Page 1

SERVICE MANUAL

CASSETTE RECEIVER

MA18220054

KS-FX384

KS-FX384

Area suffix

UI ---------------------------- India

TABLE OF CONTENTS

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2 SPECIFIC SERVICE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

COPYRIGHT © 2005 Victor Company of Japan, Limited

No.MA182

2005/4

Page 2

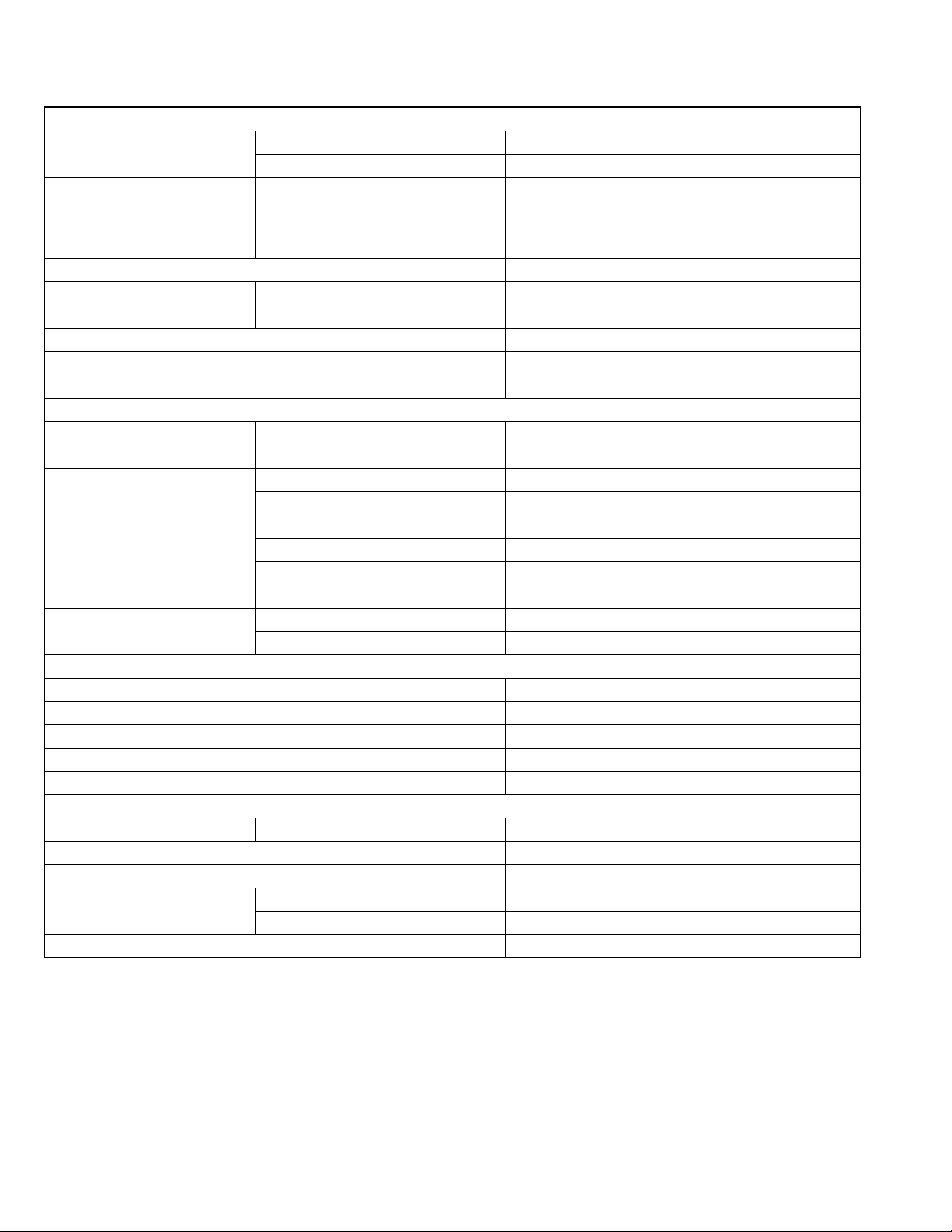

SPECIFICATION

AUDIO AMPLIFIER SECTION

Maximum Power Output Front 45 W per channel

Rear 45 W per channel

Continuous Power Output (RMS) Front 17 W per channel into 4 Ω, 40 Hz to 20 000 Hz at no more

than 0.8% total harmonic distortion.

Rear 17 W per channel into 4 Ω, 40 Hz to 20 000 Hz at no more

than 0.8% total harmonic distortion.

Load Impedance 4 Ω (4 Ω to 8 Ω allowance)

Tone Control Range Bass ±10 dB at 100 Hz

Treble ±10 dB at 10 kHz

Frequency Response 40 Hz to 20 000 Hz

Signal-to-Noise Ratio 70 dB

Line-Out Level/Impedance 2.0 V/20 kΩ load (250 nWb/m)

TUNER SECTION

Frequency Range FM 87.5 MHz to 108.0 MHz

AM 531 kHz to 1 602 kHz

FM Tuner Usable Sensitivity 11.3 dBf (1.0 µV/75 Ω)

50 dB Quieting Sensitivity 16.3 dBf (1.8 µV/75 Ω)

Alternate Channel Selectivity (400 kHz) 65 dB

Frequency Response 40 Hz to 15 000 Hz

Stereo Separation 35 dB

Capture Ratio 2.0 dB

AM Tuner Sensitivity 20 µV

Selectivity 35 dB

CASSETTE DECK SECTION

Wow & Flutter 0.15% (WRMS)

Fast-Wind Time 190 sec. (C-60)

Frequency Response 50 Hz to 14 000 Hz (Normal tape)

Signal-to-Noise Ratio 52 dB

Stereo Separation 40 dB

GENERAL

Power Requirement Operating Voltage DC 14.4 V (11 V to 16 V allowance)

Grounding System Negative ground

Allowable Operating Temperature 0°C to +40°C

Dimensions (W × H × D) Installation Size (approx.) 182 mm × 52 mm × 150 mm

Panel Size (approx.) 188 mm × 58 mm × 11 mm

Mass (approx.) 1.3 kg (excluding accessories)

Design and specifications are subject to change without notice.

1-2 (No.MA182)

Page 3

1.1 Safety Precautions

SECTION 1

PRECAUTION

!

Burrs formed during molding may be left over on some parts of the chassis. Therefore,

pay attention to such burrs in the case of preforming repair of this system.

(No.MA182)1-3

Page 4

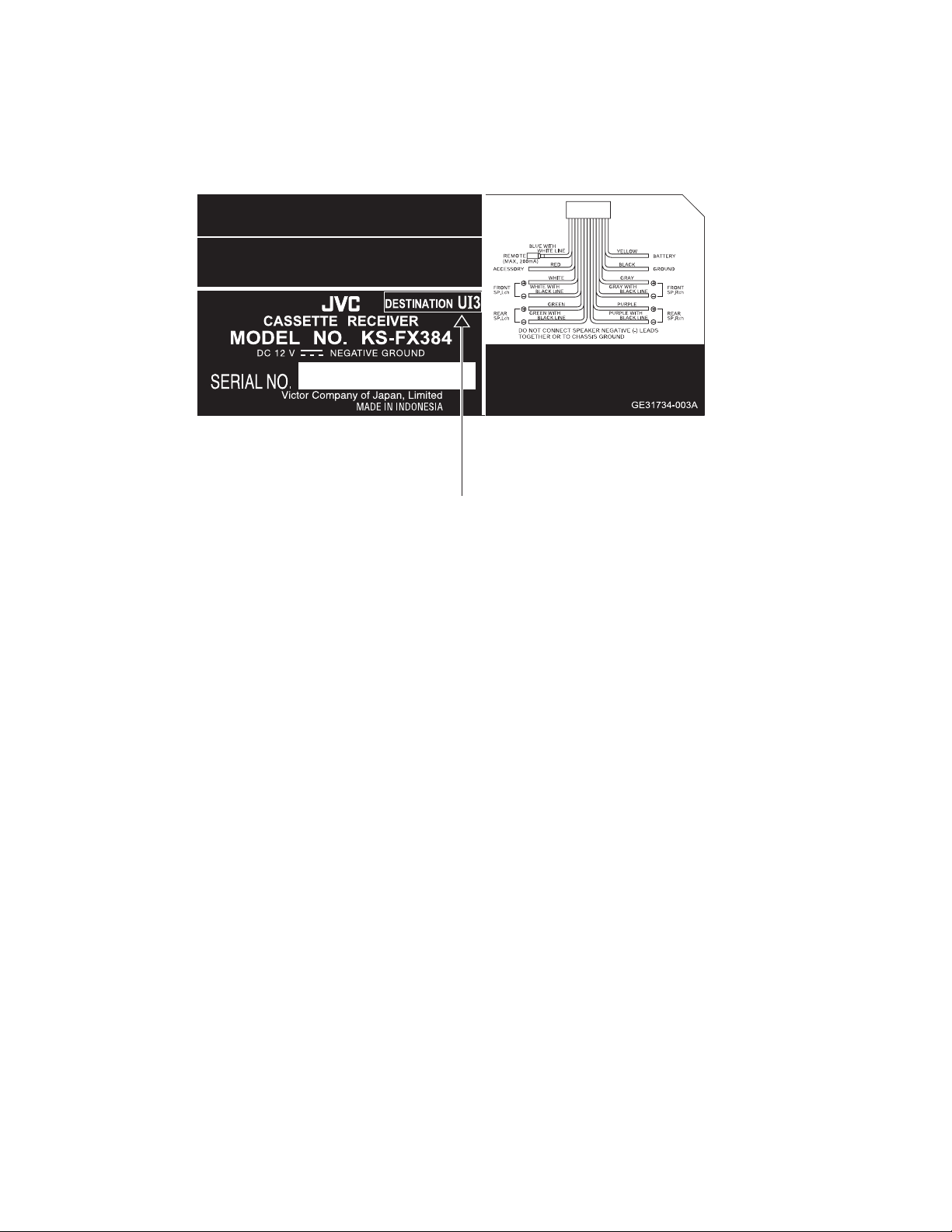

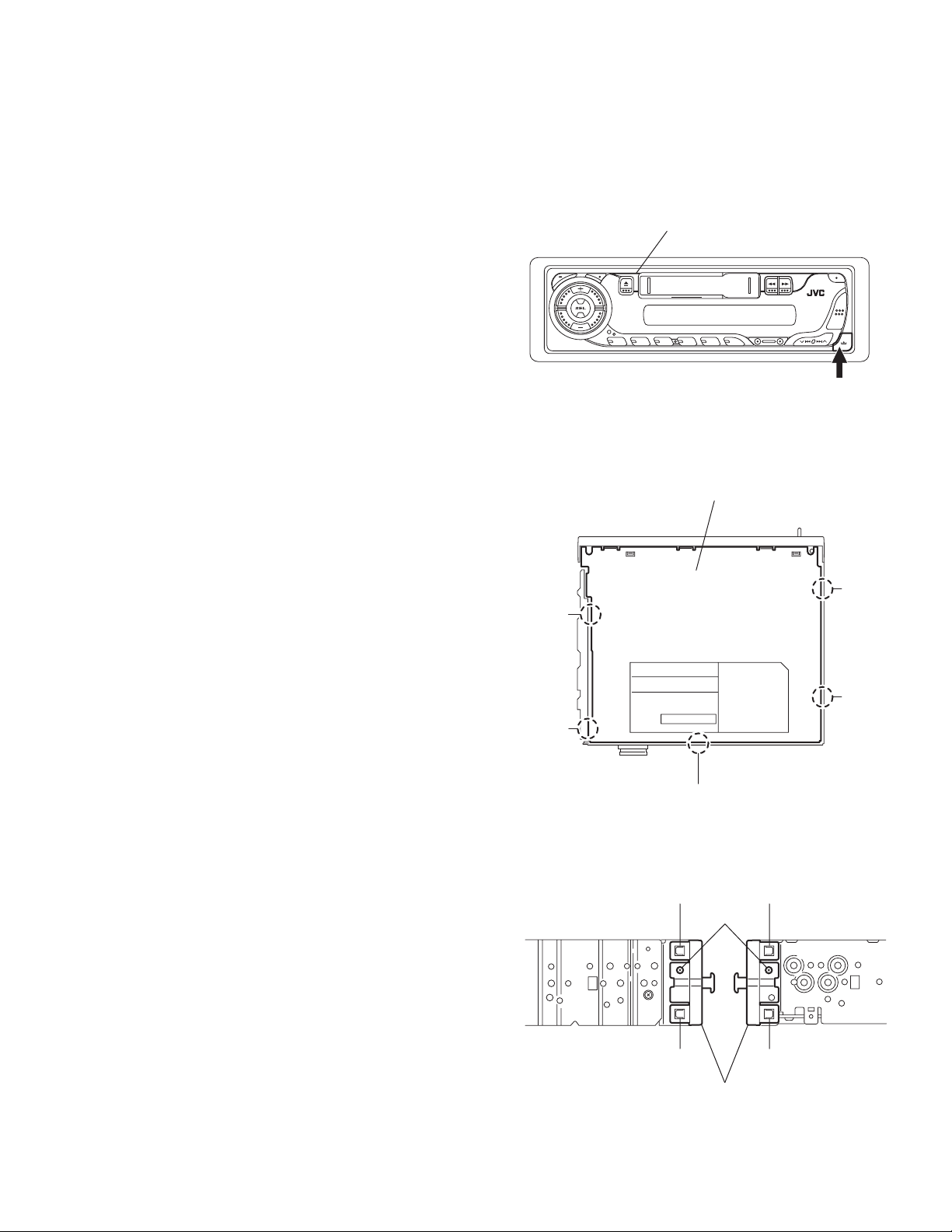

2.1 HOW TO IDENTIFY MODELS

2.1.1 NAME PLATE

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

Discernment sign

1-4 (No.MA182)

Page 5

SECTION 3

DISASSEMBLY

3.1 Main body

3.1.1 Removing the front panel assembly

(See Fig.1)

(1) Push the detach button and remove the front panel assem-

bly.

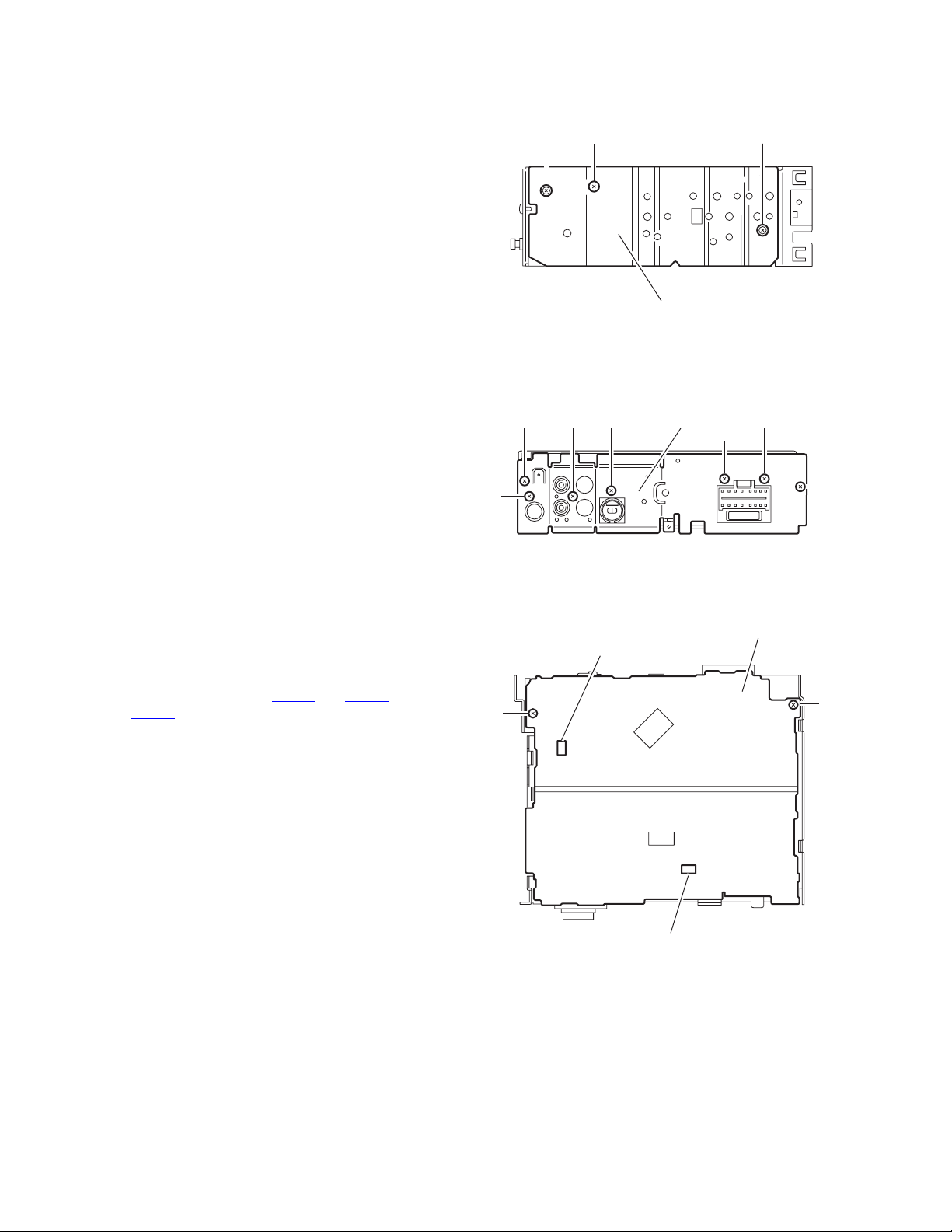

3.1.2 Removing the bottom cover

(See Fig.2)

• Prior to performing the following procedures, remove the front

panel assembly.

(1) Turn the body upside down.

(2) Insert a screwdriver under the joints to release the two

joints a on the left side, the two joints b on the right side and

the joint c on the back of the body, then remove the bottom

cover from the body.

CAUTION:

When releasing the joints using a screwdriver, do not damage

the board.

Joint a

Front panel assembly

Fig.1

Bottom cover

Detach button

Joint

b

3.1.3 Removing the front chassis assembly

(See Fig.3)

• Prior to performing the following procedures, remove the front

panel assembly and bottom cover.

(1) Remove the two screws A on each side of the body.

(2) Release the two joints d and the two joints e on the sides,

then remove the front chassis assembly toward the front.

Joint a

Joint c

Fig.2

Joint d Joint e

A

Joint d

Front chassis assembly

Fig.3

Joint e

Joint b

(No.MA182)1-5

Page 6

3.1.4 Removing the heat sink

(See Fig.4)

• Prior to performing the following procedure, remove the front

panel assembly.

(1) Remove the screw B and two screws C attaching the heat

sink on the left side of the body, and remove the heat sink.

3.1.5 Removing the rear panel

(See Fig.5)

• Prior to performing the following procedure, remove the front

panel assembly and bottom cover.

(1) Remove the two screws D, two screws E and three screws

F attaching the rear panel on the back of the body.

D

C

B

Heat sink

Fig.4

F

Rear panel

EF

C

3.1.6 Removing the main board

(See Fig.6)

• Prior to performing the following procedures, remove the front

panel assembly, bottom cover, front chassis assembly, heat

sink and rear panel.

(1) Remove the two screws G attaching the main board on the

top chassis.

(2) Disconnect the two connectors CN901

sion) or CN902 (UI3 version) on the main board from the

cassette mechanism assembly.

and CN721 (UI ver-

E

CN721(For UI version)

CN902(For UI3 version)

G

D

Fig.5

Main board

G

CN901

1-6 (No.MA182)

Fig.6

Page 7

3.1.7 Removing the cassette mechanism assembly

(See Fig.7)

• Prior to performing the following procedure, remove the front

panel assembly, bottom cover, front chassis assembly, heat

sink, rear panel and main board.

(1) Remove the four screws H attaching the cassette mecha-

nism assembly from the top chassis.

H

Cassette mechanism assembly

H

3.1.8 Removing the head amplifier board

(See Fig.8)

• Prior to performing the following procedures, remove the front

panel assembly, bottom cover, front chassis assembly, heat

sink, rear panel, main board and cassette mechanism assembly.

(1) Disconnect the wire from CJ901

board.

(2) Remove the one screw J attaching the head amplifier

board.

(3) Move the head amplifier board in the direction of the arrow

to release the two joints f, the head amplifier board can be

removed.

3.1.9 Removing the relay board

(See Fig.9)

• Prior to performing the following procedures, remove the front

panel assembly, bottom cover, front chassis assembly, heat

sink, rear panel, main board and cassette mechanism assembly.

(1) Disconnect the wire from CP722

(2) Remove the one screw K attaching the relay board.

(3) Move the relay board in the direction of the arrow to release

the joint g, the relay board can be removed.

on the head amplifier

on the relay board.

H

CJ901

Joint f

To head relay board

Top chassis

Fig.7

Head amplifier board

Joint f

J

Fig.8

Relay board

H

CP722

Joint g

Fig.9

K

(No.MA182)1-7

Page 8

3.1.10 Removing the mecha bracket

(See Fig.10)

• Prior to performing the following procedure, remove the front

panel assembly, bottom cover, front chassis assembly, heat

sink, rear panel, main board, cassette mechanism assembly,

head amplifier board and relay board.

(1) Remove the four screws L attaching the mecha bracket.

Mecha bracket

3.1.11 Removing the switch (LCD & key) board

(See Fig.11 to 13)

• Prior to performing the following procedures, remove the front

panel assembly.

(1) Remove the four screws M attaching the rear cover on the

back of the front panel assembly. (See Fig.11)

(2) Release the nine joints h, the front panel and the rear cover

become separate. (See Fig.12)

(3) Remove the switch board from the rear cover. (See Fig.13)

CAUTION:

Take care not to lose the springs.

L

L

Fig.10

M Front panel assembly

M

M M

L

L

Joint h

Fig.11

Joint h

Joint h

Fig.12

Switch (LCD & Key) board

Fig.13

1-8 (No.MA182)

Page 9

3.2 Cassette mechanism assembly

• Prior to performing the following procedures, remove the head

amplifier board, the relay board and the mechanism bracket.

3.2.1 Removing the direction switch board

(See Fig.1)

(1) Unsolder the three wires a on the direction switch board.

(2) Remove the one screw A attaching the direction switch

board.

3.2.2 Removing the FF / REW lever assembly

(See Fig.1)

(1) Remove the screw B attaching the FF / REW lever assem-

bly on the back of the cassette mechanism assembly.

(2) Remove the screw C on the upper side of the FF / REW

lever assembly.

(3) Lift and pull forward the FF / REW lever assembly to disen-

gage the joints b, c, d and e.

3.2.3 Reattaching the FF / REW lever assembly

(See Fig.1)

(1) Reattach the FF / REW lever assembly to the joint c on the

back of the chassis.

(2) Reattach the pinch-roller shaft e, the change lever d and

the return link e to the chassis.

C

FF / REW lever assembly

Joint c

3.2.4 Removing the playback head

(See Fig.2)

• Prior to performing the following procedure, remove the direc-

tion switch board and the FF / REW lever assembly.

(1) Remove the screw D attaching the playback head.

(2) Remove the C washer and pull out the FF roller.

(3) Remove the S support plate, the A arm spring (a) and (b),

the playback head.

ATTENTION:

The A arm spring (a) differs from the A arm spring (b).

3.2.5 Removing the pinch-roller (R) and (F) assembly

(See Fig.2)

• Prior to performing the following procedure, remove the direc-

tion switch board and the FF / REW lever assembly.

(1) Remove the P arm spring (f) in the pinch-roller (F) assem-

bly from the chassis.

(2) Remove the P arm spring (r) in the pinch-roller (R) assem-

bly from the chassis.

(3) Draw out the pinch roller (F) and (R) assembly from the

shaft.

ATTENTION:

The P arm spring (f) differs from the P arm spring (r).

ATTENTION:

The pinch roller (F) assembly differs from the pinch roller (R)

assembly.

Joint e

Joint d

A

Soldering a

Direction switch board

Fig.1

Pinch-roller (R) assembly

Shaft

Remove the P arm spring (r)

from the chassis.

Joint b

B

C washer

A arm spring (b)

FF roller

S support plate

D

Playback head

Pinch-roller (F) assembly

A arm spring (a)

Shaft

Remove the P arm spring (f)

from the chassis.

P arm spring (r)

P arm spring (f)

Fig.2

(No.MA182)1-9

Page 10

3.2.6 Removing the cassette hanger / cassette holder

(See Fig.3)

• Prior to performing the following procedure, remove the FF /

REW lever assembly.

(1) From the rear of the unit, bend the two tabs f outwards and

disengage the two joints g in the direction of the arrow.

(2) Push the eject lever and remove the cassette holder from

the playback head. Disengage the two joints h of the cassette hanger / cassette holder and the eject lever in the direction of the arrow.

(3) Lift the cassette hanger / cassette holder and disengage

the joint i of the return link and the eject lever.

Cassette holder

Cassette hanger

Chassis

Return link

Joint i

Eject lever

Joint h

Joint h

3.2.7 Removing the reel disc assembly

(See Fig.4)

• Prior to performing the following procedure, remove the FF /

REW lever assembly and the cassette hanger / cassette holder.

(1) Remove the C washer and pull out reel disc assembly.

ATTENTION:

Replace with a new C washer when reattaching.

3.2.8 Removing the motor assembly

(See Fig.5)

(1) Unsolder the two wires j on the motor assembly.

(2) Turn over the cassette mechanism assembly and remove

the main belt and the sub-belt from the motor pulley.

ATTENTION:

The main belt can now be removed.

(3) Remove the two screws G attaching the motor assembly.

Joint g

Flywheel (BF)

Tab f

C washer

C washer

Tab f

Fig.3

Fig.4

Main-belt

E

Joint g

Reel disc assembly

Motor assembly

Sub-belt

G

Motor pulley

1-10 (No.MA182)

Flywheel (BR)

Reel base assembly

E

Fig.5

G

Soldering j

E

F

Page 11

3.2.9 Removing the Flywheel (BF) and (BR) assembly

(See Fig.4 and 5)

• Prior to performing the following procedure, remove the cas-

sette hanger / cassette holder.

(1) From the upper side of the cassette mechanism assembly,

remove the C washer from each shaft of the flywheel (BF)

and (BR).

(2) Turn over the cassette mechanism assembly and remove

the main belt. Pull out the flywheel (BF) and (BR) downward respectively.

C washer

Reel disc assembly

C washer

Fig.4

Main-belt

Motor assembly

3.2.10 Removing the reel base assembly

(See Fig.5 and 6)

(1) Raise the part k of the reel base assembly slightly and re-

move the selector link (B) on the front side of the cassette

mechanism assembly by turning it as shown in Fig.6.

(2) Remove the three screws E and the one screw F on the

underside of the cassette mechanism assembly.

ATTENTION:

The reel base assembly is not repairable. Handle with care.

Pinch-roller (R) assembly

k

Selector link (B).

Turn the selector link (B).

Fig.6

Inside of the reel base assembly

Flywheel (BF)

Flywheel (BR)

Sub-belt

E

Reel base assembly

E

Fig.5

Motor pulley

G

E

F

G

Soldering j

Fig.7

(No.MA182)1-11

Page 12

3.2.11 Removing the mute switch board (See Fig.8)

(1) Unsolder the two wires l on the mute switch board on the

back of the cassette mechanism assembly.

(2) Remove the screw H attaching the mute switch board.

3.2.12 Removing the power switch

(See Fig.9)

• Prior to performing the following procedure, remove the motor

assembly.

(1) Unsolder the two wires m on the power switch on the side

of the cassette mechanism assembly.

(2) Remove the screw I attaching the power switch.

Cassette mechanism assembly

Soldering l

H

Fig.8

Soldering m

I

Cassette mechanism assembly

Power switch

Fig.9

Rower switch

Motor assembly

Mute switch board

1-12 (No.MA182)

Page 13

SECTION 4

ADJUSTMENT

4.1 Adjustment method

Test instruments required for adjustment

(1) Digital oscilloscope (100MHz)

(2) Frequency counter meter

(3) Electric voltmeter

(4) Wow & flutter meter

(5) Test tapes

VT724:for DOLBY level measurement

VT739:For playback frequency measurement

VT712:For wow flutter & tape speed measurement

VT703:For head azimuth measurement

(6) Torque gauge:Cassette type for CTG-N(Mechanism ad-

justment)

Measuring conditions (Amplifier section)

Power supply voltage :DC14.4V (11V to 16V allowance)

Load impedance: 4Ω(4Ωto 8Ωallowance)

Line out level/Impedance :2.0V/20kΩload (250 nWb/m)

Standard volume position

Balance and Bass, Treble volume, Fader

:Center (Indication "0")

Loudness, Dolby NR, Sound, Cruise : Off

Volume position is about 2V at speaker output with following

conditions, Playback the test tape VT721.

AM mode 999kHz/62dB, INT/400Hz, 30% modulation

signal on receiving.

FM mono mode 97.9MHz/66dB, INT/400Hz, 22.5kHz devia-

tion pilot off mono

FM stereo mode 1kHz, 67.5kHz dev. pilot 7.5kHz dev.

Output level:0dB (1µV,50Ω/open terminal)

(No.MA182)1-13

Page 14

Information for using a car audio service jig

(1) We're advancing efforts to make our extension cords common for all car audio products.

Please use this type of extension cord as follows.

(2) As a U-shape type top cover is employed, this type of extension cord is needed to check operation of the mechanism assembly

after disassembly.

(3) Extension cord : EXTKSRT002-6P ( 6 pin extension cord ) For connection bn etween mechanism assembly and main board.

(4) Check for mechanism driving section such as motor ,etc.

Disassembly method

(1) Remove the front panel assembly.

(2) Remove the bottom cover.

(3) Remove the front chassis assembly.

(4) Remove the heat sink.

(5) Remove the rear panel.

(6) Remove the main board.

(7) Reattach the heat sink with the screw B and two screws C. (Refer to Disassembly method.)

(8) Reattach the rear panel with the screw F. (Refer to Disassembly method.)

(9) Reattach the front chassis assembly with the screw A. (Refer to Disassembly method.).

(10) Reattach the front panel assembly.

(11) Confirm that current is being carried by connecting an extension cord jig.

Note:

Available to connect to the CJ701

CAUTION:

Be sure to attach the heat sink and rear panel on the power amplifier IC and regulator IC of a main board when supplying

the power.

If voltage is applied without attaching those parts, the power amplifier IC and regulator IC will be destroyed by heat.

connector when installing the front panel.

EXTKSRT002-6P

Front Panel assembly

Cassette mechanism

Extension cord

: EXTKSRT002-6P

Main board

1-14 (No.MA182)

Page 15

4.2 Arrangement of Adjusting & Test points

Cassette mechanism

(Surface)

Tape speed adjust

Motor assembly

Playback head

Azimuth screw

Head section view

Head azimuth screw

Height adjusting screw c

Fixed screw

Playback head

Height adjusting screw a

Height adjusting screw b

(No.MA182)1-15

Page 16

Item

Conditions

Adjustment and Confirmation methods

S.Values Adjust

Head

1.

azimuth

adjustment

Test tape:

SCC-1659

VT703 (10kHz)

Test tape:

VT724 (1kHz)

VT703 (10kHz)

VT721 (315Hz)

Head height adjustment

Adjust the azimuth directly. When you

adjust the height using a mirror tape,

remove the cassette housing from the

mechanism chassis.

After installing thecassette housing,

perform the azimuth adjustment.

Load the SCC-1659 mirror tape. Adjust with

1.

height adjustment screw A and azimuth

adjustment screw B so that line A of the

mirror tape runs in the center between Lch

and Rch in the reverse play mode.

After switching from REV to FWD then to

2.

REV, check that the head position set in

procedure 1 is not changed. (If the position

has shifted, adjust again and check.)

Adjust with azimuth adjustment screw B so

3.

that line B of the mirror tape runs in the

center between Lch and Rch in the forward

play mode.

Head azimuth adjustment

Load VT724 (1kHz) and play it back in

1.

the reverse play mode.

Set the Rch output level to max.

Load VT703 (10kHz) and play it back in

2.

the forward play mode. Adjust the Rch

and Lch output levels to max, with

azimuth adjustment screw B. In this case,

the phase difference should be within 45 .

Engage the reverse mode and adjust the

3.

output level to max, with azimuth

adjustment screw C.

(The phase difference should be 45 or

more.)

When switching between forward and

4.

reverse modes, the difference between

channels should be within 3dB. (Between

FWD L and R, REV L and R.)

A line

Head shield

The head is at low position

during.

B line

Head shield

The head is at High position

during REV.

Output

level:

Maximum

PBHead

FWD Adj B

REV Adj C

(0 ) (45 )

HEIGHT Adj A

phase

2.

Tape speed

and wow

flutter

confirmation

3.

Play back

frequency

response

confirmation

1-16 (No.MA182)

When VT721 (315Hz) is played back,

5.

the level difference between channels

should be within 1.5dB.

Test tape: VT712

(3kHz)

Test tape: VT724

(1kHz)

VT739

(63Hz / 1kHz / 10kHz)

The tuner section is of an adjustment-freedesign. In case the tuner is in trouble, replace the tuner pack.

Check to see if the reading of the F, counter /

1.

wow flutter meter is within 3015Hz to 3045Hz

(FWD/ REV), and less than 0.35% (JIS RMS).

In case of out of specification, adjust the

2.

motor with a built-in volume resistor.

Play test tape VT724, and set the volume

1.

position at 2V.

Play test tape VT739 and confirm.

2.

1kHz / 10kHz: -1 3dB,

1kHz / 63Hz: 0 3dB,

When 10kHz is out of specification, it will be

3.

necessary to read adjust the azimuth.

Tape speed:

3015Hz

to 3045Hz

Wow

flutter: less

than 0.35%

Speaker out

1kHz / 63Hz

: 0 3dB

1kHz / 10kHz

: -1 3dB

Built-in volume

resistor

Page 17

5.1 16 PIN CORD DIAGRAM

SECTION 5

TROUBLESHOOTING

8

7

6

5

4

3

2

1

BK

RD

NC

BL/WH

WH

GN

VI

GY

WH/BK

GN/BK

VI/BK

GY/BK

16 YL

8 BK

7 RD ACC

5 BL/WH REMOTE

4 WH

12 WH/BK

3 GN

11 GN/BK RL-

2 VI RR+

10 VI/BK

1 GY FR+

YL

NC

NC

NC

16

15

14

13

12

11

10

9

MEMORY

GND

FL+

FL-

RL+

RR-

BK

RD

BL

WH

Black

Red

Blue

White

GN

VI

GY

YL

Green

Violet

Gray

Yellow

9 GY/BK

RR

FR

FL

RL

Rear Right

Front Right

Front Left

Rear Left

FR-

REMOTE

ACC

MEMORY

GND

Remote out

ACC Line

Memory Backup Battery +

Ground

(No.MA182)1-17

Page 18

Victor Company of Japan, Limited

AV & MULTIMEDIA COMPANY CAR ELECTRONICS CATEGORY 10-1,1chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

(No.MA182)

Printed in Japan

VPT

Loading...

Loading...