Page 1

SERVICE MANUAL

YA712<Rev.002>20097SERVICE MANUAL

LCD TELEVISION

LT-32A200/AK

HIGH DEFINITION TELEVISION

There may be multiple versions of

this TV model.

The TV version is identified by the

letters next to the model number

on the TV's Rating.

(See illustration).

Use the service manual that

matches the version of the TV.

COPYRIGHT © 2009 Victor Company of Japan, Limited

MODEL NAME

LT-32A200

MODEL NO.

RATING LABEL (REAR)

TABLE OF CONTENTS

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2 SPECIFIC SERVICE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

VERSION

AK

COPYRIGHT © 2009 Victor Company of Japan, Limited

No.YA712<Rev.002>

2009/8

Page 2

SPECIFICATION

Items Contents

Dimensions ( W × H × D ) 76.0 cm × 56.3 cm × 23.4 cm (30.0" × 22.2" × 9.3") [with stand]

76.0 cm × 51.93 cm × 11.35 cm (30.0" × 20.5" × 4.5") [without stand]

Mass 9.3 kg (20.6 lbs) [with stand]

Power Input AC120 V , 60 Hz

Power Consumption 155 W (Max)

TV RF System

(Analog / Digital)

Color System (Analog) NTSC

Stereo System (Analog) BTSC (Multi Channel Sound)

Teletext System (Analog) Closed caption (T1-T4 / CC1-CC4)

TV Receiving Channels

and Frequency (Analog)

TV / CATV Total Channel 191 Channels

Intermediate Frequency

(Analog)

Color Sub Carrier Frequency (Analog) 3.58 MHz

LCD Panel 32" class (31.5" Diagonal) wide aspect (16 : 9)

Display Pixels Horizontal : 1366 dots × Vertical : 768 dots (W-XGA)

Audio Power Output 10 W + 10 W

Speaker 1.61" × 2.79", oval type × 2

Antenna Terminal

(VHF/UHF, ATSC / DIGITAL CABLE IN)

Video / Audio Input

[VIDEO]

Video / Audio Input

[COMPONENT]

Digital Input Digital(Video/Audio) HDMI 2-row 19pin connector × 3

Audio output 500mV(rms) (-4dBs), Low impedance, RCA pin jack × 2

Digital Audio output 500 mV (rms), Coaxial × 1

Remote Control Unit RM-C2150 (AA/R6 battery × 2)

Component Video

VHF Low

VHF High

Video IF

Sound IF

S-Video Mini-DIN 4 pin × 1

1080i / 720p

480p / 480i

Analog (Audio) 500mV(rms) (-4dBs), high impedance, RCA pin jack × 2

Design & specifications are subject to change without notice.

8.8 kg (19.5 lbs) [without stand]

Analog

CCIR (M)

Digital

ATSC terrestrial / Digital cable

02 ch - 06 ch : 54 MHz - 88 MHz

07 ch - 13 ch : 174 MHz - 216 MHz

UHF

14 ch - 69 ch : 470 MHz - 806 MHz

CATV

54 MHz - 804 MHz

Low Band : 02 - 06

High Band : 07 - 13

Mid Band : 14 - 22

Super Band : 23 - 36

Hyper Band : 37 - 64

Ultra Band : 65 - 94, 100 - 135

Sub Mid Band : 01, 96 - 99

45.75 MHz

41.25 MHz (4.5 MHz)

F-type connector, 75Ω unbalanced, coaxial × 1

Y: 1 V (p-p), Positive (Negative sync.), 75 Ω

C: 0.286V (p-p) (Burst signal), 75 Ω

Video 1 V (p-p), Positive (Negative sync.), 75 Ω, RCA pin jack × 1

Audio 500 mV (rms), High impedance, RCA pin jack × 2

RCA pin jack × 3

Y : 1 V (p-p) (Sync signal: 0.35V(p-p), 3-value sync.), 75 Ω

Pb/Pr : ±0.35V(p-p), 75 Ω

Y : 1 V (p-p), Positive (Negative sync.), 75 Ω

Cb/Cr : 0.7V(p-p), 75 Ω

Audio 500 mV (rms), High impedance, RCA pin jack × 2

(Digital-input terminal is not compatible with picture signals of personal computer)

Video: Supported format: 1080i / 720p / 480p / 480i

Audio: 2ch L-PCM, 32 / 44.1 / 48 KHz, 16 / 20 / 24 bit

1-2 (No.YA712<Rev.002>)

Page 3

SECTION 1

PRECAUTION

1.1 SAFETY PRECAUTIONS

(1) The design of this product contains special hardware,

many circuits and components specially for safety

purposes. For continued protection, no changes should be

made to the original design unless authorized in writing by

the manufacturer. Replacement parts must be identical to

those used in the original circuits. Service should be

performed by qualified personnel only.

(2) Alterations of the design or circuitry of the products should

not be made. Any design alterations or additions will void

the manufacturer's warranty and will further relieve the

manufacturer of responsibility for personal injury or

property damage resulting therefrom.

(3) Many electrical and mechanical parts in the products have

special safety-related characteristics. These

characteristics are often not evident from visual inspection

nor can the protection afforded by them necessarily be

obtained by using replacement components rated for

higher voltage, wattage, etc. Replacement parts which

have these special safety characteristics are identified in

the parts list of Service manual. Electrical components

having such features are identified by shading on the

schematics and by ( ) on the parts list in Service

manual. The use of a substitute replacement which does

not have the same safety characteristics as the

recommended replacement part shown in the parts list of

Service manual may cause shock, fire, or other hazards.

(4) Don't short between the LIVE side ground and

ISOLATED (NEUTRAL) side ground or EARTH side

ground when repairing.

Some model's power circuit is partly different in the GND.

The difference of the GND is shown by the LIVE : ( ) side

GND, the ISOLATED (NEUTRAL) : ( ) side GND and

EARTH : ( ) side GND.

Don't short between the LIVE side GND and ISOLATED

(NEUTRAL) side GND or EARTH side GND and never

measure the LIVE side GND and ISOLATED (NEUTRAL)

side GND or EARTH side GND at the same time with a

measuring apparatus (oscilloscope etc.). If above note will

not be kept, a fuse or any parts will be broken.

(5) When service is required, observe the original lead dress.

Extra precaution should be given to assure correct lead

dress in the high voltage circuit area. Where a short circuit

has occurred, those components that indicate evidence of

overheating should be replaced. Always use the

manufacturer's replacement components.

(6) Isolation Check (Safety for Electrical Shock Hazard)

After re-assembling the product, always perform an

isolation check on the exposed metal parts of the cabinet

(antenna terminals, video/audio input and output terminals,

Control knobs, metal cabinet, screw heads, earphone jack,

control shafts, etc.) to be sure the product is safe to operate

without danger of electrical shock.

a) Dielectric Strength Test

The isolation between the AC primary circuit and all metal

parts exposed to the user, particularly any exposed metal

part having a return path to the chassis should withstand a

voltage of 3000V AC (r.m.s.) for a period of one second. (.

. . . Withstand a voltage of 1100V AC (r.m.s.) to an

appliance rated up to 120V, and 3000V AC (r.m.s.) to an

appliance rated 200V or more, for a period of one second.)

This method of test requires a test equipment not generally

found in the service trade.

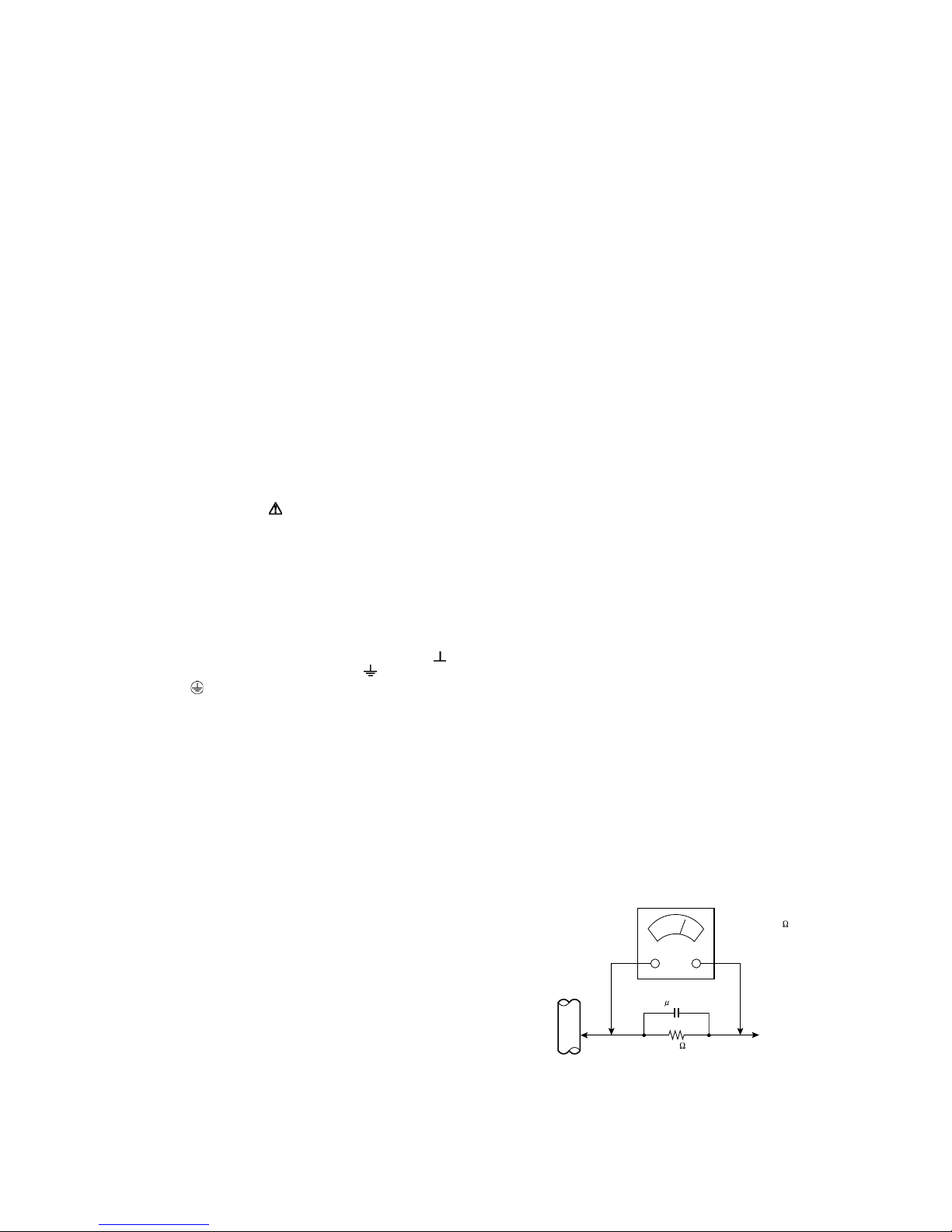

b) Leakage Current Check

Plug the AC line cord directly into the AC outlet (do not use

a line isolation transformer during this check.). Using a

"Leakage Current Tester", measure the leakage current

from each exposed metal part of the cabinet, particularly

any exposed metal part having a return path to the chassis,

to a known good earth ground (water pipe, etc.). Any

leakage current must not exceed 0.5mA AC (r.m.s.).

However, in tropical area, this must not exceed 0.2mA AC

(r.m.s.).

Alternate Check Method

Plug the AC line cord directly into the AC outlet (do not

use a line isolation transformer during this check.). Use

an AC voltmeter having 1000Ω per volt or more

sensitivity in the following manner. Connect a 1500Ω

10W resistor paralleled by a 0.15µF AC-type capacitor

between an exposed metal part and a known good earth

ground (water pipe, etc.). Measure the AC voltage

across the resistor with the AC voltmeter. Move the

resistor connection to each exposed metal part,

particularly any exposed metal part having a return path

to the chassis, and measure the AC voltage across the

resistor. Now, reverse the plug in the AC outlet and

repeat each measurement. Any voltage measured must

not exceed 0.75V AC (r.m.s.). This corresponds to

0.5mA AC (r.m.s.).

However, in tropical area, this must not exceed 0.3V AC

(r.m.s.). This corresponds to 0.2mA AC (r.m.s.).

AC VOLTMETER

(HAVING 1000 /V,

OR MORE SENSITIVITY)

0.15 F AC-TYPE

GOOD EARTH GROUND

1500 10W

PLACE THIS PROBE

ON EACH EXPOSED

ME TAL PAR T

(No.YA712<Rev.002>)1-3

Page 4

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

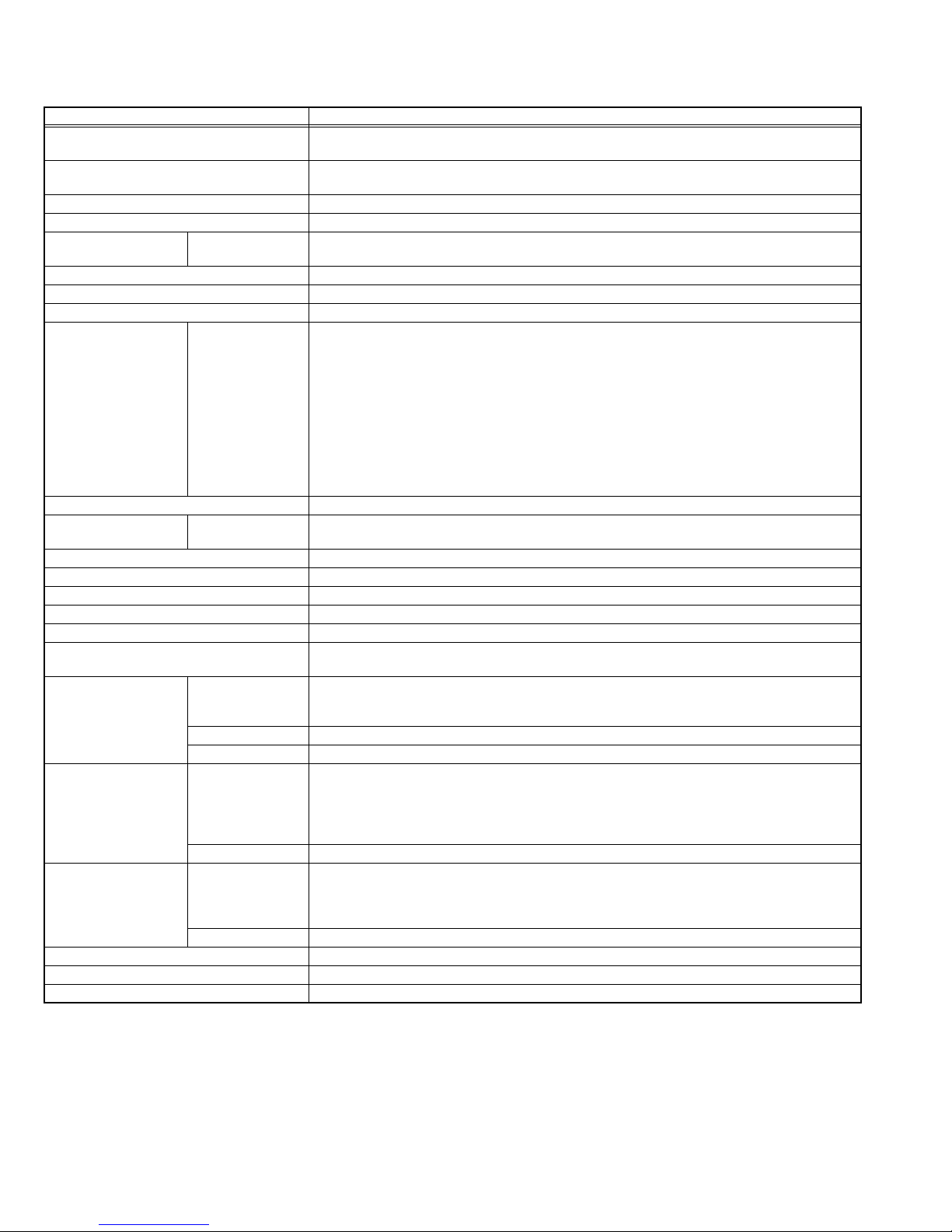

2.1 HOW TO IDENTIFY THE TRANS INVERTER

When you replace one of the below Trans Inverters on INVERTER PWB, please replace with the one that has same parts number.

For the part FU-LTZ3PZDAR007, in addition to the lot number,

the letter “DARFON 7609A” is printed on the bottom of the part.

For the part FU-LTZ3PZ0XB009, in addition to the lot number,

the letter ”3PZ0XB009 JS HVT-153” is printed on the bottom of

the part.

Do not mix different parts number’s Trans Inverter.

Part No.: FU-LTZ3PZDAR007

“

DARFON 7609A”

Lot No. Stamp

2.2 STANDARD NOTES FOR SERVICING

2.2.1 CIRCUIT BOARD INDICATIONS

(1) The output pin of the 3 pin Regulator ICs is indicated as

shown.

Part No.: FU-LTZ3PZ0XB009

“

3PZ0XB009 JS HVT-153”

Lot No. Stamp

2.2.2 PB (LEAD) FREE SOLDER

Pb free mark will be found on PCBs which use Pb free

solder. (Refer to figure.) For PCBs with Pb free mark, be sure

to use Pb free solder. For PCBs without Pb free mark, use

standard solder.

Pb free mark

Top View

Bottom View

Input

Out

(2) For other ICs, pin 1 and every fifth pin are indicated as

shown.

In

5

Pin 1

10

(3) The 1st pin of every male connector is indicated as shown.

Pin 1

1-4 (No.YA712<Rev.002>)

Page 5

2.2.3 HOW TO REMOVE / INSTALL FLAT PACK-IC

2.2.3.1 REMOVAL

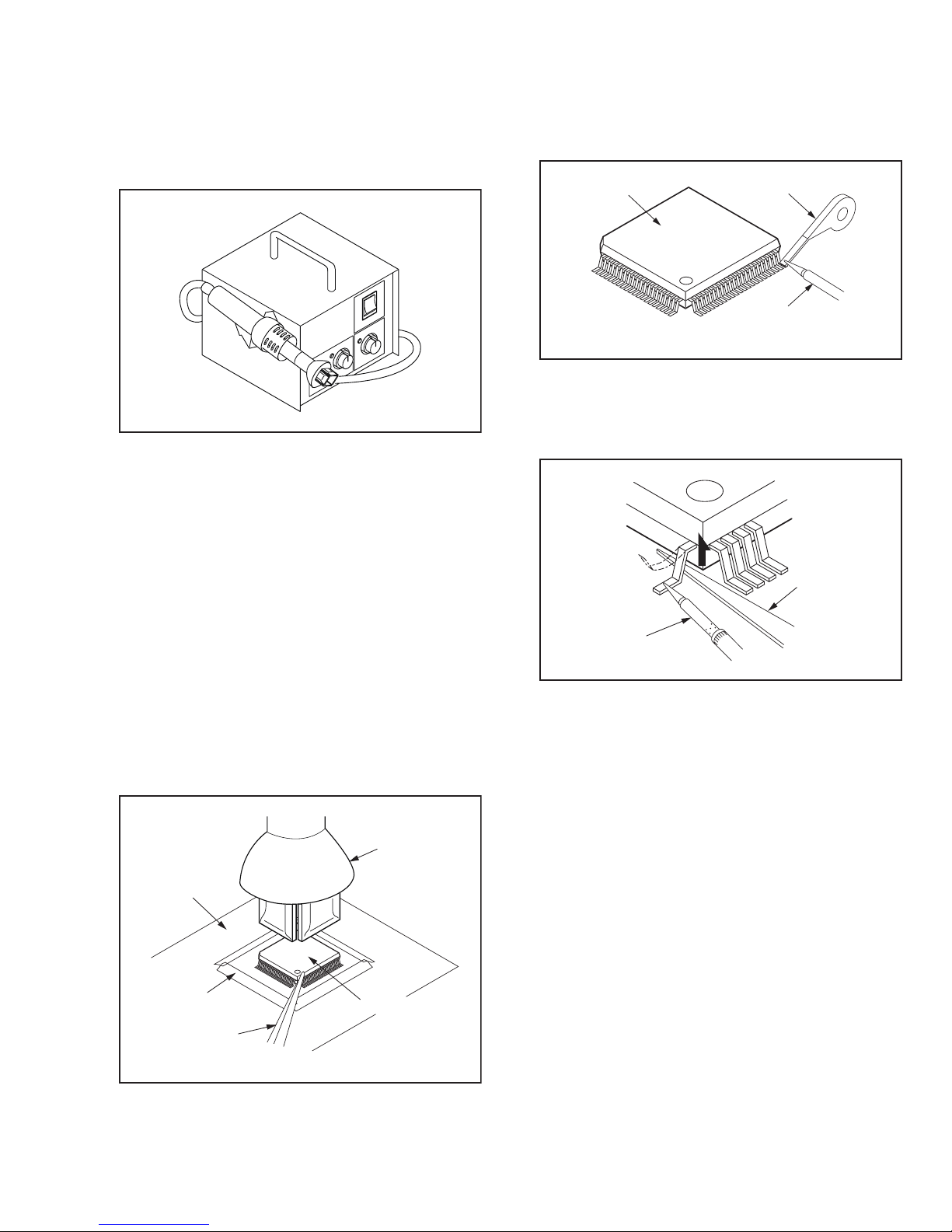

WITH HOT-AIR FLAT PACK-IC DESOLDERING MACHINE:

(1) Prepare the hot-air flat pack-IC desoldering machine,

then apply hot air to the Flat Pack-IC (about 5 to 6

seconds). (Fig.2-1)

Fig.2-1

(2) Remove the flat pack-IC with tweezers while applying

the hot air.

(3) Bottom of the flat pack-IC is fixed with glue to the PWB;

when removing entire flat pack-IC, first apply soldering

iron to center of the flat pack-IC and heat up. Then

remove (glue will be melted). (Fig.2-6)

(4) Release the flat pack-IC from the PWB using tweezers.

(Fig.2-6)

CAUTION:

(1) The Flat Pack-IC shape may differ by models. Use an

appropriate hot-air flat pack-IC desoldering machine,

whose shape matches that of the Flat Pack-IC.

(2) Do not supply hot air to the chip parts around the flat

pack-IC for over 6 seconds because damage to the

chip parts may occur. Put masking tape around the flat

pack-IC to protect other parts from damage. (Fig.2-2)

(3) The flat pack-IC on the PWB is affixed with glue, so be

careful not to break or damage the foil of each pin or

the solder lands under the IC when removing it.

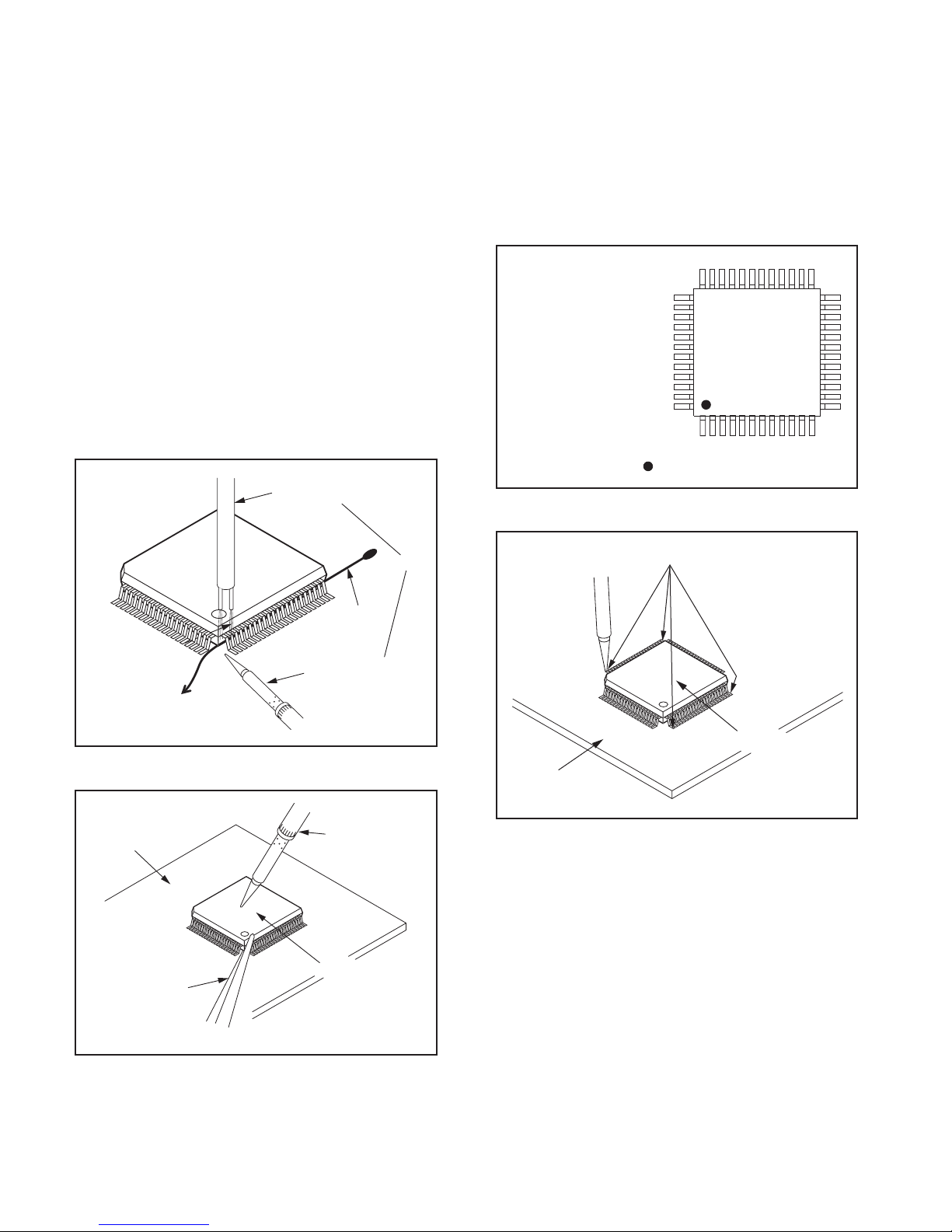

WITH SOLDERING IRON:

(1) Using desoldering braid, remove the solder from all pins

of the flat pack-IC. When you use solder flux which is

applied to all pins of the flat pack-IC, you can remove it

easily. (Fig.2-3)

Flat Pack-IC

Desoldering Braid

Soldering Iron

Fig.2-3

(2) Lift each lead of the flat pack-IC upward one by one,

using a sharp pin or wire to which solder will not adhere

(iron wire). When heating the pins, use a fine tip

soldering iron or a hot air desoldering machine. (Fig.2-4)

Sharp

Pin

Fine Tip

Soldering Iron

Fig.2-4

(3) Bottom of the flat pack-IC is fixed with glue to the PWB;

when removing entire flat pack-IC, first apply soldering

iron to center of the flat pack-IC and heat up. Then

remove (glue will be melted). (Fig.2-6)

(4) Release the flat pack-IC from the PWB using tweezers.

(Fig.2-6)

CBA

Masking

Tape

Tweezers

Fig.2-2

Hot-air

Flat Pack-IC

Desoldering

Machine

Flat Pack-IC

(No.YA712<Rev.002>)1-5

Page 6

WITH IRON WIRE:

(1) Using desoldering braid, remove the solder from all pins

of the flat pack-IC. When you use solder flux which is

applied to all pins of the flat pack-IC, you can remove it

easily. (Fig.2-3)

(2) Affix the wire to a workbench or solid mounting point, as

shown in Fig.2-5.

(3) While heating the pins using a fine tip soldering iron or

hot air blower, pull up the wire as the solder melts so as

to lift the IC leads from the PWB contact pads as shown

in Fig.2-5.

(4) Bottom of the flat pack-IC is fixed with glue to the PWB;

when removing entire flat pack-IC, first apply soldering

iron to center of the flat pack-IC and heat up. Then

remove (glue will be melted). (Fig.2-6)

(5) Release the flat pack-IC from the PWB using tweezers.

(Fig.2-6)

NOTE:

When using a soldering iron, care must be taken to ensure

that the flat pack-IC is not being held by glue. When the flat

pack-IC is removed from the PWB, handle it gently because

it may be damaged if force is applied.

2.2.3.2 INSTALLATION

(1) Using desoldering braid, remove the solder from the foil of

each pin of the flat pack-IC on the PWB so you can install

a replacement flat pack-IC more easily.

(2) The z mark on the flat pack-IC indicates pin 1. (See Fig.2-

7.) Be sure this mark matches the pin 1 on the PCB when

positioning for installation. Then presolder the four corners

of the flat pack-IC. (See Fig.2-8.)

(3) Solder all pins of the flat pack-IC. Be sure that none of the

pins have solder bridges.

Example :

Pin 1 of the Flat Pack-IC

is indicated by a " " mark.

To Solid

Mounting Point

CBA

Fig.2-5

Hot Air Blower

Iron Wire

Soldering Iron

Fine Tip

Soldering Iron

or

Fig.2-7

Presolder

Flat Pack-IC

CBA

Fig.2-8

Tweezers

Fig.2-6

1-6 (No.YA712<Rev.002>)

Flat Pack-IC

Page 7

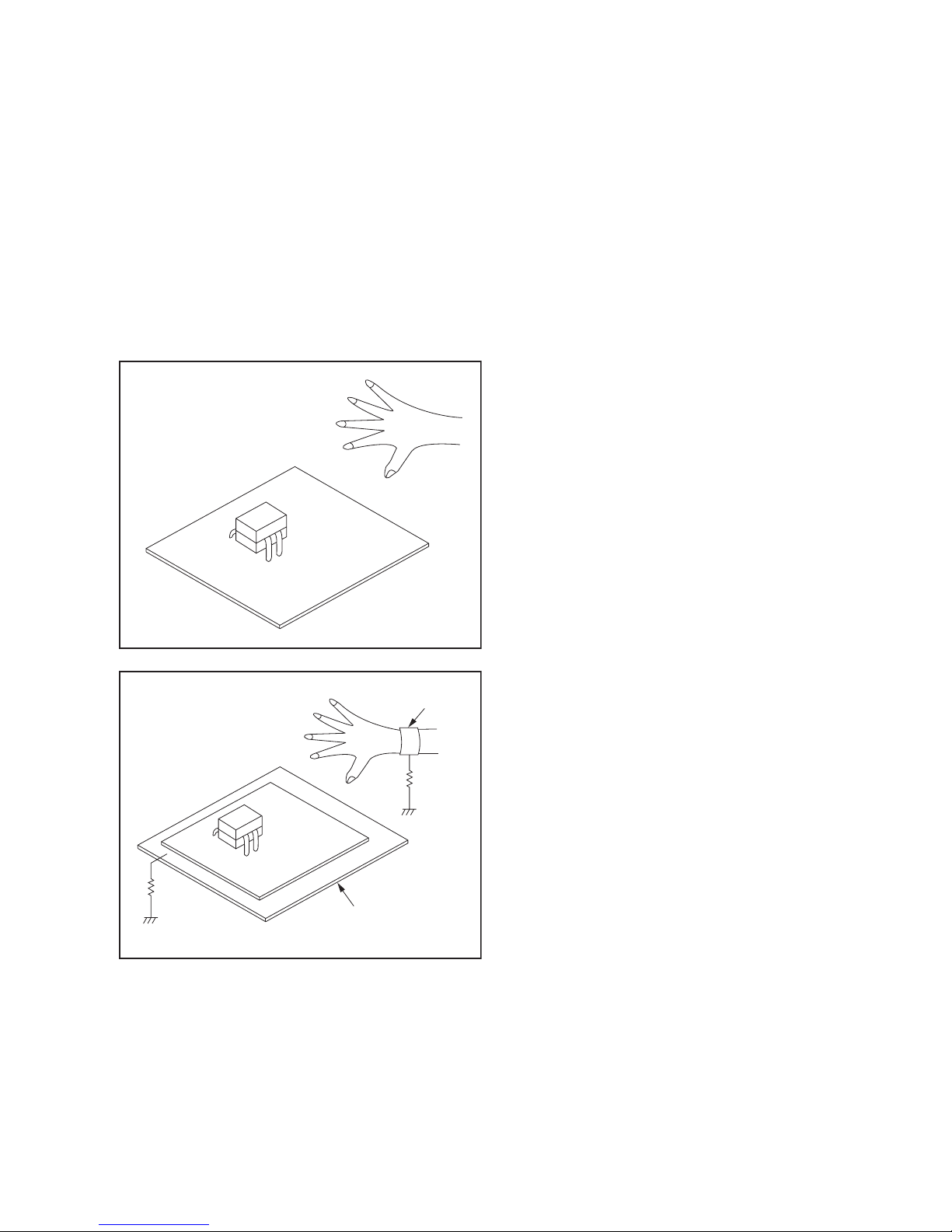

2.2.4 INSTRUCTIONS FOR HANDLING SEMICONDUCTORS

Electrostatic breakdown of the semi-conductors may occur due

to a potential difference caused by electrostatic charge during

unpacking or repair work.

2.2.4.1 Ground for Human Body

Be sure to wear a grounding band (1MΩ) that is properly

grounded to remove any static electricity that may be charged on

the body.

2.2.4.2 Ground for Workbench

Be sure to place a conductive sheet or copper plate with proper

grounding (1MΩ) on the workbench or other surface, where the

semi-conductors are to be placed. Because the static electricity

charge on clothing will not escape through the body grounding

band, be careful to avoid contacting semi-conductors with your

clothing.

<I

ncorrec

t

>

<

C

orrec

1M

CBA

t

>

CBA

Grounding Band

1M

Conductive Sheet or

Copper Plate

(No.YA712<Rev.002>)1-7

Page 8

SECTION 3

DISASSEMBLY

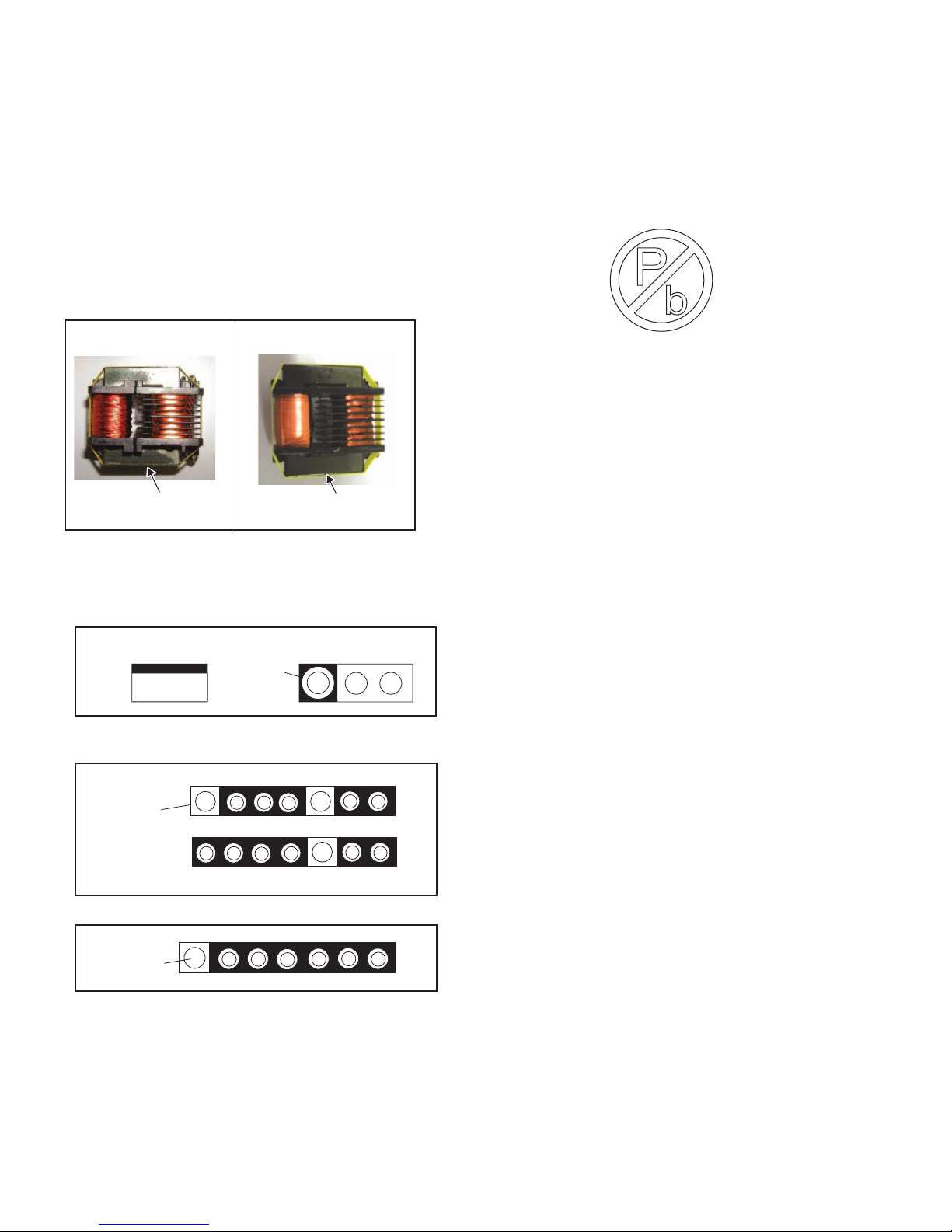

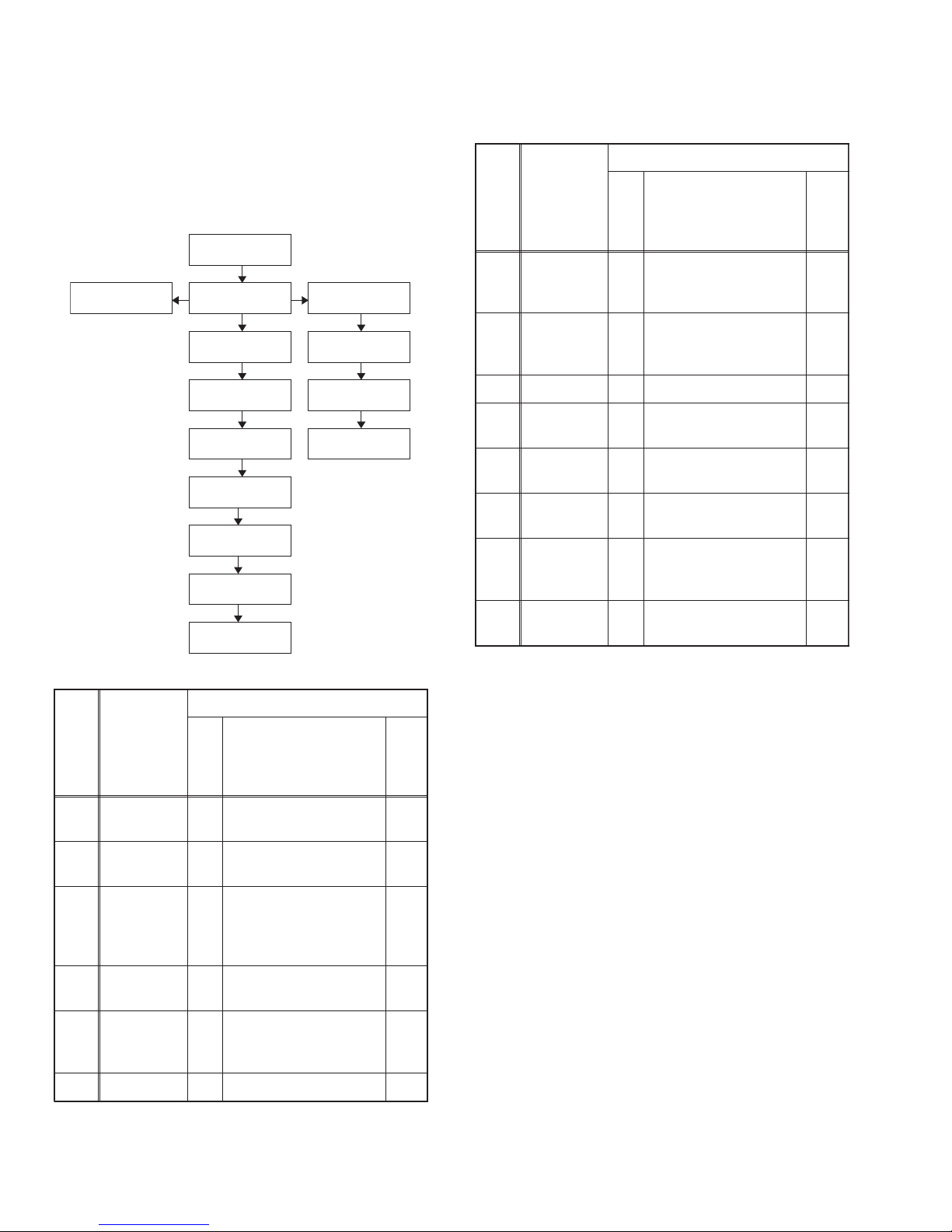

3.1 Disassembly Flowchart

This flowchart indicates the disassembly steps for the cabinet

parts, and the CBA in order to gain access to item(s) to be serviced. When reassembling, follow the steps in reverse order.

Bend, route and dress the cables as they were.

[1] Stand

Assembly

[10] Junction

CBA

3.2 Disassembly Method

[2] Rear Cabinet

[3] Inverter CBA

[4] Jack CBA

[5] Power Supply

CBA

[6] Jack Holder

[7] Digital Main

CBA Unit

[13] LCD Module

Assembly

[14] Front

Cabinet

[8] Speaker

Holder (L,R)

[9] Speaker(s)

[11] IR Sensor

CBA

[12] Function

CBA

Removal

Step/

Loc.

No.

Part

Remove/*Unhook/

Fig.

No.

Unlock/Release/

Unplug/Unclamp/

Note

Desolder

Stand

[1]

[2]

Assembly

Rear

Cabinet

D1 4(S-1) ---

D1 13(S-2), 2(S-3), 3(S-4) ---

6(S-5), *CN1001,

[3]

Inverter

CBA

D2

*CN1003, *CN1050,

D4

*CN1100, *CN1150,

---

*CN1200, *CN1900

Removal

Step/

Loc.

No.

Part

Remove/*Unhook/

Fig.

No.

Unlock/Release/

Unplug/Unclamp/

Desolder

Digital Main

[7]

CBA UnitD2D4

4(S-9), 2(S-10),

4(S-11), *CN3902,

Shield Box

Speaker

[8]

Holder

D3 *Hook ---

(L,R)

[9] Speaker(s) D3 8(S-12) ---

[10]

[11]

[12]

Junction

CBA

IR Sensor

CBA

Function

CBA

D3

Desolder ---

D4

D3

2(S-13), *CL103C ---

D4

D3

2(S-14) ---

D4

LCD

[13]

Module

D3 (S-15) ---

Assembly

Front

[14]

Cabinet

D3 --------------- ---

(1) (2) (3) (4) (5)

NOTE;

(1) Order of steps in procedure. When reassembling, follow

the steps in reverse order. These numbers are also used

as the Identification (location) No. of parts in figures.

(2) Parts to be removed or installed.

(3) Fig. No. showing procedure of part location

(4) Identification of parts to be removed, unhooked, un-

locked, released, unplugged, unclamped, or desoldered.

P = Spring, L = Locking Tab, S = Screw, H = Hex Screw,

CN = Connector * = Unhook, Unlock, Release, Unplug,

or Desolder e.g. 2(S-2) = two Screws (S-2), 2(L-2) = two

Locking Tabs (L-2)

(5) Refer to the following "Reference Notes in the Table."

Note

---

[4] Jack CBA

Power

[5]

Supply

CBA

D2

2(S-6), *CL701B ---

D4

7(S-7), *CN101,

D2

*CN301, *CN302,

D4

*CN801, *CN802

[6] Jack Holder D2 2(S-8) ---

1-8 (No.YA712<Rev.002>)

---

Page 9

(S-4)

(S-2)

[2] Rear Cabinet

[1] Stand Assembly

(S-2)

(S-1)

(S-3)

(S-4)

(S-2)

(S-4)

(S-2)

Fig. D1

(No.YA712<Rev.002>)1-9

Page 10

[3] Inverter CBA

(S-5)

(S-11)

[7] Digital Main

CBA Unit

(S-8)

[4] Jack CBA

Shield Box

[6] Jack Holder

(S-6)

(S-9)

(S-10)

(S-9)

(S-7)

(S-7)

(S-7)

(S-5)

[5] Power Supply CBA

Fig. D2

1-10 (No.YA712<Rev.002>)

Page 11

[14] Front Cabinet

[13] LCD Module

Assembly

Hook

[10] Junction

CBA

(S-12)

[9] Speaker

[8] Speaker Holder (L)

(S-15)

Hook

[8] Speaker Holder (R)

[11] IR Sensor CBA

(S-13)

(S-12)

[9] Speaker

[12] Function CBA

(S-14)

Fig. D3

(No.YA712<Rev.002>)1-11

Page 12

SECTION 4

ADJUSTMENT

4.1 GENERAL NOTE: "PWB" IS ABBREVIATION FOR

"CIRCUIT BOARD ASSEMBLY."

NOTE:

Electrical adjustments are required after replacing circuit components and certain mechanical parts. It is important to perform these adjustments only after all repairs and replacements

have been completed. Also, do not attempt these adjustments

unless the proper equipment is available.

4.2 TEST EQUIPMENT REQUIRED

(1) NTSC Pattern Generator (Color Bar W/White Window, Red

Color, Dot Pattern, Gray Scale, Monoscope, Multi-Burst)

(2) Remote control unit

(3) Color Analyzer

4.3 HOW TO MAKE THE SERVICE REMOTE CONTROL

UNIT:

Cut "A" portion of the attached remote control unit as shown in

Fig. 1.

service button

(There is a button under the plastic housing.)

4.5 PURITY CHECK MODE

This mode cycles through full-screen displays of red, green, blue,

and white to check for non-active pixels.

(1) Enter the Service mode.

(2) Each time pressing [7] button on the service remote control

unit, the display changes as follows.

Purity Check Mode

White mode

[7] button

[7] button

Black mode

[7] button

Red mode

A

4.4 HOW TO SET UP THE SERVICE MODE:

Service mode:

(1) Use the service remote control unit.

(2) Turn the power on.

(3) Press the service button on the service remote control

unit. The following screen appears.

"*" differs depending on the models.

Code :

***********-***

Pic code :

**-***-**-*****-***

MIPS :

Push 0key

Tuner :

****-*****-****

safety_Non

Safety :

[7] button

Green mode

Fig. 1

[7] button

Blue mode

[7] button

White 20% mode

Note:

When entering this mode, the default setting is White mode.

1-12 (No.YA712<Rev.002>)

Page 13

4.6 VCOM ADJUSTMENT

Test Point Adj. Point

Screen

M. EQ. Spec.

Color analyzer See below

To avoid interference from ambinent

light, this adjustment should be

performed in a dark room.

Perpendicularity

L = 3 cm

[CHANNEL UP/DOWN ]

buttons

Figure

Color Analyzer

4.7 WHITE BALANCE ADJUSTMENT

The white balance adjustment should be performed when

replacing the LCD Panel or Digital PWB.

Purpose: To mix red, green and blue beams correctly for pure

white.

Symptom of Misadjustment: White becomes bluish or reddish.

Test Point

Screen

Adj. Point Mode Input

[VOLUME

DOWN]

button

[VIDEO1]

C/D

White Raster

(APL 70%)

or

(APL 40%)

M. EQ. Spec.

Pattern Generator,

Color analyzer

x= 0.272 ± 0.005

y= 0.278 ± 0.005

Figure

To avoid interference from ambinent

light, this adjustment should be

performed in a dark room.

Perpendicularity

(1) Operate the unit for more than 20 minutes.

(2) Set the color analyzer and bring the optical receptor to the

center on the LCD-Panel surface after zero point calibration as shown above. Note: The optical receptor must be

set perpendicularly to the LCD Panel surface.

(3) Enter the Service mode.

(4) Press [3] button on the service remote control unit.

(5) Press [CHANNEL UP/DOWN] buttons on the service re-

mote control unit so that the color analyzer value becomes

minimum.

L = 3 cm

INPUT: WHITE 70%, 40%

(1) Operate the unit for more than 20 minutes.

(2) Input the White Raster(70%=70IRE, 40%=40IRE).

INPUT SIGNAL

0IRE 0IRE

100IRE

40%=40IRE

(3) Set the color analyzer to the CHROMA mode and bring the

optical receptor to the center on the LCD-Panel surface after zero point calibration as shown above.

Note: The optical receptor must be set perpendicularly to

the LCD Panel surface.

(4) Enter the Service mode. Press [VOLUME DOWN] button

on the service remote control unit and select "C/D" mode.

(5) [CUTOFF]

Press [1] button to select “COR” for Red Cutoff adjustment.

Press [3] button to select “COB” for Blue Cutoff adjustment.

[DRIVE]

Press [4] button to select “DR” for Red Drive adjustment.

Press [6] button to select “DB” for Blue Drive adjustment.

(6) In each color mode, press [CHANNEL UP/DOWN] buttons

to adjust the values of color.

(7) Adjust Cutoff and Drive so that the color temperature be-

comes 12000°K (x= 0.272 / y= 0.278 ±0.005).

Color Analyzer

Low

Hight

Light

Light

70%=70IRE

100IRE

(No.YA712<Rev.002>)1-13

Page 14

4.8 HOW TO INITIALIZE THE LCD TV/DVD

The purpose of initialization is to place the set in a new out of box

condition. The customer will be prompted to

select a language and program channels after the set has been

initialized.

To put the program back at the factory-default, initialize the LCD

TV using the following procedure.

(1) Turn the power on.

(2) To enter the service mode, press the service button on the

service remote control unit.

- To cancel the service mode, press [POWER] button on

the service remote control unit.

(3) Press [INFO] button on the service remote control unit to

initialize the LCD television.

(4) "INITIALIZED" will appear in the upper right of the screen.

"INITIALIZED" color will change to green from red when initializing is complete.

4.9 FIRMWARE RENEWAL MODE

4.9.1 EQUIPMENT REQUIRED

a. USB memory

b. Remote Control Unit

4.9.2 FIRMWARE UPDATE PROCEDURE

NOTE:

There are two states (the User Upgrade and the Factory Upgrade) in firmware update.

Software Upgrade

Software upgrade in progress. Please wait.

Do not remove the USB device or turn the TV off

while upgrade is in progress.

*1

Downloading...

0%

NOTE:

If the above screen isn’t displayed, repeat from step 1.

The appearance shown in *1 is described as follows.

Appearance State

Downloading... Downloading the firmware from the USB

memory.

Writing... Writing the downloaded firmware in flash

memory.

Checking... Checking the new firmware.

(5) When the firmware update is completed, the following will

appear on the screen.

Software Upgrade

User Upgrade Upgrade the firmware only. The

setting values are not initialized.

Factory upgrade Upgrade the firmware and initialize

the setting values.

The identification of User Upgrade and Factory Upgrade are

done by the filename.

(1) Turn the power off and unplug the AC Cord.

(2) Insert the USB memory to the USB port as shown below.

Rear Cabinet

USB Memory

The software upgrade is completed.

Remove USB storage device, unplug and replug power code.

Unplug the AC cord and kindly remove the USB memory

from the USB port. Plug the AC cord in the wall outlet again

and turn the power on.

NOTE:

When the Factory Upgrade is used, after restarting TV,

shift to initial screen menu in service mode. "INITIALIZED" will appear on the upper right of the screen. "INITIALIZED" color will change to green from red when

initializing is complete.

(3) Plug the AC cord in the wall outlet and turn the power on.

(4) The update will start and the following will appear on the

screen.

1-14 (No.YA712<Rev.002>)

Page 15

5.1 Power Supply Section

FLOW CHART NO.1

The power cannot be turned on.

SECTION 5

TROUBLESHOOTING

Is the fuse (F601) normal?

Ye s

Is normal state restored when once un

power cord is plugged again several seconds?

Ye s

Is the AL+33V line voltage normal?

Ye s

Check each rectifying circuit of the secondar

circuit and service it if def

FLOW CHART NO.2

The fuse blows out.

Check the prese

is leaking or shorted and ser

After servicing, replace the fuse.

FLOW CHART NO.3

When the output voltage fluctuates.

nce that the pr

ective.

imary component

vice it if de

plugged

fective.

No

No

No

y

See FLOW CHART No.2 <The fuse blows out.>

Check if there is any leak or short-circuiting on the

primary circuit component, and service it if defective.

(C605, D601, D602, D603, D604, Q601, Q602,

T601)

Check the presence that the rectifying diode or circuit

is shorted in each rectifying circuit of secondar

and service it if defective.

y side,

Does the photocoupler circuit on

secondary side operate normally?

Check IC601, D609, D611 and their per

circuit and service it if def

FLOW CHART NO.4

When buzz sound can be heard in the vicinity of power circuit.

Check if there is any short-circuit on the rectifying diode and the circuit

and service it if defective. (IC631, Q207, Q209, Q210, Q211, Q501, Q635, Q636, Q637, Q640, Q641, Q64

D631, D632, D633, D638, D641, D642, D646, D

FLOW CHART NO.5

AL+33V is not output.

Is approximately +34V voltage supplied to the

cathode of D638?

Check D657, R661 and their peripher

service it if defective.

the

Ye s

iphery,

ective.

647)

Ye s

y circuit, and

No

No

Check IC601, D652, Q631 and their periphery

circuit, and service it if defective.

in each rectifying circuit of the secondary side

Check C638, D638, D639 and their periphery

circuit, and service it if defective.

,

2, Q643,

(No.YA712<Rev.002>)1-15

Page 16

FLOW CHART NO.6

LCD+24.5V is not output.

Is approximately +30V voltage supplied to the collector

of Q210?

Ye s

Check Q207, Q208, D205, P-ON-H1 line and their

periphery circuit, and service it if defective.

FLOW CHART NO.7

LCD+16V is not output.

Is approximately +19V voltage supplied to the

collector of Q209?

Ye s

Is approximately +16V voltage supplied to the

base of Q209?

Ye s

Replace Q209.

FLOW CHART NO.8

INV+16V is not output.

No

No

No

See FLOW CHART No.5

Check C631, D631, D635 and their per

iphery circuit,

and service it if defective.

Check Q207, Q208, D203, D204, D211 and their

periphery circuit, and service it if defective.

Is approximately +19V voltage supplied to the

collector of Q501?

Ye s

Is approximately +16V voltage supplied to the

base of Q501?

Ye s

Replace Q501.

FLOW CHART NO.9

P-ON+7V is not output.

Is approximately +7V voltage supplied to the

collector of D646?

Ye s

Check if there is any leak or shor

t-circuit on

the loaded circuit, and service it if defective.

No

No

No

Check C631, D631, D635 and their periphery circuit,

and service it if defective.

Check Q207, Q208, D203, D204, D211 and their

periphery circuit, and service it if defective.

Check C644, D646 and their periphery circuit,

and service it if defective.

1-16 (No.YA712<Rev.002>)

Page 17

FLOW CHART NO.10

P-ON+5V is not output. (LCD+16V is outputted normally.)

Is approximately +6.8V voltage supplied to the

No

collector of Q643?

Ye s

Is approximately +6V voltage supplied to the

No

base of Q641 and the base of Q643?

Ye s

Replace Q641 and Q643.

FLOW CHART NO.11

P-ON+5V(TUNER+5V) is not output. (LCD+16V is outputted normally.)

Is approximately +6.7V voltage supplied to the

No

collector of Q640?

Ye s

Is approximately +6V voltage supplied to the

No

base of Q641 and the base of Q643(Q640)?

Ye s

Replace Q641 and Q643(Q640).

See FLOW CHART No.9

Check D645 and their periphery circuit, and service

it if defective.

See FLOW CHART No.9

Check D645 and their periphery circuit, and service

it if defective.

FLOW CHART NO.12

AL+13V(M+13V) is not output.

Is approximately +13V voltage supplied to the

cathode of D641 and D642?

Ye s

Check if there is any leak or short-circuit on

the loaded circuit, and service it if def

ective.

FLOW CHART NO.13

P-ON+3V is not output.

Is approximately +3V voltage supplied to the

cathode of D647?

Ye s

Check if there is any leak or shor

the loaded circuit, and service it if def

t-circuit on

ective.

No

No

Check C639, D642 and their periphery circuit, and

service it if defective.

Check C645, D647 and their per

service it if def

ective.

iphery circuit, and

(No.YA712<Rev.002>)1-17

Page 18

FLOW CHART NO.14

P-ON+3.3V is not output.

Is approximately +5V voltage supplied to the

cathode of D633?

Ye s

Is the "H" signal (approximately +3.5V) inputted to the

base of Q637?

Ye s

Replace Q637.

FLOW CHART NO.15

P-ON+9V is not output. (LCD+16V is outputted normally.)

Is approximately +13V voltage supplied to t

he

collector of Q642?

Ye s

Is approximately +10V voltage supplied to the

base of Q642?

Ye s

Replace Q642.

No

No

No

No

Check C633, D633 and their periphery circuit, and

service it if defective.

Check Q638, Q639, P-ON-H2 line and their periphery

circuit, and service it if def

ective.

See FLOW CHART No.12

Check D670 and their periphery circuit, and service

it if defective.

FLOW CHART NO.16

AL+3.3V is not output.

Is approximately +34V voltage supplied to the

collector of Q635?

Ye s

Is approximately +5V voltage supplied to Pin(1) of

IC631?

Ye s

Replace IC631.

FLOW CHART NO.17

LCD-6.8V is not output.

Is approximately -9V voltage supplied to the

Anode of D632?

Ye s

Is approximately -8V voltage supplied to the

base of Q211?

Ye s

No

No

No

No

See FLOW CHART No.5

Check Q635, D659 and their per

iphery circuit, and

service it if defective.

Check C632, D632 and their periphery

circuit, and service it if defective.

Check Q207, Q208, D205, P-ON-H1 line and their

periphery circuit, and service it if defective.

Replace Q211.

1-18 (No.YA712<Rev.002>)

Page 19

5.2 Video Signal Section

FLOW CHART NO.1

The key operation is not functioning.

Are the contact point and installation state of the k

switches (SW101A, SW103A~SW107A) nor

mal?

Ye s

When pressing each switches (SW101A, SW103A~

SW107A) do the voltage of Pin(29) of CN302 and

Pin(2) of CN303 increase?

Ye s

Replace Digital Main PWB Unit.

FLOW CHART NO.2

No operation is possible from the remote control unit.

Operation is possible from the remote control unit.

Is 3.3V voltage supplied to Pin(2) terminal of the

remote control receiver (RS102)?

Ye s

Is the "L" pulse sent out Pin(1) terminal of remote

control receiver (RS102) when the infrared remote

control is activated?

Ye s

Is the "L" pulse supplied to Pin(25) of CN301?

Ye s

Replace Digital Main PWB Unit.

ey

No

No

No

No

No

Re-install the switches (SW101A, SW103A~SW107A)

correctly or replace the poor switch.

Check the switches (SW101A, SW103A~SW107A)

and their periphery, and service it if defective.

Check AL+3.3V line and service it if defective.

Replace the remote control receiver(RS102)

or the remote control unit.

Check the line between Pin(1) terminal of remote

control receiver(RS102) and Pin(25) of CN301,

and service it if defective.

FLOW CHART NO.3

Picture does not appear normally.(Video input)

Are the video signal inputted to Pin

Ye s

Replace Digital Main PWB Unit or LCD Module

Assembly.

(4) of CN302?

No

Check the line between Pin(4) of CN302 and

JK752, and service it if defective.

(No.YA712<Rev.002>)1-19

Page 20

FLOW CHART NO.4

Picture does not appear normally.(Tuner input)

Are the DIF signal inputted to the Pin(26,28) of CN302?

Ye s

Replace Digital Main PWB Unit or LCD Module

Assembly.

FLOW CHART NO.5

Picture does not appear normally.(S-Video input)

Are the video signal o

utputted to the Pin(6, 8) of

CN302?

Pin(6): S-VIDEO-C

Pin(8): S-VIDEO-Y

Ye s

Replace Digital Main PWB Unit

or LCD Module

Assembly.

FLOW CHART NO.6

Picture does not appear normally.(Y/Pb/Pr input)

No

No

Check the line between Pin(26, 28) of CN302 and

Pin(10, 11) of TU301, and service it if defective.

Check the line between Pin(6, 8) of CN302 and

JK751, and service it if defective.

Are the video signal inputted to the Pin(15, 17, 19) of

CN302?

Pin(15): VIDEO-Y

Pin(17): VIDEO-Pb

Pin(19): VIDEO-Pr

Ye s

Replace Digital Main

PWB Unit or LCD Module

Assembly.

No

Check the line between Pin(15, 17, 19) of CN302

and input terminals(JK731, JK732, JK733), and

service it if defective.

1-20 (No.YA712<Rev.002>)

Page 21

5.3 Audio Signal Section

FLOW CHART NO.1

Audio is not outputted normally.(Audio input)

Are the audio(L/R) signals inputted to Pin(2, 15)

of IC771?

Ye s

Are the audio(L/R) si

gnals inputted to each pin of

CN301?

Pin(6) :

Pin(8) :

Pin(2) :

Pin(4) :

AMP(L)-OUT

AMP(R)-OUT

AUDIO(L)-OUT

AUDIO(R)-OUT

Ye s

Are the audio(L/R) signals inputted to the Pin

(1, 44)

of IC801?

Are the audio(L/R) si

gnals inputted to the Pin(3, 5)

of IC871?

Ye s

Are the audio(L/R) signals outputte

d to the Pin(1, 2)

of CN801 and CN802?

CN802: SP(L)

CN801: SP(R)

Are the audio(L/R) signals outputte

output ter

minal?

d to the audio

JK871: AUDIO(L)-OUT

JK872: AUDIO(R)-OUT

No

No

No

No

No

Ye s

No

Check the line between Pin(2, 15) of IC771 and

input terminal(JK753, JK754), and service it if

defective.

Replace Digital Main

PWB Unit.

Check the line between Pin(6, 8) of CN301 and

Pin(1, 44) of IC801, and

Check the line betw

service it if de

een Pin(2, 4) of CN301 and

Pin(3, 5) of IC871, and service it if de

fective.

fective.

Check IC801 and their periphery circuit, and

service it if def

ective.

Check SP801,SP802 and their periphery circuit,

and service it if defective.

Check the line betw

een Pin(1,

7) of IC871 and audio

output terminal(JK871, JK872), and service it if

defective.

(No.YA712<Rev.002>)1-21

Page 22

FLOW CHART NO.2

Audio is not outputted normally.(Component Audio input)

Are the audio(L/R) signals inputted to the Pin(4, 11)

of IC771?

Ye s

Are the audio(L/R) signals inputted to each pin of

CN301?

Pin(6) :

Pin(8) :

Pin(2) :

Pin(4) :

AMP(L)-OUT

AMP(R)-OUT

AUDIO(L)-OUT

AUDIO(R)-OUT

Ye s

Are the audio(L/R) signals inputted to the Pin

(1, 44)

of IC801?

Are the audio(L/R) signals inputted to the Pin(3, 5)

of IC871?

Ye s

Are the audio(L/R) signals outputte

d to the Pin(1, 2)

of CN801 and CN802?

CN802: SP(L)

CN801: SP(R)

Are the audio(L/R) signals outputte

d to the audio

output terminal?

JK871: AUDIO(L)-OUT

JK872: AUDIO(R)-OUT

No

No

No

No

No

Ye s

No

Check the line between Pin(4, 11) of IC771 and

input terminal(JK741, JK742), and service it if

defective.

Replace Digital Main PWB Unit.

Check the line between Pin(6, 8) of CN301 and

Pin(1, 44) of IC801, and service it if def

Check the line between Pin(2, 4) of CN301

Pin(3, 5) of IC871, and ser

vice it if de

ective.

f

ective.

and

Check IC801 and their periphery circuit, and

service it if def

ective.

Check SP801,SP802 and their periphery circuit,

and service it if defective.

Check the line between Pin(1, 7) of IC871 and audio

output terminal(JK871, JK872), and service it if

defective.

1-22 (No.YA712<Rev.002>)

Page 23

FLOW CHART NO.3

Audio is not outputted normally.(Tuner input)

Are the DIF signals outputted to the Pin(26, 28)

of CN302?

Ye s

Are the audio(L/R) signals inputted to each pin of

CN301?

Pin(6) :

Pin(8) :

Pin(2) :

Pin(4) :

AMP(L)-OUT

AMP(R)-OUT

AUDIO(L)-OUT

AUDIO(R)-OUT

Ye s

Are the audio(L/R) signals inputted to the Pin(1, 44)

of IC801?

Are the audio(L/R) signals inputted to the Pin(3, 5)

of IC871?

Ye s

Are the audio(L/R) signals outputted to the Pin(1, 2)

of CN801 and CN80

2?

CN802: SP(L)

CN801: SP(R)

Are the audio(L/R) signals outputte

d to the audio

output terminal?

JK871: AUDIO(L)-OUT

JK872: AUDIO(R)-OUT

No

No

No

No

No

Ye s

No

Check TU301 and their periphery circuit, and

service it if defective.

Replace Digital Main PWB Unit.

Check the line between Pin(6, 8) of CN301 and

Pin(1, 44) of IC801, and

service it if de

fective.

Check the line between Pin(2, 4) of CN301 and

Pin(3, 5) of IC871, and service it if de

fective.

Check IC801 and their periphery circuit, and

service it if def

ective.

Check SP801,SP802 and their periphery circuit,

and service it if defective.

Check the line between Pin(1, 7) of IC871 and audio

output terminal(JK871, JK872), and service it if

defective.

(No.YA712<Rev.002>)1-23

Page 24

Victor Company of Japan, Limited

Display Division 12, 3-chome, Moriya-cho, Kanagawa-ku, Yokohama-city, Kanagawa-prefecture, 221-8528, Japan

(No.YA712<Rev.002>)

Printed in Japan

VSE

Loading...

Loading...