Page 1

MA244200512

SERVICE MANUAL

CD/CASSETTE RECEIVER

KW-TC410,KW-TC411

Area suffix

UN --------------------- Indonesia

Lead free solder used in the board (material : Sn-Ag-Cu, melting point : 219 Centigrade)

TABLE OF CONTENTS

1 PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2 SPECIFIC SERVICE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

COPYRIGHT © 2005 Victor Company of Japan, Limited

No.MA244

2005/12

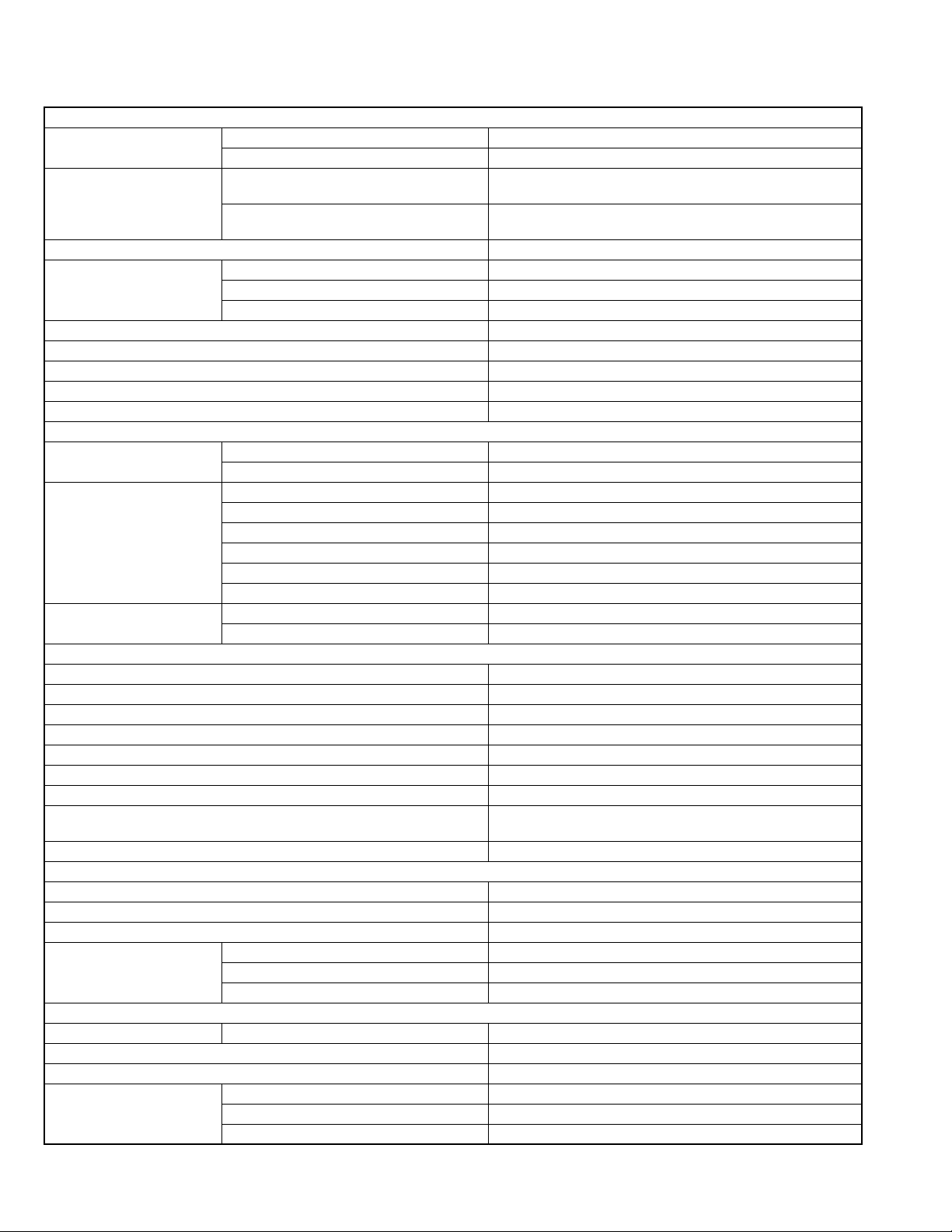

Page 2

SPECIFICATION

AUDIO AMPLIFIER SECTION

Maximum Power Output Front 50 W per channel

Rear 50 W per channel

Continuous Power Output

(RMS)

Load Impedance 4

Equalizer Control Range Low ±12 dB (60 Hz, 80 Hz, 100 Hz, 120 Hz)

Frequency Response 40 Hz to 20 000 Hz

Signal-to-Noise Ratio 70 dB

Line-Out Level/Impedance 2.0 V/20 k

Output Impedance 1 k

Other terminals CD changer, AUX (auxiliary) input jack

Frequency Range FM 87.5 MHz to 108.0 MHz

[FM Tuner] Usable Sensitivity 11.3 dBf (1.0

[AM Tuner] Sensitivity 20

Type Compact disc player

Signal Detection System Non-contact optical pickup (semiconductor laser)

Number of Channels 2 channels (stereo)

Frequency Response 5 Hz to 20 000 Hz

Dynamic Range 96 dB

Signal-to-Noise Ratio 98 dB

Wow and Flutter Less than measurable limit

MP3 Decoding Format (KW-TC411/KW-TC410 only) MPEG1/2 Audio Layer 3

WMA (Windows Media® Audio) Decoding Format (KW-TC411/KW-TC410 only) Max. Bit Rate: 192 kbps

Wow and Flutter 0.1 % (WRMS)

Fast-Wind Time 100 sec. (C-60)

Frequency Response 30 Hz to 16 000 Hz (Normal tape)

Signal-to-Noise Ratio

(Normal tape)

Power Requirement Operating Voltage DC 14.4 V (11 V to 16 V allowance)

Grounding System: Negative ground

Allowable Operating Temperature 0

Dimensions (W

× H × D) Installation Size (approx.) 178 mm × 100 mm × 158 mm

Front 19 W per channel into 4

total harmonic distortion.

Rear 19 W per channel into 4

total harmonic distortion.

Ω (4 Ω to 8 Ω allowance)

Mid ±12 dB

High ±12 dB (8 kHz, 10 kHz, 12 kHz, 15 kHz)

Ω load (full scale)

Ω

TUNER SECTION

AM 531 kHz to 1 602 kHz

µV/75 Ω)

50 dB Quieting Sensitivity 16.3 dBf (1.8

Alternate Channel Selectivity (400 kHz) 65 dB

Frequency Response 40 Hz to 15 000 Hz

Stereo Separation 30 dB

Capture Ratio 1.5 dB

µV/75 Ω)

µV

Selectivity 35 dB

CD PLAYER SECTION

Max. Bit Rate: 320 kbps

CASSETTE DECK SECTION

Dolby B NR ON 65 dB

Dolby B NR OFF 56 dB

Stereo Separation 40 dB

GENERAL

°C to +40°C

Set Size (approx.) 178 mm

Mass (approx.) 2.3 kg (excluding accessories)

× 100 mm × 177 mm

Ω, 40 Hz to 20 000 Hz at no more than 0.8%

Ω, 40 Hz to 20 000 Hz at no more than 0.8%

Design and specification are subject to change without notice.

1-2 (No.MA244)

Page 3

1.1 Safety Precautions

SECTION 1

PRECAUTIONS

!

!

Burrs formed during molding may be left over on some parts of the chassis. Therefore,

pay attention to such burrs in the case of preforming repair of this system.

Please use enough caution not to see the beam directly or touch it in case of an

adjustment or operation check.

(No.MA244)1-3

Page 4

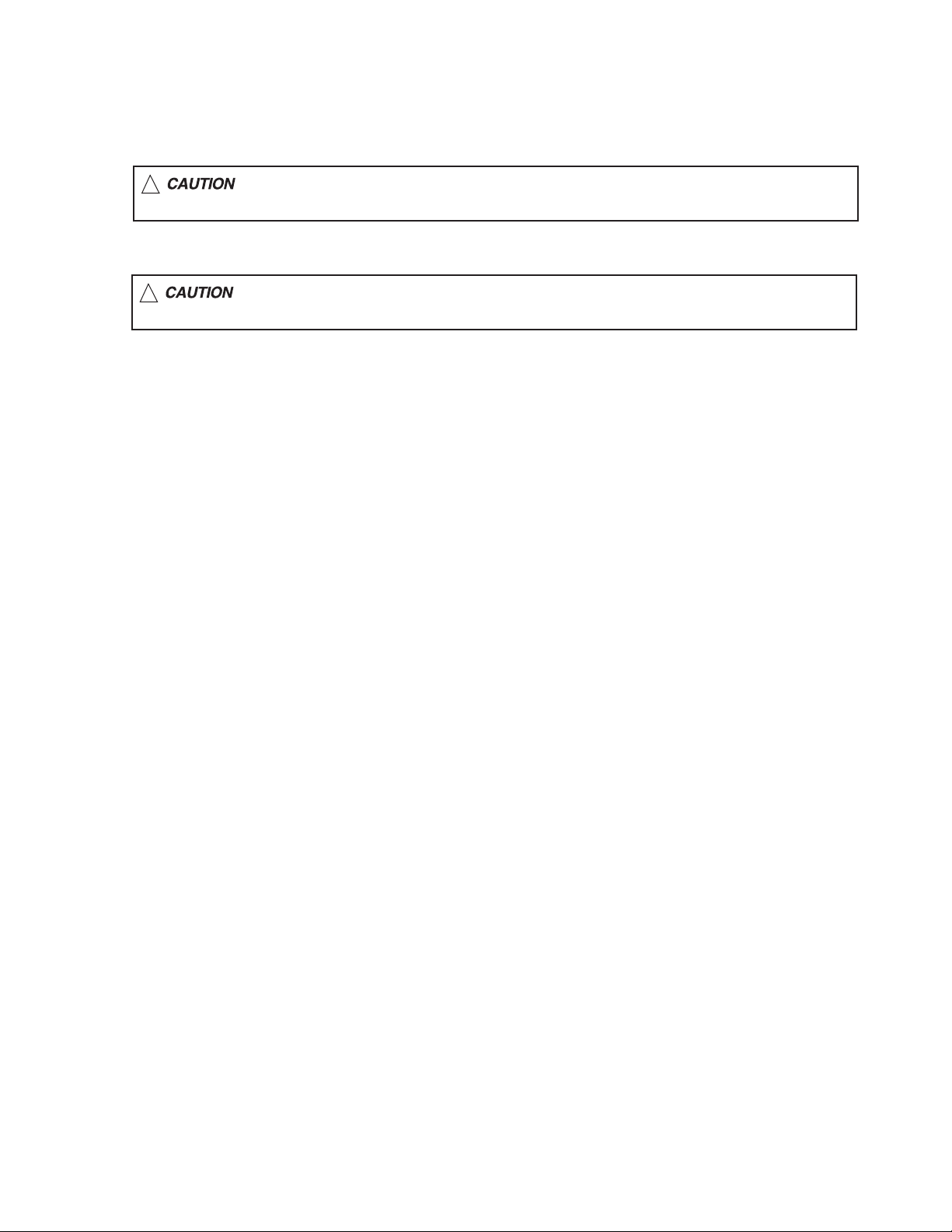

1.2 Preventing static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged, can destroy the laser

diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

1.2.1 Grounding to prevent damage by static electricity

Static electricity in the work area can destroy the optical pickup (laser diode) in devices such as CD players.

Be careful to use proper grounding in the area where repairs are being performed.

(1) Ground the workbench

Ground the workbench by laying conductive material (such as a conductive sheet) or an iron plate over it before placing the

traverse unit (optical pickup) on it.

(2) Ground yourself

Use an anti-static wrist strap to release any static electricity built up in your body.

(caption)

Anti-static wrist strap

1M

Conductive material

(conductive sheet) or iron plate

(3) Handling the optical pickup

• In order to maintain quality during transport and before installation, both sides of the laser diode on the replacement optical

pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

• Do not use a tester to check the condition of the laser diode in the optical pickup. The tester's internal power source can easily

destroy the laser diode.

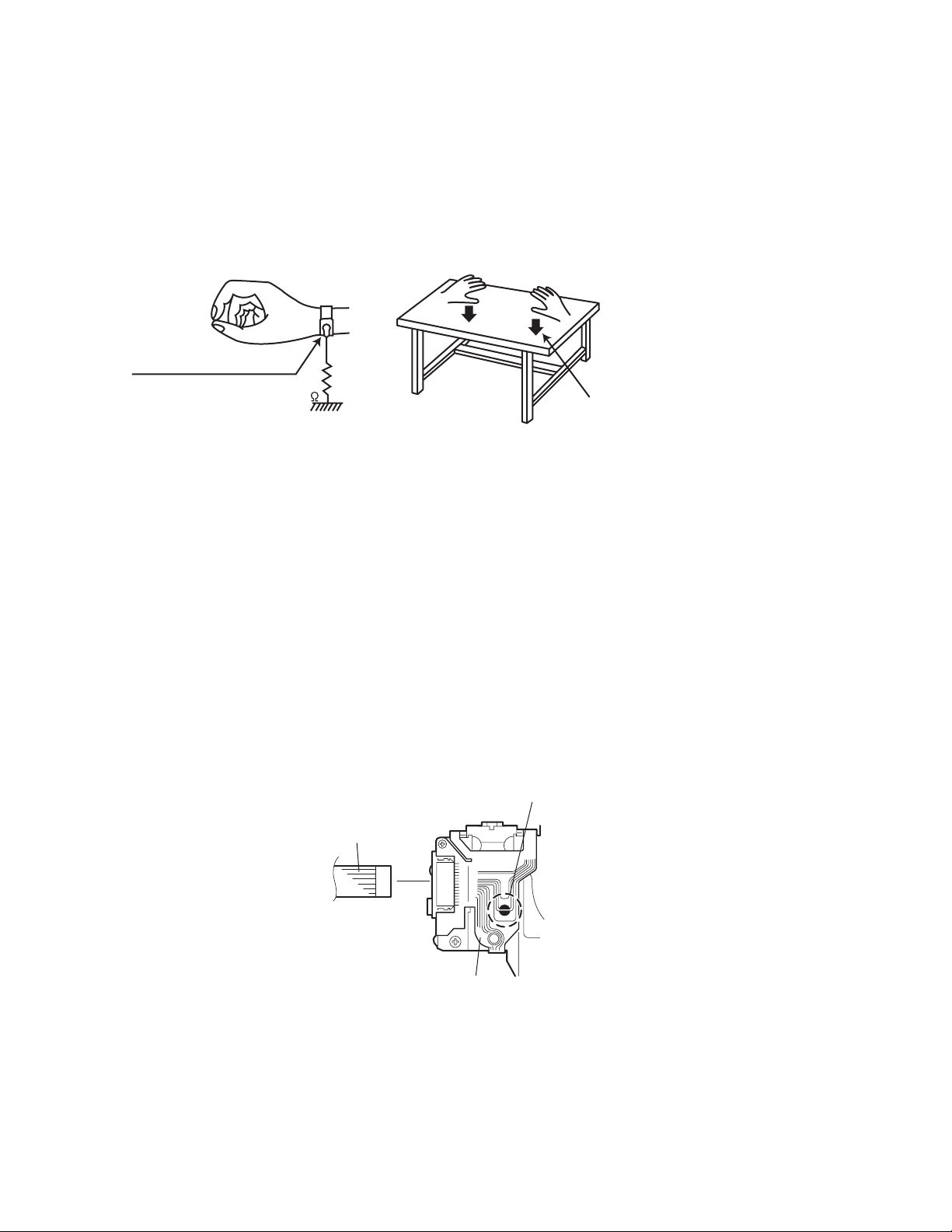

1.3 Handling the traverse unit (optical pickup)

(1) Do not subject the traverse unit (optical pickup) to strong shocks, as it is a sensitive, complex unit.

(2) Cut off the shorted part of the flexible cable using nippers, etc. after replacing the optical pickup. For specific details, refer to the

replacement procedure in the text. Remove the anti-static pin when replacing the traverse unit. Be careful not to take too long a

time when attaching it to the connector.

(3) Handle the flexible cable carefully as it may break when subjected to strong force.

(4) It is not possible to adjust the semi-fixed resistor that adjusts the laser power. Do not turn it.

1.4 Attention when traverse unit is decomposed

*Please refer to "Disassembly method" in the text for the CD pickup unit.

• Apply solder to the short land before the flexible wire is disconnected from the connector on the CD pickup unit.

(If the flexible wire is disconnected without applying solder, the CD pickup may be destroyed by static electricity.)

• In the assembly, be sure to remove solder from the short land after connecting the flexible wire.

Short-circuit point

(Soldering)

Flexible wire

1-4 (No.MA244)

Pickup

Page 5

1.5 Important for laser products

!

1.CLASS 1 LASER PRODUCT

2.DANGER : Invisible laser radiation when open and inter

lock failed or defeated. Avoid direct exposure to beam.

3.CAUTION : There are no serviceable parts inside the

Laser Unit. Do not disassemble the Laser Unit. Replace

the complete Laser Unit if it malfunctions.

4.CAUTION : The CD,MD and DVD player uses invisible

laser radiation and is equipped with safety switches which

prevent emission of radiation when the drawer is open and

the safety interlocks have failed or are defeated. It is

dangerous to defeat the safety switches.

5.CAUTION : If safety switches malfunction, the laser is able

to function.

6.CAUTION : Use of controls, adjustments or performance of

procedures other than those specified here in may result in

hazardous radiation exposure.

Please use enough caution not to

see the beam directly or touch it

in case of an adjustment or operation

check.

REPRODUCTION AND POSITION OF LABELS

WARNING LABEL

CAUTION : Visible and Invisible

CLASS 1

LASER PRODUCT

laser radiation when open and

interlock failed or defeated.

AVOID DIRECT EXPOSURE TO

BEAM. (e)

ADVARSEL : Synlig og usynlig

laserstråling når maskinen er

åben eller interlocken fejeler.

Undgå direkte eksponering til

stråling. (d)

VARNING : Synlig och

osynling laserstrålning när

den öppnas och spärren är

urkopplad. Betrakta ej

strålen. (s)

VARO : Avattaessa ja suojalukitus

ohitettuna tai viallisena olet alttiina

näkyvälle ja näkymättömälle

lasersäteilylle. Vältä säteen

kohdistumista suoraan itseesi. (f)

(No.MA244)1-5

Page 6

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

2.1 CD mechanism and cassette mechanism

For the CD mechanism, please refer the mechanism manual TN2001-1013 No.MY001.

For the Cassette mechanism, please refer the mechanism manual CDS-802JE3 No.MY002.

1-6 (No.MA244)

Page 7

SECTION 3

DISASSEMBLY

3.1 Main body section

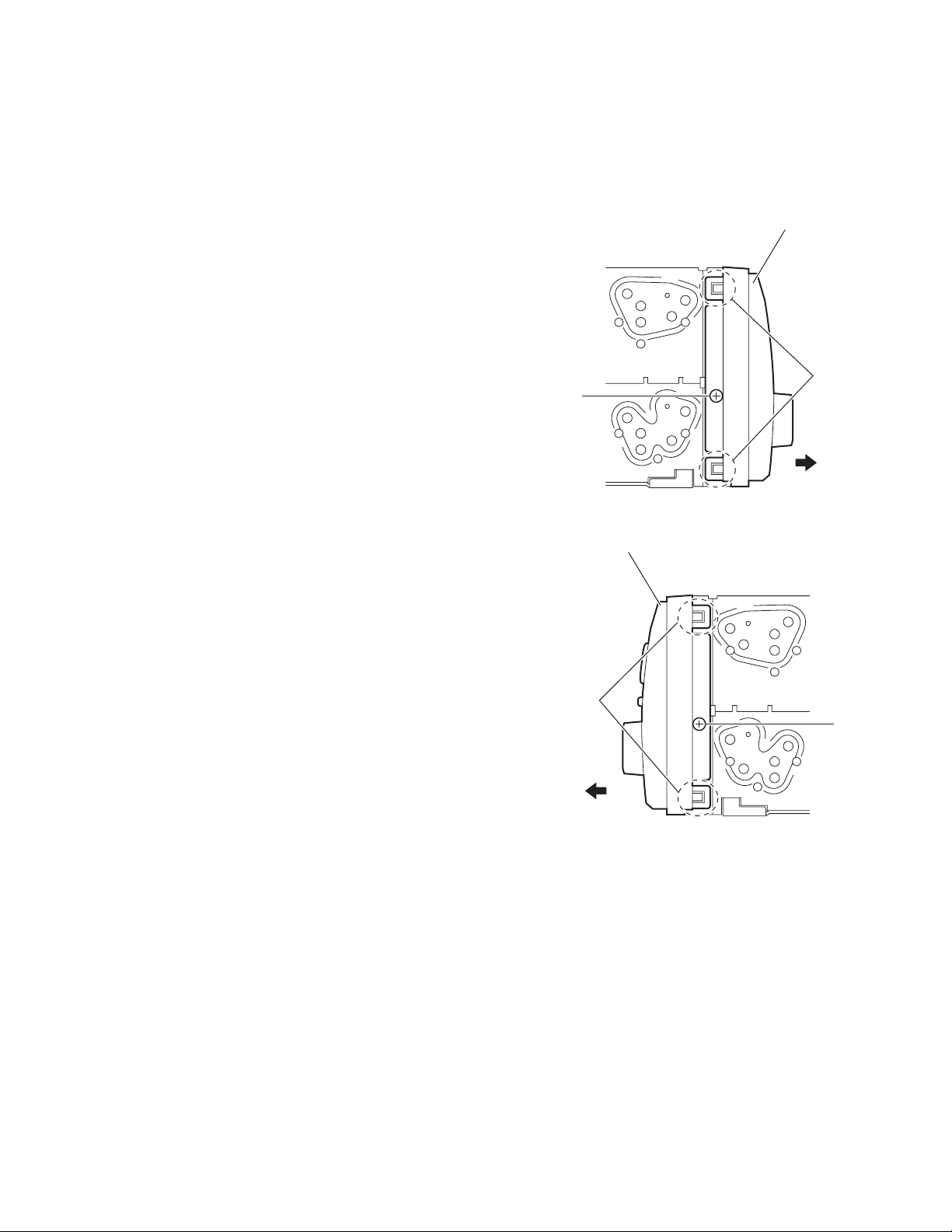

3.1.1 Removing the front panel assembly

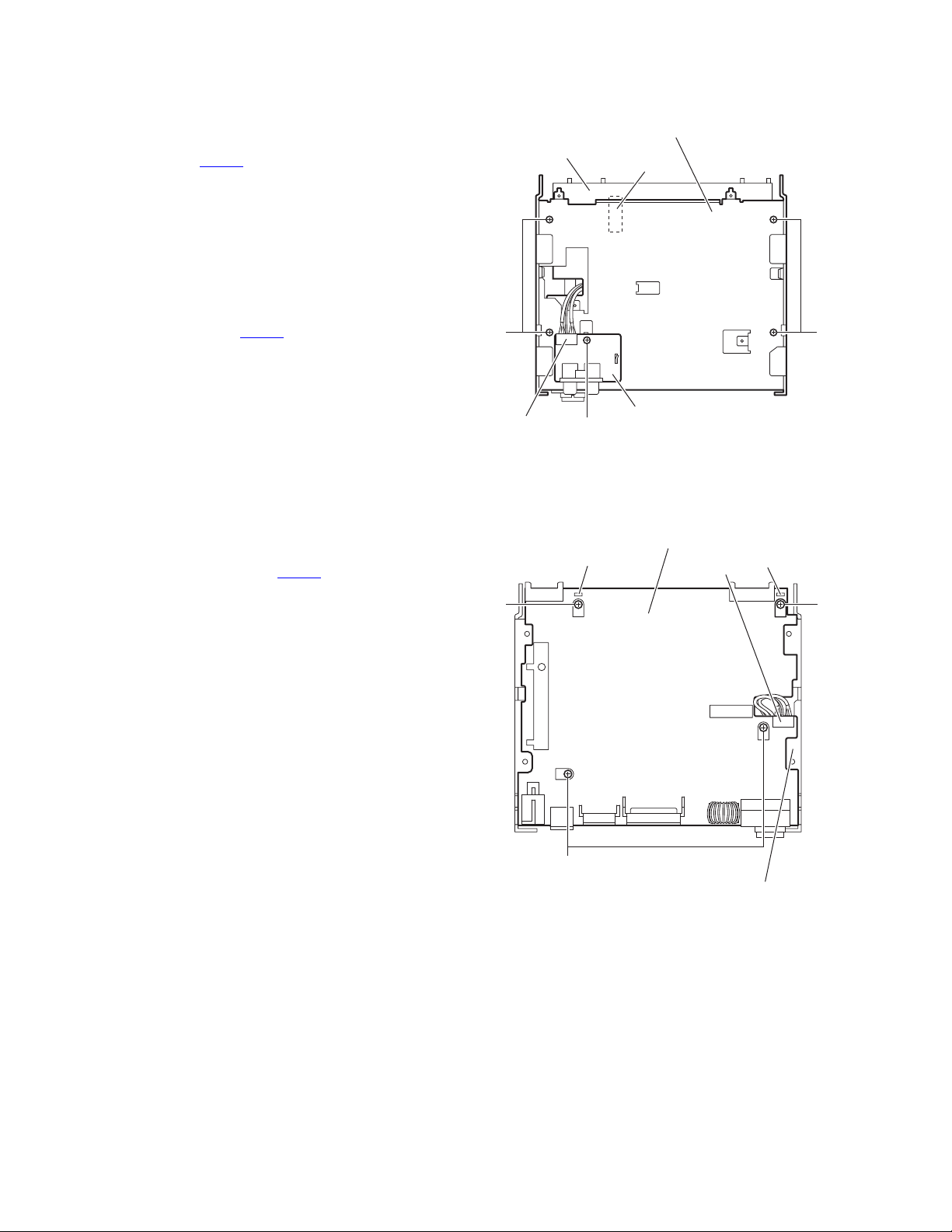

(See Figs.1 and 2)

(1) From the both side of the main body, remove the two

screws A attaching the front panel assembly. (See Figs.1

and 2.)

(2) Release the four joints a and remove the front panel as-

sembly in the direction of the arrow. (See Figs.1 and 2.)

Front panel assembly

a

A

Fig.1

Front panel assembly

a

A

Fig.2

(No.MA244)1-7

Page 8

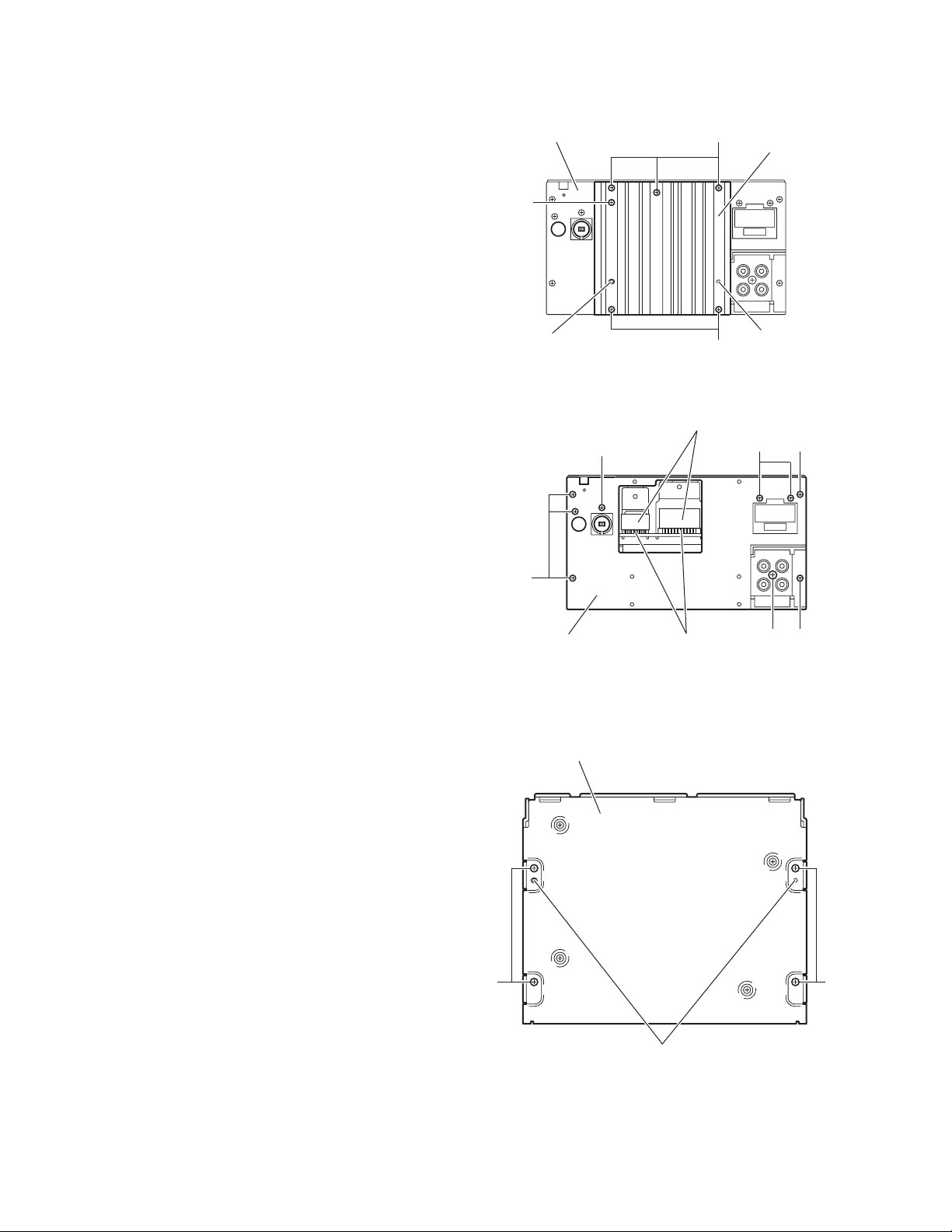

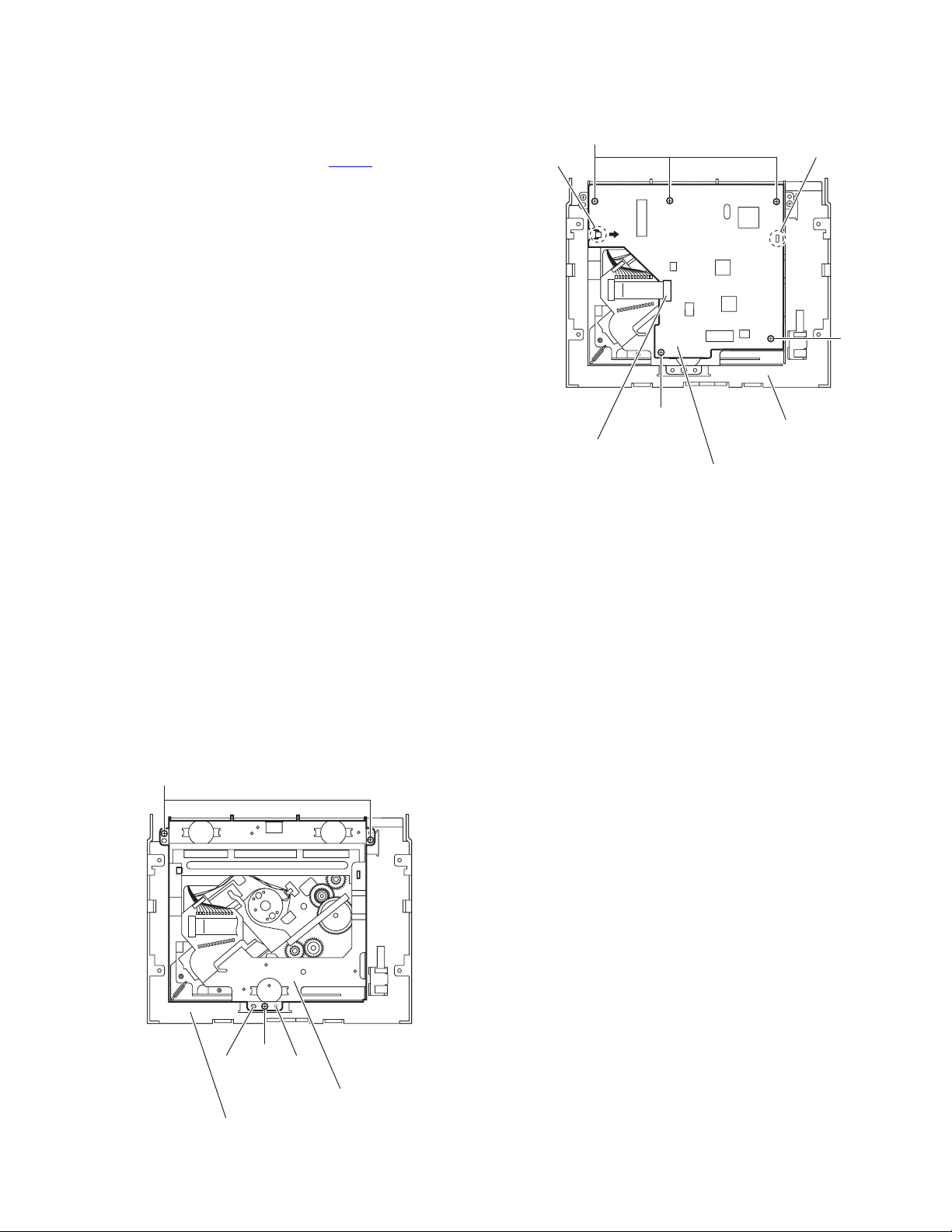

3.1.2 Removing the heat sink

(See Figs.3 and 4)

(1) From the back side of the main body, remove the six

screws B attaching the heat sink. (See Fig.3.)

(2) Remove the heat sink from the main body.

Note:

• Before attaching the heat sink, attach the cooling rubbers on

the power amplifier IC. (See Fig.4)

• When attaching the heat sink, set the projections b on the

rear bracket in the holes of the heat sink. (See Fig.3.)

3.1.3 Removing the rear bracket

(See Fig.4)

• Remove the heat sink.

(1) From the back side of the main body, remove the six

screws C, two screws D and screw E attaching the rear

bracket.

(2) Remove the rear bracket from the main body.

Rear bracket

B

C

B

B

Fig.3

Cooling rubbers

Heat sink

bb

CD

3.1.4 Removing the bottom chassis assembly

(See Fig.5)

• Remove the front panel assembly, heat sink and rear bracket.

(1) From the bottom side of the main body, remove the four

screws F attaching the bottom chassis assembly.

(2) Take out the bottom chassis assembly from the main body.

Reference:

When attaching the bottom chassis assembly, set the projections c of the main body in the holes of the bottom chassis assembly.

C

Rear bracket

Bottom chassis assembly

Power amplifier IC

Fig.4

E

C

FF

1-8 (No.MA244)

c

Fig.5

Page 9

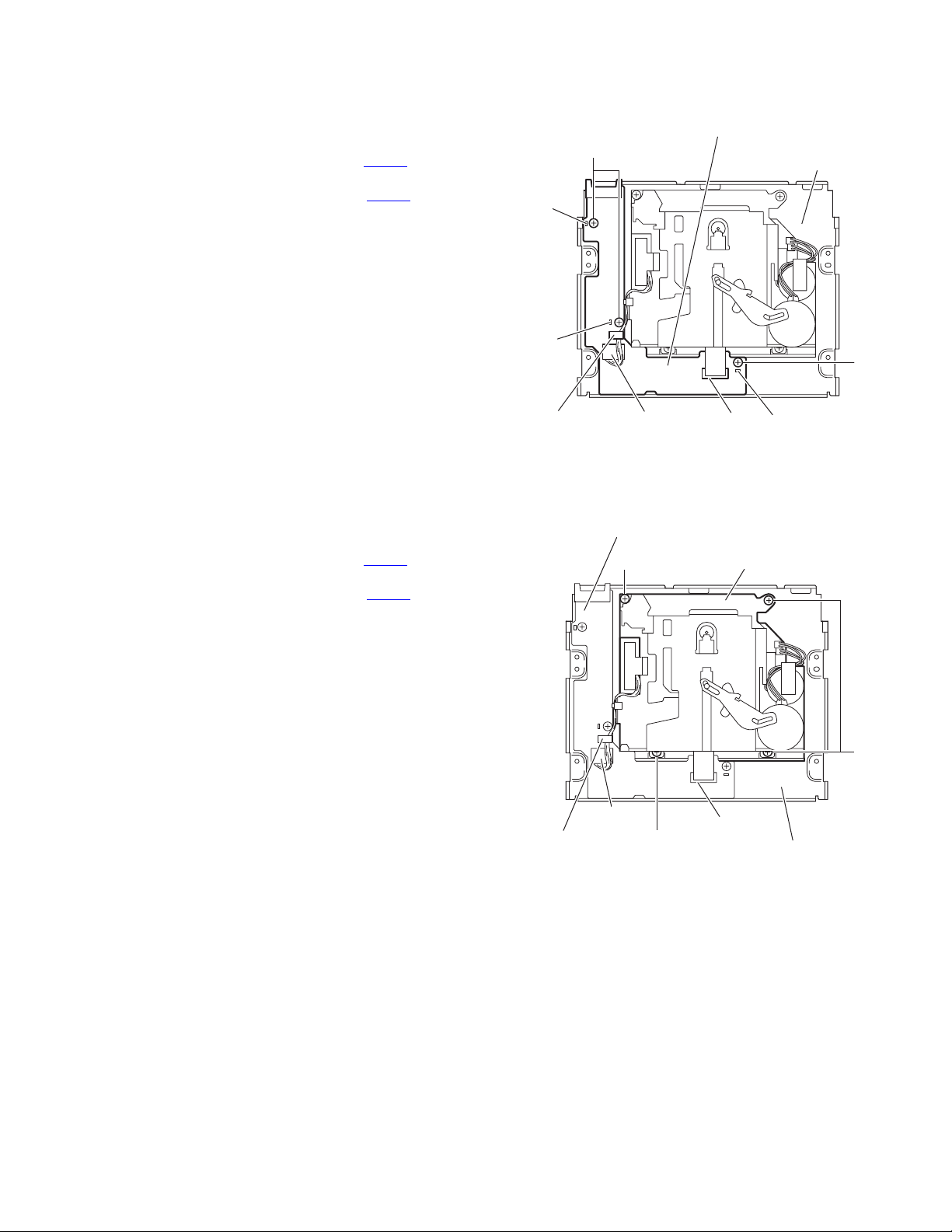

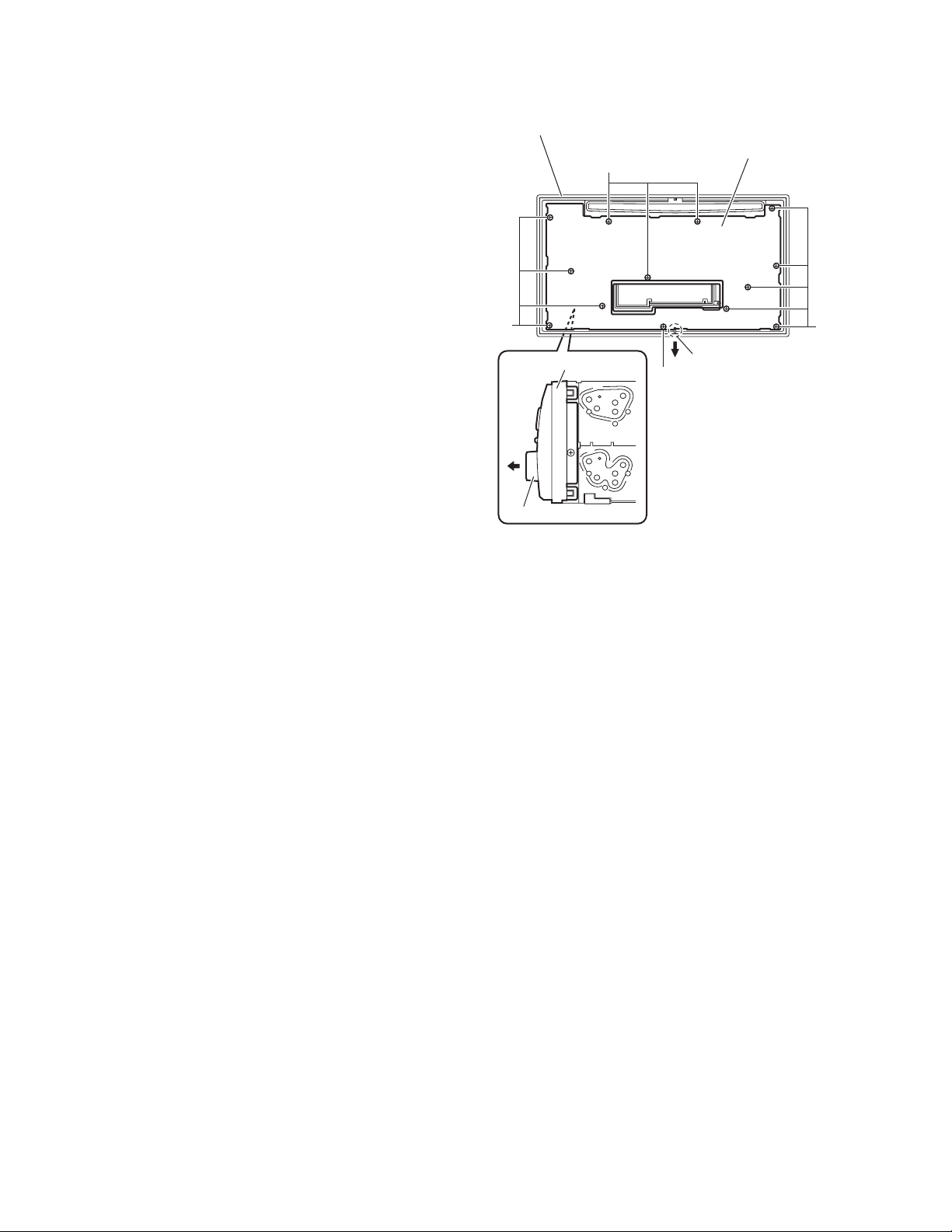

3.1.5 Removing the cassette mechanism control board

(See Fig.6)

• Remove the front panel assembly, heat sink, rear bracket and

bottom chassis assembly.

(1) From the inside of the bottom chassis assembly, discon-

nect the card wire from the connector CN403

sette mechanism control board.

(2) Disconnect the wire from the connector CN402

sette mechanism control board.

(3) Remove the three screws G attaching the cassette mech-

anism control board.

(4) Take out the cassette mechanism control board from the

bottom chassis assembly.

Reference:

• When attaching the cassette mechanism control board, set

the projections d of the bottom chassis assembly in the

holes of the cassette mechanism control board.

• After attaching the cassette mechanism control board, fix

the wire with the wire clamp as before.

on the cas-

on the cas-

Cassette mechanism control board

G

d

d

Bottom chassis assembly

G

3.1.6 Removing the cassette mechanism assembly

(See Fig.7)

• Remove the front panel assembly, heat sink, rear bracket and

bottom chassis assembly.

(1) From the inside of the bottom chassis assembly, discon-

nect the card wire from the connector CN403

sette mechanism control board.

(2) Disconnect the wire from the connector CN402 on the cas-

sette mechanism control board.

(3) Remove the four screws H attaching the cassette mecha-

nism assembly.

Reference:

After attaching the cassette mechanism control board, fix the

wire with the wire clamp as before.

on the cas-

Wire clamp

Cassette mechanism control board

H

CN402

Wire clamp

H

CN403CN402

Fig.6

Cassette mechanism assembly

CN403

Bottom chassis assembly

d

H

Fig.7

(No.MA244)1-9

Page 10

3.1.7 Removing the func board

(See Fig.8)

• Remove the front panel assembly, heat sink, rear bracket and

bottom chassis assembly.

(1) From the bottom side of the main body, disconnect the wire

from the connector CN321

(2) Remove the screw J and take out the func board from the

main body.

3.1.8 Removing the middle chassis assembly

(See Fig.8)

• Remove the front panel assembly, heat sink, rear bracket and

bottom chassis assembly.

(1) From the bottom side of the main body, remove the four

screws K attaching the middle chassis assembly.

(2) Disconnect the connector CN705

middle chassis assembly from the CD mechanism assembly in an upward direction.

on the func board.

of the main board on the

Middle chassis assembly

Main board

CN705

KK

3.1.9 Removing the main board

(See Fig.9)

• Remove the front panel assembly, heat sink, rear bracket, bot-

tom chassis assembly and middle chassis assembly.

(1) From the top side of the middle chassis assembly, discon-

nect the wire from the connector CN323

(2) Remove the four screws M attaching the main board on the

middle chassis.

(3) Remove the main board from the middle chassis.

Reference:

When attaching the main board, set the projections e of the

middle chassis in the holes of the main board.

on the main board.

M

CN321

J

e

Func board

Fig.8

Main board

CN323

e

M

1-10 (No.MA244)

M

Middle chassis

Fig.9

Page 11

3.1.10 Removing the CD mechanism control board

(See Fig.10)

• Remove the front panel assembly, heat sink, rear bracket, bot-

tom chassis assembly and middle chassis assembly.

(1) From the inside of the top chassis assembly, disconnect

the card wire from the connector CN601

anism control board.

(2) Remove the five screws N attaching the CD mechanism

control board.

(3) Lift the CD mechanism control board to remove the joint f

and remove the joint g in the direction of the arrow.

on the CD mech-

N

g

f

N

3.1.11 Removing the CD mechanism assembly

(See Fig.11)

• Remove the front panel assembly, heat sink, rear bracket, bot-

tom chassis assembly, middle chassis assembly and CD

mechanism control board.

(1) From the inside of the top chassis assembly, remove the

three screws P attaching the CD mechanism assembly.

(2) Take out the CD mechanism assembly from the top chas-

sis.

Reference:

When attaching the CD mechanism assembly, set the projections h of the top chassis assembly in the holes of the CD

mechanism assembly.

P

CN601

N

CD mechanism control board

Top chassis assembly

Fig.10

P

h h

CD mechanism assembly

Top chassis assembly

Fig.11

(No.MA244)1-11

Page 12

3.1.12 Removing the switch board

(See Fig.12)

• Remove the front panel assembly.

(1) From the inside of front panel assembly, remove the thir-

teen screws Q attaching the switch board.

(2) Remove the volume knob from the front side of the front

panel assembly in the direction of the arrow while lifting the

switch board little by little.

(3) Release the sections j while extending the lower section of

the front panel assembly in the direction of the arrow and

take out the switch board.

Front panel assembly

Switch board

Q

Q

Front panel assembly

Volume knob

Q

j

Q

Fig.12

1-12 (No.MA244)

Page 13

SECTION 4

ADJUSTMENT

4.1 Adjustment method

Test instruments required for adjustment

(1) Digital oscilloscope (100MHz)

(2) Frequency counter meter

(3) Electric voltmeter

(4) Wow & flutter meter

(5) Test tapes

• VT724...........................For DOLBY level measurement

• VT739..............For playback frequency measurement

• VT712....For wow flutter & tape speed measurement

• VT703........................For head azimuth measurement

(6) Torque gauge............................Cassette type for CTG-N

(Mechanism adjustment)

(7) Laser power meter(Reader:LP800102)

(8) Prove for MD (Reader:LP8010-02)

(9) Pre masterd disc (TGYS-1)

(10)Test disc (JVC:CTS1000)

Measuring conditions (Amplifier section)

• Power supply voltage.............. DC14.4V (11V to 16V allowance)

• Load impedance............ 4Ω (4Ω to 8Ω allowance)

• Line out level/Impedance..............1.0V/20k load (250 nWb/m)

Standard volume position

Balance and Bass, Treble volume, Fader : Center (Indication "0")

Loudness, Dolby NR, Sound, Cruise : Off

Volume position is about 2V at speaker output with following

conditions, Playback the test tape VT721.

AM mode 999kHz/62dB, INT/400Hz, 30%

modulation signal on receiving.

FM mono mode 97.9MHz/66dB, INT/400Hz, 22.5kHz

deviation pilot off mono

FM stereo mode 1kHz, 67.5kHz dev. pilot 7.5kHz dev.

Output level 0dB (1µV,50Ω/open terminal)

(No.MA244)1-13

Page 14

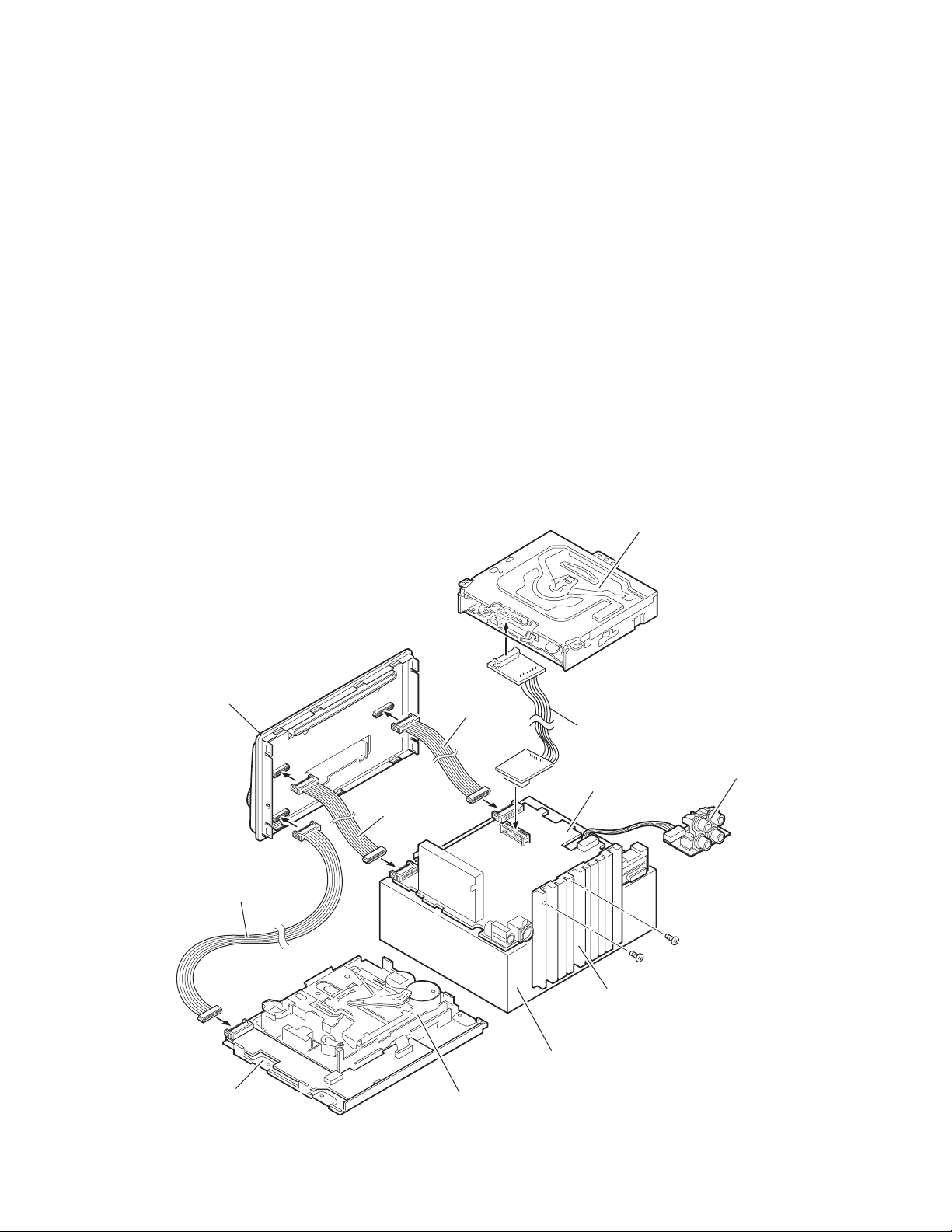

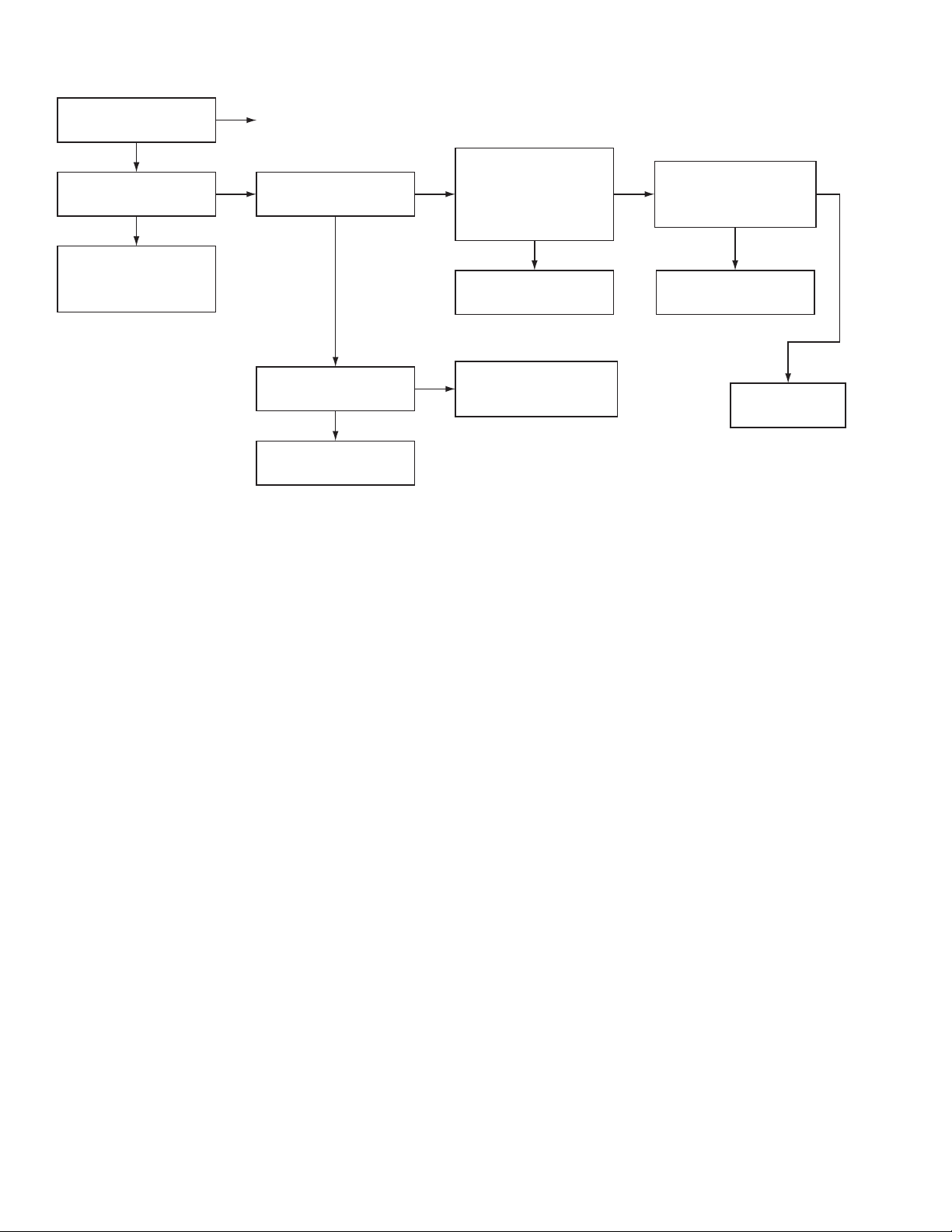

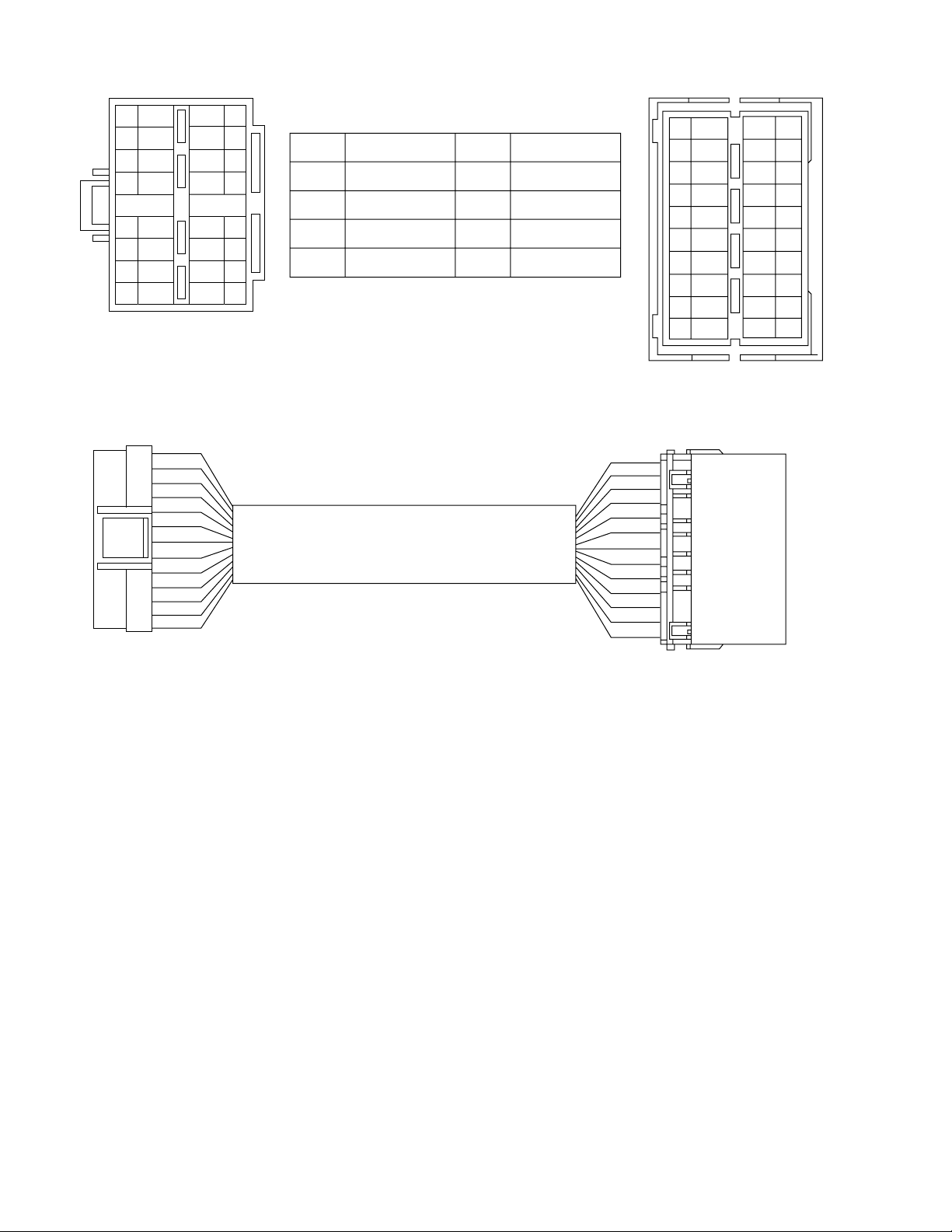

Information for using a car audio service jig

(1) We're advancing efforts to make our extension cords common for all car audio products.

Please use this type of extension cord as follows.

(2) As a U-shape type top cover is employed, this type of extension cord is needed to check operation of the mechanism assembly

after disassembly.

(3) Extension cord : EXTSH002-22P ( 22 pin extension cord ) For connection between the mechanism assembly and main board.

EXTXC004-20P ( 20 pin extension cord ) For connection between the front panel assembly and main board.

EXTXC004-16P ( 16 pin extension cord ) For connection between the front panel assembly and main board.

EXTXC004-16P ( 16 pin extension cord ) For connection between the front panel assembly and cassette mechanism assembly.

(4) Check for mechanism driving section such as motor ,etc.

Disassembly method

(1) Remove the front panel assembly.

(2) Remove the heat sink.

(3) Remove the rear bracket.

(4) Remove the bottom chassis assembly and middle chassis assembly.

(5) Remove the main board.

(6) Remove the CD mechanism assembly.

(7) Reattach the heat sink with two screws to the main board. (Refer to Disassembly method.)

(8) Connect the main board, front panel assembly, bottom chassis assembly and CD mechanism assembly with the extension

cords.

CAUTION :

Be sure to attach a heat sink on the power amplifier IC of a main board when supplying the power.

If voltage is applied without attaching the heat sink, the

power amplifier IC will be destroyed by heat.

CD mechanism assembly

Front panel assembly

EXTXC004-16P

Bottom chassis assembly

EXTXC004-20P

EXTXC004-16P

Cassette mechanism assembly

EXTSH002-22P

Main board

Heat sink

*The box etc. is used as a stand.

Func board

1-14 (No.MA244)

Page 15

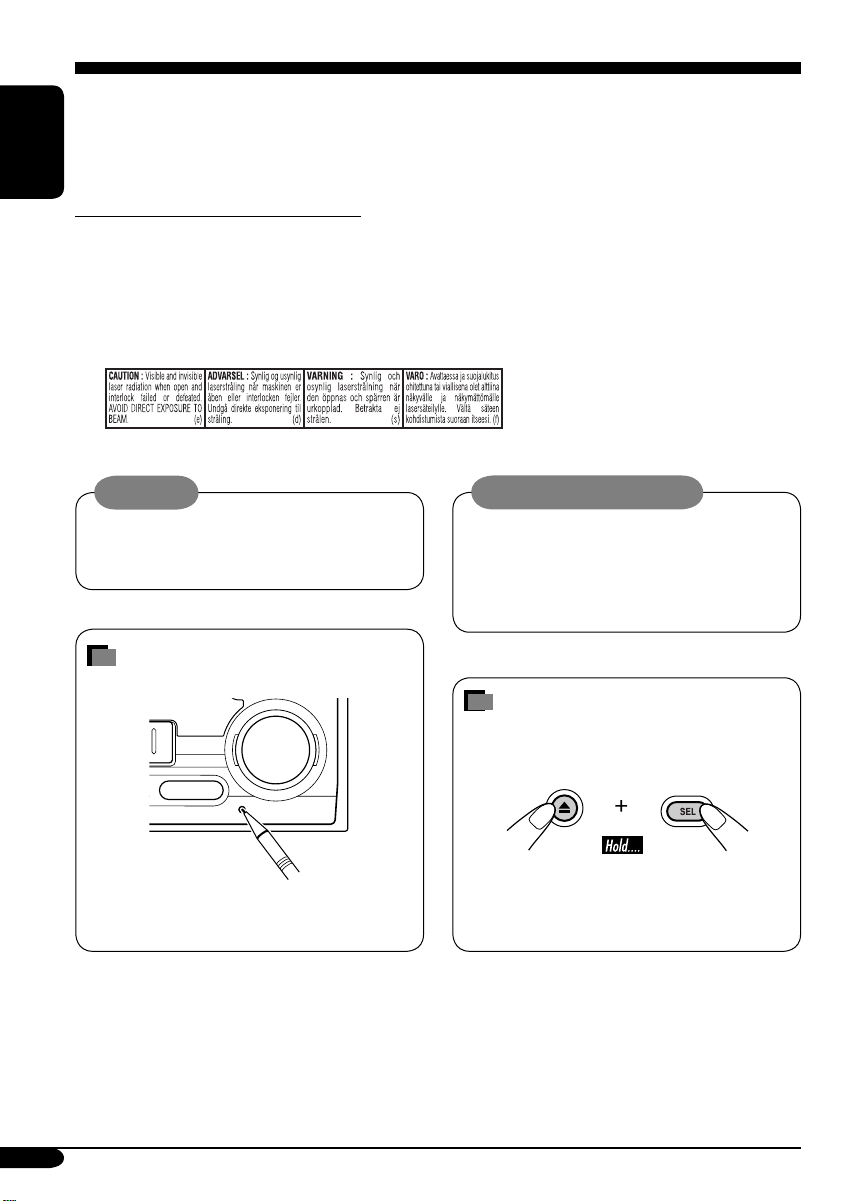

4.2 Service mode

Set up

Press POWER ON [SEL] [POWER] [CD EJECT] together more than 2 sec.

UP,DW button to select

SEL button to determination

DEL EPROM EEPROM clear

CD ERROR CD error history call change by FF button E1 to TOTAL

DEL CD CD error history clear

MAIN TEMP Templature indication of main board

VERSION Micon version indication

For next operation, service mode is stop automaticaly.

1. No input signal (key operation) more than 5 sec.

2. press other key without SEL,UP,DOWN.

3. ACC to OFF.

(No.MA244)1-15

Page 16

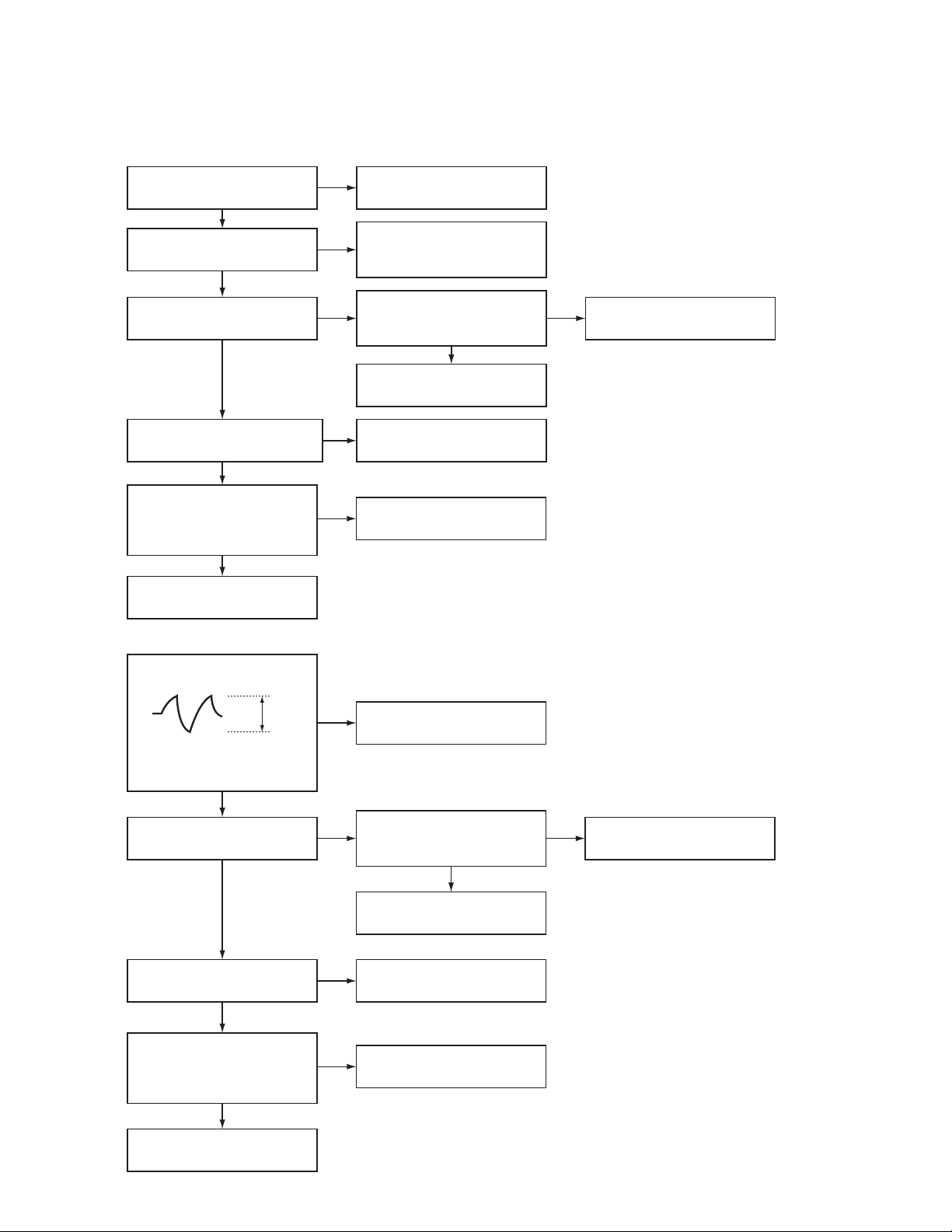

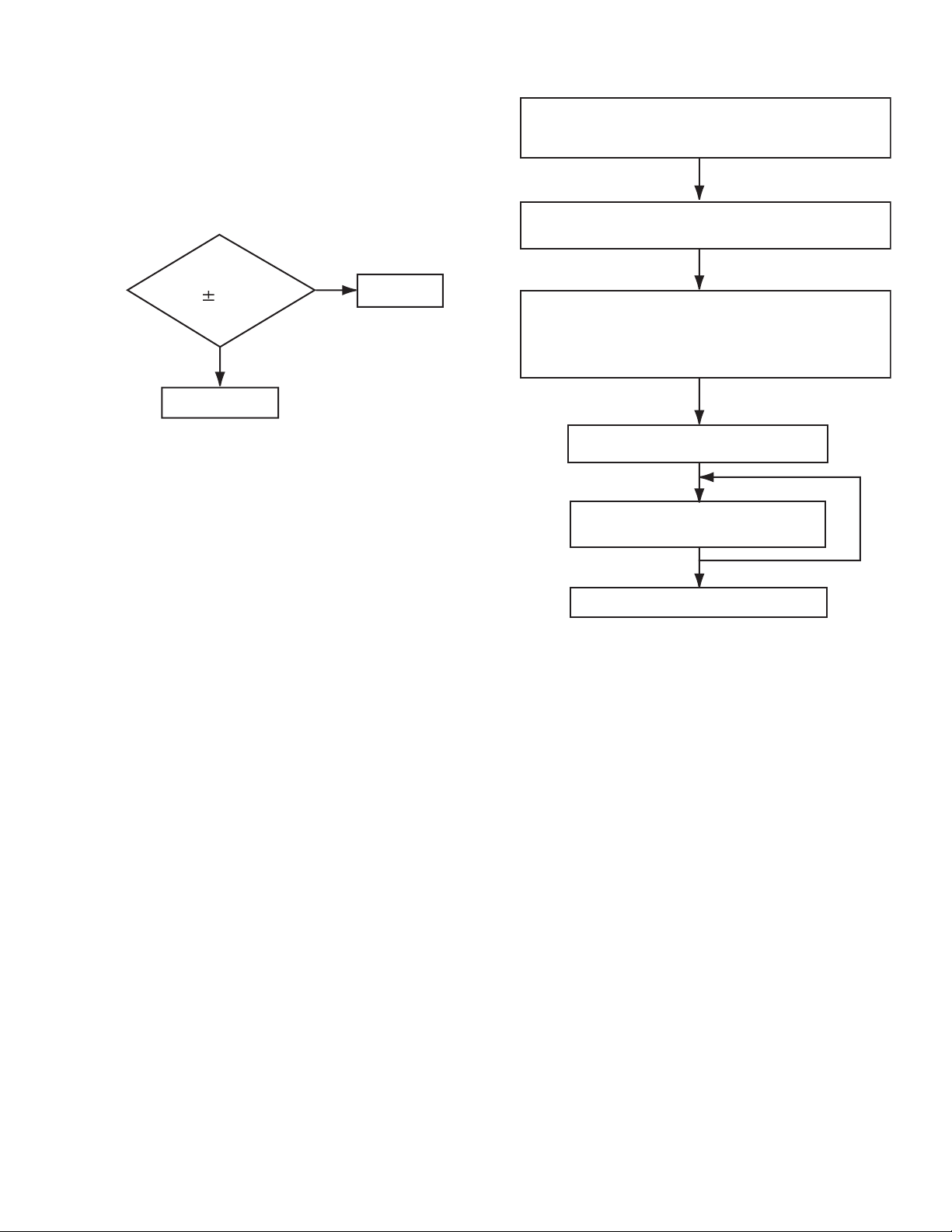

5.1 Feed section

SECTION 5

TROUBLESHOOTING

Is the voltage present at both

sides of the feed motor?

Is the voltage output at pin 17

and pin 18 of IC681?

Is the voltage input at pin 24

of IC681?

Is the voltage output at pin 40

of IC621?

Is the power supply present

at pin 6, pin 15, pin 25, pin 39,

pin 43, pin 48, pin 51 and pin

64 of IC621?

Check the connections of

CD8V power supply.

5.2 Focus section

NO

NO

NO

NO

NO

YES

YES

YES YES

YES

YES

Check the feed motor.

Check the connections

between the feed motor and

IC681.

Is the power supply present

at pin 10, pin 19 and pin 28

of IC681?

NO

Check the connections of

CD8V power supply.

Check the connections

between IC681 and IC621.

Check IC621.

Check IC681.

When the lens is moving:

4V

Does the S-search waveform

appear at IC681 pin 13 and

pin 14?

NO

Is the voltage input at pin 1

and pin 2 of IC681?

NO

Is the voltage output at pin 33

of IC621?

NO

Is the power supply present

at pin 6, pin 15, pin 25, pin 39,

pin 43, pin 48, pin 51 and pin

64 of IC621?

NO

YES

Check the pickup and

its connections.

Is the power supply present

YES YES

at pin 10, pin 19 and pin 28

of IC681?

NO

Check the connections of

CD8V power supply.

YES

Check the connections

between IC681 and IC621.

YES

Check IC621.

Check IC681.

Check the connections of

CD8V power supply.

1-16 (No.MA244)

Page 17

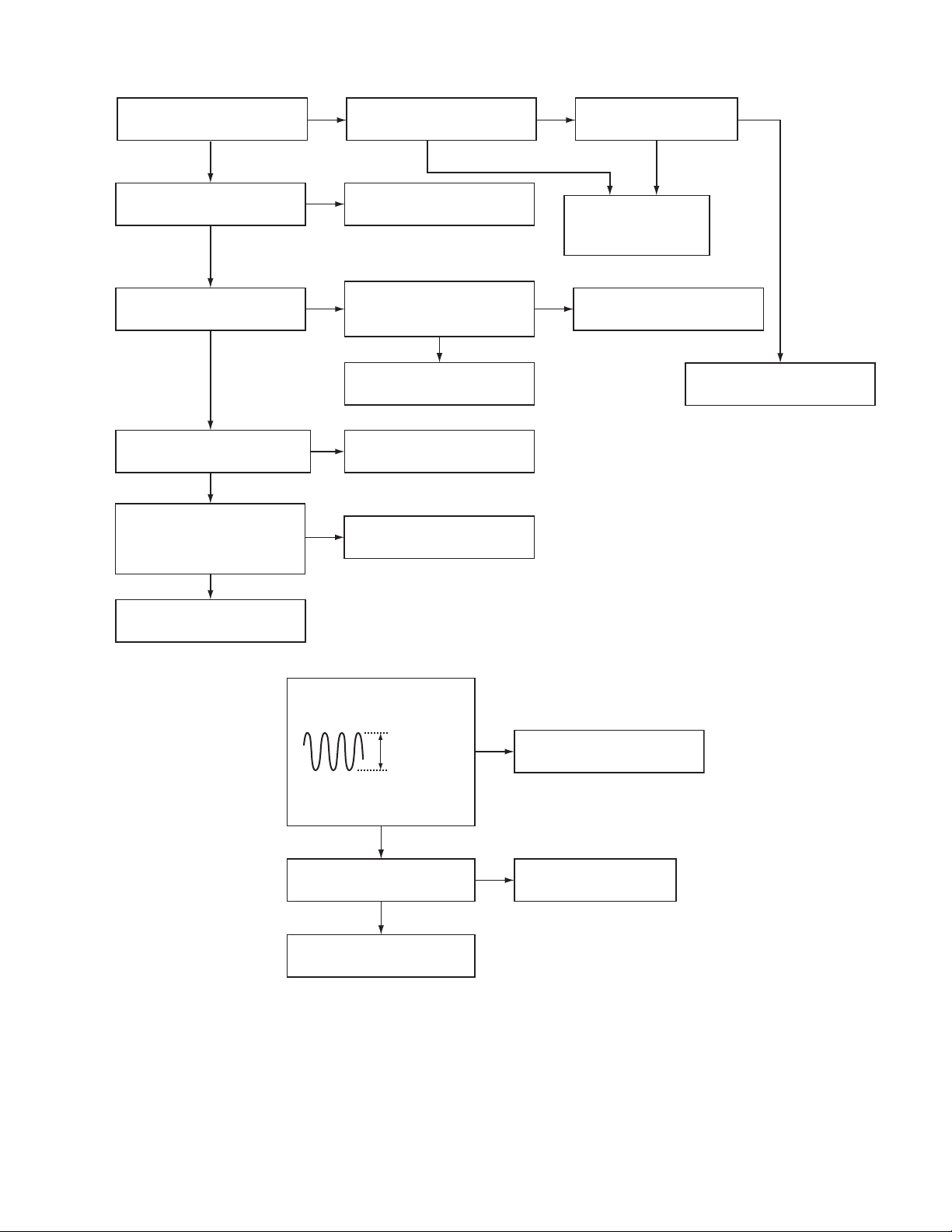

5.3 Spindle section

Is the disk rotated?

NO

Is the voltage output at pin 15

and pin 16 of IC681?

NO

Is the voltage input at pin 26

of IC681?

NO

Is the voltage output at pin 41

of IC621?

NO

Is the power supply present

at pin 6, pin 15, pin 25, pin 39,

pin 43, pin 48, pin 51 and pin

64 of IC621?

NO

YES

Does the RF signal appear at

YES

pin 19 of IC601?

YES

Check the spindle motor and

its wiring.

Is the power supply present

YES YES

at pin 10, pin 19 and pin 28

of IC681?

NO

Check the connections of

CD8V power supply.

YES

Check the connections

between IC681 and IC621.

YES

Check IC621.

Is the RF waveform at pin

19 of IC601 distorted?

NONO

Check the circuits in

the vicinity of IC601

or the pickup.

Check IC681.

YES

Proceed to the Tracking

section

Check the connections of

CD8V power supply.

5.4 Tracking section

When the disc is rotated

at first:

Approx. 1.2V

Is the tracking error signal

output at pin 11 of IC601?

NO

Check the circuits in IC601 or

the vicinity of IC601.

NO

Replace IC601 or repair the

malfunction connection point

YES

YES

Check the pickup and

its connections.

Check IC601.

(No.MA244)1-17

Page 18

5.5 Signal processing section

Is the sound output from

both channels (L, R)?

NO

No sound from either

channel.

NO

Compare the L-ch and

R-ch to locate the

defective point.

YES

Normal

YES

Is 9V present at pin 40

of IC151?

Is 9V present at pin 10

of IC901?

Check IC901 and its

peripheral circuits.

NO

NO

Is the audio signal

(including sampling

YES YES

output components)

output to pins 1 and 7 of

IC572 during playback?

NO

Check IC572 and its

peripheral circuits.

Check the connections

YES

between pin 40 of IC151

and pin 10 of IC901.

Is the audio signal output

at pin 36 and pin 37 of

IC151 during playback?

NO

Check IC151 and its

peripheral circuits.

YES

Check the power

amplifier IC181.

1-18 (No.MA244)

Page 19

5.6 Maintenance of laser pickup

(1) Cleaning the pick up lens

Before you replace the pick up, please try to clean the lens

with a alcohol soaked cotton swab.

(2) Life of the laser diode

When the life of the laser diode has expired, the following

symptoms will appear.

• The level of RF output (EFM output: amplitude of eye

pattern) will be low.

5.7 Replacement of laser pickup

Turn of the power switch and, disconnect the

power cord.

Replace the pickup with a normal one. (Refer

to "Removing the pickup unit" on the previous page.)

Is RF output

1.3 0.4Vp-p?

NO

Replace it.

YES

OK

(3) Semi-fixed resistor on the APC PC board

The semi-fixed resistor on the APC printed circuit board

which is attached to the pickup is used to adjust the laser

power.Since this adjustment should be performed to match

the characteristics of the whole optical block, do not touch

the semi-fixed resistor.

If the laser power is lower than the specified value, the laser diode is almost worn out, and the laser pickup should

be replaced. If the semi-fixed resistor is adjusted while the

pickup is functioning normally, the laser pickup may be

damaged due to excessive current.

Plug the power cord in, and turn the power on.

At this time, check that the laser emits for about

seconds and the objective lens moves up and down.

Note: Do not observe the laser beam directly.

Play a disc.

Check the eye-pattern at

pin 19 of IC601.

Finish.

(No.MA244)1-19

Page 20

5.8 16 PIN CORD DIAGRAM

8

7

6

5

4

3

2

1

BK

RD

NC

BL/WH

WH

GN

VI

GY

YL

OR/WH

NC

NC

WH/BK

GN/BK

VI/BK

GY/BK

16

15

14

13

12

11

10

BK

20

BK Black

RD

BL

WH

Red

Blue

White

GN

VI

GY

YL Yellow

OR

9

Green

Violet

Gray

Orange

19

18

17

16

15

14

13

12

11

NC

WH/BK

GY/BK

GN/BK

VI/BK

NC

NC

NC

NC

YL

OR/WH

WH

GY

GN

VI

NC

NC

RD

BL/WH

10

9

8

7

6

5

4

3

2

1

1-20 (No.MA244)

Page 21

(No.MA244)1-21

Page 22

Victor Company of Japan, Limited

Mobile Entertainment Business Group Mobile Entertainment Category 10-1,1chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

(No.MA244)

Printed in Japan

VPT

Page 23

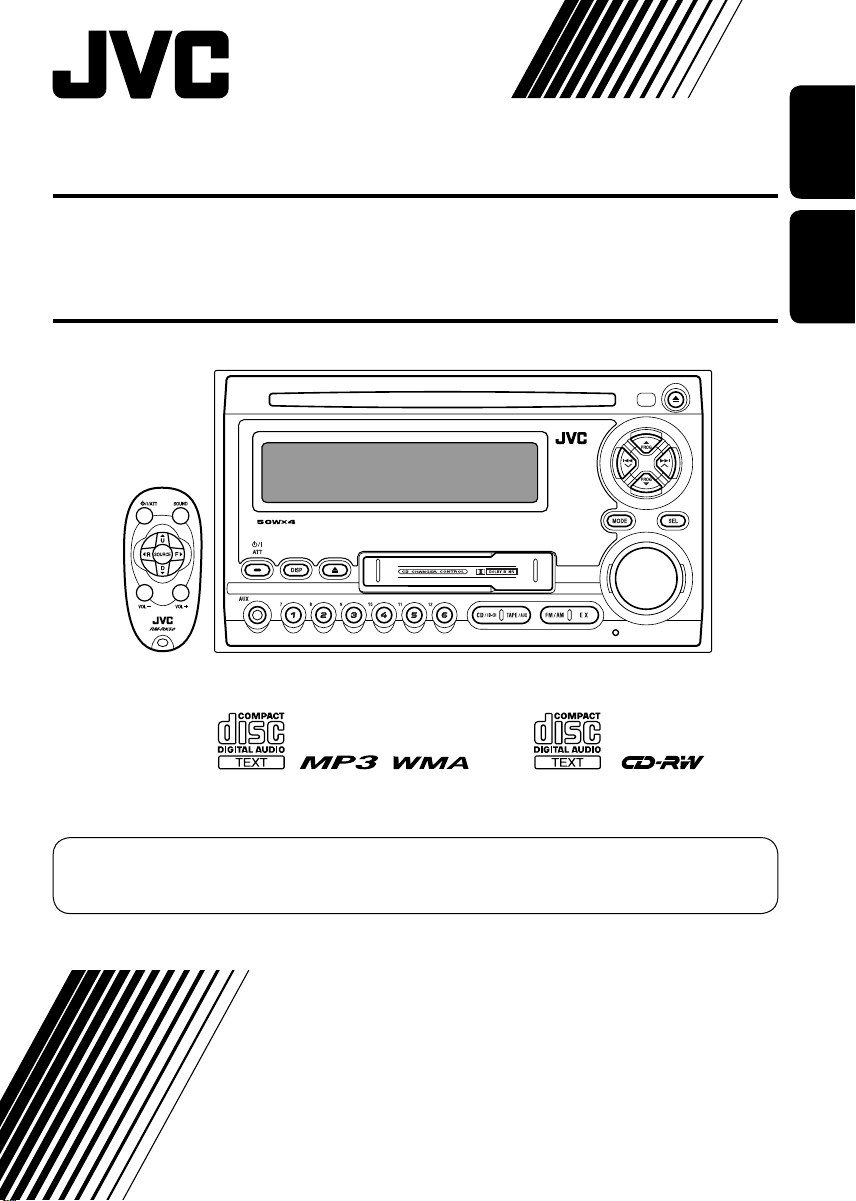

CD/CASSETTE RECEIVER

ALAT PENERIMA CD/KASET

KW-TC411/KW-TC410: KW-TC111/KW-TC110:

KW-TC411/KW-TC410/

KW-TC111/KW-TC110

KW-TC411/KW-TC410/

KW-TC111/KW-TC110

ENGLISH

INDONESIA

For canceling the display demonstration, see page 8.

Untuk membatalkan tampilan demonstrasi, lihat halaman 8.

INSTRUCTIONS

BUKU PETUNJUK

GET0315-001A

[UN]

Page 24

Thank you for purchasing a JVC product.

Please read all instructions carefully before operation, to ensure your complete understanding and to

obtain the best possible performance from the unit.

ENGLISH

IMPORTANT FOR LASER PRODUCTS

1. CLASS 1 LASER PRODUCT

2. CAUTION: Do not open the top cover. There are no user serviceable parts inside the unit; leave

all servicing to qualified service personnel.

3. CAUTION: Visible and invisible laser radiation when open and interlock failed or defeated.

Avoid direct exposure to beam.

4. REPRODUCTION OF LABEL: CAUTION LABEL, PLACED OUTSIDE THE UNIT.

Warning:

If you need to operate the unit while driving,

be sure to look ahead carefully or you may

be involved in a traffic accident.

How to reset your unit

This will reset the microcomputer. Your

preset adjustments will also be erased.

Caution on volume setting:

Discs produce very little noise compared

with other sources. Lower the volume

before playing a disc to avoid damaging

the speakers by the sudden increase of the

output level.

How to forcibly eject a disc

If a disc cannot be recognized or cannot be

ejected, eject the disc as follows.

• If this does not work, reset your unit.

• Be careful not to drop the disc when it

ejects.

2

Page 25

Contents

How to reset your unit ........................... 2

How to forcibly eject a disc ................... 2

How to read this manual ........................ 4

How to use the MODE button ............... 4

Control panel —

KW-TC410/KW-TC111/KW-TC110

Parts identification ................................. 5

Remote controller — RM-RK50

Main elements and features ................... 6

KW-TC411/

.... 5

... 6

Getting started ....................... 7

Basic operations .................................. 7

Canceling the display demonstrations ... 8

Setting the clock .................................... 8

Radio operations ................... 9

Listening to the radio ........................... 9

Storing stations in memory .................... 9

Listening to a preset station ................... 10

Scanning broadcast stations ................... 10

Assigning titles to the stations ............... 11

Disc operations ...................... 12

Playing a disc in the unit ..................... 12

Connecting the CD changer .................. 13

Playing discs in the CD changer ........... 13

Other main functions ............................. 15

Changing the display information ......... 15

Selecting the playback modes ................ 16

Tape operations ..................... 17

Playing a tape ..................................... 17

Finding the beginning of a tune ............. 17

Other convenient tape functions ............ 17

Sound adjustments ................ 18

Selecting preset sound modes

(EQ: equalizer) ................................. 18

Adjusting the sound ............................... 18

Storing your own sound adjustments ..... 19

General settings — PSM ......... 20

Basic procedure ..................................... 20

External component operations

... 22

Playing an external component ............ 22

Maintenance .......................... 23

Handling discs ....................................... 23

Handling cassettes ................................. 23

More about this unit ............... 24

Troubleshooting ..................... 27

Specifications ......................... 29

ENGLISH

For safety....

• Do not raise the volume level too much, as

this will block outside sounds, making driving

dangerous.

• Stop the car before performing any

complicated operations.

Temperature inside the car....

If you have parked the car for a long time in

hot or cold weather, wait until the temperature

in the car becomes normal before operating the

unit.

3

Page 26

How to read this manual

The following methods are used to make the

explanations simple and easy-to-understand:

• Some related tips and notes are explained in

ENGLISH

“More about this unit” (see pages 24 – 26).

• Button operations are mainly explained with

the illustrations as follows:

Press briefly.

How to use the MODE button

Press MODE repeatedly to select the different

functions available during play.

Time countdown indicator

Press repeatedly.

Press either one.

Press and hold until

your desired response

begins.

Press and hold both

buttons at the same

time.

The following marks are used to indicate...

: Built-in CD player operations.

: External CD changer operations.

Ex.: When “SSM” is selected

While listening to the radio:

• You cannot select “SSM” or “SCAN”

if you are listening to the station stored

in the EX (extra) button, see page 10 for

details.

SSM SCAN MONO

Canceled

(Station frequency)*

While listening to a disc:

–10 +10

(Track no. and

Elapsed playing time)*

While listening to a tape:

DOLBY B B.SKIP REPEAT

While adjusting the sound mode:

• Pressing MODE allows you to store the

adjusted sound mode into memory. (See

page 19 for details.)

REPEAT RANDOM

Canceled

Canceled

(Playback direction)*

INTRO

* Depending on the level meter setting. (See

page 20 for details.)

4

Page 27

Control panel —

KW-TC411/KW-TC410/KW-TC111/KW-TC110

Parts identification

Display window

1 Loading slot

2 Display window

3 0 (tape eject) button

4 DISP (display) button

5

6 Cassette compartment

7 AUX (auxiliary) input jack

8 Number buttons

9 Remote sensor

• DO NOT expose the remote sensor to

p 0 (CD eject) button

q 5 PROG (program) / ∞ PROG (program)

w 4

e SEL (select) button

r MODE button

t Control dial

y Source buttons—CD/CD-CH, TAPE/AUX,

u Reset button

(standby/on attenuator) button

strong light (direct sunlight or artificial

lighting).

buttons

/ ¢ buttons

FM/AM, EX (extra)

Display window

i Tuner reception indicators—ST (stereo),

MO (monaural)

o Disc information indicators—

(track/file), TAG (ID3 Tag), (folder)

; Text name indicators—DISC, STATION

a Main display, level meter

s Clock indicator

d EQ (equalizer) indicator

f LOUD (loudness) indicator

g

(Dolby B NR) indicator

h Playback disc indicators—MP3, WMA

j B.SKIP (blank skip) indicator

k Source display

l Level meter, volume meter, time countdown

indicator

/ Playback mode indicators—DISC,

(folder), RND (random),

RPT (repeat), INT (intro),

MAG (magazine)

z Loaded source indicators—

(tape)

(track/file),

(disc),

ENGLISH

5

Page 28

Remote controller — RM-RK50

Installing the lithium coin battery

(CR2025)

ENGLISH

• When operating, aim the remote controller

directly at the remote sensor on the unit.

Make sure there is no obstacle in between.

Warning:

• Do not install any battery other than

CR2025 or its equivalent; otherwise, it

may explode.

• Store the battery in a place where children

cannot reach to avoid risk of accident.

• To prevent the battery from over-heating,

cracking, or starting a fire:

– Do not recharge, short, disassemble,

heat the battery, or dispose of it in a fire.

– Do not leave the battery with other

metallic materials.

– Do not poke the battery with tweezers or

similar tools.

– Wrap the battery with tape and insulate

when throwing away or saving it.

Caution:

Main elements and features

1 (standby/on/attenuator) button

•

Turns the power on if pressed briefly or

attenuates the sound when the power is on.

• Turns the power off if pressed and held.

2 5 U (up) / D (down) ∞ buttons

•

Changes the FM/AM bands with 5 U only.

•

Changes the preset stations with D ∞ only.

• Changes the folder of the MP3/WMA

discs (only for KW-TC411/KW-TC410).

•

Changes the tape directions with 5 U only.

• While playing an MP3 disc on an

MP3-compatible CD changer:

– Changes the disc if pressed briefly.

– Changes the folder if pressed and held.

3 VOL – / VOL + buttons

• Adjusts the volume level.

4 SOUND button

• Selects the sound mode (EQ: equalizer).

5 SOURCE button

• Selects the source.

6 2 R (reverse) / F (forward) 3 buttons

• Searches for stations if pressed briefly.

• Fast-forwards or reverses the track if

pressed and held.

• Changes the tracks of the disc if pressed

briefly.

• Fast-forwards or reverses the tape if

pressed and held.*

• Finds the beginning of a tune (MMS)

while listening to a tape if pressed

briefly.*

* To release these operations, press 5 U.

Playback resumes.

6

Page 29

Getting started

Basic operations

~ Turn on the power.

Ÿ For FM/AM tuner

For your favorite station

• Stored your favorite

station, see page 10

for details.

! Adjust the volume.

ENGLISH

Volume level appears.

Volume level indicator

⁄ Adjust the sound as you want.

(See pages 18 and 19.)

To drop the volume in a moment (ATT)

To restore the sound, press

it again.

To turn off the power

For CD/CD-CH

For TAPE/AUX

* You cannot select these sources if they

are not ready.

7

Page 30

Canceling the display

demonstrations

ENGLISH

If no operations are done for about 20 seconds,

display demonstration starts.

[Initial: DEMO ON] —see page 20.

1

2

3

Setting the clock

1

2

Set the hour and minute.

1 Select “CLOCK HOUR,” then

adjust the hour.

2 Select “CLOCK MIN,” (minute)

then adjust the minute.

3 Finish the procedure.

Finish the procedure.

4

To activate the display demonstration

In step 3 above...

8

Page 31

Radio operations

Listening to the radio

~

Lights up when receiving an FM stereo

broadcast with sufficient signal strength.

Selected band appears.

Ÿ Start searching for a station.

2 Select the desired station frequencies.

ENGLISH

When an FM stereo broadcast is hard to

receive

1

2

Lights up when monaural mode is activated.

Reception improves, but stereo effect will

be lost.

To restore the stereo effect, repeat the same

procedure. Then, in step 2, select “MONO

OFF.”

When a station is received, searching

stops.

To stop searching, press the same

button again.

To tune in to a station manually

In step Ÿ above...

1

Storing stations in memory

You can preset six stations for each band.

FM station automatic presetting —

SSM (Strong-station Sequential

Memory)

1

Select the FM band (FM1 – FM3)

you want to store into.

To be continued....

9

Page 32

2

ENGLISH

3

“SSM” flashes, then disappears when

automatic presetting is over.

Local FM stations with the strongest signals are

searched and stored automatically in the FM

band.

Manual presetting

Ex.: Storing FM station of 92.5 MHz into the

preset number 4 of the FM1 band.

Listening to a preset station

1

2 Select the preset station (1 – 6) you

want.

or

1

2

3

Preset number flashes for a while.

Storing your favorite station into the

EX (extra) button

Ex.: Storing your favorite FM station of

92.5 MHz into the EX button

While listening to an FM station, tune in

to your favorite station, then....

To tune in to your favorite station (EX)

If you press the button

again, the previous source

will be played back again.

Scanning broadcast stations

1

2 Start scanning.

Each time a broadcast is tuned in, scanning

stops for about 5 seconds (tuned frequency

appears on the display), and you can check

what program is now being broadcast.

3 Start listening to the program.

10

Page 33

Assigning titles to the stations

You can assign titles to 30 station frequencies

(including both FM and AM). Each station

name can be assigned up to 10 characters.

However, you cannot assign title to the station

frequency stored in the EX button.

1 Tune in to the station you would like

to assign a title to.

2 Enter the assigning mode.

4 Finish the procedure.

ENGLISH

To erase the entire title

In step 3 on the left...

To change the information shown on the

display

3 Assign a title.

1 Select a character set.

2 Select a character.

3 Move to the next (or previous)

character position.

Station frequency

(and Preset no.)

* If no title is assigned, “NO NAME” appears

for a while.

Assigned title*

Available characters

Upper case

Lower case

Numbers and symbols

4 Repeat steps 1 to 3 until you

finish entering the title.

11

Page 34

Disc operations

Playing a disc in the unit

• KW-TC111/KW-TC110 cannot play back

MP3 or WMA discs in the unit.

ENGLISH

• KW-TC111/KW-TC110 can only control

MP3 discs in an MP3-compatible CD

changer.

All tracks will be played repeatedly until

you change the source or eject the disc.

• When inserting an MP3 or a WMA disc:

• When inserting an audio CD or a CD Text

disc:

Total track number

of the inserted disc

Total playing time

of the inserted disc

CD Text: Disc title/performer =

Track title appears automatically

(see page 15).

Current track

number*

Elapsed playing

2

time

2

*

To stop play and eject the disc

The source changes to the last

selected source.

12

Total folder

number

Total file

number

Disc information appears

automatically (see page 15).

Current track

number*

Elapsed playing

2

time

2

*

1

Either the MP3 or WMA indicator lights up

*

depending on the detected file.

2

*

Depending on the level meter setting. (See

page 20 for details.)

Page 35

Connecting the CD changer

Playing discs in the CD changer

Connection cord supplied for the CD changer

KW-TC411

KW-TC410

KW-TC111

KW-TC110

JVC CD changer

Before connecting the CD changer

• To prevent short circuits, it is

recommended to disconnect the car

battery’s negative terminal and make all

electrical connections before connecting

the CD changer.

• When mounting this unit into your car, be

sure to use the screws provided.

• When tightening screws or bolts, be

careful not to pinch any connection cord.

• If you are not sure how to connect the

CD changer correctly, consult your car

dealer or JVC car audio dealer, or have it

installed by a qualified technician.

About the CD changer

It is recommended to use a JVC MP3compatible CD changer with your unit.

• You can also connect other CH-X series

CD changers (except CH-X99 and

CH-X100). However, they are not

compatible with MP3 discs, so you cannot

play back MP3 discs.

• You cannot play any WMA disc in the CD

changer.

• You cannot use the KD-MK series CD

changers with this unit.

• Disc text information recorded in the CD

Text can be displayed when a JVC CD

Text compatible CD changer is connected.

All tracks of the inserted discs in the magazine

will be played repeatedly until you change

the source or eject the magazine from the CD

changer.

~

If you have changed “EXT INPUT”

*

setting to “EXT INPUT” (see page

21), you cannot select the CD

changer.

Ÿ Select a disc.

For disc number from 01 – 06:

For disc number from 07 – 12:

Selected disc number

Track number

ENGLISH

13

Page 36

• When the current disc is an MP3 disc:

ENGLISH

To fast-forward or reverse the track

Folder name*

1

Disc information appears

automatically (see page 15).

Current track

number*

Elapsed playing

2

time*

2

• When the current disc is an audio CD or a

CD Text disc:

CD Text: Disc title/performer =

Track title appears automatically

(see page 15).

Current track

number*

Elapsed playing

2

time*

2

To go to the next or previous tracks

To go to the next or previous folders—for

MP3 and WMA discs

(For MP3/WMA discs —only

for KW-TC411/KW-TC410)

(For MP3 discs)

To locate a particular track—for CD or

folder—for MP3 or WMA discs (only for

KW-TC411/KW-TC410) directly

To select a number from 01 – 06:

To select a number from 07 – 12:

1

*

“ROOT” appears if no folder is included in

the disc.

2

*

Depending on the level meter setting. (See

page 20 for details.)

14

• To use folder search on MP3/WMA discs, it

is required that folders are assigned with

2-digit numbers at the beginning of their

folder names—01, 02, 03, and so on.

To select a particular track

in a folder (for MP3 or

WMA disc):

Page 37

Other main functions

Skipping a track quickly during play

Changing the display information

ENGLISH

Only possible on JVC

MP3-compatible CD changer

• For MP3 or WMA disc, you can skip a track

within the same folder.

Ex.: To select track 32 while playing track 6

1

2

First time you press 5 PROG/∞ PROG

button, the track skips to the nearest higher

or lower track with a track number of

multiple ten (ex. 10th, 20th, 30th).

Then each time you press the button, you

can skip 10 tracks.

• After the last track, the first track will be

selected and vice versa.

–10 +10

3

While playing an audio CD or a CD

Text

While playing an MP3 or WMA disc

• When “TAG DISP” is set to

“TAG ON” (see page 21)

• When “TAG DISP” is set to

“TAG OFF”

Prohibiting disc ejection

You can lock a disc in the loading slot.

To cancel the prohibition, repeat the same

procedure.

: Current track/file number and

Elapsed playing time

3

*

If the current disc is an audio CD,

“NO NAME” appears.

4

*

If an MP3/WMA file does not have ID3 tags,

folder name and file name appear. In this

case, the TAG indicator will not light up.

15

Page 38

Selecting the playback modes

You can use only one of the following playback modes at a time.

ENGLISH

Select your desired playback mode.

1 2

Repeat play

Ex.: When “TRACK RPT” is selected

Random play

Ex.: When “DISC RND” is selected

Intro scan

Ex.: When “TRACK INT” is selected

Mode Plays repeatedly

TRACK RPT : The current track.

• RPT and

FOLDER RPT*

•

DISC RPT*

1

: All tracks of the current folder.

and RPT light up.

2

: All tracks of the current disc.

light up.

• DISC and RPT light up.

REPEAT OFF : Cancels.

Mode Plays at random

FOLDER RND*1: All tracks of the current folder,

then tracks of the next folder and so

on.

•

DISC RND : All tracks of the current disc.

• DISC and RND light up.

MAG RND*

2

• RND and MAG light up.

RANDOM OFF : Cancels.

Mode

TRACK INT : All tracks of the current disc.

• INT and

FOLDER INT*

•

DISC INT*

• DISC and INT light up.

INTRO OFF : Cancels.

2

and RND light up.

: All tracks of the inserted discs.

Plays the beginning 15 seconds of...

1

: The first track of every folder of

the current disc.

and INT light up.

: The first tracks of the inserted

discs.

light up.

1

*

Only while playing an MP3 disc or WMA disc.

2

*

Only while playing discs in the CD changer.

16

Page 39

Tape operations

Playing a tape

Playback starts automatically. When one

side of the tape reaches its end during play,

the other side of the tape automatically

starts playing. (Auto Reverse)

To change the playback direction

FWD PLAY

(Forward play)

To stop play and eject the cassette

The source changes to the last

selected source.

REV PLAY

(Reverse play)

Finding the beginning of a tune

Multi Music Scan (MMS) allows you to

automatically start playback from the beginning

of a specified tune.

Specify the tune you want to locate

(how many tunes ahead of or before the

current tune)

When the beginning

of the specified tune is

located, playback starts

automatically.

3

*

Goes back to the beginning of the current

tune.

Other convenient tape functions

1

ENGLISH

To fast-forward or rewind a tape

When the tape reaches its

end while fast-forwarding,

the tape direction will change

automatically.

To stop fast-forwarding or rewinding, press

5 PROG/∞ PROG.

Prohibiting tape ejection

You can lock a tape in the loading slot.

To cancel the prohibition, repeat the same

procedure.

2

• To turn on or off Dolby B NR*

( lights up on the display)

• To skip blank portions on the tape

( lights up on the display)

• To play the current tune repeatedly

( lights up on the display)

*4 Manufactured under license from Dolby

Laboratories. “Dolby” and the doubleD symbol are trademarks of Dolby

Laboratories.

4

17

Page 40

Sound adjustments

Selecting preset sound modes

(EQ: equalizer)

ENGLISH

You can select a preset sound mode suitable to

the music genre.

~

Ÿ

FLAT O Hard Rock O R & B O

POP O JAZZ O DanceMusic O

Country O Reggae O Classic O

USER 1 O USER 2 O USER 3 O

(back to the beginning)

To select the sound mode directly

You can select the sound mode directly using

the remote controller.

Adjusting the sound

You can adjust the sound characteristics to your

preference.

1

2

Indication Range

1

FADER*

Adjust the front and rear

speaker balance.

BAL (balance)

Adjust the left and right

speaker balance.

LOUD

(loudness)

Boost low and high

frequencies to produce a

well-balanced sound at low

volume level.

VOLUME*

Adjust the volume.

*1 If you are using a two-speaker system, set

*

*

2

the fader level to “00.”

2

Normally the control dial works as the

volume control. So you do not have to select

“VOLUME” to adjust the volume level.

3

Depending on the amplifier gain control

setting. (See page 21 for details.)

R06 (Rear only)

to

F06 (Front only)

L06 (Left only)

to

R06 (Right only)

LOUD ON

LOUD OFF

00 (min.) to

30 or 50 (max.)*

3

18

Page 41

Storing your own sound

adjustments

4 Adjust the selected sound elements

while the indication on step 3 is

shown.

You can adjust the sound modes and store your

own adjustments in memory.

1

2 Select one of the sound mode to

adjust.

Ex.: When “JAZZ” is selected

3 Select the sound elements to adjust

while the selected sound mode is

shown.

Indication

LEVEL –06

(min.) to

+06

(max.)

FREQ 60Hz

80Hz

100Hz

120Hz

WIDTH 1 (min.)

to

4 (max.)

Preset values

LOW MID HIGH

–06

(min.) to

+06

(max.)

1 (min.)

to

2 (max.)

–06

(min.) to

+06

(max.)

8kHz

10kHz

12kHz

15kHz

5 Repeat steps 3 and 4 to set (or

adjust) the other sound elements.

6 Select one of the user sound modes

(USER 1, USER 2, USER 3).

ENGLISH

LOW LEVEL O LOW FREQ. O

LOW WIDTH O MID LEVEL O

MID WIDTH O HIGH LEVEL O

HIGH FREQ. O (back to the

beginning)

• (LOW, MID, HIGH) LEVEL:

Adjust the enhancement level.

• (LOW, HIGH) FREQ:

Select the center frequency to adjust.

• (LOW, MID) WIDTH :

Select the band width level.

7 Store the adjustments.

“MEMORY” appears for a

while.

19

Page 42

General settings — PSM

Basic procedure

3 Adjust the PSM item selected.

You can change PSM (Preferred Setting Mode)

items listed in the table that follows.

ENGLISH

1

4 Repeat steps 2 and 3 to adjust the

2 Select a PSM item.

5 Finish the procedure.

Indications Selectable settings, [reference page]

DEMO MODE

Display

demonstration

CLOCK HOUR

Hour adjustment

CLOCK MIN

Minute adjustment

CLOCK DISP

Clock display

LEVELMETER

Audio level meter

DEMO ON : [Initial]; Display demonstration will be activated

DEMO OFF : Cancels.

1 – 12, [8]

[Initial: 1 (1:00)]

00 – 59, [8]

[Initial: 00 (1:00)]

CLOCK ON : Clock time is shown on the display at all times even

CLOCK OFF : [Initial];

You can select one of the four different level meter patterns or a

demonstration of all the patterns.

LEVEL ALL [Initial] O LEVEL 1 O LEVEL 2 O LEVEL 3 O

LEVEL 4 O LEVEL OFF (canceled) O (back to the beginning)

LEVEL ALL : Demonstrates all the level meter patterns, each for

LEVEL 1 LEVEL 2

automatically if no operation is done for about

20 seconds, [8].

when the unit is turned off.

on

. If the unit is turned off,

the clock time for about 5 seconds.

about 20 seconds.

other PSM items if necessary.

Clock time is shown

when the unit is turned

pressing DISP will show

20

LEVEL 3 LEVEL 4

Page 43

Indications Selectable settings, [reference page]

DIMMER

Dimmer

CONTRAST

Display contrast

SCROLL*

1

Scroll

EXT INPUT*

2

External input

AUX ADJUST

Auxiliary input

level adjustment

TAG DISP

Tag display

AMP GAIN

Amplifier gain

control

IF FILTER

IF filter

1

*

Some characters or symbols will not be shown (and will be blanked) or substituted on the

display.

2

*

Cannot be selected if the source is “CD-CH” or “EXT.”

AUTO : [Initial]; Dims the display when you turn on the

headlights.

ON : Activates dimmer.

OFF : Cancels.

1 – 10 : Adjust the display contrast to make the display indications

clear and legible.

[Initial: 5]

ONCE : [Initial]; Scrolls the disc information once.

AUTO :

Repeats scrolling (5-second intervals in between).

OFF : Cancels.

• Pressing DISP for more than one second can scroll the display regardless

of the setting.

CHANGER : [Initial]; To use a JVC CD changer, [13].

EXT INPUT : To use another external component, [22].

AUX ADJ 00 – AUX ADJ 05: Adjust the auxiliary input level

accordingly, to avoid the sudden increase of the output

level when changing the source from external component

connected to the AUX input jack on the control panel.

[Initial: AUX ADJ 00]

TAG ON : [Initial]; Shows the ID3 tag while playing MP3/WMA

tracks, [15].

TAG OFF : Cancels.

You can change the maximum volume level of this unit.

LOW PWR : VOLUME 00 – VOLUME 30 (Select this if the

maximum power of the speaker is less than 50 W to avoid

damaging the speaker.)

HIGH PWR : [Initial]; VOLUME 00 – VOLUME 50

AUTO : [Initial]; Increases the tuner selectivity to reduce noise

interference between the stations. (Stereo effect will also

be lost.)

WIDE : Subject to noise interference from adjacent stations, but

sound quality will not be degraded and will retain the

stereo effect.

ENGLISH

21

Page 44

External component operations

Playing an external component

ENGLISH

You can connect an external component to....

• CD changer jack on the rear using the Line

Input Adapter—KS-U57 (not supplied) or

AUX Input Adapter—KS-U58 (not supplied).

• AUX (auxiliary) input jack on the control panel.

To connect an external component to the CD

changer jack using KS-U57 or KS-U58

~ For selecting the external

component connected to....

• AUX input jack

• CD changer jack on the rear

using KS-U57 or KS-U58

If “EXT” does not appear, see page

21 and select the external input

(EXT INPUT).

Ÿ Turn on the connected component

and start playing the source.

! Adjust the volume.

22

External

component

KW-TC411

KW-TC410

KW-TC111

KW-TC110

Signal cord (not supplied)

⁄ Adjust the sound as you want.

(See pages 18 and 19.)

External

component

3.5mm stereo

mini plug

Page 45

Maintenance

Handling discs

Moisture condensation

Moisture may condense on the lens inside the

CD player in the following cases:

• After starting the heater in the car.

• If it becomes very humid inside the car.

Should this occur, the CD player may

malfunction. In this case, eject the disc and

leave the unit turned on for a few hours until the

moisture evaporates.

How to handle discs

When removing a disc from

its case, press down the center

holder of the case and lift the disc

out, holding it by the edges.

• Always hold the disc by the

edges. Do not touch its recording surface.

When storing a disc into its case, gently insert

the disc around the center holder (with the

printed surface facing up).

• Make sure to store discs into the cases after

use.

Center holder

Do not use the following discs:

Warped

disc

Sticker

Disc

Handling cassettes

To clean the head

ENGLISH

Sticker

residue

Stick-on

label

To keep discs clean

A dirty disc may not play correctly.

If a disc does become dirty, wipe

it with a soft cloth in a straight line

from center to edge.

• Do not use any solvent (for example,

conventional record cleaner, spray, thinner,

benzine, etc.) to clean discs.

To play new discs

New discs may have some rough

spots around the inner and outer

edges. If such a disc is used, this

unit may reject the disc.

To remove these rough spots, rub the edges

with a pencil or ball-point pen, etc.

• Clean the heads after every 10 hours of use

using a wet-type head cleaning tape (available

at an audio store).

When the head becomes dirty, you may

realize the following symptoms:

– Sound quality is reduced.

– Sound level decreases.

– Sound drops out.

• Do not touch the highly-polished head with

any metallic or magnetic tools.

To keep the tape clean

• Always store the cassettes in their storage

cases after use.

• Do not store cassettes in the following places:

– Subject to direct sunlight

– With high humidity

– At extremely hot temperatures

23

Page 46

More about this unit

Basic operations

Turning on the power

• By pressing the source buttons on the unit,

you can also turn on the power. If the source

ENGLISH

is ready, playback also starts.

Turning off the power

• If you turn off the ignition key without

turning off this unit, the unit will

automatically turn on when you turn on the

ignition key next time. If the last selected

source is ready for playback (ex. a disc

or a tape is in the unit), playback starts

automatically.

• If you turn off the power while listening to a

disc, disc play will start from where playback

has been stopped previously, next time you

turn on the power.

Selecting the sources

• When no disc or cassette is loaded in the unit,

“CD” or “TAPE” cannot be selected.

• Without connecting to the CD changer,

“CD-CH” cannot be selected.

Disc operations

• KW-TC111/KW-TC110 cannot play back

MP3 or WMA discs in the unit.

• KW-TC111/KW-TC110 can only control

MP3 discs in an MP3-compatible CD

changer.

Caution for DualDisc playback

• The Non-DVD side of a “DualDisc” does

not comply with the “Compact Disc Digital

Audio” standard. Therefore, the use of NonDVD side of a DualDisc on this product may

not be recommended.

General

• MP3 and WMA (Windows Media® Audio)

“tracks” (words “file” and “track” are used

interchangeably) are recorded in “folders.”

• This unit has been designed to reproduce

CDs/CD Texts, and CD-Rs (Recordable)/

CD-RWs (Rewritable) in audio CD (CD-DA),

MP3 and WMA format.

• When a disc has been loaded, selecting “CD”

for the playback source starts disc play.

Tuner operations

Storing stations in memory

• During SSM search...

– All previously stored stations are erased and

stations are stored newly.

– Received stations are preset in No. 1 (lowest

frequency) to No. 6 (highest frequency).

– When SSM is over, the station stored in

No. 1 will be automatically tuned in.

• When storing a station manually, a previously

preset station is erased when a new station is

stored in the same preset number.

24

Inserting a disc

• When a disc is inserted upside down, the disc

automatically ejects and the unit starts playing

the last selected source.

• Do not insert 8 cm discs (single CD) and

unusual shape discs (heart, flower, etc.) into

the loading slot.

Playing a disc

• While fast-forwarding or reversing on an MP3

or WMA disc, you can only hear intermittent

sounds.

Page 47

Playing a CD-R or CD-RW

• Use only “finalized” CD-Rs or CD-RWs.

• This unit can play back only the files of the

same type which is first detected if a disc

includes both audio CD (CD-DA) files and

MP3/WMA files.

• This unit can play back multi-session discs;

however, unclosed sessions will be skipped

while playing.

• Some CD-Rs or CD-RWs may not play

back on this unit because of their disc

characteristics, and for the following causes:

– Discs are dirty or scratched.

– Moisture condensation occurs on the lens

inside the unit.

– The pickup lens inside the unit is dirty.

– CD-R/CD-RW on which the files are

written with “Packet Write” method.

– There are improper recording conditions

(missing data, etc.) or media conditions

(stain, scratch, warp, etc.).

• CD-RWs may require a longer readout time

since the reflectance of CD-RWs is lower

than that of regular CDs.

• Do not use the following CD-Rs or CD-RWs:

– Discs with stickers, labels, or protective seal

stuck to the surface.

– Discs on which labels can be directly

printed by an ink jet printer.

Using these discs under high temperatures

or high humidity may cause malfunctions or

damages to the unit.

Playing an MP3/WMA disc

• This unit can play back MP3/WMA files

with the extension code <.mp3> or <.wma>

(regardless of the letter case—upper/lower).

• This unit can show the names of albums,

artists (performer), and ID3 Tag (Version 1.0,

1.1, 2.2, 2.3, or 2.4) for MP3 files and for

WMA files.

• This unit can display only one-byte

characters. No other characters can be

correctly displayed (see page 11).

• This unit can play back MP3/WMA files

meeting the conditions below:

– Bit rate: 8 kbps — 320 kbps

– Sampling frequency:

48 kHz, 44.1 kHz, 32 kHz (for MPEG-1)

24 kHz, 22.05 kHz, 16 kHz (for MPEG-2)

48 kHz, 44.1 kHz, 32 kHz (for WMA)

– Disc format: ISO 9660 Level 1/ Level 2,

Romeo, Joliet, Windows long file name

• The maximum number of characters for file/

folder names vary among the disc format used

(includes 4 extension characters—<.mp3> or

<.wma>).

– ISO 9660 Level 1: up to 12 characters

– ISO 9660 Level 2: up to 31 characters

– Romeo*: up to 128 (72) characters

– Joliet*: up to 64 (36) characters

– Windows long file name*: up to 128 (72)

characters

* The parenthetic figure is the maximum

number of characters for file/folder names

in case the total number of files and folders

is 313 or more.

• This unit can recognize the total of 512 files,

of 200 folders, and of 8 hierarchies.

• This unit can play back the files recorded in

VBR (variable bit rate).

The files recorded in VBR have a discrepancy

in elapsed time display, and do not show the

actual elapsed time. This difference becomes

noticeable especially after performing the

search function.

• This unit cannot play back the following files:

– MP3 files encoded with MP3i and

MP3 PRO format.

– MP3 files encoded in an unappropriated

format.

– MP3 files encoded with Layer 1/2.

– WMA files encoded with lossless,

professional, and voice format.

– WMA files which are not based upon

Windows Media

– WMA files copy-protected with DRM.

– Files which have the data such as WAVE,

ATRAC3, etc.

• The search function works but search speed is

not constant.

®

Audio.

To be continued....

ENGLISH

25

Page 48

Changing the source

• If you change the source, playback also stops

(without ejecting the disc).

Next time you select “CD” or “CD-CH” for

ENGLISH

the playback source, disc play starts from

where it has been stopped previously.

Ejecting a disc

• If the ejected disc is not removed within

15 seconds, the disc is automatically inserted

again into the loading slot to protect it from

dust. (Disc will not play this time.)

Tape operations

Playing a tape

• While locating a specified tune:

– If the tape is rewound to its beginning,

playback starts from the beginning of that

side.

– If the tape is fast-forwarded to the end, it is

reversed and played from the beginning of

the other side.

• In the following cases, Multi Music Scan

(MMS), Blank Skip, and Repeat Play may not

operate correctly:

– Tapes with tunes having long pianissimo

passages (very quiet parts) or non-recorded

portions.

– Tapes with short non-recorded sections.

– Tapes with high level noise or humming

between tunes.

– The Dolby NR setting does not match. For

example, if the tape is recorded with the

Dolby C NR.

• Do not use the following tape:

– Dirty or dusty tapes.

– Cassette with peeling labels.

– Loose tape which may become entangled

with the mechanism.

Changing the source

• If you change the source, playback also stops

(without ejecting the cassette).

Ignition key-off release

• When you turn off the ignition key with

a cassette in the compartment, the unit

automatically releases the tape from its head.

General settings—PSM

• If you change the “TAG DISP” setting from

“TAG OFF” to “TAG ON” while playing

MP3/WMA file, the tag display will be

activated when the next file starts playing.

• If you change the “AMP GAIN” setting

from “HIGH PWR” to “LOW PWR”

while the volume level is set higher than

“VOLUME 30,” the unit automatically

changes the volume level to “VOLUME 30.”

Other main functions

• If you try to assign a title to the 31st station

frequency, “NAME FULL” flashes. Delete

unwanted titles before assignment.

26

Page 49

Troubleshooting

What appears to be trouble is not always serious. Check the following points before calling a service

center.

Symptoms Remedies/Causes

• Sound cannot be heard from the

speakers.

General

• The unit does not work at all. Reset the unit (see page 2).

• SSM automatic presetting does not

work.

FM/AM

• Static noise while listening to the radio. Connect the antenna firmly.

• Disc cannot be played back. Insert the disc correctly.

• CD-R/CD-RW cannot be played back.

• Tracks on the CD-R/CD-RW cannot be

skipped.

• Disc can be neither played back nor

ejected.

Disc playback

• Disc sound is sometimes interrupted. • Stop playback while driving on rough roads.

• “NO DISC” appears on the display. Insert a correct disc into the loading slot.

• KW-TC111/KW-TC110 cannot play back MP3 or WMA discs in the unit.

• KW-TC111/KW-TC110 can only control MP3 discs in an MP3-compatible CD changer.

• Adjust the volume to the optimum level.

• Check the cords and connections.

Store stations manually.

• Insert a finalized CD-R/CD-RW.

•

Finalize the CD-R/CD-RW with the component

which you used for recording.

• Unlock the disc (see page 15).

• Eject the disc forcibly (see page 2).

• Use an unscratched disc.

• Check the cords and connections.

ENGLISH

• Disc cannot be played back. • Use a disc with MP3/WMA tracks recorded in

the format compliant with ISO 9660 Level 1,

Level 2, Romeo, or Joliet.

• Add the extension code <.mp3> or <.wma> to

the file names.

• Noise is generated. Skip to another track or change the disc. (Do not

MP3/WMA playback

• A longer readout time is required

(“CHECK” keeps flashing on the

display).

add the extension code <.mp3> or <.wma> to

non-MP3 or WMA tracks.)

Do not use too many hierarchies and folders.

To be continued....

27

Page 50

Symptoms Remedies/Causes

• Tracks do not play back in the order

ENGLISH

• Elapsed playing time is not correct. This sometimes occurs during play. This is caused

• “NO FILES” appears on the display. Insert a disc that contains MP3/WMA tracks.

MP3/WMA playback

• Correct characters are not displayed

• A cassette cannot be inserted. Insert the cassette with the exposed tape facing

• Cassette can be neither played back nor

• “NO TAPE” appears on the display. Insert a cassette correctly.

Tape playback

• Cassette tapes become hot. This is not a malfunction.

• Tape sound is at very low level and

• “NO DISC” appears on the display.

• “NO MAG” appears on the display. Insert the magazine.

• “RESET 8” appears on the display. Connect this unit and the CD changer correctly

CD changer

• “RESET 1” – “RESET 7” appears on

you have intended them to play.

(e.g. album name).

ejected.

sound quality is degraded.

the display.

Playback order is determined when the files are

recorded.

by how the tracks are recorded on the disc.

This unit can only display alphabets (upper/lower

case), numbers, and a limited number of symbols.

right.

Unlock the cassette (see page 17).

Clean the tape head using a head cleaning tape.

Insert a disc into the magazine.

and press the reset button of the CD changer.

Press the reset button of the CD changer.

• The CD changer does not work at all. Reset the unit (see page 2).

• Microsoft and Windows Media are either registered trademarks or trademarks of Microsoft

Corporation in the United States and/or other countries.

28

Page 51

Specifications

AUDIO AMPLIFIER SECTION

Maximum Power Output:

Front: 50 W per channel

Rear: 50 W per channel

Continuous Power Output (RMS):

Front: 19 W per channel into 4 Ω, 40 Hz

to 20 000 Hz at no more than 0.8%

total harmonic distortion.

Rear: 19 W per channel into 4 Ω, 40 Hz

to 20 000 Hz at no more than 0.8%

total harmonic distortion.

Load Impedance: 4 Ω (4 Ω to 8 Ω allowance)

Equalizer Control Range:

Low: ±12 dB (60 Hz, 80 Hz, 100 Hz, 120 Hz)

Mid: ±12 dB

High: ±12 dB (8 kHz, 10 kHz, 12 kHz, 15 kHz)

Frequency Response: 40 Hz to 20 000 Hz

Signal-to-Noise Ratio: 70 dB

Line-Out Level/Impedance:

2.0 V/20 kΩ load (full scale)

Output Impedance: 1 kΩ

Other terminals: CD changer, AUX (auxiliary)

input jack

TUNER SECTION

Frequency Range:

FM: 87.5 MHz to 108.0 MHz

AM: 531 kHz to 1 602 kHz

[FM Tuner]

Usable Sensitivity: 11.3 dBf (1.0 µV/75 Ω)

50 dB Quieting Sensitivity:

16.3 dBf (1.8 µV/75 Ω)

Alternate Channel Selectivity (400 kHz): 65 dB

Frequency Response: 40 Hz to 15 000 Hz

Stereo Separation: 30 dB

Capture Ratio: 1.5 dB

[AM Tuner]

Sensitivity: 20 µV

Selectivity: 35 dB

CD PLAYER SECTION

Type: Compact disc player

Signal Detection System: Non-contact optical

pickup (semiconductor laser)

Number of Channels: 2 channels (stereo)

Frequency Response: 5 Hz to 20 000 Hz

Dynamic Range: 96 dB

Signal-to-Noise Ratio: 98 dB

Wow and Flutter: Less than measurable limit

KW-TC411/KW-TC410 only:

MP3 Decoding Format:

MPEG1/2 Audio Layer 3

Max. Bit Rate: 320 kbps

WMA (Windows Media

Format:

Max. Bit Rate: 192 kbps

®

Audio) Decoding

CASSETTE DECK SECTION

Wow and Flutter: 0.1 % (WRMS)

Fast-Wind Time: 100 sec. (C-60)

Frequency Response: 30 Hz to 16 000 Hz

(Normal tape)

Signal-to-Noise Ratio: (Normal tape)

Dolby B NR ON: 65 dB

Dolby B NR OFF: 56 dB

Stereo Separation: 40 dB

GENERAL

Power Requirement:

Operating Voltage:

DC 14.4 V (11 V to 16 V allowance)

Grounding System: Negative ground

Allowable Operating Temperature:

0°C to +40°C

Dimensions (W × H × D):

Installation Size (approx.):

178 mm × 100 mm × 158 mm

Set Size (approx.):

178 mm × 100 mm × 177 mm

Mass (approx.):

2.3 kg (excluding accessories)

ENGLISH

Design and specifications are subject to change

without notice.

29

Page 52

Having TROUBLE with operation?

Please reset your unit

Refer to page of How to reset your unit

Ada MASALAH dengan cara

pengoperasian?

Setel kembali unit Anda

Lihat halaman mengenai Bagaimana mereset unit anda

EN, IN

© 2005 Victor Company of Japan, Limited

0905DTSMDTJEIN

Page 53

SCHEMATIC DIAGRAMS

CD/CASSETTE RECEIVER

KW-TC410,KW-TC411

CD-ROM No.SML200512

Area suffix

UN --------------------- Indonesia

Lead free solder used in the board (material : Sn-Ag-Cu, melting point : 219 Centigrade)

Contents

Block diagram

Standard schematic diagrams

Printed circuit boards

COPYRIGHT 2005 Victor Company of Japan, Limited.

2-1

2-2

2-6 to 8

No.MA244SCH

2005/12

Page 54

Safety precaution

!

!