Kawasaki VN1500 (1987-1999) User Manual [ru]

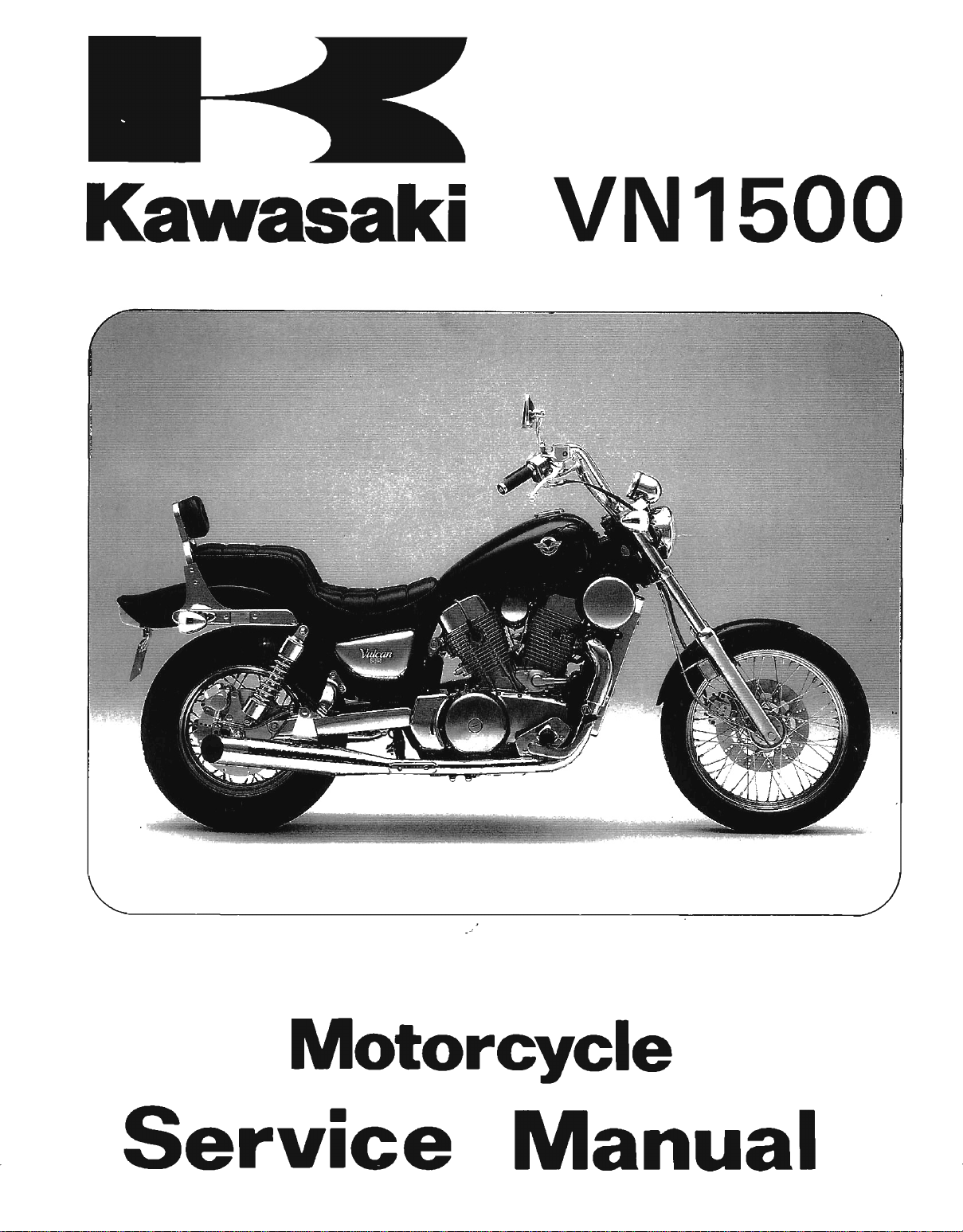

Kawasaki vN1500

Motorcycle

Service Manual

Quick

Reference

Guide

quick

This

locating a desired topic

.Bend

tab of the

the black tab

oi contents

aRefer

exact

the

required,

reference

pages

the

to the sectional

back to

desired chapter

on the edge at

page.

pages

locate the specific topic

to

guide

will assist

procedure.

or

match the black

number with

each table

table of contents

you

in

for

Kawasaki

vN1500

VNl5OOA:

VULCAN 88

VN-15

VNlSOOB:

VU LCAN 88 SE

VN-15

SE

(US

and

Canada)

(Othersl

(US

and

(Othersl

Canada)

Service

All rights

transmitted

wise, without the

Group/Kawasaki Heavy

No liability can be accepted for any

possible

The

obligation

for the latest

All information contained

the time of

use only and

@ Kawasaki Heavy

reserved. No

in any

care has been

is

right

reserved

to make

information

publication.

may not

Industries,

form

prior

such

parts

of this

or by any

written

Industries, Ltd., Japan.

taken

to make changes at any time

changes to

on

lllustrations and

depict

Ltd., 1 987, 1 990, 1 991, 1 993, 1 995,

permission

make it as complete and accurate as

to

product

in this

actual model component

Motorcycle

Manual

publication

means, electronic mechanical

inaccuracies or omissions in this

products

improvements

publication

photographs

may be reproduced, stored

of Ouality

manufactured

is based on the latest

Assurance Department/Consumer

without

incorporated

in this

parts.

1 997, 1

prior

previously.

publication

999,

photocopying,

notice and

after

product

Eighth Edition

in a retrieval system, or

publication,

possible.

without incurring an

your

See

publication.

this

information available

intended for

are

(1)

recording

although

Motorcycle dealer

: N/ar.20, 1999

or otherProducts

every

referencs

at

(K)

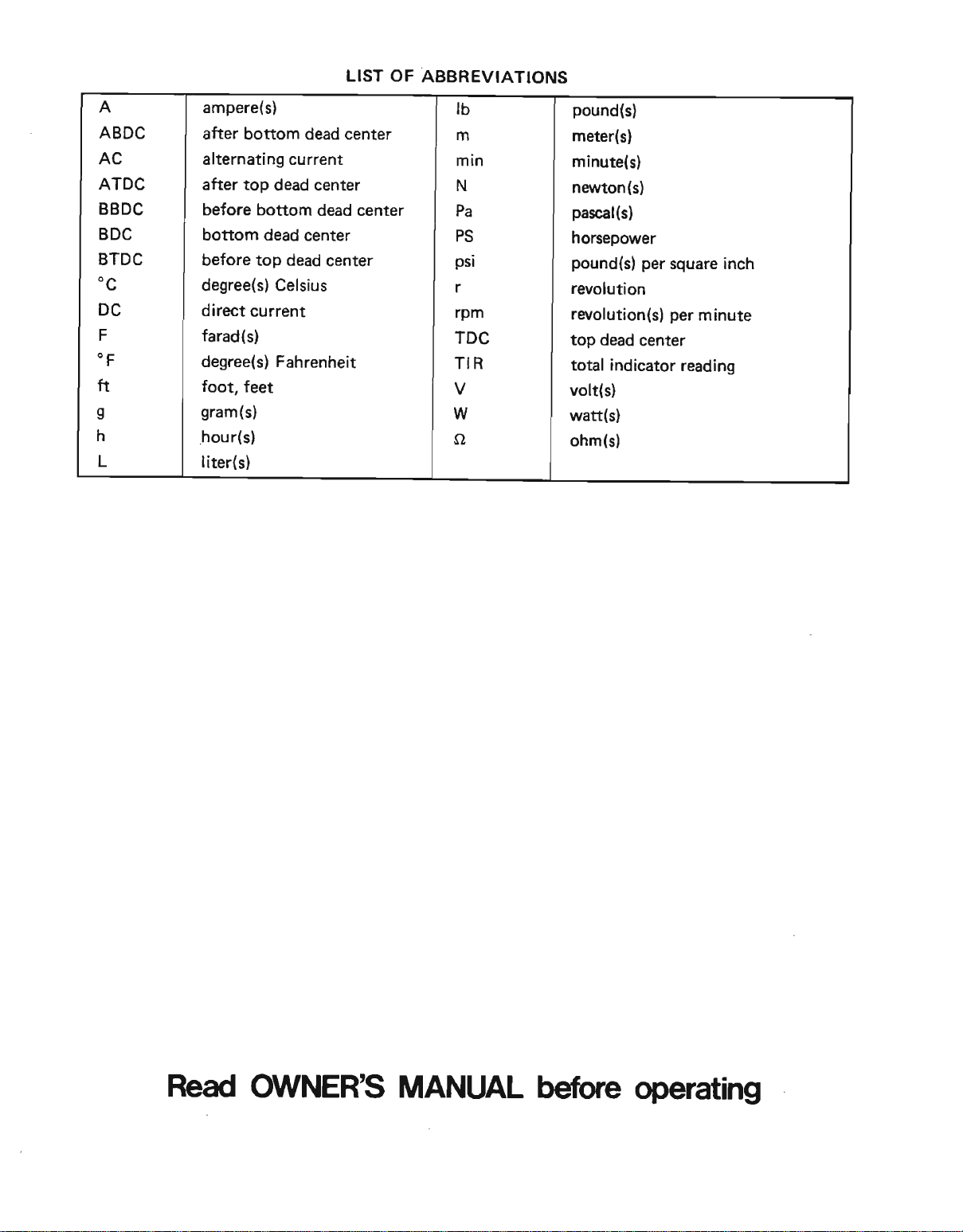

LIST OF ABBREVIATIONS

A

ABDC

AC

ATDC

BBDC

BDC

BTDC

"c

DC

F

.F

ft

s

h

L

ampere{s}

after bottom

alternating current

after

top dead center

before

boftom

before top

degree(s)

direct current

farad

degree(sl Fahrenheit

foot, feet

gram{s)

hour(sl

liter(s)

bottom

dead center

dead center

Celsius

(s)

dead

dead

center

center

tb

m

min

N

Pa

PS

psi

rpm

TDC

TIR

W

o

pound(sl

meter{s}

minute(s)

naryton(sl

pascal(s)

horseporer

pound(s)

rwolution

revolution(sl

top

total indicator r€ading

volt{s)

watt(s)

ohm(s)

per

square

per

dead center

inch

minute

Read

O,I/NER'S MANI At

before

operating

EMISSION CONTBOL

INFORMATION

protect

To

emission

ulations of the United States Environmenal

sources Board. Additionally,

system

on vehicles

1.

2. Exhaust

3. Evaporative

what

{3}

Crankcase

This system eliminates the release of

the

the

burned along with

This system

exhaust of this

been

pollutant

Vapors

phere.

in a canister when the engine is stopped.

returned to the

The

Clean

is

commonly

"Sec.

(3)(A)

(3XB)

the environment in

(1)

and exhaust emission

in compliance with applicable

sold in

vapors

engine is

Emission

carefully

203(a)

for

installed on or in a motor vehicle or motor vehicle

regulations under

or for any manufacturer or dealer knowingly

such device or element of design after such sale and delivery to the

purchaser.

for

trading motor vehicles or motor vehicle engines, or who operates a

vehicles

design installed

with regulations under this title following its sale and delivery to the

ourchaser..."

California

Emission Control System

routed through

are

operating,

Control

reduces

motorcycle.

designed

levels.

Emission Control'System

caused by

Instead,

Air Act, which is the Fede€l law

any

any

fuel vapors

fuel tank.

referred to

The follorving acts and

person

person

knowingly to remove or

the vapors

the fuel

System

the amount of

fuel

waporation in the fuel system are

to

this title

engaged in the business of repairing, servicing,

on or

which we

(2)

Kawasaki

only.

an oil separator

and air supplied

The

and constructed

are routed into

as the

remove or render ihoperative any device

Act's

the

prior

in a motor vehicle

all live, Kawasaki

control

has

incorporated

regulations

crankcase vapors

are drawn

pollutants

fuel

and ignition

to encrre an

Liquid

"tampering

causing

its

to

render

has incorporated crankcase

compliance with applicable

systems

Protection

into

by the

the

covering

thereof

sale and delivery

in

Agency

evaporative

an

the California

of

into the

to the

discharged

running engine

fuel is caught

or

intake side of the engine.

combustion

carburetion

systems

efficient

motor

provisions."

are

remove or

to

inoperative any device or

motor vehicle engine in compliance

chamber, where they are

system.

into

of this

not vented into the atmos

by a vapor separator and

vehicle

prohibited...

engine in compliance with

to the ultimate

reg-

Re

and California

emission control

Air Resources Board

atmosphere. Instead,

the atmosphere by

motorcycle have

engine with loriv exhaust

to be burned, or stored

pollution,

or element of design

render inoperative any

selling, leasing, or

Air

While

the

contains

purchaser,

ultimate

fleet of motor

element of

ultimate

(Continued

on next

page.l

phrase

. The

generally

1. Tampe ng

vices

2. Tampering

a. Maladjustment

b. use

durability

c. Addition

standards.

Permanently

d.

element

"

remove

interyreted

or

elements

of replacement

of design

or rendet

as

does not

of design in

could include

of vehicle

of the motorcycle.

of components

removing,

inoperative

follows

include

parts

of

:

the

:

components

or accessories

ot accessories

disconnecting,

the emission

NOTE

any device

temporary

order

perform

to

such that

control

or element

removal

which

that result

or rendering

systems.

or rendering

maintenance-

the emission

adversely

of

design

inoperative

standards

affect

in the vehicte

inoperative

the

any component

,,

has been

of

are exceeded.

pedotmance

exceeding

the

de-

or

or

WE RECOMMEND

FEDERAL

PENALTIES

LAW,

NOT

TAMPEBING

Federal

rendering

replacement,

purpose

th€_.

while it

been

is in use,

remored

prohibits

law

inoperative

of any

of

noise control

or

or rendered

THAT

ALL

DEALERS

THE VIOLATION

EXCEEDING

WITII

the following

by any

darice

(21

person

or element

the use

inoperative

NOISE

prior

of the

to

$1O,OOO

CONTBOL

acts

other

of

i6

vehicle

by

any

OBSERVE

OF WHICH

PER

VIOLATION.

SYSTEM

or the causing

than for

purposes

THESE

IS PUNISHABLE

PBOHIBITED

thereof:

of maintenance,

design incorporated

sale or

deliriery

after

grch

to the

device or

pervrn.

PROVISIONS

(1)

The

into

any neur

ultimate

element

OF

BY

CIVIL

removal or

repair,

vehicle'for

purchaser

o:f a".id

h.,

or

or

_Among

.

R.eplacem€nt

pltance

oRemoval

.Removal

rModifications

if

such

those

wtth Fedeftrl

of

the

of the

modifications

pre$med

asts

of_

the original

regulations.

muffler(s)

air

box or air

to the

muffrer(s)

result

to constitute

exhaust

or

any internal

box

cover.

or

air intake

in increased

tampering

system

portion

noise

tevLis.

are

the acts listed

or mriffler

of the

system

muffler(s).

by cutting,

-' --

below:

with a component

dri ing,

or

other

not

in

com-

means

Foreword

manual is designed

This

trained

However,

information

who desires

tenance

of

workshop

order to

satisfactorily,

ficient experience

the work, all adjustments,

repair should be carried out only by

mechanics.

to avoid costly mistakes, read the

oughly

before starting work, and then do

carefully in a clean area. Whenwer

tools or equipment are specified,

makeshift tools

urements can

struments are used,

tools

especially, we recommend

scheduled maintenance

ance

maintenance

in

warranty.

cycre:

oFollow

Service Manual,

.Be

maintenance.

eUse proper

cycle

that are

motorcycles

Manual.

are listed in the Pans

rFollow

fully. Don't

rRemember

tenance and repair with

pafts

mechanics in a

it contains enough

make it useful to the owner

to

perform

to

and repair work.

mechanics, the

procedures

carry

In order to

familiarize

may

For the

with

accordance with this manual may void

get

To

alert for

parts.

installed.

perform

adversely affect safe

duration of

this service manual,

or

the

the Periodic Maintenance

tools and

Special tools,

necessary

are

Genuine

procedures

the

take

to keep complete records of

proper

out

Whenever

or doubts

yourself

equipment. Precision

or

only be

and the use of substitute

repair

longest

problems

introduced

pafts provided

shortcuts.

primarily

properly

his

own basic

A

use of tools, and

must be

maintenance

the owner

his

maintenance,

the work efficiently

with the

made

be

procedure

life out of

genuine

when

Catalog.

if the

your

warranty

that all repairs

performed

and non-scheduled

gauges,

servicing

by the Special Tool

in

this

dates and any

for use

equipped

detail and basic

knowledge

basic

understood

and repair

has

ability to

qualified

text, thor-

procedures

the work

do not

proper

operation.

in accord-

Any owner

performed

not

your

Chart in the

Kawasaki Motor-

and testers

Kawasaki

as spare

manual car+

by

shop.

main-

in

insuf-

do

and

and

special

use

meas-

in-

period,

and

the

Motor-

parts

main-

new

How

product

became the

for

disassembly

chapter,

the

their

olvn

the General

gives

operations,

example,

first. The chart tells

clean

Reference

chapter.

first

section.

CAUTION

Always

practices.

oThis

tions

followed, could result in

loss of life.

oThis

tions or

served, could result in damage to or destruction of equipment.

addition

will help

information.

Use this

to

preparing

ln

into its

panicular

a

Ouick Reference Guide

The

produst,s

chapters. Each

comprehensive

Periodic Maintenance Chan

The

a time schedule

you

lf

go

and

Then.

page

Whenaner

follow safe

waming

or

caution symbol identifies special instruc-

This manual contains

to

Manual

manual, we divided

this

major systems,

manual's chapters.

system

and

systems and

Information chapter.

want spark

to the Periodic Maintenance Chart

gap

the

Guide to

use

of the chapter to

you

symbols,

rymbol

procedures

procedures

WARNING

you

distinguish

from adiustment

inspection

chapter

Table of Gontents.

for required

plug

lou

plug.

locate

the Table of Gontents

see these

operating

Next, use

the

heed

identifies special instruc-

which, if not correctly

whicfi, if

five

and CAUTION) which

These

All information

is located in a single

shows

assisB in

in turn has its

information,

hovv frequently to

Electrical

find

the Spark

WARN ING

their instructions!

and maintenance

perconal

not strictly ob-

more

different types of

systems

through

you

locating

is located in

The chart

maintenance

the

System

iniury. or

symbols

the

all

Ouick

on

Plug

and

of

for

the

(in

oThis

ular

venient

NOTE

note symbol indicates

interest for more

operation.

efficient and con-

pointr

of

partic-

.Indicates a procedural

done.

olndicates a procedural

the work

It also

CAUTION,

*

lndicates

take based

inspection in

it follows.

*lndicates

astion

conditional

of the

precedes

NOTE.

or

a conditional step

on the results of

the

a conditional

to take bas€d upon

it follows.

step

sub-step or

procedural

the text of a WARNING,

procedural

step

$b-step

work

or

how

step it follows.

what

or

the test or

step or sub-step

the results

to be

to do

action

or what

to

of the

ln most

tion of

Table

will find

require

or a locking

the system components

of

Contents. In

the instructions

qecified

chapters an.exploded

these illustrations

indicating

tightening

agent

during

assembly.

viqlv illustra-

torque, oil,

follorvs

which

parts

grease

the

you

GENERAL

INFORMATION T.1

General

Table

Before

Model

General Specifications.

Periodic

Torque and Locking Agent

Cable. Wire and

Servicing

ldentification

maintenance

. .

Hose Routing.

. . . 14

, . .

Chart.

Information

of

Contents

1-2

1-5

1-7

1€

1-12

1.2

GENERAL

INFORMATION

Before

unnecessary

included

knowledge

Especially

(1)

(2)

(3)

(4)

(5)

(5)

(7)

(8)

(9)

.

(10)

(1

1) Press

(12)

Serwicing

Before

starting

work.

wherever

is also

note

Dirt

Before removal

work

as

an abrasive

part,

clean

Battery Ground

Remove

motorcycle.

prevents:

This

sparks

Dans.

Installation,

has installation

during removal

mark

TighteningSequence

tighten them

part

all of

in this

Torque

lead

Force

especially

tapping

(particularly

Edses

with

High- Flash

available

directions

Gasket,

should

Liquid

used.

example

(Blue).

or inner

Ball

needle

with

at electrical

Generally,

and record

Generally.

and/or

them by

Service

When

torque

to serious

Common

is

Watch

A high-flash point

Do not

Follow

A

Do

for

gloves

in

regarding

O-Ring

reuse a gasket

be free

Gasket,

manufacturer's

Apply

of a non-permanent

part

installed

circumference

Bearing

not remove

bearings

the marked

to

service

Photographs,

necessary.

required

the

off any

ground

the

When

(a)

Assemblv

installation

or assembly

or

when insulling a part

to a

causing

about a

Manual.

values

damage.

sense should dictate

difficult

necessary,

for

the removal

sharp

piece

or

a

Point

North America

of foreign

Non-Permanent

sparingly'

and Needle

that

side

a motorcycle,

Nevertheless,

for

successful

following;

and disassembly,

and shorten

dust

or metal filings.

(-)

installing,.connect

possibility

the

connections

or assembly

procedures,

disassembly

the

locations

snug fit.

gas

to

edges,

Sotvent

the use

using

a ball bearing

were removed

facing

Then

or oil leakage.

quaner

the bolts,

given

are

Use

remove

tap lightly

of

especially

of thick

solvent

is

Stoddard

of any

or O-ring

matter

directions

Excessive

press

a

so that it

Bearing

out applying

careful reading

diagrams,

the life

lead

from

of accidentally

which

so

and

tighten

turn and

nuts,

in this

good quality,

a

how

or install,

using a wooden

screws held

cloth when

is recommended

and

Locking

amounts

locking

or

drivet

will

or a needle

with

notes,

even

work.

clean

the

of

the motorcycle.

the battery

positive

the

will

occur when

is the reverse

follow

they can

routing

with

during

solvent.

once it

perfectly

for

go

be installed

as much

several

them

Conversely

then remove

or screws

Service

much force

stop

by a locking

major

litting

solvent

has

Agent

cleaning

may

agent

commonly

such as a wheel

place

into

bearing unless

new

ones,

pressure

reliable

and

smooth to

of the

cautions,

a detailed

motorcycle.

turning

them.

evenly in

must

Manual,

is necessary

examine

or

the

to

(generic

been in

and

block

smoothly.

evenly with

account

before

(+)

lead

of removal

Note

or assembled

possibte.

as

bolts, nuB,

when loosening

them. Where

be

use

torque wrench,

plastic-faced

ageno in

engine

engine

reduce fire

name).

avoid

preparing

engine

available

bearing,

removal generally

as

applicable

warnings,

has limitations,

Any

dirt

For

the same

performing

firs! then

the engine

they are

parts

a

cross

tightened in

what may

disassembly

service.

it is

disconnected.

or

disassembly.

locations

or

screws,

pattern.

there

them. Either

in assembly

mallet

order

or turning

danger.

Always

The

oil or

compression

surfaces

passages

oil

in

North

should

absolutely

a suitable

section

and

enGring

any

the negative

over while

in

the

the ordlr

be

to avoid

and assembly.

it over.

mating

damages

is recommended

detailed

the

ieason,

disassembly

partially

But

ani

cable,

the

same way.

start them

This

is to

bolts,

nuts,

is a

tightening

and

too little

and disassembly.

causing

Use

an impact

damaging

A commefcial

follow

driver.

manufacturer

surfaces

where

these

and

cause

America

first

be coated

necessary.

Only

beirings.

descriptions

a

certai;

engine

defore

1-j

1c1

or too much

the

leaks.

is Loctite

amount

or other

installing

operations

tead

to

disassembled. (b)

damage

if

this

Service Manual

wire, and

all

avoid

or screws. first

sequence indication

irethod

problem.

protect

solvent

compounds

serious

with

Replace any

pr&

hose

preferable

lt is

in their

distortion

inoicated.

lf

a

driver

the

screw

your

and container

around

damage.

Lock,n

oil on tts

Install

on the race

to eliminate

have

been

of

basic

parts

will

a new

on

the

the battery.

to electrical

routing

6

holes

and

of the

loosen

rorque

commonly

the

may

pan

seems

Whenever

for

screws

heads.

hands

gasket

will

be

An

Seal

outer

ball

or

bearings

that

GENERAL

INFORMATION 1-3

forms the

the balls or needles and races, and

on

bearing until

(13)

Oil Seal

Replace

When

should be

{ace of the seal

temperature

(14)

Circlip.

Replace any circlips, retaining rings. and cotter

weakens

them only enough to

(15)

Lubrication

Engine

surfaces have an adequate

should be applied to any

be cleaned off. Deterioiated

Don't

applications

makes reference to

parts.

(16)

Electrical

All the electrical wires are either single-color or two-color and,

connected to wires of the same color. On any of the two-color

and

the secondary color.

woufd

it

press

fit with the base component to avoid damaging the bearings.

prevent

it stops at the stops

and Grease Seal

grease

oil

any

pressing

pressed

Retaining Ring. and Cotter Pin

and

wear

use

Always check

Wires

a lesser amount of a second color, so a two-color wire is identified by

be

or

in a seal which has manufacture/s marks,

place

into

is

grease

deforms them. When installing circlips and retaining

is

iust

and may be harmful if used in an application for which they are

"redlvellow"

a

with the end of the hole.

even

on the lips to reduce rubber to

install them

generally

rubbing surface which has lost its lubricative film.

any oil or

molybdenum

manufacturer recommendations

For

example, a

in

the hole or on the shaft.

seals that were

a suitable drivet which contacts evenly

using

no more.

and

its maximum while

at

lubricative film. During assembly, oil or

grease

wire il the colors were reversed to make red the main color.

has lost is lubricative

grease.

Some oils and

disulfide

yellow

races and balls or needles

removed

Before

metal

grease (MoS"

wire with

new

with

press

a shaft

friction.

pins

that

the engine

quality

greases

betore

thin

in

in the assembly ol certain engine and

)

using such special lubricants.

red stripes is refened to as a

prevents

This

from

being dented. Press a ball

ones, as

were removed with new ones,

is warming up

and may contain abrasive

particular

wires there is a

removal

it

with

in

passes

through a seal, apply a

rings,

grease (whichever

with

generally

marks facing out.

the

with

the side of seal, until the

take care

Old

should

only a

first the

to compress or expand

before all the

and

grease

be

used

not intended. This manual

few exceptions, must be

greater

amount of one

primary

severe stress

damages

is more

and dirty oil should

foreign

only in certain

color and then

"yellow/red"

seals.

Seals

little high

removal

as

rubbing

suitable)

panicles.

chassis

color

wire;

Wire

(17)

Replacement Parts

When there is a replacement instruction, replace these

These replacement

(18)

Inspection

When

damage. lf there is any doubt as to

(19)

Specifications

performance,

parts

Abrasion

Bent

Color

change

SDecification terms are defined as

"Standards":

"Service

Limits": indicate the usable

parts

have

been disassembled,

show dimensions or

replace the damaged

(cross-section)

Red

'

Wire Strands

Yellow

Red

will

be damaged

the

Crack

Dent

Deterioration

follows:

performances

parts.

or lose their

visually inspect

condition

limits. lf

of them, replace them with new ones.

which

measurement

the

Name of Wire Color

Yellow/Red

parts

original

these

new

with

function once removed.

parts

ones every time they

for the following conditions or-other

Hardening Warp

Scratch

Wear

Seizure

brand-new

parts

or systems

shows excessive

are removed.

have.

wear

or deteriorated

14

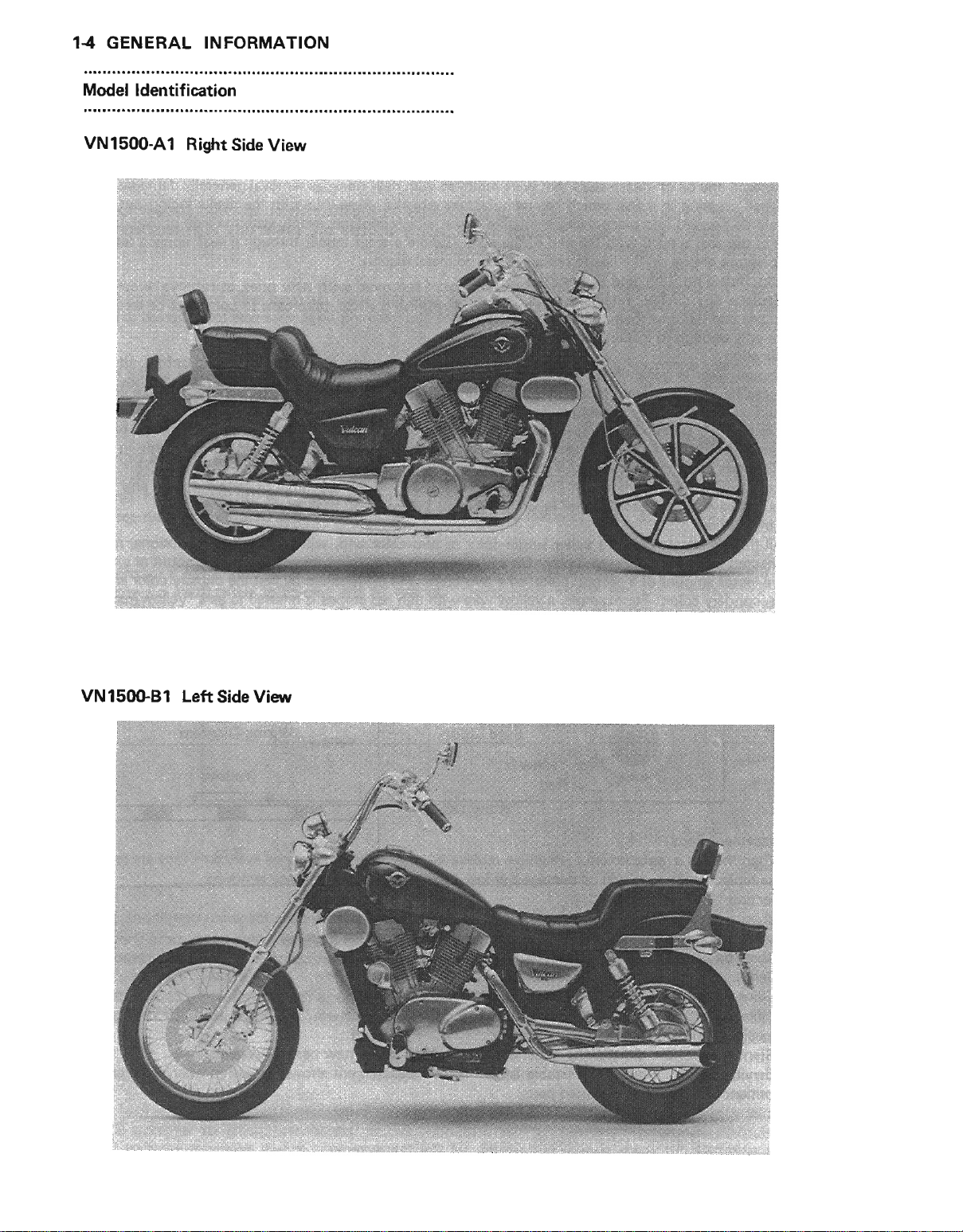

GENERAL ]NFORMATION

Model ldentification

VN1500-A1

Right

Side View

VN15qlB1

Left Side View

GENERAL

INFORMATION

16

General Specif

Items

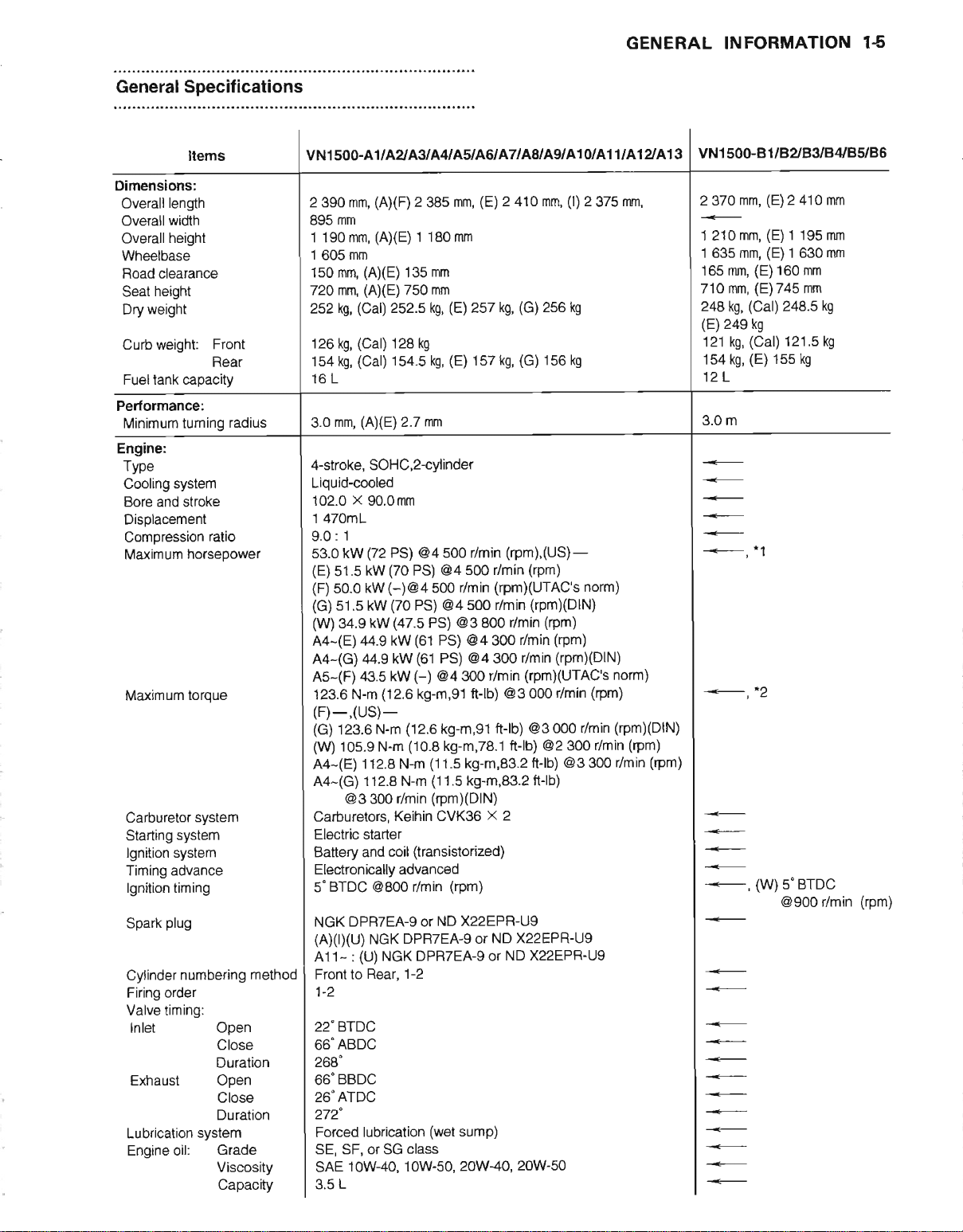

Dimensions:

Overall length

width

Overall

height

Overall

Wheelbase

Road

clearance

height

Seat

Dry weight

weight:

Curb

Fuel tank capacity

Pertormance:

lrinimum tuming

Engine:

Type

Cooling system

Bore

and

Displacement

Compression

Maximum

Maximum

Carburetor system

Starting system

lgnition

Timing advance

lgnition timing

Spark

Cylinder

Firing order

Valve timing:

Inlet Open

Exhaust Open

Lubrication system

Engine oil: Grade

Front

Rear

radius

stroke

ratio

horsepower

torque

system

plug

numbering method

Close

Duration

Close

Duralion

Viscosity

Capacity

ications

VN1 sOGAI/AZA3/A4I

2

390

895

1 190 mm,

1 605 mm

150 mm,

720 mm,

2s2 k9,

126 kg,

154 kg,

16 L

3.0

4-stroke, SOHC,2-cylinder

Liquid-cooled

102.0 x 90.0 mm

1 470mL

9.0:1

53.0 kW

(E)

(F)

(G)

(W)

A4-(E) 44.9

A4-(G) 44.9 kW

As-(F) 43.5 kW

123.6 N-m

(A)(F)

mm,

mm

(AXE)

(AXE)

(A)(E)

(Car)2s2.5

(Cal)

(Cal)

(AXE)

mm,

(72

51.5 kW

50.0 kW

kW

s1.5

34.9 kW

(12.6

750 mm

128 kg

154.s kg,

2.7

PS) @4 500

(70

(-)@4

(70

(47.5

kW

A5I A6I A7 I

2

mm,

385

1 180 mm

lS5 mm

(E)

kg,

257 k9,

(E)

1s7 kg,

nrn

r/min

PS) @4 500

500 r/min

PS) @4 500

PS)

@3

(61

PS) @4 300

(61

PS) @4 300

(-)

@4 300 r/min

kg-m,91 ft-lb)

(F)-,(us)-

(G)

123.6 N-m

(W)

105.9 N-m

A4-(E) 112.8

A4-(G)

@3

Carburetors,

Eleclric starter

Battery and

Electronically advanced

5" BTDC @800

NGK DPRTEA-g

(AXIXU)

A11- :

Front to Rear,

'l-2

22'BrDC

66"ABDC

26A"

BBDC

66.

26. ATDC

272"

Forced lubrication

SE, SF,

10W-40, 10W-50,

sAE

L

3.5

(12.6

kg-m,91 ftlb) @3

(10.8

kg-m,78.1 tt-lb) @2

(1

1.5 k9-m,83.2

N-m

112.8 N-m

300 r/min

NGK DPRTEA-g

(U)

NGK

or SG class

(1

1.5

(rpmXDlN)

Keihin

CVK36

(transistorized)

coil

(rpm)

r/min

or ND X22EPR-Ug

DPRTEA-g or ND

1-2

(wet

kg-m,83.2 ftlb)

or ND

sump)

20W-40,

AU A9I A1OI A1 1 I NA 413

(E)

2 410

(rpm),(Us)-

r/min

(rpmXUTAC's

r/min

800 r/min

@3 000 r/min

x

2

X22EPR-U9

20W-50

(l)

mm,

2 375 mm,

(G)

256 kg

(G)

156 kg

(rpm)

norm)

(rpmXDlN)

(rpm)

(rpm)

r/min

(rpmXDlN)

r/min

(rpmXUTAC's

00o r/min

300 r/min

itlb) @3 300 r/min

)Q2EPR-U9

norm)

(rpm)

GpmXDlN)

(rpm)

(rpm)

vN1 500-81/BZB3/84/85/86

(E)

mm,

2 370

1 210 mm,

1

mm,

635

165 mn,

710 mm,

248 kg,

(E)

24e ks

kg,

121

1s4 kg,

12 L

m

3.0

=-,

(E)

(E)

(E)

160 mm

(E)

745 mm

(Cal)

(Cal)

(E)

15s kg

(w)

2 410 mm

1 195 mm

1

mm

630

248.5 kg

121.5 kg

BTDC

5"

(rpm)

1€

GENERAL

INFORMATION

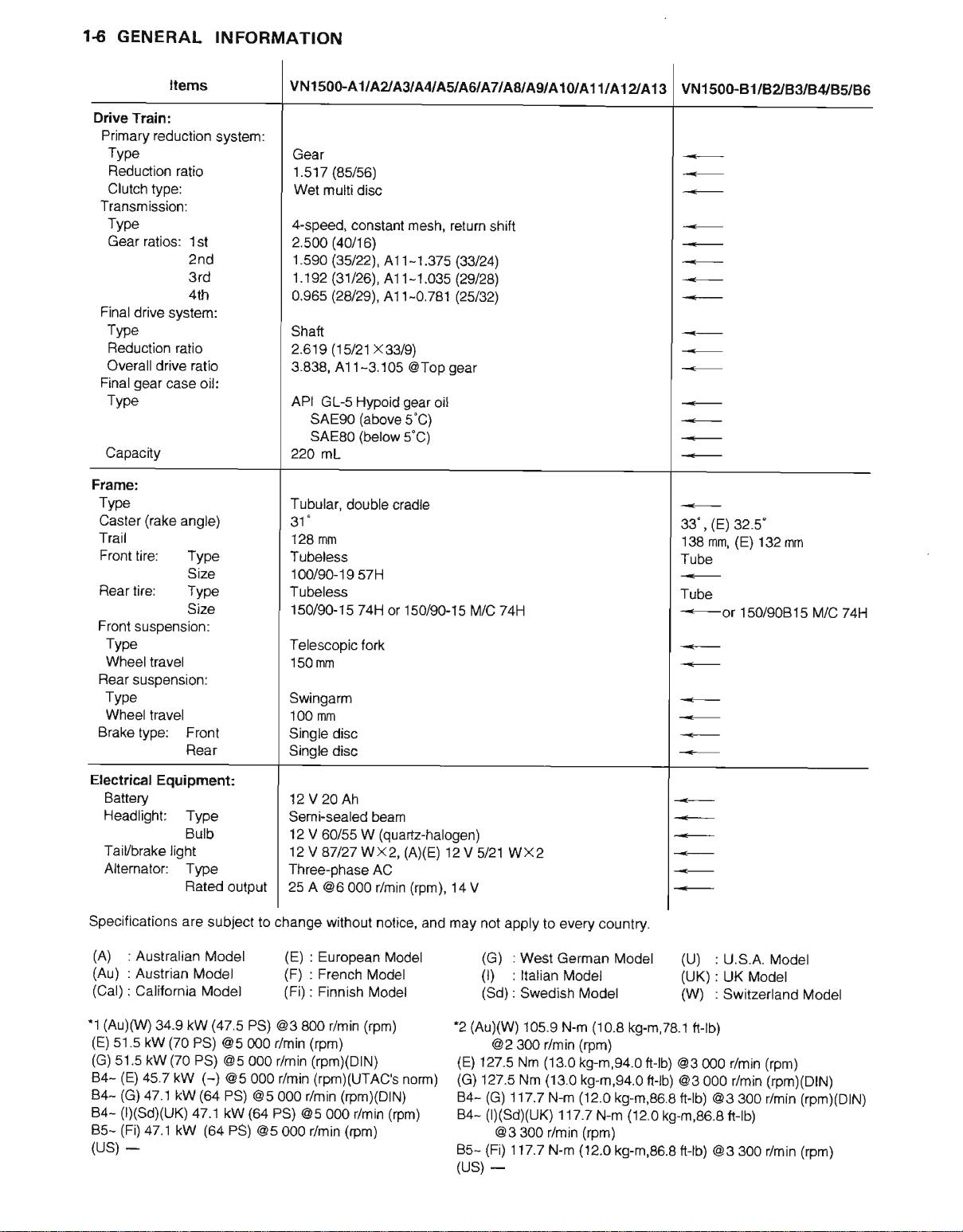

Drive

Train:

Primary

Transmission:

Final

Final

Frarne:

Type

Caster

Trail

Front

Rear

Front

Rear suspension:

Brake

reduction

Type

Reduction ratio

Clutch

lype:

Type

Gear ratios: 1st

znd

3rd

4th

drive system:

Type

Reduction

Overall

Type

Capacity

Type

Wheel travel

Type

Wheel

ratio

ratio

drive

gear

case oil:

(rake

angle)

tire: Type

Size

tire: Type

Size

suspension:

travel

type:

Front

Rear

system:

VNl500"A1IAZA3/AN

Gear

(8s/56)

1.s17

Wet multi

4-speed,

2.s00

1.s90

1.192

0.965

Shalt

2.619

3.838, 411-3.105

API

22O mL

Tubular,

31"

'128

Tubeless

100i90-19

Tubeless

15O90-15

Telescopic tork

150 mm

Swingarm

100 mm

Single disc

Single

disc

constant mesh, return

(40/16)

(35/22),

(31/26),

(28/29),

(15/21 x33/9)

GL-s Hypoid

SAE90

SAEso

mm

disc

41 1-1.375

411-1.03s

Al 1-0.781

gear

(above

(below

5"C)

double

cradle

57H

74H

o|l5cl/90-15 M/C 74H

@Top

oil

5"C)

ASIAGI A AAAgl

shift

(33t24],

(29/28)

125/32)

gear

A1U

A11tA1AA1g

vNl

500-81/B2/B3/BtyB5/B6

(E)

33'

138

Tube

Tube

=-or

32.5"

,

(E)

mm,

150/90815

132 mm

M/C 74H

Electrical Equipment:

Battery

Headlight: Type

Butb

Taiubrake

Altemator:

Specitications

Specitications

(A)

(Au)

(Cal)

"1

(Au)(W)

(E)

s1.5

(G)

s1.5 kW

(E)

84-

(G)

84-

(D(SdXUK)

84-

(Fi)

85(US) _

light

Type

Rated

are subject t(

are subject to change

: Australian

: Auslrian Model

:

Califomia Model

34.9 kW

kW

45.7 kW

47.1

47.1 kW

(70

(70

kW

Model

(47.s

PS)

@5 000 r/min

PS)

@5 @0 r/min

(-)

(64

PS)

47.1

kW

(64

12V20Ah

Semi-sealed

'12

12V

Three-phase AC

output

@5 000 r/min

PS)

25 A

(E)

(F)

(Fi)

PS) @3

@5 00o r/min

(64

800 /min

PS)

@5 000 r/min

@5 00o

beam

V 60/55 W

A7127Wxz(

@6 000 r/min

without notice,

: European

French

:

: Finnish

(rpm)

(rpmXDlN)

(rpmXUTAC's

r/min

(quartz-halogen)

Modol

Model

Model

(rpm)

(rpmXDtN)

(rpm)

(rpm)

12 V

)(E)

(rpm),

14 V

and may not

-2

(E)

norm)

(G)

8484-

85-

(us)

s/21 WX2

apply to every country.

(G)

: West

(l)

(Sd)

(AUXW)

@2 300 r/min

127.5

'i27.5

(G)

(IXSdXUK)

@3 300 r/min

(Fi)

Geman Model

: ltalian

:

117.7 N-m

117.7 N-m

Model

Swedish Model

105.9

N-m

(13.0

Nm

(13.0

Nm

117.7 N-m

-

(1o.8

kg-m,78.1

(Ipm)

kg-m,g4.O

k9.m,94.0

(12.0

(rpm)

(12.0

tr-tb)

ftlb) @3 000 r/min

kg-m,86.8

(12.0

kg-m,86.8

(U)

: U.S.A.

(UK)

:

UK Model

(W)

: Switzertand

ttlb)

@3 00o r/min

ftlb) @3 300 r/min

kg-m,86.8

ft-lb)

t-tb) @3 300 r/min

Model

Modet

(rpm)

(rpmXDtN)

(rpmxDtN)

(rpm)

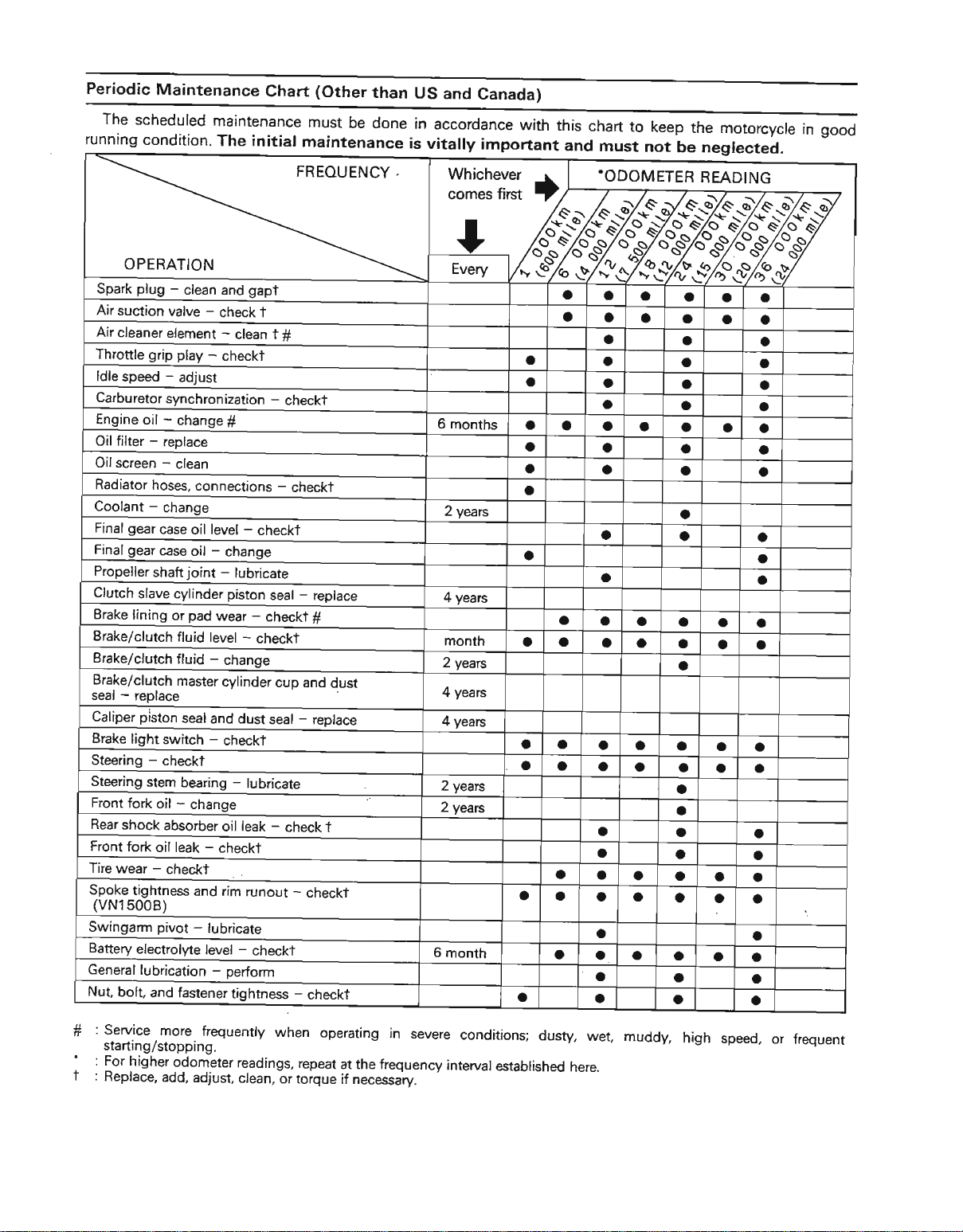

Periodic

The

running

Maintenance

scheduled

condition.

OPERATION

plug

Spark

Air

suction valve

Air

cleaner

Throttle

ldle

Carburetor

Engine

Oil lilter

Oil

Radiator

Coolant

Final

Final

Propeller

Clutch

Brake

grip

speed

oil - change

-

replace

-

screen

hoses,

-

change

gear

case

gear

case oil

shaft

slave

lining

-

synchronization

Brake/clutch

Brake/clutch

Brake/clutch

-

seal

replace

piston

Caliper

Brake light

Steering

Steering

Front

Rear

Front

Tire wear

Spoke

(vN15008)

Swingarm

Baftery

General

Nut,

switch

-

checkl

stem

fork

oil - change

shock absorber

fo*

oil leak

-

checkt

tightness

pivot

elgctrolyte

lubrication

bolt, and fastener

Chart

maintenance

The

initial

-

clean

element

play

qdiust

clean

connections

oil level

joint

cylindg

pad

or

fluid

fluid

master

seal

bearing - lubricate

and rim

-

gapt

and

-

check t

-

clean t

-

checkt

#

-

checkt

-

change

-

lubricate

piston

-

wear

levet

-

-

checkt

change

checkt

cylinder

and

dust seal - reprace

-

checkt

leak

oil

-

checkt

runout

lubricate

-

tevel

checkl

-

oerform

tightness

(Other

must

be

maintenance

FREOUENCY.

#

-

checkt

-

checkt

seal - replace

#

cup

and dust

-

check

T

-

checkt

-

checkt

than

US and

done in

is vitally

Canada)

accordance

important

6 months

yeas

2

years

4

month

yeas

2

years

4

years

4

yeats

2

years

2

6 month

with

a

a

o o

a

a

a

O

a

a

a

a

a

this

and

a

a

a

o

a

a

a

a

o

chart

must

O

o

a

a

o

o

a

a

a

a

a

a a

a

a

a a

a

a

a a

a

a

a

a

a

to keep

not

be

o

a

o

o

a

a

a

a

a

a

a

a

a

o

o

a

a

a

a

o

a

a

a

a

a

a

a

the

motorcycle

neglectei.

a

a

o

a a

o

a

a

a

a a

a

a

a

a

a

a a

good

in

o

a

o

a

o

a

o

a

a

a

a

a

a

a

a

a

a

a

a

O

a

:

Service , more.

starting/stopping.

: For

higher

:

T

heprace,

frequently

odometer

add, adJust,

when

re€dings,

ctean,

or torque if

operating in

repeat

at the frequency

necessary.

severe

interval

conditions;

established

dusty,

here.

wet, muddy,

high

speed,

or frequent

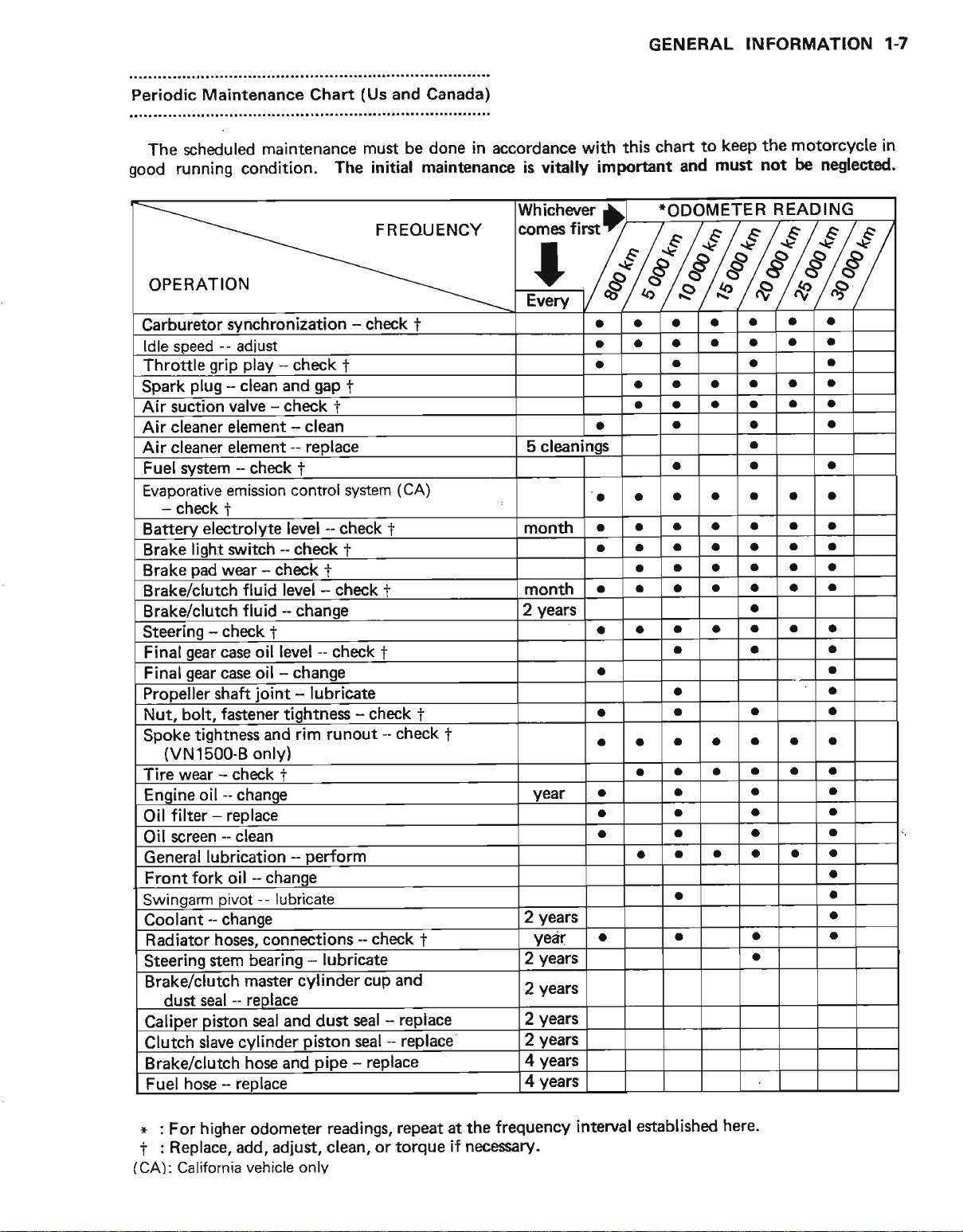

Periodic

Maintenance Chart

(Us

and Canada)

GENERAL

INFORMATION 1.7

The

good

scheduled

running condition,

maintenance

OPERATION

Garburetor

ldle soeed

Throttle

Spark

Air suction

Air cleaner

cleaner element

Air

s,ynchronization

--

adiusl

grip play

-

plug

clean and

valve - check

element

Fuel system - check

Evaporative emission

-

check

Batterv

Brake

Brake

Brake/clutch

Brake/clutch

Steerins

Final

Final

Propeller shaft

Nut, bolt.

Spoke

(VN1500-8

Iire wear - check t

Enqine oil

filter - replace

Oil

screen - clean

Oil

General

Front fork oil - chanqe

Swinqarm

Coolant

Radiator

Steering

Brake/clutch

dust seal - reolace

Caliper oiston

Clutch slave

Brake/clurch

Fuel hose - reolace

t

electrolvte

liqht

s\n,itch

wear

-

check

pad

fluid level - check

fluid - chanqe

-

check

i

qear

case oil

gear

case oil - change

ioint

fastener tightness

tightness

and

only)

-

chanqe

lubrication

--

pivot

-

change

lubricate

hoses, connections

stem bearing

master cylinder

seal

cvlinder

hose and

must be done

initial maintenance is vitally

The

in

accordance with

Whichever

FREOUENCY

comes

I

-

check

i

-

check

-

-

control system

level - check

-.

check

level - check

-

and dust

1

gap

t

J

clean

replace 5 cleaninqs

t

(CA)

t

month

f

f

I

month

2

vears

t

-

lubricate

-

check

rim runout

-

check

1

i

year a

perform

yearc

2

-

lubricate

piston

pipe

-

check

1

cup and

seal - replace

-

replace

seal

-

replace

year

years

2

years

2

yearc

2

years

2

years

4

years

4

important

first

a

o a

a

a

a

a

a

a

a

a

a

O

a

a

a

to

chart

this

and

TODOMETER

a a

a

a

a a a

a

a

a

a a a

o

a a a

a

a a

O o

o a a

a

a a

a

a a a

a

a

a

a

a a

a a

a

a

a

a a

a

a

keep the

must

motorcycle

not be neglected.

READING

a a

a

a

a a

a a a a

a a a

a a a a

a a

a a o

a

a a

a

a

a

a a

a a

a a

a a a

a

a a

a

a

a a

a a

a a

a a

a a a

a

a

in

a

o

a

a

a

a

a

o

a

a

a

a

r

: For higher odometer

: Replace, add, adjust,

t

(CA):

California vehicle only

readings, repeat at

clean, or torque

if

frequency

the

necessary.

interval eEtablished

here.

1€

GENERAL

INFORMATION

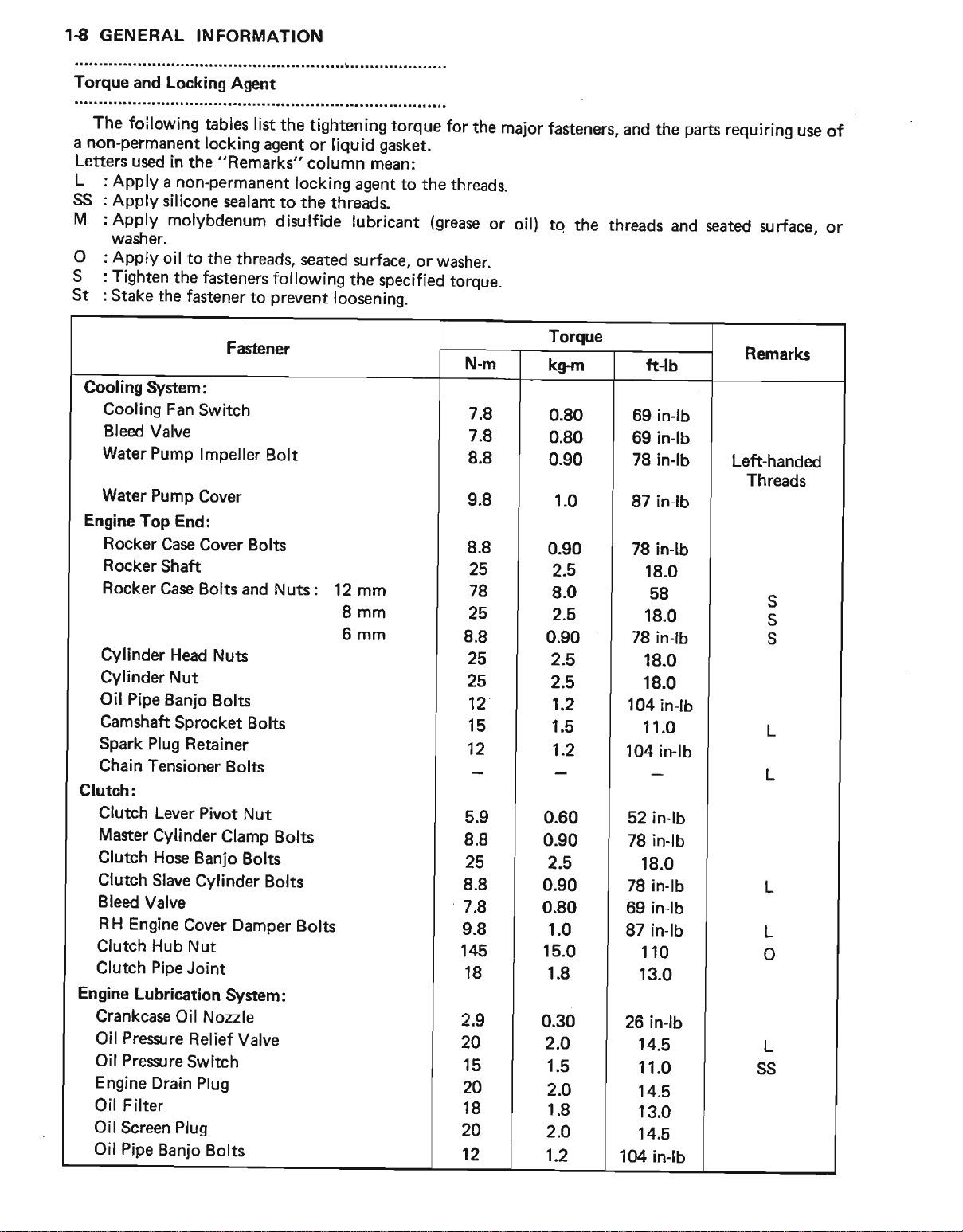

Torque

a non-permanent

Letterc

L

ss

M

o

b

st

Cooling

Engine

and

Locking

The foilowing

used in

Apply

Apply

Apply

washer.

Apply

Tighten

stake

the

a non-permanent

silicone

molybdenum

oil

to the

the fasteners

the fastener

System:

Cooling

Bleed

Fan

Valve

Water Pump

Water Pump

Top End:

Rocker

Rocker

Rocker

Cylinder

Cylinder

Oil Pipe

Camshaft

Spark Plug

Chain

Case Cover

Shaft

Case Bolts

Head

Nut

Banjo

Sprocket

Retainer

Tensioner

tables list

Switch

lmpeller

Cover

Clutch:

Clutch Lever

Master

Clutch

Clutch

Bleed

Valve

RH Engine

Clutch

Clutch

Engine

Crankcase

Oil

Oil

Engine

Oil Filter

Oil

Oil

Pioe

Lubrication

Pressre

Prescrre

Drain Plug

Screen Plug

Pipe

Pivot

Cylinder

Hose

Banio

Slave

Cylinder

Cover

Hub

Nut

Joint

Oil Nozzle

Relief

Switch

Banjo

Agent

locking

agent

"Remarks"

sealant

threads,

following

prwent

to

Fascner

Bolt

Bolts

and Nuts :

Nuts

Bolts

Bolts

Bolts

Nut

Clamp Bolts

Bolts

Bolts

Damper

System

Valve

Bolts

the tightening

or liquid

column mean:

locking

to the threads.

disrlfide

seated

agent

lubricant

zurface,

the

loosenins.

12 mm

8mm

6mm

Bolts

:

torque for

gasket.

to the

(grease

or washer.

specified

the

major

threads.

or

toroue.

N-m

7.8

7.8

8.8

9.8

8.8

25

78

25

8.8

25

25

12

15

12

5.9

8.8

25

8.8

7.8

9.8

145

18

2.9

20

15

N

18

20

12

fasteners,

oil)

tq the threads

Torque

kgrn

0.80

|

0.80

|

| 0.90

1.0

0.90

2.5

8.0

2.5

0.90

2.5

2.5

1.2

1.5

,:

0.60

0.90

2.5

0.90

0.80

1.0

15.0

1.8

0.30

2.O

1.5

2.O

1.8

2.O

1.2

and the

ft-lb

in-lb

69

69 in-lb

78 inlb

87 in-lb

78 in-lb

18.0

58

18.0

78

in{b

18.0

18.0

104

inlb

11.0

'104

in-lb

52 in-lb

78 in-lb

18.0

78 in-lb

69 inlb

87 in-lb

110

13.0

26 in-lb

14.5

11.0

14.5

13.0

14.5

l(X

in-lb

parts

requiring

and seated sr rface,

use

Remarks

Left-handed

Threads

S

S

s

L

L

o

L

SS

of

or

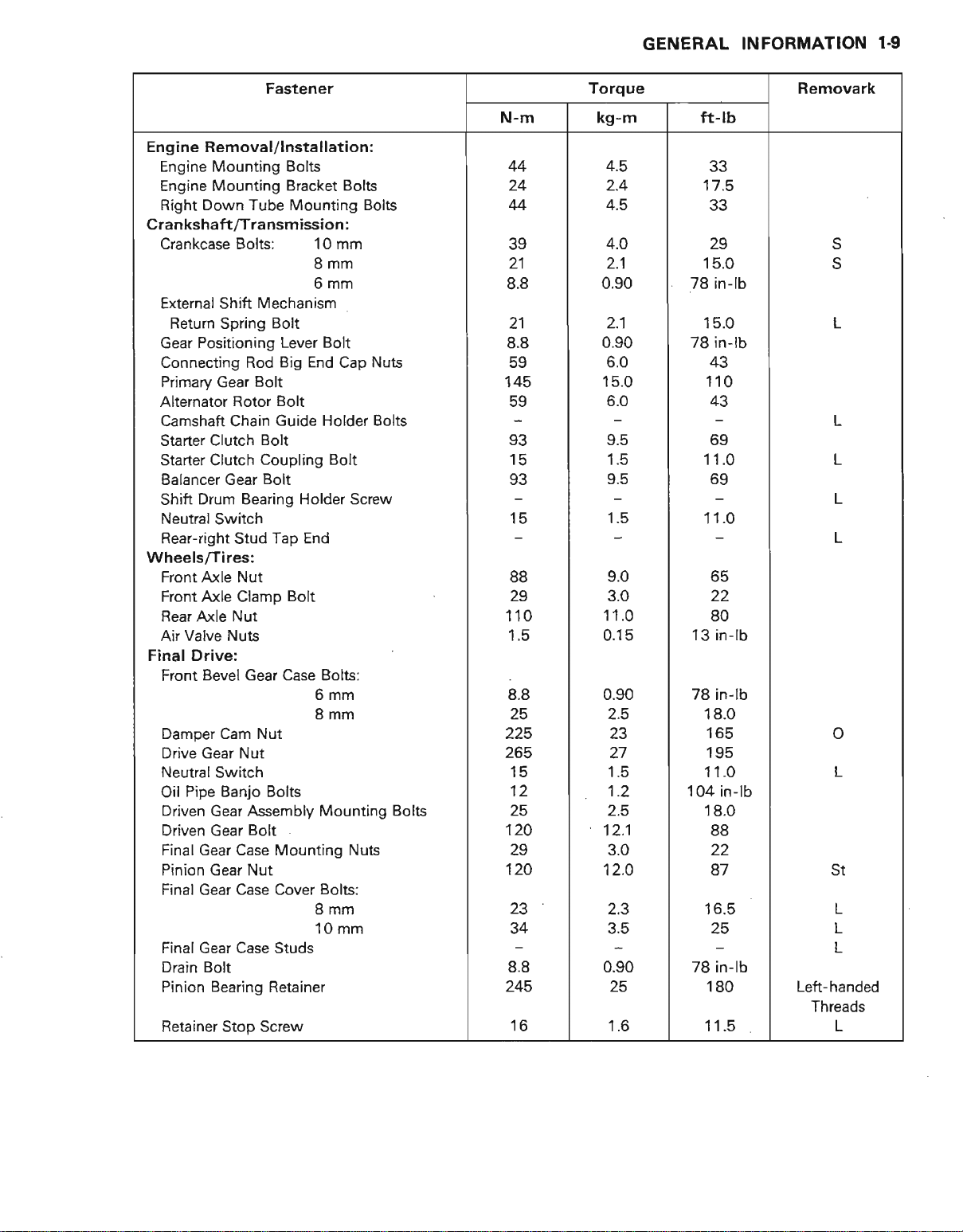

GENERAL

INFORMATION

1-9

Fastener

Engine

Crankshaft

Wheels/Tires:

Final

Removal/lnstallation:

Engine Mounting Bolts

Engine Mounting Bracket

Right Down Tube Mounting

/Transmission:

Crankcase Bolts: 10

External

Return

Gear Positioning Lever

Connecting Rod Big End Cap NUts

Primary Gear Bolt

Alternator Rotor Bolt

Camshaft Chain Guide Holder

Starter Clutch

Starter

Balancer Gear Bolt

Drum Bearing Holder

Shift

Neutral

Rear-right Stud

Front Axle Nut

Front Axle Clamp Bolt

Rear Axle

Air Valve Nuts

Drive:

Front Bevel Gear Case

Damper Cam Nut

Drive Gear Nut

Neutral Switch

Pipe Banjo Bolts

Oil

Driven Gear Assembly Mounting

Driven Gear Bolt

Final Gear Case Mounting Nuts

Pinion Gear Nut

Final Gear Case Cover Bolts:

Final Gear Case Studs

Drain

Bolt

Pinion Bearing Retainer

Retainer Stop Screw

Mechanism

Shift

Spring

Clutch Coupling

Switch

Bolt

Bolt

Tap End

Nut

Bolts

Bolts

mm

8mm

6mm

Bolt

Bolt

Screw

Bolts:

6mm

8mm

8mm

10 mm

Bolts

Bolts

N-m

44

24

44

?o

21

8.8

21

8.8

59

'|

45

93

:,5

,tt

88

29

110

1.5

8.8

25

225

265

15

12

25

120

29

120

t2

34

8.8

245

16

Torque Removark

kg-m

4.5

2.4

4.5

4.0

2.1

0.90

1.1

0.90

6.0

15.0

6.0

Y.C

ft-rb

33

'17

.5

55

29

15.0

78 in-lb

15.0

78

in-lb

+J

110

43

o:,

11.0

11 .0

L

L

L

L

9.0

?n

11.0

0.15

0.90

2.5

23

22

80

13 in-lb

78 in-lb

18.0

toc

o

27

I.C

1.2

2.5

12.1

3.0

12.O

2.3

?E

oso

25

1.6

11.0

104 in-lb

18.0

88

22

6t

1 6.5

.,8

ZS in-f

O

180

11.5

L

St

L

L

L

Left-handed

Threads

L

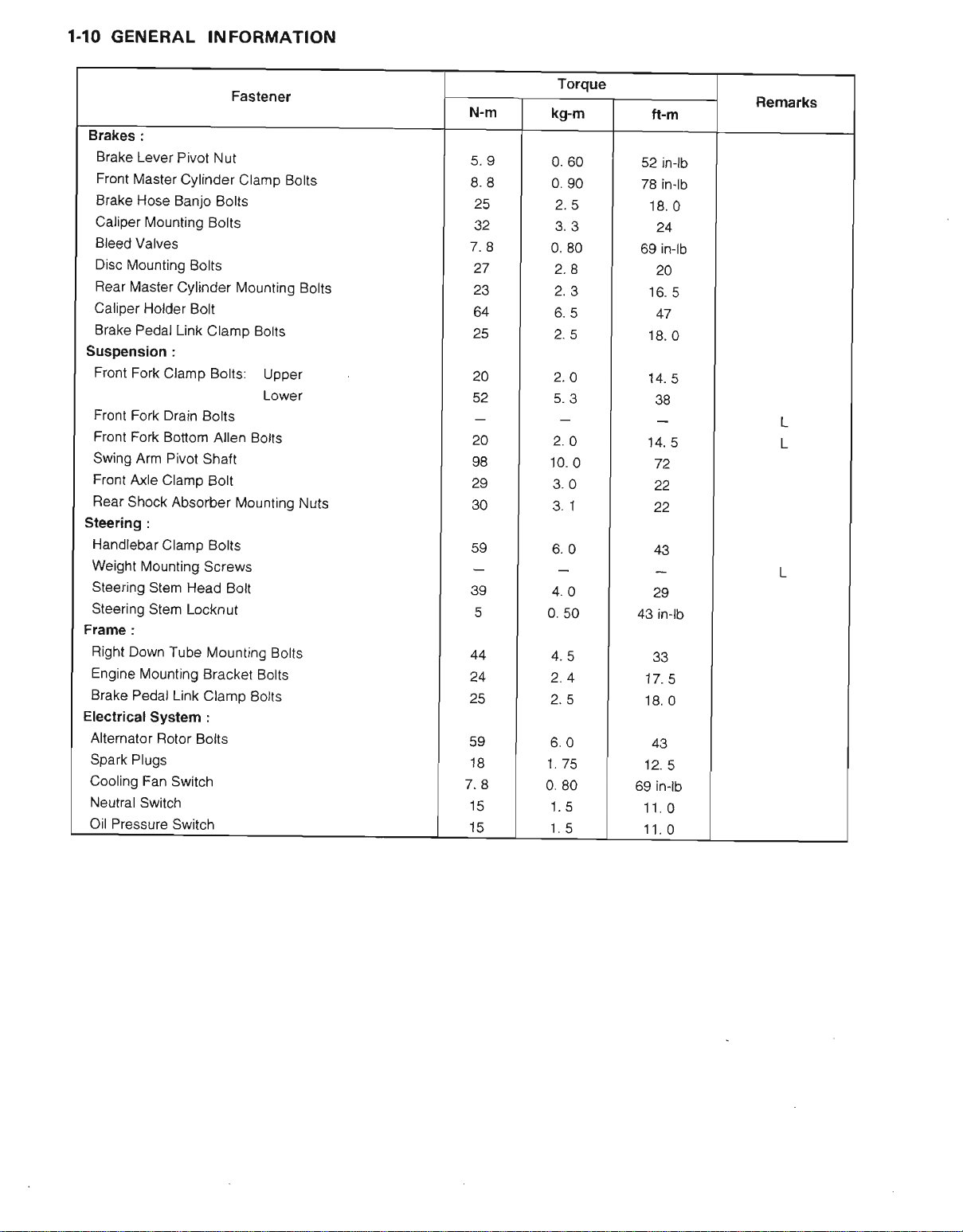

1-IO GENERAL

INFORMATION

Brakes

:

Brake

Lever Pivot Nut

Front

lvlaster

Brake

Hose Banjo

Cylinder

Caliper Mounting

Bleed

Valves

Disc

Mounting

Rear

Master

Cylinder Mounting

Caliper Holder

Brake

Pedal

Link Clamp Botts

Suspension :

Front

Fork

Clamp Bolts:

Front Fork

Front

Swing Arm

Front

Fear

Drain Bolts

Fork Bottom

Pivot

Axle

Clamp Bolt

Shock

Absorber l\ilountjng

Steering :

Handlebar

Weight

Steering

Steering

Ftame

Right Down

Engine

Brake

Electrical

Alternator

Spark

Cooling Fan

Neutral

Oil Pressure

Clamp Bolts

Mounting

Stem Head Bolt

Stem

:

Tube

Mounting

Pedal

Link

System :

Rotor Bolts

Plugs

Switch

Switch

Switch

Fastener

Clamp Bolts

Bolts

Bolts

Bolts

Bolt

Allen

Botts

Shaft

Screws

Locknut

Mounting Bolts

Bracket Bolts

Clamp Botts

Upper

LOWer

Bolts

Nuts

N-m

8.8

25

32

7.8

27

23

64

25

20

52

20

98

29

30

59

44

24

z5

59

18

7.8

15

15

Torque

kg-m

0.

60

0. 90

2.5

0. 80

2.8

2.3

6.5

2.5

2.O

5.3

2.O

10.

0

3.0

3. 1

6.0

4.O

0. 50

4.5

2.4

2.5

6.0

1.75

0. 80

'1.

5

t. c

ft-m

52 inlb

78 inlb

18.

69 in-lb

20

to. c

47

18.

0

'14.

5

38

14. 5

72

2.

22

zl3

29

43 inlb

33

17.

5

18.

0

43

't2.

5

69 inlb

11.0

11.0

Remarks

0

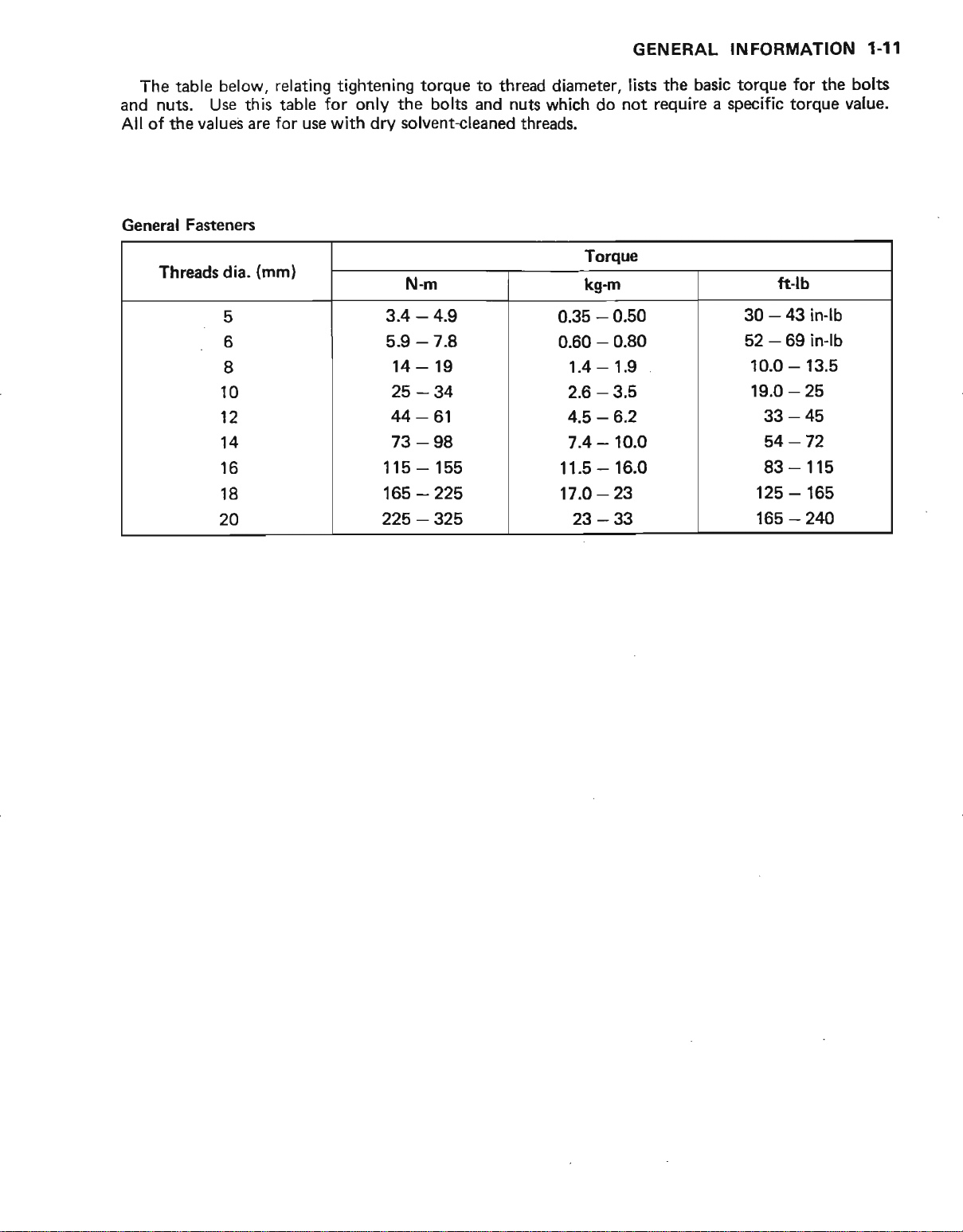

GENERAL INFORMATION

1.11

table below,

The

nuts. Use this table

and

All of the

General Fastenen

values are

Threads

dia.

c

6

8

10

12

14

16

18

20

relating tightening torque to thread diameter,

for only

for use with dry solvent+leaned

bolts and nuts

the

which do not

threads,

Torque

(mml

N-m

-

3.4

4.9

5.9 - 7.8

14-19

-34

25

-61

44

73-98

115- 155

-225

165

225-325

kgm

0.35

0.60

1.4

2.6

4.5

7.4

11.5

17.O

23 - 3:t

lists *re basic torque

require a

-

0.50

-

0.80

-

1.9

-

3.5

-6.2

-

10.O

-

16.0

-23

specific

ft-lb

-

zt3

30

-

69 in-lb

52

10.0 - 13.5

-

19.0

33-45

-72

54

83 - 115

125 - 165

-

165

for

the

torque

in-lb

25

2'10

bolts

value.

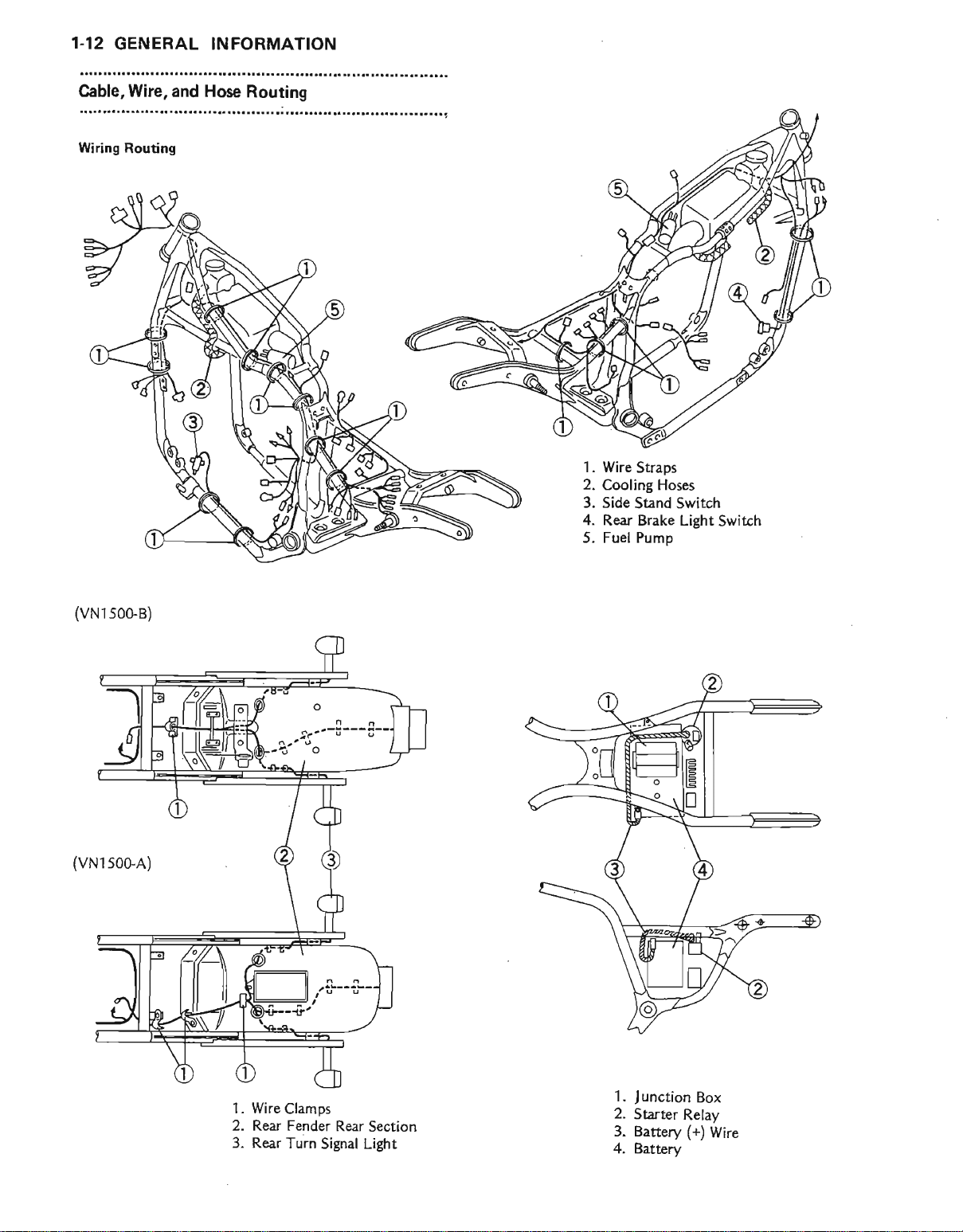

1-12

GENERAL INFORMATION

Cable,

Widng Routing

Wire,

and Hose

Routing

................;,,.......

1 . Wire

2.

3.

4. Rear Brake

5. Fuel Pump

Straps

Cooling Hoses

Side Stand Switch

Light Switch

(vN1500-B)

1. Wire

2.

3. Rear Turn

Clamps

Rear Fender Rear

Signal Light

Section

1. J unction

2. Sarter

3. Battery (+)

4.

Battery

Box

Relay

Wire

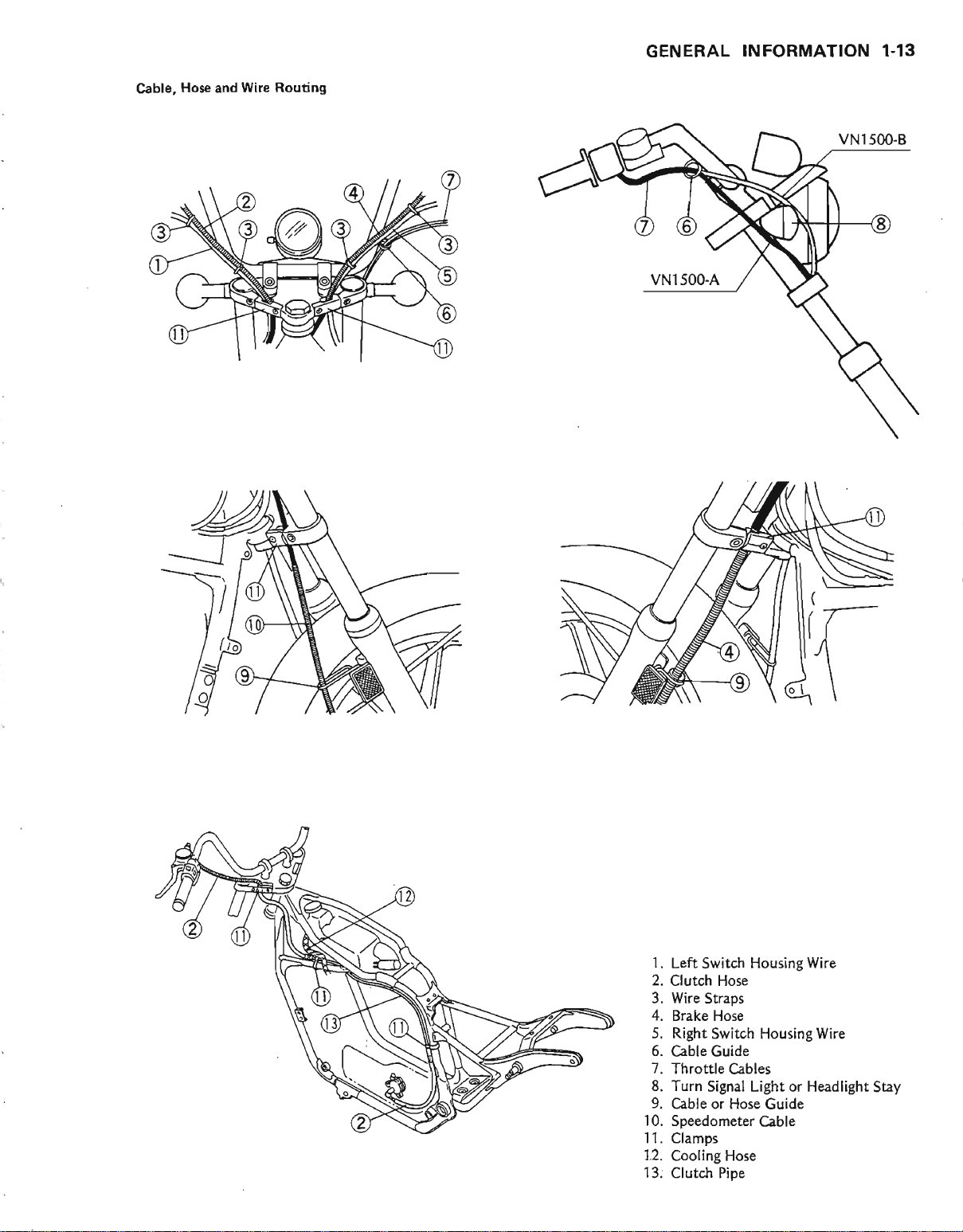

Hose and Wire Rouling

Cable,

GENERAL

INFORMATION 1.13

l. Left

2.

3. Wire

4. Bnke

5. Right

6. Cable Guide

7.

8.

9. Cable or Hose

.l0.

11.

12.

13: Clutch Pipe

Switch

Clutch Hose

Throttle

Turn Signal Light or Headlight

Speedometer Cable

Clamps

Cooling Hose

Straps

Hose

Switch

Cables

Housing Wire

Housing Wire

Guide

Stay

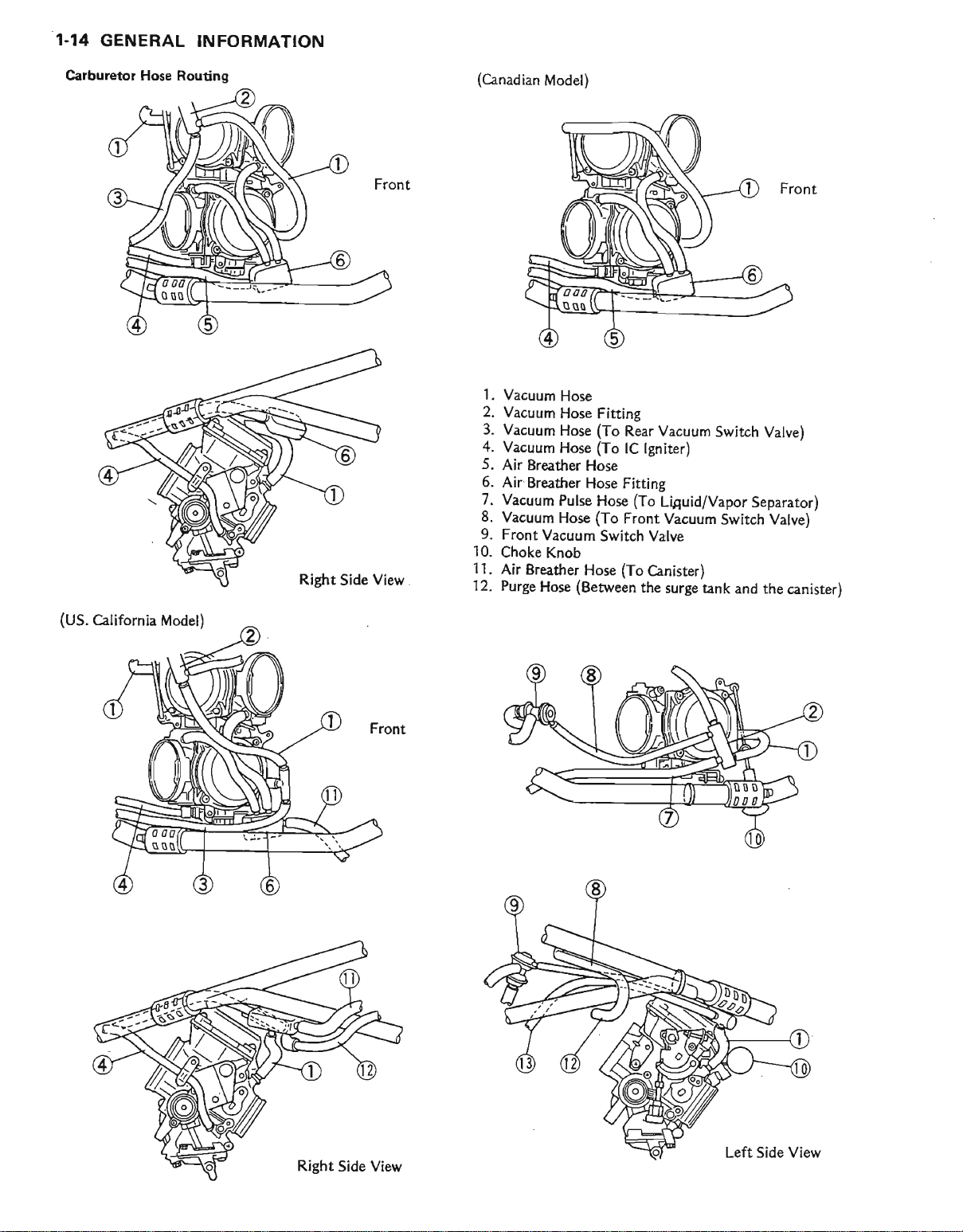

1-14

GENERAL

INFORMATION

Carburetor Hose

Routing

(Canadian

l.

Vacuum

2.

Vacuum

3.

Vacuum

4.

Vacuum

5.

Air

Breattrer

6. Air

Breather

7.

Vacuum

8.

Vacuum

9. Front

10.

Choke

l l.

Air

'12.

Breatfter

Purge

Model)

Hose

Hose

Hose

Hose

Hose

Hose Fitting

Pulse

Hose

Vacuum

Knob

Hose

(Between

Hose

Fitting

(To

Rear Vacuum

(To

IC

lgniter)

(To

Hose

(To

Switch Valve

Liguid/Vapor

Front

Vacuum

(To

Canister)

the

surge tank and

Switch Valve)

Separator)

Switch

Valve)

the canister)

(US.

California Model)

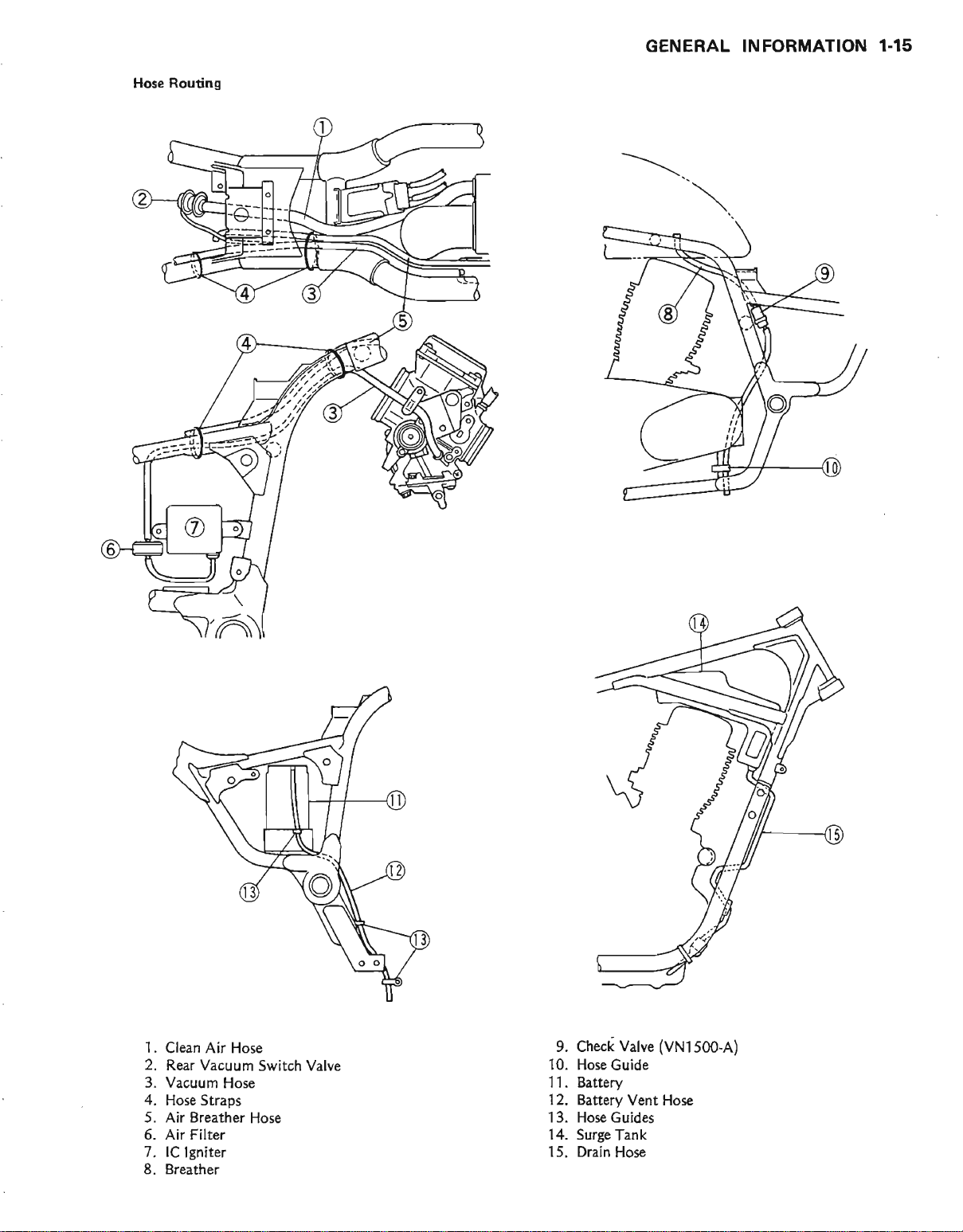

Hose Routing

GENERAL

INFORMATION 1.15

1

. Clean Air Hose

2. Rear

3. Vacuum Hose

4. Hose

5. Air

6.

7.

8.

Vacuum

Straps

Breather Hose

Filter

Air

lC lgniter

Breatier

Switch Valve

9. Check Valve

10. Hose

11. Battery

12. Battery Vent

13,

14.

15, Drain

Guide

Hose Guides

Surge Tank

Hose

(VNl500.A)

Hos€

1.16

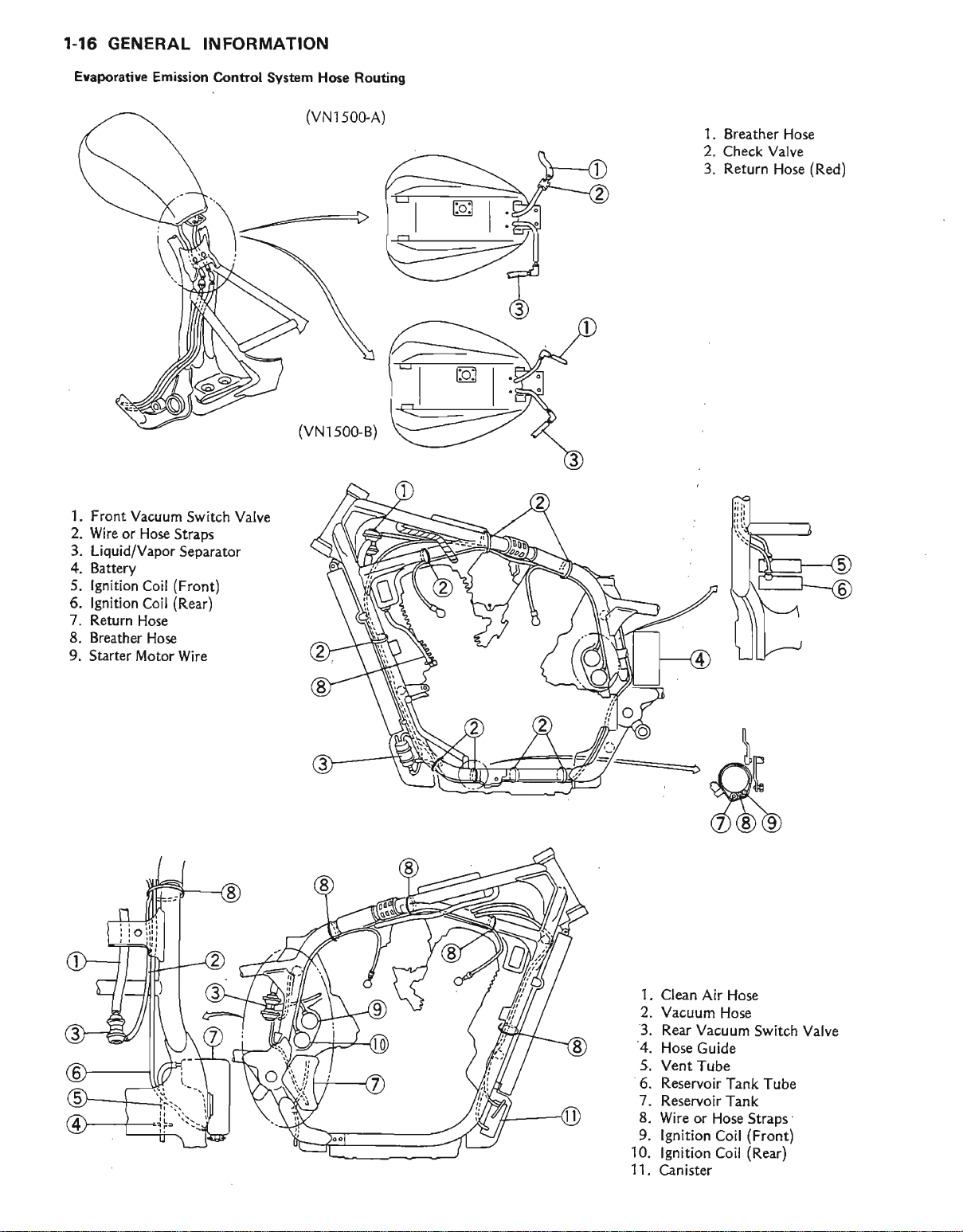

GENERAL INFORMATION

Evaporative Emission

1.

Front Vacuum

2. Wire

3. Liquid/Vapor

4. Batttry

5.

6. lgnition

7. Return

8. Breather

9.

or Hose

lgnition

Hose

Starter Motor

Coil

Coil

Hose

Straps

(Front)

(Rear)

Switch Valve

Separator

Wire

Control System Hose Routing

(vNlsoGA)

(vN1s00-B)

'..__

-E

i------E--i-

I

*l:

1.

Breather Hose

Check Valve

2.

Return Hose

3.

(Red)

1.

Clean Air

2, Vacuum

'3.

Rear Vacuum

'4.

Hose

Guide

5. Vent

6. Reservoir

7. Reservoir

8. Wire

9. lgnition

10.

11.

Tube

or Hose

lgnition

Canister

Hose

Hose

Switch Valve

Tank Tube

Tank

Straps

(Front)

Coil

(Rear)

Coil

GENERAL INFORMATION

T-17

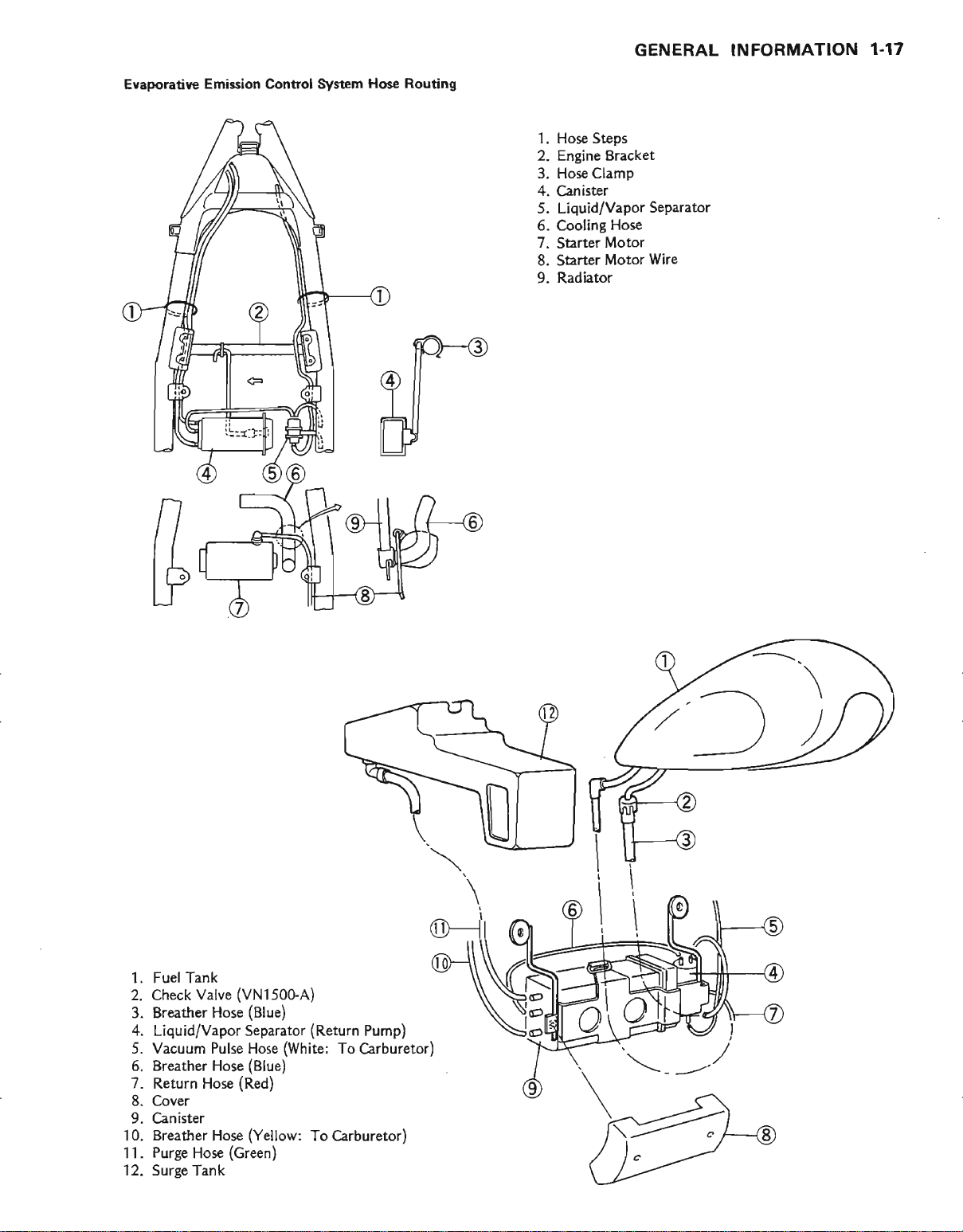

Eyaporatiye Emi$ion

control

System

Hose Routing

l. Hose St€ps

2. Engine Bracket

3. Hose Clamp

4. Canister

Hose

Motor

Motor

Separator

Wire

5.

Liquid/Vapor

5. Cooling

7. Starter

8. Starter

9. Radiator

1. Fuel Tank

2.

Check

3. Breather Hose

4.

Liquid/Vapor Separator

5. Vacuum Pulse Hose

6. Breather Hose

7. Return Hose

8. Cover

9. Canister

10. Breather Hose

11. Purge Hose

12. Surge Tank

Valve

(Green)

(VN150GA)

(Blue)

(Blue)

(Red)

(Yellow:

(Return

(White:

To Carburetor)

To Carburetor)

,/.-\

,)

Pump)

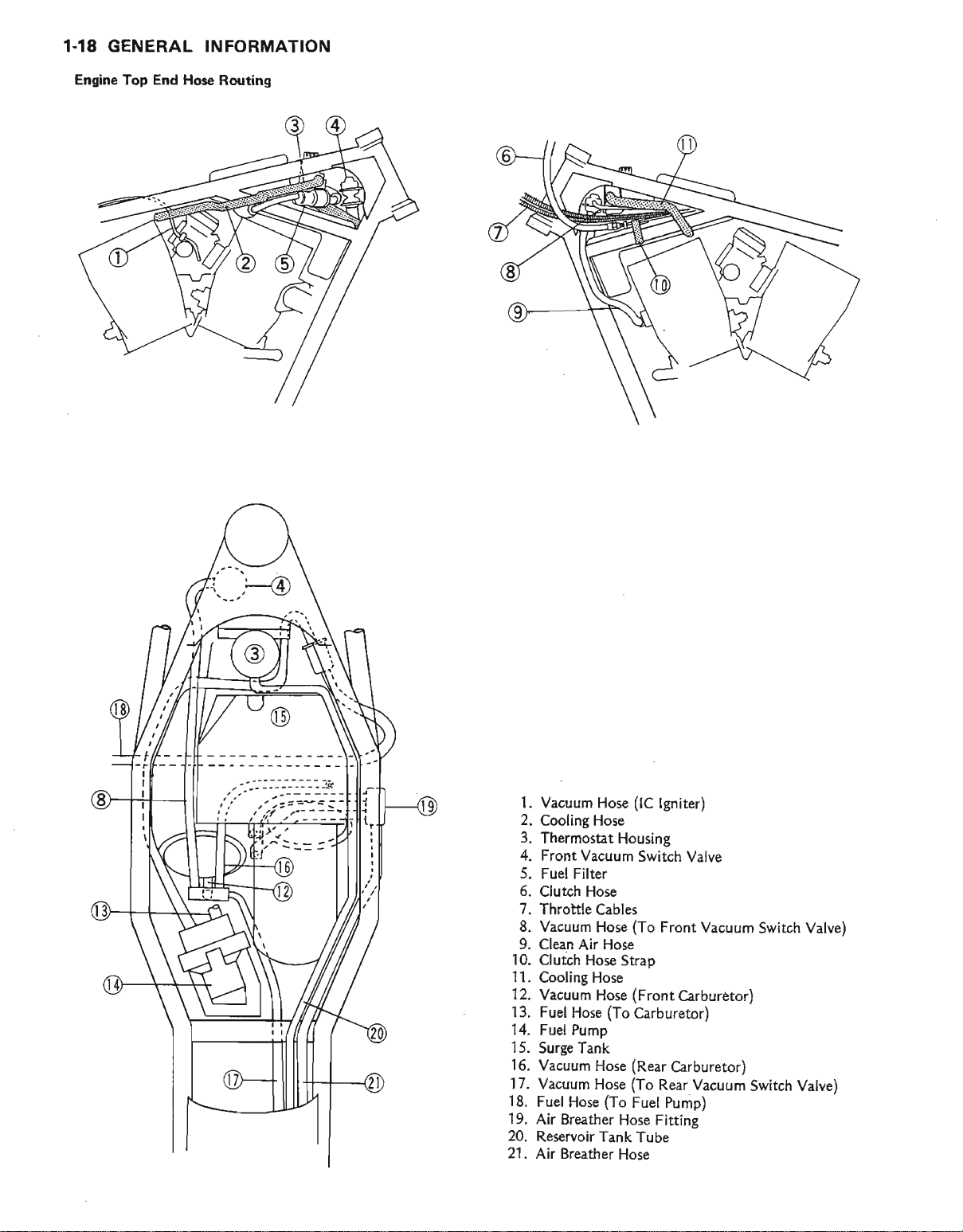

I.18 GENERAL

]NFORMATION

Engine

Top End Ho.e Routing

'!i!

,-'.------'-

1. Vacuum

2.

Cooling Hose

3. Thermostat

4.

Front Vacuum

5. Fuel Filter

5. Clut h Hose

7. Throitle

8.

Vacuum Hose

9.

Clean Air Hose

10.

Clutch Hose

11.

Cooling Hose

12. Vacuum

13.

Fuel Hose

14. Fuel

15.

Pump

Surge Tank

16. Vacuum

17. Vacuum

18.

Fuel Hose

19.

Air Breather

20.

Res€rvoir

21.

Air Breather

Hose

Housing

Cables

(To

Strap

(Front

Hose

(To

(Rear

Hose

(To

Hose

(To

Fuel Pump)

Hose

Tank

Hose

(lC

lgniter)

Switch Valve

Front Vacuum

Carburetor)

Carburetor)

Carburetor)

Rear Vacuum

Fitting

Tube

Swirch Valve)

Switch Valve)

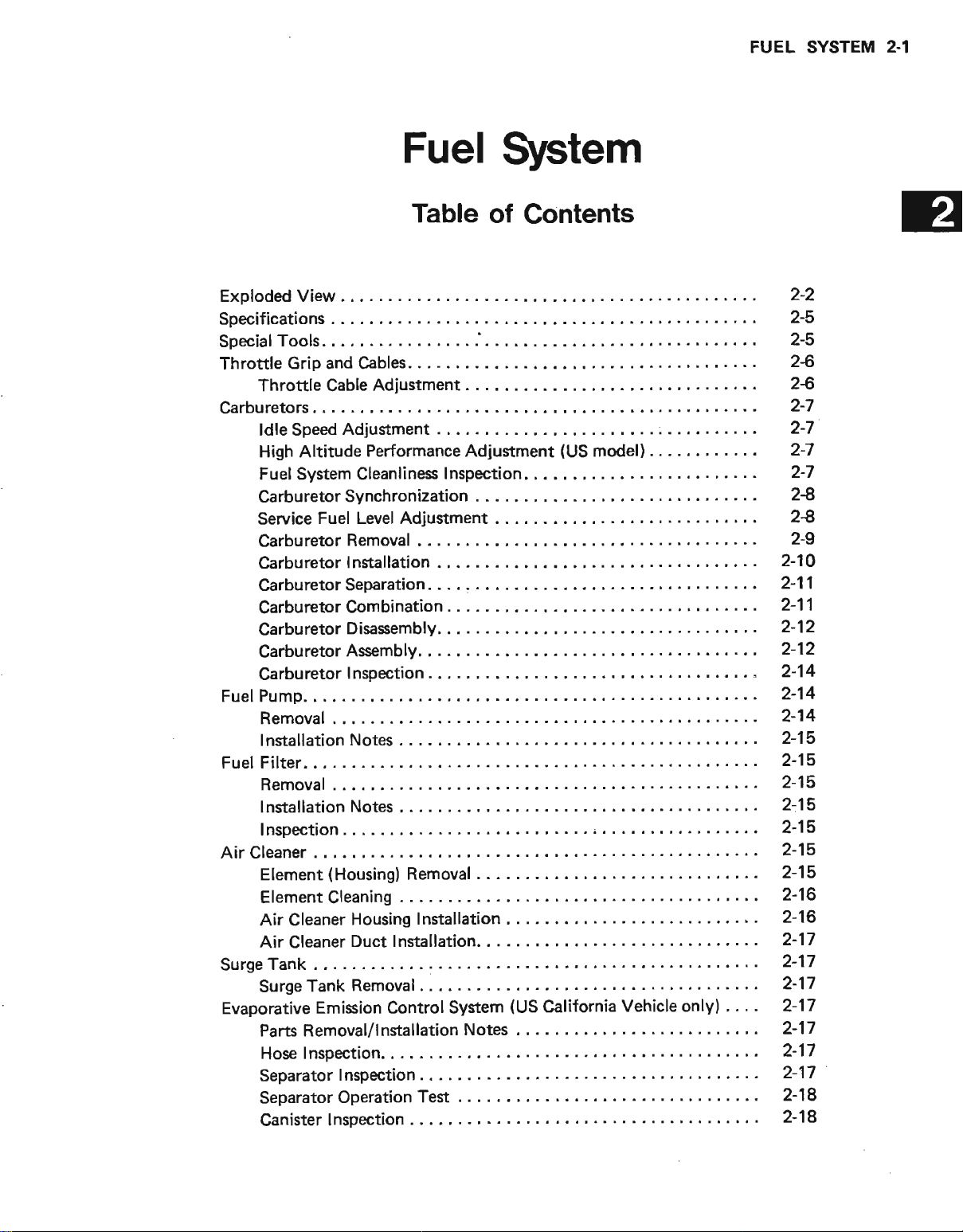

FUEL SYSTEM2-1

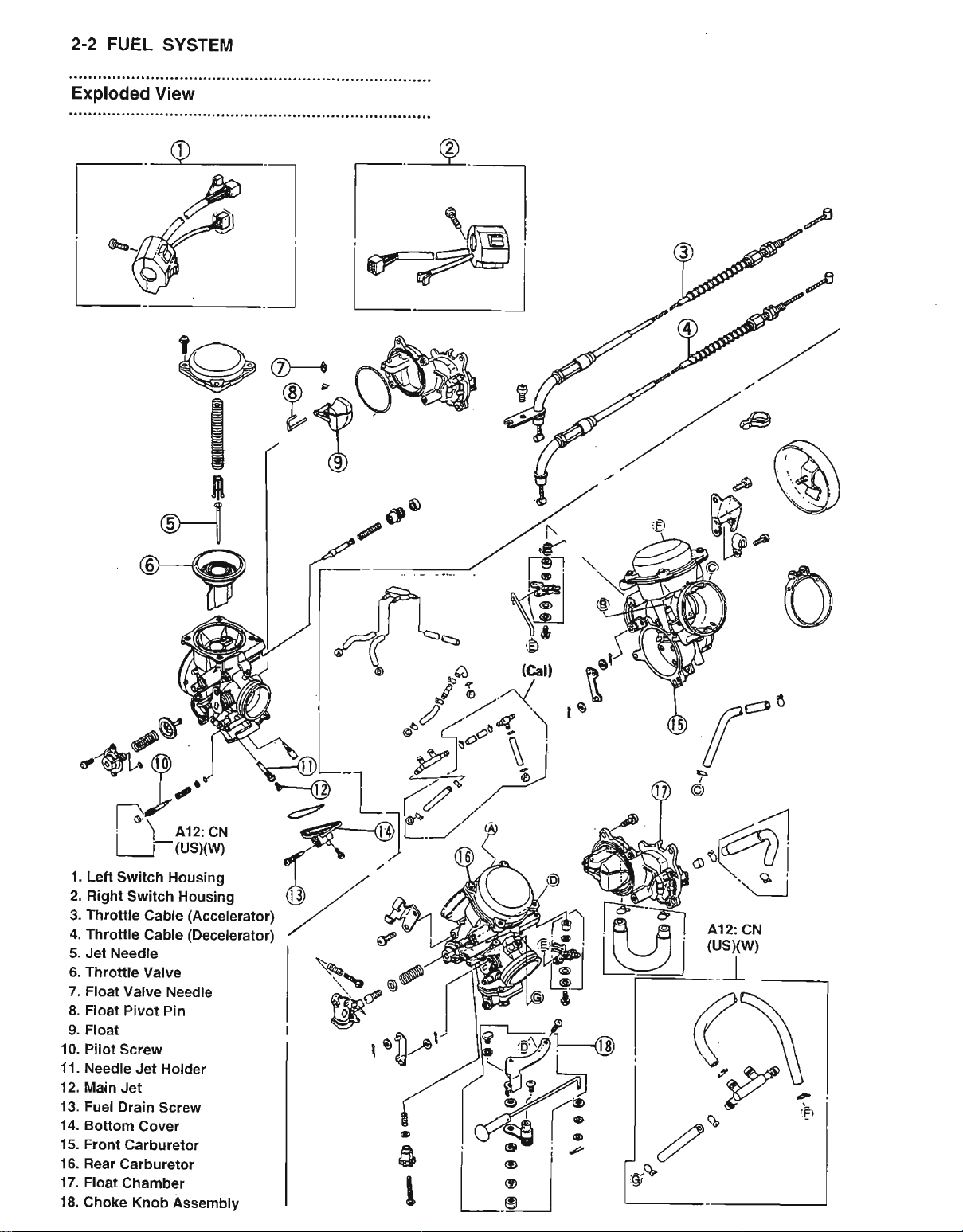

ExplodedView...

Specifications

SpecialTools.

Throttle Grip

Throttle Cable

Carburetorc,

ldle Speed

High Altitude Performance

Fuel

Carburetor

Service

Carburetor

Carburetor

Carburetor

Carburetor

Carburetor

Garburetor

Carbu

Pump.

Fuel

Removal

lnstallation

Fuel Filter.

Removal

lnstallation

Inspection

Air Cleaner

Element

ElementCleanins

Air Cleaner

Air Cleaner

Tank

Surge

Surge

Evaporative

and Cables.

Adjustment

Adiustment

System

retor

Tank Removal

Cleanliness

Synchronization

Fuel Level

Removal

I nstallation

Separation. .

Combination

Disasembly.

Assembly.

I nspection,

Notes . .

Notes . ,

(Housing)

Housing

lnstallation

Duct

Emission Control

Pans Removal/lnstallation

Hose Inspection.

Separator

Inspection

Separator Operation

Canister

Inspection

Fuel

Table

......,.'.

.

I nspection.

Adjustment . . . . .

,

. . . .

Removal

.. ....

Installation...

System

System

of

Contents

Adjustment

(US

Notes

. .

.

Test

(US

model) .

.

. .

California

Vehicle only)

' . . '

2-2

2-5

2-5

2-6

2$

2-7

2-7

2-7

2-7

24

24

2-9

2-10

211

2-11

2-12

2-12

2-14

2-14

2-14

2-15

2-15

2-15

2-15

2-15

2-15

2-15

2-16

2-16

2-17

2-17

2-17

2-17

2-17

2-17

2-17

2-18

2-18

2.2

FUEL

SYSTEM

Exploded

View

?."---x

V

6

g

g

n

!

@-_-1

@-+

va

(D

f---r

t^l

I A- |

IfrPtri

i\

€-

p

R

l,lf

re

1. Left

Switch Housing

2. Right

3. Throttle

4. Throtlle

5. Jet Needle

6.

7. Float

8.

9. Float

t0.

11.

12.

13. Fuel Drain

14. Botlom

15.

16.

17. Float

18.

Switch Housing

Cable

Cable

Throttle

Float

Pilot

Needle

Main Jet

Front

Rear Carburetor

Choke Knob

Valve

Valve Needle

Pivot Pin

Screw

Jet Holdei

Cover

Carburetor

Chambel

u)

A12: CN

(us)(vy)

(Accelerator)

(Decelerator)

Screw

Assembty

€

\s6

sBe

,u&^,

PEB

a

a

./'1

"al

""\.€

A12:

CN

(US)(w)

g

t

FUEL

SYSTEM

2.3

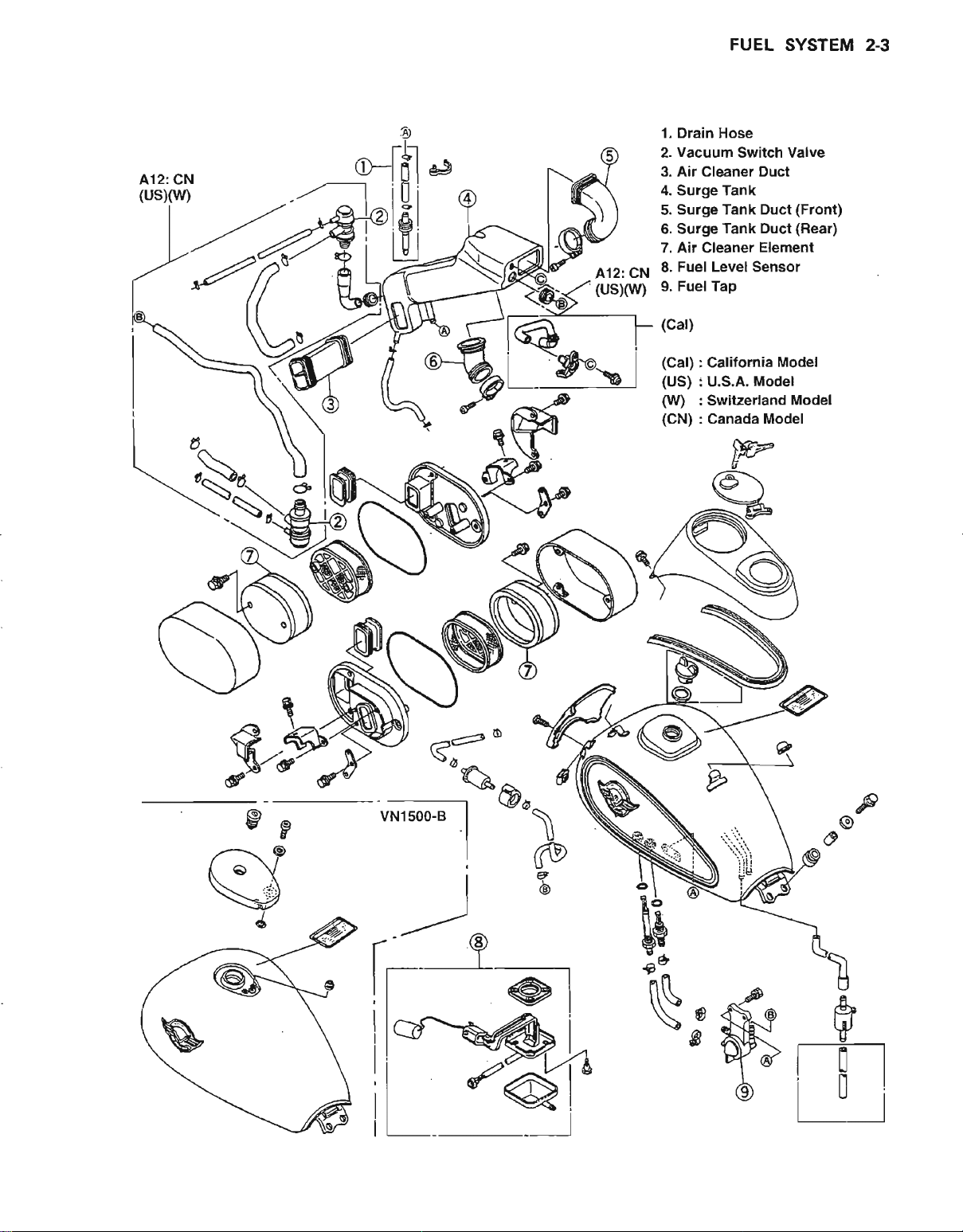

A12: CN

(usxw)

a

rlr

o-l

I iEi

frl

tui

es

i9t

u

A12:

CN

(us)w)

1. Drain Hose

2. Vacuum Switch Valve

Air

3.

Cleaner

4. Surge Tank

5. Surge

6. Surge Tank

7. Air Cleaner Element

Fuel

8,

Fuel Tap

9.

(cal)

(cal)

Calitornia Model

(us)

U.S.A.

(W)

Sruitzerland Model

(cN)

Canada

Duct

Tank Duct

Duct

Level Sensor

Model

Model

(Front)

(Rear)

u-)

<-'

------46,

vNlsoGB

I

a

I

$

A

e

\il

rT-t

i0i

tl

Loading...

Loading...