Page 1

“The Right Control for Your Application.”

12095 NW 39 Street, Coral Springs, FL 33065-2516

KB Electronics, Inc. Telephone: 954-346-4900; Fax: 954-346-3377

6LJQDO,VRODWRU6,0*3DUW1R,QVWDOODWLRQDQG:LULQJ,QVWUXFWLRQV

This document is supplied with Signal Isolator SIMG only.

Warning! Before installing the SIMG onto the KBMG, the AC power must be disconnected.

The following Installation and Wiring instructions are to be used as a supplement to the SIMG Installation and Operating Instructions Manual

(Part No. A40269). Refer to the SIMG Installation and Operating Instructions Manual for specific and external signal following connections.

See Figures 1 - 4, on page 2.

Tools required for installation: small flat blade screwdriver and long nose pliers.

Notes: 1. To install the SIMG, be sure the Top Panel of the KBMG 2-Piece Finger-Safe Cover (FSC) is not installed. 2. All trimpots and

jumpers, on the KBMG, must be set before installing the SIMG.

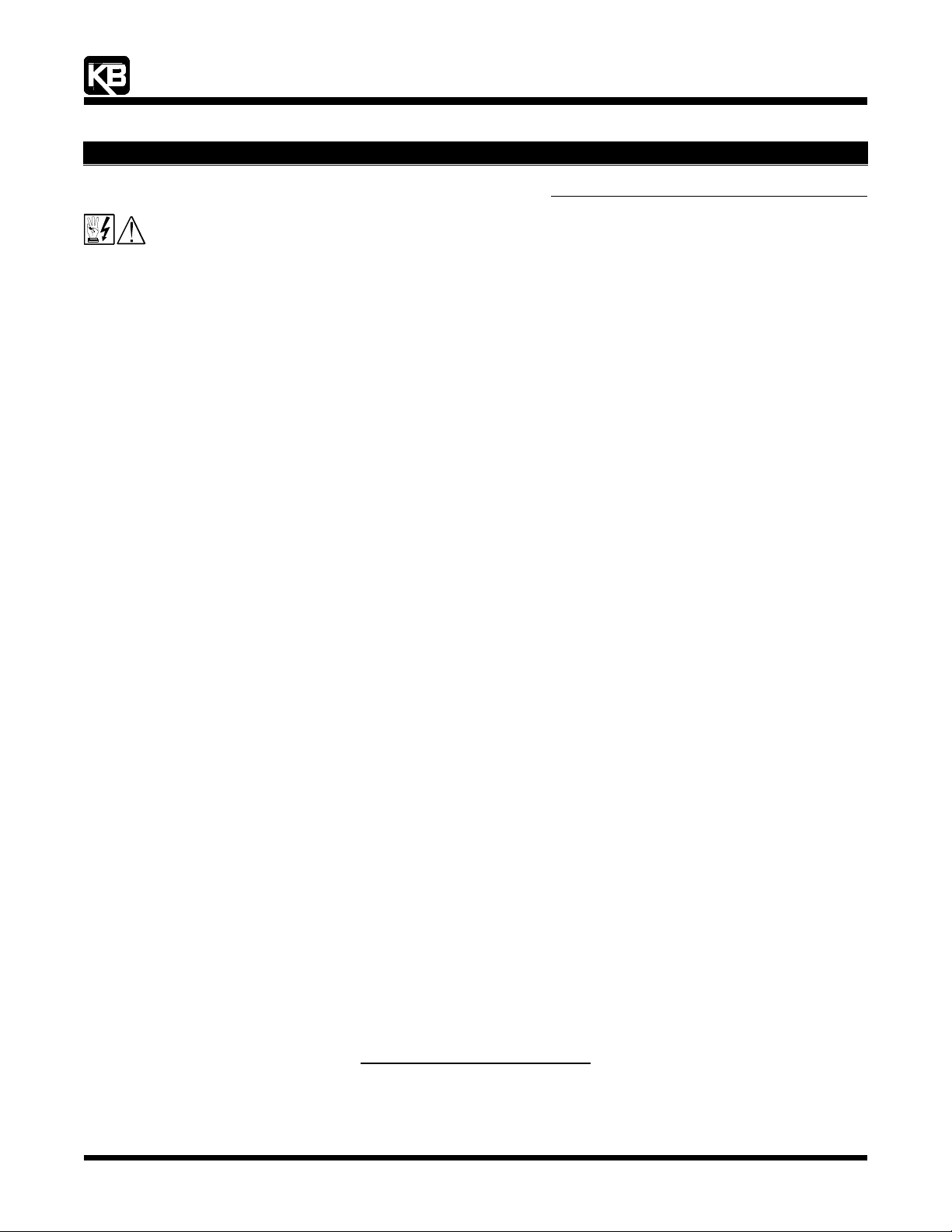

1 Preparing the KBMG Prior to Installing the SIMG - See Figure 1.

1.1 Insert the flat blade screwdriver between theKBMG PC Board and Terminal Block TB1 and gently pry it off. Discard the Terminal

Block.

Note: When prying off Terminal Block TB1, care should be taken to not scratch circuit traces that are on the PC Board surface.

1.2 Using a flat blade (or Phillips) screwdriver, remove the screw from the KBMG FSC. Retain this screw for use in Section 2.3, below.

1.3 Using long nose pliers, remove and discard the Terminal Boots that are factory installed on Terminals "F-" and "F+" on the KBMG.

2 Installing the SIMG onto the KBMG - See Figure 2.

2.1 Align and gently push the Terminal Block on the SIMG onto the Terminal Block Header on the KBMG.

2.2 Align the (3) Holes on the SIMG with the (3) Snap Posts on the KBMG FSC. Gently press the SIMG Board onto the (3) Snap Posts.

Apply pressure at each Snap Post.

2.3 Install the Screw, that was removed in Section 1.2, above, and gently tighten it to secure the SIMG onto the KBMG FSC. Do not

overtighten.

3 Wiring the SIMG After Installed onto the KBMG - See Figures 3 and 4.

Note: On older SIMG models, the Brown and Yellow Wires had to be crisscrossed. On this SIMG model, the Brown and Yellow Wires are

not crisscrossed. See Figures 2 and 3.

3.1 Carefully insert the Brown and Yellow Wires through the Retainer Clip on the KBMG FSC.

3.2 Connect the Brown Wire (larger terminal) to Terminal "F-" on the KBMG.

3.3 Connect the Yellow Wire (smaller terminal) to Terminal "F+" on the KBMG.

4 Installing the SIMG Finger-Safe Cover - See Figure 2.

Align the (4) Snap Tabs on the SIMG FSC with the (4) slots on the KBMG FSC. The Cable Shroud must be positioned over the Brown

and Yellow Wires. Apply pressure to snap the cover into position.

Note: Be sure that the Brown and Yellow Wires are centered in the Retaining Clip so the wires are not damaged by the Cable Shroud.

The SIMG installation is now complete.

(A40144) - Rev. A00 - 9/1/2004 - Z3348A00 Page 1 of 2

Page 2

“The Right Control for Your Application.”

12095 NW 39 Street, Coral Springs, FL 33065-2516

KB Electronics, Inc. Telephone: 954-346-4900; Fax: 954-346-3377

6LJQDO,VRODWRU6,0*3DUW1R,QVWDOODWLRQDQG:LULQJ,QVWUXFWLRQV

(A40144) - Rev. A00 - 9/1/2004 - Z3348A00 Page 2 of 2

Page 3

INSTALLATION AND OPERATING INSTRUCTIONS

MODEL SIMG

KB Part No. 8832 — Signal Isolator for KBMG-212D Regenerative Drive

See Safety Warning on Page 1

The information contained in this manual is intended to be accurate. However, the Manufacturer

retains the right to make changes in design which may not be included herein.

A COMPLETE LINE OF MOTOR DRIVES

© 2000 KB Electronics, Inc.

!

Pending

™

Page 4

TABLE OF CONTENTS

Section Page

i. Safety Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

I. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

II. Installation Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

III. Connections to the SIMG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

IV. Calibration Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

V. Installing the SIMG Finger-Safe Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

VI. Limited Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Tables

1. General Performance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2. Terminal Block Wiring Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3. Resistor for Signal Following from Armature Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Figures

1. Control Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2A. Mechanical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2B. Mechanical Specifications (Continued) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3. KBMG/SIMG Assembly Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4. Removing the KBMG Finger-Safe Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5. Removing Terminal Block TB1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

6. Removing the KBMG Finger-Safe Cover Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

7. Removing the KBMG Finger-Safe Cover Field Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

8. Connection Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

9. Installing Field Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

10. Voltage Following Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

11. Main Speed Potentiometer Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

12. Signal Following from Armature Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

13. Enable Switch Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

14. Removing The SIMG Finger Safe Cover Field Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

ii

Page 5

1

i. SAFETY WARNING! Please read carefully:

Be sure to follow all instructions carefully. Fire and/or electrocution can result due to

improper use of this product.

This product should be installed and serviced by a qualified technician, electrician, or

electrical maintenance person familiar with its operation and the hazard involved. Proper

installation, which includes wiring, mounting in proper enclosure, fusing or other over current protection and grounding, can reduce the chance of electric shocks, fires, or explosion in this product or products used with this product, such as electric motors, switches,

coils, solenoids, and relays. Eye protection must be worn and insulated adjustment tools

must be used when working with control under power. This product is constructed of

materials (plastics, metals, carbon, silicon, etc.) Which may be a potential hazard.

Proper shielding, grounding, and filtering of this product can reduce the emission of radio

frequency interference (RFI) which may adversely affect sensitive electronic equipment.

If information is required on this product, contact our factory. It is the responsibility of the

equipment manufacturer and individual installer to supply this safety warning to the ultimate user of this product. (SW effective 11/92)

This control contains electronic start/stop and enable circuits that can be used to start

and stop the control. However, these circuits are never to be used as safety disconnects

since they are not fail-safe. Use only the AC line for this purpose.

!

This product complies with all CE directives pertinent at the time of manufacture.

Contact factory for detailed installation instructions and Declaration of Conformity.

Page 6

I. INTRODUCTION

Thank you for purchasing the SIMG Bipolar Signal Isolator (P/N 8832). KB

Electronics, Inc. is committed to providing total customer satisfaction by producing quality products that are easy to install and operate. The SIMG is

manufactured with surface mount components incorporating advanced circuitry and technology.

The SIMG provides input isolation and is used to isolate, amplify, and condition DC voltage signals from any external source (power supplies, motors,

tachometer generators, transducers, and potentiometers). The isolated output voltage of the SIMG provides input signals to the KBMG-212D (hereinafter referred to as KBMG) Regenerative Drive (P/N 8831). In also provides isolation for motor direction switching and an isolated power supply for

transducer or potentiometer operation. The PWR LED provides indication

that power is applied.

All input connections (+15, -15, SIG, COM, and EN) are made via a barrier

terminal block and are isolated from AC line and motor wiring.

The SIMG is factory calibrated to accept a signal input voltage of -10V to

+10V DC. OFFSET and MAX trimpots are provided in order to recalibrate the

SIMG for specific applications.

2

Page 7

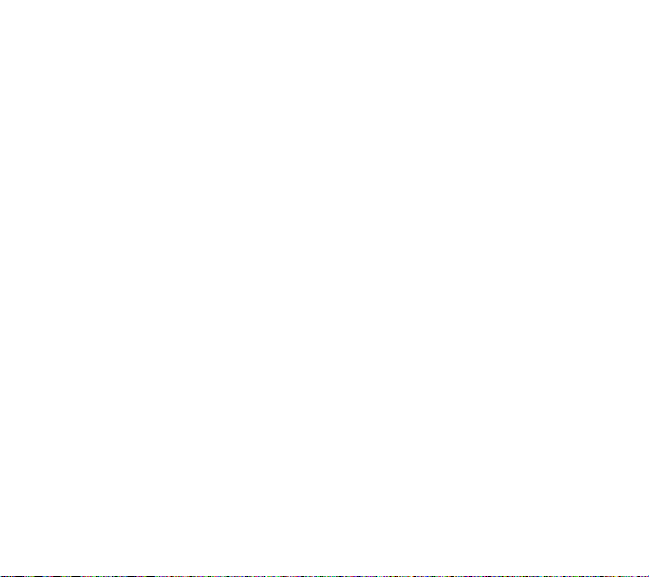

FIGURE 1 – CONTROL LAYOUT

(Illustrates Factory Setting of Jumpers and Approximate Trimpot Settings)

3

SIMG BIPOLAR SIGNAL ISOLATOR

M1

DB RESP

MAX

10A

7.5

5.0

2.5

1.7A

OFFSET

F-

M2

RACCMAXFCLIR RCL FACC

F-

F+

F+

A180

PWR

T50

T7

A90

TACH

F+

F-

CON3

CON2

T1(-)

T2(+)

ENABLE

J1

TB1

COM ENSIG

-15V+15V

L2

L1

Page 8

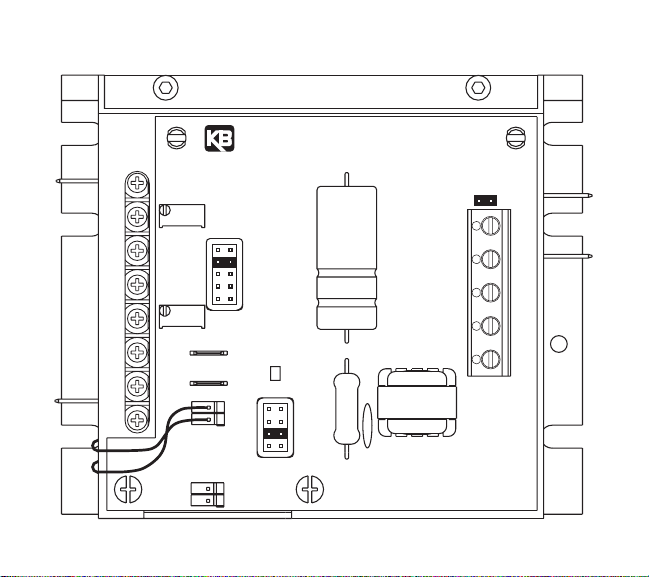

FIGURE 2A – MECHANICAL SPECIFICATIONS (INCHES / mm)

(Shown Mounted onto KBMG)

4

0.95

[24.21]

Page 9

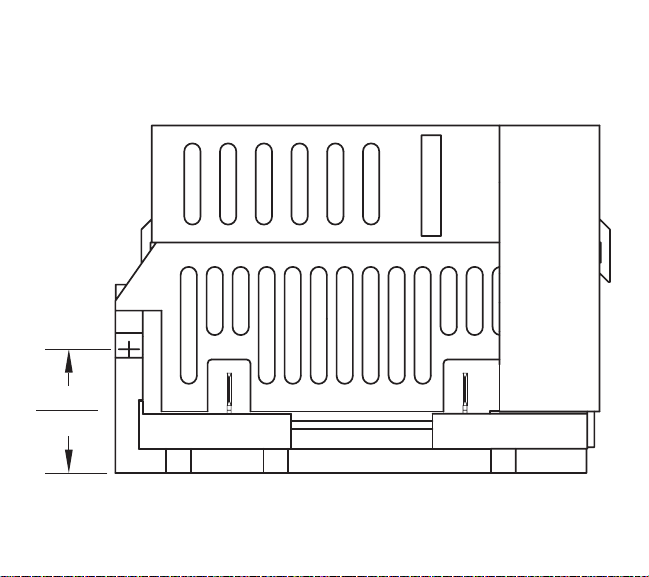

FIGURE 2B – MECHANICAL SPECIFICATIONS (INCHES / mm)

(Shown Mounted onto KBMG)

5

2.67

[67.92]

0.48

[12.32]

3.80

[96.52]

4.68

[118.99]

3.80

[96.65]

2.50

[63.50]

0.75

[19.05]

L2

L1

DB RESP

M1

0.19

[4.83] TYP

RACCMAXFCLIR RCL FACC

M2

Page 10

TABLE 1 – GENERAL PERFORMANCE SPECIFICATIONS

II. INSTALLATION INSTRUCTIONS: Mounting the SIMG onto the KBMG

See figure 3 on page 7. Note: This figure is also supplied as a separate drawing.

Warning! Make sure all power is disconnected from the KBMG before

proceeding

.

A. Removing the KBMG Finger-Safe Cover

If a finger-safe cover is not installed on the KBMG, proceed to section IIC (Modifying

the KBMG Finger-Safe cover). If a finger-safe cover is installed on the KBMG,

remove the two (2) socket head 5-40 X 5/16” screws located at the rear of the KBMG

using the supplied 3/32” hex key. Also, remove the two (2) 6-32 X 1-3/4” screws

located on either side of terminal block TB1. See figure 4 on page 8.

6

—

±5 to ±25

MAX Trimpot Range (with 10V DC Input) (% Speed)

Parameter Specification Factory Setting

Voltage Following Input Range (V DC) -10 to +10

Potentiometer Operation (kΩ) 5 —

OFFSET Trimpot Range (with 0V DC Input) (% Speed) ± 50 0

+15V DC and -15V DC Power Supply Max. Current Rating (mA DC)

0 – 110 100

25

—

Forward, Reverse, and Enable Input Switch Types

Dry Contact or

Open Collector

Input/Output Linearity (%) 0.1

—

Thermal Drift (mV/ ºC) 0.4 —

Ambient Operating Temperature Range (ºC) 0 – 50

—

!

Page 11

B. Removing Terminal Block

TB1 from the KBMG

Remove terminal block TB1 from

the KBMG by rocking it back and

forth or using a screwdriver to gently pry it off. See figure 5 on page

9. The removed terminal block

TB1 will not be used and may be

discarded.

C. Modifying the KBMG Finger-

Safe Cover

Once the KBMG finger-safe cover

is removed, it has to be modified to

accommodate the SIMG. Cut out

the finger-safe cover panel

at seven (7) places as

shown in figure 6 on page

9. (Note: Some fingersafe covers may already

have the panel removed.)

To access the field terminals (F+ and F- on the

KBMG) cut out the field

tab of the KBMG fingersafe cover at three (3)

places as shown in figure

7 on page 9.

7

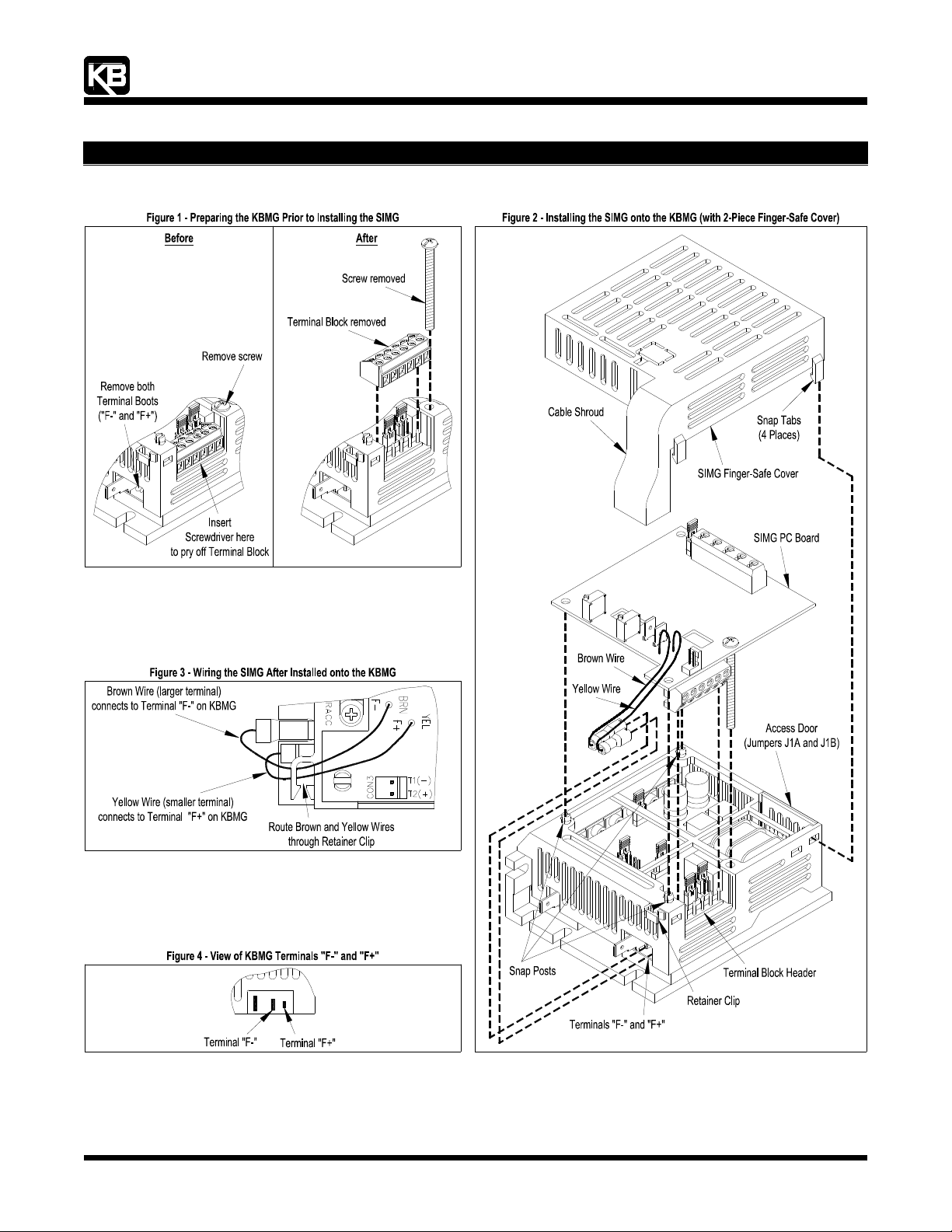

FIGURE 3 – KBMG/SIMG ASSEMBLY DIAGRAM

Snap on cover

(4 places)

SIMG

Finger-Safe Cover

6-32 x 1-3/4" Screws

(2 places)

5-40 x 5/16"

Screws

(2 places)

Cable

Assembly

Note:

Yellow to F+

Brown to F-

SIMG

KBMG

Finger-Safe Cover

KBMG

Page 12

D. Installing the KBMG Finger-

Safe Cover

Once the KBMG finger-safe

cover has been modified, it

can be installed onto the

KBMG. Initially, use only the

two (2) 5-40 X 5/16” socket

head screws, using the supplied 3/32” hex key. Do not

over tighten these screws or

damage may result to the

KBMG finger-safe cover.

Note: All jumpers on the

KBMG must be set to their

appropriate positions

before installing the

KBMG finger-safe cover.

E. Installing the SIMG onto

the KBMG

The terminal block located

on the bottom of the SIMG

plugs onto the six (6) header

pins where TB1 was

removed from the KBMG.

The two holes on the back of

the SIMG snap onto the finger-safe cover.

8

FIGURE 4 – REMOVING THE KBMG

FINGER-SAFE COVER

5-40 x 5/16"

Screws

KBMG

Finger-Safe

Cover

6-32 x 1-3/4"

KBMG

Page 13

Use the two (2) 6-32 X 1-3/4”

screws previously removed to

secure the SIMG to the KBMG. Do

not over tighten these screws or

damage may result to the SIMG and

KBMG. See figure 3 on page 7.

9

FIGURE 5 –

REMOVING

TERMINAL

BLOCK TB1

FIGURE 6 – REMOVING THE KBMG

FINGER-SAFE COVER PANEL

FIGURE 7 – REMOVING THE KBMG

FINGER-SAFE FIELD TAB

Terminal Block

TB1

KBMG

KBMG Finger-Safe Cover

Remove Panel (cut 7 places) to Install SIMG.

KBMG Finger-Safe Cover

Remove Tab (cut 3 places) to Access Field Terminals.

Page 14

FIGURE 8 – CONNECTION DIAGRAM

10

ARMATURE

M1

DB RESP

+

IR

RCL FCL MAX FACC

A

-

M2

RACC

F-

F+

-+

G

DC TACHOMETER

GENERATOR

SIMG BIPOLAR SIGNAL ISOLATOR

MAX

10A

7.5

5.0

2.5

1.7A

OFFSET

F-

F+

F+

F-

CON2

CON3

PWR

T50

T7

A180

A90

T1(-)

TACH

T2(+)

ENABLE

J1

-

FIELD

(SHUNT MOTORS ONLY)

+

L2

AC

LINE

L1

SIG COM EN

+15V -15V

TB1

GROUND

Page 15

F. Wiring the SIMG to the KBMG

See figure 8 on page 10.

The SIMG is powered from the KBMG with a connector that is installed from the

SIMG CON2 to the KBMG F+ and F- terminals. The yellow wire connects to the

KBMG F+ terminal and the brown wire connects to the KBMG F- terminal. When the

field connector is properly installed the wires should cross over each other. See figure 9. If the connector is wired incorrectly, the SIMG PWR LED will not illuminate

and the control will not operate.

Note: It is recommended that these wires be twist-

ed at least three (3) times to help reduce noise.

11

FIGURE 9 – INSTALLING

FIELD CONNECTOR

Page 16

III. Connections to the SIMG

Safety Warning! Do not use FWD-STOP-REV contacts as a safety discon-

nect since they are not fail-safe. Use only the AC line for this purpose.

Note: SIMG Enable jumper J1 must be installed, or a connection must be made

between EN and COM terminals of SIMG TB1 in order for the KBMG to operate.

A. Voltage Following

– Uses a

voltage source to vary motor

speed. See figure 10. Connect

the voltage source to TB1 terminals SIG and COM. When a

0V DC signal is applied, the

control will operate at the minimum set speed (set by the

OFFSET trimpot on the SIMG).

When a 10V DC signal is

applied, the motor will operate

at the maximum set speed (set

by the MAX trimpot on the SIMG).

Applying a positive (+) signal to SIG terminal, with respect to COM terminal, will operate the motor in the forward direction.

12

3.5

Connection Designation

Supply Wire Gauge (AWG – Cu)

Maximum Tightening Torque

(in-lbs)

MaximumMinimum

Logic Connections 24 14

TABLE 2 – TERMINAL BLOCK (TB1) WIRING INFORMATION

FIGURE 10 – VOLTAGE FOLLOWING

CONNECTION

!

± 10VDC

VDC

(KBMG Jumper J4 in 10V Position)

(SIMG Enable Jumper J1 Installed)

J1

EN COM SIG -15 +15

TB1

Page 17

Applying a negative (-) signal to SIG terminal, with respect to COM terminal, will

operate the motor in the reverse direction.

13

FIGURE 11 – MAIN SPEED POTENTIOMETER CONNECTIONS

(KBMG Jumper J4 in 15V Position, SIMG Enable Jumper J1 Installed)

A. B.

Forward Reverse

5K

5K

J1

EN COM SIG -15 +15

TB1

J1

EN COM SIG -15 +15

Unidirectional With Reversing Contact Bidirectional Potentiometer

D.

5K

J1

EN COM SIG -15 +15

REV

STOP

FWD

TB1

C.

J1

EN COM SIG -15 +15

REV FWD

5K

TB1

TB1

Page 18

B. Signal Following from

Armature Voltage – Uses

motor armature voltage as a

signal input. If the signal input

voltage applied to the SIMG is

derived from a motor armature

voltage output, it is necessary

to install a 1/4W resistor in

series with the signal lead into

the SIMG. For a 90V DC

motor, install a 150K resistor.

for a 180V DC motor, install a

330K resistor.

C. Unidirectional Potentiometer

Operation (Forward) – Uses a

potentiometer to vary motor speed.

See figure 11A on page 13.

Connect the 5K potentiometer to

TB1 terminals marked “SIG” (wiper

of potentiometer), “+15V” (high side

of potentiometer), and “COM” (low

side of potentiometer). Use the

potentiometer to vary motor speed.

If the motor is not running in the

desired direction, either reconnect

the high side of the potentiometer to TB1 terminal marked “-15V” or reverse the

motor leads.

14

330K

Armature Voltage

Range (VDC)

1/4W Resistor (Ω)

0 – ± 90 150K

0 – ± 180

FIGURE 12 – SIGNAL FOLLOWING FROM

ARMATURE VOLTAGE

TABLE 3 – RESISTOR FOR

SIGNAL FOLLOWING FROM

ARMATURE VOLTAGE

Armature

+

A

-

J1

EN COM SIG -15 +15

1/4W Resistor

(See Table 3)

TB1

Page 19

D. Unidirectional Potentiometer Operation (Reverse) – Uses a potentiometer to vary

motor speed. See figure 11B on page 13. Connect the 5K potentiometer to TB1 terminals marked “SIG” (wiper of potentiometer), “-15V” (high side of potentiometer),

and “COM” (low side of potentiometer). Use the potentiometer to vary motor speed

and the switching device to select motor direction. If the motor is not running in the

desired direction, either reconnect the high side of the potentiometer to TB1 terminal

marked “+15V” or reverse the motor leads.

E. Bidirectional Potentiometer Operation – Uses a potentiometer to vary motor

speed and direction. See figure 11C on page 13. Connect the 5K potentiometer to

TB1 terminals marked “SIG” (wiper of potentiometer), “+15V” (high side of potentiometer), and “-15V” (low side of potentiometer). Use the potentiometer to vary

motor speed and direction.

When the potentiometer is in the center position, the control output can be set to

zero, using the OFFSET trimpot. Rotating the trimpot clockwise will cause the motor

to rotate in the forward direction. Rotating the potentiometer counterclockwise will

cause the motor to rotate in the reverse direction.

F. Unidirectional Potentiometer with Reversing Contacts – Uses a potentiometer to

vary motor speed. See figure 11D on page 13. Connect the 5K potentiometer to TB1

terminals marked “SIG” (wiper of potentiometer), “+15V” (high side of potentiometer),

and “COM” (low side of potentiometer). Use the potentiometer to vary motor speed

and the switching device to select motor direction. When the potentiometer is set to

0% (fully counterclockwise), the motor will operate at the minimum set speed (set by

the OFFSET trimpot on the SIMG). When the potentiometer is set to 100% (fully

clockwise) the motor will operate at full speed (set by the MAX trimpot on the SIMG).

15

Page 20

G. Enable Switch Connection

Safety Warning!

Do

not use Enable or

Start/Stop contacts as a safety

disconnect since they are not

fail-safe. Use only the AC line

for this purpose. See figure 13.

If a Start/Stop function is

required, remove SIMG Enable

jumper J1 and wire a switch to

EN and COM terminals of

SIMG TB1. When the switch is

opened, the control will stop.

When the switch is closed, the

control will operate.

H. Tachometer Generator Connection

See figure 8 on page 10. To wire a 7V or 50V per 1000RPM tachometer generator

to the SIMG, connect the positive (+) side of the tachometer generator to terminal

“T2” and the negative (-) side of the tachometer generator to terminal “T1“ of the

SIMG.

Note: If the positive (+) and negative (-) tachometer generator connections

are not connected as described above, the motor will run at full speed only.

I. Motor Field Connection

If a shunt wound motor is used, the motor field wires connect to F+ and F- terminals

on the SIMG. To access these terminals, cut out the field tab of the SIMG finger-safe

cover at three (3) places as shown in figure 14 on page 17.

16

FIGURE 13 – ENABLE SWITCH CONNECTION

(SIMG Enable Jumper J1 Removed)

!

Enable

Open to Stop

J1

EN COM SIG -15 +15

TB1

Page 21

17

FIGURE 14 – REMOVING THE SIMG FINGER-SAFE COVER FIELD TAB

SIMG Finger-Safe Cover

Cut Out Tab (3 Places) to Access Field Terminals.

(For Shunt Wound Motors Only.)

Page 22

IV. CALIBRATION PROCEDURE

(See Safety Warning, on page 1)

The SIMG is factory calibrated, but readjustments to the OFFSET and MAX trimpots can

be made to customize for a particular signal input requirement. It may be necessary to

repeat the calibration steps to achieve accurate settings.

A. Unidirectional Voltage Following Calibration

See figure 10 on page 12.

1. Apply 0V DC input signal (or connect SIG and COM terminals).

2. Monitor the KBMG output and adjust the OFFSET trimpot on the SIMG for the

desired minimum setting.

3. Apply the maximum voltage input signal.

4. Monitor the KBMG output voltage and adjust the MAX trimpot on the SIMG for the

desired maximum setting.

B. Unidirectional Potentiometer Operation Calibration:

See figure 11A, B or C on page 13.

1. Set potentiometer to 0% rotation (fully counterclockwise).

2. Monitor the KBMG output and adjust the OFFSET trimpot on the SIMG for the

desired minimum setting.

3. Set potentiometer to 100% rotation (fully clockwise).

4. Monitor the KBMG output voltage and adjust the MAX trimpot on the SIMG for the

desired maximum setting.

18

Page 23

V. INSTALLING the SIMG FINGER-SAFE COVER

After all adjustments and wiring have been completed on the KBMG and the SIMG,

install the SIMG finger-safe cover onto the KBMG finger-safe cover by snapping the four

(4) clips of the SIMG finger-safe cover into the four (4) slots of the KBMG finger-safe

cover.

Note: Ensure that the yellow and brown field wires (from CON2 of the SIMG to F+ and

F- terminals of the KBMG) are within the shroud of the SIMG finger-safe cover. See figure 3 on page 7.

19

Page 24

– NOTES –

20

Page 25

– NOTES –

21

Page 26

VI. LIMITED WARRANTY

For a period of 18 months from the date of original purchase, KB Electronics, Inc. will

repair or replace, without charge, devices which our examination proves to be defective

in material or workmanship. This warranty is valid if the unit has not been tampered with

by unauthorized persons, misused, abused, or improperly installed and has been used in

accordance with the instructions and/or ratings supplied. The foregoing is in lieu of any

other warranty or guarantee, expressed or implied. KB Electronics, Inc. is not responsible for any expense, including installation and removal, inconvenience, or consequential

damage, including injury to any person, caused by items of our manufacture or sale.

Some states do not allow certain exclusions or limitations found in this warranty and

therefore they may not apply to you. In any event, the total liability of KB Electronics, Inc.,

under any circumstance, shall not exceed the full purchase price of this product.

(Rev 2/2000)

KB Electronics, Inc.

12095 NW 39th Street, Coral Springs, FL 33065-2516 • (954) 346-4900 • Fax (954) 346-3377

Outside Florida Call TOLL FREE (800) 221-6570 • E-mail – info@kbelectronics.com

www.kbelectronics.com

(A40269) – Rev. A – 4/2000

Loading...

Loading...