Kawasaki JET MATE Service Manual

Kawasaki

~eT

4ILl77:

Watercraft

Service Manual

beerdart

I.

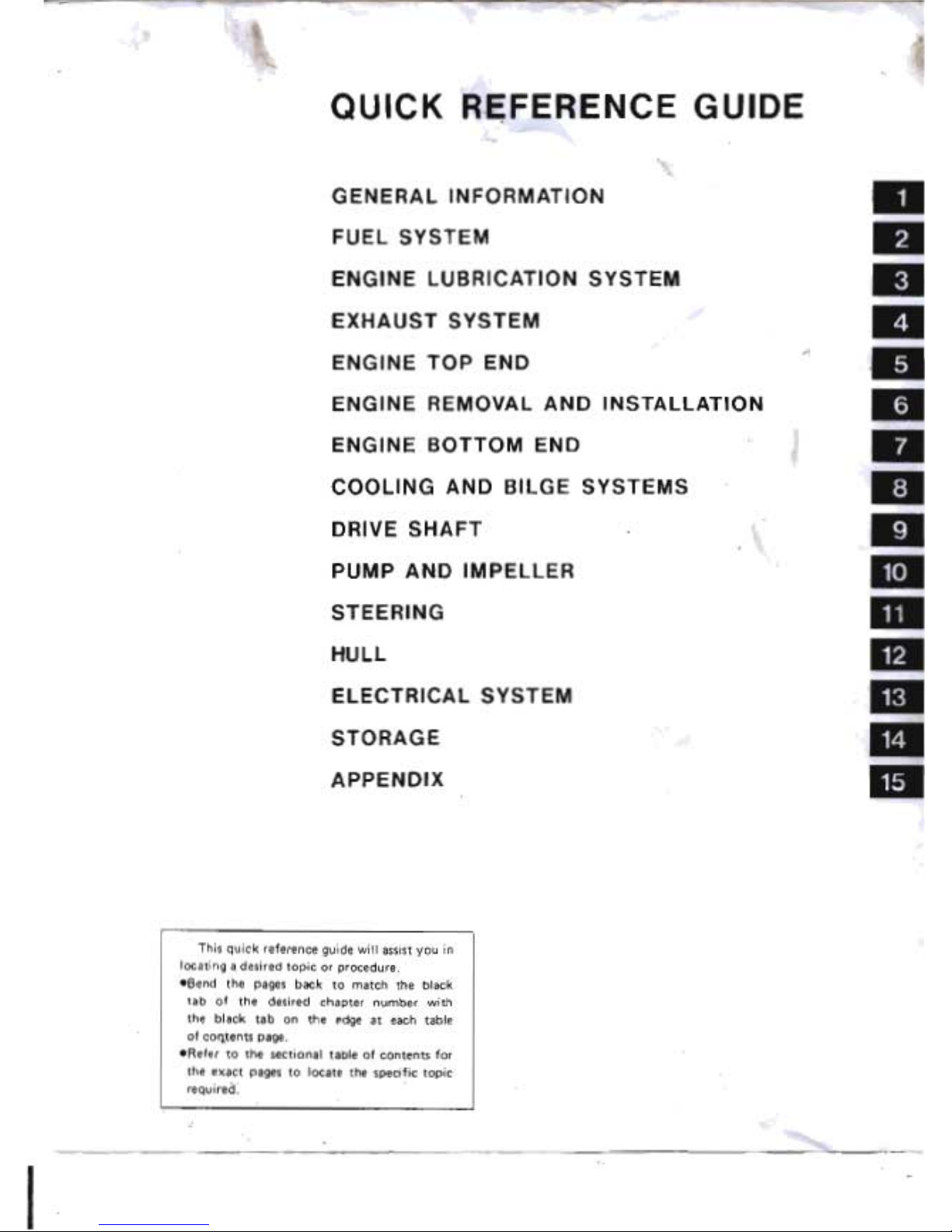

QUICK

R~FERENCE

GUIDE

,,

GENERAL

INFORMATION

FUEL

SYSTEM

ENGINE

LUBRICATION

SYSTEM

EXHAUST

SYSTEM

ENGINE

TOP

END

ENGINE

REMOVAL

AND

INSTALLATION

ENGINE

BOTTOM

END

COOLING

AND BILGE

SYSTEMS

DRIVE

SHAFT

PUMP

AND

IMPELLER

STEERING

HULL

ELECTRICAL

SYSTEM

STORAGE

APPENDIX

This

quick

reference guide will assist you

in

locating

a,

desired

topic

or

procedure.

-Bend

the

pages back

to

match

the

black

tab

of

the

desired

chapter

number

with

the

black

tab

on

the

edge

at

each table

of

cOlltents page.

-Refer

to

the

sectional table of

contents

for

the exact pages

to

locate

the

specific topic

required:

.'

beerdart

Kawasaki

Watercraft

Service Manual

All

rights reserved.

No

parts

of

this

publication

may

be

reproduced,

stored

in a retrieval system,

or

transmitted

in any form

or

by

any means, electronic mechanical

photocopying,

recording

or

otherwise,

without

the

prior

written permission

of

Quality Assurance Department/Consumer Products Group/Kawasaki Heavy Industries,

ltd.,

Japan.

No

liability can be accepted for any inaccuracies

or

omissions

in

this pUblication, although every

possible care has been taken

to

make it

as

complete and accurate as possible.

The right

is

reserved

to

make

changes

at any time

without

prior

notice

and

without

incurring

an

obligation

to

make such changes

to

products manufactured previously. See your watercraft dealer

for

the

latest information

on

product

improvements incorporated after this publication.

All information contained

in

this publication

is

based

on

the

latest

product

information available

at

the

time of publication. Illustrations and photographs

in

this publication are intended for reference

use only and may

not

depict

actual model

component

parts.

© Kawasaki

Heavy

Industries, Ltd. 1988, 1989, 1992

Third Edition

(3):

Sap. 10, 1997

(KJ

beerdart

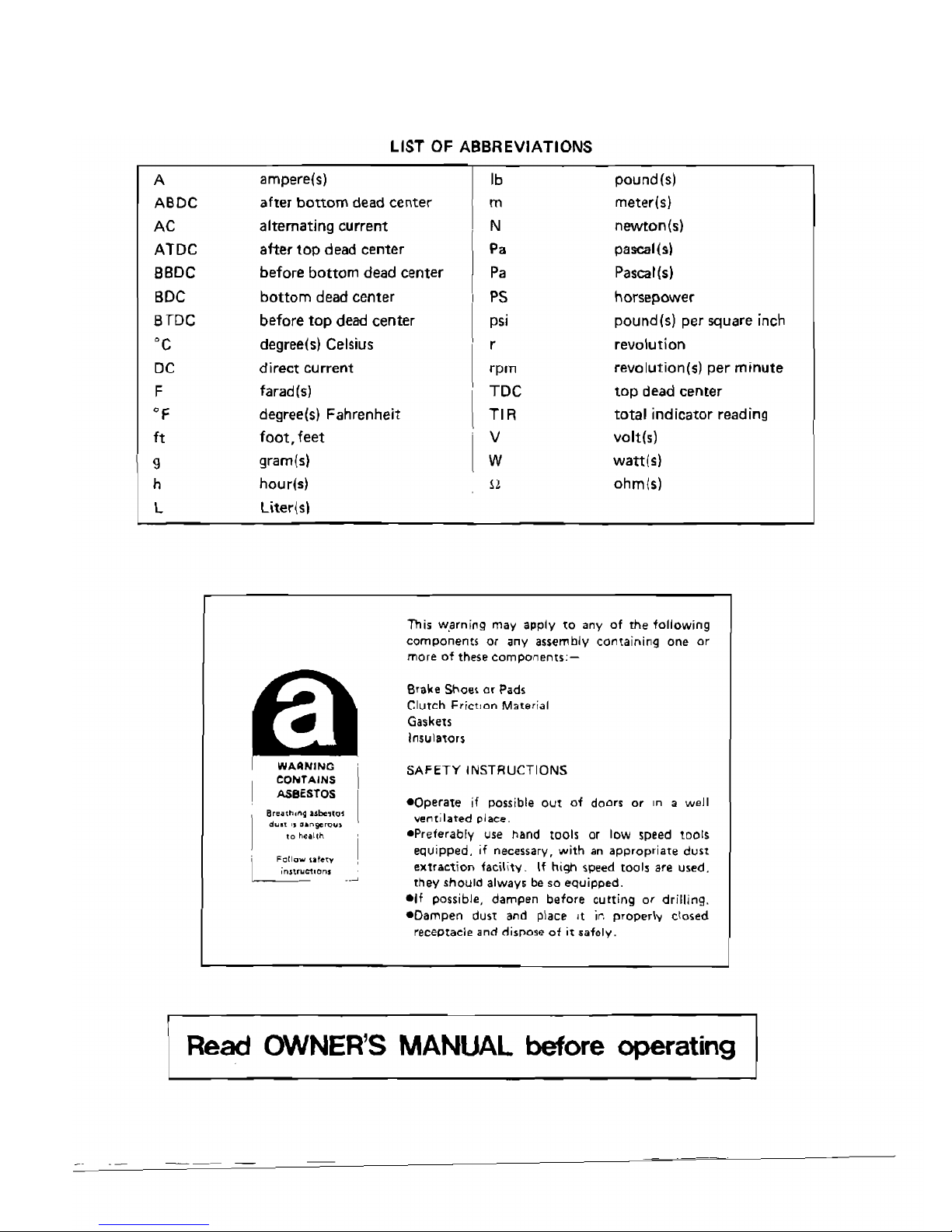

LIST

OF

ABBREVIATIONS

A

ampere{s)

Ib

pound(s)

ABDC

after

bottom

dead center m meter{s)

AC alternating current N

newton(s)

ATDC

after

top

dead center

P.

pascal(s)

BBDC before

bottom

dead center

Pa

Pascal(s)

BDC

bottom

dead center

PS

horsepower

8TDC

before top dead center

psi

pound(s) per square inch

'c

degree(s}

Celsius

r revolution

DC

direct

current

rpm

revolution(s)

per

minute

F

farad

(5)

TDC

top

dead center

'F

degree(s) Fahrenheit

TIR

total indicator reading

It

foot,

feet

V

volt(s)

9

gram(s)

W

wan(s}

h

hourIs)

!l

ohmlsl

L

Liter(s!

Bro"h,ng ..be'l<>'

d",", " ••

"go",,,.,

to

heallh

FOil""

,alew

;nn'uC1,on,

This w.arning may apply

to

any

of

the

following

components or any assembly containing one

or

more

of

these

components:-

Brake

Shoe~

or

Pads

Clutch

Friction

Material

Gaskets

Insulators

SAFETY

INSTRUCTIONS

-Operate

if

possible

OUt

of

doors

or

in

a well

ver1tilated place.

.Preferably use hand

tools

or low speed

tOOls

equipped.

if necessary.

with

an

appropriate

dust

extraction

facility.

If

high

speed

tools are used.

they

should

always be

so

equipped.

elf possible,

dampen

before

cutting

or

drilling.

-Dampen

dust

and

place it

ir.

properly

closed

receptaclE! and dispose

of

it

safely.

Read OWNER'S

MANUAL

before operating

beerdart

Foreword

•

This

manual

is

designed primarily for use

by

trained mechanics

in a properly

equipped

shop.

However, it contains enough detail

and

basic

information

to

make

it useful

to

the

owner

who desires

to

perform his own basic main-

tenance and repair work. A basic knowledge

of

mechanics, the proper

use

of

tools,

and

workshop

procedures must be understood in

order

to

carry

out

maintenance and repair

satisfactorily. Whenever

the

owner

has insuf-

ficient experience

or

doubts his

ability

to

do

the

work,

alt adjustments, maintenance,

and

repair should be carried

out

only

by

qualified

mechanics.

In order

to

perform the work efficiently

and

to

avoid costly mistakes, read the text, thor-

oughly familiarize yourself

with

the procedures

before

starting

work,

and

then

do

the

work

carefully in a clean area. Whenever special

tools

o.r

equipment

are specified,

do

not

use

makeshIft

tools

or

equipment.

Precision meas-

urements

can

only

be

made

if

the

proper

instru-

ments are used,

and

the

use

of

substitute

tools

may adversely

affect

safe

operation.

For

the

duration

of

your

warranty

period

especially. we

recommend

that

all repairs

and

scheduled

maintenance

be

performed

in accord-

ance with

this

service manual.

Any

owner

maintenance

or

repair

procedure

not

performed

in

accordance

with

this

manual may void

the

warranty.

To

get

the

longest life

out

of

your

water-

craft:

_Follow

the

Periodic

Maintenance

Chart

in

the

Service Manual.

eBe

alert

for

problems

and

non-scheduled

maintenance.

eUse

proper

tools

and

genuine

Kawasaki

water·

craft

parts. Speciai

tools,

gauges,

and

testers

that

are necessary

when

servicing KawasakI

watercrafts

are

introduced

by

the

Special

Tool

Manual.

Genuine

parts

provided as spare

parts are listed

in

the

Parts

Catalog.

e Follow

the

procedures

in this manual carefully.

Don't

take

shortcuts.

e

Remember

to

keep

complete

records

of

main-

tenance

and

repair

with

dates

and any

new

parts installed.

..................................................................

How

to

Use

this

Manual

............................................................................

In preparing

this

manual,

we

divided

the

product

into

its

major

systems.

These

systems

became

the

manual's

chapters.

All

information

for

a

particular

system

from

adjustment

through

disassembly

and

inspection

is

located

in a single

chapter.

The

Quick

Reference

Guide

shows

you

all

of

the.

product's

systems

and

assists in locating

theIr

chapters.

Each

chapter

in

turn

has its

own

comprehensive

Table

of

Contents.

The

Periodic

Maintenance

Chart

is

located

in

the

General

Information

chapter.

The

chart

gives a

time

schedule for required

maintenance

operations.

If

you

want

spark

plu.g

information,

for

example,

go

to

the

Periodic Maintenance

Chart

first. The

chart

tells

you

how frequently

to

clean

and gap

the

plug.

Next,

use

the

Ouick

Reference

Guide

to

locate

the

Electrical

System

chapter.

Then,

use

the

Table

of

Contents

on

the

first page

of

the

chapter

to

find

the

Spark

Plug section.

Whenever

you

see

these

WARNING

and

CAUTION

symbols,

heed

their

instructions!

Always

follow

safe

operating

and

maintenance

practices.

I

WARNING

I

oThis

warning

symbol

identifies special

instruc·

tions

or

procedures

which,

if

not

correctly

followe~,

could

result

in personal injury,

or

loss

of

life.

(C~UT(O]]

oThis

caution

symbol

identifies special

instruc.

tions

or

procedures

which,

if

not

strictly

ob·

served, could

result

in

damage

to

Or

destruc·

tion

of

equipment.

This

manual

contains

five

more

symbols

(in

addition

to

WARNING and CAUTION)

which

will help

you

distinguish

different

types

of

information.

beerdart

•

NOTE

o

This

note symbol indicates points

of

particular

interest

for

more

efficient

and convenient

operation.

• Indicates a procedural step

or

work

to

be

done.

olndicates a procedural sub-step

or

how to

do

the work

of

the procedural step it follows.

It also precedes

the

text

of

a WARNING,

CAUTION, or NOTE.

*Indicates a conditional step or what action

to

take based

on

the

results

of

the

test

or

inspec-

t;on

in

the

procedural step or sub-step

it follows.

?Indicates

a conditional sub-step

or

what

action to

take

based upon

the

results

of

the

conditional

step

it follows.

In

most

chapters

an exploded

view

illustra-

tion of the system components follows

the

Table

of

Contents.

In

these illustrations you

will

find

the

instructions indicating which

parts

require specified tightening

torque,

oil, grease

or

a locking

agent

during assembly.

beerdart

GENERAL

INFORMATION

1-1

•

GENERAL INFORMATION

Table of Contents

Before

Servicing

. 1-2

Model Identification _ ,

..

1-5

General Specification .

1-6

Periodic Maintenance Chart ,

..

1-7

Torque

and

Locking

Agent

.

1-8

Cable Routing .

1-

1Q

beerdart

1-2

GENERAL INFORMATION

Before Servicing

Before starting

to

service a motorcycle, careful reading

of

the

applicable section

is

recommended

to

eliminate unnecessary work. Photographs, diagrams, notes, cautions, warnings, and detailed des-

criptions have

been

included wherever necessary. Nevertheless, even a detailed

account

has limita-

tions, a certain

amount

of

basic knowledge

is

also required for successful work.

Especially note the following:

(1) Adjustments

Adjustments shall

be

made

in

accordance with

the

Periodic Maintenance Chart or whenever

troubleshooting

or

presence

of

symptoms indicate

that

adjustments may

be

required. Whenever

running

of

the

engine

is

required

during

maintenance

it

is

best

to

have

the

watercraft

in water,

000

not

run

the

engine

without

cooling

water

supply

for

more

than

15

seconds

or

severe engine and

exhaust

system

damage will occur,

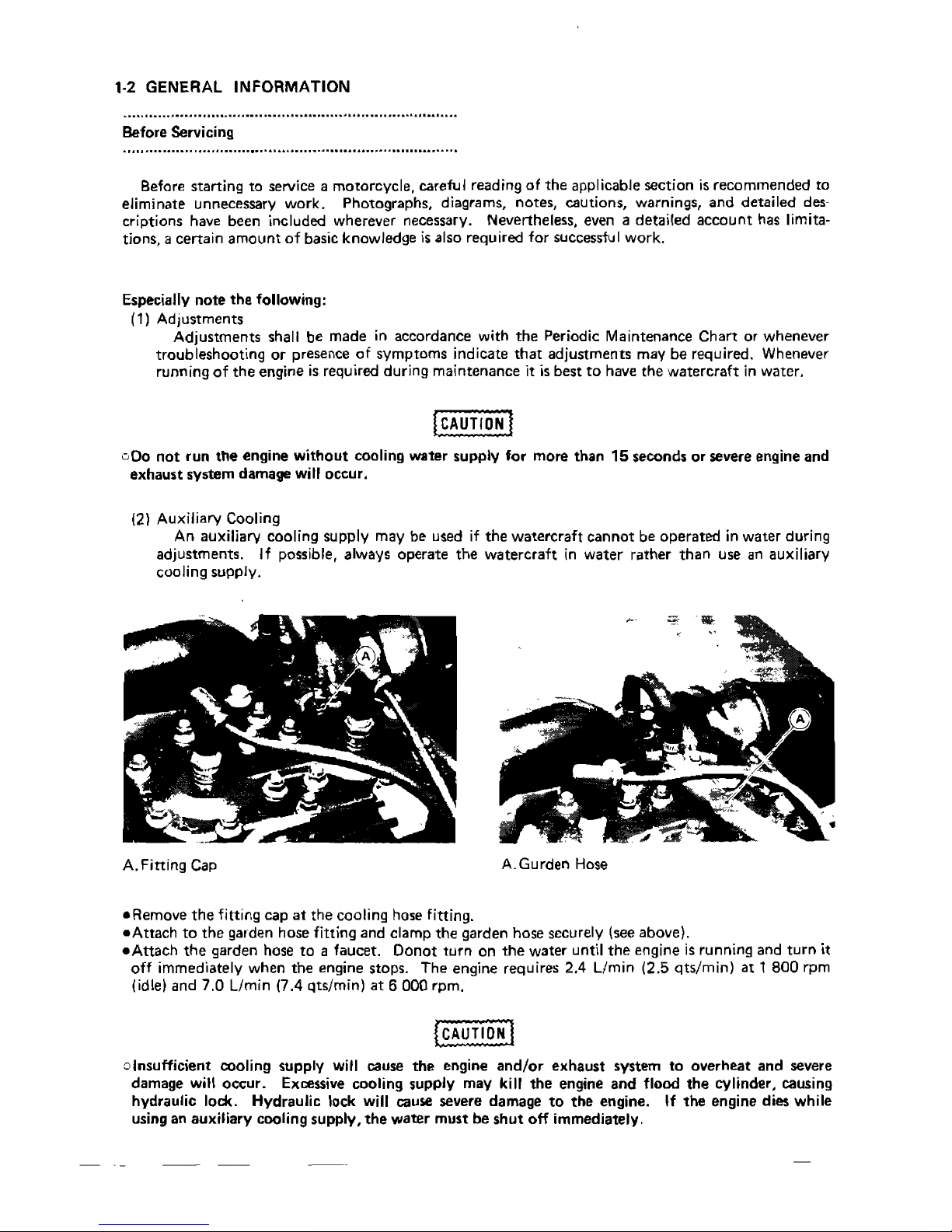

121

Auxiliary Cooling

An auxiliary cooling supply

may

be used

if

the

watercraft

cannot

be

operated

in

water

during

adjustments.

If possible, always

operate

the

watercraft

in

water

rather

than

use

an auxiliary

cooling

supply,

A. Fitting Cap

A.Gurden

Hose

_Remove

the

fitting

cap

at

the

cooling hose fitting.

-Attach

to

the

garden hose fitting and clamp

the

garden

hose

securely (see above).

_Attach

the

garden hose

to

a faucet.

Donat

turn

on

the

water

until

the

engine

is

running and

turn

it

off

immediately

when

the

engine stops.

The

engine requires

2:.4

Llmin

(2.5

qts/min)

at 1 800

rpm

(idle) and

7.0

Llmin

(7.4

qts/min)

at 6 000

rpm,

olnsufficient

cooling

supply

will cause

the

engine

and/or

exhaust

system

to

overheat

and

severe

damage

will

occur.

Excessive cooling

supply

may kill

the

engine

and

flood

the

cylinder, causing

hydraulic lock.

Hydraulic

lock will cause severe

damage

to

the

engine. If

the

engine dies while

using an auxiliary cooling

supply,

the

water

must

be

shut

off

immediately.

beerdart

GENERAL INFORMATION

1·3

(31

Dirt

Before removal and disassembly. clean the watercraft. Any sand entering

the

engine car-

buretor,

or

other

parts will work as an abrasive and

shorten

the

life

of

the

watercraft.

For

the

same reason, before installing a new part, clean

off

any

dust

or metal filings.

(4)

Battery

Ground

Remove the ground

(-I

lead from

the

battery before performing any disassembly operations

on

the

watercraft. This prevents:

(a)

the possibility

of

accidentally turning the engine over while partially disassembled.

(b) sparks

at

electrical connections which

will

occur

when

they

are disconnected.

(e) damage

to

electrical parts.

(5) Tightening Sequence

Generally. when installing a

part

with several bolts, nuts,

or

screws, they should all be started

in

their holes and tightened

to

a snug fit. Then tighten them evenly

in

a cross pattern. This

is

to

avoid distortion

of

the

part

and/or

causing gas

or

oil leakage. Conversely

when

loosening the

bolts, nuts, or screws, first loosen

all

of

them by

about a quarter

of

turn

and

then

remove them.

Where there

is

a tightening sequence indication

in

this Service Manual,

the

bolts, nuts,

or

screws must be tightened

in

the

order and method indicated.

(6) Torque

The torque values given

in

this Service Manual should always be adhered to. Either

too

little

or

too

much

torque

may lead

to

serious damage.

Use

a good quality, reliable

torque

wrench.

(7) Force

Common sense should

dictate

how much force

is

necessary

in

assembly and disassembly.

If

a part seems especially difficult

to

remove

or

install, stop and examine

what

may be causing the

problem. Whenever tapping

is

necessary, tap lightly using a wooden

or

plastic faced mallet.

Use

an

impact driver for screws (particularly for the removal

of

screws held

by

a locking agent)

in

order to avoid damaging the screw heads.

181

Edge,

Watch

for

sharp edges, especially during major engine disassembly and assembly. Protect your

hands with gloves

or

a piece

of

thick cloth when lifting

the

engine

or

turning it over.

(9)

High

Flash-point Solvent

A high fla$h-point solvent

is

recommended

to

reduce fire danger, A commercial solvent com-

monly available

in

North America

is

Stoddard solvent (generic name). Always follow manufac-

turer

and container directions regarding the use

of

any solvent.

(1OJ

Gasket, O-ring

Do

not

reuse a gasket

or

O-ring once it has been

in

service_

The

mating surfaces around the

gasket should

be

free

of

foreign

matter

and perfectly

smooth

to

avoid oil

or

compression leaks.

(11) Liquid Gasket, Non.permanent Locking Agent

Follow manufacturer's directions for cleaning and preparing surfaces

where

these compounds

will be used, Apply sparingly. Excessive amounts may block engine oil passages and cause

serious damage.

An

example

of

a non-permanent locking agent commonly available

in

North

America'is Loctite Lock'n Seal (Blue).

{12) Press

A

part

installed using a press or driver, such

as

a seal, should first

be

coated

with

oil on its

outer or inner circumference so

that

it will

go

into place smoothly.

{13)

Bal!

Bearing

When installing a ball bearing, the bearing race which

is

affected by friction should

be

pushed

by a suitable driver. This prevents severe stress on the balls and races, and prevents races and

balls from being

dented,

Press a ball bearing until it

stops

at

the

stop

in

the hole

or

on

the

shaft.

(14)

Oil

Seal and Grease Seal

Replace any oil

or

grease seals

that

were removed with new ones,

as

removal generally damages

seals.

When pressing

in

a seal which has manufacturer's marks, press it

in

with

the

marks facing out,

Seals should be pressed into place using a suitable driver, which contacts evenly with

the

side of

seal, until the face of the seal

is

even with

the

end

of

the

hole.

(15) Seal Guide

A seal guide

is

required for certain oil or grease seals during installation

to

avoid damage

to

the

seal lips. Before a shaft passes through a seal, apply a little oil, preferably high temperature

grease on

the

lips

to

reduce rubber to metal friction.

beerdart

1-4

GENERAL INFORMATION

(16) Circlip, Retaining Ring,

Cotter

Pin

Replace any circlips,

cotter

pins and retammq rings

that

were removed with new ones, as

removal weakens and deforms them. When installing circlips and retaining rings,

take

care to

compress

or

expand

them

only

enough

to

install

them

and

no

more.

(17)

Lubrication

Engine

wear

is

generally

at

its

maximum

while

the

engine

is

warming

up

and

before

all

the

rubbing

surfaces

have

an

adequate

lubricative film. During

assembly,

oil

or

grease {whichever

is

more suitable) should

be

applied

to

any rubbing surface which has lost its lubricative film. Old

grease and dirty oil should

be

cleaned off. Deteriorated grease has lost its lubricative quality and

may

contain

abrasive foreign particles.

Don't

use just any oil

or

grease. Some oils and greases

in

particular should be used

only

in

certain applications and may

be

harmful if used

in

an application

for

which

they

are

not

intend

ed.

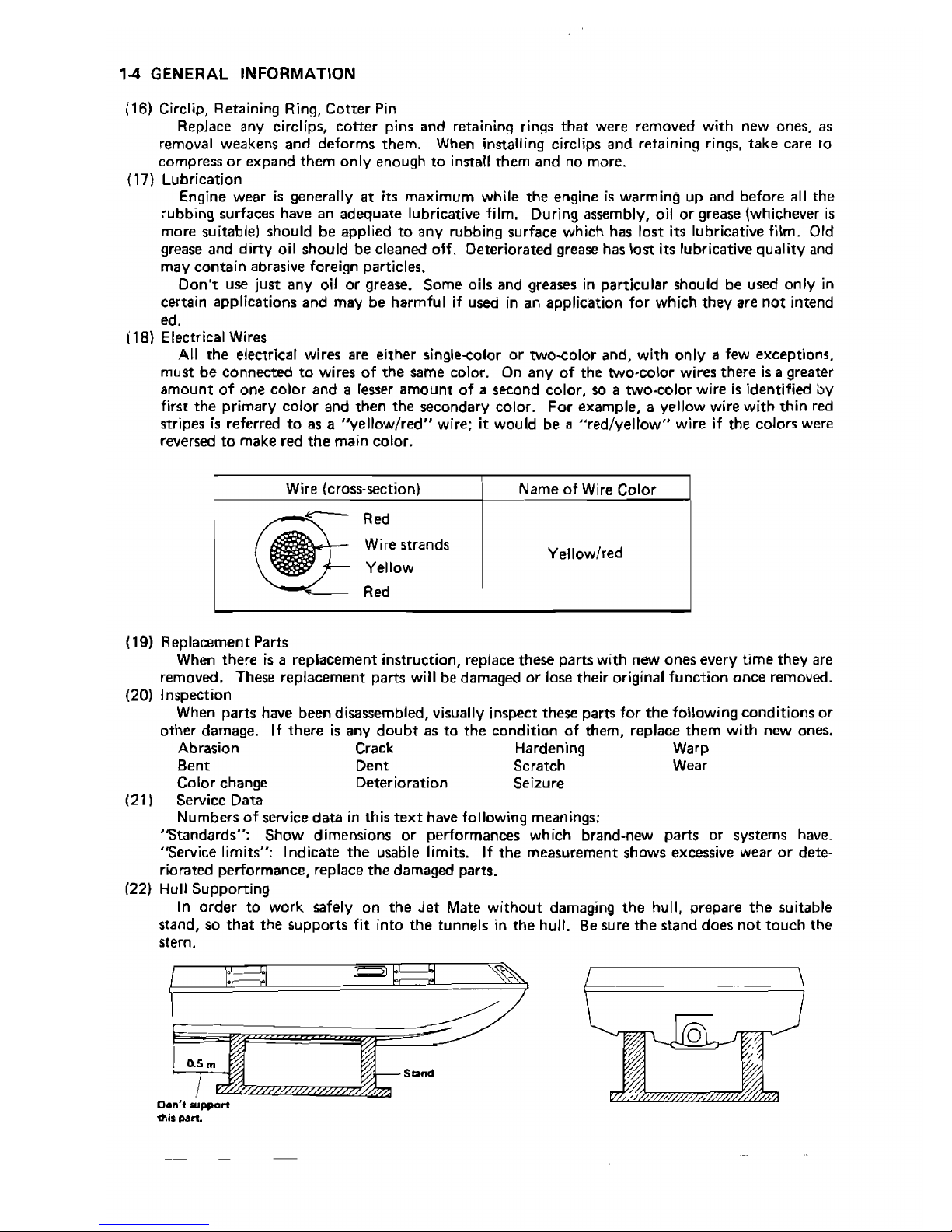

(18) Electrical Wires

All

the

electrical wires are either single-color

or

two-color and,

with

only a few exceptions,

must

be

connected

to

wires

of

the

same color.

On

any

of

the

two-color wires

there

is

a greater

amount

of

one

color

and a lesser

amount

of

a second color, so a two-color wire

is

identified by

first

the

primary

color

and

then

the

secondary color.

For

example, a yellow wire

with

thin red

stripes

is

referred

to

as a

"yellow/red"

wire; it would be a "red/yellow" wire if

the

colors were

reversed

to

make red

the

main color.

Wire (cross-section)

Name

of

Wire Color

@;

Red

Wire strands

Yellow

Red

Yellow/red

(19) Replacement Parts

When there

is

a replacement instruction, replace these parts with new

ones

every

time

they

are

removed, These replacement parts

will be damaged

or

lose their original

function

once removed.

(20) Inspection

When parts have been disassembled, visually inspect these parts

for

the

following conditions

or

other damage. If

there

is

any

doubt

as

to

the

condition

of

them, replace

them

with new ones.

Abrasion Crack Hardening Warp

Bent Dent Scratch Wear

Color change Deterioration Seizure

(211

Service Data

Numbers

of

service

data

in

this

text

have following meanings;

"Standards":

Show

dimenSions

or

performances which brand-new parts or systems have.

''Service limits": Indicate

the

usable limits. If

the

measurement shows excessive wear

or

dete-

riorated performance, replace

the

damaged parts.

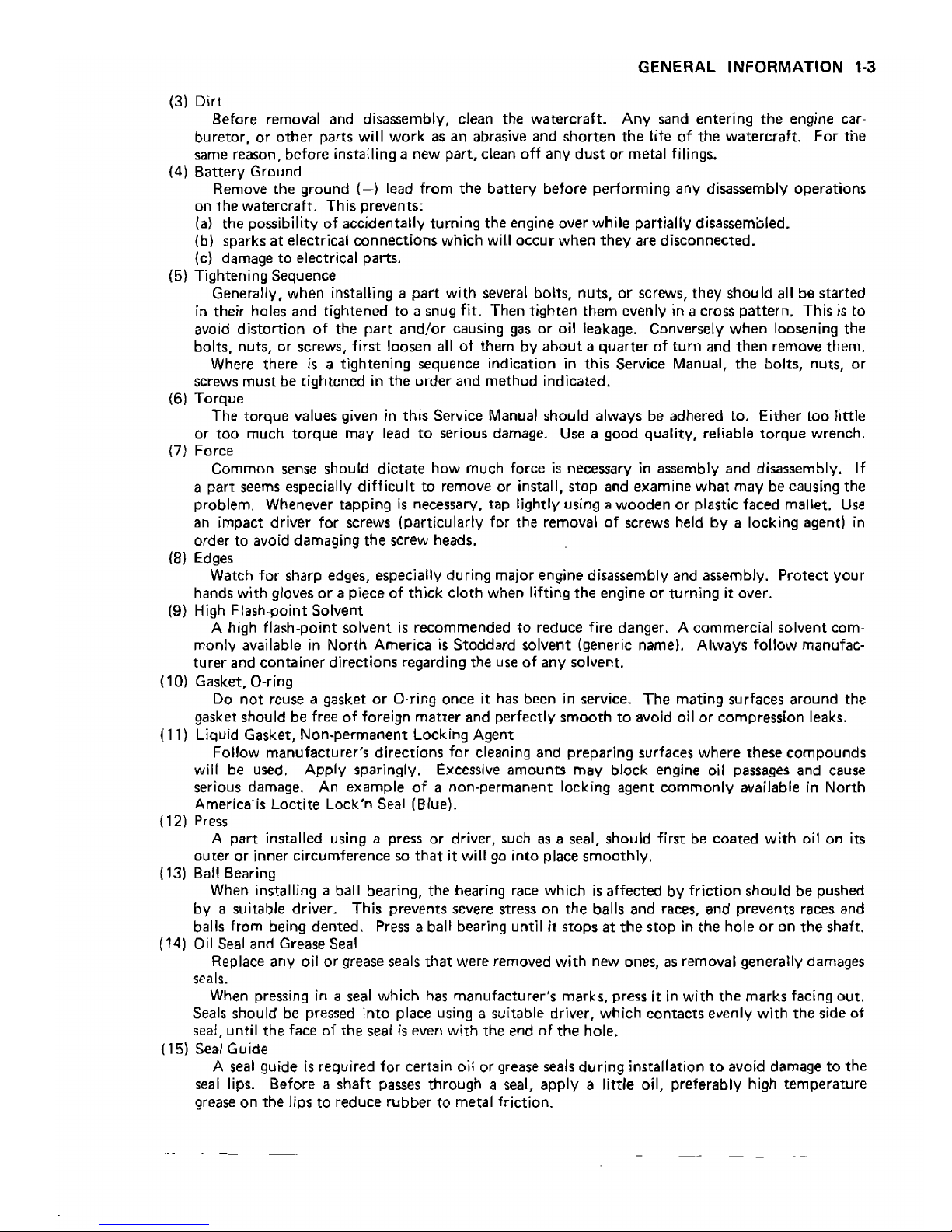

(22)

Hull

Supporting

In

order

to

work safely on

the

Jet

Mate

without

damaging

the

hull, prepare

the

suitable

stand, so

that

the

supports fit into

the

tunnels

in

the

hull.

Be

sure

the

stand does

not

touch

the

stern.

[

,)

O.5m

s~""

Don't

suplJOn

this

paM.

beerdart

,

GENERAL INFORII'IATION

'-5

Model Identification

JB650-A1

_/

JB650-A2

/

-

-------~--=;;.;..

JB65Q.A3

,

.

•

V!M¥iSB!&'

JB65Q.A4

•

_..:

.

/

. ,

-0

0%

i",,,-,,

"

_'

__

·~yCw;

,

--.

~--'iL

------_

...

beerdart

1·6 GENERAL

INFORMATION

............

- - - .

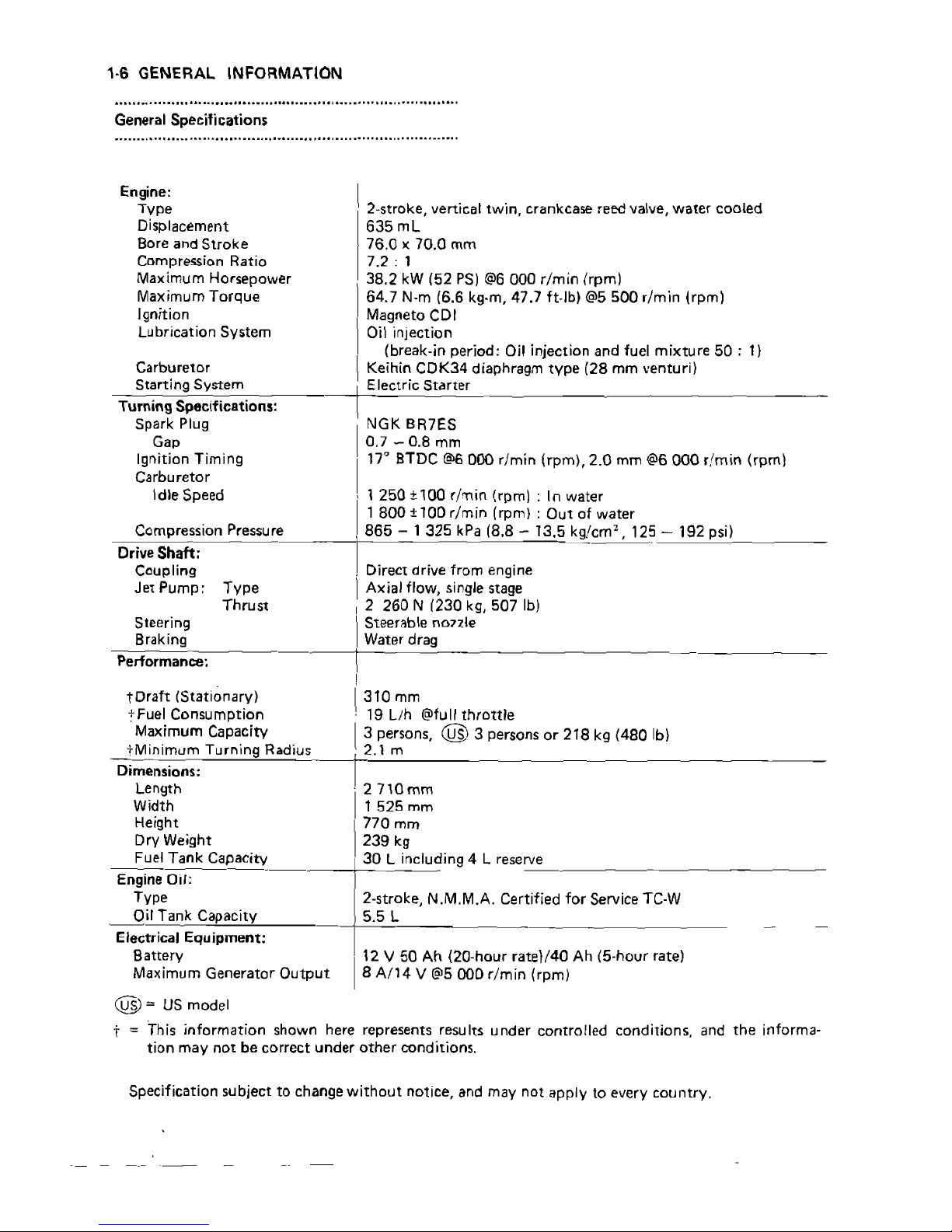

General Specifications

Engine:

Type

Displacement

Bore and

Stroke

Compression Ratio

Maximum Horsepower

Maximum

Torque

Ignition

Lubrication System

Carburetor

-=_,S:.':::"_,":::i

n~g,-,-S'cyst~e_,mc-~

Turning Specifications:

Spark Plug

Gap

Ignition Timing

Carburetor

Idle Speed

Compression Pressure

I2-stroke, vertical twin, crankcase reed valve, water cooled

635

mL

76.0 x 70.0 mm

7.2,

,

38.2

kW

152

PSI

@6

000 r/m!n Irpml

64.7

N-m

16.6 kg·m. 47.7 ft-lb)@5

500

r/min (rpm)

1

Magneto COl

I

Oil

injection

(break-in period:

Oil

injection and fuel mixture

50;

1)

I

Keihin

COK34

diaphragm

type

(28

mm

venturi)

~j

Eleetr ic

Sta

rteT

I

NGK

BR7ES

1°,7

-0.8

mm

111'"

BTDC

@6

000

r/min

(rpm), 2.0 mm

@6

000

r/min

(rpm)

' 1

250 ±100

({min (rpm) : In water

,

800

± 100

r/min

(rpm) :

Out

of water

I

865

-1325

kPa

(8.8

-13.5

kg/em;:,

125_-_'"'9:::2'-p:::s:::i)=--

_

Driv-e~S'ch-aft~-;

------~-I

.

Ccupling , Direct drive from engine

Jet

Pump:

Type

IAxial flow, single stage

Thrust , 2

260

N 1230

kg,

507

Ib)

Steering

Steer~b\e

n07Zle

Braking

I

Water drag

Performance:

I

toraft

(Stationary)

1310

mm

+Fuel Consumption ' 19

LJh

@fullthrottle

Maximum Capacity

13

persons, @ 3 persons

or

218

kg

(480

Ib)

-='c"

M=;n'-im~u'-m'--T-="'-r:::n·:::'n"gc:R'-.=d=i::.u::.'--lc'2::: ...:1-'m'-----~

~

_

Dimensions:

Length

2710mm

'I

Width 1

525

mm

Height

1770

mm

Dry Weight

239

kg

Fuel

Tank

Capacity

30

L including 4 L reserve

Engine

Oil:

Type

2-stroke,

N.M.M.A. Certified

for

Service

TC-W

Oil Tank Capacity

5.5 L

Electrical

Equipment:

Battery

'2 V 50

Ah (20-hour rate)/40

Ah

(5-hour rate)

Maximum Generator

Output

8

A/14

V@5000r/min

(rpm)

1

@:::

US

model

t

:::

This information shown here represents results under controlled conditions, and

the

informa-

tion may

not

be correct under

other

conditions.

Specification subject to change

without

notice, and may not apply to every country.

beerdart

._----------------------------------------_._--'.~~--"-'-

GENERAL INFORMATION

'-7

........................

- - - .

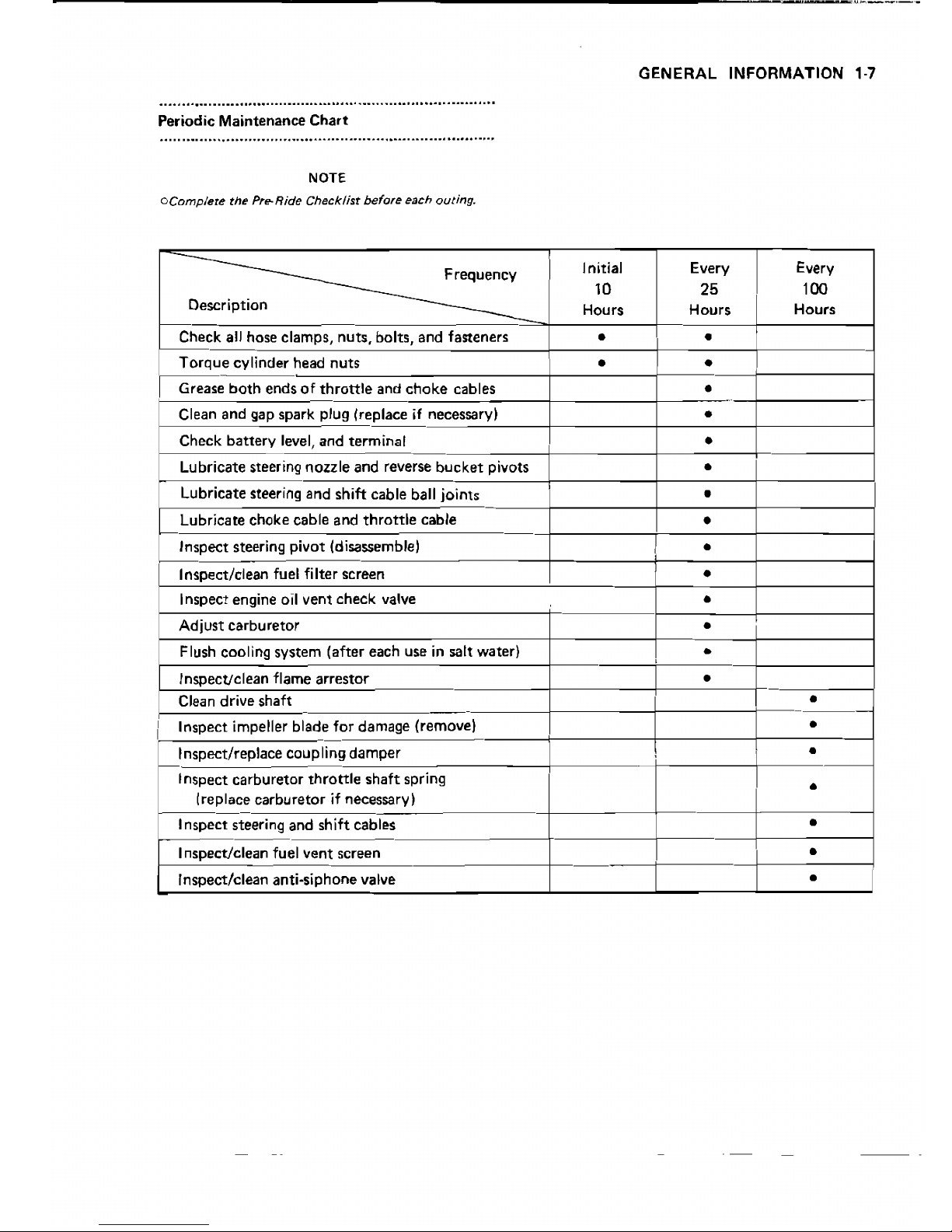

Periodic Maintenance

Chart

........................................................................

-

...

NOTE

oComp/et8

the Pre-Ride Checklist

before

each outing.

Frequency

Initial

10

Every

25

Every

100

Description

Hours

Hours

Hours

Check all hose clamps, nuts, bolts, and fasteners

• •

Torque

cylinder

head

nuts

• •

Grease

both

ends

of

throttle

and

choke

cables

•

..

Clean and gap spark

plug

(replace if necessary)

•

Check battery level, and terminal

•

Lubricate steering nOlzle and reverse bucket pivots

•

Lubricate steering and shift cable ball joints

•

Lubricate choke cable and

throttle

cable

•

Inspect steering pivot (disassemble)

•

Inspect/clean fuel filter screen

•

Inspect engine oil vent check valve

•

Adjust carburetor

•

Flush cooling system (after each use

in

salt water)

,

•

InspecUclean flame arrestor

Clean drive shaft

•

•

Inspect impeller blade

for

damage (remove)

•

Inspect/replace coupling damper

•

Inspect carburetor

throttle

shaft

spring

(replace carburetor if necessary)

•

Inspect steering and shift cables

•

Inspect/c1ean fuel vent screen

•

Inspect/clean anti-siphone valve

•

beerdart

1·8 GENERAL INFORMATION

..............................................................................

Torque and Locking Agent

.....................

-

'"

- .

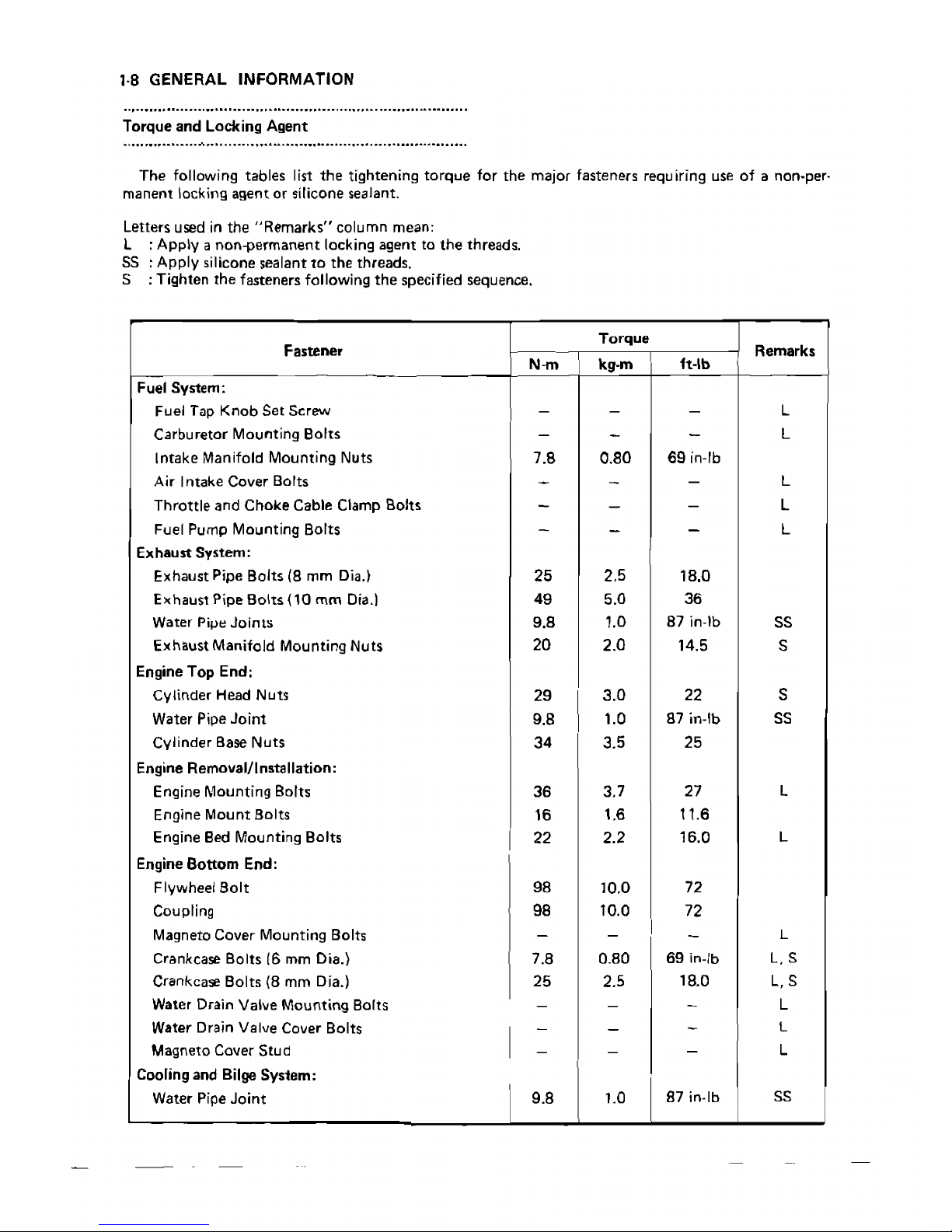

The following tables list

the

tightening

torque

for

the

major fasteners requiring use

of

a non-per-

manent locking agent or silicone sealant.

Letters

used

in the

"Remarks"

column mean:

L : Apply a non-permanent locking agent to

the

threads.

55 :

Apply

silicone sealant

to

the threads.

S : Tighten

the

fasteners following

the

specified sequence.

Fastener

N·m

Torque

kg·m

ft·lb

Remarks

Fuel System:

Fuel Tap

Knob

Set

Screw

Carburetor Mounting Bolts

Intake Manifold Mounting Nuts

Air Intake Cover Bolts

-

-

7.8

-

-

-

0.80

-

-

-

69 in-Ib

-

L

L

L

Throttle and

Choke

Cable Clamp Bolts

- -

- L

Fuel Pump Mounting Bolts

Exhaust System:

Exhaust Pipe Bolts

(8

mm

Dia.~

Exhaust Pipe Bolts {10 mm Oia.!

Water Pipe

Joints

Exhaust Manifold Mounting Nuts

-

25

49

9.8

20

-

2.5

5.0

1.0

2.0

-

18.0

36

87

in~lb

14.5

L

55

5

Engine Top End:

Cylinder Head Nuts

Water Pipe

Joint

Cylinder Base Nuts

29

9.8

34

3.0

1.0

3.5

22

87

in-Ib

25

5

S5

Engine Removal/Installation:

Engine Mounting Bolts

Engine Mount Bolts

Engine Bed Mounting Bolts

36

16

22

3.7

1.6

2.2

27

11.6

16.0

L

L

Engine

Bottom

End:

Flywheel Bolt

Coupling

Magneto Cover Mounting Bolts

Crankcase Bolts

16

mm

Dia.}

Crankca~

Bolts (8 mm Dia.)

Water Drain Valve Mounting Bo(ts

Water Drain Valve Cover Bolts

98

98

-

7.8

25

-

-

10.0

10.0

-

0.80

2.5

-

-

I

72

72

-

69

in-Ib

18.0

-

-

L

L.S

L,5

L

L

Magneto Cover Stud

I

- -

-

L

Cooling and Bilge Sys1em:

Water Pipe

Joint

9.8

1.0

87 in-Ib

55

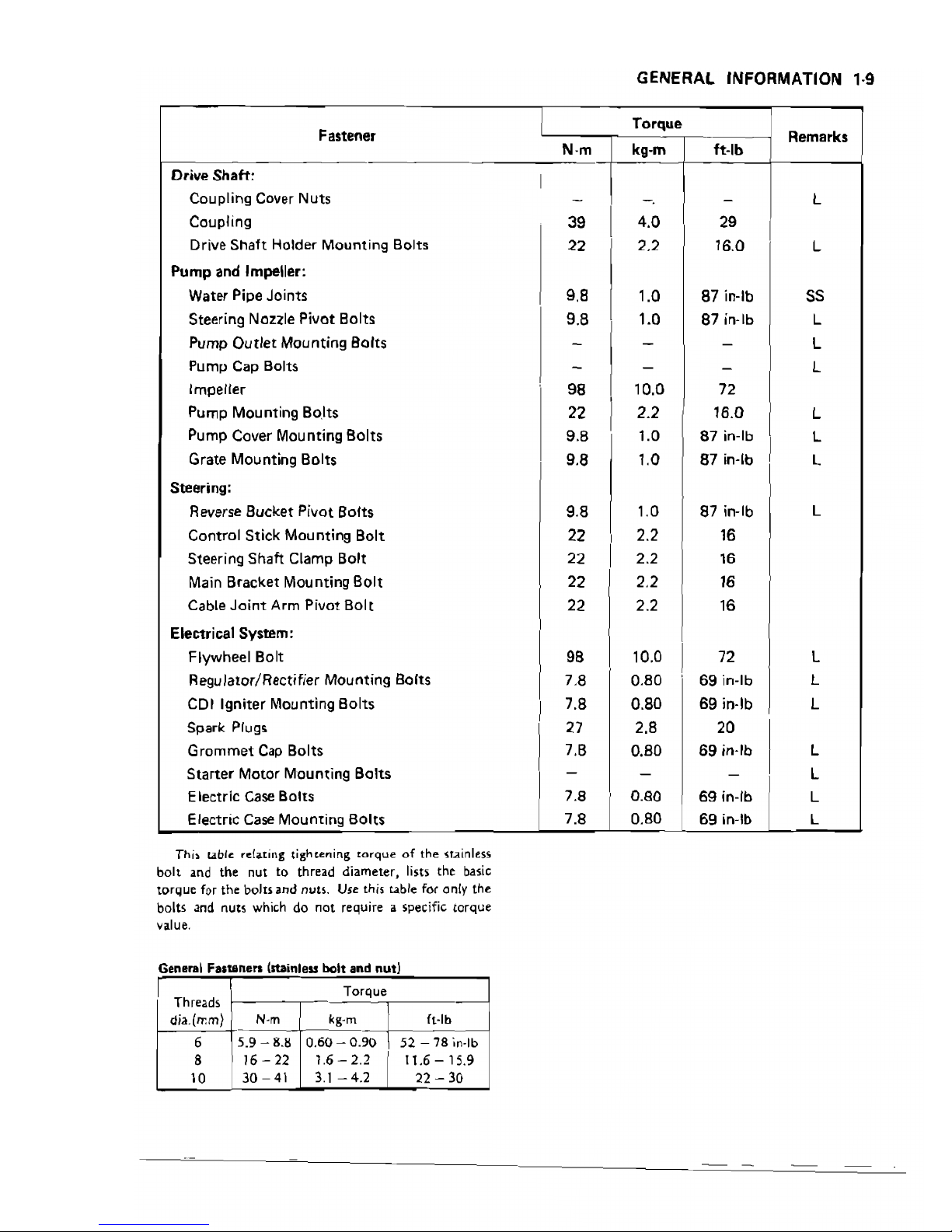

beerdart

GENERAL INFORMATION

'·9

Fastener

Torque

N·m

kg·m ft-Ib

Drive

Shaft:

I

Coupling Cover

Nuts

-

-.

-

Coupling

39

I

4.0

29

Drive

Shaft

Holder

Mounting

Bolts

22

2.2 16.0

Pump

and Impeller:

Water Pipe Joints

9.8

1.0

87 in-Ib

Steering Nozlle Pivot Bolts

9.8

1.0

87 in-lb

Pump

Outlet

Mounting Bolts

- -

-

Pump

Cap

Bolts

-

- -

Impeller

98

10.0 72

Pump

Mounting

Bo.!ts

22

I

2.2

16.0

Pump Cover

Mounting

Bolts

9.8

1.0

87

in-Ib

Grate

Mounting

Bolts

9.8

1.0

87 in-lb

Steering:

Reverse Bucket Pivot Bofts

9.8

1.0 87 in-Ib

Control Stick Mounting Bolt 22

I

2.2

16

Steering Shaft Clamp

Bolt

22 2.2

16

Main Bracket

Mounting

80lt

22

2.2

16

Cable

Joint

Arm

Pivot

Bolt

22 2.2

16

Electrical System:

Flywheel Bolt

98

10.0

I

72

Regulator/Rectifier Mounting Bolts

7.8 0.80

69

in-Ib

COl Igniter Mounting Bolts

7.8 0.80

69

in·lb

Spark

Plugs 27 2.8 20

Grommet

Cap Bolts

7.8 0.80

69

in·lb

Starter

Motor

Mounting

Bolts

-

-

-

Electric

Case

Bolts

7.8 0.80

69

in-Ib

Electric

Case

Mounting

Bolts

7.8 0.80

69

in-lb

Thb

table:

relating tightening

torque

of

the

~T.ainless

bolt and the nut to thread diameter, lists the

basic

torque for the

boJuand

nuts. Use this table

for

only the

bolts and

nut~

which do not reqUire a specific torque

value.

General

Fastenen

{stainless bolt and nut}

Remarks

l

l

SS

l

l

l

l

l

I

l

l

l

l

l

l

l

l

l

Threads

Torque

dia.(rr.m}

N·m

kg-m

ft-Ib

6

8

10

5.9

-8.1:1

16 - 22

30 -41

0.60 - 0.90

1.6 -

2.2

3.1-4.2

52

- 78

in-Ib

11.6

-15.9

22 - 30

beerdart

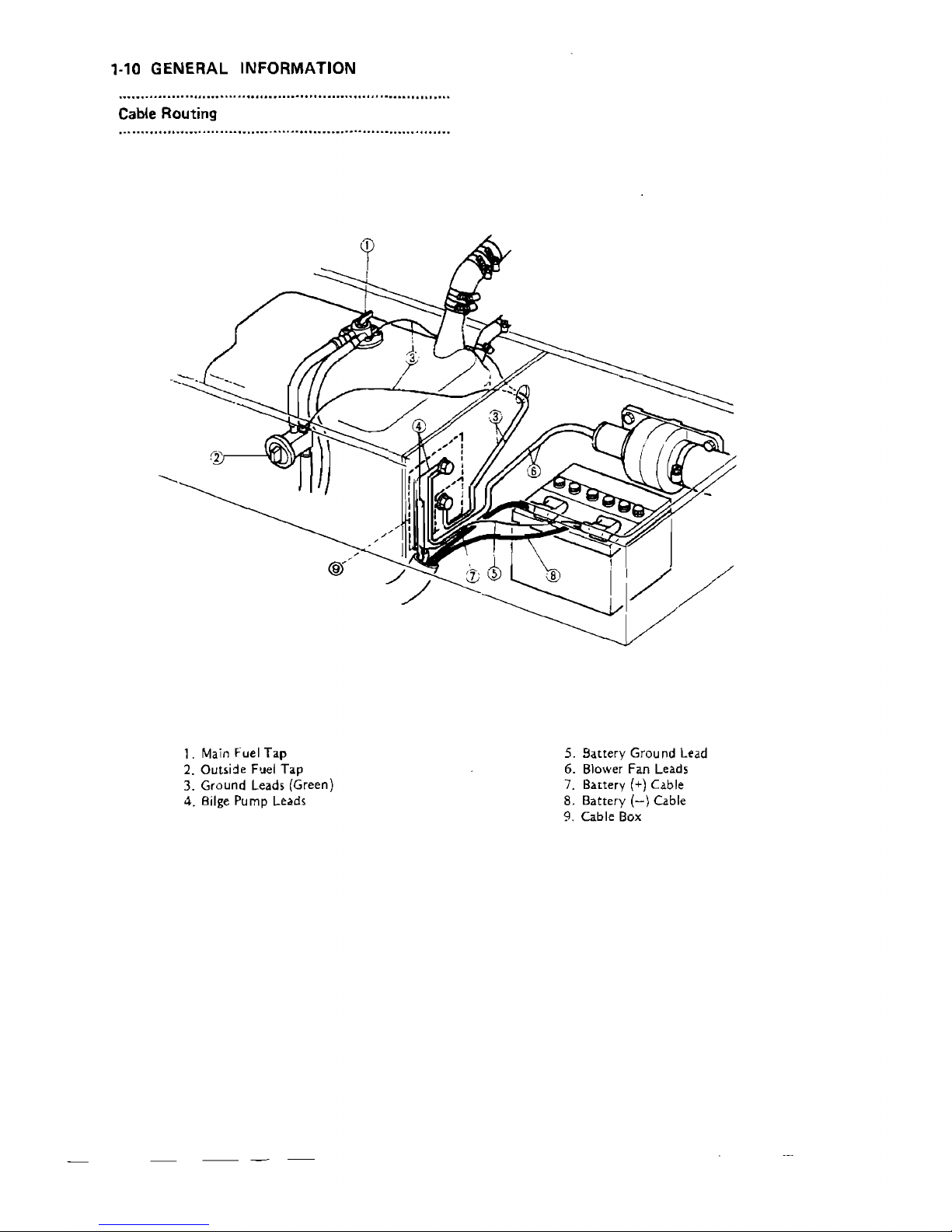

1·10 GENERAL INFORMATION

........................................

- - - .

Cable Routing

1.

Main

Fuel Tap

5. Battery

Ground

Lead

2. Outside F'Jel Tap

6. Blower Fan Leads

3.

Ground

Leads (Green)

7. Battery

(+) Cable

4.

Bilge

Pump Leads

8. Battery

(-)

Cable

9. Cable Box

beerdart

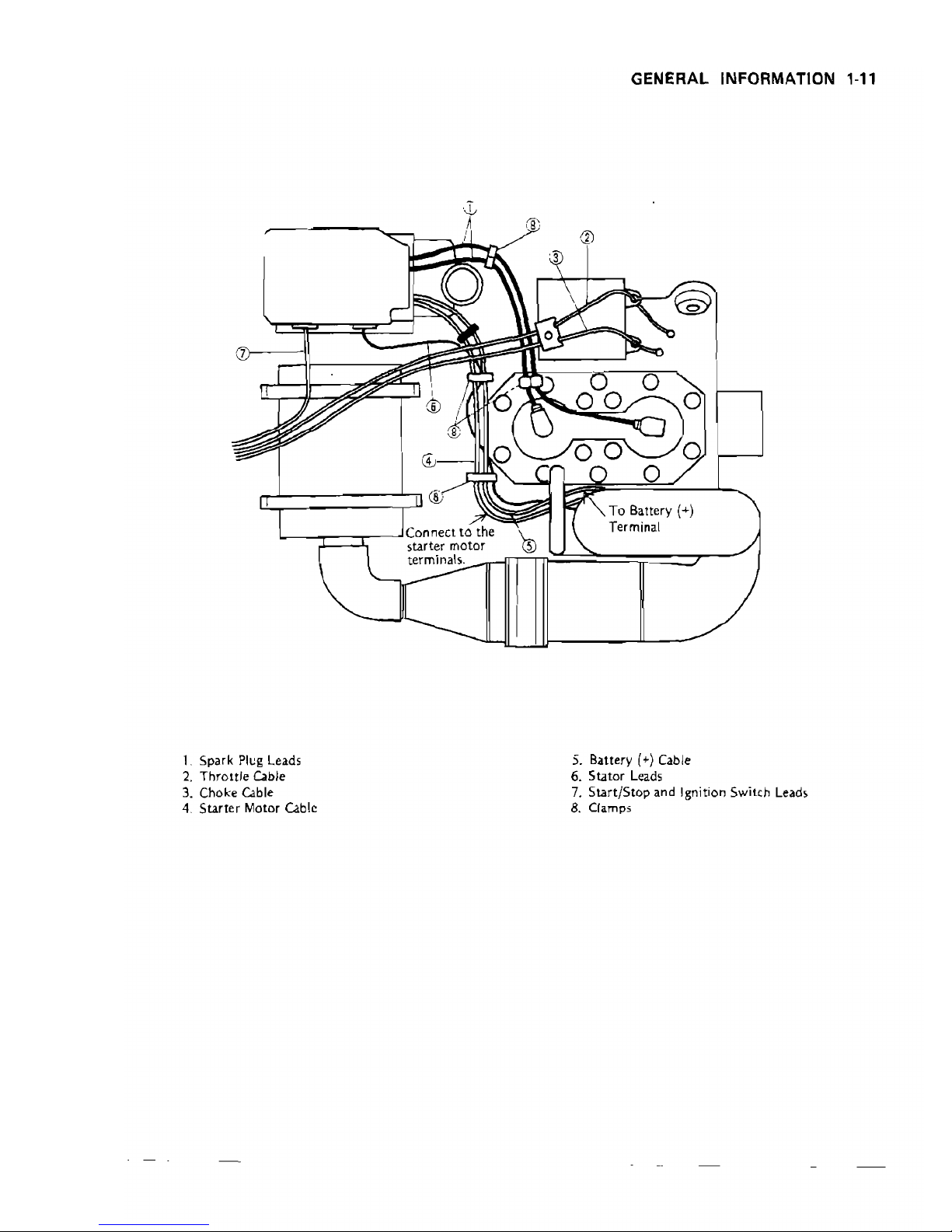

termjna~.

GENERAL INFORMATION

1-11

o

To

Battery

(4-)

3

c¢======?®

7

Terminal

L

-

=='1----"'

Connect

to

the

\-.

i

starter

m;;o~t=O.,'rlrT(;)"'nr:::==="if=:::7--~

1.

Spark

Plug Leads

5. Battery

(+)

Cable

2.

Throttle

Cable

6.

Stator

Leads

3.

Choke Cable

7.

Start/Stop and Ignition Switch Leads

4.

Starter

Motor Cable

8.

Clamps

beerdart

1-12

GENERAL INFORMATION

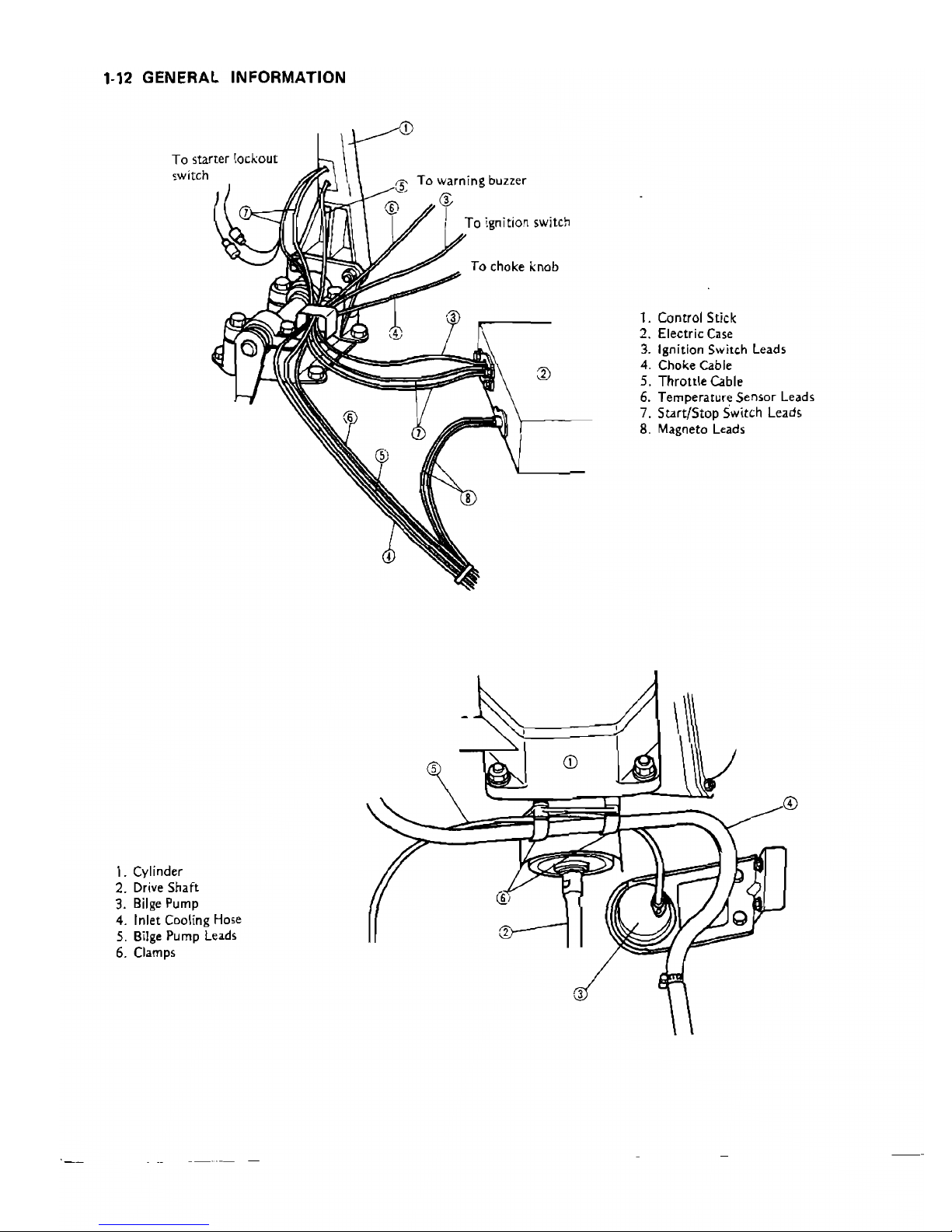

To starter I,ockout

switch

""

To warning buzzer

<1_

(j;

i

To

Ignition

switch

To choke knob

1. Control Stick

2. Electric

Case

3. Ignition Switch Leads

4. Choke Cable

5. Throttle Cable

6. Temperature Sensor Leads

7.

Start/Stop Switch Leads

8. Magneto Leads

5

1. Cylinder

2. Drive Shaft

3.

Bilge

Pump

4. Inlet Cooling Hose

2

5. Bilge Pump

leads

6. Clamps

3

beerdart

FUEL SYSTEM

2·'

FUEL SYSTEM

Table

of

Contents

Exploded

View.

. . . . . . . .

2-2

Intake

Manifold, Reed Valve

..

, • , .

2-15

Choke Cable .

2·7

Fuel Filler

and

Inspection

.

2-8

Main Fuel

Tap

Removal/

Removal .

2-9

Outside

Fuel

Tap

Removal/

High

Altitude

Carburetor

Cleaning

and

Float Arm Level

Inspection

Specifications. . . . . . . .

2-4

Removal

......•

__

_ .

2-15

Special

Tools.

. . . , , 2-4

Installation Notes

•.•

, , .

2-15

Sealant

.

2-4

Reed Valve

Inspection

.

2-15

Fuel

System

Diagram .

2-4

Valve

Holder

Inspection _ .

._

2-16

Thronle

Case

and

Cable . 2-5

Valve

Stop

Inspection .

2-16

Adjustment

.

2-5

Fuel

Tank

_ . . . . . . . .

..

. .

2-16

Removal . 2-5

Fuel

Tank

Removal _

2-16

Installation..

. _ . 2-6

Fuel

Tank

Installation

_ .

2·16

Lubrication.

. . . .

2-6

Fuel

Tank

Cleaning.

. . .

2-17

Inspection .

2-6

Fuel Filler

and

Tube

Removal .

2-17

Adjustment

. 2-7

Tube

lmtallation

__

. _ _

2-17

Removal . 2-7

Fuel Filter Screen Cleaning _ .

2-18

Installation

..

, . 2-8

Fuel

Tap

_ . 2-

18

LUbrication.

. . . . . . . . . . . . 2-8

Installation_ _

..

_ _

2-18

Fuel

Pump.

. . .

..

. .

2-9

Anti-Siphon

Valve

Inspection

....•

2-18

Installation

Note .

2-9

Installation _ .

2-19

Disassembly .

2·9

Fuel

Vent

Screen

_ _ . ,

.•...

2-19

Assembly Notes . . . . . .

2-10

Cleaning _ . . _ _

2-19

Carburetor

.

2-10

Idle

Speed

Adjustment

.

2-10

Mixture

Screw

Adjustment

.

2-10

Performance

Adjustment

. 2-11

Carburemr

Removal. . 2-11

Carburetor

Installation

.

2-

12

Carburetor

Disassemb!y .

2-12

Carburetor

Assembly .

2-13

Impection

. 2-13

and

Adjustment

.

2-14

Flame

Arrester

.

2-14

Removal.

. . . . . . . . . .

..

. .

2-14

Install~tior1

.

2-14

Cleaning

2-15

beerdart

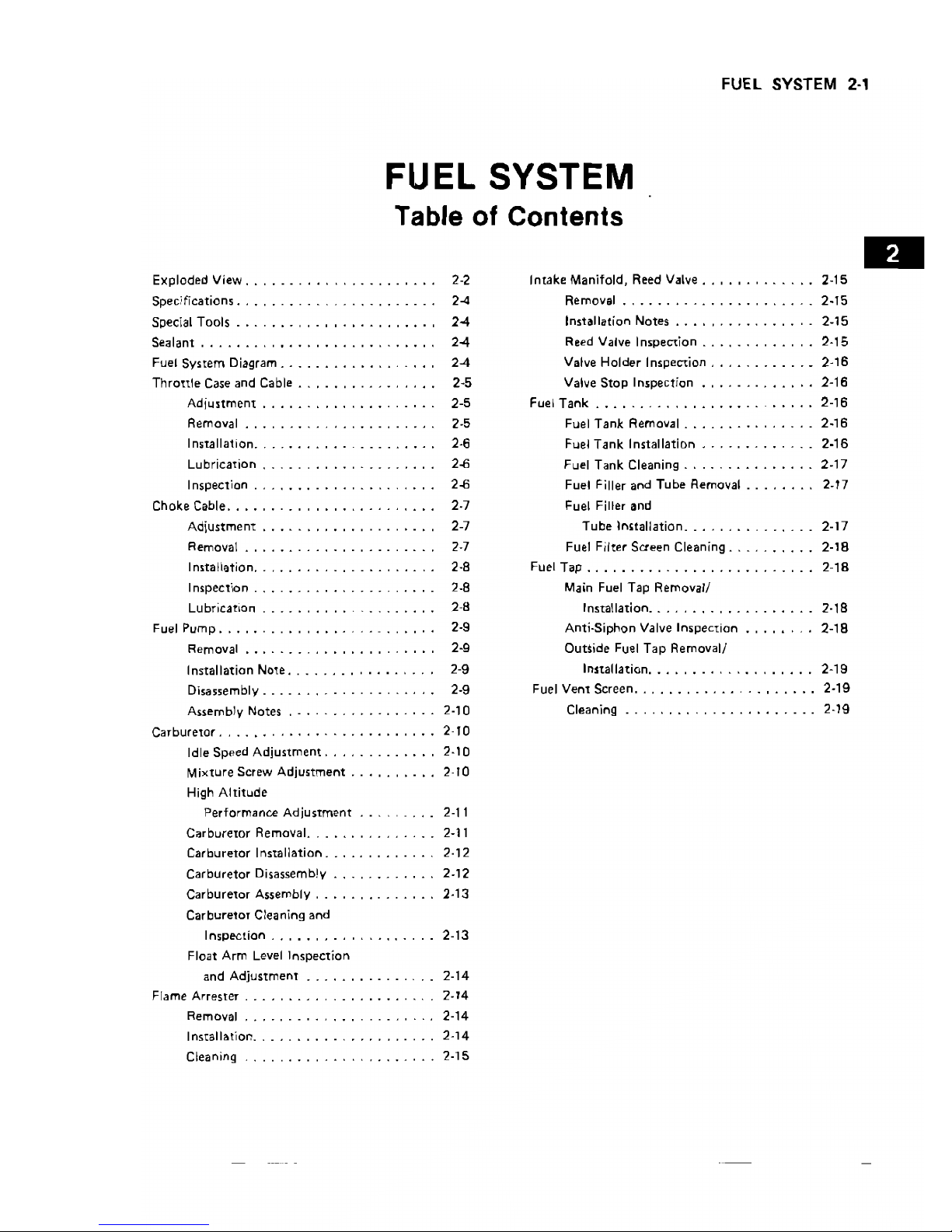

2-2 FUEL

SYSTEM

Exploded View

......................................................

-

................ I

©---~

~

~

,

,

,

,

,

,

,

, ,

!_---------------~

'90 & After

Models

,

.....

'90 & After

Models

I L

I

I

1.

Main

Jet

2. Pilot

Jet

3. Diaphragm Needle

4.

Check

Valve

I'/A

co,

)I~

i

Ih'

'~

beerdart

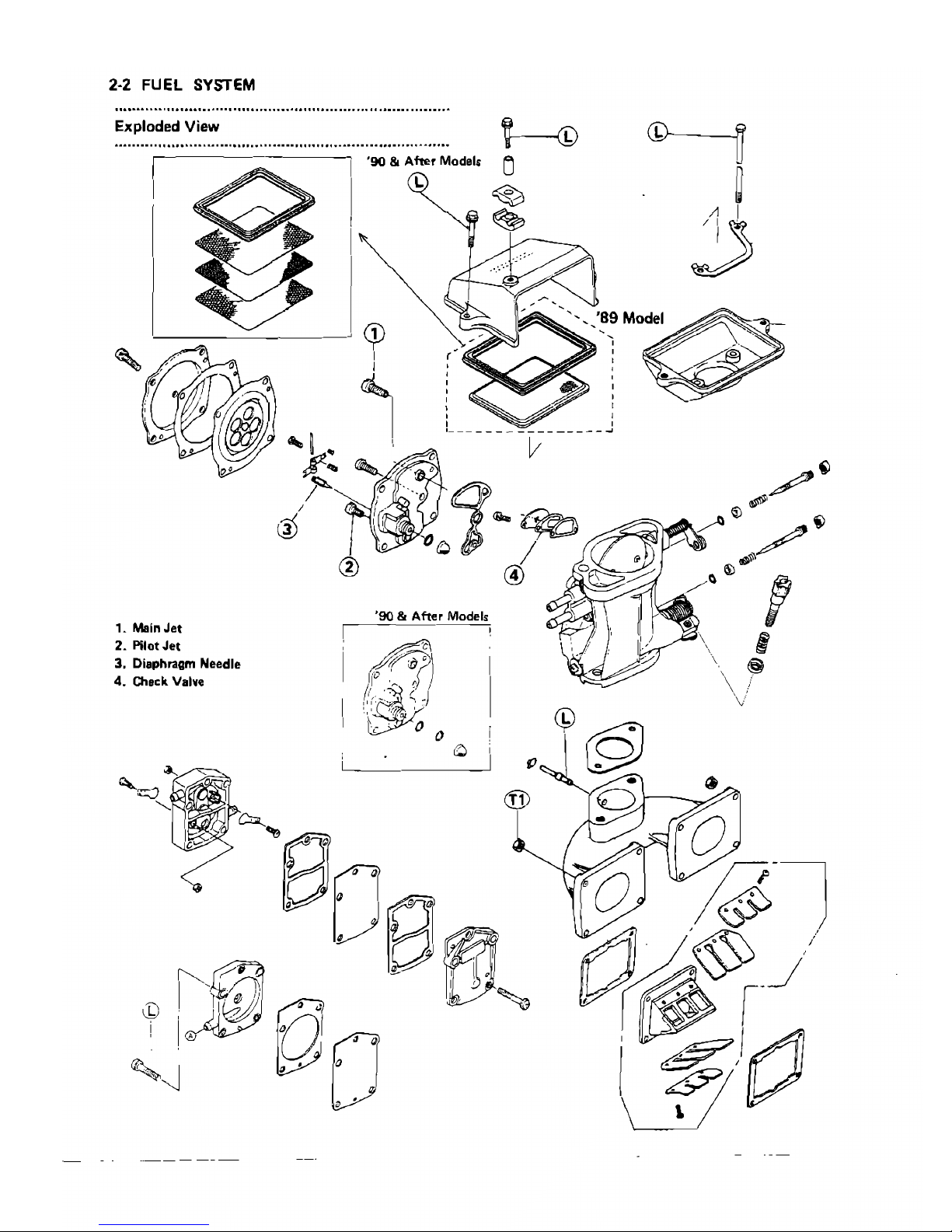

FUEL SYSTEM 2-3

/,

,

,

1

@

G

.

Apply grease. nt locking agent.

. ennane

L

.

Apply

non-p

69

in-Ibl

.

(080

kg-om,

78N-m

.

Tl:.

Tcone sealant.

SS : Apply SI I

@

7

beerdart

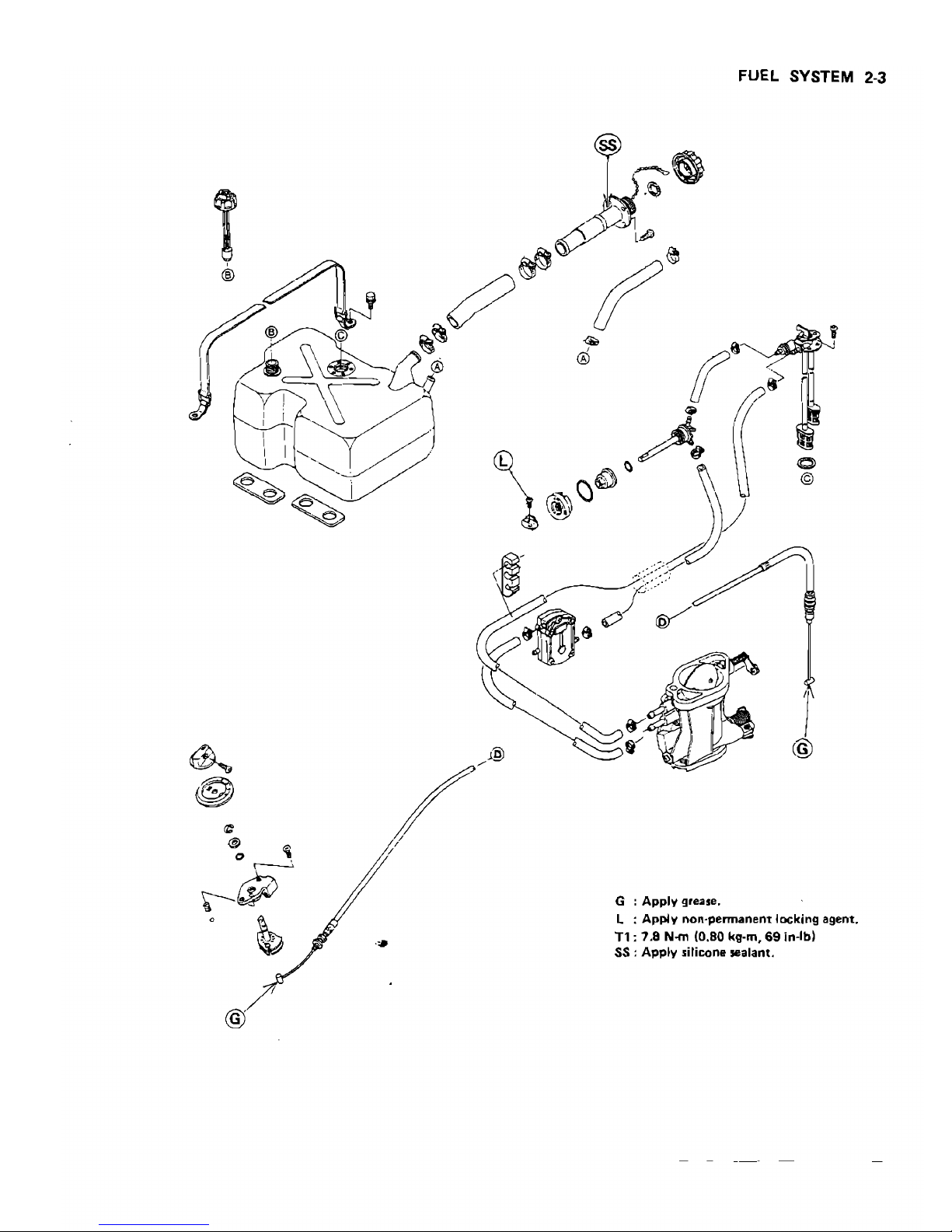

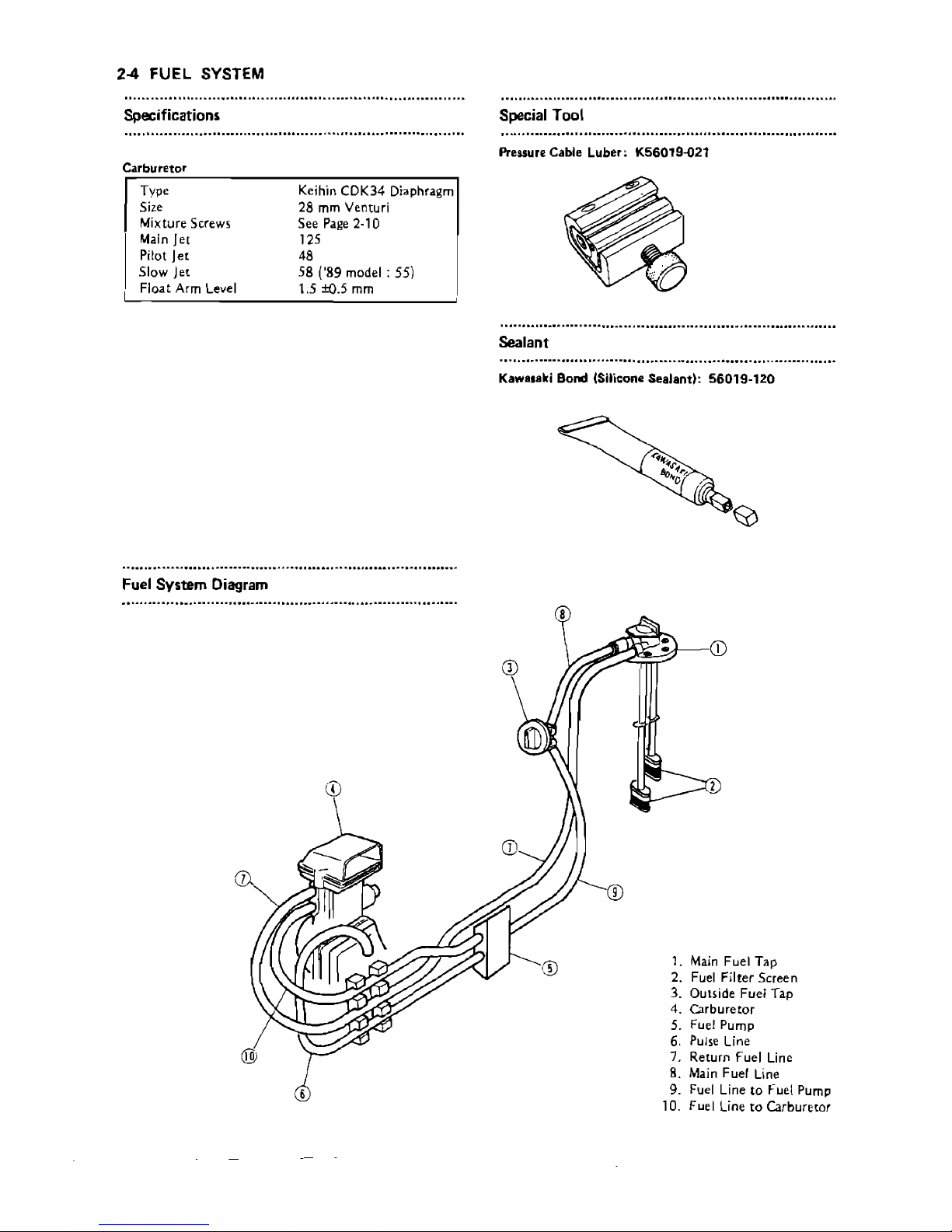

2-4 FUEL SYSTEM

.............................................................................

Specifications

.,

- , .

Carburetor

Type

5il:e

Mixture Screws

Main

Jet

Pilot

Jet

Slow Jet

Float

Arm

Level

Fuel

System

Diagram

Keihin CDK34 Diaphragm

28 mm Venturi

See

Page 2-10

125

48

58 ('89 model: 55)

1.5

±O.5

mm

W

Special Tool

Pressure Cable Luber: K56019-o21

Sealant

Kawasaki Bond (Silicone Sealant):

56019-120

:

CD

2

1.

Main

Fuel Tap

2.

Fuel

Filter Screen

3. Outside Fuel Tap

4.

Carburetor

5. Fuel Pump

6.

PUlse

Line

7. Return Fuel

Line

8.

Main

Fuel

Line

9.

Fuel

Line to Fuel

Pump

10. Fuel

Line

to

Carburetor

®

beerdart

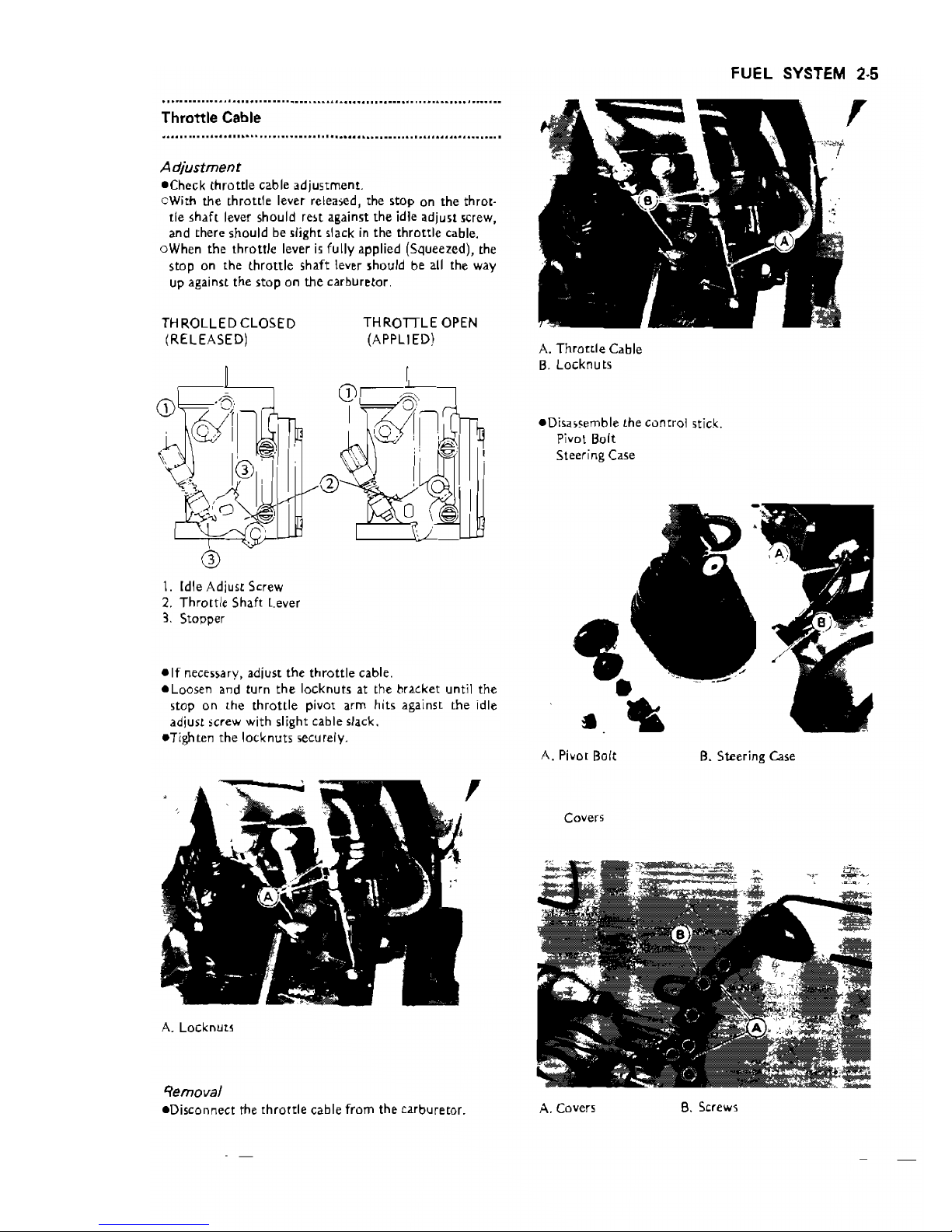

Throttle Cable

Adjustment

eCheck throttle cable

~djustment.

OWith

the throttle lever relea5ed, the stop on the throt-

tle sh.aft lever should rest

.ag.ainst

the idle adjust screw,

and there should be slight slack

in

the throttle cable.

oWhen

the

throttle lever

is

fully applied (SQueezed), the

stop on

the

throttle shaft lever should be

all

the

w.ay

up .against the stop on the c.arburetor.

THROLLED CLOSED

THROTTLE

OPEN

(RELEASED) (APPLIED)

~

,

1.

Idle Adjust Screw

2.

Throttle Shaft Lever

3.

Stopper

elf

necessary, adjust the

throttle

cable.

eLoo5en and turn

the

locknuts at the br.acket until the

stop on the

throttle

pivot arm hits .against the idle

.adjust ,crew with slight cable slack.

eTighten

the

locknuts ,ecurely.

A.

LocknuH

qemoval

eDisconnect the

throttle

cable from the

urburetor.

A.

Throttle Cable

B.

Locknuts

FUEL

SYSTEM 2·5

,

eDis<l.'>semble

the control stick.

Pivot Boft

Steering Case

'&.

.

..

A.

Pivot Bolt

Covers

B.

Steering Case

A.

Covers

B.

Screws

beerdart

2-6

FUEL SYSTEM

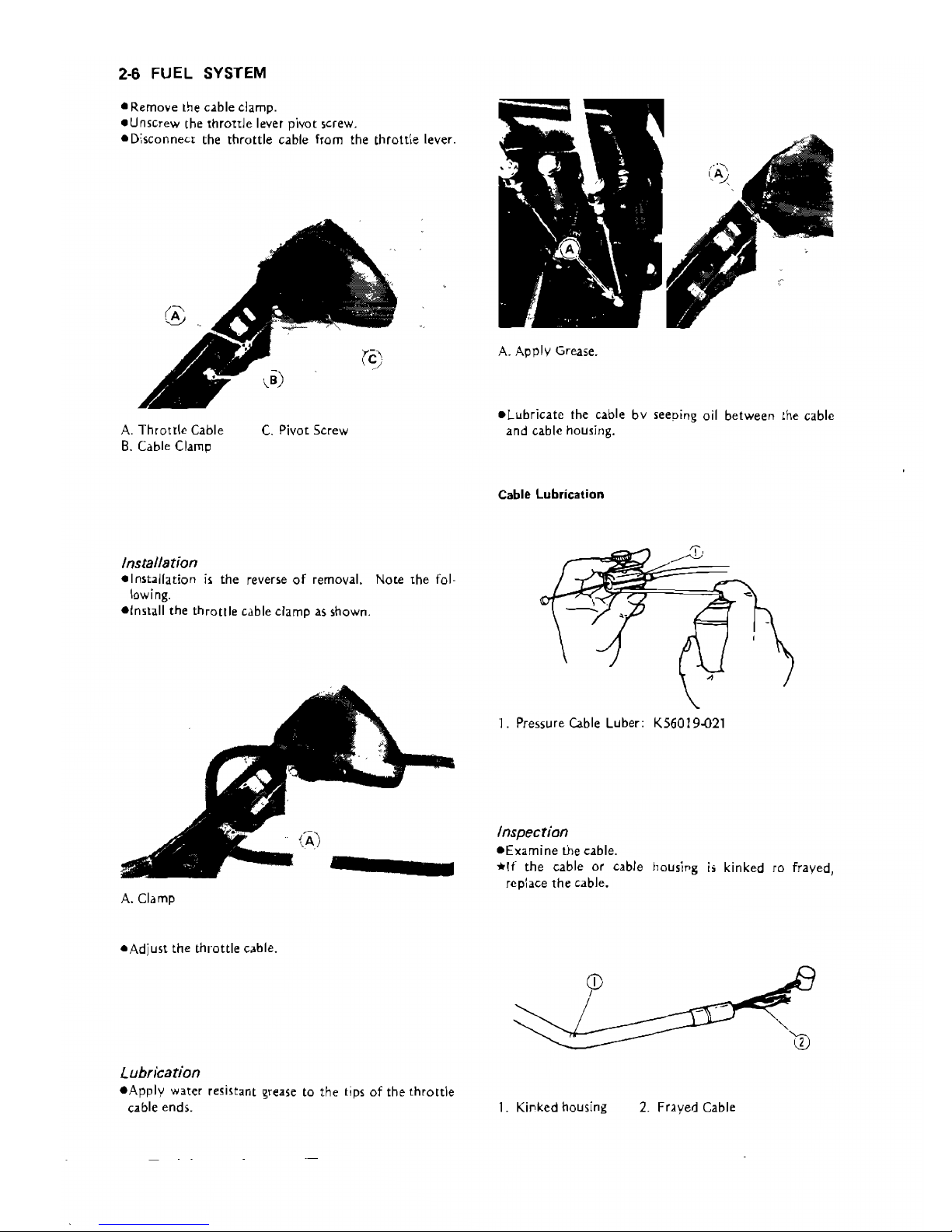

• Remove the cable clamp.

_Unscrew the

throttle

lever pivot screw.

-Disconnect the throttle cable

from

the thrott',e lever.

A.

Throttle

Cable

B.

Cable Clamp

C.

Pivot Screw

A.

Apply Grease.

eLubricate

the cable

bv

seeping oil

between

the cable

and

cable housing.

Cable lubrication

Installation

_Installation

is

the reverse

of

removal.

lowing.

elnstall

the

throttle

cable clamp

as

shown.

Note the fol-

1. Pressure Cable Luber: K56019-021

Inspection

eExamine

the cable.

*!f

the

cable

or

cable

replace

the

cable.

housing

is

kinked

fO

frayed,

A.

Clamp

_Adjust

the

throttle

C,lble.

~'

CD

,

Lubrication

eApply

water resistant grease to

the

tips

of

the

throttle

cable ends.

1.

Kinked housing 2.

FrJyed

Cable

beerdart

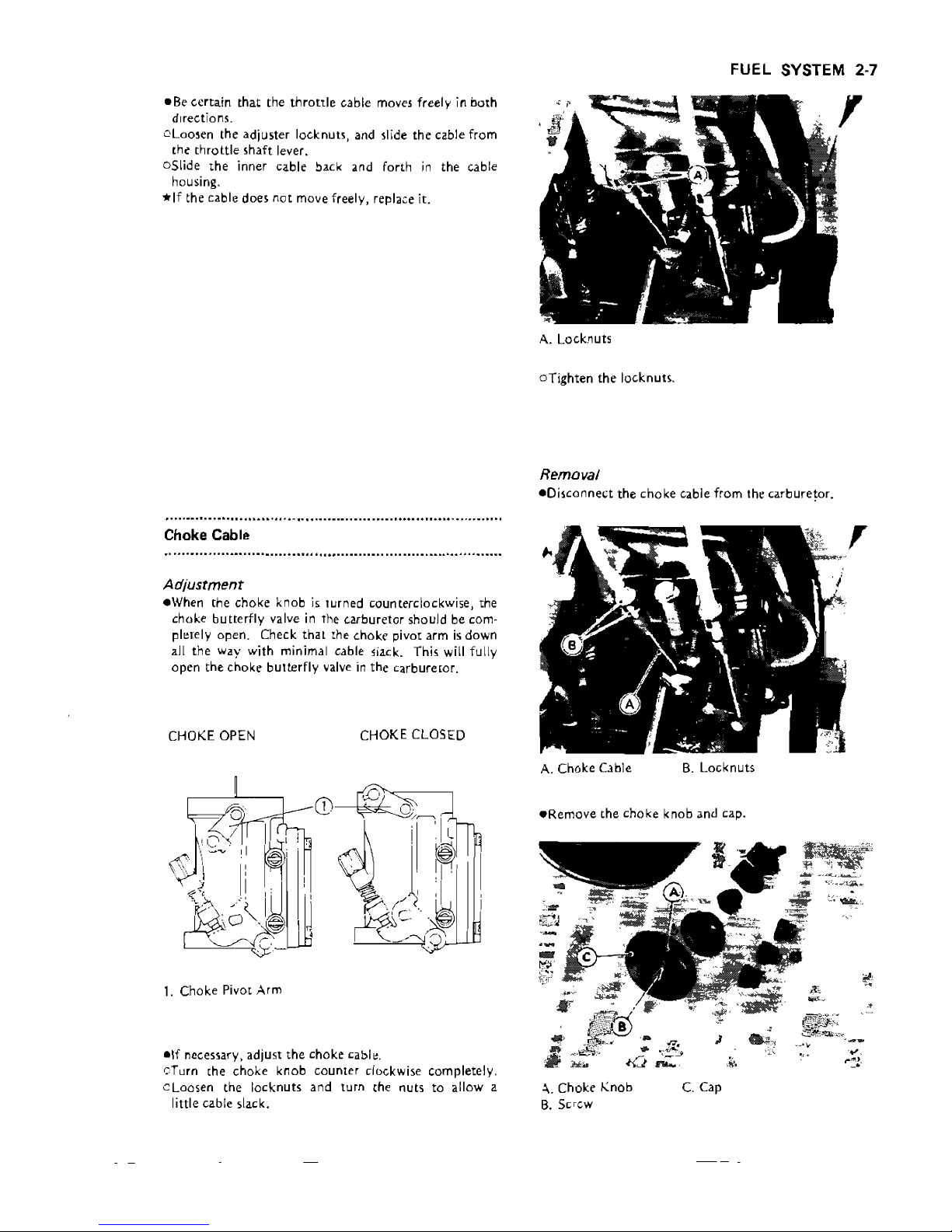

FUEL SYSTEM 2-7

_Be certain that the

throttle

cable moves freely in both

,

directions.

oLoo5en the adjuster locknuts, and slide the cable from

the

throttle

shaft lever.

oSlide

the

inner cable back and forth

in

the cable

housing.

*If

the cable does

not

move freely, replace it.

A.

Locknuts

oTighten

the locknuts.

Removal

eOi5connect

the

choke

cable from

thr

carbure!or.

Choke Cable

Adjustment

eWhen the choke knob

is

turned counterclockwise, the

choke butterfly valve

in

the carburetor should be com-

plelely open. Check

that

the choke piva[ arm

is

down

all the way with minimal cable slack. This will fully

open the

chokr

butterfly

valve

in

the carburetor.

CHOKE OPEN

CHOKE CLOSED

A. Choke Cable

B.

Locknuts

eRemove

the

choke

knob and cap.

/ '

~~~,J.

1.

Choke

Pi

VOL Arm

-If

necessary, adjust

the

chokr

cable.

cTurn

Lhe

choke knob counter clockwise completely.

cLoQsen the locknuts and turn

,he nuts

to

allow a

;.

Chokr

Knob

C.

Cap

little cable slack.

B.

Screw

beerdart

2-8

FUEL SYSTEM

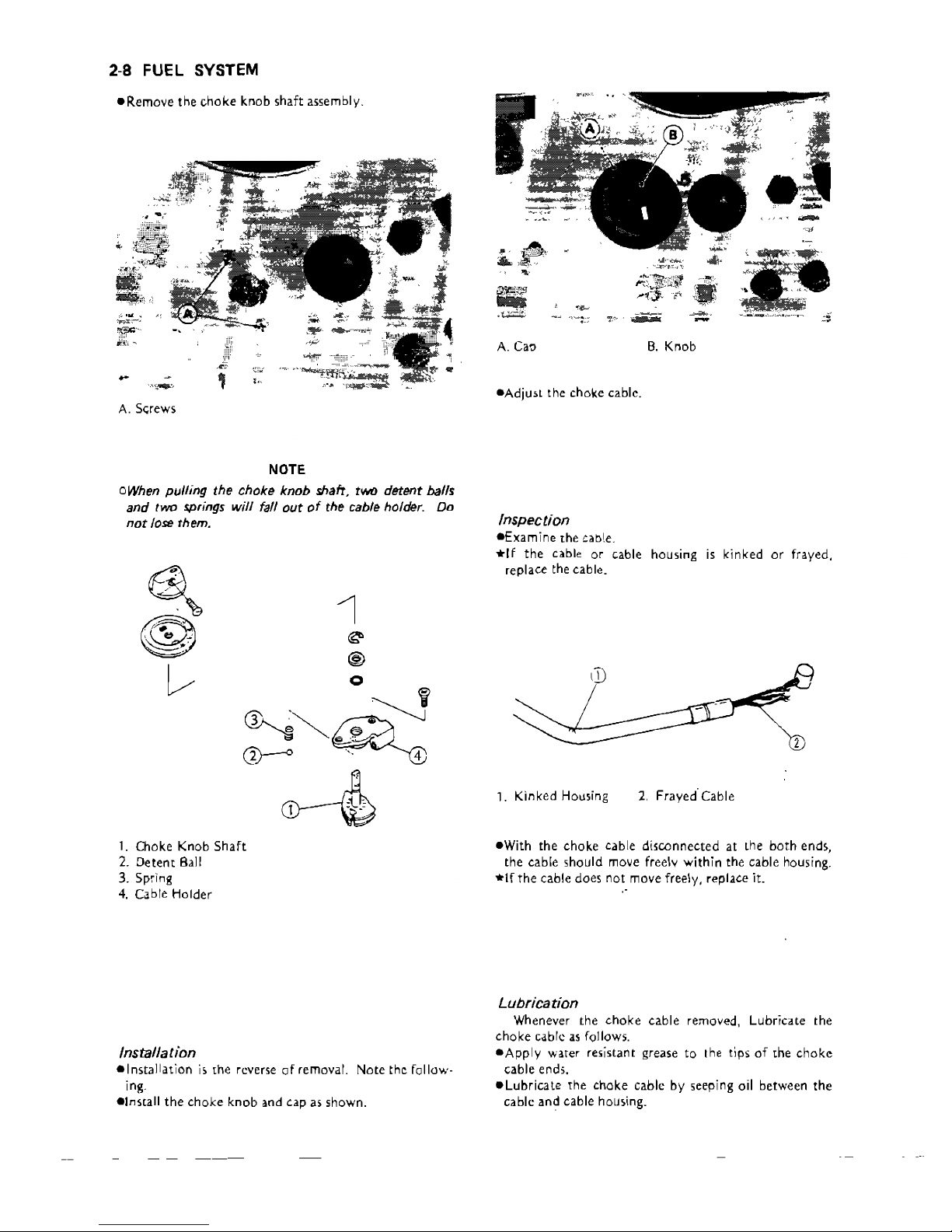

eRemove

the

choke

knob

shaft

assembly.

A.

S<;rews

NOTE

oWhen pulling the choke knob shah, two detent balls

and

ryvo

springs

will

fall

out

of

the cable holder. Do

not

lose them.

1.

Choke Knob

Shaft

2.

Detem

Ball

3. Spring

4.

Cable

Holder

Installation

_Installation

is

[he reverse

of

removal.

Note

the

follow-

ing.

elnstall the choke knob

and

cap

as

shown.

A. Cat!

B.

Knob

.Adju~t

the

choke cable.

Inspection

-Examine

the

cabl.e.

*If

the

cable

or

cable housing

is

kinked

or

frayed,

replace the cable.

CD

1. Kinked Housing

2,

Frayed'Cable

_With

the

choke

cable

disconnected

at the

both

ends,

the

cable

should

move freely

within

the

cable housing.

*lfthe

cable does

not

move freely,

,eplace

it.

..

Lubrication

Whenever the

choke

cable removed, Lubricate the

choke

cdble

dS

follow:;.

-Apply

water resistant grease

to

the tips

of

the

choke

cable ends.

_Lubricate

the choke cable by seeping oil between the

cable and cable housing.

1

beerdart

FUEL SYSTEM

2-9

A.

Fuel Pump

B.

Mounting Screws

1. Pressure Cable Luber: K56019-021

_Attached the choke cable to the carburetor and adju,t

the choke cable (see Choke Cable Adjustment).

-

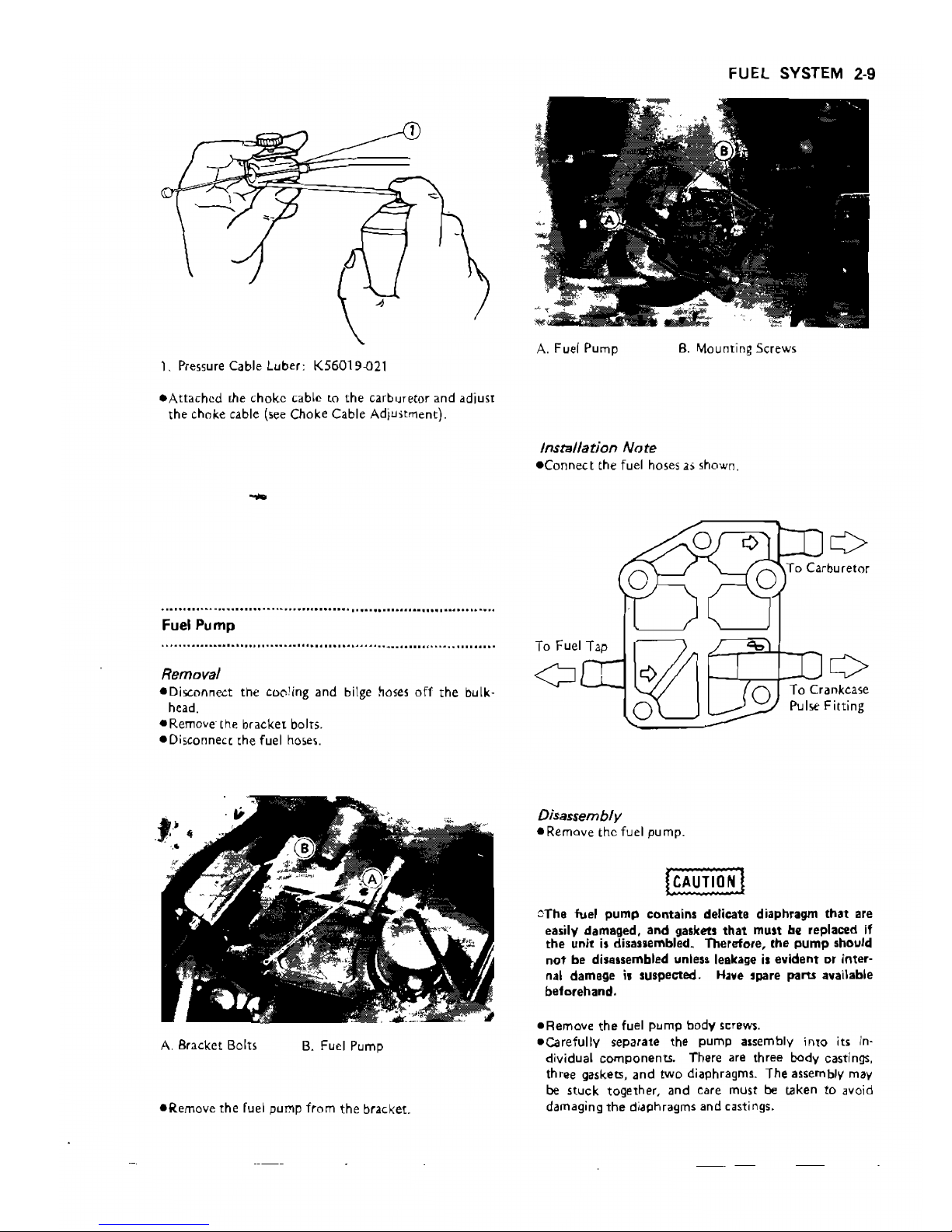

Fuel Pump

Removal

_Disconnect the c00'ing and bilge hoses

off

the

bulk-

head.

_Remove- the bracket bolts.

_Disconnect the fuel

hose~.

A.

Bracket Bolts

B.

Fuel Pump

_Remove

the

fuel pump from

the

bracket.

Installation

Note

_Connect

the fuel hoses

as

shown.

Disassembly

_ Remove the fuel pump.

0The fuel

pump

contains delicate diaphragm

that

are

easily damaged,

and

gaskets

that

must be

replaad

jf

the

unit

is

disassembled. Therefore, the

pump

should

not

be disassembled unless leakage

is

evident or inter-

nal damege

;,

suspected.

Have

spare

parts

available

beforehand.

_Remove

the

fuel pump body screm.

_carefully separate the pump assembly into its

in-

dividual COlTlponents. There are three body castings,

three gaskets,

and

two

diaphragms. The assembly may

be

stuck together, and care must

be

taken

to

,woid

damaging

the

diaphragms and castings.

beerdart

2·10 FUEL SYSTEM

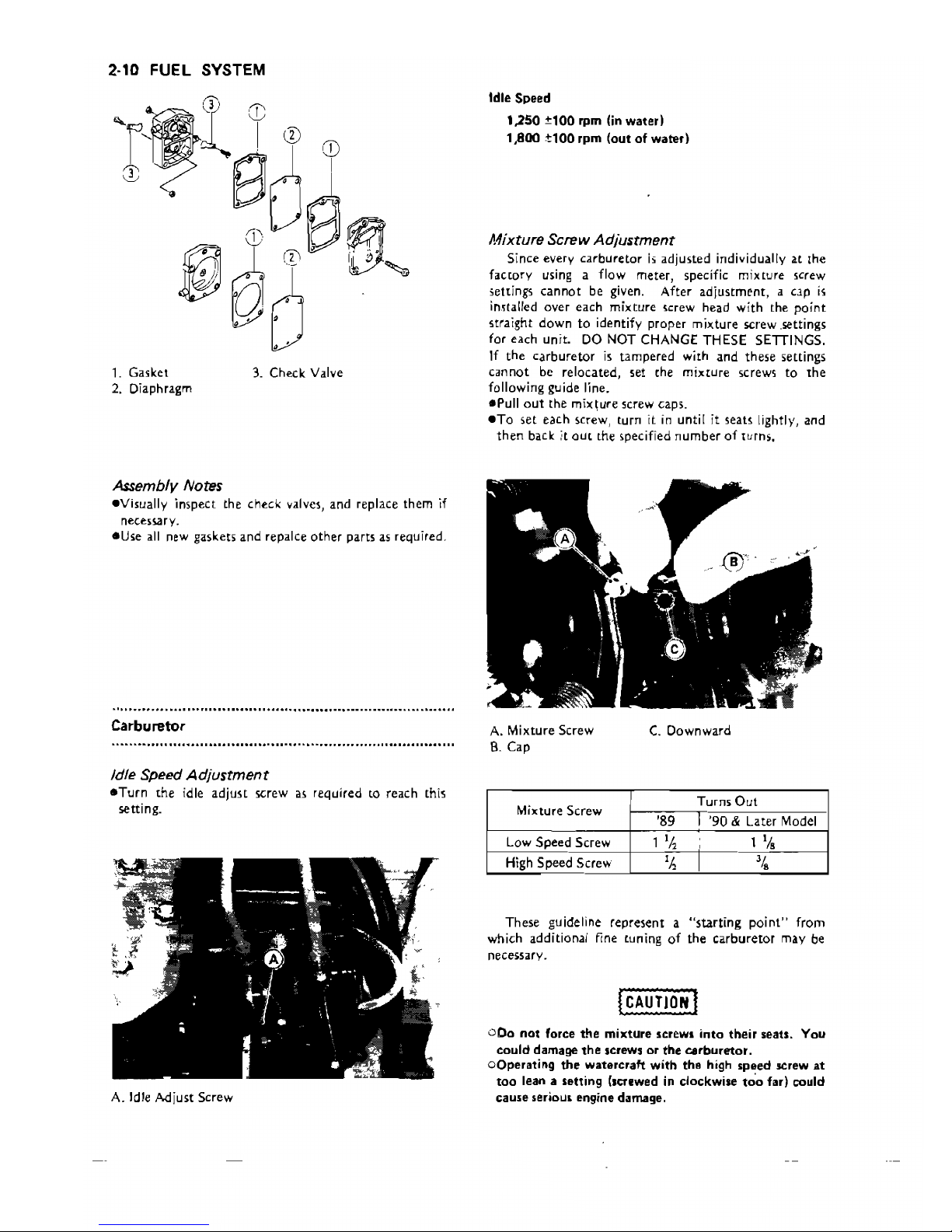

Idle Speed

,'J'\

"""

1,250 ±100

rpm

(in

water)

1,800

tl00

rpm

(out

of

water)

1

,);

Q 6

,'- " "

~

" ,

, .

1. Gasket 3. Check Valve

2.

Diaphragm

Assembly Notes

.Visually

inspect the check valves, and replace them

if

necessary.

_Use

all

new gaskets

and

repalce

other

parts

as

required.

.............

" - .

Carburetor

Idle

Speed

Adjustment

_Turn

the idle

adjust

screw

as

required to reach this

~tting.

A. Idle A.djust Screw

Mixture Screw

Adjustment

Since every

carburetor

i'i adjusted individually at

the

hcrory

using a flow meter, specific mixture screw

;;ettings

cannot

be given. After adjustment, a cap

is

imtalled over each

mixture

screw head

with

the

point

straight

down

to

identify proper mixture

~rew

,~ttings

for each unit. DO NOT CHANGE THESE SETTINGS.

If

the

carburetor

is

tampered with and these settings

cannot

be relocated, set the mixtUre screws

to

the

following guide line.

ePull

out

the mix\ure screw caps.

eTo

set each screw, turn it

in

until it seats lightly, and

then

back it oUt the specified

number

of

turns.

A. Mixture Screw

B.

Cap

C.

Downward

Mixture Screw

Turn~

Out

'89

1 Ih

'h

I

'90

& Later Model

,

1 I/

S

I

'I,

Low Speed Screw

High Speed Screw

These guideline represent a

"starting

point"

from

which additional fine tuning

of

the

carburetor

may

be

necessary.

(i:AUT(O~]

000

not

force

the

mixture screw.

into

their seats. You

could damage

the

screws

or

the

carburetor.

oOperating

the

watercraft

with

the high speed screw

at

too

lean a setting (screwed in clockwise

too

far) could

cause serious engine damage.

beerdart

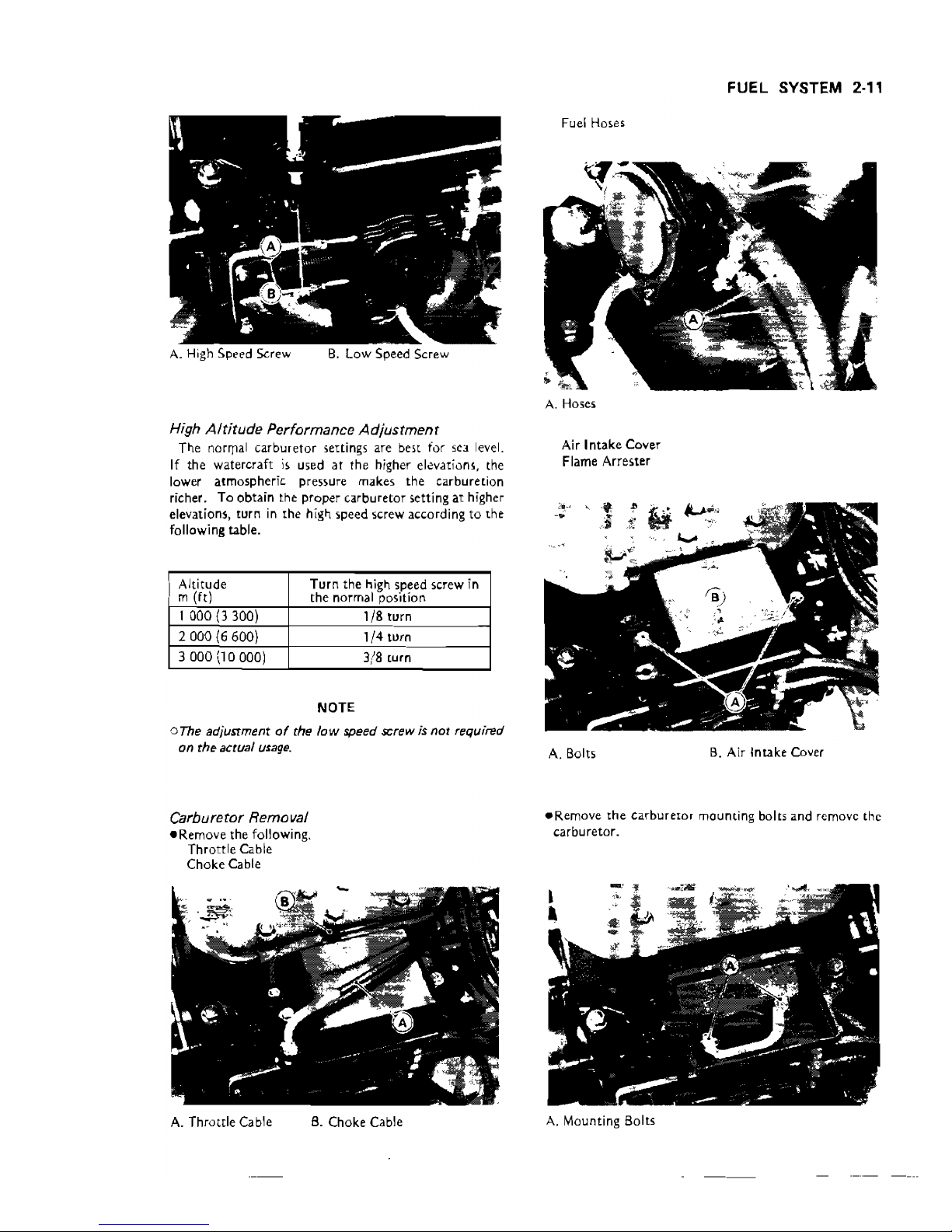

FUEL SYSTEM 2·"

A.

High

Spl.'l.'d

Screw 8.

low

Speed Screw

H;gh

Alt;tude Performance

Adjustment

The norl]lal carburetor sellings are best for sea level.

If the watercraft

is

used

at

the higher elevatiom, the

lower atmospheric pressure makes the carburetion

richer. To obtain the proper carburetor setting

aT

higher

elevations, turn

in

the high speed screw according

to

the

following table.

Altitude

m

(ft)

Turn the high speed screw

in

the normal position

1 000 (J 300)

1/8

turn

2 000

(6

600)

1/4

turn

3 000 (l 0

ODD)

3/8 turn

Fuel Hoses

A. Hoses

Air Intake Cover

Flame Arrester

NOTE

oThe adjustment

of

the low speed screw;s not required

on the actual

usage.

A.

Bolts

B.

Air Intake Cover

Carburetor Removal

eRemove

the

carburetor mounting bolts and remove the

eRemove

the following.

carburetor.

Throttle Cable

Choke Cable

A.

Throttle Cable

B.

Choke Cable

A.

Mounting Bolts

beerdart

2·12 FUEL

SYSTEM

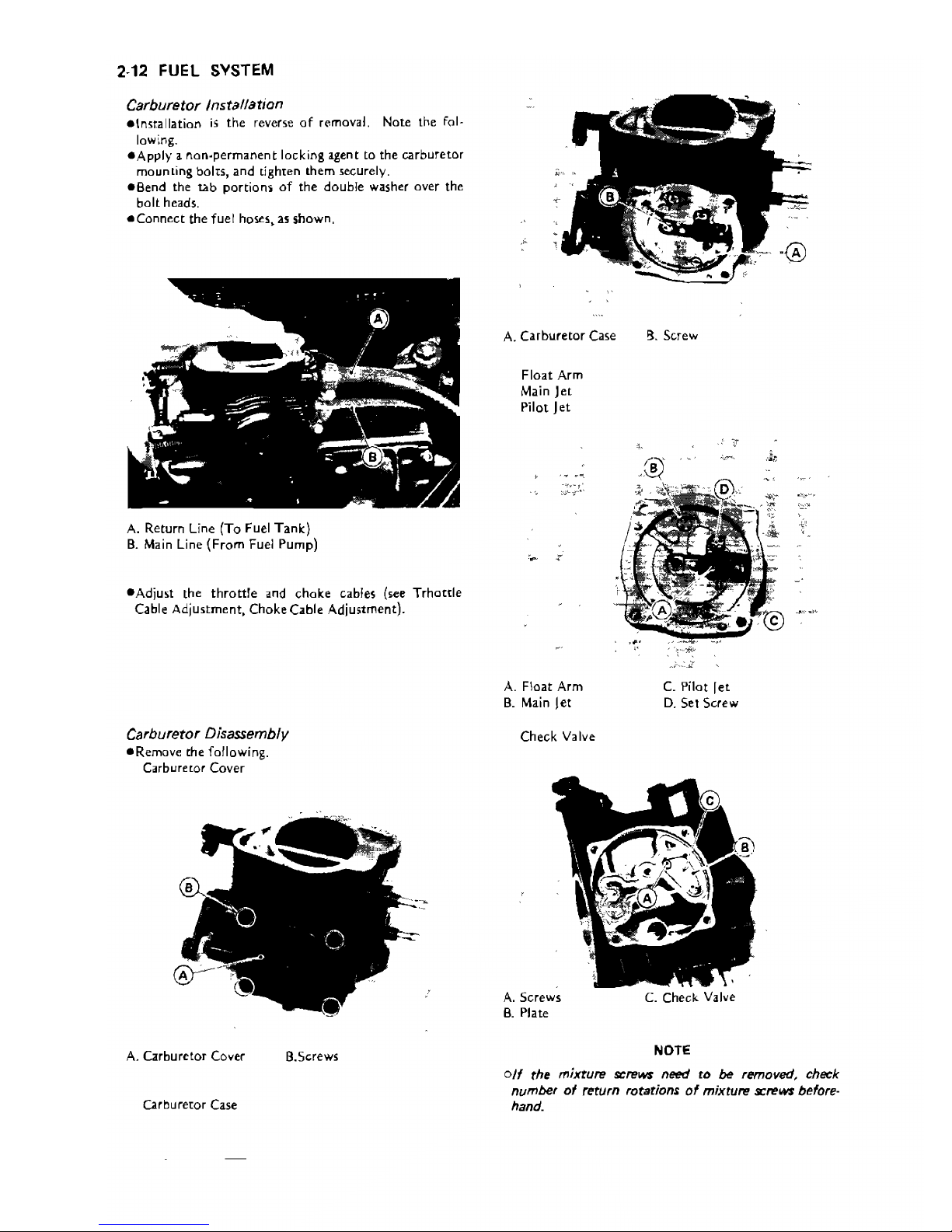

Carburetor Installation

elnstallation

is

the

reverse

of

removal. Note the fol-

lowing.

-Apply

a nan-permanent locking agent to

the

carburetor

mounting bolts,

and

tighten them securely.

eBend

the

tab

portions

of

the

double

washer over the

bolt

heads.

_Connect

the

fuel hoses, as shown,

A. Return Line (To Fuel

Tank)

B.

Main Line

(From

Fuel Pump)

-Adjust

the

throttle

and choke cables (see Trhottle

Cable Adjustment, Choke Cable Adjustment).

Carburetor Disassembly

_Remove the following.

Carburetor Cover

A.

Carburetor Cover

a.Screws

Carbureror Case

A.

Carburetor

Case

g.

Screw

Float

Arm

Main

Jet

Pilot

Jet

A.

Float

Arm

C.

Pilot

let

B.

Main

Jet

D.

Sel

Screw

Check

Valve

A.

Screws

C. Check Valve

B.

Plate

NOTE

olf

the

mixture

screws need to be removed, check

number

of

return rotations

of

mixture

screWS'

before-

hand.

beerdart

Loading...

Loading...