Page 1

Instruction Manual

Model 179A

TRMS Multimeter

01982, Keithley Instruments, Inc.

Cleveland, Ohio, U.S.A.

Document Number 32430

Page 2

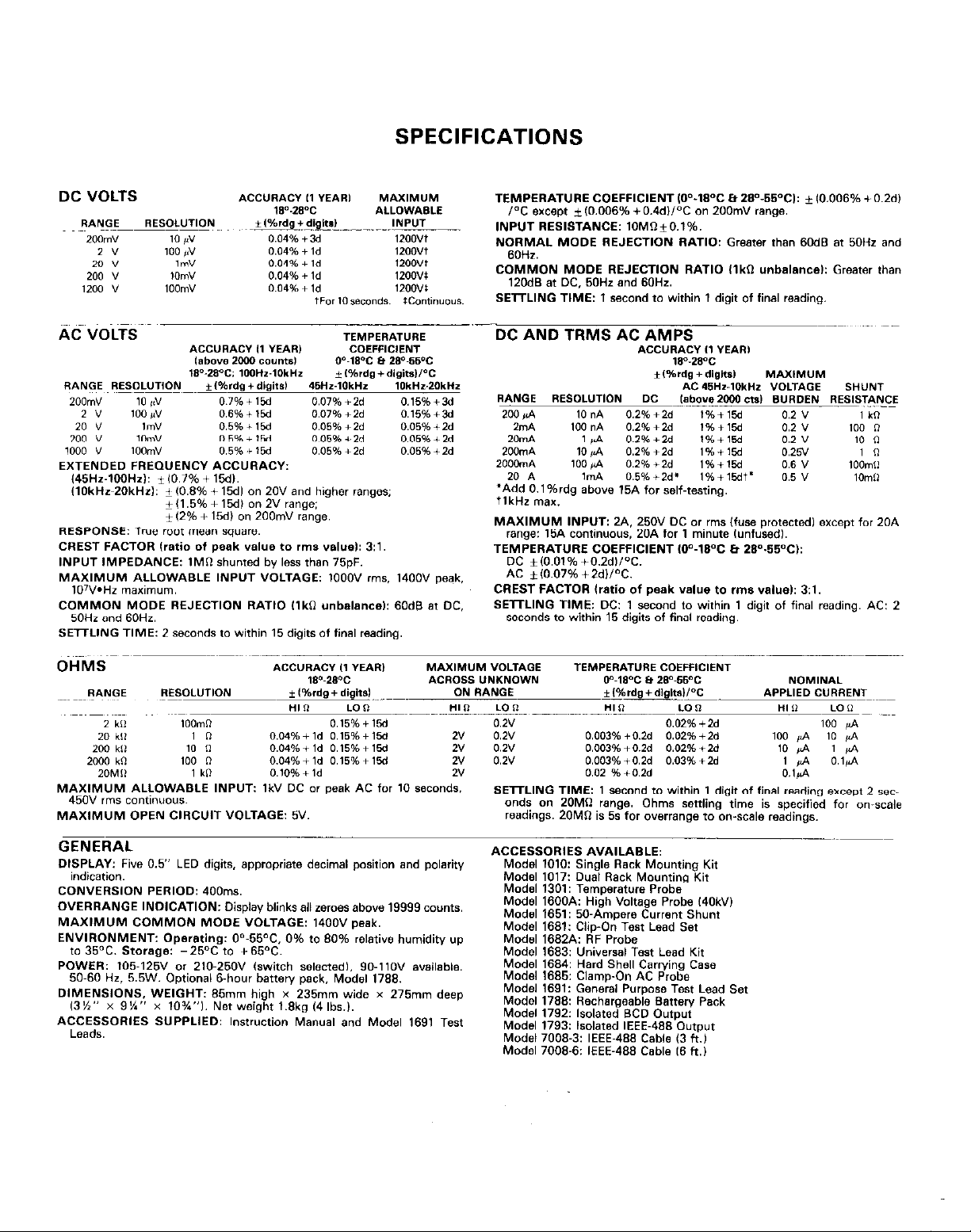

SPECIFICATIONS

DC AND TRMS AC AMPS

20 A A 0.5%+2d* l%+lEdt 0.5” ,Ornll

*Add 0.1 %rdg above 15A fo, self-testing.

tlktir max.

MAXIMUM INPUT: 24 250” DC o, rms (fuse protected, except ‘or 20A

range: l5A continuous. 20A for 1 minute lunfusedl.

TEMPERATTURE COEFFlClENT OF-18°C Et 28°-!XioC,:

DC f,O.Ol% +O.Zd,,T.

AC * lO.O7% +2dlPC.

CREST FACTOR Iratio of peak value to rms valuel: 31.

SETTLING TIME: DC: 1 second to within 1 digit of final reading. AC: 2

seconds to within 15 digits of final reading.

MAXIMUM OPEN CIRCUIT VOLTAGE: 5”

GENERAL

DISPLAY: Five 0.5” LED digits. appropriate decimal position and polarity

indication.

CONVERSION PERIOD: 4OOms.

OVERRANGE INDICATION: Display blinks all zmoes above 19999 counts.

MAXIMVM COMMON MODE VOLTAGE: ,400” oeak.

EWI,R,ONMENT: Operating: 0’

0

c. storage: -25T to +l35oc.

POWER

: 105-125” 0, 210-250” bvitch selectedl. go-,lO” available.

50~60 Hz, 5.5w. Optional B-hour batmy pack. Model 1788.

DIMENSIONS. \n

13%” x 9%” x WY,“,. Netweigirt l.Skg 14 Ix).

ACCESSORIES SUPPLIED: ,nst,wtio” Manual md Mode, ,691 Tesf

Leads.

IEIGHT: 85mm high x 235mm wide x 275mm deco

‘-55°C. 0% to 80% relative humidity up

ACCESSORIES AVAILASLE:

Model 1010: Single Rack Mounting Kit

Model 1017: Dual Rack Mounting Kit

Model 1301: Temperature Probe

Model 1600A: High Voltage Probe ,4Ok”,

Model 1651: 50.Ampere Current Shunt

Model 1581: Clip-On Test Lead Set

Model ISSZA: RF Probe

Model 1683: Universal Test Lead Kit

Model 1584: Herd She,, Carwing Case

Model ,885: Clamp-On AC Probe

Model 1591: General Purpass Test Lead Set

Model 1788: Rechargeable Smtery Pack

Model 1792: Isolated SCD Output

Model 1793: isolated IEEE-488 O”f,,uf

Model 7008-3: IEEE~488 Cable (3 ft.1

Model 7008-6: IEEE-488 Cable 18 tt.,

Page 3

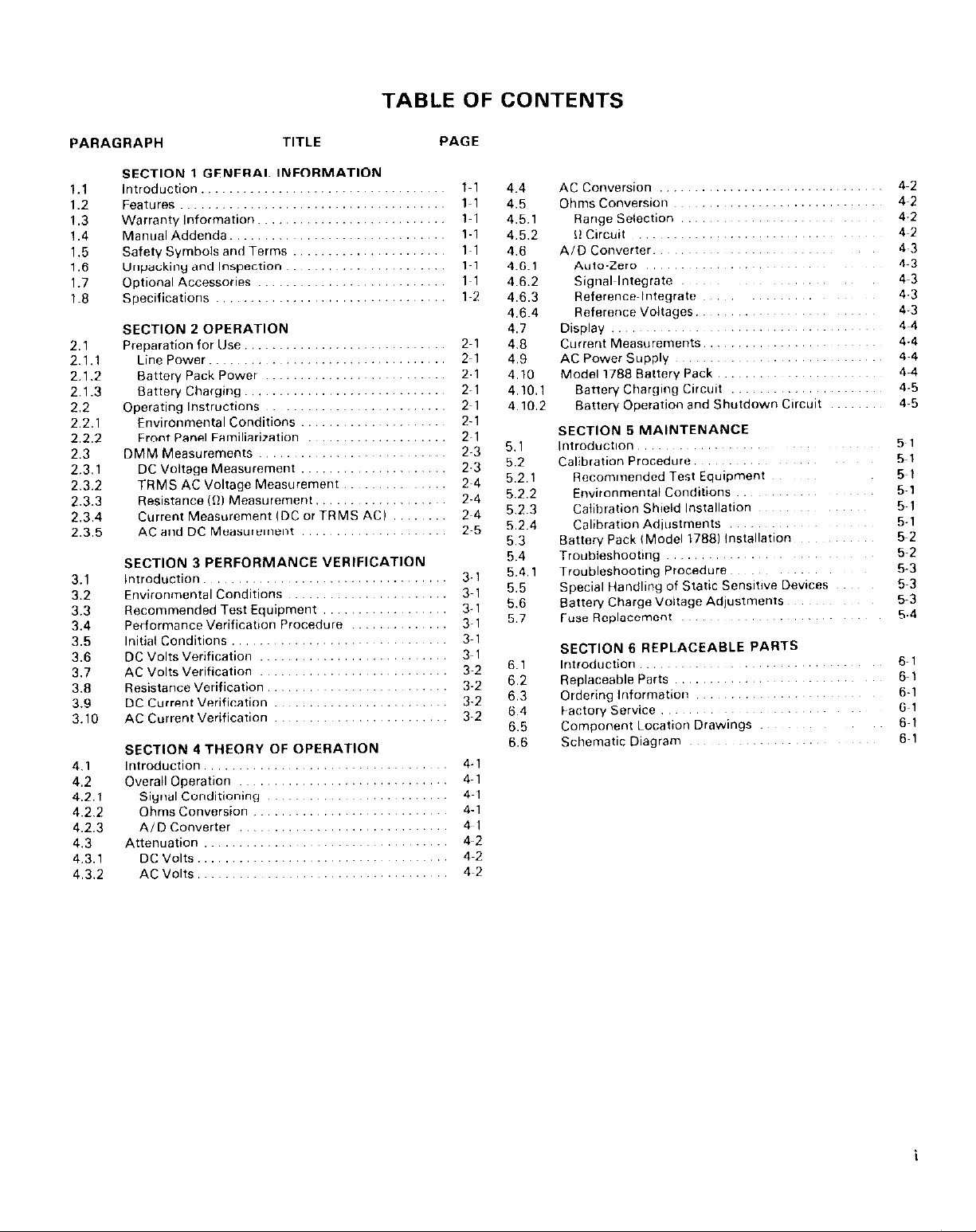

TABLE OF CONTENTS

PARAGRAPH

SECTION 1 GENERAL INFORMATION

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

2.1

2.1.1

2.1.2

2.1.3

2.2

2.2.1

2.2.2

2.3

2.3.1

2.3.2

2.3.3

2.3.4

2.3.5

3.1

3.2

3.3

3.4

3.5

3.6

3.7

3.8

3.9

3.10

4.1

4.2

4.2.1

4.2.2

4.2.3

4.3

4.3.1

4.3.2

Introduction.

Features .....................................

Warranty Information ... ...

ManualAddenda.........~

Safety Symbols and Terms

Unpacking and Inspection ..

Optional Accessories ..........................

Specifications ....... ~, .....

SECTION 2 OPERATION

Preparation for Use.,

LinePower........~.~...........~

Battery Pack Power

Battery Charging

Operating lnsfructi”ns

Environmental Conditions ...... ........

Front Panel Familiarization ..... ...... ....

DMMMeasurements ...........................

DC Voltage Measurement ...... .. ... ..

TRMS AC Voltage Measurement ..

Resistance (111 Measurement ...... ............

Current Measurement IDC or TRMS ACI .. ...

AC and DC Measurement ... .. ...... .. ..

SECTION 3 PERFORMANCE VERIFICATION

Introduction. ........ ...... ..... ... .....

Environmental Conditions ..... ......... .. ...

Recommended Test Equipment .... ..... ......

PerformanceVerification Procedure ....... .. ...

Initial Conditions .. ~,

DCVoltsVerification ...........................

AC Volts Verification

Resistance Verification.

DC Current Verification

AC Current Verification

SECTION 4 THEORY OF OPERATION

Introduction., .......... .... ~, ....... ......

Overall Operation ...

Attenuation ...................................

............

Signal Conditianing

Ohms Cowersian

A/D Converter ....

DC”o,ts........~~

AC”“,ts.............~...~

TITLE PAGE

....................

..................

....................

.....................

.. ~, ... .. .. ...

... ......... ..

..............

................

..

... ..... ...............

...............

..........

.....

...................

..

.. ... .. ... .........

.........

.....

.........

.. .. ... .. .......

......

.........................

.. .........

...........

.........

~, .... ...

..

.....

.. .. .. ...

..... .. ........

.. .. .........

~,

.............

.. ... ... .......

.. ... ...........

..................

~,

...

.....

4.4

4.5

4.5.1

4.5.2

4.6

4.6.1

4.6.2

4.6.3

4.6.4

4.7

2~1

4.8

2~1

4.9

2-l

4.10

2-1

2~1

2-1

2~1

5.1

2-3

5.2

2-3

5.2.1

2~4

..

2-4

2~4

2~5

3-1

3~1

3-1

3~1

3~1

3~1

3-2

3-2

3-2

3-2

4-1

4~1

4~1

4-1

4~ 1

4~2

4~2

4~2

5.2.2

5.2.3

5.2.4

5.3

5.4

5.4.1

5.5

5.6

5.7

6.1

6.2

6.3

6.4

6.5

6.6

SECTION 5 MAINTENANCE

Introduction., ~,

Calibration Procedure

Rccommendcd Tesr Equipment

Environmental Canditions

Calibration Shield Installation

Calibration Adjustments

Batten/ Pack iModel 17881 installation

Troubleshooting ~. ~.

Troubleshooting Procedure

Special Handling of Static Sen&e Devices

Batten/ Charge Voltage Adjustments

Fuse Replacement ~.

SECTION 6 REPLACEABLE PARTS

Introduction ~~~ ,.,, .~,.~ ~~,,,

Replaceable Parts ~. ~, ~.

Ordering Information ~.

Factory Service ~, ~, ~. ~,

Component Location Drawings

SchematicDiagram ~, ~, ~.

~, ~, ~,

~. 4~2

4~2

4-2

4~2

4~3

4-3

4~3

4-3

4-3

4~4

4-4

5~1

51

5~1

5~1

5-1

5-l

52

5-2

53

5-3

5~3

5-4

6-l

6- 1

6-l

6~1

6-l

6~1

Page 4

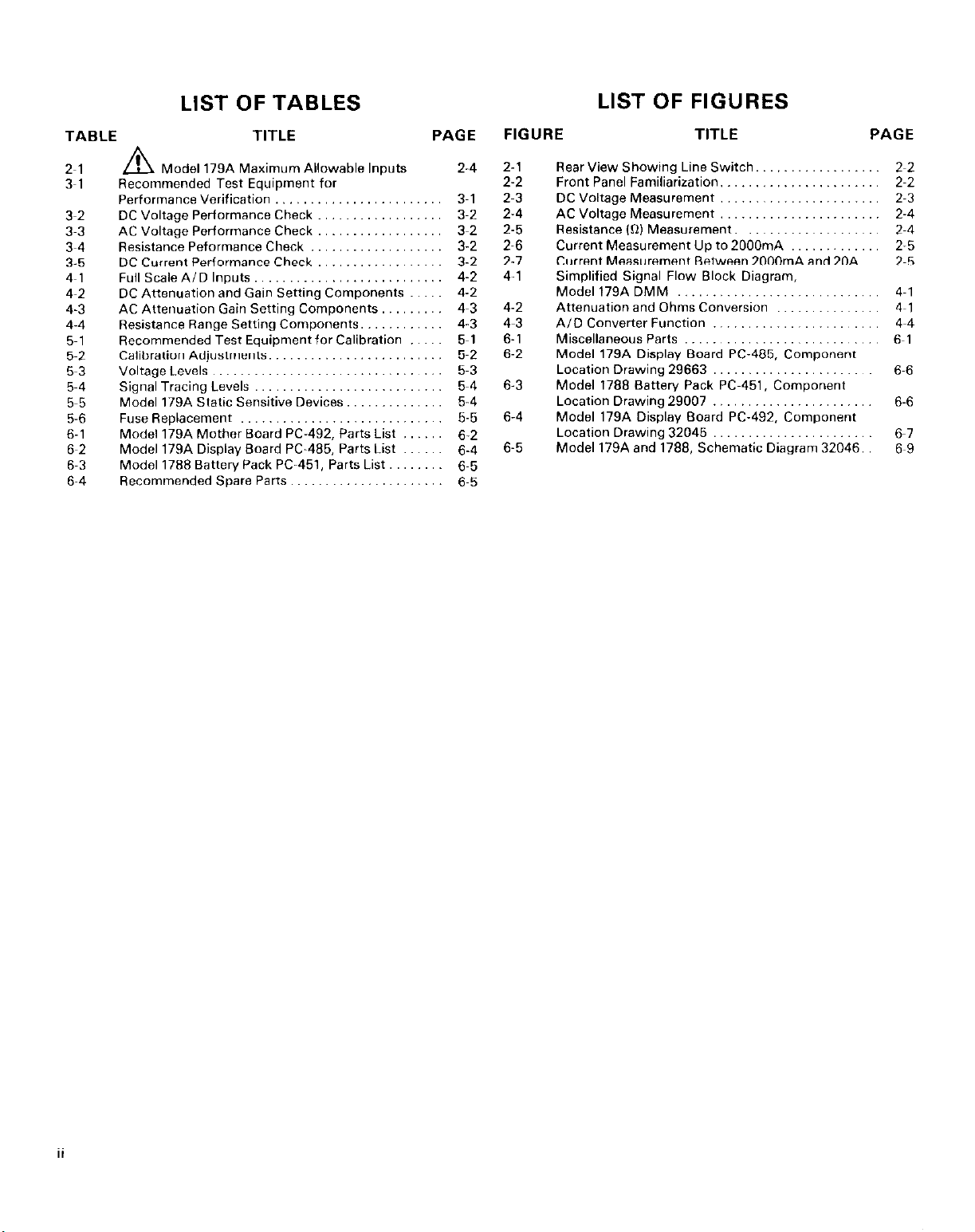

LIST OF TABLES

LIST OF FIGURES

TABLE

3-2

3~3

3~4

3-5

4~1

4-2

4-3

4-4

5~1

5~2

53

5~4

5-5

5-6

6-l

6~2

6~3

6-4

TITLE PAGE

Model 179A Maximum Allowable Inputs

Recommended Test Equipment for

Performanceverification ........................ 3-1

DC Voltage Performance Check .................. 3~2

AC Voltage Performance Check .................. 3-2

Resistance Peformance Check

DC Current Performance Check .................. 3-2

Full Scale A/D Inputs ........................... 4-2

DC Attenuation and Gain Setting Components ..... 4-2

AC Attenuation Gain Setting Components ......... 4-3

Resistance Range Setting Components ............ 4-3

Recommended Test Equipment

Calibration Adjustments ......................... 5-2

Voltage Levels ................................. 5-3

Signal Tracing Levels ...........................

Model l79A Static Sensitive Devices .............. 5-4

Fuse Replacement ............................. 5-5

Model l79A Mother Board PC-492, Parts List ...... 6.2

Model 179A Display Board PC-485, Parts List ...... 6.4

Model 1788 Battery Pack PC-451. Parts List ........ 6.5

Recommended spare parts ...................... 6~5

...................

for

Calibration ..... 5-l

2-4

3-2

5-4

FIGURE

2-1

2-2

2-3

2-4

2-5

2-6

2-7

4-1

4-2

4-3

6-l

6-2

6-3

6-4

6-5

TITLE PAGE

Rear View Showing Line Switch

Front Panel Familiarization

DC Voltage Measurement

AC Voltage Measurement

Resistance(R) Measurement.

Current Measurement Up to 2000mA

Current Measurement Between 2000mA and 20A.

Simplified Signal Flow Block Diagram,

Model 179A DMM

Attenuation and Ohms Conversion

AID Converter Function

Miscellaneous Parts

Model 179A Display Board PC-485, Component

Location Drawing 29663

Model 1788 Battery Pack PC-451. Component

Location Drawing i9007 :. .‘.

Model 179A Display Board PC-492, Component

Location Drawing 32045

Model 179A and 1788, Schematic Diagram 32046.

... ............

..... ... ......

.....................

.....................

.................

...........

2~2

2~2

2~3

2-4

2~4

2-5

2~5

4~1

4~1

4-4

6~1

6~6

6-6

Page 5

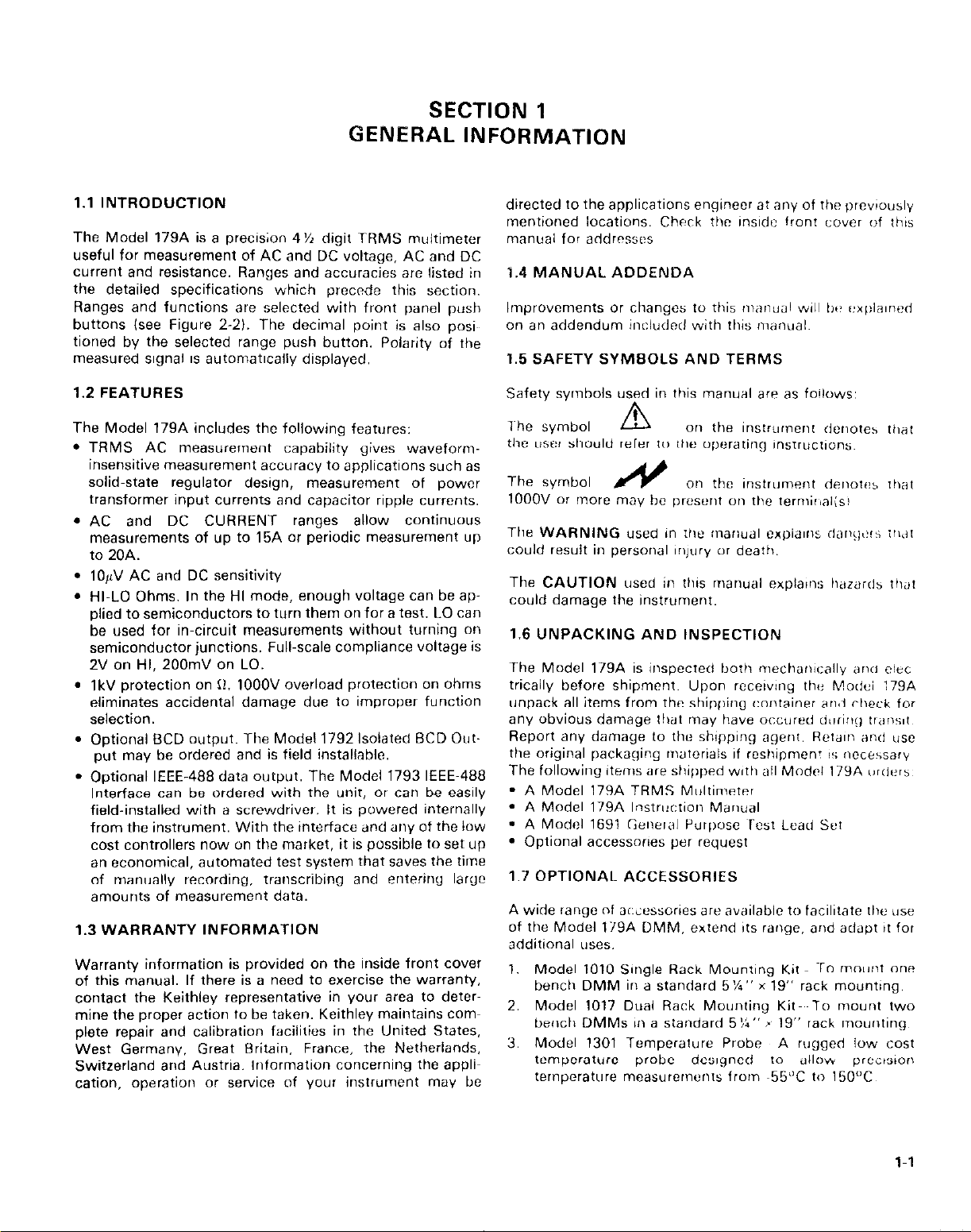

SECTION 1

GENERAL INFORMATION

1.1 INTRODUCTION

The Model 179A is a precision 4% digit TRMS multimeter

useful for measurement of AC and DC voltage, AC and DC

Current and resistance. Ranges and accuracies are listed in

the detailed specifications which precede this section,

Ranges and functions are zselected with front panel push

buttons (see Figure Z-2). The decimal point is also po$

tioned by the selected range push button. Polarity of the

measured signal is automatically displayed.

1.2 FEATURES

The Model 179A includes the following features:

l

TAMS AC measurement capability gives waveforminsensitive measurement accuracy to applications such as

solid-state regulator design, measurement of powcr

transformer input currents and capacitor ripple currents.

. AC and DC CURRENT ranges allow continuous

measurements of up to 15A or periodic measurement up

to ZOA.

l

1OpV AC and DC sensitivity

l

HI-LO Ohms. In the HI mode, enough voltage can be applied to semiconductors to turn them on for a test. LO can

be used for in-circuit measurements without turning on

semiconductor junctions. Full-scale compliance voltage is

2V on Hf. 200mV on LO.

. 1kV protection on II. 1OOOV overload protection on ohms

eliminates accidental damage due to improper function

selection.

. Optional BCD output. The Model 1792 Isolated BCD Out-

put may be ordered and is field installable.

l

Optional IEEE-488 data output. The Model 1793 IEEE-488

Interface can be ordered with the unit, or can be easily

field-installed with a screwdriver. It is powered internally

from the instrument, With the interface and any of the low

c”?.t controllers now on the market. it is possible to set up

an economical, automated test system that saves the time

of manually recording, transcribing and entering large

amounts of measurement data.

1.3 WARRANTY INFORMATION

Warranty information is provided on the inside front cover

of this manual. If there is a need to exercise the warranty.

contact the Keithley representative in your area to determine the proper action lo be taken. Keithley maintains come

plete repair and calibration facilities in the United States.

West Germany. Great tlritain, France, the Netherlands.

Switzerland and Austria. Information concerning the appli~

cation, operation or sewice of your instrument mav be

directed to the applications engineer at any of the previously

mentioned locations. Check thr inside front cover of this

manual for addwsst!s

1.4 MANUAL ADDENDA

Improvements or changes to tilis manuill will t,l, r~x~:la~ned

on an addendum in<:/udcd with this manuals

1.5 SAFETY SYMBOLS AND TERMS

Safety symbols used in this manual are as follows:

The symbol

A

on the instrument denotes that

the user should refer to the operatin:, instructions~

The symbol

1OOOV or more may bc present

on the

instrument

on

the ternlir,al(si

derrotcs Ihilt

The WARNING used in the manual exl~ia~ns rls~q,:!~ :~u!

could result in personal injury or death

The CAUTION used in illis manual axpla~n:; hazards ~hrft

could damage the instrument.

1.6 UNPACKING AND INSPECTION

The Model 179A is inspecred both mecflai~~cally ano c1e.c

tricallv before shipments Upon receiving tfw Modui 179A

unpack all items from the shipping container and check for

any obvious damage Illat may have “CCIIIZ’~ dc,rir\!j i~i~ns~t

Report any damage to the shipping agent, Rela~n anti use

the original packqing tmatcriais 11 rcst,ipmen: 1s rnccessarv

The following items are sflipped with all Modal 179A urtitils

- A Model 179A TRMS Multimeter

l

A Model 179A Instn~ctior Manual

l

A Model 1691 tane~;rl Purpose To51 Lead Set

l

Optional accessories per request

1.7 OPTIONAL ACCESSORIES

A wide range of accessories are available to facilitate the use

of the Model 179A DMM. extend its range. and adapt it for

additional uses.

1. Model 1010 Single Rack Mounting Kit To mount one

bench DMM in a standard 5%” x 19” rack mounting.

2. Model 1017 Dual Rack Mounting Kit&To mount two

berlcfi DMMs in a standard 5%” I 19” rack amounting

3. Model 1301 Temperature Probe A rugged low cost

temperature probe deslgncd to allow precision

temperature rneasuremcn~s from ~55“C to 150°C

1-l

Page 6

Range: -55oc to 15ooc

Output: lmVI°C; compatible with any DMM with at

least 10MII input impedance

Accuracy: kZ°C from O” to 100°C; f3”C from -55’

to O°C and 100° to 150°C

Power: 9V alkaline or C-Zn (NEDA 16041 battery.

4. Model 1600A High Voltage Probe extends the DMM to

40kV.

Maximum Input: 40kV DC or peak AC to 300Hz

Input Resistance: IOOOMR

Division Ratio: 1OOO:l (into lOMa)

Ratio Accuracy (into lOM12 DMM): +2.5% from 1kV

to 40kV DC; -3dB at 300Hr AC

Operating Temperature: O” to 50°C

5. Model 1651 50.Ampere Current Shunt-The external

0.00112 + 1%.

measurements from O-50A DC and 20.50A AC.

6. Model 1681 Clip-On Test Lead Set contains two leads,

1.2m (48 inches) long terminated with banana plugs and

spring action clip-on probes.

7. Model 1682A RF Probe permits voltage measurements

from IOOkHz to 250MHr.

AC to DC transfer accuracy: +ldB from 1OOkHz

to 250MHz at IV, peak responding, calibrated

in rms of a sine wave. compatible with instruments

with lOML2 input resistance

Voltage Range: 0.25V to 15V rms

Maximum Allowable Input: 42V AC peak, ZOOV (DC

+ AC peak1

8. Model 1683 Universal Test Lead Kit consists of two test

leads. 1.2m (48 inches) long with 12 screw-in tips, 2

banana plugs, 2 spade lugs, 2 alligator clips with boots,

2 needle tips with chucks and 4 heavy duty tip plugs.

9. Model 1684 Hard Shell Carrying Case-Hard vinyl case,

1OOmm x 300mm x 350mm (4” x 13” x 14”) has a fitted

4.terminal shunt permits current

foam insert with room for the Model 179A, instruction

manual and small accessories.

10. Model 1685 Clamp-On AC Probe measures AC current

by clamping onto a single conductor. Interruption of the

current path is unnecessary. The Model 1685 detects

current by sensing the magnetic field produced by the

current flow.

Range: 2, 20 and 200A rms

Accuracy: i-4% of range at 60Hz; *6% of range at

5OHz

Temperature Coefficient: iO.O5%/‘C on 20A and

200A range; +0.3%/OC on 2A range

Maximum Allowable Current: 300A rms

Maximum Conductor Voltage: 600V rms

Conversion Ratio: O.lV/A rms

11. Model 1691 General Purpose Test Lead Set consists of

two 0.9lmm (36 inches) test leads with probe tips terminated in banana plugs.

12. Model 1788 Rechageable Battery Pack provides six

hours minimum operation from full charge, recharges

within 14 hours and is field installable.

13. Model 1792 Isolated BCD Output provides parallel BCD

data output including sign, overrange and busy. Field installable.

14. Model 1793 Isolated IEEE-488 Interface-Field in-

stallable option provides isolated data output. Switchselectable TALK ONLY or ADDRESSABLE modes.

Mounts within and powered by the Model 179A. Model

7008 IEEE-488 cable is available.

1.8 SPECIFICATIONS

For Model 179A detailed specifications, refer to the

specifications that precede this section.

1-2

Page 7

SECTION 2

OPERATION

2.1 PREPARATION FOR USE

The Model 179A is shipped ready to use. The instrument

may be powered from line voltage or from rechargeable bat-

teries (when the optional Model 1788 Rechargeable Battery

Pack is installedl.

21.1 Line Power

The Model 179A is provided with a three-wire line cord

which mates with third-wire grounded receptacles. Connect

the instrument to AC line power as follows:

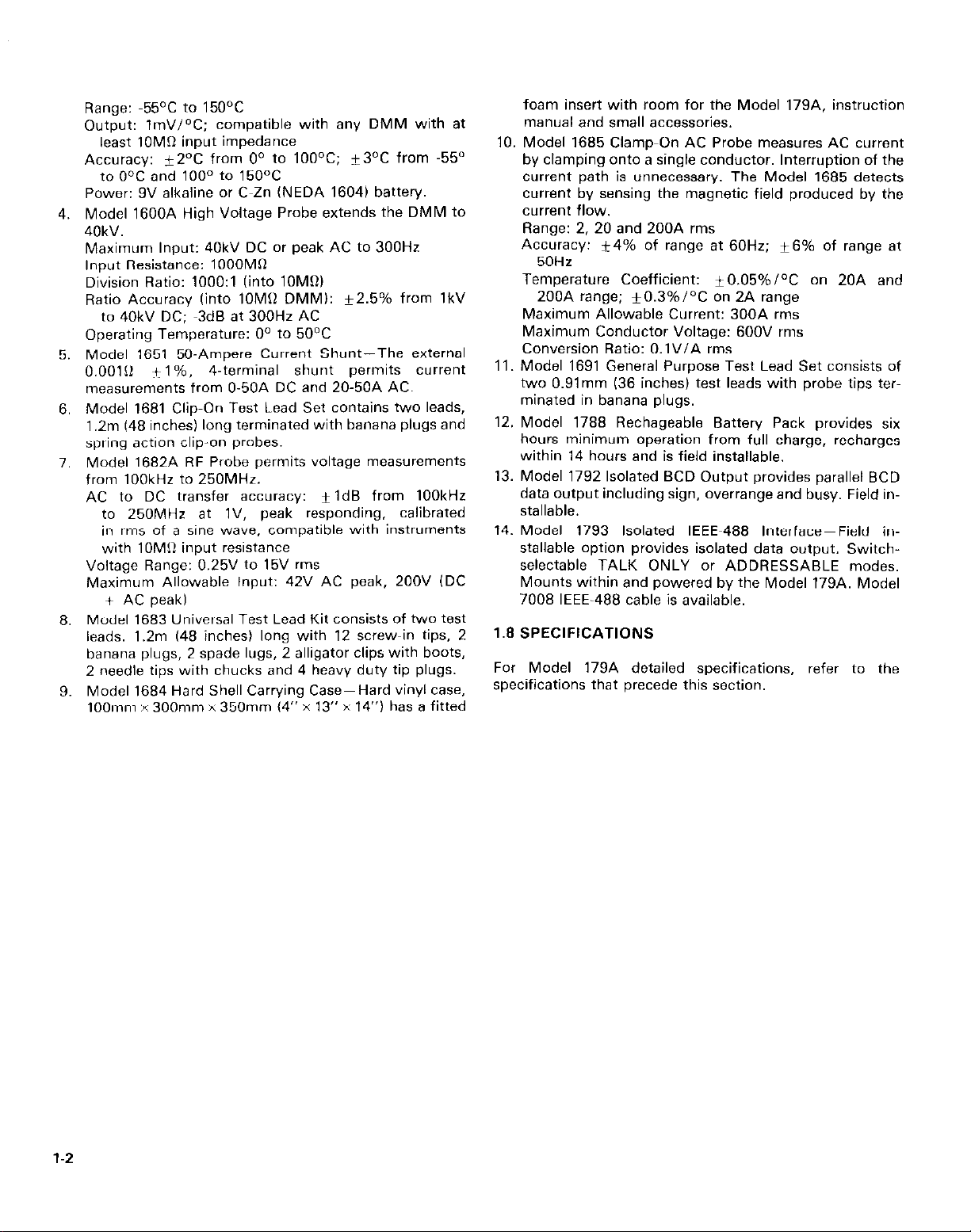

1. Set the LINE VOLTAGE switch an the back of the instrument to correspond to line voltage available. Ranges are

105 to 125 volts and 210 to 250 volts AC as shown in

Figure 2-l.

CAUTION

Connect only to the line voltage

selected. Application of incorrect

voltage can damage the instrument.

2. Plug the power cord into a properly grounded outlet.

WARNING

Ground the instrument through a properly grounded receptacle before operation. Failure to ground the instrument

can result in severe injury or death in the

event of short circuit or malfunction.

2.1.2 Battery Pack Power

The Model 179A may also be operated from rechargeable

sealed lead-acid batteries contained in the optional Model

1788 Battery Pack. The battery pack will operate the 179A

for up to six hours. Circuits within the battery pack will

automatically shut down the instrument when the battery

charge is insufficient to maintain accurate readings. Refer to

Section 5, paragraph 5.3 for installation procedures.

2.1.3 Battery Charging

After the Model 1788 Battery Pack is installed in the Model

179A it can be charged and recharged as follows:

1. Connect the instrument to line power as described in

paragraph 2.1.1.

2. With the power switch off, the battery charge circuitry is

automatically engerized to charge the battery at the max-

imum rate. When the battery pack is first installed, or if it

is completely discharged, allow it to charge for at least 14

hours,

NOTE

For maximum battery life, do not allow the

battery pack to remain completely discharg-

ed. Constant charging will not harm either

the battery pack or the instrument. Allowing

the batten, pack to discharge below 7.2V

and remain discharged will ruin the battery

pack.

3. When the 179A is in use on line power, the bart~?ry

charger maintains a trickle charge on the battery pack.

2.2 OPERATING INSTRUCTIONS

2.2.1 Environmental Conditions

All measurements should be made at iii, ;Imlwnt

temperature within the range of O°C to 55°C. anti with a

relative humidity of 0% to 80% up to 35OC. For instliii w:~s

above 35OC derate humidity 3% per “C up to 55”C, If tilt sn

strument has been subjected to extremes of temperature,

allow sufficient time for internal temperatures to react1 cnw

ronmental conditions. Typically, it takes orx hwIr !o

stabilize a unit that is 10°C 118”Fl out of spei:lf!ixi

temperature range.

2.2.2 Front Panel Familiarization

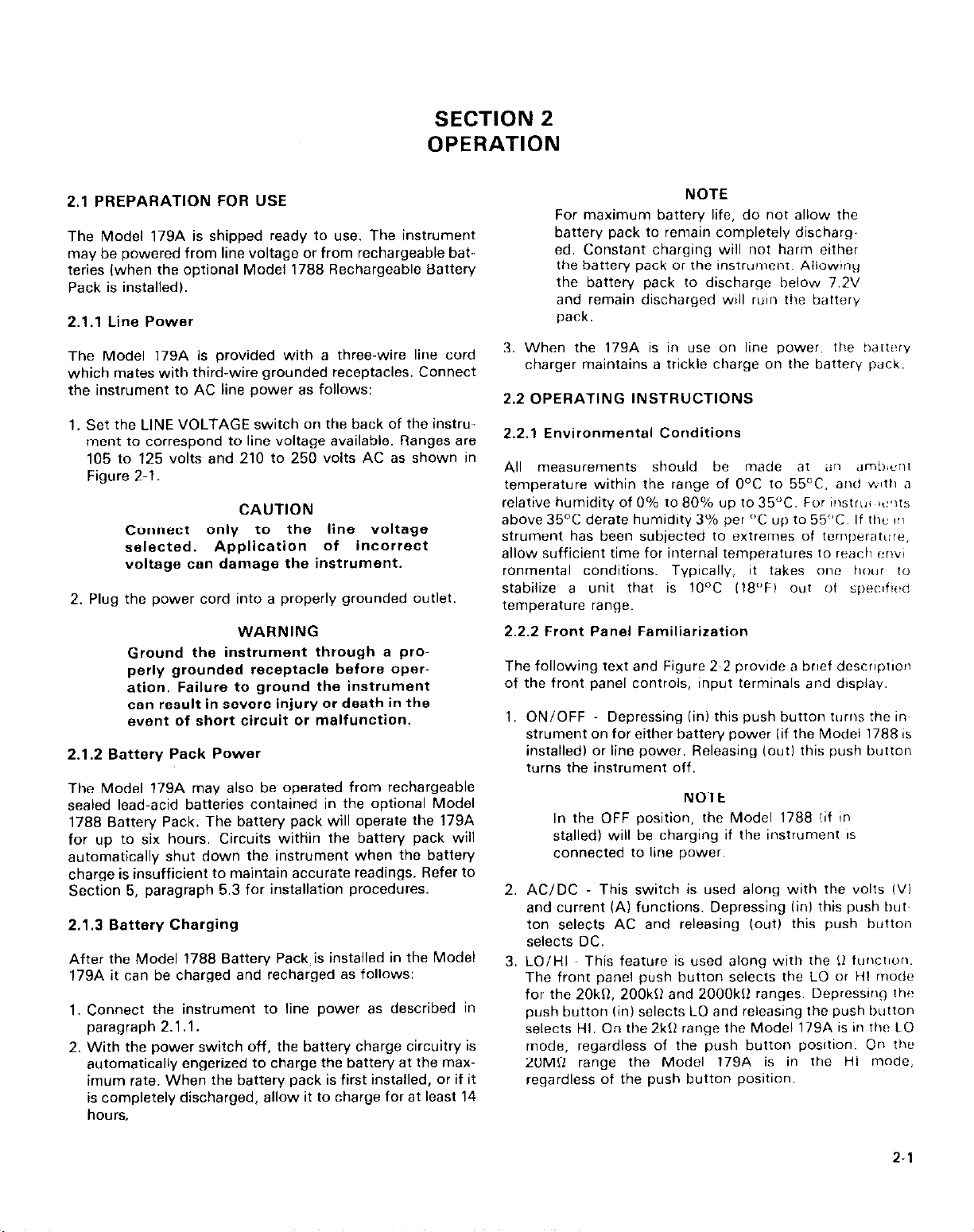

The following text and Figure 2~2 provide a brief description

of the front panel controls, input terminals and display.

ON/OFF Depressing (in) this push button turns the ins

strument on for either battery power lif the Model 1788 is

installed) or line power. Releasing (out1 this push button

turns the instrument off.

NOTE

In the OFF position, the Model 1788 !if in

stalled) will be charging if the instrument 1s

connected to line power.

AC/DC This switch is used along with the volts IV1

and current (A) functions. Depressing linl this push butt

ton selects AC and releasing lout) this push button

selects DC.

LO/HI This feature is used along with the !! funcllon.

The front panel push button selects the LO or HI mode

for the 20kR. 200k12 and 2000kU ranges. Depressiw the

push button lin) selects LO and releasing the push button

selects HI. On the 2kI2 range the Model 179A is in rhc LO

mode, regardless of the push button position. On the

20MR range the Model 179A is in the HI mode,

regardless of the push button position.

2-l

Page 8

These adjustments are used only for calibration. They are not intended for

adjustment during operation.

Figure 2-l. Rear View Showing Line Switch

2-2

MlNUS SIGN DISPLAYED

PLVS SIGN IMPLIED

OVERRANGE IS INDICATED BY A FLASHING “0000” EXCEPT

ON THE 1000 VOLT RANGE

‘MENT

Figure 2-2. Model 179A Front Panel View

Page 9

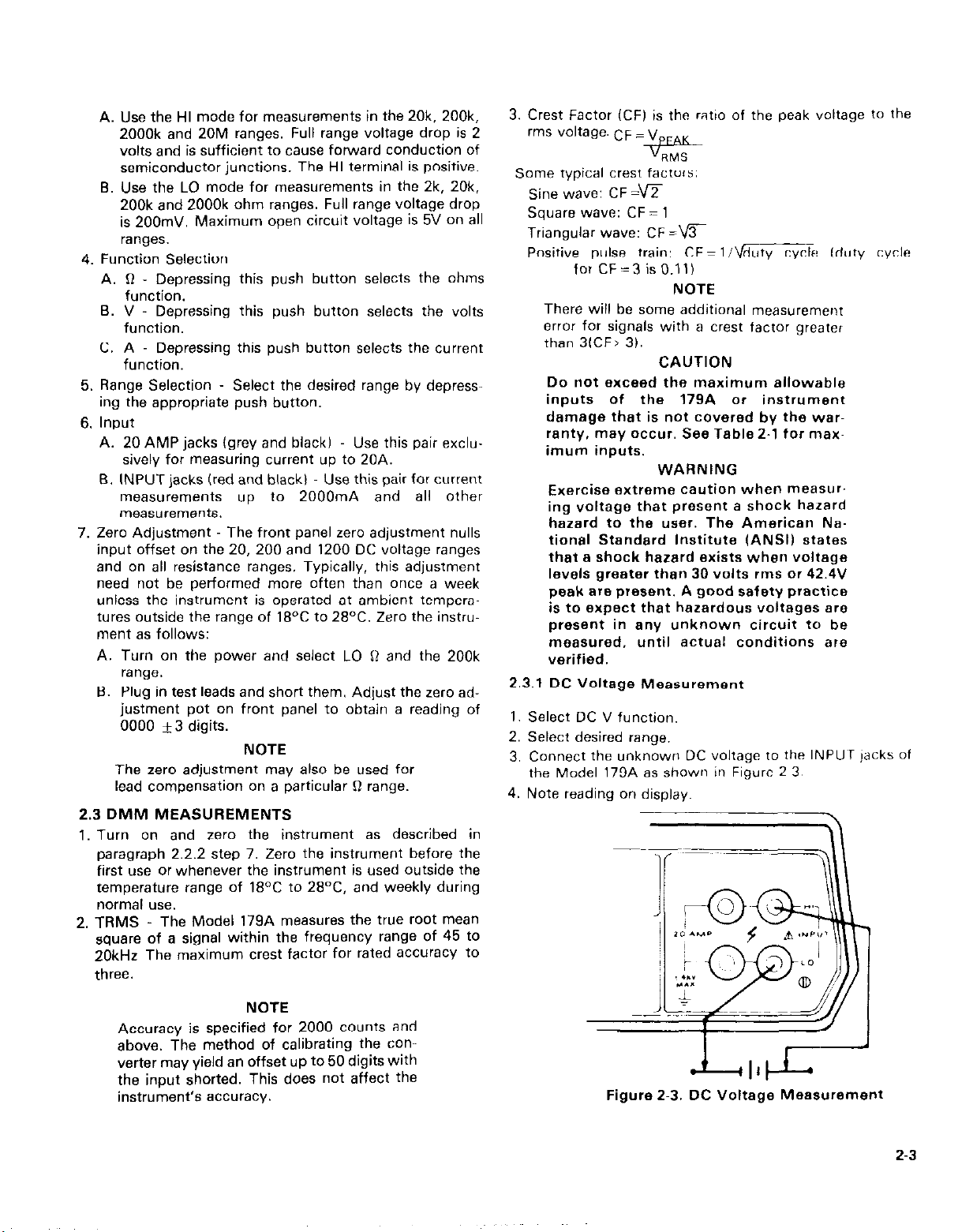

A. Use the HI mode for measurements in the 20k. 200k.

2000k and 20M ranges. Full range voltage drop is 2

volts and is sufficient to cause forward conduction of

semiconductor junctions. The HI terminal is positive.

B. Use the LO mode for measurements in the 2k, 20k.

200k and 2000k ohm ranges. Full range voltage drop

is 2OOmV. Maximum open circuit voltage is 5V on all

ranges.

4. Function Selection

A. R Depressing this push button selects the ohms

function.

B. V Depressing this push button selects the volts

function.

C. A Depressing this push button selects the current

function.

5. Range Selection Select the desired range by depress-

ing the appropriate push button.

6. Input

A. 20 AMP jacks (grey and black) Use this pair exclu-

sively for measuring current up to 20A.

6. INPUT jacks (red and black1 Use this pair for current

measurements up to 2000mA and all other

measurements.

7. Zero Adjustment The from panel zero adjustment nulls

input offset on the 20, 200 and 1200 DC voltage ranges

and on all resistance ranges. Typically. this adjustment

need not be performed more often than once a week

unless the instrument is operated at ambient temperatures outside the range of 1WC to 28OC. Zero the instrument as follows:

A. Turn on the power and select LO II and the 200k

range.

E

Plug in test leads and short them. Adjust the zero adjustment pot on front panel to obtain a reading of

0000 +3 digits.

NOTE

The zero adjustment may also be used for

lead compensation on a particular R range.

2.3 DMM MEASUREMENTS

1. Turn on and zero the instrument as described in

paragraph 2.2.2 step 7. Zero the instrument before the

first use or whenever the instrument is used outside the

temperature range of 18OC to 28OC. and weekly during

normal use.

2. TRMS The Model 179A measures the true root mea”

square of a signal within the frequency range of 45 to

20kHz The maximum crest factor for rated accuracy to

3. Crest Factor (CF) is the ratio of the peak voltage to the

r”X

Vdtag‘3

CF = V

e-

Some typical crest factors:

Sine wave: CF =E

Square wave: CF = 1

Triangular wave: CF =w

Positive pulse train: CF- l/Vdufy cycle (duty cycle

forCF=3is0.11)

NOTE

There will be some additional measurement

error for signals with a crest factor greater

than 3lCF> 3).

CAUTION

Do not exceed the maximum allowable

inputs of the 179A or instrument

damage that is not covered by the warranty, may occur. See Table 2-l for max-

imum inputs.

WARNING

Exercise extreme caution when measuring voltage thaf present a shock hazard

hazard to the user. The American National Standard Institute (ANSI) etetes

that e shock hazard exists when voltage

levels greeter then 30 volts rms or 42.4V

peak are present. A good safety practice

is to expect that hazardous volfages ere

present in sny unknown circuit fo be

measured, until actual conditions are

verified.

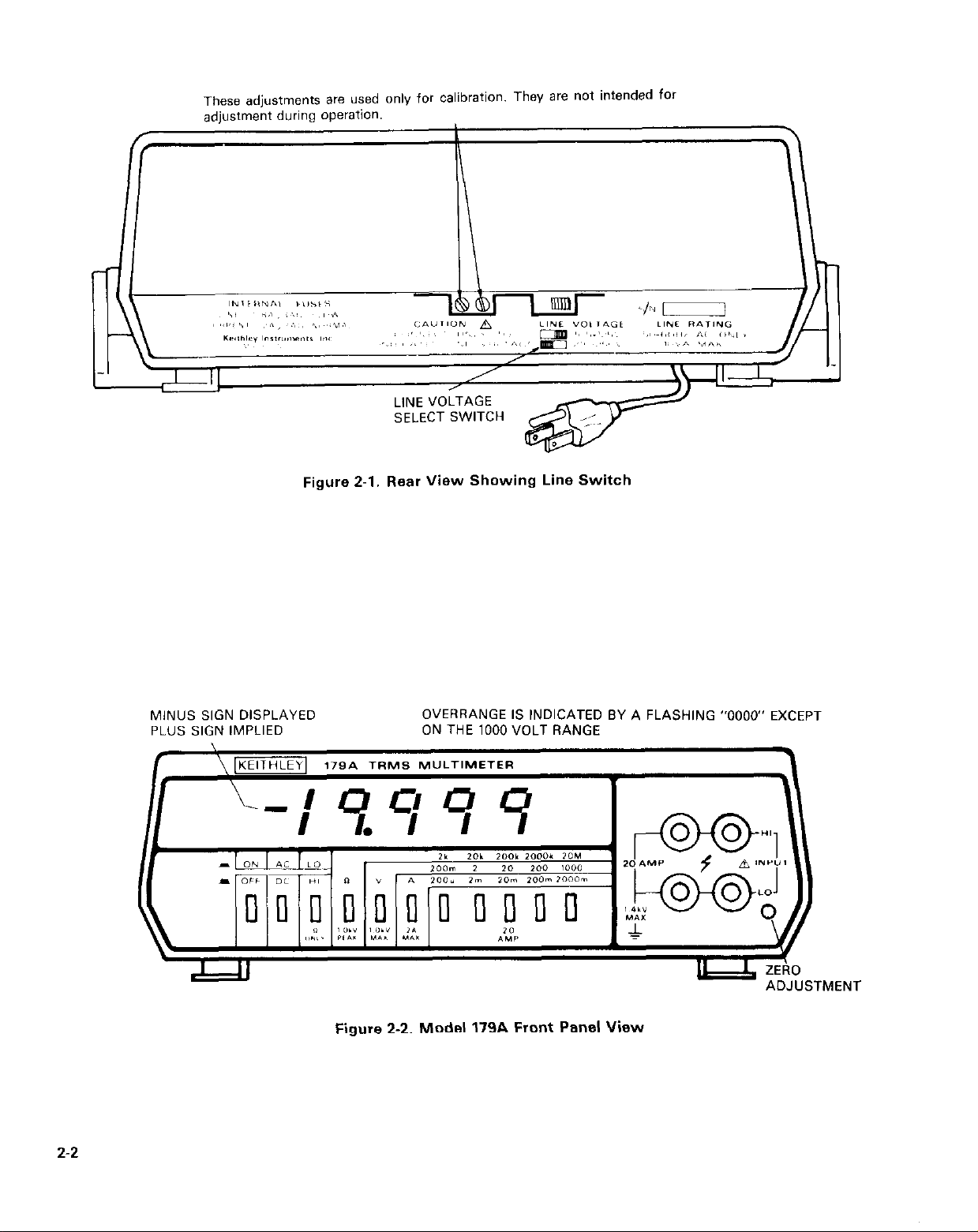

2.3.1 DC Voltage Measurement

1. Select DC V function.

2. Select desired range.

3. Connect the unknown DC voltage to fhe INPU~r jacks of

the Model 179A as shown in Figure 2~3.

4. Note reading on display.

NOTE

Accuracy is specified for 2000 counts and

above. The method of calibrating the converter may yield an offset up to 50 digits with

the input shorted, This does not affect the

instrument’s accuracy.

Figure 2.3. DC Voltage Measurement

2-3

Page 10

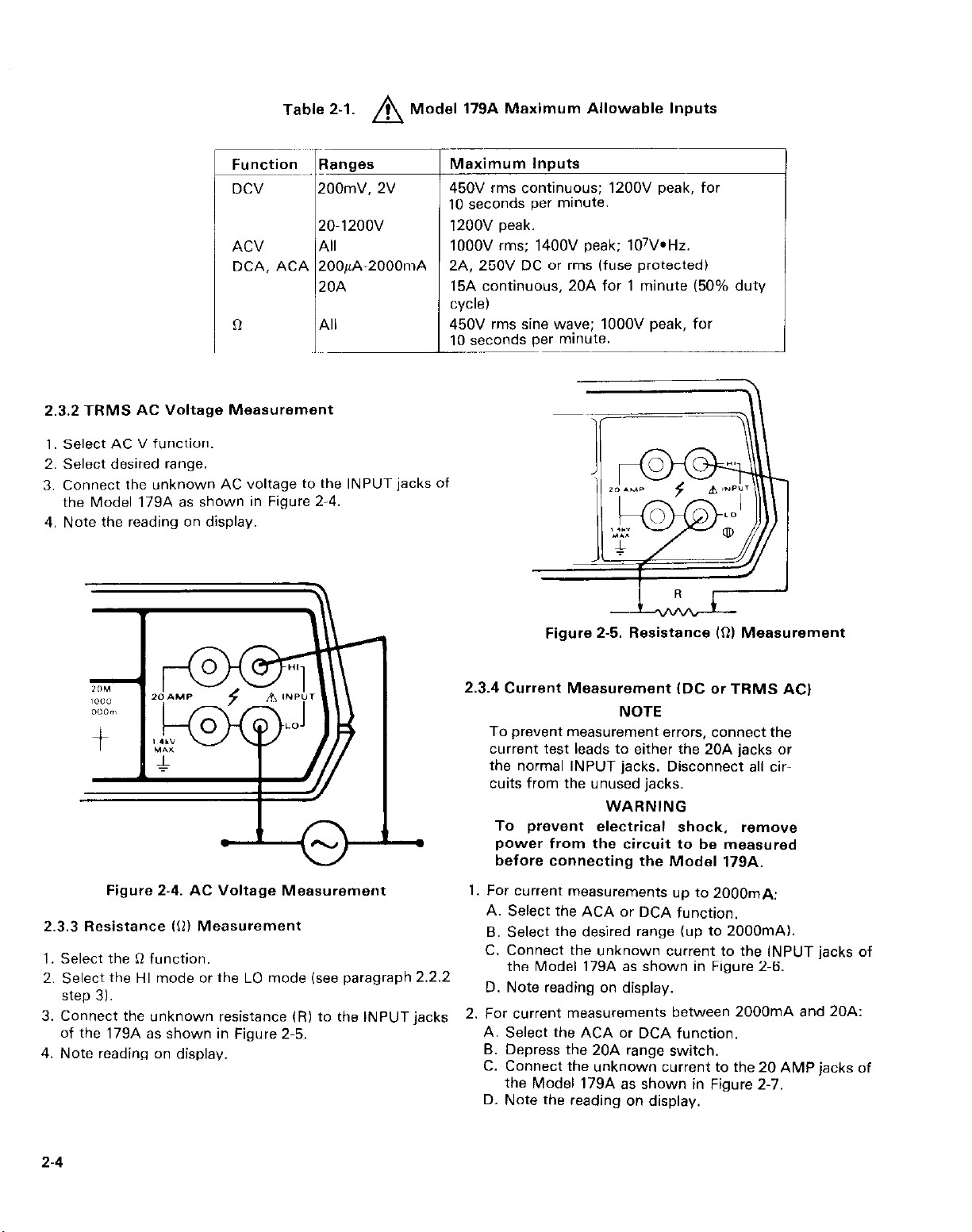

Table 2-1. A Model 179A Maximum Allowable Inputs

2.3.2 TRMS AC Voltage Measurement

1. Select AC V function

2. Select desired range.

3. Connect the unknown AC voltage to the INPUT jacks of

the Model 179A as shown in Figure 2-4.

4. Note the reading on display.

-Maximum Inputs

450V rms continuous; 1200V peak, for

lo seconds per minute.

1200V peak.

1OOOV rms; 1400V peak; 107WHz.

2A, 250V DC or rms (fuse protected)

15A continuous, 20A for 1 minute (50% duty

cycle1

450V rms sine wave; 1OOOV peak, for

lo seconds per minute.

Figure 2-4. AC Voltage Measurement

2.3.3 Resistance III) Measurement

1. Select the 12 function.

2. Select the HI mode or the LO mode (see paragraph 2.2.2

SteD 31.

3. Connect the unknown resistance (RI to the INPUT jacks

of the 179A as shown in Figure 2-5.

4. Note reading on display.

Figure 2-5. Resistance InI Measurement

2.3.4 Current Measurement IDC or TRMS AC)

NOTE

To prevent measurement errors, connect the

current test leads to either the 20A jacks or

the normal INPUT jacks. Disconnect all circuits from the unused jacks.

WARNING

To prevent electrical shock, remove

power from the circuit to be measured

before connecting the Model 179A.

1. For current measurements up to 20OOmA:

A. Select the ACA or DCA function,

B. Select the desired range (up to 2000mA).

C. Connect the unknown current to the INPUT jacks of

the Model 179A as shown in Figure 2-6.

D. Note reading on display.

2. FW current measurements between 2000mA and 20A:

A. Select the ACA or DCA function.

B. Depress the 20A range switch.

C. Connect the unknown current to the 20 AMP jacks of

the Model 179A as shown in Figure 2.7.

D. Note the reading on display.

2-4

Page 11

Figure 2-6. Current Measurements up to 2006mA

NOTE

Up to 15A may be applied continuously

without degradation of the measurement

due to self-heating effects. For currents between 15A and 20A. specified accuracy can

only be obtained when measurements are

limited to a 50% duty cycle (i.e., apply the

current for a maximum of one minute and

then allow et least one minute for cooling

before the next measurement).

NOTE

The test leads used must be capable of

handling 20A and it is recommended that

they be twisted (see Figure 2-71 to minimize

external fields which could affect the Model

179A or other equipment. Also, keep the

test leads as short es possible to mlnlmlze

voltage drop.

Figure 2-7. Current Measurements Between 2000mA

and 20A

2.3.5 AC + DC Measurement

Use the Model 179A to meawre TRMS on ;I sigrw WIWII

has both AC and DC components as lollows:

1. Measure and record the TRMS AC con~~onent as

described in paragraph 2.3.2.

2. Measure and record the DC component as descritxxl III

paragraph 2.3.1.

3. Compute the rms value from the followim] e(/uat~on

ERMs im

2-512-6

Page 12

Page 13

SECTION 3

PERFORMANCE VERIFICATION

3.1 INTRODUCTION

Performance verification may be done upon receipt of the

instrument to ensure that no damage or misadjustment has

occurred during transit. Verification may also be performed

whenever there is question of the instrument’s accuracy and

following calibration if desired.

NOTE

For instruments that are still under warranty

(less than 12 months since date of

shipment), whose performance falls outside

specifications at any point, contact your

Keithley representative or the factory imp

mediately.

3.2 ENVIRONMENTAL CONDITIONS

Measurements should be made at 18-28°C and at less than

80% relative humidity.

3.3 RECOMMENDED TEST EQUIPMENT

Table 3-l lists all the test equipment required for verifi-

cation. If alternate equipment is used, the alternate test

equipment’s specifications must be at least as good as the

equipment specifications listed in Table 3~1.

3.4 PERFORMANCE VERIFICATION PROCEDURE

Use this procedure to verify the Model 179A’s accuracy. If

the Model 179A is out of spec. proceed to maintenance

(calibration) Section 5, unless the Model 179A is under

warranty.

NOTE

Verification should be performed by

qualified personnel using accurate and

reliable test equipment.

WARNING

Some procedures require the use of

high voltage. Take care to prevent contact with live circuits which could cause

electrical shock resulting in injury or

death.

3.5 INITIAL CONDITIONS

Before

must meet the following conditions:

1. If the instrument has been subjected to extremes of

2. Turn on the 179A DMM and allow it to warm up for ten

3. Zero the instrument as described in paragraph 2.2.2

3.6 DC VOLTS VERIFICATION

1. Select the DC V function.

2. Connect the DC Calibrator iltem A, Table 3~11 ro the

3. Select the 200mV range. and apply positive 1OOmVDC to

4. Select each remaining range and apply ihe required

5. Repeat all checks with negative voltage.

beginning the verification procedure, the instrument

temperature, allow internal temperatures to stabilize for

one hour minimum at the environmental conditions

specified in paragraph 3.2.

minutes. The instrument may be operated from either

line power or battery pack power. as Ion51 as the battery

pack has been fully charged as described m paragraph

2.1.3.

stea 7.

instrument.

the DMM. The reading must be within the limits specified

in Table 3~2.

voltage as specified in Table 3~2. verify that the reading is

within specifications.

Table 3-l. Recommended Test Equipment for Performance Verification

MFR MODEL

Fluke

Fluke

Fluke

ESI

Valhalla 2500E

343A

5200A

5215A

RS725

DC Calibrator

AC Calibrator

Decade Resistor

Current Calibrator

SPECIFICATION

.~~

D.lV, 1v. 1ov. 1oov. 1ooov

f 0.002% or zouv

.lV, 1v. 1ov. 1oov

* .022%

1ooov @t .044%

1.9kR. 19k12. 190kI1

1.9MR. lOM12, ,O.Ol%

lOO,‘A, lmA, lOmA. lOOmA,

1A. 10A. +0.03%

3-l

Page 14

Table 3-Z. DC Voltage Performance Check

Table 3-4. Resistance Performance Check

Allowable Readings

v&age

200mV

2v

2ov

zoov

12oov

3.7 AC VOLTS VERIFICATION

1. Select the AC V function.

2. Connect the AC Calibrator (Item B, Table 3-l) to the

DMM. Set the calibrator frequency to 1kHz.

3. Set the DMM to the 200mV range and apply 1OOmV AC

to the DMM. The reading must be within the limits

specified in Table 3.3.

4. Select the 2. 20 and 200 volt ranges and apply the re-

quired voltages es specified in Table 3-3. Verify that the

readings are within specifications.

5. To check the 1OOOV range, connect the AC Calibrator

Amplifier (Item C, Table 3-l) to the output of the AC

Calibrator per the manufacturer’s instructions. Set it for

en output of 1OOOV AC rms and verify that the DMM

reading is within the specified limits.

Range

200mV

2v

2ov

2oov

1ooov

lOO.OOmV

1 .oooov

1o.ooov

1oo.oov

1ooo.ov

Table 3-3. AC Voltage Performance Check

at 180 to 28OC

99.93 to 100.07

0.9995 to 1.0005

9.995 to 10.005

99.95 to 100.05

999.5 to 1000.5

Allowable Readings

99.15 to 100.85

0.9925 to 1.0075

9.935 to 10.065

99.35 to 100.65

393.5 to 1006.5

Resistance

19.000kR

190.00kR

1.9000k12

19.000Mn

1.9000k0

19.000kI2

190.00k11

1900.0k$2

3.9 DC CURRENT VERIFICATION

1. Select the DC A function.

2. Connect the DC current source (Item E. Table 3-l!to the

DMM.

3. Select the 200/iA range and apply a current of lOO.OOfiA

to the DMM. The reading must be within the limits in

Table 3-5.

4. Select each range and apply the required current as

specified in Table 3-5. Verify that the reading is within

specifications.

Table 3-5. DC Current Performance Check

3.10 AC CURRENT VERIFICATION

Allowable Reading!

at 18” to 28°C

18.991 to 19.009k11

189.91 to 190.09kR

:899.1 to 1900.9kR

18.980 to 19.020MI2

1.8957 to 1.9043kR

18.957 to 19.043kR

189.57 to 190.43k12

1895.7 to 1904.3k12

I

Allowable Readings

to 28°C

99.78 to 100.22pA

0.9978 to 1.0022mA

9.978 to 10.022mA

99.78 to 100.22mA

997.8 to 1002.2mA

9.348 to 10.052A

3.8 RESISTANCE VERFICATION

1. Select the a function.

2. Set the HI/LO push button to HI and select the 20kQ

range.

3. Connect the decade resistor (Item D, Table 3-l) to the

DMM.

4. Set the decade resistor to zero and measure the

resistance of the test leads. Subtract this reading from

the displayed reading in all of the following steps.

5. Set the decade resistor to 19.000k12. Verify that the

reading is within the limits specified in Table 3.4.

6. Select the next range and measure the next resistance es

specified in Table 3-4. Verify that each reading is within

specifications. Test the remaining ranges in the table,

switching the HI/LO push button es indicated.

3-2

Since AC Current uses the same circuitry as AC Volts and

DC Current already checked in paragraphs 3.6 and 3.9, no

additional accuracy checks are necessary.

Page 15

SECTION 4

THEORY OF OPERATION

4.1 INTRODUCTION

This section contains circuit descriptions for the Model

179A DMM and Model 1788 Battery Pack. An overall signal

flow block diagram is provided in Figure 4-l. An overall

schematic diagram, drawing 32046, is contained at the end

of this manual.

2. In the ACV mode, AC inputs pass through the attenuator

on all ranges. The input is scaled to 2V rm:; full scale, ins

eluding X10 amplification for the 200mV ranges The

TRMS converter outputs a positive DC signal propor~

tional to the true root mean square AC signal. This DC

signal is the AID input. In the ACA mode, shunt voltage

is treated as a 200mV signal,

Figure 4-1. Simplified Signal Flow Block Diagram.

Model 179A DMM

4.2 OVERALL OPERATION

The Model 179A DMM uses a 2V or 200mV full scale analog

to digital (AID) converter with a 4% digit multiplexed

display. Signal conditioning permits the AID converter

handle full scale AC and DC voltage and current measurements over five decades, and to measure resistance over

five ranges.

4.2.1 Signal Conditioning

Signal conditioning includes DC attenuation (except on the

2V and 200mV ranges). AC attenuation, X10 amplification,

AC to DC conversion, ohms conversion and current shunts

as shown in Figure 4-2.

1. In the DCV mode, signal conditioning to the AID converter is an active attenuator, except on the two lowest

ranges. The A/D input is ~V,,~,o* Rf/FiI (Rf-feedback)

resistance, RI = input resistance), except on the lowest

ranges or under overload conditions. In the DCA mode,

the voltage across the shunt resistor is applied to the AID

converter with 200mV giving a full scale reading.

10

Figure 4-2. Attenuation and Ohms Conversion

4.2.2 Ohms Conversion

Resistance measurements are made by configuring the ate

tenuator as a resistance to voltage converter. Attenuator

stage voltage feedback resistors R, function as amplifier in

put resistance connected to either O.lV reference lLOt or

the l.OV reference (HI). The unknown resistance is con

netted as a feedback resistor around the atterwat~on

amplifier. The resulting voltage applied to the A/D cow

verter is proportional to the unknown resistance.

4.2.3 A/D Converter

The A/D converter is a large scale integration (LSII

ratiometric device. Converter output is a multiplexed five

digit binary coded decimal IBCD) number which is equal !(I

4-l

Page 16

the ratio of input voltage to reference voltage. A separate

clock circuit supplies a 1OOkHz timing input to the integrated

circuit, which also multiplexes the BCD output. Full scale

A/D inputs for various ranges and functions are listed in

Table 4-l.

Table 4-l. Full Scale A/D Inputs

DCV

DCV

200mV

2, 20, 200

Full Scale

A/D Input

200mV

2v

Reference

Voltage

O.lV

l.OV

1200v

ACV

DCA

ACA

11

All

All

All

HI

LO

2V

200mV

2v

2v

200mV

l.OV

O.lV

l.OV

l.OV

O.lV

4.3 ATTENUATION

When measuring AC and DC voltages, input signal condi-

tioning is provided by inverting amplifier UlOl and addi~

tional components as described below.

4.3.1 DC Volts

Input resistance is set by R102 and R103. During calibration,

R103 is adjusted to obtain a total input resistance of 10MIl.

Zero adjustments are provided for UlOl since an amplifier

output resolution of lO!V is required for LO resistance

measurements.

1. On the 2V and 200mV ranges. input HI is connected to

the A/D converter through protection resistors R106.

R135G and R136. Diode-connected FETs Q106 and Q107

clamp the AID input during overload.

2. On the 20, 200 and 1200 volt ranges, the amount of ate

tenuation is selected by switching feedback resistors into

the attenuator with relays KlOl, K102 and K103. Gain

setting components and attenuation values are listed in

Table 4-2.

Table 4-2. DC Attenuation and Gain Setting

Components

R&ly/

Attenuation

Switch

Signal Bypasses

attenuator

KlOl

K102

K103

0.1

0.01

0.001

4.3.2 AC Volts

Input resistance is 1MR IRlOl). Shunt capacitance is

typically less than 75pF. Additional conditioning is as

f0ll0ws:

1. For all ranges except the 200mV range. the amount of attenuation is selected by switching feedback resistors into

the attentator with relays KlOl through K104. For the

200mV range, non-inverting X10 amplifier U102 boosts

the signal to a 2V full scale. Gain setting components and

attenuation values are listed in Table 4-3.

2. On the 200mV and 2V ranges. high frequency compensation is adjusted with capacitor Cl1 1, as shown in Table

4.3. On the 20V range, adjustment is performed with

C112. On the 200 and 1000 volt ranges, adjustment is

performed with C106. Some low frequency rolloff is introduced by input blocking capacitor C105. and AC converter input capacitors Cl15 and C116.

4.4 AC CONVERSION

The AC converter is a monolithic TRMS module. Output

Avg (V 12 Potentiometer R143 provides gain adjust-

VDC =J---.

ment, and R142 establishes output zero. Settling time and

ripple are determined by Cl10 and C120. LOW frequency

rolloff is a function of C120.

4.5 OHMS CONVERSION

During calibration, the lOML2 input resistance CR102 and

R103) and all attenuator feedback resistors are adjusted for

both ratio and absolute value. Therefore. these resistors can

also serve as reference for resistance measurements. In the

11 mode, the attenuation (feedback) resistors are discam

netted from the output of the attenuation amplifier (UlOl)

and are connected instead to the A/D converw reference

voltage. Since two reference voltages and two AID cow

verter gains are available, the Model 179A DMM provides

the option of measuring resistance with the sense current

reduced by a factor of ten.

4.5.1 Range Selection

Operation of the range push buttons selects range resistors

to provide the reference current listed in Table 4-4. Opera-

tion of the HI/LO push button selects the 1V or O.lV

reference respectively on the 20k11, 200kn and 2OOOk(2

ranges. Relay K105 is always energized in the R mode.

4.5.2 R Circuit

For resistance measurements, relay K105 and terminals 4, 5

and 6 of the I2 push button connect the input HI terminal

directly to the amplifier summing node. Input LO is discon-

nected from ground and is connected to the A/D converter

input through the protection components described below.

The unknown resistance (Rx) then becomes the amplifier

feedback resistance.

1. Current flow in the unknown resistance is from input HI

to Input LO. At full scale, the voltage acr”ss R,is either

2V (HI) or 200mV (LO). Reference source loadmg does

not affect accuracy since the AID ““nverter is

ratiometric.

4-2

Page 17

Table 4.3. AC Attenuation Gain Setting Components

200mV

2V

2ov

2oov

1000v

“Signal applied to X10 AC amplifier U102

Alla. R126 KlOl

R119. R127 K102

R120: R128 / K103

R121. R122.

R129

Table 4-4. Resistance Range Setting Components

Attenuation Freq. Camp.

Capacitors

llX10’) ClO6, Cl11

1

0.1 C106, Cl12

0.01

0.001 C106, Cl14

C106. Cl11

C106. Cl13

Range Resistors

R121, R122. R129

R120, R128

R119, R127

R118, R126

R102. R103

2. The HI terminal is clamped to analog common by 0101

and Q102. The instrument protection network at the

amplifier output consists of a pulldown resistance iR104

and CR103, CR104and CR1051. R104sinksapproximaW

ly 150,tA. During in~range measurements. this current is

supplied by the reference voltage through CR105 and

voltage through the amplifier iU101) and CR104.

Overloads with input HI positive are sustained by CR105;

diodes CR103 and CR104 sustain negative overloads.

Open circuit voltage is set to less than 5V by R150 and

R151 through CR103 and CR105. AID protection in ff is

the same as in V except R105 is substituted for R106.

4.6 A/D CONVERTER

The A/D converter operates on the dual slope principle. The

timing is divided into three periods as described below.

Operation with high and low reference voltages is described

separately in paragraph 4.6.4.

4.6.1 Auto-Zero

The auto-zero period IA. Figure 4-31 is 1OOms in length,

which corresponds to 10,000 clock pulses. During this

period, reference voltage V,,, (see paragraph 4.6.4) is

stored on capacitor C124. Capacitor Cl17 stores

VREF + VOSl -vos2.

4.6.2 Signal-Integrate

The -i(rnal-integrate period (6, Figure 4-3) is 1OOms In

length, The A/D input is buffered by U104 lsee paragraph

4.6.4) and integrated by U103. Positive signals generate a

K104

K103 lOO,,A

K102

KlOl

1

1000 switch,

I Nom. lREF

1~~ in LO !!

’ lOO,<A

lO,,A

lO,<A i l,,A

negative-going ramp at the integrator output (pit, 14,. bvi,iie

negative signals produce a positive~going ramp The level of

the integrated signal at the end of the signal-integrate period

is proportional to the average of the applied signal during

this period. Since signal integration continues for 100ms.

the A/D converter exhibits high normal mode iejectlw for

AC signals in multiples of 10Hr. paticularly the 50 and 60Hr

line frequencies.

4.6.3 Reference-Integrate

The reference~integrate period IC or D, Figure 4 31 is 200ms

or 20,000 counts in length. During this period, the ins

tegrator is returned to baseline level by applying a reference

voltage of a polarity opposite to that of the siyxl. A

posltlve~golng ramp is obtained by grounding the Ibl.ffer ins

put, while negative going ramp is produced by the integral

tion of 2XV,,, ithal is, V,,, + the voltage stored on C1241.

The time, or number of clock pusles reqGred for d~scfiarge

is proportional to the signal input. Digital output is from

latches within U106 which store the number of clock pulses

required for the integrator to return to baseline level. The

maximum count during this period is 20,000 which cork

responds to a discharge period of 200ms or full scale input.

4.6.4 Reference Voltages

Reference voltage VREF rmay be either 1V or O.lV. The

voltages are provided by a divider across a temperature

compensated rener diode. An operational amplifier on U103

provides the zener with a self~regulating bias. Use of the

O.lV reference increases converter sensitivity to 200mV full

scale, permitting accurate LO ohms operation. 1OrV resolu~

tion on DC voltage measurements, and DC amperage

4-3

Page 18

Figure 4-3. A/D Converter Function

measurements with a full scale burden of 200mV. Increased

sensitivity is accomplished by switching input buffer U104

into a gain of 10 configuration by turning on Q105. Auto-

zero charging on Cl24 is to a 1OOmV reference instead of a

1V reference. Integrator and comparator voltage levels are

unaffected by buffer gain. Buffer offset voltage is zeroed.

4.7 DISPLAY

Five LED indicators are driven by U201, which is a CMOS

BCD to seven segment decoder/driver with bipolar current-

sourcing outputs. Segment currents are limited to approximately 20mA peak by resistor network R202. The LED

readout is a multiplexed, common-cathode configuration

with Darlington array U202 sequentially sinking current

from each digit. Blanking of the overrange digit is ac-

complished by gates U107A and U107B. Emitter-follower

Q108 ensures that CMOS-compatible levels are maintained

on U107A. pin 1, regardless of the loading of U202. The

minus polarity readout is blanked on AC voltage and

resistance ranges by contacts on the push button switch.

Proper decimal point position is determined by the combination of function and range selected.

4.8 CURRENT MEASUREMENTS

In the A mode, the signal is switched into one of six current

shunts ahead of the attenuator section. For DC current

measurements, the shunt voltage drop is applied directly to

the AID converter input at 200mV full scale. For AC current

measurements, the shunt voltage drop is treated as a

200mV AC signal and passes through the AC attenuator

and the X10 AC amplifier. Overload clamping occcurs at

three diode voltage drops which is a level high enough to

permit high crest factor current waveforms.

4.9 AC POWER SUPPLY

When the DMM is operated from AC line power, the power

supply furnishes f5, + 15 and -15 volts from regulators

VR104, VR102 and VRlOl, respectively. Full-wave rectified

AC from bridge rectifiers CR101 and CR102 is filtered by

reservoir capacitors C108, Cl04 and Cl03 and is applied to

the linear voltage regulators.

4.10 MODEL 1788 BAlTERY PACK

When the Model 1788 Battery Pack is installed in the DMM,

S102 must be set to the BAT position to provide additional

secondary voltage for battery charging. 5102 also switches

4-4

Page 19

the input to VR104 from bridge rectifier CR101 to batteries

87301. Four 2V, 2.5 ampere-hour lead-acid cells supply approximately 9.8V at full charge. After six hours of use on

battery power. the battery pack should be recharged to en-

sure long battery life.

4.10.1 Battery Charging Circuit

While the DMM is plugged into line power and the battery

pack is installed, battery charging proceeds as follows:

1. Full wave rectified voltage from CR101 is applied to the

anode of Q301. which is an SCR which regulates charging voltage. When 0301 is triggered on by a sufficient

gate-cathode voltage differential, the batteries receive

charge. Charging continues as long as the bridge output

voltage exceeds battery voltage by 1V or more. Resistor

R304 limits charging current when recharging a set of

completely discharged ceils. A filtered positive output

from CR102 lor T301l provides the necessary gate turn-

on bias through R306, and diode CR301. Resistor R303

ensures proper high temperature operation on 0301.

2. When the battery voltage reaches the preset float voltage

of 9.N. zener VR301 conducts sufficient current to turn

on 0302 and thus remove the gate trigger voltage from

Q301. Float voltage is adjusted with R301. This is a factory adjustment which normally does not need field readjustment.

4.10.2 Battery Operation and Shutdown Circuit

The DMM operates as follows on battery power:

1. When the power is turned on, the batteries are connected

to the input of VR104 to supply + 5V for the logic, display

and the clock circuit. The clock output is applied to the

AID converter as described in paragraph 4-6 and also to

U301, which is a divide-by~four binary counter. The outs

puts of U301 drive a DC to DC inverter which is synchro~

nired to the AID converter to filter out invr?rter noise. The

25kHz operating frequency is optimal for the small

transformer size, and results in low switchtng losses.

Blocking capacitors C301 and C302 protect Q307 and

Q308 from damage if the drive is lost. Two half~wave reck

tifiers (CR304 and CR3051 on the secondary of 7301 provide rectified AC to filter capacitors C304 and C305

which provide power to + 15V and ~15V regulators

VFi102 and VRlOl.

2. To prevent permanent loss of battery capacity caused by

deep discharge. a shutdown circuit stops operation on

battery power when the battery voltage drops below apt

proximately 7.2V. Shutdown is performed by micropower

voltage detector U302. The open-collector output U302.

pin4) saturates low and turns off pass transistor 0309

when the input voltage (at U302, pin 3) drops below

1.15V (typical). Resistor R314 provides sufficient

hysteresis to prevent discharge from resuming when the

battery voltages rises following disconnection of the load.

4.5/4-6

Page 20

Page 21

SECTION 5

MAINTENANCE

5.1 INTRODUCTION

This section contains calibration, installation and service in-

formation for the Models 179A DMM and 1788 Battery

Pack.

5.2 CALIBRATION PROCEDURE

Calibration should be performed yearly (every 12 months) or

whenever performance verification (see Section 3) indicates

that the Model 179A is out of specifications. If any step in

the calibration procedure cannot be performed properly,

refer to paragraph 5.4 for troubleshooting information or

contact your Keithley representative or the factory.

5.2.1 Recommended Test Equipment

Recommended test equipment for calibration is listed in

Table 5-l. Alternate test equipment may be used, However,

the accuracy of the alternate test equipment must be at

least 10 times better than the instrument specification, or

equal to Table 5-l specifications.

5.2.2 Environmental Conditions

Calibration should be performed under laboratory condi-

tions having an ambient temperature of 20’ to 26’C (68’ to

78OF). and a relative humidity of less than 80%.

5.2.3 Calibration Shield Installation

If the Model 1788 Battery Pack is installed in the instrument

it must be removed and the calibration shield reinstalled

before calibration.

WARNING

Disconnect the line cord before retn~v-

ing the case cover.

1, Turn off the power and disconnect the line cord. Remove

the four screws from the bottom of the case and separate

the top cover from the bottom cover.

2. Push back the ground clip (shown in Figure 6~1 j from the

upper side of the battery pack and remove the battery

pack from the spacers.

3. Calibration may be performed on battery power as long

as the battery pack is sufficiently charged. Leave the bats

tery pack plugged into the instrument, but set the hattery

pack behind the DMM on the bench or table.

4. Set the calibration shield in place on the spacers The

shield should read correctly when viewed from the front

of the instrument.

5. Slide the ground clip over the top of the calibration, shield

so that it contacts the upper surface of the shield

6. If battery power is not to be used, plug in the i~nt! cord

(make wre the BAT/LINE switch is in the line position 11

the battery pack is not instailedl.

5.2.4 Calibration Adjustments

WARNING

Some procedures require the use of

high voltage. Take care to prevent cow

tact with live circuits which could cause

electrical shock resulting in injury or

death.

1. Refer to Table 5-2 and perform the listed adjustments III

the sequence indicated. Note that the step sequence 1s

indicted on the calibration shield by boxed numerals, The

sequence must be followed exactly because the ad~usl~

ments are interrelated and dependent on the preceding

steps.

NOTE

Perform step 5 only if Fill2 is installed, It

not, proceed to step 6.

2. If the indicated adjust:nent cannot be mado to obtain the

specified reading,

troubleshooting information.

refer to paragraph 5.4 for

Table 5-l. Recommended Test Equipment for Calibration

Item Description

A DC Calibrator

B AC Calibrator

C Decade Resistor

Specification

O.lV, lV, 1ov. lOOV, 1ooov

*0.002% or 2opv

.lV, lV, 1ov. 1oov

* .022%

1.9kR. 190kR, i 0.01%

t

Model

343A

5200A

RS725 1

5-l

Page 22

5.3 BAlTERY PACK IMODEL 17881 INSTALLATION

WARNING

Disconnect the line cord before remov-

ing the case cover.

1. Turn off the power and disconnect the line cord. Remove

four screws from the bottom of the case and separate the

top cover from the bottom cover.

2. Lift off the calibration shield, and save it for later use. The

four plastic spacers must remain in place on the upright

studs projecting through the main circuit board.

NOTE

Do not discard the calibration shield. This

shield must be reinstalled during calibration,

as described in paragraph 5.2.3.

3. Set the BAT/LINE switch to the BAT position show” in

Figure 6-l Note that the battery pack will not operate

properly if this switch is not in the BAT position.

4. Remove fuse F301 on the battery pack.

5. Install the battery pack in the instrument so that it rests

on the plastic spacers. The ground clip must make contact with the upper side of the battery pack plate.

6. Carefully align the battery pack plug with connector

P1004 on the circuit board. Push the plug firmly onto the

connector until the lip on the plug engages the lip on the

connector to lock the plug in place.

CAUTION

Make sure the connector is aligned so

that all pins mate properly, otherwise

damage to the DMM will result.

7 Install fuse F301. Reinstall top cover and secure with four

screws.

8. Charge the battery pack as described in paragraph 2.1.3.

5.4 TROUBLESHOOTING

The troubleshooting information in this section is intended

for usa by qualified personnel who have a basic understand-

ing of analog and digital electronic principles and con-

ponents used in a precision electronic test instrument.

NOTE

For instruments that are still under warranty

(less than 12 months since date of

shipment), whose performance falls outside

specifications at any point, contact your

Keithlev representative or the factory

immediately.

The troubleshooting information provided includes checking the power supplies, clock, voltage references and signal

tracing 1 volt rms up to the processor lU106). It is strongly

recommended that the Theory of Operation (Section 4) be

utilized along with schematic diagram 32046.

Table 5-2. Calibration Adjustments

Adjustment

Point

R107

RI08

RI07

R149

R112

R149

R127

R129

A103

R126

R128

R142

RI43

R142

R143

Cl06

Cl12

Cl11

5” QLO

6 IlLO

7 RHI

8 IlLO

9 DCV

Range

2V

200mV

2v

200kI2

200kR

200kR

Input

+ 1.9v

+ 190mV

+1.9v

Short

Short

Short

200kII 190kR

2kR

1.9kfl

2oov + 19ov

2ov +19v

1ooov + 1ooov

2ov 1V at 1kHr

2ov 1OV at 1kHz

2ov 1V at 1kHz

2ov

2oov

1OV at lkHr

1OOV at 1OkHr

2ov 1OV at 1OkHz

2v 1V at 1OkHz

*Perform Step 5 only if R112 is installed. If it is not, proceed to Step 6.

Desired

Reading

1.9000

190.00

1.9000

Sat Front

Panel Zero to

Mechanical Center

OO.O+ 10 digits

00.00 +2 digits

190.00

1.9000

190.00

19.000

1000.0

1.000

10.000

1.000

10.000

100.00

10.000

1 .oooo

Test Equipment

(see Table 5-l)

DC Calibrator (A)

DC Calibrator

DC Calibrator

NO!lt?

None

None

Decade Resistor (C)

Decade Resistor

DC Calibrator

DC Calibrator

DC Calibrator

AC Calibrator (B)

AC Calibrator

AC Calibrator

AC Calibrator

AC Calibrator

AC Calibrator

AC Calibrator

5-2

Page 23

5.4.1 Troubleshooting Procedure

I. Remove the top cover per instructions in paragraph 5.23

step 1.

WARNING

High voltage is present with the top

cover removed. Take care to prevent

contact with line circuits which could

cause electrical shock resulting in injury

or death.

2. To gain access to the test points:

A. Remove the Calibration Shield, if installed.

8. If the Model 1788 Battery Pack is installed, leave it

plugged into the instrument but set it behind the

Model 179A on the bench or table.

3. Turn the Model 179A ON and check the power supplies,

clock and reference voltages per Table 5-3.

4. Select the ACV function and 2 volt range of the Model

179A. Input a 1 volt rms sine wave (lkHz1 into the Model

179A and check signals per Table 5-4.

NOTE

Test points 1 through 10 and the power supply and clock pads are called out on the

Model Board (PC-492). Test points 11

through 14 are not called out on the Model

1788 Battery Pack board (PC-541). Use the

schematic diagam and component layout

drawing to located these test points.

Table 5-3. Power Supplies, Clock and Reference Voltages

5.5 SPECIAL HANDLING OF STATIC SENSITIVE

DEVICES

CMOS devices are designed to function at high impedance

levels. Normal static charge can destroy these devices.

Table 5-5 lists all static sensitive devices for the Model 179A,

Steps 1 through 7 provide instructions on how to avoid

damaging these devices.

1. Devices should be handled and transported in protective

containers, antistatic tubes or conductive foam.

2. Use a properly grounded work bench and a grounding

WrIststrap.

3. Handle device by the body only.

4. PCBs must be grounded to bench while inserting] ~WICL’S.

5. Use antistatic solder suckers.

6. Use grounded tip soldering irons.

7. After devices are soldered or inserted into sockets they

are protected and normal handling can resume.

5.6 BATTERY CHARGE VOLTAGE ADJUSTMENT

Perform the following steps if it is determined that the

Model 1788 battery charge voltage needs adjusting.

1. Remove the top cove,.

2. Connect the Model 179A 10 line power and turn the

instrument OFF.

5-3

Page 24

3. Turn R301 (see Figure 6-l) fully counter-clockwise (“XIXimum charge rate) and monitor battery voltage (BT301)

for ) 9.8V. Fully charged cells require several minutes to

reach this level. Discharged cells require several hours.

CAUTION

Charging to greater than 10 volts for

longer than 30 minutes will reduce battery life.

4. When cells reach 9.8V. turn the Model 179A ON and ad-

just R301 to maintain 9.8V across BT301.

5~ Turn the Model 179A OFF, disconnect line power and

reinstall the top cover,

Table 5-4. Signal Tracing Levels

“hocks

Nttenuator (UlOl) Output TP-5

5.7 FUSE REPLACEMENT

The line fuse and current fuse are located internally in the

Model 179A. The battery fuse if located on the battery pack

PC-board. Turn off, unplug and remove the top cover of the

instrument. Referring to Figure 6-l for exact fuse location,

replace blown fuses with those indicated in Table 5-6.

CAUTION

Installing a higher rated fuse than the

one specified could result in damage to

the instrument.

Test

Point

Signal

IXMS Converter Input

AID Converter:

A/D Converter Input

U104 (buffer) u104

Input and Output

Integrator

Auto-Zero Cap

Table 5.5. Model 179A Static Sensitive Devices

Reference

Designation

UlOl

u103

u104

U106

u107

u201

u301

Keithley

Part Number

IC-165

LSI-12

IC-175

LSI-11

IC-102

IC-168

IC-103

TP-9

TP-10

pins 3 and 6

TP-7

TP-6

Table 5-6. Fuse Replacement

~~

5-4

Page 25

SECTION 6

REPLACEABLE PARTS

6.1 INTRODUCTION

This section contains replacement parts information, a

schematic diagram and component layouts for the Model

179A.

6.2 REPLACEABLE PARTS

Parts are listed alpha-numerically in order of their circuit

designation. Table 6-l contains parts list information for the

Model 179A Mother Board PC-492. Table 6-2 contains a

parts list for the Model 179A Display Board PC-485. Table

6-3 contains a parts list for the Model 1788 Battery Pack

PC-451, Miscellaneous replaceable parts not listed in a table

can be identified in Figure 6-l. Table 6-4 contains a complement of spare parts that can be ordered to maintain up to 10

Model 179A DMMS for approximately one year.

6.3 ORDERING INFORMATION

To place an order, or to obtain information concerning

replacement parts, contact your Keithley representative or

the factory. See the inside front cover for addresses. When

ordering include the following information:

1. Instrument Model Number

2. Instrument Serial Number

3. Part Description

4. Circuit Description (if applicable1

5. Keithley Part Number

6.4 FACTORY SERVICE

If the instrument is to be returned to the factory for service,

please complete the service form which follows this section

and return it with the instrument.

6.5 COMPONENT LAYOUTS

Figure 6-Z-Model 179A Display Board PC~485, Drawing

No. 29663.

Figure 6.3-Model 1788 Battery Pack PC-451. Drnwlng ~0~

29007.

Figure 6-4-Model 179A Mother Board PG492, Drawing

No. 32045.

6.6 SCHEMATIC DIAGRAM

Figure 6.5%Model 179A and 1788~-Drawing No. 32046~

Figure 6-l. Miscellaneous Parts

6-l

Page 26

Table 6-l. Model 179A Mother Board PD-492, Parts List

Circuit

Desig.

Cl01

Cl02

Cl03

Cl04

Cl05

Cl06

Cl07

Cl08

Cl09

Cl10

Cl11

Cl12

Cl13

Cl14

Cl15

Cl16

Cl17

Cl18

Cl19

Cl20

Cl21

Cl22

Cl23

Cl24

Cl25

CR101

CR102

CR103

CR104

CR105

CR106

CR107

CR108

CR109

CRllO

CR111

CR112

CR113

FlOl

F102

JlOOl

J1002

J1003

JlOO4’

J1005

J1006

J1007

J1008

J1009

JlOlO

KlOl

KlO2

K103

K104

K105

PlOOl”

P1002”

P1003

P1004

P1005

P1006

P1007

Description

4.7,tF. 25VDC, 20%. +~ 100%. Aluminum Electrolytic

4.7&F, 25VDC. -20%. ~4~ 100%. Aluminum Electrolytic

470h~F. 35V, Aluminum Electrolytic

470,rF. 35V. Aluminum Electrolytic

O.l,iF, 1OOOV. MPF

.25-l .5pF, ZOOOV. Teflon Trimmer

1000pF. 5OOV. 5%, Polystyrene

2200,tF. 15V, Aluminum Electrolytic

3.3pF. tO.SpF, SOVDC, Ceramic Disc

l,iF, 1OOV. 10%. MPF

.25~1.5pF, ZOOOV, Teflon Trimmer

1.9~15.8pF. 25OV. Trimmer

IlOpF, SOOVDC, 1%. Silver Mica

11OOpF. SOOVDC, 5%. Dipped Mica

33aF. 16VDC. 10%. Aluminum Electrolytic

33pF; 16VDC; 10%; Aluminum Elect&ic

l,iF, 1OOV. 10%. MPF

.22,iF, ZOOVDC, 10%. MPF

NOT USED

l,,F. 1OOV. 10%. MPF

4:71;F, ZSGDC, Rio%, 4~ 100%. Aluminum Electrolytic

4.7nF. 25VDC. -20%. + 100%. Aluminum Electrolytic

.l,,F, ZOOV, 20%. MPF

4,iF. 1OOV. 10%. MPF

100pF. 1OOOV. Ceramic Disc

Bridge Rectifier, 1OOV. 2A

Bridge Rectifier, IA. 400V

Silicon Rectifier, lA, 1OOOV

Silicon Rectifier, IA. IOOOV

Silicon Rectifier, lA, 1OOOV

Rectifier, 75mA. 75V

Rectifier. 75mA. 75V

Rectifier, 75mA. 75V

Rectifier, 75mA. 75V

Rectifier. 75mA. 75V

Bridge Rectifier, 5A. 50V

Rectifier, 3A. 50V

Rectifier. 75mA. 75V

Fuse. Slo-610, l/XA, 25OV. 3AG

Fuse. ZA, 25OV. 3AG

8 Pin Female Connector

10 Pin Female Connector

3Pin Connector HousIng

8 Pin Connector Housing

Banana Jack, Black

Banana Jack, Red

NOT USED

14 Pin Socket

Banana Jack. Black

Banana Jack, Gray

5V. Reed Type, Relay

5V, Reed Type, Relay

5V. Reed Type, Relay

5V. Reed Type, Relay

5V. Reed Type, Relay

8 Pin Male Connector

10 Pin Male Connector

3 Pin Male Connector

8 Pin Male Connector

NOT USED

NOT USED

Line Cord

Location

Sch.

n-7

D-7

C-8

C-8

C-3

D-2

D-3

C~7

E-2

G-2

D-2

D-2

D-2

D-1

F-2

F~2

J~3

J~2

F~3

D-8

D-8

G-4

H-2

F-5

C-6

c-7

E~3

E-3

E-3

D~8

J-2

J-2

K-3

J-3

A-3

A-4

H-l

B-7

A-3

H-7

H-6

B-8

D-8

A-4

A-3

K-5

A~5

A-5

B-8

B-8

A-8

A-8

A-8

H-7

H-6

B-8

D-5

Pcb.

D-4

E-4

E-5

E-5

F-5

F-4

F-4

D-3

E-3

E-3

E-3

E-3

F-3

F-3

E-3

E-3

D-2

D-2

F-l

D-2

D-2

E-2

E-l

F-2

D-5

D~5

F~5

F~5

G~5

D-4

D~2

D-2

F-2

F~2

G~3

G~2

c-2

D~4

F~3

H~5

H~2

D-5

G-2

-

E-4

F-4

F-4

F-4

F-4

G-5

G-2

D-5

D-3

Keithley

Part No.

c-314-4.7

c-314-4.7

C~289~470

C-289-470

C-285-.1

Cl84

c-306~.001

c-290-2200

c~291-3.3p

G294~1

C~l84

c-339

C~278~1 lop

C-236-1 100~

C~321~33

C-321~33

C~294-1

c-269~.22

C~294~1

c~314-4.7

c-314-4.7

C~306~. 1

C~294~4

c-64..loop

RF~36

RF-52

RF~50

RF-50

RF-50

RF~28

RF-28

RF-28

RF-28

RF-28

RF-36

RF-34

HF.28

FU-20

FU-13

CS~356~4

CS-356-5

CS-287-3

CS-287-8

!3J-11-O

BJ-11~2

so-70

BJ-11-O

BJ-Il..8

RL~56

RL~56

RL-59

RL-59

RL-59

cs-355.4

cs-355-5

CS-288-3

CS-288-8

co-9

6-2

Page 27

Table 6-1. Model 179A Mother Bord PC-492, Parts List (Cont.)

Circuit

Desig.

(1101

0102

a103

a104

a105

al06

at07

al08

RlOl

R102

A103

R104

R105

R106

R107

A108

R109

RllO

All1

R112’

R113

R114

R115

R116

R117

R118

R119

R120

R121

R122

R123

R124

R126

R126

A128

I3129

R130

R131

R132

R133

A134

R135

R136

R137

R138

R139

R140

R141

A142

A143

R144

R145

R147

R148

R149

R150

R151

R152

R153

Description

N-Chan. JFET

N~Chan: JFET

N-Ghan. JFET. 2N4392

N-Ghan. JFET. 2N4392

N-Chan, JFET. 2N4392

N-Chan, JFET

N-Chan, JFET

NPN, Switch, 2N3904

IMR. 0.5%. 2W. Metal Film

9.88M. 0.5%, .5W, 12OOV. Metal Film

200kR. 10%. Cermet Trimmer

100kR. 10%. 2W. Composition

47k11, 10%. 2W. Composition

47kR. 10%. 2W. Composition

lOOR, 10%. Cermet Trimmer

2OOIl. 10%. Cermet Trimmer

8.98kR. O.l%, O.lW. Metal Film

4.59kI1. 0.1%. O.lW, Metal Film

931lX 1%. li8W. Metal Film

50kII. 10%. Cermer Trimmer

NOT USED

750kn. 5%. 1/4W, Compositon

lOOR, 1%. 1/8W, Metal Film

4.99kR. .l%. l/low. Metal Film

44.Sk12. .l%, l/low. Metal Film

998kR. .l%, 1/4W, Metal Film

99.8kII. .l%, 114W. Metal Film

9.98kR. ,196, l/lOW. Metal Film

1.002kR. 10%. l/low, Metal Film

270kn. 5%. 114W. Composition

.898R. .l%, 5w. ww

.lR. .l%. 7.5W. Composition

12011, 5%. 1/4W. Composition

5kR. 10%. Cermet Trimmer

500R. lo%, Cermet Trimmer

5011. 10%. Cermet Trimmer

50k0. 10%. Cermet Trimmer

1430, .l%. l/low. Metal Film

8560, .l%, l/low. Metal Film

100kR. 1%. l/lOW. Metal Film

26.7kR. 1%. li8W. Metal Film

3.01kQ. 1%. li8W. Metal Film

Thick Film Network

47kll. 10%. WW. Composition

90, 0.5w. 0.1%. ww

SOOR, 0.1%. 112W. Metal Film

Son, 1/2W. .l%, Metal Film

llkll. 1%. li8W. Metal Film

19.6kII. 1%. l/EW. Metal Film

50k12. 10%. Cermet Trimmer

5000, lo%, Cermet Trimmer

NOT USED

NOT USED

47kn. 5%. 114W, Composition

22Mn. lo%, 1/4W, Composition

200kn. 10%. Cermet Trimmer

3.3kl2, 5%. 114W, Composition

12k0, 5%. 114W. Composition

R162, R153 and UR105 are part of a selected set

R152. R153 and UR105 are part of a selected set

LOCefiOfl

Sch. Pcb.

D~3

E-4

D-3 E~4

H~2

H-2

D-2

C~2

J~3 c-2

G-3

E~2

G-4 F-2

H-6 G~2

D-3

D~2

c-2

E~4

G~4

0~4

E-5

F~5

F-5

F-5

F-5

G-5

J~l D-3

J~l

J-l

J-l

D-3

D~3

D-3

J-l D-3

E-3 E~3

D-3 E-3

D-3 E~3

E~2

E-2

D-2

E-3

E~3

E~3

D-2 E~3

D-2

D-l

D~l

8-4

F~3

F~3

F-3

F~3

8-4 F-2

G-7 G-3

D-2

D-2

D-2

E-3

E-3

F-3

E-l F-3

J-2 D-2

J~2 D-2

J~2 D-2

J-2 D-2

J-3 E-2

Several E~2

F~4 F-2

8-4 F-3

c-4 F-3

E-4 F-3

J-l D-2

J-2 D-2

G-3

E-2

G-2 E-2

F-5 G-2

F-5 G-2

D-3 G-l

E-3

F-5

F-3 F-5

J-l

D-3

J~l D~3

.~~

Keithley

Part No.

TG-139

TG-139

TG-77

TG-77

TG~77

TG-139

TG~l39

TG~47

R~267-IM

R-265.9.68M

RP~89~200k

ROD-100k

R~3~47k

R-3~47k

RP-64~100

R-64~200

R-263.8.98k

R~263~4.59k

R-88-931

RP-97.50k

R~76~750k

R-68-,00

R-263~4.99k

R-263.44.9k

R~264~998k

A-26399.8k

R-263~9~981

A-263.1.002k

R-76~270k

R~310-,898

R-262~.1000

R~76~120

RP~S7~5k

RP-97-500

RP~S7~50

RP~S7~50k

R-263-143

R-263-856

R~HE~lOOk

R-88.26.7k

R-88~3 Olk

TF~~65

R-3-47k

R-252-S

R-168-900

R-169-90

R-88-l 1 k

R-ES-19.6k

RP-97.50k

RP~S7~500

R-76~47k

R-76~22M

RP-89.200k

R-76.3.3k

R~76~12k

R.88.SEL

.a 5

R-88.SEL $!

Page 28

Table 6-1. Model 179A Mother Board PC-492, Parts List (Cont.1

Circuit

Desig.

R154

R155

R156

SlOl

s102

~~~.~s103~~ ,~~~~

TlOl

TlOl

UlOl

u102

u103

u104

u105

U106

u107

VRlOl

VR102

VR103

VR104

VR105

Description

0.010. 0.25%. 7.5W. WW, 4-Terminal

Thick Film Network

10kO 5%. 114W. Composition

Line Voltage Selector

Line/Battery

~~~~7ISt~t~n~~Pushbutton

~~.~~~~~;fo;mei po;;ei(sf Jo

Transformer Power (Japanese Version lOOl2OOVI

Bl-FET Operational Amplifier 8 Pin TO-99

Operational

4% Digit Analog-Processor

Operational Amplifier, 8 Pin, T0~5

TRMS Converter

+ 15V. 3-Term, LO-Powel

NOT USED

+ 5V. 3.Term, TO-220

Reference Zener. (VR105. R152 and R153 are part

Amplifier, 8 Pin. Dip

of a selected set

YlOl

‘J1004 is located on PC-451 (1788 Battery Pack1

“PlOOl and P1002 are located on PC-485 (Display Board)

*R112 may or may not be installed

Ouartz, *O.l%. 10OkHr

Location

Sch.

K~1

A-8

G-4 E~2

B-7 D~4

C-6

A-5

C-6 D-5

C-6

D-3 E~4

E-2 E-3

K~2

H~2

F-2

J-4 E~2

Several

C~8

C-8

D-7

J-2

F~5 F-l

P&.

G-2

F-4

D-4

G-4

D-5

D~2

E-2

D-2

G-2

E-5

E-5

D-4

D-2

Keithley

Part No.

R-274-.01

TF-103~1

R~76-IOk

SW-318

SW-397

2?@6Sti fu2

TR~l68

TR-169

IC-165

IC~l67

LSl~l2

IC-‘176

IC.172~1

tst-H; ,y,,.&x

IC~lO2

lC~253

IC-170

IC-93

2 s7w

DZ~58

CR~8

--

Circuit

Desig.

c201

DS201

DS202

DS203

DS204

DS205

R201

R202

u201

u202

PlOOl

P1002

Table 6.2. Model 179A Display Board PC-485, Parts List

Description

4.7pF, 25VDC.

f 1 LED Digit

7 Segment LED Digit

7 Segment LED Digit

7 Segment LED Digit

7 Segment LED Digit

1200, 114W, 5%. Composition

47R. Thick Film Network

Segment Drive

Digit Driver

8 Pin Male Connector