Kawasaki VULCAN 1600 CLASSIC Service Manual

VULCAN 1600 CLASSIC

VN1600 CLASSIC

Motorcycle

Service Manual

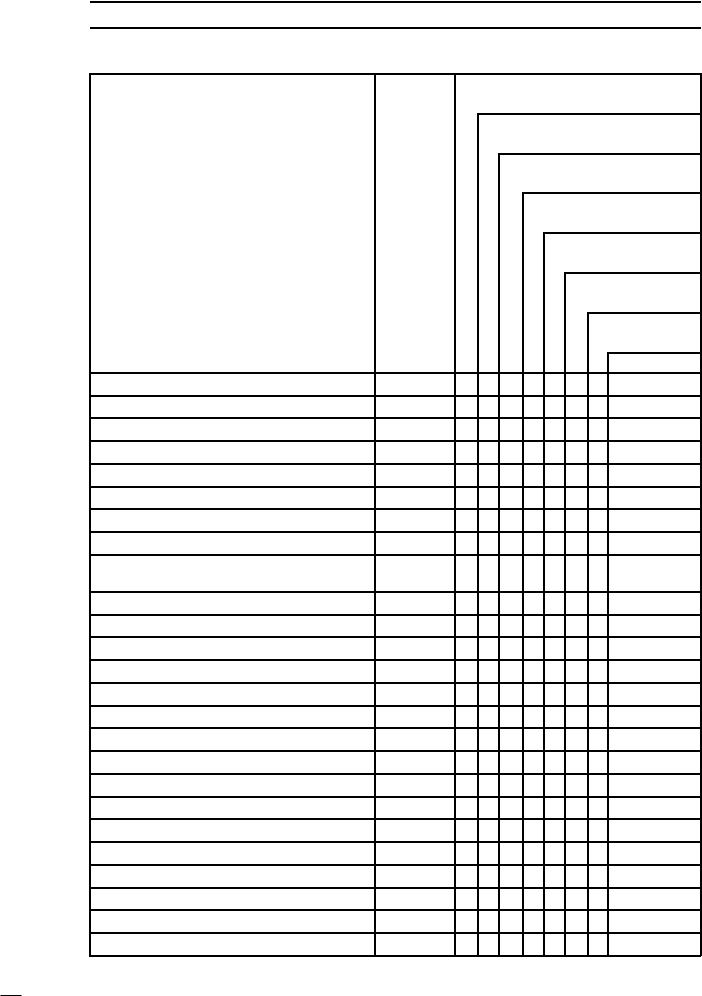

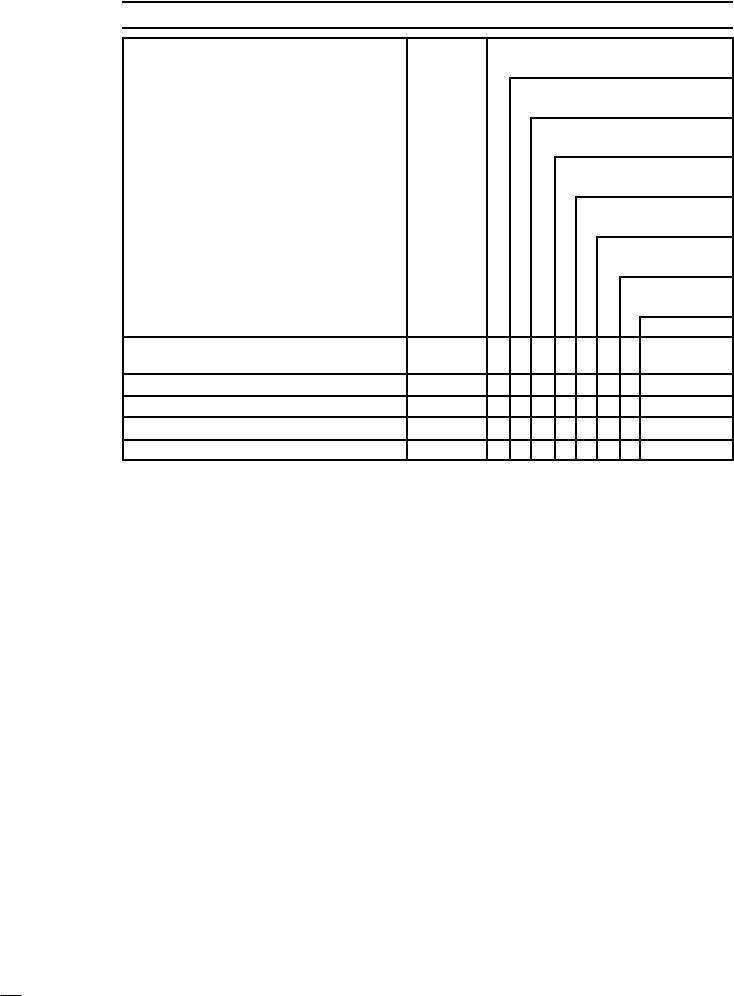

Quick Reference Guide

|

|

|

|

|

|

|

|

|

General |

Information |

1 |

j |

|

|

|

|

|

|

|

|

|

|

Periodic |

Maintenance |

2 |

j |

|

|

|

|

|

|

|

|

|

|

Fuel |

System (DFI) |

3 |

j |

|

|

|

|

|

|

|

|

|

|

Cooling System |

4 |

j |

||

|

|

|

|

|

|

|

|

|

Engine |

Top End |

5 |

j |

|

|

|

|

|

|

|

|

|

|

Clutch |

|

6 |

j |

|

|

|

|

|

|

|

|

|

|

Engine |

Lubrication System |

7 |

j |

|

|

|

|

|

|

|

|

|

|

Engine |

Removal/Installation |

8 |

j |

|

|

|

|

|

|

|

|

|

|

Crankshaft/Transmission |

9 |

j |

||

|

|

|

|

|

|

|

|

|

Wheels/Tires |

10 |

j |

||

|

|

|

|

|

|

|

|

|

Final |

Drive |

11 |

j |

|

|

|

|

|

|

|

|

|

|

Brakes |

|

12 |

j |

|

|

|

|

|

|

|

|

|

|

Suspension |

13 |

j |

||

|

|

|

|

|

|

|

|

|

Steering |

|

14 |

j |

|

|

|

|

|

|

|

|

|

|

Frame |

|

15 |

j |

|

|

|

|

|

|

|

|

|

|

Electrical System |

16 |

j |

||

This |

quick |

reference guide will assistAppendix |

17 |

j |

|||||||||

you in locating |

a |

desired |

topic or |

pro |

|

|

|

|

|||||

cedure. |

|

|

|

|

|

|

|

|

|

|

|

|

|

•Bend the |

pages |

back |

to |

match |

the |

|

|

|

|

||||

black |

tab |

of |

the |

desired |

chapter |

num |

|

|

|

|

|||

ber |

with |

|

the |

black tab on the edge at |

|

|

|

|

|||||

each table of contents page. |

|

|

|

|

|

||||||||

•Refer to |

the sectional |

table |

of contents |

|

|

|

|

||||||

for the |

exact |

pages |

to locate the |

spe |

|

|

|

|

|||||

cific |

topic |

required. |

|

|

|

|

|

|

|

|

|||

VULCAN 1600 CLASSIC

VN1600 CLASSIC

Motorcycle

Service Manual

|

All |

rights |

reserved. |

No |

|

parts |

of |

this |

publication |

may |

be |

reproduced, |

stored |

in |

a |

retrieval |

syste |

||||||||||||

transmitted |

|

in |

any |

form |

|

|

or by any means, electronic mechanical photocopying, |

recording |

or |

otherwis |

|||||||||||||||||||

without the prior written permission of Quality Assurance Department/Consumer Products & Machinery |

|||||||||||||||||||||||||||||

Company/Kawasaki Heavy |

|

Industries, Ltd., |

Japan. |

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||

|

No liability can |

be |

accepted |

for |

any |

inaccuracies isorsionsomin |

this |

publication, |

although |

every possible |

|

||||||||||||||||||

care has been taken to |

|

make it as |

complete and accurate as possible. |

|

|

|

|

|

|

|

|

||||||||||||||||||

|

The |

right |

is |

reserved |

|

to make |

changes |

at |

any time without |

prior |

notice |

and without incurring an ob |

|||||||||||||||||

to |

|

make |

|

such |

changes |

|

to |

products |

manufactured |

previously. |

See |

your |

Motorcycle |

dealer |

for |

the |

la |

||||||||||||

information |

|

on |

product improvements incorporated after |

this |

publication. |

|

|

|

|

|

|

|

|

|

|||||||||||||||

|

All information |

contained |

|

in |

this |

publication is |

basedthe lateston |

product information |

available |

at |

the |

time |

|

||||||||||||||||

of |

|

publication. |

Illustrations |

|

and photographs in |

this publication are intended |

for |

reference |

use |

only and |

m |

||||||||||||||||||

not |

depict |

|

actual |

model |

|

component |

parts. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

© |

|

2003 |

Kawasaki |

Heavy |

|

Industries, |

Ltd. |

|

|

|

Second Edition (1) |

: |

Aug. |

25, |

2003 (M) |

|

|

||||||||||||

|

|

|

|

LIST |

OF |

ABBREVIATIONS |

|

|

|

|

A |

ampere(s) |

|

|

|

lb |

pound(s) |

|

|

||

ABDC |

after |

bottom |

dead center |

m |

meter(s) |

|

|

|||

AC |

alternating |

current |

|

min |

minute(s) |

|

|

|||

ATDC |

after |

top |

dead center |

N |

newton(s) |

|

|

|||

BBDC |

before |

bottom |

dead |

center |

Pa |

pascal(s) |

|

|

||

BDC |

bottom dead |

center |

|

PS |

horsepower |

|

||||

BTDC |

before |

top |

dead center |

psi |

pound(s) |

per |

square inch |

|||

°C |

degree(s) |

Celsius |

|

r |

revolution |

|

|

|||

DC |

direct |

current |

|

|

r/min, rpm |

revolution(s) per minute |

||||

F |

farad(s) |

|

|

|

TDC |

top |

dead |

center |

||

°F |

degree(s) |

Fahrenheit |

|

TIR |

total |

indicator |

reading |

|||

ft |

foot, feet |

|

|

|

V |

volt(s) |

|

|

||

g |

gram(s) (mass) |

|

W |

watt(s) |

|

|

||||

h |

hour(s) |

|

|

|

Ω |

ohm(s) |

|

|

||

kg |

(mass) |

|

|

|

|

|

|

|

|

|

kgf |

(force) |

|

|

|

|

|

|

|

|

|

L |

liter(s) |

|

|

|

|

|

|

|

|

|

Read OWNER’S MANUAL before operating.

|

|

|

|

|

|

|

|

|

|

|

EMISSION |

CONTROL |

|

INFORMATION |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||

|

To protect the environment in |

which |

we |

|

all live, |

Kawasaki |

|

has incorporated |

crankcase |

emis |

|

||||||||||||||||||||||||||||||||||||||||||||

sion |

(1) |

and |

|

exhaust |

emission (2) |

|

control |

systems in |

compliance |

|

with |

|

applicable |

|

regulations |

of |

|

||||||||||||||||||||||||||||||||||||||

the United States Environmental Protection Agency and California Air |

Resources |

Board. |

Addi |

|

|||||||||||||||||||||||||||||||||||||||||||||||||||

tionally, |

|

Kawasaki |

has incorporated |

|

an |

|

evaporative |

emission |

control |

system |

(3) in |

compliance |

|

|

|||||||||||||||||||||||||||||||||||||||||

with applicable regulations of the |

|

California |

Air |

Resources |

|

Board on |

|

vehicles |

sold in |

California |

|

||||||||||||||||||||||||||||||||||||||||||||

only. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1. |

Crankcase |

|

Emission |

Control System |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||

This system eliminates the release |

|

of crankcase |

|

vapors into |

|

the atmosphere. Instead, the vapors |

|

||||||||||||||||||||||||||||||||||||||||||||||||

are |

routed |

through |

an |

oil separator |

|

to |

|

thedeinletof sithe |

engine. |

|

While the |

engine is |

|

operating, |

|

|

|

||||||||||||||||||||||||||||||||||||||

the vapors are drawn into combustion chamber, |

where |

|

they |

|

are |

burned |

along |

with the |

fuel |

and |

air |

||||||||||||||||||||||||||||||||||||||||||||

supplied |

by |

the |

|

fuel injection |

system. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

2. Exhaust Emission Control System |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||

This |

system |

|

reduces |

the amount |

|

of |

|

pollutants |

|

discharged into |

|

the |

atmosphere |

by |

the |

exhaust |

|

||||||||||||||||||||||||||||||||||||||

of this |

motorcycle. |

|

The |

fuel, ignition, |

|

and |

|

exhaust |

|

systems of this motorcycle have been carefully |

|

||||||||||||||||||||||||||||||||||||||||||||

designed and constructed to ensure an |

|

efficient |

|

engine |

with low |

exhaust |

pollutant levels. |

|

|

|

|

||||||||||||||||||||||||||||||||||||||||||||

The exhaust system of this model motorcycle |

|

manufactured |

|

primarily |

|

for |

|

sale in |

California in |

|

|||||||||||||||||||||||||||||||||||||||||||||

cludes |

a |

|

catalytic |

converter |

system. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

3. Evaporative Emission Control System |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||

Vapors |

caused |

|

by |

fuel |

evaporation in |

|

the |

|

fuel |

|

system |

are |

|

not |

|

vented into |

the |

atmosphere. |

In |

||||||||||||||||||||||||||||||||||||

stead, |

fuel |

vapors |

are |

routed |

into |

|

the |

|

|

running |

|

engine |

to |

|

be |

|

burned, |

|

or |

|

stored |

in |

a |

canister |

whe |

||||||||||||||||||||||||||||||

the |

engine is |

stopped. |

Liquid |

|

fuel |

is |

caught |

|

by |

|

a |

vapor separator and returned to the fuel tank. |

|||||||||||||||||||||||||||||||||||||||||||

|

The Clean Air Act, which is the Federal law |

|

covering motor |

vehicle |

|

pollution, |

contains |

what is |

|

||||||||||||||||||||||||||||||||||||||||||||||

commonly referred |

to |

as |

the |

Act’s |

|

"tampering |

provisions." |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||

|

"Sec. 203(a) The following acts and the causing thereof |

|

are |

|

prohibited... |

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||||||||||

(3)(A) for |

any |

|

person |

to |

remove |

or |

|

render inoperative |

any |

|

device |

|

or |

|

element |

of |

|

design installed |

|

||||||||||||||||||||||||||||||||||||

|

|

on or in |

|

a |

|

motor |

vehicle |

or |

motor |

vehicle |

|

engine in |

compliance |

|

with |

|

regulations |

under |

|

this |

|

||||||||||||||||||||||||||||||||||

|

|

title |

prior |

to its |

sale |

and |

delivery to |

the |

ultimate |

|

purchaser, |

or |

for |

any |

|

manufacturer |

or |

dealer |

|||||||||||||||||||||||||||||||||||||

|

|

knowingly to |

|

remove |

or |

render |

|

inoperative |

|

any such device or element of design |

after |

|

such |

||||||||||||||||||||||||||||||||||||||||||

|

|

sale and delivery to the ultimate purchaser. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||

(3)(B) for |

any |

|

person |

engaged in the |

|

business |

|

of repairing, |

|

servicing, |

selling, leasing, |

or trading |

|

||||||||||||||||||||||||||||||||||||||||||

|

|

motor |

vehicles or motor vehicle engines, |

|

or |

who operates a fleet of motor vehicles know |

|||||||||||||||||||||||||||||||||||||||||||||||||

|

|

ingly |

to |

|

remove |

or |

render inoperative |

any |

|

device or element of design installed on or in a |

|||||||||||||||||||||||||||||||||||||||||||||

|

|

motor vehicle or motor vehicle |

|

engine |

|

in |

|

compliance |

|

with regulations |

under |

this |

title |

follow |

|

||||||||||||||||||||||||||||||||||||||||

|

|

ing its |

sale |

and |

delivery |

to |

the |

|

ultimate |

purchaser..." |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

NOTE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

The |

phrase |

"remove |

or |

render inoperative |

any |

|

device |

or |

|

element |

|

of |

|

design" |

|

has |

been |

gener |

|||||||||||||||||||||||||||||||||||||

○interpreted as |

follows: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

1. Tampering |

does |

not include |

|

the |

|

temporary removal |

|

or |

rendering inoperative |

of |

de |

|

|

|||||||||||||||||||||||||||||||||||||||||

|

|

vices |

or |

elements |

of |

|

design in |

|

|

order |

to |

perform |

|

maintenance. |

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||

|

2. Tampering could include: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

a.Maladjustment |

of |

vehicle |

components |

|

such |

|

that |

|

|

the |

|

emission |

|

standards |

are |

ex |

|

|||||||||||||||||||||||||||||||||||||

|

|

ceeded. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

b.Use |

of |

|

replacement |

parts |

|

or |

|

|

accessories |

which |

|

adversely |

|

affect |

the |

|

performance |

|

||||||||||||||||||||||||||||||||||||

|

|

or durability of the motorcycle. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||

|

c.Addition |

of components |

or |

accessoriesat thresult in |

the |

vehicle |

exceeding the |

stan |

|

|

|

||||||||||||||||||||||||||||||||||||||||||||

|

|

dards. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

d.Permanently removing, |

|

disconnecting, |

|

or |

|

rendering inoperative |

|

any |

|

component or |

|

|

|

|

||||||||||||||||||||||||||||||||||||||||

|

|

element of |

|

design |

of |

|

the |

emission |

|

control |

|

systems. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||

WE RECOMMEND THAT ALL DEALERS OBSERVE THESE |

|

PROVISIONS |

|

OF |

FEDERAL |

LAW, |

|

||||||||||||||||||||||||||||||||||||||||||||||||

THE VIOLATION |

|

OF |

WHICH IS PUNISHABLE BY CIVIL |

PENALTIES |

|

NOT EXCEEDING |

|

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||

$10,000 |

|

PER |

VIOLATION. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

TAMPERING WITH NOISE CONTROL SYSTEM PROHIBITED

Federal law |

prohibits the following acts or the causing thereof: (1) The removal or rendering |

|

||||||||||||||||||||||||||

inoperative |

by any |

|

person other |

than |

for purposes |

of maintenance, repair, or replacement, |

of any |

|

||||||||||||||||||||

device |

or |

element |

of |

design incorporated |

into |

any |

new vehicle for the purpose of |

noise |

control |

|||||||||||||||||||

prior |

to its |

sale |

or delivery |

to |

the |

ultimate |

purchaser |

or |

while it is in |

use, |

or (2) |

the use of |

the |

|||||||||||||||

vehicle |

after |

such |

device |

or |

|

element |

of |

design |

has |

been |

removed |

or |

rendered |

inoperative |

by |

|||||||||||||

any |

person. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Among those |

acts |

presumed |

to |

constitute |

tampering |

are |

the acts listed |

below: |

|

|

|

|||||||||||||||||

•Replacement |

|

of |

|

the |

original |

|

exhaust |

system |

or |

muffler |

with a component |

not in |

compliance |

|

||||||||||||||

with |

Federal |

regulations. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

•Removal of |

the |

muffler(s) |

or |

|

any internal |

portion |

of the |

muffler(s). |

|

|

|

|

|

|

||||||||||||||

•Removal of |

the |

|

air |

box |

or |

|

air |

box |

cover. |

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

•Modifications |

|

to |

|

the |

muffler(s) or |

air inlet system |

by |

cutting, |

drilling, |

or |

other means if such |

|

||||||||||||||||

modifications |

|

result in increased |

noise levels. |

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

Foreword

This manual is designed primarily for use by |

How |

to |

|

Use |

|

|

|

This |

|

Manual |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||

trained |

|

mechanics in |

|

|

a |

|

properly equipped shop. |

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||

However, |

it |

|

contains |

|

|

enough |

detail and |

basic in |

In |

preparing this |

manual, |

|

we |

|

divided |

the |

prod |

||||||||||||||||||||||||||||||||||||||||||||||||

formation |

to |

|

make it useful to |

|

the |

|

owner |

who |

|

de |

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||

sires |

|

to |

|

perform |

|

his |

|

|

own |

|

basic |

|

maintenance |

|

|

uct into its |

major |

systems. |

|

|

These |

systems |

be |

||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

and |

|

|

|

the |

manual’s chapters. All information |

|||||||||||||||||||||||||||||||||||||||||||||||||||||

repair |

|

work. |

|

A |

|

basic |

|

knowledge |

|

of |

|

|

|

|

|

|

|

came |

|

||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

mechanics, |

|

|

|

particular |

system |

from |

|

adjustment |

through |

|||||||||||||||||||||||||||||||||||||||||||||||||||

the |

proper |

use |

|

|

of |

|

|

tools, |

|

and |

|

|

workshop |

|

|

|

|

|

for a |

|

|

||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

proce |

|

|

|

|

|

|

and inspection |

|

|

is |

|

located in |

a |

sin |

|||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

disassembly |

|

|

|

|||||||||||||||||||||||||

dures must be understood in order to carry out |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||||||

maintenance |

|

and |

|

|

repair |

|

|

satisfactorily. |

When |

gle |

chapter. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||

ever |

|

the |

|

owner |

|

|

has |

|

|

insufficient |

|

experience |

|

or |

The |

|

|

Quick |

Reference |

|

|

Guide |

shows |

you |

|

all |

|||||||||||||||||||||||||||||||||||||||

doubts |

|

his |

|

ability |

|

|

|

to |

|

do |

the |

|

|

work, |

all |

|

|

|

|

of the |

|

product’s system |

and |

|

assists in locating |

|

|||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

adjust |

|

chapters. |

Each chapter in |

|

turn |

has |

its |

own |

||||||||||||||||||||||||||||||||||||||||||||||||

ments, |

|

maintenance, |

|

|

and |

|

repair |

|

should |

be |

|

|

|

|

their |

|

|

||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

car |

|

|

|

|

|

|

|

|

Table |

of |

|

Contents. |

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||||||||||||

ried |

out |

only |

by |

|

qualified mechanics. |

|

|

|

|

|

|

|

comprehensive |

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

andThe |

|

Periodic |

Maintenance |

Chart is located |

in |

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||

In |

|

order |

|

to |

|

perform |

|

the |

|

work |

efficiently |

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||

to avoid |

|

costly |

|

mistakes, |

|

read |

|

|

the |

text, |

|

|

|

|

the |

Periodic |

Maintenance |

|

|

|

chapter. |

The |

|

chart |

|||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

thor |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

required maintenance |

|||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

gives a time schedule for |

|

|||||||||||||||||||||||||||

oughly familiarize yourself with the |

procedures operations. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||||||||||||||

before starting work, and then do the |

work care |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||||||

fully in |

a |

clean |

|

area. |

|

Whenever |

|

special tools |

|

or |

If |

you |

want |

spark |

plug information, |

for |

exam |

||||||||||||||||||||||||||||||||||||||||||||||||

equipment are |

|

specified, |

|

|

do |

not |

|

use |

|

|

|

|

|

|

ple, |

go |

|

to the Periodic Maintenance Chart first. |

|||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

makeshift |

|

chart |

tells |

you |

|

how |

|

|

|

frequently to |

clean |

and |

|||||||||||||||||||||||||||||||||||||||||||||||||

tools |

|

|

or |

equipment. |

|

|

|

Precision |

|

measurements |

|

The |

|

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

gap |

|

the |

plug. |

Next, |

use |

|

the |

Quick Reference |

||||||||||||||||||||||||||||||||||||||||||||||||||

can |

only |

|

be |

made if |

|

|

the |

|

proper instruments |

|

are |

|

|

|

to locate |

the |

Periodic |

Maintenance |

chap |

||||||||||||||||||||||||||||||||||||||||||||||

used, |

|

and |

|

the |

|

use |

|

|

of |

|

substitute |

tools |

may |

|

Guide |

||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

ad |

Then, |

use |

the |

Table |

|

|

of Contents |

on |

the first |

|||||||||||||||||||||||||||||||||||||||||||||||||

versely affect safe |

|

|

operation. |

|

|

|

|

|

|

|

|

|

|

|

|

|

ter. |

|

|

||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

warranty |

|

|

|

|

|

page |

|

|

of |

the |

chapter |

to |

|

|

find |

|

the |

Spark |

Plug sec |

||||||||||||||||||||||||||||||||||||||||||

For |

|

the |

|

duration |

|

|

of |

|

|

the |

period, |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||

we recommend |

|

that |

|

|

all |

|

repairs |

|

and |

scheduled tion. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||

maintenance |

|

be |

|

|

performed in |

accordance |

with |

|

|

Whenever you see these WARNING and |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

CAUTION |

symbols, |

heed |

|

|

|

their |

instructions! |

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||

this |

service |

|

manual. |

|

|

Any |

|

owner |

|

maintenance |

|

or |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||

repair |

|

procedure |

|

not |

|

|

performed in |

accordance |

|

Always follow safe operating and maintenance |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

practices. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||||||||||

with |

|

this |

manual |

|

may |

|

void |

|

the |

|

warranty. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

WARNING |

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||

To |

|

get |

the longest life |

|

out |

|

of |

|

your |

vehicle: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||||||

•Follow |

|

the |

|

Periodic |

|

|

Maintenance |

Chart in |

|

the |

|

This |

|

warning |

symbol |

|

|

|

identifies |

special |

|

||||||||||||||||||||||||||||||||||||||||||||

Service |

Manual. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

instructions |

or |

procedures |

|

which, |

if |

|

not |

|

|||||||||||||||||||||||||||||

•Be |

|

|

alert |

|

for |

|

|

problems |

|

and |

|

non-scheduled |

|

correctly |

followed, |

could |

|

result |

in |

per |

|

||||||||||||||||||||||||||||||||||||||||||||

maintenance. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Mo sonal |

|

injury, |

or |

loss |

|

|

|

of |

life. |

|

|

|

|

|

|

|

|||||||||||||||||||||||

•Use |

proper |

tools |

|

|

and |

|

genuine |

|

Kawasaki |

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||||||||||||||||

torcycle |

|

parts. |

|

|

|

Special |

|

tools, |

|

|

gauges, |

|

and |

|

|

|

|

|

|

|

|

|

CAUTION |

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||

testers that are necessary when servicing |

|

This |

|

|

caution |

symbol |

|

|

|

identifies |

special |

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||

Kawasaki |

motorcycles |

|

are introduced |

by |

|

the |

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||

Special Tool Catalog or Manual. |

|

Genuine |

|

instructions |

or procedures which, if not |

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

parts provided as spare parts |

|

are listed in |

|

the |

strictly |

observed, |

|

could |

|

result |

in |

dam |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

Parts Catalog. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

age |

|

to |

or |

destruction |

|

|

of |

|

equipment. |

|

|

|

||||||||||||||||||||||||

•Follow |

|

the |

|

procedures |

|

|

in |

this |

|

manual |

|

care |

This |

|

manual |

contains |

|

four |

|

more |

symbols (in |

||||||||||||||||||||||||||||||||||||||||||||

fully. |

|

Don’t |

|

take |

|

|

shortcuts. |

|

|

|

|

|

|

|

|

|

|

|

|

addition |

|

to |

WARNING and |

|

|

|

CAUTION) which will |

|

|||||||||||||||||||||||||||||||||||||

•Remember |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||

|

to |

|

keep |

|

|

complete |

records |

of mainhelp |

|

you |

distinguish |

|

different |

|

types |

of |

informa |

||||||||||||||||||||||||||||||||||||||||||||||||

tenance |

|

and |

|

repair |

|

|

with |

dates |

and |

any |

|

new |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||

parts installed. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

tion. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

NOTE |

|

|

|

|

|

|

|

|

|

|

|

|

This |

note |

symbol indicates |

points |

of |

par |

|||||||||||

○ticular interest |

for |

more |

efficient and |

con |

|

||||||||||||

|

venient operation. |

|

|

|

|

|

|

|

|

|

|

|

|||||

•Indicates |

a |

procedural |

|

step |

or |

work |

to |

be |

|||||||||

|

done. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Indicates |

a |

procedural |

sub-step |

|

or how |

|

to |

do |

||||||||

○the work of the procedural |

step |

it |

follows. |

It |

|||||||||||||

|

also precedes the text of a NOTE. |

|

|

|

|

||||||||||||

|

Indicates |

a |

conditional |

step |

or |

|

what |

action |

to |

||||||||

|

|

||||||||||||||||

|

|

||||||||||||||||

|

take |

based on |

the |

results |

of |

the |

|

test |

or inspec |

||||||||

|

tion in |

the |

procedural |

step or |

sub-step it |

fol |

|||||||||||

|

lows. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

In most |

chapters an exploded |

view illustration |

|||||||||||||||

of the system components follows the Table of |

|||||||||||||||||

Contents. |

|

In |

these illustrations |

you |

|

will find |

the |

||||||||||

instructions indicating |

which parts |

require |

spec |

|

|||||||||||||

ified tightening torque, oil, grease or |

a locking |

||||||||||||||||

agent |

during |

assembly. |

|

|

|

|

|

|

|

|

|

|

|||||

GENERAL INFORMATION 1-1

General |

Information |

1 |

Table |

of Contents |

|

Before Servicing..................................................................................................................... |

|

1-2 |

Model Identification.............................................................................................................. |

... |

1-7 |

General Specifications........................................................................................................ |

.. |

1-9 |

Unit Conversion Table............................................................................................................ |

|

1-11 |

1-2 GENERAL INFORMATION

Before |

Servicing |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

Before |

starting |

to |

perform |

an inspection |

|

service |

or |

carry out |

a |

disassembly and |

reassembly |

opera |

|||||||||||

tion |

on |

a |

motorcycle, |

read |

the |

|

precautions |

givenow. Tobelfacilitate |

actual operations, |

notes, illustra- |

|

||||||||||||

tions, |

photographs, |

cautions, |

and |

detailed descriptions |

have been |

included in each chapter wherever |

|||||||||||||||||

necessary. This |

section |

explains |

|

the items |

|

that require particular attention during the removal and |

|||||||||||||||||

reinstallation or disassembly and reassembly of general parts. |

|

|

|

|

|||||||||||||||||||

Especially |

|

note |

the |

following: |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

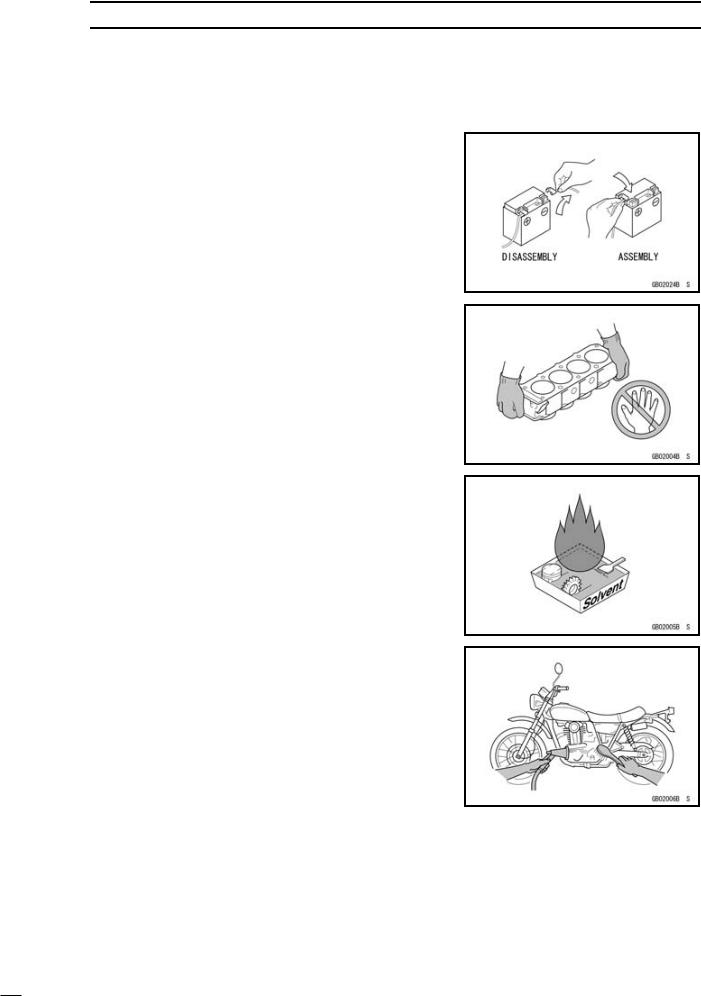

Battery |

Ground |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

Before completing any service on the motorcycle, |

|

|

|

|

|

||||||||||||||||||

nect the |

battery wires |

from |

the |

battery to |

|

prevent the |

|

|

|

|

|

||||||||||||

from |

accidentally |

turning over. Disconnect |

|

the |

ground |

|

|

|

|

|

|||||||||||||

(–) first |

and |

then |

the |

positive (+). |

When |

completed with |

|

|

|

|

|||||||||||||

service, |

first |

connect |

the positive (+) wire |

to |

the |

positive |

|

|

|

|

|||||||||||||

terminal |

of the |

battery |

|

then |

the |

negative (–) |

wire |

to |

|

|

|

|

|

||||||||||

ative |

terminal. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

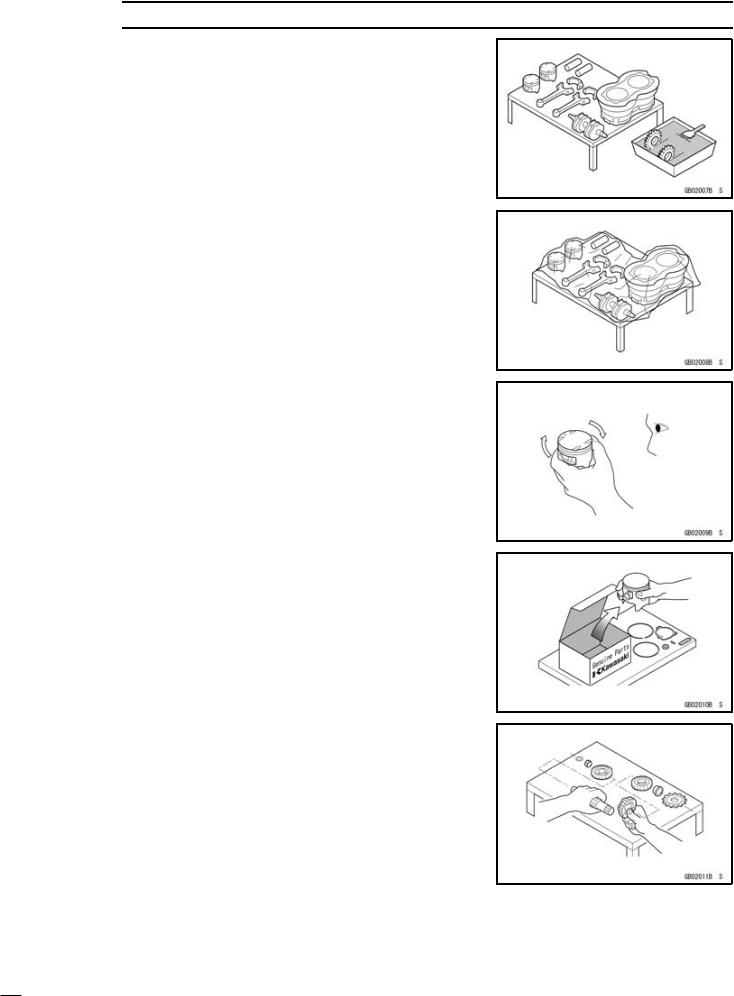

Edges |

of |

Parts |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

Lift large |

or |

heavy |

parts |

wearing |

gloves |

|

to |

prevent |

|

|

|

|

|

||||||||||

from |

possible |

sharp |

edges |

on |

the |

parts. |

|

|

|

|

|

|

|

|

|

||||||||

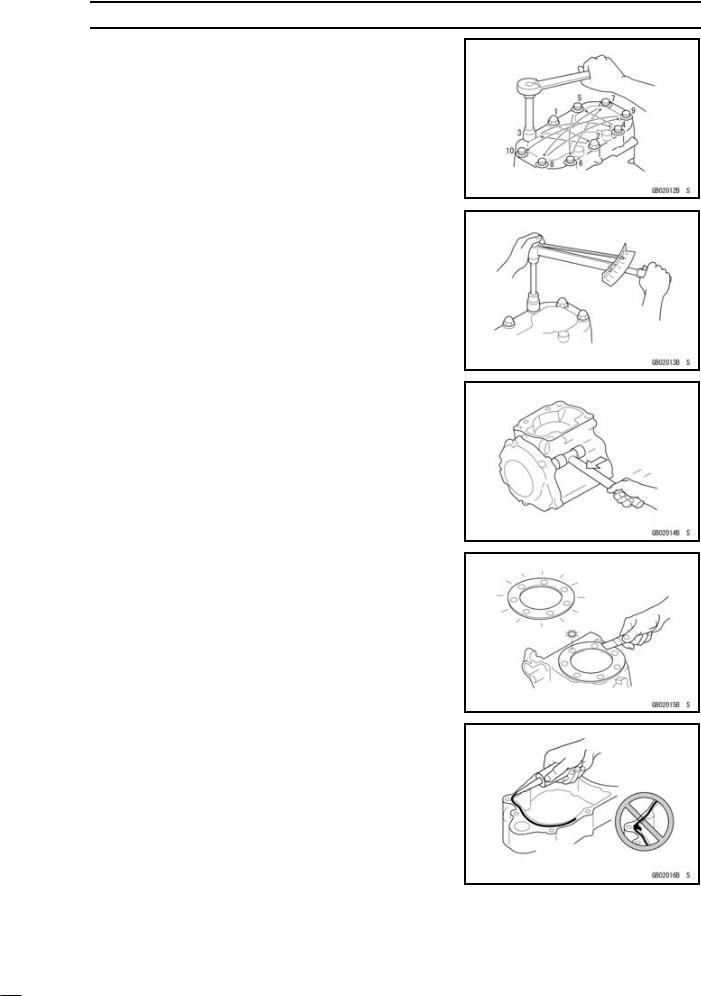

Solvent |

|

|

|

Use |

a high |

flush |

point solvent when cleaning parts |

flush |

point solvent |

should be used according to |

|

of the solvent |

manufacturer. |

||

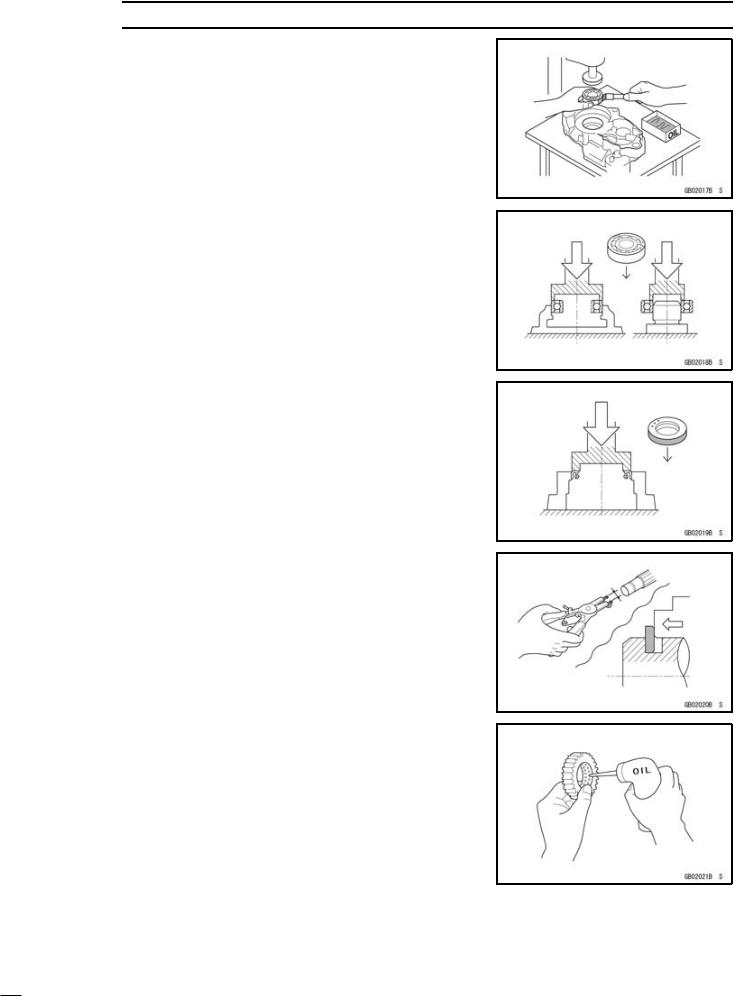

Cleaning vehicle before disassembly |

|

Clean the vehicle thoroughly before disassembly. Dirt |

|

other foreign |

materials entering into sealed areas during |

hicle disassembly can cause excessive wear and |

|

performance |

of the vehicle. |

|

|

|

|

|

|

|

|

GENERAL INFORMATION 1-3 |

Before Servicing |

|

|

|

|

|

|

||

Arrangement and Cleaning |

of |

Removed Parts |

||||||

Disassembled parts are easy to |

confuse. |

Arrange |

||||||

parts |

according |

to the |

order |

|

the |

parts were |

disassembled |

|

and |

clean the |

parts in |

order |

|

prior |

to assembly. |

||

Storage |

of Removed Parts |

|

|

||||

After all the |

parts including |

subassembly parts |

have |

|

|||

cleaned, |

store |

the |

parts |

in |

a clean area. |

Put a |

|

or plastic sheet over the parts to protect from |

any |

||||||

materials |

that |

may |

collect |

before re-assembly. |

|

||

Inspection |

|

|

||

Reuse |

of worn or damaged parts may lead to serious |

|||

cident. |

Visually inspect |

removed parts for corrosion, |

||

oration, |

or other damage. Refer to the appropriate |

|||

of this |

manual |

for service limits on individual parts. |

||

the |

parts if any damage has been found or if the part |

|||

yond |

its service limit. |

|

||

Replacement |

Parts |

|

||

Replacement Parts must be KAWASAKI genuine |

||||

recommended by KAWASAKI. Gaskets, O-rings, Oil |

||||

Grease |

seals, |

circlips |

or cotter pins must be replaced |

|

new |

ones whenever |

disassembled. |

||

Assembly Order |

|

|

|

||

In |

most cases |

assembly |

order |

is the reverse |

of |

bly, |

however, if assembly |

order is provided in |

this |

||

Manual, follow |

the procedures |

given. |

|

||

1-4 GENERAL INFORMATION

Before |

Servicing |

|

|

|

|

|

|

|

|||

Tightening |

Sequence |

|

|

|

|

|

|

|

|||

Bolts, nuts, or screws must be tightened according |

|||||||||||

specified sequence to prevent case |

warpage or |

deformation |

|||||||||

which can lead |

to |

malfunction. |

|

If |

|

the |

specified tightening |

||||

sequence is |

not indicated, |

tighten |

|

the fasteners |

alternating |

||||||

diagonally. |

|

|

|

|

|

|

|

|

|

|

|

Tightening |

Torque |

|

|

|

|

|

|

|

|

||

Incorrect |

|

torque |

applied |

to |

a |

|

bolt, |

nut, |

or screw |

||

lead to serious damage. Tighten fasteners to the |

|||||||||||

torque using a good quality torque wrench. |

|

||||||||||

Often, the tightening sequence is followed twice- |

|||||||||||

tightening |

and |

final |

tightening |

with |

torque wrench. |

||||||

Force |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Use common sense during disassembly and assembly, |

|||||||||||||||||||

excessive |

force |

can |

cause |

expensive or hard to repair |

|||||||||||||||

age. |

When |

necessary, |

|

remove |

screws |

|

that |

have |

|||||||||||

-permanent |

locking |

|

agent |

|

applied using |

an impact |

|

driver |

|||||||||||

Use a plastic-faced mallet whenever tapping is necessary |

|||||||||||||||||||

Gasket, |

O-ring |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Hardening, |

shrinkage, |

|

|

or |

damage |

of |

both |

|

|

|

|||||||||

and O-rings after disassembly can reduce sealing |

|||||||||||||||||||

formance. Remove old gaskets and clean the |

|

||||||||||||||||||

surfaces |

thoroughly |

so |

|

that |

no |

gasket |

material |

|

or |

||||||||||

material |

remains. |

|

|

Install |

|

new |

gaskets |

and |

replace |

||||||||||

O-rings when re-assembling |

|

|

|

|

|

|

|

|

|

||||||||||

Liquid |

Gasket, |

Locking |

|

Agent |

|

|

|

|

|

|

|

|

|||||||

For |

applications |

|

that |

require |

Liquid |

Gasket |

or |

|

a |

|

|||||||||

agent, |

clean |

the |

|

surfaces |

so |

that |

no |

oil residue |

remains |

||||||||||

fore applying liquid |

|

gasket |

or locking |

agent. Do |

not |

|

|||||||||||||

them excessively. Excessive application can clog oil |

|||||||||||||||||||

sages |

and |

cause |

|

serious |

damage. |

|

|

|

|

|

|

|

|||||||

GENERAL INFORMATION 1-5

Before Servicing

Press |

|

|

|

|

For |

items |

such |

as bearings or oil |

seals that |

pressed into |

place, |

apply small amount |

of oil to the |

|

tact area. Be sure to maintain proper alignment |

||||

smooth |

movements |

when installing. |

|

|

Ball Bearing |

and |

Needle |

Bearing |

|

|

|

Do not remove pressed ball or needle unless |

||||||

absolutely necessary. Replace with new ones whenever |

||||||

removed. Press bearings with the manufacturer and |

||||||

marks facing |

out. Press |

the |

bearing into |

place |

by |

|

pressure on the correct bearing race as shown. |

||||||

Pressing the incorrect race |

can cause |

pressure between |

||||

the inner and |

outer |

race |

and result in bearing |

damage |

||

Oil Seal, |

Grease |

Seal |

|

|

Do |

not remove pressed oil or grease seals unless |

|||

is necessary. Replace with new ones whenever |

||||

Press |

new oil seals |

with manufacture |

and size marks |

|

out. |

Make |

sure the seal is aligned |

properly when |

|

Circlips, Cotter |

Pins |

|

|

|

|

|

|

|

|

|

||||||

Replace circlips or cotter pins that were removed with |

||||||||||||||||

ones. Install |

the |

circlip |

with its sharp |

edge |

facing |

|

||||||||||

and its |

chamfered |

side |

facing inward to |

prevent |

the |

clip |

||||||||||

being |

pushed |

|

out |

of |

its |

groove |

when |

loaded. |

Take |

|||||||

not |

to |

open |

|

the |

|

clip excessively |

when installing |

to |

|

|||||||

deformation. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Lubrication |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

It is important |

|

to lubricate |

rotating |

or |

sliding |

parts |

|

|||||||||

assembly to |

minimize wear |

during initial |

operation. |

Lubri |

||||||||||||

cation |

points |

|

are |

|

called out |

throughout |

this |

manual, |

||||||||

the |

specific |

oil |

or |

grease |

as |

specified. |

|

|

|

|

||||||

1-6 GENERAL INFORMATION

Before |

Servicing |

|

|

|

|

||

Direction |

of |

Engine |

Rotation |

|

|

|

|

When |

rotating the |

crankshaft |

by |

hand, |

the free |

||

amount of rotating direction will |

affect |

the |

adjustment |

||||

tate |

the |

crankshaft to positive direction (clockwise |

|||||

from |

output |

side). |

|

|

|

|

|

Electrical Wires |

|

|

|

|

|

A two-color wire is identified first by |

the |

primary color |

|||

then |

the stripe |

color. Unless instructed |

otherwise, |

electrical |

|

wires |

must be |

connected to those |

of |

the same |

color |

GENERAL INFORMATION 1-7

Model Identification

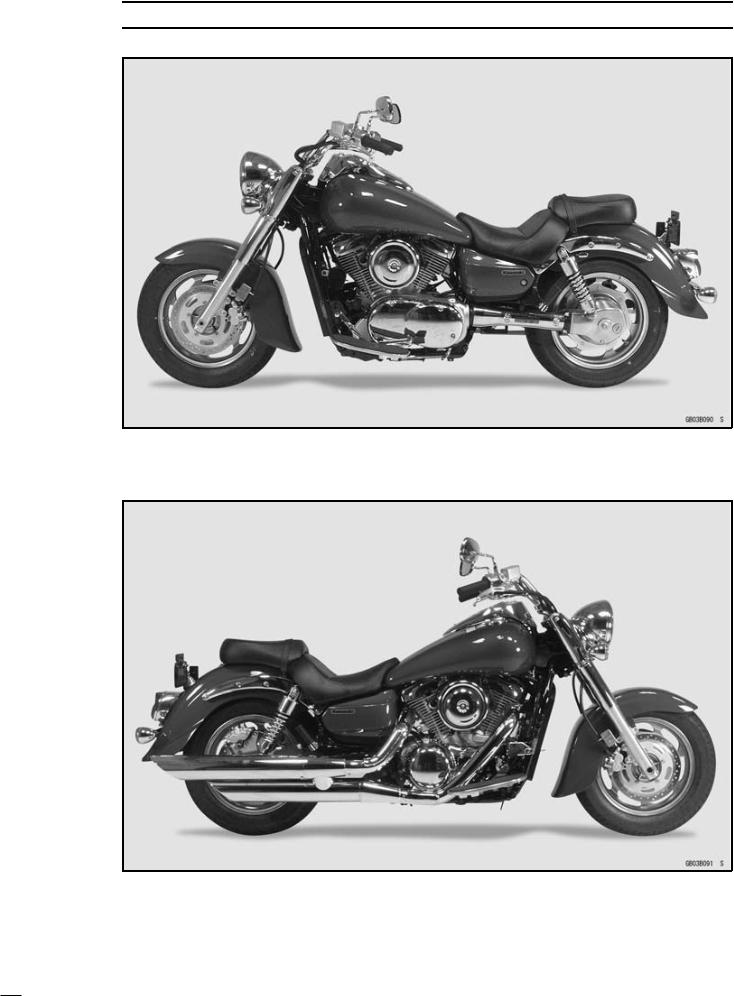

VN1600-A1 (US, and Canada) Left Side View:

VN1600-A1 (US, and Canada) Right Side View:

1-8 GENERAL INFORMATION

Model Identification

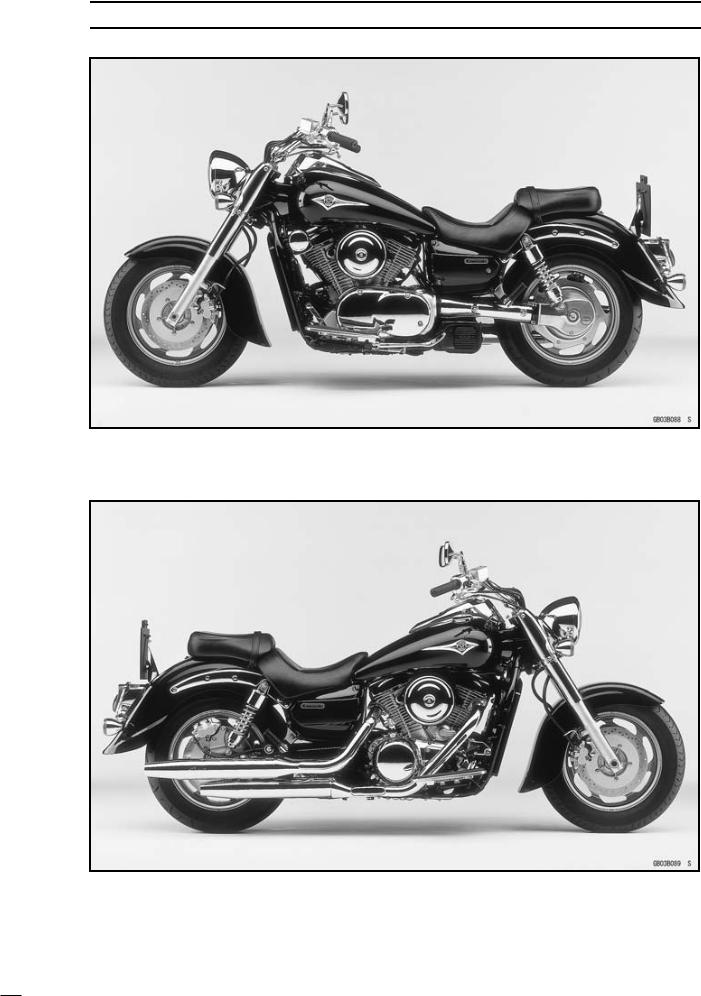

VN1600-A1 (Europe) Left Side View:

VN1600-A1 (Europe) Right Side View:

|

|

|

|

|

|

|

|

|

|

|

|

|

GENERAL |

INFORMATION |

1-9 |

|||||

General |

Specifications |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

Dimensions: |

Items |

|

|

|

|

|

|

|

|

|

VN1600-A1 |

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

Overall |

length |

2 |

505 |

|

mm |

|

(98.62 |

in.) |

|

|

|

|

|

|

||||||

Overall |

width |

1 |

040 |

|

mm |

(40.9 |

in.), |

(AU) |

990 mm |

(39 |

in.) |

|

||||||||

Overall |

height |

1 |

130 |

|

mm |

|

(44.5 |

in.) |

|

|

|

|

|

|

||||||

Wheelbase |

|

1 680 mm (66.1 in.) |

|

|

|

|

|

|

||||||||||||

Road |

clearance |

130 |

mm |

(5.12 |

in.) |

|

|

|

|

|

|

|||||||||

Seat |

height |

|

680 |

mm |

(26.8 |

in.) |

|

|

|

|

|

|

||||||||

Dry mass |

|

|

306 |

kg |

|

(675 |

lb), |

(AU) |

307 |

kg |

(677 |

lb) |

|

|

||||||

Curb |

mass: |

Front |

156 |

kg |

|

(345 |

lb) |

|

|

|

|

|

|

|

||||||

|

|

|

|

Rear |

181 |

kg |

|

(399 |

lb), |

(AU) |

182 |

kg |

(401 |

lb) |

|

|

||||

Fuel |

tank |

capacity |

20 L (5.3 US gal) |

|

|

|

|

|

|

|||||||||||

Fuel |

|

|

|

|

Unleaded and high-octane gasoline |

|

|

|

||||||||||||

Performance: |

|

(see |

|

VN1600-A1 |

Owner’s Manual) |

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

Minimum |

turning radius |

3.5 |

|

m |

|

(11.5 |

ft) |

|

|

|

|

|

|

|

|

|||||

Engine: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Type |

|

|

|

|

4-stroke, SOHC, V2-cylinder |

|

|

|

|

|

||||||||||

Cooling |

system |

Liquid-cooled |

|

|

|

|

|

|

|

|

|

|||||||||

Bore |

and |

stroke |

102 |

× |

|

95 |

mm |

(4.02 |

× 3.74 in.) |

|

|

|

||||||||

Displacement |

|

1 |

552 |

|

mL |

(94.70 |

cu |

in.) |

|

|

|

|

|

|||||||

Compression |

ratio |

9.0 |

|

: |

1 |

|

|

|

|

|

|

|

|

|

|

|

||||

Maximum |

horsepower |

49 |

|

kW |

(67 |

|

PS) @ 4 700 r/min |

(rpm), |

(CA) (CAL) (US) – |

|||||||||||

Maximum |

torque |

127 |

N·m |

(12.95 |

kgf·m, |

93.7 |

ft·lb) @ 2 |

700 |

r/min |

(rpm), |

||||||||||

|

|

|

|

|

(CA) |

|

(CAL) |

(US) |

– |

|

|

|

|

|

|

|||||

Carburetion |

system |

DFI (Digital Fuel Injection) System |

|

|

|

|||||||||||||||

Starting |

system |

Electric |

starter |

|

|

|

|

|

|

|

|

|||||||||

Ignition |

system |

Battery |

and |

|

coil |

(transistorized) |

|

|

|

|

||||||||||

Timing |

advance |

Electronically |

|

advanced |

(digital) |

|

|

|

|

|||||||||||

Ignition |

timing |

From |

0° |

BTDC |

@ 950 |

r/min |

(rpm)25° BTDC |

@ 4 |

500 |

|||||||||||

|

|

|

|

|

r/min |

(rpm) |

|

|

|

|

|

|

|

|

|

|

||||

Spark |

plugs |

|

NGK DPR6EA-9 or ND X20EPR-U9 |

|

|

|

||||||||||||||

Cylinder |

numbering method |

Front |

to |

Rear, |

1-2 |

|

|

|

|

|

|

|||||||||

Firing |

order |

|

1-2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

Valve |

timing: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

Inlet |

|

|

|

Open |

22° |

BTDC |

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

Close |

66° |

ABDC |

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

Duration |

268° |

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Exhaust |

|

Open |

66° |

BBDC |

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

Close |

26° |

ATDC |

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

Duration |

272° |

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Lubrication |

system |

Forced |

lubrication |

(wet |

sump) |

|

|

|

|

|||||||||||

Engine |

oil: |

Type |

API SE, SF or SG class |

|

|

|

|

|

||||||||||||

|

|

|

|

|

API SH or SJ class with JASO MA |

|

|

|

||||||||||||

|

|

|

|

Viscosity |

SAE10W-40 |

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

Capacity |

3.5 |

|

L |

|

(3.7US qt, |

when engine |

is completely disassembled |

|||||||||

|

|

|

|

|

and |

dry) |

|

|

|

|

|

|

|

|

|

|

|

|||

1-10 GENERAL INFORMATION

General |

Specifications |

|

|

|

|

|

|

|

|

|||||

Drive |

Train: |

Items |

|

|

|

|

|

|

|

VN1600-A1 |

||||

|

|

|

|

|

|

|

|

|

|

|

||||

Primary |

reduction |

system: |

|

|

|

|

|

|

|

|

||||

Type |

|

|

|

|

|

Gear |

|

|

|

|

|

|||

Reduction |

ratio |

|

|

1.517 |

(85/56) |

|

|

|||||||

Clutch |

type |

|

|

|

|

Wet |

multi |

disc |

|

|||||

Transmission: |

|

|

|

|

|

|

|

|

|

|

||||

Type |

|

|

|

|

|

5-speed, constant mesh, return shift |

||||||||

Gear ratios: |

|

1st |

|

2.500 |

(40/16) |

|

||||||||

|

|

|

|

|

|

2nd |

|

1.590 |

(35/22) |

|

||||

|

|

|

|

|

|

3rd |

|

1.192 |

(31/26) |

|

||||

|

|

|

|

|

|

4th |

|

0.965 |

(28/29) |

|

||||

Final |

drive |

system: 5th |

|

0.781 |

(25/32) |

|

||||||||

Type |

|

|

|

|

|

Shaft |

|

|

|

|

|

|||

Reduction |

ratio |

|

|

2.619 |

(15/21 |

× |

33/9) |

|||||||

Overall |

drive |

ratio |

|

3.105 |

@ Top |

gear |

||||||||

Final |

gear |

case |

oil: |

|

|

|

|

|

|

|

|

|||

Grade |

|

|

|

|

|

API Service Classification: GL-5 Hypoid gear oil |

||||||||

Viscosity |

|

|

|

|

SAE90 (above 5°C), SAE80 (below 5°C) |

|||||||||

Capacity |

|

|

|

|

200 |

mL |

|

(6.76 |

US oz) |

|||||

Frame: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Type |

|

|

|

|

|

|

Tubular, |

double |

cradle |

|||||

Caster |

(rake angel) |

|

32° |

|

|

|

|

|

|

|||||

Trail |

|

|

|

|

|

|

|

168 mm |

(6.61 |

in.) |

||||

Front |

tire: |

|

|

Type |

|

Tubeless |

|

|

|

|

||||

|

|

|

|

|

|

Size |

|

130/90 - 16 M/C 67H |

||||||

Rear |

tire: |

|

|

Type |

|

Tubeless |

|

|

|

|

||||

|

|

|

|

|

|

Size |

|

170/70B16 M/C |

75H |

|||||

Front |

suspension: |

Type |

|

Telescopic |

fork |

|

||||||||

|

|

|

|

|

|

Wheel |

travel |

150 |

mm |

|

(5.91 |

in.) |

||

Rear |

suspension: |

Type |

|

Swingarm |

|

|

|

|

||||||

|

|

|

|

|

|

Wheel |

travel |

95 |

mm |

(3.74 |

in.) |

|||

Brake |

Type: |

|

Front |

|

Dual |

disc |

|

|

|

|||||

Electrical |

Equipment:Rear |

|

Single |

disc |

|

|

||||||||

Battery |

|

|

|

Capacity |

12 |

V |