'".

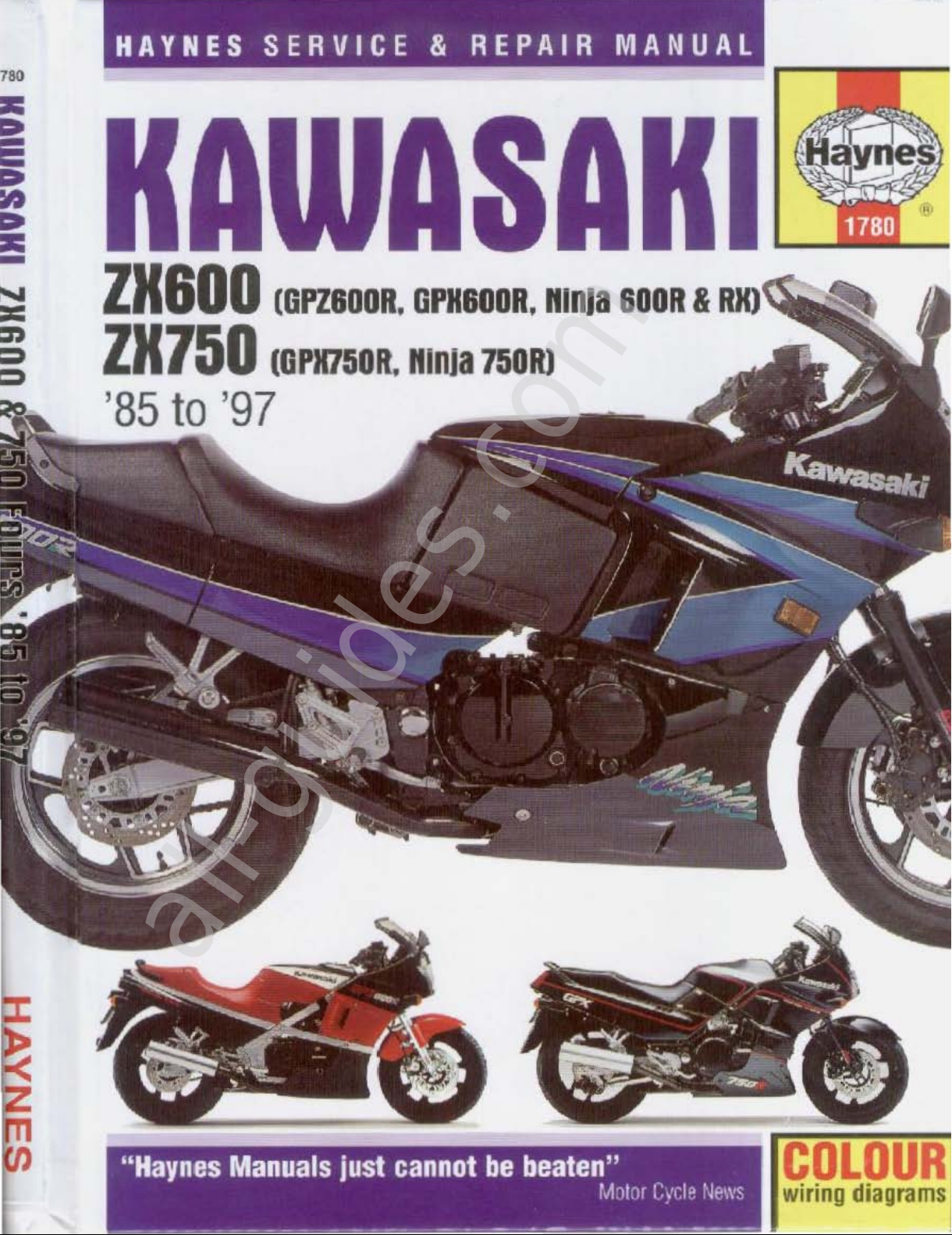

HAYNES

SERVICE

&

REPAIR

MANUAL

(GPZ600R.

GPH600R.

nlDJa

600R

&

ZH750

(GPH750R. ninja

750R)

'85

to

'97

"Haynes Manuals just cannot

be

beaten"

M:Jlor

C\'CIe

News

-

--

-------

COLOUR

wiring

diagrams

All manuals and user guides at all-guides.com

all-guides.com

•

Kawasaki

ZX600

&

750

Fours

Service and Repair Manual

by Bob Henderson

and John H Haynes

Member of the Guild of Motoring Writers

Models

covered

ZX600A (GPZ600R). 592cc. UK 1985 through 1990

ZX600A (Ninja 600R). 592cc. US 1985 through 1987

ZX600B alumininum frame model (Ninja 600RX). 592cc. US 1987

ZX600C (GPX600R). 592cc.

UK

1988 through 1996

ZX600C (Ninja 600R). 592cc. US 1988 through 1997

ZX750F (GPX750A). 748cc. UK 1987 through 1991

ZX750F (Ninja 7S0R). 748cc. US 1987 through 1990

C H

ayne.

Pubtlahlng 1999

A book

In

lhe

Hayne.

Service and Repair Manual

Serl"

PrInted in the USA

Haynes Publishing

Sparkford, Yeovil, Somerset 8A22 7 JJ, England

Hayn

es Nort

h America, Inc

(178()-.260-3Y3)

All

lights

,..

..

rHd.

No

part

of

this

book

may

be

reproduced

or

trans

mitted

In any

lorm

or

by

any

means,

electronic

or

machanical,

including

photoeopyil'lg,

rKOrding

or

by

any

information

ItOf'lllil8

or

rwtrieval system,

withotlt

pennl,lIon

In

writing

from

tIw

eopyright

holder.

861

Lawrence

Drive,

Newbury Park, California 91320, USA

ISBN 1

85980

230 4

Libllory

01

CongrHl

Catalog

Card

Numt:.r

81.12743

British Ubrary Cataloguing In

Pub~cation

o.ta

A catalogue record lor this book is

a~ailabkllrom

the Bntl$h Ubrary.

Edit

ions

Haynes

4, Rue

de

l'Abreuvoir

92415 COURBEVOIE CEDEX, France

Hayn

es

Publishing Nordiska

AS

Box 1504,

751

45

UPPSAlA,

Sweden

All manuals and user guides at all-guides.com

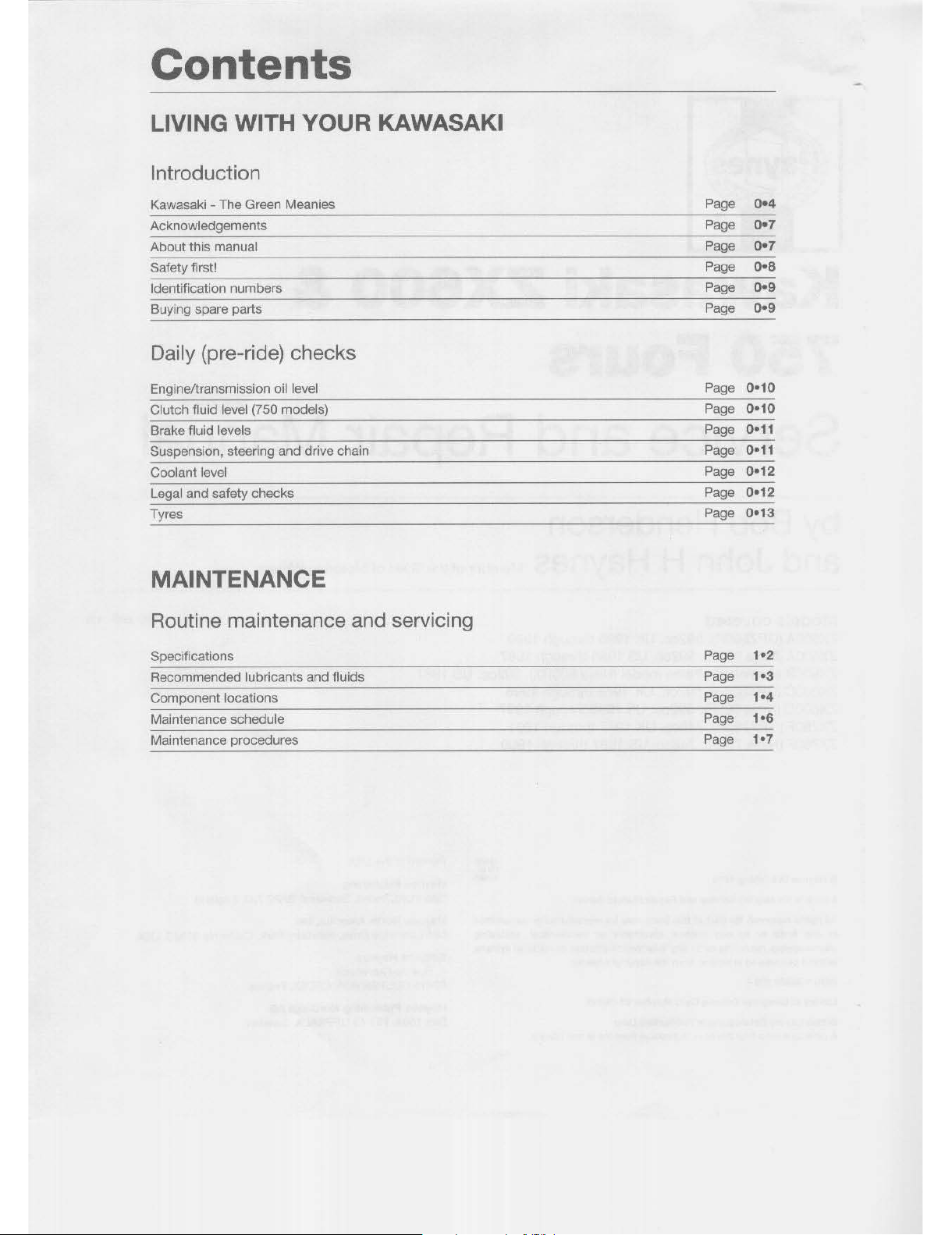

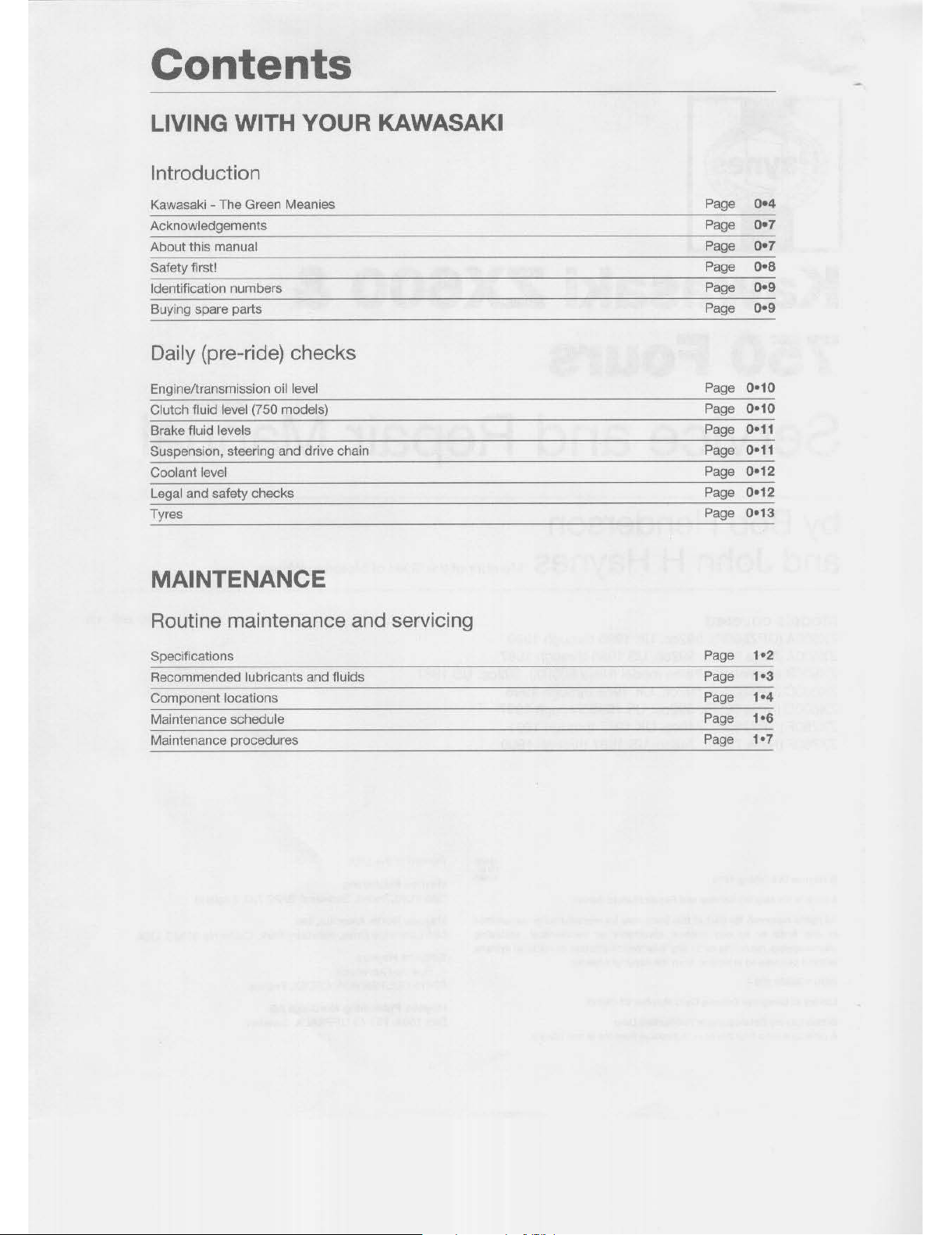

Contents

LIVING WITH YOUR KAWASAKI

Introduction

Kawasaki - The Green Meanies

Page

0·'

Acknowledgements

Page

0·7

About this manual

Page

0·7

Safety first!

Page

0·8

Identification numbers

Page

0·.

Buying spare parts

Page

0·9

Daily (pre-ride) checks

Engine/transmission oil level

Page

0-10

Clutch fluid level (750 models)

Page

0-10

Brake fluid levels

Page

0-11

Suspension, steering and drive chain

Page

0-11

Coolant level

Page

0-12

Legal and safety checks

Page

0-12

Tyres

Page

0-13

MAINTENANCE

Routine maintenance and servicing

Specifications

Page

'·2

Recommended lubricants and fluids

Page

'·3

Component locations

Page

,.,

Maintenance schedule

Page

,

..

Maintenance procedures

Page

'·7

All manuals and user guides at all-guides.com

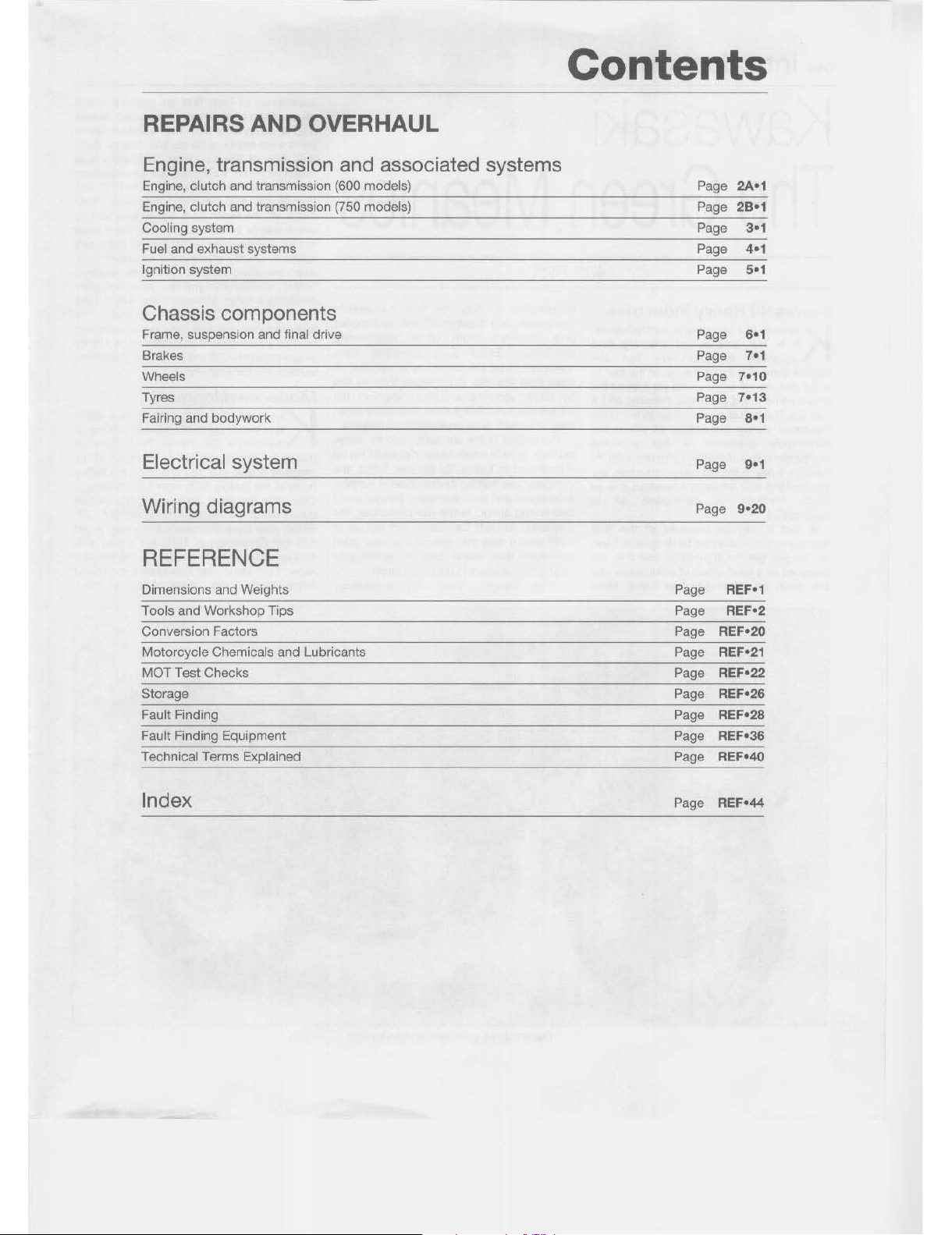

REPAIRS AND OVERHAUL

Engine, transmission and associated systems

Engine,

clutch

and transmission

(BOO

models)

Engine,

clutch

and transmission (750 models)

Cooling

system

Fuel and exhaust systems

Ignition system

Chassis components

Frame, suspension and final

drive

Brakes

Wheels

Tyres

Fairing

and

bodywork

Electrical system

Wiring diagrams

REFERENCE

Dimensions and Weights

Tools and Workshop Tips

Conversion

Factors

Motorcycle Chemicals and Lubricants

MOT Test Checks

Storage

Fault Finding

Fault Finding Equipment

Technical

Terms

Explained

Index

Contents

Page

2A.'

Page

28-1

Page

3·,

Page

4·'

Page

5·'

Page

6·'

Page

7·'

Page

7-10

Page

7-13

Page

8·,

Page

9·,

Page

9·20

Page

REF·1

Page

REF-2

Page

REF-20

Page

REF-21

Page REF·22

Page REF·26

Page REF-28

Page

REF-36

Page REF·40

Page REF-44

All manuals and user guides at all-guides.com

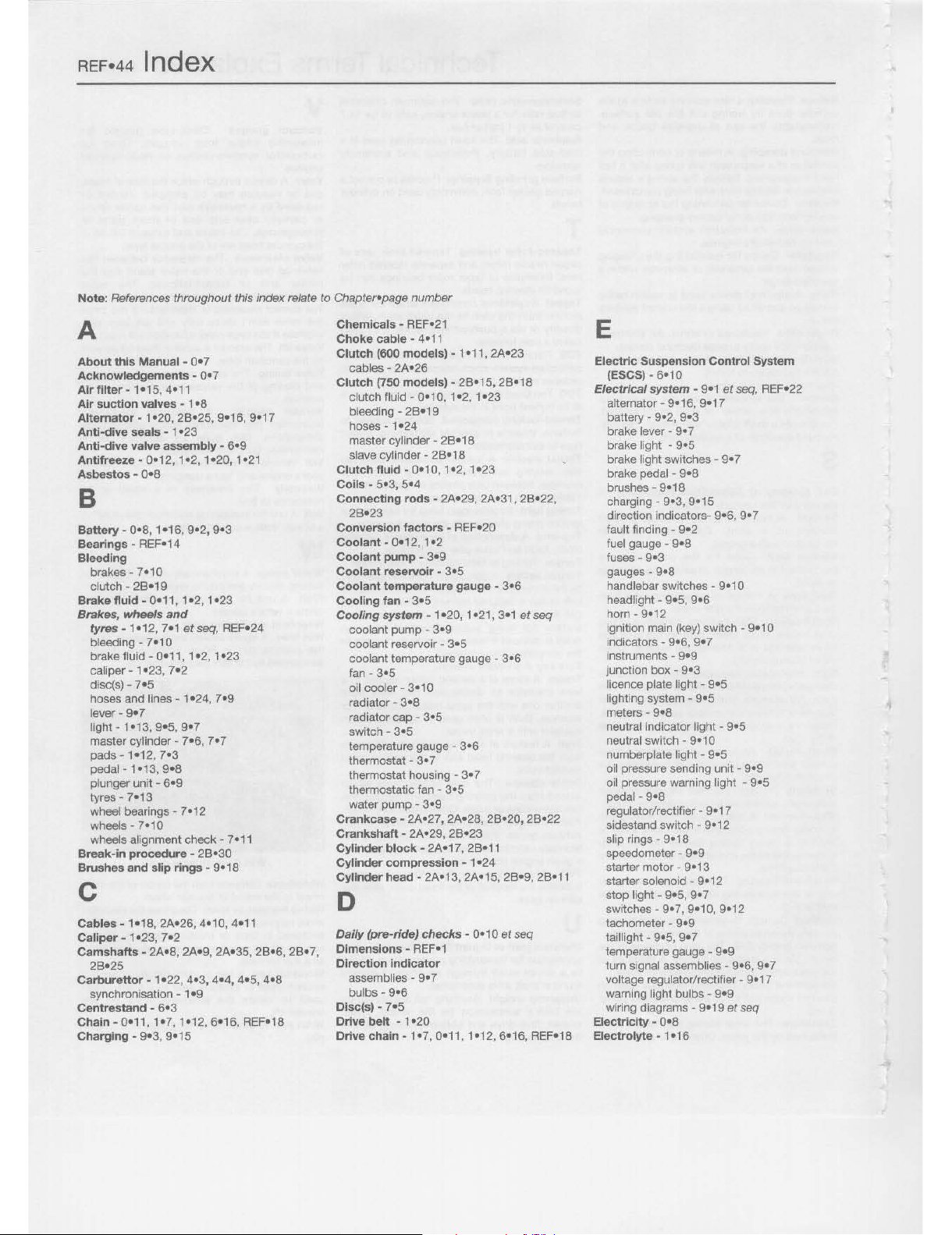

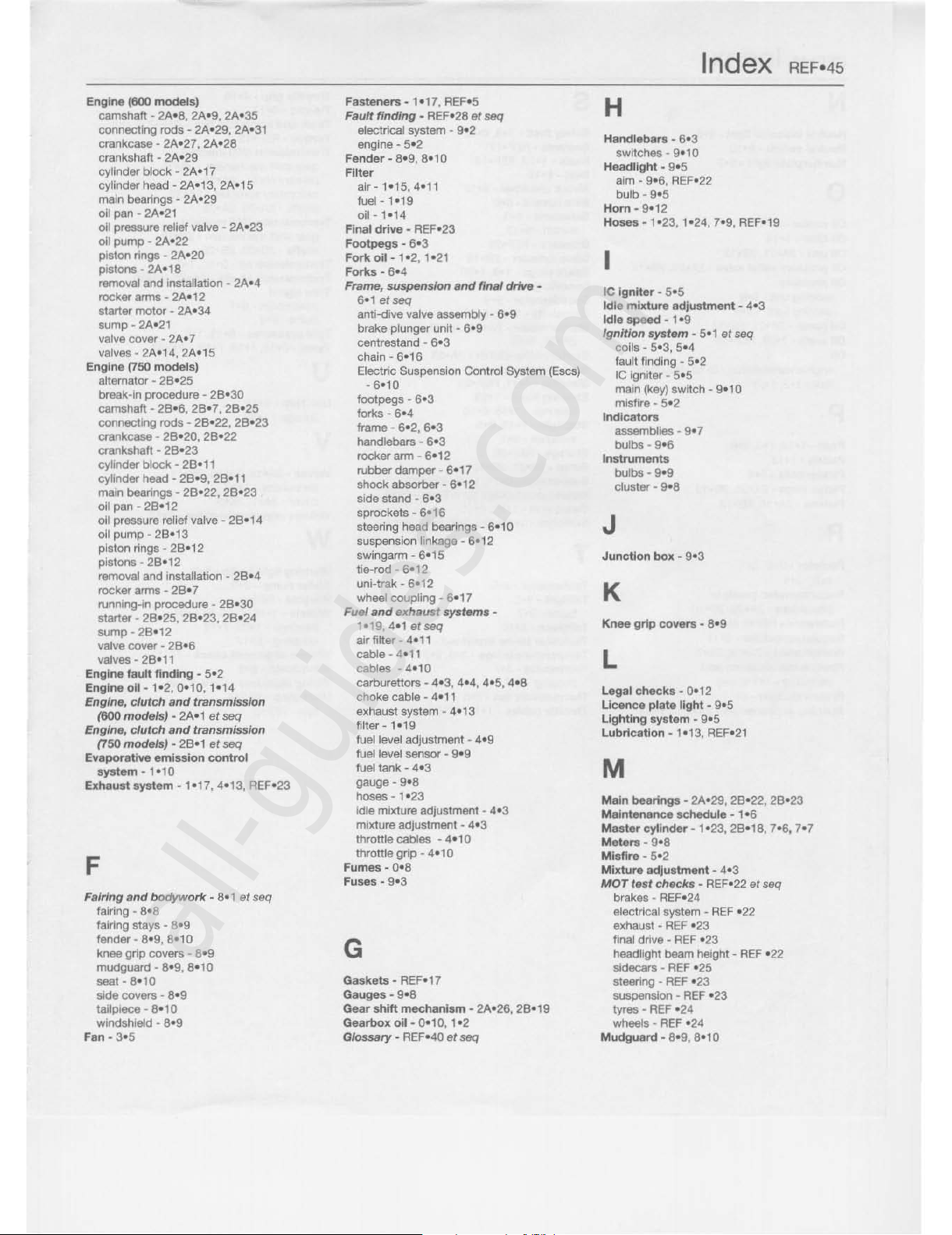

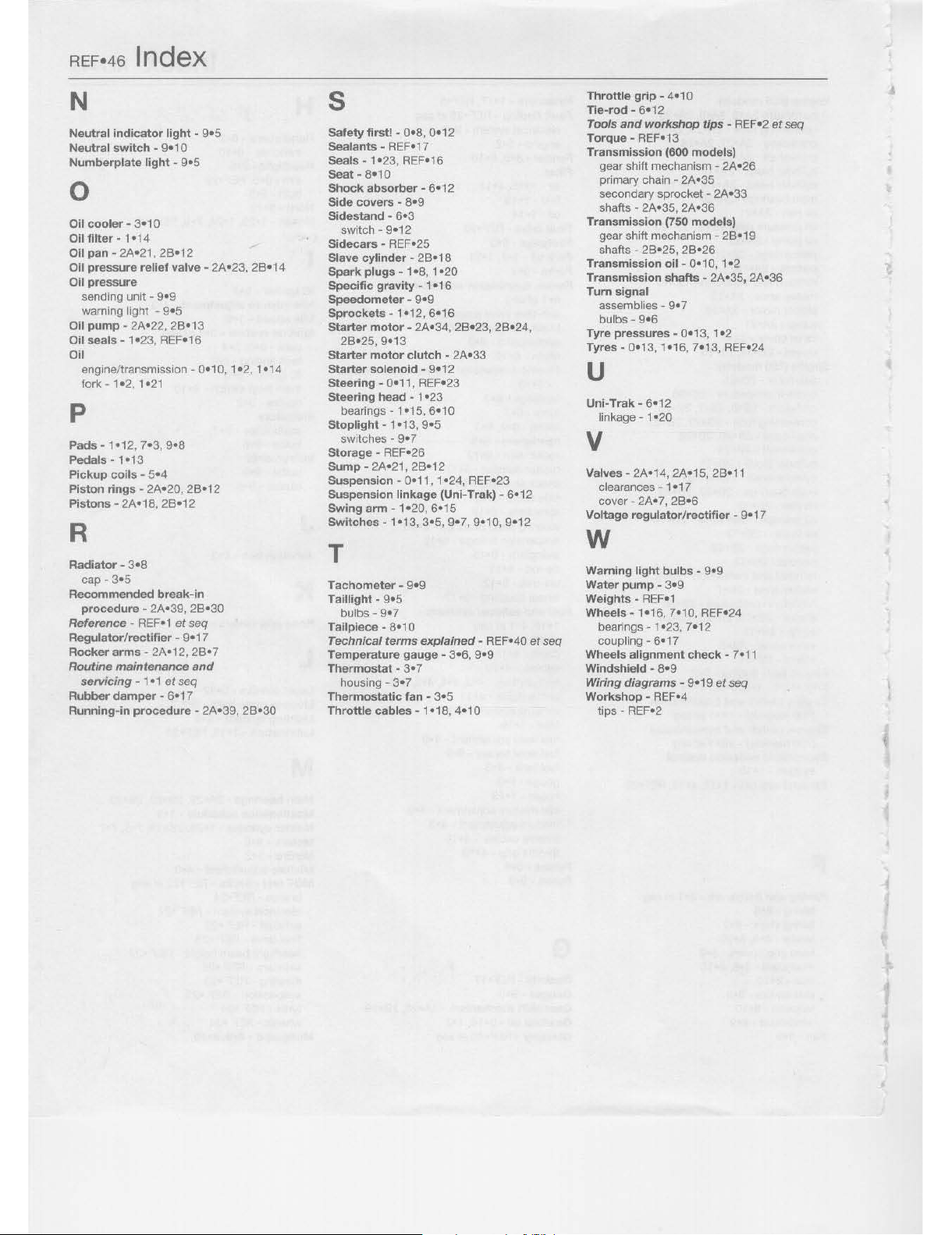

REF-44 Index

Note: Referern;es throughout this index relata to Chapter-page number

A

About

this

Manual·

0-7

Acknowledgements·

0-7

Air

fiher·

'-15,

4-11

Air

suction

valves -

,-a

Alternator -'-20,

28-25,

9-16,

9-17

Anti·dive

seals -'-23

Anti-dive

valve

assembly

-

6-9

Antifreeze -0-12,

'-2,

'-20,

,-21

Asbestos -

o-a

B

Battery·

o-a,

'-16,9-2,9-3

Bearings·

REF·14

Bleeding

brakes -

7-10

clutch -

28-19

Brake fluid - 0-11,

'*2,

'*23

Brakes, wheels

and

tyres

-

'*12,

7-'

ot seq,

REF·24

bleeding -7-10

brake fiuid - 0-11,

'*2,

'-23

caliper -

'-23,

7-2

disc(s) - 7-S

hoses and lines

-'-24,

7-9

lever -

9-7

light -'*13, 9-5,

9-7

master cylinder - 7-6,

7-7

pads-,·,2,7-3

pedal-I-13,

g-a

plunger unit -

6-9

tyres

-7-13

wheel bearings -

7-12

wheels -

7-10

wheels alignment

check

- 7-11

Break-in

procedure

-

28-30

Brushes

and

slip

rings -9-18

c

Cables -

1-18

, 2A-26, 4-10, 4-11

Caliper

- 1-23,

7-2

Camshafts

- 2A-8, 2A-9, 2A-35,

28-6, 28-7,

28-25

Carburenor

- 1-22, 4-3,

4-4,

4-5,

4-8

synchronisation -

1-9

Centrestand -6-3

Chain -

0-11,

1-7,

1-12,

6-16,

REF-18

Charging -9-3,

9-15

Chemicals

- REF-21

Choke

cable

- 4-11

Clutch

(600 models) - 1-11, 2A-23

cables - 2A-26

Clutch

(750 models) - 2S-15,

28-18

clutch fluid -

0-10,1-2,1-23

bleeding

-2S-19

hoses -

1-24

master cylinder -

28-18

slave cylinder -

28-18

Clutch

fluid

- 0-10,

1-2,

1-23

Coils

- 5-3,

5-4

Connecting

rods

- 2A-29, 2A-31 ,

28-22

,

28-23

Conversion

factors

- REF-20

Coolant·

0-12,1-2

Coolant

pump -3-9

Coolant

reservoir -3-5

Coolant

temperature

gauge -3-6

Cooling

fan -3-5

Cooling

system

- 1-20, 1-21, 3-1

et

seq

coolant pump -

3-9

coolant res9I'Voir -

3-5

coolant temperature gauge -

3-6

fan -

3-5

011

cooler -

3-10

radiator -

3-8

radiator

cap -3-5

switch -

3-5

temperature gauge -

3-6

thermostat -

3-7

thermostat housing -

3-7

thermostatic fan -

3-5

water

pump -3-9

Crankcase

- 2A-27, 2A-28,

28-20,

28-22

Crankshaft

- 2A-29,

28-23

Cylinder

block

- 2A-17, 28-11

Cylinder

compression -1-24

Cylinder

head

- 2A-13, 2A-15,

28-9,

28-11

D

Daily (pre-ride)

checks -0-10

et

seq

Dimensions -REF-l

Dlrectlon

Indicator

assemblies -

9-7

bulbs -

9-6

Disc(s) -

7-5

Drive beH -

1-20

Drive

chain

-1-7,

0-11, 1-12, 6-16, REF-18

E

Electric

Suspension

Control

System

(ESCS) -

6-10

Electrical

system

- 9-1

et

seq,

REF-22

alternator-g-16,

9-17

battery - 9-2,

9-3

brake lever -g-7

brake light -

9-5

brake light switches -

9-7

brake pedal -

9-8

brushes -

9-18

charging - 9-3,

9-15

direction indicators- 9-6,

9-7

fault finding -

9-2

fuel gauge -

9-8

fuses -

9-3

gauges -

g-a

handlebar switches - 9-1 0

headlight - 9-5,

9-6

horn -

9-12

ignition main

(key)

switch -

9-10

indicators - 9-6, 9_7

instruments -

g-g

junction box -

9-3

licence plate light -

9-5

lighting system -

9-5

meters -

g-a

neutral indicator light -

9-5

neutral switch -

9-10

numberplate light -

9-5

oil pressure sending unit -

g-g

oil pressure warning light -

9-5

pedal -

g-a

regulator/rectifier -

9-17

sidestand switch - 9-12

slip

rings -

9-18

speedometer -

g-g

starter motor -

9-13

starte!' solenoid - 9-12

stop light - 9-5,

9-7

switches - 9-7, 9-10, 9-12

tachometer -

g-g

taillight - 9-5,

9-7

temperature gauge -

g-g

tum signal assemblies - 9-6,

9-7

voltage regulatorlrectifier - g-17

warning light bulbs -

g-g

wiring diagrams -

9-19

et

seq

Electricity -o-a

Electrolyte -

'-16

•

All manuals and user guides at all-guides.com

Engi

ne

1600

models)

camshaft - lA-

a,

lA

-g, 2A-

35

connecting rods - 2A*29, 2A-

31

crankcase -

2A

*27, 2A*28

crankshaft -2A*29

cylinder block - 2A· 17

cylinder head - 2A* 13, 2A*15

main

bearings -

2A

. 29

oil pan -2A-

21

oil pressure relief valve -2A*23

011

pump - 2A-

22

Piston rings - 2A-20

pistons - 2A*18

removal

and

installation - 2A. 4

rocker

arms

- 2A· 12

starter

motor

-

2A

*34

sump - 2A-

21

valve cover -ZA-?

valves - 2A* 14, 2A-IS

Engin

e (750

models)

alternator -28-25

break-In procedure

-26*

30

camshaft -28-

6,

2S-

7, 28-25

connecting rods -2S-22, 2S*23

crankcase

-28*20, 28-22

crankshaft

-

28

-23

cylinder block - 2B- l1

cylinder

head

-

28-9,

2B-

l1

main bearings -

28*22, 28*

23

oil pan -28*12

011

pressure relief valve -28- 14

011

pump

-

2a*13

piston rings -

28

-12

pistons -

28

-12

removal and installation -28*4

rocker arms - 2B. 7

running-In procedure -28*

30

starter -

28

*25, 2S*23, 2S.

24

sump -

28

-12

valve

cover

-

2S

-6

valves -

28

· "

Engine fautt

finding

- S. 2

Engine

oil - 1.

2,

0

.'

0,

1· 14

Engine

, c

lut

ch

and

transmission

(600

model

s) - 2A

.l

at

seq

Englna, clutch

and

transmis

sion

(750modfl/s)

- 2

8.1

at

seq

EvaporativfI flmission

controi

system

-'·

'0

Exhaust system

- ' .

'7, 4.'3,

REF· 23

F

Fairing

and

bodyworlc - a

-I

et

seq

fairing - 8-8

fairing stays - a- g

fendS!"

- 8-

9,

8. 10

knee grip

COVefS

- a. g

mudguard - 8-

9,

8· 10

seat -8·

'0

side

COVefS

- 8 -9

tailpiecfl - 8-10

windshlflld -

8. 9

Fan

- 3-S

Fasteners-I-

17, REf-S

Fault

finding

- REF-28

fit

seq

electricai systfIITI - 9-2

flngine - S-2

Fflnder-a-g, a-l

0

Filter

ai

r -I-IS, 4-

11

luel-I

-19

oil-I

-14

Final

drive -REF

-23

Footpegs

- 6-3

ForlI;

oil-

' -2, ' .

21

Forks

- 6. 4

Frame,

suspension

and

I/na/

drive-

6. 1

at

seq

anti-dive valve assembly - 6-9

brake plunger unit - 6-9

centrestand - 6-3

chain - 6

-'

6

Electr

iC

Suspension Control Systam (Escs)

- 6-10

footpegs - 6-3

forKs - 6· 4

frame - 6-

2,

6· 3

handlebars

- 6· 3

rocker

ann

- 6

·'

2

rubber

damper

- e- 17

shock absorber - 6-

12

side stand - 6-3

sprockets - 6

.'

6

steering head bearings - 6· 10

suspension linkage - e-12

swingarm - e-

IS

tia-rod - 6- 12

uni-trak - 6-

12

wheel coupling - 6- 17

Fuel and

exhaust

systems-

' ·

'9,4·'atseq

air fin

er-4

· "

cable - 4·

1,

cables

-4

-10

carburetlors - 4.

3,

4-4,

4-

5, 4-8

choke cab

la

- 4-

11

exhaust system -4-13

fil

ter-

I-1

9

fuel level adjustment -

4_

9

fuel level

S8flSOf

- g-g

fuel tank - 4-3

gauge - g-a

hoses

-'

· 23

Idle mixture adjustment - 4. 3

mixture adjustment

- 4- 3

thro

tt

le cables - 4- 10

throttle

grip·

4-1 0

Fumfls

- o·a

Fuses - 9· 3

G

Gaskets

- REF- 17

Gauges

-9

· 8

Gear

shift

mechanism

- 2A-26, 28·

'9

Gearbox

oil

- 0- 10,1- 2

Glossary -

REF

· 40

at

seq

Index REF

o

45

H

Ha

ndlebar.

- 6-3

switCh&$;

- 9-10

Headlight

- g- S

aim - 9-6,

REF-22

bulb - 9-5

Hom - 9-

12

Hoses

-'

-23, 1-

24,

7-

9,

REF-19

I

Ie

IgnHer - 5-S

Idle mi

xture adjustment

- 4-3

Idle s

peed

- ,-g

Ignition

system

- 5-' et seq

colis - 5-

3,

S- 4

fault finding - 5-2

Ie

Igniter - 5-S

main (key) switch - 9-1 0

misfire - 5-2

Indicat

ors

assemblies·9

-7

bulbs - g. e

Instruments

bulbs - 9-9

cluster - 9-8

J

Junction

box

- 9-3

K

Knee

grip

C

OYilf'S

- a·9

L

Legal chec

ks - 0.

,2

Ucence pla

te

light

- 9. 5

Ughtlng system

- 9-S

Lubrication

- 1-

13,

REF-21

M

Main

bearing

s -

2A

-29,

28

·22, 28-23

Maintenance sc

hedute -

1.

6

Ma

ster

cylinder -1.

23, 28-18, 7.

6,

7-7

Met.,..

- g- a

Misfir

e - 5-2

Mixture

adjustment

- 4- 3

MOT

test cheeks -

REF

-22

et

seq

brakes -

REF

-24

electrical system -

REF -22

exhaust -

REF -23

final drive -

REF

-23

headlight beam height -

REF

-22

sidecars

-

REF

. 25

steering -

REF

.23

suspension -

REF

. 23

tyres -

REF -24

wheels -

REF

-24

Mudguard

- a-g, a-

l0

All manuals and user guides at all-guides.com

all-guides.com

REFo46 Index

N

Neutral

indicator

light

- 905

Neutral

switch

- 9010

Numberplate

light -90S

o

Oilcooler-3010

Oilfitter-'·14

Oil

pan

-

2Ao21 , 28.12

all

pressure

relief

valve - 2Ao23,

28.14

all

pressure

sending unit - gog

warning light - 905

all

pump

- 2Ao22,

2S.13

Oil

seals

-'.23,

REF.16

Oil

engine/transmission -

0.'0,

'02,

,.14

fOrK-,02,

1021

p

Pads

,'.12,

703, goa

Pedals

-'.13

Pickup coils - 504

Piston rings - 2Ao20,

28.12

Pistons

- 2Ao18,

28.12

R

Radiator

- 308

cap - 305

Recommended

break-in

procedure

- 2Ao39, 28030

Reference

- REF-,

at

seq

Regulator/rectifier

- go17

Rocker

arms

- 2Ao12, 2S07

Routine maintenance and

servicing -

,.,

at seq

Rubber

damper

- 6017

Running-in

procedure

- 2Ao39, 2S030

s

Safety

first!

- ooa,

0.12

Sealants

- REFo17

Seals

-,023,

REF-16

Seat -a-lO

Shock

absorber -6-12

Side

covers -a-g

Sidestand -6-3

switch -

9-12

Sidecars

- REF-25

Slave

cylinder -2B-18

Spark

plugs -1-a,

'-20

Specific

gravity

- 1

-16

Speedometer -9-9

Sprockets

-1-12,

6-16

Starter

motor -2A-34,

28-23,

2S-24,

2S-25,

9-13

Starter

motor

clutch·

2A-33

Starter

solenoid·

9-12

Steering

- 0-11, REF-23

Steering

head -'-23

bearings - 1-15,

6-10

Stoplight -1-13,

9-5

switches -

9-7

Storage

- REF-26

Sump

- 2A-21 ,

2S-12

Suspension -0-11,

1-24, REF-23

Suspension

linkage

(Uni-Trak) - 6-12

Swing

arm -1-20,

6-15

Switches

-1-13,

3-5,

9-7,

9-1O,

9-'2

T

Tachometer -9-9

Taillight -9-5

bulbs -

9-7

Taitplece

- a-1 a

Technical

terms

explained

- REF-40

et

seq

Temperature

gauge -3-6,

g-g

Thermostat -3-7

housing -

3-7

Thermostatic

fan -

3-5

Throttle

cables -1-18,4-10

Throttle

grip -4-10

Tie-rod -6-12

Tools

snd

worlcshop

tips

- REF-2

at

seq

Torque

- REF-13

Transmission

(BOO

models)

gear shift mechanism -

2A-26

primary chain -

2A-35

secondary sprocket -

2A-33

shafts - 2A-35,

2A-36

Transmission

(750

models)

gear shift mechanism -

2S-1g

shafts - 2S-25,

2S-26

Transmission

oil-

a-la,

1-2

Transmission

shafts

- 2A-35,

2A-36

Tum

signal

assemblies -

g-7

bulbs -

9-6

Tyre

pressures

- 0-13,

1-2

Tyres - 0-13, 1-16, 7-13, REF-24

u

Unl-Trak -6-12

linkage -

1-20

v

Valves - 2A-14, 2A-15, 2S-11

clearances

-'-17

cover - 2A-7,

2S-6

Voltage

regulator/rectifier -9-17

w

Warning

light

bulbs -g-g

Water

pump -3-9

Weights

- REF-1

Wheels

·1-16,

7-10, REF-24

bearings

- 1-23,

7-12

coupling -

6-17

Wheels

alignment

check

-7-11

Windshield -8-9

Wiring

diagrams -g-1g

et

seq

Workshop

- REF-4

tips - REF-2

•

l

•

•

1

I

C

I

I

•

•

All manuals and user guides at all-guides.com

•

Kawasaki

ZX600

&

750

Fours

Service and Repair Manual

by Bob Henderson

and John H Haynes

Member of the Guild of Motoring Writers

Models

covered

ZX600A (GPZ600R). 592cc. UK 1985 through 1990

ZX600A (Ninja 600R). 592cc. US 1985 through 1987

ZX600B alumininum frame model (Ninja 600RX). 592cc. US 1987

ZX600C (GPX600R). 592cc.

UK

1988 through 1996

ZX600C (Ninja 600R). 592cc. US 1988 through 1997

ZX750F (GPX750A). 748cc. UK 1987 through 1991

ZX750F (Ninja 7S0R). 748cc. US 1987 through 1990

C H

ayne.

Pubtlahlng 1999

A book

In

lhe

Hayne.

Service and Repair Manual

Serl"

PrInted in the USA

Haynes Publishing

Sparkford, Yeovil, Somerset 8A22 7 JJ, England

Hayn

es Nort

h America, Inc

(178()-.260-3Y3)

All

lights

,..

..

rHd.

No

part

of

this

book

may

be

reproduced

or

trans

mitted

In any

lorm

or

by

any

means,

electronic

or

machanical,

including

photoeopyil'lg,

rKOrding

or

by

any

information

ItOf'lllil8

or

rwtrieval system,

withotlt

pennl,lIon

In

writing

from

tIw

eopyright

holder.

861

Lawrence

Drive,

Newbury Park, California 91320, USA

ISBN 1

85980

230 4

Libllory

01

CongrHl

Catalog

Card

Numt:.r

81.12743

British Ubrary Cataloguing In

Pub~cation

o.ta

A catalogue record lor this book is

a~ailabkllrom

the Bntl$h Ubrary.

Edit

ions

Haynes

4, Rue

de

l'Abreuvoir

92415 COURBEVOIE CEDEX, France

Hayn

es

Publishing Nordiska

AS

Box 1504,

751

45

UPPSAlA,

Sweden

All manuals and user guides at all-guides.com

Contents

LIVING WITH YOUR KAWASAKI

Introduction

Kawasaki - The Green Meanies

Page

0·'

Acknowledgements

Page

0·7

About this manual

Page

0·7

Safety first!

Page

0·8

Identification numbers

Page

0·.

Buying spare parts

Page

0·9

Daily (pre-ride) checks

Engine/transmission oil level

Page

0-10

Clutch fluid level (750 models)

Page

0-10

Brake fluid levels

Page

0-11

Suspension, steering and drive chain

Page

0-11

Coolant level

Page

0-12

Legal and safety checks

Page

0-12

Tyres

Page

0-13

MAINTENANCE

Routine maintenance and servicing

Specifications

Page

'·2

Recommended lubricants and fluids

Page

'·3

Component locations

Page

,.,

Maintenance schedule

Page

,

..

Maintenance procedures

Page

'·7

All manuals and user guides at all-guides.com

REPAIRS AND OVERHAUL

Engine, transmission and associated systems

Engine,

clutch

and transmission

(BOO

models)

Engine,

clutch

and transmission (750 models)

Cooling

system

Fuel and exhaust systems

Ignition system

Chassis components

Frame, suspension and final

drive

Brakes

Wheels

Tyres

Fairing

and

bodywork

Electrical system

Wiring diagrams

REFERENCE

Dimensions and Weights

Tools and Workshop Tips

Conversion

Factors

Motorcycle Chemicals and Lubricants

MOT Test Checks

Storage

Fault Finding

Fault Finding Equipment

Technical

Terms

Explained

Index

Contents

Page

2A.'

Page

28-1

Page

3·,

Page

4·'

Page

5·'

Page

6·'

Page

7·'

Page

7-10

Page

7-13

Page

8·,

Page

9·,

Page

9·20

Page

REF·1

Page

REF-2

Page

REF-20

Page

REF-21

Page REF·22

Page REF·26

Page REF-28

Page

REF-36

Page REF·40

Page REF-44

All manuals and user guides at all-guides.com

0-4

Introduction

Kawasaki

The

Green

Meanies

by

Julian

Ryder

Kawasaki

Heavy

Industries

K:

wasaki is a company

of

contradictions.

It

Is

the smallest of the big

four

apanase manufacturers

but

the

biggest company, it was the last

of

the four to

make and markel

motorcycles yet

it

owns the

oldest

name

in

the

Japanese Industry. and it

was

the

first to

sel

up

a factory in

the

USA.

Kawasaki Heavy Industries, of which the

motorcycle

operation is

but a small

component,

is a massive

company

with

its

heritage firmly

in

the old heavy industries like

shipbuilding and railways; nowadays it

is

as

much

Involved

in

aerospace

as

In

motorcycles.

In

fact it may be because

of

this that

Kawasaki's motorcycles have always been

quirky, you get

the

impression

that

they are

designed by a

small group

of

enthusiasts

who

are given an

admirably

free hand,

More

realistical ly, it

may

be that

Kawasaki's

designers have

experience

with

techniques

and

materials

from

other

engineering

disciplines, Either way, Kawasaki have

managed

to

be

the

factory

who

surprise us

more than the rest, Quite often, they do this

by

totally

ignoring a

market

segment

the

others are

scrabbling

over,

but

more

often

they hit us with pure, undiluted performance,

The origins

of

the

company, and its name,

go back to 1878 when

Shozo Kawasaki set

up

a dockyard in Tokyo,

8y

the late 1930s, the

company was making its own

steel

in

massive

steelworks and manufacturing railway

locos

and

rolling

stock,

In

the

run

up

to war,

the

Kawasaki Aircraft

Company

was

set

up

in

1937

and

it was this arm

of

the

now

giant

operation

that

would

look

to

motorcycle

engine manufacture

in

post-war Japan,

They

bought

their

high-technology

Th

e

H1

three cylinder

two-stroke

500

experience to

bear

first on engines which

were

sold on to a number

of

manufacturers

as

original equipment. 80th two- and four-stroke

units

were made, a 58

cc

and

148

cc

OHC

unit. One

of

the

customer

companies

was

Meihatsu Heavy

Industries, another company

within the Kawasaki group, which

in

1961

was

shaken

up

and renamed Kawasaki

Auto

Sales,

At

the

same time,

the

Akashi factory

which was

to

be

Kawasaki's main production

facility until the Kobe earthquake

of

1995, was

opened,

Shorlly

afterwards, Kawasaki

took

over

the

ailing

Meguro

company,

Japan's

oldest

motorcycle

maker,

thus

instantly

obtaining a range

of

bigger bikes which were

marketed

as Kawasaki-Meguros, The

following year, the first bike to be made and

sold

as

a Kawasaki was produced, a 125

cc

single called the

88

and

in

1963 a motocross

version, the

88M

appeared,

Model

development

~

wasaki's

first appearance on a road-

race circuit came

in

1965 with a batch

of

isc-valve

125

tWins, They were

no

match

for

the

opposition

from Japan in

the

shape

of

Suzuki and Yamaha or for the fading

force

of

the factory MZs from East Germany,

Only

after

the

other Japanese factories had

pulled out

of

the class did Kawasaki win,

With

8ritish rider Dave Simmonds becoming World

125

GP

Champion in 1969 on a bike that

looked

astonishingly

similar

to

the

original

racer, That same year Kawasaki reorganised

once

again, this

time

merging three

All manuals and user guides at all-guides.com

all-guides.com

companies

to form

Kawasaki

Heavy

Industries. One

of

the

new

organisation's

objectives was

to

take motorcycle production

forward and exploit markets outside Japan.

KHI achieved

that

target

immediately

and

sel

out

their stall

for

the

future

with

the

astonishing

and frightening

HI.

This three-

cylinder air-cooled 500

cc

two-stroke was

arguably

the

first

modern

pure

performance

bike

to

hit

the market. It hypnotised a

who

le

generation

of

motorcyclists

who'd

never

before encountered such a ferocious, wheelie

inducing power band or such shattering

straight-line

speed

allied to

questionable

handling.

And

as for the 750

cc

version

"'_

The triples perfectly suited the late '60s,

fitting in well with the student demonstrations

of

1968

and

the

anti-establishment

ethos

of

the

Summer

of

Love.

Unfortunately,

the

011

crisis would

put

an

end

to

the thirsty strokers

but Kawasaki had another high-performance

ace

up

their

corporate

sleeve.

Or

rather they

thought they did.

Introduction 0-5

The

1968

Tokyo

Show

saw

probably

the

single

most

significant

new

motorcycle

ever

made

unveiled:

the

Honda

CB750.

At

Kawasaki it

caused a major

shock,

for

they

also had a

750

cc

four,

code-named

New

York Steak, almost ready

to

roll and it was a

double,

rather

than single,

overhead

cam

motor. Bravely, they

took

the

decision

to

go

ahead - but

with

the

motor

taken

out

to

900

cc. The result

was

the

ZI,

unveiled

at

the

1972 Cologne

Shaw

. It was a bike straight out

of

the

same

mould

as

the

H1, scare stories

spread

about

unmanageable power,

dubious

straight-line stability and frightening handling,

none

of

which

stopped

the

sales

graph

rocketing

upwards

and

led

to

the

coining

of

the term

'superbike'.

While rising fuel

prices

cut short development

of

the big two-strokes,

The

first

Superbike,

Kawasaki

'S 900

cc

Z1

the

Z1

went

on

to

found a dynasty, indeed its

genes

can

still

be

detected

in

Kawasaki's

latest

products

like the ZZ-R1100 (Ninja ZX-

11).

This is

another

characteristic

of

the

way

Kawasaki operates.

Models

quite

often have

very long lives,

or

gradually evolve. There is

no

major difference between that first

Z1

and

the air-cooled GPz range.

Add

water-cooling

and

you

have

Ihe

GPZ900,

which

in

turn

metamorphosed

into

the

GPZ1000RX

and

then the ZX-10 and the

ZZ-Rl1oo.lndeed,

the

last

three

models

share the

same

58

mm

One

of

the

two-stroke

engined

KH

and

KE

range -the

KH125EX

stroke. The bikes are obviously very different

but

it's

difficult

to

put

your

finger on exactly

why.

Other

models

have remained

effectively

untouched for over a decade: the

KH

and

KE

single-cylinder

air-coo

led

two-stroke

learner

bikes,

the

GT550 and 750 Shaft-drive hacks

favoured by big city despatch riders and the

GPz305 being prime examples. It's only when

they

step

outside

the

performance field

that

Kawasakis seems less sure. Their first factory

customs

were

dire,

you

simply

got

the

impression that the team that designed them

didn't

have their heart

In

the

job. Only when

the Classic range appeared

in

1995 did they

get it right.

Racing success

K

awasaki also have a

more

focused

approach

to

racing than

the

other

factories.

The

policy has always

been

to

race the road bikes and with just a couple of

exceptions

that's

what

they've

done. Even

Simmonds'

championship

winner

bore

a

strong

resemblance

to

the

twins they were

selling in the late '60s and racing versions

of

the 500 and 750

cc

triples were also sold as

over-the-counter

racers,

the

HIR

and H2R.

The 500 was in the forefront

of

the two-stroke

assault on

MV

Agusta but wasn't a Grand Prix

winner. It was the 750 that made the

impact

and carried the factory's image

in

F750 racing

against the

Suzuki triples and Yamaha fours.

The factory's decision

to

use green, usually

regarded as an unlucky colour

in

sport, meant

its

bikes

and personnel

stood

out

and

the

phrase 'Green Meanies' fitted them perfectly.

The

ZI

motor

soon became a lull 1000 cc and

powered

Kawasaki's

assault in

F1

racing,

notably in endurance which Kawasaki saw as

All manuals and user guides at all-guides.com

0

0

6 Introduction

being most closely related to its road bikes.

That

didn't

stop

them dominating 250 and

350 cc GPs with a tandem twin two-stroke

in

the

late

'70s

and

early '80s,

but

their

path-

breaking monocoque 500 while a race winner

never

won

a world litle. When Superbike

arrived,

Kawasaki's

road 750s

weren't

as

track-friendly as the opposition's oul-and-out

race replicas. This makes Scott Russell's

World title on the ZXR750 in 1993 even

more praiseworthy,

for

the

homologation bike, the ZXR750RR, was

much heavier and much more of a road

bike than

the

Italian

and

Japanese

competition.

The

company's

Supersport

600

contenders

have similarly been

more

sports-tourers

than race-

replicas,

yet

they

too

have

been

competitive

on

the

track. Indeed,

the flagship bike, the ZZ-R1100,

Is

most

definitely a sports

tourer

capable

of

carrying

two

people and

their

luggage at high speed

in

comfort

all day and then doing it again the next

day. Try that on one

of

the race replicas

and

you'll

be in need

of a course

of

treatment from a chiropractor.

Through

doing

it

their way Kawasaki

developed a brand

loyalty

for

their

performance

bikes

that

kept

the

Z1

's

derivatives

in

production

until

the

mid-'80s

The GT750 • a

favourit

e hack

for

despatc

h rid

ers

and tumed the bike into a classic in its model

life. You could even argue that the

Z1

lives on

in

the shape

of

the 1100 Zephyr's GPz11 00-

derived motor. And

thaI's

another Kawasaki

invention, the

retro bike. But when you look

at what many commentators refer to

as

the

relro

boom,

especially in

Japan, you find that it

is

no such thing. II is the

Zephyr

boom.

Just

another

example

of

Japan's most surprising

motorcycle

manufacturer

getting

it

right again.

The

high-perform

ance ZXR750

All manuals and user guides at all-guides.com

The ZX600 and 750 Fours

F

or a first go, the ZX600A (GPZ600R

in

the UK, Ninja

60DR

in

the

US)

wasn't

bad.

In

fact it was marvelous. Up until

ils

introduction

in 1985,

Kawasaki

had

never made a water-cooled bike. Their air-

cooled ZX models (note the

lower-case

'zed'

in

the UK GPz designation denoting

air cooling. a capital means liquid

cooled) middleweights had ruled the

roost since the start

of

the decade,

advancing

through

the

usual

Kawasaki progression

of

naked

twin-shock bike, naked

monoshocker, then growing a

bikini fairing, a half fairing and a

full fairing in successive years.

The

ZX600A, though. hit the

ground running as a fully-enclosed

water-cooled bike with the full set

of

mid

'80s trickery including a

16-

inch front wheel and suspension

equipped with anti-dive and adjustable air

pressure and damping. Critically, it was a year

ahead of the Honda

CBR600 and

swept

all

before it

in

the

middleweight

sales stakes.

Nevertheless, there were

two

sets

of

modifications; the first was a new set of disc

brakes

for the A4 model of 1988, the second a

major

reworking of engine internals for the A5

of 1989 which increased

power

by

9%

and

peak torque by

13%.

This

didn't

really

do

much for sales as by then the modern 6005

had

arrived.

The

ZX600A's chassis package was all new

but

the

motor was

based

around the old 52.4

mm

stroke of the GPz550 with the bore taken

out

2 mm to 60 mm, another typical piece of

Kawasaki

evolution.

As

was

the

ZX600C

model

(GPX6OQR

in

the UK, Ninja 600R in the

US)

which arrived

in

1988. The engine - at the

bottom end

at

least - was the

same

as the

ZX600A

but up top the drive for inlet efficiency

led

the

valves to

be

operated by short rocker

arms

pivoting

in

ball and pillow mountings as

opposed to the cam

lobes

operating

on

Acknowledgements

O

ur

thanks are due to Kawasaki Motors

(UK)

Ltd

for

permission

to

reproduce

certain illustrations used

In

this

manual.

We would also like to thank the Avon

Rubber

Company,

who

kindly

supplied

Information and technical assistance on tyre

fitting, and NGK

Spark

plugs

(UK)

Ltd

for

information on spark plug maintenance and

electrode conditions.

Thanks are also due

to

the Kawasaki

Information

Service and Kel Edge for

supplying colour transparencies. The main

front

cover

photograph

was

taken

by Phil

Flowers. The Introduction, "Kawasaki -

The

Green Meanies" was written by Julian

Ryder.

buckets

over the

top

of

the

valve stem. The new design allowed

the inlet tracts to be straightened out.

Externally, the

ZX600G was slimmer and a

lot easier on the eyes than the

ZX600A,

although that pearlescent white

paintwork

does

look a lillie

dated

in the late '90s!

Naturally, Kawasaki added loads of lightness,

bring it down a Whopping 25 kg to 180 kg but

didn't go with the trend back to bigger wheals

sean

on

the competition, giving it a 16-incher

at the back

as

well

as

the fronl. It had the full

set of '805 high-tech

but

the electronic anti-

dive system (ESGS) was quietly dropped on

later models. The character of the bikes were

very similar; both needed to be revved and

worked

hard

to

get

the best

out

of

them,

although there is no

doubt

that the ZX600C

doesn't

Just

look more modern, it goes that

way, too.

The

ZX600A

now

looks

like a 50ft all

rounder

but

in its day it was a cutting edge

sportster. The

ZX600C was much harsher

(especially the rear suspension) and

more

About

this

Manual

T

he aim of this manual is to help you gel

the best value from your motorcycle. It

can

do

so

in

several ways. It can help

you decide what

work must be done, even if

you choose

to

have it

done

by

a dealer: it

provides information and procedures

for

routine maintenance and servicing; and It

offers

diagnostic

and repair procedures

to

follow when trouble occurs.

We hope you use the manual to tackle the

work

yourself. For many simpler jobs, doing it

yourself

may

be

quicker

than arranging

an

appointment

to

get the

motorcycle

into

a

dealer

and making the

trips

to leave it and

pick

it up. More importantly, a lot of money

can be

saved by avoiding the expense the

Introduction 0· 7

Kawasaki

ZX600C

focused, but by the

time

it hit the market it had the CBR600 to

deal with.

The

bigger

ZX750F (GPX750R

in

the UK,

Ninja

750R

in

the

US)

had similar problems as

it tried to make up for the

flop

that was the

ZX750G (GPZ750R), only more of them; the

FZ,

VFR

and GSX-R 750s. This time the new

bike wasn't a derivation of a

previous model

as the brand

new

68 x 51.5 mm bore and

stroke show, dimensions which, incidentally,

were carried

over to the ZXR750. Externally it

looked so like the

600 that it was difficult to

know which was which without looking

at

the

decals. The 18-inch rear wheel

on

the 750

was a visual clue, though. It rode like the

smaller bikes, too, with a pronounced

reluctance to

do

anything

In

the low

or

mid-

range followed by a manic rush at the top end.

The chassis seemed to tighten up when you

hit the

power

and

what

seemed like a soft,

gutless bike

in

town turned into a rev hound

when you hit the open road;

all the classic

characteristics of a sporty

KawasakI.

shop must pass on to you to cover Its labour

and

overhead costs.

An

added benefit

is

the

sense of satisfaction

and accomplishment

that you

feal after doing the job yourself.

References

to

the left

or

right side of the

motorcycle

assume you are sitting on the

seat, facing forward.

We

take

great

pride

in

the

accuracy

of

information

given

in

this

manual,

but

motorcycle

manufacturers

make

alterations

and design

changes

during

the

production

run

of a particular

motorcycle

of

which

they

do

not

inform

us. No liability

can

be

accepted

by

the

authors

or

publishers

for

loss,

damage

or

injury

caused

by

any

errors

in,

or

omissions

from,

the

information

given.

All manuals and user guides at all-guides.com

o·s Safety first!

Professional mechanics are trained

in

safe

work

ing

procedures.

However

enthusiastic

you may

be

about

getting on with

the

job

al

hand, take

the

time

to

ensure

that

your safety

IS

not put at risk. A

moment's

lack

of

attention

can

result

in an

accident,

as

can

failure

to

observe

simple

precautions.

There will always be new ways of having

accidents,

and

the

following

is

not

a

comprehensive list of all dangers; it is

intended

rather

to

make

you

aware

of

the

risks

and

to

encourage a safe

approach

to

all

work

you carry

out

on

your

bike.

Asbestos

• Certain friction. insulating, sealing

and

other

products

- such as

brake

pads,

clutch

linings, gaskets. etc. -

contain

asbestos.

Extreme care must

be

taken to avoid

Inhalation

of

dust from such products since it

is hazardous

to

health.

If

in

doubt,

assume

that they

do

contain asbestos.

Fire

• Remember at all times that petrol is highly

flammable. Never smoke

or

have any kind

of

naked

flame

around,

when

working

on

the

vehicle, But

the

risk

does

not

end

there - a

spark caused by an electrical short-circuit, by

two

metal surfaces contacting each other, by

careless

use

of

tools, or

even by

static

electricity built

up

In your body under certain

conditions, can ignite petrol vapour, which

in

a confined

space

is highly explosive, Never

use

petrol as a cleaning

solvent,

Use an

approved safety solvent.

Remember ...

x

Don

't

start

the

engine

without

first

ascertaining

that

the

transmission

is

in

neutral.

X Don't suddenly remove the pressure cap

from a hot cooling system - cover it

with

a

cloth and release

the

pressure gradually first,

or

you may get scalded

by

escaping

coo

lant.

It Don't

attempt

to

drain oil until

you

are

sure it has

cooled

sufficiently

to

avoid

scalding you.

It

Don

't

grasp

any

part

of

the

engine

or

exhaust

system

without

first

ascertaining

that it

Is

cool enough not to

bum

you.

X

Don

't

allow

brake

fluid

or

antifreeze

to

contact the machiFle's paintwork

or

plastic

components.

It

Don't siphon

toxic

liquids

such

as fuel.

hydraulic

fluid

or

antifreeze by

mouth,

or

allow them to remain on

your

skin.

X Don't inhale dust - it may be injurious to

health (see Asbestos heading).

It

Don't allow any spilled oil

or

grease

to

remain on the floor - wipe it

up

right away,

before

someone slips on it.

X

Don't

use

iii-fitting

spanners

or

other

tools wh ich may slip

and

cause injury.

X Don't lift a heavy component which may

be

beyond your

capability·

get

assistance.

•

Always

disconnect

the

battery

earth

terminal before working on any part

of

the fuel

or

electrical system,

and

never

risk spilling

fuel on to a hot engine

or

exhaust.

•

tt

is recommended that a fire extinguisher

of

a type suitable for fuel and electrical fires is

kept handy

in

the garage

or

workplace

at

all

times, Never

try

to extinguish a fuel

or

electrical fire with water,

Fumes

• Certain

fumes

are highly

toxic

and can

qu i

ckly

cause

unconsciousness

and

even

death if inhaled to any extent,

Petrol

vapour

comes into this category, as do the vapours

from

certain

solvents

such

as

trichloro-

ethylene, Any draining

or

pouring

of

such

volatile fluids

should

be

done

in a wel l

ventilated area,

• When using cleaning fluids and solvents,

read

the

instructions

carefully, Never

use

materials

from

unmarked

containers -they

may give off poisonous vapours,

• Never run the engine

of

a motor vehicle

in

an

enclosed space such as a garage, Exhaust

fumes

contain

carbon

monoxide

which

is

extremely poisonous; if you need

to

run the

engine, always do so in the open air or at least

have

the

rear

of

the

vehic

le outSi

de

the

workplace,

The

battery

• Never cause a spark,

or

allow a naked

light near the vehicle's battery,

It will normally

be giving

off

a certain amount

of

hydrogen

gas, which is highly explosive,

X

Don't

rush

to

finish a

job

or

take

unverified short cuts.

It

Don't

allow

child

ren

or

animals in

or

around an unattended vehicle.

X

Don't

Inflate a tyre

above

the

recommended

pressure. Apart from

overstressing the carcass, In extreme cases

the

lyre

may

blow

off forcibly.

.....

Do

ensure that the mact1ine is supported

securely

at

aU

times.

This

is

especialty

important when the machine is blocked

up

to aid wheal

or

fOf!<;

removal.

V Do take care when attempting

10

loosen

a stubborn nut

or

bolt. It

Is

generally better

to

pull on a spanner, rather than push,

so

that

if

you

slip, you fall

away

from

the

machinE)

rather than onto it.

V

Do

wear eye

protection

when

using

power

tOOls

such

as

drill,

sander, bench

grooer

etc.

V

Do

UM a barrier

cream on

your

hands

prior

to

undertaking

dirty

jobs

- It will

protect

your skin from infection as well

as

making the dirt easier to remove afterwards;

but

make sure

your

hands aren't fell

slippery. Note that long-term

contact

with

used engine

Oil

can be a health hazard.

.....

Do

keep

loose

clothing

(cuffs. ties

etc

.

and long hair)

well out

of

the

way

of

moving

mechanical parts.

•

Always

disconnect

the

battery

ground

(earth) terminal before working on the fuel or

electrical systems (except where noted),

• If possible, loosen the filler plugs or cover

when

charging

the

battery

from

an external

source,

Do not charge at

an

excessi

ve

rate

or

the battery may burst.

•

Take care when topping up, cleaning

or

carrying

the

battery

, The acid electrolyte,

evenwhen

diluted,

is very corrosive and

should not be

allowed to contact the eyes or

skin, Always wear rubber gloves and goggles

or

a face shield, If you ever need to prepare

el

ectrolyte

yourself, always

add

the acid

slowly to the water; never

add

the water to the

acid,

Electricity

• When

using

an el

ectric

power

tool,

inspection light

etc" always ensure that

the

appliance

is

correctly

connected to its plug

and

that,

where

necessary, it is properly

grounded

(earthed), Do

not

use

such

appliances

in

damp

conditions

and, again,

beware

of

creating

a spark

or

applying

excessive heat in

the

vicinity

of

fuel

or

fuel

vapour. Also ensure that the appliances meet

national safety standards,

• A severe electric

shock

can result from

touching certain parts

of

the electrical system,

such as the spark plug wires

(HT leads), when

the

engine is running

or

being cranked,

particu lariy

if

components

are

damp

or

the

insulation is defective. Where an electronic

ignition system

is

used, the secondary (HT)

voltage is much higher and could prove fatal.

.....

Do remove rings, wristwatch etc., before

working on

the

vehicle - especially the

electricai system.

tI

Do keep your

wo

rk area tid

y·

it is only

too

easy to fall

over

articles left lying

around.

tI

Do exercise caution when compressing

springs

for

removal

or

Installation. Ensure

that t

he

tension is applied and released in a

controlled

manner, using suitable

tools

which preclude the possibility of the spring

escaping violently,

tI

Do

ensure that any lifting tackle used has

a

sa

fe working load rating adequate for the

job

.

tI

Do

get

someone

to

check

periodically

that

all is well, when working alone on the

vehicle.

.....

Do carry out work

in

a logical sequence

and

check

tha

t everything

is

correctly

assembled and tightened afterwards.

V

Do

remember that your vehicle's safety

affects

that

of

yourself and others.

If

In

doub

t on any point, get professtonal advice.

•

If

in

spite

of

followi

ng

these precautions,

you are unfortunate enough to injure

yourself,

seek medical attention

as

soon as

possible.

All manuals and user guides at all-guides.com

Frame and

engine

numbers

The frame serial

number

Is

stamped

into the

right side

of

the steering head and the engine

serial number is stamped

Into the right engine

case.

Both

of

these

numbers

should

be

recorded and

kept

in a safe place

so

they can

be furnished

to

law

enforcement

officials

In

the event of theft.

The frame serial number. engine serial

number and carburetor identification

number

shou ld also

be

kepi

in

a handy place (such

as

with your driver's licence) so they are always

available when purchasing

or

ordering parts

lor your machine.

The

frame

number

Is s

tamped

on

the

right

side

of

the s

teering

head

The

engine

number

(arrow) is

sta

mped Int

o

the

top

of

the

crankcase,

just

inboard

of

the cover

Buying

spare

parts

Once you have found all

Ihe

IdentificatIon

numbers. record them for reference when

buying parts. Since the manufacturers change

specifications, parts and vendors (companies

that manufacture various components on the

machine), providing the

10

numbers

is

the only

way to be reaSOflBbly sure

that

you ara buying

the correct parts.

Whenever possible,

take

the

worn

part to

the dealer

so

dlrecl comparison

With

the

new

Identification numbers 0. 9

US

models

US models covered

by

this manual are

as

follOWS:

ZX600A (Ninja

BOOR)

.........

..

Al

(1985),

A2

(1986),

A3

(1987)

ZX600B

- Aluminum frame model . Bl (1987)

ZX600C (Ninja 600R) •

Cl

(1968), C2 (1989), C3 (1990), C4 (1991),

C5 (1992). C6 (1993). C7 (1994), C8 (1995),

C9

(1996),

Cl0

(1997)

ZX750F (N'nja 7saR)

Fl

(1987), F2 (1988),

F3

(1989),

F4

(1990)

UK

ZX600 A

models

(GPZ600R):

Year

MOdel

Code

Initial

frame

number

Initial engine

number

ZX600AEOOOOOI

on

ZX600AE025001 on

ZX600AE052040 on

ZX6OOZE052{)4()

on

ZX6OOAE069501

on

1985 ZX600 A 1 ZX6OOA-000001

on

1986 ZX600

A2

ZX6QOA·025001 on

1987 ZX600

A3

ZX6OOA-Q46001on

1968 ZX600

A4/MA

ZX6OOA..05400t on

1989/90 ZX600

A!SIASA

ZX6OOA·055801 on

UK

ZX600 C

models

(GPXSOOR):

Year

MOdel

Code

Initial

frame

number

Initial

engine

number

ZX600AE052040

on

ZX600AE069501

on

ZX6OOAf069501 on

ZXSOOAE069501

on

ZXSOOAE069501

on

1988 ZX600

C1

ZX600C-OOOOOlon

1989

ZXSOOC2

ZX600C-Ol1SOlon

1990-92 ZX600 C3 ZX600C..QI9001 on

1993 ZX600

C6

ZXeooc.eooool

on

1994-96

ZX600C7

ZX6OOC-6015510n

UK

ZX750F

models

(GPX750R):

Year

Model

Code

Initial

frame

number

Initial

engine

number

ZX750FEOOOOOt

to

018000

ZX750FE01800t

10024000

ZX750FE02400t on

1987 ZX750

Fl

ZX750F·OOOOOI

to 016200

1988 ZX750

F2

ZX750F-016201100202oo

1989-91 ZX750

F3

ZX750F-020201

on

componeot can

be

made. Along the trail from

the

manufacturer

10

the parts shelf, there are

numerous

places that the part can end

up

with

the wrong number

or

be

listed iocolTeclly.

The

two

places to purchase new parts

fOl"

your

motorcycle·

the accessory

stOl"e

and the

franchised

dealer·

diller

in the type

of

parts

they carry. While dealers can obtain

virtually

ev9fy

part for your motorcycle, the accessory

dealer is usually limited to nOflTlal high wear

items

such

as

shock

absorbers.

tune-up

parts, various engine gaskets, cables. chains.

brake

parts,

etc.

Rarely will an accessory

outlet

have

major

suspension

components,

cytinders. transmiSSion gears,

or

cases.

Used

parts

can

be

obtained for roughly half

the price

of

new ones.

but

you can't always

be

sure

of

what you're getting. Once aga,n, take

your worn part to the breaker (wrecking yard)

for direct comparison.

Whether buying new, used

or

rebuilt parts,

the

best

course

Is

to

deal

directly

With

someone

who

specialises in parts for your

particular make.

All manuals and user guides at all-guides.com

all-guides.com

0-1 0 Daily (pre-ride)

checks

1

Engine/transmission

oil level

Before

you

start:

'"

Take

the motorcycle

on

a short

run

to allow

It

to

reach normal operating temperature.

Caution: Do not run the engine

in

8n

enclosed space

suc

h as a garage or shop.

'"

Stop the engine and support the

motorcycle

In an

upright

position

on

level

ground

. Position

the

motorcycle

on

its

ceotrestand. Allow it to stand undisturbed

lor

five ffiloules to allow Ihe oil level

10

stabilise.

The

correct

oil

• Modem, high-revving

IH1gines

place great

demands

on

their

oil. It is very

important

that

the

correct oil for your bjke is used,

• Always

top

up

with a

good

quality

011

of

the specified

type

and

viSCOSity

and

do

not

OyertJII

the

engine.

"'.",.

API grade

SG

Oil

visecnlty

Cold d,mates

SAE

lOWf40

or

lOW/50

Warm climates

SAE

20Wf40

or

20W/5O

v'The

oil level is viewed through

the

window

In

Ihe clutch cover on the righi-hand side

of

the

engine.

Wipe

Ihe glass clean

before

Inspection to make the check

easier.

Bike

care:

• If

you

have to add oil frequently, you should

check

whether

you

have any oil leaks. If there

Is

no

sign

of

011

leakage

from

the

joints

and

gaskets the engine could be burning oil (see

Fault Finding).

2

If the level is below

the

MIN

line,

remove

the

filler

cap

from

the

top

of

the

clutch

cover

...

2

Clutch

fluid

level (750 models)

A

Wamlng:

Brake

and

clutch

,

hydraulic

fluid

can

hann

your

•

eyes

and

damage

painted

surlaces.,

so

use

extreme

caution

whfNJ

handling

and

pouring

it. Do

not

use

fluid

that

has

been

standing

Op6n

for

some time, as it absorbs moisture from

the

sir

which

can

cause

a

loss

of

clutch

effectiveness.

Before

you

start:

."

PoSition the motorcycle on Its centrestand

and

turn

the

handlebars

until

the

top

01

the

master cylinder

IS

as level as

possible

.

2

Remove

the

two

screws

to free

the

reservoir cap.

."

Make

sure you have

the

correct

hyd

raulic

Huid.

DOT 4 is recommended.

Bike

care:

•

If

the

fluid

reservoir

requires repeated

topping-up this is

an

Indication

of

an hydraulic

leak

somewhere In the system, which should

be

investigated immediately.

•

Check

for

signs

of

fluid leakage from the

hydraulic hoses

and

components

- If found,

rectify immediately.

• Check the operation

of

the clutch; if there is

evidence

of

air

In

the

system (spongy feel to

lever), it must

be

bled (Chapter 28).

Top

up

with new clean hydraulic Huid

of

the recommended type

so

that the level

is

above

the

LOWER level mark.

Take

care

to

avoid spills (see

Wam

lng above).

1

The oil level should lie between Ihe MAX

and MIN level lines on the window

3

...

and

top

up

with

the

recommended

grade and type

of

oil, to bfing the level

up

to the MAX line on the window.

1

Clutch fluid level is checked via

sightglass

- It

must

be above LOWER

level

mark(arrow).

4

Ensure

thai

the

diaphragm

Is

correctly

folded before Installing

the

cover.

All manuals and user guides at all-guides.com

Daily (pre-ride)

checks

D

."

3

Brake

fluid

levels

Wamlng: Brake and clut

ch

AI

hydraulic fluid

can ha

rm your

~

ey

es a

nd

damage pa

inted

s

urface

s,

so

us

e

extrem

e

ca

ution when handling B

nd

pouring it Bnd cover

surrounding

surfaces

with

ra

g. Do not

use

fluid

that

has

been

stand

ing open

for

some

tim

e,

as

It

abs

orb

s

moisture

from the air

which can cause a

da

ngerous

/0$$

of

braking

effectivene"-

Before you start:

."

Position

the motOfcycle

on

Its centrestand,

and turn the handlebars until the

top

of the

Iront brake master cylinder Is

as

level

as

possible. Remove the righ t side cover (see

Chapter

8)

to

access

the

rear brake fluid

reservoir.

".

Make sure you have the correct hydraulic

fluid·

DOT 4

is

recommended.

Wrap a rag

around the reservoir being

worked

on

to

ensure that any spillage

does

not come into

contact with painted surfaces.

3

Top

up

with

new

clean hydraulic fluid

of

the recommended type, until the level Is

abo

.... e the

LOWER mark:.

Tak:e

care

to

avoid spills (see Wa

ming

above).

Bike

care:

• The fluid in

the

front and rear brak:e master

cylinder

reser

....

oirs

will

drop

slightly

as

the

brak:e pads wear

down.

Remo

....

e the right side

co

....

er

for

access

to

the

rear brak:e

fluid

reservoir.

•

If

either

fluid

reservoir

requires

repeated

topping-up

thiS is an indication

of

an hydraulic

leal<;

somewhere in the system. which should

be

inlJeStigated immediately.

1 The front brak:e flUid le'lel is check:ed via

the

sightglass In the reservoir - it must

be

atxNe

the LOWER

le

....

el marll; (arrow).

4

Ensure

that the

diaphragm

is

correctly

seated before Installing the

co

....

er.

4 Suspension,

steering

and

drive

chain

Suspension and Steering: Drive chain:

• Check: for

signs

of

fluid leak:age from

the

hydraulic hoses

and

components

- If found,

rectify

Immediately.

•

Check:

the operation

of

both brak:es before

tak:ing

the

machine

on

the

road; if there is

e

....

idence

of

air

In

the

system (spongy feel

to

le

....

er

or

pedaQ,

It must

be

bled

as

described In

Chapter

7.

2

If

the

le

....

el

is

below

the

LOWER level

marll;, remo

....

e the

two

screws (arrows)

to

free the reservoir cover, theo remo

....

e the

cover, and

diaphragm.

5

The rear brak:e fluid

le

....

el can

be

seen

through

the

translucent

body

of

the

reservoir. The fluid must lie between the

LOWER and

UPPER

level mark:s.

Top

up

as

described for the !root reservoir.

•

Check:

that the front and rear suspension operates smoothly without

binding.

• Check:

that

the

drive chain slack:

isn't

e)(cessi

....

e,

and

adjust

if

necessary (see Chapter 1),

• Check

that

the

suspension is adjusted as required.

.

If

the chain looks dry, lubricate It (see Chapter

1),

• Check that

the

steering moves smoothly from Iock:-to-Iock.

All manuals and user guides at all-guides.com

0'12

Daily (pre-ride) checks

5

Coolant

level

.&

Waming: DO

NOT

remove the

,

radiator

pressure

cap

to

lKkJ

• coo/ant. Topping up is done lila

the

coo/ant

reservoir

tank

fil/er.

DO

NOT

leave

open

conte/nttrS

of

coolant

about,

as

It Is poisonous.

Before

you

start:

.....

Make

sure

you

have a supply

of

coolant

available

(a

millture of 50%

sotl

water and

50%

corrosion

Inhibited

ethylene

glycol

antifreeze is needed),

1

On ZX600A

and

B models check coolant

level

through the slot In the lower fairing.

level

shOl.lld

lie

between lower mark (1)

and

full

mark

(2). Top

up

via filler

cap

(3).

II'

Place

the

motorcycle

on

its

centrestand

whilst checking the level. Make sure the

motorcycle

is on level ground,

ttl

Make

sure

the

engIne IS cOld. Do

not

perlorm

this

check

just

after

the

engine has

been run.

Bike care:

• Use only the specified coolant

mixture,

It

Is

important that antifreeze

is

used In the cooling

system

all year round,

not

just

during

the

winter months. Don"

top-up

with waler alone,

as the antifreeze will become

100

diluted.

2

On

ZX600C

models

tum

the

hancfIebars

to

the right and

look

Into the

left

side

of

the

upper

fairing

to

check

Ihe

coolant

level.

View level through

WindOW

(1).

Level

should lie

between

fun

(2)