Page 1

FS 2000

1.250-101

www.karcher.com

5.959-271 A2002423 02/03

Page 2

FS 2000 2

Betriebsanleitung 3

Ersatzteilliste 229

Operating Instructions 17

Spare Parts List 229

Notice d'instructions 31

Liste des pièces de rechange 229

Istruzioni per l'uso 45

Elenco pezzi di ricambio 229

Gebruiksaanwijzing 59

Reserveonderdelenlijst 229

Instrucciones de servicio 73

Lista de piezas de requesto 229

Manual de instruçoes 87

Lista de pecas sobresselentes 229

ПдзгЯет лейфпхсгЯбт

бнфбллбкфйкб

102

229

Driftsvejledning 117

Reservedelsliste 229

Bruksveiledning 131

Reservedels liste 229

Driftinstruktion 145

Reservdelslista 229

Käyttöohje 159

Varaosalista 229

Üzemeltetési utasítás 173

Cserealkatrészlista 229

Návod k obsluze 187

Seznam náhradních dílů 229

Navodilo za uporabo 201

Seznam rezervnih delov 229

Instrukcja obsługi 215

Lista części zamiennych 229

Page 3

English FS 2000 17

CONTENTS

For your safety! 18

Personal Protective

Equipment 18

Emergency procedures 18

Environmental protection 18

Range of applications 19

Overview 19

Transport 19

Before first-time operation 20

Mounting handle 20

Mounting bracket 20

Each time before operation 20

Checking/closing valves 20

Filling with cleaning

agent/disinfectant 21

Connecting to the mains 22

Operation 22

Shampooing/cleaning 23

Spraying/disinfection 23

Each time after usage 24

Dissipating pressure 24

Switching off the cleaner 24

Draining pressure vessel 24

Flushing pressure vessel 26

Care 26

Reccommended

cleaning agents 27

Cleaning agent overview 28

Fault tracing instructions 28

Detaching cover 28

Accessories 30

Technical data 30

Page 4

English FS 2000 18

FOR YOUR SAFETY!

Study operating instructions

carefully prior to initial start-up!

∗

Only to be operated by qualified

personnel

∗

Unit must be accompanied by

operating instructions if passed on

to third parties

∗

Never make any modifications to

unit

∗

Do not fix hand gun trigger in

position

∗

Do not leave unit unattended

∗

Do not allow children near the

cleaner

∗

Always have damaged piping and

hoses replaced immediately by

After-Sales Service

∗

Make sure piping and hoses are

never kinked, routed over sharp

edges or trapped

Electrical safety

∗

Class I units are only to be

connected to properly earthed

power sources.

∗

All parts carrying electricity in the

work zone must be protected

against water jets.

∗

Only connect unit to sockets

provided with 30 mA residual-

current-operated circuit breaker.

∗

Operation prohibited in baths and

with user standing in water.

National regulations

∗

Operation in Germany is subject

to the guidelines on liquid-jet units

(spraying devices)

ZH 1/406 and the accident

prevention regulations (UVV) BGV

D15 Working with Liquid-Jet Units

as issued by the Principal

Organisation of the Commercial

Employers' Liability Insurance

Associations. In line with

UVV BGV D15 high-pressure

spraying devices must be checked

every 12 months by a qualified

expert, with the results of checking

being recorded in writing.

Information can be obtained from

your retailer.

ZH 1/406 and UVV BGV D15

are available from

Carl HeymannsVerlag KG,

Luxemburger Str. 449,

50939 Cologne.

∗

Observe appropriate regulations

applicable to operation in other

countries.

Commercial applications

∗

In Germany, mobile units for

commercial use are subject to

safety checking in accordance

with VDE Standards.

∗

Observe appropriate regulations

applicable to units for commercial

use in other countries.

∗

Heed appropriate safety

regulations for use at petrol

stations or in other hazardous

environments.

Safety features

∗

Unit is switched off on exceeding

operating pressure.

∗

Safety valve opens if pressure

switch is defective.

∗

Motor is switched off in the event

of overload/overheating.

Personal Protective Equipment

Hazards associated with cleaning

agent!

∗

Observe cleaning

agent/disinfectant manufacturer's

notes on safety and handling

∗

Never allow to come into contact

with eyes and skin

∗

Always wear protective clothing,

as well as mask, protective

goggles, rubber boots and rubber

gloves

∗

Thoroughly wash contaminated

protective clothing with water

Emergency procedures

∗

Heed applicable company

instructions

∗

Observe cleaning

agent/disinfectant manufacturer's

notes on safety and handling

ENVIRONMENTAL PROTECTION

Items used when working, such as

cleaning agent/disinfectant and

contaminated maintenance

materials, are to be deposited at a

special collection point.

Packaging materials, metal and

plastic containers are to be set

aside for recycling as appropriate.

Page 5

English FS 2000 19

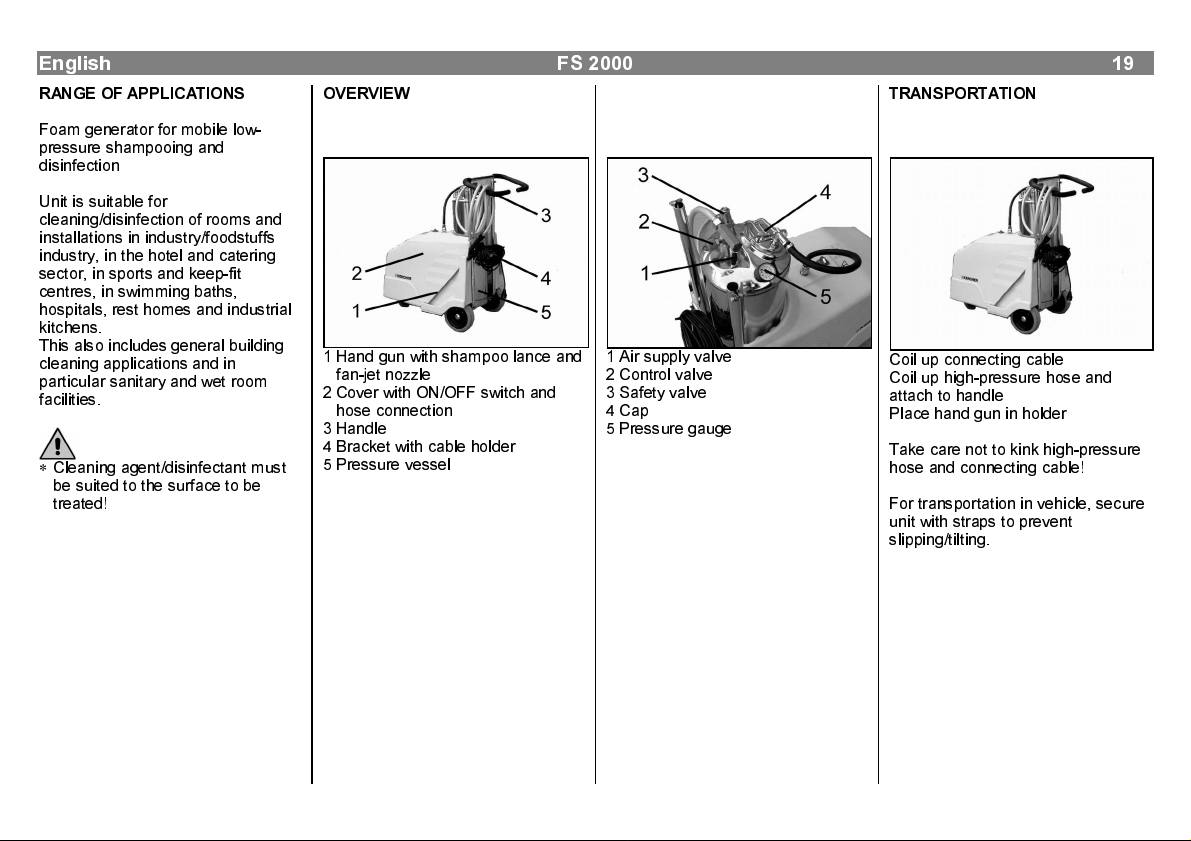

RANGE OF APPLICATIONS

Foam generator for mobile low-

pressure shampooing and

disinfection

Unit is suitable for

cleaning/disinfection of rooms and

installations in industry/foodstuffs

industry, in the hotel and catering

sector, in sports and keep-fit

centres, in swimming baths,

hospitals, rest homes and industrial

kitchens.

This also includes general building

cleaning applications and in

particular sanitary and wet room

facilities.

∗

Cleaning agent/disinfectant must

be suited to the surface to be

treated!

OVERVIEW

1 Hand gun with shampoo lance and

fan-jet nozzle

2 Cover with ON/OFF switch and

hose connection

3 Handle

4 Bracket with cable holder

5 Pressure vessel

1 Air supply valve

2 Control valve

3 Safety valve

4 Cap

5 Pressure gauge

TRANSPORTATION

Coil up connecting cable

Coil up high-pressure hose and

attach to handle

Place hand gun in holder

Take care not to kink high-pressure

hose and connecting cable!

For transportation in vehicle, secure

unit with straps to prevent

slipping/tilting.

Page 6

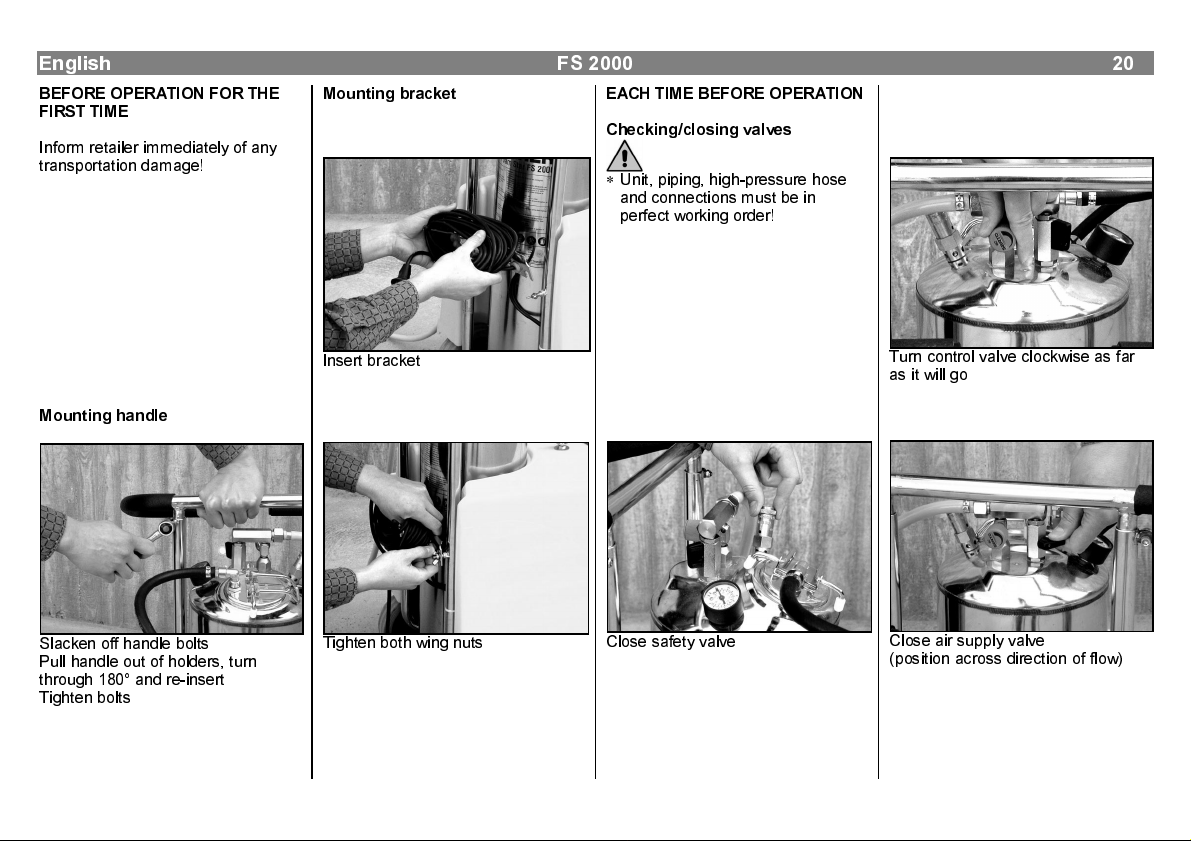

English FS 2000 20

BEFORE OPERATION FOR THE

FIRST TIME

Inform retailer immediately of any

transportation damage!

Mounting bracket

EACH TIME BEFORE OPERATION

Checking/closing valves

∗

Unit, piping, high-pressure hose

and connections must be in

perfect working order!

Mounting handle

Slacken off handle bolts

Pull handle out of holders, turn

through 180° and re-insert

Tighten bolts

Insert bracket

Tighten both wing nuts

Close safety valve

Turn control valve clockwise as far

as it will go

Close air supply valve

(position across direction of flow)

Page 7

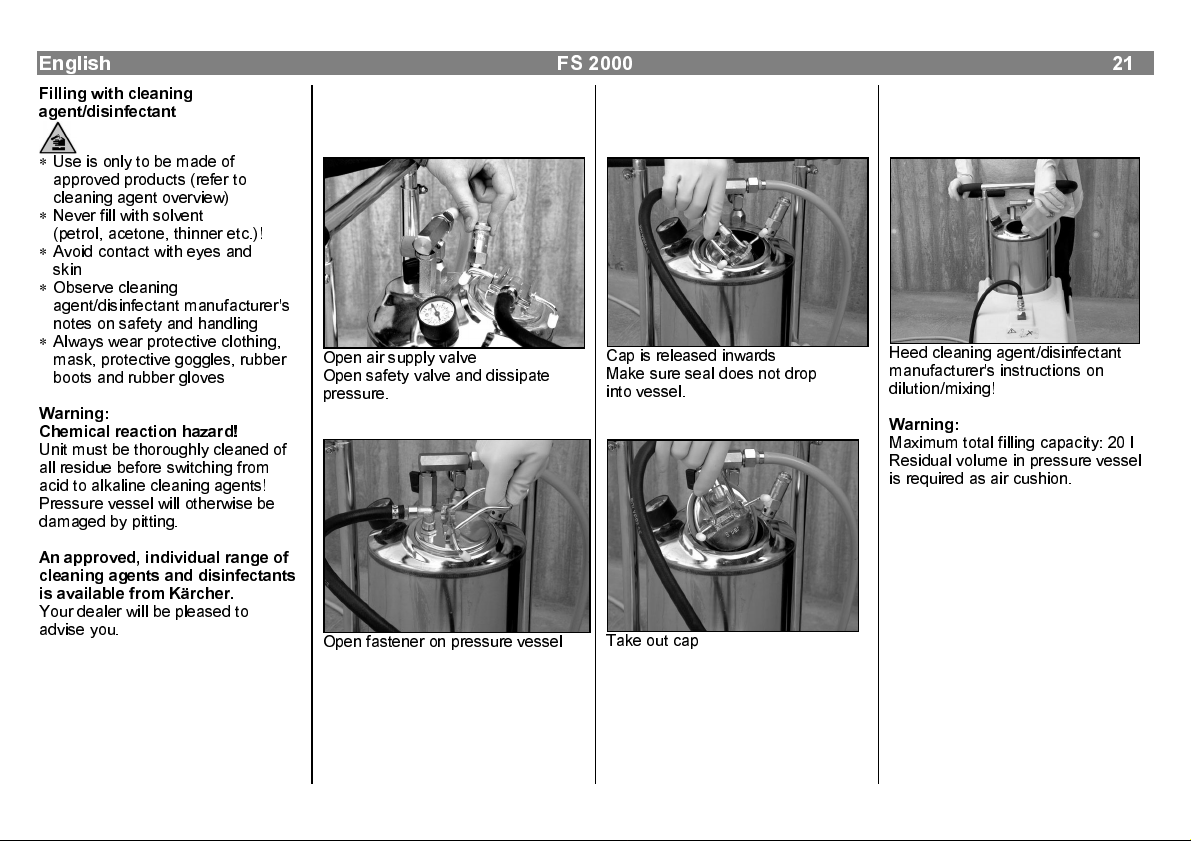

English FS 2000 21

Filling with cleaning

agent/disinfectant

∗

Use is only to be made of

approved products (refer to

cleaning agent overview)

∗

Never fill with solvent

(petrol, acetone, thinner etc.)!

∗

Avoid contact with eyes and

skin

∗

Observe cleaning

agent/disinfectant manufacturer's

notes on safety and handling

∗

Always wear protective clothing,

mask, protective goggles, rubber

boots and rubber gloves

Warning:

Chemical reaction hazard!

Unit must be thoroughly cleaned of

all residue before switching from

acid to alkaline cleaning agents!

Pressure vessel will otherwise be

damaged by pitting.

An approved, individual range of

cleaning agents and disinfectants

is available from Kärcher.

Your dealer will be pleased to

advise you.

Open air supply valve

Open safety valve and dissipate

pressure.

Open fastener on pressure vessel

Cap is released inwards

Make sure seal does not drop

into vessel.

Take out cap

Heed cleaning agent/disinfectant

manufacturer's instructions on

dilution/mixing!

Warning:

Maximum total filling capacity: 20 l

Residual volume in pressure vessel

is required as air cushion.

Page 8

English FS 2000 22

Insert cap in pressure vessel

opening

Flip over fastener and press down

as far as it will go

Connect air hose

Connect to mains

∗

Only work with dry hands

∗

Supply voltage must coincide with

voltage on rating plate

∗

Always completely unwind

extension cable

∗

Permissible cross-section up to

10 m: 1,5 mm², in excess of the

above 2,5 mm²

∗

Only connect splash-proof

extension cables

∗

Extension cable must not be in

water

∗

Only connect unit to sockets

provided with 30 mA residual-

current-operated circuit breaker.

∗

Operation prohibited in baths and

with user standing in water.

−

For connected loads, refer to

Technical Data

OPERATION

∗

Always wear protective clothing,

mask, protective goggles, rubber

boots and rubber gloves

∗

Only use unit in well ventilated

areas

∗

Never blow into clogged

nozzles or valves

∗

Never reach beneath cover

with unit connected to mains

∗

Avoid contact with hot

components such as compressor

and hose connection

∗

Keep unauthorised persons,

children and animals away from

work area

∗

Unit is only to be used in

upright position!

∗

Never expose unit to sunlight

when pressurised!

Fit cap

Warning:

Sealing ring must make uniform

contact with pressure vessel

opening!

Set ON/OFF switch to „0“

Insert power plug

∗

Never use on materials containing

asbestos, silicone, lead or other

hazardous substances!

Page 9

English FS 2000 23

Warning:

Chemical reaction hazard!

Unit must be thoroughly cleaned of

all residue before switching from

acid to alkaline cleaning agents!

Pressure vessel will otherwise be

damaged by pitting.

−

Flushing pressure vessel

(refer to Flushing pressure vessel)

Note:

Pressure = 5,5 bar:

Compressor cuts out

Pressure = 4 bar:

Compressor cuts in again

Shampooing/cleaning

Give control valve 2,5 anti-clockwise

turns

Set ON/OFF switch to „I“

Allow operating pressure to build up

(compressor cuts out)

Actuate hand gun

Note:

Set shampooing mode at control

valve:

Turning anti-clockwise =

Shampoo becomes moister

Turning clockwise =

Shampoo becomes drier

Spraying/disinfection

−

Mounting fan-jet nozzle

(accessory, not part of scope of

delivery)

Mount nozzle

−

Stopping machine

−

Dissipate pressure

−

Fit nozzle with cap nut

Note:

Use control valve to set delivery

rate:

Turning anti-clockwise =

Higher delivery rate

Turning clockwise =

Lower delivery rate

Kärcher Tip:

Pay careful attention to instructions

of disinfectant manufacturer.

−

Mounting shampoo nozzle

(pre-assembled, part of scope of

delivery)

Open air supply valve

(position in direction of flow)

Kärcher Tip:

A longer exposure time makes

severe, stubborn soiling easier to

remove.

This applies particularly to cleaning

of exhaust air ducts, corners and

awkwardly shaped surfaces.

Close air supply valve

(position across direction of flow)

Set ON/OFF switch to „I“

Allow operating pressure to build up

(compressor cuts out)

Actuate hand gun

Page 10

English FS 2000 24

EACH TIME AFTER USAGE

Switching off the cleaner

Draining pressure vessel

∗

Avoid contact with eyes and skin

∗

Observe cleaning

agent/disinfectant manufacturer's

notes on safety and handling

∗

Always wear protective clothing,

mask, protective goggles, rubber

boots and rubber gloves

−

Pull power plug

−

Dissipate pressure

Set ON/OFF switch to „0“

Dissipating pressure

Open air supply valve

Open safety valve and dissipate

pressure.

Pull power plug

Coil up connecting cable

Coil up high-pressure hose and

attach to handle

Place hand gun in holder

If period of non-operation is more

than 1 week drain and flush

pressure vessel.

If period of non-operation is less

than 1 week, cleaning

agent/disinfectant can be left in

pressure vessel.

In this case, dismantle and rinse

nozzle.

Pull off air hose

If vessel is nearly empty (light):

Slacken off bracket and lift out tank.

Page 11

English FS 2000 25

If tank is full (heavy):

Pull hose with hand gun through

handle

Slacken off bracket and hold

pressure vessel

Lift out pressure vessel

Open fastener on pressure vessel

Cap is released inwards

Make sure seal does not drop into

vessel.

Take out cap

Pour cleaning agent/disinfectant into

original container

Tightly seal original container

Danger of poisoning!

∗

Take utmost care to avoid water

pollution

∗

Never pour cleaning

agent/disinfectant into other

containers (bottles, cans etc.)

Page 12

English FS 2000 26

Close air supply valve

(position across direction of flow)

Turn control valve anti-clockwise

Insert power plug

Set ON/OFF switch to „I“

Actuate hand gun until fluid in

pressure vessel has been used up

CARE

−

Stopping machine

−

Dissipate pressure

−

Drain pressure vessel

−

Flushing pressure vessel

Only use a damp cloth for cleaning

the cleaner

Wipe over with clean, dry cloth

Do not use chemical cleaning

agents!

Rinse out pressure vessel with

water and leave standing open to

dry

Danger of poisoning!

∗

Never blow into clogged nozzles

or valves

∗

Take utmost care to avoid water

pollution

Clean fan jet nozzle by hand/with

tooth brush

Insert cap in pressure vessel

opening

Fit cap

Warning:

Sealing ring must make uniform

contact with pressure vessel

opening!

Flip over fastener and press down

as far as it will go

Insert pressure vessel in unit

Secure bracket

Connect air hose

Flushing pressure vessel

Warning:

Chemical reaction hazard!

Unit must be thoroughly cleaned of

all residue before switching from

acid to alkaline cleaning agents!

Pressure vessel will otherwise be

damaged by pitting.

−

Stopping machine

−

Dissipate pressure

−

Drain pressure vessel

Fill pressure vessel with water

Warning:

Water temperature max. 50 °C

Volume max. 20 l

−

Close pressure vessel

Page 13

English FS 2000 27

RECOMMENDED CLEANING

AGENTS

Sector

Foodstuffs industry

Industry and commerce

Agriculture

Buildings

Use

−

Facade cleaning

−

−

Equipment and components

−

Floors (tiles)

−

−

Disinfection

−

Floors (sanitary facilities)

−

Workshop floors

−

Disinfection

−

Vehicles, agricultural machinery

−

Milking areas, milk tanks

−

Floors (tiles, glazed tiles)

−

Floors (marble, terrazzo)

−

Floors (synthetic)

−

Floors (linoleum)

−

Sanitary facilities

−

Disinfection

−

Toilet cleaning

Specially suited cleaning agents

RM 56 / RM 57 / RM 58 / RM 59 /

RM 732

RM 56 / RM 58 / RM 59 / RM 732

RM 56 / RM 57 / RM 58 / RM 59 /

RM 732

RM 732 / RM 735

RM 59

RM 56 / RM 58

RM 732 / RM 735

RM 56 / RM 58

RM 59 / RM 732 / RM 735

RM 56 / RM 57 / RM 58

RM 56 / RM 57 / RM 58

RM 56 / RM 57 / RM 58 / RM 59

RM 57

RM 732 / RM 735

RM 59 / RM 732 / RM 735

RM 59 / RM 735

Suitable cleaning agents

RM 735

RM 735

RM 735

--

RM 732 / RM 735

RM 57 / RM 732 / RM 735

--

RM 57

--

RM 732 / RM 735

RM 732 / RM 735

RM 732 / RM 735

RM 732 / RM 735

--

RM 58

RM 732

Page 14

English FS 2000 28

CLEANING AGENT OVERVIEW

Designation

RM 56

Gel cleaner, alkali

20 l – container

RM 57

Shampoo, neutral

20 l container

RM 58

Shampoo, alkaline

20 l container

RM 59

Shampoo, acidic

20 l container

RM 732

Disinfection cleaner

10 l container

RM 735

Disinfectant

10 l container

Order no. Country

Always use order number. of

appropriate country

6.290-704 D, A, GB, I, GR,

NL, B, F

6.290-725 SF, S, N, DK, E,

P, PL

6.291-572 D, A, GB, I, E, GR

6.291-632 SF, S, N, DK, NL, B, F

6.291-582 D, A, GB, I, E, GR

6.291-633 SF, S, N, DK, NL, B, F

6.291-592 D, A, GB, I, E, GR

6.291-634 SF, S, N, DK, NL, B, F

6.291-382 D, A, GB, I, E, GR

6.291-383 SF, S, N, DK, NL, B, F

6.291-384 D, A, GB, I, E, GR

6.291-385 SF, S, N, DK, NL, B, F

FAULT INDICATIONS

Detaching cover

−

Stopping machine

−

Dissipate pressure

−

Slacken off both wing nuts of

vessel bracket

−

Pull off air hose

Lift cover over base frame on either

side

Carefully lift cover off base frame

and lay aside

To fit, start by inserting one side

beneath frame.

Pressing briefly from above engages

cover on other side.

Page 15

English FS 2000 29

Fault

Pressure in fluid tank decreases

Pressure/cleaning agent loss at

hose or hand gun

Compressor not functioning

properly

Fluid tank defective or severely

dented

Nozzle not spraying evenly

Cause

−

Safety valve open

−

Pressure gauge leaking

−

Hose connections leaking

−

Seals damaged

−

Hose cracked or porous, hand gun

leaking.

−

Mains connection defective

−

Motor protection switch tripped

−

--

−

Nozzle dirty or defective

Solution

Close safety valve

Tighten pressure gauge threaded

connection

Tighten hose connections

Replace seals

Tighten hose connections

Have hose/hand gun replaced by

After-Sales Service or qualified

personnel.

Check mains cable

Check hose and switch connection

Allow motor to cool down for at least

5 min with cover open.

Press in motor protection switch.

Have unit checked by After-Sales

Service if motor protection switch is

repeatedly tripped.

Replace fluid tank

Clean or replace nozzle

Check hose and switch connection

Motor protection switch

Page 16

English FS 2000 30

ACCESSORIES

TECHNICAL DATA

Designation Order no..

Metering unit DS1 6.394-053

For pre-mixing of cleaning agent

and water for mixing ratios between

0,3 % and 30 %

Fan jet nozzle 6.415-166

∗

Spray angle 110°

∗

Nozzle size 040

For pre-spraying and when working

with disinfectants

Interchangeable

container, 20 l 6.991-045

Facilitates working with different

cleaning and disinfecting agents

Mains

connection 230 V (1~50/60 Hz)

Compressor

Drive unit AC motor

Rated voltage 230 V (1~50/60 Hz)

Rated current

consumption 1,5 kW

Rotational speed 1400 1/min

Displacement 150 l/min

Volumetric flow at 6 bar 95 l/min

Maximum pressure 8 bar

Operating pressure 4...5,5 bar

Shampoo unit

Perm. operating

pressure max. 6 bar

Perm. operating

temperature 50 °C

Fluid tank capacity 20 l

Delivery of control valve at

−

1,5 revs approx. 0,4 l/min

−

2,5 revs approx. 1,0 l/min

−

4,0 revs approx. 1,7 l/min

Shampooing capacity

with 20 l tank 10m²/l

(122 °F)

Weights

Net weight FS 2000 40 kg

Fluid tank (20 l) 23 kg

Noise emission

Sound pressure level

(EN 60704-1) 76 dB(A)

Page 17

FS 2000 229

Page 18

EG - KONFORMITÄTSERKLÄRUNG

Hiermit erklären wir, daß die nachfolgend bezeichnete Maschine aufgrund ihrer Konzipierung

und Bauart sowie in der von uns in Verkehr gebrachten Ausführung den einschlägigen

grundlegenden Sicherheits- und Gesundheitsanforderungen den unten aufgeführten EG-

Richtlinien entspricht. Bei einer nicht mit uns abgestimmten Änderung der Maschine verliert

diese Erklärung ihre Gültigkeit.

Produkt: Niederdruckreiniger

Typ: 1.250-xxx

Einschlägige EG-Richtlinien

EG-Maschinenrichtlinie (98/37/EG); EG Niederspannungsrichtlinie (73/23/EWG)geändert durch

93/68/EWG; EG-Richtlinie Elektromagnetische Verträglichkeit (89/336/EWG) geändert durch

91/263/EWG, 92/31/EWG, 93/68/EWG

Angewandte harmonisierte Normen:

DIN EN 60335-1, DIN EN 60335-2-79, DIN EN 55014-1:2000 + A1:2001, DIN EN 55014-2:1997,

DIN EN 61000-3-2:2000; DIN EN 61000-3-3:1995 + A1:2001

Angewandte nationale Normen:

Prüfgrundsätze des Hauptverbandes der gewerblichen Berufsgenossenschaft

Kehrsaugmaschinen.Es ist durch interne Maßnahmen sichergestellt, daß die Seriengeräte immer

den Anforderungen der aktuellen EG-Richtlinien und den angewandten Normen entsprechen.

Die Unterzeichnenden handeln im Auftrag und mit Vollmacht der Geschäftsführung.

TRB

DÉCLARATION DE CONFORMITÉ EUROPÉENNE

Par la présente, nous déclarons que la machine ci-après répond, de par sa conception et sa con-

struction ainsi que de par le modèle que nous avons mis sur le marché, aux exigences de

sécurité et d’hygiène en vigueur de la directive européenne.

En cas de modification de la machine effectuée sans notre accord, cette déclaration sera

caduque.

Produit: Nettoyeur basse pression

Type: 1.250-xxx

Directives européennes en vigueur:

Directive européenne sur les machines (98/37/EG); Directive européenne sur les basses

tensions (73/23/EWG)modifiée par 93/68/EWG; Directive européenne sur la compatibilité

électromagnétique (89/336/EWG) modifiée par 91/263/EWG, 92/31/EWG, 93/68/EWG

Normes harmonisées appliquées:

DIN EN 60335-1, DIN EN 60335-2-79, DIN EN 55014-1:2000 + A1:2001, DIN EN 55014-2:1997,

DIN EN 61000-3-2:2000, DIN EN 61000-3-3:1995 + A1:2001

Normes nationales appliquées:

La conformité permanente des appareils de série avec les exigences consignées dans les

directives actuelles de la CE et avec les normes appliquées est garantie par des mesures

internes. Les soussignés agissent par ordre et avec les pleins pouvoirs de la Direction

commerciale.

TRB

EU DECLARATION OF CONFORMITY

We hereby declare that the equipment described below conforms to the relevant fundamental

safety and health requirements of the appropriate EU Directives, both in its basic design and

construction as well as in the version marketed by us. This declaration will cease to be valid if

any modifications are made to the machine without our express approval.

Product: Low-pressure cleaner

Model: 1.250-xxx

Relevant EU Directives:

EU Machinery Directive (98/37/EG); EU Low-Voltage Equipment Directive (73/23/EWG)amended

by 93/68/EWG; EU Directive on Electromagnetic Compatibility (89/336/EWG) amended by

91/263/EWG, 92/31/EWG, 93/68/EWG

Harmonised standards applied:

DIN EN 60335-1, DIN EN 60335-2-79, DIN EN 55014-1:2000 + A1:2001, DIN EN 55014-2:1997,

DIN EN 61000-3-2:2000, DIN EN 61000-3-3:1995 + A1:2001

Relevant EU Directives:

Appropriate internal measures have been taken to ensure that series-production units conform at

all times to the requirements of current EU Directives and relevant standards. The signatories are

empowered to represent and act on behalf of the company management.

TRB

DICHIARAZIONE DI CONFORMITÀ CE

Dichiariamo con la presente, che la macchina qui di seguito indicata, in base alla sua concezione

e al tipo di costruzione, e nella versione da noi introdotta sul mercato, è conforme ai relativi

requisiti fondamentali di sicurezza e di sanità delle direttive della CE.

In caso di modifica apportate alla macchina senza il nostro accordo, questa dichiarazione perde

la sua validità.

Prodotto: Pulitrice a bassa pressione

Tipo: 1.250-xxx

Direttive CE pertinenti:

Direttiva macchine (98/37/EG); Direttiva bassa tensione (73/23/EWG)modificata dalle

93/68/EWG; Direttiva compatibilità elettromagnetica (89/336/EWG)modificata dalle 91/263/EWG,

92/31/EWG, 93/68/EWG

Norme armonizzate applicate:

DIN EN 60335-1, DIN EN 60335-2-79, DIN EN 55014-1:2000 + A1:2001, DIN EN 55014-2:1997,

DIN EN 61000-3-2:2000, DIN EN 61000-3-3:1995 + A1:2001

Norme nazionali applicate:

Mediante accorgimenti interni, è stato assicurato che gli apparecchi di serie siano sempre

conformi ai requisiti delle attuali direttive CE e alle norme applicate. I firmatari agiscono su

incarico e con i poteri dell’Amministrazione.

TRB

Page 19

EU-CONFORMITEITSVERKLARING

Hiermee verklaren wij dat de hierna vermelde machine op grond van haar concipiëring en

constructie en in de door ons in omloop gebrachte uitvoering beantwoordt aan de desbetreffende

veiligheids- en gezondheidsvoorschriften van de EG-richtlijnen.

Na een wijziging aan de machine die niet in overleg met ons wordt uitgevoerd, verliest deze

verklaring haar gel

Product: lagedrukreiniger

Type: 1.250-xxx

Desbetreffende EG-richtlijn:

EG-machinerichtlijn (98/37/EG); EG-laagspanningsrichtlijn (73/23/EWG)

gewijzigd door 93/68/EWG; EG-richtlijn elektromagnetische verenigbaarheid (89/336/EWG)

gewijzigd door 91/263/EWG, 92/31/EWG, 93/68/EWG

Toegepaste geharmoniseerde normen:

DIN EN 60335-1, DIN EN 60335-2-79, DIN EN 55014-1:2000 + A1:2001, DIN EN 55014-2:1997,

DIN EN 61000-3-2:2000, DIN EN 61000-3-3:1995 + A1:2001

Toegepaste nationale normen:

Door interne maatregelen is er voor gezorgd dat de standaard-apparaten altijd beantwoorden

aan de eisen van de actuele richtlijnen en de toegepaste normen.

De ondergetekenden handelen in opdracht en op volmacht van de bedrijfsleiding.

TRB

CE - DECLARAÇÃO DE CONFORMIDADE

Nós declaramos pelo presente instrumento que a máquina abaixo indicada corresponde, na sua

concepção, fabricação bem como no tipo por nós comercializado, às exigências básicas de

segurança e de saúde da directiva da CE.

Se houver uma modificação na máquina sem o nosso consentimento prévio, a presente

declaração perderá a sua validade.

Produto: lavadora de baixa pressão

Tipo: 1.250-xxx

Directivas aplicáveis da CE:

Directiva de máquinas (98/37/EG); Directiva de baixa tensão (73/23/EWG)

modificada pela 93/68/EWG; Directiva de compatibilidade electromagnética (89/336/EWG)

modificada 91/263/EWG, 92/31/EWG, 93/68/EWG

Normas harmonizadas aplicadas:

DIN EN 60335-1, DIN EN 60335-2-79, DIN EN 55014-1:2000 + A1:2001, DIN EN 55014-2:1997,

DIN EN 61000-3-2:2000, DIN EN 61000-3-3:1995 + A1:2001

Normas nacionais aplicadas:

Assegura-se, através de medidas internas da empresa, que os aparelhos de série correspondem

sempre às exigências das directivas actualizadas da CE e às normas aplicadas.

Os abaixo assinados, actuam e representam através de procuração a gerência.

TRB

DECLARACIÓN DE CONFORMIDAD DE LA UNIÓN EUROPEA

Por la presente declaramos los abajo firmantes que la máquina designada a continuación

cumple, tanto por su concepción y clase de construcción como por la ejecución que hemos

puesto en circulación, las normas fundamentales de seguridad y protección de la salud

formuladas en las directivas comunitarias correspondientes.

La presente declaración pierde su validez en caso de alteraciones en la máquina efectuadas sin

nuestro consentimiento explícito.

Producto: aparato de limpieza de baja presión

Modelo: 1.250-xxx

Directivas comunitarias aplicables:

Directiva comunitaria sobre máquinas (98/37/EG); Directiva comunitaria sobre equipos de baja

tensión (73/23/EWG)modificada mediante 93/68/EWG; Directiva sobre compatibilidad

electromagnética (89/336/EWG) modificada mediante 91/263/EWG, 92/31/EWG, 93/68/EWG

Normas armonizadas aplicadas:

DIN EN 60335-1, DIN EN 60335-2-79, DIN EN 55014-1:2000 + A1:2001, DIN EN 55014-2:1997,

DIN EN 61000-3-2:2000, DIN EN 61000-3-3:1995 + A1:2001

Normas nacionales aplicadas:

Mediante una serie de medidas internas, queda asegurado que los aparatos y equipos de serie

cumplan siempre las exigencias formuladas en las directivas comunitarias actuales y en las

normas correspondientes a aplicar.

Los firmantes actúan autorizados y con poder otorgado por la dirección de la empresa

TRB

Дюлщуз рйуфьфзфбт åê

ЕмеЯт, дзлюнпхме ìå ôçí рбспэуб, üôé ôï мзчЬнзмб ðïõ чбсбкфзсЯжефбй рбсбкЬфщ,

ëüãù ôïõ учедйбумпэ êáé ôïõ фсьрпх кбфбукехЮт, üðùò êáé ëüãù ôçò рбсбллбгЮт

ðïõ дйбфЯиефбй áðü ìáò óôçí бгпсЬ, бнфбрпксЯнефбй óôéò учефйкЭт âбуйкЭт брбйфЮуейт

буцблеЯбт êáé хгеЯбт ôùí Пдзгйюн ÅÊ. Óå ресЯрфщуз бллбгюн óôï мзчЬнзмб чщсЯт

рспзгпэменз ухнненьзуз ìáæß ìáò, рбэей íá йучэей ç рбспэуб дЮлщуз.

Рспъьн: УхукехЮ

Фэрпт: 1.250-xxx

УчефйкЭт ПдзгЯет ÅÊ:

ПдзгЯб ÅÊ учефйкЬ ìå ôéò мзчбнЭт (98/37/EG); ПдзгЯб ÅÊ ðåñß чбмзлЮт фЬузт

(73/23/EWG)ðïõ фспрпрпйЮизке ìå ôçí ПдзгЯб 93/68/EWG; ПдзгЯб ÅÊ ðåñß

злекфспмбгнзфйкЮт óõìâбфьфзфпт (89/336/EWG) ðïõ фспрпрпйЮизке ìå ôçí ПдзгЯб

91/263/EWG, 92/31/EWG, 93/68/EWG

ЕнбсмпнйумЭнб рсьфхрб ðïõ Эчпхн ецбсмпуиеЯ:

DIN EN 60335-1, DIN EN 60335-2-79, DIN EN 55014-1:2000 + A1:2001, DIN EN 55014-

2:1997,DIN EN 61000-3-2:2000, DIN EN 61000-3-3:1995 + A1:2001

ЕинйкЬ рсьфхрб ðïõ Эчпхн ецбсмпуиеЯ:

Ìå лзциЭнфб еущфесйкЬ мЭфсб Ý÷åé еобуцблйуиеЯ, üôé ïé ухукехЭт уейсЬт кбфбукехЮт

бнфбрпксЯнпнфбй рЬнфб óôéò брбйфЮуейт ôùí ерйкбЯсщн пдзгйюн ÅÊ êáé óôá

ецбсмпуиЭнфб рсьфхрб. Ïé хрпгсЬцпнфет енесгпэн ìå енфплЮ êáé кбфьрйн

еопхуйпдьфзузт ôçò ГенйкЮт Дйеэихнузт.

TRB

Page 20

EU-OVERENSSTEMMELSESERKLÆRING

Hermed erklærer vi at nedenstående maskine på grund af sin udformning og konstruktion i den

udførelse, i hvilken den sælges af os, overholder EU-direktivernes relevante, grundlæggende

sikkerheds- og sundhedsmæssige krav.

Hvis maskinen ændres uden aftale med os, mister denne attest sin gyldighed.

Produkt: Lavtryksrenser

Type: 1.250-xxx

Relevante EU-direktiver:

EU-maskindirektiv (98/37/EG); EU-lavspændingsdirektiv (73/23/EWG)som ændret ved

93/68/EWG; EU-direktiv om elektromagnetisk kompatibilitet (89/336/EWG) som ændret ved

91/263/EWG, 92/31/EWG, 93/68/EWG

Harmoniserede standarder, der blev anvendt:

DIN EN 60335-1, DIN EN 60335-2-79, DIN EN 55014-1:2000 + A1:2001, DIN EN 55014-2:1997,

DIN EN 61000-3-2:2000, DIN EN 61000-3-3:1995 + A1:2001

Nationale standarder, der blev anvendt:

Interne forholdsregler sikrer, at serieapparaterne altid opfylder kravene fra de aktuelle EU-

direktiver og de standarder, der blev anvendt: Underskriverne handler på forretningsledelsens

vegne og med dennes fuldmagt.

TRB

FÖRSÄKRAN OM ÖVERENSSTÄMMELSE

Härmed försäkrar vi att den enligt nedan angivna maskinen till konstruktion, byggnadssätt och i

av oss levererat utförande motsvarar tillämpliga baskrav beträffande säkerhet och hälsa enligt

EU-direktiven.

Vid ändringar på maskinen som icke avtalats med oss upphör denna försäkran att gälla.

Produkt: Lågtrycksaggregat

Typ: 1.250-xxx

Tillämpliga EU-direktiv:

EG maskindirektiv (98/37/EG); EG lågspänningsdirektiv (73/23/EWG)

ändrat genom 93/68/EWG; EG direktiv för elöverkänslighet (89/336/EWG) ändrat genom

91/263/EWG, 92/31/EWG, 93/68/EWG

Tillämpade harmoniserade normer:

DIN EN 60335-1, DIN EN 60335-2-79, DIN EN 55014-1:2000 + A1:2001, DIN EN 55014-2:1997,

DIN EN 61000-3-2:2000, DIN EN 61000-3-3:1995 + A1:2001

Tillämpade nationella normer:

Vi har genom interna åtgärder säkerställt, att serietillverkade maskiner alltid motsvarar aktuella

EU-direktiv och tillämpade normer.

De undertecknade agerar på uppdrag av och med fullmakt av företagsledningen.

TRB

EU-KONFORMITETSERKLÆRING

Vi erklærer herved at maskinen som er beskrevet nedenfor, i konstruksjon og utførelse tilsvarer

markedsførte modell og er i overensstemmelse med de gjeldende og grunnleggende sikkerhets-

og helsekrav i EU-direktivet.

Denne erklæring mister sin gyldighet dersom maskinen endres uten etter avtale med oss.

Produkt: Lavtrykksspyler

Type: 1.250-xxx

Gjeldende EU-direktiv:

EU-direktiv for maskiner (98/37/EG); EU-direktiv for lavspenning (73/23/EWG)

endret ved 93/68/EWG; EU-direktiv for elektromagnetisk toleranse (89/336/EWG)endret ved

91/263/EWG, 92/31/EWG, 93/68/EWG

Anvendte overensstemmende normer:

DIN EN 60335-1, DIN EN 60335-2-79, DIN EN 55014-1:2000 + A1:2001, DIN EN 55014-2:1997,

DIN EN 61000-3-2:2000, DIN EN 61000-3-3:1995 + A1:2001

Anvendte nasjonale normer:

Gjennom interne tiltak er det sikret at serieproduserte maskiner alltid er i overensstemmelse med

kravene i de aktuelle EU-direktiver og anvendte normer.

Undertegnede handler etter oppdrag og med fullmakt fra ledelsen.

TRB

EU-VAATIMUSTENMUKAISUUSVAKUUTUS

Me vakuutamme, että alla mainittu tuote vastaa suunnittelultaan ja rakenteeltaan sekä

valmistustavaltaan EU-direktiivien asianomaisia turvallisuus- ja terveysvaatimuksia.

Jos koneeseen tehdään muutoksia, joista ei ole sovittu kanssamme, tämä vakuutus ei ole enää

voimassa.

Tuote: Pienpainepesuri

Tyyppi: 1.250-xxx

Asianomaiset EU-direktiivit:

EU-konedirektiivi (98/37/EG); EU-pienjännitedirektiivi (73/23/EWG)muutettu 93/68/EWG; EU-

direktiivi sähkömagneettinen yhteensopivuus (89/336/EWG) muutettu 91/263/EWG, 92/31/EWG,

93/68/EWG

Sovelletut harmonisoidut normit:

DIN EN 60335-1, DIN EN 60335-2-79, DIN EN 55014-1:2000 + A1:2001, DIN EN 55014-2:1997,

DIN EN 61000-3-2:2000, DIN EN 61000-3-3:1995 + A1:2001

Sovelletut kansalliset normit:

Sisäisin toimenpitein varmistetaan, että sarjatuotantolaitteet vastaavat aina voimassaolevien EU-

direktiivien vaatimuksia ja sovellettuja normeja.

Allekirjoittaneet toimivat yrityksen johdon toimeksiannosta ja valtuuttamina.

TRB

Page 21

EG – KONFORMITÄSI NYILATKOZAT

Ezennel kijelentjük, hogy az alábbiakban megnevezett gép az alapgondolata és típusa, valamint

a forgalomba hozott kivítelezése miatt megfelel az alábbiakban felsorolt EG-irányelvek

megfelelő alapvető biztonsági- és egészségi követelményeinek. Ez a nyilatkozat elveszíti az

érvényességét egy a gépnek velünk nem egyeztetett változtatása esetén.

Termék: Kisnyomású tisztító

Typ: 1.250-101 FS 2000

A megfelelő irányelvek

21/1998.(IV.17) IKIM & 14/1999.(III.31)GM 1999.04; 79/1997.(XII.31) IKIM 1999.04;

31.1999.(VI.6) GM-KHVM

Alkalmazott nemzeti szabványok:

DIN EN 60335-1, DIN EN 60335-2-79, DIN EN 55014-1:2000 + A1:2001, DIN EN 55014-2:1997,

DIN EN 61000-3-2:2000, DIN EN 61000-3-3:1995 + A1:2001

Alkalmazott nemzeti szabványok:

A Szakmai szövetkezetek főszövetségének a seprőszívógépekre vonatkozó vizsgálati alapelvei.

Belső intézkedések által biztosítva van, hogy a sorozatgyártásu készülékek mindig az aktuális

EG-irányelveknek és alkalmazott szabványoknak megfelelnek.

Az aláírók az üzletvezetés megbízására és meghatalmazása szerint járnak el.

TRB

EU – POTRDILO O USTREZNOSTI

Internimi ukrepi je bilo ugotovljeno, da serijsko preizvajani aparat odgovarjajo aktualnim

navodilom EU in uporabljenim štandartom. Podpisane osobe se pogovarjajo v poverjenju in s

pooblastilom vodstva podjetja.

Produkt: Nizkotlačni čistilni stroj

Tip: 1.250-xxx

Pripadna navodila EU

Navodila EU za stroje (98/37/EG); Navodila EU za opremo delujočo s nizko napetostjo

(73/23/EWG)

spremenjeno navodilom 93/68/EWG; Navodila EU za elektromagnetično spojilnost

(89/336/EWG) spremenjeno navodilom 91/263/EWG, 92/31/EWG, 93/68/EWG

Uporabljeni harmonizirani štandarti:

DIN EN 60335-1, DIN EN 60335-2-79, DIN EN 55014-1:2000 + A1:2001, DIN EN 55014-2:1997,

DIN EN 61000-3-2:2000, DIN EN 61000-3-3:1995 + A1:2001

Uporabljeni narodni štandarti:

Kontrolna načela Zveze industrijskih obrtnih združb za pometalne stroje

Internimi ukrepi je bilo ugotovljeno, da serijsko preizvajani aparat odgovarjajo aktualnim

navodilom EU in uporabljenim štandartom. Podpisane osobe se pogovarjajo v poverjenju in s

pooblastilom vodstva podjetja.

TRB

PROHLÁŠENÍ O SPLNĚNÍ SMĚRNIC EU

Tímto prohlašujeme, že označený stroj vyhovuje po stránce své koncepce a konstrukce a také

svým provedením příslušným požadavkům z hlediska bezpečnosti a ochrany zdraví při práci

podle níže uvedených směrnic EU. Při úpravě stroje provedené bez našeho souhlasu ztrácí toto

prohlášení svou platnost.

Produkt: Nízkotlaký čisticí stroj

Typ: 1.250-xxx

Související směrnice

170/97; 168/97; 169/97

Použité harmonizované normy:

DIN EN 60335-1, DIN EN 60335-2-79, DIN EN 55014-1:2000 + A1:2001, DIN EN 55014-2:1997,

DIN EN 61000-3-2:2000, DIN EN 61000-3-3:1995 + A1:2001

Použité národní normy:

Kontrolní zásady Svazu průmyslových oborových společenstev pro zametací strojeInterní

opatření zajišťují, že sériově vyráběné přístroje vyhovují aktuálním směrnicím EU a použitým

normám. Podepsané osoby jednají v pověření a se zplnomocněním vedení podniku.

TRB

OŚWIADCZENIE O ZGODNOŚCI Z NORMAMI WE

Niniejszym oświadczamy, że typ konstrukcyjny i koncepcja, jak również dostarczona przez nas

wersja opisanej poniżej maszyny spełniają odnośne, podstawowe wymagania, dotyczące

bezpieczeństwa pracy i ochrony zdrowia, zawarte w wymienionych poniżej wytycznych WE. W

przypadku nieuzgodnionej z nami modyfikacji maszyny oświadczenie niniejsze traci swoją

ważność.

Produkt: myjka niskociśnieniowa

Typ: 1.250-xxx

Odnośne wytyczne WE

Wytyczne dotyczące maszyn WE (98/37/EG); Wytyczna WE dotycząca niskiego napięcia

(73/23/EWG) znowelizowana przez 93/68/EWG; Wytyczna WE dotycząca zgodności

elektromagnetycznej (89/336/EWG) znowelizowana przez 91/263/EWG, 92/31/EWG,

93/68/EWG

Wykorzystane normy sharmonizowane:

DIN EN 60335-1, DIN EN 60335-2-79, DIN EN 55014-1:2000 + A1:2001, DIN EN 55014-2:1997,

DIN EN 61000-3-2:2000, DIN EN 61000-3-3:1995 + A1:2001

Wykorzystane normy krajowe:

Zasady badań Głównego Związku Stowarzyszeń Zawodowych Rzemieślników w RFN dotyczące

zamiatarek-odkurzaczy mechanicznych.Procedury wewnątrzzakładowe zapewniają, że

urządzenia produkowane seryjnie zawsze odpowiadają wymaganiom aktualnych wytycznych WE

i stosownych norm. Podpisujący działają z polecenia zarządu firmy i posiadają jego

pełnomocnictwo.

TRB

Page 22

5.957-718 (10/02)

Alfred Kärcher Kommanditgesellschaft. Sitz Winnenden. Registergericht: Waiblingen, HRA 169.

Persönlich haftende Gesellschafterin. Kärcher Reinigungstechnik GmbH. Sitz Winnenden, 2404

Registergericht Waiblingen, HRB

Geschäftsführer: Dr. Bernhard Graf, Hartmut Jenner, Georg Metz

Alfred Kärcher GmbH & Co.

Cleaning Systems

Alfred-Kärcher-Straße 28-40

P.O.Box 160

D-71349 Winnenden

Tel.:++49 7195 14-0

Fax :++49 7195 14-2212

Loading...

Loading...