10 allow sufficient time fix the preamp to settIe After Ihe

delay and another preamp zero, an AID zero takes place.

Notice the two zemes are different in value Another 200msec

May occurs ;ind rhc whole phase starts over again

5-18. Display Board

The Display Board c~rcwtry has two dwe c~rcuils [hiit operate

the display. The segment drive circuitry iQ201 thru 02081 is

connected 1” all displays in parallel. The digit dwe circuitry

crrablos all segments of a single digit one at a time. AlI signals

are referenced to dIgital common. Check these circuits per

Table 5-5

5.19. Nanovolt Preamp Noise Troubleshooting

BegIrl the troubleshooting procedure by checking thp 2V

range. If this range is noisy, the AID or digital circiriiry zxe

most likely at fault If the 2v range is quiet, the nan”v”lt

Pr”aKlP IS l”“St Ilk+ al fault C”“,,,“r,ents suspected o,

generating noise should be checked. That is, the noise level of

the device should be measured and verified as out of spec

before replacing the device.

MODEL 181

shunt.

MonitorU404 Pin 7forareadingof lessthan%X. If PinGis

B.

within +2V, proceed to Step 2. If Pin 7 is greater than ?2V

reselect Fi423 and Fi424 per the following procedure.

5-8

,tep

Item/Component

I

2

U203. PI” 14

3

U203, Pin 8

4

U203. Pin I

5

U203, Pi11 3, 4, 5, 6,

10. 11, 12. 13

6

UZOl. Pin I, 13, 9, 7

11202. I’ln 1, 13, 9.

I

0201 208

8

US202~20/

Plrl 1.

0, 10

9

.11008,

IO

J1008.

II

.11008,

12

.11008, P,r, 10

2. 4. 6. /.

Pin 13

Pin 12

Pin i,

TABLE 5-5

DISPLAY

Required Condition

l~urn on P”WCi

Sdf!Cl zomv DC range

Slrorl l”““,

7

irgrncnt Dwcrs

3111,x11 of SC(~II,P,,,

lrlvers, collcclois 0,

~2O?~Q208

‘IPSS s201, s207. Szot

‘rf?ss s202. S206, S20$

‘ross S203, S?O5. S21(

Prc?ss S204.

S211

i

3

1

Page 36

MODEL 191

FIGURE 5-8. 49OkHz Clock lpsdcm 2Vlcm

IU309A Pin 3)

FIGURE 5-9. 2.4kHz Clock .Zpx/cm 2VlCm FIGURE 5-9. 2.4kHz Clock .Zpx/cm 2VlCm

(U105 Pin 11 (U105 Pin 11

FIGURE 511. Input Disable !Yhssc/cm 2Vlcm

rJlOl0 Pin 21

FIGURE 5-12. AT101 Output 10mseclcm 2Vlcm

(AT101 Pin 41

FIGURE 5-10. Input Disable lOmsec/cm 2Vlcm

1111278 Pin 5)

FIGURE 5-13. Strobe Pulses 1Omseclcm 2VIcm

(AT102 Output Pin 41

5-9

Page 37

MAINTENANCE

MODEL 181

FIGURE 5.14. AT103 Output 1Omseclcm 2Vlcm

(AT103 Pin 4)

FIGURE 5-15. AT104 Output Wmseclcm ZV/cm

(AT104 Pin 4)

FIGURE 5-17. Integrator Output lOmsec/cm .SVlcm

(U306 Pin 61

FIGURE 5-18. A/D Output Buffer Output

1OkWdCm

knitter of 03131

5V/Cm

5-10

FIGURE 5-16. V-F Output lOmsec/cm 2Vlcm

(U126 Pin 13)

Page 38

MODEL 161

MAINTENANCE

C. Setting Offset Null

1. Remove R423 and R424.

2. Place a 20KR potentiometer across the three Berg pins on

the preamp board. Connect the wiper of the pot to the center Berg pin (pin B). Connect the other pins of the pot to the

other two Berg pins (pins A,B).

3. Select the 2mV range and short the input.

4. Adjust the 20KR potentiometer until the U404 Pin 6 is less

than 0.5V. Measure the resistance of the potentiometer

from the wiper to both ends.

5. Replace R423 and R424 with the nearest value 1% film resisters as measured on the potentiometer.

5.22, Buffer Check

A. Select the *own” range, Short the l”P”,~

9. Monitor U401 Pin 1 and verify ihe noise level as less than 20

pV peps If the noise level is greater than 2OpV p-p, replace

U401~ Refer to Figures 5~19 and 5~20 for Norse level, The

output of U401 is sensitive to probe capaclrance~ Isolate

with a lK resistor. if UW IS quiet, proceed to Paragraph

5-23.

b23,

Input Current Check

A~ Select the 20mV range, lns~all a shlelded 1MIl resistor

across the input, Select the foilow~ny funcl~ons DampIng

In. Filter In. Hi Res oft

B, Check the display for less than 503 drglts If Ihe reading IS

o,,t of spec. note whether /I IS positive or negative

C I, ,ha d,sp,ily IS negative. and greater

gate lead of D416 from fhe PC t,o;~rd and !heil check 01r!

d,sp,ay for icss than 500 dIgi& If fhe d,srl,ny is sttli our 01

spec, replace Cl419 and Q420 and resolder rhe Yale Of

Q416~

524.

Bootstrap Check

MO”,,O, u404 P,” 3 for less than 1Op” ,I p noise Monllor 1,404

P,n 1 lor less than IOaV pip n”,sc If Pin 1 115s il qrrs~r

anmu”, of noise than Pin 3. replxt? lJ4W

525. Low Noise Supply Check

A~ Select the 20mV range, Morwor the Norse levr:, on WC5 PI”

5, Verify that if is less than IOpV p p If PI” 5 noee ievel $5

yreater than lO,‘V p-up. the possible causes are corn

ponents VA404 and CH406

than

Fao rQ!s. I!11 Itw

D. +VR have been writed as havlny less than 1OpV p

noise. If this is not the case. examne the assocetec come

ponents C412. C413. R421. R422 and I7413 for poor solder

joints or defects. Do not advance 10 rhe next step unless

+ VR noise level IS less than 1OpV p-p.

5-25. Current Bias Check

5.27. Input FET Replacement

A~ If the 161 is still noisy after all the

been made. the problem IS apparenrly the ~npul FET 0413A

and 6,

8, Replace Q413A and 6 w,th KcWey Par, No XIX,9 which 1s

a mstched Seth Rcseicc, R423 i,nd R424 irs s,;rwd I”

Paragraph 5~21~ Vcr~fy “o,se and dr,,, perform;,ricc

previous

checks have

5-11

P

Page 39

MAINTENANCE

MODEL 181

5-25. Nanovolt Preemp Troubleshooting

The Nanovolt Preamp Operation is explained in the Theory of

Operation. It is recommended that the troubleshooter read the

Nanovolt Preamp section of the Theory of Operation before

troubleshooting the Preamp. The following Table 56 is a step

by step procedure to breakdown and isolate the problem

quickly and easily.

5-W. IEEE Bus Circuit Troubleshooting

Bus address toggle switches iS103) set the Bus address, The

address cannot be changed while power is applied, To change

this address, select new address by 5103 and cycle the poww

Visually check the 181 display to see that it is “peratlng

properly. If it is nonfunctional, flickering or displaying

incorrect data then check the display circuit UllO, “201.

U202, U203, Q201-0208. If the display is “perat,ng

properly, then proceed to Step 2.

Program the controller to input any command string and

output data. Check buffers U133 and U134 for input and

output of data. Check T/R1 (Pin 271 and T/R2 IPin 281 of

U131 for toggling 10 to 5V switching).

Check t” see that tha Bus Address can he changed, Turn

off the instrument and toggle in a different Bus Address.

Turn power on and see that the new Bus Address is

present by appropriate controller address.

5-31. DIA Circuit Troubleshooting

Visually check the 181 display t” see if it is cperatlng

properly. If it is nonfunctional, flickering or displaying

incorrect data then check the display circuit UllO, U201,

U202, U203. 0201-0208~ If the display is operating

properly, then proceed to Stop 2.

Input a ramp voltage of -2V t” +2V at a .5Hz rate f” the

Banana Jacks on the 2V range. Using an oscilloscope

measure the signals located on Pins 4-15 of Ull7. The

signals should he switching from 0 volts to + Svoits (f”ggl~

ingl. This should be done with the Analog Output Gain

Switch t” Xl. If the pinsare toggling proceed to theanalog

section of the D/A circuit. If the pins are not toggling pr”~

teed t” Step 3.

Monitor bits 1~4 of “117 to see that they are toggling. If

they are not toggling, check UllO. If the pins are toggling,

then proceed to Step 4.

Monitor bits 5-12 of U117 to see that they are toggling~ If

they are not toggling and Pin 11 (Enable of U1161 is

toggling, then Ul16 is had. If Pin 11 (Enable of 1161 is not

toggling, then check UllO. if Pin 5~12 of U117are toggling,

then the digital section of the D/A circuit is functioning

properly.

FIGURE 5-22. Quiet U401 lOpV/cm 5Omsfcm

5-29. DC Volts Attenuator Troubleshooting

The DC Volts Attenuator is made up of a precision voltage

divider iR313A. B, C and D, R314, R315, R309, R3lO and

R3111, ranging relays iK301 and K3021 and input protection

FETs ID301 and Q3021. The Attenuator is located on the

Analog Board PC-529. The Attenuator divides the input signal

1” the appropriate switching FET.

5-12

5.32. Switch Input Section Troubleshooting

The switch input section is shown on Schematic 30583D.

Sheet 2 of 2 and consists of UlM, Q102, RlOl, R129, and

R133.

Check that the Front Panel Range and Function Switches

opera” properly. Also check that the appr”pr,ate frequency

was displayed upon power up. II the Front Panel Switchs

operate properly and the appropriate frequency was displayed

upon power up, then the Switch Input Section IS operating

properly. If the Front Panel Switches are not operating

properly or an inappropriate reading for frequency was

displayed upon power up, then check UlM, QlO2, RlOl, RI29

and Rl33~

Page 40

I

MODEL 181

MAINTENANCE

TABLE 6-6

PREAMP TROUBLESHOOTING

Required Conditions

t1ov flO%

2

Berg Pin C

3 U402 Pin 13

4 u402 Pi” 14

5 u403 Pin 13 0 to

6 Drain of Q413A 55v ?:5%

0412 PI” 6 ibase,

7

Drain of 04138 5~5V +5%

0412 Pin lbasel

8 Cl412 Pin 7

9 U404 Pin 1

10 U4olB Pi” 5 ‘0 1” 1v pulses

11 u401v Pins 6 and

12 U401A Pin 8

13 U40lA Pin 4

14 U401A Pin 3

15 U4OlA Pins 1 and

lOmV applied 10 the mV irlput terminal with 20mV range selected

/ ‘010 IV p”lses

2 ‘0 10 IV

1ov i 10%

0 to 15v pLIk?s

0 lo 15v prllses

15v pulses.

corresponds to Step 3

pulses

1ov ~! 5%

ov t5omv

+ 5,6V + 1O”h

5,6V f 10%

‘0 to IV pu,srrs

NOTE: All voltages referred Io Input LO with Input shortened arId 2OmV r;~ngti st!lc!i:tr!d

TABLE 5~7

DC” ATTENUATOR TROUBLESHOOTING

itep Item/Component

1

KC301 Pin 7

2

3 source of Q3c4

4 I

5

K302 Pin 7

source Of Q3@4

Required Conditions

Select 2v range

Apply 1V.

Read IV input signal

Read IV input signal

Select 2ov range

Apply IOV 10 irrput

Read 1V

Sclcct 2cnv range

Apply 1oOV 10 input

Road IV

Select low/ range

Read 1V

Remarks

K301 is engaged

Page 41

MAINTENANCE

5.33. Digital Troubleshooting

1 Monitor the clock on the $2 Line (Pin 37 or UlO91 lor a

1MHr square wave.

MODEL 181

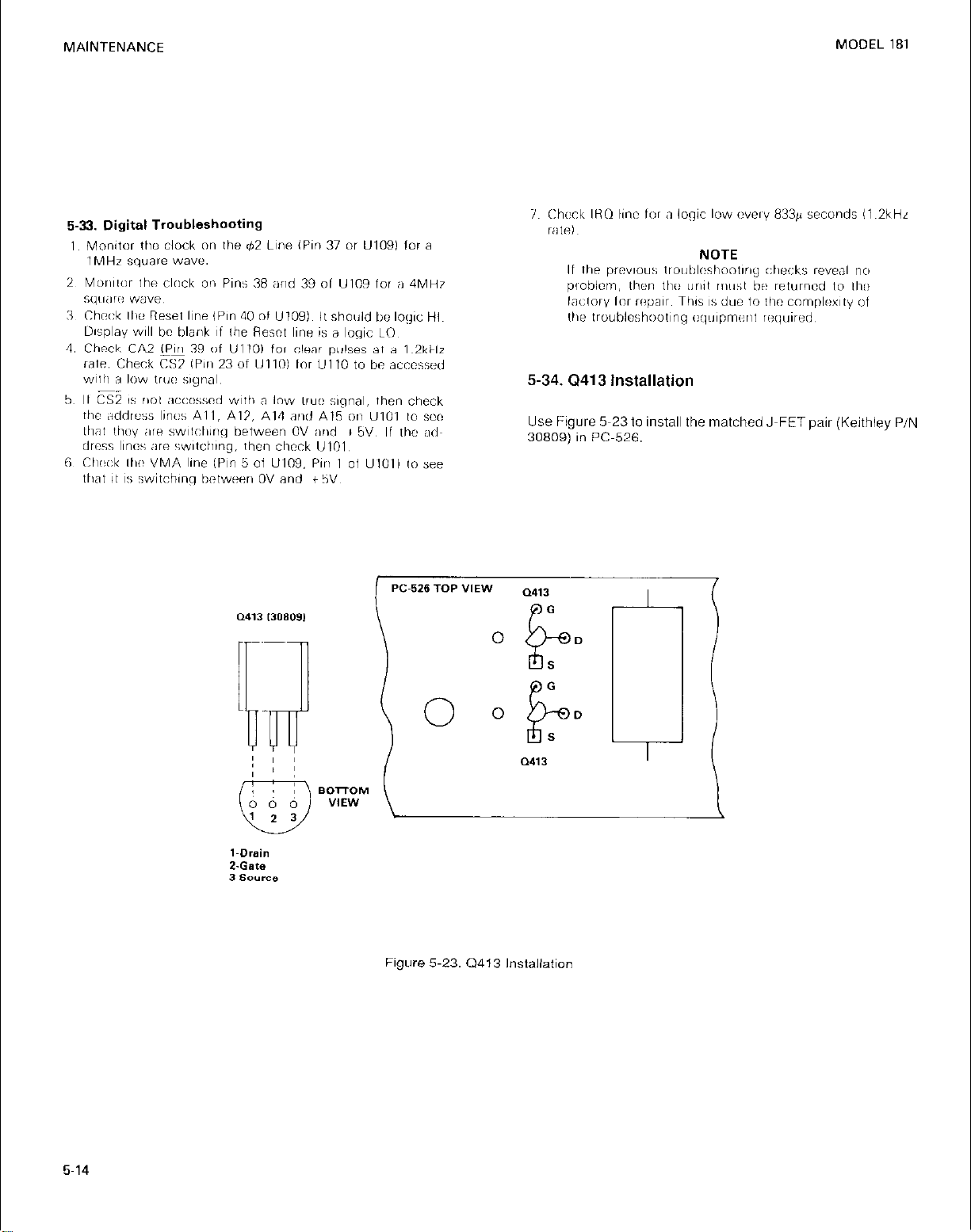

5-34. (2413 Installation

Use Figure 5~23 lo install the matched J-FET pair (Keithley P/N

308091 in PC~526.

5-14

Figure 5-23. Q413 Installation

Page 42

I

MODEL 181

REPLACEABLE PARTS

Section 6. Replaceable Parts

6-l. GENERAL

This section contains information for ordering replacement

parts. The Replaceable Parts List is arranged in alphabewal

order of the circuit designations of ihe components. Across-

reference list of manufacturers conlaining their addresses IS

given in Table 6~1.

6-2. Ordering Information

Toplacean order or lo obtain information concerning repiace~

ment parfscontactyour Keithley representativeor rhe factory.

See the inside front cover for addresses. When oiderlng.

include the following information:

A, Instrument Model Number

8. Instrument Serial Number

C. Part Description

D, Circuit Deslgnatlon (if applicable)

E. Keithley Parr Number

6-3. Factory Service

Circuit

Desig.

AT-101

AT-102

AT-103

AT-104

AT-105

C-101

c-102

c-103

c-104

Description

Opt0 Isolator

Opt0 Isolator

Opt0 Isolator

opt0 Isolator

Opt0 isolator

.l!JF. lb”, cer0

.luF, 16V, CerD

.luF, 16V. CerD

.l,,F, 16V, CerO

TABLE 6 -1

Replaceable Parts List

PC-531 - Schematic 305830

Schematic

Location

E2

E3

E4

E4

16

85'

05'

E61

A5l

PC-Board

Item No.lLocation

195/o*

196/02

197m3

198,“3

199,03

4fA3

5/A2

6102

I/C2

nfr.

Code

MOT

MOT

MOT

MOT

MOT

CLR

CLB

CLR

CLB

Mfr.

Desig.

MOC5005

HOC5005

MOCS005

MOC5005

MOC5005

"K16-104

UK16-104

UKlfi-104

UK16-104

Keithley

Part NO.

IC-292

it-292

IC-292

IC-292

IC-292

C-23G.l

C-238-.1

C-238-.1

C-238-.1

c-105

C-106

c-107

C-108

c-109

c-110

c-111

.006&F, 5OOV, CerD

22pF. 1OOOV. CerD

22pF, IOOOV, CerD

.luF, 16V, CerO

.l.F, 16V, CerD

390pF, 5OOV, CerD

.I,,F, 16V, CerD

E5'

R41

841

821

031

65

E2l

3fC2

9lC2

lOlC2

11,82

12182

13lC4

14/02

SK

CLR

CLR

CLR

CLR

CLR

CLR

5HGAD68

00220

1)11220

UK,6-104

UKlh-104

DO391

"K16-104

C-22..""6R

C-64-22pF

C-64-22pF

C-23%.1

C-23&.1

C-22-390pF

C-23%.1

Page 43

I

REPLACEABLEPARTS

MODEL 18,

TABLE 6-l

Replaceable Parts List

PC-531 - Schematic 305830

(Continued)

Circuit

Oesig.

c-112

c-113 .l!JF, 16V, tern

c-114

C-115 .luF, 16V, CerD

C-116 .lpF. 16V. Cer" G4' 19/1)2 CLR

c-117 .luF, 16V, CerO

C-118

c-119 68PF, 1ooov, CWO F41 22103 CLB DO-680 C-64.6RpF

c-120

C-121 .,pF, 16V, CerO

c-122 .l,,F, 16V, CerD F5l 25lE3 CLB UK16-104 C-238-.1

c-123 6.BuF. 25V, Electro 02 26lE2 NlC 25UKB6RROM

C-124

c-125 15OOuF, 25V, Electra

C-126 1500uF, 25V. Electra Cl 29lF2 NIC 25ULA1500 c-314-1500

Description

.lpF, 16V, cero

.luF, 10, h-D

.luF, 16V, CerO

47pF, lOOOV, CerD F51 23/03

15OOuF, 29, Electra c2

Schematic PC-Board

Location Item N&/Location Code Oesig. Part No.

E2l

E4l 16103 CLB UK16-104

E4'

F6l lR/O3

G5l

F3'

F4'

Cl

15/02 CLR

17,"3

20/E2 CLB

2l/E3 CLR

24/04 CLR

2?/F2

28lE2

Mfr. Mfr. Keithley

UK16-104 C-23-.1

C-23*-.1

CLR

CLR

ERI Type 83X

NIC 251lLA15""

NIC

UK16-104 C-23&.1

,X16-104 C-23&.1

UK16-104 C-238-.1

UK16-104 C-238-.1

UK16-104 C-238-.1

C-64.47pF

UK16-104 C-23R-.I

C-314-6.8

c-314-1500

25ULA1500 c-314-1500

C-127 K.&F, 25V, Electra

C-128 6.&F, 25V, Electra D2 31/F3 NIC 25UKB6RRUM C-314-6.8

c-129 22OOpF. 5OOV. CerD

c-130 lO,OOOuF, IOV, Electra C4 33,F3

c-131 .OZuF, 5OOV, CerD A4 34/G2

C-132

c-133 6.&F, 25V, Electra 03 36/F4

c-134

c-135

C-136

c-137

C-138

c-139 47OpF. ZOOOV, Cer"

c-140 68OPF. 2ooov, CWD

CR-101 Diode

CR-104

6.&F, 25V, Electra 03 35lF4

IOOuF, 35V, Electra c3 37IF4 NIC 35ULAlOO

IOOuF, 35V, Electra c3 38lG4

.I,,F, 16V, k-0

IuF, 5OV, Polycarb 05

IuF, 2OV, Tant Cl'

Rectifier Bridqe

"1 30/E3

--

G2 4O/F4

03 45/03

03

fl4

B4

32/F4

41lC4 EC, 625BIA105 C-215-1

42/R2 SIE

46fD3

E4

53IF4

NIC 25UKR6RRDM C-314-6.X

ERI

NIC 1nuP1n.000 c-304-10.000

ERI TYPE811 c-22-.02

NIC 25UKB6RRD17 C-314-6.8

NIC 25UKB6R8017 C-314-6.8

NIC 35ULAlOO c-295-1(30

CLR UK16-104 C-238-.1

AC1 470pF

ACI 6ROPF

F-I

G-I 2735

TYPE831

82lA105K020N C-204-1

lN46fl7

C-22.2200pF

c-295-100

C-324.470pF

C-324-6BOpF

RF-41

RF-48

Page 44

I

MODEL181

TABLE h-l

Replaceable Parts List

PC-531 - Schematic 305830

(Continued)

REPLACEABLE PARTS

Circuit

Oesig. Oescription

CR-105 Rectifier Rridqe

CR-106

CR-107

F-101

F-10,

JlOOl Binding Post (Red)

J1002

51003

J1004

51005

J1006

JlOll

51012 Connector

L-101

PI007

Rectifier Bridge

Rectifier Bridge

Fuse 1/4A (115V)

Fuse 1/8A (230V)

Dinding Post (Black) A2

Millivolt Input Connector A2

Binding Post (Red) n5

Binding Post (Black)

IEEE Connector

power connector

100uH Choke F4 60,03

12 Pin Connector

Schematic PC-Board

Location

Bl

B2

n3

A3

A3

Al