Page 1

SERVICE MANUAL

DVD RECEIVER WITH MONITOR

MA493<Rev.002>20115SERVICE MANUAL

KW-ADV794J, KW-AVX640E, KW-AVX640J,

KW-AVX646EU, KW-AVX646U, KW-AVX648UF,

KW-AVX740E, KW-AVX740EE, KW-AVX740J,

KW-AVX746A, KW-AVX746EU, KW-AVX746U,

KW-AVX746UT, KW-AVX748JW

KW-ADV794/KW-AVX740/

KW-AVX746/KW-AVX748

KW-ADV794J/KW-AVX640J/

For

KW-AVX740J/KW-AVX748JW

KW-AVX740/KW-AVX640/

KW-AVX746/KW-AVX646/

COPYRIGHT © 2011 Victor Company of Japan, Limited

Lead free solder used in the board (material : Sn-Ag-Cu, melting point : 219 Centigrade)

Lead free solder used in the board (material : Sn-Cu, melting point : 230 Centigrade)

KW-AVX740E,EE/KW-AVX640E/

KW-AVX746EU/KW-AVX646EU

For KW-ADV794/

KW-AVX648

For

For

For

KW-ADV794J/

KW-AVX740J/

KW-AVX640J

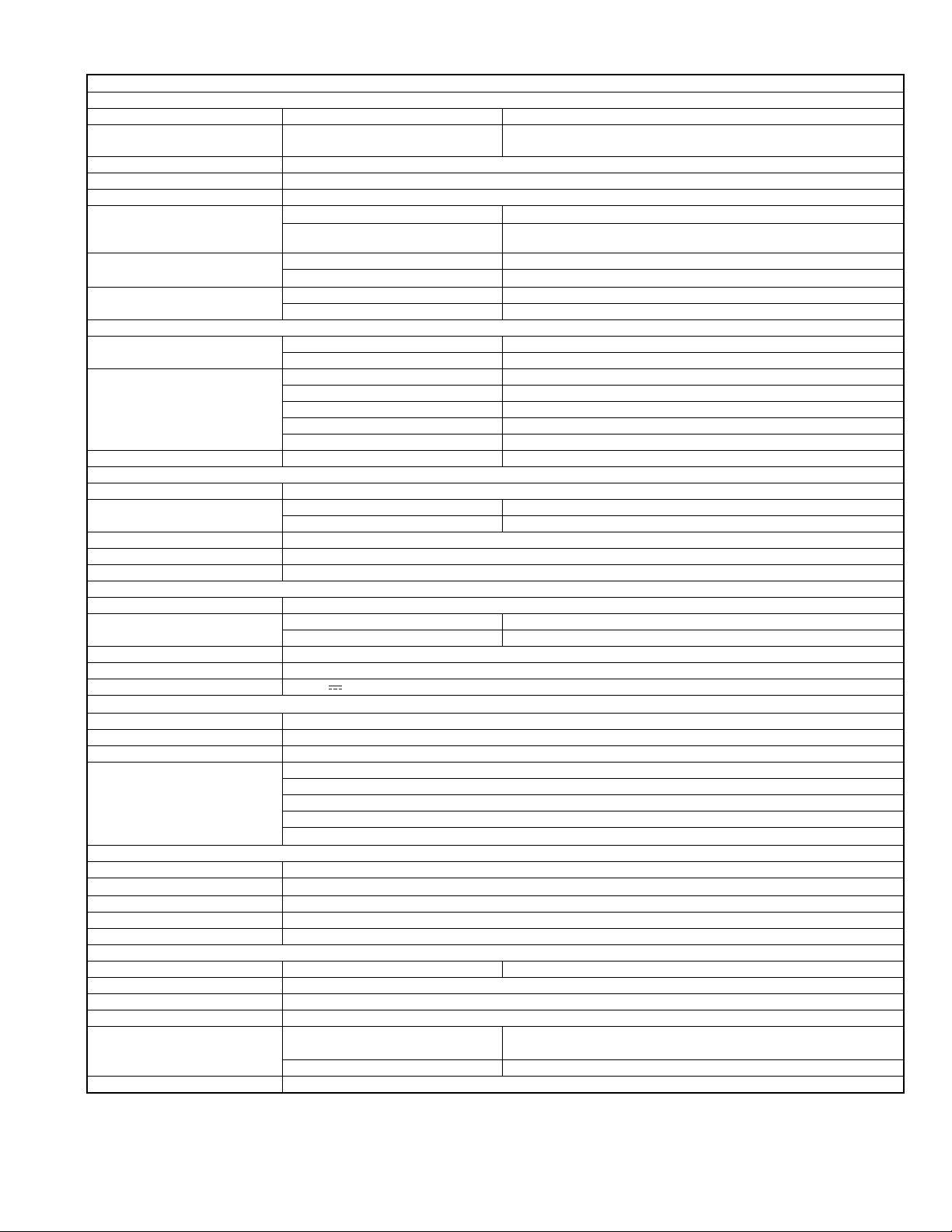

TABLE OF CONTENTS

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

2 SPECIFIC SERVICE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

COPYRIGHT © 2011 Victor Company of Japan, Limited

No.MA493<Rev.002>

2011/5

Page 2

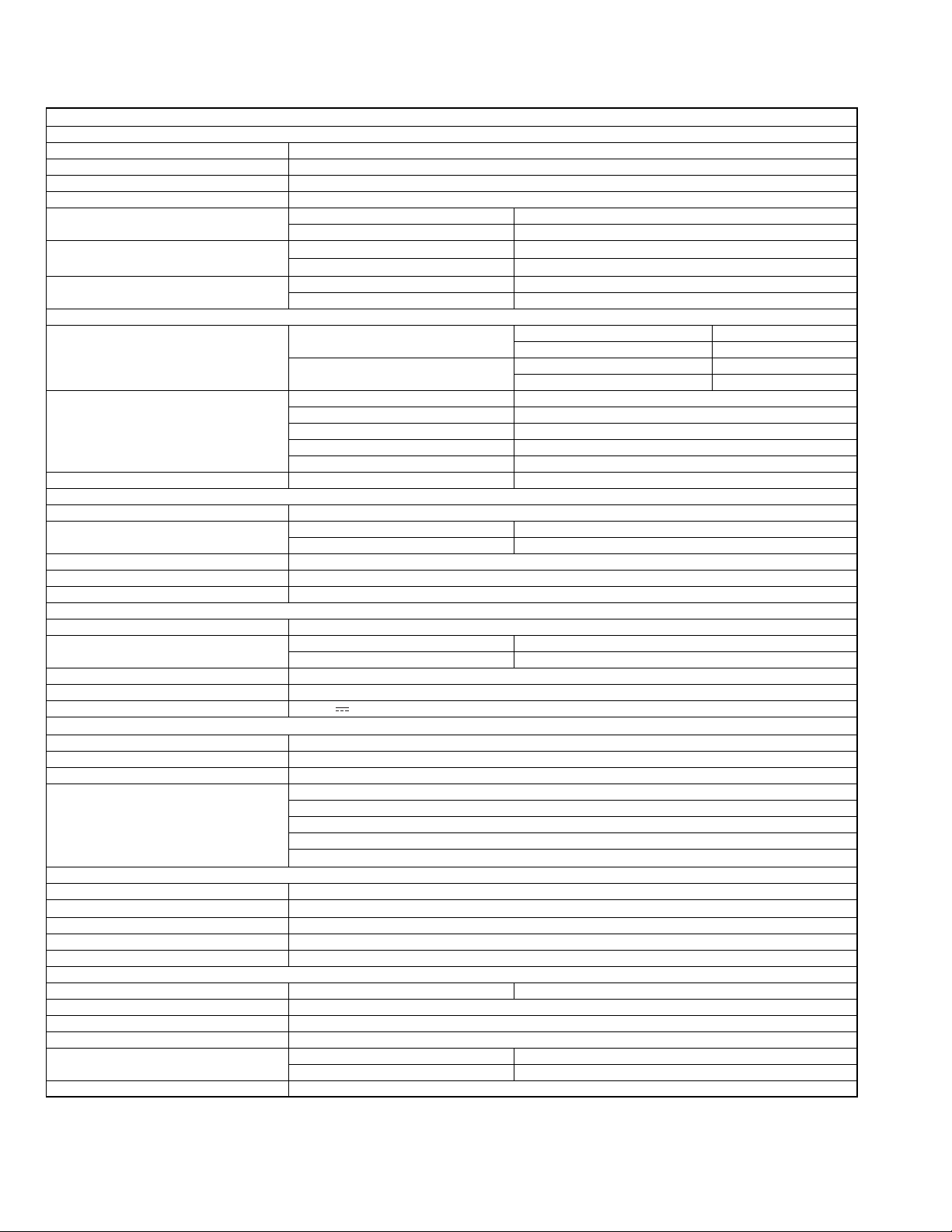

SPECIFICATION

KW-ADV794J/KW-AVX748JW/KW-AVX740J/KW-AVX640J

AMPLIFIER

Power Output 20 W RMS × 4 Channels at 4 Ω and

Signal-to-Noise Ratio 80 dBA (reference: 1 W into 4 Ω)

Load Impedance 4 Ω (4 Ω to 8 Ω allowance)

Equalizer Control Range Level ±12 dB

Audio Output Level

FRONT OUT, REAR OUT, SUBWOOFER OUT

Video Output (composite)

VIDEO OUT

Other Terminals Input

FM/AM TUNER

Frequency Range FM with channel interval set to 200 kHz 87.9 MHz to 107.9 MHz

FM Tuner Usable Sensitivity 9.3 dBf (0.8 µV/75 Ω)

AM Tuner Sensitivity/Selectivity 20 µV/40 dB

DVD/CD

Signal Detection System Non-contact optical pickup (semiconductor laser)

Frequency Response DVD, fs=48 kHz/96 kHz 16 Hz to 22 000 Hz

Dynamic Range 93 dB

Signal-to-Noise Ratio 95 dB

Wow and Flutter Less than measurable limit

USB

USB Standards USB 2.0 Full Speed

Data Transfer Rate

Compatible Device Mass storage class

Compatible File System FAT 32/16/12

Max. Current DC 5 V 1A

BLUETOOTH (Only for KW-ADV794/KW-AVX748/KW-AVX740)

Version Bluetooth 2.0 certified

Output Power +4 dBm Max. (Power class 2)

Service Area Within 10 m (10.9 yd)

Profile

MONITOR

Screen Size 6.1 inch wide liquid crystal display

Number of Pixel

Drive Method TFT (Thin Film Transistor) active matrix format

Color System NTSC/PAL

Aspect Ratio 16:9 (wide)

GENERAL

Power Requirement Operating Voltage DC 14.4 V (11 V to 16 V allowance)

Grounding System Negative ground

Allowable Storage Temperature -10°C to +60°C (14°F to 140°F)

Allowable Operating Temperature 0°C to +40°C (32°F to 104°F)

Dimensions (W × H × D) Installation Size (approx.) 182 mm × 111 mm × 160 mm (7-3/16” × 4-3/8” × 6-5/16”)

Mass (approx.) 2.3 kg (5.1 lbs) (including the Trim plate and Sleeve)

*1 Only for KW-ADV794/KW-AVX748/KW-AVX740

*2 Only for KW-ADV794/KW-AVX740/KW-AVX640.

Design and specifications are subject to change without notice.

If a kit is necessary for your car, consult your telephone directory for the nearest car audio speciality shop.

Line-Out Level/Impedance 4 V/20 kΩ load (full scale)

Output Impedance 1 kΩ

Color System

Video-Out Level/Impedance 1 Vp-p/75Ω

Others Expansion port*2, OE REMOTE, RGB input

AM with channel interval set to 10 kHz 530 kHz to 1 700 kHz

50 dB Quieting Sensitivity 16.3 dBf (1.8 µV/75 Ω)

Alternate Channel Selectivity (400 kHz) 65 dB

Frequency Response 40 Hz to 15 000 Hz

Stereo Separation 40 dB

VCD/CD 16 Hz to 20 000 Hz

Full Speed Maximum 12 Mbps

Low Speed Maximum 1.5 Mbps

HFP (Hands-Free Profile) 1.5

OPP (Object Push Profile) 1.1

A2DP (Advanced Audio Distribution Profile) 1.2

AVRCP (Audio/Video Remote Control Profile) 1.3

PBAP (Phone Book Access Profile) 1.0

1 152 000 pixels : 800 (horizontal) × 3 (RGB) × 480 (vertical)

Panel Size (approx.) 188 mm × 117 mm × 10 mm (7-7/16” × 4-5/8” × 7/16”)

≤ 1% THD+N

PAL/NTSC

LINE IN, VIDEO IN, CAMERA IN, USB input, MIC IN*1, AUX, Antenna input

with channel interval set to 50 kHz 87.5 MHz to 108.0 MHz

with channel interval set to 9 kHz 531 kHz to 1 611 kHz

1-2 (No.MA493<Rev.002>)

Page 3

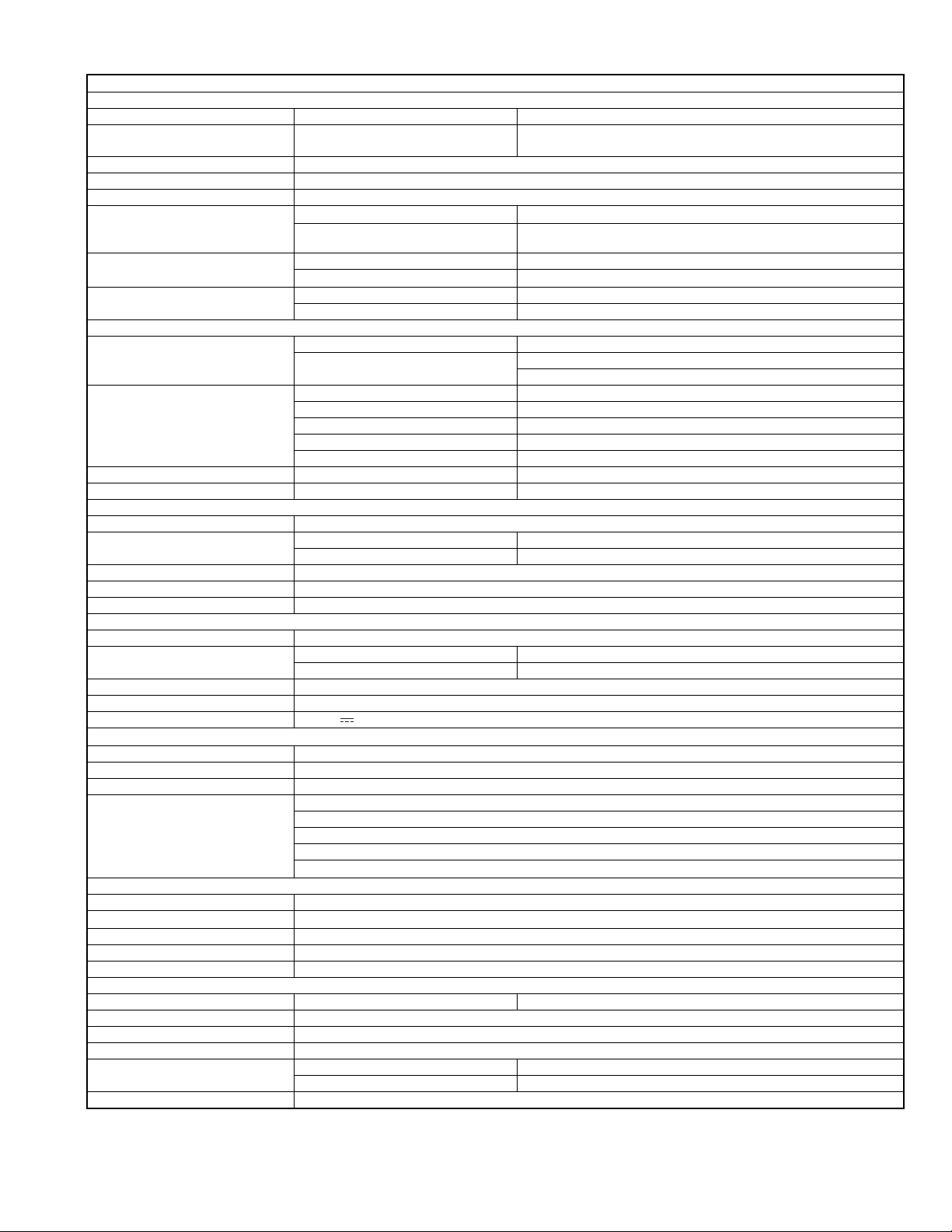

KW-AVX740E/KW-AVX640E/KW-AVX746EU/KW-AVX646EU

AMPLIFIER

Maximum Power Output Front/Rear 50 W per channel

Continuous Power Output (RMS) Front/Rear 20 W per channel into 4 Ω, 40 Hz to 20 000 Hz at no more than 0.8%

total harmonic distortion

Load Impedance 4 Ω (4 Ω to 8 Ω allowance)

Equalizer Control Range Level ±12 dB

Signal-to-Noise Ratio 70 dB

Audio Output Level

FRONT OUT, REAR OUT,

SUBWOOFER OUT

Video Output (composite)

VIDEO OUT

Other Terminals Input

FM/AM TUNER

Frequency Range FM 87.5 MHz to 108.0 MHz

FM Tuner Usable Sensitivity 9.3 dBf (0.8 µV/75 Ω)

MW Tuner Sensitivity/Selectivity 20 µV/40 dB

LW Tuner Sensitivity 50 µV

DVD/CD

Signal Detection System Non-contact optical pickup (semiconductor laser)

Frequency Response DVD, fs=48 kHz/96 kHz 16 Hz to 22 000 Hz

Dynamic Range 93 dB

Signal-to-Noise Ratio 95 dB

Wow and Flutter Less than measurable limit

USB

USB Standards USB 2.0 Full Speed

Data Transfer Rate Full Speed Maximum 12 Mbps

Compatible Device Mass storage class

Compatible File System FAT 32/16/12

Max. Current DC 5 V 1A

BLUETOOTH (Only for KW-AVX740A/KW-AVX746)

Version Bluetooth 2.0 certified

Output Power +4 dBm Max. (Power class 2)

Service Area Within 10 m

Profile

MONITOR

Screen Size 6.1 inch wide liquid crystal display

Number of Pixel

Drive Method TFT (Thin Film Transistor) active matrix format

Color System PAL/NTSC

Aspect Ratio 16:9 (wide)

GENERAL

Power Requirement Operating Voltage DC 14.4 V (11 V to 16 V allowance)

Grounding System Negative ground

Allowable Storage Temperature -10°C to +60°C

Allowable Operating Temperature 0°C to +40°C

Dimensions (W × H × D) Installation Size (approx.) 182 mm × 111 mm × 160 mm

Mass (approx.) 2.3 kg (including the Trim plate and Sleeve)

Line-Out Level/Impedance

Output Impedance

Color System PAL/NTSC

Video-Out Level/Impedance

Others OE REMOTE, RGB input

AM (MW) 531 kHz to 1 611 kHz

50 dB Quieting Sensitivity 16.3 dBf (1.8 µV/75 Ω)

Alternate Channel Selectivity (400 kHz) 65 dB

Frequency Response 40 Hz to 15 000 Hz

Stereo Separation 40 dB

VCD/CD 16 Hz to 20 000 Hz

Low Speed Maximum 1.5 Mbps

HFP (Hands-Free Profile) 1.5

OPP (Object Push Profile) 1.1

A2DP (Advanced Audio Distribution Profile) 1.2

AVRCP (Audio/Video Remote Control Profile) 1.3

PBAP (Phone Book Access Profile) 1.0

1 152 000 pixels : 800 (horizontal) × 3 (RGB) × 480 (vertical)

Panel Size (approx.) 188 mm × 117 mm × 10 mm

4 V/20 kΩ load (full scale)

1 kΩ

1 Vp-p/75 Ω

LINE IN, VIDEO IN, CAMERA IN, USB input, MIC IN*, AUX, Aerial input

(LW) 153 kHz to 279 kHz

* Only for KW-AVX740,KW-AVX746

Design and specifications are subject to change without notice.

(No.MA493<Rev.002>)1-3

Page 4

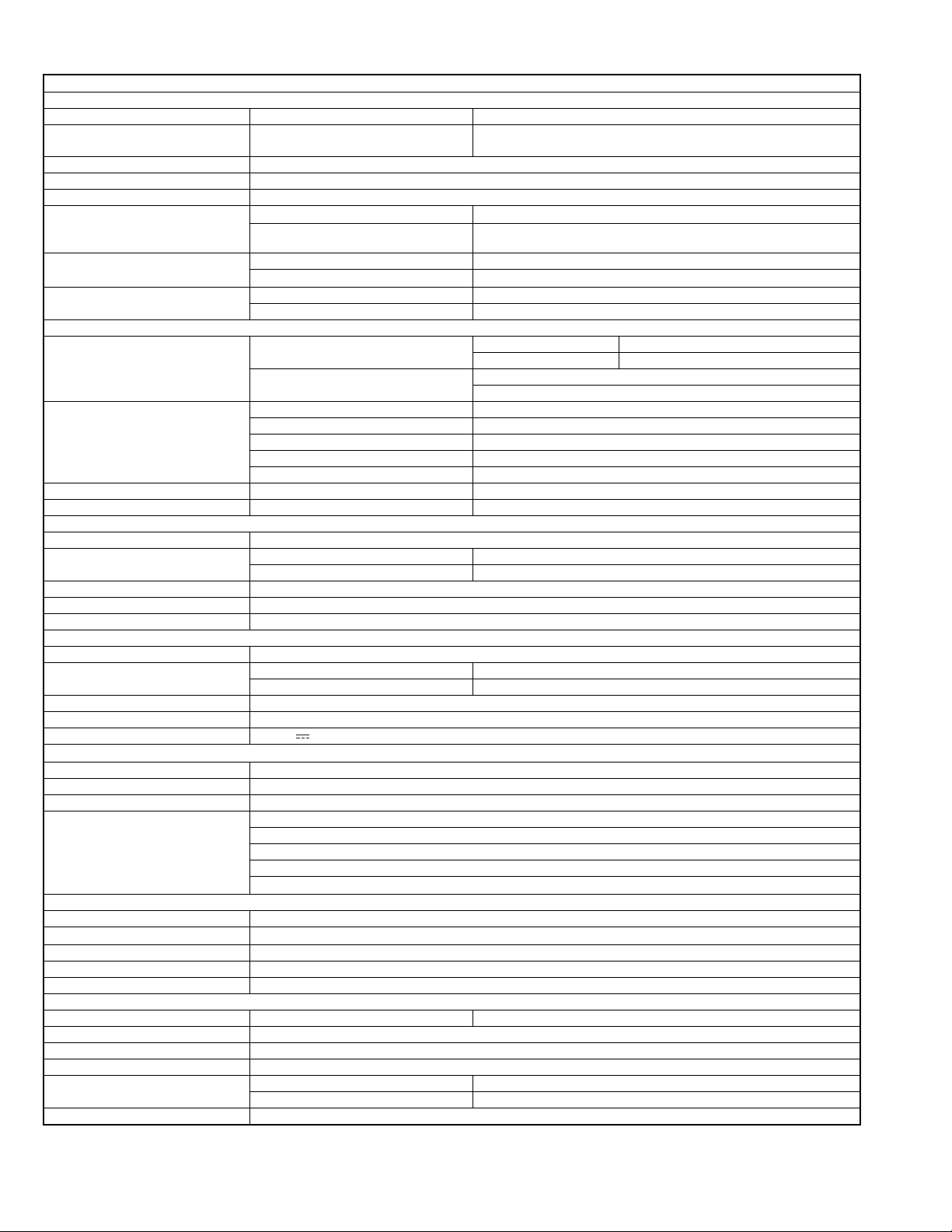

KW-AVX740EE

AMPLIFIER

Maximum Power Output Front/Rear 50 W per channel

Continuous Power Output (RMS) Front/Rear 20 W per channel into 4 Ω, 40 Hz to 20 000 Hz at no more than 0.8%

total harmonic distortion

Load Impedance 4 Ω (4 Ω to 8 Ω allowance)

Equalizer Control Range Level ±12 dB

Signal-to-Noise Ratio 70 dB

Audio Output Level

FRONT OUT, REAR OUT,

SUBWOOFER OUT

Video Output (composite)

VIDEO OUT

Other Terminals Input

FM/AM TUNER

Frequency Range

FM Tuner Usable Sensitivity 9.3 dBf (0.8 µV/75 Ω)

MW Tuner Sensitivity/Selectivity 20 µV/40 dB

LW Tuner Sensitivity 50 µV

DVD/CD

Signal Detection System Non-contact optical pickup (semiconductor laser)

Frequency Response DVD, fs=48 kHz/96 kHz 16 Hz to 22 000 Hz

Dynamic Range 93 dB

Signal-to-Noise Ratio 95 dB

Wow and Flutter Less than measurable limit

USB

USB Standards USB 2.0 Full Speed

Data Transfer Rate Full Speed Maximum 12 Mbps

Compatible Device Mass storage class

Compatible File System FAT 32/16/12

Max. Current DC 5 V 1A

BLUETOOTH

Version Bluetooth 2.0 certified

Output Power +4 dBm Max. (Power class 2)

Service Area Within 10 m

Profile

MONITOR

Screen Size 6.1 inch wide liquid crystal display

Number of Pixel

Drive Method TFT (Thin Film Transistor) active matrix format

Color System PAL/NTSC

Aspect Ratio 16:9 (wide)

GENERAL

Power Requirement Operating Voltage DC 14.4 V (11 V to 16 V allowance)

Grounding System Negative ground

Allowable Storage Temperature -10°C to +60°C

Allowable Operating Temperature 0°C to +40°C

Dimensions (W × H × D) Installation Size (approx.) 182 mm × 111 mm × 160 mm

Mass (approx.) 2.3 kg (including the Trim plate and Sleeve)

Design and specifications are subject to change without notice.

Line-Out Level/Impedance

Output Impedance

Color System PAL/NTSC

Video-Out Level/Impedance

Others OE REMOTE, RGB input

FM

AM (MW) 531 kHz to 1 611 kHz

50 dB Quieting Sensitivity 16.3 dBf (1.8 µV/75 Ω)

Alternate Channel Selectivity (400 kHz) 65 dB

Frequency Response 40 Hz to 15 000 Hz

Stereo Separation 40 dB

VCD/CD 16 Hz to 20 000 Hz

Low Speed Maximum 1.5 Mbps

HFP (Hands-Free Profile) 1.5

OPP (Object Push Profile) 1.1

A2DP (Advanced Audio Distribution Profile) 1.2

AVRCP (Audio/Video Remote Control Profile) 1.3

PBAP (Phone Book Access Profile) 1.0

1 152 000 pixels : 800 (horizontal) × 3 (RGB) × 480 (vertical)

Panel Size (approx.) 188 mm × 117 mm × 10 mm

4 V/20 kΩ load (full scale)

1 kΩ

1 Vp-p/75 Ω

LINE IN, VIDEO IN, CAMERA IN, USB input, MIC IN, AUX, Aerial input

FM1, FM2 87.5 MHz to 108.0 MHz

FM3 65.00 MHz to 74.00 MHz

(LW) 153 kHz to 279 kHz

1-4 (No.MA493<Rev.002>)

Page 5

KW-AVX746A/KW-AVX746U,UT/KW-AVX646U,KW-AVX648UF

AMPLIFIER

Maximum Power Output Front/Rear 50 W per channel

Continuous Power Output (RMS) Front/Rear 20 W per channel into 4 Ω, 40 Hz to 20 000 Hz at no more than 0.8% total

harmonic distortion

Load Impedance 4 Ω (4 Ω to 8 Ω allowance)

Equalizer Control Range Level ±12 dB

Signal-to-Noise Ratio 70 dB

Audio Output Level

FRONT OUT, REAR OUT,

SUBWOOFER OUT

Video Output (composite)

VIDEO OUT

Other Terminals Input

FM/AM TUNER

Frequency Range FM 87.5 MHz to 108.0 MHz

FM Tuner Usable Sensitivity 9.3 dBf (0.8 µV/75 Ω)

AM Tuner Sensitivity/Selectivity 20 µV/40 dB

DVD/CD

Signal Detection System Non-contact optical pickup (semiconductor laser)

Frequency Response DVD, fs=48 kHz/96 kHz 16 Hz to 22 000 Hz

Dynamic Range 93 dB

Signal-to-Noise Ratio 95 dB

Wow and Flutter Less than measurable limit

USB

USB Standards USB 2.0 Full Speed

Data Transfer Rate Full Speed Maximum 12 Mbps

Compatible Device Mass storage class

Compatible File System FAT 32/16/12

Max. Current DC 5 V 1A

BLUETOOTH (Only for KW-AVX746)

Version Bluetooth 2.0 certified

Output Power +4 dBm Max. (Power class 2)

Service Area Within 10 m

Profile

MONITOR

Screen Size 6.1 inch wide liquid crystal display

Number of Pixel

Drive Method TFT (Thin Film Transistor) active matrix format

Color System PAL/NTSC

Aspect Ratio 16:9 (wide)

GENERAL

Power Requirement Operating Voltage DC 14.4 V (11 V to 16 V allowance)

Grounding System Negative ground

Allowable Storage Temperature -10°C to +60°C

Allowable Operating Temperature 0°C to +40°C

Dimensions (W × H × D)

Mass (approx.) 2.0 kg

Line-Out Level/Impedance

Output Impedance

Color System PAL/NTSC

Video-Out Level/Impedance

Others OE REMOTE, RGB input

AM 531 kHz to 1 611 kHz

50 dB Quieting Sensitivity 16.3 dBf (1.8 µV/75 Ω)

Alternate Channel Selectivity (400 kHz) 65 dB

Frequency Response 40 Hz to 15 000 Hz

Stereo Separation 40 dB

VCD/CD 16 Hz to 20 000 Hz

Low Speed Maximum 1.5 Mbps

HFP (Hands-Free Profile) 1.5

OPP (Object Push Profile) 1.1

A2DP (Advanced Audio Distribution Profile) 1.2

AVRCP (Audio/Video Remote Control Profile) 1.3

PBAP (Phone Book Access Profile) 1.0

1 152 000 pixels : 800 (horizontal) × 3 (RGB) × 480 (vertical)

Installation Size (approx.)

Panel Size (approx.) 188 mm × 117 mm × 10 mm

4 V/20 kΩ load (full scale)

1 kΩ

1 Vp-p/75 Ω

LINE IN, VIDEO IN, CAMERA IN, USB input, MIC IN*, AUX, Aerial input

182 mm × 111 mm × 160 mm

180 mm × 100 mm × 160 mm (KW-AVX648)

* Only for KW-AVX746

Design and specifications are subject to change without notice.

(No.MA493<Rev.002>)1-5

Page 6

SECTION 1

PRECAUTION

1.1 Safety Precautions

(1) This design of this product contains special hardware and

many circuits and components specially for safety purposes. For continued protection, no changes should be made

to the original design unless authorized in writing by the

manufacturer. Replacement parts must be identical to

those used in the original circuits. Services should be performed by qualified personnel only.

(2) Alterations of the design or circuitry of the product should

not be made. Any design alterations of the product should

not be made. Any design alterations or additions will void

the manufacturers warranty and will further relieve the

manufacture of responsibility for personal injury or property

damage resulting therefrom.

(3) Many electrical and mechanical parts in the products have

special safety-related characteristics. These characteristics are often not evident from visual inspection nor can the

protection afforded by them necessarily be obtained by using replacement components rated for higher voltage, wattage, etc. Replacement parts which have these special

safety characteristics are identified in the Parts List of Service Manual. Electrical components having such features

are identified by shading on the schematics and by ( ) on

the Parts List in the Service Manual. The use of a substitute

replacement which does not have the same safety characteristics as the recommended replacement parts shown in

the Parts List of Service Manual may create shock, fire, or

other hazards.

(4) The leads in the products are routed and dressed with ties,

clamps, tubings, barriers and the like to be separated from

live parts, high temperature parts, moving parts and/or

sharp edges for the prevention of electric shock and fire

hazard. When service is required, the original lead routing

and dress should be observed, and it should be confirmed

that they have been returned to normal, after reassembling.

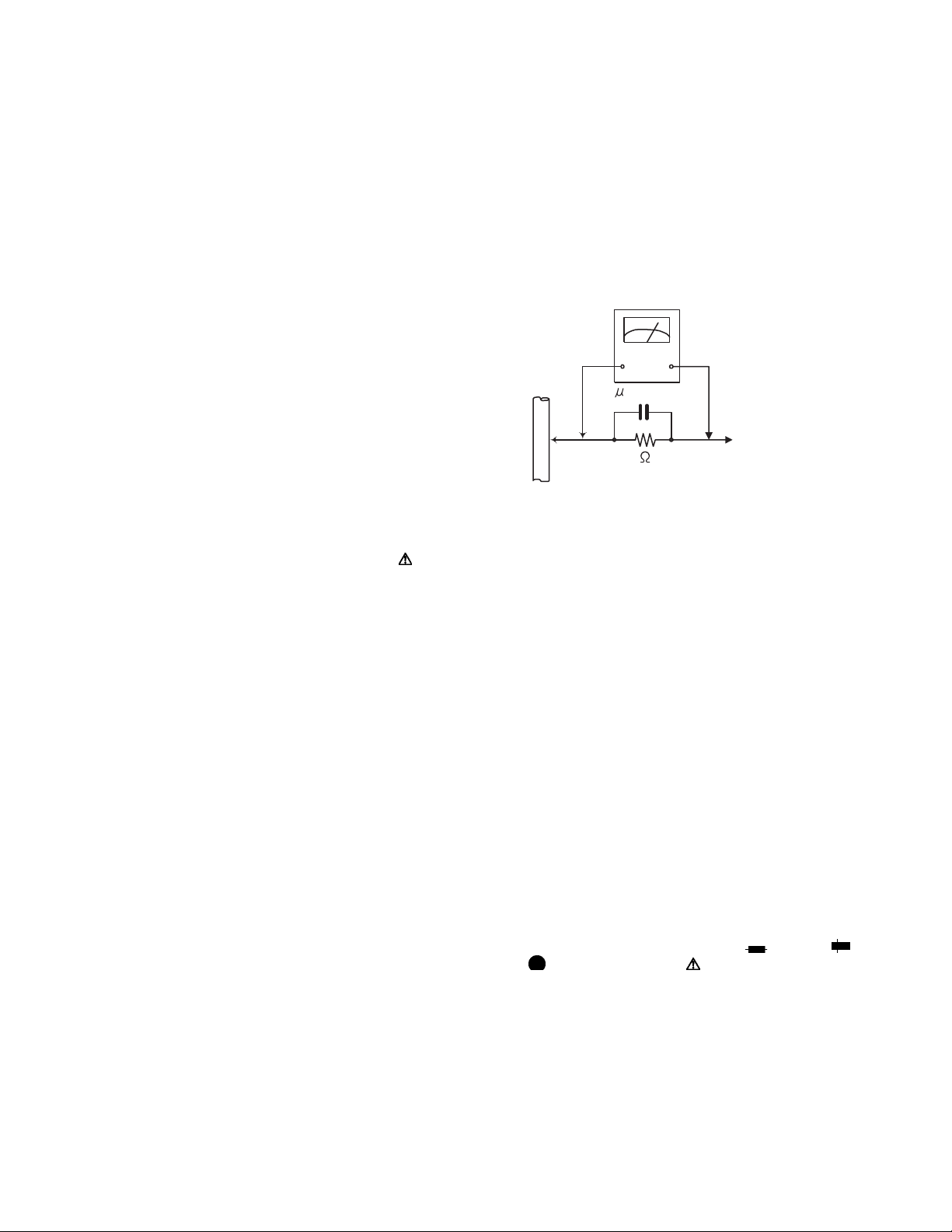

(5) Leakage shock hazard testing

After reassembling the product, always perform an isolation check on the exposed metal parts of the product (antenna terminals, knobs, metal cabinet, screw heads,

headphone jack, control shafts, etc.) to be sure the product

is safe to operate without danger of electrical shock.Do not

use a line isolation transformer during this check.

• Plug the AC line cord directly into the AC outlet. Using a

"Leakage Current Tester", measure the leakage current

from each exposed metal parts of the cabinet, particularly any exposed metal part having a return path to the

chassis, to a known good earth ground. Any leakage current must not exceed 0.5mA AC (r.m.s.).

• Alternate check method

Plug the AC line cord directly into the AC outlet. Use an

AC voltmeter having, 1,000Ω per volt or more sensitivity

in the following manner. Connect a 1,500Ω 10W resistor

paralleled by a 0.15µF AC-type capacitor between an exposed metal part and a known good earth ground.

Measure the AC voltage across the resistor with the AC

voltmeter.

Move the resistor connection to each exposed metal

part, particularly any exposed metal part having a return

path to the chassis, and measure the AC voltage across

the resistor. Now, reverse the plug in the AC outlet and

repeat each measurement. Voltage measured any must

not exceed 0.75 V AC (r.m.s.). This corresponds to 0.5

mA AC (r.m.s.).

AC VOLTMETER

(Having 1000

ohms/volts,

or more sensitivity)

0.15 F AC TYPE

Place this

probe on

1500 10W

Good earth ground

1.2 Warning

(1) This equipment has been designed and manufactured to

meet international safety standards.

(2) It is the legal responsibility of the repairer to ensure that

these safety standards are maintained.

(3) Repairs must be made in accordance with the relevant

safety standards.

(4) It is essential that safety critical components are replaced

by approved parts.

(5) If mains voltage selector is provided, check setting for local

voltage.

1.3 Caution

Burrs formed during molding may be left over on some parts

of the chassis.

Therefore, pay attention to such burrs in the case of preforming repair of this system.

1.4 Critical parts for safety

In regard with component parts appearing on the silk-screen

printed side (parts side) of the PWB diagrams, the parts that are

printed over with black such as the resistor ( ), diode ( )

and ICP ( ) or identified by the " " mark nearby are critical

for safety. When replacing them, be sure to use the parts of the

same type and rating as specified by the manufacturer.

(This regulation dose not Except the J and C version)

each exposed

metal part.

1-6 (No.MA493<Rev.002>)

Page 7

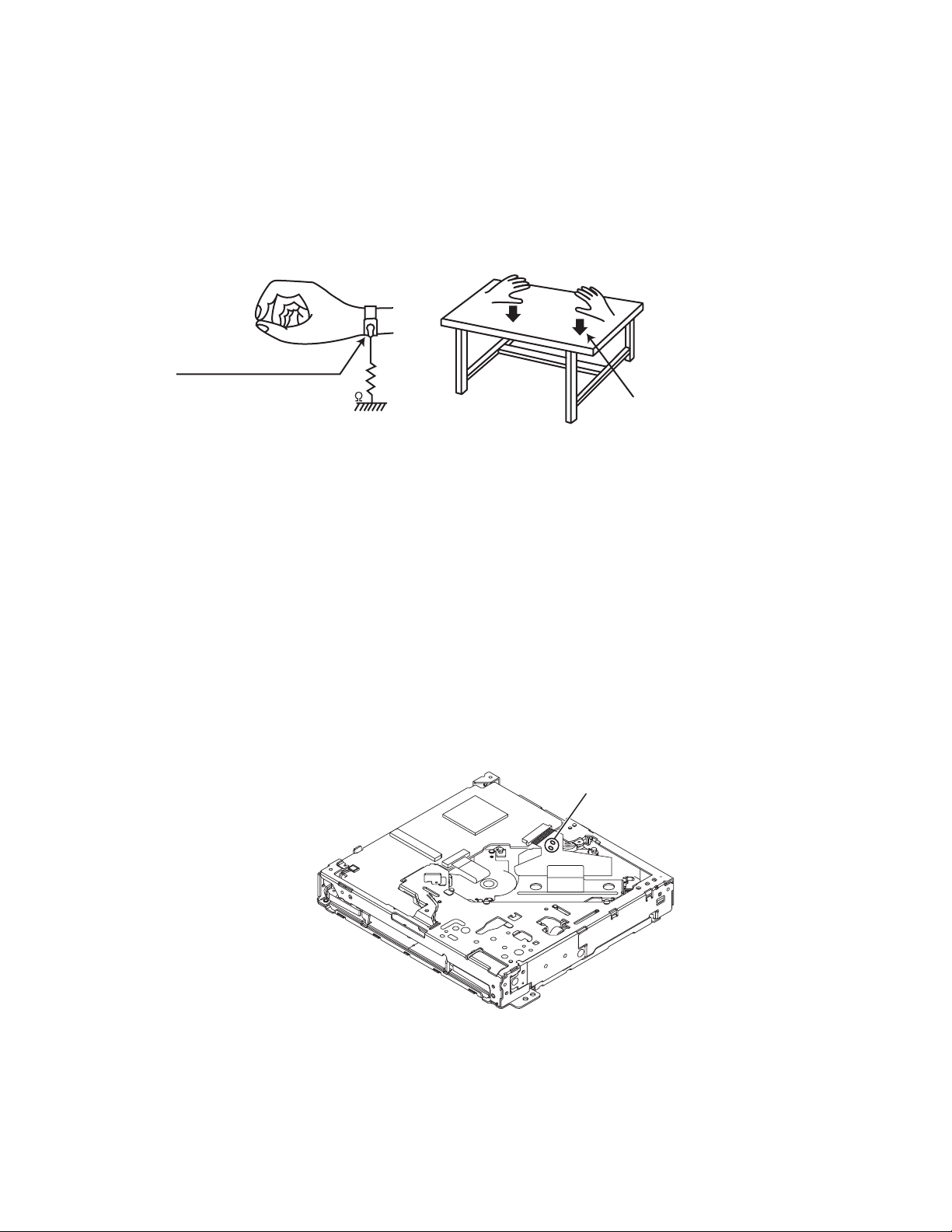

1.5 Preventing static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged, can destroy the laser

diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

1.5.1 Grounding to prevent damage by static electricity

Static electricity in the work area can destroy the optical pickup (laser diode) in devices such as laser products.

Be careful to use proper grounding in the area where repairs are being performed.

(1) Ground the workbench

Ground the workbench by laying conductive material (such as a conductive sheet) or an iron plate over it before placing the

traverse unit (optical pickup) on it.

(2) Ground yourself

Use an anti-static wrist strap to release any static electricity built up in your body.

(caption)

Anti-static wrist strap

1M

Conductive material

(conductive sheet) or iron plate

(3) Handling the optical pickup

• In order to maintain quality during transport and before installation, both sides of the laser diode on the replacement optical

pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

• Do not use a tester to check the condition of the laser diode in the optical pickup. The tester's internal power source can easily

destroy the laser diode.

1.6 Handling the traverse unit (optical pickup)

(1) Do not subject the traverse unit (optical pickup) to strong shocks, as it is a sensitive, complex unit.

(2) Cut off the shorted part of the flexible cable using nippers, etc. after replacing the optical pickup. For specific details, refer to the

replacement procedure in the text. Remove the anti-static pin when replacing the traverse unit. Be careful not to take too long a

time when attaching it to the connector.

(3) Handle the flexible cable carefully as it may break when subjected to strong force.

(4) It is not possible to adjust the semi-fixed resistor that adjusts the laser power. Do not turn it.

1.7 Attention when traverse unit is decomposed

*Please refer to "Disassembly method" in the text for the pickup unit.

• Apply solder to the short land before the card wire is disconnected from the connector on the pickup unit.

(If the card wire is disconnected without applying solder, the pickup may be destroyed by static electricity.)

• In the assembly, be sure to remove solder from the short land after connecting the card wire.

Solder short part

(No.MA493<Rev.002>)1-7

Page 8

1.8 Important for laser products

1.CLASS 1 LASER PRODUCT

2.CAUTION :

(For U.S.A.) Visible and/or invisible class II laser radiation

when open. Do not stare into beam.

(Others) Visible and/or invisible class 1M laser radiation

when open. Do not view directly with optical instruments.

3.CAUTION : Visible and/or invisible laser radiation when

open and inter lock failed or defeated. Avoid direct

exposure to beam.

4.CAUTION : This laser product uses visible and/or invisible

laser radiation and is equipped with safety switches which

prevent emission of radiation when the drawer is open and

the safety interlocks have failed or are defeated. It is

dangerous to defeat the safety switches.

5.CAUTION : If safety switches malfunction, the laser is able

to function.

6.CAUTION : Use of controls, adjustments or performance of

procedures other than those specified here in may result in

hazardous radiation exposure.

!

Please use enough caution not to

see the beam directly or touch it

in case of an adjustment or operation

check.

REPRODUCTION AND POSITION OF LABELS and PRINT

WARNING LABEL and PRINT

1-8 (No.MA493<Rev.002>)

Page 9

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

This service manual does not describe SPECIFIC SERVICE INSTRUCTIONS.

SECTION 3

DISASSEMBLY

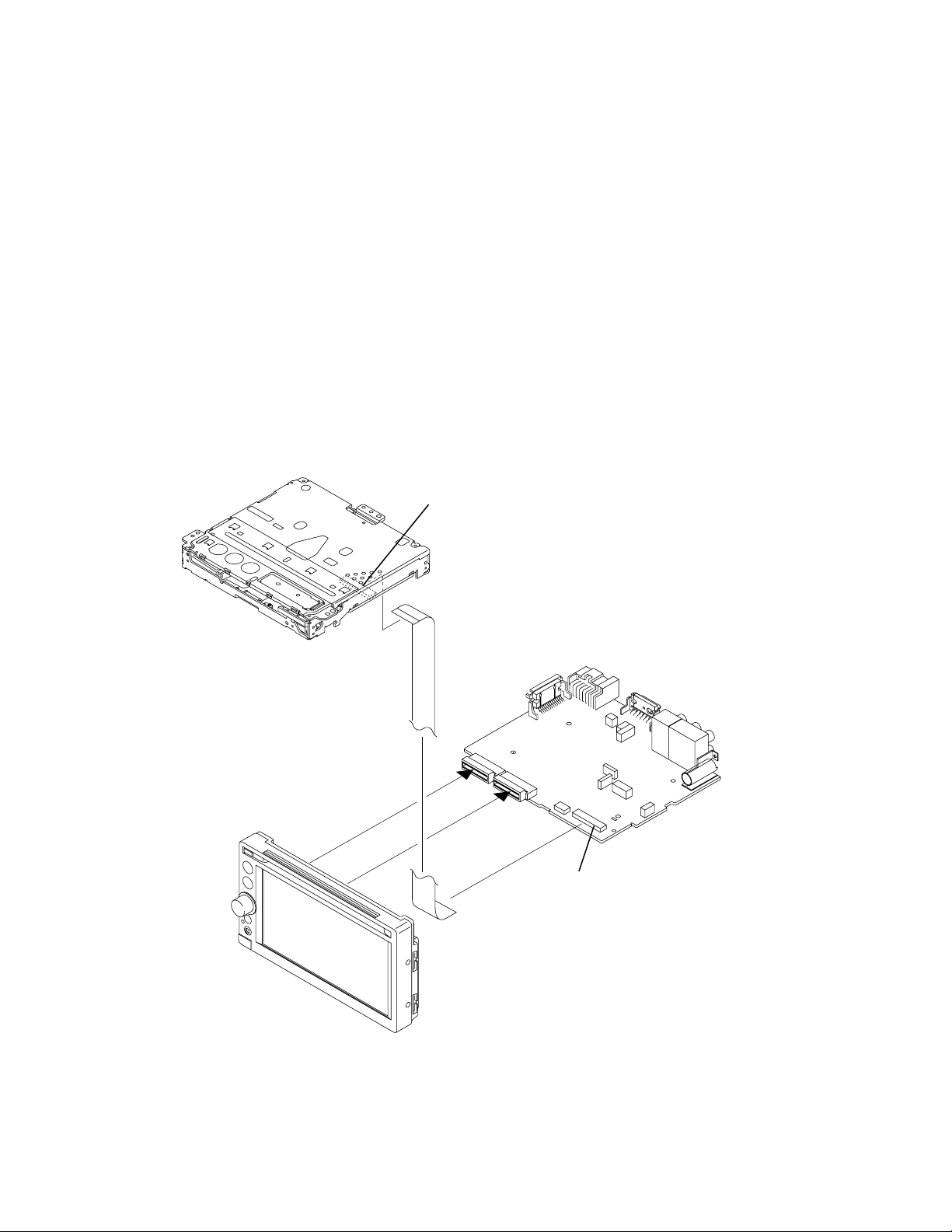

3.1 Main body (Used model: KD-AVX740)

3.1.1 Removing the Front chassis (See Fig.1 and 2)

(1) Remove the three screws A. (See Fig.1)

(2) Disengage two hooks a engaged the Front chassis. (See

Fig.1)

a

A

Fig.1

(3) Remove the four screws B attaching the both side of the

Front chassis. (See Fig.2)

(4) Disengage two hooks b engaged both side of the Front

chassis. (See Fig.2)

3.1.2 Removing the Heat sink (See Fig.3)

(1) Remove the three screws C and two screws D attaching

the Heat sink.

C

D

Fig.3

3.1.3 Removing the Rear heat sink (See Fig 4)

(1) Remove the two screws E and two screws F attaching the

Rear heat sink

EF

Fig.2

b

B

Fig.4

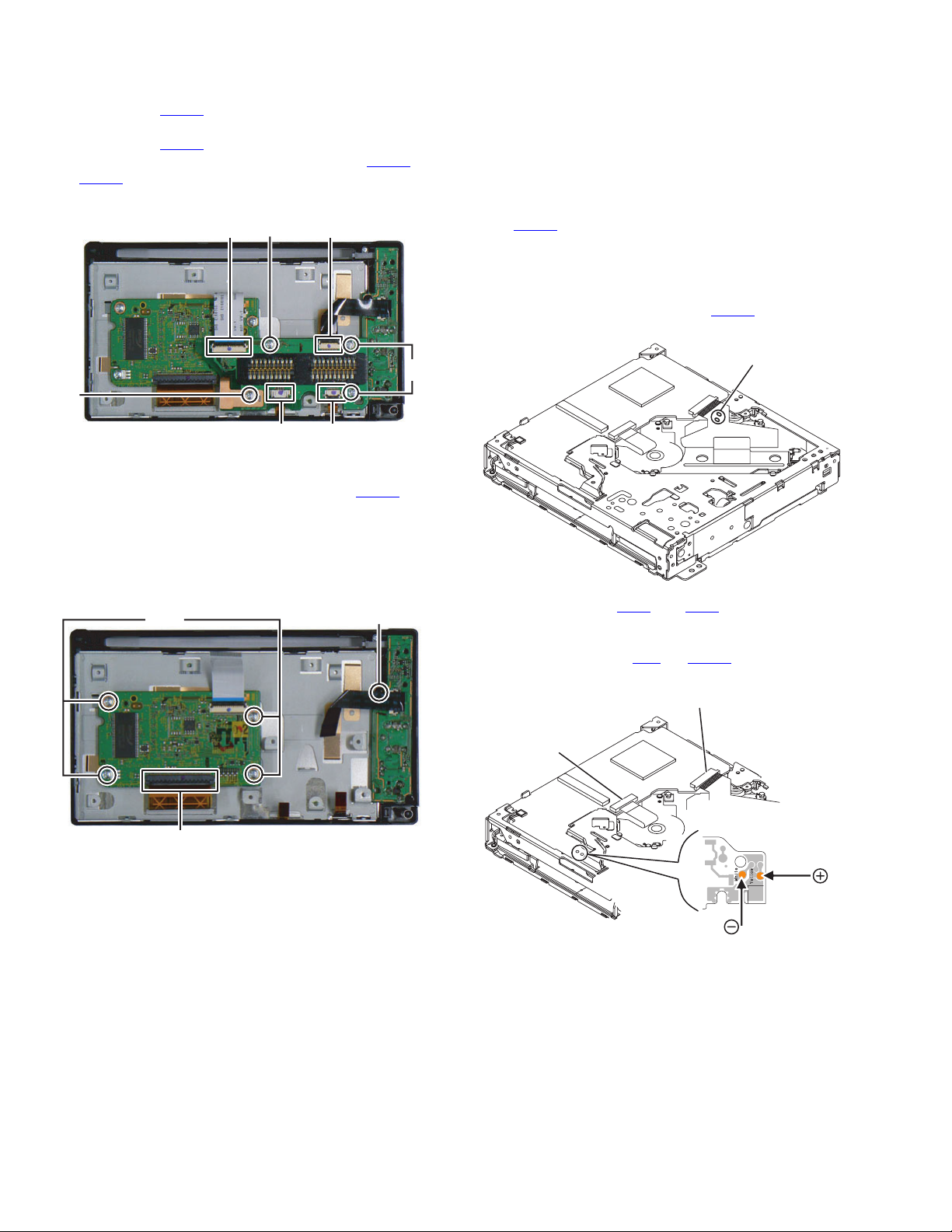

3.1.4 Removing the DVD mechanism (See Fig.5, 6, 7, 8, 9)

(1) Disconnect the card wire from DVD mechanism connected

to connector CN105

of the Main board. (See Fig.5)

CN105

Fig.5

(No.MA493<Rev.002>)1-9

Page 10

(2) Remove the two screws G attaching the Top chassis. (See

Fig.6)

G

(5) Remove the three screws K attaching the DVD mecha-

nism. (See Fig.9)

K

K

Fig.6

(3) Remove the one screw H attaching the Top chassis. (See

Fig.7)

H

Fig.7

(4) Remove the four screws J attaching the Top chassis. (See

Fig.8)

J

Fig.9

3.1.5 Removing the BT amp board (See Fig.10)

(1) Disconnect the card wire from Main board connected to

connector CN311

(2) Disconnect connector wire from Sub amp board connected

to connector CN341

(3) Remove the four screws L attaching the BT amp board.

CN311

3.1.6 Removing the Sub amp board (See Fig.11, 12)

(1) Remove the one screw M attaching the Sub amp board.

(See Fig.11)

of the BT amp board.

of the BT amp board.

CN341

Fig.10

L

1-10 (No.MA493<Rev.002>)

Fig.8

M

Fig.11

Page 11

(2) Disconnect the card wire from Main board connected to

connectors CN201

Fig.12)

(3) Disconnect the Car cable connected to connector CN104

of the Main board. (See Fig.12)

(4) Disconnect the Car cable connected to connector CN241

of the Sub amp board. (See Fig.12)

(5) Remove the three screws N attaching the Sub amp board.

(Se Fig.12)

CN104

CN201

CN202

and CN202 of the Sub amp board. (See

3.1.8 Removing the Center chassis (See Fig.15)

(1) Remove the four screws R attaching the Center chassis.

R

R

N

CN241

Fig.12

3.1.7 Removing the Rear panel (See Fig.13, 14)

(1) Disconnect the connector wire from Car cable connected to

connector CN101 of the Main board. (See Fig.13)

(2) Disconnect the connector wire from FAN connected to con-

nector CN112 of the Main board. (See Fig.13)

N

Fig.15

3.1.9 Removing the Main board (See Fig.16)

(1) Remove the four screws S attaching the Main board.

S

Fig.16

3.1.10 Removing the Rear cover (See Fig.17)

(1) Remove the four screws T and four screws U attaching the

Rear cover.

(2) Disengage the four hooks c engaging the Rear cover.

S

CN101

(3) Remove the six screws P and two screws Q attaching the

Rear panel. (Se Fig.14)

CN112

Fig.13

P

P

Q

Fig.14

c

c

T

T

U

Fig.17

(No.MA493<Rev.002>)1-11

Page 12

3.1.11 Removing the Panel-B board (See Fig.18)

V

(1) Disconnect the card wires from Panel-A board connected

to connector CN603

of the Panel-B board.

(2) Disconnect the card wires from Panel-B board connected

to connector CN604

of the Panel-B board.

(3) Disconnect the FPC connected to connectors CN604

of the Panel-B board.

CN605

(4) Remove the four screws V attaching the Panel-B board.

V

CN604CN603

V

and

3.2 DVD mechanism assembly section

3.2.1 Removing the Traverse mechanism assembly (See

Fig.1 to 6)

(1) Solder the short land section on the flexible wire of pickup.

(See Fig.1)

Caution:

* Solder the short land section on the flexible wire of pickup

before disconnecting the flexible wire form the connector

on the Front end board.

CN101

If the flexible wire is disconnected without attaching the

solder, the pickup may be destroyed by static electricity.

* When attaching the Traverse mechanism assembly, remove the solder from the short land section after connection

the flexible wire to the connector CN101

on the Front end

board.

Solder short part

CN606

CN605

Fig.18

3.1.12 Removing the Panel-A board (See Fig.19)

(1) Disconnect the FPC connected to connector CN501

Panel-A board.

(2) Remove the four screws W attaching the Panel-A board.

3.1.13 Removing the SW board (See Fig.19)

(1) Remove the volume knob

(2) Remove the one screw X attaching the SW board.

W

X

CN501

Fig.19

of the

Fig.1

(2) Voltage supply to TP79

and TP81 approx DC 3.0V until

Clamper is shift to loading complete position. (See Fig.2)

(3) Disconnect the flexible wires from Traverse mechanism assembly

connected to connector CN1

and CN101 of the Front end board.

(See Fig.2)

CN101

CN1

TP79 TP81

TP79

R317

TP67

R312

R21

R357

TP81

TP92

CENTER

D-

DGND_7

WOOFER

Voltage supply

position

Fig.2

1-12 (No.MA493<Rev.002>)

Page 13

(4)

Remove the five screws A attaching the Top cover assembly. (See Fig.

3)

A

Fig.3

(5) From the bottom side, disconnect the connector wire from

Top cover assembly connected to connector CN2

Front end board. (See Fig.4)

CN2

of the

3.2.2 Removing the Front end board (See Fig.7)

(1) Remove the Motor wires from loading motor soldered to

and TP81 of the Front end board.

TP79

(2) Remove the two screws B attaching the Front end board.

TP81

TP79

B

B

Fig.7

3.2.3 Removing the Loading arm assembly (See Fig.8)

(1) Remove the Loading arm spring L from Loading arm assembly.

(2) Slide to left side and then disengage hook a then hook b.

hook b

Loading arm

assembly

hook

a

Fig.4

(6) From the bottom side, remove the spring from Traverse

mechanism assembly. (See Fig.5)

Fig.5

(7) From the top side, pull up the traverse mechanism and disengage

three dumper positions. (See Fig.6)

Loading arm spring L

Fig.8

3.2.4 Removing the Gear base assembly (See Fig.9, 10)

(1) Remove the Loading arm spring L. (See Fig.9)

Loading arm

spring L

(Different color sprin

Fig.6

Dumper

Fig.9

(No.MA493<Rev.002>)1-13

Page 14

(2) Remove the two screws C attaching the Gear base assembly.

r

(See Fig.10)

C

Fig.10

3.2.5 Removing the Loading arm holder. (See Fig.11)

(1) Remove the two screws D attaching the Loading arm holder.

(2) Remove the Loading arm spring R.

D

Loading arm

holder

3.2.7 Removing the Slide cam assembly (See Fig.13)

(1) Slide to backward the Slide cam assembly and the remove

the Slide cam spring.

(2) Slide to frontward the slide cam assembly, and then take

out it.

Slide cam assembly

Slide cam spring

Fig.13

3.2.8 Removing the Photo board (See Fig.14)

(1) Pressing the hook c and then slide to backward (slide to the

arrow side) the Disc plate.

(2) Remove the one screw F attaching the Photo board.

hook

c

hook

c

Loading arm

spring R

Fig.11

3.2.6 Removing the Loading moor assembly (See Fig.12)

(1) Remove the three screws E attaching the Loading motor

assembly.

E

Photo board

F

Fig.14

3.2.9 Removing the Loading motor (See Fig.15 to 18)

(1) Remove the A wheel gear. (See Fig.15)

A Wheel gea

Fig.15

1-14 (No.MA493<Rev.002>)

Fig.12

Page 15

(2) Remove the A worm gear, M connect gear and M wheel

t

gear by sequentially. (See Fig.16)

A worm gear

M connect gear

M wheel gear

3.2.10 Removing the Roller assembly (See Fig.19)

(1) Remove the Slit washer.

(2) Remove the R middle gear.

(3) Remove the R connect gear.

(4) Snap off the part a of the Roller assembly.

Lift up the part b of the Roller assembly, and then release part

(5)

(When release part c, R collar R is easy to come off, does not lose it).

CAUTION:

When reattach the Roller assembly, Middle gear should keep

direction and Slit washer should be change new part.

R middle gear

Direction

R collar

c

Fig.16

(3) Remove the two screws G attaching the Loading motor.

(Se Fig.17)

G

Fig.17

(4) When attaching the Loading motor, motor wire should arrange

to figure. (See Fig.18)

Wire arrangement

Fig.18

R connect gear

Slit washer

part c

part a

part b

Fig.19

3.2.11 Removing the Roller (See Fig.20)

(1) Remove the Slit washer.

(2) Pull out the Roller shaft.

CAUTION:

When reattach the Roller shaft, Slit washer should be change new part.

slit

keep direction

keep direction

sli

small side

Fig.20

(No.MA493<Rev.002>)1-15

Page 16

SECTION 4

ADJUSTMENT

4.1 Service mode

4.2 Test instruments required for adjustment

(1) Digital oscilloscope (100MHz)

(2) Digital tester

(3) Test Disc

(4) Extension cable :EXTXD001-50PF (CN403 --- CN105)

4.5 Dummy load

Exclusive dummy load should be used for AM and FM.

For FM dummy load, there is a loss of 6dB between SSG output and antenna input.

The loss of 6dB need not be considered since direct reading of figures are applied in this working standard.

4.6 How to connect the extension cable for adjusting

Caution:

Be sure to attach the heat sink and rear bracket onto the power amplifier IC and regulator IC respectively, before supply the power.

If voltage is applied without attaching these parts, the power amplifier IC and regulator IC will be destroyed by heat.

4.3 Standard measuring conditions

Power supply voltage DC14.4V(10.5 to 16V)

Load impedance 20K ohm (2 Speakers connection)

Output Level Line out 2.5V (Vol. MAX)

4.4 Standard volume position

Balance and Bass &Treble volume : lndication"0"

Loudness : OFF

CN403

EXTXD001-50PF

CN105

1-16 (No.MA493<Rev.002>)

Page 17

4.7 Service mode

4.7.1 Set to Service Mode.

MENU

Area A Area B

TOUCH PANEL

(Multiplex push timing chart.)

[MENU] Key ON (HOLD)

[Area A] Key ON

[Area B] Key ON

Shift to Service Mode

4.7.2 Service mode menu

SYS Vxxxx TUN:x TEMPERATURE SYS V: System micon version.

APP Axxxx MON:x DVD CHECK MODE APP A: Apprication software version

DATA Vxxxx TOU:x RUNNING MODE DATA V: Imae data version

DISC Vxxxx ERROR DIAG/DATA DISC V: DVD module version

Macrovision xxxx Macrovision: Macrovision version

DivX xxxx DivX: DivX version

BT Vxxx RDS TEST MODE BT V: Bluetooth firmware version

Span x BT MIC TEST Span x: No use

SYS-Area: x BT DONGLE CHECK SYS-Area: System area and Model name

DISC-Area: xx reg: x FIRM UPDATE MODE DISC-Area: Disc area reg: Region

S,No xxxxxxxx TUN: S meter level offset adjust Y=Adjust OK N=Not adjust

INITIALIZE ALL

BACK EXIT

MON: Monitor Adjust Y= Adjust OK N=Not adjust

TOU: Touch panel adjust Y= Adjust OK N=Not adjust

INITIALIZE ALL

Initialized content.

Backup memory. Installer memory. User memory. Tuner area setting.

Error history. Diag data. EEPROM in the DVD module.

EEPROM in the bluetooth module.

TEMPERATURE

Temperature display of DVD module.

DVD CHECK MODE

.

See "DVD CHECK MODE” for details.

RUNNING MODE (No use)

ERROR DIAG/DATA (Error history display)

DVD ERROR: Error history of DVD module.

DVD ERROR TOTAL xxxx

E1:xxxxxx E2:xxxxxx E3:xxxxxx

xxxxxx xxxxxx xxxxxx xxxxxx xxxxxx

DVD ERROR CLR

MECHA ERROR CLR

MECHA ERROR: Error history of

door mechanism.

(Except KW-AVX64x series)

Power detected: Frequency in which

MECHA ERROR TOTAL xxxx

E1:xxxxxx E2:xxxxxx E3:xxxxxx

xxxxxx xxxxxx xxxxxx xxxxxx xxxxxx

DC ERROR CLR

power supply is turned on.

DISC EJECT: Eject frequency.

Power supply CLR key (No display)

DC1 OK DC2 0

Power detected (xxxxxx)

DISC EJECT xxxtimes

BACK EXIT

RDS TEST MODE (No use)

BT MIC TEST (Except KW-AVX64x series)

BT MICROPHONE TEST

IN PROGRESS

BACK EXIT

The voice from microphone is output to the speaker.

If the "BACK" button or "EXIT" button is pudhed, the test is ended.

The come off the mode, power supply off is done.

BT DONGLE CHECK (No use)

FIRM UPDATE MODE

When the firmware updated, it uses it.

(No.MA493<Rev.002>)1-17

Page 18

DVD CHECK MODE

xxxxxxxx DVDx1 JITTER MODE

xxxx xxxx SEARCH & JITTER

MONITOR

DVDx1 PLAY

NORMAL PLAY STOP

EF OUT-TRACKING OFF EJECT

EF IN-TRACKING OFF LOAD

CD-LASER ON SLEEP

DVD-LASER ON EEPROM DATA OSD

Command Mechanism unit operation Indication contents

NORMAL PLAY Start at normal speed

Laser current value, jitter value

(After start, jitter is measured by an inner position.)

EF OUT-TRACKING OFF Tracking off the outermost position of CD For EF phase error

EF IN-TRACKING OFF Tracking off the innermost position of CD For EF phase error

CD-LASER ON CD_LD lights and laser current is displayed. Laser current value, jitter value

DVD-LASER ON DVD_LD lights and laser currrent is displayed Laser current value, jitter value

DVDx1 JITTER MODE DVD x1 jitter measuring mode

Laser current value, jitter value

(for use in mechanism adjustment)

SEARCH & JITTER The search and jitter measurement to an appointed

position of DVD.

Position measured with VT-501

jitter value

MONITOR Monitor terminal setting

DVDx1 PLAY DVD x1 stopped start

Not displayed.

(After start, jitter is measured by an inner position.)

STOP Disc stopped, LD-OFF Not displayed.

EJECT EJECT Not displayed.

LOAD LOADING Not displayed.

SLEEP SLEEP Not displayed.

EEPROM DATA OSD EEPROM DATA (Only Engineer use)

1-18 (No.MA493<Rev.002>)

Page 19

5.1

16PIN CORD DIAGRAM

5.1.1 Except Europe

SECTION 5

TROUBLESHOOTING

1

16

2

9

10

12

11

8

7

6

5

3

2

1

BK

YL

RD

GN

GN / BK

VI

VI / BK

WH

WH/BK

GY/BK

BL

BL/WH

RD

BK

GN

GN/BK

VI/BK

VIGY

LB/YL

BR

OR/WH

YL

10

11

12

134

14

15

16

9

GN

VI

LB

YL

BR

OR

Green

Violet

Light Blue

Yellow

Brown

Orange

White

WH

BK

Black

GY

Gray

BL Blue

Red

RD

15

13

4

3

14

8

7

5

6

OR / WH

LB / YL

BL

BL / WH

BR

WH

WH / BK

GY

GY / BK

(No.MA493<Rev.002>)1-19

Page 20

5.1.2 For Europe

8

7

6

5

4

3

WH

WH/BK

GY/BK

GY

NC

BL/WH

GN

GN/BK

VI/BK

VI

LB/YL

BR

10

11

12

13

14

White

WH

Black

BK

GY

BL

RD

Gray

Blue

Red

9

GN

VI

LB

YL

BR

OR

Green

Violet

Light Blue

Yellow

Brown

Orange

2

16

1

14

15

3

9

10

12

11

8

7

5

6

13

2

1

RD 1

YL 1

BK

BR

OR / WH

BL / WH

GN

GN / BK

VI

VI / BK

WH

WH / BK

GY

GY / BK

LB / YL

RD1

BK

OR/WH

YL1

15

16

1

VI

3

GY

5

WH

7

GN

2

4

6

8

VI/BK

GY/BK

WH/BK

GN/BK

RD 3

9

NC

10

11

13

BL/WH

RD2

15 16

NC

12

14

BR

YL2

OR/WH

BK

RD 2

15

YL 2

12

16

10

14

13

7

8

1

2

5

6

3

4

1-20 (No.MA493<Rev.002>)

Page 21

(No.MA493<Rev.002>)1-21

Page 22

Victor Company of Japan, Limited

Mobile Entertainment Division 2967-3, Ishikawa-machi, Hachioji-shi, Tokyo, 192-8525, Japan

(No.MA493<Rev.002>)

Printed in Japan

VSE

Loading...

Loading...