Page 1

SERVICE MANUAL

DVD RECEIVER WITH MONITOR

MA473<Rev.002>20106SERVICE MANUAL

KW-ADV793J, KW-AVX730E, KW-AVX730EE, KW-AVX730J,

KW-AVX735EU, KW-AVX735U, KW-AVX735UN, KW-AVX736A,

KW-AVX736EU, KW-AVX736U, KW-AVX736UN, KW-AVX736UT,

KW-AVX736UW, KW-AVX738JW, KW-AVX830E, KW-AVX830J,

KW-AVX835EU, KW-AVX835U, KW-AVX835UN, KW-AVX836A,

KW-AVX836EU, KW-AVX836U, KW-AVX836UN, KW-AVX836UT,

KW-AVX836UW, KW-AVX838JW, KW-AVX838UF

Only for J/JW

Only for KW-AVX830J/

KW-ADV793/KW-AVX730J

Only for E/EU

COPYRIGHT © 2010 Victor Company of Japan, Limited

Lead free solder used in the board (material : Sn-Ag-Cu, melting point : 219 Centigrade)

Lead free solder used in the board (material : Sn-Cu, melting point : 230 Centigrade)

Except J/JW

TABLE OF CONTENTS

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

2 SPECIFIC SERVICE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-31

COPYRIGHT © 2010 Victor Company of Japan, Limited

No.MA473<Rev.002>

2010/6

Page 2

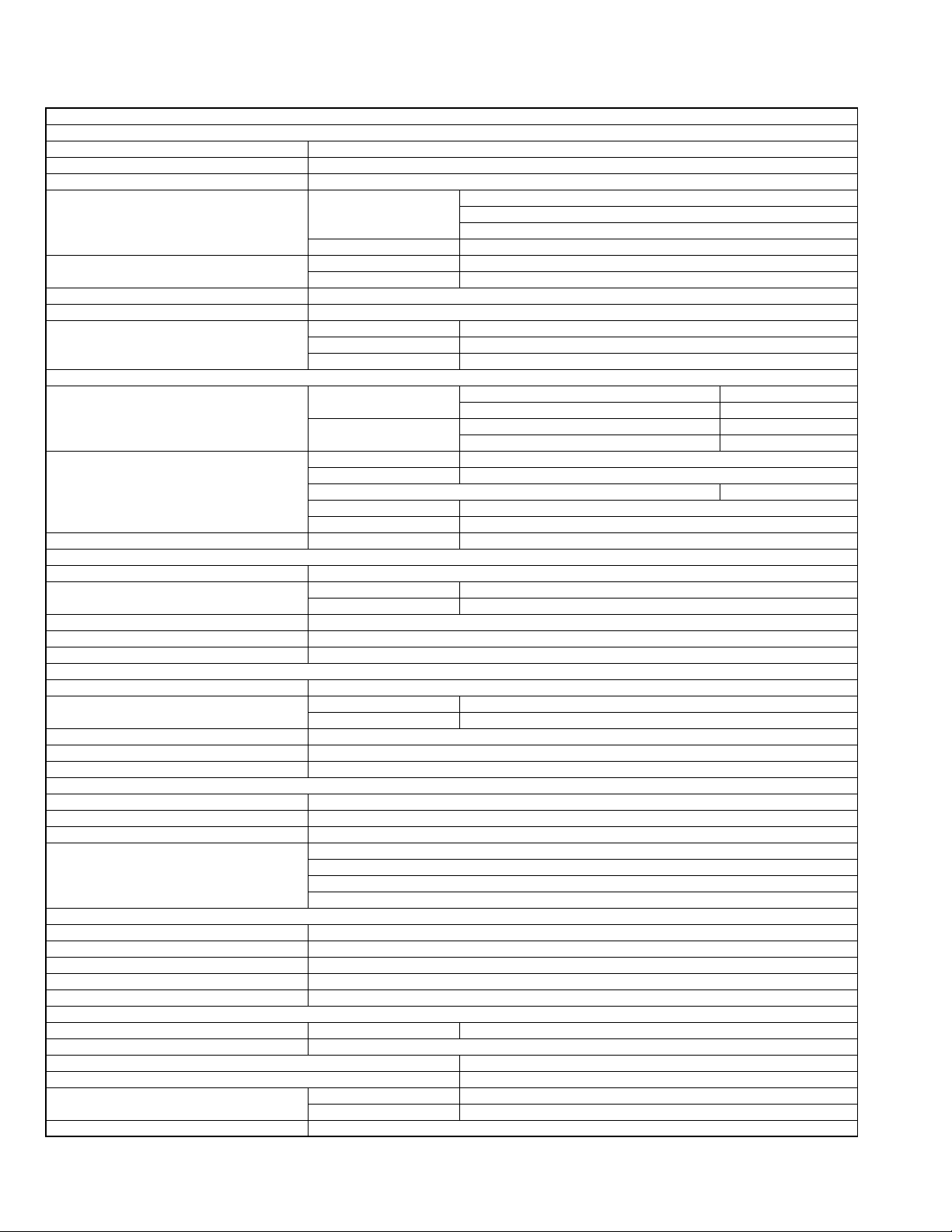

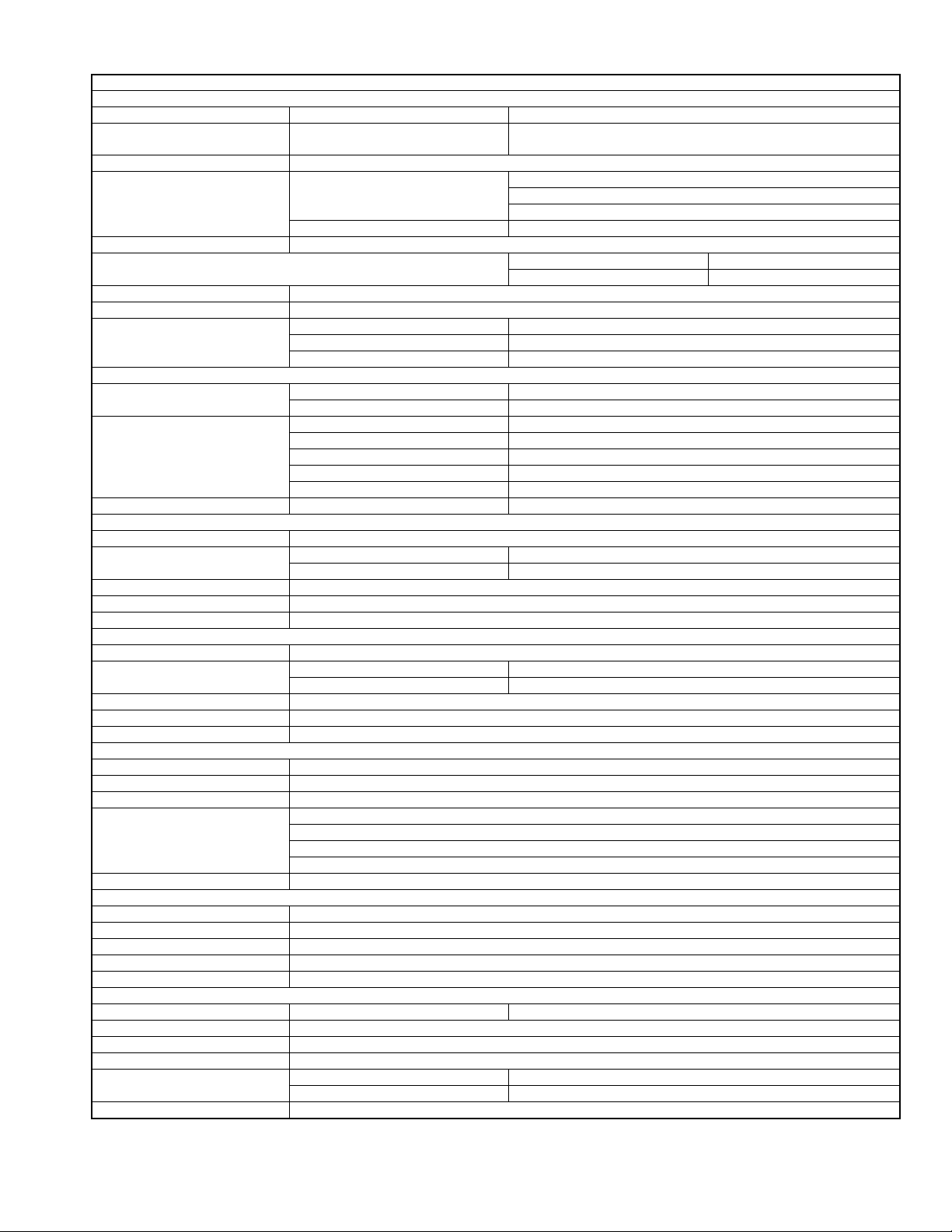

SPECIFICATION

KW-AVX838/KW-AVX830/KW-ADV793/KW-AVX738/KW-AVX730 J/JW

AMPLIFIER

Power Output 20 W RMS × 4 Channels at 4 Ω and < = 1% THD+N

Signal-to-Noise Ratio 80 dBA (reference: 1 W into 4 Ω)

Load Impedance 4 Ω (4 Ω to 8 Ω allowance)

Equalizer Control Range Frequencies Low: 60 Hz, 80 Hz, 100 Hz, 200 Hz

Mid: 500 Hz, 1 kHz, 1.5 kHz, 2.5 kHz

High: 10 kHz, 12.5 kHz, 15 kHz, 17.5 kHz

Level ±12 dB

Audio Output Level

FRONT OUT, REAR OUT, SUBWOOFER OUT

Color System NTSC

Video Output (composite) 1 Vp-p/75 Ω

Other Terminals Input LINE IN, VIDEO IN, CAMERA IN, USB input, MIC IN*, Antenna input

FM/AM TUNER

Frequency Range FM with channel interval set to 100 kHz or 200 kHz 87.5 MHz to 107.9 MHz

FM Tuner Usable Sensitivity 9.3 dBf (0.8 µV/75 Ω)

AM Tuner Sensitivity/Selectivity 20 µV/40 dB

DVD/CD

Signal Detection System Non-contact optical pickup (semiconductor laser)

Frequency Response DVD, fs=48 kHz/96 kHz 16 Hz to 22 000 Hz

Dynamic Range 93 dB

Signal-to-Noise Ratio 95 dB

Wow and Flutter Less than measurable limit

USB

USB Standards USB 2.0 Full Speed

Data Transfer Rate Full Speed Maximum 12 Mbps

Compatible Device Mass storage class

Compatible File System FAT 32/16/12

Max. Current DC 5 V 500 mA

BLUETOOTH (Only for KW-AVX838/KW-AVX830)

Version Bluetooth 2.0 certified

Output Power +4 dBm Max. (Power class 2)

Service Area Within 10 m (10.9 yd)

Profile HFP (Hands-Free Profile) 1.5

MONITOR

Screen Size 7 inch wide liquid crystal display

Number of Pixel 336 960 pixels: 480 × 3 (horizontal) × 234 (vertical)

Drive Method TFT (Thin Film Transistor) active matrix format

Color System NTSC/PAL

Aspect Ratio 16:9 (wide)

GENERAL

Power Requirement Operating Voltage DC 14.4 V (11 V to 16 V allowance)

Grounding System Negative ground

Allowable Storage Temperature -10°C to +60°C (14°F to 140°F)

Allowable Operating Temperature 0°C to +40°C (32°F to 104°F)

Dimensions (W × H × D) Installation Size (approx.) 182 mm × 111 mm × 160 mm (7-3/16” × 4-3/8” × 6-5/16”)

Mass (approx.) 2.8 kg (6.2 lbs) (including the Trim plate and Sleeve)

* Only for KW-AVX838/KW-AVX830.

Design and specifications are subject to change without notice.

Line-Out Level/Impedance 5 V/20 kΩ load (full scale), 2.5 V20 kΩ load (full scale) for KW-AVX730

Output Impedance 1 kΩ

Output 2nd AUDIO OUT*

Others Expansion port, OE REMOTE

with channel interval set to 50 kHz 87.5 MHz to 108.0 MHz

AM with channel interval set to 10 kHz 530 kHz to 1 710 kHz

with channel interval set to 9 kHz 531 kHz to 1 602 kHz

50 dB Quieting Sensitivity 16.3 dBf (1.8 µV/75 Ω)

Alternate Channel Selectivity (400 kHz) 65 dB

Frequency Response 40 Hz to 15 000 Hz

Stereo Separation 40 dB

VCD/CD 16 Hz to 20 000 Hz

Low Speed Maximum 1.5 Mbps

OPP (Object Push Profile) 1.1

A2DP (Advanced Audio Distribution Profile) 1.2

AVRCP (Audio/Video Remote Control Profile) 1.3

Panel Size (approx.) 188 mm × 117 mm × 10 mm (7-7/16” × 4-5/8” × 7/16”)

1-2 (No.MA473<Rev.002>)

Page 3

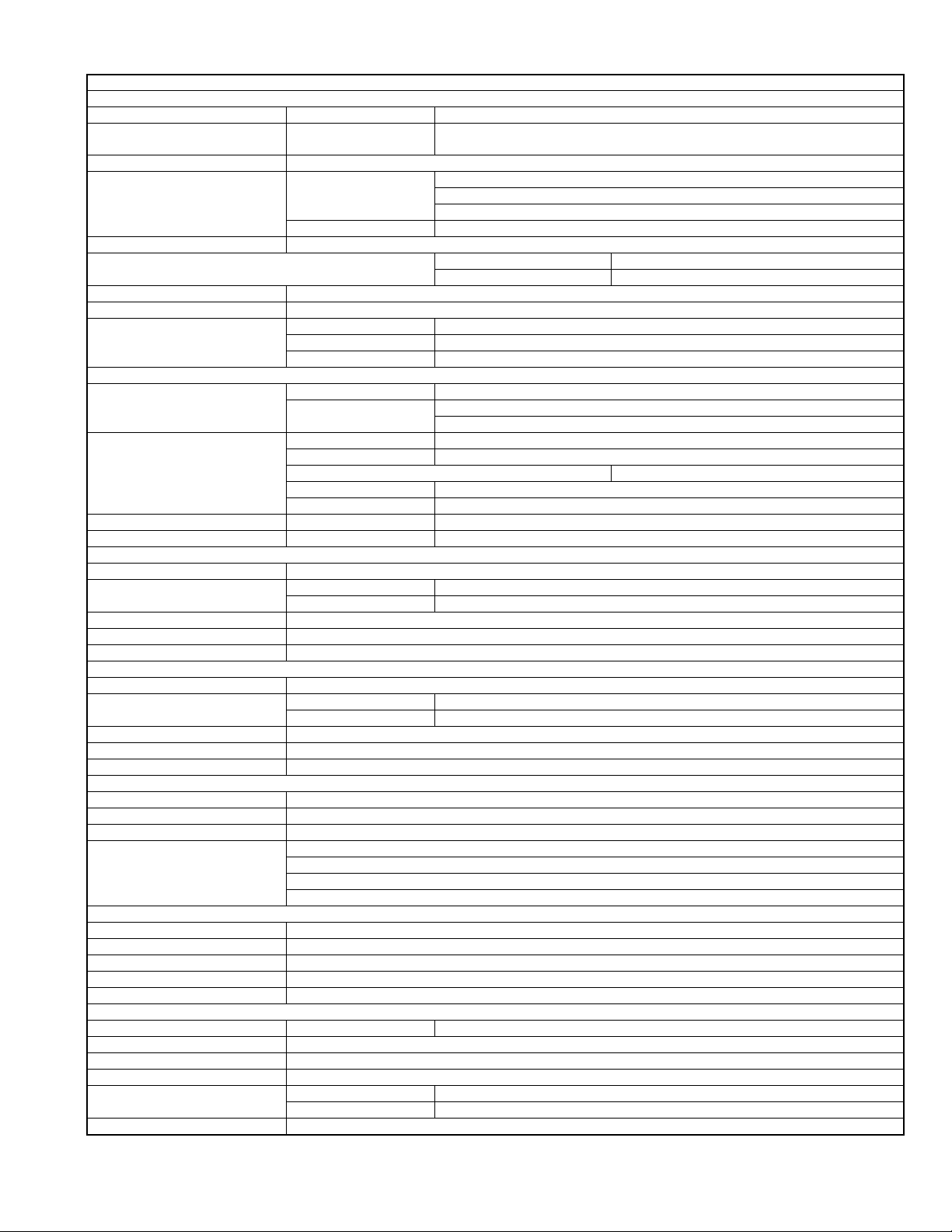

KW-AVX836/KW-AVX835/KW-AVX736/KW-AVX735 Europe

AMPLIFIER

Maximum Power Output Front/Rear 50 W per channel

Continuous Power Output (RMS) Front/Rear 20 W per channel into 4 Ω, 40 Hz to 20 000 Hz at no more than 0.8% total harmonic

Load Impedance 4 Ω (4 Ω to 8 Ω allowance)

Equalizer Control Range Frequencies Low: 60 Hz, 80 Hz, 100 Hz, 200 Hz

Level ±12 dB

Signal-to-Noise Ratio 70 dB

Audio Output Level

FRONT OUT, REAR OUT, SUBWOOFER OUT

Color System NTSC/PAL

Video Output (composite) 1 Vp-p/75 Ω

Other Terminals Input LINE IN, VIDEO IN, USB input, MIC IN*, Aerial input

Output 2nd AUDIO OUT*

Others OE REMOTE, RGB input

FM/AM TUNER

Frequency Range FM 87.5 MHz to 108.0 MHz

AM (MW) 522 kHz to 1 620 kHz

FM Tuner Usable Sensitivity 9.3 dBf (0.8 µV/75 Ω)

50 dB Quieting Sensitivity 16.3 dBf (1.8 µV/75 Ω)

Alternate Channel Selectivity (400 kHz) 65 dB

Frequency Response 40 Hz to 15 000 Hz

Stereo Separation 40 dB

MW Tuner Sensitivity/Selectivity 20 µV/40 dB

LW Tuner Sensitivity 50 µV

DVD/CD

Signal Detection System Non-contact optical pickup (semiconductor laser)

Frequency Response DVD, fs=48 kHz/96 kHz 16 Hz to 22 000 Hz

VCD/CD 16 Hz to 20 000 Hz

Dynamic Range 93 dB

Signal-to-Noise Ratio 95 dB

Wow and Flutter Less than measurable limit

USB

USB Standards USB 2.0 Full Speed

Data Transfer Rate Full Speed Maximum 12 Mbps

Low Speed Maximum 1.5 Mbps

Compatible Device Mass storage class

Compatible File System FAT 32/16/12

Max. Current DC 5 V 500 mA

BLUETOOTH (Only for KW-AVX836/KW-AVX835)

Version Bluetooth 2.0 certified

Output Power +4 dBm Max. (Power class 2)

Service Area Within 10 m

Profile HFP (Hands-Free Profile) 1.5

OPP (Object Push Profile) 1.1

A2DP (Advanced Audio Distribution Profile) 1.2

AVRCP (Audio/Video Remote Control Profile) 1.3

MONITOR

Screen Size 7 inch wide liquid crystal display

Number of Pixel 336 960 pixels: 480 × 3 (horizontal) × 234 (vertical)

Drive Method TFT (Thin Film Transistor) active matrix format

Color System PAL/NTSC

Aspect Ratio 16:9 (wide)

GENERAL

Power Requirement Operating Voltage DC 14.4 V (11 V to 16 V allowance)

Grounding System Negative ground

Allowable Storage Temperature -10°C to +60°C

Allowable Operating Temperature 0°C to +40°C

Dimensions (W × H × D) Installation Size (approx.) 182 mm × 111 mm × 160 mm

Panel Size (approx.) 188 mm × 117 mm × 10 mm

Mass (approx.) 2.8 kg (including the Trim plate and Sleeve)

distortion

Mid: 500 Hz, 1 kHz, 1.5 kHz, 2.5 kHz

High: 10 kHz, 12.5 kHz, 15 kHz, 17.5 kHz

Line-Out Level/Impedance 5 V/20 kΩ load (full scale)

Output Impedance 1 kΩ

(LW) 144 kHz to 279 kHz

* Only for KW-AVX836/KW-AVX835

Design and specifications are subject to change without notice.

(No.MA473<Rev.002>)1-3

Page 4

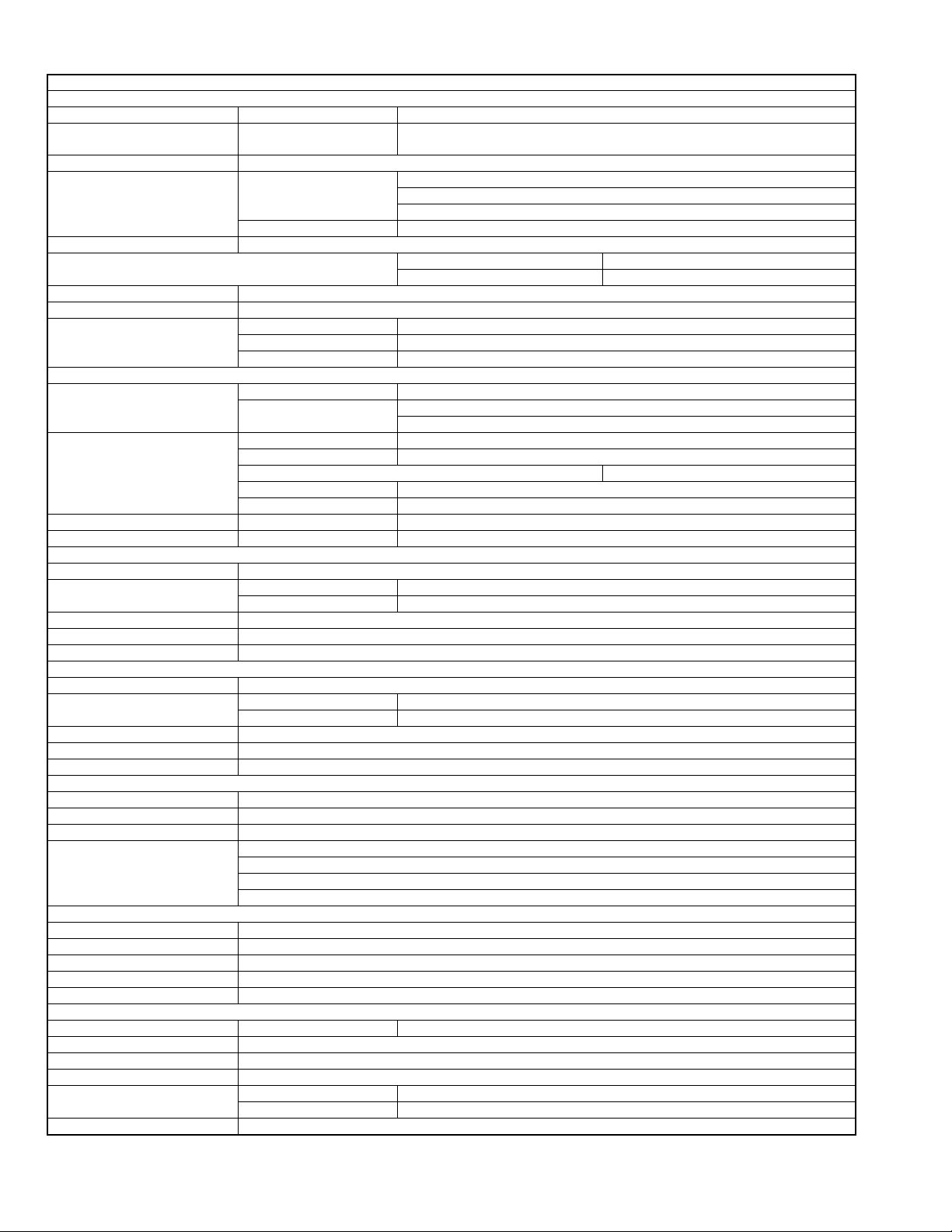

KW-AVX830/KW-AVX730 Europe

AMPLIFIER

Maximum Power Output Front/Rear 50 W per channel

Continuous Power Output (RMS) Front/Rear 20 W per channel into 4

Load Impedance 4 Ω (4 Ω to 8 Ω allowance)

Equalizer Control Range Frequencies Low: 60 Hz, 80 Hz, 100 Hz, 200 Hz

Level ±12 dB

Signal-to-Noise Ratio 70 dB

Audio Output Level

FRONT OUT, REAR OUT, SUBWOOFER OUT

Color System PAL

Video Output (composite) 1 Vp-p/75 Ω

Other Terminals Input LINE IN, VIDEO IN, CAMERA IN*1, USB input, MIC IN*1, Aerial input

Output 2nd AUDIO OUT*1

Others Expansion port*2, OE REMOTE

FM/AM TUNER

Frequency Range FM 87.5 MHz to 108.0 MHz

AM (MW) 522 kHz to 1 620 kHz

FM Tuner Usable Sensitivity 9.3 dBf (0.8

50 dB Quieting Sensitivity 16.3 dBf (1.8 µV/75 Ω)

Alternate Channel Selectivity (400 kHz) 65 dB

Frequency Response 40 Hz to 15 000 Hz

Stereo Separation 40 dB

MW Tuner Sensitivity/Selectivity 20 µV/40 dB

LW Tuner Sensitivity 50 µV

DVD/CD

Signal Detection System Non-contact optical pickup (semiconductor laser)

Frequency Response DVD, fs=48 kHz/96 kHz 16 Hz to 22 000 Hz

VCD/CD 16 Hz to 20 000 Hz

Dynamic Range 93 dB

Signal-to-Noise Ratio 95 dB

Wow and Flutter Less than measurable limit

USB

USB Standards USB 2.0 Full Speed

Data Transfer Rate Full Speed Maximum 12 Mbps

Low Speed Maximum 1.5 Mbps

Compatible Device Mass storage class

Compatible File System FAT 32/16/12

Max. Current DC 5 V 500 mA

BLUETOOTH (Only for KW-AVX830)

Version Bluetooth 2.0 certified

Output Power +4 dBm Max. (Power class 2)

Service Area Within 10 m

Profile HFP (Hands-Free Profile) 1.5

OPP (Object Push Profile) 1.1

A2DP (Advanced Audio Distribution Profile) 1.2

AVRCP (Audio/Video Remote Control Profile) 1.3

MONITOR

Screen Size 7 inch wide liquid crystal display

Number of Pixel 336 960 pixels: 480

Drive Method TFT (Thin Film Transistor) active matrix format

Color System PAL/NTSC

Aspect Ratio 16:9 (wide)

GENERAL

Power Requirement Operating Voltage DC 14.4 V (11 V to 16 V allowance)

Grounding System Negative ground

Allowable Storage Temperature -10

Allowable Operating Temperature 0°C to +40°C

Dimensions (W × H × D) Installation Size (approx.) 182 mm × 111 mm × 160 mm

Mass (approx.) 2.8 kg (including the Trim plate and Sleeve)

°C to +60°C

Panel Size (approx.) 188 mm × 117 mm × 10 mm

× 3 (horizontal) × 234 (vertical)

distortion

Mid: 500 Hz, 1 kHz, 1.5 kHz, 2.5 kHz

High: 10 kHz, 12.5 kHz, 15 kHz, 17.5 kHz

Line-Out Level/Impedance

Output Impedance 1 kΩ

(LW) 144 kHz to 279 kHz

µV/75 Ω)

Ω, 40 Hz to 20 000 Hz at no more than 0.8% total harmonic

5 V/20 kΩ load (full scale)

*1 Only for KW-AVX830. *2 Only for KW-AVX730.

Design and specifications are subject to change without notice.

1-4 (No.MA473<Rev.002>)

Page 5

KW-AVX836/KW-AVX835/KW-AVX736/KW-AVX735 Asia & Oceania

AMPLIFIER

Maximum Power Output Front/Rear 50 W per channel

Continuous Power Output (RMS) Front/Rear 20 W per channel into 4

Load Impedance 4 Ω (4 Ω to 8 Ωallowance)

Equalizer Control Range Frequencies Low: 60 Hz, 80 Hz, 100 Hz, 200 Hz

Level ±12 dB

Signal-to-Noise Ratio 70 dB

Audio Output Level

FRONT OUT, REAR OUT, SUBWOOFER OUT

Color System NTSC/PAL

Video Output (composite) 1 Vp-p/75 Ω

Other Terminals Input LINE IN, VIDEO IN, USB input, MIC IN*, Antenna input

Output 2nd AUDIO OUT*

Others OE REMOTE, RGB input

FM/AM TUNER

Frequency Range FM 87.5 MHz to 108.0 MHz

AM 531 kHz to 1 602 kHz

FM Tuner Usable Sensitivity 9.3 dBf (0.8

50 dB Quieting Sensitivity 16.3 dBf (1.8 µV/75 Ω

Alternate Channel Selectivity (400 kHz) 65 dB

Frequency Response 40 Hz to 15 000 Hz

Stereo Separation 40 dB

AM Tuner Sensitivity/Selectivity 20 µV/40 dB

DVD/CD

Signal Detection System Non-contact optical pickup (semiconductor laser)

Frequency Response DVD, fs=48 kHz/96 kHz 16 Hz to 22 000 Hz

VCD/CD 16 Hz to 20 000 Hz

Dynamic Range 93 dB

Signal-to-Noise Ratio 95 dB

Wow and Flutter Less than measurable limit

USB

USB Standards USB 2.0 Full Speed

Data Transfer Rate Full Speed Maximum 12 Mbps

Low Speed Maximum 1.5 Mbps

Compatible Device Mass storage class

Compatible File System FAT 32/16/12

Max. Current DC 5 V 500 mA

BLUETOOTH (Only for KW-AVX836/KW-AVX835)

Version Bluetooth 2.0 certified

Output Power +4 dBm Max. (Power class 2)

Service Area Within 10 m

Profile HFP (Hands-Free Profile) 1.5

OPP (Object Push Profile) 1.1

A2DP (Advanced Audio Distribution Profile) 1.2

AVRCP (Audio/Video Remote Control Profile) 1.3

Max. Current DC 5 V 54.3 mA

MONITOR

Screen Size 7 inch wide liquid crystal display

Number of Pixel 336 960 pixels: 480

Drive Method TFT (Thin Film Transistor) active matrix format

Color System PAL/NTSC

Aspect Ratio 16:9 (wide)

GENERAL

Power Requirement Operating Voltage DC 14.4 V (11 V to 16 V allowance)

Grounding System Negative ground

Allowable Storage Temperature -10

Allowable Operating Temperature 0°C to +40°C

Dimensions (W × H × D) Installation Size (approx.) 180 mm × 100 mm × 160 mm

Mass (approx.) 2.6 kg

°C to +60°C

Panel Size (approx.) 171 mm × 97 mm × 28 mm

× 3 (horizontal) × 234 (vertical)

total harmonic distortion

Mid: 500 Hz, 1 kHz, 1.5 kHz, 2.5 kHz

High: 10 kHz, 12.5 kHz, 15 kHz, 17.5 kHz

Line-Out Level/Impedance 5 V/20 kΩ load (full scale)

Output Impedance 1 kΩ

µV/75 Ω)

Ω, 40 Hz to 20 000 Hz at no more than 0.8%

* Only for KW-AVX836/KW-AVX835.

Design and specifications are subject to change without notice.

(No.MA473<Rev.002>)1-5

Page 6

1.1 Safety Precautions

SECTION 1

PRECAUTION

!

!

Burrs formed during molding may be left over on some parts of the chassis. Therefore,

pay attention to such burrs in the case of preforming repair of this system.

Please use enough caution not to see the beam directly or touch it in case of an

adjustment or operation check.

1-6 (No.MA473<Rev.002>)

Page 7

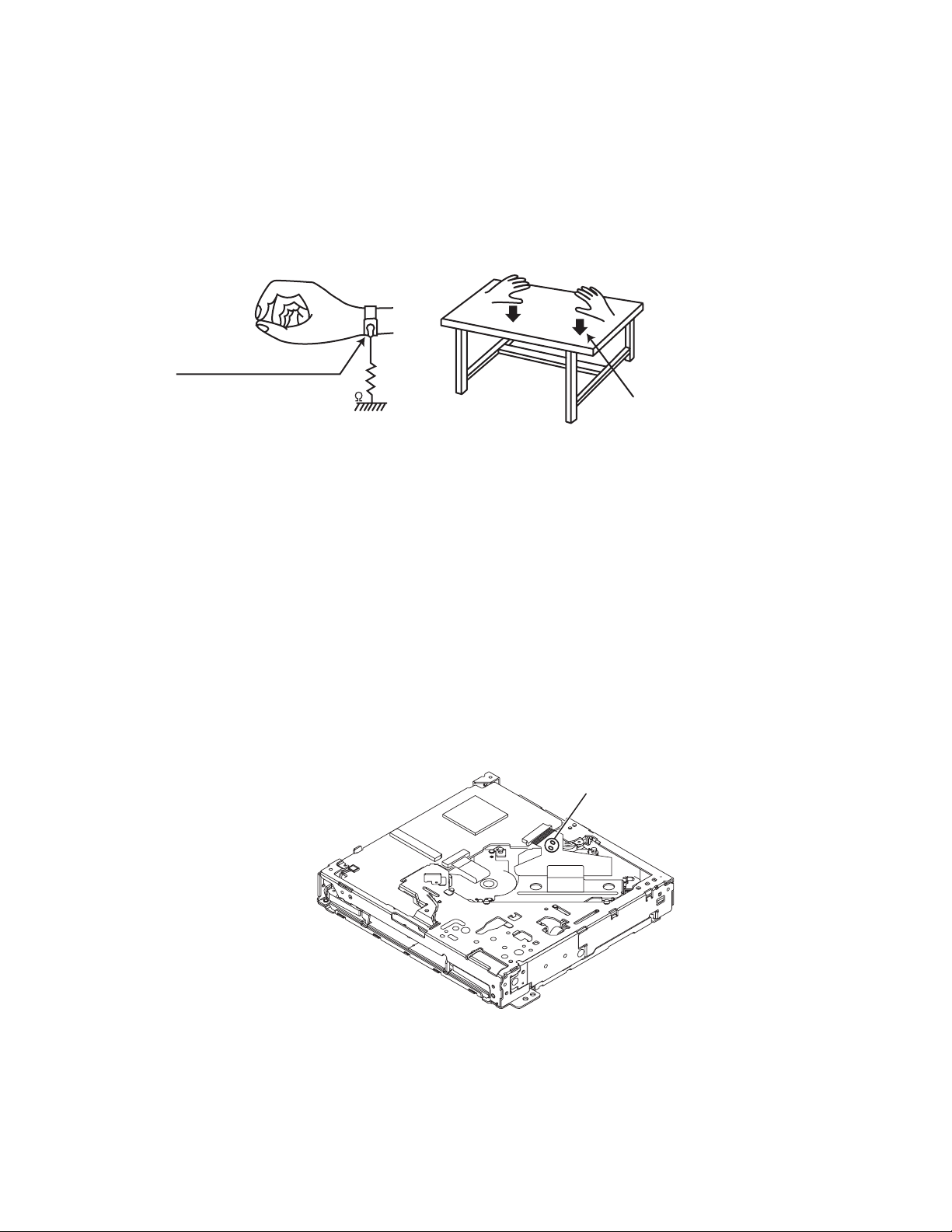

1.2 Preventing static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged, can destroy the laser

diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

1.2.1 Grounding to prevent damage by static electricity

Static electricity in the work area can destroy the optical pickup (laser diode) in devices such as laser products.

Be careful to use proper grounding in the area where repairs are being performed.

(1) Ground the workbench

Ground the workbench by laying conductive material (such as a conductive sheet) or an iron plate over it before placing the

traverse unit (optical pickup) on it.

(2) Ground yourself

Use an anti-static wrist strap to release any static electricity built up in your body.

(caption)

Anti-static wrist strap

1M

Conductive material

(conductive sheet) or iron plate

(3) Handling the optical pickup

• In order to maintain quality during transport and before installation, both sides of the laser diode on the replacement optical

pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

• Do not use a tester to check the condition of the laser diode in the optical pickup. The tester's internal power source can easily

destroy the laser diode.

1.3 Handling the traverse unit (optical pickup)

(1) Do not subject the traverse unit (optical pickup) to strong shocks, as it is a sensitive, complex unit.

(2) Cut off the shorted part of the flexible cable using nippers, etc. after replacing the optical pickup. For specific details, refer to the

replacement procedure in the text. Remove the anti-static pin when replacing the traverse unit. Be careful not to take too long a

time when attaching it to the connector.

(3) Handle the flexible cable carefully as it may break when subjected to strong force.

(4) It is not possible to adjust the semi-fixed resistor that adjusts the laser power. Do not turn it.

1.4 Attention when traverse unit is decomposed

*Please refer to "Disassembly method" in the text for the pickup unit.

• Apply solder to the short land before the card wire is disconnected from the connector on the pickup unit.

(If the card wire is disconnected without applying solder, the pickup may be destroyed by static electricity.)

• In the assembly, be sure to remove solder from the short land after connecting the card wire.

Solder short part

(No.MA473<Rev.002>)1-7

Page 8

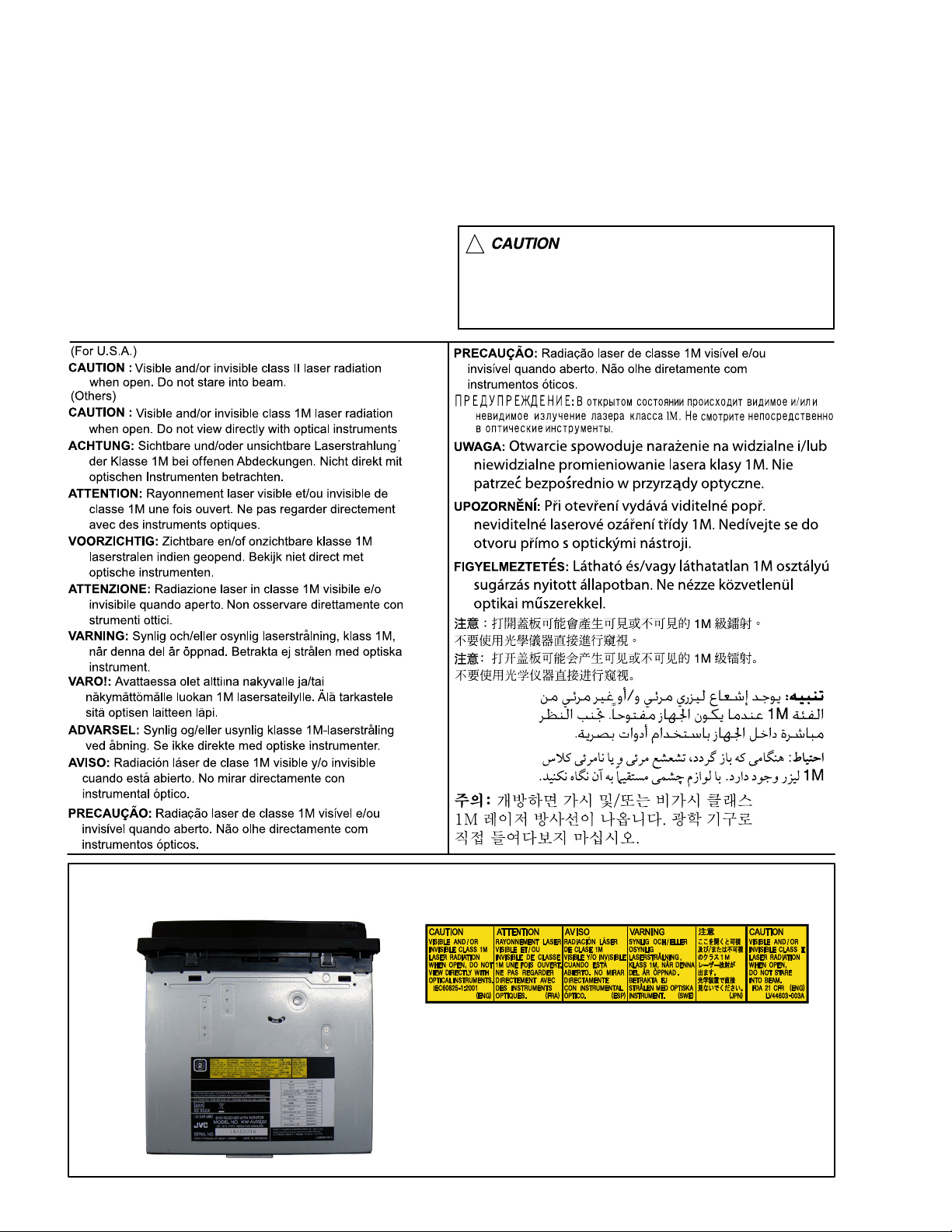

1.5 Important for laser products

1.CLASS 1 LASER PRODUCT

2.CAUTION :

(For U.S.A.) Visible and/or invisible class II laser radiation

when open. Do not stare into beam.

(Others) Visible and/or invisible class 1M laser radiation

when open. Do not view directly with optical instruments.

3.CAUTION : Visible and/or invisible laser radiation when

open and inter lock failed or defeated. Avoid direct

exposure to beam.

4.CAUTION : This laser product uses visible and/or invisible

laser radiation and is equipped with safety switches which

prevent emission of radiation when the drawer is open and

the safety interlocks have failed or are defeated. It is

dangerous to defeat the safety switches.

5.CAUTION : If safety switches malfunction, the laser is able

to function.

6.CAUTION : Use of controls, adjustments or performance of

procedures other than those specified here in may result in

hazardous radiation exposure.

!

Please use enough caution not to

see the beam directly or touch it

in case of an adjustment or operation

check.

REPRODUCTION AND POSITION OF LABELS and PRINT

WARNING LABEL and PRINT

1-8 (No.MA473<Rev.002>)

Page 9

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

This service manual does not describe SPECIFIC SERVICE INSTRUCTIONS.

(No.MA473<Rev.002>)1-9

Page 10

SECTION 3

DISASSEMBLY

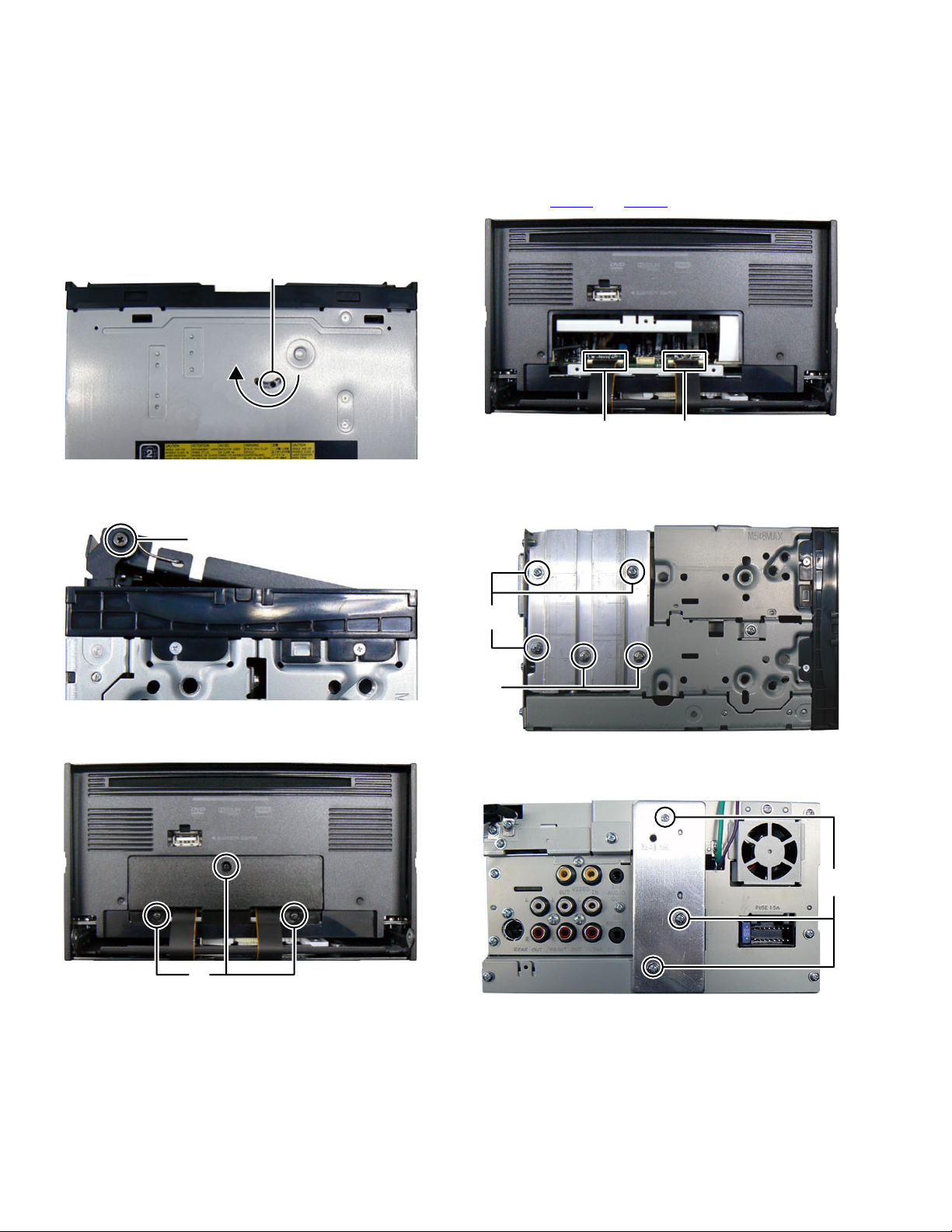

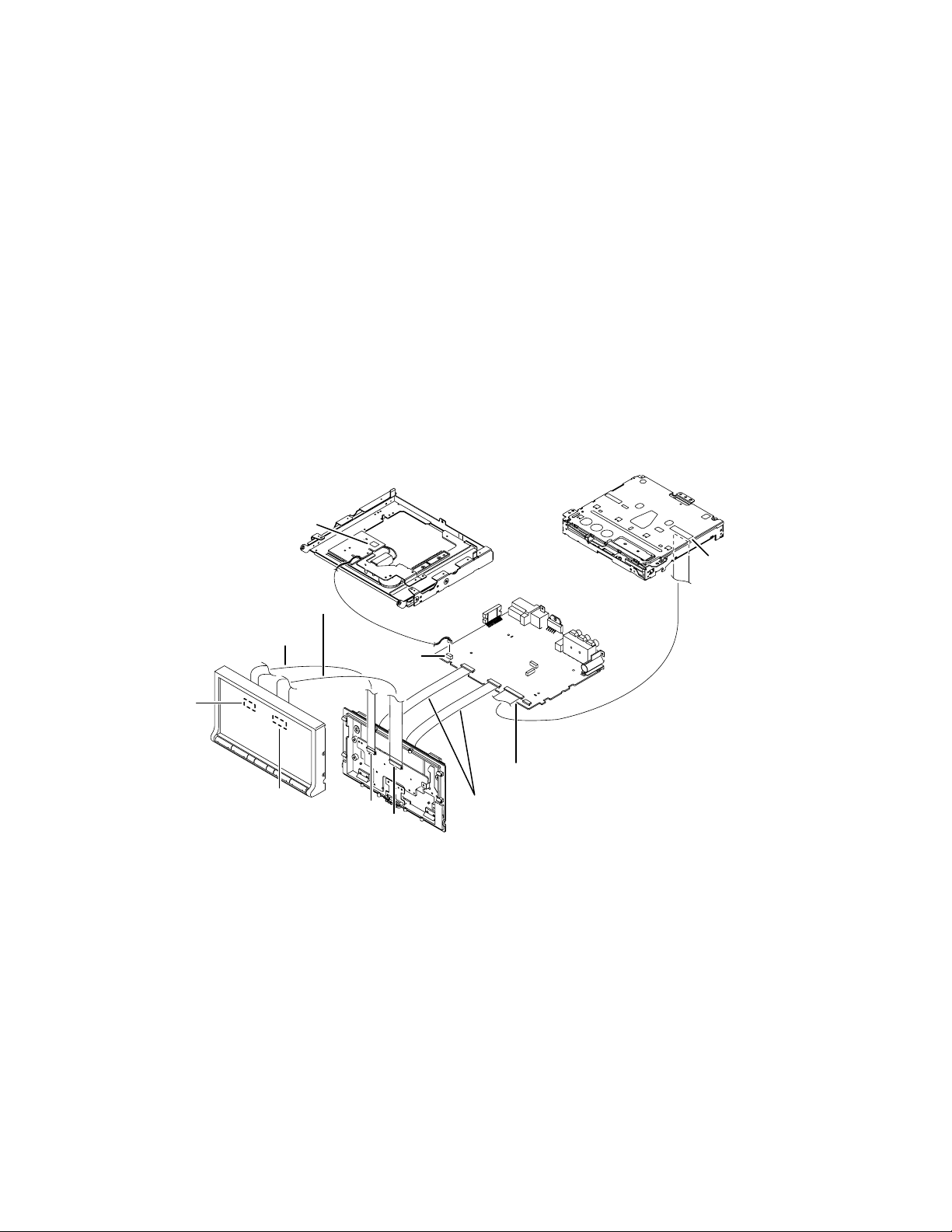

3.1 Main body (Used model: KW-AVX810)

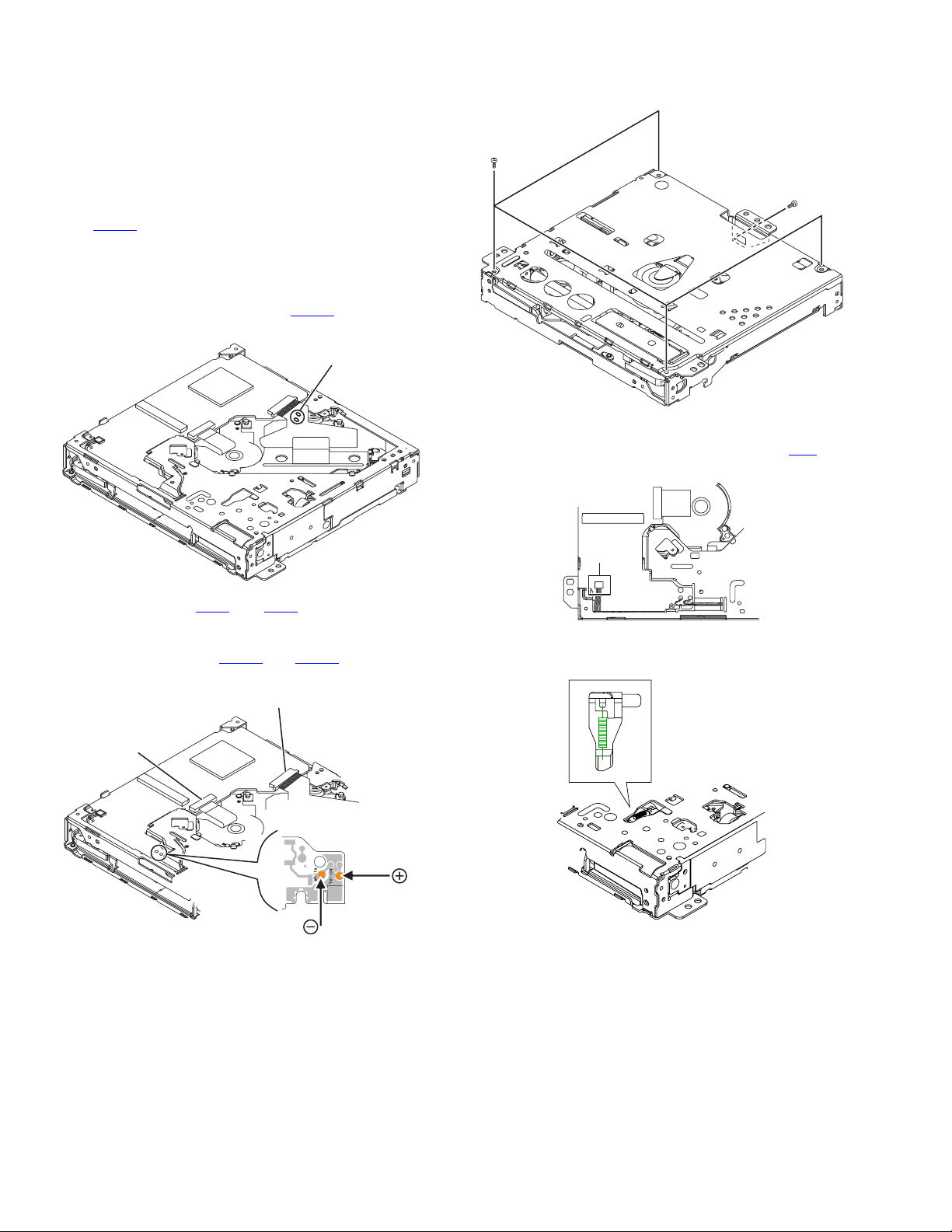

3.1.1 Removing the Front panel (See Fig.1, 2, 3, 4)

(1) From the bottom side of the main body, insert the screw-

driver to hole of the third gear from hole a of the bottom

chassis, and then turn the gear to clockwise until Front

panel comes up. (See Fig.1)

hole a

Fig.1

(2) Remove the two screws A attaching the both side of the

Front panel. (See Fig.2)

(4) Disconnect the FPC from Front panel connected to con-

nectors CN106

3.1.2 Removing the Heat sink (See Fig.5)

(1) Remove the three screws C and two screws D attaching

the Heat sink.

and CN107 of the Main board. (See Fig.4)

CN106CN107

Fig.4

A

Fig.2

(3) Remove the three screws B attaching the FPC cover. (See

Fig.3)

B

Fig.3

C

D

Fig.5

3.1.3 Removing the Rear heat sink (See Fig 6)

(1) Remove the three screws E attaching the Rear heat sink.

E

Fig.6

1-10 (No.MA473<Rev.002>)

Page 11

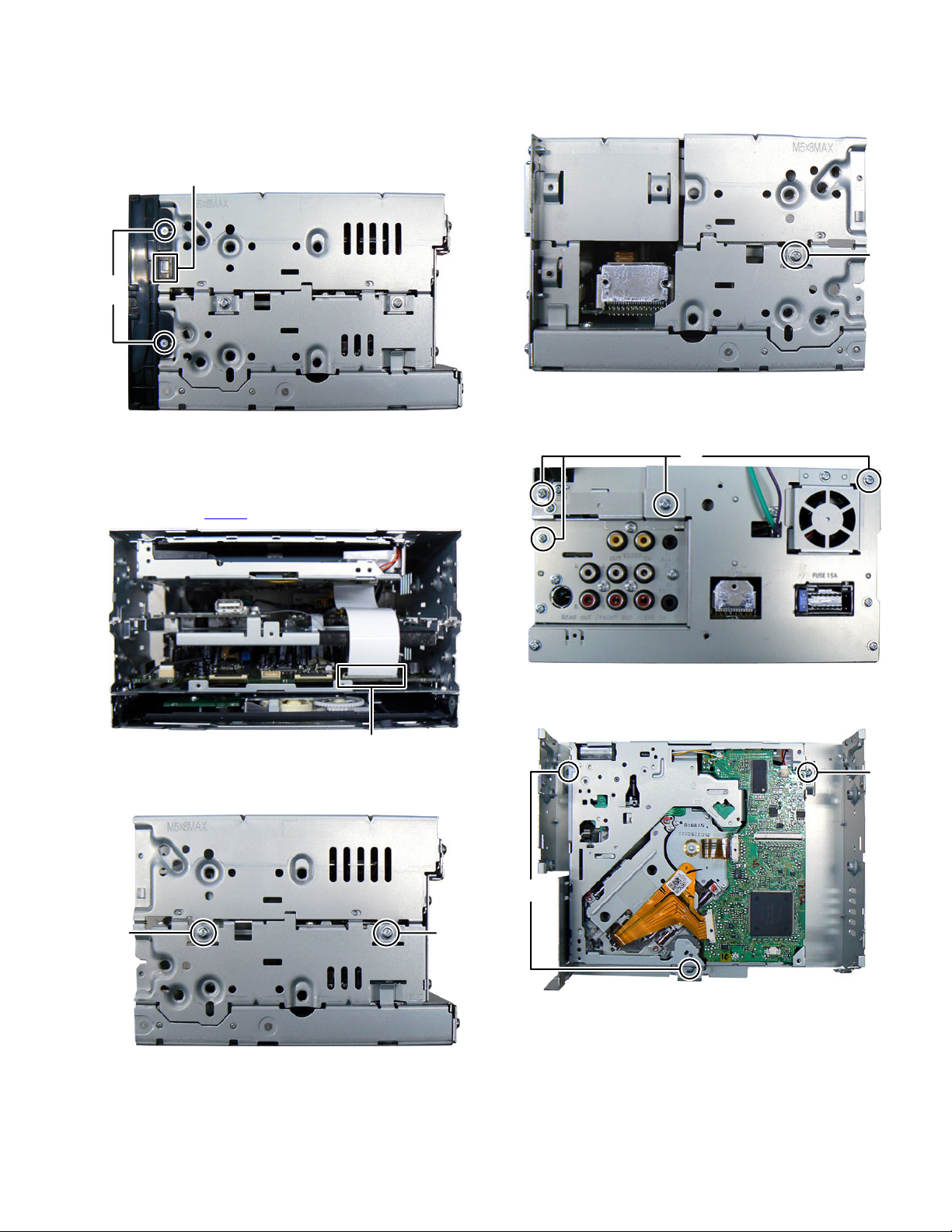

3.1.4 Removing the Front chassis (See Fig.7)

(1) Remove the four screws F attaching the both side of the

Front chassis.

(2) Disengage two hooks a engaged both side of the Front

chassis.

hook

a

F

Fig.7

3.1.5 Removing the DVD mechanism (See Fig.8, 9, 10, 11,

12)

(1) Disconnect the card wire from DVD mechanism connected

to connector CN105

of the Main board. (See Fig.8)

(3) Remove the one screw H attaching the Top chassis. (See

Fig.10)

H

Fig.10

(4) Remove the four screws J attaching the Top chassis. (See

Fig.11)

J

Fig.11

(5) Remove the three screws K attaching the DVD mecha-

nism. (See Fig.12)

CN105

Fig.8

(2) Remove the two screws G attaching the Top chassis. (See

Fig.9)

K

GG

Fig.12

Fig.9

K

(No.MA473<Rev.002>)1-11

Page 12

3.1.6 Removing the BT amp board (See Fig.13)

(1) Disconnect the card wire from Main board connected to

connector CN311

(2) Disconnect Car cable connected to connector CN341

the BT amp board.

(3) Remove the four screws L attaching the BT amp board.

of the BT amp board.

3.1.8 Removing the Rear panel (See Fig.16, 17)

(1) Disconnect the connector wire from Car cable connected to

of

connector CN101

(2) Disconnect the connector wire from FAN connected to con-

nector CN112

of the Main board. (See Fig.16)

of the Main board. (See Fig.16)

CN101

CN311 CN341

Fig.13

3.1.7 Removing the Sub amp board (See Fig.14, 15)

(1) Remove the one screw M attaching the Sub amp board.

(See Fig.14)

M

Fig.14

(2) Disconnect the card wire from Main board connected to

connector CN201

(3) Disconnect the Car cable connected to connector CN241

of the Sub amp board. (See Fig.15)

(4) Remove the three screws N attaching the Sub amp board.

(See Fig.15)

of the Sub amp board. (See Fig.15)

L

CN112

Fig.16

(3) Remove the six screws P and two screws Q attaching the

Rear panel. (Se Fig.17)

P

Q

Fig.17

3.1.9 Removing the Center chassis (See Fig.18)

(1) Remove the three screws R attaching the Center chassis.

R

P

R

CN201

N

CN241

1-12 (No.MA473<Rev.002>)

Fig.15

N

Fig.18

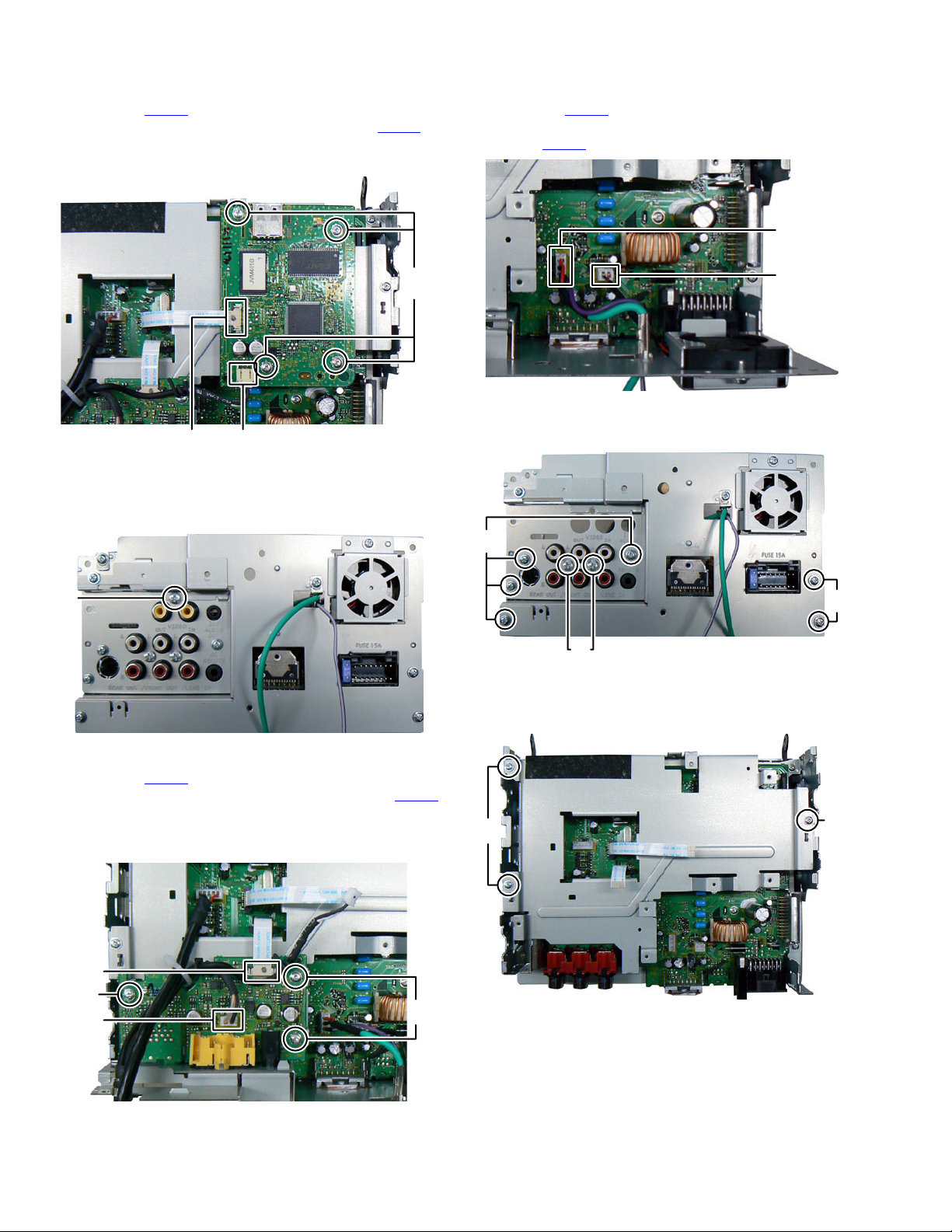

Page 13

3.1.10 Removing the Main board (See Fig.19)

(1) Disconnect the connector wire from Door switch board con-

nected to connector CN109

(2) Remove the four screws S attaching the Main board.

of the Main board.

CN109

3.1.12 Removing the Front board (See Fig.22)

(1) Remove the five screws V attaching the Front board.

S

Fig.19

3.1.11 Removing the Rear cover (See Fig.20, 21)

(1) Remove the ten screws T and five screws U attaching the

Rear cover. (See Fig.20)

UU

T

T

T

Fig.20

(2) Disconnect the card wires from Front board connected to

connector CN401

Panel-B board. (See Fig.21)

of the Panel-A board and CN601 of the

CN401

T

S

V

Fig.22

3.1.13 Removing the Panel-A board (See Fig.23)

(1) Disconnect the FPC connected to connector CN501

Panel-A board.

(2) Remove the four screws W attaching the Panel-A board.

W

W

CN501 CN604 CN605

Fig.23

3.1.14 Removing the Panel-B board (See Fig.23)

(1) Disconnect the FPC connected to connectors CN604

CN605

of the Panel-B board.

(2) Remove the three screws X attaching the Panel-B board.

V

of the

X

and

CN601

Fig.21

(No.MA473<Rev.002>)1-13

Page 14

3.2 DVD mechanism assembly section

3.2.1 Removing the Traverse mechanism assembly (See

Fig.1 to 6)

(1) Solder the short land section on the flexible wire of pickup.

(See Fig.1)

Caution:

* Solder the short land section on the flexible wire of pickup

before disconnecting the flexible wire form the connector

on the Front end board.

CN101

If the flexible wire is disconnected without attaching the

solder, the pickup may be destroyed by static electricity.

* When attaching the Traverse mechanism assembly, remove the solder from the short land section after connection

the flexible wire to the connector CN101

on the Front end

board.

Solder short part

(4) Remove the five screws A attaching the Top cover assembly.

(See Fig.3)

A

Fig.3

(5) From the bottom side, disconnect the connector wire from

Top cover assembly connected to connector CN2

Front end board. (See Fig.4)

of the

Fig.1

(2) Voltage supply to TP79

and TP81 approx DC 3.0V until

Clamper is shift to loading complete position. (See Fig.2)

(3) Disconnect the flexible wires from Traverse mechanism assembly

connected to connector CN101

and CN164 of the Front end

board. (See Fig.2)

CN101

CN164

TP79 TP81

TP79

R317

TP67

R312

R21

R357

TP81

TP92

CENTER

D-

DGND_7

WOOFER

Voltage supply

position

Fig.2

CN2

Fig.4

(6) From the bottom side, remove the spring from Traverse

mechanism assembly. (See Fig.5)

Fig.5

1-14 (No.MA473<Rev.002>)

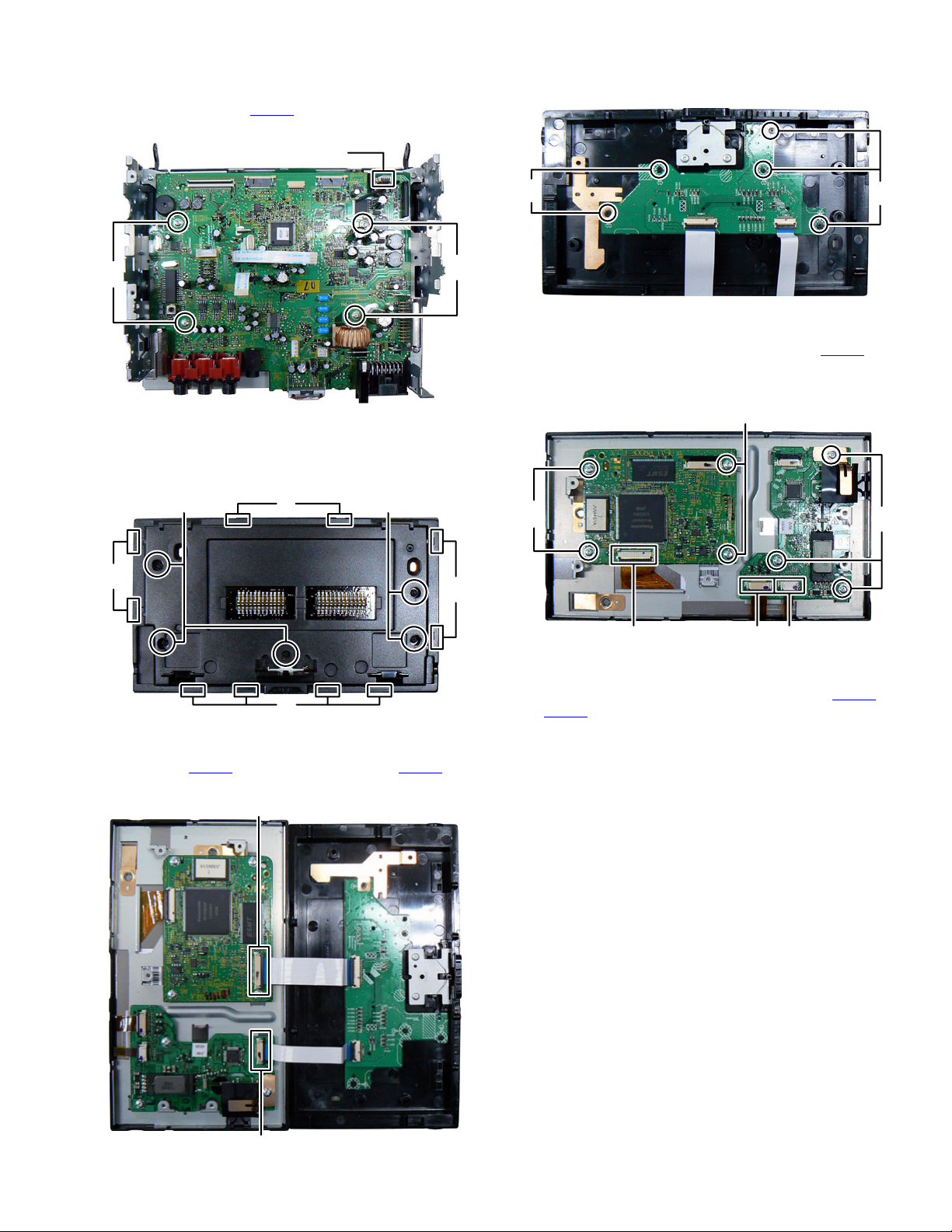

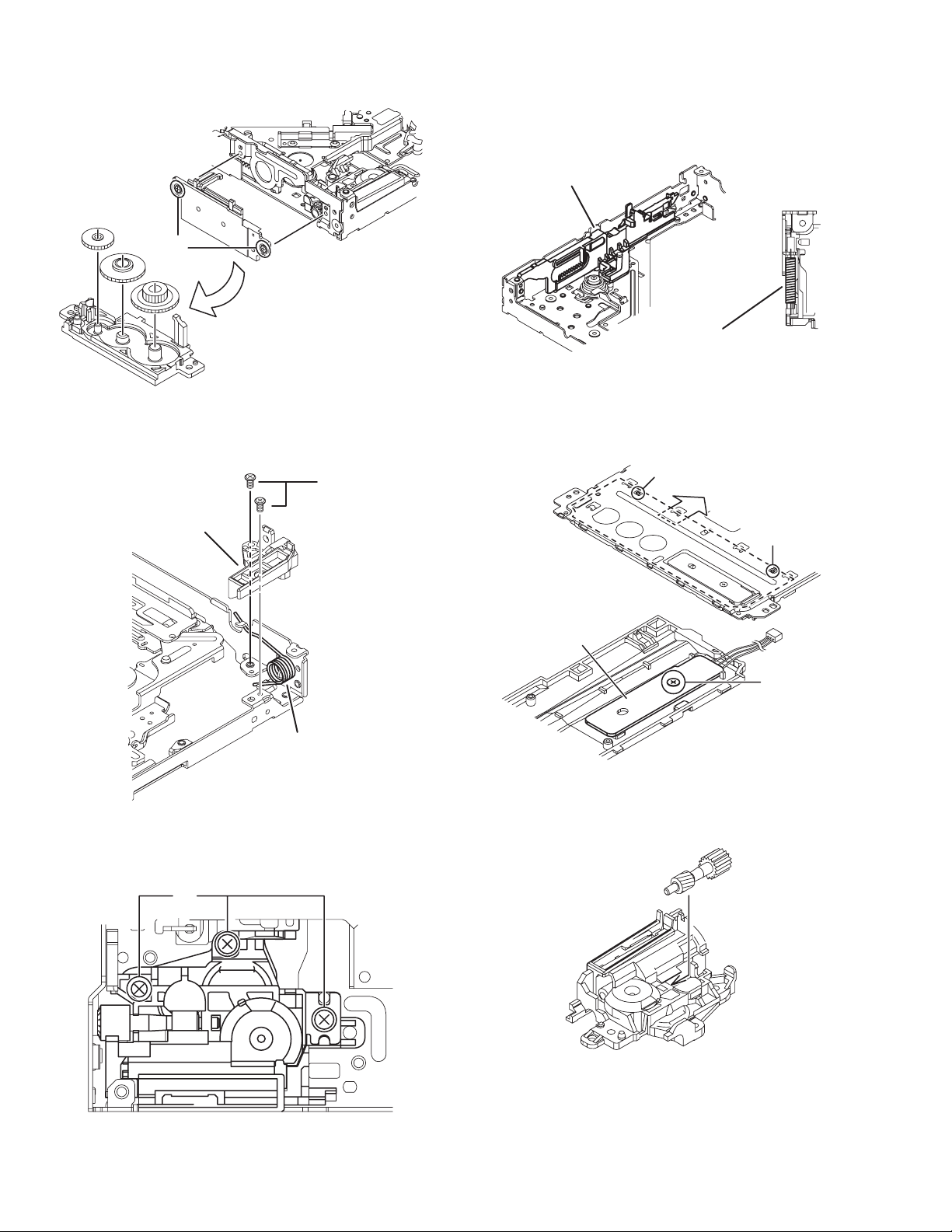

Page 15

(7) From the top side, pull up the traverse mechanism and disengage

three dumper positions. (See Fig.6)

Dumper

(same color spring)

Dumper

(Different color spring)

Fig.6

3.2.2 Removing the Front end board (See Fig.7)

(1) Remove the Motor wires from loading motor soldered to

and TP81 of the Front end board.

TP79

(2) Remove the two screws B attaching the Front end board.

TP81

3.2.3 Removing the Loading arm assembly (See Fig.8)

(1) Remove the Loading arm spring L from Loading arm assembly.

(2) Slide to left side and then disengage hook a then hook b.

hook b

Loading arm

assembly

hook

Loading arm spring L

a

B

TP79

B

Fig.8

3.2.4 Removing the Gear base assembly (See Fig.9, 10)

(1) Remove the Loading arm spring L. (See Fig.9)

Fig.7

Loading arm

spring L

Fig.9

(No.MA473<Rev.002>)1-15

Page 16

(2) Remove the two screws C attaching the Gear base assembly.

r

(See Fig.10)

C

Fig.10

3.2.5 Removing the Loading arm holder. (See Fig.11)

(1) Remove the two screws D attaching the Loading arm holder.

(2) Remove the Loading arm spring R.

D

Loading arm

holder

3.2.7 Removing the Slide cam assembly (See Fig.13)

(1) Slide to backward the Slide cam assembly and the remove

the Slide cam spring.

(2) Slide to frontward the slide cam assembly, and then take

out it.

Slide cam assembly

Slide cam spring

Fig.13

3.2.8 Removing the Photo board (See Fig.14)

(1) Pressing the hook c and then slide to backward (slide to the

arrow side) the Disc plate.

(2) Remove the one screw F attaching the Photo board.

hook

c

hook

c

Loading arm

spring R

Fig.11

3.2.6 Removing the Loading moor assembly (See Fig.12)

(1) Remove the three screws E attaching the Loading motor

assembly.

E

Photo board

F

Fig.14

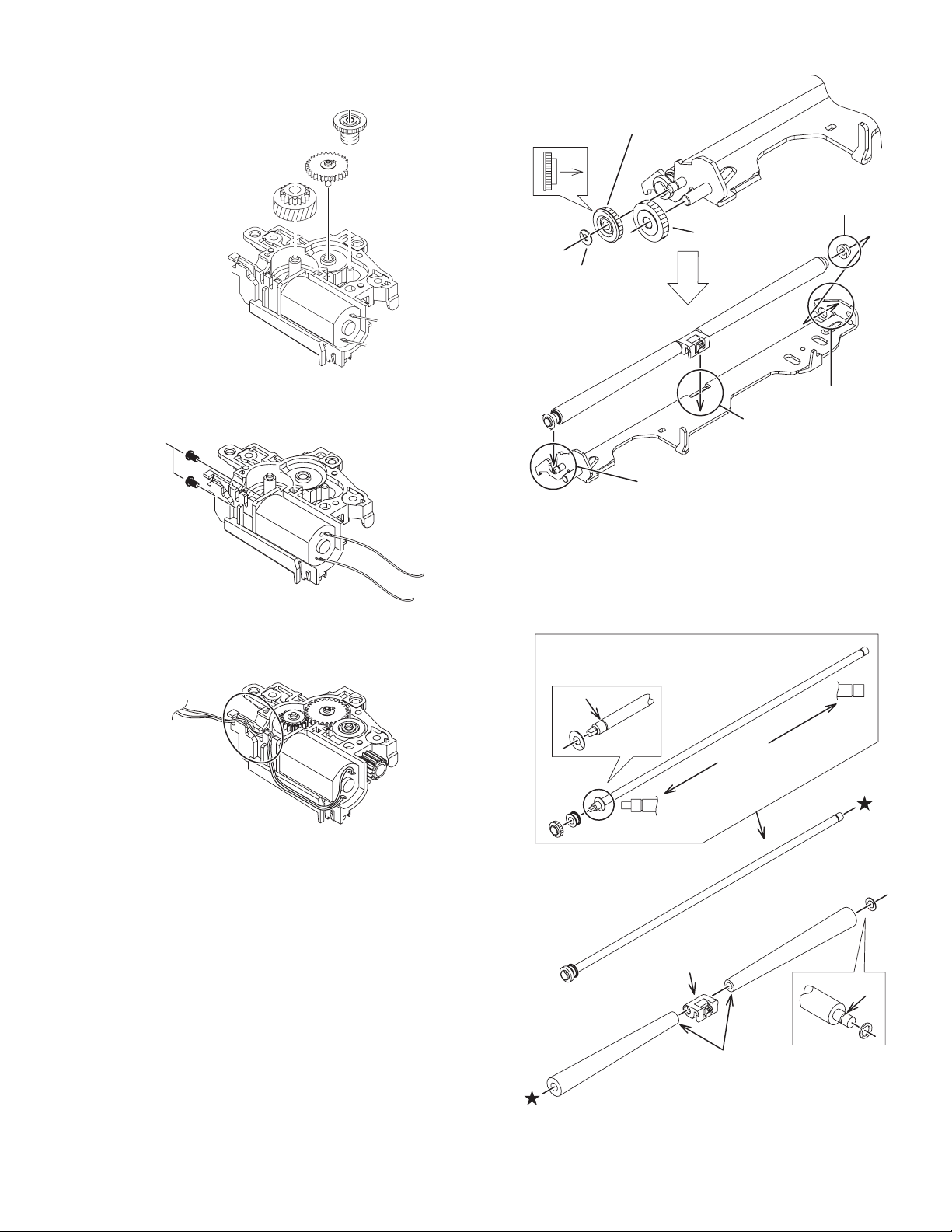

3.2.9 Removing the Loading motor (See Fig.15 to 18)

(1) Remove the A wheel gear. (See Fig.15)

A Wheel gea

Fig.15

1-16 (No.MA473<Rev.002>)

Fig.12

Page 17

(2) Remove the A worm gear, M connect gear and M wheel

gear by sequentially. (See Fig.16)

A worm gear

M connect gear

M wheel gear

Fig.16

(3) Remove the two screws G attaching the Loading motor.

(Se Fig.17)

G

Fig.17

(4) When attaching the Loading motor, motor wire should arrange

to figure. (See Fig.18)

Direction

R middle gear

R collar R

R connect gear

Slit washer

part c

part a

part b

Fig.19

3.2.11 Removing the Roller (See Fig.20)

(1) Remove the Slit washer.

(2) Pull out the Roller shaft.

CAUTION:

When reattach the Roller shaft, Slit washer should be change

new part.

Wire arrangement

Fig.18

3.2.10 Removing the Roller assembly (See Fig.19)

(1) Remove the Slit washer.

(2) Remove the R middle gear.

(3) Remove the R connect gear.

(4) Snap off the part a of the Roller assembly.

(5) Lift up the part b of the Roller assembly, and then release

part c (When release part c, R collar R is easy to come off,

does not lose it).

CAUTION:

When reattach the Roller assembly, Middle gear should keep

direction and Slit washer should be change new part.

slit

keep direction

keep direction

slit

small side

Fig.20

(No.MA473<Rev.002>)1-17

Page 18

SECTION 4

ADJUSTMENT

4.1 Test instruments required for adjustment

(1) Digital oscilloscope (100MHz)

(2) Digital tester

(3) Test Disc

(4) Extension cable :

EXTXD001-50PF (CN403 --- CN105)

EXTCN001-6P (CN351 --- CN109)

EXTDV002-28PF (CN401 --- CN653)

EXTDV002-16PF (CN601 --- CN654)

4.4 Dummy load

Exclusive dummy load should be used for AM and FM.

For FM dummy load, there is a loss of 6dB between SSG output and antenna input.

The loss of 6dB need not be considered since direct reading of figures are applied in this working standard.

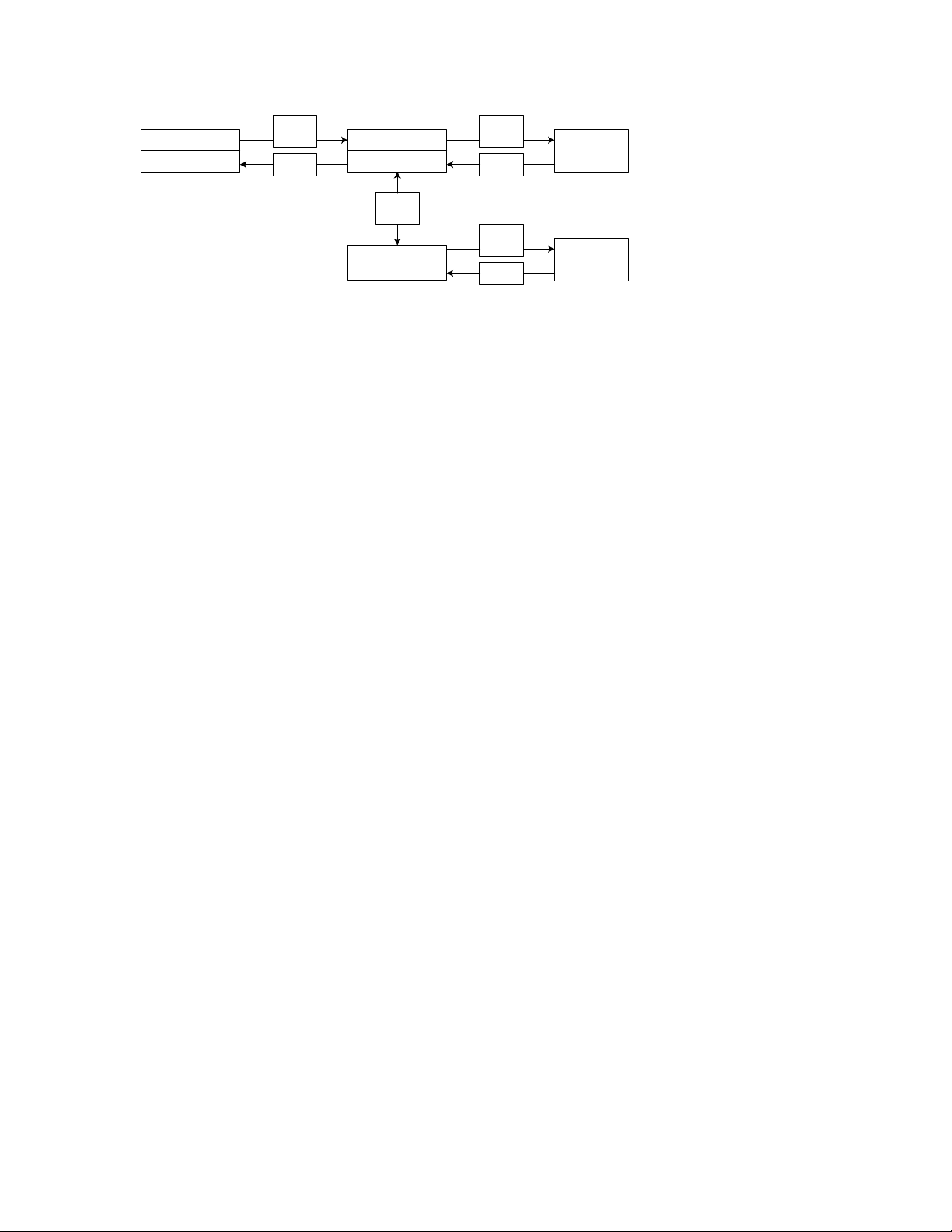

4.5 How to connect the extension cable for adjusting

Caution:

Be sure to attach the heat sink and rear bracket onto the power amplifier IC and regulator IC respectively, before supply the power.

If voltage is applied without attaching these parts, the power amplifier IC and regulator IC will be destroyed by heat.

CN351

4.2 Standard measuring conditions

Power supply voltage DC14.4V(10.5 to 16V)

Load impedance 20K ohm (2 Speakers connection)

Output Level Line out 2.5V (Vol. MAX)

4.3 Standard volume position

Balance and Bass &Treble volume : lndication"0"

Loudness : OFF

CN403

CN601

EXTDV002-28PF

EXTDV002-16PF

CN401

CN654

EXTCN001-6P

CN109

EXTXD001-50PF

CN105

use original wire

CN653

1-18 (No.MA473<Rev.002>)

Page 19

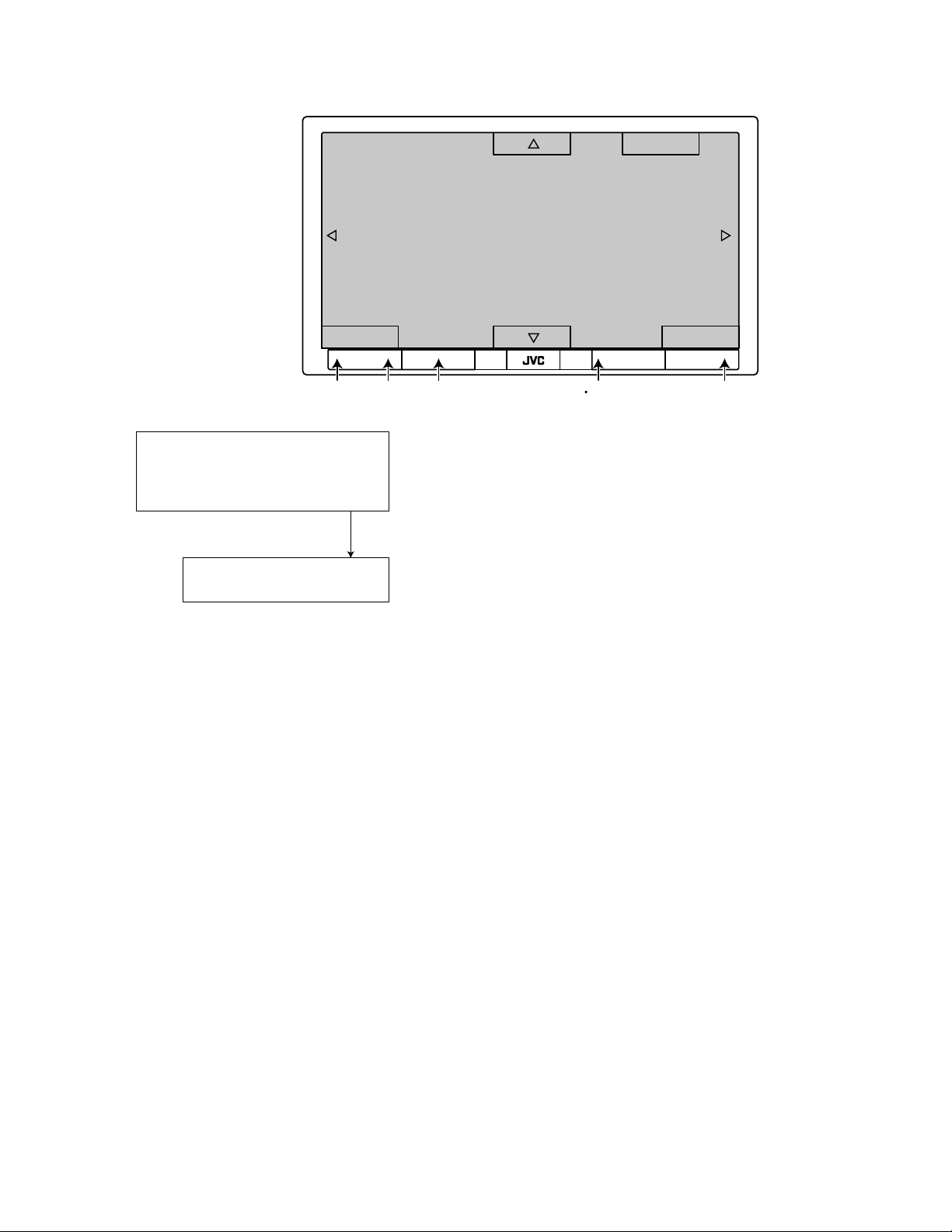

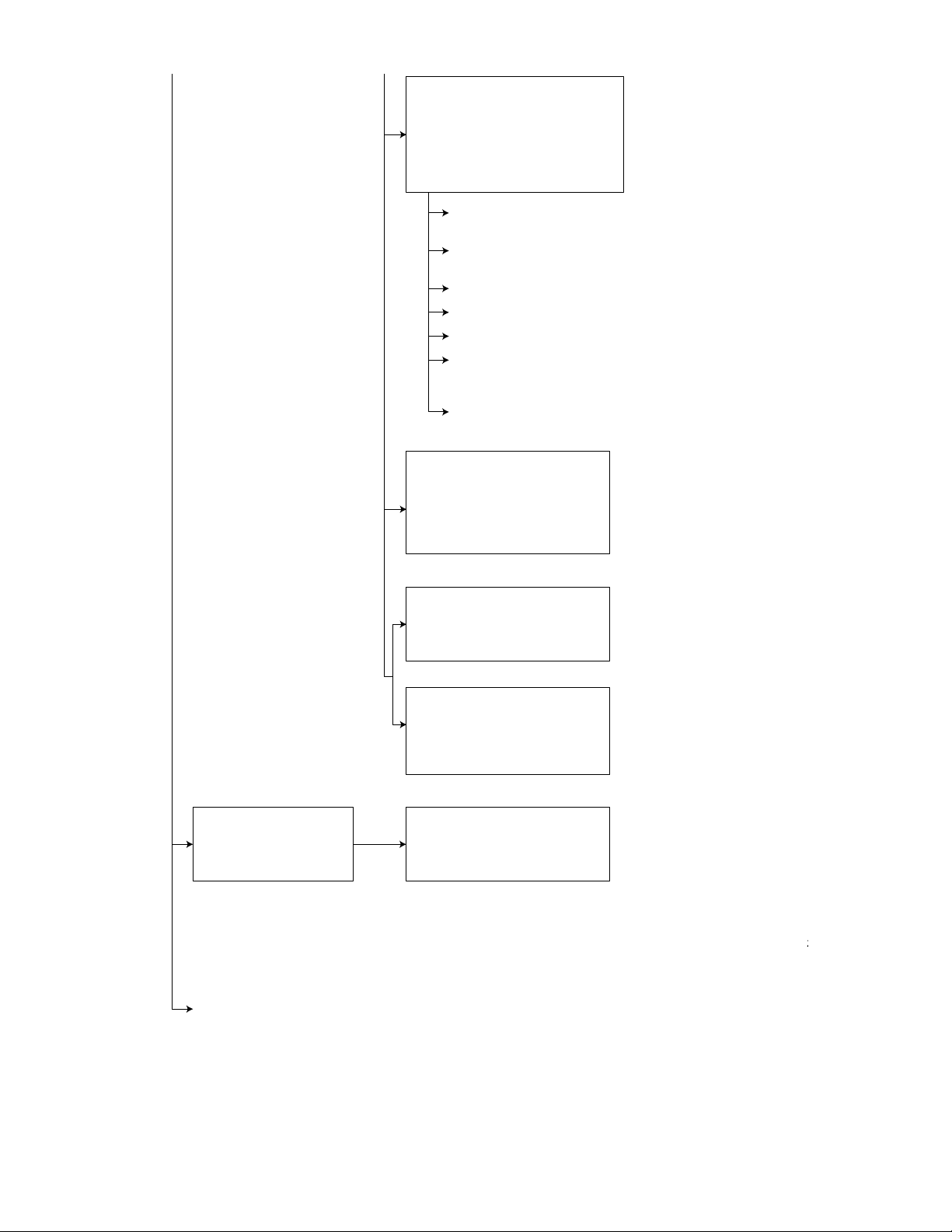

4.6 Service mode

UP Button

ENTER

TOUCH PANEL

DOWN Button

[Back] [Exit]

[STANDBY/ON ATTENUATOR] [DISP] [VOL]

4.6.1 Service mode 1 (Indication of a service mode 1 is nothing.)

Keep this state more 2 seconds

while continuing pressing the

[STANDBY/ON ATTENUATOR] button

and [OPEN] button sequentially.

Screen indication

NO EJECT?

EMERGENCY EJECT?

*1

Exchanging it operate a menu of a service mode with the [UP] button

*2

and [DOWN] button. Operate choice of a menu with a [ENTER] button.

*1 : When an [ENTER] button is pushed in NO EJECT indication, it is set

by an EJECT prohibition mode.

When an [ENTER] button is pushed in EJECT OK indication, it is set

by a normal mode.

*2 : Forced EJECT movement

A screen becomes normal indication after an [ENTER] button was pushed.

[MENU TP/TY]

FF ButtonREW Button

[OPEN]

(No.MA473<Rev.002>)1-19

Page 20

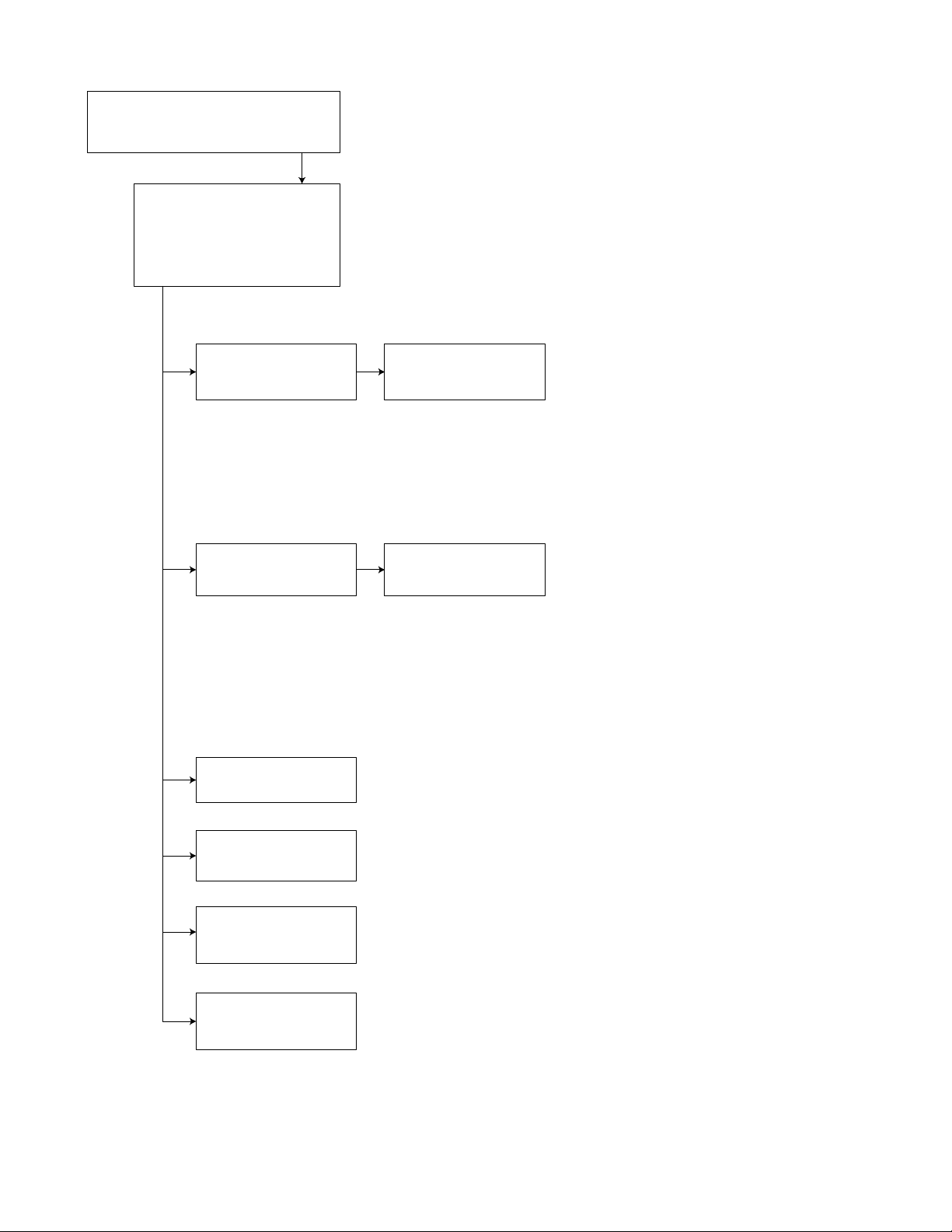

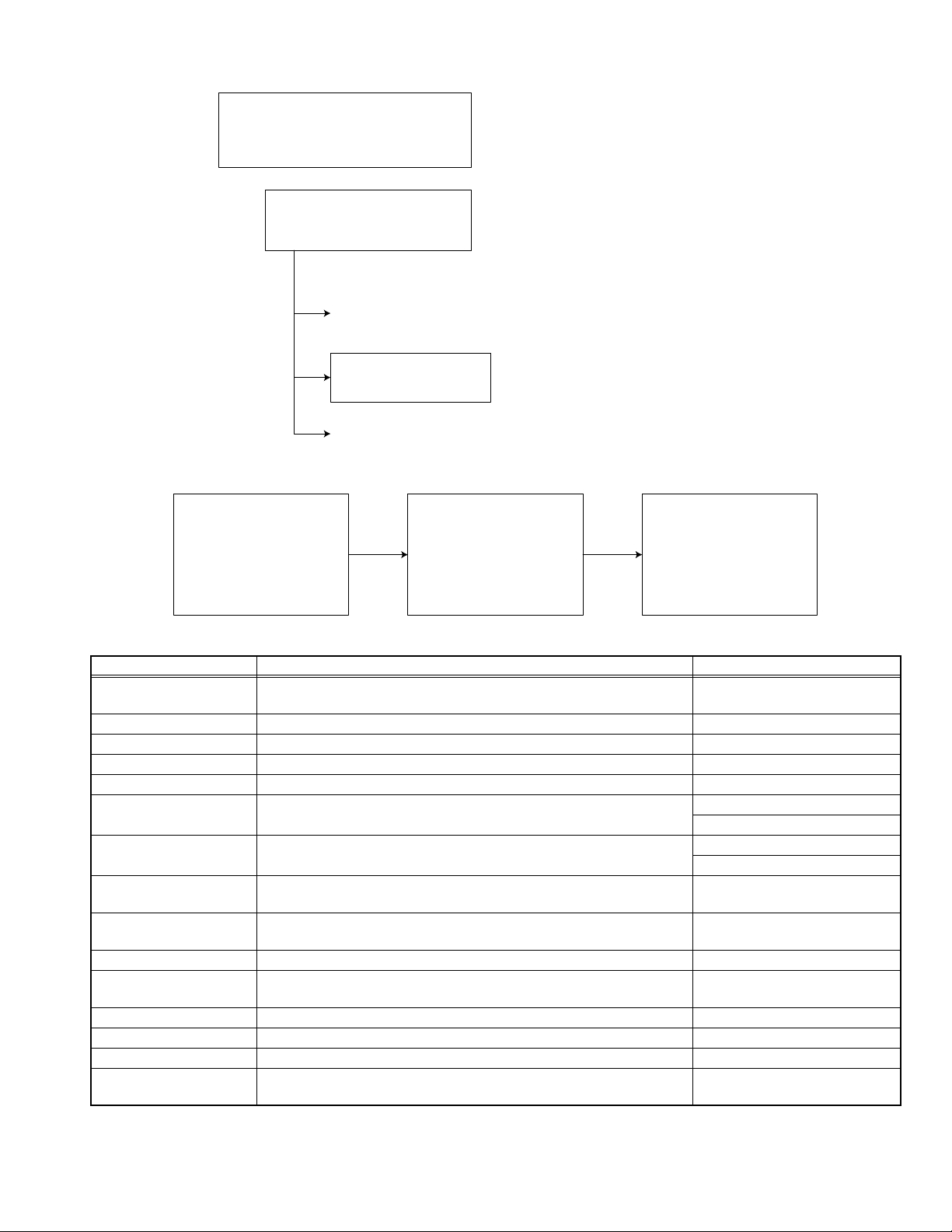

4.6.2 Service mode 2

Keep this state more 2 seconds

[MENU or TP/PTY] button, [DISP]

button and TOUCH PANEL [DOWN]

button sequentially.

Screen indication

SERVICE MODE 2

INITIALIZE ALL

INITIALIZE

INITIALIZE DVD

INITIALIZE BT

TOUCH PANEL CALIBRATION

TOUCH PANEL CHECK MODE

Exchanging it operate a menu of a service mode with the [UP] button

and [DOWN] button. Operate choice of a menu with a [ENTER] button.

INITIALIZE ALL

. . .

NOW

INITIALIZE ALL

INITIALIZE ALL

. . .

NOW

INITIALIZE

INITIALIZE DVD

INITIALIZE DVD

OK **

INITIALIZE BT

INITIALIZE BT

OK **

INITIALIZE ALL (Each EEPROM is

INITIALIZE ALL

OK **

INITIALIZE

OK **

Full initialization of EEPROM of a DVD unit

( It is included a permanent domain)

After clear completion, this indication is continued

till an effective key is input.

Full initialization of EEPROM of Bluetooth module

After clear completion, this indication is continued

till an effective key is input.

initialized by a factory shipment state.)

*Main micon EEPROM initialization

(user entry domain, error history, speaker

setting, subarea of J-version, data to pre-set)

*Panel micon EEPROM initialization

(picture adjustment data)

*DVD unit EEPROM initialization

(except a permanent domain)

*Bluetooth module EEPROM initialization

*After clear completion, a screen returns to

normal indication after OK indication was

displayed for three seconds.

INITIALIZE

(Initialization of a user area of each EEPROM)

*Main micon EEPROM initialization

(a user entry domain )

(a user entry domain, speaker setting, subarea

of J-version, data to pre-set )

*Panel micon EEPROM initialization

(picture adjustment data )

*DVD unit EEPROM initialization

(except a permanent domain)

*Bluetooth module EEPROM initialization

*After clear completion, a screen returns to

normal indication after OK indication was

displayed for three seconds.

TOUCH PANEL CALIBRATION

++

+

TOUCH PANEL CHECK MODE

1-20 (No.MA473<Rev.002>)

+

+

+

+

+

Push the center of a + character displayed in turn.

+

The confirmation mode that the calibration of the

+

touch panel was performed definitely.

*Return to previous menu with a [DISP] button.

Page 21

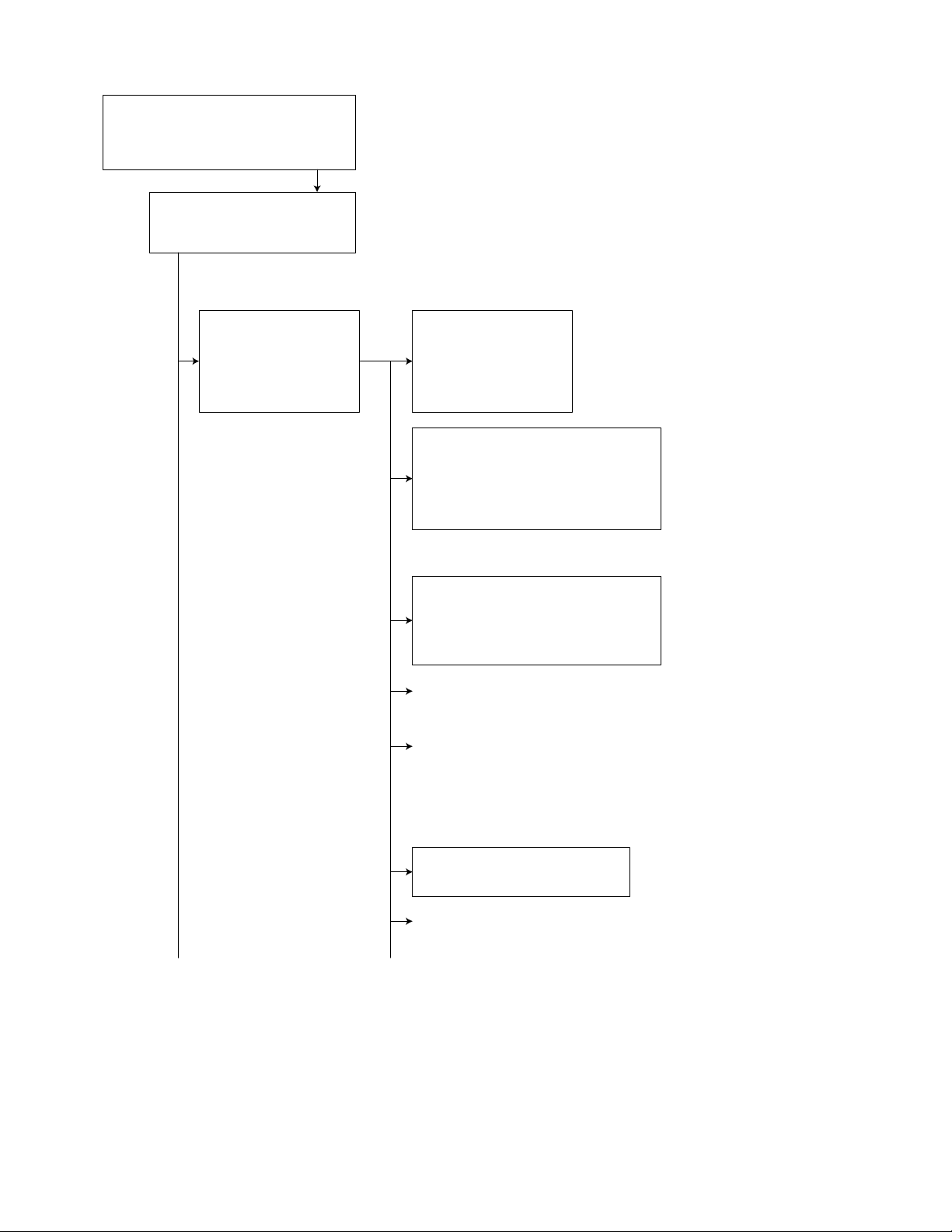

4.6.3 Service mode 3

Keep this state more 2 seconds

while continuing pressing the

[MENU or TP/PTY] button, [VOLUME -]

button and TOUCH PANEL [DOWN]

button sequentially.

Screen indication

SERVICE MODE 3

SERVICE MODE

INITIALIZE ALL

RUNNING MODE

Exchanging it operate a menu of a service mode with the [UP] button

and [DOWN] button. Operate choice of a menu with a [ENTER] button.

SERVICE MODE

SERVICE MODE

VERSION

AREA/REGION

TEMPERATURE

MEMORY CHECK

DVD NTSC/PAL

DVD CHECK MODE

*Exchanging it operate a menu

of a service mode with the [UP]

button and [DOWN] button.

*Operate choice of a menu with

a [ENTER] button.

*Return to previous menu with

a [BACK] button.

SERVICE MODE

ERROR READ

ERROR CLEAR

BT VERSION

VERSION

MAIN

DISC

Macrovision

PN

SW BT MODULE

V**** [**]

****

****

V**** V**** [**] V**** ** *

V***

Micon version indication

*Main micon version and ROM

correction version

*DVD module version

Macrovision version

*Panel micon version and ROM

correction version

*Software version of BT module

AREA/REGION

SYS-AREA

DISC-AREA

REGION

PANEL-AREA

TEMPERATURE Temperature data reading

*Temperature data by the temperature sensor in the main micon and DVD module

is read every 5 seconds and displayed in hex numbers.

MEMORY CHECK ( It is displayed only at the time of the disc insertion )

Memory residual quantity indication mode

*Data residual quantity of a disc is displayed by LCD.

*About the playback control-related key ([FSKIP], [BSKIP], [UP], [DOWN], [VOL]),

only movement is effective.

Indication does not change as memory residual quantity indication.

*About cancellation of this mode, press the [STANDBY/ON ATTENUATOR] button.

DVD NTSC/PAL

NTSC

PAL

DVD CHECK MODE

*See "DVD CHECK MODE h for details.

: **

: **

: *

: **

Area and region indication

Main micon area

DVD module area

Region

Panel area

DVD picture change

DVD unit output picture setting (NTSC)

DVD unit output picture setting (PAL)

(No.MA473<Rev.002>)1-21

Page 22

ERROR READ

p

n

z

o

n

DVD ERROR READ

MECHA ERROR READ

DISC COM ERROR READ

PNL RST ERROR READ

PNL COM ERROR READ

DC OK

READ ALL

DVD ERROR READ

Reading of a DVD unit error history

MECHA ERROR READ

Reading of a door mechanism error history

DISC COM ERROR READ (Only Engineer use)

PNL RST ERROR READ (Only Engineer use)

PNL COM ERROR READ (Only Engineer use)

DC OK

DC offset error information.

* See "DC offset error information" for details.

READ ALL (Only Engineer use)

Reading of a main micon EEPROM (All contents)

INITIALIZE ALL

. . .

NOW

INITIALIZE

RUNNING MODE

*See "Running mode" for details.

ERROR CLEAR

DVD ERROR CLEAR

MECHA ERROR CLEAR

DISC COM ERROR CLEAR

PNL PST ERROR CLEAR

PNL COM ERROR CLEAR

DC ERROR CLEAR

* KW-AVX830 series

BT VERSION

SW BT CORE

SW BT MODULE

ADR-

* KW-AVX730 series

BT VERSION

SW BT CORE

HW BT MODULE

SW BT MODULE

SW HIDEAWAY

ADR-

INITIALIZE

OK **

***

***

***********

***

***

***

***

***********

Clear of each error history

A screen returns to following

indication after clear completion.

Bluetooth version indication

Software version of BT core

Software version of BT Module

BT Address

Bluetooth version indication

*It is displayed in Bluetooth unit co

Software version of BT core

Hardware version of BT Module

Software version of BT Module

Software version of BT Hideaway

BT Address

INITIALIZE ALL (Each EEPROM is

by a factory shipment state.)

*Main micon EEPROM initialization

(user entry domain, error history, s

setting, subarea of J-version, data

*Panel micon EEPROM initializatio

(picture adjustment data)

*DVD unit EEPROM initialization

(except a permanent domain)

*Bluetooth module EEPROM initiali

*After clear completion, a screen re

normal indication after OK indicati

displayed for three seconds.

1-22 (No.MA473<Rev.002>)

Page 23

4.6.4 Service mode 4

Keep this state more 2 seconds

while continuing pressing the

[MENU or TP/PTY] button, [VOLUME -]

button and TOUCH PANEL [ DOWN]

button sequentially.

Screen indication

SERVICE MODE 4

RDS S MODE

MONITOR S MODE

HD RADIO S MODE

Exchanging it operate a menu of a service mode with the [UP] button

and [DOWN] button. Operate choice of a menu with a [ENTER] button.

RDS S MODE

*RDS service mode

MONITOR S MODE

R/W CHROMA

DATA CLEAR

HD RADIO S MODE

*It is displayed in HD Radio unit connection.

*See "Monitor adjustment" for details.

CHROMA DATA read/write

Clear of CHROMA DATA (return to an initial value)

4.7 DVD check mode

DVD CHECK MODE

NORMAL PLAY

EF OUT-TRACKING OFF

EF IN-TRACKING OFF

CD-LASER ON

DVD-LASER ON

DVDx1 JITTER MODE

DVD CHECK MODE

EEPROM DATA DISP

EEPROM DATA CLEAR

TEMPERATURE

SEARCH & JITTER

MONITOR

PLAY

DVD CHECK MODE

STOP

OPEN

CLOSE

Exchanging it operate a menu of a service mode with the [UP] button and [DOWN] button. Operate choice of a menu with a [ENTER]

button.

Command Mechanism unit operation Indication contents

NORMAL PLAY Start at normal speed

Laser current value, jitter value

(After start, jitter is measured by an inner position.)

EF OUT-TRACKING OFF Tracking off the outermost position of CD For EF phase error

EF IN-TRACKING OFF Tracking off the innermost position of CD For EF phase error

CD-LASER ON CD_LD lights and laser current is displayed. Laser current value, jitter value

DVD-LASER ON DVD x1 jitter measuring mode (for use in mechanism adjustment) Laser current value, jitter value

EEPROM DATA DISP Contents of EEPROM is displayed. EEPROM address

EEPROM contents

EEPROM DATA CLEAR Contents of EEPROM is initialized. EEPROM address

EEPROM contents

TEMPERATURE Temperature indication Temperature is displayed in hex

numbers.

SEARCH & JITTER The search and jitter measurement to an appointed position of DVD. Position measured with VT-501

jitter value

MONITOR Monitor terminal setting

DVDx1 PLAY DVD x1 stopped start

Not displayed.

(After start, jitter is measured by an inner position.)

STOP Disc stopped, LD-OFF Not displayed.

EJECT EJECT Not displayed.

LOAD LOADING Not displayed.

EEPROM DATA OSD EEPROM DATA (Only Engineer

use)

(No.MA473<Rev.002>)1-23

Page 24

4.8 DC offset error information

Display indication

DC OK

DC ERROR

VOL

push

BACK

DC 1 OK

DC 1 ERROR

VOL

push

BACK

VOL

push

VOL

push

DC 2 X

4.8.1 DC offset error distinction.

(1) DC ERROR 1

When improper connection or other DC offset errors are detected.

"PROTECT" blinks to the display.

It is possible to return even times how many by reset.

(2) DC ERROR 2

When the DC offset error is detected due to the trouble of the capacitor.

zThe number of times that detected in the case of less than 3 times.

"PROTECT" blinks to the display.

It is possible to return to the 3rd times by reset.

zWhen the detected number becomes 4 times.

"PROTECT" lights to the display.

It is fixed that trouble occurs internally, and reset doesn't return either.

( Operation other than the Power on/off, Eject, Reset, and Service mode are prohibited with "PROTECT" lit.

4.8.2 Error content confirmation.

Whether it turns on power and the "PROTECT" display appears are confirmed.

(1) When the "PROTECT" display appears.

The content of the DC offset error is confirmed in the Service mode.

* Because it takes DC offset protection, the following is displayed.

(1-1) When "DC1 ERROR" is displayed. (DC ERROR1)

zForecast cause

It comes in contact with improper connection or GND of the speaker wiring.

It is confirmed that there is no improper connection of the speaker wiring and pushes reset.

zWhen "PROTECT" is not displayed, it is unquestionable.

The error data of EEPROM, it deletes it. (CLR DC1)

zWhen "PROTECT" is still displayed.

The DC offset has been generated by the reasons other than the improper connection.

Forecast cause: Power AMP is broken.

After parts are exchanged, reset is confirmed pushing again.

(1-2) When "DC2 X" is displayed. (DC ERROR2)

* As for X, the detected number is displayed. (0-4)

* When X is 0, it is unquestionable because the DC offset has never been detected.

When leak of capacitor is detected, it is displayed.

It is confirmed that there is no problem in the capacitor and deletes the error data of EEPROM. (CLR DC2)

It is confirmed that reset is pushed and "PROTECT" is not displayed.

BACK

CLR DC1 VOL push to confirm

CLR DC2 VOL push to confirm

After above-mentioned (1-1) and (1-2) are executed, the connect of the DC offset error is confirmed in the Service mode.

If the part displayed as "DC ERROR" becomes "DC OK", it is unquestionable.

(2) When the "PROTECT" display doesn't appear.

The content of the DC offset error is confirmed in the Service mode.

(2-1) When "DC OK" is displayed, it is unquestionable because the DC offset has not been detected in the past.

(2-2) When "DC ERROR" is displayed, the confirmation similar to (1-1) and (1-2) is done because there is a history that detected

the DC offset error in the past.

1-24 (No.MA473<Rev.002>)

Page 25

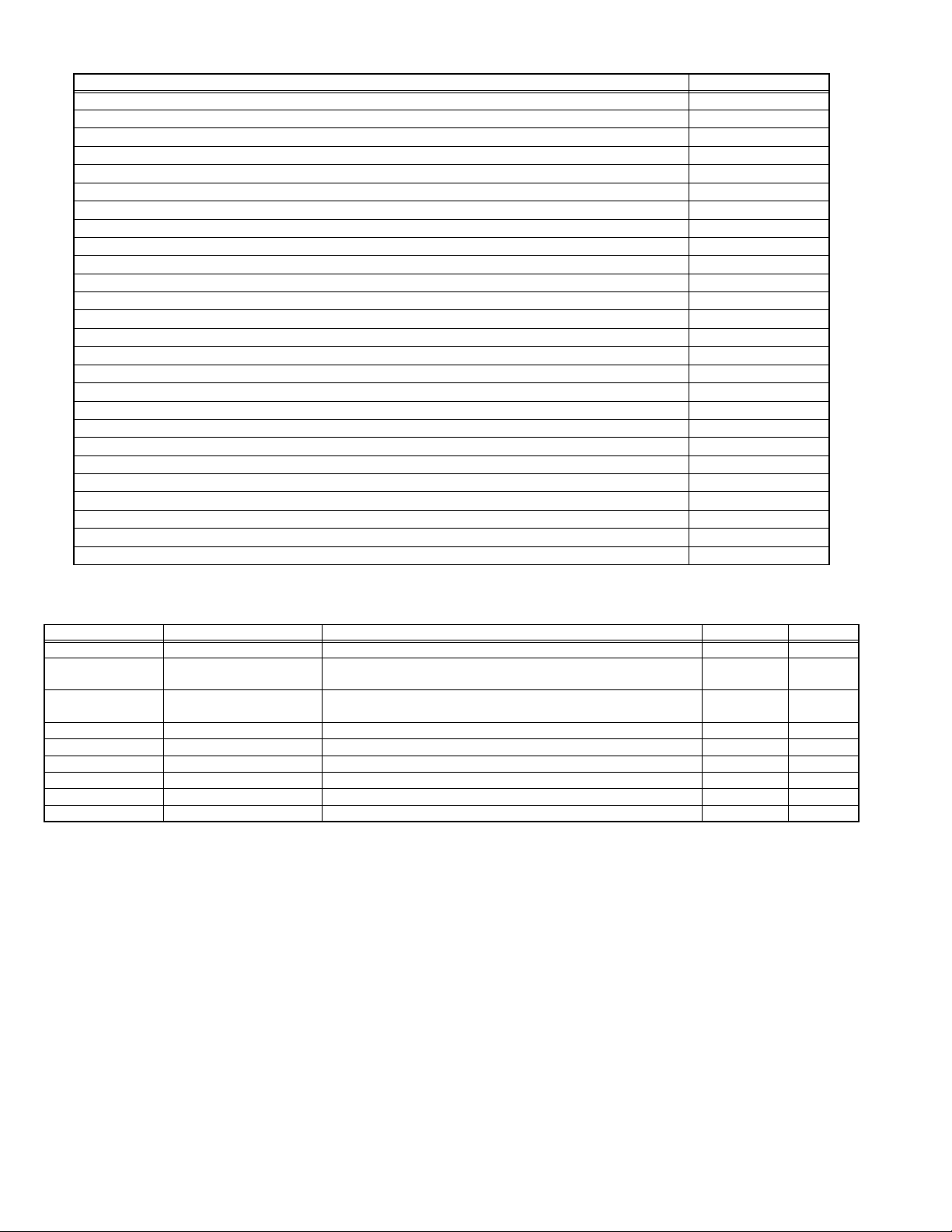

4.9 Error code tables

4.9.1 Mechanism error code

Error contents Details Error code Detailed error code

Disc loading error

(3) D1 time out 09 0013

Eject error

(3) B1 time out

(4) C1 time out

Error in loading wait Loading of a running mode Disc was pulled out in a wait. 09 0031

4.9.2 Disc error code

Error contents Details Error code Detailed error code

TOC read error TOC lead movement of a CD is not completed. 84 0059

First track access error Even if TOC reading passes after the end with CD running mode for

30 seconds, the first track access is not finished.

Last track access error Even if first track passes after the end with CD running mode for 30

seconds, the last track access is not finished.

T1 access error Even if T1 access passes in a DVD running mode for 30 seconds,

it is not finished.

T12 access error Even if T12 access passes in a DVD running mode for 30 seconds,

it is not finished.

T24 access error Even if T24 access passes in a DVD running mode for 30 seconds,

it is not finished.

Read-in area read error Read-in area read operation of DVD is not completed. 84 0072

DVD L1 layer adjustment error

DVD L0 layer adjustment error

NO DISC judgment Judgment without disc 80 0090

It is NO DISC by start failure Start is impossible 80 0091

It is stopped by playback inability.

Logic format NG Logic format analysis inability or non-correspondence logic format 80 0094

Seek access error It cannot arrive at an aim address even if it passes for 15 seconds. 80 0095

Adjustment of L1 layer of DVD is not finished normally.

(including focus jump failure)

Adjustment of L0 layer of DVD is not finished normally.

(including focus jump failure)

Stop in running mode playback 80 0093

01

01

0023

0024

80 0060

80 0061

80 0069

80 0070

80 0071

80 0074

80 0075

4.9.3 Error codes of panel mechanism

* As for two columns of the beginning of the error code, as for error contents, two columns of middle, number of the pulse counts, last

two columns are a purpose position and movement directions.

Error contents code

Time out OB

Position error by the external force OC

Abnormal voltage (1) F3

Abnormal voltage (2) F5

Abnormal voltage (3) F7

Abnormal voltage (4) F8

When assumed last two columns XY;, as for X, as for purpose

position, Y, is a movement direction.

Purpose position X

CLOSE 1

5 degrees 2

10 degrees 3

15 degrees 4

20 degrees 5

25 degrees 6

30 degrees 7

OPEN 8

Movement direction Y

Open direction 0

Close direction 1

(No.MA473<Rev.002>)1-25

Page 26

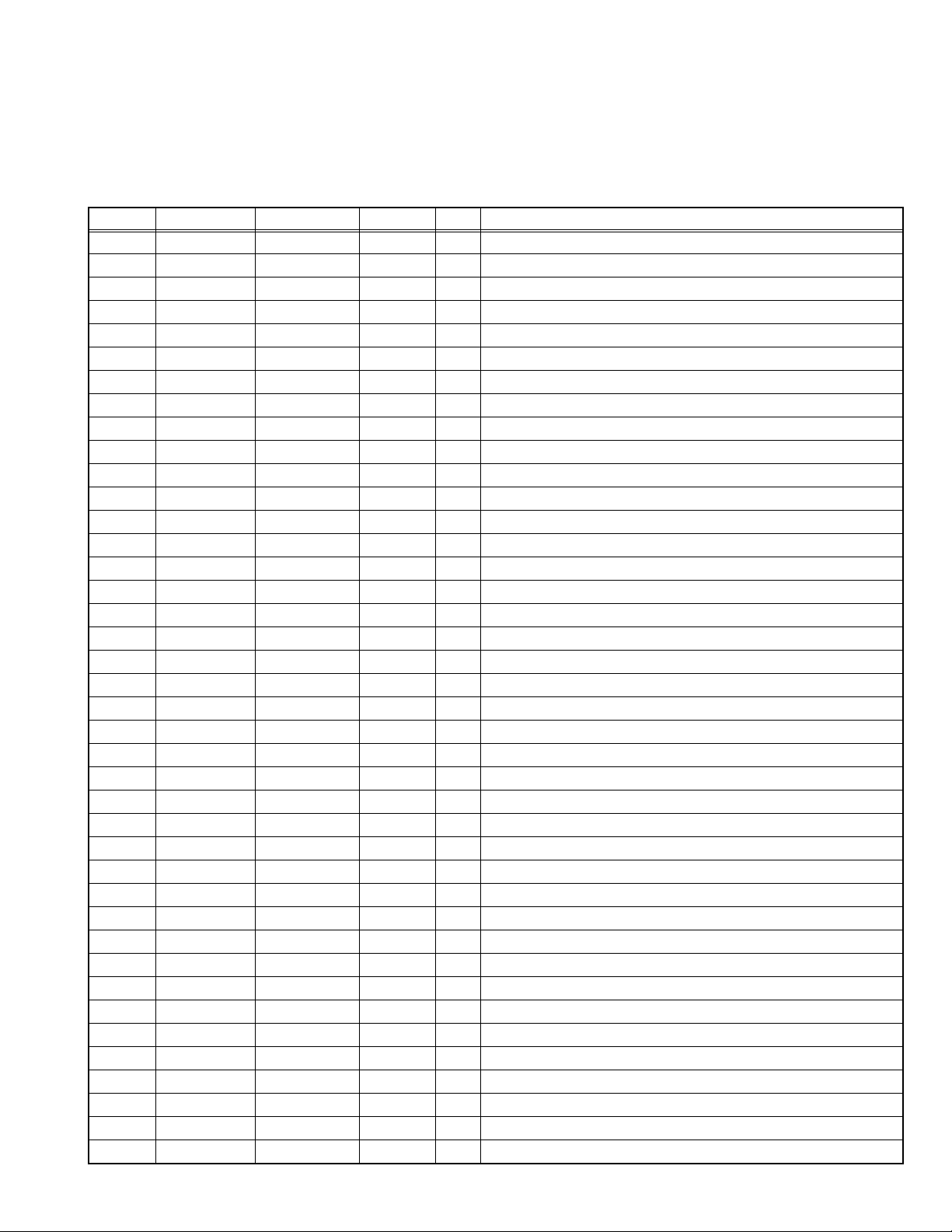

Detail Error code

It is time-out during movement to the closed position. 0B**11

It is time-out during 5 degrees tilt movement.(open direction) 0B**20

It is time-out during 5 degrees tilt movement.(close direction) 0B**21

It is time-out during 10 degrees tilt movement.(open direction) 0B**30

It is time-out during 10 degrees tilt movement.(close direction) 0B**31

It is time-out during 15 degrees tilt movement.(open direction) 0B**40

It is time-out during 15 degrees tilt movement.(close direction) 0B**41

It is time-out during 20 degrees tilt movement.(open direction) 0B**50

It is time-out during 20 degrees tilt movement.(close direction) 0B**51

It is time-out during 25 degrees tilt movement.(open direction) 0B**60

It is time-out during 25 degrees tilt movement.(close direction) 0B**61

It is time-out during 30 degrees tilt movement.(open direction) 0B**70

It is time-out during 30 degrees tilt movement.(close direction) 0B**71

It is time-out during movement to the open position. 0B**80

It is position error during close position stop. 0C0011

It is position error during 5 degree tilt position stop. 0C0020

It is position error during 10 degree tilt position stop. 0C0030

It is position error during 15 degree tilt position stop. 0C0040

It is position error during 20 degree tilt position stop. 0C0050

It is position error during 25 degree tilt position stop. 0C0060

It is position error during 30 degree tilt position stop. 0C0070

It is position error during open position stop. 0C0080

Detect abnormal voltage (1) F3**XY

Detect abnormal voltage (2) F5**XY

Detect abnormal voltage (3) F7**XY

Detect abnormal voltage (4) F8**XY

Note: "**" of the above error code is the number of the pulse counts at the time of the error outbreak.

4.10 Running mode

Indication Explanation Operation contents of 1 cycle In mecha error In disc error

RUNNING1 MECHA Door mecha running 1 Panel close ↔ Panel open - RUNNING2 MECHA Door mecha running 2 Panel close → 5 degrees → 10 degrees → 15 degrees → 20 degrees

→ 25 degrees → 30 degrees → anel open

RUNNING3 MECHA Door mecha running 3 Panel → close → 5 degrees →

grees → Panel close

RUNNING4 DVD DVD+Door mecha running1 Loading → Eject → Wait for 5 seconds+Door open/close Stop RUNNING5 DVD DVD+Door mecha running2 Loading → Eject → Wait for 5 seconds+Door open/close Retry RUNNING6 DVD DVD+Door mecha running3 Loading → Playback → Eject → Wait for 5 seconds+Door open/close Stop Stop

RUNNING7 DVD DVD+Door mecha running4 Loading → Playback → Eject → Wait for 5 seconds+Door open/close Retry Stop

RUNNING8 DVD DVD+Door mecha running5 Loading → Playback → Eject → Wait for 5 seconds+Door open/close Stop Retry

RUNNING9 DVD DVD+Door mecha running6 Loading → Playback → Eject → Wait for 5 seconds+Door open/close Retry Retry

···· → 30 degrees → ···· → 5 de-

--

--

* Cancellation of running1,2 and 3 : Press the [EJECT] key

* In running 1,2 and 3 cancellation, a door does not stop at the position and moves to a panel position.

* Cancellation of running4 to 9 : Press the [POWER] key

* The number of count and an error cord are displayed in running.

Playback contents in a running mode

•CD

The first track is played for 30 seconds.

→ The last track is played for 30 seconds.

(The last track is played in the case of less than till the last for 30 seconds.)

•DVD

2layer disc (Pit disc)

Title 1 (the L0 layer internal circumference) is played for 30 seconds.

→ Title 24 (L1layer internal circumference) is played for 30 seconds.

→ Title 12 (L0 layer circumference) is played for 30 seconds.

2layer disc (Recordable disc)

Title 1 (the L0 layer internal circumference) is played for 30 seconds. → Title 13 (L0 layer circumference) is played for 30 seconds.

→ Title 24 (L1layer internal circumference) is played for 30 seconds.

1layer disc

First chapter of title 1 is played for 30 seconds. → The last chapter of title 1 is played for 30 seconds.

1-26 (No.MA473<Rev.002>)

Page 27

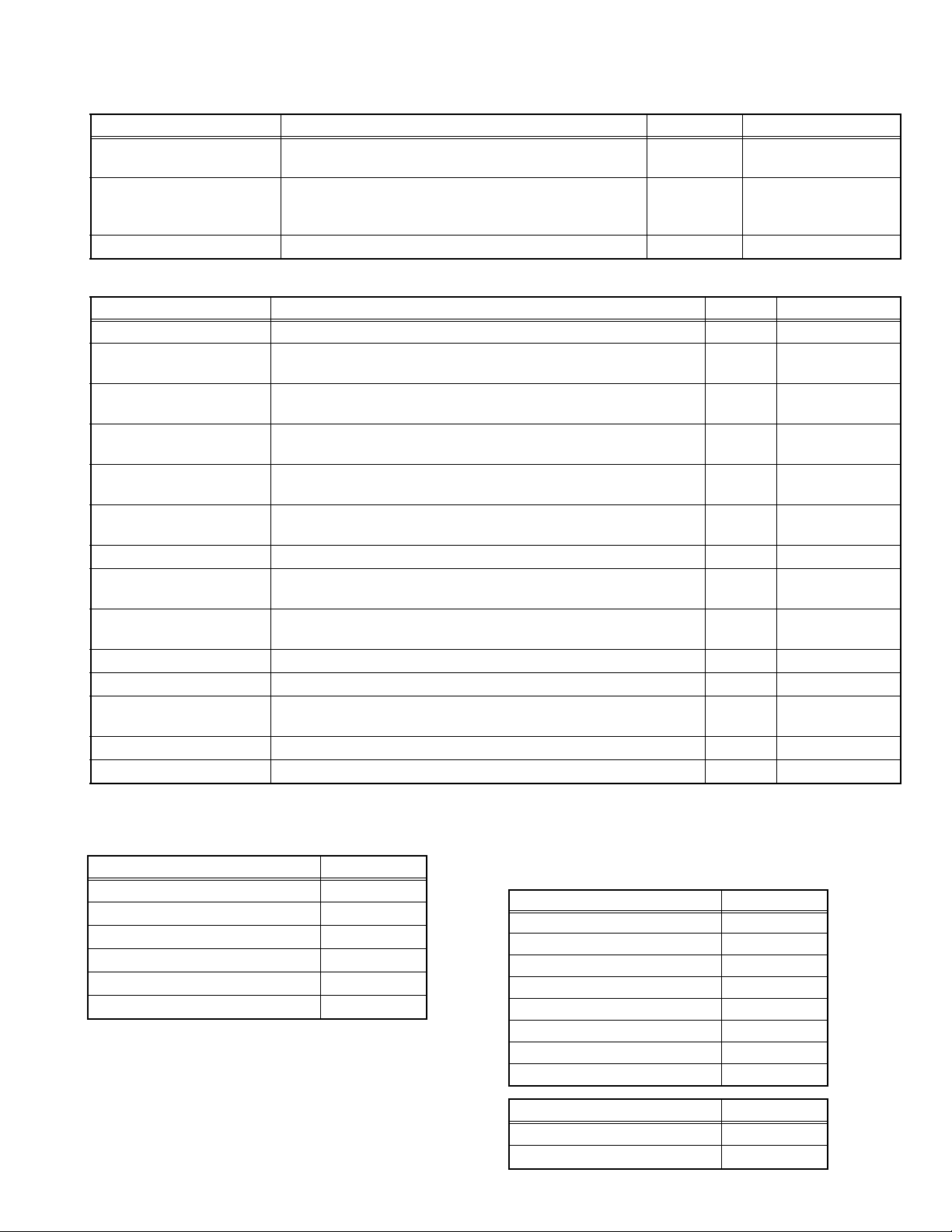

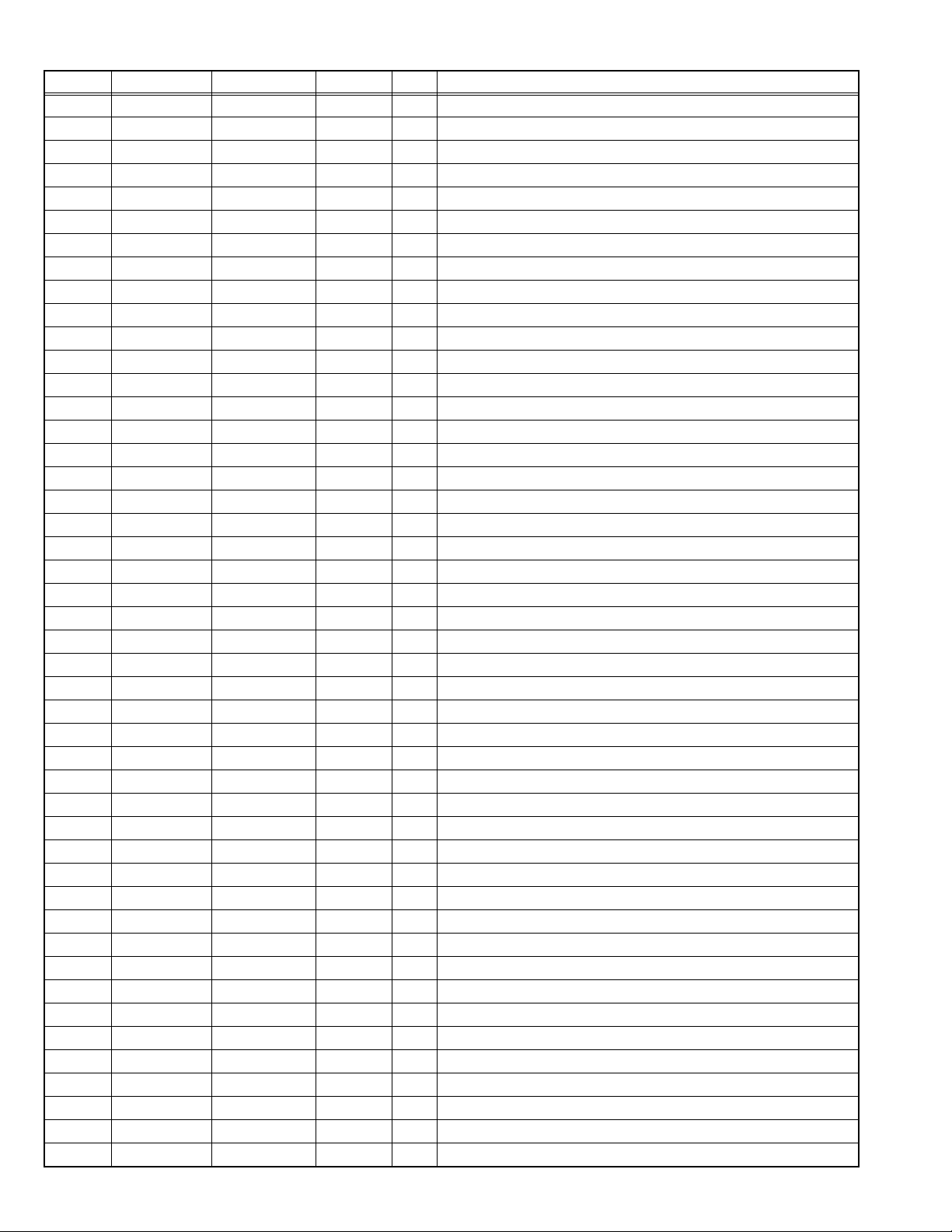

4.11 Monitor adjustment

* When adjusting, switch on the main unit and insert a test disc (VT-501). And play the test disc and pause it.

(1) Set the service mode 4.

(2) Exchanging it operate a menu of a service mode with the [UP] button and [DOWN] button.

(3) Change data with the [B.SKIP]/[F.SKIP] buttons.

(4) Write data with a [ENTER] button.

R/W CHROMA

Indication Minimum value Maximum value Initial value ---- Detail

00001 00000 00001 00000 Fix Color amplitude revision ON/OFF

00002 00000 00003 00000 Adjust Color amplitude revision CAS

00003 00000 00063 00000 Adjust Color amplitude revision APC

00004 00000 00003 00000 Adjust Color amplitude revision CUS

00005 00000 00063 00000 Adjust Color amplitude revision APU

00006 00000 00001 00000 Adjust Black level extension ON/OFF

00007 00000 00001 00001 Fix Black level extension FUNCTION

00008 00000 00511 00176 Adjust Black level extension START POINT

00009 00000 00511 00128 Adjust Black level extension OFFSET

00010 00000 00255 00128 Adjust Enhancer revision effect adjustment (NTSC)

00011 00000 00255 00128 Adjust Enhancer revision effect adjustment (PAL)

00012 00000 00255 00064 Adjust Limiter of the horizontal enhancer (NTSC)

00013 00000 00255 00068 Adjust Limiter of the horizontal enhancer (PAL)

00014 00000 00255 00000 Adjust Filter choice of the horizontal enhancer (NTSC)

00015 00000 00255 00000 Adjust Filter choice of the horizontal enhancer (PAL)

00016 00000 00003 00001 Adjust Tap change of the brightness outline revision (NTSC)

00017 00000 00003 00001 Adjust Tap change of the brightness outline revision (PAL)

00018 00000 00127 00000 Adjust Adjustment of the quantity of brightness outline core ring (NTSC)

00019 00000 00127 00000 Adjust Adjustment of the quantity of brightness outline core ring (PAL)

00020 00000 00006 00000 Adjust Adjustment of the brightness outline revision gain (NTSC)

00021 00000 00006 00000 Adjust Adjustment of the brightness outline revision gain (PAL)

00022 00000 00255 00125 Adjust Change in TINT of the whole picture (NTSC)

00023 00000 00255 00125 Adjust Change in TINT of the whole picture (PAL)

00024 00000 00255 00090 Adjust Change with the deepness of the color of the whole picture (NTSC)

00025 00000 00255 00100 Adjust Change with the deepness of the color of the whole picture (PAL)

00026 00000 00255 00131 Adjust Tint adjustment (NTSC)

00027 00000 00255 00131 Adjust Tint adjustment (PAL)

00028 00000 00255 00043 Adjust Color adjustment (NTSC)

00029 00000 00255 00043 Adjust Color adjustment (PAL)

00030 00000 00511 00094 Fix Set the offset DC of the input video signal (NTSC)

00031 00000 00511 00094 Fix Set the offset DC of the input video signal (PAL)

00032 00000 00001 00000 Adjust Quantity of transmission revision of the YUV DC

00033 00000 00255 00016 Adjust Quantity of transmission revision of the YUV DC

00034 00000 01023 00320 Adjust Contrast adjustment between the black - white (NTSC)

00035 00000 01023 00322 Adjust Contrast adjustment between the black - white (PAL)

00036 00000 00511 00348 Adjust Conversion coefficients from YUV to RGB (PRCL)

00037 00000 00255 00210 Adjust Conversion coefficients from YUV to RGB (PBCL)

00038 00000 00255 00210 Adjust Conversion coefficients from YUV to RGB (YCL)

00039 00000 00255 00158 Adjust Conversion coefficients from YUV to RGB (BCL)

00040 00000 00511 00267 Adjust Conversion coefficients from YUV to RGB (RCL)

(No.MA473<Rev.002>)1-27

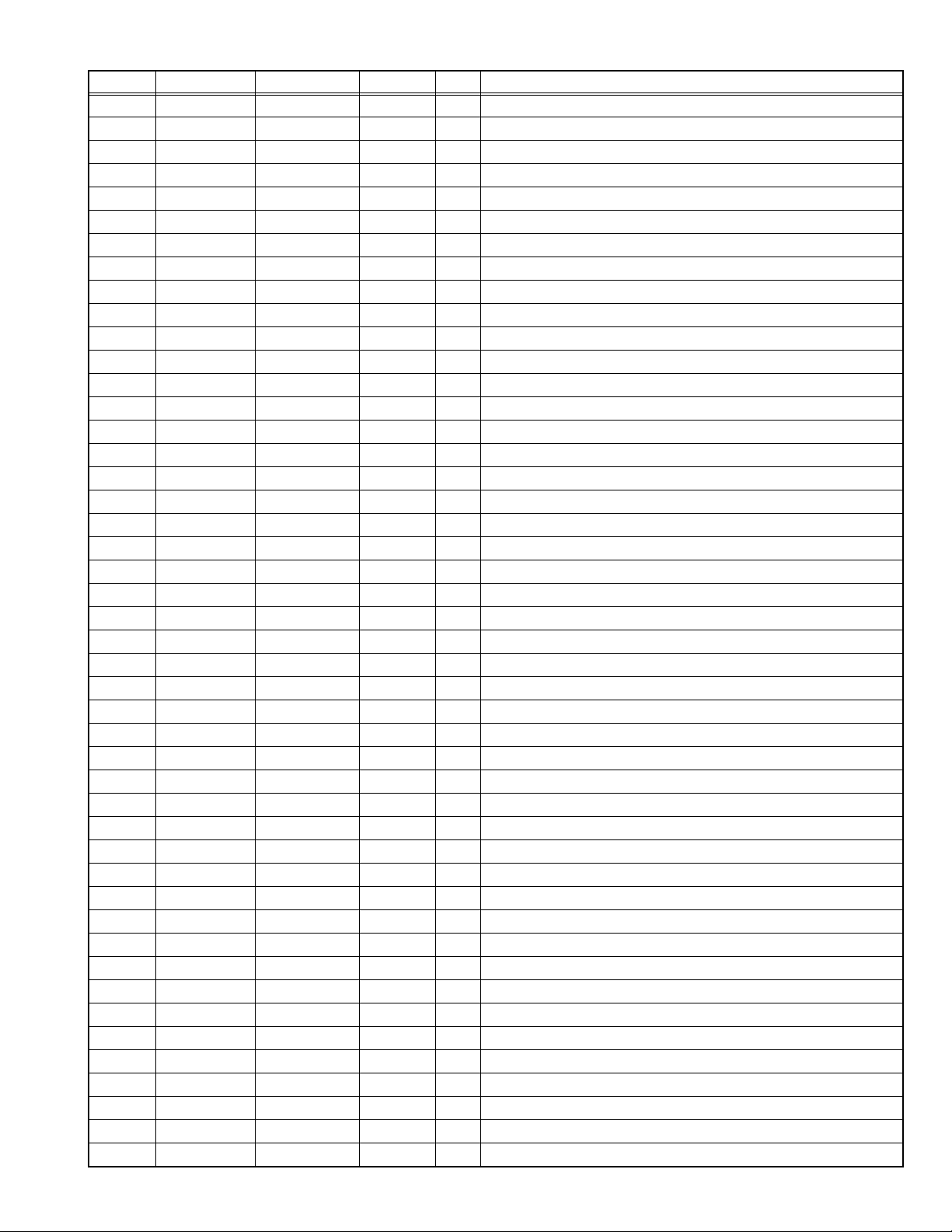

Page 28

Indication Minimum value Maximum value Initial value ---- Detail

00041 00000 00001 00001 Fix Noise shaving (NTSC)

00042 00000 00001 00001 Fix Noise shaving (PAL)

00043 00000 00127 00027 Adjust Black level adjustment (NTSC)

00044 00000 00127 00026 Adjust Black level adjustment (PAL)

00045 00000 00127 00058 Adjust Gain setting of Red signal (NTSC)

00046 00000 00127 00059 Adjust Gain setting of Red signal (PAL)

00047 00000 00127 00057 Adjust Gain setting of Green signal (NTSC)

00048 00000 00127 00059 Adjust Gain setting of Green signal (PAL)

00049 00000 00127 00054 Adjust Gain setting of Blue signal (NTSC)

00050 00000 00127 00053 Adjust Gain setting of Blue signal (PAL)

00051 00000 00127 00059 Adjust Set the cut-off of the Red signal (NTSC)

00052 00000 00127 00059 Adjust Set the cut-off of the Red signal (PAL)

00053 00000 00127 00059 Adjust Set the cut-off of the Green signal (NTSC)

00054 00000 00127 00059 Adjust Set the cut-off of the Green signal (PAL)

00055 00000 00127 00061 Adjust Set the cut-off of the Blue signal (NTSC)

00056 00000 00127 00061 Adjust Set the cut-off of the Blue signal (PAL)

00057 00000 00001 00000 Adjust ON/OFF change of the gamma revision

00058 00000 00255 00007 Adjust Adjust 1 gamma revision point position of a Red signal

00059 00000 00255 00015 Adjust Adjust 2 gamma revision point position of a Red signal

00060 00000 00255 00023 Adjust Adjust 3 gamma revision point position of a Red signal

00061 00000 00255 00031 Adjust Adjust 4 gamma revision point position of a Red signal

00062 00000 00255 00039 Adjust Adjust 5 gamma revision point position of a Red signal

00063 00000 00255 00047 Adjust Adjust 6 gamma revision point position of a Red signal

00064 00000 00255 00055 Adjust Adjust 7 gamma revision point position of a Red signal

00065 00000 00255 00032 Adjust Appoint gamma revision gain 1 of the Red signal

00066 00000 00255 00032 Adjust Appoint gamma revision gain 2 of the Red signal

00067 00000 00255 00032 Adjust Appoint gamma revision gain 3 of the Red signal

00068 00000 00255 00032 Adjust Appoint gamma revision gain 4 of the Red signal

00069 00000 00255 00032 Adjust Appoint gamma revision gain 5 of the Red signal

00070 00000 00255 00032 Adjust Appoint gamma revision gain 6 of the Red signal

00071 00000 00255 00032 Adjust Appoint gamma revision gain 7 of the Red signal

00072 00000 00255 00032 Adjust Appoint gamma revision gain 8 of the Red signal

00073 00000 00255 00007 Adjust Adjust 1 gamma revision point position of a Green signal

00074 00000 00255 00015 Adjust Adjust 2 gamma revision point position of a Green signal

00075 00000 00255 00023 Adjust Adjust 3 gamma revision point position of a Green signal

00076 00000 00255 00031 Adjust Adjust 4 gamma revision point position of a Green signal

00077 00000 00255 00039 Adjust Adjust 5 gamma revision point position of a Green signal

00078 00000 00255 00047 Adjust Adjust 6 gamma revision point position of a Green signal

00079 00000 00255 00055 Adjust Adjust 7 gamma revision point position of a Green signal

00080 00000 00255 00032 Adjust Appoint gamma revision gain 1 of the Green signal

00081 00000 00255 00032 Adjust Appoint gamma revision gain 2 of the Green signal

00082 00000 00255 00032 Adjust Appoint gamma revision gain 3 of the Green signal

00083 00000 00255 00032 Adjust Appoint gamma revision gain 4 of the Green signal

00084 00000 00255 00032 Adjust Appoint gamma revision gain 5 of the Green signal

00085 00000 00255 00032 Adjust Appoint gamma revision gain 6 of the Green signal

00086 00000 00255 00032 Adjust Appoint gamma revision gain 7 of the Green signal

1-28 (No.MA473<Rev.002>)

Page 29

Indication Minimum value Maximum value Initial value ---- Detail

00087 00000 00255 00032 Adjust Appoint gamma revision gain 8 of the Green signal

00088 00000 00255 00007 Adjust Adjust 1 gamma revision point position of a Blue signal

00089 00000 00255 00015 Adjust Adjust 2 gamma revision point position of a Blue signal

00090 00000 00255 00023 Adjust Adjust 3 gamma revision point position of a Blue signal

00091 00000 00255 00031 Adjust Adjust 4 gamma revision point position of a Blue signal

00092 00000 00255 00039 Adjust Adjust 5 gamma revision point position of a Blue signal

00093 00000 00255 00047 Adjust Adjust 6 gamma revision point position of a Blue signal

00094 00000 00255 00055 Adjust Adjust 7 gamma revision point position of a Blue signal

00095 00000 00255 00032 Adjust Appoint gamma revision gain 1 of the Blue signal

00096 00000 00255 00032 Adjust Appoint gamma revision gain 2 of the Blue signal

00097 00000 00255 00032 Adjust Appoint gamma revision gain 3 of the Blue signal

00098 00000 00255 00032 Adjust Appoint gamma revision gain 4 of the Blue signal

00099 00000 00255 00032 Adjust Appoint gamma revision gain 5 of the Blue signal

00100 00000 00255 00032 Adjust Appoint gamma revision gain 6 of the Blue signal

00101 00000 00255 00032 Adjust Appoint gamma revision gain 7 of the Blue signal

00102 00000 00255 00032 Adjust Appoint gamma revision gain 8 of the Blue signal

00103 00000 00255 00110 Adjust Adjust the horizontal indication point of the picture (NTSC)

00104 00000 00255 00110 Adjust Adjust the horizontal indication point of the picture (PAL)

00105 00000 00255 00026 Adjust Adjust the vertical indication point of the picture (NTSC)

00106 00000 00255 00026 Adjust Adjust the vertical indication point of the picture (PAL)

00107 00000 00127 00042 Adjust AD clock gain adjustment (NTSC)

00108 00000 00127 00042 Adjust AD clock gain adjustment (PAL)

00109 00000 00007 00001 Adjust Noise reduction of the Y signal (NTSC)

00110 00000 00007 00001 Adjust Noise reduction of the Y signal (PAL)

00111 00000 00003 00032 Adjust Choose a YC separation filter (NTSC)

00112 00000 00003 00048 Adjust Choose a YC separation filter (PAL)

00113 00000 00007 00000 Adjust Color pulling out filter setting (NTSC)

00114 00000 00007 00000 Adjust Color pulling out filter setting (PAL)

00115 00000 00007 00001 Adjust Choose com movement mode and color BPF (NTSC)

00116 00000 00007 00004 Adjust Choose com movement mode and color BPF (PAL)

00117 00000 01023 00180 Adjust Vertical dot cancellation setting (NTSC)

00118 00000 01023 00180 Adjust Vertical dot cancellation setting (PAL)

00119 00000 00063 00001 Adjust Noise reduction setting (NTSC)

00120 00000 00063 00001 Adjust Noise reduction setting (PAL)

00121 00000 01023 00338 Adjust Quantity of brightness adjustment setting (NTSC)

00122 00000 01023 00338 Adjust Quantity of brightness adjustment setting (PAL)

00123 00000 00255 00168 Adjust Brightness gain adjustment (NTSC)

00124 00000 00255 00168 Adjust Brightness gain adjustment (PAL)

00125 00000 00511 00140 Adjust Color signal output level setting (NTSC)

00126 00000 00511 00096 Adjust Color signal output level setting (PAL)

00127 00000 00006 00004 Adjust ACC movement mode setting

00128 00000 00255 00033 Adjust

00129 00000 00255 00033 Adjust C signal filter characteristic setting of the Y/C separation part (PAL)

00130 00000 16383 02464 Adjust Amplitude killer off level setting

00131 00000 16383 02472 Adjust Amplitude killer on level setting

00132 00000 00127 00071 Adjust Clamp DC level adjustment setting

C signal filter characteristic setting of the Y/C separation part (NTSC)

(No.MA473<Rev.002>)1-29

Page 30

Indication Minimum value Maximum value Initial value ---- Detail

00133 00000 00015 00015 Adjust Clamp speed adjustment setting

00134 00000 00063 00049 Adjust Noise filter band setting of horizontal synchronization signal and ver-

tical synchronizing signal (NTSC)

00135 00000 00063 00049 Adjust Noise filter band setting of horizontal synchronization signal and ver-

tical synchronizing signal (PAL)

00136 00000 65535 14976 Adjust Horizontal phase comparison gain setting (NTSC)

00137 00000 65535 14976 Adjust Horizontal phase comparison gain setting (PAL)

00138 00000 00063 00055 Adjust Horizontal loop filter setting 1

00139 00000 00015 00010 Adjust Horizontal loop filter setting 2

00140 00000 00015 00007 Adjust Horizontal loop filter setting 3

00141 00000 00015 00001 Adjust Synchronization separation burst clock setting (NTSC)

00142 00000 00015 00001 Adjust Synchronization separation burst clock setting (PAL)

00143 00000 00255 00252 Adjust

00144 00000 00255 00252 Adjust

Free run center value setting of horizontal synchronization signal (NTSC)

Free run center value setting of horizontal synchronization signal (PAL)

00145 00000 00511 00326 Fix DOKIDET 01

00146 00000 00511 00082 Fix DOKIDET 02

00147 00000 00511 00033 Fix DOKIDET 03

00148 00000 00026 00019 Adjust Horizontal synchronizing signal beginning position and setting regis-

ters (NTSC)

00149 00000 00026 00019 Adjust Horizontal synchronizing signal beginning position and setting regis-

ters (PAL)

00150 00000 00255 00128 Adjust Subcareer center frequency setting (NTSC)

00151 00000 00255 00000 Adjust Unused

00152 00000 00255 00128 Adjust Subcareer center frequency setting (PAL)

00153 00000 00255 00000 Adjust Unused

00154 00000 00255 00018 Adjust Coordinate the delay of the C signal with a Y signal (NTSC)

00155 00000 00255 00023 Adjust Coordinate the delay of the C signal with a Y signal (PAL)

00156 00000 00255 00125 Adjust Coordinate the VCOM amplitude of the LCD (NTSC)

00157 00000 00255 00123 Adjust Coordinate the VCOM amplitude of the LCD (PAL)

00158 00000 00255 00000 Adjust Unused

00159 00000 00255 00000 Adjust Unused

00160 00000 00020 00004 Adjust Set a variable range of the indication VSYNC frequency (NTSC)

00161 00000 00020 00009 Adjust Set a variable range of the indication VSYNC frequency (PAL)

00162 00040 00110 00090 Adjust Set time when indication VSYNC frequency changes (NTSC)

00163 00040 00110 00060 Adjust Set time when indication VSYNC frequency changes (PAL)

00164 00000 00007 00000 Adjust CLAMP MODE (NTSC)

00165 00000 00007 00000 Adjust CLAMP MODE (PAL)

1-30 (No.MA473<Rev.002>)

Page 31

5.1 16PIN CORD DIAGRAM

5.1.1 Except Europe

SECTION 5

TROUBLESHOOTING

1

16

2

15

13

8

GN/BK

7

6

VI/BK

5

4

BL/WH

3

2

1

BK

YL

RD

OR/WH

BR

GN

VI

BL

RD

BK

WH

WH/BK

GY/BK

GY

BR

YG

OR/WH

YL

9

10

11

12

13

14

15

16

BK

RD

BL

WH

VI

GN

Black

Red

Blue

White

Violet

Green

GY

BR

YG

OR

YL

Gray

Brown

Yellow Green

Orange

Yellow

10

12

11

14

3

4

8

7

5

6

9

BL/WH

BL

GN

GN/BK

VI

VI/BK

WH

WH/BK

GY

GY/BK

YG

(No.MA473<Rev.002>)1-31

Page 32

5.1.2 For Europe

8

7

6

5

4

3

2

1

2

16

1

3

13

15

GN

GN/BK

VI/BK

VI

NC

BL/WH

RD

BK

RD1

YL1

BK

BL/WH

BR

OR/WH

WH

WH/BK

GY/BK

GY

BR

YG

OR/WH

YL

9

10

11

12

13

14

15

16

BK

RD

BL

WH

VI

GN

Black

Red

Blue

White

Violet

Green

RD3

GY

BR

YG

OR

YL

Gray

Brown

Yellow Green

Orange

Yellow

RD2

YL2

7

4

8

5

1

3

2

5

7

6

NC

NC

BL/WH

RD

BR

YL

OR/WH

BK

2

4

6

8

10

12

11

14

8

7

5

6

9

GN

GN/BK

VI

VI/BK

WH

WH/BK

GY

GY/BK

YG

7

8

1

2

5

VI/BK

VI

1

6

GY

3

3

4

WH

5

GN

7

GY/BK

WH/BK

GN/BK

2

4

6

8

1-32 (No.MA473<Rev.002>)

Page 33

<MEMO>

(No.MA473<Rev.002>)1-33

Page 34

Victor Company of Japan, Limited

Mobile Entertainment Division 10-1,1chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

(No.MA473<Rev.002>)

Printed in Japan

VSE

Page 35

REVISION INFORMATION

DVD RECEIVER WITH MONITOR

KW-ADV793J, KW-AVX730E, KW-AVX730EE, KW-AVX730J,

KW-AVX735EU, KW-AVX735U, KW-AVX735UN, KW-AVX736A,

KW-AVX736EU, KW-AVX736U, KW-AVX736UN, KW-AVX736UT,

KW-AVX736UW, KW-AVX738JW, KW-AVX830E, KW-AVX830J,

KW-AVX835EU, KW-AVX835U, KW-AVX835UN, KW-AVX836A,

KW-AVX836EU, KW-AVX836U, KW-AVX836UN, KW-AVX836UT,

KW-AVX836UW, KW-AVX838JW, KW-AVX838UF

■ OVERVIEW

Add KW-AVX730J.

■ DETAILS

COVER SECTION

Title Line No.MA473<Rev.001> No.MA473<Rev.002> Description

Revision Rev.001 Rev.002

Issue Date 2010/04 2010/06

Model No. KW-ADV793J, KW-AVX730E, KW-AVX730EE,

Cover Illustration ILLUSTRATION(ma473_0001.png) ILLUSTRATION(ma473_0001.png)

SPECIFICATION 2

11

KW-AVX735EU, KW-AVX735U, KW-AVX735UN,

KW-AVX736A, KW-AVX736EU, KW-AVX736U,

KW-AVX736UN, KW-AVX736UT, KW-AVX736UW,

KW-AVX738JW, KW-AVX830E, KW-AVX830J,

KW-AVX835EU, KW-AVX835U, KW-AVX835UN,

KW-AVX836A, KW-AVX836EU, KW-AVX836U,

KW-AVX836UN, KW-AVX836UT, KW-AVX836UW,

KW-AVX838JW, KW-AVX838UF

KW-AVX838/KW-AVX830/KW-ADV793/KWAVX738 J/JW

Audio Output Level

FRONT OUT, REAR OUT, SUBWOOFER

OUT

Line-Out Level/Impedance

5 V/20 kΩ load (full scale)

KW-ADV793J, KW-AVX730E, KW-AVX730EE,

KW-AVX730J, KW-AVX735EU, KW-AVX735U,

KW-AVX735UN, KW-AVX736A, KW-AVX736EU,

KW-AVX736U, KW-AVX736UN, KW-AVX736UT,

KW-AVX736UW, KW-AVX738JW, KW-AVX830E,

KW-AVX830J, KW-AVX835EU, KW-AVX835U,

KW-AVX835UN, KW-AVX836A, KW-AVX836EU,

KW-AVX836U, KW-AVX836UN, KW-AVX836UT,

KW-AVX836UW, KW-AVX838JW, KW-AVX838UF

KW-AVX838/KW-AVX830/KW-ADV793/KWAVX738/KW-AVX730 J/JW

Audio Output Level

FRONT OUT, REAR OUT, SUBWOOFER OUT

Line-Out Level/Impedance

5 V/20 kΩ load (full scale), 2.5 V20 kΩ load (full

scale) for KW-AVX730

COPYRIGHT © 2010 Victor Company of Japan, Limited

MA473-R002

2010/06

Page 36

STANDARD SCHEMATIC DIAGRAMS

!

Description of Major ICs

Diagram Name No.MA473<Rev.001> No.MA473<Rev.002> Description

Menu IC451: JVM452C IC451: JVM498A

PARTS LIST

MODEL No. LIST

Model No. No.MA473<Rev.002>

KW-ADV793J 01

KW-AVX730E 02

KW-AVX730EE 03

KW-AVX730J 04

KW-AVX735EU 05

KW-AVX735U 06

KW-AVX735UN 07

KW-AVX736A 08

KW-AVX736EU 09

General assembly [M1MM]

Symbol or

!

M1MM 36 ------------ LV11671-002A MID CHASSIS (Addition) 1 04

M1MM 134 ------------ LV39220-001A NAME PLATE (Addition) 1 04

<Rev.001> <Rev.002>

Part No.

DVD mechanism (FMU-XD6-11D) [MJMM]

Symbol or

MJMM 50 CM-FMUXD5D CM-FMUXD3D TRA MECHA UNIT 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

<Rev.001> <Rev.002>

Part No.

Model No. No.MA473<Rev.002>

KW-AVX736U 0A

KW-AVX736UN 0B

KW-AVX736UT 0C

KW-AVX736UW 0D

KW-AVX738JW 0E

KW-AVX830E 0F

KW-AVX830J 10

KW-AVX835EU 11

KW-AVX835U 12

Part Name Description Qty Models

Part Name Description Qty Models

0D,0E,0F,10,11,12,13,14,15,16,17,18,

19,1A,1B

Model No. No.MA473<Rev.002>

KW-AVX835UN 13

KW-AVX836A 14

KW-AVX836EU 15

KW-AVX836U 16

KW-AVX836UN 17

KW-AVX836UT 18

KW-AVX836UW 19

KW-AVX838JW 1A

KW-AVX838UF 1B

Panel-A board [02]

Symbol or

!

! 02 IC451 ------------ JVM498A PROGRAMED IC (Addition) 1 04

<Rev.001> <Rev.002>

Part No.

Part Name Description Qty Models

Packing and accessories [M3MM]

Symbol or

!

M3MM A1 ------------ LVT2086-001B INST BOOK (Addition) 1 04

M3MM A2 ------------ LVT2086-002B INST BOOK (Addition) 1 04

M3MM A3 ------------ LVT2087-001B INSTALL MANUAL (Addition) 1 04

M3MM A4 ------------ LVT2087-002B INSTALL MANUAL (Addition) 1 04

M3MM P1 ------------ LV39223-001A CARTON (Addition) 1 04

M3MM P4 ------------ QPC03504015PG POLY BAG (Addition) 1 04

<Rev.001> <Rev.002>

Part No.

Part Name Description Qty Models

2 (MA473-R002)

Page 37

(MA473-R002) 3

Page 38

Victor Company of Japan, Limited

Mobile Entertainment Division 10-1,1chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

(MA473-R002)

Printed in Japan

No.MA473<Rev.001> VSE

Page 39

SCHEMATIC DIAGRAMS

31

DVD RECEIVER WITH MONITOR

KW-ADV793J KW-AVX730E KW-AVX730EE

KW-AVX730J KW-AVX735EU KW-AVX735U

KW-AVX735UN KW-AVX736A KW-AVX736EU

KW-AVX736U KW-AVX736UN KW-AVX736UT

KW-AVX736UW KW-AVX738JW KW-AVX830E

KW-AVX830J KW-AVX835EU KW-AVX835U

KW-AVX835UN KW-AVX836A KW-AVX836EU

KW-AVX836U KW-AVX836UN KW-AVX836UT

KW-AVX836UW KW-AVX838JW KW-AVX838UF

(No.MA473<Rev.002>)1/

Page 40

■ PRECAUTIONS ON SCHEMATIC DIAGRAMS

z Due to the improvement in performance, some part numbers shown in the circuit diagrams

may not agree with those indicated in the Parts List.

z The parts numbers, values and rated voltage etc. in the Schematic Diagrams are for

reference only.

z Since the circuit diagrams are standard ones, the circuits and circuit constants may be

subject to change for improvement without any notice.

■ PRECAUTIONS ON PARTS LIST

z

The parts identified by the symbol are critical for safety. Whenever replacing these parts, be sure to

use specified ones to secure the safety.

z

The parts not indicated in this Parts List and those which are filled with lines --- in the Parts No.

columns will not be supplied.

z

P.W. BOARD Ass'y will not be supplied, but those which are filled with the Parts No. in the Parts No.

columns will be supplied.

z

When ordering chips, screws etc., place bulk orders (unit of tens) whenever possible to improve

shipping efficiency.

z

There are cases where the actual implemented parts in the sets and the service parts are different.

When ordering parts, make sure to refer to the Parts List.

■

PRECAUTIONS ON SERVICE

Certain parts of the power circuits and the GNDs differ according to the models. Care must be

taken for the following points as the differences are indicated separately in the LIVE GND ( ) and

the ISOLATED (NEUTRAL) GND ( ).

1. Do not touch the LIVE GND, or do not touch the LIVE GND and the ISOLATED (NEUTRAL)

GND at the same time. It may cause an electric shock.

Before pulling out the chassis or other parts, make sure to pull out the power cord from the

wall outlet first.

2. Do not short circuit between the LIVE GND and ISOLATED (NEUTRAL) GND, or never

measure the LIVE GND and ISOLATED (NEUTRAL) GND at the same time using measuring

instruments (oscilloscope, etc.). It may blow fuses or damage other parts.

■ DEVIATION TOLERANCE RANGE

DEVIATION TOLERANCE RANGE

F G J K M N R H Z P

± 1% ± 2% ± 5% ±10% ±20% ±30%

+30%

-10%

+50%

-10%

+80%

-20%

+100%

-0%

31

(No.MA473<Rev.002>)2/

Page 41

Q8203Q8202

Q8201

17.2V/-15V SW.REG

Q8104

Q8103Q8102

Q8101

3.3V SW.REG

Q8032

Q8031

USB

5V REG

Q8021

Q3501

Q1961

Q1951

ILUM

Q1941

PARK.BLK

Q1931

TEL MUTE

Q1507Q1506

Q1505

Q1504

Q1503Q1502

SW MUTING

Q1401

-9V REG.

Q1321

Q1304

MUTE

STBY

Q1303

Q1221

Q1121

L.O.MUTING

Q981

Q972

PS2

Q971

Q951

BUZZER

Q922

Q921

FAN CONTROL

Q881

Q875Q871

SW

Q822

Q821

Q802

Q801

Q799

MUTING

Q791

Q304

Q302

Q301

Q105

Q103

Q101

Q7

Q4

PHOTO SW

Q2

PANEL DRIVER

IC981

IC931

JVC BUS

IC821

3.3V

SW.REG

CNTROL

IC803

IC802

5V SWREG.

IC801

REGULATOR

IC731

RESET

IC721

EEPROM

IC701

CPU

IC502IC501

IC481

EPROM

DAC

IC400

IC399

SDRAM

IC398

FLASH ROM

IC351

PANEL SW /

PHOTO SENSOR

IC308

48MHz

1.2V_REG

IC302

IC301

DV5

QD1

QD2

SE2

SE1

SE3

IC141

E.VOLUME

IC131

IC121

BOOST

AMP

IC111

IC101

POWER AMP.

IC31

RDS

IC11

FM/AM TUNER

IC10

IC9

IC8

IPOD DECODER

IC7

MPX

3.2V_REG

IC3

IC1

DRIVER

,

to

DAC4

DGND

DETACH

BTTX, BTRX, BTRST, BT_MUTE_CTL

Used on

KW-AVX83x

models only

MIC CABLE

CN341

USB FRONT

DONGL

CN301

CN241

see 2/2 for

the details

see 2/2 for the details

see 2/2 for the details

see 2/2 for the details

CFL PWB

KEY PWB

CN501

PANEL-A PWB

LCD

MODULE

CN603

CN631

TOUCH

PANEL

CN604

CN605

see 2/2 for the details

see 2/2 for the details

NAVI_R, NAVI_G

NAVI_B, CSYNC

EXT_NAVI_DATA

1/2

BT PWB

CN311

VIDEO_M_SW1

VIDEO_M_SW2