Page 1

Operator’s Manual

Model 181

Digital Nanovoltmeter

01982. Keithley Instruments, Inc

Cleveland, Ohio, U.S.A.

Document Number 32421

Page 2

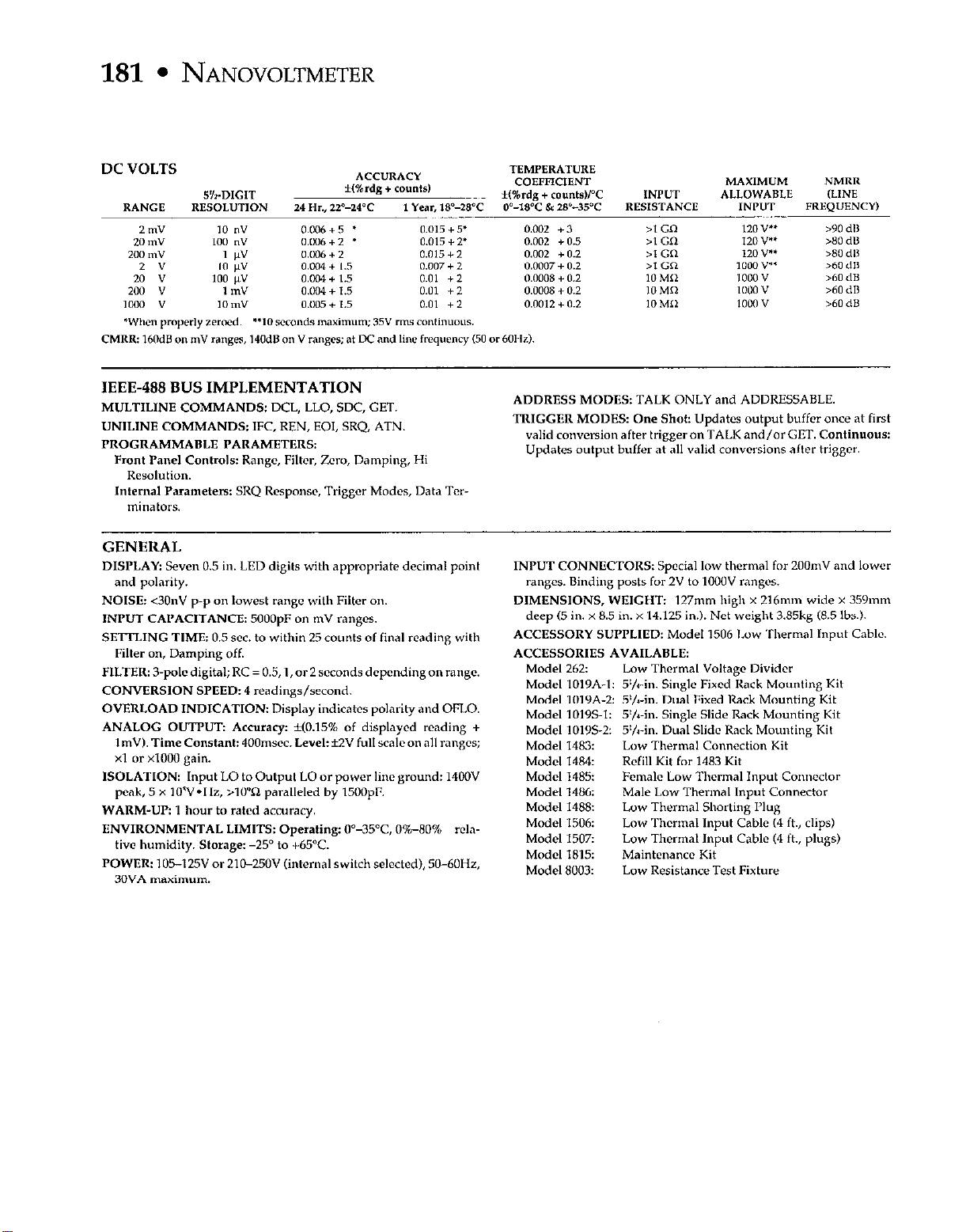

181

l

NANOVOLTMETER

IEEE-488 BUS IMPLEMENTATION

MULTlLlNE COMMANDS: DCL, LLCJ, xc, GET.

“NlLINE COMMANDS: IFC, REN, EOI, SRQ, ATN.

PROGRAMMABLE PARAMETERr3

Front Panel Controls: Range, Filter, Zero, Damping, Hi

Resoluli”“.

Internal Pnrametea: SRQ Rcsponsc, Trigger Modes, Data Ter-

minators.

GENERAL

DISPLAY: Seven 0.5 in. LED digits with appropriate decimal point

and polarity.

NOISE: <30”” p-p on lowest range wit,, Filter on.

lNP”T CAPACITANCE: 5OOOpF on mV ranges.

SETTLING TIME: 0.5 sec. to within 25 COLMS of final reading with

Fikr on, Damping off.

FILTER: 3-polcdigital; RC = 0.5.l.or2 wands dcpcndingonrangc.

CON”CRSlON WEBI): 4 readings/second.

OVERLOAD INDICATION: Display indicates polarity and OFI.0.

ANALOG OUTPUT: Accuracy: +(0.15% of displayed reading +

ImW Time Constant: 400mscc. Level: f2V full scale on all rongcs;

xl or xl000 gain.

ISOLATION: Input LO to Output LO or power line ground: ,400”

peak, 5 x IOW*Hz, >I09 paralleled by 150OpF.

WARM-UP: 1 hour to r&cd accuracy.

ENVIRONMENTAL LIMITS: Operating: 0”35”C, O%-80% *da-

tive humidity. Storage: -25” to +WC.

POWER: 105-123’ or 21~25OV (internal switch selected), 50-6OHz,

30Vh maximum.

ADDRESS MODES: TALK ONLY and ADDRESSABLE.

TRIGGlX MODES: One Shot: Updatcs output buffer once at first

valid conversion after triggeronTALKand/arG~T. Continuous:

Updates output buffer at al, valid ~onwr~ion~ after trigger.

INFUT CONNECTOR% Special low thermal for 2”OmV and lower

ranges. Binding posts for 2V to lOO”V ranges.

DIMENSIONS, WEIGHT: 127mm high x 21hmm wide x 359mm

deep (5 in. x 8.5 in. x 14.125 in.). Net weight 3.85kg (8.5 Ibs.).

ACCESSORY SUPPLIED: Model ,506 Low ‘Thermal fnput Cable.

ACCESSORfES AVAILABLE:

Model 262: Low Thermal Voltage Divider

Model 1019A-1: 5%-i,,. Single Fixed Rack Mounting Kit

Model 1019A-2: 5’/rin. Dual Fixed Rack Mounting Kit

Model 1019SI: 5’,~-in. Single Slide Rack Mounting Kit

Model 1019S.2: Y/1-in. Dual Slide Rack Mounting Kit

Model 1483: Low Thermal Connechan Kit

Model 1484:

Madcl1485: Fcmalc Low Thermal Input Conneck!r

Model 1486: Male Low Thermal Input Connector

Model 1488: Low Thermal Shorting I’lug

Made, 1506: Low Thermal Input Cable (4 ft., clips)

Model 1507:

Model ,815: Maintcnancc Kit

Model 8003: Low Resistance Test Fixture

&fill Kit for 1483 Kit

Low Thermal Input Cable (4 ft., plugs)

Page 3

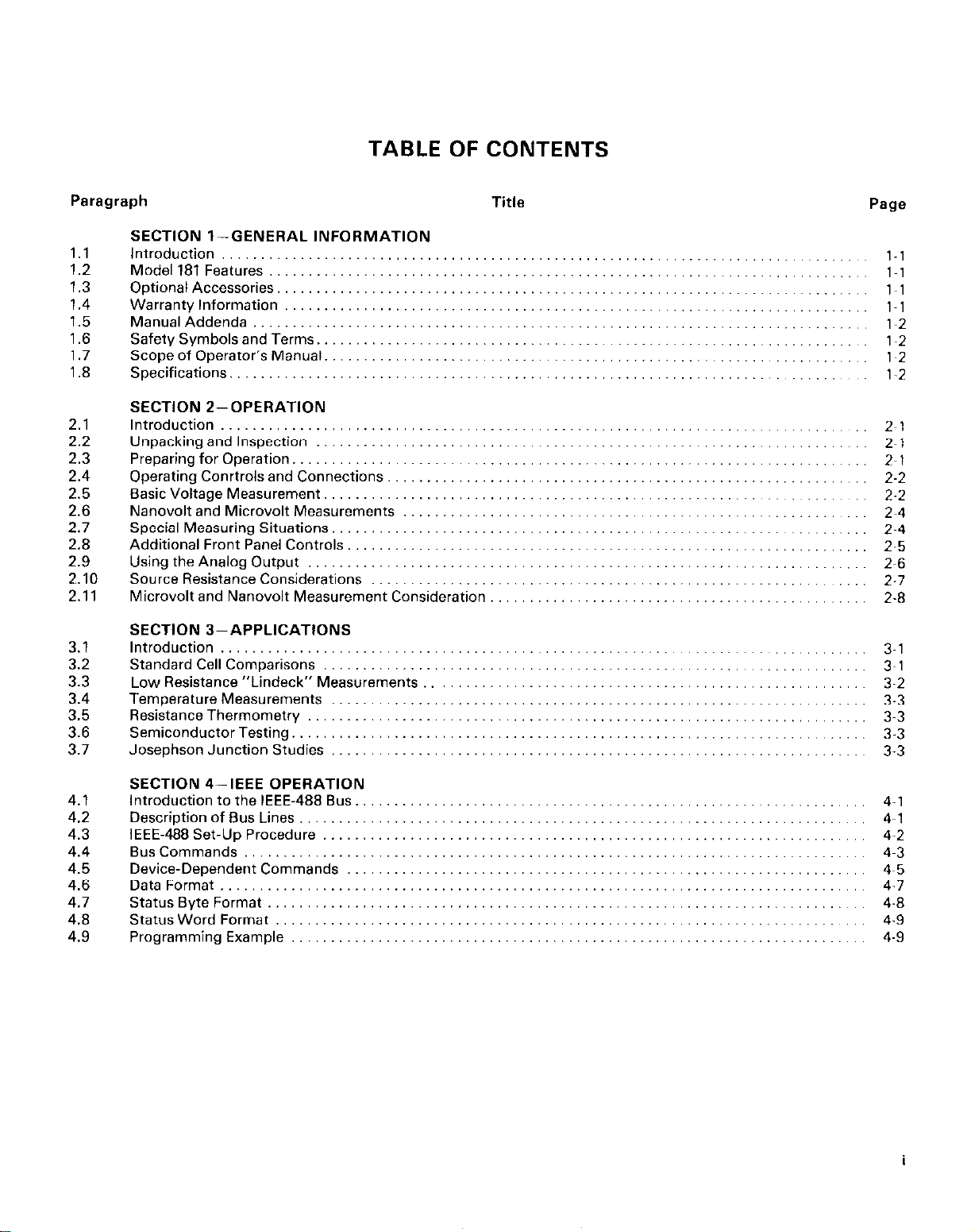

TABLE OF CONTENTS

Paragraph

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

2.1

2.2

2.3

2.4

2.5

2.6

2.7

2.8

2.9

2.10

2.11

3.1

3.2

3.3

3.4

3.5

3.6

3.7

Title

SECTION l-GENERAL INFORMATION

Introduction.. ...............................................................................

Model181 Features.. .........................................................................

Optional Accessories

Warranty Information .........................................................................

ManualAddenda..

SafetySymbolsandTerms .....................................................................

ScopeofOperator’sManual...........................................................~.~~ .....

Specifications ................................................................................

SECTION 2-OPERATION

Introduction.. ................................................................................

Unpackingandlnspection

PreparingforOperation.................................................................~...~

Operating Conrtrolsand Connections

BasicVoltageMeasurement..........................................................~.~

Nanovolt and Microvolt Measurements

Special Measuring Situations

Additional Front Panel Controls. .................................................................

UsingtheAnalogOutput .......................................................................

Source Resistance Considerations ..........................................................

Microvolt and Nanovolt Measurement Consideration

SECTION 3-APPLICATIONS

Introduction.. ................................................................................

StandardCellComparisons .....................................................................

Low Resistance “Lindeck” Measurements

TemperatureMeasurements .........................................................

ResistanceThermometry .......................................................................

SemiconductorTesting .........................................................................

JosephsonJunctionStudies ....................................................................

..........................................................................

...........................................................................

............................................................

.............................................................

....................................................... ...

....................................................................

...............................................

..................................................... ..

........

........

..........

....

...

Page

l-l

1~1

1~1

l-l

1~2

1~2

1~2

1-2

2~1

2~1

2~1

2-2

2-2

2~4

2-4

2-5

2~6

2-J

2-8

3-1

3~1

3-2

3-3

3~3

3-3

3-3

4.1

4.2

4.3

4.4

4.6

4.6

4.7

4.8

4.9

SECTION 4-IEEE OPERATION

Introduction to the IEEE-488 Bus .................................................................

Descriptionof BusLines ........................................................................

IEEE-488Set-UpProcedure.. ...................................................................

BusCommands.. .............................................................................

Device-Dependentcommands ..................................................................

Data Format.. ................................................................................

StatusByte Format.. ..........................................................................

StatusWordFormat ...........................................................................

ProgrammingExample .........................................................................

4-1

4-l

4-2

4-3

4~5

4-7

4-8

4-9

4-9

Page 4

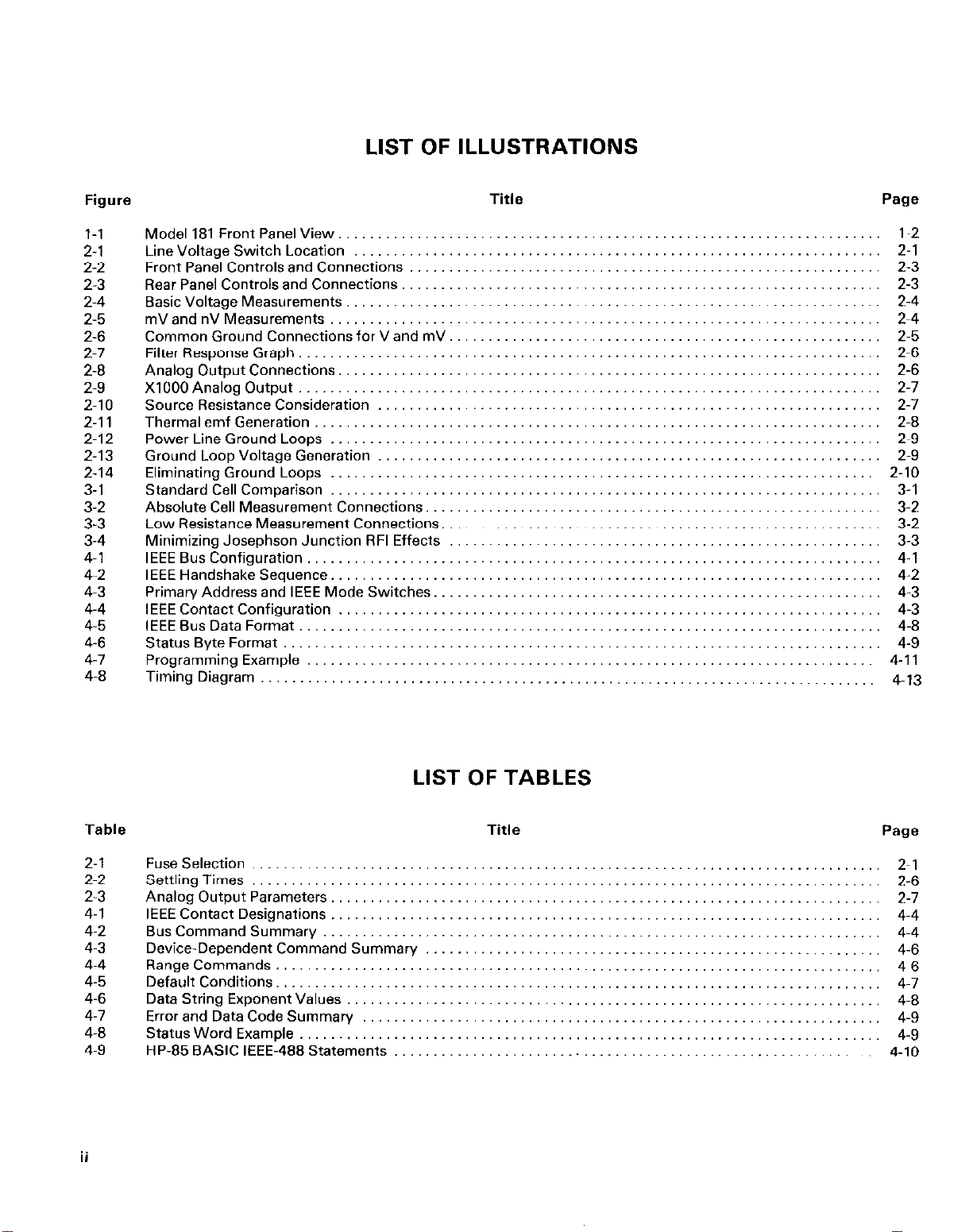

LIST OF ILLUSTRATIONS

Figure

l-l

2-1

2-2

2-3

2-4

2-5

2-6

2-7

2-8

2-9

2-10

2-11

2-12

2-13

2-14

3-l

3-2

3-3

3-4

4-1

4-2

4-3

4-4

4-5

4-6

4-7

4-8

Model 181 Front Panel View. .............

Line Voltage Switch Location ............

Front Panel Controls and Connections

Rear Panel Controls and Connections.

Basic Voltage Measurements.

mV and nV Measurements ...............

Common Ground Connections for V and mV

Filter Response Graph. ..................

Analog Output Connections ..............

Xl000 Analog Output ...................

Source Resistance Consideration .........

Thermal emf Generation .................

Power Line Ground Loops ...............

Ground Loop Voltage Generation .........

Eliminating Ground Loops ...............

Standard Cell Comparison ...............

Absolute Cell Measurement Connections.

Low Resistance Measurement Connections.

Minimizing Josephson Junction RFI Effects

IEEE Bus Configuration ..................

IEEEHandshakeSequence ...............

Primary Address and IEEE Mode Switches.

IEEE Contact Configuration ..............

IEEE Bus Data Format ...................

Status Byte Format .....................

Programming Example ..................

Timing Diagram .......................

............

.....

.....

..

Title Page

......

......

......

......

......

......

......

......

......

......

......

......

......

......

......

......

......

......

......

.....

......

......

......

......

......

......

......

......

......

......

......

......

......

......

......

......

......

......

......

.....

......

......

......

......

......

......

......

......

......

......

......

......

......

......

......

......

......

......

......

......

......

......

......

.....

......

......

......

......

......

......

......

......

......

......

......

......

......

......

......

......

......

......

......

......

......

......

.....

..........

.......... 2-l

.......... 2-3

.......... 2-3

.......... 2-5

.......... 2-6

.......... 2-6

.......... 2-7

.......... 2-7

.......... 2-8

.......... 2-9

......... 2-10

..........

.......... 3-2

..........

.......... 4-l

.......... 4-2

..........

.......... 4-8

.......... 4-9

......... 4-11

l-2

2-4

2-4

2-9

3-l

3-2

3-3

4-3

4-3

4-13

Table

2-l

2-2

2-3

4-l

4-2

4-3

4-4

4-5

4-6

4-7

4-8

4-S

ii

Fuse Selection .........................

Settling Times .........................

Analog Output Parameters. ..............

IEEE Contact Designations ...............

Bus Command Summary ................

Device-Dependent Command Summary

Range Commands ......................

Default Conditions. .....................

Data String Exponent Values .............

Error and Data Code Summary ...........

Status Word Example ...................

HP-85 BASIC IEEE-488 Statements .......

LIST OF TABLES

...

......

......

......

......

......

......

......

......

......

., ....

Page

2-l

2-6

2-7

4-4

4-4

4-6

4-6

4-7

4-8

4-9

4-9

4-10

Page 5

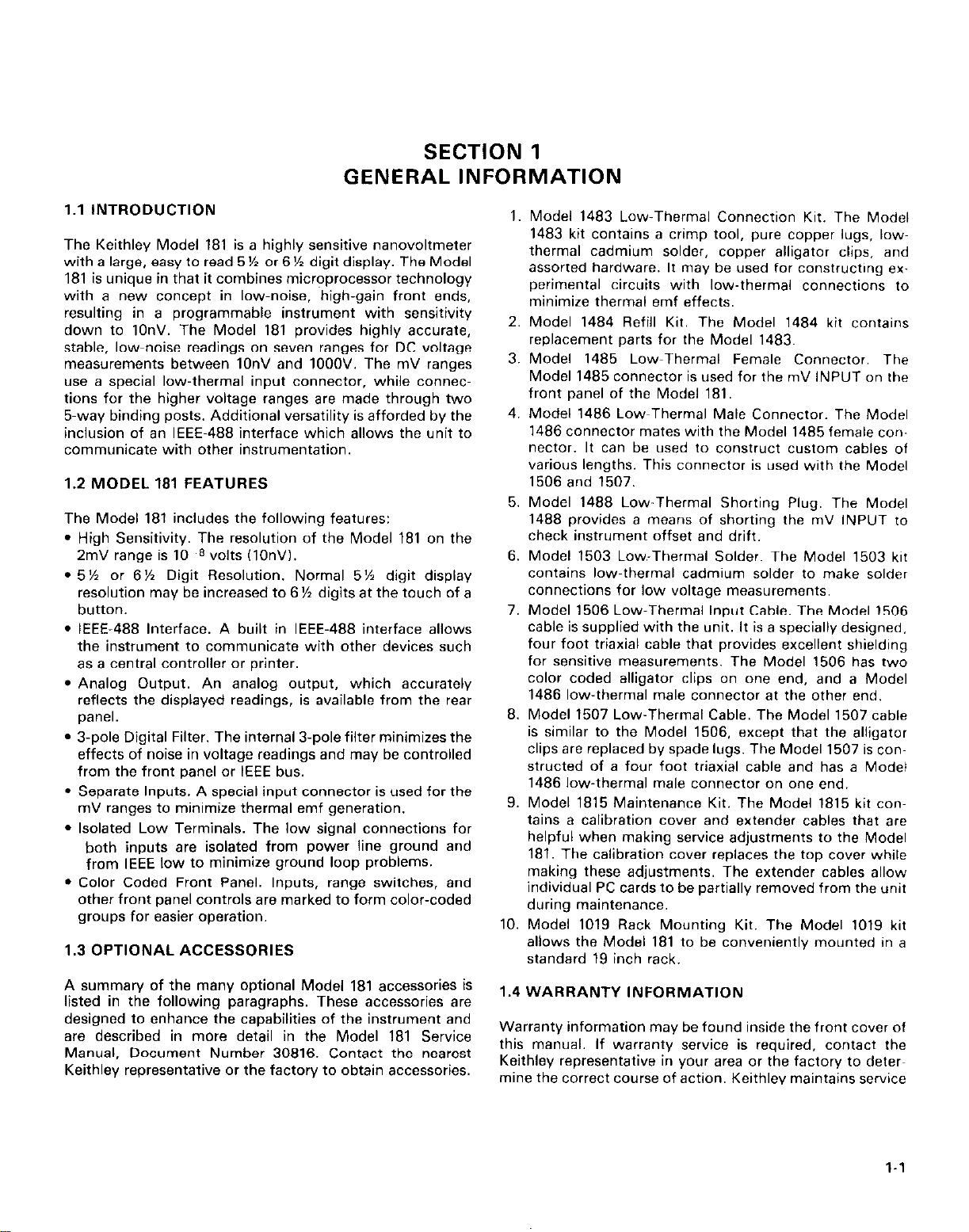

SECTION 1

GENERAL INFORMATION

1.1 INTRODUCTION

The Keithley Model 181 is a highly sensitive nanovoltmeter

with a large, easy to read 5 K or 6 ‘/ digit display. The Model

181 is unique in that it combines microprocessor technology

with a new concept in low-noise, high-gain front ends,

resulting in a programmable instrument with sensitivity

down to 10nV. The Model 181 provides highly accurate,

stable, low-noise readings on seven ranges for DC voltage

measurements between 1OnV and 1OOOV. The mV ranges

use a special low-thermal input connector, while connections for the higher voltage ranges are made through two

S-way binding posts. Additional versatility is afforded by the

inclusion of an IEEE-488 interface which allows the unit to

communicate with other instrumentation.

1.2 MODEL 181 FEATURES

The Model 181 includes the following features:

l

High Sensitivity. The resolution of the Model 181 on the

2mV range is IO ~* volts (10nV).

l

5% or 6% Digit Resolution. Normal 5% digit display

resolution may be increased to 6 % digits at the touch of a

button.

l

IEEE-488 Interface. A built in IEEE-488 interface allows

the instrument to communicate with other devices such

as a central controller or printer.

l

Analog Output. An analog output, which accurately

reflects the displayed readings, is available from the rear

pallel.

l

3-p& Digital Filter. The internal 3-p& filter minimizes the

effects of noise in voltage readings and may be controlled

from the front panel or IEEE bus.

l

Separate Inputs. A special input connector is used for the

mV ranges to minimize thermal emf generation.

l

Isolated Low Terminals. The low signal connections for

both inputs are isolated from power line ground and

from IEEE low to minimize ground loop problems.

l

Color Coded Front Panel. Inputs, range switches, and

other front panel controls are marked to form color-coded

groups for easier operation.

1.3 OPTIONAL ACCESSORIES

1

Model 1483 Low-Thermal Connection Kit. The Model

1483 kit contains a crimp tool, pure copper lugs, Lowe

thermal cadmium solder, copper alligator clips, and

assorted hardware. It may be used for constructing experimental circuits with low-thermal connections to

minimize thermal emf effects.

2

Model 1484 Refill Kit. The Model 1484 kit contains

replacement parts for the Model 1483.

3

Model 1485 Low-Thermal Female Connector. The

Model 1485 connector is used for the mV INPUT on the

front panel of the Model 181.

4

Model 1486 Low-Thermal Male Connector. The Model

1486 connector mates with the Model 1485 female connector. It can be used to construct custom cables of

various lengths. This connector is used with the Model

1506 and 1507.

5

Model 1488 Low-Thermal Shorting Plug. The Model

1488 provides a means of shorting the mV INPUT to

check instrument offset and drift.

6

Model 1503 LawThermal Solder. The Model 1503 kit

contains low-thermal cadmium solder to make solder

connections for low voltage measurements.

7

Model 1506 Low-Thermal Input Cable. The Model 1506

cable is supplied with the unit It is a specially designed,

four foot triaxial cable that provides excellent shielding

for sensitive measurements. The Model 1506 has two

color coded alligator clips on one end, and a Model

1486 low-thermal male connector at the other end.

8

Model 1507 Low-Thermal Cable. The Model 1507 cable

is similar to the Model 1506. except that the alligator

clips are replaced by spade lugs. The Model 1507 is cons

strutted of a four foot triaxial cable and has a Model

1486 low-thermal male connector on one end.

9

Model 1815 Maintenance Kit. The Model 1815 kit cons

tains a calibration cover and extender cables that are

helpful when making service adjustments to the Model

181. The calibration cover replaces the top cover while

making these adjustments. The extender cables allow

individual PC cards to be partially removed from the unit

during maintenance.

10

Model 1019 Rack Mounting Kit. The Model 1019 kit

allows the Model 181 to be conveniently mounted in a

standard 19 inch rack.

A summary of the many optional Model 181 accessories is

listed in the following paragraphs. These accessories are

designed to enhance the capabilities of the instrument and

are described in more detail in the Model 181 Service

Manual, Document Number 30816. Contact the nearest

Keithley representative or the factory to obtain accessories.

1.4 WARRANTY INFORMATION

Warranty information may be found inside the front cover of

this manual. If warranty service is required, contact the

Keithley representative in your area or the factory to detw

mine the correct course of action. Keithlev maintains service

l-l

Page 6

facilities in the United States, West Germany, Great Britain,

France, the Netherlands, Switzerland and Austria. lnforma-

tion concerning the application, operation or service of your

instrument may be directed to the applications engineer at

any of the previously mentioned locations. Check inside

front cover of this manual for addresses.

1.5 MANUAL ADDENDA

Because of a policy of constant improvement, it may

become necessary to make changes to the unit. Any modifi-

cations will be listed in an addendum attached to the inside

back cover of this manual. Be sure to note these changes

before attempting to operate the instrument.

1.6 SAFETY SYMBOLS AND TERMS

Safety symbols used in this manual are as follows:

The WARNING used in this manual explains dangers that

could result in personal injury or death.

The CAUTION used in this manual explains hazards that

could damage the instrument.

1.7 SCOPE OF OPERATOR’S MANUAL

This manual is intended to familiarize the operator with the

operating controls and features of the Model 181 nanovolto-

meter. Some of the items covered in this manual include:

basic and nanovolt measurement techniques, possible problems that could result when making measurements, addi-

tional Model 181 uses, operation of the Model 181 on the

IEEE-488 bus, and programming examples. For technical information including performance verification, theory of

operation, and maintenance procedures, refer to the Model

181 Service Manual.

The symbol

A on the instrument denotes that the

user should refer to the operating instructions.

The symbol 1/2)

on the ,nstrument denotes that 1OOOV

or more may be present on the terminal(s).

1.8 SPECIFICATIONS

For Model 181 detailed specifications, refer to the specifications that precede this section.

1-2

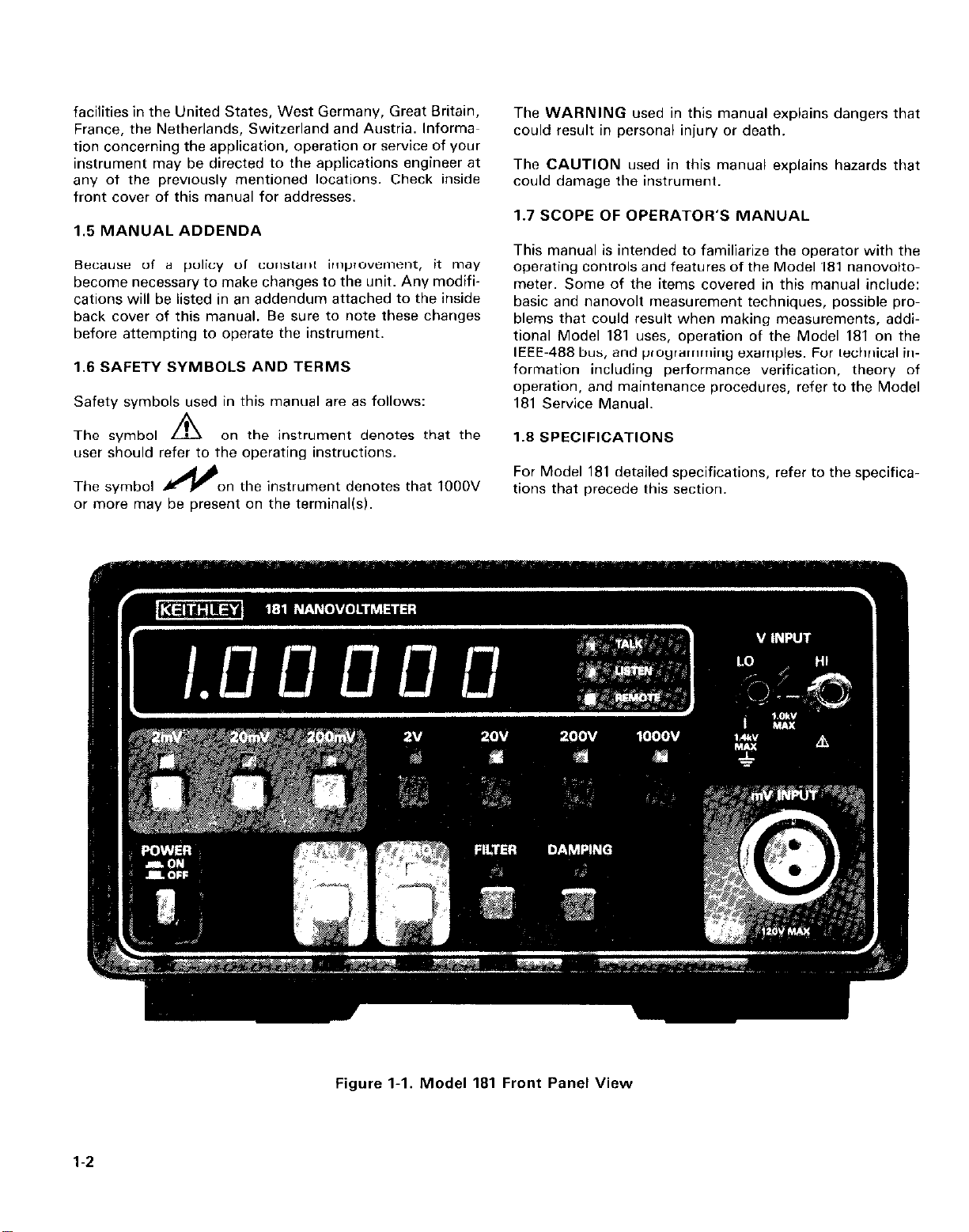

Figure l-l. Model 181 Front Panel View

Page 7

SECTION 2

OPERATION

2.1 INTRODUCTION

This section contains information needed for basic Model

181 operation. Be sure to read this entire section before

attempting to operate the unit.

2.2 UNPACKING AND INSPECTION

The Model 181 was carefully inspected before shipment.

Upon receiving the unit, unpack all the items from the shipping carton and check for any damage that might have

occurred during shipment. Report any damage to the shipping agent at once. Save the original packing material for

possible future reshipment. Contact your nearest Keithley

representative or the factory if the unit fails to function

properly.

The following items are included with every Model 181

shipment:

1. Model 181 Nanovoltmeter

2. Model 181 Operator’s Manual

3. Model 181 Service Manual

4. Model 1506 Low-Thermal Input Cable

5. List of computer programs.

6. Additional accessories as ordered.

2.3 PREPARING FOR OPERATION

transformer must be installed. Contact your

Keithley representative or the factory for

information.

To remove the top cover. remove the two screws securing

the cover to the rear panel. Then lift off the cover from the

back until the tabs at the front of the cover clear the front

panel. Then remove the cover entirely.

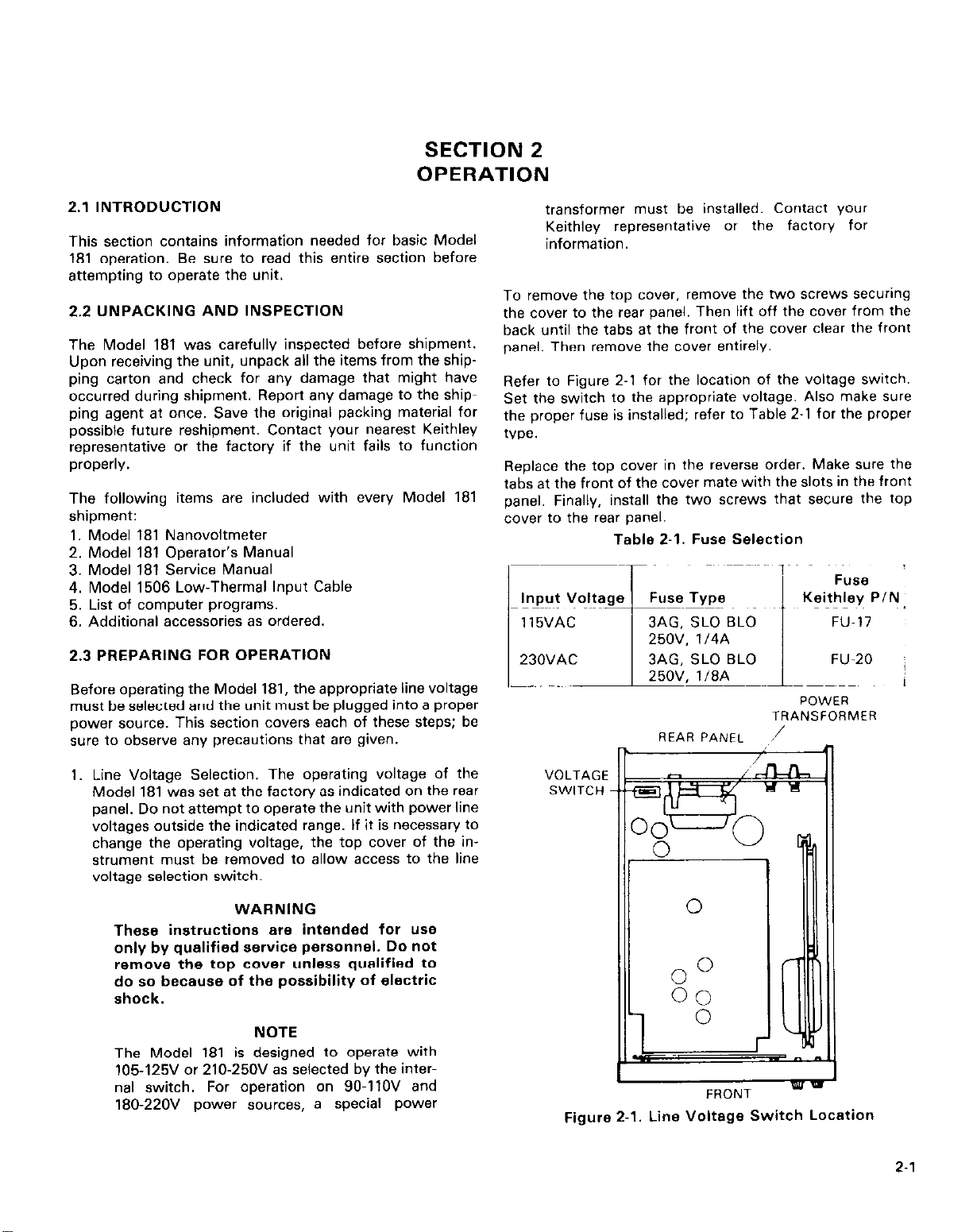

Refer to Figure 2-1 for the location of the voltage switch.

Set the switch to the appropriate voltage. Also make sure

the proper fuse is installed; refer to Table 2-l for the proper

type.

Replace the top cover in the reverse order. Make sure the

tabs at the front of the cover mate with the slots in the front

panel. Finally, install the two screws that secure the top

cover to the rear panel.

Table 2-1. Fuse Selection

3AG. SLO BLO

3AG. SLO BLO

Before operating the Model 181, the appropriate line voltage

must be selected and the unit must be plugged into a proper

power source. This section covers each of these steps; be

sure to observe any precautions that are given.

1. Line Voltage Selection. The operating voltage of the

Model 181 was set at the factory as indicated on the rear

panel. Do not attempt to operate the unit with power line

voltages outside the indicated range. If it is necessary to

change the operating voltage, the top cover of the instrument must be removed to allow access to the line

voltage selection switch.

WARNING

These instructions are intended for use

only by qualified service personnel. Do not

remme the top cover unless qualified to

do so because of the possibility of electric

shock.

NOTE

The Model 181 is designed to operate with

105.125V or 210.250V as selected by the inter-

nal switch. For operation on 90.IlOV and

180.22OV power sources, a special power

POWER

TRANSFORMER

REAR PANEL

/

/

FRONT

/-

WV=

VOLTAGE VOLTAGE

SWITCH SWITCH

Figure 2-l. Line Voltage Switch Location

Y

2-l

Page 8

2.

Power Line Connection. The Model 181 power cord is

supplied with a 3.prong plug that is designed to be used

with grounded outlets. Connect the female end of this

cord to the power receptacle on the rear panel of the

unit. Connect the other end to an appropriate power

SO”,lX.

CAUTION

Make sure the proper line voltage is

selected as described in the last section.

Failure to do so may result in damage to

the instrument,

possibly voiding the

warranty.

3.

Power-up Procedure. Once the power connections have

been made, the unit may be turned on by depressing the

front panel power switch. The Model 181 display should

show the line frequency and software revision level (e.g.

F60 b7) for approximately one second. After that, the

unit will revert to the normal display mode. In addition,

the 1OOOV range indicator light should be on. This is one

of the power-on default conditions that are explained

more fully in paragraph 4.5.

2.4 OPERATING CONTROLS AND CONNECTIONS

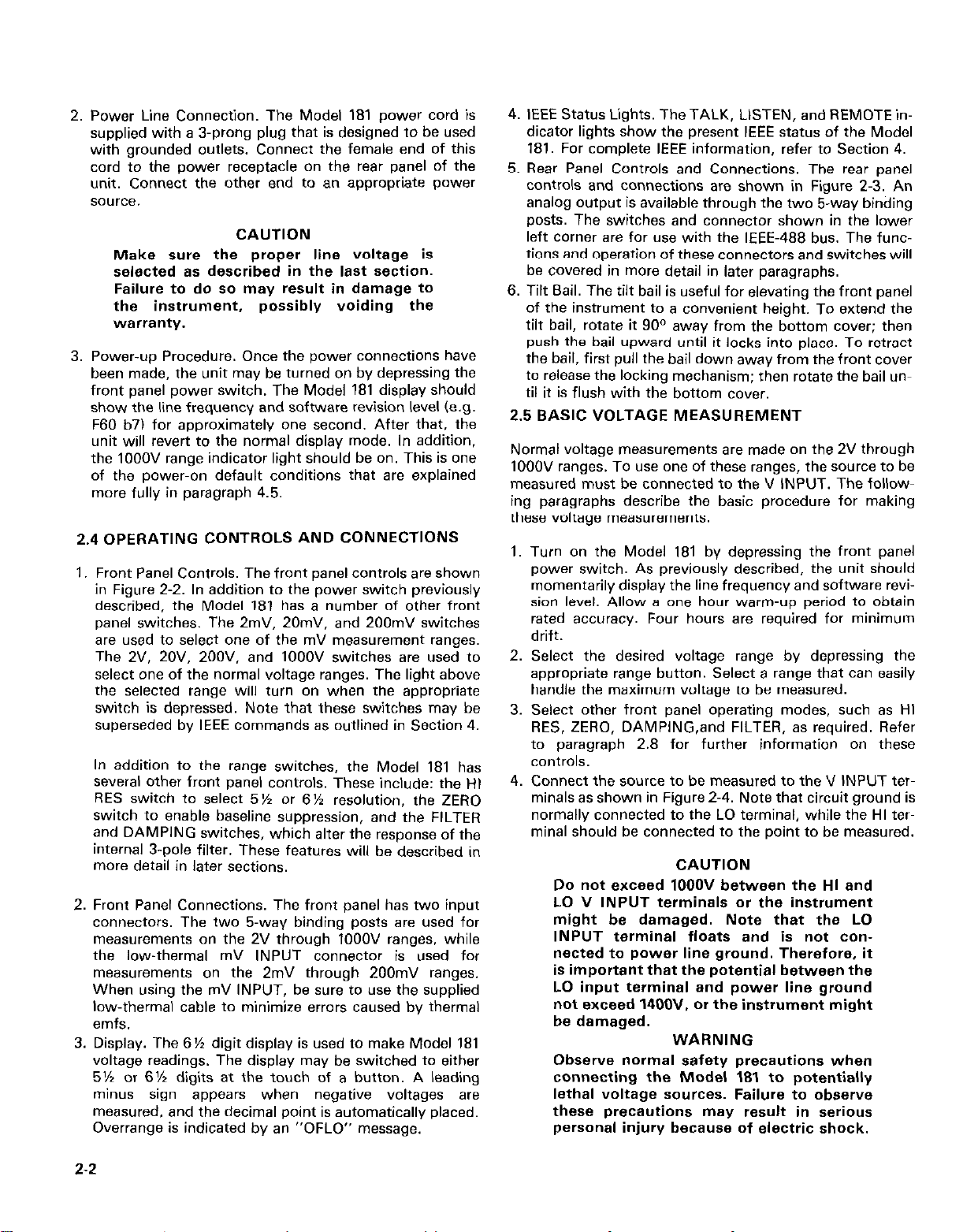

Front Panel Controls. The front panel controls are shown

in Figure 2-2. In addition to the power switch previously

described, the Model 181 has a number of other front

panel switches. The 2mV. 20mV. and 200mV switches

are used to select one of the mV measurement ranges.

The 2V. 2OV. 2OOV. and 1OOOV switches are used to

select one of the normal voltage ranges. The light above

the selected range will turn on when the appropriate

switch is depressed. Note that these switches may be

superseded by IEEE commands as outlined in Section 4.

In addition to the range switches, the Model 181 has

several other front panel controls. These include: the HI

RES switch to select 5% or 6% resolution, the ZERO

switch to enable baseline suppression, and the FILTER

and DAMPING switches, which alter the response of the

internal 3-pole filter. These features will be described in

more detail in later sections.

Front Panel Connections. The front panel has two input

connectors. The two 5.way binding posts are used for

measurements on the 2V through 1OOOV ranges, while

the low-thermal mV INPUT connector is used for

measurements on the 2mV through 200mV ranges.

When using the mV INPUT, be sure to use the supplied

low-thermal cable to minimize errors caused by thermal

emfs.

Display. The 6% digit display is used to make Model 181

voltage readings. The display may be switched to either

5% or 6% digits at the touch of a button. A leading

minus sign appears when negative voltages are

measured, and the decimal point is automatically placed.

Overrange is indicated by an “OFLO” message.

4. IEEE Status Lights. The TALK, LISTEN, and REMOTE indicator lights show the present IEEE status of the Model

181. For complete IEEE information, refer to Section 4.

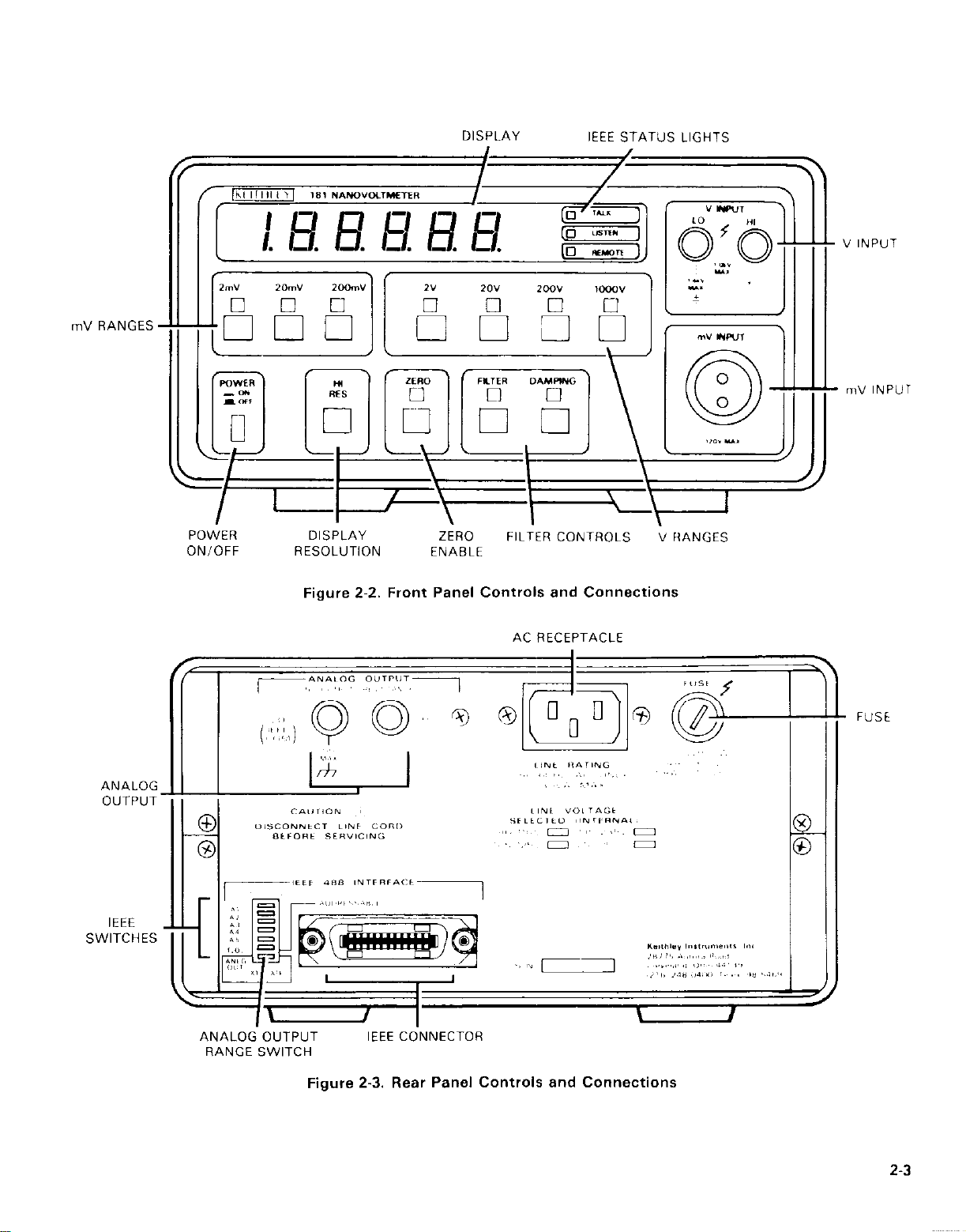

5. Rear Panel Controls and Connections. The rear panel

Controls and connections are shown in Figure 2-3. An

analog output is available through the two 5-way binding

posts. The switches and connector shown in the lower

left corner are for use with the IEEE-488 bus. The functions and operation of these connectors and switches will

be covered in more detail in later paragraphs.

6. Tilt Sail. The tilt bail is useful for elevating the front panel

of the instrument to a convenient height. To extend the

tilt bail, rotate it 90’ away from the bottom cover; then

push the bail upward until it locks into place. To retract

the bail, first pull the bail down away from the front cover

to release the locking mechanism; then rotate the bail until it is flush with the bottom cover.

2.5 BASIC VOLTAGE MEASUREMENT

Normal voltage measurements are made on the 2V through

IOOOV ranges. To use one of these ranges, the source to be

measured must be connected to the V INPUT. The follow-

ing paragraphs describe the basic procedure for making

these voltage measurements.

Turn on the Model 181 by depressing the front panel

power switch. As previously described, the unit should

momentarily display the line frequency and software revision level. Allow a one hour warm-up period to obtain

rated accuracy. Four hours are required for minimum

drift.

Select the desired voltage range by depressing the

appropriate range button. Select a range that can easily

handle the maximum voltage to be measured.

Select other front panel operating modes, such as HI

RES, ZERO, DAMPING,and FILTER, as required. Refer

to paragraph 2.8 for further information on these

controls.

Connect the source to be measured to the V INPUT terminals es shown in Figure 2-4. Note that circuit ground is

normally connected to the LO terminal, while the HI terminal should be connected to the point to be measured.

CAUTION

Do not exceed IOOOV between the HI and

LO V INPUT terminals or the instrument

might be damaged. Note that the LO

INPUT terminal floats and is not connected to power line ground. Therefore, it

is important that the potential between the

LO input terminal and power line ground

not exceed 14OOV. or the instrument might

be damaged.

WARNING

Observe normal safety precautions when

connecting the Model 181 to potentially

lethal voltage sources. Failure to observe

these precautions may result in serious

personal injury because of electric shock.

2-2

Page 9

mV RANGES

DISPLAY

IEEE STATUS LIGHTS

- mV INPUT

ANALOG

OUTPUT

POWER

ON/OFF

0

II I

RESOLUTION

Figure 2-2. Front Panel Controls and Connections

^ ^ ^ .

U,SLUNNC

DISPLAY

* ,\

A?

ZERO

FILTER CONTROLS

V HANGES

ENABLE

AC RECEPTACLE

I ,Nt ClArlNG

.,,,,,. ,,, :r,. ,...

1

,. t.;,

,.,. ,,I_, . “,.L

ANALOG OUTPUT

RANGE SWITCH

IEEE CONNECTOR

Figure 2.3. Rear Panel Controls and Connections

2-3

Page 10

5. Observe the display; if an “OFLO” is shown, switch to

the next higher range. Use the lowest range possible to

make the measurement. This procedure will achieve the

best resolution.

6. Make the voltage reading. The display shows the reading

directly in DC volts with a leading minus sign for negative

voltages. No conversion is necessary as the decimal

point is automatically placed on all ranges.

7. The Model 181 input impedance is greater than 10% on

the 2V range and equal to lOMl7 on the 20V through

IOOOV ranges. Thus, loading should not be a problem

except with very high source resistance values. Refer to

paragraph 2.10 for precautions to be taken under those

conditions.

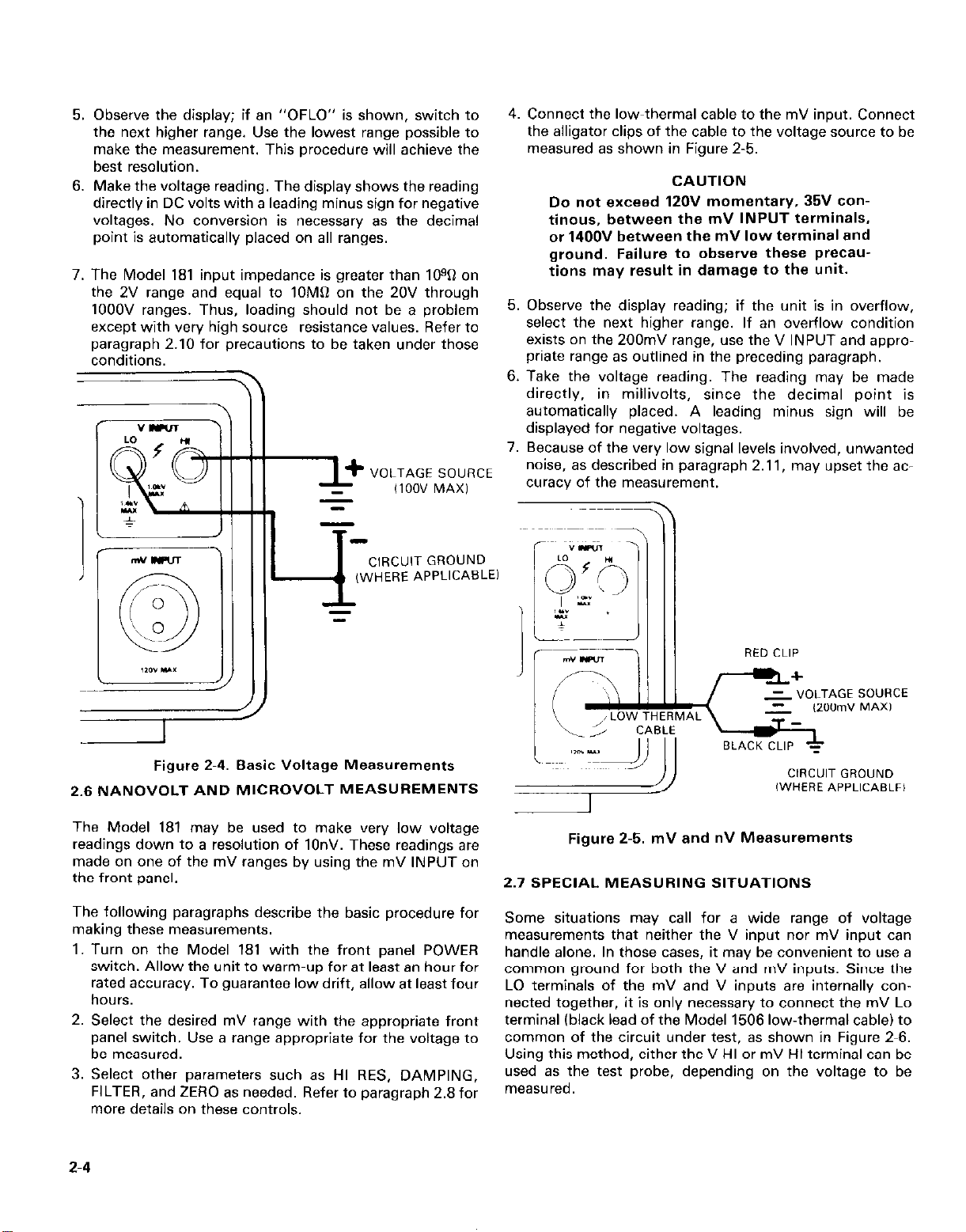

VOLTAGE SOURCE

,100” MAX,

7

-

CIRCUIT GROUND

,WHERE APPLICABLE1

-L

-

i

-I-

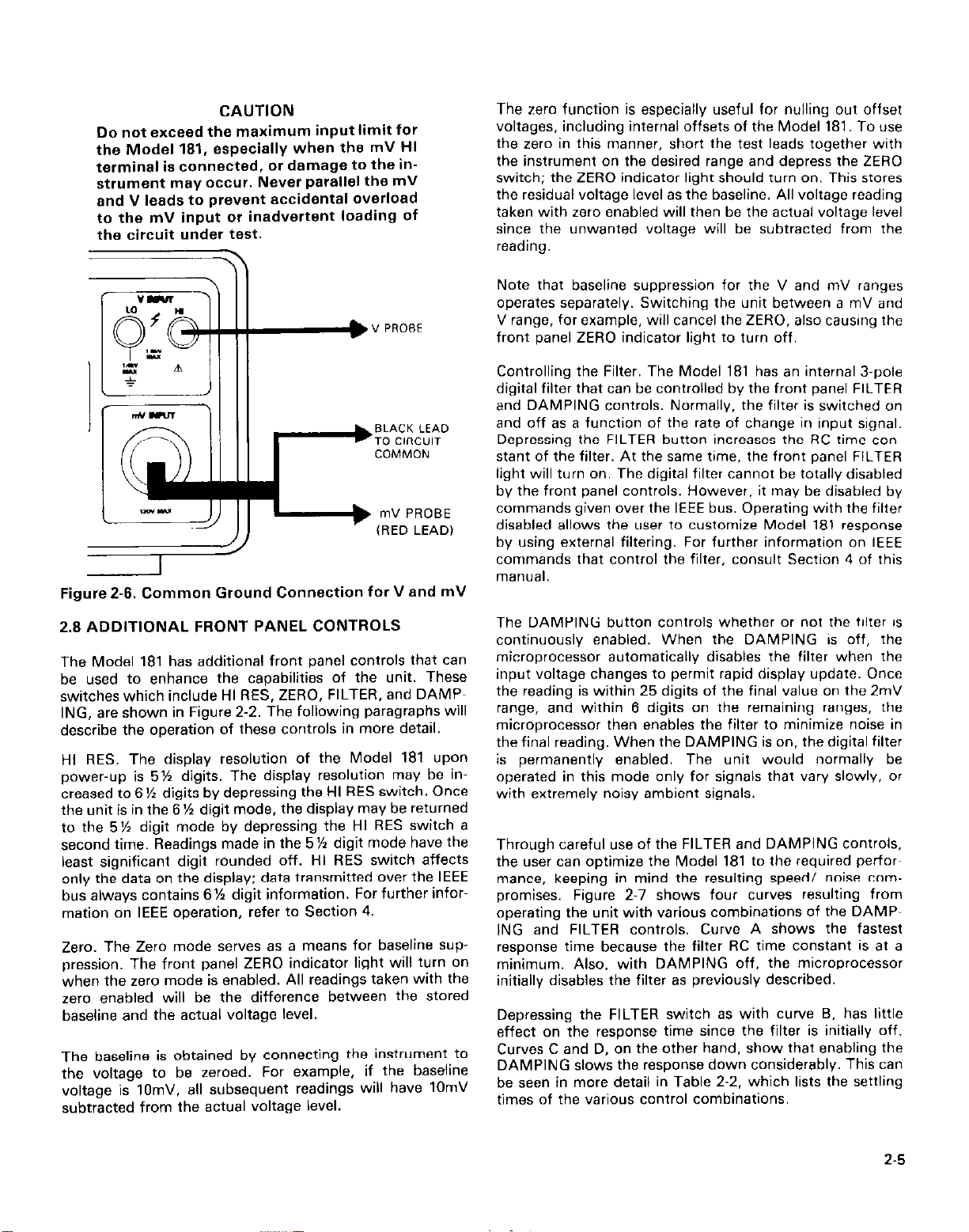

4. Connect the low-thermal cable to the mV input. Connect

the alligator clips of the cable to the voltage source to be

measured as shown in Figure 2-5.

CAUTION

Do not exceed 120V momentary. 35V con-

tinous, between the mV INPUT terminals.

or 1400V between the mV low terminal and

ground. Failure to observe these precau-

tions may result in damage to the unit.

5. Observe the display reading; if the unit is in overflow,

select the next higher range. If an overflow condition

exists on the 200mV range, use the V INPUT and appropriate range as outlined in the preceding paragraph.

6. Take the voltage reading. The reading may be made

directly, in millivolts,

automatically placed. A leading minus sign will be

displayed for negative voltages.

7. Because of the very low signal levels involved, unwanted

no,se, as CleSCrlDea I” paragrapn z.11, may upset the ac-

curacy of the measurement.

since the decimal point is

^

Figure 2-4. Basic Voltage Measurements

NANOVOLT AND MICROVOLT MEASUREMENTS

2.6

The Model 161 may be used to make very low voltage

readings down to a resolution of 10nV. These readings are

made on one of the mV ranges by using the mV INPUT on

the front panel.

The following paragraphs describe the basic procedure for

making these measurements.

1. Turn on the Model 181 with the front panel POWER

switch. Allow the unit to warm-up for at least an hour for

rated accuracy. To guarantee low drift, allow at least four

hours.

2. Select the desired mV range with the appropriate front

panel switch. Use a range appropriate for the voltage to

be measured.

3. Select other parameters such as HI RES, DAMPING,

FILTER, and ZERO as needed. Refer to paragraph 2.8 for

more details on these controls.

2-4

I

Figure 2-5. mV and nV Measurements

2.7 SPECIAL MEASURING SITUATIONS

Some situations may call for a wide range of voltage

measurements that neither the V input nor mV input can

handle alone. In those cases, it may be convenient to use a

common ground for both the V and mV inputs. Since the

LO terminals of the mV and V inputs are internally connected together, it is only necessary to connect the mV Lo

terminal (black lead of the Model 1506 low-thermal cable) to

common of the circuit under test, as shown in Figure 2-6.

Using this method, either the V HI or mV HI terminal can be

used as the test probe, depending on the voltage to be

measured.

Page 11

CAUTION

Do not exceed the maximum input limit for

the Model 181, especially when the mV HI

terminal is connected. or damage to the in-

strument may occur. Never parallel the mV

and V leads to prevent accidental overload

to the mV input or inadvertent loading of

the circuit under test.

Figure 2-6. Common Ground Connection for V and mV

The zero function is especially useful for nulling out offset

voltages, including internal offsets of the Model 181. To use

the zero in this manner, short the test leads together with

the instrument on the desired range and depress the ZERO

switch; the ZERO indicator light should turn on. This stores

the residual voltage level as the baseline. All voltage reading

taken with zero enabled will then be the actual voltage level

since the unwanted voltage will be subtracted from the

reading.

Note that baseline suppression for the V and mV ranges

operates separately. Switching the unit between a mV and

V range, for example, will cancel the ZERO, also causing the

front panel ZERO indicator light to turn off.

Controlling the Filter. The Model 181 has an internal 3-p&

digital filter that can be controlled by the front panel FILTER

and DAMPING controls. Normally, the filter is switched on

and off as a function of the rate of change in input signal.

Depressing the FILTER button increases the RC time conk

stant of the filter. At the same time, the front panel FILTER

light will turn on. The digital filter cannot be totally disabled

by the front panel controls. However, it may be disabled by

commands given over the IEEE bus. Operating with the filter

disabled allows the user to customize Model 161 response

by using external filtering. For further information on IEEE

commands that control the filter, consult Section 4 of this

manual.

2.8 ADDITIONAL FRONT PANEL CONTROLS

The Model 181 has additional front panel controls that can

be used to enhance the capabilities of the unit. These

switches which include HI RES, ZERO, FILTER, and DAMP-

ING, are shown in Figure 2-2. The following paragraphs will

describe the operation of these controls in more detail.

HI RES. The display resolution of the Model 181 upon

power-up is 5% digits. The display resolution may be increased to 6 % digits by depressing the HI RES switch. Once

the unit is in the 6% digit mode, the display may be returned

to the 5% digit mode by depressing the HI RES switch a

second time. Readings made in the 5% digit mode have the

least significant digit rounded off. HI RES switch affects

only the data on the display; data transmitted over the IEEE

bus always contains 6% digit information. For further infor-

mation on IEEE operation, refer to Section 4.

Zero. The Zero mode serves as a means for baseline sup-

pression. The front panel ZERO indicator light will turn on

when the zero mode is enabled. All readings taken with the

zero enabled will be the difference between the stored

baseline and the actual voltage level.

The baseline is obtained by connecting the instrument to

the voltage to be zeroed. For example, if the baseline

voltage is IOmV, all subsequent readings will have 1OmV

subtracted from the actual voltage level.

The DAMPING button controls whether or not the filter is

continuously enabled. When the DAMPING is off, the

microprocessor automatically disables the filter when the

input voltage changes to permit rapid display update. Once

the reading is within 25 digits of the final value on the 2mV

range, and within 6 digits on the remaining ranges. the

microprocessor then enables the filter to minimize noise in

the final reading. When the DAMPING is on. the digital filter

is permanently enabled. The unit would normally be

operated in this mode only for signals that vary slowlv, or

with extremely noisy ambient signals.

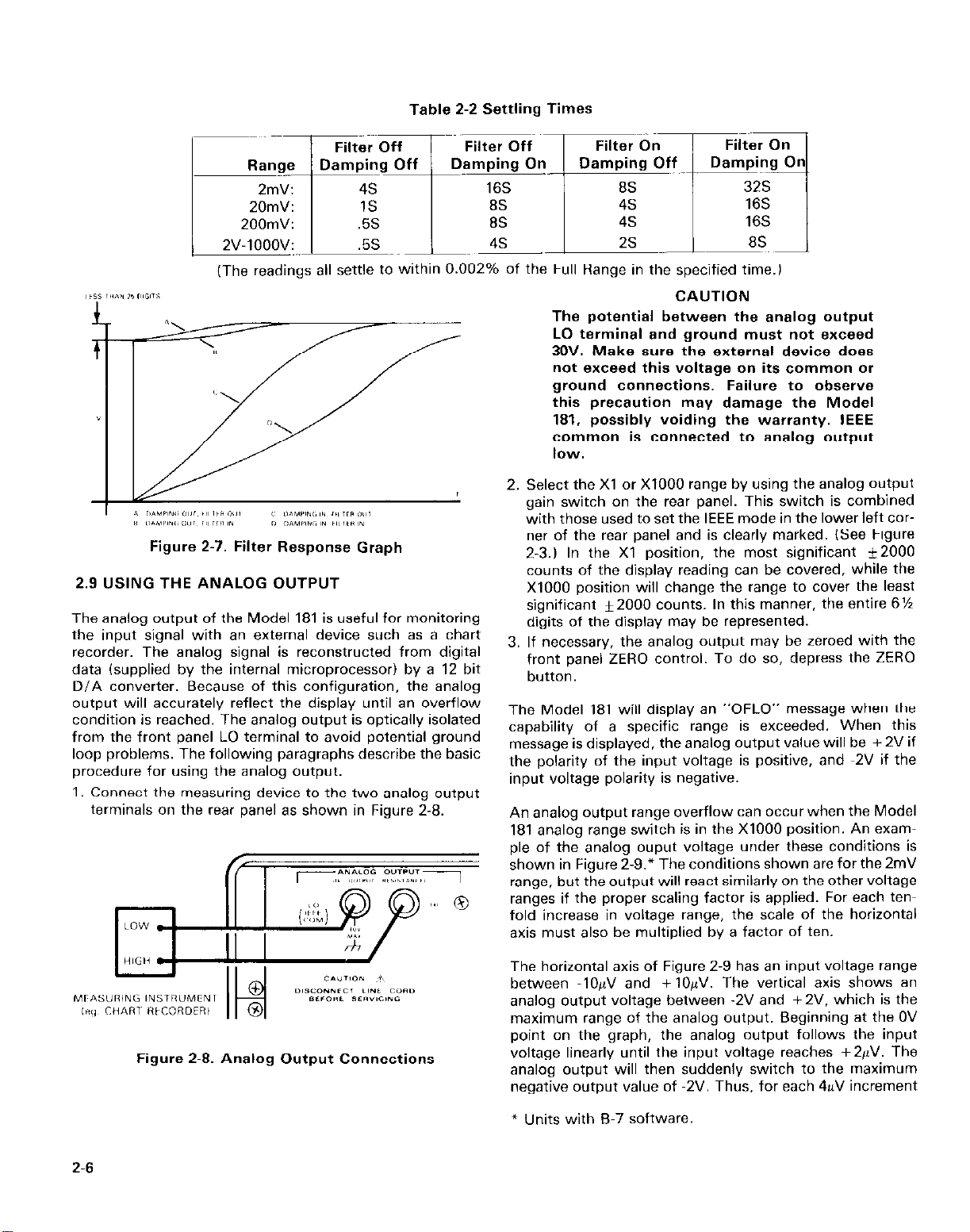

Through careful use of the FILTER and DAMPING controls,

the user can optimize the Model 161 to the required perfw

mance, keeping in mind the resulting speed/ noise compromises. Figure 2-7 shows four curves resulting from

operating the unit with various combinations of the DAMPS

ING and FILTER controls. Curve A shows the fastest

response time because the filter RC time constant is at a

minimum. Also, with DAMPING off, the microprocessor

initially disables the filter as previously described.

Depressing the FILTER switch as with curve 6, has little

effect on the response time since the filter is initially off.

Curves C and D, on the other hand, show that enabling the

DAMPING slows the response down considerably. This can

be seen in more detail in Table 2-2, which lists the settling

times of the various control combinations.

2-5

Page 12

Table 2-2 Settling Times

~~~~~-~~~~“~~~~~

(The readings all settle to within 0.002% of the Full Range in the specified time.)

2.9 USING THE ANALOG OUTPUT

The analog output of the Model 181 is useful for monitoring

the input signal with an external device such as a chart

recorder. The analog signal is reconstructed from digital

data (supplied by the internal microprocessor) by a 12 bit

D/A converter. Because of this configuration, the analog

output will accurately reflect the display until an overflow

condition is reached. The analog output is optically isolated

from the front panel LO terminal to avoid potential ground

loop problems. The following paragraphs describe the basic

procedure for using the analog output.

1. Connect the measuring device to the two analog output

terminals on the rear panel as shown in Figure 2-8.

CAUTION

The potential between the analog output

LO terminal and ground must not exceed

30V. Make sure the external device does

not exceed this voltage on its common or

ground connections. Failure to observe

this precaution may damage the Model

181. possibly voiding the warranty. IEEE

common is connected to analog output

IOW.

Select the Xl or Xl000 range by using the analog output

gain switch on the rear panel. This switch is combined

with those used to set the IEEE mode in the lower left cor-

ner of the rear panel and is clearly marked. (See Figure

2.3.) In the Xl position, the most significant +2000

counts of the display reading can be covered, while the

Xl000 position will change the range to cover the least

significant f2000 counts. In this manner, the entire 6%

digits of the display may be represented.

If necessary, the analog output may be zeroed with the

front panel ZERO control. To do so, depress the ZERO

button.

The Model 181 will display an “OFLO” message when the

capability of a specific range is exceeded. When this

message is displayed. the analog output value will be + 2V if

the polarity of the input voltage is positive, and -2V if the

input voltage polarity is negative.

An analog output range overflow can occur when the Model

181 analog range switch is in the Xl000 position. An example of the analog ouput voltage under these conditions is

shown in Figure 2-9.” The conditions shown are for the 2mV

range. but the output will react similarly on the other voltage

ranges if the proper scaling factor is applied. For each ten-

fold increase in voltage range, the scale of the horizontal

axis must also be multiplied by a factor of ten.

2-6

Figure 2-8. Analog Output Connections

The horizontal axis of Figure 2-9 has an input voltage range

between -10&V and +lOpV. The vertical axis shows an

analog output voltage between -2V and +ZV. which is the

maximum range of the analog output. Beginning at the OV

point on the graph, the analog output follows the input

voltage linearly until the input voltage reaches +2pV. The

analog output will then suddenly switch to the maximum

negative output value of -2V. Thus, for each 4uV increment

* Units with B-7 software.

Page 13

in input voltage, the output pattern repeats. ihe action of

the analog output for negative input voltages is the same,

except that the slope of the graph is negative for these

negative-going input voltages.

Figure 2-9. Xl000 Analog Output

By counting the number of repeating waveforms on a chart

recorder, the user can easily determine the actual voltage at

the input, even though the range of the analog output was

exceeded. If, for example, the +lV point on the second

peak with a positive-going slope is noted, it can be clearly

determined that the input voltage was +5@V at that particular time.

A summary of analog output information is shown in Table

2.3. Each range of input values corresponds to the incre-

ment necessary to cause the output to go through its entire

0 to 2V range. Note that the sensitivity is increased by a fac-

tor of a thousand on the Xl000 range. For example, when

the Model 181 is in the 200mV range, and the analog switch

is in the Xl position, the output voltage will swing from 0 to

2V in a smooth manner as the input voltage increases

gradually from 0 to 200mV. When the analog output switch

is changed to the Xl000 position, the input need only swing

between 0 and 2OOpV to obtain the same voltage swing at

the analog output. Beyond those input limitations, the out-

put voltage will repeat as shown in Figure 2-9.

The output resistance of the analog ouput is Ikll for all

voltage ranges regardless of the position of the analog range

switch. Thus, loading problems caused by external devices

are minimized. To keep loading errors below I%, the input

resistance of any device connected to the analog output

should be greater than lOOk0.

Table 2-3. Analog Output Parameters

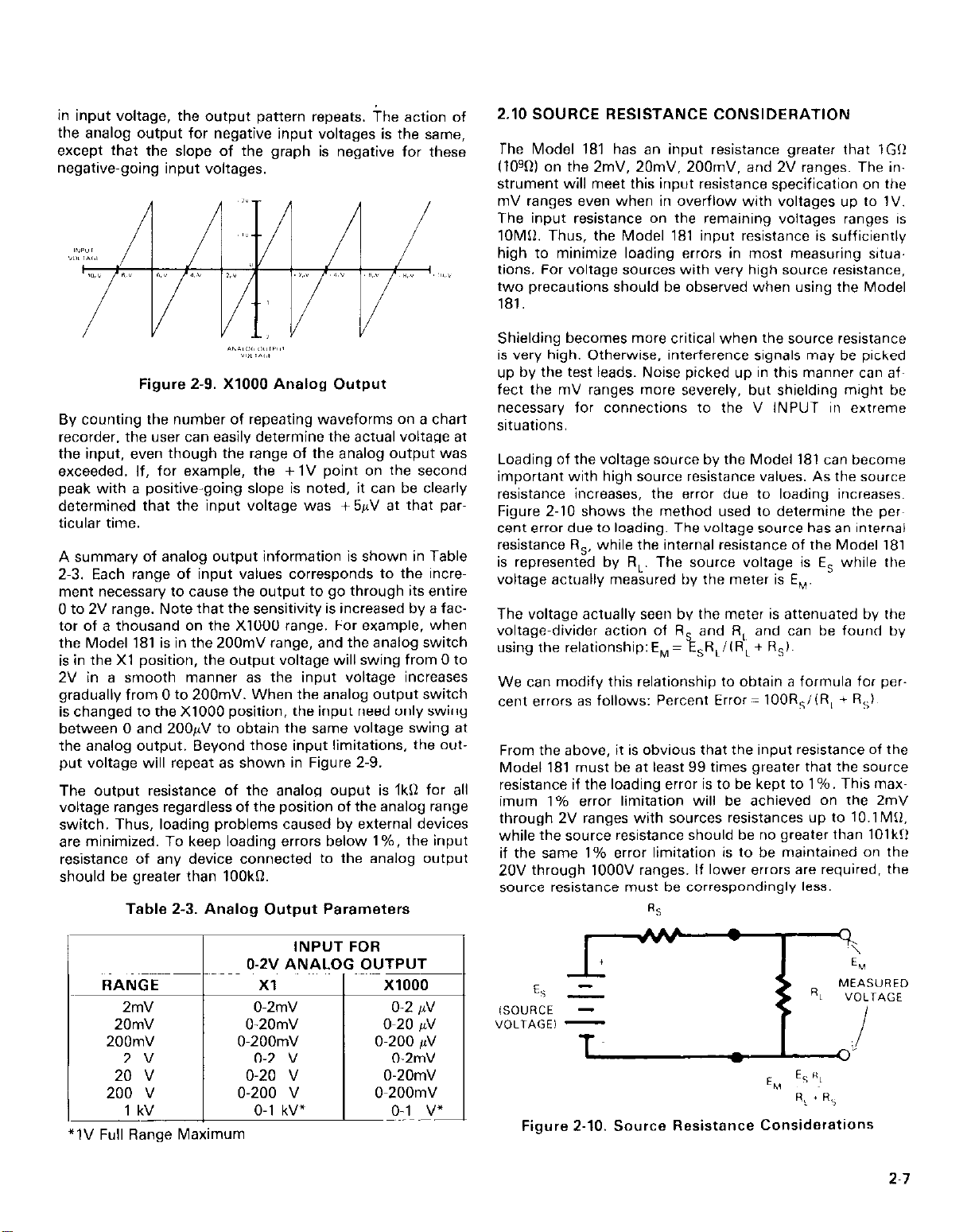

2.10 SOURCE RESISTANCE CONSIDERATION

The Model 181 has an input resistance greater that IGIl

flO% on the 2mV. 20mV. 200mV. and 2V ranges. The in-

strument will meet this input resistance specification on the

mV ranges even when in overflow with voltages up to 1V.

The input resistance on the remaining voltages ranges is

lOML2. Thus, the Model 181 input resistance is sufficiently

high to minimize loading errors in most measuring situations. For voltage sources with very high source resistance,

two precautions should be observed when using the Model

181.

Shielding becomes more critical when the source resistance

is very high. Otherwise, interference signals may be picked

up by the test leads. Noise picked up in this manner can affect the mV ranges more severely. but shielding might be

necessary for connections to the V INPUT in extreme

situations.

Loading of the voltage source by the Model 181 can become

important with high source resistance values. As the source

resistance increases, the error due to loading increases.

Figure Z-10 shows the method used to determine the Peru

cent error due to loading. The voltage source has an internal

resistance R,, while the internal resistance of the Model 181

is represented by R,. The source voltage is E, while the

voltage actually measured by the meter is E,.

The voltage actually seen by the meter is attenuated by the

voltage-divider action of R and R, and can be found by

using the relationship: E, = &R,IIRL + I?,).

We can modify this relationship to obtain a formula for per-

cent errors as follows: Percent Error = lOOR,/(R, * R,i~

From the above, it is obvious that the input resistance of the

Model 181 must be at least 99 times greater that the source

resistance if the loading error is to be kept to 1%. This maximum 1% error limitation will be achieved on the 2mV

through 2V ranges with sources resistances up to lO.lMI1,

while the source resistance should be no greater than IOlklI

if the same 1% error limitation is to be maintained on the

2OV through IOOOV ranges. If lower errors are required, the

source resistance must be correspondingly less.

Rs

20mV

200mV

2v

20 v

200 v

1 kV

*IV Full Range Maximum

INPUT FOR

IG OUTPUT

Figure 2-10. Source Resistance Considerations

2-7

Page 14

2.11 MICROVOLT AND NANOVOLT MEASUREMENT

CONSIDERATIONS

Low level voltage measurements are subject to various

types of noise that can make it difficult to obtain accurate

voltage readings. Since the measuring instrument cannot

distinguish between signal and noise voltages, the presence

of unwanted low level signals can seriously affect a

measurement. Some of the phenomena that can cause unwanted noise include: thermocouples (thermoelectric

effects), flexing of coaxial cables (triboelectric effects), and

the battery action of two terminals (galvanic action). The

following paragraphs will discuss potential noise sources in

more detail.

Source Resistance Noise, Noise that is present in the source

resistance itself is frequently the determining factor in the

ultimate resolution of a measurement system. The amount

of noise in a given resistance is given by the Johnson Noise

‘wE”= ~+:;;Js:

Noise Bandwidth in Hertz

. L’

IL

At a room temperature of 293’=K (20°C). the above can be

simplified to read: E.,,= 1.27~ IO- lm

It has been statistically shown, that p-p n&e is aPProximately five times the rms noise 99% of the time. From this

relationship, we

E

=6.35~1O-‘~F

0~”

From the preceding equations it is immediately obvious

that the noise voltage can be reduced by lowering the

temperature, reducing the resistance, or narrowing the

bandwidth. Reducing the resistance is not very useful

because the signal voltage will be reduced more than the

noise. For example, decreasing the resistance of a current

shunt by a factor of 100 will reduce the signal voltage by a

factor of 100 as well; the noise, however, will be reduced

only by a factor of 10.

Very often, cooling is the only practical method available to

reduce the noise. Here again, the reduction available is not

as large as it seems because the noise reduction is related to

the square root of the change in temperature. For example,

to cut the noise voltage in half, the temperature must be

decreased from ‘293°K to 73.25OK. a fourfold decrease.

Source Resistance in Ohms

Temperature OK

Boltrman’s Constant Il.38 x 10-23)

can

equate

the following:

Thermoelectric potentials. Thermal emf’s are small electric

potentials generated by differences in the temperature at

the junction of two dissimilar metals.

Thermal emf’s are particularly troublesome at the low signal

levels measured by the mV ranges. To minimize thermal emf

drift, use copper leads to connect the circuit to the instrument. The Model 1506 low-thermal cable supplied with the

Model 181 is ideal for this purpose. Other suitable lowthermal items are listed in paragraph 1.3 Optional

Accessories.

Even with low-thermal cables and connectors, thermal

emf’s can still be a problem in some cases. It is especially

important to keep the two materials forming the junctions at

the same temperature. Keeping the two junctions close

together is one way to minimize such thermal problems. In

some cases, connecting the two junctions together with

good thermal contact to a common heat sink may be

required.

Most good electrical insulators have good thermal insulation

characteristics as well. In cases where such low-thermal

conductivity may be a problem, special insulators that combine high electrical insulating properties with high thermal

conductivity may be used. Some examples of materials with

low electrical conductivity and high thermal conductivity

are: hard anodized aluminum, beryllium oxide, specially

filled epoxy resin, sapphire, and diamond.

Oxidation of leads and connectors can also lead to thermal

emf problems. When copper oxidizes, for example, the

resulting copper to copper oxide junction can cause thermal

emf’s as high as lOOOpV/OC. Thus, it is imperative that all

connections be kept as clean as possible.

Figure 2-l 1 shows a representation of how thermal emf’s

between two dissimilar metals are generated. The test leads

are made of the A material, while the B material is ~the

source under test. The temperatures between the junctions

are represented by T, and T,. To find the thermal emf for the

circuit, the following relationship pay be used:

E, = Q,,(T, T>,

-Temperature of the A to B

junction in OC or OK.

Temperature of the B to A

junction in OC or OK.

Thermoelectric coefficient of material A

with respect to B, given in aVI°C.

As an example of determining noise voltage generation,

assume that the Model 181 is connected to a voltage source

with an internal resistance of lOk!l. At a room temperature

of 20°C (293’K). the p-p noise voltage generated cwer a

bandwidth of 0.5Hz will be:

E

=6.35x 10~~‘“jUOx 103)(0.5)

P’P

E,~,=4.5x lo-*V=45nV

2-6

1

Figure Z-11. Thermal EMF Generation

I

Page 15

In the unlikely avant the two junction temperatures are identical, the thermal emf’s will exactly cancel, since the

generated potentials oppose one another. More often, the

two junctions temperatures will differ, and considerable

thermal emf’s will be generated.

A typical test set up might have one or more copper to

cadmium-tin junctions. Typically. such a junction has a thermoelectric coefficient of O.~FV/~C. Since the two materials

will frequently have a several-degree temperature differential, it is easy to see how thermal potentials of several

microvolts can be generated, even if reasonable precautions

are taken.

Magnetic fields. When a conductor cuts through magnetic

lines of force, a very small currant is generated. This

phenomenon will frequently cause unwanted signals to

occur in the test leads of a measuring instrument. If the conductor has sufficient length, even weak magnetic fields

such as the earth’s can create sufficient signals to upset

voltage measurements in the nanovolt or millivolt ranges.

Thus, several precautions may be taken if magnetic-field in-

duced signals become a problem.

Reducing the length of the leads or minimizing the exposed

circuit area are two ways these effects can be minimized. In

extreme cases, magnetic shielding may be required. Special

metals with high permeability at low flux densities (such as

mu metal) are effective in this application.

Figure Z-12. Power Line Ground Loops

To see how a ground loop can affect the voltage readings,

refer to Figure Z-13. The source to be measured is connected to the nanovoltmeter through the customary HI and

LO leads. The resistance of the LO terminal connection is

represented by R,. This resistance is usually very low

about 0.111, but even this low value can be significant if the

circulating current is high enough.

Even in cases where the conductor is stationary,

magnetically induced signals may be a problem. Fields may

be produced by various signals such as the AC power line

voltage. Large inductors such as power transformers are

very good magnetic field generators, so care must be taken

to keep the measuring circuit a good distance away from

these potential noise sources.

At high current levels, even a single conductor can generate

significant fields. These effects can be minimized by using

twisted pairs; using this method, the resulting fields will be

largely cancelled out.

Ground Loops. When two or more devices are connected

together, care must be taken to avoid unwanted signals

caused by ground loops. Ground loops usually occur when

sensitive instrumentation, such as the Modal 181. is con-

nected to other instrumentation with more than ona Signal

return path. One of these return paths may be power lina

ground. The resulting ground loop causes CUrrant t0 flow

through the instrument LO signal leads and than back

through the power line ground (See Figure Z-12). Bacausa

of this circulating currant, a small but undesireable voltage

is developed between the LO terminals of the two instruments. This voltage will be added to the swrca voltage.

upsetting the measurement.

GROUND

Figure Z-13. Ground Loop Voltage Generation

The source voltage is Es, while the ground loop currant is I,.

The actual voltage seen by the nanovoltmeter is the sum of

the source voltage and the IR drop across the LO lead connections, and can be found by using the relationship:

E,,=Es+I,R,

Thus, for a IOOnV source voltage, an R, value of 0.111, and a

IOOnA ground loop currant, the total voltage actually seen

by the instrument will be 1lOnV. creating an error of 10%.

Figure Z-14 shows a configuration that will eliminate this

type of ground loop problem. Here, only the center instrument is connected to ground. Ground loops are not normally a problem with the Model 181 because the LO input

terminals are isolated from power line ground. However, the

mV INPUT and V INPUT LO terminals should not be externally connected together as this will create a ground loop.

Also, since other instruments may not be designed in the

same way, they may cause ground loop problems even

though the Model 181 is isolated. When in doubt, consult

the manual for other instrumentation in the test setup.

2-9

Page 16

ments. With either type of RFI, the affect on instrument performance can be considerable if enough of the unwanted

signal is present.

P”WGR LINC mO”No

I

Figure 2-14. Eliminating Ground Loops

~RFI. Radio Frequency Interference (RF11 is a general term to

describe electromagnetic interference over a wide range of

frequencies across the spectrum. RFI can be especially

troublesome at the low signal levels measured on the mV

ranges, but it may also affect readings on the higher voltage

ranges in extreme cases.

RFI can be caused by steady-state sources such as TV or

radio broadcast signals, or it can result from impulse

sources, as in the case of arcing in high voltage environ-

RFI can be minimized by taking one or more of several

precautions when operating the Model 181 in such environ-

ments. The most obvious method for minimizing these

effects is to keep the instrument as far as possible away

from the source. Shielding the instrument, voltage source,

and test leads will often reduce RFI to an acceptable level. In

extreme cases, a specially constructed screen room may be

required to sufficiently attenuate the troublesome signal.

The internal 3-p& filter within the Model 181 may help

reduce RFI in home situations. For more serious RFI pro-

blems, the user is encouraged to try more effective external

shielding.

2-10

Page 17

SECTION 3

APPLICATIONS

3.1 INTRODUCTION

The high sensitivity and very high input impedance of the

Model 181 makes it ideal for critical measurements ordinary

DVM’s are unable to handle. Some of these applications, including standard cell comparison and low resistance

measurements, are covered in the following paragraphs.

3.2 STANDARD CELL COMPARISONS

The Model 181 may be used for making standard cell com-

parisons without the usual problems caused by different

ground connections. The input low terminals on the instru-

ment are isolated from ground, eliminating the possibility of

shorting out one of the cells when the input connections are

reversed.

The greatest concern when making such comparisons is the

effect of the measuring instrument on the standard cell

voltage. The Model 181 input characteristics minimize these

effects because of high input impedance and very low offset

current.

The equivalent circuit for making standard cell comparisons

is shown in Figure 3-l. V, and V, represent the two standard

cells being compared, and are connected to the HI and LO

mV INPUT terminals as shown. The common terminals of

the two cells are normally connected to earth ground to pre-

vent electrostatic pickup. Because of the high impedance

nature of the measurement, it may be necessary to shield

the two standard ceils. This shield should also be connected

to earth ground as shown in Figure 3-l.

The amount of current and charge drawn from the cells in

Figure 3-1 is determined by the common-mode and normalmode impedances. The common-mode impedance appears

only across V, and is represented by the parallel comblna-

tion of R,, (> 109% and Cc, (O.O015,,F.) Under typical

laboratory conditions lless than 60% relative humidity). the

value of R,,

ally be assumed to be infinite. The capacitance of the Model

1506 low-thermal cable makes up the larger portion of C,,.

If the input capacitance should have a detrimental effect on

standard cell performance, its value may be essentially

balanced out by connecting a 15OOpF capacitor between

the input HI terminal and earth ground. Since C,, will rarely

affect cell performance, this balancing technique is not

usually necessary.

The normal-mode impedance is represented by the parallel

combination of R,, and C,,. This normal-mode impedance

appears between the LO and HI input terminals. The actual

amount of charge and current drawn from the two cells

depends on the voltage difference between them (V,~V,I.

Typically, the potential difference between V, and V, is 1mV

or less, resulting in a charge of approximately 10 l2

coulombs that must be supplied by the two cells. In addi~

tion. an input offset current of less than 50pA is drawn from

the cells under test. Any effects from internal spikes pm

duced by the input multiplexing FET’s will be at a minimum,

as the spikes will occur at the 4Hr multiplexing rate.

When on the mV ranges. the Model 181 will maintain its

high input resistance characteristics ( ) 10%) for all voltages

up to lV, even during range changes or when in overload.

However, the input impedance drops substantially if the 1V

limitation is exceeded. To avoid possible cell degredation

under such conditions, it is recommended that a series

resistance 1 MR or greater be connected in series with one of

the cells, as shown in Figure 3-l. where R, is connected be-

tween V, and the input HI terminal. This safeguard will also

protect the cells from degradation in case of improper con-

nections. This resistance. Rs. can be shorted Out after an on

scale indication is observed, and the reading can then be

made in the normal manner.

is in the lo”12 to 1O’21l range. and may genw

Figure 3-I. Standard Cell Comparison

With this connection, it is assumed that the Model 181 is

connected to the power line with the standard 3.prong plug.

Since the power line ground is also connected to earth

ground, the complete ground connections will be made

through the ground wire in the line cord of the instrument.

The basic procedure for making standard cell measurements

involves connecting the two cells for comparison to the mV

INPUT and sening up the Model 181 as follows:

1. Turn on the power to the Model 181 and allow a one hour

warm-up period for the best accuracy. A four hour period

is required to minimize drift.

2. Connect the cells to the Model 181 as shown in Figure

3-1, Use the low-thermal cable and mV INPUT on the ins

strument. Include a lMI2 resistor for R, if the cells ate to

be protected from accidental loading during set-up.

3-l

Page 18

3. Select the appropriate mV range and observe the reading.

If the display reading jumps around excessively, enable

the damping with the front panel DAMPING switch.

4. Observe the readings; once the display has stabilized,

short R, (if connected), and take the voltage readings.

5. Remove the short from R, and reverse the lead connec-

tions to V, and V,. The LO terminal should now be con-

nected to V, and the HI terminal should be connected to

V,. Disable the damping to reduce settling time. Once the

reading has stabilized, enable the damping again, if

necessary. Once again, short R, and record the display

reading.

6. The standard cell difference may be found by averaging

the absolute values of the two readings as follows:

Cell Difference = (Reading In Step 41 + 1 Reading In Step 51

2

This averaging method is necessary to cancel thermal

effects, but either reading alone may be sufficiently accurate if precautions to minimize thermal emf generation are

observed. The ZERO button may be used to null any

residual offset. Also, only copper to copper connections

should be used to minimize such thermal effects. As always,

the connections should be kept as clean as possible, or the

resulting copper to copper oxide junctions may create substantial thermal emf voltage, upsetting the measurement.

range for input voltages above 200mV; the input impedance

on the mV ranges drops to IkR for inputs greater than IV.

Figure 3-Z. Absolute Cell Measurement Connections

3.3 LOW RESISTANCE “LINDECK” MEASUREMENTS

As with the standard cell comparisons, the high resolution

of the Model 181 gives the instrument a definite advantage

in speed and convenience over potentiometer systems traditionally used to make low resistance measurements.

The method just described is useful for comparing two standard cell voltages. However, some situations may call for

the measurement of a single cell alone. For measuring

absolute standard cell voltages, it is best to use the2V range

because the input impedance is greater than IOQ.

NOTE

Since the input impedance on the ZOV-1OOOV

ranges drops to lOM12, those voltage ranges are

unsuitable for making absolute standard cell

voltage measurements.

Figure 3-2 shows the connections for making absolute standard cell voltage measurements. Once again, R, is to be left

in the circuit until the reading is actually taken. The basic

procedure for making the absolute voltage measurement is

as follows:

1. Turn on the instrument and allow a one hour warm-up

period. Four hours are required to minimize drift,

2. Connect the standard cell to the instrument as shown in

Figure 3-2. Be sure to include R, to protect the cell,

3. Switch the instrument to the 2V range and observe the

reading. Be sure the reading is on range.

4. Short out R, and take voltage reading. Once the reading

is complete, remove the short from R,.

The method used with the Model 181 places a current

source in parallel with the low resistance to be measured, as

shown in Figure 3-3. The problem with such measurements

has generally been the trade-off between the power level required and the sensitivity of the instrument. In a circuit with

a .Olfl resistance, a current source delivering only IOmA will

provide a resolution of 0.01% with the Model 181 on the

2mV range. In contrast, a 1pV resolution DVM would require a current of IA. With the Model 181 measurement, the

power level in the resistor will be only 1pW. whereas the

measurement made with the DVM would result in a power

level of IOmW in a .OlR resistance.

With this method, the resistance may be found simply by

dividing the voltage reading by the current source value.

With a 1OmA current source and ,010 resistance, for exam-

ple, a voltage of IOOpV will be developed across the

measured resistance.

MODEL 181

Care should be taken when making absolute readings in this

way. If higher voltage ranges are used, the lower input im-

pedance will degrade cell performance. Do not use the mV

3-2

Figure 3-3. Low Resistance Measurement Connections

Page 19

3.4 TEMPERATURE MEASUREMENTS

The Model 181 may be used with thermocouples or ther-

mopiles to monitor small temperature changes down to a

resolution of ~O.OOl°C. Connections should be made using

appropriate low-thermal materials such as those supplied

with the Model 1483 Low-Thermal Connection Kit.

Although some shielding is recommended, the high AC re-

jection of the instrument eliminates most of the problems

normally caused nearby AC operated equipment such as

heaters, fans, pumps, etc.

The rear panel analog output may be used along with a

chart recorder to provide a continuous, permanent record of

temperature changes. Alternately, the Model 181 may be

connected to the IEEE-488 bus to allow easy transfer of

temperature data to a printer or computer. With a suitable

controller, the user may take full advantage of Model 181

capabilities, providing full automation of such temperature

tests.

appropriate controller and other instrumentation, virtually

complete automation of the necessary instrumentation

curve measurements may be obtained.

Josephson Junction measurements are especially vulnw

able to the effects of high frequency EMI (Electromagnetic

Interference) and RFI (Radio Frequency InterferenceI. Much

of this interference may be generated by the microprocessor

based instrumentation itself. Still other forms of interference may come from the outside environment. In either

case, care must be taken to minimize the coupling of these

unwanted signals to the device under test. The almost 1”~

evitable high-frequency coupling of unwanted RFI to the

Josephson Junction itself will significantly affect the I-V

characteristics of the device, rendering the data useless in

many cases. The Model 181 has been carefully designed to

minimize common-mode RFI that may be coupled through

the input cable to the device under test. However. depend

ding on the measuring environment, additional precautions

may be required.

3.5 RESISTANCE THERMOMETRY

The Model 181 may be used for resistance thermometry

where small deviations are measured with nW power dissipation levels. A stable current source may be used to provide the necessary constant low-level current. A typical

resolution, using a IOOOfl germanium thermometer (at

4.2”K) is O.OOOZ°C, with a power dissipation of only 1nW.

(lo-SW).

The floating input of the Model 181 eliminates the problems

usually encountered when floating four-terminal measurements are made. Note that the Model 181 may be used with

a wide range of source resistances, because of the high

input impedance of the unit. As with other Model 181 applications, thermometry measurements may be controlled

over the IEEE-488 bus.

3.6 SEMICONDUCTOR TESTING

The Model 181 may be used for semiconductor testing on

an automated production-line basis. Sensitive measure-

ments can be made on semiconductor devices to determine

gain stability, temperature coefficient, etc., without the

loading errors associated with many types of equipment. By

applying proper programming techniques, a high level of

automation through use of the IEEE-488 bus can be

achieved.

Two methods of minimizing RFI effects are shown in Figure

3-4. The device under test is placed within a shielded booth,

which is connected to earth ground. Also, a ferrite inductor

is placed in series with the HI input lead of the lowthermal

cable. This inductor is made up of 4 turns of #28 wire wound

around a Keithley CT-7 ferrite core (Fai-rite #2643000701 I.

Note that the inductor is placed just outside the shield, right

at the point where the input cable enters the shielded area.

These precautions should eliminate all but the most stubborn RFI problems. In more extreme situations. a second

inductor, identical to the first, may be connected in series

with the LO input in a similar manner.

3.7 JOSEPHSON JUNCTION STUDIES

The Model 181 can be used for Josephson Junction studies,

where speed and high sensitivity are a primary requirement.

Josephson Junction I-V characteristics can be easily plotted

using the Model 181 in conjunction with other instrumenta-

tion connected to the IEEE-488 bus. Through the use of an

Figure 3-4. Minimizing Josephson Junction RFI Effects

3-313-4

Page 20

Page 21

SECTION 4

IEEE OPERATION

4.1 INTRODUCTION TO THE IEEE-488 BUS

The Model 181 has a built in IEEE-488 bus that allows the

user to give commands and read data via an external device.

All the front panel operating modes except power on-off

may be controlled by commands given over the bus.

The Model 181 may be commanded over the bus when the

rear panel TO/ADDRESSABLE switch is in the

ADDRESSABLE position. When in the TO (talk only) mode,

the Model 181 merely outputs data on the bus: no com-

mands may be given when the unit is in this mode. For fur-

ther information on changing the mode of operation, see

paragraph 4.3

A typical bus set-up for controlled operation is shown in

Figure 4-l. A typical system will have one controller and

several other instruments to which commands are given.

Generally, there are three catagories that describe device

operation. These catagories are: controller: talker; listener.

The controller does what its name implies: it controls the

other instruments on the bus. A talker sends data, while a

listener receives data. Depending on the type of instrument,

any particular device may be a talker only, a listener only. or

both a talker and a listener. The Model 181 is capable of

being both a talker and a listener, but does not have the

capability of being a controller.

Any given system can have only one controller, but any

number of talkers or listeners may be present up to the hardware constraints of the bus (see paragraph 4.2). Several

devices may be commanded to listen at once, but only one

talker can be active at any given time.

Before a device can talk or listen, it must be appropriately

addressed. Devices are selected on the basis of their primary

address. To avoid confusion, the addressed device is sent a

talk or listen command derived from its primary address.

The primary address of the Model 181 is set to 5 at the factory, but may be changed at the user’s discretion as outlined

in paragraph 4.3.

NOTE

Each device on the bus must have a unique

primary address. Failure to observe this condition may result in erratic operation.

The IEEE-488 bus is made up of 16 signal lines and 8 ground

lines. Eight of these signal lines are used for data, three of

the lines control the handshake, and the remaining five lines

manage the operation of the bus. The data lines are used for

both data and commands. The three handshake lines ensure

that all devices properly receive data, while the management lines control the remaining bus functions.

4.2 DESCRIPTION OF BUS LINES

The IEEE-488 bus may have up to 15 devices connected at

the same time. Each signal line is inverted so that low is

true. The following paragraphs briefly describe the purpose

of these lines, which are shown in Figure 4-1.

1. Bus Management Lines. These 5 lines are used to control

the bus and send certain single line commands. The

single-line commands that affect Model 181 operation are

explained in mcxe detail in paragraph 4.4

4-l

Page 22

A. IFC, Interface Clear: Used to send the IFC command

to set the bus to a known state.

B. REN, Remote Enable: Used to send the REN com-

mand to set up instruments on the bus for remote,

operation.

C. EOI, End or Identify: Used to send the END command

that usually terminates a multi-byte transfer sequence.

D. SRQ, Service Request: Used by an external device to

request service from the controller.

E. ATN, Attention: Used by the controller to indicate

whether the data bus contains data or commands.

2. Handshake Lines. The IEEE-488 bus uses three handshake lines that operate in an interlocked sequence. This

method ensures reliable data transfer regardless of the

transfer rate. Generally, data transfer will occur at a rate

determined by the slowest active device on the bus.

The three handshake lines are: DAV (data validl, NRFD

(not ready for data), and NDAC (not data accepted). The

device that is the source of the data controls the state of

the DAV line, while the NRFD and NDAC lines are controlled by the device accepting data.

The complete handshake sequence for one byte of data is

shown in Figure 4-2. Once the date byte is placed on the

date bus, the source checks to see that NRFD is high,

and NDAC is low, indicating that all devices on the bus

are ready for data. Once this condition is met, the source

sets the DAV line low, indicating the data is valid. The

NRFD line then goes low; the NDAC line will go high

once all the devices have accepted the data. Each device

will release the NDAC line at its own rate, but the NDAC

line will not go high until the slowest device has accepted

the data.

DAV

SOURCE

NRFD

NDAC

I

I

I

I

I

I

I

I

DATA

TRANSFER

BEGINS

I

I

DATA

TRANSFER

ENDS

ACCEPTOR

ACCEPTOR

Figure 4-2. IEEE Handshake Sequence

After the NDAC line goes high, the source then sets the

DAV line high, indicating that date is no longer valid. The

NDAC line then goes low. Finally, the NRFD line is

gradually released by each of the devices at their own

rates, until the NRFD line finally goes high when the

slowest device is ready, and the bus is set to repeat the

sequence with the next data byte.

The sequence just described is used for both data

transfer and the multiline commands. For further information on these commends, refer to paragraph 4.4.

The IEEE-488.1978 standard uses the terminology just

described for the three handshake lines. In some cases,

DAC is substituted for NDAC, and RFD is used in place

of NFRD when referring to those two bus lines. Except

for that terminology, the operation of these lines is identical to the sequence just described.

Data Lines. The IEEE-488 bus uses B data lines that allow

data to be transmitted or received one byte at a time.

These lines, which use the convention DlOl through

D108 rather than the usual D0 through D7 terminology,

are used to transmit both data and the multiline com-

mands, and are bi-directional. Like the remaining bus

lines, the date lines are inverted so that low is true.

4.3 IEEE-488 SET-UP PROCEDURE

Before the Model 181 can be used with the IEEE-488 bus,

the IEEE mode and primary address selector switches must

be set to the appropriate positions. Also, the instrument

must be connected to the bus with a suitable IEEE-488 con-

nector as described in this section. The IEEE-488 connector

and associated switches may be found in the lower left cor-

ner of the rear panel.

1. IEEE Mode Selection. The Model 181 may be set for

either talk only (TO) or addressable operation by setting

the TO/ADDRESSABLE switch on the rear panel to the

desired position. In the addressable mode, the unit may

be controlled by commands given over the bus. For a

description of these commends, refer to paragraphs 4.4

end 4.5. When in the talk only mode, the Model 181 will

ignore any commends given over the bus, but will transmit its normal data string to an external device one byte at

a time, as requested. For formatting of the date string,

see paragraph 4.6.

2. Primary Address Selection. If the Model 181 is to be used

in the addressable mode, the primary address switches

must be set to the correct value. The method used to

determine the primary address depends on the controller

used, but, generally, the numeric value specified in the

controller’s programming language must be the same as

the numeric value set with the Model 181’s primary ad-

dress switches. As shown in Figure 4-3, the Model 181

primary address in set to 5 at the factory; however, any

value between O-30 may be used as long es the value

used in the controller program agrees with the selected

value on the instrument.

4-2

Page 23

NOTE

Both the primary address switches and the

TO/ADDRESSABLE switch are read only upon

power-up. If the switch positions are changed,

the instrument must be turned off and then